Patents

Literature

255 results about "Chain scission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chain scission is a term used in polymer chemistry describing the degradation of a polymer main chain. It is often caused by thermal stress (heat) or ionizing radiation (e.g. light, UV radiation or gamma radiation), often involving oxygen. During chain cleavage, the polymer chain is broken at a random point in the backbone to form two - mostly still highly molecular - fragments.

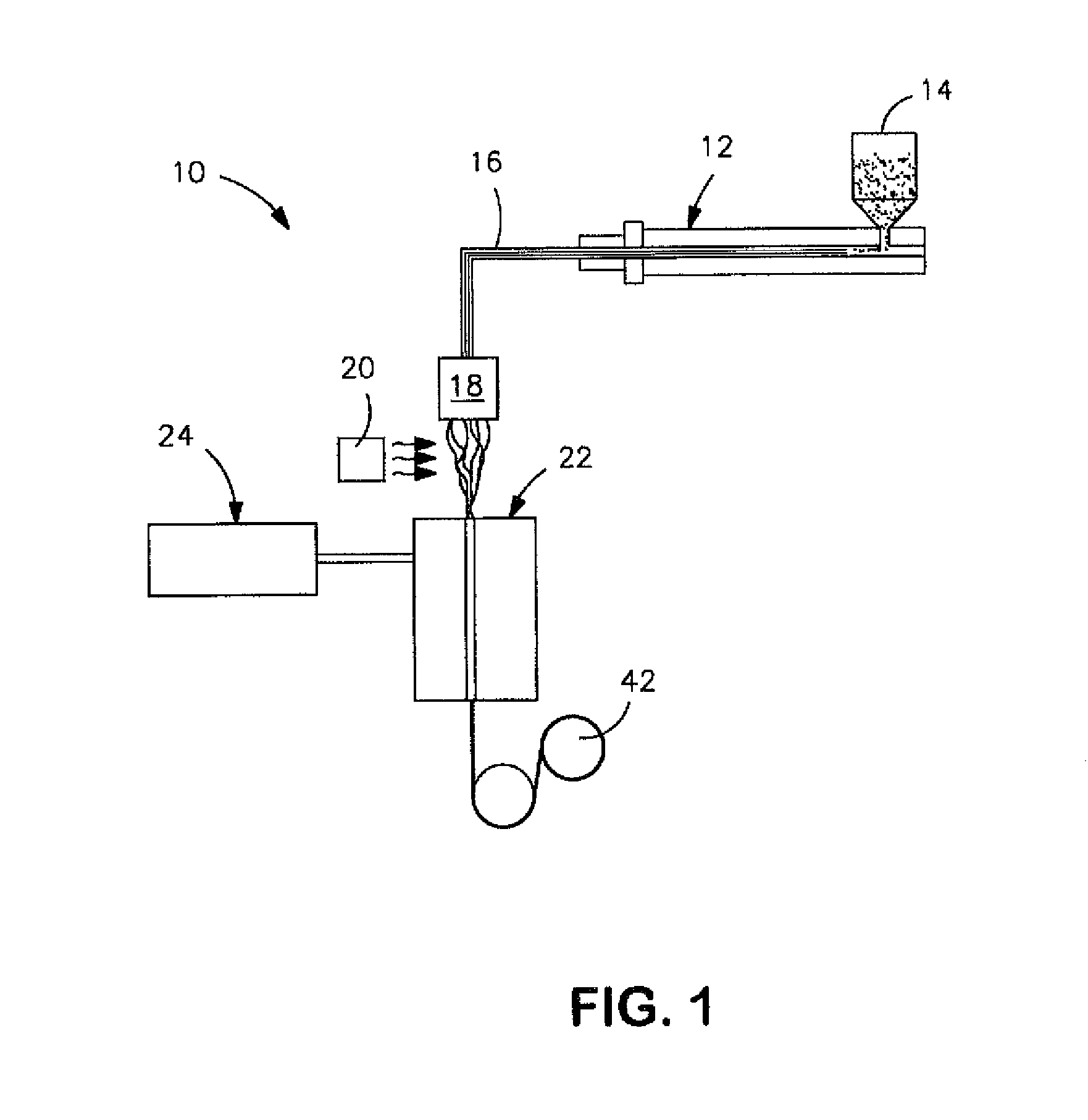

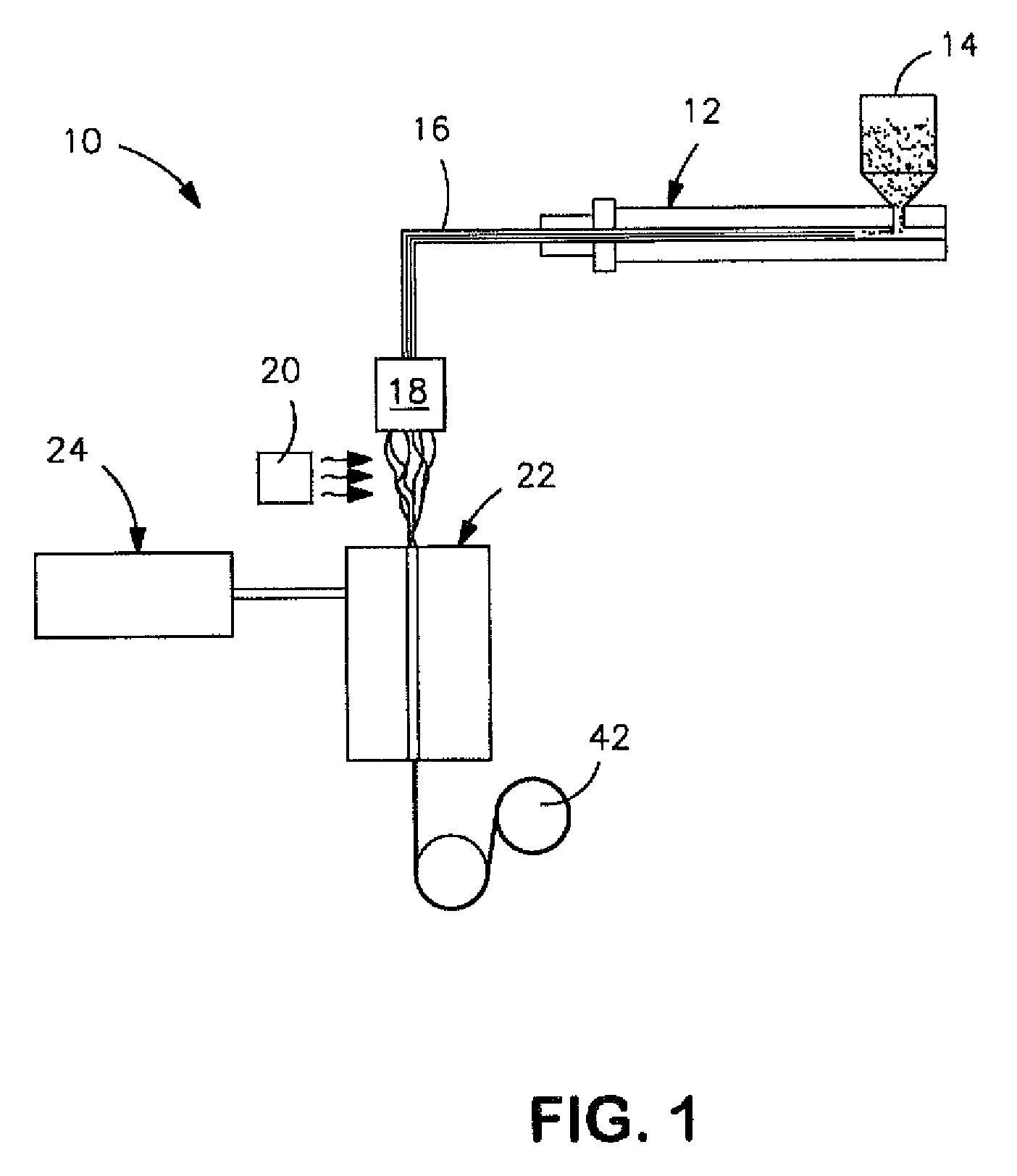

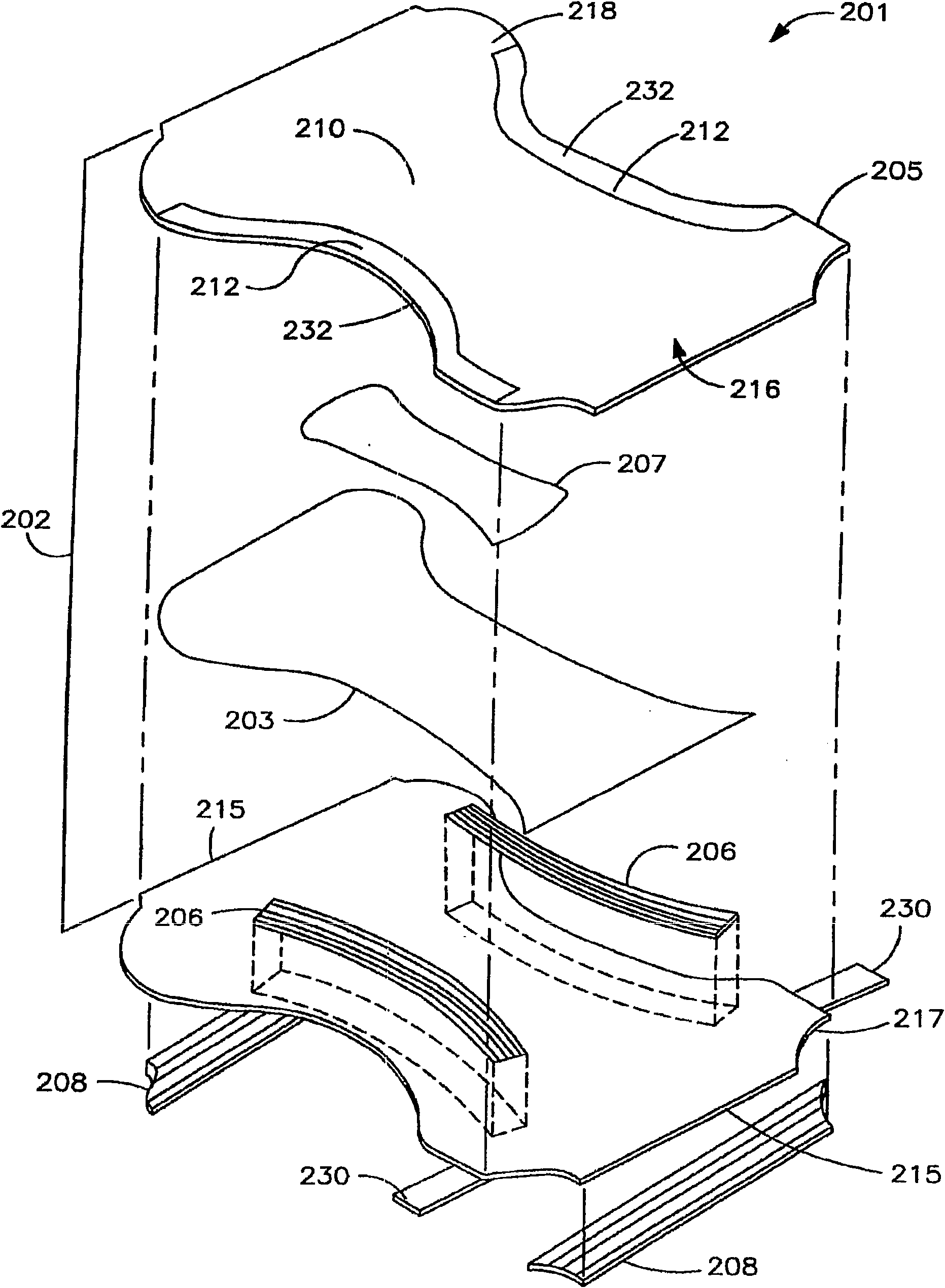

Modified Polylactic Acid Fibers

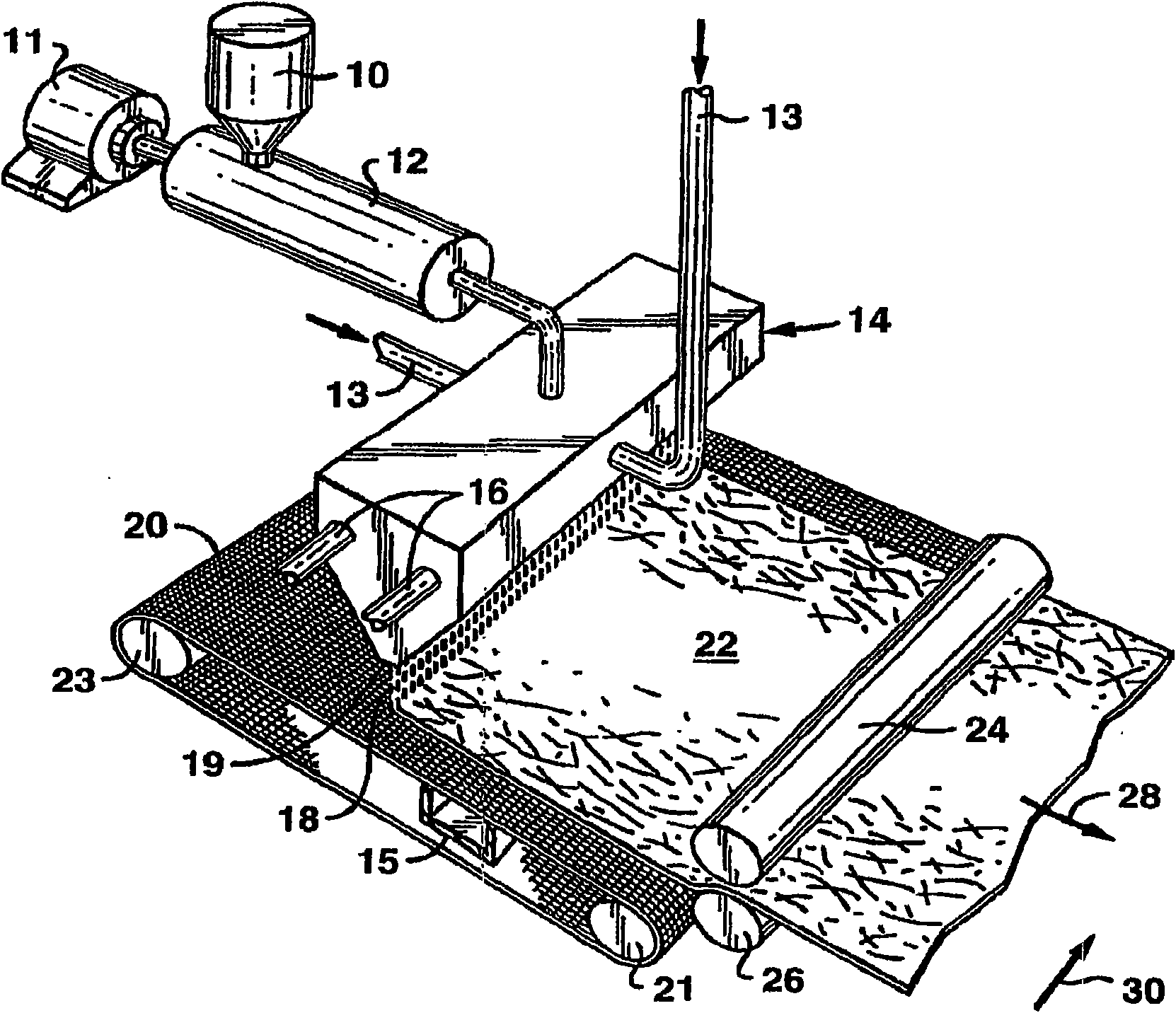

ActiveUS20120040582A1Improve responseMelt spinning methodsWoven fabricsChain scissionGlass transition

A method for forming biodegradable fibers is provided. The method includes blending polylactic acid with a polyepoxide modifier to form a thermoplastic composition, extruding the thermoplastic composition through a die, and thereafter passing the extruded composition through a die to form a fiber. Without intending to be limited by theory, it is believed that the polyepoxide modifier reacts with the polylactic acid and results in branching of its polymer backbone, thereby improving its melt strength and stability during fiber spinning without significantly reducing glass transition temperature. The reaction-induced branching can also increase molecular weight, which may lead to improved fiber ductility and the ability to better dissipate energy when subjected to an elongation force. To minimize premature reaction, the polylactic acid and polyepoxide modifier are first blended together at a relatively low temperature(s). Nevertheless, a relatively high shear rate may be employed during blending to induce chain scission of the polylactic acid backbone, thereby making more hydroxyl and / or carboxyl groups available for subsequent reaction with the polyepoxide modifier. Once blended, the temperature(s) employed during extrusion of the blended composition can be selected to both melt the composition and initiate a reaction of the polyepoxide modifier with hydroxyl and / or carboxyl groups of the polylactic acid. Through selective control over this method, the present inventors have discovered that the resulting fibers may exhibit good mechanical properties, both during and after melt spinning.

Owner:KIMBERLY-CLARK WORLDWIDE INC

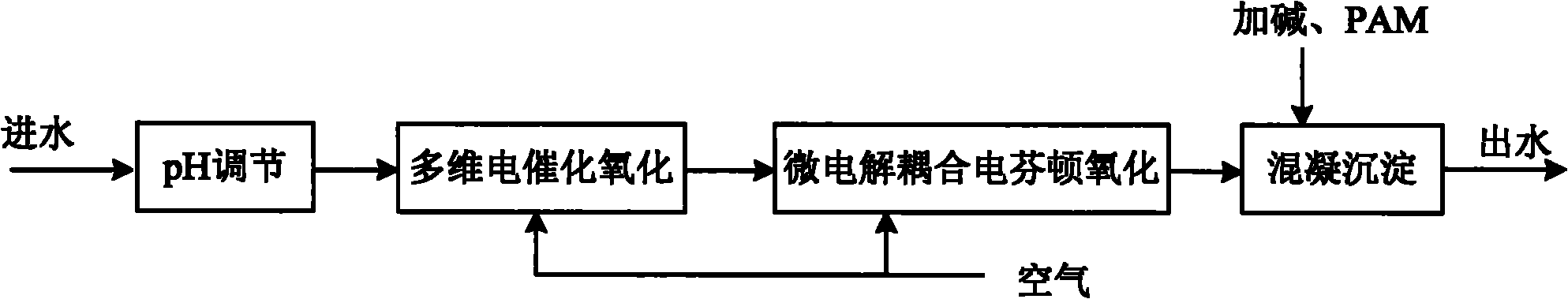

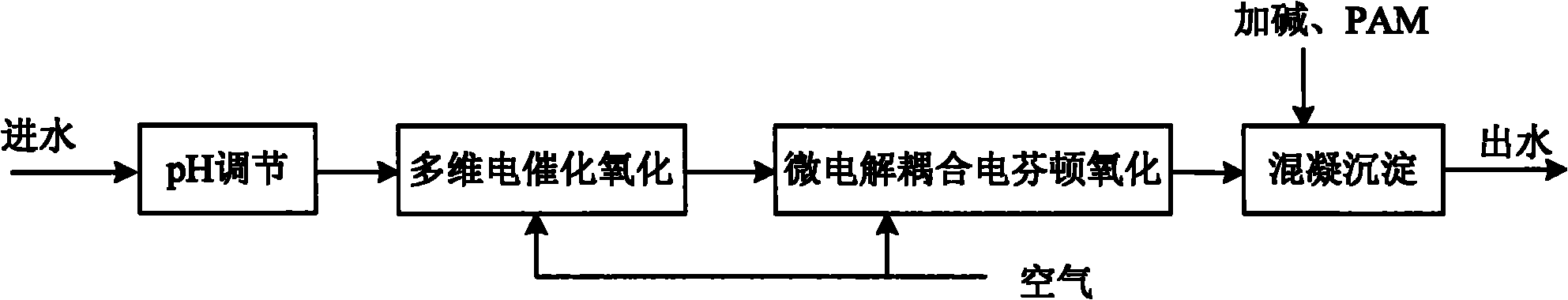

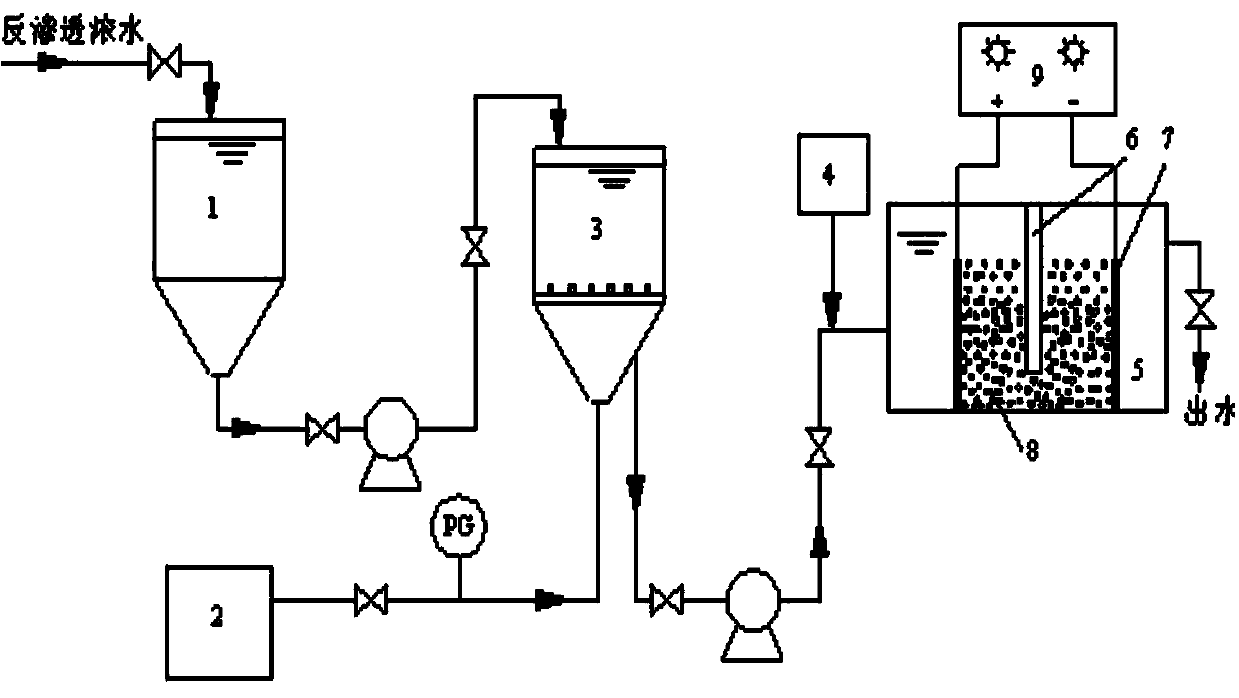

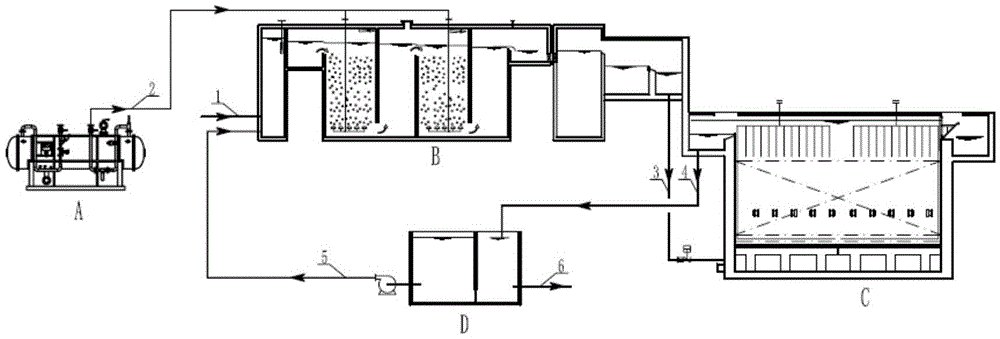

Technology for processing high-concentration organic wastewater in composite electrochemical method

ActiveCN101955280AStrong oxidation abilityIncrease oxidation potentialWater contaminantsMultistage water/sewage treatmentChemical treatmentHigh concentration

The invention relates to a technology for processing high-concentration organic wastewater in a composite electrochemical method, which comprises the main four steps of: pH adjustment, multidimensional electrocatalytic oxidization processing, micro coupling electric fenton reaction oxidation processing and coagulating sedimentation processing. The invention has the technical advantage that the technology has good breaking, chain scission, degradation effects to benzene ring organics, heterocyclic organics, polycyclic organics, macromolecule organics and sustaining organics, which have the most difficulty to degradation. Besides, the technology has no obvious selection to various kinds of high-concentration organic wastewater, has broad-spectrum processing effect, and is an effective measurement for pre-processing to high-concentration organic wastewater having difficulty to degradation. The invention is characterized in that the technology uses second-grade electrochemical processing equipment to realize third-grade advanced oxidation combination processing, effectively utilizes H2O2 and Fe2+ generated by the second-grade electrochemical processing equipment, and makes fenton oxidated and coupled in a micro reactor. During the technological processes, the oxidation capacity is strong to weak, and has reasonable distribution. The pH valve of wastewater does not need repeatedly adjusting. The invention has the obvious characteristics of low electric consumption, little medicine consumption, high processing efficiency, and good controllability.

