Production method for reaction-agglomerated particles, production method for positive electrode active material for lithium ion cell, production method for lithium ion cell, lithium ion cell, and apparatus for production of reaction-agglomerated particles

A positive electrode active material and lithium-ion battery technology, applied in the direction of active material electrodes, methods of granulating raw materials, battery electrodes, etc., can solve the problems that high performance cannot be expected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0190] (Example 1) Example of nickel manganese cobalt hydroxide

[0191] As the reaction material A, nickel sulfate, manganese sulfate, and cobalt sulfate were prepared into a 1.6 M liquid at a ratio of 1:1:1. As the reaction material B, 25% concentration of sodium hydroxide was used, and as the reaction material C, 25% concentration of ammonia water was used. In order to carry out a specific reaction, ammonium sulfate, hydrogen peroxide, ethanol, glycerin, etc. were added to the reaction material A to adjust the solvent, and an example in which 0.1 M ammonium sulfate was added is shown here.

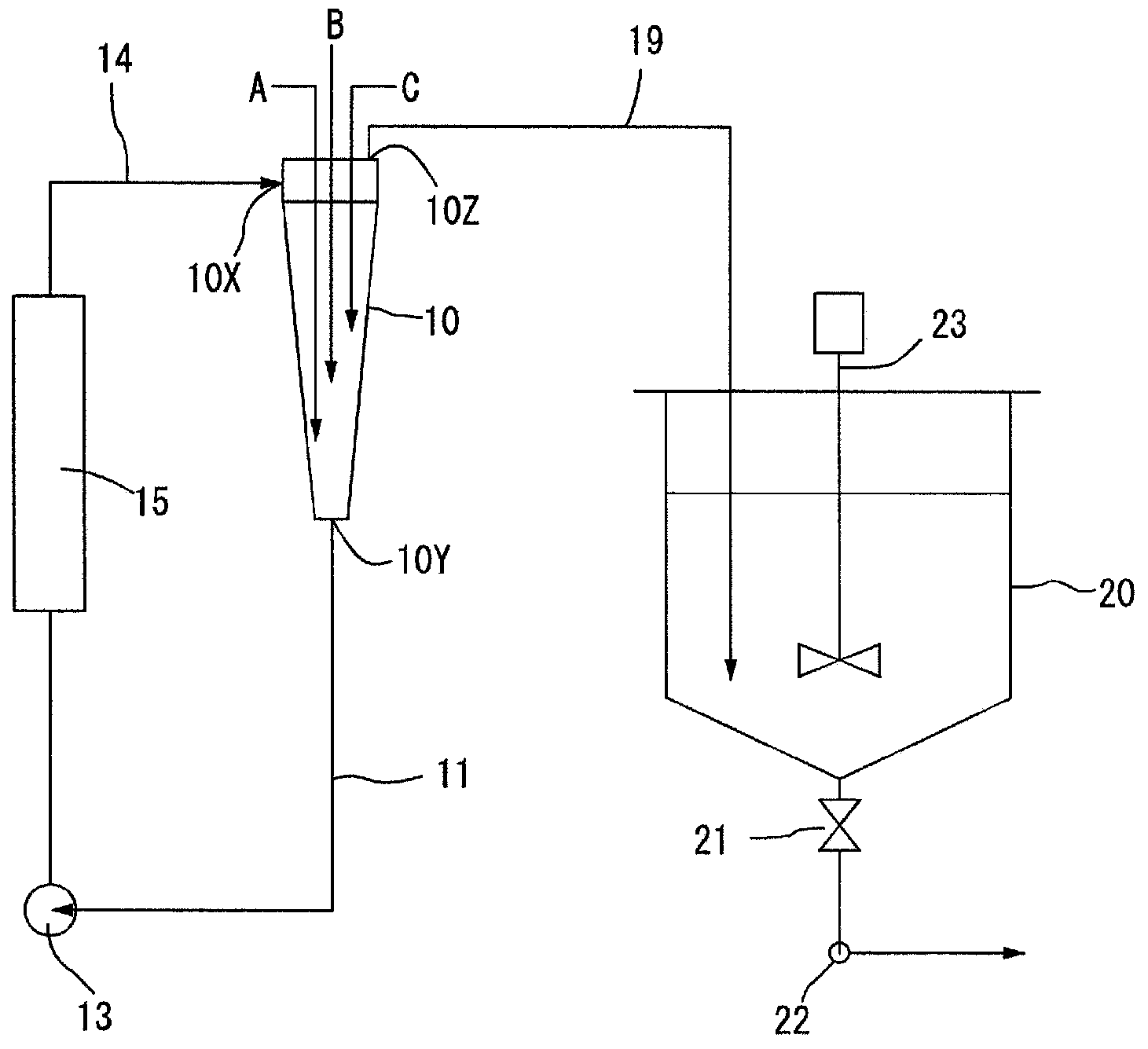

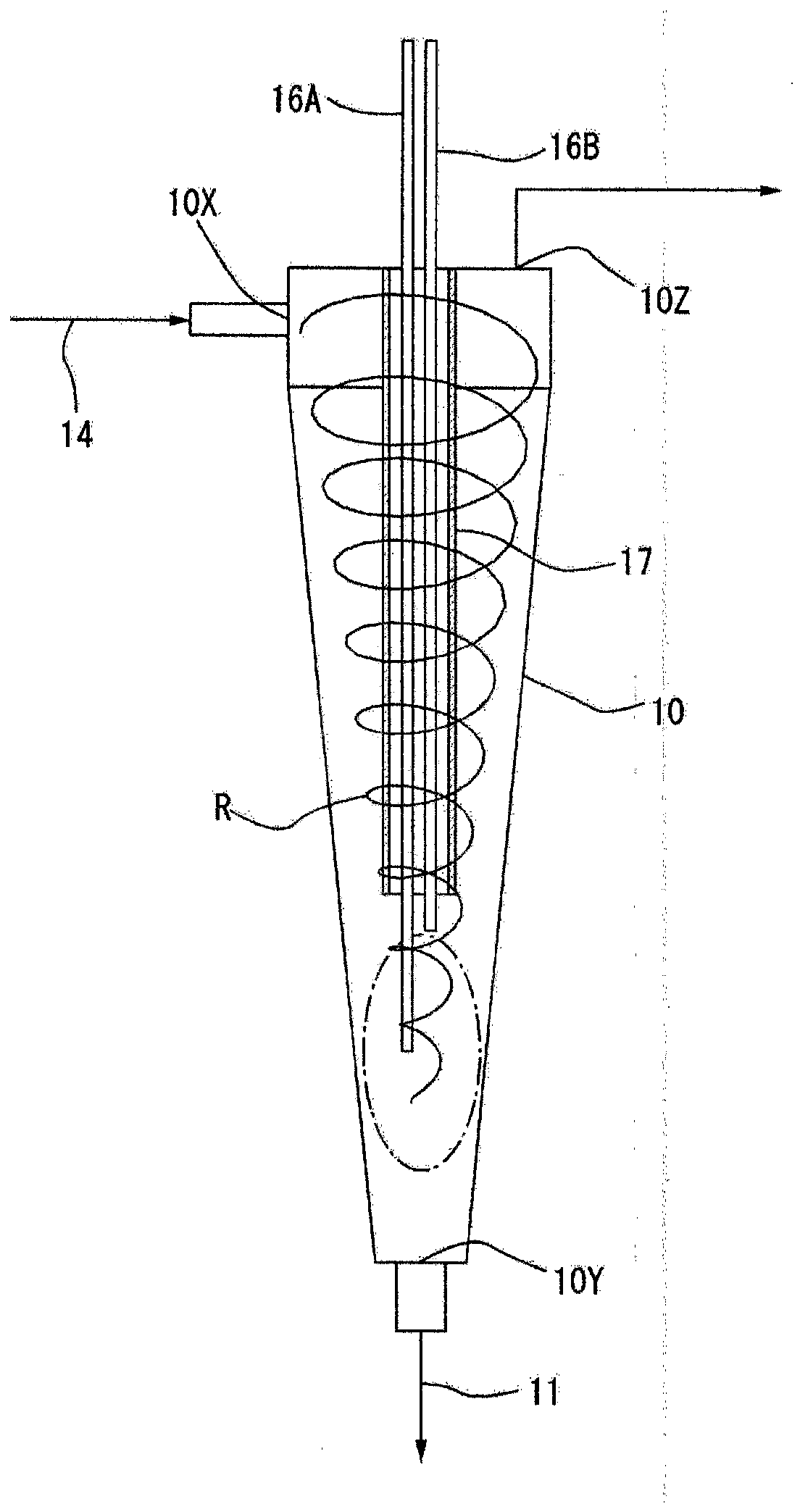

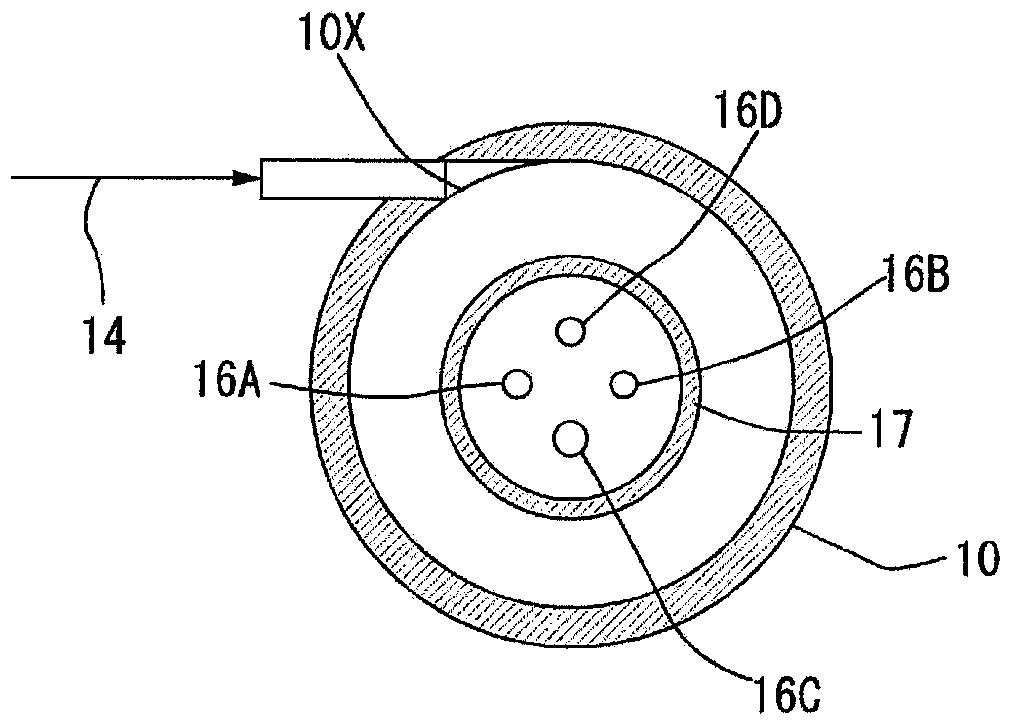

[0192] exist Figure 1 to Figure 4 In the manner of the above, the reaction material A, the reaction material B and the reaction material C are injected into the reaction processor 10 .

[0193] As the starting mother liquor, what was obtained by adding 40 g of ammonia water to 2 kg of ion-exchanged water was used.

[0194] The circulating pump was operated at 20 L / min, A was injecte...

Embodiment 2

[0218] (Example 2) Example of nickel manganese carbonate

[0219] As the reaction material A, nickel sulfate and manganese sulfate were prepared into a 1.6M liquid at a ratio of 1:2. As the reaction material B, 15% concentration of ammonium bicarbonate was used, and as the reaction material C, 25% concentration of ammonia water was used. In order to carry out a specific reaction, ammonium sulfate, hydrogen peroxide, ethanol, glycerin, etc. were added to the reaction material A to adjust the solvent, and an example in which 0.1 M ammonium sulfate was added is shown here.

[0220] exist Figure 1 to Figure 4 In the manner of the above, the reaction material A, the reaction material B and the reaction material C are injected into the reaction processor 10 .

[0221] As the starting mother liquor, what was obtained by adding 300 g of ammonia water to 6 kg of ion-exchanged water was used.

[0222] The circulating pump was operated at 20 L / min, A was injected at about 260 g / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com