Patents

Literature

37results about How to "Stable operating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

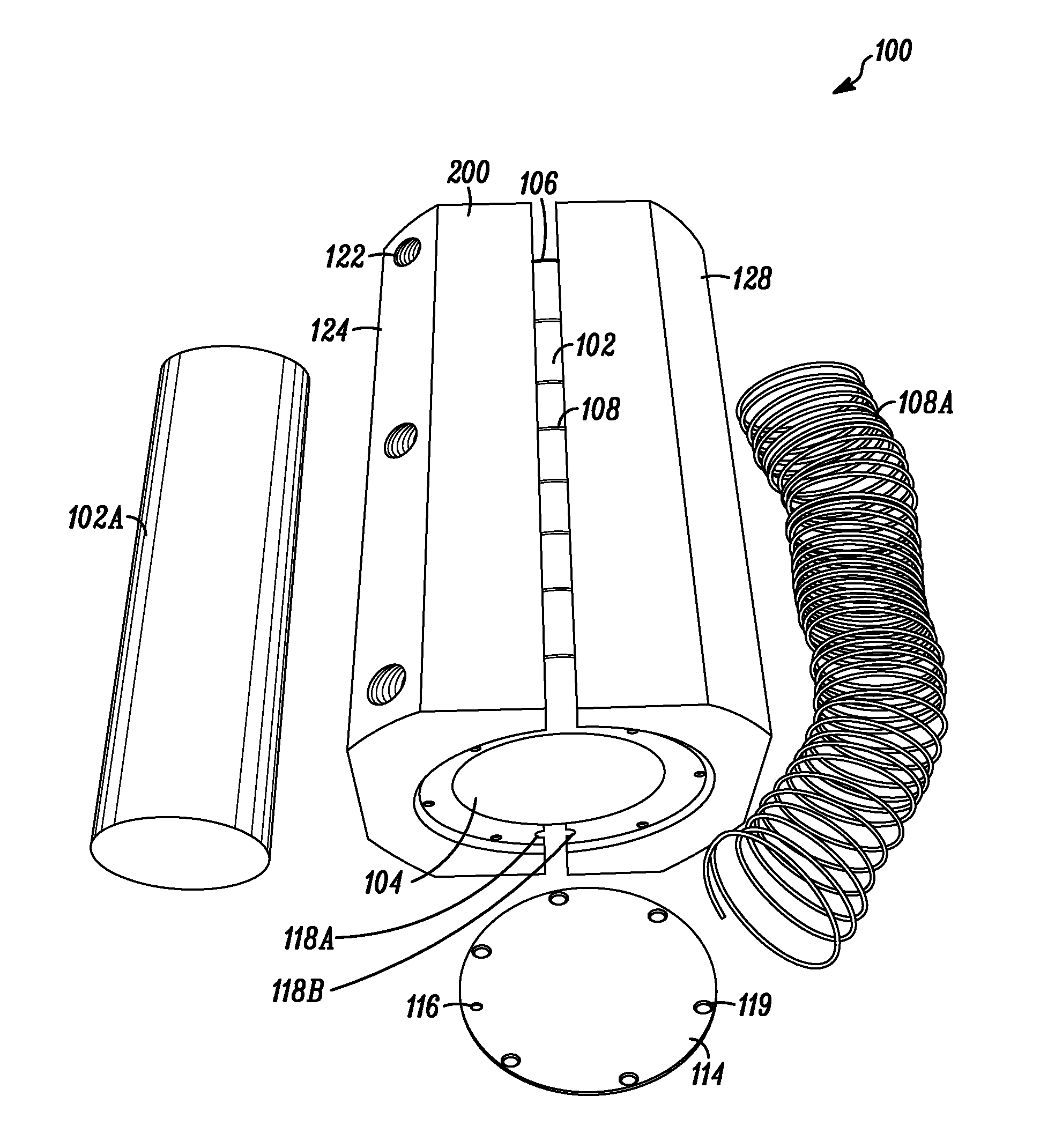

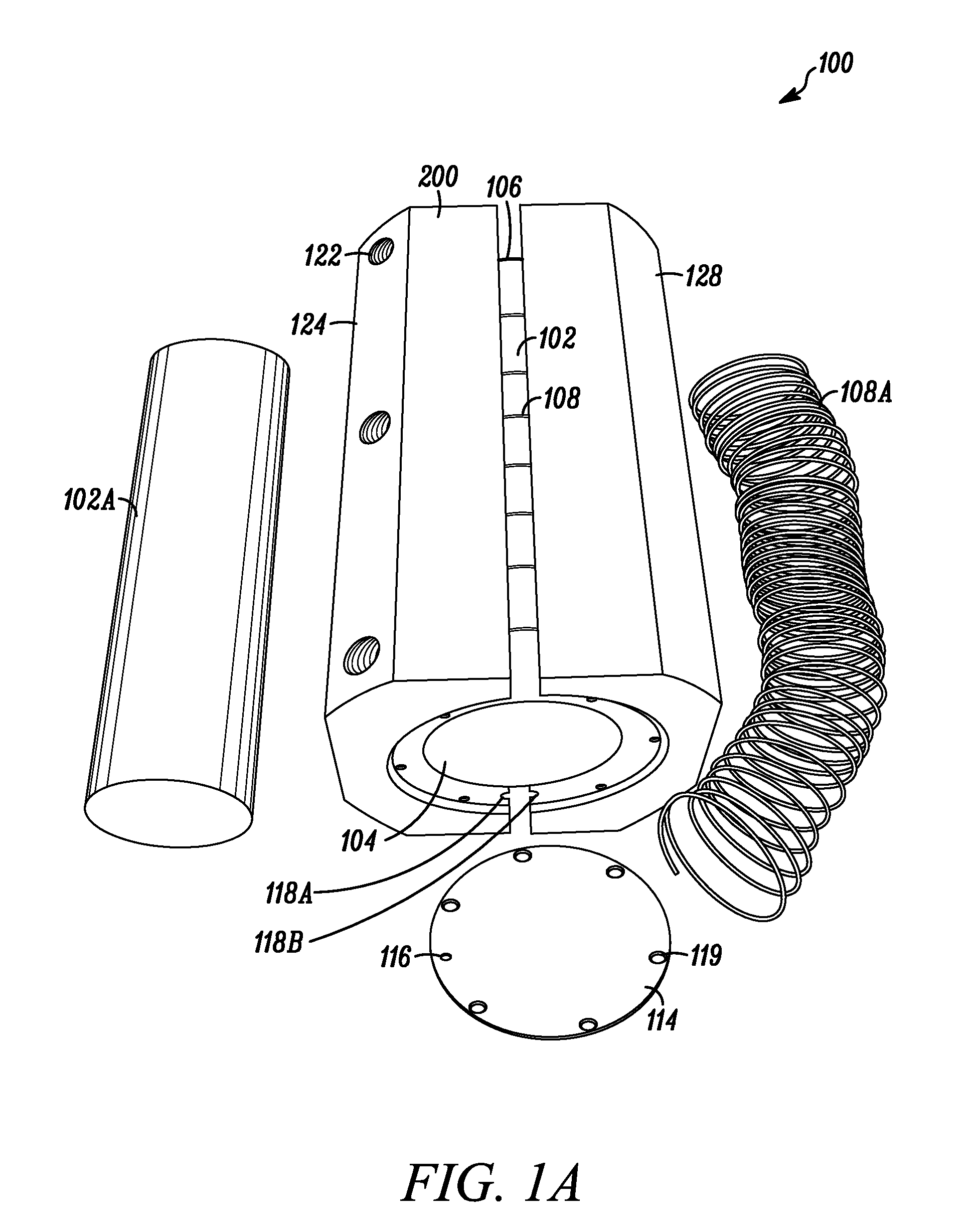

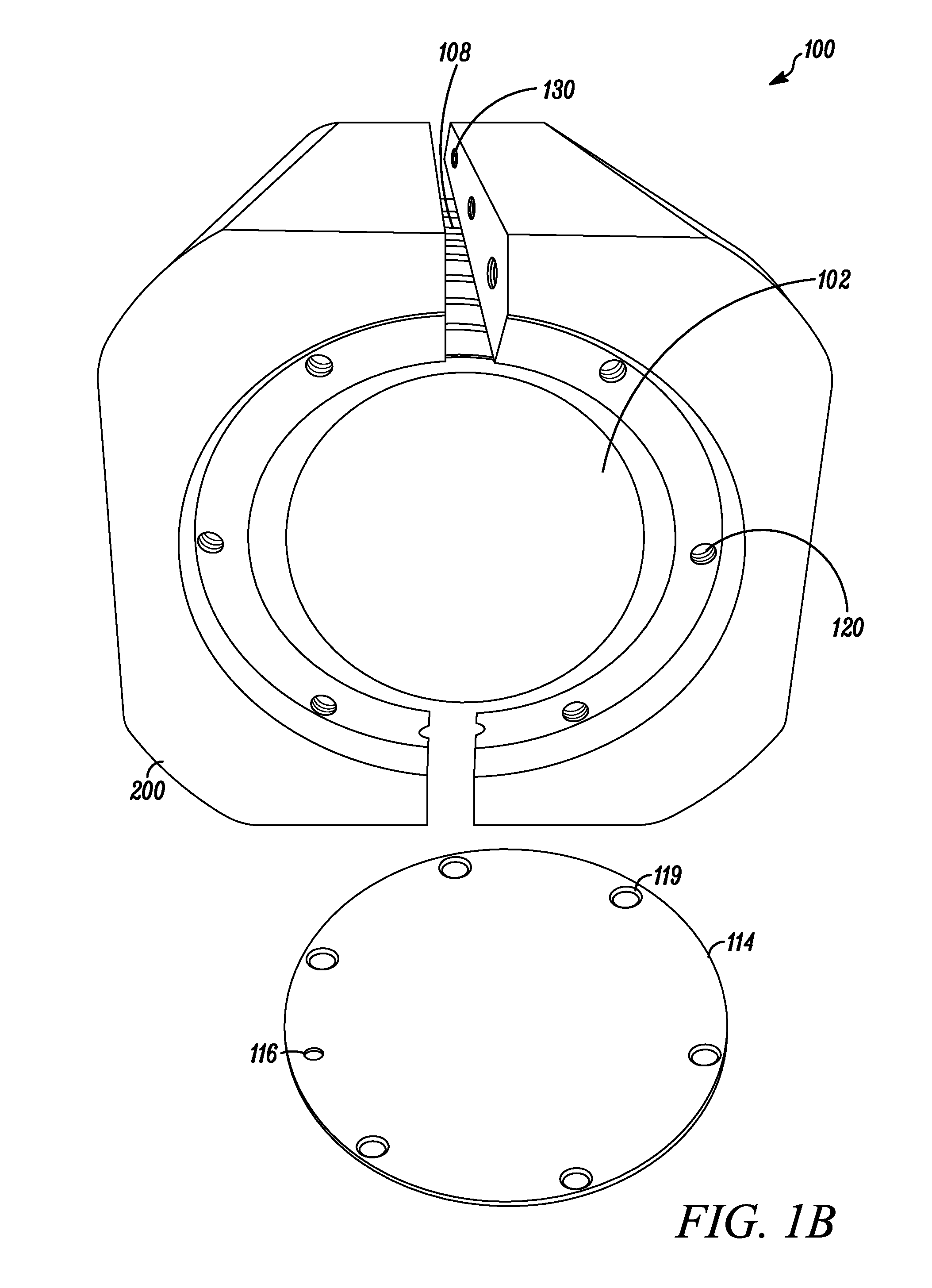

Process and apparatus for continuous flow synthesis of nanocrystals

InactiveUS20110229397A1Stable operating temperatureFlexible designGaseous chemical processesSamplingContinuous flowReaction timing

Novel reactor, systems and methods of preparing nanocrystals in a continuous flow-through process are provided. The novel reactor is highly configurable and can be modified to achieve desired reaction times of a flow through mixture. The reactor is designed to provide uniform, efficient heating of the reaction mixture.

