Patents

Literature

46results about How to "Increase the average particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving efficiency of perovskite solar cell

InactiveCN111599923APromote secondary growthIncrease the average particle sizeSolid-state devicesSemiconductor/solid-state device manufacturingPtru catalystHole transport layer

The invention provides a method for improving the efficiency of a perovskite solar cell. The method comprises the following steps: depositing a layer of lithium-magnesium heavily doped nickel oxide asa hole transport layer on an ITO glass substrate; then respectively spin-coating the surface with a perovskite precursor solution A and a doped precursor solution, wherein the perovskite precursor solution A is prepared by adding methylamine iodine and lead iodide into a DMF solvent and uniformly mixing, and the doped precursor solution is prepared by adding bismuth nitrate, potassium bromide anda guanidyl catalyst into a perovskite precursor solution B prepared from methylamine iodine, lead iodide and a DMF solvent. According to the method provided by the invention, a perovskite absorptionlayer with a double-layer structure is formed by adding a secondary growth process on the basis of an original crystal growth process, so that the carrier transfer efficiency in perovskite is effectively improved, and the photoelectric conversion efficiency of the solar cell is improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

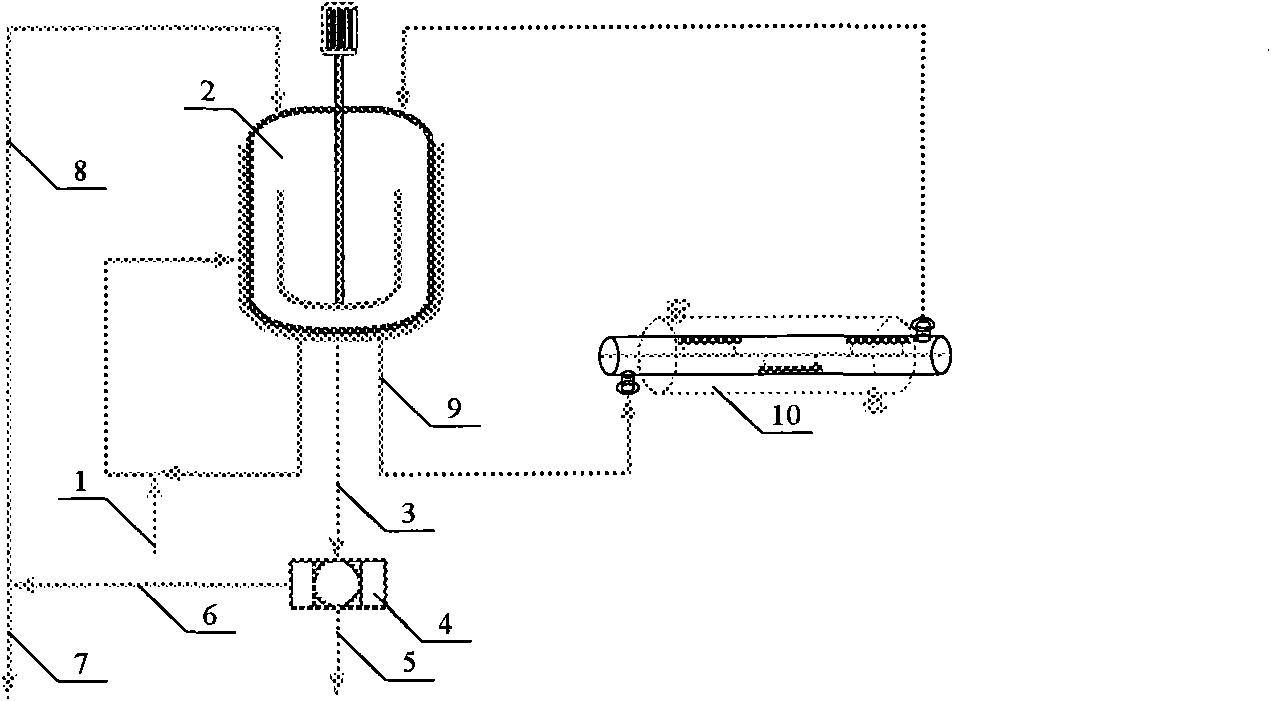

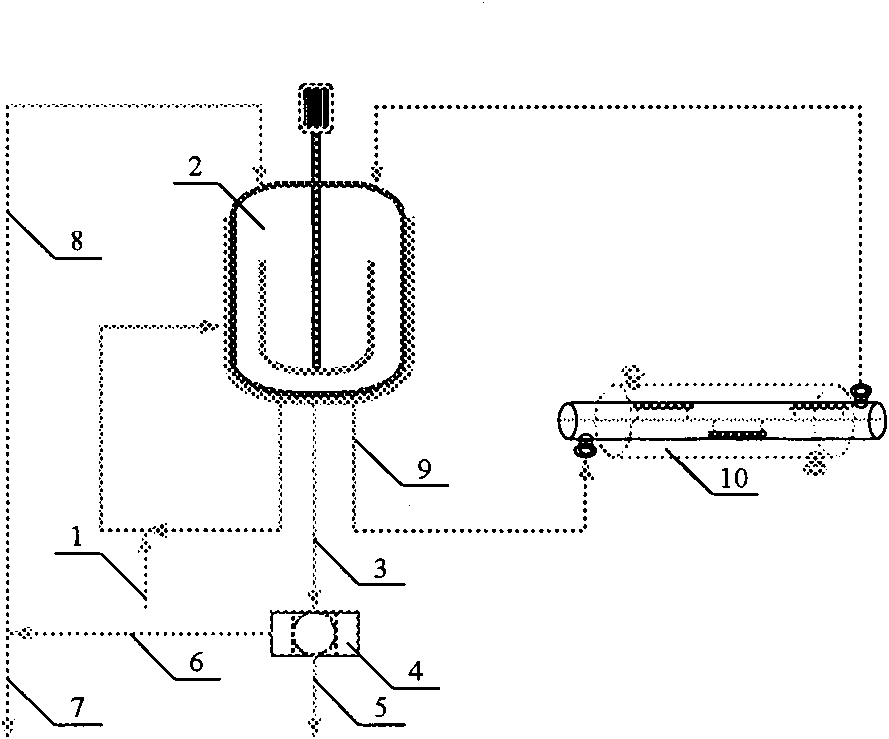

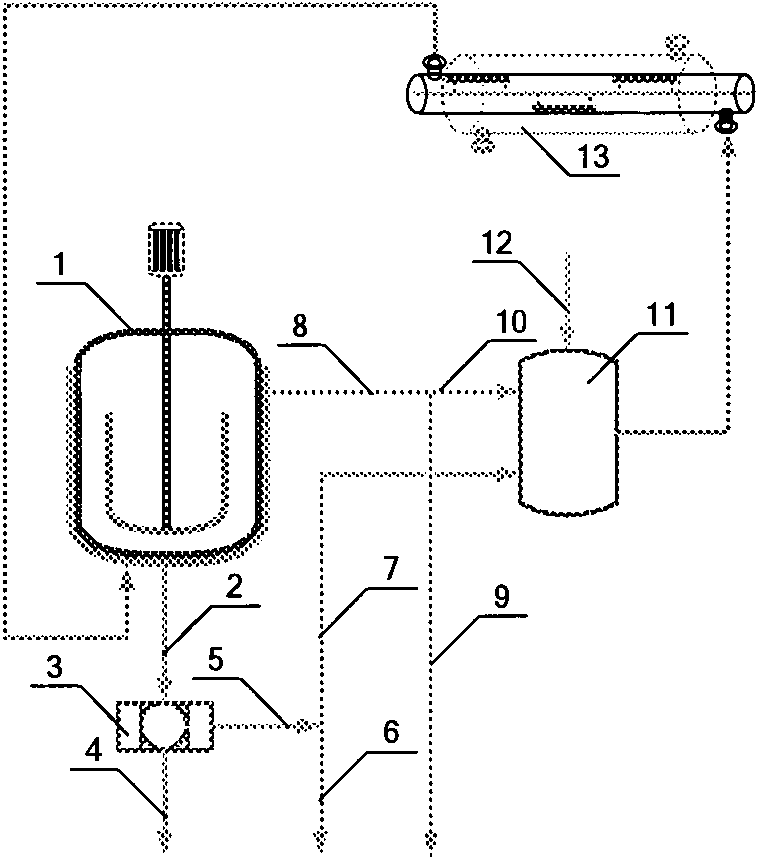

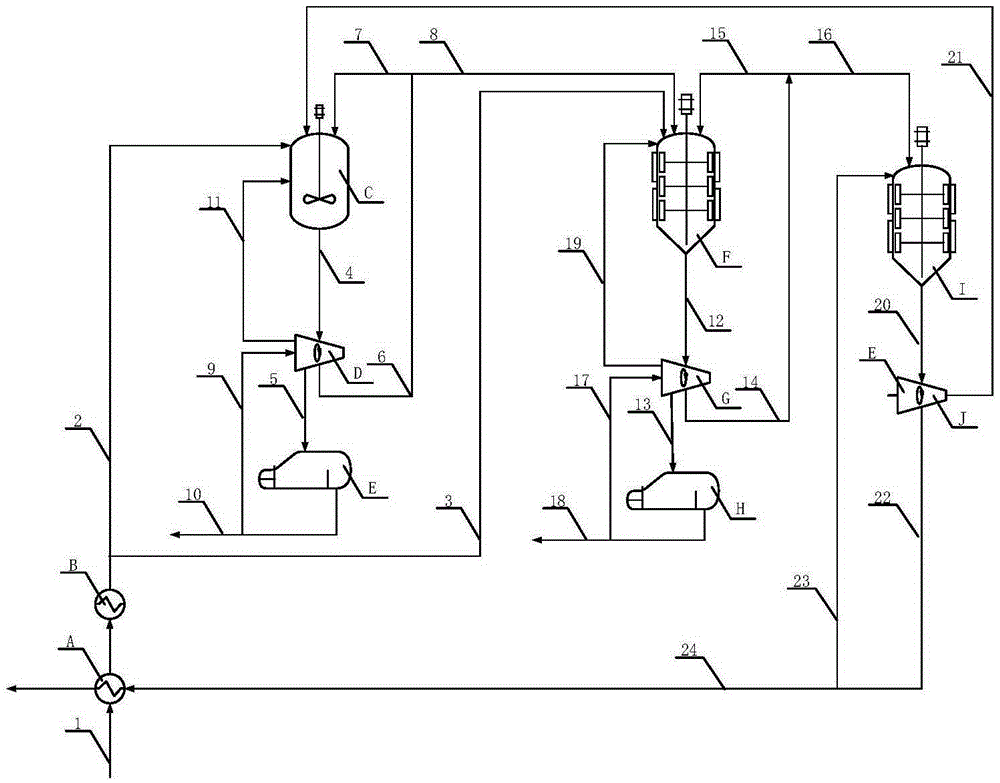

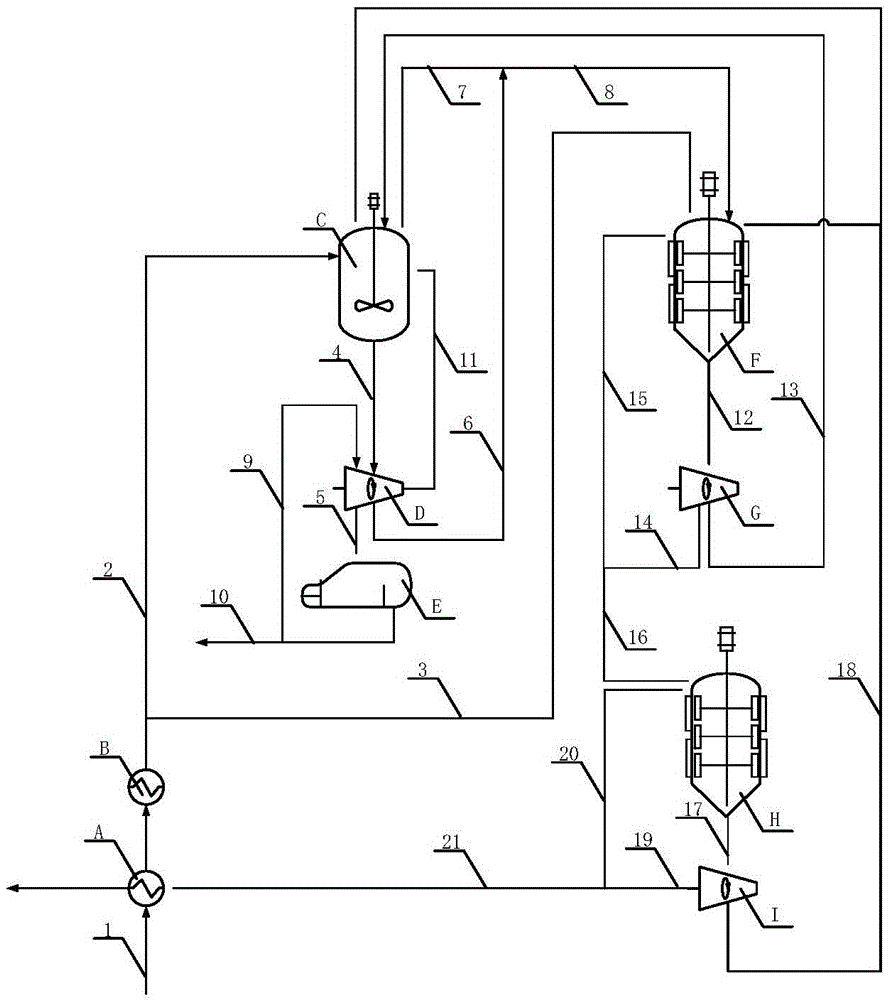

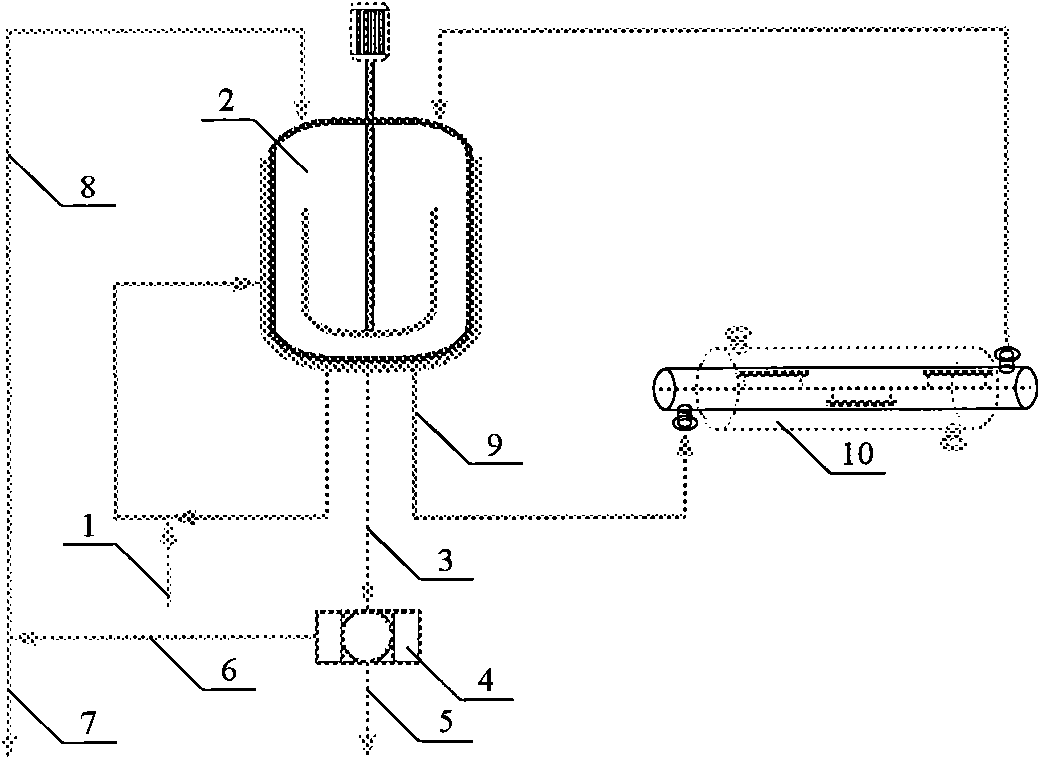

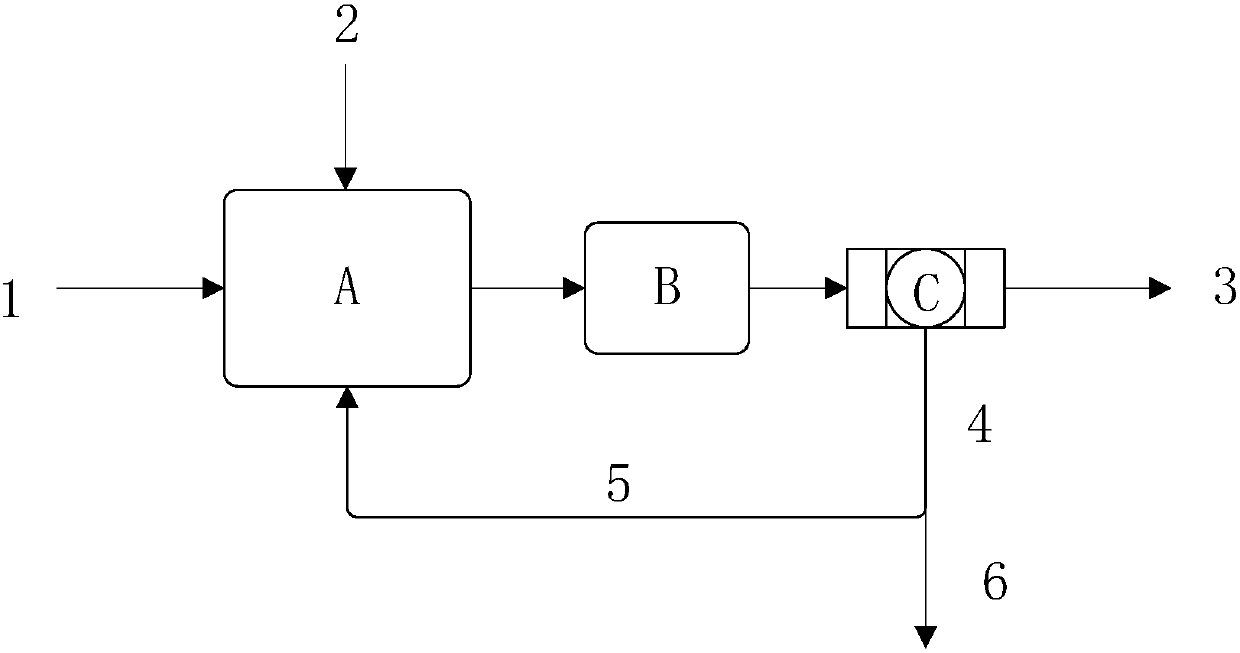

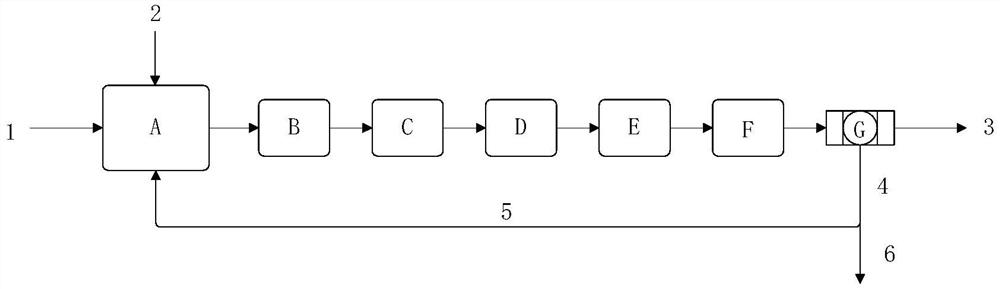

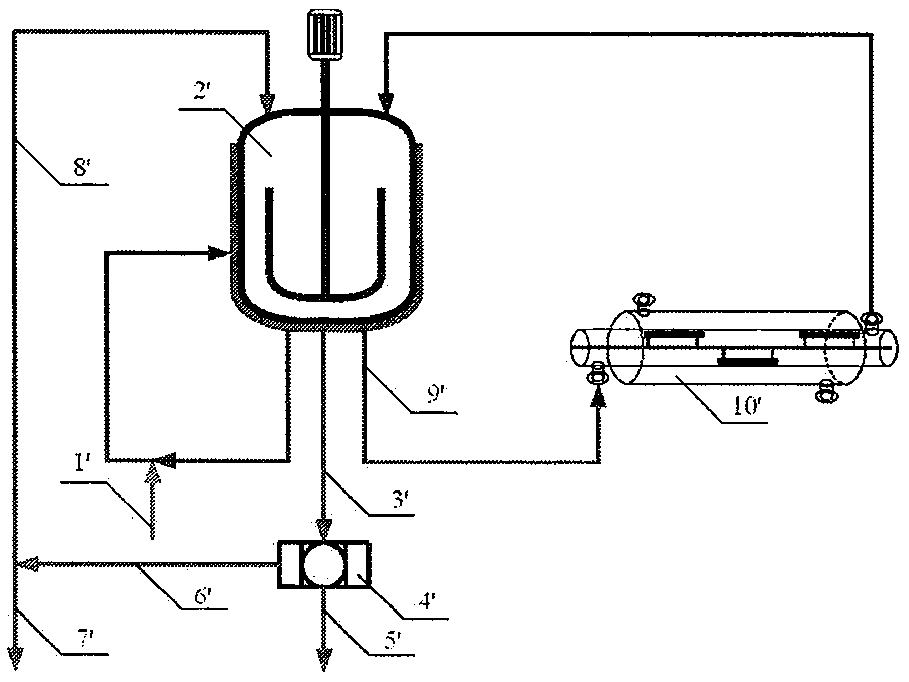

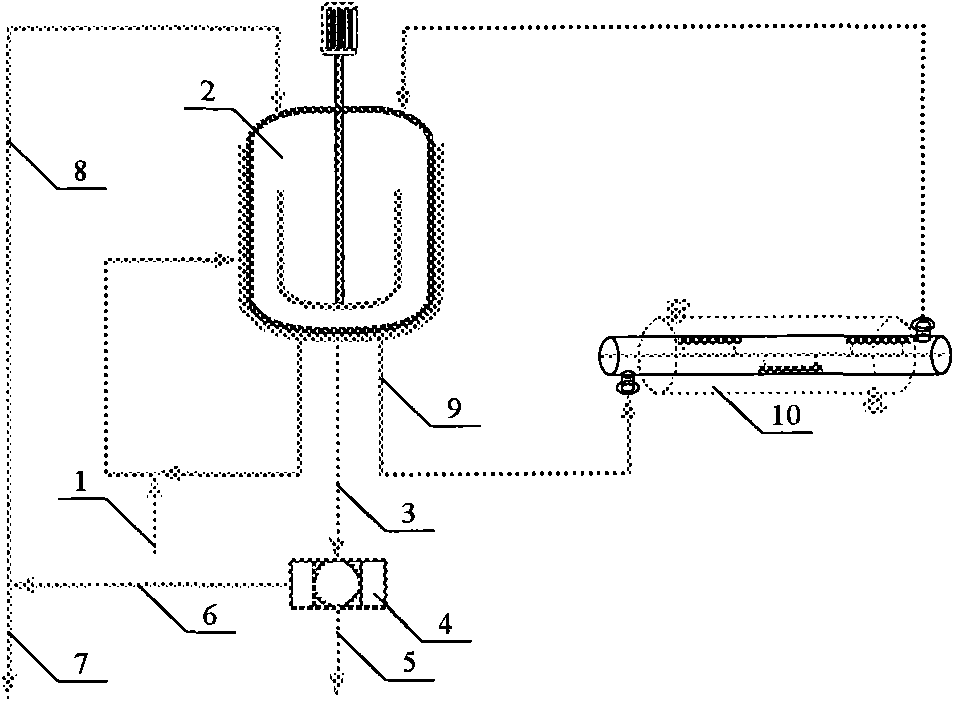

Crystallizing method utilizing external circulation of crystal slurry

ActiveCN102371080AIncrease the average particle sizeImprove technical effectSolution crystallizationCrystallisation purification/separationFiltrationSlurry

The invention relates to a crystallizing method utilizing external circulation of crystal slurry, and is mainly used for solving the problems of small crystal particle size and frequent cleaning of a crystallizer in the prior art. The crystallizing method is characterized in that: the raw materials are introduced into a kettle type crystallizer for crystallization, the crystal slurry in the kettle type crystallizer flows out from the lower part of the kettle type crystallizer by two parts, the crystal slurry I is subjected