Patents

Literature

2173results about How to "Good spreadability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

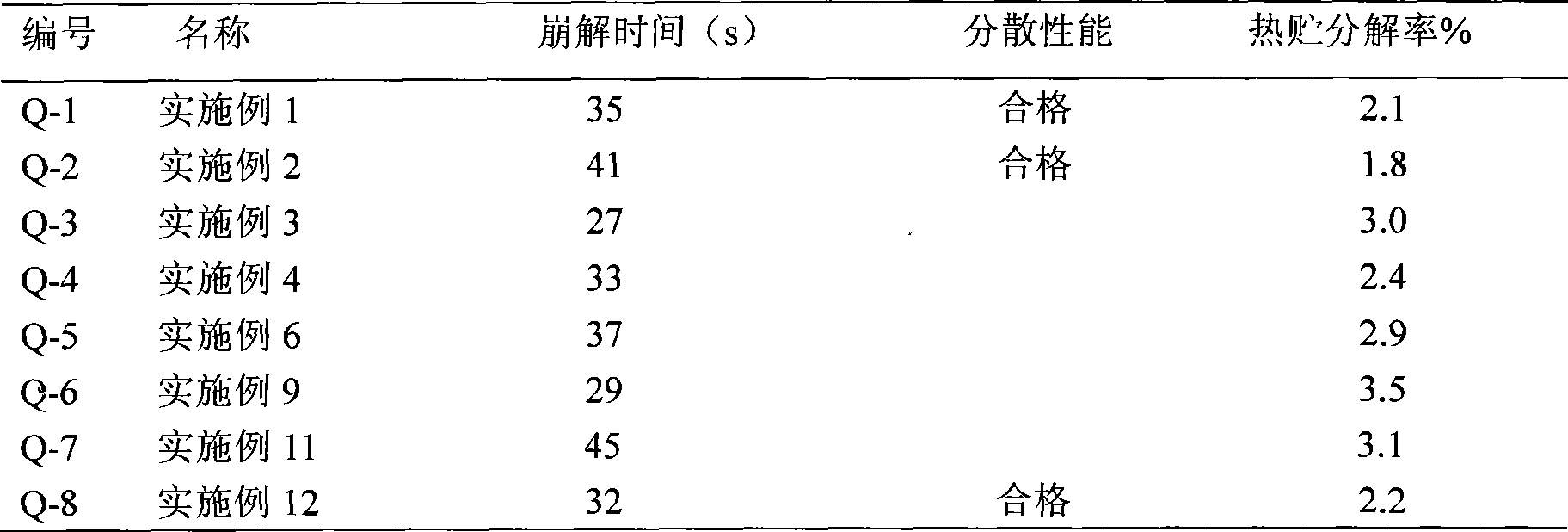

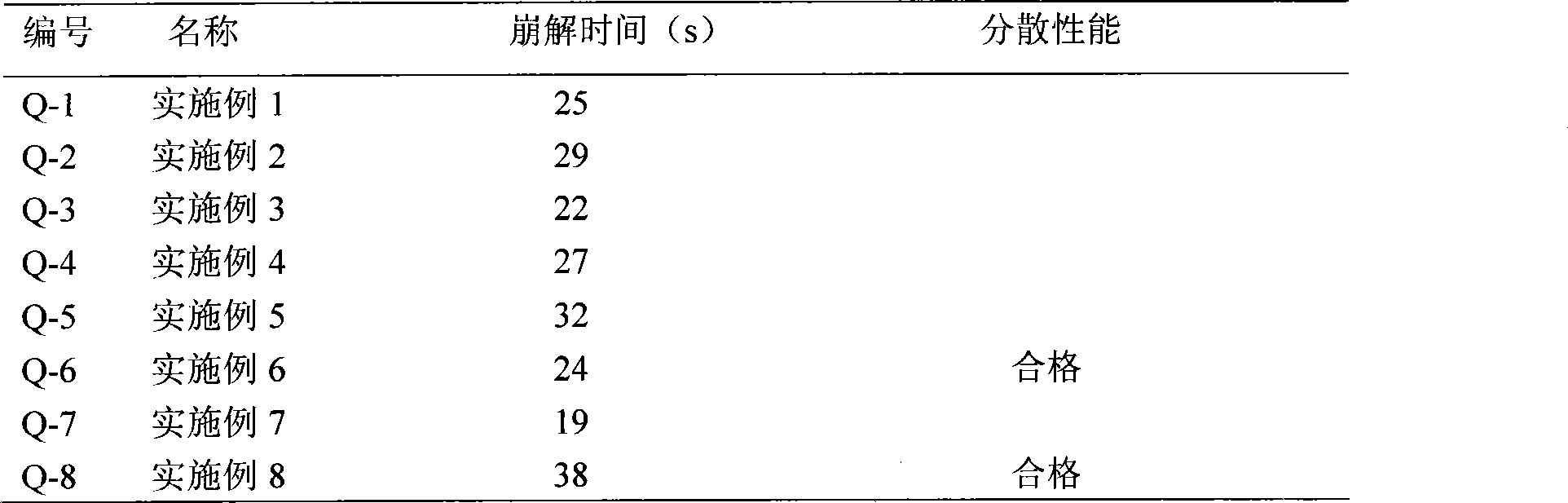

Fertilizer water-dispersion granule and preparation thereof

The invention relates to a fertilizer water dispersible granule and a method for preparing the same. The fertilizer water dispersible granule comprises one or more of plant nutrient substances and at least one surfactant which are processed to prepare the regular or irregular granular water dispersible granule. The fertilizer water dispersible granule consists of the following raw materials in portion by weight: 5 to 95 portions of the plant nutrient substance, 1 to 40 portions of the surfactant and 0 to 94 portions of an assistant. The invention has a preferential proposal: the plant nutrient substance comprises monopotassium phosphate, boric acid or borax, humic acid and salt thereof. The fertilizer water dispersible granule also comprises one or more of growth regulators. In addition, the fertilizer water dispersible granule can also comprise a disintegrating agent, an adhesive, a filler, a colorant and other assistants. The preparation method comprises: the metering, pulverization, even mixing, pelletization and drying of formula materials to obtain the fertilizer water dispersible granule. The fertilizer water dispersible granule has rapid disintegrating and dissolving (dispersing) speed in water, is fully dissolved, does not block a nozzle and a drop irrigation pipeline, is uneasy to absorb moisture, has high content of effective compositions, low packaging, storage, transportation, metering and use cost and high utilization rate of the effective compositions, reduces waste and environmental pollution, is widely applied to economic crop, gardening, lawn and urban greening and has extremely wide market application prospect.

Owner:SHENZHEN LANGTAI BIOTECH

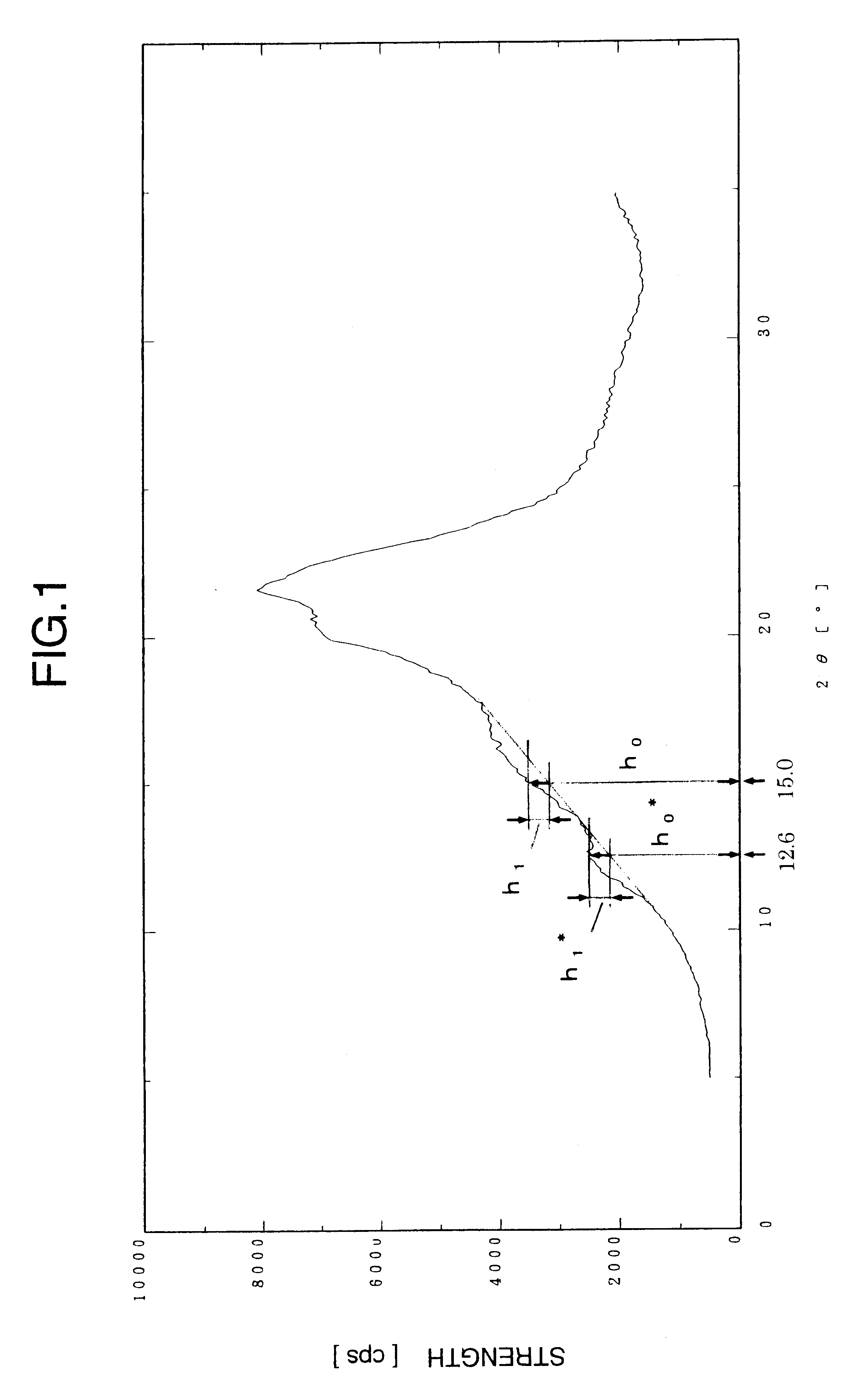

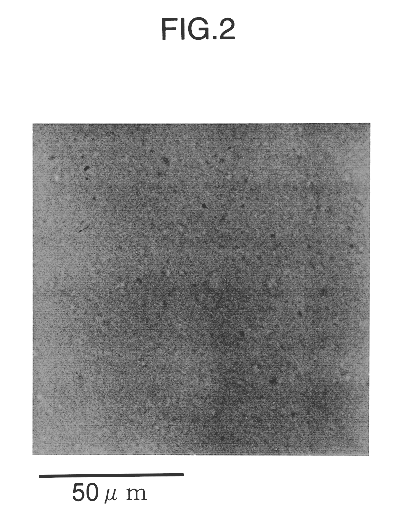

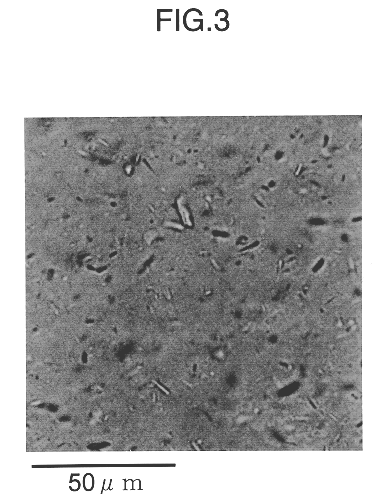

Cellulose dispersion

InactiveUS6541627B1Good dispersionImprove stabilitySugar derivativesCellulose coatingsCelluloseDispersion stability

