Patents

Literature

98 results about "Total removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

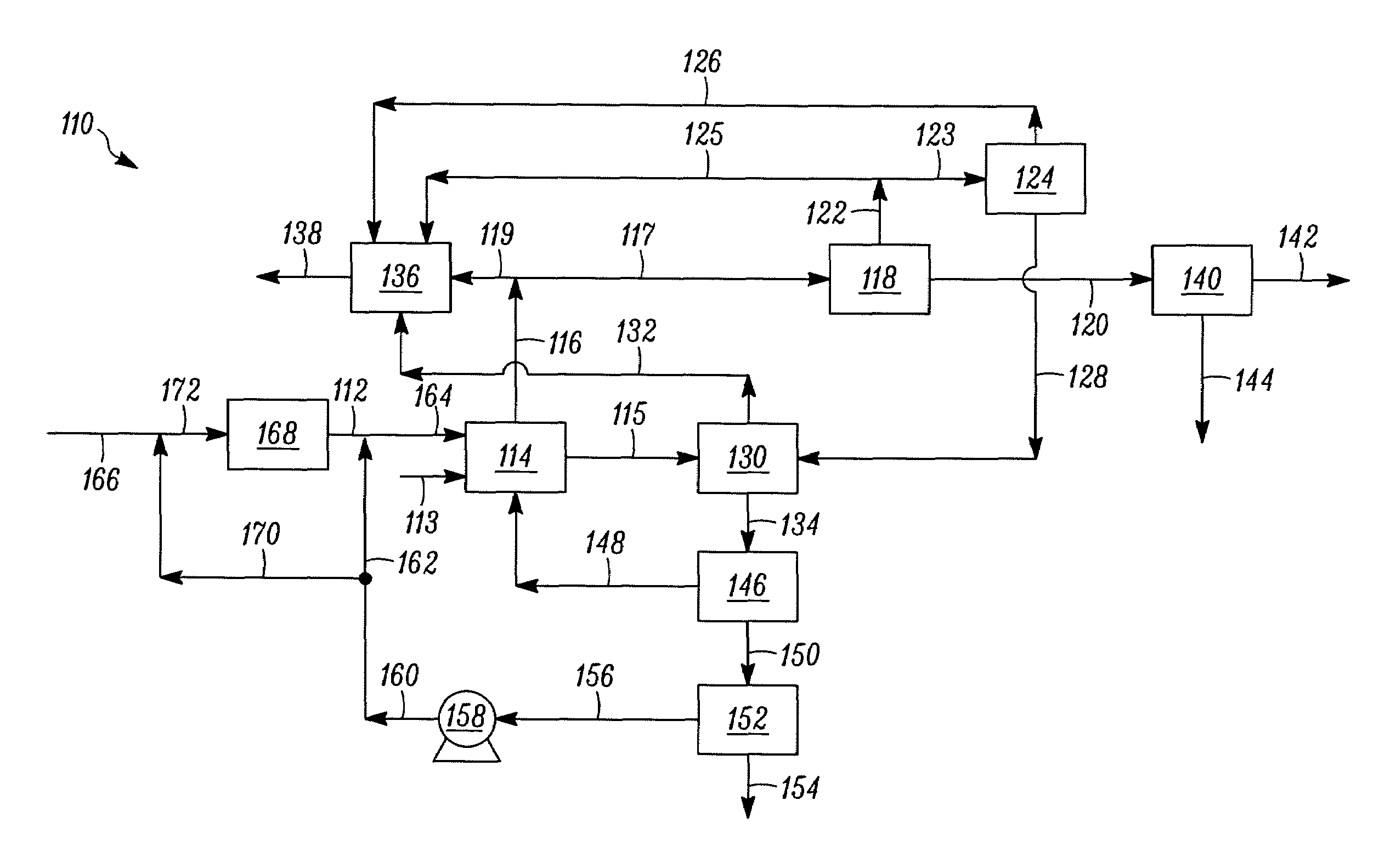

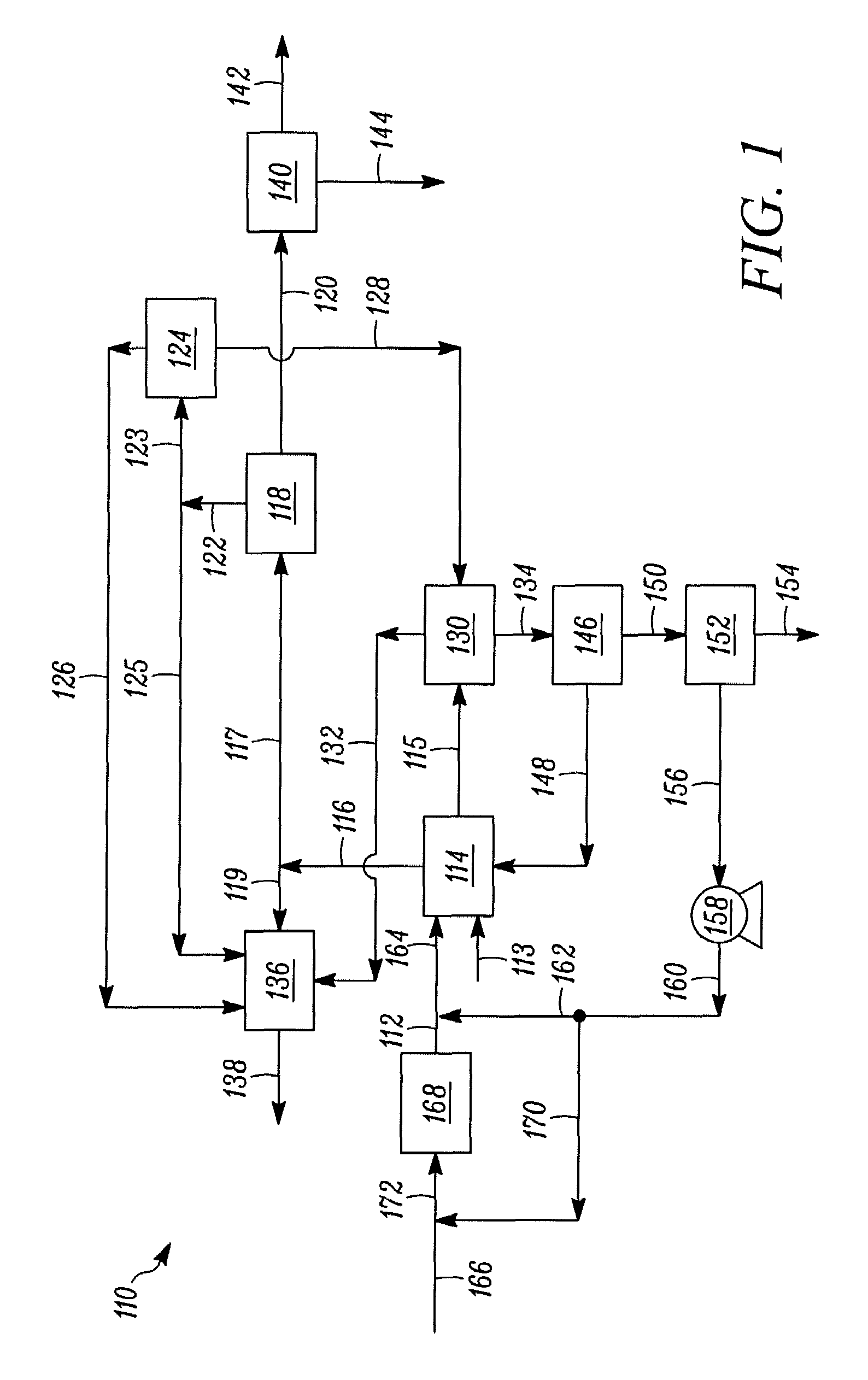

