Patents

Literature

131 results about "Monoethylene Glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mono Ethylene Glycol (MEG) is an essential component used as raw material in diverse industrial processes such as the manufacture resins, polyester, fibers and various types of films. It is a colorless liquid which has a syrup-like consistency.

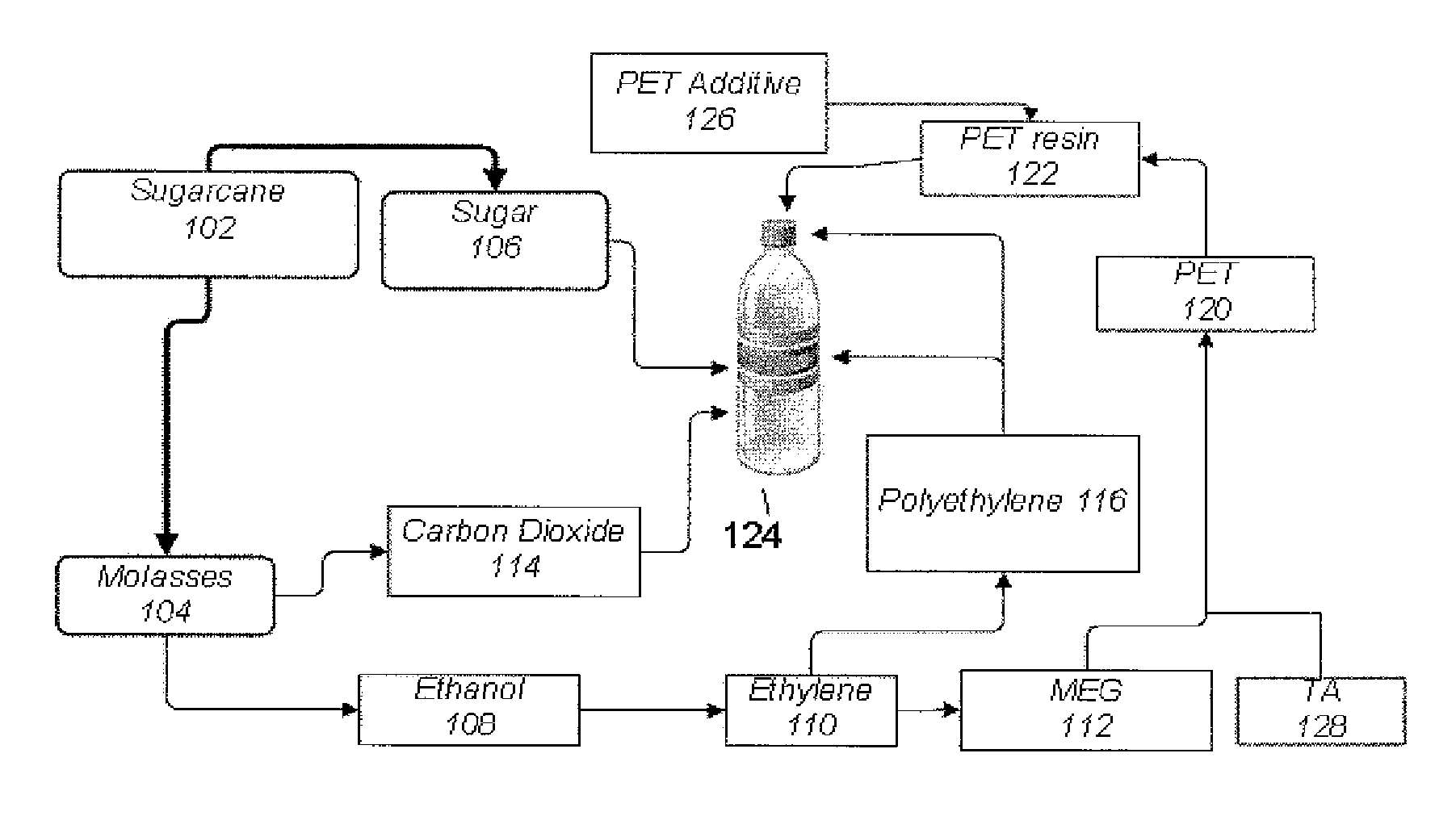

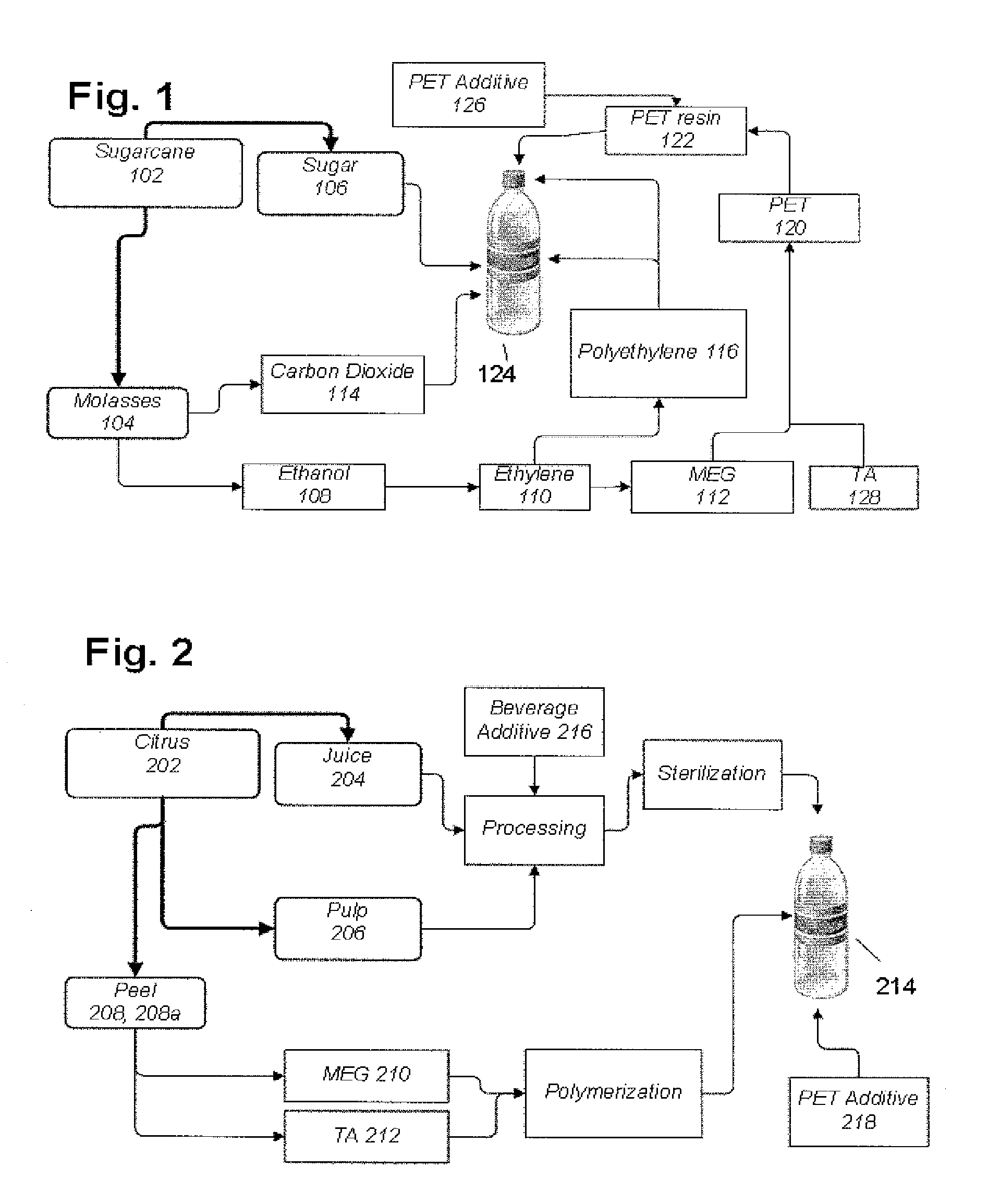

Bio-based polyethylene terephthalate packaging and method of making thereof

InactiveUS20100028512A1Flexible coversWrappersPolyethylene terephthalatePolyethylene terephthalate glycol

This invention relates to a method of making a bio-based PET packaging and particularly to a method of producing a bio-based PET from at least one bio-based material comprising: a) forming at least one PET component from at least one bio-based material, wherein the at least one PET component is selected from a monoethylene glycol (“MEG”), a terephthalic acid (“TA”), and combinations thereof; (b) processing said bio-based PET component into a bio-based PET.

Owner:THE COCA-COLA CO

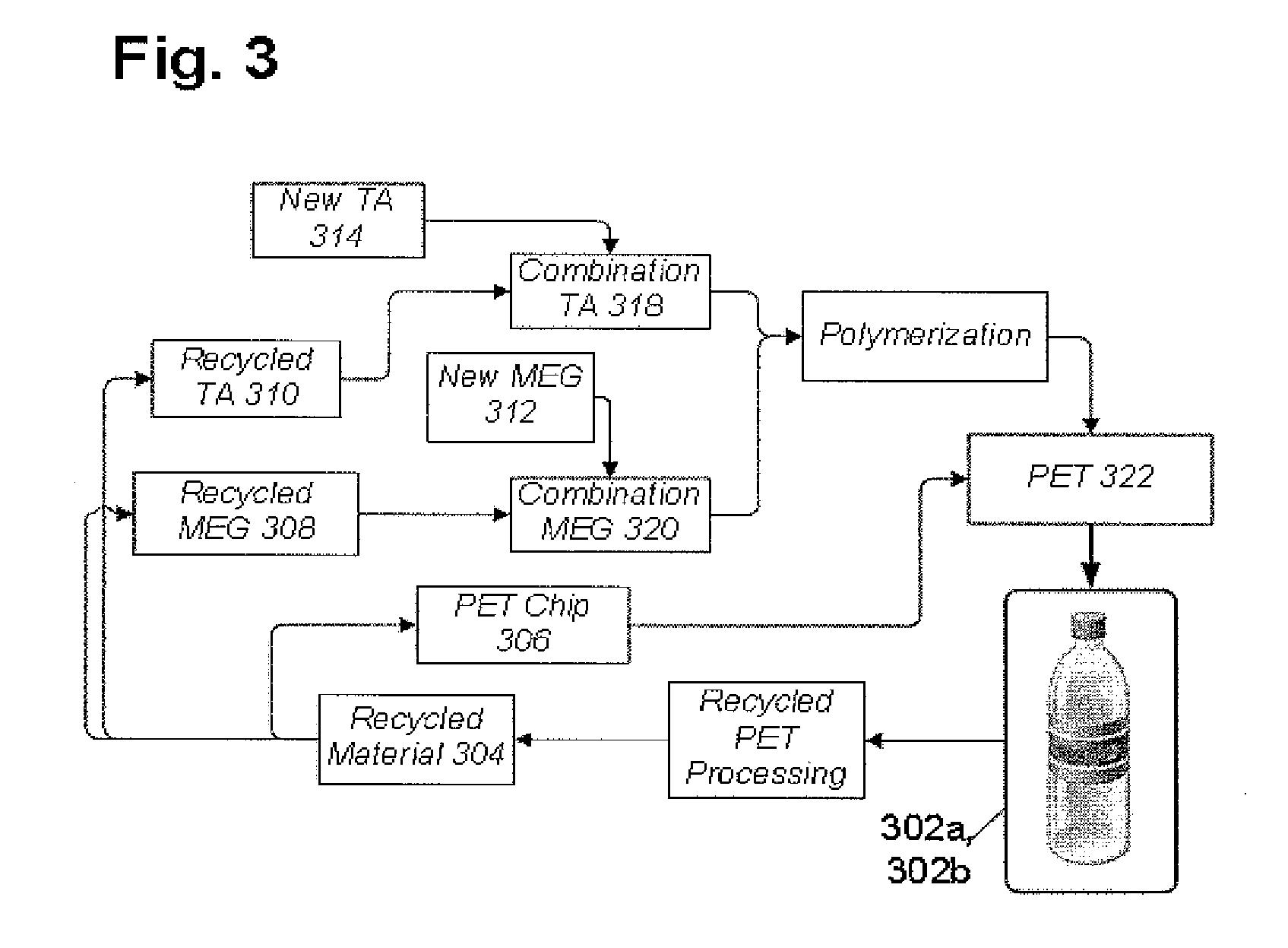

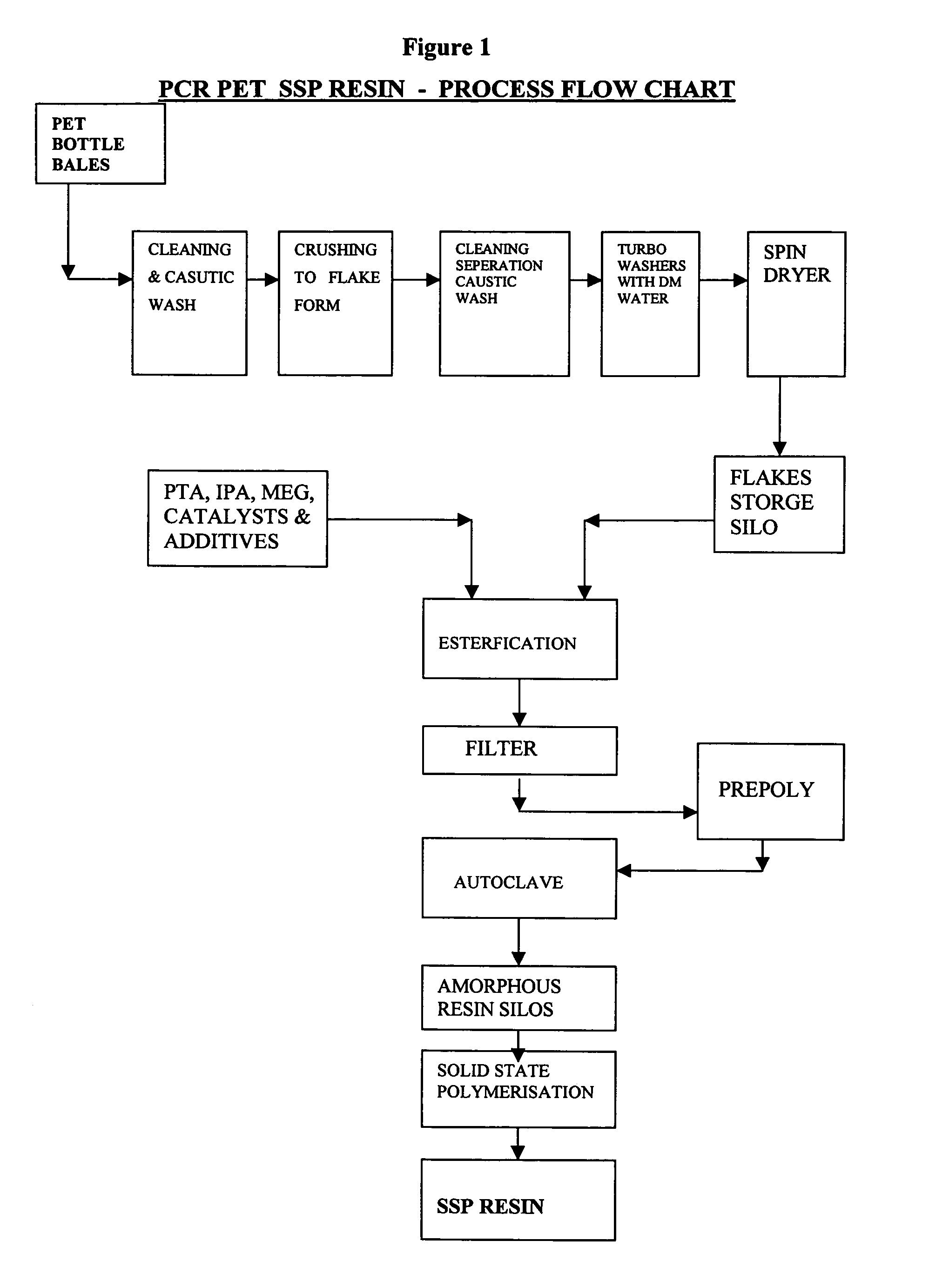

Process for controlled polymerization of a mixed polymer

InactiveUS7297721B2Reduce the degree of polymerizationReduce usageProductsReagentsPolymer scienceMonoethylene Glycol

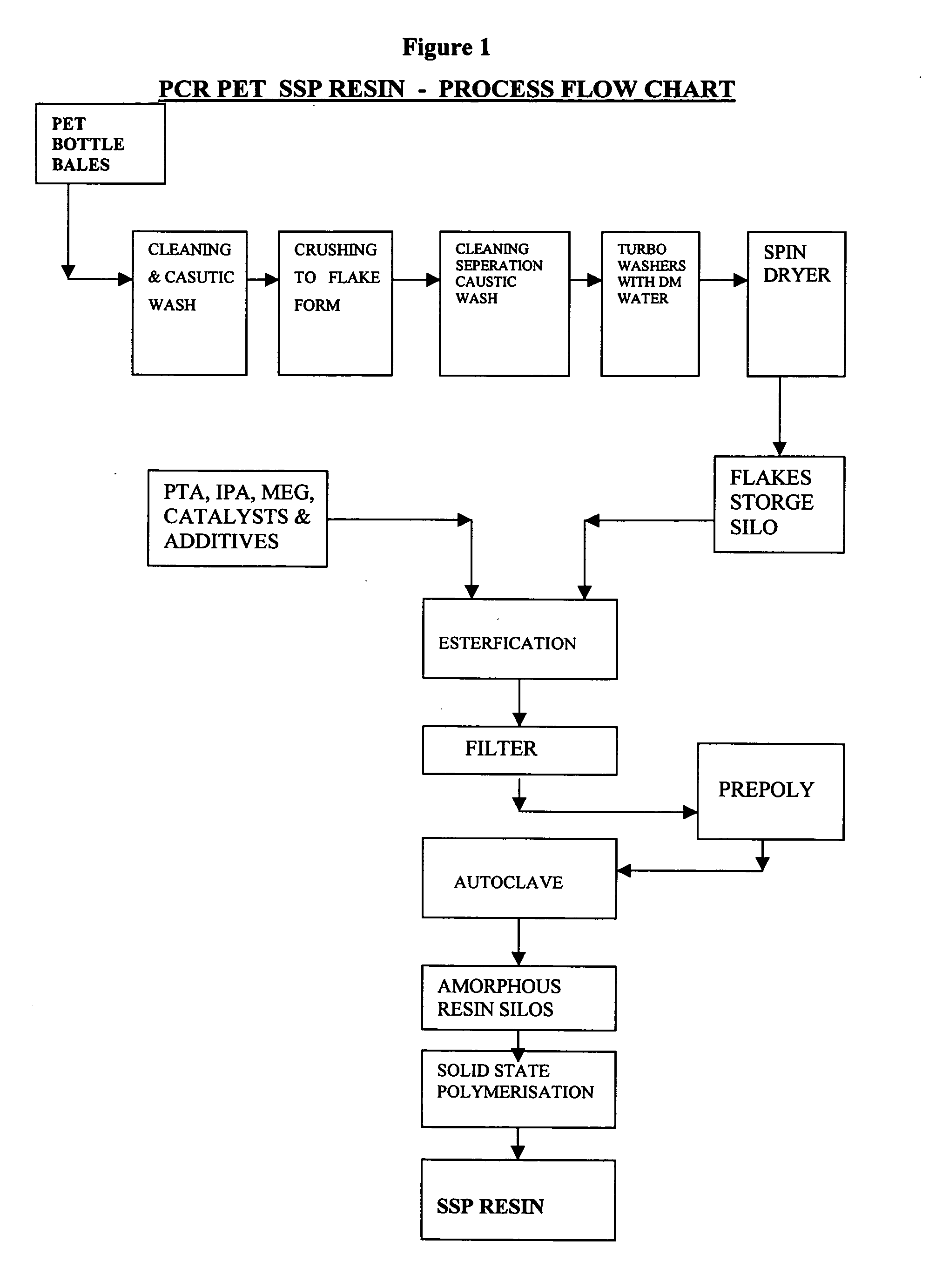

The present invention provides a process for the preparation of high molecular weight crystalline Polyethyleneterephthalate (PET) using up to 50% of Post consumer recycled PET flakes along with Pure Terephthalic Acid (PTA), Isophthalic Acid (IPA) and Mono Ethylene Glycol (MEG) as a virgin raw material, in the presence of a combination of catalysts and additives to obtain an intermediate prepolymer heel having a low degree of polymerization further subjecting to autoclaving to yield an amorphous melt and followed by solid state polymerization.

Owner:FUTURA POLYESTERS LTD

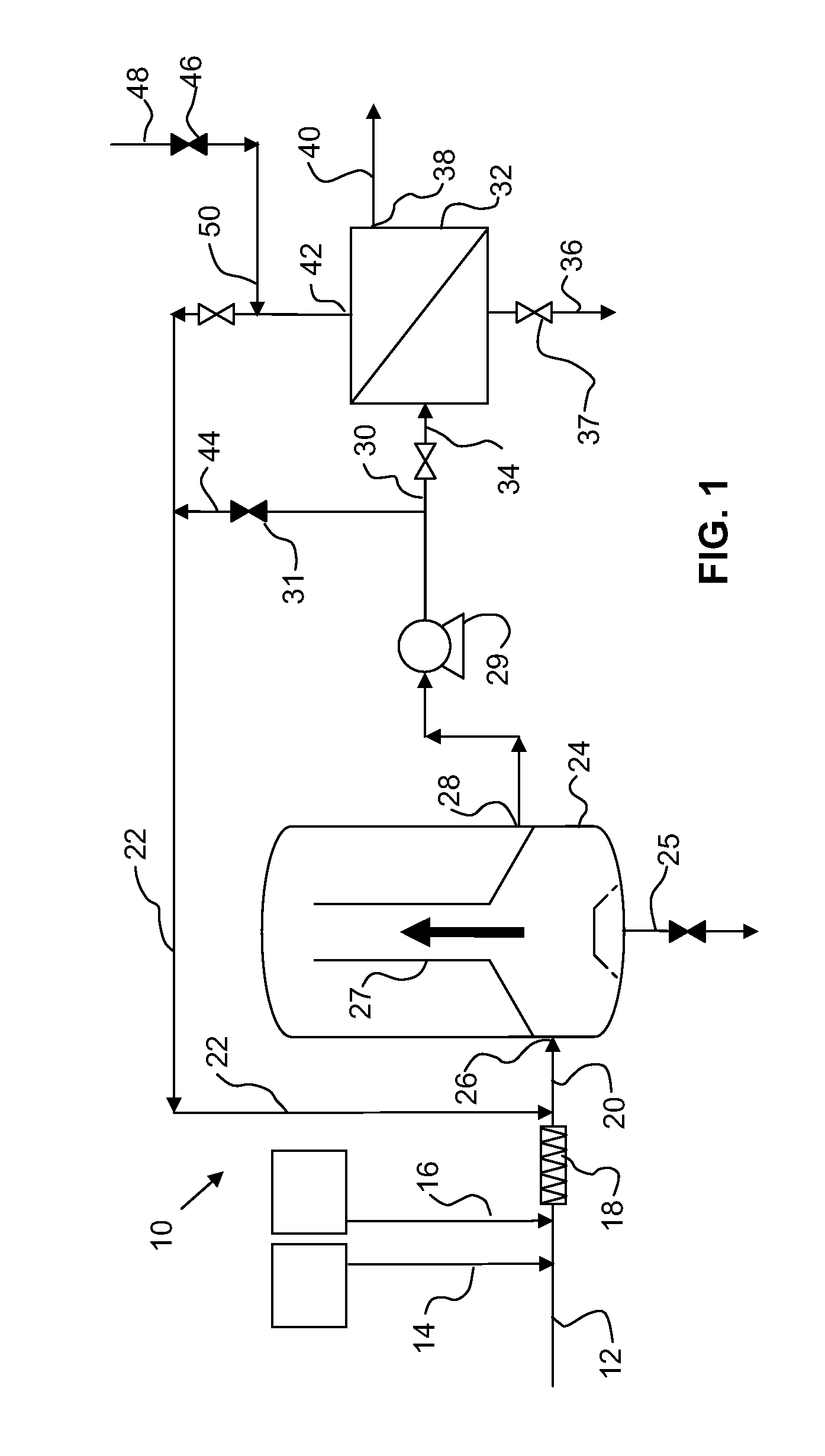

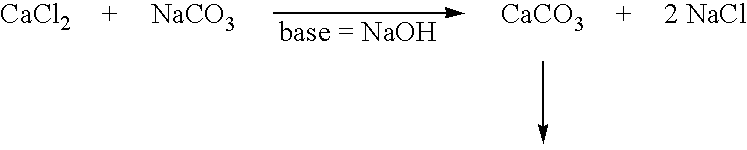

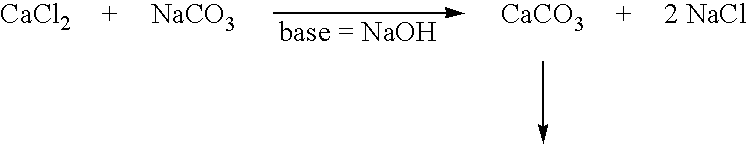

Removing solids in monoethylene glycol reclamation

The seeding of calcium carbonate into a calcium chloride-contaminated monoethylene glycol (MEG) stream accelerates the growth of calcium carbonate particles to a size that enhances their removal from the stream by filtration. A seeding vessel allows the calcium carbonate particles a time period to grow. Sodium carbonate may be added to the contaminated stream to facilitate calcium carbonate particle growth. A recycle seeding conduit may recycle seeds from a filtration unit to the seeding vessel. A base such as sodium hydroxide may be added to accelerate the precipitation process.

