Patents

Literature

127results about "Fractional crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brine purification

InactiveUS20100219372A1Increase contentLower levelTreatment using aerobic processesIsotope separationSaline waterCarbon adsorption

Process and apparatus for reducing organic content of brine comprising subjecting a brine solution to at least two purification treatments selected from electrochemical treatment, chlorinolysis, or other chemical oxidation treatment, carbon adsorption, extraction, biological treatment and chrystallizing treatment; wherein the organic content of purified brine is sufficiently low to enable sense of the purified brine in an industrial process.

Owner:DOW GLOBAL TECH LLC

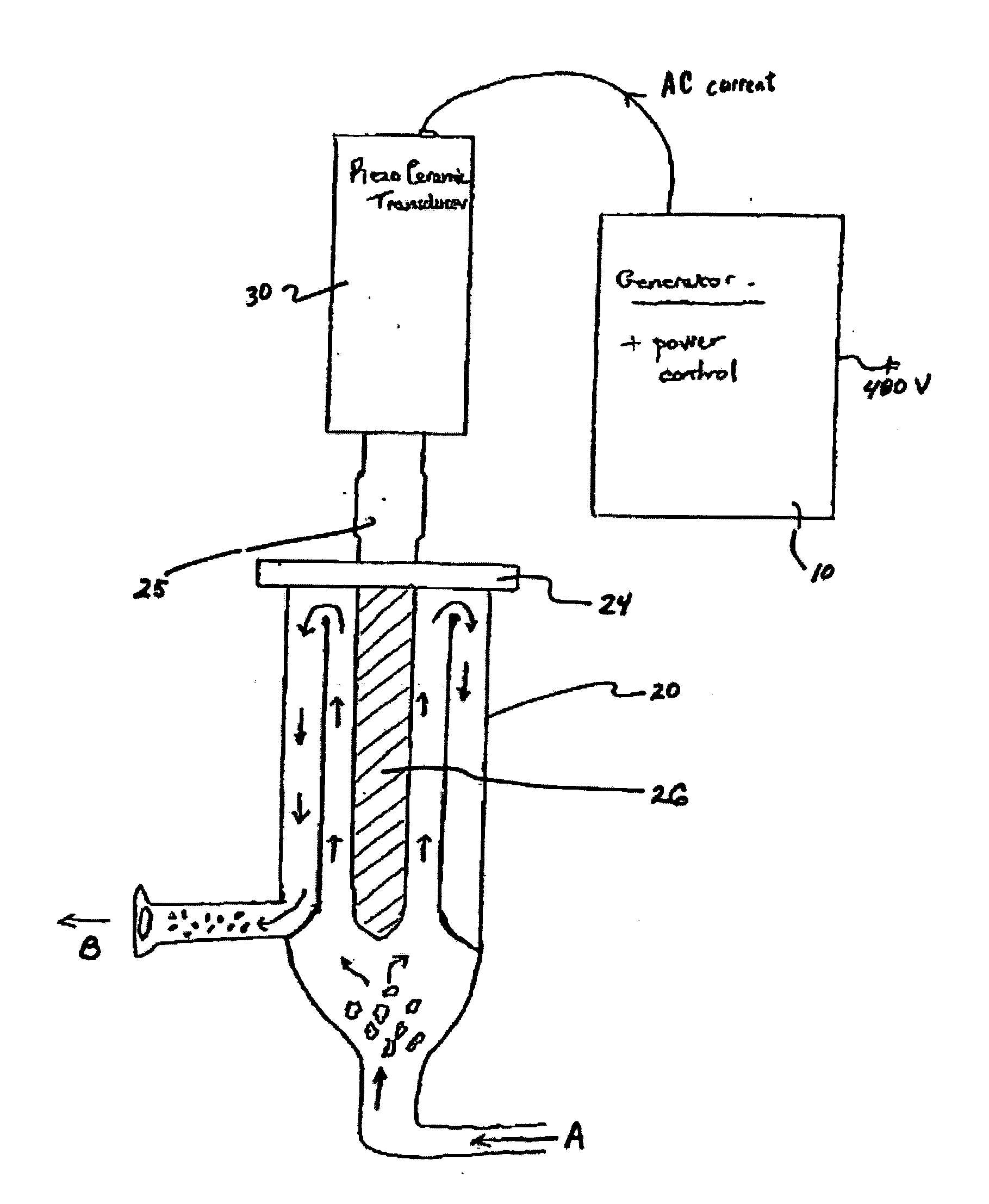

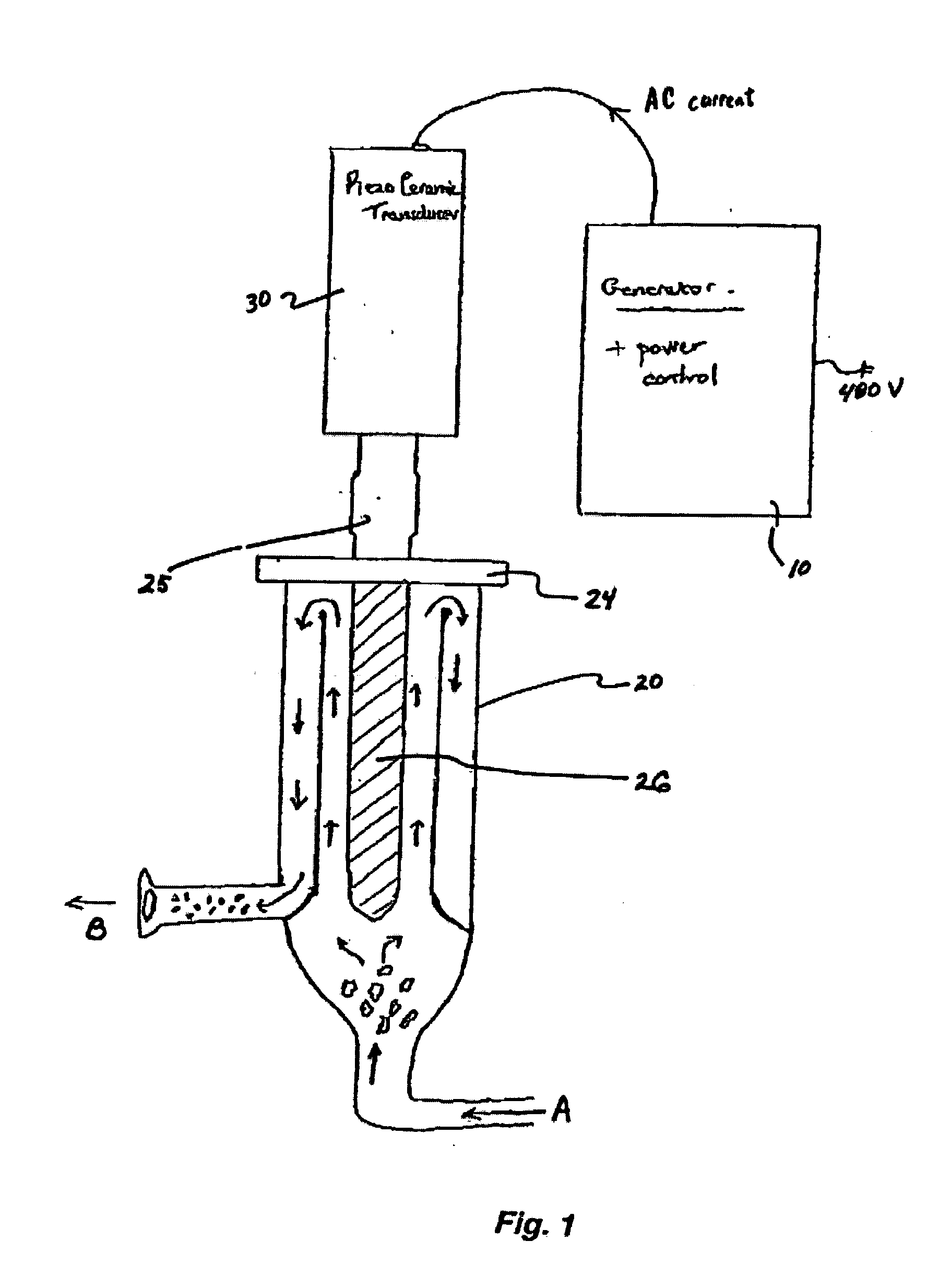

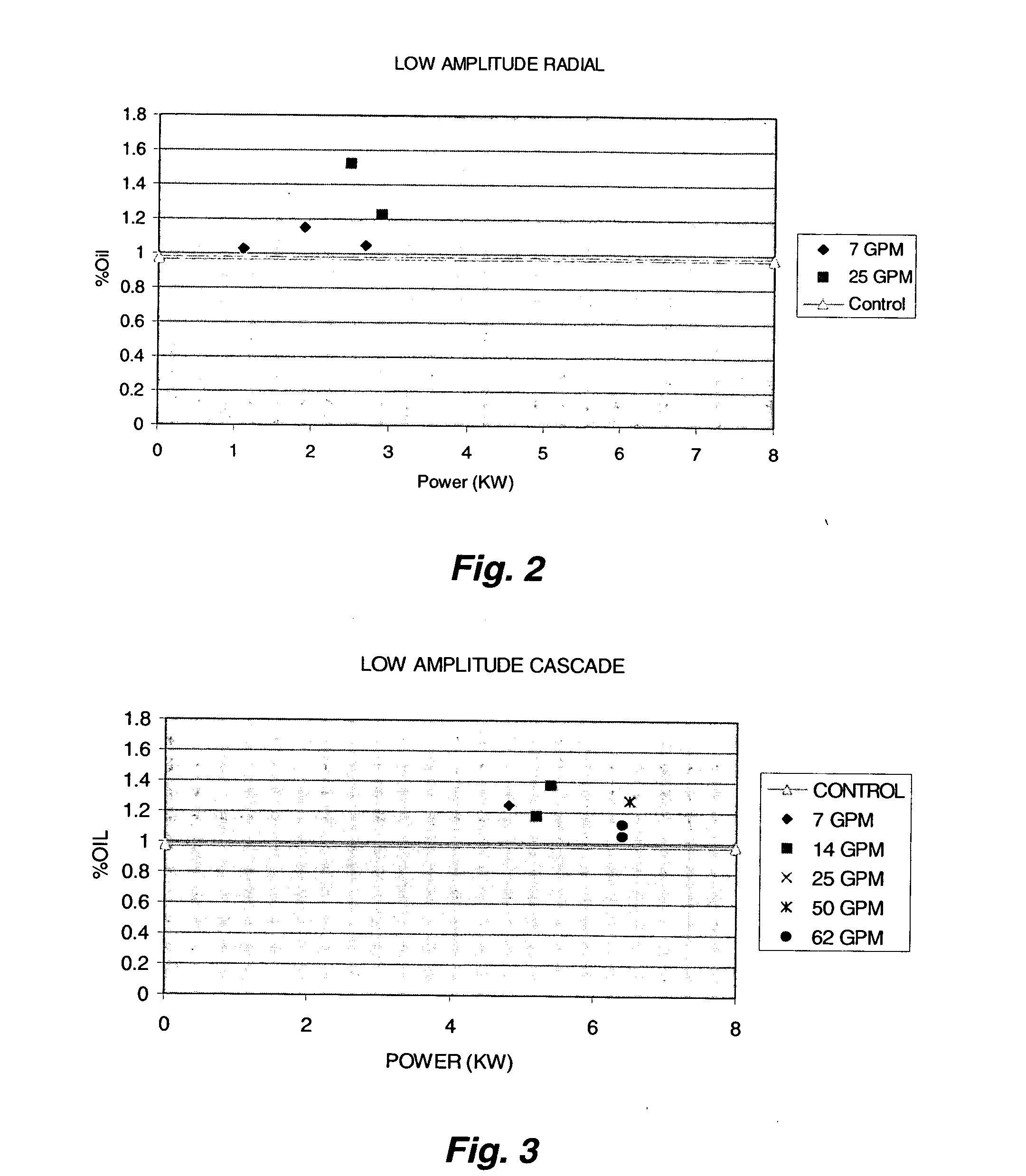

Process and apparatus for enhancing peel oil extraction

InactiveUS20060204624A1Promote recoveryEfficient and cost-effectiveSedimentation separationBakery productsCitrus fruitUltrasonic generator

A process of enhancing peel oil extraction from citrus fruit comprises providing a mixture containing citrus solids and water, subjecting the citrus solids and water mixture to high power ultrasonic energy under conditions sufficient to separate peel oil from the citrus solids, and recovering the peel oil. An apparatus for extracting peel oil from citrus fruit comprises an extractor, a conduit for flowing a citrus mixture containing citrus solids and water, and an ultrasonic generator for subjecting the citrus mixture to high power ultrasonic energy to separate peel oil from the citrus solids. In another embodiment, sonic energy is used to de-emulsify peel oil in a citrus mixture.

Owner:CARGILL INC

Method for the purification of a crude acrylic acid melt

InactiveUS7112695B2Organic compound preparationProduct crystals bed crystallizationPurification methodsChemistry

In a process for the purification of a crude acrylic acid melt, the crude acrylic acid melt is converted, under the action of low temperatures, into a crude acrylic acid suspension consisting of acrylic acid crystals and residual melt, and the acrylic acid crystals of the crude acrylic acid suspension are freed from remaining residual melt in a wash column, the production of the acrylic acid crystals of the crude acrylic acid suspension being carried out in the presence of water, the wash column being a wash column with forced transport of the acrylic acid crystals and the wash liquid used being the melt of acrylic acid crystals purified in the wash column.

Owner:BASF AG

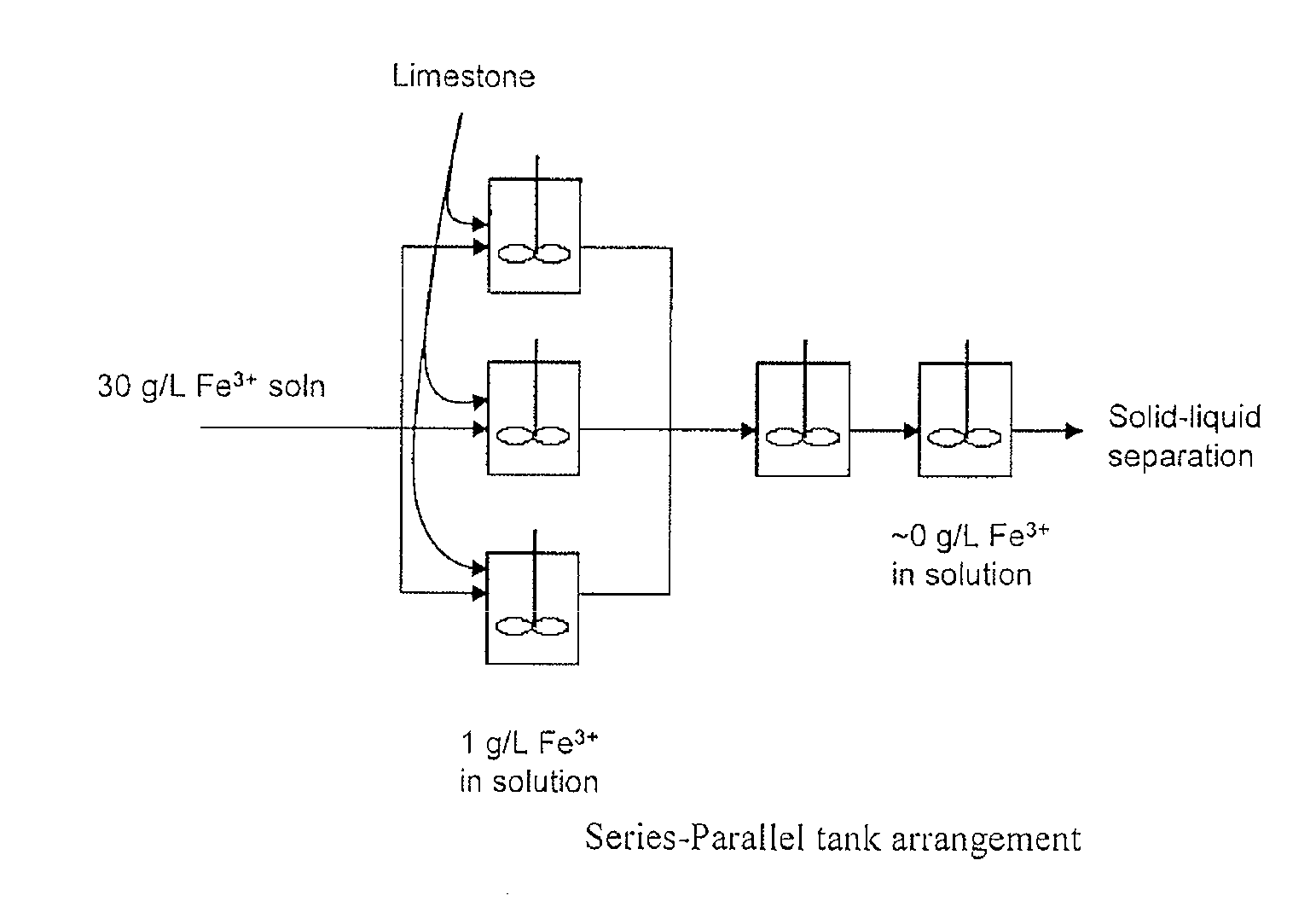

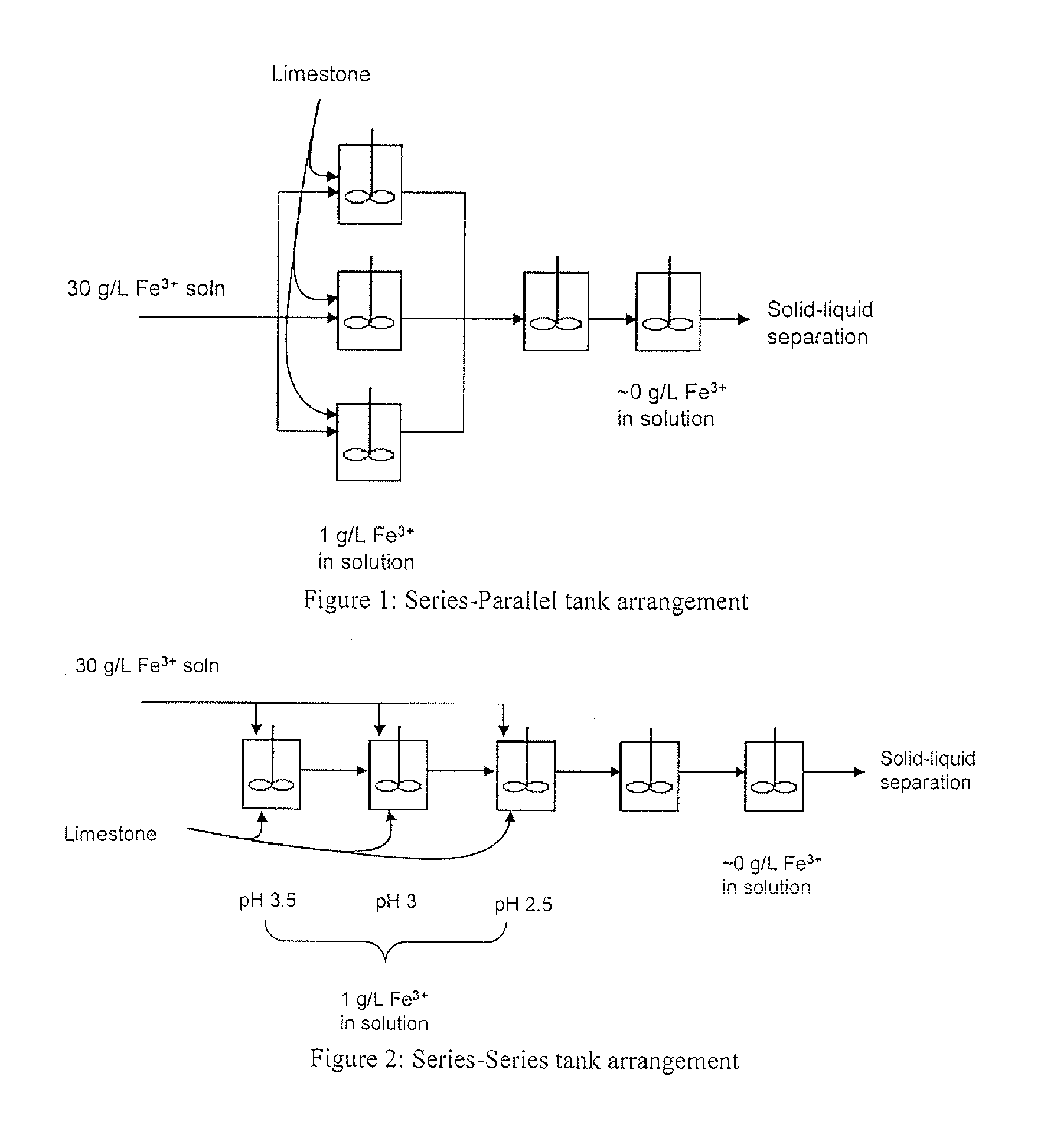

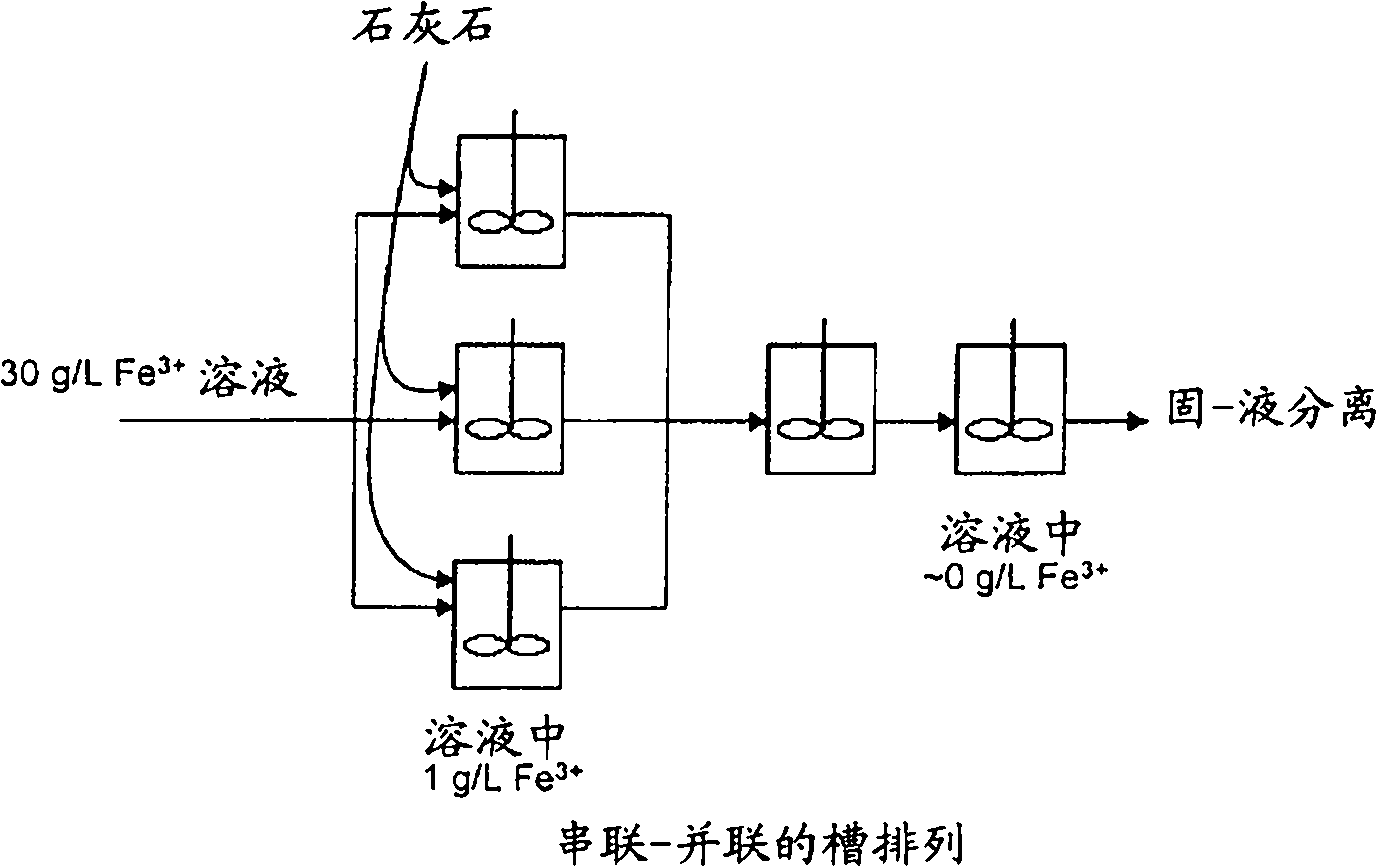

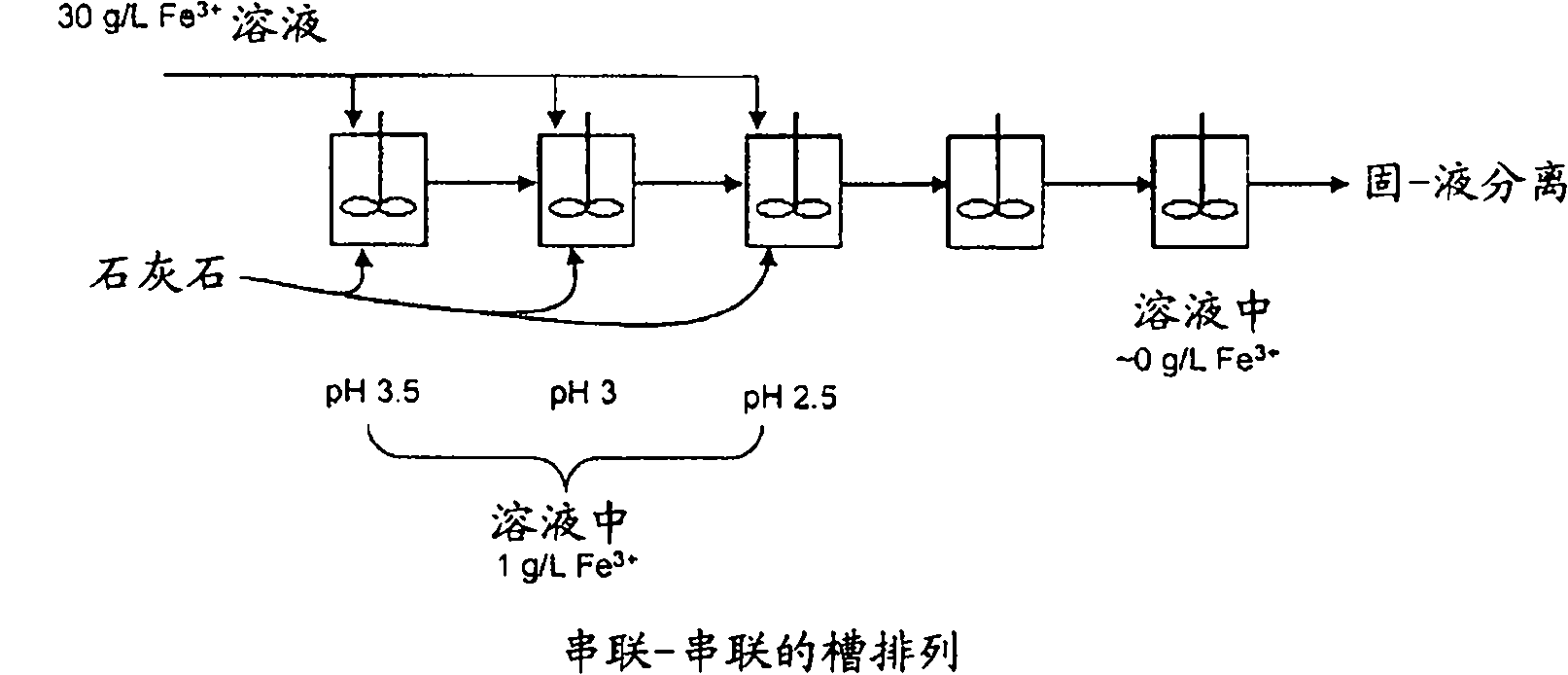

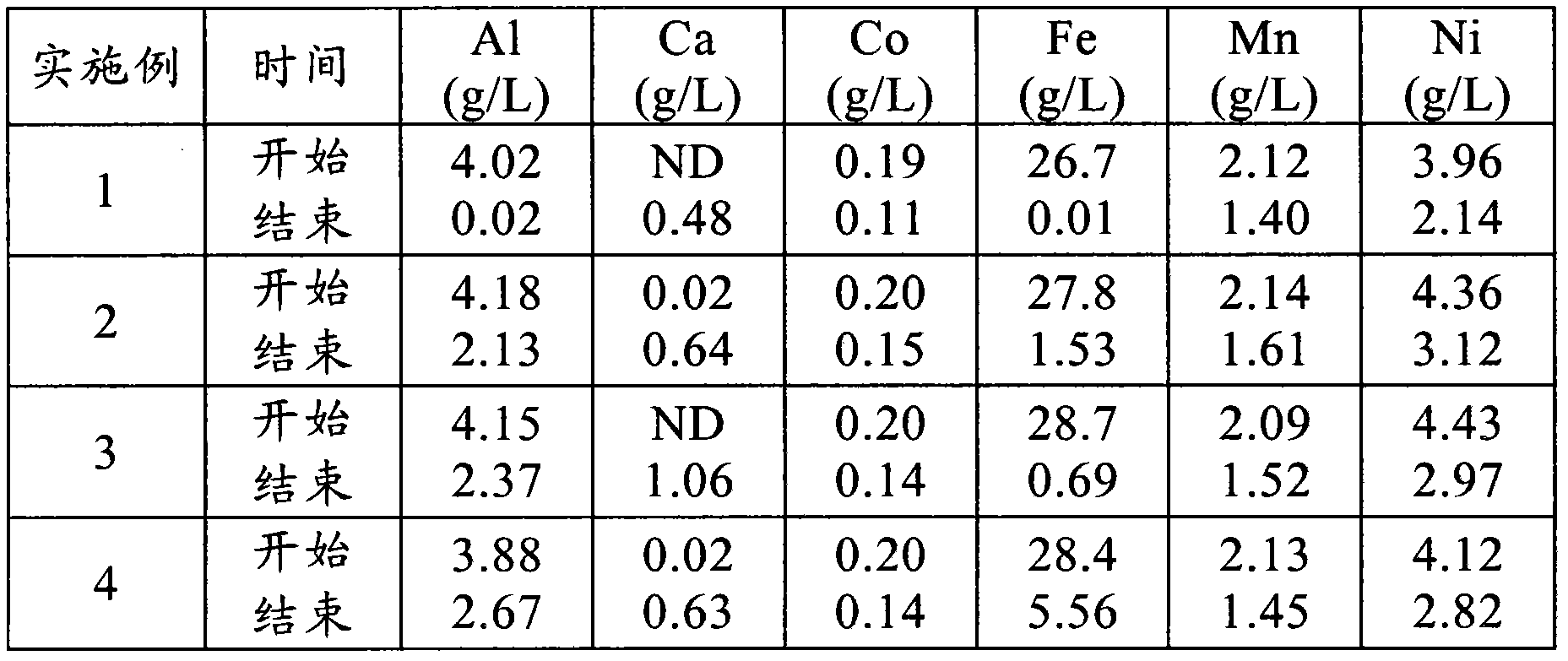

Iron Precipitation

InactiveUS20110120267A1Reduce lossesIncreased formationSolvent extractionIron compoundsFerric hydroxide oxideResidence time

A process for the treatment of a solution containing at least ferric ions, and one or more metal values, said process including the step of maintaining a controlled concentration of ferric ions in solution for a sufficient residence time to control iron hydroxide or oxide crystal growth, and precipitating the iron as a relatively crystalline iron hydroxide or oxide while minimising the loss of the ore or more metal values with the iron hydroxide or oxide.

Owner:BHP BILLITON SSM TECH PTY LTD

Washing Apparatus, A Method Of Purifying A Wash Material And Use Of The Washing Apparatus

ActiveUS20060013748A1Exhaust apparatusElement comparisonBiomedical engineeringEnvironmental engineering

Owner:EVONIK SUPERABSORBER GMBH

Process for purifying removal of acrylic acid, methacrylic acid, n-vinylpyrrolidone or p-xylene crystals from their suspension in mother liquor

ActiveUS20090018347A1Organic compounds purification/separation/stabilisationOrganic compound preparationHeat flowWater vapor

A process for purifying removal of acrylic acid, methacrylic acid, N-vinylpyrrolidone or p-xylene crystals from their suspension in mother liquor by means of a wash column with forced transport, whose shell of the process chamber is a metal wall, the wash column additionally being enveloped by a thermal insulation material having a water vapor barrier and a specific heat flow of >0.1 W / m2 and <10 W / m2 flowing into the process chamber through the metal wall of the wash column.

