Patents

Literature

310 results about "Plant Gums" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polysaccharide gums from PLANTS.

Modulation of plant xylan synthases

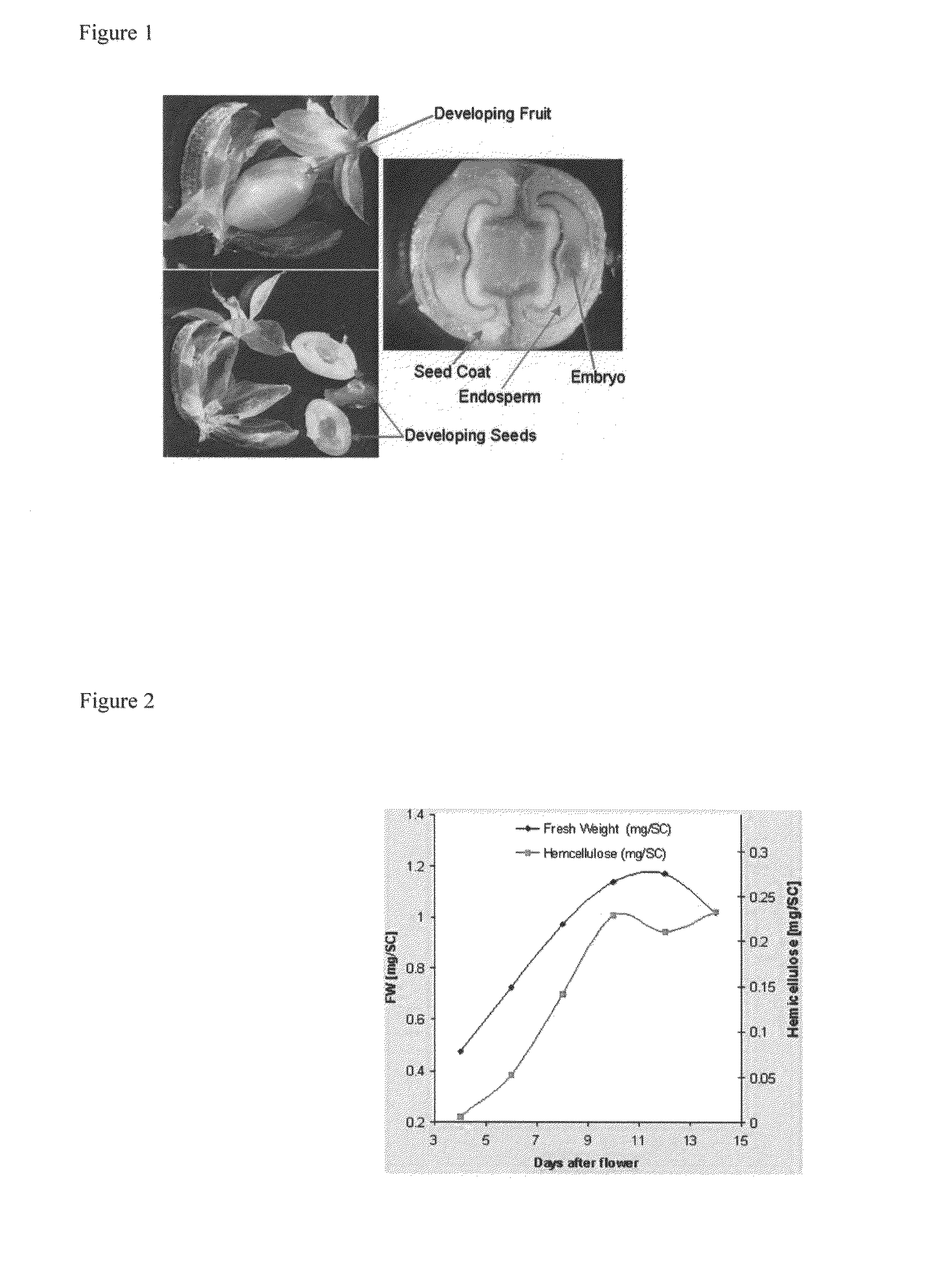

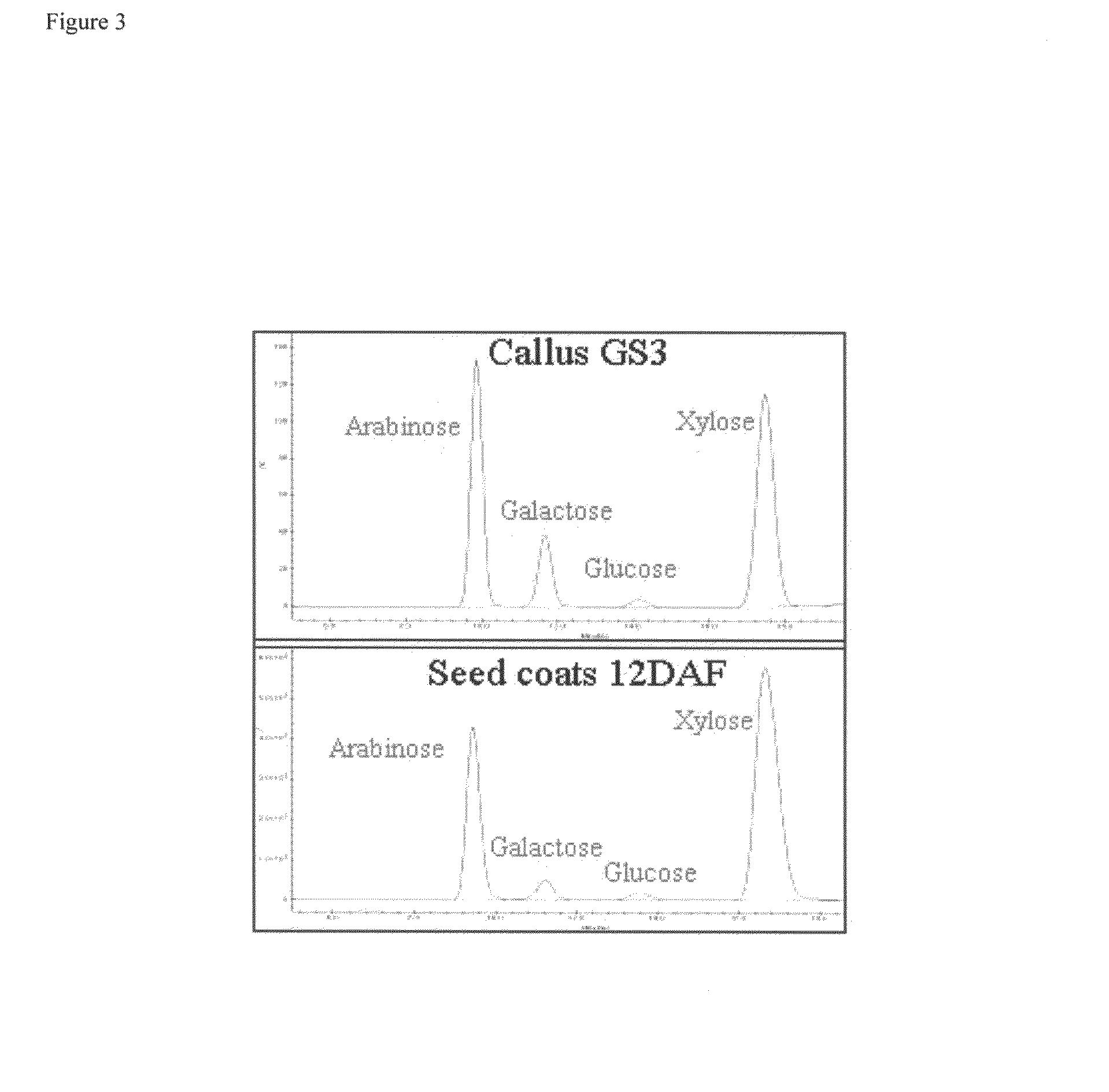

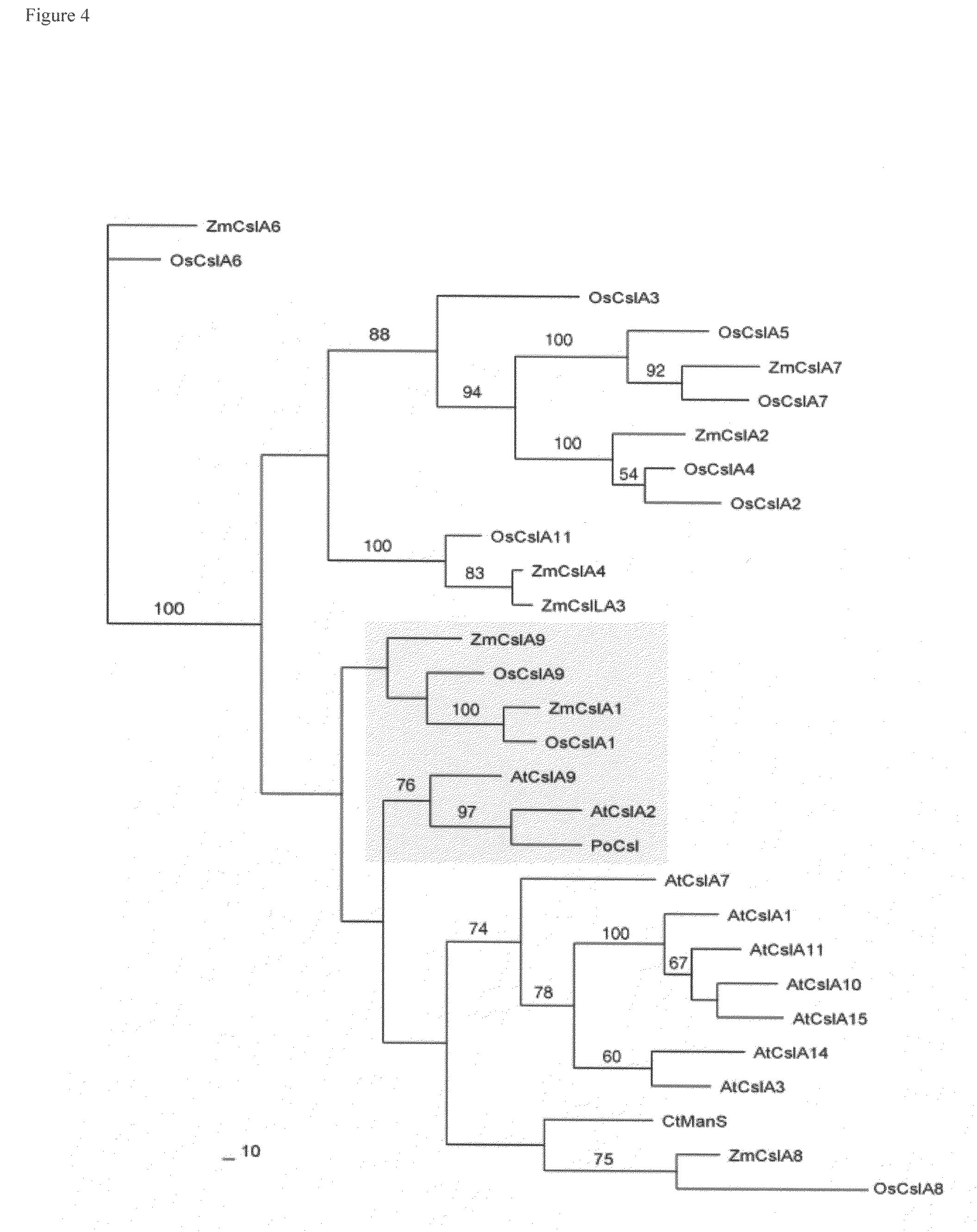

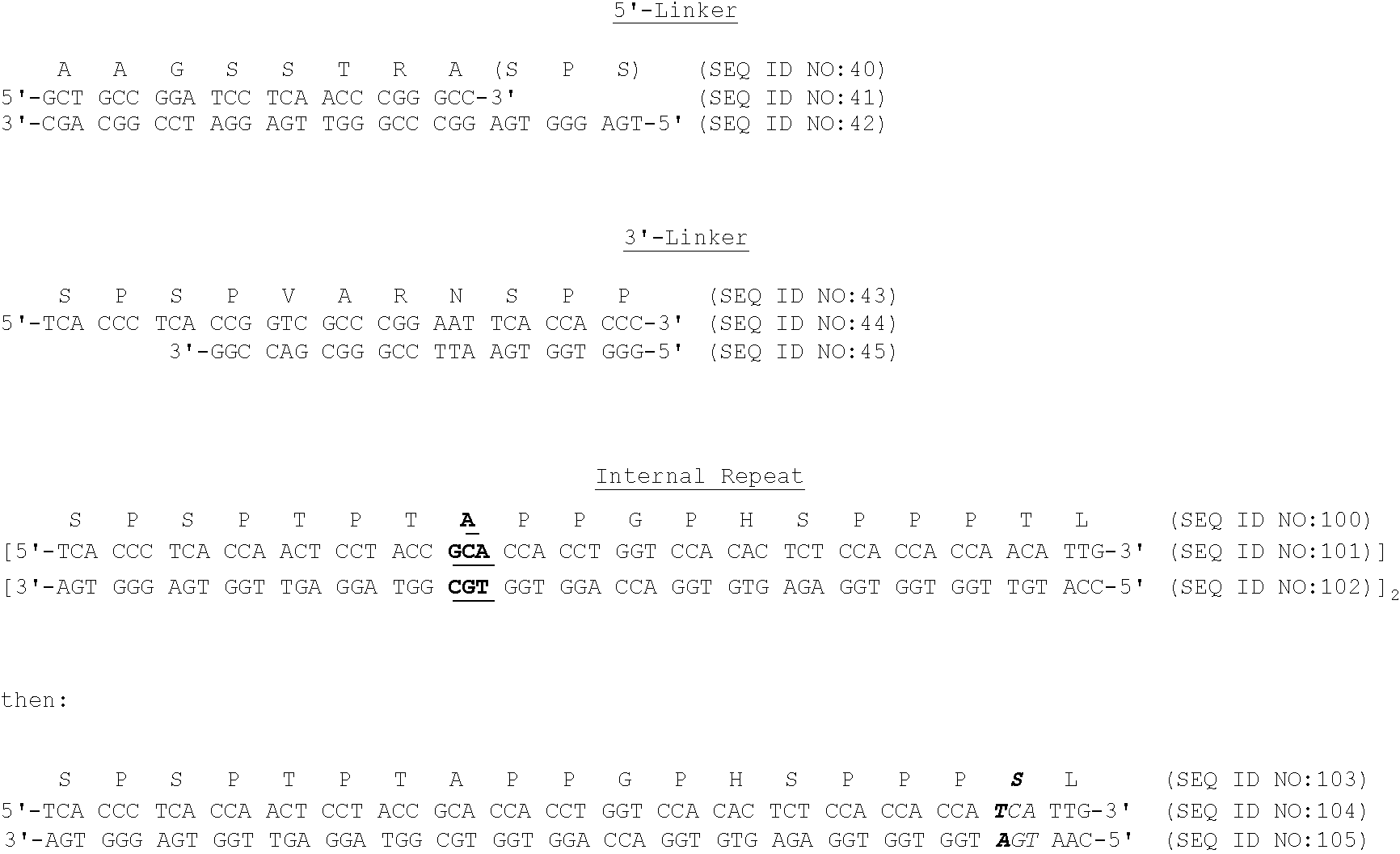

The present invention provides compositions and methods for manipulation of plant arabinoxylose and plant xylan synthases. Compositions include novel nucleotide sequences encoding xylan synthases and biologically active variants thereof. The invention also includes the discovery xylan synthase activity is a property of CslA polypeptides. Further provided are methods for xylose manipulation using the sequences disclosed herein. One method comprises stably incorporating into the genome of a plant cell, a CslA encoding nucleotide sequence operably linked to a heterologous promoter and regenerating a stably transformed plant. Methods for enhancing digestibility of plants and improving gum production in plants are also provided.

