Patents

Literature

296results about "Cyanogen compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

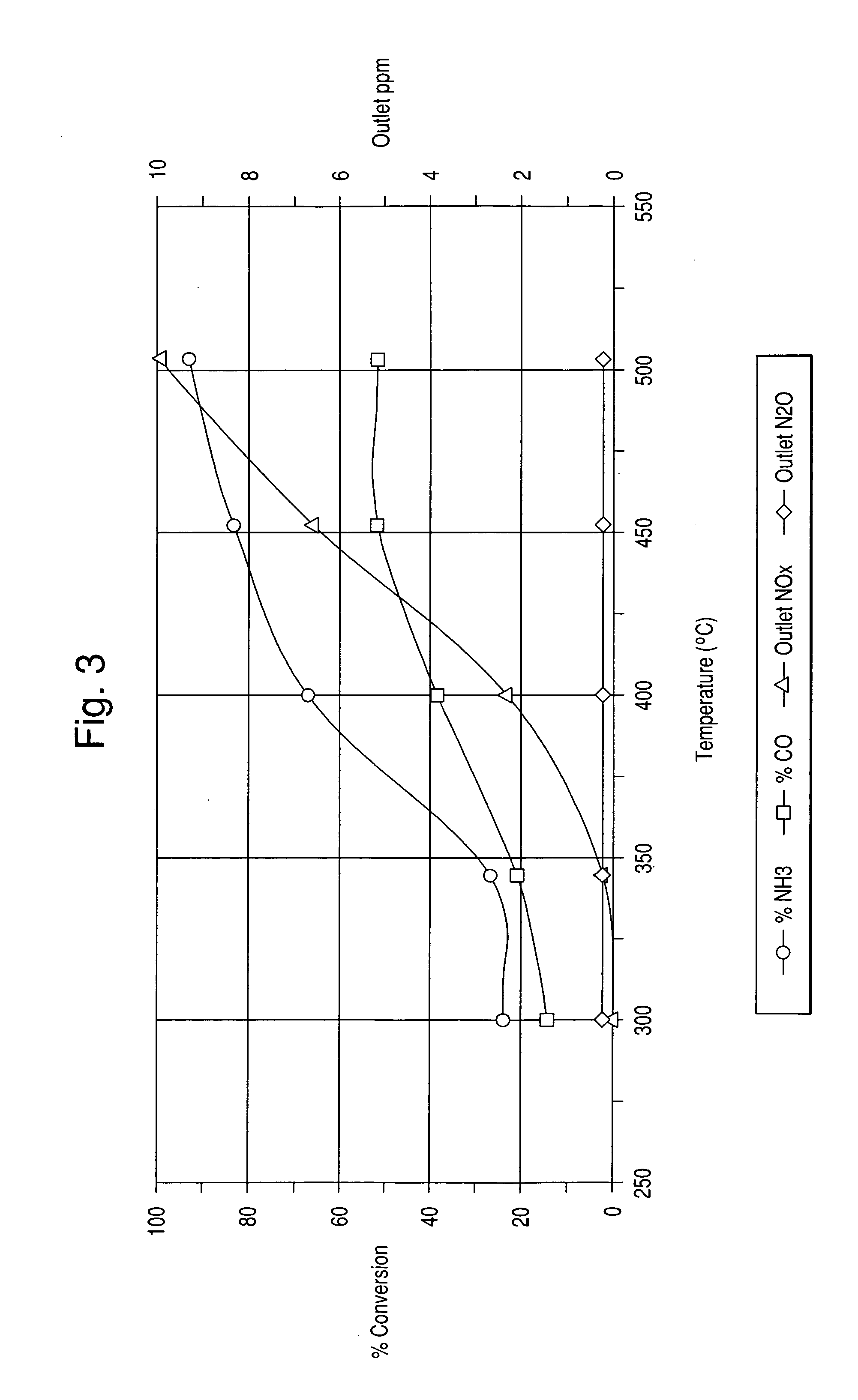

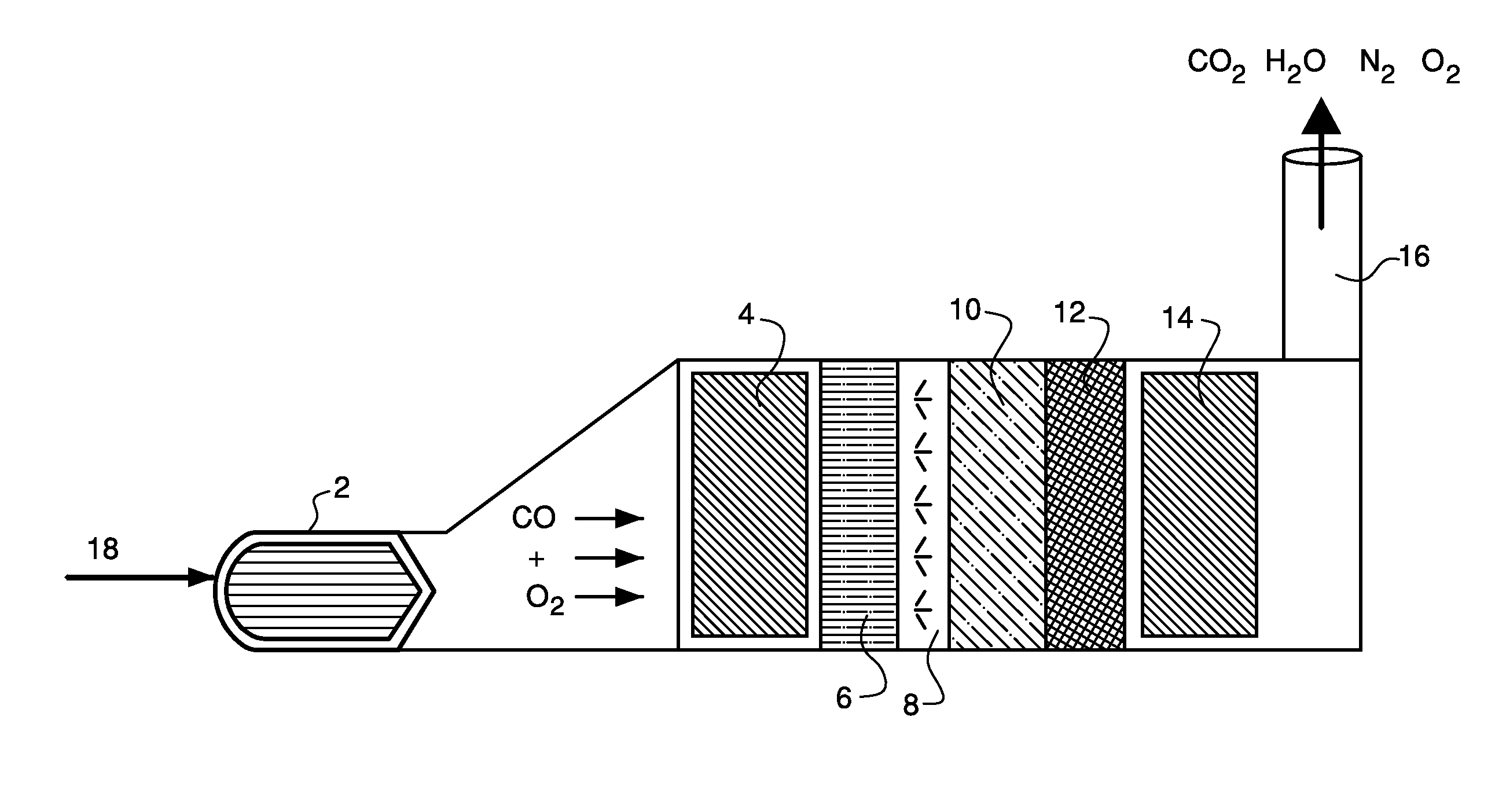

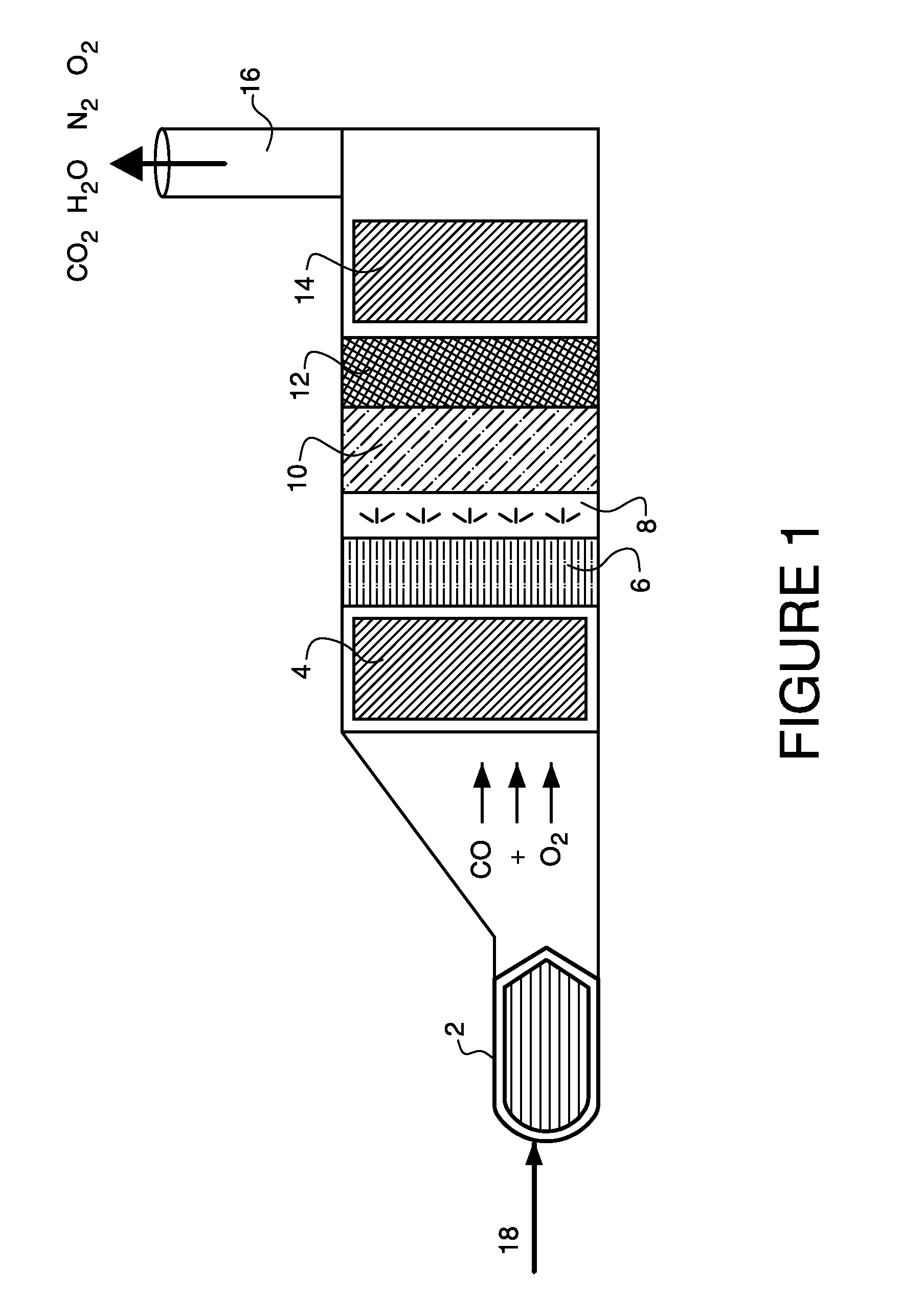

Controlled spectrum ultraviolet radiation pollution control process

InactiveUS7498009B2Cost effectiveEasy to adaptCombination devicesOrganic chemistryEnvironmental engineeringNitrogen oxide

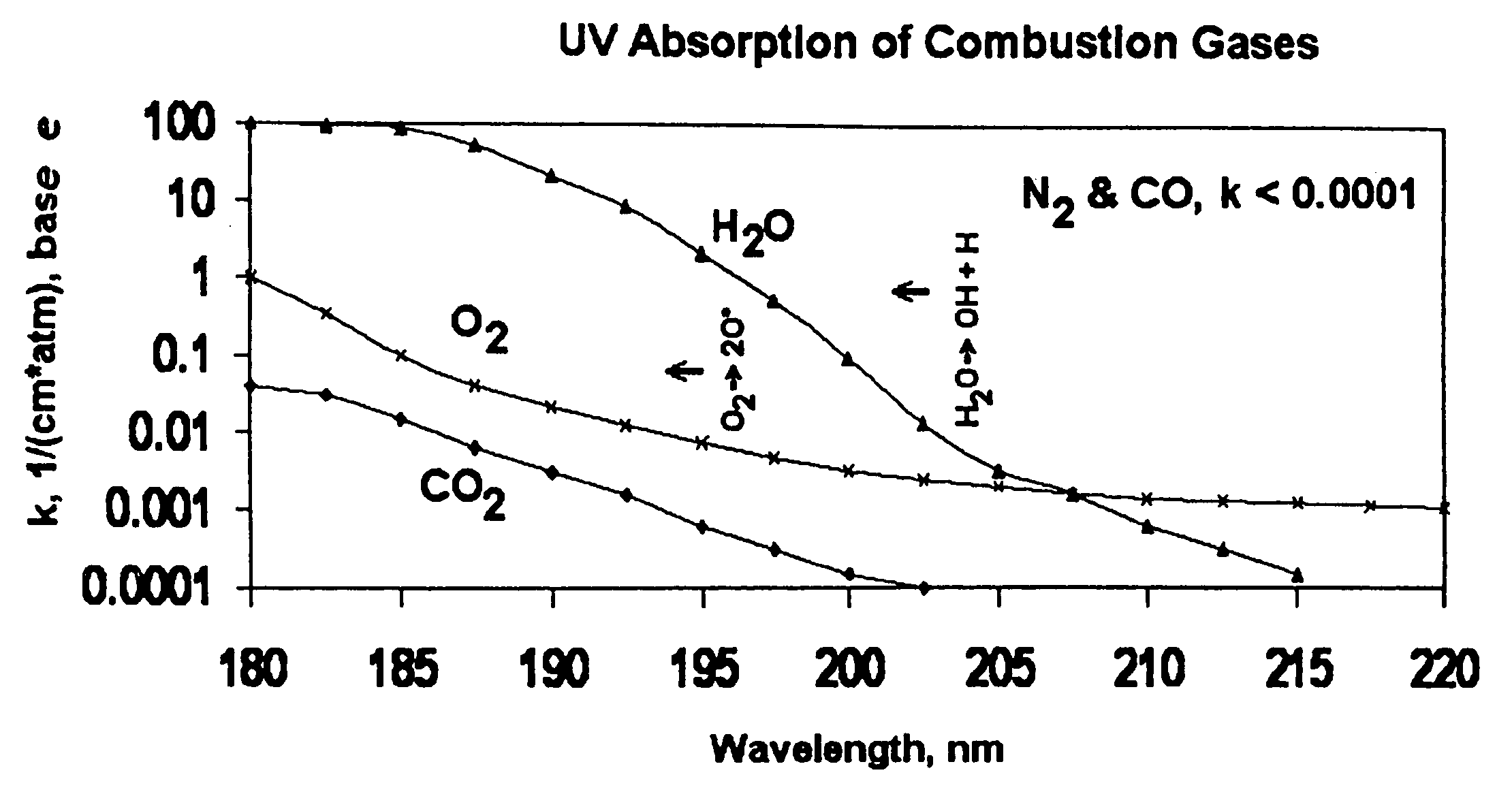

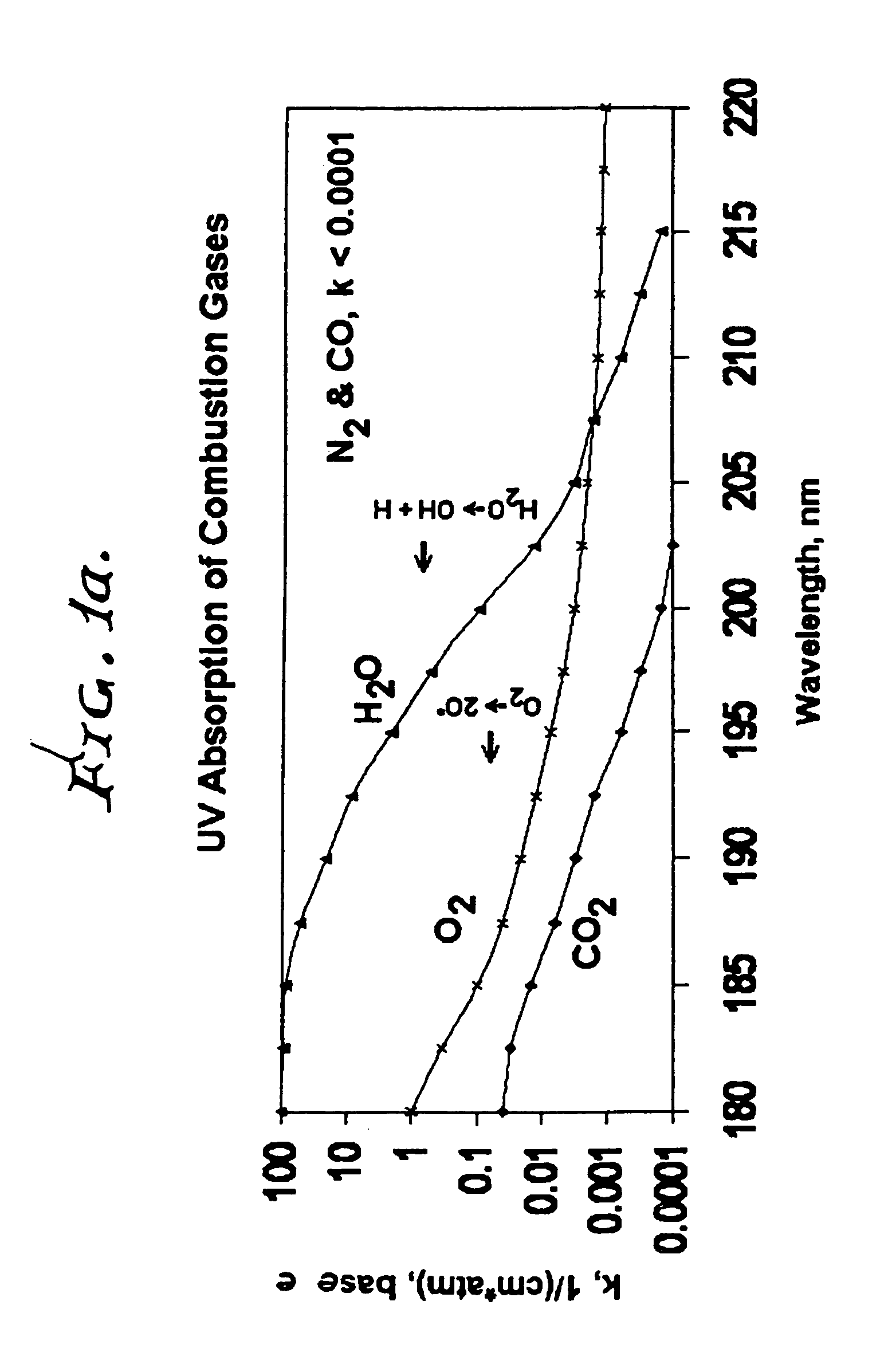

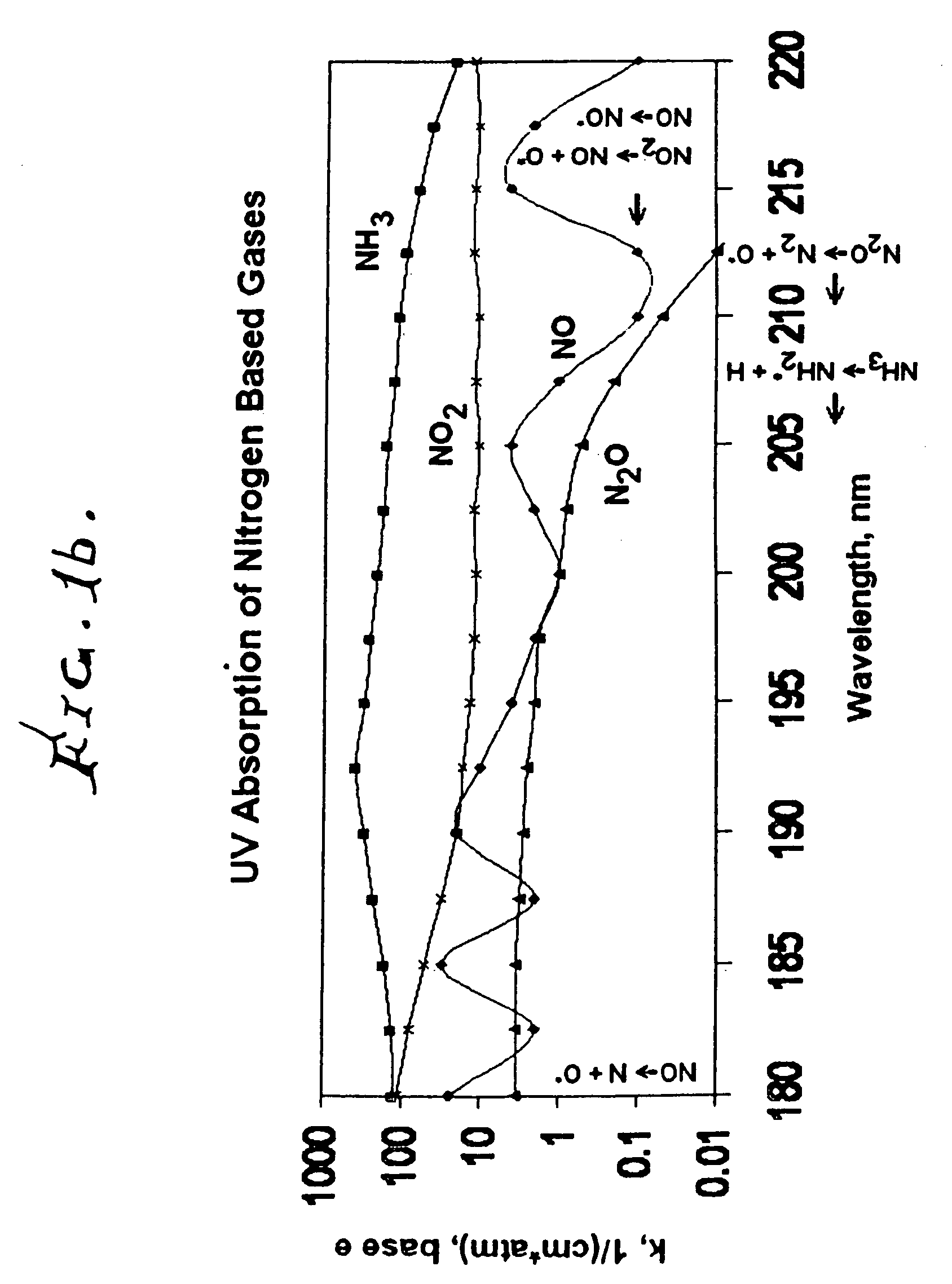

A method for reducing or substantially eliminating oxides of nitrogen from an effluent gas stream, that includes providing a source of ultraviolet radiation with a precise wavelength, adding ammonia or an ammonia based reagent to the effluent stream, upstream of the ultraviolet radiation source, controllably operating the ultraviolet radiation source to irradiate the effluent stream flowing in the duct and substantially reducing or eliminating oxides of nitrogen by promotion a reaction of ammonia with the oxides of nitrogen to produce N2 and H2O, and also thereby destroying any surplus ammonia. This process can also be modified to oxidize carbon monoxide and VOC's to CO2 and H2O.