Owner:南京赛佳环保实业有限公司

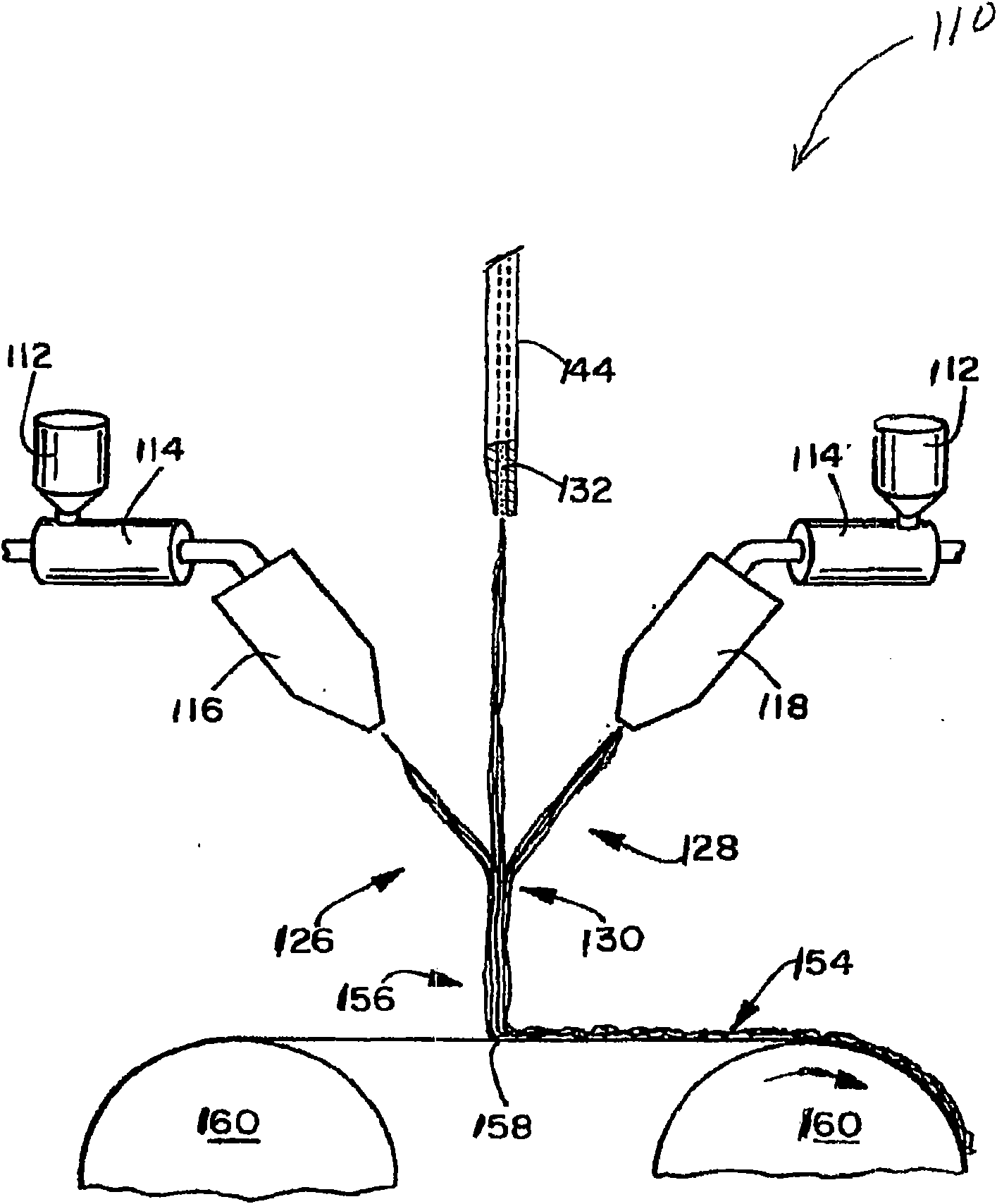

Biodegradable polylactic acids for use in forming fibers

A method for forming a biodegradable polylactic acid suitable for use in fibers is provided. Specifically, a polylactic acid is melt processed at a controlled water content to initiate a hydrolysis reaction. Without intending to be limited by theory, it is believed that the hydroxyl groups present in water are capable of attacking the ester linkage of polylactic acids, thereby leading to chain scission or “depolymerization” of the polylactic acid molecule into one or more shorter ester chains. The shorter chains may include polylactic acids, as well as minor portions of lactic acid monomers or oligomers, and combinations of any of the foregoing. By selectively controlling the hydrolysis conditions (e.g., moisture and polymer concentrations, temperature, shear rate, etc.), a hydrolytically degraded polylactic acid may be achieved that has a molecular weight lower than the starting polymer. Such lower molecular weight polymers have a higher melt flow rate and lower apparent viscosity, which are useful in a wide variety of fiber forming applications, such as in the meltblowing of nonwoven webs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

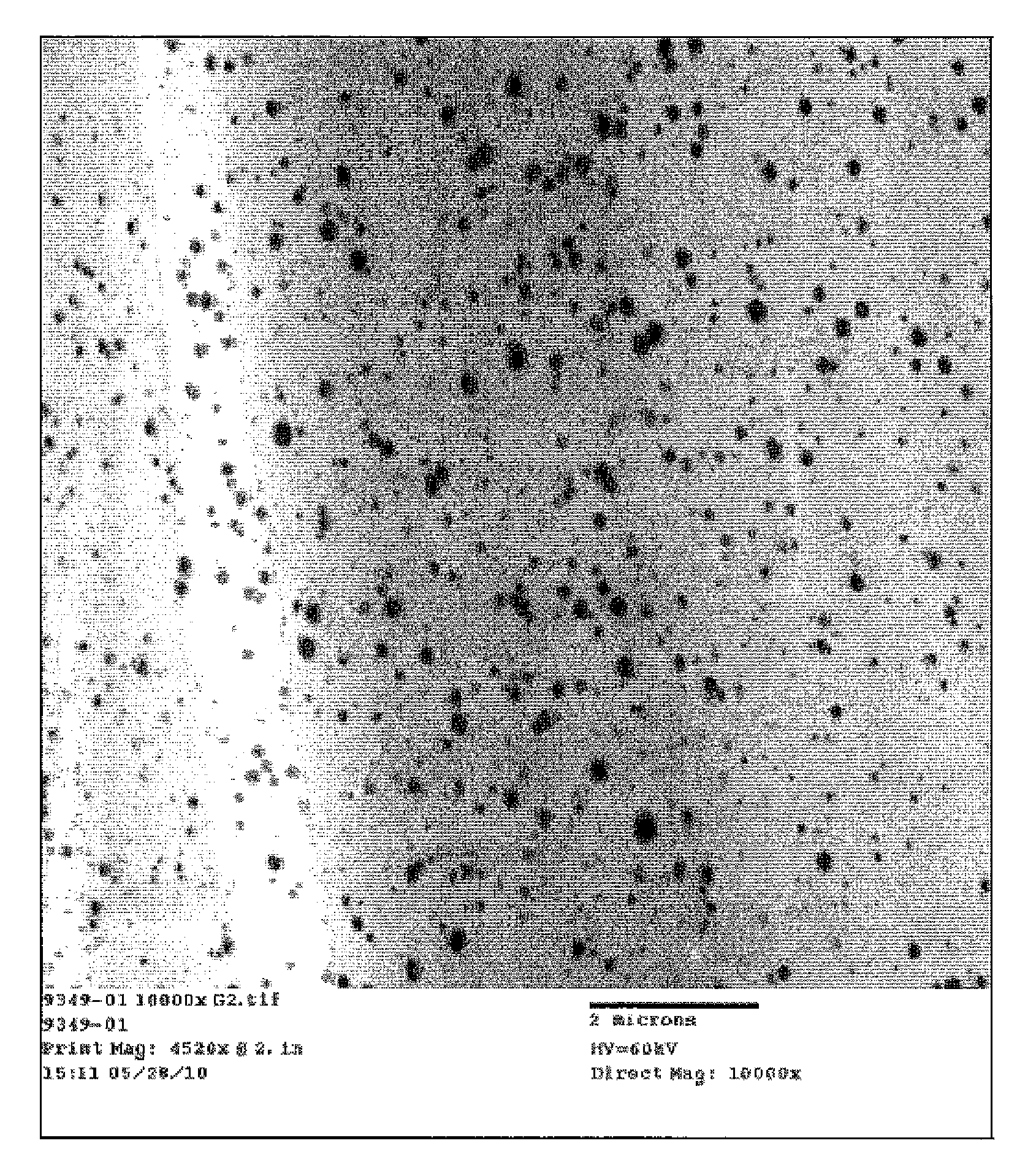

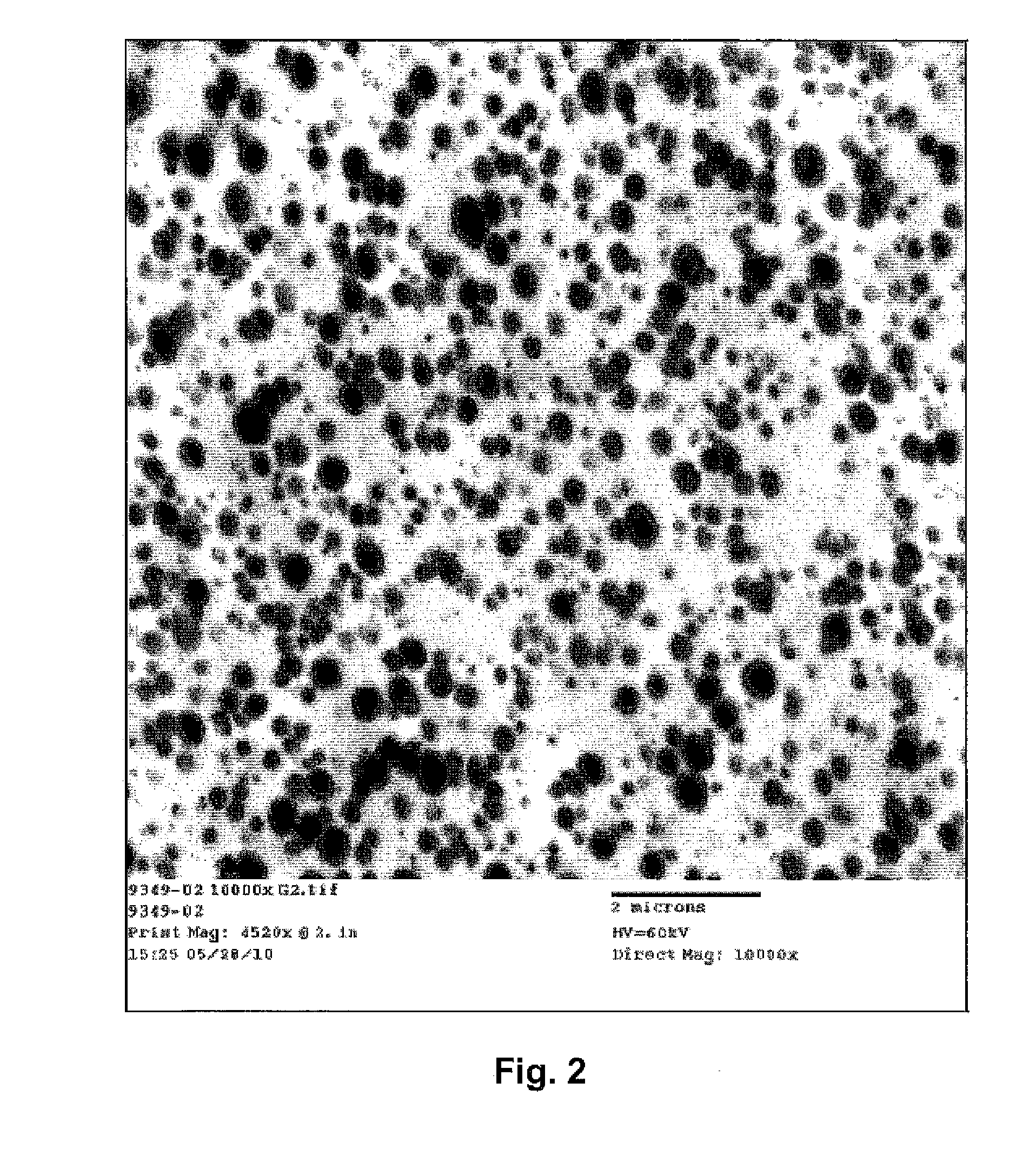

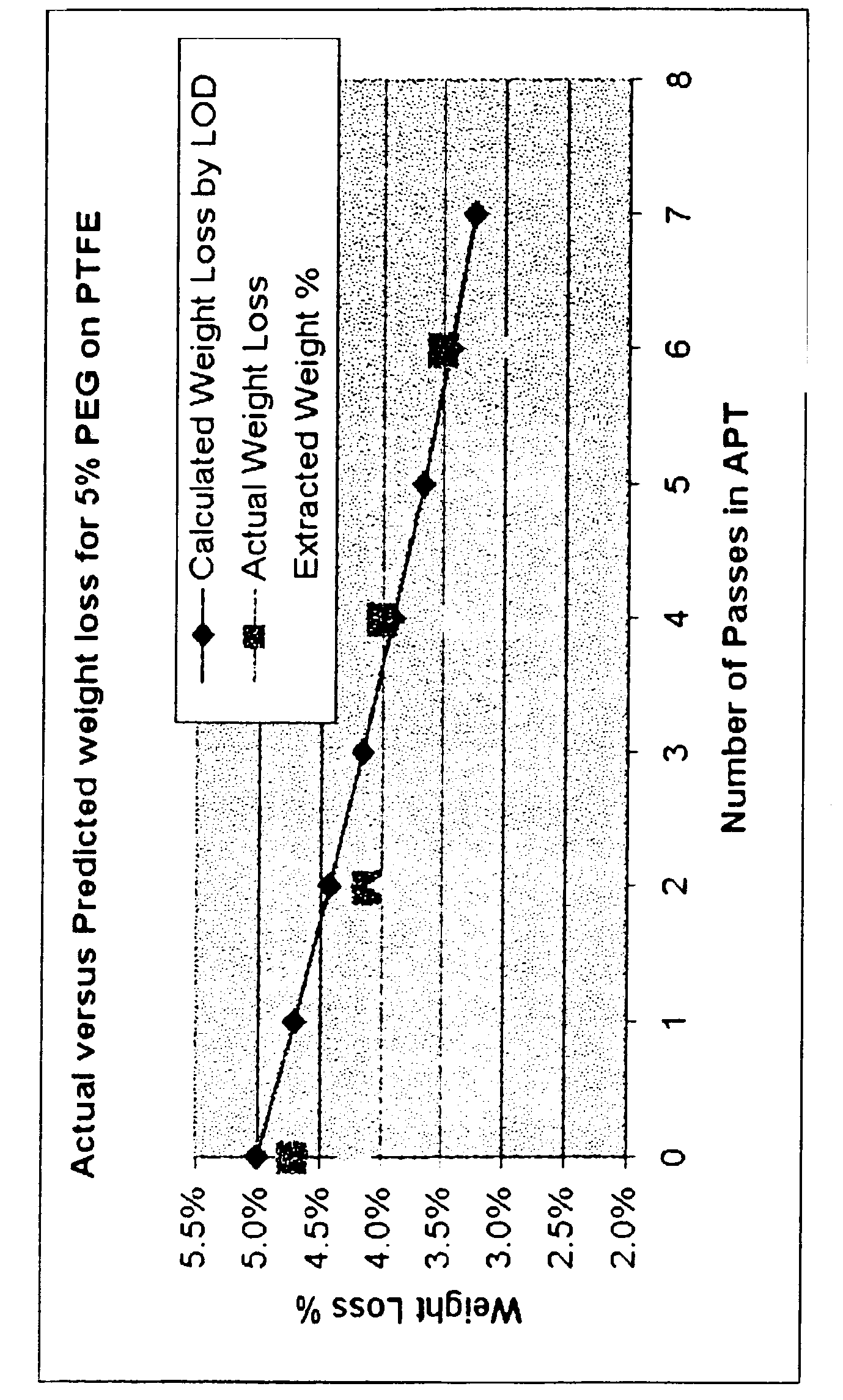

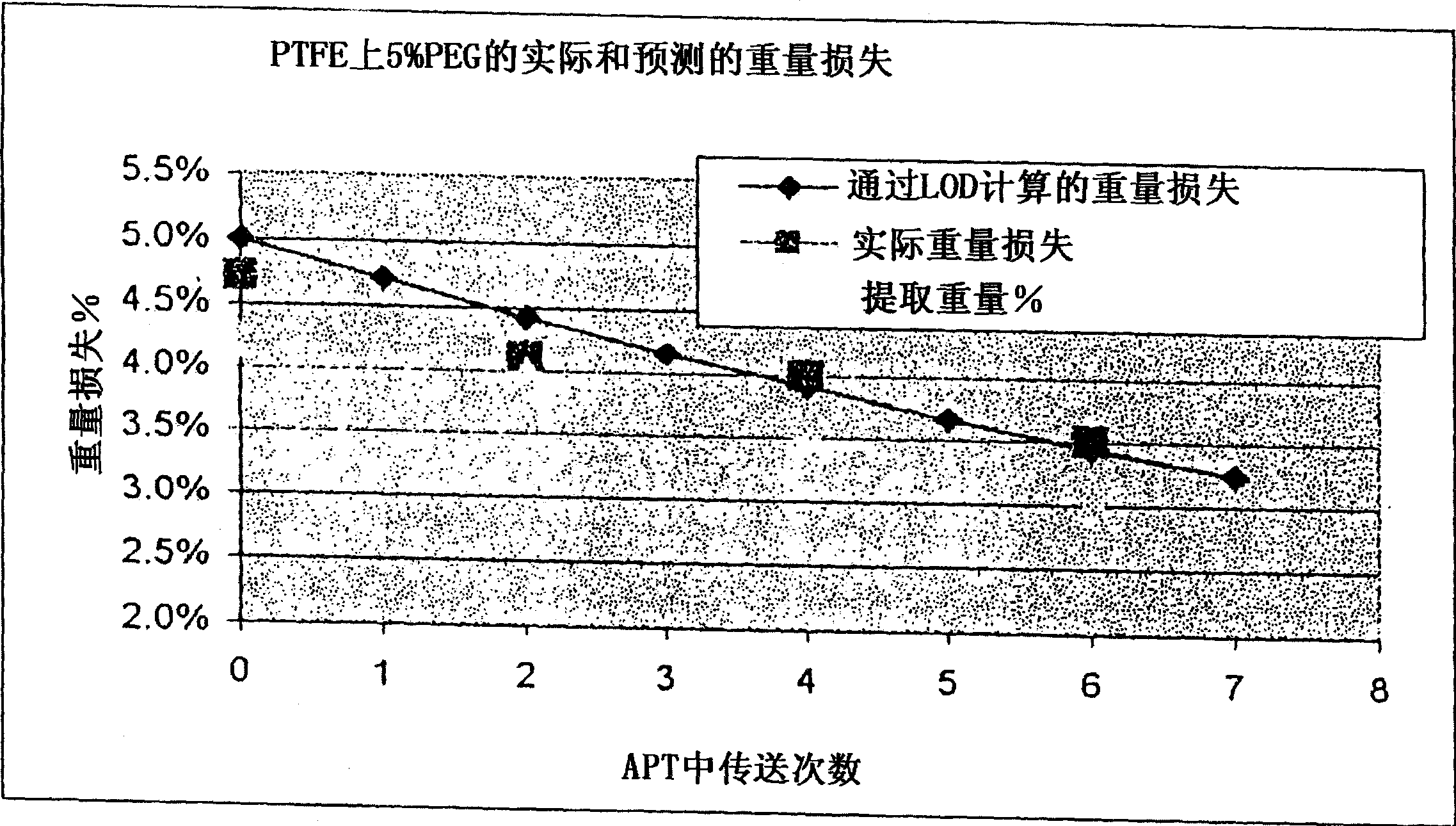

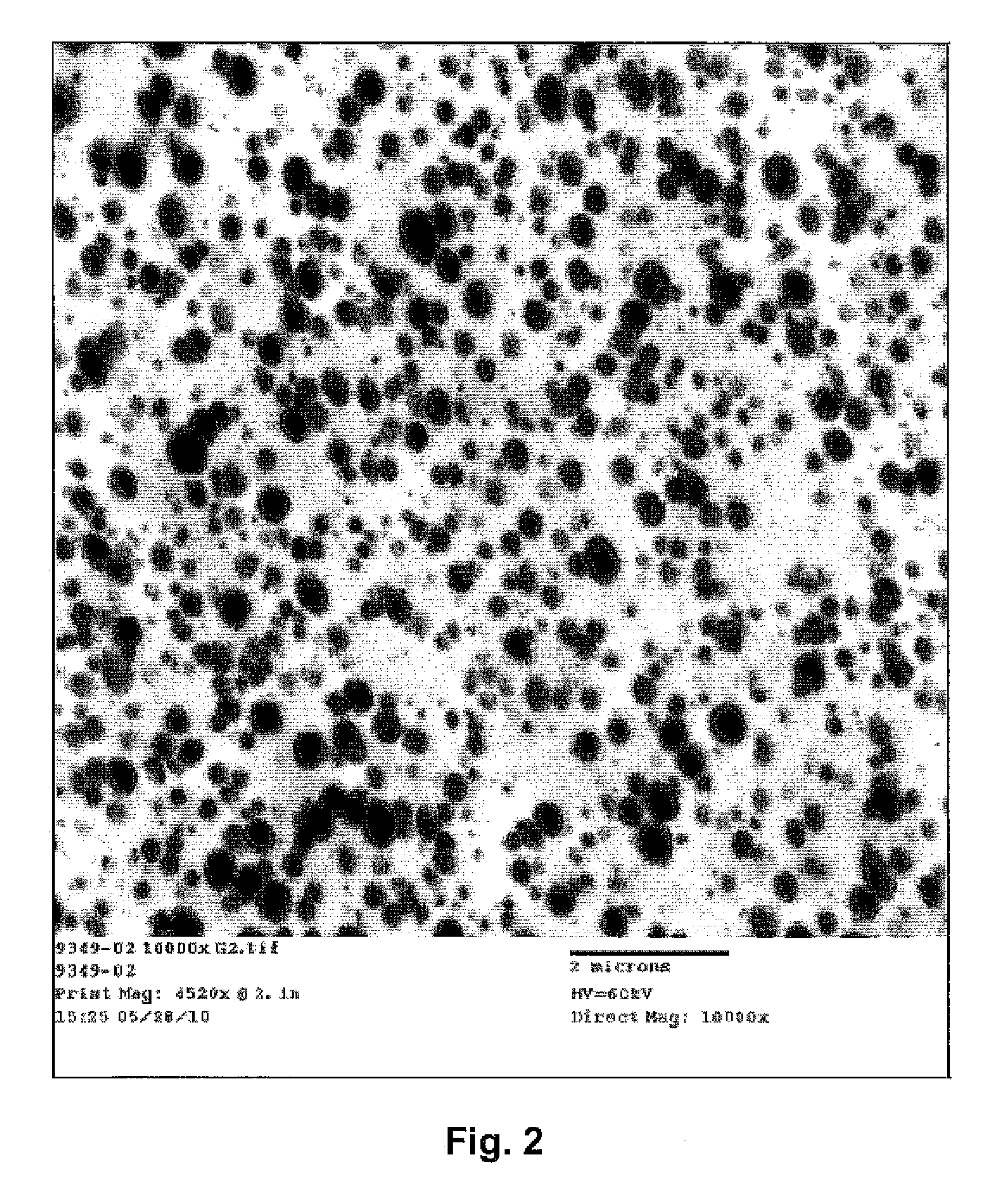

Method of treating fluoropolymer particles and the products thereof

InactiveUS7220483B2Reducing and increasing molecular weightEasy to brakeRadiation applicationsPretreated surfacesPolymer scienceChemical species

Fluoropolymer particles are subjected to high energy treatment so as to change the chemical functionality of the particle surfaces and thereby change the surface characteristics of the particles. These characteristics improve the usefulness of these particles and can make them highly dispersible, even in water. The surface treated fluoropolymer particles are subject to a chemical crosslinking process, or alternatively, are subject to a high energy treatment process, and may optionally be pretreated with a macromolecular chemical species prior to the foregoing processes. The high energy treatment can be used to both surface treat the fluoropolymer particles and in some embodiments, may also cause chain scission of the fluoropolymers to thereby reduce the molecular weight of the fluoropolymer particles. The surface treated fluoropolymer particles can be used to form fluoropolymer coatings on various substrates.

Owner:LAUREL PROD

Method of treating fluoropolymer particles and the products thereof

Fluoropolymer particles are subjected to high energy treatment so as to change the chemical functionality of the particle surfaces and thereby change the surface characteristics of the particles. These characteristics improve the usefulness of these particles and can make them highly dispersible, even in water. The surface treated fluoropolymer particles are subject to a chemical crosslinking process, or alternatively, are subject to a high energy treatment process, and may optionally be pretreated with a macromolecular chemical species prior to the foregoing processes. The high energy treatment can be used to both surface treat the fluoropolymer particles and in some embodiments, may also cause chain scission of the fluoropolymers to thereby reduce the molecular weight of the fluoropolymer particles. The surface treated fluoropolymer particles can be used to form fluoropolymer coatings on various substrates.