Owner:PIONEER HI BRED INT INC

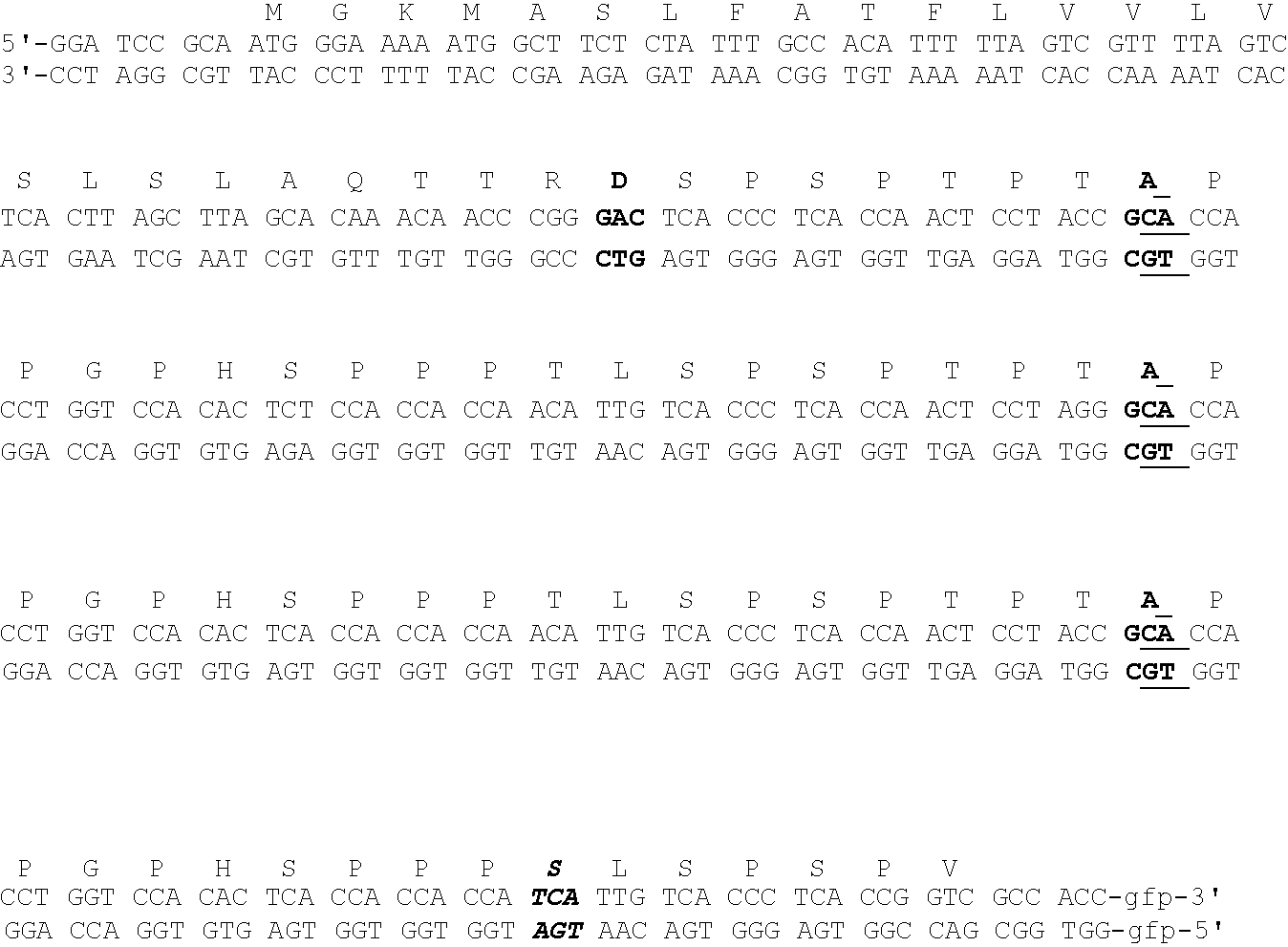

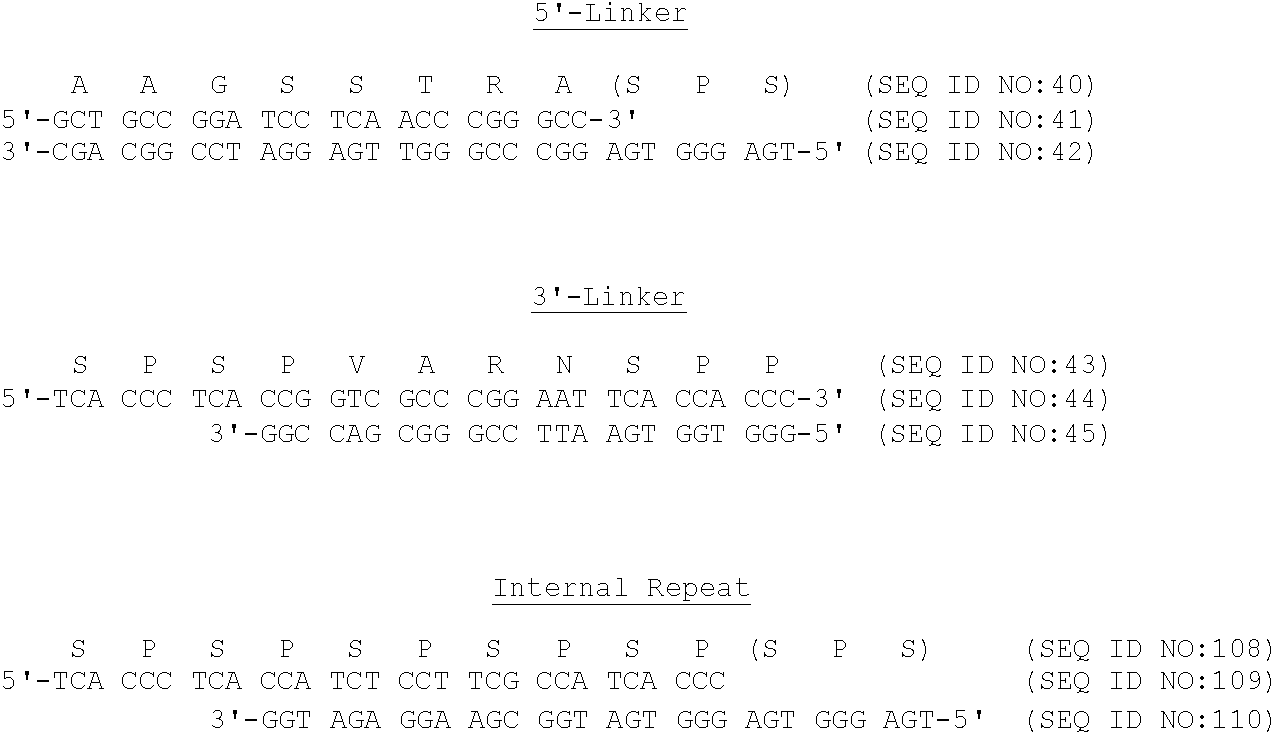

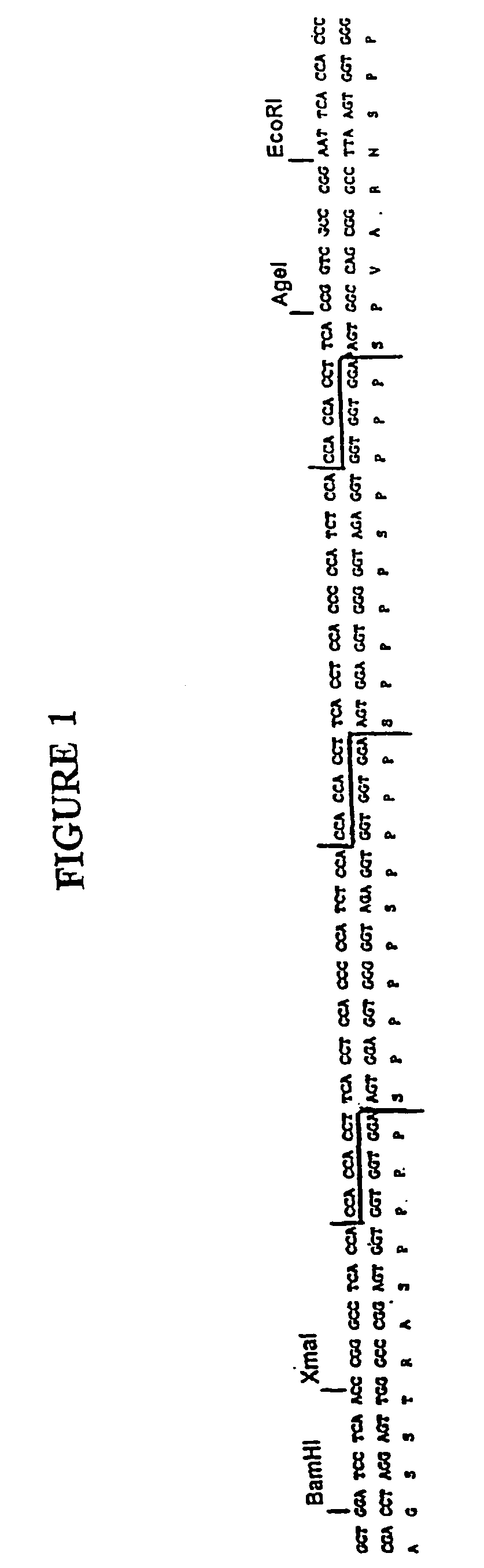

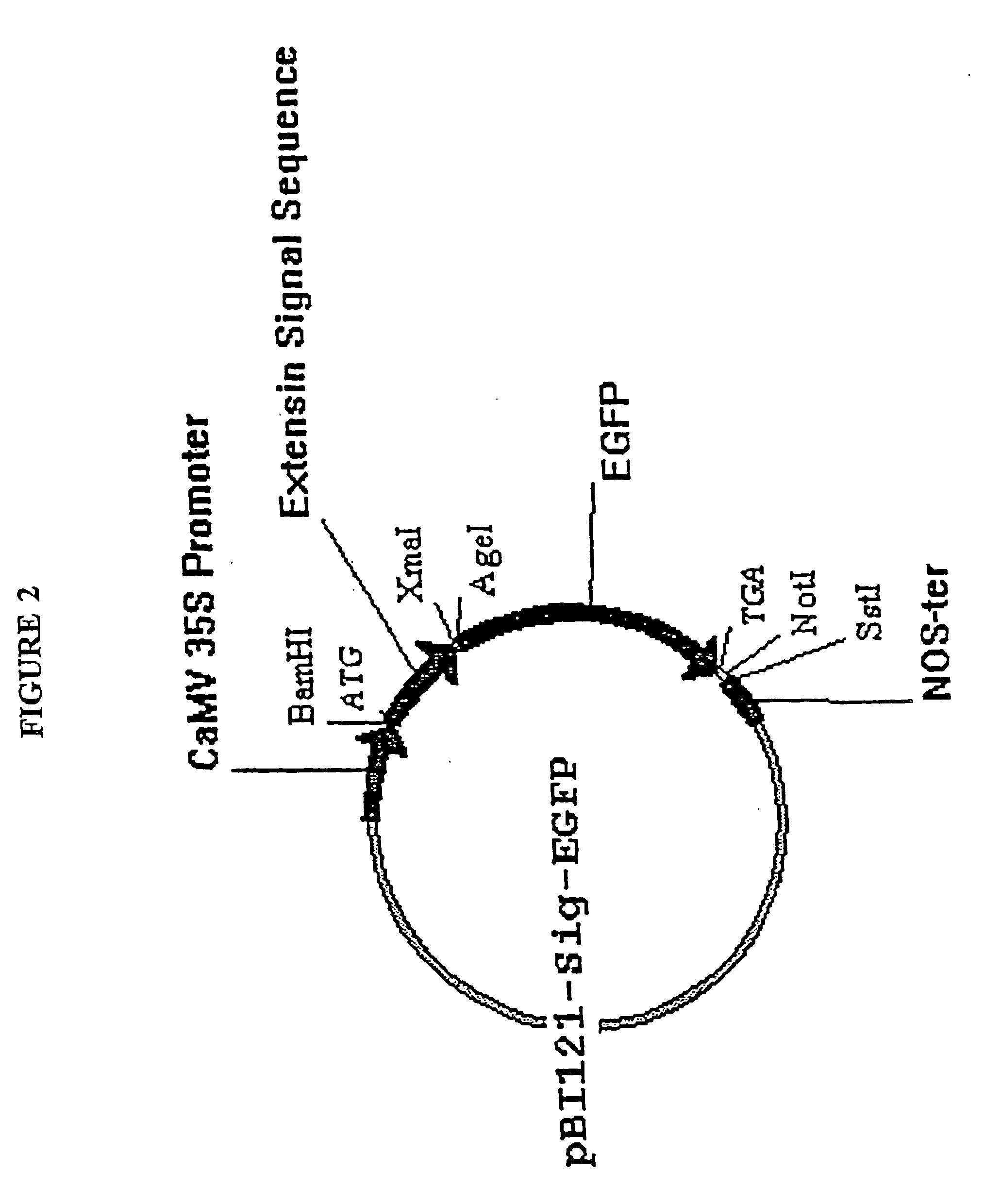

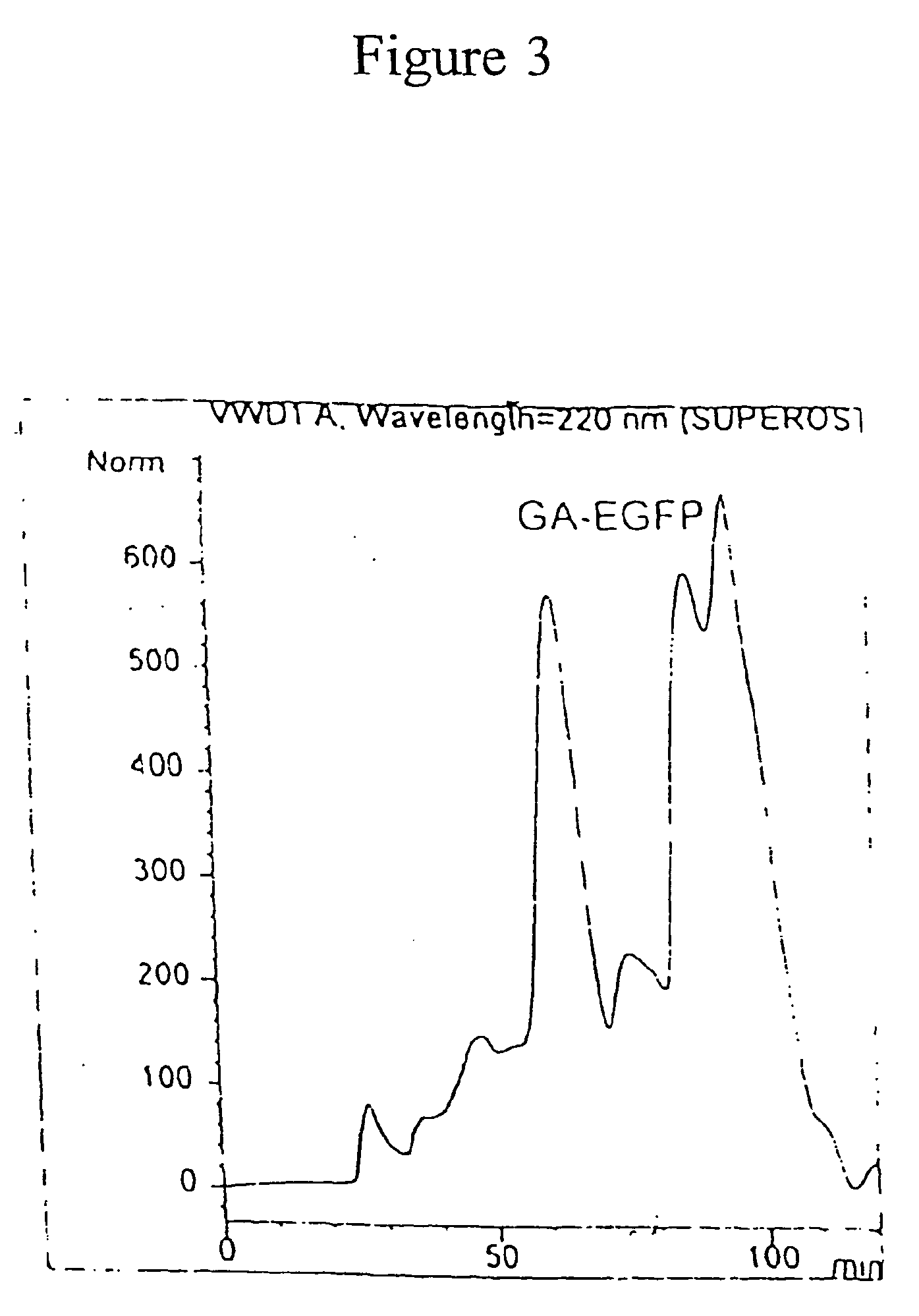

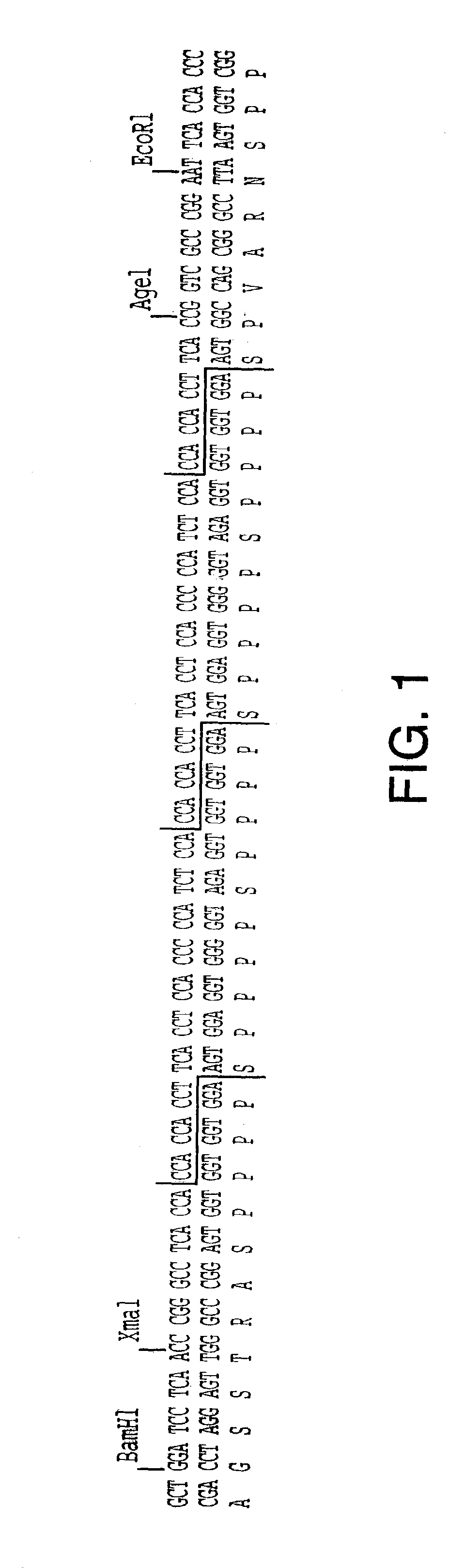

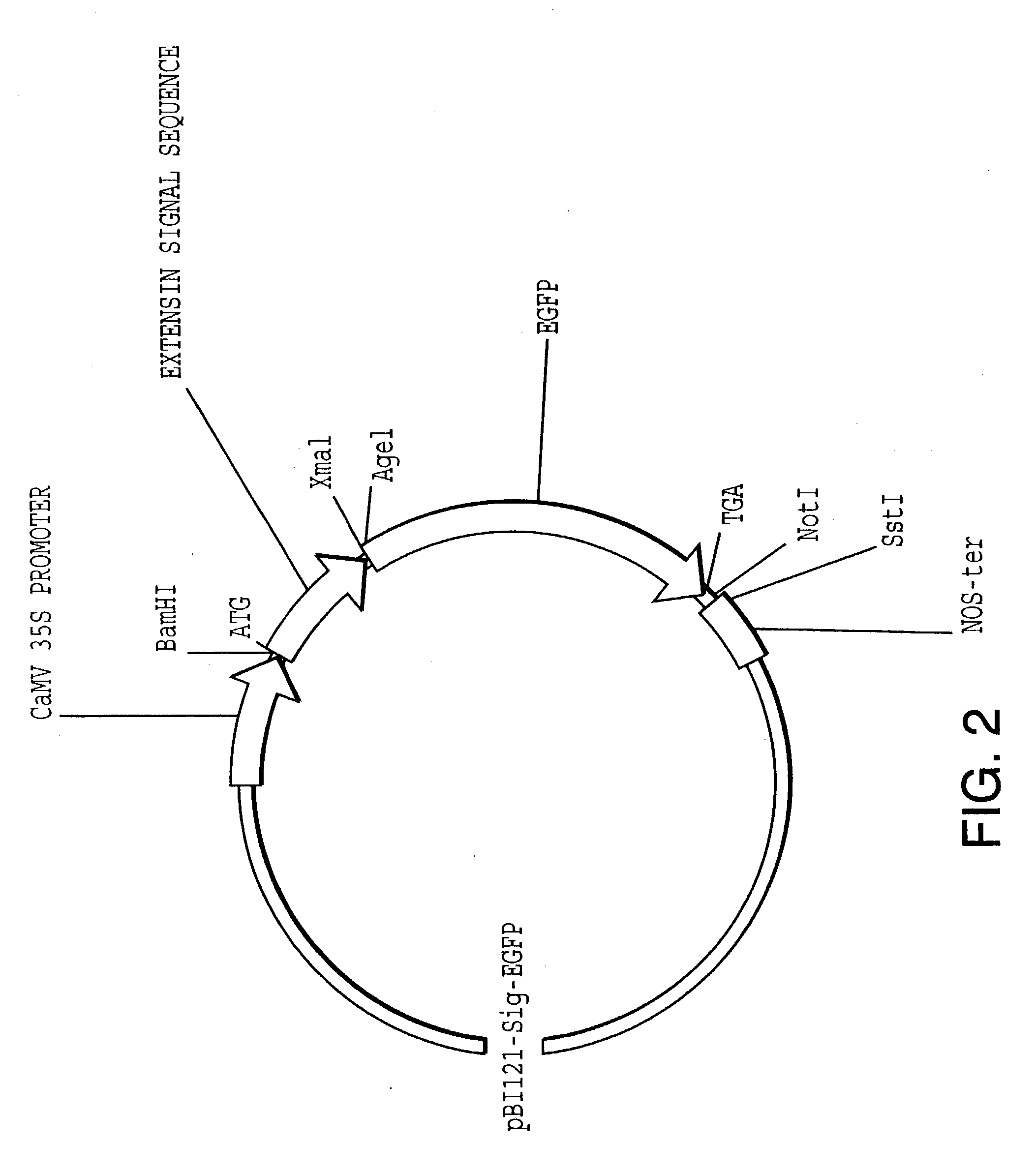

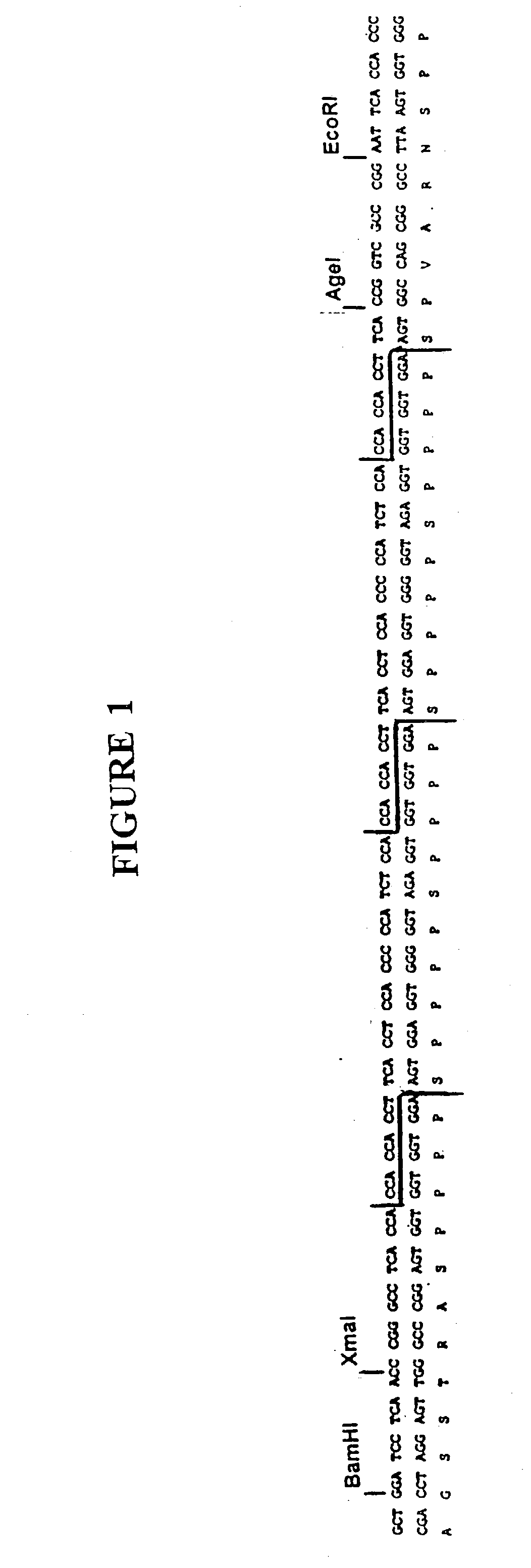

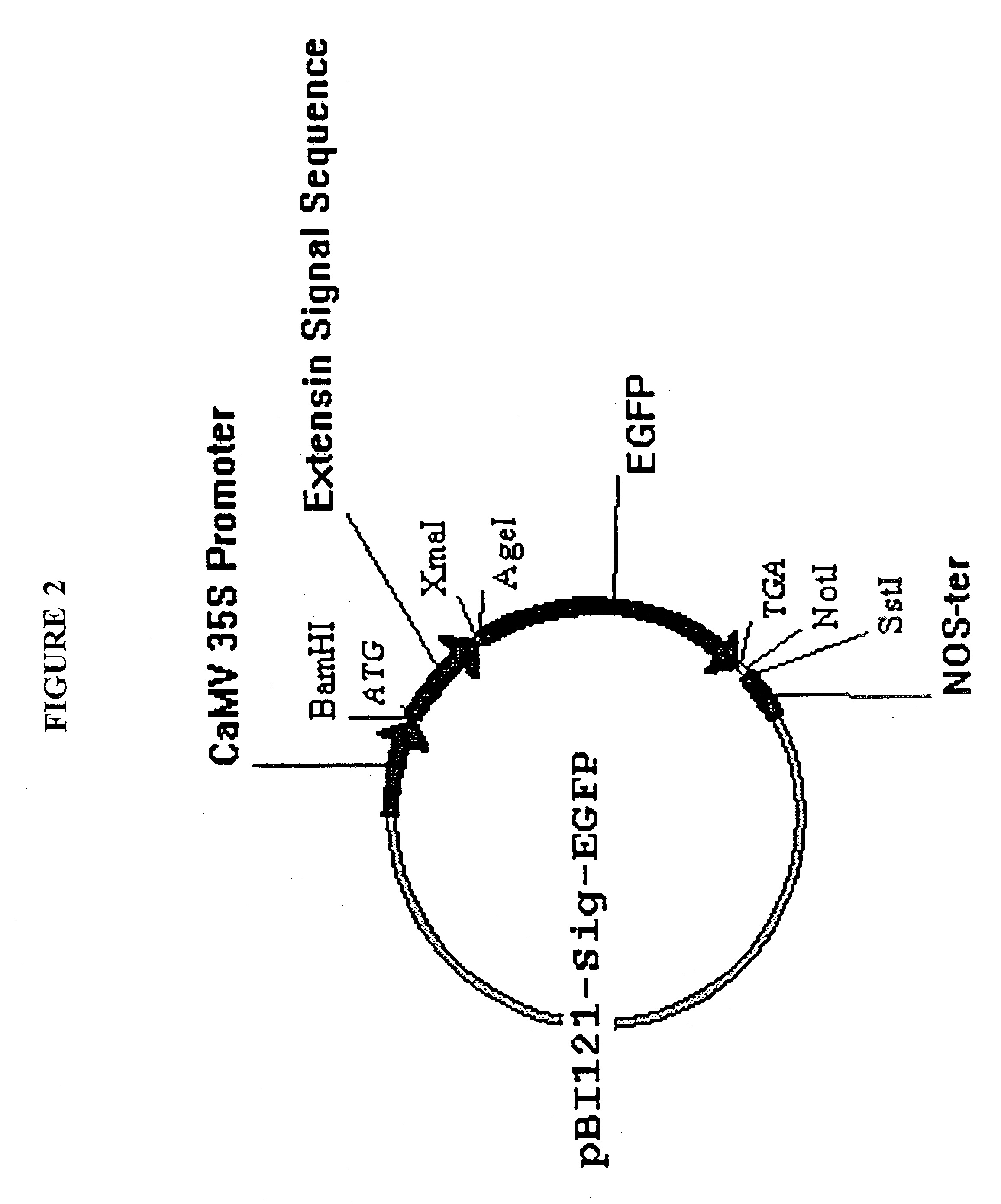

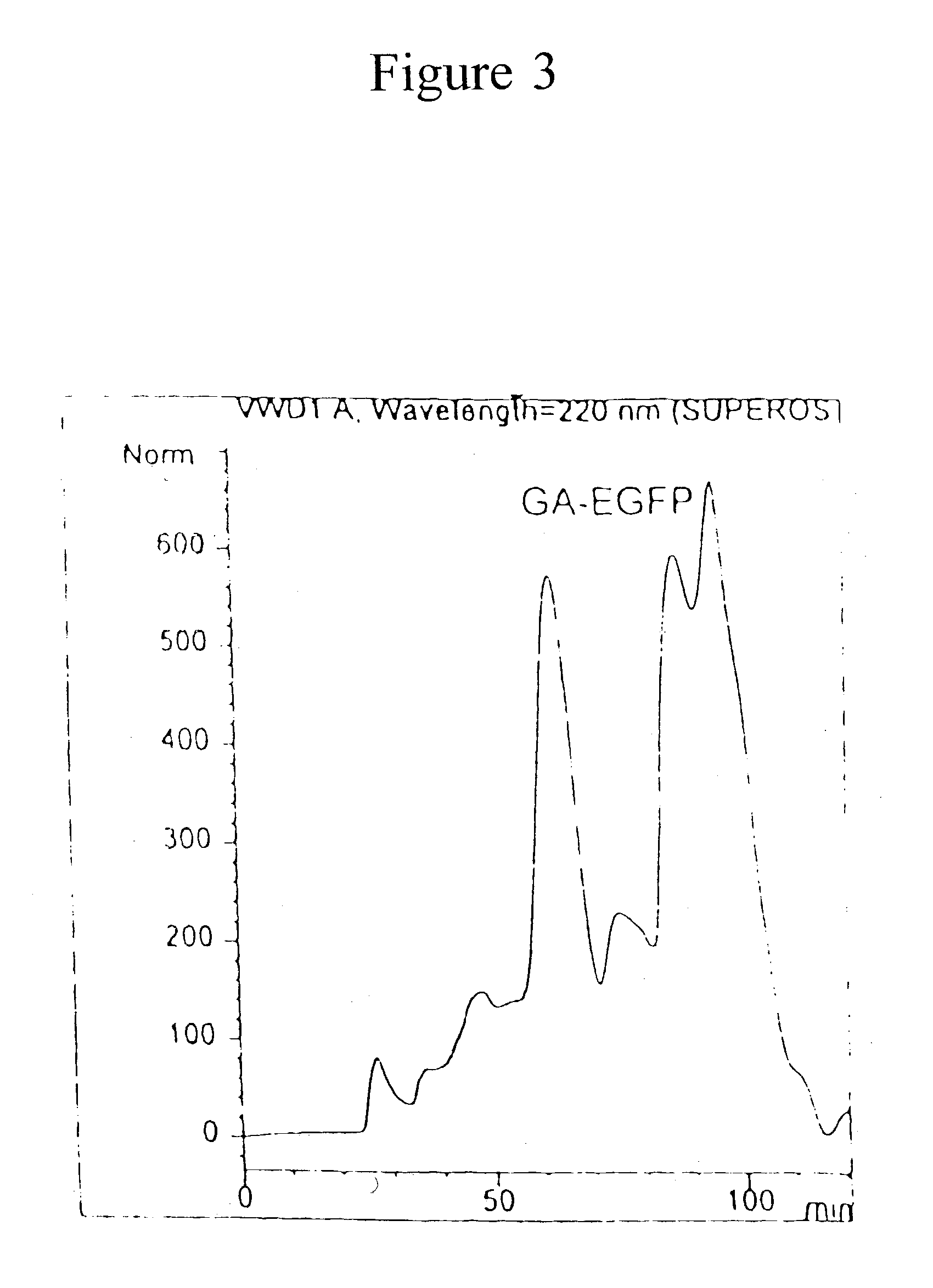

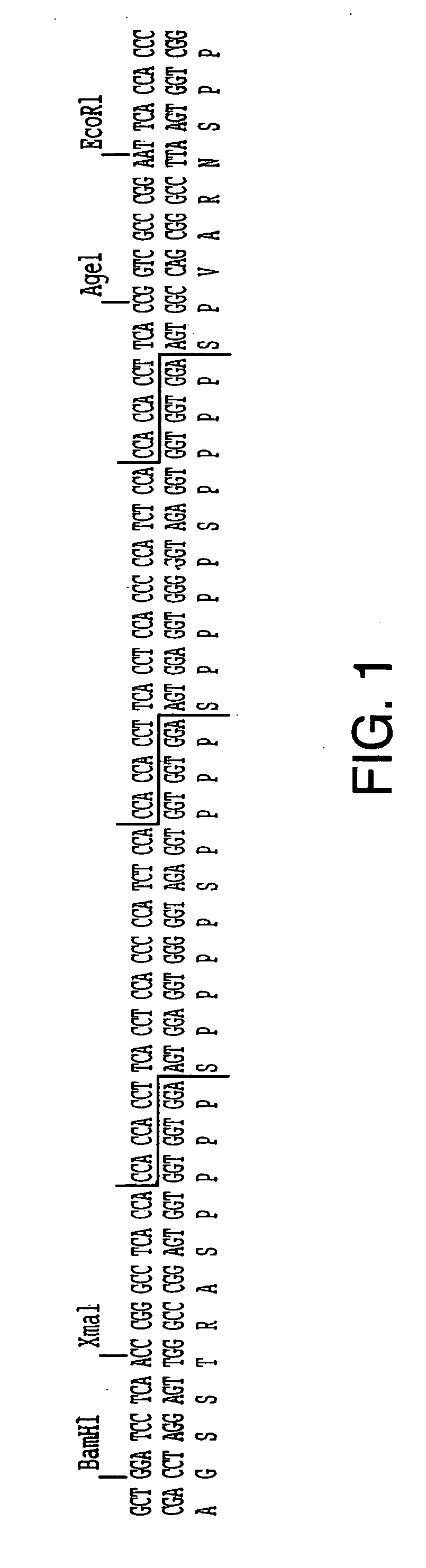

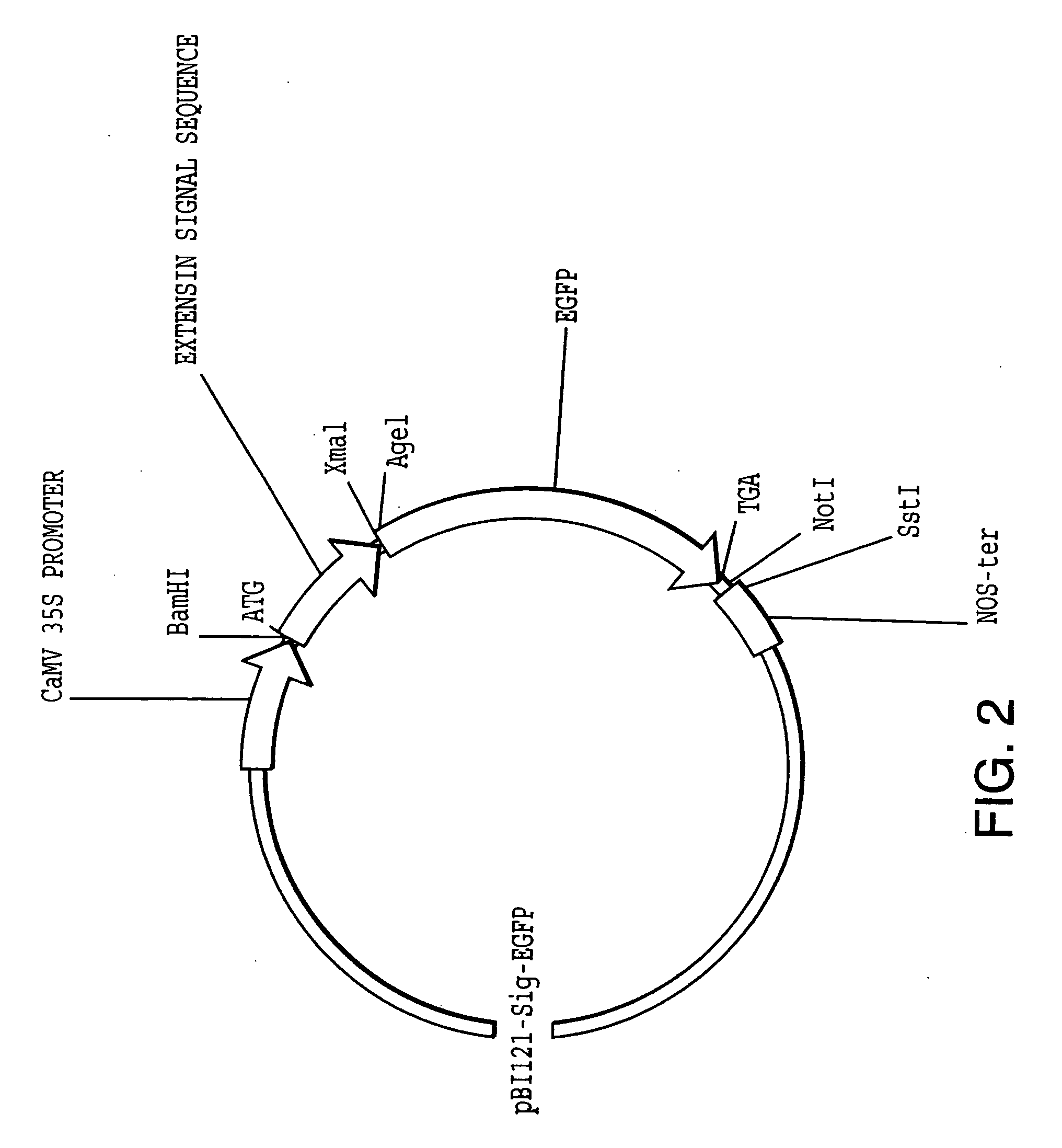

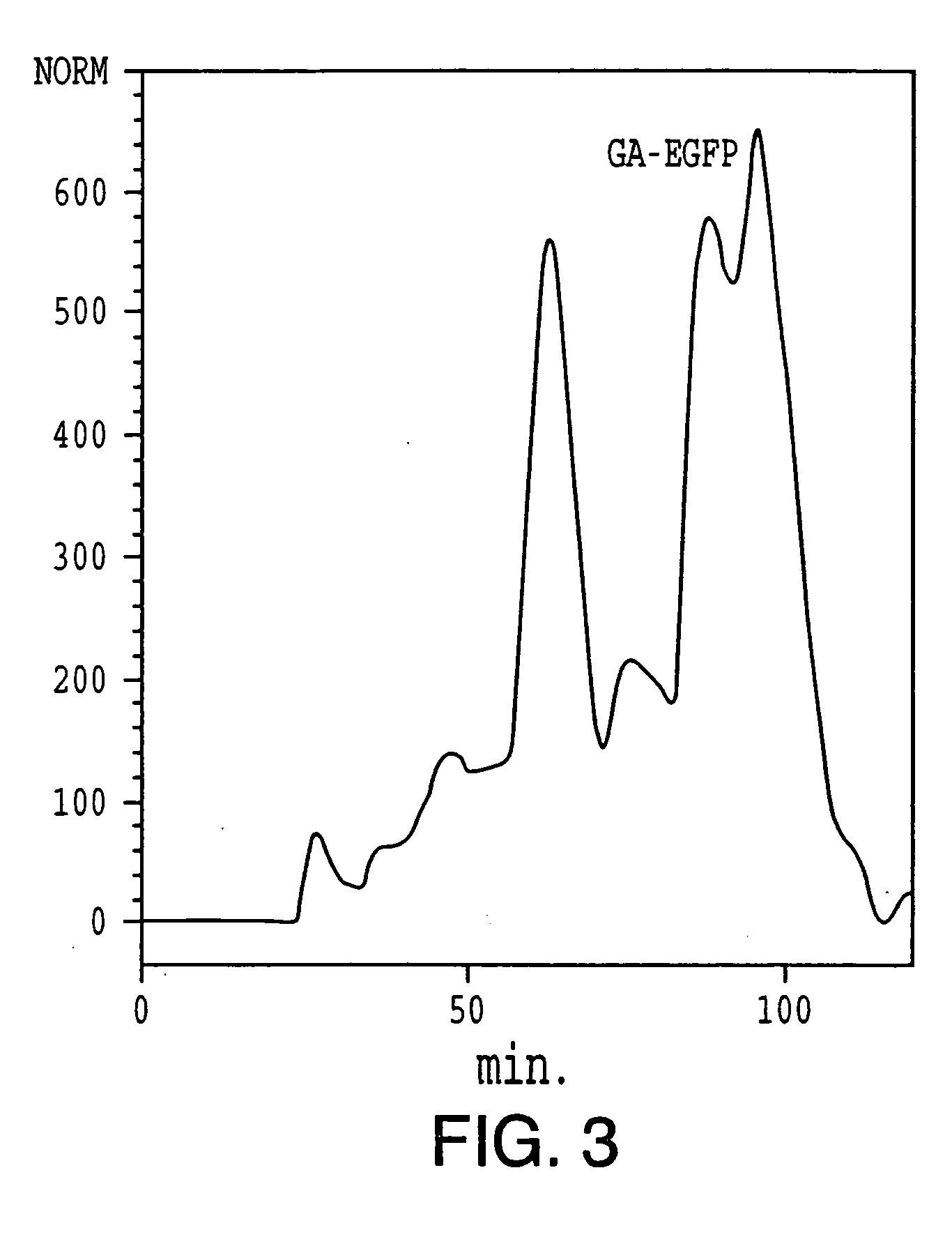

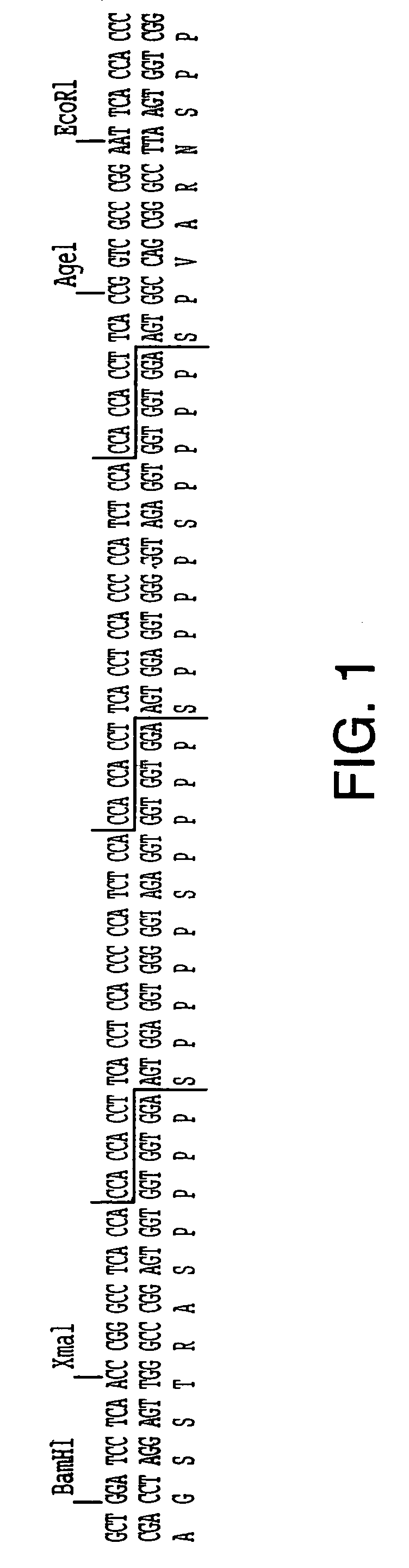

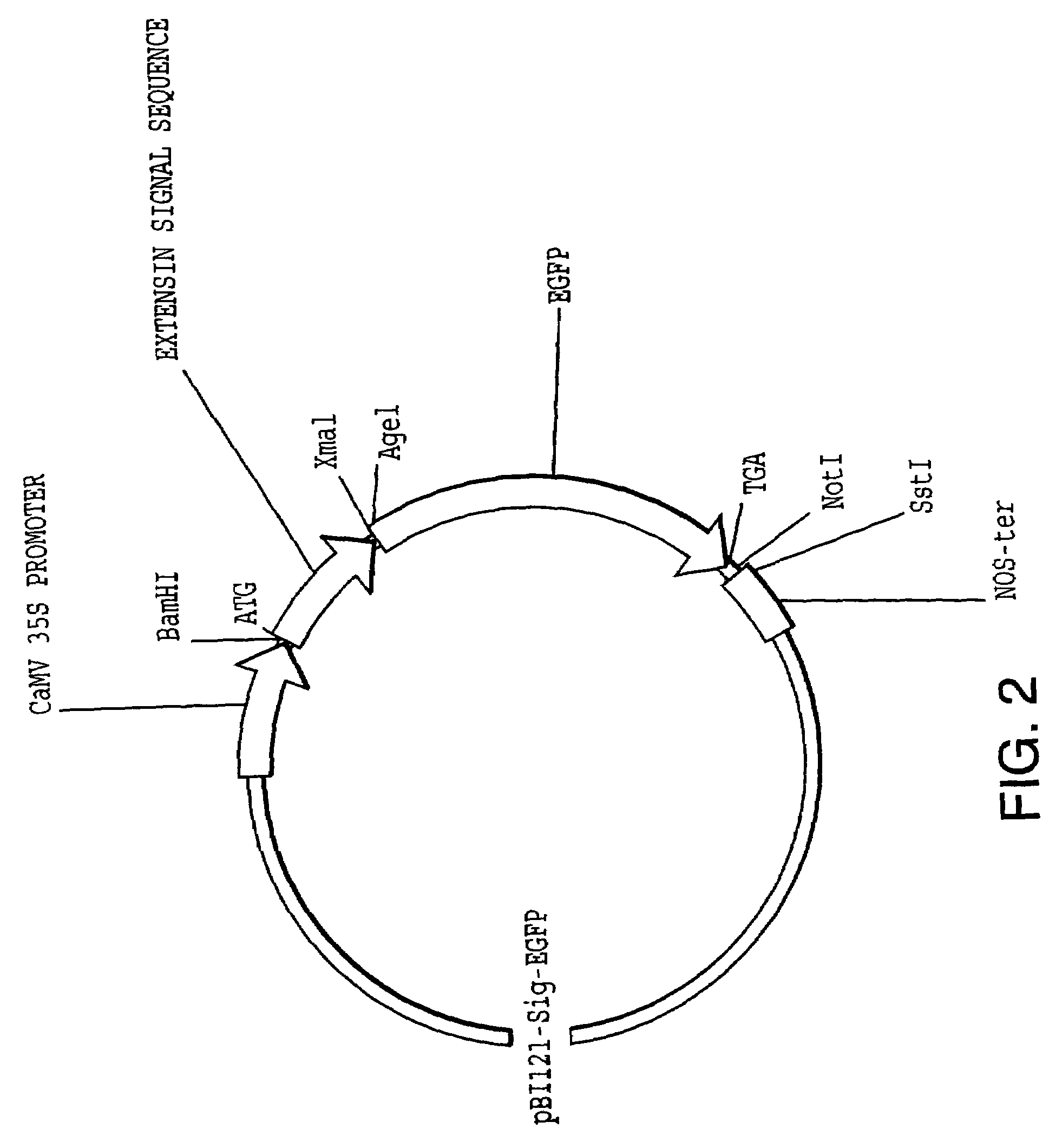

Synthetic genes for plant gums and other hydroxyproline-rich glycoproteins

InactiveUS6639050B1Enhance molecular packingEasy to identifyBacteriaAntibody mimetics/scaffoldsBiotechnologyHydroxyproline

A new approach in the field of plant gums is described which presents a new solution to the production of hydroxyproline(Hyp)-rich glycoproteins (HRGPs), repetitive proline-rich proteins (RPRPs) and arabinogalactan-proteins (AGPs). The expression of synthetic genes designed from repetitive peptide sequences of such glycoproteins, including the peptide sequences of gum arabic glycoprotein (GAGP), is taught in host cells, including plant host cells.

Owner:OHIO UNIV TECH TRANSFER OFFICE TECH & ENTERPRISE BUILDING

Edible film compositions

InactiveUS20060024425A1Reduced gumminessReduced off-flavorsConfectioneryPharmaceutical delivery mechanismViscosityChemistry

The present invention provides edible film formulations using low viscosity hydrolyzed vegetable gum as a film forming component.

Owner:WM WRIGLEY JR CO

Agronomic crop stalk medium density fiberboard using natural rubber and manufacturing method therefor

InactiveCN101367227AIncrease profitInhibition releaseFlat articlesDomestic articlesFiberStearic acid

