Patents

Literature

116 results about "Shunt operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The operation. Shunt surgery is carried out by a neurosurgeon, a specialist in brain and nervous system surgery. The procedure is carried out under general anaesthetic and usually takes 1 to 2 hours. You may need to stay in hospital for a few days after the operation to recover.

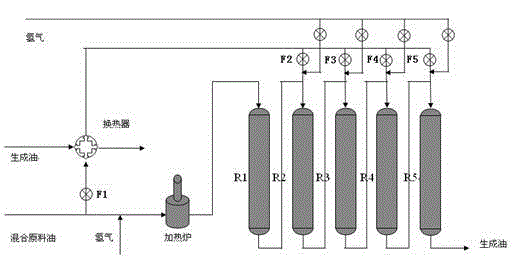

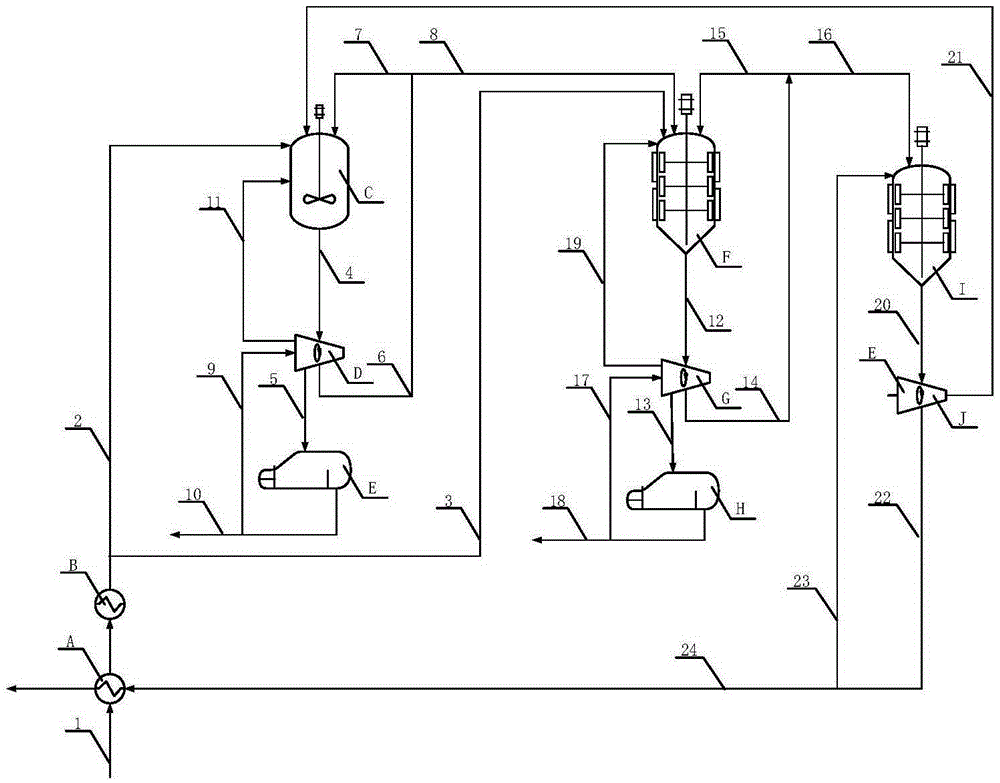

Residual oil hydrotreating method

ActiveCN103059931AThe effect of hydrotreating is not reducedIncrease flexibilityTreatment with hydrotreatment processesHydrogenEngineering

The invention discloses a residual oil hydrotreating method. According to the method, under hydrotreating conditions, a residual oil raw material and hydrogen pass through at least 4 reactors connected in series in order, all the reactors except the last one are provided with a protective agent and a demetallization catalyst, and along the material flowing direction, the ratios of the protective agent and the demetallization catalyst decrease gradually in the downstream reactors. After the equipment operates for 700-4000h, shunt operation is carried out. The feeding amount of a first reactor is reduced or maintained constant. The feeding amount of each reactor between the first reactor and the last reactor is increased, and the increased residual oil raw material is injected at the inlets of the middle reactors. Compared with the prior art, the method provided in the invention can obviously prolong the operation period of residual hydrogenation equipment, and make the effective utilization rate of the catalyst and the equipment running time achieve consistency, thereby enhancing the equipment running efficiency and improving the economical efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

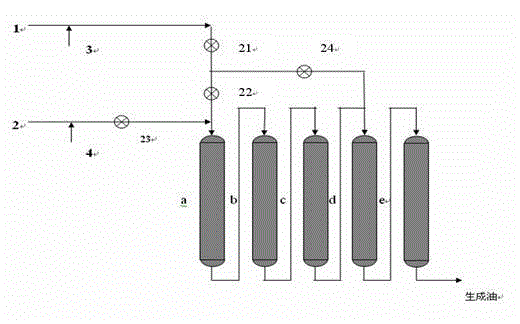

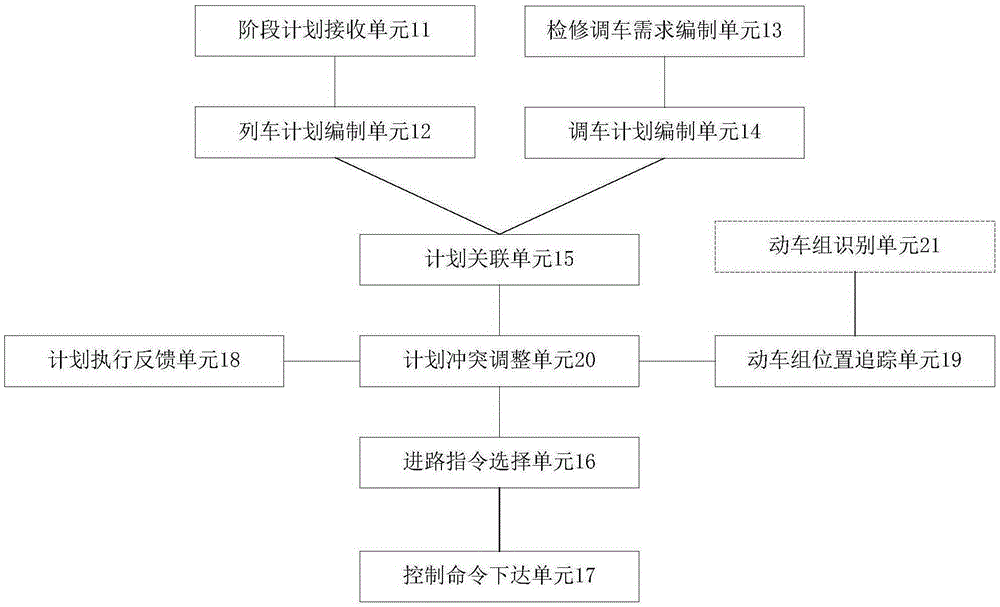

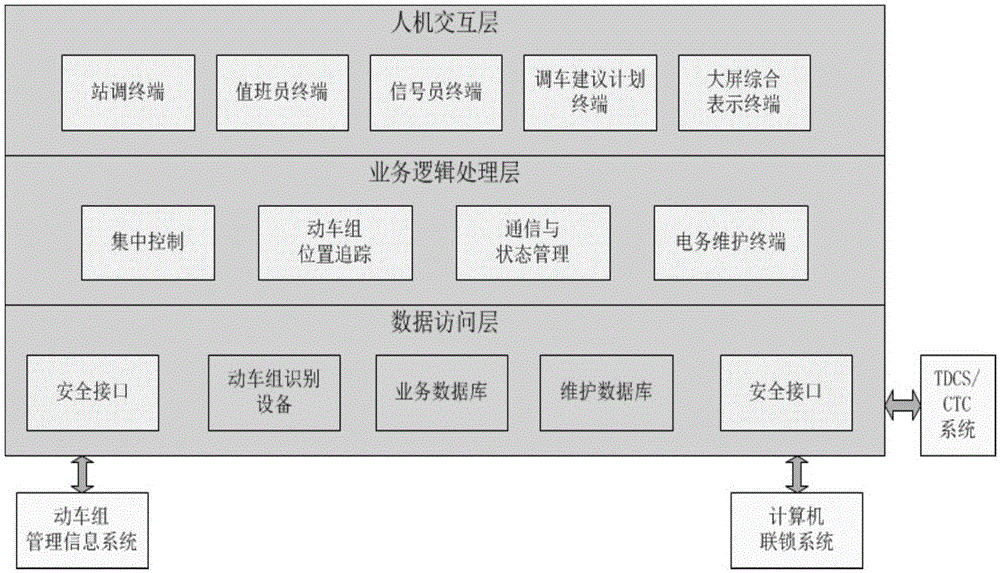

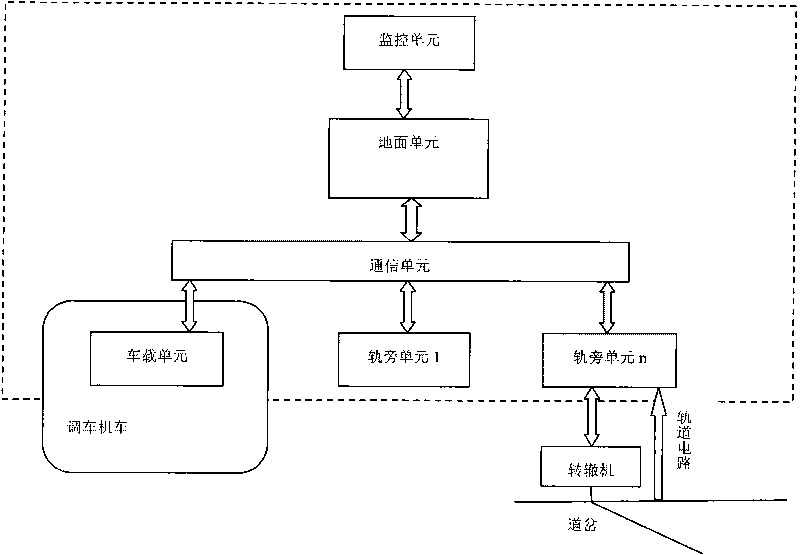

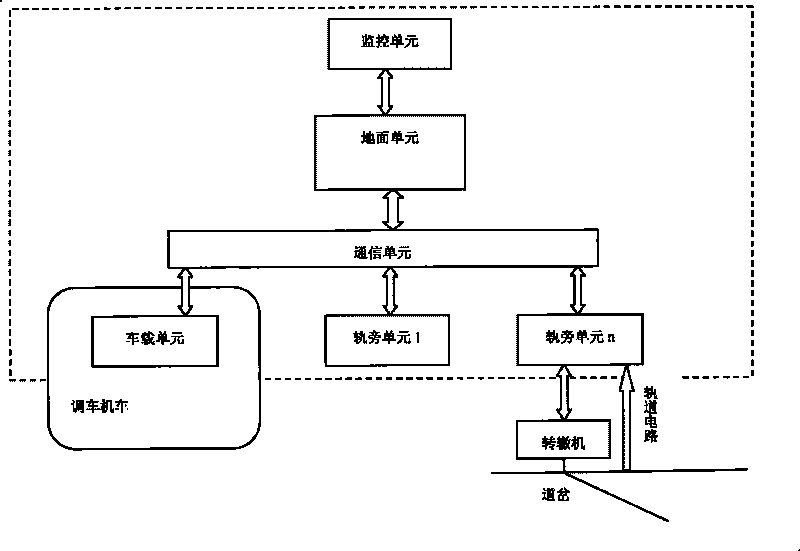

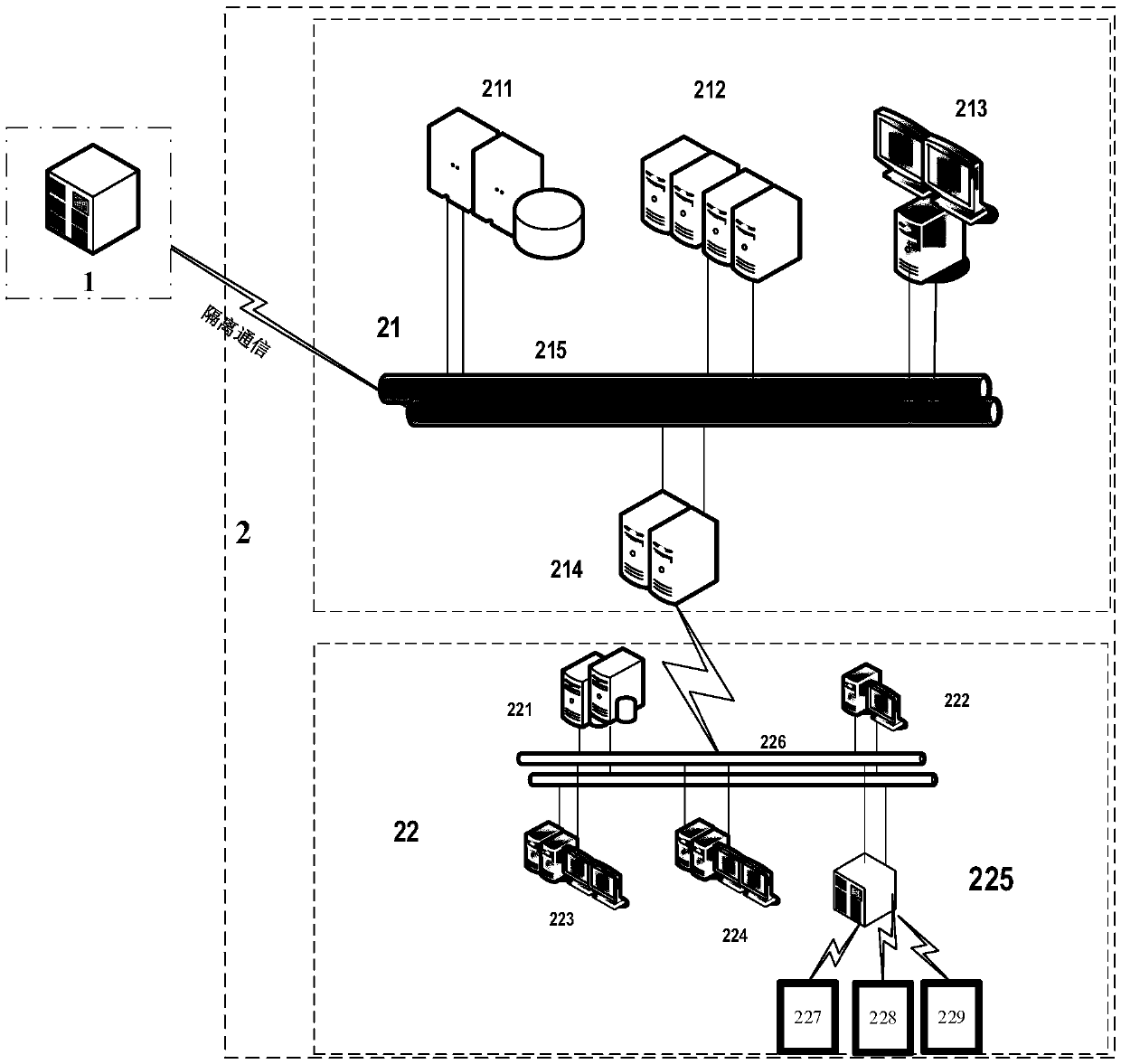

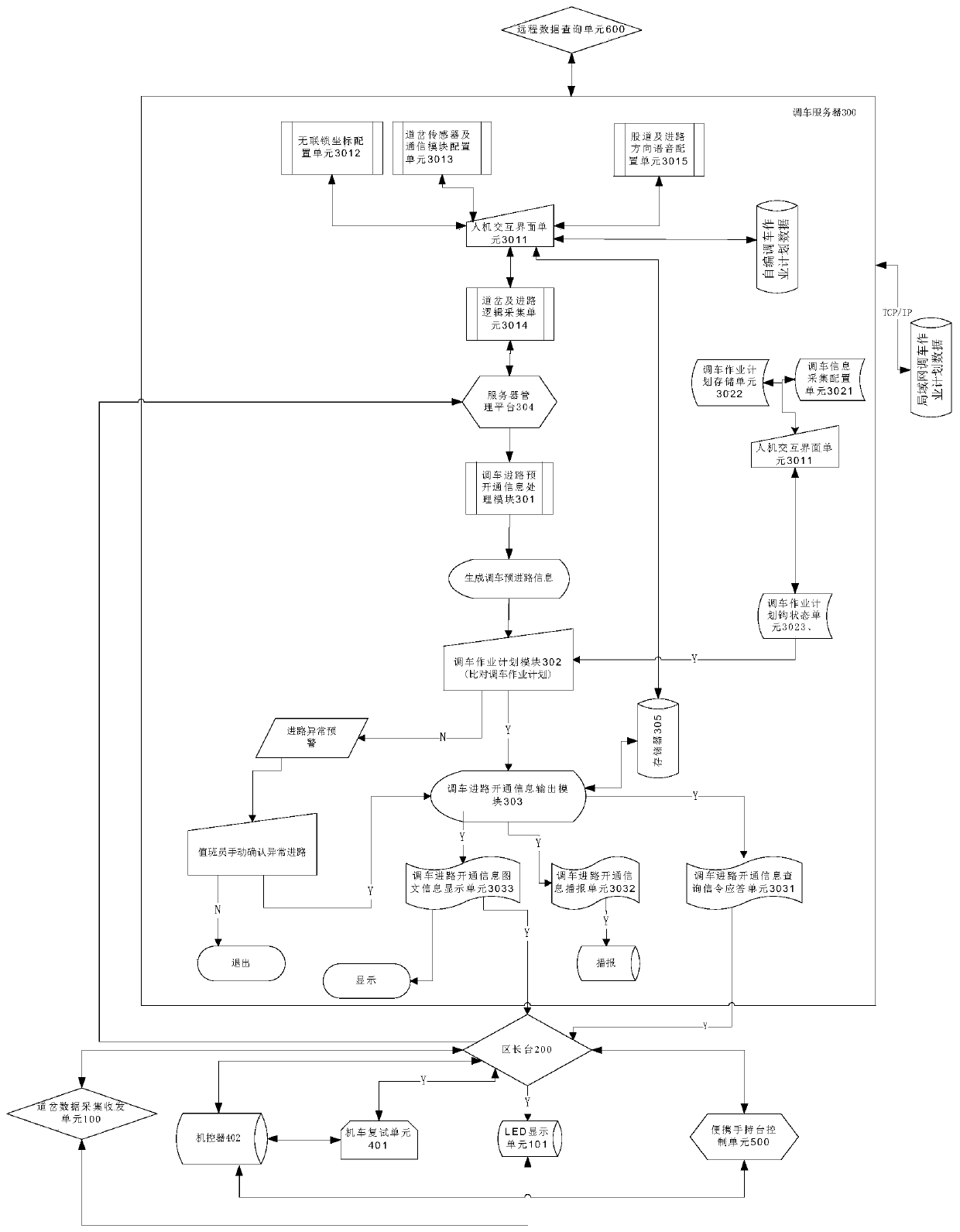

Multiple-unit train maintenance base (station) centralized control system

ActiveCN105278379AFully automatedMeet the needs of on-site production operationsProgramme control in sequence/logic controllersControl systemLocation tracking

The invention discloses a multiple-unit train maintenance base (station) centralized control system. The control system includes a train operation adjustment plan receiving unit, a train plan adjustment unit, a shunting suggestion plan making unit, a shunting plan adjustment unit, a plan correlation unit, a route command scheme selection unit, a control command issue unit, a plan conflict adjustment unit, a plane execution feedback unit and a multiple-unit train location tracking unit and a multiple-unit train identification unit. With the multiple-unit train maintenance base (station) centralized control system of the invention adopted, scheduling personnel of a multiple-unit train maintenance base (station) and a multiple-unit train maintenance unit can perform centralized control on signal equipment in the maintenance base and unit, directly command and manage trains and shunting operation, and automation of a scheduling process of the multiple-unit train maintenance base (station) and the multiple-unit train maintenance unit can be realized. The multiple-unit train maintenance base (station) centralized control system is a key link for realizing management and control integration of the multiple-unit train maintenance base (station) and the multiple-unit train maintenance unit, and can fully meet on-site production operation needs and can assist in improving production efficiency and work quality.

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

Railway station control method

ActiveCN101758839AMeet the requirements of flexible shuntingClassification yard switching systemsRailway traffic control systemsLogical operationsEngineering

The invention discloses a railway station control method, which can carry out decentralized control on turnout junctions on the approach and use a virtual signal controller to openly command the shunting operation on the ground and the locomotive to realize the control function of the approach and the safety protection functions of ground approach interlocking and using approach of the locomotive under the condition without a ground shunting signal mechanism on the basis of the approach handling operation promoted on the locomotive by carrying out the centralized control on the logical operation output.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

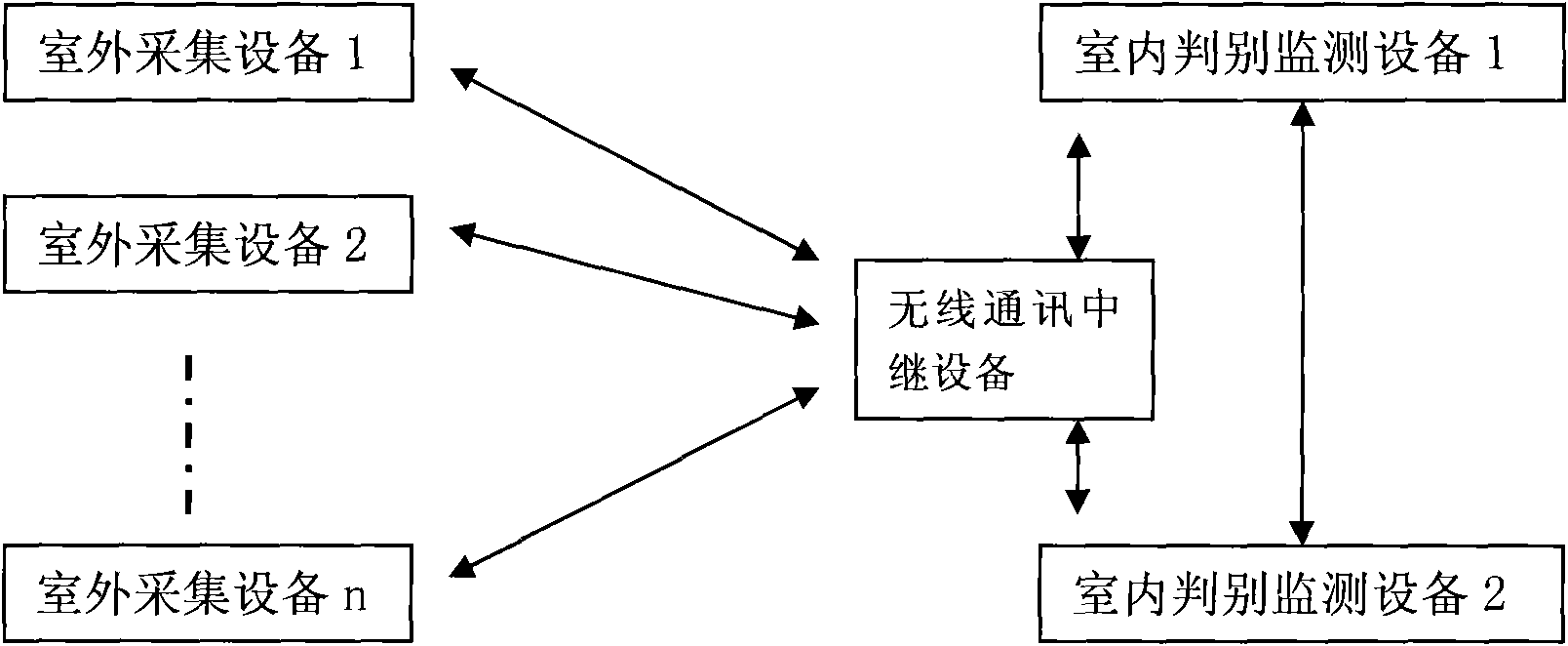

Monitoring system of railway derailer state

InactiveCN101590863APrecise positioningAccurately locate the fault locationRailway signalling and safetyLocation statusMonitoring system

The invention discloses a monitoring system of railway derailer state, which is characterized in that the monitoring system comprises an outdoor acquisition device and an indoor discriminating and monitoring device which are connected with each derailer, wherein, the indoor discriminating and monitoring device successively inquires the outdoor acquisition device in a railway station via a radio path; after receiving inquiry instruction, the outdoor acquisition device encodes according to derailer position state information collected by a sensor and sends the information back to the indoor discriminating and monitoring device; and the indoor discriminating and monitoring device discriminates, treats and displays signals. Thus, loaders and operation rooms can know the derailer state of each loading and unloading line of each railway station in time so as to ensure safe loading and unloading operation and shunting operation of freight stations.

