Patents

Literature

221results about "Product crystals bed crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for the purification of a crude acrylic acid melt

InactiveUS7112695B2Organic compound preparationProduct crystals bed crystallizationPurification methodsChemistry

In a process for the purification of a crude acrylic acid melt, the crude acrylic acid melt is converted, under the action of low temperatures, into a crude acrylic acid suspension consisting of acrylic acid crystals and residual melt, and the acrylic acid crystals of the crude acrylic acid suspension are freed from remaining residual melt in a wash column, the production of the acrylic acid crystals of the crude acrylic acid suspension being carried out in the presence of water, the wash column being a wash column with forced transport of the acrylic acid crystals and the wash liquid used being the melt of acrylic acid crystals purified in the wash column.

Owner:BASF AG

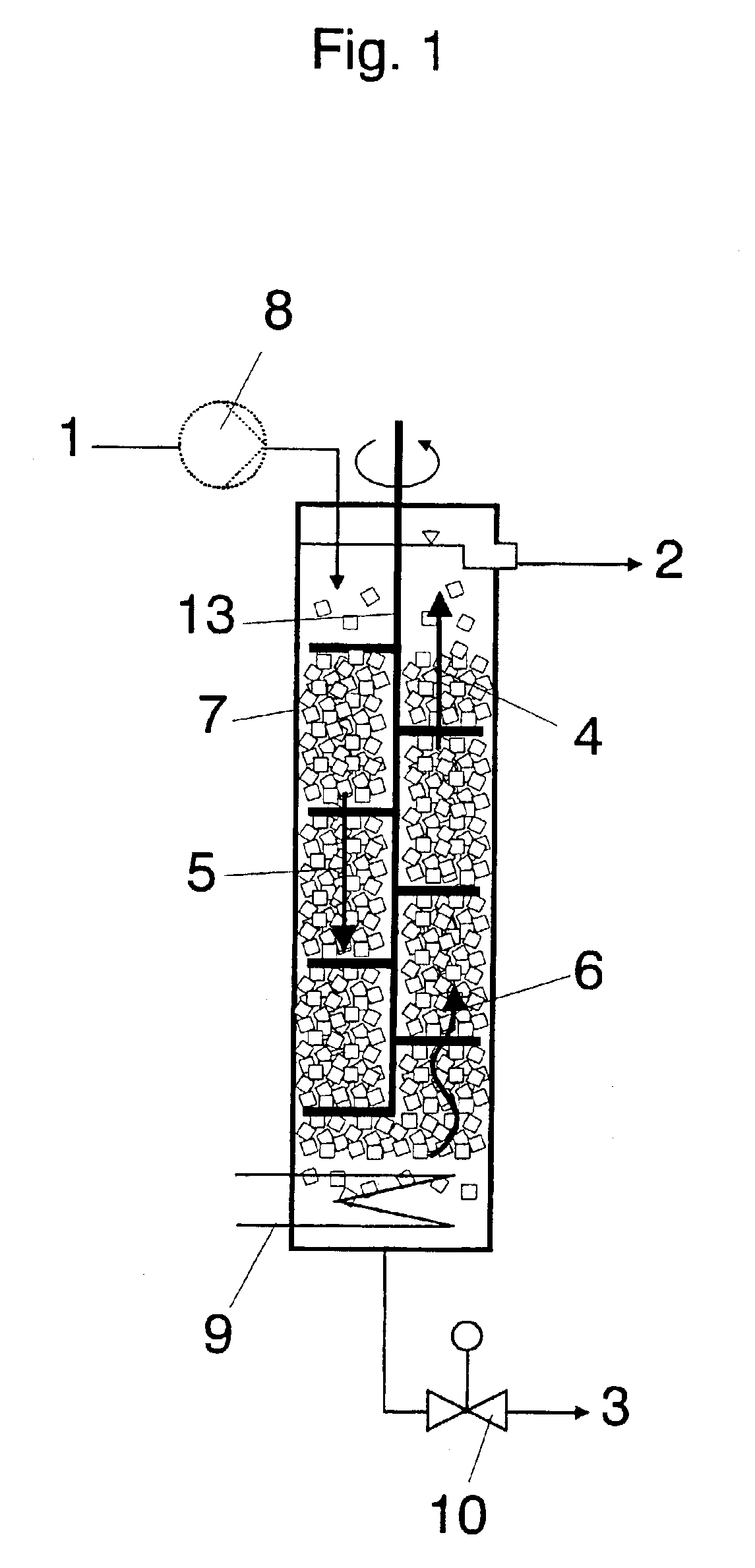

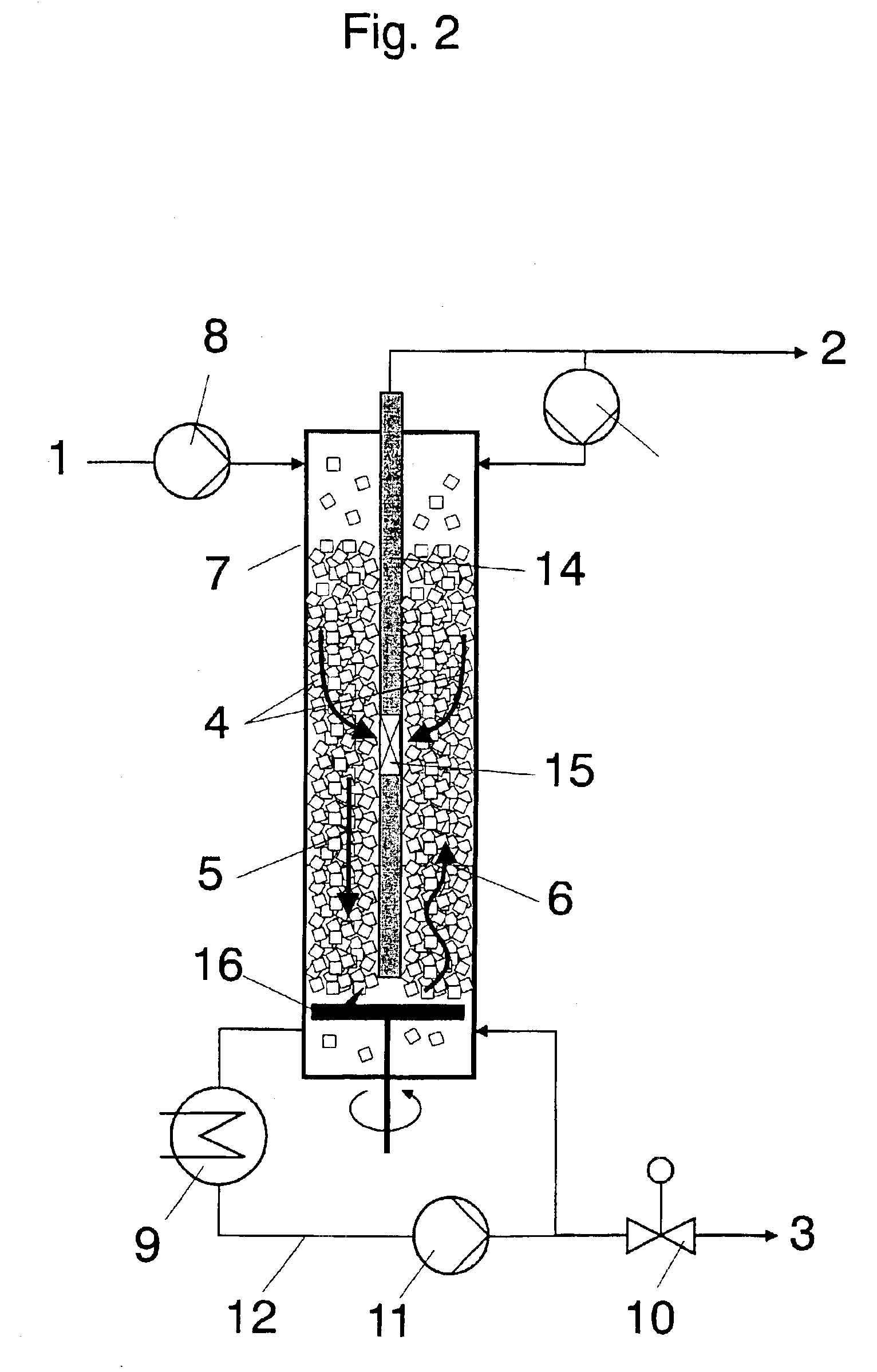

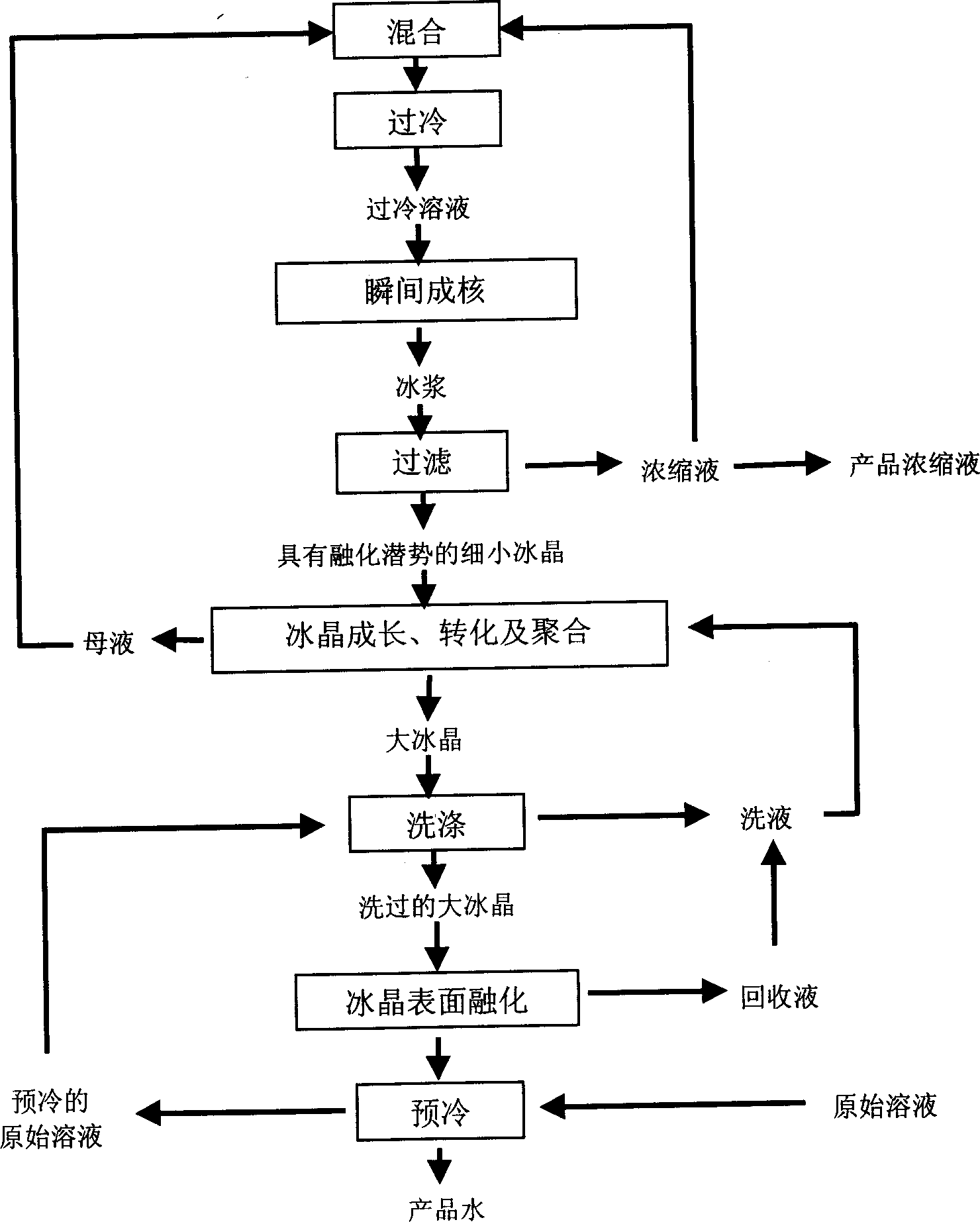

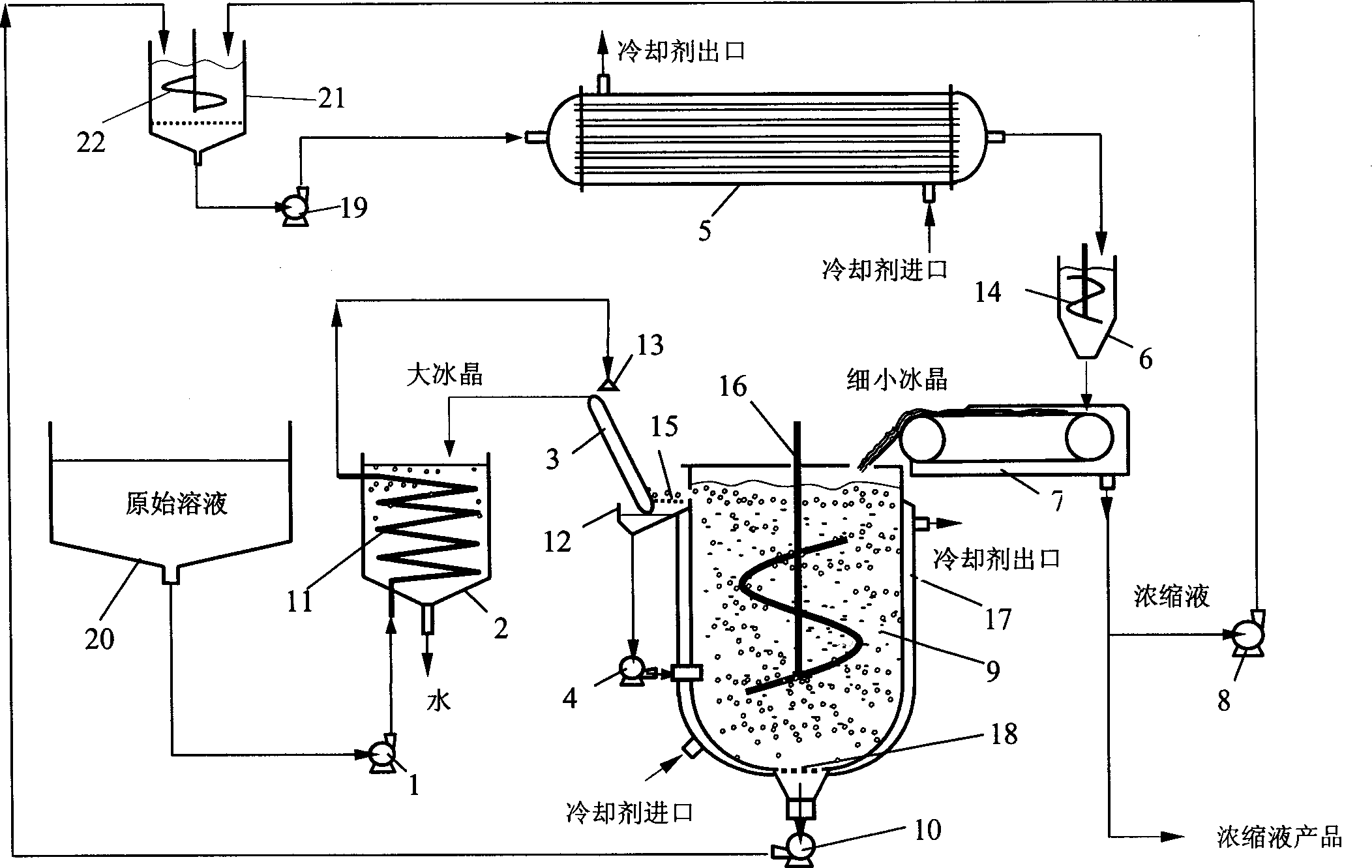

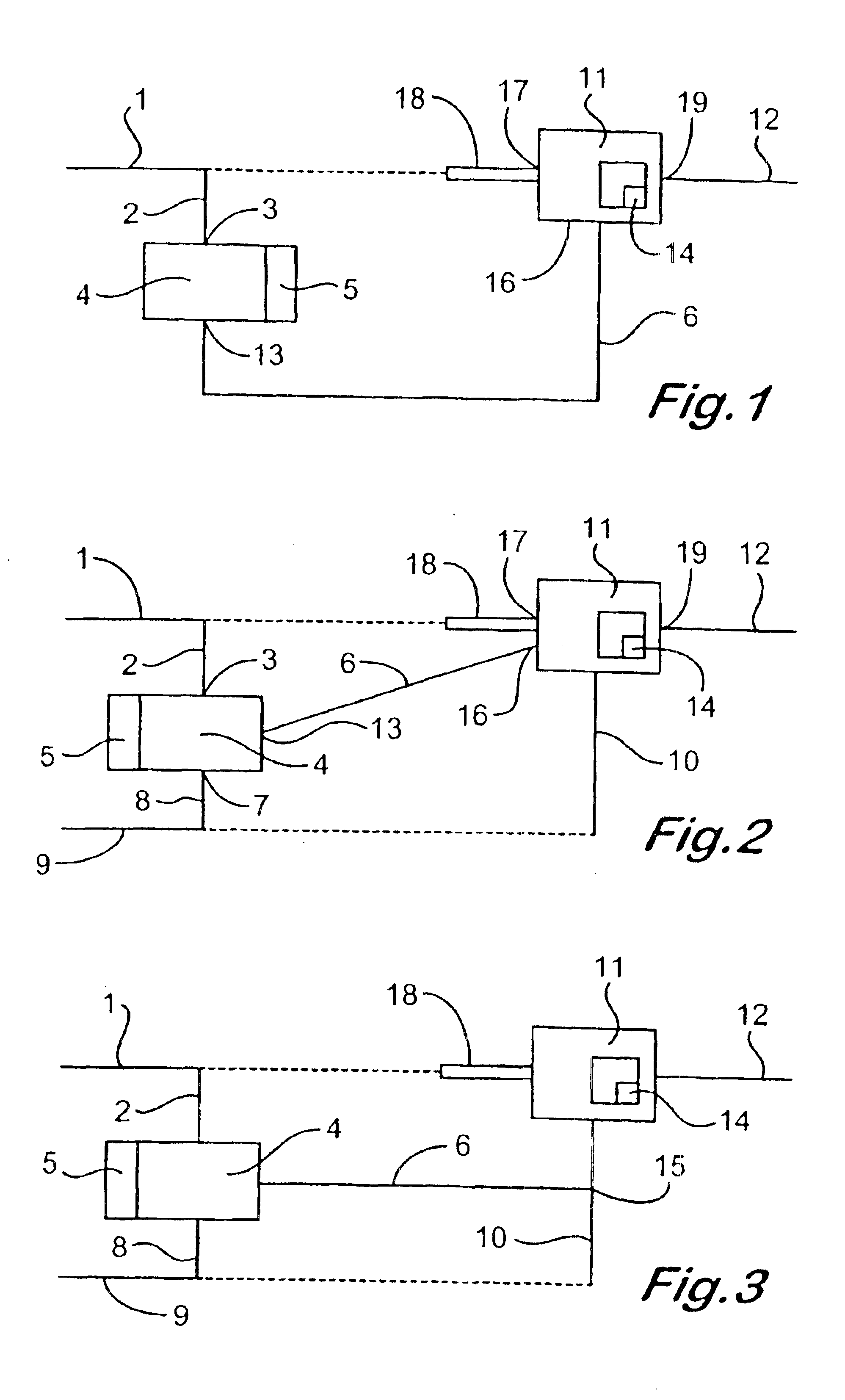

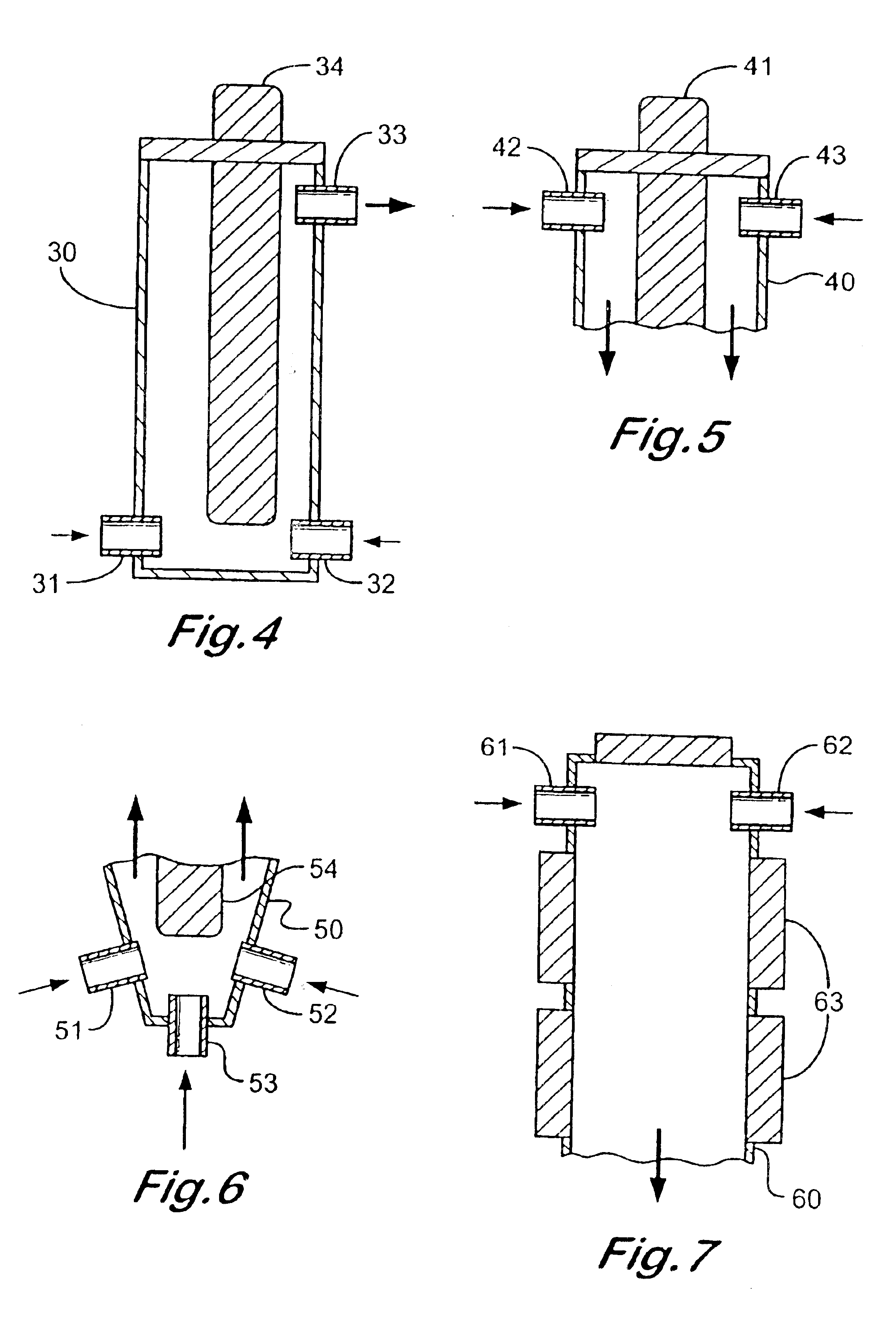

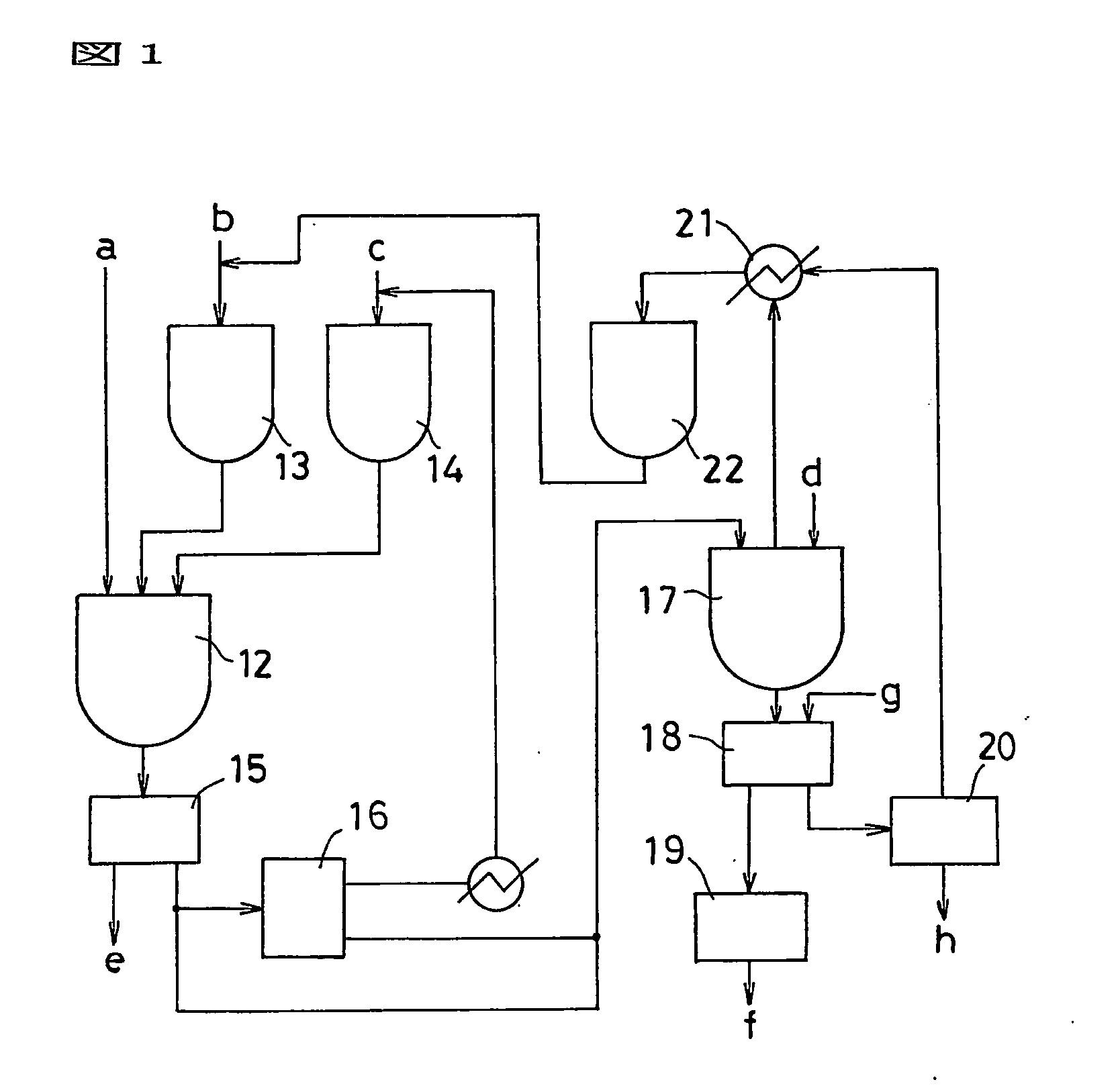

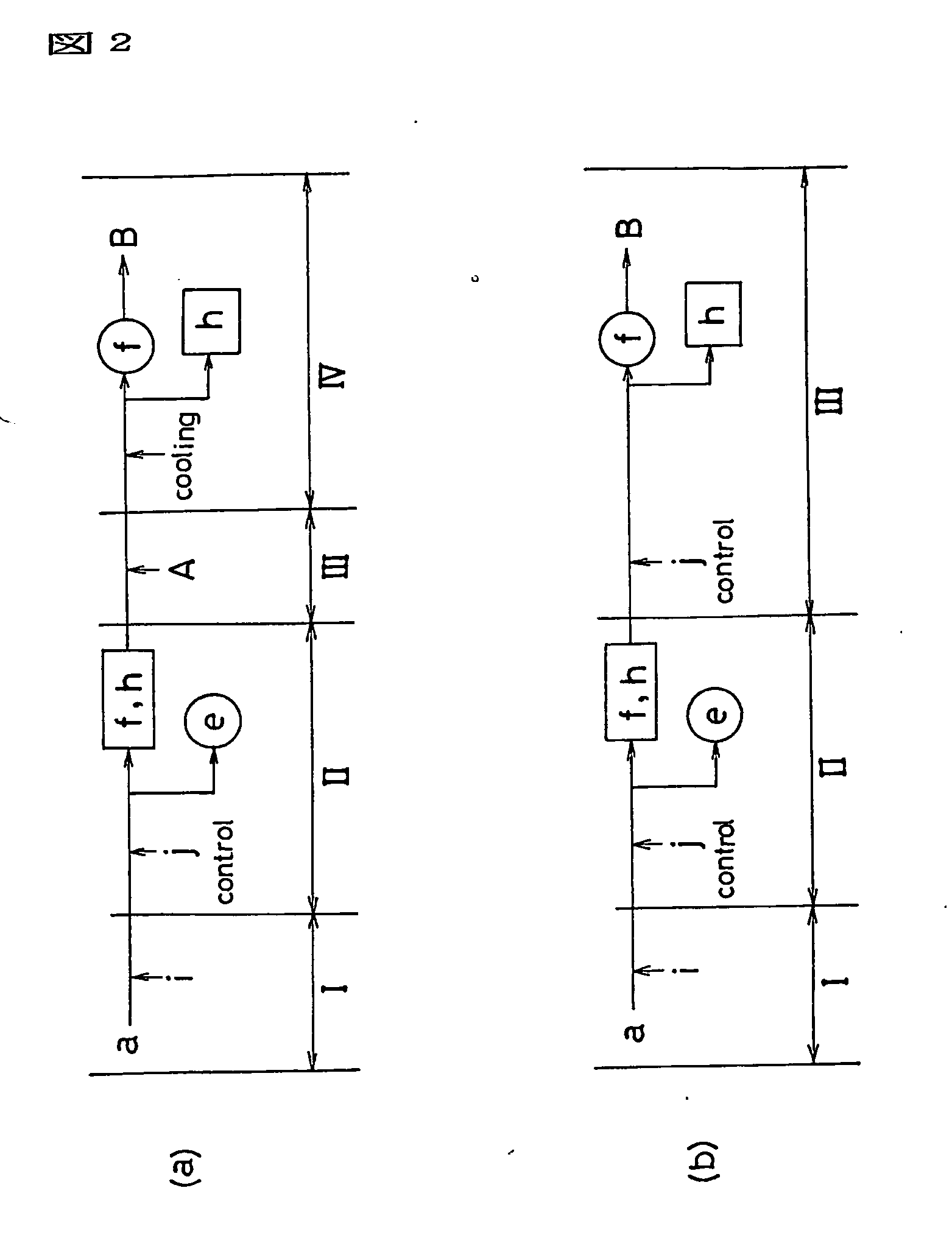

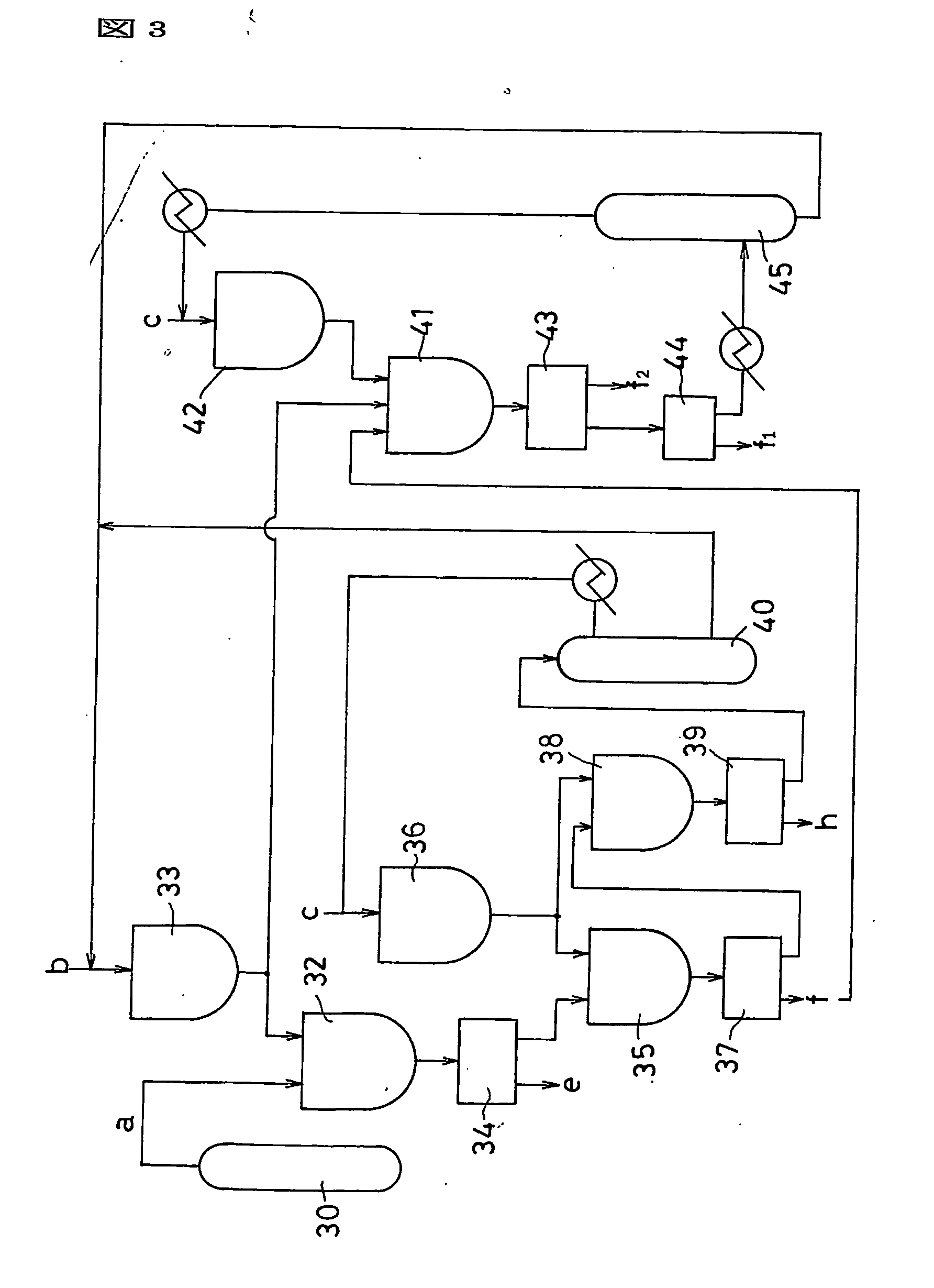

Freeze concentration for aqueous solutions

The invention is an efficient physical method of freezing and concentrating aqueous solutions based on the transformation of ice crystals. It results in a very high ice crystal growth rate, produces granular, aggregated large ice crystals without internal entrainment, and avoids scraping of ice crystals during freezing to save energy. The method mainly consists of the following processes: cooling the solution to a supercooled state without nucleation or ice formation on the heat transfer surface; instantly nucleating the supercooled solution to produce fine ice crystals and concentrating the solution; with the help of absorption-exotherm The growth, transformation and polymerization of ice crystals in a well-balanced and controlled environment produce large, granular or spherical ice crystals at high rates. Both single-stage and multi-stage operations can be used in this method and the main steps can be arranged flexibly. The equipment for implementing this method mainly includes refrigeration heat exchangers, nucleators, filters and multifunctional crystallizers, each of which has its own characteristics to meet the requirements of the method.