Owner:CAMERSON INT CORP

Process for controlled polymerization of a mixed polymer

InactiveUS20050187306A1Reduce the degree of polymerizationReduce usageProductsReagentsPolymer scienceHigh pressure

The present invention provides a process for the preparation of high molecular weight crystalline Polyethyleneterephthalate (PET) using up to 50% of Post consumer recycled PET flakes along with Pure Terephthalic Acid (PTA), Isophthalic Acid (IPA) and Mono Ethylene Glycol (MEG) as a virgin raw material, in the presence of a combination of catalysts and additives to obtain an intermediate prepolymer heel having a low degree of polymerization further subjecting to autoclaving to yield an amorphous melt and followed by solid state polymerization.

Owner:FUTURA POLYESTERS LTD

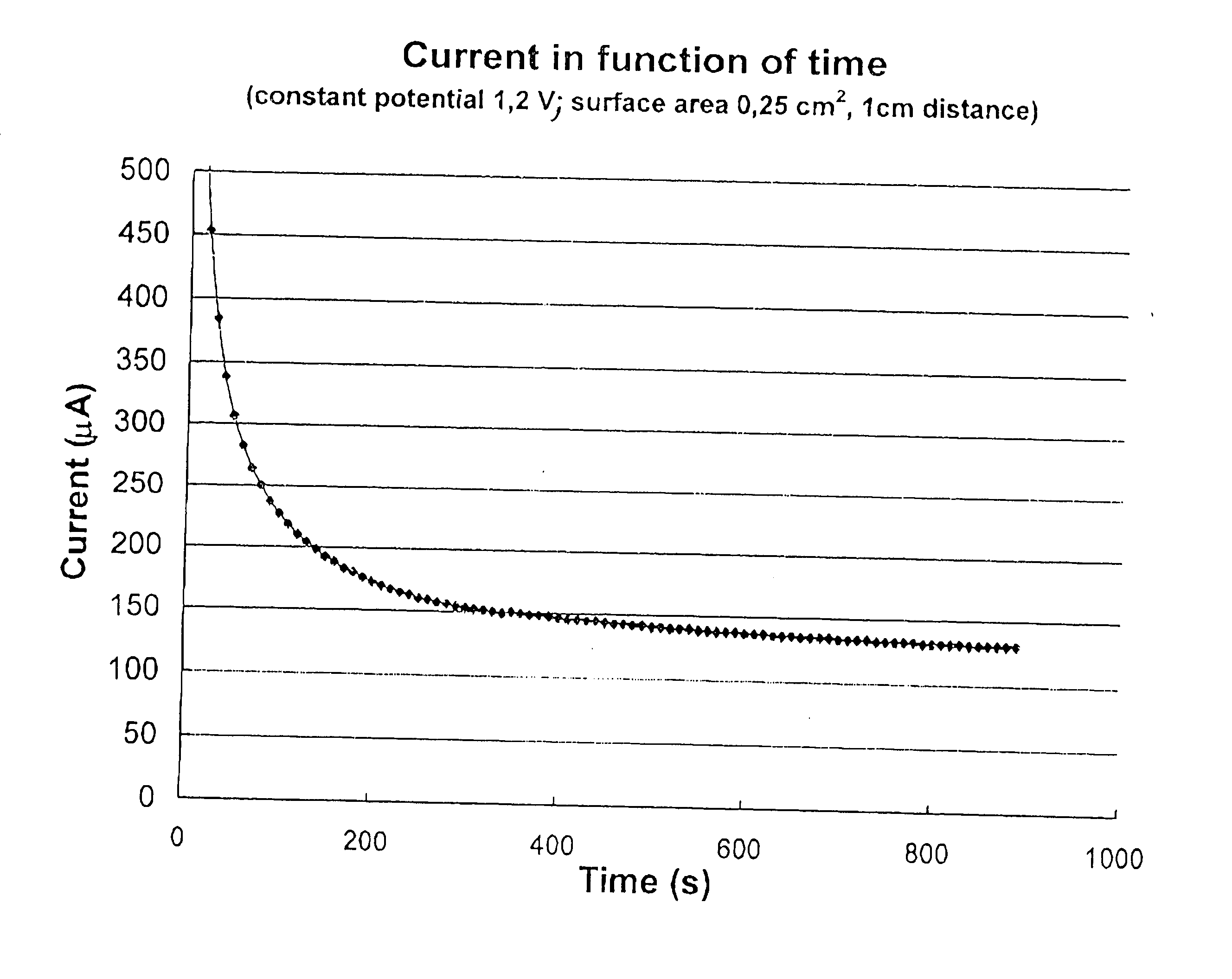

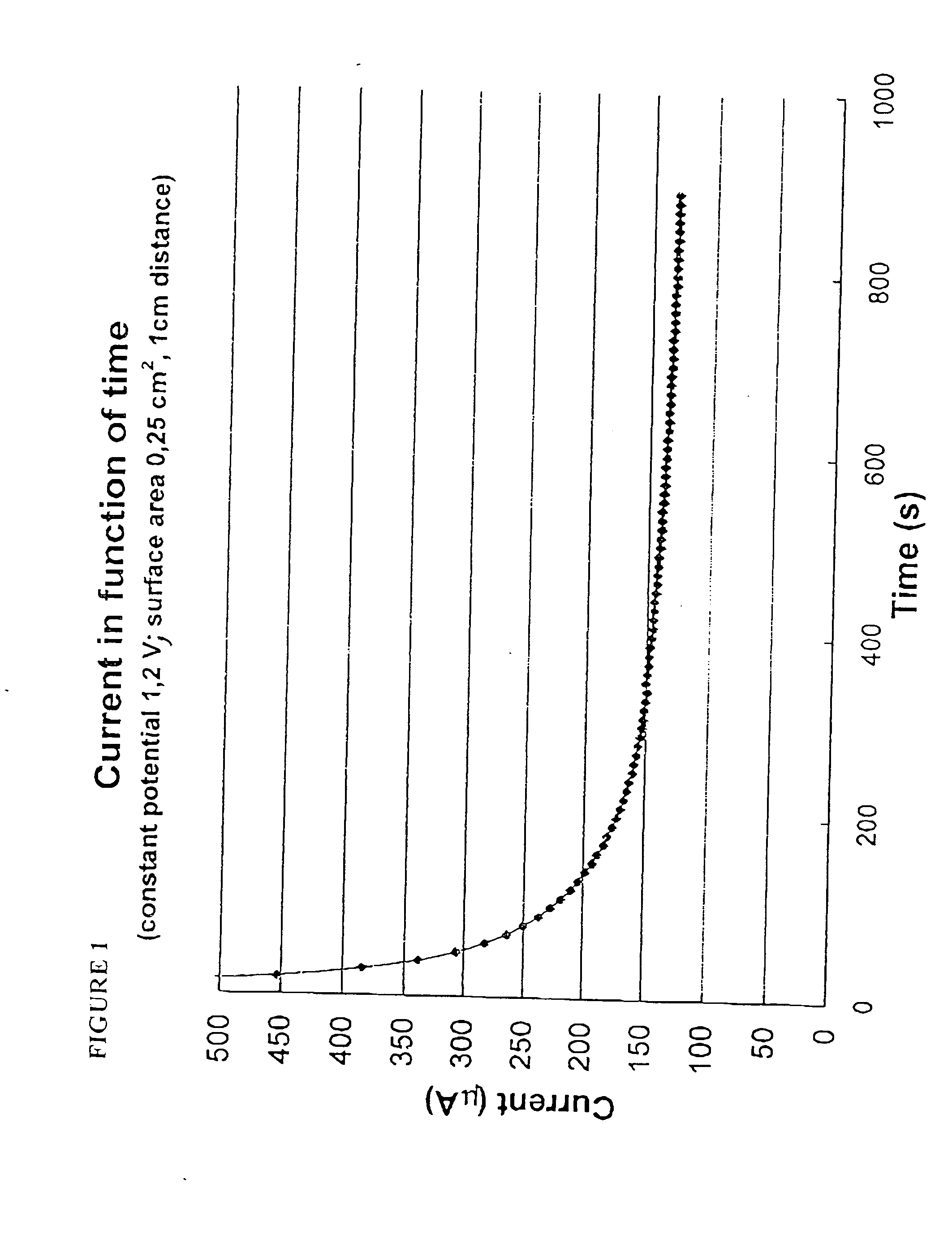

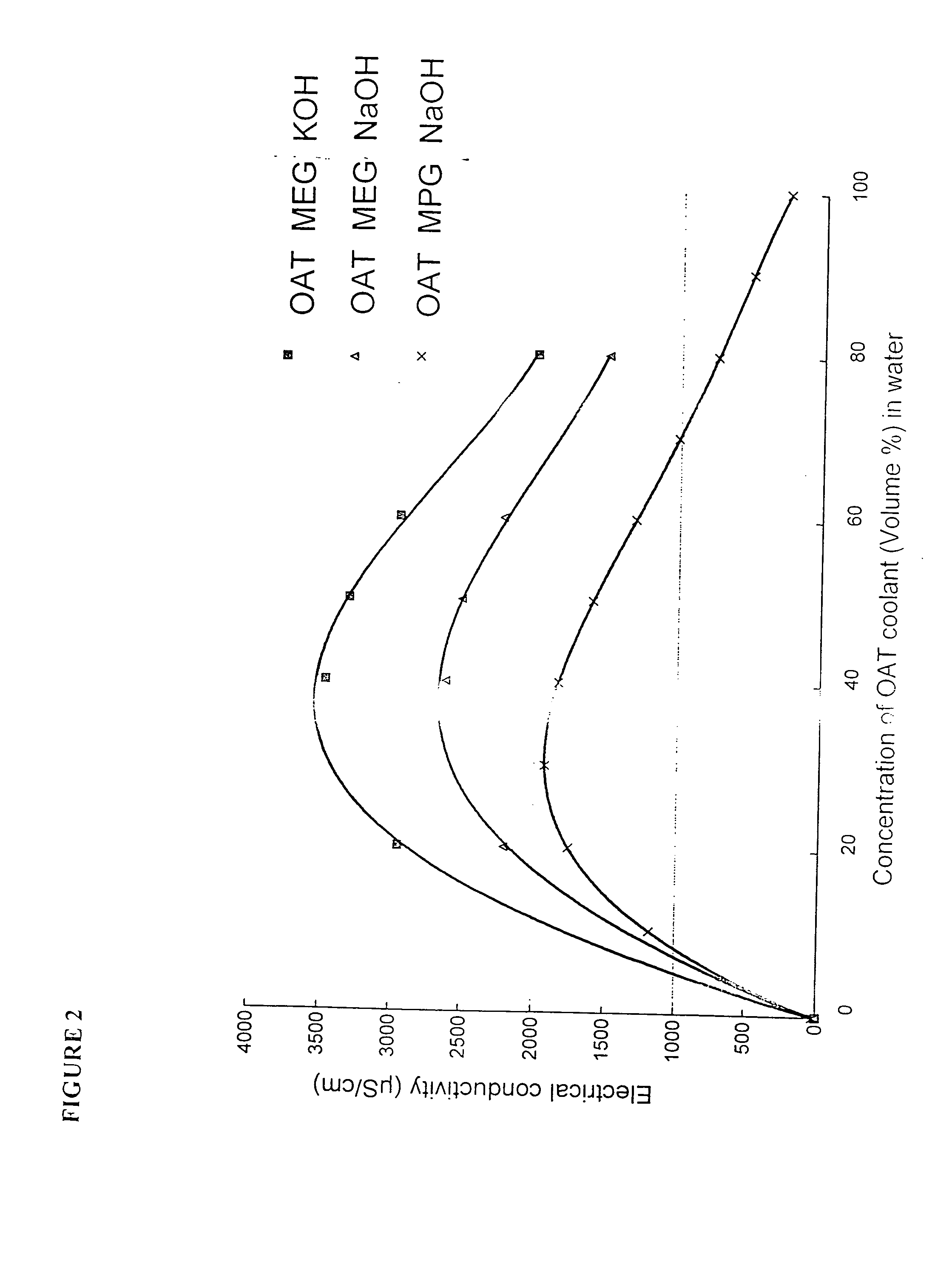

Corrosion inhibiting compositions and methods for fuel cell coolant systems

InactiveUS20050051754A1Low conductivityImprove conductivityOther chemical processesDomestic cooling apparatusTriazole antifungalsDepressant

Carboxylic acids or the salts thereof are suitable for use in cooling systems where low electrical conductivity is required. The compositions are of particular use in fuel cell stacks. The preferred salts are those of amines. The salts can be used with a liquid alcohol freezing point depressant such as monoethylene glycol. Thiazoles and / or triazoles may be included, as well as other corrosion inhibitors known in the art.

Owner:ARTECO NV

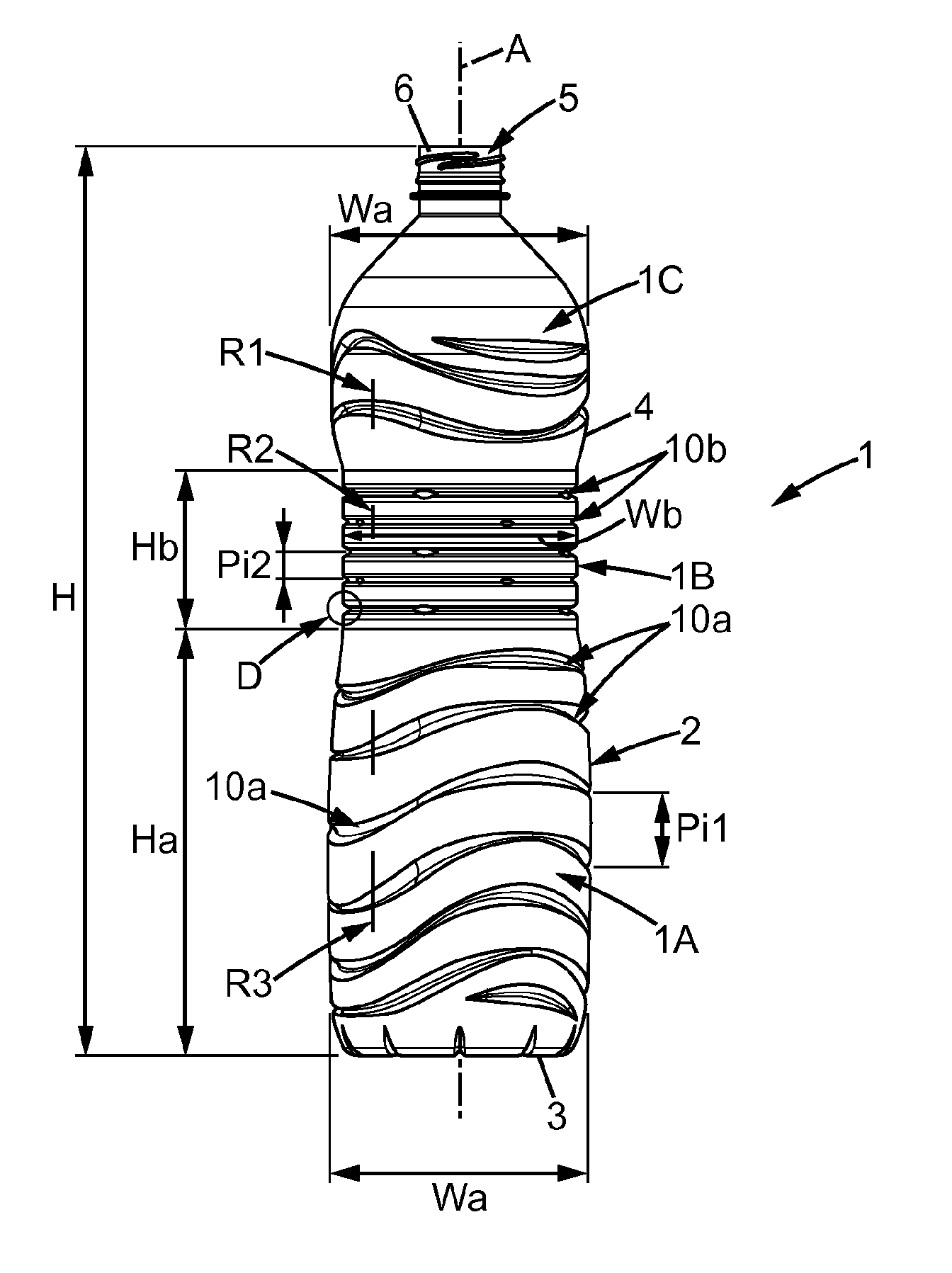

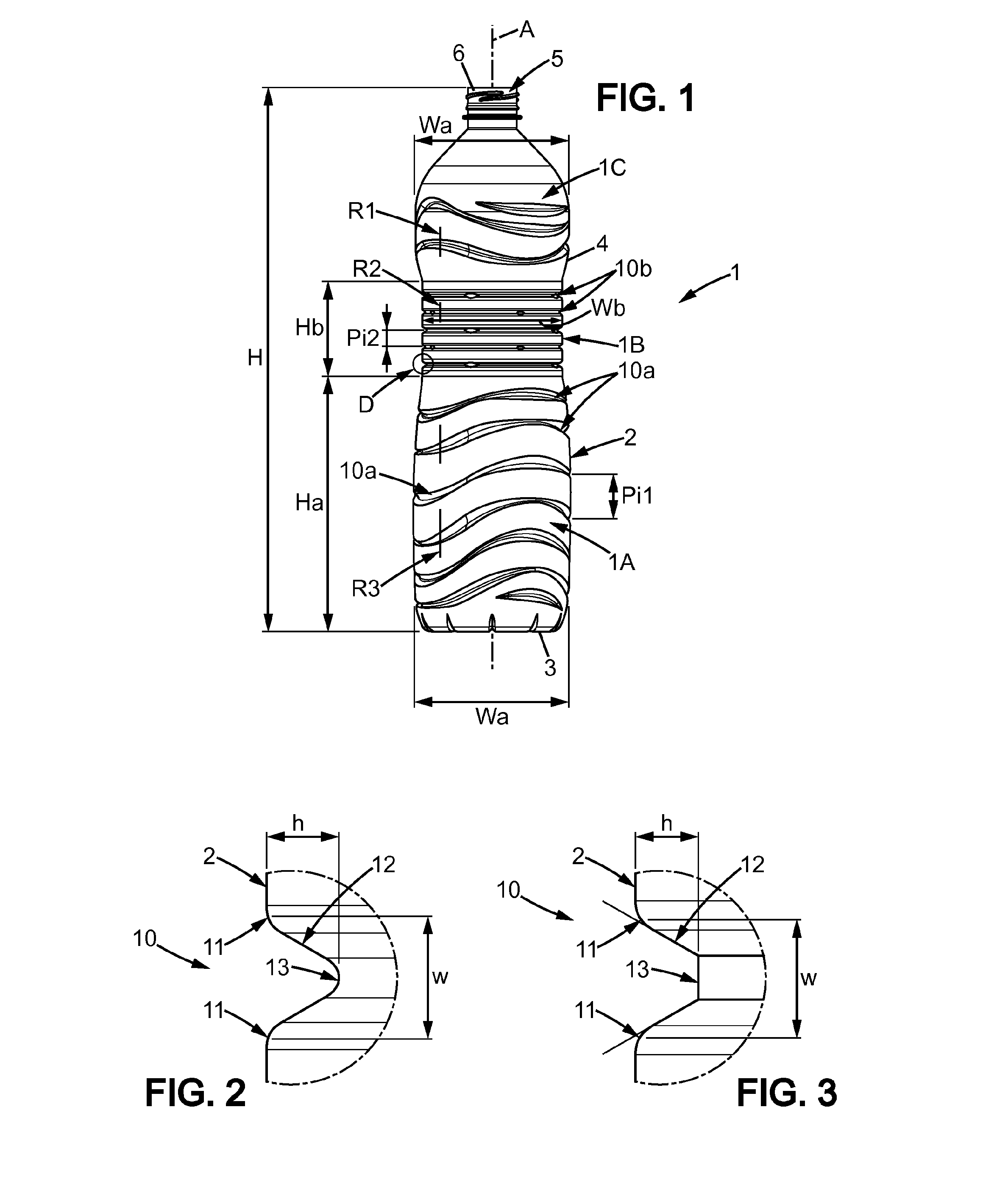

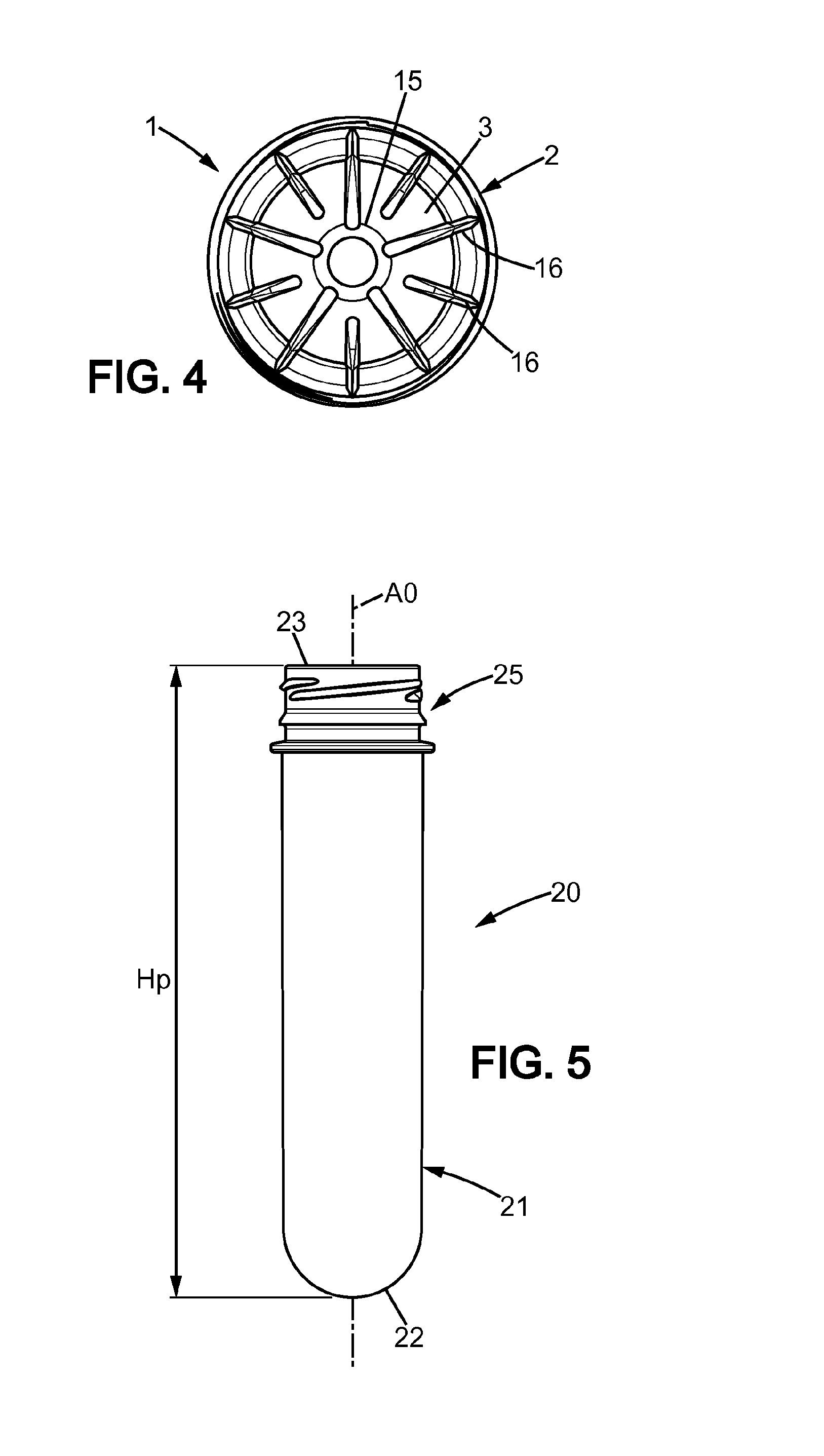

Bottle, method of making the same and use of fdca and diol monomers in such bottle

A bottle (1) comprising an envelop (2) defining a housing, said bottle being molded from at least one thermoplastic polymer of at least one FuranDiCarboxylic Acid (FDCA) monomer, preferably 2,5-FuranDiCarboxylic Acid (2,5-FDCA) monomer, and at least one diol monomer, preferably monoethylene glycol (MEG) monomer, wherein the envelop is provided with at least one imprint (10a, 10b).