Owner:北京人和路通科技有限公司

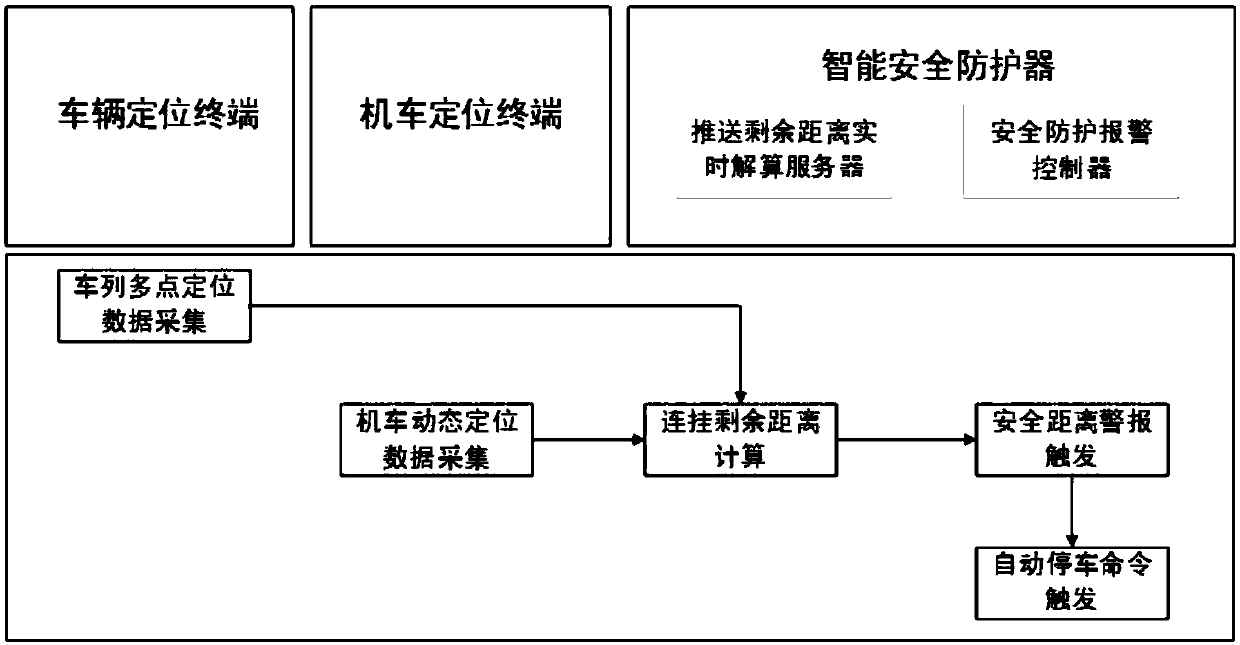

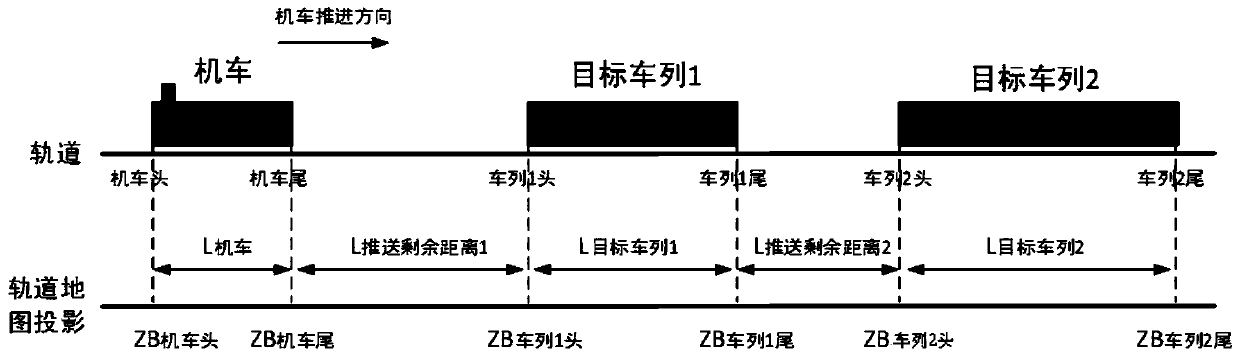

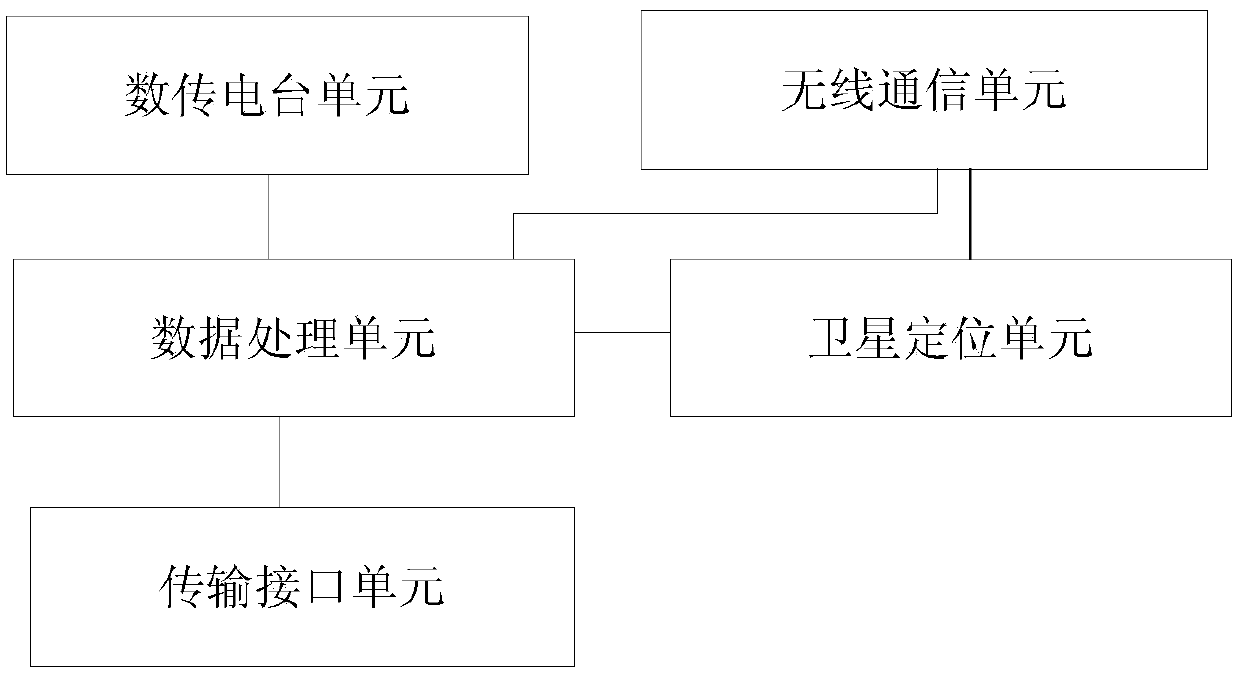

Intelligent safety protection system for railway plane shunting operation based on satellite positioning

InactiveCN109606428ASolve the problem of overspeed connectionImprove securityRailway signalling and safetyProtection systemSecurity level

The invention discloses an intelligent safety protection system for railway plane shunting operation based on satellite positioning. The intelligent safety protection system comprises a locomotive positioning terminal, a vehicle positioning terminal and an intelligent security protector. Aiming at the pain point of a crash safety accident caused by accurate traditional plane shunting propulsion distance judgment, satellite high-precision positioning as well as a geographic information system technology is applied in an integrated way; a locomotive propulsion residual distance solving model isresearched and developed; the train length, the increase or the decrease in the train length of a locomotive, the propulsion residual distance and the like are calculated by utilizing multi-point positioning data; a control trigger based on logic judgment realizes locomotive approaching phased alarm and automatic parking. The intelligent safety protection system disclosed by the invention realizesthe digitization of plane shunting operation management from a source through real-time high-precision positioning, solves the problem of locomotive over-speed connection and provides a brand-new safety and technical guarantee means for effective improvement on the security level and the operation efficiency of plane shunting operation.

Owner:TRANSPORTATION & ECONOMICS RES INST CHINA ACAD OF RAILWAY SCI CORP LTD

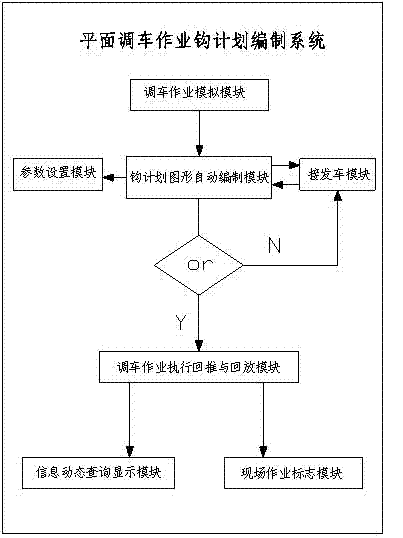

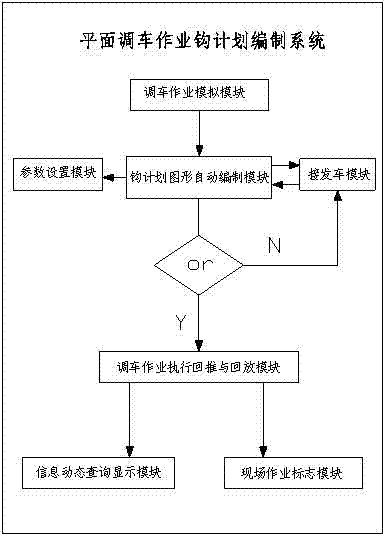

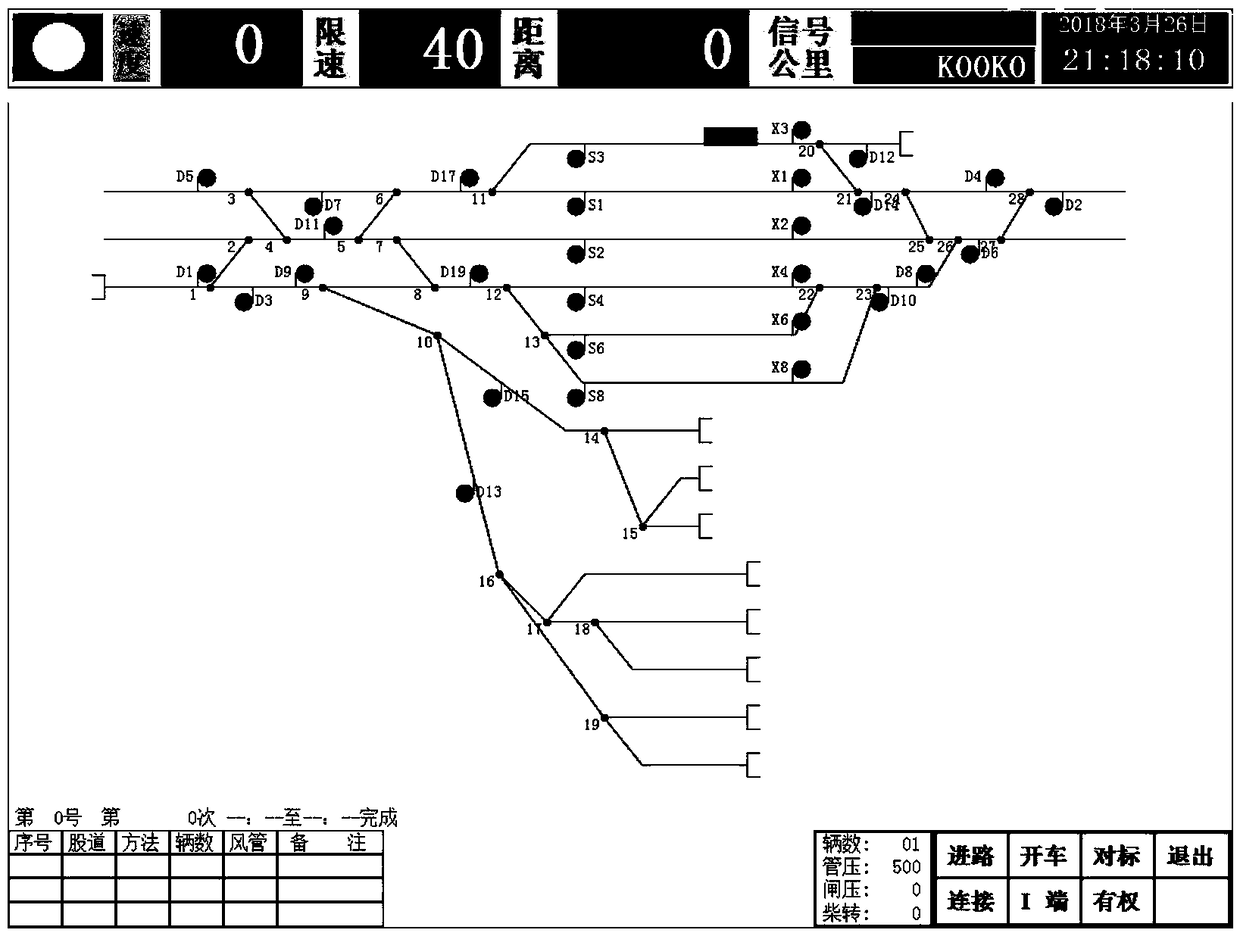

Flat shunting operation hook planning system

InactiveCN102310873AReduce distanceFunction increaseSignal boxes station blockingGraphicsProgram planning

The invention relates to a flat shunting operation hook planning system, which is in a modularized structure. Each module comprises a hook plan pattern automatic planning module, a parameter setting module, a train reception and starting module, a shunting operation simulation module, a shunting operation executing pushback and play-back module, an information dynamic inquiry and display module and an in-site operation mark module. A system formed by the modules is connected with a transportation management information system (TMIS) of the existing station, the data of the train list information after departure of a TIMS database can be automatically read and written, train units are clicked by a mouse on a lane chart and are dragged to the required position after the grouping by planning personnel according to station sending and taking operation tasks, and one batch of shunting operation plans can be planed and completed.

Owner:张伯敏 +2

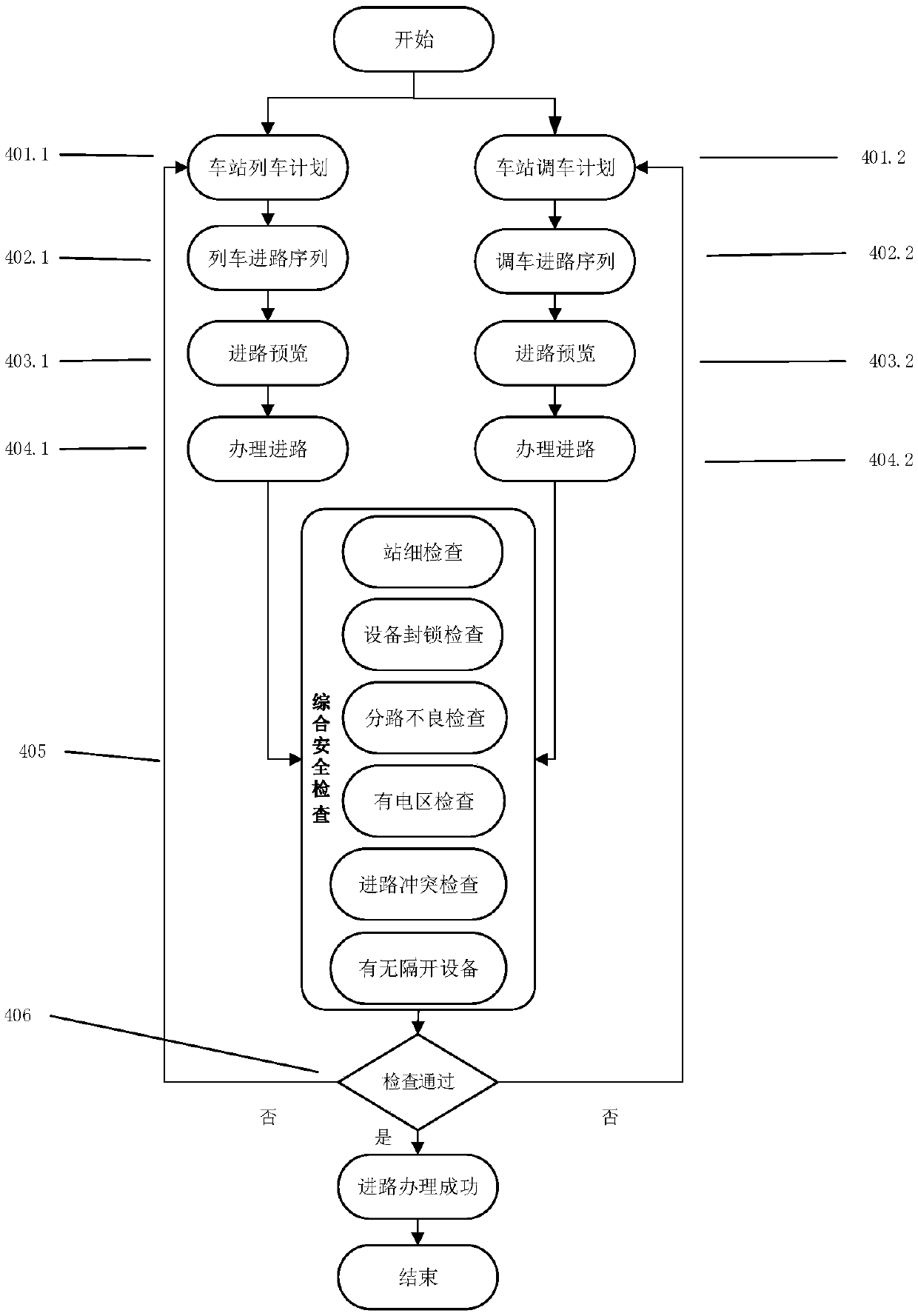

CTC3.0-based comprehensive safety inspection method and device for trains and shunting routes

PendingCN109591857AAdapt to traffic command requirementsWide applicabilityRailway traffic control systemsEngineeringReliability engineering

The invention relates to CTC3.0-based comprehensive safety inspection method and device for trains and shunting routes. According to the method, safety logic inspection is carried out on running operation and shunting operation through an autonomous machine in a unified way; the autonomous machine carries out safety inspection on the trains and shunting routes during processing; and moreover, onlythe routes passing through the inspection can be successfully processed. Compared with the prior art, the method and the device are capable of effectively improving the comprehensive operation safetyof train shunting, and the like.

Owner:CASCO SIGNAL

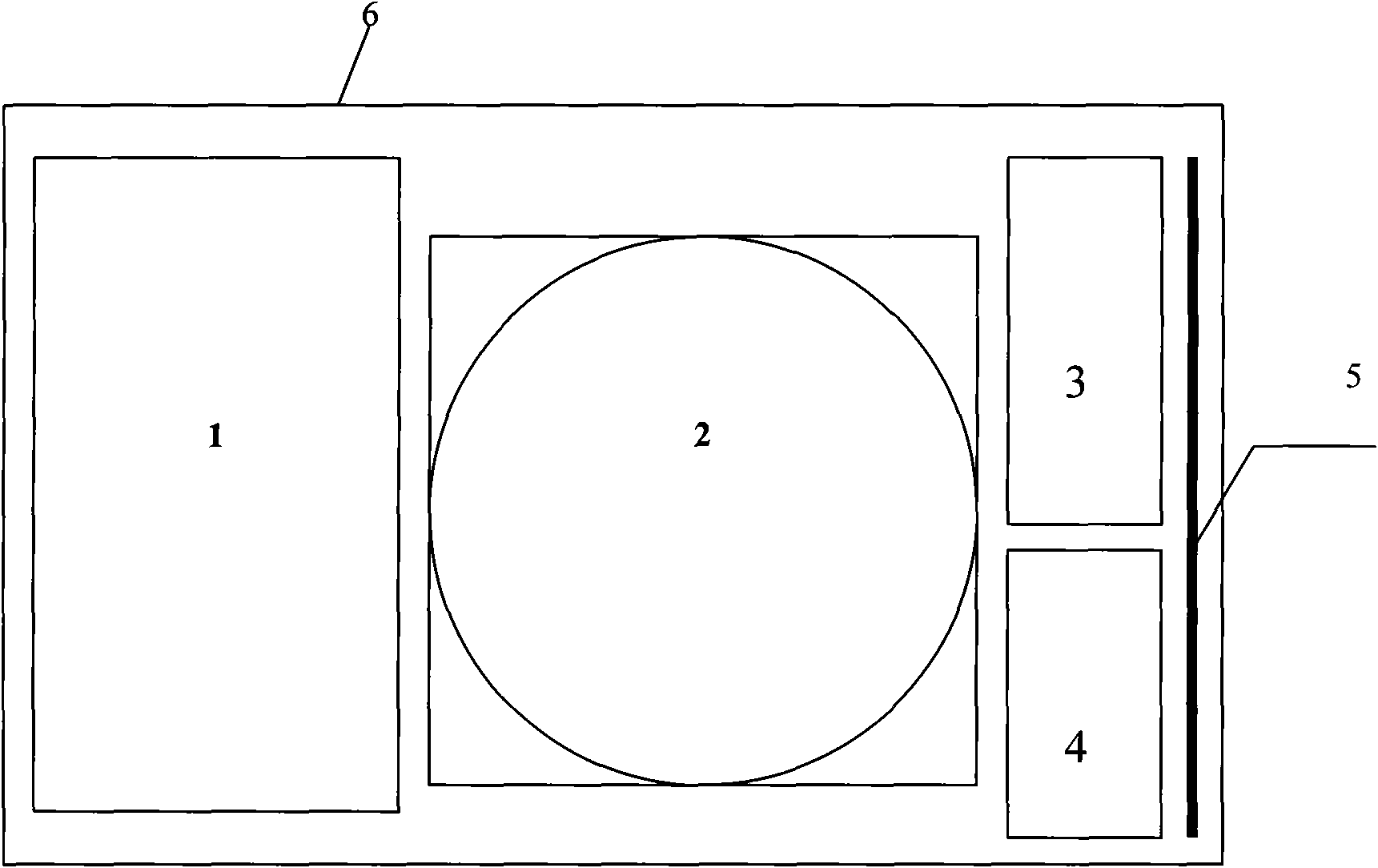

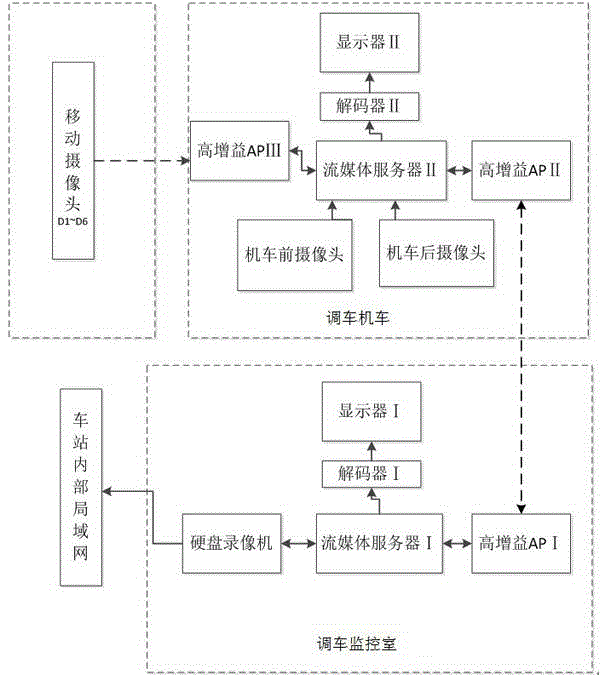

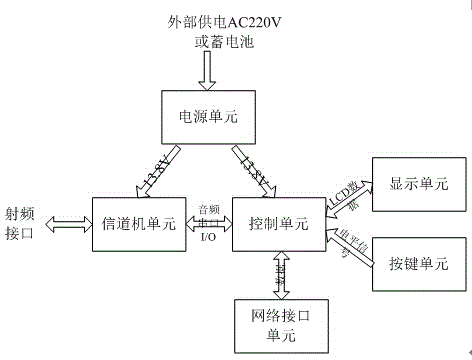

Wireless video monitoring system for railway shunting operation

InactiveCN104486583AEnsure safetyImprove efficiencyClosed circuit television systemsWireless videoDisplay device

The invention discloses a wireless video monitoring system for railway shunting operation, and relates to a wireless video monitoring system which comprises a fixed monitoring device arranged inside a shunting monitoring room, and a moving monitoring device arranged outside a room, wherein the fixed monitoring device comprises a stream media server I, a decoder I, a display I, a hard disc video and a high gain AP I; the moving monitoring device comprises a stream media server II, a decoder II, a display II, a high gain AP II, a high gain AP III, front cameras in front of a locomotive, rear cameras behind the locomotive, and moving cameras. A shunting driver can watch the front and rear situations of the locomotive and the situations of shunting operators through the display device of the moving monitoring device, images can be also transmitted to the fixed monitoring device inside the shunting monitoring room through the moving monitoring device, a yardmaster can monitor the shunting situation in the monitoring room, and by the adoption of the wireless video monitoring system for railway shunting operation, the whole shunting operation process is visible, the security of shunting operation is ensured, and the shunting operation efficiency is improved.