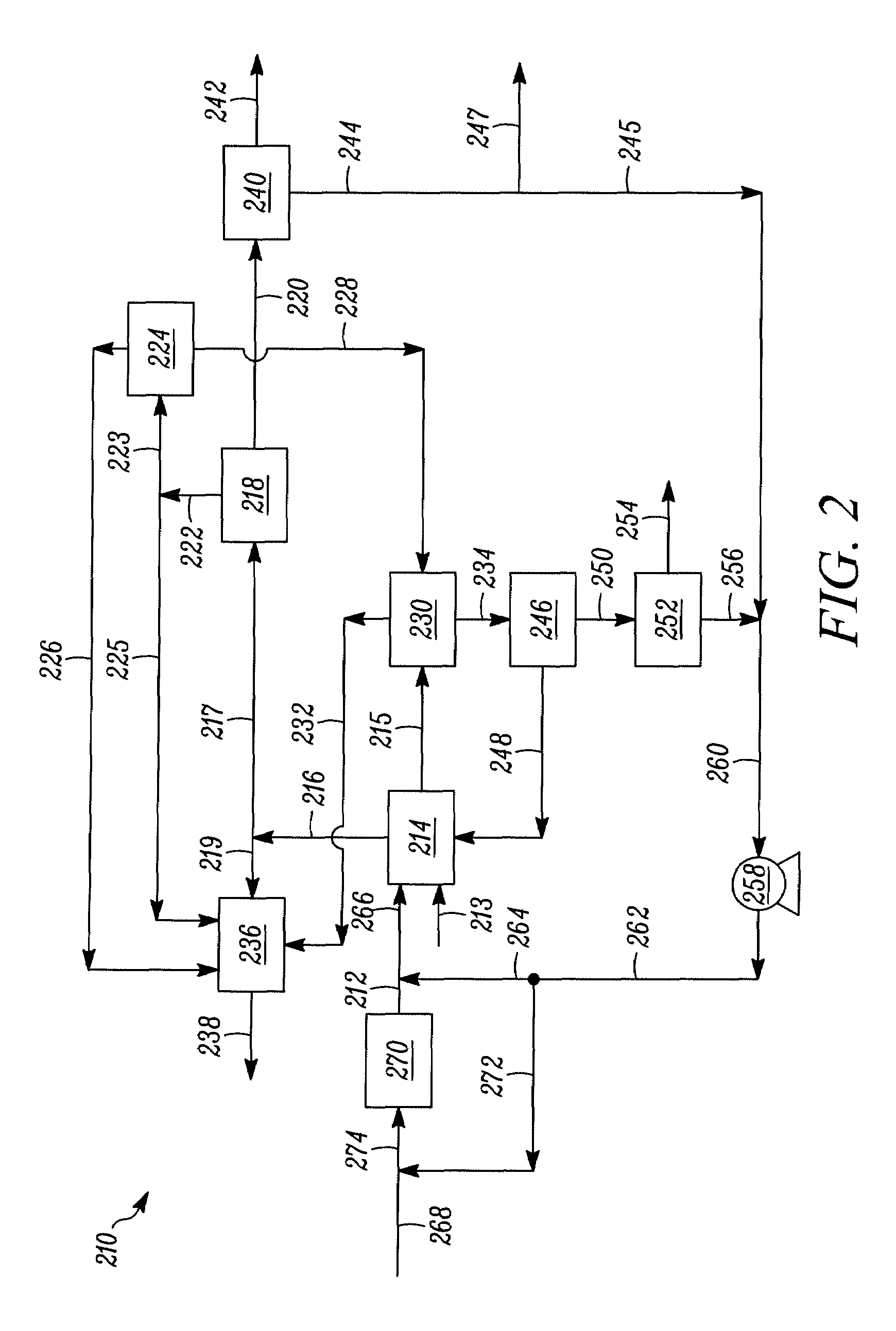

Integrated separation and purification process

InactiveUS7637984B2Improved arrangementSimple processGas treatmentCarbon compoundsMostly TrueSelexol