to separation by a solid-liquid separator to obtain crystals and crystal filtration mother liquor, and the crystal slurry II is subjected to heat exchange by a sleeve type crystallizer and then returned to the kettle type crystallizer, wherein the weight ratio of the crystal slurry I to the crystal slurry II is (1:1)-(1:50); and the crystals are used as a product to be discharged, the crystal filtration mother liquor is divided into two parts, the first part namely crystal filtration mother liquor I which accounts for 5-95wt% of the crystal filtration mother liquor is discharged, and the second part namely crystal filtration mother liquor II which accounts for 5-95wt% of the crystal filtration mother liquor is returned to the kettle type crystallizer together with the crystal slurry II. The technical scheme that the raw materials are introduced to the kettle type crystallizer directly or being mixed with the crystal slurry II better solves the problems, thus the crystallizing method can be used in industrial crystal production.

Owner:CHINA PETROLEUM & CHEM CORP +1

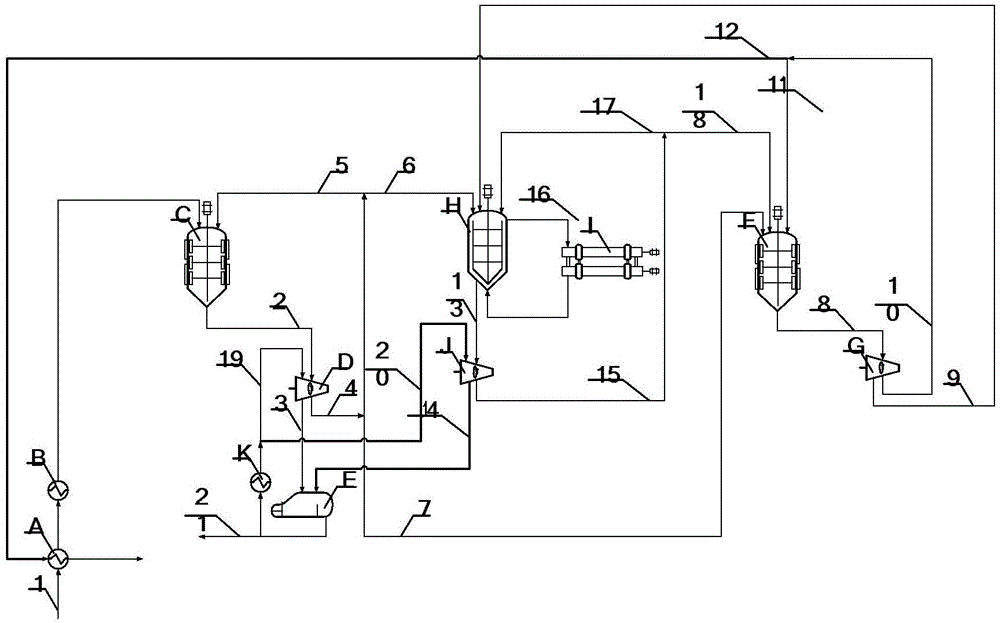

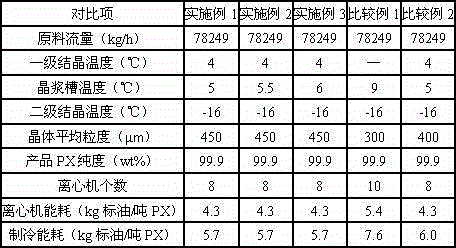

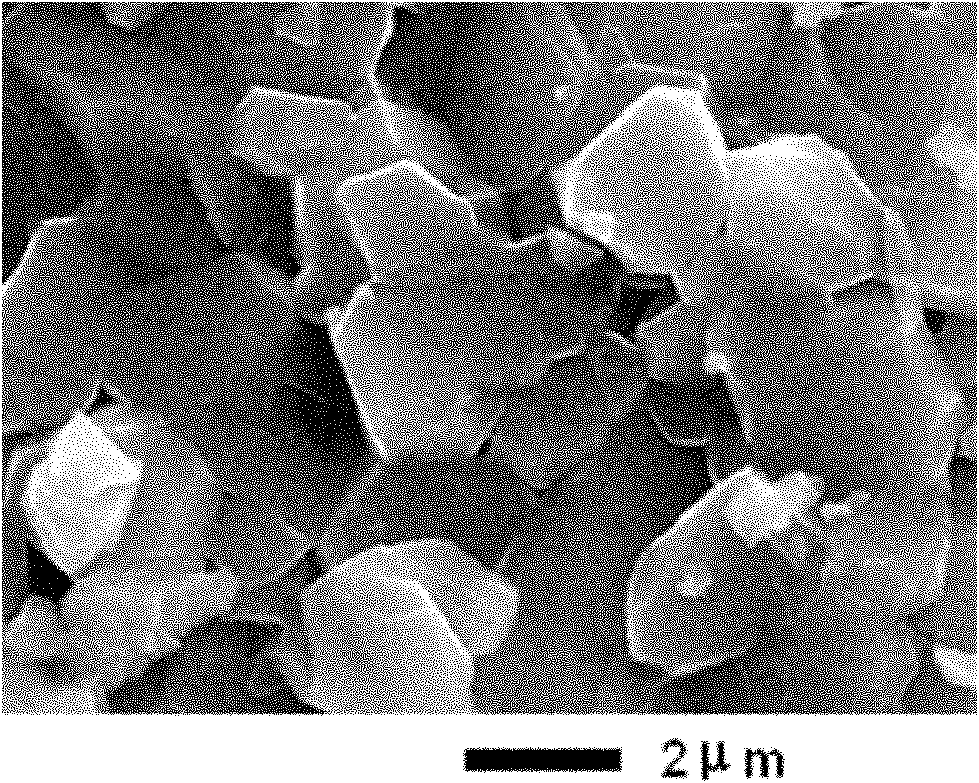

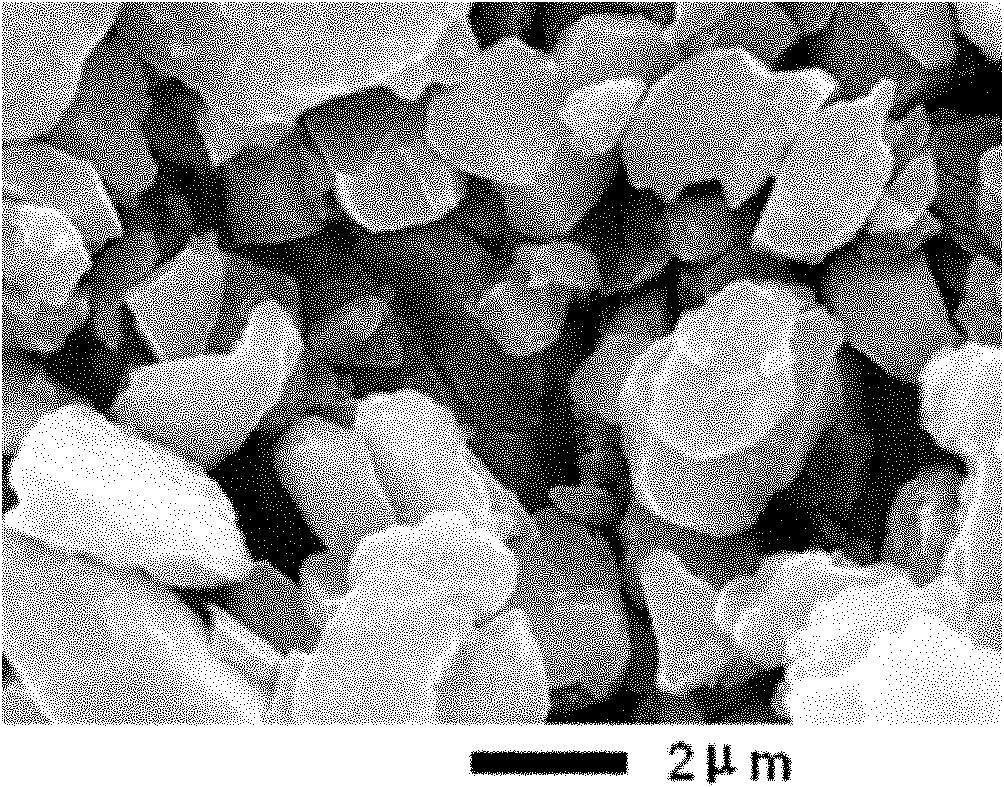

Method for producing paraxylene by using multistage suspension crystallization process

ActiveCN104557433AReduce energy consumptionImprove washing effectCrystallisation purification/separationPhysical chemistryDimethylbenzenes

The invention relates to a method for producing dimethylbenzene by using a multistage suspension crystallization process, mainly solving the problems that the energy consumption is high, crystals are hard to wash, and products are unstable in quality and yield in the prior art. The method comprises the following steps: separating out partial dimethylbenzene products through a high-temperature primary crystallization process; separating out the residual paraxylene by using a secondary crystallization process; collecting crystals in the secondary crystallization process by using a crystal slurry tank with a thickening function; carrying out pulpifying washing and heating aging on the low-temperature crystals prepared by the temperature secondary crystallization process by using a high-temperature primary crystallization mother liquid so that the purity of the product is ensured, thereby obtaining the residual paraxylene products; and thickening the crystal slurry in the bottom of the crystal slurry tank and then introducing thickened crystal slurry into a solid-liquid separator to be separated. The method can be applied to production of paraxylene crystals.