Owner:LIFE TECH CORP

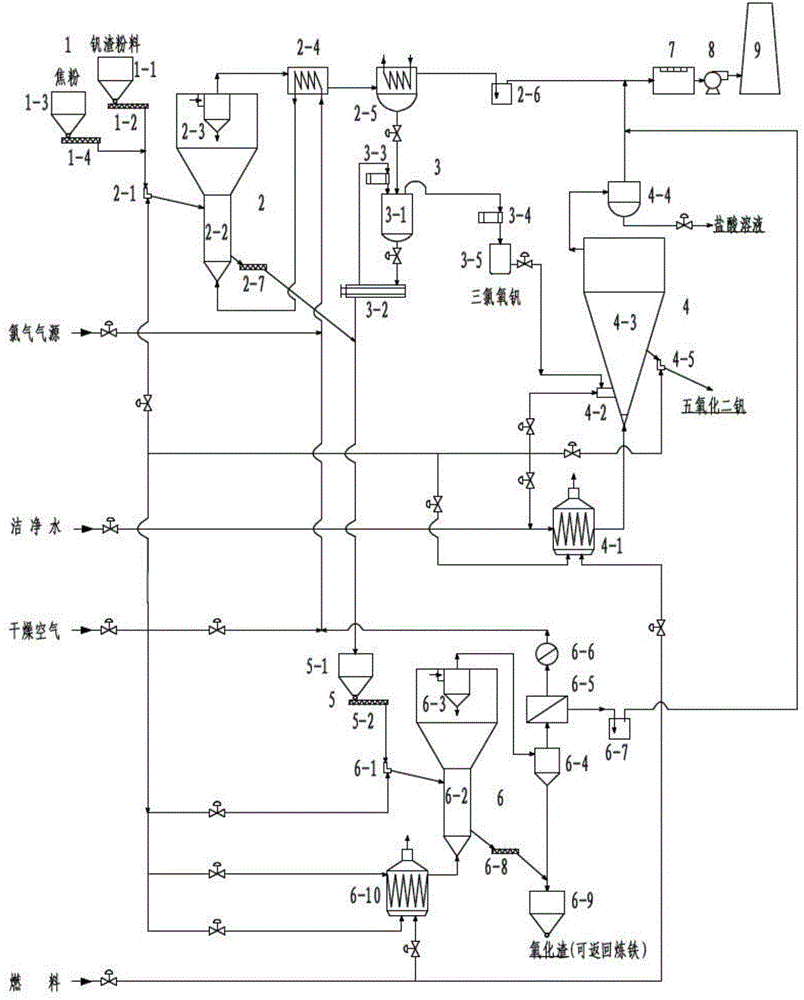

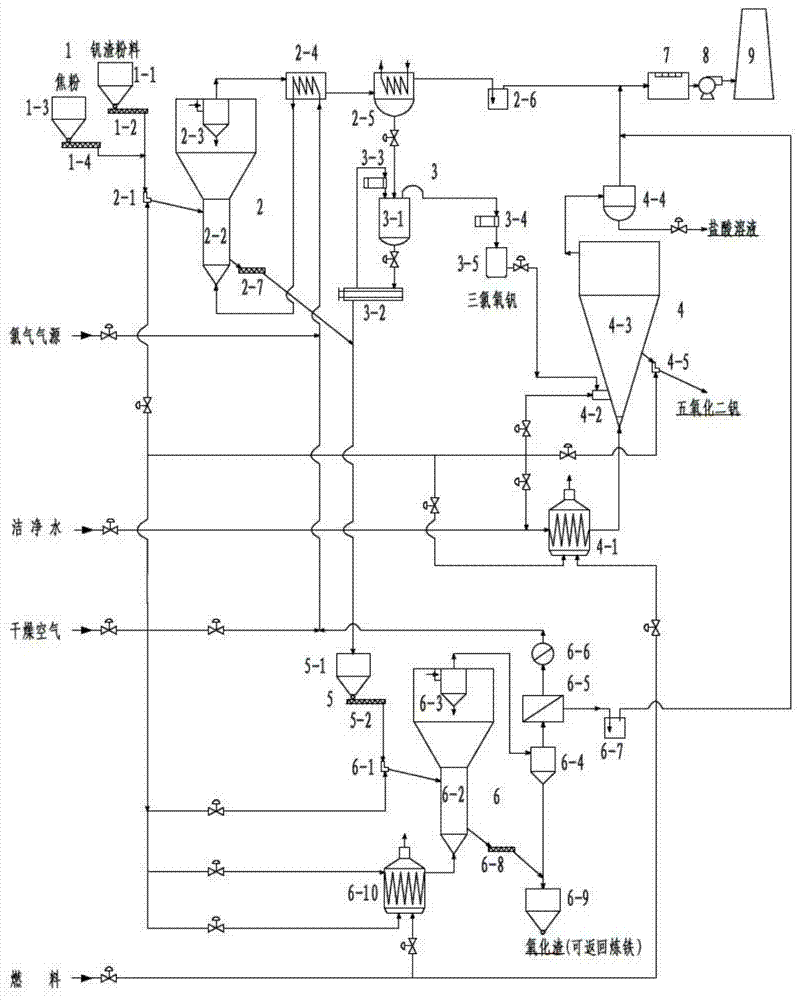

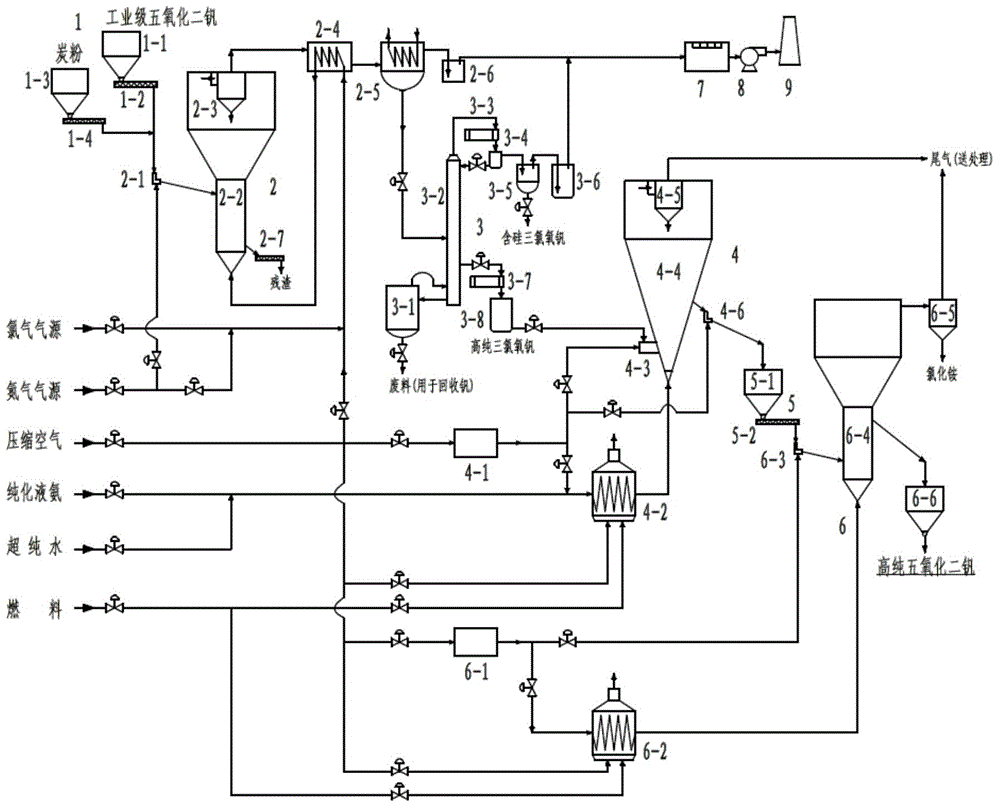

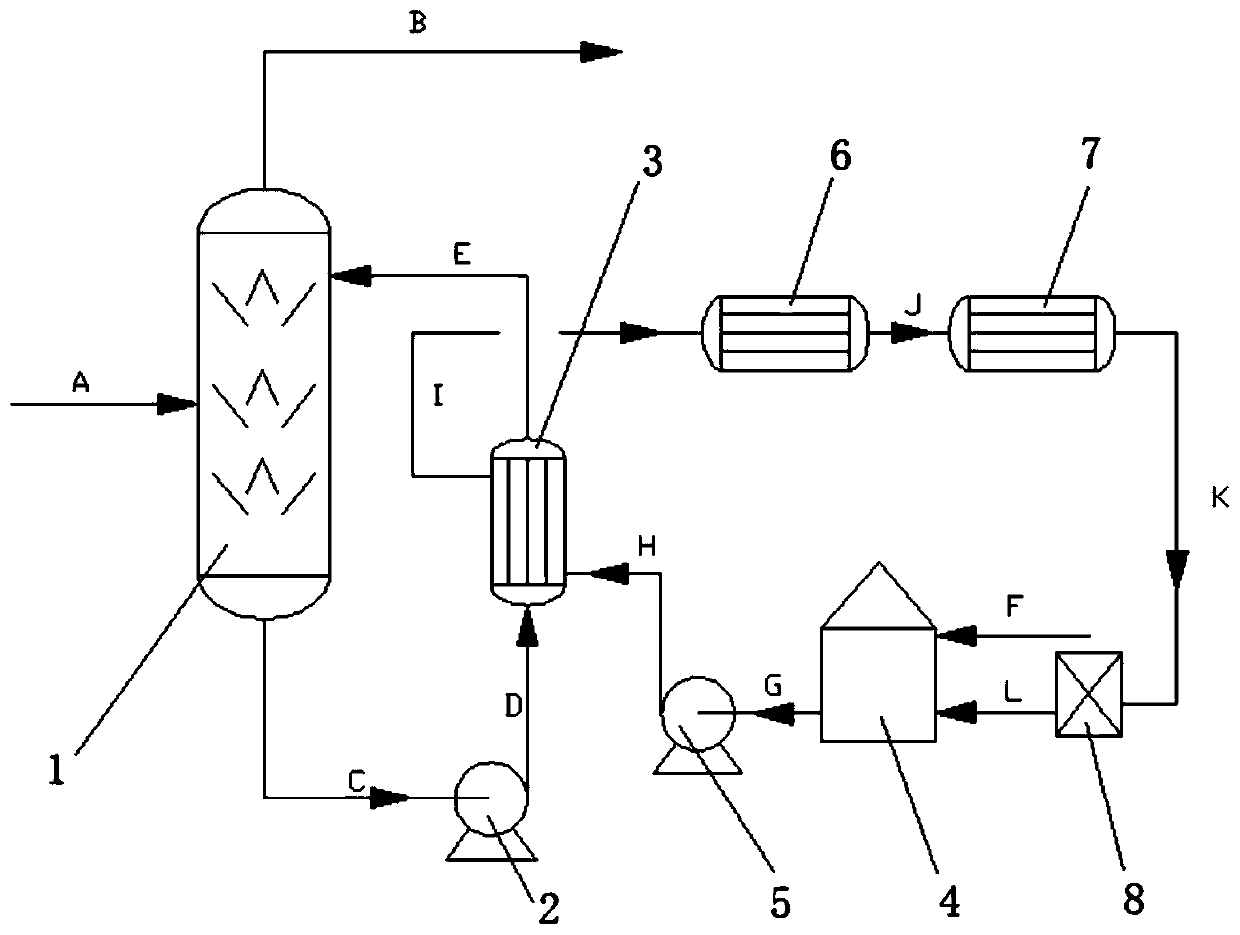

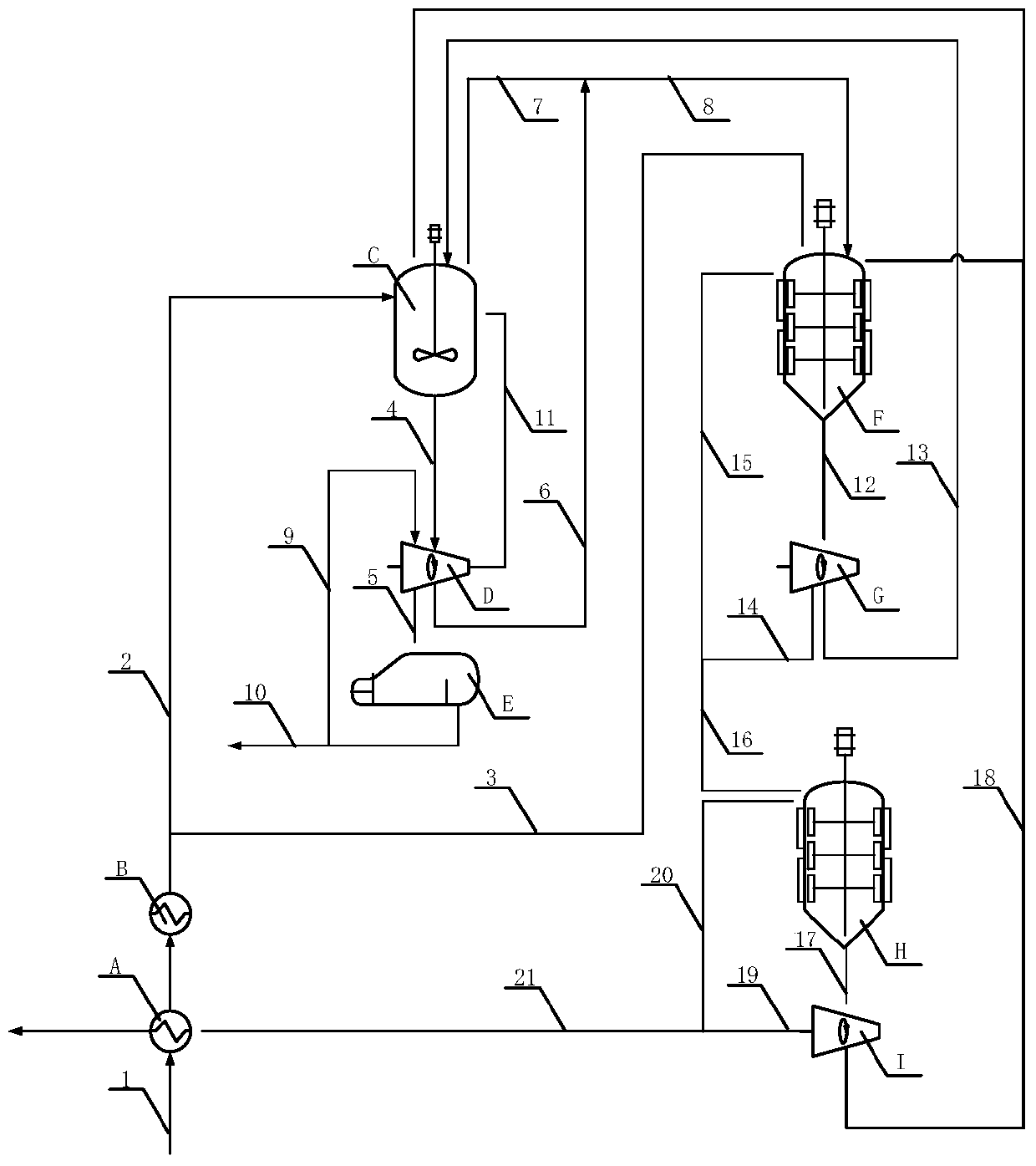

System and method for high-efficiency extraction of vanadium from vanadium slag through chlorination

ActiveCN105986126AAchieve warm-upUniform temperature distributionVanadium oxidesProcess efficiency improvementFlue gasPrecipitation

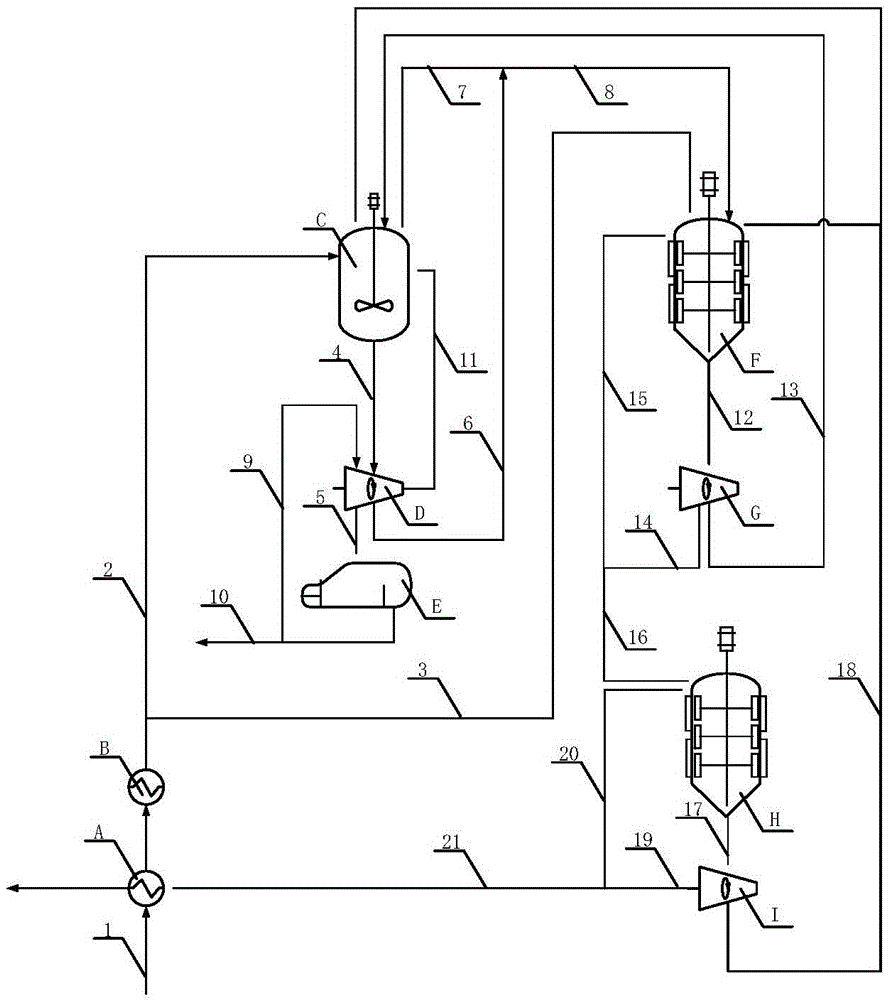

The invention specifically discloses a system and method for high-efficiency extraction of vanadium from vanadium slag through chlorination, belonging to the fields of chemical engineering and metallurgy. By means of heat exchange between chlorination gas and chlorination flue gas, the chlorination gas is preheated; a proper amount of air is added to allow a part of coke powder to combust, thus providing a balanced supply of heat during the process of chlorination; by means of high-temperature fluidization oxidation of chlorinated slag, the chlorinated slag is treated in a comprehensive manner, and the chlorine gas is recycled; furthermore, by means of vapor-phase hydrolysis of the chlorination product vanadium oxytrichloride, a powdered vanadium pentoxide product and a hydrochloric acid byproduct are obtained; so the efficiency of chlorination is improved, the consumption of chlorine gas is reduced, the harm of the chlorinated slag is eliminated, and the problem of ammonia-nitrogen pollution caused by conventional ammonium salt precipitation is prevented. The system and method provided by the invention are applicable to extraction of vanadium from vanadium slag containing 10 to 28 wt% of V2O5 through chlorination and have the advantages of high efficiency, low energy consumption, no pollution, good economic performance, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A system and method for efficiently chlorinating vanadium from vanadium slag

ActiveCN105986126BAchieve warm-upUniform temperature distributionVanadium oxidesProcess efficiency improvementSlagGas phase

Provided are a system and method for highly effective chlorination and vanadium extraction from vanadium slag. By means of heat exchange between a chlorination gas and a chlorination flue gas, a chlorination gas is preheated and an appropriate amount of air is added, which causes coke powder to partially combust, thus providing a balanced supply of heat during the process of chlorination; also, by means of high-temperature fluidization oxidation of the chlorinated slag, the chlorinated slag is used in a comprehensive manner, and the chlorine gas is recycled; further, by means of vapor-phase hydrolysis of the vanadium oxytrichloride product of chlorination, a powdered divanadium pentoxide product is obtained; the reaction efficiency of chlorination is improved, the consumption of chlorine gas is reduced, the harm of chlorinated slag is eliminated, and the pollution problem caused by conventional ammonium salt precipitation is prevented.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

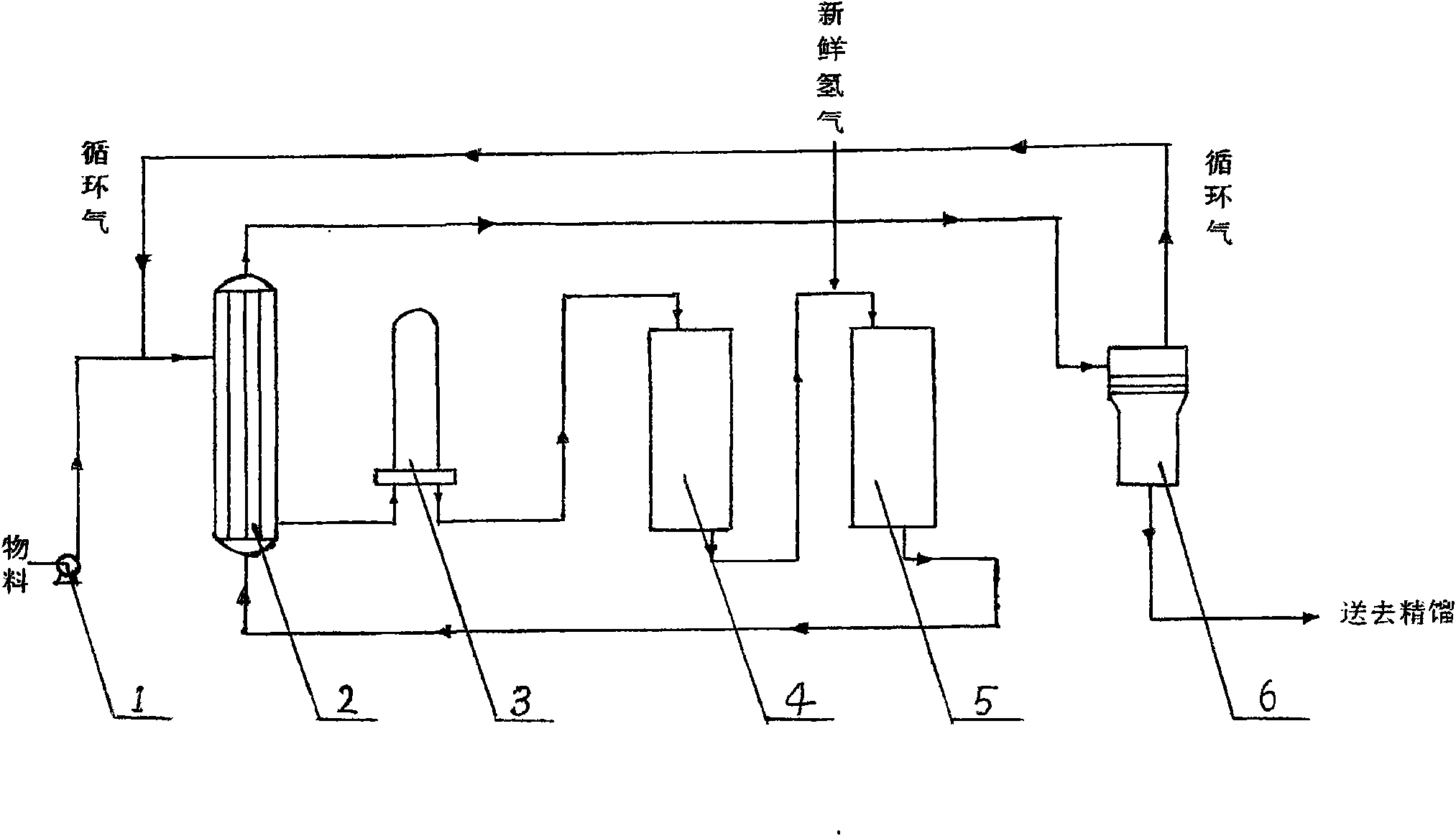

Method for preparing fatty alcohol through fixed bed hydrogenation by using fatty acid methyl ester

InactiveCN101633602AInhibition releaseStable operating temperatureOrganic compound preparationHydroxy compound preparationFixed bedAcid value

The invention provides a method for preparing fatty alcohol through fixed bed hydrogenation by using fatty acid methyl ester, which overcomes the defect that an adiabatic reactor cannot perform heat exchange, has no need of changing the prior device and process, and has the advantages of saving energy and improving the safety of a reaction device. The method comprises the following steps: adding methanol of which the purity is more than or equal to 99.8 weight percent into the fatty acid methyl ester of which the acid value (AV) is less than or equal to 0.8 percent of KOHmg / g, wherein the volume ratio of the fatty acid methyl ester to the methanol is 8-12:1; and using the methanol to release and absorb reaction heat in the process so that the temperature of a fixed bed catalytic hydrogenation reactor is kept relatively constant and side reactions are reduced. The reactants can be fatty acid methyl esters of C8-C18, such as methyl esterification products and the like of natural coconut oil, palm oil and palm nut oil. The fatty acid methyl ester can be obtained through the alcoholysis of the fatty acid and can also be obtained from markets, and the purity of the obtained fatty alcohol is more than 99.7 percent. The yield of the fatty acid methyl ester is more than 96 percent.

Owner:上海中远化工有限公司

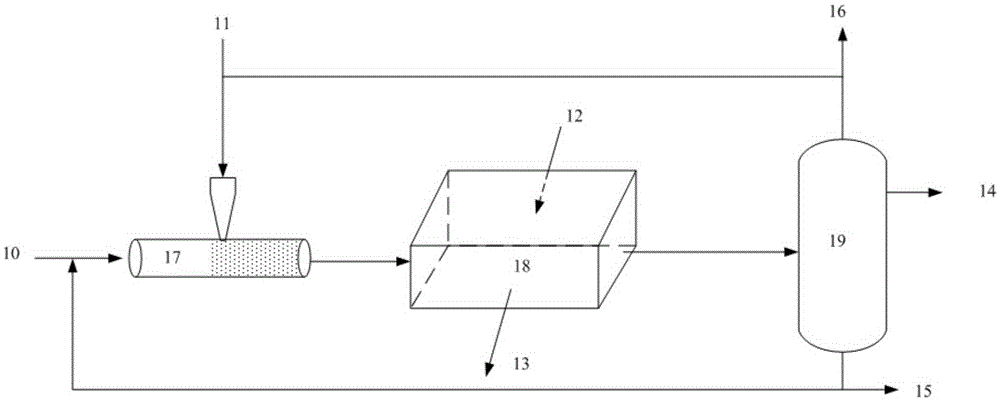

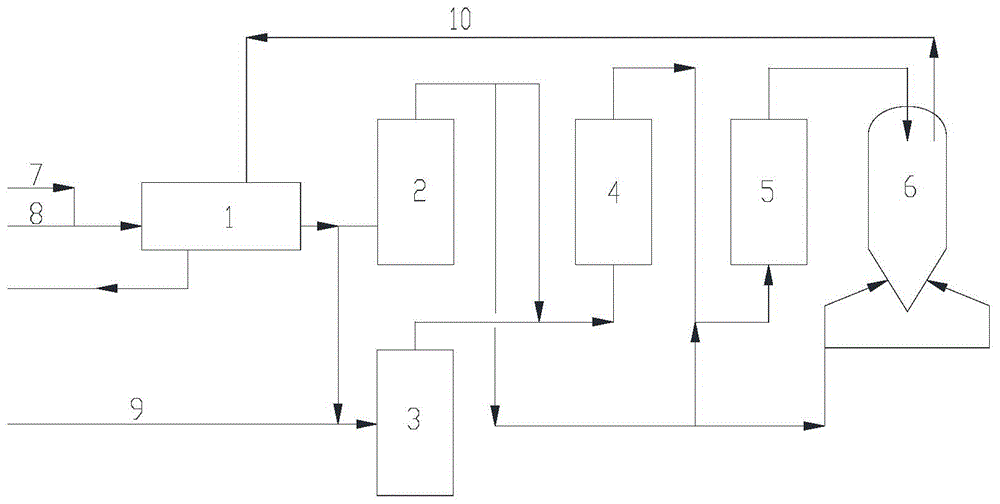

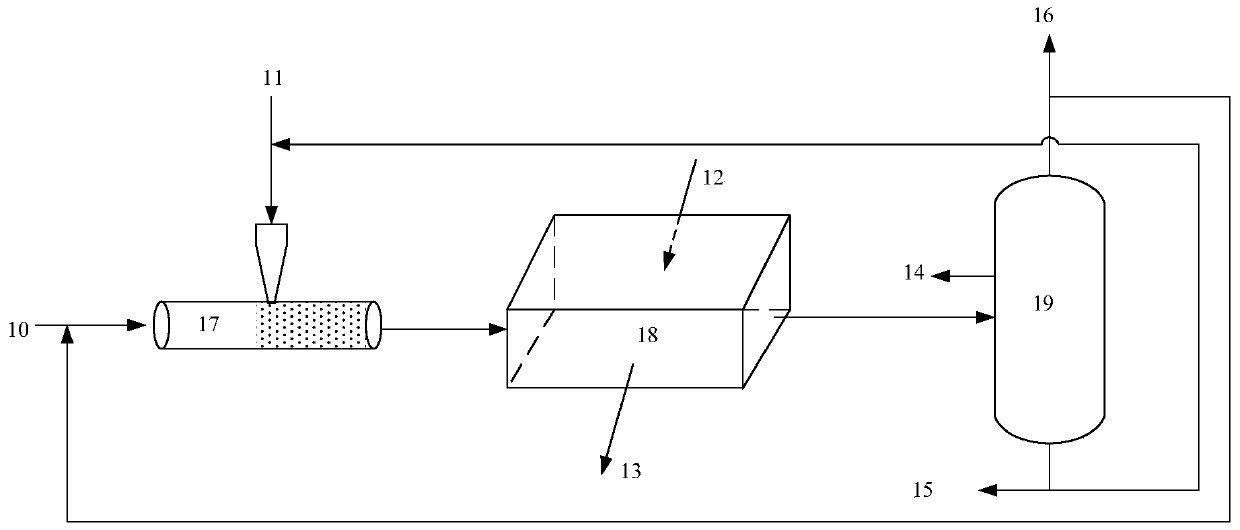

A Fischer-Tropsch synthetic reaction method

ActiveCN106635117ASafe operating temperatureStable operating temperatureLiquid hydrocarbon mixture productionHydrocarbon oils treatmentMicroreactorSyngas

A Fischer-Tropsch synthetic reaction method is provided. After synthetic gas is dispersed into gas bubbles by a dispersing structure, the gas bubbles are fed into a mixer and fully mixed with a catalyzing solution containing a nanometer catalyst, and the fully mixed reaction stream enters a reaction micro-channel of a microreactor through a stream inlet and is subjected to a Fischer-Tropsch synthetic reaction to produce a hydrocarbon product. Heat generated by the reaction is released through heat exchange with a heat exchange medium in a heat exchange micro-channel, the reaction temperature in the micro-channel of the reactor is 100-250 DGE C, and the reaction pressure is 0.5-4.0 MPa. Materials discharged at a product outlet of the microreactor are synthetic gas, a gas-phase reaction product, a liquid phase containing the nanometer catalyst and a liquid phase reaction product, and are fed into a separator and subjected to gas liquid separation. A liquid phase discharged from a liquid phase hydrocarbon outlet of the separator is a hydrocarbon product. According to the method, the microreactor is adopted, and reaction devices are small in size and compact in structure and have characteristics of good mobility and low investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

System and method for purifying and producing high-purity vanadium pentoxide powder

ActiveCN105984896AAchieve warm-upUniform temperature distributionNitrogen compoundsTransportation and packagingDistillationCalcination

The invention discloses a system and method for purifying and producing high-purity vanadium pentoxide powder, belonging to the fields of chemical engineering and materials. According to the invention, fluidizing low-temperature chlorination is used for converting industrial-grade vanadium pentoxide into vanadium oxytrichloride; through heat exchange between fluidization gas and chlorination flue gas, chlorination gas is preheated; a proper amount of air is added to allow a part of coke powder to combust, thus providing a balanced supply of heat during the process of chlorination, improving chlorination efficiency, and ensuring good selectivity of low-temperature chlorination; and the vanadium oxytrichloride is subjected to fluidized-vapor-phase ammoniation after distillation and purification and further to fluidized calcination to produce a high-purity vanadium pentoxide product. The system and method have the advantages that raw materials are good in adaptability, only a small amount of ammonia-nitrogen wastewater is discharged, low energy consumption in production and low cost in operation are realized, product quality is stable, etc.; and the system and method are applicable to large-scale industrial production of high-purity vanadium pentoxide having a purity of 4N or higher and have good economic benefits and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

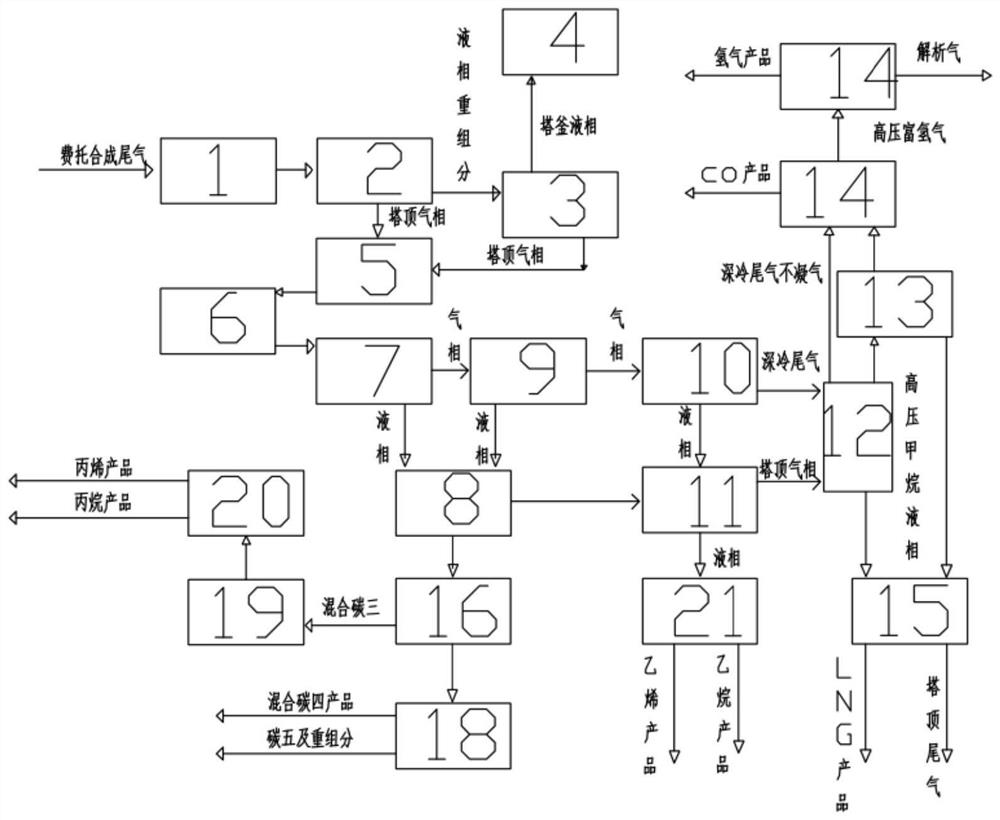

Method for purifying and refining ethyl acetate in high purity

ActiveCN1696104AEasy to operateStable operating temperatureOrganic compound preparationCarboxylic acid esters preparationAcetic acidEthyl ester

A process for preparing high-purity ethyl acetate features that the water, ethanol, acetic acid, ethyl acetate and the light component containing aldone and ester are proportionally loaded in the a purifying-refining tower from the chosen position and the operating reflux ratio is controlled to be (0.3-2.5):1.