Increasing the economic and environmental compatibility in treatment processes in sour gas production. For 25 yr, Mobil Erdgas Erdoel GmbH (MEEG) has been treating considerable amounts of sour gas in N. Germany. In 9 fields with different gas qualities, there are ca 30 producing wells. The main processes of the sour gas production and treatment are described. The gas is dried at the well site and if the reservoir pressure is not sufficient, compressed for transportation to the central processing facility. In most cases the use of sulfur solvents is necessary at the wells. Natural gas scrubbers for the total removal of hydrogen sulfide and Claus units with downstream units to obtain sulfur are utilized. To increase the environmental compatibility and economics, a number of secondary processes have been introduced for emission control; glycol stripping; and the Purisol, Selexol, Sulfinol, and Claus processes.

Owner:UOP LLC

Process for the reduction of sulphur content in FCC heavy gasoline

A process for the reduction of sulphur content in a FCC gasoline includes fractionation of the FCC gasoline into three fractions: a light fraction comprising 50-80% of the FCC gasoline, an intermediate boiling fraction comprising 10-30% of the FCC gasoline, and a heavy fraction comprising 5-20% of the FCC gasoline. The heaviest fraction is hydrotreated in the first bed of a hydrotreater at conditions that result in essentially total removal of the sulphur. The effluent from the first bed is quenched with the intermediate fraction. The combined oil stream is hydrotreated in a second and final bed in the hydrotreater at conditions that ensure the required overall sulphur reduction.

Owner:HALDOR TOPSOE AS

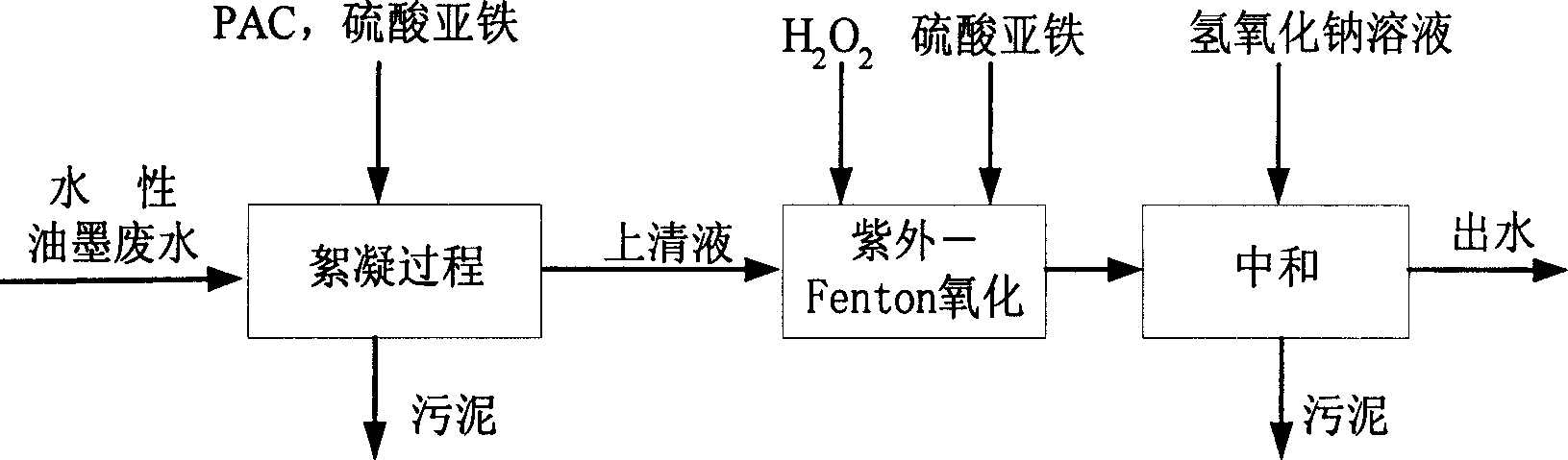

Aqueous ink waste water disposal process

InactiveCN1765762ASatisfy the requirement of complete decolorizationAchieve emission standardsWater/sewage treatment by irradiationWater/sewage treatment by neutralisationSludgeUltraviolet lights

The invention discloses a treatment for ink sewage, which comprises: adding proper PAC as flocculant in sewage, mixing round quickly, and adding proper ferrous sulfate as coagulant aid; mixing, depositing; using the supernatant for UV / Fenton oxidation under ultraviolet light; before oxidation, using hydrochloric acid to regulate solution pH value to optimal, adding given superoxol and ferrous sulfate; after reaction, adjusting solution to neutrality with superoxol and get rid of iron ion; depositing, and separating out water. The treated water has 97-100% transmittance with total removal rate to COD more than 93% that are between highest limit of second and third class discharge standard (GB 8978-1996).

