Flexible method for the treatment of a solvent, such as monoethylene glycol, used in the extraction of natural gas

A solvent and pretreatment technology, applied in the direction of separation methods, mining fluids, chemical instruments and methods, etc., can solve problems such as difficulty in adapting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

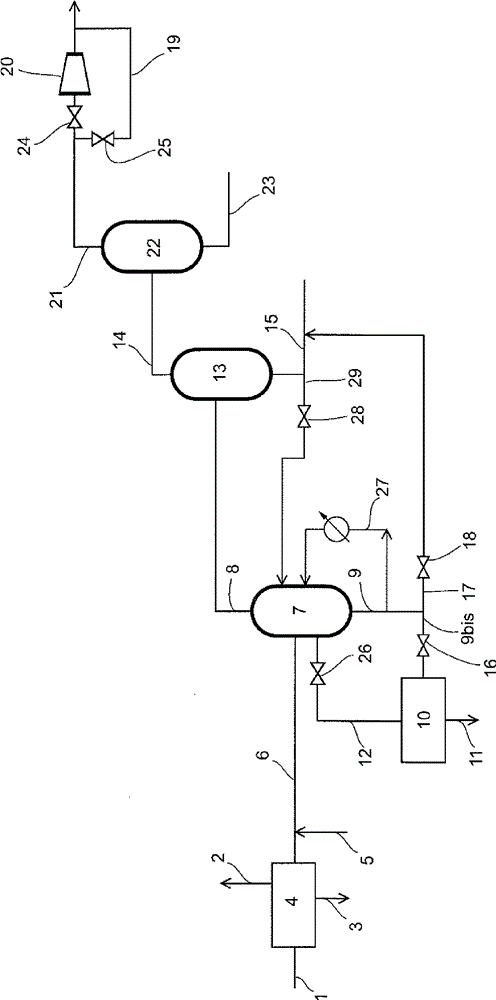

[0038] will refer to figure 1 The present invention is described with the layout of the present invention: the solvent is MEG, but the diagram can be described with any other solvent defined in the present invention; "MEG" can be replaced by "solvent".

[0039] Pretreatment is advantageously carried out upstream of the appropriate process.

[0040] The MEG to be processed (supplied via line 1 ) is typically separated in tank 4 from gases (exit via line 2 ) and condensate from hydrocarbons (exit via line 3 ). Trace or small amounts of hydrocarbons, condensate or gases may remain, depending on the strength of the separation.

[0041] The obtained MEG contains water and salt. It is optionally neutralized, for example using sodium hydroxide (supplied via line 5).

[0042] Preferably, MEG is separated from gases, condensates and hydrocarbons, followed by neutralization.

[0043] The MEG was also preheated.

[0044] The MEG to be treated contains a high proportion of water (typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com