Owner:梁保民 +1

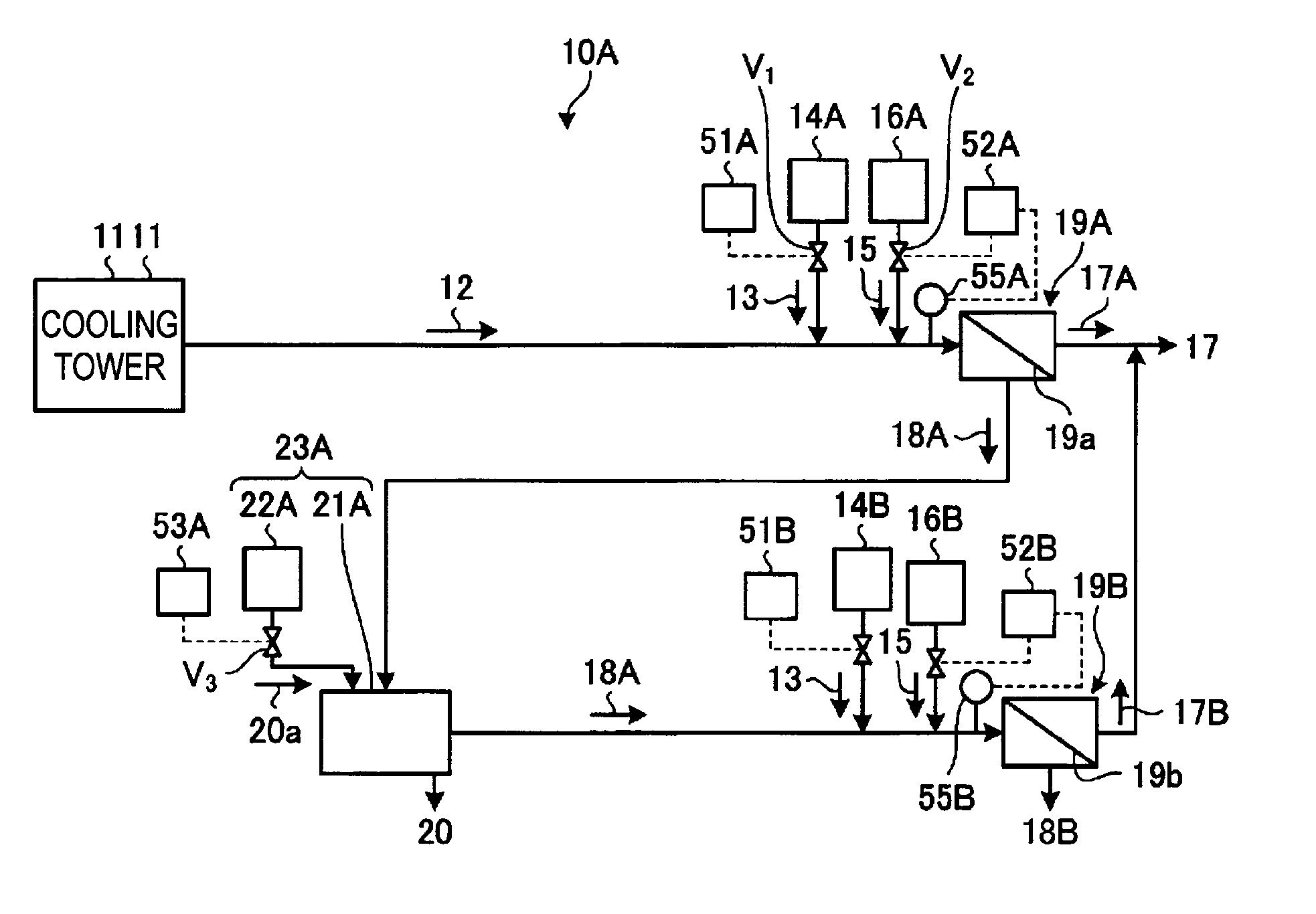

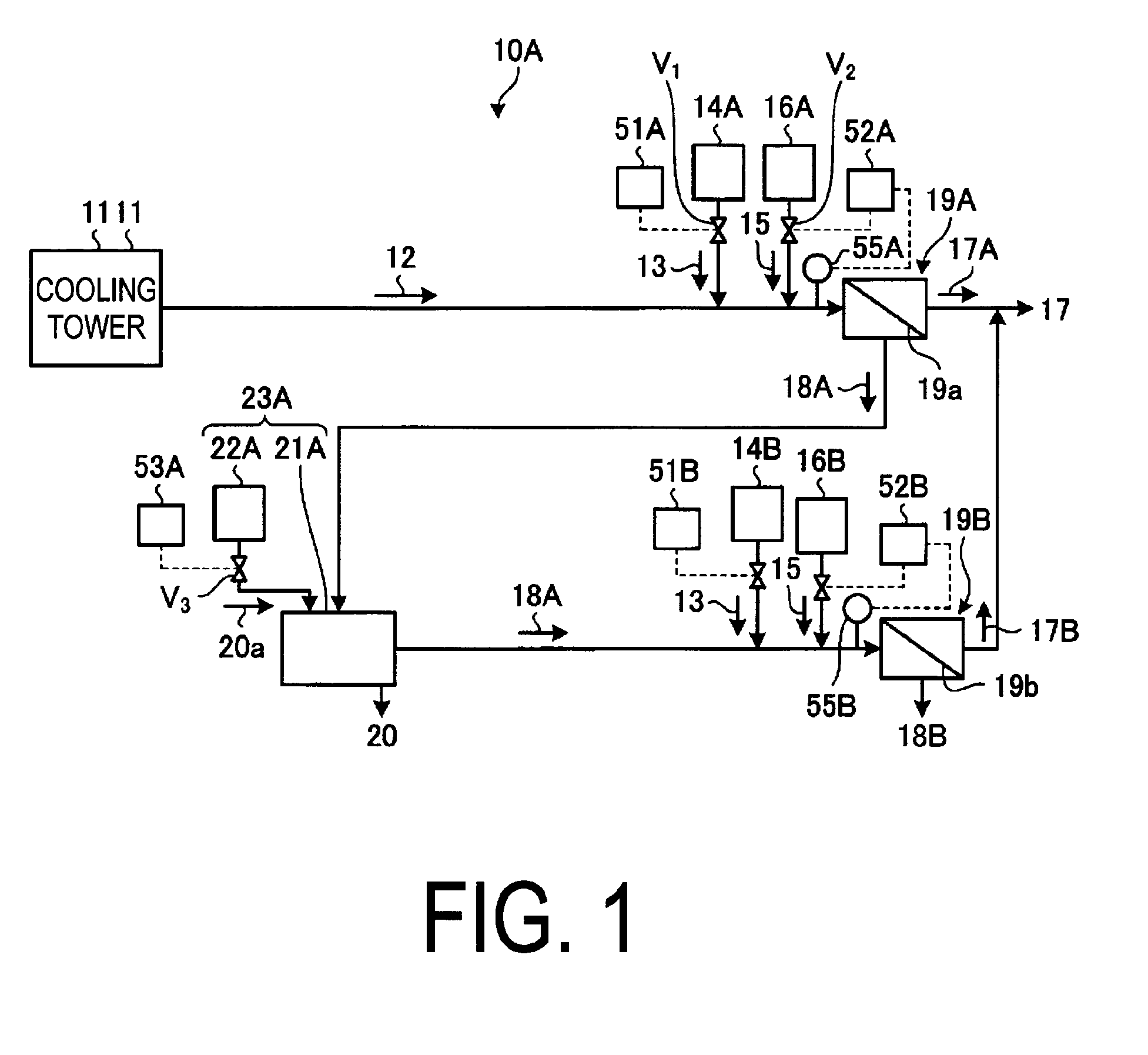

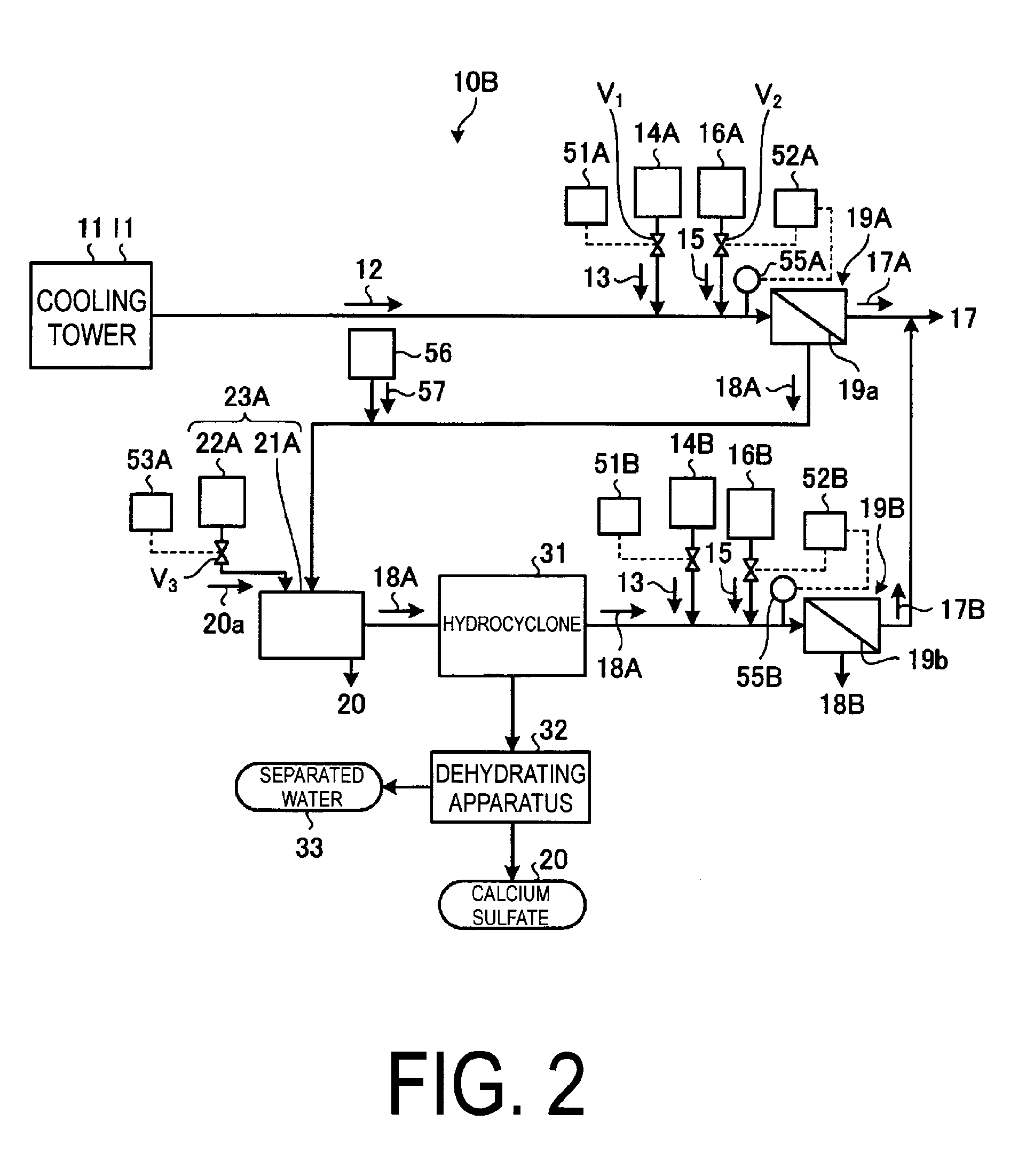

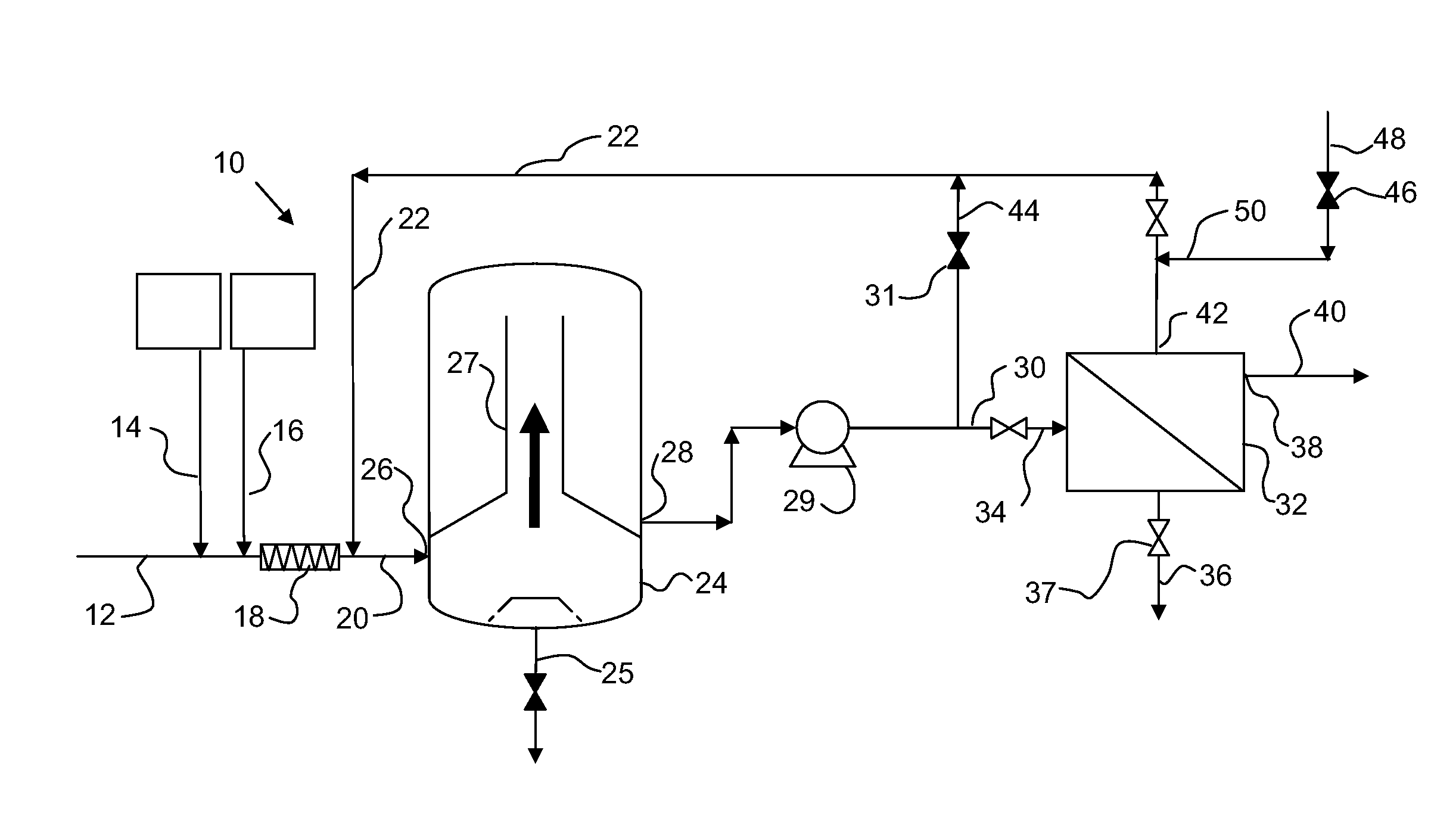

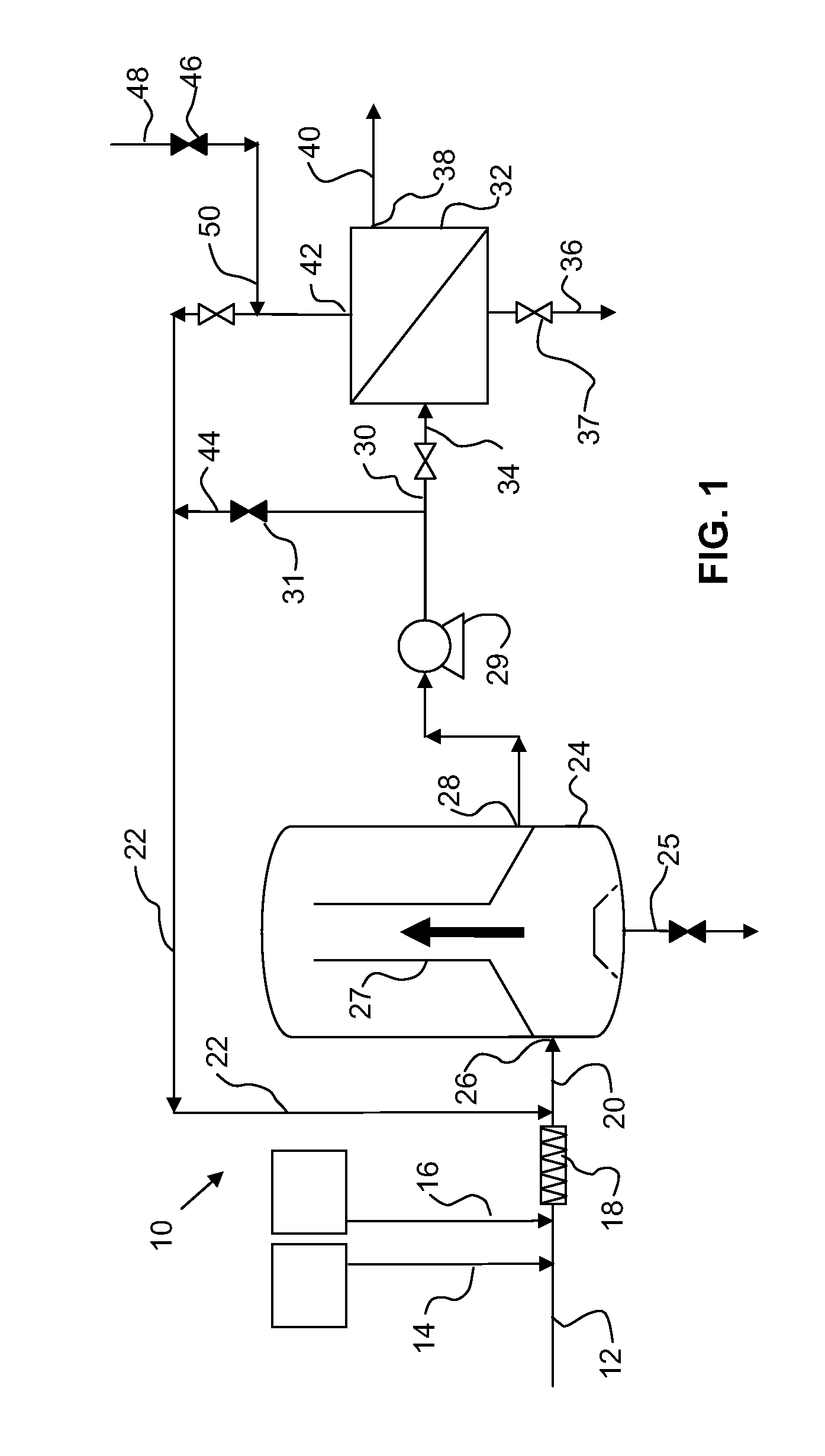

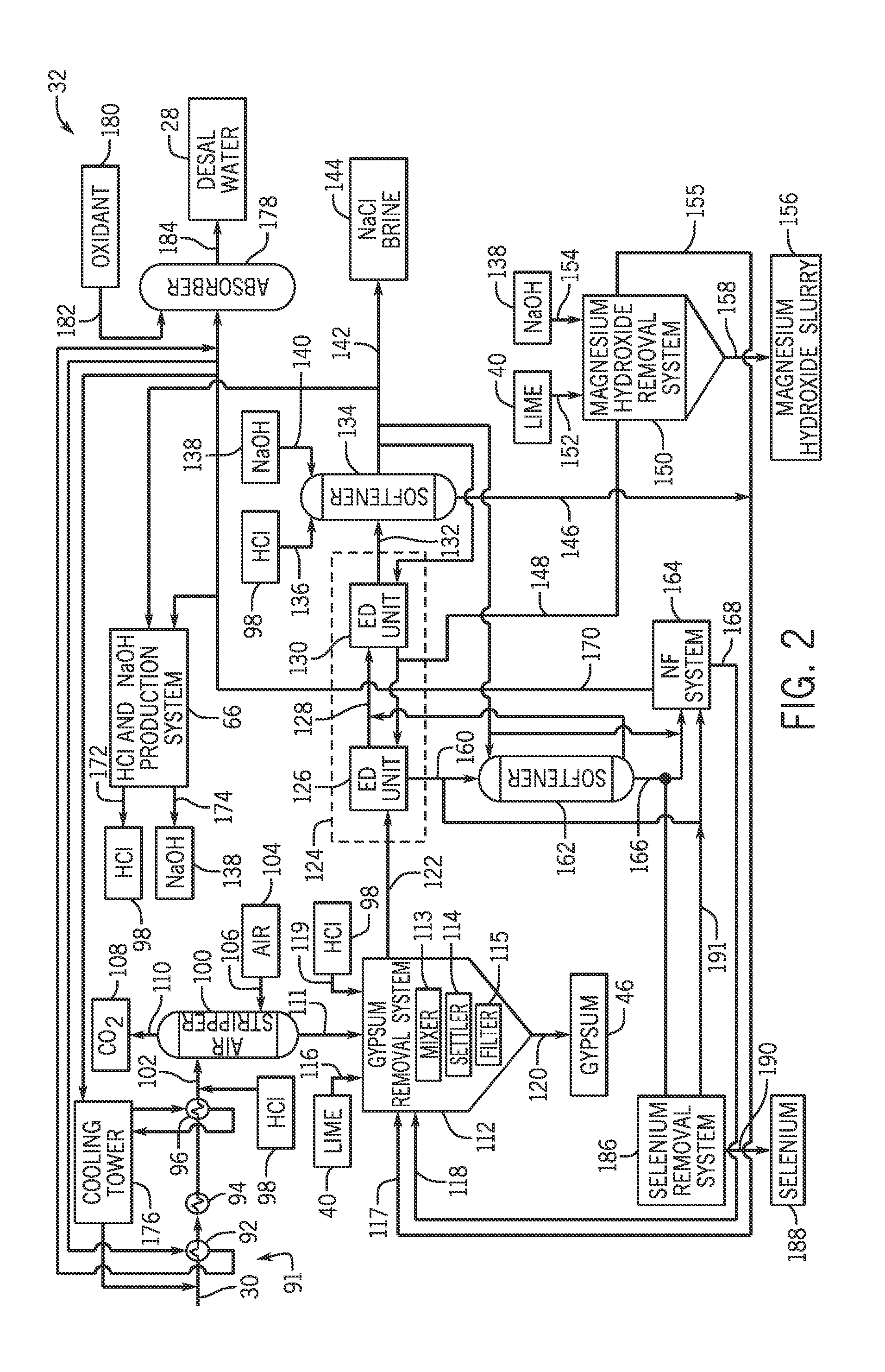

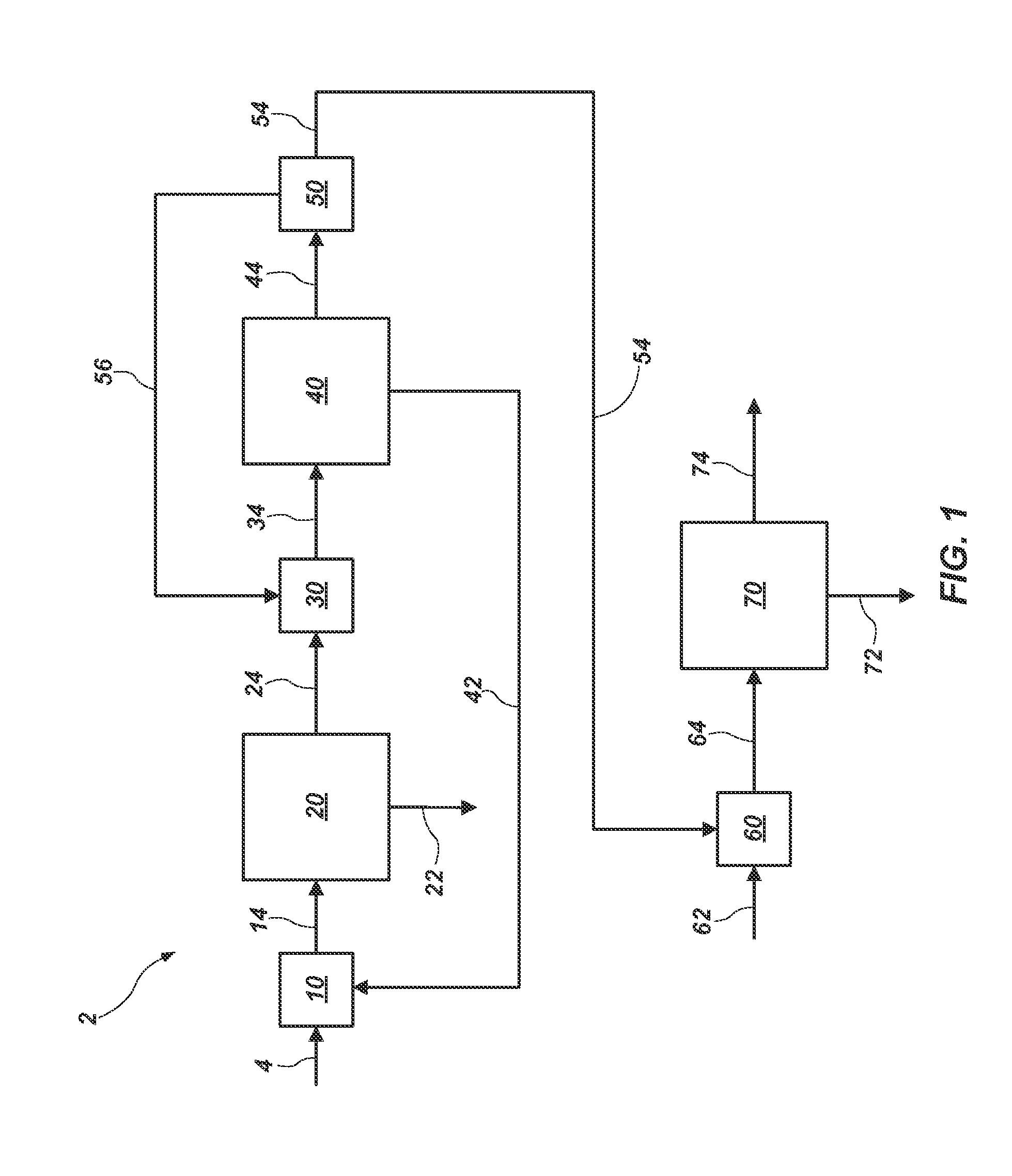

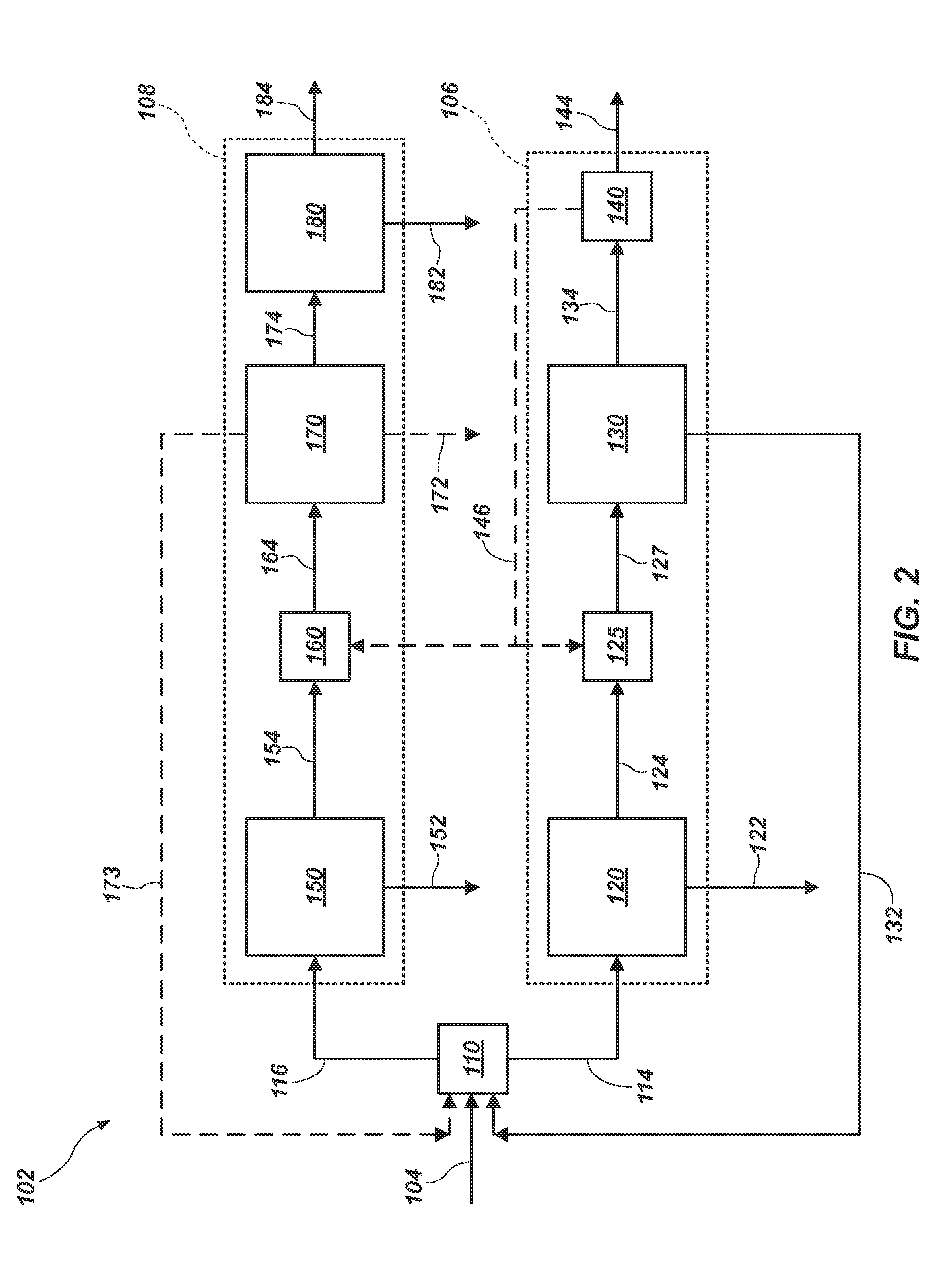

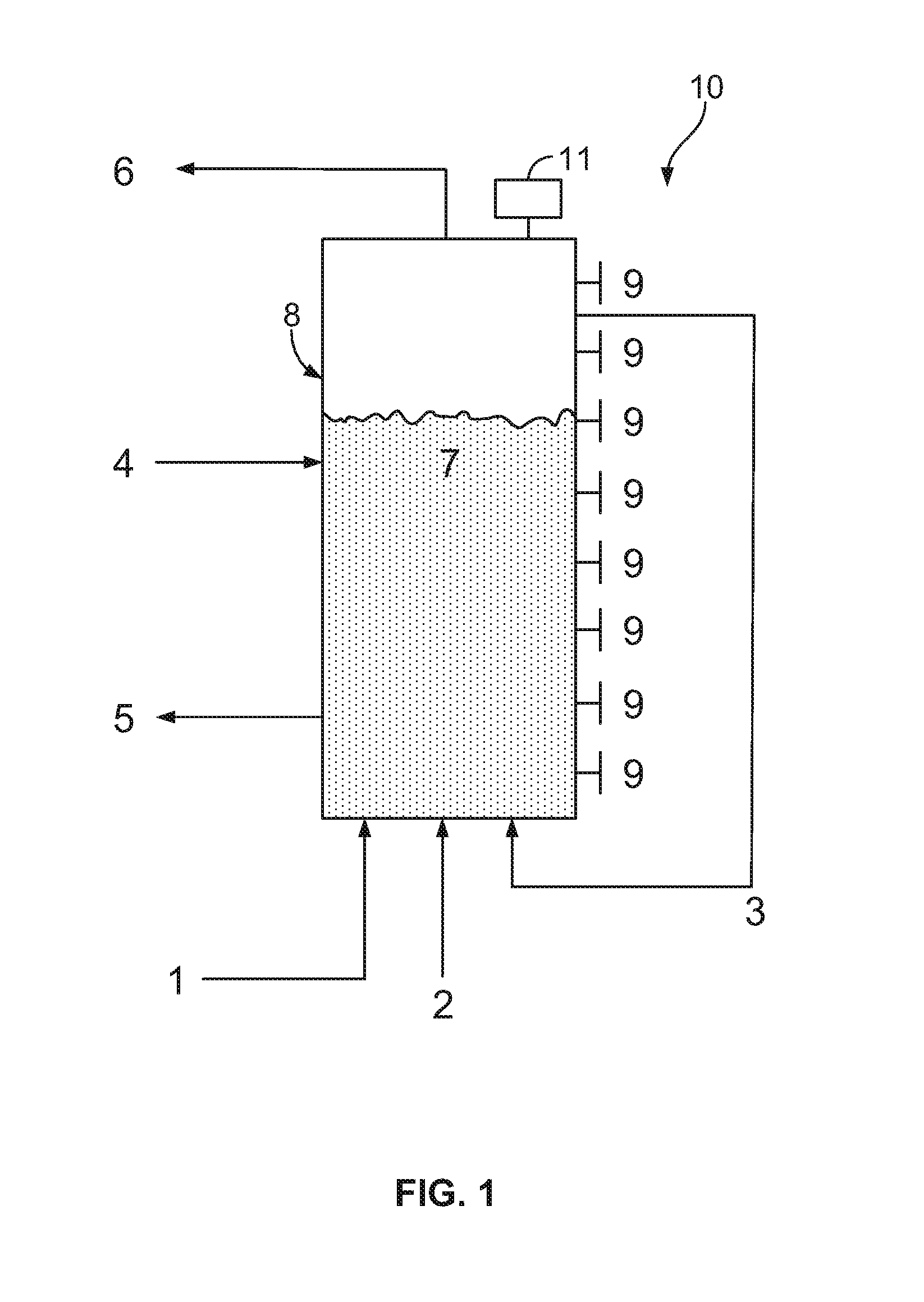

Water treatment system, water treatment method, cooling facility and power generating facility

InactiveUS20160115061A1Liquid degasificationGeneral water supply conservationWater treatment systemCooling tower

A water treatment system provided with: a first scale inhibitor-supplying unit which supplies a scale inhibitor to a blowdown water, the blowdown water being water to be treated that is generated in a cooling tower and contains at least a salt and silica; a first pH-adjusting unit which adjusts the pH of the blowdown water, to which the scale inhibitor has been supplied using a pH adjusting agent; a first desalinating apparatus which is provided downstream of the first pH-adjusting unit, removes the salt in the blowdown water, and separates the water into a first reclaimed water and a first concentrated water; and a first crystallizing unit which is provided downstream of the first desalinating apparatus and has a first crystallizing tank for calcium sulfate from the first concentrated water and a first seed crystal-supplying unit for supplying calcium sulfate seed crystals of calcium sulfate to the first crystallizing tank.