Owner:DANA UV

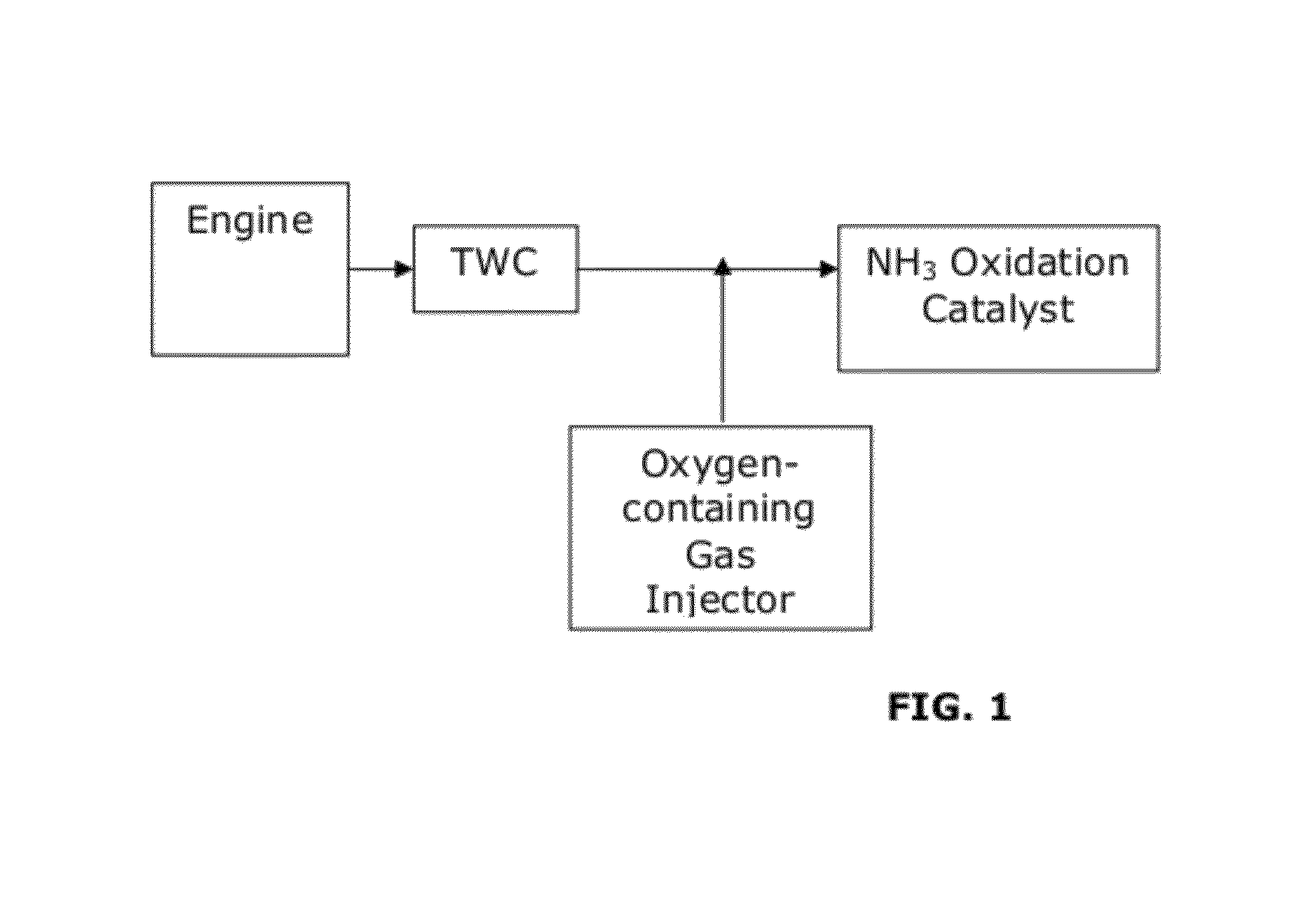

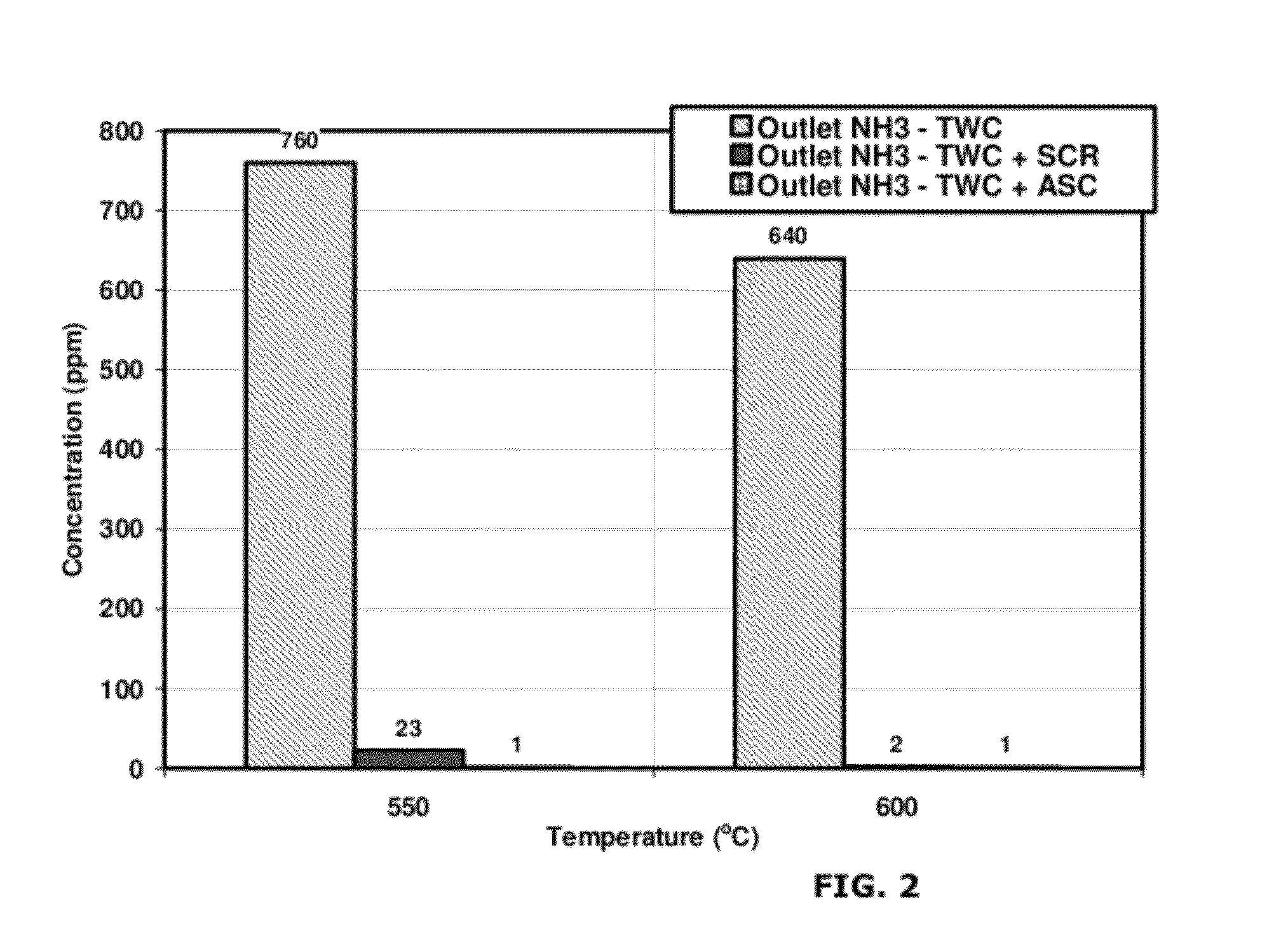

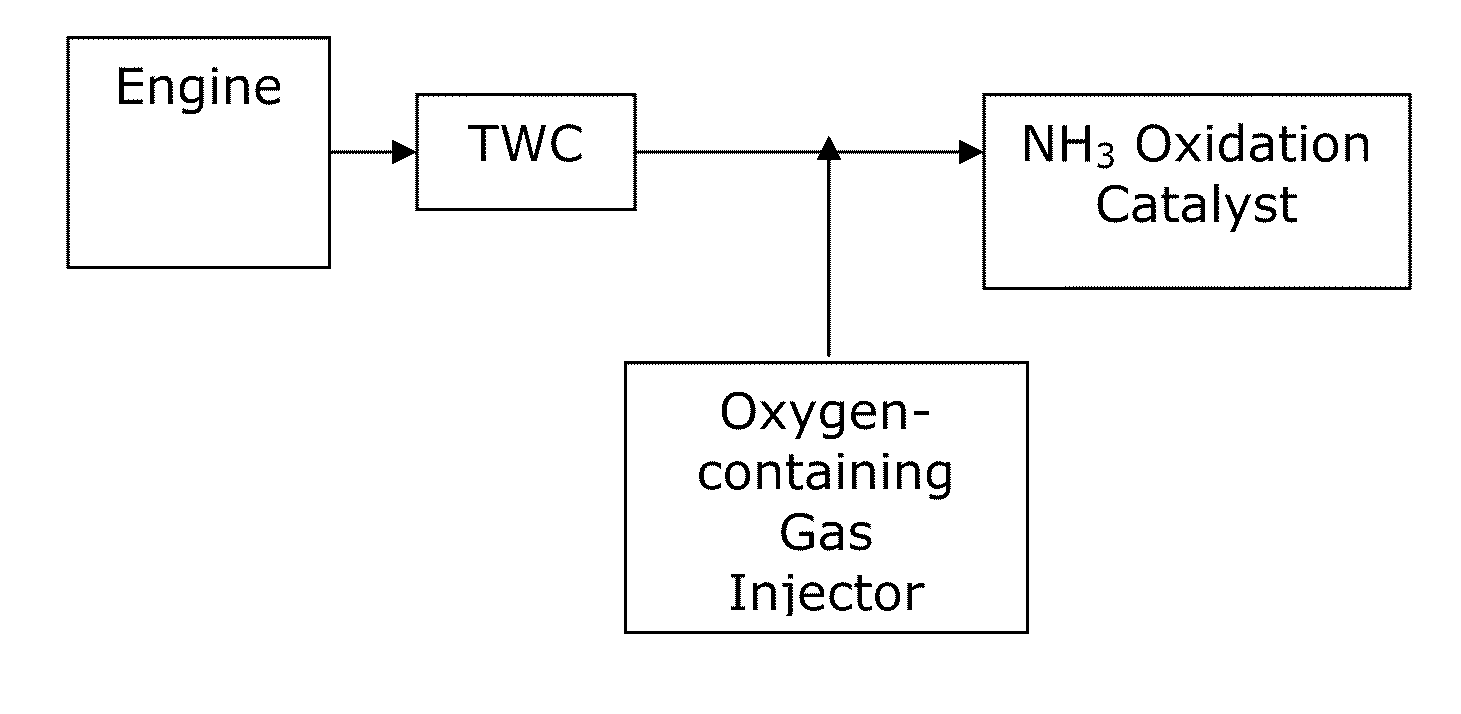

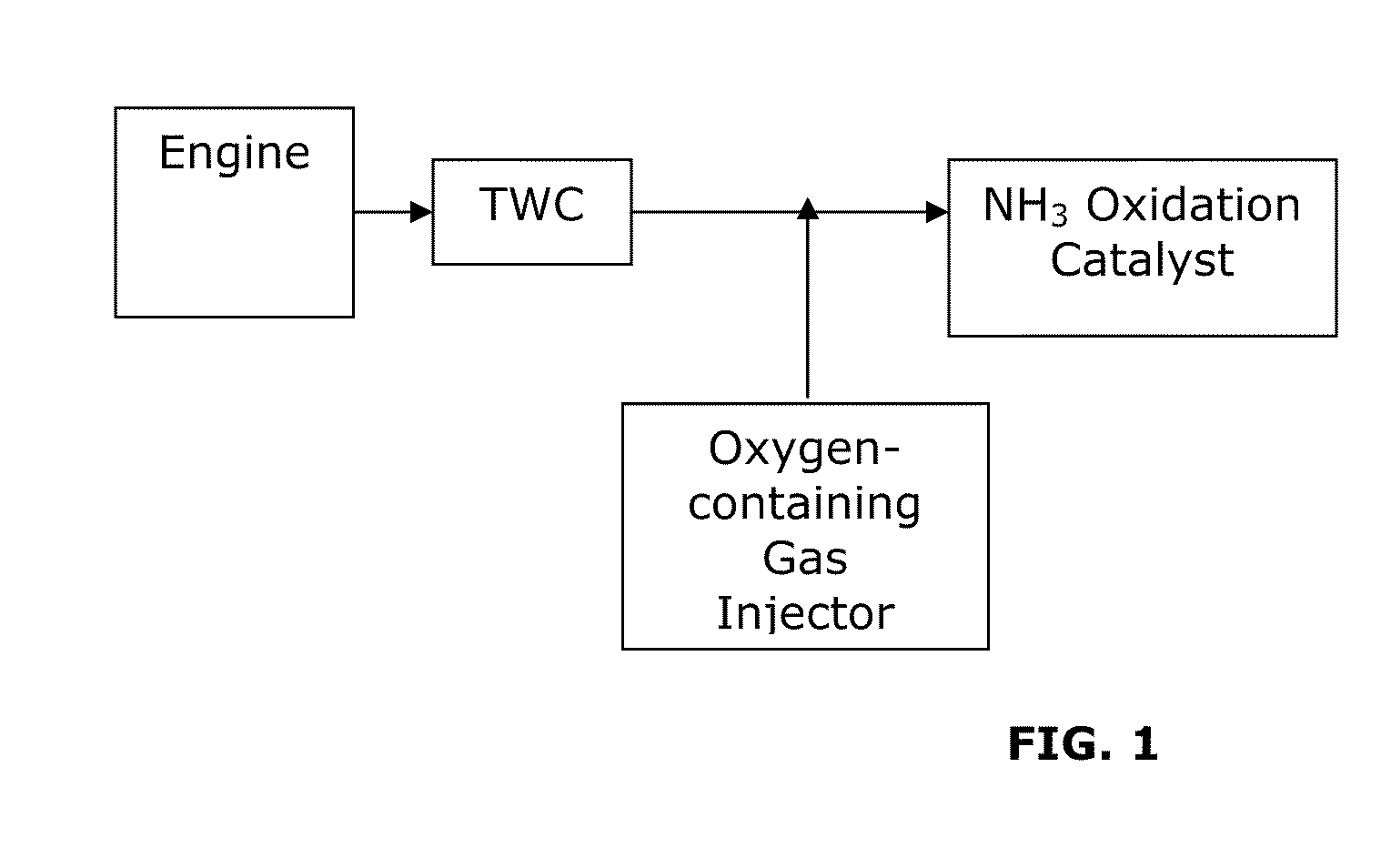

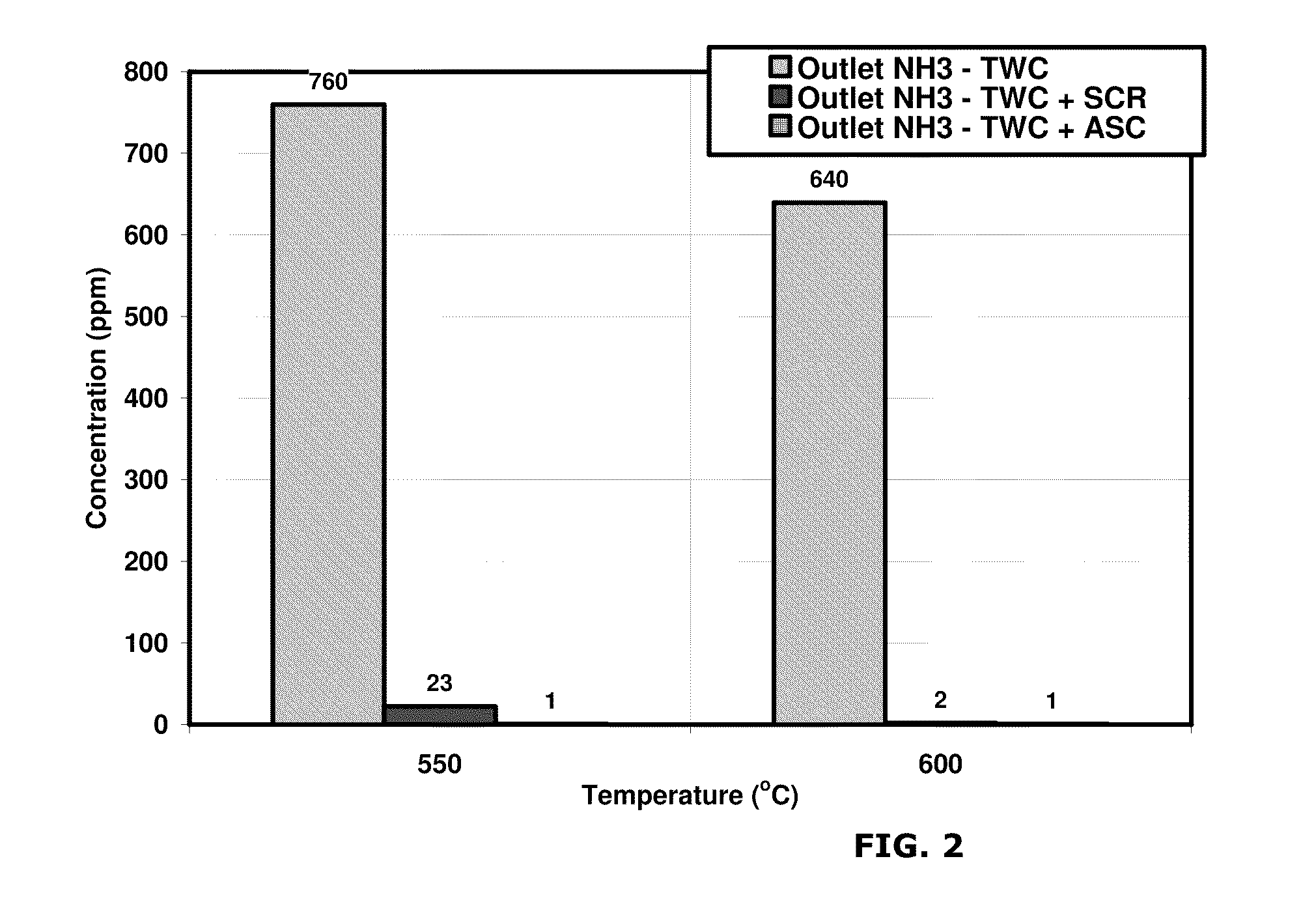

Catalysts for the reduction of ammonia emission from rich-burn exhaust

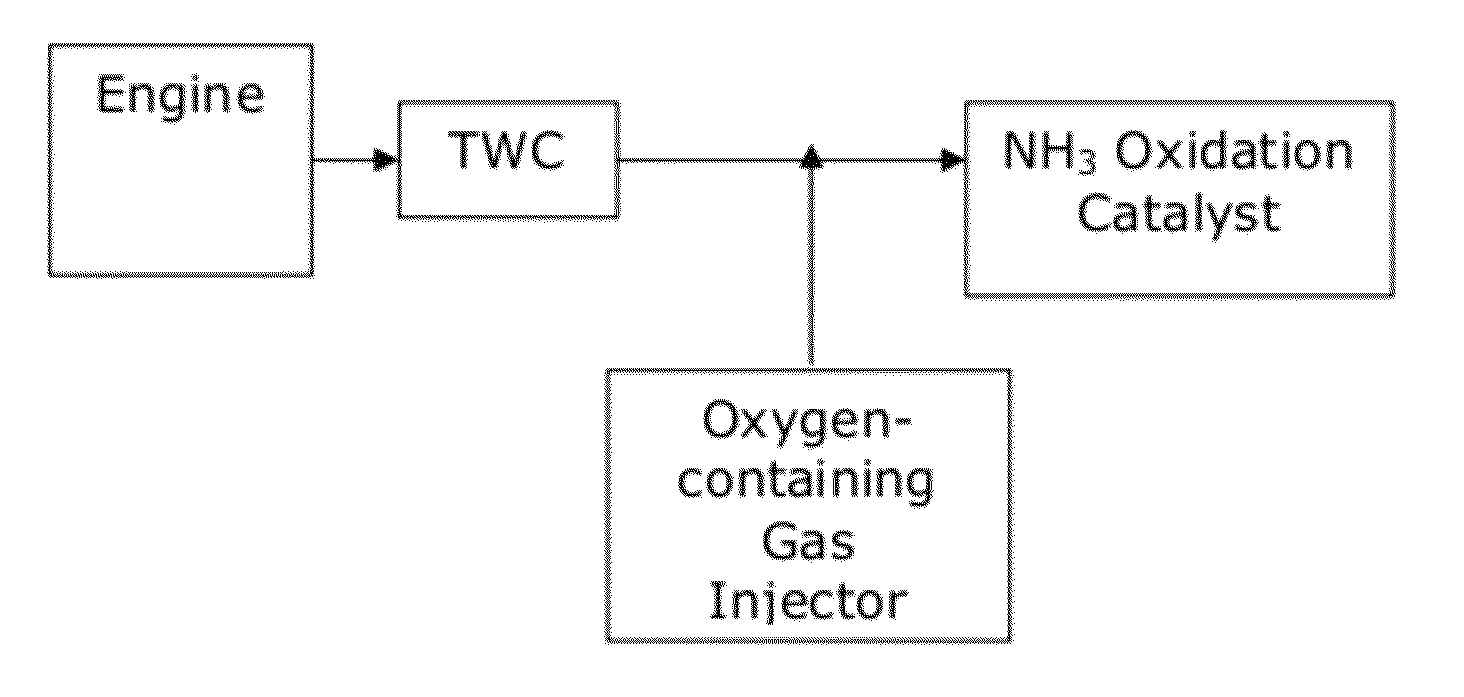

A system for reducing ammonia (NH3) emissions includes (a) a first component comprising a first substrate containing a three-way catalyst, wherein the first component is disposed upstream of a second component comprising a second substrate containing an ammonia oxidation catalyst, wherein said ammonia oxidation catalyst comprises a small pore molecular sieve supporting at least one transition metal; and (b) an oxygen-containing gas input disposed between the components. For example, a CHA Framework Type small pore molecular sieve may be used. A method for reducing NH3 emission includes introducing an oxygen-containing gas into a gas stream to produce an oxygenated gas stream; and exposing the oxygenated gas stream to an NH3 oxidation catalyst to selectively oxidize at least a portion of the NH3 to N2.

Owner:JOHNSON MATTHEY PLC

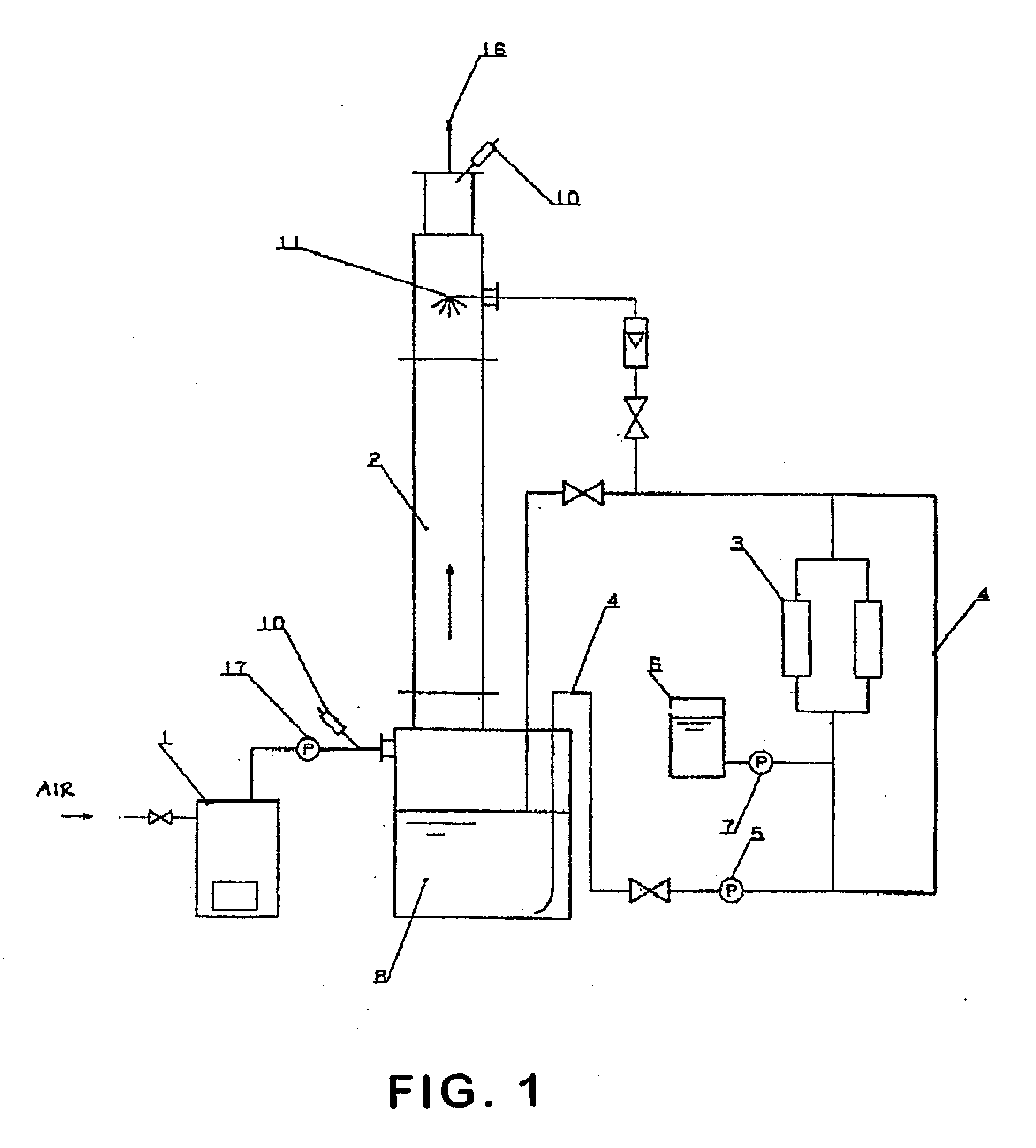

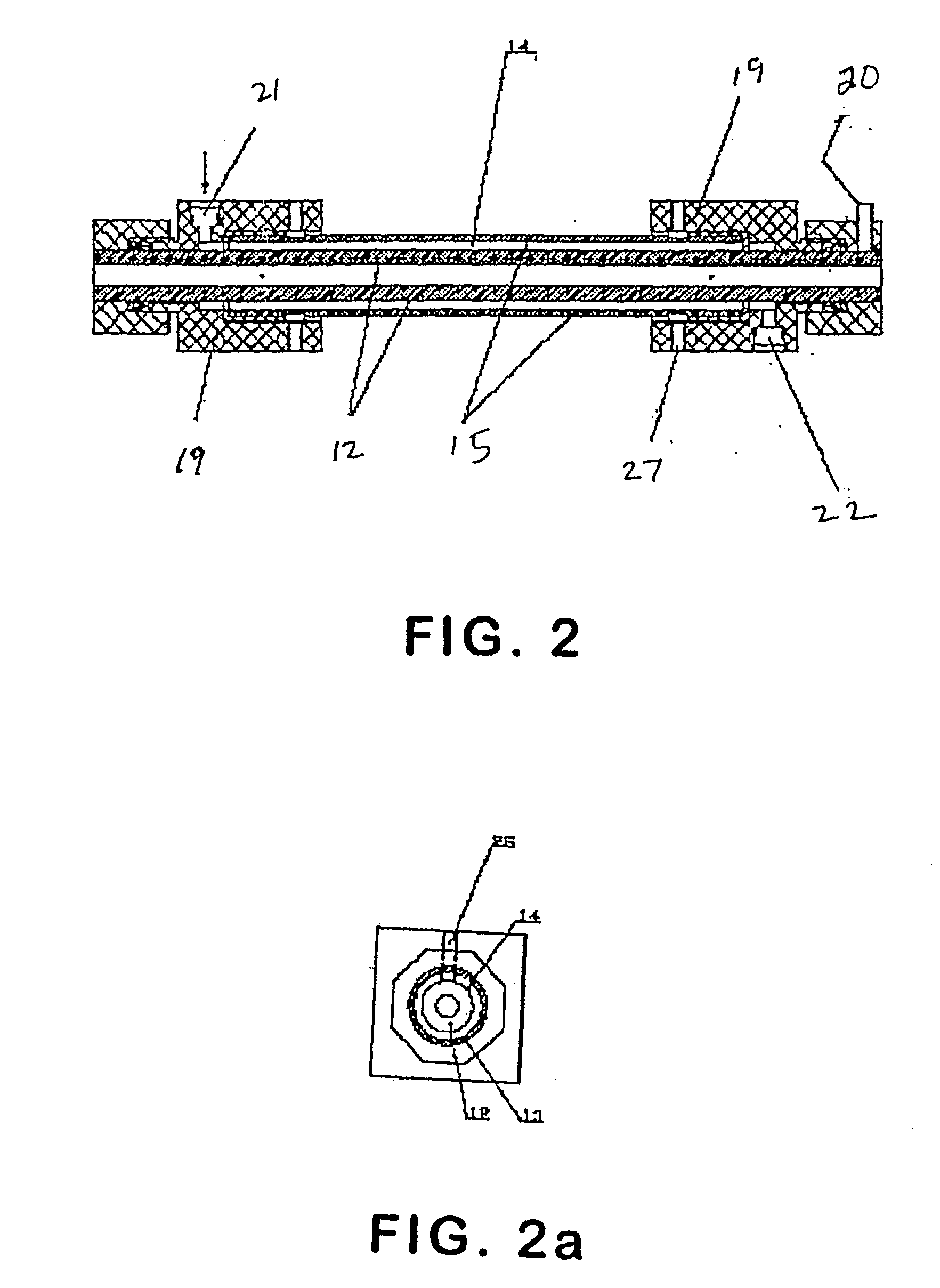

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20030164309A1Easy can be electrolyzedHigh densityCyanogen compoundsLighting and heating apparatusHazardous substancePotassium hydroxide

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogen acid such as hypochlorous acid soda, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:OMEGA CO LTD

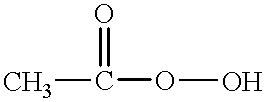

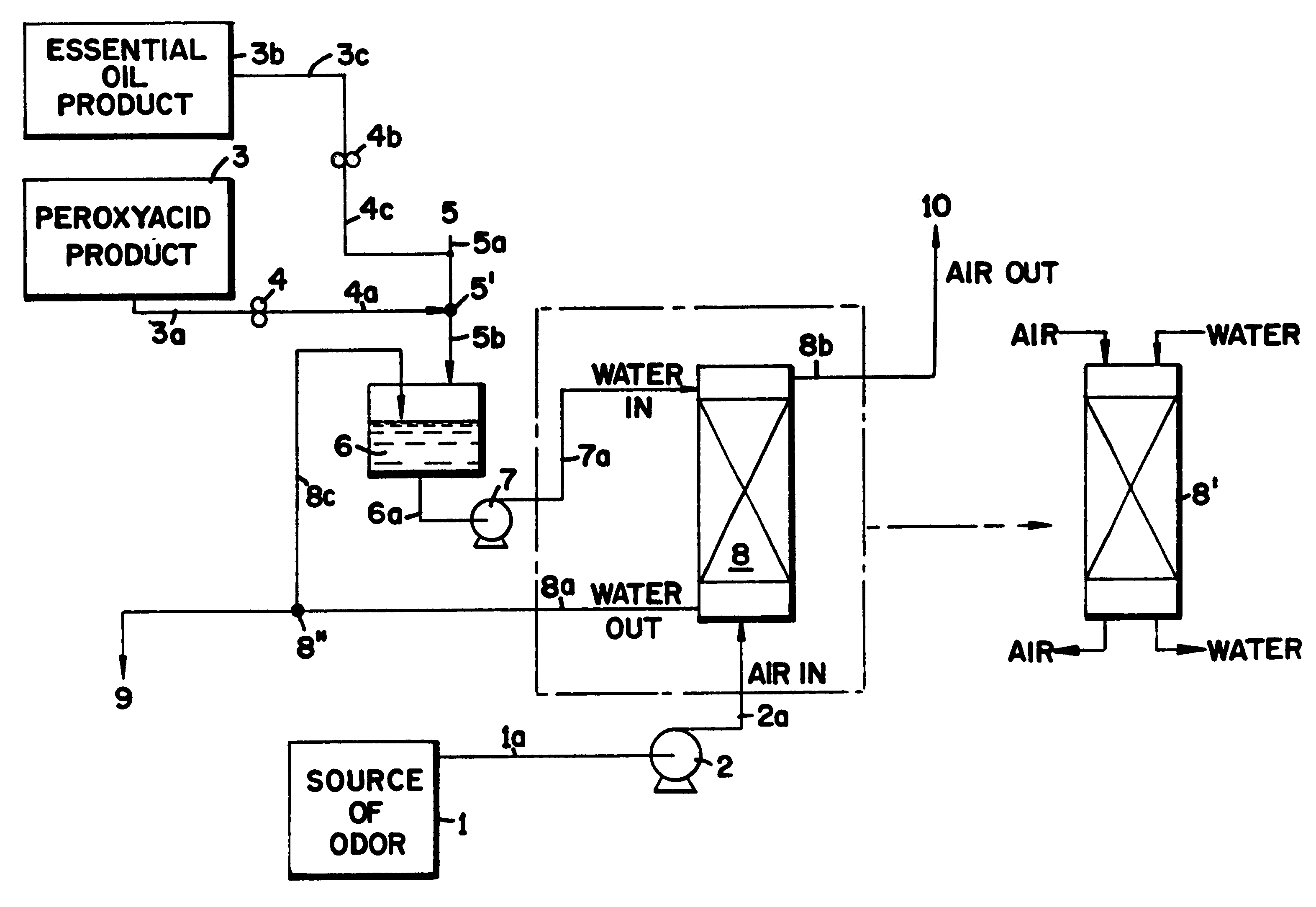

Simultaneous use of peroxygen and olefin compound in odor reduction

InactiveUS6277344B1Improved malodor removalEnhanced mass transferCyanogen compoundsOrganic chemistryGas phasePeroxy acid

Disclosed is a process for the treatment of a plant fluid effluent containing odor compounds including an alkyl mercaptan or an alkyl thiol, an amine compound, ammonia, hydrogen sulfide and mixtures thereof by contacting the plant effluent in either a counterflow or cocurrent flow process. In the process, the effluent is contacted with an aqueous solution comprising a peroxyacid compound and one or more essential oils. When contacted with the peroxyacid, odor compounds in the effluent are oxidized and converted from the gaseous phase into a chemically modified highly aqueous soluble phase in the aqueous treatment. In this way, odor removal from the gas is preferred and odor compounds are efficiently transferred into the aqueous treatment solution. The use of such a process produces a significant improvement in odor quality index as measured by a conventional process using an expert panel when compared to conventional treatment methods.

Owner:ECOLAB USA INC

Methods and devices for reducing hazardous air pollutants

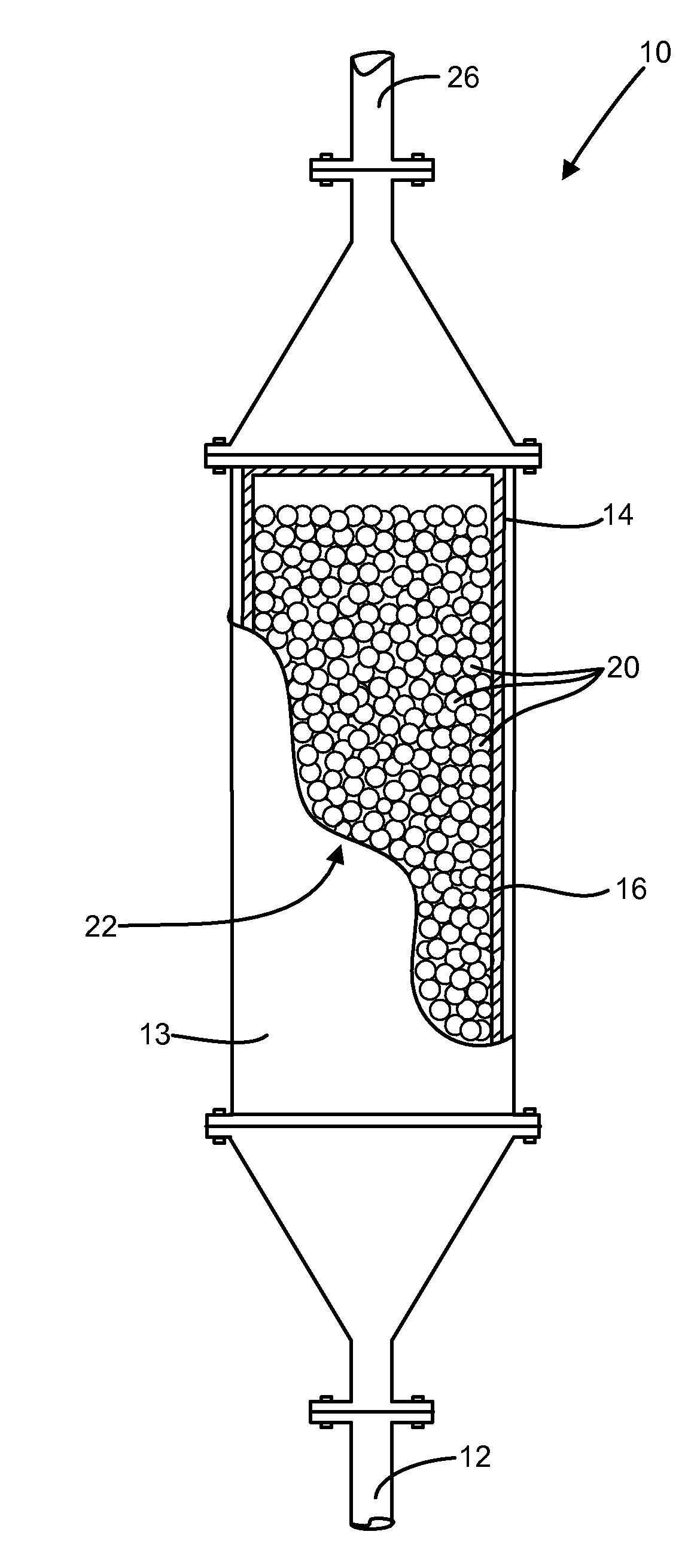

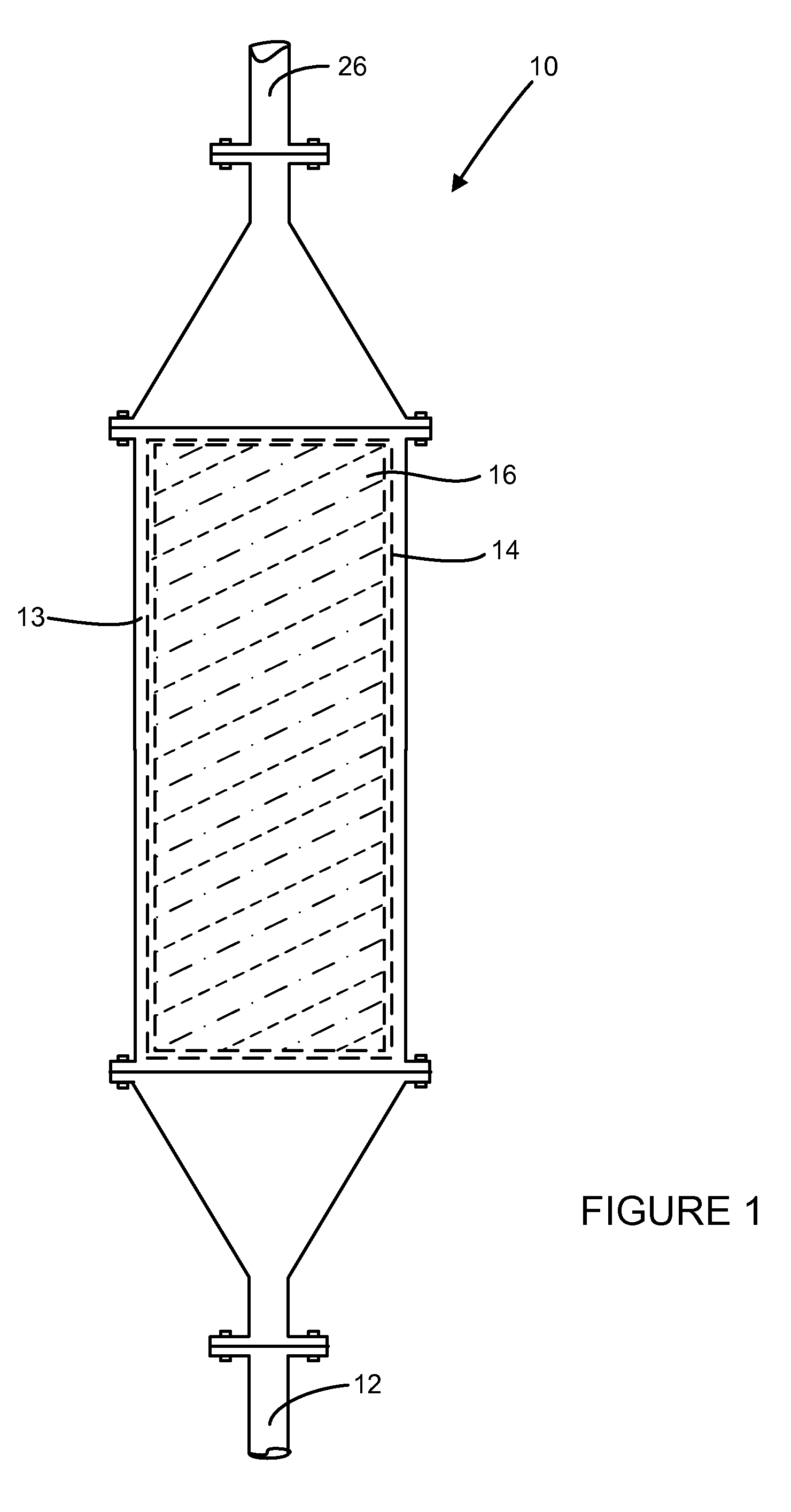

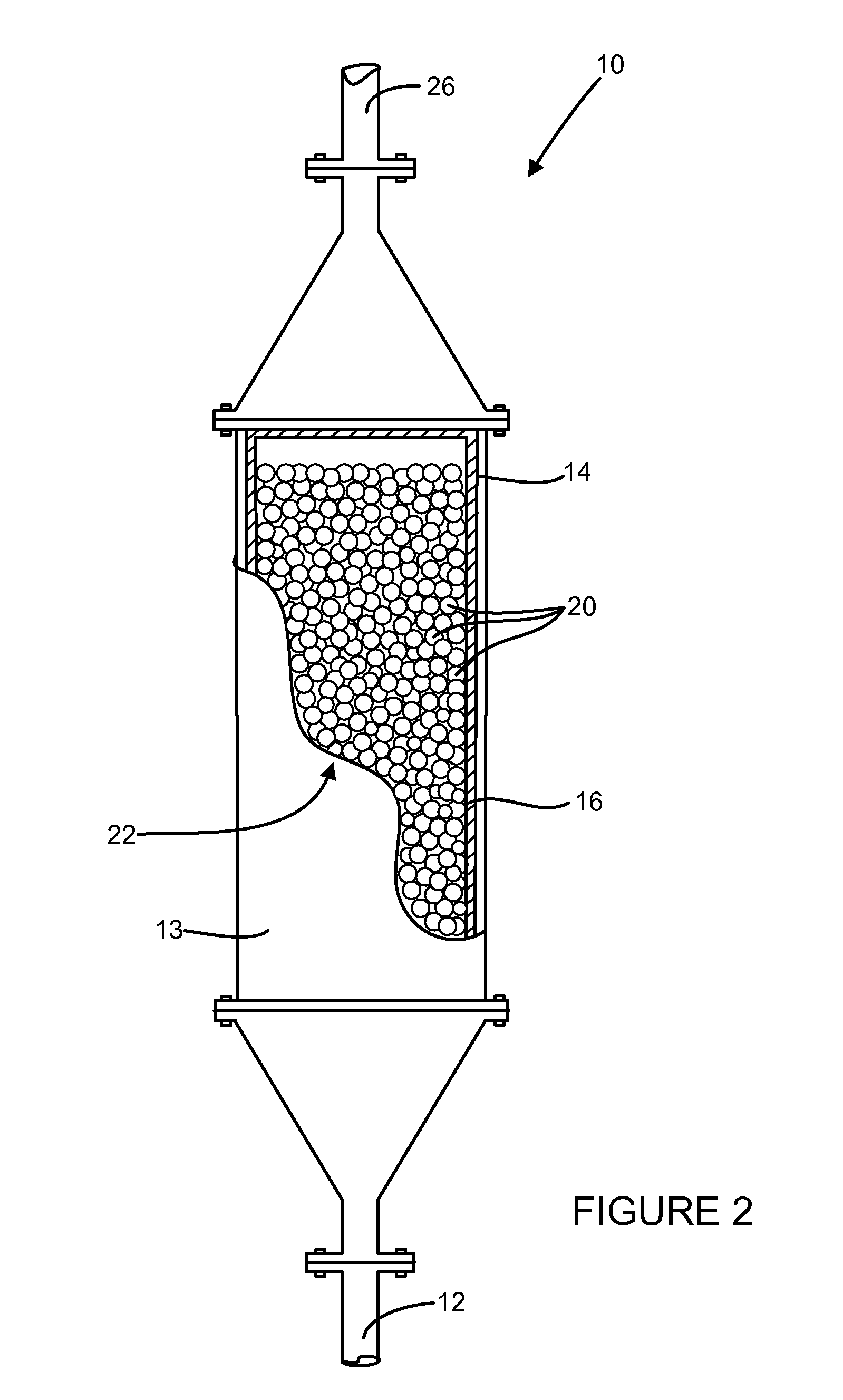

ActiveUS20090081093A1Reduce pollutionReduce the amount requiredCombination devicesCyanogen compoundsSlagSolid particle

The disclosure provides methods and systems for sequestering and / or reducing sulfur oxides, nitrogen oxides and / or carbon dioxide present in industrial effluent fluid streams. A solid particulate material comprising a slag component, a binder component (distinct from the slag component), and optionally water is formed and then contacted with the effluent fluid stream to reduce at least one of the sulfur oxides, nitrogen oxides, and / or carbon dioxide. The contacting of the effluent stream may occur in a packed bed reactor with the solid dry particulate material. Methods of reducing pollutants from exhaust generated by combustion sources, lime and / or cement kilns, iron and / or steel furnaces, and the like are provided.