Owner:BASF AG

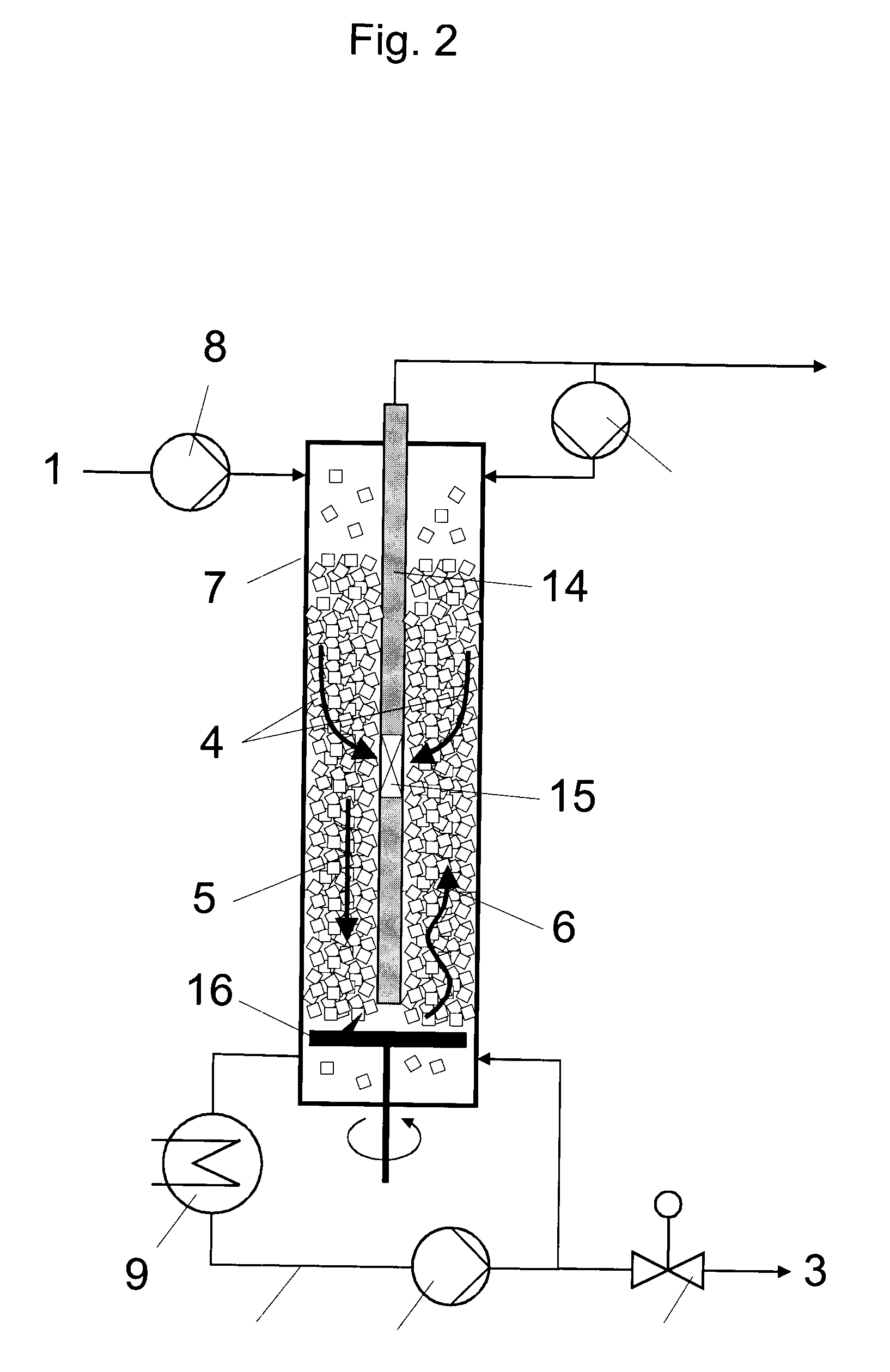

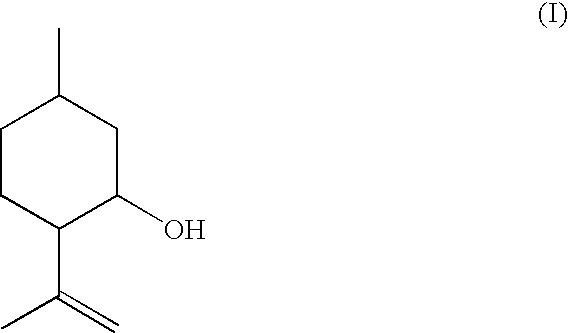

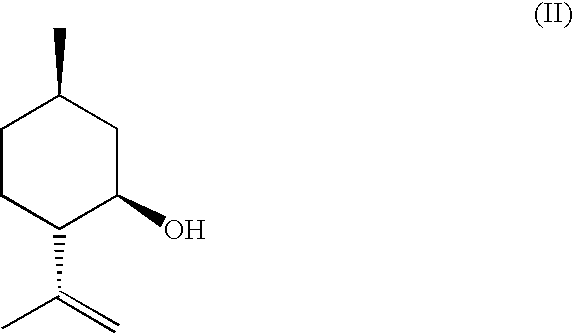

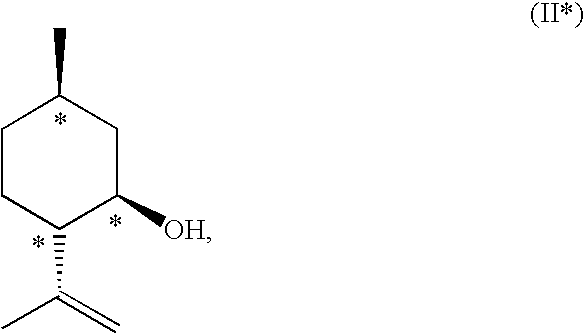

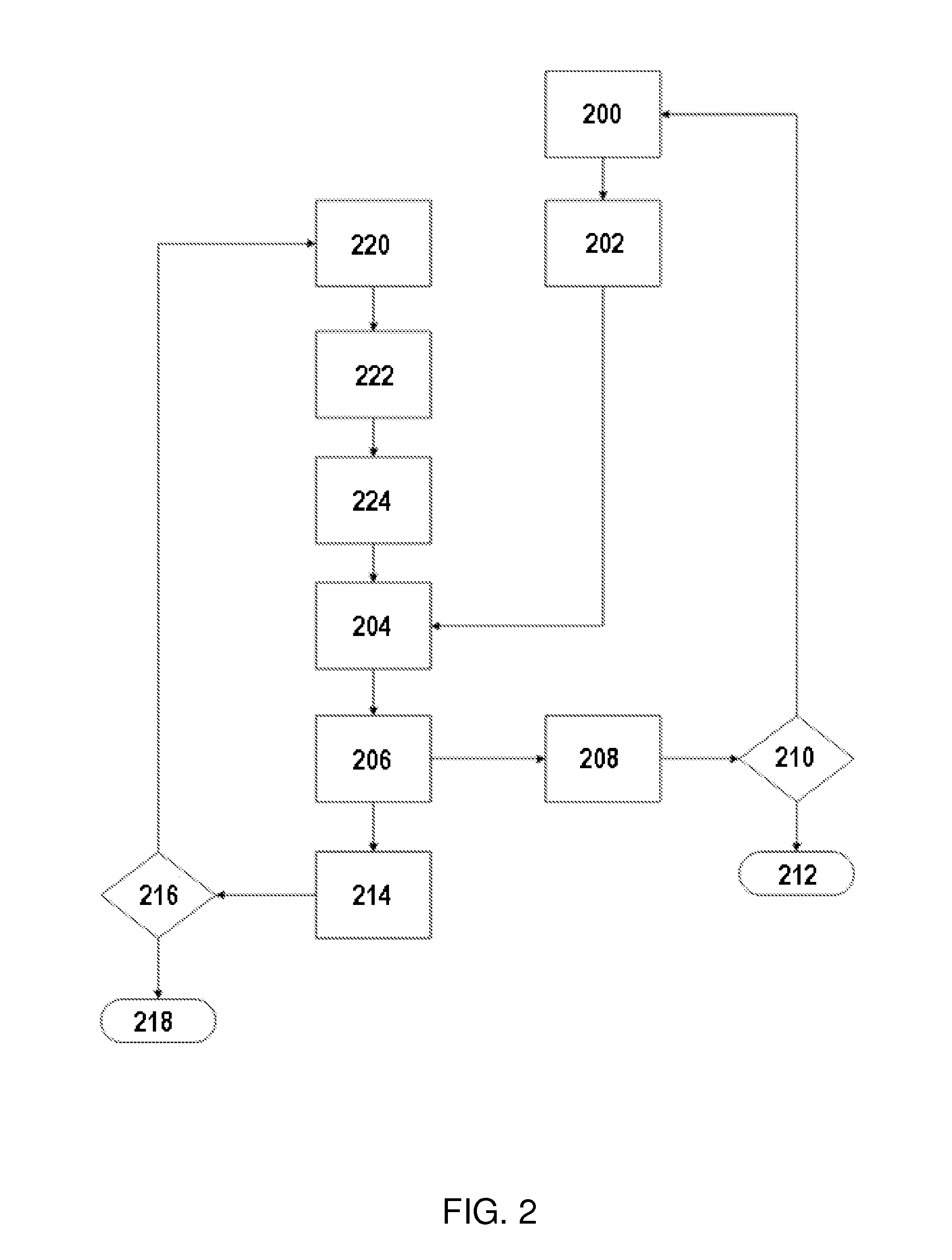

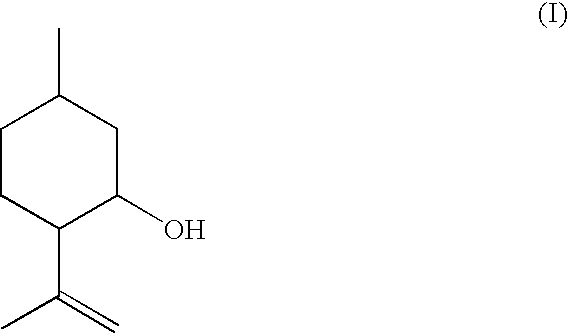

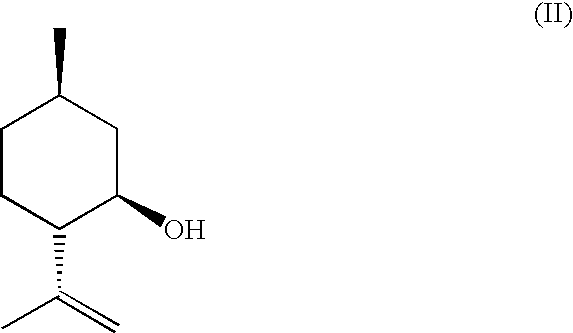

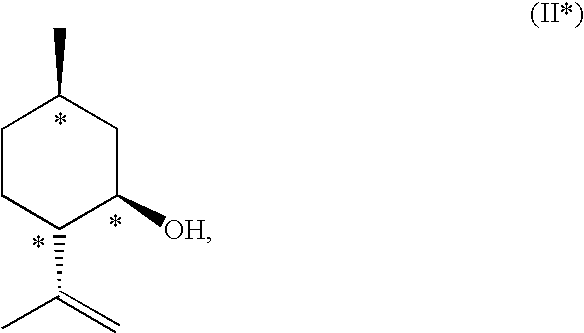

Method for the Production of Enriched Isopulegol

ActiveUS20080214877A1Easy to disassembleIncrease in the enantiomeric excessOxygen-containing compound preparationOrganic compound preparationMentholPolymer science

The present invention relates to a process for preparing enriched isopulegol by crystallization from a melt comprising isopulegol. The invention relates specifically to a process for preparing enantiomerically enriched n-isopulegol proceeding from optically active isopulegol having a relatively low enantiomeric excess by crystallization from the melt. The invention further relates to a process for preparing menthol proceeding from enantiomerically and / or diastereomerically enriched n-isopulegol prepared by crystallization from the melt.

Owner:BASF AG

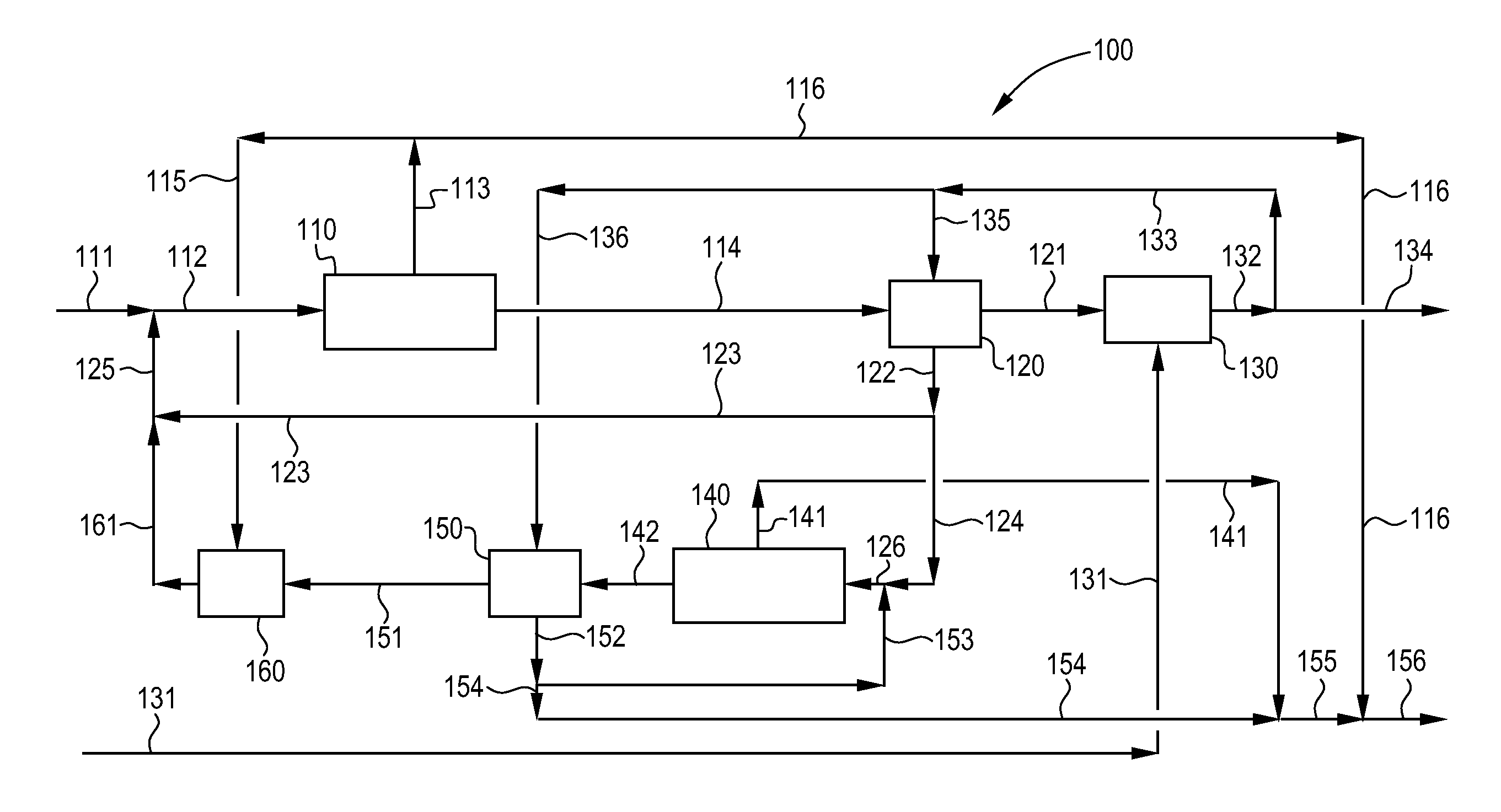

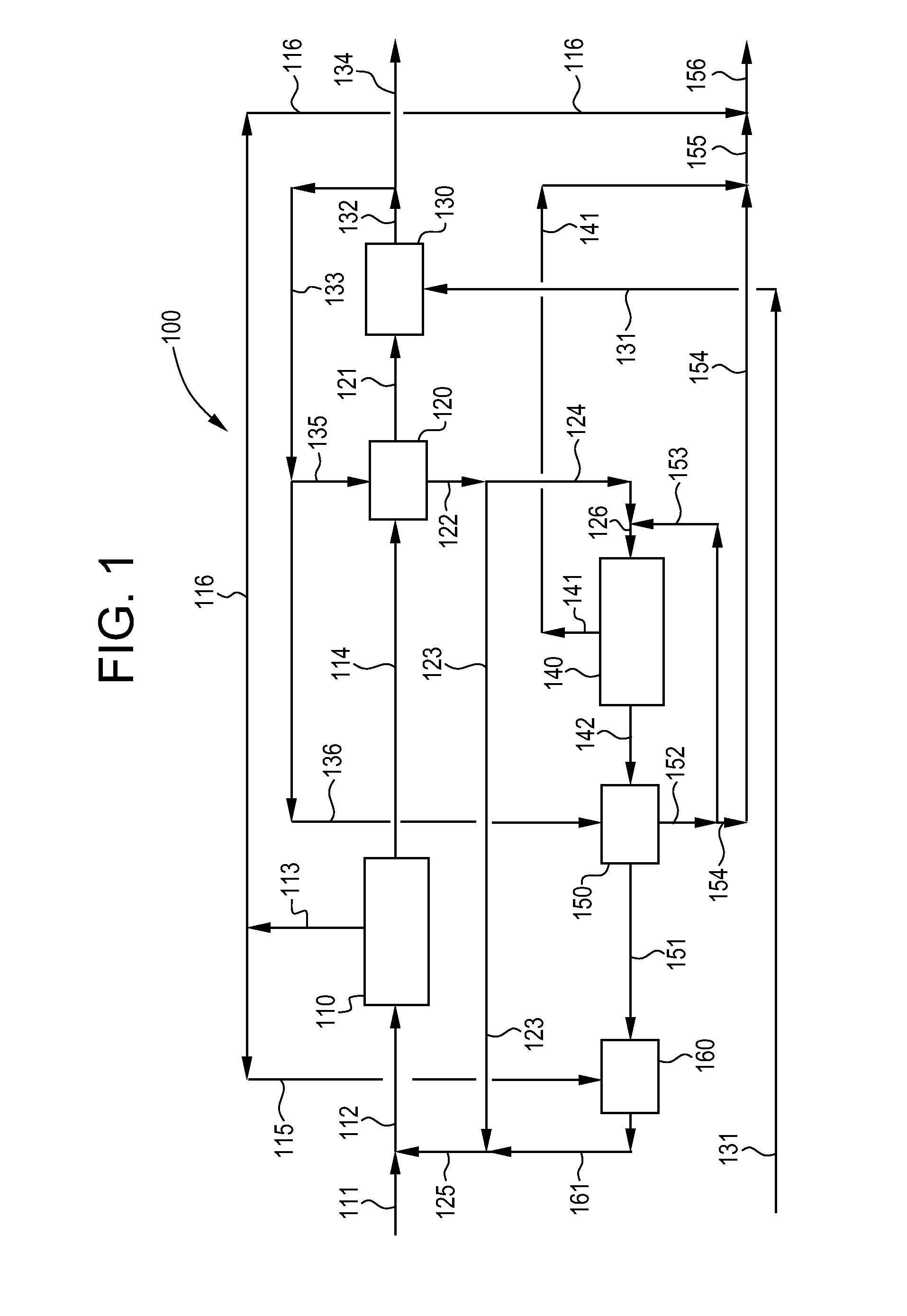

Process and apparatus for purification of industrial brine

Processes and apparatus for purifying brine are provided including (1) providing an aqueous brine solution comprising one or more inorganic salts and one or more organic compounds and (2) conducting at least one unit operation for removing organic compounds from the brine solution to obtain a purified brine solution.

Owner:BLUE CUBE IP

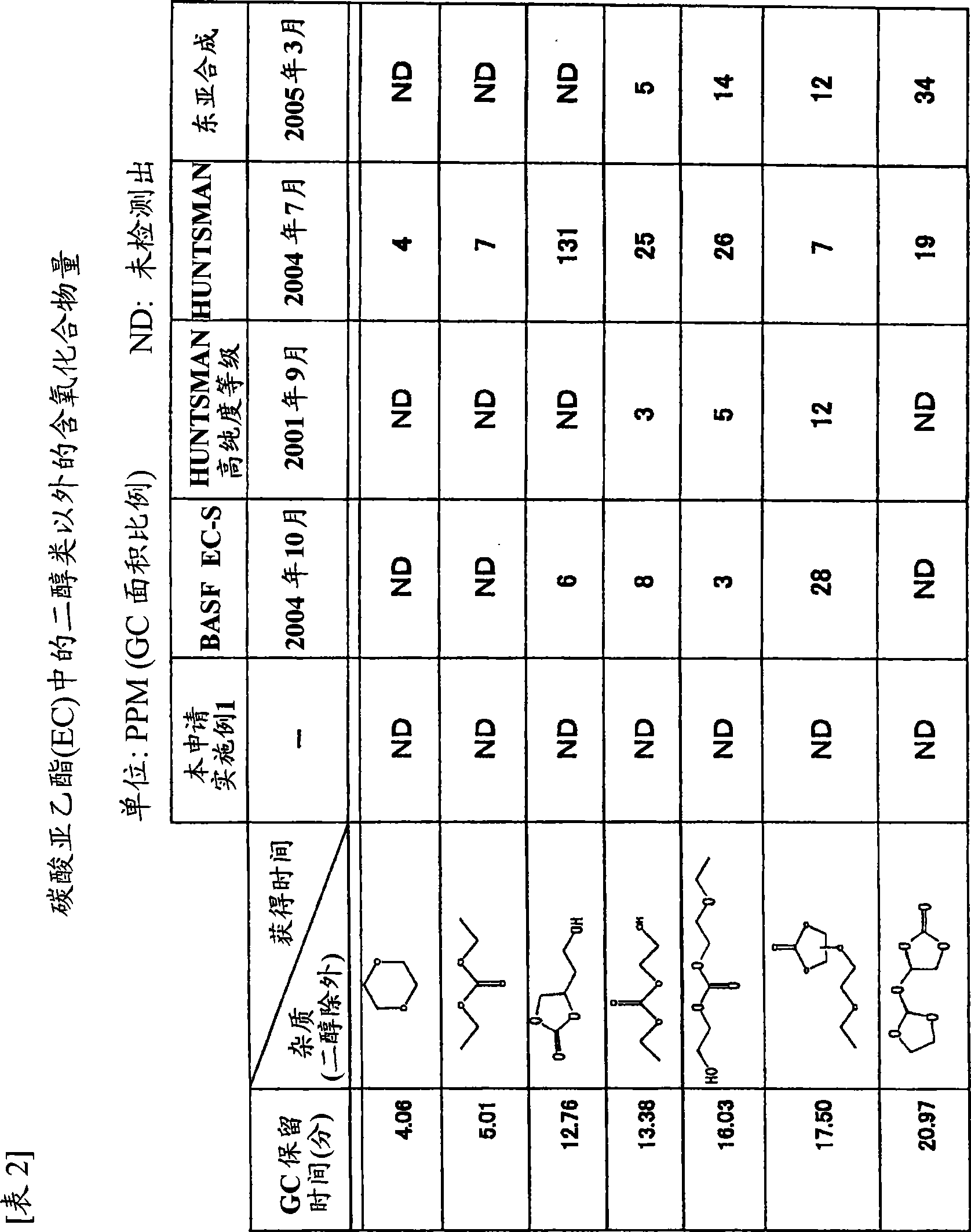

Method of purifying ethylene carbonate, process for producing purified ethylene carbonate and ethylene carbonate

ActiveCN101400667AReduce contentHigh puritySolution crystallizationHeat exchange cooling cystallizationEthyl esterDiol

Ethylene carbonate in which the content of especially diols has highly been reduced is provided. There is provided a method of purifying ethylene carbonate, including causing crude ethylene carbonate crystal to descend from a superior part of tower, melting the crude ethylene carbonate crystal in a tower bottom, withdrawing portion of the obtained melt from the tower, causing the rest of the melt to ascend as a reflux liquid and realizing countercurrent contact of the melt with the descending crude ethylene carbonate crystal, characterized in that a solid / liquid countercurrent contact region of constant temperature is created.