Owner:MITSUBISHI HEAVY IND ENG LTD

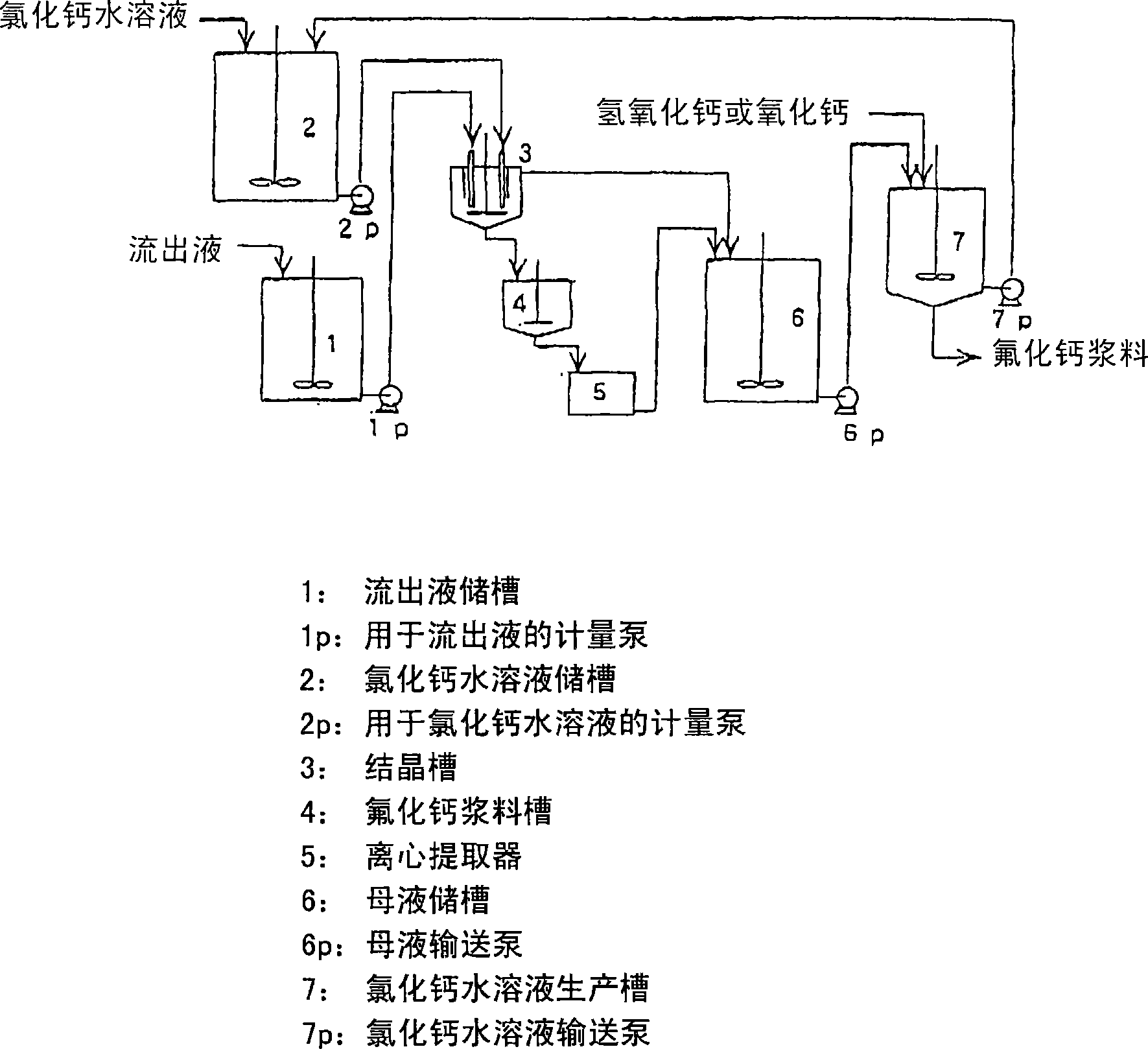

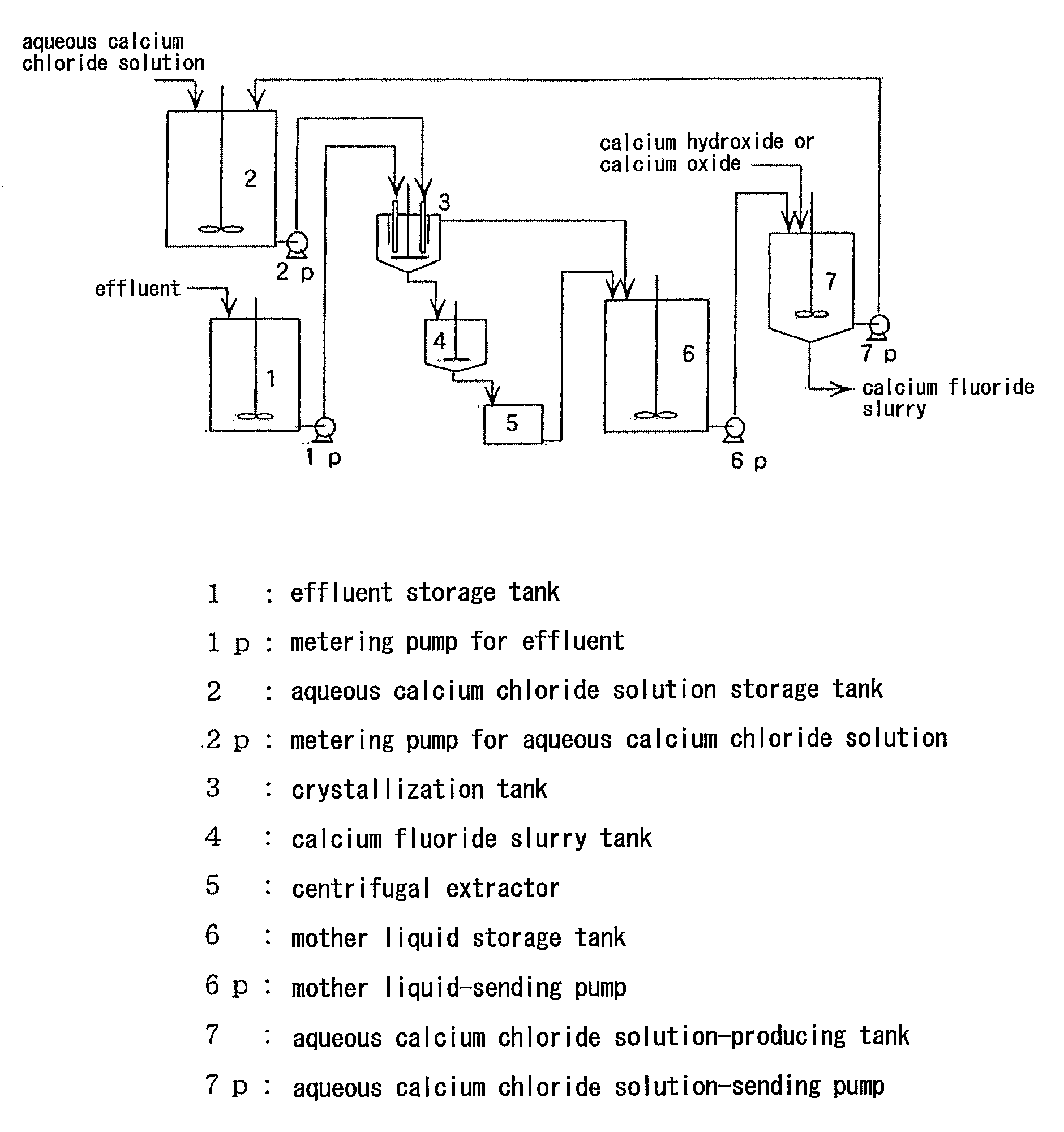

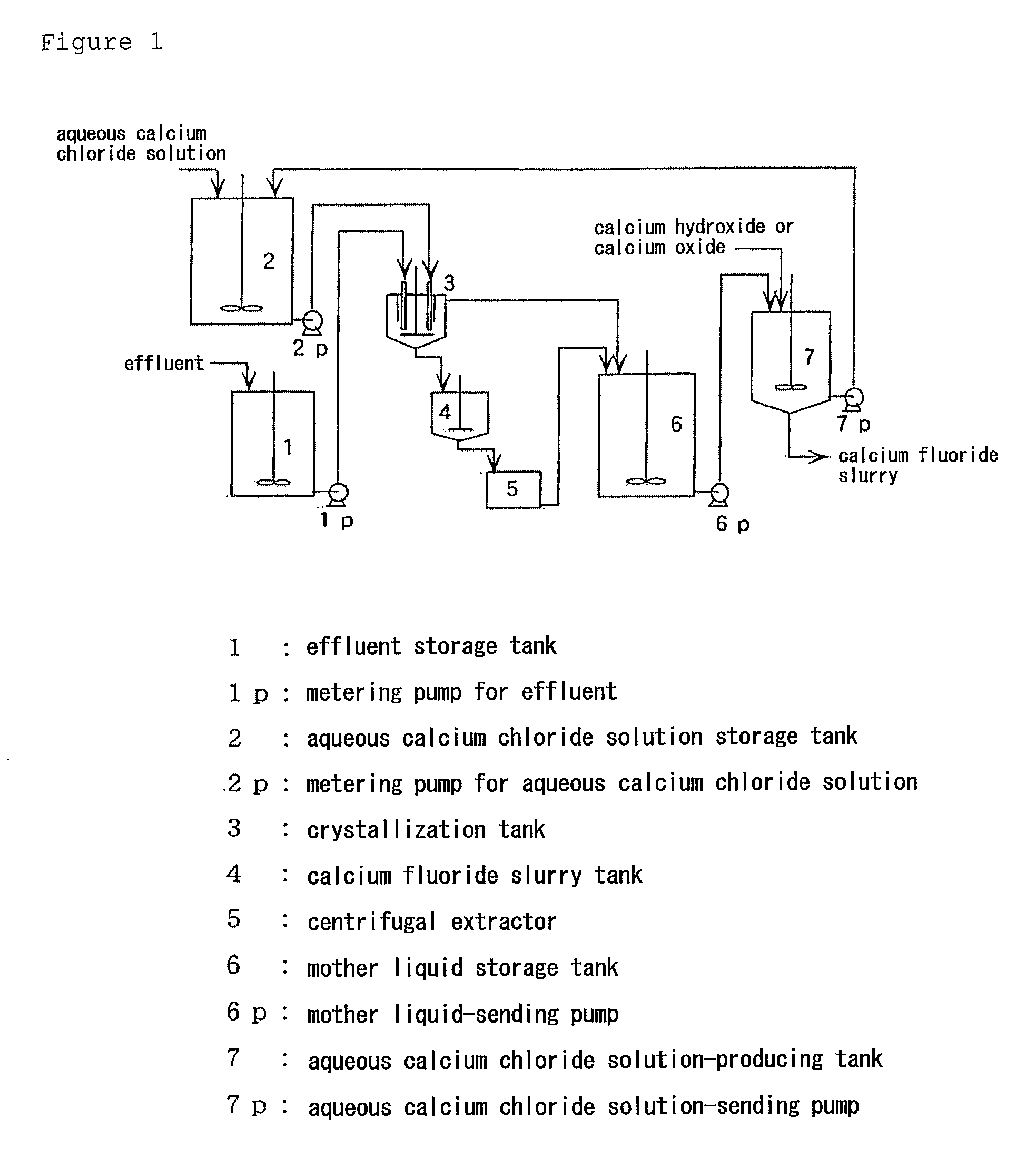

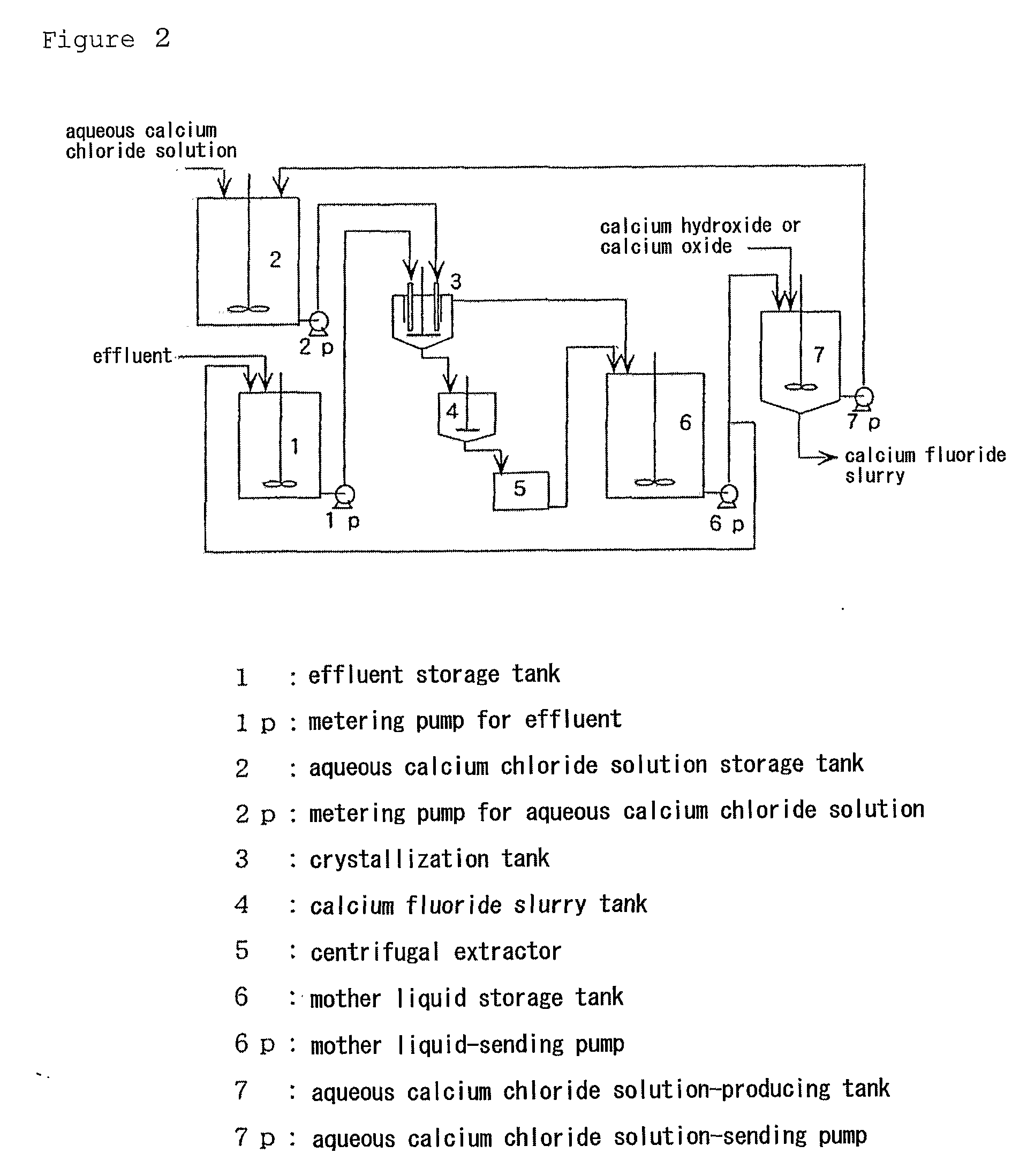

Method for producing calcium fluoride, reusing method and recycling method thereof

ActiveCN1906129AWater treatment parameter controlSpecific water treatment objectivesSolubilityLarge particle

In order to recycle the fluoride, calcium fluoride having a particle size and purity suitable for the production of hydrogen fluoride is recovered from the fluoride-containing effluent or the hydrofluoric acid-containing effluent. The method involves reacting a fluoride-containing effluent or a hydrofluoric acid-containing effluent with an aqueous solution of calcium chloride under acidic conditions formed by hydrochloric acid, under which calcium fluoride has a relatively high solubility. Calcium fluoride can be precipitated with high purity and large particle size. The hydrochloric acid residue from or formed by the reaction reacts with inexpensive calcium compounds such as calcium hydroxide, calcium oxide, and calcium carbonate to produce an aqueous calcium chloride solution that is reused to treat effluents containing hydrofluoric acid . The obtained calcium fluoride can be used as a raw material for producing hydrogen fluoride, and the remaining calcium chloride aqueous solution can be provided for other industrial purposes.

Owner:MORITA CHEMICAL IND CO LTD

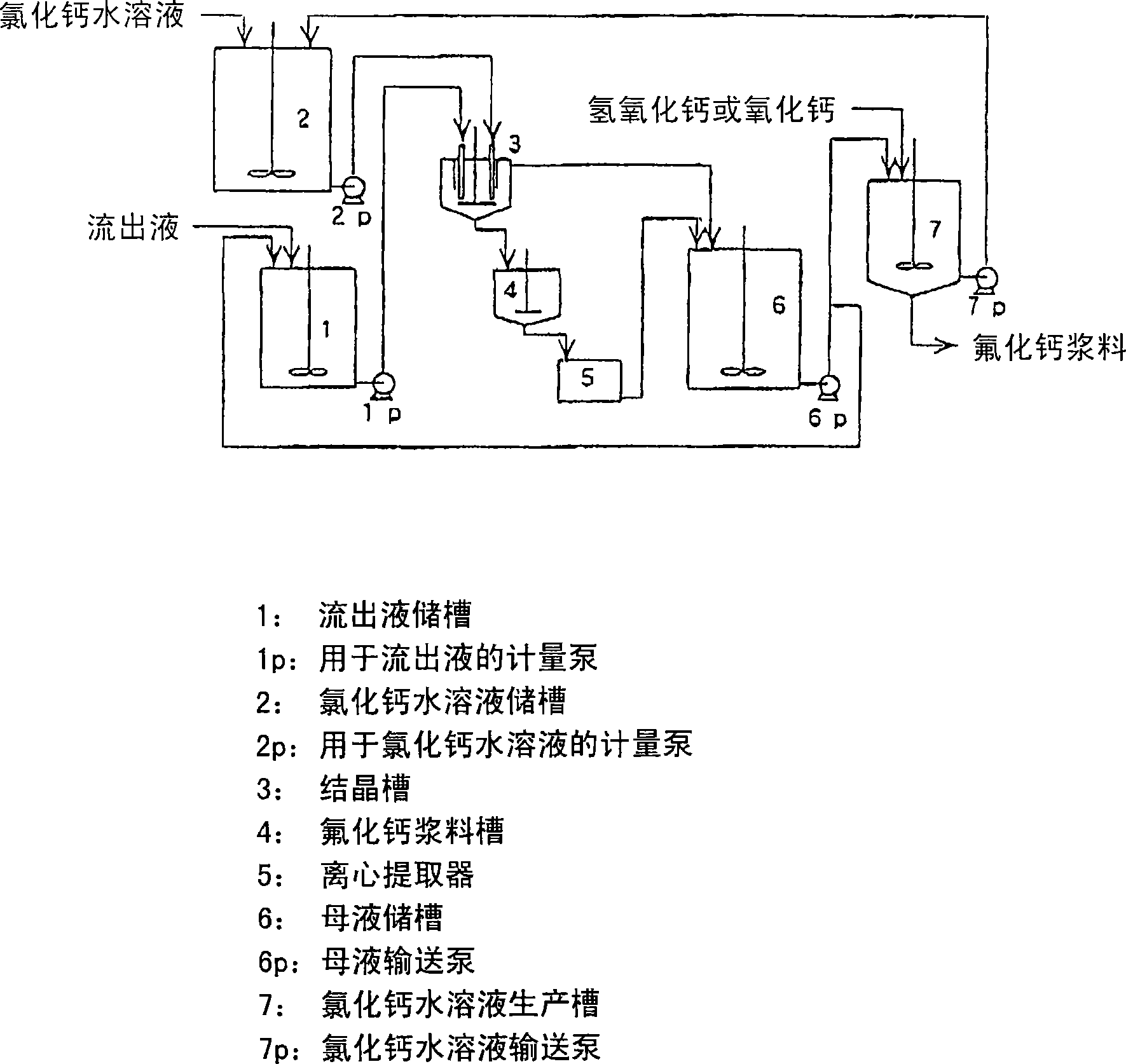

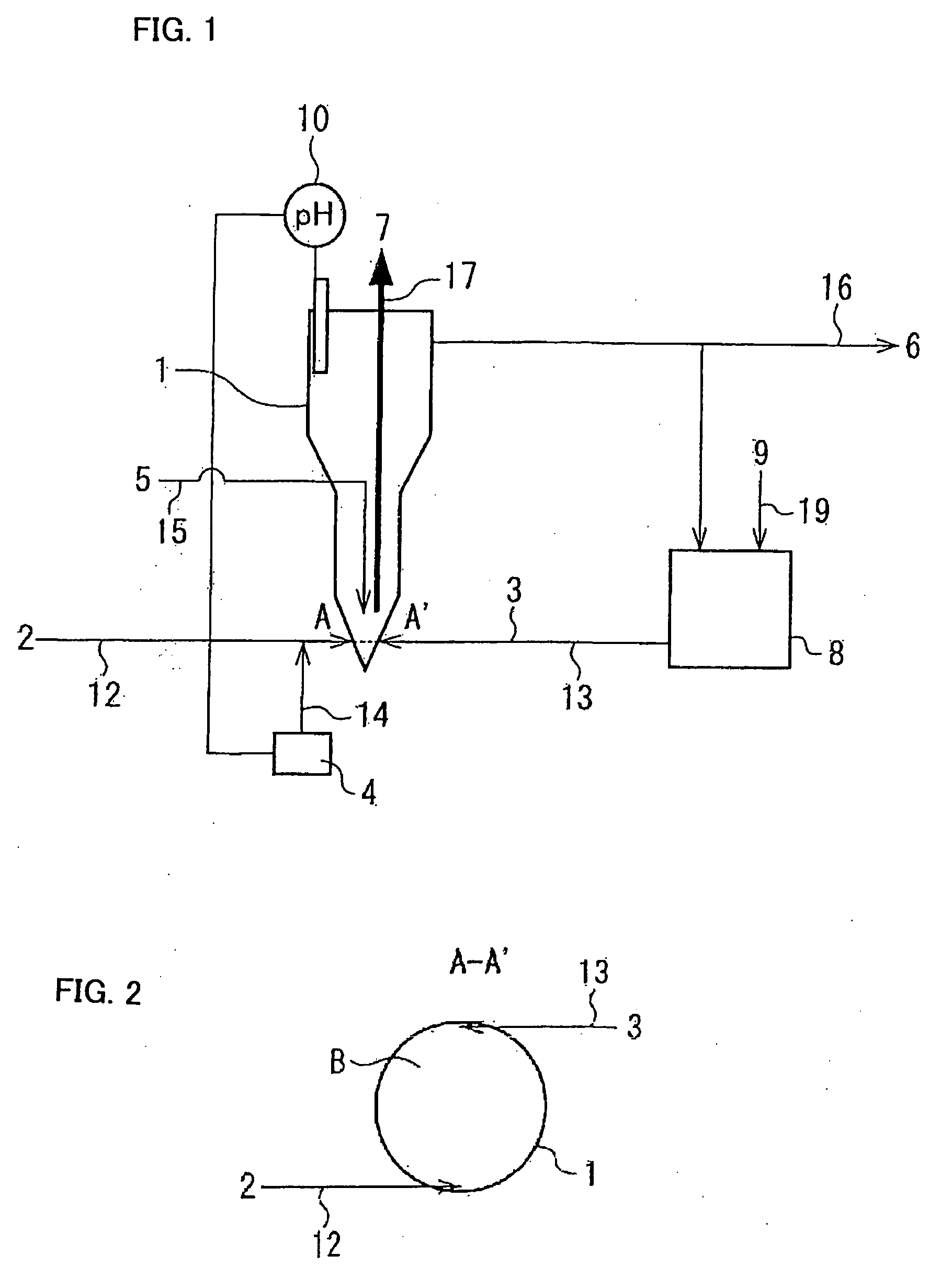

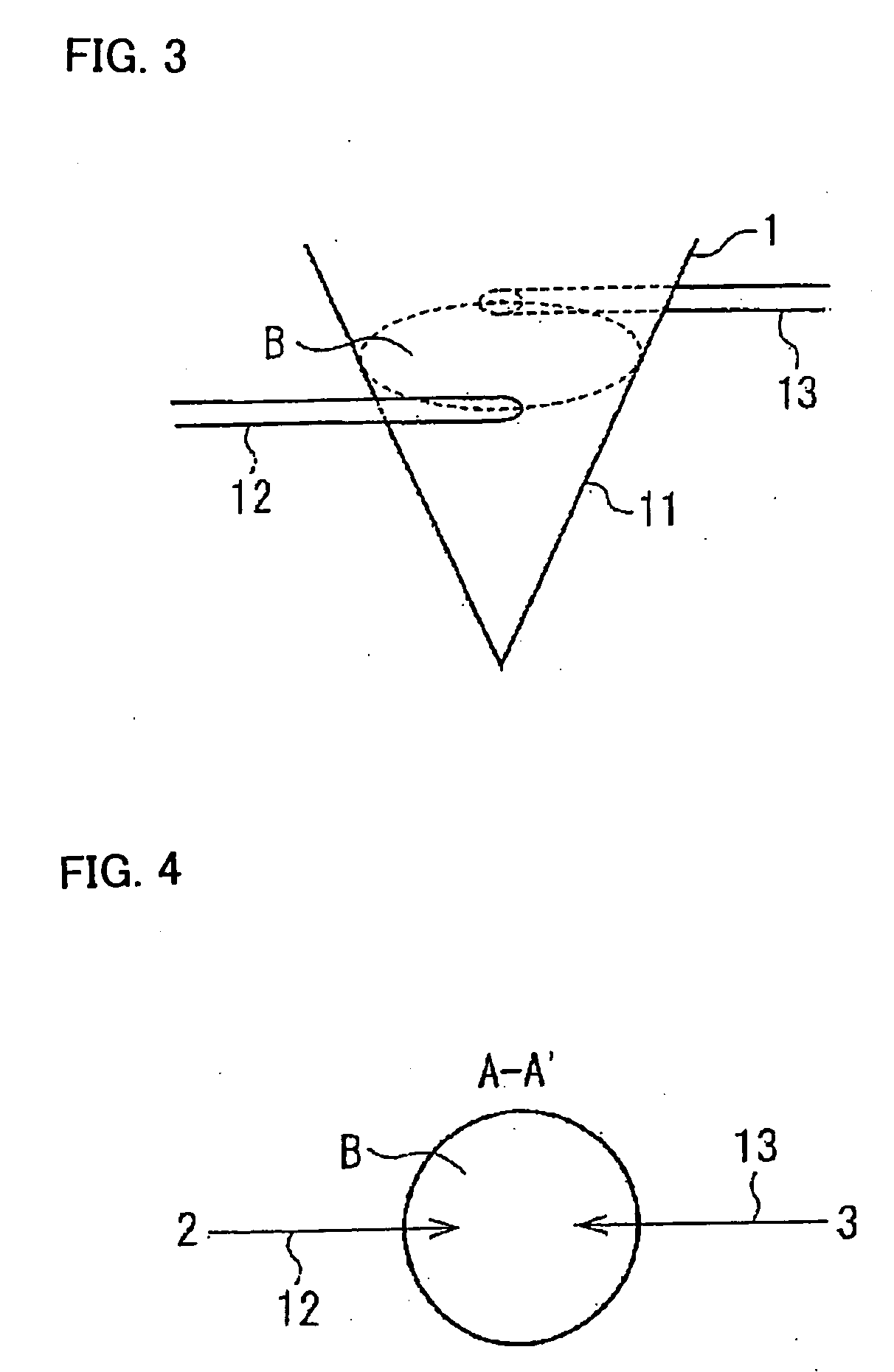

Method and apparatus for removing ions in liquid through crystallization method

InactiveUS20060196835A1MoreMix thoroughlyWater/sewage treatment by centrifugal separationWater contaminantsPhysical chemistryChemical agent

It is an object of the present invention to improve the phosphorus recovery rate in a method and apparatus for removing ions to be removed in a liquid to be treated by crystallizing out crystal particles of a poorly soluble salt of the ions to be removed in the liquid to be treated in a crystallization reaction tank. As one means for attaining this object, in one embodiment of the present invention there is provided a method for removing ions to be removed in a liquid to be treated by crystallizing out crystal particles of a poorly soluble salt of the ions to be removed in the liquid to be treated in a crystallization reaction tank, which comprises adding a chemical agent required for the crystallization reaction into a part of a treated liquid flowing out from the crystallization reaction tank and dissolving the chemical agent therein, and supplying the resulting solution into the crystallization reaction tank as a circulating liquid, wherein the liquid to be treated and the circulating liquid are introduced into the crystallization reaction tank tangentially to a transverse section of the crystallization reaction tank.

Owner:EBARA CORP

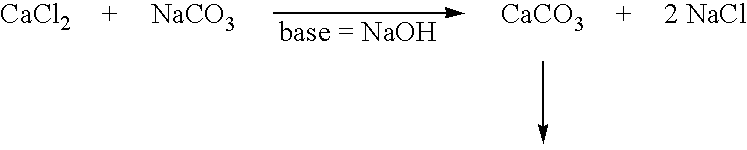

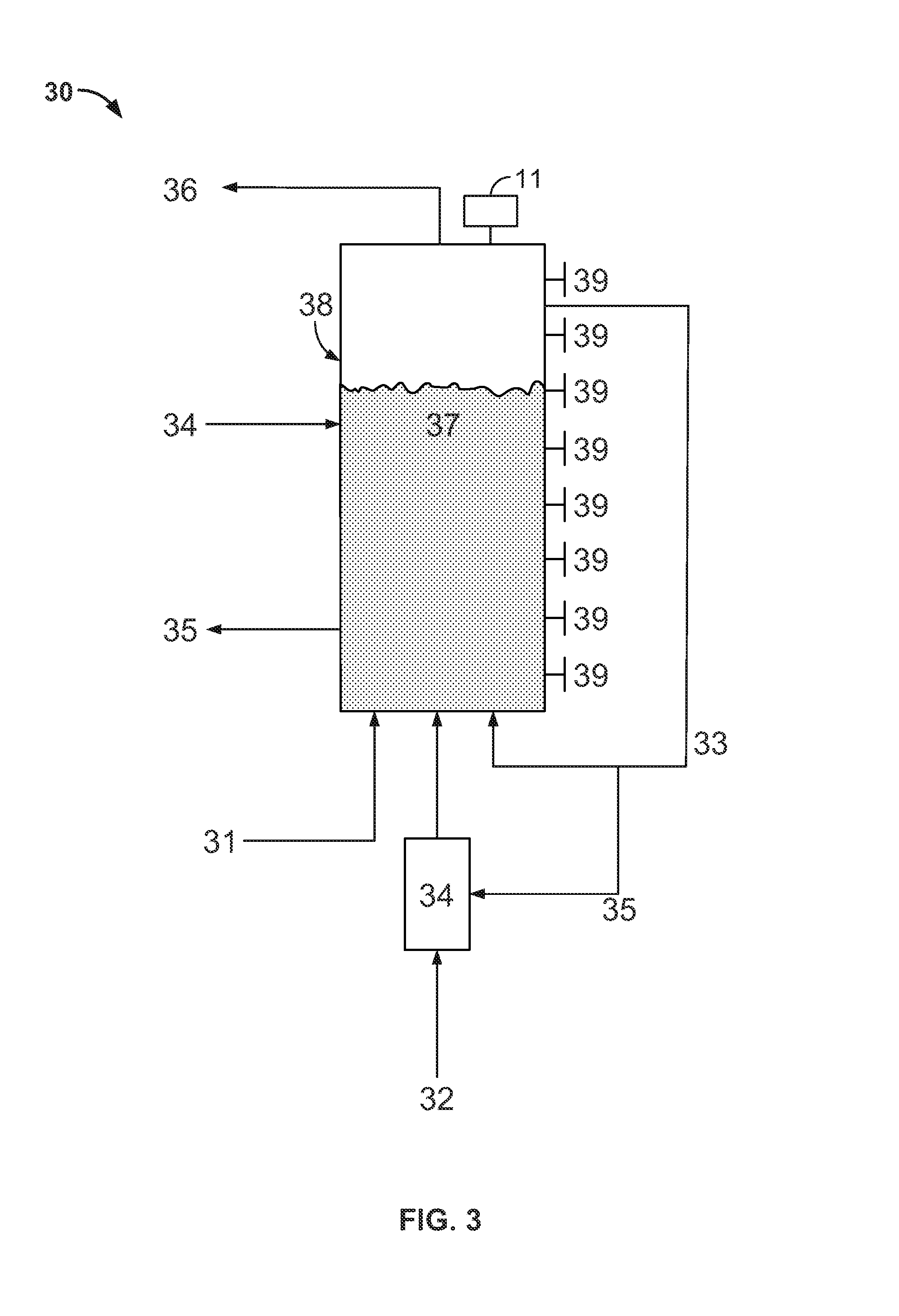

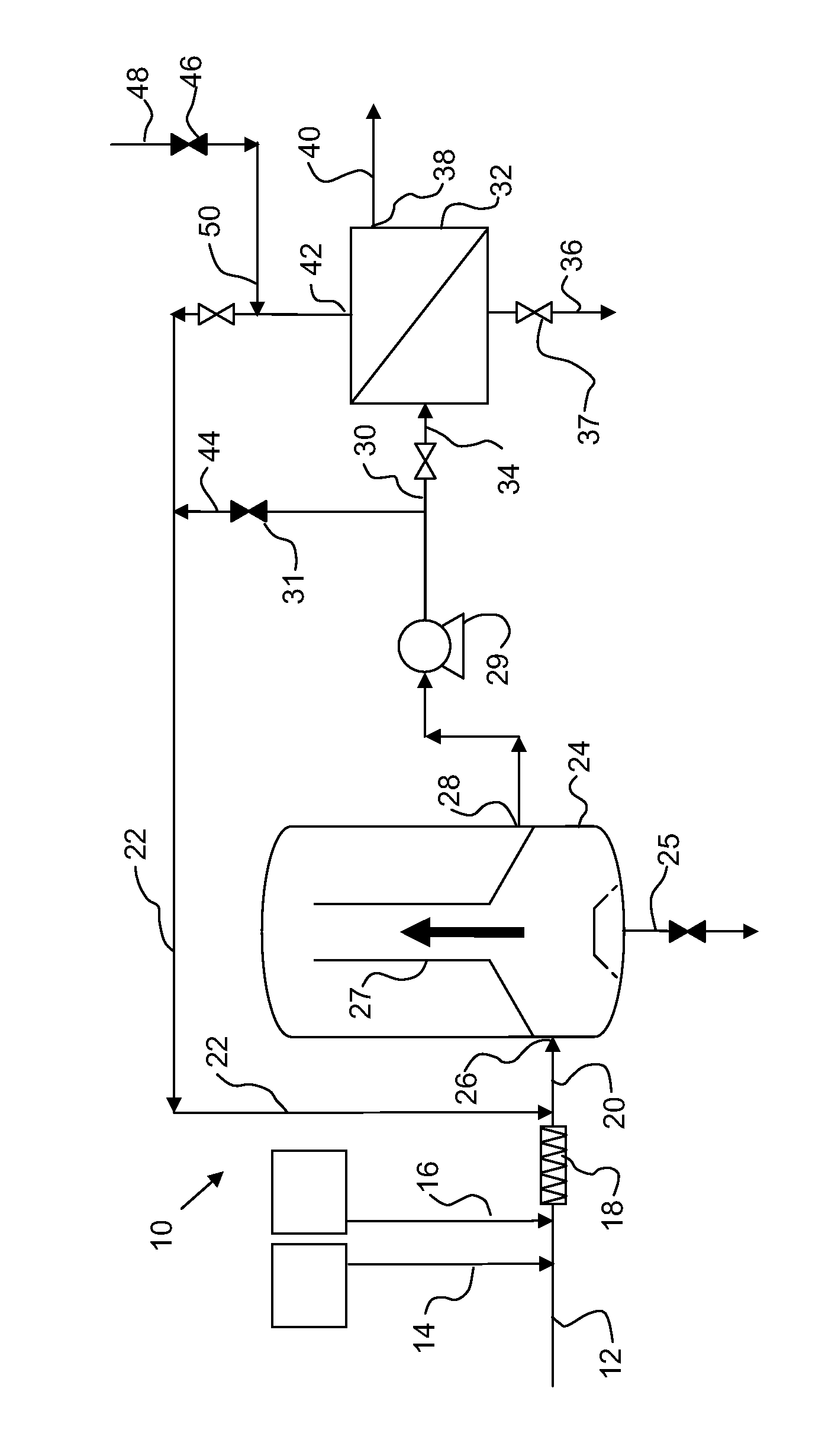

Removing solids in monoethylene glycol reclamation

The seeding of calcium carbonate into a calcium chloride-contaminated monoethylene glycol (MEG) stream accelerates the growth of calcium carbonate particles to a size that enhances their removal from the stream by filtration. A seeding vessel allows the calcium carbonate particles a time period to grow. Sodium carbonate may be added to the contaminated stream to facilitate calcium carbonate particle growth. A recycle seeding conduit may recycle seeds from a filtration unit to the seeding vessel. A base such as sodium hydroxide may be added to accelerate the precipitation process.

Owner:CAMERSON INT CORP

Process for purifying removal of acrylic acid, methacrylic acid, n-vinylpyrrolidone or p-xylene crystals from their suspension in mother liquor

ActiveUS20090018347A1Organic compounds purification/separation/stabilisationOrganic compound preparationHeat flowWater vapor

A process for purifying removal of acrylic acid, methacrylic acid, N-vinylpyrrolidone or p-xylene crystals from their suspension in mother liquor by means of a wash column with forced transport, whose shell of the process chamber is a metal wall, the wash column additionally being enveloped by a thermal insulation material having a water vapor barrier and a specific heat flow of >0.1 W / m2 and <10 W / m2 flowing into the process chamber through the metal wall of the wash column.