Owner:SHANGHAI HUAYI ENERGY CHEM

Temperature control method for slurry bed reactor, design method and application thereof

InactiveCN104888666AImprove running stabilityStable temperatureTemperature control using electric meansChemical/physical processesAutomatic controlHydrodesulfurization

The invention provides a temperature control method for a slurry bed reactor, a design method and the application thereof. The method comprises the step of injecting a coolant in pipes in front of the inlets of a reactors at all levels. The pipes are connected with at least one coolant pipeline to realize the temperature control. The coolant is composed of cold hydrogen and cold oil. According to the method, the method can be applied to reactors during the heavy oil hydrodesulfurization process, the direct coal liquefaction process and the oil-coal mixing process. Through adjusting the number of coolant pipelines and the flow of the coolant, the reaction temperature of the reactor can be controlled. The method is easy to realize during the project implementation process, and facilitates the automatic control. Meanwhile, the operation stability of the reactor is improved. Cold hydrogen and cold oil are necessary raw materials for the reaction, and the forestage reaction heat of the reactor is fully utilized. Therefore, the efficient utilization of heat is realized. The method is especially suitable for second-stage reactors and third-stage reactors. For first-stage reactors, the temperature control effect can still be realized through respectively heating two ways of hydrogen and then mixing up the two ways of hydrogen.

Owner:CATECH TECH

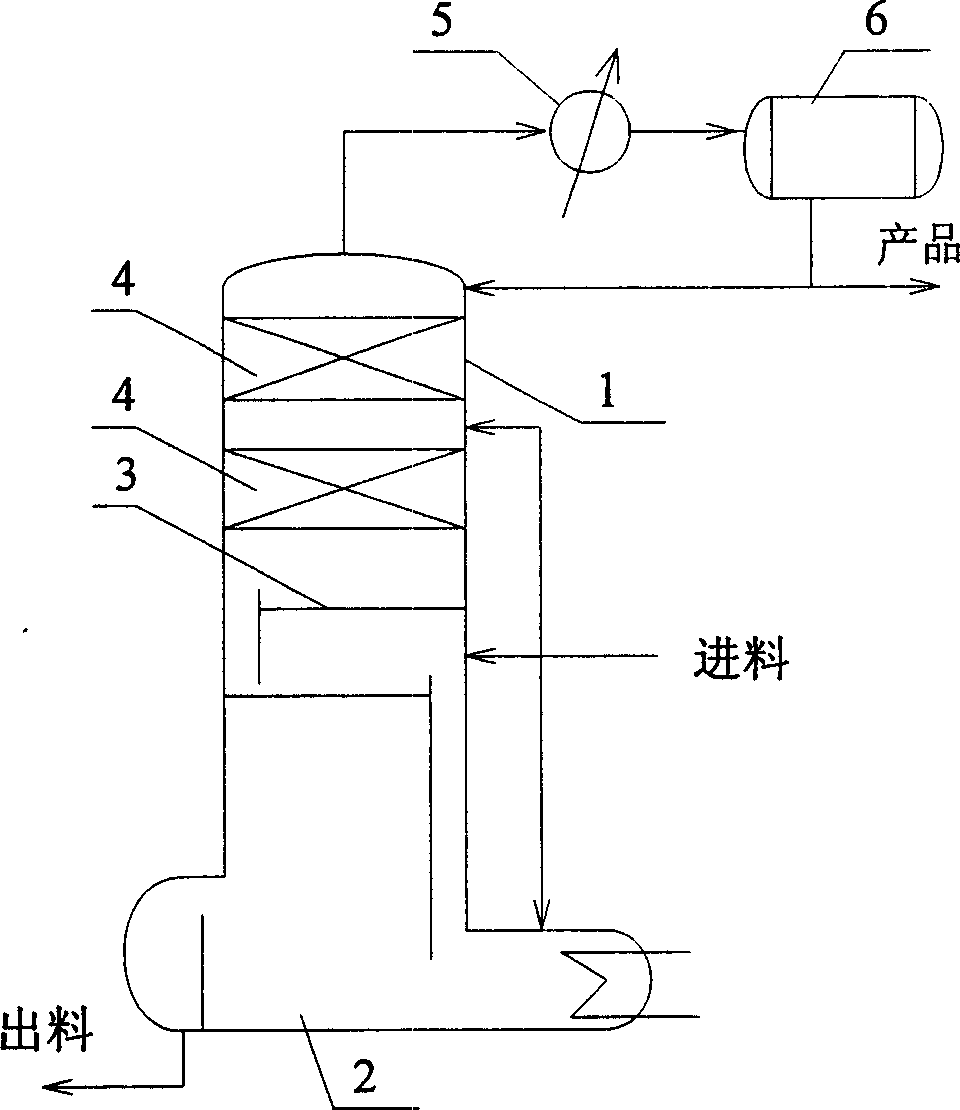

Multistage suspension melting crystallization method for separating p-xylene

ActiveCN106831301AIncrease the average particle sizeEasy to operateChemical industryCrystallisation purification/separationChemistryHigh energy

The invention relates to a multistage suspension melting crystallization method for separating p-xylene. The multistage suspension melting crystallization method comprises the following steps: carrying out shunt operation on raw materials, carrying out multistage crystallization on a part of the raw materials, directly obtaining a p-xylene crystal, then using the rest of the raw materials to carry out pulping washing and warming aging on a low-temperature crystal in an aging kettle, and obtaining a p-xylene product. Stable operation of the aging kettle is guaranteed by adjusting the amount and temperature of the raw materials entering the aging kettle, and then the stability of product purity and yield is guaranteed. Through the technical scheme adopted in the invention, the problems of unstable operation of the aging kettle and high energy consumption existing in the prior art are preferably solved, and the method can be used in the crystallization production of the p-xylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

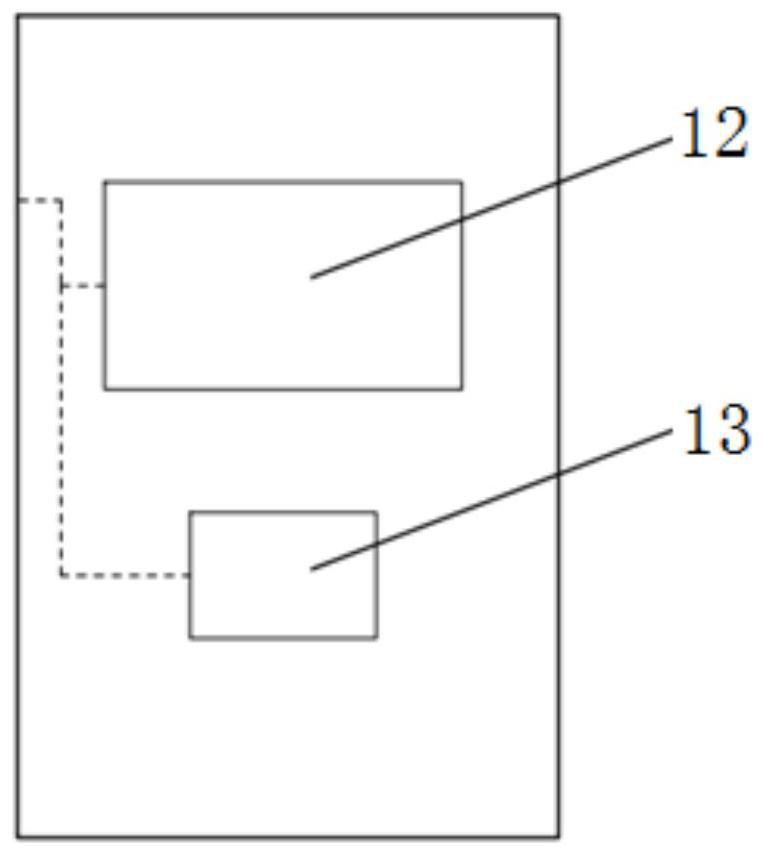

Fischer-Tropsch synthesis tail gas recycling system process

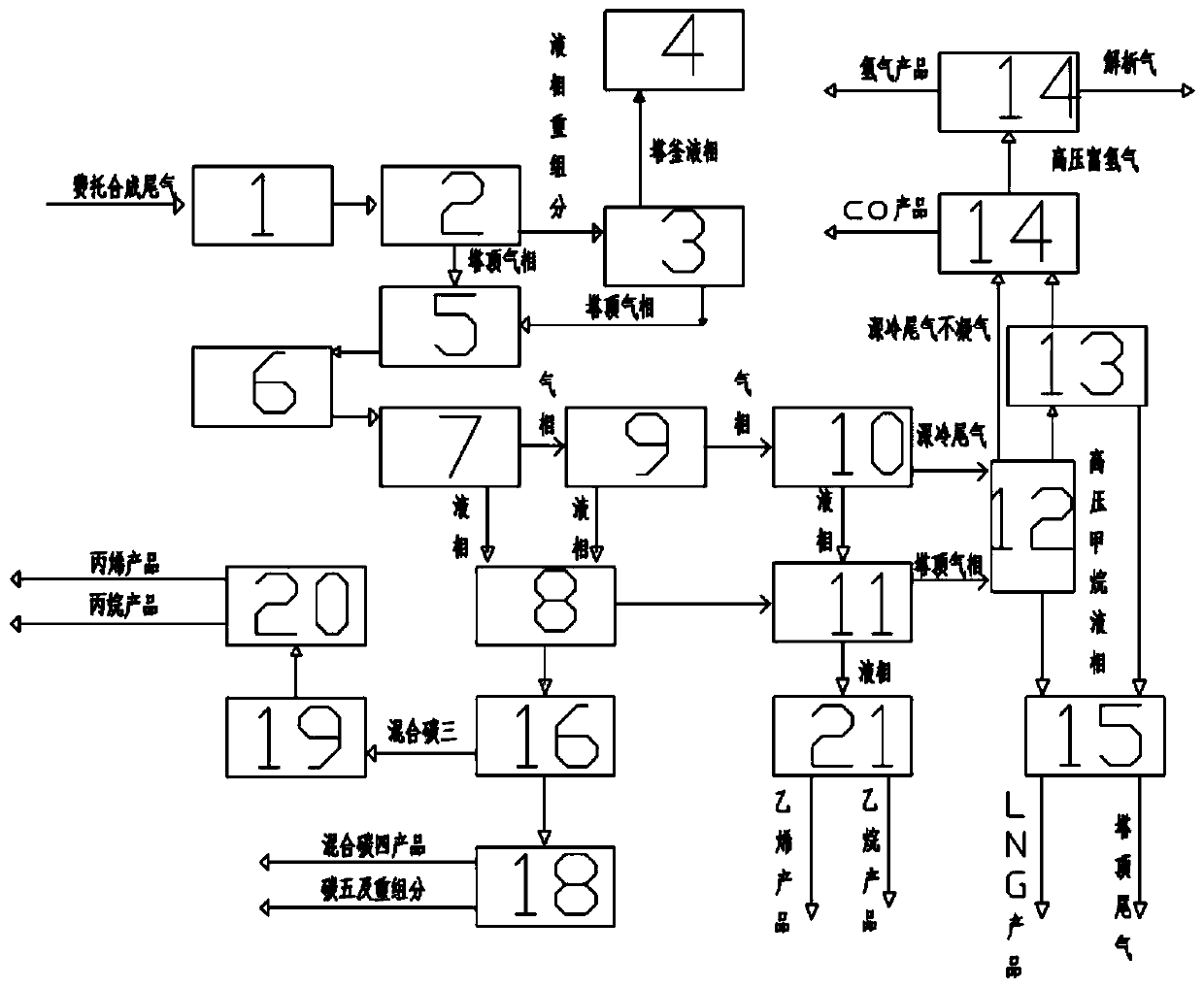

The invention discloses a Fischer-Tropsch synthesis tail gas recycling system process. The process comprises the following steps that a Fischer-Tropsch synthesis tail gas is purified and then enters adeep cooling separation system, the purified Fischer-Tropsch synthesis tail gas is cooled and liquefied, and carbon II, carbon III and heavier components are recycled; methane in the tail gas is condensed and liquefied to prepare an LNG product; and hydrogen and carbon monoxide are purified through a PSA device. According to the Fischer-Tropsch synthesis oil tail gas deep-cooling recycling process, the components with high economic value such as ethylene, propylene and the like are recycled, the raw material gas such as the hydrogen and carbon monoxide of the Fischer-Tropsch synthesis reaction are recycled, and the methane in the tail gas is prepared into LNG or CN.

Owner:北京恒泰洁能科技有限公司

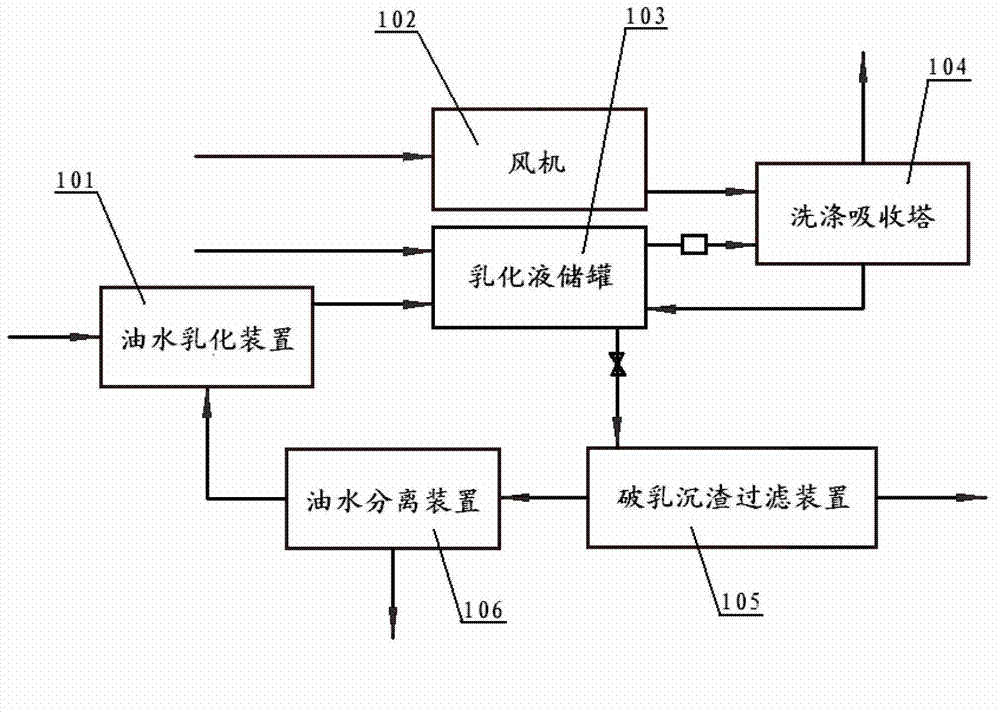

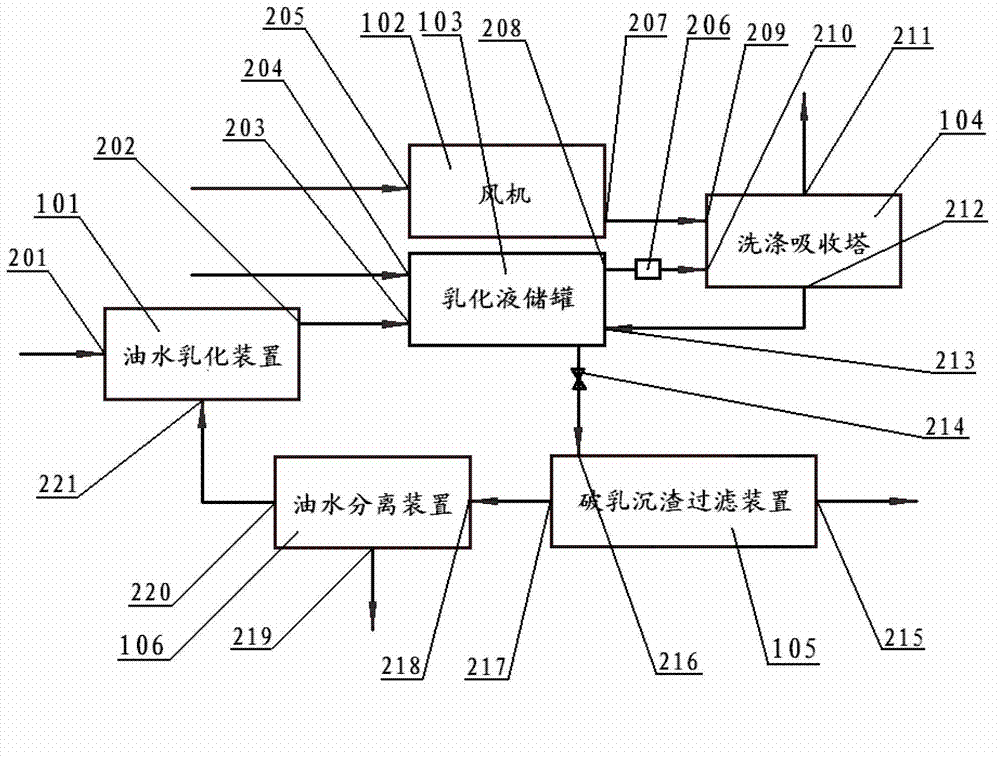

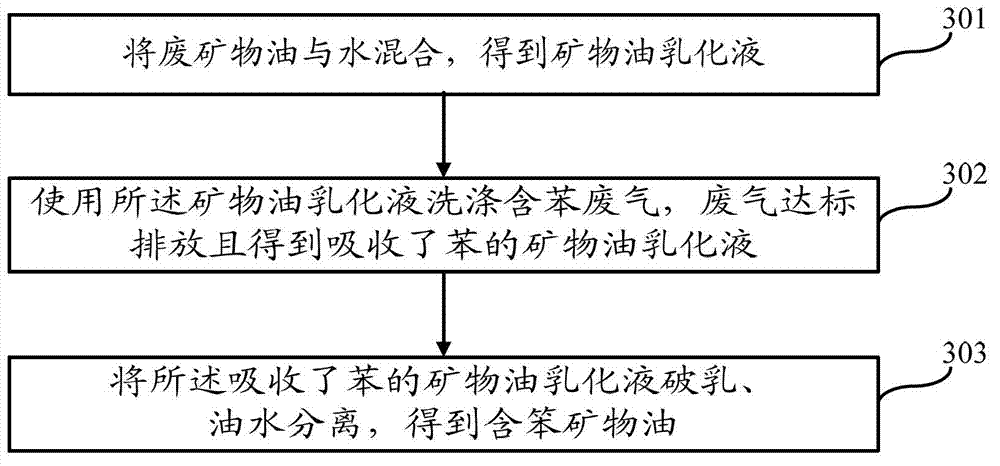

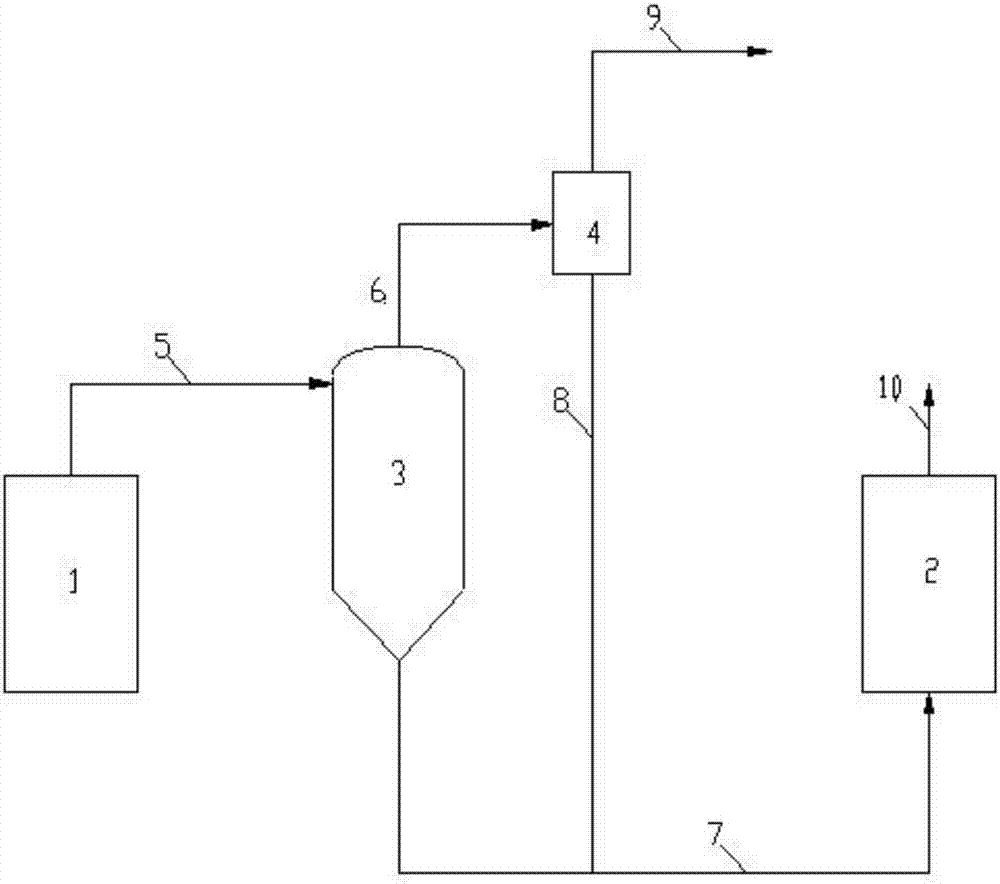

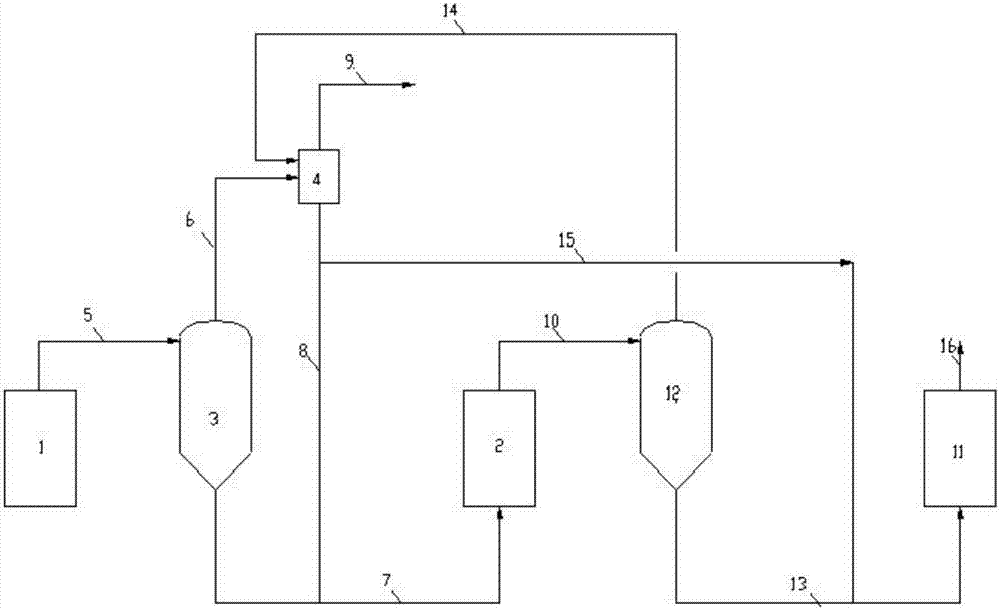

Method for purifying benzene containing waste gas and recycling benzene and system thereof

InactiveCN103170217AHigh calorific valueGood economic benefitsDispersed particle separationBenzeneEmulsion

The invention relates to the field of waste gas treatment, and in particular relates to a method for purifying benzene containing waste gas and recycling benzene and a system using the method. The method comprises the following steps of: mixing waste mineral oil with water to obtain a mineral oil emulsion; washing and absorbing the benzene containing waste gas by using the mineral oil emulsion to discharge the up-to-standard waste gas and obtain the benzene absorbed mineral oil emulsion; and breaking the benzene absorbed mineral oil emulsion, and carrying out oil-water separation to obtain the benzene containing mineral oil. The system comprises an oil-water emulsifier unit, an emulsion storage tank, a washing absorbing tower, an emulsion breaking sediment filter device, and an oil-water separation device, wherein the oil-water emulsifier unit is connected with the emulsion storage tank, the emulsion storage tank is connected with the washing absorbing tower through a pump and is connected with the emulsion breaking sediment filter device through a valve, and the emulsion breaking sediment filter device is connected with the oil-water separation device. The method for purifying the benzene containing waste gas and recycling the benzene and the system by using the method provided by the invention treat wastes with processes of wastes against one another, turn waste into wealth, and are low in cost, high in efficiency, energy-saving, environment-friendly, and safe.