Owner:DES EAUX MINERALES DEVIAN

Solutions and Catalysts Comprising Group VI Metal, Group VIII Metal, Phosphorus and An Additive

ActiveUS20120145600A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyethylene glycolMonoethylene Glycol

This invention provides a process for forming a solution composition, which process comprises forming a primary solution by bringing together, in an aqueous medium, i) at least one phosphorus compound, ii) at least one Group VI metal compound, iii) at least one Group VIII metal compound, and iv) an additive which is a) tetraethylene glycol, b) polyethylene glycol having an average molecular weight in the range of about 200 to about 400, c) a mixture of tetraethylene glycol and polyethylene glycol having an average molecular weight in the range of about 200 to about 400, or d) a mixture of (1) tetraethylene glycol and / or polyethylene glycol having an average molecular weight in the range of about 200 to about 400 and (2) one or more of monoethylene glycol, diethylene glycol, and triethylene glycol. The molar ratio of additive to the total moles of Group VI metal and Group VIII metal is above 0.30:1, and the atomic ratio of phosphorus to Group VI metal is at least about 0.33:1. Optionally, the primary solution is heated at a temperature above about 40° C. to form a heated solution. The heated solution is optionally cooled to form a cooled solution. Also provided are compositions formed by such processes, processes for forming catalyst compositions from these compositions, and catalyst compositions formed by these processes.