Owner:BASF AG

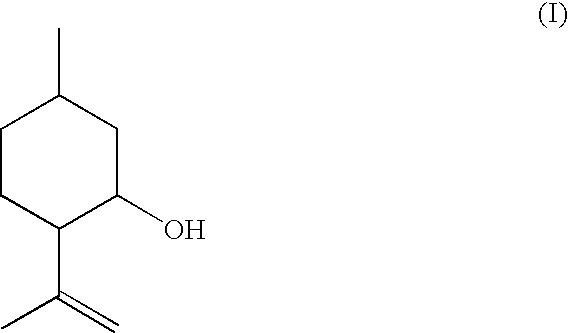

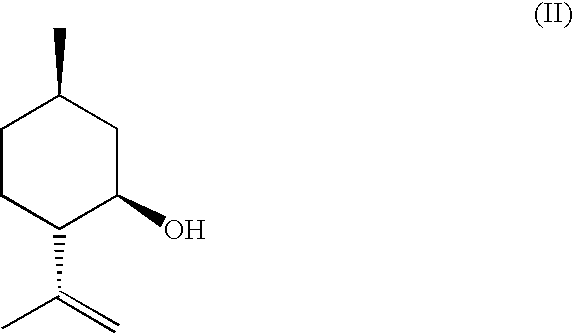

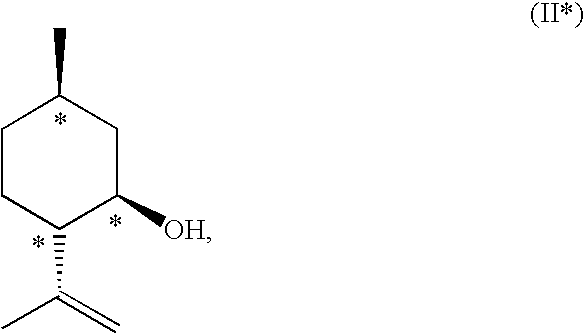

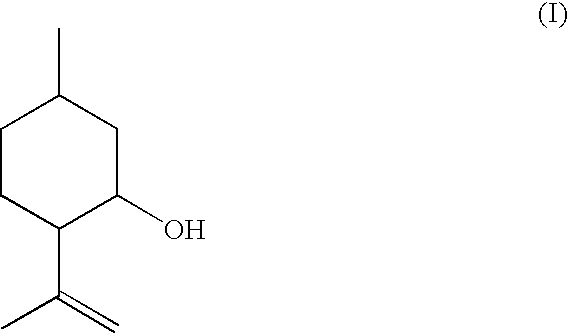

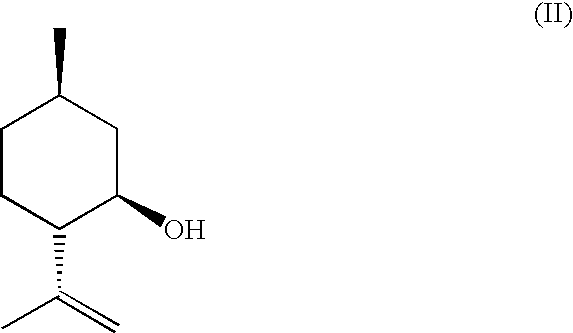

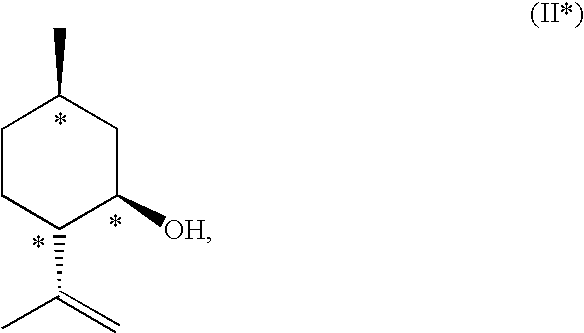

Method for the Production of Enriched Isopulegol

ActiveUS20080214877A1Easy to disassembleIncrease in the enantiomeric excessOxygen-containing compound preparationOrganic compound preparationMentholPolymer science

The present invention relates to a process for preparing enriched isopulegol by crystallization from a melt comprising isopulegol. The invention relates specifically to a process for preparing enantiomerically enriched n-isopulegol proceeding from optically active isopulegol having a relatively low enantiomeric excess by crystallization from the melt. The invention further relates to a process for preparing menthol proceeding from enantiomerically and / or diastereomerically enriched n-isopulegol prepared by crystallization from the melt.

Owner:BASF AG

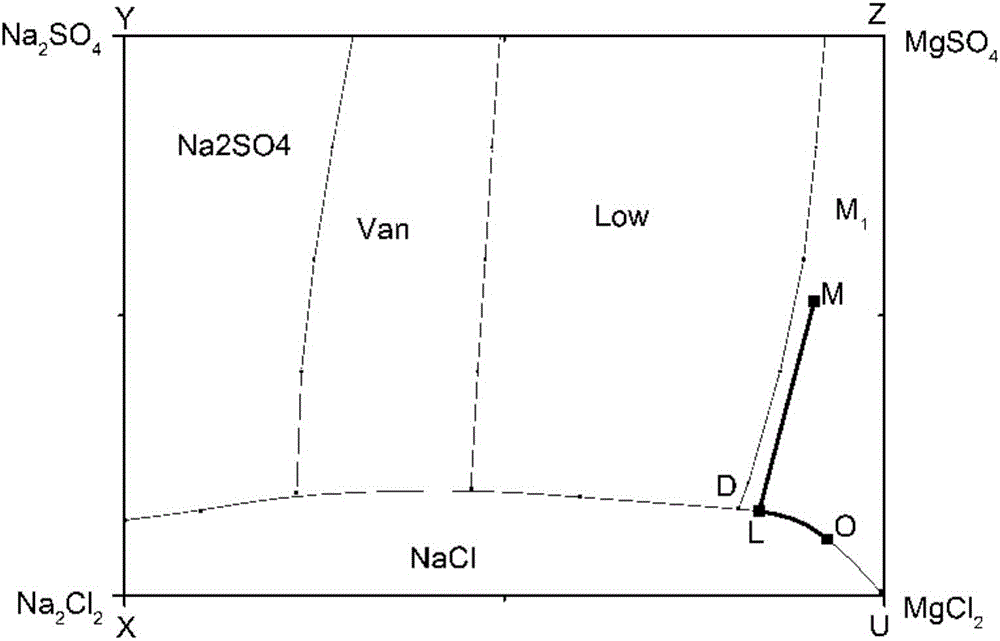

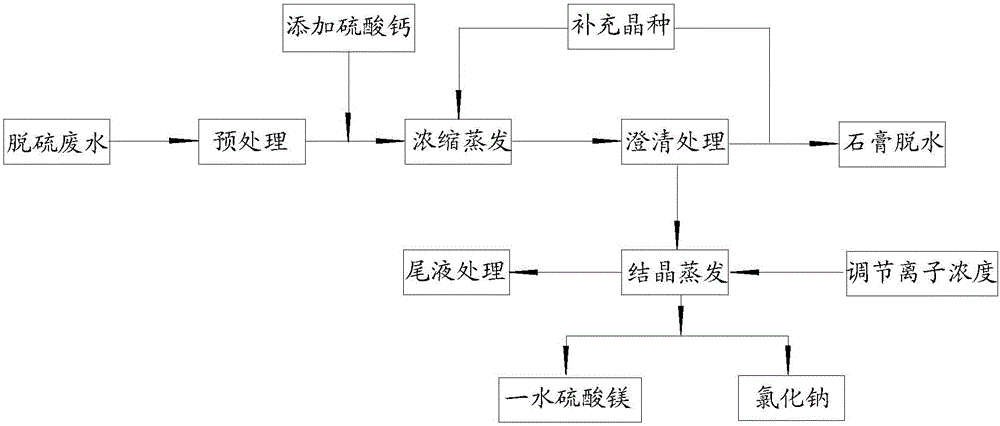

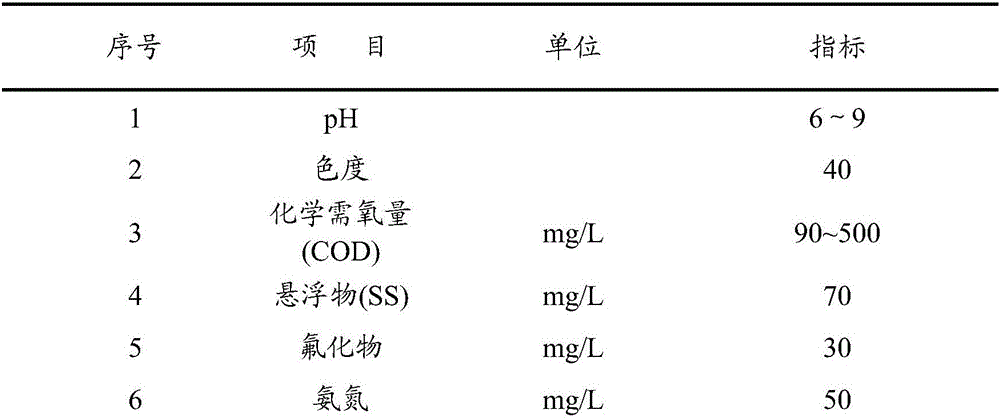

Desulfurization wastewater resourceful treatment method

ActiveCN105906125ALow running costLow investment costWaste water treatment from gaseous effluentsMultistage water/sewage treatmentEvaporationPre treatment

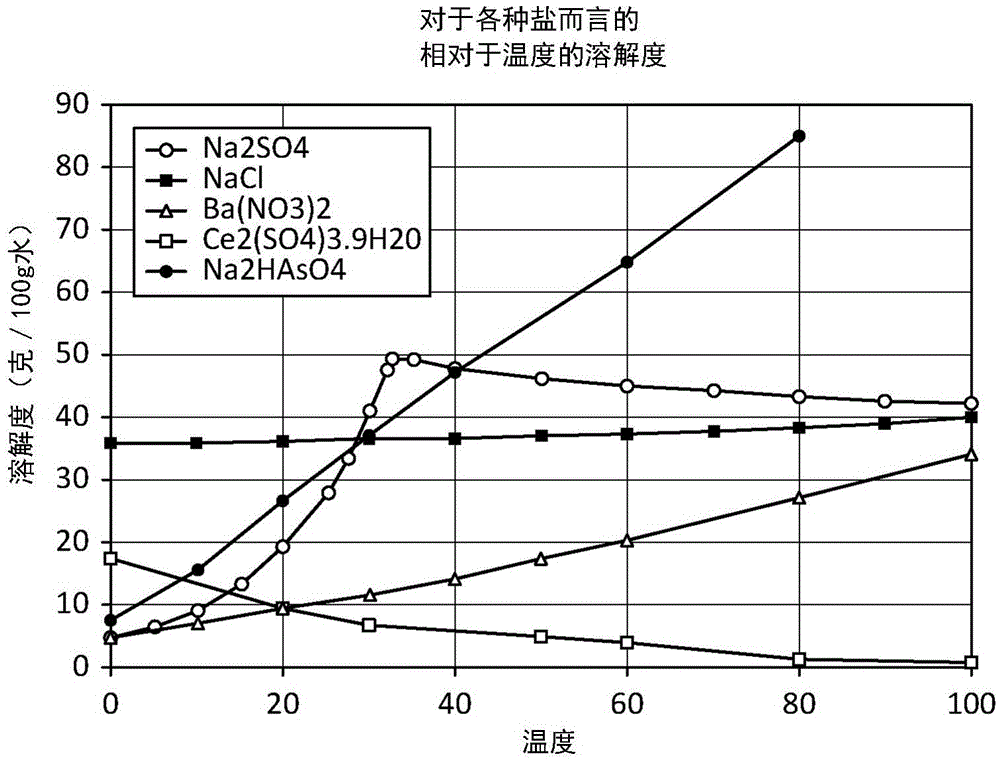

The invention relates to a desulfurization wastewater resourceful treatment method. The method comprises the following steps of 1, pretreatment, wherein suspended solids in desulfurization wastewater are removed; 2, concentration evaporation, wherein wastewater is subjected to evaporation treatment, in the initial stage of evaporation, calcium sulfate crystals are put into the wastewater, and after evaporation is ended, wastewater is cleared up; 3, crystallization evaporation, wherein the concentration of ions in wastewater is adjusted, crystallization points of the solution are made to fall into a crystallization region of a magnesium sulfate monohydrate salt or crystallization regions of magnesium sulfate monohydrate and sodium chloride salts, and then wastewater is subjected to evaporation crystallization; 4, crystallization salt separation, wherein the obtained mixed salt is separated to obtain a magnesium sulfate monohydrate crystallization salt and a sodium chloride crystallization salt. According to the desulfurization wastewater resourceful treatment method, the investment and operation costs are low, and two high-value industrial salts of magnesium sulfate and sodium chloride can be obtained.

Owner:GUANGDONG DEGA POWER ENVIRONMENTAL PROTECTION TECH CO LTD

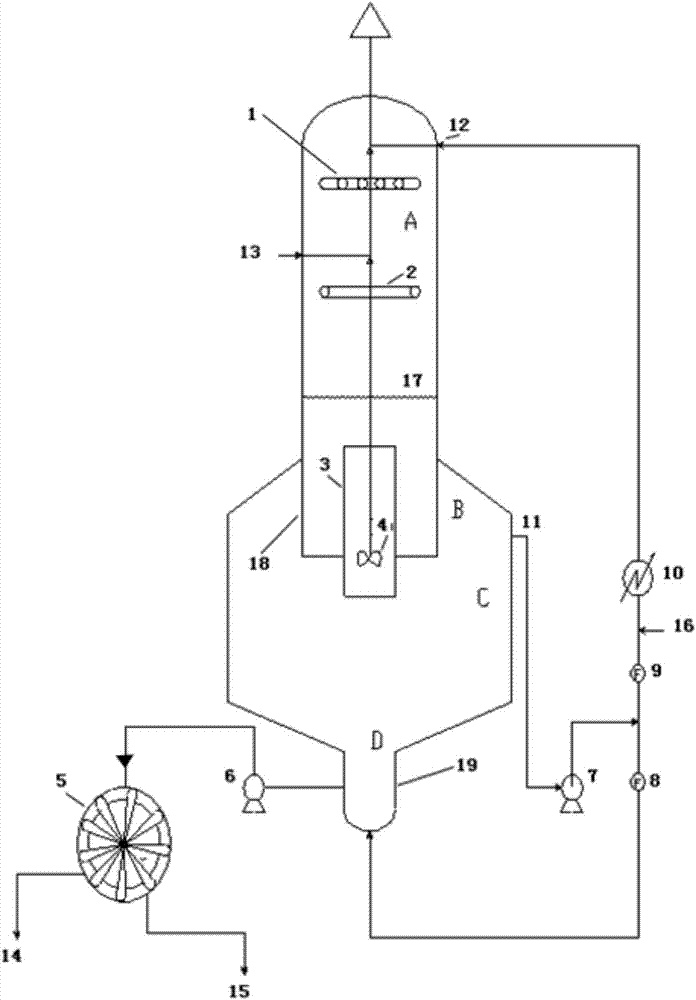

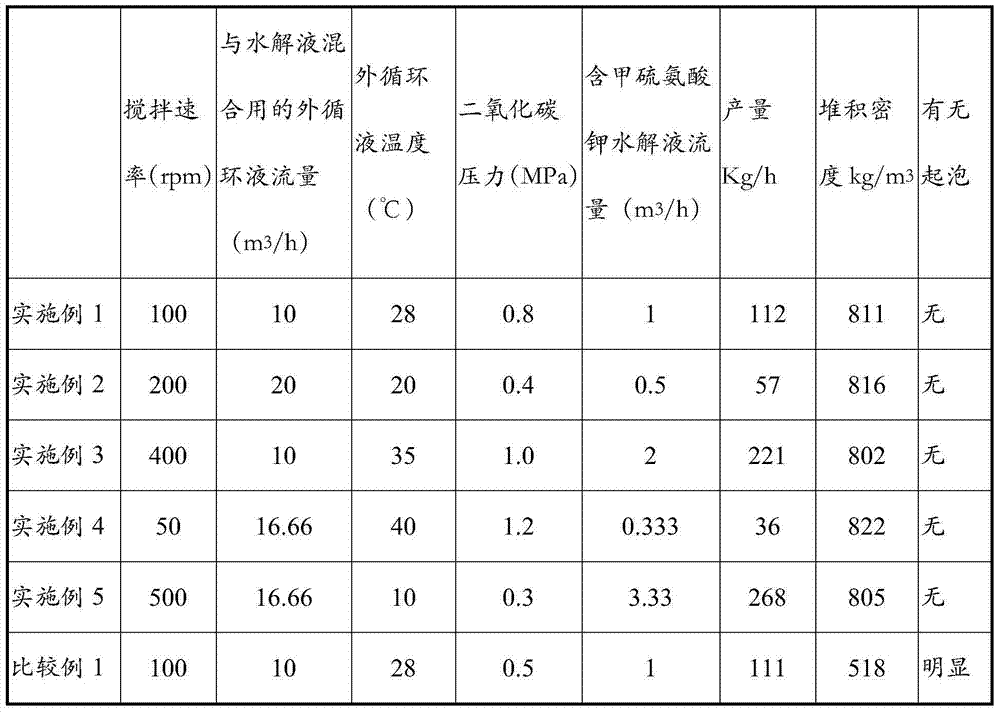

Method for continuously preparing high-bulk density methionine crystals

ActiveCN104744326AImprove product qualityImprove efficiencyOrganic chemistryOrganic compound preparationHydantoin derivativesHydrolysate

The invention relates to a method for continuously preparing high-bulk density methionine crystals. The process of the method is as follows: a hydrolysate, which is obtained from reaction of 5-(beta-methylthioethyl)hydantoin and a potassium carbonate solution, is mixed with an outside circular material from a DTB neutralization crystallizer with a gas phase neutralization section, the mixture is cooled and enters a liquid distributor in a neutralization area in the upper part of the crystallizer, the mixture is sprayed in drops or trickles into carbon dioxide gas for neutralization reaction, and then falls naturally into a crystallization area in the lower part to be mixed with a material in the area, the mixture grows on tiny crystals in a system to form crystals with larger grain sizes, and meanwhile new crystal nucleuses are formed; in a deposition area in the middle part of the crystallization area, the crystals with larger grain sizes sink into a washing leg, the tiny crystals circulate along with the outside circular material, a part of the outside circular material is used for washing the crystals in the washing leg, and the other part of the outside circular materials is mixed with the hydrolysate; the crystals in the washing leg are separated, washed and then dried to obtain the high-bulk density methionine product.

Owner:SHANDONG XINHECHENG AMINO ACID +2

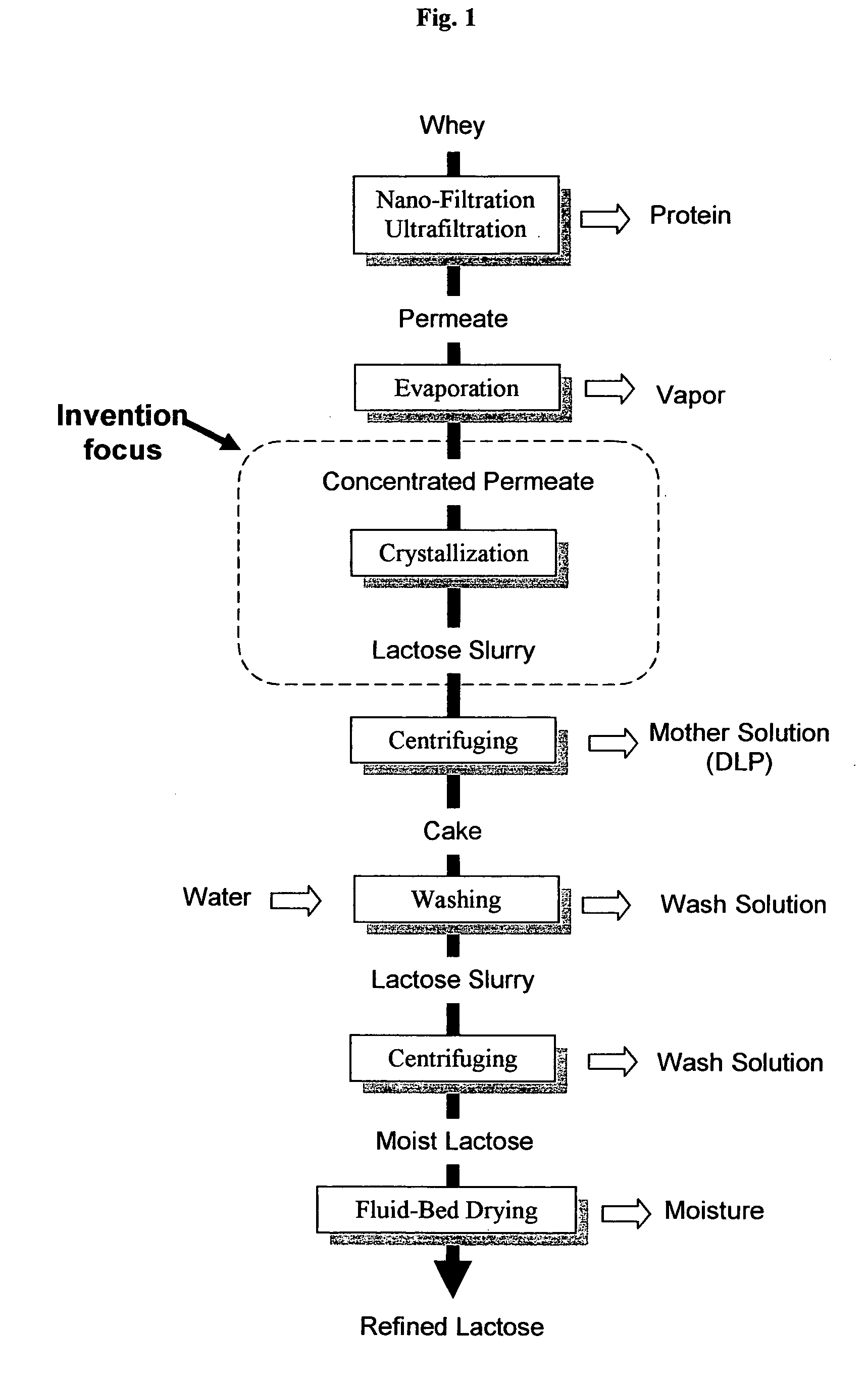

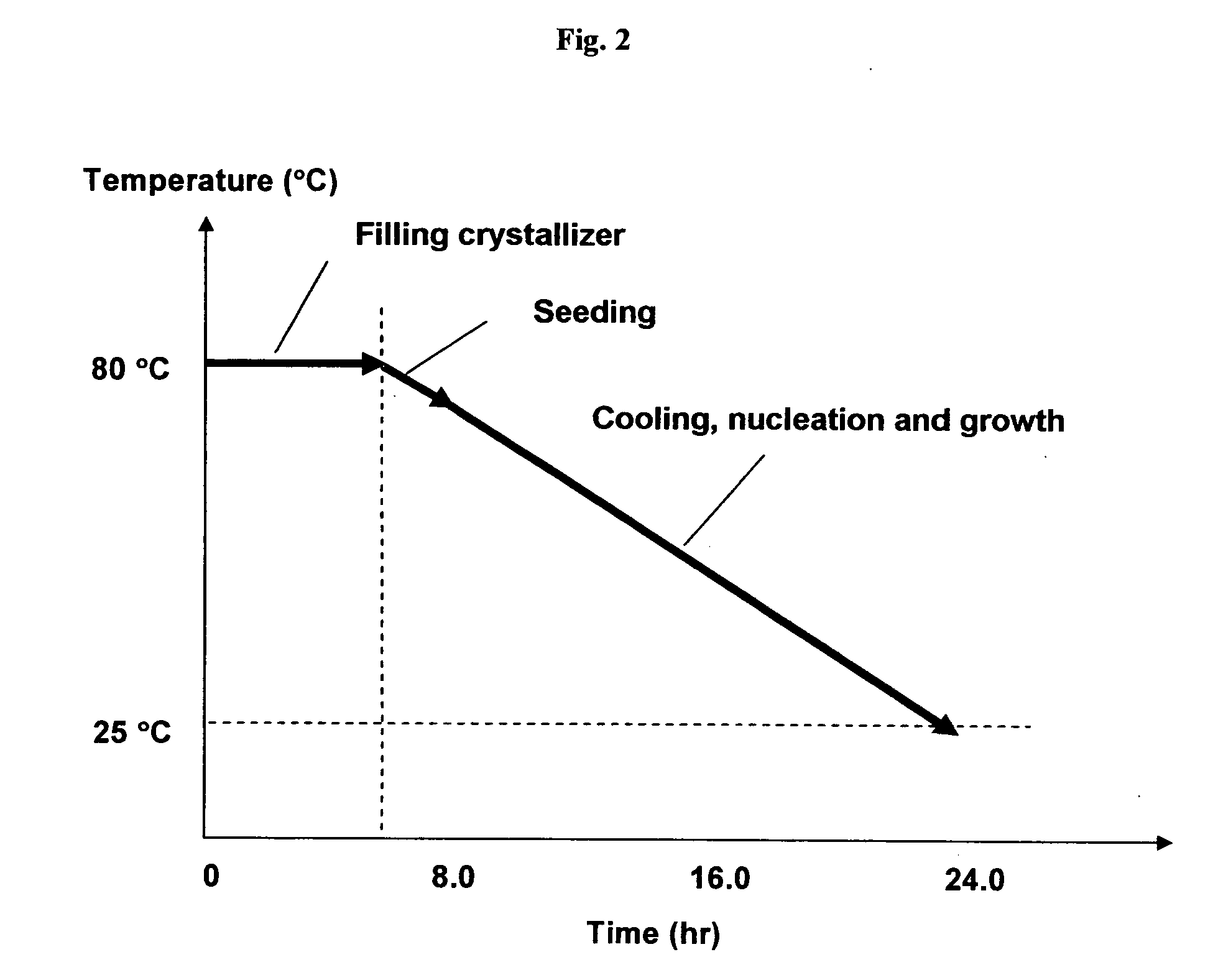

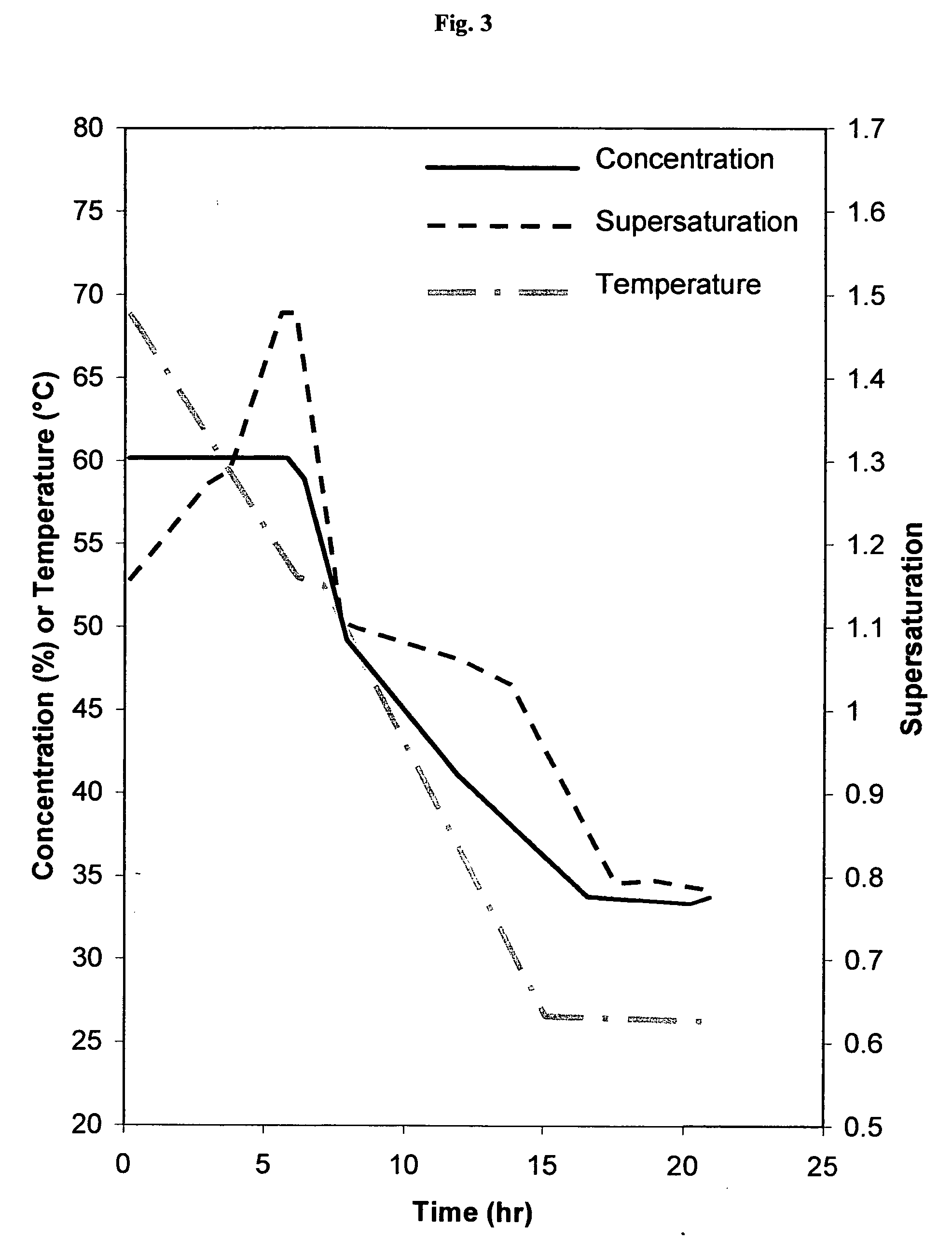

Crystal refining technologies by controlled crystallization

InactiveUS20060128953A1Short timeQuality improvementDisaccharidesProduct crystals bed crystallizationIsothermal crystallizationChemistry

A method is provided for making large, uniform and individual crystals from aqueous solutions including the steps of obtaining a concentrated aqueous solution by means of evaporation; rapidly cooling the solution from a post-evaporation high temperature to a first lower temperature, wherein the first lower temperature is lower than the post-evaporation high temperature and further wherein the first lower temperature is an isothermal crystallization temperature of said solution; generating a batch of initial nuclei by inducing nucleation at the first lower temperature and starting crystal growth; uniformly spreading the initial nuclei into a bulk solution; maintaining simultaneous and rapid growth of crystals from the nuclei at the first lower temperature for a predetermined length of time; continuing the growth of the crystals to produce large, uniform and individual crystals for a predetermined length of time at a temperature that varies gradually from between a first lower temperature to a second lower temperature, wherein the second lower temperature is a temperature lower than the first lower temperature and further wherein the second lower temperature is an end temperature of crystallization; and recovering the large, uniform and individual crystals. Parameters and a system for producing lactose monohydrate crystals using the method are also provided.

