Patents

Literature

790results about How to "Not easy to absorb moisture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fertilizer water-dispersion granule and preparation thereof

The invention relates to a fertilizer water dispersible granule and a method for preparing the same. The fertilizer water dispersible granule comprises one or more of plant nutrient substances and at least one surfactant which are processed to prepare the regular or irregular granular water dispersible granule. The fertilizer water dispersible granule consists of the following raw materials in portion by weight: 5 to 95 portions of the plant nutrient substance, 1 to 40 portions of the surfactant and 0 to 94 portions of an assistant. The invention has a preferential proposal: the plant nutrient substance comprises monopotassium phosphate, boric acid or borax, humic acid and salt thereof. The fertilizer water dispersible granule also comprises one or more of growth regulators. In addition, the fertilizer water dispersible granule can also comprise a disintegrating agent, an adhesive, a filler, a colorant and other assistants. The preparation method comprises: the metering, pulverization, even mixing, pelletization and drying of formula materials to obtain the fertilizer water dispersible granule. The fertilizer water dispersible granule has rapid disintegrating and dissolving (dispersing) speed in water, is fully dissolved, does not block a nozzle and a drop irrigation pipeline, is uneasy to absorb moisture, has high content of effective compositions, low packaging, storage, transportation, metering and use cost and high utilization rate of the effective compositions, reduces waste and environmental pollution, is widely applied to economic crop, gardening, lawn and urban greening and has extremely wide market application prospect.

Owner:SHENZHEN LANGTAI BIOTECH

Instant edible fungus product and its production process

InactiveCN1337178AMushroom shape is normalSimple processFood preparationNutrient contentReady to serve

The present invention relates to a kind of edible fungus ready-to-serve product and its preparation method, including two products of ready-to-serve soup concentrate and flavouring powder. It adopts several fresh edible fungus sporocarps as raw material, and adopts the following steps: weighing, cleaning, pulverizing, flavouring, cooking, high-temp. steaming and heating, canning, sealing and sterilizing to obtain soup concentrate, or directly spraying, drying to obtain the invented flavouring powder with colour, smell and taste of edible fungus and rich nutrients. When used, it is mixed with boiling water, and can be eaten.

Owner:北京罗萌创业生物技术开发有限公司

Soluble granule of glyhosate ammonium and preparation method

ActiveCN101564044ANot easy to agglomerateNot easy to thinBiocideAnimal repellantsPhosphatePolluted environment

The invention provides a formula of soluble granule (WSG) of glyhosate ammonium and a preparation method. The formula includes 50-95 percent of glyhosate ammonium, 0.5-25 percent of glyphosate synergistic agent, 0.27-40 percent of phosphate, 0-10 percent of filler, 0.1-0.5 percent of xanthan gum and water. The product is stable in property and not prone to absorb moisture, and the production process is simple and smooth, does not pollute the environment and meets environment-protective requirements.

Owner:SHANGHAI XIANGLIN AGRI TECH CO LTD

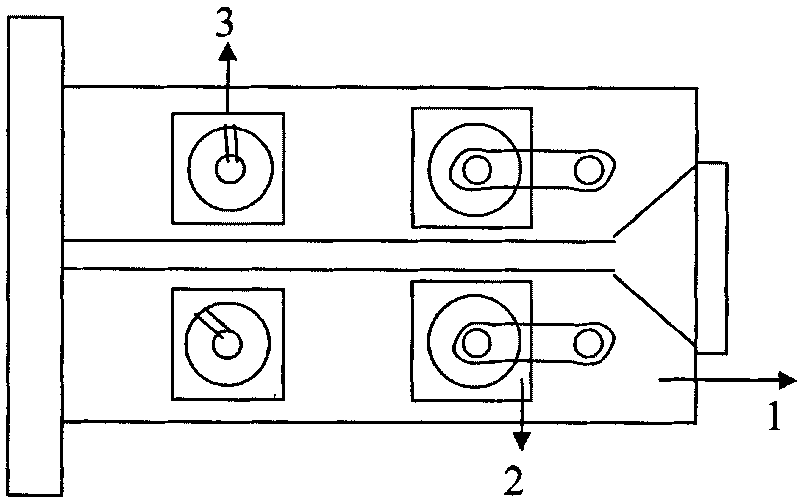

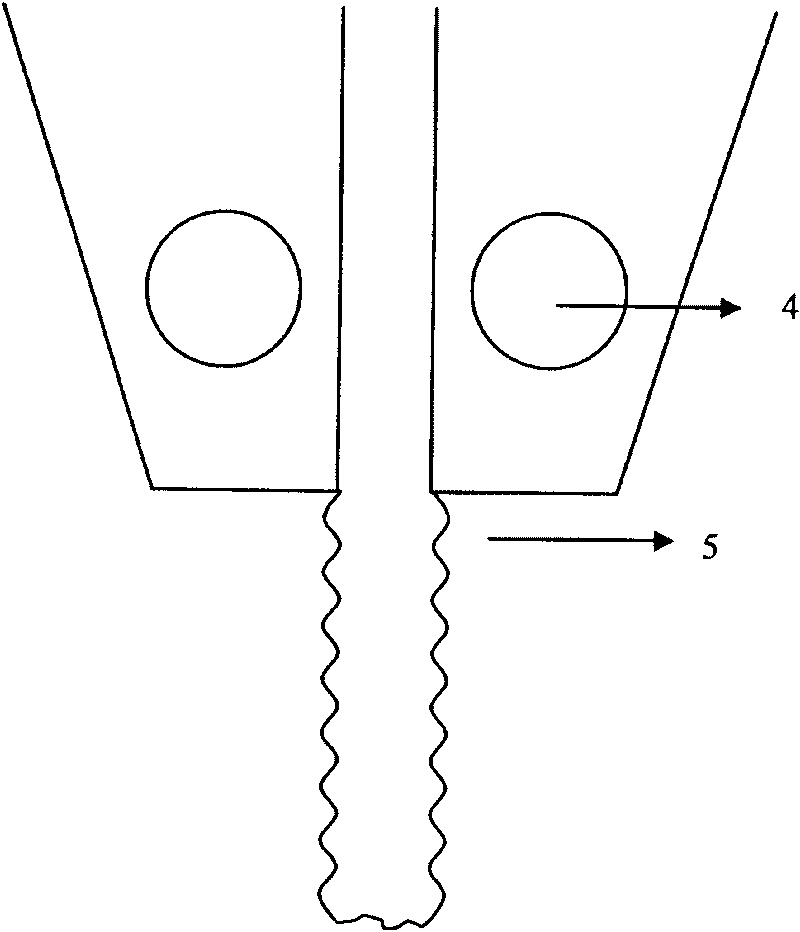

Large-scale continuous energy-saving fluidized bed spray granulation drying process

InactiveCN102274703AAdaptableNo pyrolysis problemsDrying solid materials with heatGranulation by liquid drop formationPrillEngineering

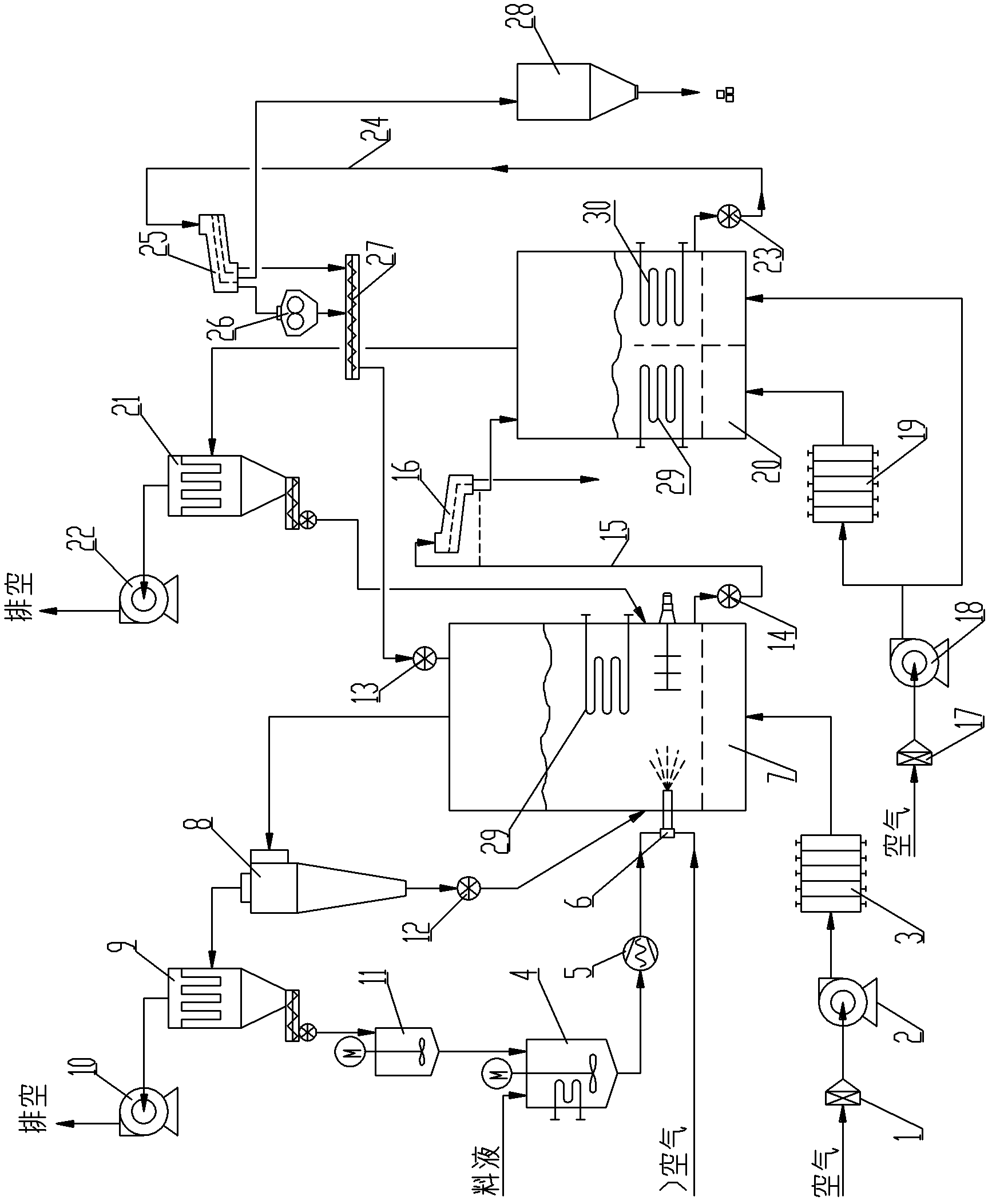

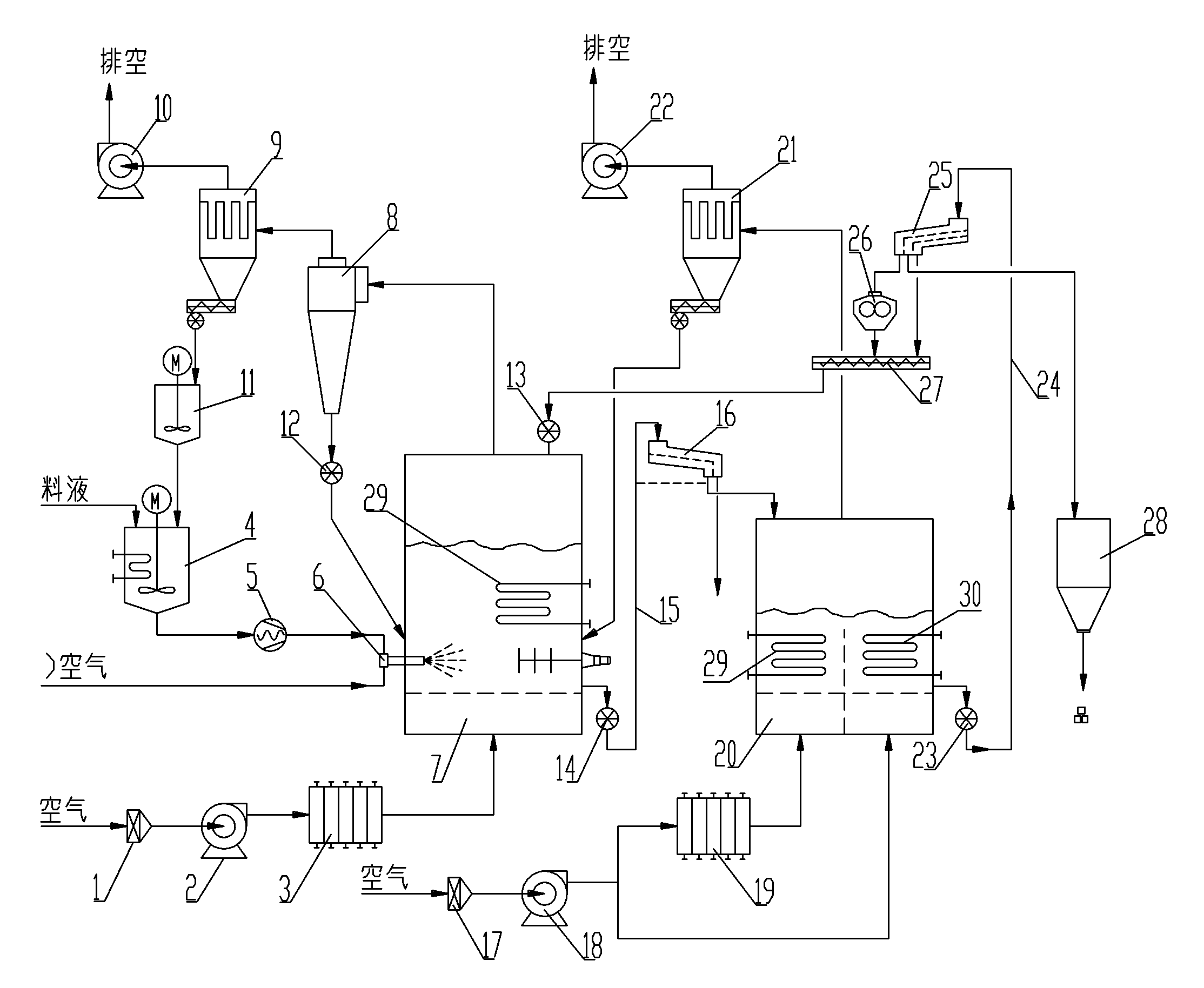

The invention discloses a large-scale continuous energy-saving fluidized bed spray granulation drying process, which belongs to the granulation drying technology. The surface of the seed crystal particles in the granulation fluidized bed is dried under the combined heating of the hot air and the built-in heater. The discharged materials are first screened out of lumps and oversized particles, and then sent to the cooling fluidized bed After the discharged materials are screened, the materials larger than the qualified particle size are crushed by the crusher, and then returned to the granulation fluidized bed together with the material smaller than the qualified particle size as crystal seeds for re-granulation, and the qualified particle size is sent to the into the finished product silo. The invention has strong material adaptability, can obtain granular products with large specific gravity, high strength, good sphericity, uniform particle size, and is not easy to absorb moisture, and realizes continuous large-scale production. Pollution and other characteristics.

Owner:山东奥诺能源科技股份有限公司

Premelting slag for RH vacuum treatment deep desulfurization of ultra low carbon steel

The RH vacuum treatment deep desulfurization premelting slag for ultra-low-carbon steel comprises: 48~56% CaO, 33~43% Al2O3, 0.2~5.0% MgO, 2.5~6.0% SiO2ú¼TiO2íœ1.9, Cíœ0.05 and impurity, and is prepared by electric melting the material of super 60-65% limestone and 35-40% Al2O3 powder (Al-content more than 96%). This invention improves desulfurization capacity, produces Ca(AlO2)2 convenient to preserving, and has little corrosion to RH groove.

Owner:BAOSHAN IRON & STEEL CO LTD

Auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and application thereof

ActiveCN101862458AReduce dosageHigh softening pointGranular deliveryMacromolecular non-active ingredientsFlavorMedicine

The invention relates to an auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and an application thereof. The auxiliary material combination comprises 10 to 90 percent of betadex and 10 to 90 percent of maltodextrin or dextrine. The application of the auxiliary material combination is: after being dissolved in hot water, the auxiliary material combination is added into extract obtained by extracting Chinese medicine or is directly added into extract to be uniformly mixed and to be atomized and dried; when adding the auxiliary material combination, the temperature of the extract is 50 to 100 DEG C, relative density of the extract is 1.02 to 1.20 (60 DEG C), air inlet temperature for atomizing drying is 140 to 190 DEG C, and the air outlet temperature is 75 to 100 DEG C. by adopting the auxiliary material combination, under the same atomizing and drying condition, the consumed quantity of the auxiliary material is less, the consumption quantity of the auxiliary material can be reduced by more than 30 percent, the auxiliary material with the same quantity is added for atomizing and drying, the softening point of the extract can be improved during the atomizing and drying process, the wall is difficult to be adhered during the atomizing process, the fluidity of the atomizing and drying powder is good, the atomizing and drying powder is difficult to be moistened, the dispersion of the flavor can be effectively prevented during the atomizing and drying process, and the original flavor of the extract is maintained.