Owner:MITSUBISHI RAYON CO LTD +1

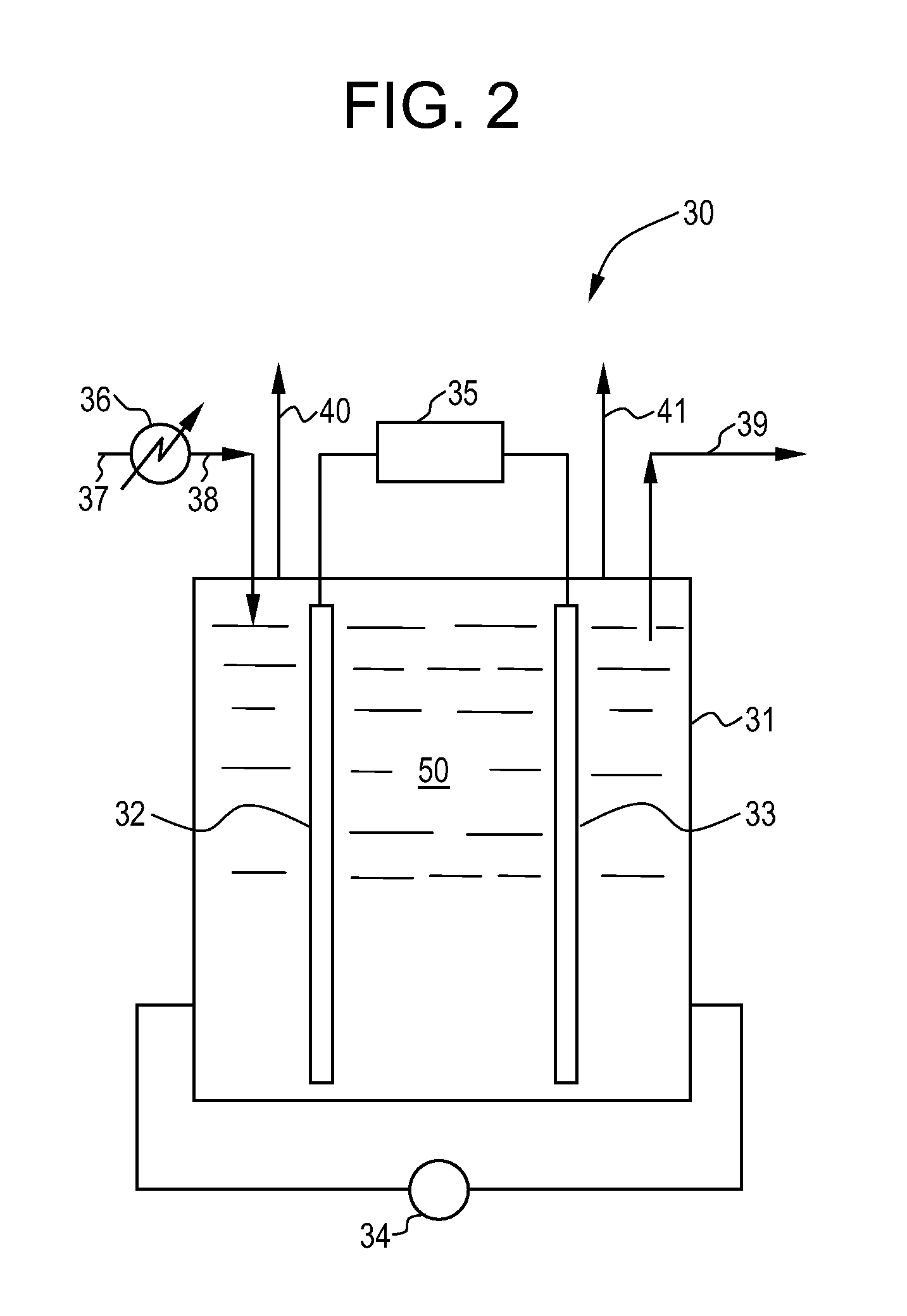

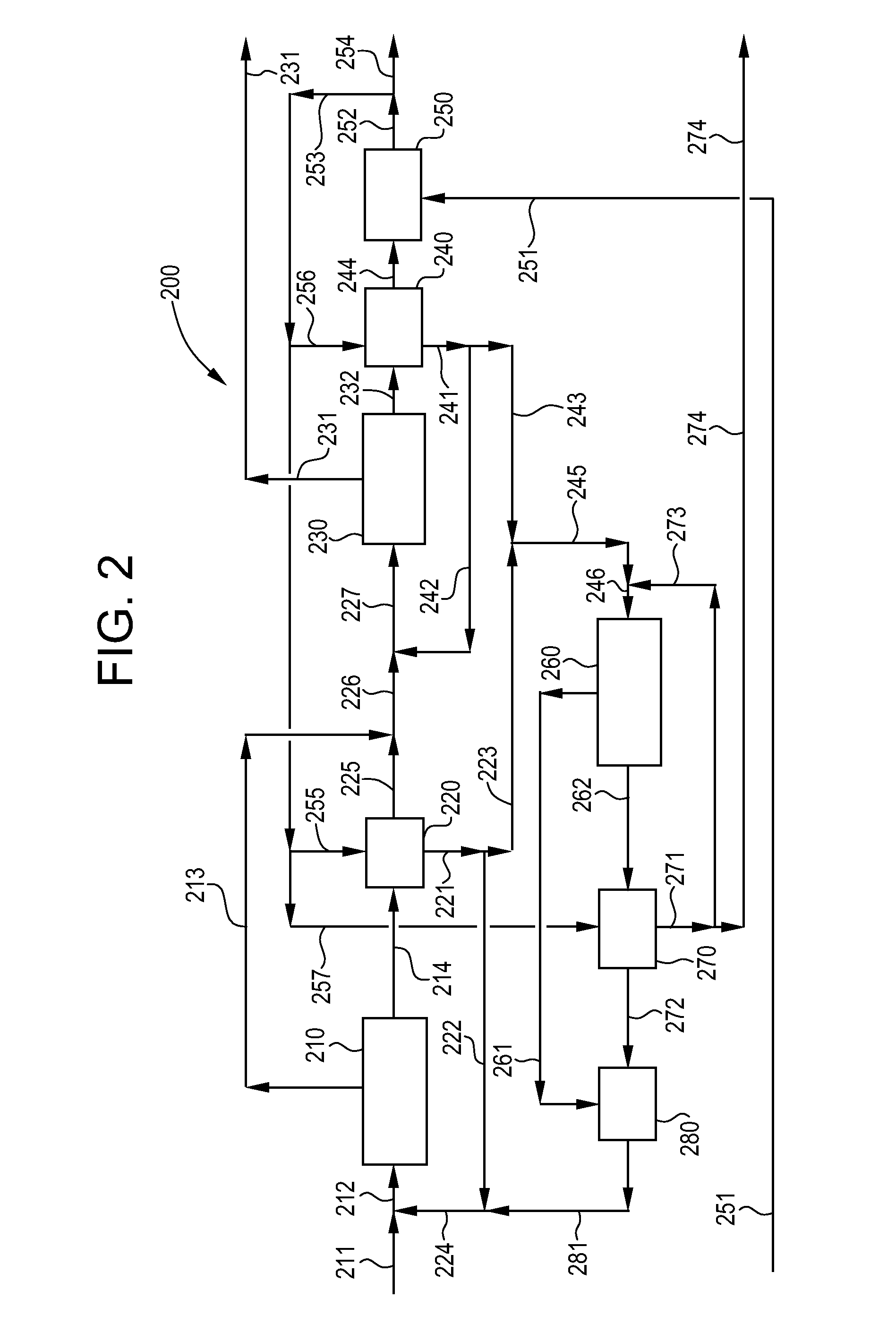

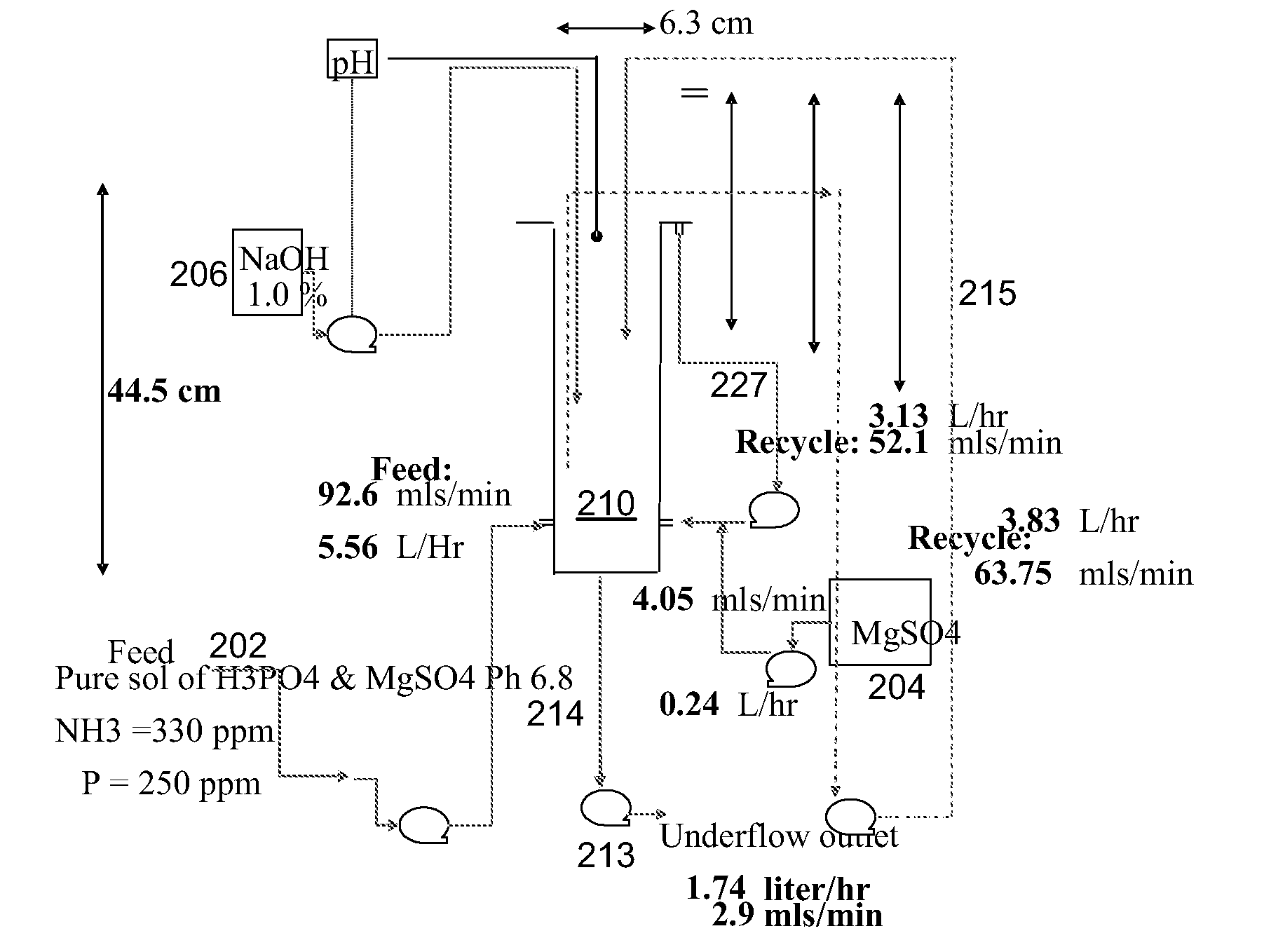

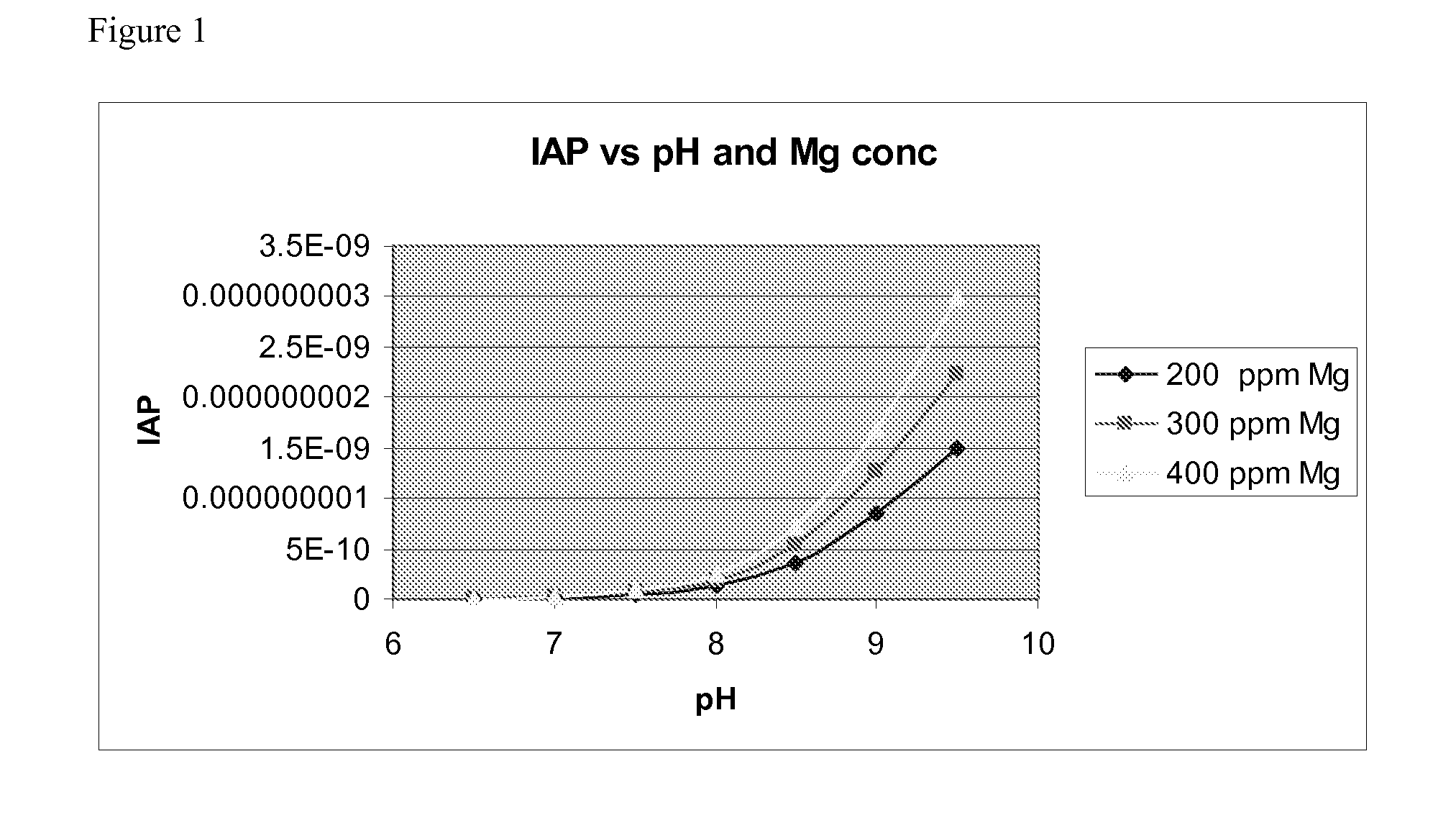

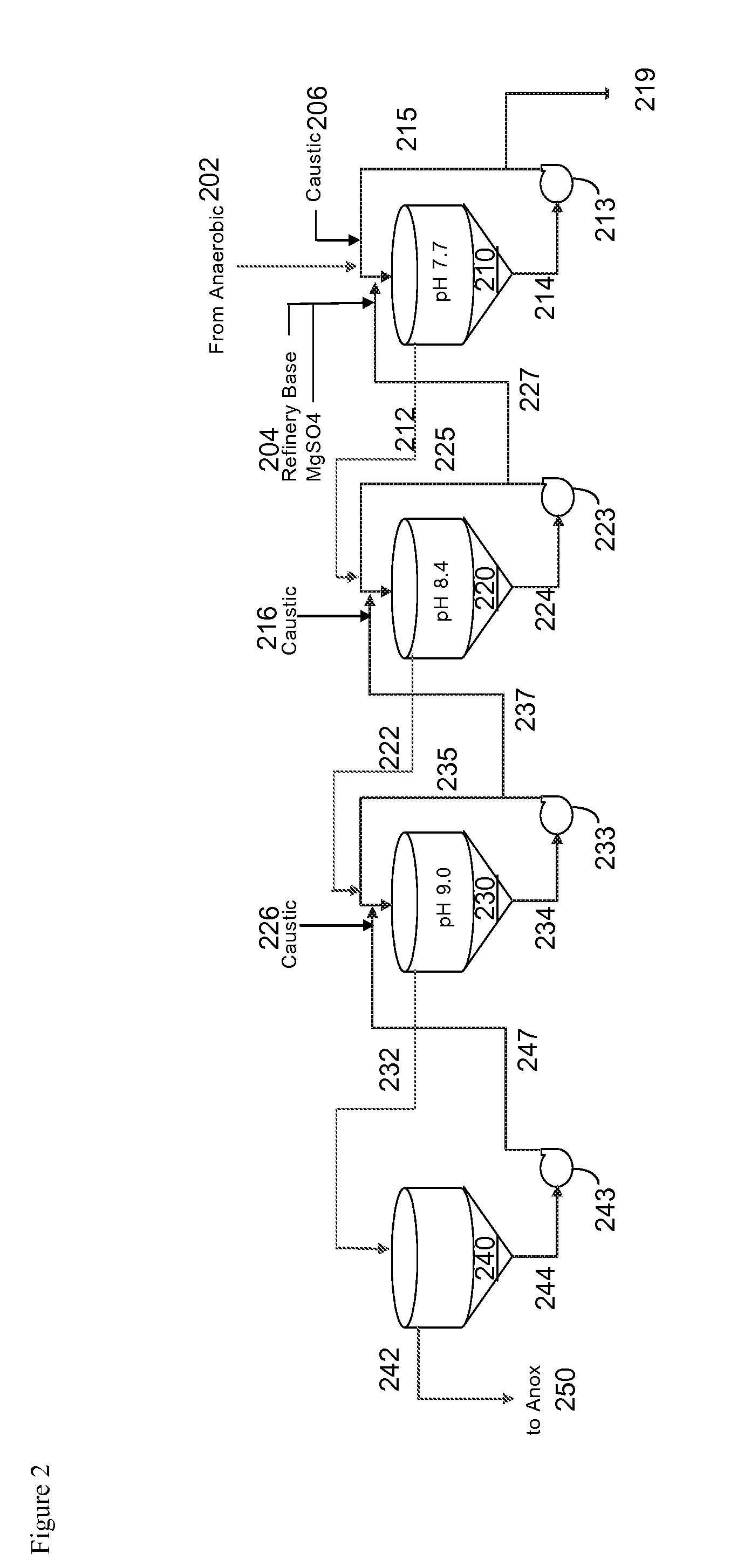

System and Process for Removal of Phosphorous and Ammonia from Aqueous Streams

InactiveUS20080308505A1Degree of reductionReduce solubilityOther chemical processesWater contaminantsWater flowAmmonia

We disclose a process for the removal of phosphorous and ammonia from an aqueous stream by contacting the aqueous stream with magnesium and base in a first zone having a first pH, to form an (n−1)th mixed stream and a first portion of struvite; separating the (n−1)th mixed stream from the first portion of struvite; removing at least some struvite from the first portion of struvite; contacting the (n−1)th mixed stream with base in an nth zone, wherein n is an integer incrementing from 2 to nmax, wherein nmax is an integer from 2 to about 5, and wherein the nth zone has an nth pH higher than the (n−1)th pH, to form an nth mixed stream and an nth portion of struvite, except no base is added and the nth pH need not be higher than the (n−1)th pH when n=nmax; separating the nth mixed stream from the nth portion of struvite; returning the nth portion of struvite to the (n−1)th zone; and, if n<nmax, incrementing n and repeating the second contacting, second separating, and returning steps, or, if n=nmax, releasing the nth mixed stream to a treated water tank. We also disclose a system which can be used for performing the method.

Owner:JANSEN ROBERT +7

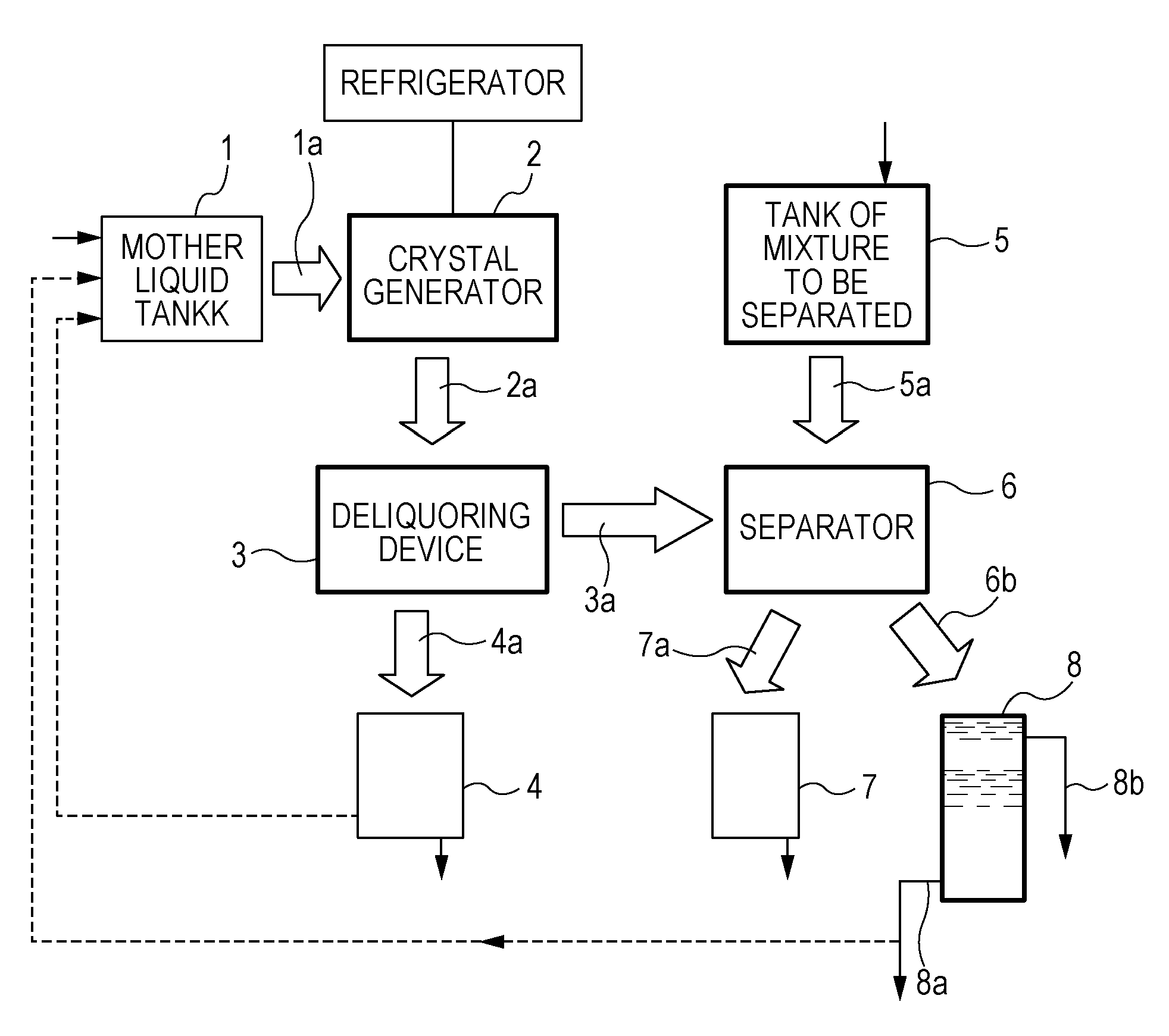

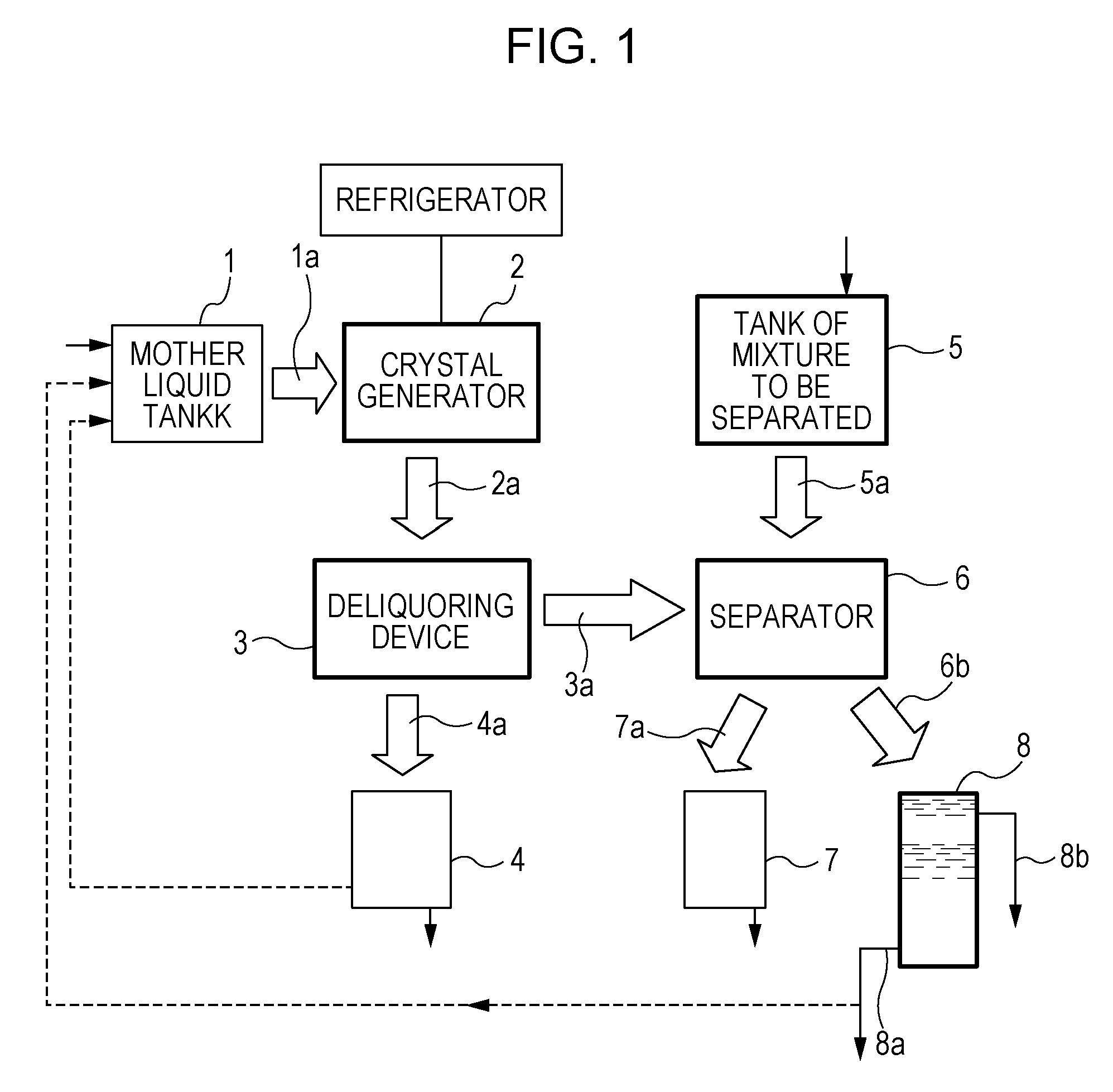

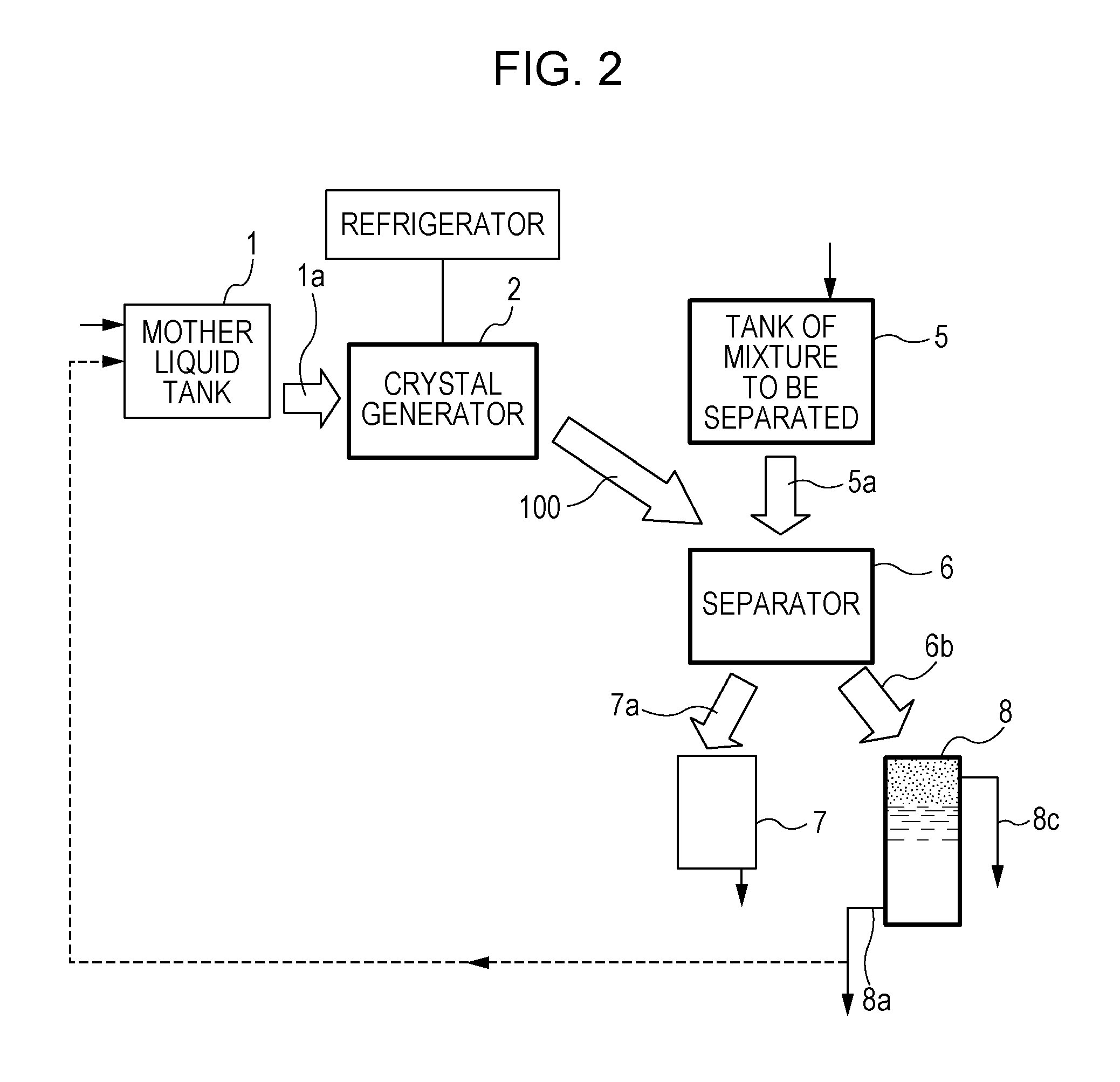

Method and apparatus using deliquescent filter for separating mixture

ActiveUS20110079044A1Easy to separateLiquid suspension thickening by filtrationRotary centrifugesFilter mediaChemistry

The present invention provides a method and apparatus for separating a mixture to be separated (solid-liquid or liquid-liquid mixture) using a deliquescent filter medium. The mixture to be separated is separated into a liquid passing through a filter layer of the filter medium and a captured material captured in the filter layer.

Owner:JO

Iron precipitation

InactiveCN102066589AReduce lossesGuaranteed uptimeSolution crystallizationProcess efficiency improvementFerric hydroxideIron oxide

A process for the treatment of a solution containing at least ferric ions, and one or more metal values, includes the step of maintaining a controlled concentration of ferric ions in solution for a sufficient residence time to control iron hydroxide or oxide crystal growth, and precipitating the iron as a relatively crystalline iron hydroxide or oxide while minimising the loss of the ore or more metal values with the iron hydroxide or oxide.

Owner:BHP BILLITON SSM TECH PTY LTD

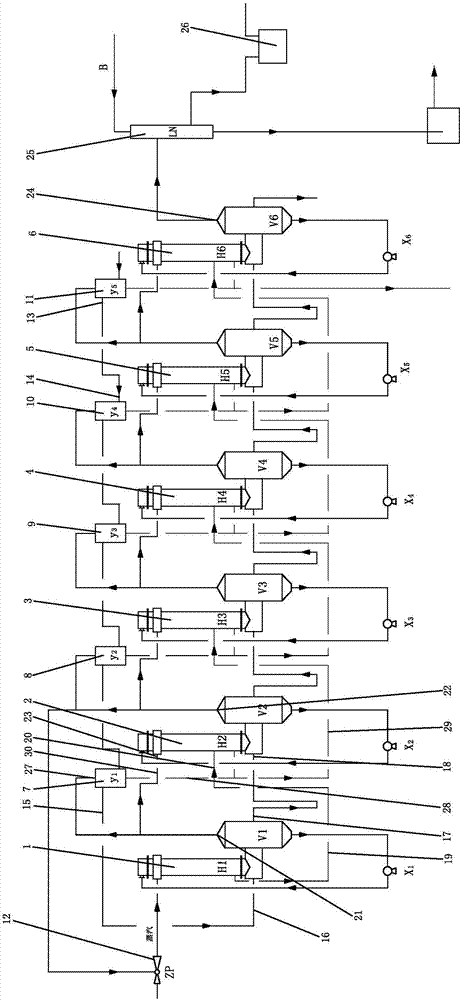

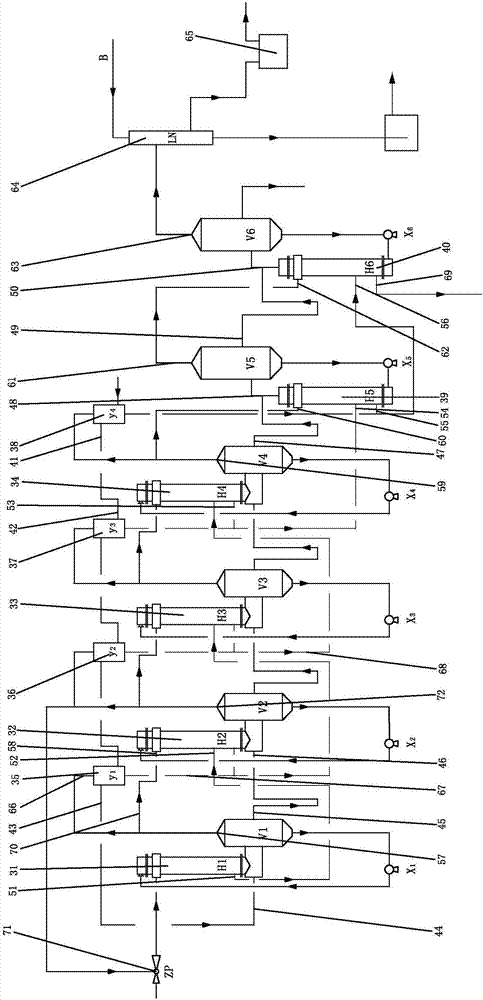

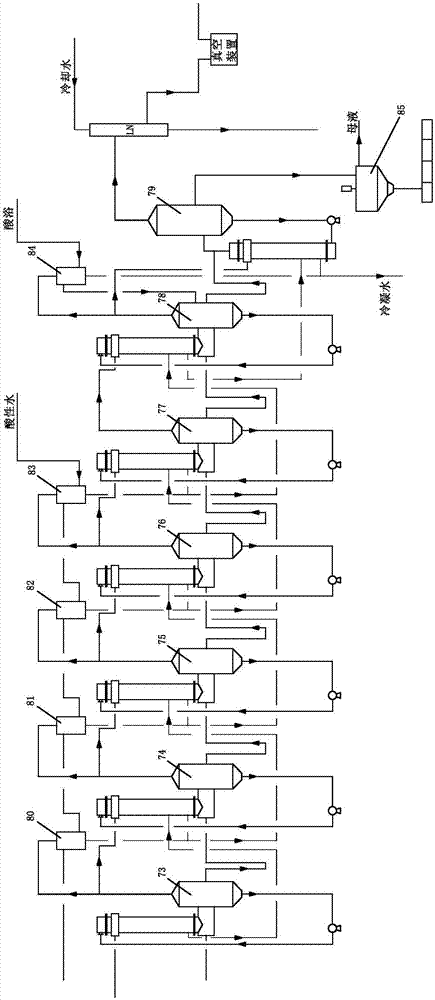

Multi-effect evaporation concentration technology, multi-effect evaporation crystallization technology and multi-effect evaporation concentration device of solution containing sulfuric acid and sulfate

The invention discloses a multi-effect evaporation concentration technology, a multi-effect evaporation crystallization technology and a multi-effect evaporation concentration device of a solution containing sulfuric acid and sulfate. The technologies and the device are characterized in that low-temperature-difference heat transfer flow evaporation is adopted; step-by-step secondary steam series preheating is adopted; an acid bath is led as an evaporation crystallization carrier; and last-effect or last-two-effect evaporation crystallization is adopted. The evaporation concentration and crystallization device mainly comprises (1-n)-effect evaporation crystallizers, (1-n)-effect circulating pumps, 1-(n-1)- or 1-(n-2)-stage preheaters, condensers and vacuum devices. According to the technologies and the device, a steam-water ratio of acid bath 5-7-effect evaporation crystallization reaches an advanced level of 0.17-0.19; a steam-water ratio of acid water and two-bath 6-8-effect evaporation crystallization reaches an advanced level of 0.13-0.15; a steam-water ratio of a low-concentration acid water 7-9-effect evaporation concentration device can further reach an advanced level of 0.09-0.11, but the state-of-the-art steam-water ratio of 16-stage flash evaporation crystallization is 0.255 in the current industry.

