Large-scale continuous energy-saving fluidized bed spray granulation drying process

A technology of fluidized bed spraying and drying process, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., which can solve the problems of small environmental pollution and achieve the effects of small environmental pollution, uniform particle size and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

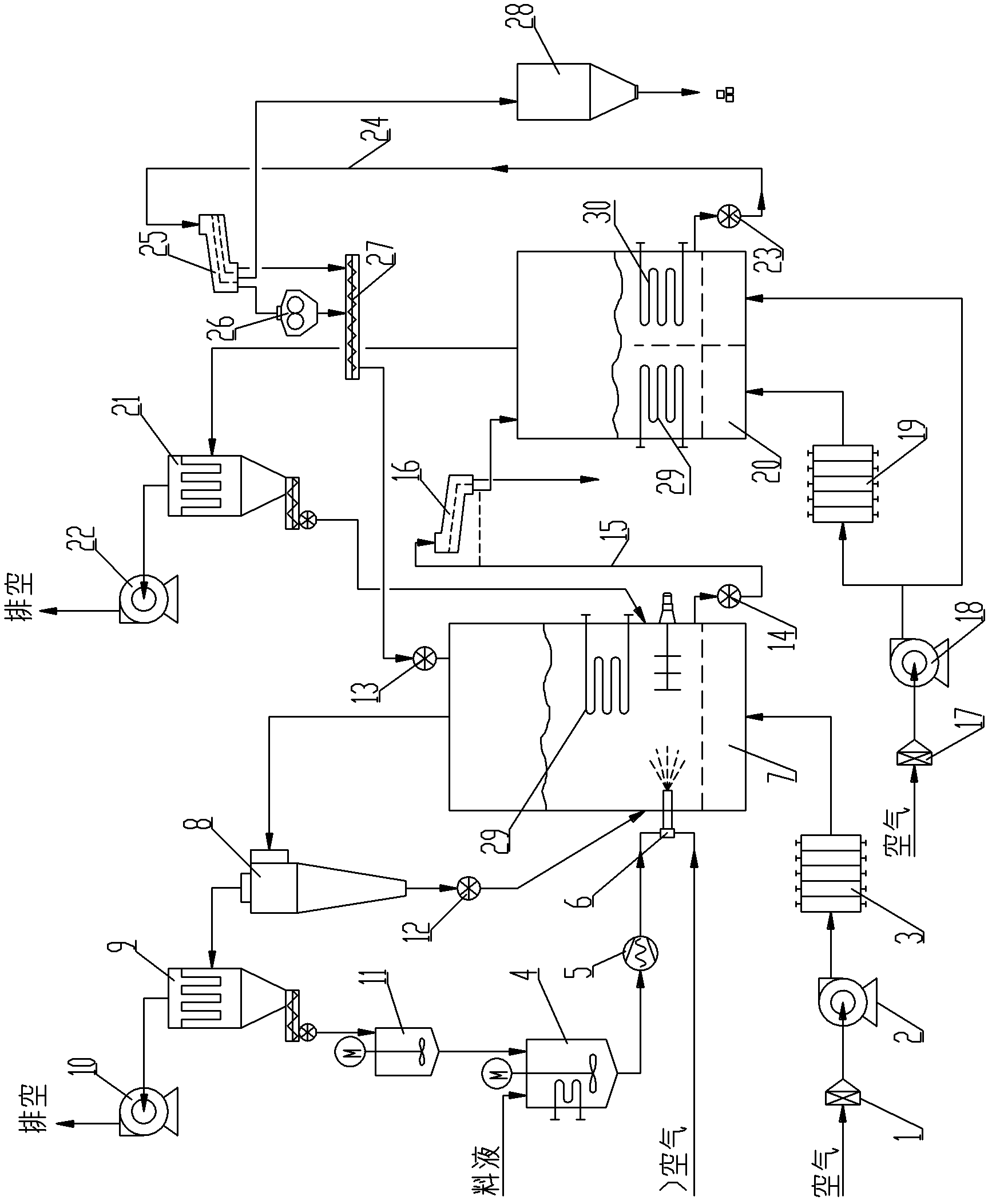

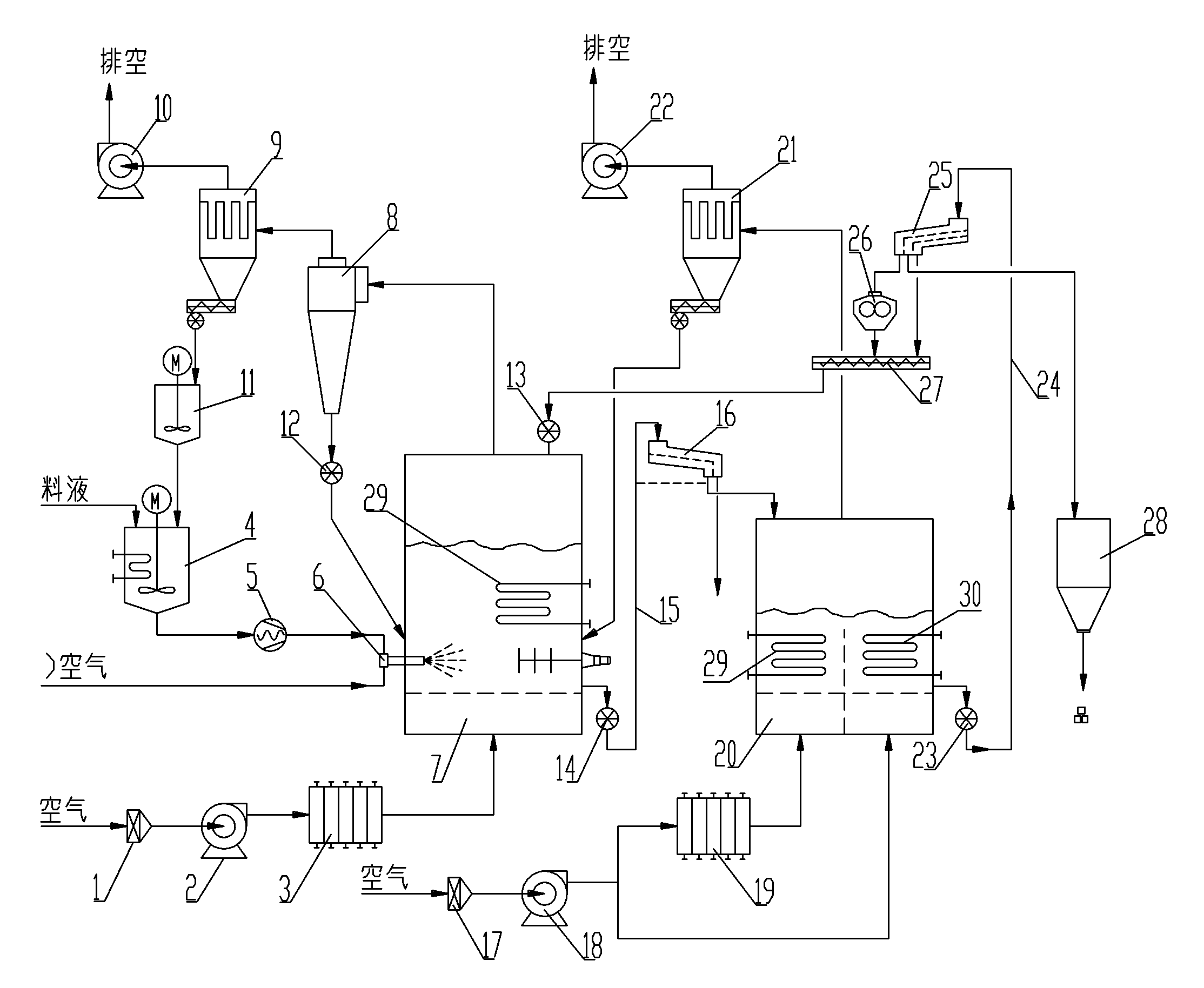

[0014] Refer to the attached figure 1 The large-scale continuous energy-saving fluidized bed spray granulation drying process of the present invention is described in detail below.

[0015] The large-scale continuous energy-saving fluidized bed spray granulation drying process of the present invention comprises the following steps: the spray granulation and drying processes are completed in the granulation fluidized bed 7 . The feed liquid in the slurry tank 4 is pressurized and transported to the two-fluid spray gun 6 by the feed pump 5, and is atomized into fine droplets under the action of compressed air, and is evenly sprayed on the liquid in the fluidized state in the granulation fluidized bed 7. The surface of the seed crystal particles grows gradually through agglomeration and coating, and is dried under the combined heating of the hot air and the built-in heater 29 in the granulation fluidized bed 7, and passes through the granulation fluidized bed 7 The material disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com