Owner:LAUREL PROD

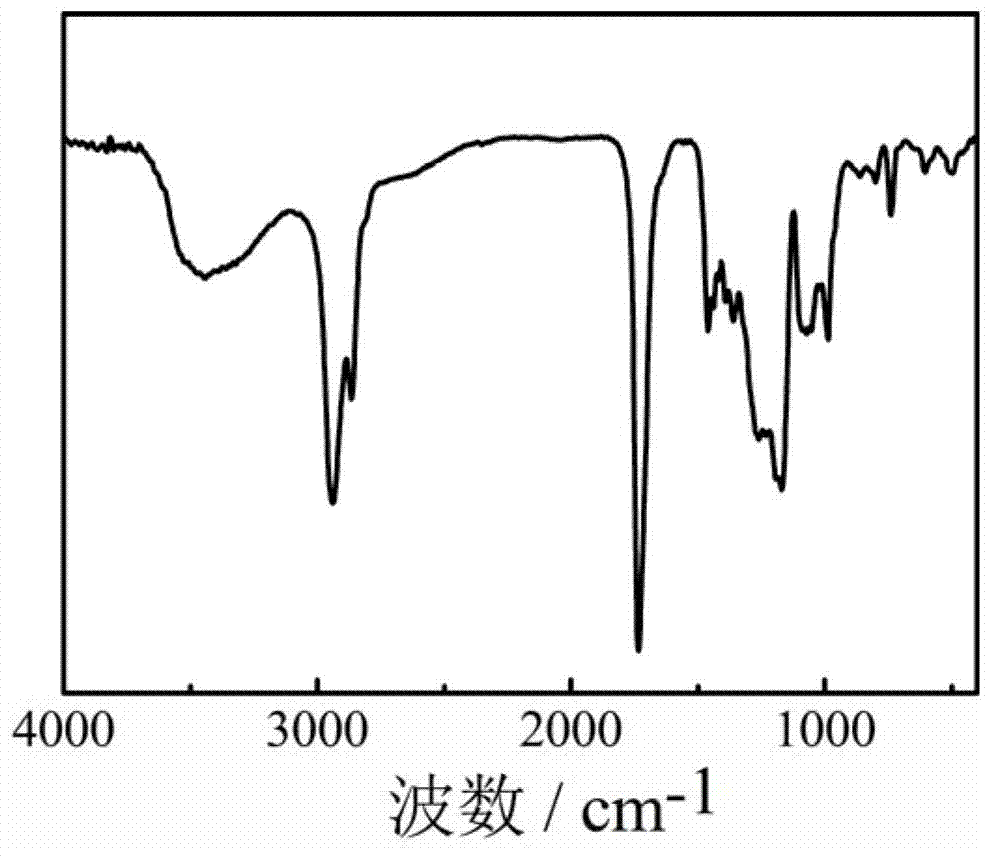

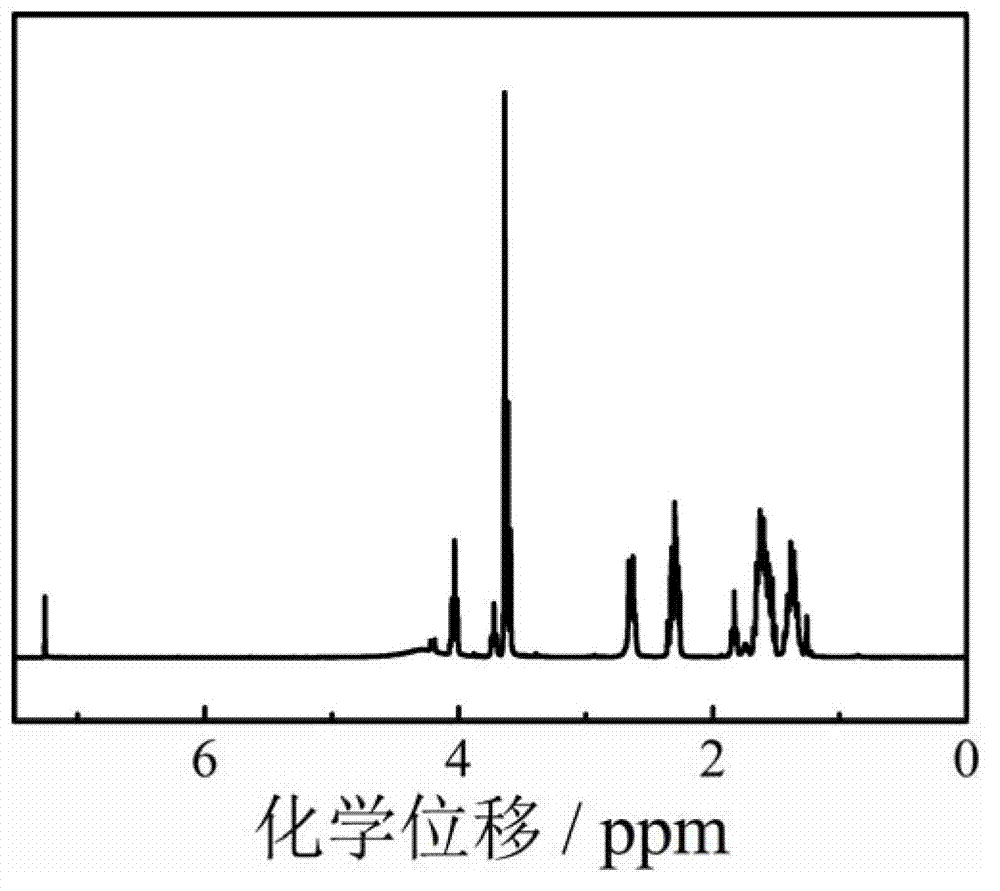

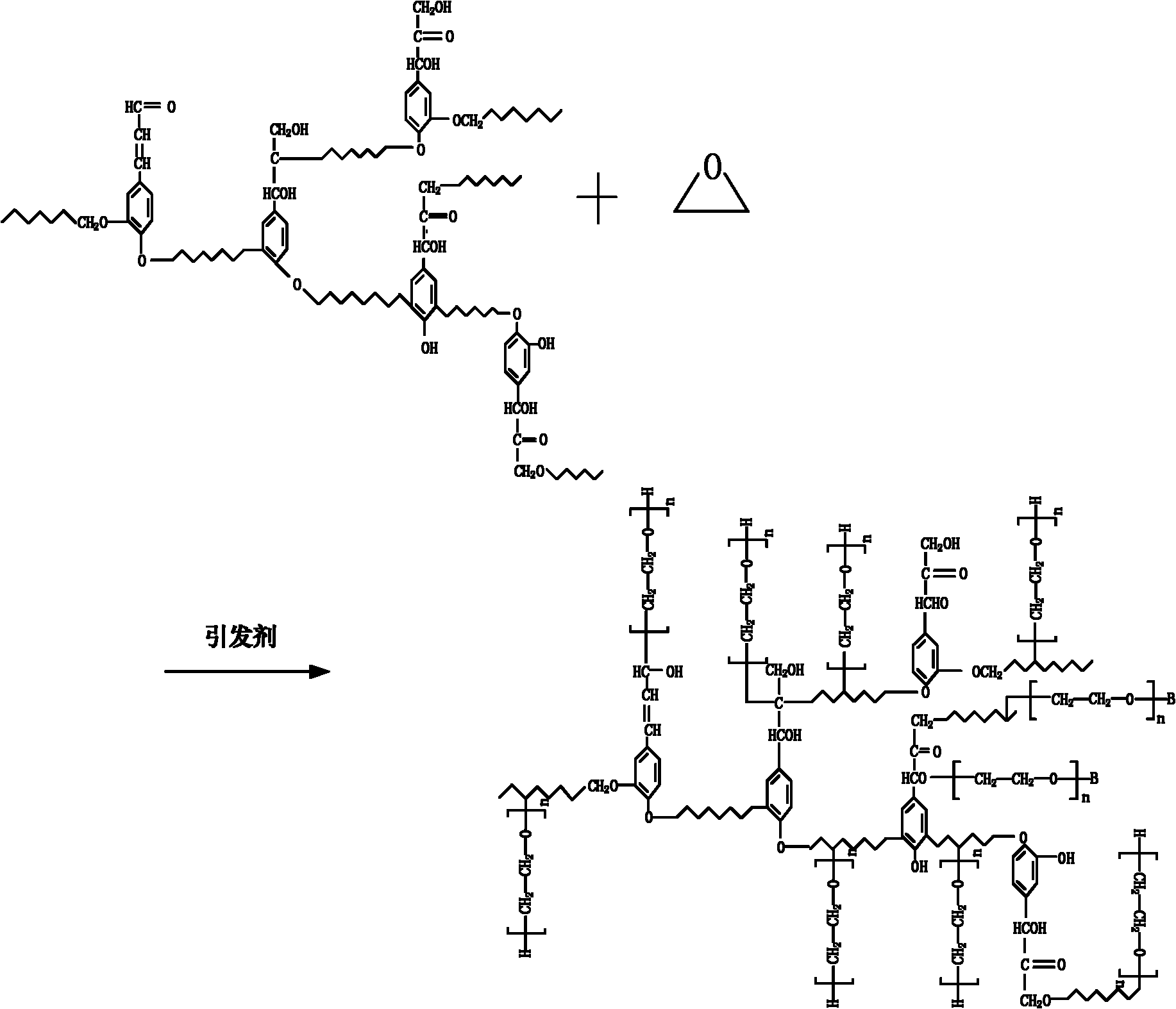

Preparation method and application of main chain fracture type polyacrylic acid silane ester resin

ActiveCN103396513AEfficient regulated releaseMake sure to keepAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention discloses a preparation method and an application of main chain fracture type polyacrylic acid silane ester resin. The method comprises the following steps of: mixing a cyclic monomer, a vinyl monomer and a vinyl silane ester monomer in a solvent according to a proportion, and then, adding a composite initiator accounting for 0.01-5% of the total mass percent of the monomers, and reacting at a temperature of 25-150 DEG C under the protection of argon or nitrogen to prepare the main chain fracture type polyacrylic acid silane ester resin; and the monomers are composed of 5-95wt% of cyclic monomer, 0-90wt% of vinyl monomer and 5-95wt% of vinyl silane ester monomer. According to the resin obtained by the invention, the side chain silane ester can hydrolyze under the action of seawater and the polyester chain segment of a main chain can generate chain scission under the action of seawater, thereby solving the dependence of traditional self-polishing materials on navigational speed, effectively regulating and controlling a stain-proofing agent to release at a constant speed, maintaining active substances on the coating surface of a ship and well meeting the anti-fouling requirements of ships, submarines and offshore production platform facilities with low navigational speeds.

Owner:SOUTH CHINA UNIV OF TECH

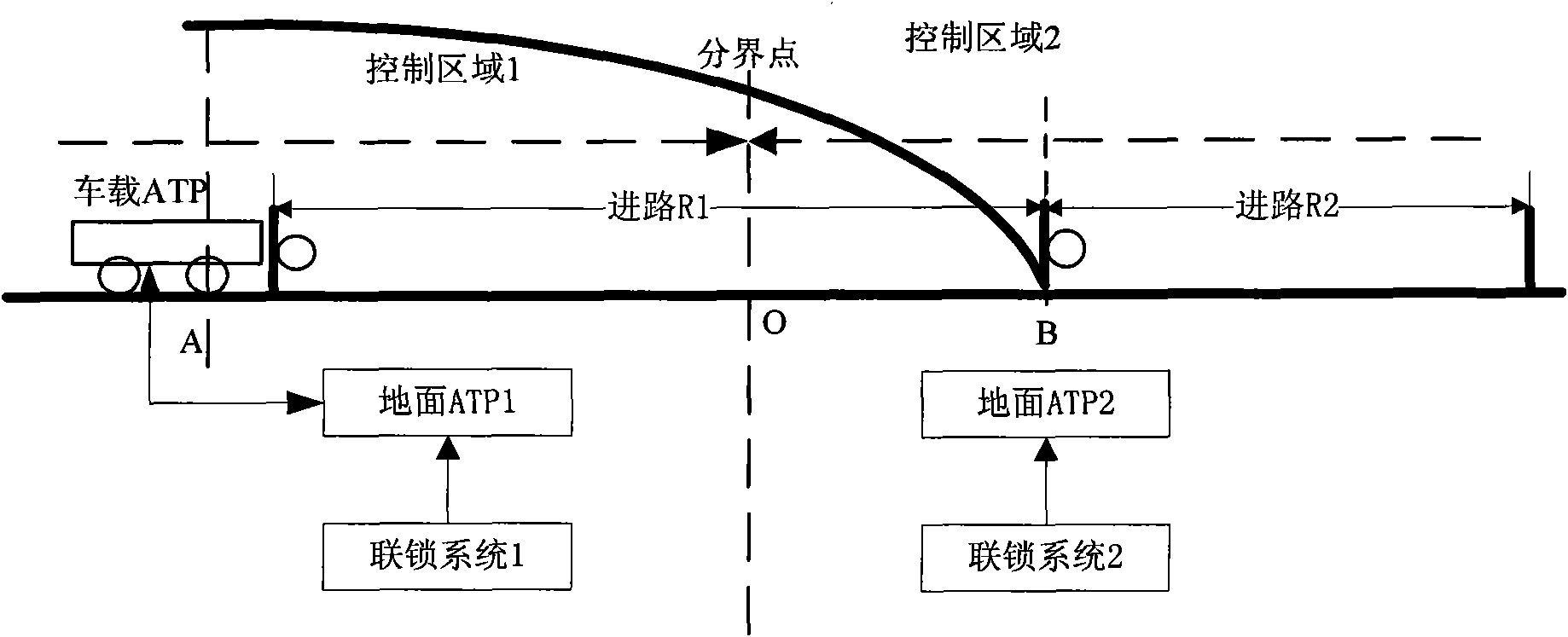

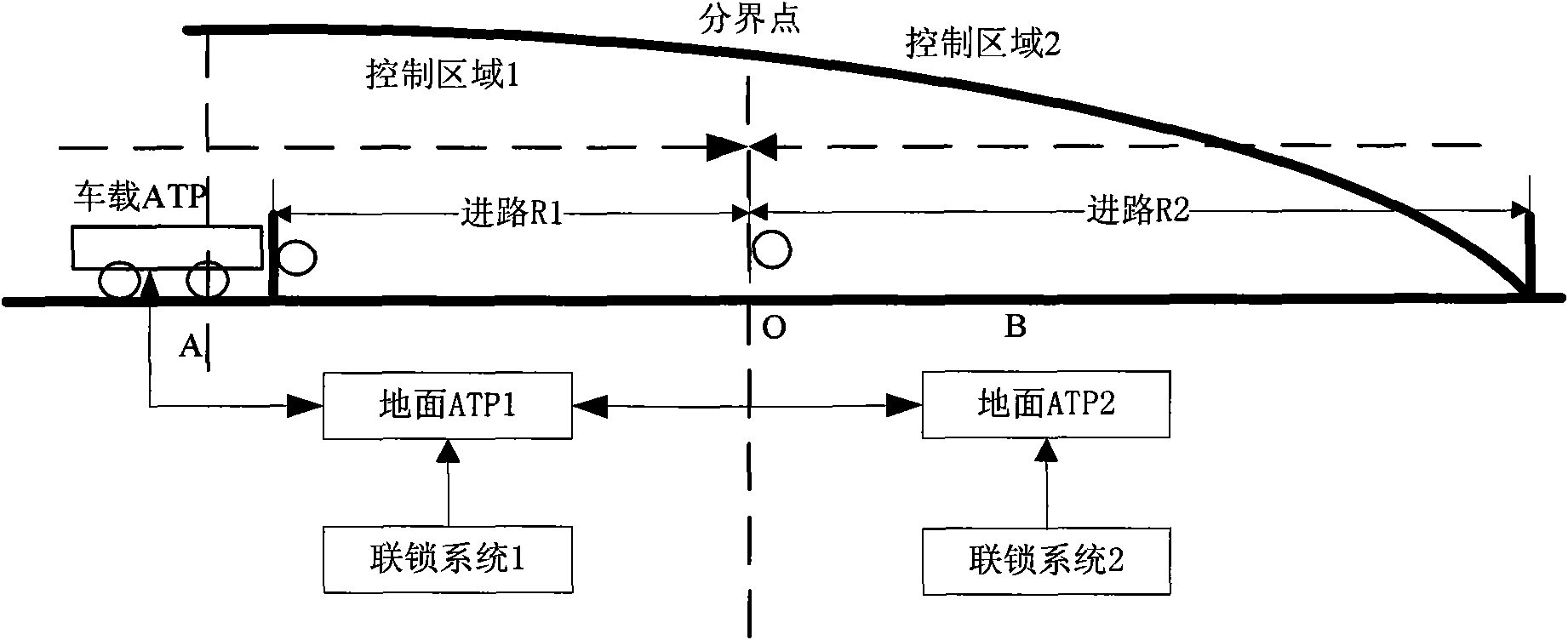

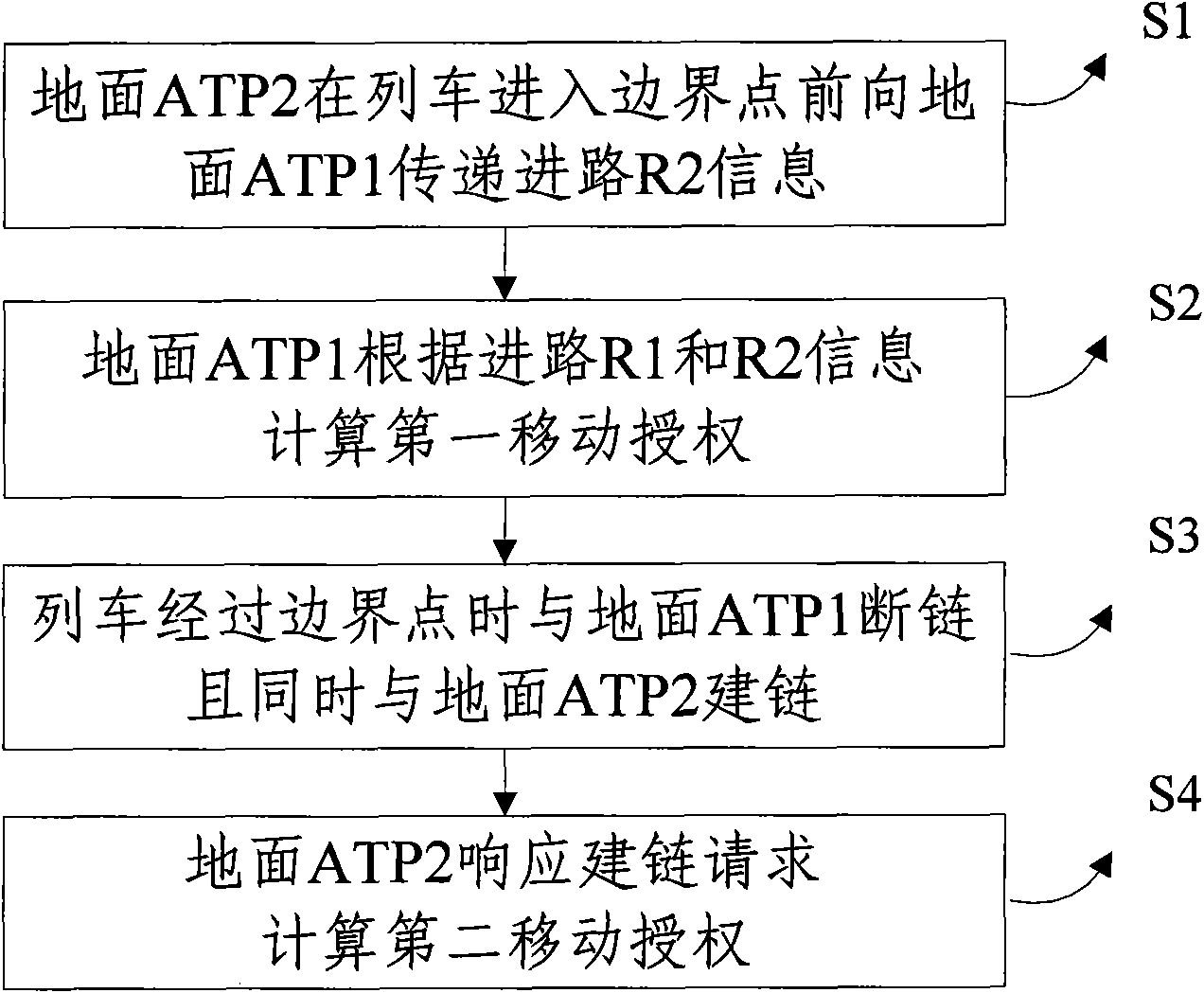

Safety protection method of CBTC (Communication Based Train Control) system during crossing control area

ActiveCN101927775AReasonable free settingWill not cause "lost car" phenomenonConnection managementRailway signalling and safetyChain scissionEngineering

The invention provides a safety protection method of a CBTC system during crossing a control area, which comprises the steps: S1: when the train enters the boundary areas of a first and a second ground ATP systems, the first and the second ground ATP systems mutually transmit the information of access roads R1 and R2 of respective control areas; S2: the first ATP calculates first moving authorization information according to the information of the access roads R1 and R2 and transmits the information to a vehicle-mounted ATP; S3: when the train passes through the boundary point of the boundary area and enters the control area of the second ATP, the vehicle-mounted ATP transmits chain-scission request information to the first ground ATP system and transmits chain-building request information to the second ground ATP system; and S4: the second ground ATP system responses the chain-building request information, calculates second moving authorization information according to the information of the access road R2 and transmits the second moving authorization information to the vehicle-mounted ATP. The invention can ensure that the arrangement of the access road R2 in the boundary point can not be limited; the vehicle-missing phenomenon can not appear when the train breaks down in OB zones; and the cost of the system can be simultaneously reduced.

Owner:TRAFFIC CONTROL TECH CO LTD

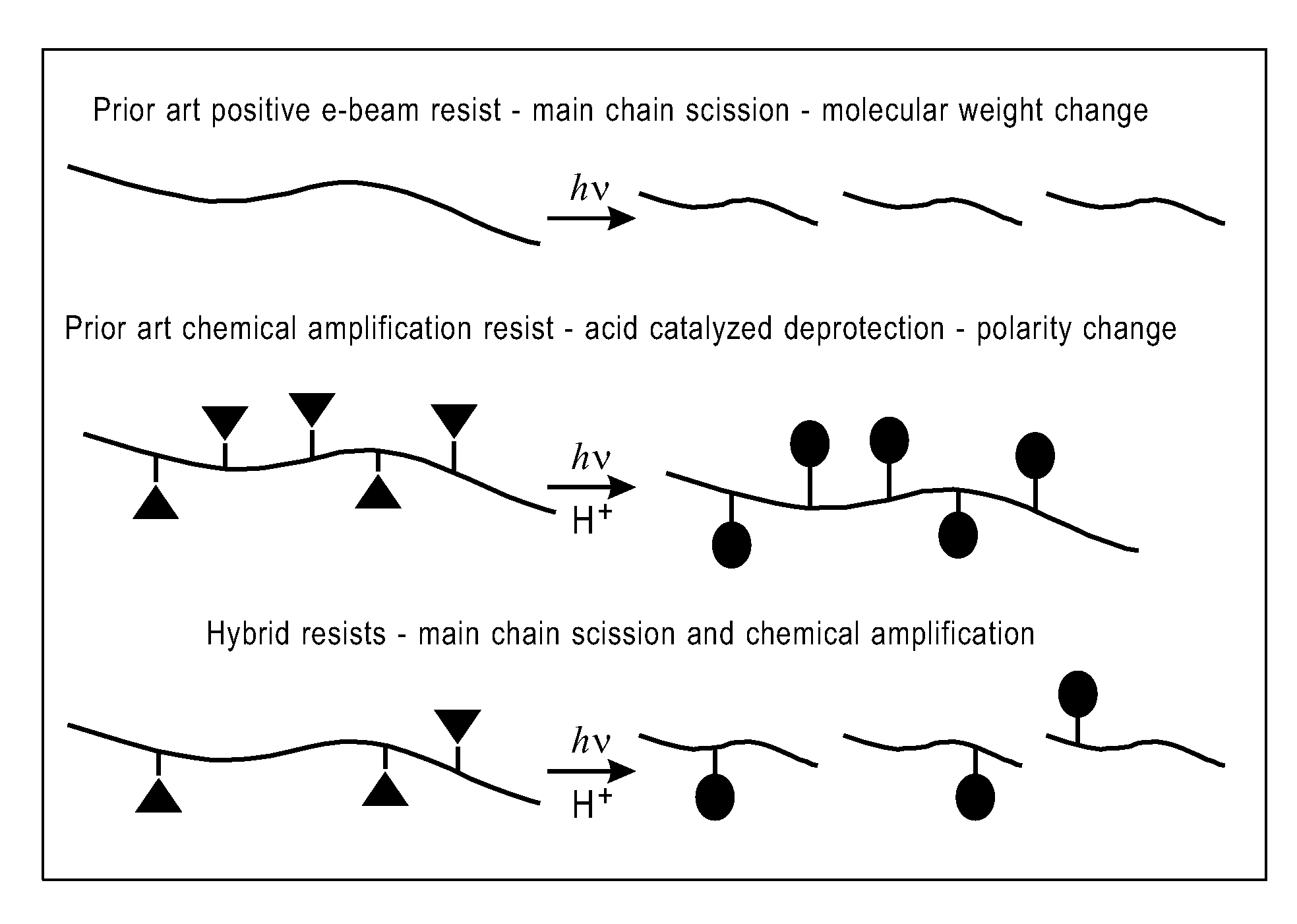

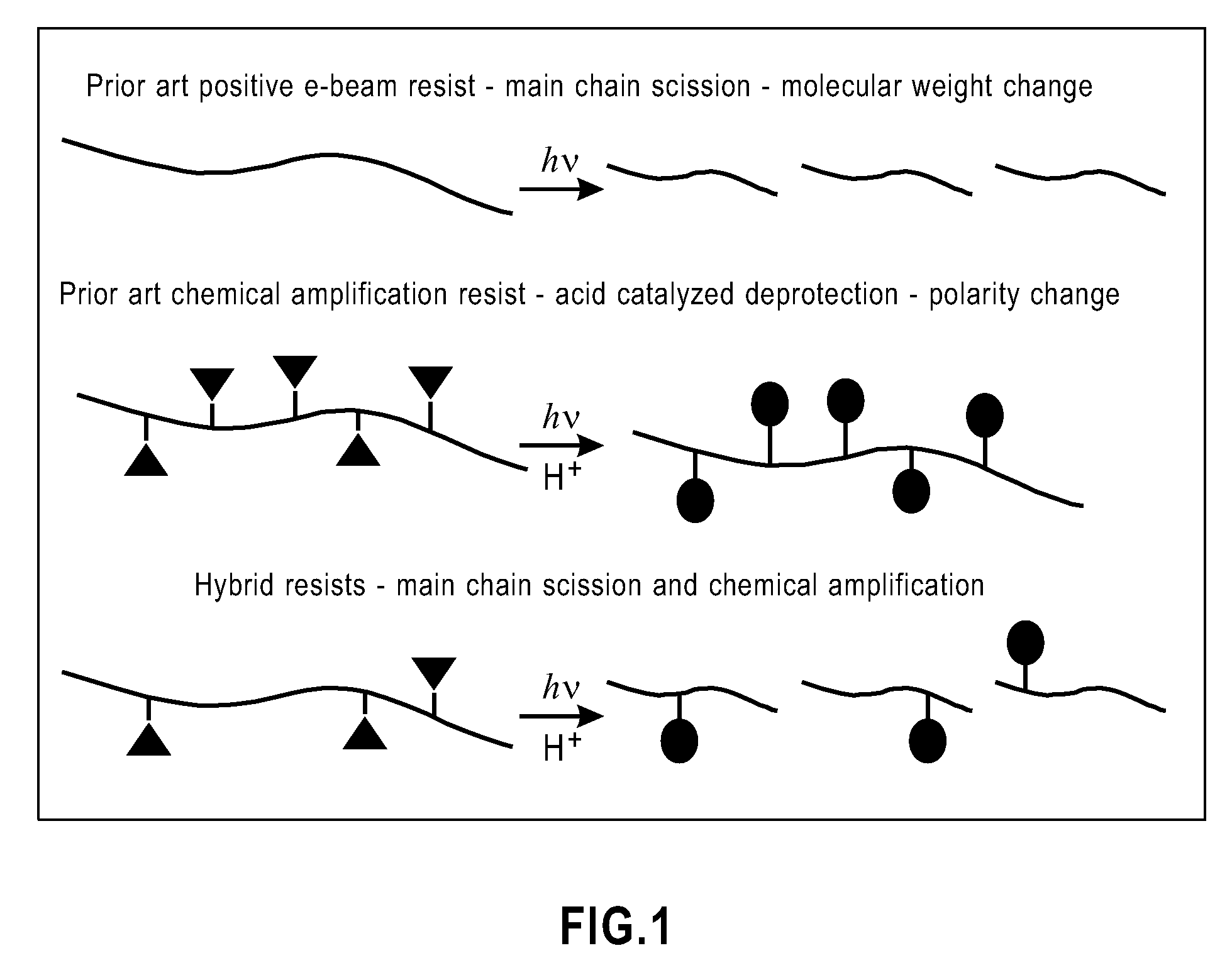

Photoresist compositions and methods of use

InactiveUS20100203450A1Photosensitive materialsPhotomechanical exposure apparatusChain scissionAcid catalyzed

A photoresist composition comprises a polymer capable of radiation induced main chain scission and acid-catalyzed deprotection, wherein the polymer is derived by free radical polymerization of two or more monomers, each having an alpha-substituent on a polymerizable vinyl group; and a photochemical acid generator.