Owner:WISCONSIN ALUMNI RES FOUND

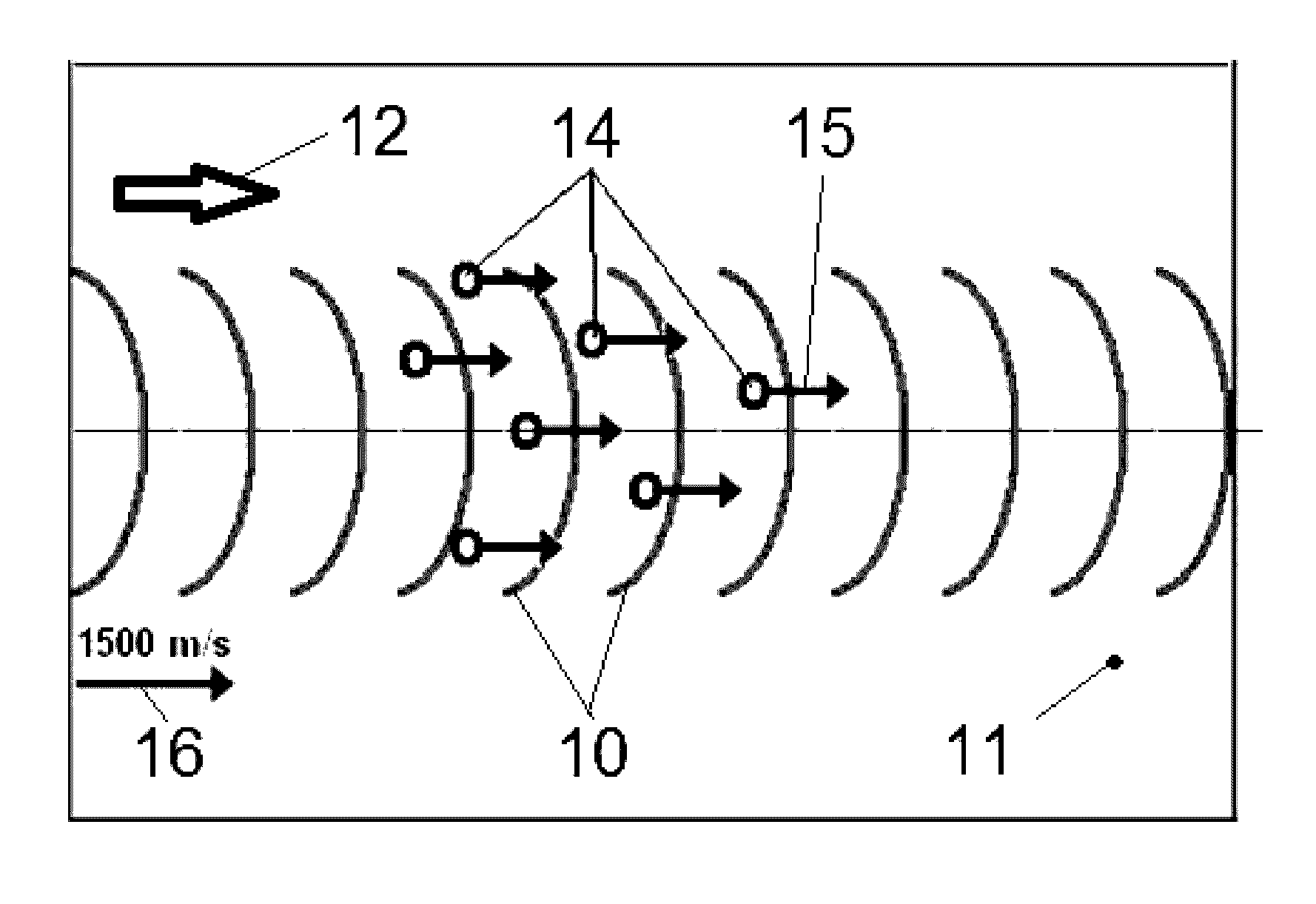

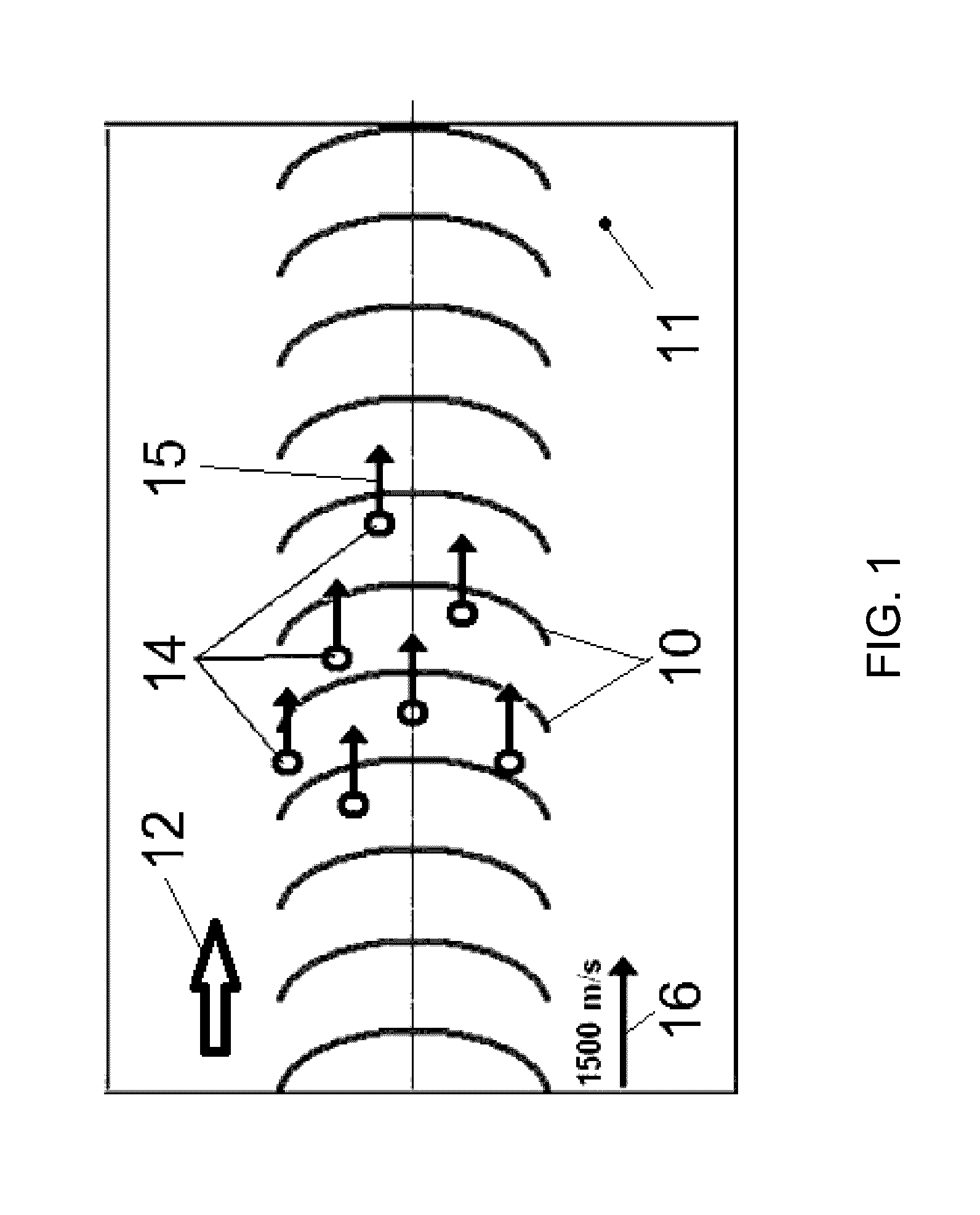

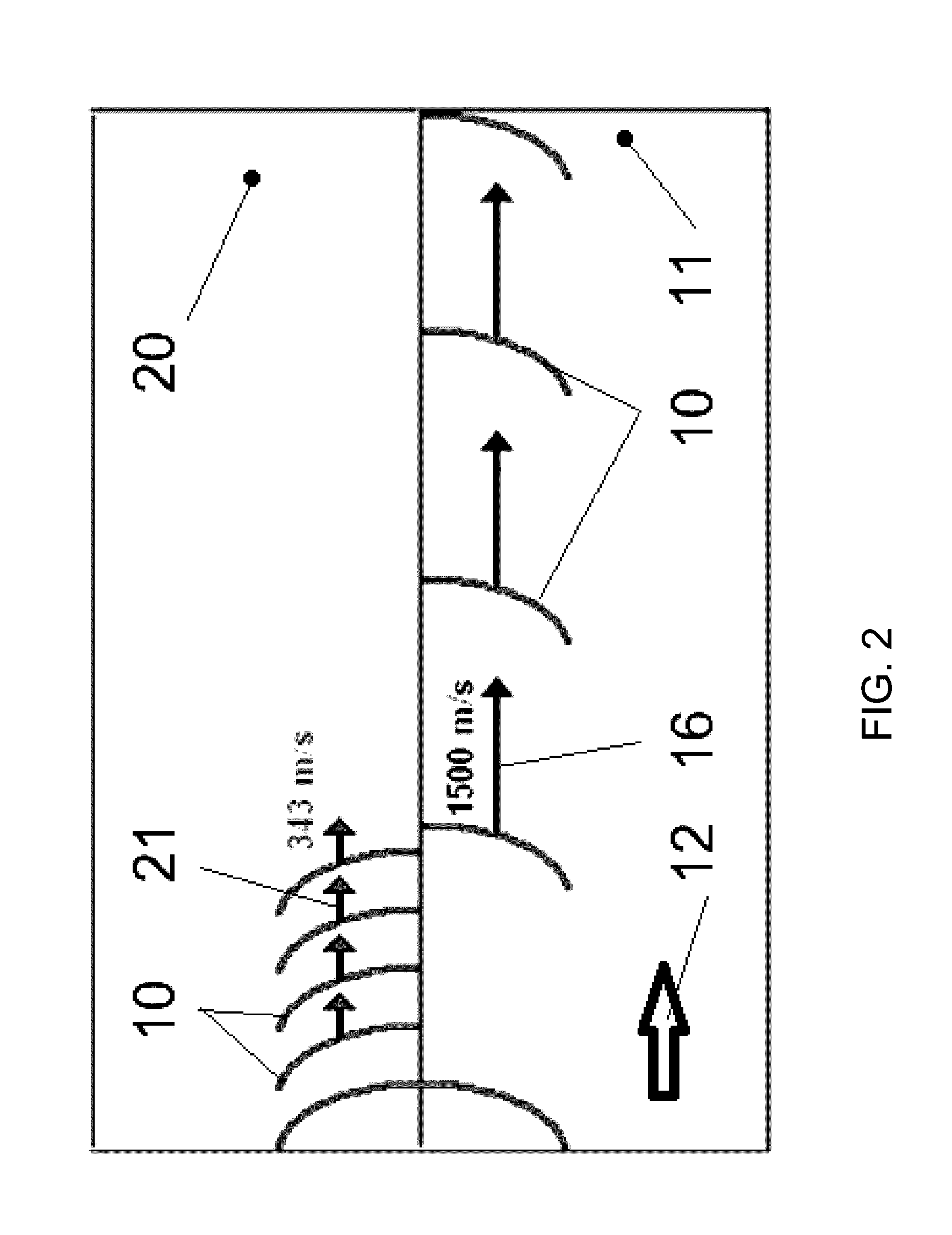

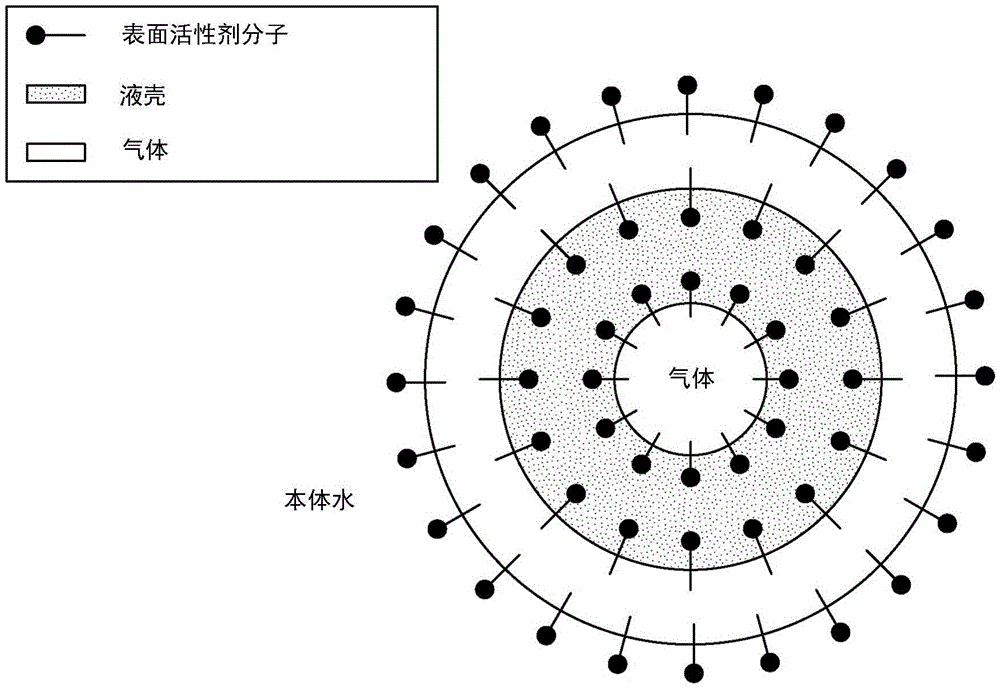

Water desalination using freeze crystallization and acoustic pressure shock waves

ActiveUS20170057843A1Enhancing of acoustic pressure shock wave effectImprove desalination efficiencyGeneral water supply conservationSeawater treatmentShock waveSaline water

A method of desalinating water through application of acoustic pressure shock waves to a slush to separate ice crystals from brine and recovering desalinated water from the separated ice crystals.

Owner:SANUWAVE INC

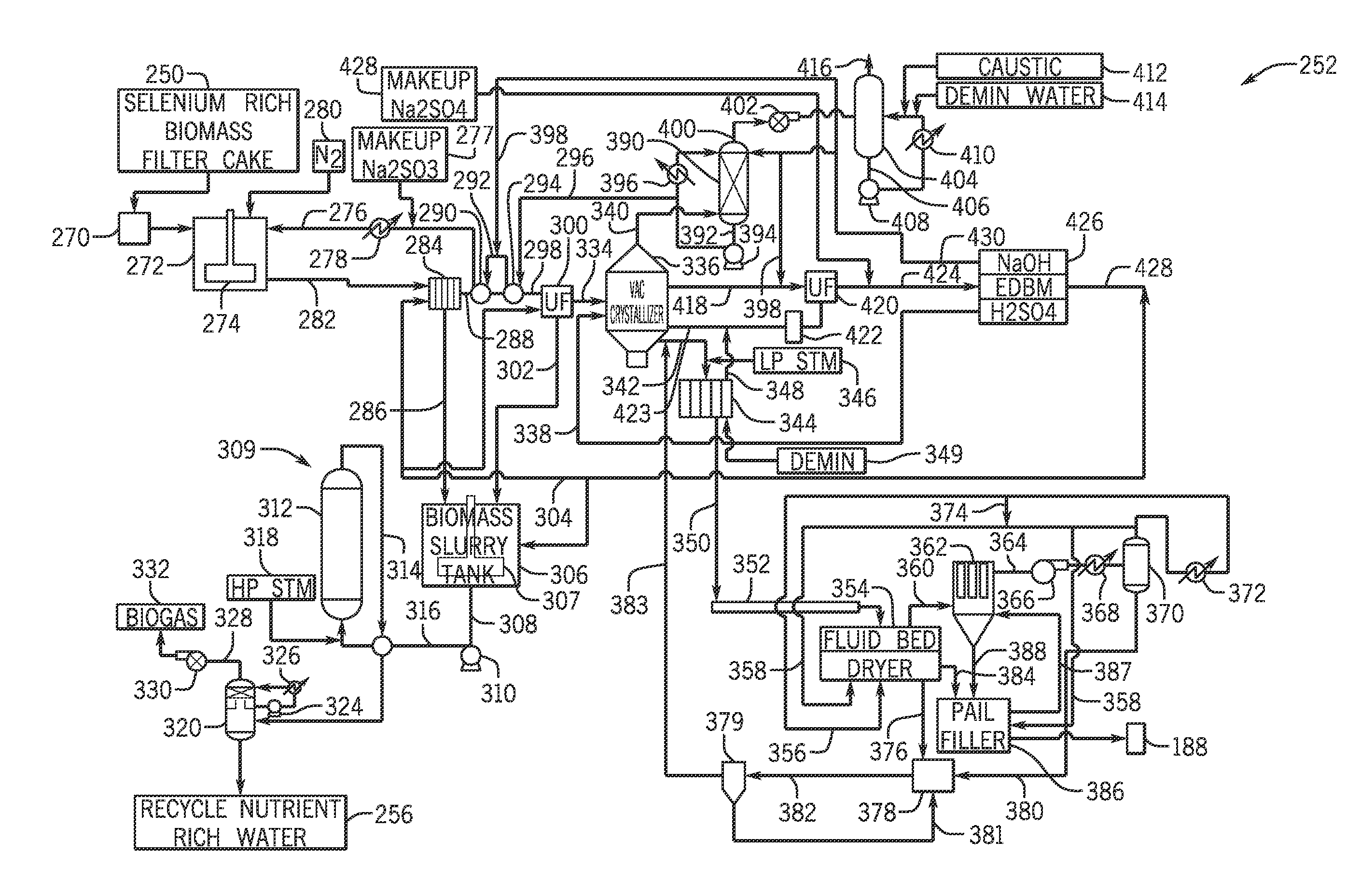

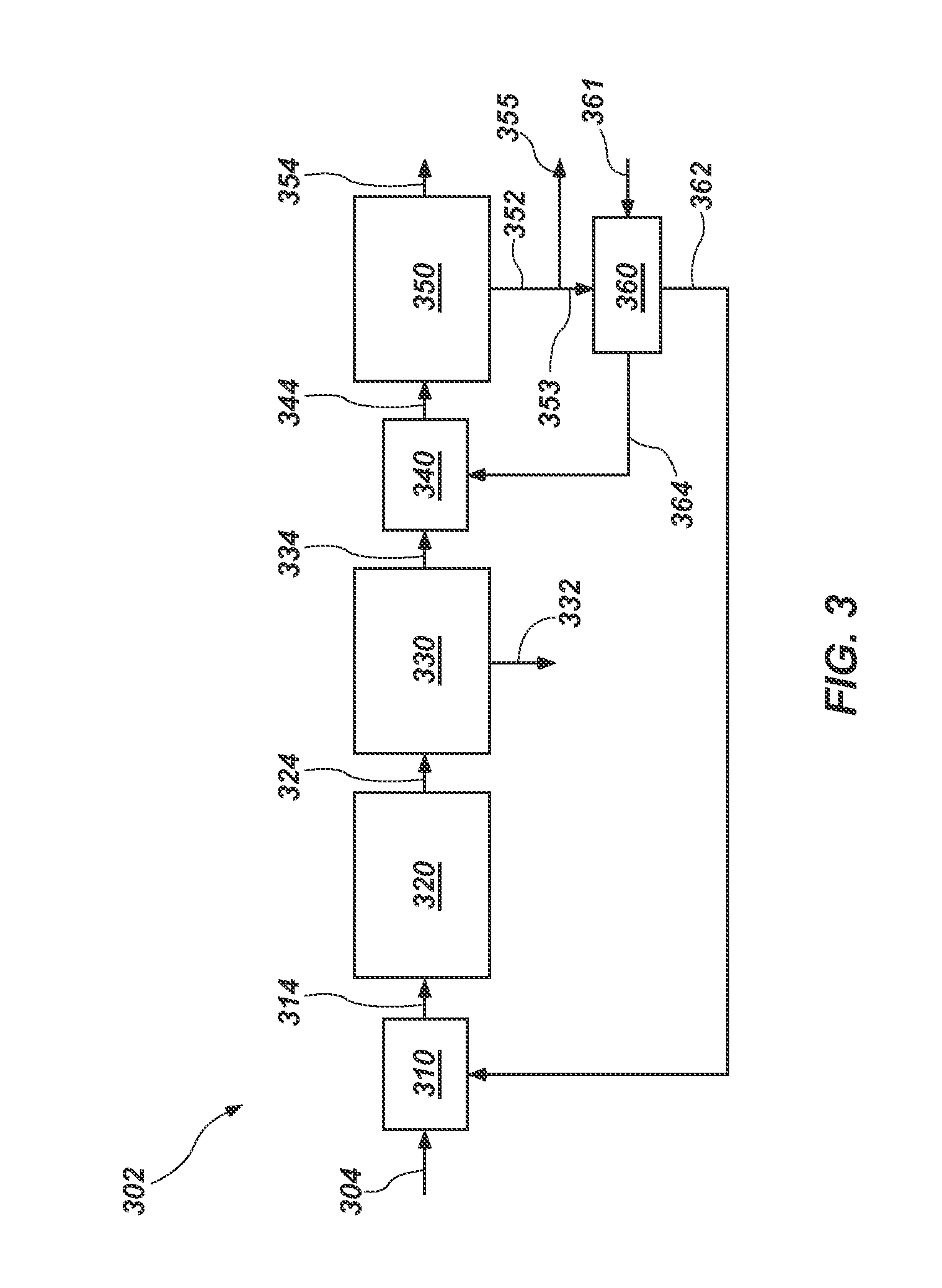

System for removing selenium from a feed stream

ActiveUS20140045248A1Increase the amount of heatingHigh large amountWater contaminantsProduct crystals bed crystallizationSe elementSulfur dioxide

A system for removing selenium from a solid feed stream includes a selenium dissolver configured to selectively dissolve elemental selenium from the solid feed stream and to produce a selenium rich solution and a crystallizer coupled to the selenium dissolver and configured to receive the selenium rich solution from the dissolver, to add an acid to the selenium rich solution, to remove purified selenium from the selenium rich solution, and to remove sulfur dioxide from the selenium rich solution.

Owner:ENVIRO WATER MINERALS COMPANY

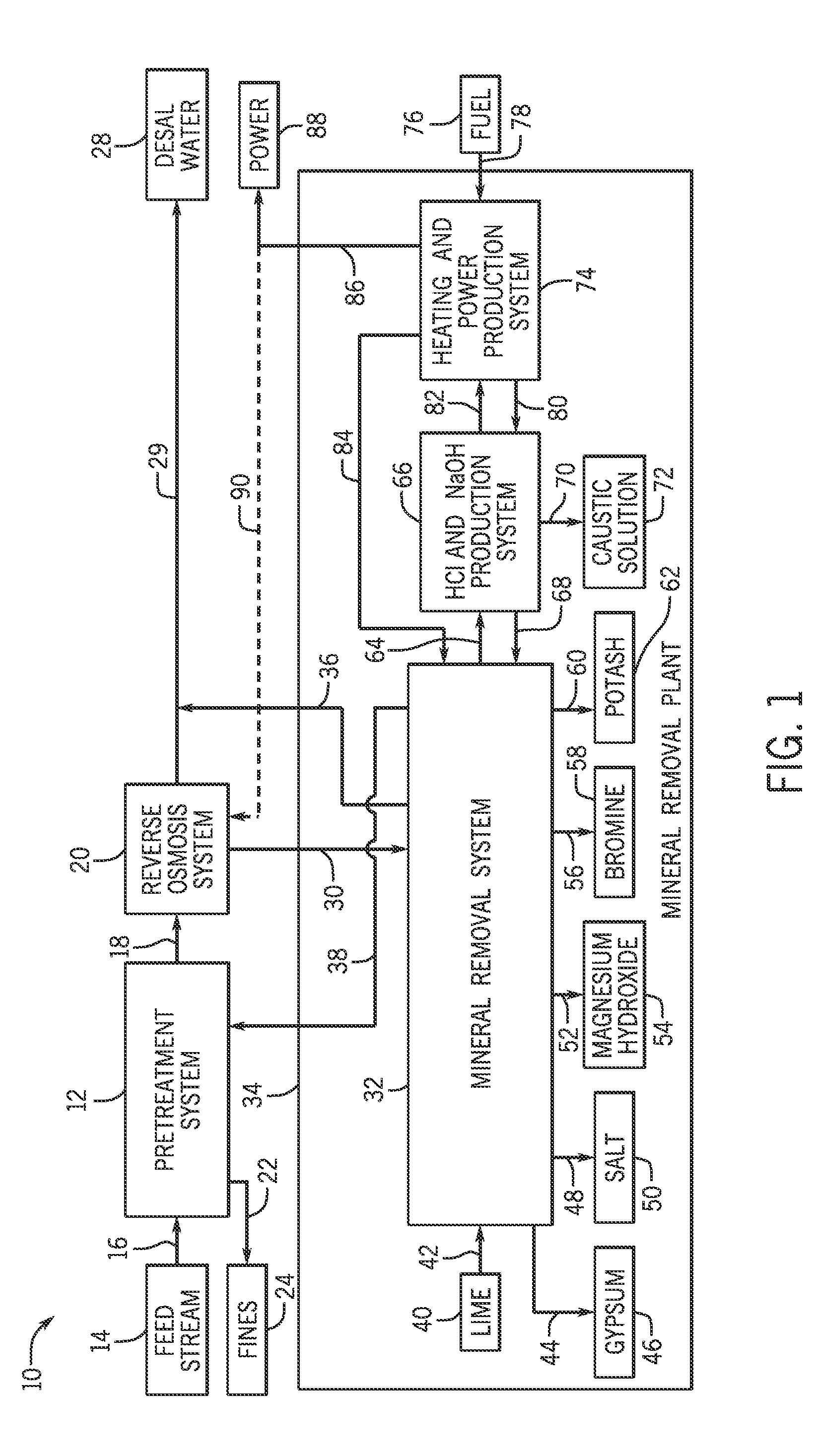

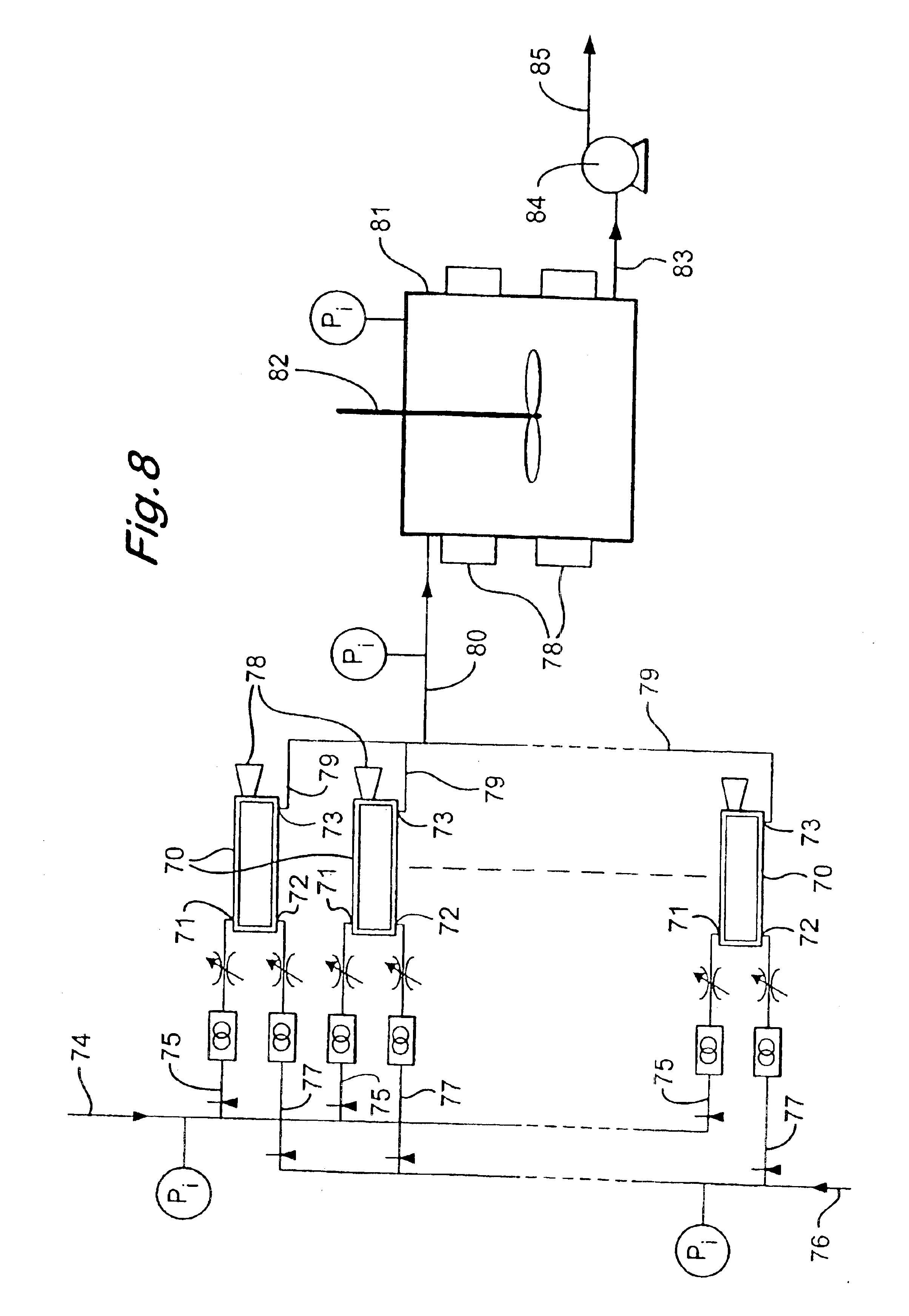

Methods of processing solutions of potassium sulfate and magnesium sulfate, methods of producing potassium sulfate, and related systems

ActiveUS20140072507A1Economic value maximizationIncrease productionOther chemical processesDouble sulfate preparationPotassium sulfateAqueous solution

Methods of processing an aqueous solution comprising potassium sulfate and magnesium sulfate include crystallizing K2SO4, crystallizing recycle crystals, and mixing at least a portion of the recycle crystals with the aqueous solution. Systems for processing potassium sulfate and magnesium sulfate include a first crystallizer and a second crystallizer in fluid communication with the second mix tank. The second crystallizer is structured and adapted to precipitate recycle crystals from the concentrated liquor to form a potassium-depleted recycle brine. The recycle crystals precipitated in the second crystallizer have a composition suitable to be recycled to the first crystallizer to increase the production of SOP.

Owner:INTERCONTINENTAL POTASH CORP USA

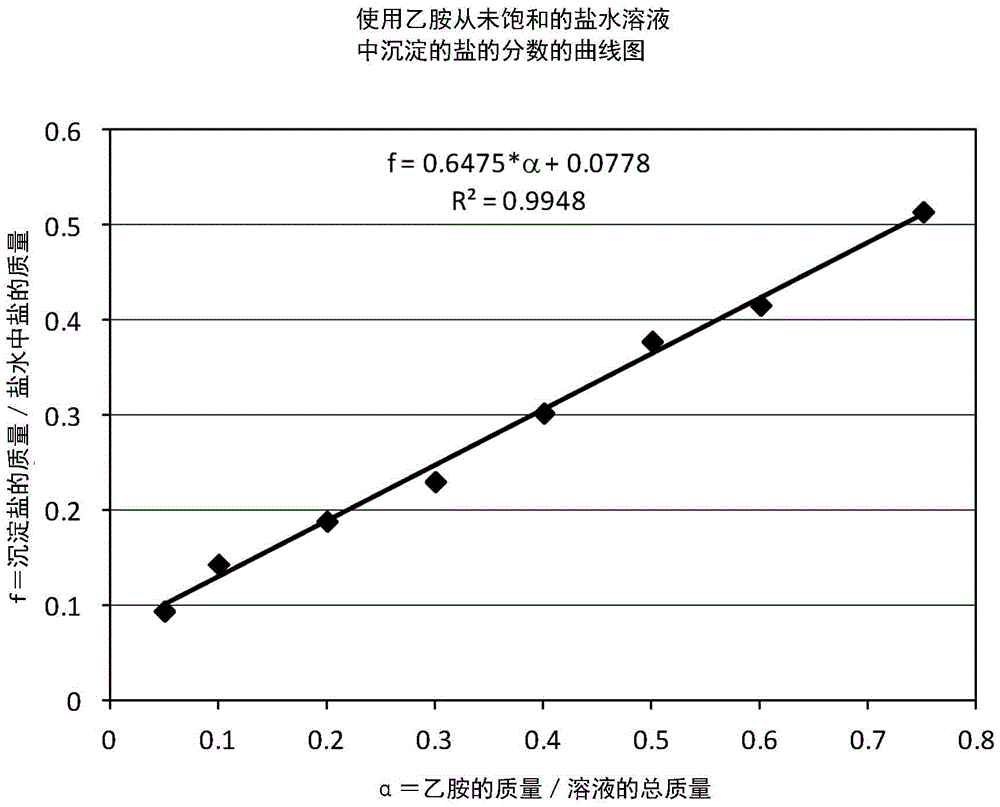

Dissolved air flotation, antisolvent crystallisation and membrane separation for separating buoyant materials and salts from water

InactiveCN105451888AAchieve separationIncrease in sizeWaste water treatment from quariesSeawater treatmentInorganic saltsStrontium

Provided are systems, methods, and apparatus for removing materials from liquid, such as water. The system, methods, and apparatus allow for separation of neutrally buoyant materials from liquid via flotation to or near the surface of the liquid via air bubbles. The system, methods, and apparatus allow for the selective separation of an element, such as strontium, from the liquid. The system, methods, and apparatus allow for precipitating a water soluble salt or water soluble salts from water, including adding a water-miscible solvent to a water solution including an inorganic salt. And, the system, method and apparatus also allow for the separation of the precipitated salt, and for separation of the solvent from the water.

Owner:ADVANCED WATER RECOVERY

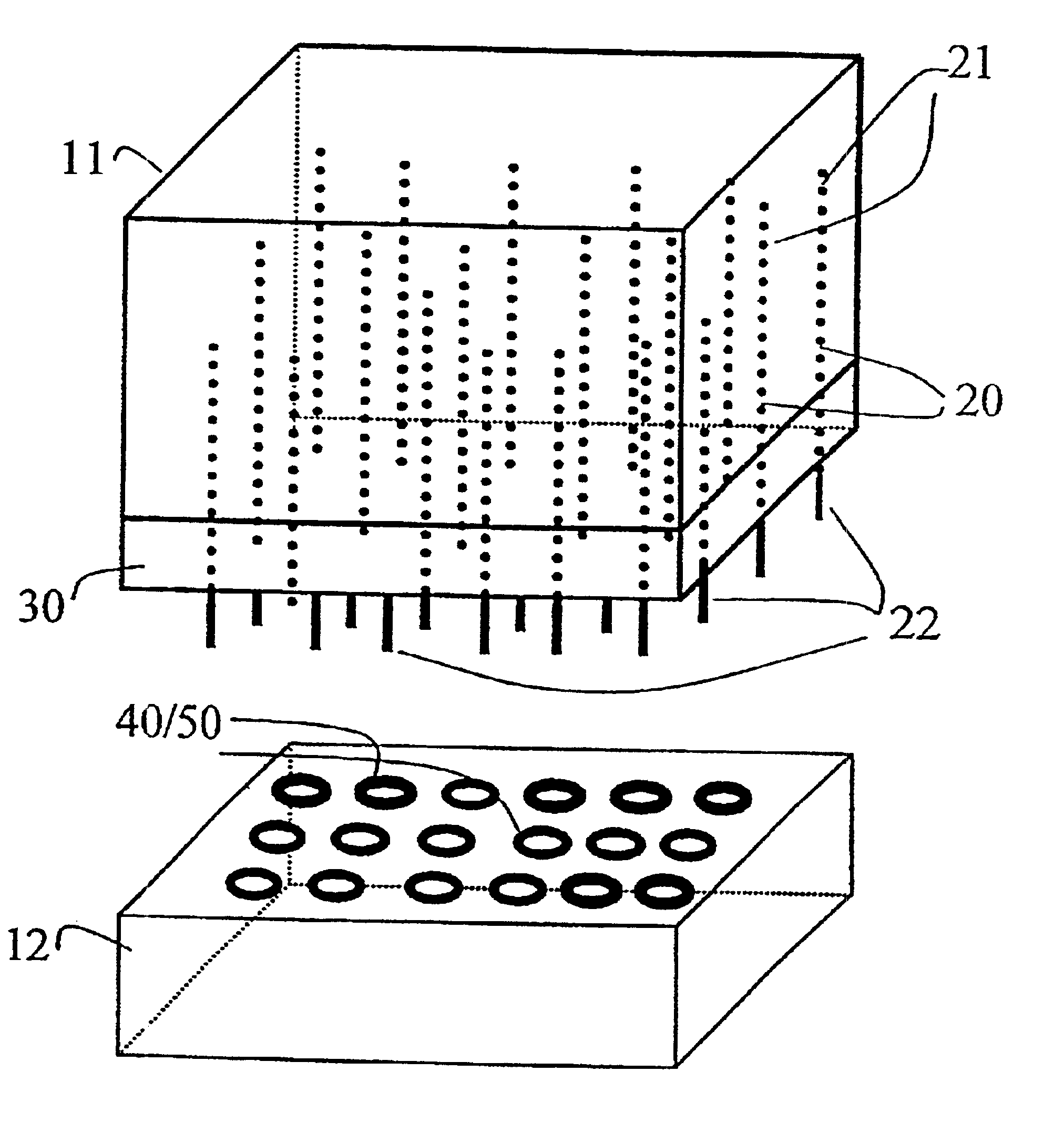

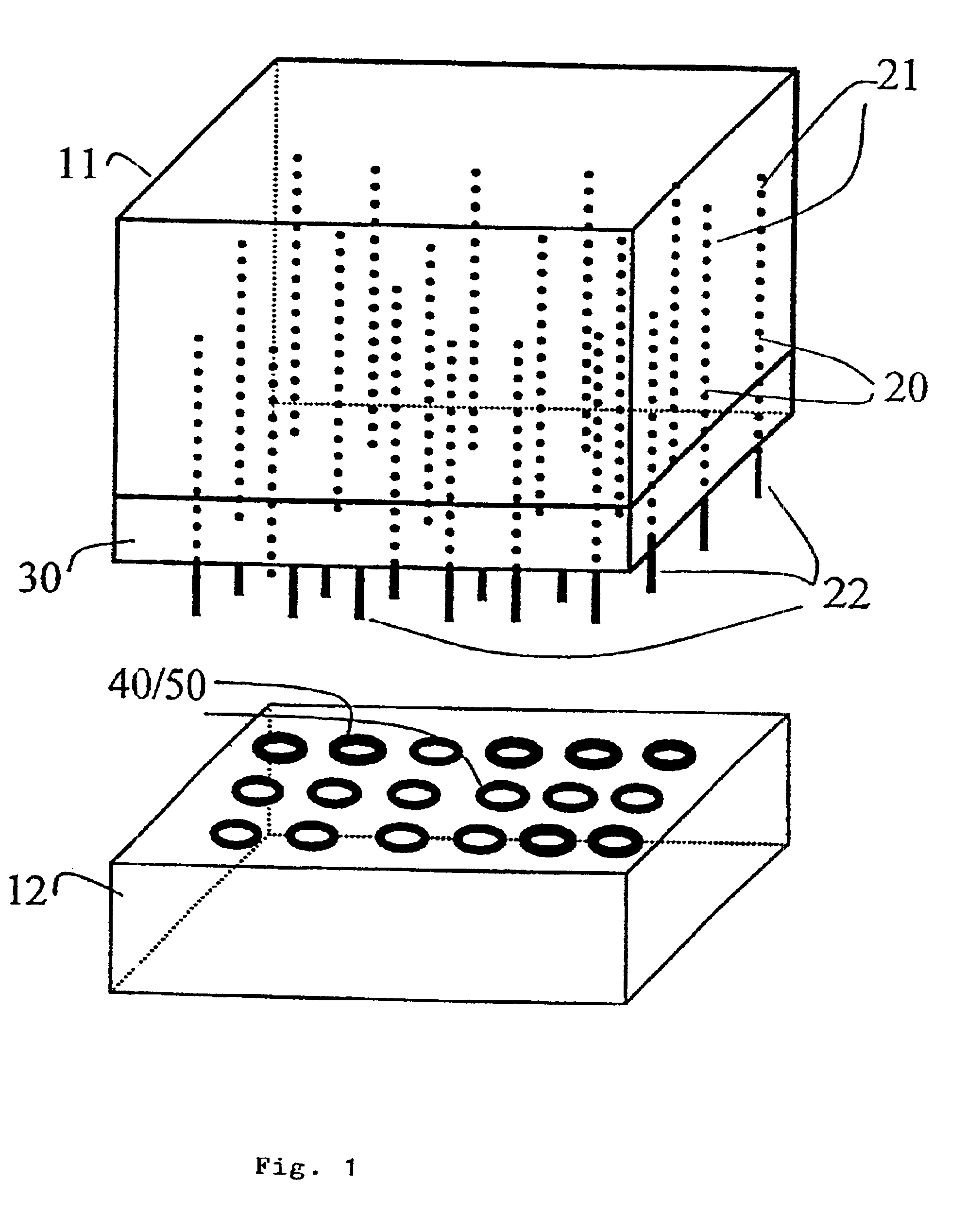

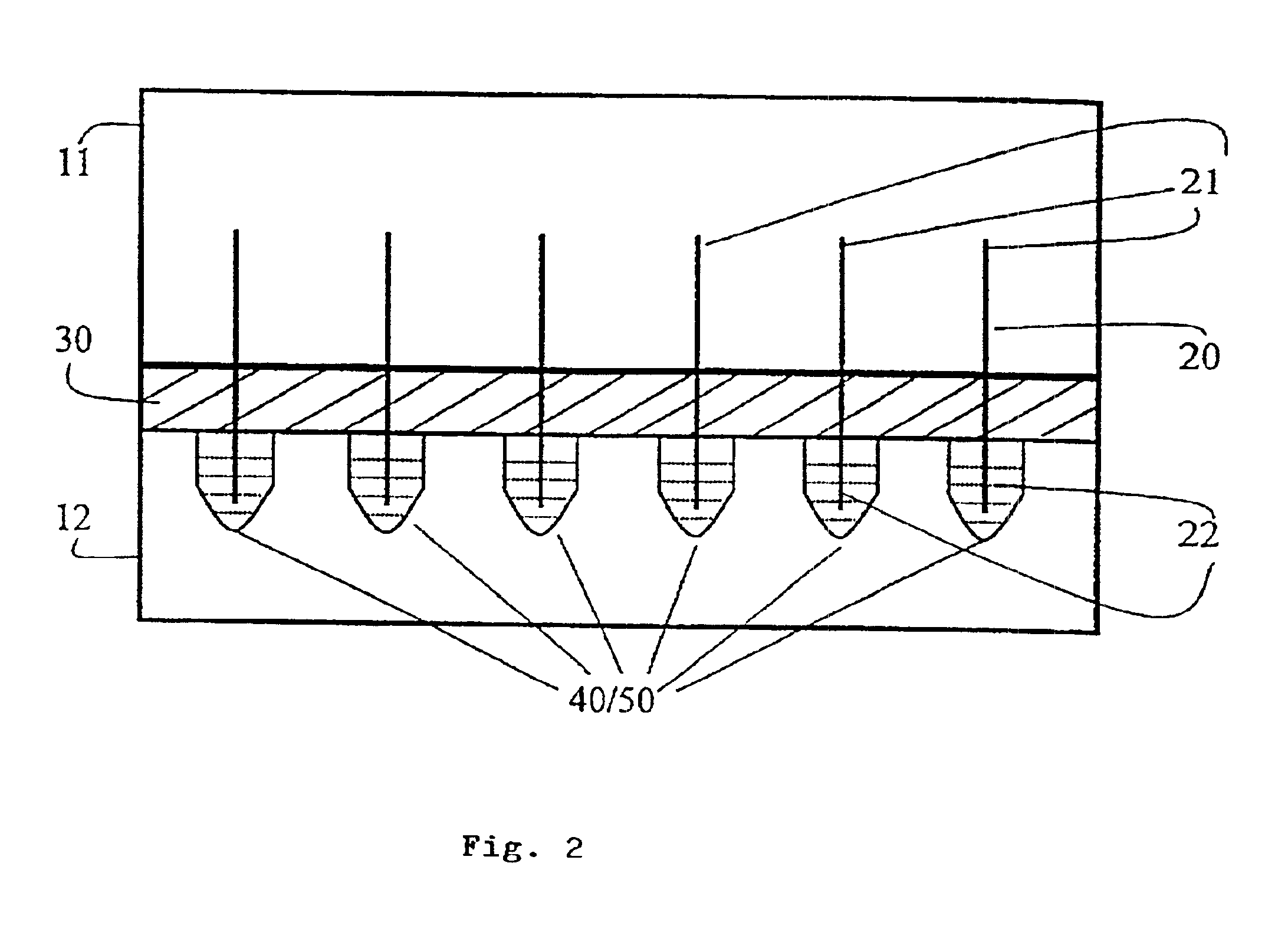

Device and method for concentration of samples by microcrystallization

InactiveUS6878553B1Easy to disassembleSequential/parallel process reactionsWithdrawing sample devicesTemperature controlCrystallization

A device and method for simultaneously concentrating a plurality of samples in small volumes based on the principle of cystallization. The device comprises a device for concentrating a plurality of samples comprising: a first temperature control means (12) having a plurality of container means (40 / 50) for containing said plurality of samples; a second complementary temperature control means (11) having a plurality of conducting means (22) which are adapted to be inserted in respective samples in said plurality of container means (40 / 50); and insulating means (30) for insulating said first temperature control means (12) from said temperature control means (11) such than an amount of heat from said plurality of samples is dissipated through said plurality of conducting means (22).