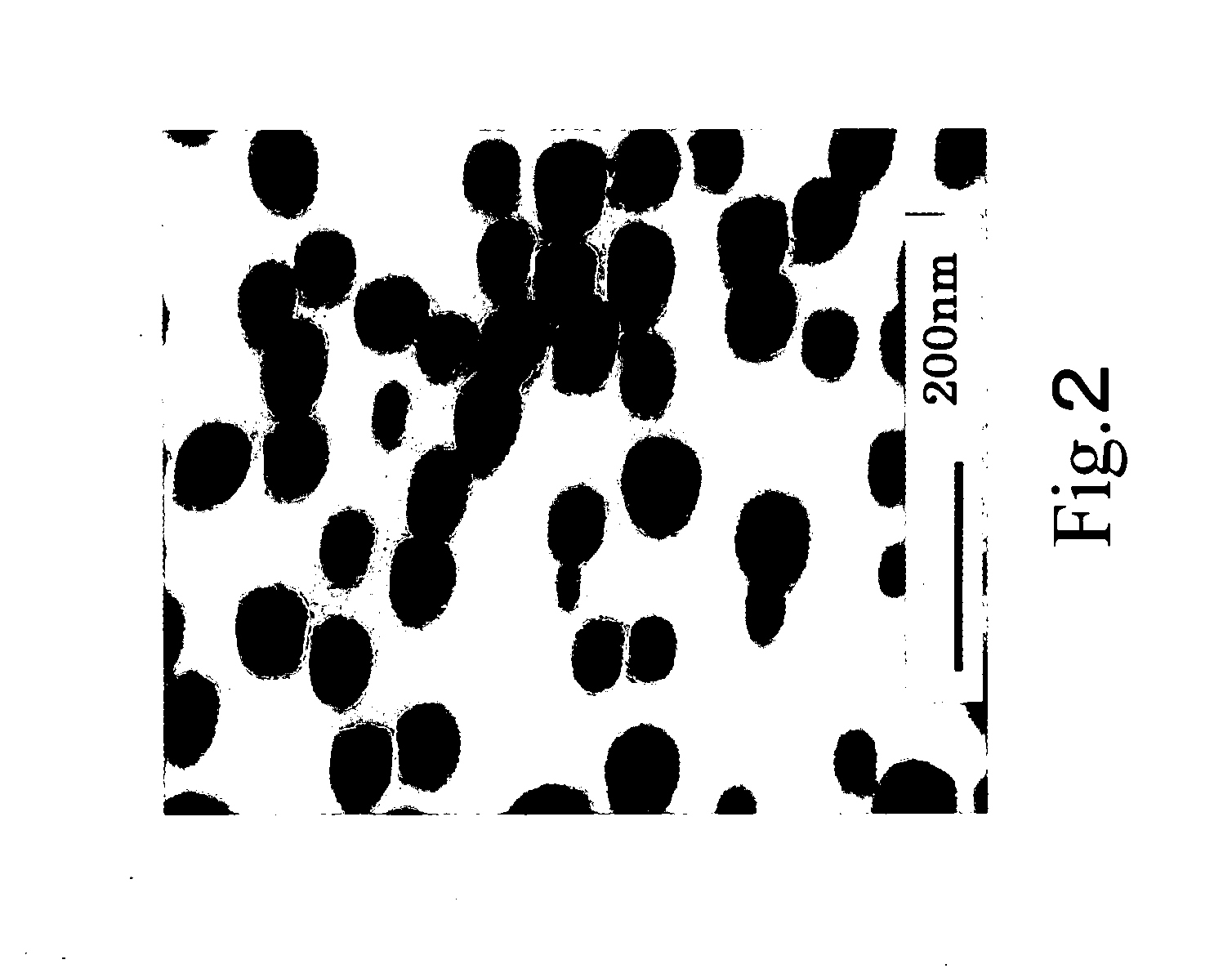

A cellulose dispersion which is a dispersion comprising a dispersing medium and a cellulose having a fraction of cellulose I type crystal component of not more than 0.1 and a fraction of cellulose II type crystal component of not more than 0.4 and in which the average particle diameter of the constitutive cellulose is not more than 5 mum. A cellulose particulate and a cellulose composite particulate which have an average particle diameter of 0.2 to 20 mum, a ratio of long diameter (L) to short diameter (D) observed through a scanning electron microscope (L / D) of not more than 1.2 and a coefficient of aggregation of 1.0 to 3.0. The present invention provides a cellulose dispersion which has an excellent effect such as dispersion stability or the like and is high in transparency. Moreover, it provides a cellulose particulate and a cellulose composite particulate which have such performances as no rough feel, excellent rolling properties, high dispersibility and the like.

Owner:ASAHI KASEI KK

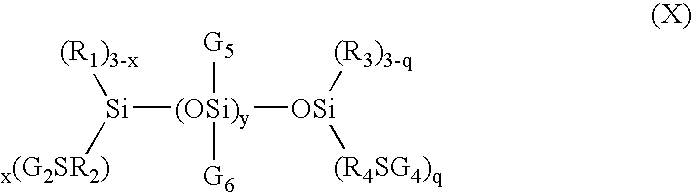

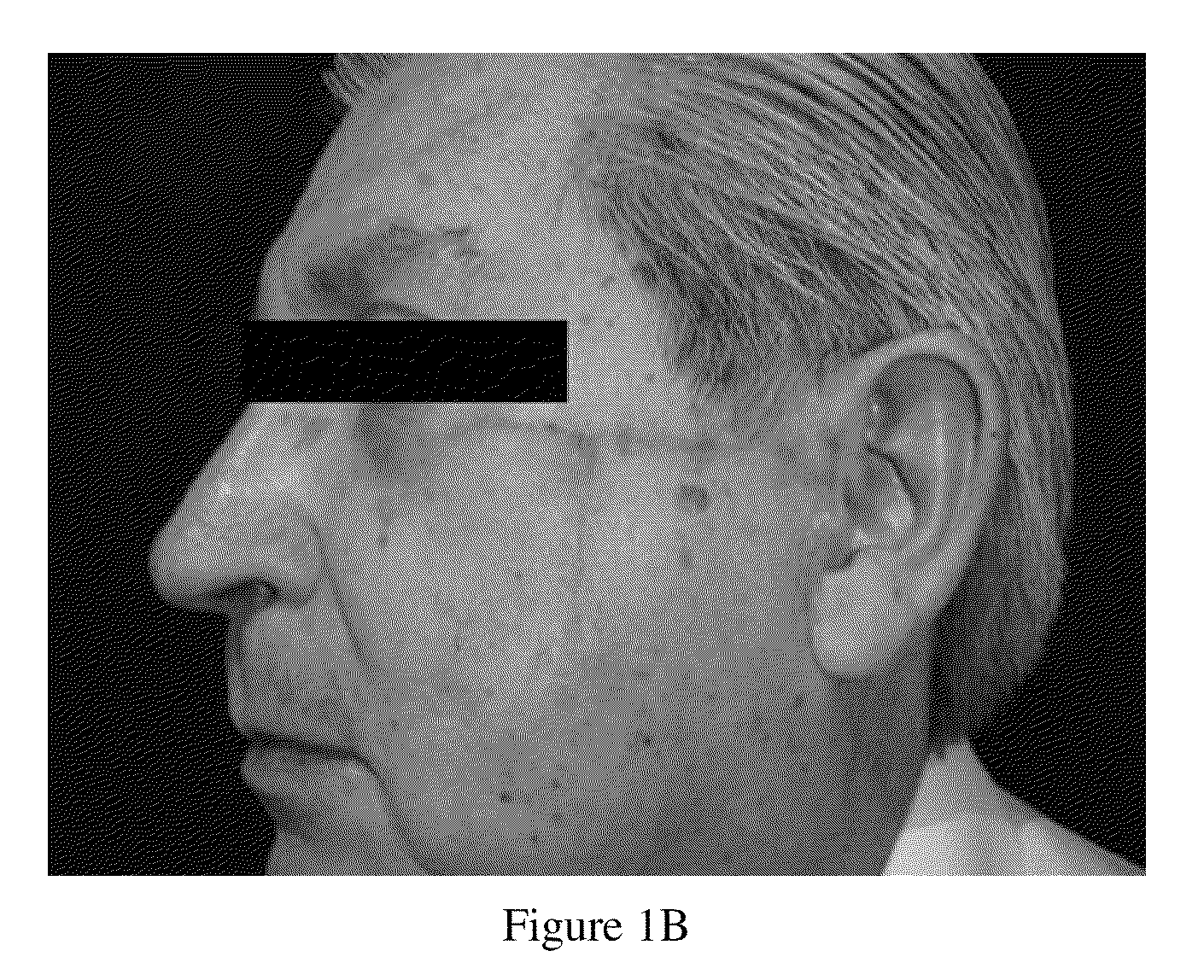

Polyether-modified polysiloxanes with block character and use thereof for producing cosmetic formulations

InactiveUS20070128143A1Easy to combineGood skin feelCosmetic preparationsHair cosmeticsType distributionSA copolymer

The invention provides a method of producing organomodified siloxanes with domain-type distribution obtained by partial or complete reaction of A) hydrogensiloxanes with a degree of distribution (persistency ratio) (η) of components [A] and [B] in the copolymer [AB]η=[A][B][AB]of η>1, preferably >1.1, in particular ≧1.2, with B) olefinically and / or acetylenically unsaturated compounds, the compounds resulting therefrom and their use.

Owner:EVONIK GOLDSCHMIDT GMBH

Nano-Fiber Compound Solutions, Emulsions And Gels, Production Method Thereof, Nano-Fiber Synthetic Papers, And Production Method Thereof

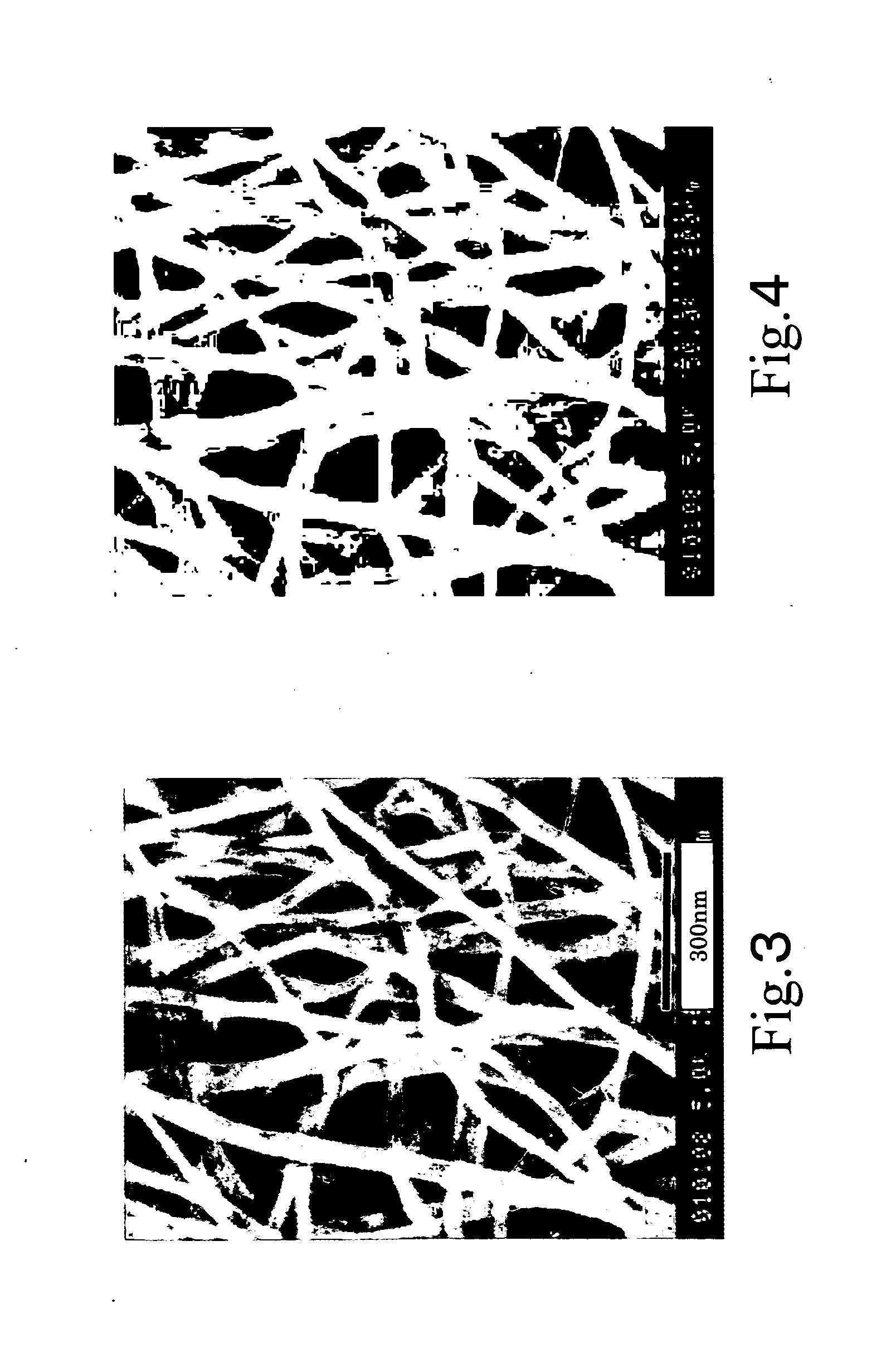

ActiveUS20070196401A1High affinitySoft skinCosmetic preparationsNon-fibrous pulp additionDispersion stabilityEmulsion

This invention provides compound solutions, emulsions and gels excellent in homogeneous dispersibility and long-term dispersion stability and also excellent in the properties as cosmetics, using disarranged nanofibers not limited in either form or polymer, widely applicable and small in the irregularity of single fiber diameter. This invention also provides a method for producing them. Furthermore, this invention provides synthetic papers composed of fibers, small in pore area and uniform in pore size, using disarranged nanofibers, and also provides a method for producing them. This invention provides compound solutions, emulsions, gels and synthetic papers containing disarranged nanofibers of 1 to 500 nm in number average diameter and 60% or more in the sum Pa of single fiber ratios.

Owner:TORAY IND INC

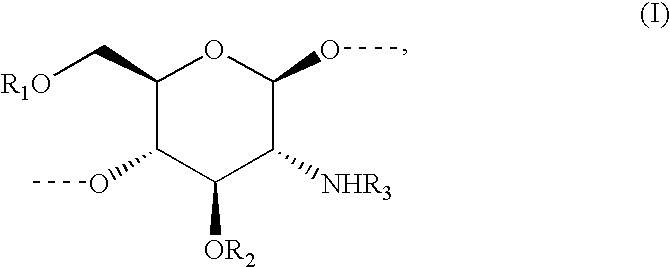

Hair treatment compositions containing N-hydroxy-alkyl-O-benzyl chitosans and methods of using same

InactiveUS20050226838A1EffectiveMaintain good propertiesCosmetic preparationsHair cosmeticsMedicineAdditive ingredient

The hair treatment composition contains preferably from 0.01 to 20 percent by weight of at least one N-hydroxyalkyl-O-benzyl chitosan and from 0.01 to 20 percent by weight of at least one other hair treatment effective ingredient. The at least one N-hydroxyalkyl-O-benzyl chitosan has at least one hydroxylalkyl group, preferably a hydroxyethyl, hydroxypropyl or hydroxybutyl group, and has from 2 to 20 carbon atoms. Various methods of treating hair with hair treatment compositions containing one or more of the N-hydroxyalkyl-O-benzyl chitosans are described.

Owner:WELLA AG

Water soluble effervescence composition and method of making the same

InactiveCN101423443AFast disintegrationQuick Dissolution (Dispersion)Carbon dioxide producing fertilisersMatrix fertilisersAdhesiveAdditive ingredient

The invention relates to an effervescent composition of a water-soluble fertilizer and a preparation method thereof. The effervescent composition contains one or a plurality of plant nutrient substances and one or a plurality of compounds which are contacted with water to generate gas. The effervescent composition comprises an optimized proposal that the plant nutrient substance is monopotassium phosphate. The effervescent composition can be also added with acid, a plant growth conditioner, a surfactant, a filler, a disintegrating agent, an adhesive, dye, a lube and the like. The preparation method comprises the following steps: ingredients are weighed, mixed, pulverized, pelletized and dried to obtain the effervescence composition. The effervescent composition can be manufactured through a routine production process, has rapid disintegrating and dissolving (diffusing) speed in the water, does not block a spray head or drip a pipeline, is uneasy to absorb dampness, has high content of effective compositions, low packaging, storage, metering and using cost and high utilization rate of the effective compositions, reduces waste and pollution to environment, is widely applied to economic crops, gardening, lawns and urban landscaping and has wide market application prospect.