Owner:ALBEMARLE EURO

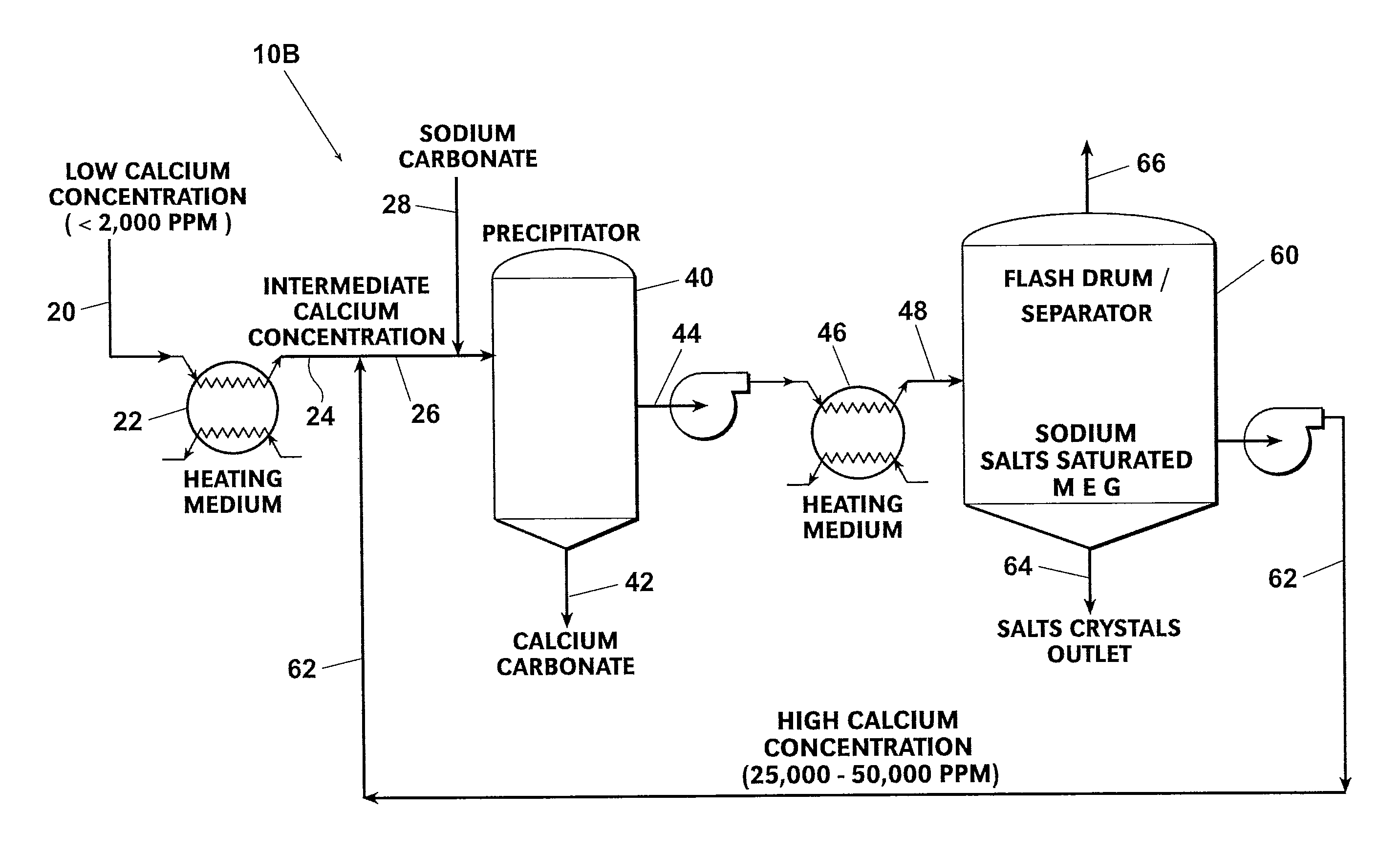

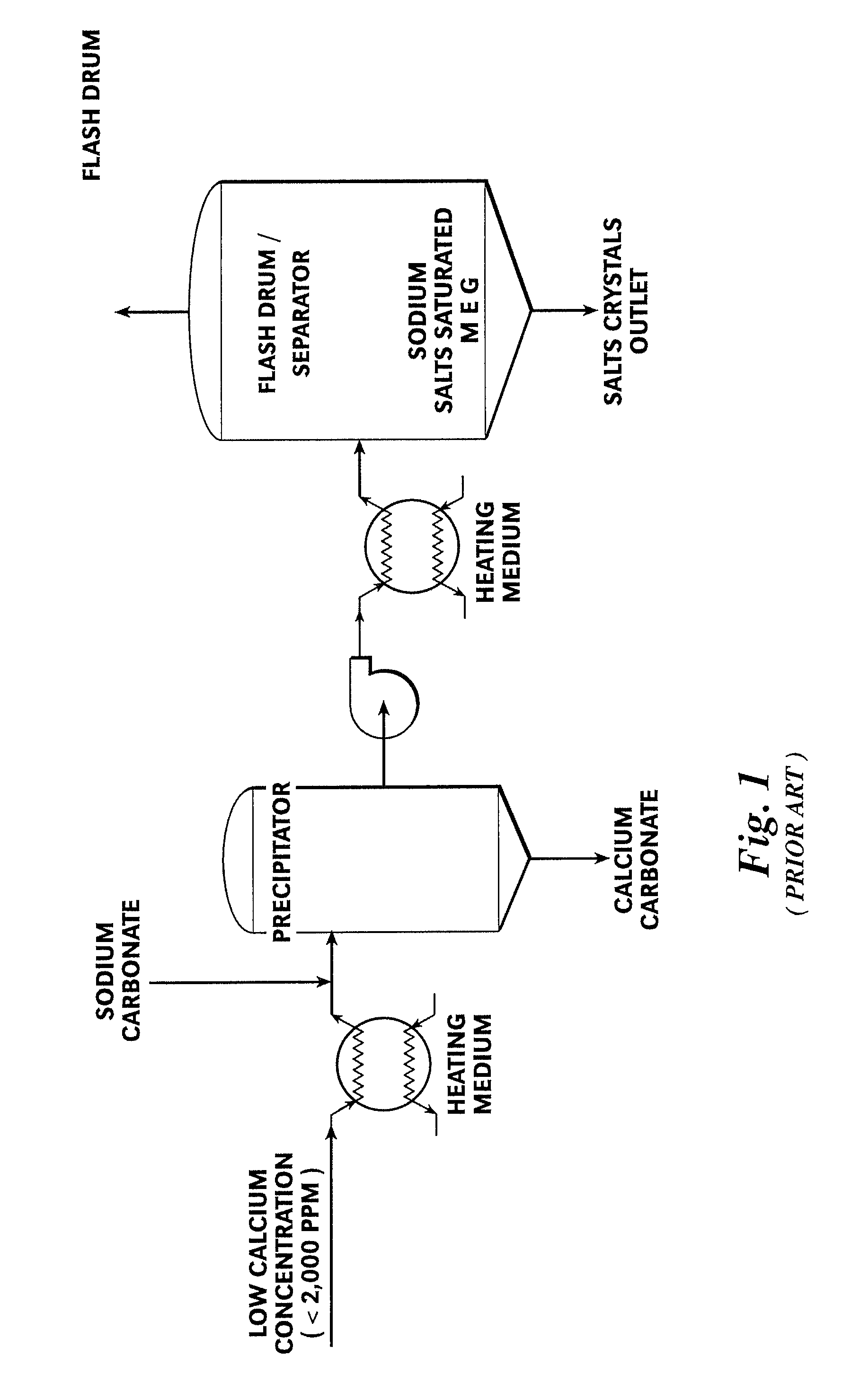

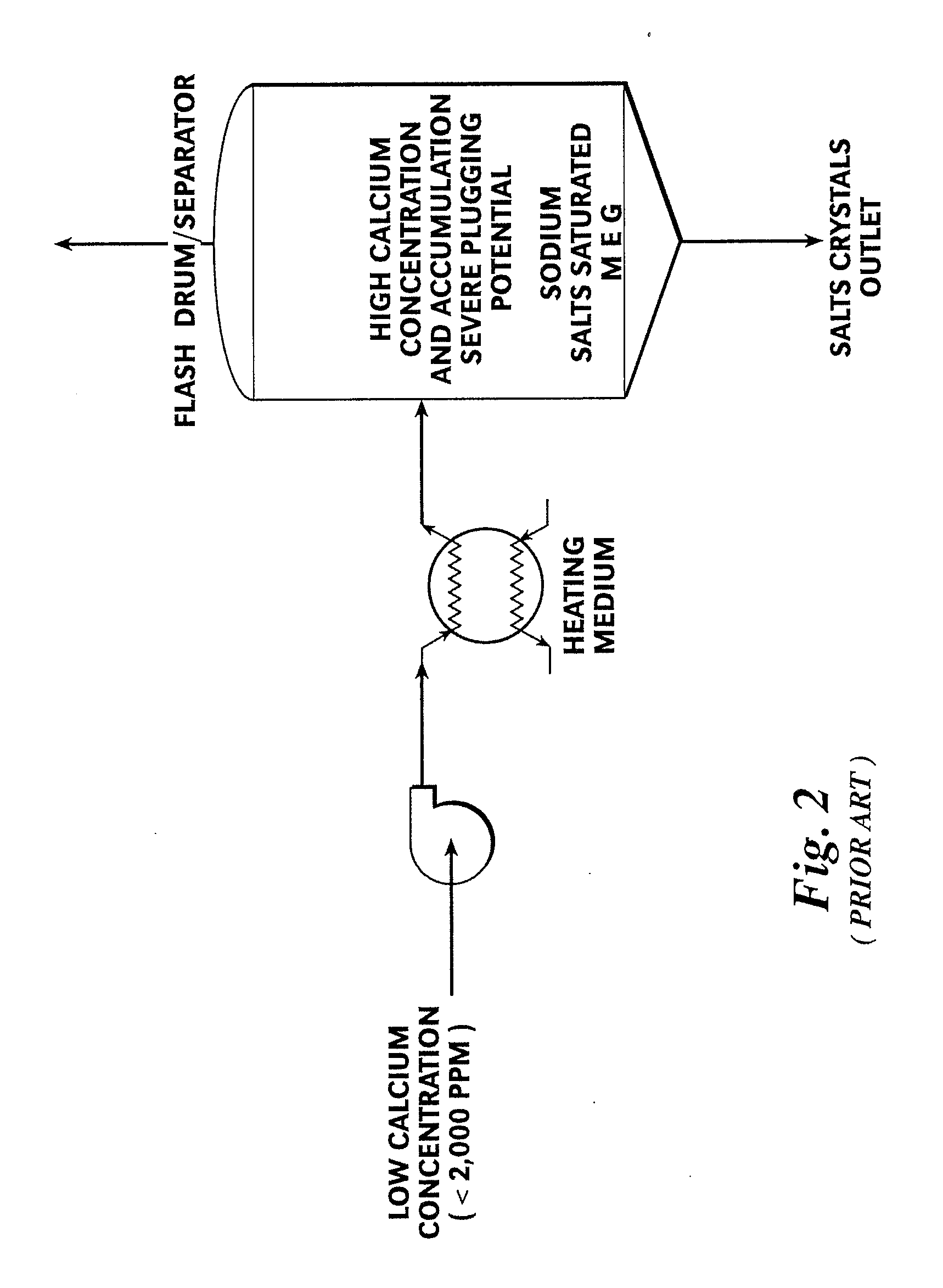

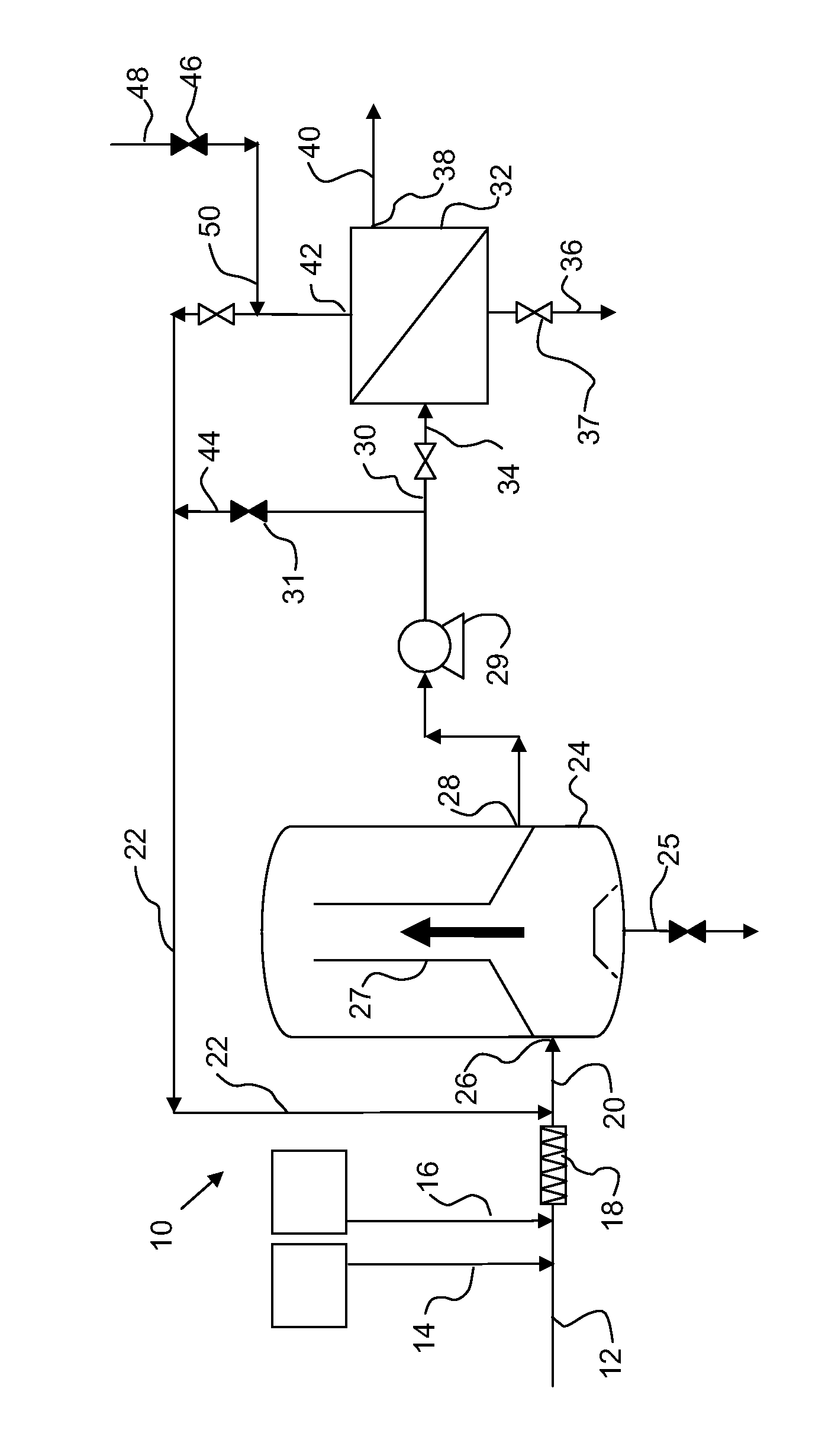

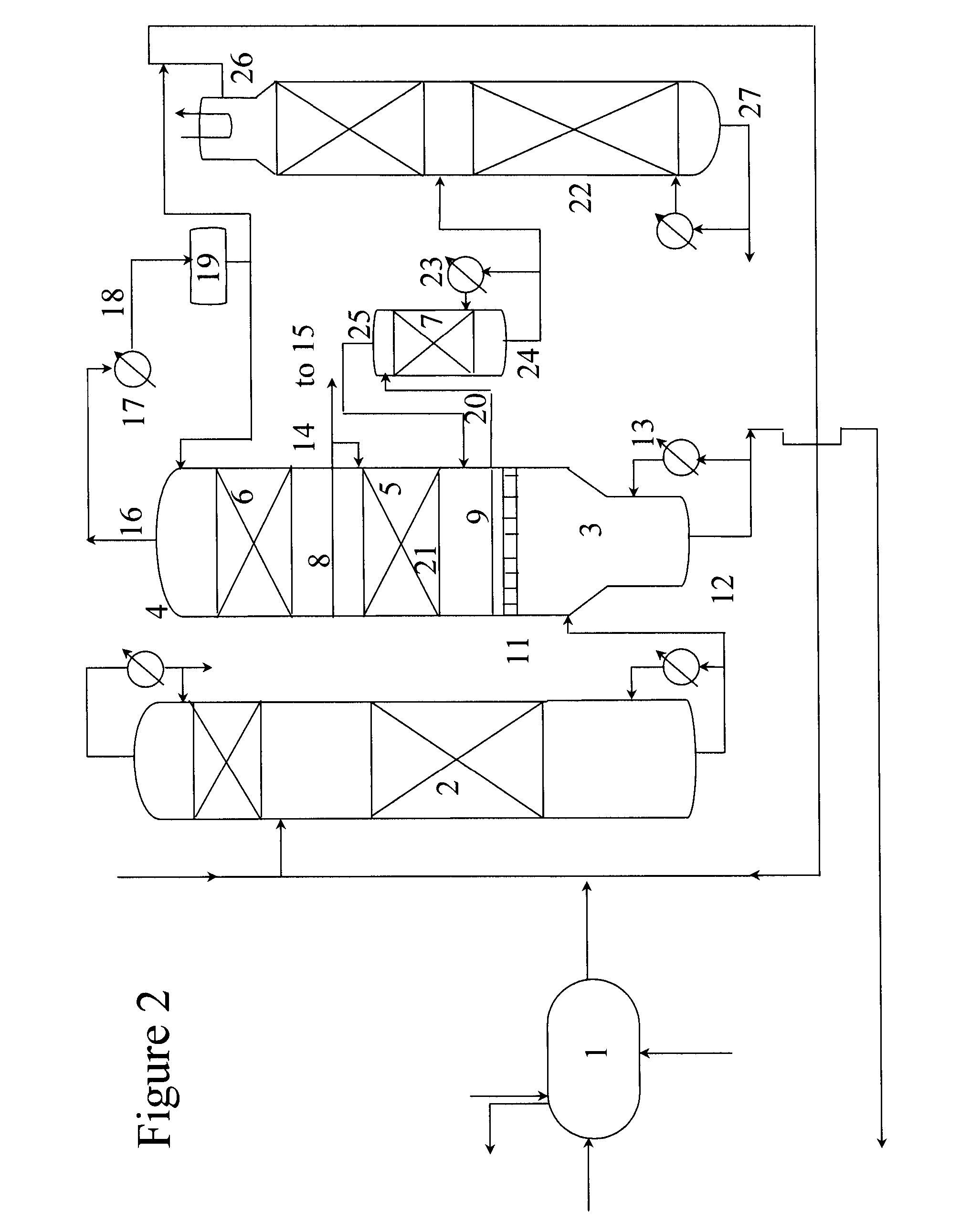

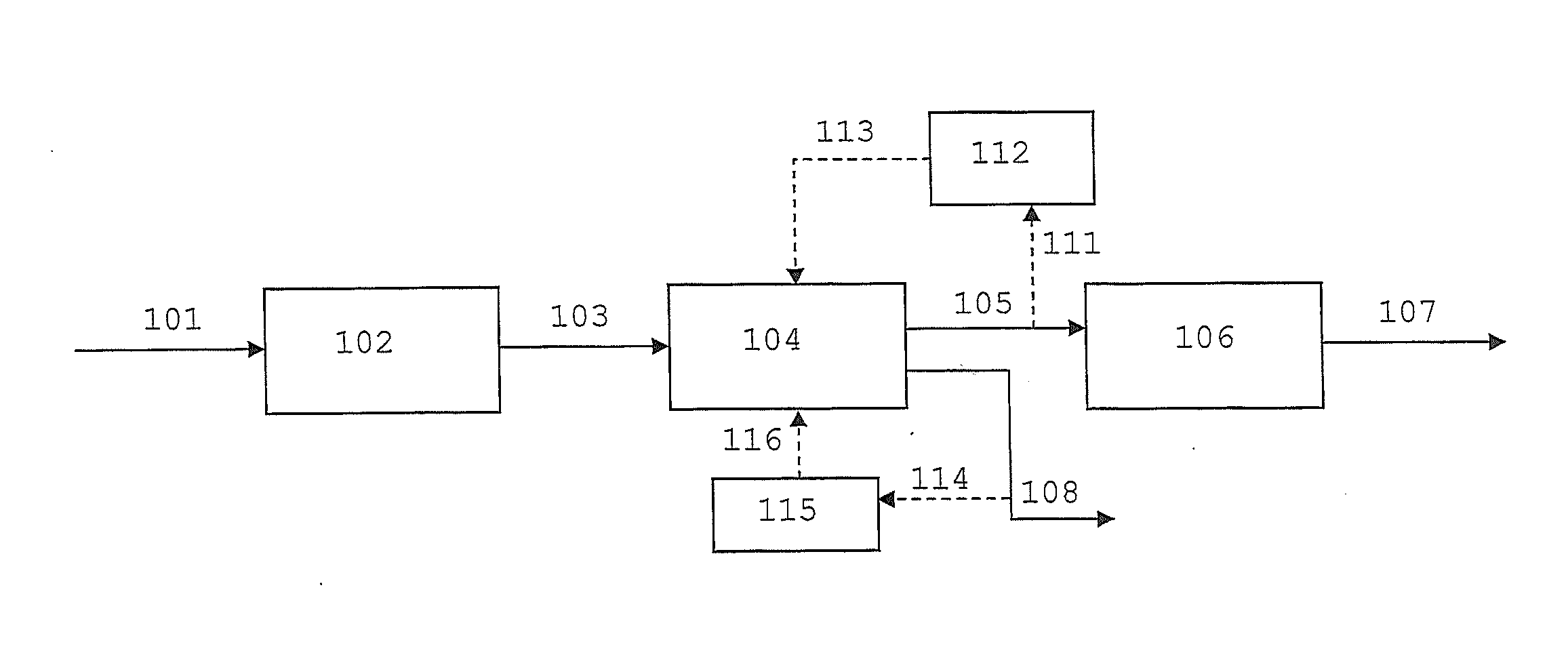

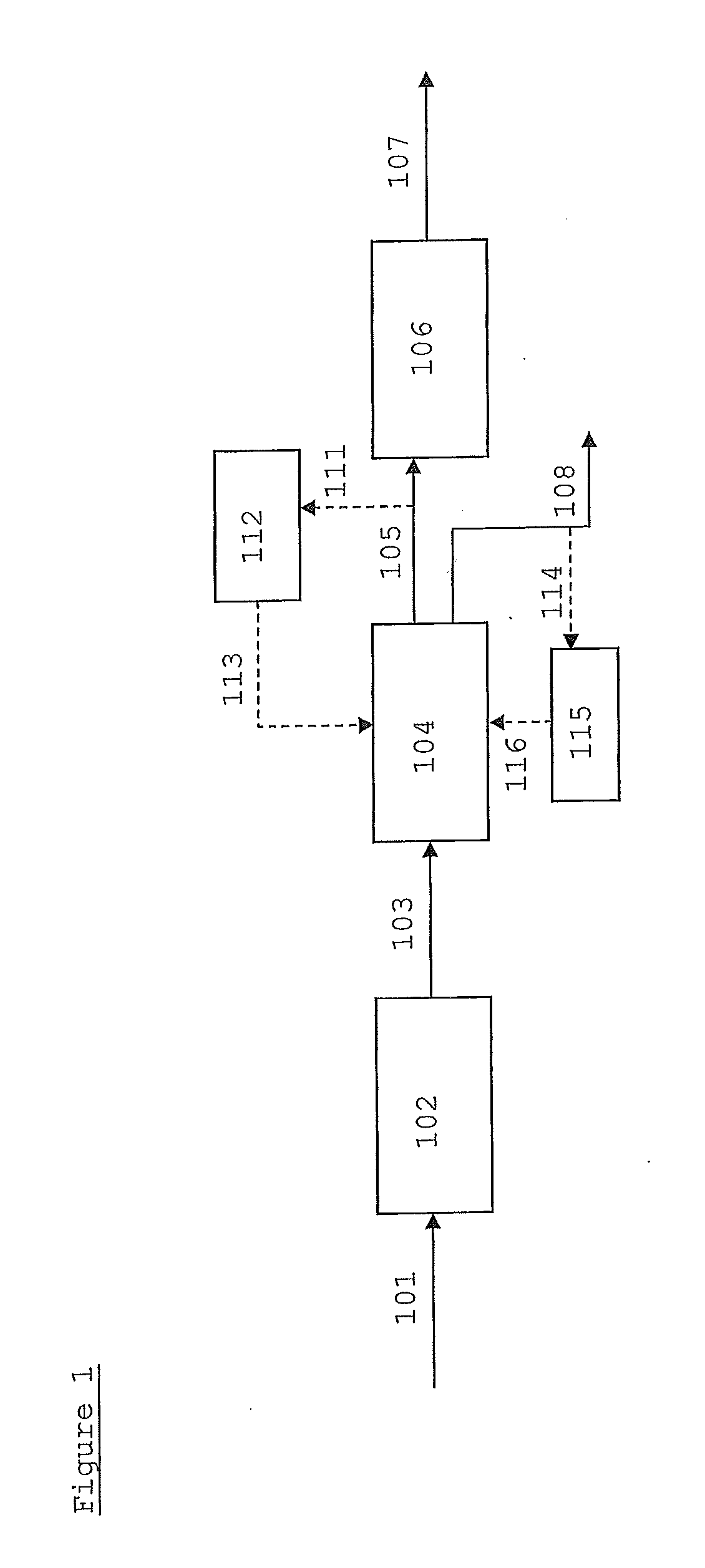

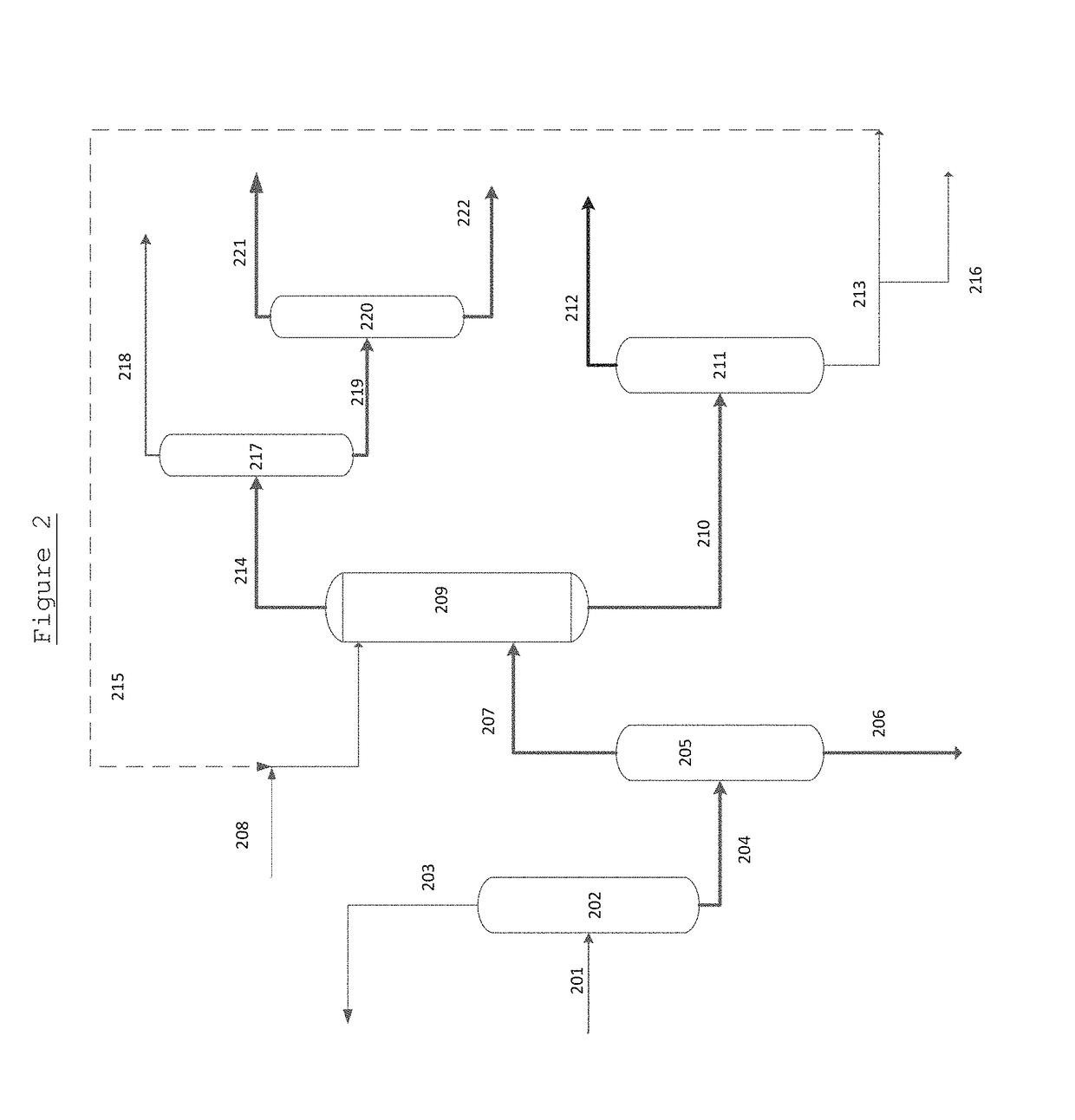

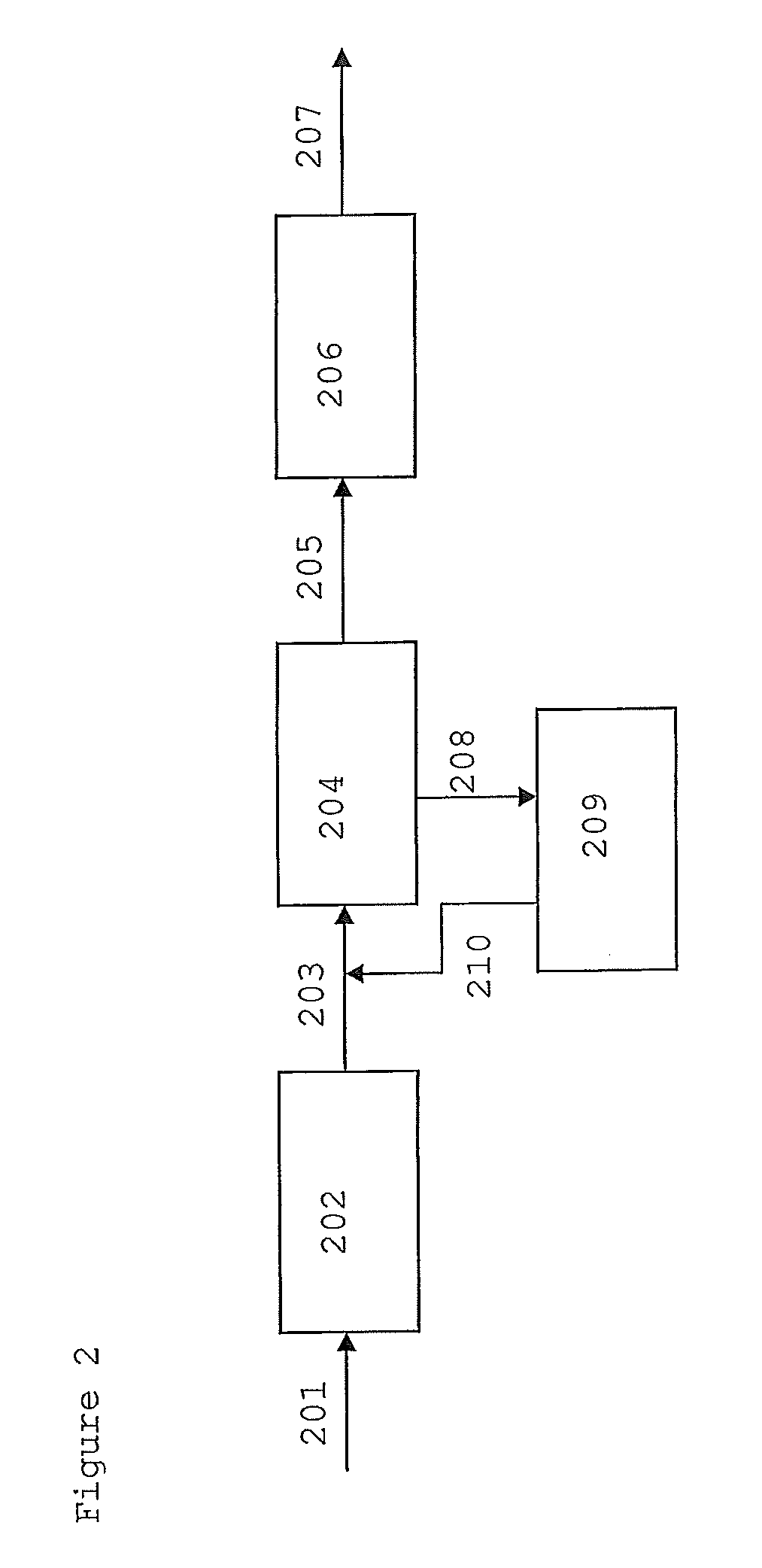

Process Scheme to improve Divalent Metal Salts Removal from Mono Ethylene Glycol (MEG)

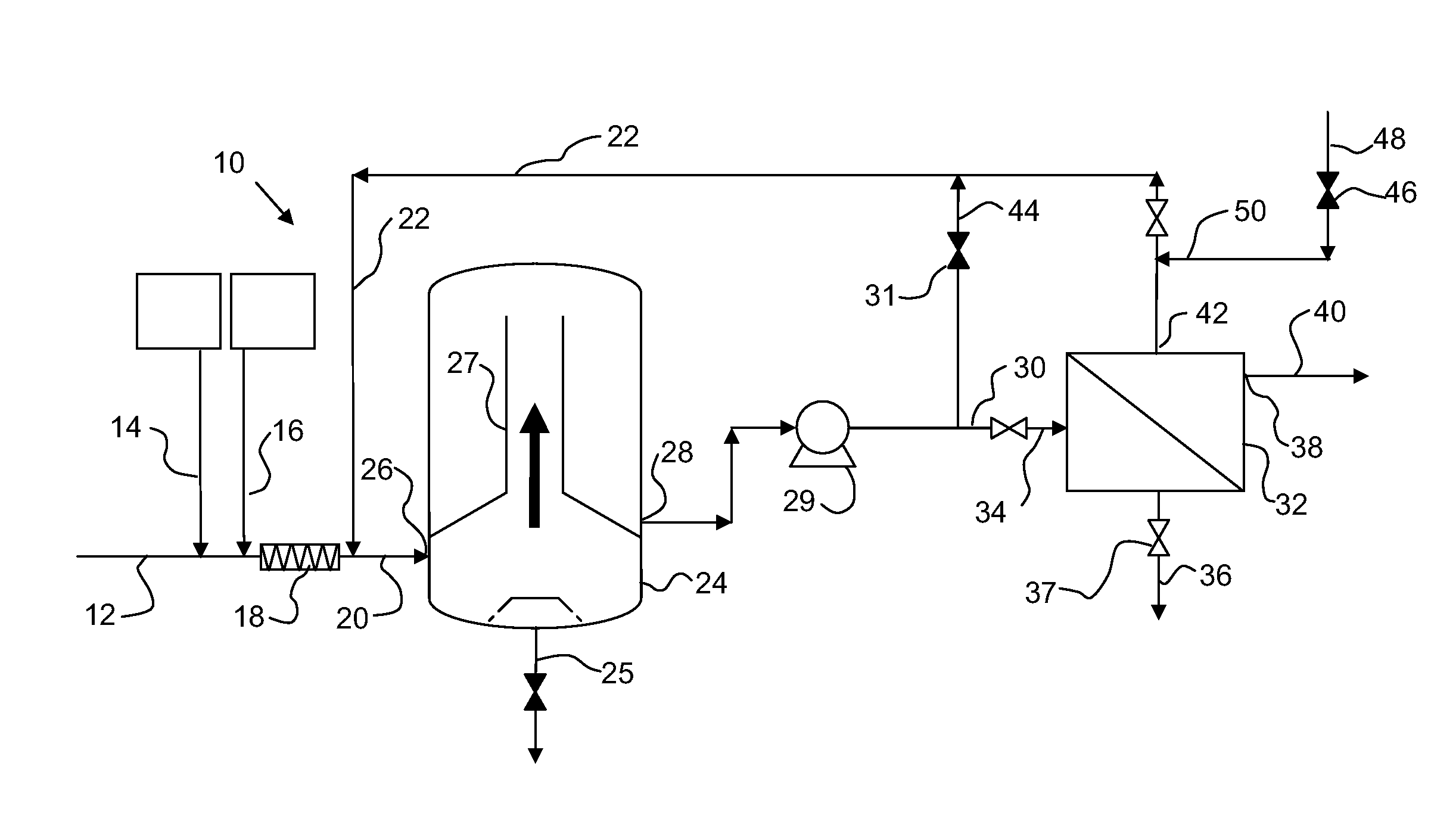

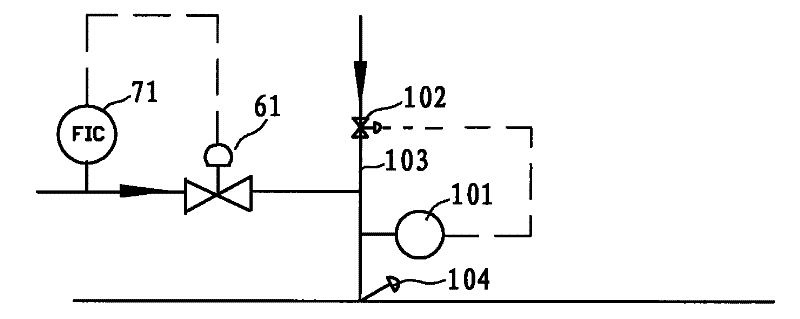

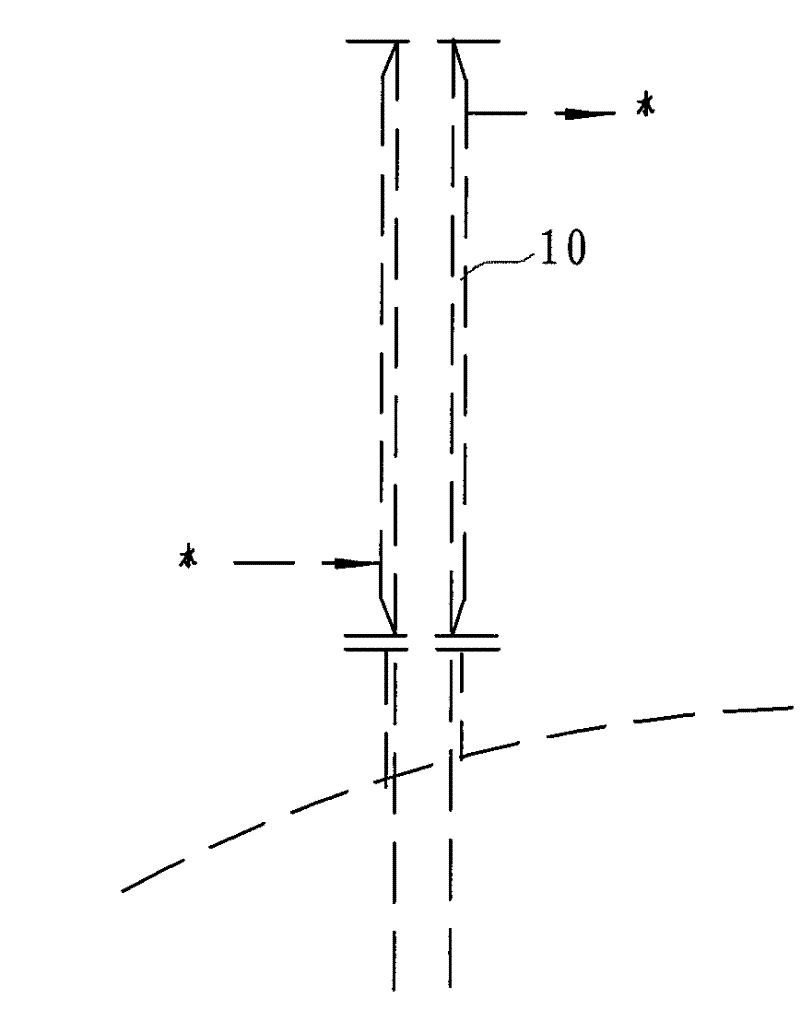

ActiveUS20130118989A1Less floor-space/volumeSpeed reactionGas treatmentMultiple-effect/fractional condensationStream flowDivalent metal

A MEG reclamation process includes the step of increasing above 2,000 ppm the divalent metal salts concentration of a rich (wet) MEG feed stream flowing into a precipitator. The increasing step includes routing a salts-saturated MEG slipstream from the flash separator it to the precipitator. The slipstream may be mixed with a fresh water feed stream, a portion of the rich MEG feed stream, or some combination of the two. The rich MEG feed stream also may be split into two streams, with a portion of the stream being heated and routed to the flash separator and the other portion being combined as above with the removed slipstream. The process can be performed on the slipstream after dilution and prior to entering the precipitator or after being loaded into the precipitator. Removal of the insoluble salts may be done in either a batch or continuous mode.

Owner:CAMERSON INT CORP

Positive photosensitive resist release agent compositions

InactiveCN101017333AImprove solubilityExcellent peelabilityPhotosensitive material processingSolubilityResist

This invention discloses one positive light anti-erosion agent peeling agent combination, which comprises the following parts: a, occupying organic amine for weight of 10 to 50; b, monoethylene glycol monoalkyl ether for weigth of 0 to 70 percent; c, non photon electrode solvent for weight of 20 to 90; d, based on the said three component total weight for 0.01 to 10 non-ion surface active agent. This invention relates to positive light anti-erosion peel agent combination to etch process with excellent solve property and peeling property of pattern film for light resistance.