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

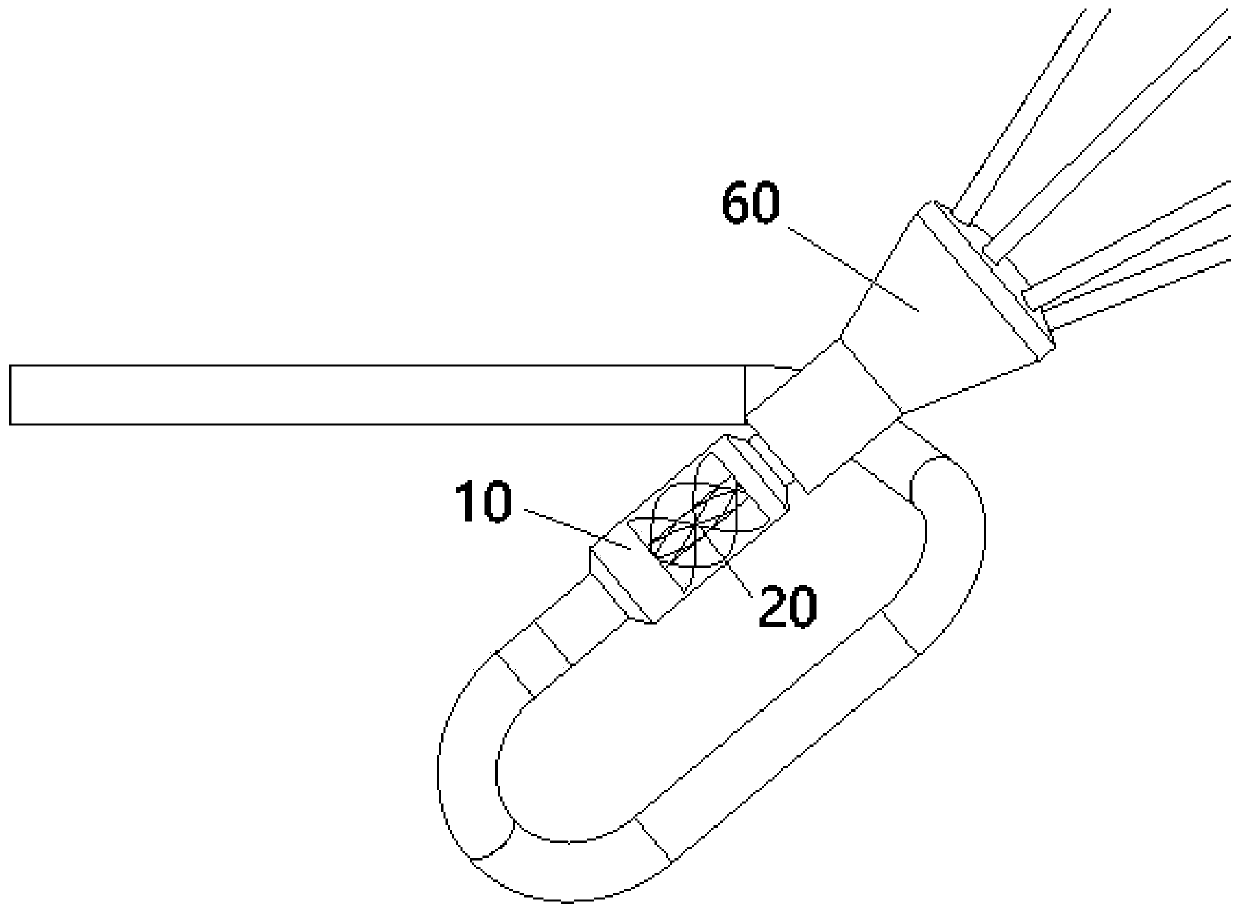

Intelligent train coupler system

ActiveCN107685743ASolve operational problemsTime consuming to solveDraw-gearRailway employeeMultiple sensor

The invention relates to an intelligent train coupler system. The intelligent train coupler system is a connecting device between trains, and the system is used to replace a traditional tight-lock coupler and used for achieving automatic train shunting operation. The system comprises an automatic train coupler body, a physical range finder, a distance / train speed analyzer, a drive operation converter, sensors and the like, wherein the train coupler body contains multiple sensors. By the intelligent train coupler system, operation transformation of a rail transit combination-separation combinedtransportation mode can be well achieved, labor burden and mental pressure of railway staff can be lowered favorably, shunting operation quality and efficiency are increased, the mechanism constraintof the highest design capacity of railway transportation can be broken through hopefully, huge productivity potential can be exploited, and the railway transportation is allowed to well satisfy the needs of social and economic development.

Owner:SHANGHAI WIND NEW ENERGY TECH

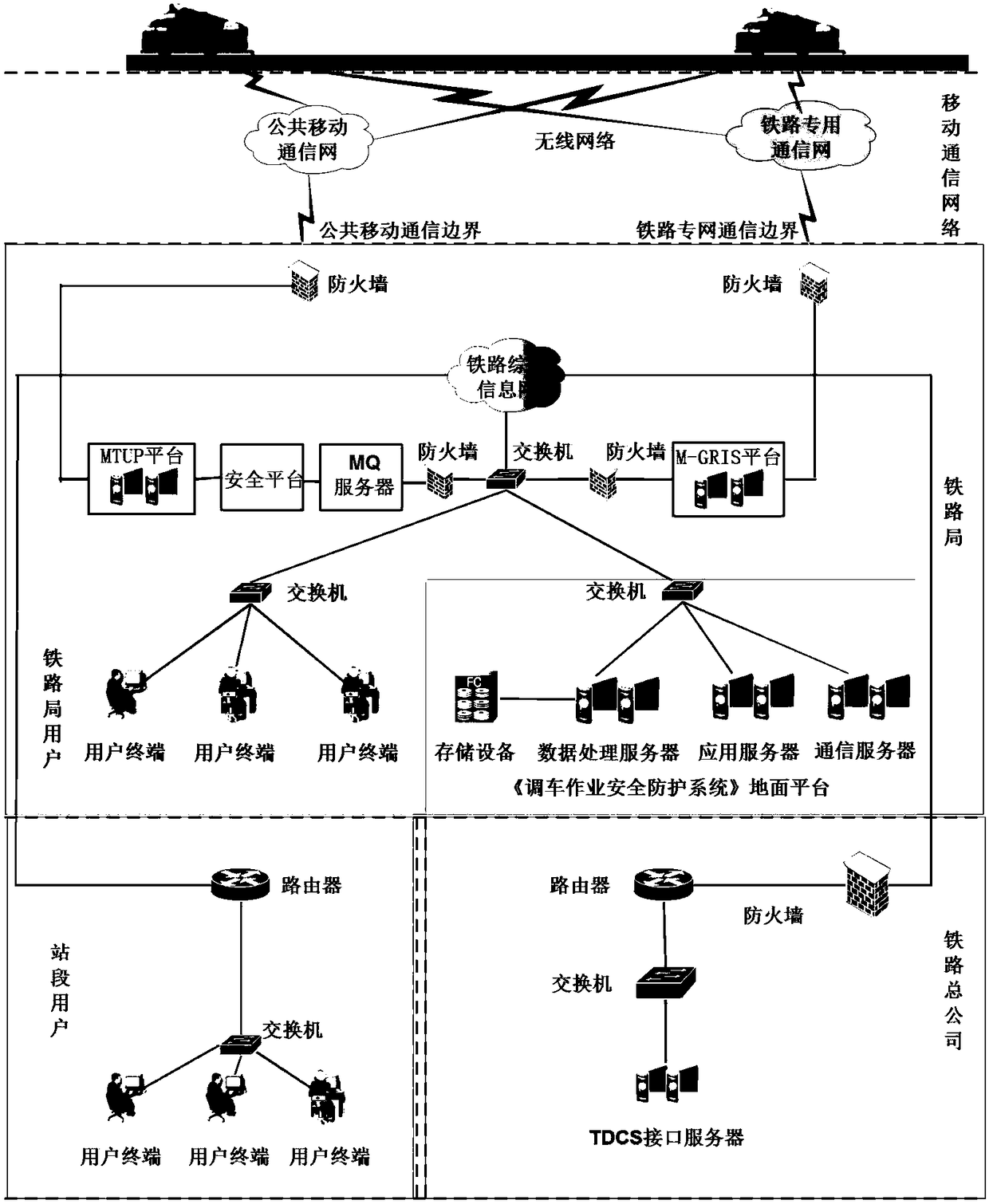

Shunting protection device based on TDCS information

ActiveCN108639110ASolve the problem of lack of effective technical defense meansReduce security risksParticular environment based servicesRailway traffic control systemsTelecommunicationsInformation networks

Owner:西北铁道电子股份有限公司

Automatic management method for shunting operation notice sheet in shunting monitoring system

ActiveCN104943712AImplement automatic updatesImprove realization rateRailway traffic control systemsResourcesMonitoring systemAutomatic processing

The invention relates to an automatic management method for a shunting operation notice sheet in a shunting monitoring system. The automatic management method for the shunting operation notice sheet in the shunting monitoring system comprises the following steps that 1, operation sheet information related to locomotives is recorded in real time; 2, the state of a shunting operation sheet is updated in real time; 3, the operation sheet is processed by the adoption of the mode of combining manpower and automatic operation sheet processing. Compared with the prior art, the automatic management method for the shunting operation notice sheet in the shunting monitoring system has the advantages that the automatic management of the operation sheet is added, the update of the operation sheet by the manpower is reduced, and the automation of the operation sheet state update is achieved.

Owner:CASCO SIGNAL

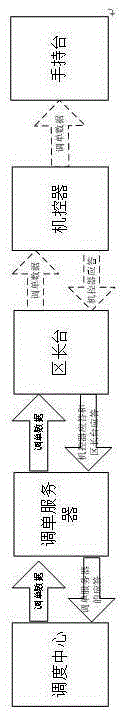

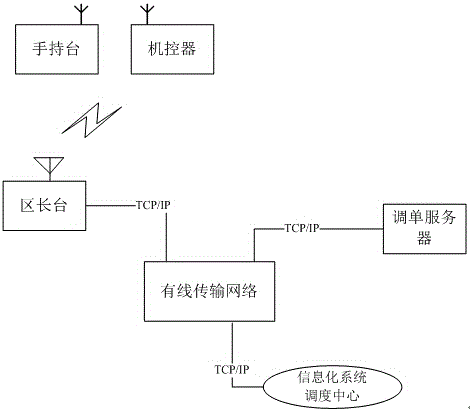

Single transmission system for railway flat shunting operation and control method

ActiveCN105416346ASolve the difficulty of inconvenient transmissionImprove shunting operation efficiencyRailway traffic control systemsIp addressComputer science

The invention relates to a single transmission system for railway flat shunting operation and a control method. A shunting order server analyzes data and reads IP addresses of warden radios from the data. The data are sent to the warden radios through the shunting order server according to the IP addresses and recorded at the same time. After the warden radios receive the data, response information is sent to the shunting order server, the data are analyzed, and the serial numbers of shunting teams are read; according to the serial numbers of the shunting teams, the data are sent to corresponding machine controllers through the warden radios and recorded at the same time through the warden radios; after the machine controllers receive the data, the response information is sent to the warden radios, the data are analyzed, the shunting order content is read, display of a liquid crystal screen is controlled, meanwhile the data are sent to handheld radios in the same group to be recorded; and after the handheld radios receive the data, the data are analyzed, the shunting order content is read, and display of the liquid crystal screen is controlled. The single transmission system has the beneficial effects that the single transmission efficiency of shunting operation is improved, shunting staff can check shunting orders conveniently, and shunting operation orders can be updated and treated in real time.

Owner:天津七一二移动通信有限公司

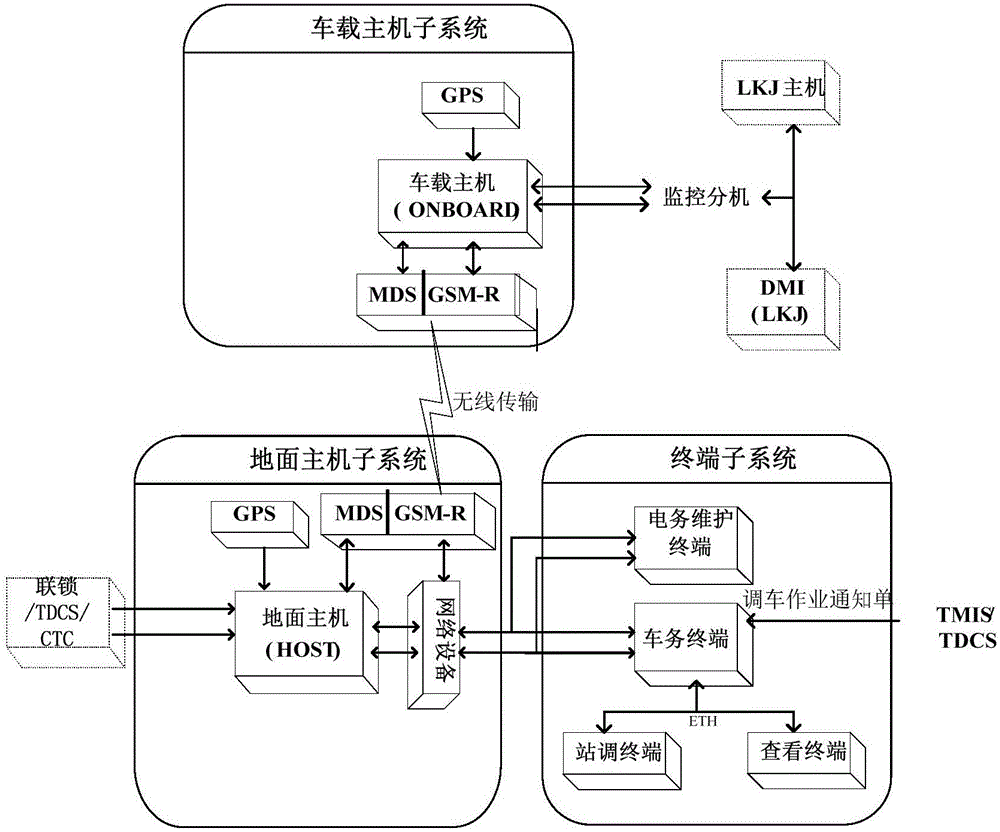

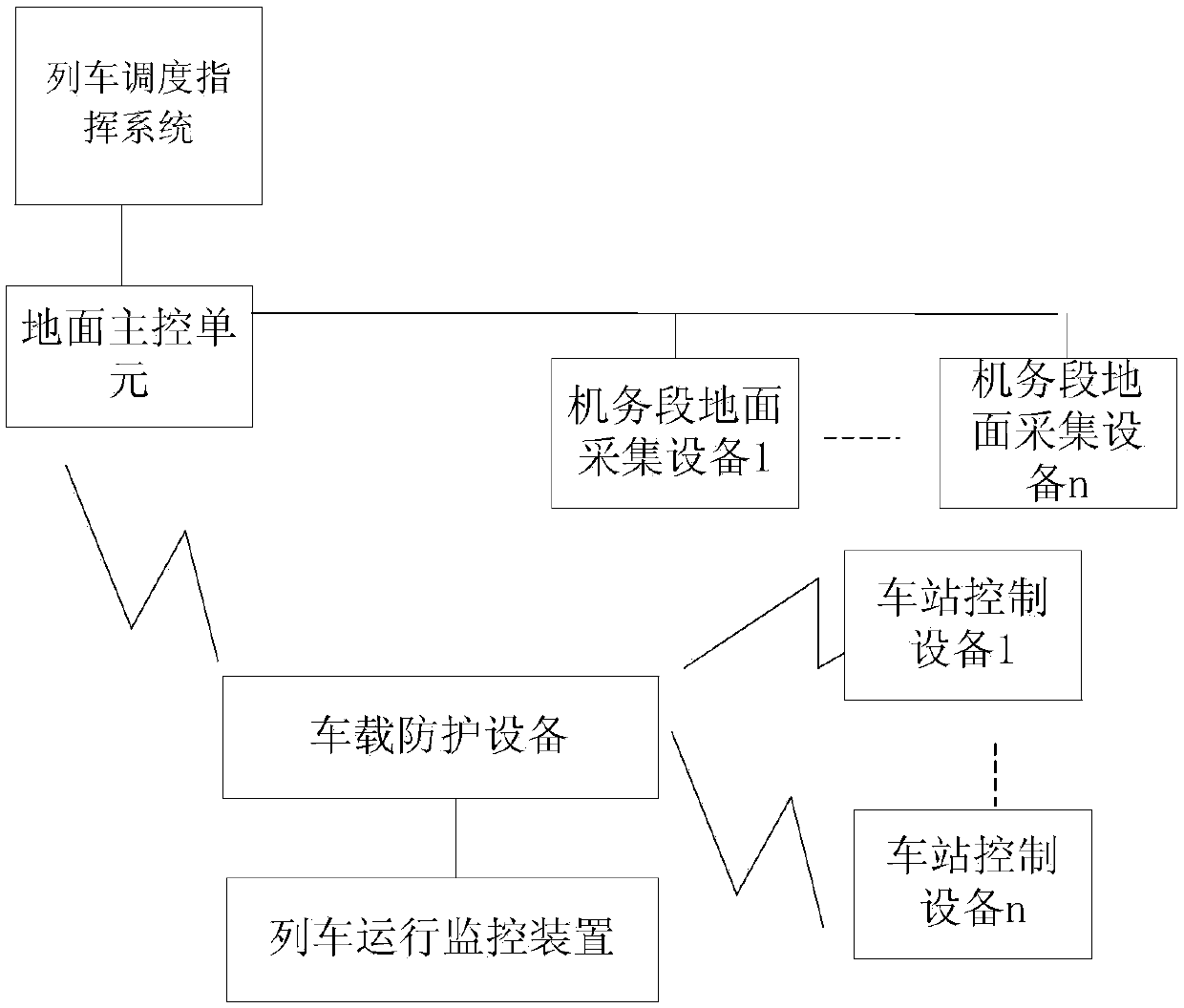

Shunting operation safety auxiliary protection system and method

The invention discloses a shunting operation safety auxiliary protection system and method. The system herein comprises: vehicular protection equipment arranged on a leading locomotive, capable of locating a locomotive and in communicated connection with a train operation monitoring device of the leading locomotive; a surface master control unit arranged in a railway administration, in communicated connection with a train scheduling command system and surface acquisition devices of locomotive depots, and capable of acquiring local shunting operation control information of the railway administration; a plurality of station control devices each correspondingly arranged at a station, wherein each station control device can acquire station linkage equipment state information of the corresponding station and transmit to the vehicular protection equipment, the vehicular protection equipment can transmit the received local shunting operation control information of the railway administration and / or station linkage equipment state information to the train operation monitoring device to control locomotives, and can transmit lifting information to the train operation monitoring device. The system herein can monitor the operation position of the leading locomotive, so that shunting operation safety of the leading locomotive is effectively improved.