Owner:许达人 +1

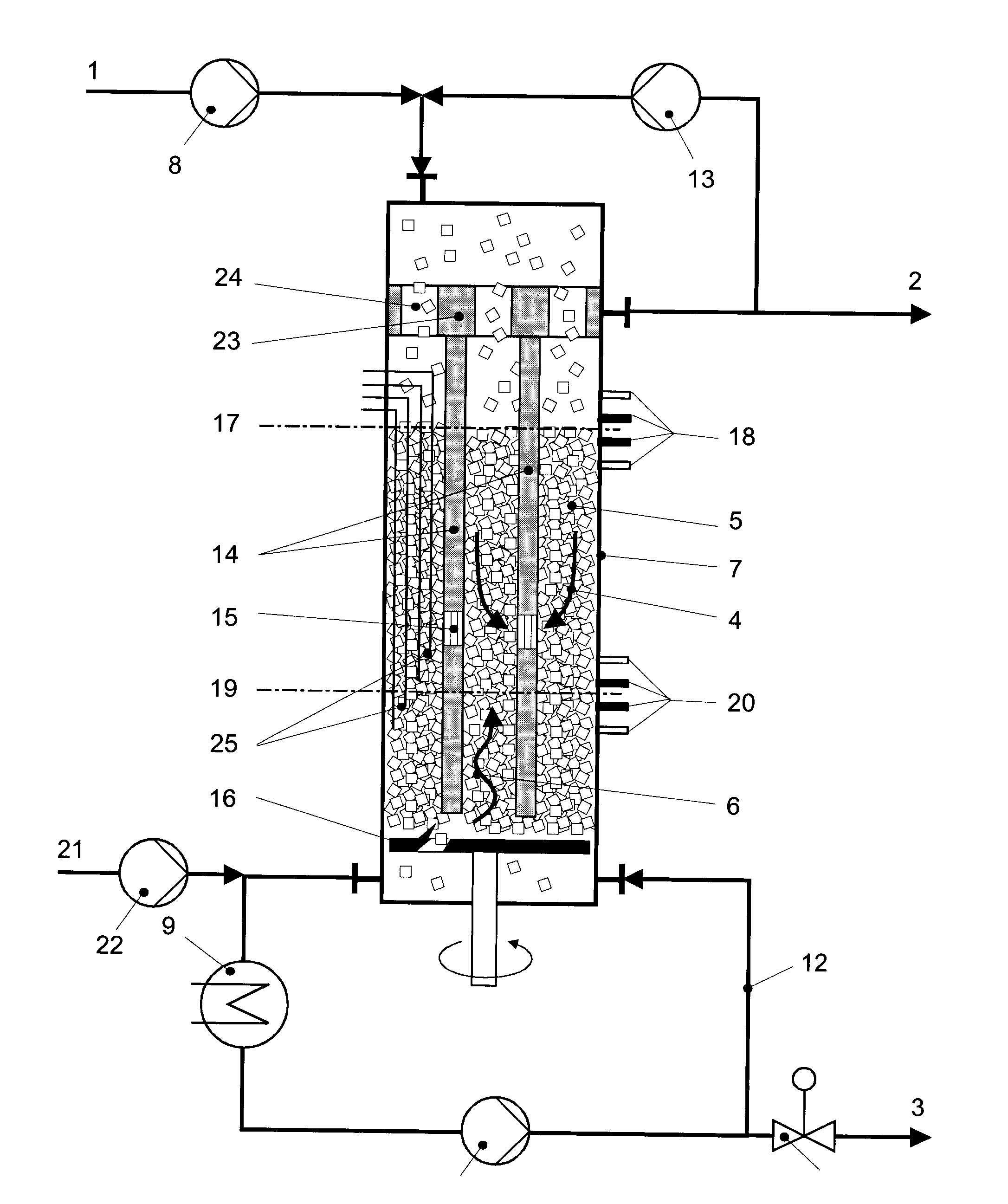

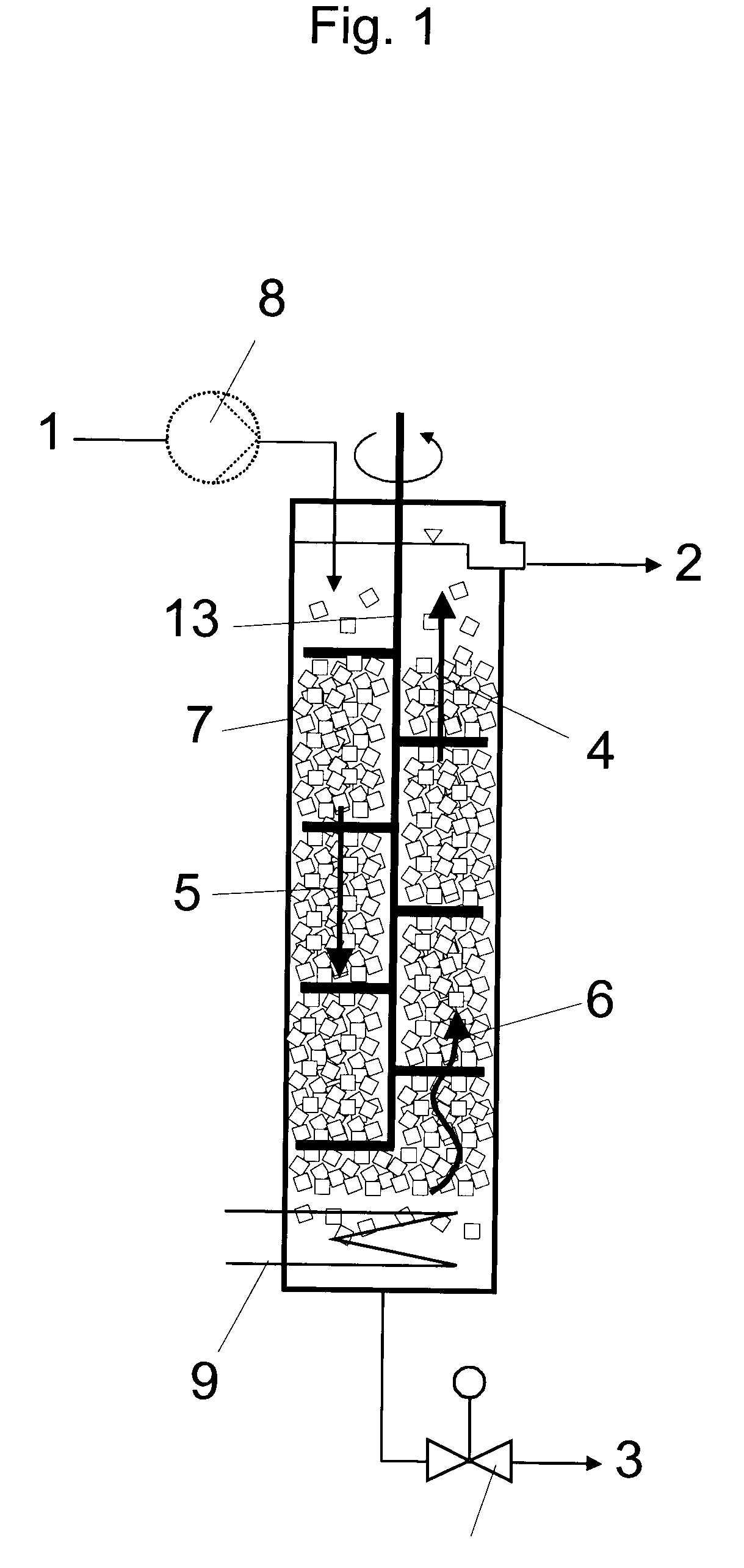

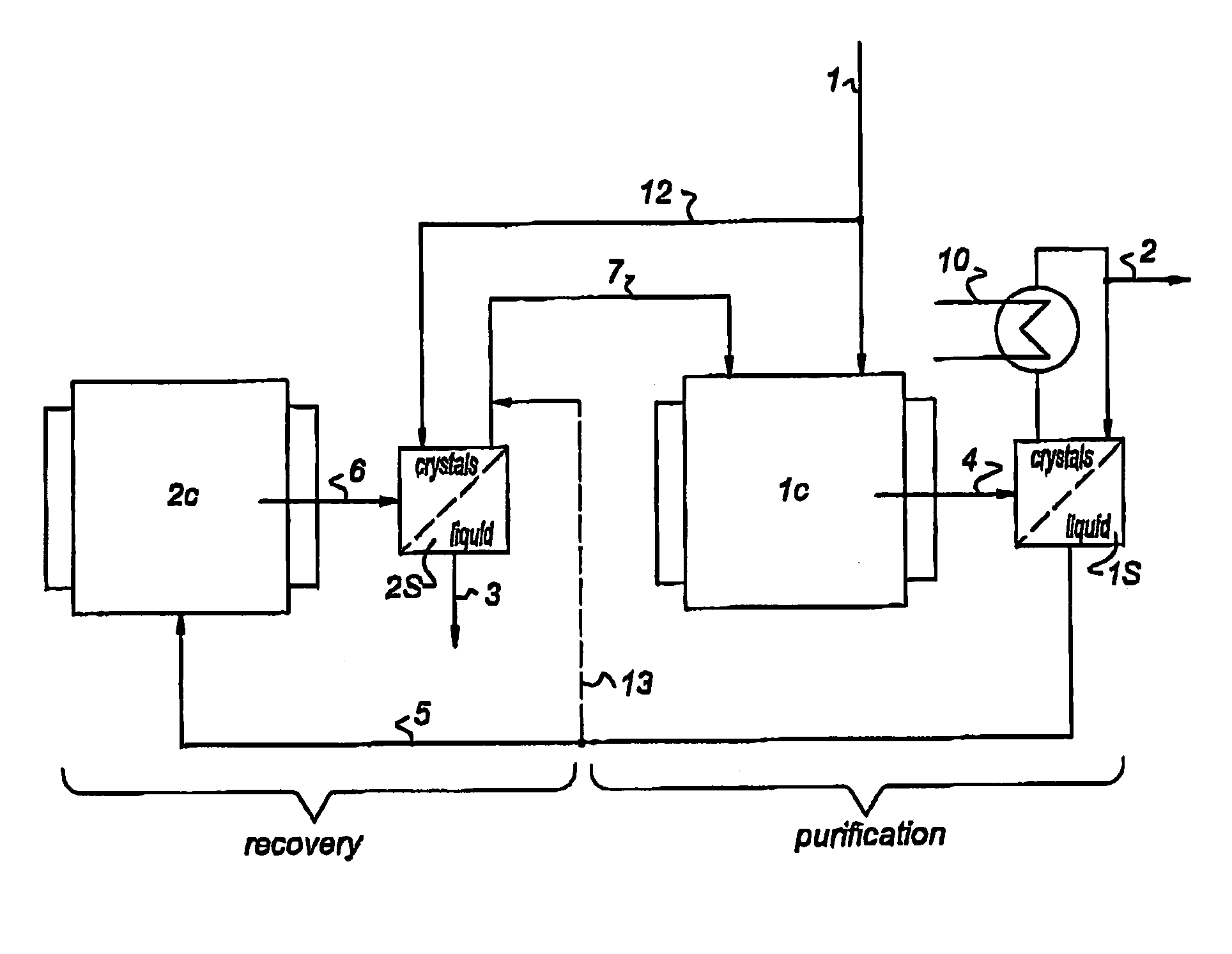

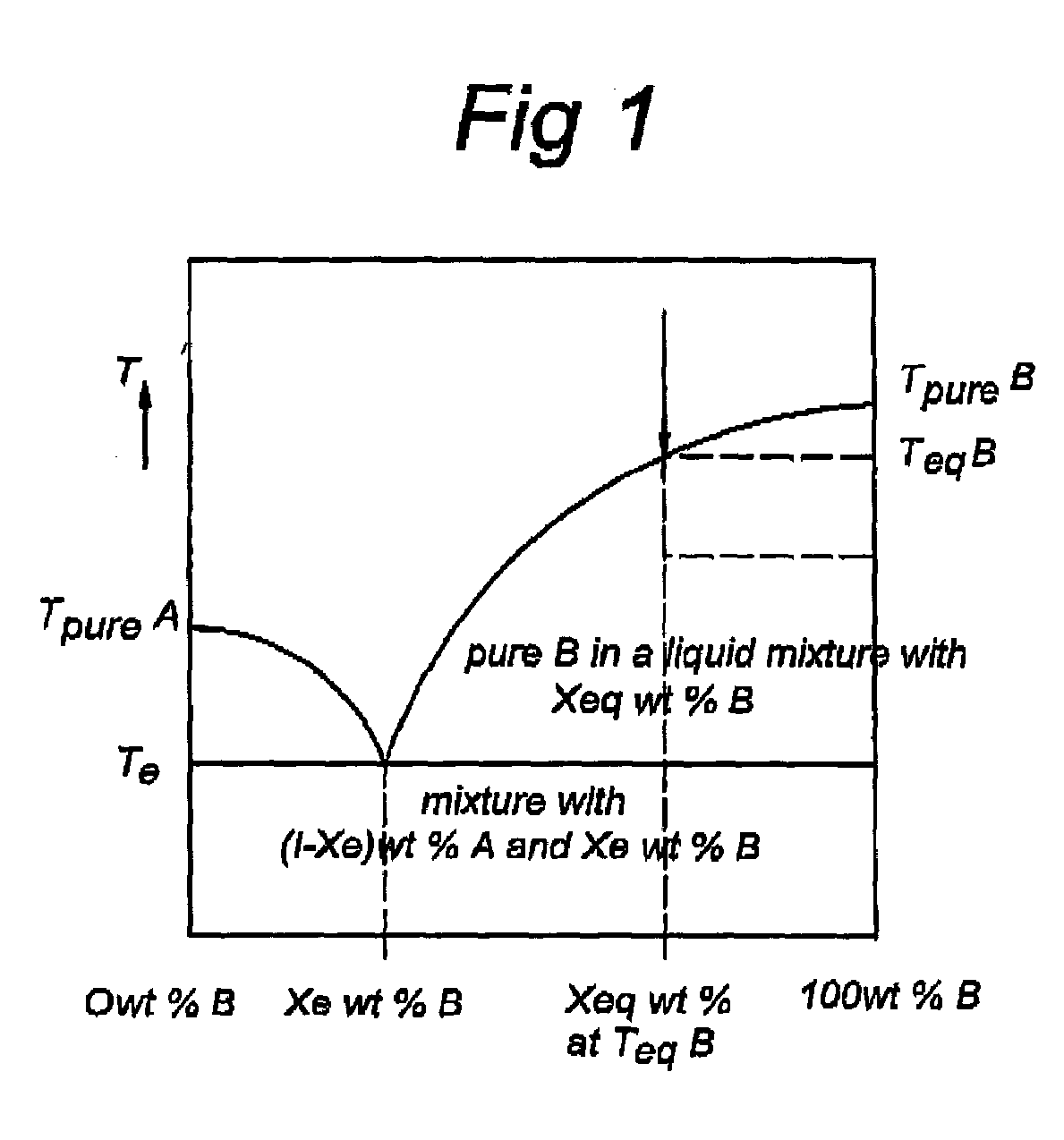

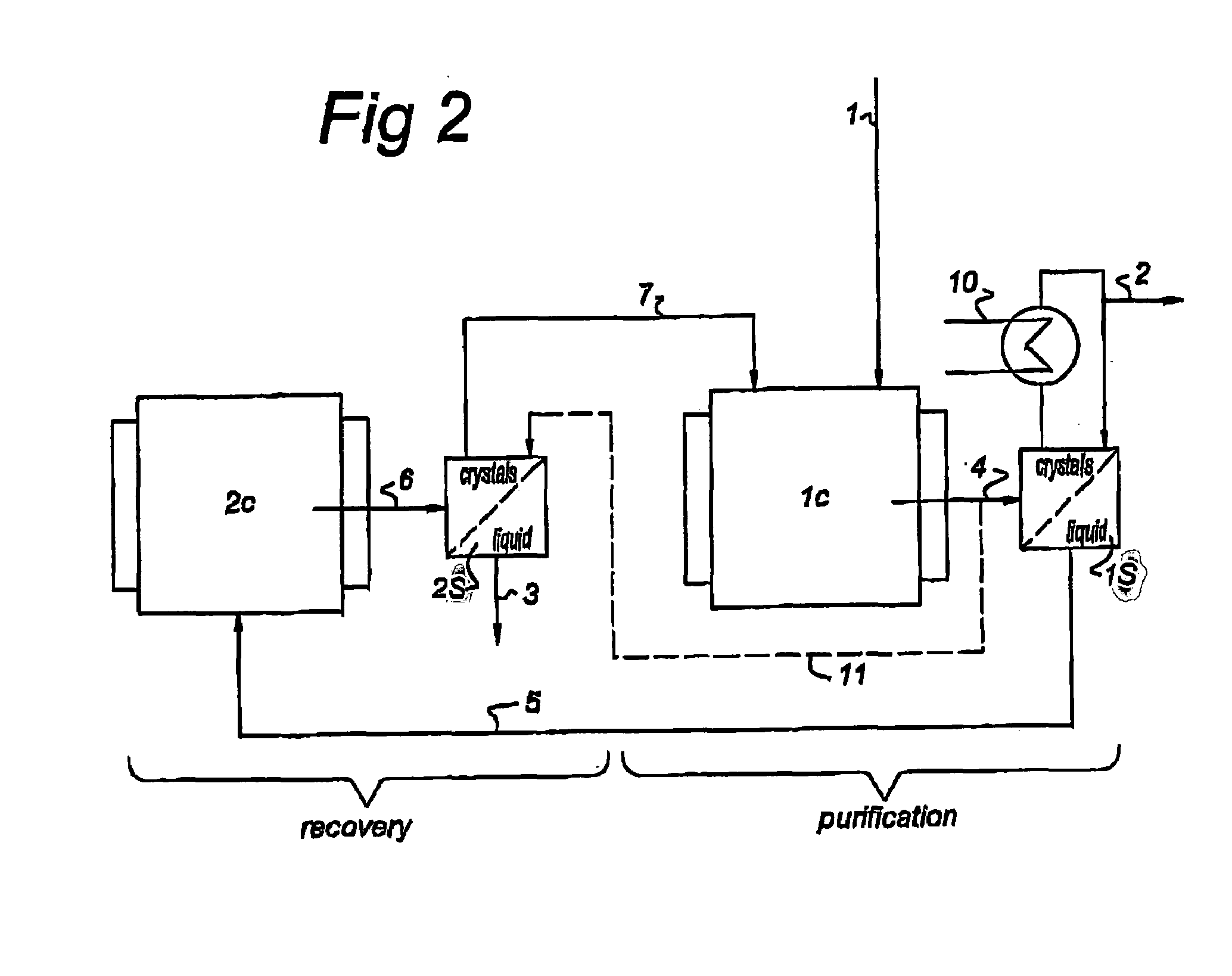

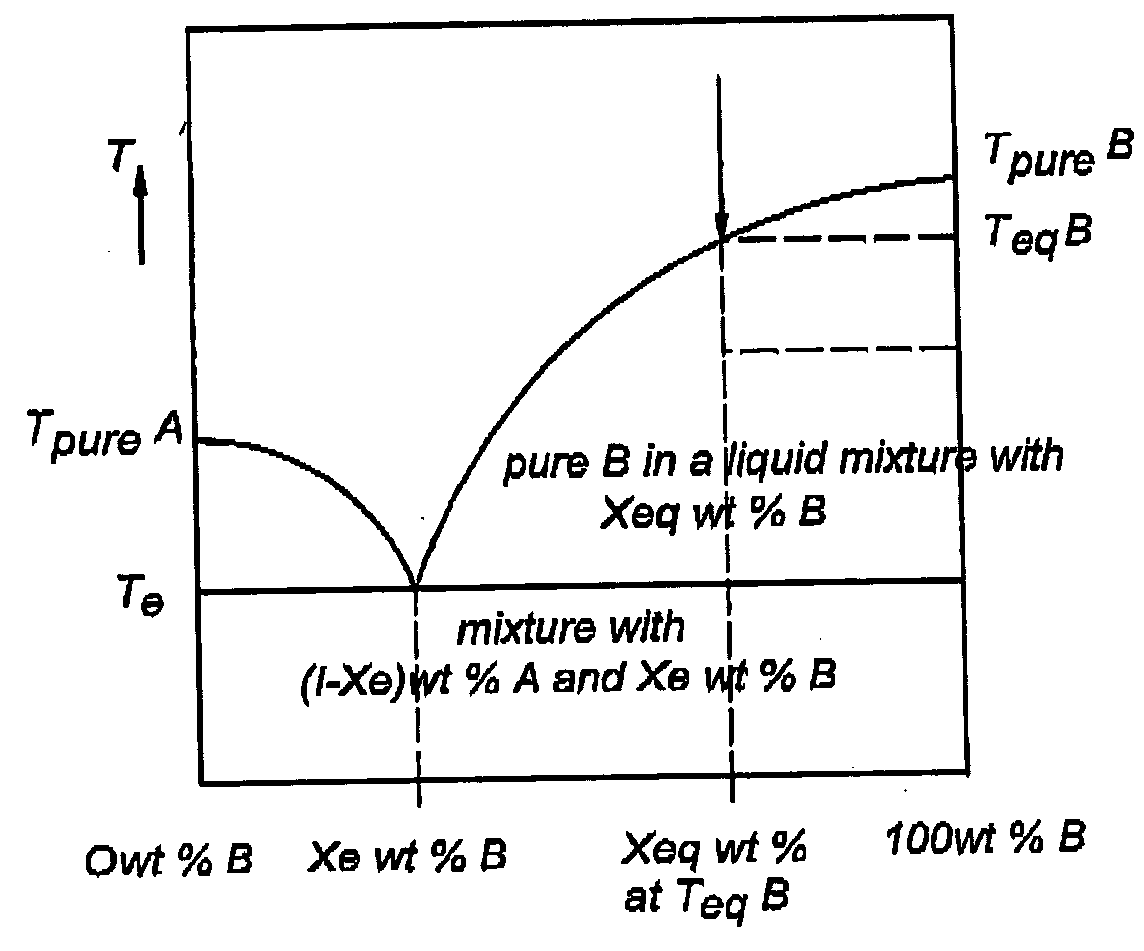

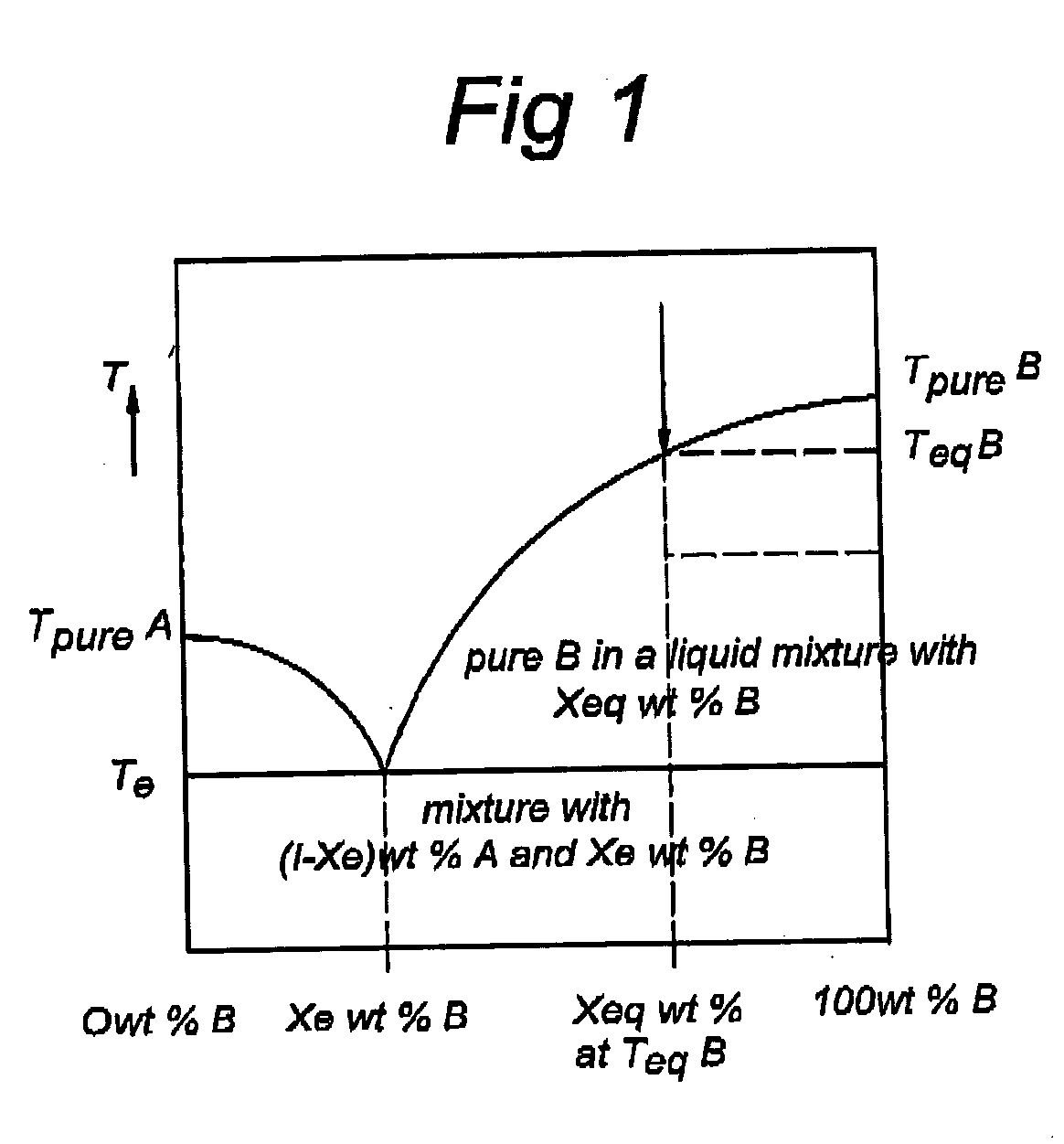

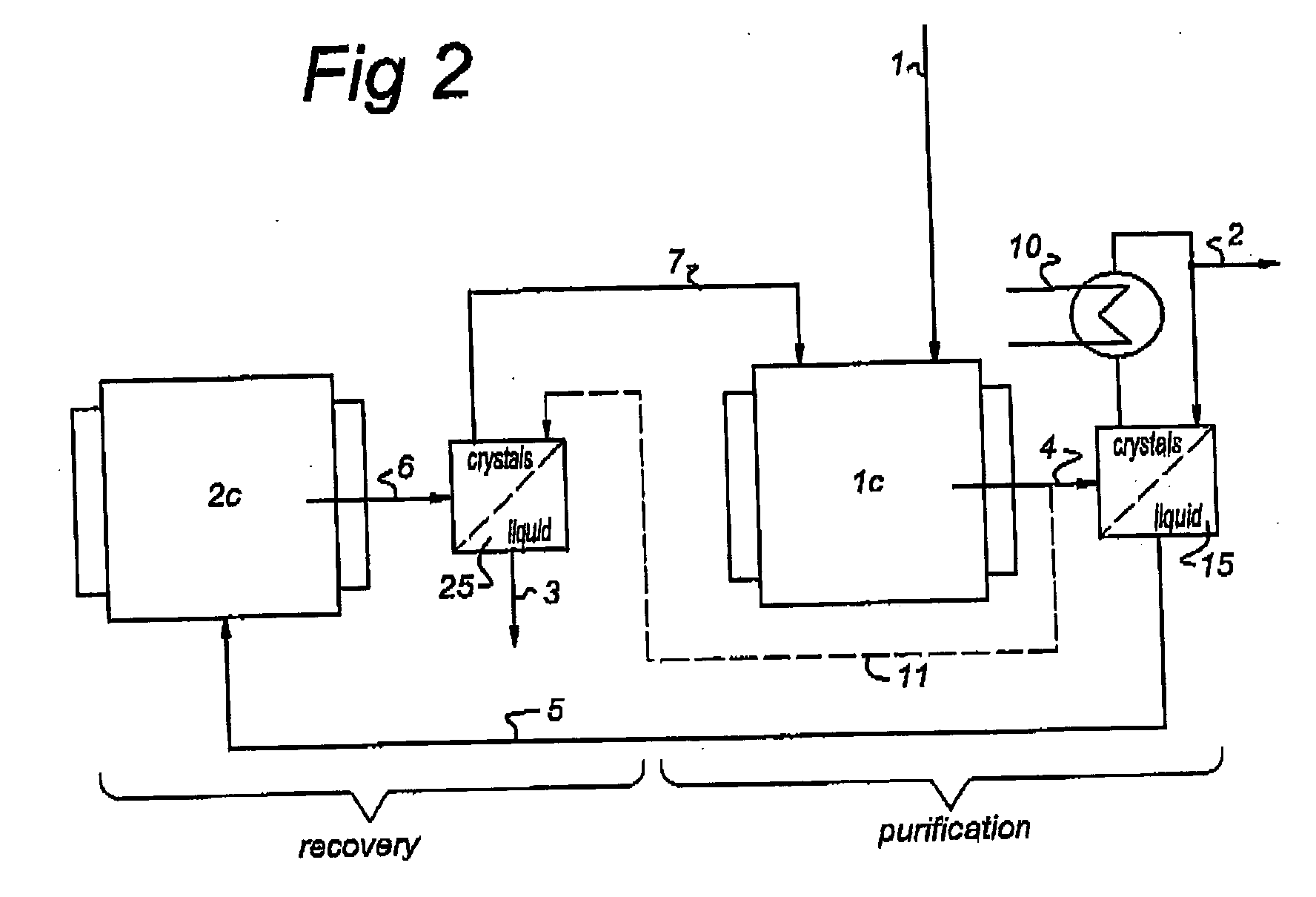

Method and apparatus for recovering a pure substance from an impure solution by crystallization

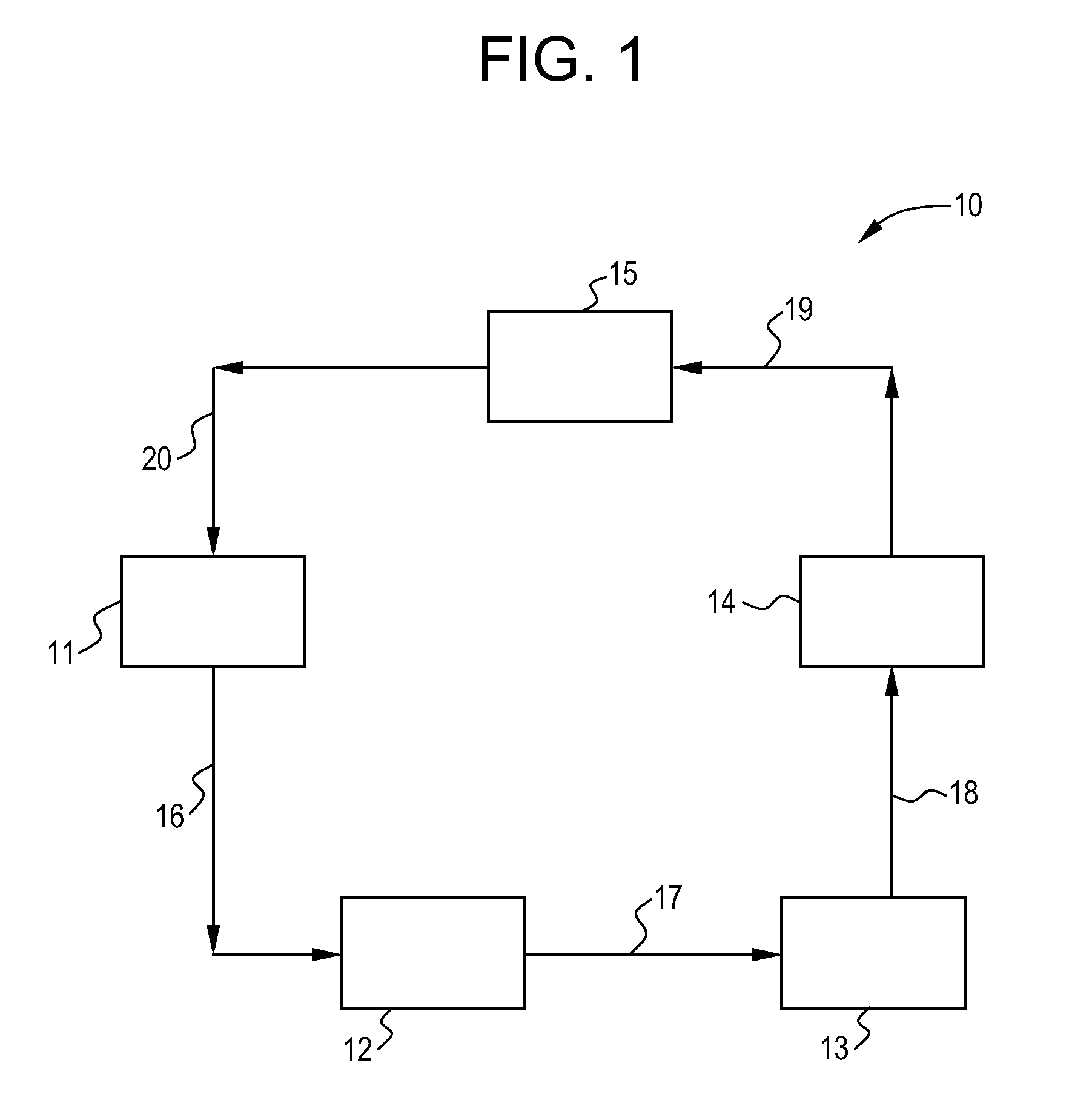

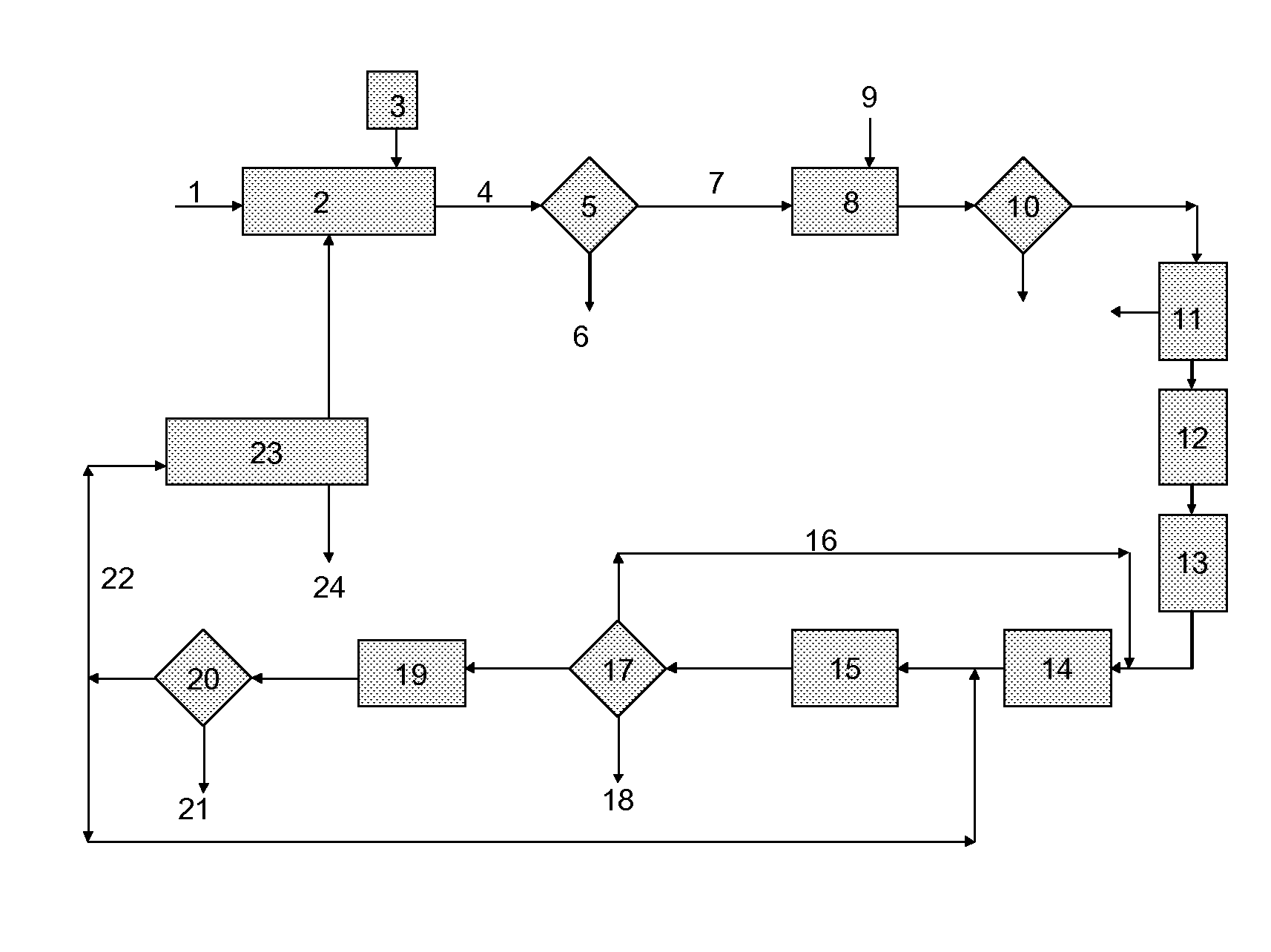

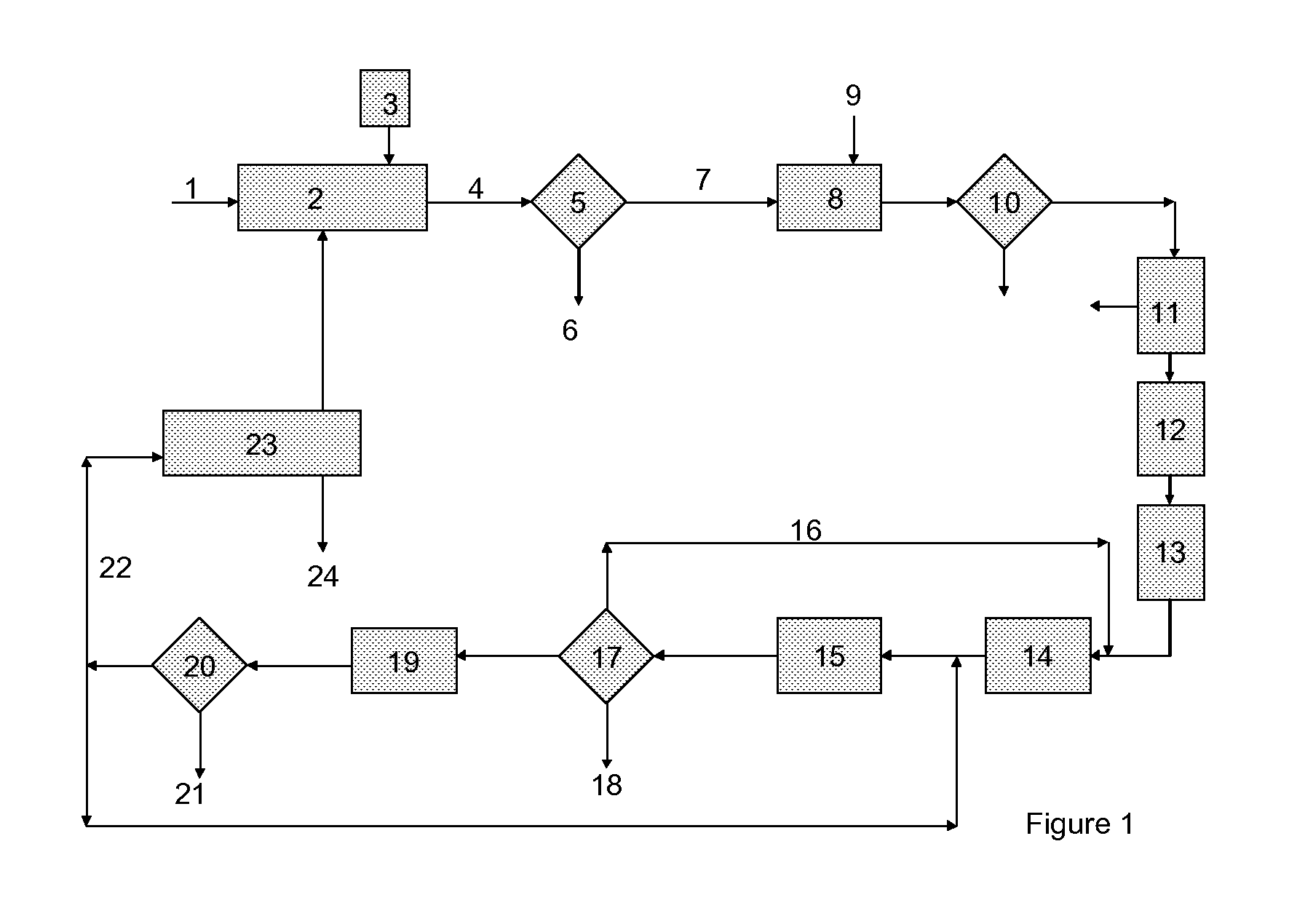

The invention relates to an apparatus for the purification of a substance from a solution, a suspension or a mixture of liquids by crystallization, preferably in a continuous manner. The apparatus comprises a first crystallizer (1c) comprising an input (1) for receiving a liquid comprising the substance and an output (4) for discharging a slurry of liquid and crystals. The apparatus comprises also a first separator (1s) connected to the output 4 of the first crystallizer (1c) having a product output (2), and being with a residue output (5) connected to an input of a second crystallizer (2c), and a second separator (2s) being with an input connected to an output (6) of the second crystallizer (2c), a crystal output (7) of the second separator (2s) being connected to an input of the first crystallizer (1c).