Owner:DONGJIN SEMICHEM CO LTD

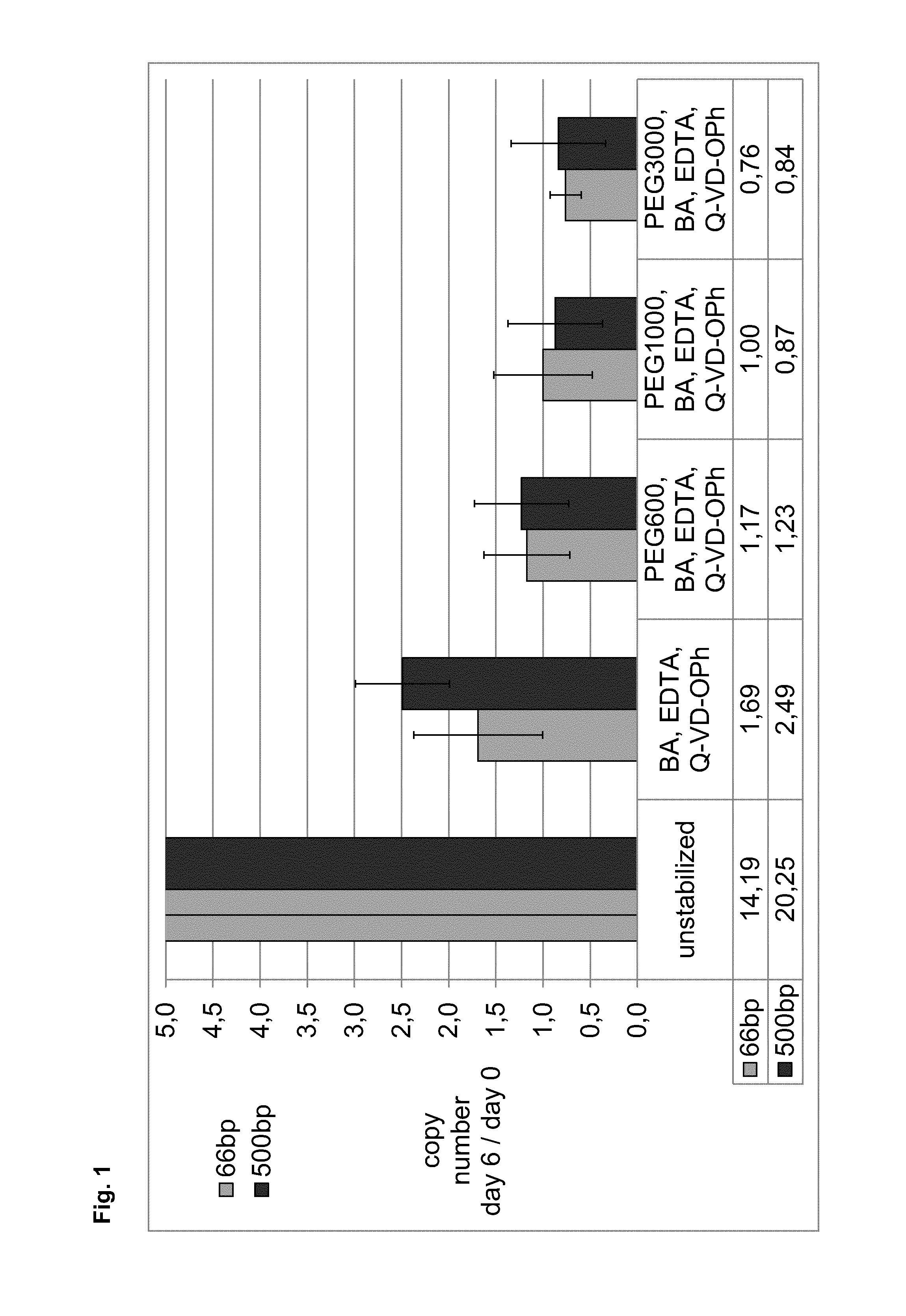

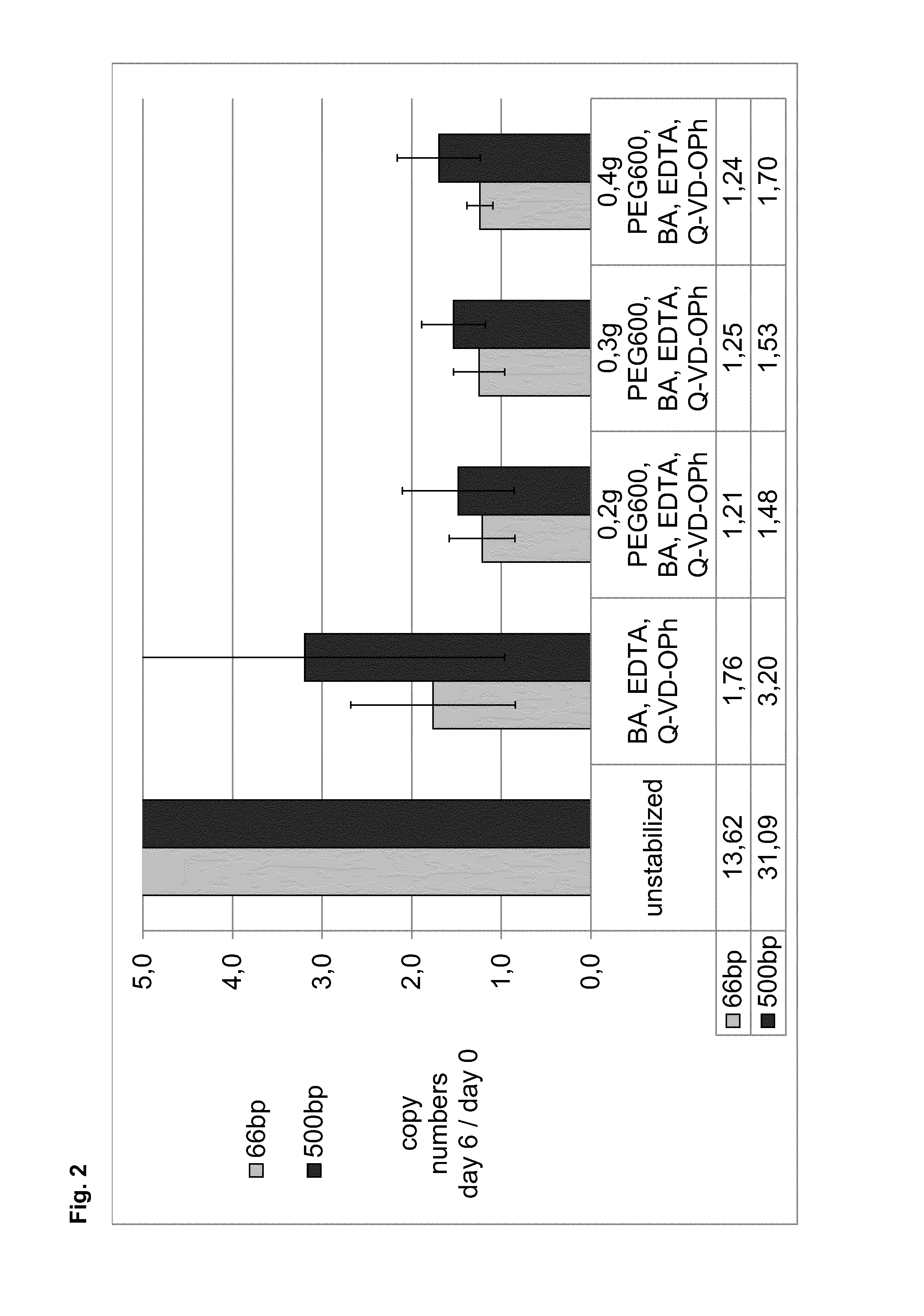

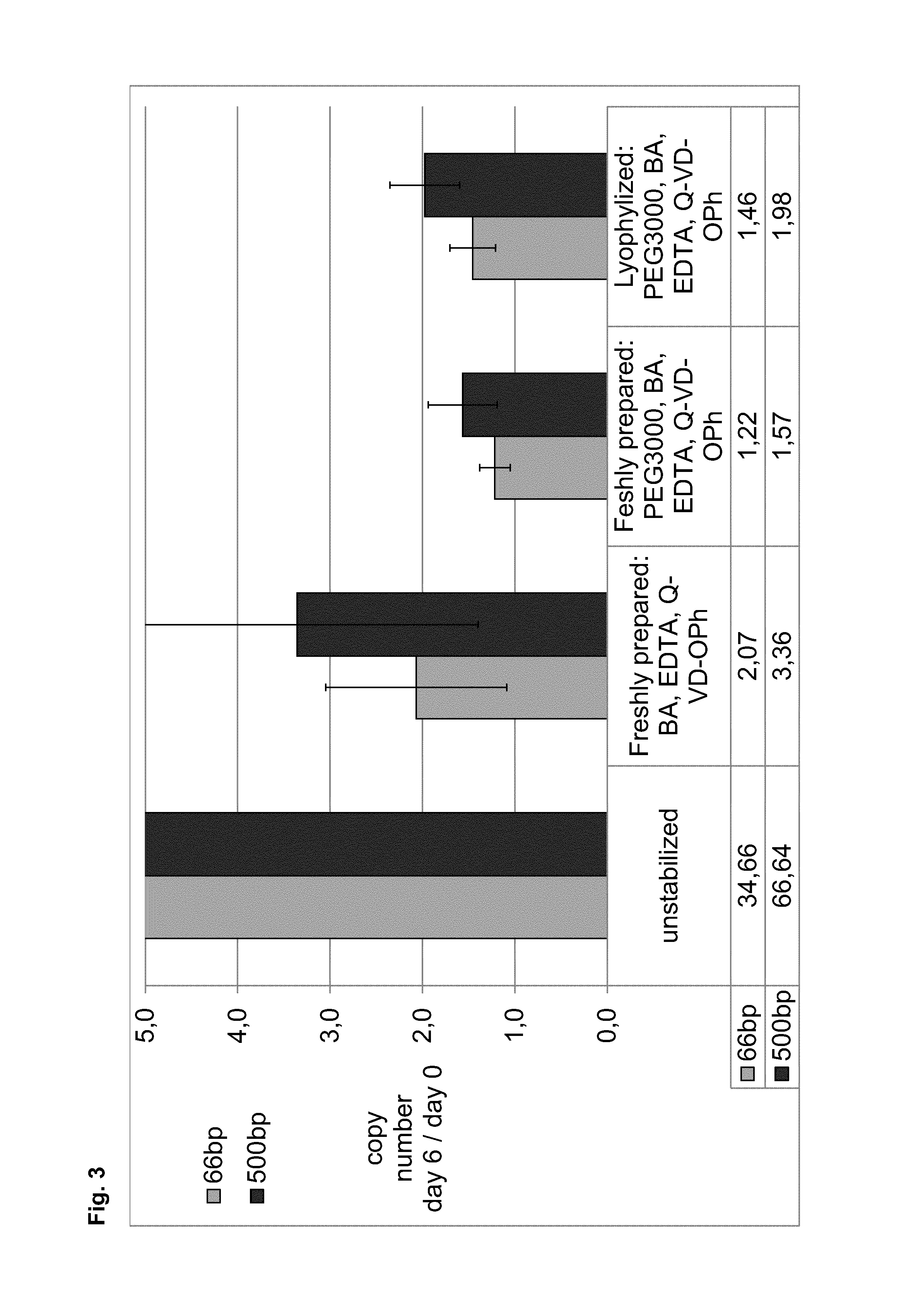

Stabilization and isolation of extracellular nucleic acids

PendingUS20160374330A1Improve stabilityEfficientlyMicrobiological testing/measurementDead animal preservationGlycol synthesisMonoethylene Glycol

The present invention provides methods, compositions and devices for stabilizing the extracellular nucleic acid population in a cell-containing biological sample using a poly(oxyethylene) polymer or mono-ethylene glycol as stabilizing agent.

Owner:QIAGEN GMBH

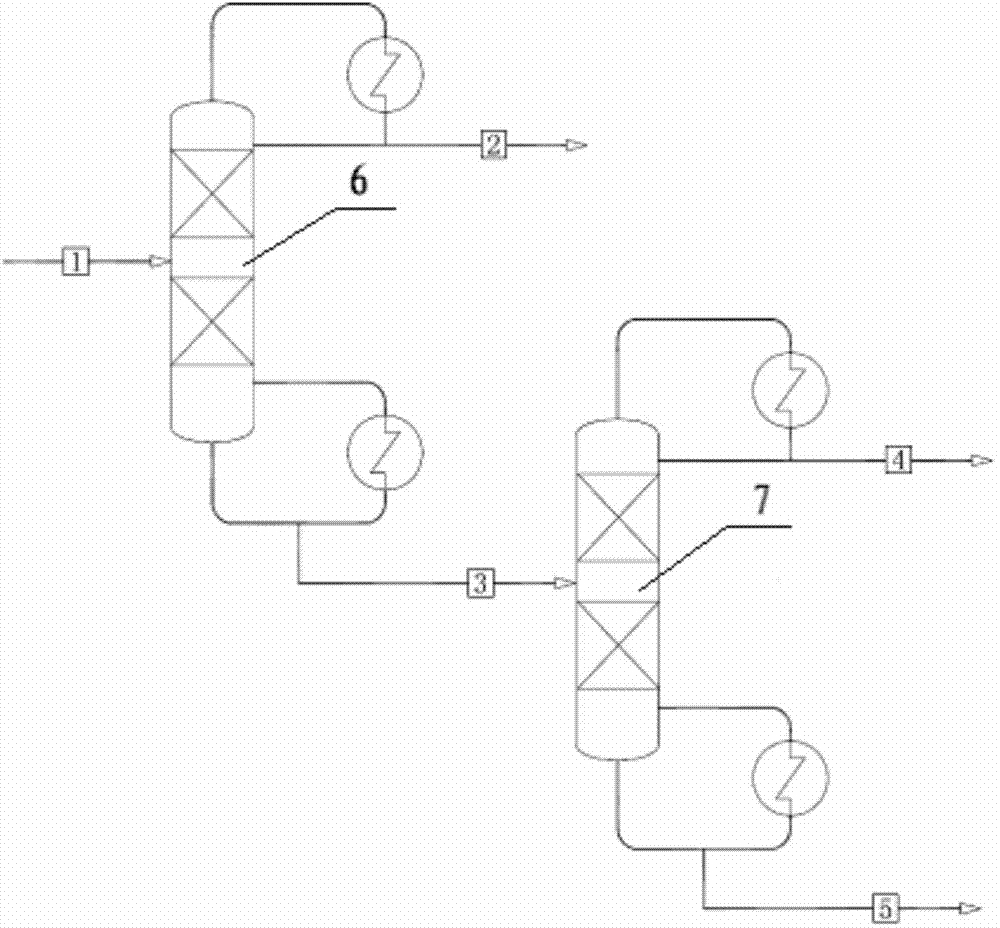

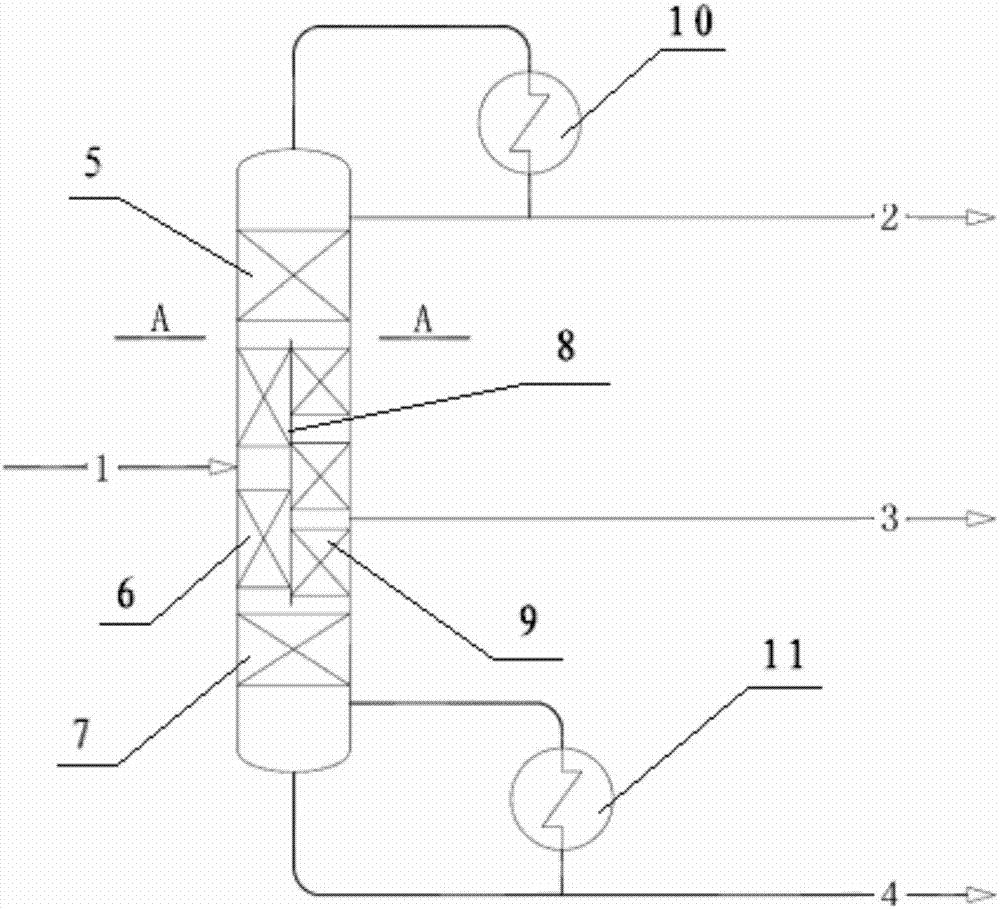

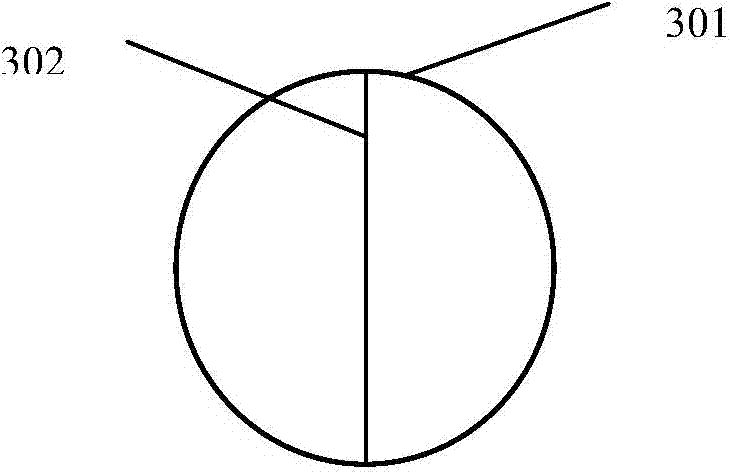

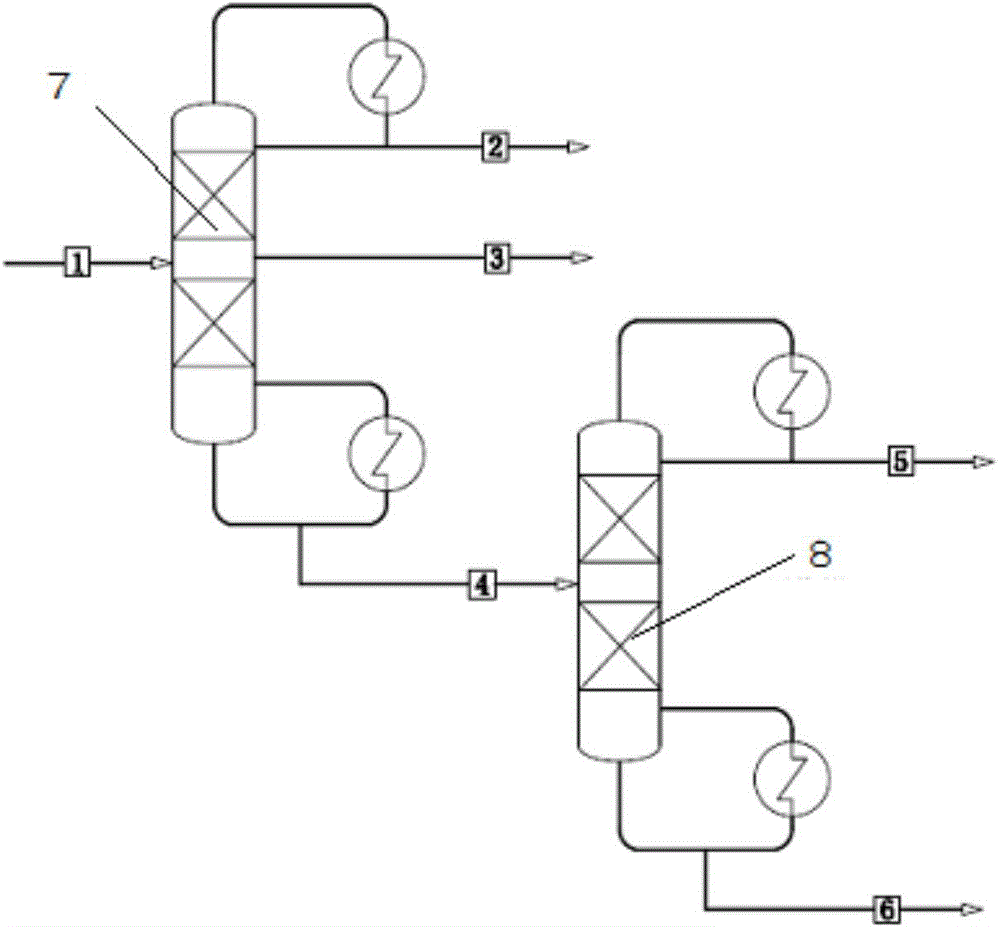

Method for separating ethylene glycol mixture series

ActiveCN103694088ALess investmentTotal heat transfer load reductionEther separation/purificationOrganic compound preparationHigh energyDiethylene glycol

The invention relates to a method for separating ethylene glycol mixture series, mainly solving the problems of complex separation flow of existing ethylene glycol mixture series, low separation purity, high investment and high energy consumption. The above technical problems are well solved by adopting the method characterized by using a mixture containing mono ethylene glycol (MEG), diethylene glycol (DEG) and poly(ethylene glycol) (TEG) as the raw material, enabling the raw material to firstly enter one side of a dividing wall section of a dividing wall rectifying column, obtaining a material flow containing DEG on the other side of the dividing wall section through separation, obtaining a material flow containing TEG at the bottom of a stripping section below the dividing wall section of the dividing wall rectifying column and obtaining a material flow containing MEG at the top of a rectifying section above the dividing wall section of the dividing wall rectifying column. The method can be used for separating the ethylene glycol mixture series.

Owner:SINOPEC SHANGHAI ENG +1

Cement grinding aid

The invention is a cement grinding aid, which is made by adding propylene glycol, monoethylene glycol, trolamine, diethylene glycol, urea, soda to the filtered sulphite liquor. The cement grinding aid not only can help improve output of cement, but also effectively limit temperature of a ball grinder in the normal range during cement production; the cement grinding aid further helps maintain normal operation of the ball grinder, and prevent a huge amount of dust and environmental pollution.

Owner:周金平

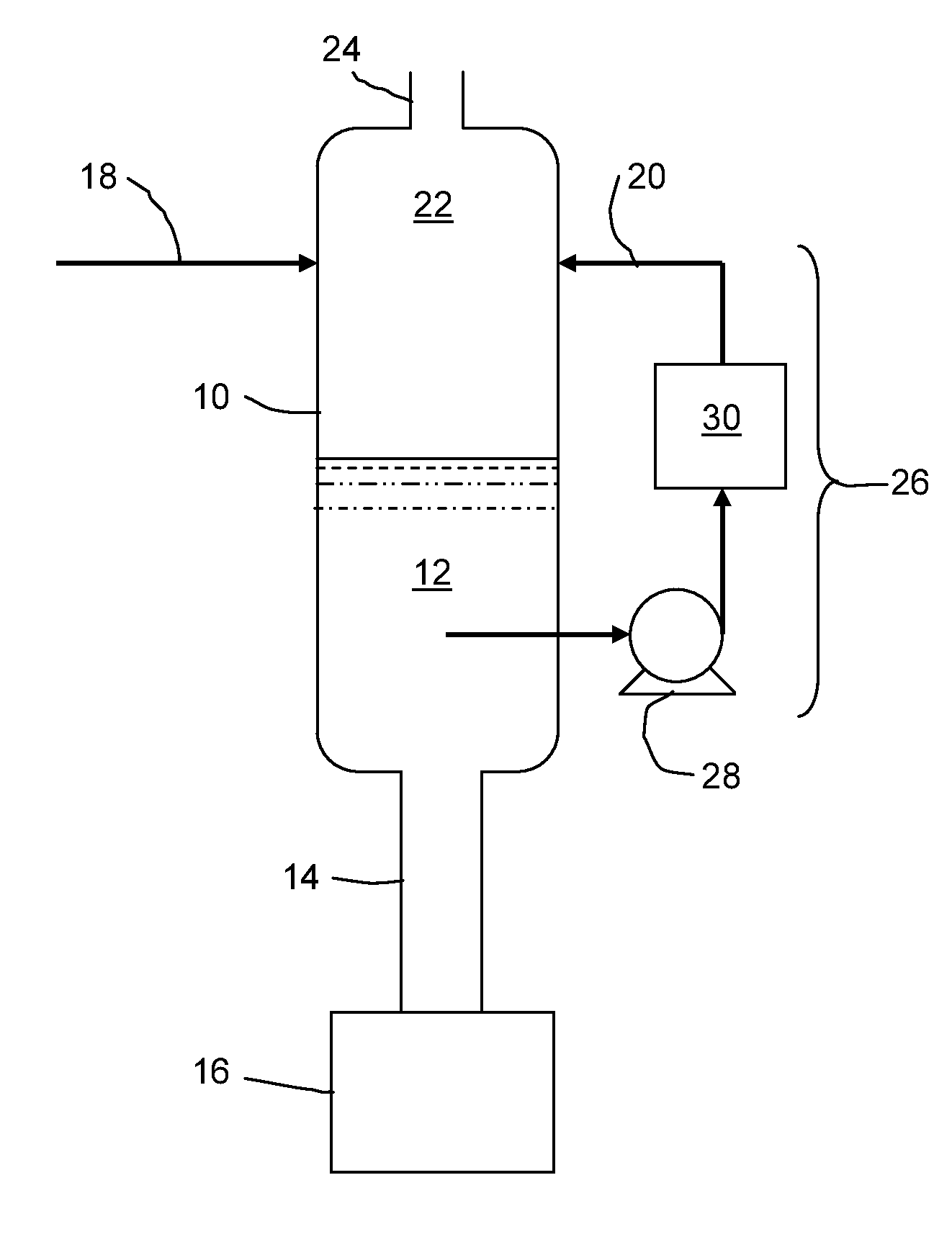

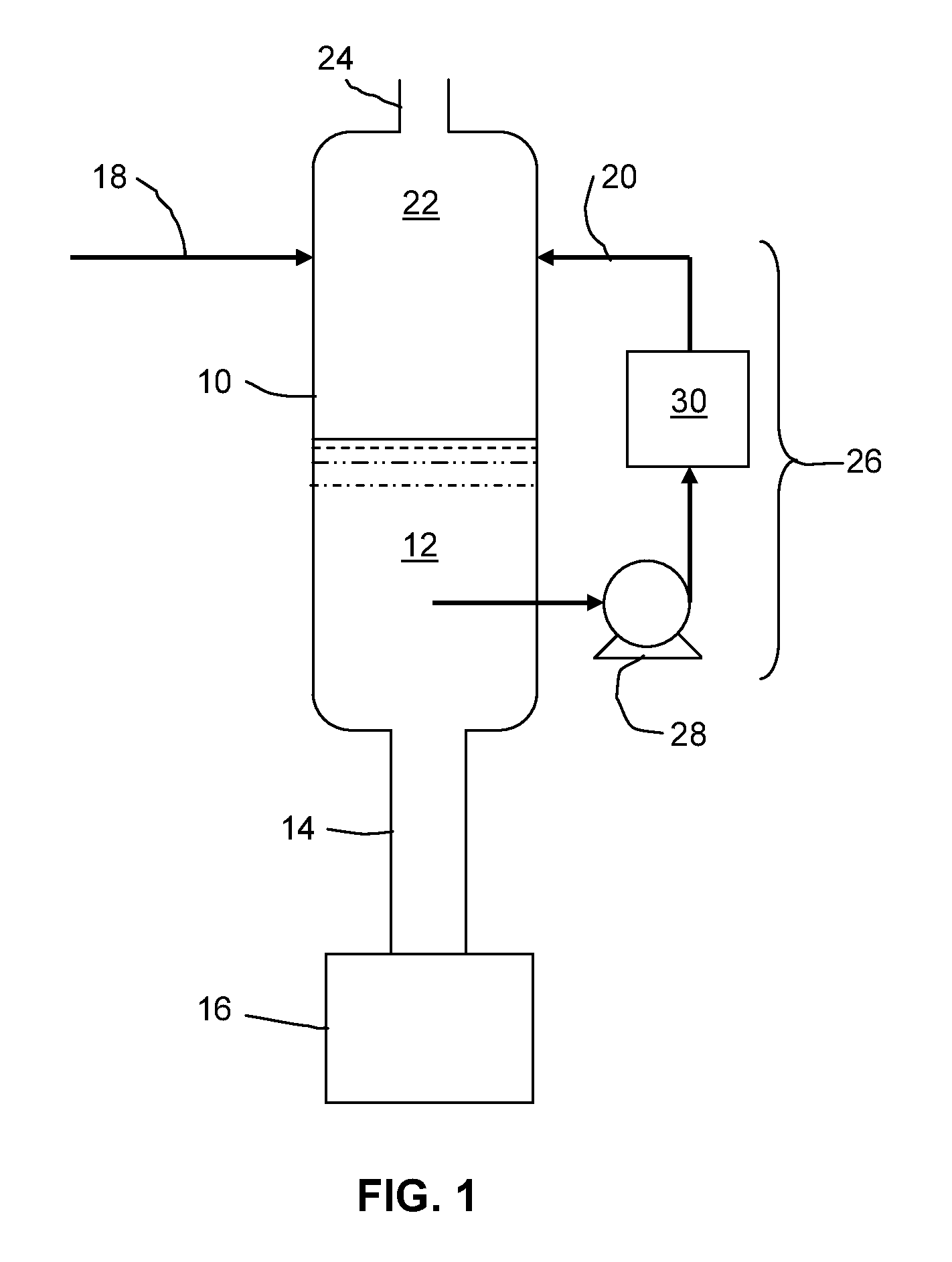

Removing solids in monoethylene glycol reclamation

The seeding of calcium carbonate into a calcium chloride-contaminated monoethylene glycol (MEG) stream accelerates the growth of calcium carbonate particles to a size that enhances their removal from the stream by filtration. A seeding vessel allows the calcium carbonate particles a time period to grow. Sodium carbonate may be added to the contaminated stream to facilitate calcium carbonate particle growth. A recycle seeding conduit may recycle seeds from a filtration unit to the seeding vessel. A base such as sodium hydroxide may be added to accelerate the precipitation process.