Owner:NAT UNIV OF SINGAPORE

Reduction in mineral salt deposition

InactiveUS6881231B2Energy was cheapEffective controlCalcium/strontium/barium carbonatesMagnesium chloridesAqueous solutionSolid surface

A composition for reducing deposition of a mineral salt from an aqueous supersaturated solution onto a solid surface in contact with the aqueous supersaturated solution which composition comprises a dispersion of either (i) seed crystals of the mineral salt in an aqueous solution of the mineral salt or (ii) seed crystals of a salt isomorphous with the mineral salt in an aqueous solution of the isomorphous salt wherein the dispersed seed crystals are of Mean particle size of less than 2.5 microns.

Owner:ASYMPTOTE

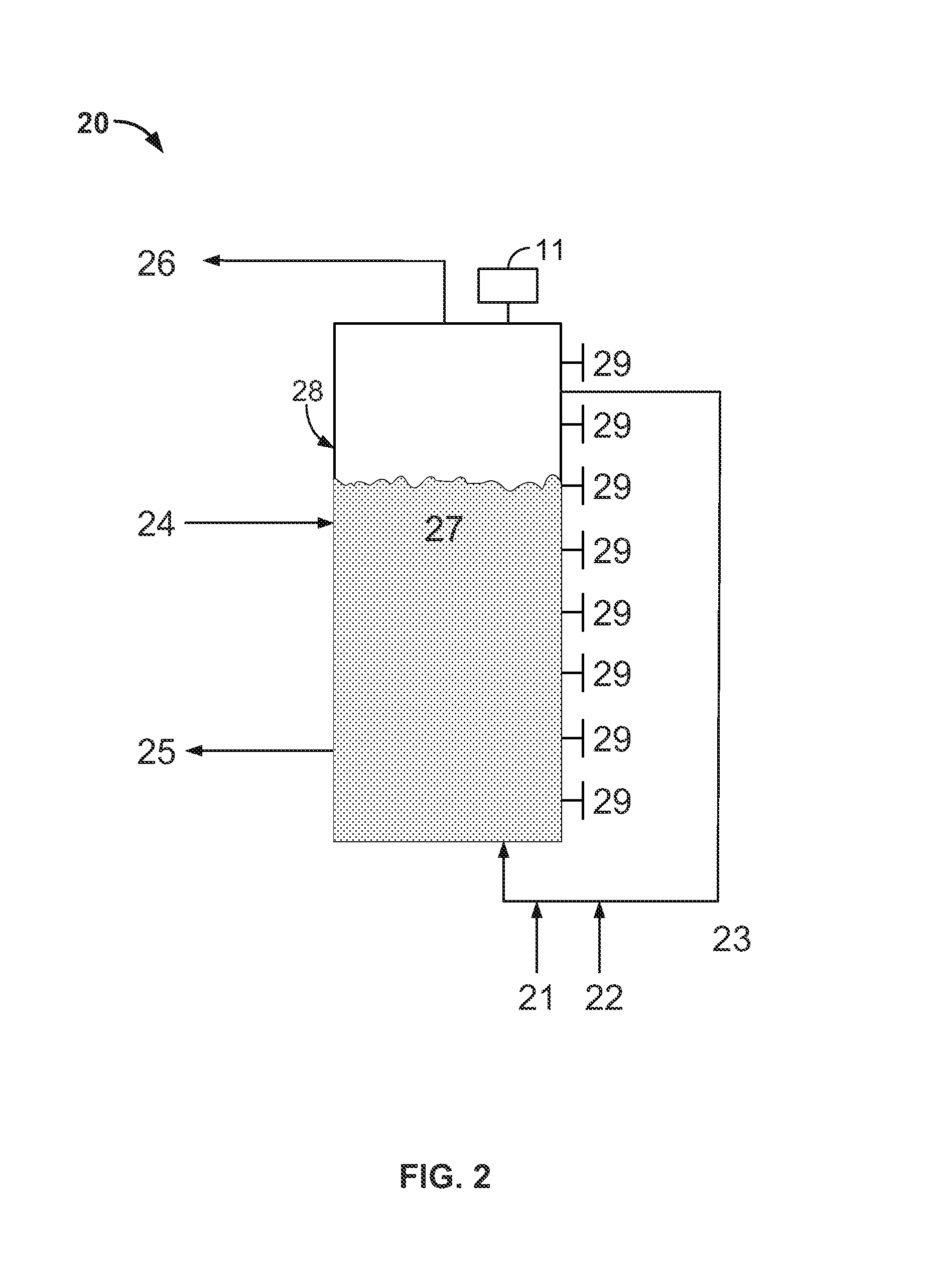

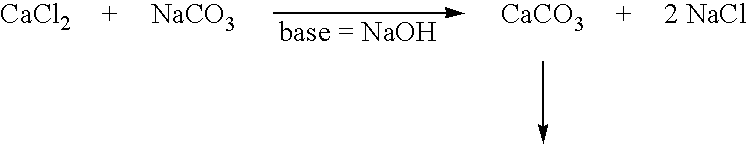

Recovering a caustic solution via calcium carbonate crystal aggregates

ActiveUS20150329369A1Reduce porosityHigh hardnessCalcium/strontium/barium carbonatesPulp liquor regenerationFluidized bedSlurry

Techniques for growing crystalline calcium carbonate solids such that the crystalline calcium carbonate solids include a volume of 0.0005 mm3 to 5 mm3, include a slaker to react quicklime (CaO) and a low carbonate content fluid to yield a slurry of primarily slaked lime (Ca(OH)2); a fluidized-bed reactive crystallizer that encloses a solid bed mass and includes an input for a slurry of primarily slaked lime, an input for an alkaline solution and carbonate, and an output for crystalline calcium carbonate solids that include particles and an alkaline carbonate solution; a dewatering apparatus that includes an input coupled to the crystallizer and an output to discharge a plurality of separate streams that each include a portion of the crystalline calcium carbonate solids and alkaline carbonate solution; and a seed transfer apparatus to deliver seed material into the crystallizer to maintain a consistent mass of seed material.

Owner:CARBON ENG LTD

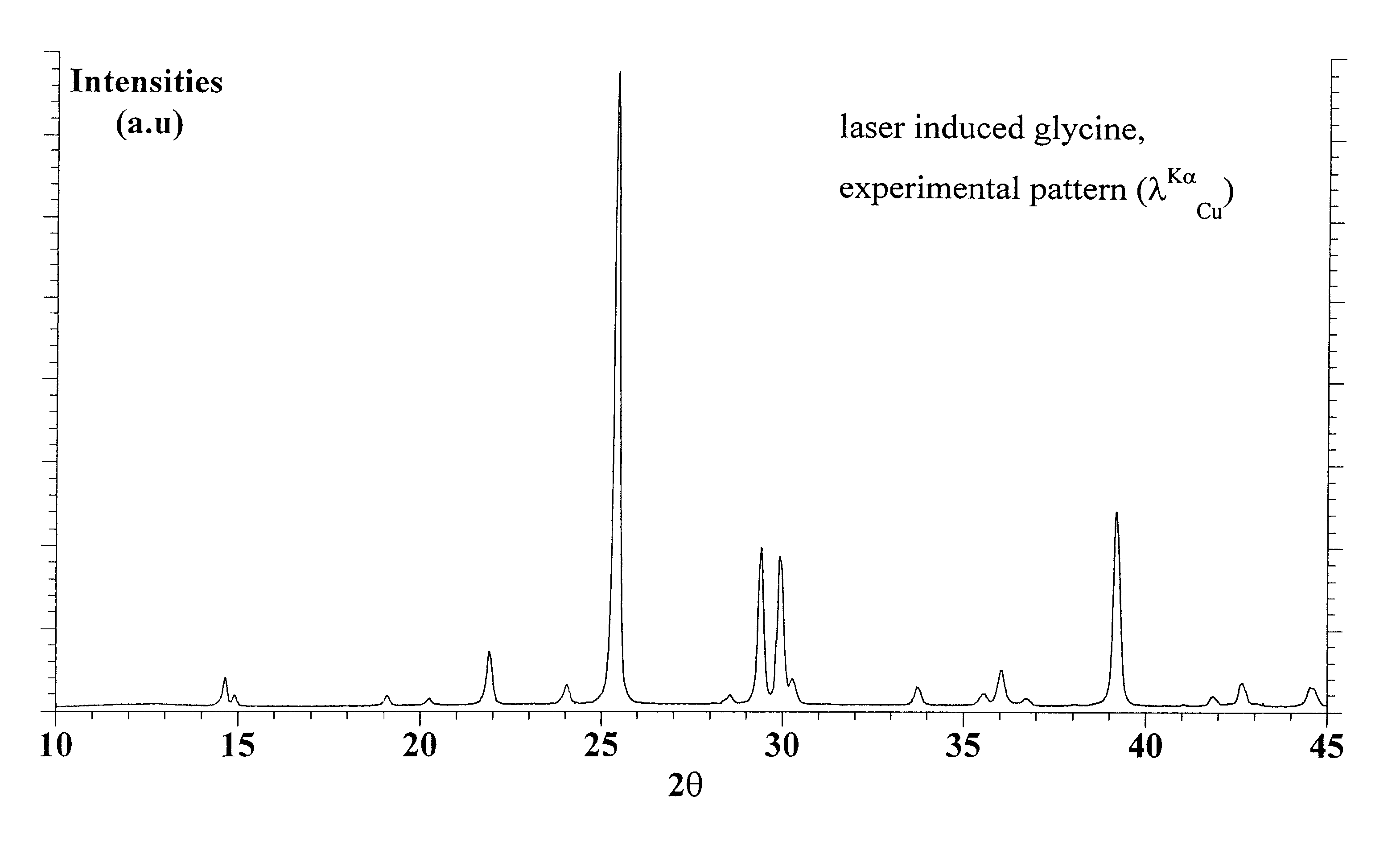

Method for using laser light to control crystal form

InactiveUS6426406B1Organic chemistry methodsCarboxylic acid esters preparationCrystal structureLaser light

A method to prepare new or unexpected polymorphs of materials which have not been observed, or to obtain a known polymorph under different conditions than those in which it is usually made, by using a laser to cause nucleation and crystal growth to occur in a supersaturated solution in such a way as to obtain a crystal structure which would not normally appear without the use of the laser.

Owner:INTELLECTUAL VENTURES HLDG 19

Process for production of fullerenes and method for separation thereof

InactiveUS20050232846A1Material nanotechnologyFullerenesPolycyclic aromatic hydrocarbonProduction rate

A process for the production of fullerenes by which a high-purity fullerene can be separated at high productivity from a mixture comprising a fullerene, a polycyclic aromatic hydrocarbon component, and a carbonaceous polymeric component and which comprises the step (A) of preparing a mixture comprising a fullerene, a polycyclic aromatic hydrocarbon component, and a carbonaceous polymeric component, the step (B) of separating this mixture into a polycyclic aromatic hydrocarbon component and a mixture of a fullerene and a carbonaceous polymeric component, and the step (C) of separating this mixture into a fullerene and a carbonaceous polymeric component.

Owner:MITSUBISHI CHEM CORP

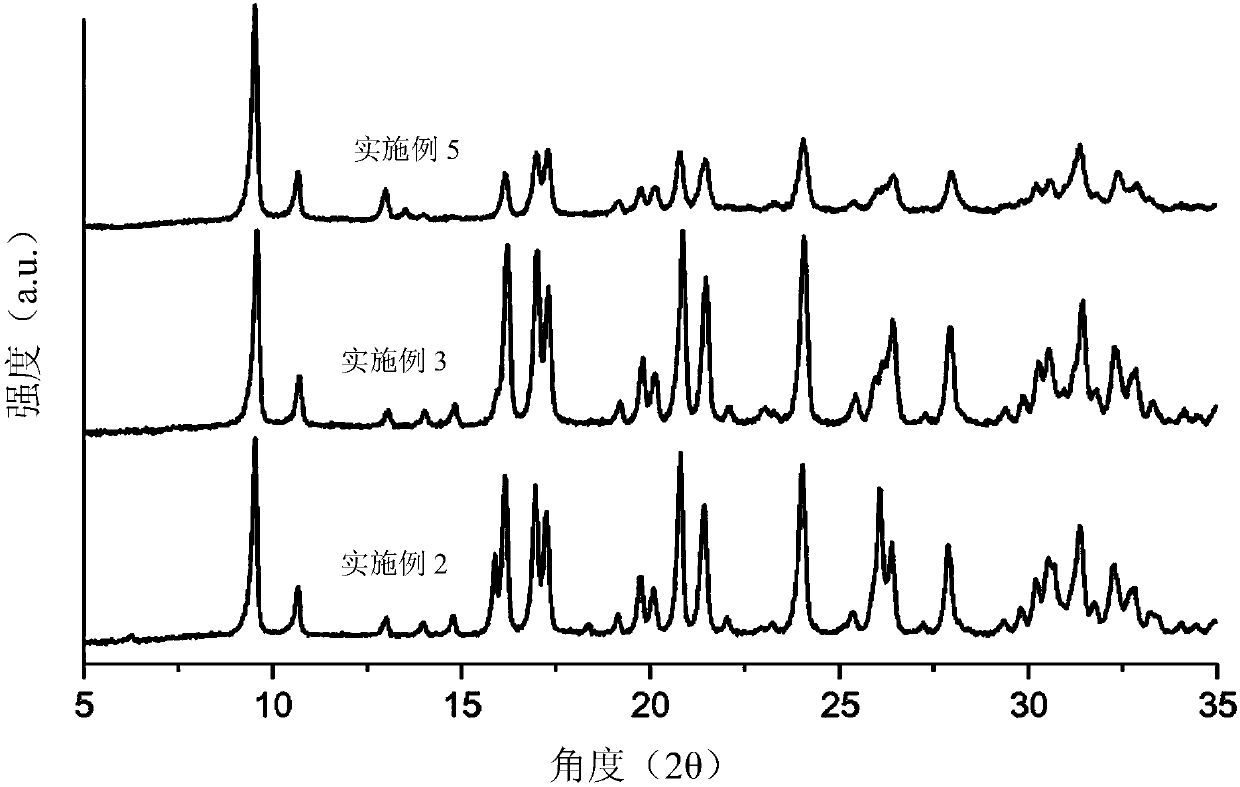

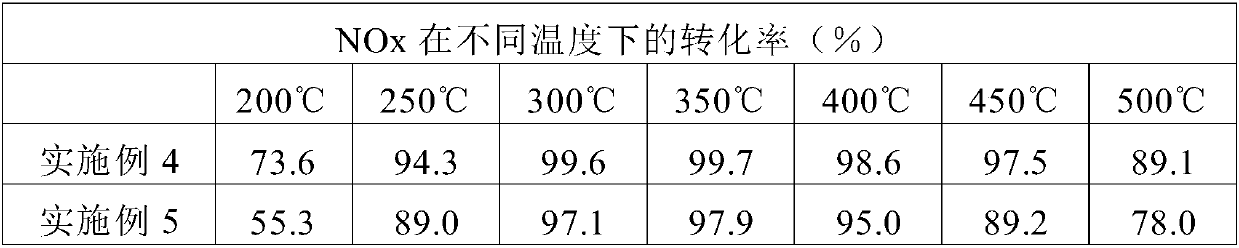

Method for preparing the silicoaluminate form of the aei zeolite structure with high yields, and application in catalysis of method

The invention discloses a method for preparing the silicoaluminate form of the AEI zeolite structure with high yields, and application in catalysis of the method. The present invention relates to a new process for synthesising the silicoaluminate form of the AEI zeolite structure based on the use of another zeolite, zeolite Y, as the only source of silicon and aluminum, in order to obtain high synthesis yields (greater than 80%) in the absence of any other source of silicon, phosphine-derivedcationsand fluoride anions in the synthesis medium. The N, N-dimethyl-3,5-dimethylpiperidinium cation may be used as the OSDA, and the FAU crystal structure is transformed into the AEI crystal structure with high yields. It also discloses the preparation of catalysts based on the silicoaluminateform ofthe AEI crystal structure, wherein Cu atoms have been introduced, and the subsequent application thereof as a catalyst, preferably in the SCR of NOx.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

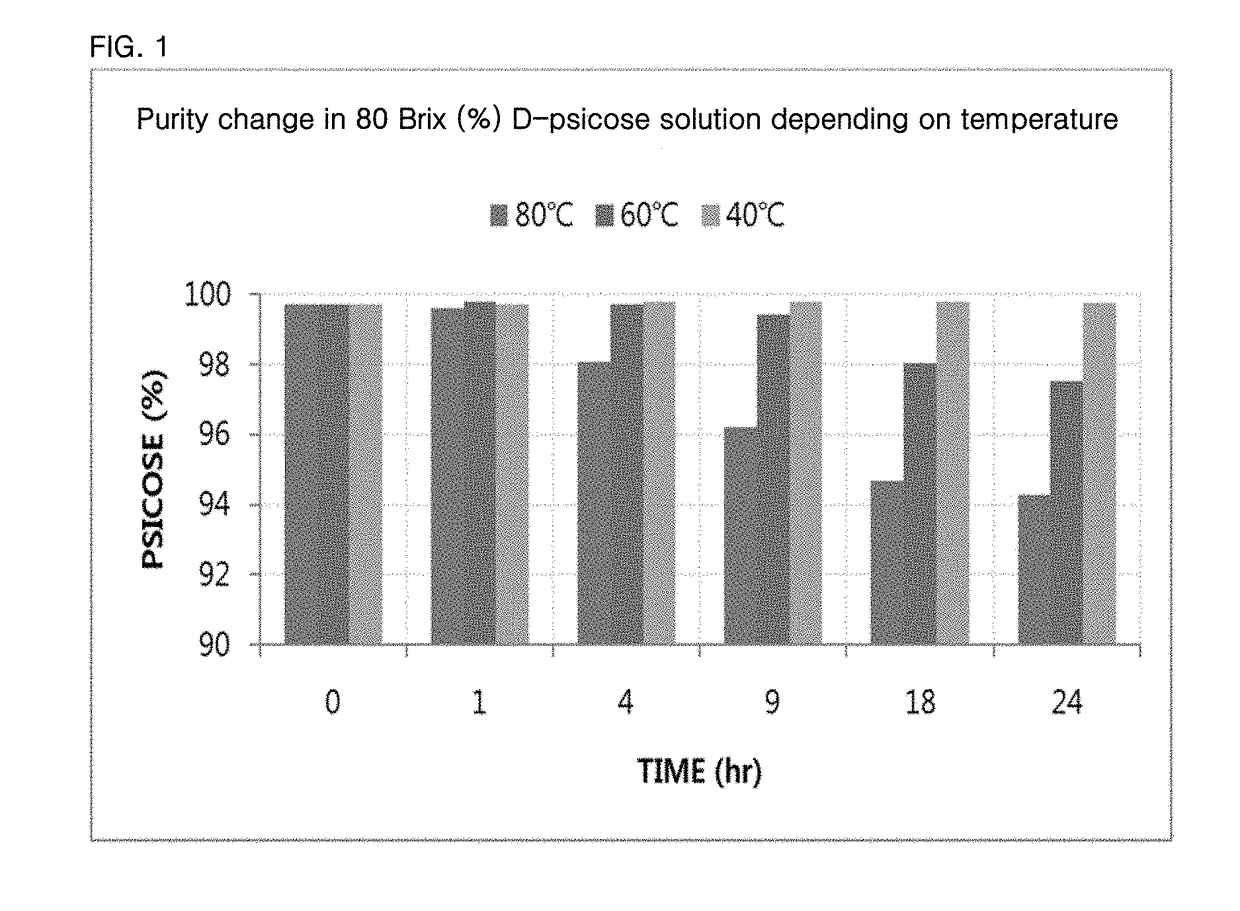

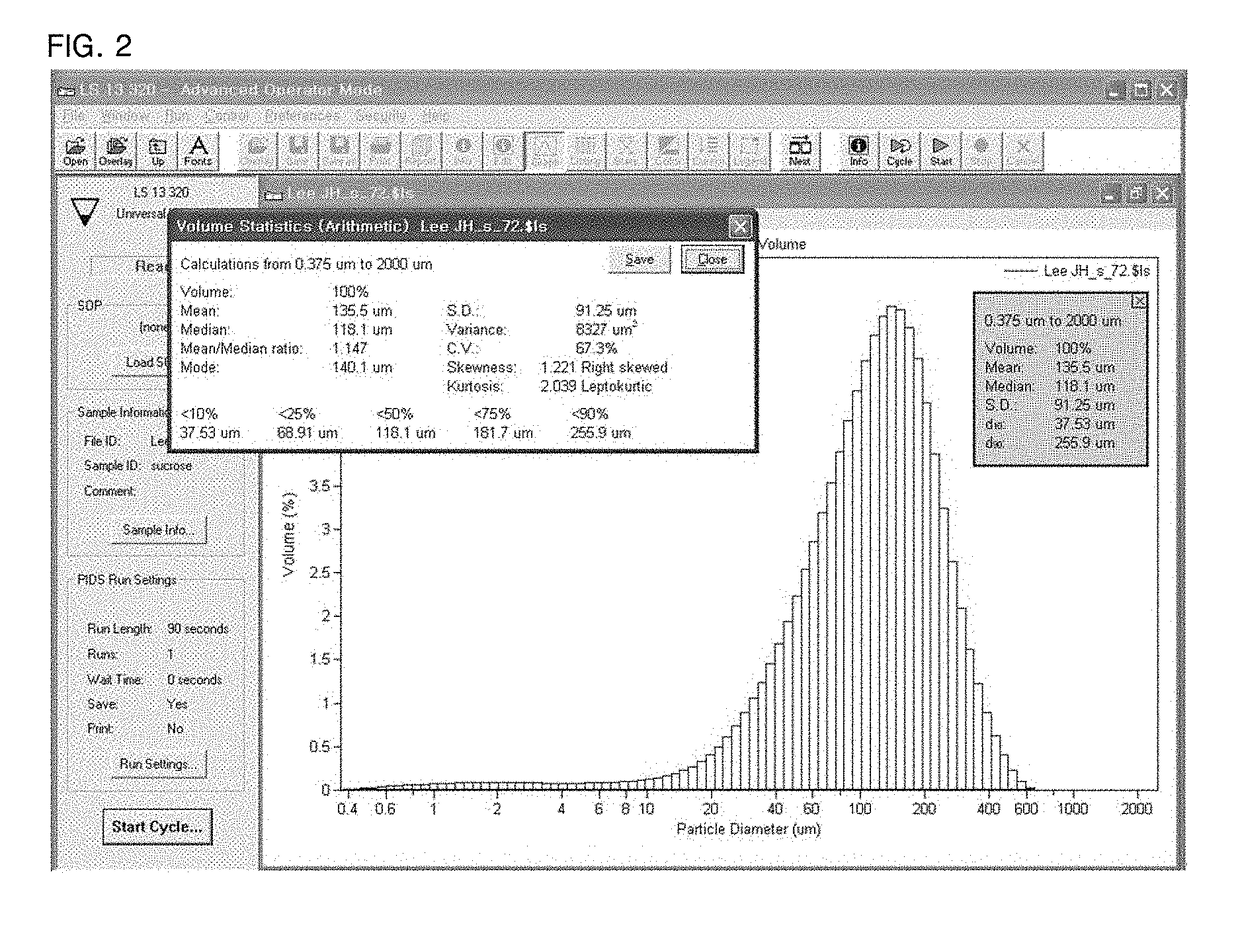

Method for preparing d-psicose crystal

ActiveUS20170313734A1Reduce lossesEasy to separateCation exchanger materialsOrganic anion exchangersOrganic solventPsicose

A method for producing high purity D-psicose crystals having a purity of 98% (w / w) or more and a grain size of MA200 or more. The method includes: removing impurities from a D-psicose solution to obtain a purified D-psicose solution; concentrating the purified D-psicose solution; cooling the concentrated D-psicose solution to 30° C. to 40° C. through a heat exchanger; seed crystallizing the D-psicose solution at 30° C. to 40° C. to obtain a seed crystallized massecuite; and full-scale crystallizing the seed crystallized massecuite. The method can produce pure D-psicose crystals in a suitable form for industrial application through an economical crystallization process from the D-psicose solution without using organic solvents.