Owner:NIRO PROCESS TECH

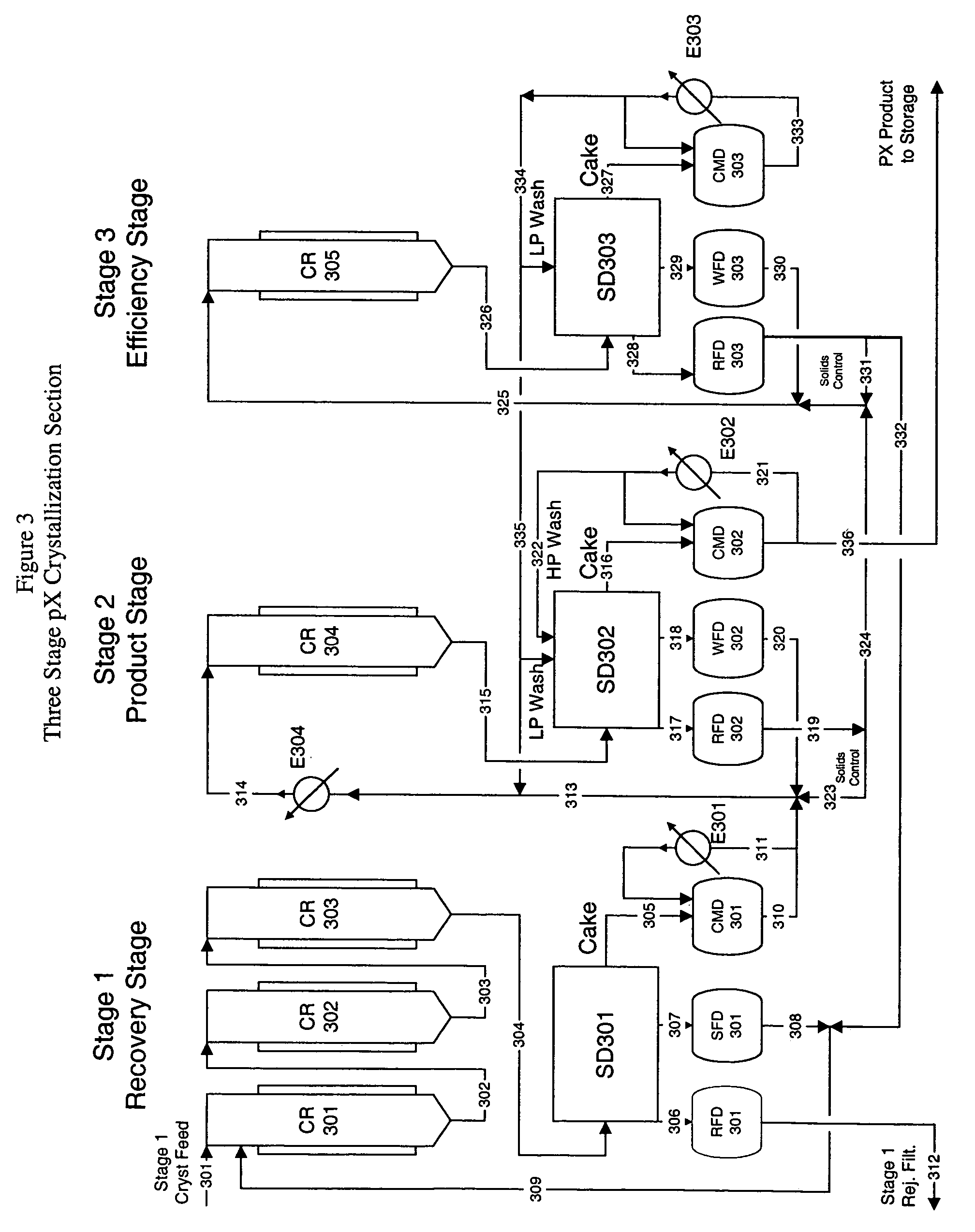

Process for recovering paraxylene utilizing ammonia absorption refrigeration

ActiveUS7405340B2Eliminate the problemLow costHydrocarbonsHeat exchange cooling cystallizationTolueneAmmonia

A process for recovering paraxylene from a substantially hydrocarbon feedstock. The recovery comprises cooling the hydrocarbon feedstock in at least one refrigerated crystallization stage that is indirectly refrigerated by evaporating at least a portion of a substantially liquid stream comprising ammonia. The crystallization stage may also be cooled by an ethylene refrigerant, which has been cooled by heat exchange with a substantially liquid stream comprising ammonia. The process further comprises a series of cooling substeps. This invention is also directed to an ammonia absorption refrigeration process powered by an enthalpy source from or near a paraxylene recovery unit.