Owner:CAMERSON INT CORP

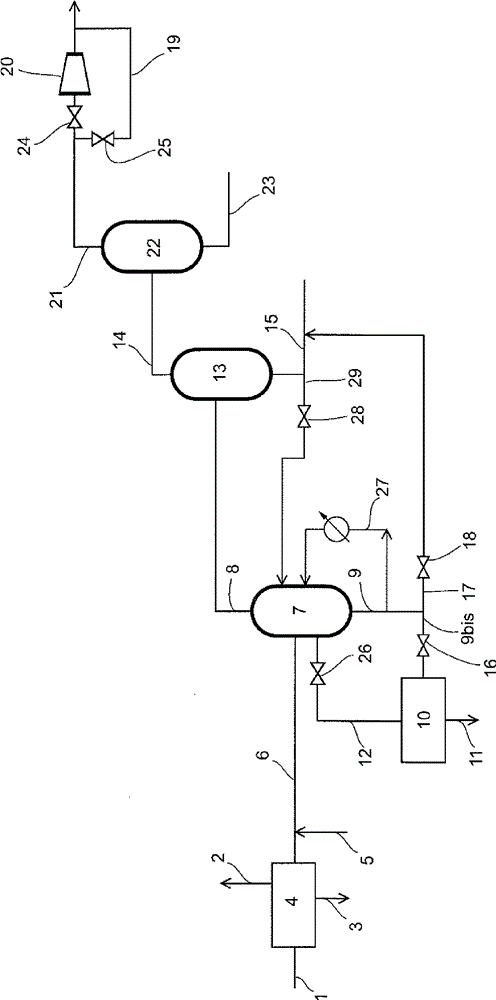

Flexible method for the treatment of a solvent, such as monoethylene glycol, used in the extraction of natural gas

InactiveCN104645651AOrganic compound preparationDispersed particle separationBoiling pointDiethylene glycol

The invention concerns a flexible process for purifying a solvent which inhibits the formation of hydrates during gas processing, in particular monoethylene glycol (MEG), said solvent having a boiling point which is higher than that of water and, at least at one point in time, being mixed with water and salts, the process operating in a different manner with the same facility as a function of the quantity of salts in the MEG to be treated. The process operates in accordance with a phase known as reclaiming (separation of salts under vacuum followed by vacuum distillation) when the salts content exceeds the precipitation threshold and if not, the process operates in a regeneration phase (absence of separation of salts and no operation under vacuum). Advantageously, the change is made under the control of means for testing the salts.

Owner:PROSERNAT SA

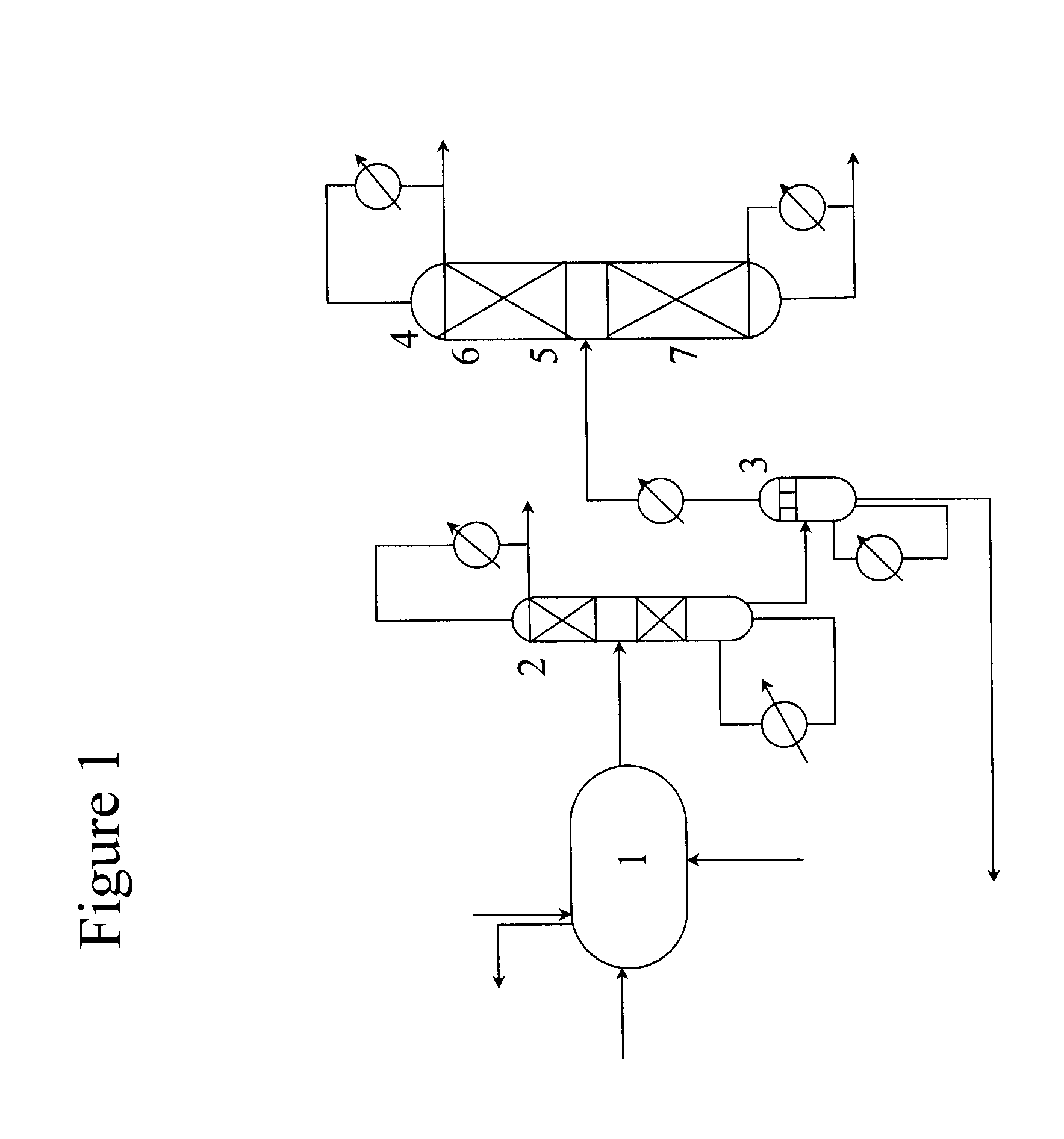

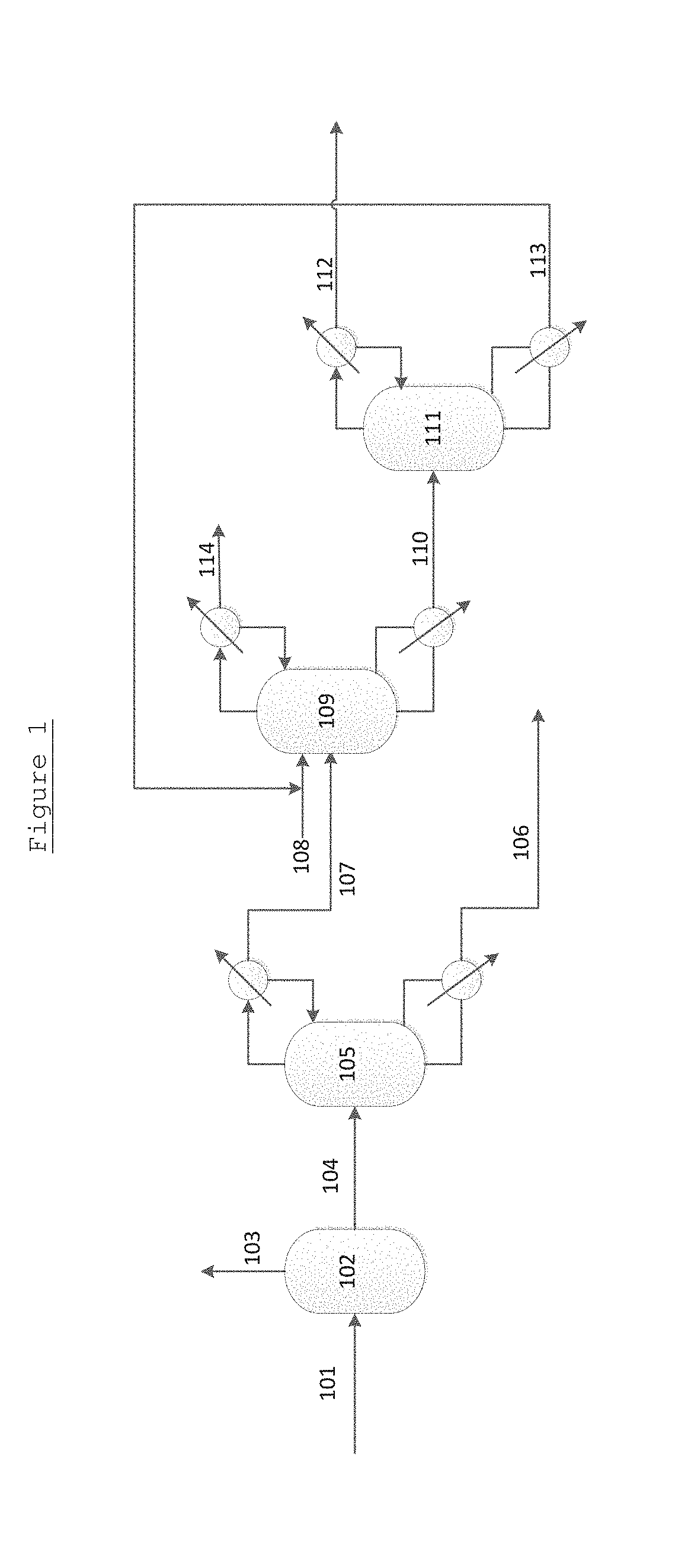

Glycol separation and purification

ActiveUS20080081933A1Net energy savingAvoid the needGaseous chemical processesOrganic compound preparationGas phaseMonoethylene Glycol

A process and an apparatus for the separation of a homogeneous catalyst solution from crude monoethylene glycol (MEG) and for purifying MEG is disclosed. The process comprises separating catalyst solution by evaporating crude MEG and feeding crude MEG to a rectification section, a stripping section, and thence to a pasteurisation section, each section operated at subatmospheric pressure of 0.5×105 Nm−2 or less, the rectification and pasteurisation sections being at pressure less than that of the catalyst separation section, wherein the process provides a pressure differential across the catalyst separation and rectification sections and wherein vapour phase crude MEG from the catalyst separation section is fed as substantially vapour phase feed to the rectification section. The apparatus comprises a catalyst separation section, an MEG rectification section, a stripping section and a pasteurisation section, wherein the MEG rectification and pasteurisation sections are located within a MEG purification column, and the catalyst separation section is either located in the MEG purification column or in a separate upstream vessel, and wherein the separation section provides a crude MEG feed inlet to the MEG rectification section and an outlet for separated catalyst, wherein the crude MEG feed inlet to the MEG rectification section is a vapour feed inlet.

Owner:SHELL OIL CO

Liquid Crystal Aligning Agent and Liquid Crystal Alignment Layer Formed Using the Same

InactiveUS20080213510A1Good spreadabilityGood adhesivenessLiquid crystal compositionsThin material handlingCrystallographyLiquid-crystal display

A liquid crystal aligning agent suitable for use in the production of a liquid crystal display device is provided. The liquid crystal aligning agent comprises at least one polymer selected from a polyamic acid and a soluble polyimide, an aprotic polar solvent and monoethylene glycol dimethyl ether or dipropylene glycol dimethyl ether. The liquid crystal aligning agent has satisfactory printability. Further provided is a liquid crystal alignment layer formed using the aligning agent. The liquid crystal alignment layer is highly uniform.

Owner:CHEIL IND INC

Method for producing ethylene glycol by catalysis rectification

InactiveCN101121640AAddress reactivityResolve separabilityMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionState of artHydration reaction

The present invention relates to a method for producing ethylene alcohol by a catalyzing and distilling method, which is to solve the problems in the existing technology that: the existing method needs multi towers or multi reaction devices and steps to realize the reaction and separation; besides the benefit ratio for non-phase catalyzing single ethylene alcohol is much lower. The present invention adopts water and ethylene oxide as the material, and takes the reaction and separation operations in a catalyzing and distilling tower; so the two processes including the hydration reaction for ethylene oxide and the separation reaction for the ethylene alcohol. The catalyzer used in the present invention adopts an acidic or alkaline organic material or inorganic material or the composite material; the method can solve the problem greatly, which can be uses in the industrial production of ethylene alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the preparation of monoethylene glycol

The invention provides a process for the preparation of monoethylene glycol from sucrose comprising the steps of: i) hydrolysing sucrose to form a reaction product stream comprising glucose and fructose; ii) separating the reaction product stream comprising glucose and fructose into a fructose or fructose derivative rich stream and a glucose rich stream; and iii) contacting the glucose rich stream with hydrogen in a reactor in the presence of a solvent and a catalyst system with catalytic hydrogenation abilities to produce a product stream comprising monoethylene glycol.