Owner:陇西一方制药有限公司

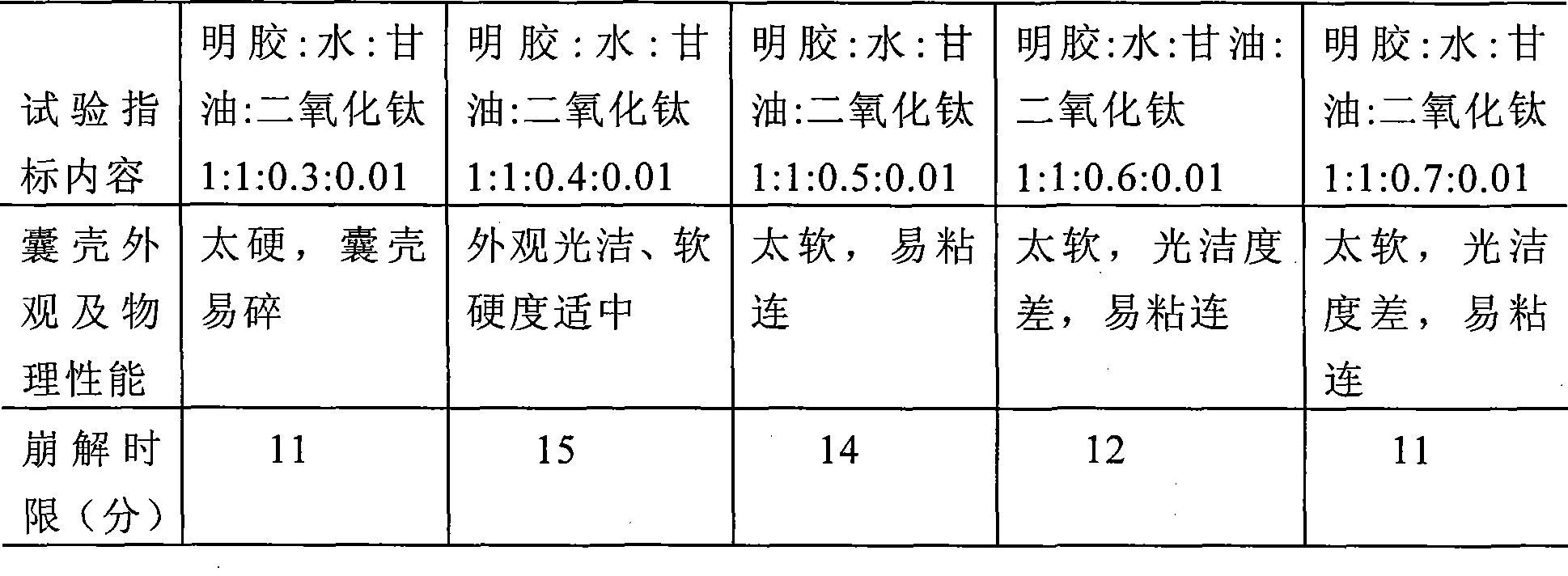

Niuhuangshangqing soft capsule and preparation method thereof

ActiveCN101444570AAvoid volatile lossPrevent oxidationHydroxy compound active ingredientsComponent separationVegetable oilMoisture absorption

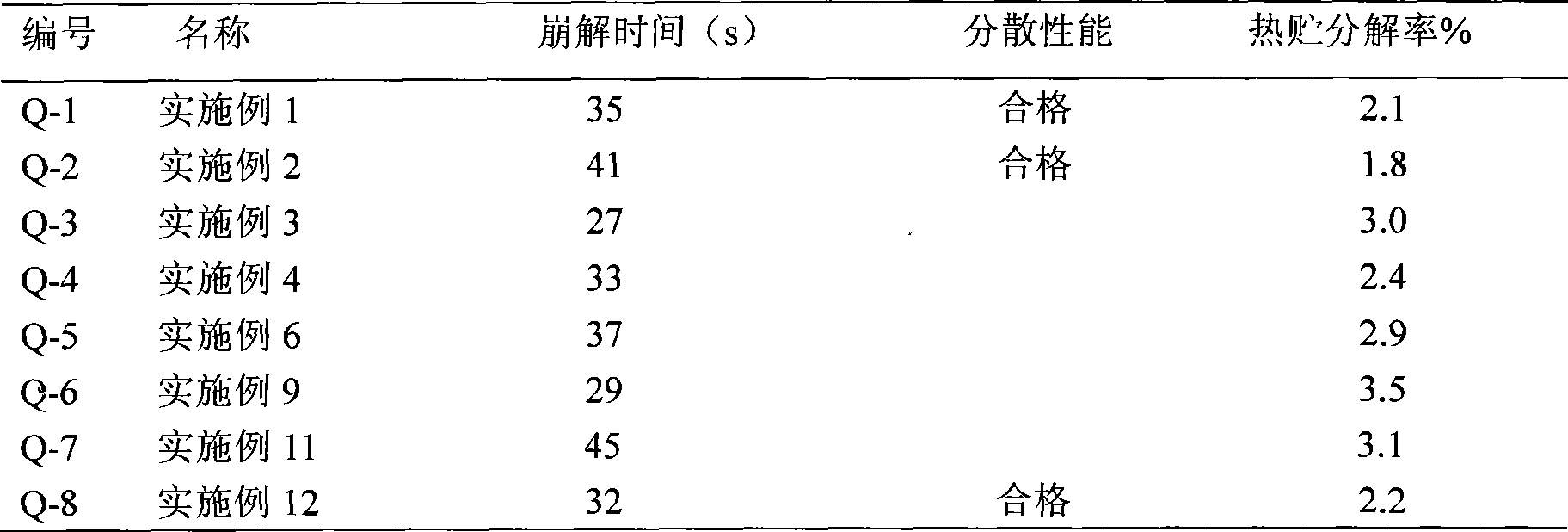

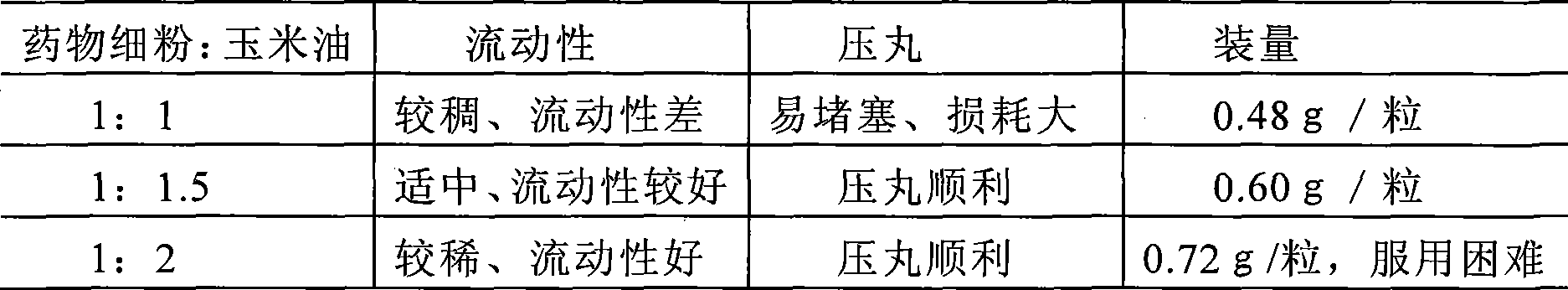

The invention relates to a Niuhuangshangqing soft capsule and a preparation method thereof, as well as a quality control method of capsule contents. The Niuhuangshangqing soft capsule comprises contents and capsule shell. The contents include an extent of Chinese medicinal materials in Niuhuangshangqing prescription and a dispersion medium with a weight ratio of 1:(1-2), wherein, the dispersion medium is vegetable oil. The soft capsule is prepared by extracting effective components from Chinese medicinal materials in Niuhuangshangqing prescription in accordance with the properties of the effective components by using different modern extraction techniques and making into soft capsule. The soft capsule has embedding and masking effects, and can prevent volatilization loss of oil components and oxygenation or photodecomposition of effective components. The soft capsule also has the advantages of rapid disintegration, uniform dispersion, high bioavailability, good stability of effective components, low liability of moisture absorption, good air tightness, direct intestinal absorption after disintegration, masking of unpleasant odors of effective components, convenience for administration and carrying, and so on.

Owner:TAIJI GROUP

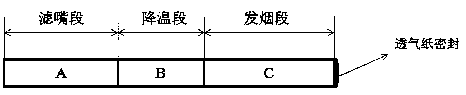

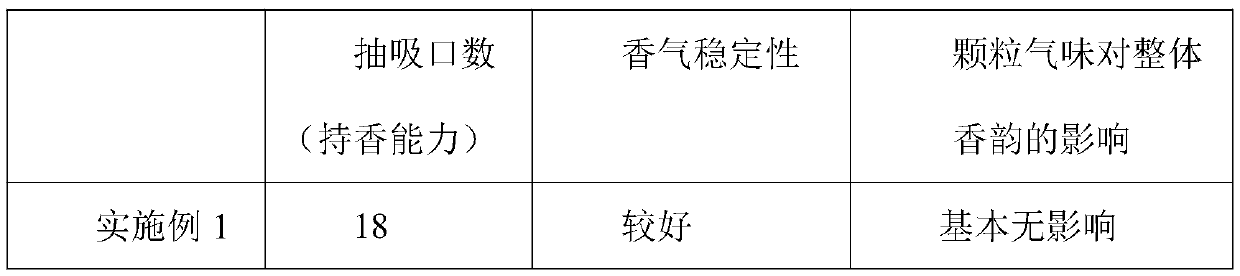

Preparation method of smoking section of granular heat-not-burn cigarette

ActiveCN110876487AHigh adsorption propertiesGood scent release effectTobacco preparationCigar manufactureBurn cigarettePorous particle

The invention discloses a preparation method of a fuming section of a granular heat-not-burn cigarette. The cigarette comprises a filter tip section, a cooling section and a fuming section; the fumingsection is of a closed structure sealed by breathable paper, the length of the fuming section ranges from 15 mm to 20 mm, aroma-attached particles are arranged in the fuming section, and aroma-attached particles prepared by adopting natural animals and plants such as turf, cuttlebone, coconut shells and washed tobacco stems as raw materials are arranged in the fuming section. The closed heating non-combustion cigarette smoke generation section is adopted, due to the fact that the adsorption characteristic of the porous particles is obviously higher than that of the tobacco sheets, the smoke generation agent carrying capacity of the particle type smoke generation section can be 2-3 times that of the sheet type smoke generation section, the fragrance slow release effect is better, moistureabsorption is not likely to happen, and the stability is better.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Low calorie candy made from luohanguo and its production

A low-caloricity grosvenor momordica fruit sugar suitable for the patients of diabetes, obesity, and cardiovascular and cerebrovascular diseases is prepared from grosvenor momordica fruit through choosing, crushing, extracting in water, filtering, adsorbing, eluting, concentrating, drying, mixing with vegetative polybasic alditol, recrystallizing, and drying.

Owner:GUILIN SHILI SCI & TECH COMPANY

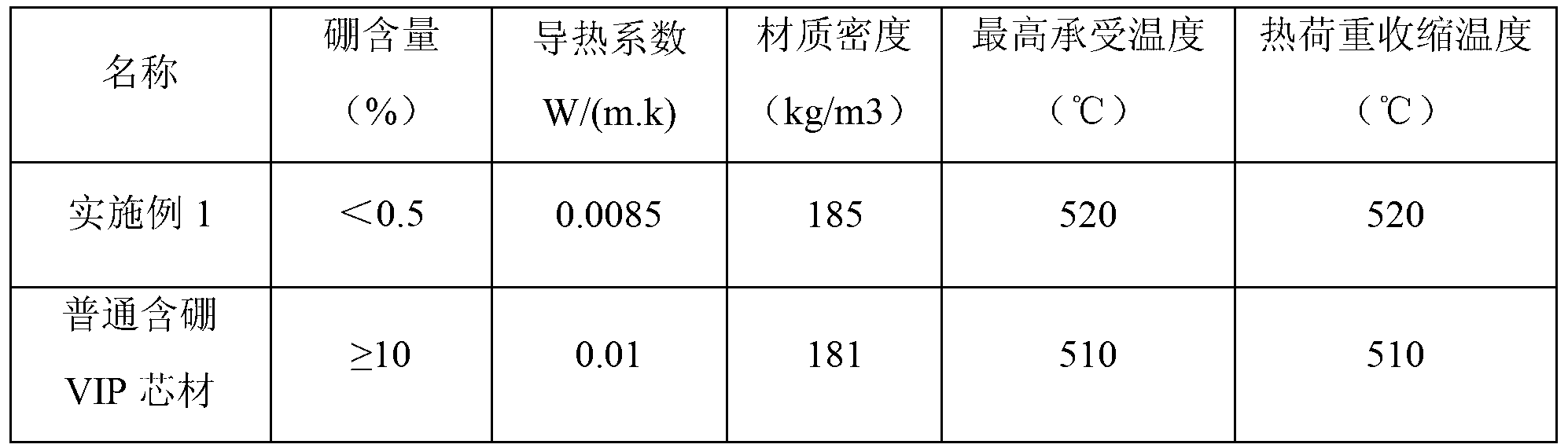

Novel glass fiber vacuum insulation panel core and preparation method

ActiveCN103244793ALower boron contentImprove insulation effectFibreboardThermal insulationAir filtrationGlass fiber

The invention discloses a novel glass fiber vacuum insulation panel core. The vacuum insulation panel core is made of low-boron glass cellucotton which has the boric mass percentage of less than 0.5% and the diameter of 0.5-1.0 micrometer. The invention further discloses a preparation method of the vacuum insulation panel core, which comprises the following steps of: (1) selecting the low-boron glass cellucotton, (2) beating and dispersing the selected low-boron glass cellucotton to obtain slurry, (3) diluting the slurry, (4) deslagging the slurry of Step (3) and preparing wet paper in a wet forming manner, (5) dehydrating the wet paper of Step (4); and (6) drying the wet paper of Step (5). The glass fiber air filtration paper has outstanding comprehensive performances; the preparation process is pollution-free; and the service life is long.

Owner:宣汉正原微玻纤有限公司

Pre-molten low-melting point composite calcium aluminate desulfurizer and its prepn.

The invention discloses a kind of premelt-type, low-melting point, calcium aluminate complex desulfurizing agent and its preparation method, which is prepared according to the below components and proportion (weight): aluminum alum earth (calculated according to the Al2O3 content) 30-60%, and calcium oxide 40-70%. In advance perform passivating treatment on calcium oxide, then mix all the components according to the required proportion, then smelt them in the electric stove or the reflecting stove, then cool them, and by crashing, prepare the particle-shape or powder-shape desulfurizing agent. By the premelting treatment, the melting point of desulfurizing agent lowers to 1250-1400 centigrade, which obviously raises its desulfurizing rate in the molten iron molten steel and shortens the reactive time and production cycle.