Owner:C QUEST TECH

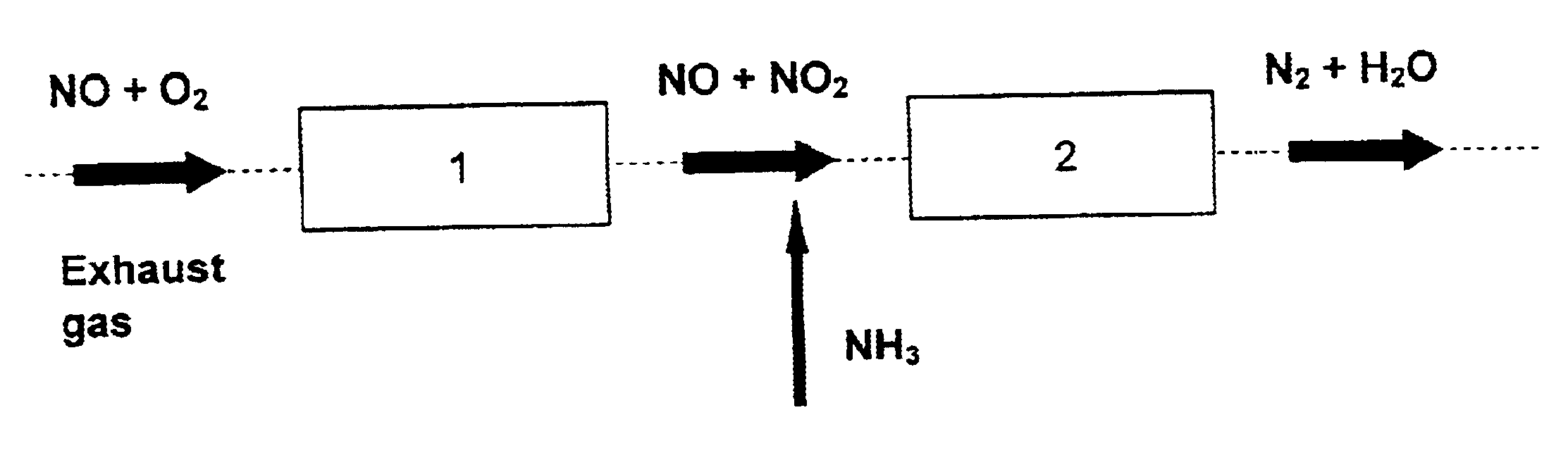

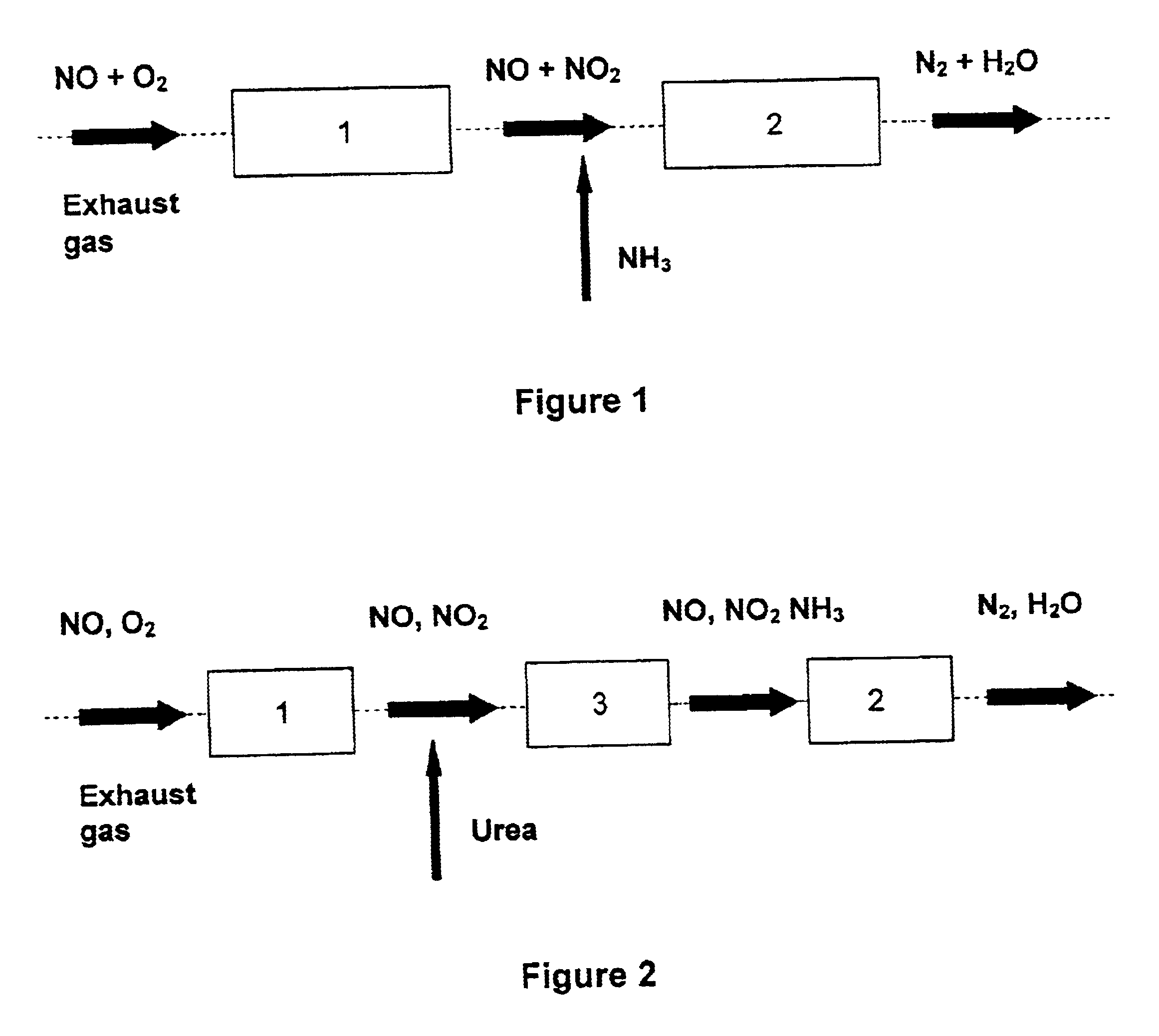

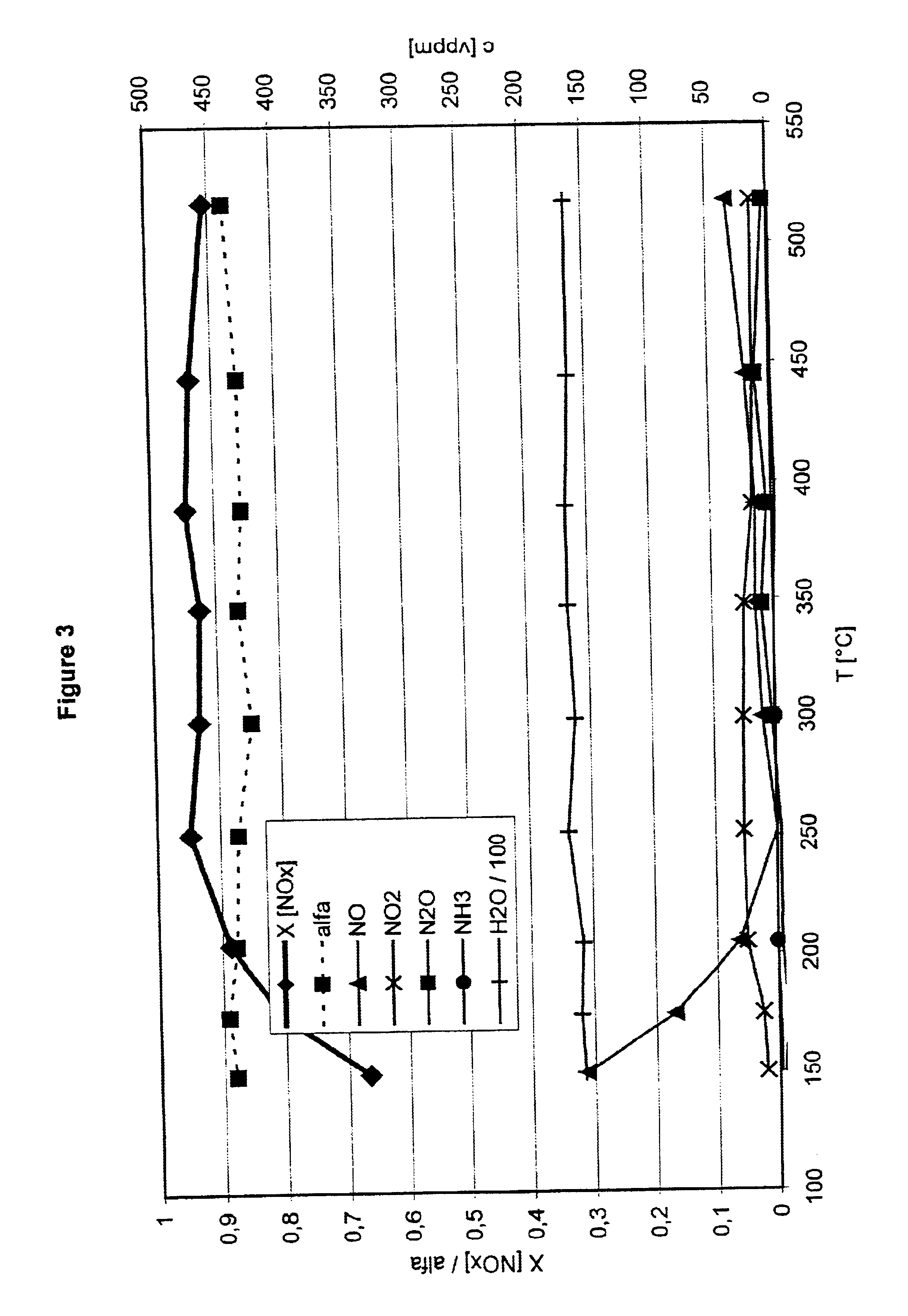

Process and catalyst for reducing nitrogen oxides

InactiveUS6843971B2High activityDelay agingCyanogen compoundsInternal combustion piston enginesInternal combustion engineChemistry

A process for reducing the nitrogen oxides present in a lean exhaust gas from an internal combustion engine by selective catalytic reduction on a reduction catalyst using ammonia, wherein a fraction of the nitrogen monoxide present in the exhaust gas is oxidized to nitrogen dioxide before the exhaust gas, together with ammonia, is passed over the reduction catalyst. The reduction catalyst contains a zeolite exchanged with transition metals and oxidation of the nitrogen monoxide is performed in such a way that the exhaust gas contains 30 to 70 vol. % of nitrogen dioxide before contact with the reduction catalyst.

Owner:UMICORE AG & CO KG

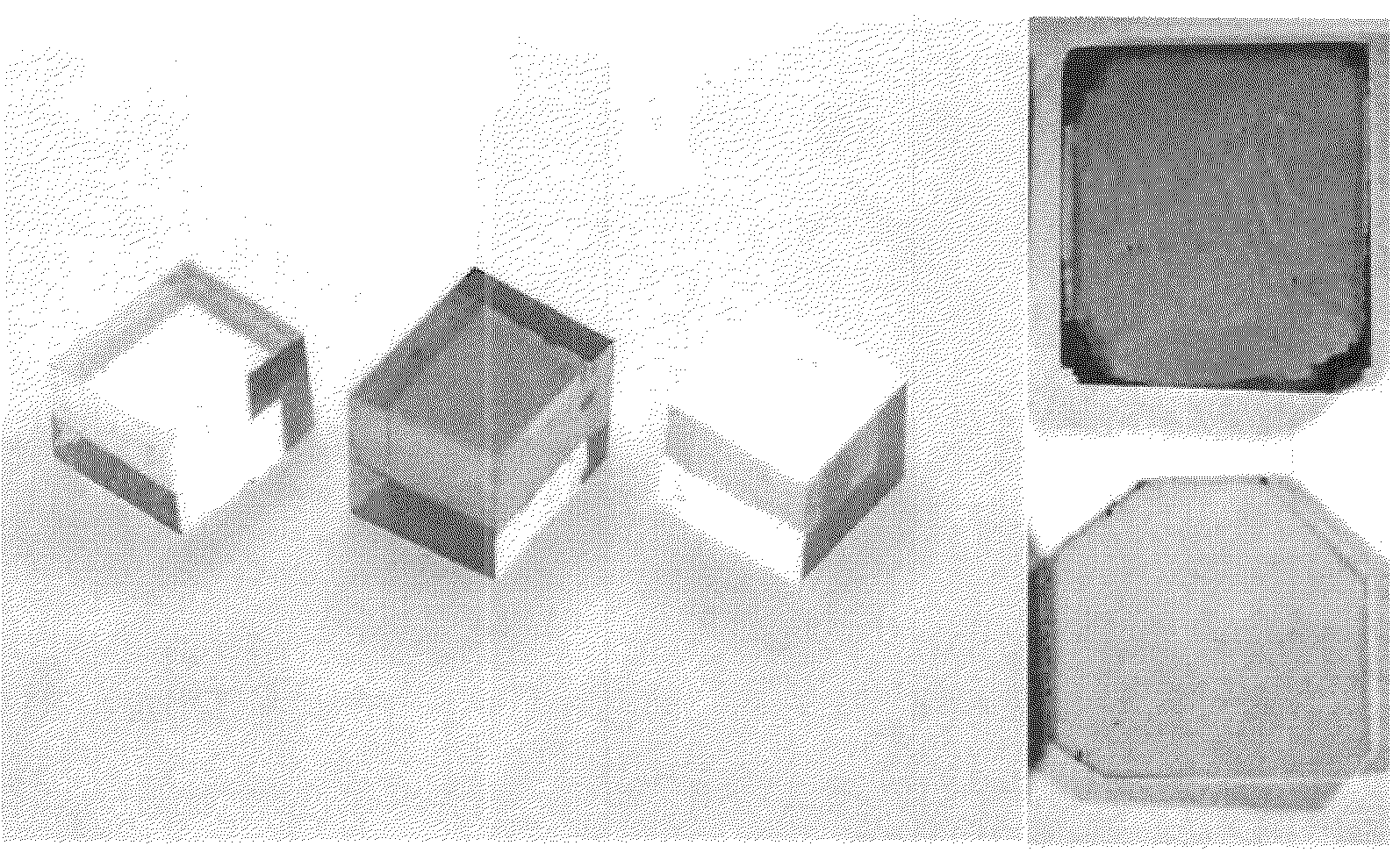

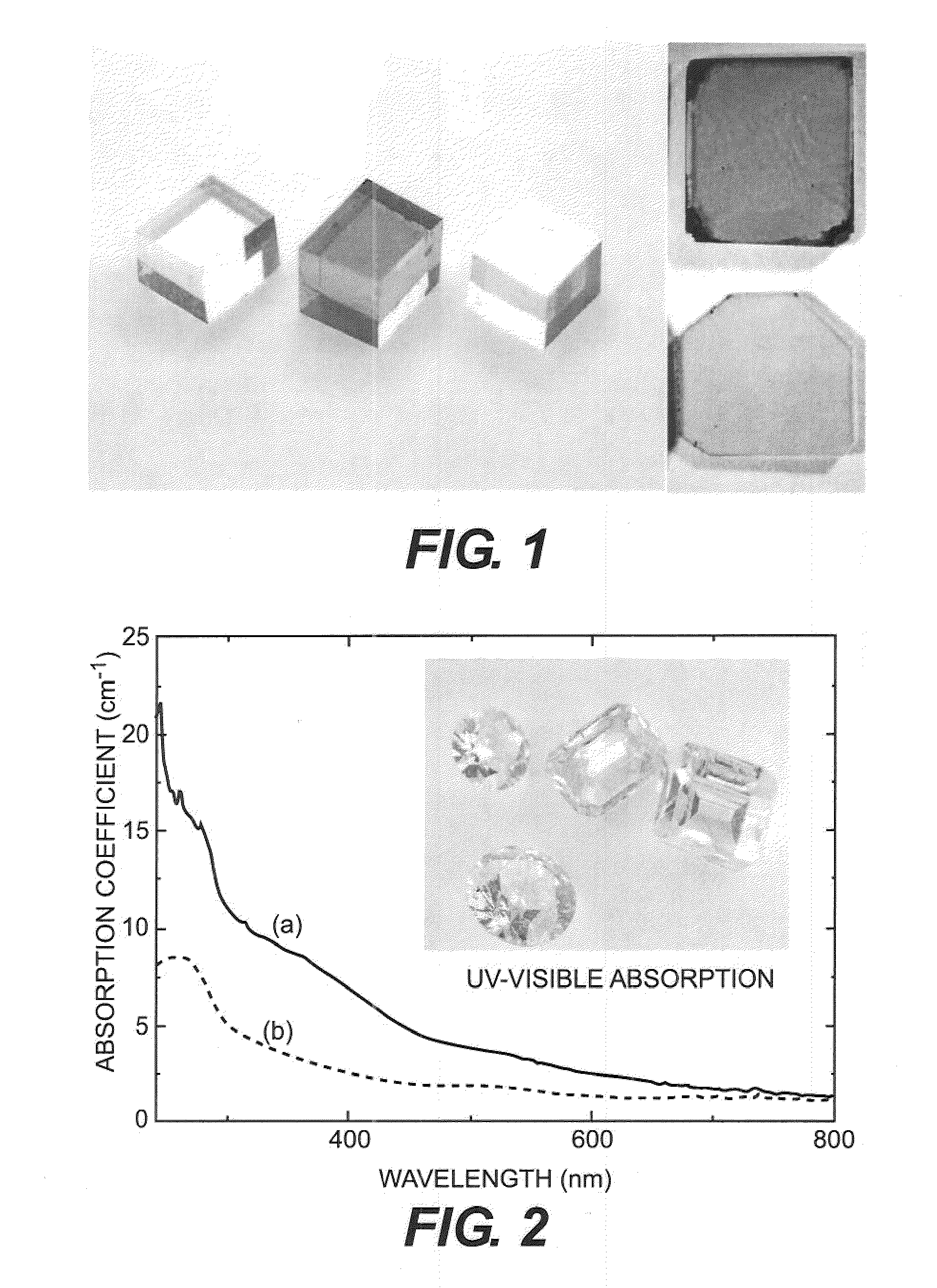

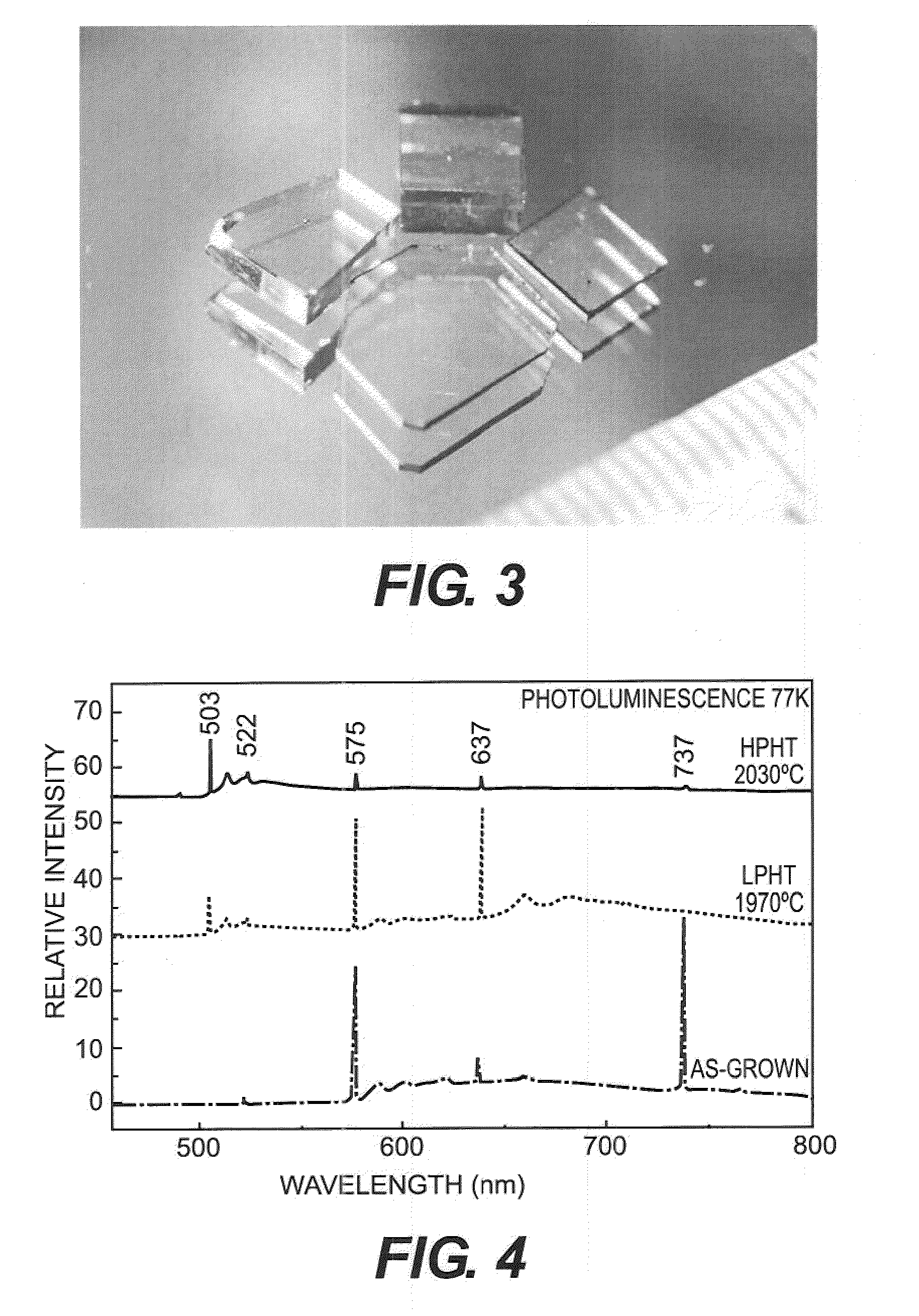

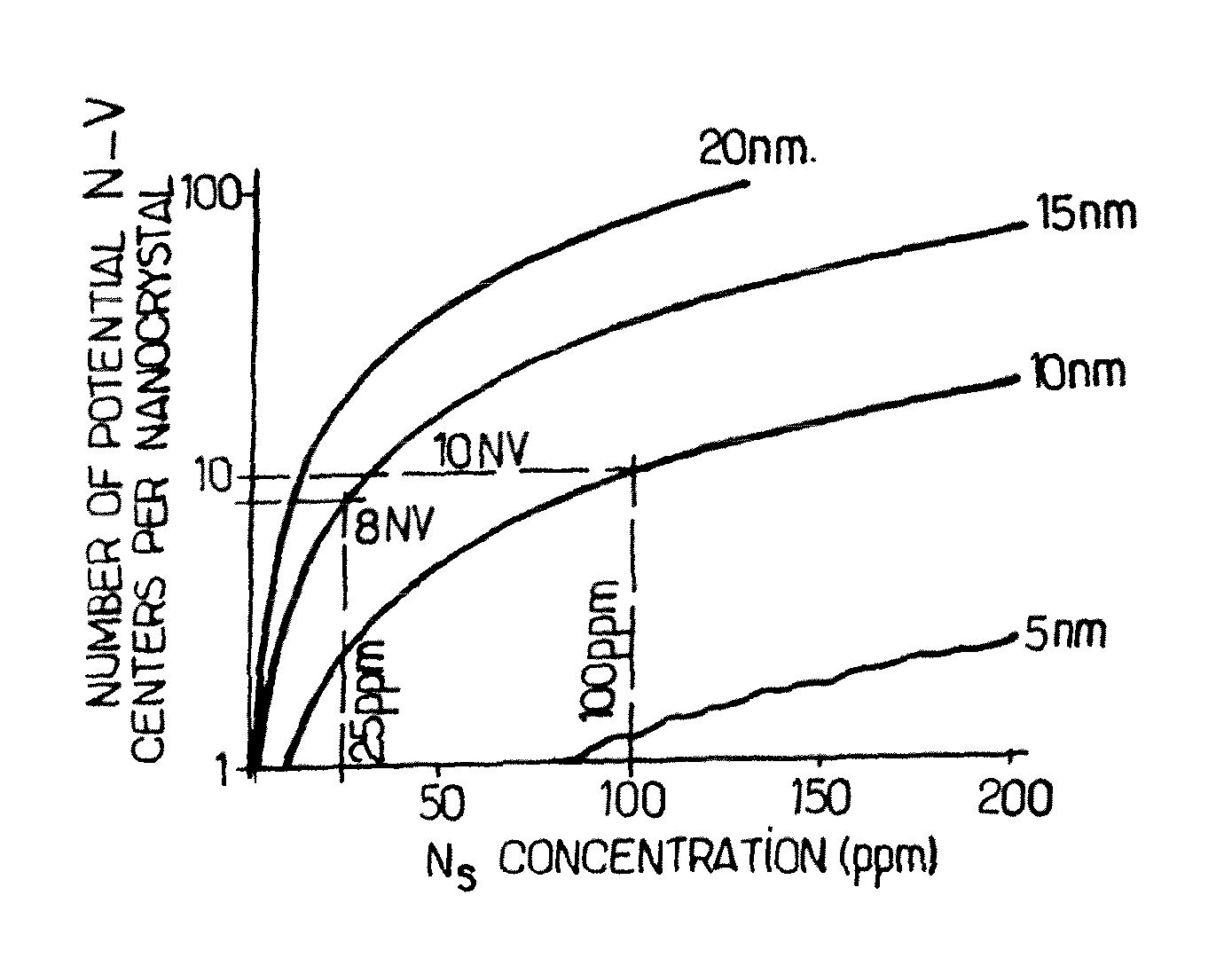

Enhanced Optical Properties of Chemical Vapor Deposited Single Crystal Diamond by Low-Pressure/High-Temperature Annealing

InactiveUS20100104494A1Good optical performanceIncrease probabilityPolycrystalline material growthCyanogen compoundsOptical propertyGas phase

The method of improving the optical properties of single crystal CVD diamond which comprises annealing the crystals at a temperature of up to 2200° C. and a pressure below 300 torr.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

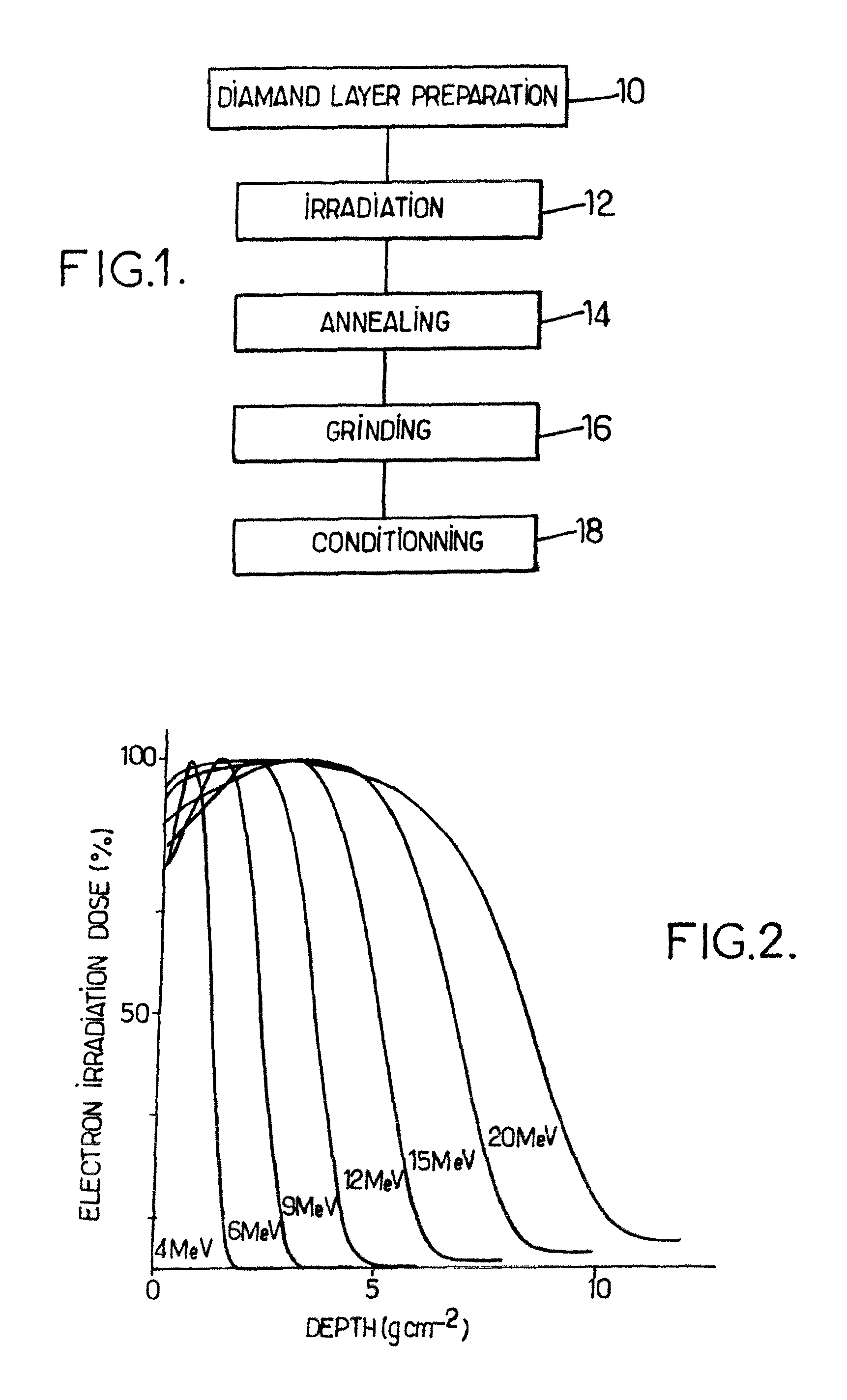

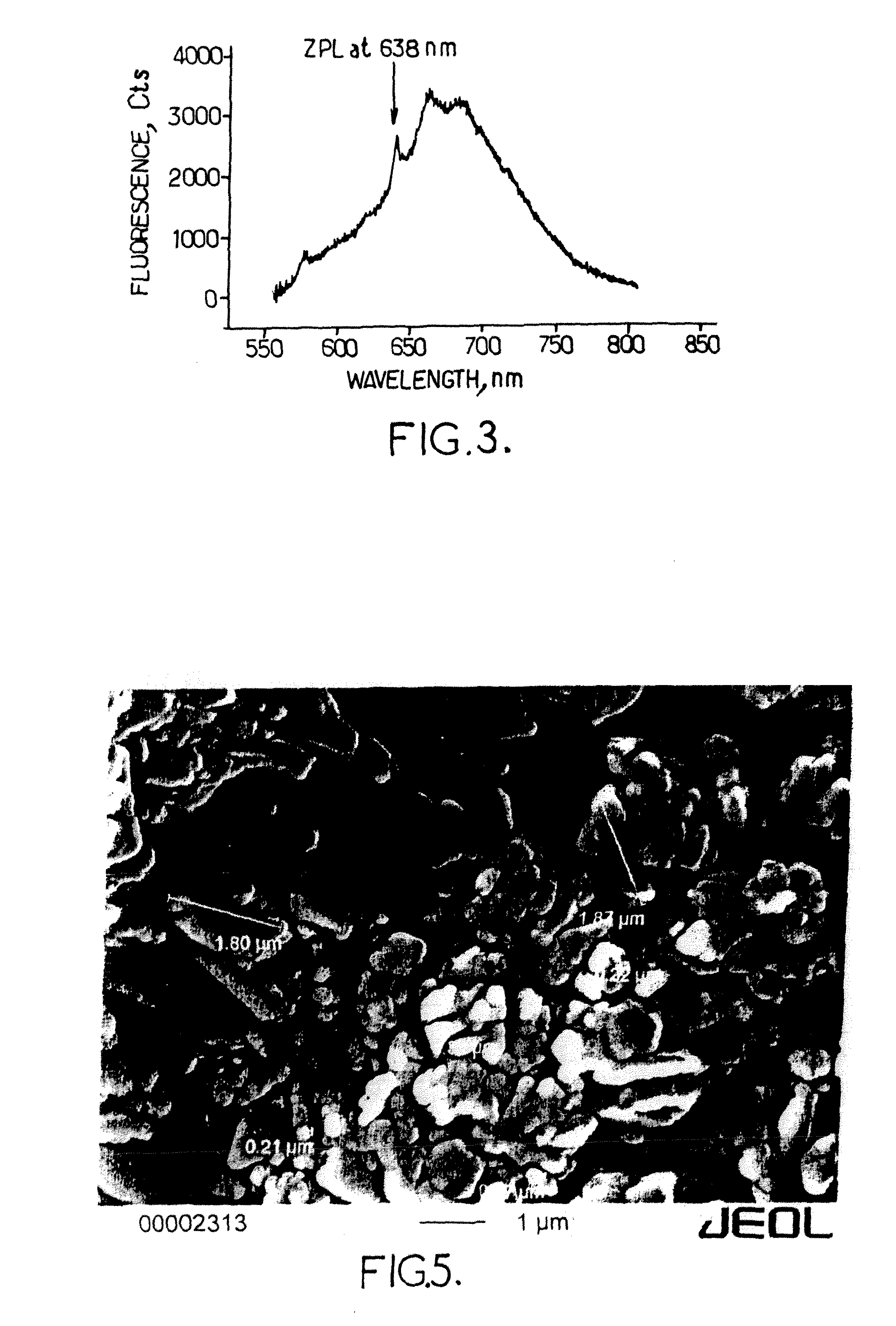

Method to produce light-emitting nano-particles of diamond

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM)