Owner:李竑

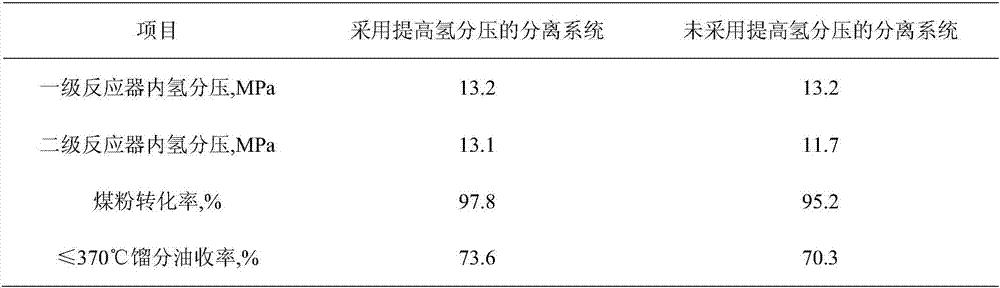

Method for increasing partial hydrogen pressure of hydrogenation reaction system, and design method and application thereof

InactiveCN106957681AImprove conversion rateHigh yieldTreatment with hydrotreatment processesGas phaseHydrogen pressure

The invention provides a method for increasing the partial hydrogen pressure of a hydrogenation reaction system, and a design method and an application thereof, which are used for increasing the partial hydrogen pressure of the hydrogenation reaction system and belong to the fields of petroleum chemistry and coal chemistry. The hydrogenation reaction system comprises at least two reactors. The method comprises the following steps that materials discharged from the former-stage reactor firstly enter a separating system for increasing the partial hydrogen pressure to conduct separation, then non-hydrogen components obtained are separated and discharged, and hydrogen components and liquid-solid phases enter the next-stage reactor. The materials from an outlet of the former-stage reactor are effectively separated by the separating system, the liquid-solid phase enters the next-stage reactor, and the gas phase is separated again, so that after the concentration of the hydrogen in the gas phase is increased, and the hydrogen enters the next-stage reactor. The method provided by the invention has the advantages that the partial hydrogen pressure of the next-stage reactor can be increased, the reaction depth can be effectively increased, the material conversion ratio and the light-oil yield can be increased, the space speed of the next-stage reactor also can be increased and the energy consumption can be reduced.

Owner:CATECH TECH

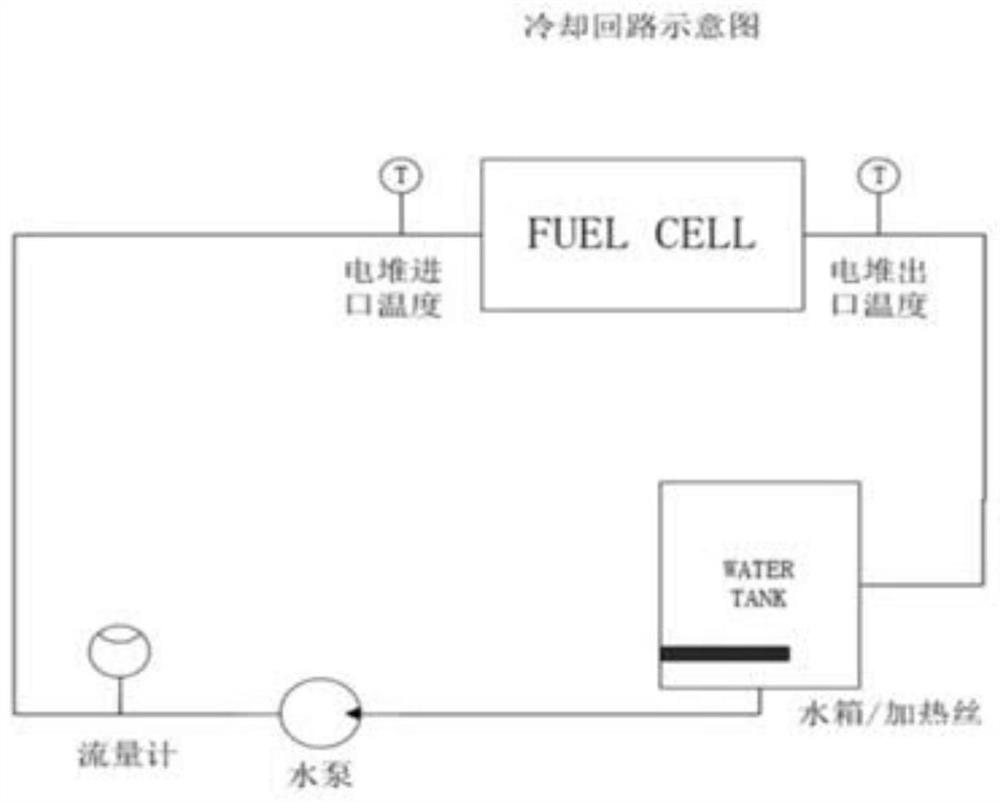

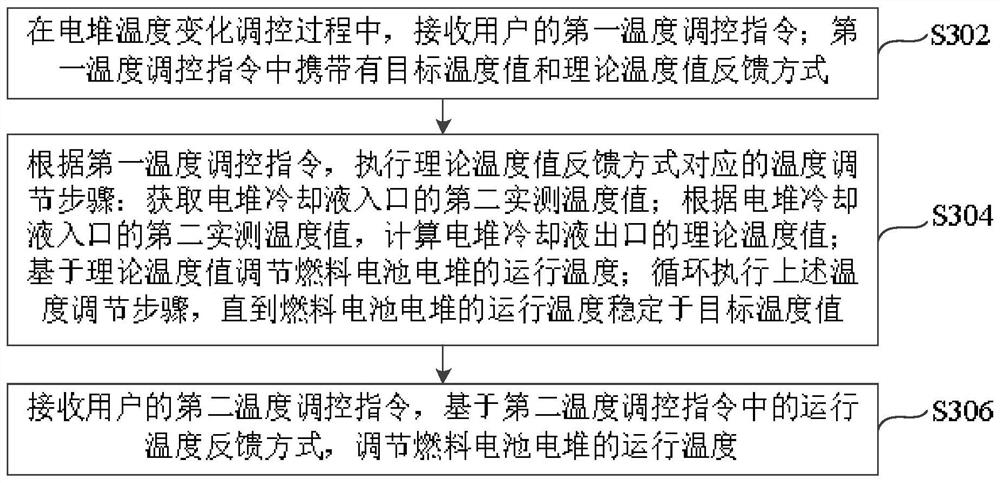

Fuel cell stack operation temperature control method, device and system

ActiveCN113809370AImprove regulation efficiencyStable operating temperatureFuel cell heat exchangeFuel cell controlTemperature controlFuel cells

The invention provides a fuel cell stack operation temperature control method, device and system. The method comprises the steps of receiving a first temperature regulation and control instruction of a user in a stack temperature change regulation and control process, according to the first temperature regulation and control instruction, executing a temperature regulation step corresponding to the theoretical temperature value feedback mode, acquiring a second actually measured temperature value of the stack cooling liquid inlet, calculating a theoretical temperature value of a stack cooling liquid outlet according to the second actually measured temperature value of the stack cooling liquid inlet, adjusting the operating temperature of the fuel cell stack based on the theoretical temperature value, circularly executing the temperature adjusting step until the operating temperature of the fuel cell stack is stabilized at the target temperature value, and receiving a second temperature regulation and control instruction of the user, and adjusting the operating temperature of the fuel cell stack based on an operating temperature feedback mode in the second temperature regulation and control instruction. The regulation efficiency of the operating temperature of the fuel cell stack can be improved, the accuracy of temperature control is improved, and fluctuation is eliminated.

Owner:苏州中车氢能动力技术有限公司

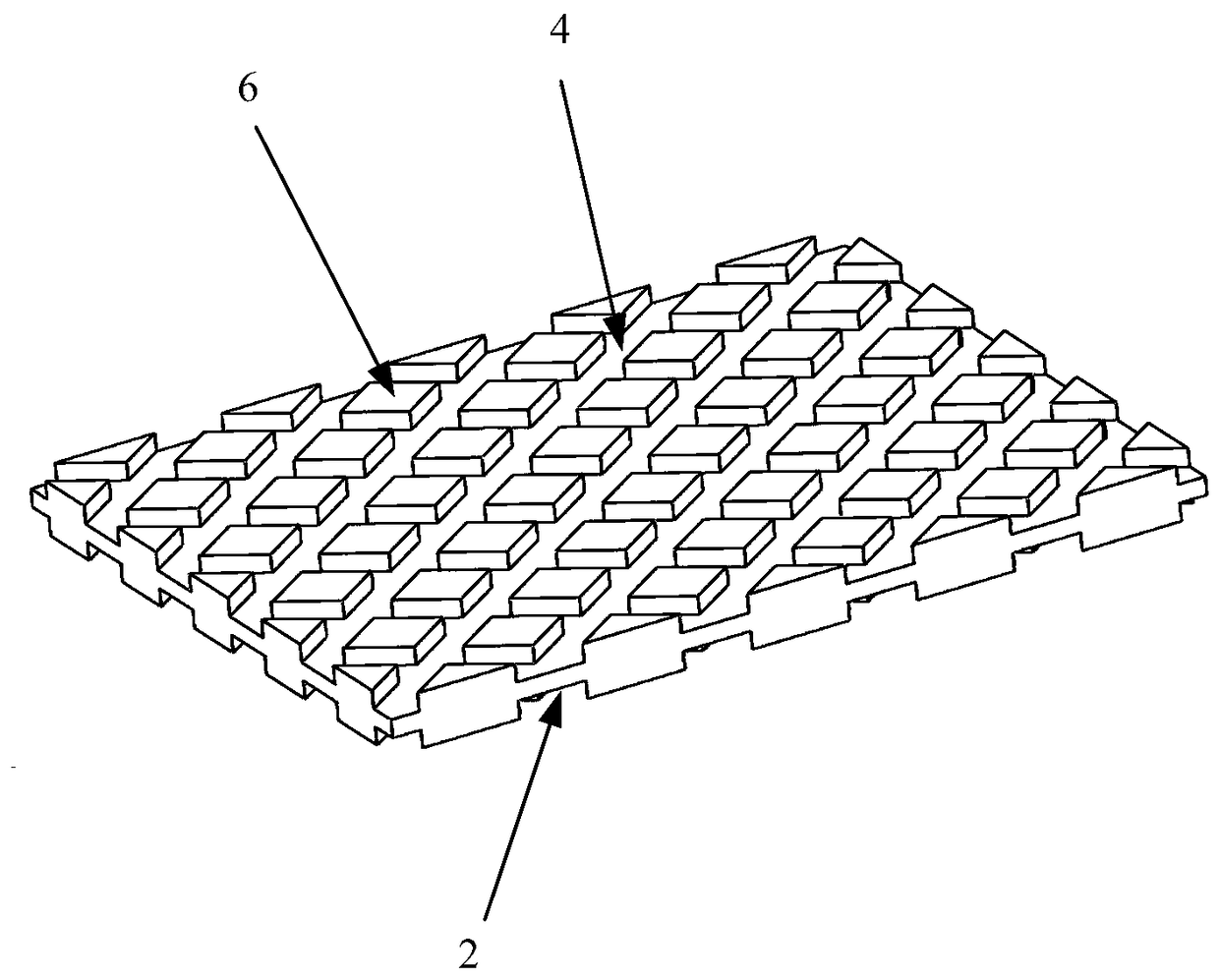

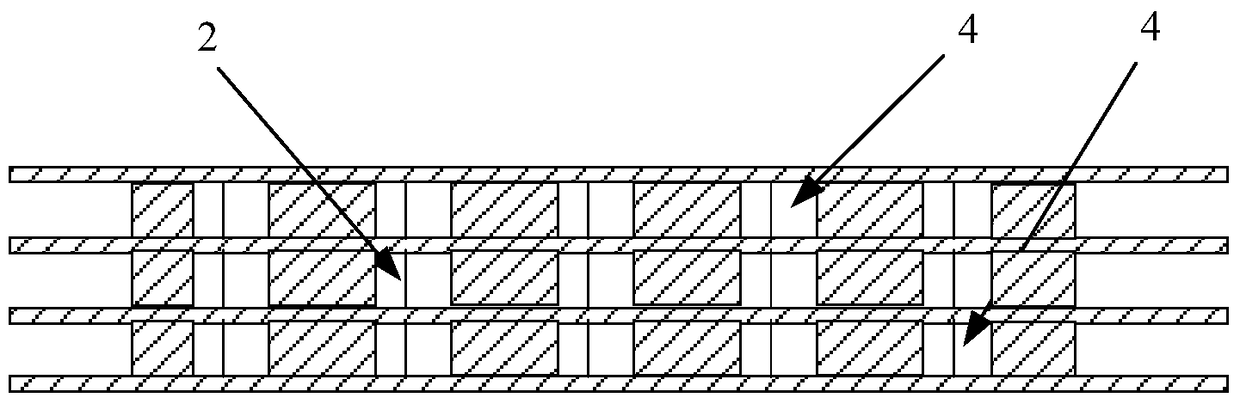

A kind of Fischer-Tropsch synthesis reaction device and Fischer-Tropsch synthesis method

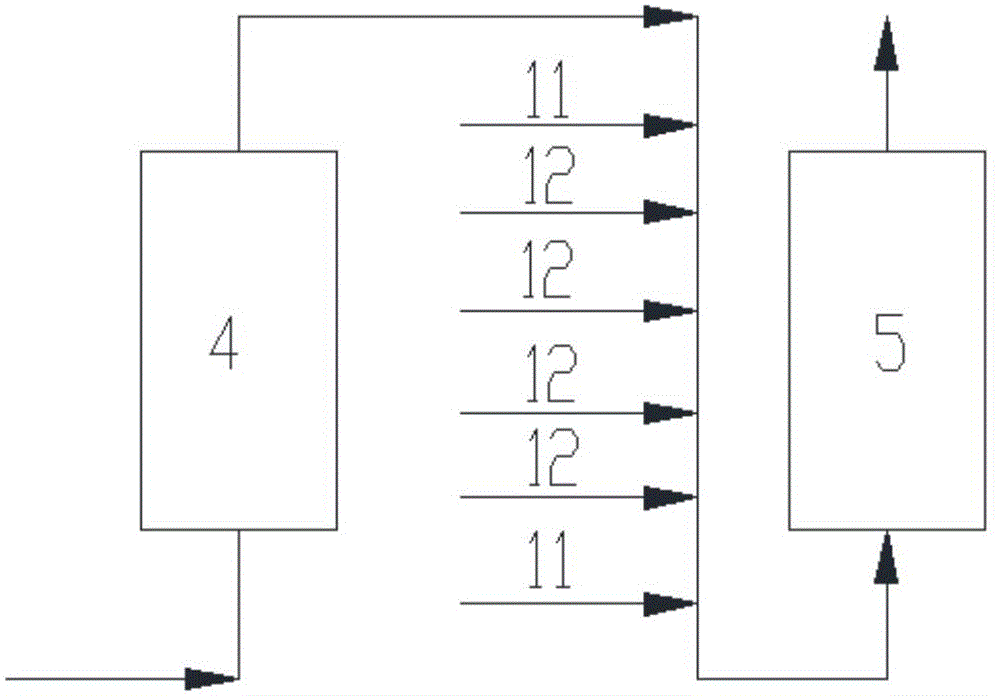

ActiveCN106622058BSafe operating temperatureStable operating temperatureLiquid hydrocarbon mixture productionChemical/physical/physico-chemical processesMicroreactorSynthesis methods

The invention relates to a Fischer-Tropsch synthesis reaction apparatus and a Fischer-Tropsch synthesis method. The reaction apparatus comprises a mixer, a micro-reactor and a separator which are connected in order, wherein the micro-reactor is composed of a material flow inlet, a reaction micro channel, a heat exchange micro channel and a product outlet, the material flow inlet is communicated with one end of the reaction micro channel, the other end of the reaction micro channel is communicated with the product outlet, the heat exchange micro channel is not communicated with the reaction micro channel, wherein, the cross-sectional area of the reaction micro channel is 0.01-100 mm<2>, and the distance between the adjacent reaction micro channels is 0.5-20 mm. The Fischer-Tropsch synthesis reaction apparatus employs the micro-reactor, and has the advantages of small reaction equipment volume and compact structure, and has the characteristics of good mobility and low investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