Owner:盛富春

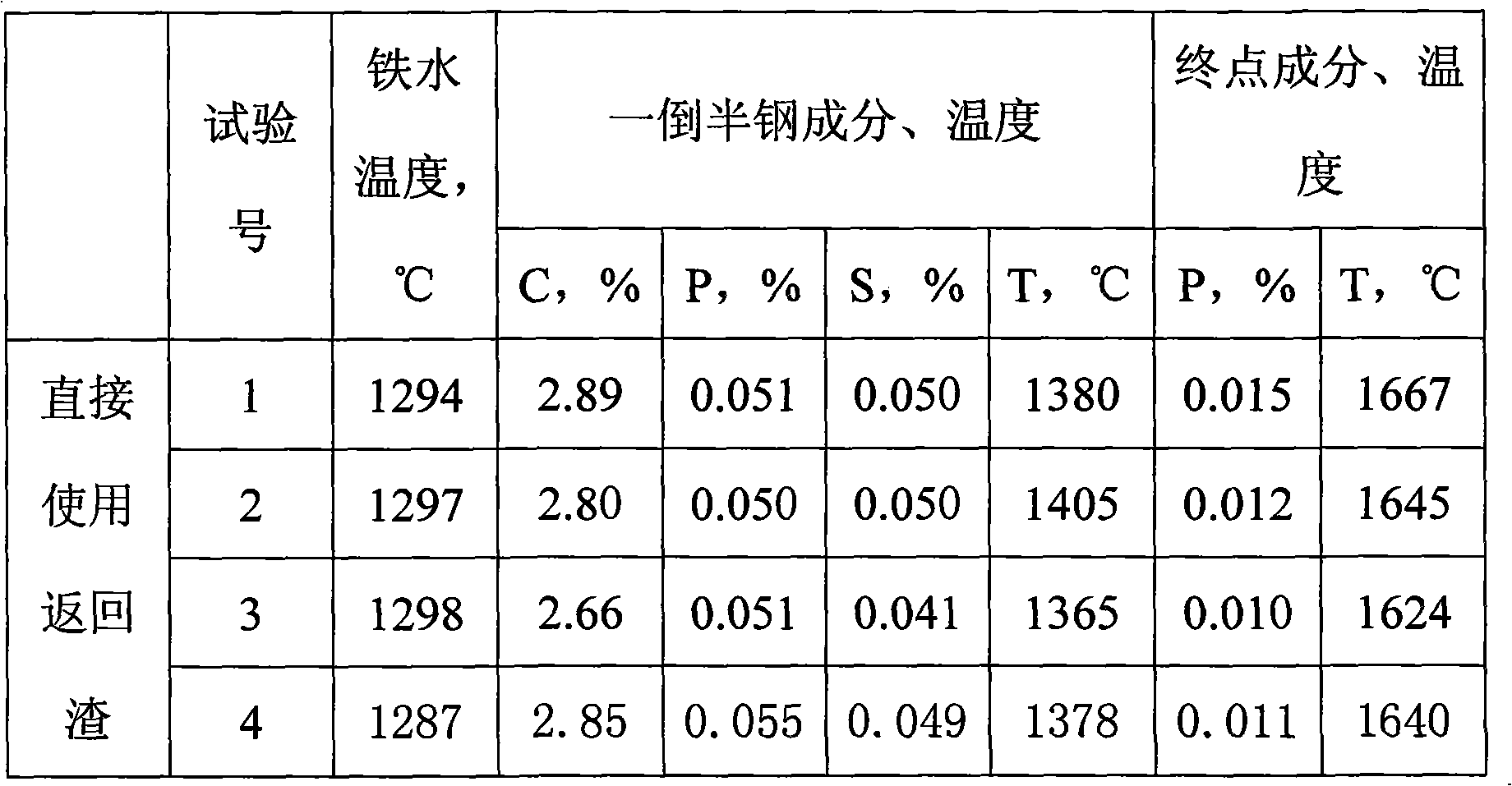

Compound dephosphorization agent with converter slag as raw material and preparing method thereof

The invention discloses a molten iron pretreatment compound dephosphorization agent with converter slag as the raw material, and the compound dephosphorization agent contains the following raw materials by weight: 45 to 55 percent of converter slag, 3 to 5 percent of quartz sand, 22 to 34 percent of steel-rolling iron sheet, 3 to 6 percent of bauxite, 10 to 14 percent of soda and 0 to 5 percent of fluorite; the raw materials meeting the ingredient demands are evenly mixed according to the proportions after being crushed, and then the product with the diameter being 20 to 50mm is produced after ball-milling, screen separation, palletizing and drying. The compound dephosphorization agent realizes cyclic utilization of the converter slag which accounts for 45 to 55 percent, thus reducing the produced slag amount in the steel-making process and the environmental load; the converter slag contains plenty of CaO and FeO, which can reduce consumption of lime to a certain degree, thus increasing the metal yield rate and reducing the steel-making cost; the compound dephosphorization agent has low melting point, slag can be formed fast, the liquidity is good, thus shortening the treatment time, the dephosphorizing efficiency is high, and the dephosphorized final slag has low alkalinity and low melting point.

Owner:CHONGQING UNIV

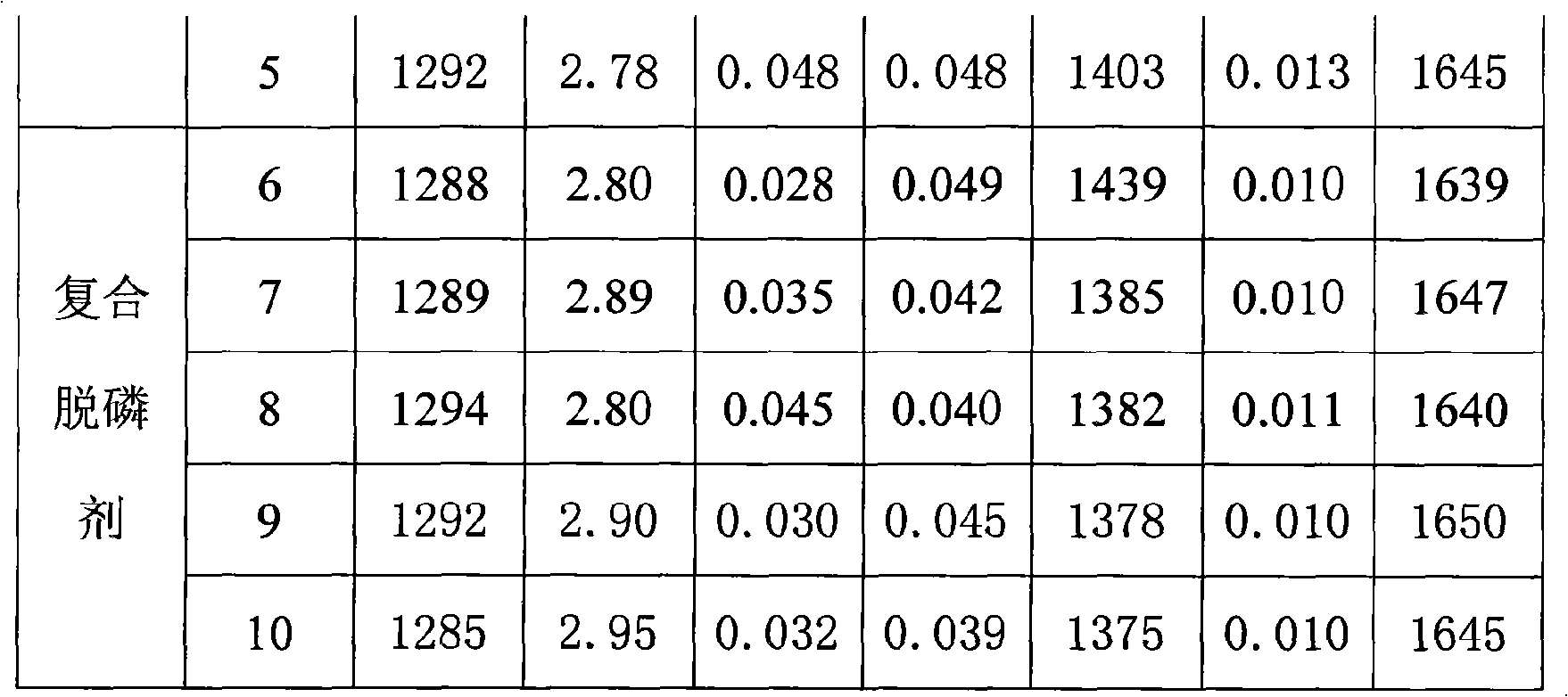

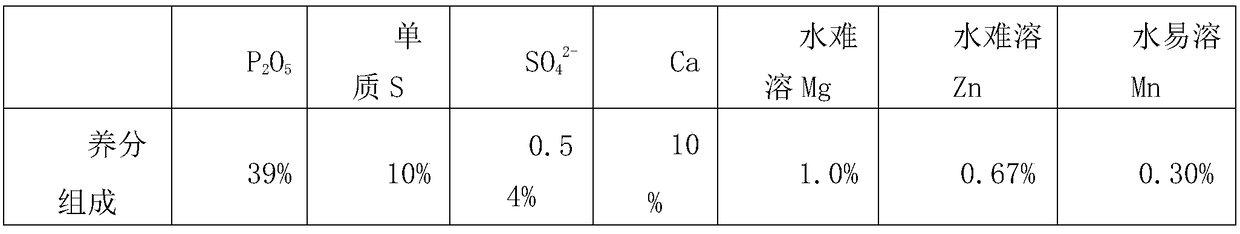

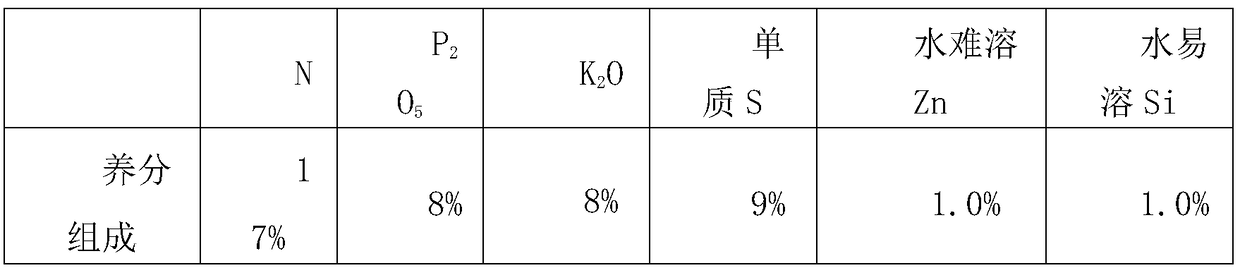

Medium trace element mixture and preparation method of medium trace element-wrapped fertilizer

InactiveCN108976018AEasy to accumulateImprove securityMagnesium fertilisersAlkali orthophosphate fertiliserLiquid stateSulfur

The invention relates to a medium trace element mixture and a preparation method of a medium trace element-wrapped fertilizer. The medium trace element mixture is prepared from the following components: 50% to 90% of sulfur, 5% to 20% of swelling material, and 5% to 45% of medium trace element other than sulfur. The preparation method comprises the following steps: adding the medium trace elementand the swelling material into liquid sulfur and evenly mixing. The preparation method of the medium trace element-wrapped fertilizer comprises the following steps: placing the conventional granular fertilizer in a wrapping device with a heating function, after heating the medium trace element mixture to a certain temperature, spraying on the surface of the granular fertilizer, and forming a medium trace element film on the surface of the fertilizer by cooling and curing. The medium trace element mixture and the preparation method of the medium trace element-wrapped fertilizer provided by theinvention have the advantages that the medium trace elements are quickly and flexibly added; the problem of uniform dispersion of the medium trace elements in soil is solved, and the local poisoning is avoided; the film formed by wrapping the medium trace element material is firmly combined with fertilizer particles, and is not easy to fall off; fast-acting and long-acting combined medium trace element materials can be wrapped, which is beneficial to the nutritional needs of crops in the whole growth cycle.

Owner:HUBEI FORBON TECH

Heat and sound insulation explosion preventing film and production method and application thereof

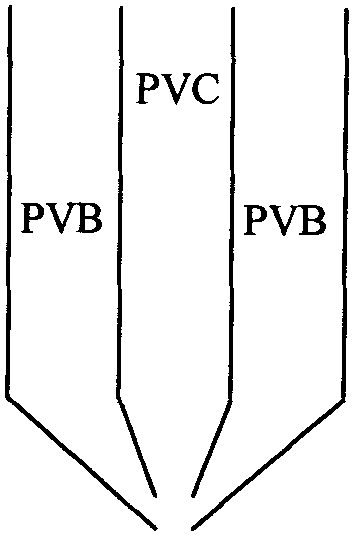

InactiveCN101700707AExcellent heat and sound insulationGood heat insulationSynthetic resin layered productsAntioxidantUltraviolet

The invention relates to a heat and sound insulating material, in particular to a production method and application of a heat and sound insulation explosion preventing film. The heat and sound insulation explosion preventing film comprises three layers of materials, wherein the middle layer is polyvinyl chloride, and both side layers are polyvinyl butyral; an infrared absorbing agent, an ultra-violet absorbing agent, a hindered amine light stabilizer and an antioxidant are respectively added into the middle layer and both side layers; and the infrared absorbing agent is a mixture of nano titanium dioxide and nano calcium hexaboride. In the preparation method, the film is obtained on the basis of a multi-layer coextrusion casting film extruding technology by optimizing the process condition. The heat and sound insulation explosion preventing film is mainly used for being made into laminated glass. The explosion preventing film has favorable heat and sound insulating function and overcomes the defect of easy shrinkage and deformation in the production of traditional plastic films.

Owner:深圳市宝龙盈捷光电科技有限公司

Method of extracting abalone protein peptides by subcritical water assisted enzymolysis and product

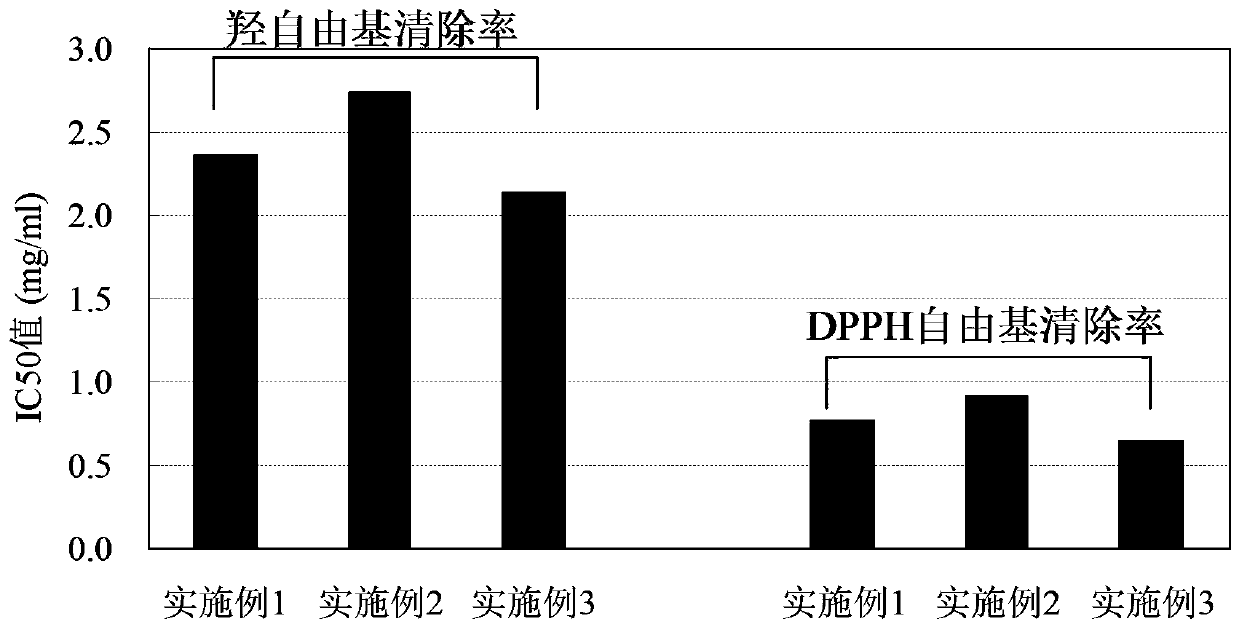

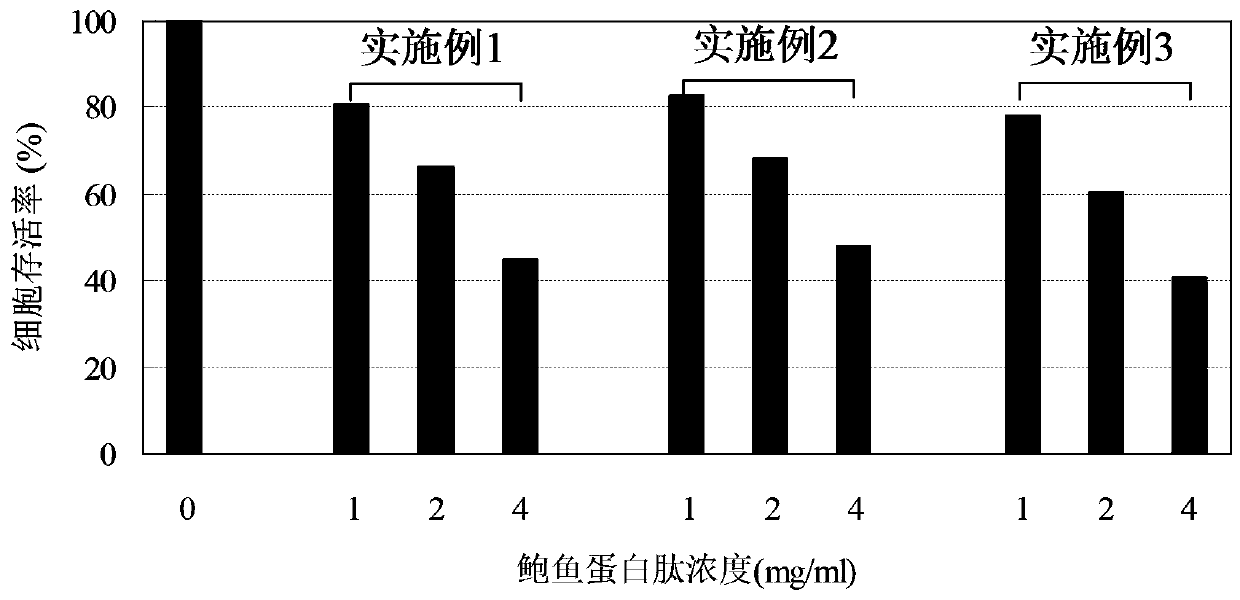

ActiveCN107556364AReduce pollutionEfficient use ofPeptide preparation methodsFermentationPectinaseWater assisted

The invention discloses a method of extracting abalone protein peptides by subcritical water assisted enzymolysis and a product. The technical process comprises the following steps: by taking abaloneviscera as a raw material, firstly treating the abalone viscera with subcritical water to extract proteins; then performing enzymolysis on the extracted proteins by means of pectinase and protease; preparing abalone protein peptide powder by means of column chromatography isolation, nanofiltration membrane concentration, vacuum concentration and spray drying; and developing a functional health-care product by using the abalone protein peptide powder. The technology provided by the invention improves the conventional technology of preparing protein peptides by enzymolysis, and extracts abaloneprotein peptides by subcritical water assisted enzymolysis, so that the dosage of enzymes can be reduced, the production time can be shortened to a great extent, and the production cost is lowered. Moreover, the prepared abalone protein peptides have good antioxidant and anti-tumor functions, thereby providing conditions for application and popularization of abalone protein peptides.