The invention provides a crop straw medium density fiberboard by natural gum. Raw materials of the medium density fiberboard comprise crop straw fiber, a bonding agent, a waterproof and lubricating agent and a flame retardant, wherein the bonding agent is natural gum and comprises plant gum and animal gum; the waterproof and lubricating agent is natural wax, stearic acid or stearate; and the flame retardant is non-toxic and harmless flame retardant. The mixture ratio for all the raw materials by weight percent is: 75 to 93 percent of the crop straw fiber, 1 to 8 percent of the bonding agent (dried), 0.5 to 8 percent of the waterproof and lubricating agent, and 5.5 to 23.5 percent of the flame retardant. All the raw materials are produced into a finished product through mixing, sizing, spreading, prepressing, hot pressing and edge cutting; and microwave is used for auxiliary heating in the hot pressing phase. The crop straw medium density fiberboard by the natural gum can realize complete degradation under natural condition after the medium density fiberboard is abandoned or destroyed without any nonreversible destruction to the environment, so the production and application of the crop straw medium density fiberboard realize complete sustainability and recyclability, and have significant realistic and historic significance.

Owner:张东旭

Film-forming agent composition and starchiness vegetable adhesive containing the composition

InactiveCN101245157APromote digestion and absorptionReduce breakage rateMicroballoon preparationMicrocapsule preparationMicrobial pollutionAdhesive

The invention provides a film forming compound with modified starch as the main component, a film forming material containing the compound, and more particularly a hard-shell natural capsule made from the compound. The compound contains no or very little animal protein such as gelatin, etc. The compound can partially or completely replace the gelatin from animals for producing natural hard-shell capsules. The prepared natural capsule shell product has the advantages of excellent film forming property, high strength, good flexibility, high transparency, decomposability and microbial pollution resistance. The main component of the compound, modified starch, has stable quality and highly controllable performance.

Owner:长春大成特用玉米变性淀粉开发有限公司

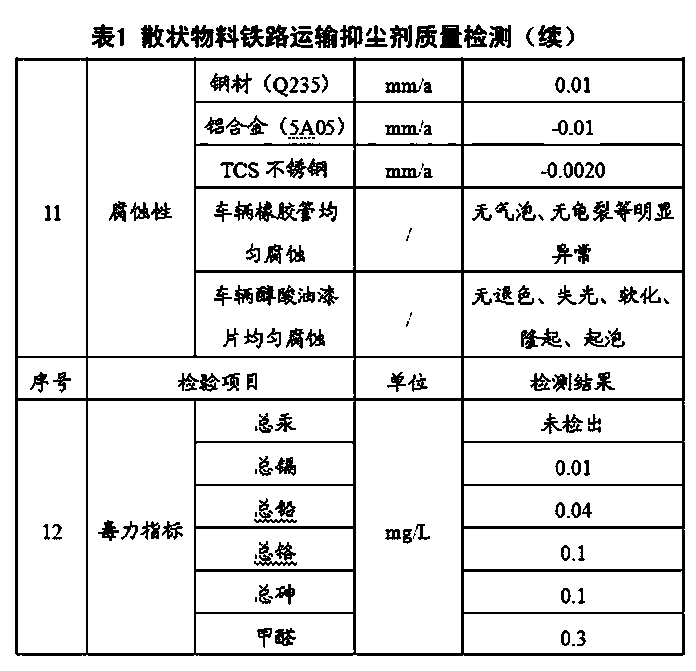

Dust inhibiting agent used during railway transportation process of powdered materials and preparation method thereof