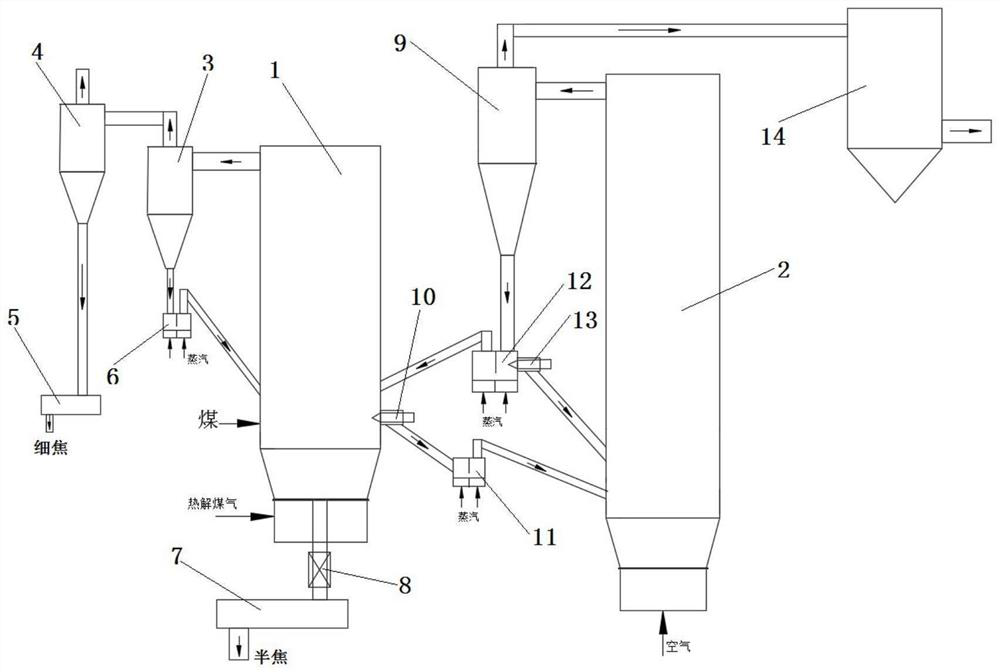

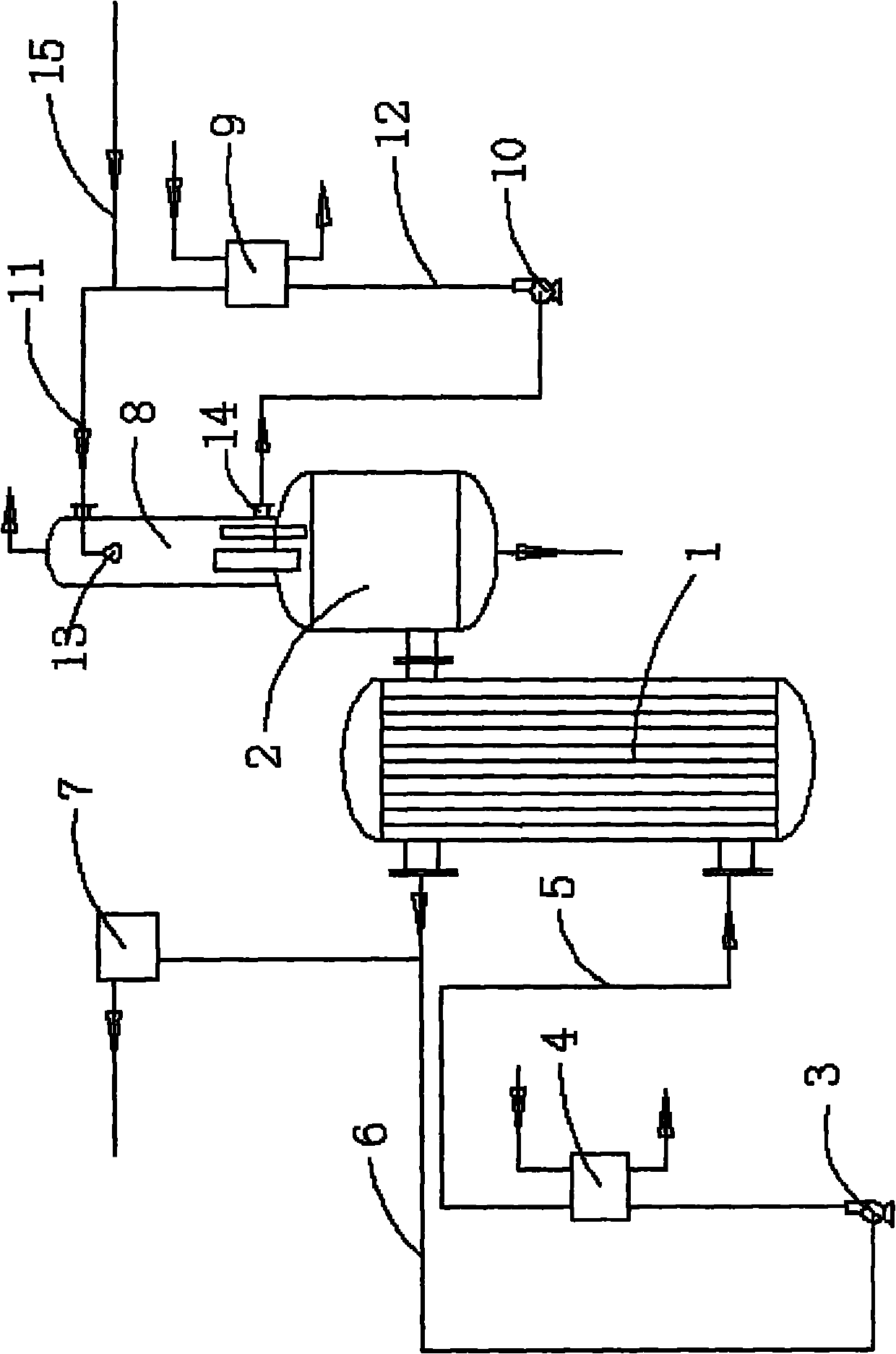

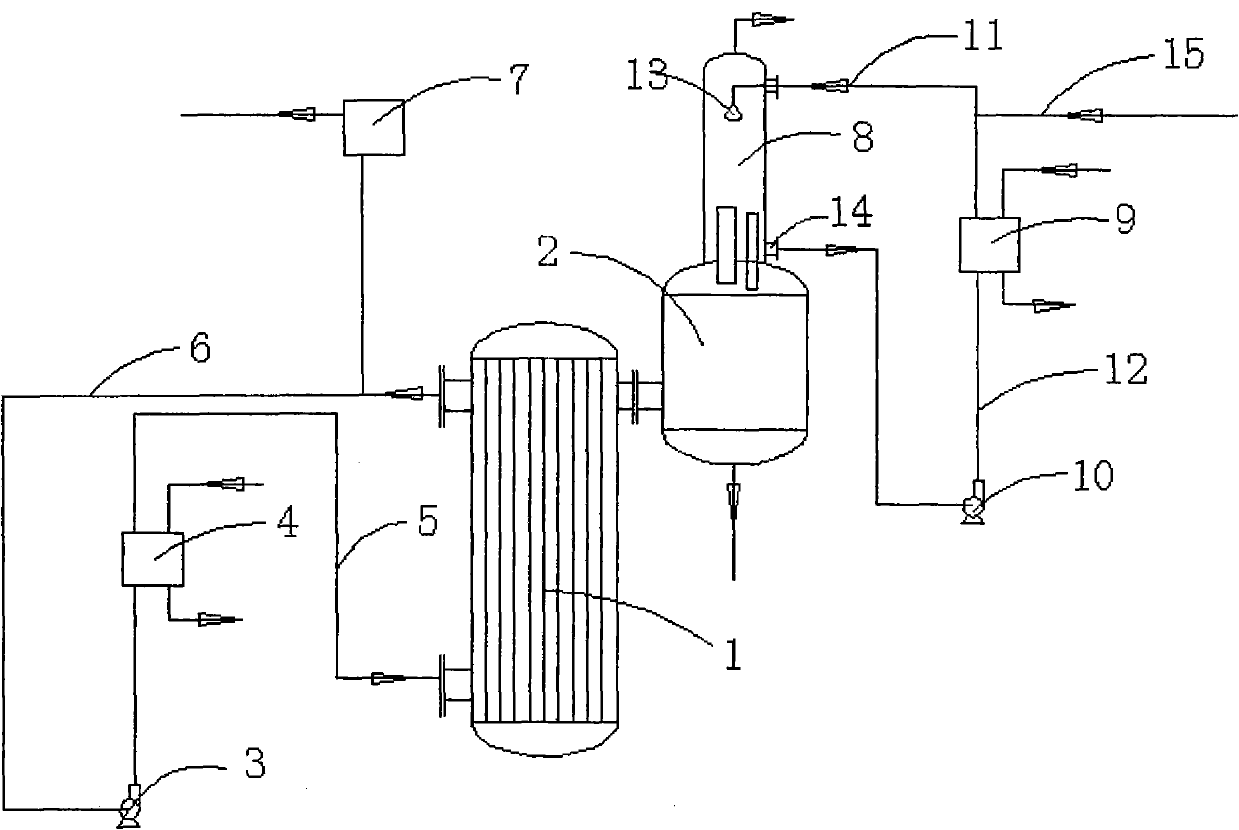

Double fluidized bed material circulation control system and control method

PendingCN114381305AControl operating temperatureStable operating temperatureDirect heating destructive distillationGasification processes detailsFluidized bedControl system

The invention discloses a double-fluidized-bed material circulation control system and a control method. The system comprises a fluidized bed semi-coke heating furnace, a high-temperature cyclone separator and a fluidized bed pyrolyzing furnace which are connected in sequence, an upper outlet of the fluidized bed semi-coke heating furnace is communicated with an upper inlet of the fluidized bed pyrolyzing furnace; a top outlet of the high-temperature cyclone separator is communicated with the burnout furnace, and a bottom outlet of the high-temperature cyclone separator is connected with the first return feeder; a high-temperature conical valve is arranged on the side surface of the first return feeder and is connected with a first heating furnace inlet in the side wall of the lower part of the fluidized bed semi-coke heating furnace; a top outlet of the first return feeder is communicated with a first pyrolyzing furnace inlet in the side wall of the lower part of the fluidized bed pyrolyzing furnace; and a first high-temperature coke discharge valve is also arranged on the side wall of the lower part of the fluidized bed pyrolyzing furnace, and is connected with a second heating furnace inlet in the side wall of the lower part of the fluidized bed semi-coke heating furnace through a third return feeder. According to the invention, the control method is simple and reliable, and the pyrolysis efficiency and the product yield of the coal can be improved.

Owner:ZHEJIANG UNIV

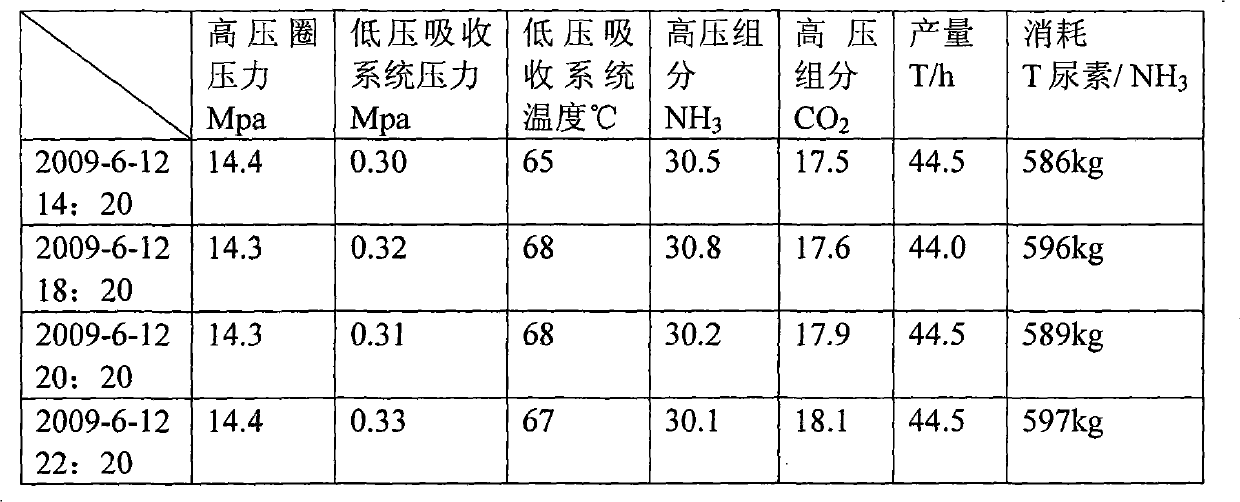

Improved device of low-pressure system of carbon dioxide air stripping urea device

InactiveCN102020590AThere will be no shortage of waterIncrease washing sectionUrea derivatives preparationProductsEngineeringChiller

The invention discloses an improved device of a low-pressure system of a carbon dioxide air stripping urea device. The device comprises a low-pressure methylamine condenser, a liquid level tank, a first pump group, a first circulating cooler, a first circulated cooling water inlet pipe and a first circulated cooling water outlet pipe, wherein any section of the first circulated cooling water inlet pipe or the first circulated cooling water outlet pipe is communicated with a water supply tank. In the invention, the water supply tank is additionally arranged to continuously supply water to the system so as to balance the working pressure of low-pressure circulating water; and after the improved device is used, the pressure and the temperature of the system do not greatly fluctuate any more, and the circulating water system cannot be short of water, thereby the operation pressure and the operation temperature of the system are stabilized. A washing section is additionally arranged between the liquid level tank and a subsequent section device, thus system carries less liquid, absorbs less pressure and recovers more energy, the consumption is lowered and the output is increased.

Owner:江苏晋煤恒盛化工股份有限公司

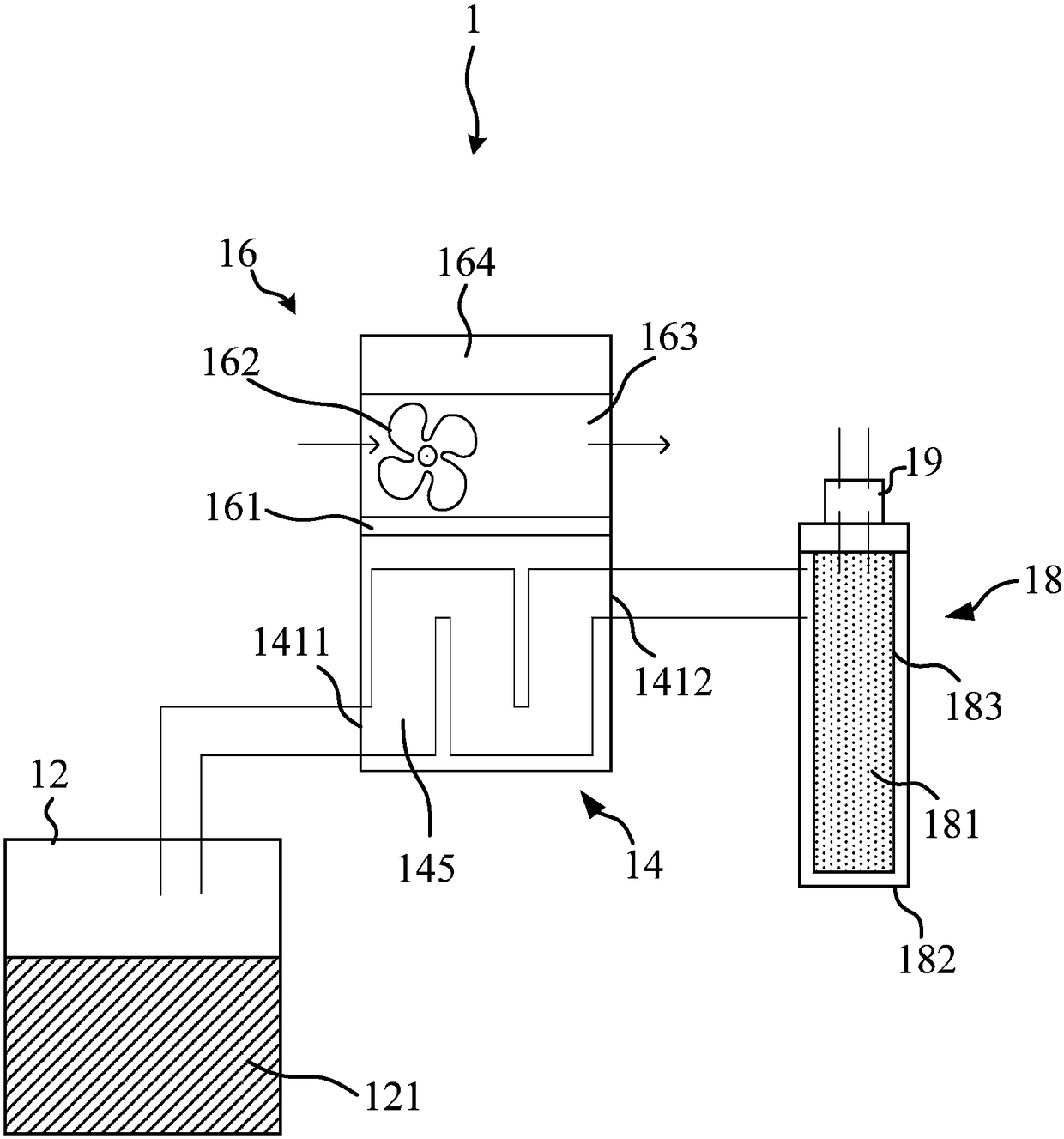

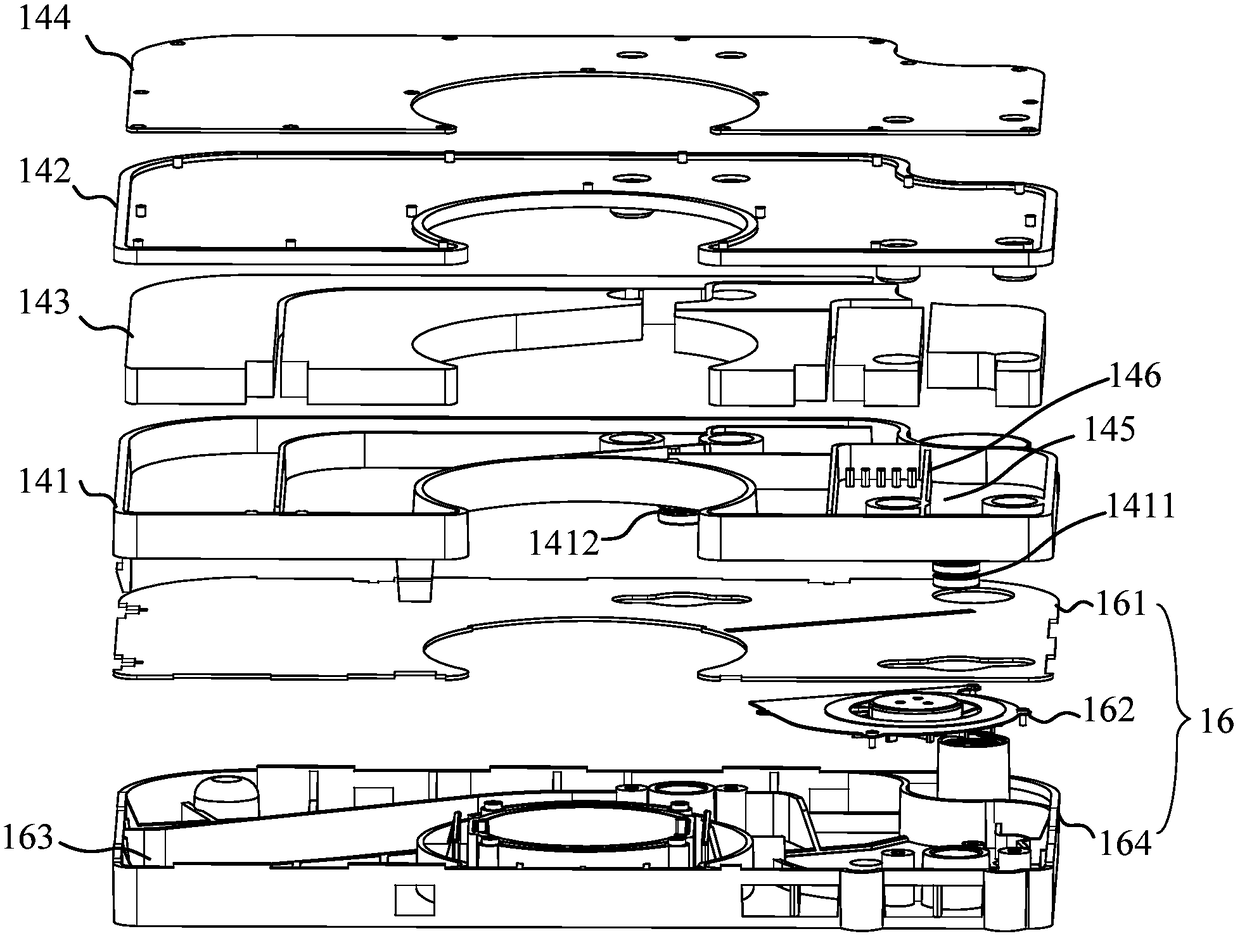

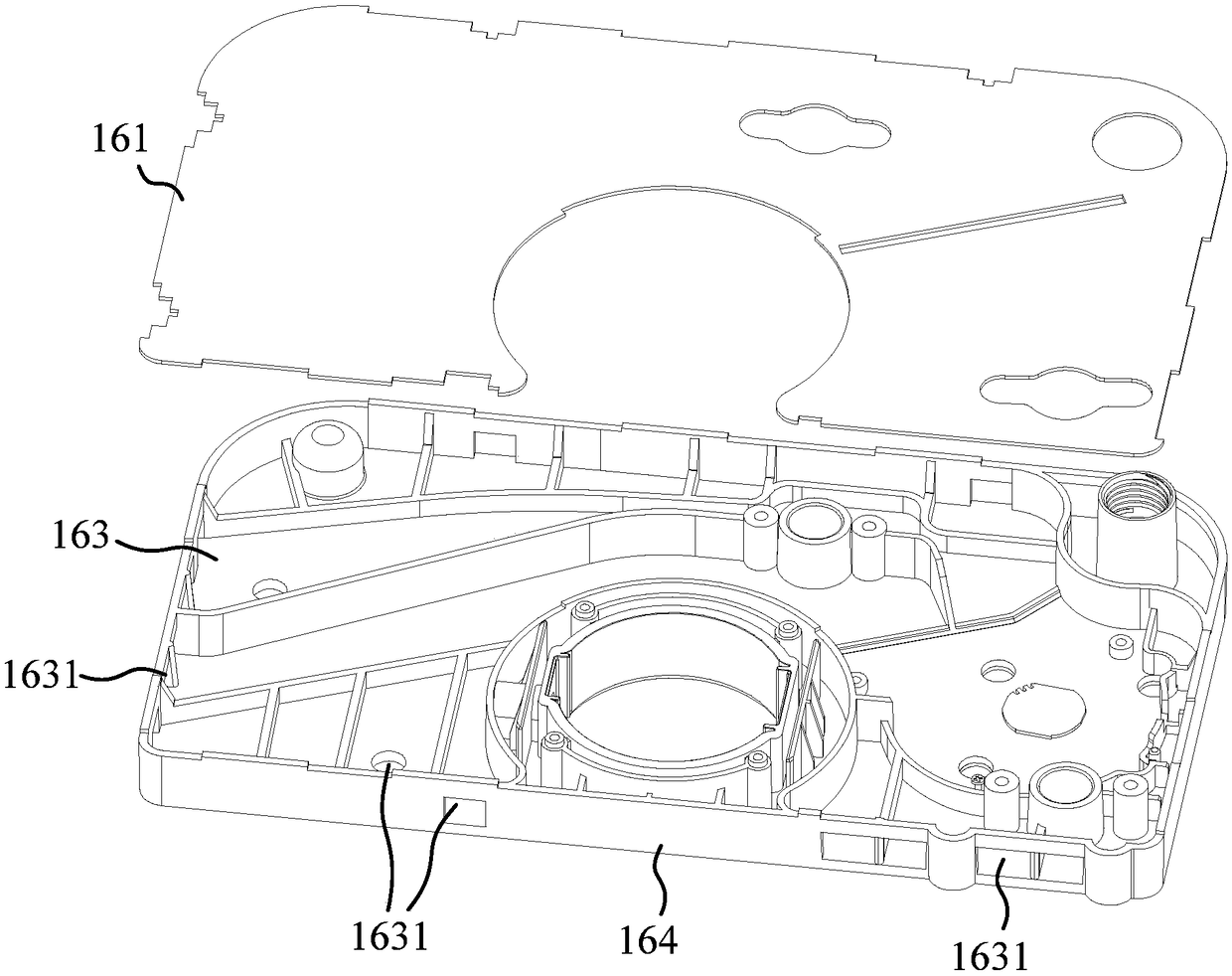

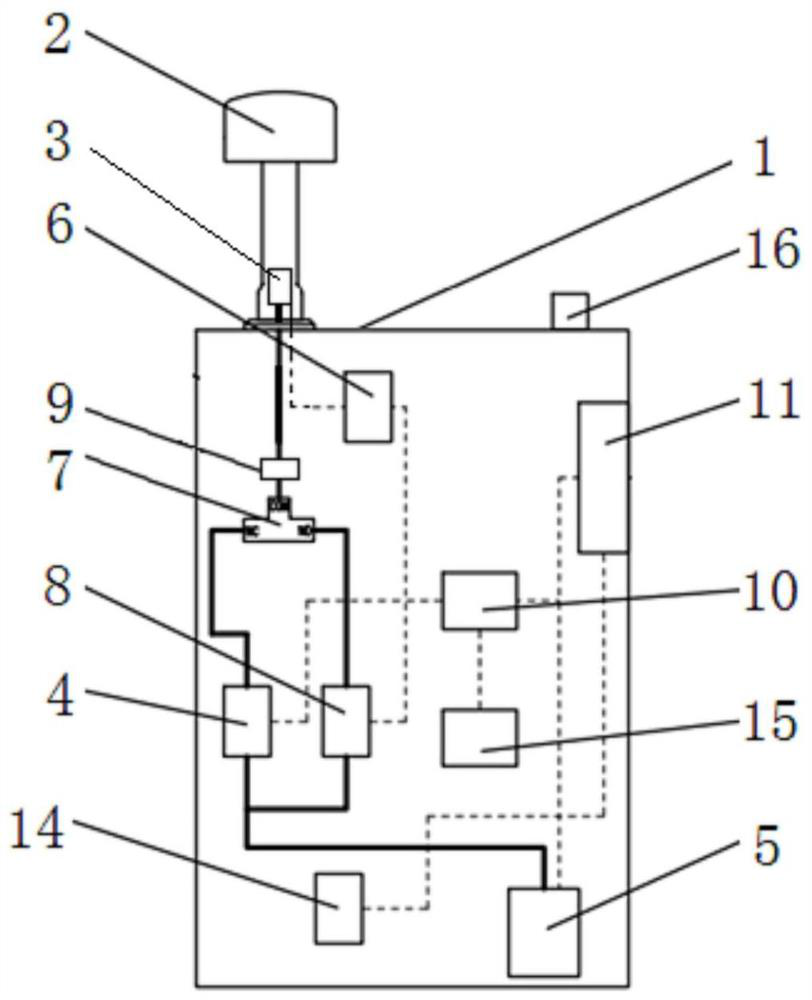

Gas generator

The invention provides a gas generator. The gas generator comprises an electrolyzing device, a condensing and filtering device and a heat dissipation device; the electrolyzing device is used for electrolyzing electrolysis water contained in the electrolyzing device to generate hydrogen gas; the condensing and filtering device is coupled with the electrolyzing device and used for receiving and filtering the hydrogen gas produced by the electrolyzing device; and the heat dissipation device comprises a heat dissipation sheet and a heat dissipation fan, and the heat dissipation fan is used for driving external air to flow through the heat dissipation sheet arranged on the condensing and filtering device to cool the condensing and filtering device. According to the gas generator, the stable gasgenerator operation temperature is kept by means of the gas generated through cooling of the condensing and filtering device and the heat dissipation device and the elements that the gas flow, and then the possibility that the elements are damaged due to high temperature and high humidity is reduced.