Owner:SHENZHEN LANGTAI BIOTECH

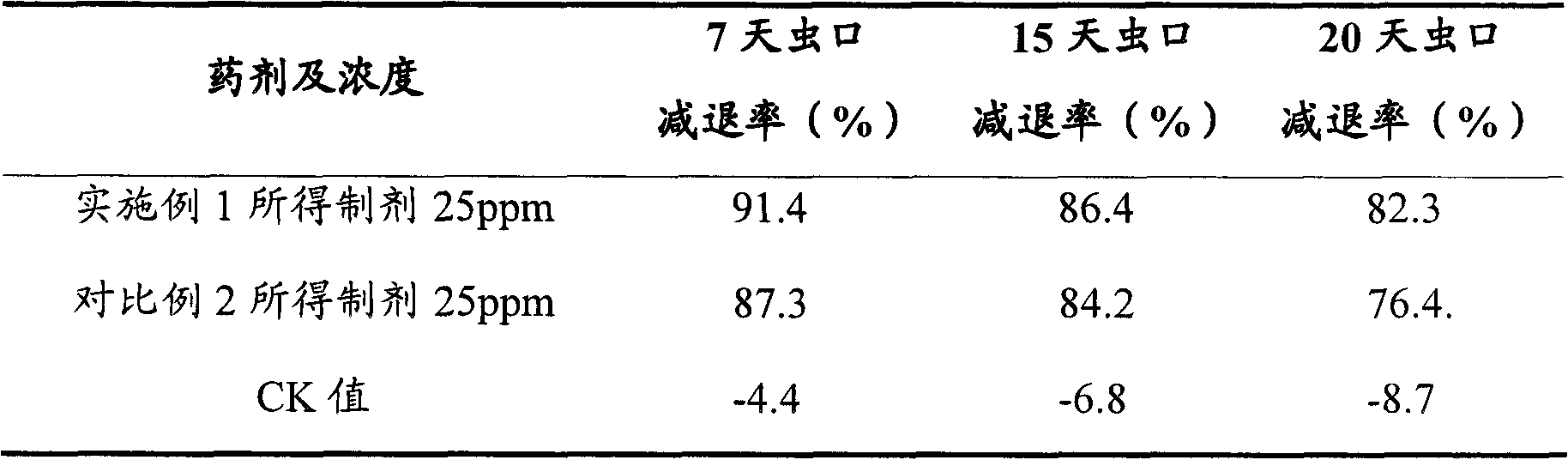

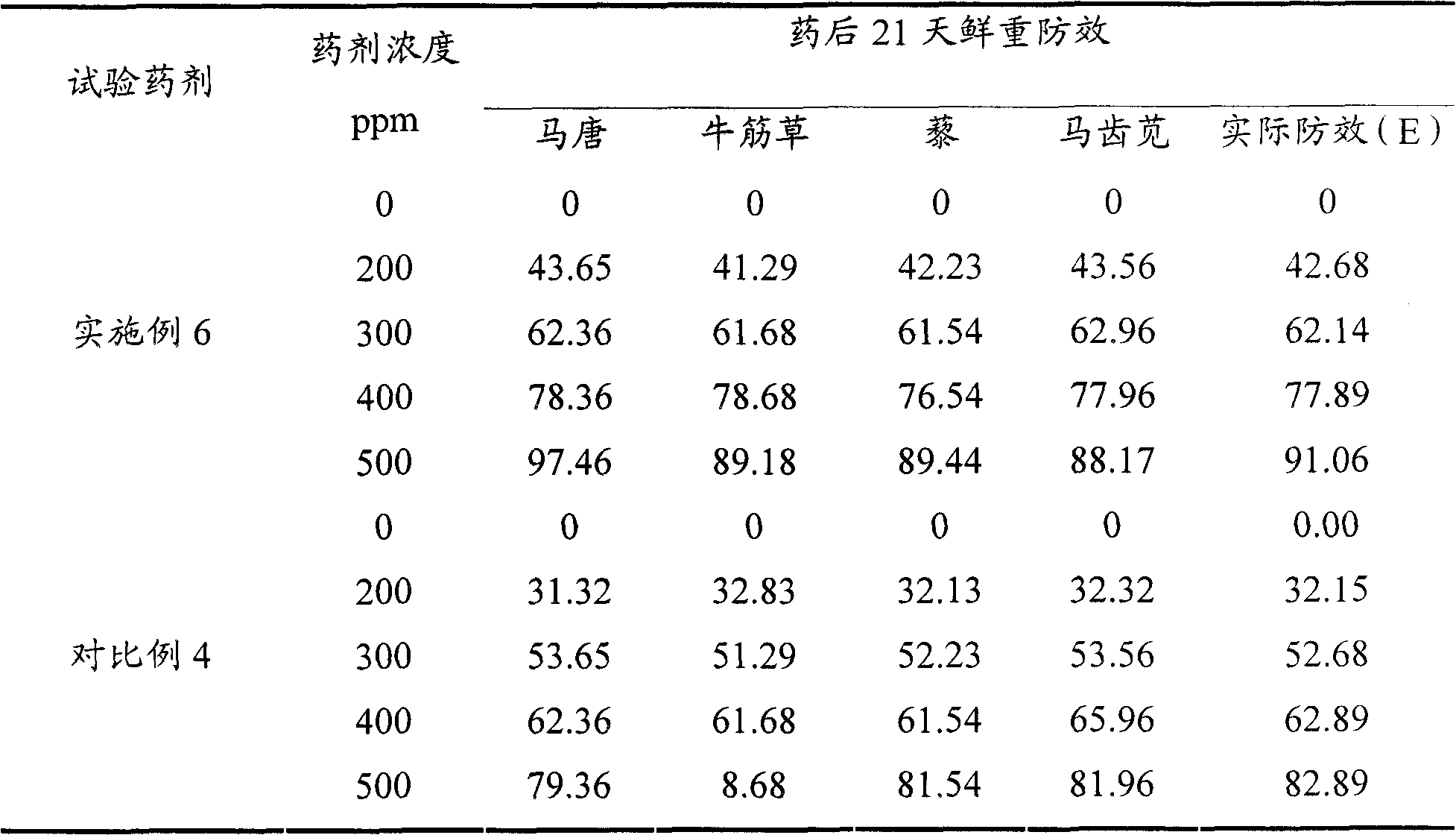

Pesticide oil suspension agent and preparation method thereof

ActiveCN101785455ASmall particle sizeGood spreadabilityBiocideFungicidesDispersion stabilityVegetable oil

The invention provides a pesticide oil suspension agent and a preparation method thereof; the pesticide oil suspension agent contains a pesticide active component, emulsifier, defoamer and a dispersion medium; and the dispersion medium is methyl oleate or the mixture of oil methyl ester and vegetable oil. The method for preparing the pesticide oil suspension agent comprises the following steps that: the dispersion medium and the emulsifier are mixed and emulsified; other components are added in to be mixed into pulp; and the pulp is ground by a grinder to prepare the oil suspension agent. Thepesticide oil suspension agent of the invention has small average grain size and high dispersion stability, has good extendibility and permeability on plant leaves, and improves the medicine effect of the product; and the preparation method of the pesticide oil suspension agent has simple process and low cost, facilitates industrial production, and has wide production application prospect.

Owner:SHENZHEN NOPOSION AGROCHEM

Clear cleansing detergent systems

InactiveUS6642198B2Good spreadabilityMild to skin and eyePowder deliveryCosmetic preparationsPolymer sciencePolyol

The present invention is directed to detergent compositions that not only have superior viscosity, spreadability, and clarity properties but also do not cause significant irritation to the skin and eyes. More specifically, acrylic polymeric thickeners are combined with polyol glycol thickeners in order to achieve such properties in detergent compositions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Clear cleansing detergent systems

InactiveUS20020123438A1Good spreadabilityMild to skinPowder deliveryCosmetic preparationsPolymer sciencePolyol

The present invention is directed to detergent compositions that not only have superior viscosity, spreadability, and clarity properties but also do not cause significant irritation to the skin and eyes. More specifically, acrylic polymeric thickeners are combined with polyol glycol thickeners in order to achieve such properties in detergent compositions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Color-changing wallpaper adhesive primer/activator

InactiveUS6894095B2Speed up the flowGood spreadabilityNon-macromolecular adhesive additivesControlling laminationAdhesiveColor changes

Adhesives and primer compositions that include water, a polymer and a pH indicator. The adhesives and primers have a visually-detectable color when wet, and preferably dry to a clear or transparent film, while having good flow and spreadability. The adhesives and primers provide a visual indication of wetness by including a pH indicator such that when the composition is wet, the pH indicator is colored such that the color and the intensity of the color provides a visual indication of wetness; sufficiency of thickness; and uniformity of application of the adhesive or primer.

Owner:ROMAN DECORATING PRODS

Cosmetic compositions containing swelled silicone elastomer powders and gelled block copolymers

InactiveUS20050220745A1Little phase separationMore aesthetic appealCosmetic preparationsHair cosmeticsSilicone ElastomersCopolymer

Owner:LOREAL SA

Use of high-purity phenylsilsesquioxane liquids for the preparation of cosmetic and pharmaceutical compositions

InactiveUS20030077240A1Feel goodBroaden applicationCosmetic preparationsSilicon organic compoundsSilanolOrganic compound

Owner:CLARIANT INT LTD

Anti-wrinkle and anti-aging cosmetic and preparation method thereof

ActiveCN104856928ASoft skinGood spreadabilityCosmetic preparationsToilet preparationsBiotechnologyFacial skin

The invention discloses an anti-wrinkle and anti-aging cosmetic and a preparation method thereof, and belongs to the technical field of cosmetics. The anti-wrinkle and anti-aging cosmetic contains the following raw materials: 1%-3% of an emulsifier, 5%-15% of a humectant, 5%-15% of an emollient, 2%-6% of active matters and the balance of water, wherein the active matters are trifluoroacetyl tripeptide-2 and a skincare composition of glycerinum and glucosan, an echinacea extract and a white truffle extract; the skincare composition has a synergistic effect in improvement of the skin elasticity. The cosmetic disclosed by the invention is capable of increasing the skin elasticity, reducing fine lines and wrinkles of facial skin and relieving skin dropping and sagging and wrinkles, and simultaneously has the characteristics of being light in texture and easy to absorb.

Owner:TIANJIN YU MEI JING GRP

High-entropy alloy brazing filler metal for welding TA2 and 0Cr18Ni9Ti and preparation method thereof

InactiveCN101590574AHigh strengthImprove toughnessWelding/cutting media/materialsSoldering mediaElectric arc furnaceHigh entropy alloys

The invention discloses a high-entropy alloy brazing filler metal for welding TA2 and 0Cr18Ni9Ti. The brazing filler metal comprises the following compositions according to atomic percentage: 20 to 25 percent of Ti, 25 to 30 percent of Cu, 20 to 25 percent of Ni, 15 to 20 percent of Fe, 10 to 13 percent of Cr, 0.5 to 5 percent of Sn, 0.01 to 2 percent of In, and 0.01 to 2 percent of Ga. The invention also discloses a method for preparing a high-entropy alloy brazing filler metal foil, which comprises the following steps: smelting the compositions to obtain high-entropy master alloy in steps by a super-high vacuum arc furnace; and controlling the linear speed of a roller at 5 to 40m / s by a single roller rapid setting device to obtain the high-entropy alloy brazing filler metal foil. The high-entropy alloy brazing filler metal has good flexibility, and is convenient for processing and assembling; and in welding, the high-entropy alloy brazing filler metal has good matching property with welded metal and alloy, brazing seams have excellent corrosion resistance and are single-phase fcc solid solution tissues, and joints have high comprehensive mechanical performance.

Owner:XIAN UNIV OF TECH

Nanometer conductive silver paste and preparing method thereof

InactiveCN104240793AGood silver powder solubilityModerate boiling pointNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePlasticizer

The invention relates to a nanometer conductive silver paste and a preparing method thereof. The nanometer conductive silver paste is characterized in that mass percentage content of the components are as follows: 20-90% of a silver powder, 0.01-5% of a high-molecular resin, 0.01-5% of an organic silicone oil, 0.01-10% of a thickening agent 1, 0.01-5% of a thickening agent 2, 0.01-5% of a plasticizer, 0.5-1% of a dispersant, 0.5-1% of a leveling agent, 5-20% of a solvent 1, and 5-20% of a solvent 2. The nanometer conductive silver paste of the invention has a remarkable low-temperature sintering property and saves energy. A formed circuit has advantages of high conductivity, high adhesiveness and high hardness. A selected Teslin substrate is degradable and environment-friendly. The nanometer conductive silver paste has wide application prospect in paste application fields of RFID electronic label, LED circuit board, touch screen circuit, etc.

Owner:NANO TOP ELECTRONICS TECH

Transparent solid oil cosmetics

ActiveUS20060280763A1High transparencyLarge transmittanceCosmetic preparationsHair removalWaxDiisostearyl malate

A solid cosmetic comprising components (A), (B), (C), and (D) below: (A) a polyamide resin; (B) diisostearyl malate; (C) a polyglyceryl isostearate; and (D) a liquid oil; and not containing a wax when the component (A) comprises only an ester-terminated polyamide resin.