Owner:CHINA PETROLEUM & CHEM CORP +1

Magneto-plumbite type permanent magnetic ferrite and manufacturing method thereof

The invention discloses a magneto-plumbite type permanent magnetic ferrite and a manufacturing method thereof, and belongs to the field of permanent magnetic ferrites. The main components of the permanent magnetic ferrite are shown in (CaO)x.(R2O3)y.(Fe2O3)n, wherein R is at least one element of La, Nd and Pr and certainly comprises La; and a compound additive SrmMpBzOm+p+2z serving as an auxiliary component is added, wherein M is at least one element of Co, Zn, Ni, Mn and Cu and certainly comprises Co, and x, y, n, m, p and z in the formula represent the molar ratio of the added main metal elements respectively. An optimized process design is adopted, and the autonomously developed compound additive SrmMpBzOm+p+2z is added, so that the liquid phase sintering of a product is facilitated, the grain structure of the product is improved, and even if low-cost iron scale is taken as a main raw material, a magnet with high magnetic performance is manufactured under the condition of small substitution amount of the cobalt element.

Owner:自贡市江阳磁材有限责任公司

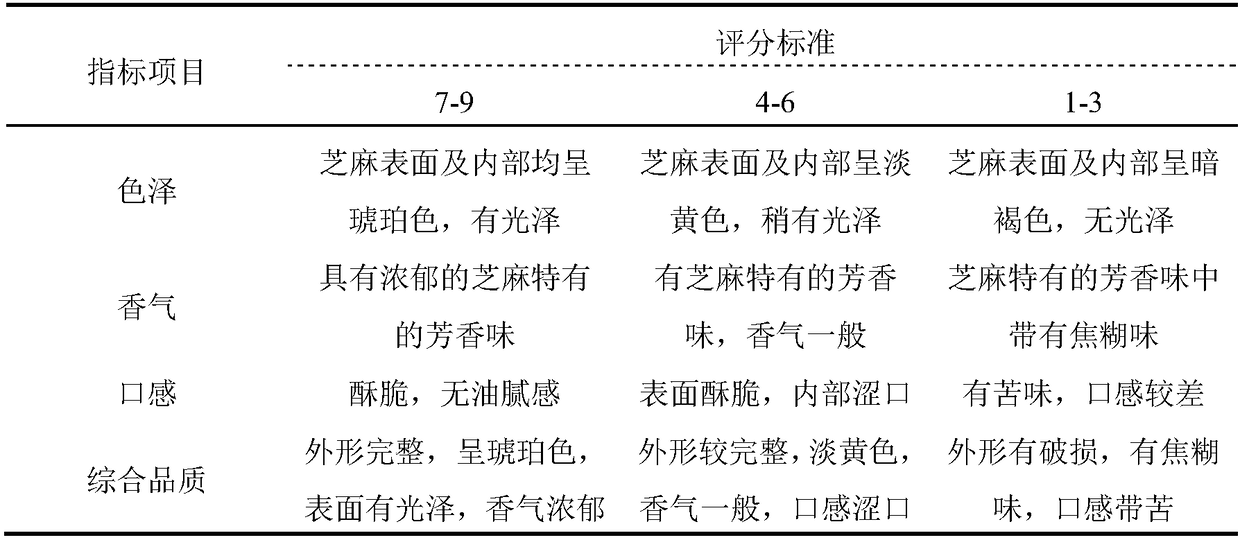

Sesame sauce and processing method thereof

The invention provides sesame sauce and a processing method thereof. The sesame sauce includes the following constituents in parts by weight: sesame 100, oil 6.5-7.5, an emulsifying agent 0.001-0.25,wherein the emulsifying agent includes the following constituents in parts by weight: sucrose esters 0.03-0.18 and monostearin 0.07-0.18. The sesame sauce is prepared by the method including the processes of roasting and grinding the sesame. According to the invention, through adopting a scientific formula and preparation process, the viscosity coefficient of the sesame sauce is increased from 2.3778 to 29.0216 and the stability coefficient of the sesame sauce is increased from 81.60% to 99.31%. Meanwhile, no oil phase is precipitated and yield is increased by about 23%.

Owner:HUAZHONG AGRI UNIV

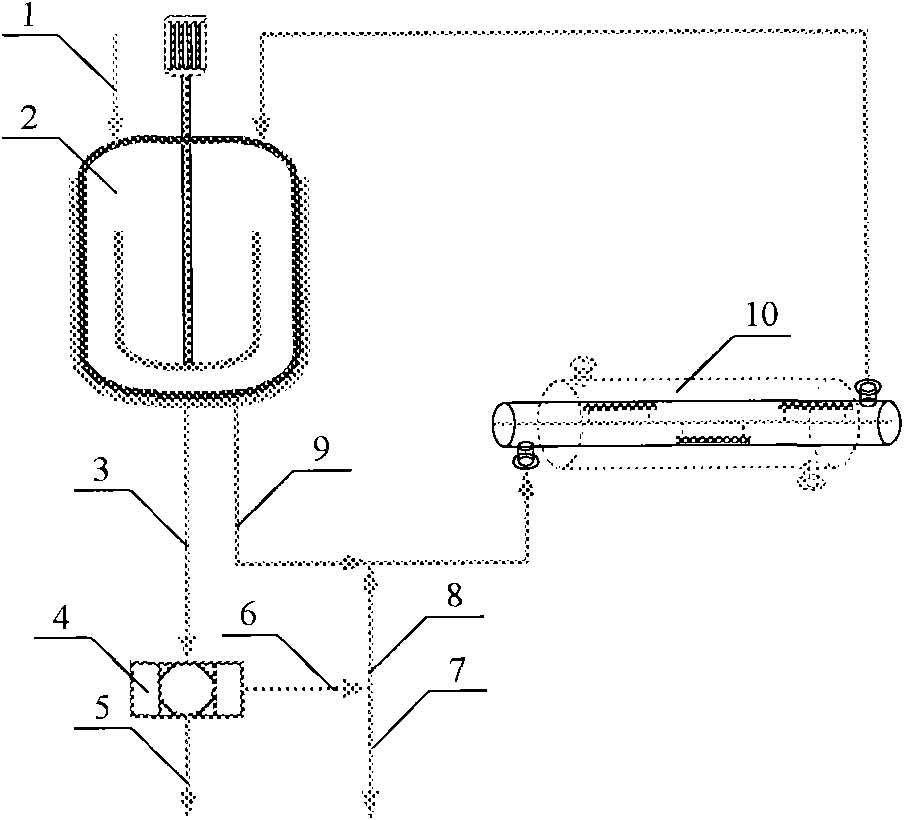

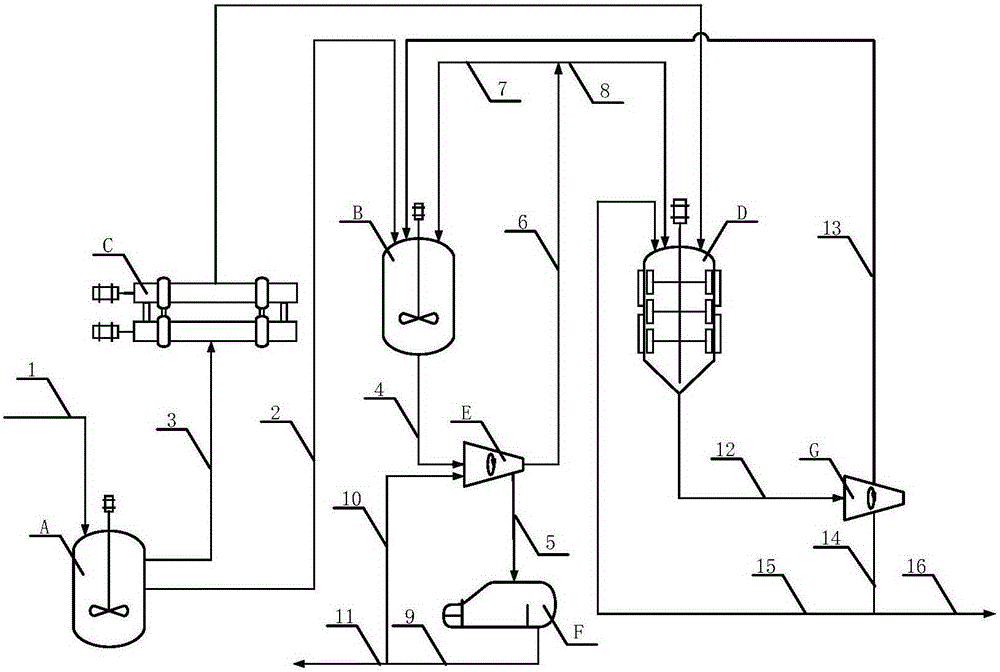

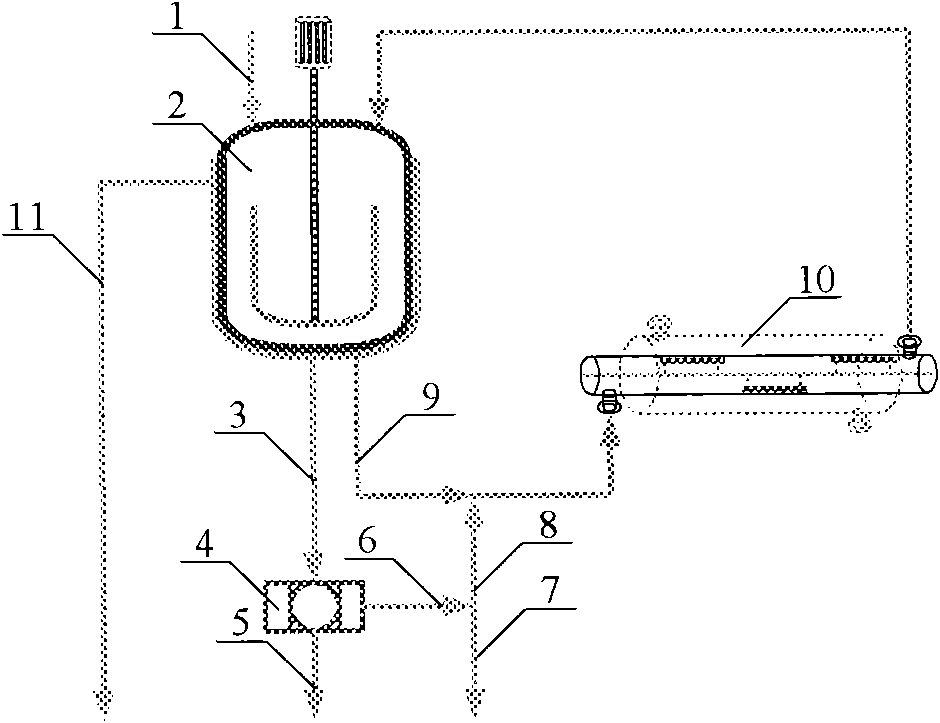

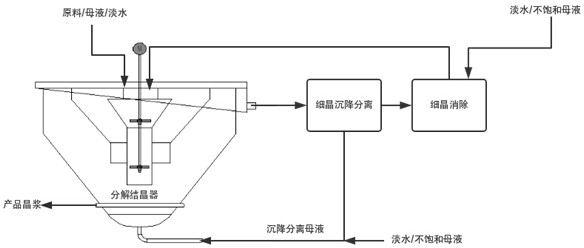

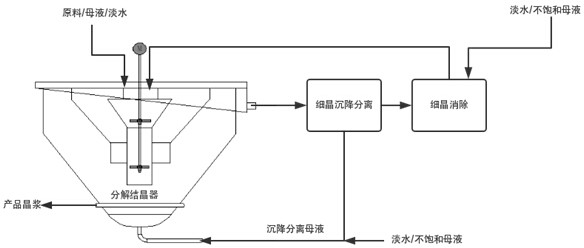

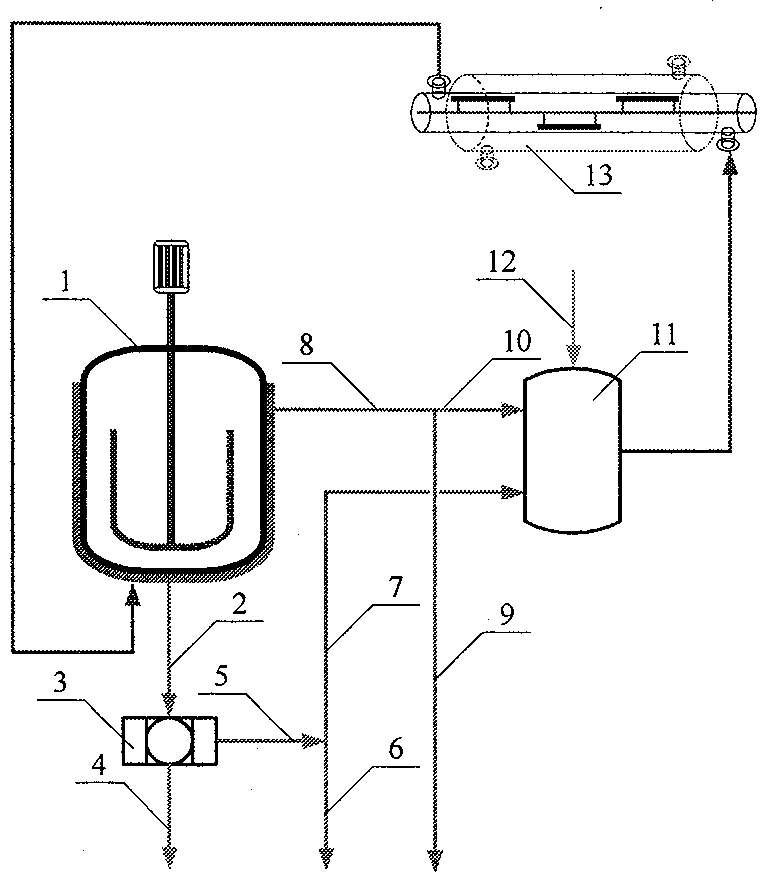

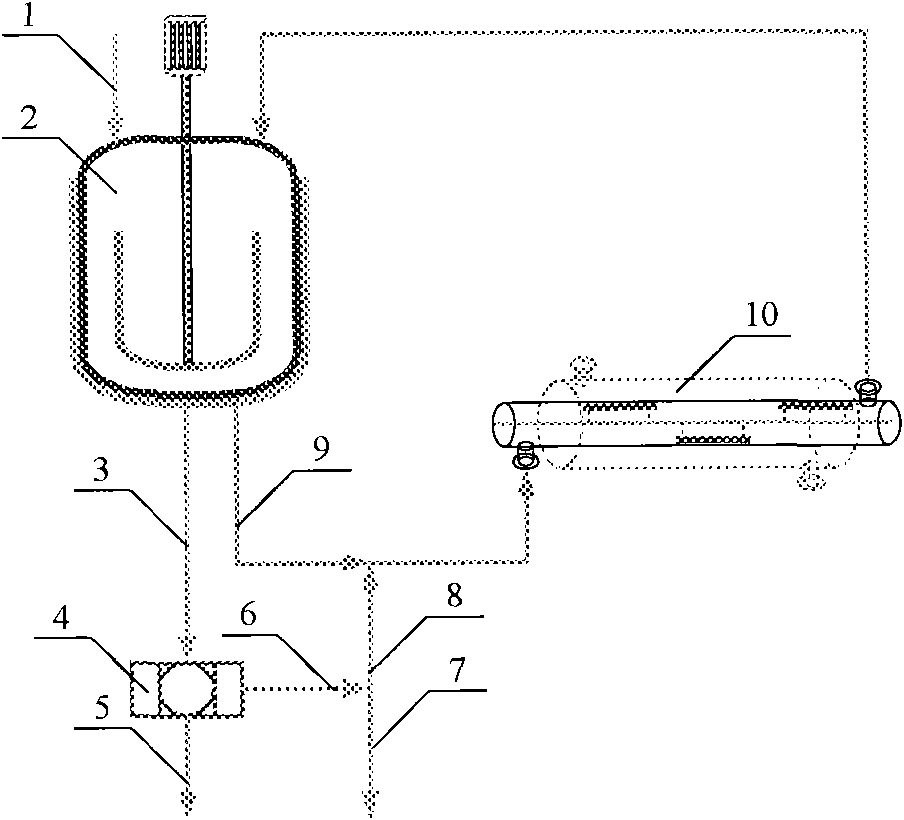

Crystallization method with a fine crystal elimination

ActiveCN102371081AIncrease the average particle sizeSolution crystallizationCrystallisation purification/separationGranularitySlurry

The invention relates to a crystallization method with a fine crystal elimination, which mainly solves the problems of small crystal granularity and frequent crystallizer cleaning in the prior art. The invention is characterized in that crystallized clear mother liquor in a kettle-type crystallizer flows out from the upper part of the crystallizer, the crystallized clear mother liquor is divided into two streams, a first stream I of the crystallized clear mother liquor which takes account for 5-95% of weight is discharged, a second stream II of the crystallized clear mother liquor which takes account for 5-95% of weight enters in an intermediate groove; crystal slurry in the kettle-type crystallizer flows out from the lower part of the crystallizer and separated by a solid-liquid separator to obtain crystals, and crystallized and filtered mother liquor; crystals as products are discharged, the crystallized and filtered mother liquor is divided into two streams, a first stream I of the crystallized and filtered mother liquor which takes account for 5-95% of weight is discharged, a second stream II of the crystallized and filtered mother liquor which takes account for 5-95% of weight enters in the intermediate groove or directly returns to the kettle-type crystallizer; the raw material enters into the intermediate groove, the material in the intermediate groove is performed heat exchange through a tubular type crystallizer and returned to the kettle-type crystallizer; wherein the weight ratio of the crystallized clear mother liquor to the crystallized and filtered mother liquor is 0.1:1-10:1. The technical scheme better solves the problems, and can be used in industrial crystallization production.