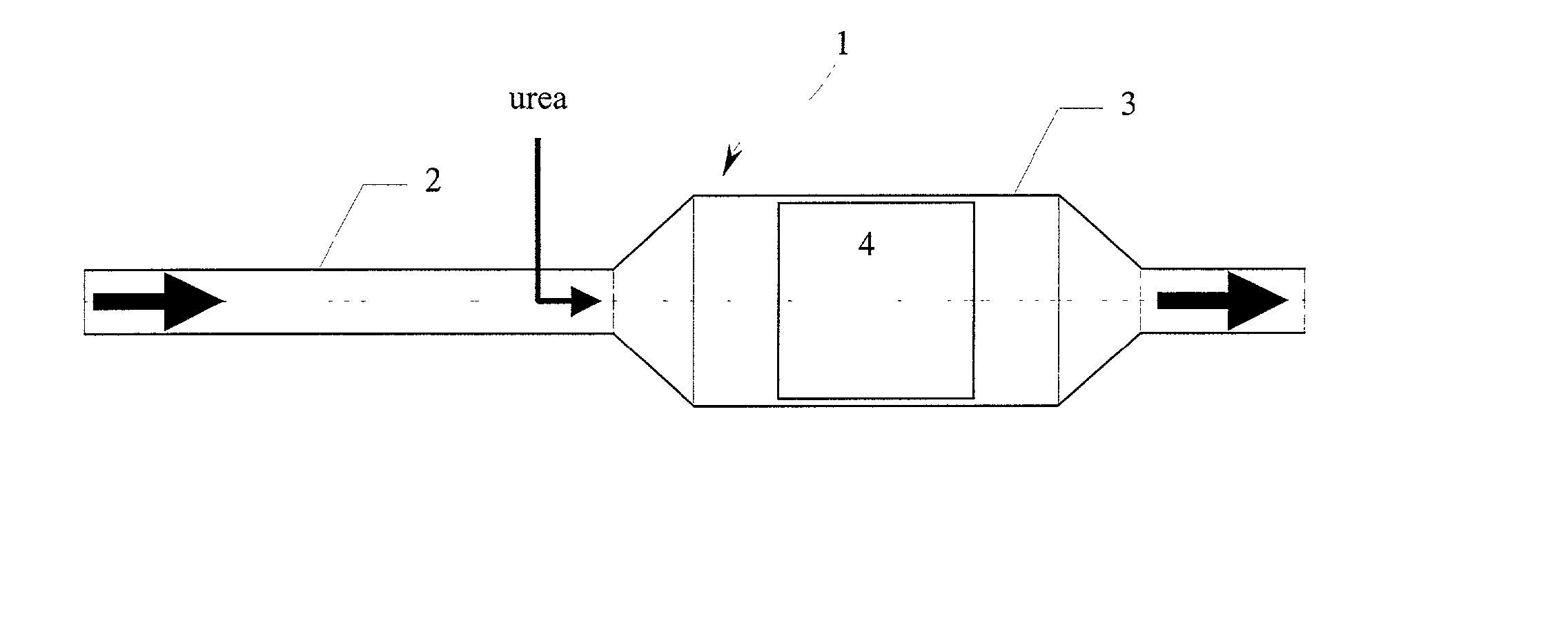

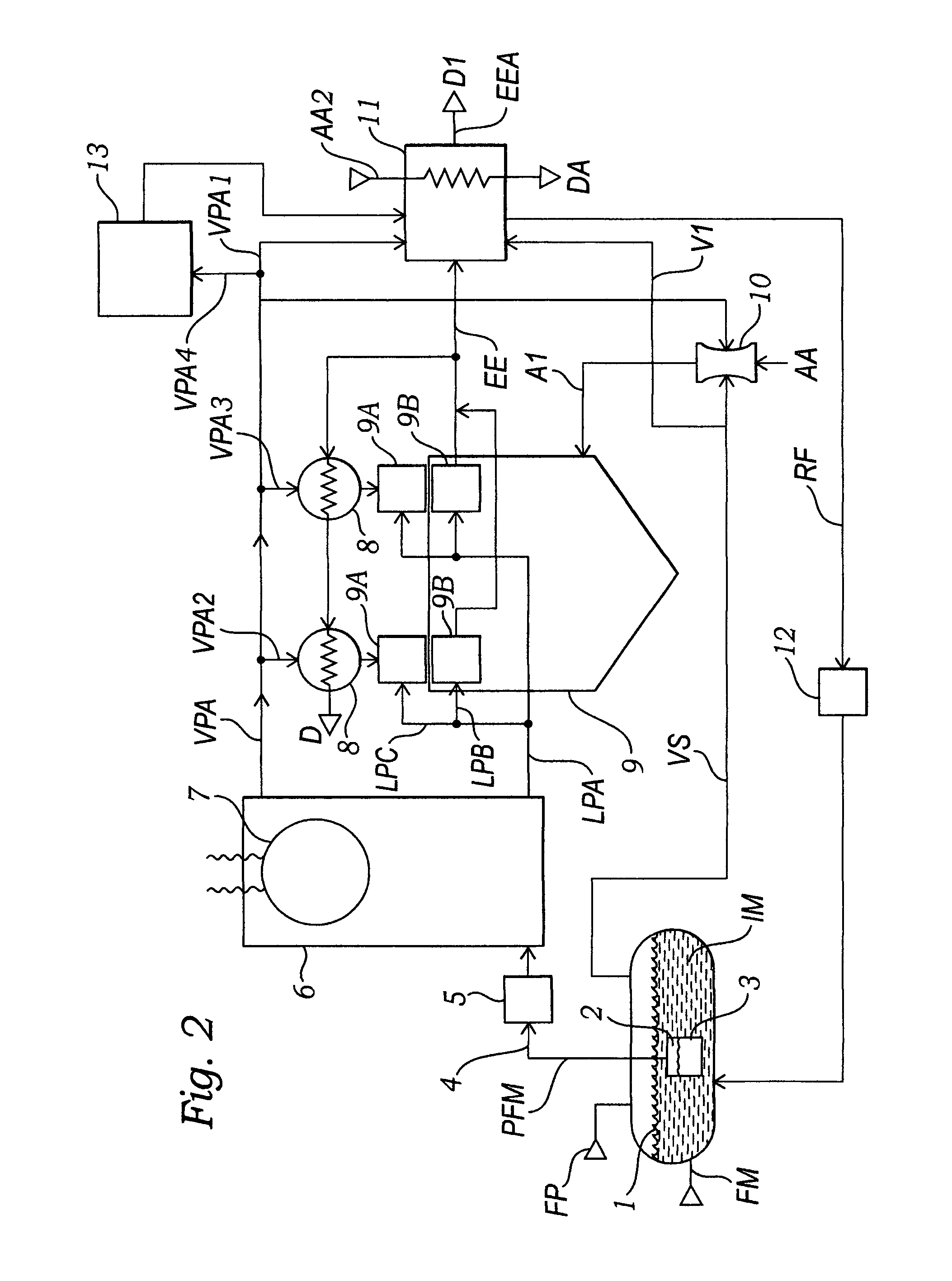

Exhaust gas treatment unit for the selective catalytic reduction of nitrogen oxides under lean exhaust gas conditions and a process for the treatment of exhaust gases

InactiveUS20020054844A1Facilitated releaseCombination devicesCyanogen compoundsNitrogen oxidesActive component

An exhaust gas treatment unit for the selective catalytic reduction of nitrogen oxides under lean exhaust gas conditions which contains at least one catalyst with catalytically active components for selective catalytic reduction (SCR components). The exhaust gas treatment unit is characterised in that the catalyst also contains, in addition to SCR components, at least one storage component for nitrogen oxides (NOx components).

Owner:UMICORE AG & CO KG

Combustion emission-reducing method

InactiveUS8206470B1Reduce the amount requiredReduce nitrogen oxide emissionsCyanogen compoundsInternal combustion piston enginesCombustionFuel efficiency

In one embodiment, a fluid mixture composition is used at least in part as a fuel for engine-powered transportation vehicles, the mixture comprising an initial concentration of an ammonia-like reductant component and an initial concentration of an ammonia-like carrier component. The mixture may also include an optional third hydrocarbon component, e.g., gasoline or diesel fuel, with modified properties when compared to conventional gasolines or diesel fuels. The mixture is separated into a first and a second stream, with the majority of the first stream being used as a fuel for the engine and at least a first portion of the second stream being injected into the engine exhaust gases to reduce NOx emissions. A second portion of the second stream is aspirated into the engine and a lean air / fuel ratio may be used to improve fuel efficiency.

Owner:JACOBSON WILLIAM O

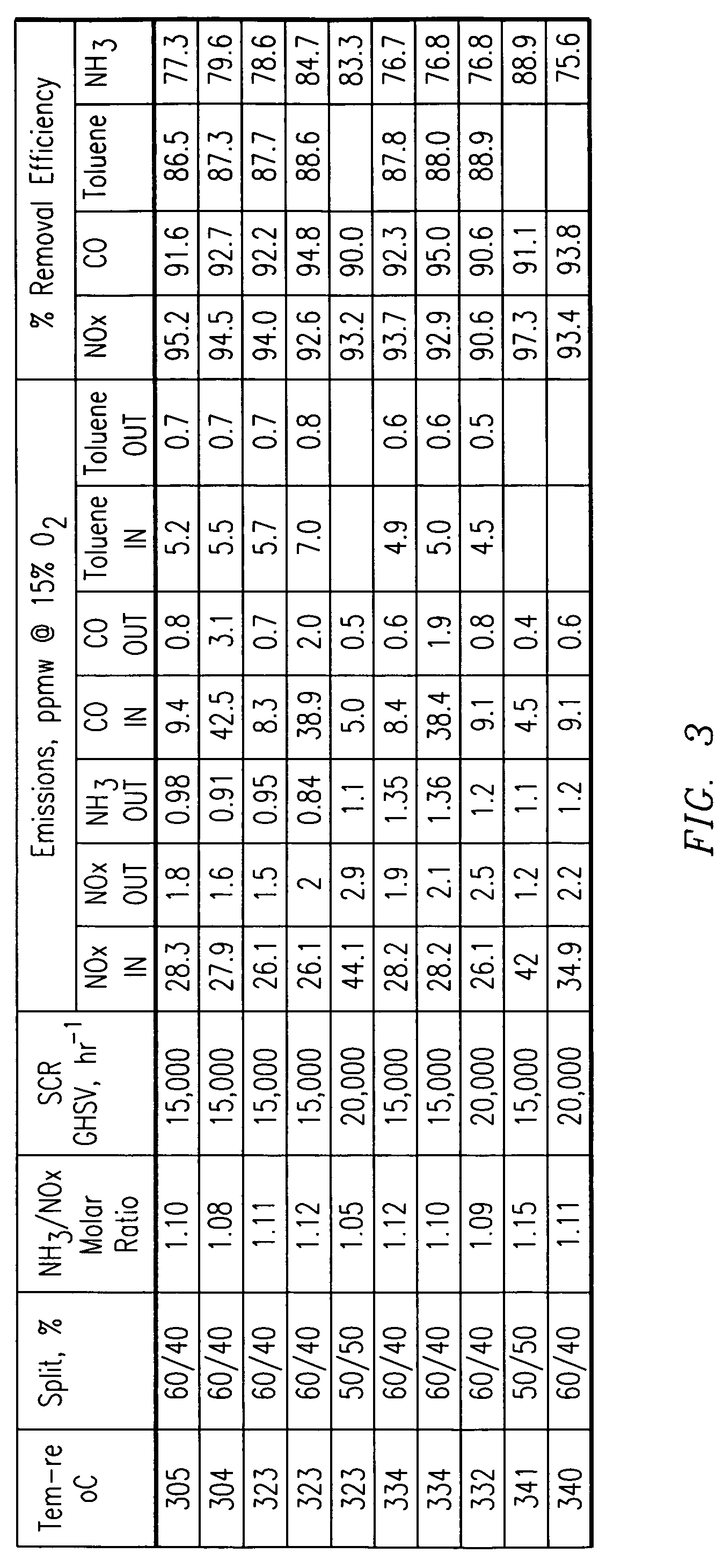

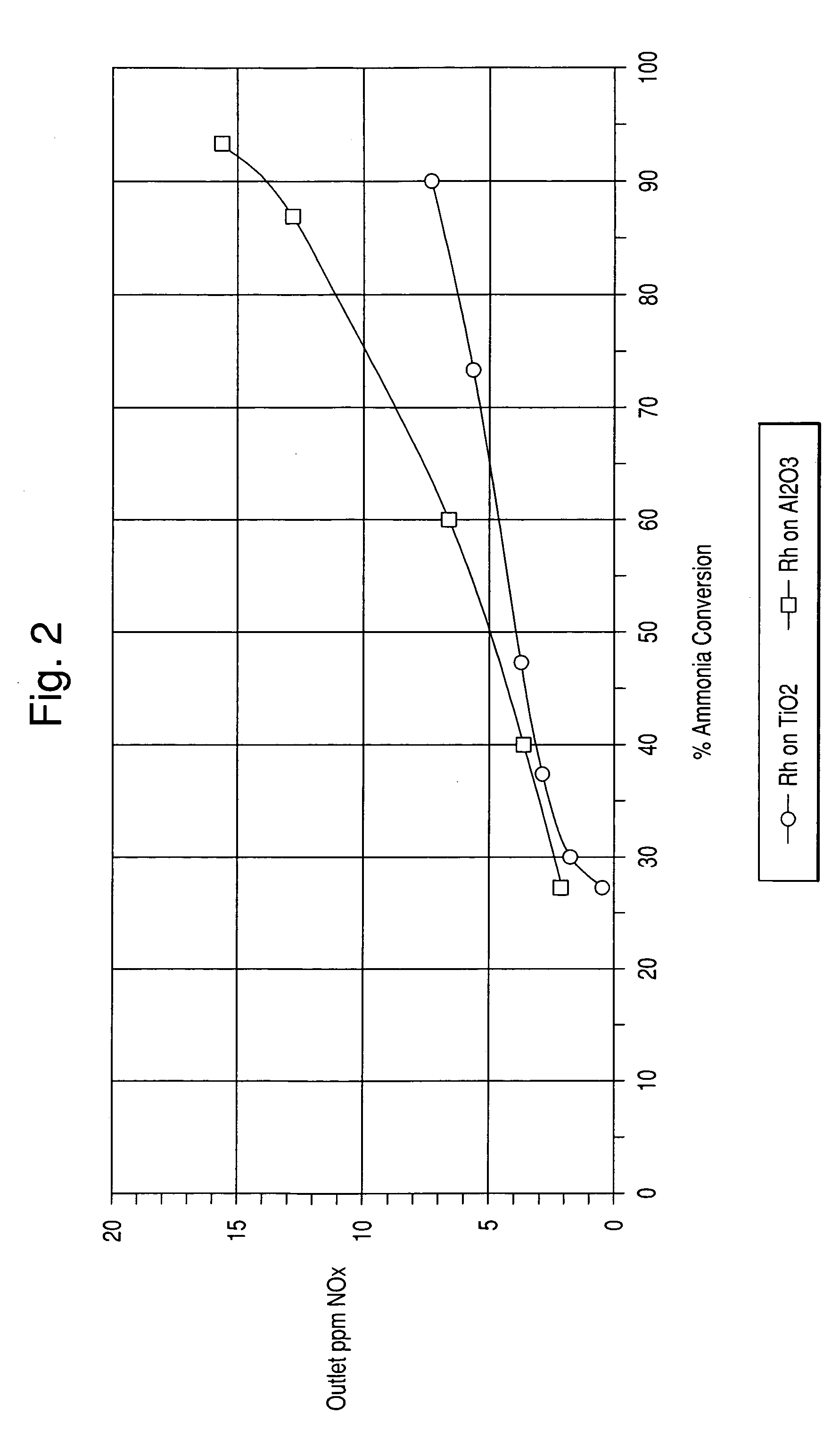

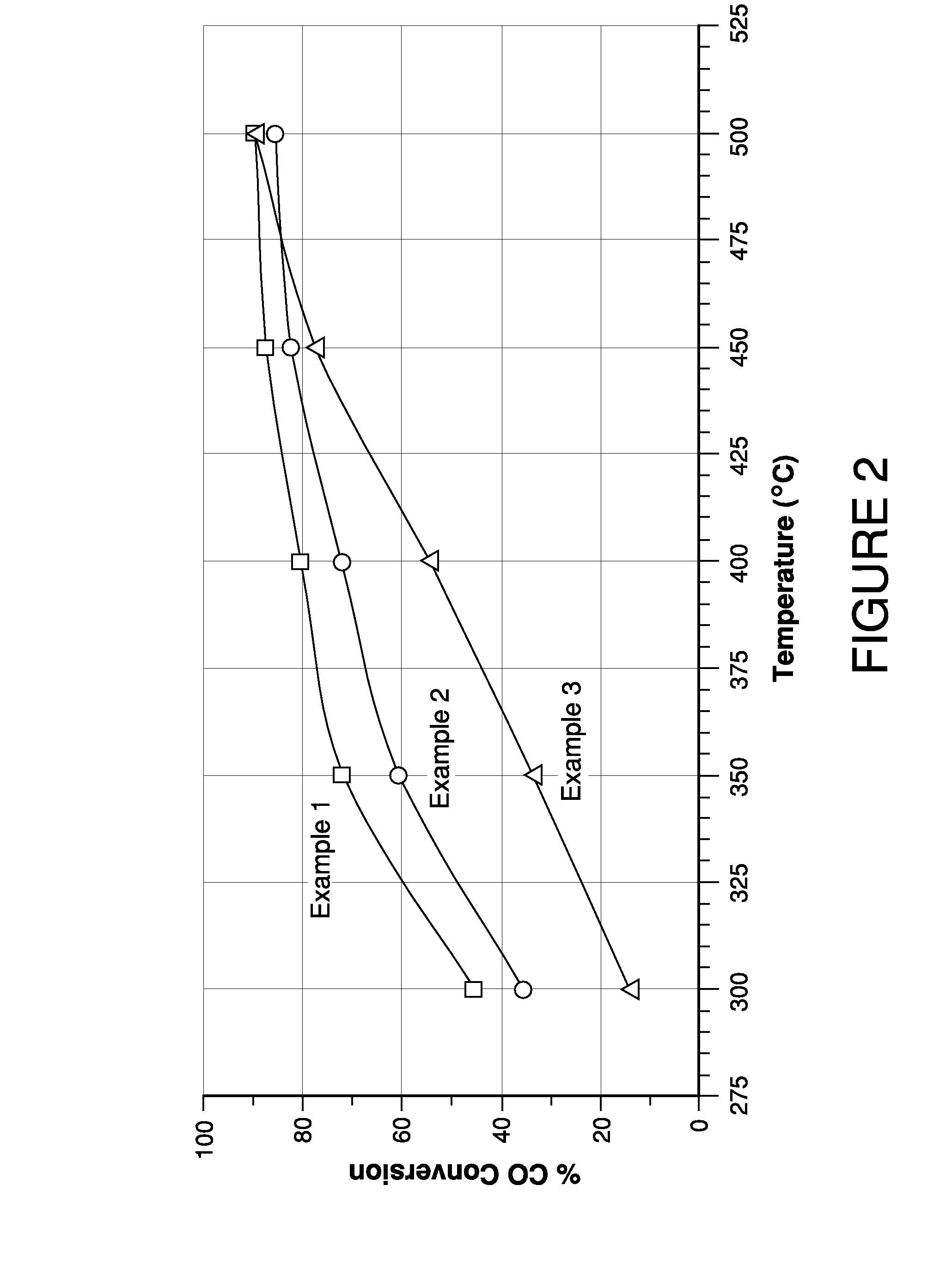

Ammonia oxidation catalyst for the coal fired utilities

InactiveUS7393511B2Undesirable emission levelNo sulfurCyanogen compoundsNitrogen compoundsSulfur dioxideCarbon monoxide

A process is described that removes by oxidation the excess ammonia (NH3) gas from flue gases that have been subjected to selective catalytic reduction (SCR) of oxides of nitrogen (NOx) by ammonia injection. The inventive process incorporates a secondary catalyst of precious metal and vanadia on a metal oxide such as titania to catalyze the oxidation of both ammonia and carbon monoxide (CO) while maintaining sulfur dioxide (SO2) levels.

Owner:BASF CATALYSTS LLC

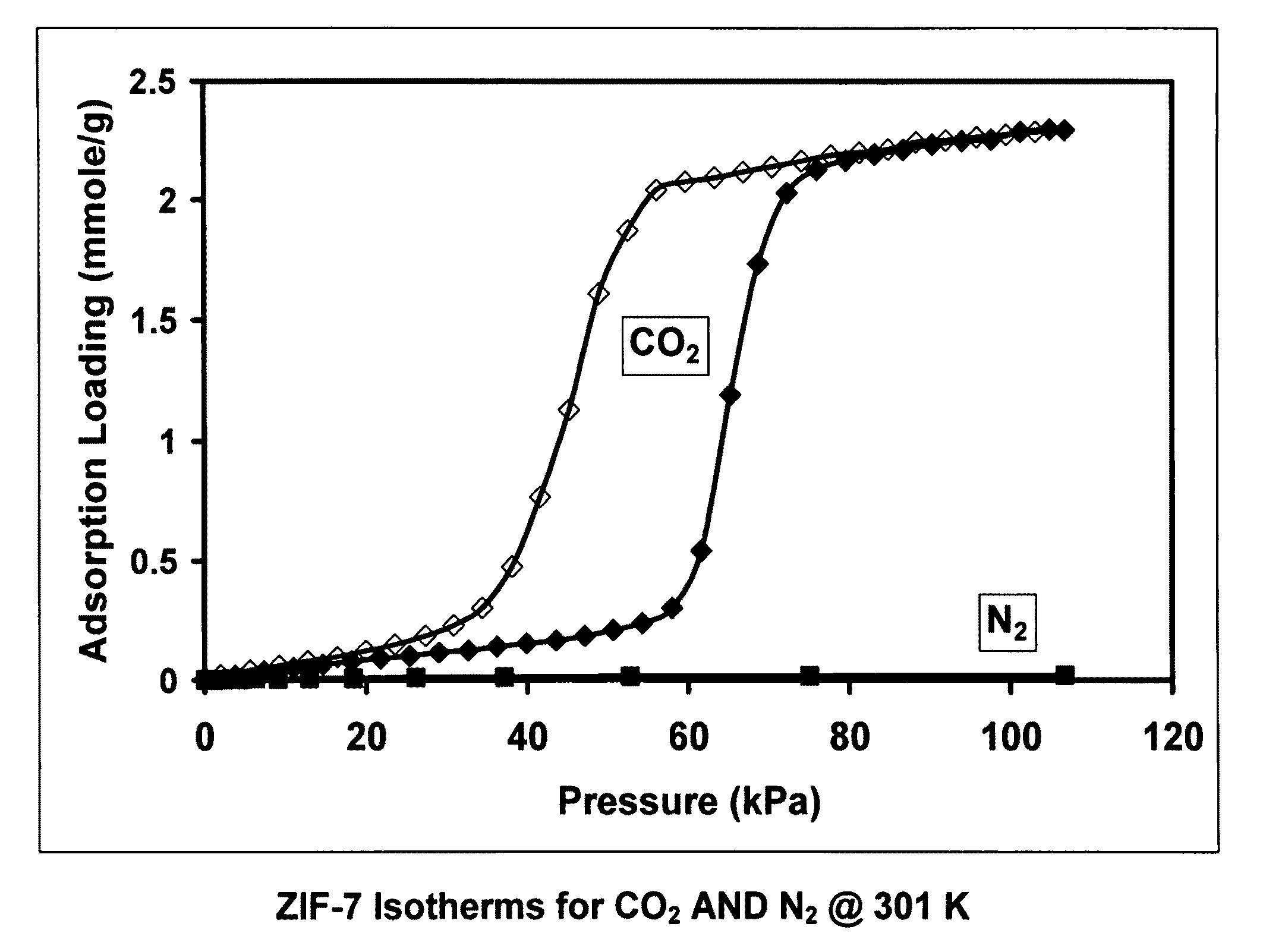

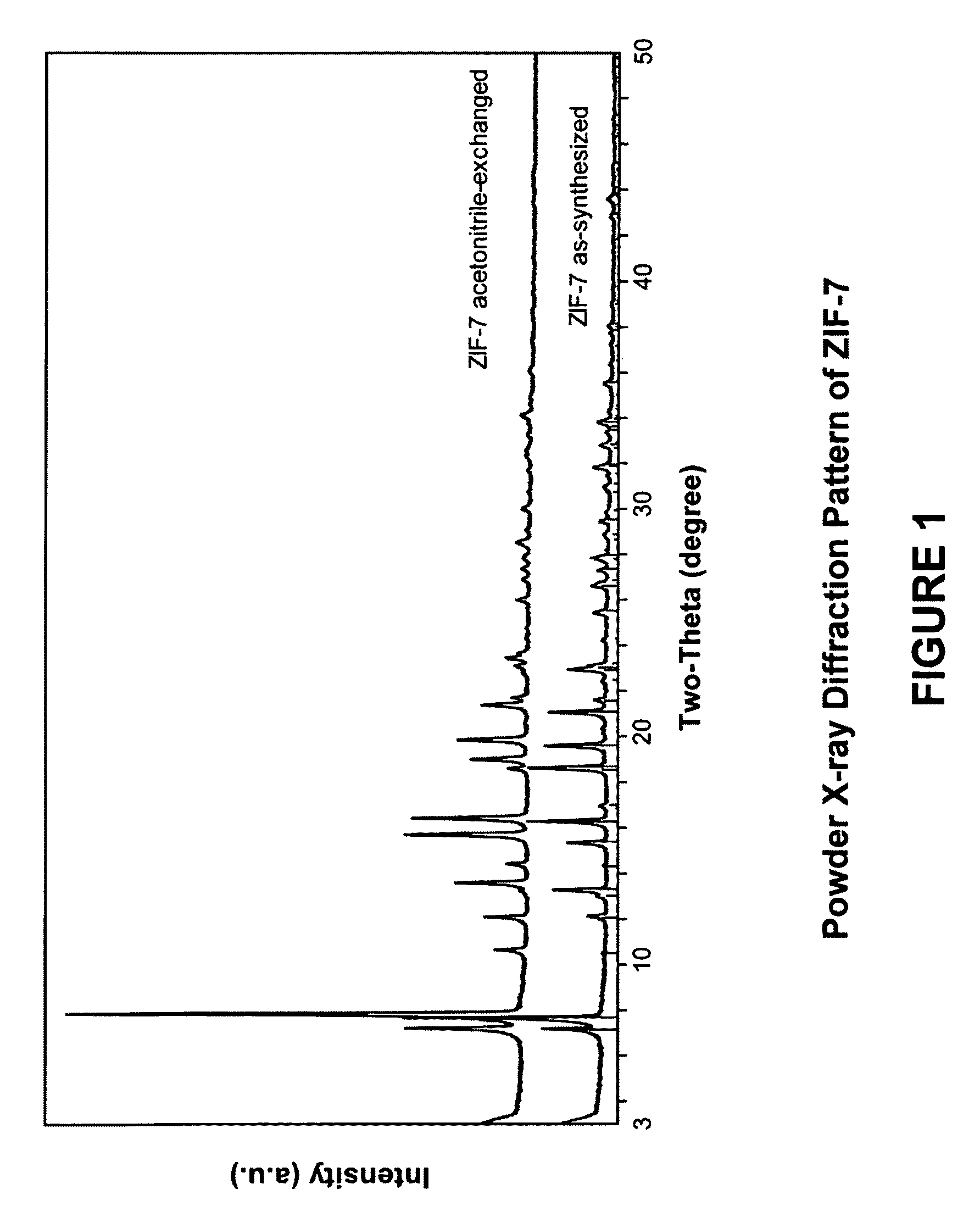

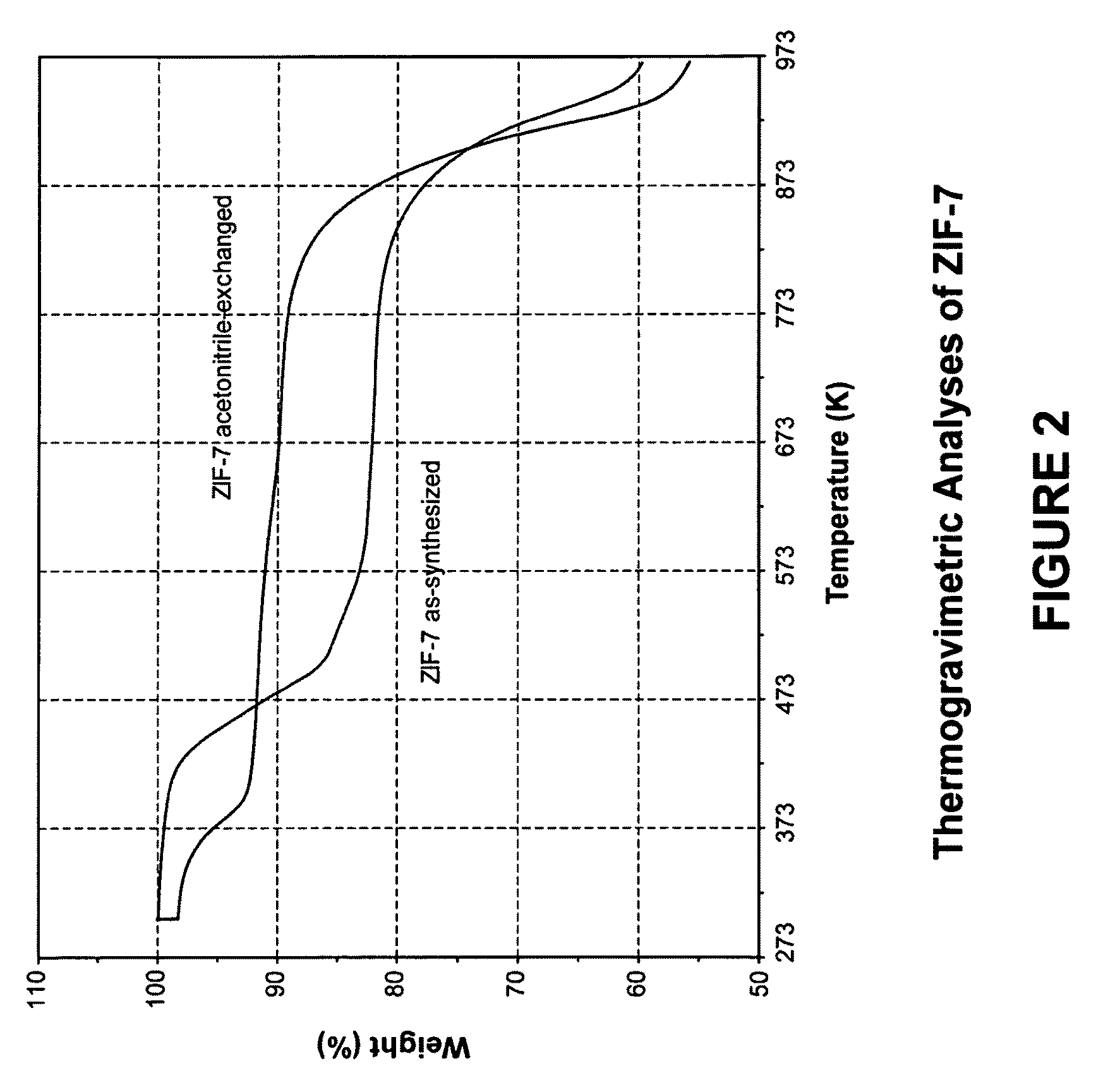

Separation of carbon dioxide from nitrogen utilizing zeolitic imidazolate framework materials

The present invention relates to the selective separation of carbon dioxide (“CO2”) from nitrogen (“N2”) in streams containing both carbon dioxide and nitrogen utilizing a zeolitic imidazolate framework (“ZIF”) material. Preferably, the stream to be separated is fed to the present process in a substantially gaseous phase. In preferred embodiments, the current invention is utilized in a process to separate carbon dioxide from combustion gas (e.g., flue gas) streams preferably for sequestration of at least a portion of the carbon dioxide produced in combustion processes.

