Method of replacing dispersion medium

A dispersion medium and replacement tank technology, applied in separation methods, chemical instruments and methods, crystallization separation, etc., can solve problems such as difficult operation and distributor blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Examples are given below to describe the embodiment of the present invention in more detail. However, the present invention is not limited to these Examples.

reference example 1

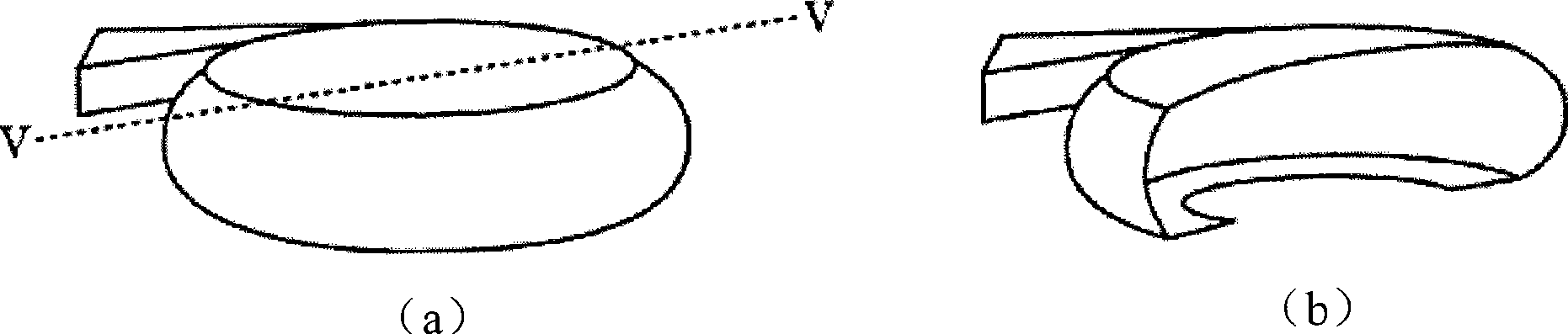

[0052] use for observation Figure 5 In the experimental apparatus of the dispersion state shown, the dispersion state in the tank 1 (diameter 2m, height 4m) was examined. A water slurry (concentration of sand: 35% by weight) of sand with adjusted particle size (average particle size: 95 μm) was used as the raw slurry. The raw slurry is put into the tank 1, and in order not to accumulate sand at the bottom, the circulating pump 2 is used to circulate the raw slurry to the raw slurry supply port 5 through the electromagnetic flowmeter 4 and the flow regulating valve 3.

