Wastewater advanced treatment method using post-ozonation reflux and secondary oxidation

A technology of ozone oxidation and advanced treatment, which is applied in the direction of oxidized water/sewage treatment, biological water/sewage treatment, degassed water/sewage treatment, etc. It can solve the difficulty of film formation in biological aerated filters and reduce the total removal rate of the overall process , high investment and operating costs, etc., to achieve the effect of low construction and operating costs, efficient and stable operation, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

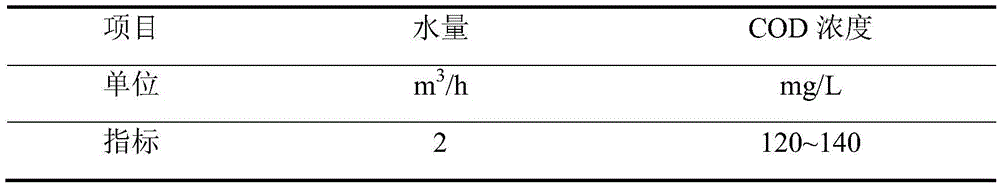

[0024] The raw water sample for the pilot test is the effluent from the secondary settling tank of the sewage treatment plant of a refining and chemical enterprise. The water quality and quantity are as follows:

[0025]

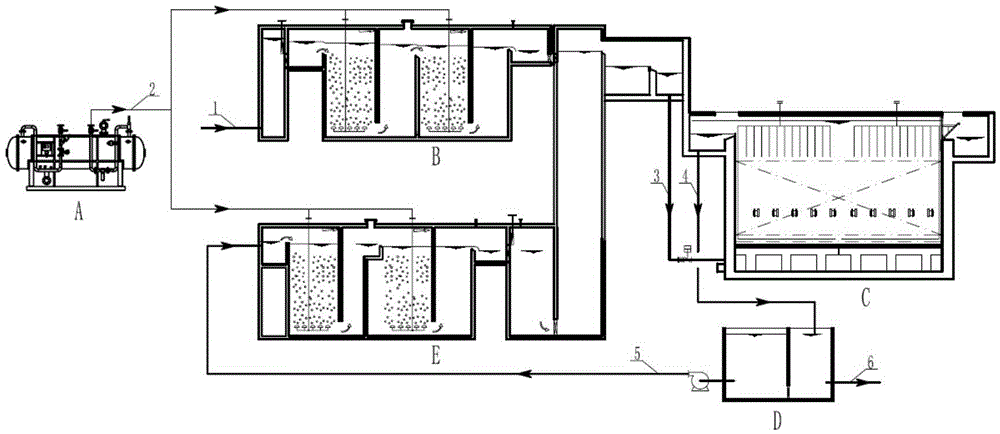

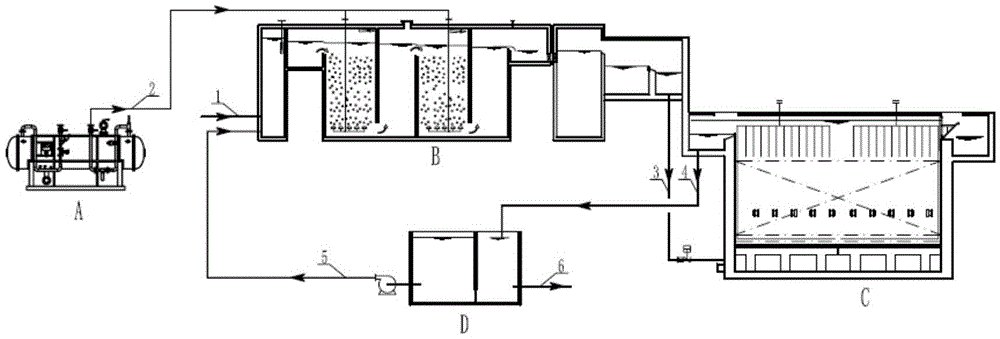

[0026] Raw water first enters the former ozone oxidation tank B, stays for 45min, and the ozone produced by the ozone generator A is added to the former ozone oxidation tank B through the ozone dosing pipeline 2, and the ozone dosage is 2kgO 3 / kgCOD, the COD removal rate of ozone oxidation before control is 35%. The effluent from the front ozone oxidation pool B enters the BAF pool C through channels, and the filtration rate of the BAF pool is controlled at 4m / h. Take 25%, 50%, 75%, 100% respectively, stay for 45min, and then add 2kgO 3 / kgCOD, the COD removal rate of ozone oxidation after control is 35%. The effluent from the ozone oxidation tank E is sent back to the BAF tank C for further processing.

[0027] The COD removal rate of the whole proce...

Embodiment 2

[0032] Guarantee that other conditions are constant among the embodiment 1, rear ozone dosage is 2.5kgO 3 / kgCOD, the COD removal rate of ozone oxidation after control is 50%.

[0033] The COD removal rate of the whole process sewage is as follows:

[0034]

[0035] When the reflux ratio is 25%, 50%, 75%, and 100%, the highest COD removal rate of the whole process is 61%, 64.5%, 67.2%, and 69.3%.

[0036] When the COD removal rate of post-ozone oxidation is increased, the total COD removal rate of the overall process is significantly improved. Similarly, the higher the reflux ratio, the higher the COD removal rate.

Embodiment 3

[0038] Ensure that other conditions remain unchanged in Example 1, cancel the rear ozone oxidation pool E, and part of the sewage in the clear water pool directly returns to the front ozone oxidation pool B.

[0039] The COD removal rate of the whole process sewage is as follows:

[0040]

[0041] When the reflux ratio is 25%, 50%, 75%, and 100%, the highest COD removal rate of the whole process is 61%, 63%, 64%, and 64.8%.

[0042] When the total ozone dosage is the same, it has the same effect as in Example 1 when only increasing the reflux without the post-ozone oxidation pool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com