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

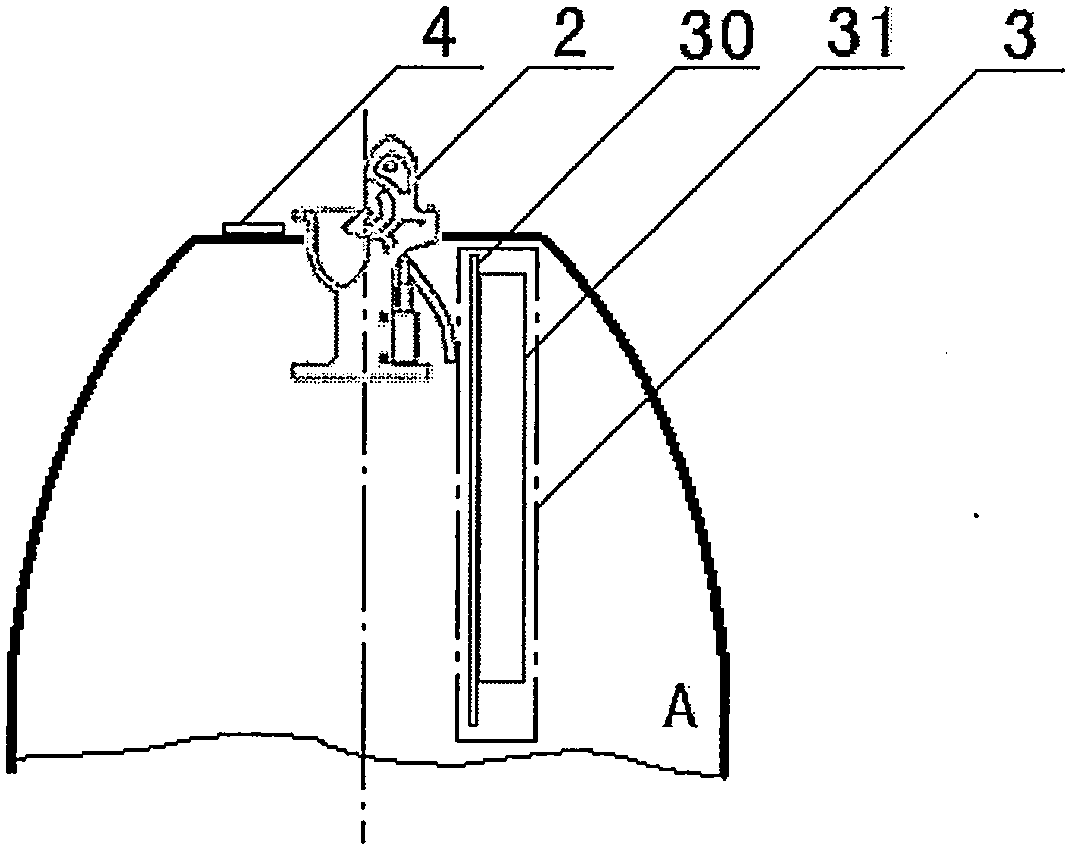

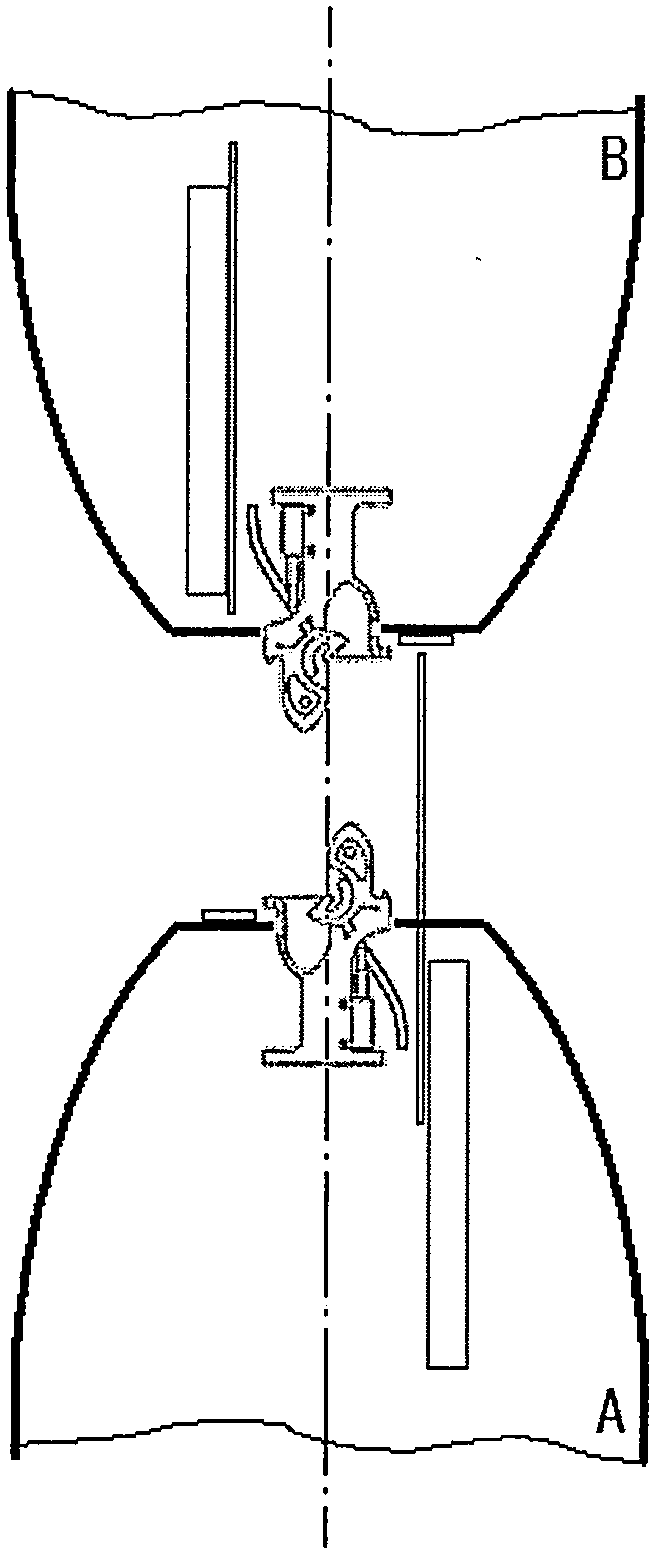

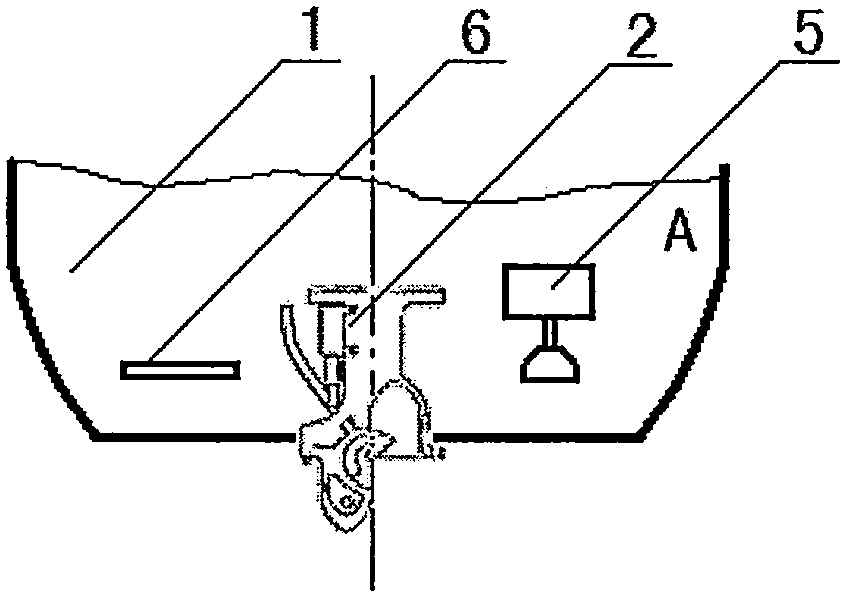

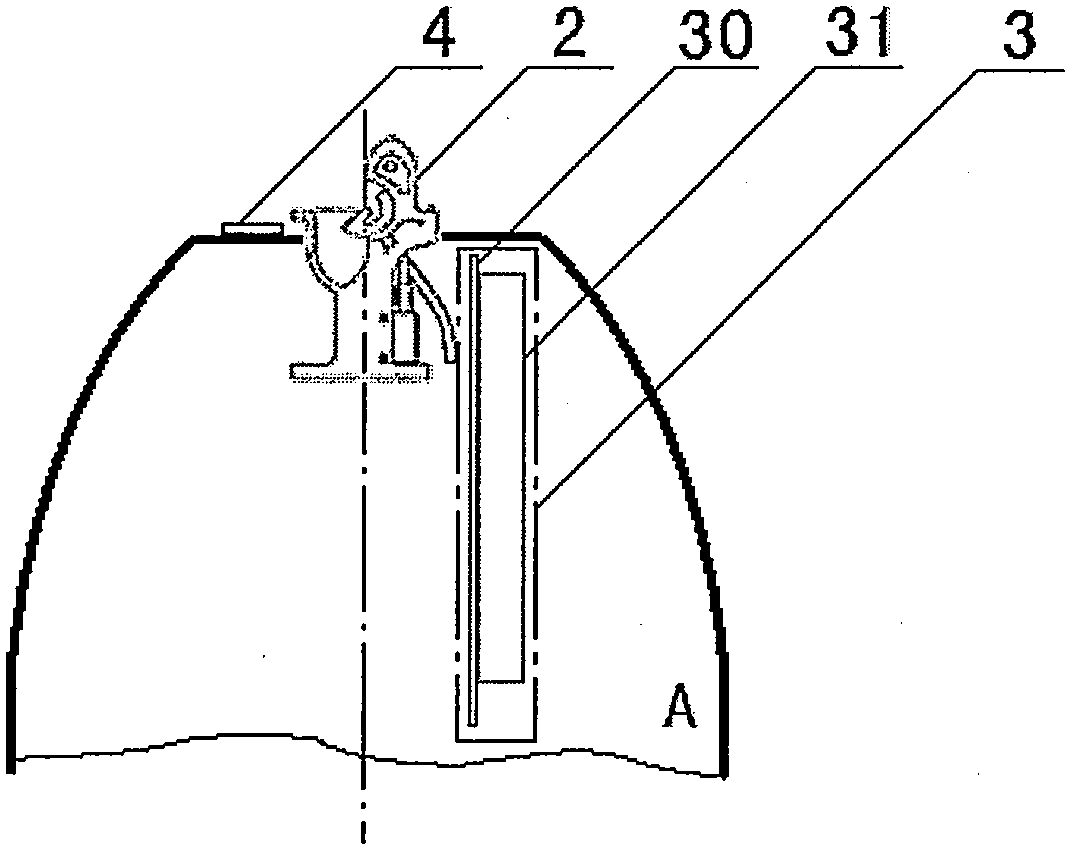

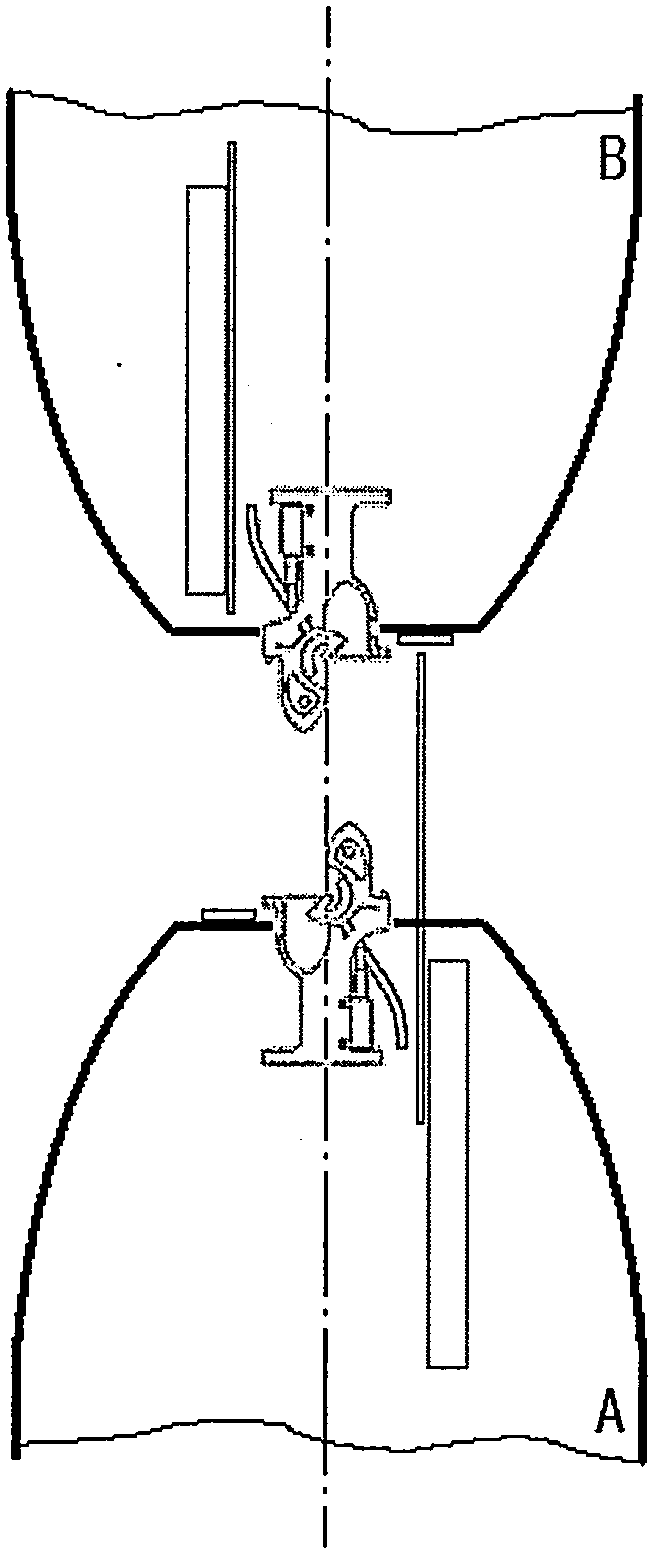

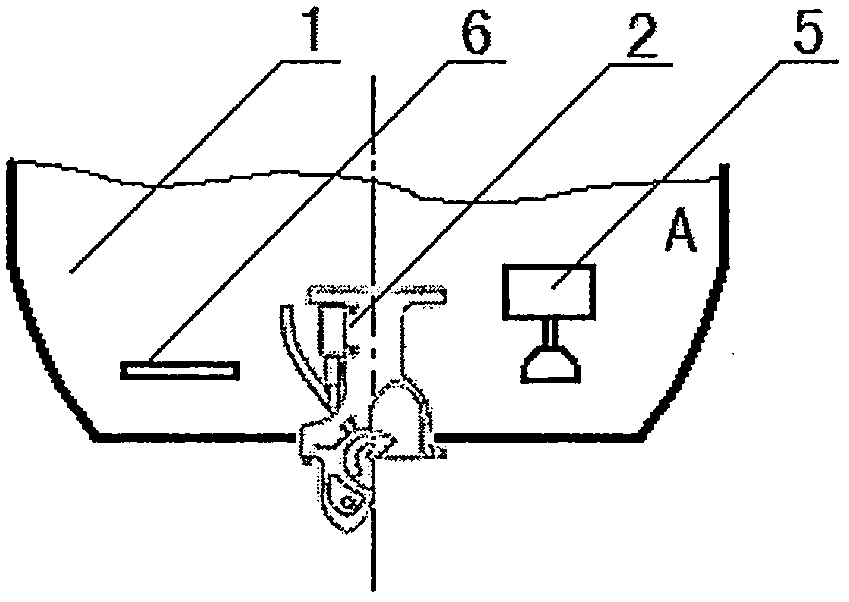

Turbulence flow device, shunt assembly and air conditioning unit

PendingCN110530071AImprove uniformityImprove heat transfer effectMechanical apparatusEvaporators/condensersFlow diverterPhase state

The invention provides a turbulent flow device, a shunt assembly and an air conditioning unit. The turbulent flow device comprises a pipe body and a spiral turbulent flow body, the front end of the pipe body is used for feeding liquid, and the rear end of the pipe body is used for discharging liquid to a shunt. The spiral turbulent flow body is fixedly arranged in the pipe body and is used for conducting turbulent flow operation on the fluid passing through the pipe body to enable the fluid to be in an annular flow pattern. By adopting the technical scheme of the invention, before a refrigerant is led to the shunt, the refrigerant firstly passes through the flow disturbing device, enters the pipe body and then is subjected to turbulent flow operation under the action of the spiral flow disturbing body, so that the fluid is in the annular flow pattern, the gas-liquid two-phase states are symmetrically distributed along a circumferential direction, the favorable inlet conditions are provided for the shunt operation of the shunt, the shunt uniformity is improved, and an evaporator achieves the optimal heat exchange capacity.

Owner:GREE ELECTRIC APPLIANCES INC

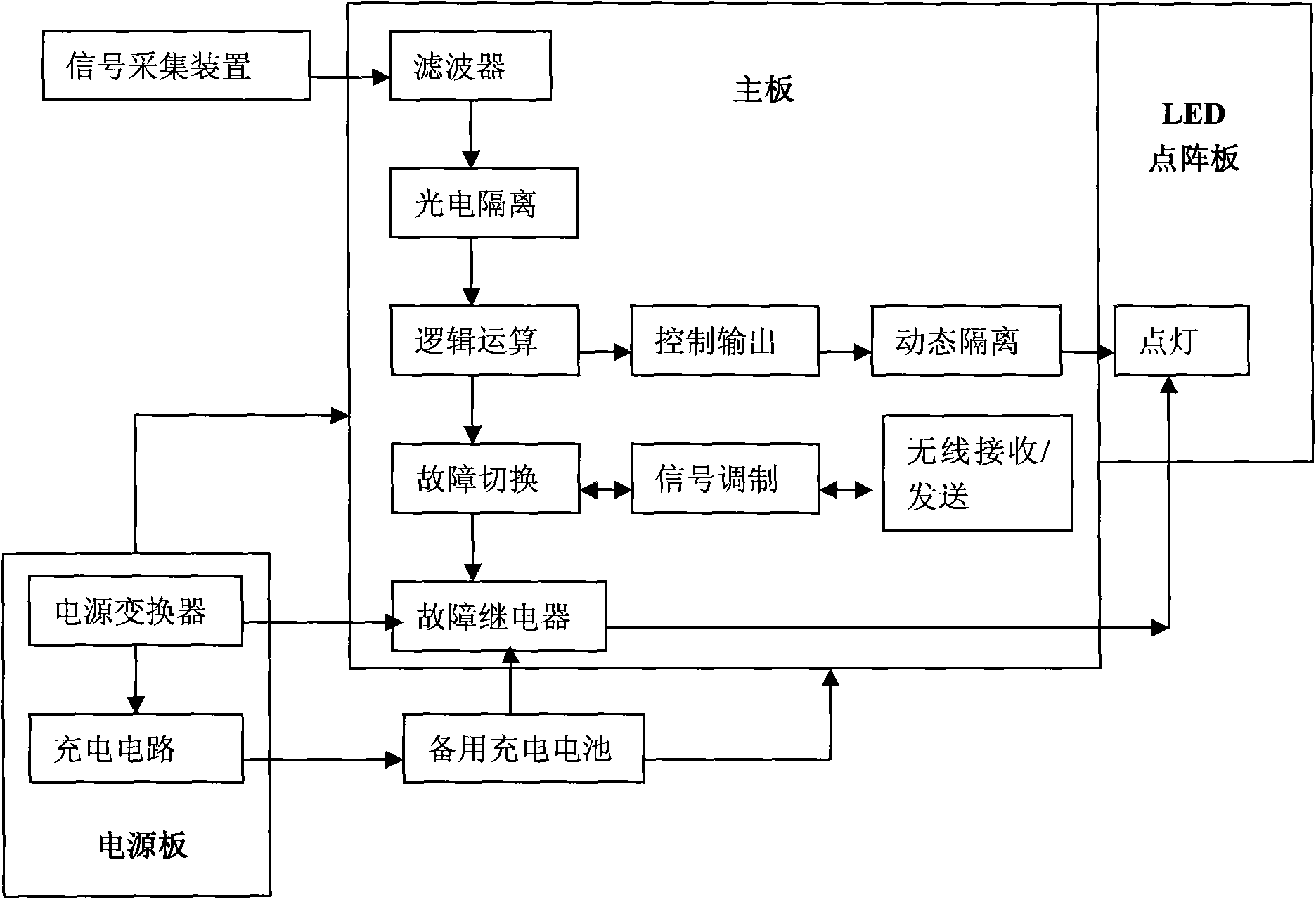

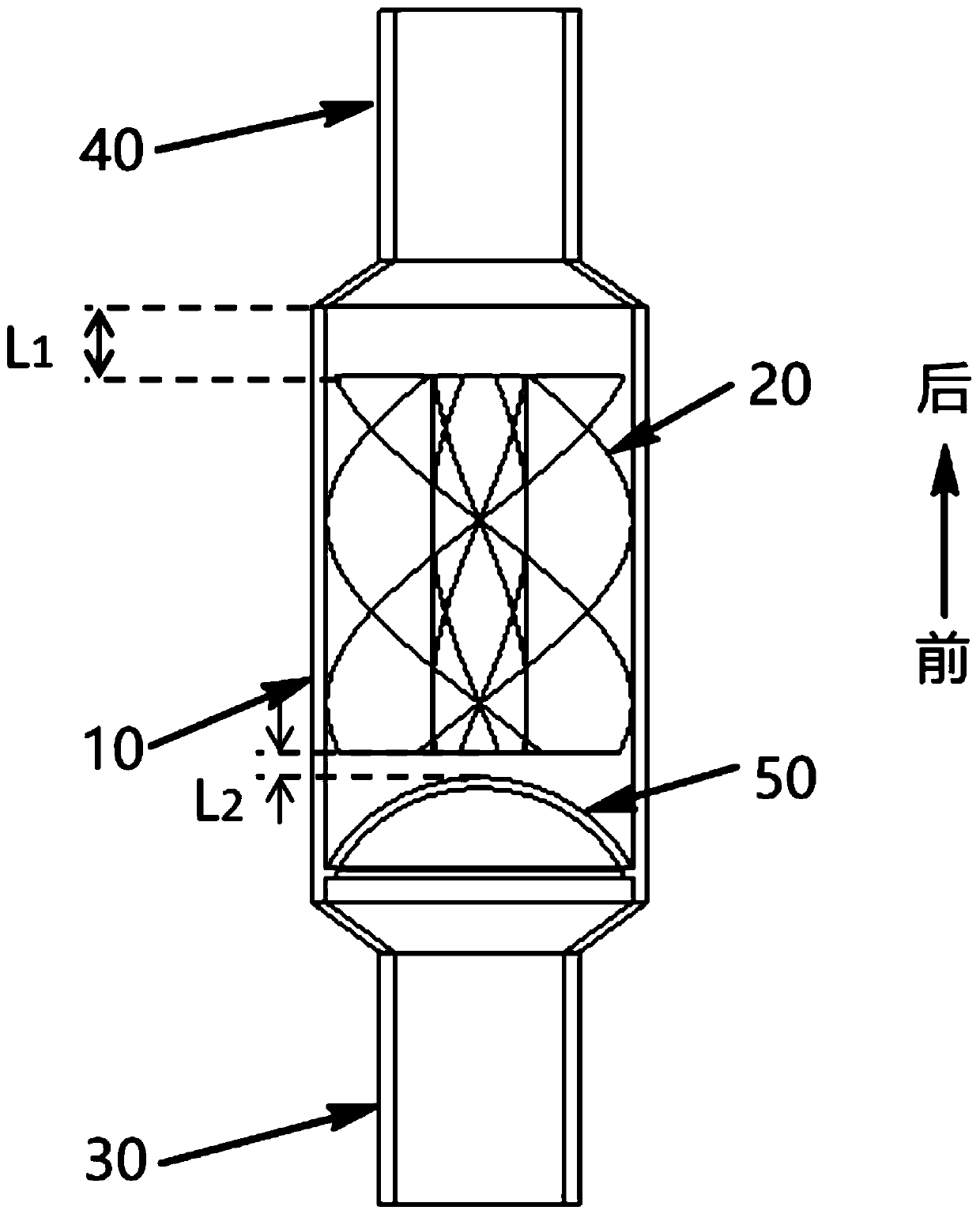

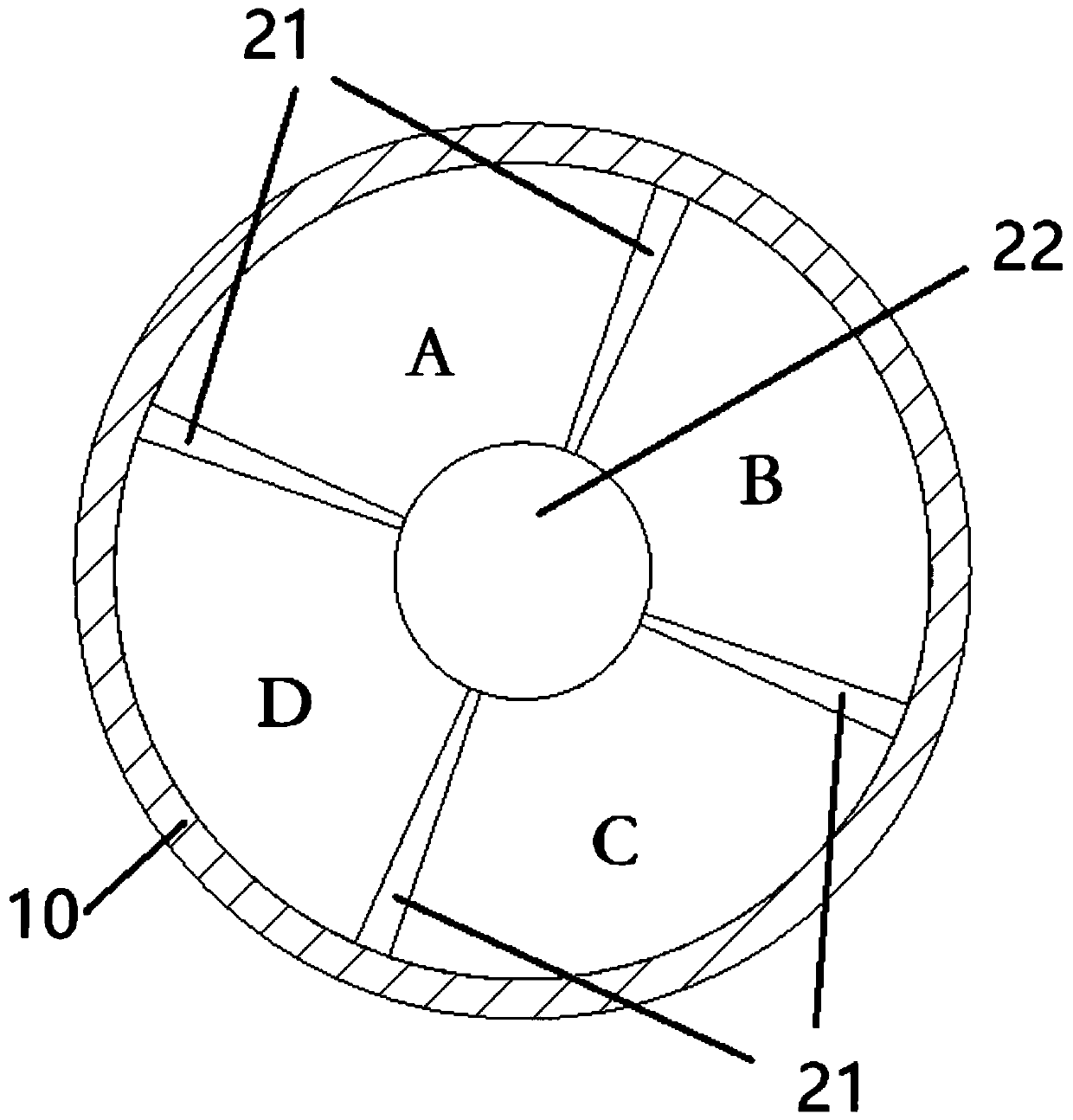

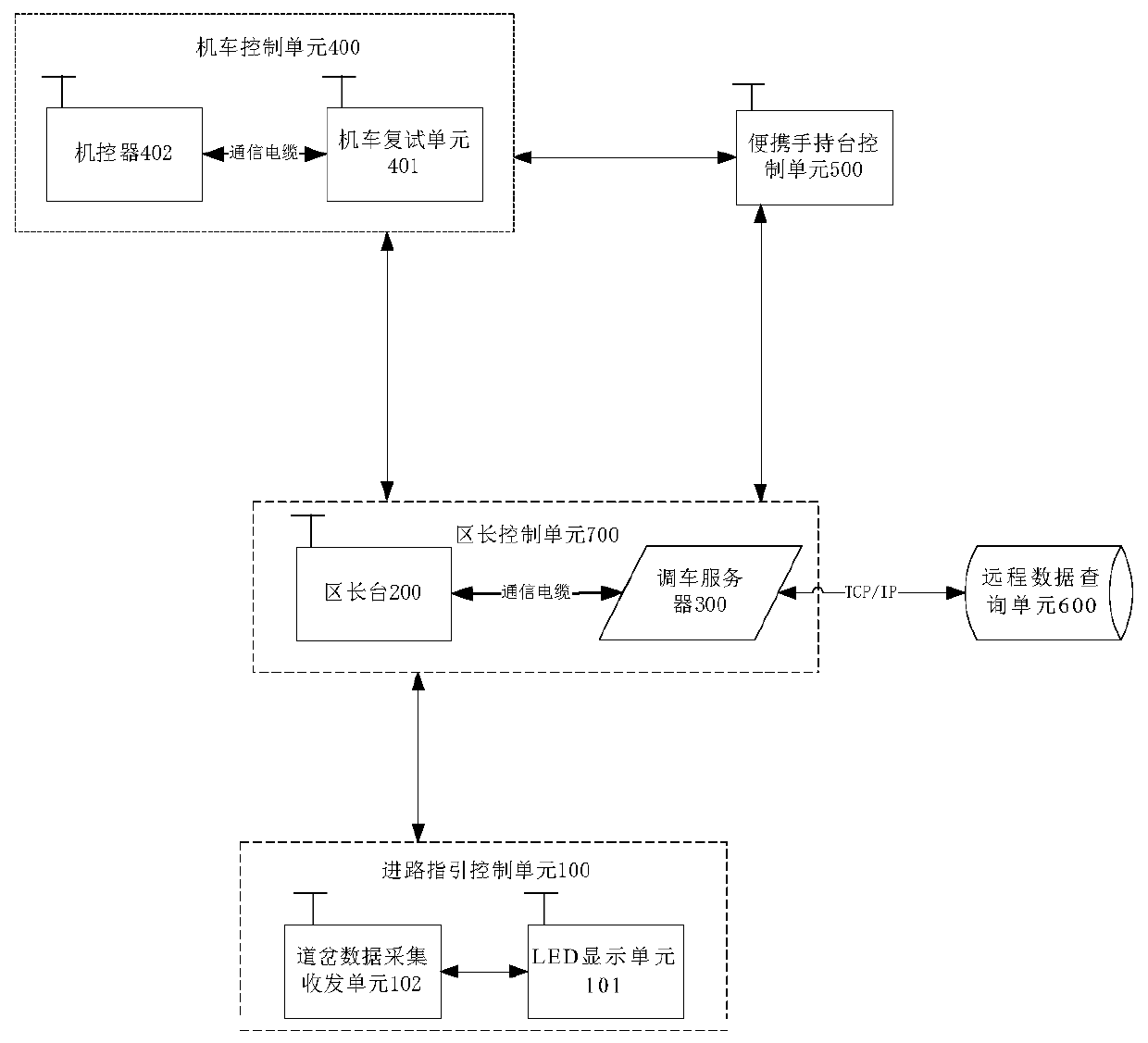

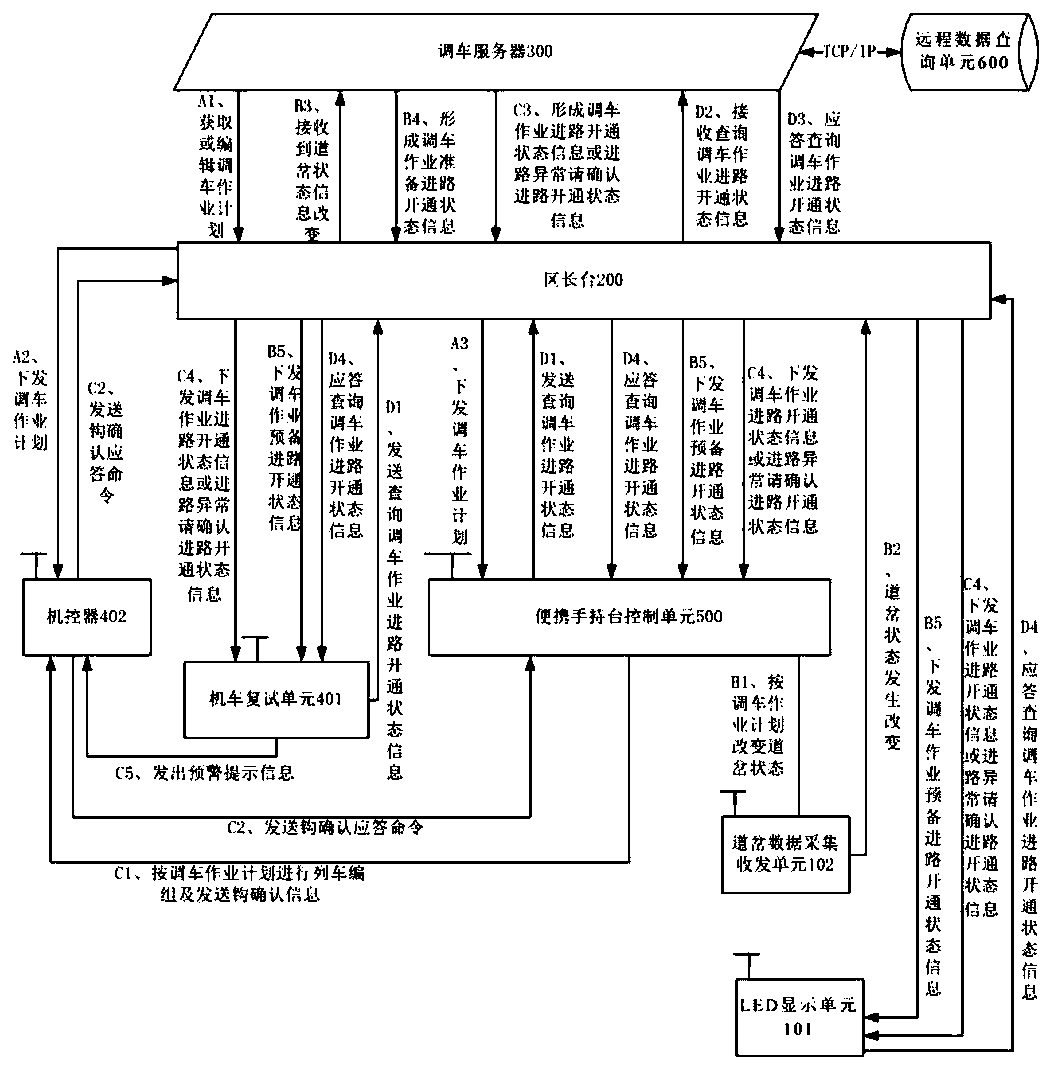

Radio shunting signal lamp indication system and method with function of shunting route guidance in non-interlocking areas

ActiveCN110203256AIncreased guard signalIntuitive reflectionRailway traffic control systemsSignal boxes station blockingGuidance controlDerailment

The invention relates to a radio shunting signal lamp indication system and method with a function of shunting route guidance in non-interlocking areas, and belongs to the technical field of shuntingin the railway transportation process. The radio shunting signal lamp indication system comprises a locomotive control unit, an area manager control unit, a route guidance control unit, a portable handheld radio control unit, a remote data query unit and other structures. In addition to a function of command for shunting operations, the radio shunting signal lamp indication system also has a function of route query for the shunting operations, and can avoid incorrect operations or incorrect confirmation caused by human factors, thereby avoiding the occurrence of incorrect routing, switch splitting and even train derailment accidents. The radio shunting signal lamp indication system not only provides a safety guarantee for the shunting operations but also reduces the labor intensity of operators, thereby improving the efficiency of the shunting operations and the sorting capacity of a station.