Owner:KOKYU ALCOHOL KOGYO

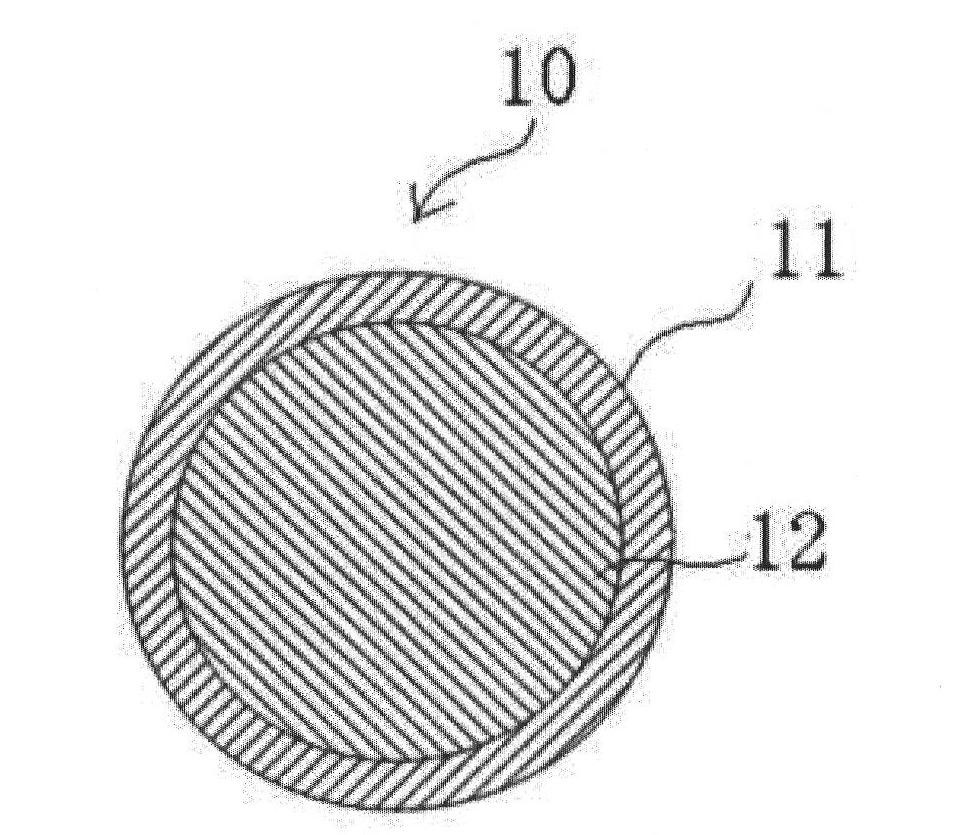

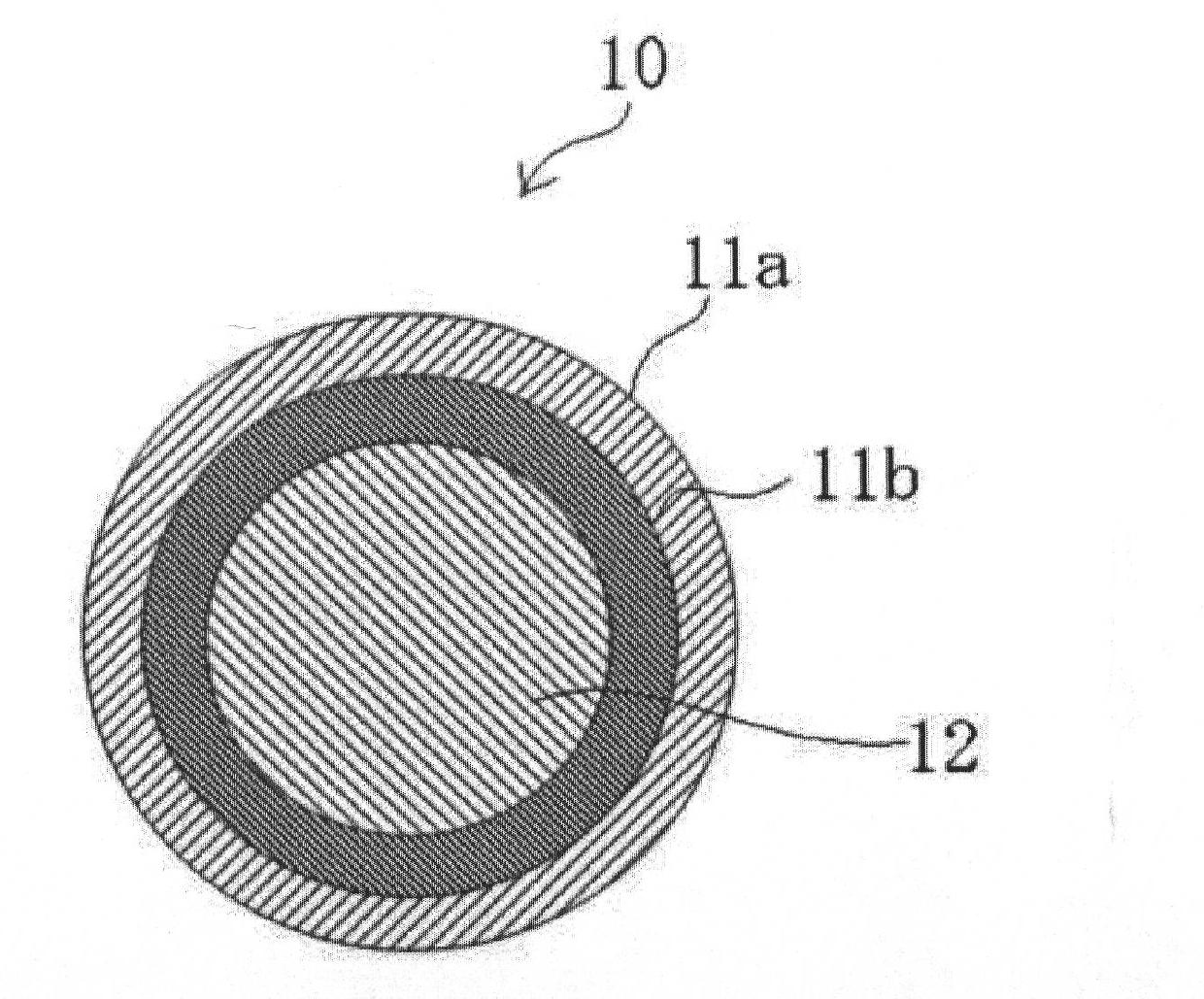

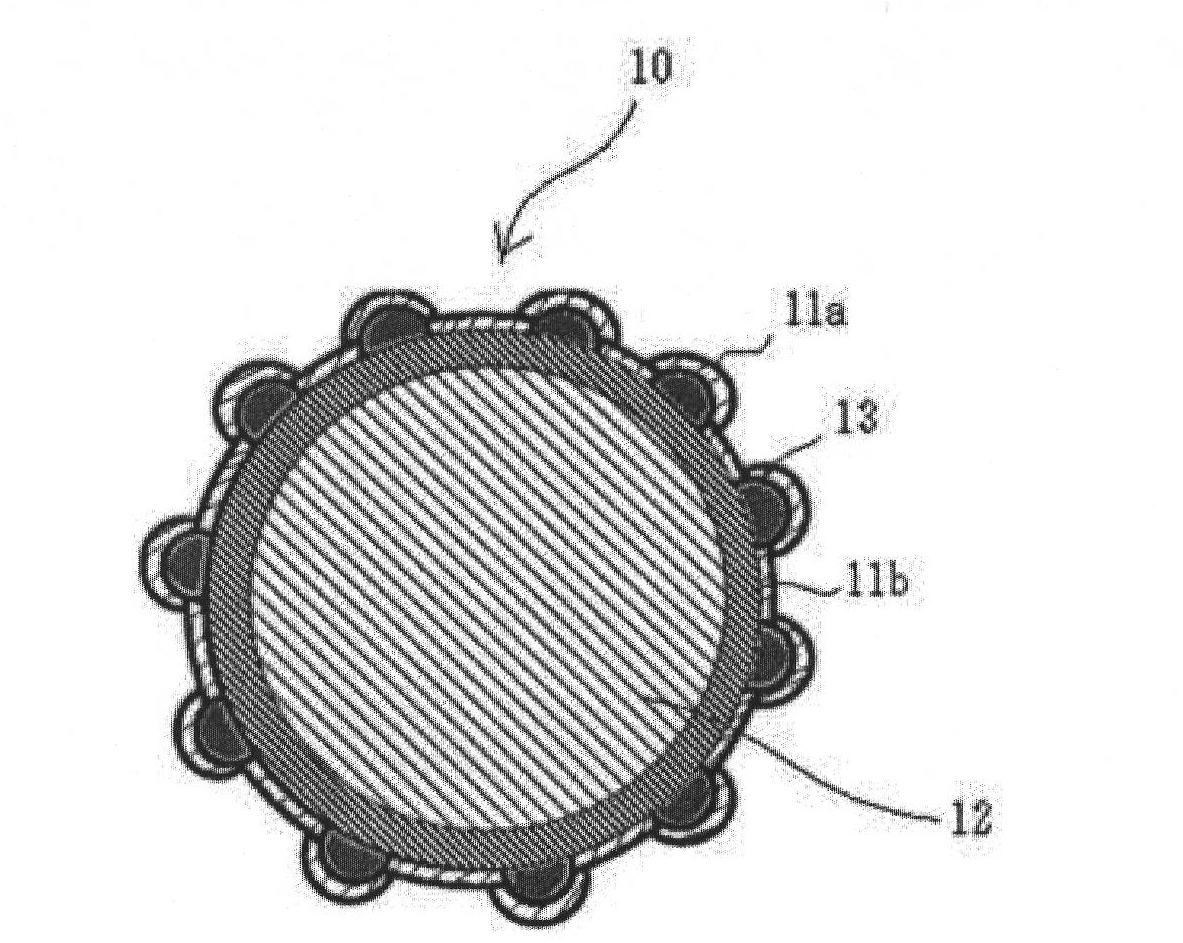

Conductive particle, anisotropic conductive film, joined body, and connecting method

ActiveCN102089832AGood spreadabilitySuppress stressPrinted circuit assemblingNon-insulated conductorsAnisotropic conductive filmElectrical connection

Disclosed are conductive particles wherein stress can be suppressed by improving spreadability while maintaining high hardness (cracks hardly occur even when the particles are crushed during the connection). The conductive particles assure sufficient electrical connection reliability not only for ITO substrates but also for IZO substrates. An anisotropic conductive film comprising the conductive particles, a joined body comprising the anisotropic conductive film, and a connecting method using the anisotropic conductive film are also disclosed. Each of the conductive particles comprises a polymer fine particle and a conductive layer formed on the surface of the polymer fine particle, and is characterized in that the outermost shell of the conductive layer is composed of a nickel-palladium alloy layer.