Owner:林信涌

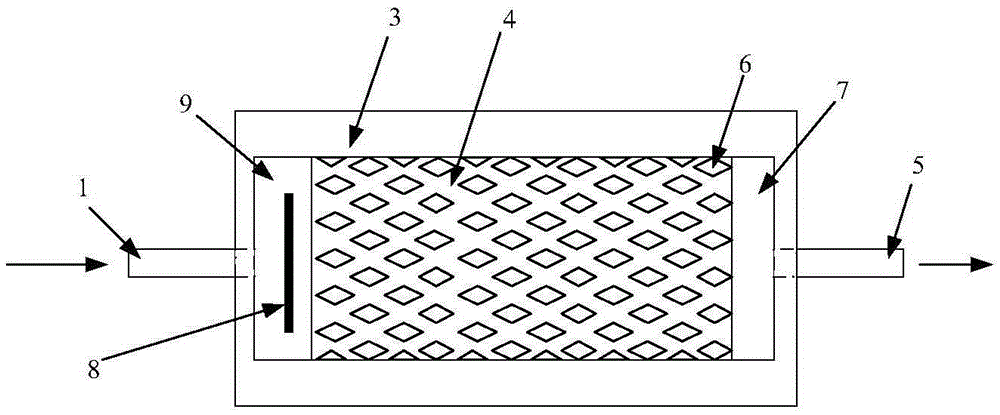

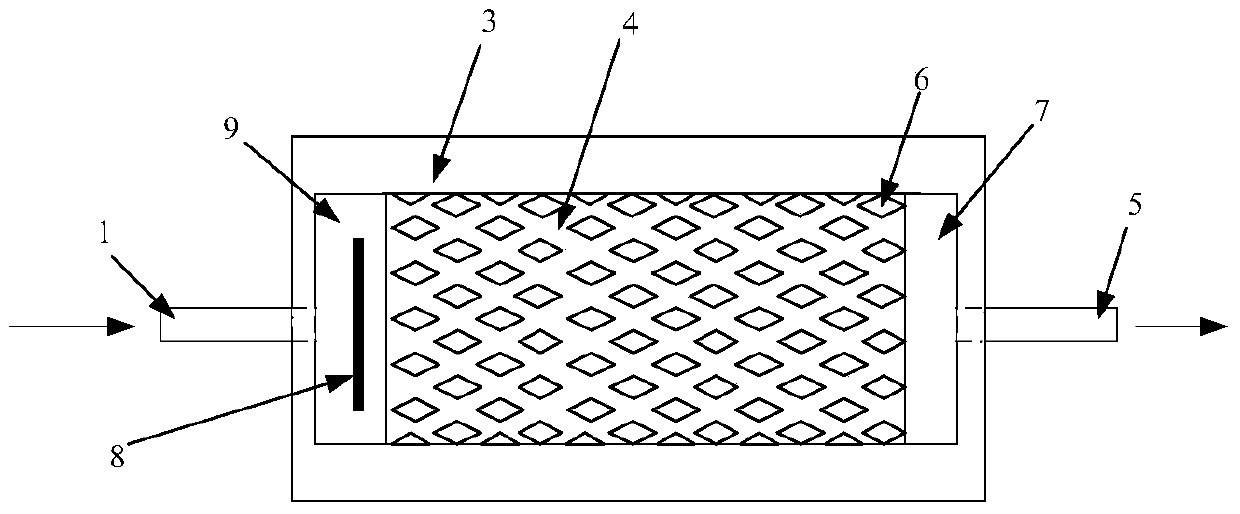

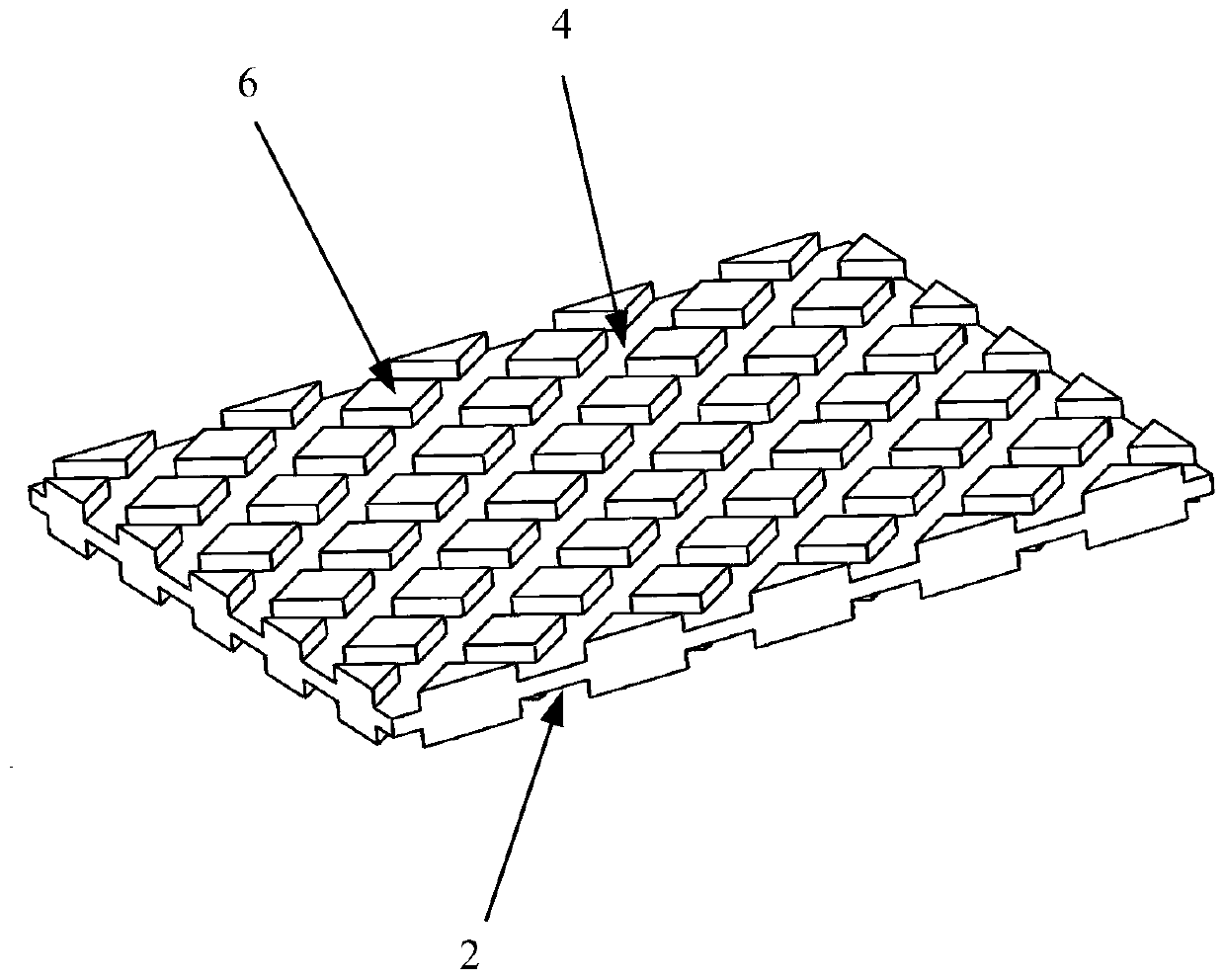

A kind of Fischer-Tropsch synthesis microreactor and Fischer-Tropsch synthesis method

ActiveCN106622057BReduce volumeCompact structureChemical/physical/physico-chemical microreactorsLiquid hydrocarbon mixture productionMicroreactorSynthesis methods

The invention provides a Fischer-Tropsch synthesis microreactor and a Fischer-Tropsch synthesis method. The microreactor comprises a gas phase inlet, a reaction micro-channel, a heat exchange micro-channel and a product outlet, wherein the gas phase inlet is communicated with one end of the reaction micro-channel; the other end of the reaction micro-channel is communicated with the product outlet; the heat exchange micro-channel is not communicated with the reaction micro-channel; the reaction micro-channel adopts a net-shaped cross structure; the heat exchange micro-channel also adopts the net-shaped cross structure; the reaction micro-channel is coated with a catalyst layer; a catalyst is selected from one or a mixture of metallic elements including iron, cobalt, nickel and ruthenium. The Fischer-Tropsch synthesis microreactor is small in size and compact in structure and has the characteristics of good movability and low investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

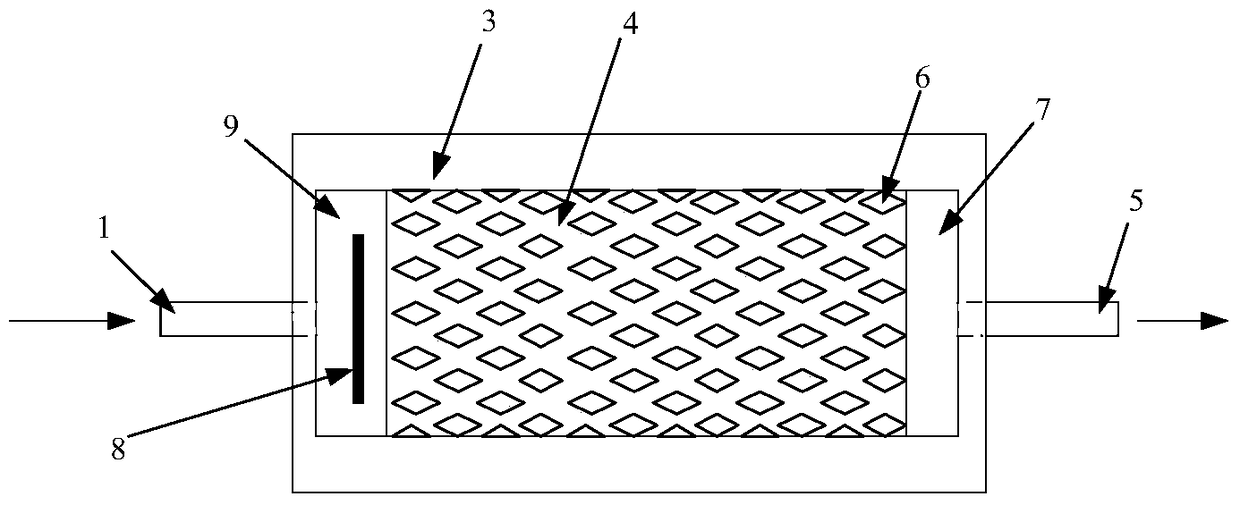

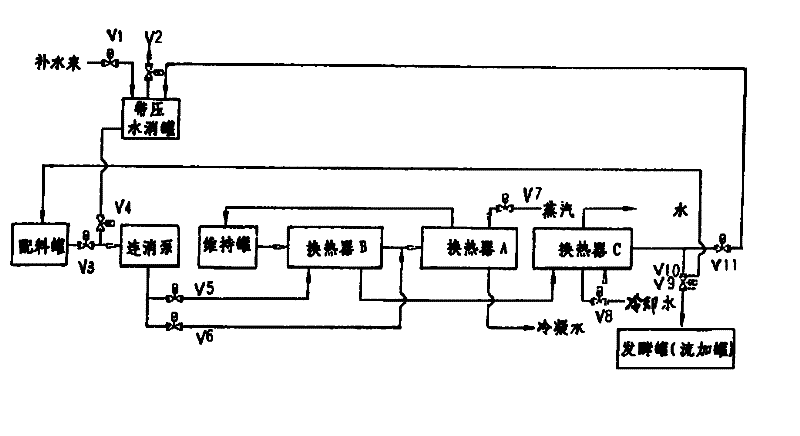

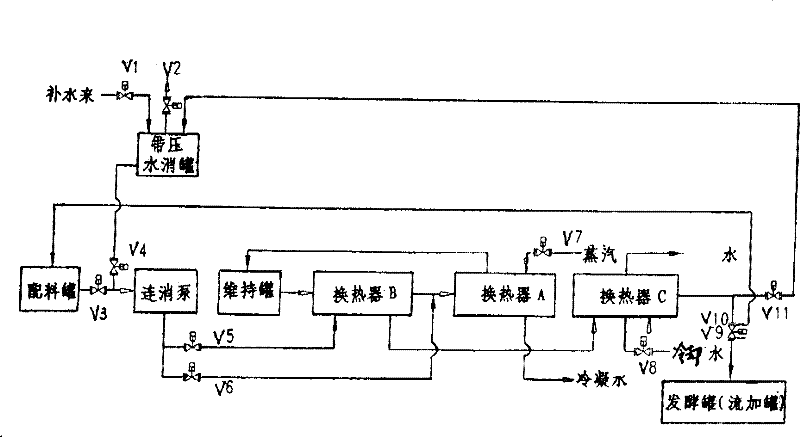

Pressurized hot water sterilization process and equipment pipeline configuration of continuous sterilization system for aerobic microbe fermentation culture medium or fed-batch material

ActiveCN102600490AStable operating temperaturePrevent scalingHeatSterilization processEnvironmental engineering

The invention relates to a pressurized hot water sterilization process and equipment pipeline configuration of a continuous sterilization system for aerobic microbe fermentation culture mediums or fed-batch materials. The process comprises the following steps that: 1) a pressurized water sterilization tank is fully filled with water, g air in the tank is exhausted, water in the tank is connected with a heat exchanger A through a continuous sterilization pump and the water is heated; 2) hot water returns back to the pressurized water sterilization tank along a culture medium or fed-batch material inlet pipeline through a maintaining tank before the hot water enters a fermentation tank or a fed-batch tank, and after the designated liquid level is reached, inlet water and outlet water enter a closed circulation mode, the water is continuously and cyclically heated, the temperature of the water in the tank is continuously increased and non-condensable gas is continuously exhausted; and 3) when the temperature of the water reaches 100 DEG C, an exhaust valve is closed and corresponding internal pressure of the water sterilization tank is increased with the increase of the temperature of the water, and when the temperature of the water reaches 125-130 DEG C, the inlet water and the outlet water of the system enter a pressurized closed circulation mode and then water sterilization of the system is conducted immediately. The pressurized hot water sterilization process and the equipment pipeline configuration of the continuous sterilization system for aerobic microbe fermentation culture mediums or fed-batch materials have the advantages that the pressurized sterilizing water production process is stable, continuous and reliable, the safety of the continuous sterilization system for culture mediums or fed-batch materials in the fermentation engineering is improved, the heat loss of the pressurized sterilizing water is fewer and the energy consumption is reduced.

Owner:CHINA LIGHT IND INT ENG CO LTD

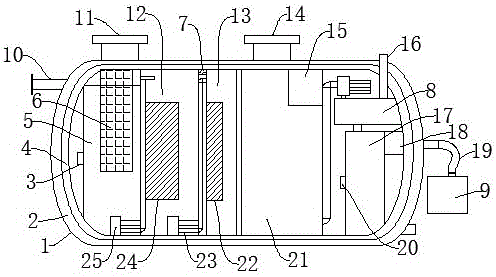

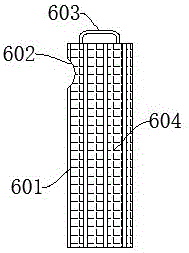

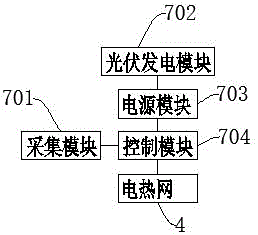

Working method of buried sewage treatment equipment

InactiveCN106830564AImprove processing efficiencyImprove adaptabilityWater treatment parameter controlSludge treatmentSewage treatmentEnergy conservation

The invention relates to buried sewage treatment equipment. The buried sewage treatment equipment comprises a capsule-shaped tank body, a water inlet pipe positioned at one end of the tank body, and a repair pipe positioned in the middle position of the top of the tank body, wherein an insulation board having the same shape as the tank body is arranged on the inner side of the tank body; an electric heating net is arranged on the inner side of the insulation board; a first drainage pipe is mounted on one side of the top of the tank body. The buried sewage treatment equipment can be heated according to the ambient temperature inside the equipment so as to ensure that the running temperature of inner components inside the equipment is stable; moreover, the buried sewage treatment equipment can be effectively and thermally insulated to reduce the influence of the ambient temperature on the sewage treatment efficiency so as to improve the sewage treatment efficiency of the equipment and improve the environmental adaptability of the equipment; furthermore, odor generated in the sewage treatment process can be effectively treated so as to reduce the influence on a surrounding environment; in addition, through an own power supply, energy is saved and the using cost of the equipment is reduced.

Owner:段遵虎

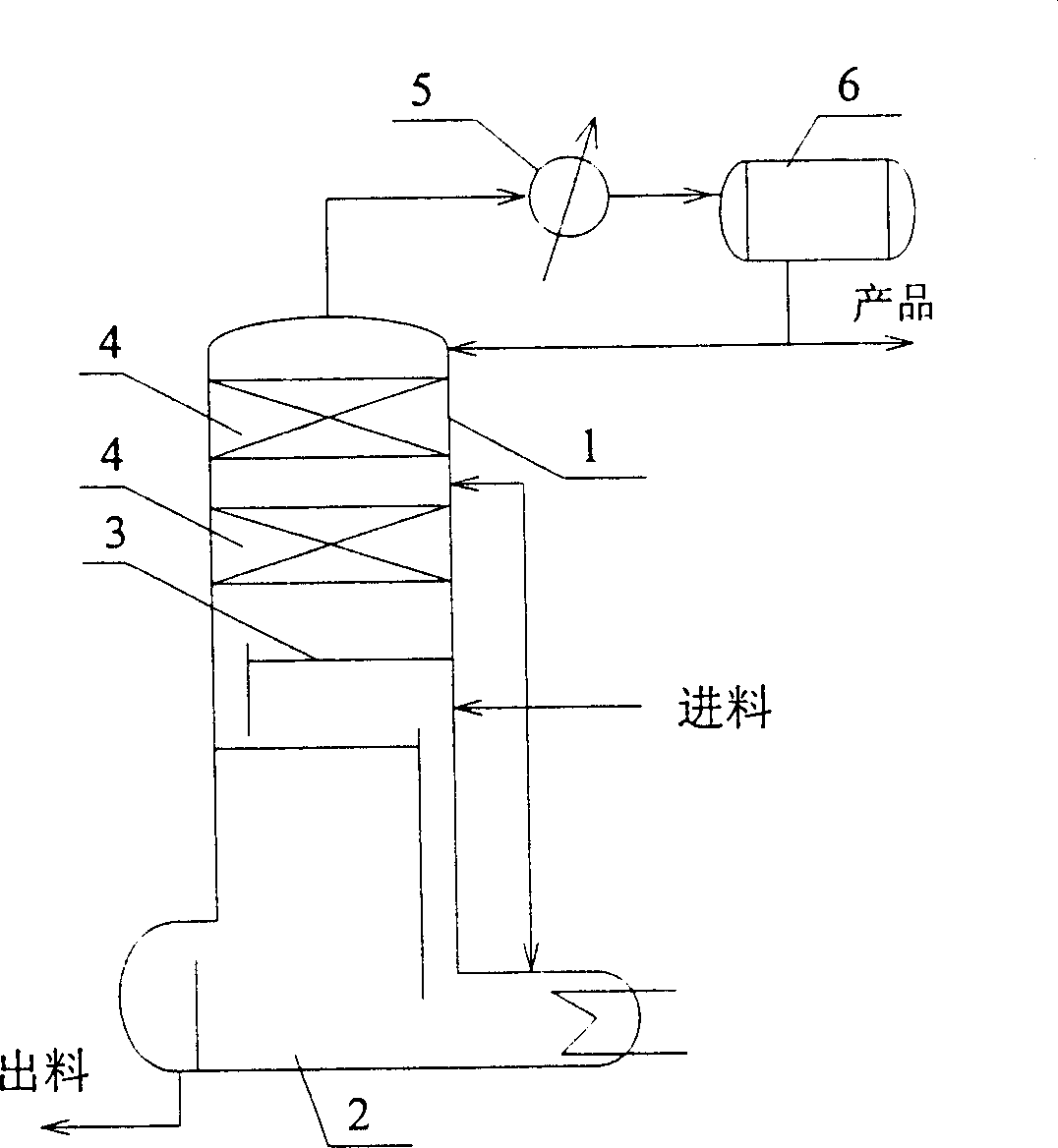

Air ion detection device and calibration method thereof

ActiveCN110487886BGuaranteed measurement accuracyStable airflowMaterial analysis by electric/magnetic meansCoaxial cableEngineering

The invention discloses an air ion detection device and a calibration method thereof. The device includes: case, sampling head, sensor, mass flow controller, vacuum pump, micro-current amplifier, control module and power module; the case is a constant temperature case, and the sampling head is detachably installed outside the case for collecting air and sensor Inside the sampling head, the bottom of the sensor is connected to the mass flow controller and the vacuum pump in turn through the gas pipe, the sensor’s collection rod is connected to the micro-current amplifier through the BNC connector and the coaxial cable, and the control module is connected to the mass flow controller, the vacuum pump and the micro-current amplifier respectively. Connection for controlling the air flow and calculating the air ion concentration, the power module is connected to the control module. The air ion detection device and its calibration method of the present invention can detect and control the air flow passing through the sensor in real time, and can perform irregular calibration on the air flow and the amplifier, so as to ensure the measurement accuracy of the air ion concentration.