Owner:昆明聚讯科技有限公司

Multistage suspension melting crystallization method for separating p-xylene

InactiveCN106831303AIncrease the average particle sizeEasy to operateCrystallisation purification/separationHigh energyCrystallization

The invention relates to a multistage suspension melting crystallization method for separating p-xylene. The multistage suspension melting crystallization method comprises the following steps: carrying out shunt operation on raw materials, carrying out multistage crystallization on a part of the raw materials, directly obtaining a p-xylene product, then using the rest of the raw materials to carry out pulping washing and warming aging on a low-temperature crystal in an aging kettle, and obtaining residual p-xylene product. Stable operation of the aging kettle is guaranteed by adjusting the amount and temperature of the raw materials entering into the aging kettle, and then the stability of product purity and yield is guaranteed. Through the technical scheme adopted in the invention, the problems of unstable operation of the aging kettle and high energy consumption existing in the prior art are preferably solved, and the method can be used in the crystallization production of the p-xylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

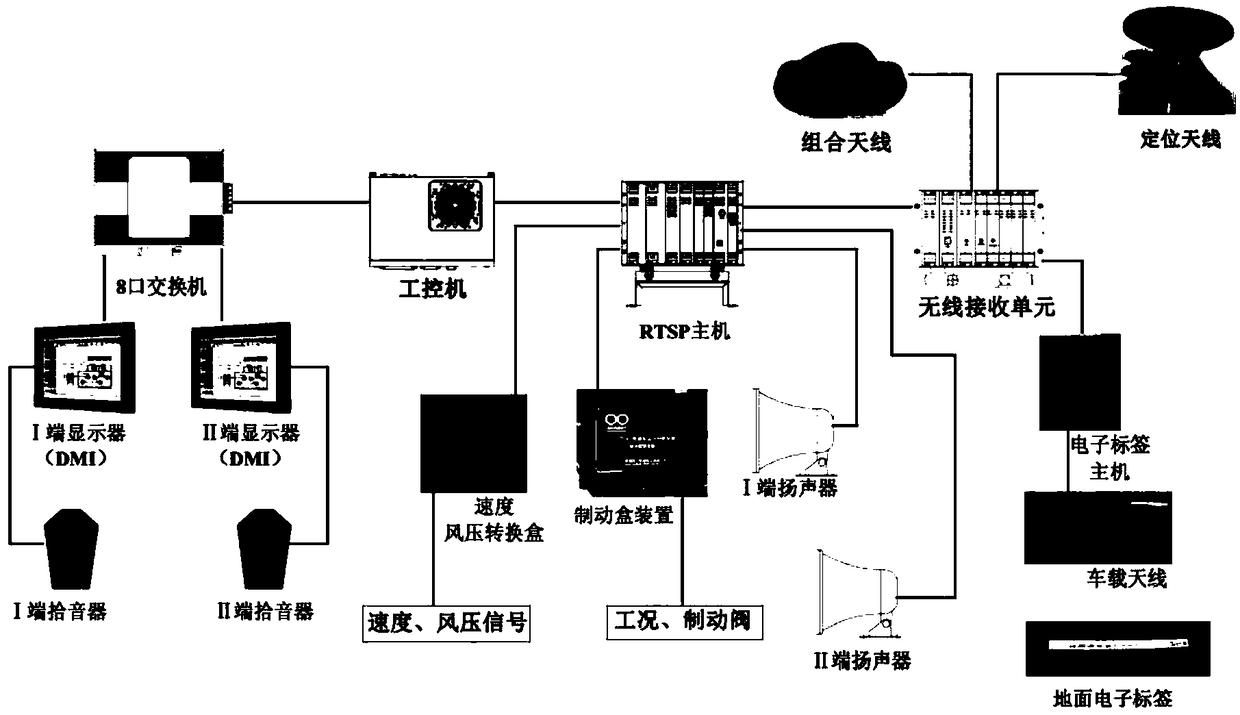

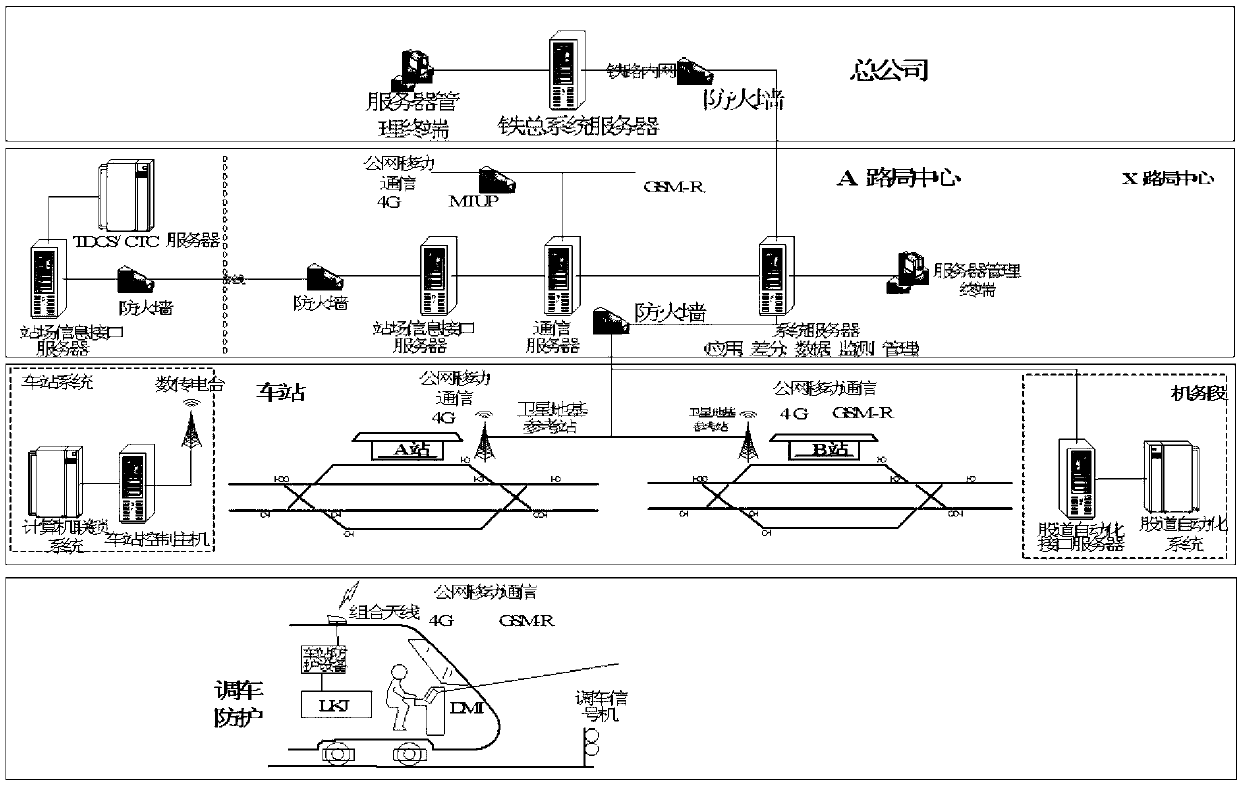

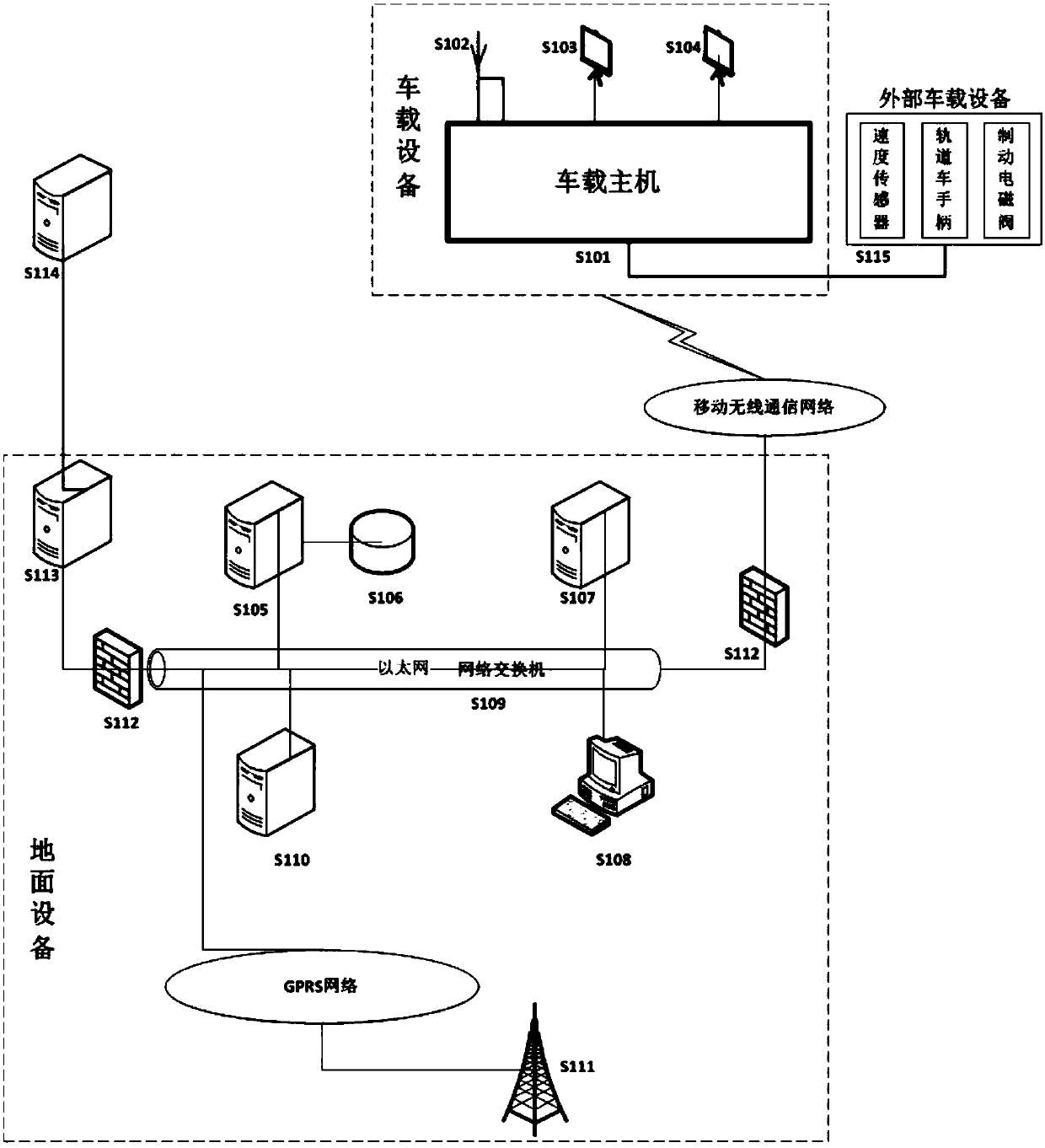

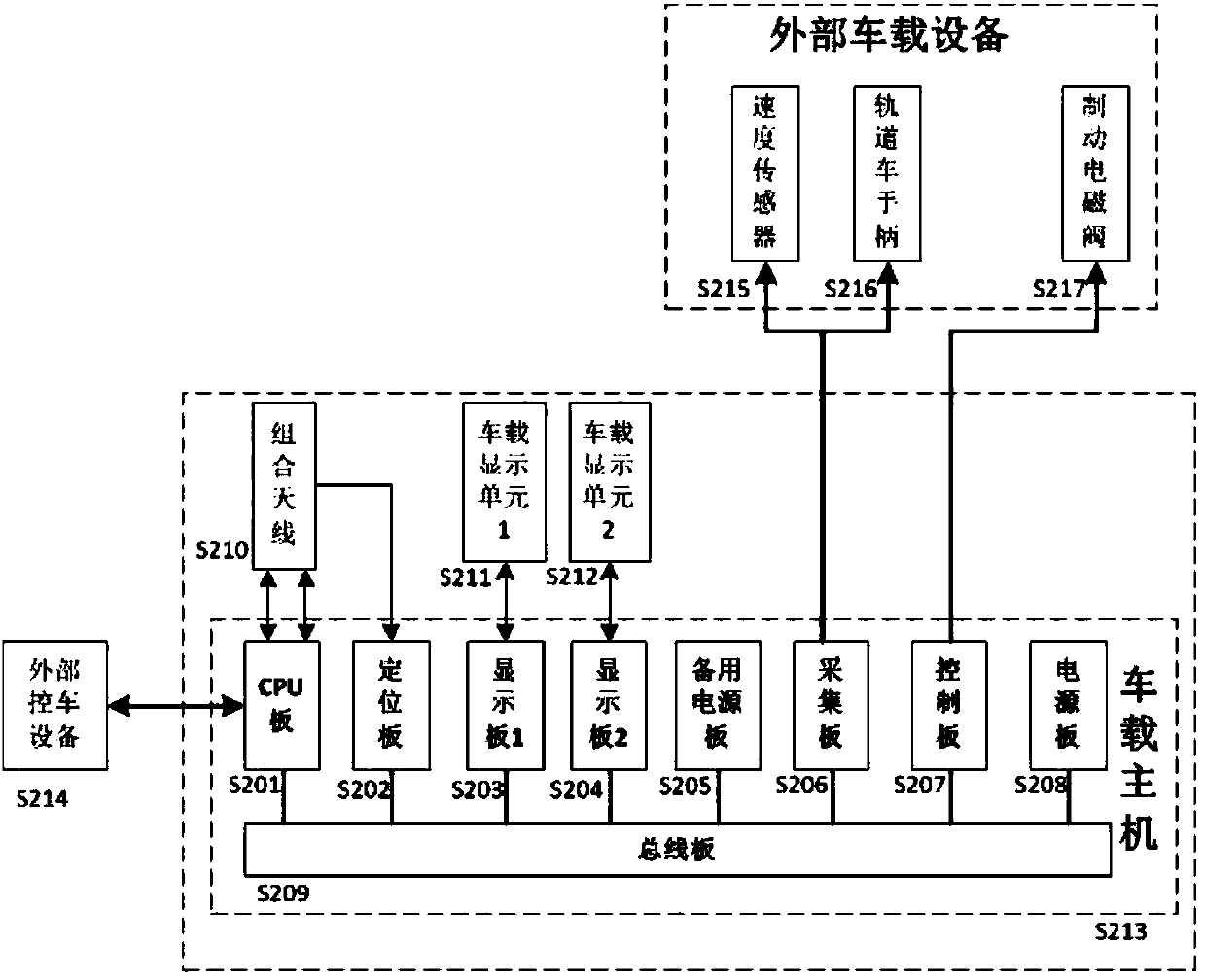

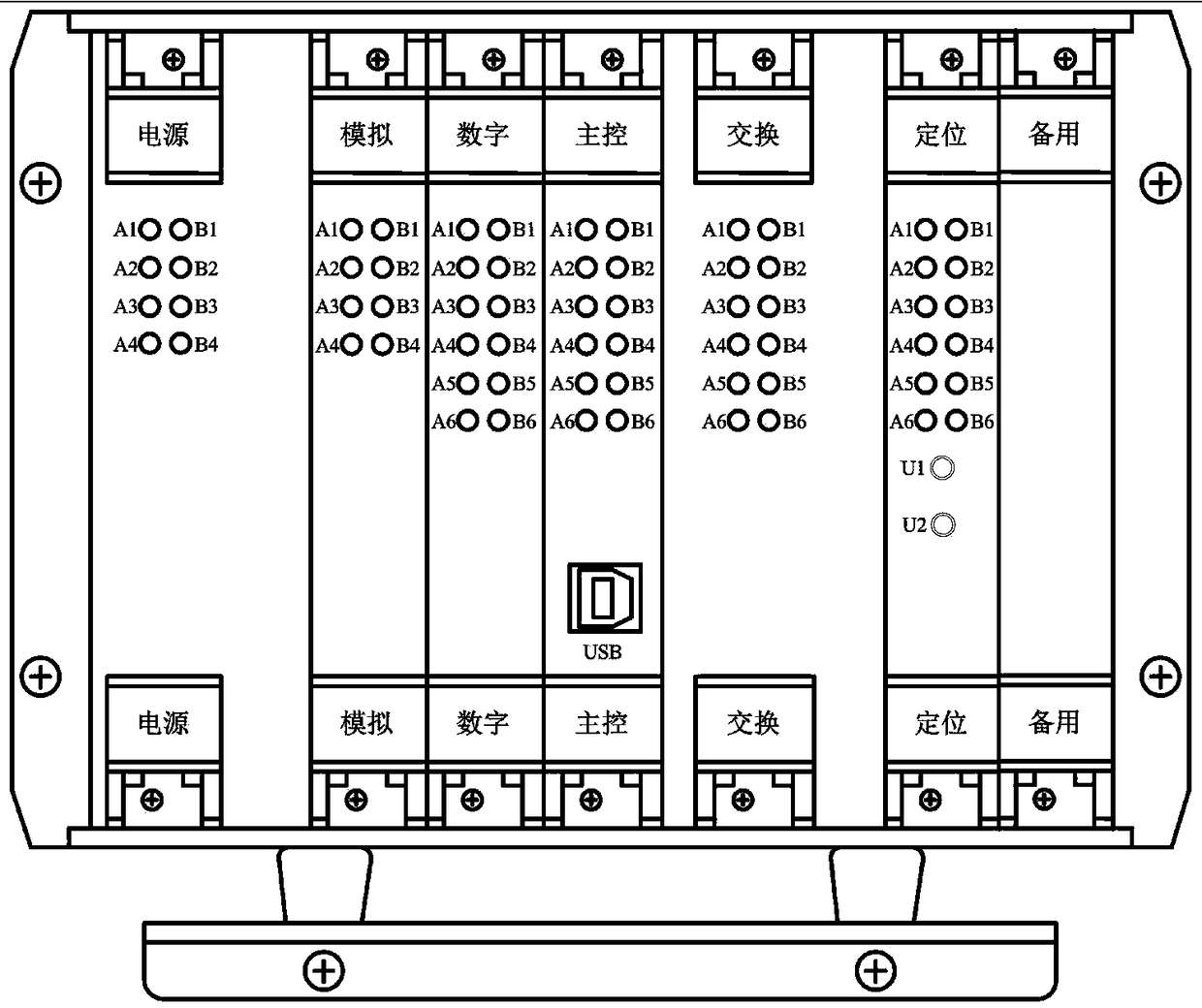

Shunting operation safety control system and method for non-electric-area rail car

PendingCN110091896ASolve the safety protection problem of shunting operationEasy to useRailway traffic control systemsTerminal serverControl system

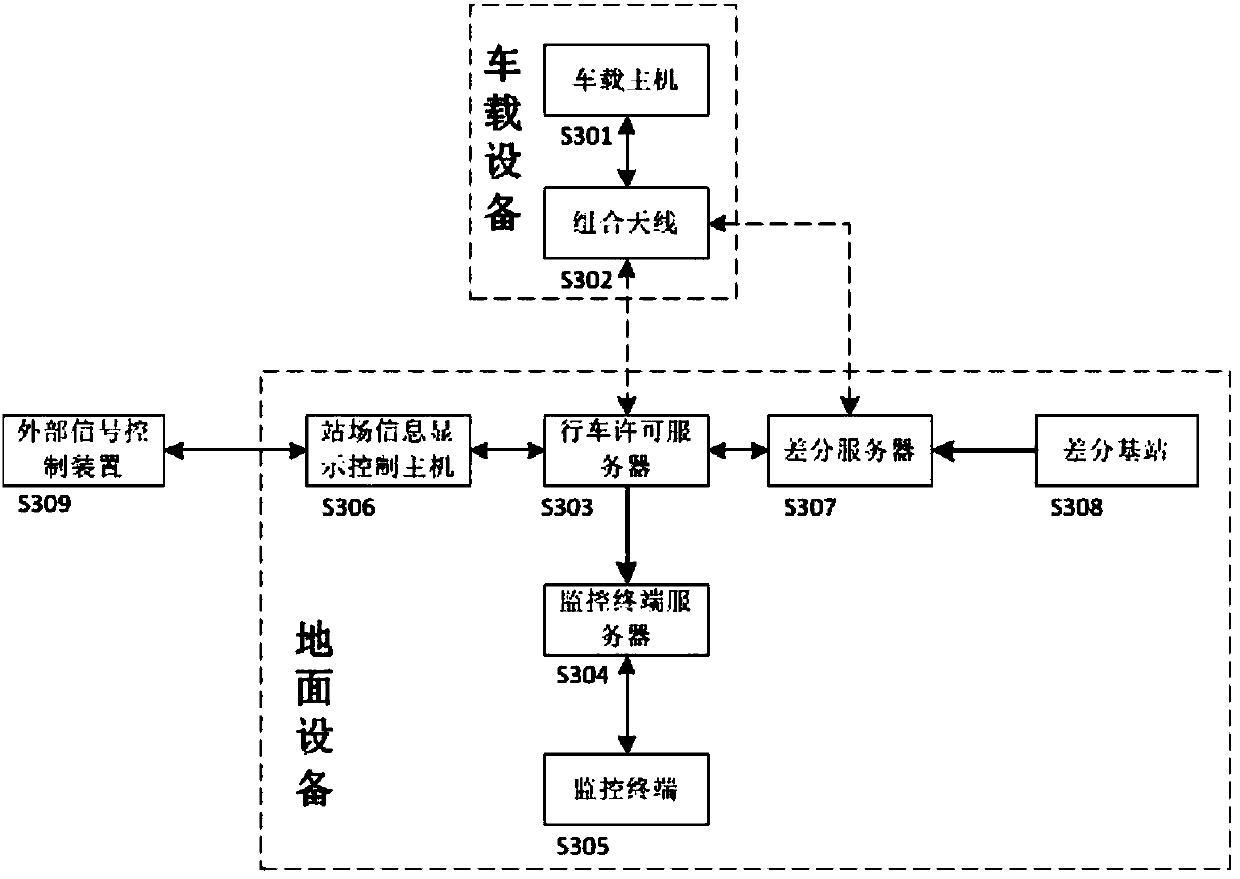

A shunting operation safety control system for a non-electric-area rail car realizes safety protection in the shunting operation process of the non-electric-area station rail car, and prevents accidents in the shunting operation process of the non-electric-area rail car. The shunting operation safety control system for the non-electric area rail car comprises a vehicle-mounted device and a grounddevice. The vehicle-mounted device comprises a vehicle-mounted host, a combined antenna and a vehicle-mounted display unit. The ground device comprises a Beidou differential base station, a station information display control host, a driving permission operation server, a storage device, a monitoring terminal server, a differential server, a network switch, a firewall and a monitoring terminal. The advantages are that the satellite differential positioning technology, the signal control technology, the mobile wireless communication technology and the computer remote control technology are adopted, so accurate positioning of the position of the rail car, station signal collection and control, wireless communication between the rail car and the ground and the like are achieved, and the safety protection problem of shunting operation of the station rail car in the non-electric area is effectively solved.

