Plant gum fracturing fluid and method for recycling flow-back fluid of plant gum fracturing fluid

A technology of glue fracturing fluid and flowback fluid, which is applied in the field of vegetable glue fracturing fluid and its flowback fluid recycling, can solve the problems of reducing the viscosity of fracturing fluid, affecting construction reliability, and non-reusable liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

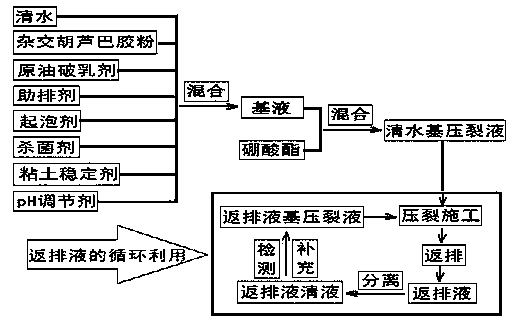

[0135] according to figure 1 As shown, add 980 m3 water into the container with a total capacity of 1000m3 on site, start the vacuum jet pump circulation, slowly add 3500 Kg hybrid fenugreek powder through the suction port of the jet pump, and then respectively 5000Kg drainage aid, 1000Kg fungicide, 5000Kg clay stabilizer, 5000Kg foaming agent, 500Kg pH regulator, continue to circulate until the liquid is fully mixed to form a clean water-based fracturing fluid L2-1 with a hybrid fenugreek powder concentration of 0.35%.

[0136] During the first fracturing operation, while pumping solution L2-1, mix 6000Kg of borate and base fluid L2-1 at the ratio of "base fluid L2-1: borate = 100Kg: 0.6Kg" The water-based fracturing fluid is formed and used for fracturing of natural gas wells with a well temperature within 100-130°C.

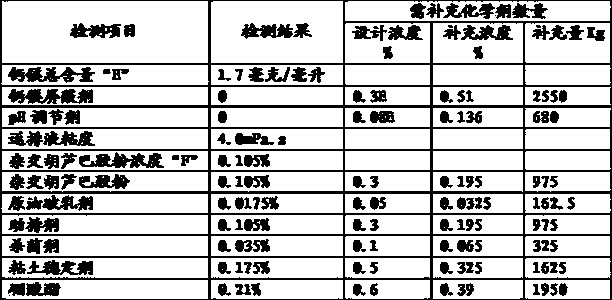

[0137] The fracturing flowback fluid after the first fracturing was 810 m3. The flowback fluid was desanded with a settling separation tank to separate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com