Owner:DEXERIALS CORP

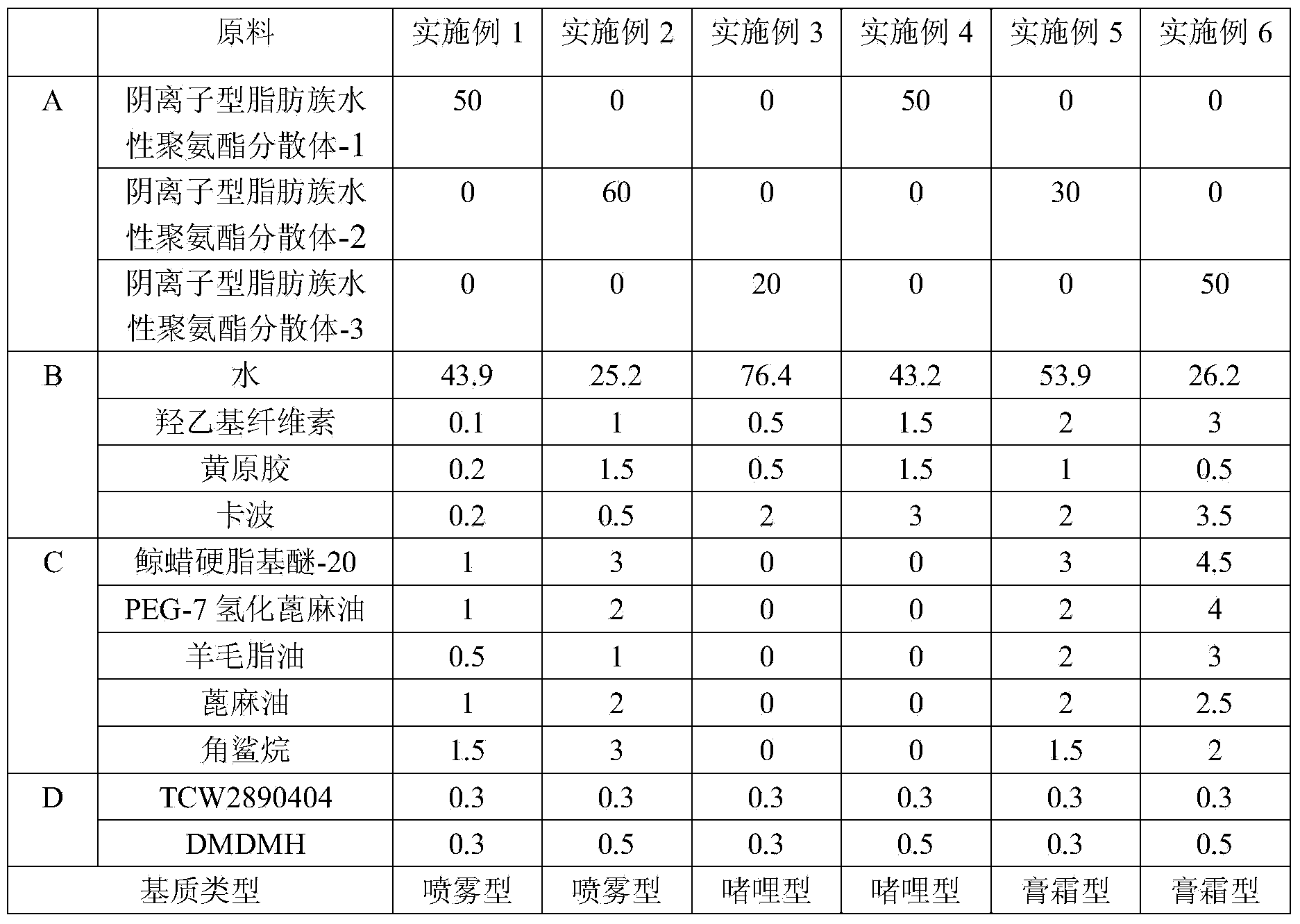

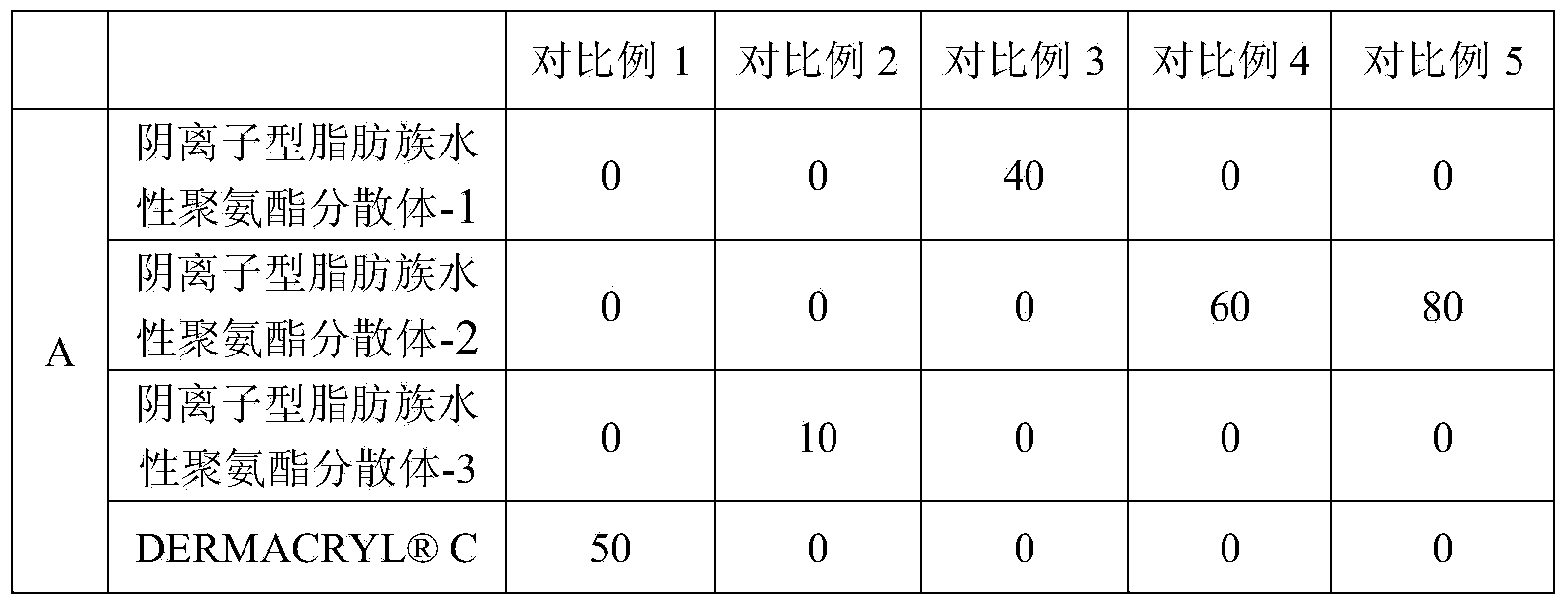

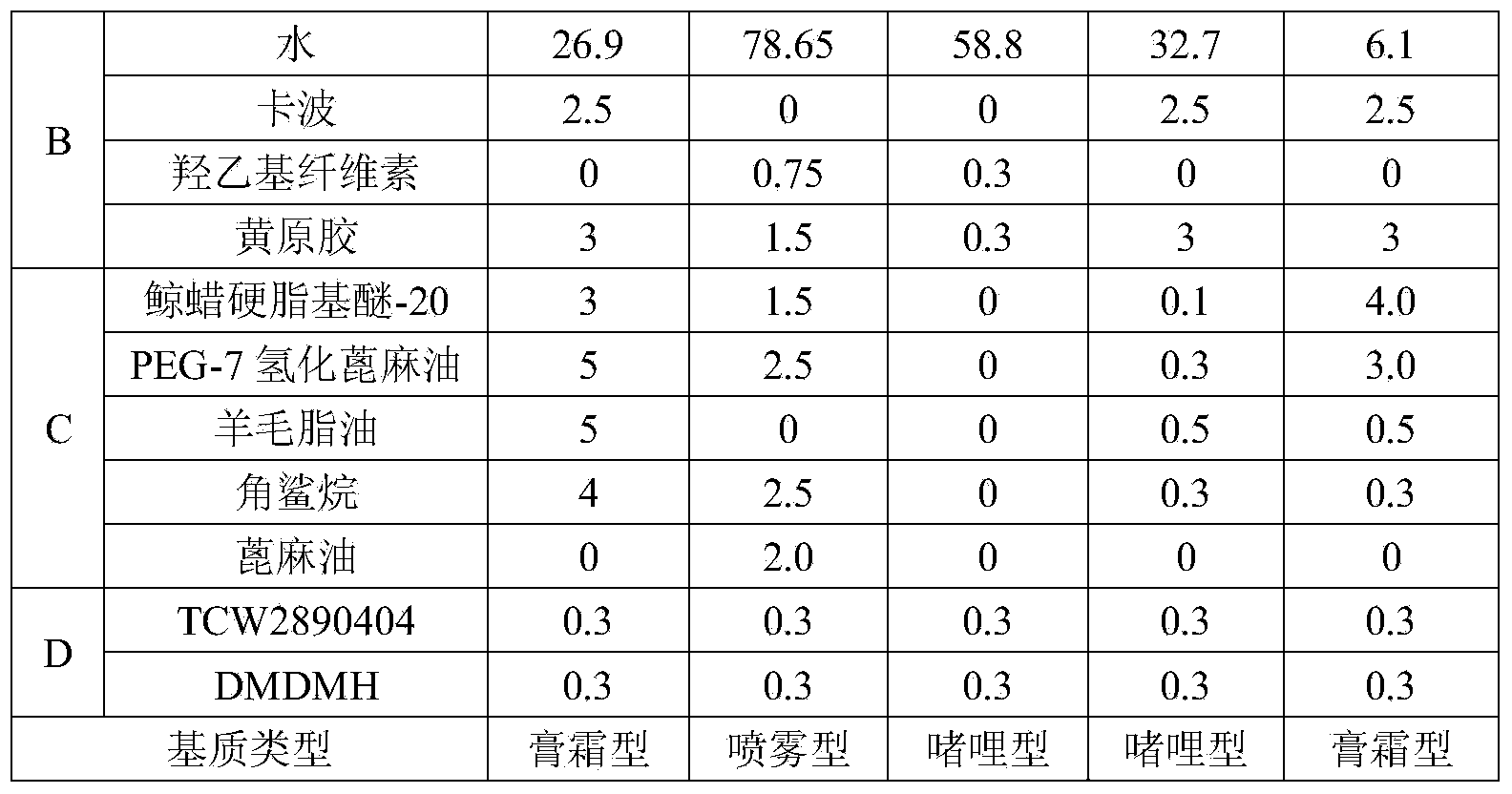

Strippable facial mask substrate based on waterborne polyurethane dispersoid

ActiveCN104352359AAvoid stimulationEasy to cleanCosmetic preparationsToilet preparationsFacial skinChemistry

The invention discloses a strippable facial mask substrate based on waterborne polyurethane dispersoid. The strippable facial mask substrate takes the waterborne polyurethane dispersoid as a main ingredient and is matched with a thickening agent, an emulsifying agent, grease, a preservative, essence and the like. During use, the skin is uniformly coated with the strippable facial mask substrate, the strippable facial mask substrate can be completely attached to facial skin to form a film, and the film is breathable and is not tight after formed; the facial mask substrate further has the efficacy of skin tightness; and during stripping, the substrate is wetted by water, a facial mask can be taken down like voile, tearing pain feeling is avoided, no residue is left, and perfect stripping is realized. The strippable facial mask substrate has good compatibility with active functional components, essence containing moisturizing ingredients, whitening ingredients, anti-aging ingredients and the like can be added to prepare facial masks with various effects, meanwhile, the strippable facial mask substrate can be applied to the fields of strippable hand masks, neck masks, leg masks, body masks and the like.

Owner:WANHUA CHEM GRP +2

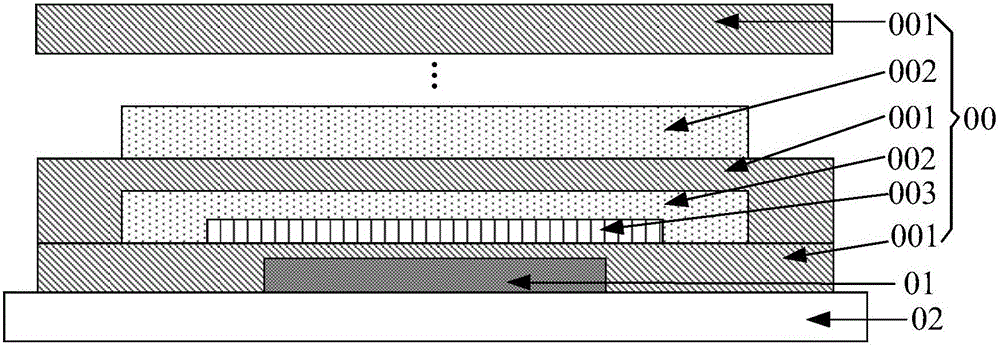

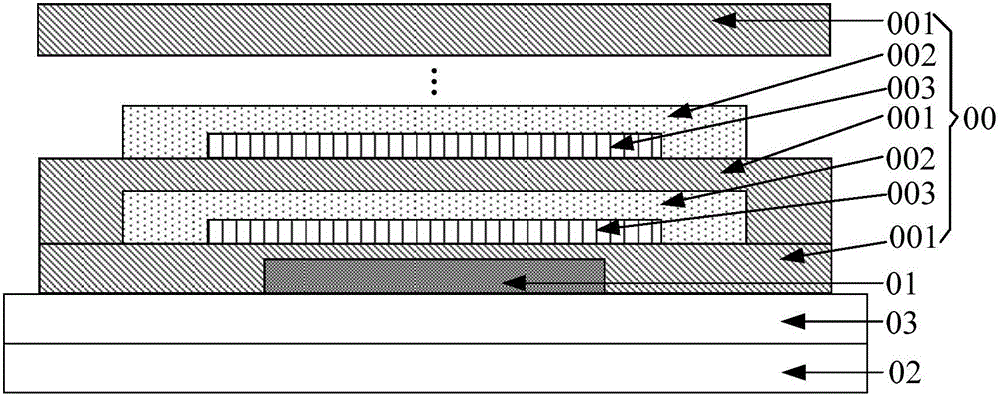

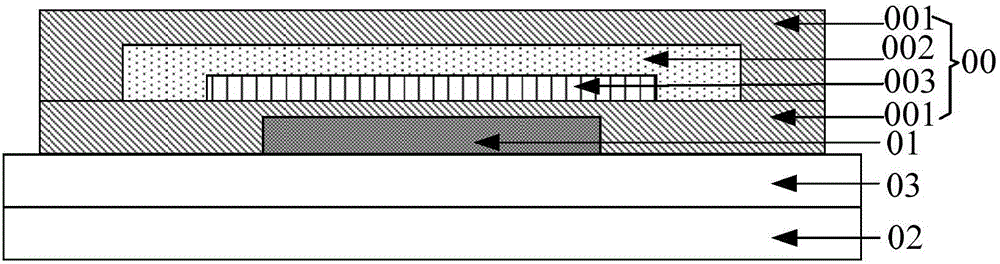

Thin-film packaging structure and display device

InactiveCN105789257AEasy to crackEasy to fillSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a thin-film packaging structure and a display device, and belongs to the technical field of packaging of display devices. The thin-film packaging structure comprises a plurality of film layers, wherein the plurality of film layers coat the outer side of a to-be-packaged device and include alternately stacked inorganic layers and organic layers; in the plurality of film layers, the film layers at the inner sides and the outer sides of the plurality of film layers all are inorganic layers; in the plurality of film layers, an auxiliary spreading layer is formed between the first inorganic layer and the first organic layer; the hydrophilic-hydrophobic property of the auxiliary spreading layer is the same as that of the first organic layer; the first inorganic layer is the film layer, in contact with the to-be-packaged device, in the plurality of film layers; and the first organic layer is the organic layer in contact with the first inorganic layer. According to the thin-film packaging structure, the problem of relatively poor filling effects of the organic layers on cracks and defects in the inorganic layers is solved; improvement of the filling effects of the organic layers on the cracks and defects in the inorganic layers is achieved; and the thin-film packaging structure is suitable for packaging of the display device.