Owner:EXXON RES & ENG CO

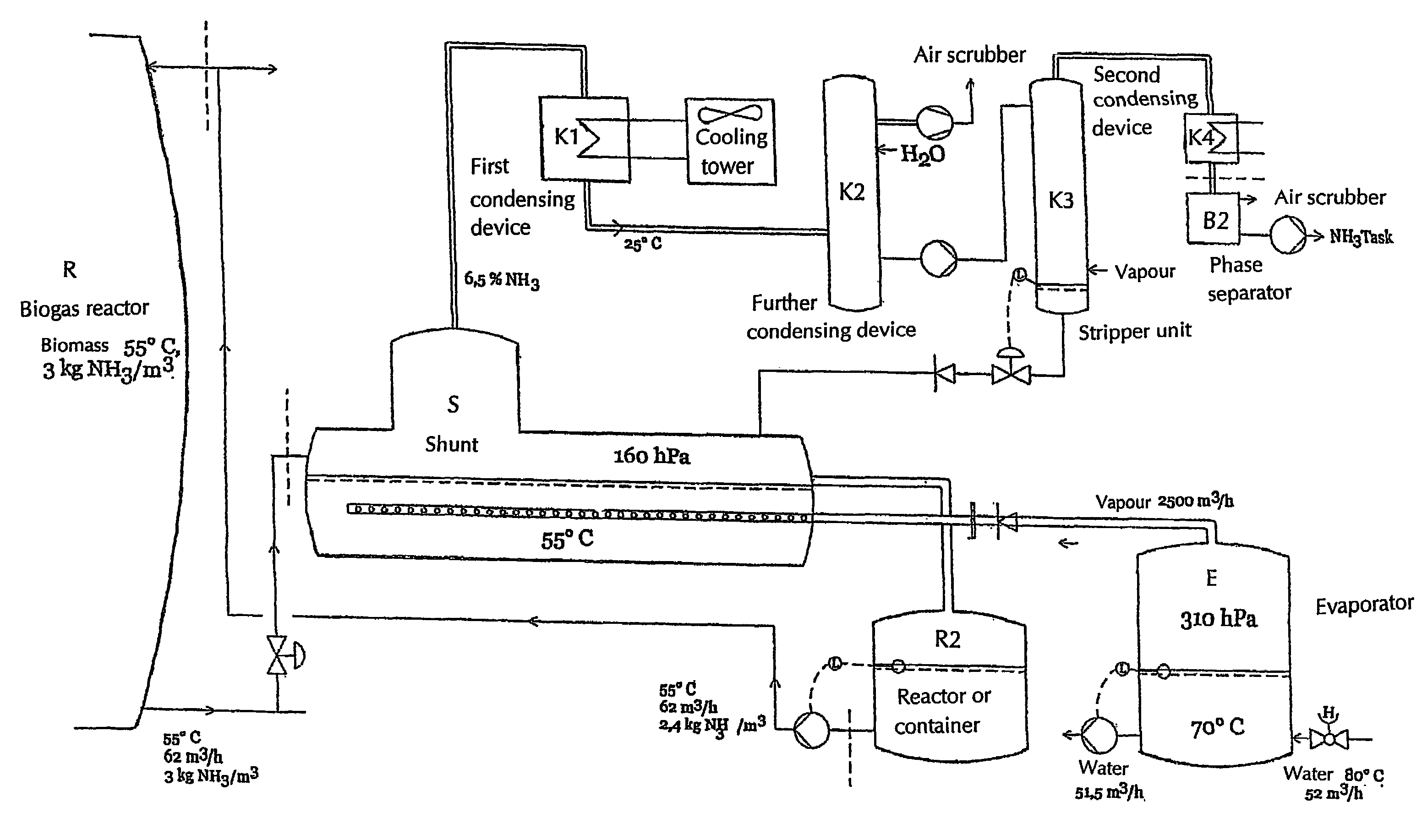

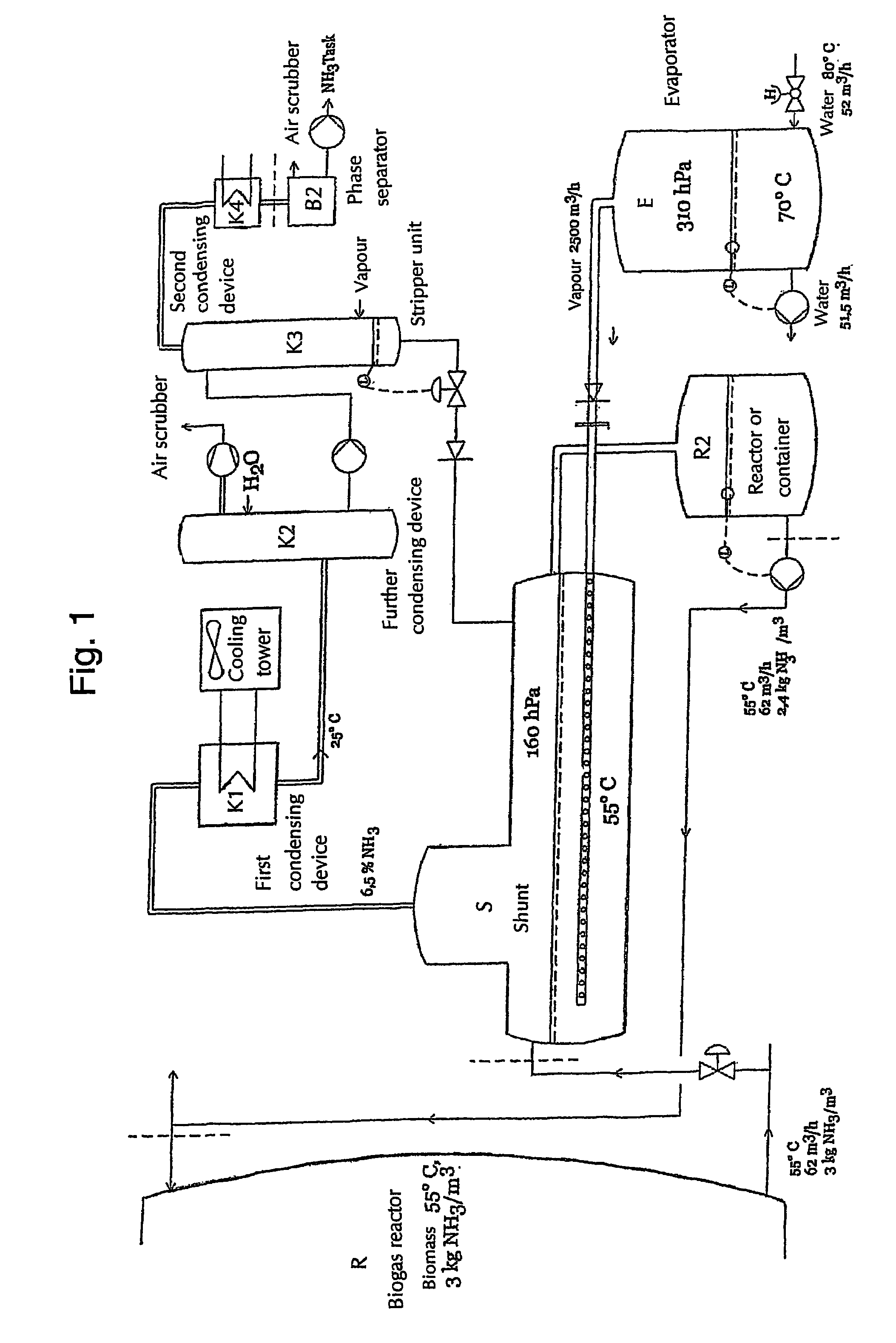

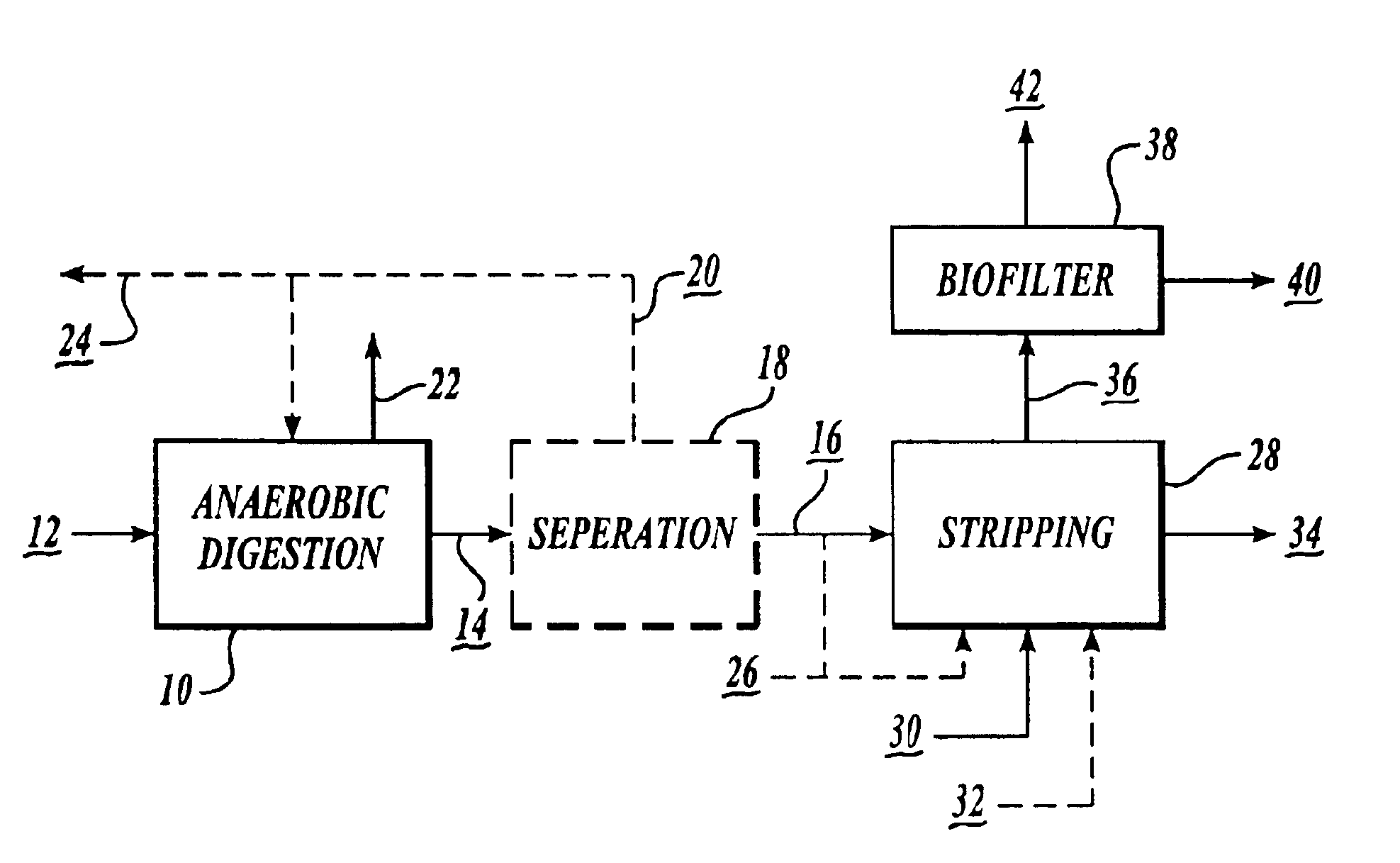

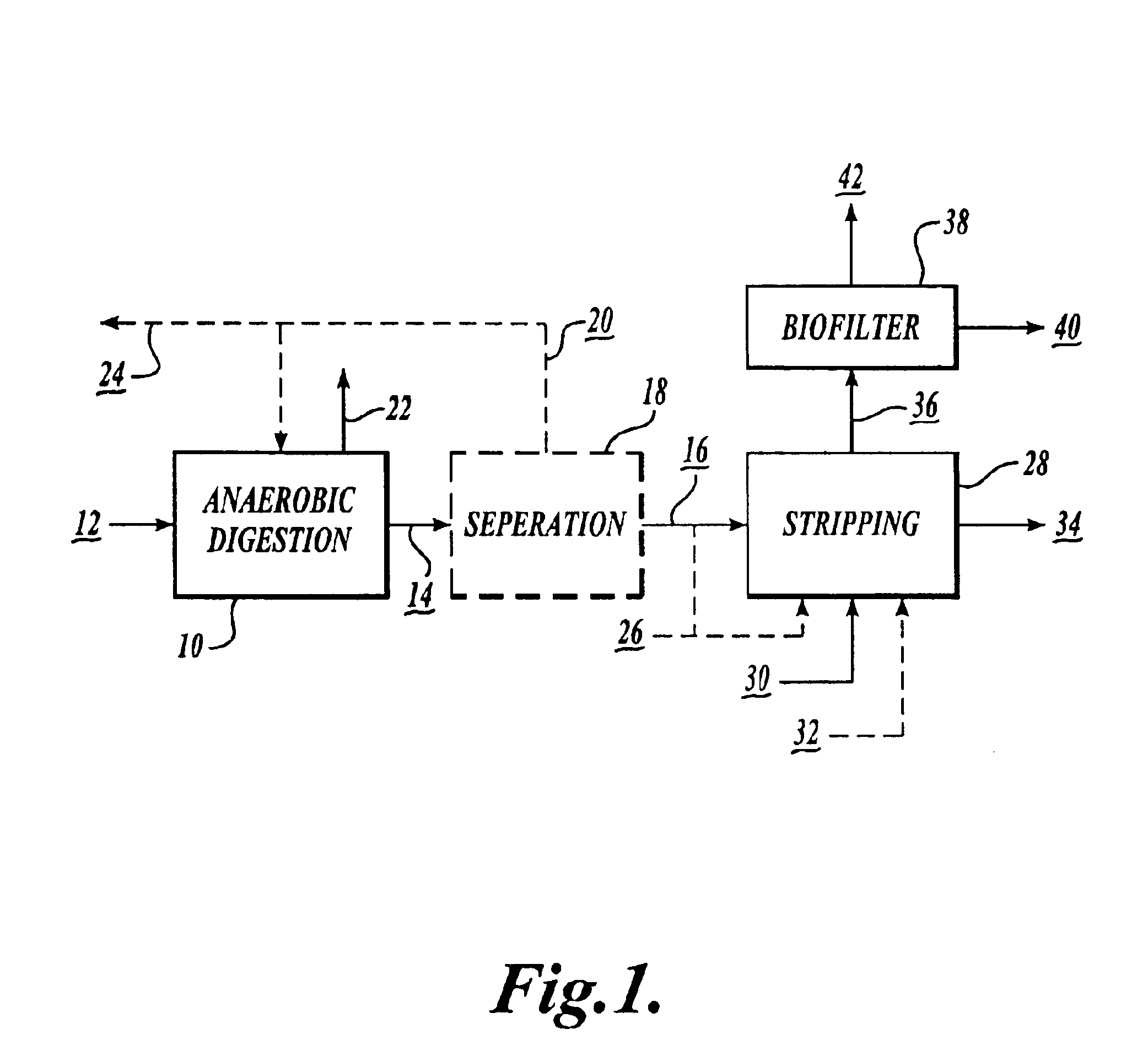

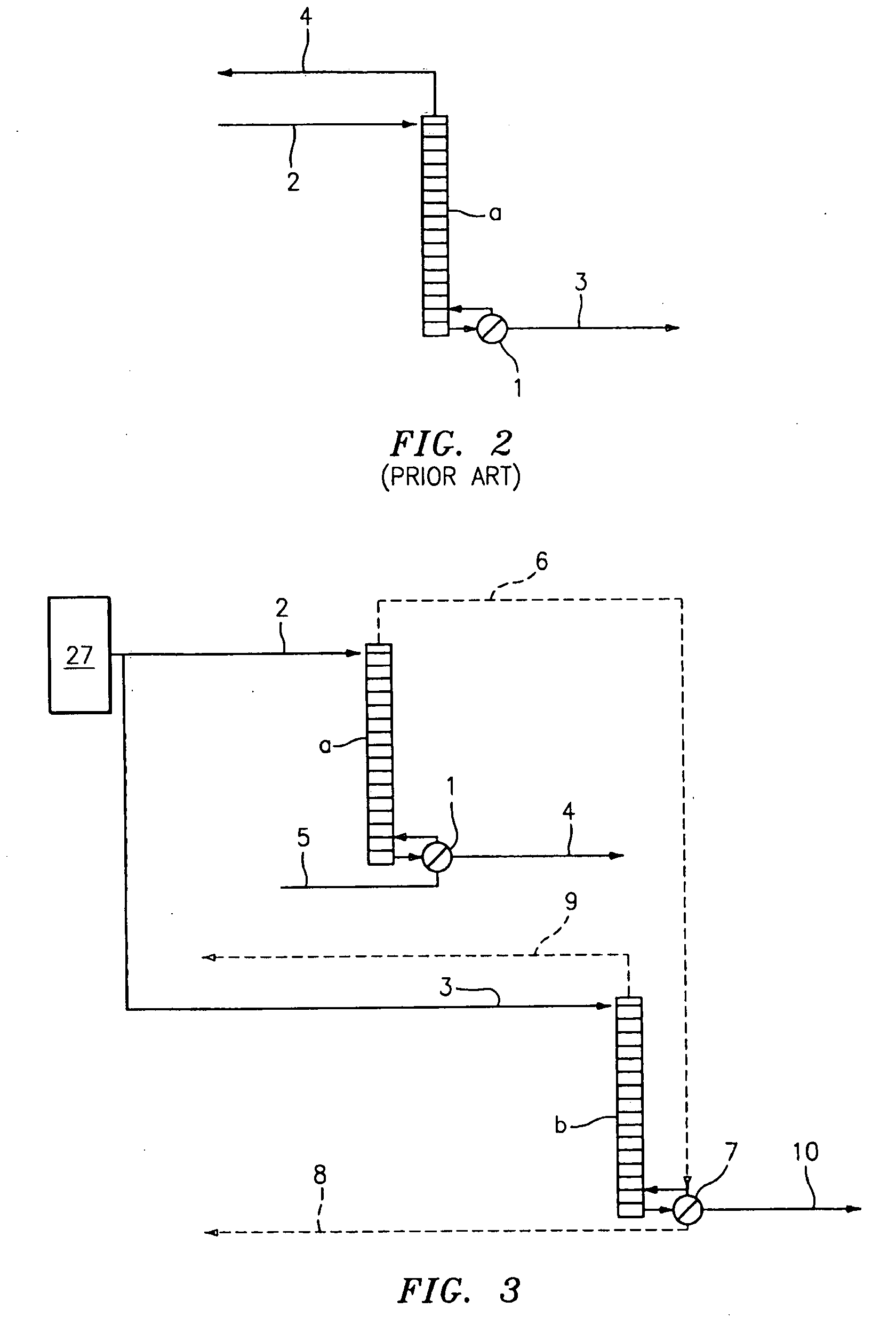

Method and device for stripping ammonia from liquids

InactiveUS7416644B2Simple and economic in operationLow-valuedBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumHigh pressure

Owner:GFE PATENT AS

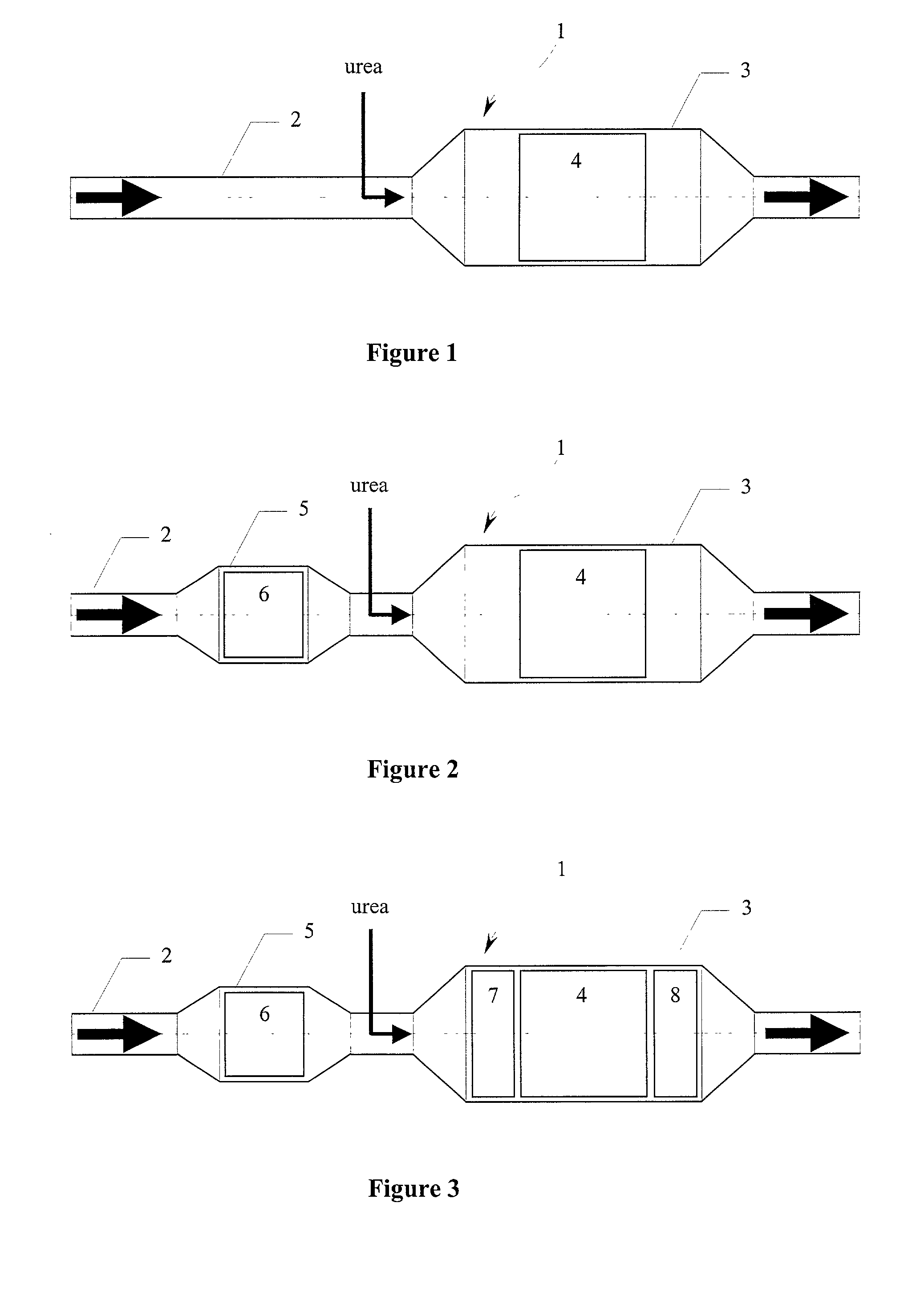

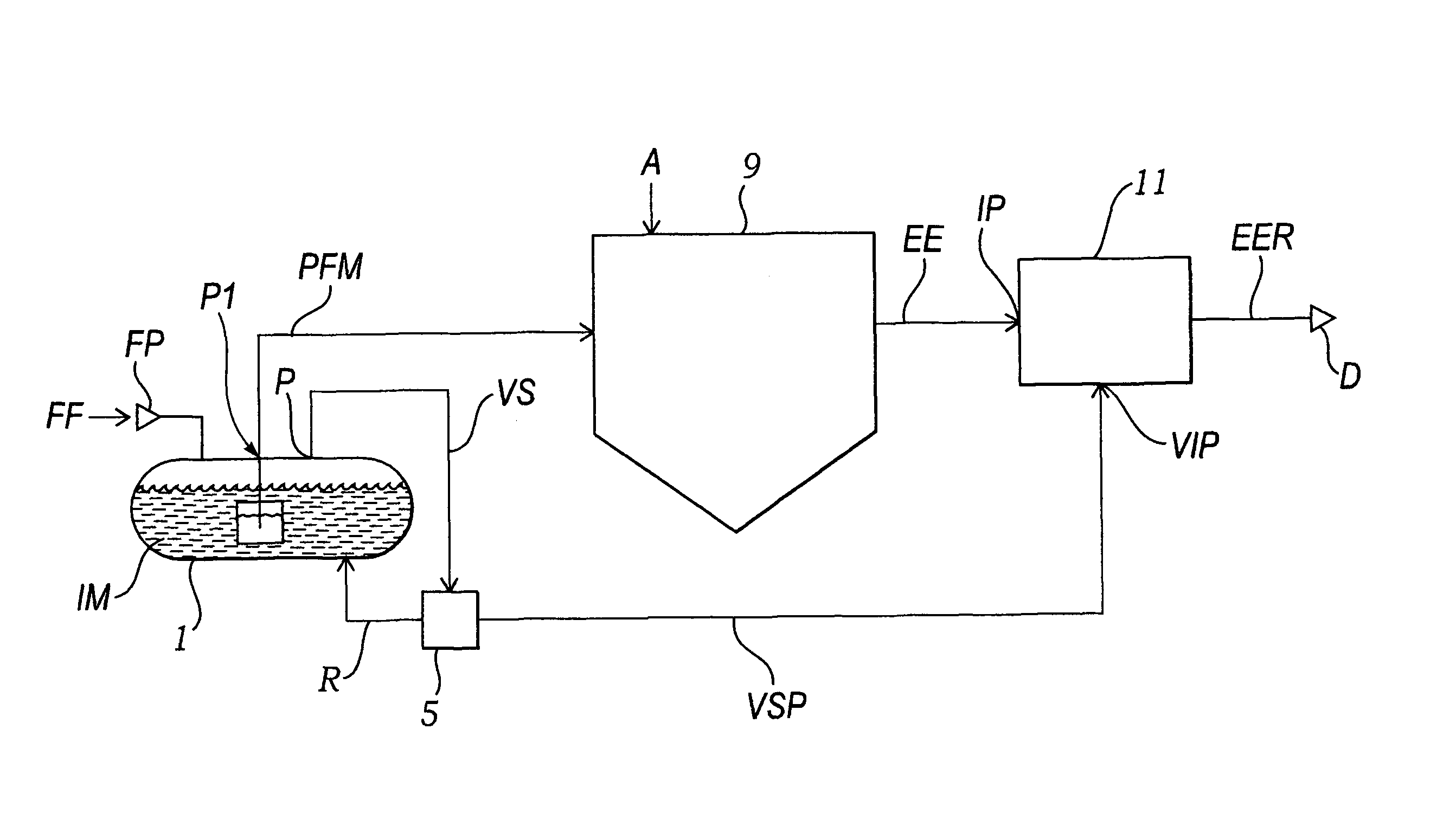

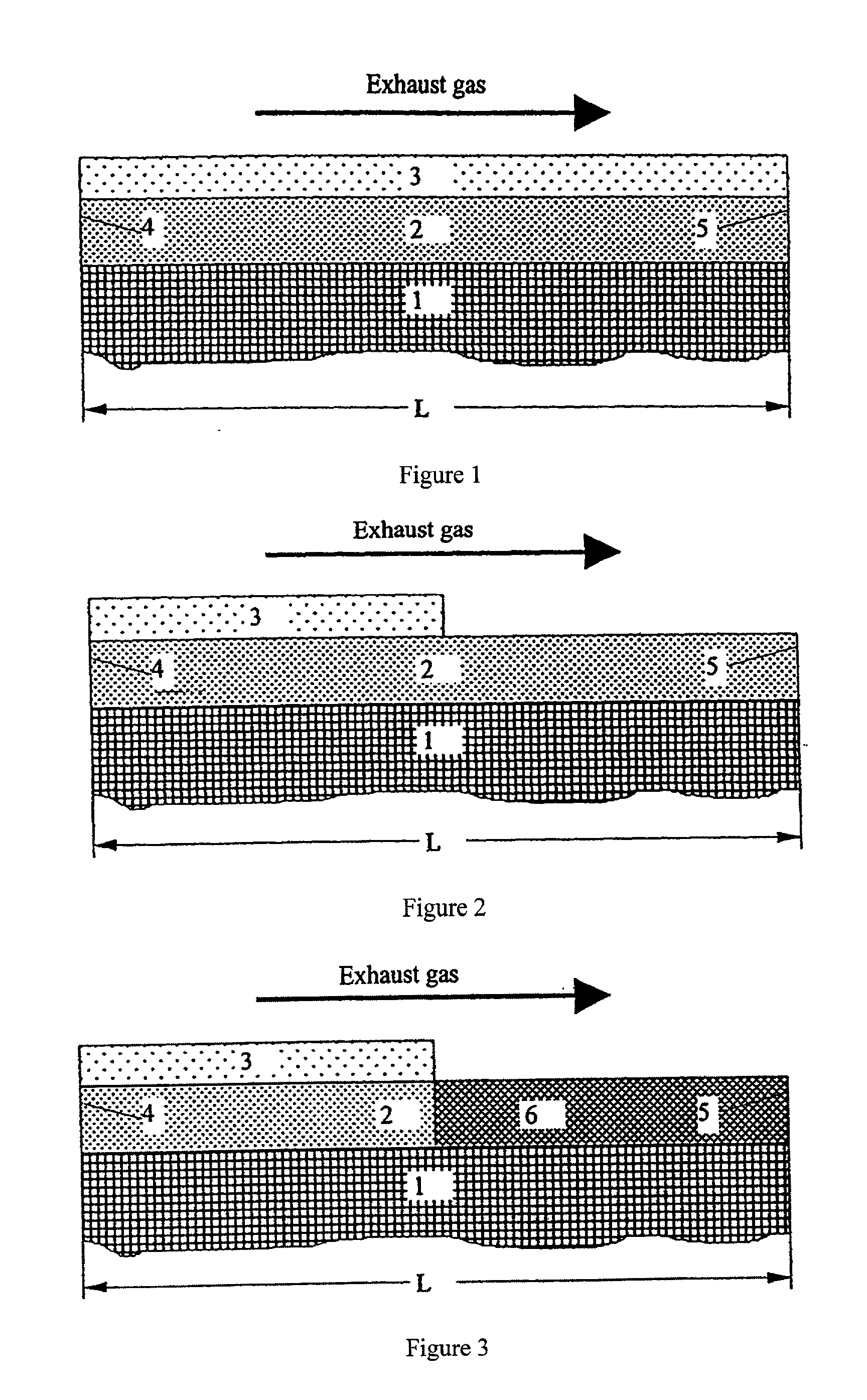

Structured catalysts for selective reduction of nitrogen oxides by ammonia using a compound that can be hydrolyzed to ammonia

InactiveUS20020025905A1Shorten the lengthImprove catalytic performanceCyanogen compoundsNitrogen compoundsCatalytic functionNitrogen oxide

A structured catalyst for selective reduction of nitrogen oxides with ammonia using an ammonia-supplying compound. The catalyst is preferably used for exhaust gas treatment of diesel vehicles powered by diesel motors. The catalyst is characterized by the fact that it contains a reduction catalyst for selective reduction of nitrogen oxides with ammonia and a hydrolysis catalyst for the hydrolysis of urea, where the hydrolysis catalyst is applied in the form of a coating onto the reduction catalyst. By this arrangement of the two catalytic functions in one catalyst the exhaust gas system can be made very compactly and space saving. Moreover, advantageous synergistic effects result from the direct contact of the hydrolysis catalyst and the reduction catalyst.