Owner:CHINA PETROLEUM & CHEM CORP +1

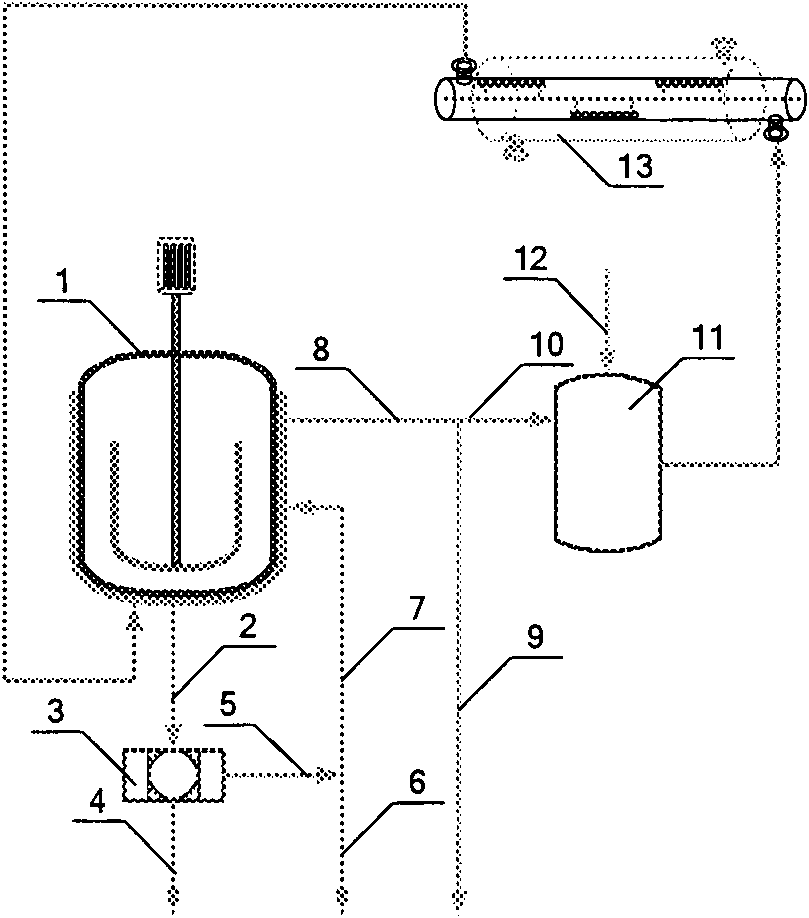

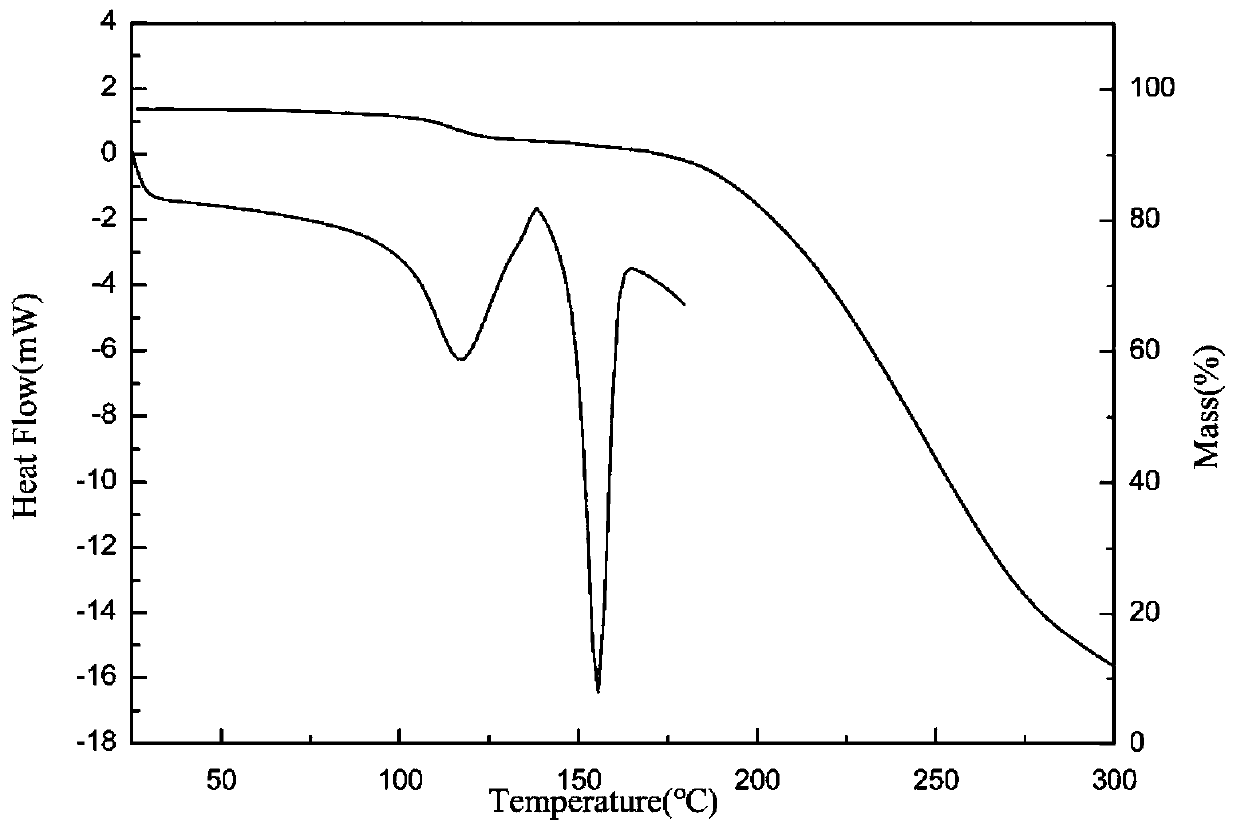

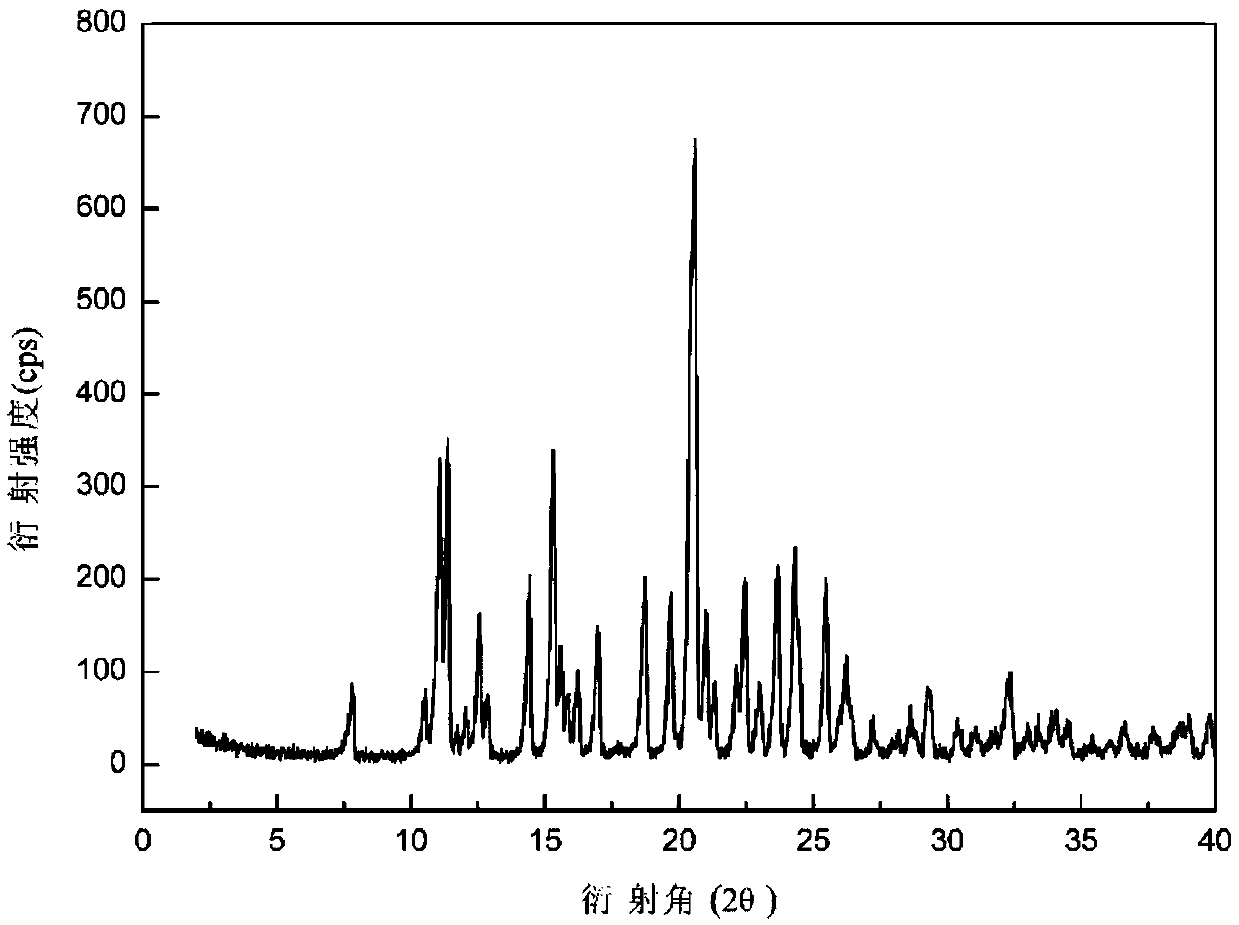

Hydrate of micheliolide dimethylamine fumarate, preparation method and application thereof

ActiveCN111303100AIncrease the average particle sizeNo coalescenceOrganic active ingredientsOrganic chemistry methodsDimethylaminesPatent medicine

The invention relates to a hydrate of micheliolide dimethylamine fumarate, a preparation method and application thereof, wherein the hydrate is a crystal form D, is high in crystallinity, smooth in particle surface, free of coalescence, high in bulk density and good in flowability, and has good stability and good reproducibility. The preparation method comprises the following steps: under stirringeffect, adding dimethylamine micheliolide and fumaric acid into a mixed solvent system with a constant temperature of 30-70 DEG C, carrying out reaction crystallization; and filtering after the reaction is finished, and drying the filtered solid at normal pressure to obtain the micheliolide dimethylamine fumarate crystal form D. The preparation method is simple, the product yield is high, and themethod is suitable for later preparation of patent medicines, and is beneficial to large-scale production.

Owner:ACCENDATECH +1

Multistage suspension melting crystallization method for separating p-xylene

InactiveCN106831303AIncrease the average particle sizeEasy to operateCrystallisation purification/separationHigh energyCrystallization

The invention relates to a multistage suspension melting crystallization method for separating p-xylene. The multistage suspension melting crystallization method comprises the following steps: carrying out shunt operation on raw materials, carrying out multistage crystallization on a part of the raw materials, directly obtaining a p-xylene product, then using the rest of the raw materials to carry out pulping washing and warming aging on a low-temperature crystal in an aging kettle, and obtaining residual p-xylene product. Stable operation of the aging kettle is guaranteed by adjusting the amount and temperature of the raw materials entering into the aging kettle, and then the stability of product purity and yield is guaranteed. Through the technical scheme adopted in the invention, the problems of unstable operation of the aging kettle and high energy consumption existing in the prior art are preferably solved, and the method can be used in the crystallization production of the p-xylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating paraxylene by using suspension melt crystallization

InactiveCN106831312AProduct purity and stable yieldIncrease crystal sizeOrganic chemistry methodsCrystallisation purification/separationChemistrySeed crystal

The present invention relates to a method for separating paraxylene by using suspension melt crystallization. The method comprises the steps: branching raw materials, adjusting the quantity and the temperature of the raw materials entering an aging kettle to ensure that the operation in the aging kettle is stable so as to further ensure product purity and yield stabilization; and feeding part of the raw materials into a pre-cooling device for cooling, and generating part of crystals as seed crystals of a crystallizer, so that the crystal granularity in the crystallizer is increased, and further the follow-up solid-liquid separation efficiency is improved; and a technical scheme adopted in the present invention can well solve problems that the operation in the aging kettle is unstable, the crystal granularity is low, and the energy consumption in production is high in the prior art, so that the method can be used for production of paraxylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