Owner:BEIJING SHENGTONGHE TECH CO LTD

A Fischer-Tropsch synthesis tail gas recovery and utilization system process

ActiveCN110631326BEasy to handleIncrease profitSolidificationLiquefactionProcess engineeringSeparation system

The invention discloses a Fischer-Tropsch synthesis tail gas recovery and utilization system process. After the Fischer-Tropsch synthesis tail gas is purified, it enters a cryogenic separation system, the purified Fischer-Tropsch synthesis tail gas is cooled and liquefied, and carbon 2, carbon 3 and heavier components are recovered. ; Condensate and liquefy the methane in the tail gas to make LNG products; Purify hydrogen and carbon monoxide through the PSA device. This Fischer-Tropsch synthetic oil tail gas cryogenic recovery process not only recovers components with high economic value such as ethylene and propylene, but also recovers the raw material gas hydrogen and carbon monoxide of the Fischer-Tropsch synthesis reaction, and converts the methane into LNG.

Owner:北京恒泰洁能科技有限公司

Method for purifying and refining ethyl acetate in high purity

ActiveCN1312105CEasy to operateStable operating temperatureOrganic compound preparationCarboxylic acid esters preparationAcetic acidEthyl ester

A process for preparing high-purity ethyl acetate features that the water, ethanol, acetic acid, ethyl acetate and the light component containing aldone and ester are proportionally loaded in the a purifying-refining tower from the chosen position and the operating reflux ratio is controlled to be (0.3-2.5):1.

Owner:SHANGHAI HUAYI ENERGY CHEM

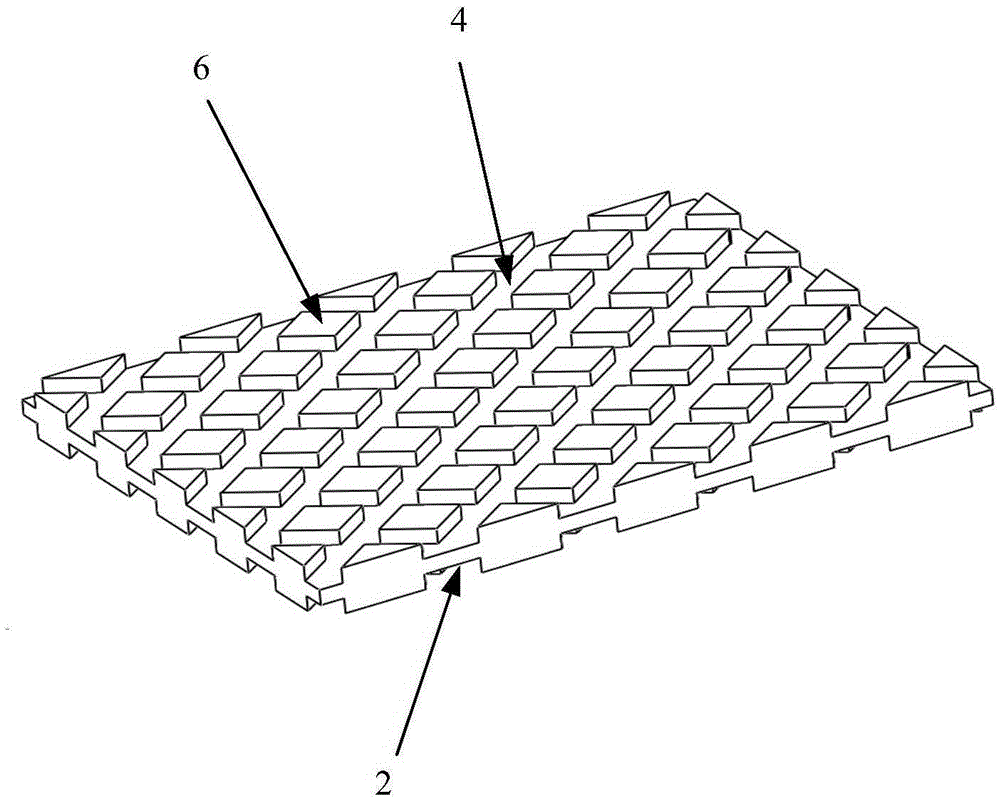

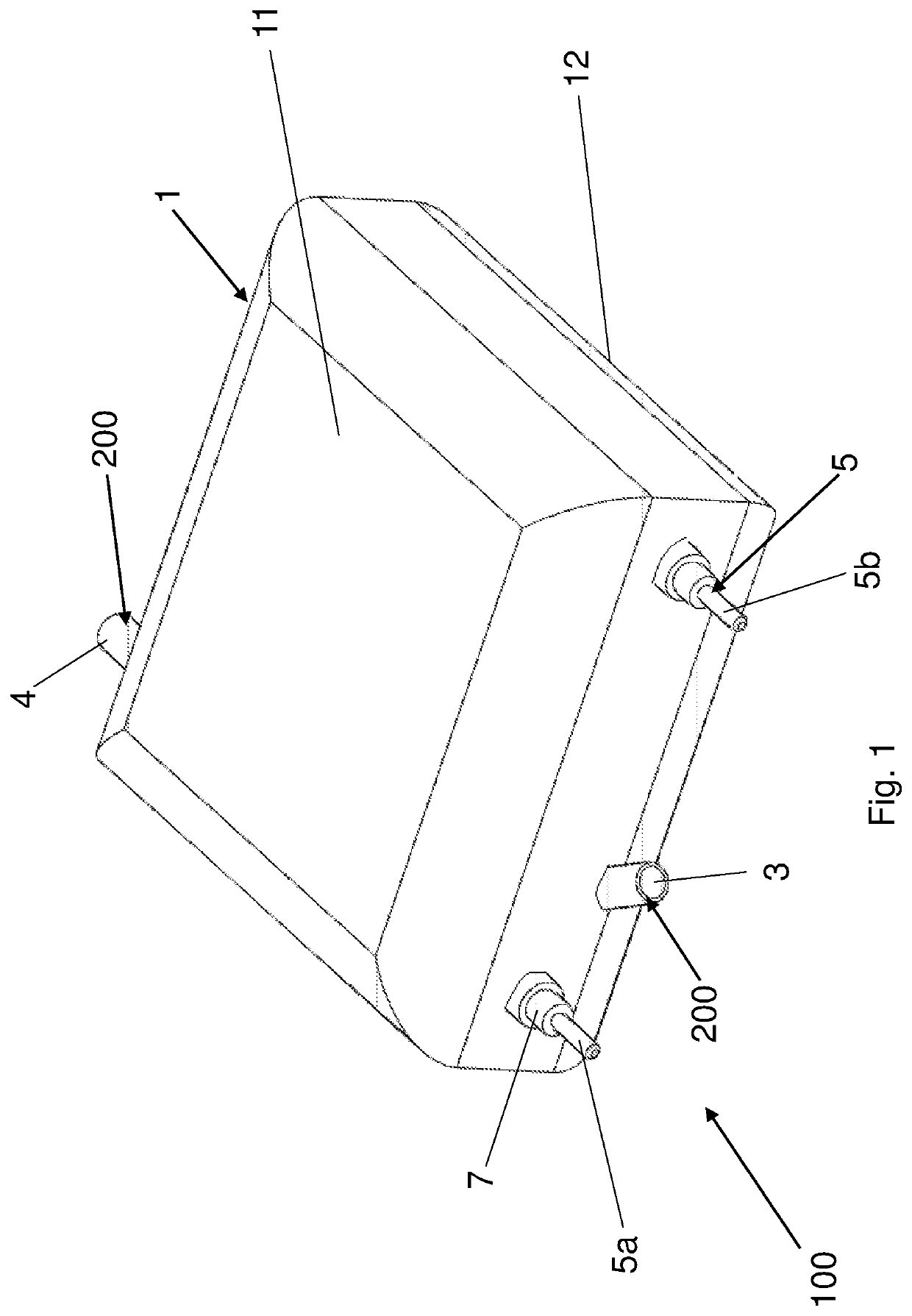

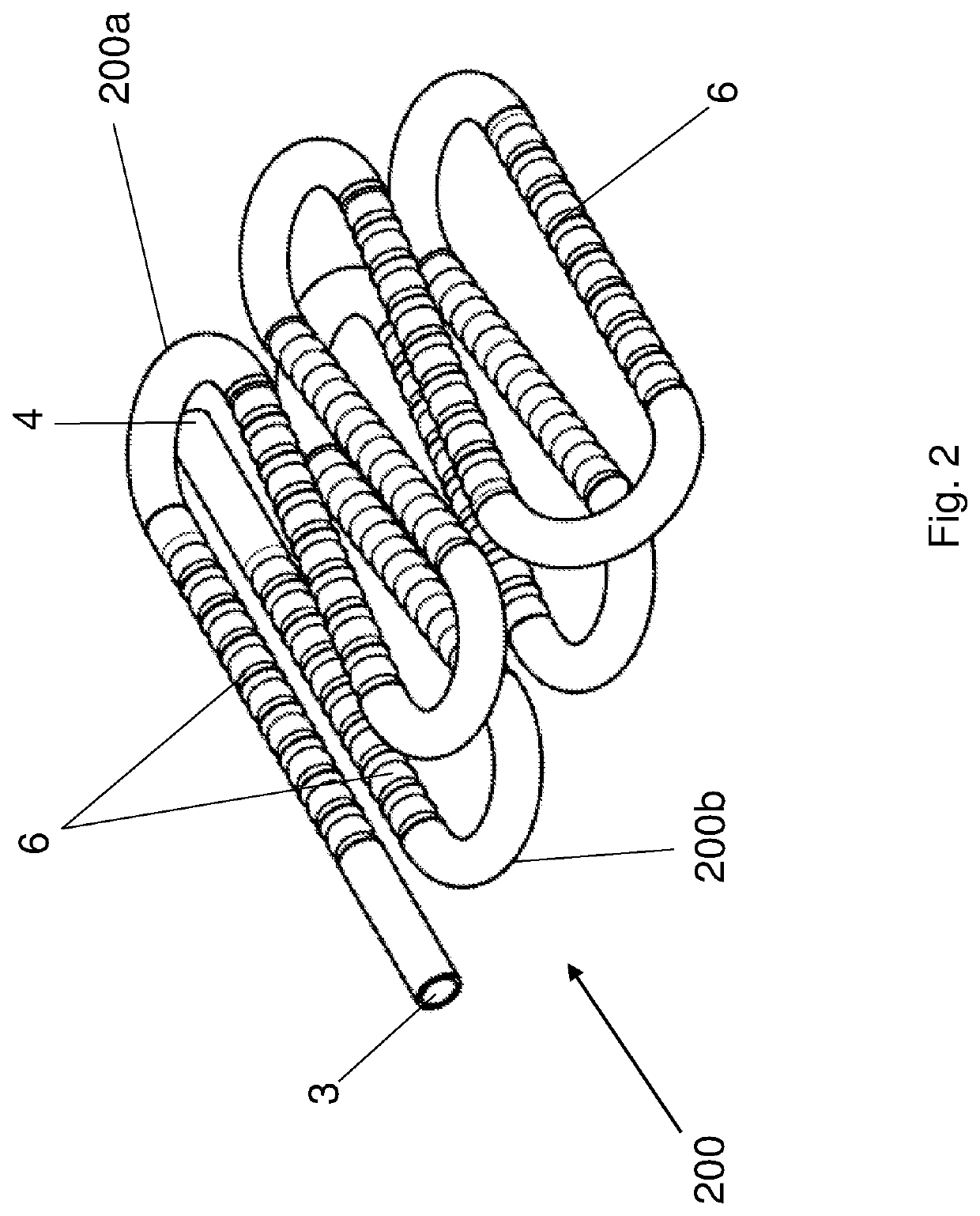

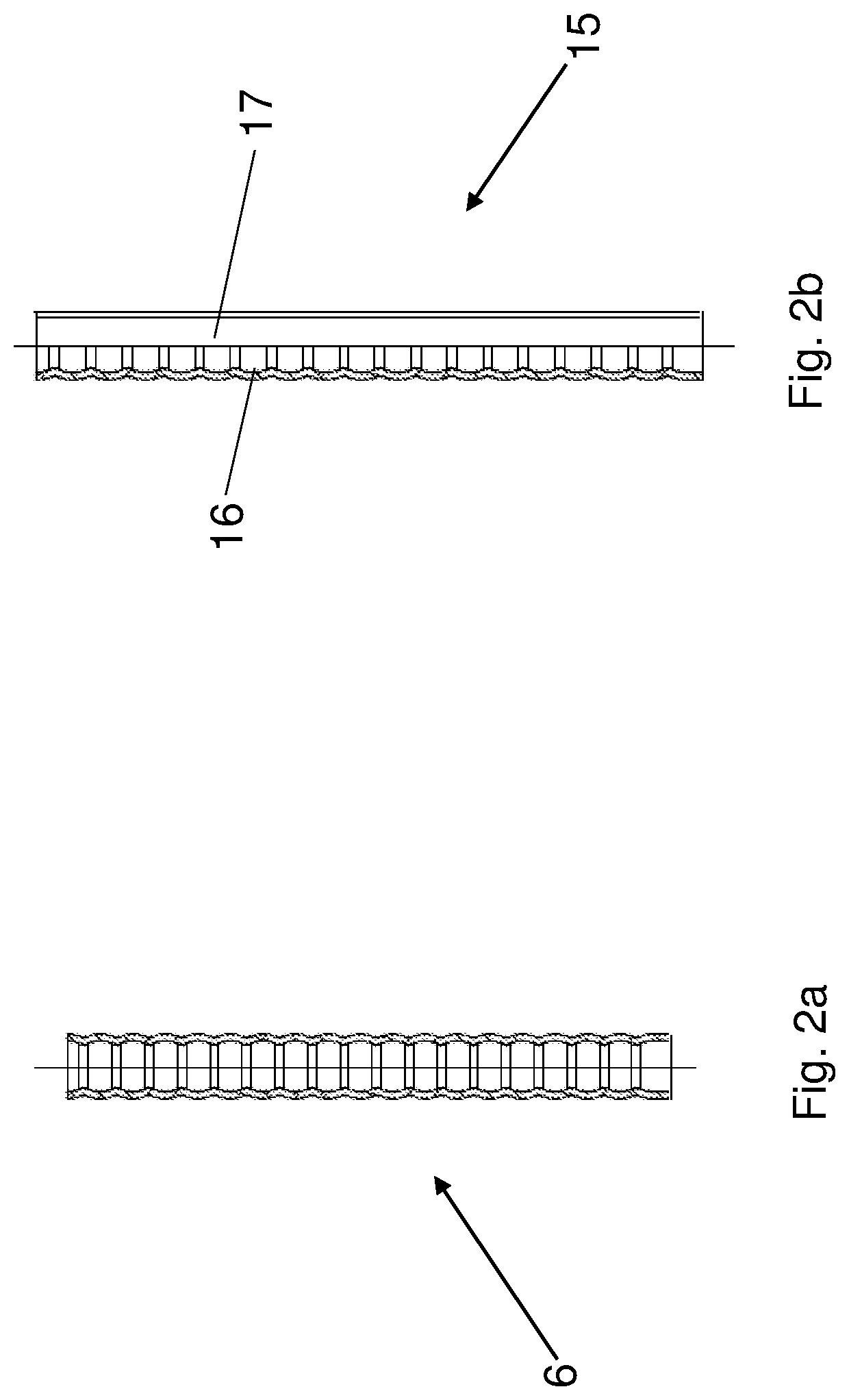

Thermal block for heating liquids

ActiveUS10638874B2Stable working temperatureShort heating timeBeverage vesselsWater heatersEngineeringMechanical engineering

A thermal block (100) for heating a liquid, comprises: —a tube (200) for the passage of liquid, provided with an inlet (3) and an outlet (4) and with at least one segment (200) with corrugated walls (6), —a massive block (1) co-molded outside said pipe (200) so that the inlet (3) and the outlet (4) are outside the massive block (1), —one resistive element (5) for heating the massive block (1).

Owner:I R C A S P A IND RESISTENZE CORAZZATE E AFFINI

Heat recovery method of washing tower process water

InactiveCN111282372AStable operating temperatureMeet needsGeneral water supply conservationDistillation regulation/controlProcess engineeringChiller

The invention discloses a heat recovery method of washing tower process water, which comprises the following steps: a liquid level of a heat-removed water buffer tank is established through desalted water F, the desalted water F is used as a source of heat-removed water, and heat-removed water G flows out of the bottom of the heat-removed water buffer tank to a heat-removed water circulating pump;and an inlet of the heat-removed water circulating pump receives heat-removed water G from the heat-removed water buffer tank, heat-removed water H is obtained after pressurization, and the heat-removed water H is sent to a shell pass inlet of a washing water cooler to serve as a cold source of the washing water cooler. On the premise of not increasing the consumption of circulating water and steam, the heat balance problem of the system is solved, the operating temperature of the washing tower is stabilized, scaling is avoided, the heat exchange efficiency of a heat exchanger is guaranteed,the overhaul frequency of the heat exchanger is reduced, and the yield of the device is increased.