Owner:CENT GLASS CO LTD +1

Modified polylactic acid fibers

A method for forming biodegradable fibers is provided. The method includes blending polylactic acid with a polyepoxide modifier to form a thermoplastic composition, extruding the thermoplastic composition through a die, and thereafter passing the extruded composition through a die to form a fiber. Without intending to be limited by theory, it is believed that the polyepoxide modifier reacts with the polylactic acid and results in branching of its polymer backbone, thereby improving its melt strength and stability during fiber spinning without significantly reducing glass transition temperature. The reaction-induced branching can also increase molecular weight, which may lead to improved fiber ductility and the ability to better dissipate energy when subjected to an elongation force. To minimize premature reaction, the polylactic acid and polyepoxide modifier are first blended together at a relatively low temperature(s). Nevertheless, a relatively high shear rate may be employed during blending to induce chain scission of the polylactic acid backbone, thereby making more hydroxyl and / or carboxyl groups available for subsequent reaction with the polyepoxide modifier. Once blended, the temperature(s) employed during extrusion of the blended composition can be selected to both melt the composition and initiate a reaction of the polyepoxide modifier with hydroxyl and / or carboxyl groups of the polylactic acid. Through selective control over this method, the present inventors have discovered that the resulting fibers may exhibit good mechanical properties, both during and after melt spinning.

Owner:KIMBERLY-CLARK WORLDWIDE INC

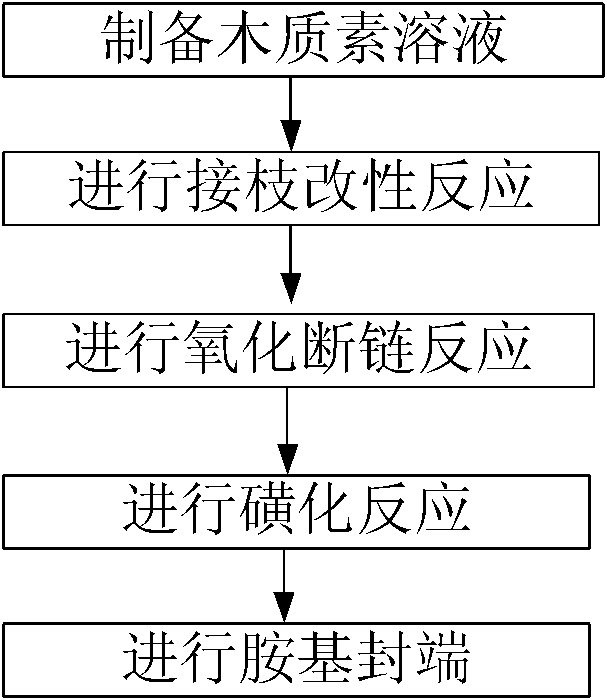

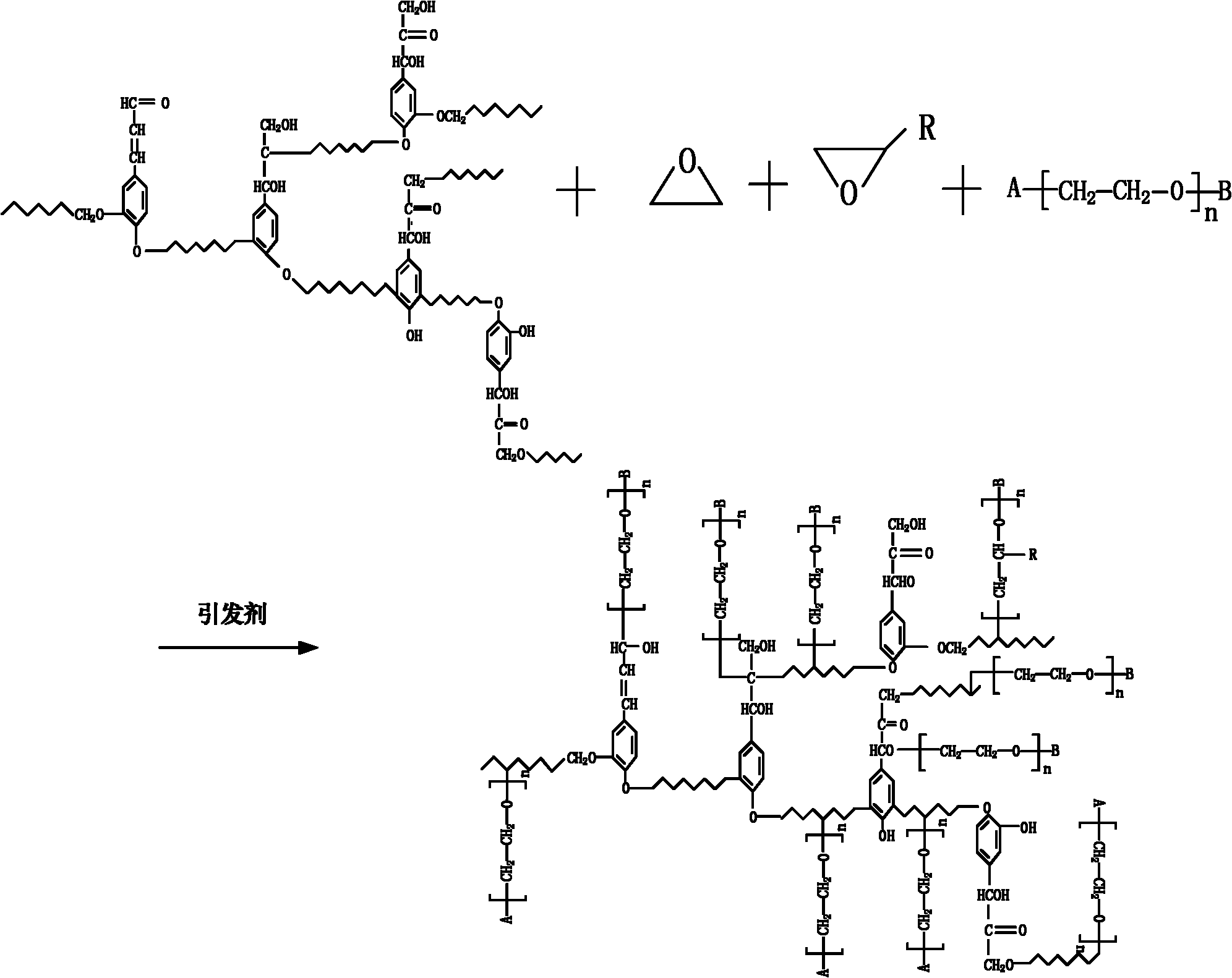

Preparation method of polycarboxylic acid water reducing agent compound

The invention proposes a preparation method of a polycarboxylic acid water reducing agent compound. The preparation method comprises the following steps: (1) preparing a lignin solution; (2) heating a reaction vessel in a water bath for graft modification and catalytic oxidation chain scission reaction regardless of sequence; (3) carrying out sulfonation reaction; and (4) carrying out amino blocking. The preparation method of the poly(carbolic acid) water reducing agent compound provided by the invention can be used for not only reducing the retardation and other defects of the traditional lignin water reducing agent, but also improving the water reduction rate, improving the compatibility with other polycarboxylic acids, simultaneously improving the performance of the polycarboxylic acid, overcoming the defect of the single use of the pure polycarboxylic acid, and improving the impurity sensitivity, bleeding property, workability, slump keeping property and the like of concrete components.