Owner:SHELL USA INC

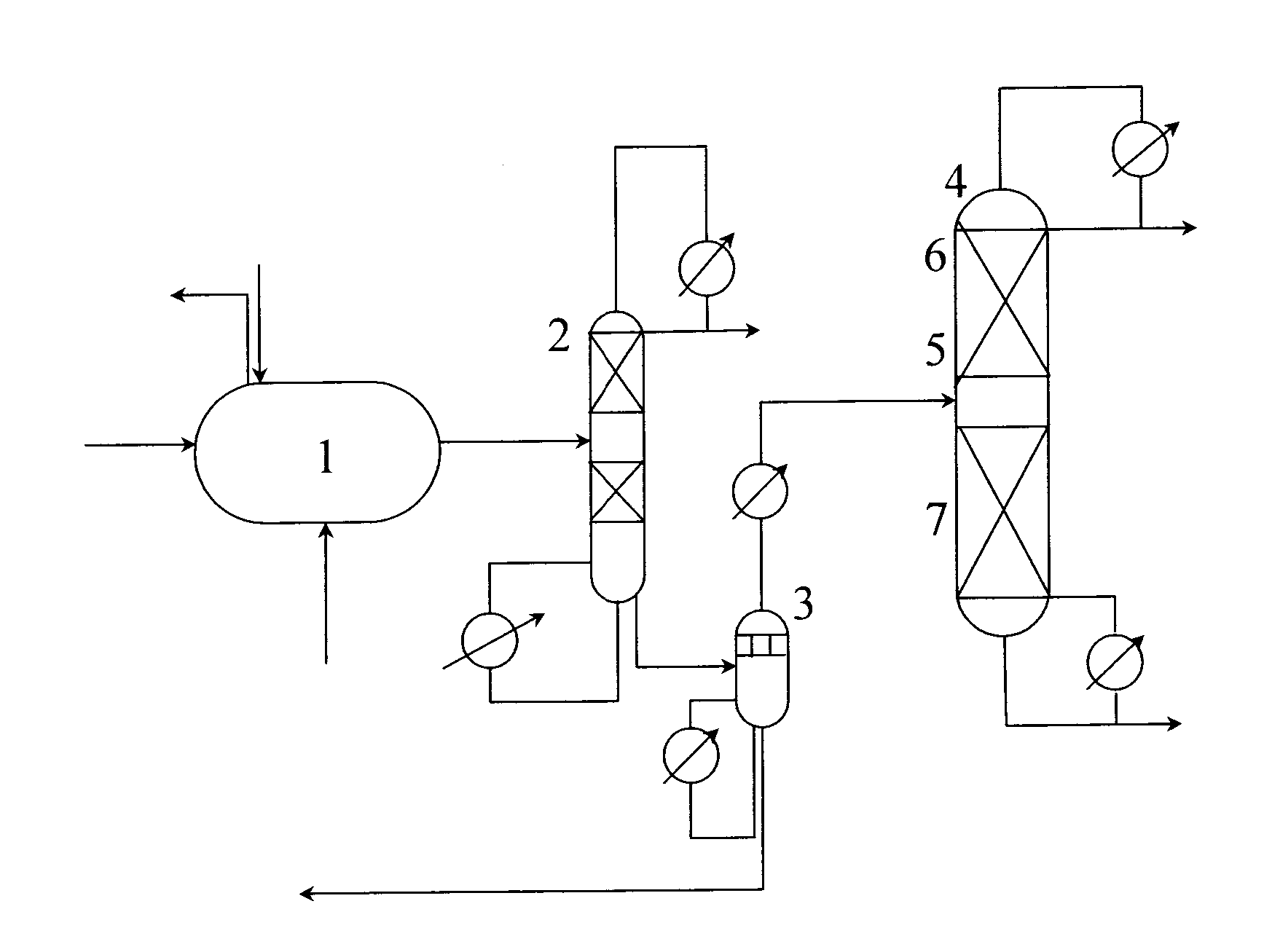

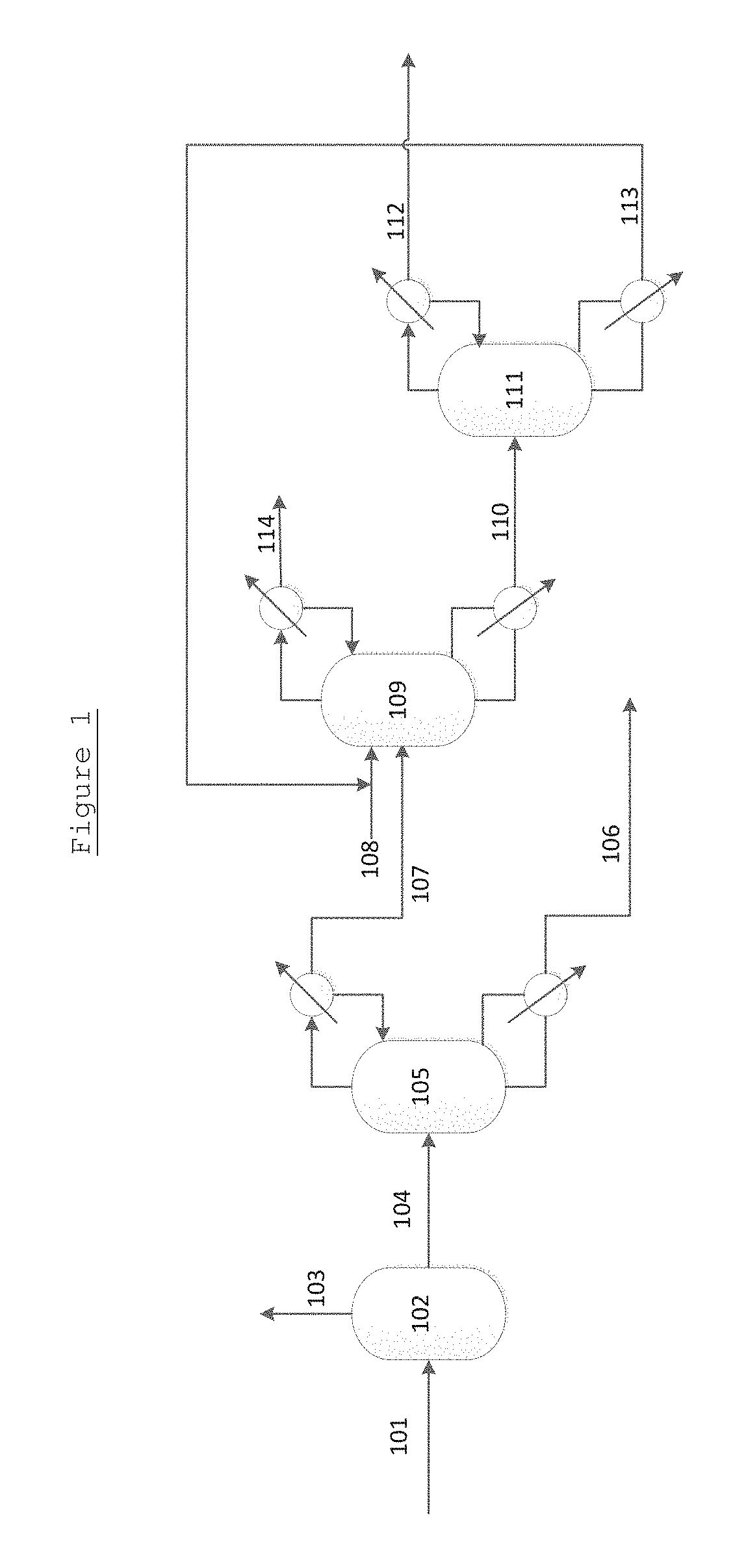

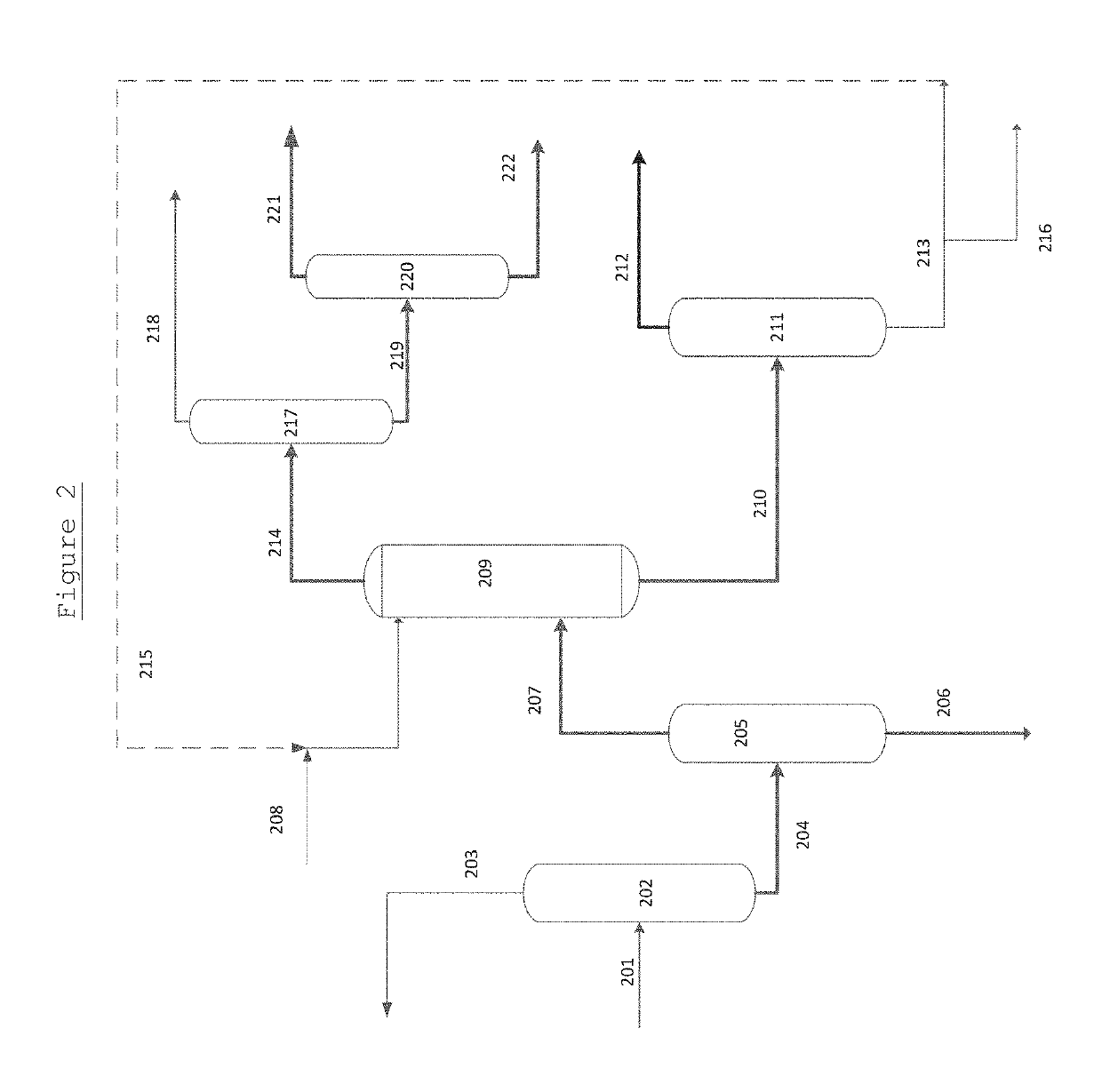

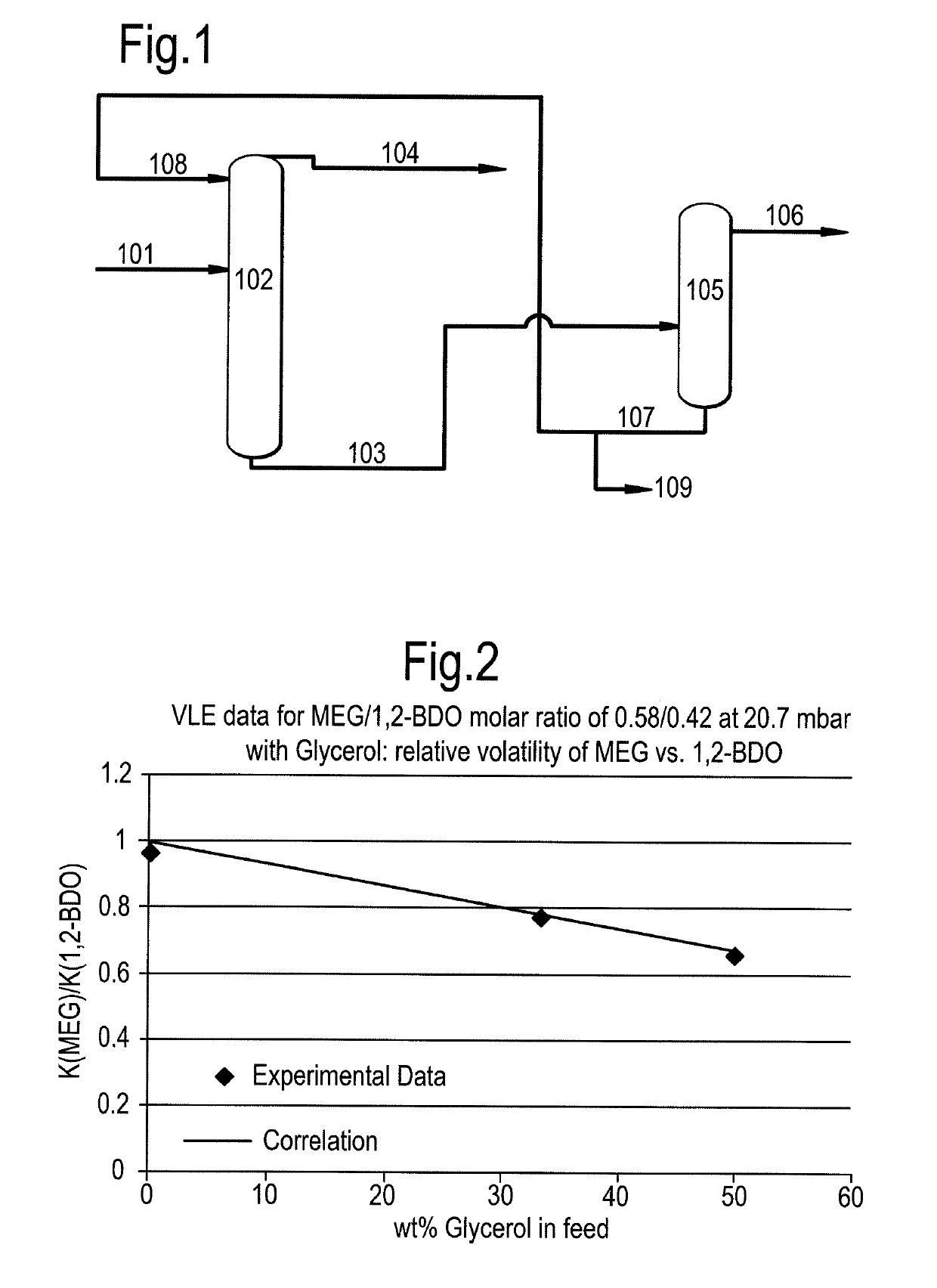

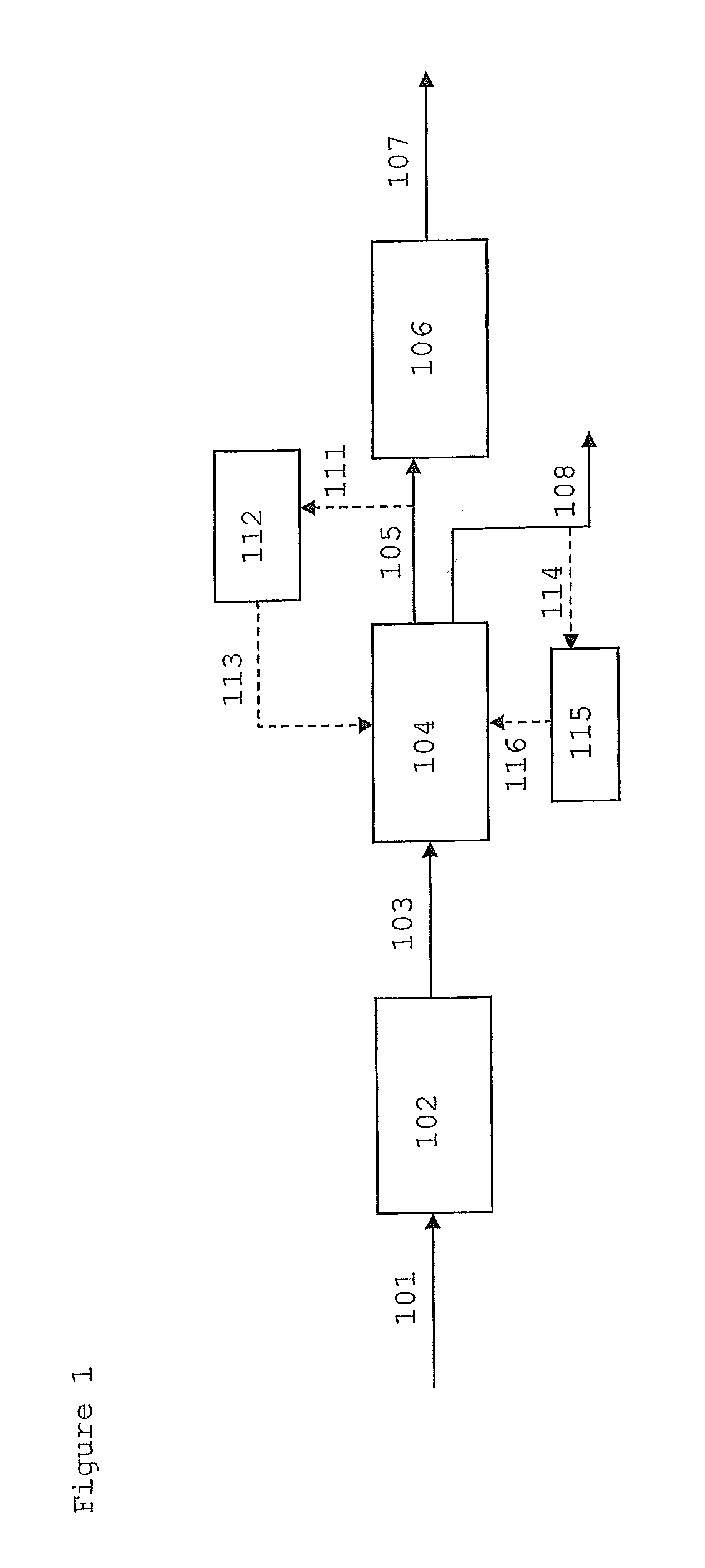

Process for the separation of glycols

ActiveUS20190062244A1High purityAffect volatilityOrganic compound preparationHydroxy compound preparationAlcoholBoiling point

A process for the production of high purity mono-ethylene glycol (MEG) from a product stream of a saccharide hydrogenolysis process. The process having the steps of: (i) removing solvent from the product stream to provide a solvent-lean product stream; (ii) subjecting the solvent-lean product stream to distillation to provide a bottoms stream comprising high boiling by-products and a top stream comprising a mixture comprising MEG and 1,2-butanediol (1,2-BDO); (iii) providing said mixture having MEG and 1,2-BDO as a feed to a distillation column; (iv) providing a feed comprising an extractant of C3 to C6 alcohols and mixtures thereof to the distillation column above the mixture comprising MEG and 1,2-BDO; (v) removing a stream comprising MEG and the extractant as a bottoms stream from the distillation column; and (vi) subjecting the stream comprising MEG and the extractant to distillation to provide a top stream comprising high purity MEG.

Owner:SHELL USA INC

Process for the separation of glycols

ActiveUS10308577B2High purityAffect volatilityOrganic compound preparationHydroxy compound preparationAlcoholBoiling point

A process for the production of high purity mono-ethylene glycol (MEG) from a product stream of a saccharide hydrogenolysis process. The process having the steps of: (i) removing solvent from the product stream to provide a solvent-lean product stream; (ii) subjecting the solvent-lean product stream to distillation to provide a bottoms stream comprising high boiling by-products and a top stream comprising a mixture comprising MEG and 1,2-butanediol (1,2-BDO); (iii) providing said mixture having MEG and 1,2-BDO as a feed to a distillation column; (iv) providing a feed comprising an extractant of C3 to C6 alcohols and mixtures thereof to the distillation column above the mixture comprising MEG and 1,2-BDO; (v) removing a stream comprising MEG and the extractant as a bottoms stream from the distillation column; and (vi) subjecting the stream comprising MEG and the extractant to distillation to provide a top stream comprising high purity MEG.

Owner:SHELL USA INC

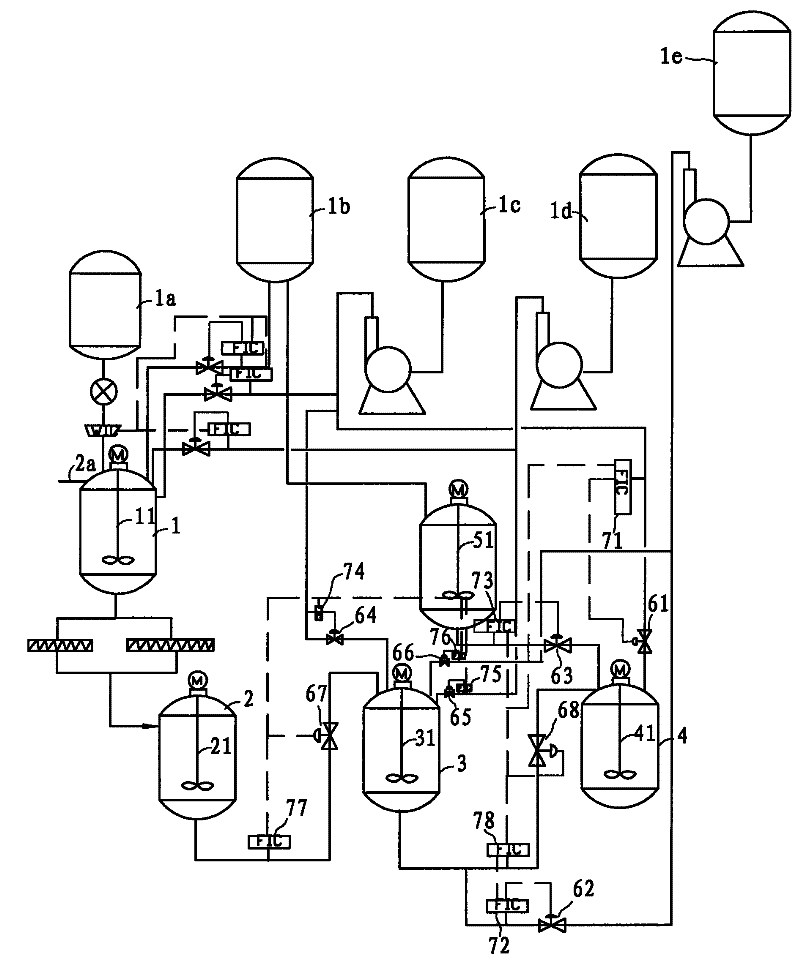

Production equipment for PET (poly(ethylene terephthalate)) chip

The invention relates to a production equipment for a PET (poly(ethylene terephthalate)) chip, which comprises a slurry tank, a first esterification reactor, a second esterification reactor, a mixing tank, a pre-condensation-polymerization reactor and a final condensation polymerization reactor, wherein the slurry tank is provided with a PTA (purified terephthalic acid) adding port, an MEG (monoethylene glycol) adding port, an IPA (isophthalic acid) adding port, a toner adding port and a heat absorbent adding port, the discharge port of the mixing tank is connected with the pre-condensation-polymerization reactor through a discharge pipe, and the second esterification reactor is connected with a first toner adding pipe, a heat absorbent adding pipe and a first stabilizer adding pipe; and the pre-condensation-polymerization reactor is connected with a second toner adding pipe and a second stabilizer adding pipe. Compared with the prior art, the production equipment for the PET chip provided by the invention has the advantages of changing the adding mode and adding point of additives, optimizing production process, guaranteeing the stable control of production process, and realizing low transition time, few transition materials and low production cost during variety conversion.

Owner:ZHEJIANG WANKAI NEW MATERIAL

Short contact, elevated temperature meg reclamation

ActiveUS20170015613A1Organic compound preparationHydroxy compound preparationResidence timeHeat transfer fluid

Monoethylene glycol (MEG) may be reclaimed by a process that includes contacting a MEG-water-salt stream with a heat transfer fluid and then flash separating the MEG and water in the flash separator vessel where the pressure is higher than 0.3 barA (0.03 MPa), the temperature is in the range of above 120° C. to about 250° C., and the residence time of the MEG and water ranges from about 1 second to about 10 minutes, and then removing the MEG and water in an overhead of the flash separator vessel and removing the salt from the flash separator vessel. In some embodiments it is expected that the temperature of the process may range from above 165° C. to about 250° C. and / or that the pressure may be atmospheric.

Owner:CAMERSON INT CORP

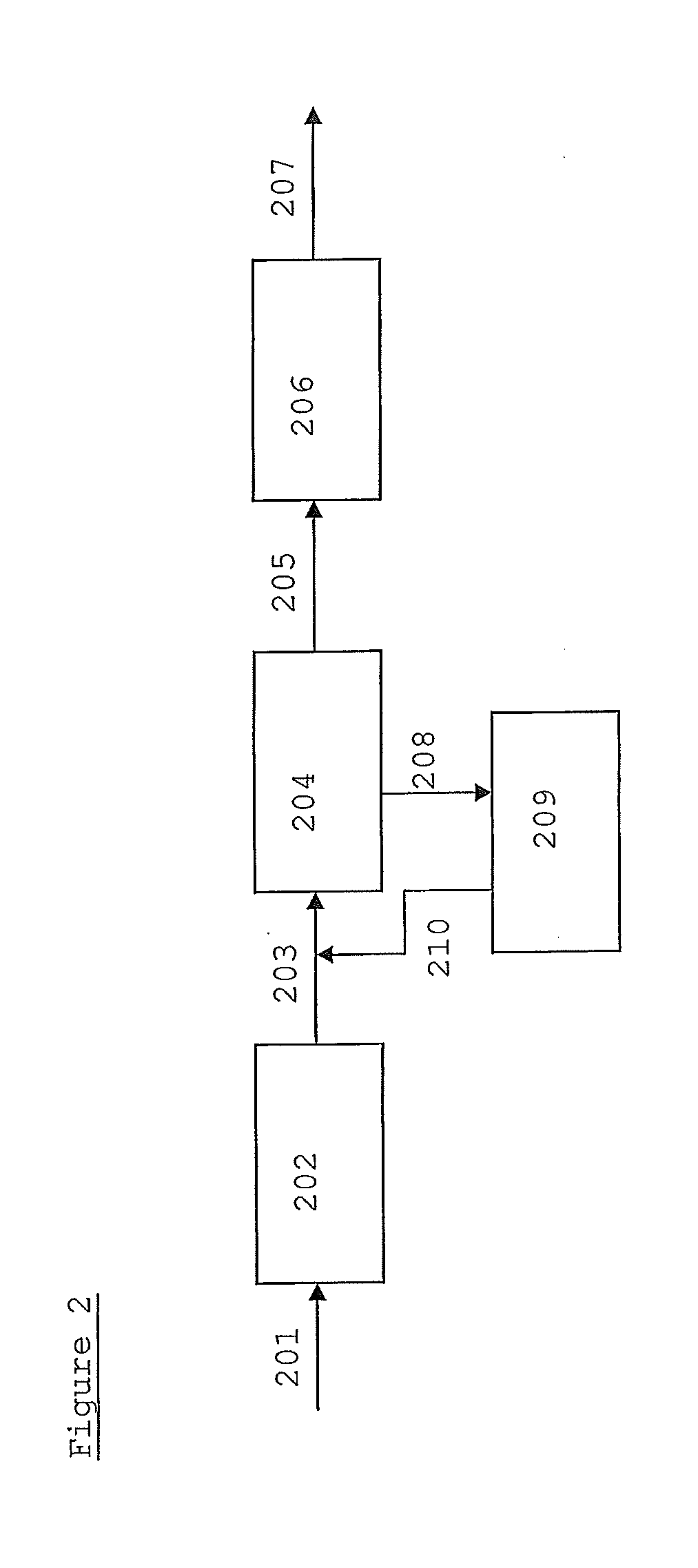

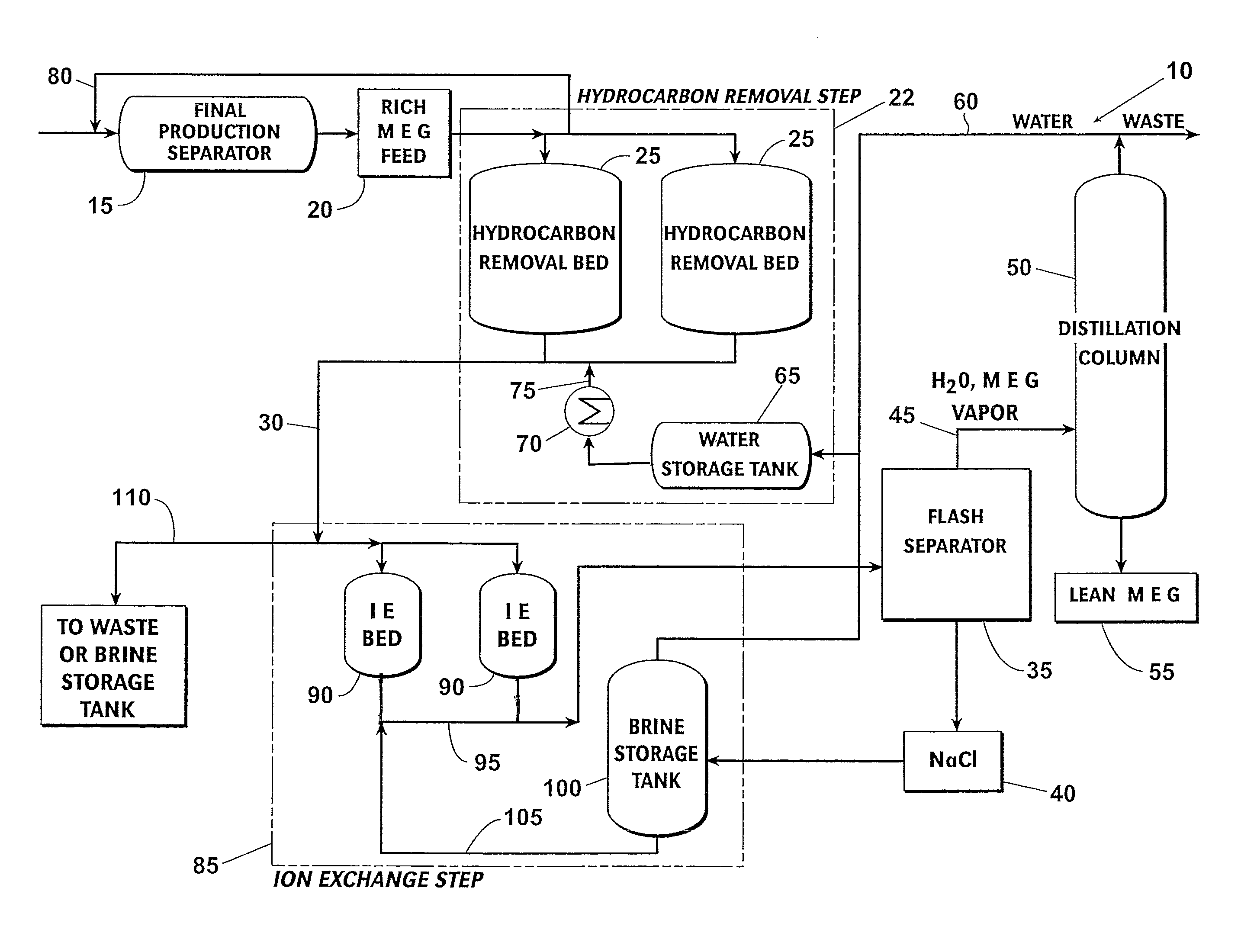

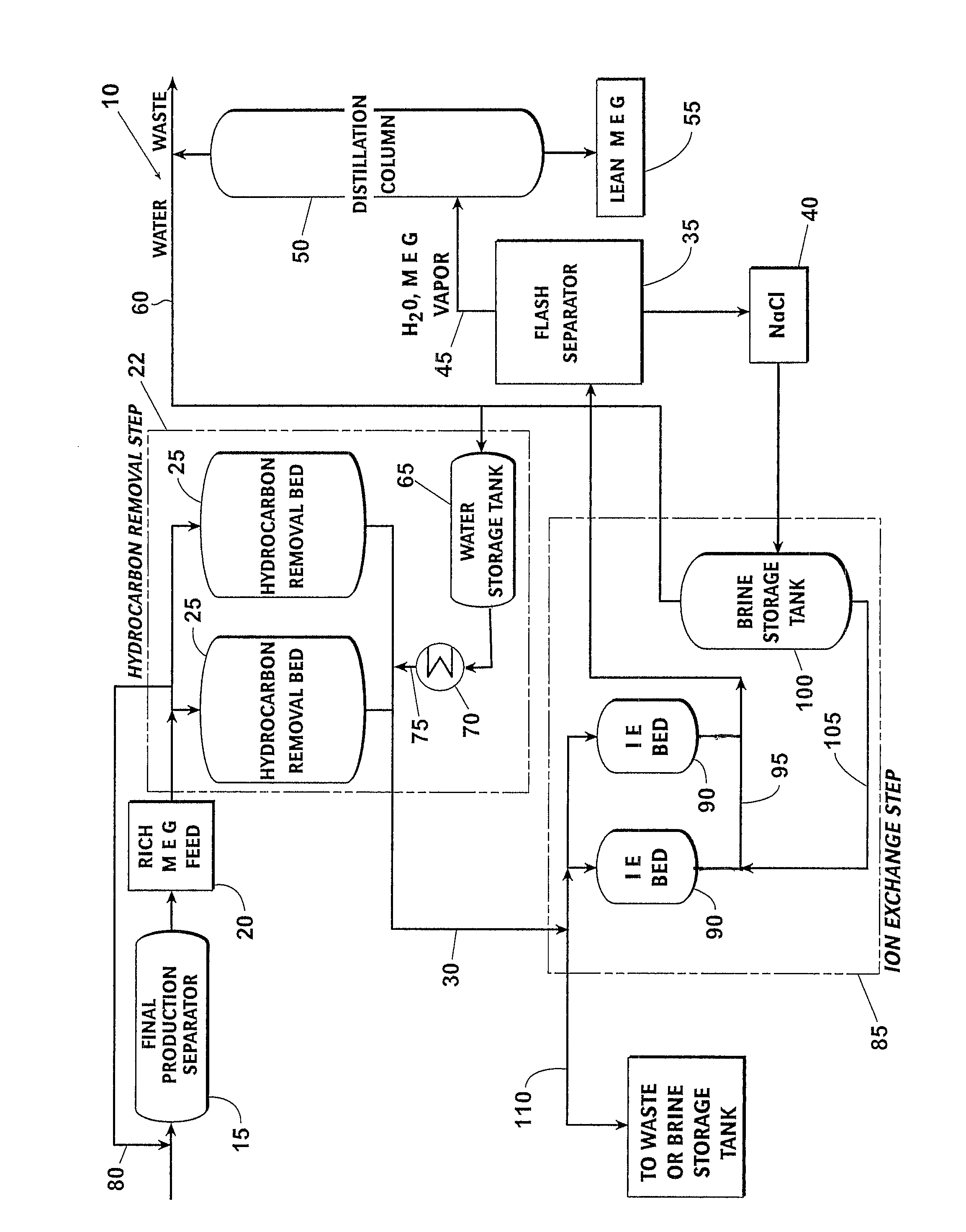

Hydrocarbon and Divalent Cation Removal from Rich Mono ethylene Glycol (MEG) Feed Streams by Regenerable Filters

InactiveUS20140058140A1Simplify hydrocarbonSimplify divalent cation removal processOxygen-containing compound preparationOrganic compound preparationStream flowSorbent

A system and process for removing hydrocarbons and divalent cations from a rich MEG feed stream is presented. A hydrocarbon removal bed containing a solid adsorbent material adsorbs the hydrocarbons in the rich MEG feed stream as it passes through the hydrocarbon removal bed. After the hydrocarbons have been removed, the rich MEG feed stream flows through an ion exchange bed containing an ion exchange resin in order to remove divalent cations. The rich MEG feed stream then flows through a flash separator and a distillation column to reclaim MEG. Spent solid adsorbent material in the hydrocarbon removal beds and spent ion exchange resin in the ion exchange beds may be regenerated in place using by-products of the MEG reclamation process.