Owner:UMICORE AG & CO KG +1

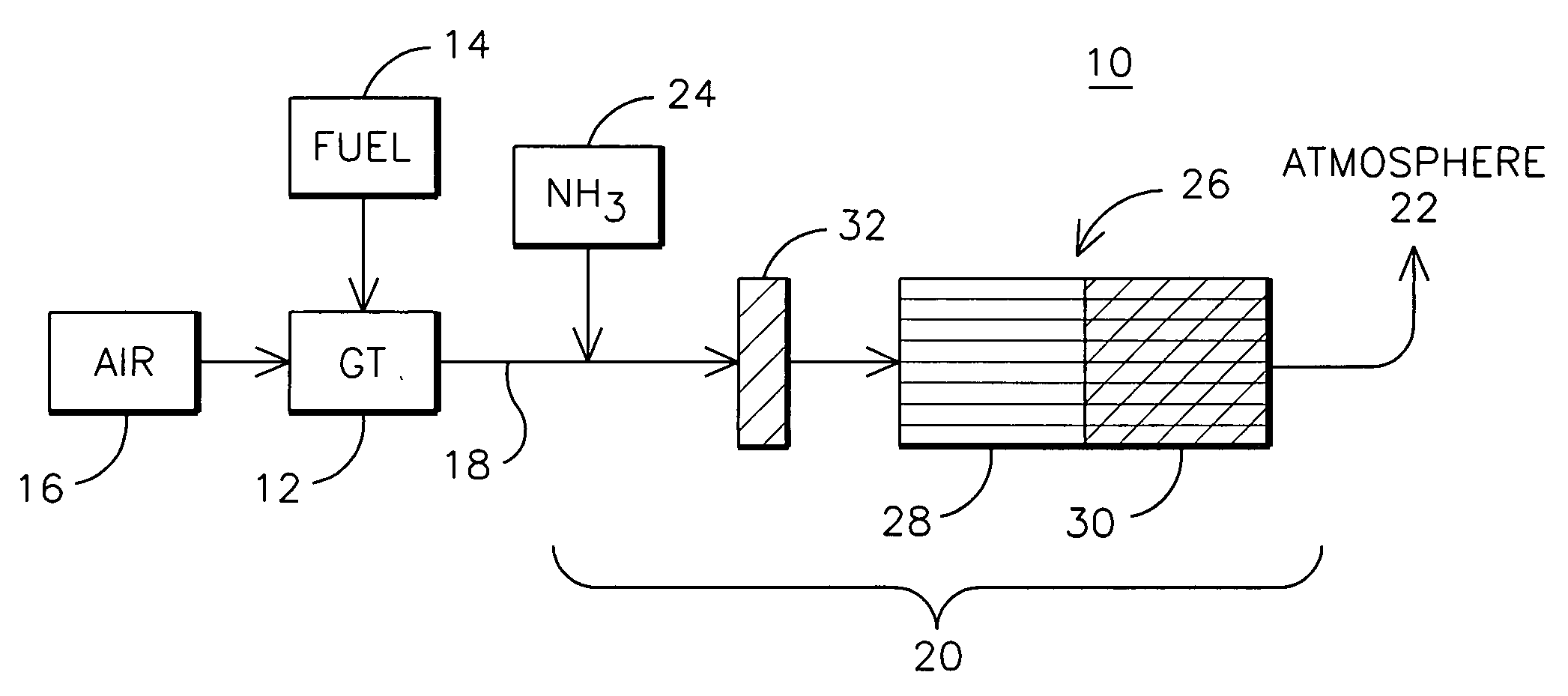

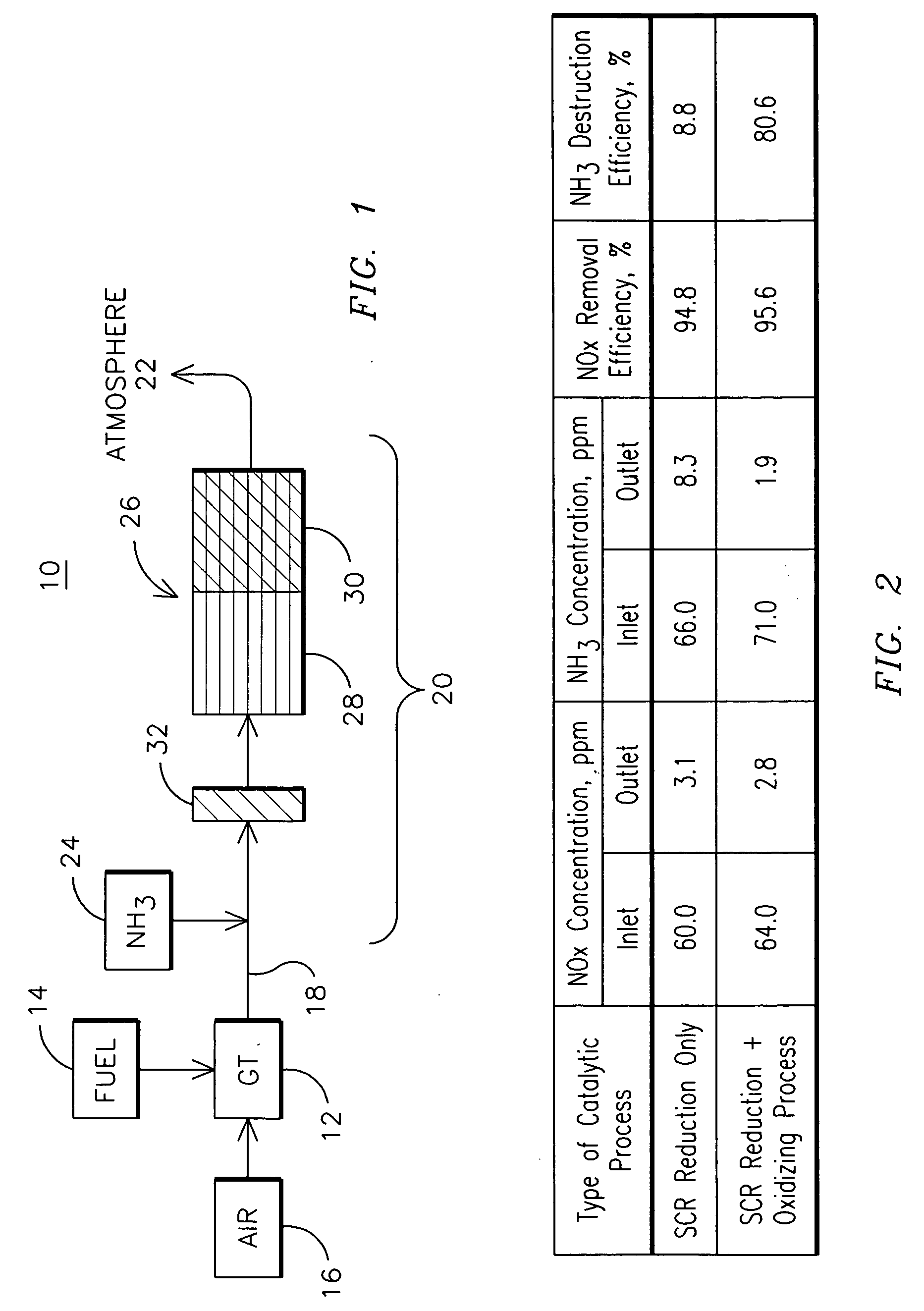

Apparatus and method for catalytic treatment of exhaust gases

An exhaust gas treatment apparatus (20) for reducing the concentration of NOx, HC and CO in an exhaust gas stream (18) such as produced by a gas turbine engine (12) of a power generating station (10). The treatment apparatus includes a multifunction catalytic element (26) having an upstream reducing-only portion (28) and a downstream reducing-plus-oxidizing portion (30) that is located downstream of an ammonia injection apparatus (24). The selective catalytic reduction (SCR) of NOx is promoted in the upstream portion of the catalytic element by the injection of ammonia in excess of the stoichiometric concentration, with the resulting ammonia slip being oxidized in the downstream portion of the catalytic element. Any additional NOx generated by the oxidation of the ammonia is further reduced in the downstream portion before being passed to the atmosphere (22).

Owner:SIEMENS ENERGY INC

Nitrogen recovery system and method

InactiveUS6866779B1Less greenhouse gasGood health benefitsBio-organic fraction processingCyanogen compoundsLiquid wasteNitrate

A process for the recovery of nitrogen from anaerobically digested liquid waste and for the collection of the nitrogen as nitrate compounds that can be used to produce fertilizer and compost, includes stripping ammonia from anaerobically digested liquid waste, and converting the ammonia into nitrates via nitrification.

Owner:ENVIRONMENTAL ENERGY & ENG

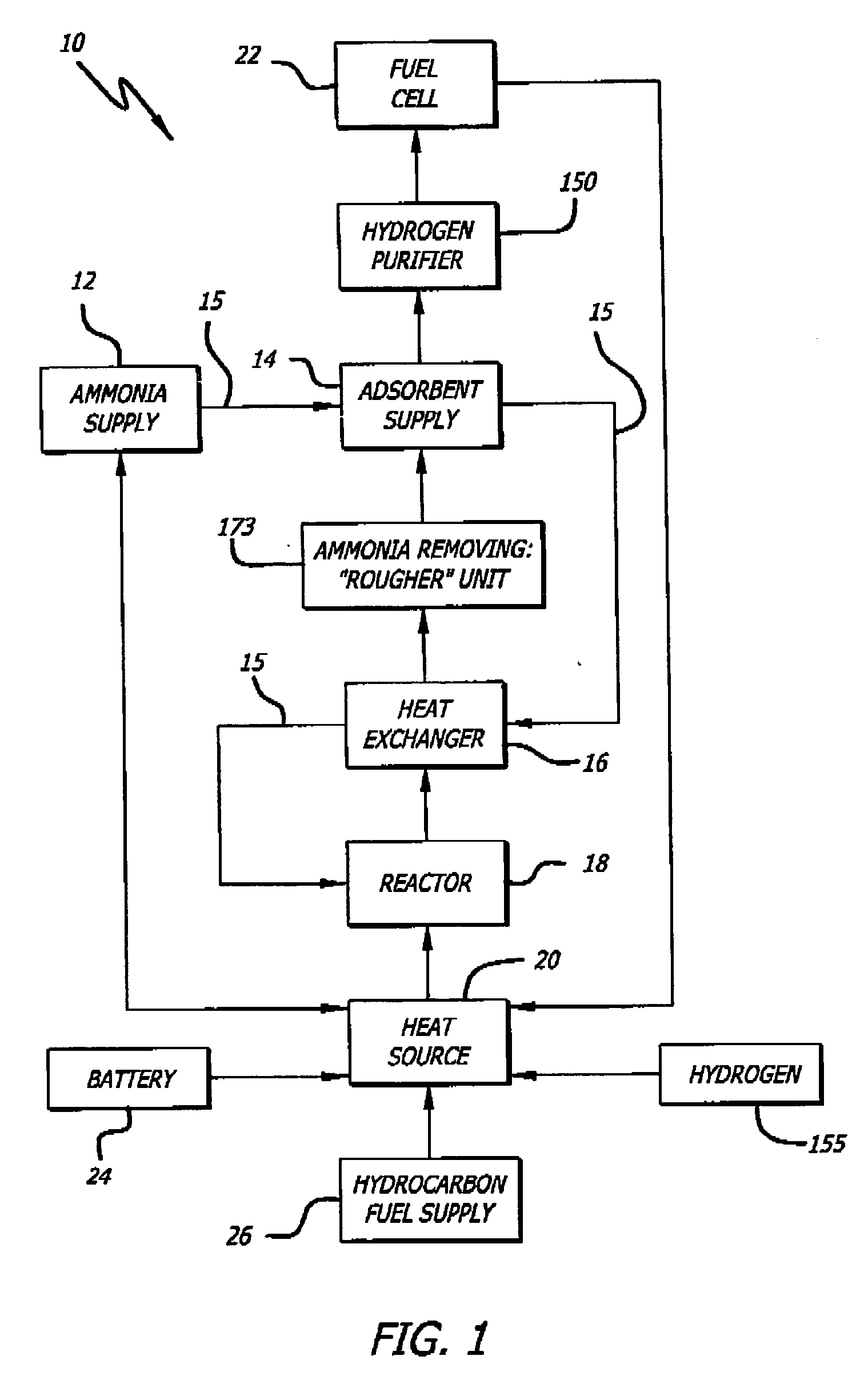

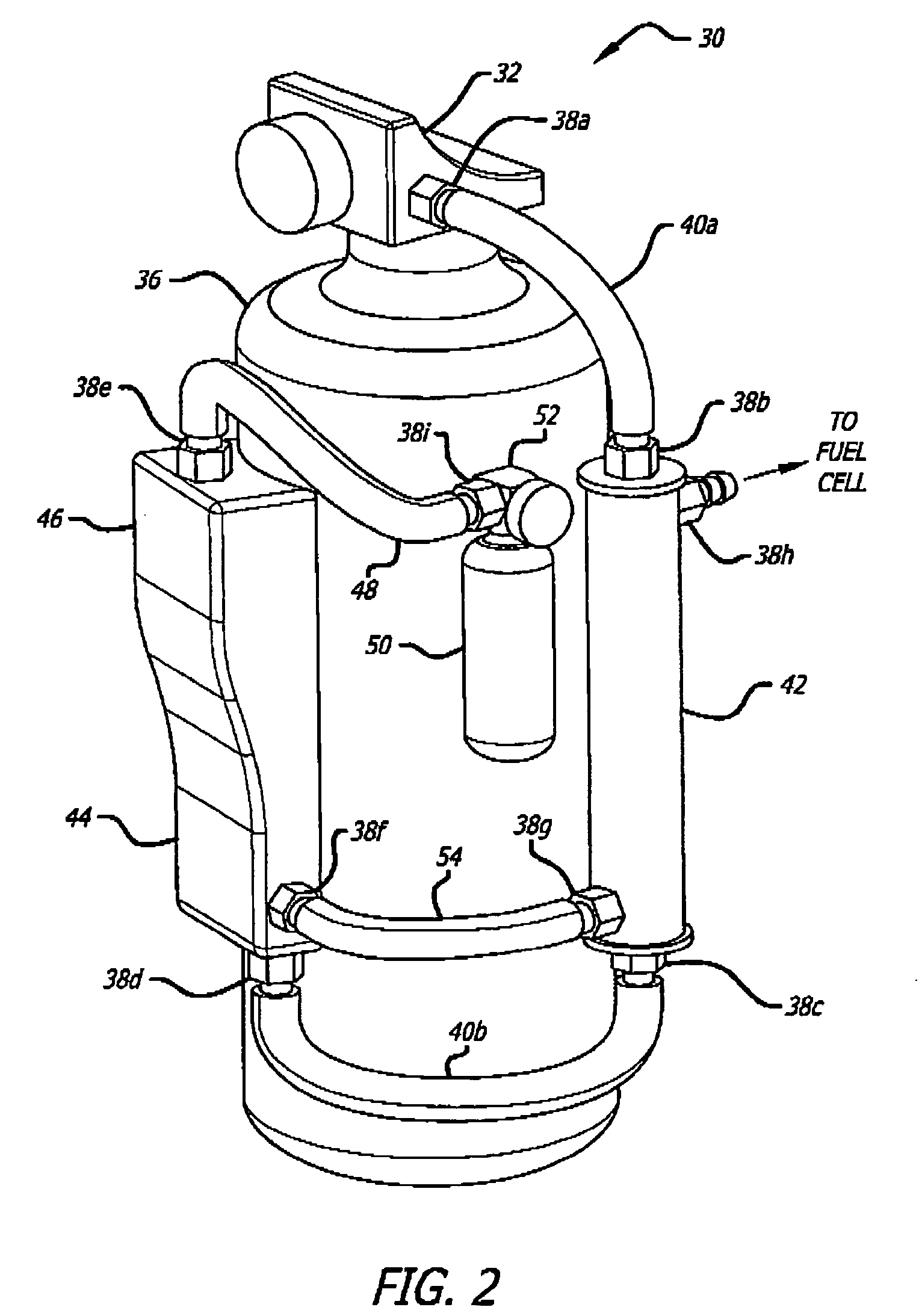

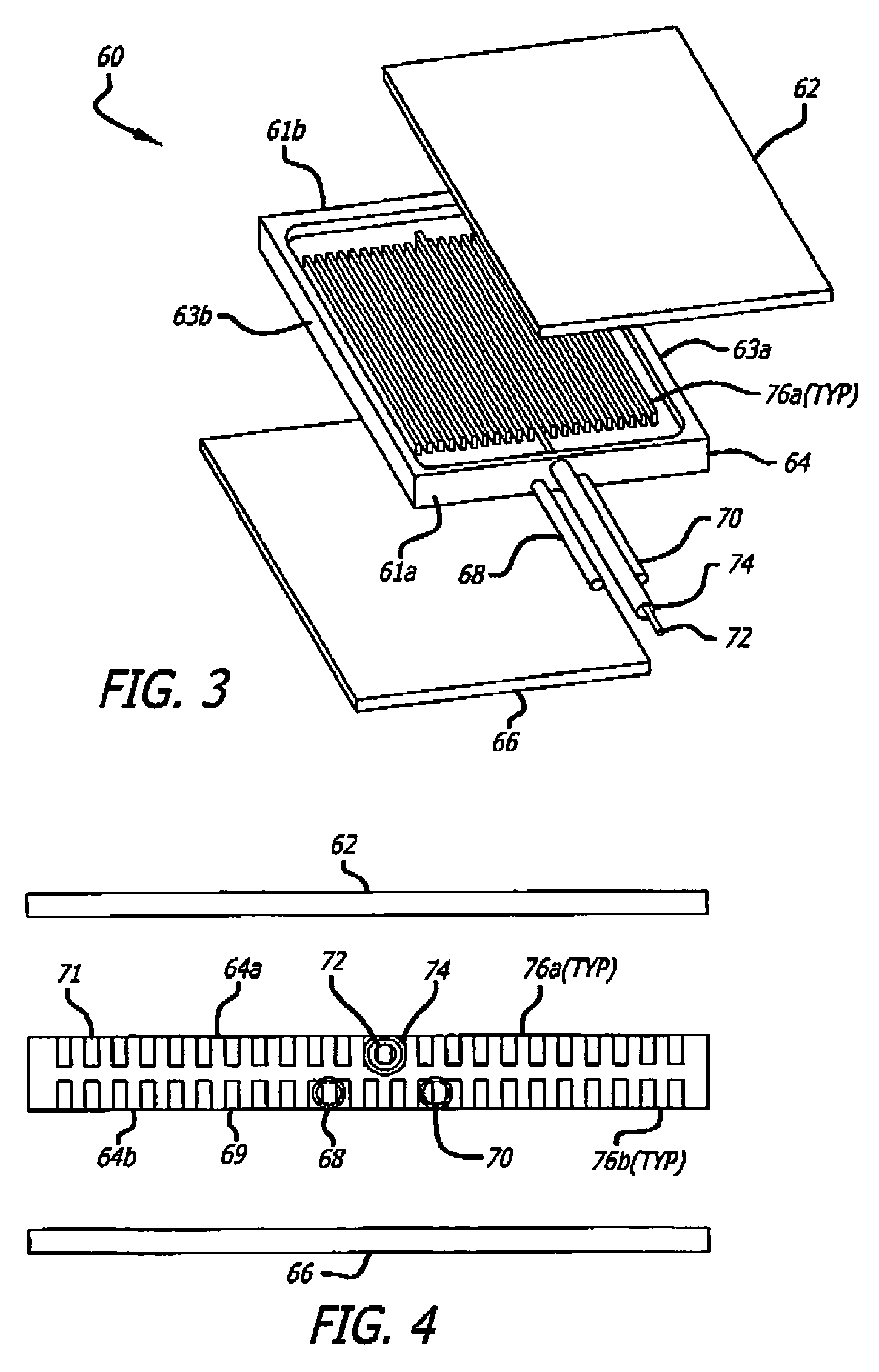

Ammonia-based hydrogen generation apparatus and method for using same

InactiveUS20060112636A1Reduce manufacturing costImprove heat transfer effectCyanogen compoundsNitrogen compoundsHydrogenCombustion chamber

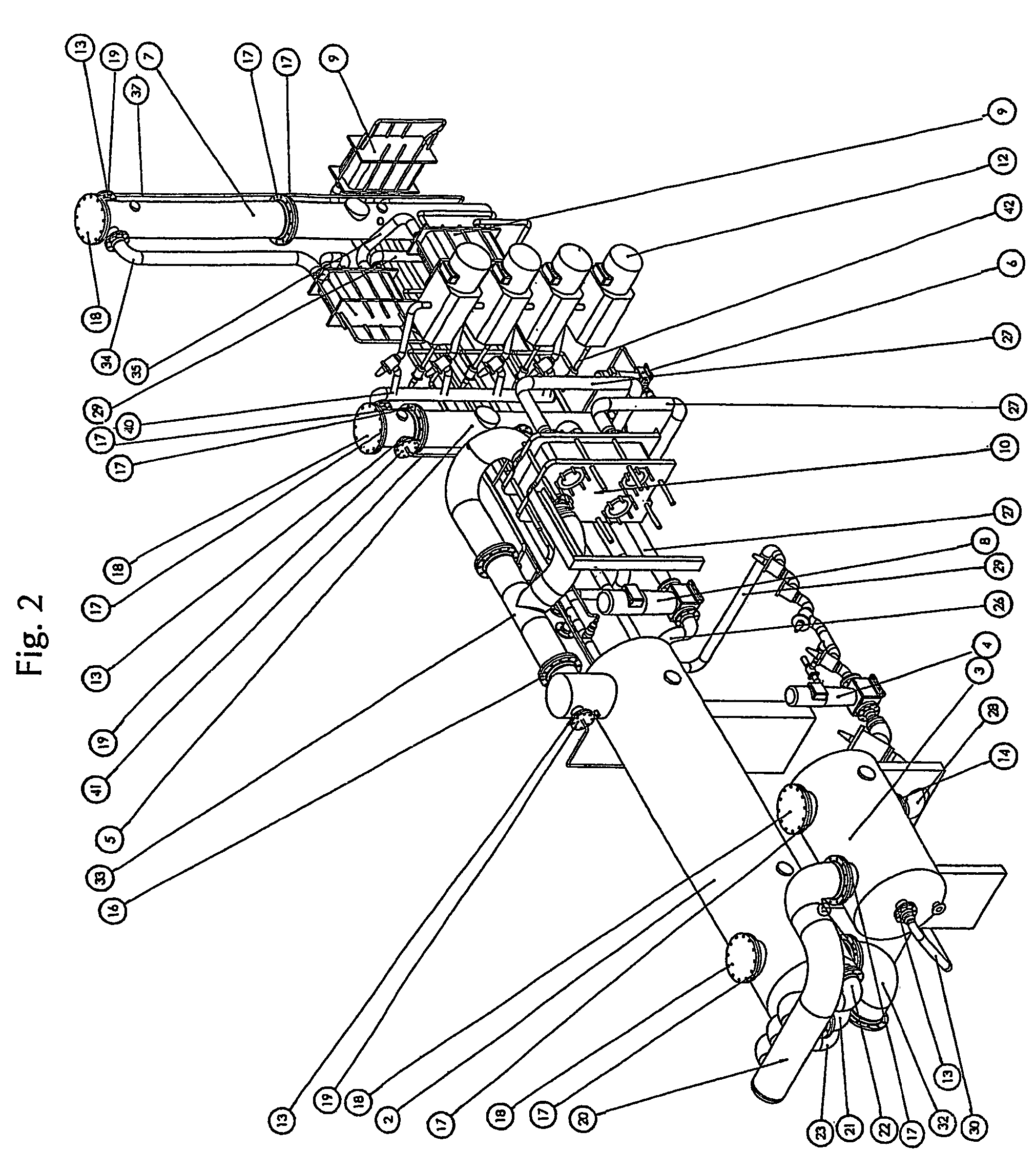

The present disclosure provides teachings relating to ammonia-based hydrogen generation apparatus and associated methods of use. Exemplary methods and apparatus comprise a thermocatalytic hydrogen generation reactor which includes a reaction chamber containing a catalyst-coated substrate, and a combustion chamber containing a catalyst-coated substrate. Exemplary catalyst-coated substrates include, but are not limited to, metal foam, monolith, mesh, ceramic foam or ceramic monolith.

Owner:INTELLIGENT ENERGY INC

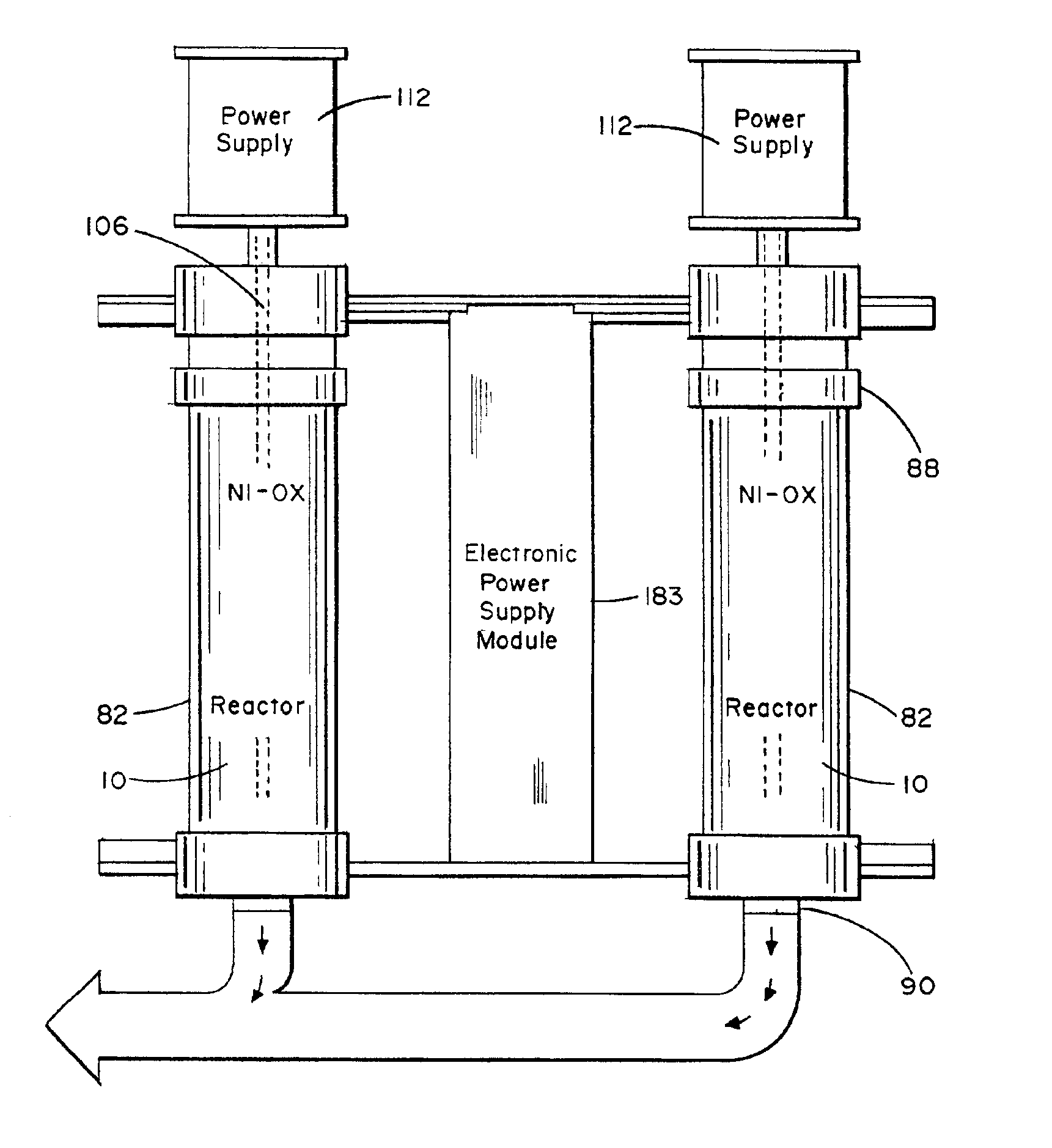

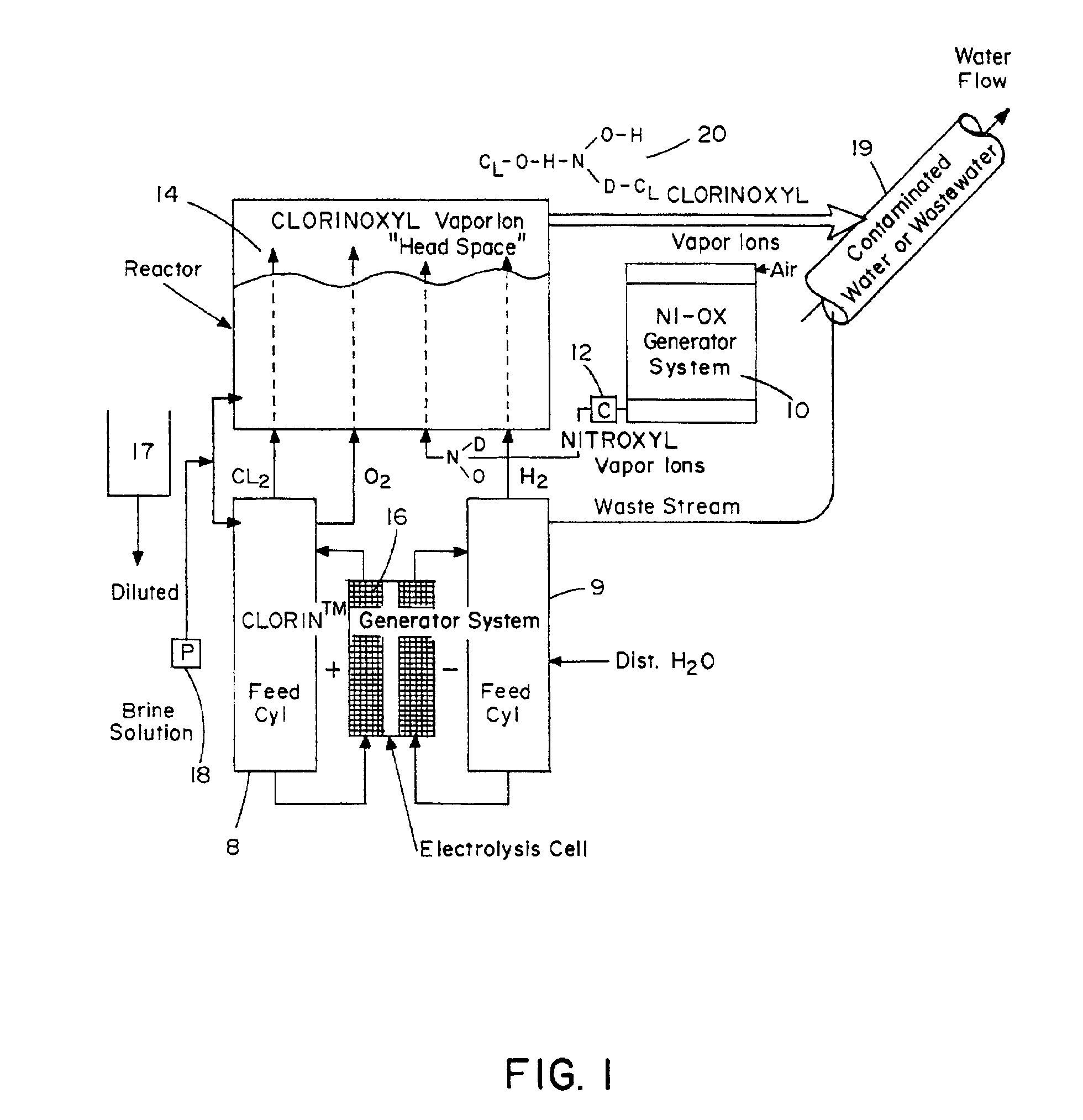

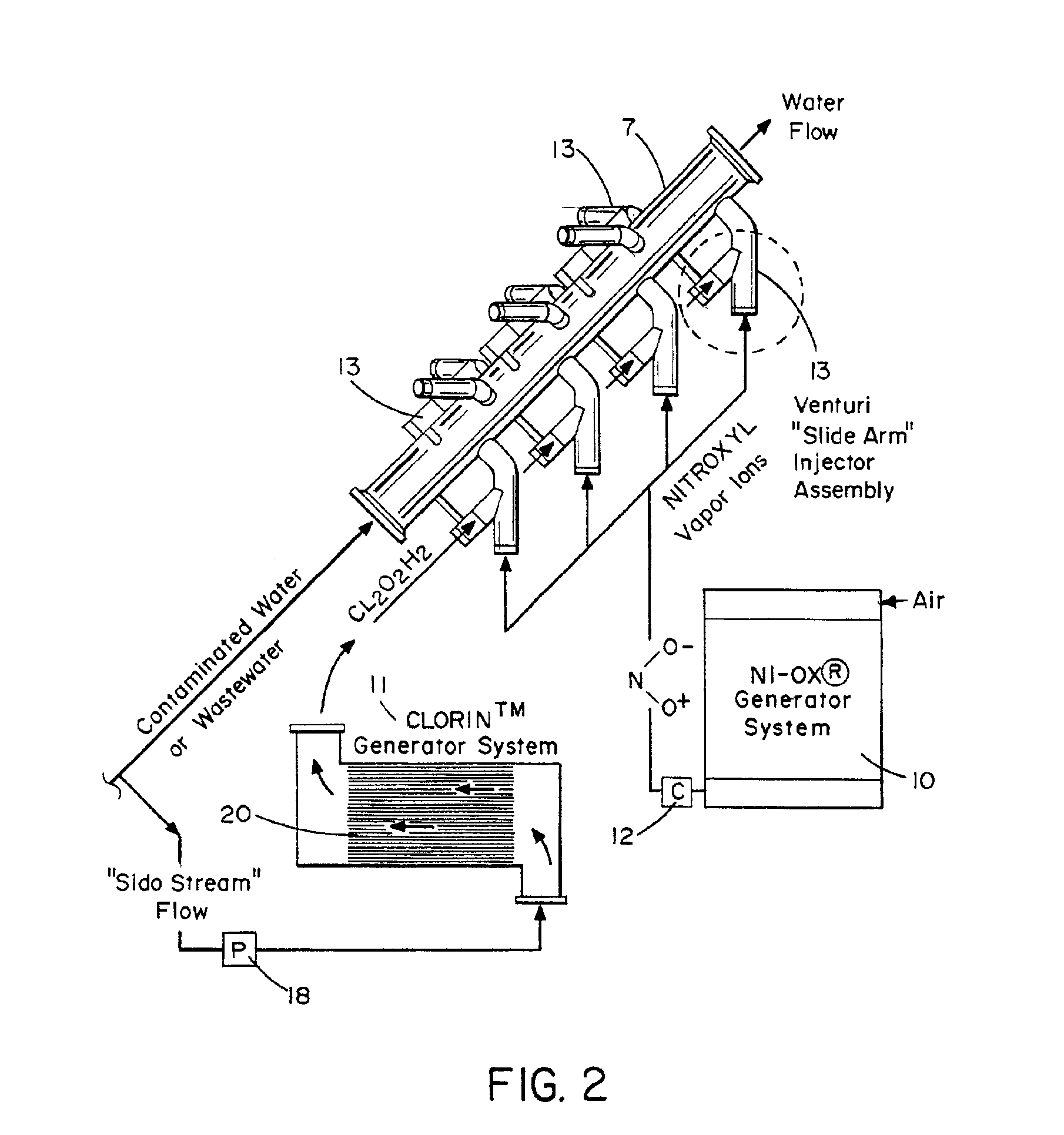

Non-chemical water treatment method and apparatus employing ionized air purification technologies for marine application

InactiveUS6923901B2Reduce maintenanceReduce energy costsCyanogen compoundsNitrogen compoundsElectrolysisDihydrogen oxide

Contaminated water, particularly, ballast water, blackwater, galley water, accommodation water, laundry water, fresh water and seawater, is disinfected by admixture of a highly reactive gas stream containing ions of oxygen and nitrogen, formed by exposure of air to short-wavelength ultraviolet radiation, and of chlorine, formed in situ by electrolysis of salt in the water. Solids removal can be accomplished by electrophoresis in the same unit employed for electrolysis to release chlorine, or in a separate unit. Heavy metals maybe removed by plating or sacrificing electrodes.