Owner:BP CORP NORTH AMERICA INC

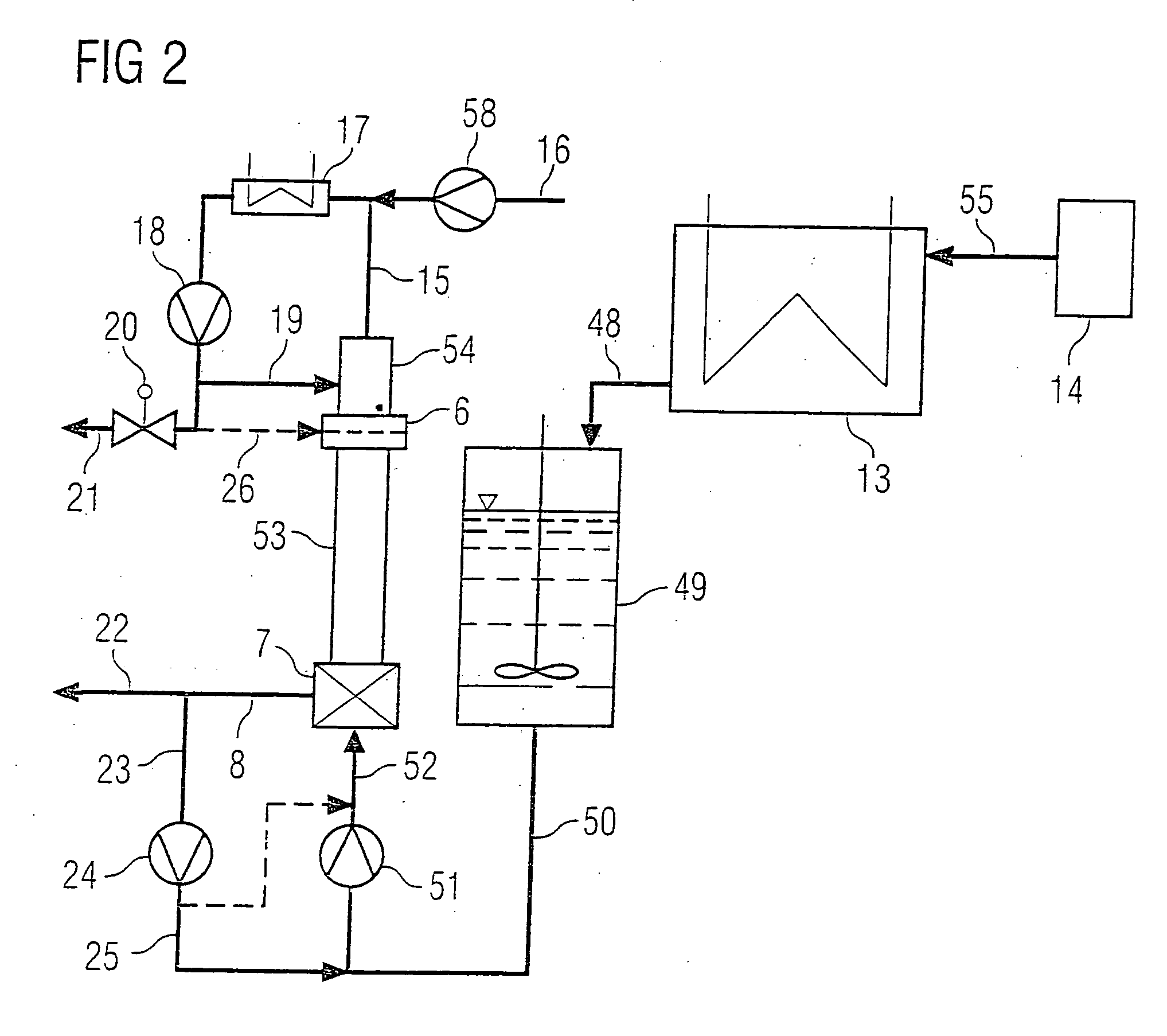

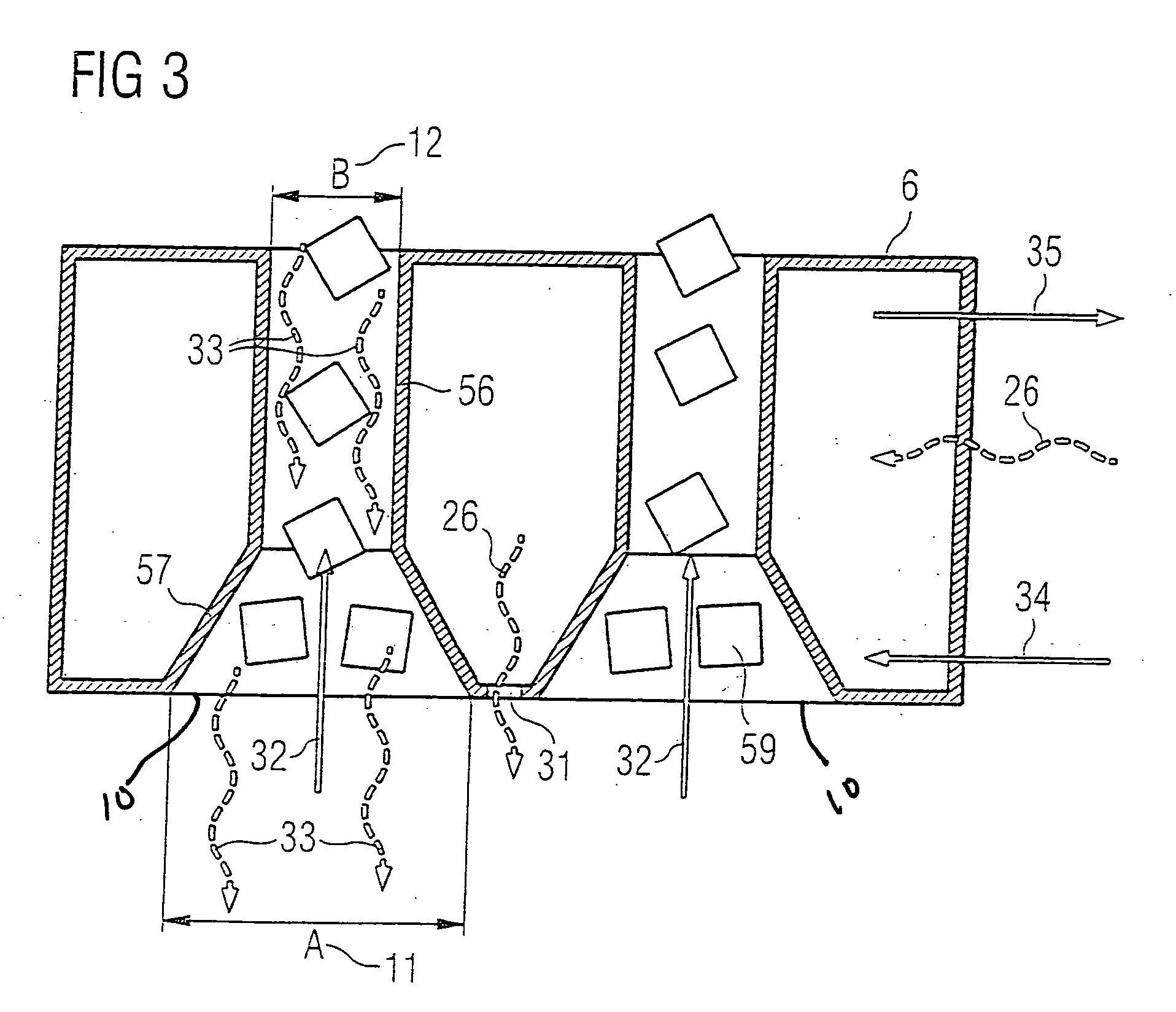

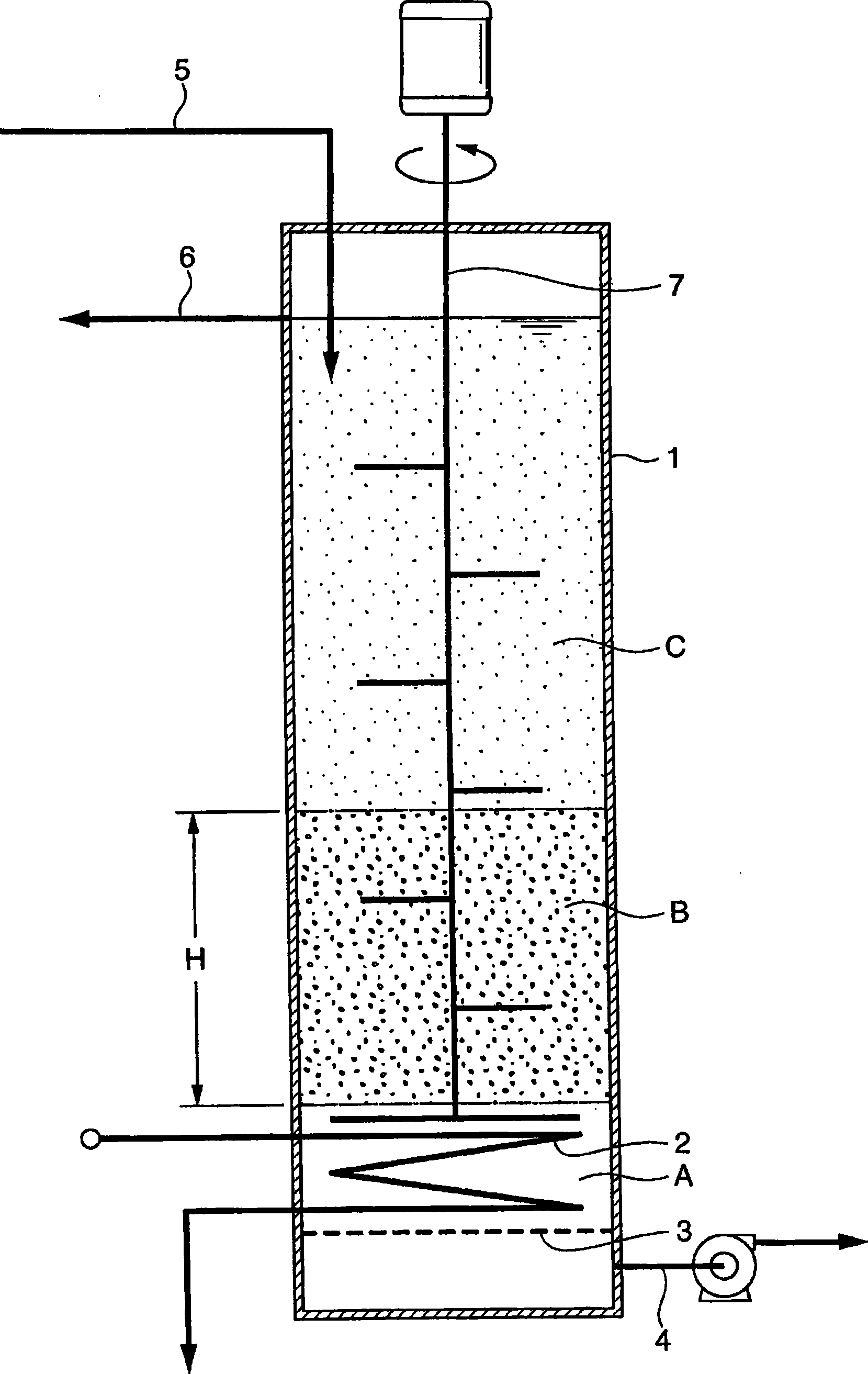

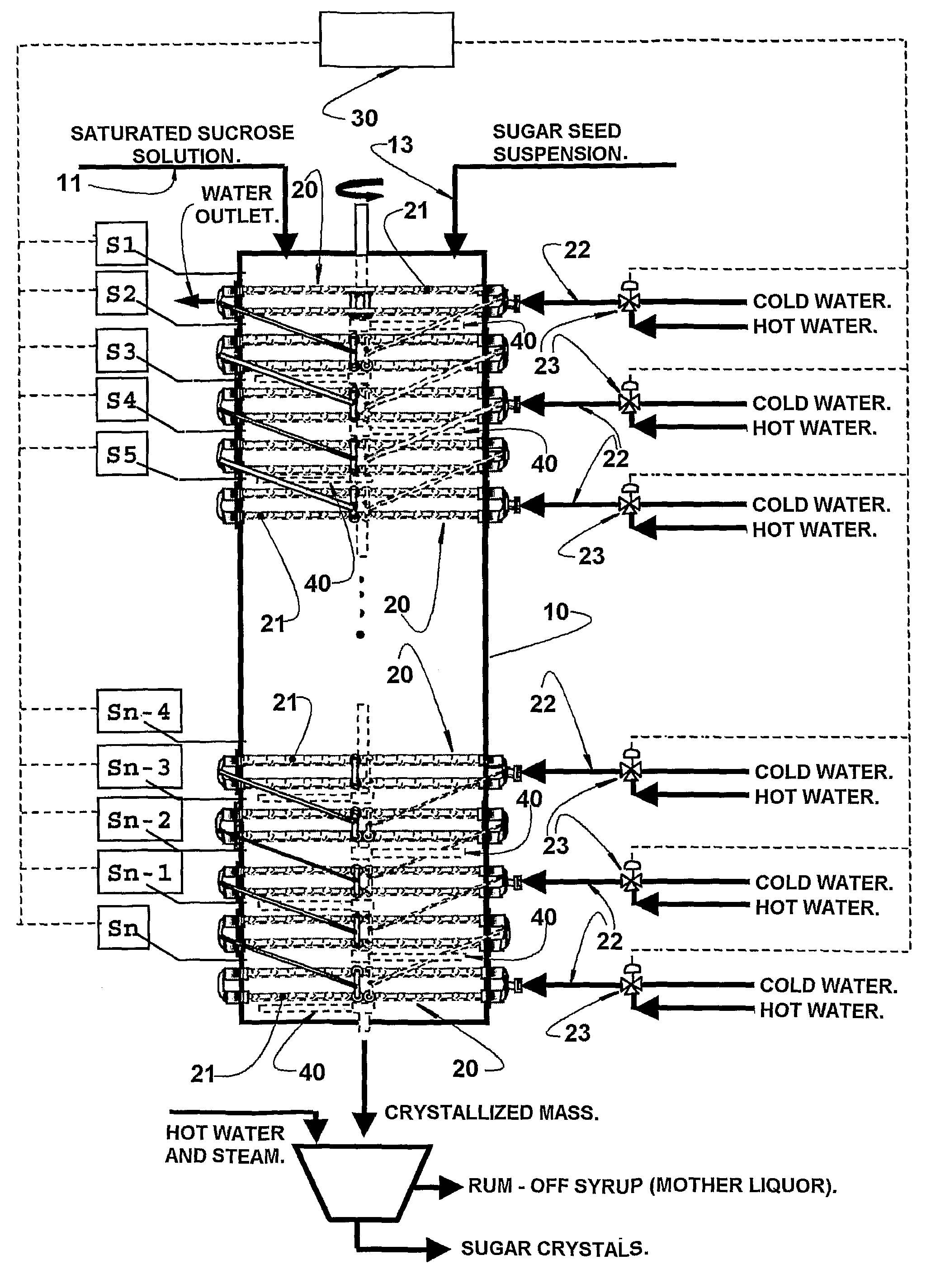

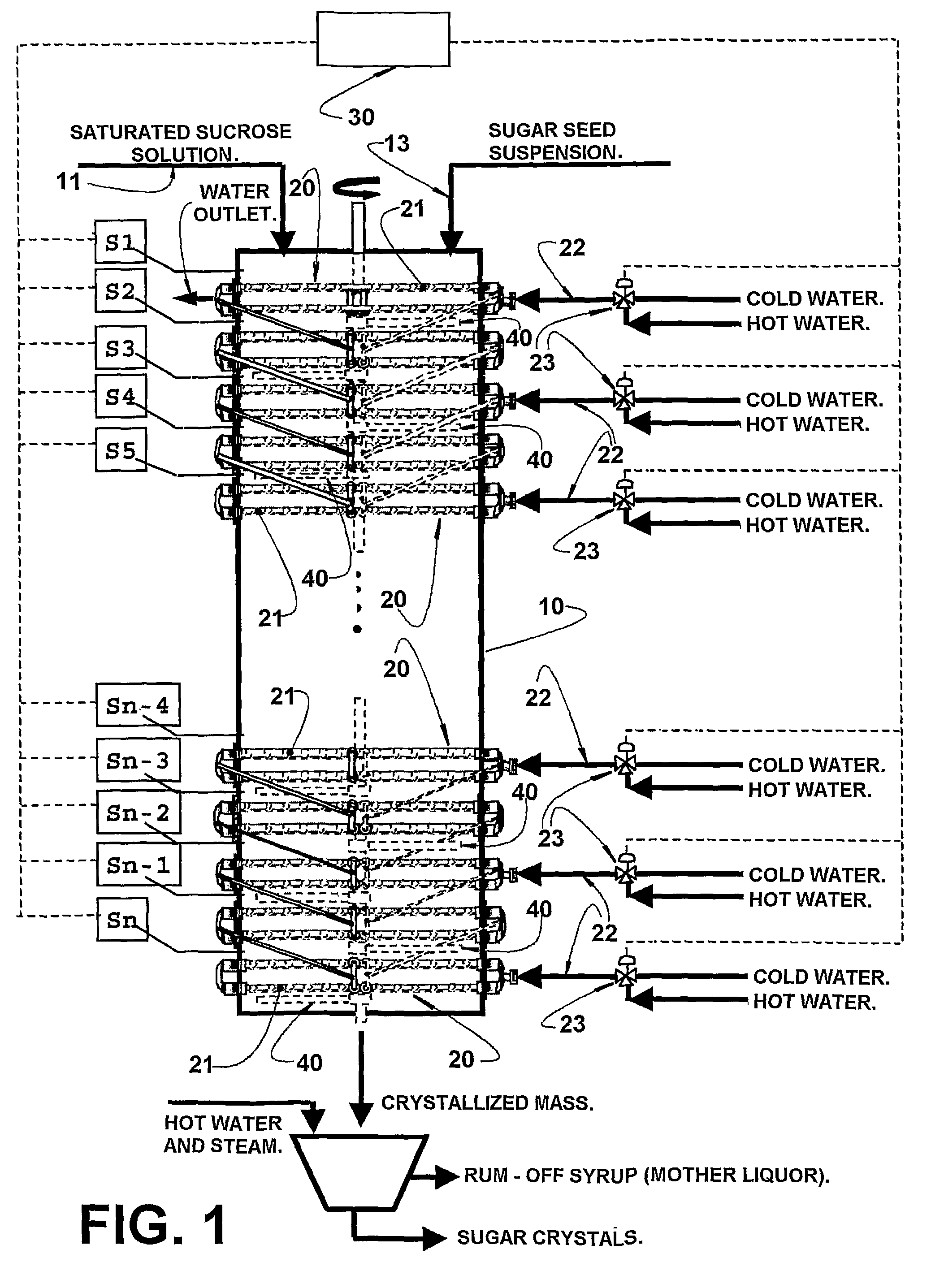

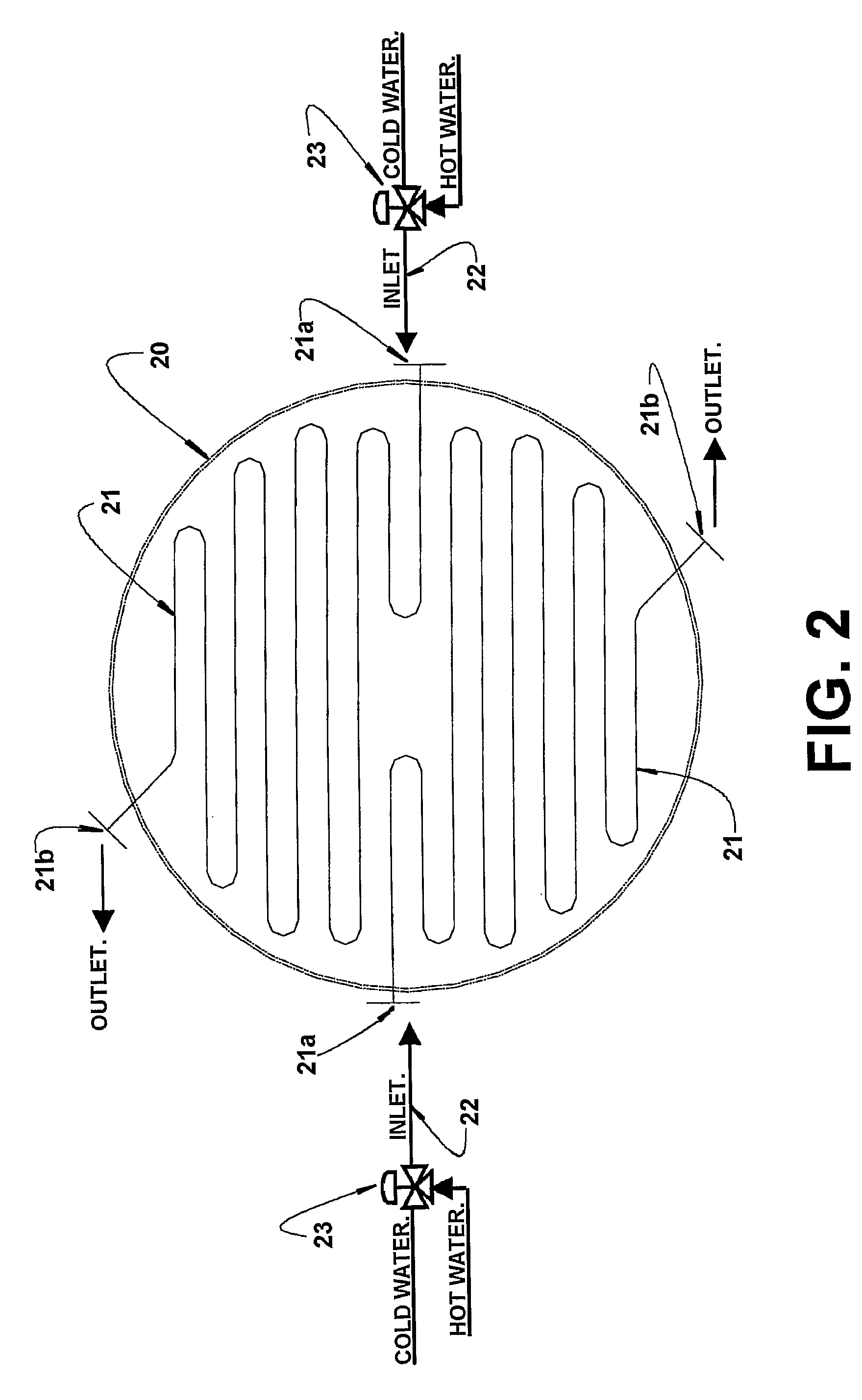

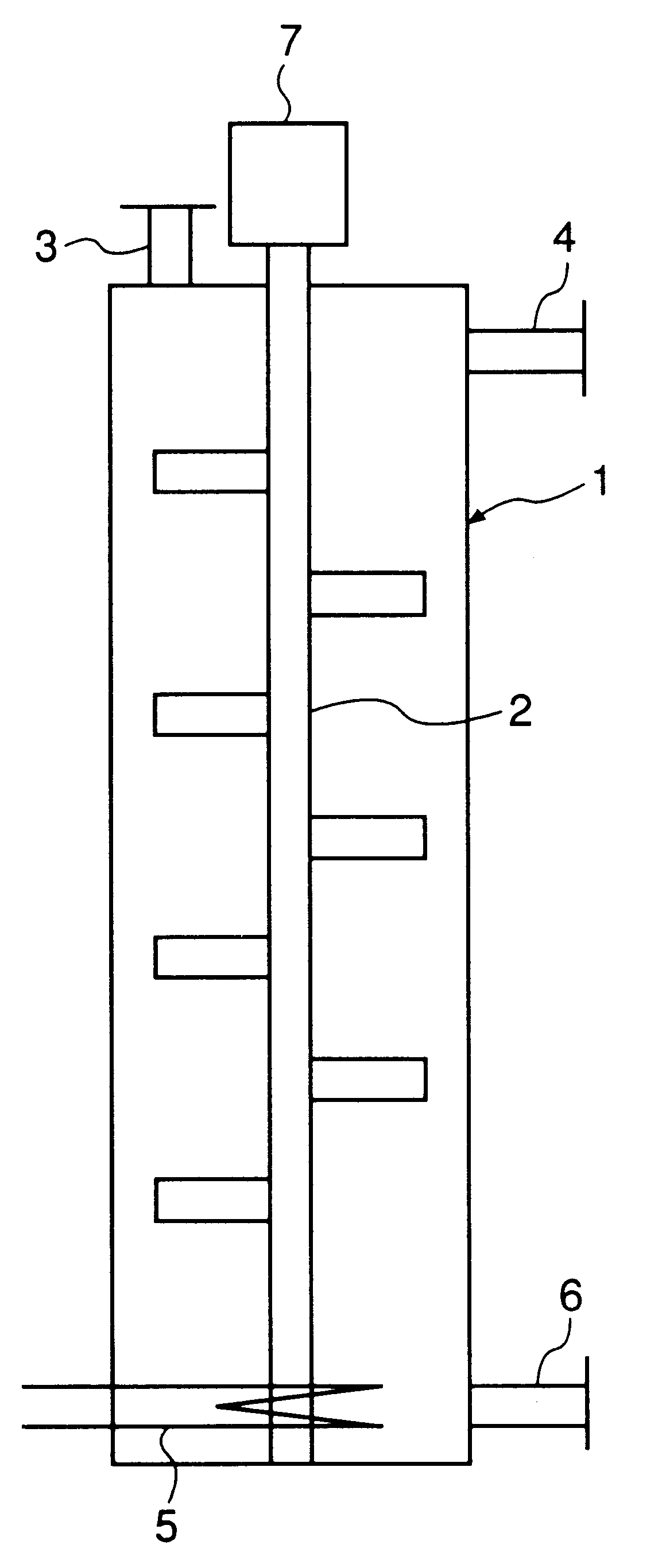

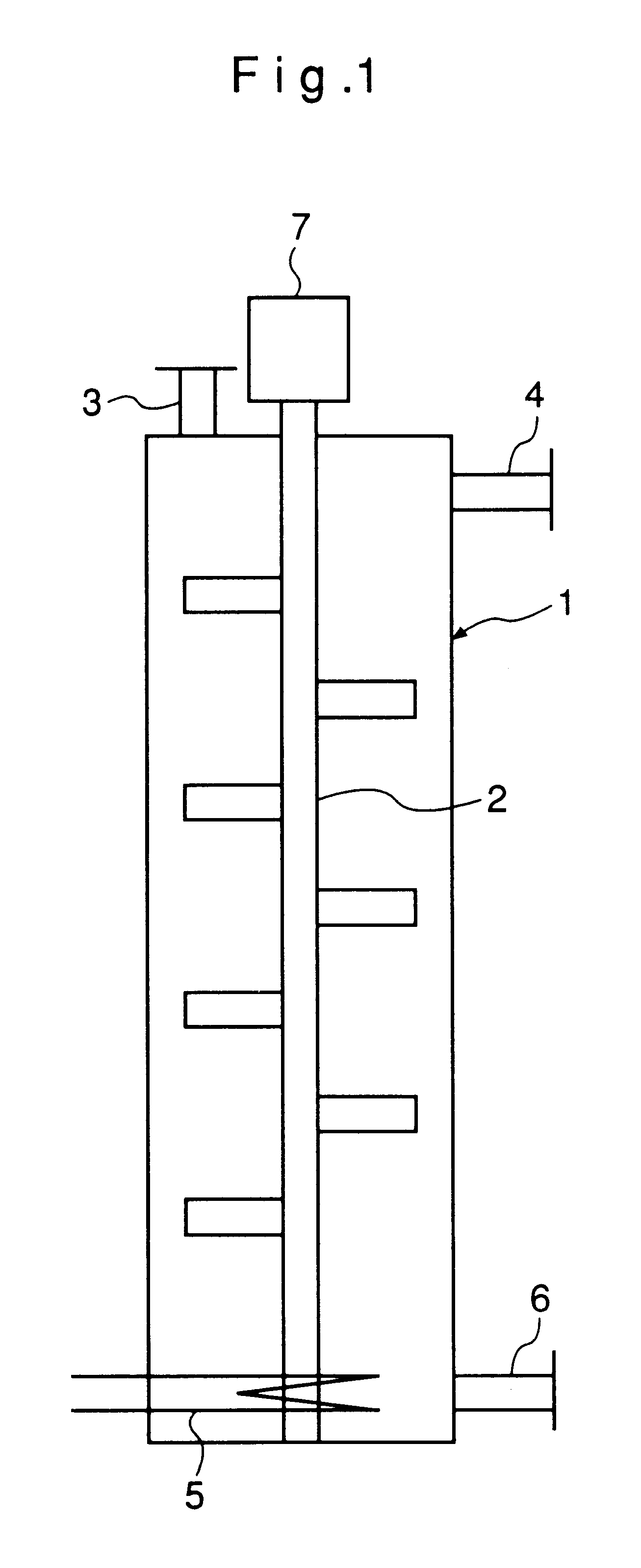

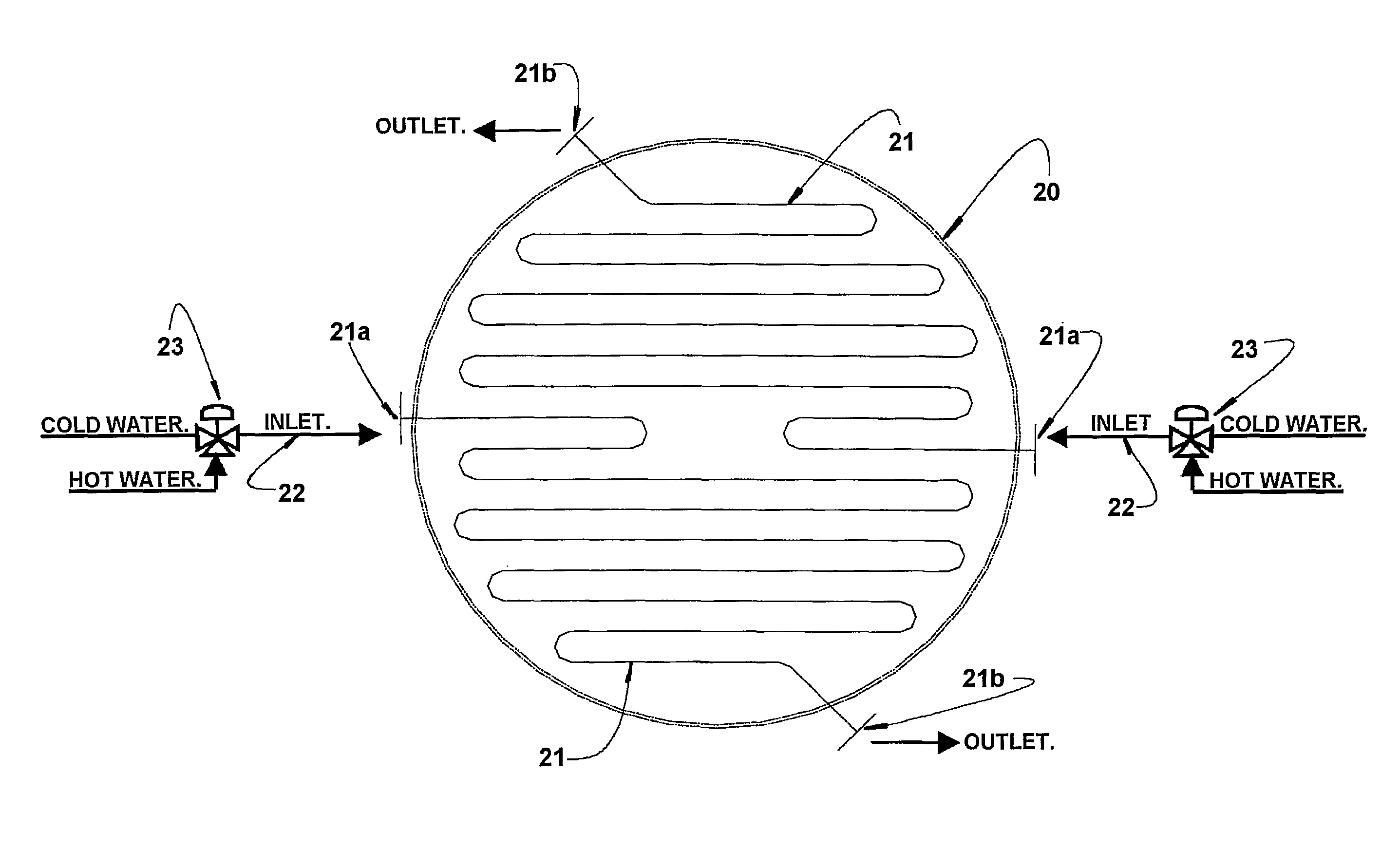

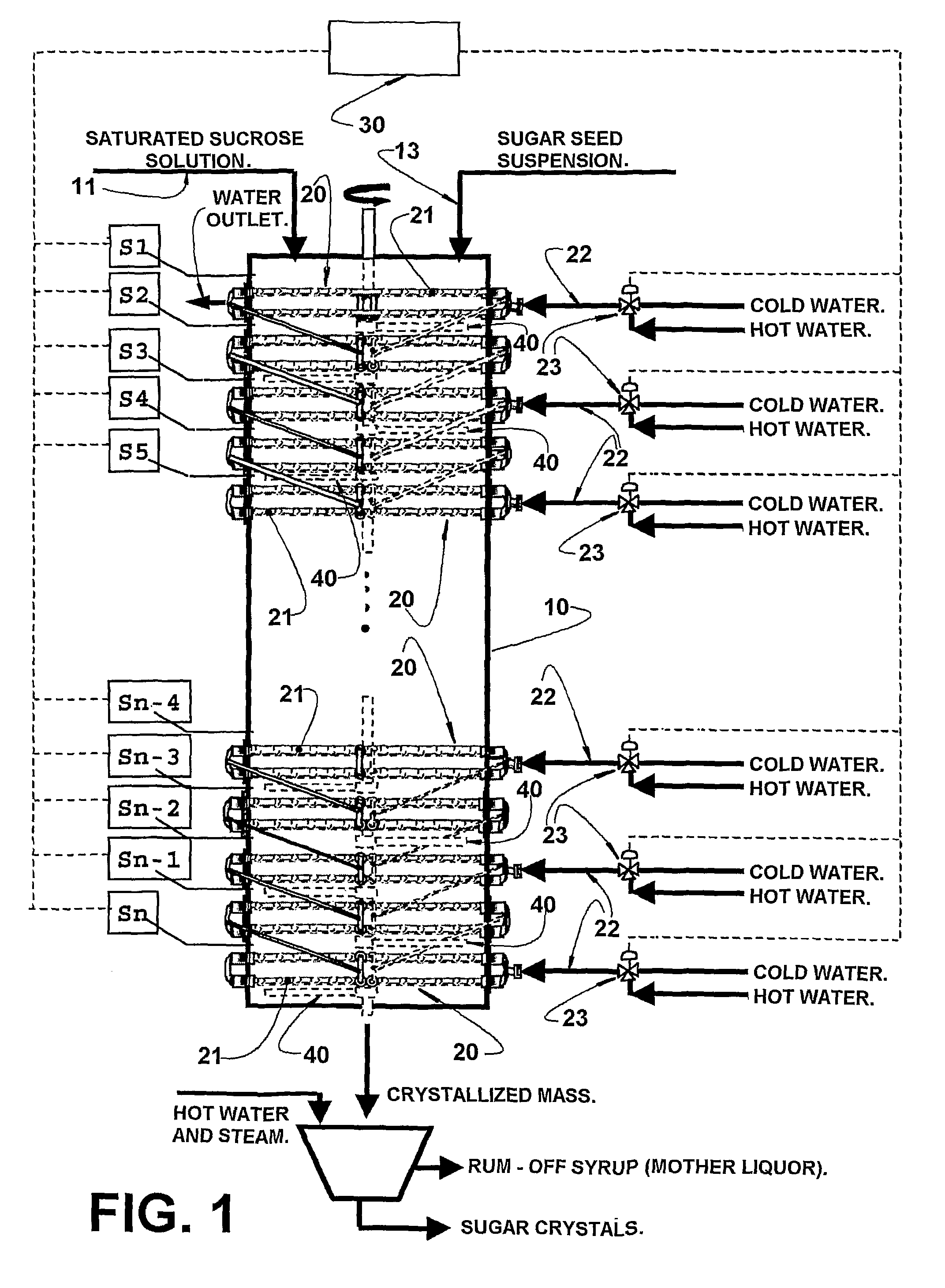

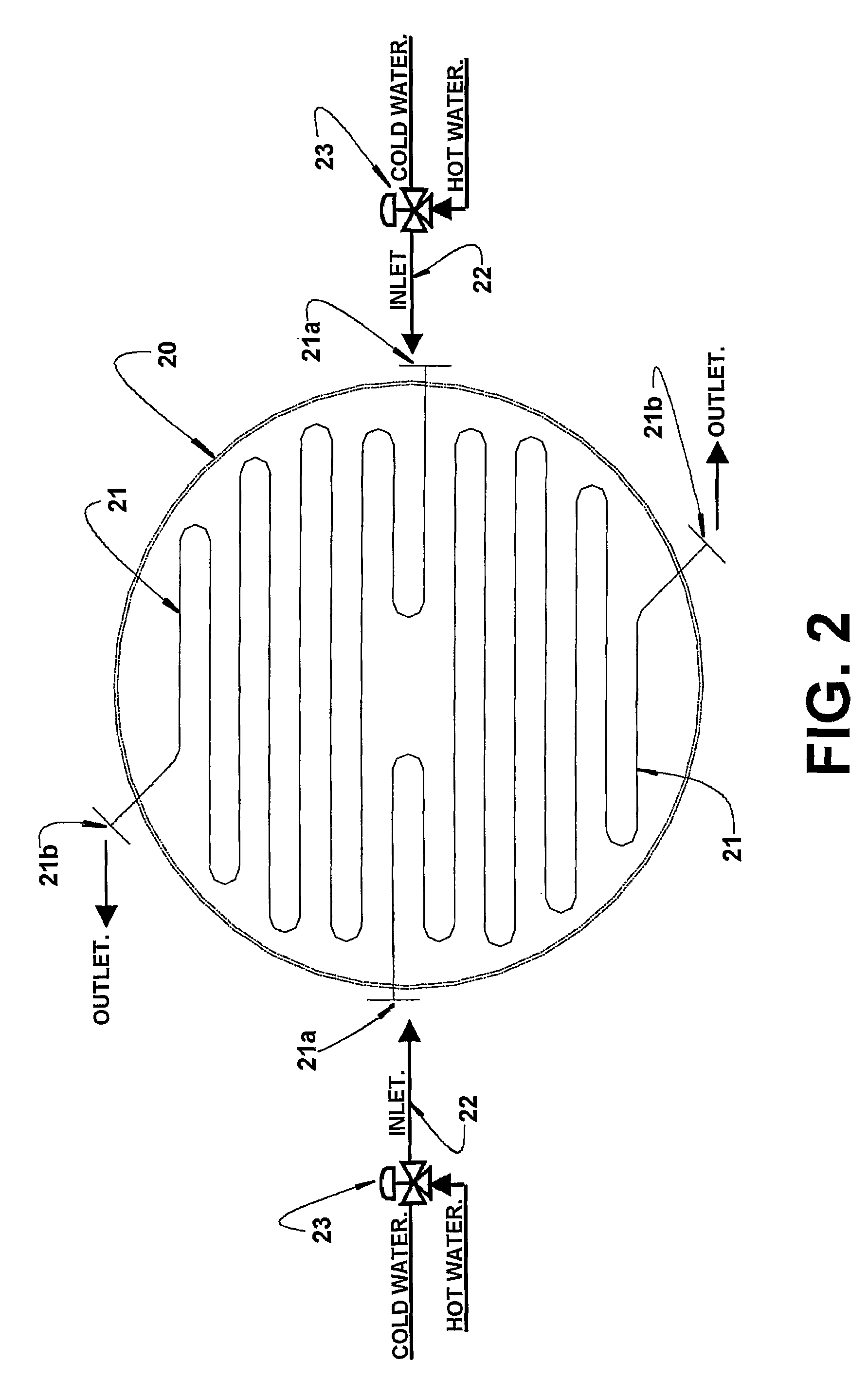

Process and equipment for sugar crystallization by controlled cooling

InactiveUS20100275907A1Sugar crystallisationHeat exchange cooling cystallizationContinuous flowSucrose solution

A process is proposed for crystallizing, by progressively cooling, in multiple stages arranged in series in a crystallization vessel (10), a descending continuous flow of a saturated sucrose solution at a temperature from about 78° to about 120° C., each stage maintaining the sucrose solution being crystallized at a predetermined temperature, until reaching a temperature from about 25 to 40° C., obtaining substantially pure sucrose crystals. A suspension containing sugar seeds is introduced in the crystallizing equipment, in the first stage, jointly with the saturated sucrose solution of 1.05-1.15. In another embodiment of the invention, the saturated solution is fed and its temperature is controlled, already in the first stage of the vessel (10), to obtain a supersaturation between 1.05 and 1.15, inducing the formation of small crystals used as crystallization seeds.

Owner:DEDINI S A IND DE BASE

Methods, devices, and systems for the separation and concentration of isotopologues

Owner:EXELON GENERATION CO LLC

Method for the production of enriched isopulegol

ActiveUS7868211B2Oxygen-containing compound preparationOrganic compound preparationMentholPolymer science

The present invention relates to a process for preparing enriched isopulegol by crystallization from a melt comprising isopulegol. The invention relates specifically to a process for preparing enantiomerically enriched n-isopulegol proceeding from optically active isopulegol having a relatively low enantiomeric excess by crystallization from the melt. The invention further relates to a process for preparing menthol proceeding from enantiomerically and / or diastereomerically enriched n-isopulegol prepared by crystallization from the melt.

Owner:BASF AG

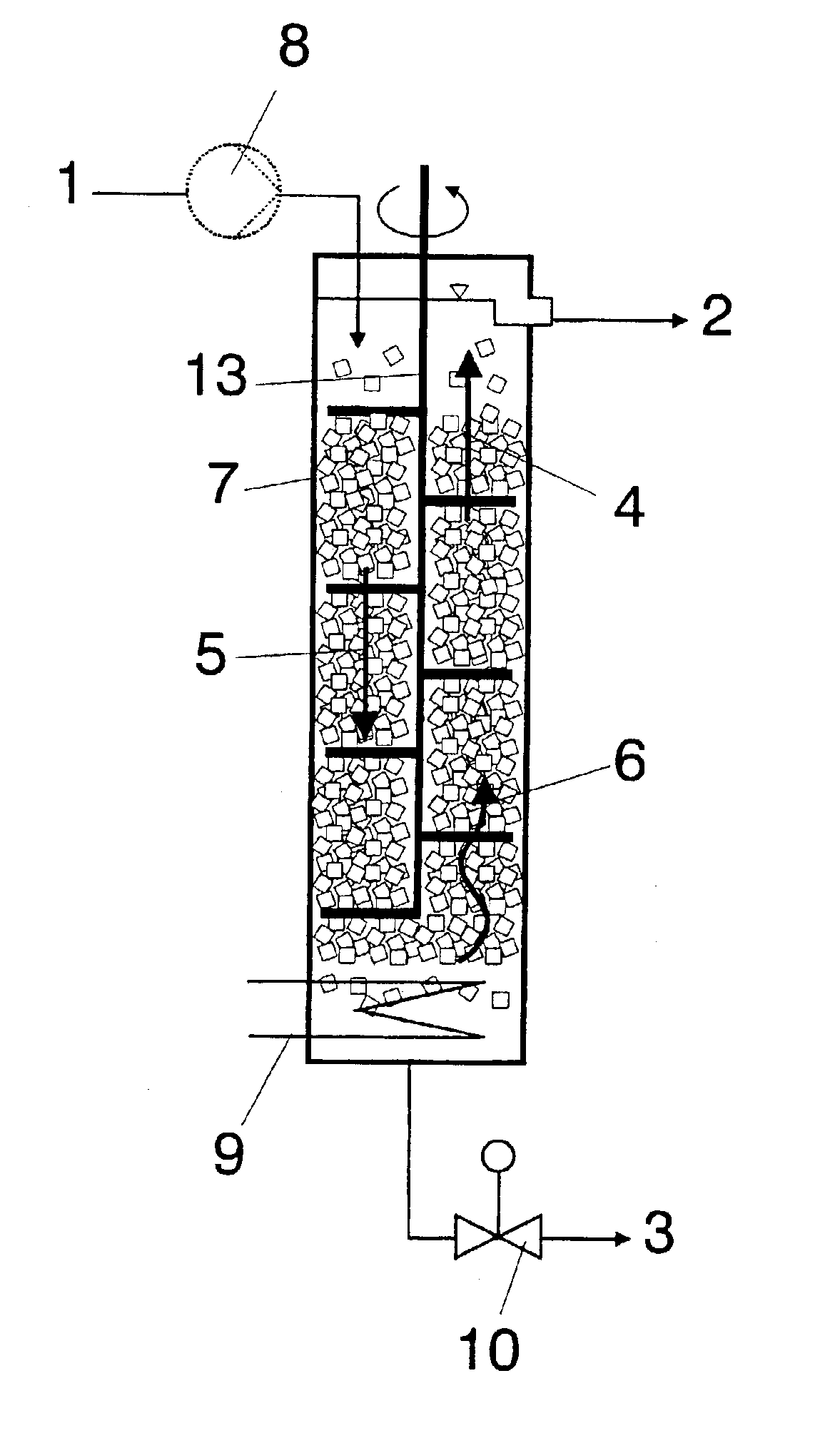

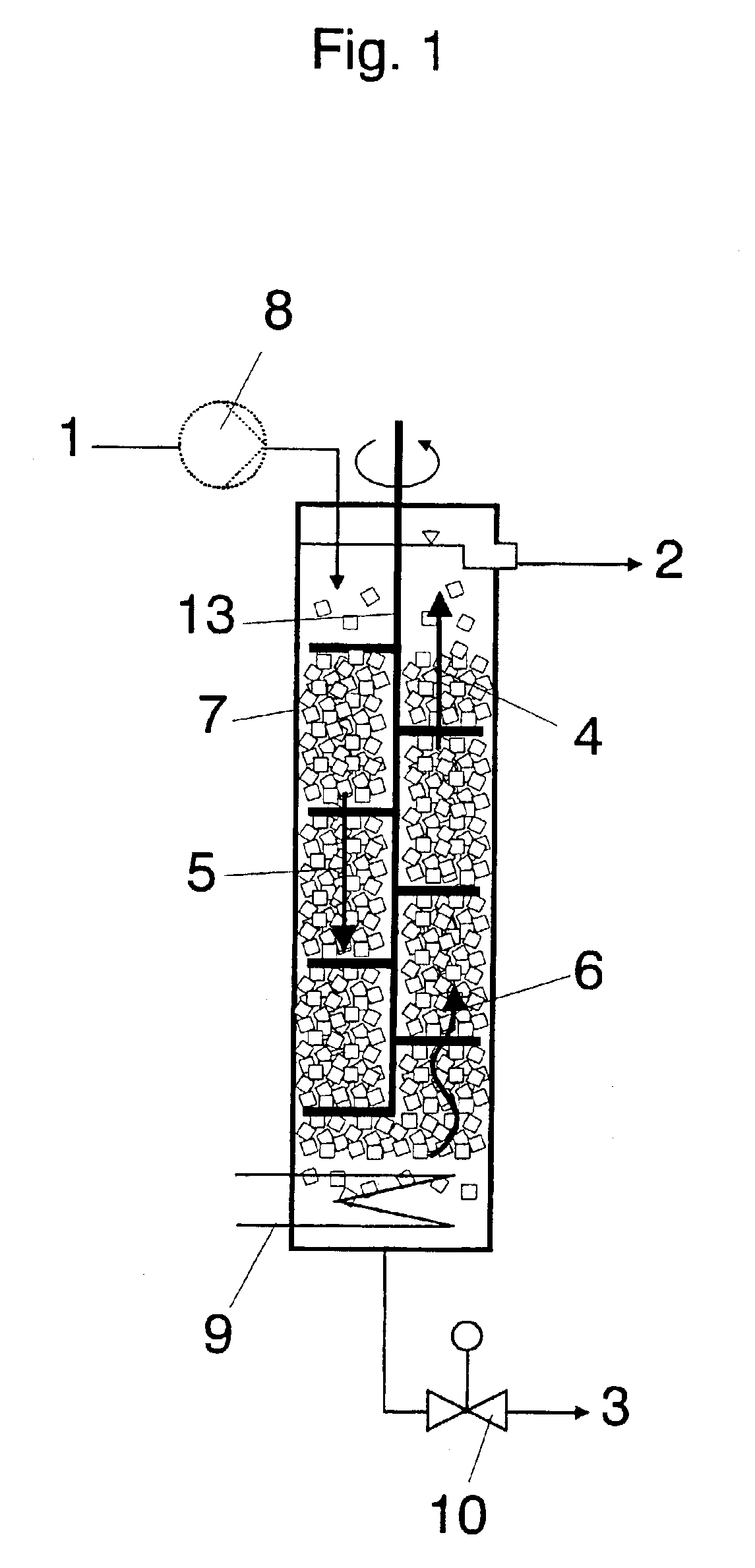

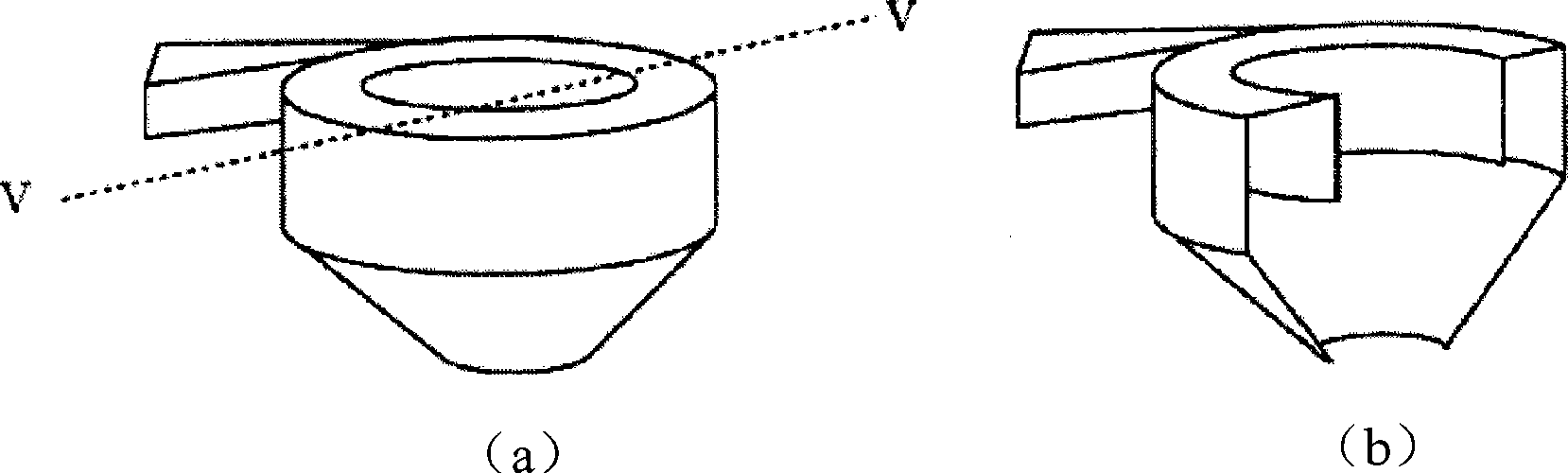

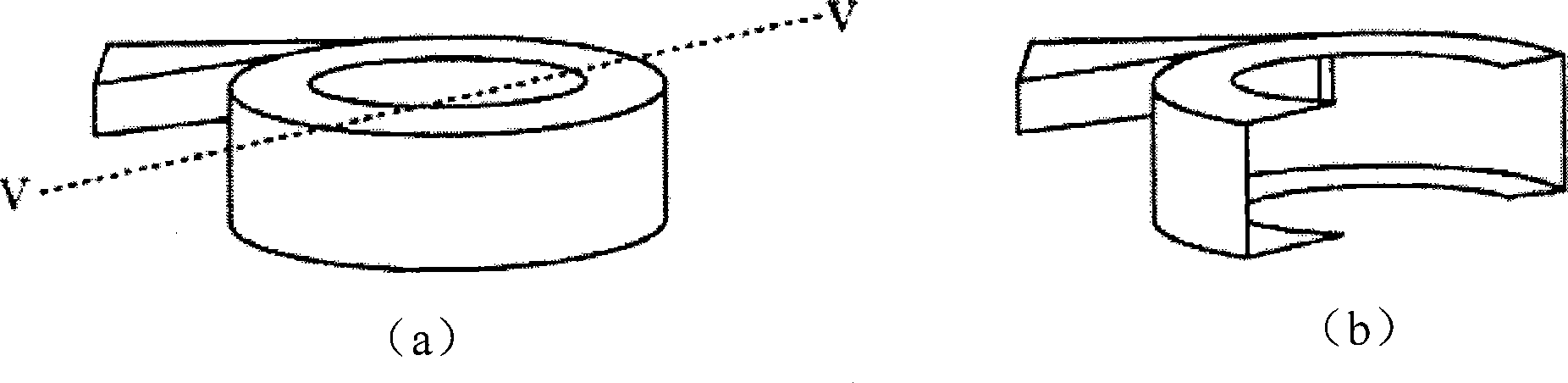

Fractionation processes and devices for oils and fats

ActiveUS20090264667A1Little hold-upEasy to useFatty oils/acids recovery from wasteShaking/oscillating/vibrating mixersEngineeringSolvent

The invention provides operating the dry or solvent fractionation of oils and fats in a crystallizer comprising a crystallization vessel (1,2), an agitator, cooling means and a drive, wherein said drive provides said agitator with an oscillating motion, and / or a rotating motion around an axis, with the proviso that each point of said agitator moves at substantially the same linear speed.The invention also provides a crystallizer comprising a crystallization vessel (1,2) having a polygonal cross-section, an agitator and a drive, wherein said drive provides said agitator with an oscillating motion, and wherein said agitator is not inclined to the moving direction.

Owner:DESMET BELGIUM

Method of refining benzoic acid

InactiveUS6211404B1Organic compound preparationSolid sorbent liquid separationBenzoic acidCounter current

This invention relates to a process for purifying benzoic acid continuously to a purity of 99.9% or more by introducing crystals of crude benzoic acid with a bulk density of 0.2 g / cm3 or more and an average particle diameter of 0.3 mm or more into a continuous crystallization apparatus equipped with a stirrer and a heating device from the upper portion of the apparatus, effecting counter-current contact of the falling crystals of crude benzoic acid with the melt generated by heating with the heating device, withdrawing the purified benzoic acid as melt from the lower portion of the apparatus, and withdrawing the mother liquor from the upper portion of the apparatus. The process makes it possible to prepare high-purity benzoic acid continuously in a relatively simple apparatus at high efficiency.

Owner:NIPPON STEEL CHEMICAL CO LTD

Continuous fractionation of triglyceride oils

ActiveUS20130123524A1Lower energy requirementsSave on infrastructureFatty oils/acids recovery from wasteFatty acids production/refiningPhysical chemistryTriglyceride

A continuous process for the dry fractionation of edible oils and fats using one or more crystallisers in series, said process comprising the steps of: (a) providing a molten fat; (b) continuously feeding said molten oil or fat to the first of said one or more crystallisers in series in which the fat is gradually cooled by using heat exchangers containing a cooling medium so that a crystal slurry is formed, each of said one or more crystallisers exhibiting a temperature gradient, the temperature at the point where the molten or partially crystallised fat enters one of the crystallisers being higher than that at the point where the slurry leaves that crystalliser; (c) continuously withdrawing said slurry from the last of said one or more crystallisers; (d) separating said crystal slurry by filtration in a filter cake and a filtrate, wherein said process further comprises the step of at least partially melting fat encrustations deposited on said heat exchangers; and an oil fraction produced by therefrom.

Owner:DESMET BELGIUM

Method and apparatus for recovering a pure substance from an impure solution by crystallization

ActiveUS20050074378A1Reduce complexityReduce the numberLiquid solutions solvent extractionHeat exchange cooling cystallizationEngineeringSlurry

The invention relates to an apparatus for the purification of a substance from a solution, a suspension or a mixture of liquids by crystallization, preferably in a continuous manner. The apparatus comprises a first crystallizer (1c) comprising an input (1) for receiving a liquid comprising the substance and an output (4) for discharging a slurry of liquid and crystals. The apparatus comprises also a first separator (1s) connected to the output 4 of the first crystallizer (1c) having a product output (2), and being with a residue output (5) connected to an input of a second crystallizer (2c), and a second separator (2s) being with an input connected to an output (6) of the second crystallizer (2c), a crystal output (7) of the second separator (2s) being connected to an input of the first crystallizer (1c).