Owner:XIAMEN DAOZHIYUAN BIOTECH

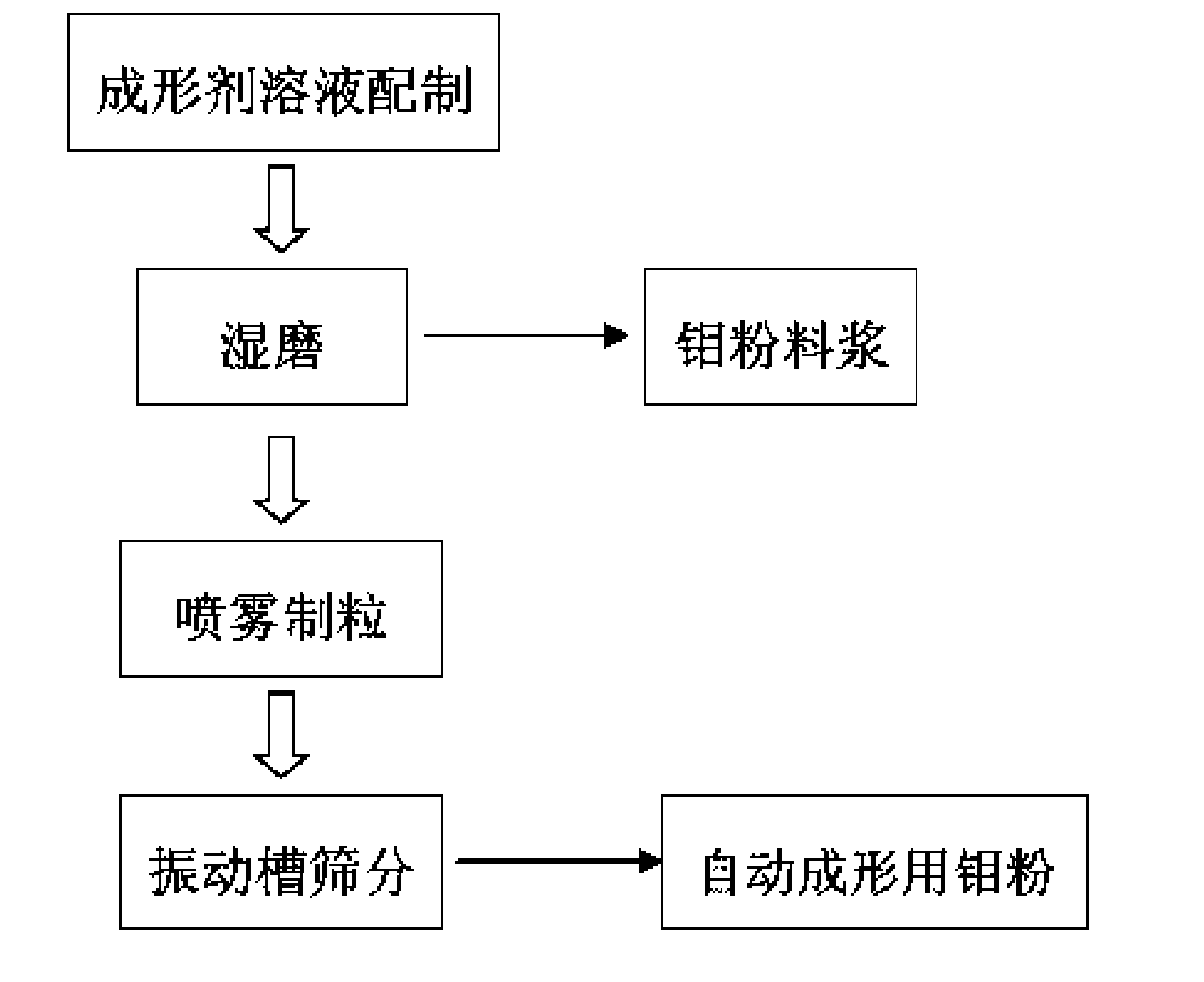

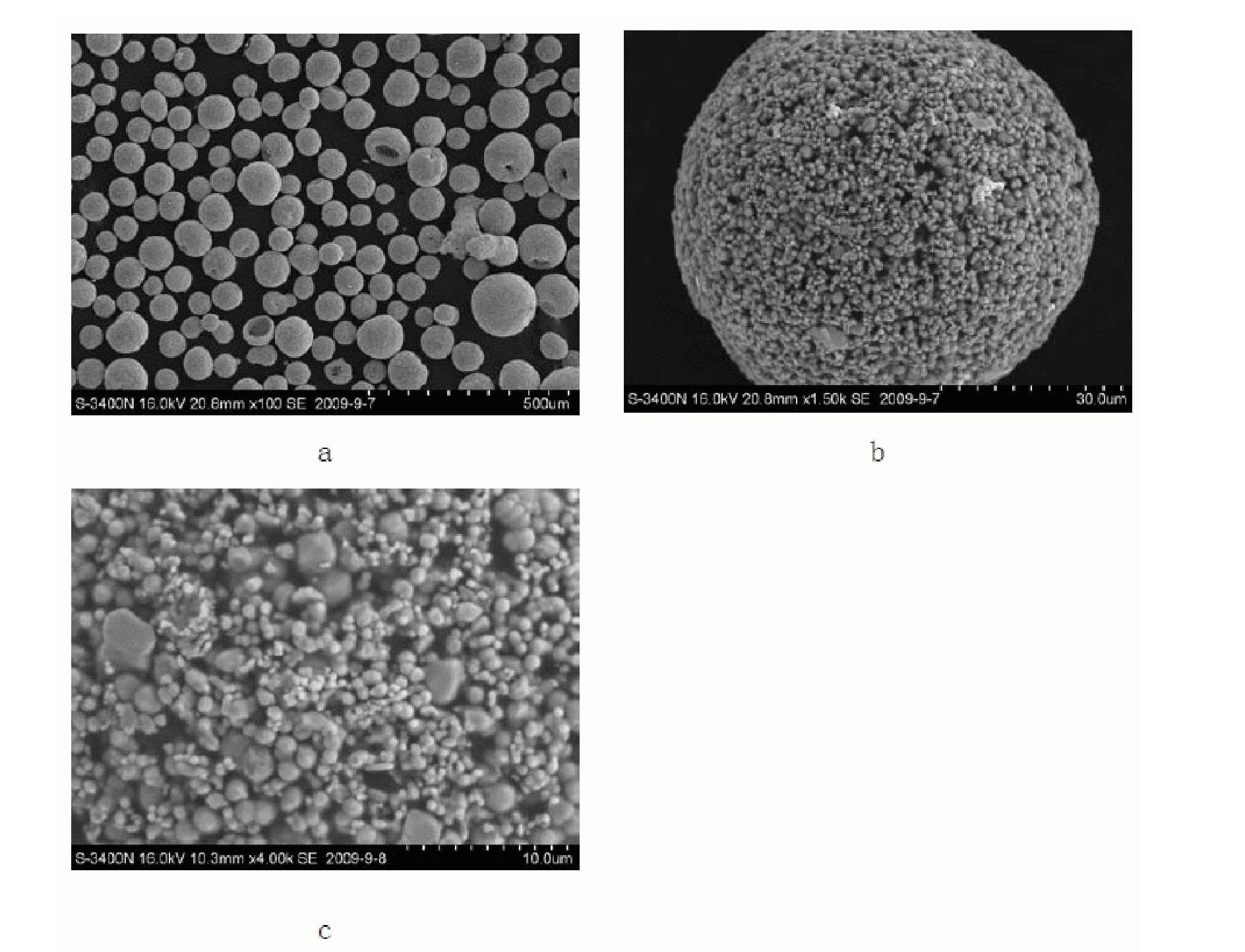

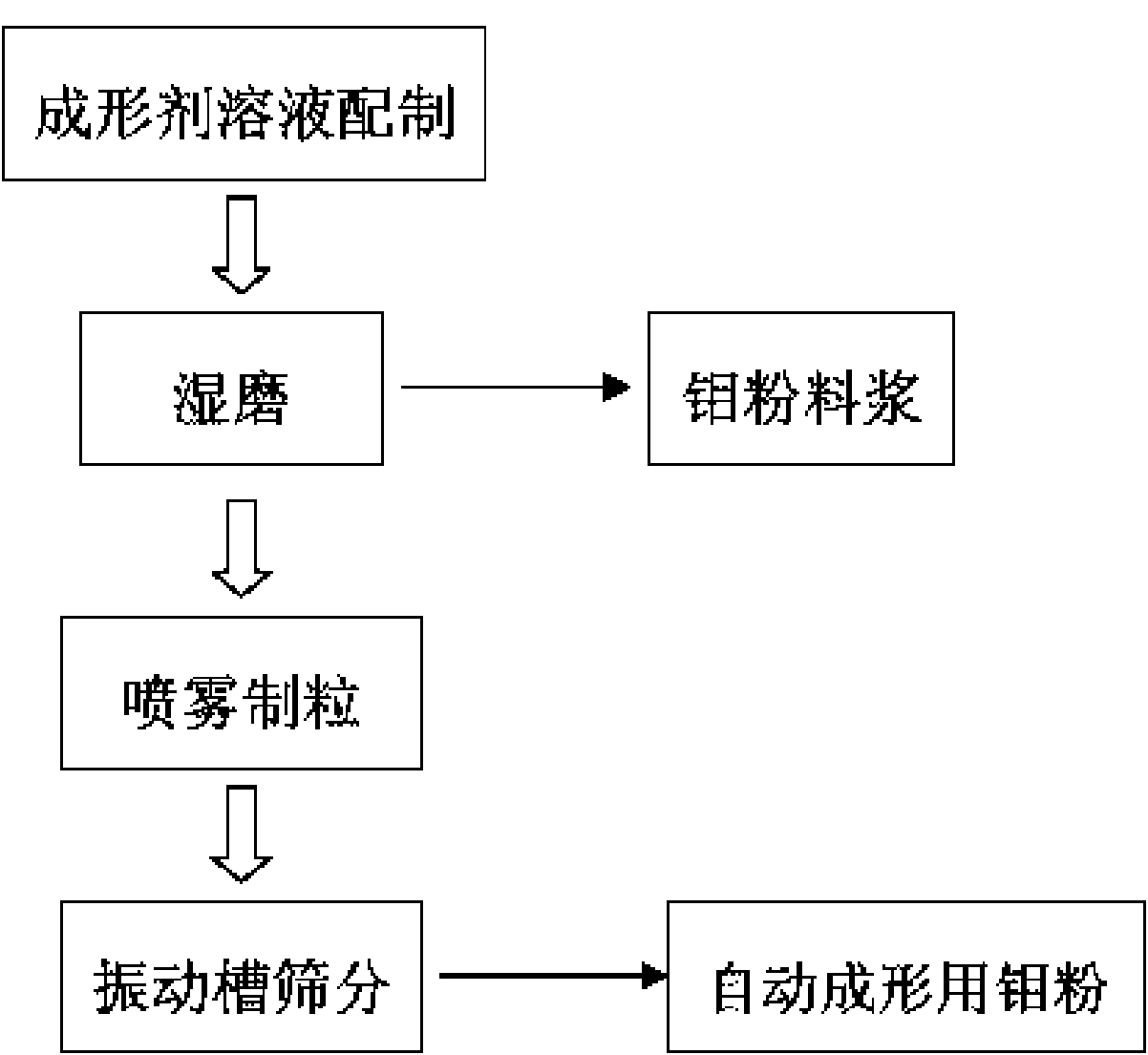

Special molybdenum powder used for automatic forming and preparation method thereof

The invention discloses a special molybdenum powder which is directly used for the automatic forming of precision devices of the machinery industry and the electronic industry. The invention is characterized in that the molybdenum powder comprises the following materials according to the parts by mass: 96.6-99.5 parts of primary molybdenum powder, 0.5-2.4 parts of polyvinyl alcohol, 0-0.4 part of polyethylene glycol, 0-0.5 part of metallic stearate and 0-0.15 part of ammonium polyacrylate. The molybdenum powder has good flowability, high apparent density and appropriate particle size distribution and has the self-lubricating action in the process of the automatic forming. The invention also discloses a preparation method of the special molybdenum powder, which comprises the processes: (1) forming agent solution is prepared by the polyvinyl alcohol, the polyethylene glycol, water and other additives; (2) wet grinding is carried out on the primary molybdenum powder, metallic balls and the forming agent solution by proportion in a ball milling tank to prepare molybdenum powder slurry; (3) spray drying is carried out on the prepared molybdenum powder slurry for granulation; (4) the prepared molybdenum powder is collected by a vibrating screen arranged at the discharge hole of a spray drying tower. The preparation method has the greatest advantages of the special molybdenum powder used for the automatic forming can be prepared by one step, the efficiency is high, the cost is low, and the industrialization and no pollution can be realized.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