Owner:CJ CHEILJEDANG CORP

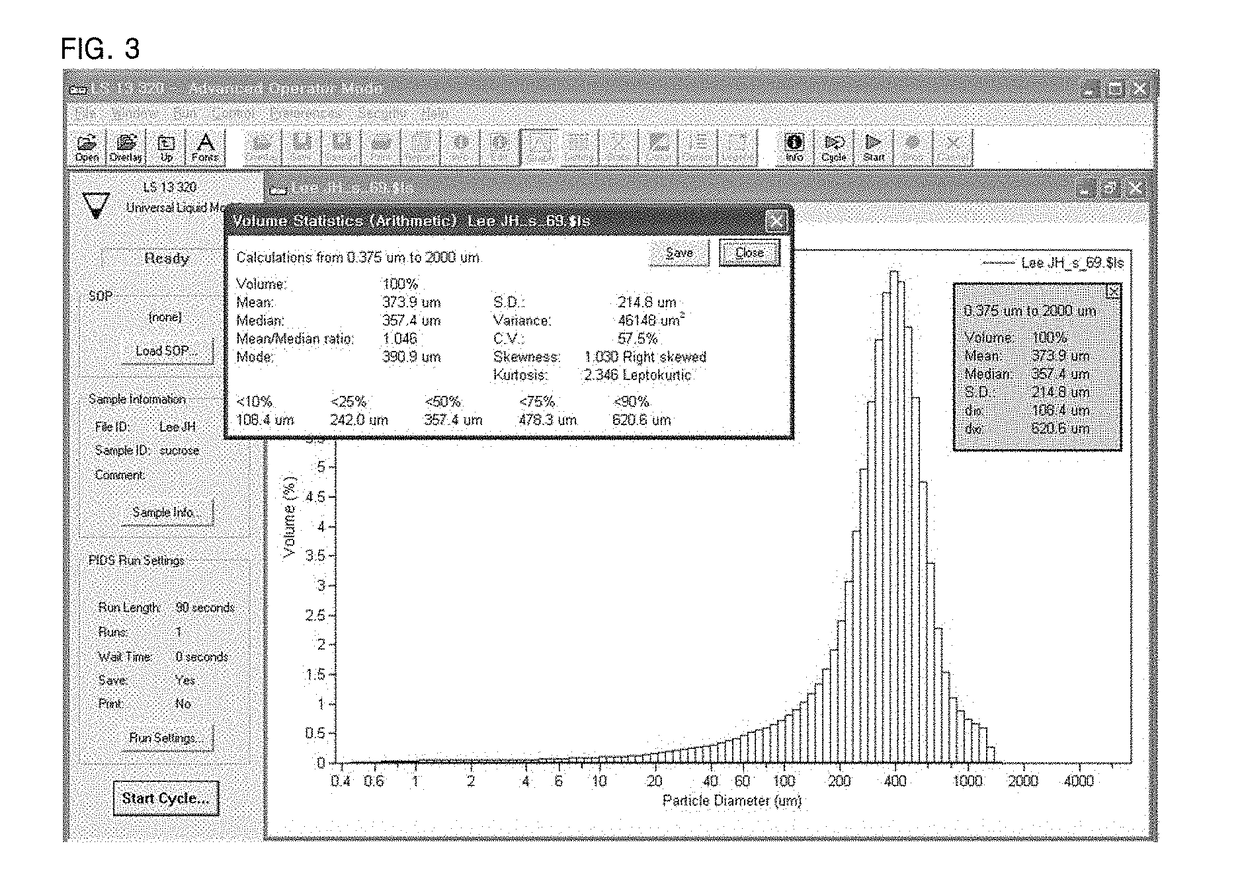

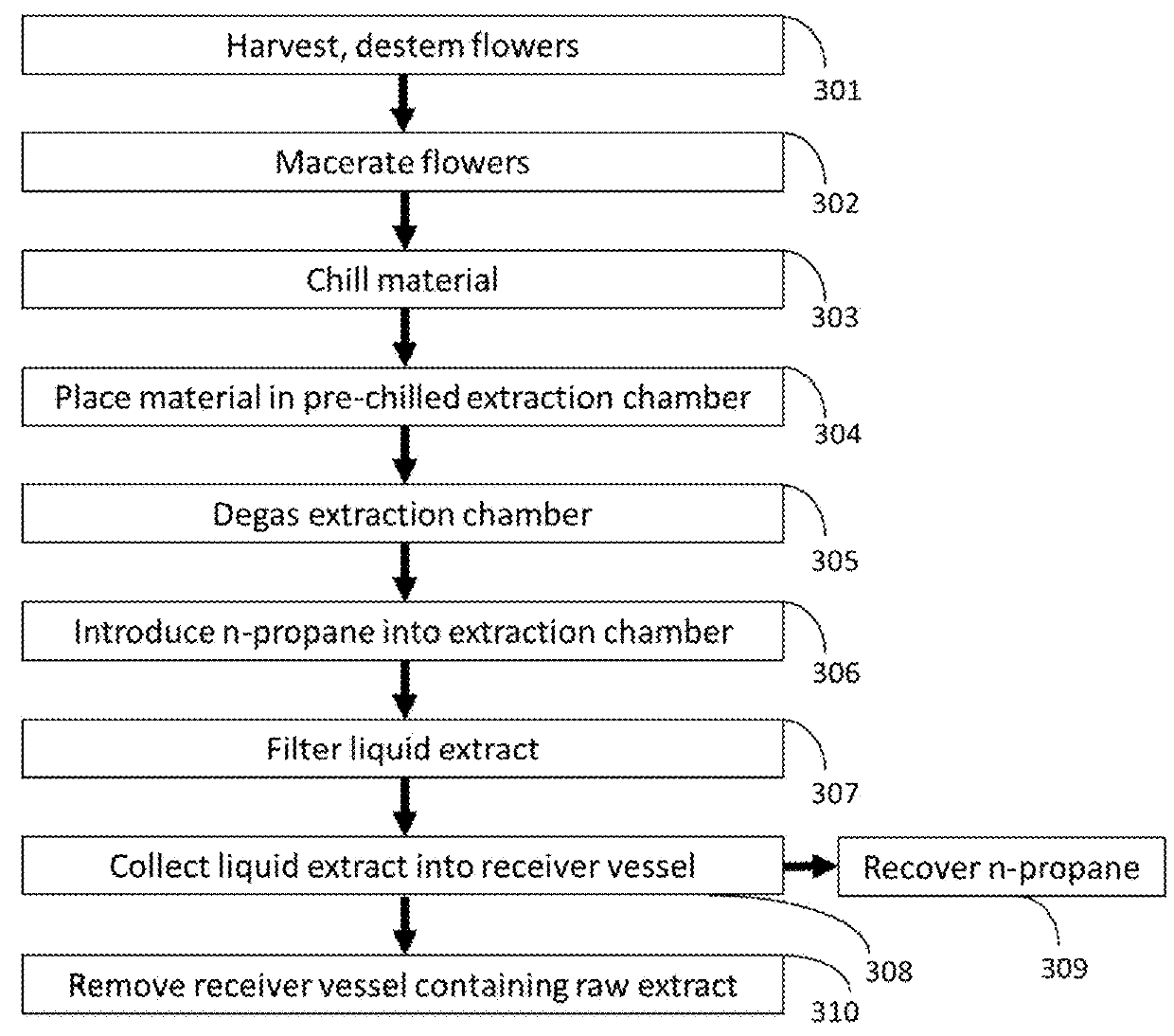

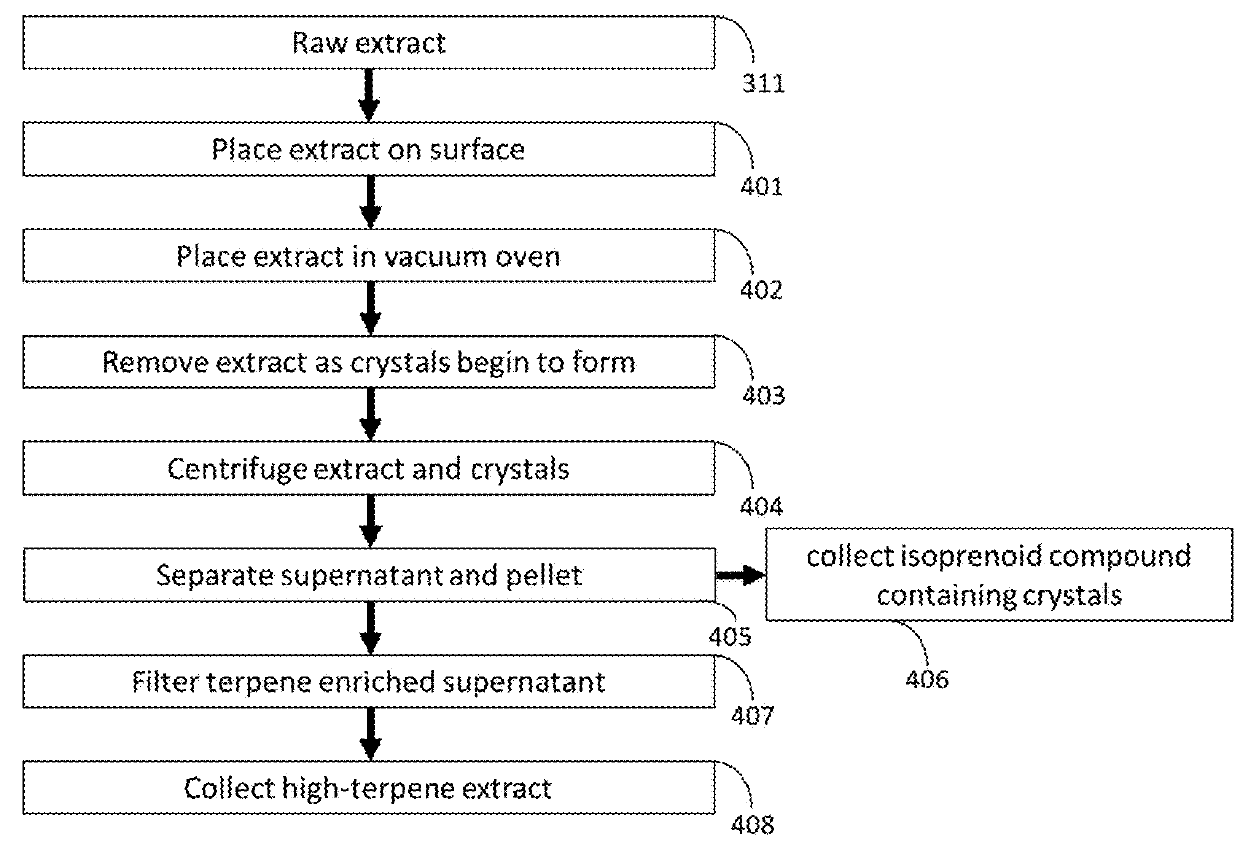

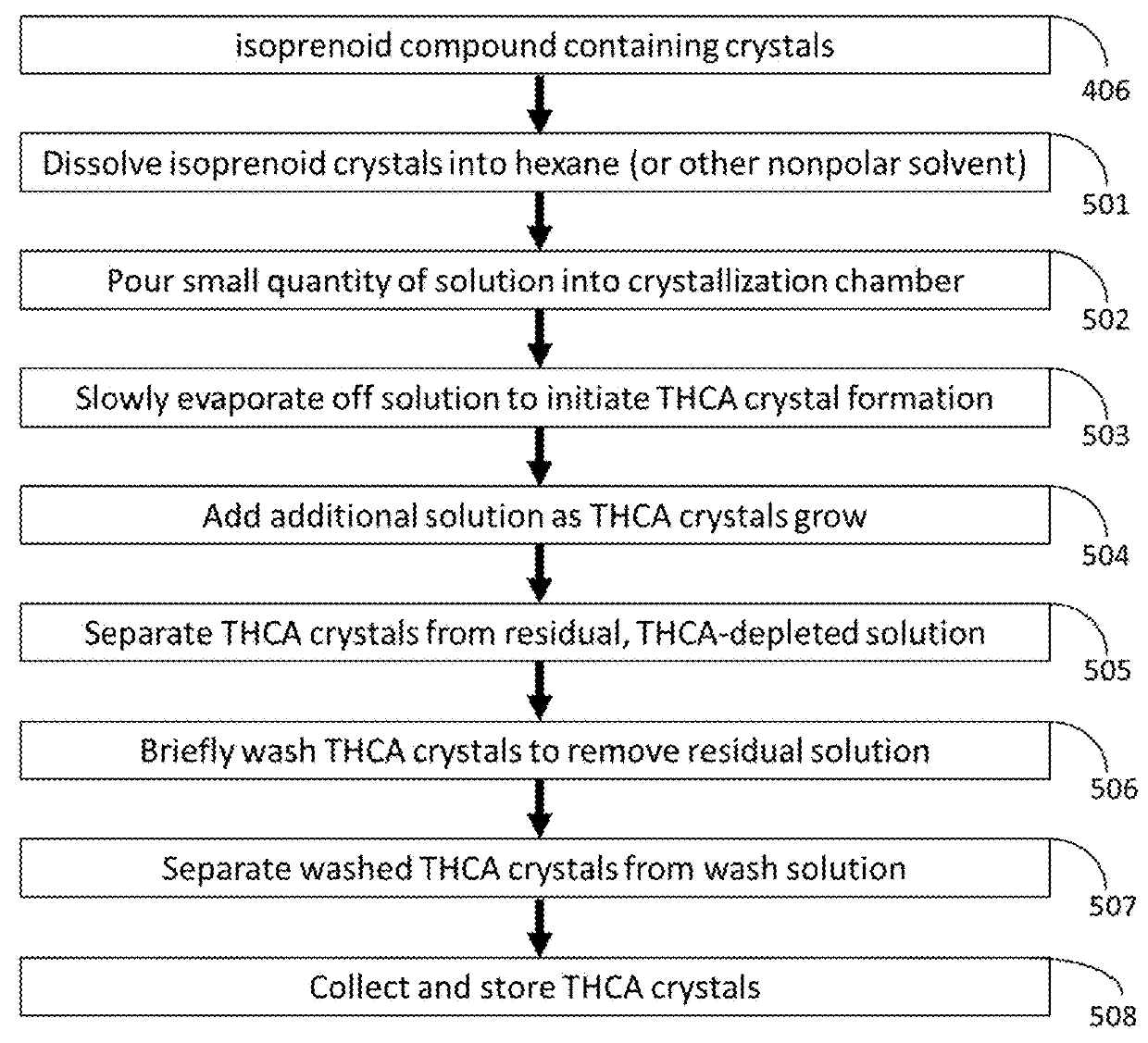

Methods for Purification of Non-Psychoactive Isoprenoid Compounds from Biological Extracts

ActiveUS20180273501A1Improve stabilityPrevent degradationOrganic chemistry methodsCentrifugal force sediment separationCannabisPrenylation

A method for the extraction and isolation of the terpene and isoprenoid compounds from plant material, followed by a centrifugal force induced selective crystallization of isoprenoids resulting in a separation of terpene and isoprenoid fractions. This this method is suitable for the extraction of cannabinoids from Cannabis and the enrichment tetrahydrocannabinolic acid and reduction of tetrahydrocannabinol in an extract. The purity of tetrahydrocannabinolic acid resulting from centrifugal crystallization is such that dissolution and selective recrystallization of tetrahydrocannabinolic acid is possible resulting in >99.9% pure tetrahydrocannabinolic acid, w / w.

Owner:CONCENTRATED CONSULTING GRP LLC

Method for the production of enriched isopulegol

ActiveUS7868211B2Oxygen-containing compound preparationOrganic compound preparationMentholPolymer science

The present invention relates to a process for preparing enriched isopulegol by crystallization from a melt comprising isopulegol. The invention relates specifically to a process for preparing enantiomerically enriched n-isopulegol proceeding from optically active isopulegol having a relatively low enantiomeric excess by crystallization from the melt. The invention further relates to a process for preparing menthol proceeding from enantiomerically and / or diastereomerically enriched n-isopulegol prepared by crystallization from the melt.

Owner:BASF AG

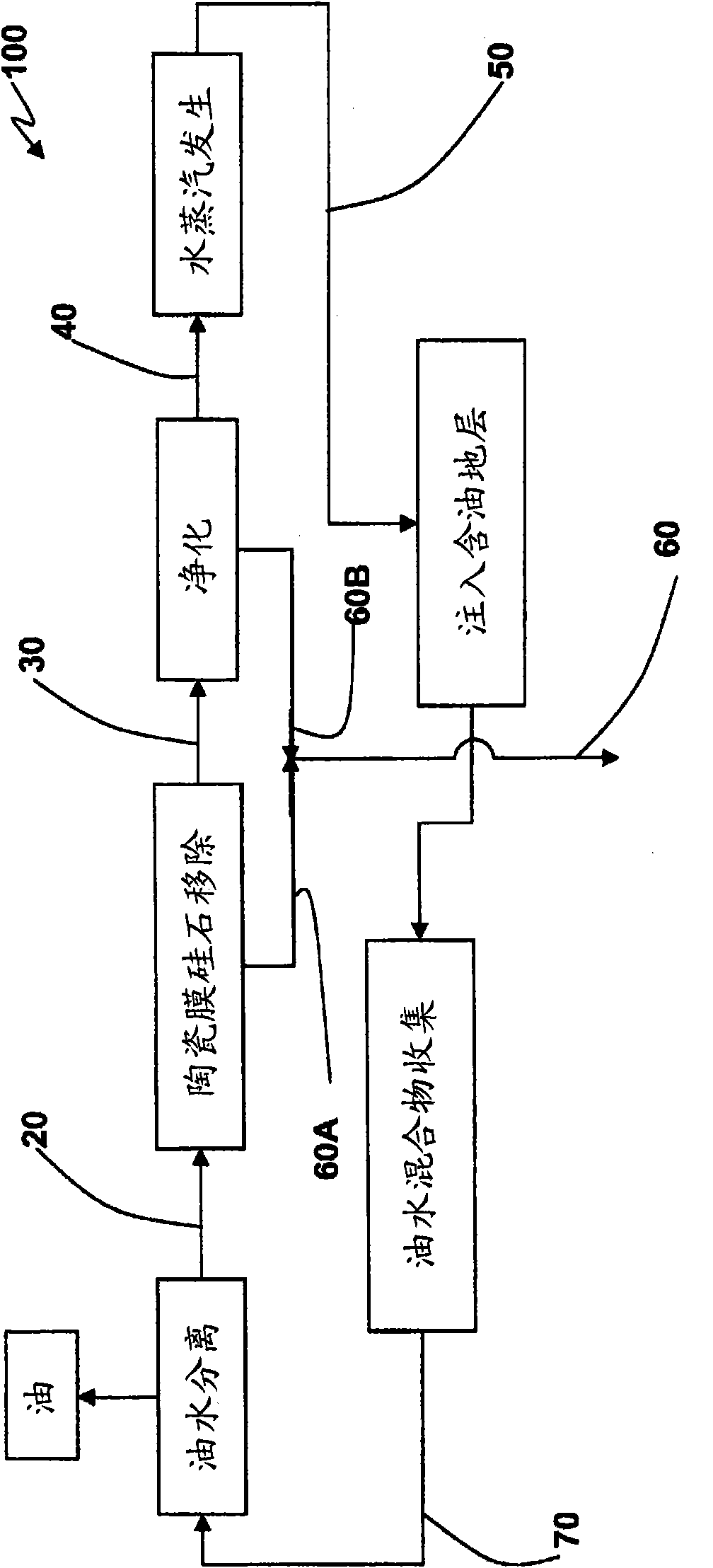

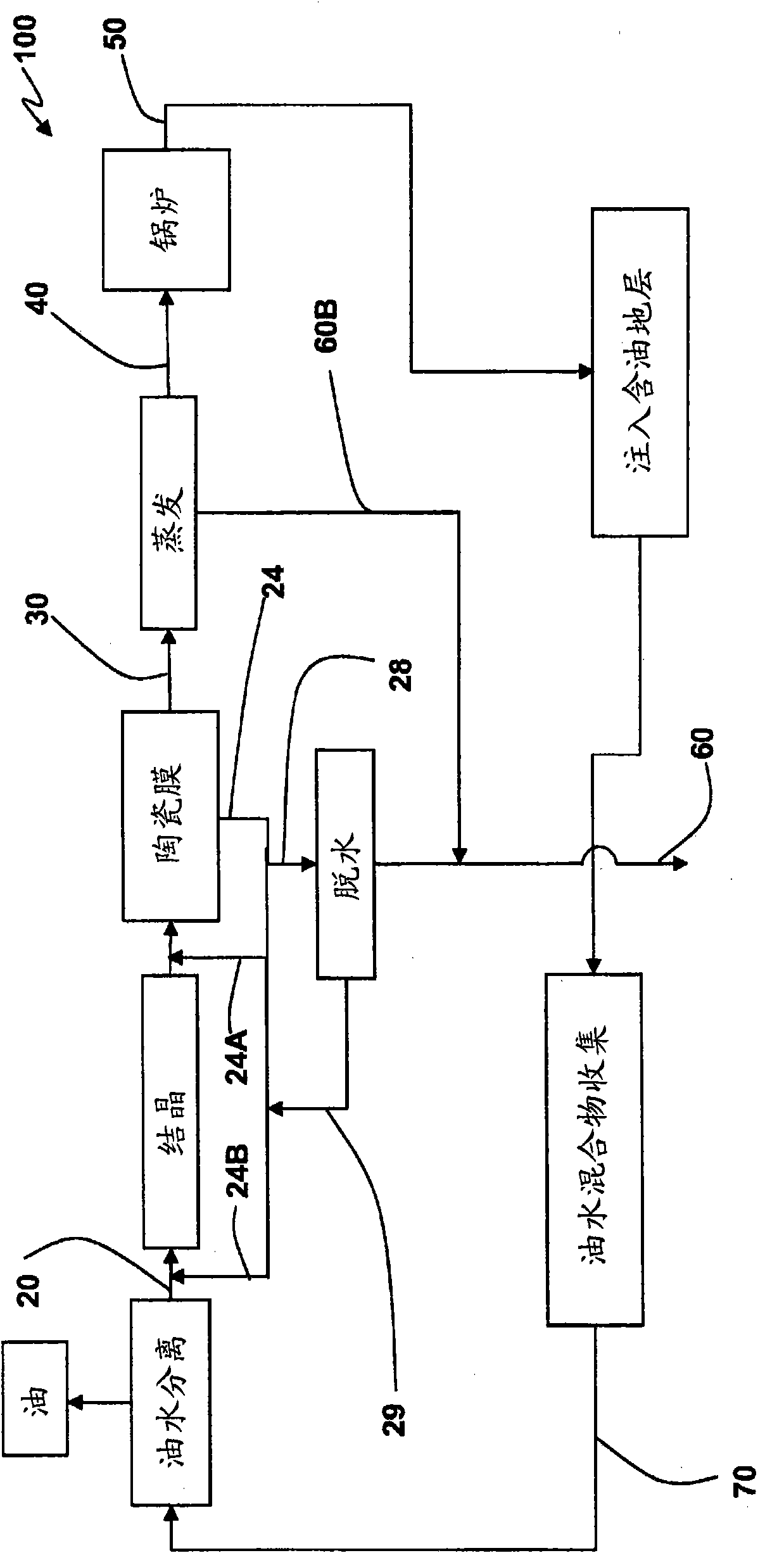

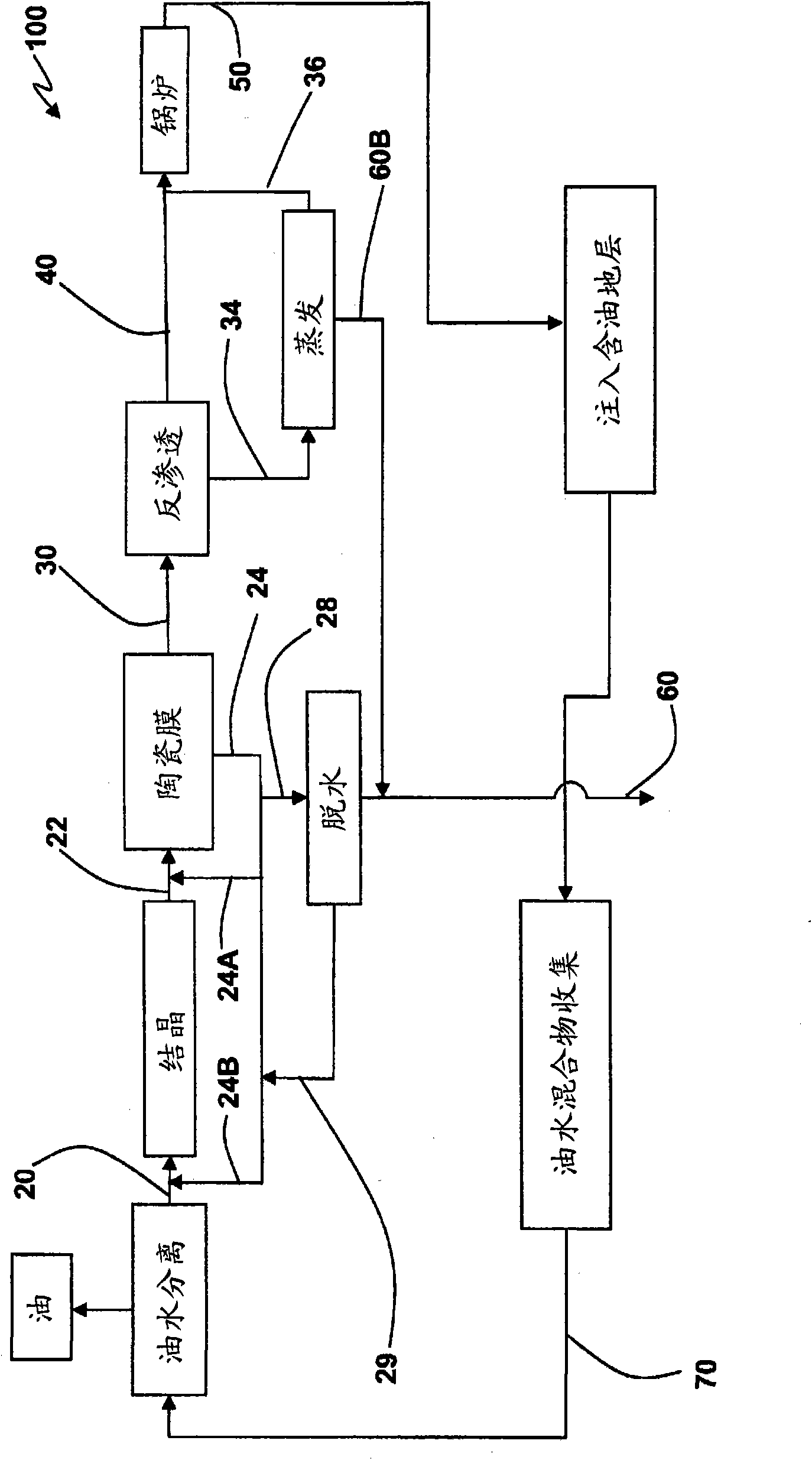

Process for recovering heavy oil utilizing one or more membranes

An oil recovery process utilizes one or more membranes to remove silica and / or oil from produced water. In one method, the process includes separating oil from produced water and precipitating silica. The produced water having the precipitated silica is directed to a membrane, such as a ceramic membrane, which removes the precipitated silica from the produced water. In some cases, residual oil ispresent and is also removed by the membrane.

Owner:VEOLIA WATER SOLUTIONS & TECH NORTH AMERICA

Method For Producing Calcium Fluoride, Reusing Method And Recycling Method Thereof

InactiveUS20090180947A1Large particle sizeHigh purityMagnesium fluoridesWater treatment parameter controlRecovery methodSolubility

To recycle fluoride by recovering calcium fluoride having a particle size and purity suitable for production of hydrogen fluoride, from a fluoride-containing effluent or a hydrofluoric acid-containing effluent. This method comprises reacting the fluoride-containing effluent or the hydrofluoric acid-containing effluent with an aqueous calcium chloride solution, under an acidic condition with hydrochloric acid where calcium fluoride has a comparatively high solubility. Calcium fluoride having a high purity and a large particle size can be deposited. The hydrochloric acid residues from the reaction or formed through the reaction is reacted with an inexpensive calcium compound such as calcium hydroxide, calcium oxide and calcium carbonate to produce an aqueous calcium chloride solution, and the aqueous calcium chloride solution is reused for the treatment of the hydrofluoric acid-containing effluent. The calcium fluoride obtained can be used as a raw material as it is for producing hydrogen fluoride, and the surplus aqueous calcium chloride solution can be supplied for other industrial uses.

Owner:MORITA CHEMICAL IND CO LTD

Removing solids in monoethylene glycol reclamation

The seeding of calcium carbonate into a calcium chloride-contaminated monoethylene glycol (MEG) stream accelerates the growth of calcium carbonate particles to a size that enhances their removal from the stream by filtration. A seeding vessel allows the calcium carbonate particles a time period to grow. Sodium carbonate may be added to the contaminated stream to facilitate calcium carbonate particle growth. A recycle seeding conduit may recycle seeds from a filtration unit to the seeding vessel. A base such as sodium hydroxide may be added to accelerate the precipitation process.

Owner:CAMERSON INT CORP

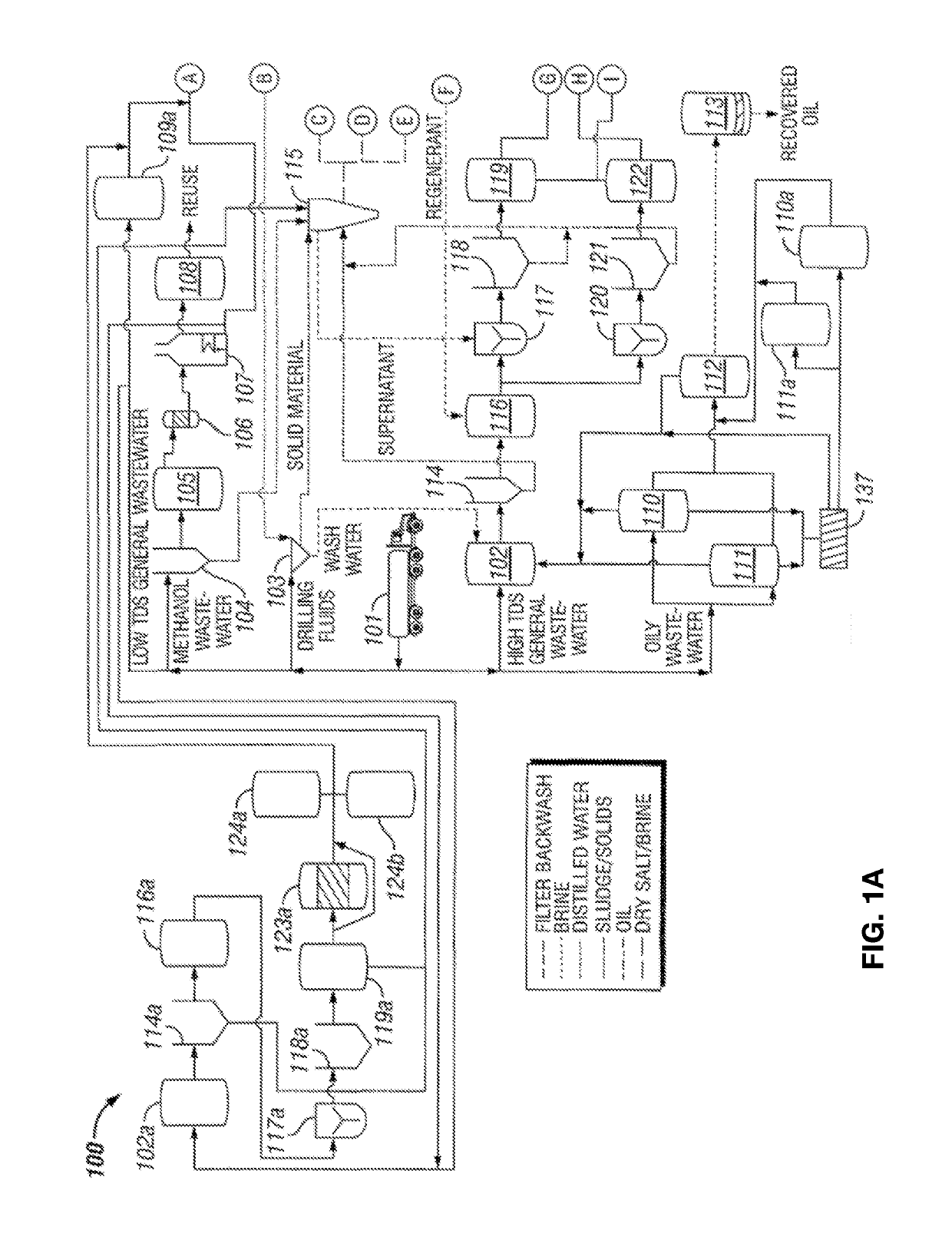

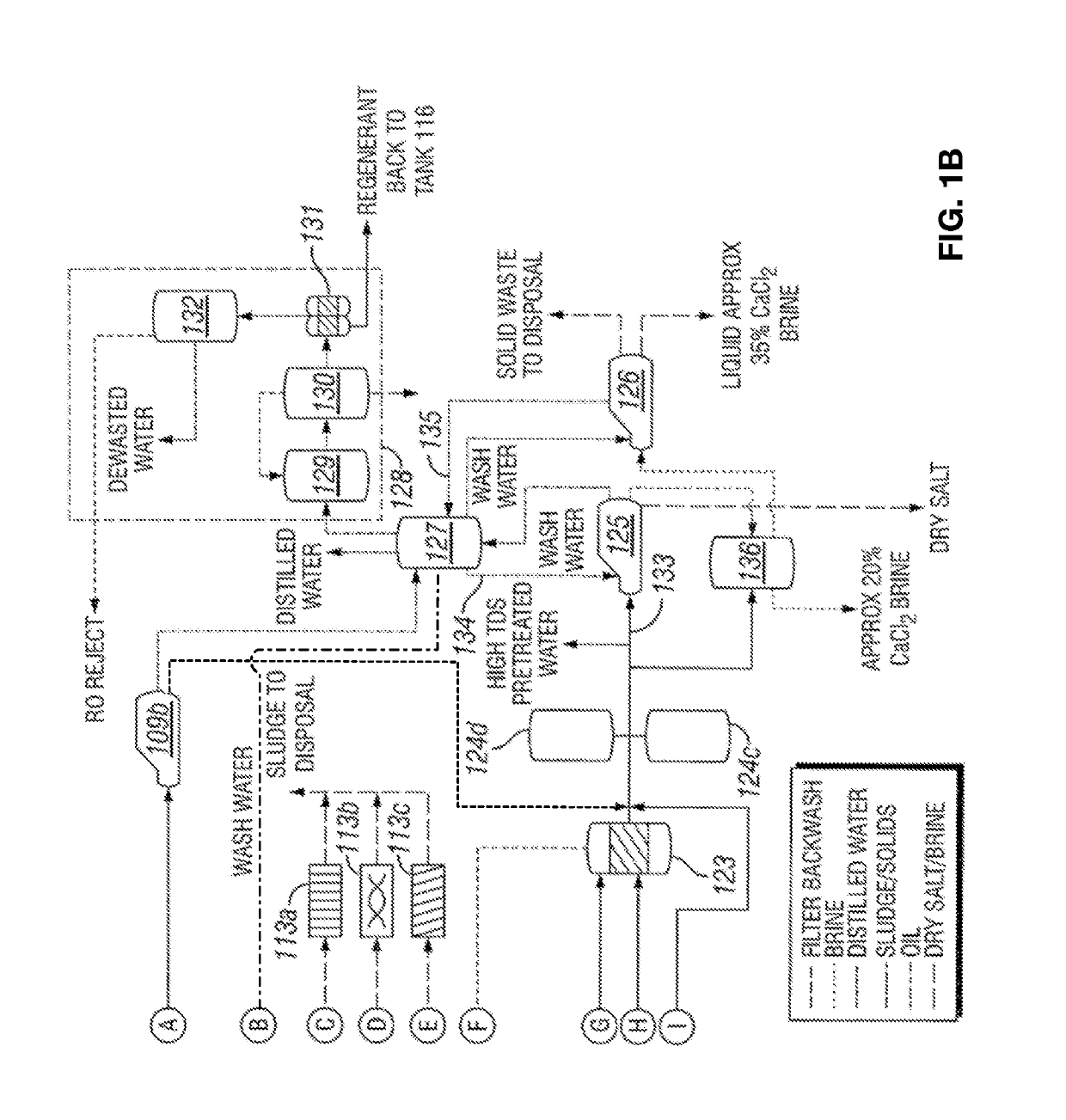

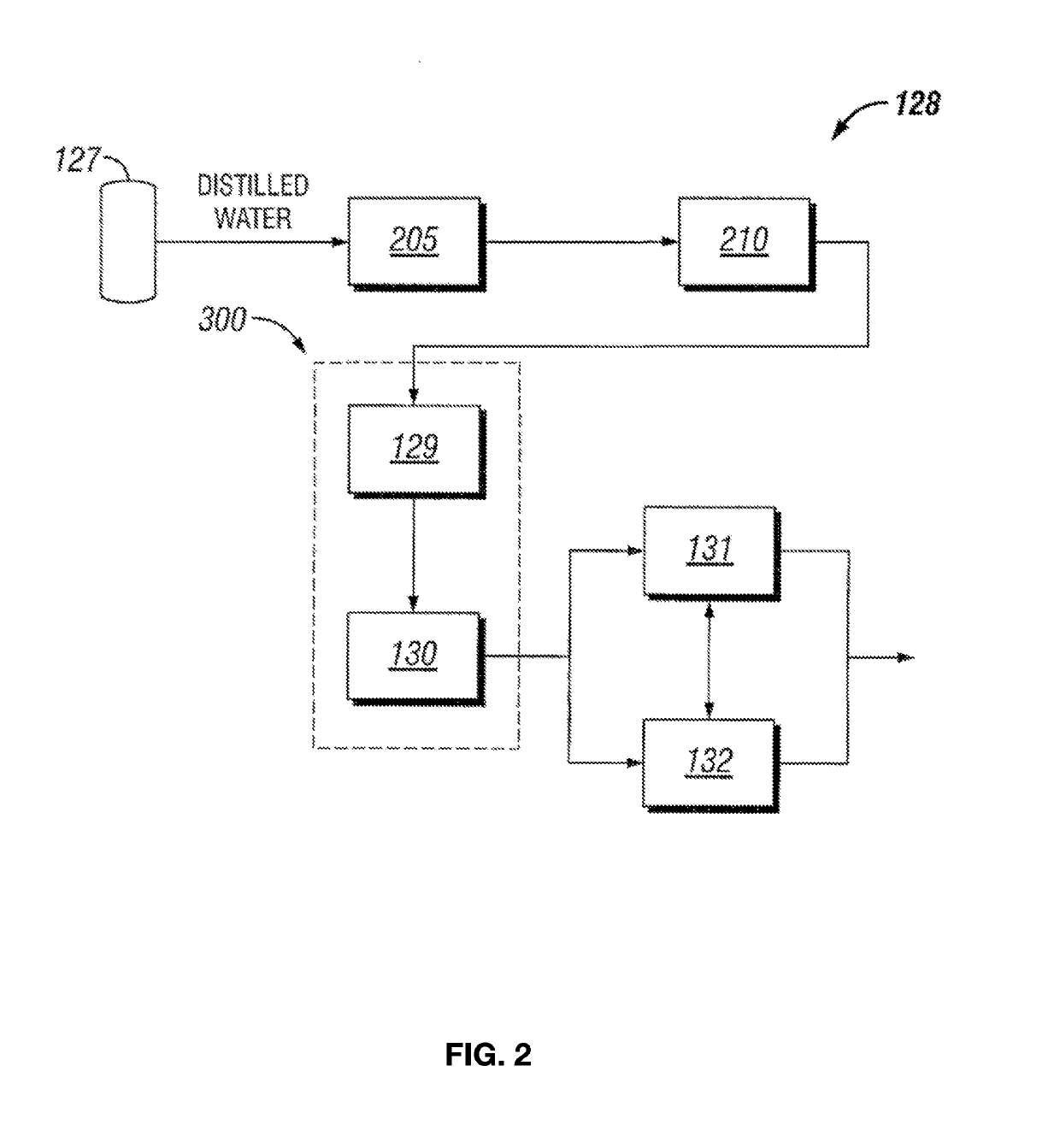

Method and System for Treating Wastewater

ActiveUS20190119130A1Increase concentrationReduce concentrationWaste water treatment from quariesWater contaminantsWastewaterDistilled water

Methods and systems for treating brine to produce distilled water and dried NaCl are disclosed. The brine enters a crystallization plant and is heated. Once heated, the brine is circulated to an evaporator. The evaporator increases the concentration of NaCl in the brine to a point about the super saturation level. Once above the super saturation level, NaCl crystals are formed. The larger crystals are circulated to a centrifuge for drying and the smaller crystals are recirculated through the evaporator for continued growth. The NaCl crystals are dried in the centrifuge.