The invention relates to a dust inhibiting agent used during the railway transportation process of powdered materials and a preparation method thereof, the dust inhibiting agent comprises the following raw materials: polyvinyl alcohol, starch, polyacrylamide, carboxymethyl cellulose, natural plant glue, a surfactant, an antifreeze auxiliary agent, and a bacteriostatic agent. The dust inhibiting agent provided by the invention can inhibit the dust pollution brought by railway transportation of powdered materials, especially inhibits the PM 2.5, is capable of solving the antifreeze problem when using the dust inhibiting agent in winter, and achieves the goals of safety and environment-friendliness.

Owner:北京安平联合环保科技有限公司

Synthetic genes for plant gums and other hydroxyproline-rich glycoproteins

InactiveUS20060252120A1Maximize number of cellSugar derivativesDepsipeptidesBiotechnologyHydroxyproline

A new approach in the field of plant gums is described which presents a new solution to the production of hydroxyproline(Hyp)-rich glycoproteins (HRGPs), repetitive proline-rich proteins (RPRPs) and arabinogalactan-proteins (AGPs). The expression of synthetic genes designed from repetitive peptide sequences of such glycoproteins, including the peptide sequences of gum arabic glycoprotein (GAGP), is taught in host cells, including plant host cells.

Owner:KIELISZEWSKI MARCIA

Synthetic genes for plant gums and other hydroxyproline-rich glycoproteins

InactiveUS20040009555A1Easy to transformMaximizing numberPeptide/protein ingredientsAntibody mimetics/scaffoldsArabinogalactan proteinHydroxyproline

A new approach in the field of plant gums is described which presents a new solution to the production of hydroxyproline(Hyp)-rich glycoproteins (HRGPs), repetitive proline-rich proteins (RPRPs) and arabinogalactan-proteins (AGPs). The expression of synthetic genes designed from repetitive peptide sequences of such glycoproteins, including the peptide sequences of gum arabic glycoprotein (GAGP), is taught in host cells, including plant host cells.

Owner:OHIO UNIV TECH TRANSFER OFFICE TECH & ENTERPRISE BUILDING

Konjak jelly and processing method thereof