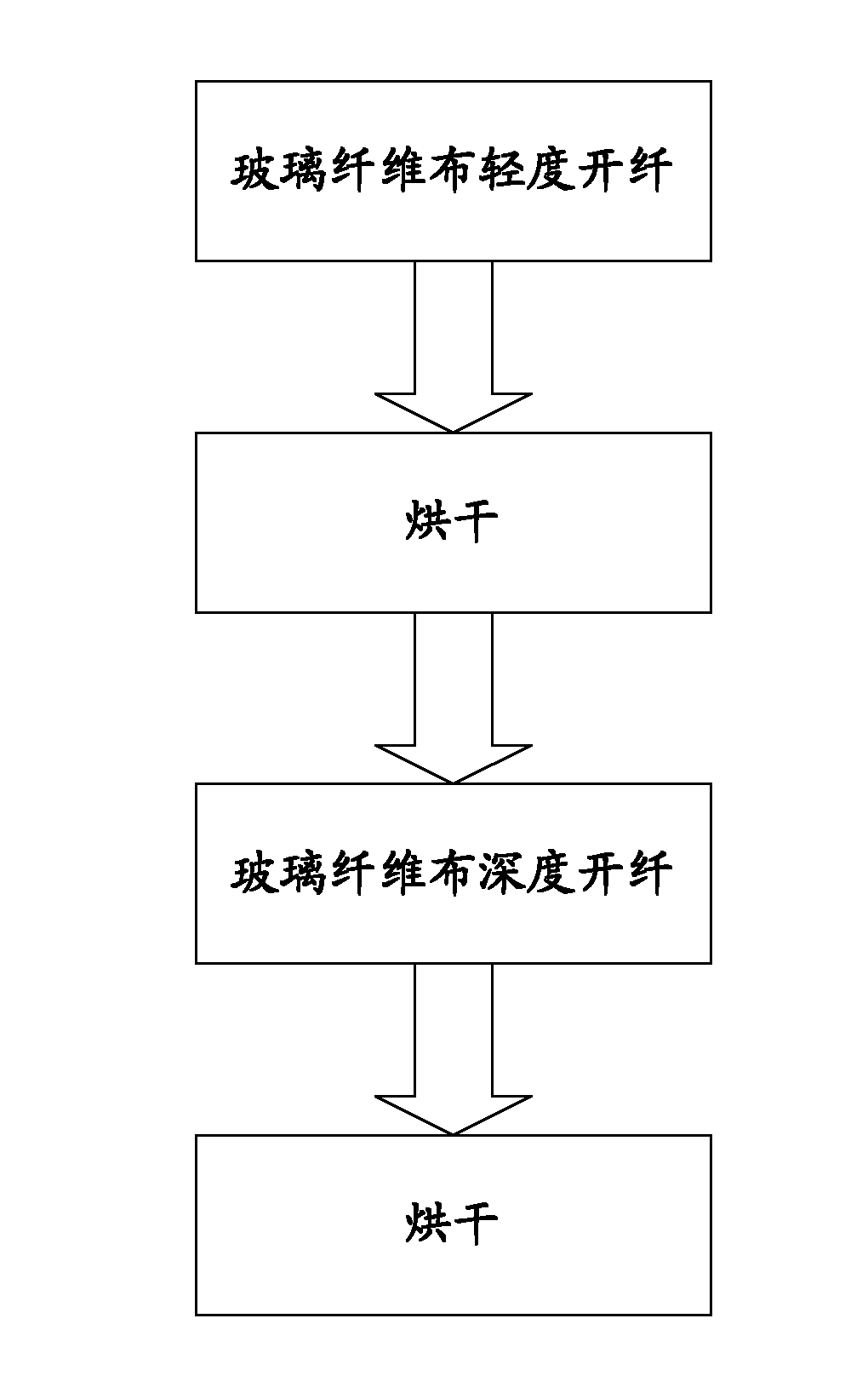

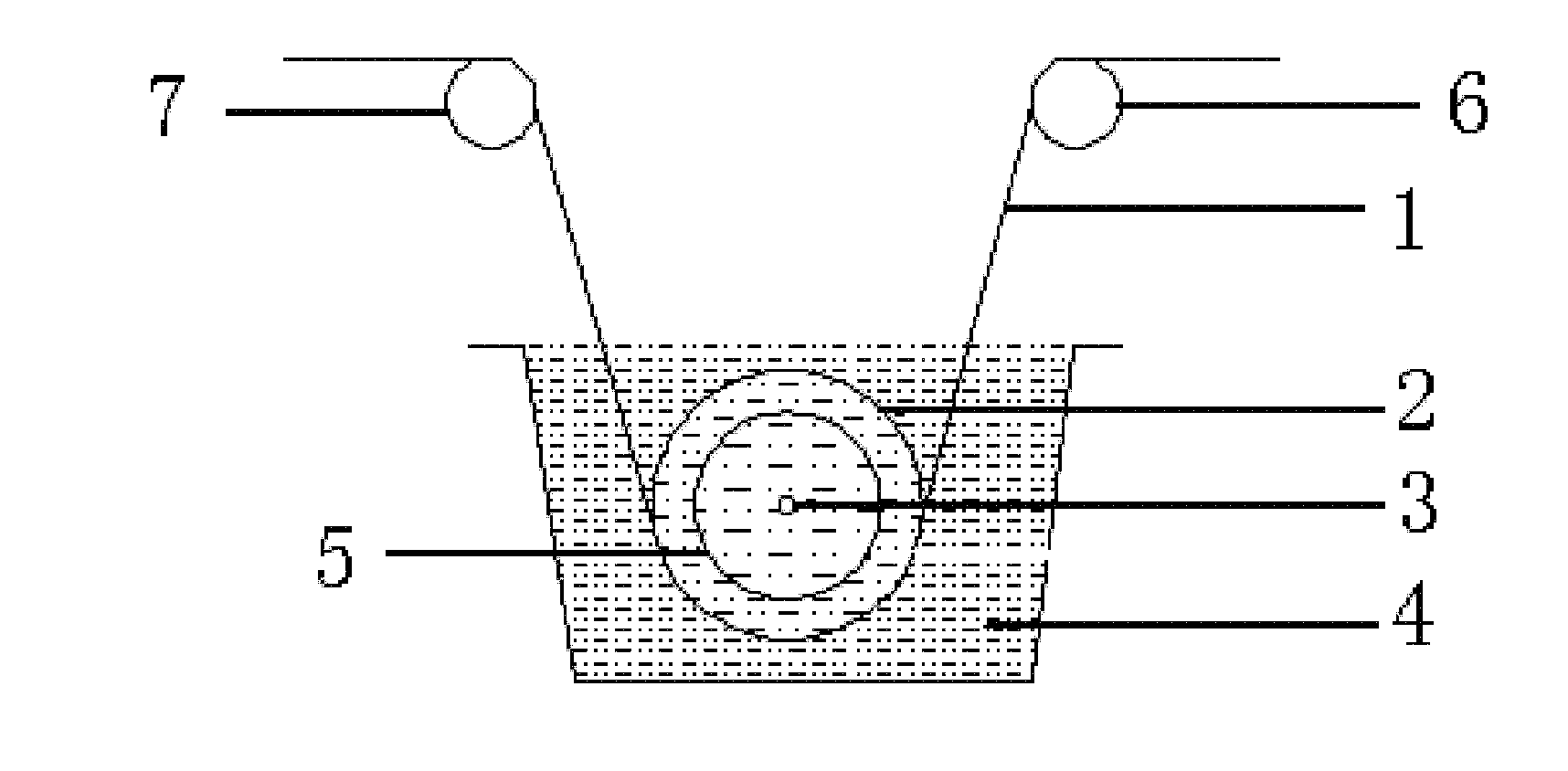

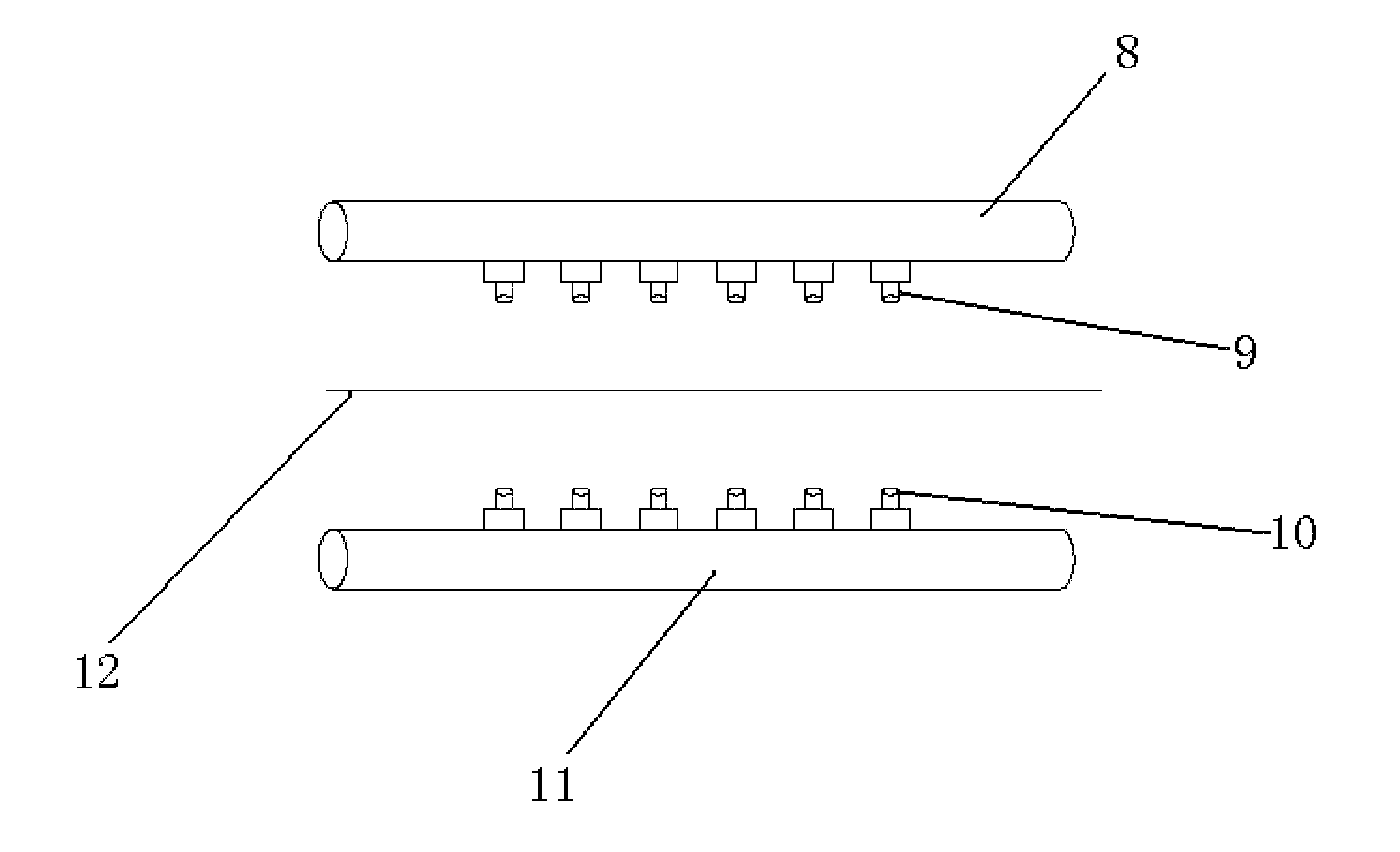

Ultra-high-performance electronic glass fiber cloth production process

ActiveCN102758335ADense surfaceFlat surfaceTextile treatment by spraying/projectingTextile shapingWeft yarnImpact pressure

The invention discloses an ultra-high-performance electronic glass fiber cloth production process which specifically includes the steps: A, slightly splitting electronic glass fiber cloth; B, drying the slightly split electronic glass fiber cloth; C, deeply splitting the dried electronic glass fiber cloth; and D, drying the deeply split electronic glass fiber cloth so that ultra-high-performance electronic glass fiber cloth is obtained. During slight splitting, cloth surfaces are humidified by a water-washing oscillating trough, so that warp and weft yarns are bulked, and fibers are loosened; and during deep splitting, purified water is sprayed from holes of nozzles to be directly jetted to the cloth surfaces, the front and the back of the glass fiber cloth are sprayed by water columns, the warp and weft yarns are broken apart after the cloth surfaces are subjected to impact pressure of the purified water columns, the compactness of the glass fiber cloth is greatly reduced, and gaps among the warp and weft yarns are mostly filled by loose single fibers to be smaller, so that the surfaces of the glass fiber cloth become dense and uniform, and the surfaces of the glass fiber cloth are smoother after splitting.

Owner:建滔(清远)电子材料有限公司

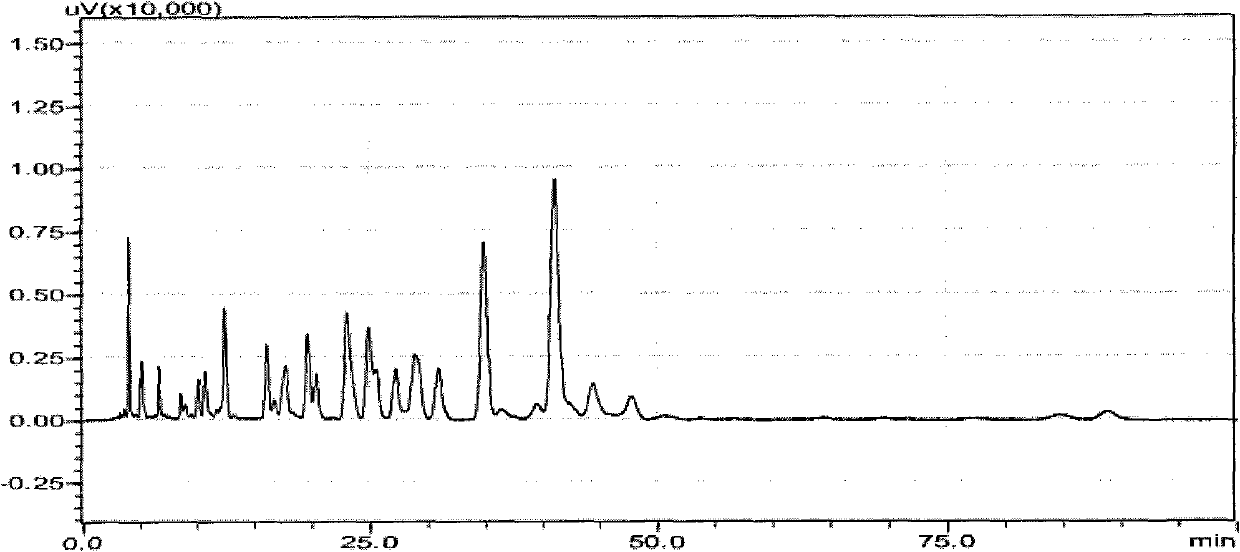

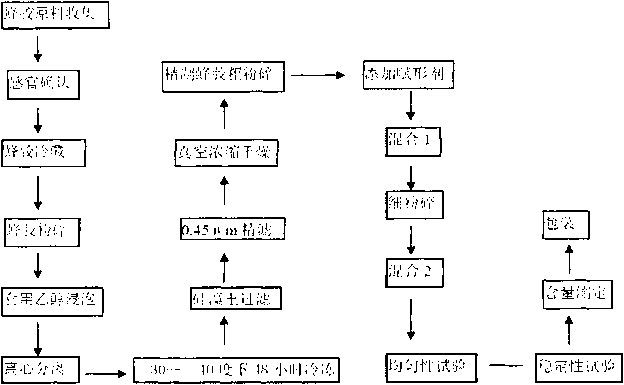

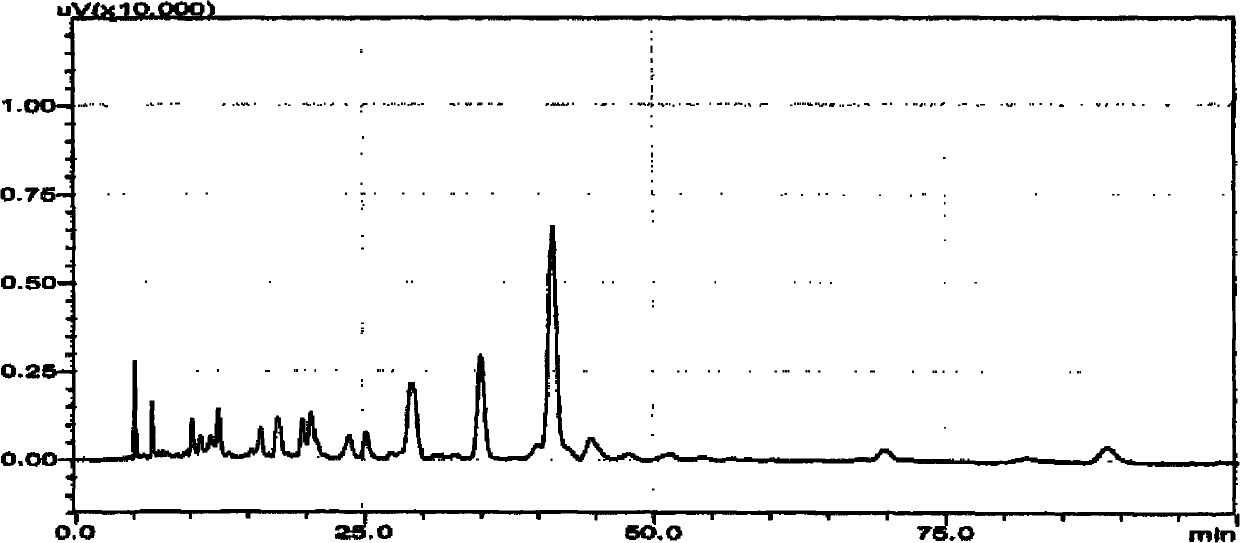

Method for preparing real substance sample for authentication of propolis liquid phase fingerprint

ActiveCN101957349AAnalysis method is simpleQuality improvementComponent separationWater bathsPropolis

The invention relates to a method for preparing a real substance sample for authentication of a propolis liquid phase fingerprint. At present, the mature method for authenticating poplar gum and propolis is unavailable. The method comprises the processes of preparing a propolis substance sample and a poplar gum substance sample. The process of preparing the propolis substance sample comprises thefollowing steps of: soaking the propolis in 95 percent edible ethanol; drying the refined propolis liquid in vacuum in a water bath at the temperature of 80 to 95 DEG C; and mixing the crushed refined propolis and an excipient, and sieving the mixture with an 80-mesh sieve to obtain the propolis substance sample. The process of preparing the poplar gum substance sample comprises the following steps of: heating polar-water mixed liquid to over 90 DEG C; pressing the liquid to obtain a polar liquid; after cooking the polar liquid, soaking the polar liquid in the 95 percent edible ethanol; drying the refined polar gum liquid in vacuum in the water bath at the temperature of 80 to 95 DEG C; and mixing the crushed refined polar gum liquid and the excipient, and sieving the mixture with the 80-mesh sieve to obtain the poplar gum substance sample. The method has the advantages of reasonable and scientific preparation, strong operability and application to effective authentication of the false propolis prepared from polar sprouts.

