Bone repairing material and preparation method thereof

A bone repair and molecular weight technology, applied in the field of medical materials, can solve the problems of difficult postoperative observation, high requirements for storage conditions, high pH value, etc., achieve a high level of sterility assurance, improve faster degradation, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

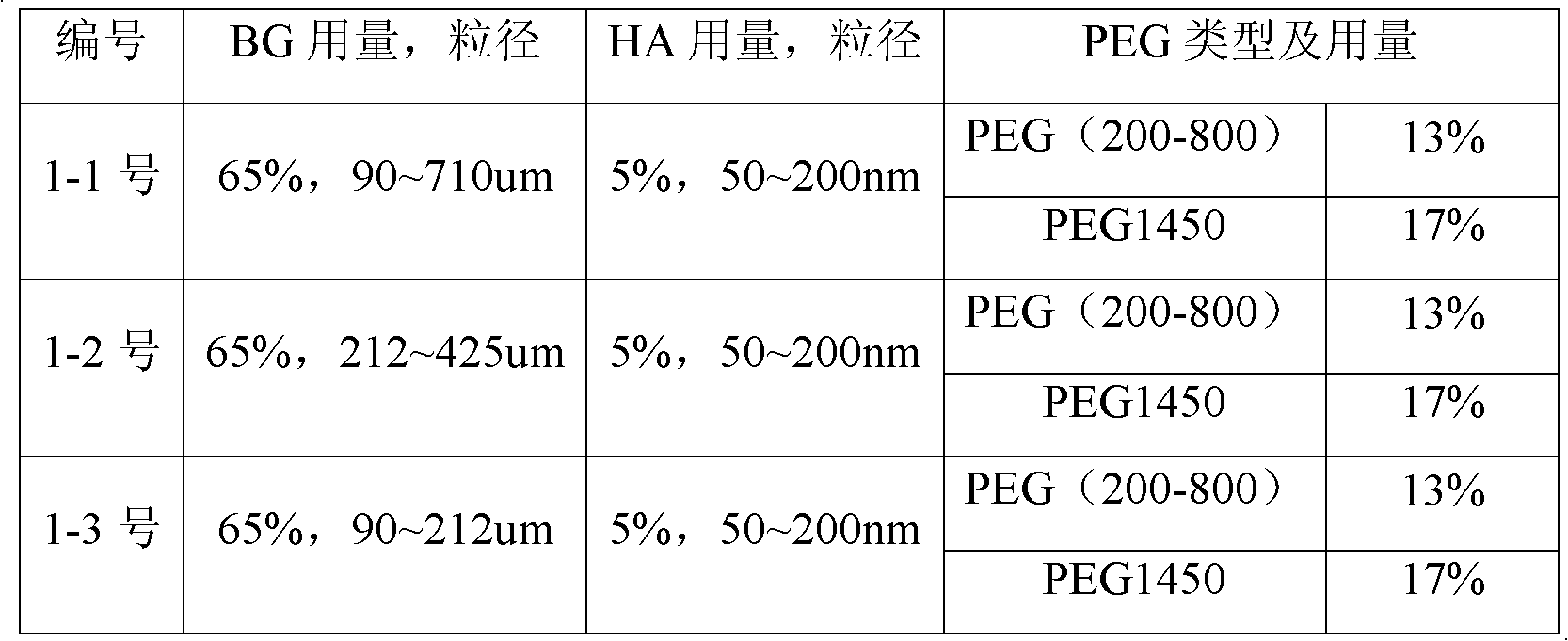

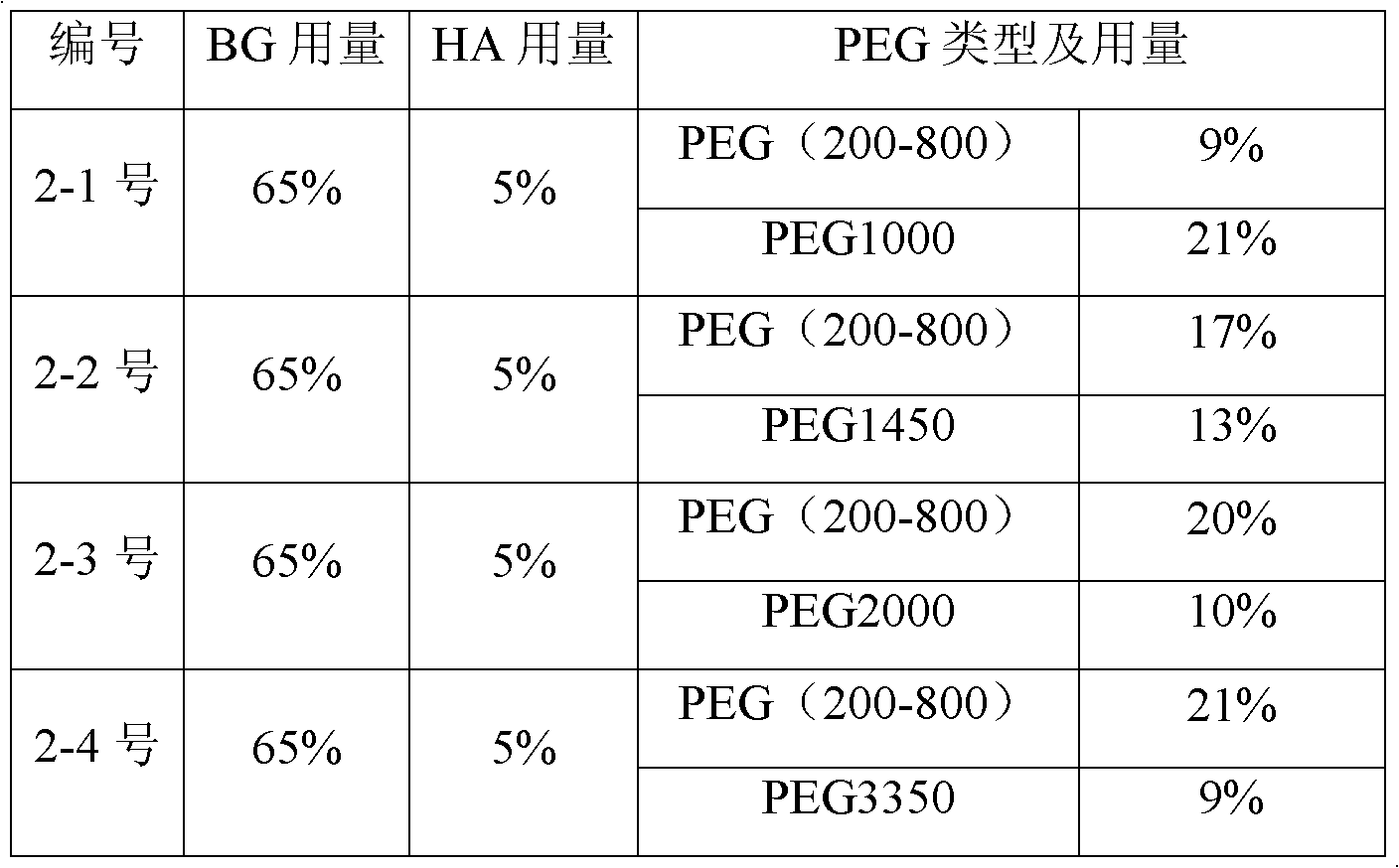

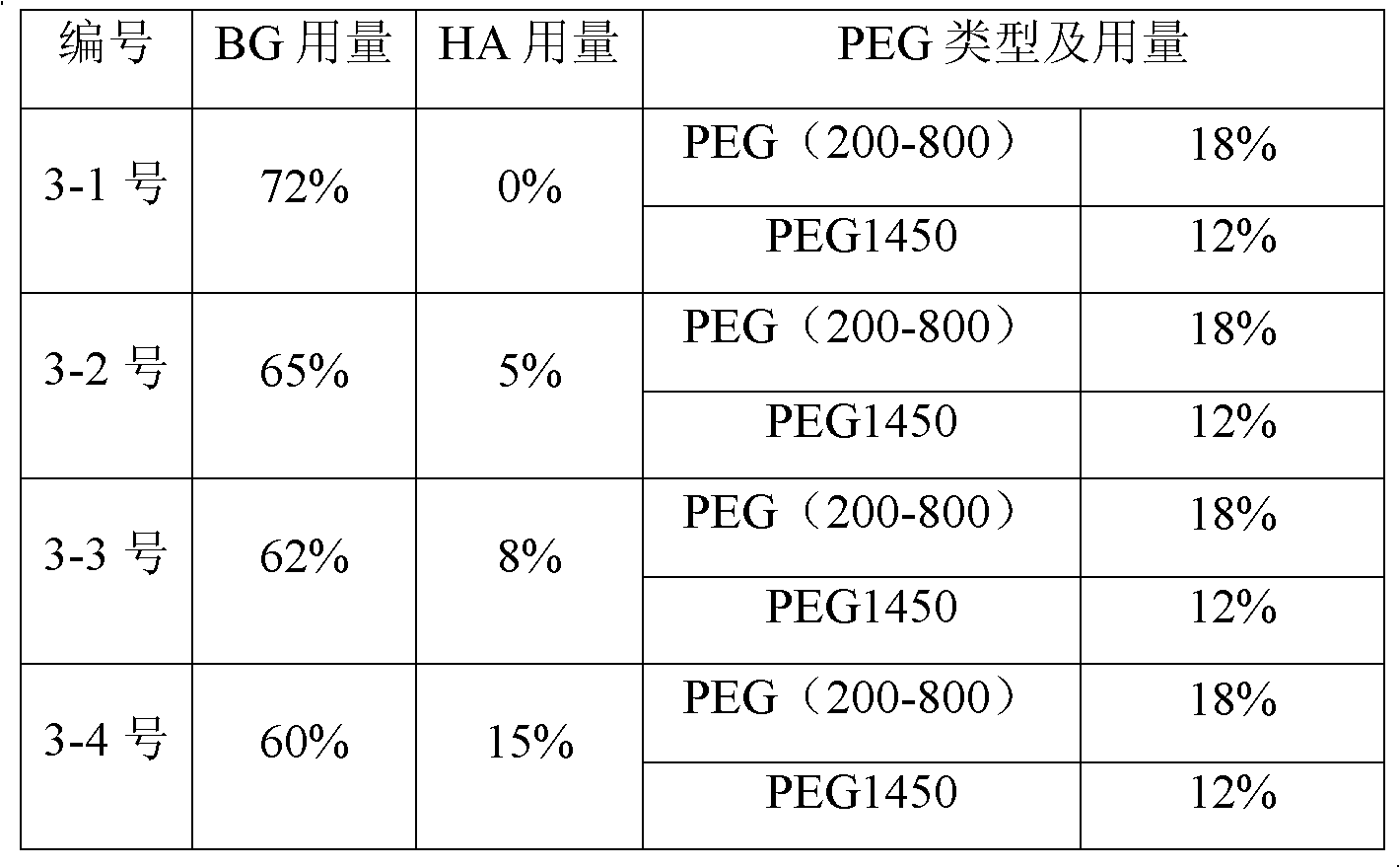

Examples

preparation example Construction

[0049] The preparation method of bone repair material of the present invention is:

[0050] (1) When the bone repair material does not contain hydroxyapatite:

[0051] A. After PEG is melted into a liquid state at a temperature of 60-120°C, PEG mixture I is formed;

[0052] B. Mix PEG mixture I with bioactive glass, and mix uniformly to obtain mixture II;

[0053] C. Mixture II is sterilized at high temperature (1-4h) under the protection of an inert gas; preferably sterilized at a temperature of 150-250°C, and the inert gas is carbon dioxide, nitrogen or helium;

[0054] D. After sterilization, stir the mixture II while cooling down, and stop stirring when the temperature drops to 30-40°C to obtain an ointment.

[0055] (2) When the bone repair material contains hydroxyapatite:

[0056] A. Mix hydroxyapatite and PEG, control the temperature at 60-120°C, melt into a liquid state, add dispersant such as silane coupling agent or sodium polyacrylate (the purpose of adding disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com