Owner:NIRO PROCESS TECH

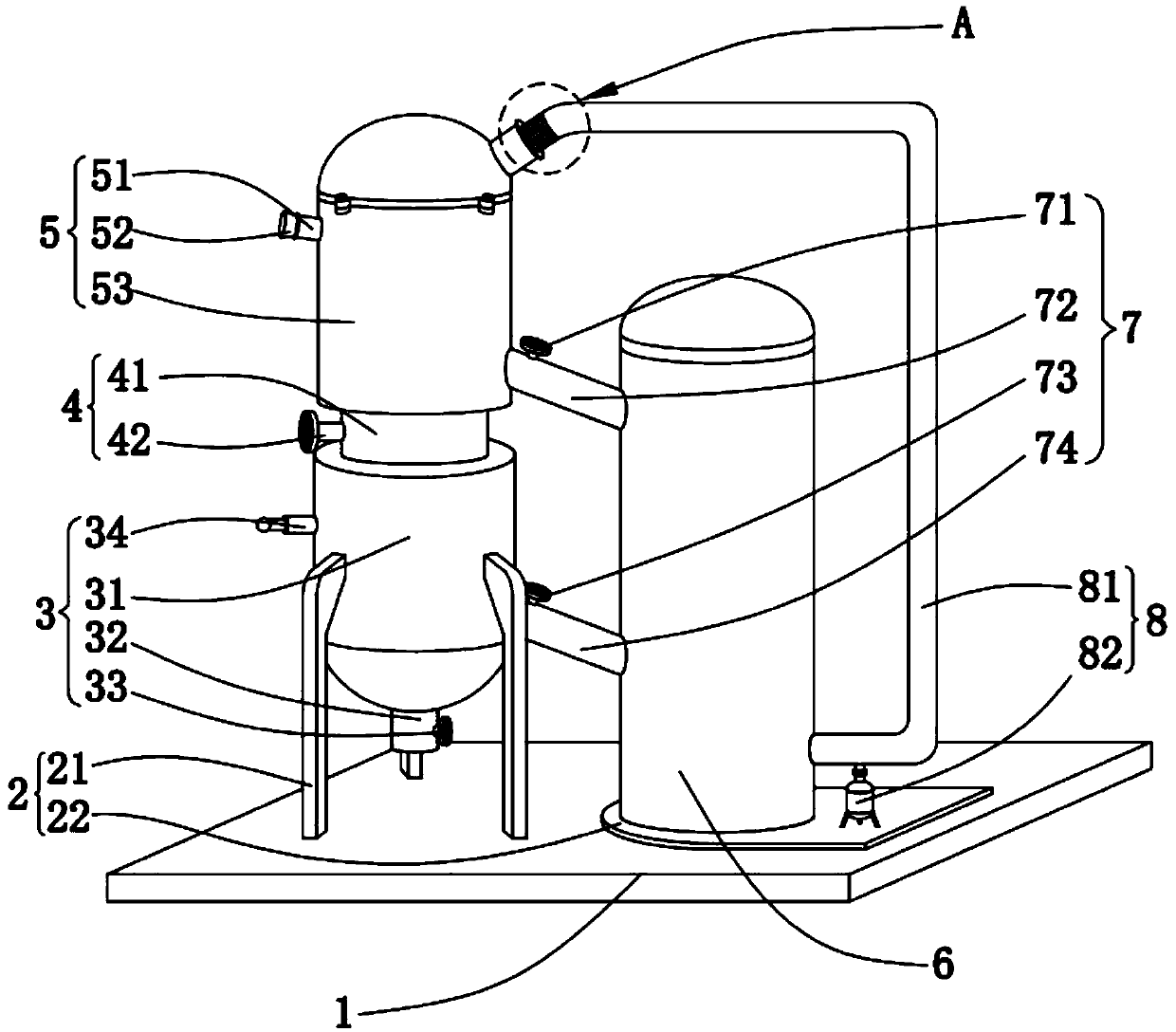

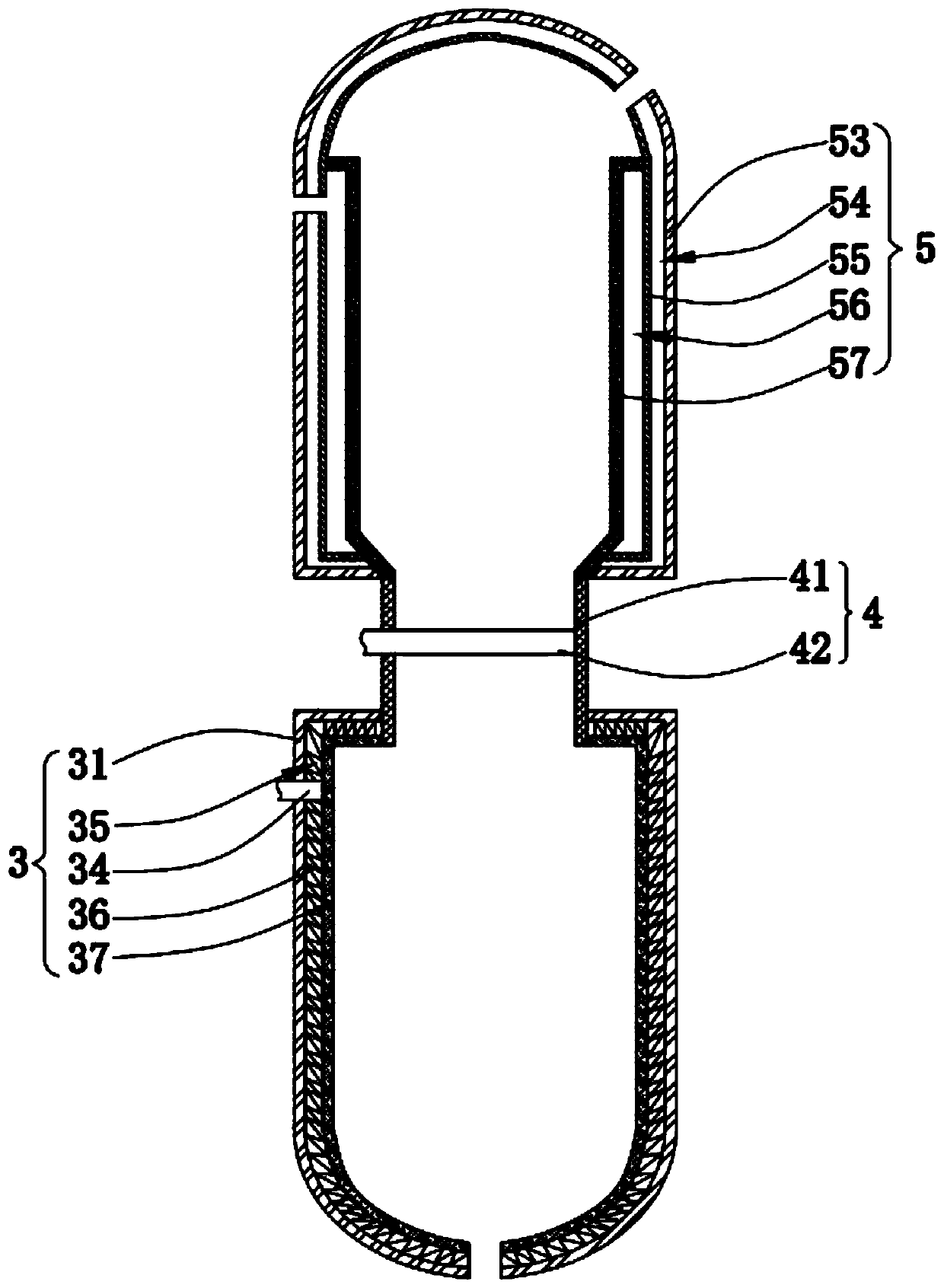

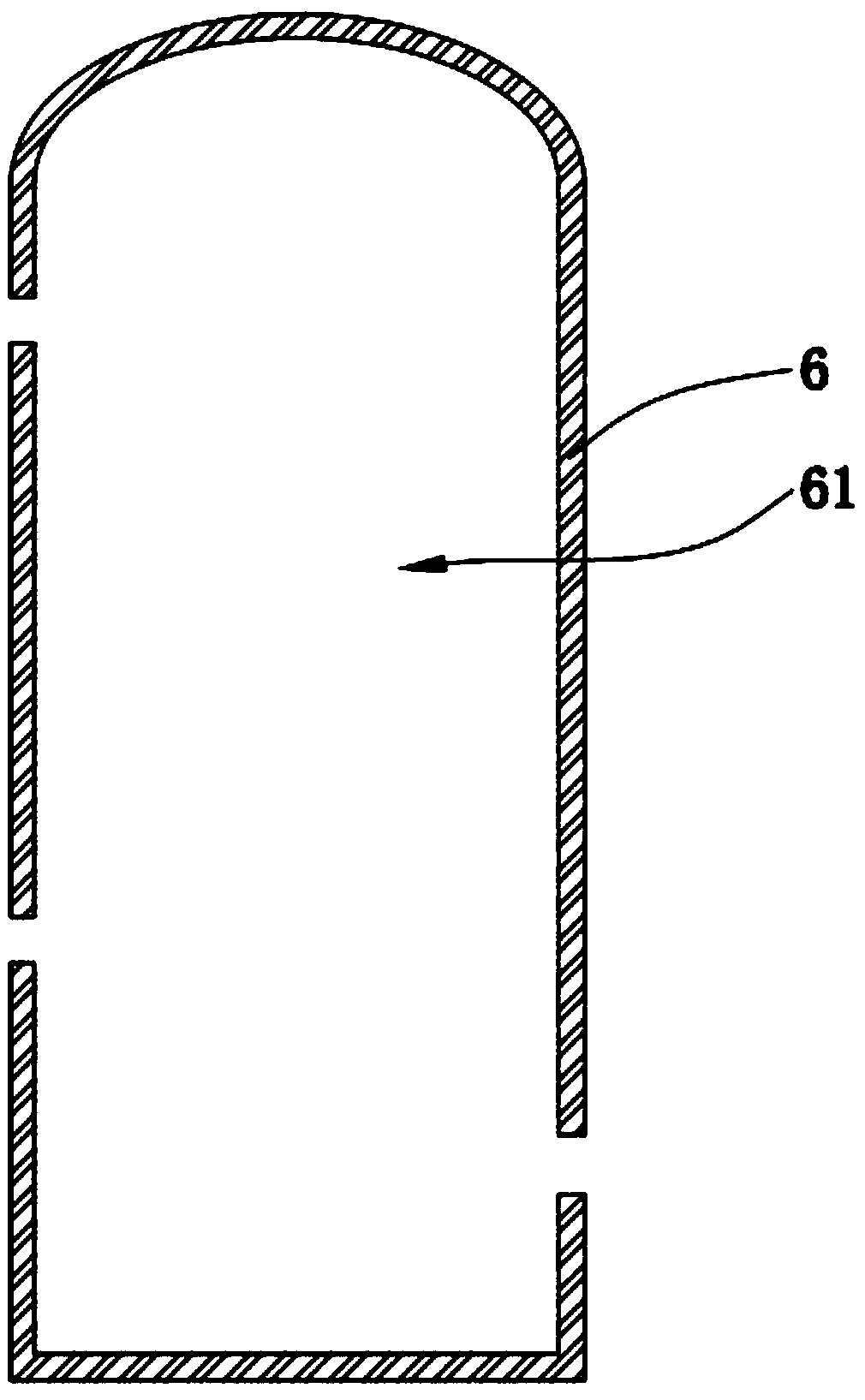

Static state fusing crystallizer used for material purifying and separating

ActiveCN109621478AAvoid wastingEasy to operateFractional crystallizationPulp and paper industryPure crystal

Owner:山西鑫海翔新材料有限公司

Filter melting method for separating mixtures

ActiveUS9248455B2Easy to separateLiquid suspension thickening by filtrationRotary centrifugesFilter mediaLiquid solid

The present invention provides a method and apparatus using a meltable filter medium for separating a mixture to be separated (liquid-solid or liquid-liquid mixture). The mixture to be separated is separated into a liquid passing through a filter layer of the filter medium and a captured material captured in the filter layer. The filter medium and the captured material are separated by melting the filter medium.

Owner:JO

Process and equipment for sugar crystallization by controlled cooling

InactiveUS8475597B2Sugar crystallisationHeat exchange cooling cystallizationContinuous flowSucrose solution

A process is proposed for crystallizing, by progressively cooling, in multiple stages arranged in series in a crystallization vessel (10), a descending continuous flow of a saturated sucrose solution at a temperature from about 78° to about 120° C., each stage maintaining the sucrose solution being crystallized at a predetermined temperature, until reaching a temperature from about 25 to 40° C., obtaining substantially pure sucrose crystals. A suspension containing sugar seeds is introduced in the crystallizing equipment, in the first stage, jointly with the saturated sucrose solution of 1.05-1.15. In another embodiment of the invention, the saturated solution is fed and its temperature is controlled, already in the first stage of the vessel (10), to obtain a supersaturation between 1.05 and 1.15, inducing the formation of small crystals used as crystallization seeds.

Owner:DEDINI S A IND DE BASE

Method of replacing dispersion medium

InactiveCN101472876AEvenly dispersedEasy to operateLiquid displacementFractional crystallizationSlurryTerephthalic acid

A method of replacing the first dispersion medium of a raw slurry composed of a first dispersion medium and crystal terephthalic acid with a second dispersion medium. The raw slurry is fed to a vertically extending cylindrical part of cyclone-shaped nozzle disposed in a superior portion of replacement vessel of dispersion medium replacing apparatus from its tangential direction and undergoes circular motion along the inner wall surface of the cylindrical part. The raw slurry in circular motion is discharged from an opening disposed in a vertically inferior portion of the cylindrical part and dispersed in a second dispersion medium fed from an inferior portion of the replacement vessel. The slurry after replacement composed mainly of crystal terephthalic acid and the second dispersion medium is drawn out from the inferior portion of the replacement vessel, while the first dispersion medium is drawn out from the superior portion of the replacement vessel.

Owner:MITSUBISHI GAS CHEM CO INC

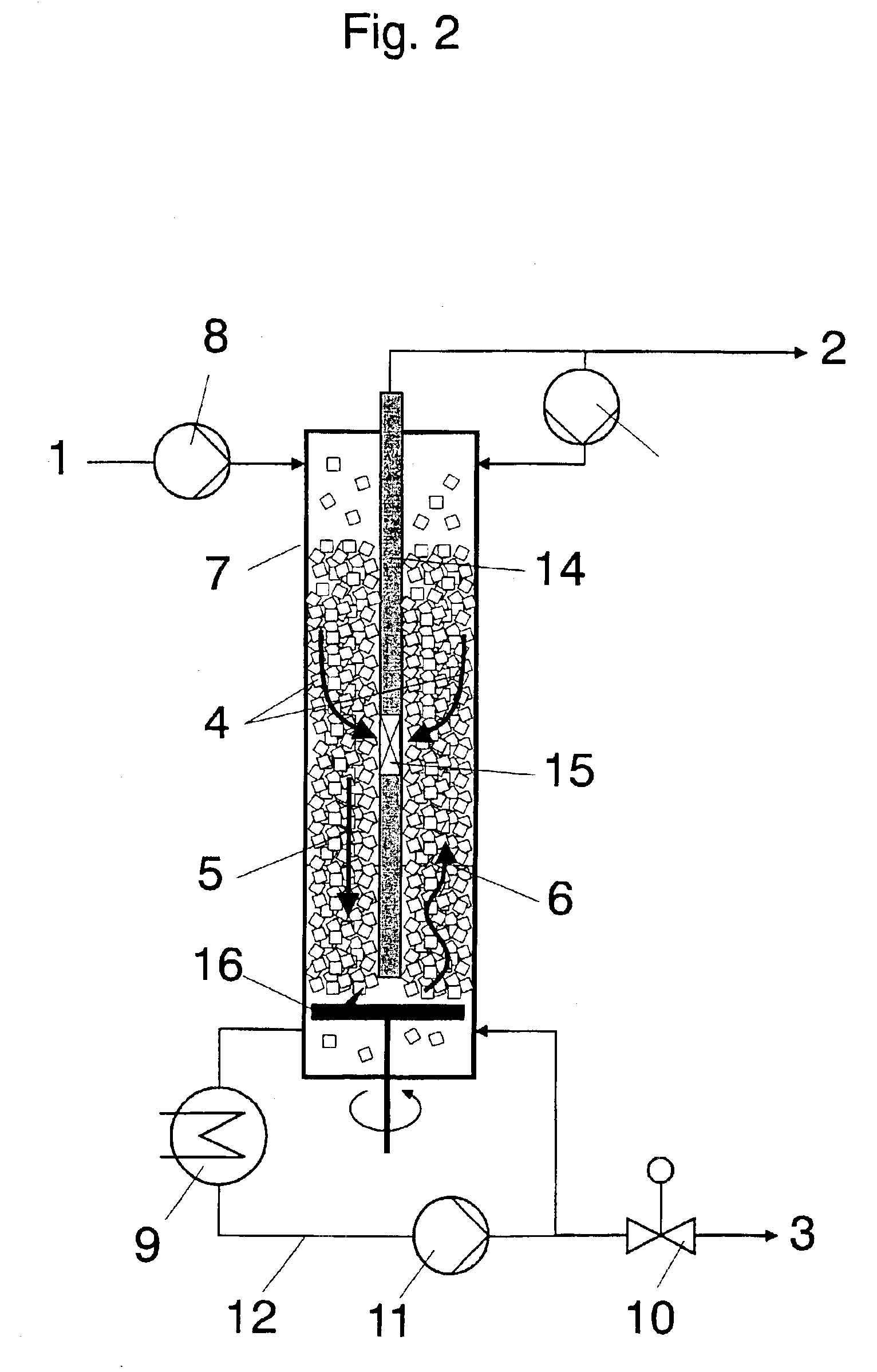

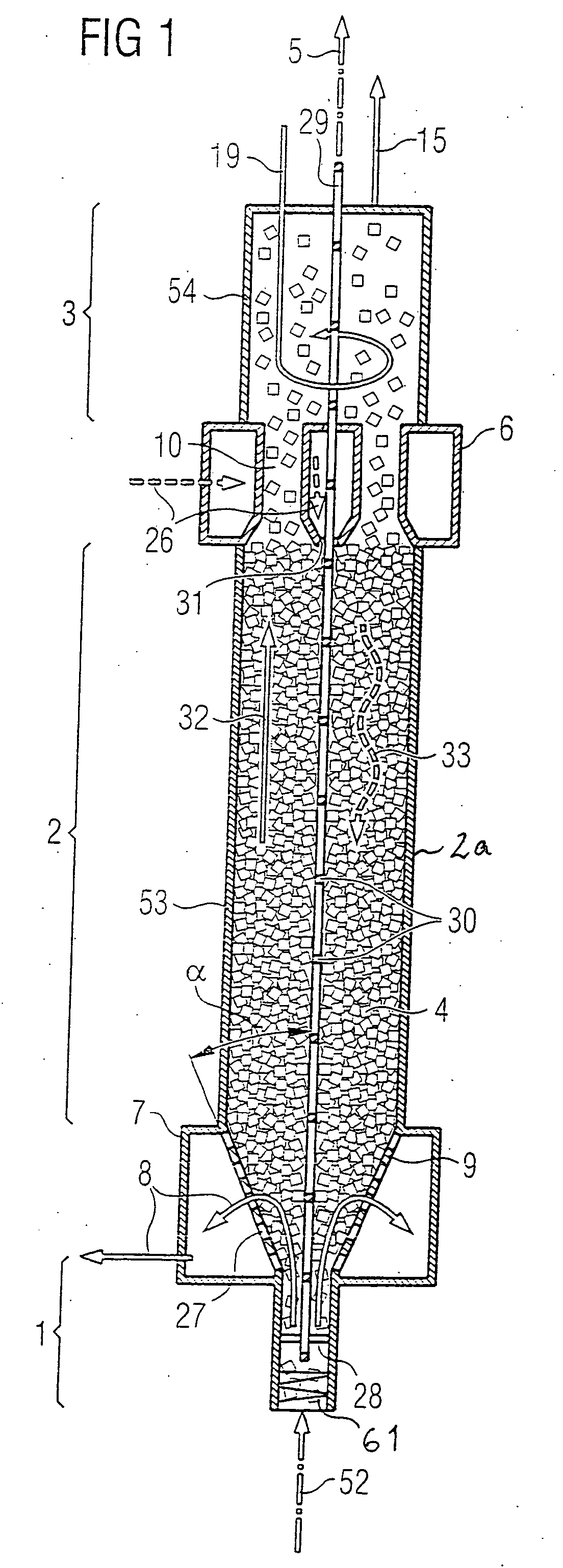

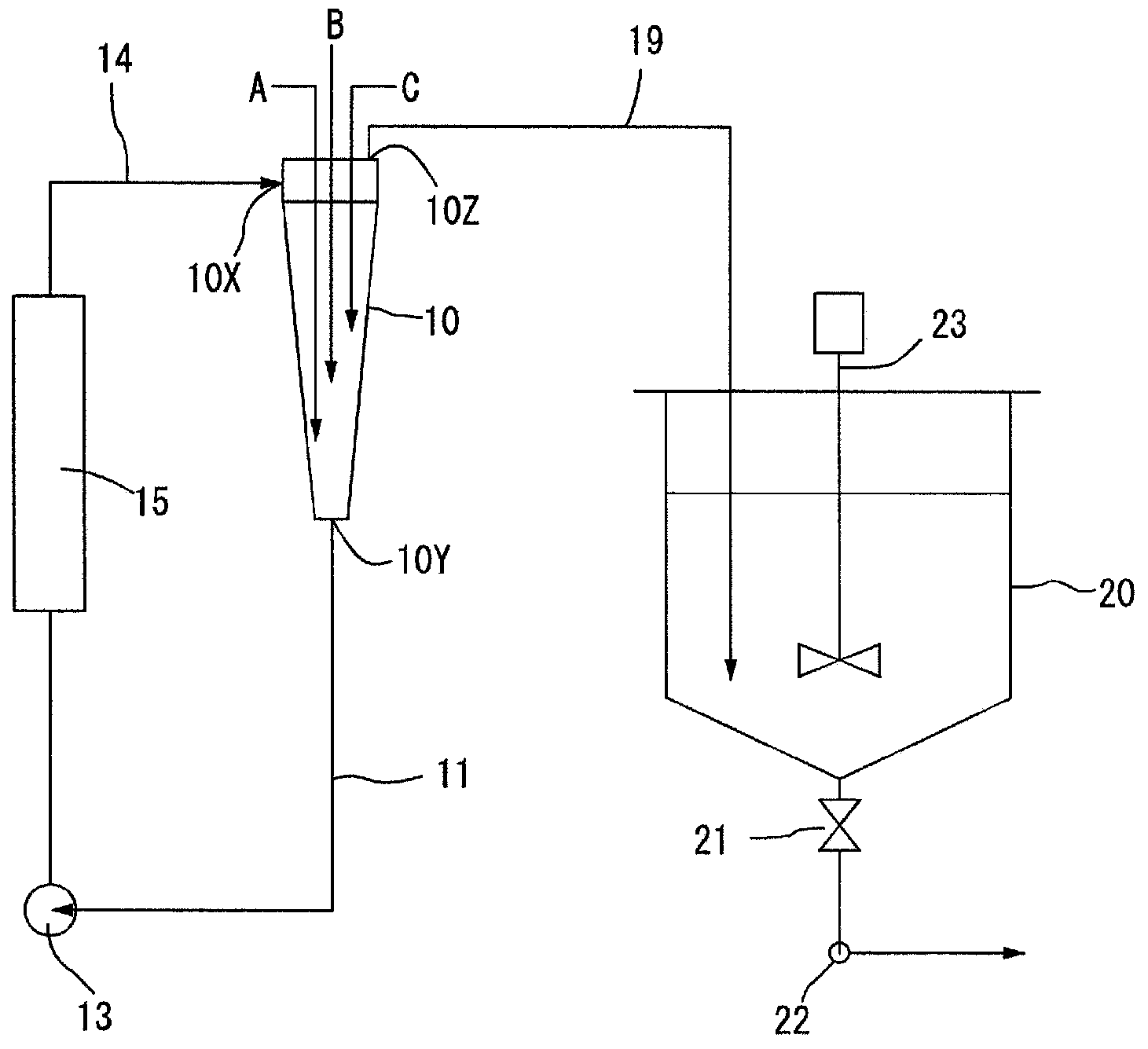

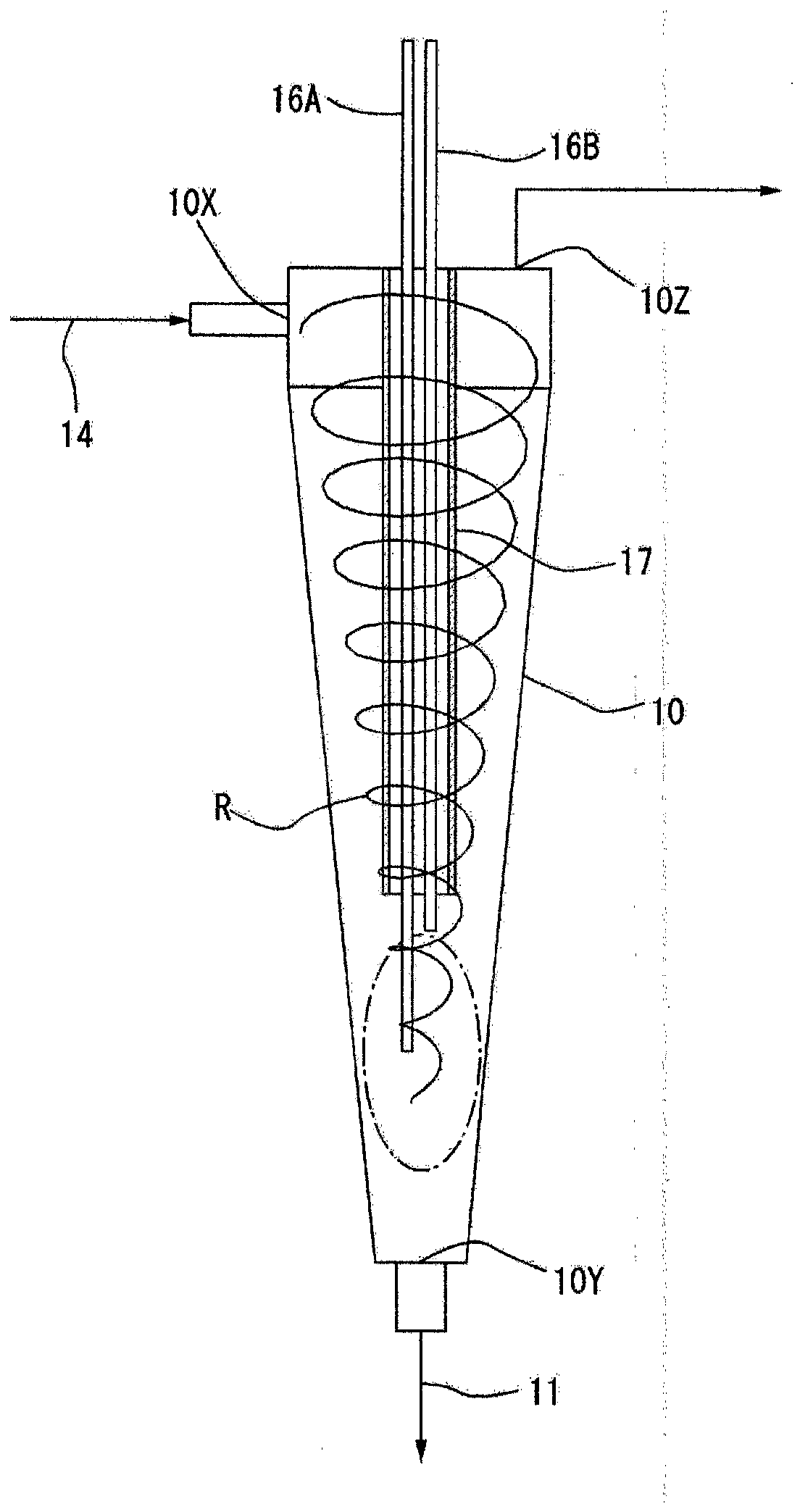

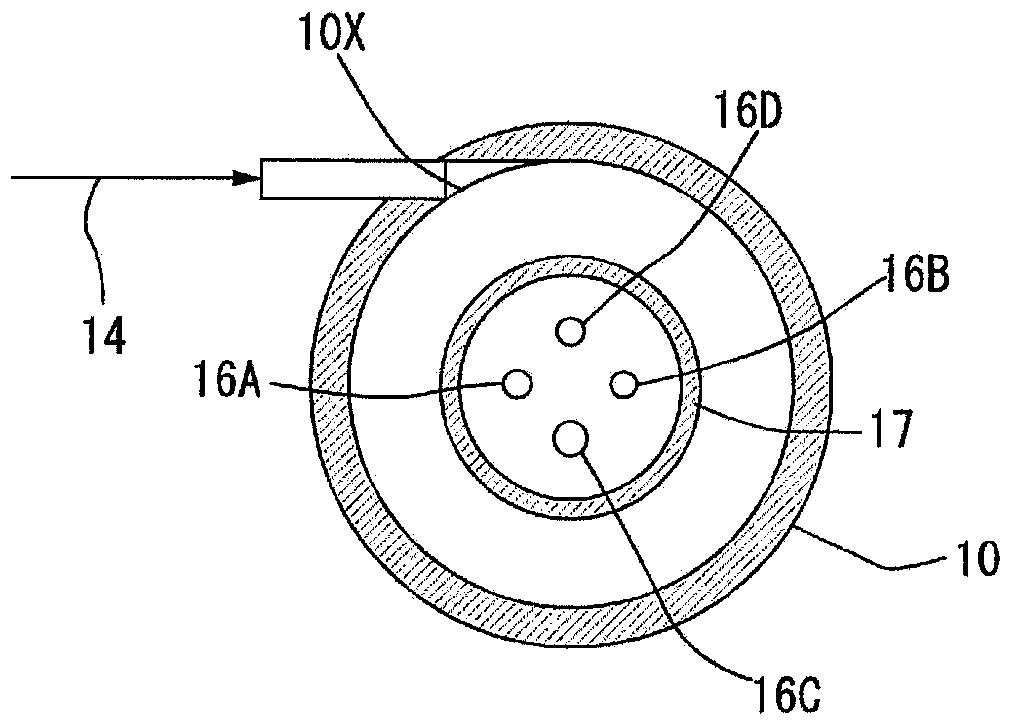

Production method for reaction-agglomerated particles, production method for positive electrode active material for lithium ion cell, production method for lithium ion cell, lithium ion cell, and apparatus for production of reaction-agglomerated particles

ActiveCN104412420APrevent adhesionSmall particle sizeProcess control/regulationGranule coatingLithiumPhysical chemistry

[Problem] The flow of liquid within a reaction treatment vessel (10) is directed into a spiral flow, added liquids (A, B) containing inorganic substances to be added are injected into the reaction site inside the reaction treatment vessel (10) at locations towards the center from the inside surface of the reaction treatment vessel (10), and reaction treatment is carried out.

Owner:TSUKISHIMA KIKAI CO LTD

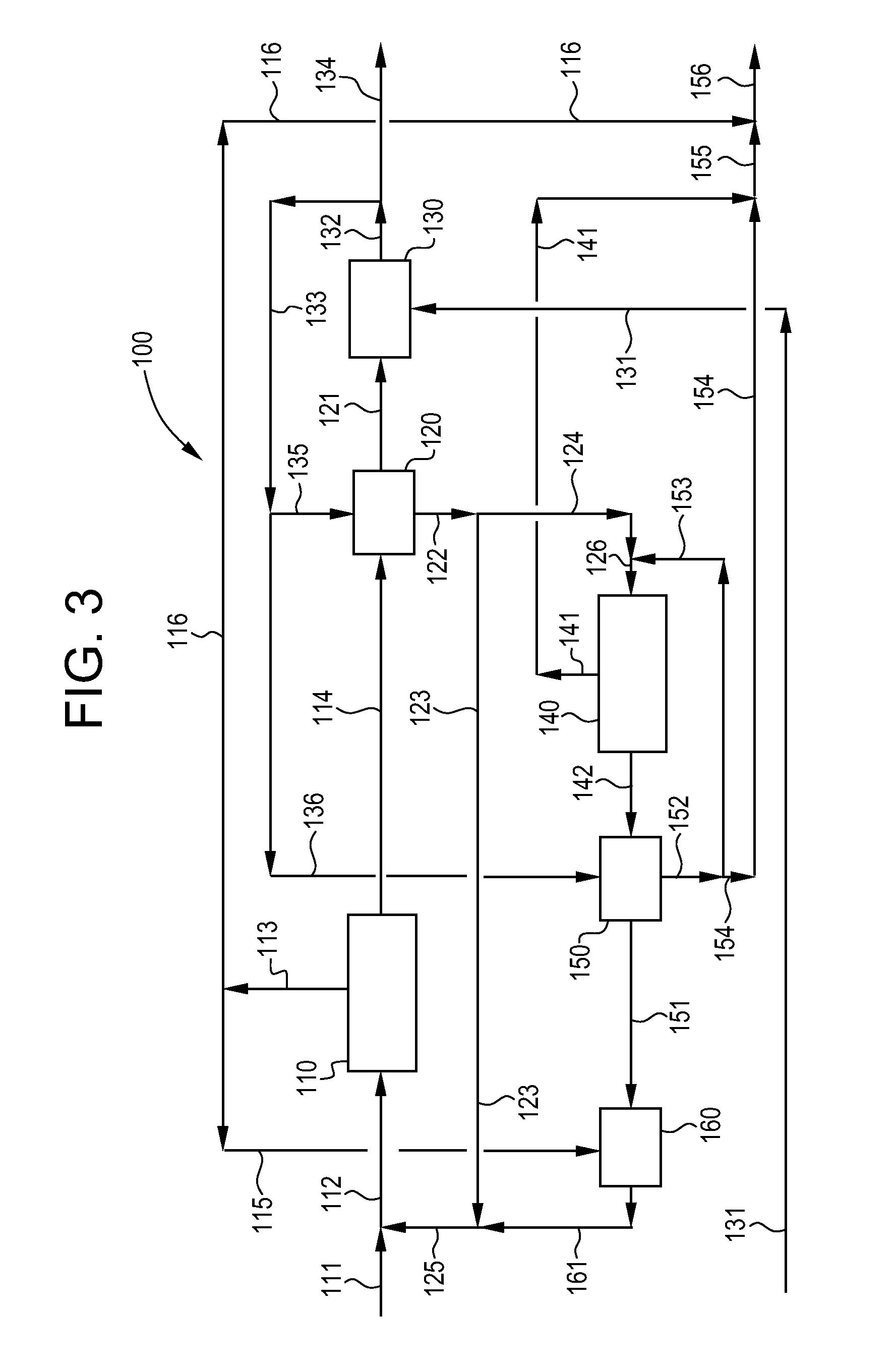

Process for the combined regeneration of soluble salts contained in a residue of an industrial process

ActiveUS20120205253A1Electrolysis componentsProduct crystals bed crystallizationImpurityNuclear chemistry

Process for the combined regeneration of at least two soluble salts contained in a residue of an industrial process comprising heavy metals, comprising: adding an amount of reactive aqueous solution needed to completely dissolve the salts which are desired to be regenerated to the residue; subjecting the resulting aqueous suspension to a separation to obtain an aqueous production solution on the one hand and insoluble impurities on the other hand, which are removed; successively subjected the aqueous production solution to at least two selective crystallization steps intended to crystallize, separately, the at least two soluble salts which are desired to be regenerated, which are washed, dried and regenerated separately; and adjusting the concentration of at least one of the soluble salts to be regenerated in the aqueous production solution, at the moment when such solution is subjected to the step of crystallization of this salt, to give rise to the selective crystallization of this salt, by addition of a controlled amount of this salt to the aqueous production solution upstream of the crystallization step.