Owner:杭州蜂之语蜂业股份有限公司

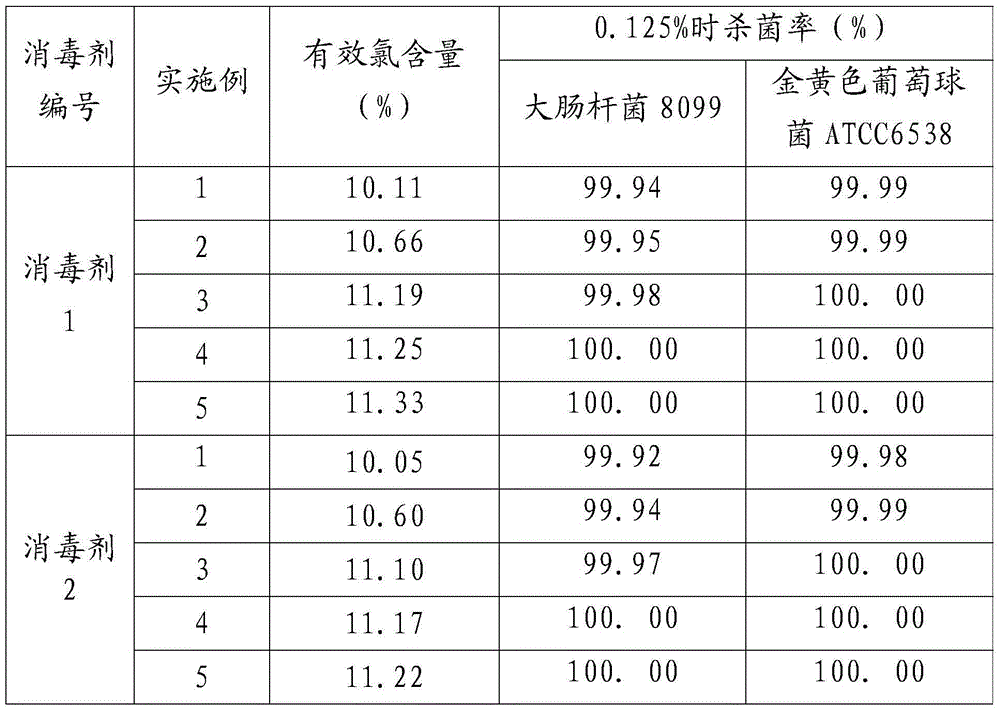

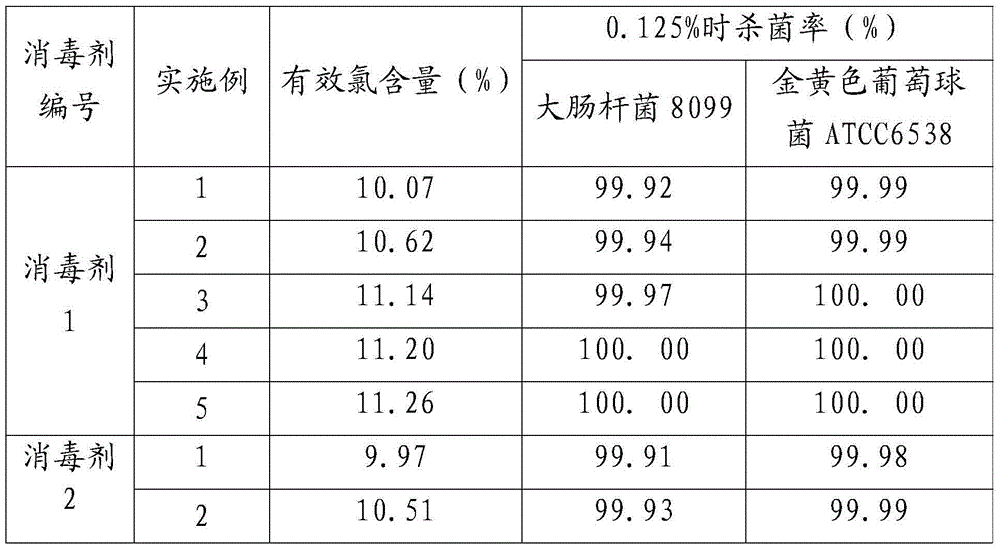

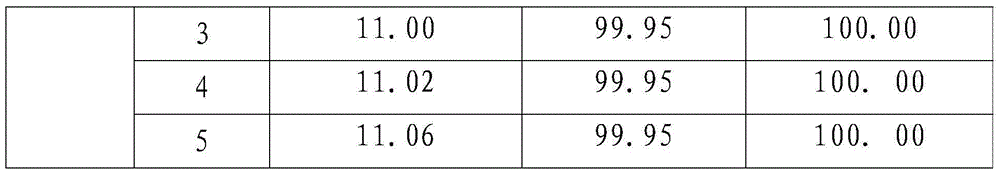

Compound potassium hydrogen persulfate powder sanitizer and preparation method thereof

ActiveCN105360162ANot easy to absorb moistureComponent stabilityBiocideDisinfectantsMoisture absorptionHydroxymethyl cellulose

The invention provides a compound potassium hydrogen persulfate powder sanitizer and a preparation method thereof. The sanitizer contains a sodium chloride wrapping substance. The sodium chloride wrapping substance is composed of a wrapped core material and a wrapping wall material, wherein the wrapping wall material is any one of high polymer slow release carriers including starch, methylcellulose, hydroxymethyl cellulose, Arabic gum and polyacrylic resin. Compared with an ordinary compound potassium hydrogen persulfate powder sanitizer with unwrapped sodium chloride, the compound potassium hydrogen persulfate powder sanitizer is not prone to moisture absorption, capable of preventing sodium chloride from making contact with an react with other components and high in stability.

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE

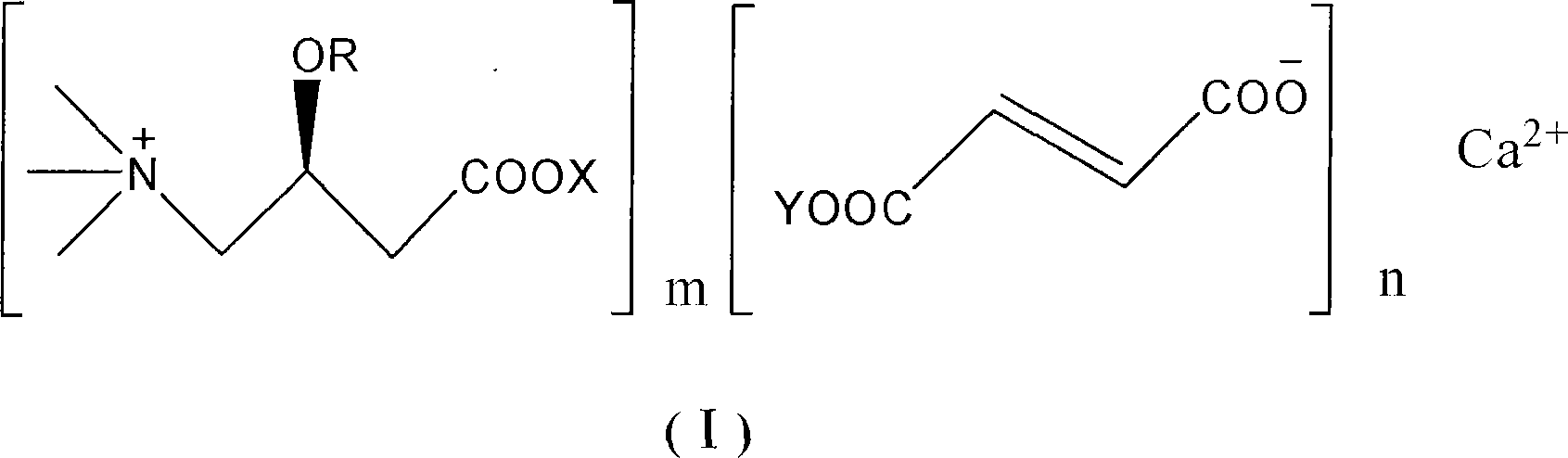

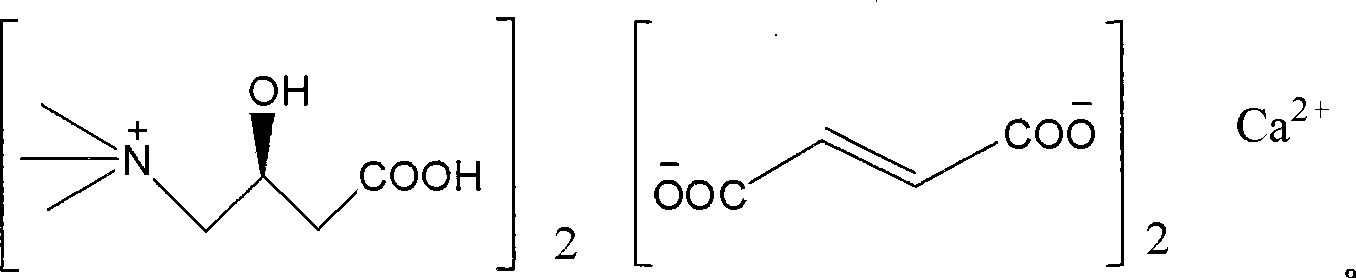

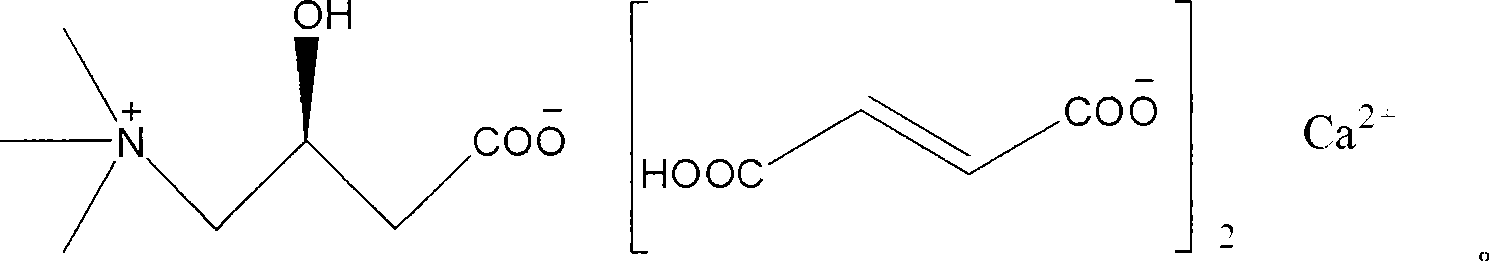

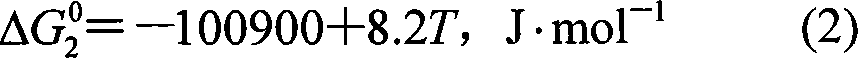

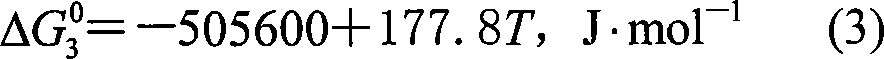

Levulorotation carnitine calcium fumarate and its preparing method and use

ActiveCN101209975ASuitable for oralNot easy to absorb moistureNervous disorderPeptide/protein ingredientsSolubilityFiltration

The invention relates to an L-carnitine calcium fumarate and a preparation method and usages thereof. The L-carnitine calcium fumarate is characterized by oral intake, stability and no-hygroscopicity, and has stronger and more functions of nutrition and treatment, compared with corresponding internal salt and good water solubility; the preparation method is: the calcium furmarate is dissolved in the water and added with calcic alkali for reaction with the temperature increasing to 70 to 90 DEG C for 2 to 8 hours and then water is evaporated by reducing pressure. The solid obtained by drying is added into ethanol and evenly mixed, with the L-carnitine added for reaction with the temperature at 60 to 70 DEG C for 1 to 6 hours, then the mixture is put into a refrigerator for refrigeration for 2 to 8 hours and the L-carnitine calcium fumarate is finally obtained by suction and filtration; the composition containing the L-carnitine calcium fumarate can be made into one or more excipients acceptable on pharmacology, particularly solid and liquid oral intake preparation, such as powdered drug, granules, tablets, capsules, oral liquid, etc., is preferred and the solid and liquid oral intake preparation can be used for food / nutrition additives for people, or feed additives for animals, including additives for calcium supplement.

Owner:リャオニンコンセプヌトラシーオーエルティーディー

Fireworks and crackers blasting-agent composition

The invention discloses a fireworks and crackers blasting-agent composition. Agents in the fireworks and crackers blasting-agent composition include, by weight, 40%-60% of potassium perchlorate, 15%-30% of potassium acid phthalate, 10%-20% of a metal-filled multi-walled carbon nanotube, 5%-10% of metal oxide and 3%-5% of black powder, the multi-walled carbon nanotube is filled with one or more combinations of metals of aluminum, silver, iron, nickel, potassium, magnesium, lithium, sodium and the like, and the metal oxide is one or more combinations of ferroferric oxide, iron sesquioxide, copper oxide, manganese oxide, zinc oxide, cobalt oxide and aluminum oxide. The fireworks and crackers blasting composition agents free from metal powder are obviously improved in security coefficient, the explosion dynamics of the agents is high, burning rate of bright points is high, shelf life is long and blasting effect is good.

Owner:WANZAI JIANKUN CHEM

Magnesium desulphurization method for molten iron pretreatment and powder used thereby

The invention belongs to the steel metallurgic technical field and in particular relates to a hot metal pretreatment magnesium desulfurization method and the adopted powder, wherein, the powder comprises magnesium metal powder and is characterized in that the powder also comprises premelting magnesium desulfurization accelerating agent which is made from blast furnace slag and lime through production processes such as raw material selection, impurity removal and drying, mix crushing and passivating treatment; by means of the prior blowing equipment, the magnesium metal powder and the premelting magnesium desulfurization accelerating agent are mixed according to a certain proportion or are jointly injected into hot metal for desulfurization. The method is simple and feasible and the made powder can replace pure lime powder, therefore, the invention has the advantages of energy saving, high efficiency and environmental protection; moreover, the method can greatly reduce the pretreatment cost of hot metal and increases hot metal yield.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

Production method of paper pulp molded product

InactiveCN105908578ANot easy to absorb moistureNot easy to lose powderNon-fibrous pulp additionPaper/cardboardShell moldingMoisture absorption

The invention provides a production method of a paper pulp molded product with the smooth surface. The production method includes the following steps that 1, after paper pulp fibers, water and a polyacrylamide resin solution are mixed and stirred, pulp is obtained; 2, under the negative pressure condition, the pulp is sucked and dewatered, and a paper pulp molded wet blank with the water content being 60%-70% is obtained; 3, the paper pulp molded wet blank with the water content being 60%-70% is subjected to heat setting, and a paper pulp molded dry blank with the water content of 6%-10% is obtained. The production method has the advantages that the pulp is sucked and dewatered under the negative pressure condition, polyacrylamide reticular molecular structures in the pulp are centralized on the surface of the wet blank, a smooth film is formed on the surface of the pulp molded product after heat setting, and moisture absorption and powder falling are not likely to happen.