Owner:ZHEJIANG GONGSHANG UNIVERSITY

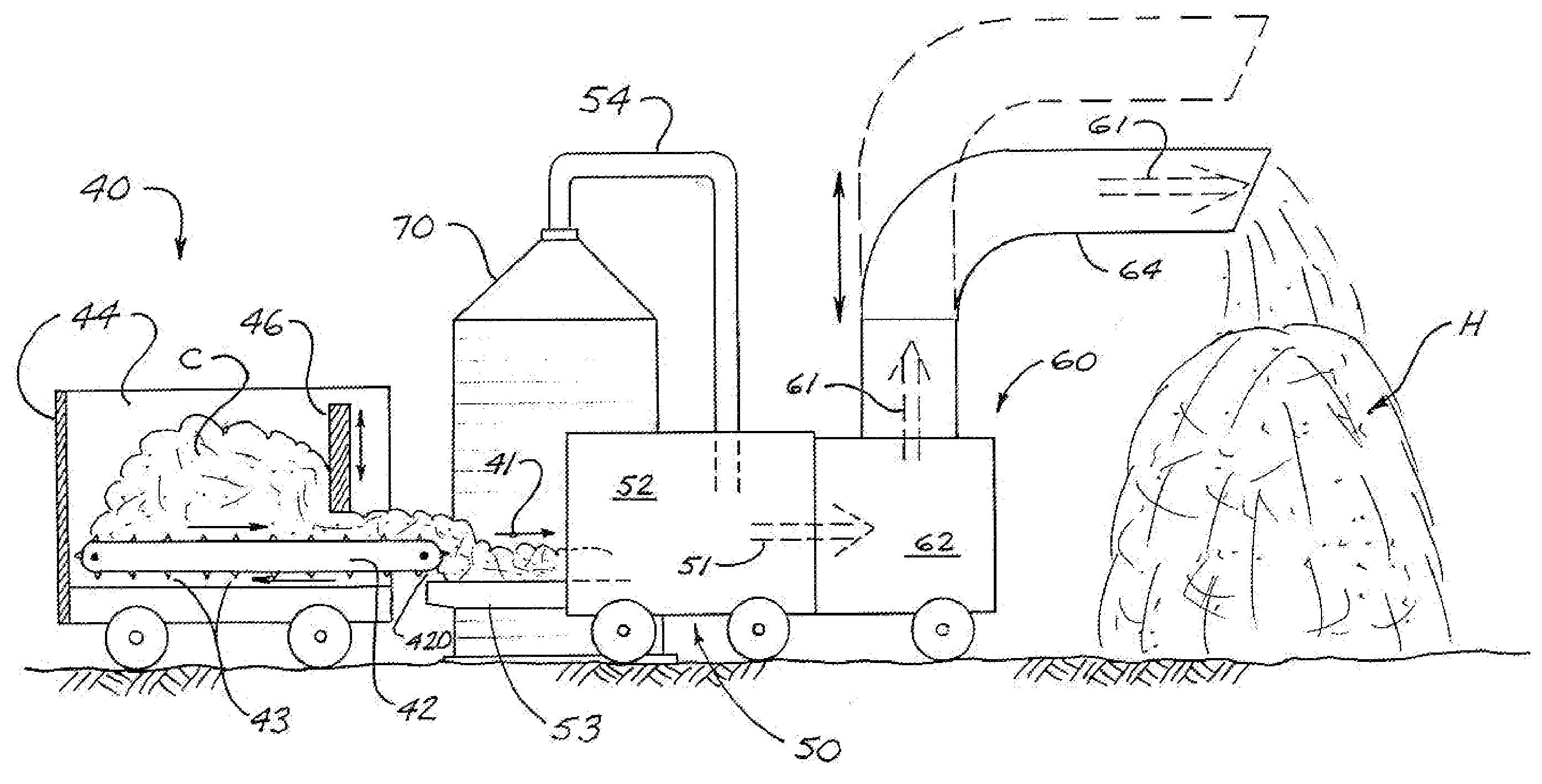

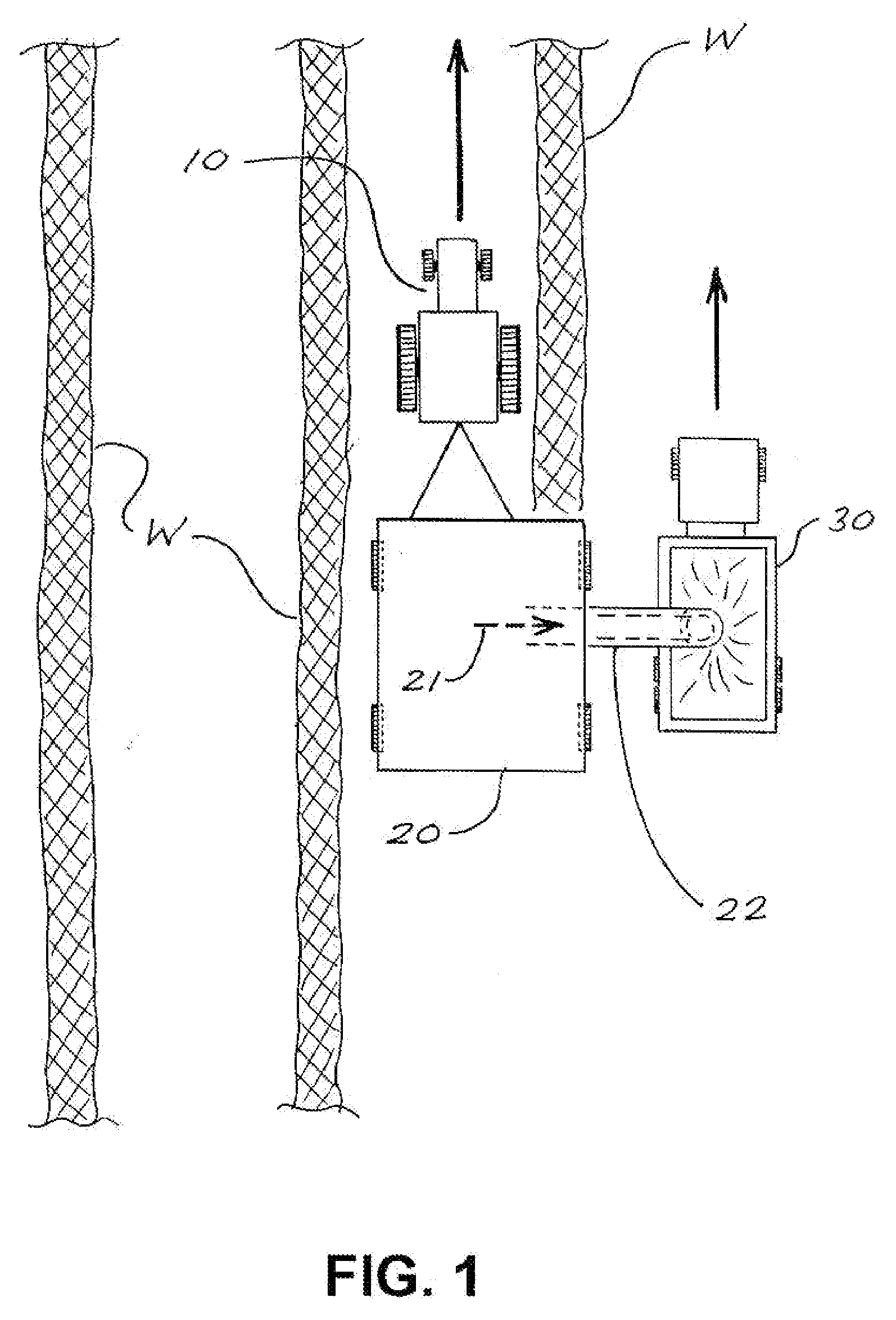

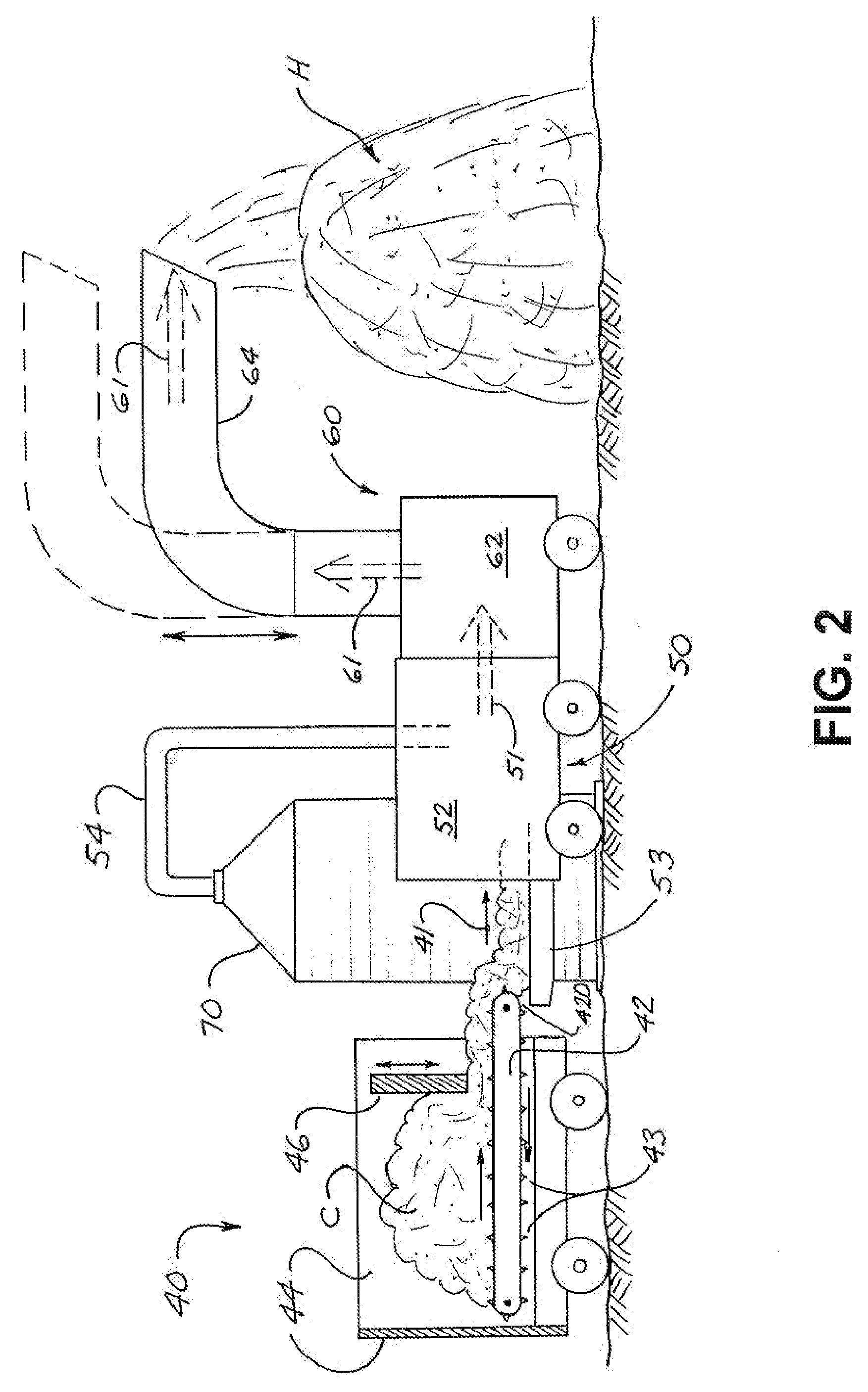

Crop processing method and apparatus

InactiveUS20090017885A1Easy constructionLower requirementHarvestersThreshersMass storageGrain storage

