Glycol separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

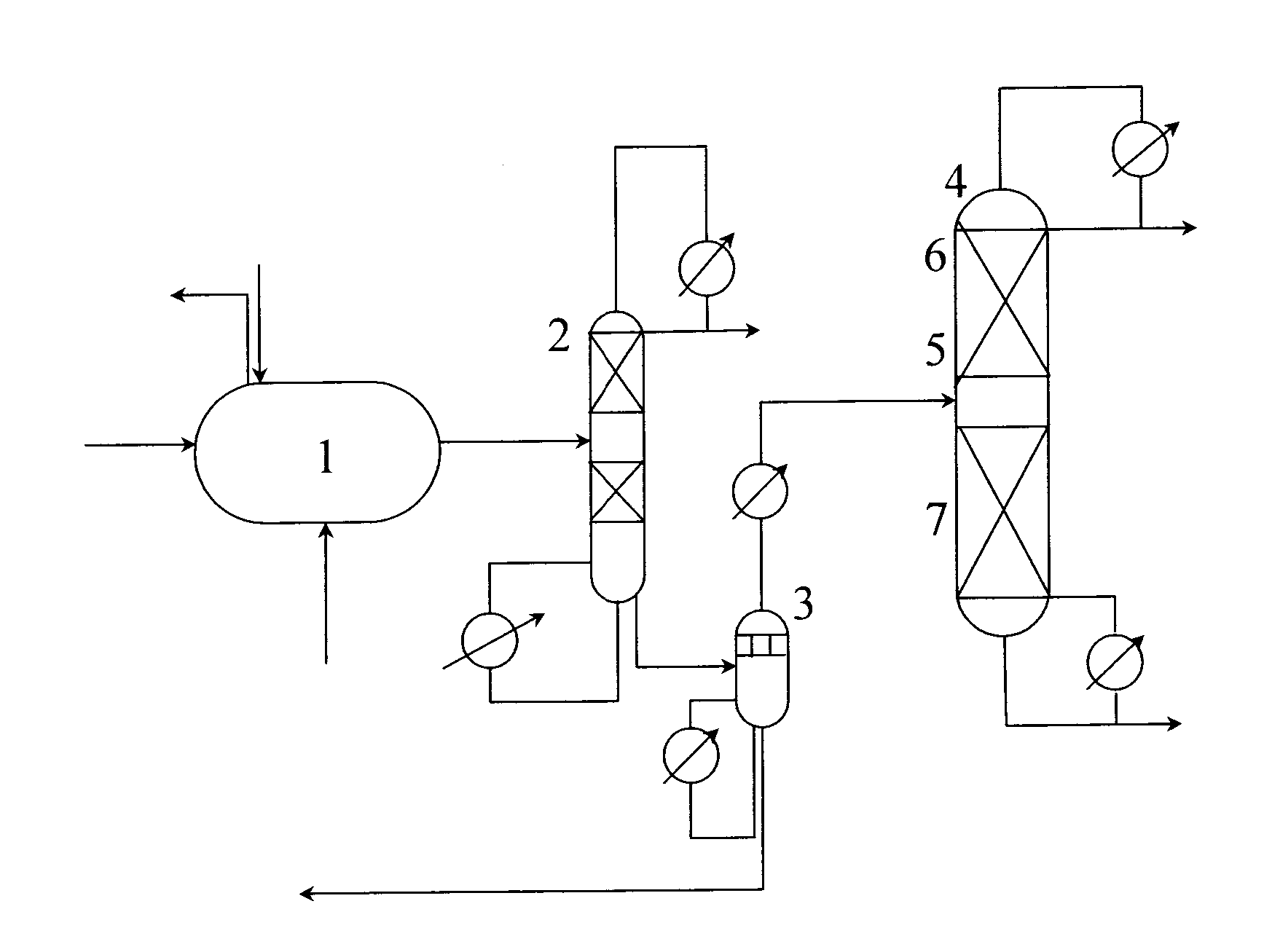

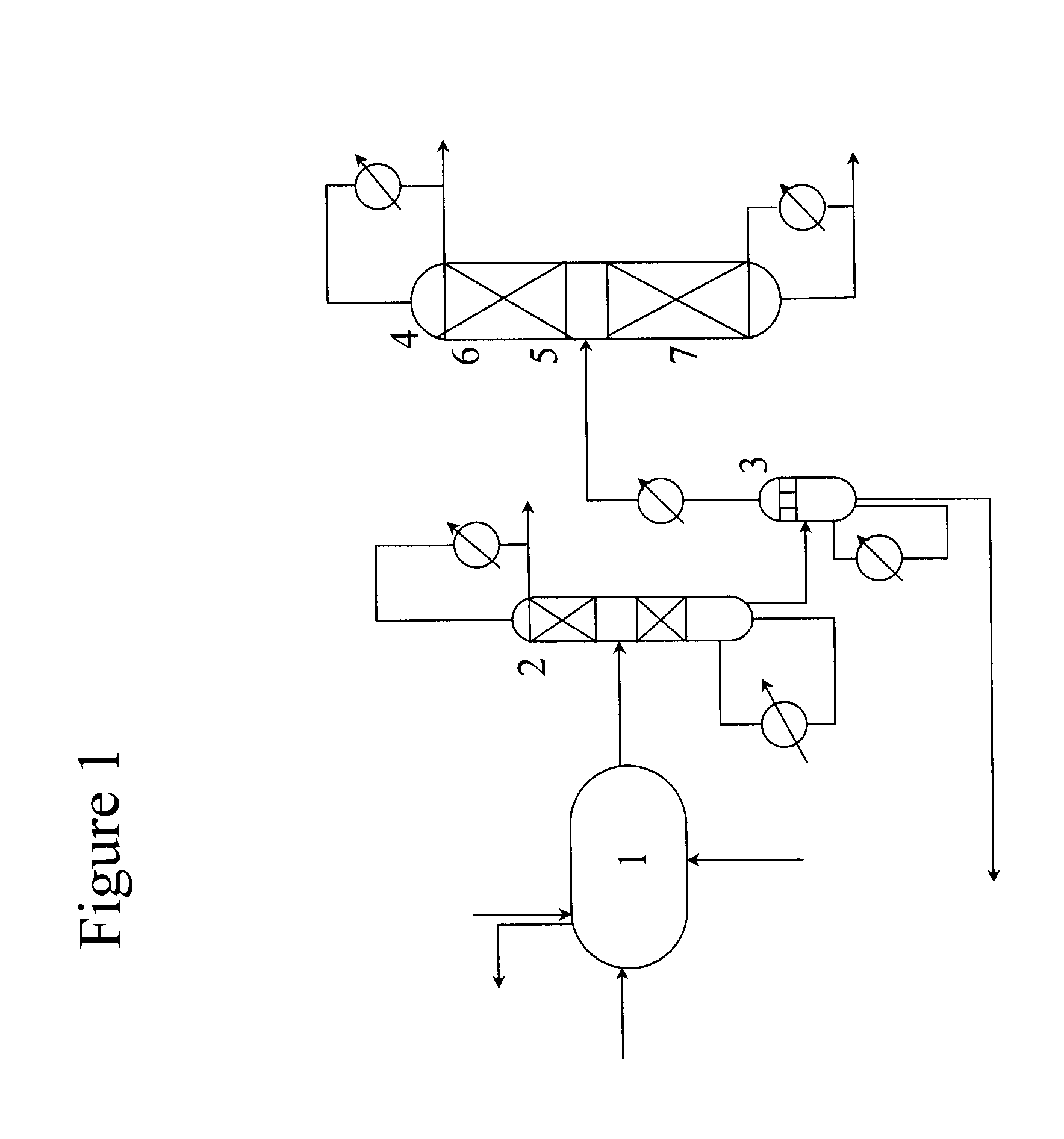

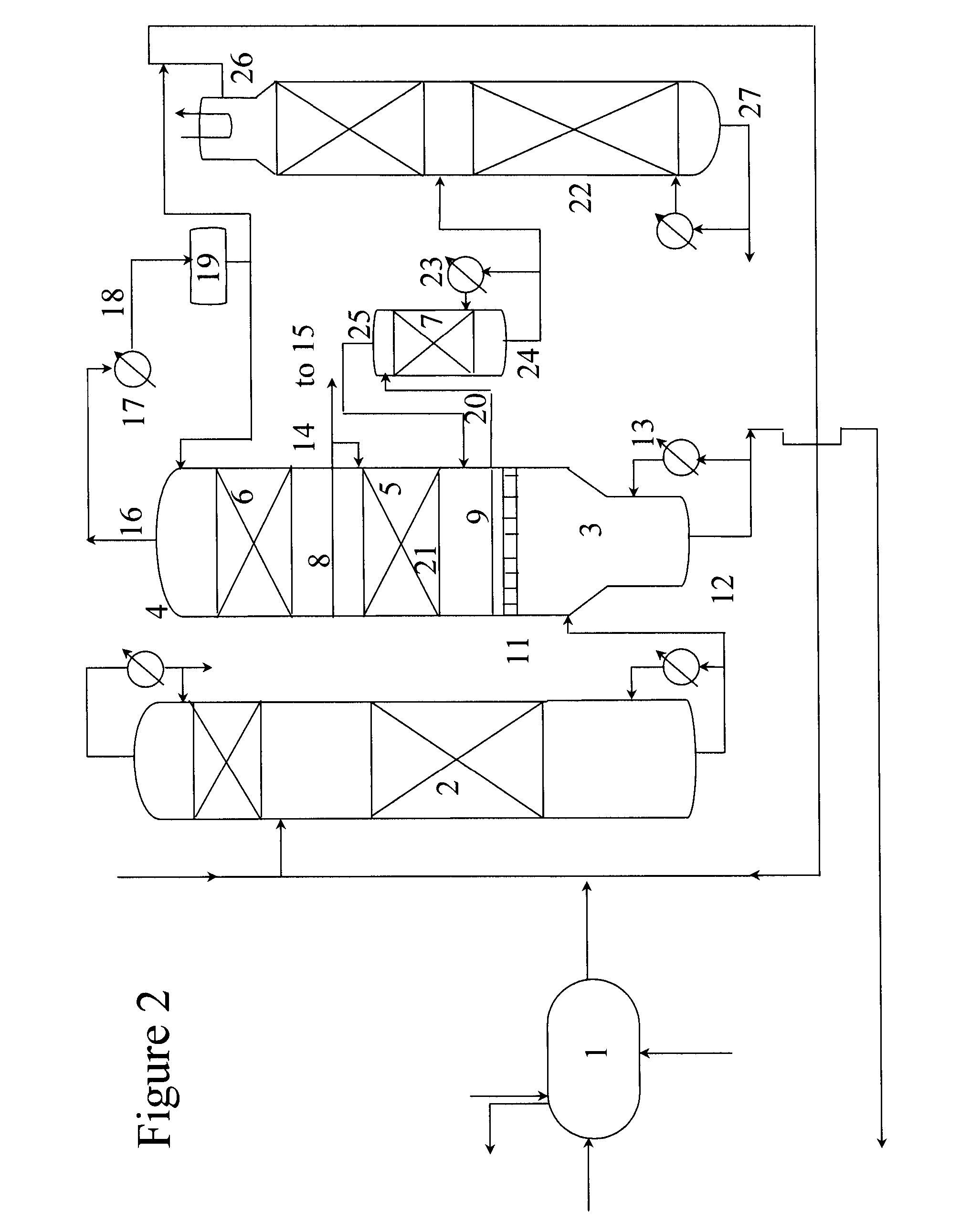

[0020] Typically the process and apparatus of the invention separate catalyst solution derived from a glycol dehydrator section. Catalyst solution is substantially or predominantly liquid phase, although it may include vapour, on entry to the separation section. Catalyst solution comprises catalyst in crude MEG. In the separation section, heat input to a temperature as hereinafter described preferably generates a flash separation of crude MEG whereby vapour phase crude MEG is separated from a solution of greater than 0 wt % to 95 wt % catalyst in crude MEG which is recycled for further use in the EO to MEG conversion reaction. As hereinbefore described, the vapour phase crude MEG is fed to the rectification section where mass transfer between liquid phase and vapour phase confers a rectification, separating MEG as overhead from diethylene glycol (DEG) and higher boiling glycols. Separated MEG rises to a pasteurisation section where further mass transfer between the phases confers a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com