Residual oil hydrotreating method

A treatment method, the technology of residual oil hydrogenation, which is applied in the field of residual oil hydrogenation, can solve the problems of unreachable reaction temperature, lowering, and inability to realize operation, and achieve the effects of improving effective utilization rate, stable product properties, and extending operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

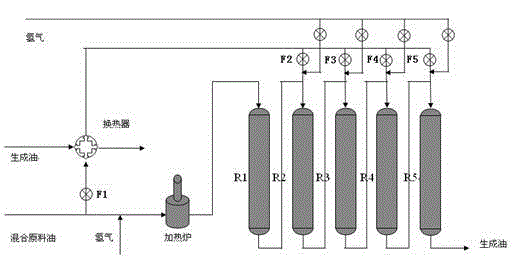

Embodiment 1

[0039] Such as figure 1 As shown, according to the residual oil hydroprocessing method provided by the present invention, a fixed-bed hydroprocessing experimental device has been designed by itself. Each reactor of the device has an effective volume of 3L. Such 5 reactors are used in series, and the feedstock oil is from top to bottom. The following process flow. Wherein the second, third, fourth and fifth reactor upper inlets are additionally equipped with quenching feed pipelines for the split part of raw material oil. In this test, FZC series residue hydrotreating catalysts developed by Fushun Petrochemical Research Institute were used, including hydrogenation protection agent (FZC-1 series), hydrodemetallization catalyst (FZC-2 series), hydrodesulfurization catalyst (FZC -3 series) and hydrodenitrogenation and carbon removal catalysts (FZC-4 series).

[0040] The catalyst loading results of each reactor are:

[0041] The catalysts loaded from top to bottom in R1 reactor...

Embodiment 2

[0051] Such as figure 1 The shown fixed-bed hydrotreating experimental device, the process flow remains the same as in Example 1.

[0052] The loading results of catalysts in R1, R2, R3, R4 and R5 reactors are shown in Table 4.

[0053] Table 4 Catalyst loading ratio of each reactor

[0054] reactor R1 R2 R3 R4 R5 FZC-11A, v% 2 2 - - - FZC-12A, v% 10 10 5 2 - FZC-13A, v% 1.5 1.5 1.5 1.5 - FZC-28AM (thick strip), v% 1.5 1.5 1.5 1.5 - FZC-28A, v% 30 15 10 - - FZC-28, v% 55 20 20 10 - FZC-204, v% - 30 30 35 - FZC-33, v% - 20 12 20 10 FZC-34, v% - - 20 30 10 FZC-41A, v% - 80 Total, v% 100 100 100 100 100

[0055] After the catalyst is filled and the device is airtight and qualified, vulcanization and feed oil switching are carried out. After the reaction activity of the catalyst is stable, at a reaction pressure of 16 MPa, an average reaction temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com