Owner:CHACHA FOOD CO LTD

Hollow capsule of natural plant gum and its preparing process

Said invention relates to formula and preparation of plant hollow capsule for packaging powdered preparation, which is composed of 16-25 % of vegetable gelatin, 2.0-5.0 % of intensifier, 0.02-0.026 % of surface active agent, 0.15-0.20 % of moistening agent, the others is water. The said vegetable gelatin is one of or both of pectin and carrageenin, said intensifier is one kind or more than one kind of chitosan, carboxymethyl starch and hydroxyporpyl cellulose. Said surface active agent is sodium dodecyl sulfate. Said moistening agent is glycerol. Said plant hollow capsule has good stability, stored for long time and also can be produced by utilizing the equipment used in producing capsule from geltin.

Owner:ZHEJIANG YAOLIAN CAPSULES

Novel synthetic genes for plant gums

InactiveUS20040009557A1Maximize number of cellHigh activityAntibody mimetics/scaffoldsImmunoglobulinsBiotechnologyHydroxyproline

A new approach in the field of plant gums is described which presents a new solution to the production of hydroxyproline(Hyp)-rich glycoproteins (HRGPs), repetitive proline-rich proteins (RPRPs) and arabino-galactan proteins (AGPs). The expression of synthetic genes designed from repetitive peptide sequences of such glycoproteins, including the peptide sequences of gum arabic glycoprotein (GAGP), is taught in host cells, including plant host cells.

Owner:OHIO UNIV TECH TRANSFER OFFICE TECH & ENTERPRISE BUILDING

Synthetic genes for plant gums and other hydroxyproline-rich glycoproteins

InactiveUS20050074838A1Maximize number of cellFacilitate slow-release drug deliveryBacteriaAntibody mimetics/scaffoldsBiotechnologyHydroxyproline

A new approach in the field of plant gums is described which presents a new solution to the production of hydroxyproline(Hyp)-rich glycoproteins (HRGPs), repetitive proline-rich proteins (RPRPs) and arabinogalactan-proteins (AGPs). The expression of synthetic genes designed from repetitive peptide sequences of such glycoproteins, including the peptide sequences of gum arabic glycoprotein (GAGP), is taught in host cells, including plant host cells.