Owner:BOE TECH GRP CO LTD

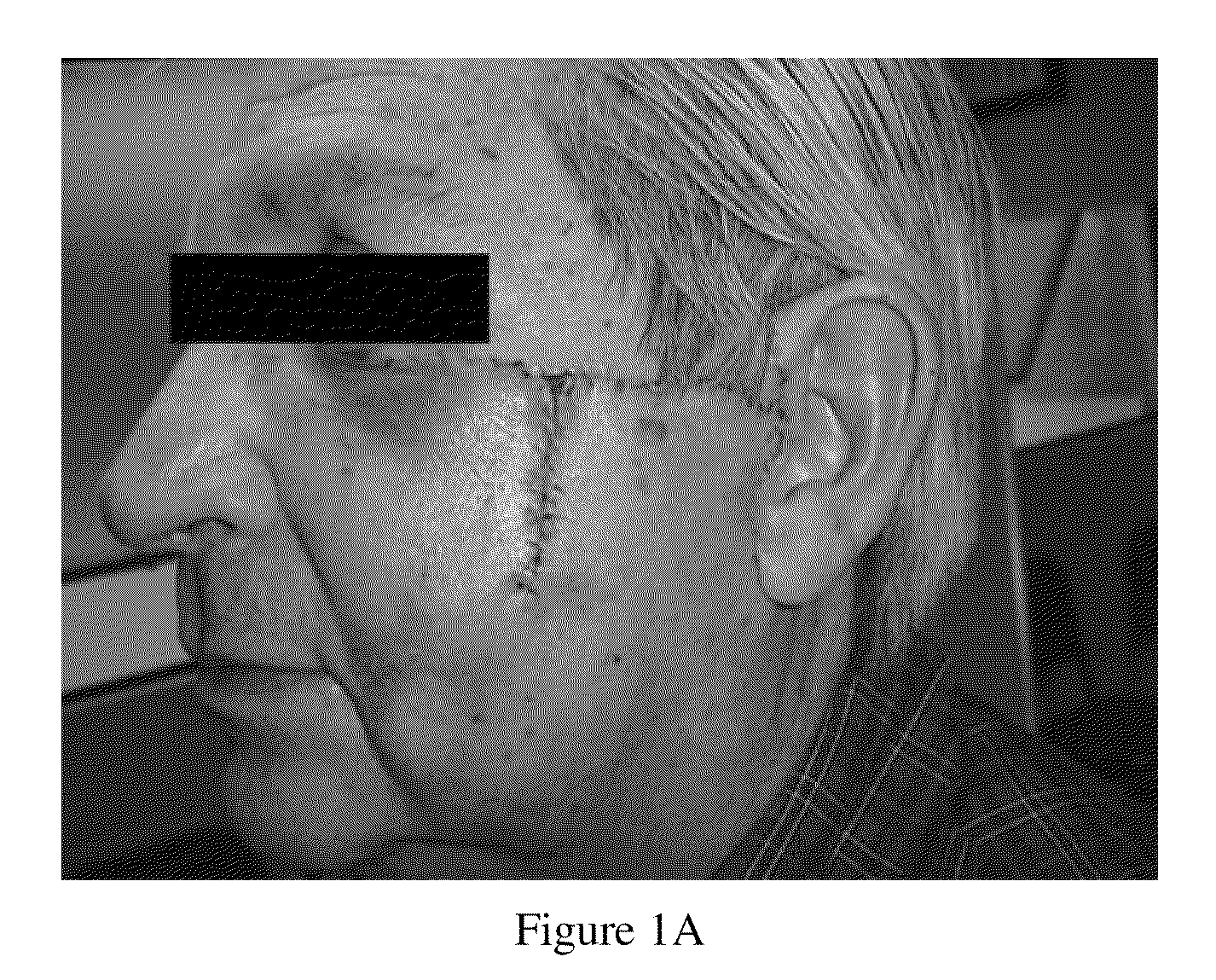

Silicone gel-based compositions for wound healing and scar reduction

ActiveUS20090143333A1Reduce formationGood lookingBiocideSilicon compound active ingredientsWound healingSilicone Gels

This invention is a composition comprising a cyclic siloxane, a silicone occlusive fluid, a silicone occlusive gel, and a silicone resin powder. The composition is useful for wound healing.

Owner:VALEANT PHARMA INT

Sugar-free bread and method for producing the same

The invention relates to a sugar-free bread, characterized by comprising the materials with the following components: high-gluten flour 150-900 parts, low-gluten flour 200-800 200-800 parts, water-free ghee 50-200 parts, sugar-free modifier 50-200 parts, sugar-free milk 10-150 parts, egg 50-10 parts, bread modifier 1-20 parts, yeast 10-20 parts, ghee 200-800 parts. The inventive technology avoids coldness or heat in fed materials contacted with yeast, causing the yeast to exert optimal fermentation ability. The prepared sugar-free nutritious bread is deeply favored by wide consumers.

Owner:天津金世制药有限公司

Leave-on compositions for personal care

InactiveUS20030086888A1Easy to spreadGood spreadabilityOrganic active ingredientsCosmetic preparationsPersonal careEmulsion

The present invention relates to leave-on compositions for personal care comprising trimethylsilylalkylsilsesquioxanes, particularly trimethylsilyl-n-octylsilsesquioxanes (Caprylyl Trimethicones). Said trimethylsilylalkylsilsesquioxanes are especially useful in formulating emulsions.

Owner:CLARIANT LIFE SCI MOLECULES SPA

Low solid content halogenide-free water-based type cleaning-free scaling powder

InactiveCN101327552AHigh activitySolve the defect of insufficient wettabilityWelding/cutting media/materialsSoldering mediaWater basedAviation

The present invention relates to a medium-and-high-activity, low-solid-content halideless water-based type wash-free soldering flux which is applicable to the spraying process, the foaming process and the dipping process. The soldering flux is composed of the following weight proportions of substances: 1 percent to 4 percent of promoting agent, 0.5 percent to 1.5 percent of filmerformer, 20 percent to 40 percent of latent solvent, 0.1 percent to 2 percent of wetting agent and 0.01 percent to 0.1 percent of corrosion inhibitor, and the rest is deionized water. The soldering flux of the present invention does not contain halogen and colophony; soldering material can have good spreadability; a PCB board can have good solder permeability; soldering spots are plump and shiny; the surface of the soldered PCB board has no visible residues and is not eroded, and the surface insulation resistance is high; under the normal temperature, the soldering flux does not absorb moisture and cannot be decomposed, and a washing process can be omitted. Since the deionized water is used as solvent, the soldering flux does not contain any volatile organic substance, so the soldering flux cannot be ignited and does not explode, and therefore the soldering flux is environment-friendly. The soldering flux is applicable to the wave-soldering or dip-soldering production line of various printed boards in the fields of communication, aviation, computers, etc.

Owner:DONGGUAN YONGAN TECH

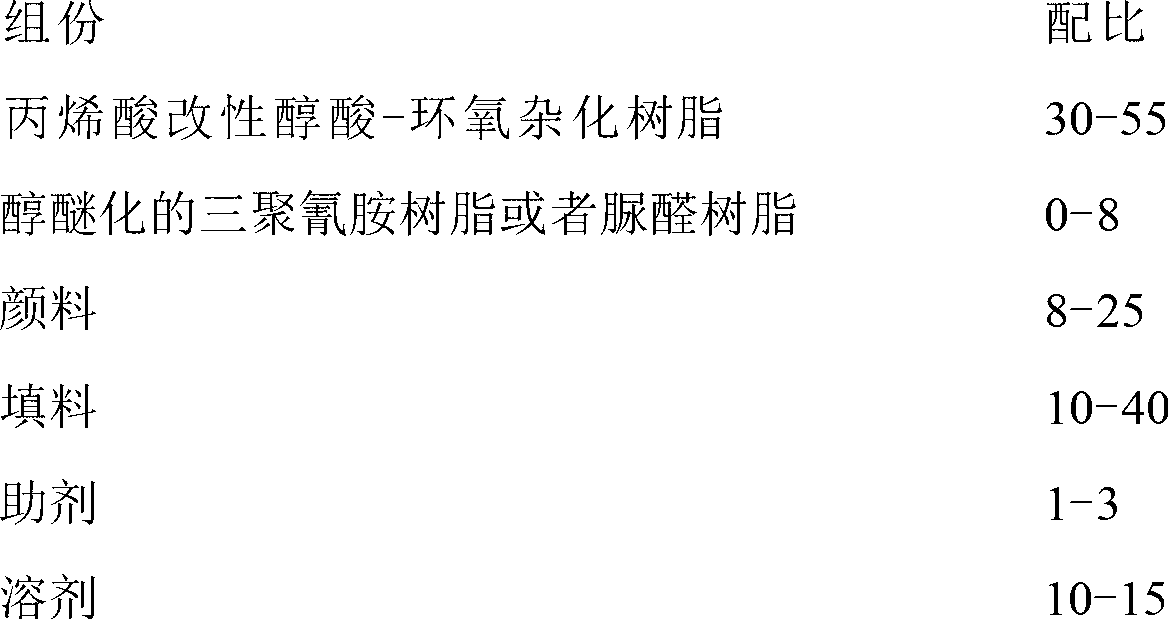

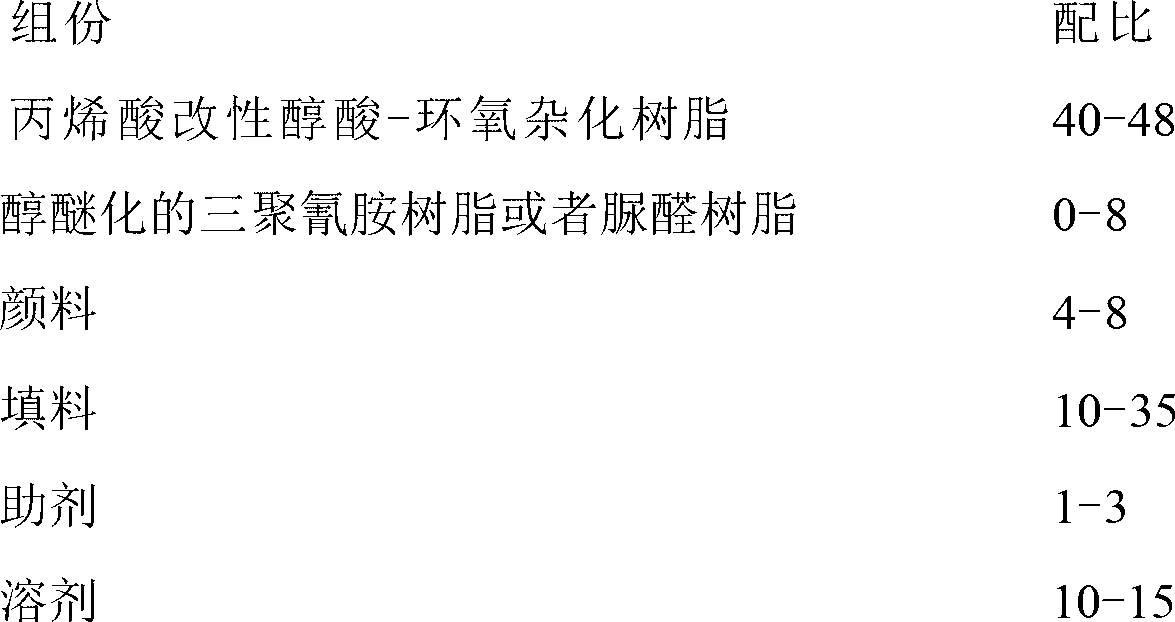

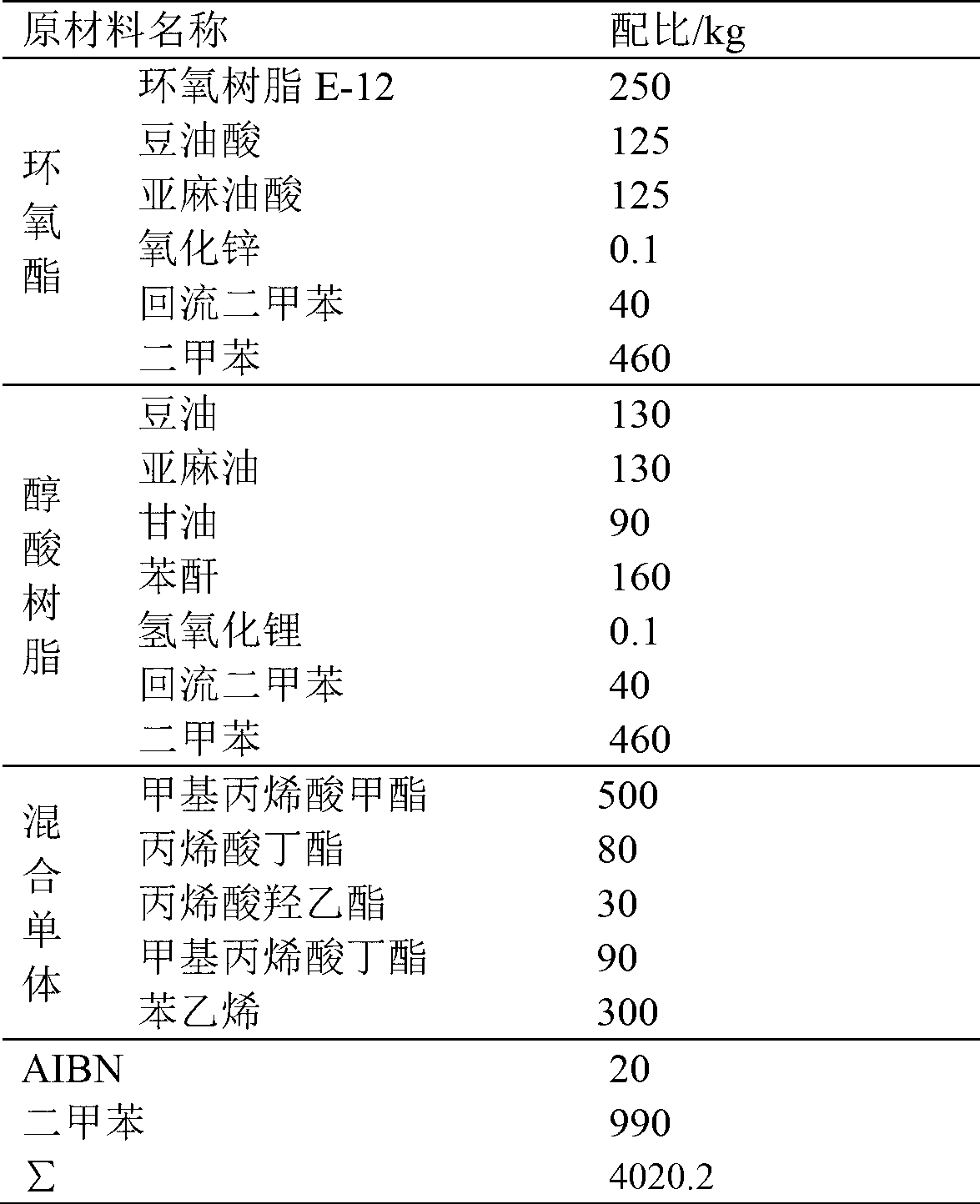

Acrylic-modified alcohol acid-epoxy ester hybrid resin and paint thereof

The invention relates to an acrylic-modified alcohol acid-epoxy ester hybrid resin which is prepared by the following steps: carrying out high-temperature esterification reaction on an epoxy resin and fatty acid under the action of an esterification catalyst to obtain epoxy ester; carrying out alcoholysis on vegetable oil and polyalcohol at high temperature, cooling, and adding polybasic acid for esterification, thereby obtaining an alkyd resin; and adding acrylic monomers into the epoxy ester-alkyd resin mixed solution, and carrying out graft polymerization under the action of an initiator to obtain the hybrid resin. The hybrid resin can be used as a main film forming material to prepare a high-temperature baking varnish together with a crosslinking agent. The high-temperature baking varnish can be used as various curtain-coating mirror back paints, including silver mirror back paints, aluminum mirror back paints, glass paints and the like, can satisfy the technological requirements for application of curtain coating production lines of which the width exceeds 3m, has a stable curtain coating, and can become completely dry after being baked at 150-130 DEG C for 3-5 minutes. The product has the advantages of low-temperature quick drying, high hardness, excellent adhesive force, dampness-heat resistance, chemical resistance, salt-fog resistance and the like.