In a method for processing swathed crops, the entire cut crop is picked from the field and transported to a processing facility located away from the field. The processing facility has a threshing apparatus which separates grain from the cut crop, leaving a crop residue comprising plant stalks, chaff, and other constituents of the cut crop. The separated grain is conveyed from the threshing apparatus to a grain storage bin or directly to a transport truck for delivery to a grain terminal. The processing facility also includes crop residue handling means for conveying crop residue to a bulk storage pile, to a baling machine, or to some other selected location. The method makes field baling operations unnecessary, thus expediting the total removal of the crop from the field.

Owner:HALLS FLOYD W

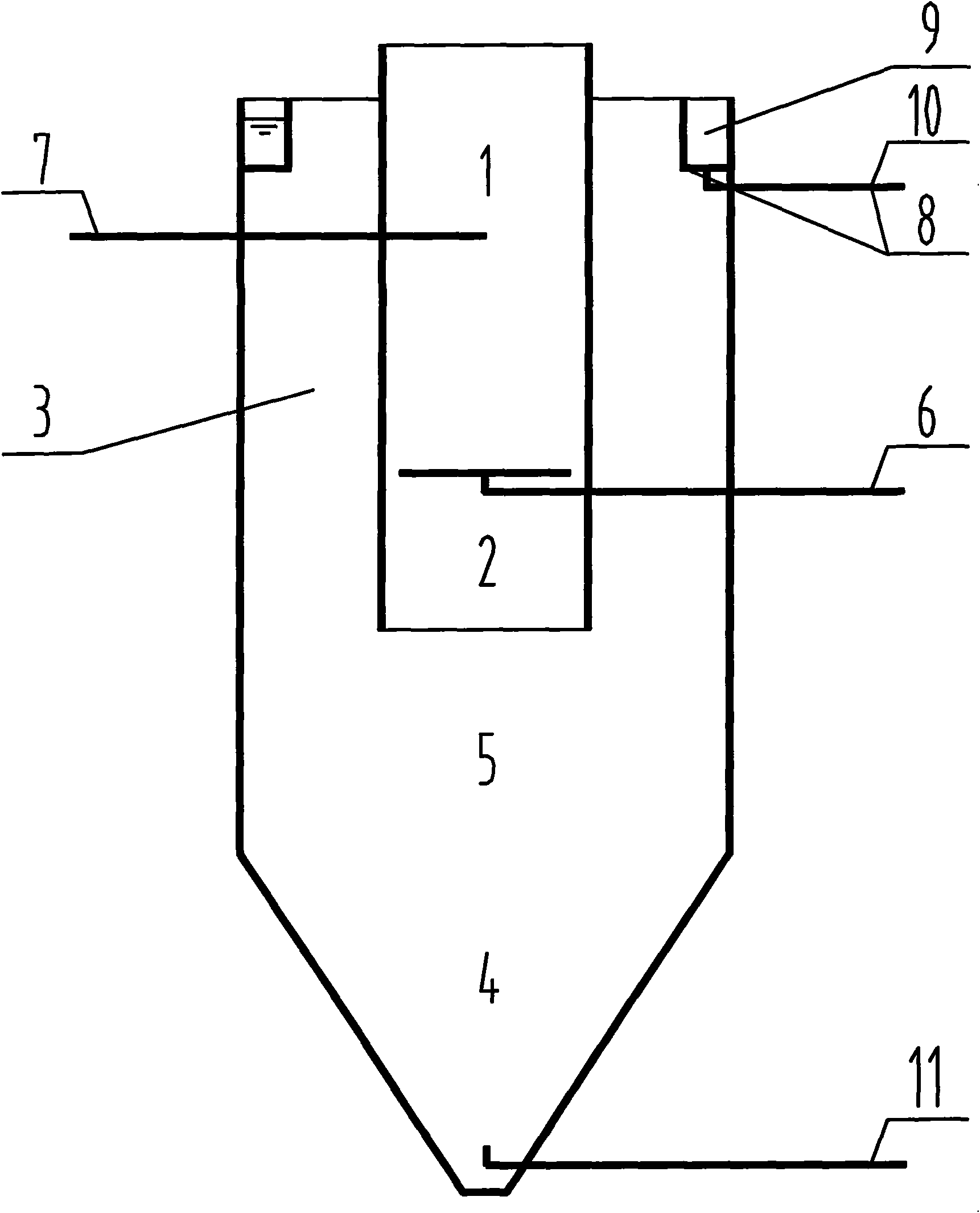

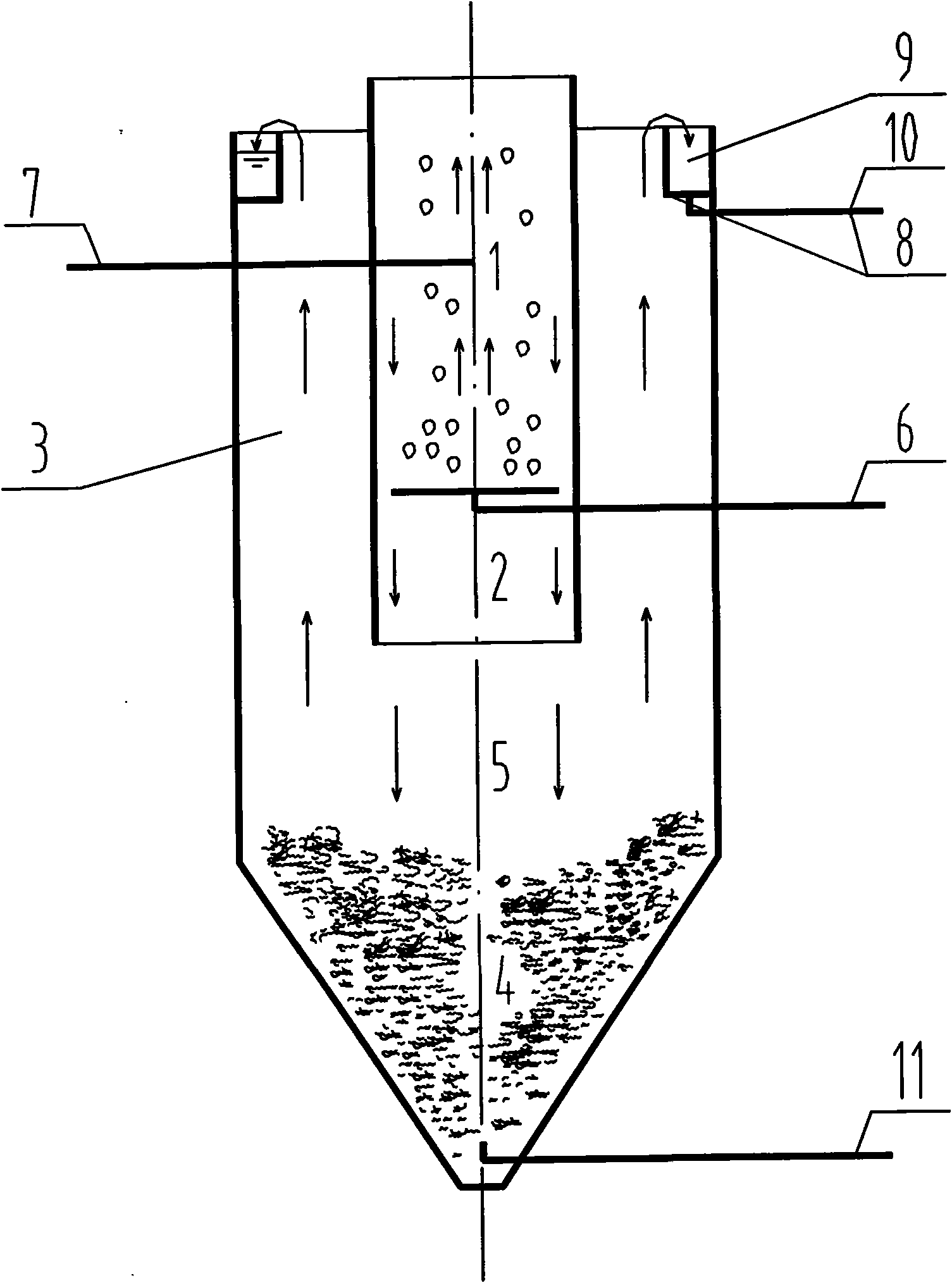

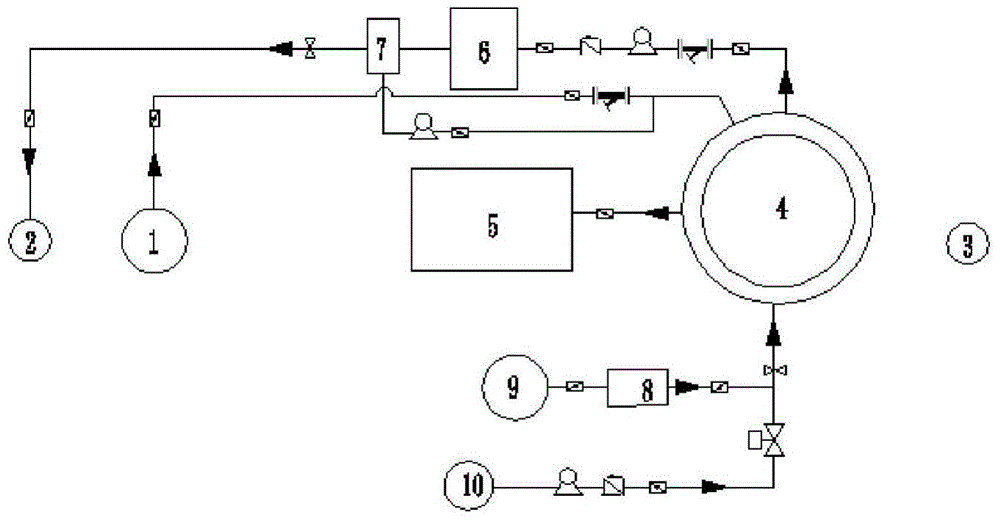

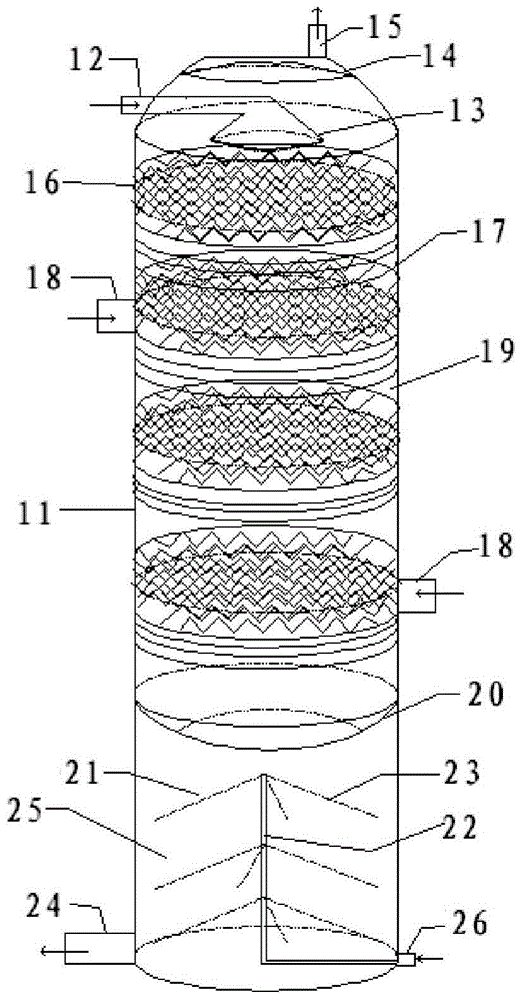

Phosphor recovery crystallization reactor and phosphor recovery method

ActiveCN101602535AHigh recycling efficiencyLow costPhosphorus halides/oxyhalidesWater/sewage treatmentRecovery methodHigh concentration

The invention relates to a phosphor recovery crystallization reactor and a phosphor recovery method. The reactor is in inner-outer dual barrel structure, wherein the inner barrel is disposed at the center position of the outer barrel. The reactor includes an aeration stripping area, a crystallization reaction area, a precipitation