Owner:OHIO UNIV TECH TRANSFER OFFICE TECH & ENTERPRISE BUILDING

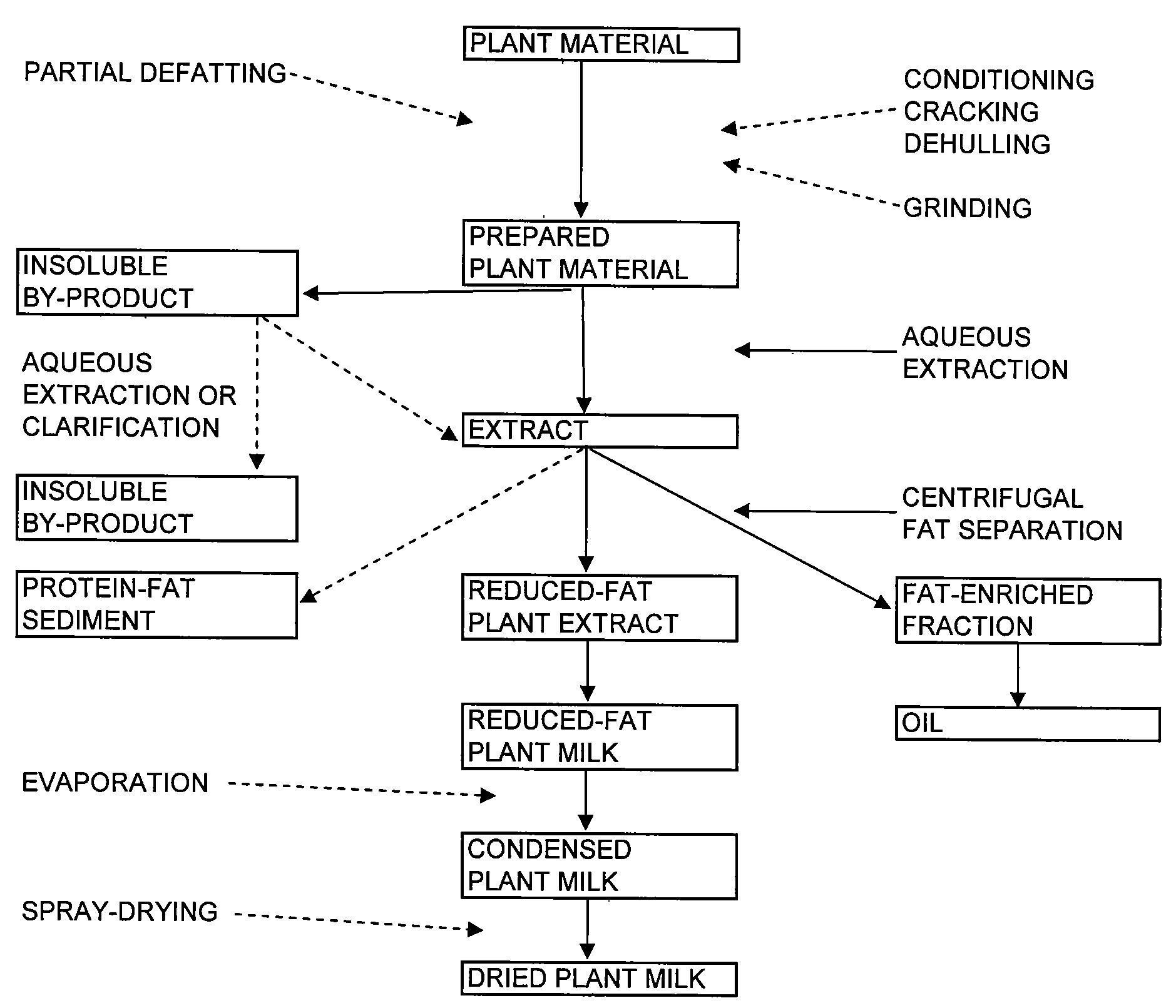

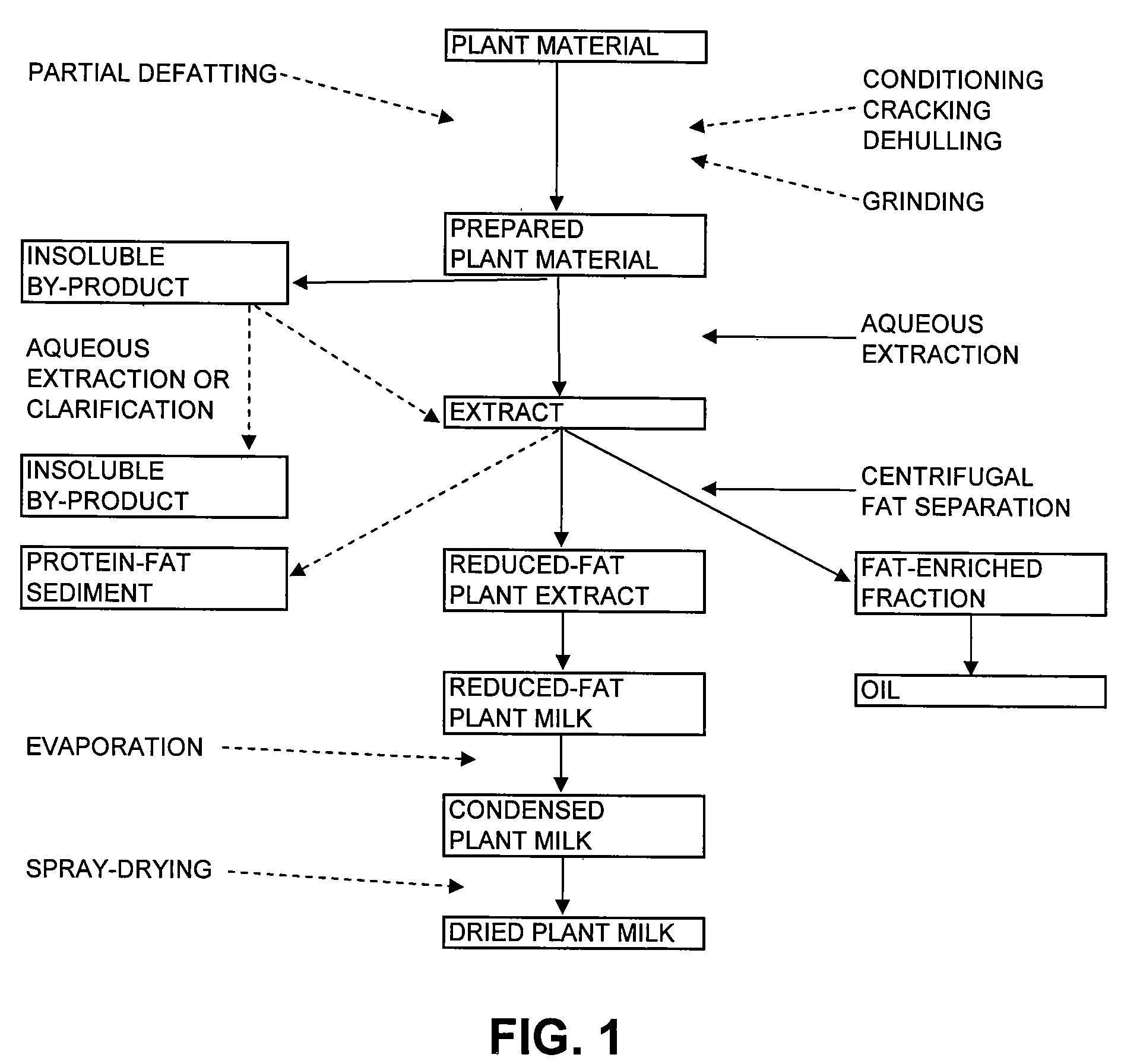

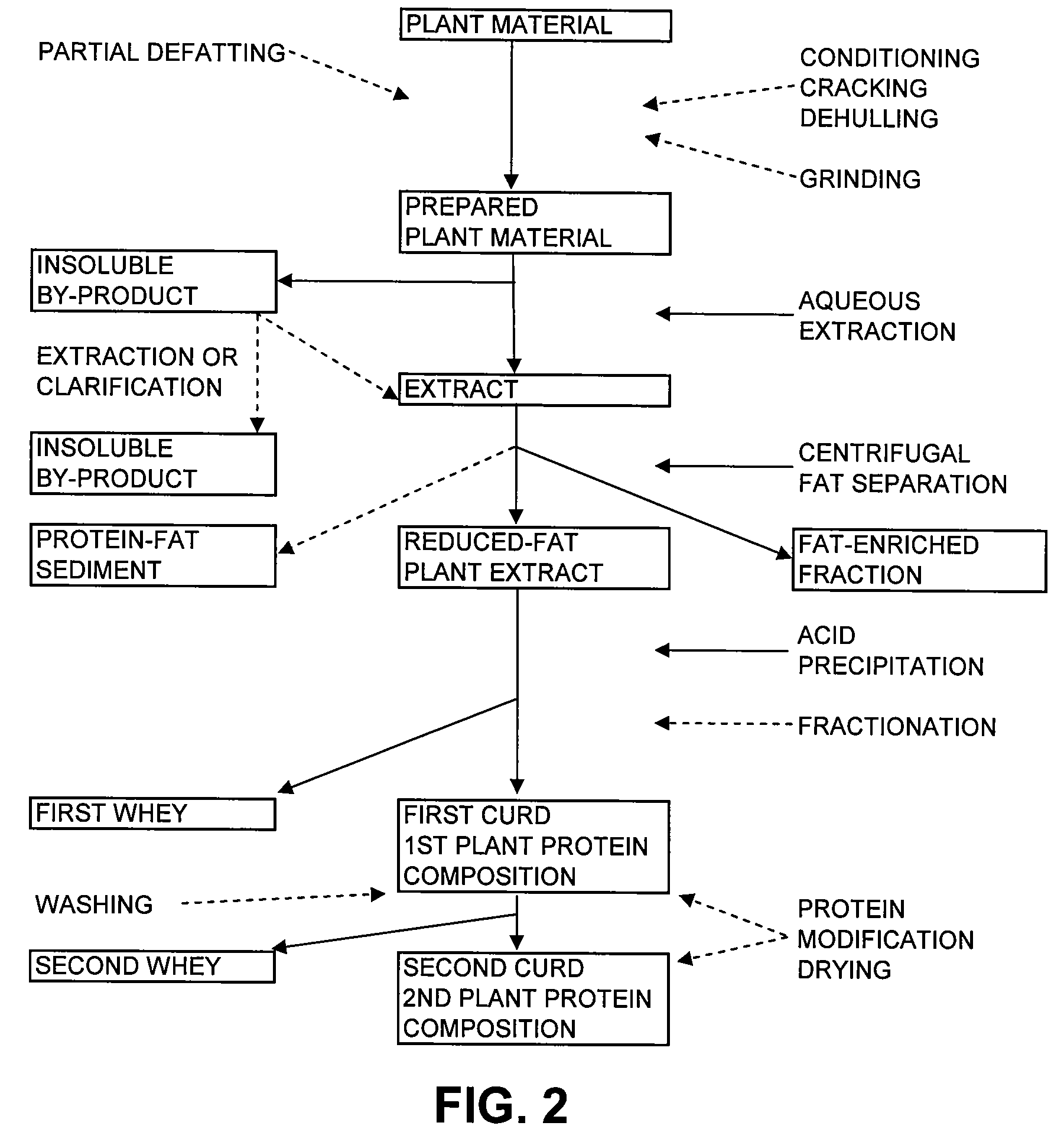

Methods of separating fat from non-soy plant materials and compositions produced therefrom

Disclosed are methods for separating non-soy plant materials to produce a fat-enriched fraction, a reduced-fat plant extract, reduced-fat plant protein compositions, a crude oil, plant gums, a degummed oil and a protein-fat sediment. Also disclosed are food products containing or prepared from the reduced-fat extracts, fat-enriched fraction, gums, oils, protein-fat sediments and reduced-fat protein compositions.

Owner:SPECIALTY PROTEIN PRODRS

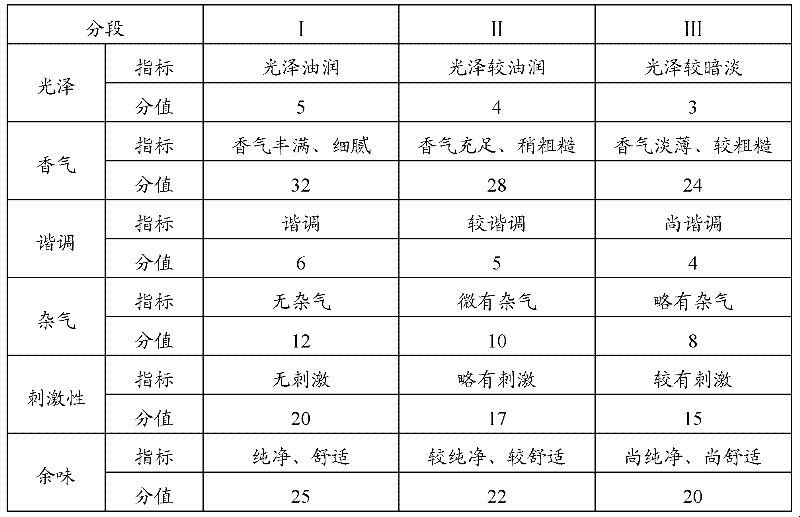

Agilawood slice fragrant silks and preparation method thereof

The invention relates to the field of the processing of Chinese herbal medicines, in particular to agilawood slice fragrant silks and a preparation method thereof. The agilawood slice fragrant silks are prepared from agilawood, natural plant powder and natural gelatine, can meet the new requirement of the public on fragrance taste of agilawood fragrance and has the characteristic of portable use. The invention also provides a cigarette containing the agilawood slice fragrant silks, and the cigarette is elegant and lasting in fragrance and meets the national standard.

Owner:JILIN TOBACCO IND

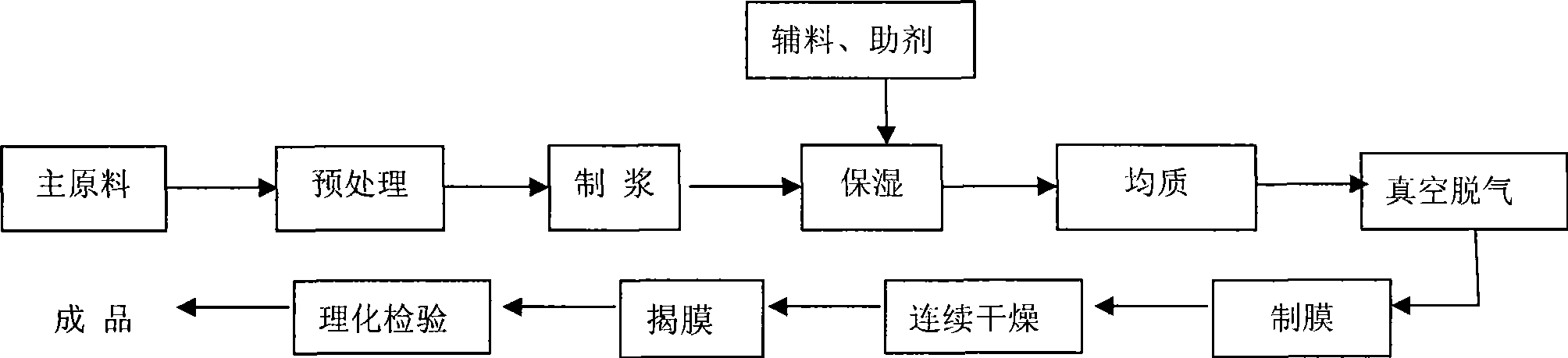

Edible packaging film and preparation method thereof

InactiveCN101496559AEasy and cheapImprove mechanical propertiesFlexible coversWrappersSucroseVegetable oil

The invention relates to an edible packaging film. The prior potato starch edible packaging material is undesirable in comprehensive mechanical performance and has a moisture sensitivity problem in use. The formula of the invention uses potato starch as a base material and adopts auxiliary materials including carboxycellulose, animal gum and / or vegetable gelatin, glyceride, glycerin, vegetable oil and sucrose ester or lecithin. The manufacturing process of the packaging film comprises: weighing the base material, adding water into the base material and stirring the mixture till the base material dissolves, moisturizing the solution, adding the auxiliary materials into the solution, homogenizing the mixture, vacuum degassing the mixture, film making, continuous drying the mixture, stripping film, inspecting the film, and obtaining the finished product. The physical and mechanical performance of the edible packaging film reaches the requirements on food inner packaging materials, and the edible packaging film has high isolating and sealing performance such as oxygen resistance, damp resistance and oil resistance and dispersibility in boiling water.