Owner:HENAN LANXIN TECH

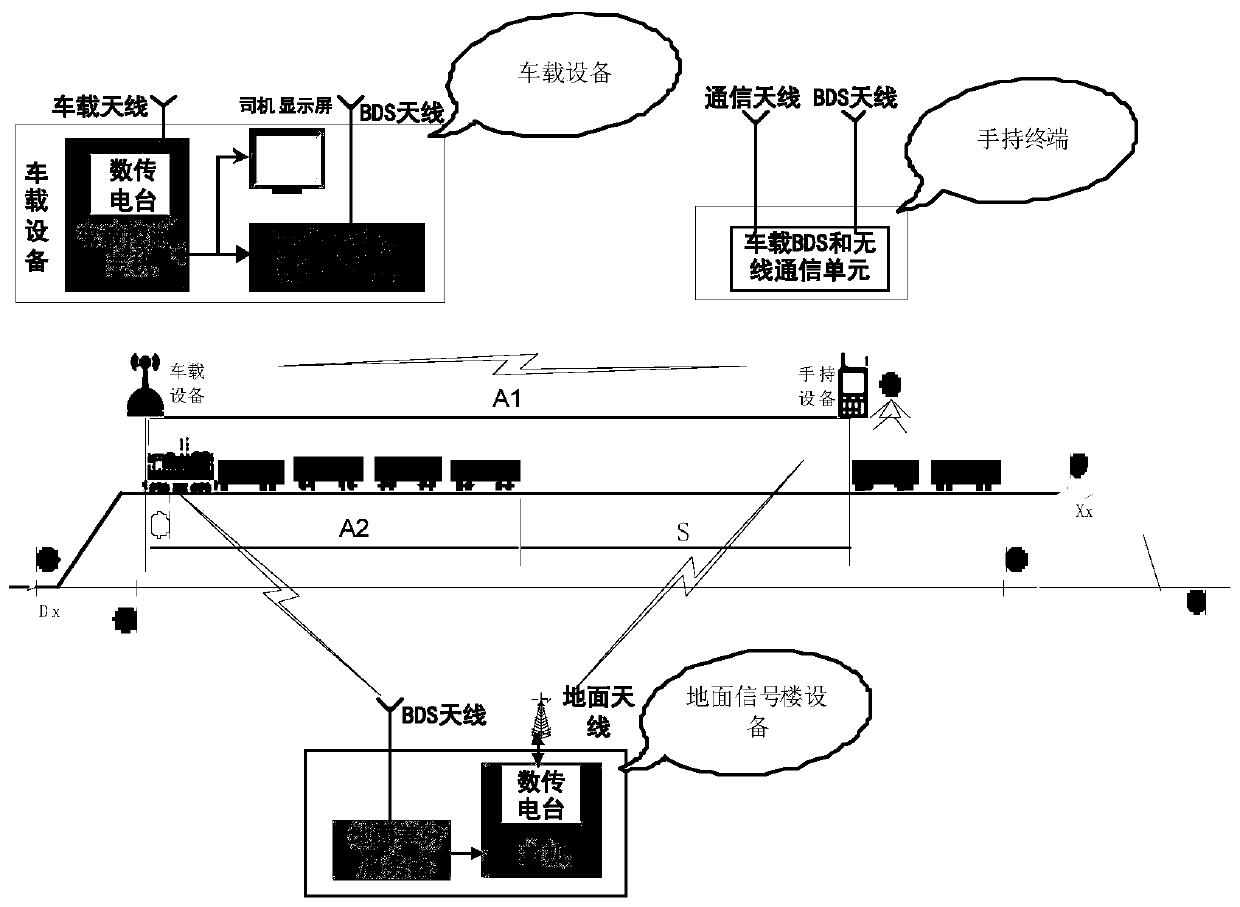

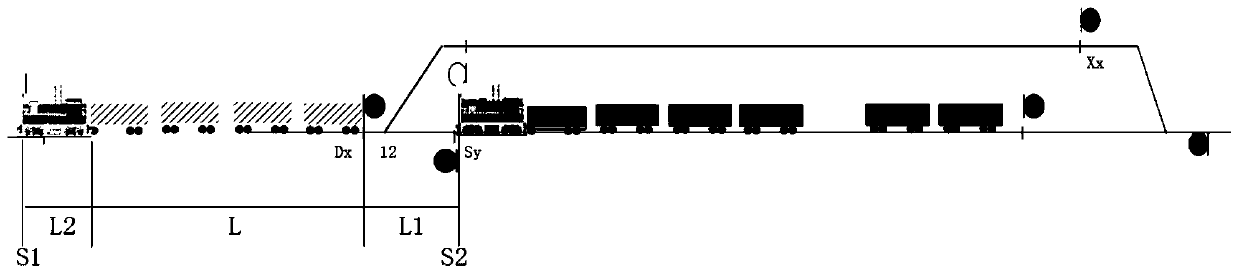

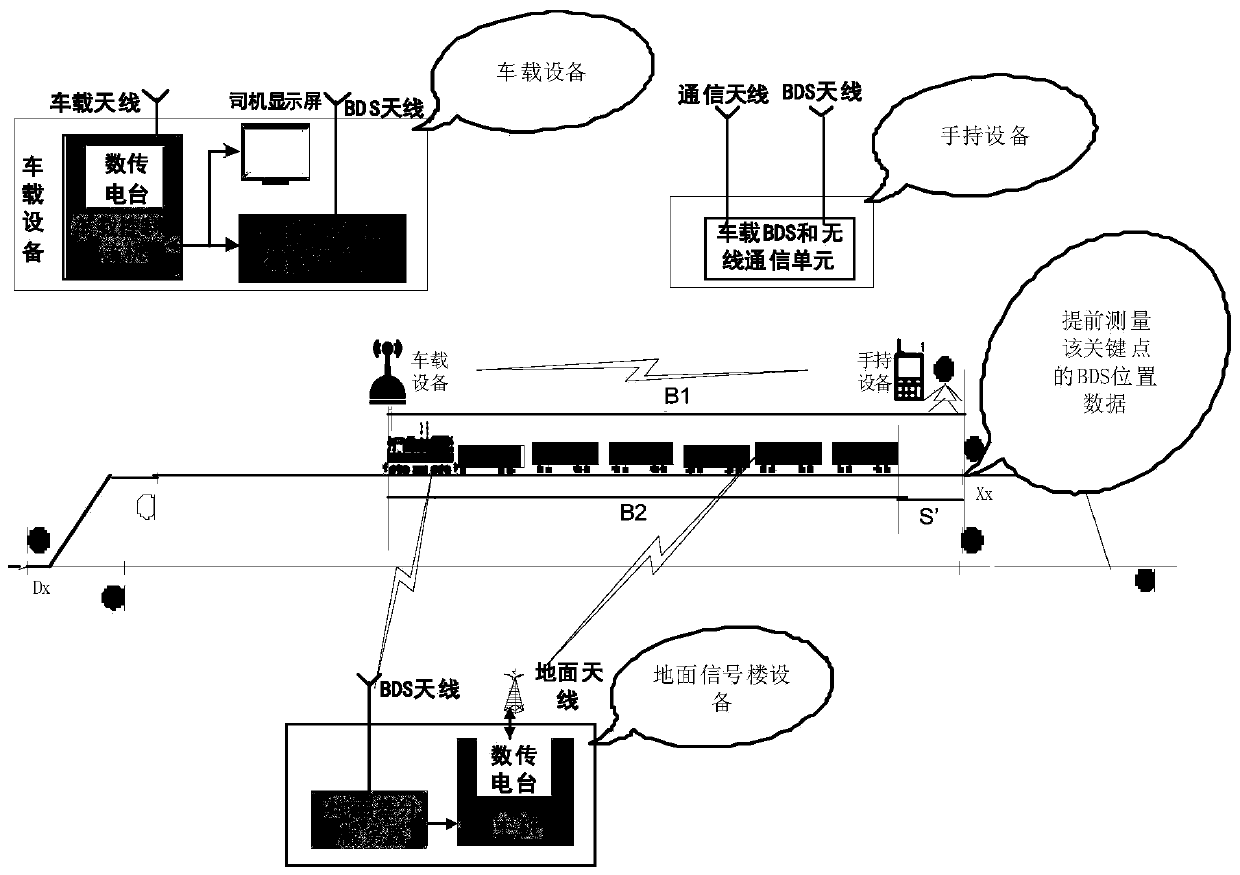

Distance calculation implementation method of shunting operation key points in station track on basis of BDS and STP

ActiveCN110525484AIntuitive and effective grasp of positionIntuitive and effective grasp of the situationRailway traffic control systemsSignalling indicators on vehicleSimulationControl limits

The invention discloses a distance calculation implementation method of shunting operation key points in a station track on the basis of BDS and STP. A current homemade mature Beidou navigation system(BDS) and a differential positioning technology are adopted, and the positions of a shunting locomotive, shunting team operation staff and a connecting-hanging point are calculated accurately; according to the trajectory characteristic of the STP system in shunting operation, the distance between the key protective point and the front end of a train set during movement in the shunting operation process is calculated, the accurate distance is provided for the STP system, and the train controlled limit speed is calculated and serves as a train controlled basis. Meanwhile, the position and operation condition information of the operation shunting team members in the field can be effectively grasped by direct viewing, vehicles of the station track in a station are evaluated, then marshallingparking capacity calculation is performed, and the truest station track parking capacity information is provided for the station scheduling.

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

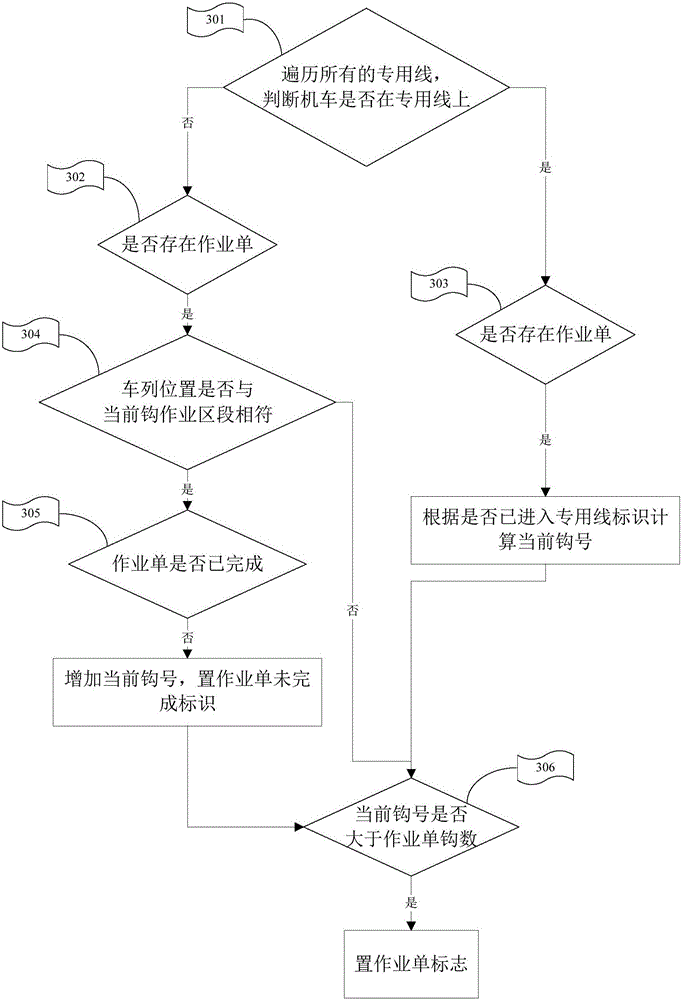

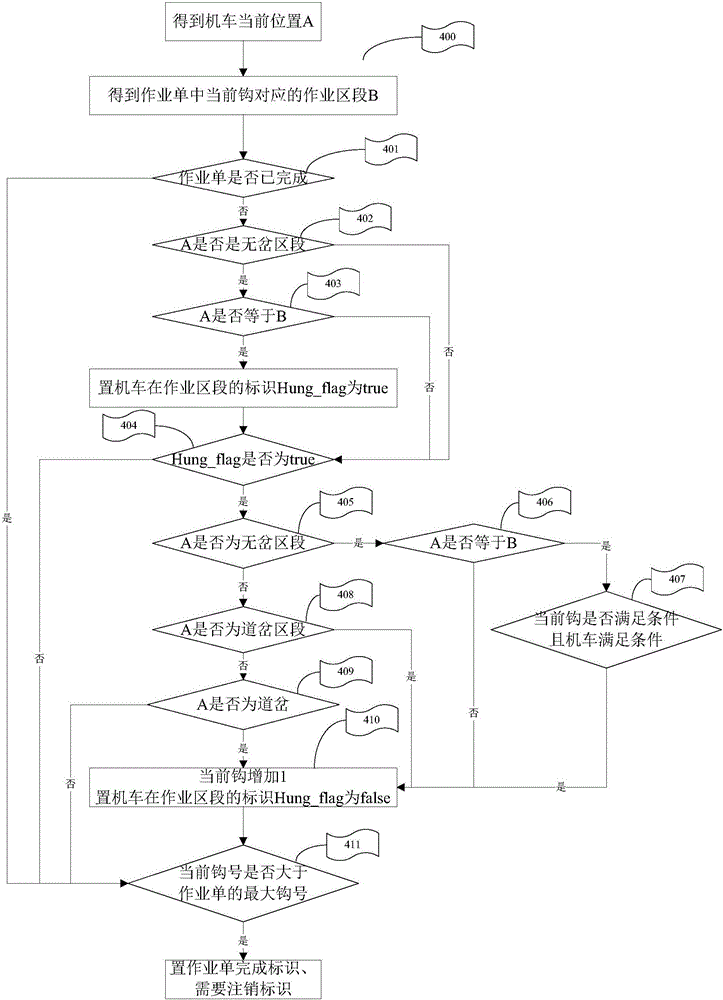

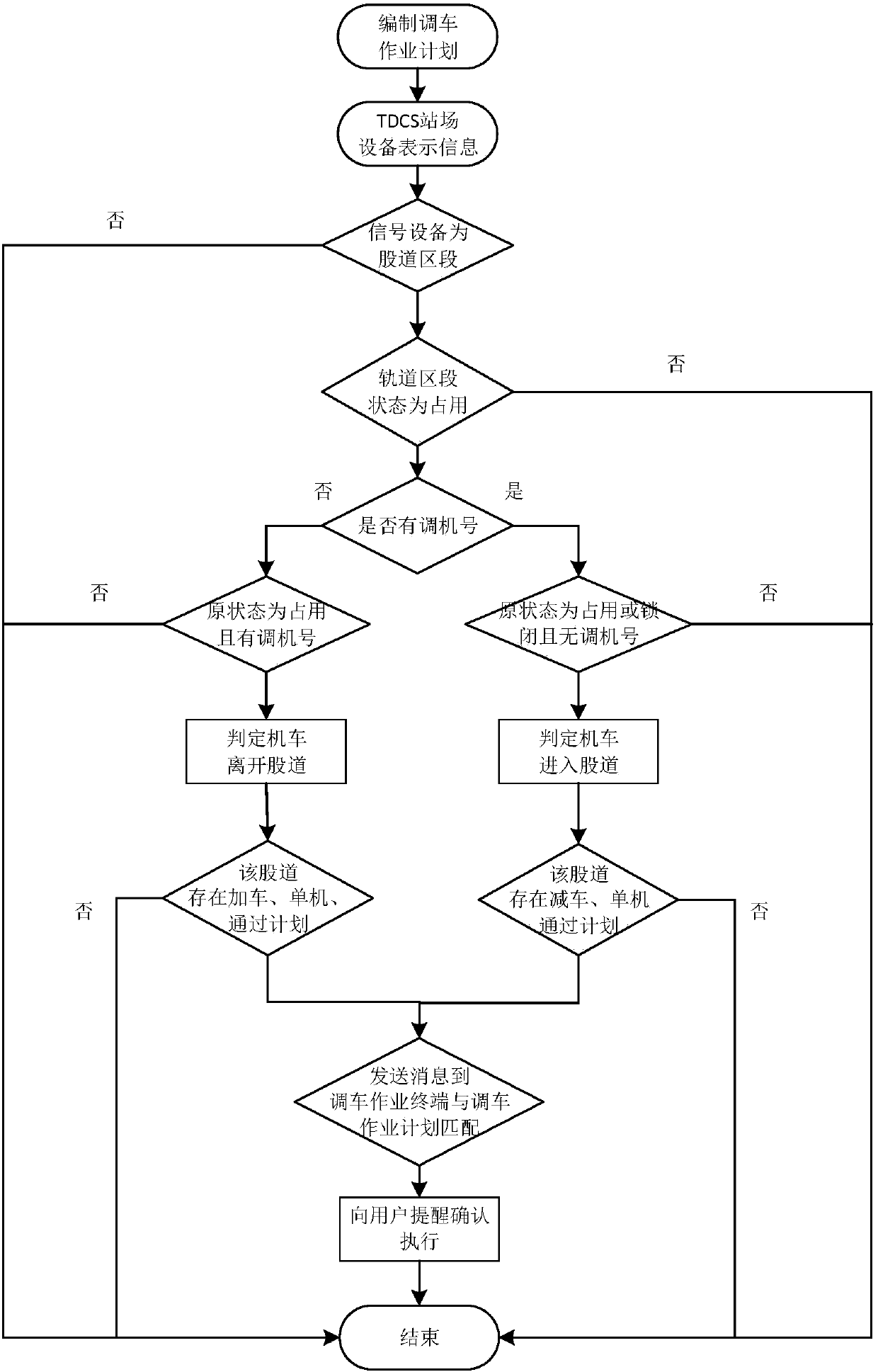

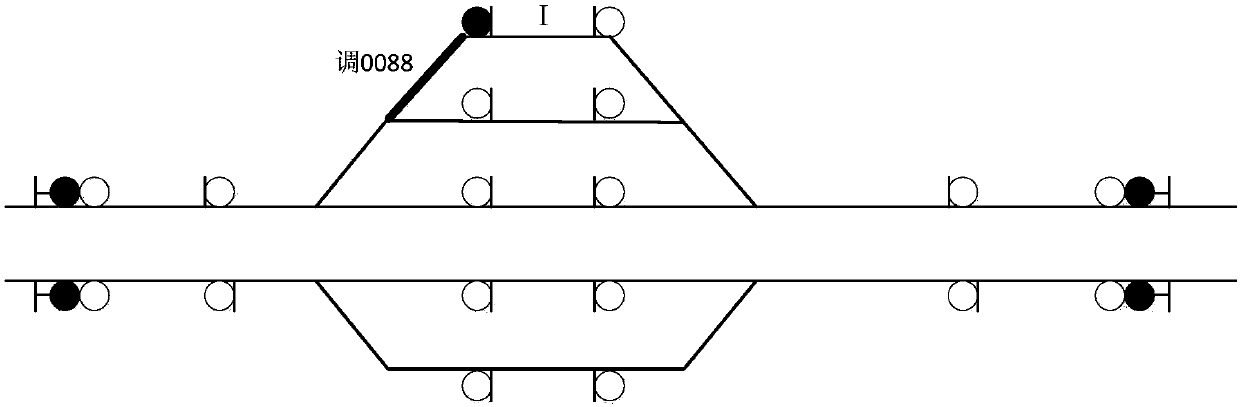

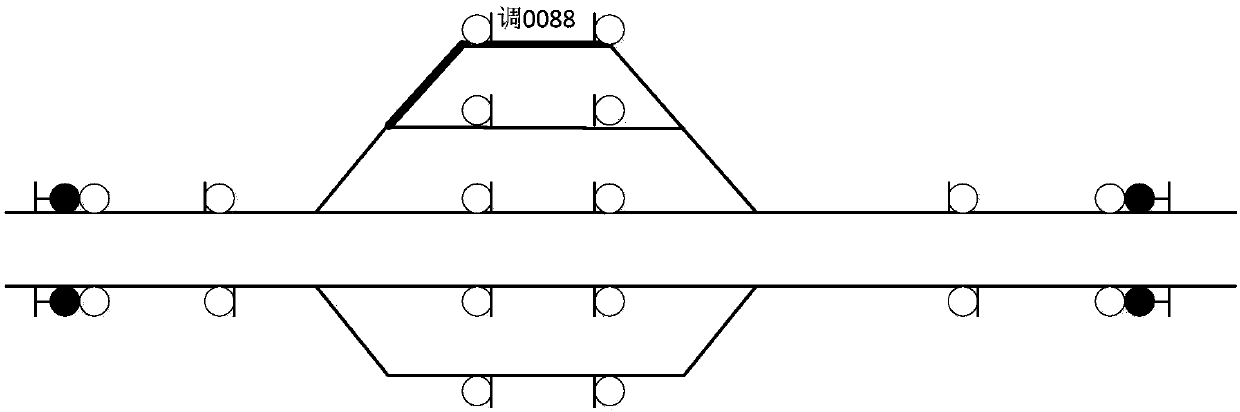

Method for tracking and judging shunting hook plan execution state by using TDCS (train operation dispatching command system) adjustment number

ActiveCN107792121ALess investmentAdd shunting operation logic processing moduleRailway traffic control systemsProgram planningCommand system

The invention relates to a method for tracking and judging a shunting hook plan execution state by using a TDCS (train operation dispatching command system) adjustment number. The method includes thefollowing steps that (1) a shunting operation sheet is drawn up according to a shunting plan; (2) a shunting operation hook plan execution logic processing module judges the locomotive running direction according to the change of TDCS station information, and by combining the locomotive position, the locomotive running direction, a station signal equipment logic diagram and the shunting operationsheet plan execution position, whether a message is sent to a shunting operation terminal or not is judged; (3) the shunting operation terminal matches the received message with the shunting plan according to the received message and reminds a user; and (4) the user determines and back-feeds the shunting operation sheet execution state. Compared with the prior art, the method has the advantages ofbeing wide in application, less in investment in equipment and capable of effectively judging the shunting hook execution state.

Owner:CASCO SIGNAL

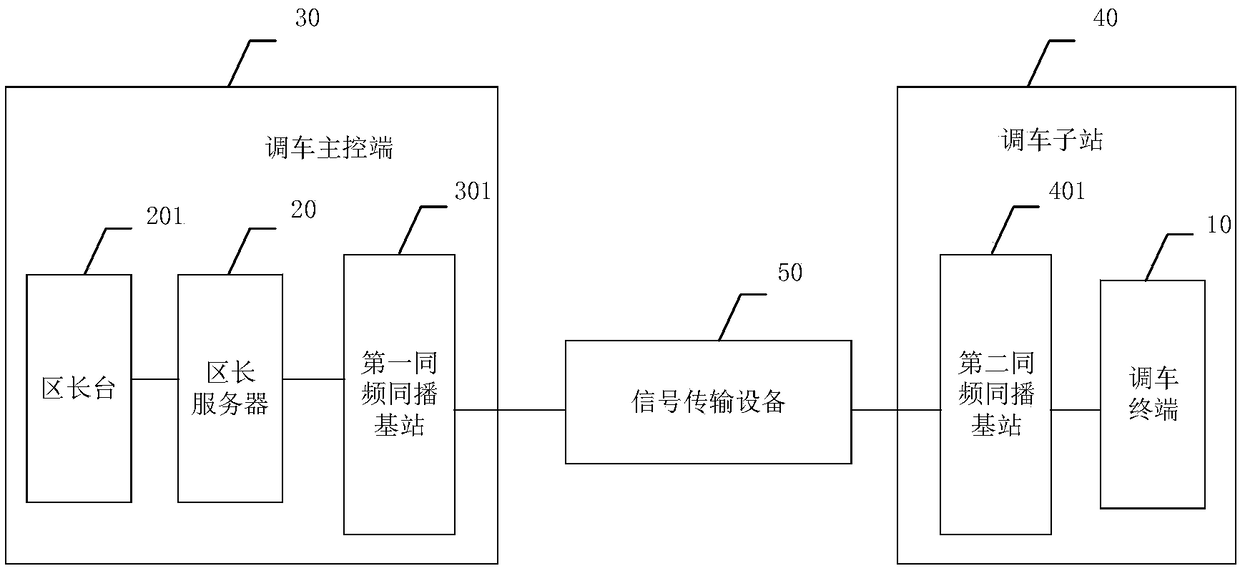

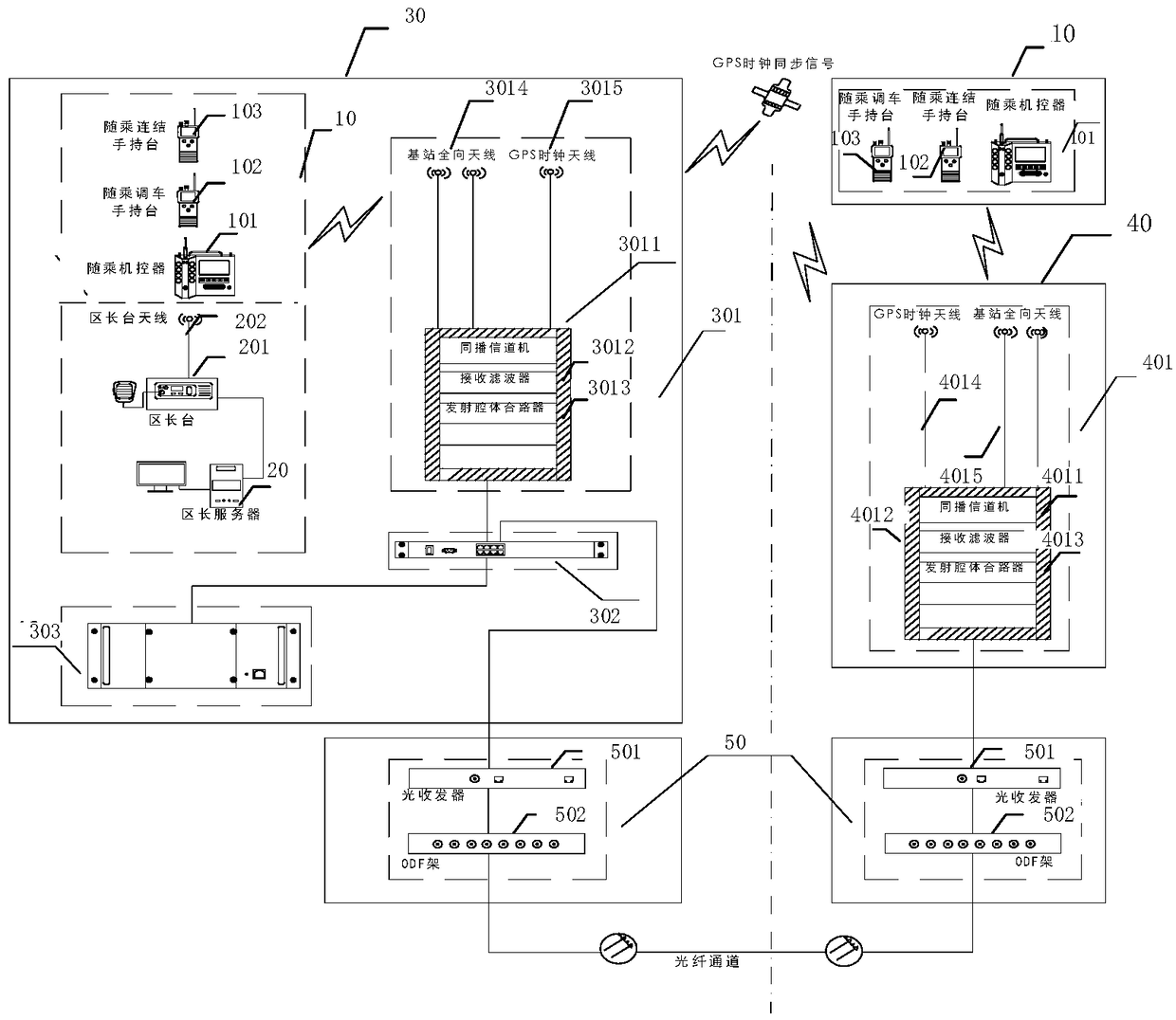

Railway flat shunting system

PendingCN108791373ATo achieve the purpose of unified managementTo achieve the purpose of signal interactionRailway traffic control systemsHigh level techniquesTarget signalComputer terminal

The invention discloses a railway flat shunting system. Signal transmission equipment is used for transmitting signals in a first co-frequency multicast base station in a shunting main control end tosecond co-frequency multicast base stations of all shunting sub-stations, so that the purpose of signal interaction between the shunting main control end and each shunting sub-station is achieved. Then, after a target signal is sent from a zone length platform and a zone length server, the target signal is transmitted to the second co-frequency multicast base stations by the first co-frequency multicast base station, and finally, the second co-frequency multicast base stations are used for transmitting the target signal to shunting terminals. In this way, the shunting terminals can carry out shunting operation on stations corresponding to the shunting sub-stations according to the target signal. Therefore, the shunting operation of all the shunting sub-stations can be realized by the shunting main control end, so that the purpose of carrying out unified management on the shunting operation of each railway station is achieved, and waste of manpower and resources is avoided.