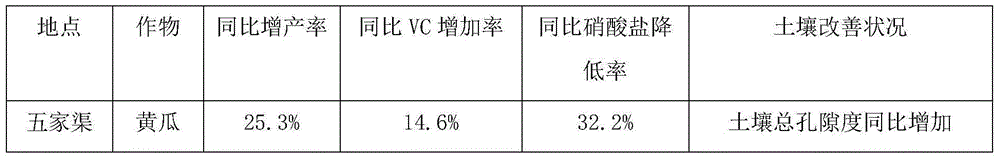

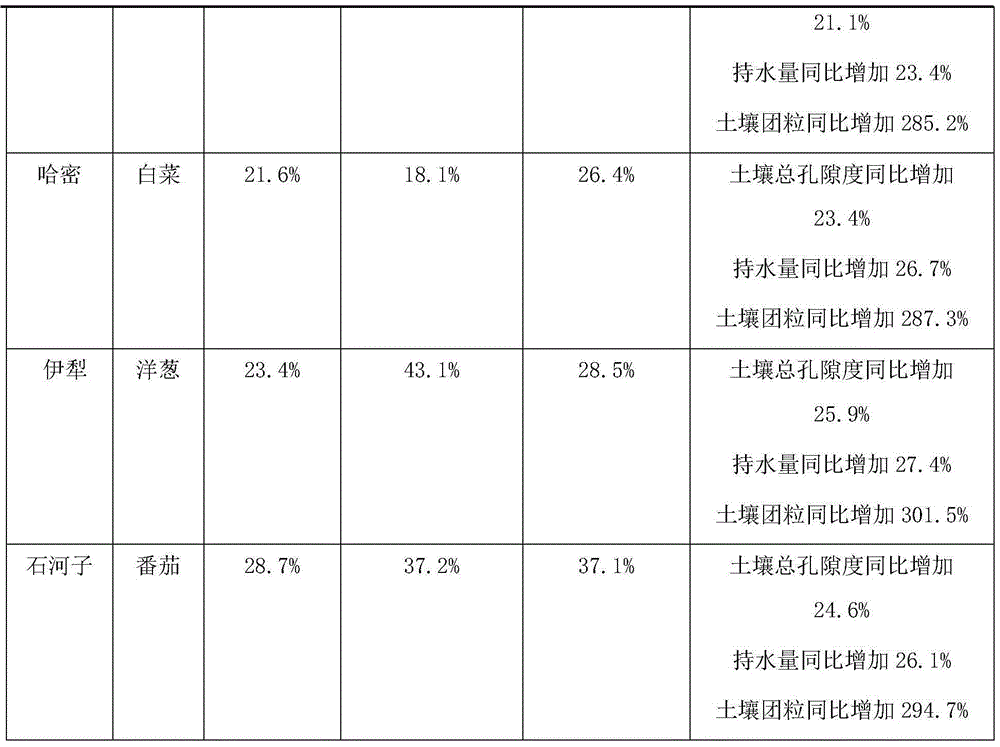

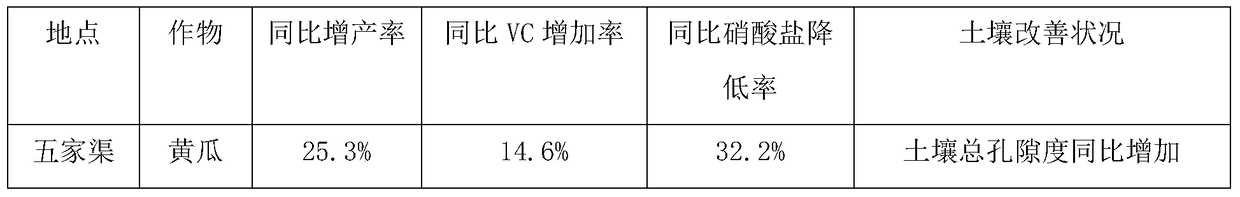

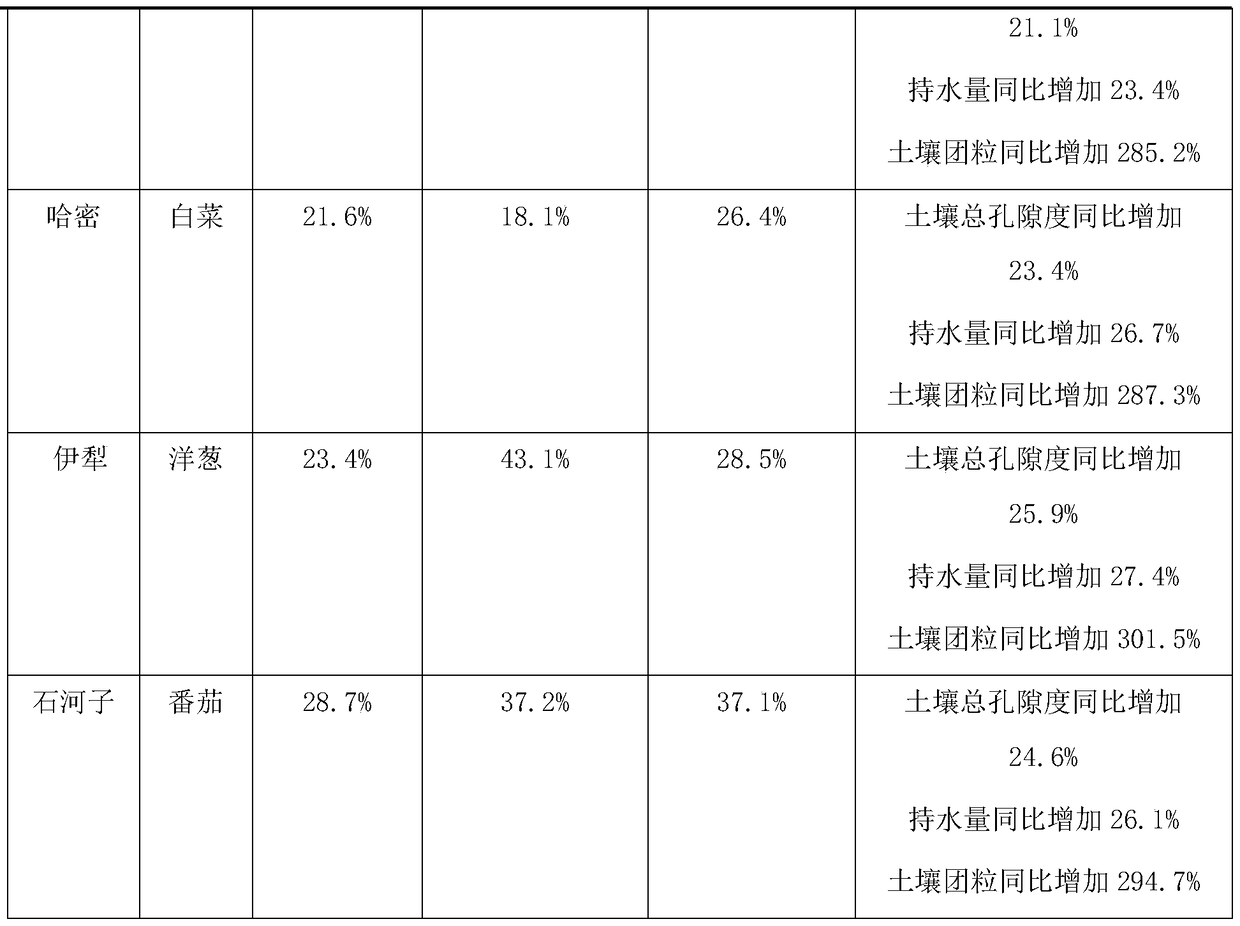

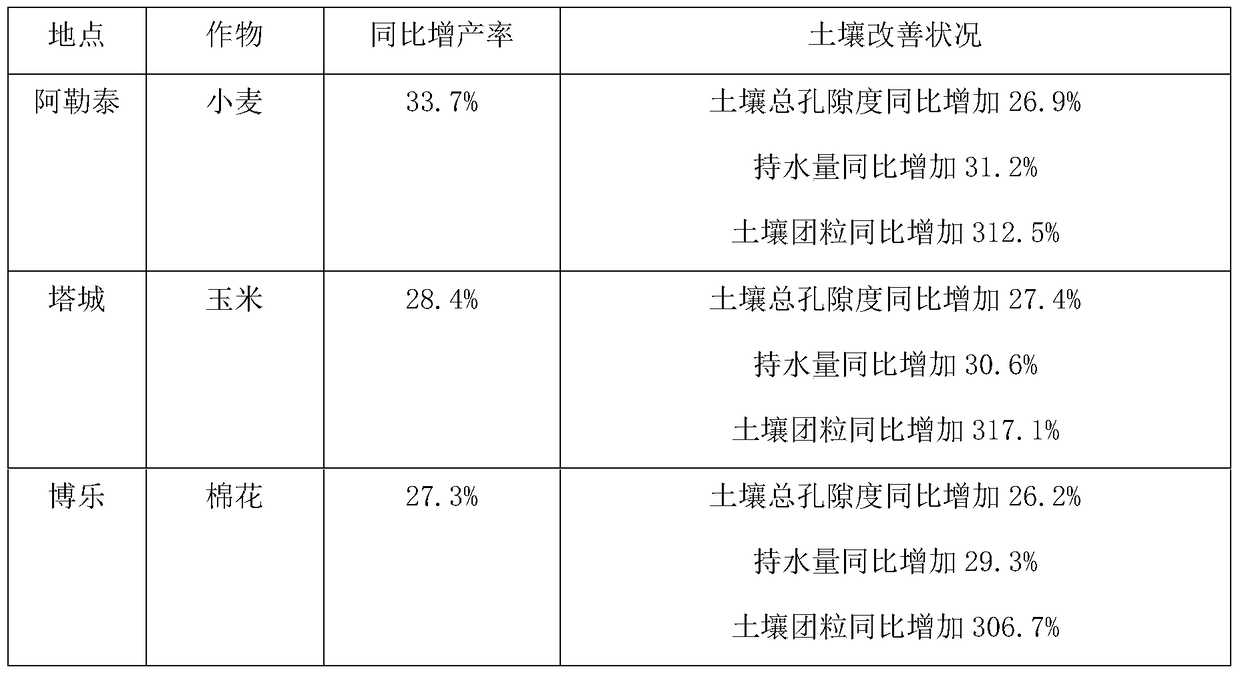

Water-soluble organic humic acid fertilizer and application thereof to promotion of plant yield increment and soil improvement

ActiveCN105198660AHigh porosityImprove water holding capacityFertilizer mixturesNaphthylacetic acidBorax

The invention provides a water-soluble organic humic acid fertilizer and application thereof to promotion of plant yield increment and soil improvement. The preferable water-soluble organic humic acid fertilizer is prepared from compound microorganisms and the following raw materials in parts by weight: 35 parts of water-soluble potassium humate, 16 parts of urea, 9 parts of potassium sulfate, 8 parts of monoammonium sulfate, 3 parts of zinc sulfate, 4 parts of borax, 2 parts of ammonium molybdate, 1.2 parts of hxanoic acid 2-(diethylamino) ethyl ester, 0.9 part of compound sodium nitrophenolate, 0.9 part of alpha-sodium naphthylacetate and 40 parts of water, wherein the total biomass of compound microorganisms in every kg of the water-soluble organic humic acid fertilizer is larger than or equal to 1.2*10<10>cfu. In addition, the invention also provides application of the water-soluble organic humic acid fertilizer to promotion of plant yield increment and soil improvement.

Owner:吉木乃县金世宝农业节水科技有限责任公司

Method for controlling continuous reaction crystal size of 2,4-dichlorphenoxyacetic acid

ActiveCN104276944AFine granularityHigh yieldPreparation from carboxylic acid saltsCarboxylic compound separation/purificationAfter treatmentRetention time

The invention relates to a method for controlling a continuous reaction crystal size of a herbicide 2,4-dichlorphenoxyacetic acid. The method comprises the following steps: (1) preparing a 80-100 DEG C saturated or nearly saturated solution of a 2,4-dichlorphenoxyacetic acid salt, and 10-38% hydrochloric acid respectively; (2) in a crystallizer, continuously adding the 2,4-dichlorphenoxyacetic acid salt solution and the hydrochloric acid prepared in the step (1), wherein a molar ratio of the 2,4-dichlorphenoxyacetic acid salt to hydrochloric acid is 1 to (1-1.2), controlling the crystallization temperature at 20-60 DEG C, controlling the retention time to 2-10 hours, continuously discharging the material to an after-treatment process to obtain the 2,4-dichlorphenoxyacetic acid product. According to the crystal size control method disclosed by the invention, the 2,4-dichlorphenoxyacetic acid salt is dissolved at a high temperature, the 2,4-dichlorphenoxyacetic acid salt solution and hydrochloric acid are subjected to a continuous reaction crystallization process in the crystallizer at a low temperature, so that the problems that the 2,4-dichlorphenoxyacetic acid product produced by the process of performing acidification reaction at a high temperature and then cooling for crystallizing is low in purity and small in crystal size and easily causes equipment corrosion are solved. The method has the advantages that the prepared produce has a great crystal size and a high purity, energy consumption is low, equipment corrosion is hardly caused, the operation is simplified and the process is easily controlled automatically.

Owner:TIANJIN UNIV OF SCI & TECH +1

Multistage suspension melting crystallization method for separating p-xylene

ActiveCN106831301AIncrease the average particle sizeEasy to operateChemical industryCrystallisation purification/separationChemistryHigh energy

The invention relates to a multistage suspension melting crystallization method for separating p-xylene. The multistage suspension melting crystallization method comprises the following steps: carrying out shunt operation on raw materials, carrying out multistage crystallization on a part of the raw materials, directly obtaining a p-xylene crystal, then using the rest of the raw materials to carry out pulping washing and warming aging on a low-temperature crystal in an aging kettle, and obtaining a p-xylene product. Stable operation of the aging kettle is guaranteed by adjusting the amount and temperature of the raw materials entering the aging kettle, and then the stability of product purity and yield is guaranteed. Through the technical scheme adopted in the invention, the problems of unstable operation of the aging kettle and high energy consumption existing in the prior art are preferably solved, and the method can be used in the crystallization production of the p-xylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

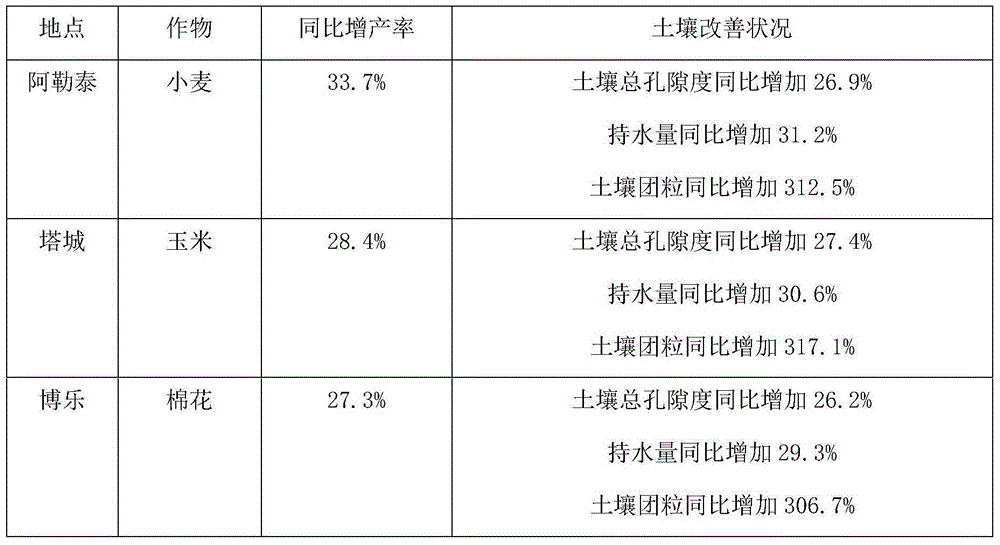

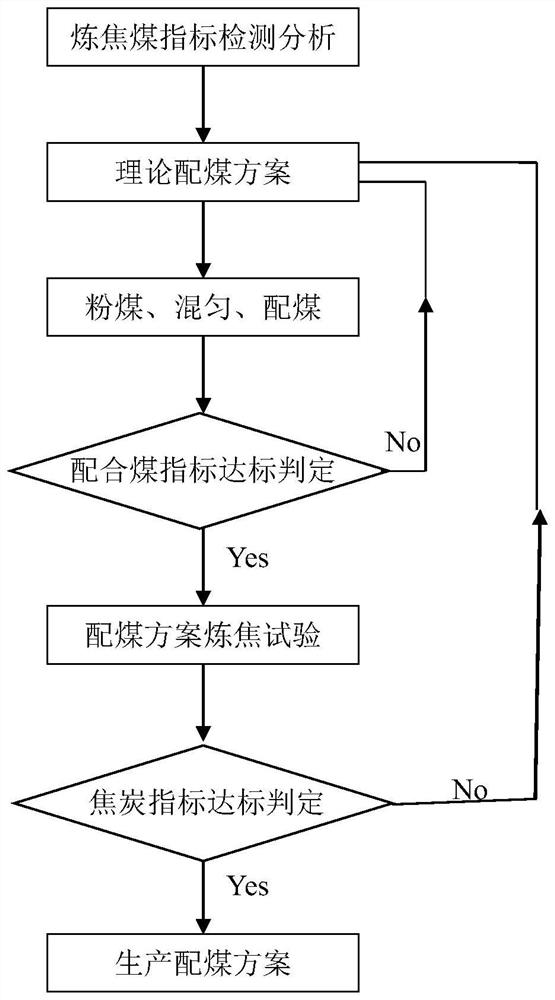

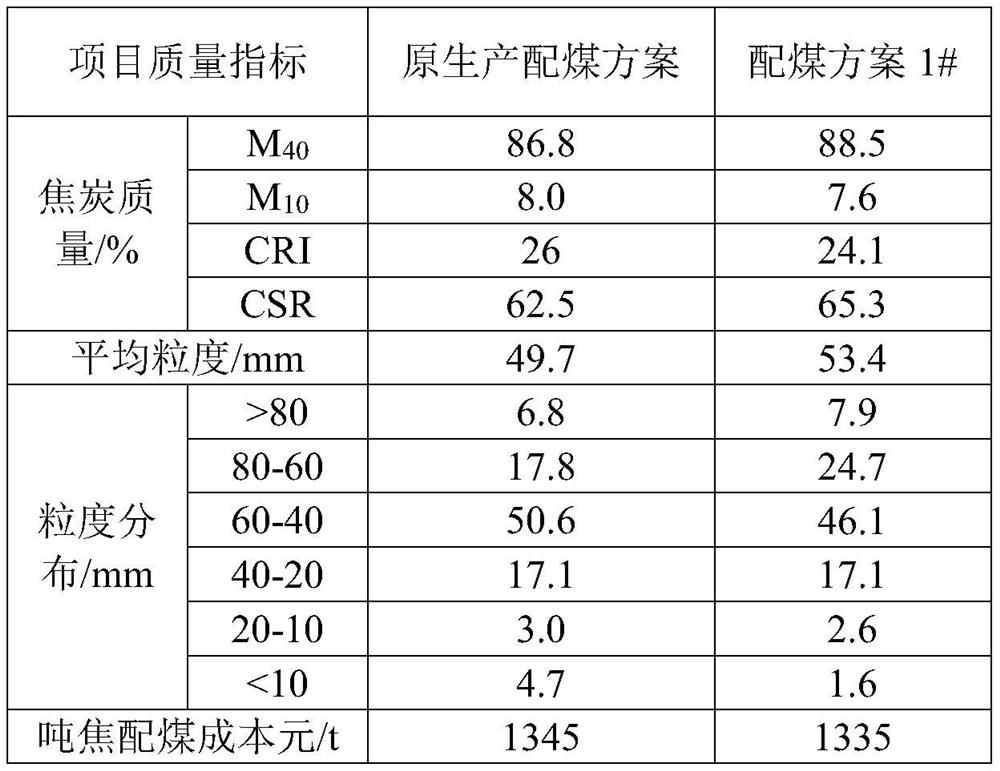

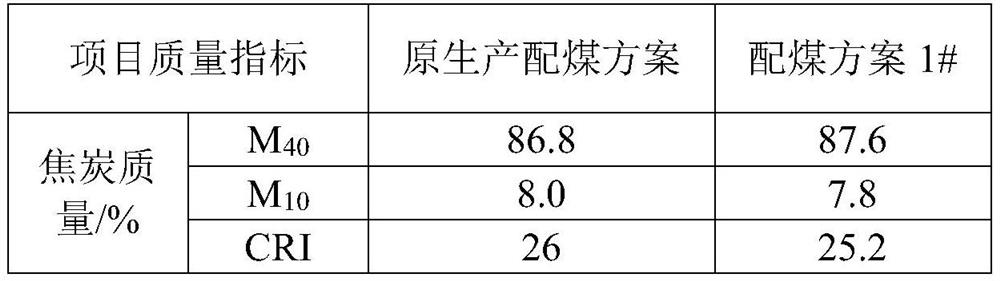

A coking coal blending method for increasing the average particle size of coke and improving the particle size distribution of coke

ActiveCN111253961BImprove particle size distributionImprove breathabilityFuel testingMaterial analysis by optical meansPhysical chemistryProcess engineering

The invention relates to a coking coal blending method for increasing the average particle size of coke and improving the particle size distribution of coke. Coal quality indicators are measured for each coking single coal used in production. The various coal types determined by quantitative indicators such as microscopically inert component content, maximum capacity for inertness, capacity for inertness, initial softening temperature, and solidification temperature are formulated into blended coal according to the mass ratio, so that the blended coal meets the content of microscopically inert components in coal. 17% ≤ X0 ≤ 30%, the maximum capacity index L satisfies 35 ≤ L ≤ 50, the total expansion degree is 100-350, and the coal blending plan is defined as coking if the test coking verification result index reaches the coking production coke index requirement range Coal blending scheme for production. The invention increases the average particle size of the coke, optimizes the distribution of the particle size of the coke, and improves the gas permeability of the coke in the charge of the blast furnace.