Owner:HUATING COAL GRP

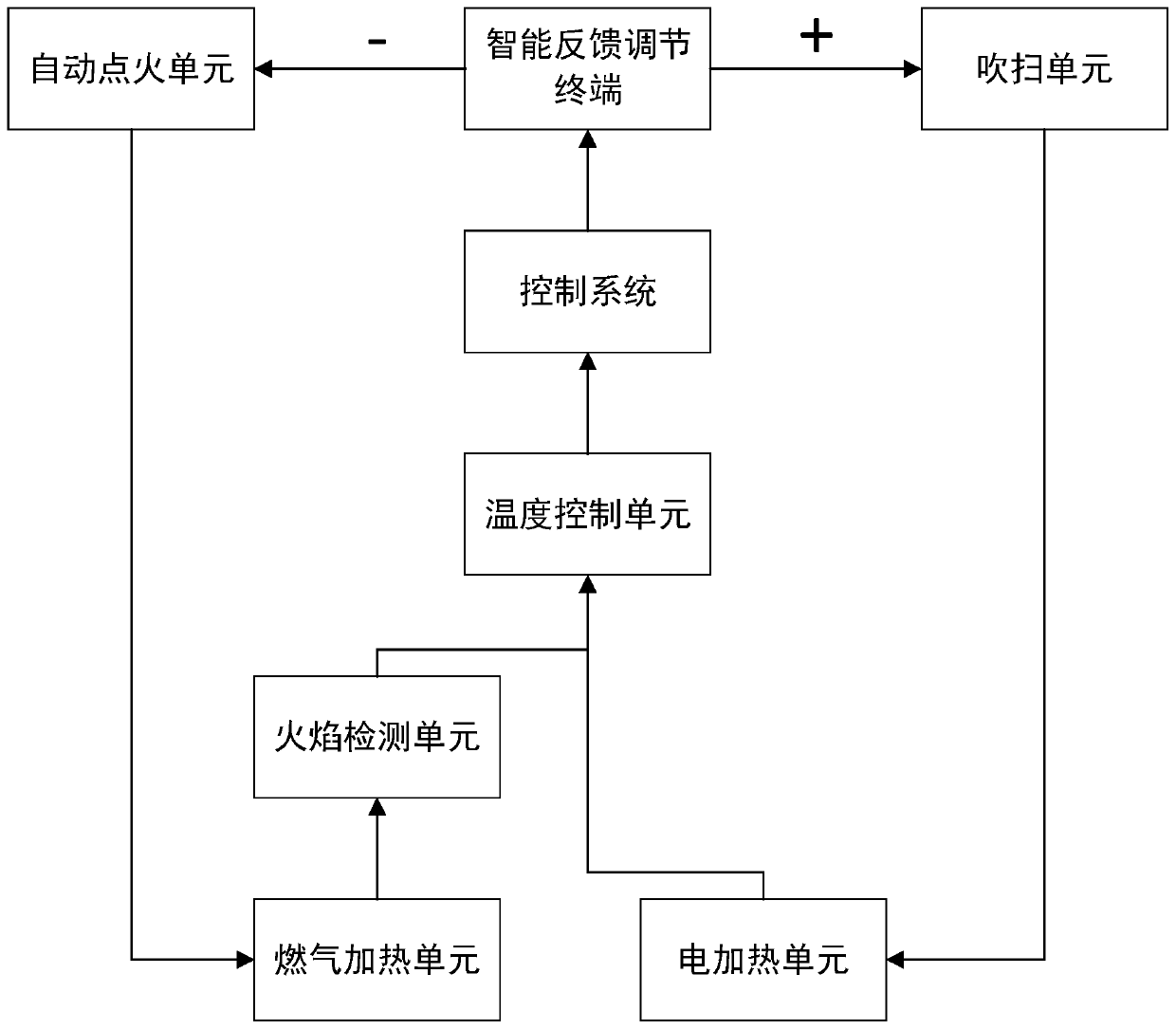

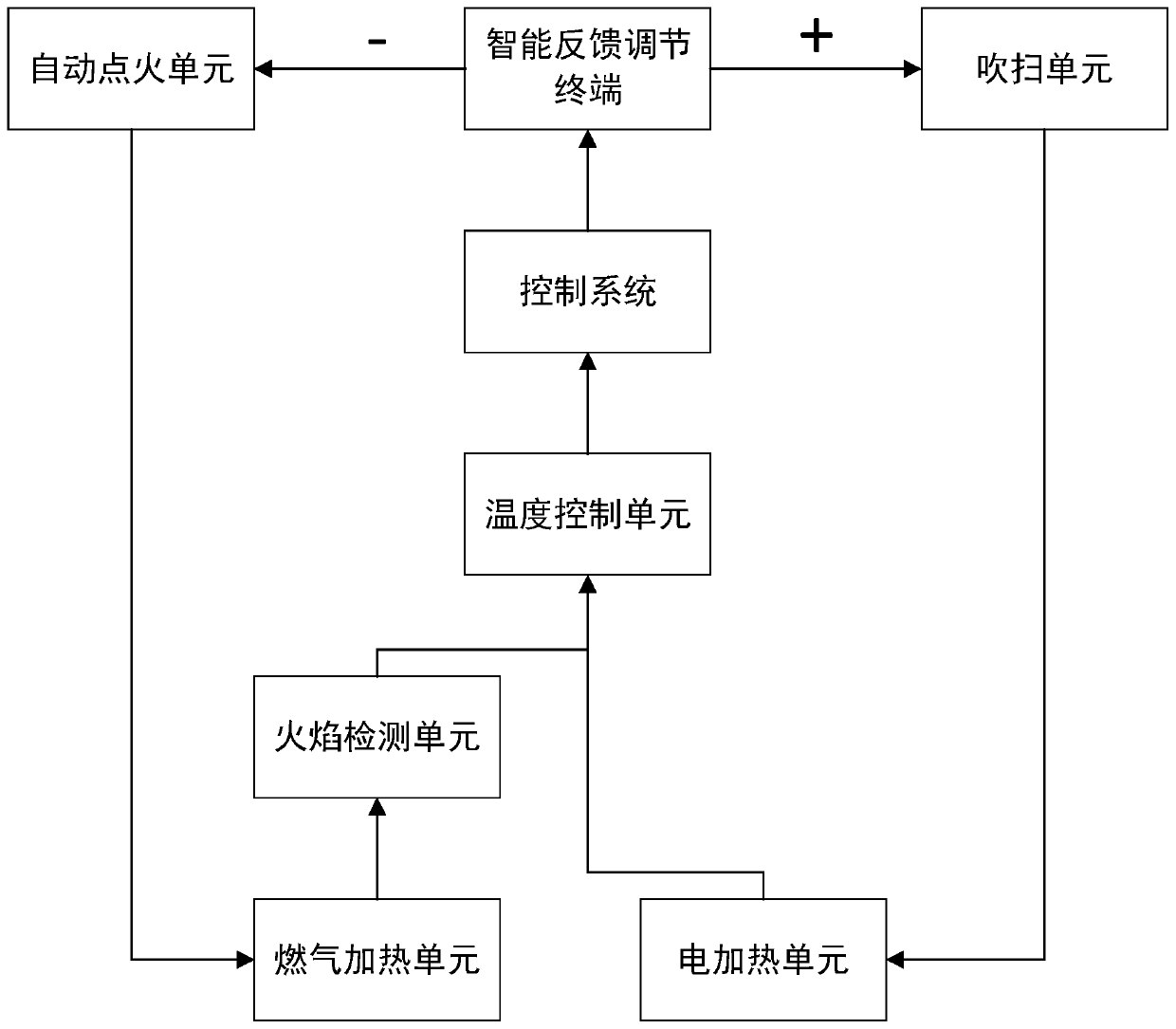

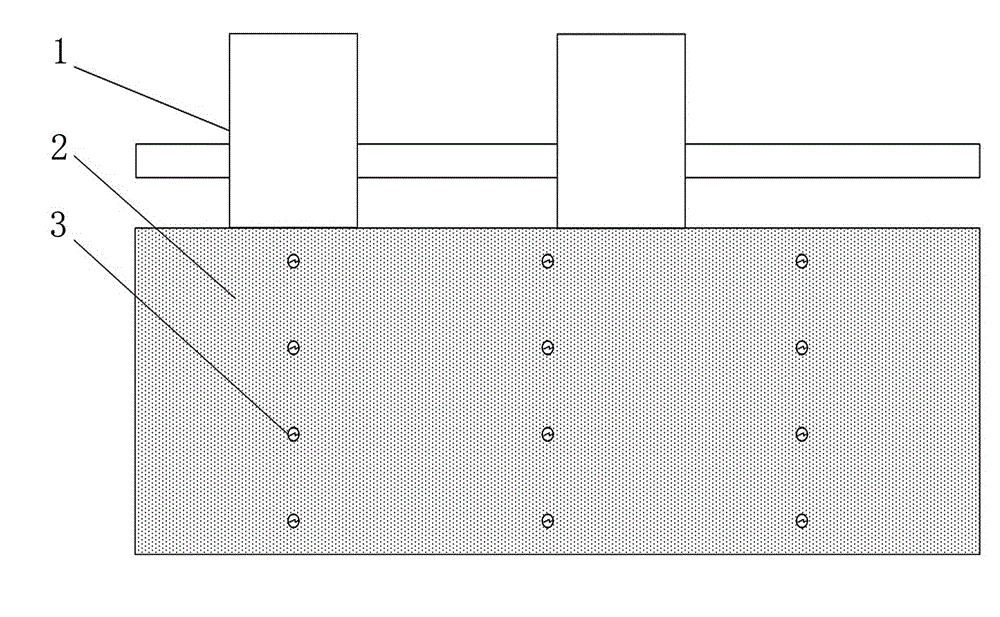

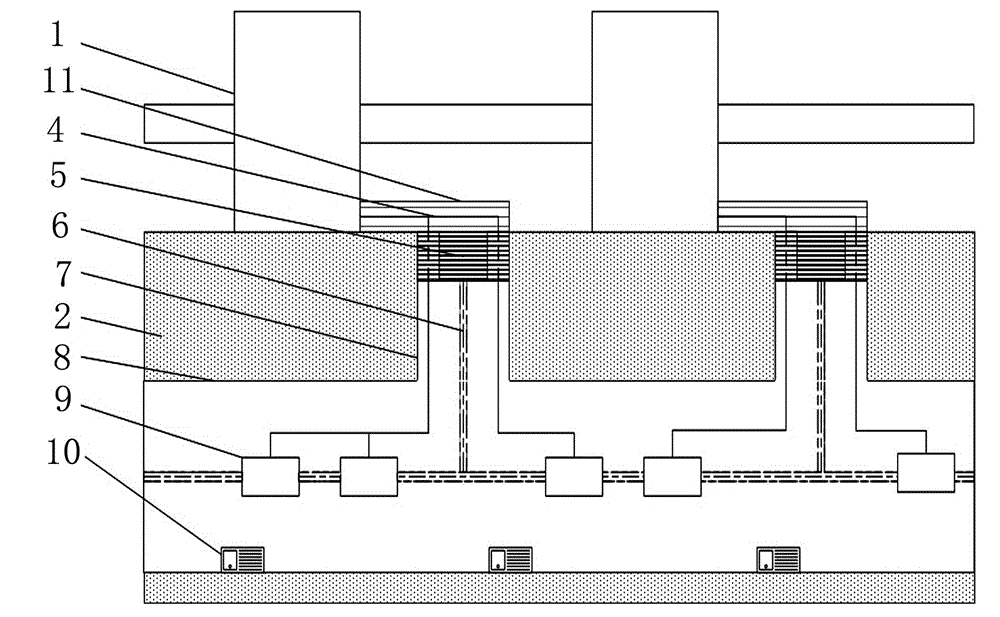

Intelligent manufacturing special network data acquisition and temperature control system

InactiveCN109976414AStable operating temperatureAuxillary controllers with auxillary heating devicesAutomatic controlData acquisition

The invention relates to an intelligent manufacturing special network data acquisition and temperature control system comprising an intelligent feedback adjustment terminal, a control system, an automatic ignition unit, a blowing unit, a flame monitoring unit, an automatic temperature control unit, a gas heating unit and an electric heating unit, wherein the flame monitoring unit collects the heating temperature of a burner of the gas heating unit; the automatic temperature control unit collects the temperature data of the flame monitoring unit and the temperature data of the electric heatingunit, and uploads the collected temperature data to the control system; the intelligent feedback adjustment terminal receives the temperature data uploaded by the control system; when the temperatureis lower than the initial forging temperature of the workpiece, the gas heating unit is driven by the automatic ignition unit to continue heating; and when the temperature is higher than the heating processing temperature of the workpiece, the blowing unit performs the blowing and cooling. The system provided by the invention realizes the automatic start and stop of the heating furnace, the automatic adjustment of the flame and the automatic shutdown when flameout according to the change of the temperature.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Pipeline-type transformer substation secondary equipment underground arrangement system and method

The invention relates to the technical field of arrangement systems and methods for transformer substation secondary equipment, in particular to a pipeline-type transformer substation secondary equipment underground arrangement system and method. Secondary equipment pipelines are arranged on the lower part of transformer substation primary equipment; pipeline inlets in the tops of the secondary equipment pipelines are connected with pipeline inlet enclosing devices; extraction guide rails and wiring sleeves are arranged in the secondary equipment pipelines; secondary connecting lines are arranged in the wiring sleeves; transformer substation secondary equipment is connected to the extraction guide rails; the transformer substation primary equipment is connected with the transformer substation secondary equipment through the secondary connecting lines; and monitoring sensors and environment monitoring and ventilating devices are further arranged in the secondary equipment pipelines. A stable running temperature is provided for the transformer substation secondary equipment through an underground constant-temperature environment, and the temperature control effect is not influenced by the reliability of a heating device and the environmental change of a transformer substation. A communicated running space is adopted, so that the heat exchange effect is uniform, and the system has high running stability and high adaptability in different climatic environments and is suitable for in-place arrangement of the transformer substation secondary equipment.

Owner:STATE GRID CORP OF CHINA +1

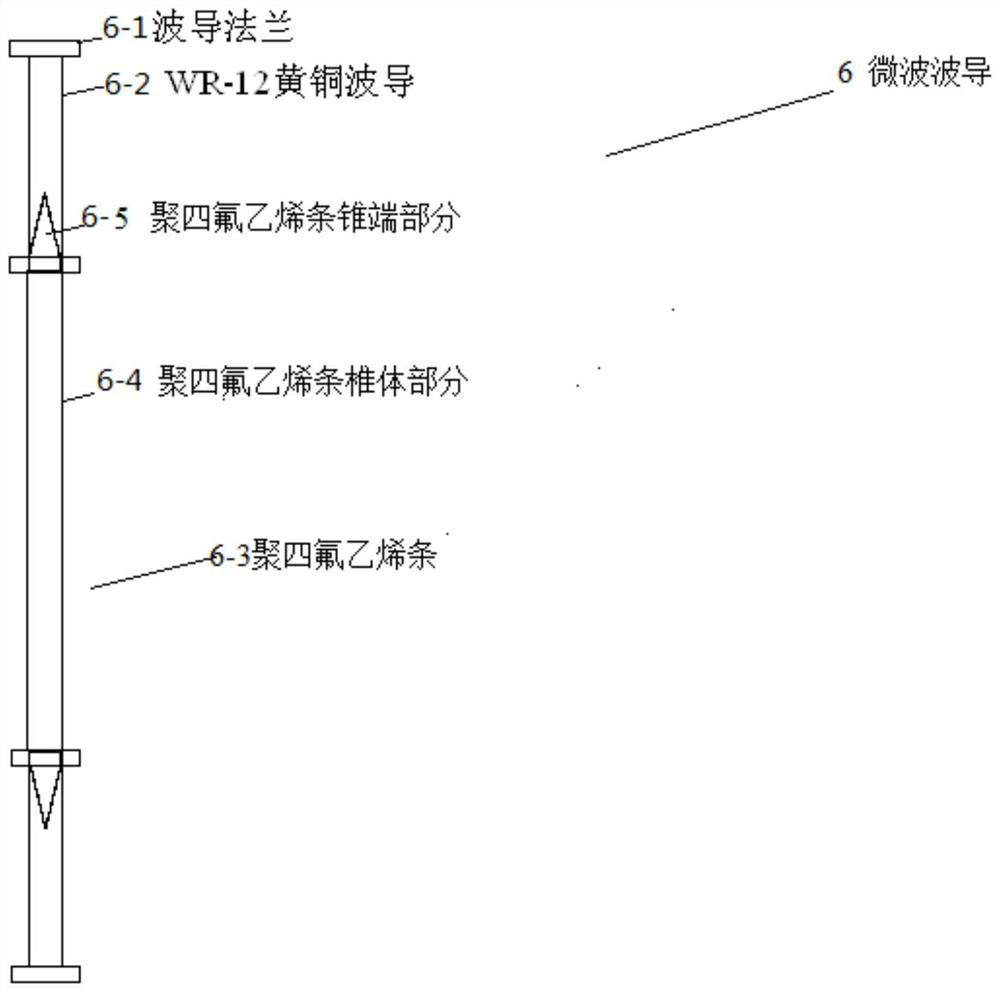

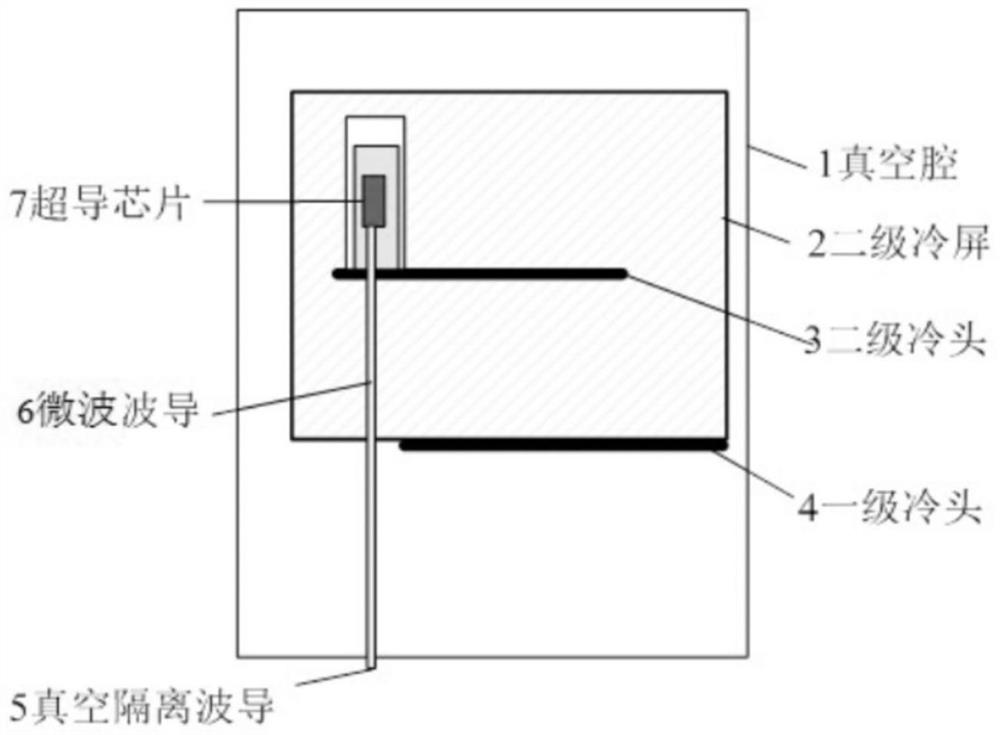

Microwave waveguide for quantum voltage device and quantum voltage device

ActiveCN114389000AReduce heat conduction powerReduce weight and sizeModifications by conduction heat transferWaveguidesWaveguide flangeMaterials science

The invention discloses a microwave waveguide for a quantum voltage device and the quantum voltage device. The microwave waveguide of the quantum voltage device comprises a waveguide flange; the brass waveguide is connected with the waveguide flange; the polytetrafluoroethylene strip comprises a cone part and cone end parts located at the two ends of the cone part, the cone end parts are of cone tip structures, and the cone part is inserted into the brass waveguide. According to the microwave waveguide provided by the invention, the polytetrafluoroethylene material with low thermal conductivity is added into the microwave waveguide, and the thermal conductivity of the polytetrafluoroethylene strip is far lower than that of metal, so that the heat transfer power of the microwave waveguide can be greatly reduced, the temperature of a low-temperature area is prevented from rising under the condition that the refrigerating capacity of a refrigerating machine is limited, and the operation condition of a quantum superconducting chip is met.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Method for separating p-xylene by multistage suspension melt crystallization

ActiveCN106831301BIncrease the average particle sizeFlexible temperature settingChemical industryCrystallisation purification/separationHigh energyPhysical chemistry

The invention relates to a multistage suspension melting crystallization method for separating p-xylene. The multistage suspension melting crystallization method comprises the following steps: carrying out shunt operation on raw materials, carrying out multistage crystallization on a part of the raw materials, directly obtaining a p-xylene crystal, then using the rest of the raw materials to carry out pulping washing and warming aging on a low-temperature crystal in an aging kettle, and obtaining a p-xylene product. Stable operation of the aging kettle is guaranteed by adjusting the amount and temperature of the raw materials entering the aging kettle, and then the stability of product purity and yield is guaranteed. Through the technical scheme adopted in the invention, the problems of unstable operation of the aging kettle and high energy consumption existing in the prior art are preferably solved, and the method can be used in the crystallization production of the p-xylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

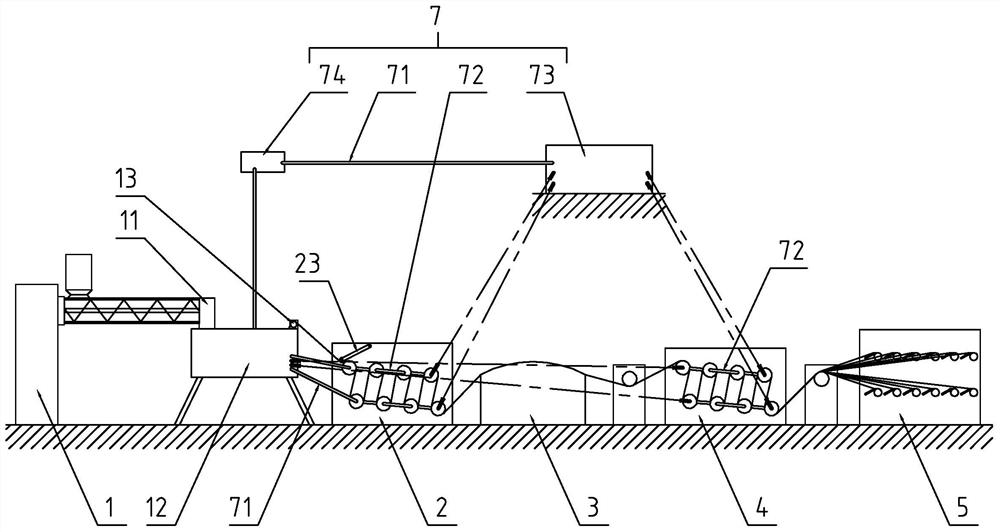

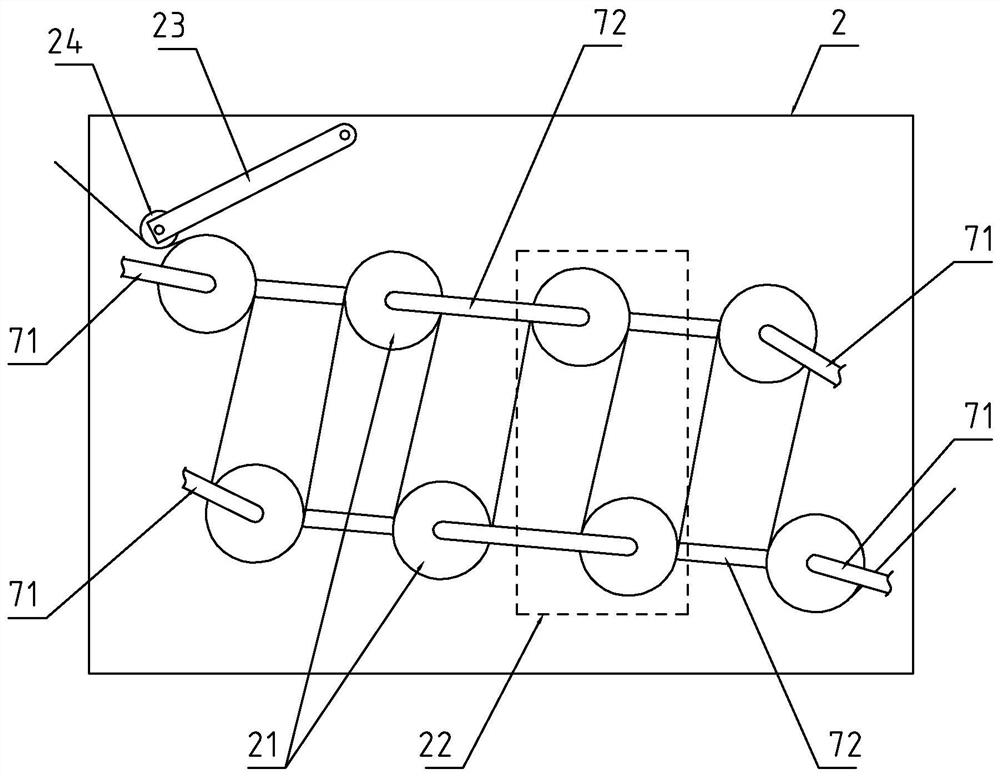

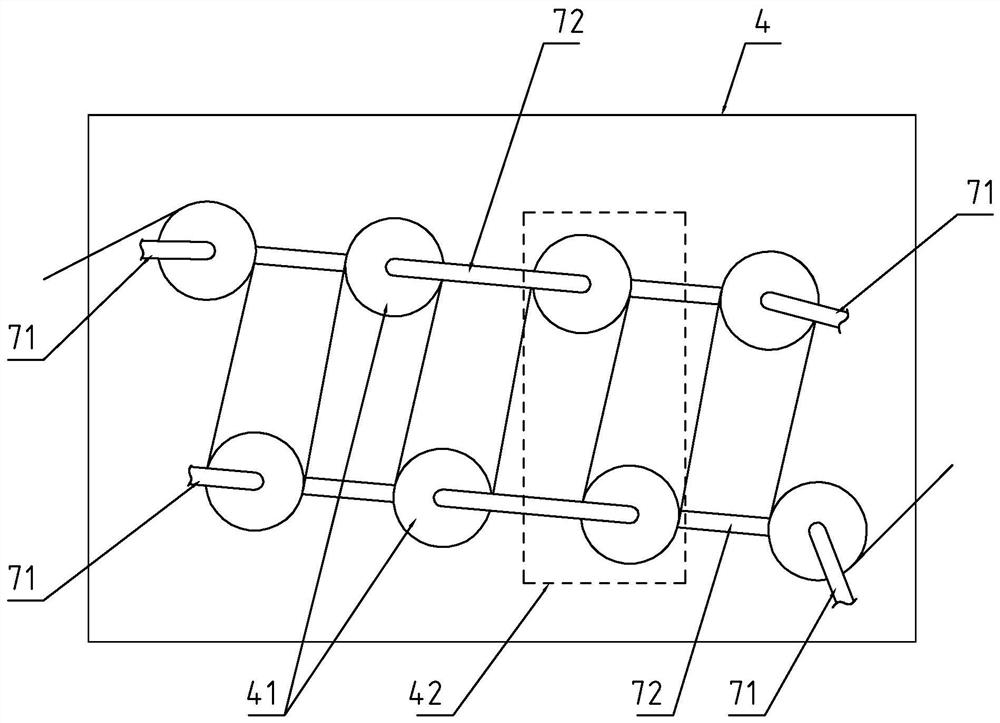

Traction device for wire drawing machine

The invention discloses a traction device for a wire drawing machine. According to the technical scheme, the traction device for the wire drawing machine is characterized by comprising a wire drawingmain machine, a flat film traction mechanism, a cutting mechanism, a flat wire traction mechanism and a winding mechanism, wherein the flat film traction mechanism comprises a plurality of flat film traction rotating rollers, and the flat wire traction mechanism comprises a plurality of flat wire traction rotating rollers. Each flat film traction roller and each flat wire traction roller respectively comprise a traction roller body, a liquid inlet pipe and an overflow pipe, wherein the liquid inlet pipe, the overflow pipe and the traction roller body are coaxially arranged and are of a hollowtubular structure, the traction roller body comprises a liquid containing cavity, the inner diameter of the liquid containing cavity is larger than that of the liquid inlet pipe and that of the overflow pipe, heat conduction liquid is conveyed into the liquid containing cavity through the liquid inlet pipe, heat can be transmitted to a flat film or a flat wire wound on the traction roller body, redundant heat conduction liquid can overflow from the overflow pipe at the other end in the process that the heat conduction liquid is continuously conveyed into the liquid containing cavity from the liquid inlet pipe at one end, and the wire drawing effect and the machining efficiency of the wire drawing machine are improved.

Owner:温州品鑫包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com