Owner:李柯庆

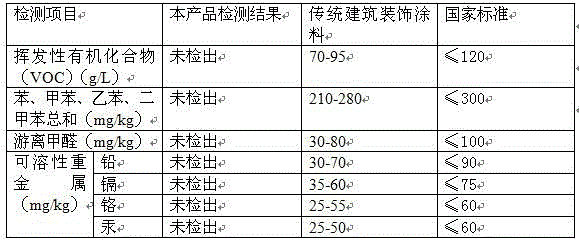

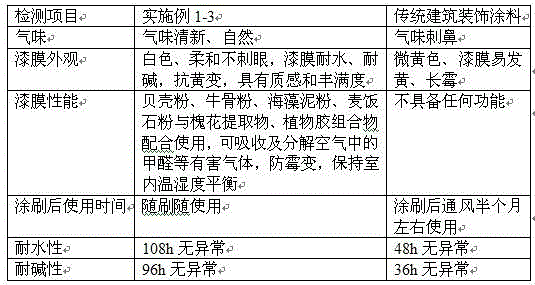

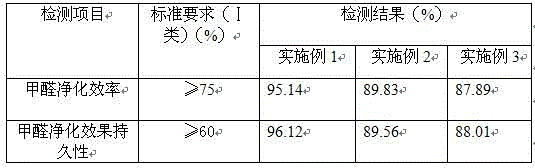

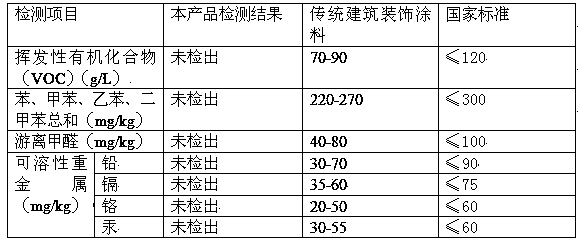

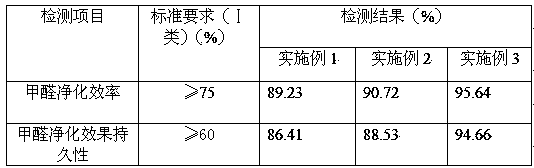

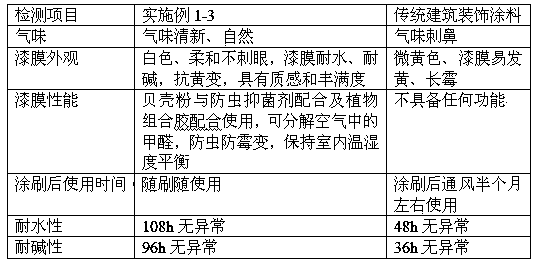

Environmental-protection coating and preparation method

The invention discloses an environmental-protection coating which is composed of following components, by weight, 200-300 parts of water, 1-3 parts of an alkaloid composition, 1-3 parts of an wetting agent, 4-6 parts of a dispersing agent, 4-6 parts of a defoaming agent, 200-250 parts of titanium dioxide, 40-80 parts of talcum powder, 30-70 parts of seaweed mud powder, 30-70 parts of bovine bone powder, 30-70 parts of shell powder, 30-50 parts of medical stone powder, 200-250 parts of an acrylic emulsion, 20-50 parts of a vegetable gum composition, 15-30 parts of glycerin, 2-4 parts of alcohol and 2-4 parts of an extract of flos sophorae. The invention is simple in technology and low in cost. With combination of components such as the shell powder and the like with the extract of flos sophorae, functions such as strong adsorption, sterilization, and anti-mildew are achieved and the coating is fresh in small. The coating is free of toxic substances such as formaldehyde and the like and can absorb harmful substances volatilized from in-door floors. In addition, the coating has excellent air penetrability so that a wall surface has a breathing function and in-door air humidity can be adjusted automatically.

Owner:浙江绿财新材料科技有限公司

Premix auxiliary and preparation method thereof

ActiveCN104083768AGood gelImprove gelationPharmaceutical non-active ingredientsCapsule deliveryCarrageenanPlant Gums

The invention discloses a premix auxiliary and a preparation method thereof. The premix auxiliary comprises the following components in parts by weight: 10-20 parts of hydroxypropyl starch, 5-10 parts of starch, 0.5-2 parts of arabic gum, 0.5-5 parts of carrageenan, 0.5-2 parts of guar gum, 0.5-5 parts of xanthan gum and 0-5 parts of colorant. After a proper amount of water or glycerinum is added into the premix auxiliary to form a solution, and the viscosity is regulated to a proper range by production equipment according to practice to prepare capsules, so that the production procedures are greatly reduced, the requirement on process parameters is simple, the production time is greatly shortened, and the product quality is stable. Furthermore, the premix auxiliary disclosed by the invention does not contain a gelatin component, and the prepared capsule is a plant capsule with higher safety and better stability and is suitable for wide applicable crowd.

Owner:HUNAN ER KANG PHARMA

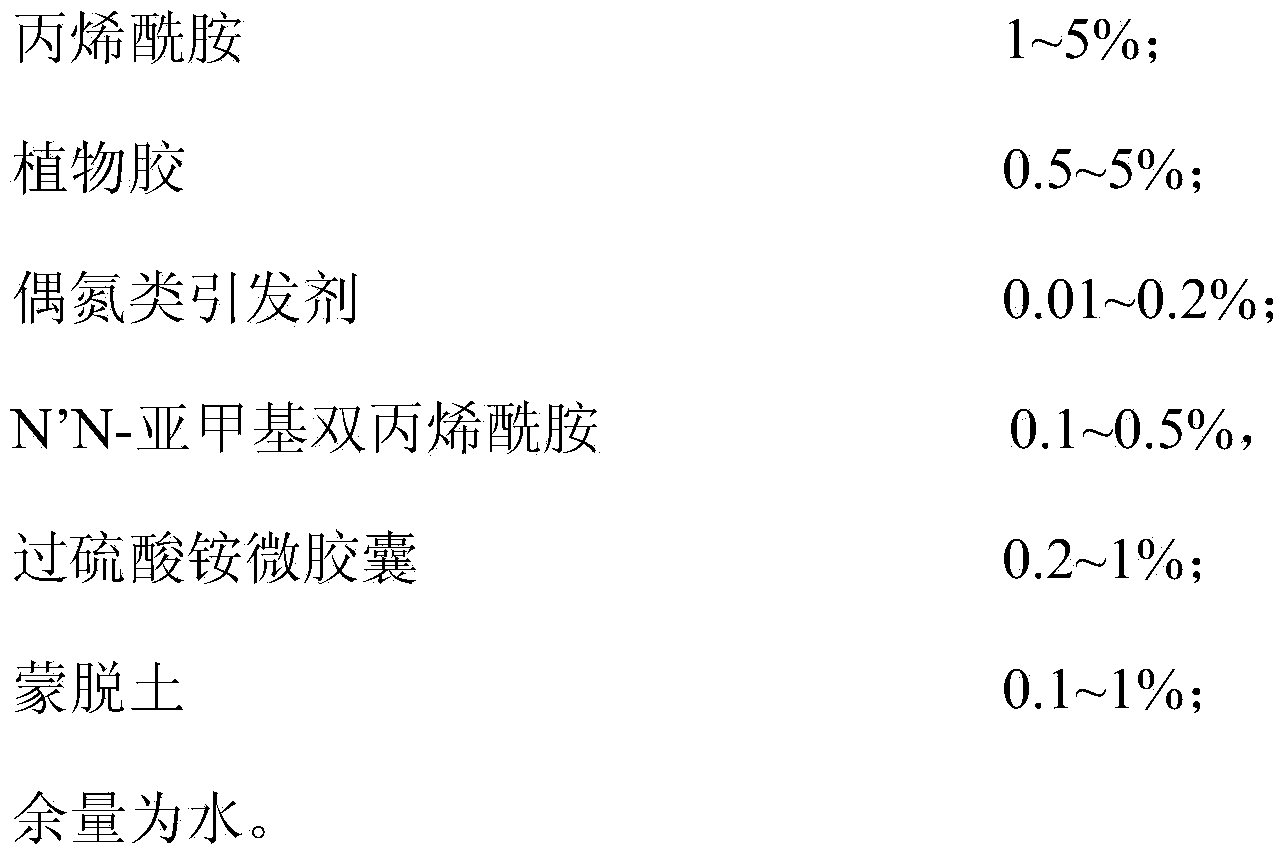

Chemical sealing rubber plug in snubbing operation string as well as preparation method and application of chemical sealing rubber plug

InactiveCN103725275ARealize self-degradation and breaking glueEasy to operateDrilling compositionSealing/packingCross-linkPolymer science

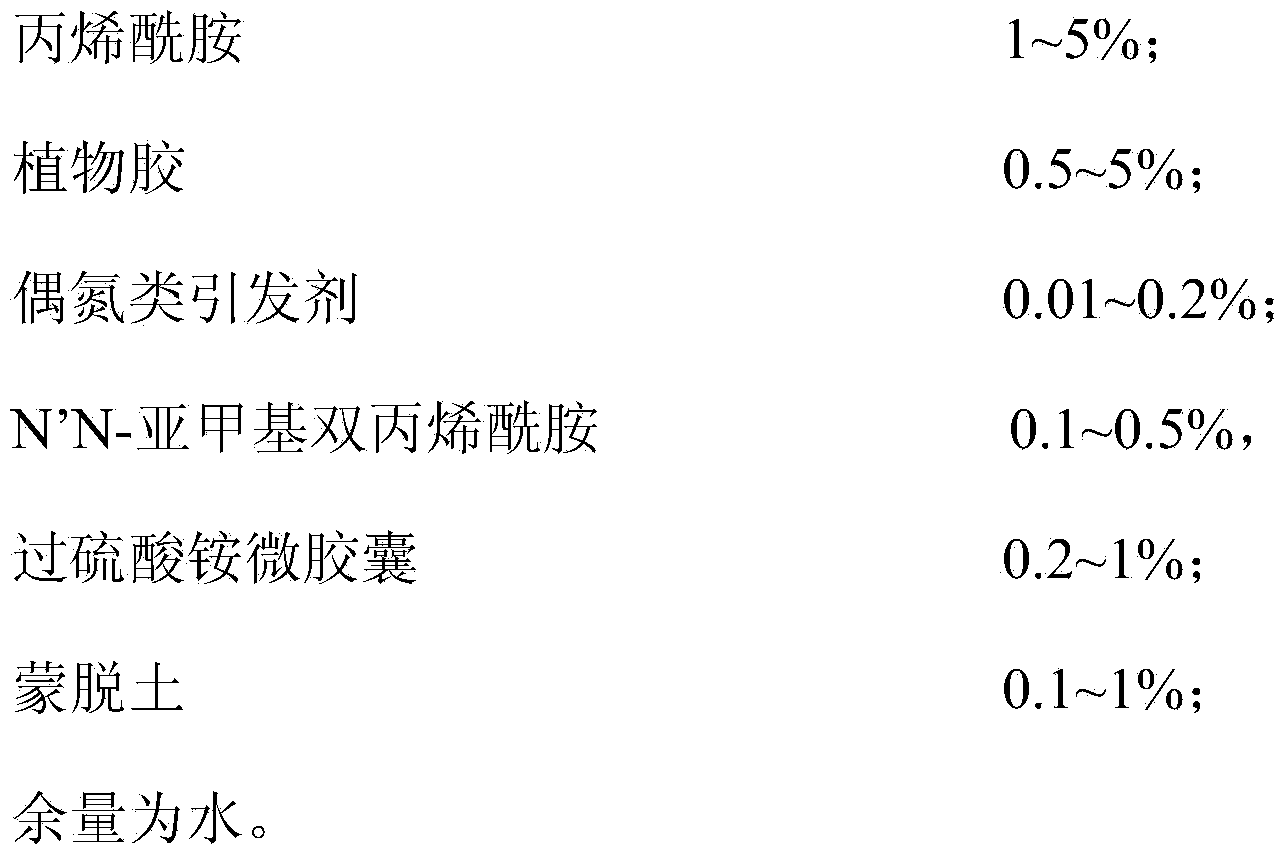

The invention discloses a chemical sealing rubber plug in a snubbing operation string as well as a preparation method and application of the chemical sealing rubber plug. The chemical sealing rubber plug is prepared by uniformly dispersing 1-5wt% of acrylamide, 0.5-5wt% of vegetable gelatin, 0.01-0.2wt% of azo initiator, 0.1-0.5wt% of N', N-methylene bisacrylamide and 0.1-1wt% of montmorillonoid in water, and adding 0.2-1wt% of ammonium persulfate microcapsule. The ammonium persulfate microcapsule is added when pumping the chemical sealing rubber plug to an oil tube in a use process and after the process stops for 30-120min, thus obtaining the chemical sealing rubber plug in a snubbing operation string. Maximum compression strength of the cross-linked and solidified chemical sealing rubber plug liquor can reach 40MPa under well temperature of 50-120 DEG C, and automatic degradation and gel breaking can be realized after 2-7 days.

Owner:CNPC BOHAI DRILLING ENG

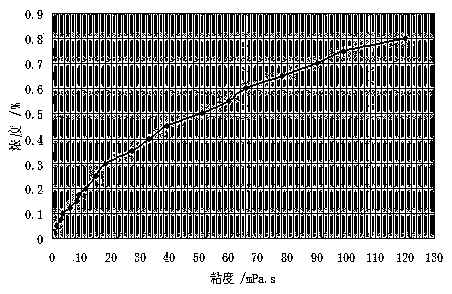

Method for preparing fracturing fluid by utilizing seawater

InactiveCN103289668AStrengthen on-site operationsReduce construction costsDrilling compositionPlant GumsFracturing fluid

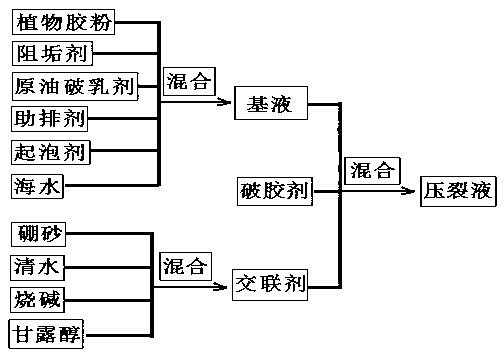

The invention discloses a method for preparing a fracturing fluid by utilizing seawater. The method comprises the following steps of: preparing a base fluid by 0.25-2.0 b (b represents unit part by weight) of antisludging agent, 0.25-1.0 b of plant gelatine powder, 0.01-1.0 b of crude oil emulsion breaker, 0.01-1.0 b of clean up additive, 0.00-1.0 b of foaming agent and 94.0-99.48 b of seawater; and preparing a cross-linking agent by 5-30 b of borax, 5-40 b of mannitol, 1-20 b of caustic soda and 10-89 b of fresh water. 100 c (c represents unit part in volume) of base fluid, cross-linking agent of which the volume is 0.1%-2.0% of the volume of the base fluid in part by volume, and gel breaker of which the volume is 0.001%-0.1% of the volume of the base fluid in part by weight are together added and mixed to prepare the fracturing fluid. According to the invention, 94.0-99.48 parts of seawater is used for preparing the base fluid, except the necessary chemical agents, all the base fluid part is prepared from seawater, so the site operation is simple and convenient, and the cost is lower; and the fracturing fluid thickener adopts natural plant gelatine powder.

Owner:湖北菲特沃尔科技有限公司

Walling paint and preparation method thereof

ActiveCN103881498AInflatable bustyGood decorative functionAntifouling/underwater paintsPaints with biocidesPlant GumsGlycerol

The invention discloses a walling paint which is composed of the following components in parts by weight: 250-300 parts of water, 2-4 parts of alkaloid, 2-4 parts of wetting agent, 3-6 parts of dispersant, 3-5 parts of defoaming agent, 150-250 parts of titanium white, 40-75 parts of talcum powder, 90-180 parts of shell powder, 200-250 parts of acrylate emulsion, 30-60 parts of vegetable jelly composition, 15-35 parts of glycerol, 2-4 parts of ethanol and 3-5 parts of vermin-proof bacteriostatic agent. The paint has the advantages of simple preparation technique and low cost, has favorable vermin-proof and bacteriostatic effects by the combination of the shell powder and vermin-proof bacteriostatic agent, can not easily generate molds on the wall surface, and smells fresh. The paint is free of formaldehyde, benzene, ammonia and other volatile toxic substances, and can absorb formaldehyde and other substances emitted by floor, furniture and the like. The paint has favorable air permeability, enables the wall surface to have the function of ventilation, and automatically regulates the indoor air humidity.