Owner:ANGANG STEEL CO LTD

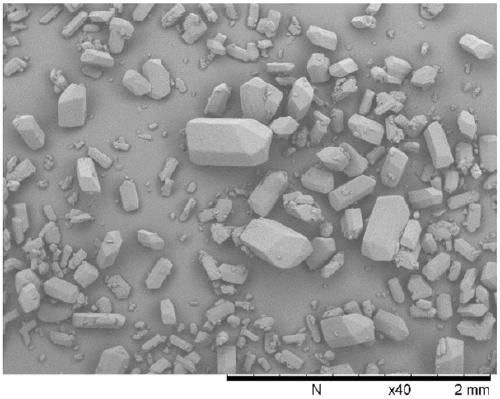

Preparation method of mendozite

InactiveCN105692672AIncrease the average particle sizeAluminium sulfatesAluminum sulphatePhysical chemistry

The invention relates to a preparation method of mendozite. The preparation method comprises mixing aluminum sulfate, sodium sulfate and water at a temperature of 80-100 DEG C so that the mixture undergoes a reaction, carrying out evaporative concentration on the reaction product, adding seeds into the product and carrying out cooling crystallization to obtain mendozite crystals. The preparation method has the characteristics of uniform particle size distribution and large average particle size.

Owner:WUHAN UNIV OF SCI & TECH

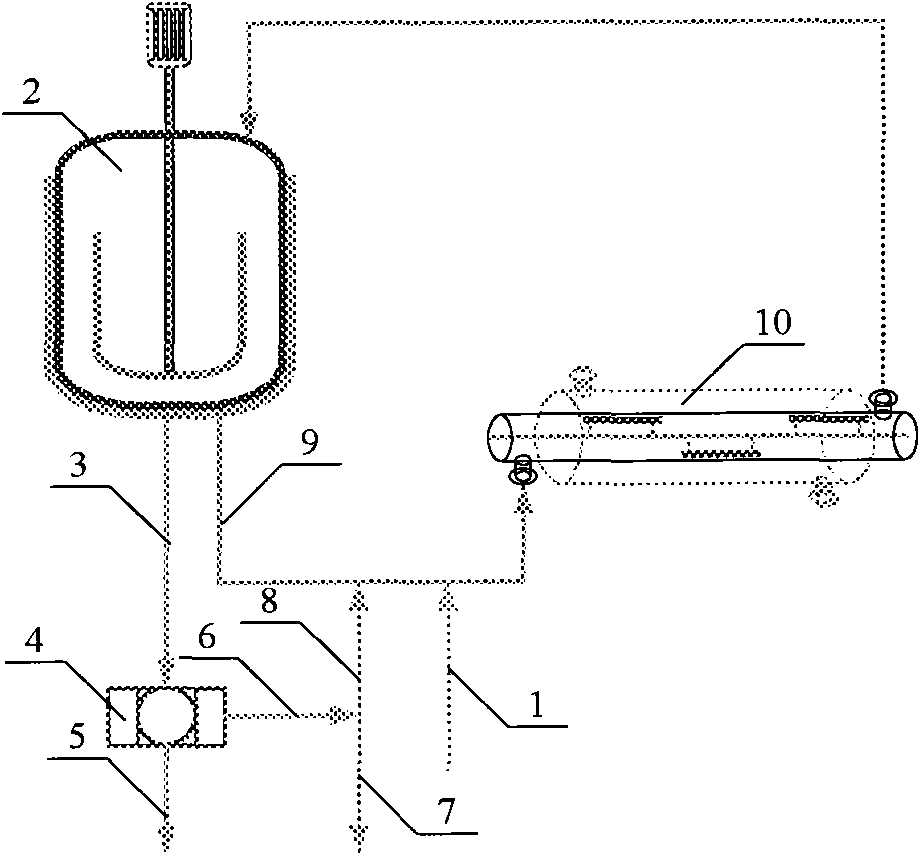

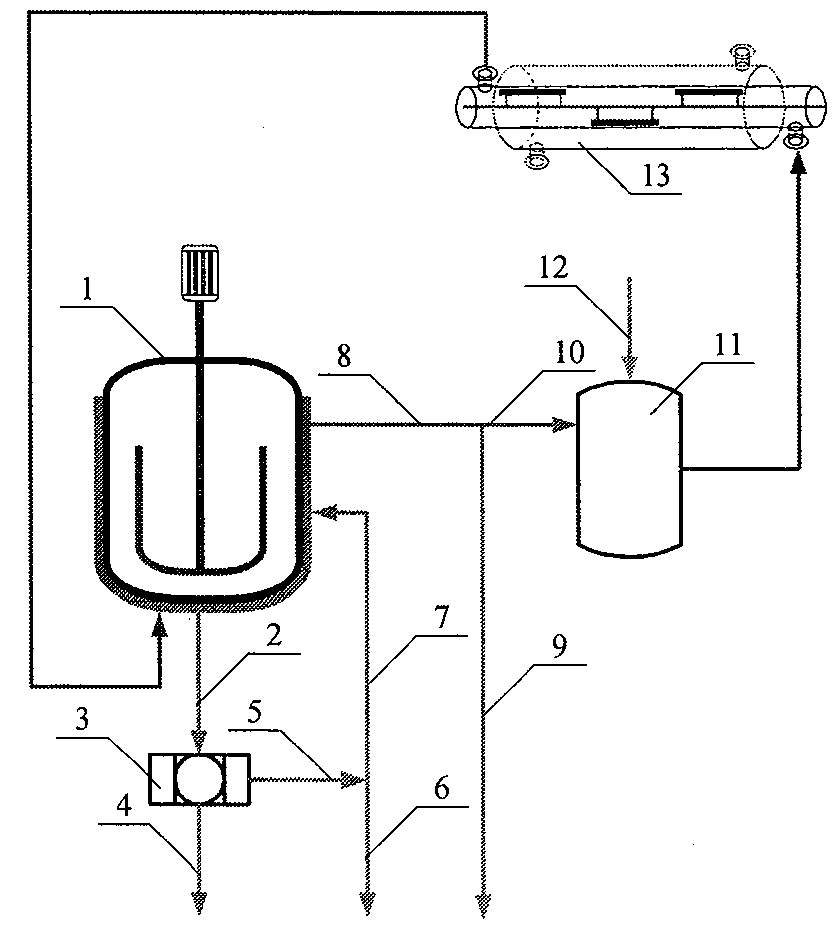

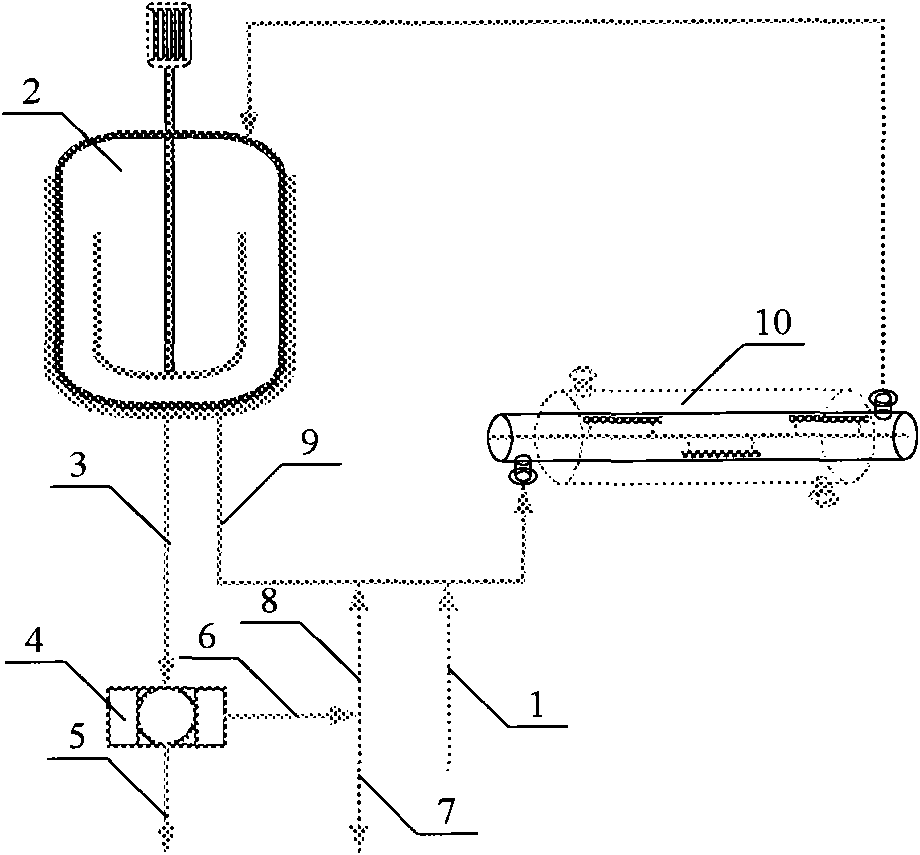

Crystallization method with overflow of clear mother liquor

ActiveCN102371082AIncrease the average particle sizeImprove technical effectSolution crystallizationRaw materialMother liquor

The invention relates to a crystallization method with an overflow of a clear mother liquor, mainly solving the problems of small crystal size and frequent cleaning of the crystallizer existing in the prior art. The invention is characterized in that: raw material enters in a kettle-type crystallizer for crystallization; crystallized clear mother liquor in the kettle-type crystallizer flows out from the upper portion of the crystallizer; the crystal mush in the kettle-type crystallizer is divided into two parts- crystal mush I and crystal mush II, which flow out from the lower portion of the crystallizer; the crystal mush I is subject to separation through a solid-liquid separator to obtain crystals and crystallized filtrated mother liquor, the crystal mush II is subject to heat transfer through a jacketed crystallizer and returns to the kettle-type crystallizer, wherein, the weight ratio of the crystal mush I to the crystal mush II is 1:1-1:50; the crystals are discharged as products; the crystallized filtrated mother liquor is divided into two streams, the crystallized filtrated mother liquor I accounting for 5-95 wt% of the crystallized filtrated mother liquor is discharged, the crystallized filtrated mother liquor II accounting for 5-95 wt% of the crystallized filtrated mother liquor is mixed with the crystal mush II and then returns to the kettle-type crystallizer; raw material enters in the kettle-type crystallizer after mixing with the crystal mush II or directly enters in the kettle-type crystallizer, and the weight ratio of the crystallized mother liquor to the crystallized filtrated mother liquor I is 0.1:1-10:1. The invention can be applied in the industrial crystallization production.

Owner:CHINA PETROLEUM & CHEM CORP +1

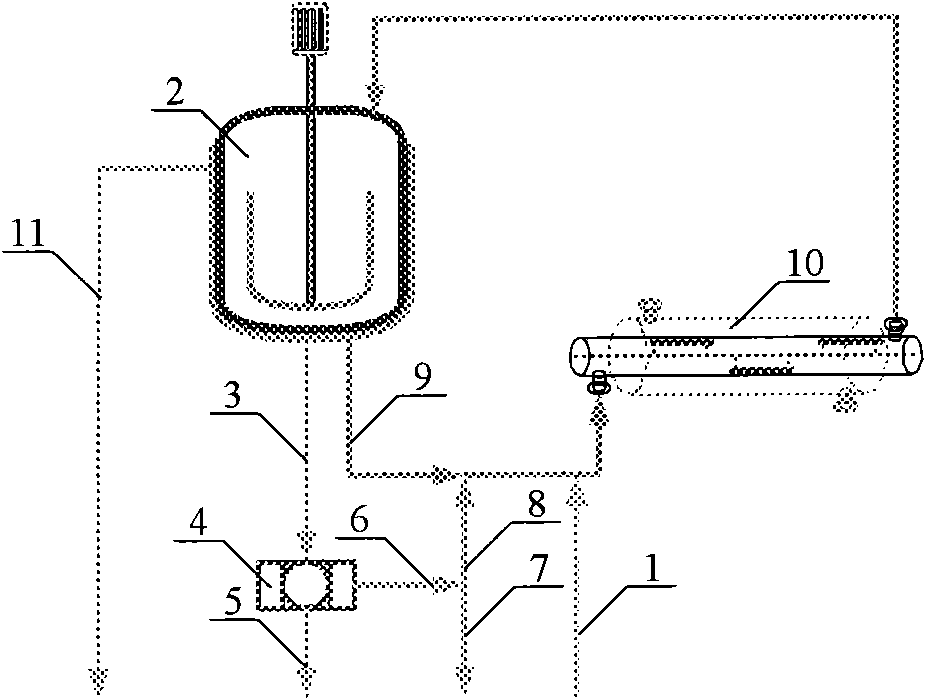

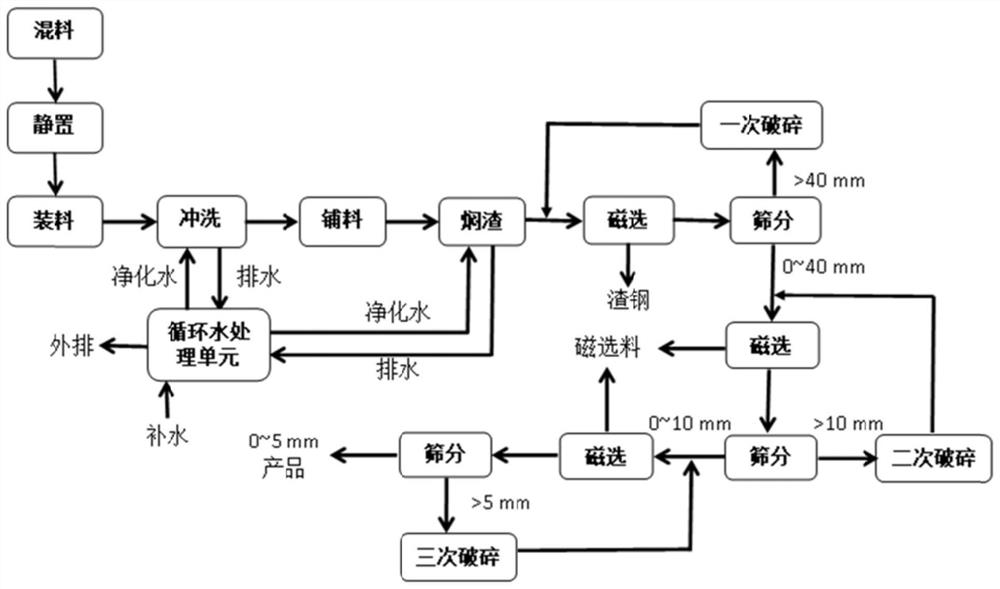

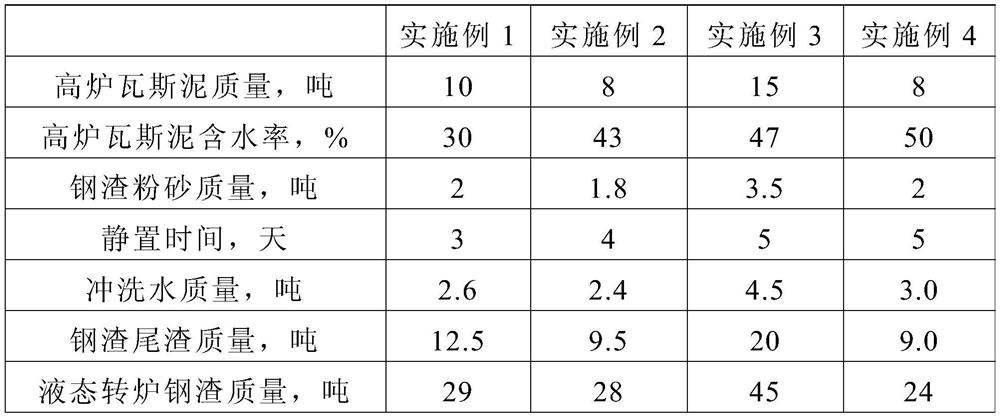

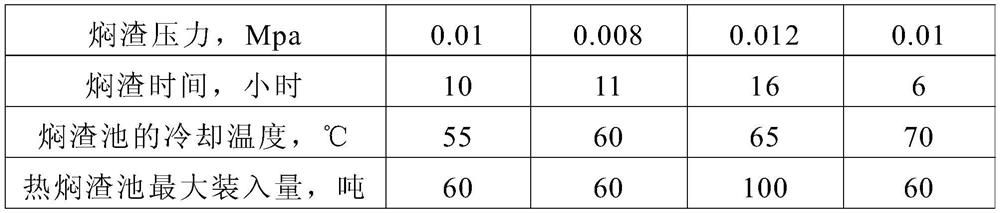

Method for resourceful treatment of blast furnace gas mud by using slag braising process

ActiveCN112125540ASolve the problem of high content of impurity elementsReduce investmentCement productionSlagCaking

The invention relates to the technical field of resource utilization of blast furnace gas, in particular to a method for resourceful treatment of blast furnace gas mud by using a slag braising process. The method comprises the following steps of: (1) uniformly mixing blast furnace gas mud and steel slag silt to obtain a first mixture, and making the first mixture stand still to cake the first mixture; (2) putting the caked first mixture into a hot braising slag pool, and flushing the first mixture by using water fetching equipment; (3) conducting slag braising treatment, specifically, pouringliquid converter steel slag into the heat braising slag pool, and covering the first mixture with the liquid converter steel slag, covering the heat braising slag pool with a cover, pumping water intothe liquid converter steel slag through water pumping equipment, and making an obtained mixture stand still to obtain a dried second mixture; and (4) performing crushing and magnetic separation on the second mixture to obtain a material with the particle size of 0-5 mm and adopting the material as a cement iron correction material. The method has the characteristics of low cost and few impuritiesin the obtained cement iron correction material, and can be used for large-scale production.