Owner:DONGGUAN DANGNA PRINTING CO LTD

Wet precoated sand

ActiveCN101934350AImprove bindingGood refinement effectFoundry mouldsFoundry coresCouplingMoisture absorption

The invention discloses wet precoated sand, which comprises raw sand, a binding agent, a curing agent, a coupling agent and a lubricating agent. The amounts of the curing agent and the coupling agent are respectively 50-70% and 0.5-1% of the amount of the binding agent; the amounts of the binding agent and the lubricating agent are respectively 3-5% and 0.2-0.8% of the amount of the raw sand; the binding agent comprises the following components in part by weight: 70-80 parts of phenolic resin, 10-20 parts of quartz powder and 5-15 parts of fire clay; the coupling agent is a silane coupling agent; and the wet precoated sand has the tensile strength not less than 4 MPa and the gas-generating amount not more than 19. The wet precoated sand not only has relatively small degree of roughness, relatively strong cohesive property, but also has relatively good density, difficult moisture absorption and difficult dryness absorption and can be stored for a long time in a daily environment.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

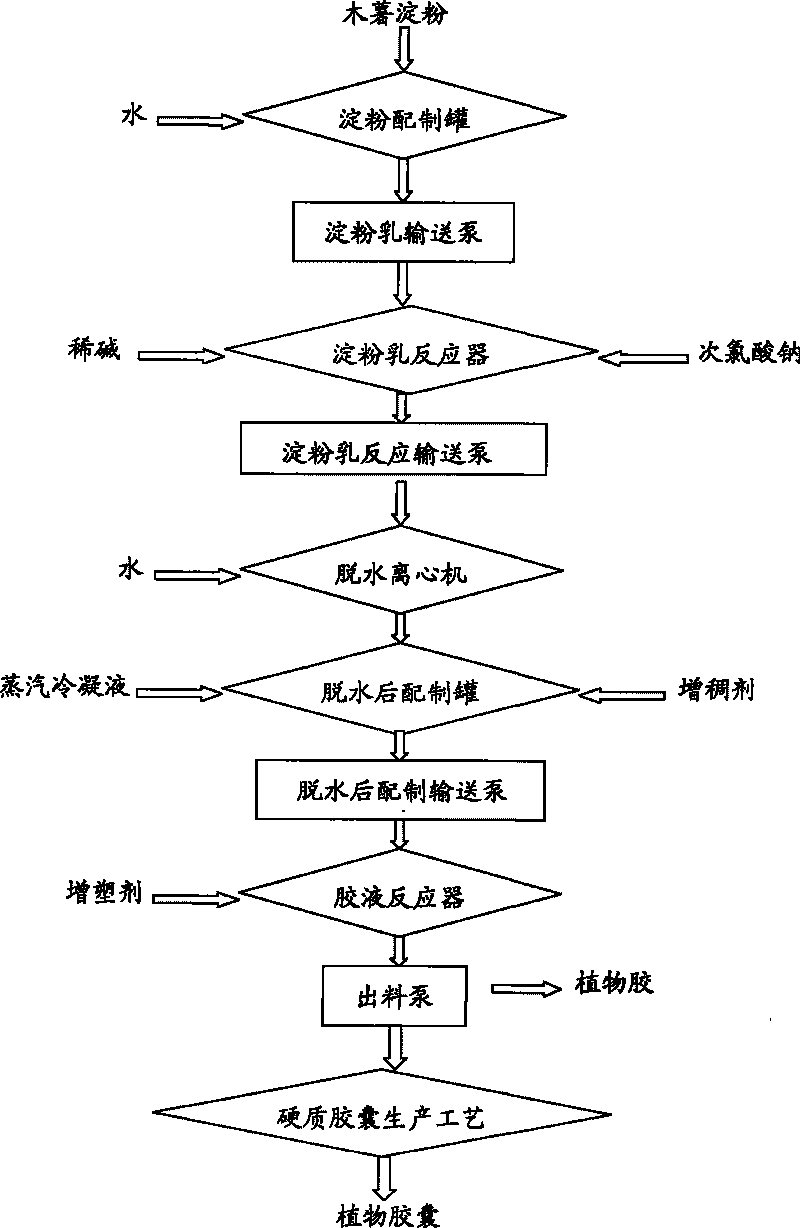

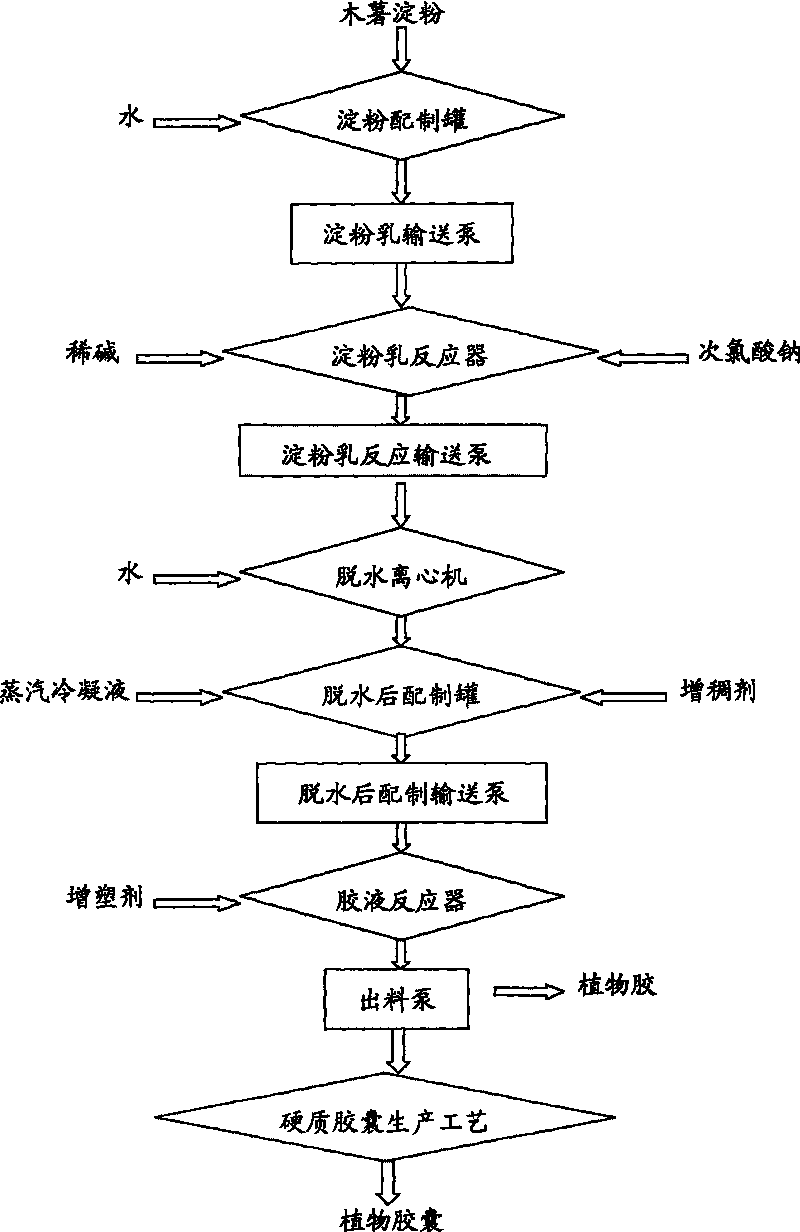

Technique of preparing cassava starch plant gum, the plant gum prepared thereby and plant capsules

ActiveCN101338045BIncrease planting areaReduce consumptionPharmaceutical non-active ingredientsCapsule deliveryBiotechnologyPlant Gums

The invention relates to a preparation method for cassava starch vegetable gum and vegetable gum and a vegetable capsule which are prepared by the preparation method. The preparation method mainly comprises the following steps: preparing starch milk, gelatinization reaction, dehydration, washing, preparation after dehydration and obtaining gel solution. The preparation method for cassava starch vegetable gum and the vegetable gum and the vegetable capsule which are prepared by the preparation method of the invention have stable product performance, low water content, wide application range, easy storage, no contamination, green environmental protection, wide raw material resources, simple preparation method and easy control.

Owner:刘雨微

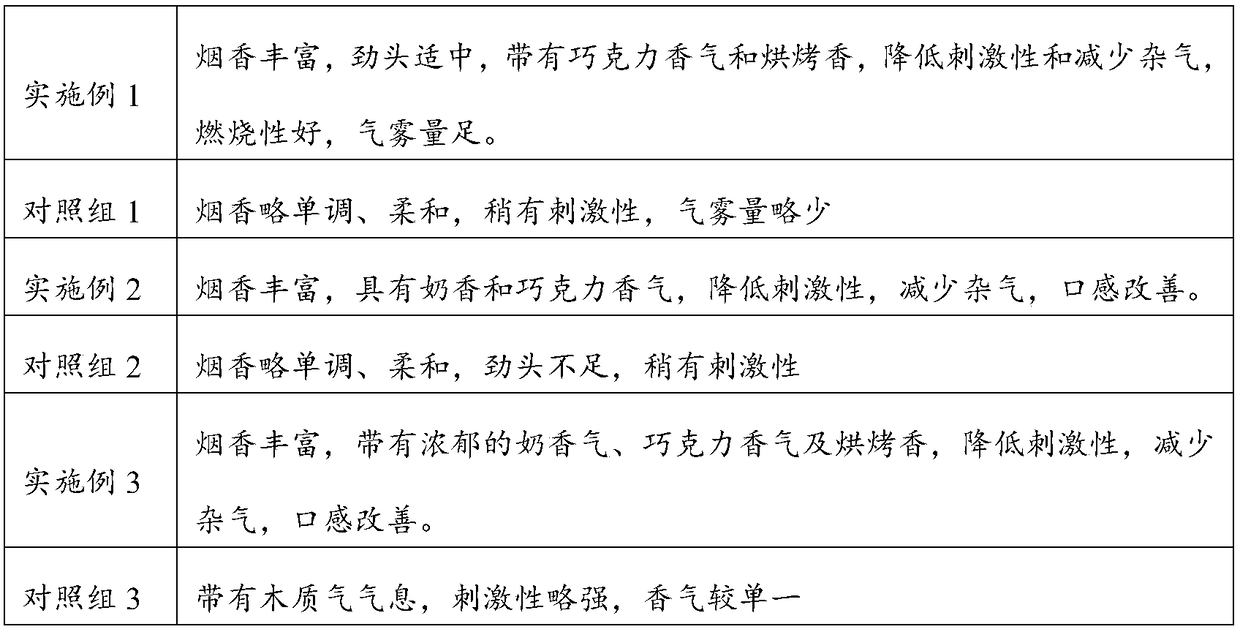

Improving the quality of non-combustible recycled tobacco leaves heated by thick slurry method and its application

ActiveCN109156882AImprove adsorption capacityEasy to separate by filtrationTobacco preparationMaillard reactionCooking & baking

The invention provides a process method for improving the quality of non-combustible recycled tobacco leaf heated by thick slurry method and application thereof, A technology for manufacture the heated non-combustible recycle tobacco leaf by the thick slurry method, a material is added in two steps to prepare a homogenate. The composite biological agent is absorbed through the biomaterial immobilized carry. A tobacco raw material is pretreated by adsorption fermentation, subsequent to filt removal of that carrier, secondly, the pretreated tobacco raw material is subjected to high-temperature catalytic lignin pyrolysis under the alkaline condition to increase fragrance and prickle and Maillard reaction to increase fragrance, then when the heated non-combustible recycled tobacco leave is prepared by the conventional process of thick slurry method, wherein the tobacco leaves are rich in fragrance, have beautiful milk fragrance, chocolate fragrance and baking fragrance, have moderate strength, lower irritation and spicy taste, and improve smell and reduce wood flavor; In the new heating non-combustible cigarette application, harmonious and beautiful aroma, improve smoke aroma, improvedtaste, comfortable taste.