Owner:常州市弘可利办公用品有限公司 +1

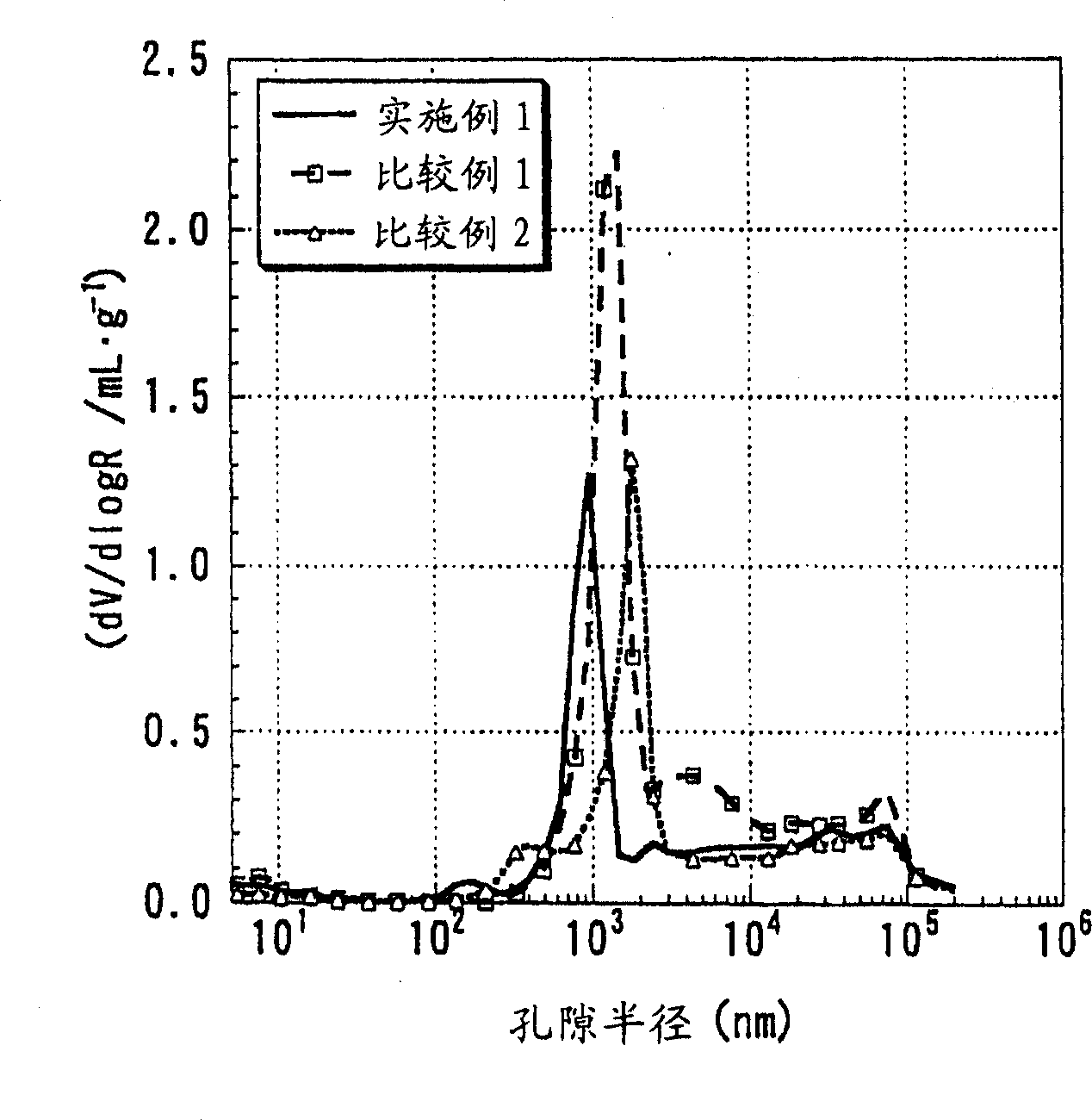

Lithium composite oxide particle for positive electrode material of lithium secondary battery, and lithium secondary battery positive electrode and lithium secondary battery using the same

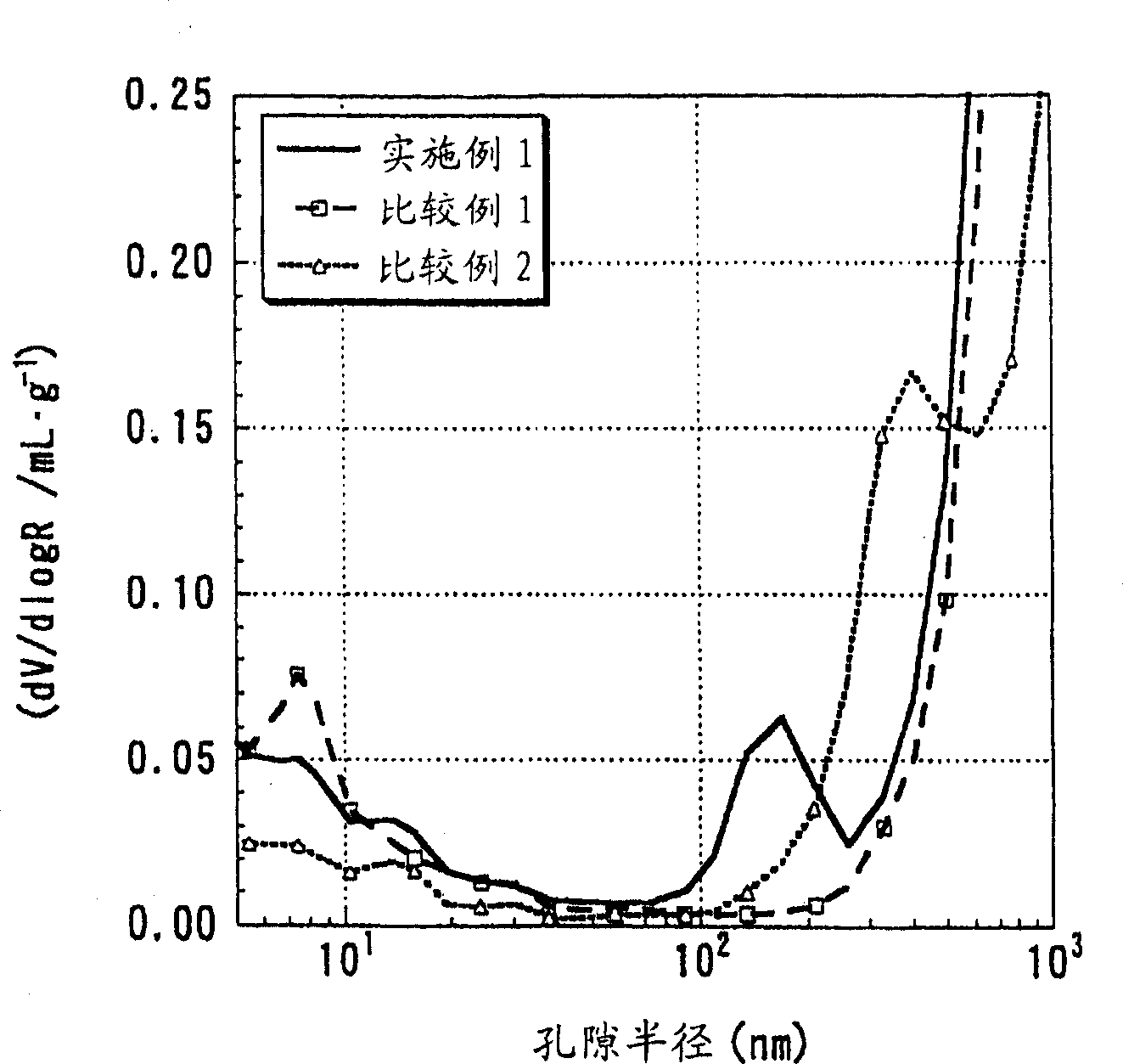

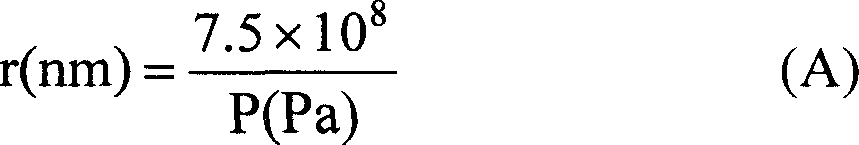

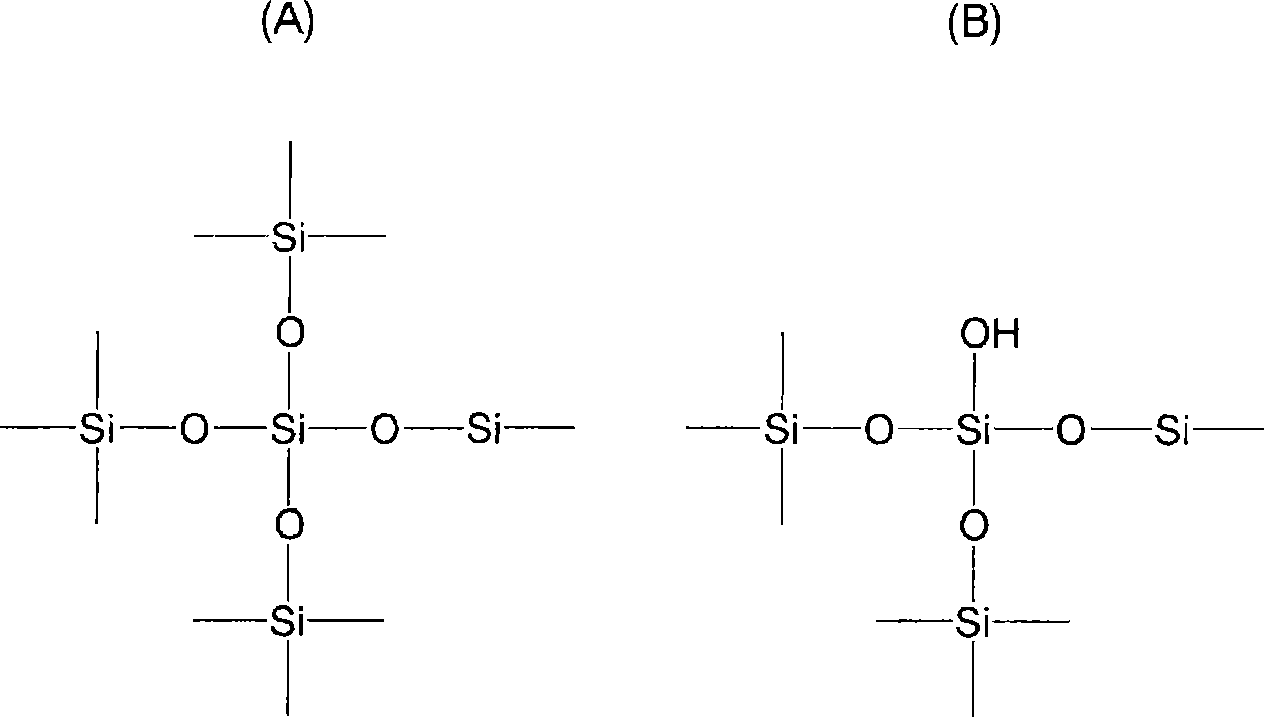

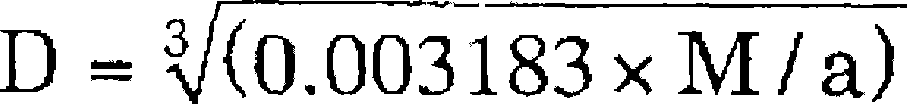

ActiveCN1856890AImproved low temperature load characteristicsExcellent spreadabilityActive material electrodesSecondary cellsPore distributionComposite oxide

An improved positive electrode material for lithium secondary battery that enhances the low temperature load characteristics of battery and further enhances coatability at the fabrication of positive electrode. In the measurement according to the mercury penetration method, the following condition (A) is satisfied and simultaneously at least one of the following conditions (B) and (C) is satisfied. Condition (A) On the mercury penetration curve, the quantity of mercury penetration at a pressure increase from 50 MPa to 150 MPa is 0.02 cm<3> / g or less. Condition (B) On the mercury penetration curve, the quantity of mercury penetration at a pressure increase from 50 MPa to 150 MPa is 0.01 cm<3> / g or more. Condition (C) The average pore radius is in the range of 10 to 100 nm, and further the pore distribution curve has a main peak whose peak top exists at a pore radius ranging from 0.5 to 50 mum and a subpeak whose peak top exists at a pore radius ranging from 80 to 300 nm.

Owner:MITSUBISHI RAYON CO LTD

Liquid rinse-off compositions for personal care comprising a trimethyl-silylalkylsilsesquioxane

InactiveUS6489274B1Increase the gloss and sheen of the hairImprove skinCosmetic preparationsHair cosmeticsPersonal careTrimethylsilyl

This invention relates to liquid rinse-off compositions for personal care comprising trimethylsilylalkylsilsesquioxanes, particularly trimethylsilyl-n-octylsilsesquioxanes (Caprylyl Trimethicones). Preferably the rinse-off compositions are shampoos containing pearlescent and / or opacifying agents.

Owner:CLARIANT FIANCE (BVI) LTD

Coating composition and its manufacturing method, and resin molding and its manufacturing method

ActiveCN101208397AGood spreadabilityGood lookingLiquid surface applicatorsSilicaVitrificationCoated surface

A coating composition excellent in applicability and / or appearance of coated surface, which can give resin moldings having antisweating effect, moisture-conditioning effect, stainproofness and cooling effect (moisture-release cooling effect and / or moisture-release heat-absorbing effect) and / or high endurance. A coating composition comprising an inorganic porous material, a binder resin and a solvent as the essential components, which satisfies the following requirements: (1) the inorganic porous material contains at least one silicon compound, (2) the binder resin has (a) a hydroxyl number of solid matter of 5 to 80 mgKOH / g and (b) a glass transition temperature (Tg) of -5 to 40 C, and (3) the solvent contains at least one organic solvent.