separation area, a high concentration phosphor mud area and a buffering area, wherein the crystallization reaction area communicates with the precipitation separation area through the upper portion of the buffering area, so that the sewage water after the crystallization reaction in the crystallization reaction area flows into a precipitation separation area without affecting the high concentration phosphor mud area. The invention fully utilizes effective ingredients in the anaerobic treated water of the high concentration waste water of domestic animal and poultry, enhances pH value of the anaerobic treated water by aeration stripping, removes phosphor in the form of crystal of ammoniomagnesium phosphate using relatively high concentration of phosphor and ammonian in the waste water of domestic animal and poultry. The total removal rate of the phosphor can reach 50-60% without any chemical agents added. Phosphor is recovered in form of crystals, which is beneficial to utilization of the recovered phosphor.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

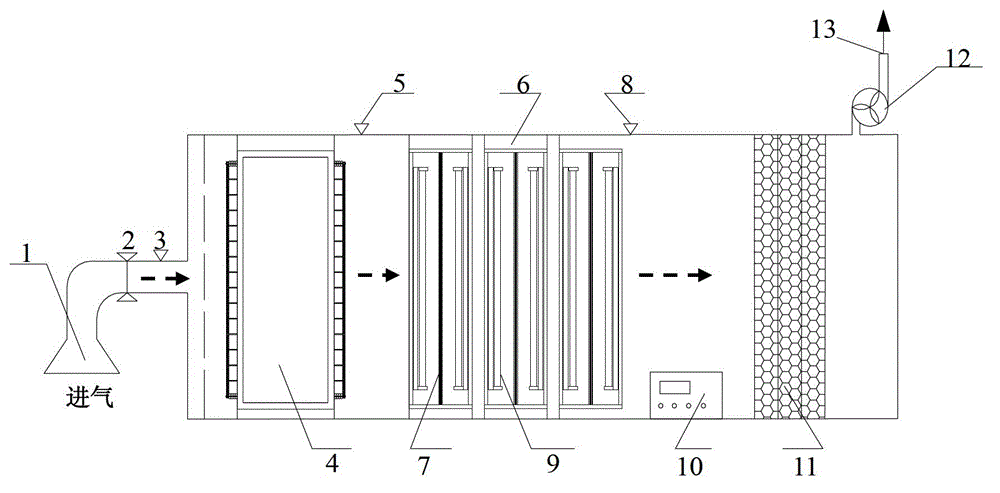

Integrated physical chemistry purification method for treating complex industry organic waste gas, device and application

ActiveCN102941005ARemove shadowsExtend your lifeElectrostatic separationDispersed particle separationParticulatesPhotocatalytic reaction

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Fire coal combustion improver