Owner:HUBEI CHINA TOBACCO IND

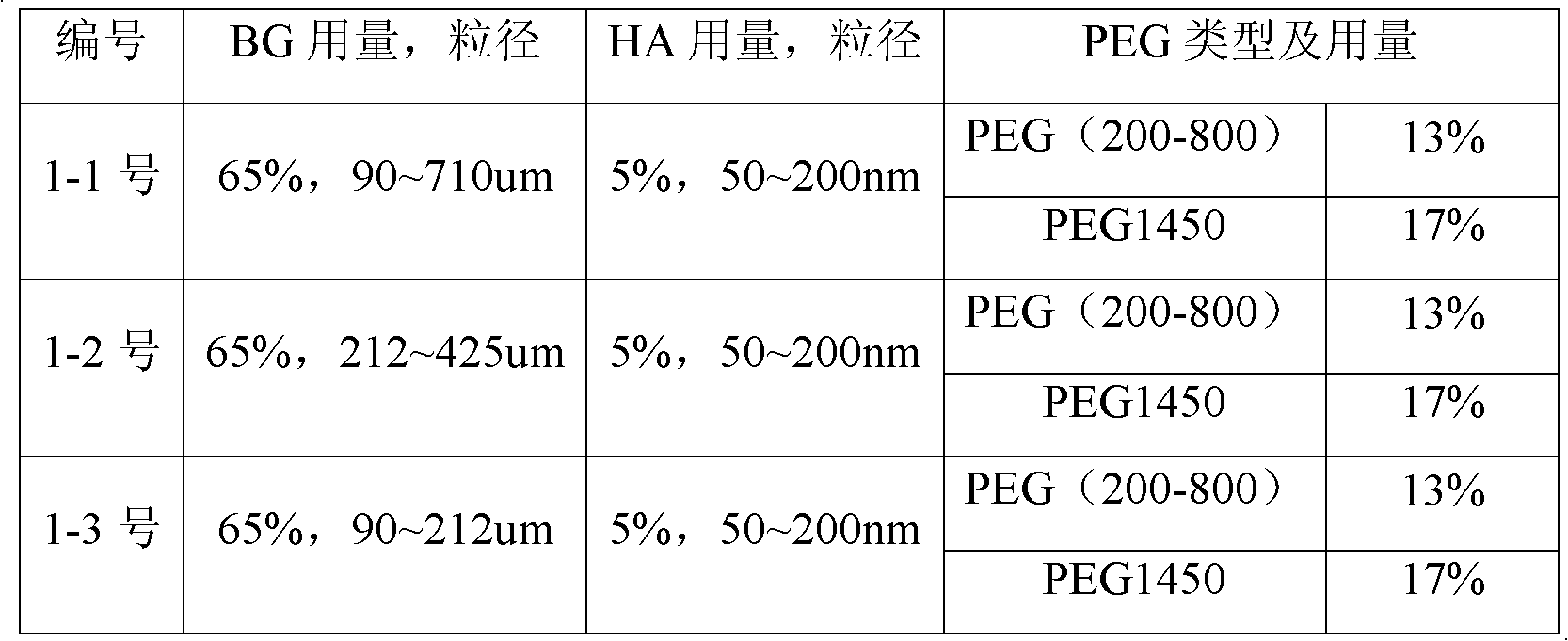

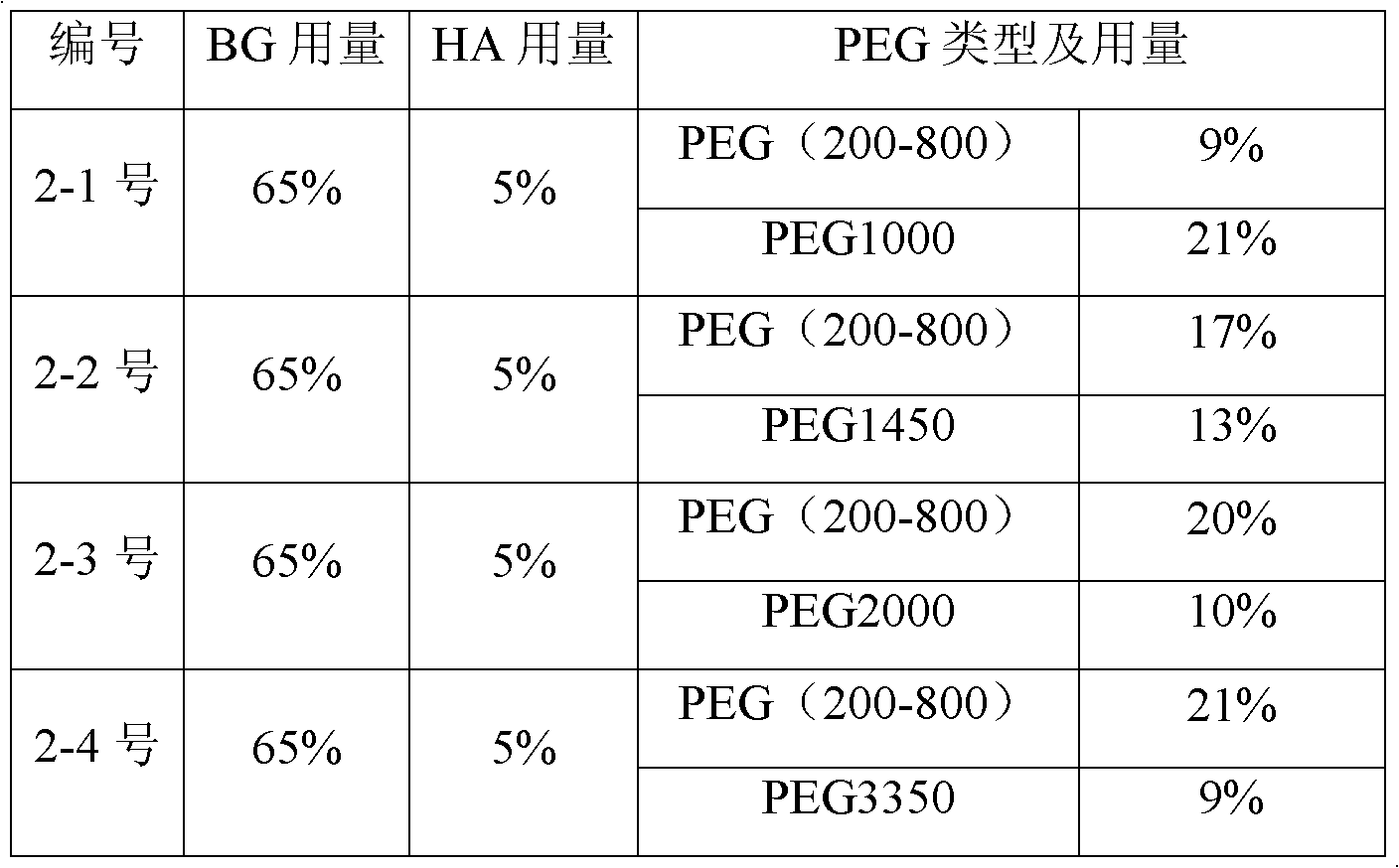

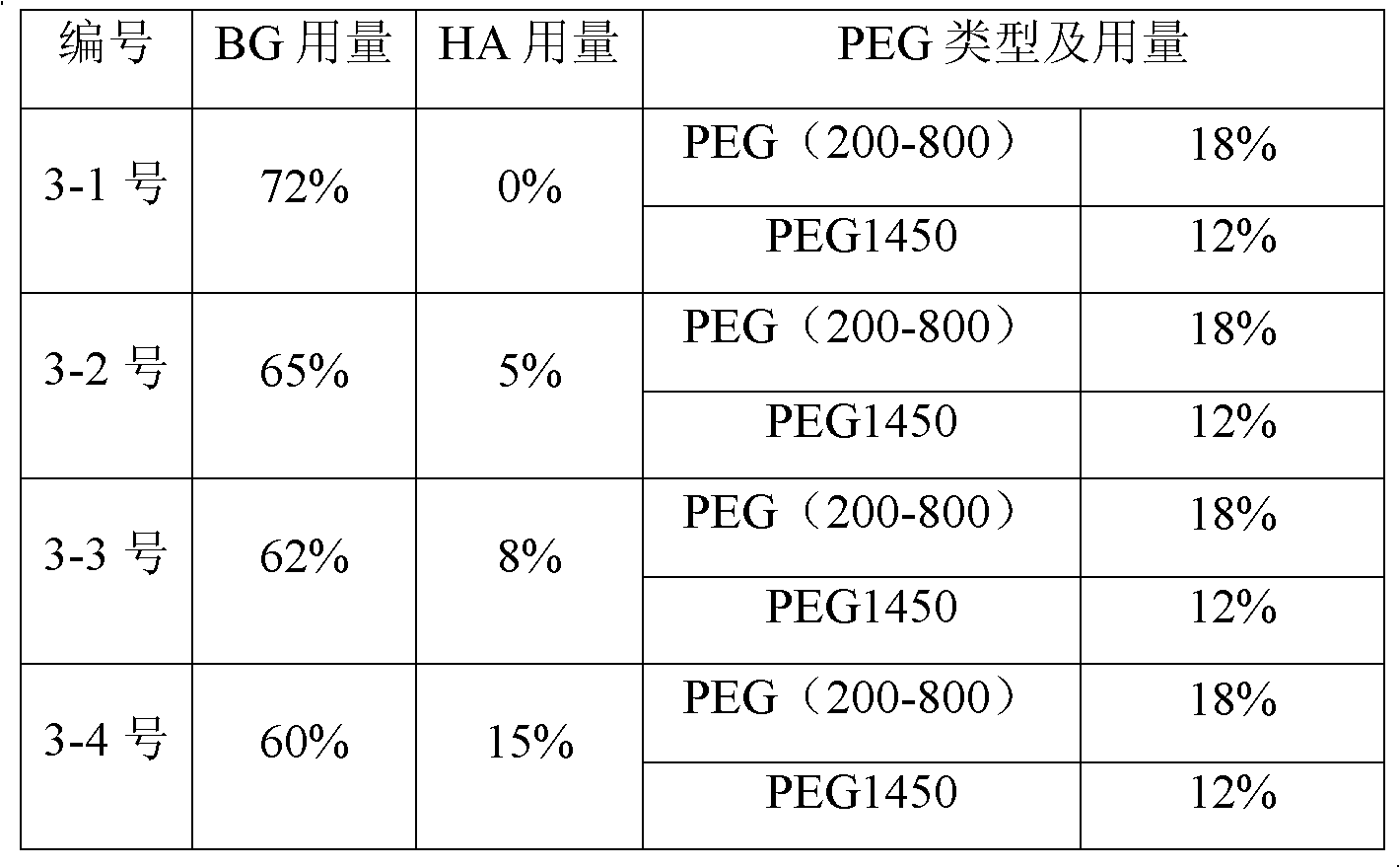

Bone repairing material and preparation method thereof

ActiveCN102488927ATransport without refrigerationReduce the risk of growthProsthesisPolyethylene glycolBiocompatibility Testing

The invention relates to a bone repairing material and a preparation method thereof, belongs to the field of medical materials, and aims at providing a bone repairing material which is less influenced by the changes of ambient temperature and humidity and is more stable. The bone repairing material is prepared from the following components in percentage by weight: 60-75% of bioactive glass with particle size of 212-425 mu m, 25-40% of PEG (polyethylene glycol) and 0-15% of hydroxyapatite with particle size of 50-200 nm. According to the bone repairing material provided by the invention, high-molecular-weight PEG is used as a plasticizing agent, and low-molecular-weight PEG is used as a softening agent or lubricant, thus the ointment product can be in any shapes, and the product has the characteristics of being more stable and better biocompatibility and safety. The bone repairing material has the advantages of being convenient for storage and transport, needing no cold storage measure, being difficult in moisture absorption, threshing, sand falling and hand sticking, and being obvious in postoperative X-ray development and postoperative recovery observation.

Owner:成都迪康中科生物医学材料有限公司

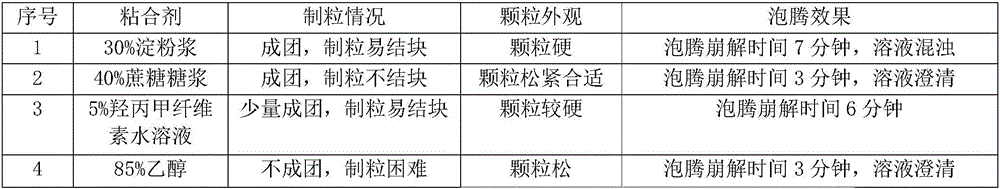

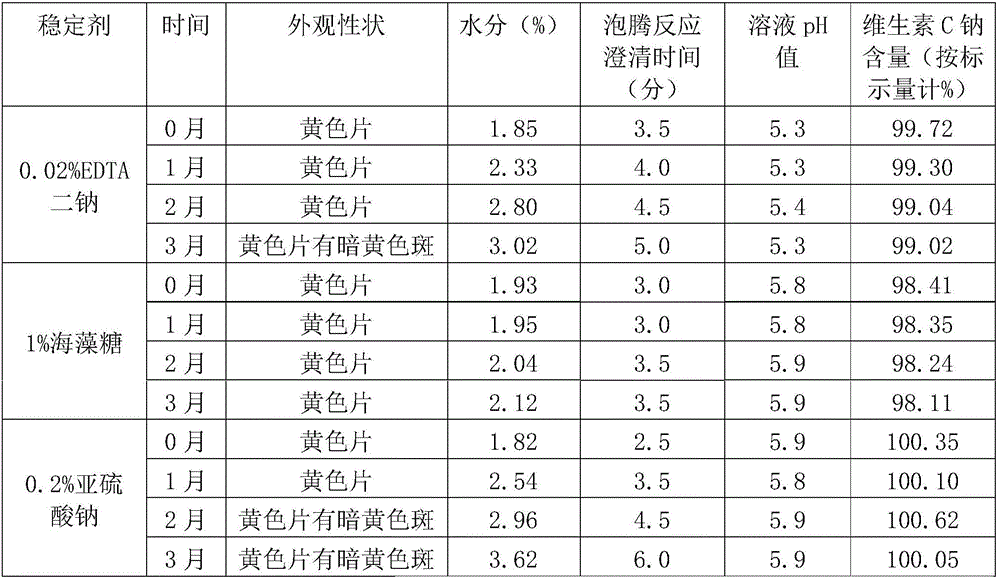

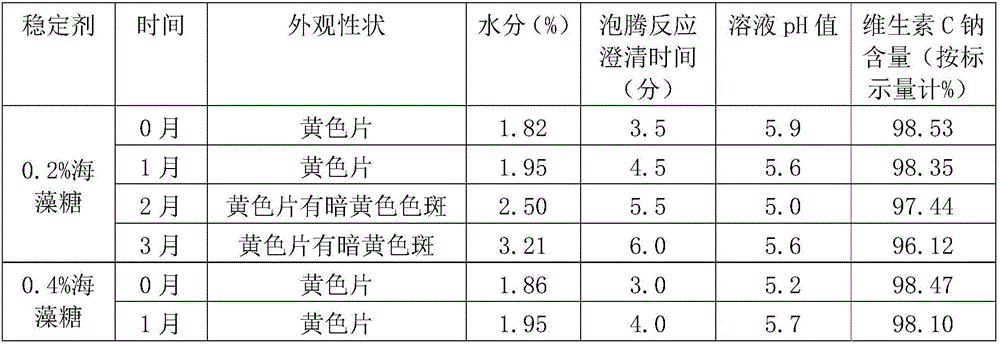

Effervescent tablet containing vitamin C sodium and preparation method of effervescent tablet

InactiveCN106420655ASuitable for long-term useTake applicableOrganic active ingredientsNervous disorderSodium bicarbonateEffervescent tablet

The invention discloses an effervescent tablet containing vitamin C sodium. The effervescent tablet is prepared from the following components in parts by weight: 200-1120 parts of the vitamin C sodium, 560-1300 parts of tartaric acid, 600-1500 parts of sodium bicarbonate and 200-600 parts of sucrose. The effervescent tablet containing the vitamin C sodium provided by the invention aims at solving the problems of an existing vitamin C effervescent tablet which is high in acidity after being dissolved, relatively serious in irritation to oral cavities, throats and esophagi as well as to gastric mucosae and not applicable to long-term taking, the problems that in a storage process, vitamin C can become oxidized and invalid easily and the effervescent tablet is easily affected with damp and easily absorb moisture, and the like; and the preparation (the effervescent tablet) is simple and convenient and is stable in quality.

Owner:GUANGXI SANPOTEL HEALTH IND CO LTD

Method for preparing bacillus subtilis preparation

ActiveCN101558763AHigh content of active ingredientsEfficient removalBiocideMicroorganism based processesUltrafiltrationFiltration

The invention provides a method for preparing a bacillus subtilis preparation, and relates to a method for preparing a microorganism preparation. The method solves the problems of the prior method for preparing bacillus subtilis preparation such as high preparation cost, and low content of effective ingredients and short preservation period of prepared product. The method comprises the following steps that: 1, bacillus subtilis B10 is fermented to obtain fermentation broth; 2, the fermentation broth is subjected to ultrafiltration membrane separation to obtain antibiotic solution and germ solution; 3, the antibiotic solution is subjected to ultrafiltration membrane filtration to obtain antibiotic permeate liquid; 4, the antibiotic permeate liquid is subjected to nanofiltration membrane filtration once again to obtain antibiotic concentrated liquid; and 5, the antibiotic concentrated liquid and the germ solution in the step two are mixed into powder through spray drying so as to obtain the bacillus subtilis preparation. The preparation method has low cost, and the prepared product has good quality and long shelf life, and can be stored for over 2 years without deterioration under the sealing condition.

Owner:德强生物股份有限公司

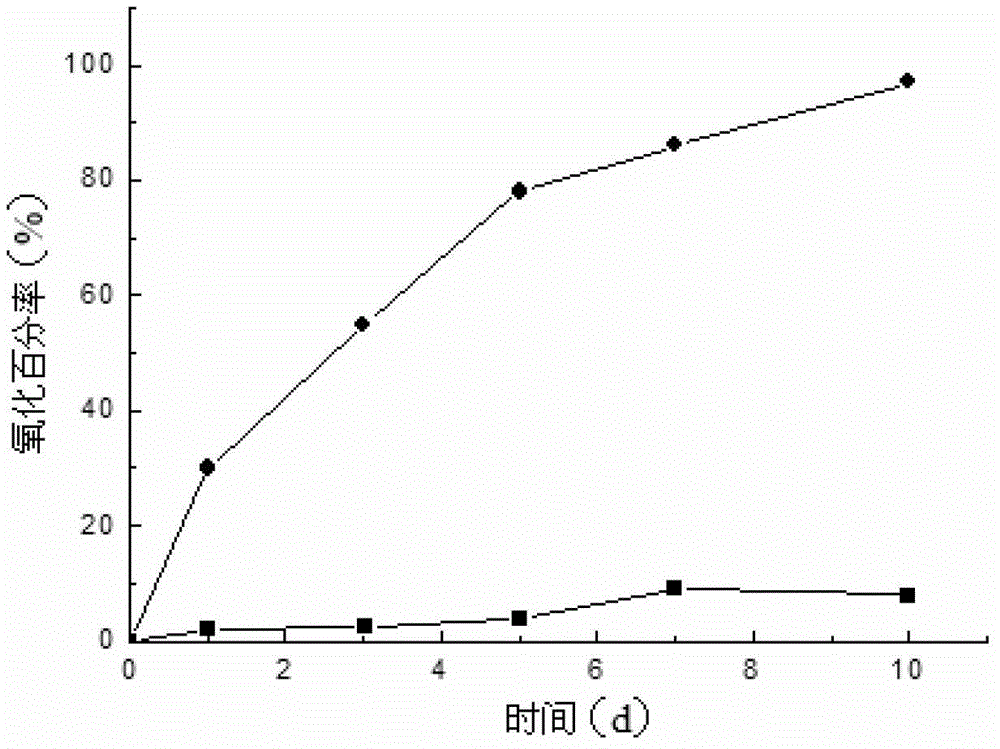

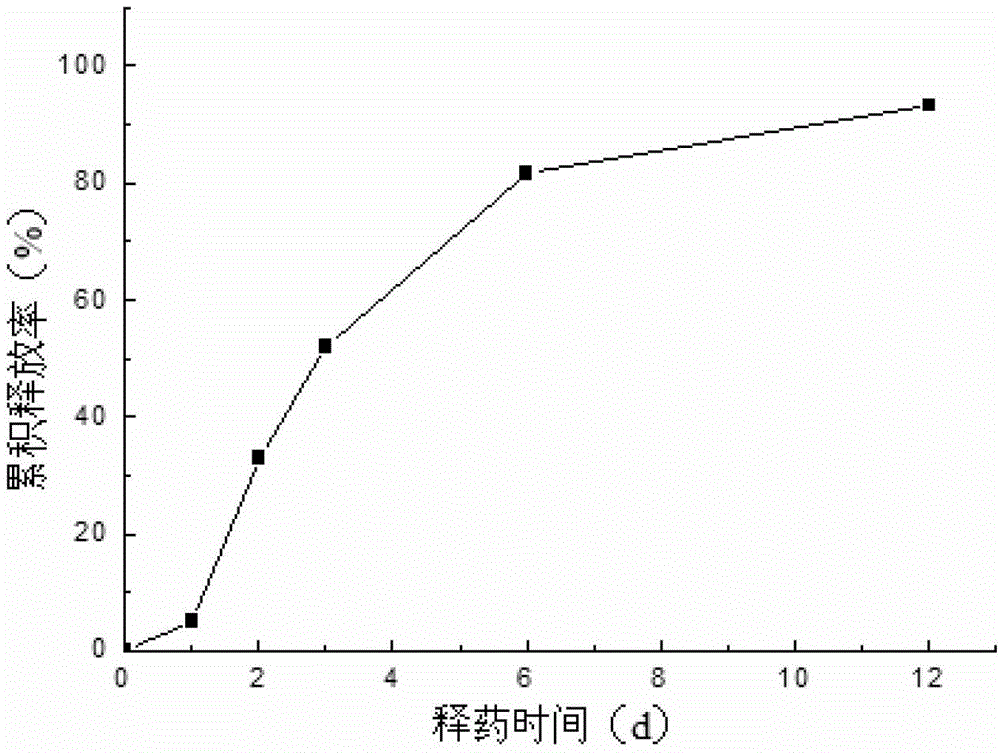

Method for preparing micro-capsule by taking xanthan gum and gelatine as wall materials through complex coacervation method

InactiveCN103142551ASimple particle size distributionUniform particle size distributionMacromolecular non-active ingredientsMicrocapsulesEmulsionOxidation resistant

The invention relates to the technical field of preparation of micro-capsules, in particular to a method for preparing a micro-capsule by taking xanthan gum and gelatine as wall materials through a complex coacervation method. The invention aims to solve the problems of being low in micro-capsule encapsulation efficiency and large in grain diameter prepared by the current method. The preparation method comprises the following steps of: 1, preparing gelatine solution; 2, preparing xanthan gum solution; 3, preparing steady O / W type emulsion, and then adding the xanthan gum solution to obtain mixed solution; 4, adding a curing agent after adjusting pH of the mixed solution; and 5, drying to obtain the micro-capsule. The method disclosed by the invention has the advantages that the encapsulation efficiency can be above 90%; the drug loading capacity can be up to 70% maximally; if being placed below 60 DEG C for 10 days, the micro-capsule is only oxidized by 3-8%; the antioxidant ability is strong; in the event of carrying out an in-vitro drug release test, the whole drug releasing time is 12 hours; the accumulated release rate can be above 90%; the slow-release effect is good; and the method disclosed by the invention is mainly used for preparing the micro-capsule by taking xanthan gum and gelatine as the wall materials through the complex coacervation method.

Owner:HEILONGJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com