Owner:兖矿能源集团股份有限公司

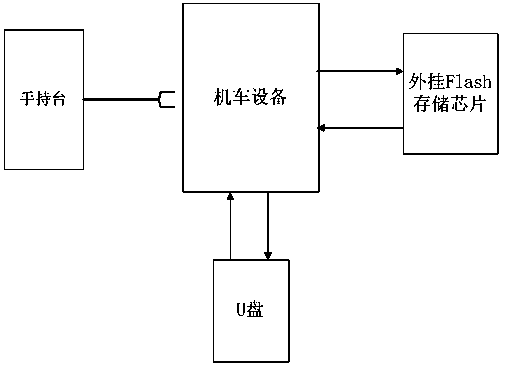

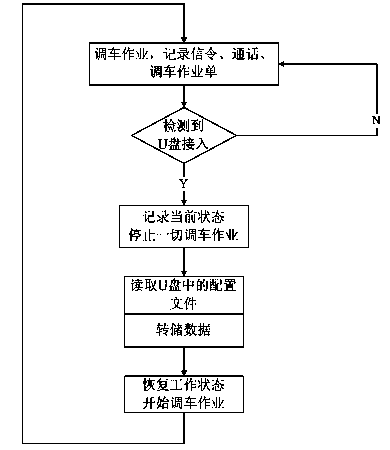

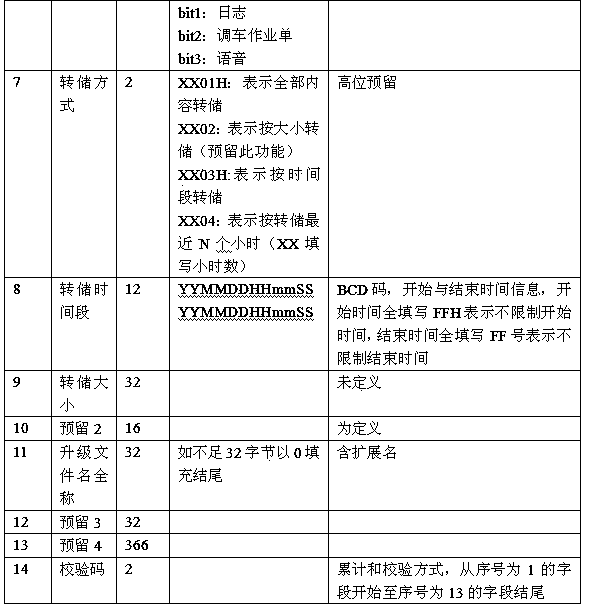

Data recording and U disk exporting method of digital balanced shunting system

ActiveCN103558997AEffective and informativePromote reductionInput/output to record carriersData contentData recording

The invention relates to a data recording and U disk exporting method of a digital flat regulation system. Locomotive equipment packs data of shunting operation and then writes into a permanent memory plug-in Flash memory chip to store during communication according to the agreement on recording; the packed data content comprises real-time time, type, a frequency group, direction and an ID (Identifier); the reliability and the accuracy are guaranteed through data check; during operation of an application program of the locomotive equipment, the locomotive equipment detects whether a U disk is accessed constantly, and reads a configuration file in the U disk and determines to dump all or a part of recorded content if detecting that the U disk is accessed; the data which are transferred out by the locomotive equipment are written into the U disk in the form of a file. The method has the beneficial effects that both the communication and the user operation between the locomotive equipment and a handset can be recorded, the recorded effective information is rich, a working process is convenient to reduce, a part of or all the data can be selectively exported according to the configuration file when the U disk exports the data, and the method is flexible in dumping, convenient, quick and easy to operate.

Owner:天津七一二移动通信有限公司

Shunting signal anti-overrunning system for locomotive

InactiveCN101306692AEnsure safetySolving Security Monitoring IssuesRailway signalling and safetyTransceiverGps receiver

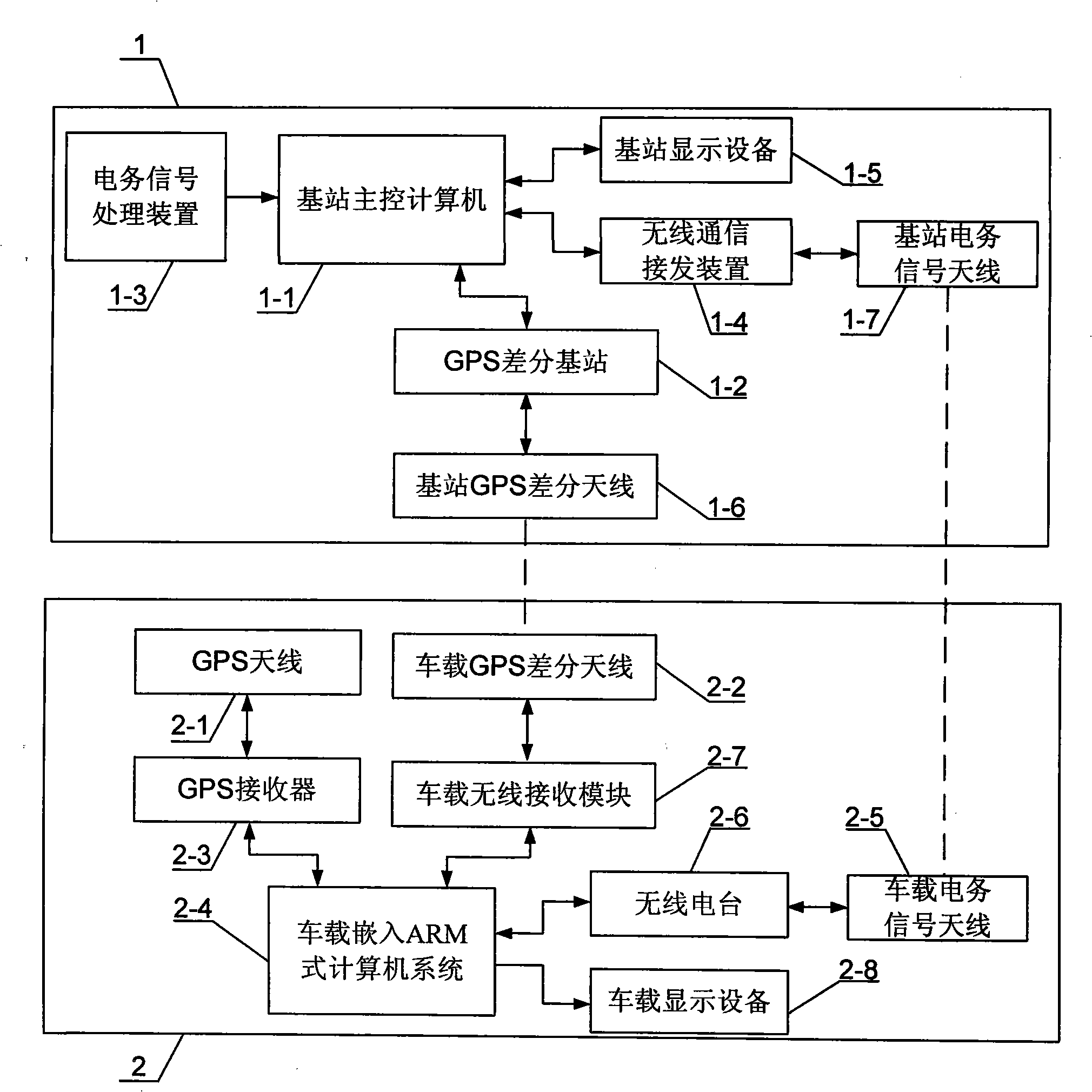

A locomotive shunting signal overrunning opposition system relates to a locomotive dispatching system which can solve the shortcomings that the prior shunting system has no signals of a track and a ground device can not be arranged. Output and inlet ends of a base station main control computer which is connected with an electrical signal processing device are respectively connected with input and output ends of a wireless communication transceiver which is connected with a base station electrical signal antenna and a GPS differential base station which is connected with a base station GPS differential antenna; input and output ends of a GPS receiver which is connected with a GPS antenna are connected with first input and output ends of a vehicle mounted embedded ARM computer system, second and third input and output ends of the vehicle mounted embedded ARM computer system are respectively connected with input and output ends of a wireless radio and a vehicle mounted wireless receiving module, the other input and output ends of the wireless radio are connected with a vehicle mounted electrical signal antenna, the other input and output ends of the vehicle mounted wireless receiving module are connected with a vehicle mounted GPS differential antenna; and an output end of the vehicle mounted embedded ARM computer system is connected with a vehicle mounted display device. The system of the invention can effectively protect the safety of shunting operation and better solve the problem of safety monitoring.

Owner:哈尔滨精达自动化技术开发有限责任公司

Flat shunting system

ActiveCN110509961AImprove securityEnsure safetyRailway traffic control systemsProgram planningReliability engineering

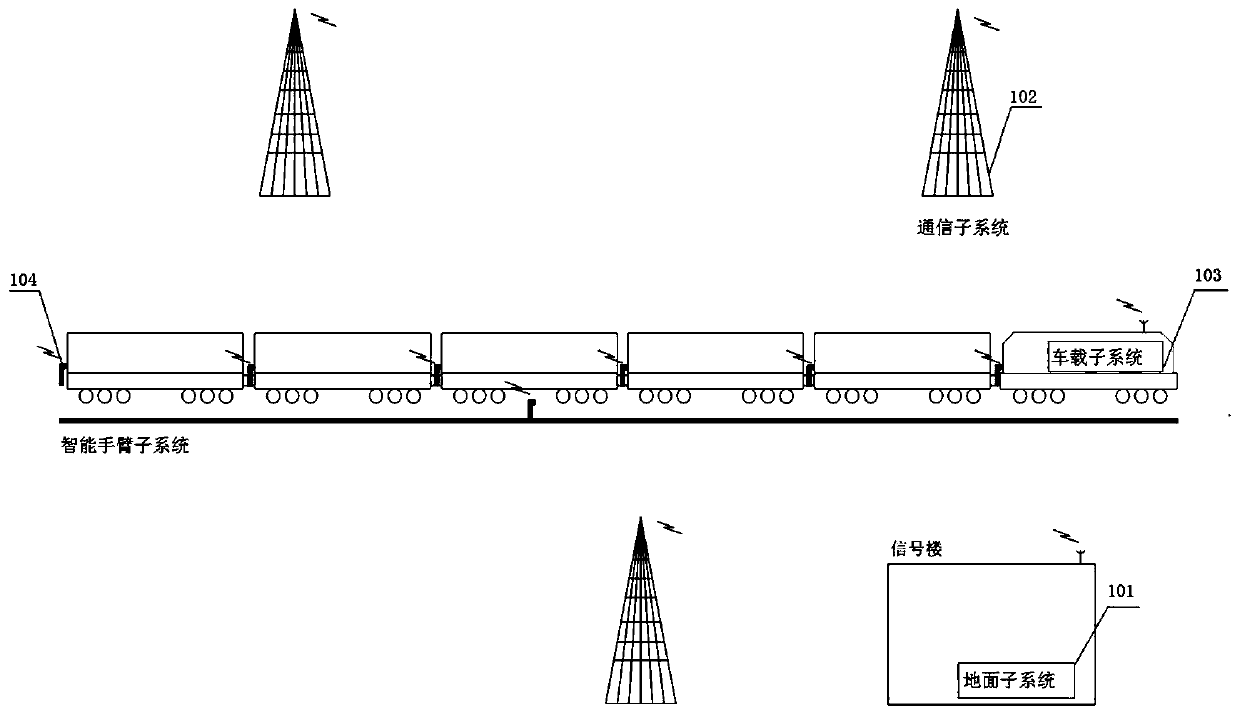

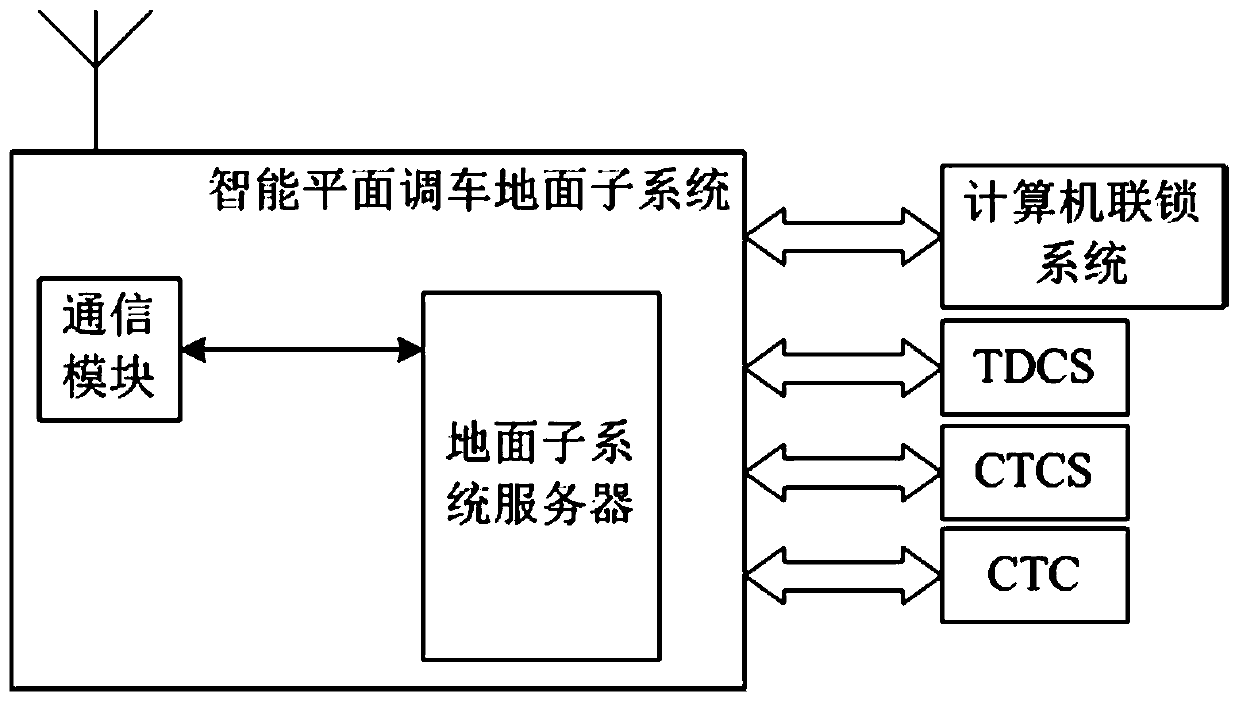

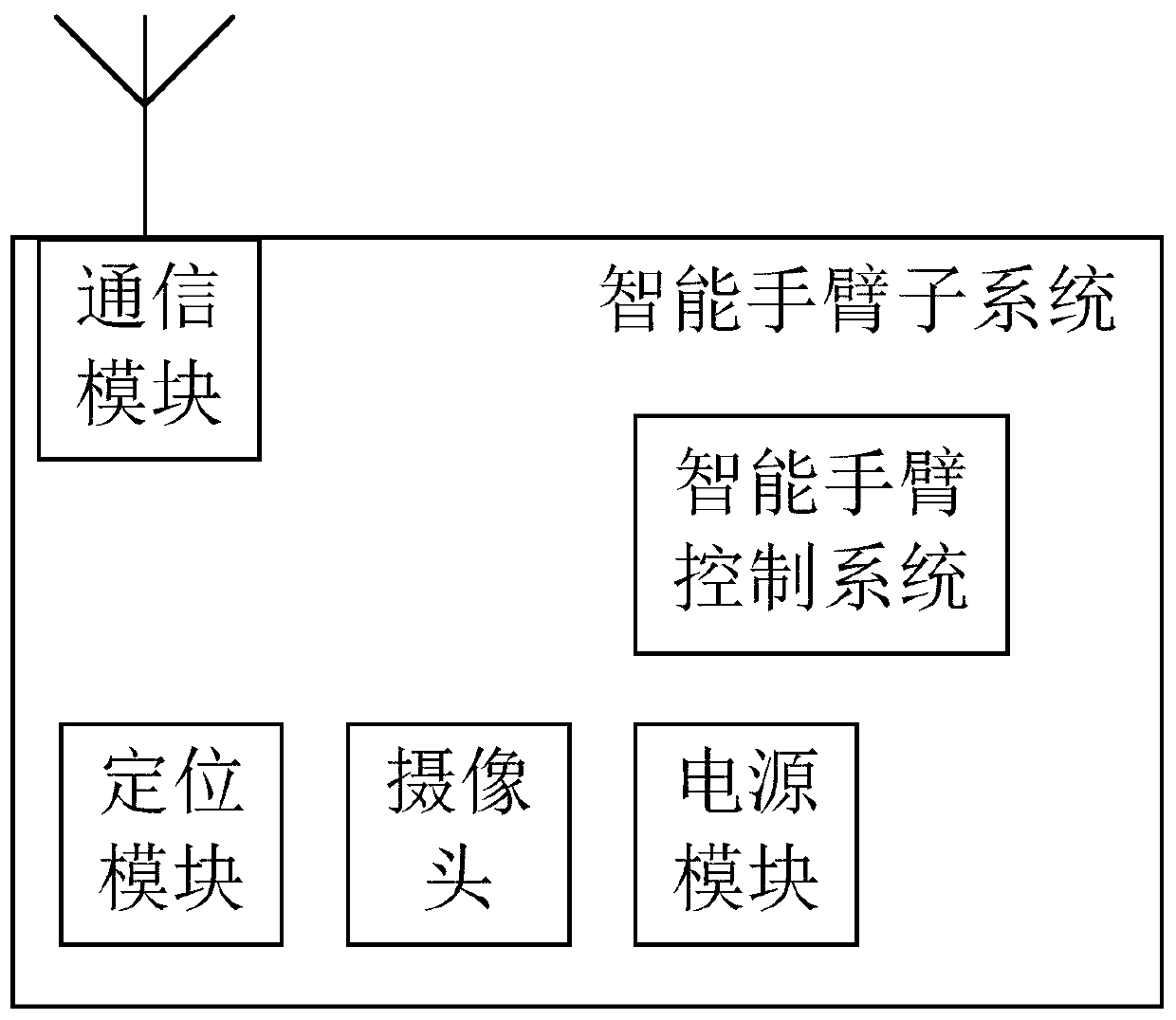

The embodiment of the invention provides a flat shunting system. The system includes a ground subsystem, a communication subsystem, a vehicle-mounted subsystem and an intelligent arm subsystem, the ground subsystem is used for obtaining station status information and an operation plan, and sending the station status information and the operation plan to the vehicle-mounted subsystem, the communication subsystem is used for communication among the ground subsystem, the vehicle-mounted subsystem and the intelligent arm subsystem, the vehicle-mounted subsystem is used for displaying after receiving the station status information and the operation plan, and information interaction with the intelligent arm subsystem to realize locomotive control of shunting operation, and according to information interaction of the intelligent arm subsystem and the vehicle-mounted subsystem, corresponding shunting operation is realized through an intelligent arm at the preset position of a carriage. According to the system, the number of shunting operating personnel is decreased, the personnel working intensity is reduced, human factors are reduced to the minimum limit, thus the shunting operation efficiency is greatly improved, and the safety of shunting operation is further improved.

Owner:BEIJING CENTURY DONGFANG COMMUNICATION EQUIPMENT CO LTD

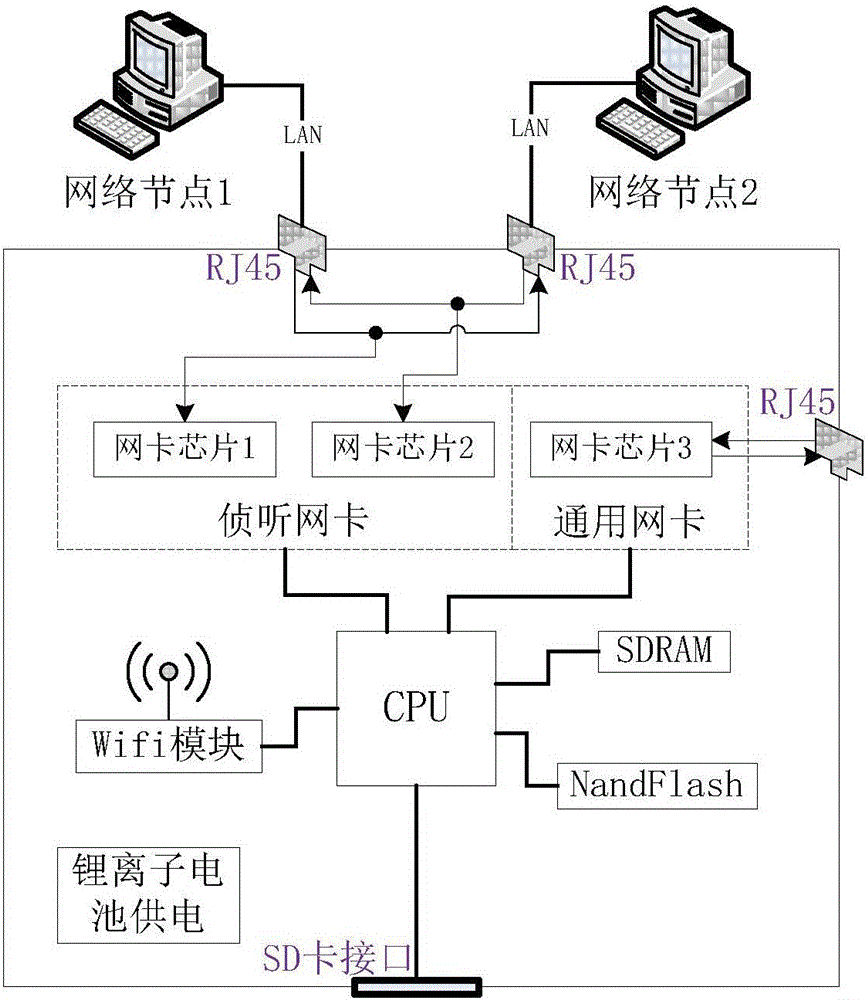

Non-injection type network interception apparatus

The invention discloses a non-injection type network interception apparatus which enables interception, processing and forwarding of bidirectional data on a communication link without any effect on an original data connection route; the non-injection type network interception apparatus can be applied to any occasion having needs for bidirectional interference-free interception of Ethernet communication among network nodes. Two pairs of data transmission lines of the original data route are subjected to parallel shunting operation via the interception apparatus, then the data transmission lines are connected into an interception network interface card; bidirectional data on a network communication link is simultaneously received via the interception network interface card; a network card drive of an embedded operating system of the interception apparatus is also employed; bidirectional passive non-coupling interception can be performed on a data flow of the communication link. When data is transmitted bi-directionally between two network nodes, the interception apparatus can monitor communication data packets on a transmission line. The interception apparatus provides multiple kinds of input interfaces and output interfaces, original data intercepted can be subjected to data processing operation via a user application program and a high-performance CPU, and processing results can be output via the output interfaces.