Owner:IONZ BLUEWATER SOLUTIONS +1

Ammonia oxidation catalyst for the coal fired utilities

InactiveUS20060182676A1Reduce ammonia concentrationLower emission levelsCyanogen compoundsNitrogen compoundsNitrogen gasSulfur dioxide

A process is described that removes by oxidation the excess ammonia (NH3) gas from flue gases that have been subjected to selective catalytic reduction (SCR) of oxides of nitrogen (NOx) by ammonia injection. The inventive process incorporates a secondary catalyst of precious metal and vanadia on a metal oxide such as titania to catalyze the oxidation of both ammonia and carbon monoxide (CO) while maintaining sulfur dioxide (SO2) levels.

Owner:BASF CATALYSTS LLC

Ammonia Decomposition Catalyst and Process for Decomposition of Ammonia Using the Catalyst

InactiveUS20090060809A1Improve decomposition abilitySuppress generationCyanogen compoundsMolecular sieve catalystsHigh concentrationCatalytic decomposition

Disclosed is a catalyst useful for catalytic decomposition of high concentration ammonia, and also disclosed is a process for decomposing ammonia using the catalyst. As the ammonia decomposion catalyst, a catalyst which supports a metallic element selected from Fe, Co, Ni and Cu by ion exchange method on porous silica alumina having an Si / Al atomic ratio of 1 to 90 and a specific surface area of 200 to 900 m2 / g and contains a noble metal selected from Ru, Rh, Pd, Ir and Pt in an amount of 10 to 500 ppm based on the total mass of the catalyst is useful.

Owner:SUD CHEM CATALYSTS JAPAN

Structured catalysts for selective reduction of nitrogen oxides by ammonia using a compound that can be hydrolyzed to ammonia

InactiveUS6713031B2Shorten the lengthImprove catalytic performanceCyanogen compoundsNitrogen compoundsCatalytic functionNitrogen oxide

Owner:UMICORE AG & CO KG +1

Catalysts for the reduction of ammonia emission from rich-burn exhaust

ActiveUS20110182791A1High selectivityEmission reductionCombination devicesCyanogen compoundsMolecular sievePtru catalyst

A system for reducing ammonia (NH3) emissions includes (a) a first component comprising a first substrate containing a three-way catalyst, wherein the first component is disposed upstream of a second component comprising a second substrate containing an ammonia oxidation catalyst, wherein said ammonia oxidation catalyst comprises a small pore molecular sieve supporting at least one transition metal; and (b) an oxygen-containing gas input disposed between the components. For example, a CHA Framework Type small pore molecular sieve may be used. A method for reducing NH3 emission includes introducing an oxygen-containing gas into a gas stream to produce an oxygenated gas stream; and exposing the oxygenated gas stream to an NH3 oxidation catalyst to selectively oxidize at least a portion of the NH3 to N2. The method may further include the step of exposing a rich burn exhaust gas to a three-way catalyst to produce the gas stream comprising NH3.

Owner:JOHNSON MATTHEY PLC

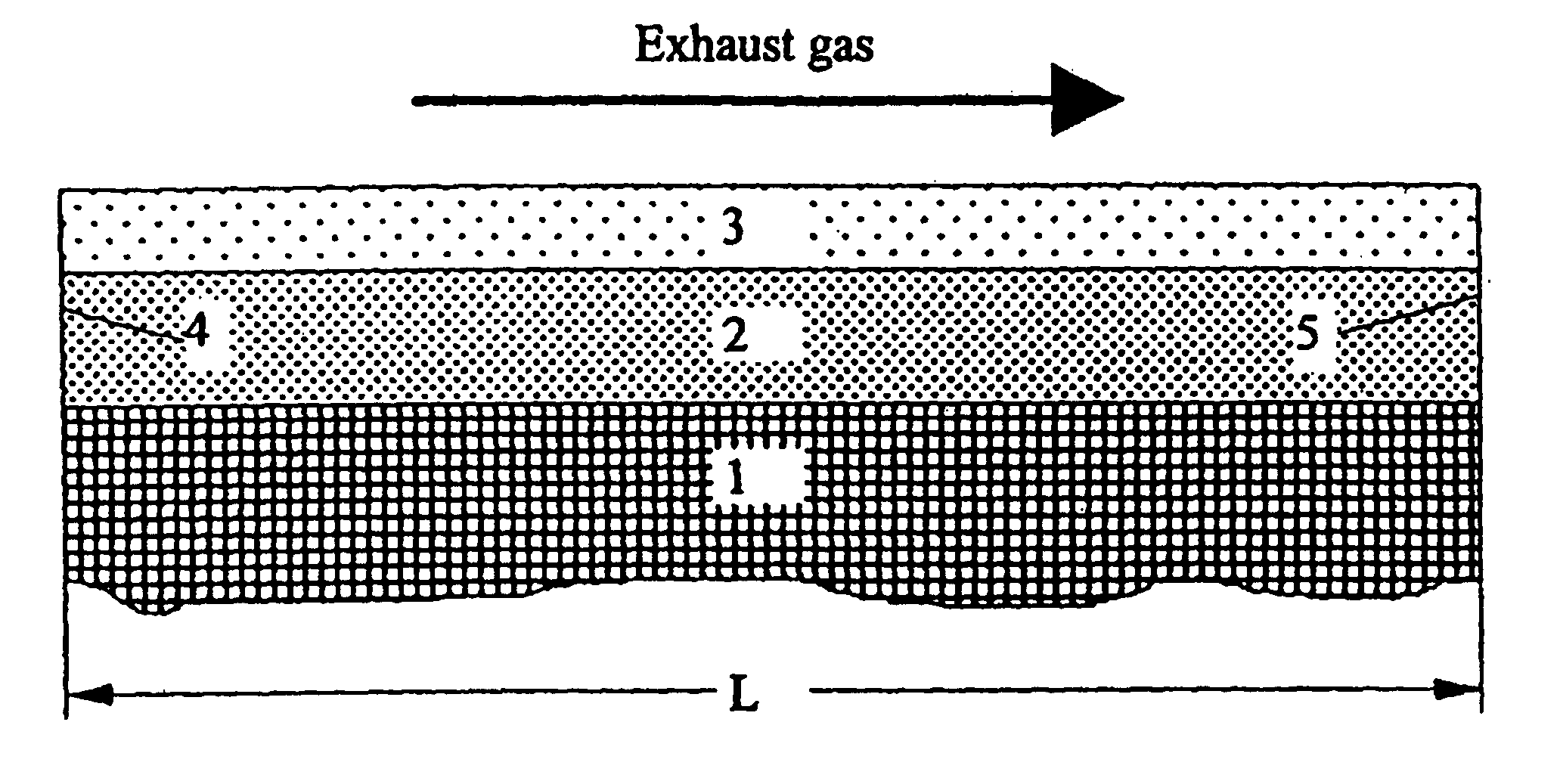

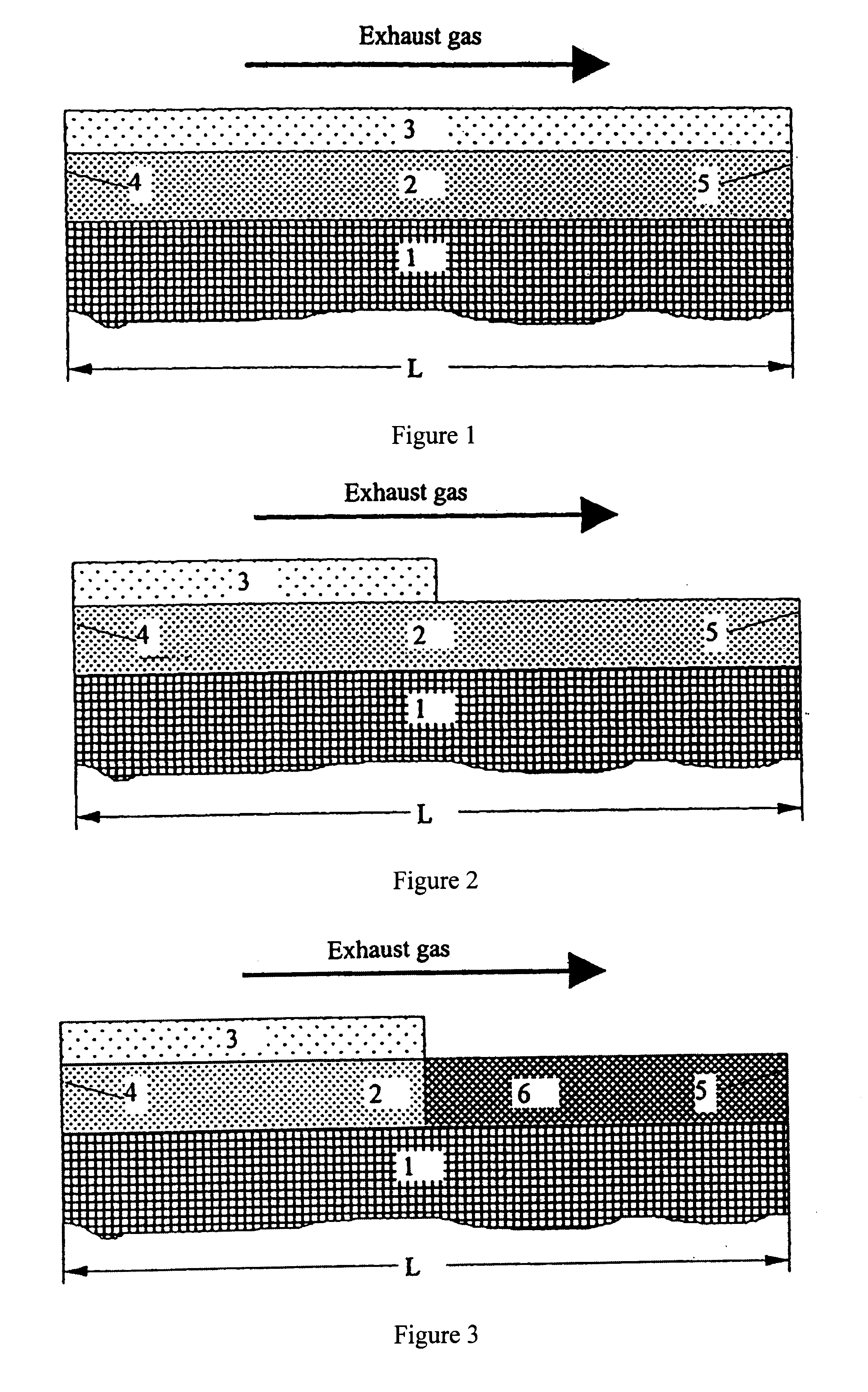

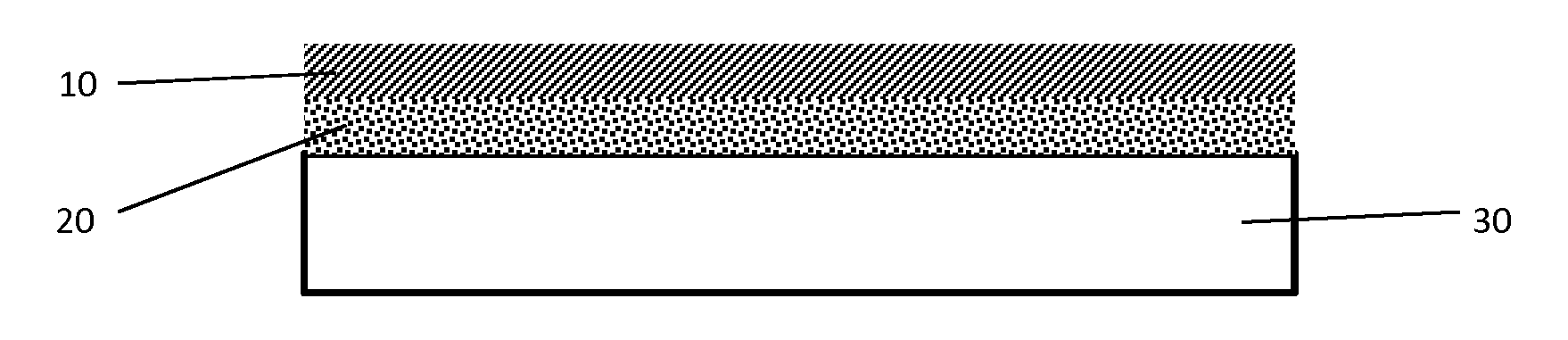

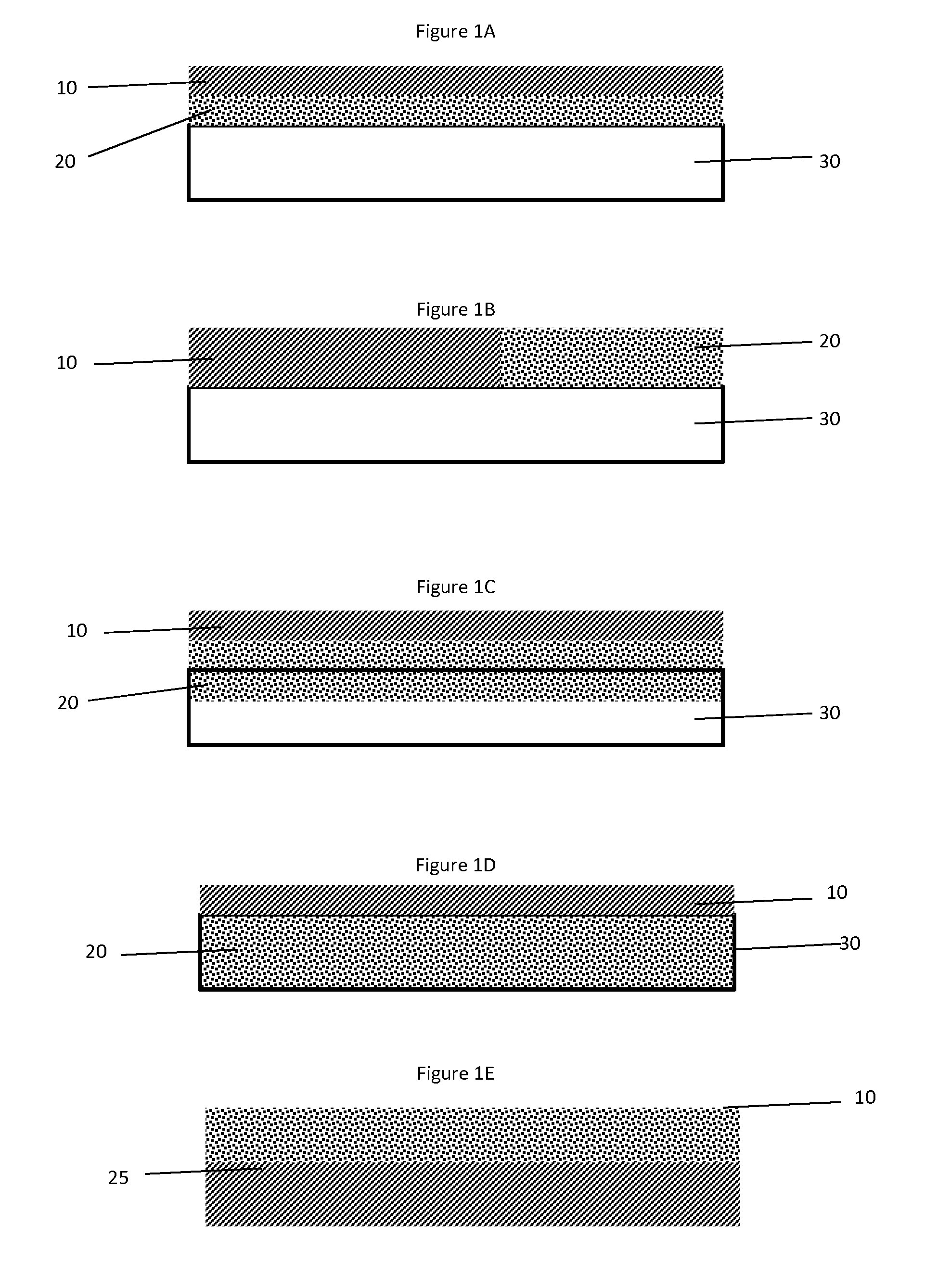

Layered ammonia oxidation catalyst

The invention pertains to a layered ammonia oxidation catalyst. The layered catalyst causes ammonia to be selectively oxidized in the presence of an oxidant such as air, while minimizing the formation of nitrogen oxides (NOx). The layered catalyst comprises a refractory oxide support such as gamma alumina upon which a platinum component is deposited and a vanadia component is deposited on the platinum. The catalyst is preferably disposed on a substrate such as a metal foil whose surface contains a “herringbone” pattern.

Owner:BASF CATALYSTS LLC

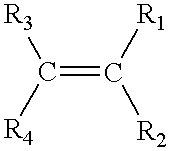

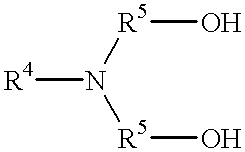

Process for the purification of gases

InactiveUS6277345B1Improve efficiencyIncreased gas throughputHydrogenOrganic chemistryPoly(ethylene glycol) dimethyl etherHydrogen

The present invention relates to the use of an absorption liquid for purifying a gas by removal of gaseous, acidic impurities. The gas to be purified can be any gas, such as synthesis gas or natural gas, which contains gaseous, acidic impurities such as CO2, H2S, SO2, CS2, HCN, COS or mercaptans. The absorption liquid comprises:A) from 0.01 to 4% by weight of at least one compound of the formulaB) from 0.001 to 8.0% by weight of water, andC) at least one polyalkylene glycol alkyl ether of the formulato 100% by weight,whereR1 is C1-C4-alkyl,R2 is ethylene or 2-methylethylene,R3 is hydrogen or C1-C4-alkyl,R4 is hydrogen or C1-C4-alkyl,R5 is C1-C4-alkylene andX is an integer from 1 to 10. The amine may be N-methyldiethanolamine and the ether may be polyethylene glycol dimethyl ether.

Owner:CLARIANT PROD DEUT GMBH

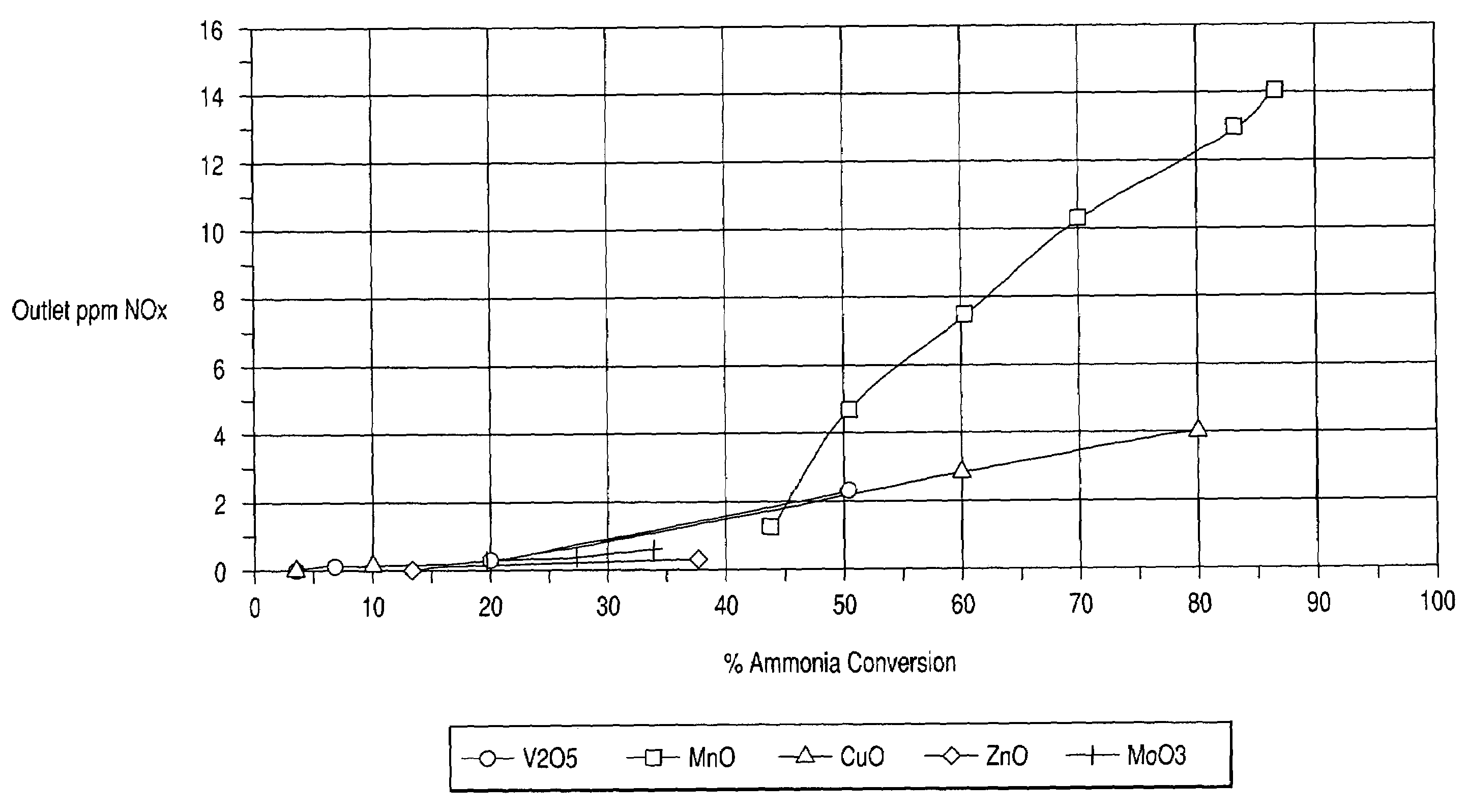

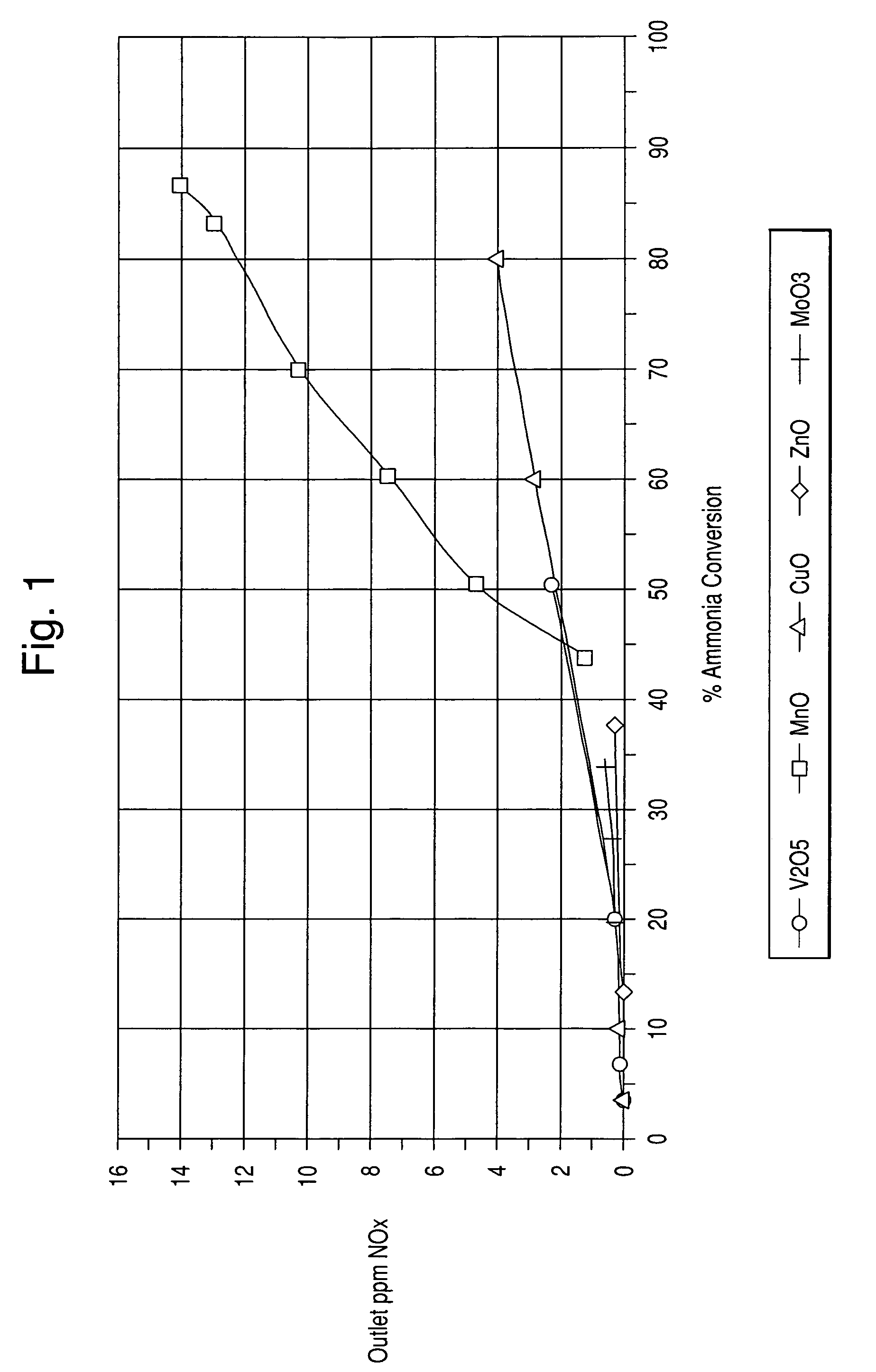

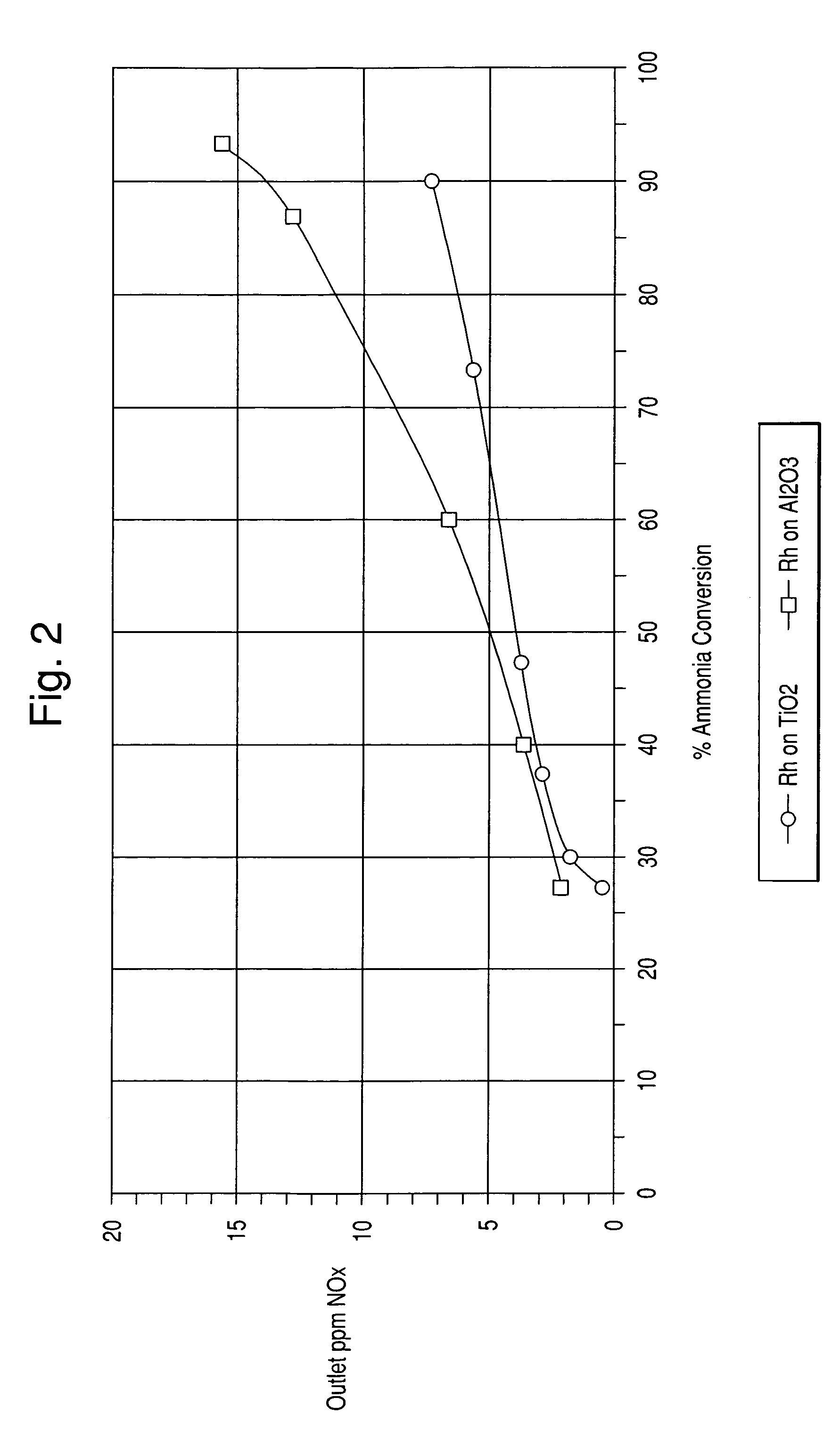

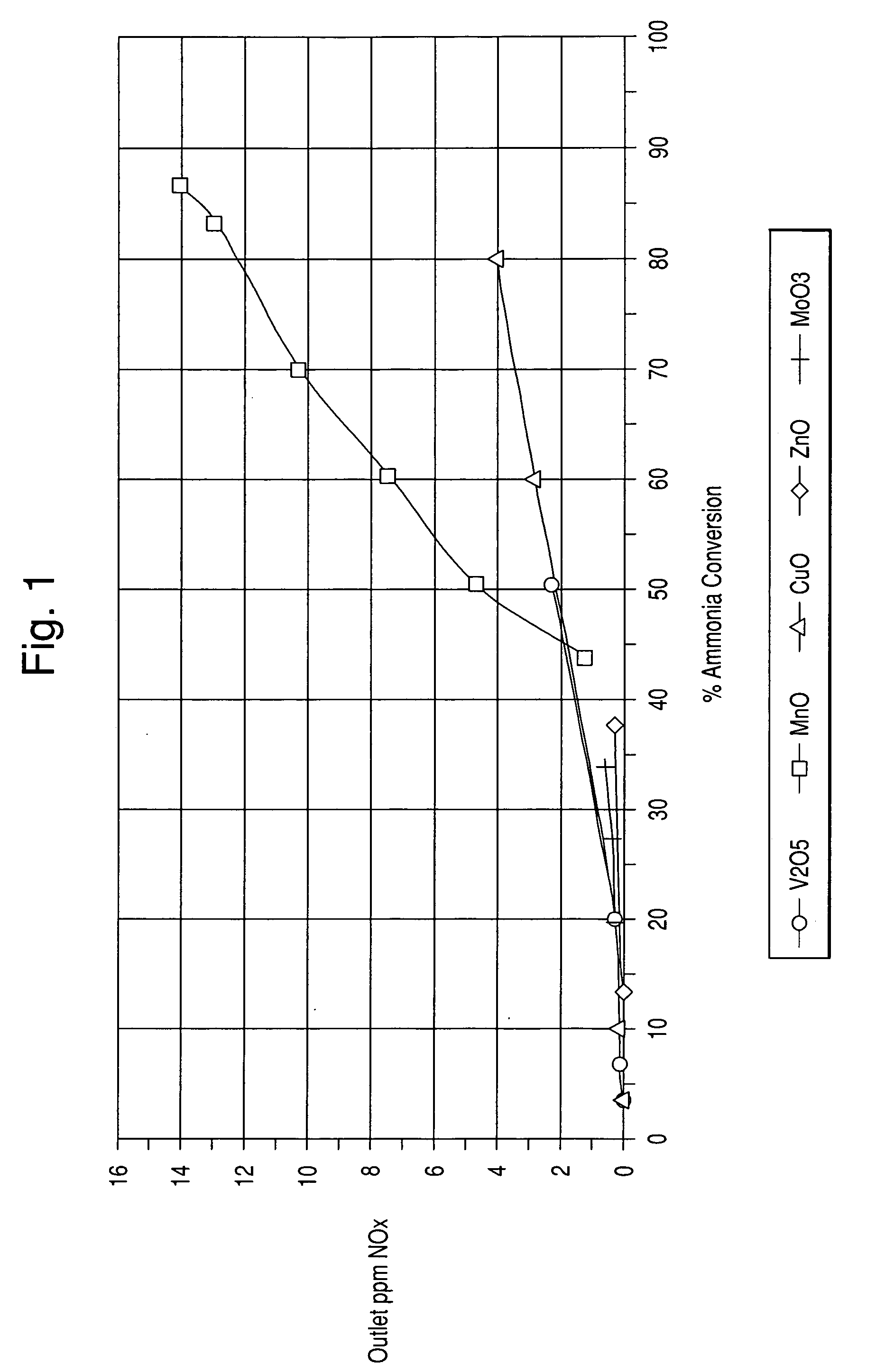

Catalysts for dual oxidation of ammonia and carbon monoxide with low to no NOX formation

InactiveUS20080112870A1Increase costLow costCombination devicesCyanogen compoundsTransition metalOxide

Catalysts, catalyst systems, and methods for removing ammonia and / or carbon monoxide in flue gases are provided where ammonia is used with a selective catalytic reduction catalyst for reducing oxides of nitrogen. A dual oxidation catalyst generally comprises an alkali component, a transition metal, and a metal oxide support. This catalyst is also substantially free from precious metal components and effective for substantially simultaneously oxidizing ammonia (NH3) and carbon monoxide (CO) when placed in an exhaust gas stream. The catalyst is effective to provide low ammonia to nitrogen oxides selectivity.