Owner:武汉钢铁有限公司

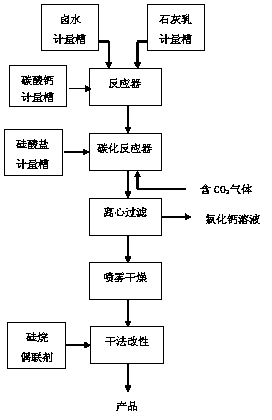

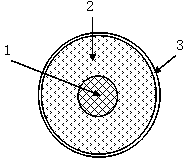

Preparation method for compound-type inorganic flame retardation powder material with dual core-shell structure

ActiveCN103819936ASolve the problem of too small granularityGood dispersionInorganic pigment treatmentDual coreCarbonization

The invention discloses a preparation method for a compound-type inorganic flame retardation powder material with a dual core-shell structure, which comprises the following steps: 1) simultaneously and continuously adding a lime milk fluid suspension with 30g / l-150g / l of calcium hydrate content and a brine solution with 50g / l-200g / l of magnesium chloride concentration in a calcium carbonate suspending liquid with 10g / l-50g / l of content, wherein the mol ratio of added magnesium chloride to calcium hydrate is 1.0-1.2: 1.0, and the mol ratio of calcium carbonate to magnesium hydroxide generated by a subsequent reaction is 0.01-0.10: 1.0; 2) reacting magnesium chloride and calcium hydrate in the above mixed liquor, and then insulating and aging to generate a reaction fluid suspension; 3) adding an alkali-silica metal salt solution in the reaction fluid suspension, introducing CO2-containing gas for a carbonization reaction to generate a carbonization fluid suspension; and 4)filtering and drying the carbonization fluid suspension to obtain the inorganic flame retardation powder material. The method has the characteristics of simple process, easy acquisition of raw material and low cost; and the product has the advantages of large granularity, good dispersibility, easy organic modification and good flame retardation effect.

Owner:连云港倍特超微粉有限公司

Method for purifying crude 2,6-naphthalic acid

InactiveCN107840789AReduce circulationReduce energy consumptionBulk chemical productionCarboxylic compound separation/purificationSolubilityHigh energy

The invention provides a method for purifying crude 2,6-naphthalic acid. The method comprises the following steps: mixing crude 2,6-naphthalic acid with water to form crude 2,6-naphthalic acid slurryand carrying out heating to a supercritical state with a temperature of 375 to 450 DEG C and a pressure of 22 to 60 MPa for dissolving; subjecting 2,6-naphthalic acid dissolved in the supercritical state to cooling and crystallization; and subjecting the 2,6-naphthalic acid slurry having undergone cooling and crystallization to solid-liquid separation so as to obtain a 2,6-naphthalic acid product.The method provided by the invention overcomes the problems of low solubility of 2,6-naphthalic acid in solvents, great slurry circulation volume and high energy consumption in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

High purity big granule industrial anhydrous sodium sulphate production method

InactiveCN100545091CIncrease the average particle sizeQuality improvementAlkali metal sulfite/sulfate purificationCycloneCyclonic separation

A production method of high-purity large-grain industrial anhydrous sodium sulfate, comprising the following steps: ① extracting raw nitric water from a mine, and injecting it into the mine layer with waste water; ② treating the raw nitric water; ③ V-effect evaporation and crystallization; ④ centrifuging Dehydration; ⑤hot air drying; ⑥cyclone separation; ⑦sieving; ⑧quantitative packaging. It is characterized by the V-effect evaporation and crystallization process, which adopts a new production process of external heating forced V-effect reverse circulation vacuum evaporation, which changes the positive circulation structure of the existing evaporation tank, so that the material liquid coming out of the circulation pipe on the heating chamber is tangential Entering the lower cone of the evaporation chamber, the feed liquid spirals up in the evaporation chamber. According to the centrifugal working principle, the clear liquid rises to the liquid level in the evaporation chamber along the center of the tank, and then axially discharges to the lower circulation pipe after entering the central tube. , enter the heating tube to recirculate and heat again, and the crystals with large particles settle down along the wall of the evaporation tank and enter the crystallizer to continue to grow. The process can increase the average particle size of sodium sulfate crystals, making the particle size ≥ 65 mesh, and can reduce dust emission and environmental pollution.

Owner:HUNAN XINLI CHEM

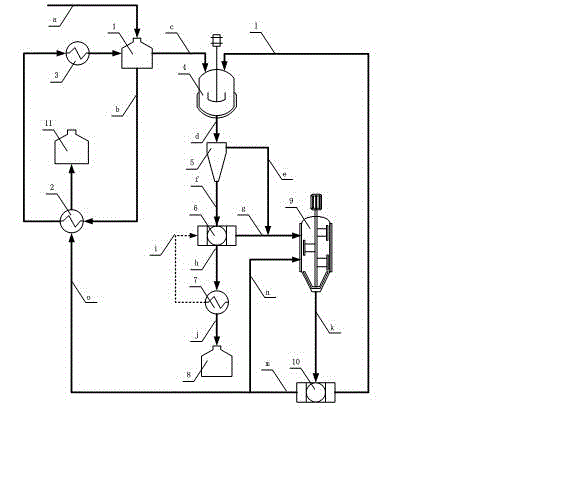

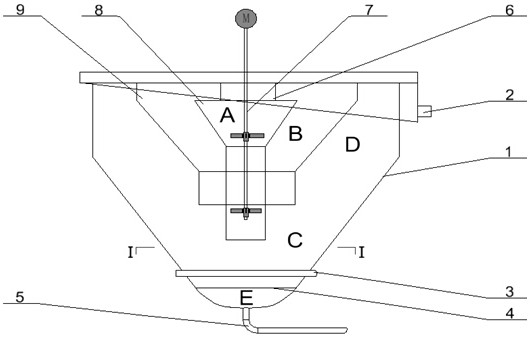

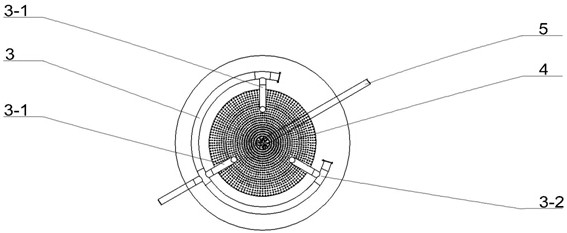

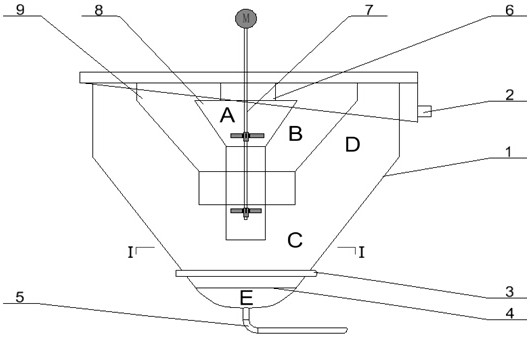

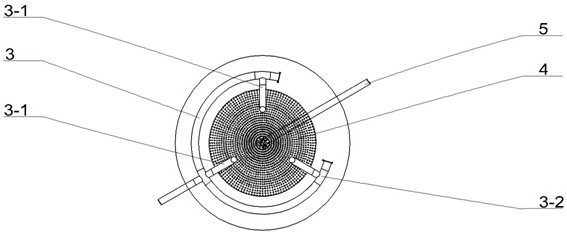

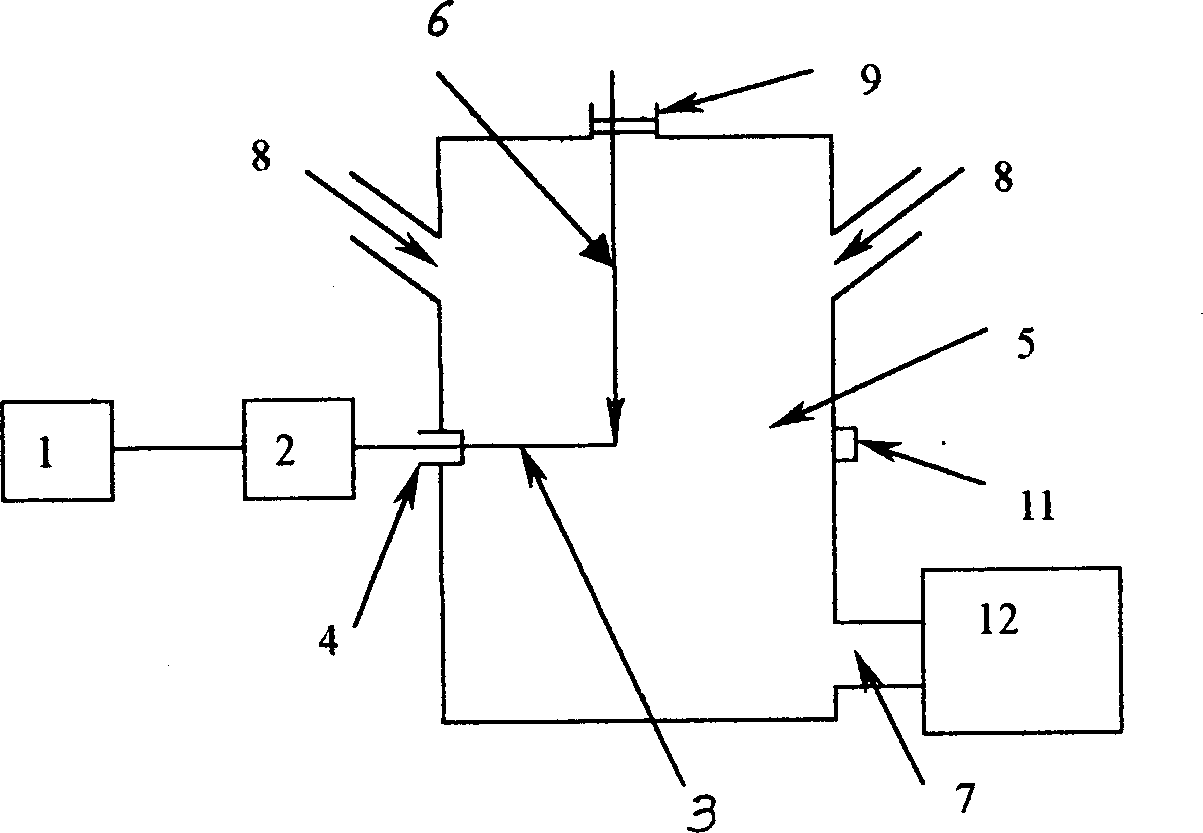

Circulating fluidized bed decomposition crystallization device and decomposition crystallization method

ActiveCN111643924AAverage grain sizeIncrease the average particle sizeSolution crystallizationProduct crystals bed crystallizationMetallurgyFluidized bed

The invention discloses a circulating fluidized bed decomposition crystallization device and a decomposition crystallization method. The circulating fluidized bed decomposition crystallization devicecomprises a decomposition crystallization device body; a mother liquor overflow groove is formed in the upper part of the decomposition crystallization device body; an inner guide cylinder and an outer guide cylinder are arranged in the decomposition and crystallization device body; a crystal slurry discharge pipeline is arranged at the lower part of the decomposition and crystallization device; aliquid supplementing opening is formed in the bottom of the decomposition and crystallization device body, a main stirring device is arranged in the decomposition and crystallization device body, a stirring shaft and blades of the main stirring device extend into the inner guide cylinder, and a liquid distribution plate is arranged in the decomposition and crystallization device body and locatedbetween the crystal slurry discharge pipeline and the liquid supplementing opening; the invention further comprises the circulating fluidized bed decomposition and crystallization method. The decomposition and crystallization method can be used for preparing potassium chloride through carnallite decomposition and crystallization and can also be used for crystallization production of potassium sulfate through potassium chloride and sulfate double decomposition and crystallization, the height-diameter ratio of the decomposition and crystallization device is reduced, the raw material entrainmentrate is reduced, and meanwhile the average particle size of the product can be increased.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

A kind of humic acid water-soluble organic fertilizer and its application in promoting plant production and improving soil

Owner:吉木乃县金世宝农业节水科技有限责任公司

The production method of high-purity 2,6-naphthalene dicarboxylic acid

ActiveCN107840791BReduce circulationReduce energy consumptionCarboxylic compound separation/purificationSolubilityHigh energy

The invention provides a kind of high-purity 2,6 naphthalene dicarboxylic acid production method, comprises the following steps: (1) thick 2,6 naphthalene dicarboxylic acid is mixed with water, forms thick 2,6 naphthalene dicarboxylic acid slurry, (2) Heating the crude 2,6-naphthalene dicarboxylic acid slurry to 300°C-375°C, 8MPa-22MPa subcritical state; (3) cooling and crystallizing the dissolved 2,6-naphthalene dicarboxylic acid, (4) cooling crystallization The 2,6-naphthalene dicarboxylic acid slurry is subjected to solid-liquid separation to obtain high-purity 2,6-naphthalene dicarboxylic acid product; The problem of high circulation volume and high energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

A circulating fluidized bed decomposition crystallization device and decomposition crystallization method

ActiveCN111643924BGuaranteed yieldReduce the amount of finesSolution crystallizationProduct crystals bed crystallizationFluidized bedPhysical chemistry

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

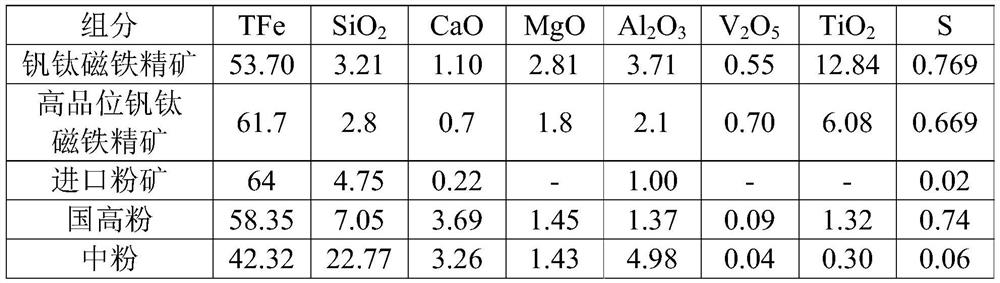

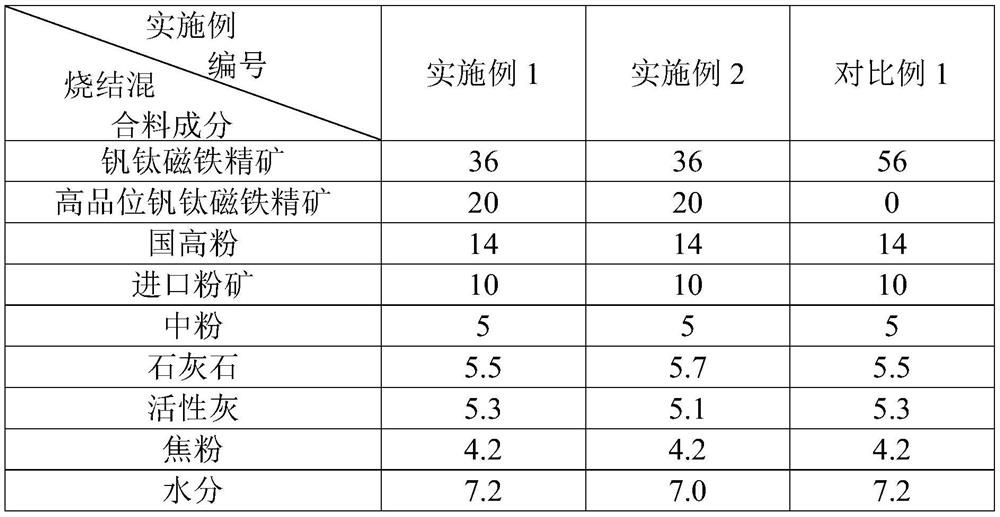

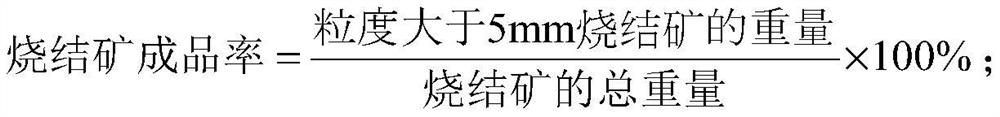

A method for improving the quality of sintered ore of vanadium-titanium magnetite concentrate

ActiveCN110564953BIncrease the average particle sizeIncreased drum strengthOre concentrateRaw material

The invention relates to the technical field of iron and steel metallurgy, and discloses a method for improving the quality of vanadium titanium magnetite concentrate sinter. The method comprises thefollowing steps: (1) drily mixing a sintering raw material and return mine, and thus obtaining a dry material; (2) adding water to the obtained dry material for primary mixing and secondary mixing, and controlling the water content of the obtained sintering mixture to be 7-7.2 wt%; and (3) distributing, igniting and sintering the obtained sintering mixture. High-grade vanadium titanium magnetite concentrate is added into vanadium titanium magnetite concentrate, and meanwhile the water content of the sintering mixture and the ratio of active ash in the sintering raw material are controlled to improve the tumbler strength of the sinter, so the quality of the vanadium titanium sinter is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