Owner:XIAN AEROSPACE PROPULSION TECH INST

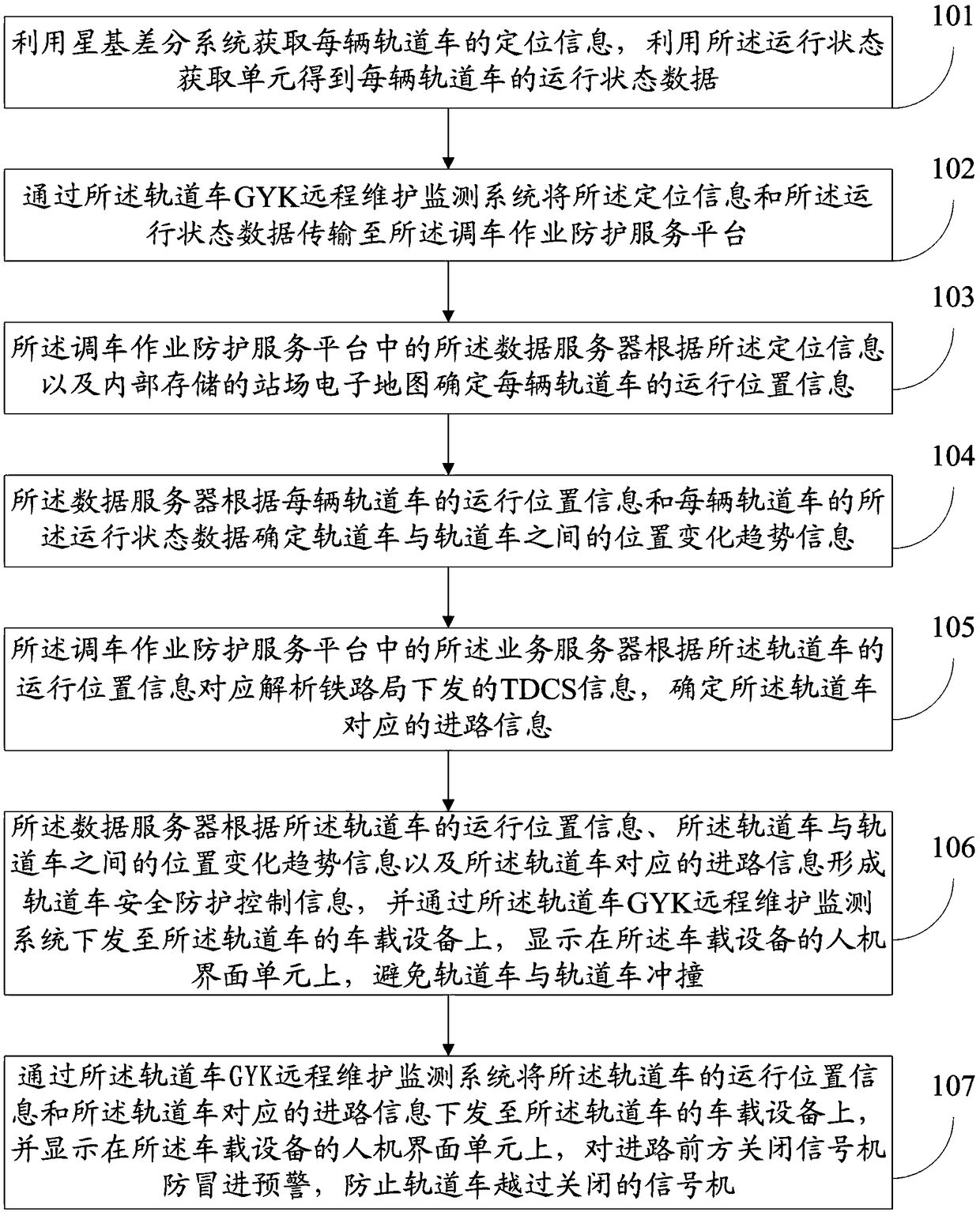

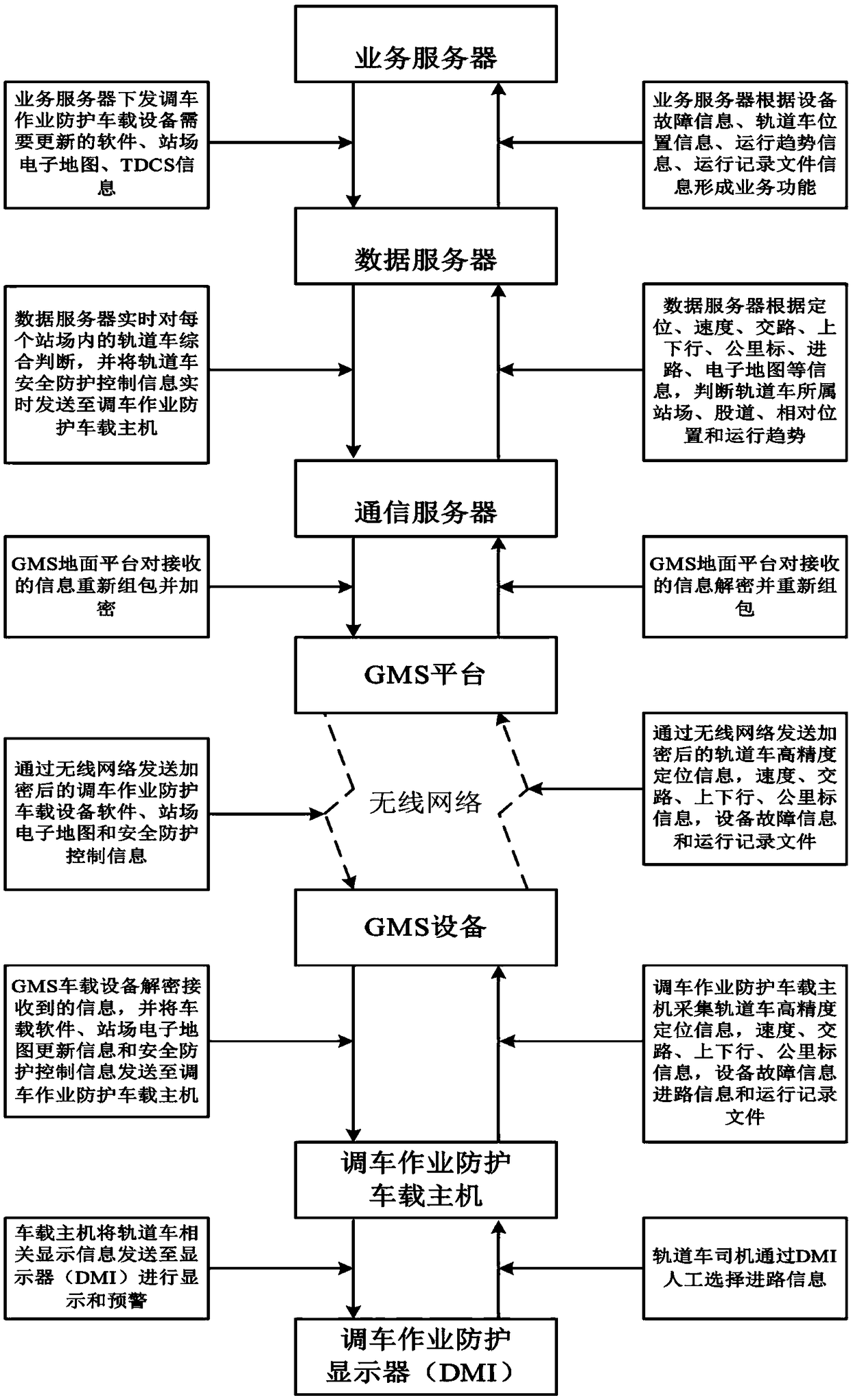

Railcar shunting operation protection method

ActiveCN109484431AAvoid collisionImprove securityRailway traffic control systemsReturn functionEngineering

The invention discloses a railcar shunting operation protection method. The method mainly comprises the steps of remote automatic updating of car-mounted equipment software and a station map through aGMS platform, realization of a remote return function for fault information, running state information, running position information and running record files of car-mounted equipment, and remote transmission of comprehensively processed safety protection car control information through a railcar. A shunting operation protection service platform carries out comprehensive processing according to high-precision positioning information of the railcar, information of the station map and route information obtained after analysis to obtain safety protection control information required for shuntingoperation; the safety protection control information is transmitted to the railcar car-mounted equipment in real time through the GMS platform, anti-overrunning, anti-overtaking and anti-collision functions of the railcar during shunting are achieved, the problem that current railcar shunting operation lacks effective technical protection means can be solved, and the safety risk of the shunting operation is reduced.

Owner:西北铁道电子股份有限公司

Operation method of intelligent coupler system

ActiveCN109421766AReduce labor intensityReduce mental burdenAutomatic systemsRailway couplingsCarrying capacityCoupling

An intelligent coupler system is an automatic train connecting device for realizing automation of multiple unit train shunting operation instead of a traditional tight-lock coupler. The invention provides a novel transporting method; and according to the novel transporting method, through soft and hard combination of a rail traffic separating and connecting combined transporting mode and the intelligent coupler system, transformation of the shunting operation from manual operation to automatic operation is realized to satisfy a demand of frequent coupling or decoupling operation in the separating and connecting combined transporting; in particular, the realization of a novel operation mode of dynamic disconnection preferably develops the advantage of large carrying capacity of railway; andtherefore, the shortcoming of poor rail traffic mobility is overcome. The novel transporting method is expected to break through mechanism restriction of railway transporting highest design capacityand generate huge capacity potential.

Owner:SHANGHAI WIND NEW ENERGY TECH

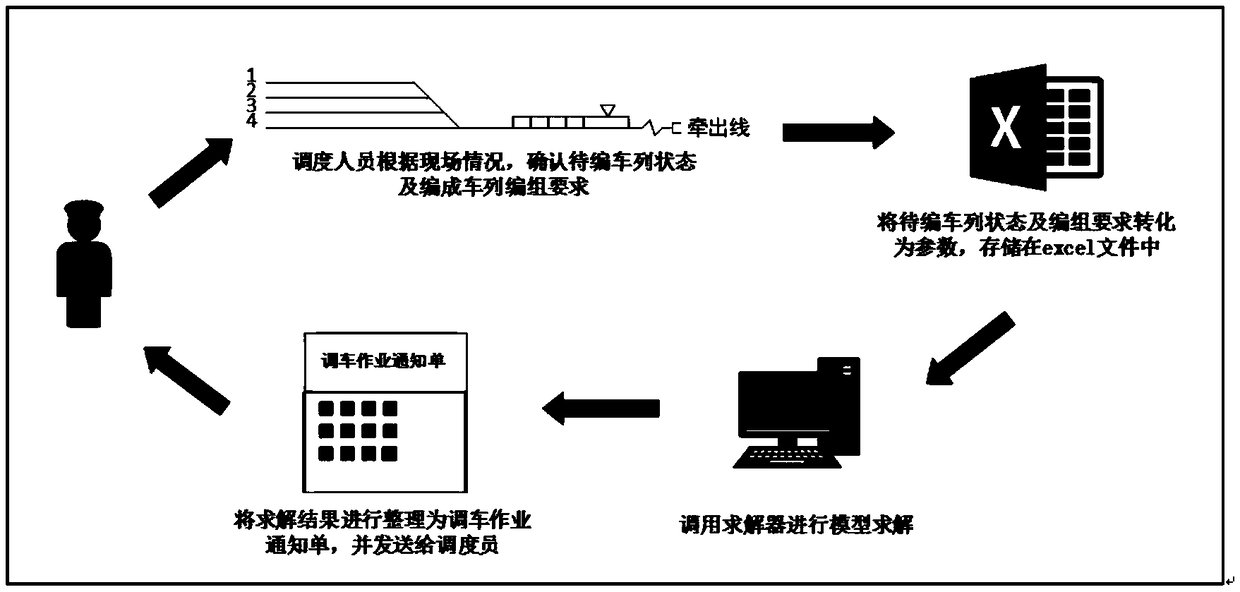

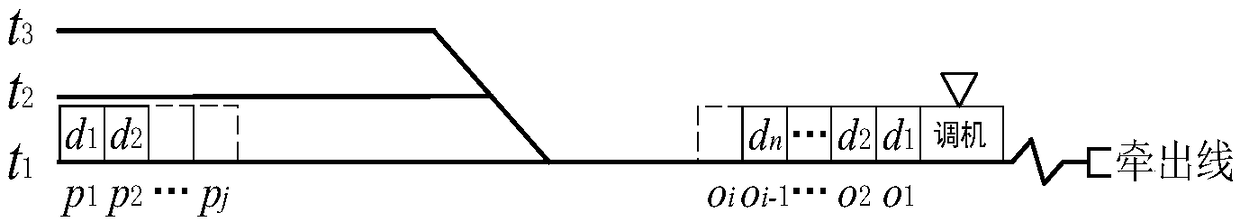

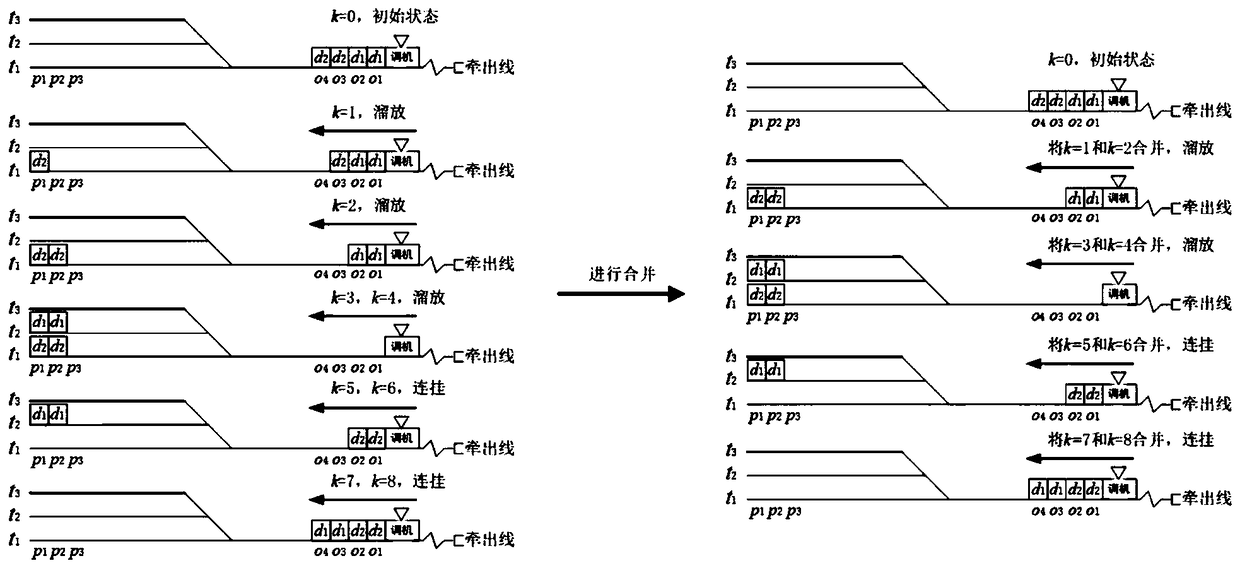

Train detaching and attaching shunting operation plan compilation method

The invention discloses a train detaching and attaching shunting operation plan compilation method. The method comprises the following steps: establishing an integer model of train detaching and attaching shunting operation plan compilation; designing a branch delimitation algorithm according to the railway shunting operation characteristics, and inputting initial status and compiled status of a to-be-compiled train column into an algorithm program according to a form specified by the algorithm; using the algorithm to solve the shunting operation plan compilation problem; integrating results of the algorithm into a shunting operation schedule meeting shunting operation requirements; and outputting the integrated shunting operation schedule. The method has advantages that 1, the integer planning model is used to describe a shunting operation process without the need for using empirical rules to screen shunting schemes, and the established model automatically formulates a shunting scheme, which meets the requirements, according to the requirements of an objective function; and 2, the model considers total shunting operation quantity in the shunting operation process, optimizes shunting hook quantity and shifting vehicle quantity as a whole, and minimizes the shunting operation quantity.

Owner:SOUTHWEST JIAOTONG UNIV

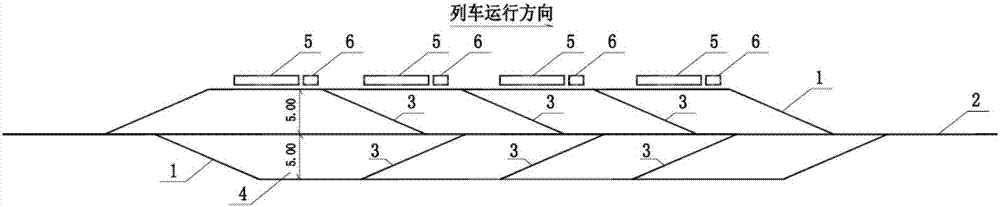

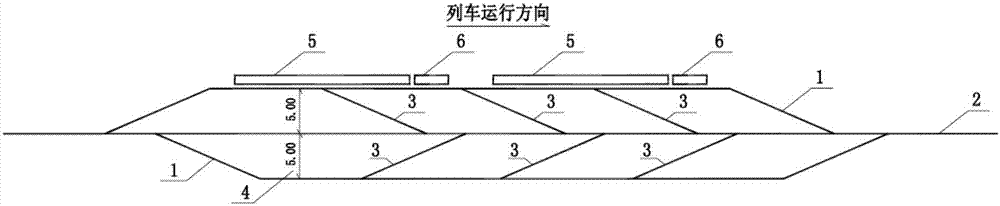

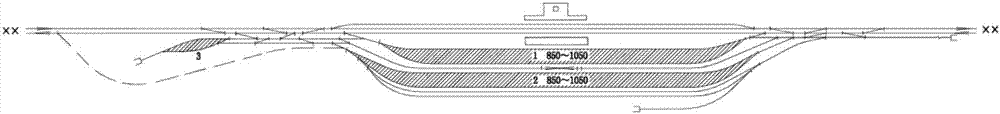

Wire harness structure design of "2 arrival and departure tracks and 1 locomotive running track between 2 arrival and departure tracks" in heavy haul railway marshalling yard

InactiveCN107226094ALarge volumeReasonable layoutRailway componentsRailway stationEngineeringHeavy load

The invention discloses a wire harness structure design of "2 wire clips and 1 machine travel" in a heavy-duty railway yard. The structure adapts to the transportation organization characteristics of heavy-duty railways, and meets the requirements of 5000t and 10000t trains combined into 20,000-ton long trains, or 20,000-ton trains The large columns are decomposed into short columns of 5000t and 10000t. Including heavy-duty train depot operation process and operation time, wiring harness structure, line speed quantity, waist fork setting and line spacing layout. The structure consists of two 2800m-long arrival and departure lines, one machine-running line and three sets of waist forks. It not only satisfies the conditions for changing locomotives on the side of the arrival and departure line, but also serves as a safe parallel approach for short trains to arrive and pick up cars, forming a wiring harness consisting of 2 arrival and departure lines and 1 locomotive routing, that is, "2 lines Clip 1 machine away" wiring harness simple structure layout pattern. The invention has a simple structure, can meet the two requirements of receiving and dispatching trains and shunting operations at the same time, further enriches and improves the vehicle flow organization of the heavy-duty railway transportation, and improves the transportation capacity and efficiency of the heavy-duty railway.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

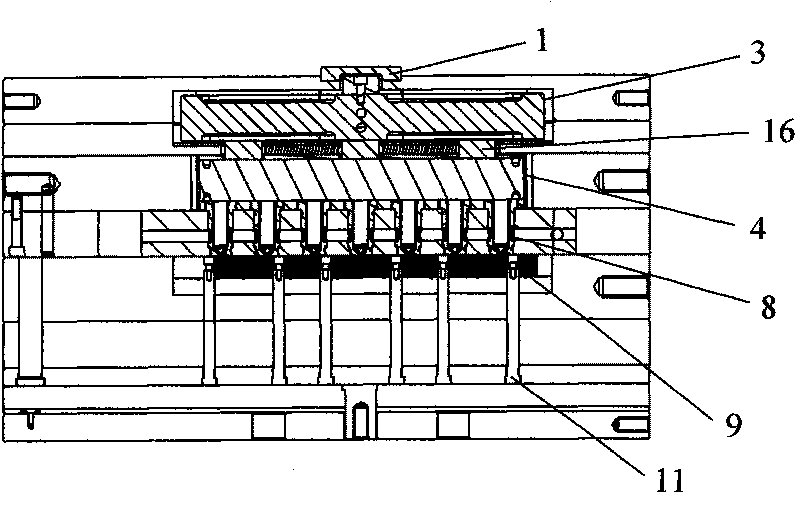

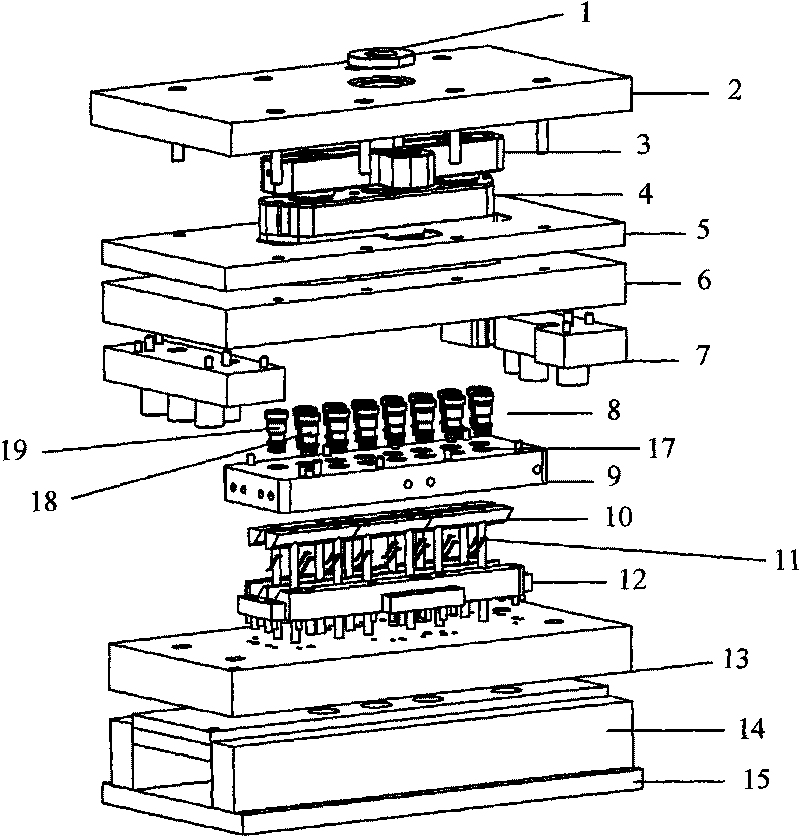

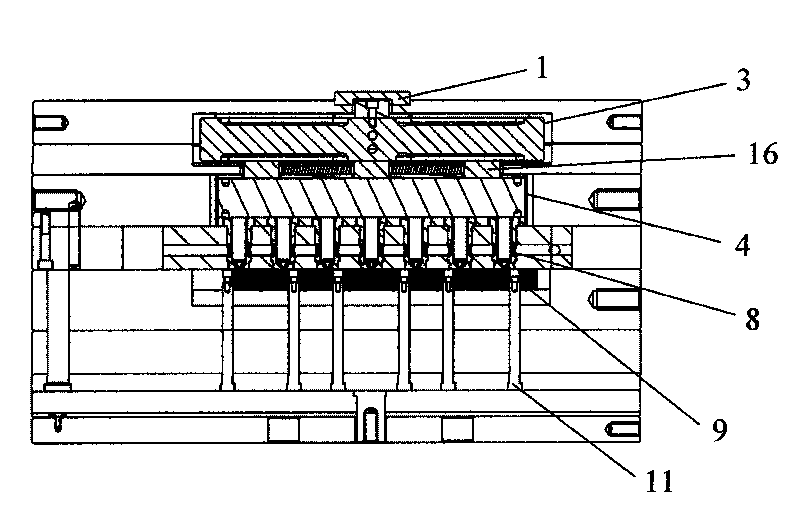

Layered hot runner mold

The invention relates to a layered hot runner mold, wherein runners in a shunting mechanism are communicated with runners in hot nozzles; the shunting mechanism consists of at least two layers of shunting plates and at least two layers of shunting nozzles; the two layers of shunting plates and the two layers of shunting nozzles are communicated with each other; the first layer of sprue bushings are arranged on the surface of a mold base panel; the number of the second layer of shunting nozzles is at least two, and the shunting nozzles are arranged between the two layers of shunting plates; the first layer of shunting plates and the second layer of shunting plates are respectively connected with the mold base panel and a hot runner subplate; both ends of each hot nozzle are respectively connected with a plate A and a front mold core, and at least four hot nozzles are arranged and sequentially arrayed. The layered hot runner mold has reasonable structural design and can carry out shunting operations on material solutions, carry out injection molding simultaneously through the hot nozzles, shorten the manufacturing and molding period, save plastic raw materials, reduce the waste, improve the production quality, eliminate subsequent working procedures and be beneficial to the production automation and the expansion of the application range of a molding process.

Owner:深圳市安高模具有限公司 +2

Railroad wireless signal, and system for accurate shunting operation

InactiveCN101049834ARealize automatic monitoring and protectionSimple installation and constructionTelephonic communicationRadio transmissionHand heldTrack circuit

A system for the wireless signaling and accurate switching job of railway features that an induction mode is used to acquire the information from the signaling equipment of railway and the wireless communication is used between wireless signal responder, locomotive monitor, the monitor at railway station, and the hand-held mobile responder.

Owner:陈笠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com