Polyurethane foam with soft surface touch

A technology of polyurethane foam and copolymer, which is applied in the field of polyurethane foam and can solve the problems of expensive preparation

Active Publication Date: 2012-09-12

DOW GLOBAL TECH LLC

View PDF14 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

While TPR has a good "feel" and relative ease of processability that are sought or preferred by many consumers, it is unfortunately relatively expensive to manufacture compared to polyurethane foam

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

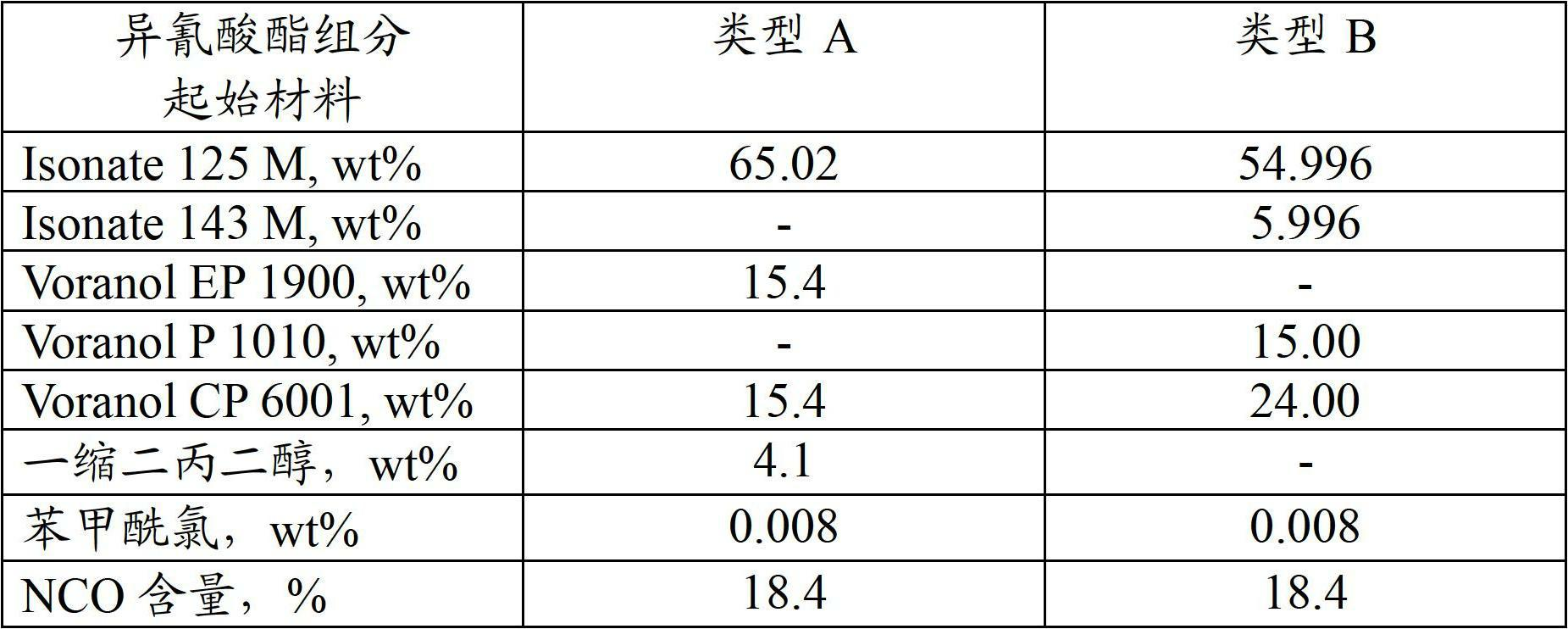

[0083] Example 1 and Example 2 differ in the type of copolymer polyol used. The polyol 3 based material (Example 1 ) showed better performance in terms of low surface hardness and high resistance to compression at 25% deformation.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Login to View More

