Recovering purified water and potassium chloride from spent basic hydrogen peroxide

a technology of basic hydrogen peroxide and purified water, which is applied in the direction of detergent compounding agents, fire extinguishers, other chemical processes, etc., can solve the problems of product excessively contaminated with bhp chemicals, process is generally unsuitable for mobile or transportable applications, and washing with water is generally impractical for this application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following detailed description is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any expressed or implied theory presented in the preceding technical field, background, brief summary or the following detailed description.

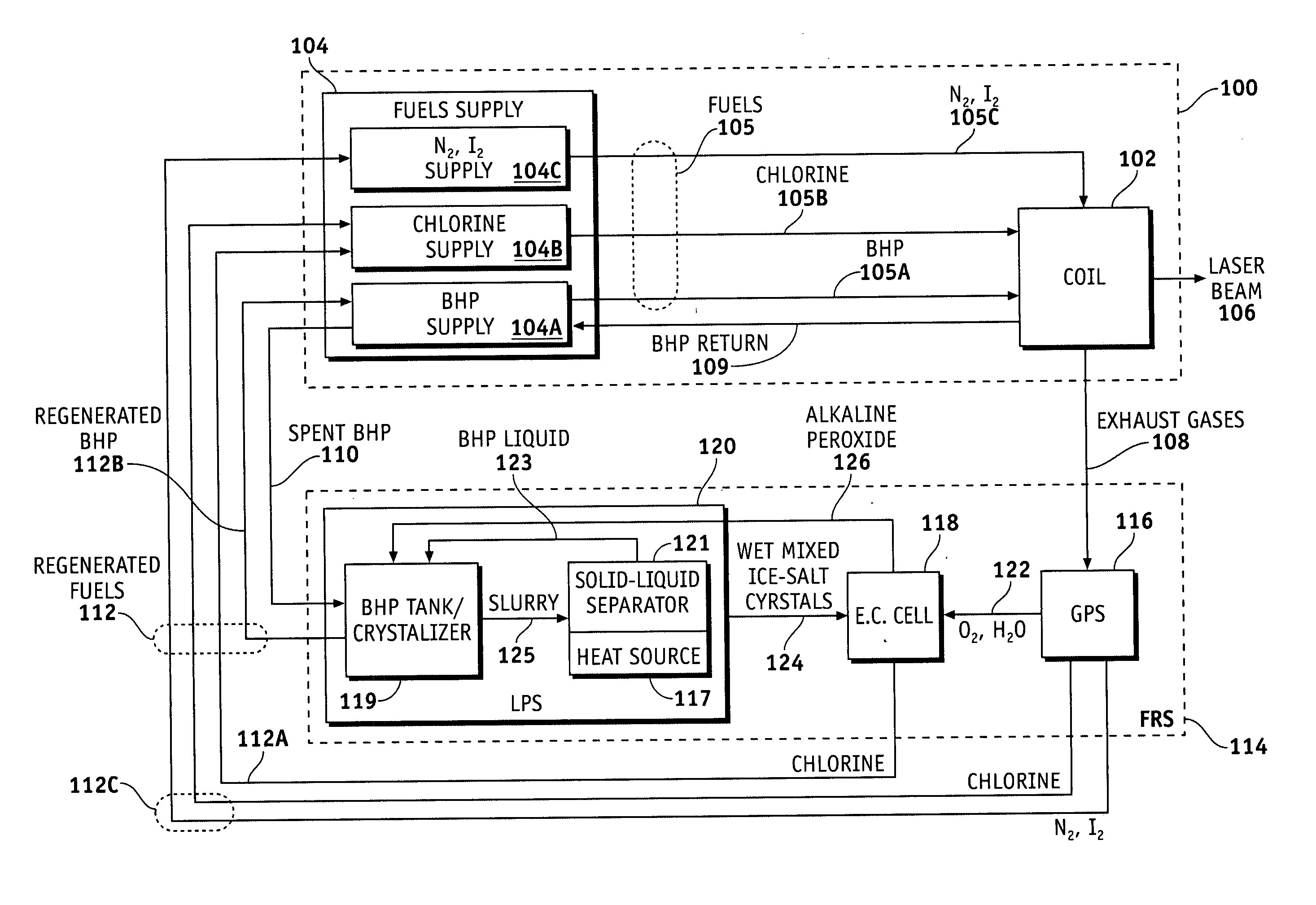

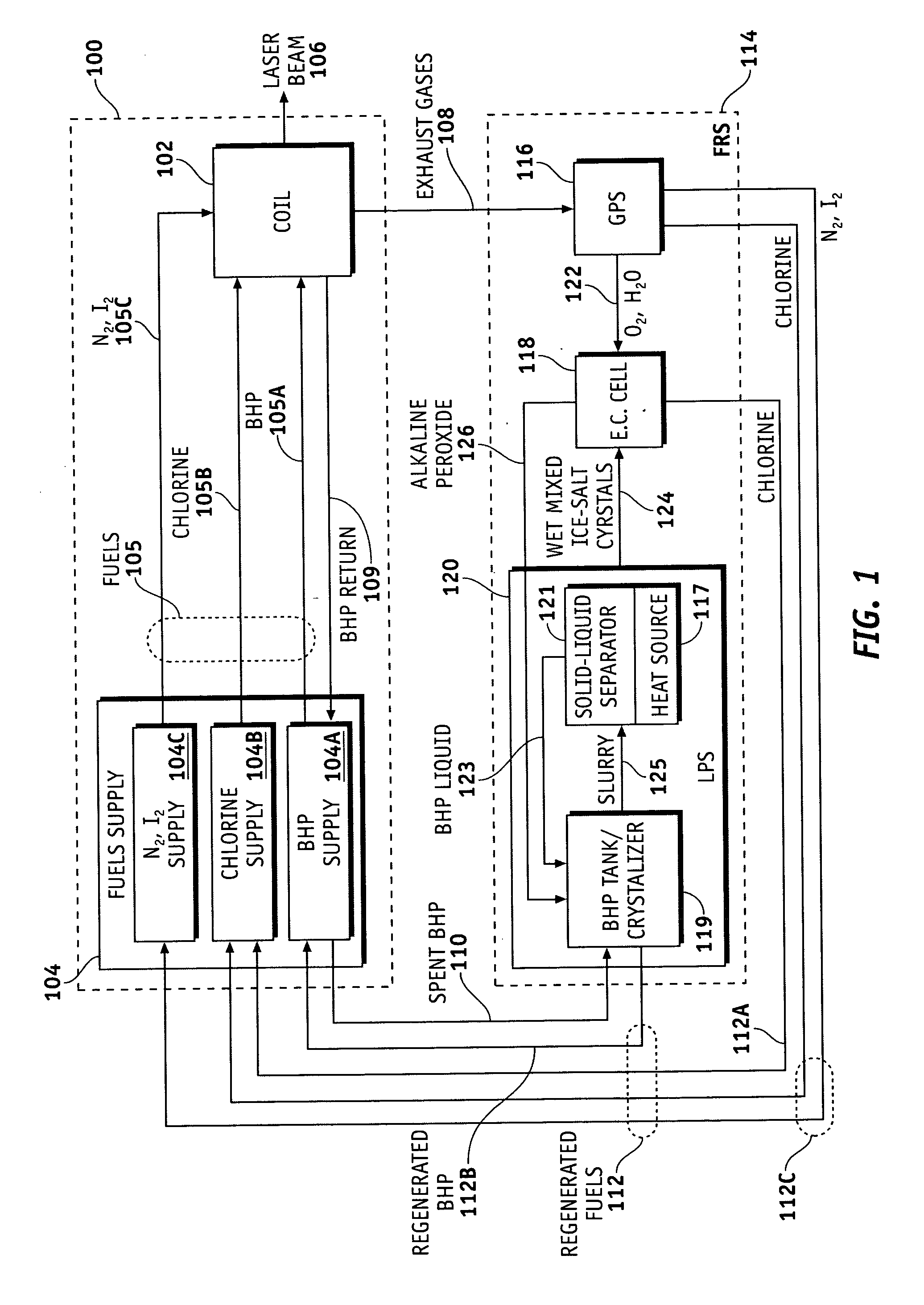

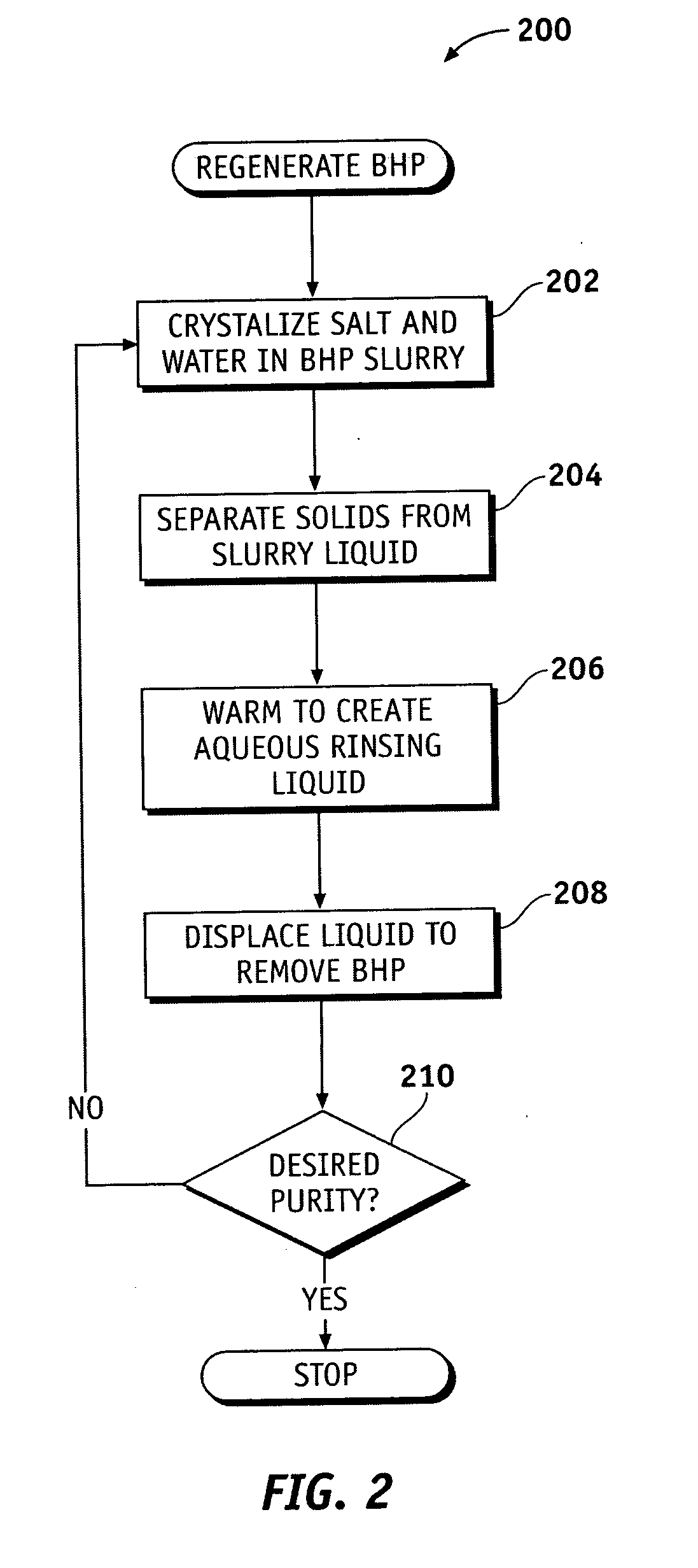

[0012] Various embodiments of the present invention pertain to the area of fuels regeneration for a COIL laser system. One aspect of the fuels regeneration process is the removal and purification of the water and salt by-products from the spent BHP emitted from the lasing process. In an exemplary liquid processing system, the spent BHP is frozen into a slurry of ice (water crystals) and salt crystals in spent BHP aqueous solution, and then separated into liquid and wet solid portions. To remove even more BHP from the wet crystals, a water displacement process may be provided to enable an aqueous wash to operate at temperatures below the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| output power | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com