Owner:BASF CATALYSTS LLC

Acid-impregnated activated carbon and methods of forming and using the same

An acid-impregnated activated carbon matrix is formed from a carbonaceous material by the addition of a mineral acid, and may be used to chemisorb ammonia from a gas stream. The ammonia reacts with the acid to form a fertilizer salt. The spent matrix may be used as a fertilizer, or the fertilizer salt may be elutriated from the matrix.

Owner:SULVARIS INC

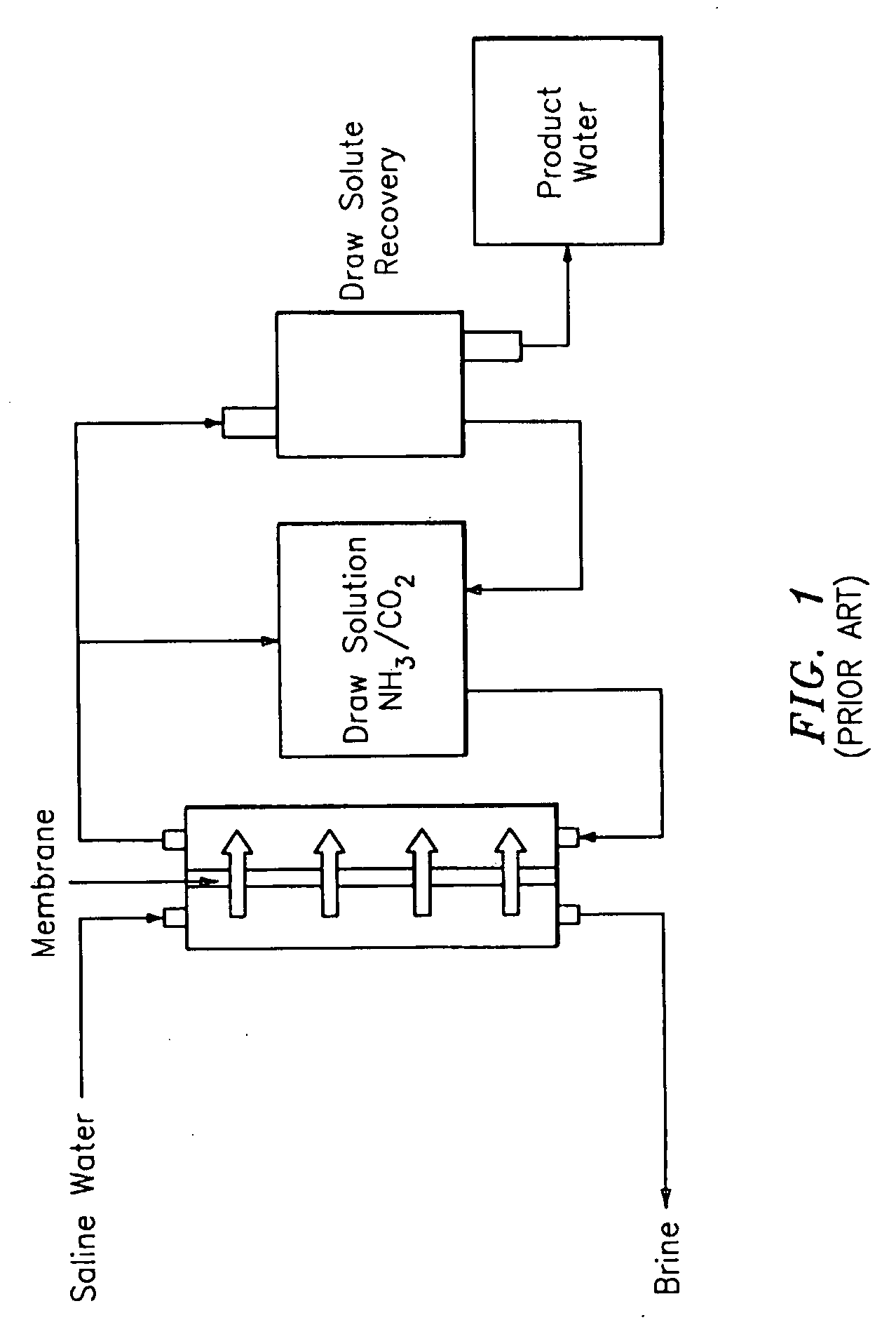

Multi-Stage Column Distillation (MSCD) Method for Osmotic Solute Recovery

ActiveUS20090297431A1Improve heating efficiencyImprove efficiencyLiquid separation auxillary apparatusCyanogen compoundsWater desalinationFractionating column

A method and apparatus for separating draw solution solutes and product solvent from a draw solution using a plurality of distillation columns. In one embodiment, the draw solution is used in a Forward Osmosis (FO) water desalination process. In this embodiment, the draw solution is directed to the plurality of distillation columns in parallel while the energy stream (heat) is directed to the plurality of distillation columns in series such that the efficiency of heat use is improved and in turn the cost of the heat is reduced.

Owner:YALE UNIV

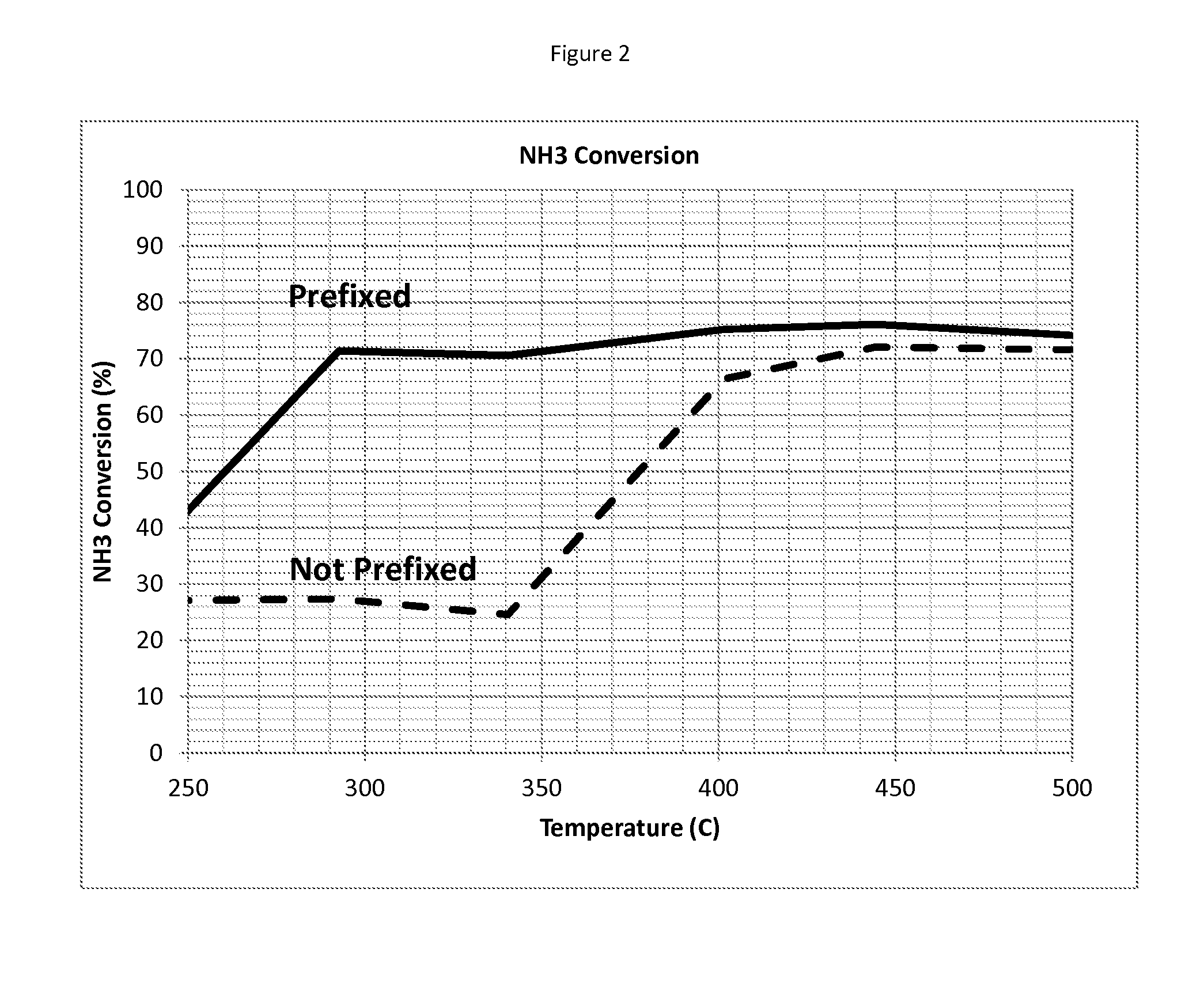

Ammonia oxidation catalyst

ActiveUS20140154163A1High catalytic activityImproving low temperature ammonia conversionCombination devicesCyanogen compoundsPtru catalystSilicon oxide

Provided is a catalyst article for treating an emission gas comprising (a) a noble metal catalyst layer comprising one or more noble metals disposed on a first refractory metal oxide support; and (b) a vanadium catalyst layer comprising vanadium pre-fixed on a second refractory metal oxide support selected from alumina, titania, zirconia, ceria, silica, and mixtures of these, wherein the first catalyst layer is in physical contact with said second catalyst layer. Also provided is a method for making such a catalyst article, a method for treating gas emissions using such an article, and an emission gas treatment system incorporating such an article.

Owner:JOHNSON MATTHEY PLC

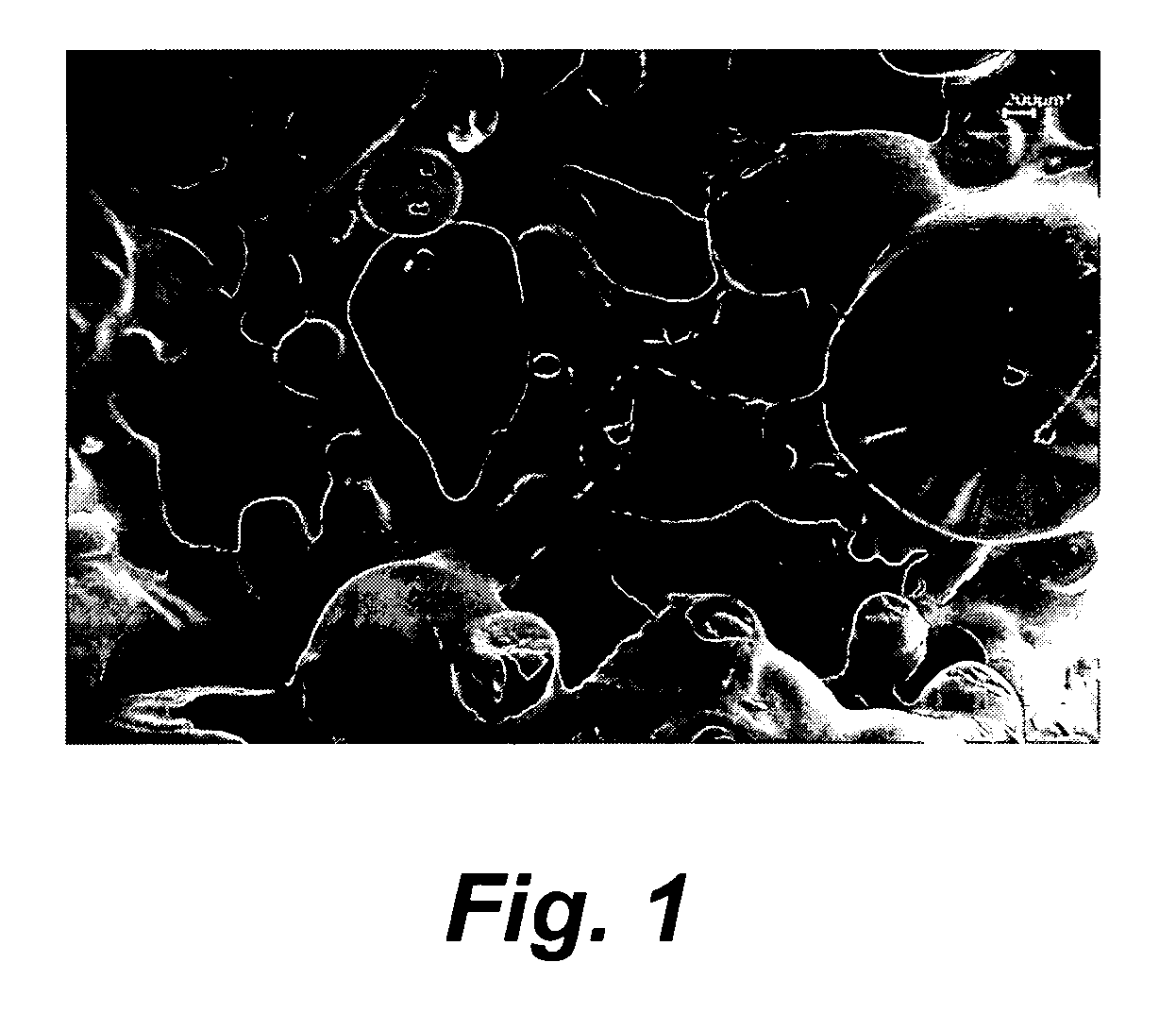

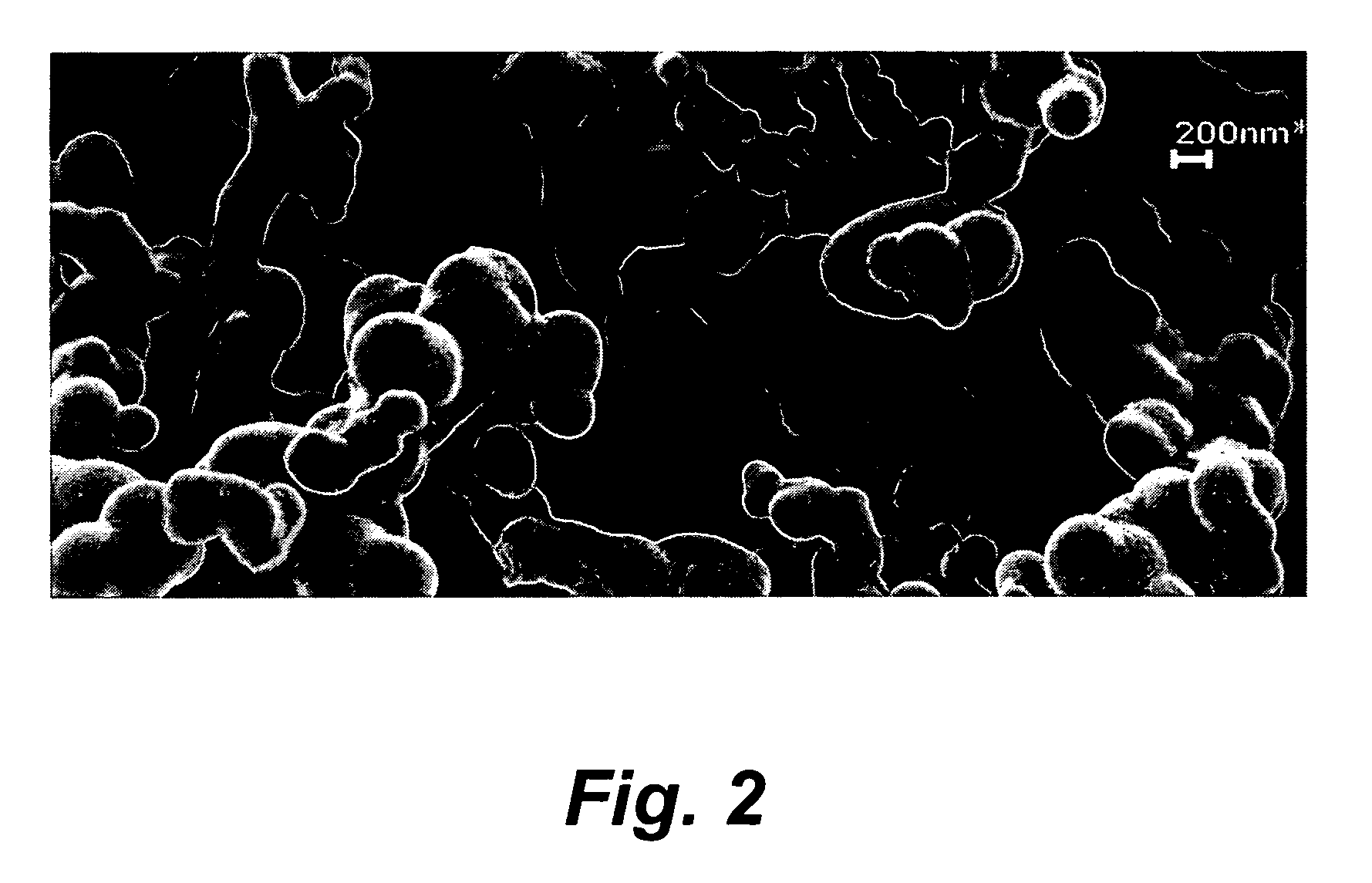

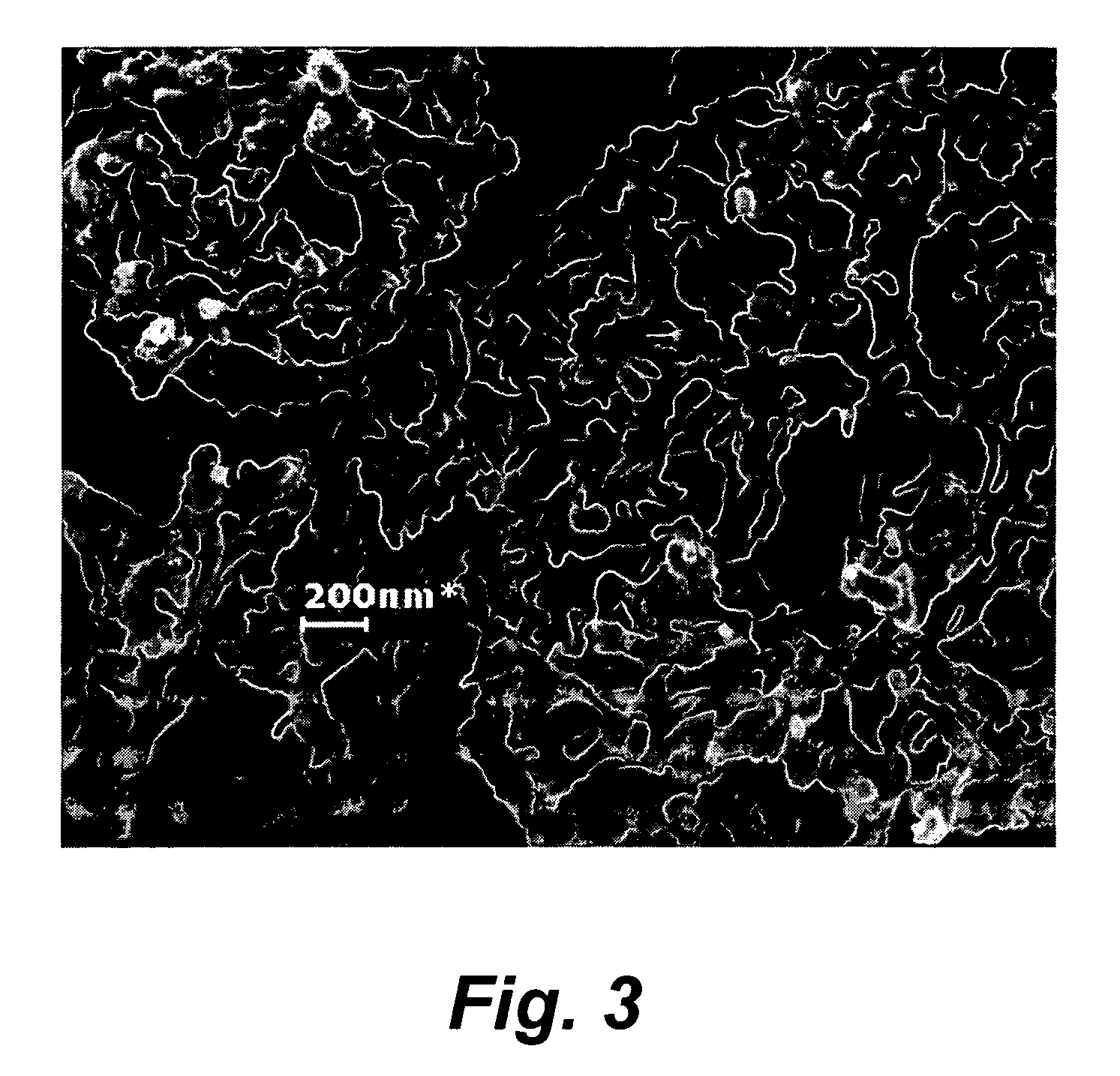

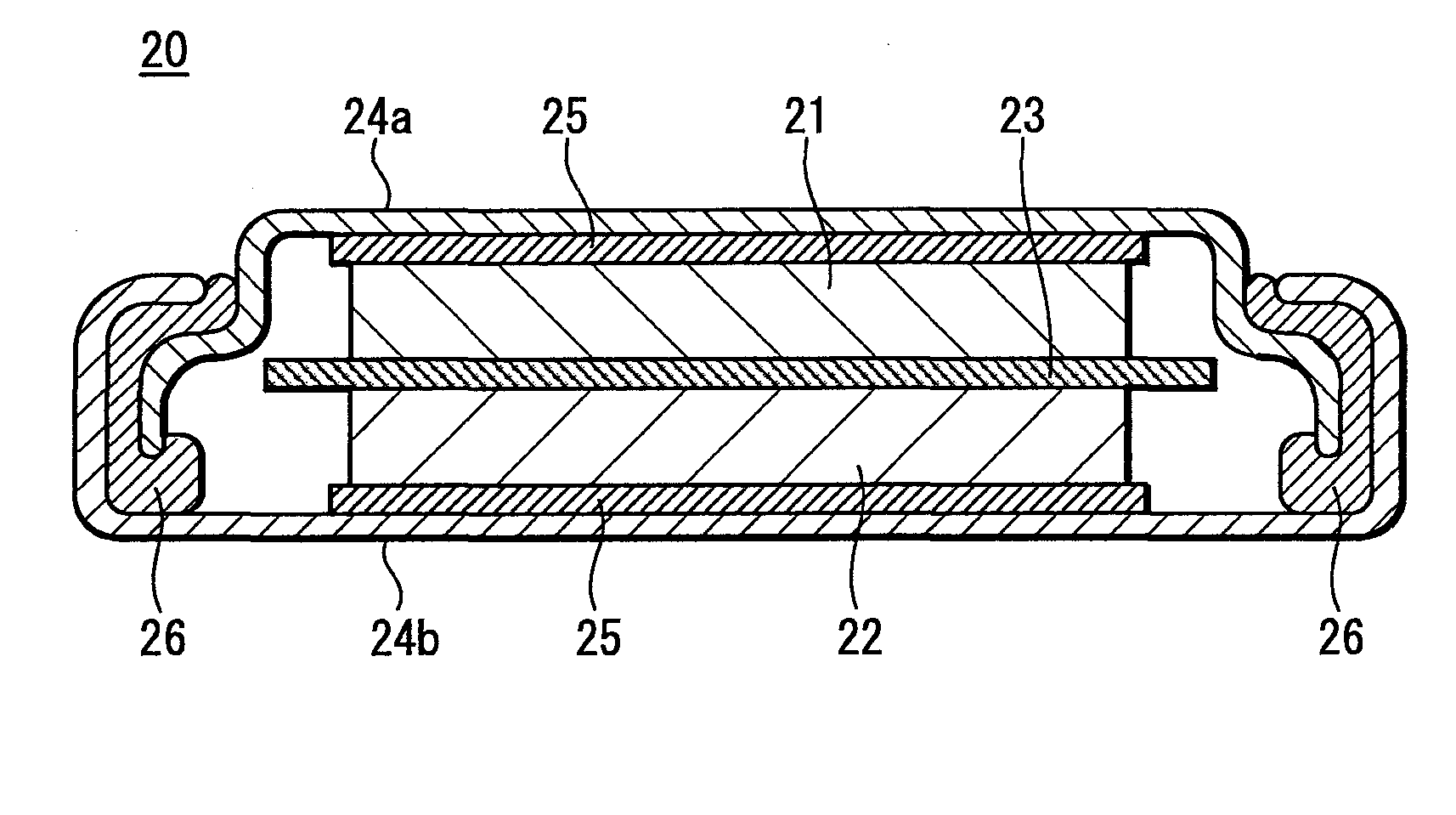

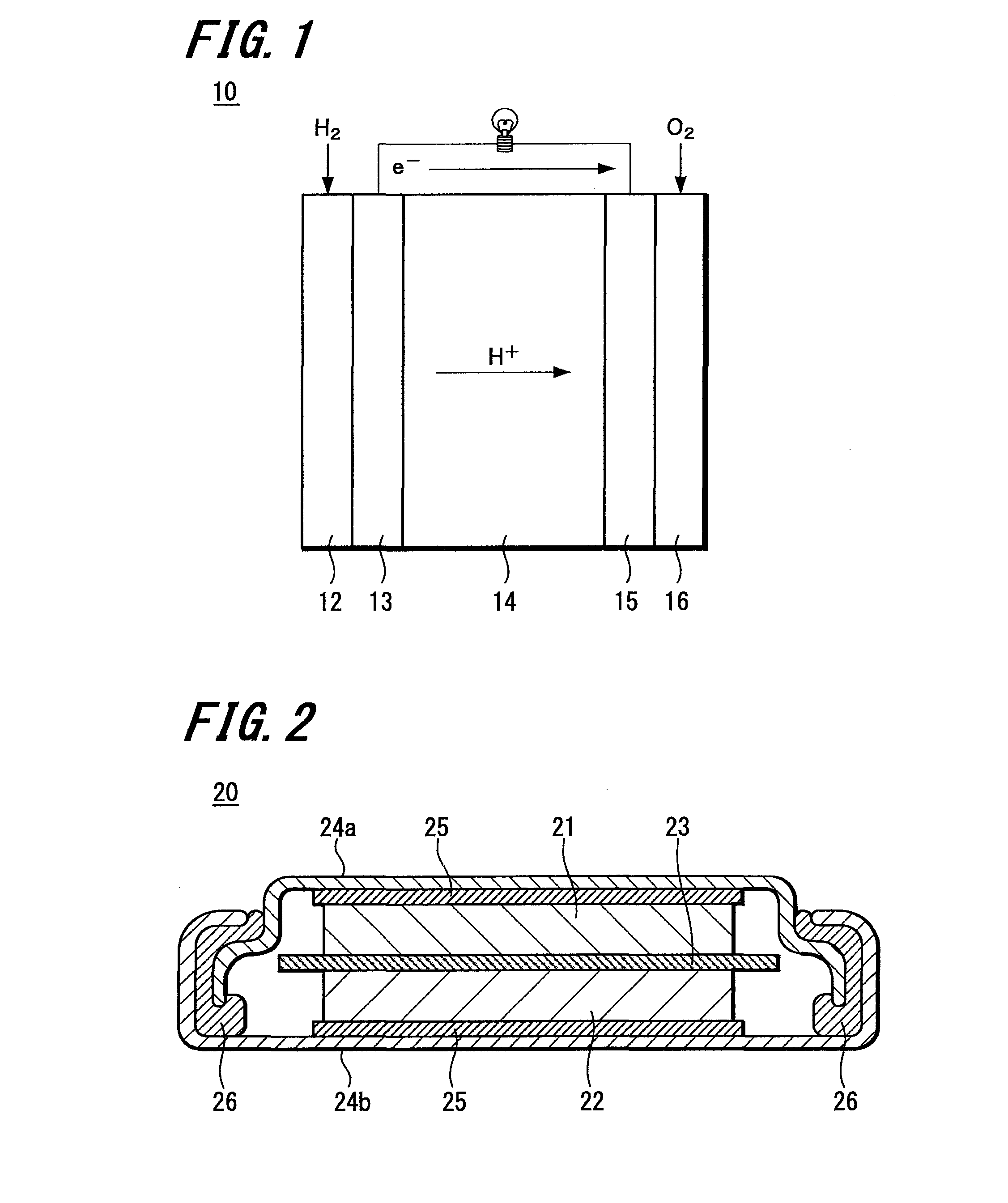

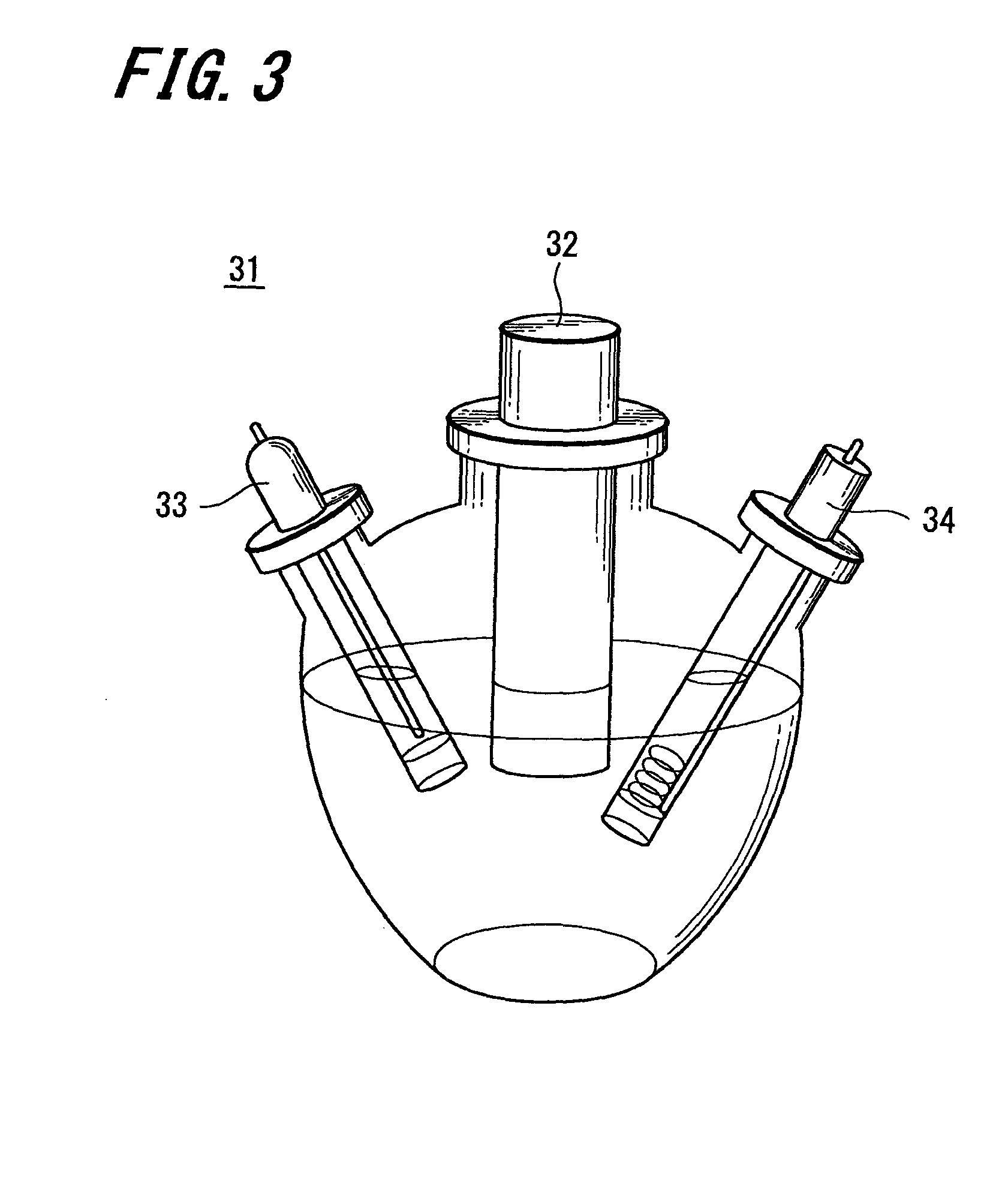

Carbon catalyst, slurry containing the carbon catalyst, process for producing carbon catalyst, and fuel cell, storage device, and environmental catalyst each employing carbon catalyst

InactiveUS20100323272A1Reduced responseImprove responseMaterial nanotechnologyCyanogen compoundsFiberFuel cells

The present invention is made to provide a carbon catalyst capable of preventing the coarsening of particles of nanoshell structure of carbon which causes reduction in activity for oxygen reduction reaction. The carbon catalyst is produced by the steps of: preparing a carbon precursor polymer; mixing a transition metal or a compound of the transition metal into the carbon precursor polymer; spinning the mixture of the carbon precursor polymer and the transition metal or the compound of the transition metal into fibers; and carbonizing the fibers.

Owner:GUNMA UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com