Owner:宋玉军

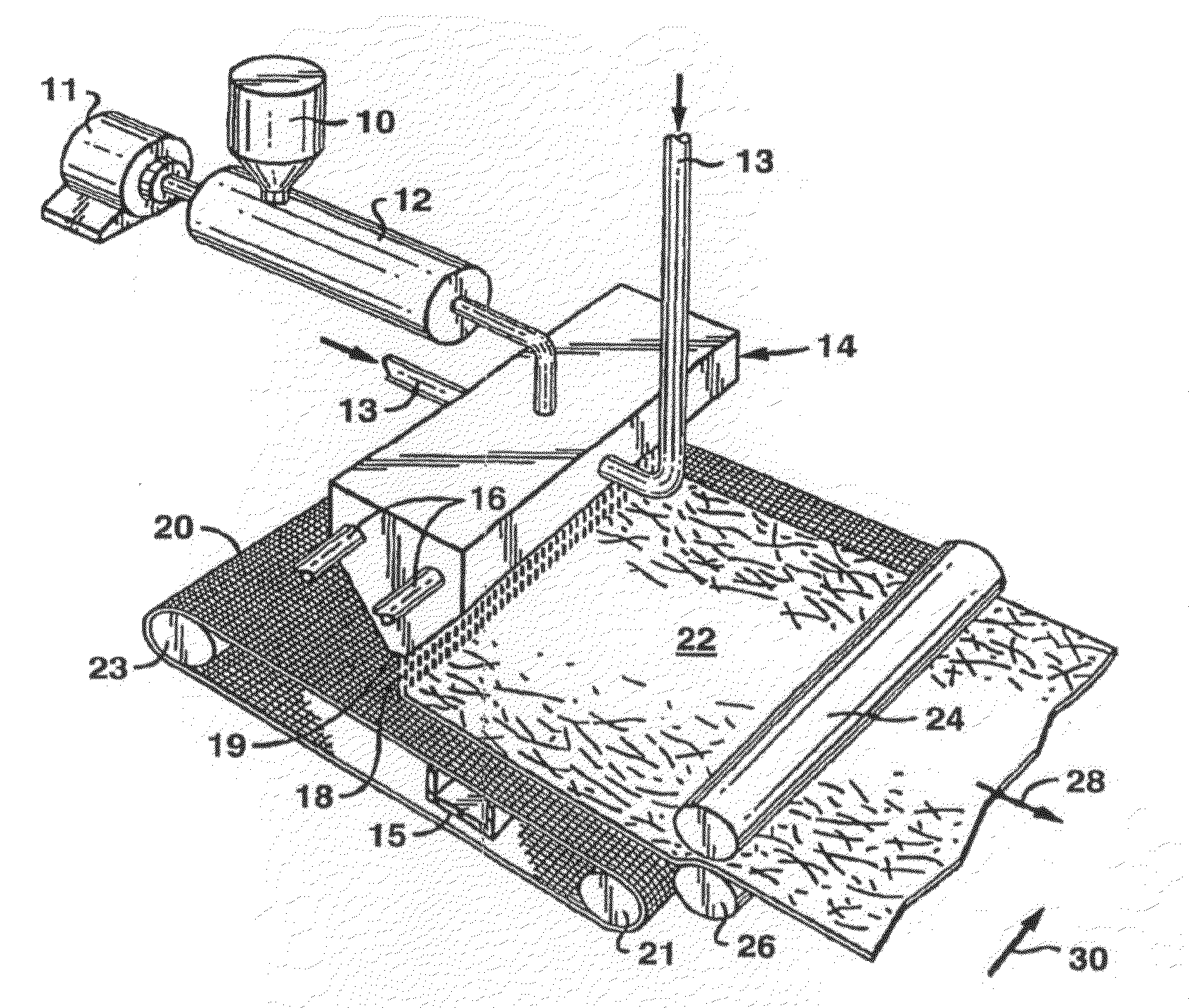

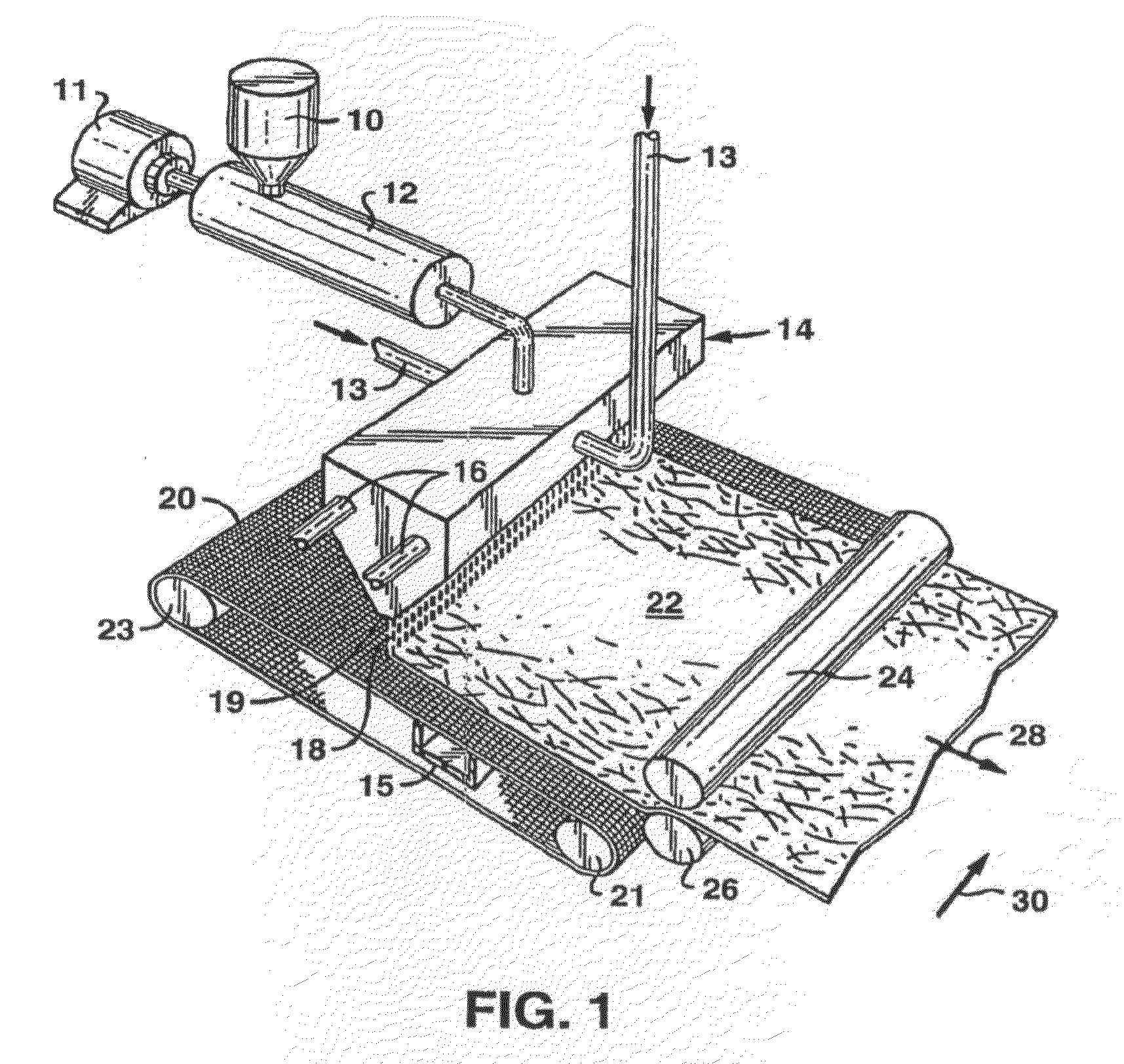

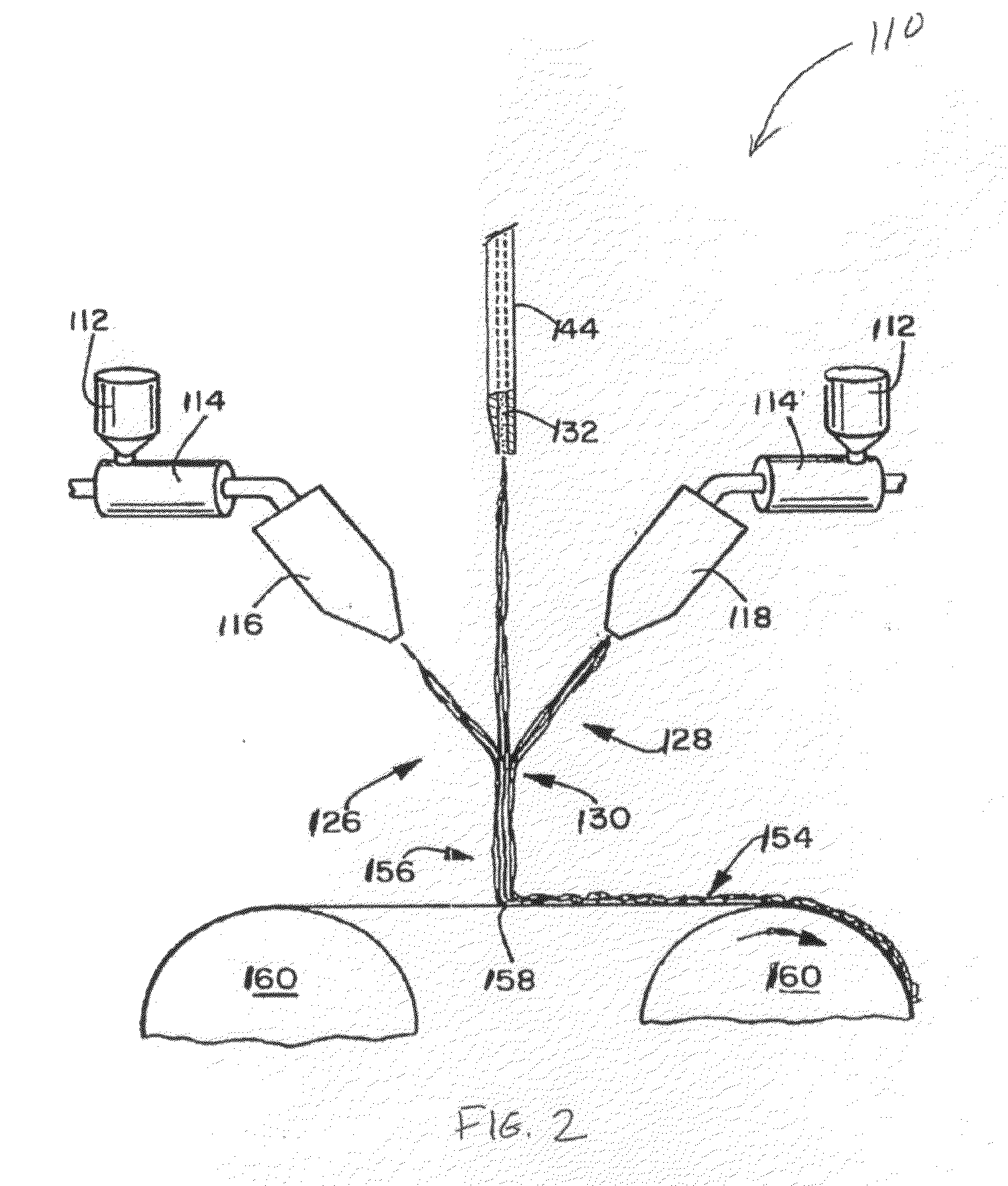

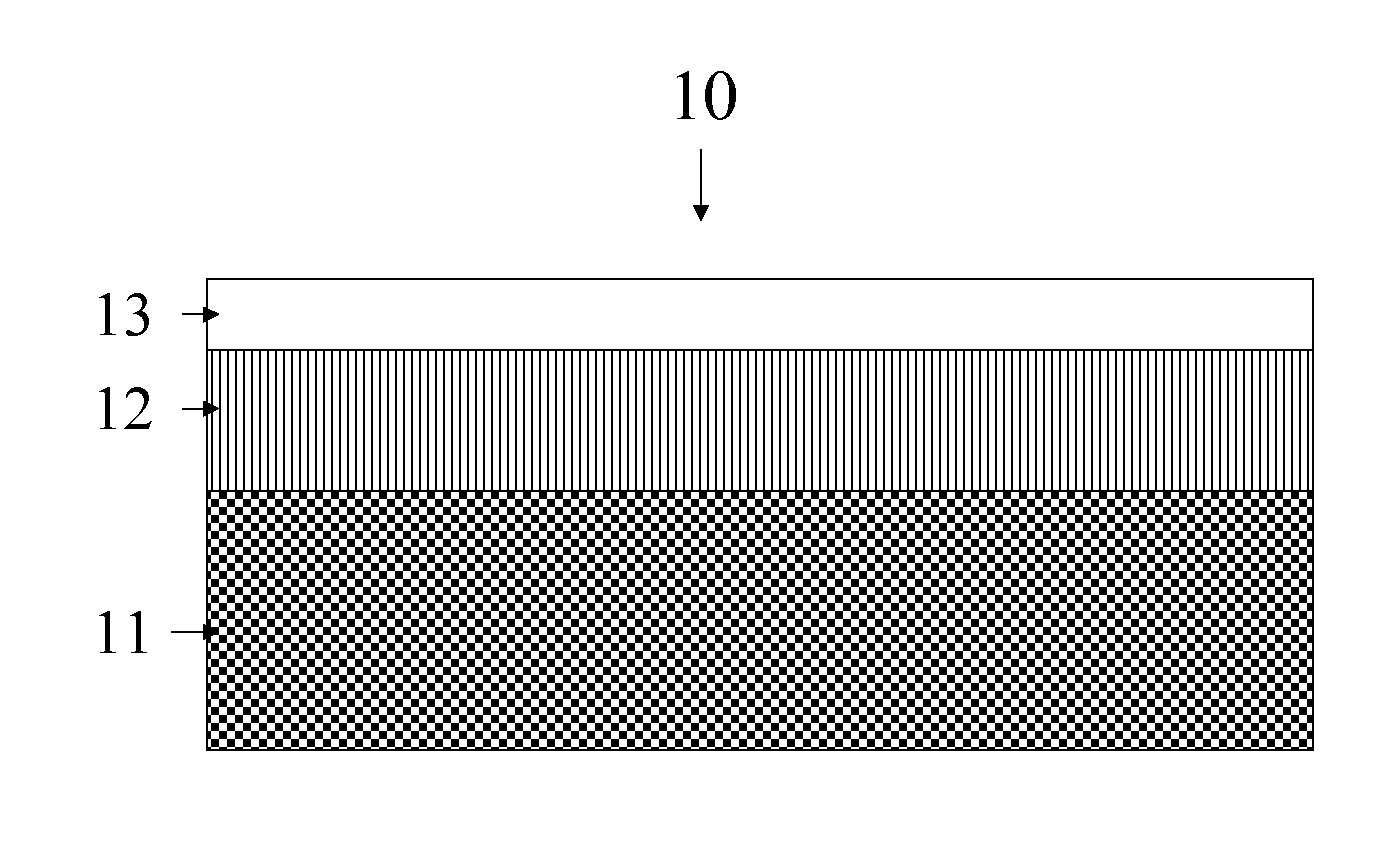

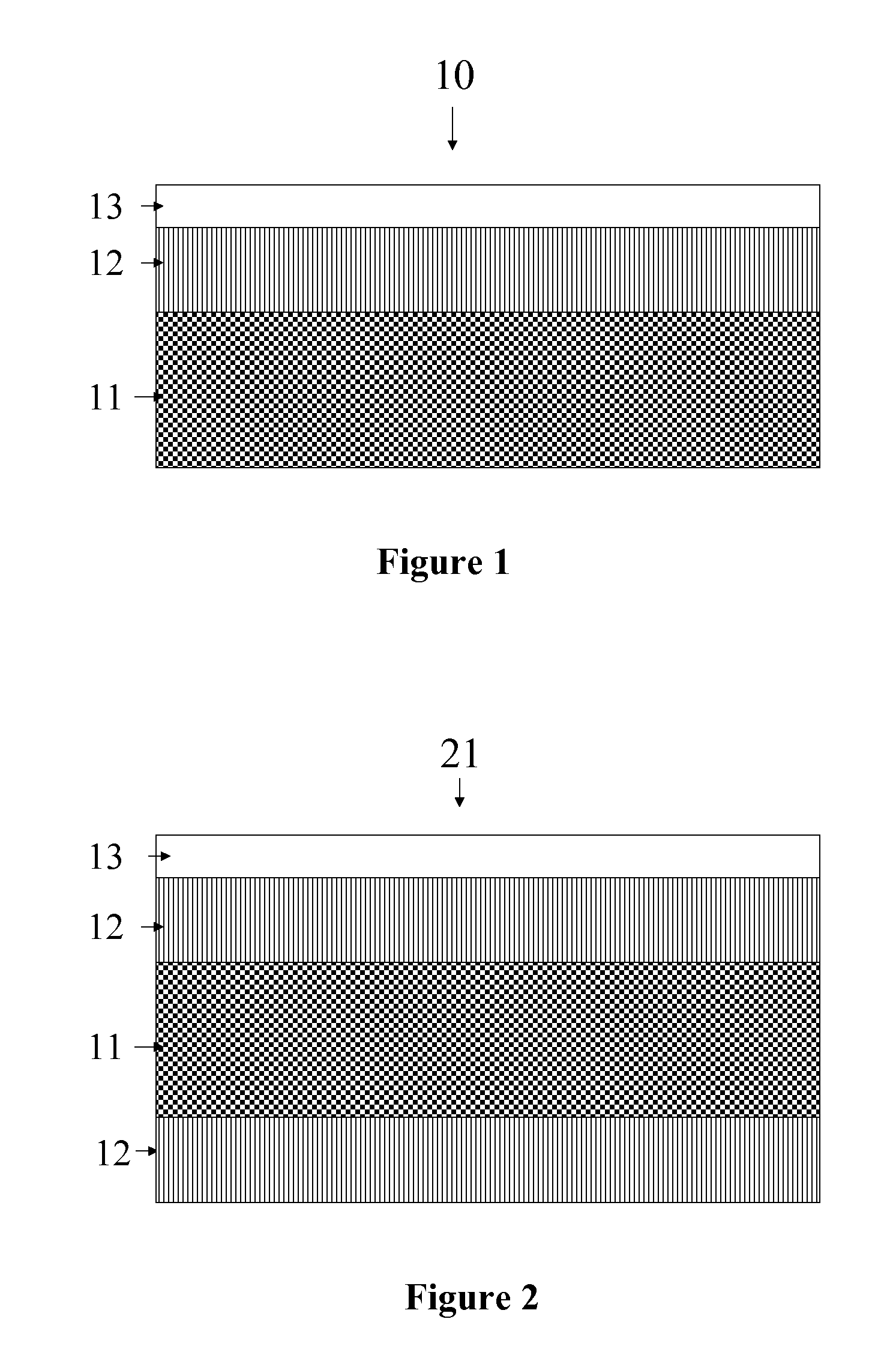

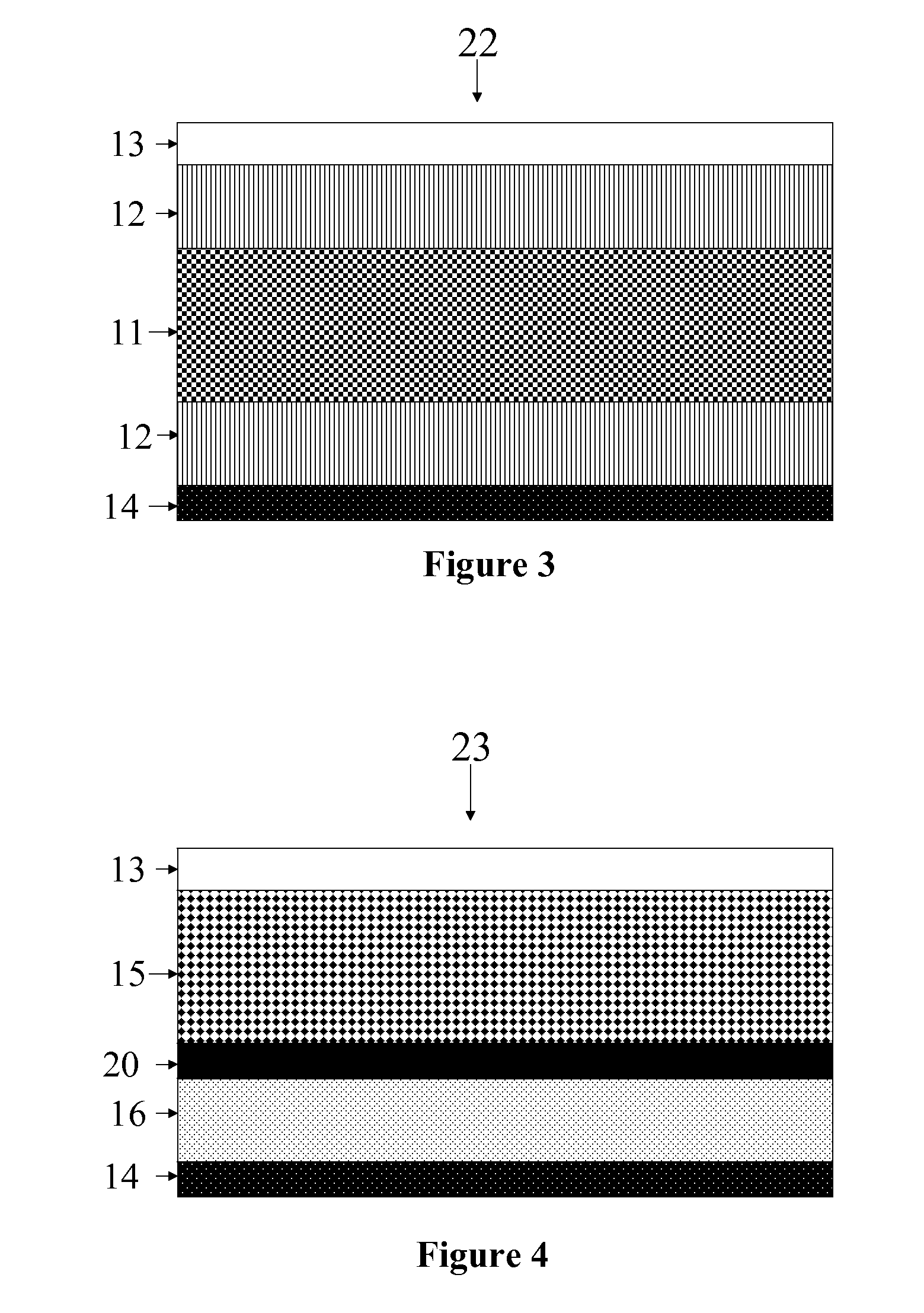

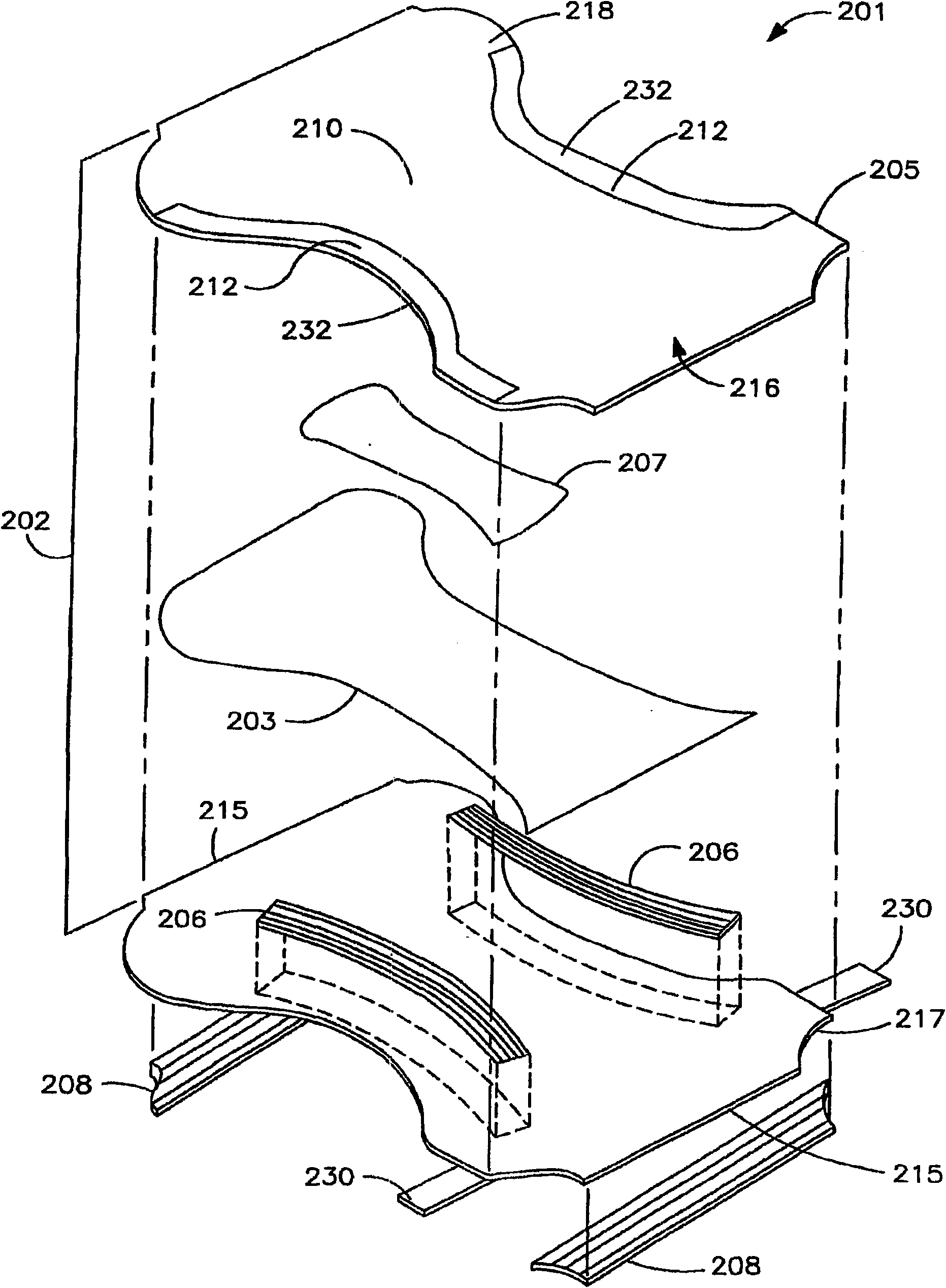

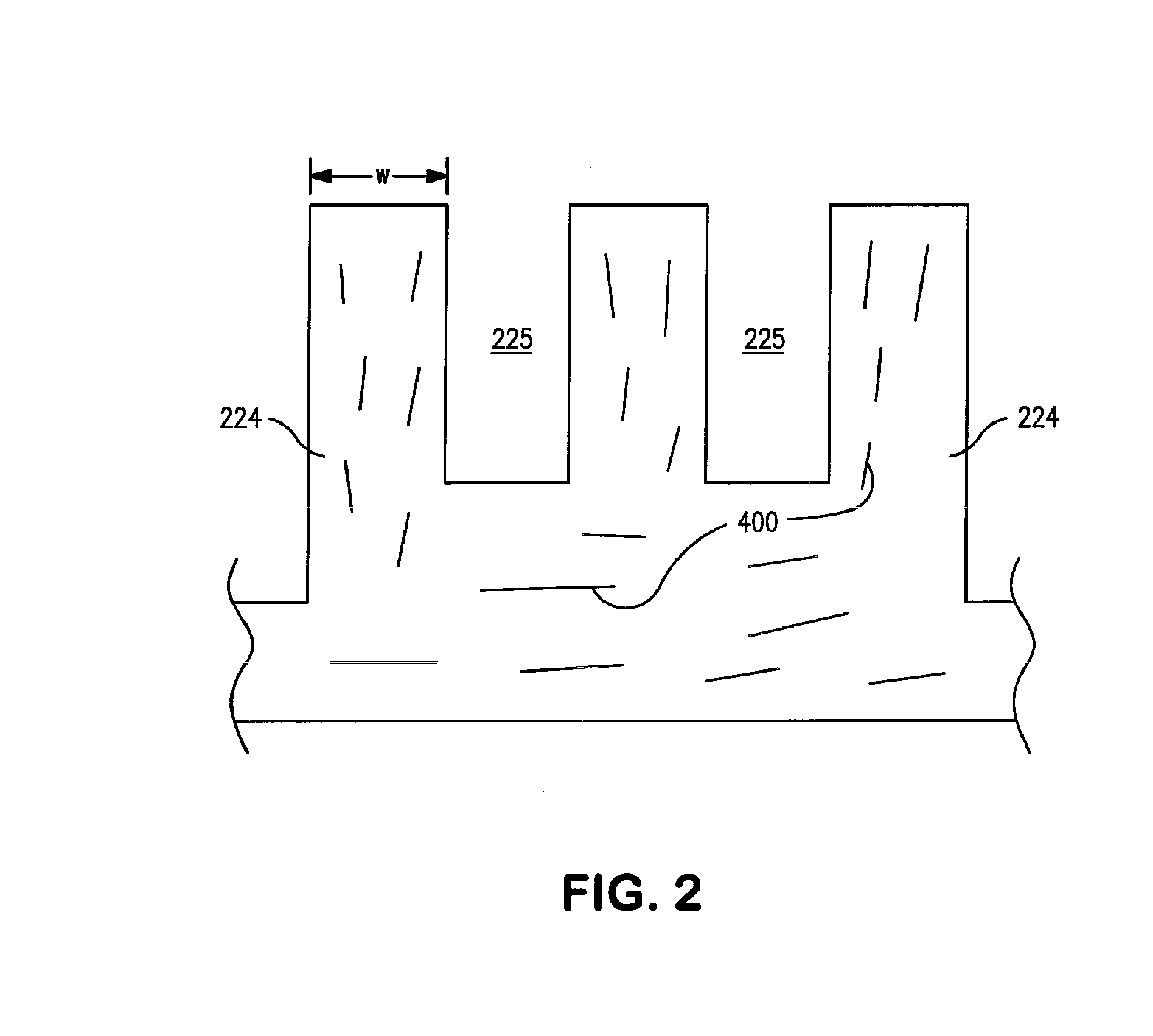

Skid resistant surfaces

InactiveUS7634877B2Good for scrollingIncrease coefficient of frictionTreadsRoof covering using flexible materialsChain scissionEngineering

Pedestrian trafficable skid-resistant flexible articles are described. These articles include a flexible substrate having a non-skid coating comprising polymer units that degrade upon exposure to light and / or heat, preferably via chain scission. These articles may be applied to trafficable surfaces such as roof and floors. Articles in the form of roof underlayments having a skid-resistant surface are described in particular.

Owner:GCP APPL TECH INC

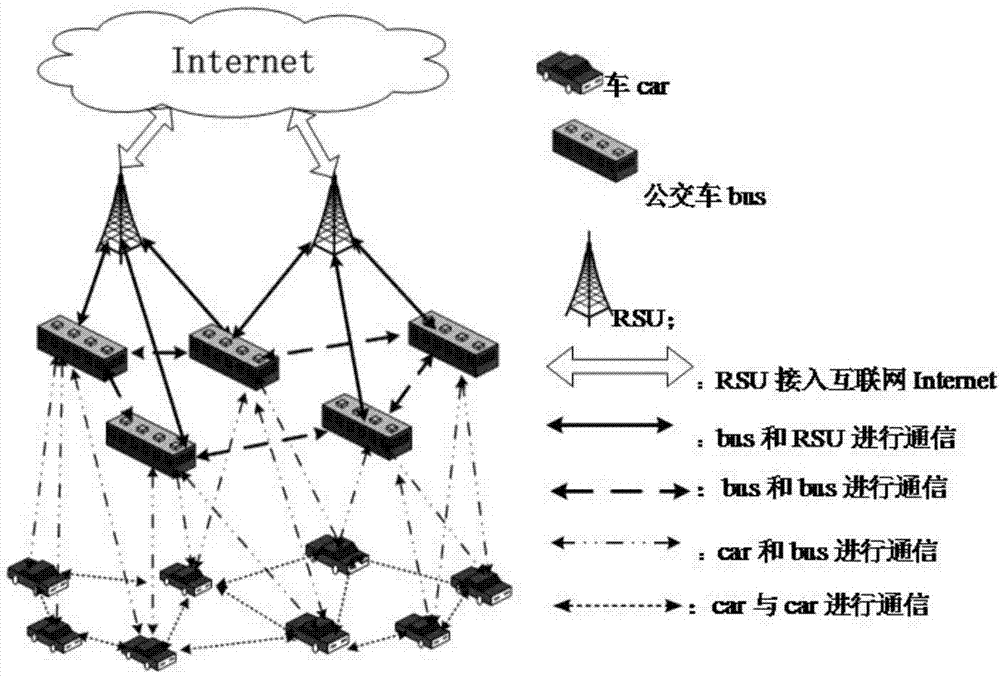

Multimedia cooperative sharing method based on P2P-BT in VANET

The invention belongs to the technical field of mobile communication and discloses a multimedia cooperative sharing method based on a P2P-BT in a VANET. Firstly, to implement a PB-MCSM well in the VANET, a VANET hierarchical structure is established according to characteristics of a general P2P-BT in combination with the characteristics and motion trail of different vehicles in the VANET; then a multimedia query algorithm based on distributed Tracker servers is proposed for a problem that the multimedia resource query rate is low in the VANET; and then a tree-shaped returning algorithm based on indirect reciprocity game is proposed so that it is ensured that a vehicle also uploads while downloading and thus transmission delay caused by selfishness and chain scission is solved. The beneficial effects and advantages of the multimedia cooperative sharing method based on the P2P-BT in the VANET are that the method is capable of simulating the multimedia transmission state of nodes under a practical environment and applicable to a selfish VANET environment. Experiments show that the method improves successful query rate and returning rate of multimedia resources in the VANET and reduces returning delay in a returning process and improves the satisfaction degree of a vehicle user.

Owner:DALIAN UNIV OF TECH

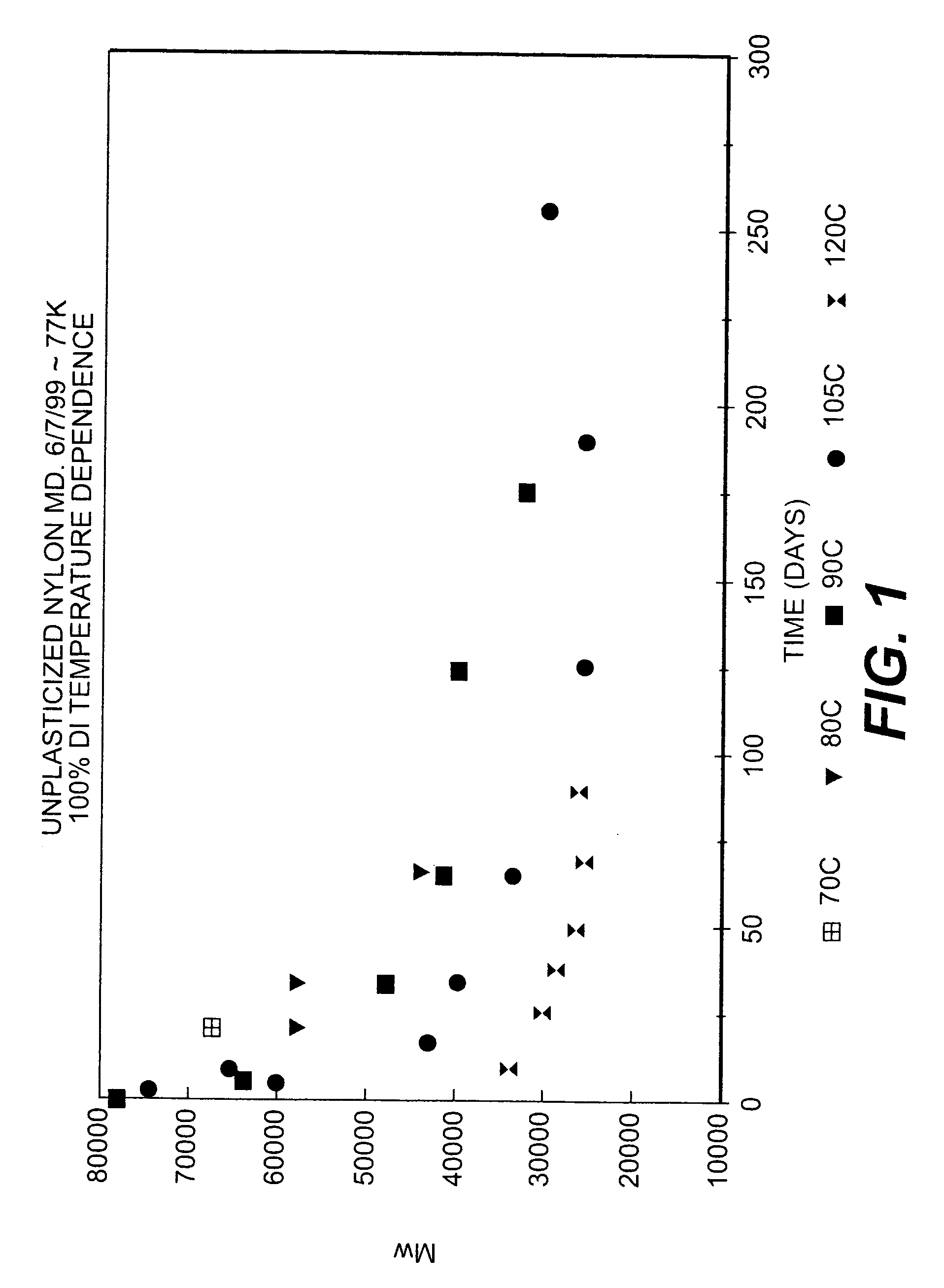

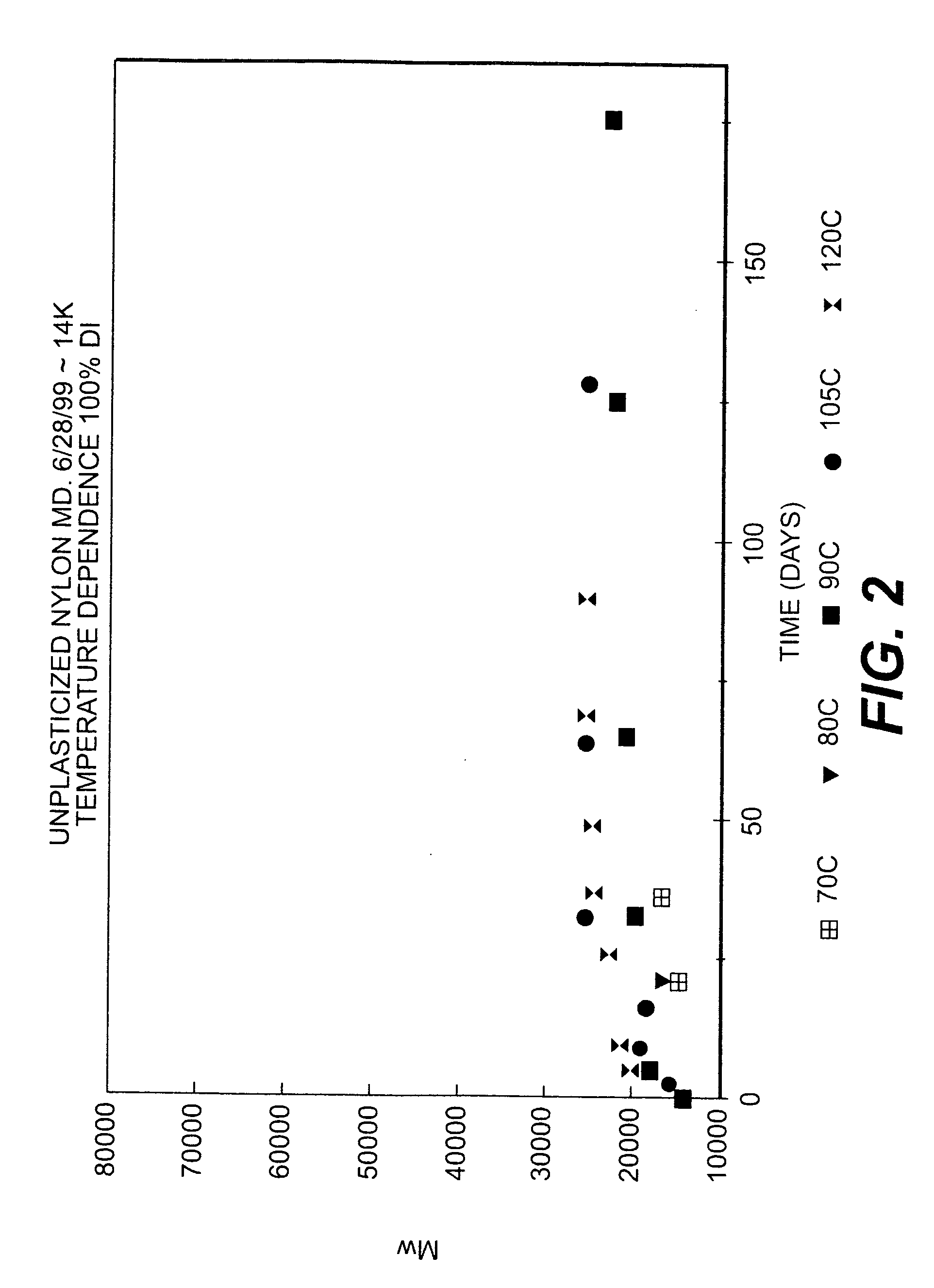

Method for extending the useable life of a polyamide pipe liner during use in a water-oil gas environment

Polyamide liners used in sub sea and over ground transport operations, such as nylon (11), are handled in a way which increases the rate of chain recombination relative to the competing process of chain scission. This enhances and increased the useable life of the polyamide liner by effectively reducing its rate of aging. The can be accomplished by incorporating a chain extender or desiccant into the polyamide liner, incorporating hydrophobic moieties or hydrophobic polymers into the polyamide liner, or by providing a sheath which is less permeable to water at the inner surface of the polyamide liner. Rejuvenation of the polyamide liner can also be achieved by heat treatment of the polyamide liner by hot air, hot oil or gas, or other hot liquids that are at a temperature above 1000° C. Rejuvenation may be enhanced by including a chain extender or desiccant to a hot oil, gas, or other liquid that is exposed to the polyamide liner.

Owner:KRANBUEHL DAVID E

Catalyst for hydrogen production by catalytic reforming with biological oil and preparation method

InactiveCN102974362AHigh hydrogen contentHigh calorific valueHydrogenChemical recyclingCatalytic reformingChain scission

The invention relates to a catalyst for hydrogen production by catalytic reforming with biological oil and a preparation method. The catalyst comprises catalyst active components and a catalyst carrier; the catalyst active components refer to the following components in percentage by weight of 10-15 wt% of Ni, 5-13 wt% of Mo, 5-10 wt% of Fe and the balance being attapulgite and sepiolite mixed clay pit catalyst carrier. The catalyst provided by the invention has the advantages of large surface area, strong absorption function and strong promotion function; the cheap and easiest available attapulgite and sepiolite mixed clay pit are used as the catalyst carrier; and the catalyst active components comprise nickel, molybdenum and iron composite components, so that the molecules of the biological oil are subjected to splitting and chain scission to form high-quality synthesis gas of low-molecule hydrocarbon and high-content hydrogen. The catalyst provided by the invention has the advantages of simple catalyst preparation, large strength, strong catalyst activity, and regeneration. Not only can the catalyst be used for hydrogen production by catalytic reforming with the biological oil, but also the catalyst can be applied to direct hydrogen production by catalytic gasification with biomass.