Abstract

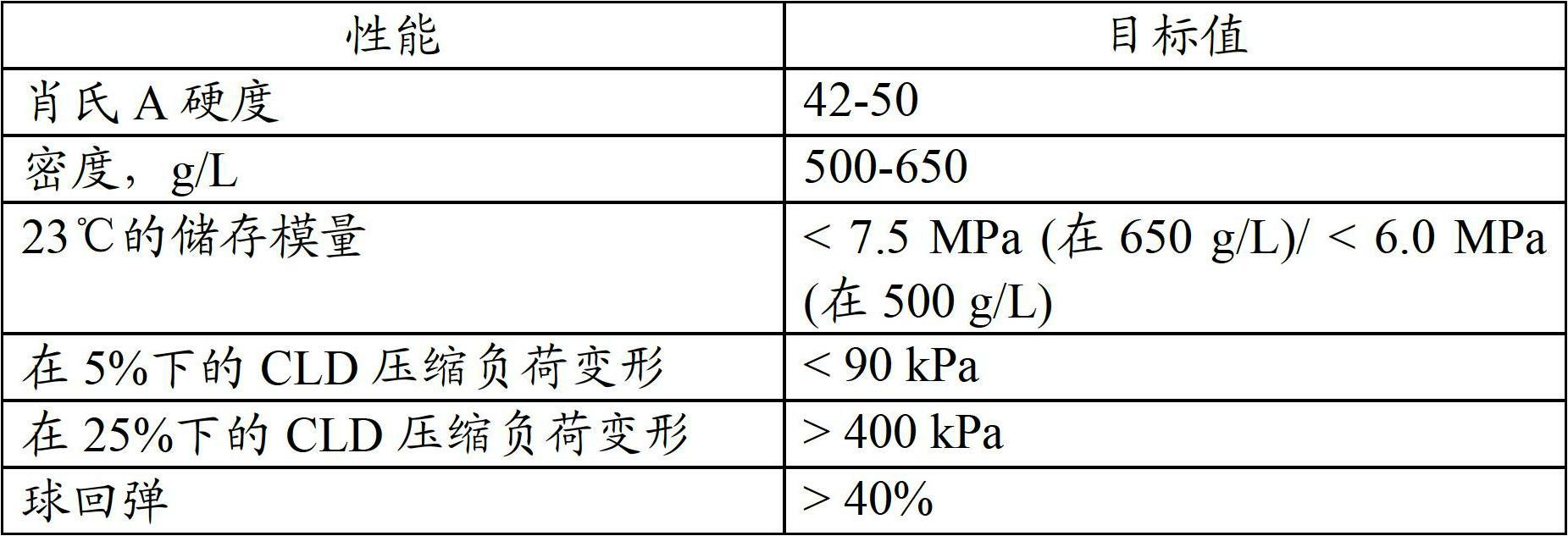

A polyurethane foam, suitable for shoe soles in particular, and a process to prepare it. This polyurethane has a touch that is similar to that of thermoplastic styrene-butadiene-styrene rubber, but offers reduced cost and easy processability. It is prepared from a formulation including a polyether triol with a hydroxyl value of from 25 to 30 and a molecular weight from 5000 to 7000 g / mol; a polyether diol with a hydroxyl value of from 25 to 30 and a molecular weight from 3000 to less than 5000 g / mol; from 2 to 7 wt% of monoethylene glycol, butanediol, hexanediol or neopentyl glycol as a chain extender; a copolymer polyether polyol having a styrene acrylonitrile solids content of at least 30 wt% and an average hydroxyl number of at least 18; an isocyanate component; and a blowing agent that includes water.

Description

[0001] background 1. Technical field [0002] The present invention relates to the field of polyurethane foams. More particularly, it relates to the field of polyurethane foams with improved surface properties and compressive strength. 2. Background technology [0003] It is known that polyurethane foams can be obtained by reacting isocyanate components with active hydrogen-containing components, such as polyester or polyether polyols, and optionally blowing agents. For processing convenience, it is advantageous in some cases to use isocyanate-terminated prepolymers as the isocyanate component. Such prepolymers can be prepared, for example, by reacting an excess of an aromatic diisocyanate with a relatively low molecular weight diol, such as dipropylene glycol and / or tripropylene glycol. The blowing agent can be an inert physical blowing agent, such as a chlorofluorocarbon, and / or a reactive blowing agent, such as water. The preparation of polyurethane foams by these meth...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G18/12C08G18/32C08G18/48C08G18/63

CPCC08G18/12C08G18/3206C08G18/4812C08G18/4841C08G18/632C08G2410/00C08G2110/0066C08G2110/0083C08G18/6674

Inventor A.本维努蒂

Owner DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com