Owner:MITSUBISHI CHEM CORP

Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and preparation method thereof

InactiveCN102319963AReduce brittlenessImprove surface activityWelding/cutting media/materialsSoldering mediaSlagAlloy

The invention relates to an Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and a preparation method thereof. The components of the aluminum-based brazing filler metal are 7 to 13 percent by weight of Si, 5 to 11 percent by weight of Cu, 4 to 11 percent by weight of Zn, 1 to 6 percent by weight of Sn, 1 to 3 percent by weight of Ni, 0.02 to 0.3 percent by weight of Ce, 0.01 to 0.1 percent by weight of Sr, 0.01 to 0.2 percent by weight of Zr and the balance of Al. The process flow for preparing the aluminum-based brazing filler metal is that: pure aluminum is added into a graphite crucible and covered by flux for aluminum under the condition of 800 DEG C to 900 DEG C, and slag is removed after melting; the aluminum-based intermediate alloy of high-melting point elements and flux for aluminum are added at the same time, and melting, stirring and slag removal are carried out; the aluminum-based intermediate alloy of low-melting point elements is added under the protection of nitrogen, and melting and stirring are carried out; the mixture of argon and hexachloroethane is added to carry out refining, and standing and slag removal are carried out; the intermediate alloy of trace elements is added, and melting and stirring are carried out; secondary refining and slag removal are carried out; and under the protection of nitrogen, casting formation is carried out. The Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal has the advantages of low melting point, high strength, high toughness, high corrosion-resistant property and good wetting property and spreadability.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

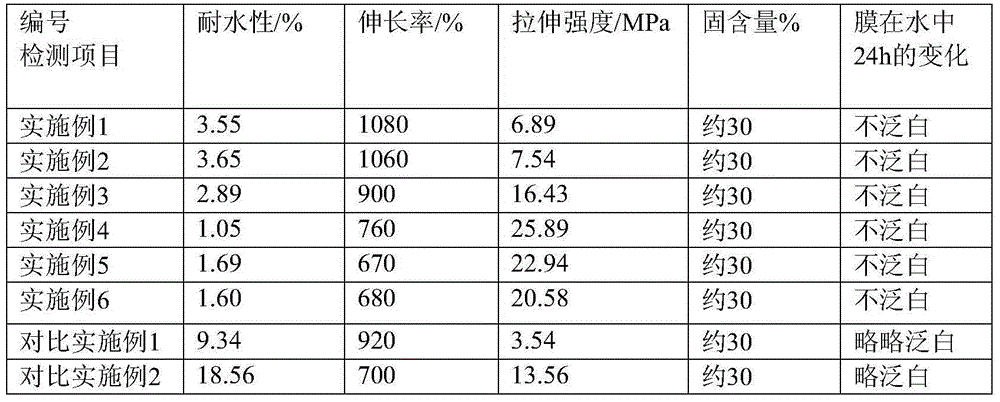

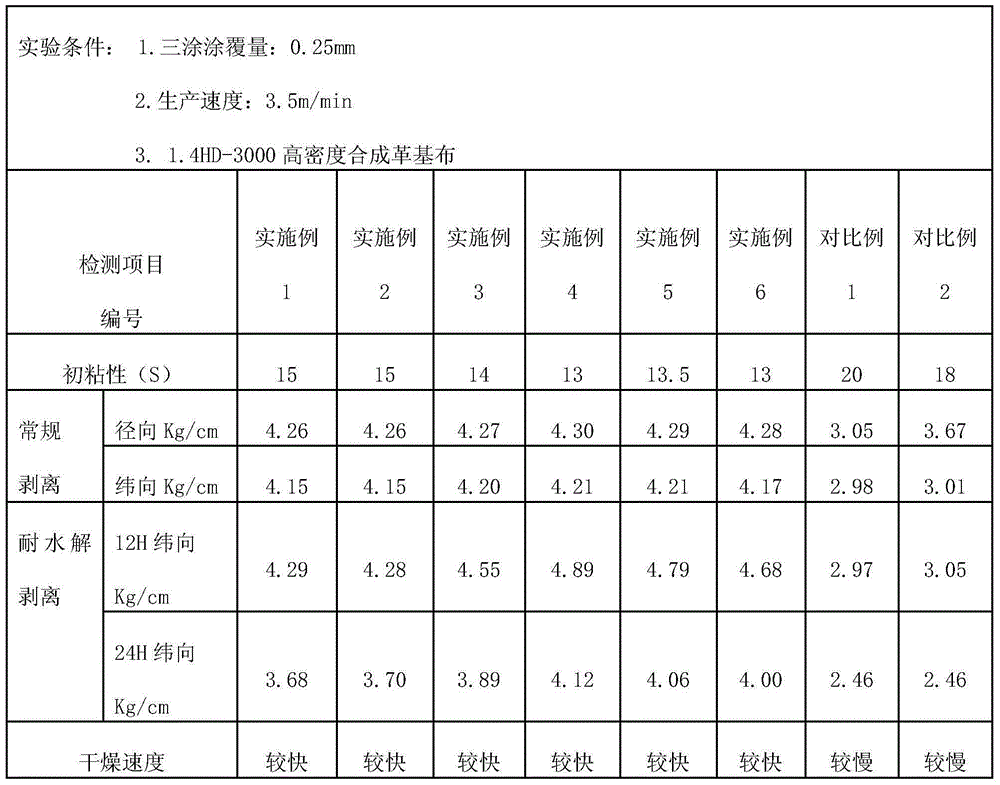

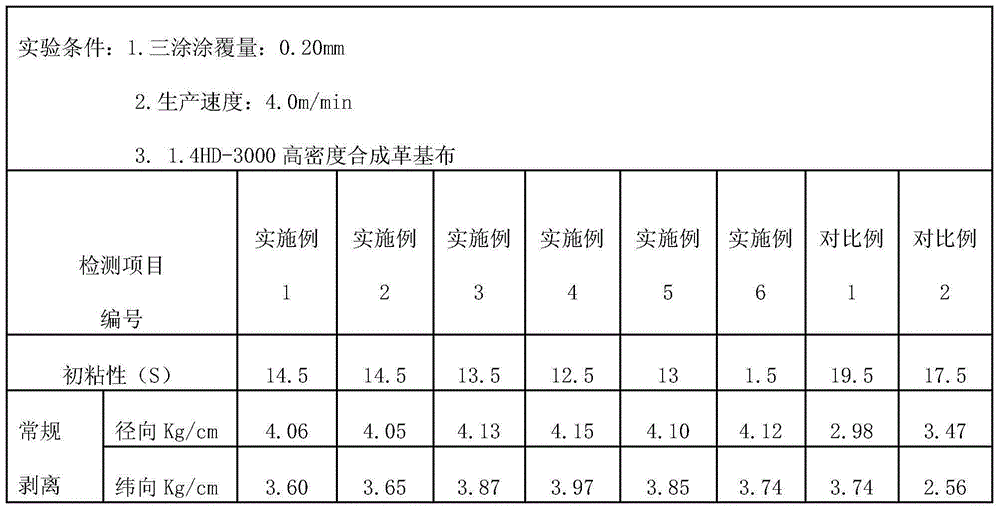

Synthetic leather binding agent and preparation method thereof

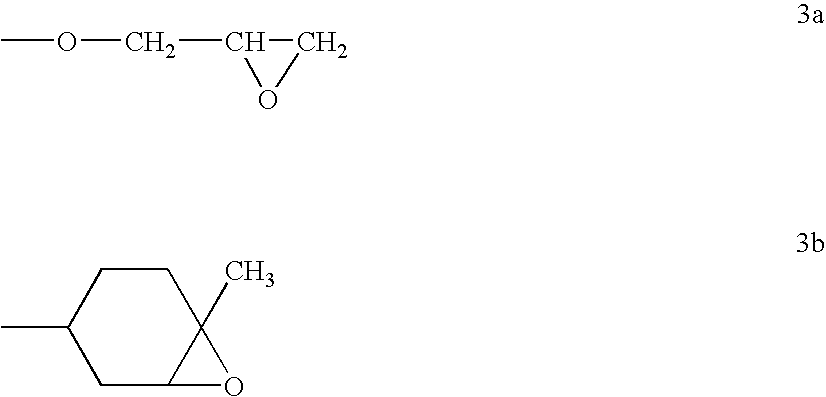

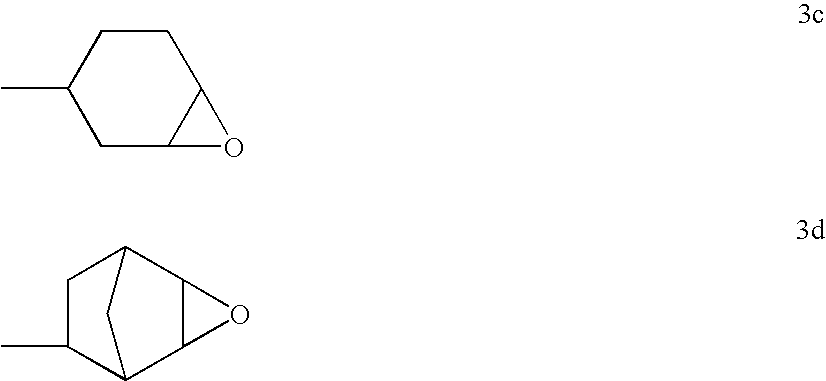

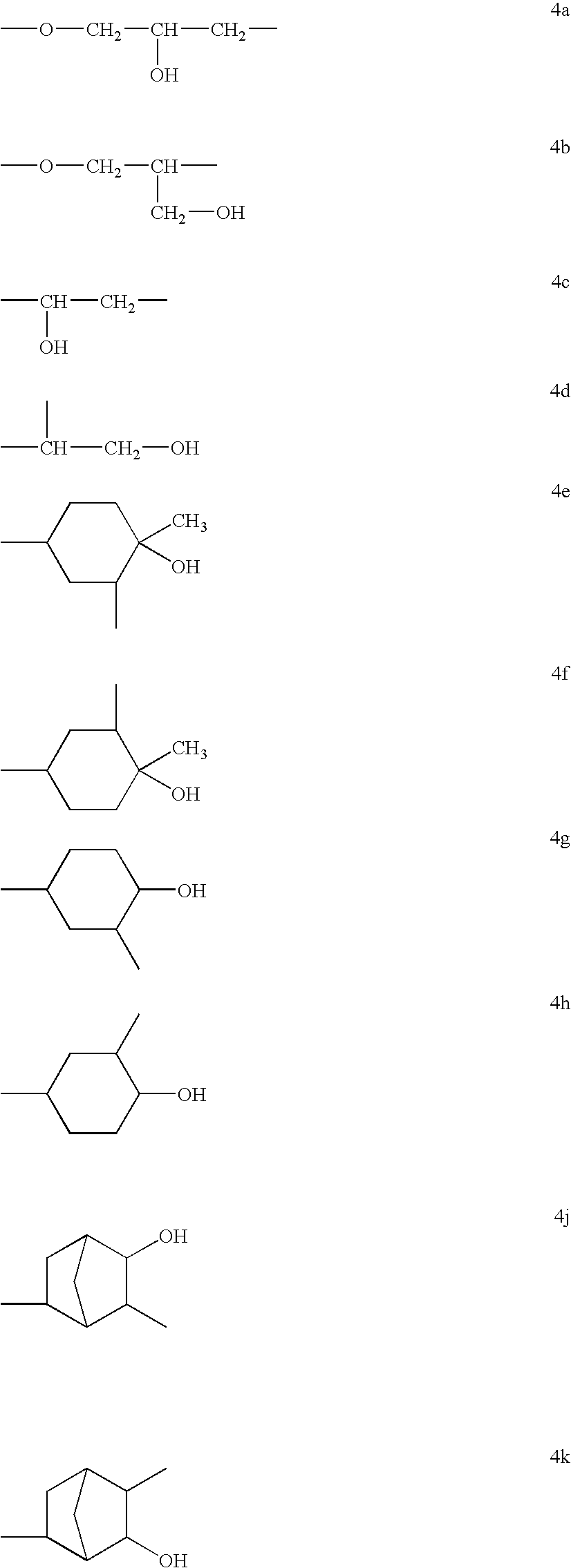

ActiveCN105062403AGood light fastnessImprove initial tack performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAlcohol

The invention provides a synthetic leather binding agent and a preparation method thereof. The synthetic leather binding agent is mainly prepared from polyhydric alcohol, diisocyanate, catalysts, epoxy resin and the like. According to the synthetic leather binding agent and the preparation method thereof, chemical modification is conducted on waterborne polyurethane through the epoxy resin, the high degree of branching of the epoxy resin is introduced into a main chain of polyurethane, and the initial adhesion, the peel strength, the drying rate and the water resistance of a dispersion liquid film are improved. The synthetic leather binding agent prepared through the method has good environment protectability. Dispersion liquid has the advantages of being high in initial adhesion, good in peel strength, high in drying rate and excellent in water resistance. Meanwhile, the good levelling property and spreadability are achieved. The using condition of the synthetic leather binding agent is met.

Owner:SHANDONG TIANQING TECH DEV

Paint for continuous casting pouring box work liner and preparing technique thereof

ActiveCN101508586AGood spreadabilityGood application effectMelt-holding vesselsFiberSodium phosphates

The invention discloses a painting for continuously cast pouring basket working lining and a producing technique thereof. The components of the painting is as follows according to parts by weight: 50-90 parts of forsterite raw material, 10-50 parts of magnesia, and 3-5 parts of composite additive, wherein the composite additive is at least one of organic fiber, paper fiber, lime, trimeric sodium phosphate, sodium hexametahposphate, clay or silicate. The producing technique of the painting is evenly mixing and stirring the forsterite raw material, the magnesia and the composite additive according to the parts by weight to lead the mixture to show no evident white trace, thereby obtaining the painting used for the continuously cast pouring basket working lining. The painting has excellent smearing, sintering, anti-scouring, anti-dreg erosion and anti-peeling properties, is free from collapsing and pollution, is environment-friendly, and has long service life, low production cost and simple and convenient preparation method.

Owner:WUGANG REFRACTORY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com