Owner:HUZHOU BAISHENG PAINT

Soft capsule and preparing method thereof

InactiveCN101069678AFast disintegrationNot easy to agePharmaceutical non-active ingredientsCapsule deliveryParaffin waxPolymer science

The present invention provides a soft capsule and its preparation method. The composition of said soft capsule includes (by wt%) 8-45% of prolanpolysaccharide 0.01-2.5% of plant gelling agent, 1-15% of plasticizer, 33-89% of oil solution, 0.1-1% of paraffin wax, 0.01-1% of coloring matter and 0.9%-12% of water. Said invention also provides the concrete steps of its preparation method.

Owner:广东富味健康科技有限公司

Degradable seedling culture cup

The invention discloses a degradable seedling culture cup, which comprises the following components in parts by weight: 10-20% of waste paper pulp, 50-75% of plant fiber and 5-10% of adhesive, wherein the waste paper pulp is formed by directly pulping recycled waste paper without deinking and disinfecting processing, production cost is low, the plant fiber is formed by smashing straws, and the adhesive is vegetable gelatin. According to the degradable seedling culture cup disclosed by the invention, the recycled waste paper and straws are used as main raw materials to make waste profitable, and cost is lowered. After the waste paper pulp and the adhesive are used, the toughness of the degradable seedling culture cup is improved, and the usability is improved. In addition, the seedling culture cup degrading time is prolonged by the adhesive, more time is obtained for the market sale of a new seedling growth and culture mechanism, and therefore, the degradable seedling culture cup is worth popularizing.

Owner:YUANCHENG ENVIRONMENT CO LTD

Impervious blocking agent

The invention relates to an impervious blocking agent, and belongs to the technical field of oilfield drilling. The impervious blocking agent comprises the following components in percentage by weight: 40-80% of superfine calcium carbonate, 20-60% of fiber material, 0-10% of vegetable glue and 0-10% of diluter. With the adoption of the impervious blocking agent, the filter loss of drilling fluid can be reduced, the pore space of an oil layer is blocked, an oil gas layer is protected, and the sealing quality of a micro-crack oil layer and high-permeability oil layer well cementation is improved.

Owner:DAQING HEZHENG CHEM

Graft type fracturing fluid and preparation process thereof

The present invention relates to grafting type fracturing fluid comprising grafting type glue 0.4-1.0 wt %, metal cross-linking agent 0.05-0.7wt %, cracking oxidant 0.05-0.5wt % and water for the rest. The grafting type fracturing fluid of the present invention may be used to replace glue of natural plant material, and has water insoluble matter content as low as 1.0-3.0 wt %, residue after cracking of 20-60 mg / L and low cost.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

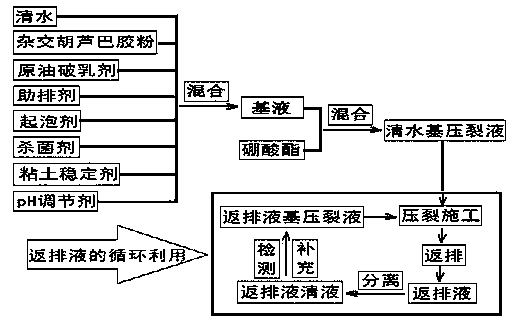

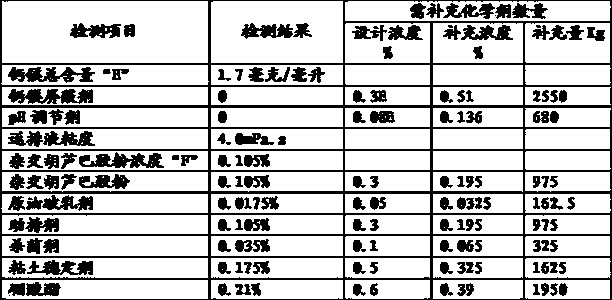

Plant gum fracturing fluid and method for recycling flow-back fluid of plant gum fracturing fluid

InactiveCN103881690AAvoid continuous viscosity reductionGuarantee unimpededFluid removalDrilling compositionDemulsifierFoaming agent

The invention discloses plant gum fracturing fluid and a method for recycling flow-back fluid of the plant gum fracturing fluid. The method for recycling the flow-back fluid of the plant gum fracturing fluid comprises the steps of firstly, preparing 99.82-61.2 parts of clean water, 0.15-0.8 part of hybrid fenugreek gelatin powder, 0-1.0 part of a crude oil demulsifier, 0-2.0 parts of a discharge aiding agent, 0-2.0 parts of a foaming agent, 0-1.0 part of a sterilizing agent, 0-2.0 parts of a clay stabilizer, 0-10.0 parts of a pH value regulator and 0.03-20.0 parts of borate into clean water based fracturing fluid, and then performing fracturing construction; then, separating crude oil and solid-phase particles in the fracturing fluid after fracturing construction to obtain a low-back fluid clear solution; preparing 20-99.98 parts of the low-back fluid clear solution, 0-36.2 parts of clean water, 0.01-5.0 parts of a calcium-magnesium shielding agent, 0-0.8 part of the hybrid fenugreek gelatin powder, 0-1.0 part of the crude oil demulsifier, 0-2.0 parts of the discharge aiding agent, 0-2.0 parts of the foaming agent, 0-1.0 part of the sterilizing agent, 0-2.0 parts of the clay stabilizer, 0.01-10.0 parts of the pH value regulator and 0-20.0 parts of borate into flow-back fluid based fracturing fluid, and performing fracturing construction again; finally, continuously recycling the flow-back fluid after fracturing according to the proportion of the flow-back fluid based fracturing fluid.

Owner:湖北菲特沃尔科技有限公司

Algae clay mineral environmentally-friendly inner wall coating

ActiveCN102337064AHigh hiding powerGood weather resistanceAntifouling/underwater paintsPaints with biocidesHigh resistanceClay minerals

The invention discloses an algae clay mineral environmentally-friendly inner wall coating, which is prepared from the following components in parts by weight: 310-360 parts of water, 0.8-3 parts of alkaloid, 2-8 parts of dispersant, 1-2 parts of wetting agent, 1-2 parts of defoaming agent, 100-200 parts of decolorized algae clay powder, 150-250 parts of titanium pigment, 20-60 parts of talcum powder, 20-30 parts of pure acrylic acid emulsion, 25-75 parts of vegetable gum, 10-15 parts of glycerin, 1-5 parts of 75 percent ethanol and 1-2 parts of disinfectant. The inner wall coating has the advantages of nontoxicity, harmlessness, convenience for constructing, extremely strong peculiar smell adsorbing function, capability of purifying indoor air, plump paint film, smooth handfeel, high air permeability, wall surface breathing function, capability of regulating indoor humidity environment, high alkali resistance, high water resistance, high chemical corrosion resistance, high erosion resistance, high heat resistance, high freezing resistance, high ageing resistance, high covering power, high adhesion and the like.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Synthetic genes for plant gums and other hydroxyproline-rich glycoproteins

Owner:OHIO UNIV TECH TRANSFER OFFICE TECH & ENTERPRISE BUILDING

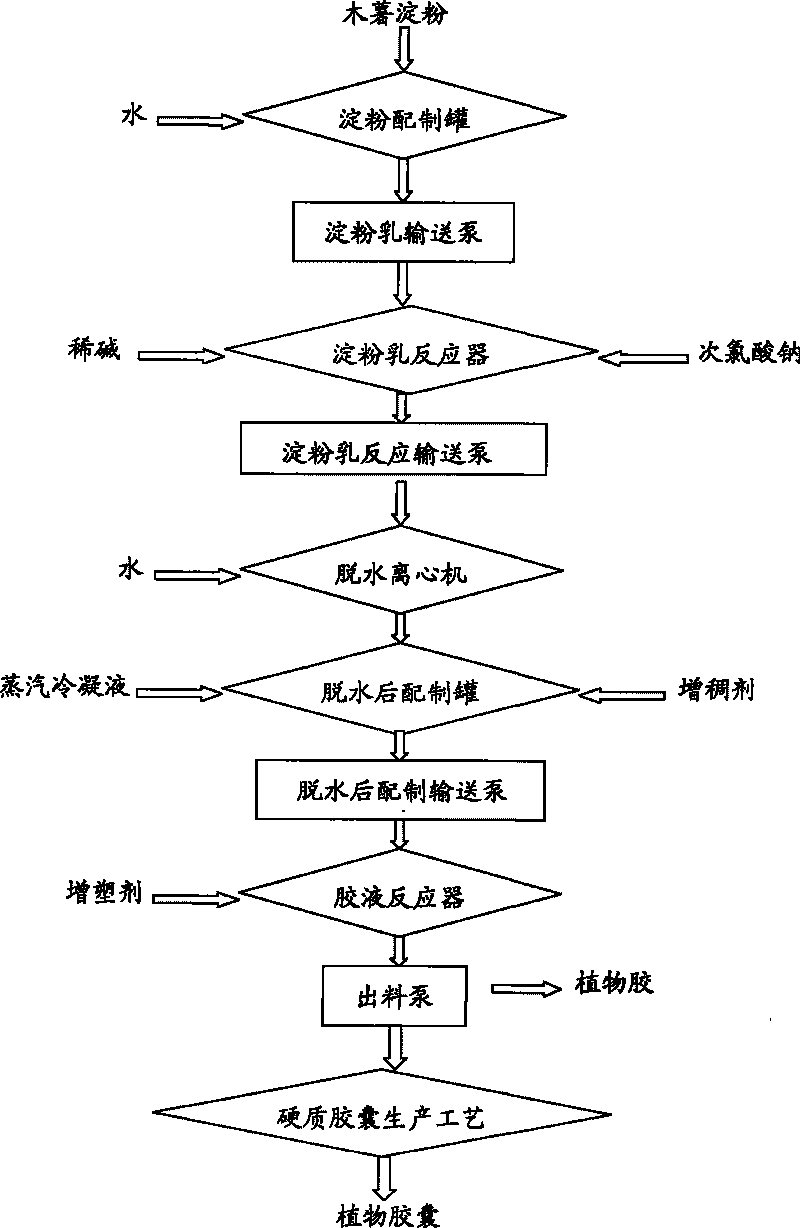

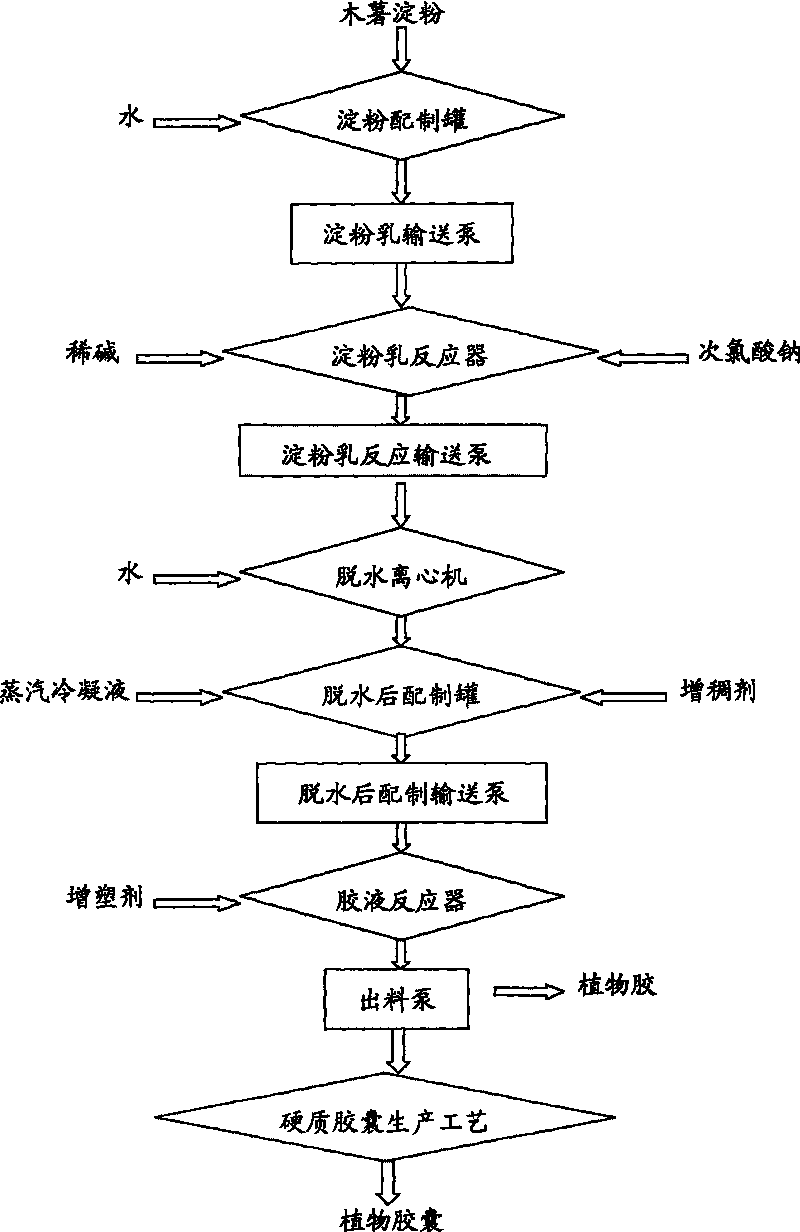

Technique of preparing cassava starch plant gum, the plant gum prepared thereby and plant capsules

ActiveCN101338045BIncrease planting areaReduce consumptionPharmaceutical non-active ingredientsCapsule deliveryBiotechnologyPlant Gums

The invention relates to a preparation method for cassava starch vegetable gum and vegetable gum and a vegetable capsule which are prepared by the preparation method. The preparation method mainly comprises the following steps: preparing starch milk, gelatinization reaction, dehydration, washing, preparation after dehydration and obtaining gel solution. The preparation method for cassava starch vegetable gum and the vegetable gum and the vegetable capsule which are prepared by the preparation method of the invention have stable product performance, low water content, wide application range, easy storage, no contamination, green environmental protection, wide raw material resources, simple preparation method and easy control.

Owner:刘雨微

Gelatine drilling fluid additive and preparation method thereof

The invention discloses a gelatine drilling fluid additive and a preparation method thereof. The preparation method comprises the following steps of: performing the procedures of washing for removing impurities, flaking, drying, fine crushing and crude fiver removal on shaved nanmu materials, thus obtaining shaved nanmu gelatine; and then uniformly stirring and mixing the shaved nanmu gelatine with bentonite, sodium carbonate, polyacrylamide and carboxymethyl cellulose, thus obtaining the gelatine drilling fluid additive. The main material, namely the shaved nanmu gelatine, of the gelatine drilling fluid additive is easy to get, and thus the gelatine drilling fluid additive has good industrialization prospect, and can replace macro guar gum drilling fluid additives at present. When being applied to the field of drilling engineering, the gelatine drilling fluid additive provided by the invention is strong in inhibiting capability, good in de-filtration effect and excellent in lubricating performance, has the characteristics of being green, environment-friendly and reproducible, and has broad development and utilization prospect.

Owner:何洪城

Silica microcapsules and methods of preparing same

Disclosed is a microcapsule containing: (i) a microcapsule core having an active material, and (ii) a microcapsule wall formed of a first polymer and second polymer. The first polymer is a sol-gel polymer. The second polymer is gum arabic, purity gum ultra, gelatin, chitosan, xanthan gum, plant gum, carboxymethyl cellulose, sodium carboxymethyl guar gum, or a combination thereof. The weight ratiobetween the first and second polymer is 1:10 to 10:1. Also disclosed are processes for preparing the microcapsule and uses of the microcapsules in consumer products.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com