Owner:SOLVAY SA

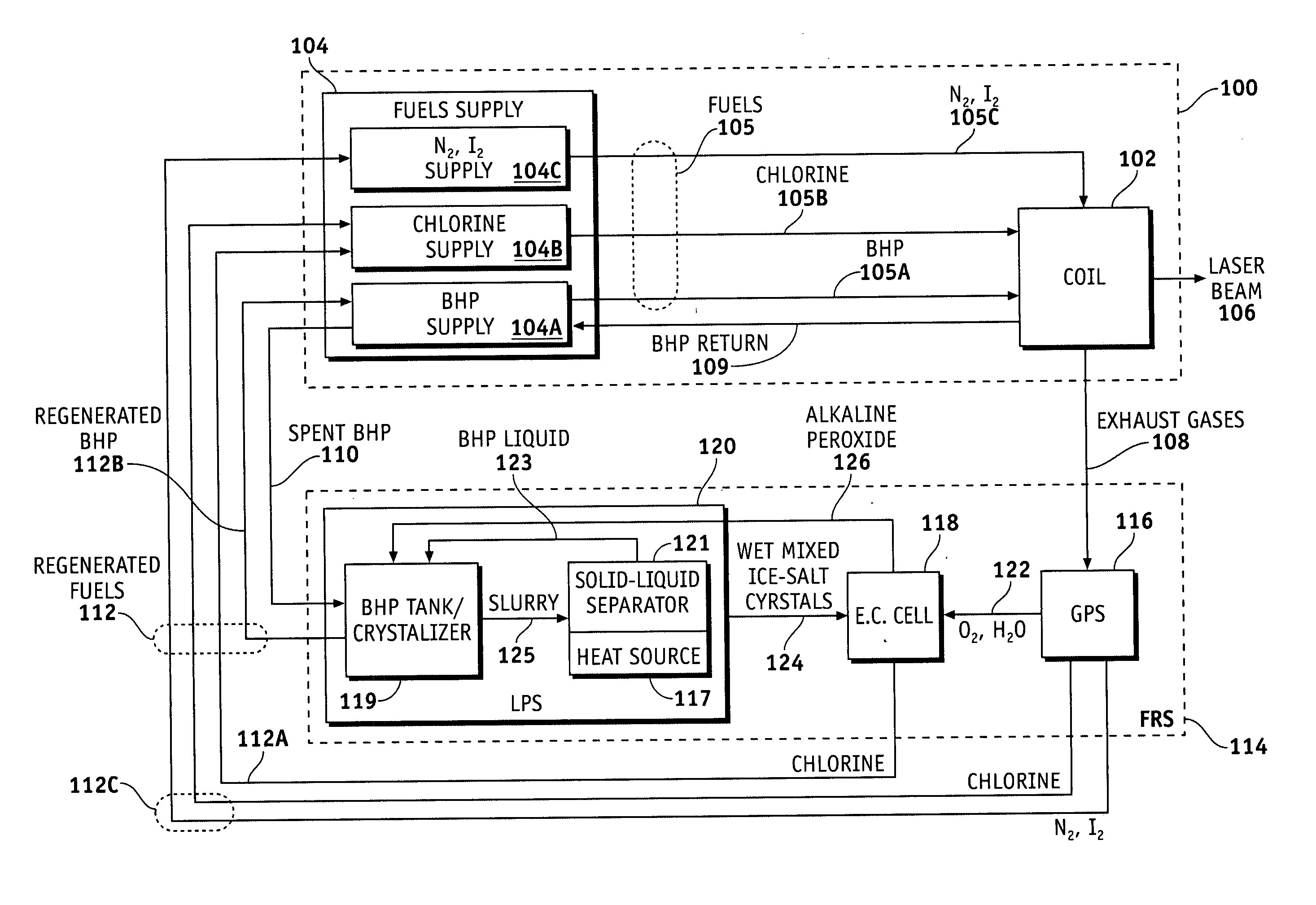

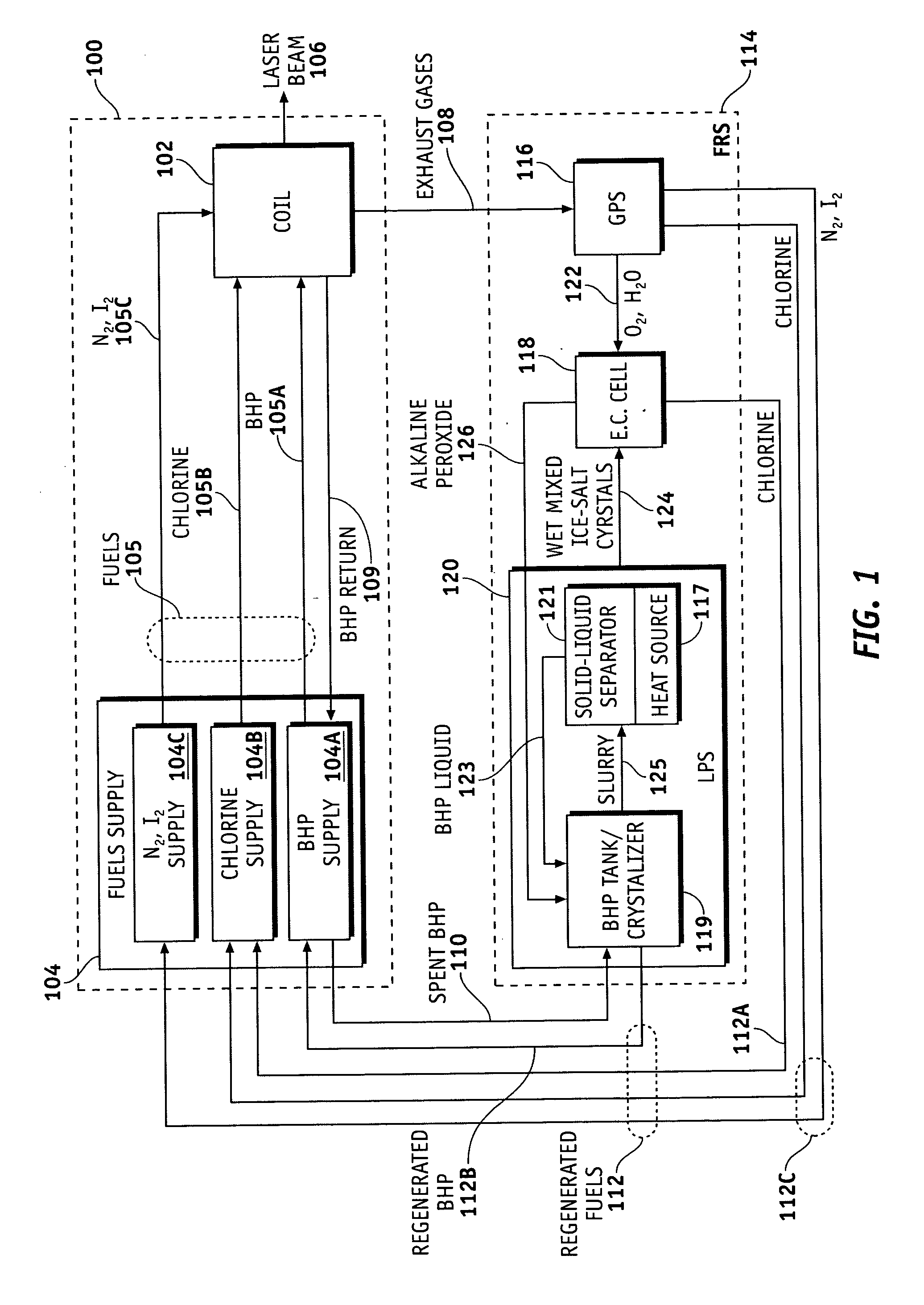

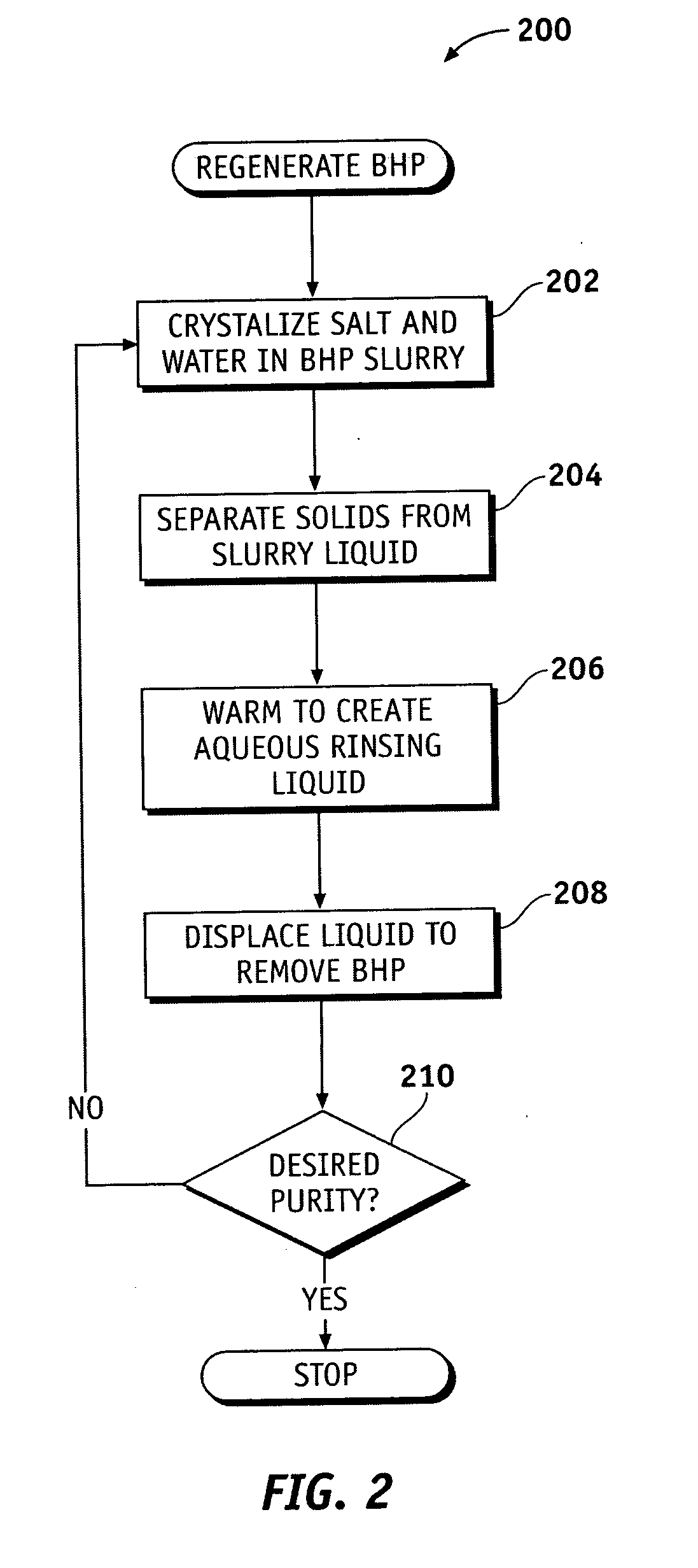

Recovering purified water and potassium chloride from spent basic hydrogen peroxide

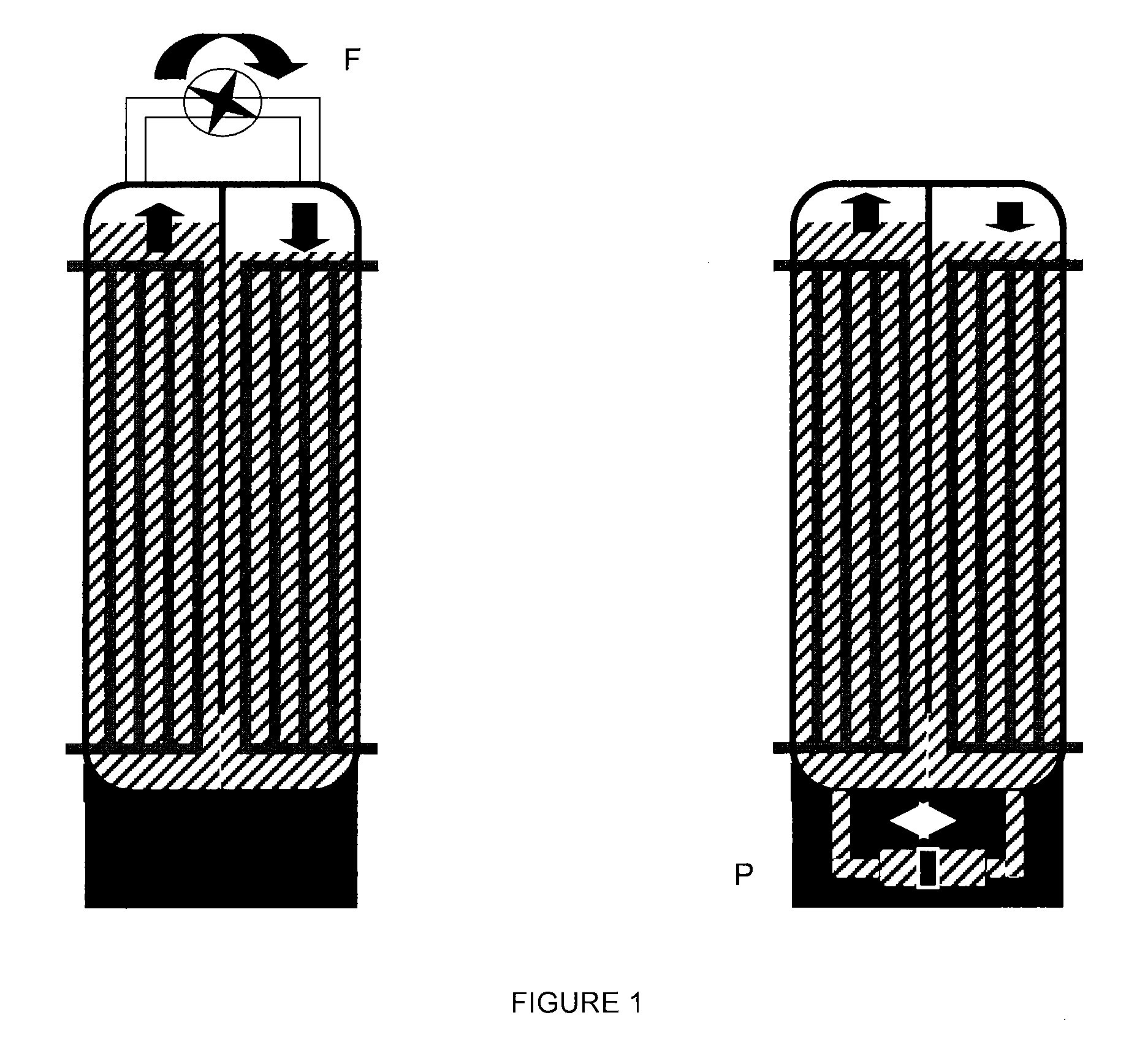

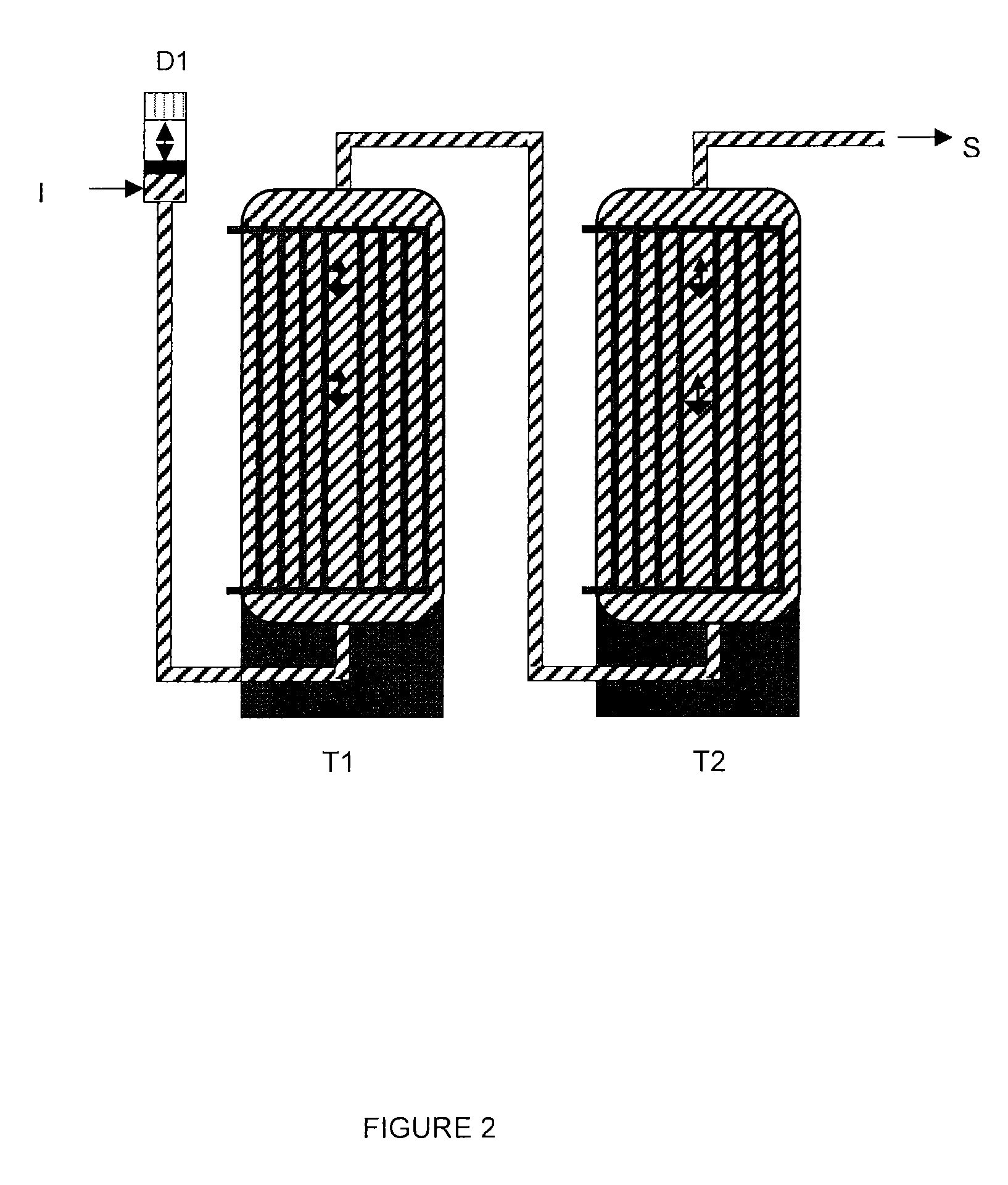

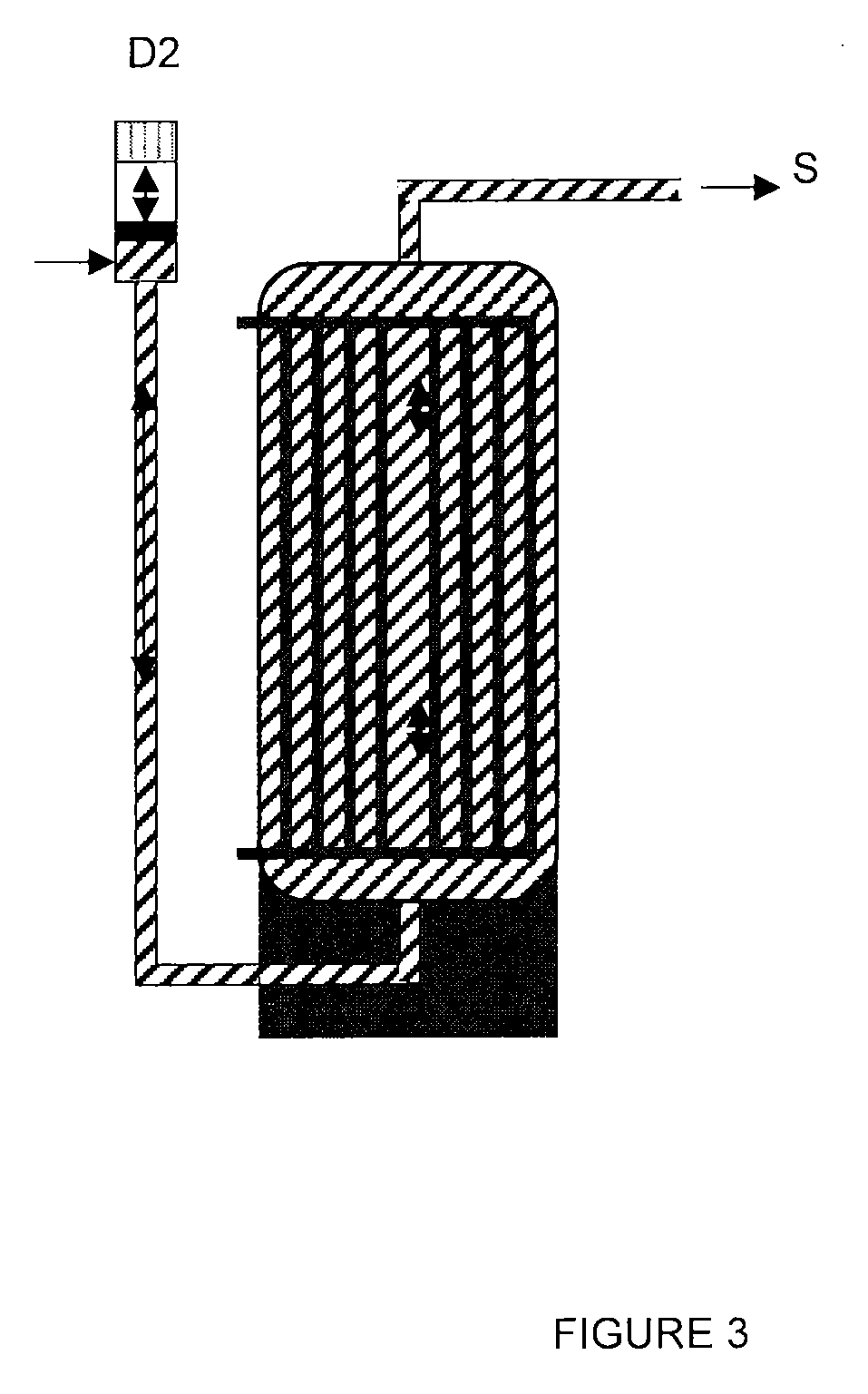

Methods and apparatus are provided for the removal and purification of the water and salt by-products from spent BHP emitted from a lasing process. The apparatus comprises a liquid processing system that freezes the water and salt by-products into a slurry, and then separates out the water (as ice) and salt components by filtering in a centrifuge. In order to remove as much residual BHP from the wet mixed ice-salt component as possible, a heat source is used to partially melt ice crystals, thereby generating an aqueous rinsing liquid on the surface of the wet mixed ice-salt crystals. The applied centrifugal force causes a continual displacement of the liquid film wetting the surface, so that it becomes progressively diluted. As such, the purification of the mixture of ice and salt crystals is implemented with an aqueous (water) rinse that is unaffected by the sub-freezing temperatures within the centrifuge. The separation and purification may also be performed with a filter in which the conventional built-in water rinse is replaced with a heat source. The filter's driving force, for example gas pressure or vacuum, would be continuously applied during warming.

Owner:THE BOEING CO

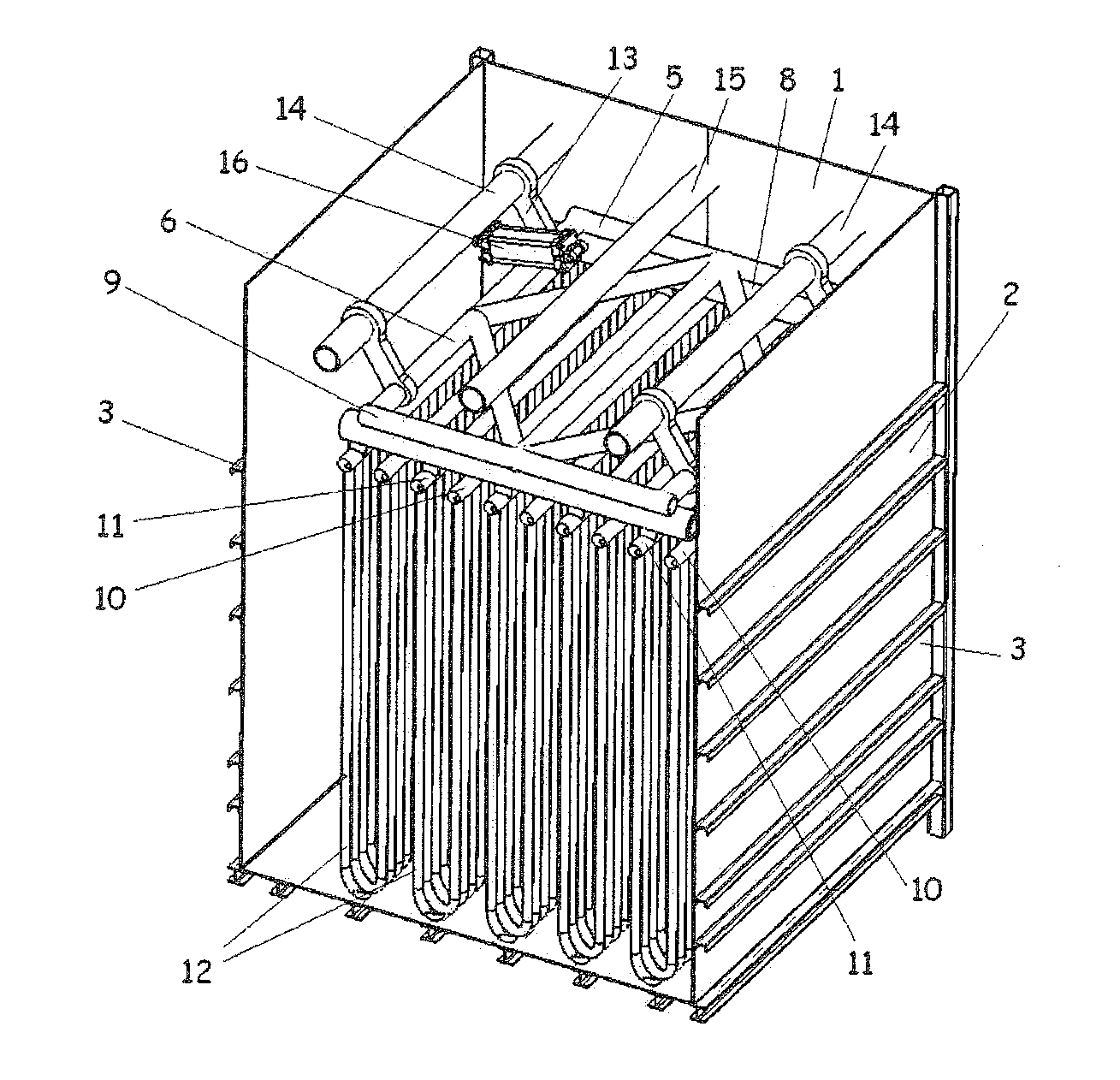

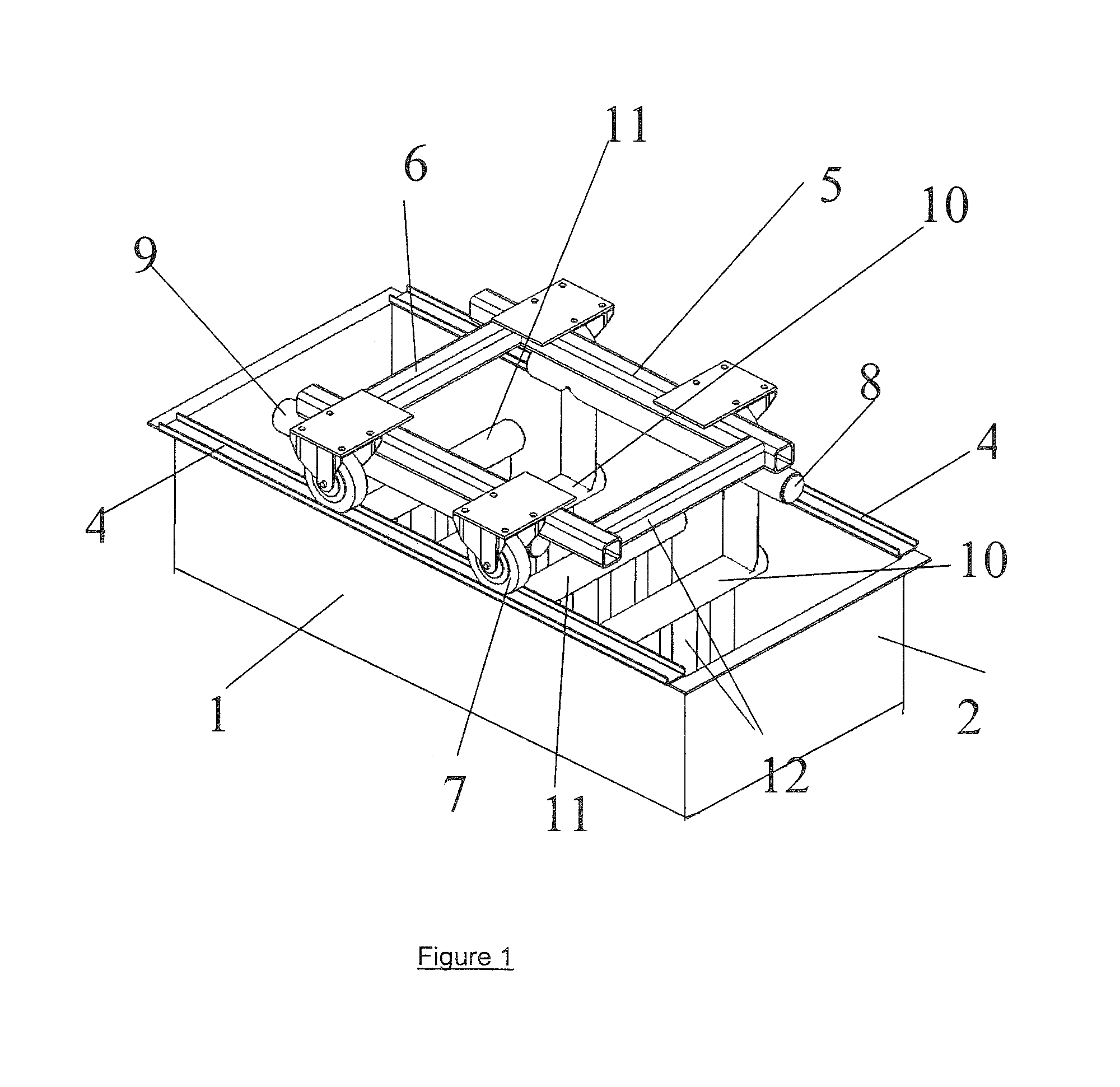

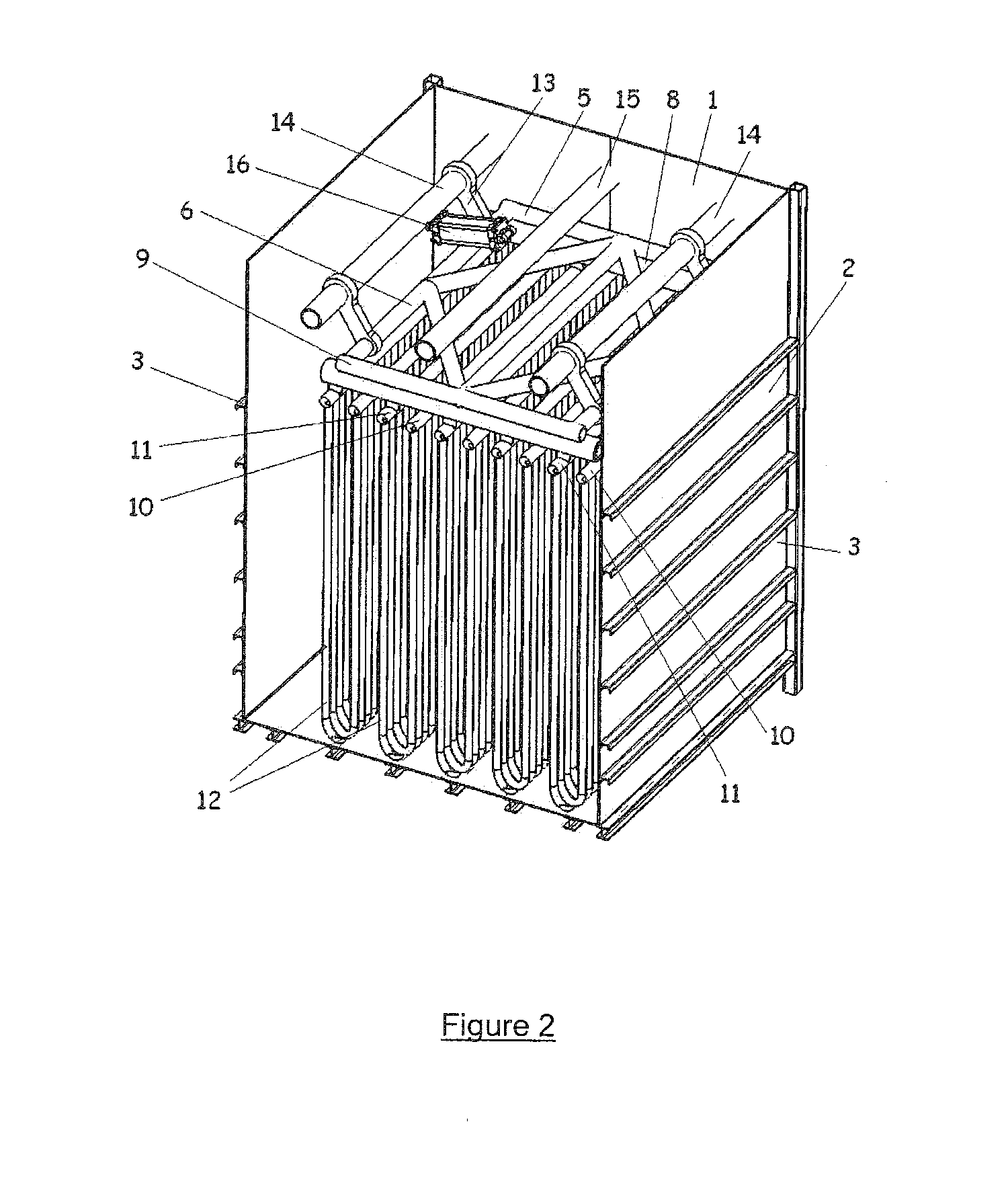

Crystallization apparatus and process for molten fats

ActiveUS20090246339A1Reduce construction costsPromote crystallizationJuice extractionFatty-oils/fats separationMolten saltFractionation

Methods and apparatus are described for the production of a crystal slurry during the crystallization step of fractionation processes of edible oils and fats and related oil derivatives. The crystallization process for edible oil and fats is carried out in a crystallizer with stationary heat exchange elements, wherein the contents of said crystallizer are made to move along said heat exchange elements in an oscillatory manner without the use of an internal agitator. The crystallizer for edible oil and fats with stationary heat exchange elements is also described.

Owner:DESMET BELGIUM

Popular searches

Loose filtering material filters Cartridge filters Sustainable biological treatment Gravity filters Stationary filtering element filters Moving filtering element filters Water/sewage treatment by oxidation Water/sewage treatment by electrochemical methods Multistage water/sewage treatment Water/sewage treatment by sorption

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com