Owner:CAMERSON INT CORP

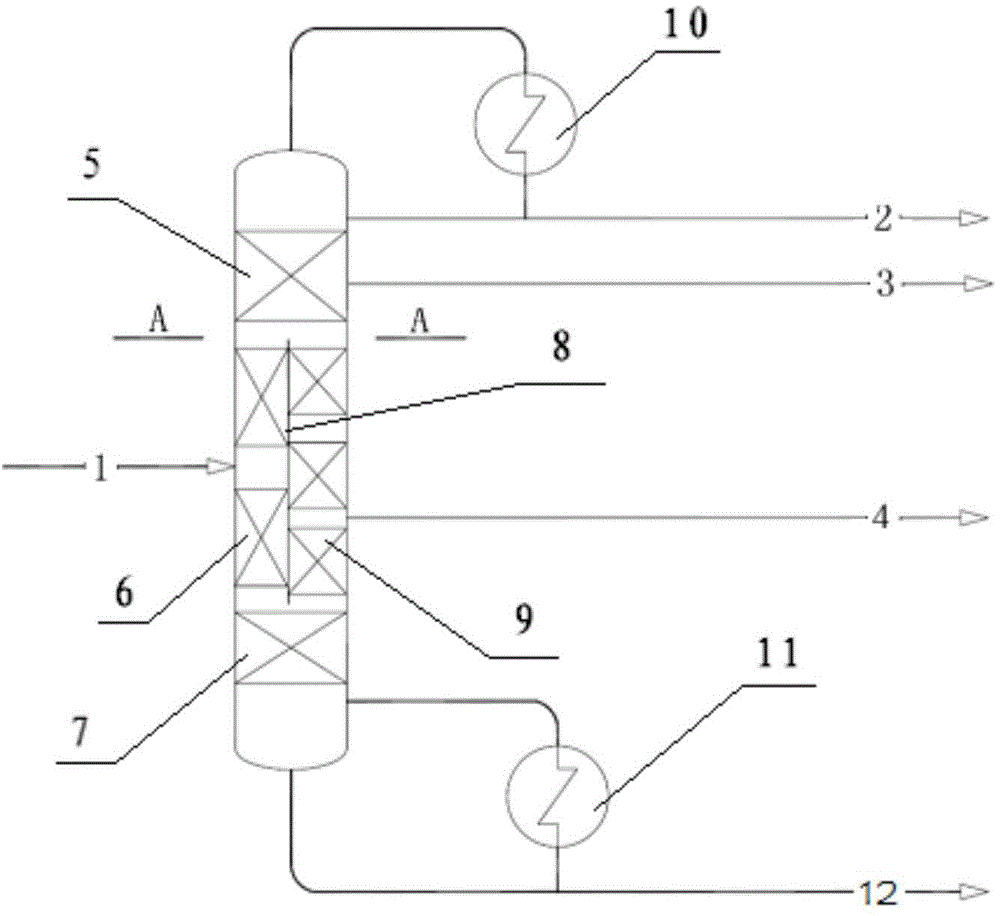

Mono-ethylene glycol purification and recovery method

ActiveCN104370704AEasy to purifyImprove recycling effectOrganic compound preparationHydroxy compound preparationRecovery methodDistillation

The invention relates to a mono-ethylene glycol purification and recovery method and aims to mainly solve the problems of complexity, low separation purity, large investment and high energy consumption of existing separation processes. The mono-ethylene glycol purification and recovery method includes: taking a mixture containing water, MEG (mono-ethylene glycol), DEG (diethylene glycol) and TEG (triethylene glycol) as raw materials, enabling the raw materials to enter one side of a dividing-wall section of a dividing-wall distillation column for separation, withdrawing recovered MEG products from the other side of the dividing-wall section, obtaining material flow containing the DEG and the TEG from the bottom of a stripping section below the dividing-wall section of the dividing-wall distillation column, obtaining material flow containing the water and the MEG from the top of a distillation section above the dividing-wall section of the dividing-wall distillation column, and performing side withdrawing to obtain MEG products from the distillation section above the dividing-wall section of the dividing-wall distillation column. According to the technical scheme, the mono-ethylene glycol purification and recovery method well solves the above technical problems and can be used for purification and recovery of mono-ethylene glycol.

Owner:SINOPEC SHANGHAI ENG +1

Process for the separation of glycols using glycerol

ActiveUS10246390B2Organic compound preparationDistillation regulation/controlFractionating columnGlycerol

A process for the separation of monoethylene glycol (MEG) and 1,2-butanediol (1,2-BDO) from a first mixture including MEG and 1,2-BDO, the process including providing the first mixture of MEG and 1,2-BDO as a feed to a distillation column. The process also includes providing a feed comprising glycerol to the distillation column above the first mixture. The process also includes operating the distillation column at a temperature in the range of from 50 to 250° C. and a pressure in the range of from 0.1 to 400 kPa. The process also includes removing a stream comprising MEG and glycerol as a bottoms stream from the distillation column and removing a stream comprising 1,2-BDO above the point at which the feed comprising glycerol is provided to the distillation column.

Owner:SHELL OIL CO

Process for the preparation of monoethylene glycol

Owner:SHELL USA INC

Polyurethane foam with soft surface touch

A polyurethane foam, suitable for shoe soles in particular, and a process to prepare it. This polyurethane has a touch that is similar to that of thermoplastic styrene-butadiene-styrene rubber, but offers reduced cost and easy processability. It is prepared from a formulation including a polyether triol with a hydroxyl value of from 25 to 30 and a molecular weight from 5000 to 7000 g / mol; a polyether diol with a hydroxyl value of from 25 to 30 and a molecular weight from 3000 to less than 5000 g / mol; from 2 to 7 wt% of monoethylene glycol, butanediol, hexanediol or neopentyl glycol as a chain extender; a copolymer polyether polyol having a styrene acrylonitrile solids content of at least 30 wt% and an average hydroxyl number of at least 18; an isocyanate component; and a blowing agent that includes water.

Owner:DOW GLOBAL TECH LLC

Modified polybutylene naphthalate for improved performance and process of making thereof

The present invention relates to a process for preparing transparent polybutylene naphthalate polyester, for improving barrier performance of polyesters used in making of monolayer or multilayer containers, comprising steps of: a) mixing butane diol with polymerization catalysts, monoethylene glycol, color toner, and at least one crystallization suppressing agent, wherein said crystallization suppressing agent controls the rate of crystallization so as to control size and shape of crystals to ensure transparency; b) reacting said mixture with naphthalene dicarboxylic acid or ester thereof to obtain oligomerized product via esterification or ester interchange; c) polymerizing said oligomer using at least one polymerization catalyst to obtain amorphous polybutylene naphthalate polyester chips; d) crystallizing said polybutylene naphthalate polyester chips; and e) subjecting said polyester chips to solid state polymerization to upgrade the intrinsic viscosity (I.V.) up to more than 0.40 dl / gm.

Owner:ESTER IND

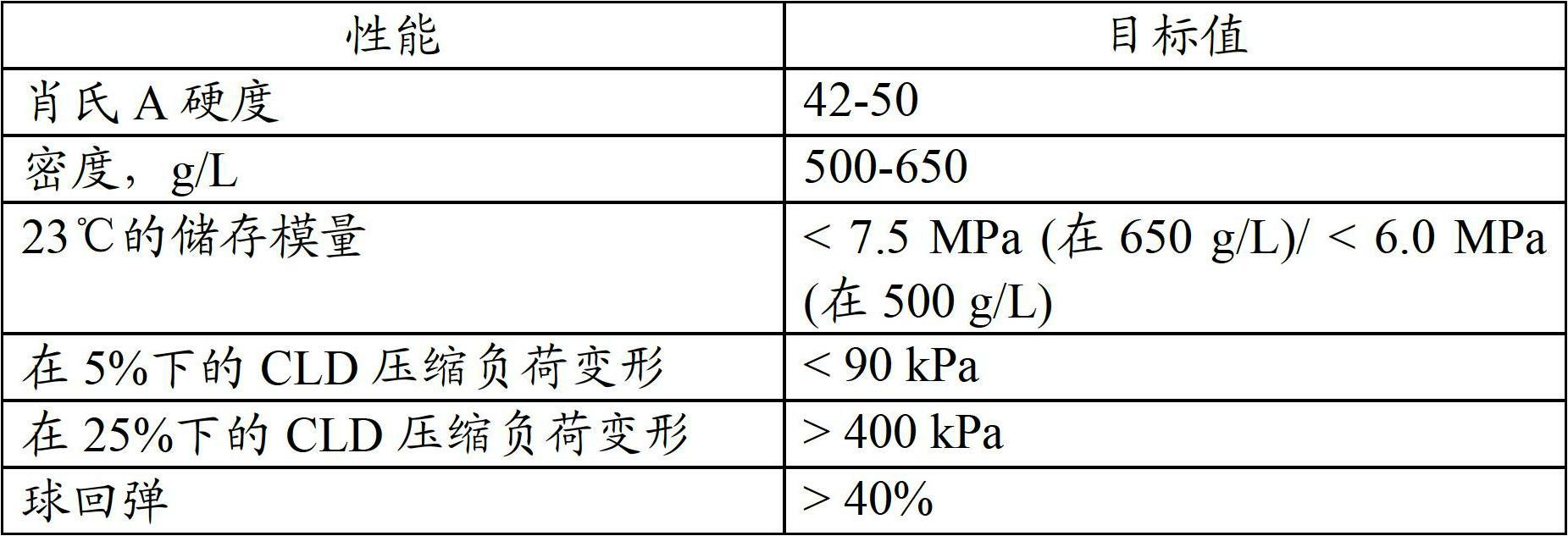

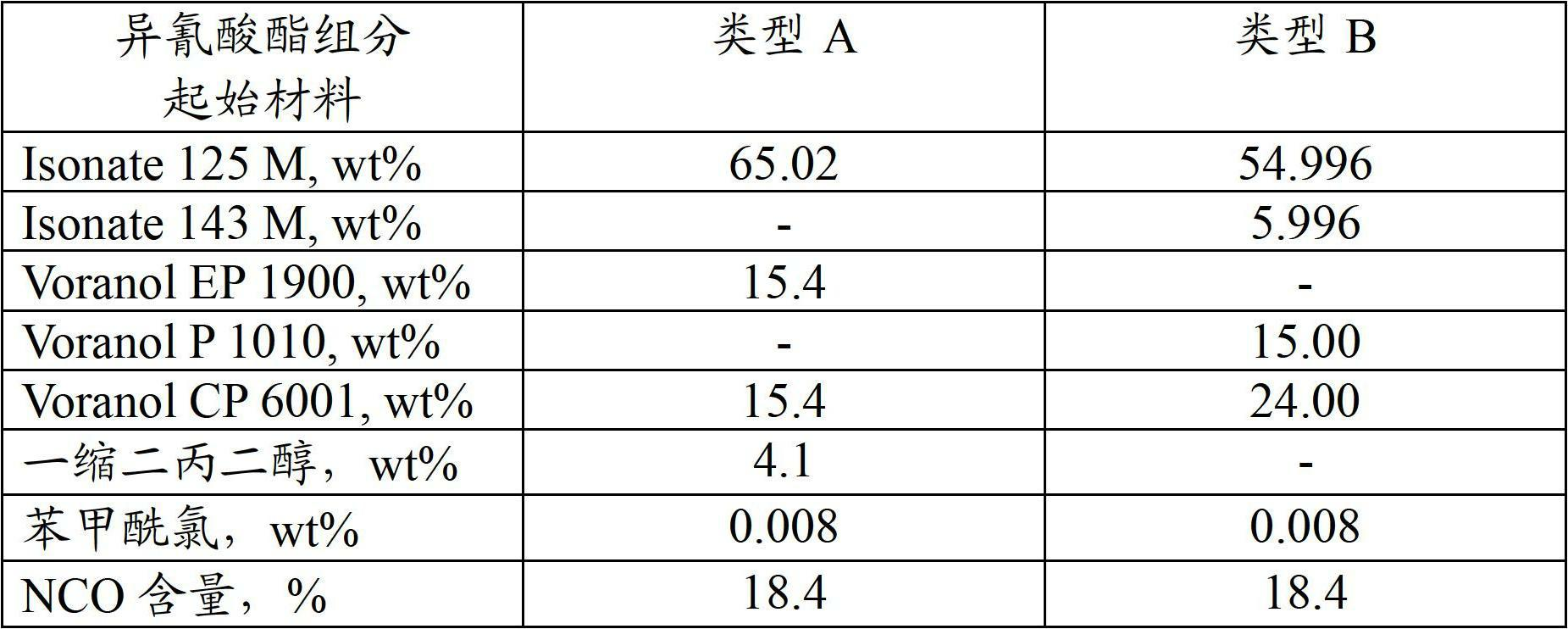

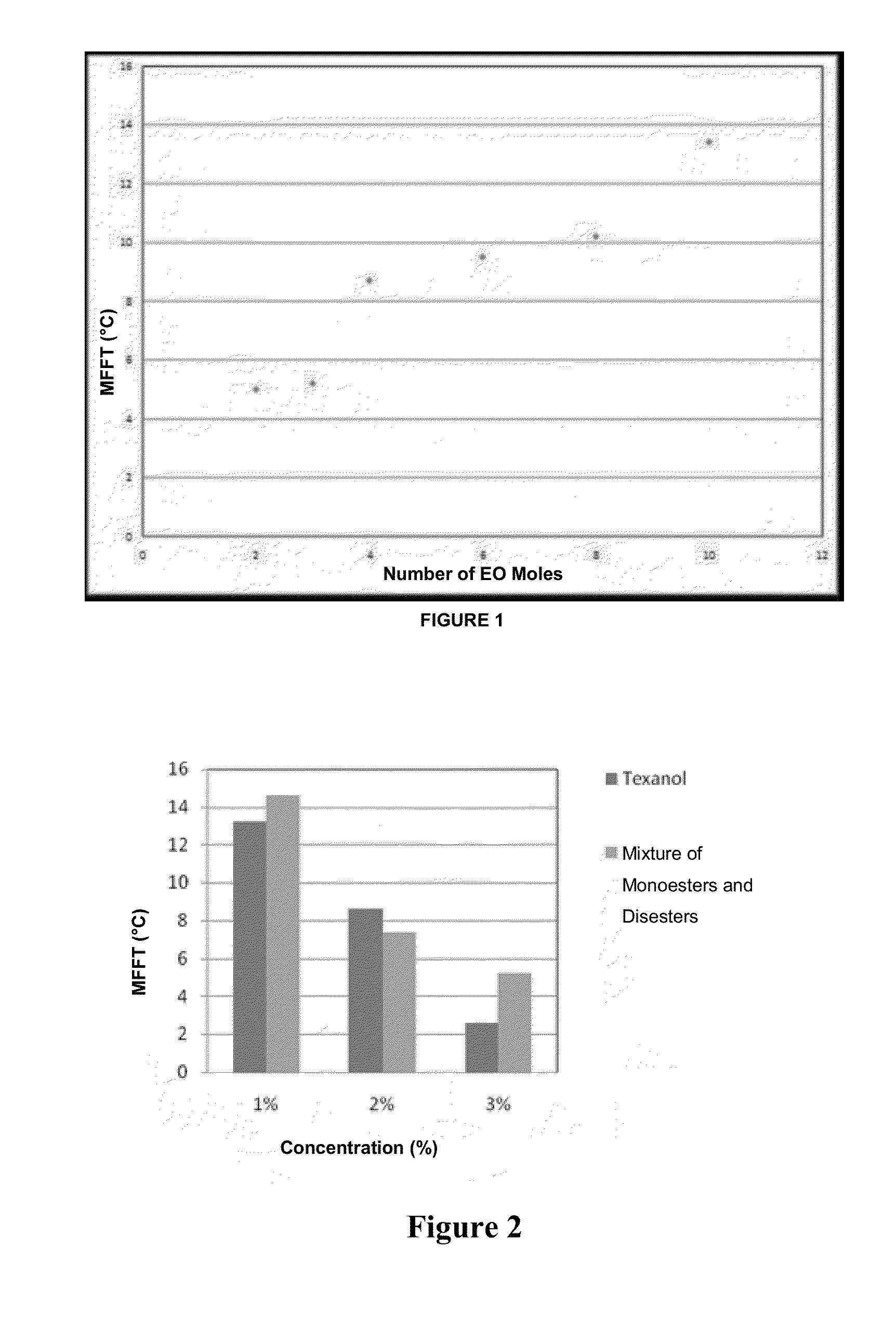

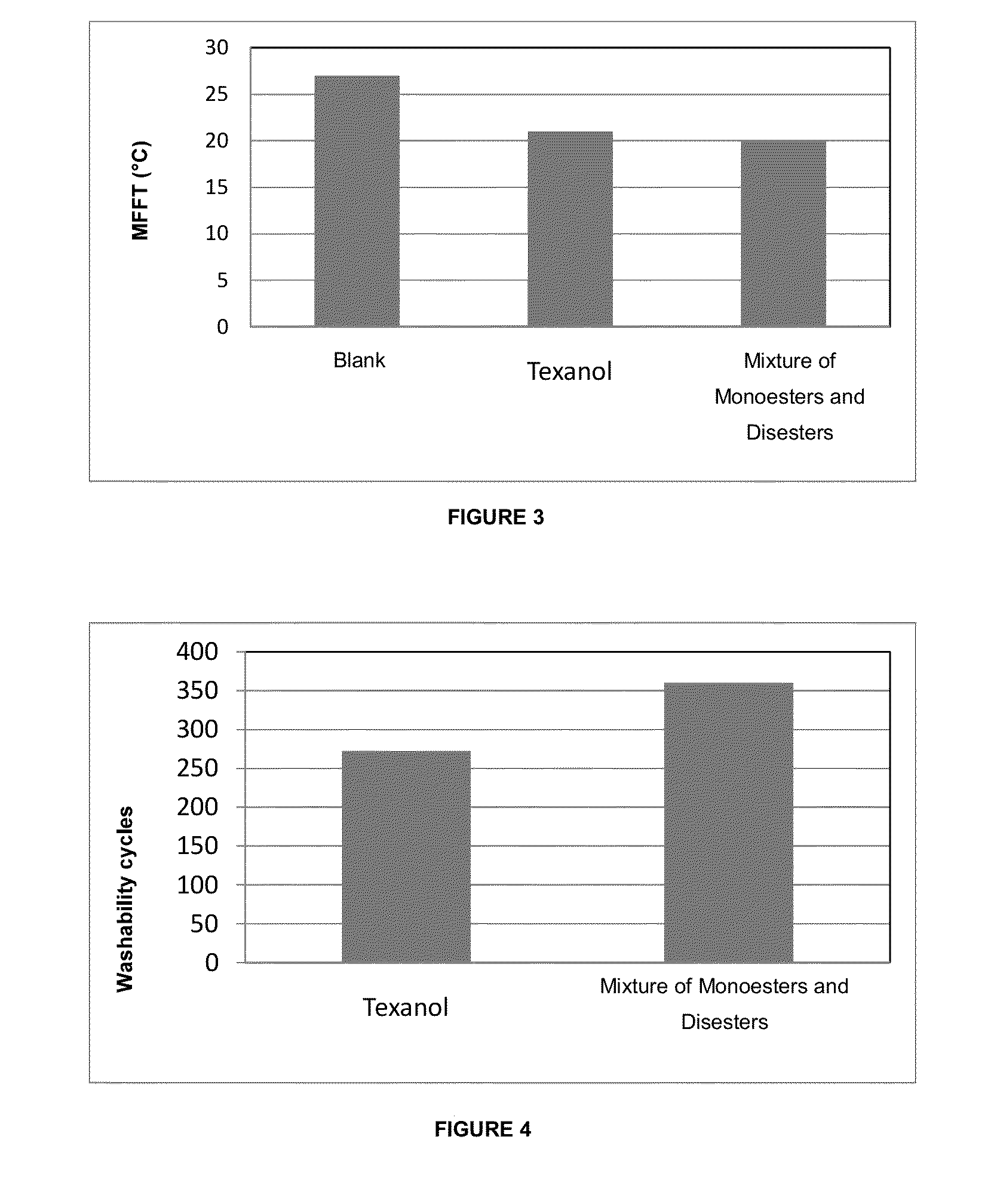

Green coalescent agent composition containing mixtures of monoesters and diesters

ActiveUS20140096701A1Non-macromolecular adhesive additivesOrganic compound preparationTransesterificationPolyethylene glycol

The present invention relates to the use of mixtures of monoesters and diesters as coalescing agents. Monoesters and diesters according to the present invention were obtained by ethoxylation of fatty acids, and / or by direct esterification of fatty acids with monoethylene glycol or polyethylene glycol. Fatty acids used in the present invention have 4 to 22 carbon atoms and can be saturated or unsaturated, linear or branched.In particular, the invention is directed to a composition of coalescing agents comprising: (i) mixtures of (RCOO(EO)nH) monoesters and diesters; and, (ii) mixtures of (RCOO(EO)nH) monoesters and diesters obtained from the ethoxylation of fatty acids, and / or direct esterification of fatty acids with ethylene glycol derivatives, and / or transesterification, wherein the monoesters are present in an amount of 90 to 10 mass % and diesters are present in an amount of 10 to 90 mass %.

Owner:OXITENO S A IND E COMERCIO

A process for preparation of modified polyethylene terphthalate with improved barrier, mechanical and thermal properties and products thereof

The present invention relates to a copolyester having intrinsic viscosity greater than 0.50 dL / gm, comprises: terephthalate polyester composition; and a modified transparent polybutylene naphthalate, wherein the modified polybutylene naphthalate comprises naphthalene dicarboxylic acid, 1,4-butane diol, and isophthalic acid or monoethylene glycol or diethylene glycol or cyclohexane dimethanol or polyethylene naphthalate, nucleating agent, and a modified nanoclay.

Owner:ESTER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com