Circulating fluidized bed decomposition crystallization device and decomposition crystallization method

A technology of circulating fluidized bed and crystallization device, applied in the field of circulating fluidized bed, can solve the problems of large circulating volume of mother liquor, prolonging the residence time of undissolved raw materials, increasing the height-diameter ratio of the device, etc., so as to improve the average particle size of products and reduce raw materials. Entrainment rate, the effect of reducing the aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment.

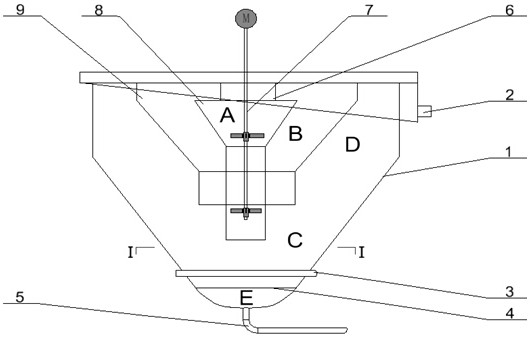

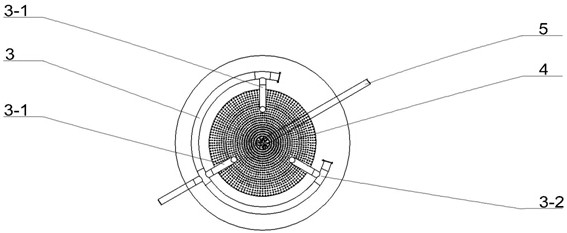

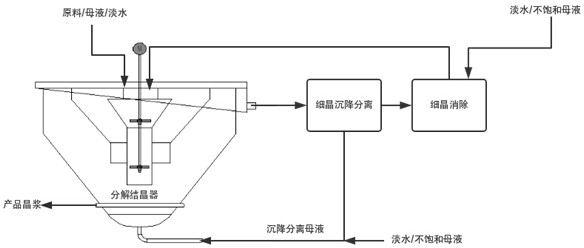

[0036] Such as Figure 1-2 As shown, this embodiment includes a decomposition and crystallization device body 1, a mother liquor overflow tank 2 is provided on the upper part of the decomposition and crystallization device body 1, and an inner guide tube 8 and an outer guide tube 9 are provided in the decomposition and crystallization device body 1 The bottom of the decomposition and crystallization device body 1 is provided with a magma discharge pipe 3, the bottom of the decomposition and crystallization device body 1 is provided with a liquid replenishment port 5, and the decomposition and crystallization device body 1 is provided with a main stirring device 7. The stirring shaft and blades of the stirring device 7 go deep into the inner guide tube, and the liquid distribution plate 4 is arranged in the body 1 of the decomposition and crystallization device, and the liquid distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com