Owner:ANHUI UNIV OF SCI & TECH

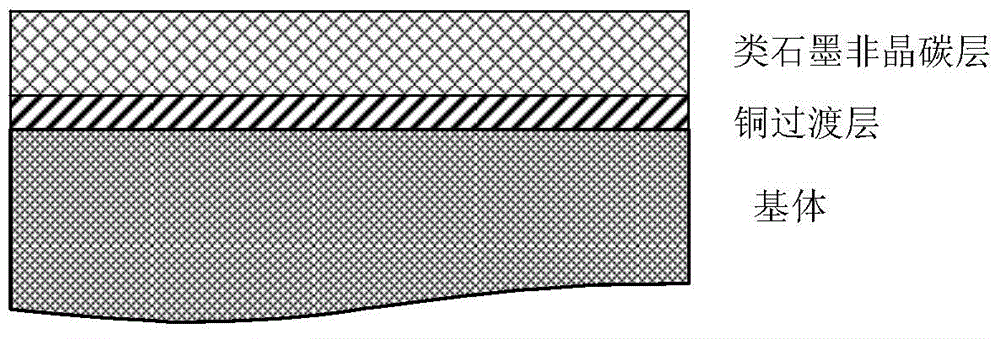

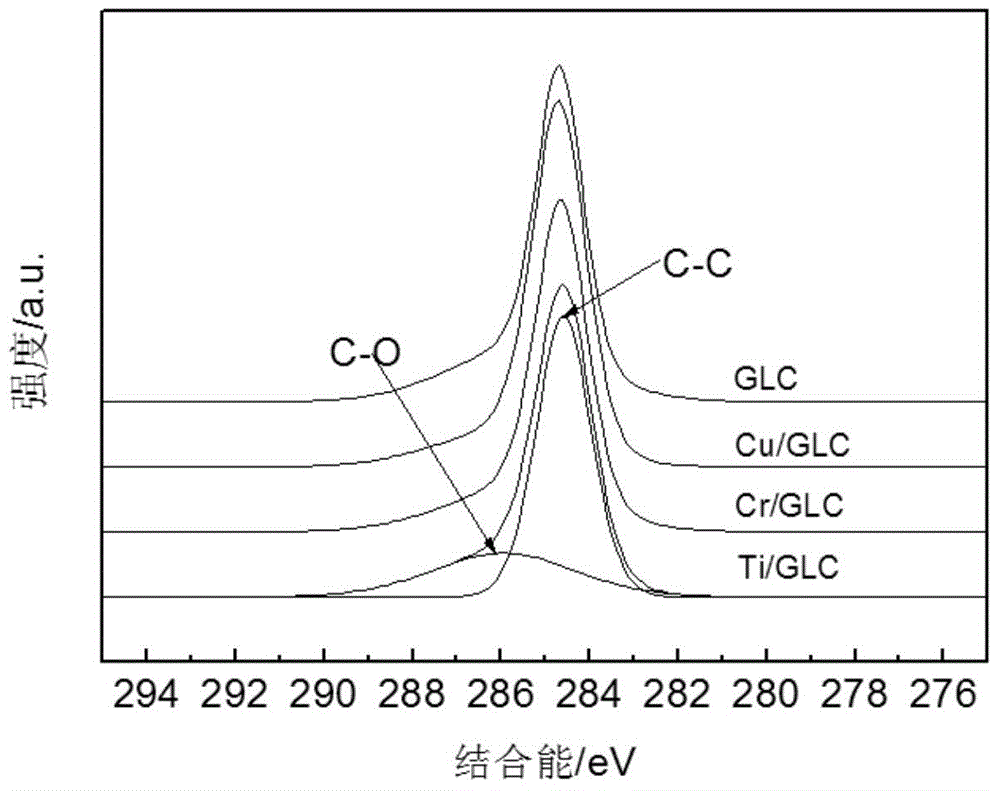

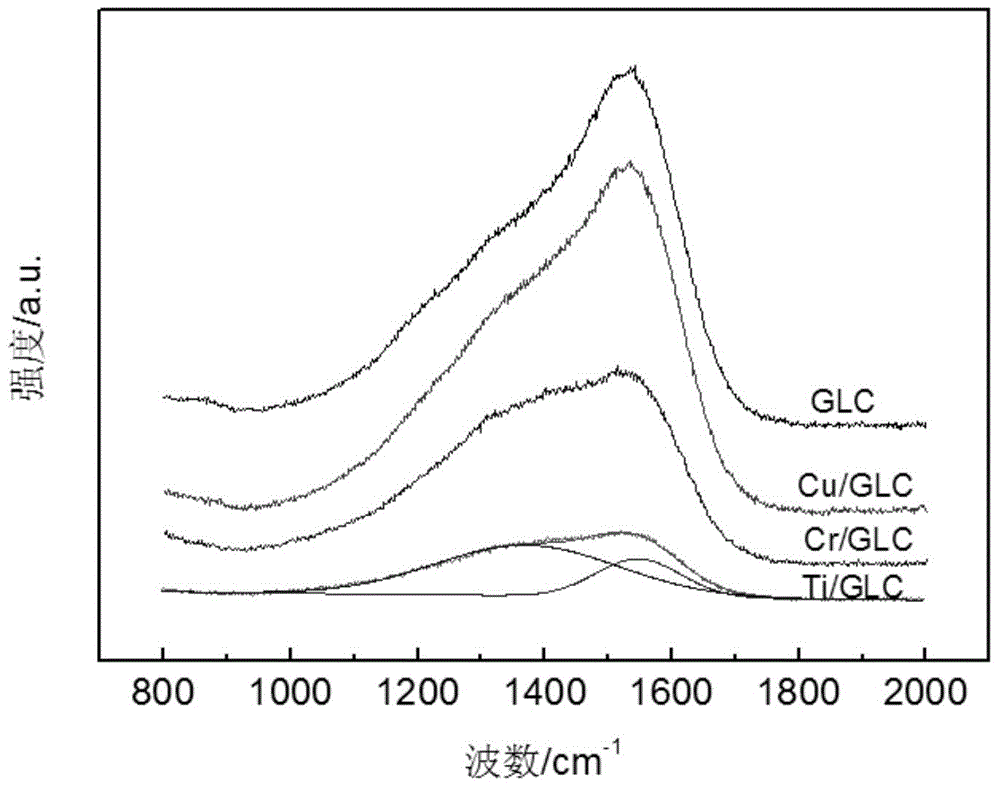

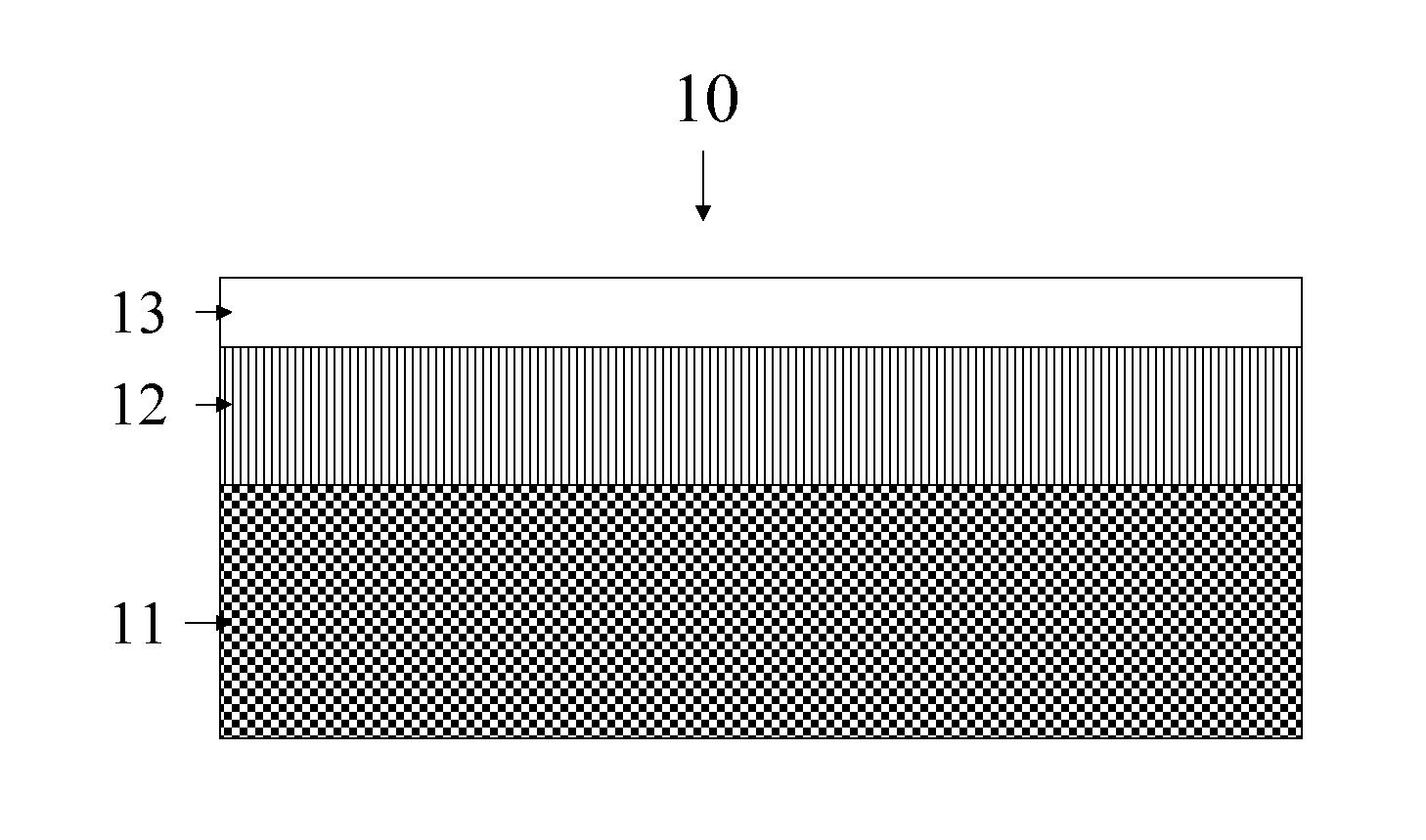

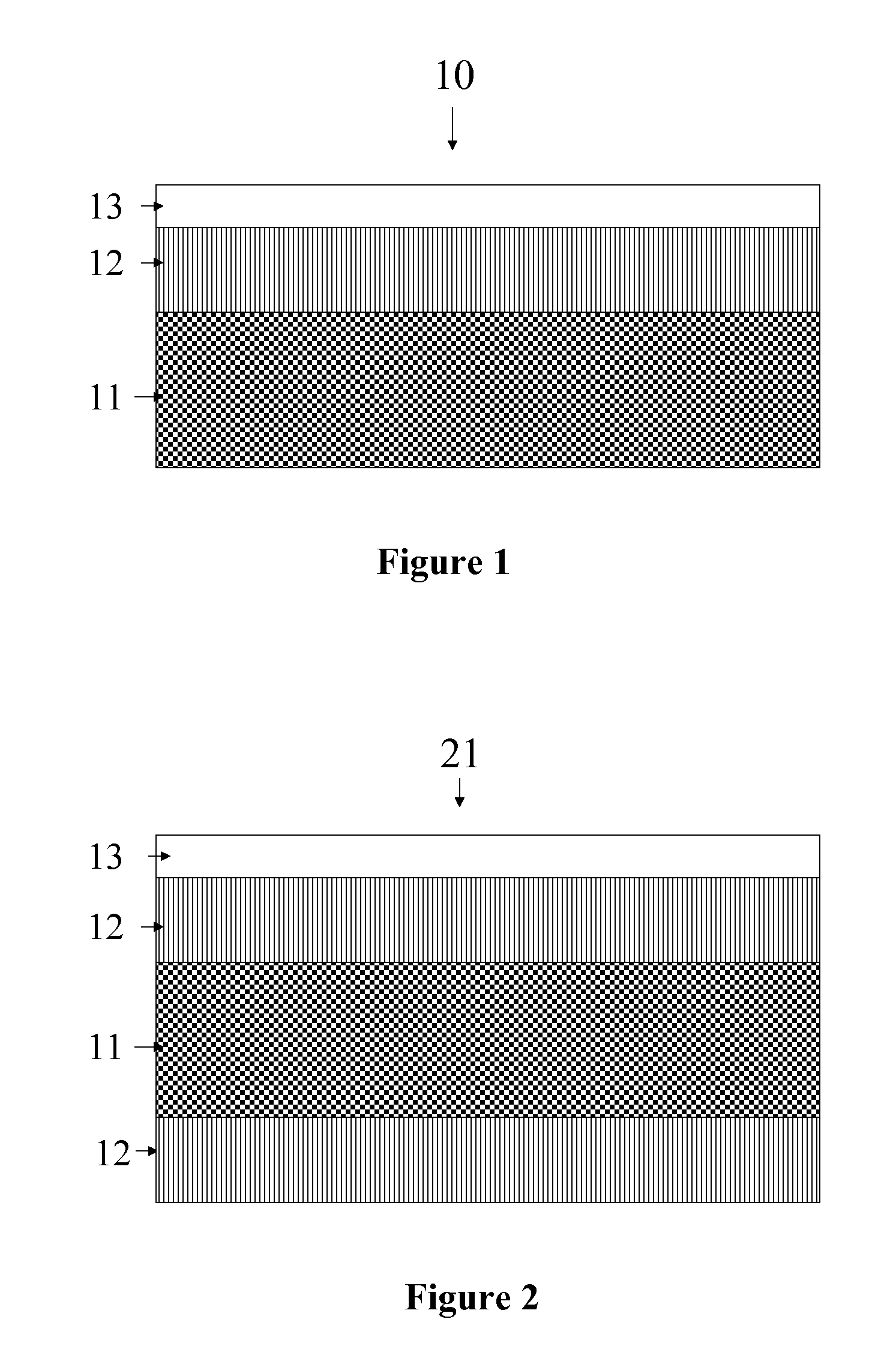

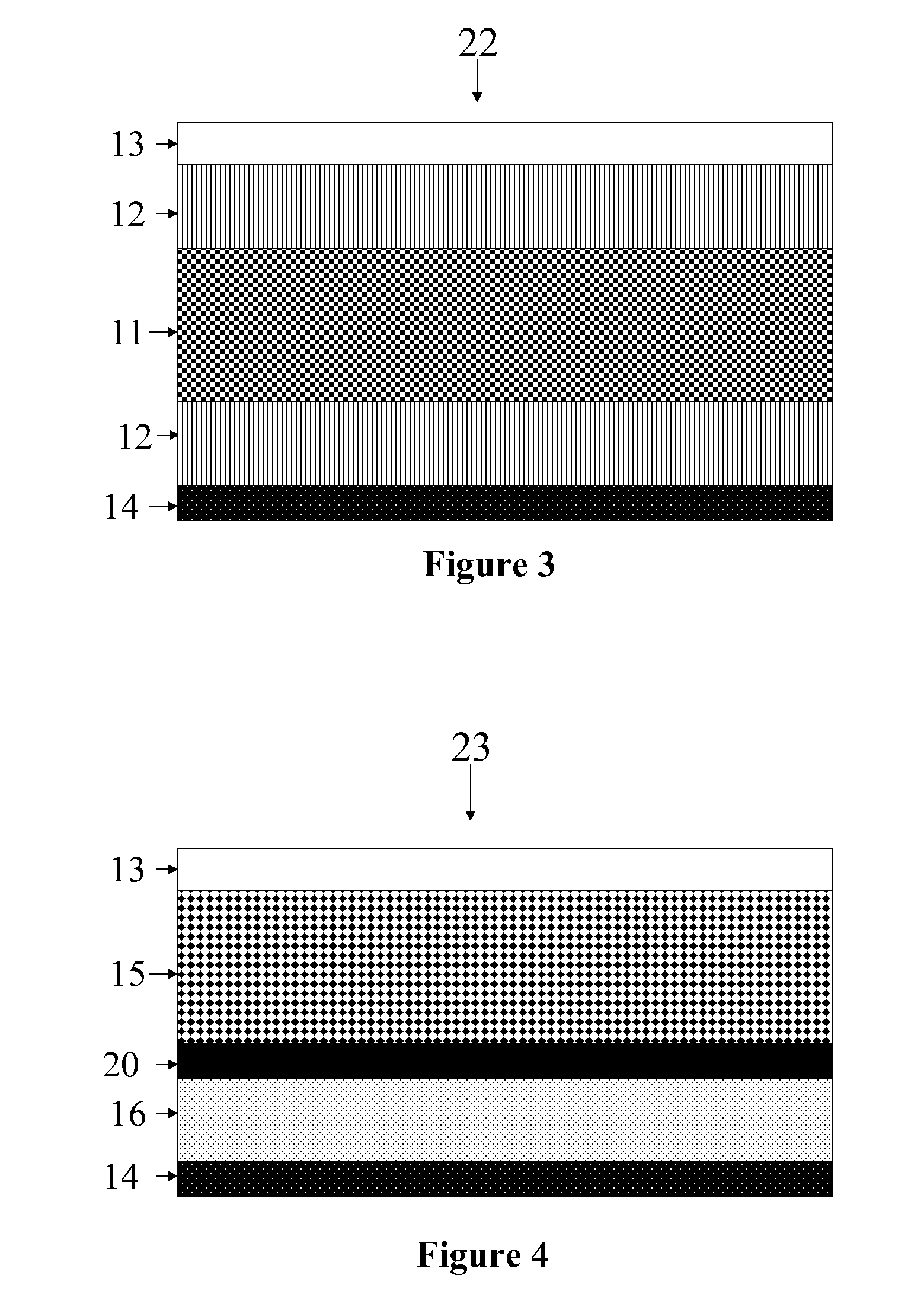

Carbon-based coating having high electrical conductivity on surface of substrate and preparation method of coating

InactiveCN104388902ALow resistivityMultiple free electronsVacuum evaporation coatingSputtering coatingCarbon coatingSurface layer

The invention provides a carbon-based coating having high electrical conductivity on the surface of a substrate. The coating is composed of a copper transition layer and a graphite-like amorphous carbon surface layer; the deposition method of the coating is a DC magnetron sputtering method. Compared with the prior art, the carbon-based coating having high electrical conductivity on the surface of the substrate is capable of ensuring that the structure of the amorphous carbon coating is mainly in the sp2 bond state to reduce the specific resistance, and meanwhile, the copper transition layer is advantageous for inducing the chain scission of the aromatic cyclic sp2 structure in the graphite-like amorphous carbon surface layer and more sp2 chain structures can be formed to increase free electrons, and therefore, the specific resistance of the carbon coating is further reduced and the electrical conductivity of the same is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Skid Resistant Surfaces

InactiveUS20090193743A1Readily unrollableIncrease coefficient of frictionTreadsRoofingChain scissionEngineering

Pedestrian trafficable skid-resistant flexible articles are described. These articles include a flexible substrate having a non-skid coating comprising polymer units that degrade upon exposure to light and / or heat, preferably via chain scission. These articles may be applied to trafficable surfaces such as roof and floors. Articles in the form of roof underlayments having a skid-resistant surface are described in particular.

Owner:GCP APPL TECH INC

Biodegradable polyesters for use in forming fibers

A method for forming a biodegradable polyester suitable for use in fibers is provided. Specifically, a biodegredable polyester is melt processed at a controlled water content to initiate a hydrolysis reaction. Without intending to be limited by theory, it is believed that the hydroxyl groups present in water are capable of attacking the ester linkage of the polyester, thereby leading to chain scission or ''depolymerization'' of the polyester molecule into one or more shorter ester chains. By selectively controlling the reaction conditions (e.g., water content, temperature, shear rate, etc.), ahydrolytically degraded polyester may be achieved that has a molecular weight lower than the starting polymer. Such lower molecular weight polymers have a higher melt flow rate and lower apparent viscosity, which are useful in a wide variety of fiber forming applications, such as in the meltblowing of nonwoven webs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Ultralow Viscosity Liquid Crystalline Polymer Composition

InactiveUS20140004328A1Liquid crystal compositionsSynthetic resin layered productsLiquid crystallineOligomer

A thermoplastic composition that comprises a thermotropic, liquid crystalline polymer and a combination of certain types of flow modifiers is provided. More particularly, one type of flow modifier that is employed in the composition is a functional compound (e.g., hydroxy-functional, carboxy-functional, etc.) that can react with the backbone of the polymer. In certain cases, for instance, the functional compound can initiate chain scission of the polymer, which reduces the molecular weight, and in turn, the melt viscosity of the polymer under shear. An additional non-functional compound is also employed to help reduce the melt viscosity to the desired “ultralow” levels without having a significant impact on the mechanical properties. The non-functional compound is, more specifically, an aromatic amide oligomer that can alter intermolecular polymer chain interactions without inducing chain scission to any appreciable extent, thereby further lowering the overall viscosity of the polymer matrix under shear.