Owner:EUREKA RESOURCES

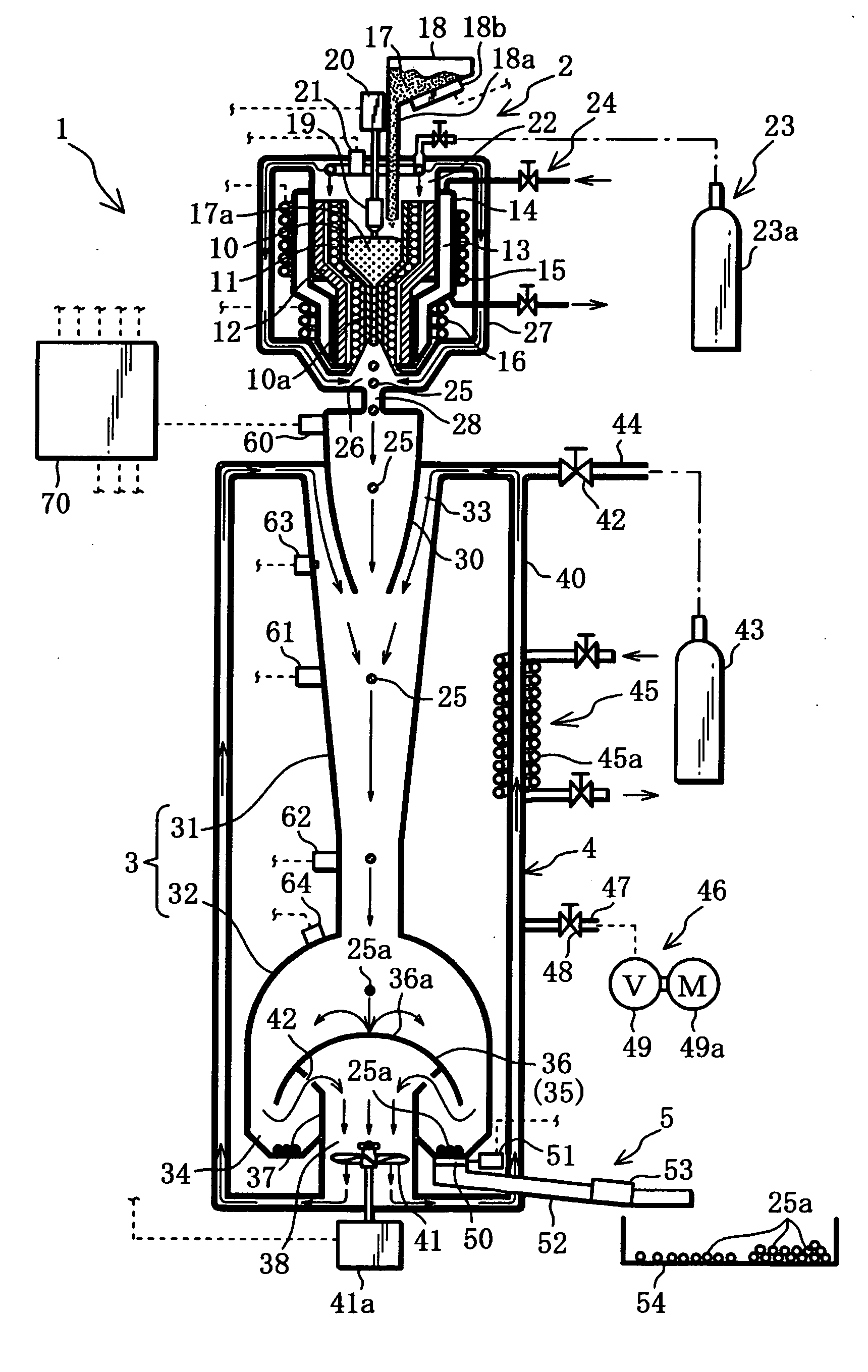

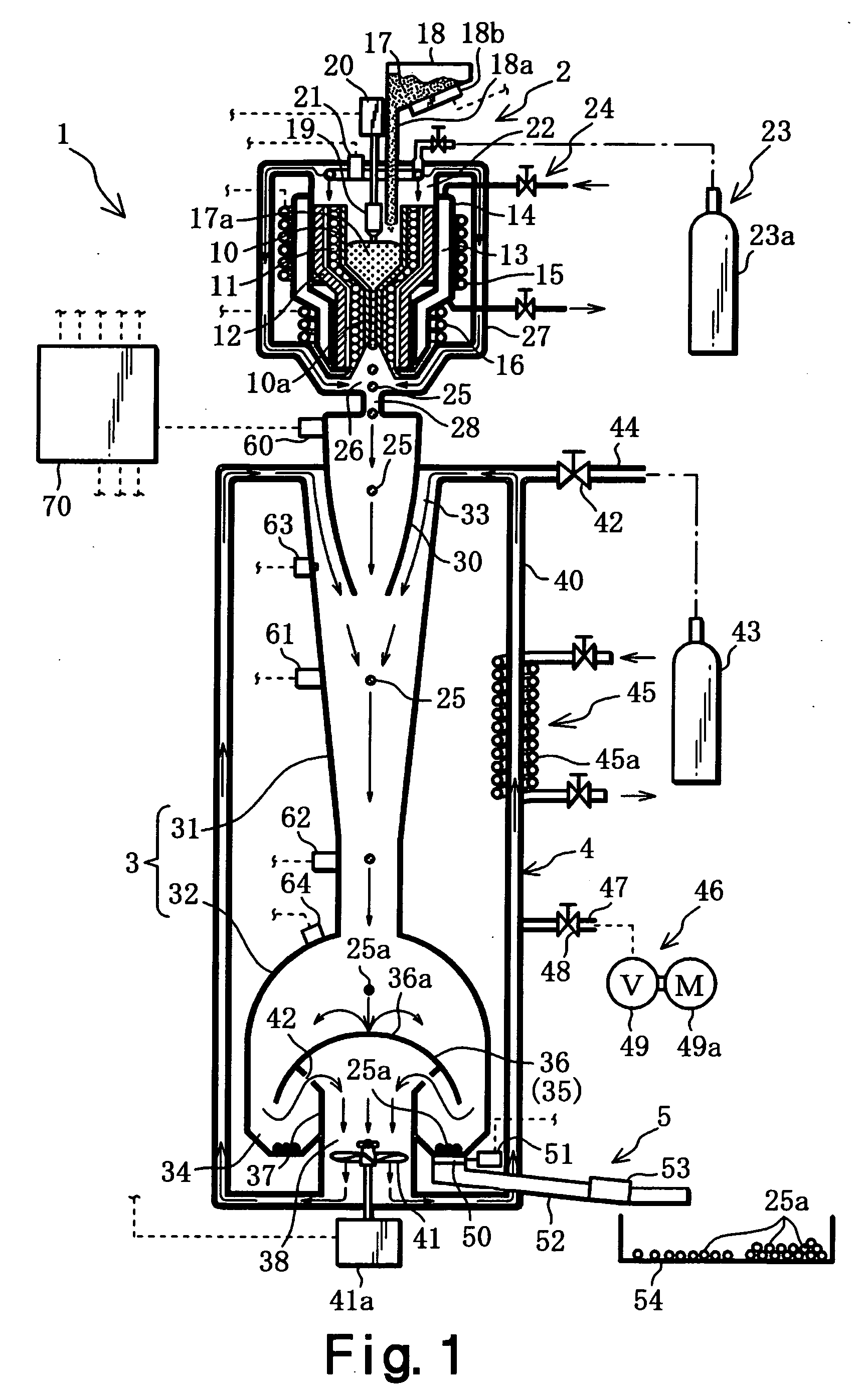

Drop tube type granular crystal producing device

InactiveUS20060070652A1Reduce drop heightEffectively cool the meltAfter-treatment apparatusPolycrystalline material growthParticulatesFree falling

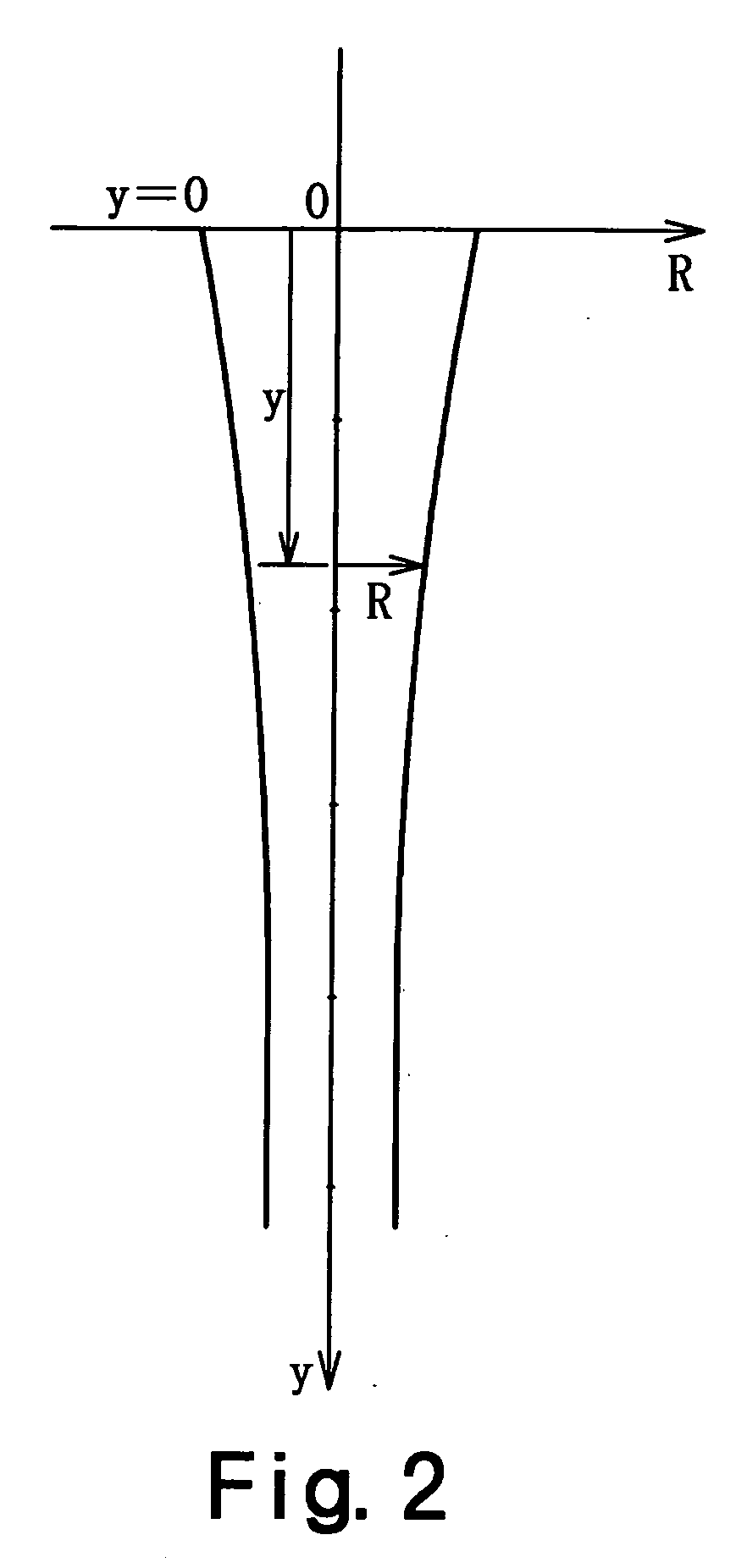

A drop tube type particulate crystalline body producing device is a device for creating a substantially spherical crystalline body by solidifying a particulate melt of an inorganic material while allowing it to free-fall inside a drop tube. This device 1 has a melt formation device 2, drop tube 3, gas flow formation means for forming inside the drop tube 3 a gas flow of cooling gas, and recovery mechanism 5 for recovering a crystalline body 25a from the lower end of the drop tube 3. The drop tube 3 comprises an introducing tube 30, cooling tube 31, and solidification tube 32, where the cooling tube 31 is configured such that the cross sectional area thereof becomes smaller toward the bottom such that the cooling gas flow speed becomes substantially equal to the free fall speed of the particulate melt, and the solidification tube 32 is connected to the lower end of the cooling tube 31 and has a cross sectional area enlarged discontinuously from the lower end of the cooling tube 31. In a proximity of the upper end of the solidification tube 32, the flow speed of the cooling gas is rapidly reduced and the gas pressure increases, whereby a crystal nucleus is generated in the melt in a supercooled state, and the melt is crystallized at once.

Owner:SPHELAR POWER

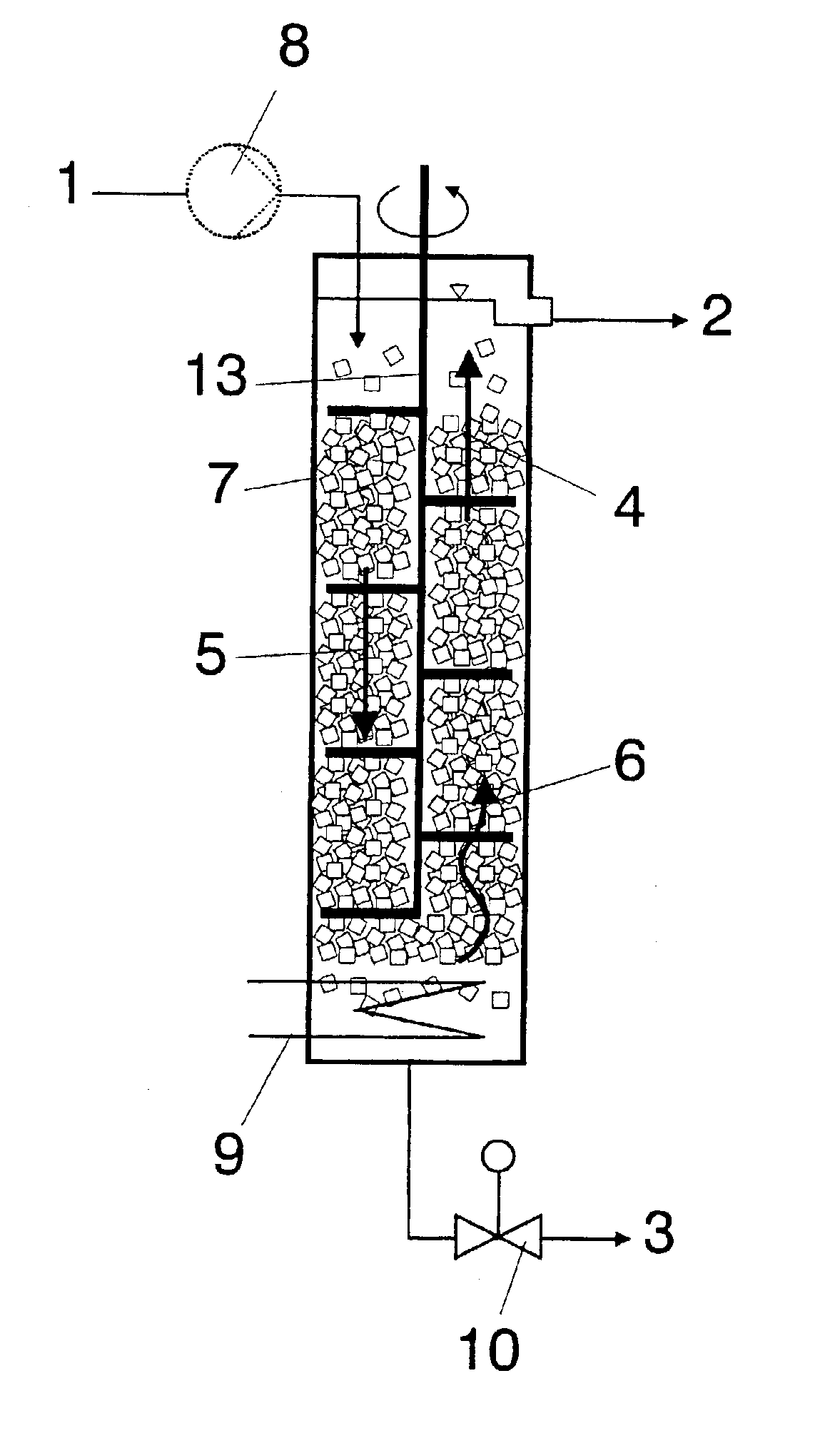

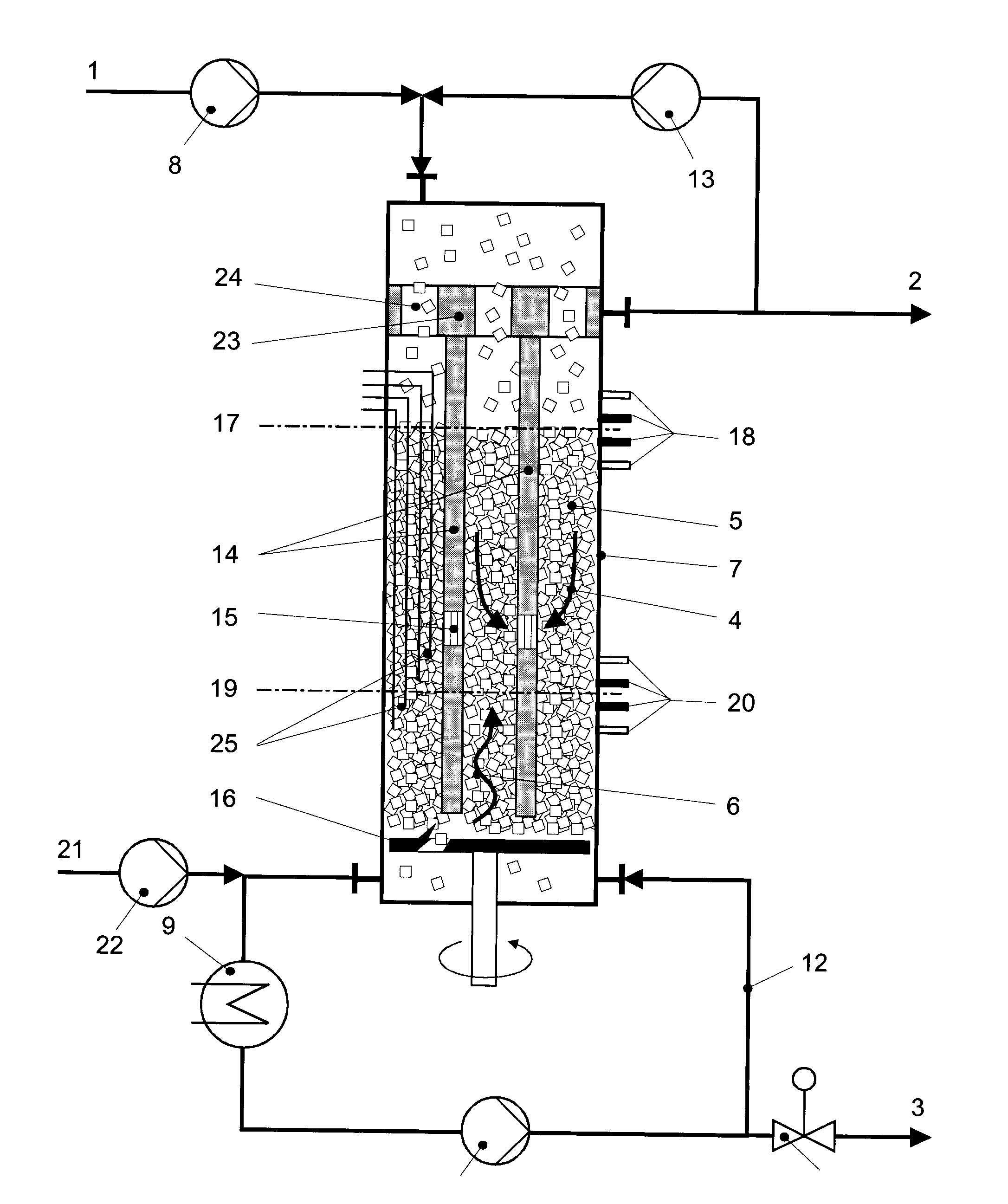

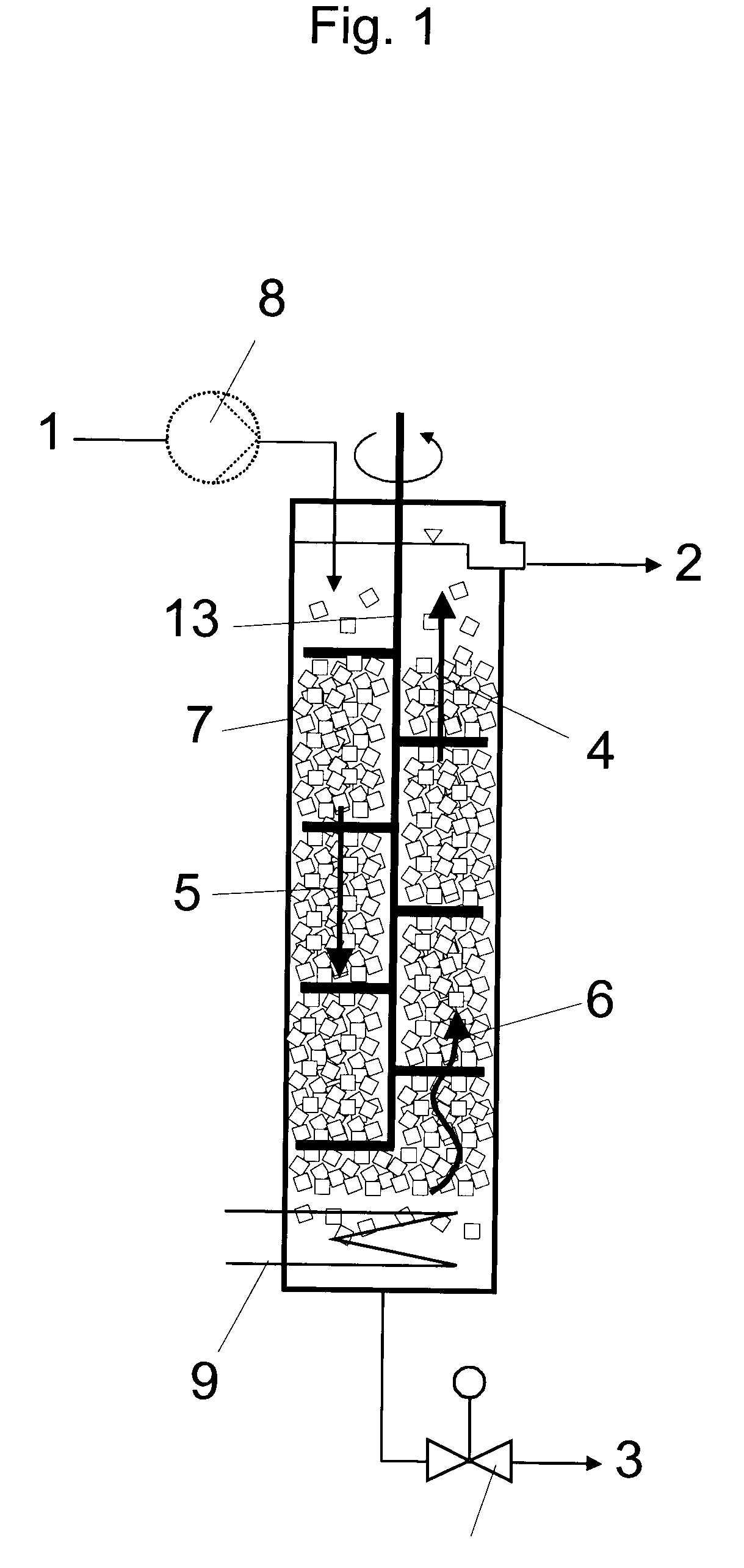

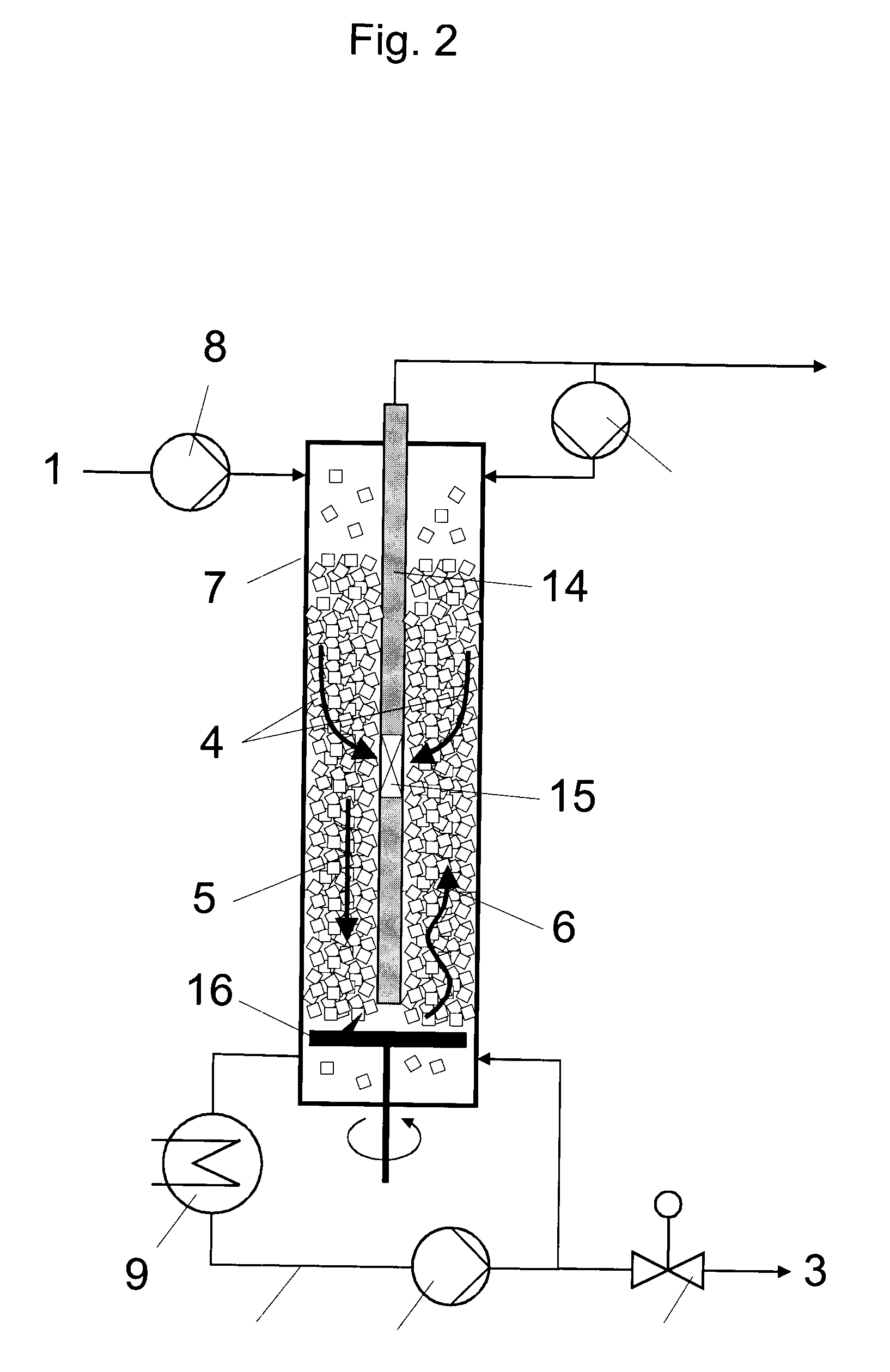

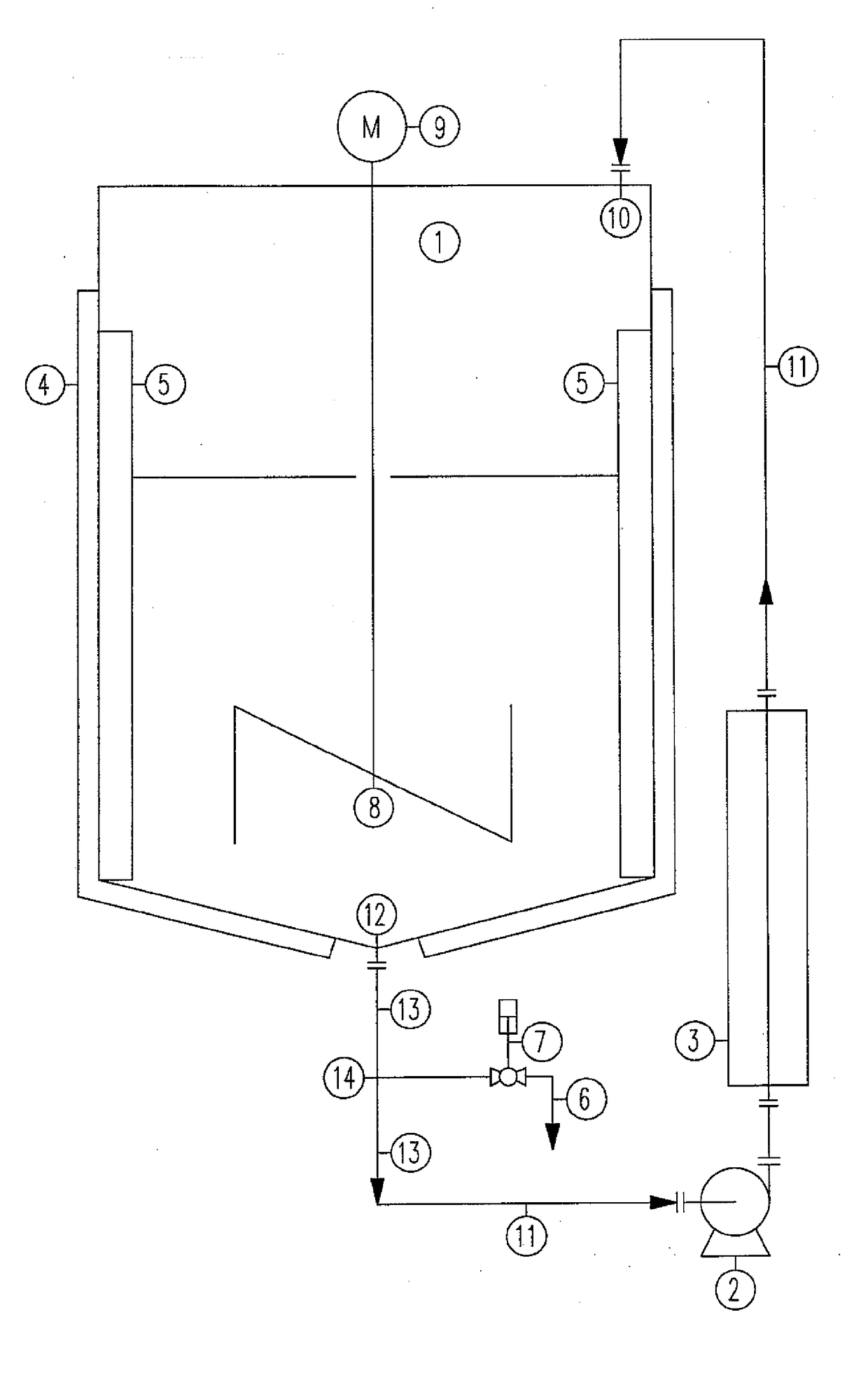

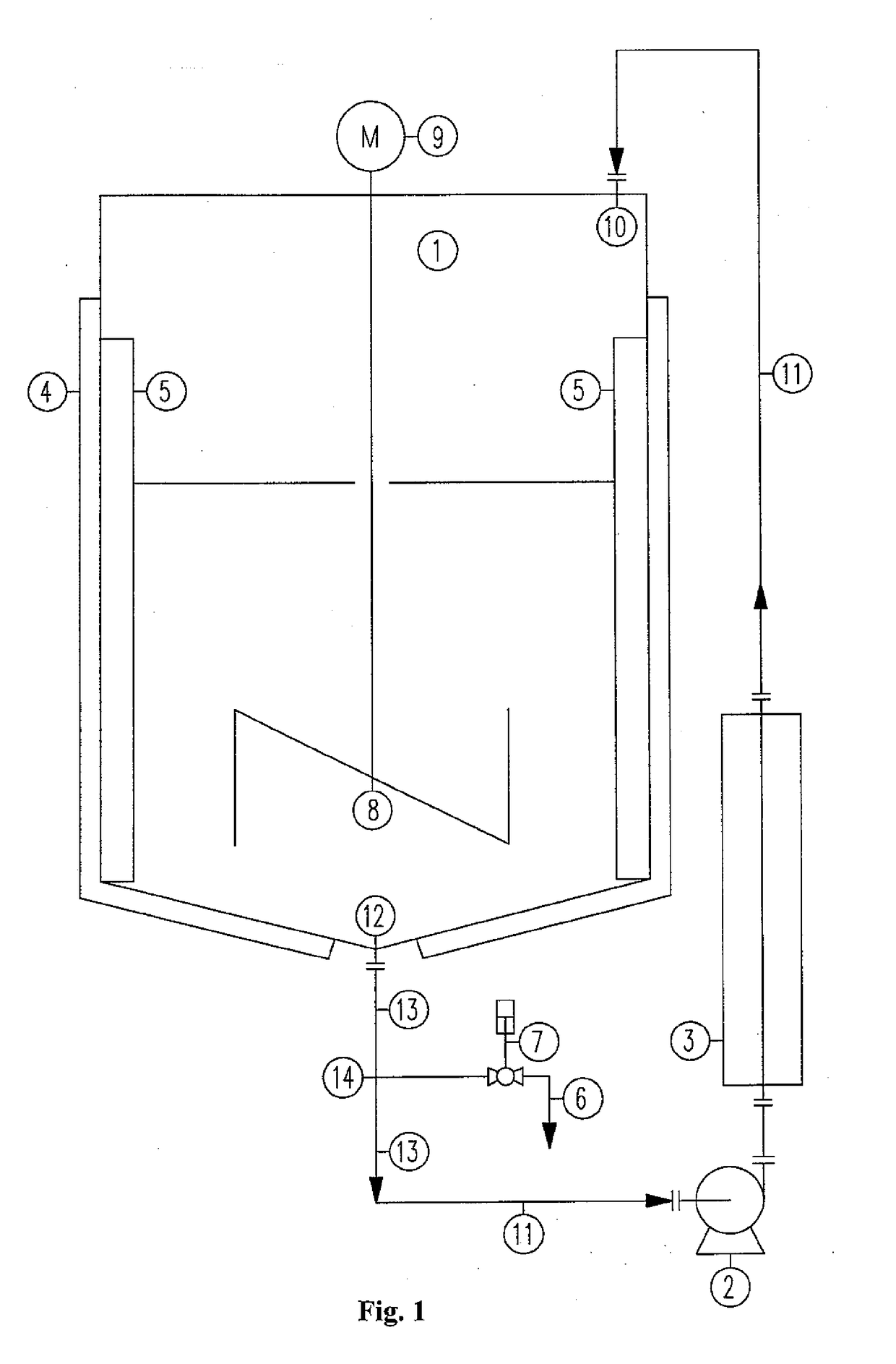

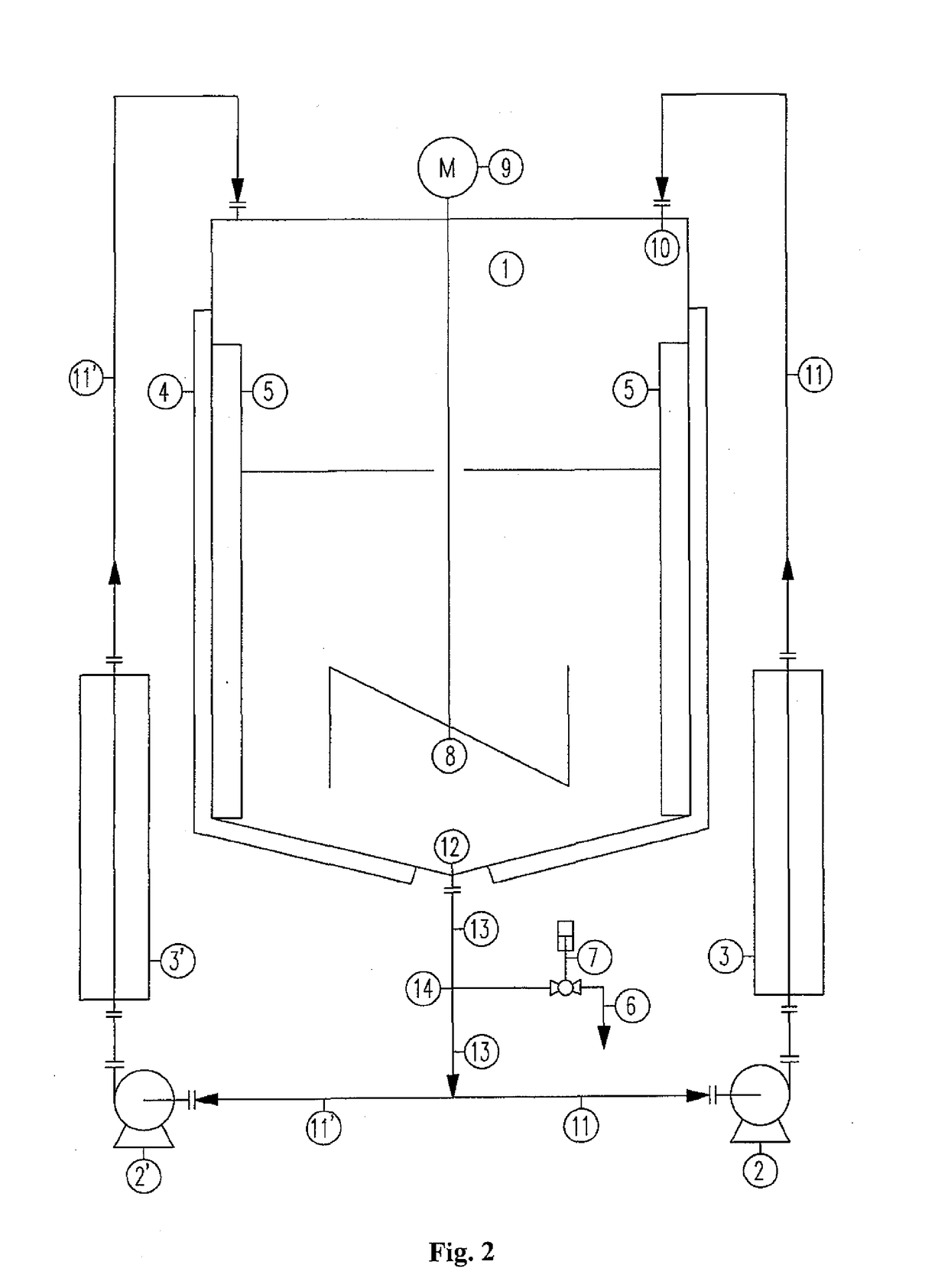

Discontinuous crystallization unit for the production of ball-shaped crystals

InactiveUS20170128854A1Easy to controlPolycrystalline material growthFrom normal temperature solutionsCooling curveCirculator pump

Owner:ERUCA TECH SRO

Popular searches

Heat exchange cooling cystallization Fractional crystallization Carboxylic compound separation/purification Crystallization plant arrangements Treatment involving filtration Solid sorbent liquid separation Water/sewage treatment by neutralisation Differential sedimentation Water/sewage treatment by ion-exchange Nature of treatment water

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com