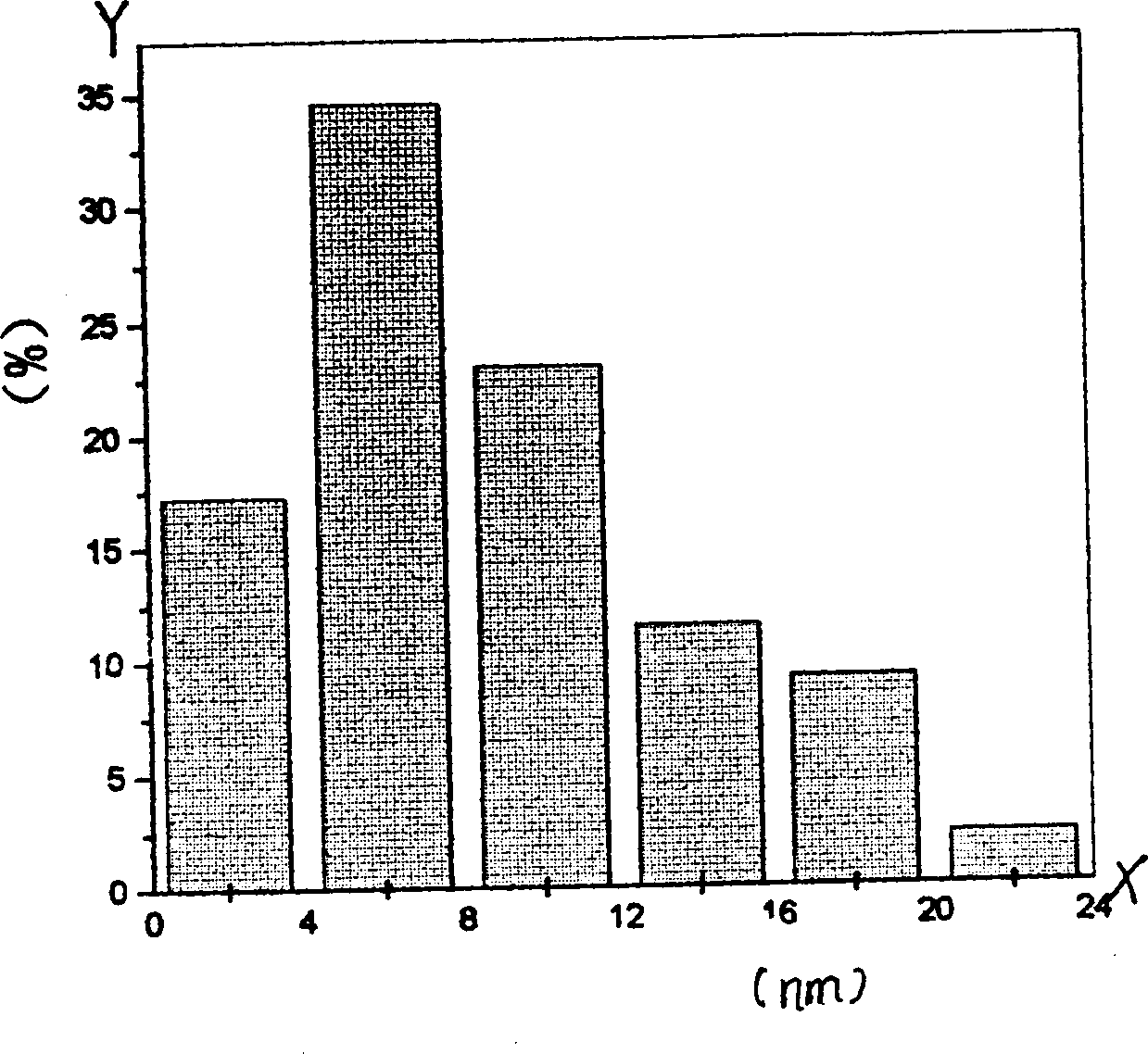

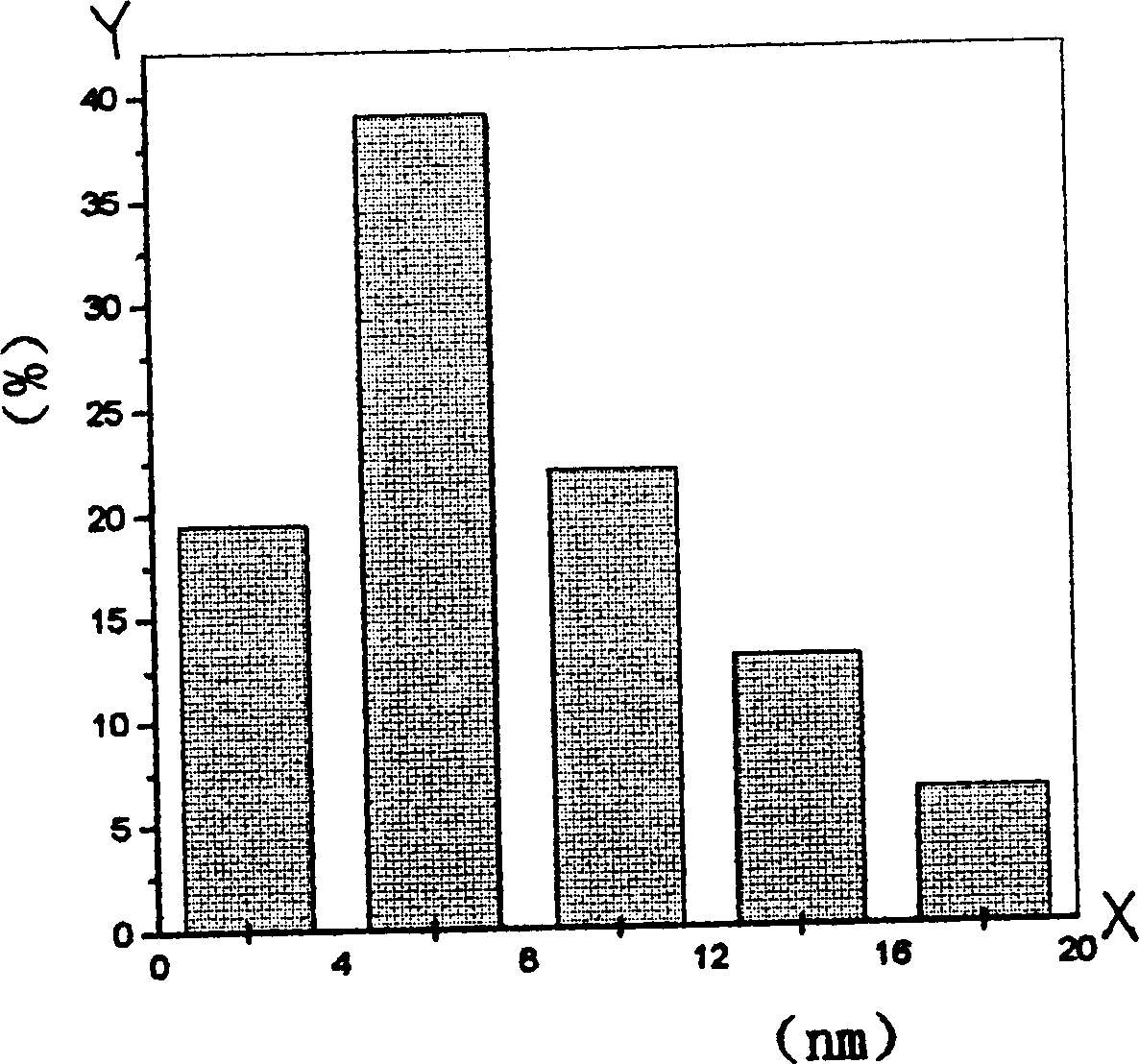

Superfine powder preparing method

In the present invention the fine wire in basically even thickness is fed to a vacuum reaction chamber continuously, and its end is ablated by focused laser beam or electron beam to produce integral explosive evaporation. While laser beam or electron beam acts, inert gas or reactive gas in proper flow rate is led into the reaction chamber to maintain reaction chamber pressure in 10 Pa to 10 Kpa, and the produced superfine powder is collected by using a powder collector. The target material may be preheated. Using the present invention can prepare high-purity superfine powder with small average size and narrow size distribution in high yield.

Owner:HUAZHONG UNIV OF SCI & TECH

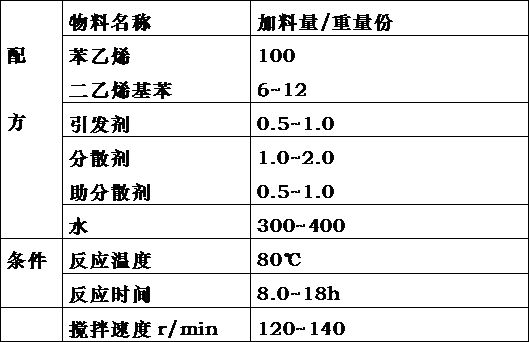

Catalyst for preparing methyl methacrylate, and preparation method and esterification preparation process thereof

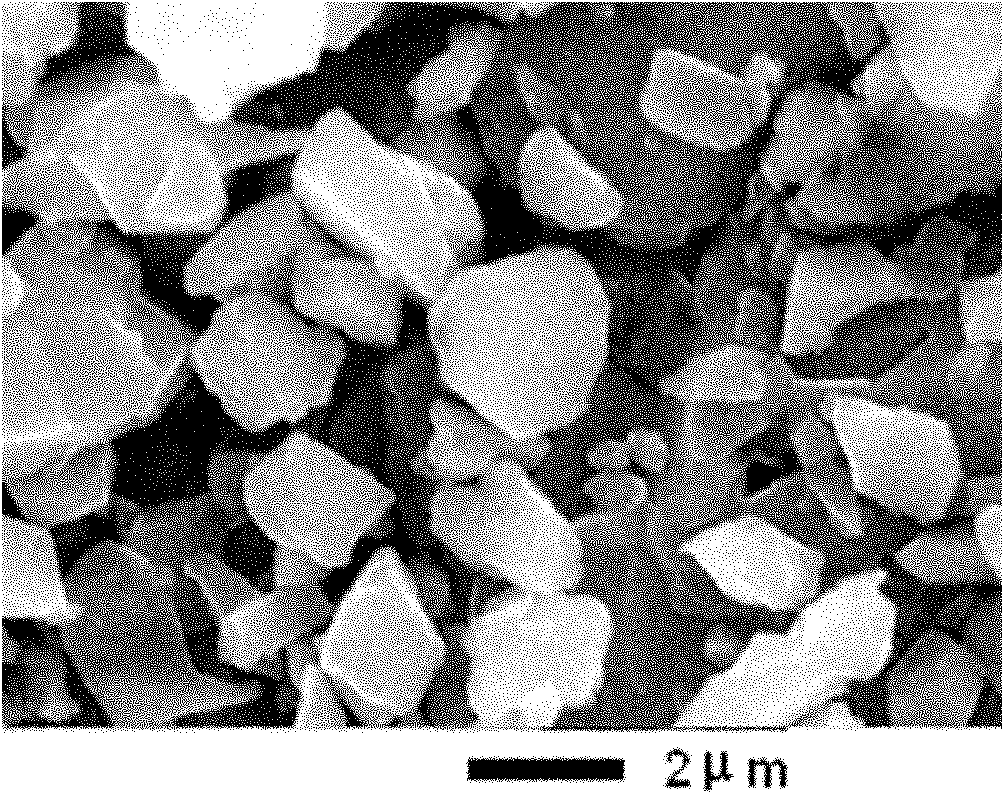

PendingCN112705266AUniform particlesHigh viscosityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

The invention discloses a catalyst for preparing methyl methacrylate, a preparation method of the catalyst and a esterification preparation process. The catalyst for preparing methyl methacrylate is a styrene cationic resin catalyst, the use amount of divinyl benzene accounts for 6-12% of the mass of styrene, a pore-foaming agent is one of hexane or heptane, a dispersing agent is polyvinyl alcohol, anauxiliary dispersing agent is polyacrylamide, and a sulfonating agent in sulfonation is a dichloroethane or dichloropropene solution of sulfur trioxide. According to the methyl methacrylate esterification preparation process applying the catalyst, the molar ratio of methanol to methacrylic acid is (1.6-2.0): 1, and methyl methacrylate is prepared under the conditions that the reaction pressure is 1.0-1.5 MPa, the air speed is 0.3-0.5 h < -1 > and the reaction temperature is 70-90 DEG C. According to the technical scheme, preparation of methyl methacrylate is simplified, and the method has the reaction effects of avoiding hot spots and being high in conversion rate.

Owner:丹东明珠特种树脂有限公司

Crystallization method with a fine crystal elimination

ActiveCN102371081BIncrease the average particle sizeSolution crystallizationCrystallisation purification/separationPhysical chemistryMother liquor

The invention relates to a crystallization method with a fine crystal elimination, which mainly solves the problems of small crystal granularity and frequent crystallizer cleaning in the prior art. The invention is characterized in that crystallized clear mother liquor in a kettle-type crystallizer flows out from the upper part of the crystallizer, the crystallized clear mother liquor is divided into two streams, a first stream I of the crystallized clear mother liquor which takes account for 5-95% of weight is discharged, a second stream II of the crystallized clear mother liquor which takes account for 5-95% of weight enters in an intermediate groove; crystal slurry in the kettle-type crystallizer flows out from the lower part of the crystallizer and separated by a solid-liquid separator to obtain crystals, and crystallized and filtered mother liquor; crystals as products are discharged, the crystallized and filtered mother liquor is divided into two streams, a first stream I of the crystallized and filtered mother liquor which takes account for 5-95% of weight is discharged, a second stream II of the crystallized and filtered mother liquor which takes account for 5-95% of weight enters in the intermediate groove or directly returns to the kettle-type crystallizer; the raw material enters into the intermediate groove, the material in the intermediate groove is performed heat exchange through a tubular type crystallizer and returned to the kettle-type crystallizer; wherein the weight ratio of the crystallized clear mother liquor to the crystallized and filtered mother liquor is 0.1:1-10:1. The technical scheme better solves the problems, and can be used in industrial crystallization production.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for recovering high-quality industrial salt from desulfurization wastewater in coal-fired power plants

ActiveCN105601022BImprove product qualityRealize resourcesWater contaminantsTreatment involving filtrationFlocculationResource utilization

Owner:武汉科技大学资产经营有限公司

A kind of manufacture method of heterosexual rubber magnetic powder

ActiveCN101996719BIncrease the average particle sizeImprove physical propertiesInorganic material magnetismInductances/transformers/magnets manufacturePolymer scienceFrit

The present invention relates to a kind of manufacturing method of heterosexual rubber magnetic powder, according to the following steps: (1) the molar ratio of each raw material satisfies the molecular formula SrO nFe2O3; (2) mixing materials; Burning; (4) Mixing and fine grinding; (5) Tempering; (6) Washing treatment; (7) Drying, crushing, sieving, and finished product; wherein, the molar ratio of the main raw materials satisfies the molecular formula SrO·nFe2O3. In addition, the best sintering temperature A of SrO·nFe2O3 strontium ferrite: 1090°C-1100°C, heat preservation for 1-2 hours, and the sintering temperature B: 1065-1075°C. The manufacturing method of the heterosexual rubber magnetic powder of the present invention can significantly improve the performance of the magnetic powder and the particle size of the finished product, so as to improve the physical properties of the rolled sheet and solve the problem of difficult upper roll during subsequent processing.

Owner:FOSHAN CITY BALING ELECTRIC MOTOR +1

Crystallizing method utilizing external circulation of crystal slurry

ActiveCN102371080BIncrease the average particle sizeSolution crystallizationCrystallisation purification/separationFiltrationEngineering

The invention relates to a crystallizing method utilizing external circulation of crystal slurry, and is mainly used for solving the problems of small crystal particle size and frequent cleaning of a crystallizer in the prior art. The crystallizing method is characterized in that: the raw materials are introduced into a kettle type crystallizer for crystallization, the crystal slurry in the kettle type crystallizer flows out from the lower part of the kettle type crystallizer by two parts, the crystal slurry I is subjected to separation by a solid-liquid separator to obtain crystals and crystal filtration mother liquor, and the crystal slurry II is subjected to heat exchange by a sleeve type crystallizer and then returned to the kettle type crystallizer, wherein the weight ratio of the crystal slurry I to the crystal slurry II is (1:1)-(1:50); and the crystals are used as a product to be discharged, the crystal filtration mother liquor is divided into two parts, the first part namely crystal filtration mother liquor I which accounts for 5-95wt% of the crystal filtration mother liquor is discharged, and the second part namely crystal filtration mother liquor II which accounts for 5-95wt% of the crystal filtration mother liquor is returned to the kettle type crystallizer together with the crystal slurry II. The technical scheme that the raw materials are introduced to the kettle type crystallizer directly or being mixed with the crystal slurry II better solves the problems, thus the crystallizing method can be used in industrial crystal production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com