Owner:TICONA LLC

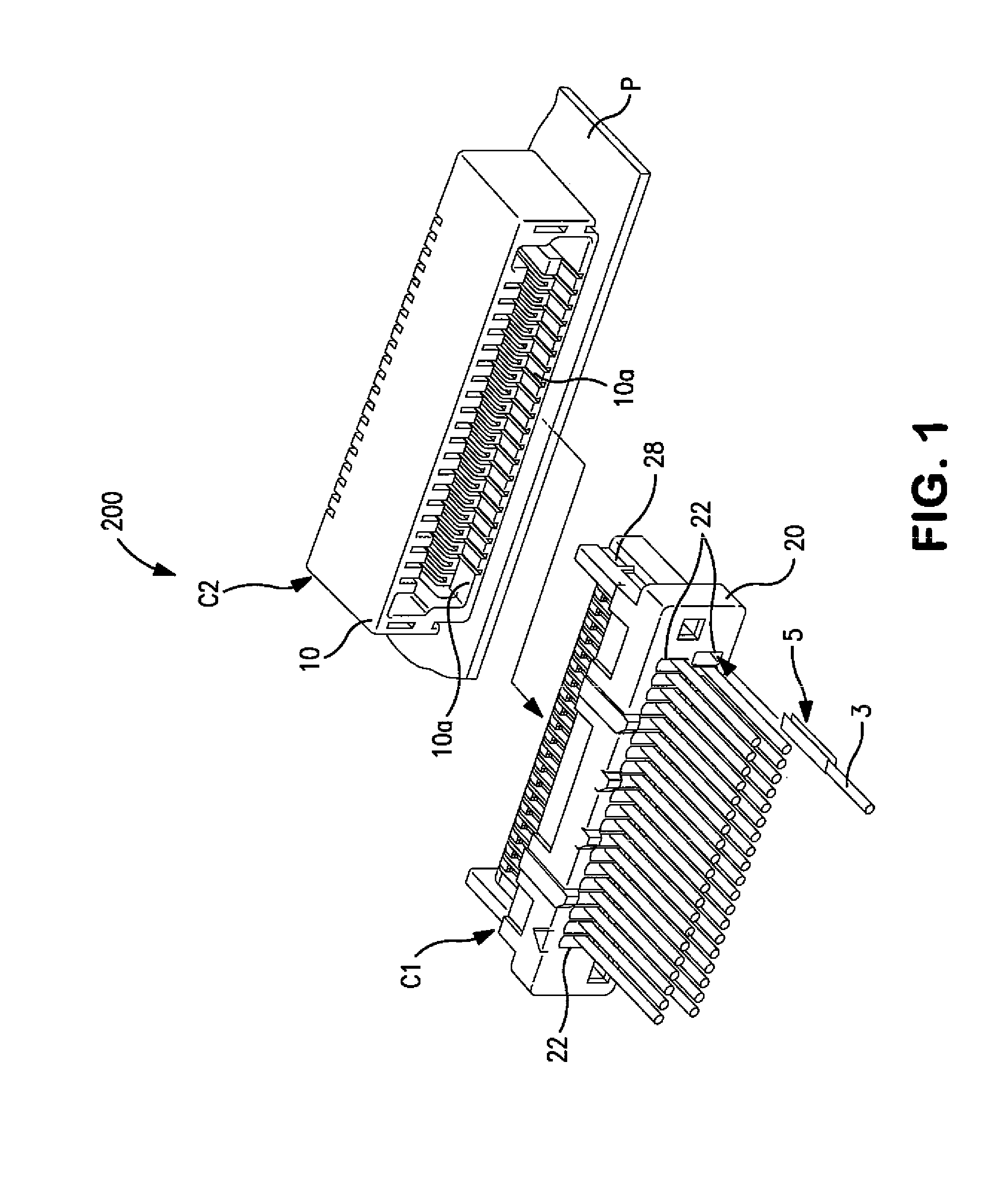

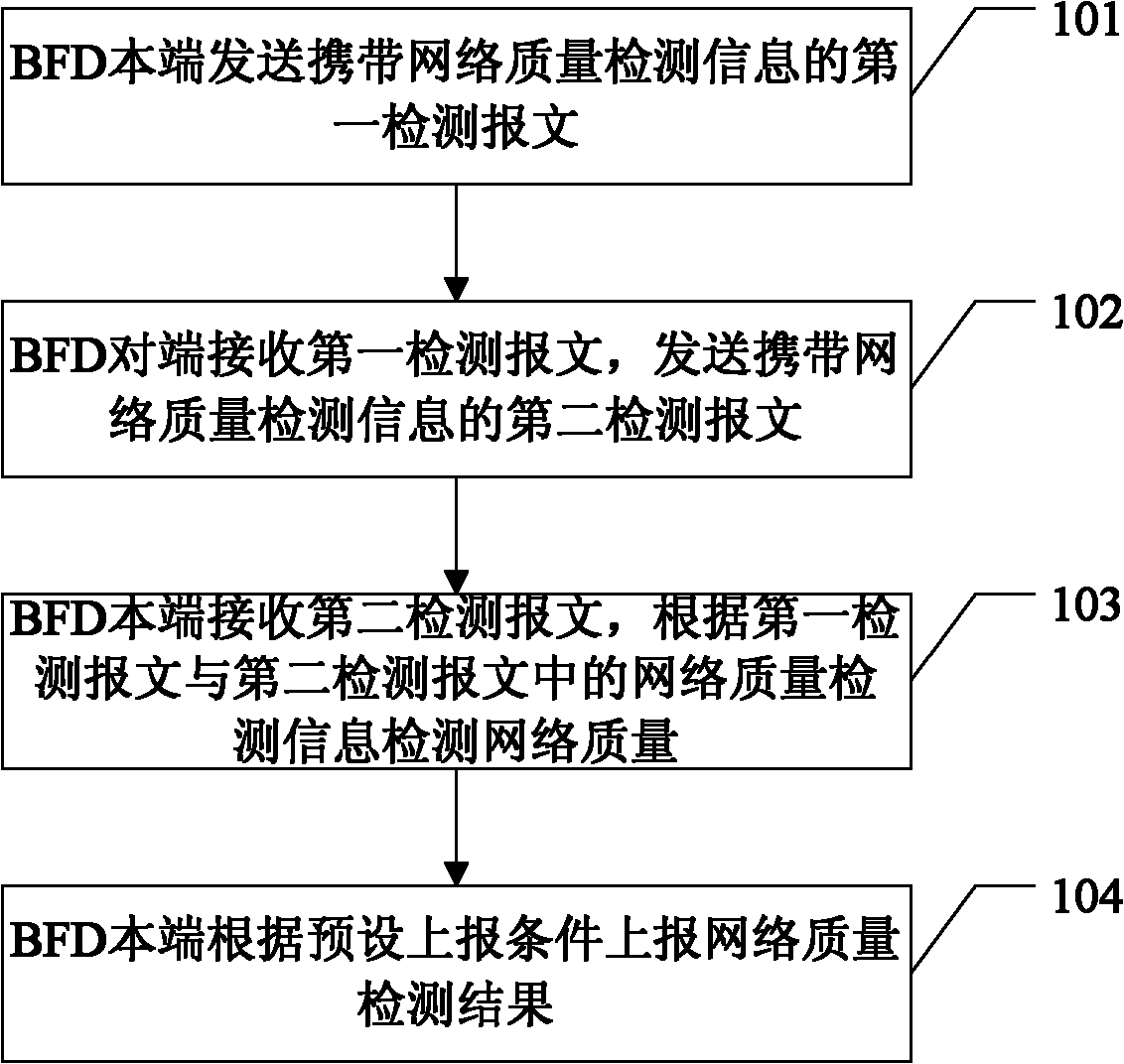

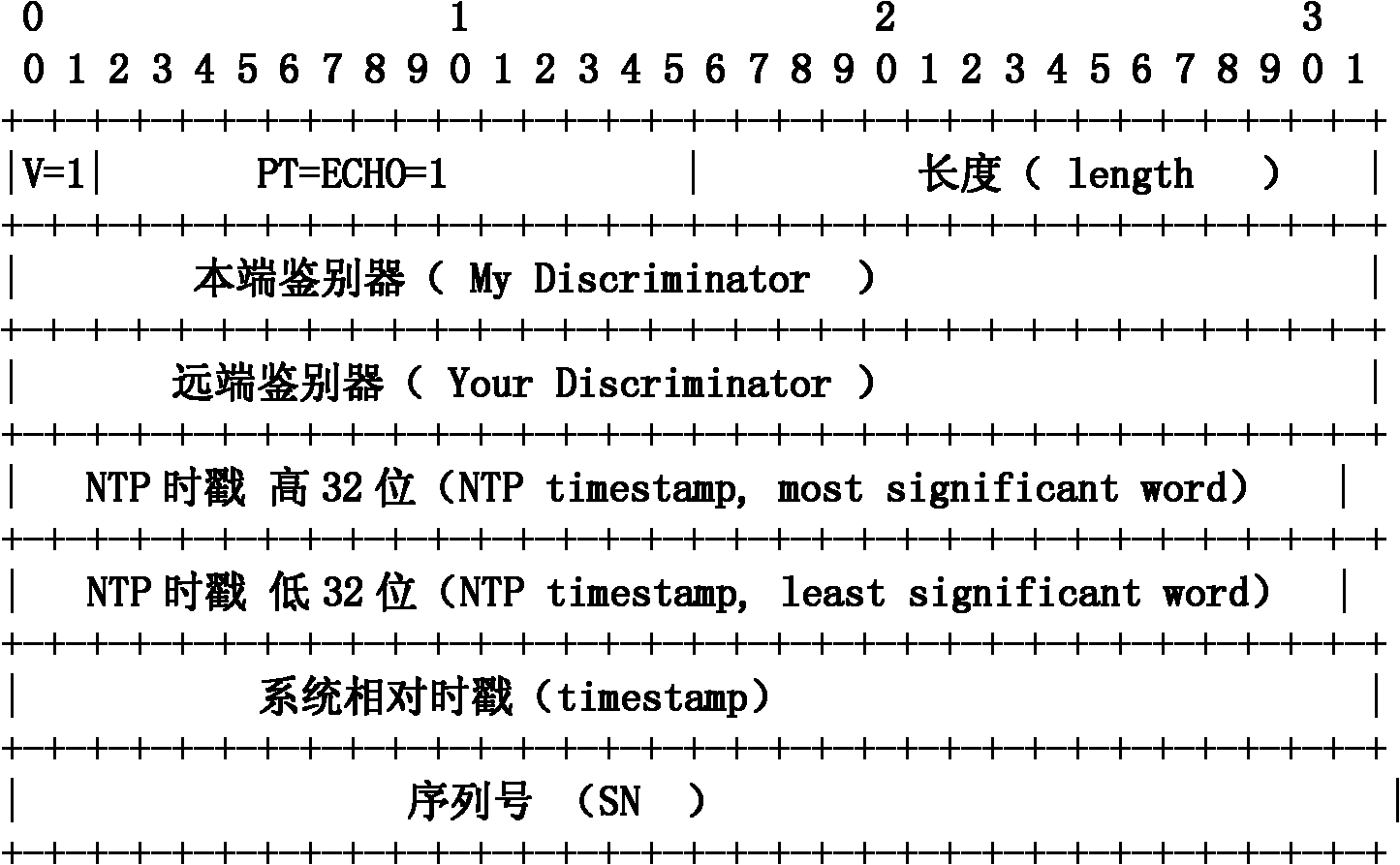

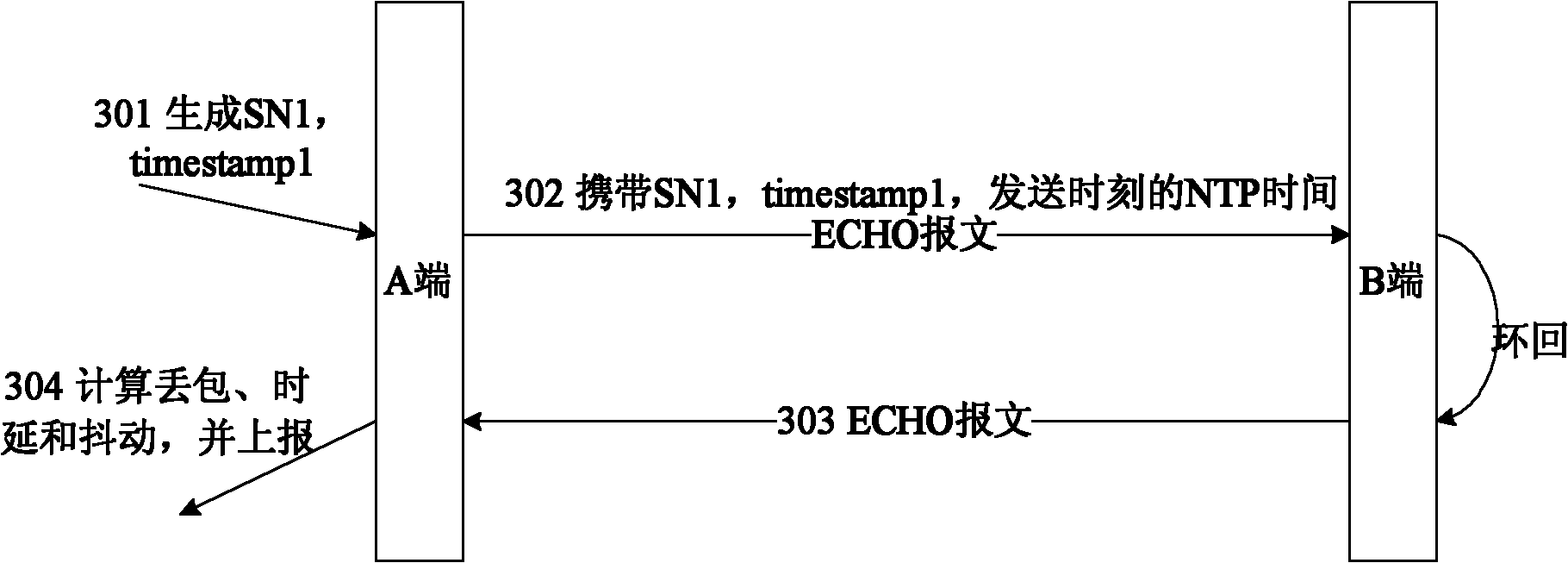

Bidirectional forwarding detection (BFD) method and system

The invention relates to a bidirectional forwarding detection (BFD) method and a BFD system. The BFD method comprises the following steps that: a BFD home terminal transmits a first detection message which carries network quality detection information; a BFD opposite terminal receives the first detection message and transmits a second detection message which carries the network quality detection information; the BFD home terminal receives the second detection message and detects network quality according to the network quality detection information of the first detection message and the second detection message; and the BFD home terminal reports a network quality detection result according to a preset reporting condition. The BFD method and the BFD system can effectively prevent chain scission.

Owner:ZTE CORP

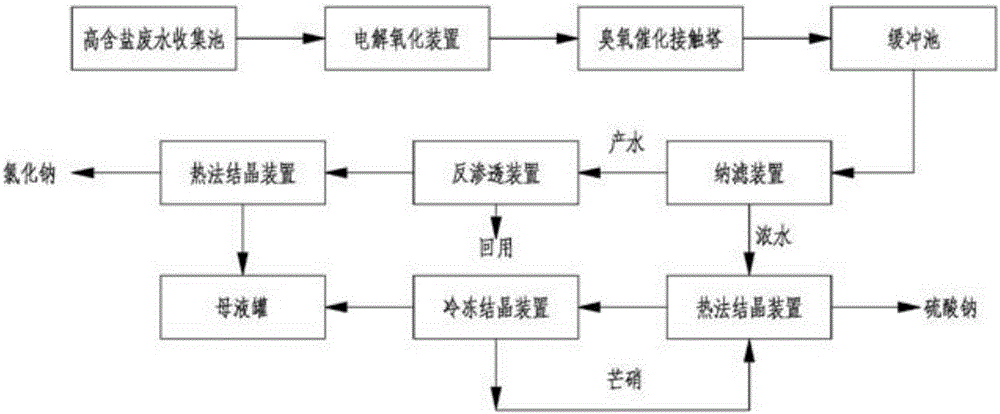

Quality-divided resourceful treatment method for coal chemical industry high-salt-content wastewater

InactiveCN106186487AReduce pollutionGood for qualityMultistage water/sewage treatmentWater/sewage treatment by heatingElectrolysisChain scission

The invention discloses a quality-divided resourceful treatment method for coal chemical industry high-salt-content wastewater. The coal chemical industry high-salt-content wastewater enters an electrolytic oxidation device, a part of COD extremely difficult to degrade is removed, loop opening and chain scission are conducted on macromolecular organic matter, electrolytic oxidation device effluent enters an ozone catalytic-oxidation device to further remove the organic matter, ozone catalytic-oxidation device effluent enters a buffer pool to decompose residual ozone, wastewater in the buffer pool enters a nanofiltration device for separation, a main component on the nanofiltration produced water side is NaCl, main components on the nanofiltration concentrated water side are NaCl and Na2SO4, the nanofiltration produced water is further concentrate and reused through reverse osmosis, the concentrated water crystallizes by adopting a hot method, industrial-grade NaCl is recovered, and 'hot-method crystallization + freezing crystallization' is conducted on the nanofiltration concentrated water to recover industrial-grade Na2SO4. The quality-divided resourceful treatment method facilitates resource recovery, is stable and reliable in treating effect and moderate in construction, operation and maintenance cost.

Owner:EAST CHINA ENG SCI & TECH +1

Polyvinyl alcohol mircrobubbles and preparing method thereof

The invention provides polyvinyl alcohol mircrobubbles and a preparing method thereof. The method includes the following steps: firstly, dissolving polyvinyl alcohol in a solvent to obtain a polyvinyl alcohol water solution; then adding an oxidizing agent in the polyvinyl alcohol water solution and fully heating and stirring the mixture to enable hydroxide radicals in two vinyl alcohol units connected head to head to be oxidized into formyl groups and enable the formyl groups to be subjected to chain scission, so as to prepare a water solution containing polyvinyl alcohol chain scission products; then adding acid in the water solution containing the polyvinyl alcohol chain scission products and adjusting the pH value to 1-4, so as to obtain a mixed solution; stirring; enabling cross-linking reaction to occur between the polyvinyl alcohol chain scission products in the mixed solution to form microbubble films, so as to obtain polyvinyl alcohol mircrobubbles, as the solvent, wrapped by the microbubble films.

Owner:SHENZHEN INST OF ADVANCED TECH

Biodegradable polylactic acids for use in forming fibers

Owner:KIMBERLY-CLARK WORLDWIDE INC

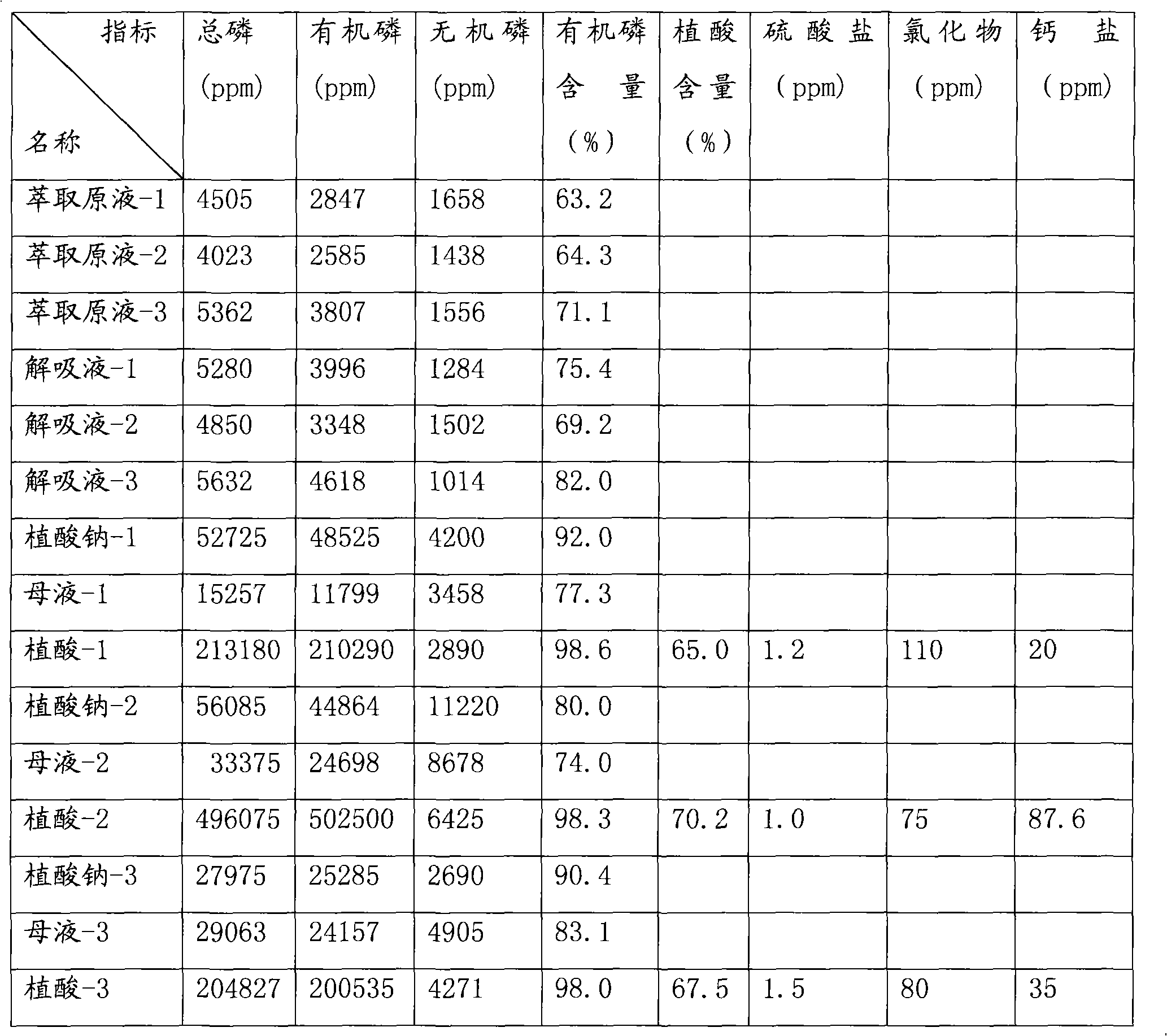

Method for extracting phytic acid

InactiveCN101602777AIncrease contentHigh purityGroup 5/15 element organic compoundsSolubilityChain scission

The invention discloses a method for extracting a phytic acid, which is prepared by the following seven steps of extraction, flocculation, adsorption, edulcoration, desorption, concentration and crystallization, and hydrolysis and chain scission. The method uses the solubility difference to effectively remove inorganic phosphate impurities in the phytic acid, and the organic phosphorus content of the prepared phytic acid solution can reach over 90 percent of the total phosphorus content. The method is simple in process and less in raw material consumption, reduces the environmental pollution, and has wide industrial application prospect.

Owner:COFCO BIOTECHNOLOGY CO LTD

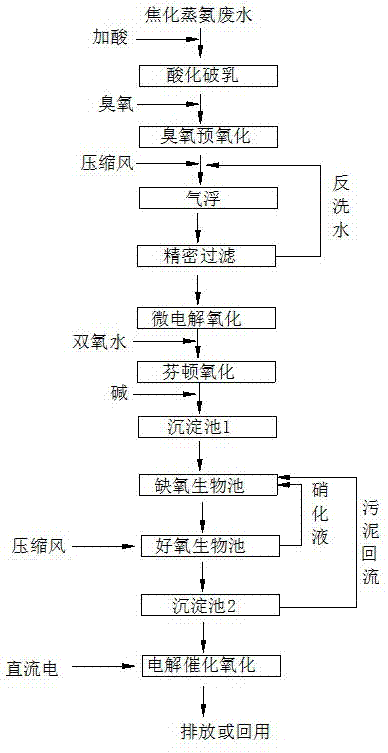

Advanced treatment method for coking distilled ammonia wastewater

InactiveCN107487966AGood removal effectPerfect pretreatment processFatty/oily/floating substances removal devicesTreatment using aerobic processesElectrolysisChemical oxygen demand

The invention discloses an advanced treatment method for coking distilled ammonia wastewater. The advanced treatment method comprises the following treatment steps: a, an acidification demulsification step of demulsifying coal tar in an emulsified state to turbid liquid, and controlling the pH value of acidizing fluid to be 1.5-3.5, wherein the demulsification time is 1-3 hours; b, an ozone pre-oxidation step of promoting the coal tar to separate out and oxidizing phenols and cyanogens dissolved in water; c, an air flotation step of separating the demulsified coal tar from water; d, a precision filtering step of performing secondary dephenolization and oil removal; e, a microelectrolysis step of removing partial organic matters and performing ring-opening chain scission on the organic matters, wherein the pH value of inflow water is controlled to be 2-3, the pH value of effluent is controlled to be 3-4, and the microelectrolysis time is 15-120 minutes; f, a Fenton oxidation step; g, a removed anoxic / aerobic bio-chemical step; and h, an electrolytic catalytic oxidation step of performing advanced treatment on organic matters and ammonia nitrogen. The treatment effect can reach the emission concentration limit requirements on COD (Chemical Oxygen Demand), ammonia nitrogen and total nitrogen in Integrated Wastewater Discharge Standard GB8978-1996.