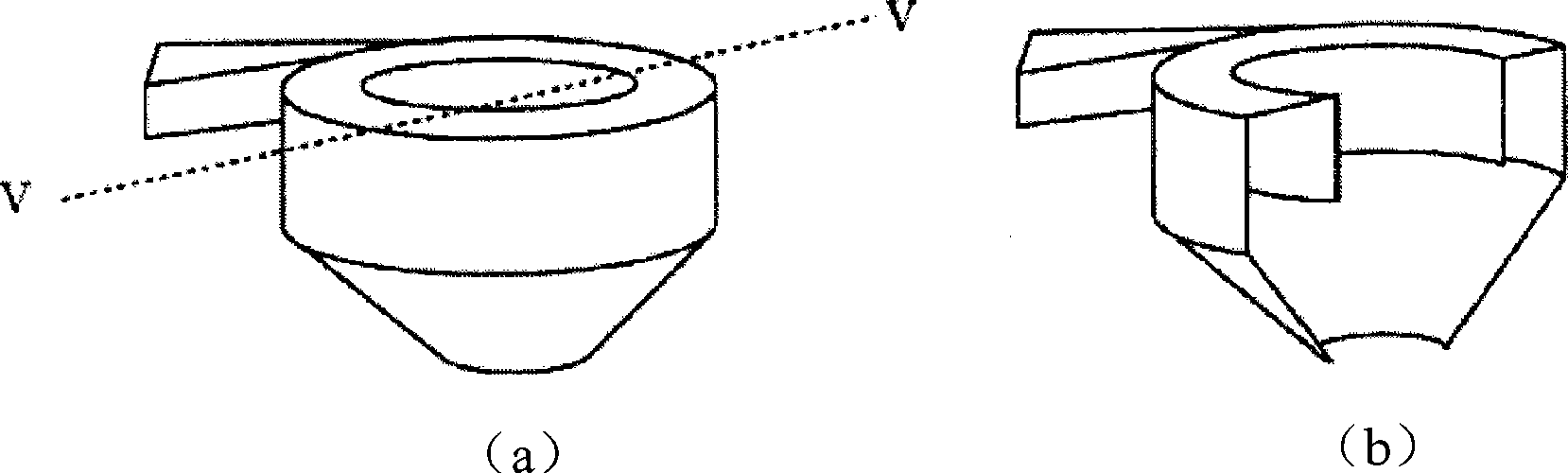

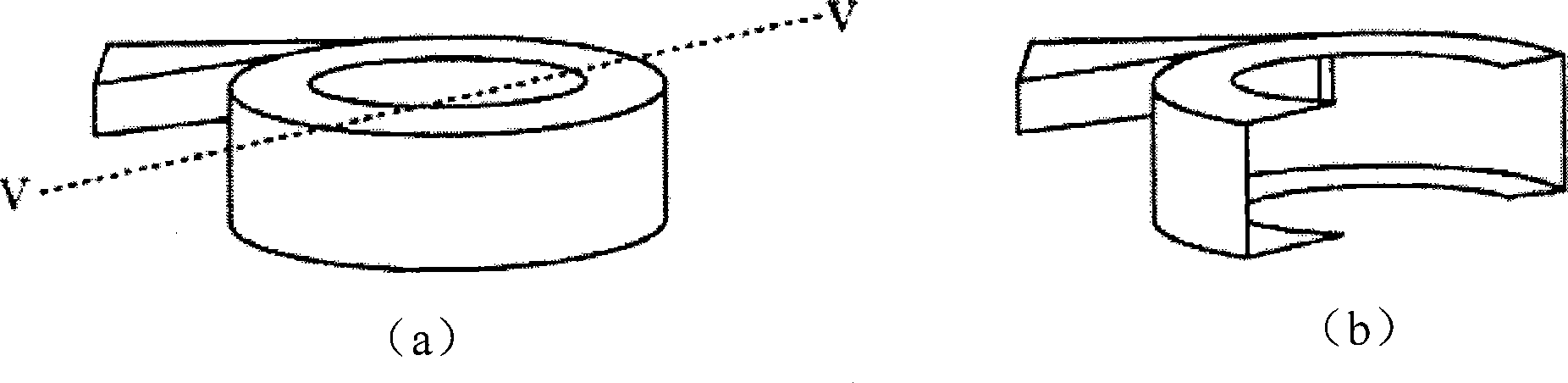

[0053] The circulating raw slurry is supplied to the swirl nozzle 6, and flows out into the tank 1 while maintaining a circular motion for dispersion. The structure of swirl nozzle 6 is as Figure 6 shown. The raw pulp supply part 11 is connected to the cylindrical part 10, and supplies raw pulp from the tangential direction of the cylindrical part 10. An opening 8 (opening diameter 0.58 m) and an opening 9...

Embodiment 1

[0061] Use with Figure 9 A device with the same structure was replaced with a dispersion medium. As the replacement tank, a closed container made of stainless steel with an inner diameter of 30 cm and a height of 100 cm was used.

[0062] A stainless steel airtight container was filled with water at 100° C., and the raw slurry containing 30% by weight of terephthalic acid and using water as the first dispersion medium was supplied to the same swirl nozzle as in Example 1 at 770 kg / h. Water as a second dispersion medium was supplied at a rate of 560 kg / h from the lower part of the substitution tank. The replacement slurry containing terephthalic acid crystals and the second dispersion medium is mainly taken out from the lower part of the replacement tank, and the first dispersion medium is mainly taken out from the upper part of the replacement tank. Dispersion medium replacement was carried out continuously for one week, and problems such as clogging did not occur.

[0063...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com