Owner:SHANDONG LONGANTAI ENVIRONMENTAL PROTECTION SCI TECH CO LTD

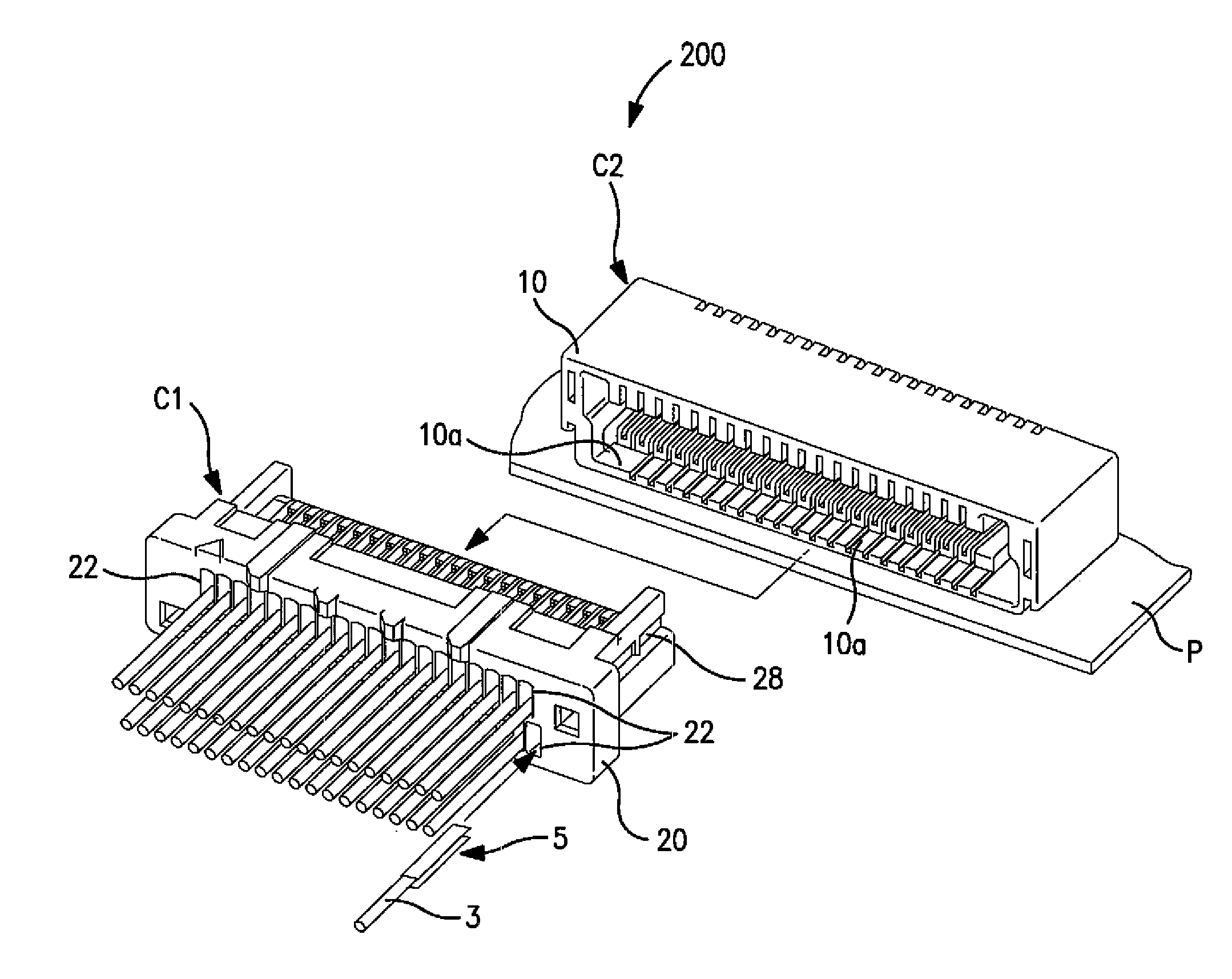

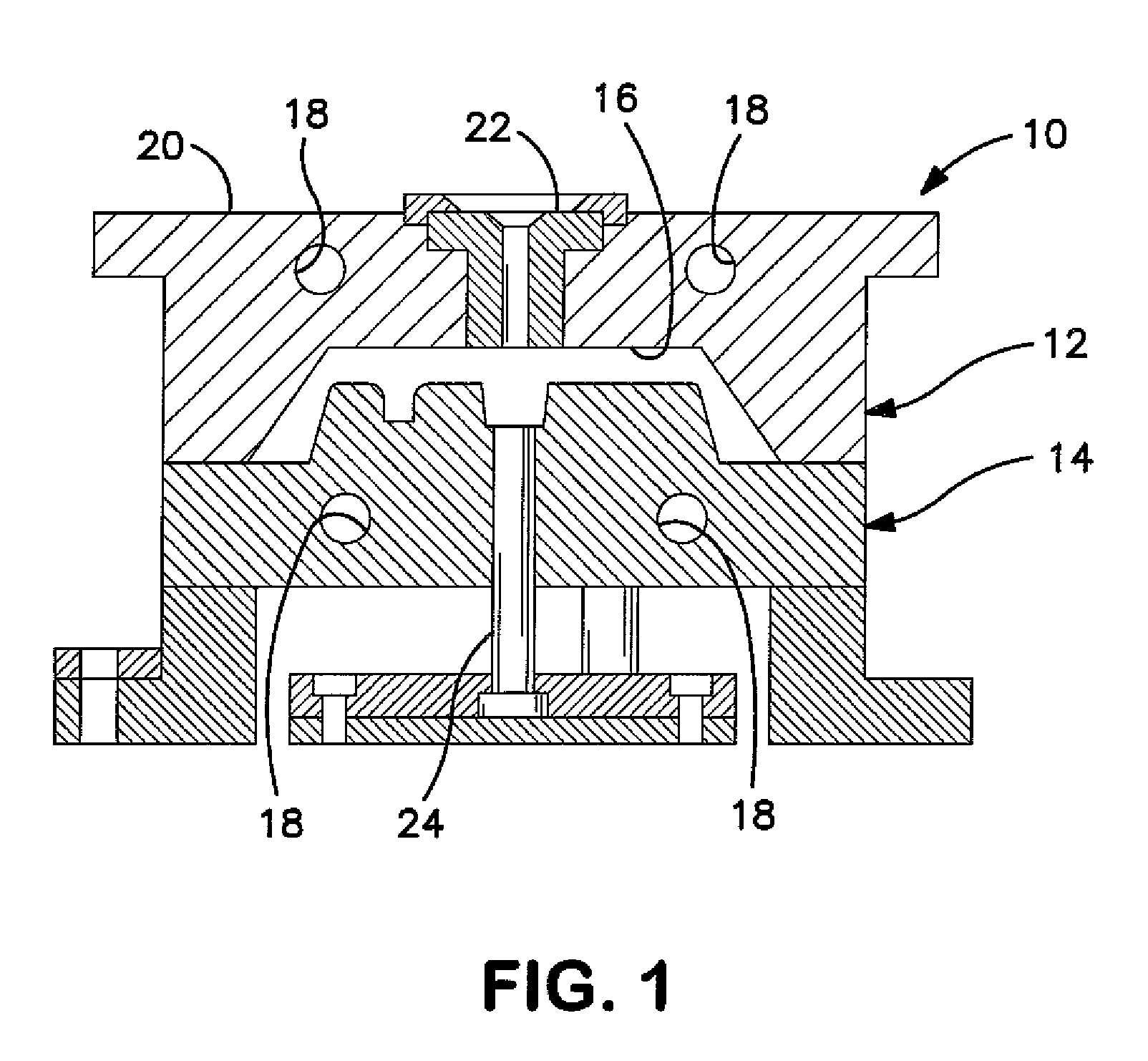

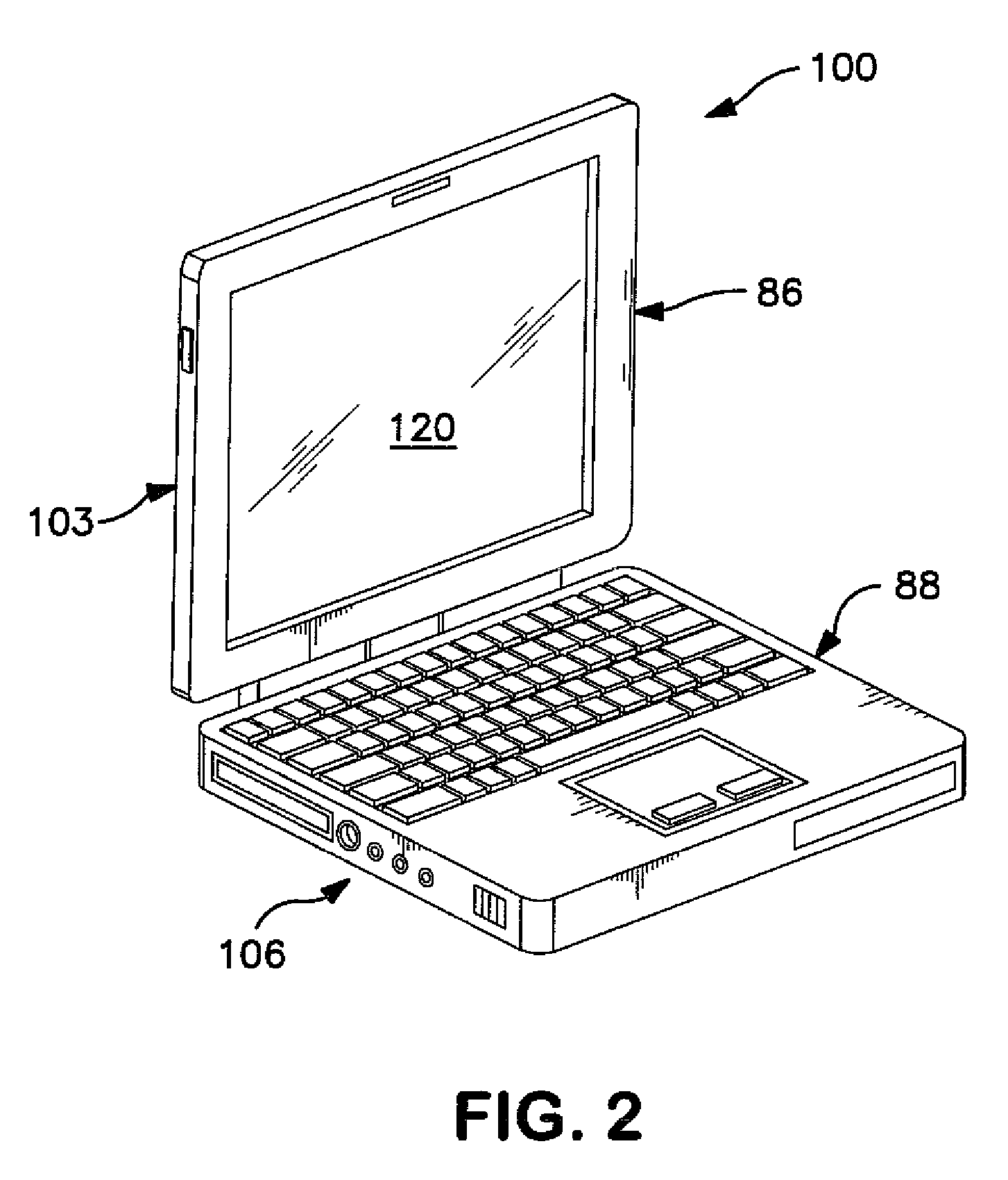

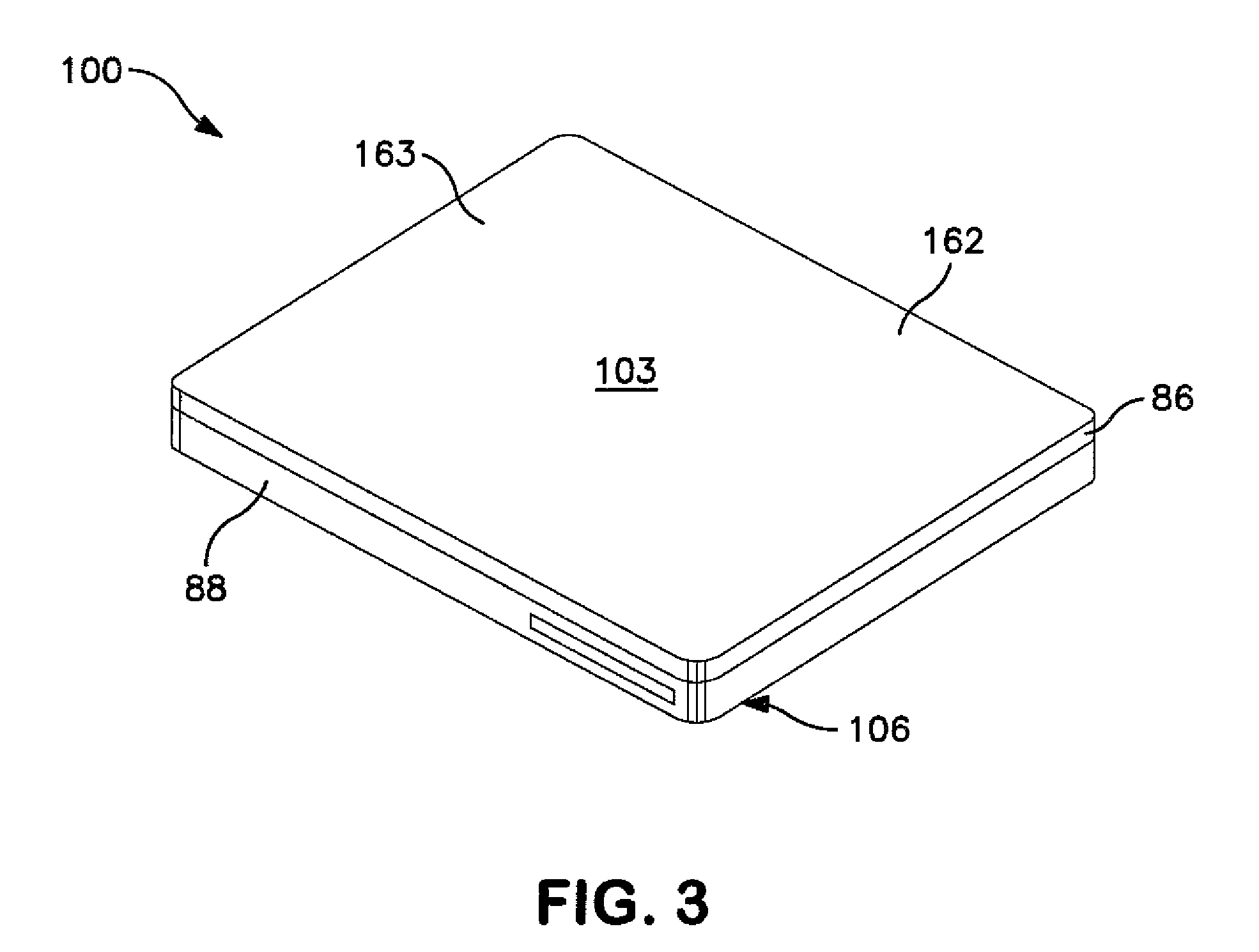

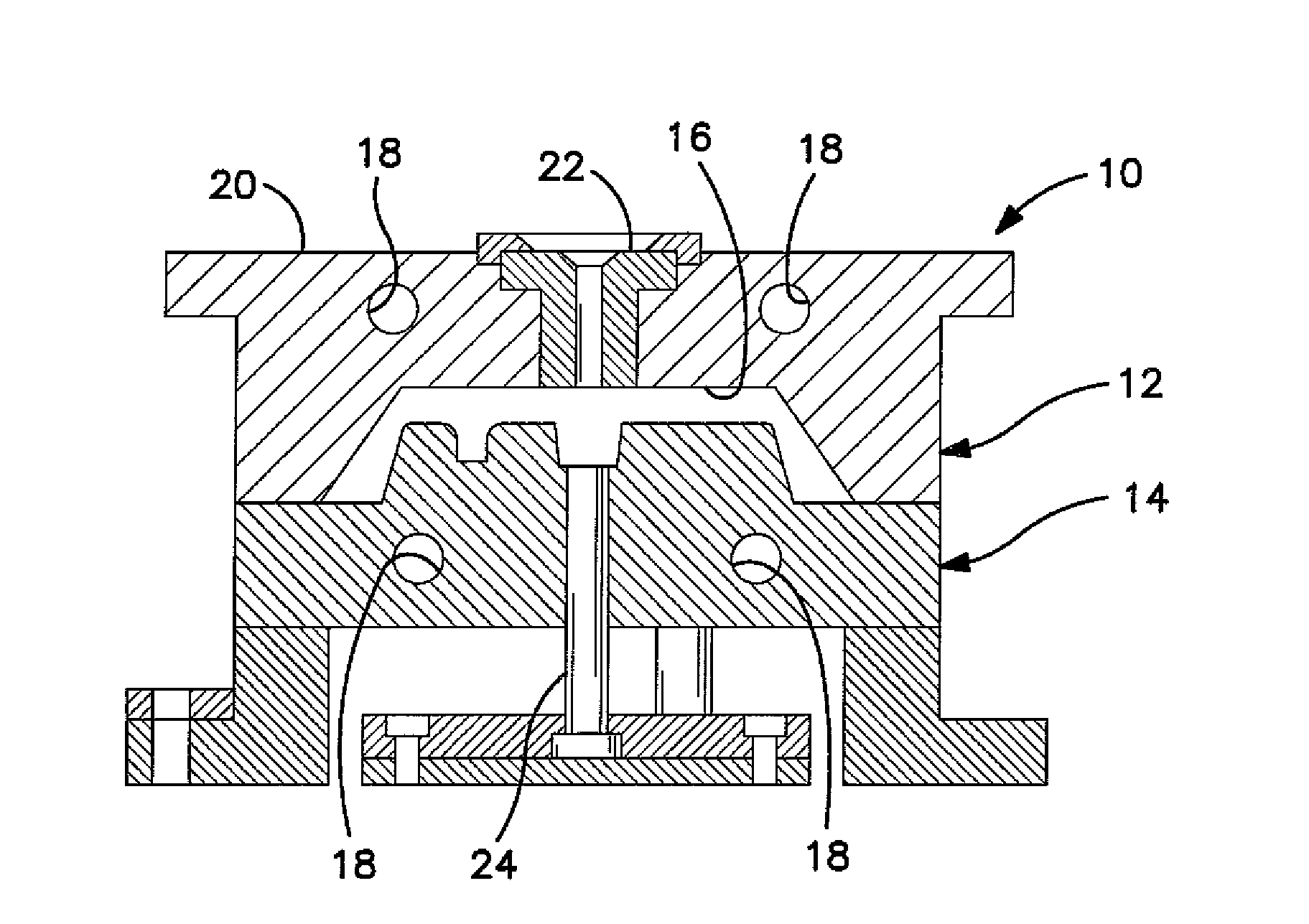

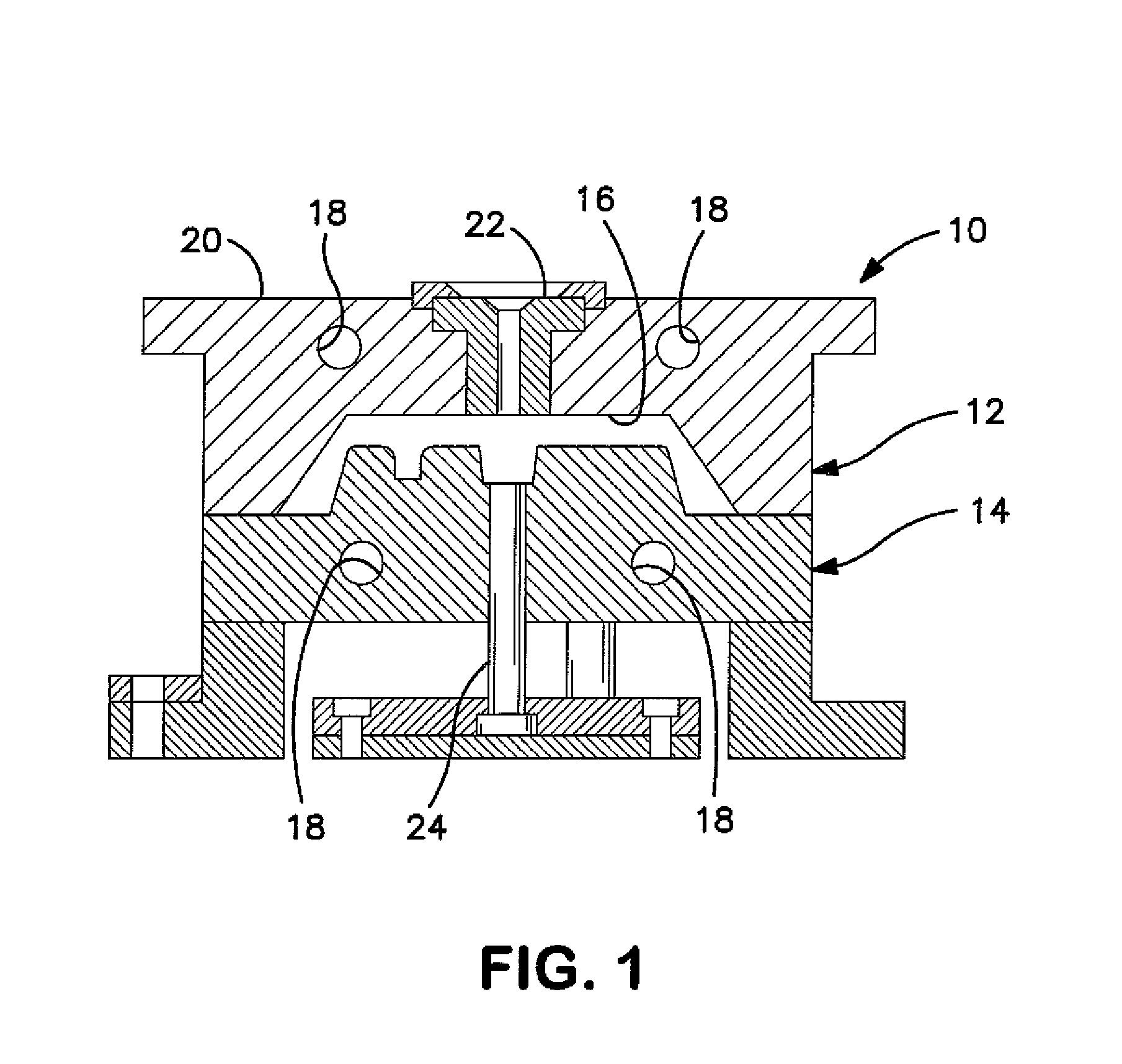

Housing for a portable electronic device

An injection molded housing for a portable electronic device is provided. The housing contains a thermoplastic composition that includes a polyarylene sulfide melt processed in the presence of a disulfide compound and a filler. Without intending to be limited by theory, it is believed that the disulfide can undergo a chain scission reaction with the starting polyarylene sulfide to lower its melt viscosity, which can lead to decreased attrition of the filler and thus improved mechanical properties. Due to this ability to reduce viscosity during melt processing, the present inventors have discovered that relatively high molecular weight polyarylene sulfides can be fed to the extruder with little difficulty.

Owner:TICONA LLC

Housing for a Portable Electronic Device

An injection molded housing for a portable electronic device is provided. The housing contains a thermoplastic composition that includes a polyarylene sulfide melt processed in the presence of a disulfide compound and a filler. Without intending to be limited by theory, it is believed that the disulfide can undergo a chain scission reaction with the starting polyarylene sulfide to lower its melt viscosity, which can lead to decreased attrition of the filler and thus improved mechanical properties. Due to this ability to reduce viscosity during melt processing, the present inventors have discovered that relatively high molecular weight polyarylene sulfides can be fed to the extruder with little difficulty.

Owner:TICONA LLC

Preparation of low molecular plant gum

InactiveCN101475775AAvoid continuous viscosity reductionStable rheologyNatural resin processDrilling compositionChemical reactionChain scission

The invention relates to a method for preparing low-molecular vegetable gum through chain scission of macromolecular vegetable gum by a physical or chemical method. At present, a fracturing fluid used in fracturing reconstruction of an oil gas field is the fracturing fluid mainly taking macromolecules as a thickening agent, influences reliability in construction and is easy to cause pollution to environment. Through a chemical degradation method, the macromolecular vegetable gum in an ethanol and water solution has chemical reaction with inorganic alkali, inorganic acid or organic acid, so that part of a macromolecular chain of the macromolecular vegetable gum is fractured, and the low-molecular vegetable gum having molecular weight of between 10,000 and 400,000 is obtained. When the low-molecular vegetable gum is used as the fracturing fluid, return liquid can be recycled after the construction so as to save a large quantity of water resource and chemical agents; and the method effectively reduces and avoids environmental pollution caused by the emission of waste liquid.

Owner:QINGYANG CHANGQING DOWN HOLE OILFIELD AUXILIARIESCO

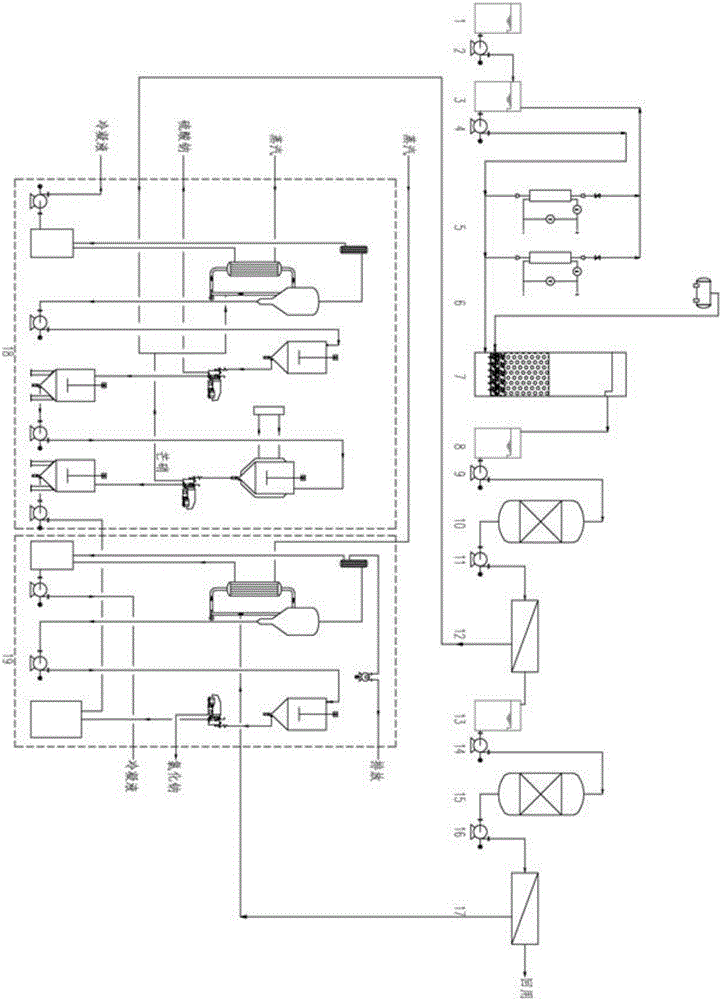

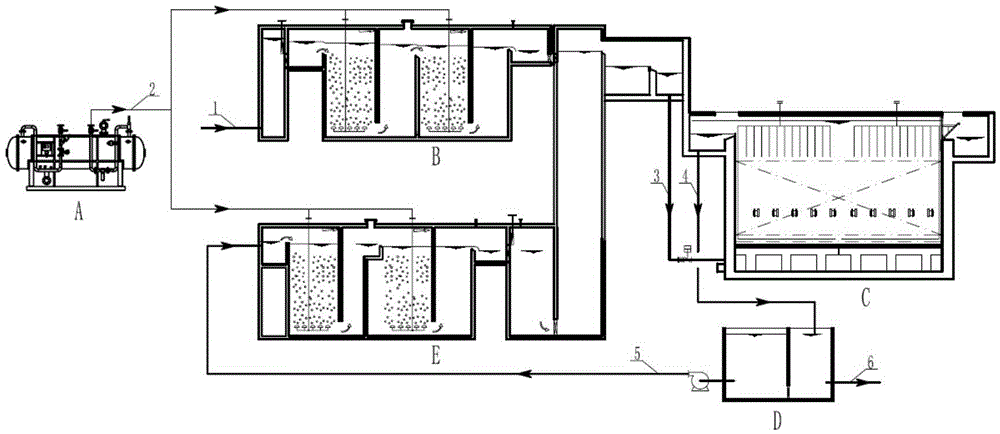

Ozone and photoelectrocatalysis combined treatment method of reverse osmosis membrane concentrated water in refinery waste water

The invention discloses an ozone and photoelectrocatalysis combined treatment method of reverse osmosis membrane concentrated water in refinery waste water. The method is characterized in that the method comprises the steps that the reverse osmosis membrane concentrated water in the refinery waste water is pretreated by an ozone oxidation technology at normal temperature and pressure; nondegradable organic matters in the water are subjected to open loop and chain scission; and the nondegradable organic matters in the water are removed effectively by a photoelectrocatalysis oxidation advanced treatment technology. The reverse osmosis membrane concentrated water finally achieves standard emission by the technologies. A particular technological process is as follows: the reverse osmosis membrane concentrated water is homogenized by a regulating basin (1), and enters an ozone preoxidation tank (3) through a water supply pump; the concentrated water and ozone provided by an ozone reactor (2) are mixed sufficiently and react in the tank; a photoelectric assistant (4) is added to outflowing water; the outflowing water is pumped into a photoelectrocatalysis oxidation reactor (5); and then the outflowing water flows into a clean water basin.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Wastewater advanced treatment method using post-ozonation reflux and secondary oxidation

ActiveCN105601038ABreak through the biochemical limitHigh removal rateWater contaminantsMultistage water/sewage treatmentRefluxChemical oxygen demand

The invention discloses a wastewater advanced treatment method using post-ozonation reflux and secondary oxidation. The wastewater advanced treatment method is characterized in that a post-ozonation reflux technology is added on the basis of a traditional ozone and biofilter combined process, and a reflux ratio is reasonably designed, so that the removing efficiency of COD (Chemical Oxygen Demand) in biorefractory wastewater is further improved, and the problem that the removing efficiency of the COD by a first-stage ozone and biofilter combined process is limited is effectively solved. The method comprises the following steps of firstly, allowing wastewater subjected to secondary treatment to enter into a front ozone oxidation pond, and feeding ozone to improve the biodegradability of the wastewater; secondly, allowing effluent from the front ozone oxidation pond to enter into a BAF (Biological Aerated Filter) for biological treatment, and enabling drained water to enter into a clean water basin; thirdly, elevating part of the wastewater in the clean water basin to enter into a rear ozone oxidation pond, and performing ring opening and chain scission by ozone oxidation again; fourthly, refluxing effluent from the rear ozone oxidation pond to the BAF, and jointly performing biological treatment on the effluent from the rear ozone oxidation pond and the effluent from the front ozone oxidation pond. According to the method disclosed by the invention, the selectivity of ozone oxidation is fully utilized, and the biochemical limit of hard biodegradable wastewater is broken through.

Owner:北京翰祺环境技术股份有限公司

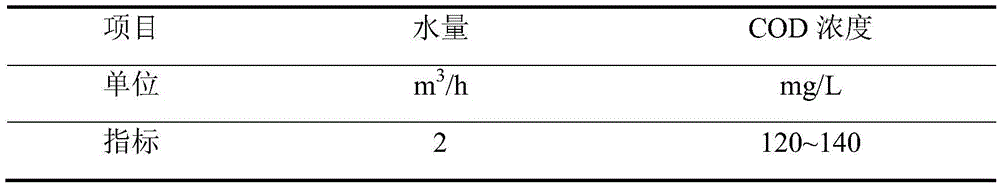

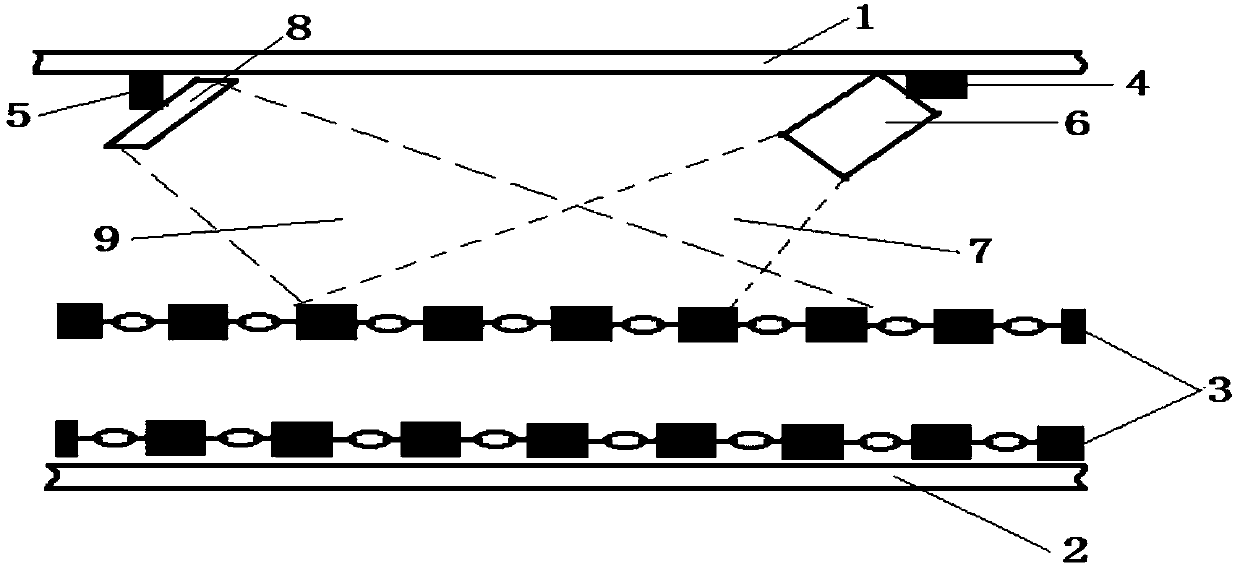

Machine vision-based system for detecting abnormal state of scraper

InactiveCN107944342ASave human effortRealize remote controlCharacter and pattern recognitionMachine visionChain scission

The invention discloses a machine vision-based system for detecting an abnormal state of a scraper. The system is characterized by at least comprising an image collection unit and a data processing unit, wherein the image collection unit comprises a video camera and an auxiliary light source; the video camera is used for collecting a video image of a running state of a scraper plate; the auxiliarylight source is used for illuminating the surface of the scraper plate; the data processing unit is used for receiving and processing video image data output by the video camera, and when the scraperis stopped due to tilting and chain scission, storing and recording a field video image, and sending a fault alarm signal; the data processing unit performs tagging on the video image output by the video camera by utilizing an image coordinate system; an image detection region is manually set in the video image; at least two scraper plates are shot in the image detection region; a virtual standard line is set in the image detection region; and the virtual standard line is parallel to the longest edges of the upper surfaces of the shot scraper plates. An equipment stop fault due to the scraperplate tilting and the chain scission can be detected in a scraper running process.

Owner:TIANJIN MEITENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com