InactiveCN102191110AImprove operational safetyExtended service lifeSolid fuelsChromium trioxideDolomite

The invention relates to an improvement of a fire coal combustion improver. The improved fire coal combustion improver is characterized by being prepared by compounding and mixing the following components: 20 to 30 weight percent of dolomite powder, 5 to 15 weight percent of dicyclopentadieny iron, 3 to 10 weight percent of chromium trioxide, 3 to 10 weight percent of manganese dioxide, 3 to 15 weight percent of magnesium nitrate, 3 to 15 weight percent of sodium dichromate and / or potassium dichromate, 3 to 18 weight percent of zinc oxide, 15 to 30 weight percent of active clay. The fire coal combustion improver has a plurality of functions of combustion acceleration, sulfur solidification, smoke abatement and the like; the thermal efficiency of a boiler can be improved by 3 to 8 percent; the coal-saving efficiency is up to 5 to 15 percent; the Ringelmann smoke blackness is less than 1; the total removal rate of SO2, NOx and the like is 25 to 60 percent, and the combustion improver has remarkable coal-saving and environmental-protection effect. Since the combustion effect is improved, the inferior coal (such as coal gangue), which is difficult to combust normally, is combusted and comes into play. After the long use, the boiler is not corroded, the scaling of the calcium sulfate in the boiler can be reduced, the operation safety of the boiler can be improved and the service life of the boiler can be prolonged.

Owner:YIXING KEQI CHEM

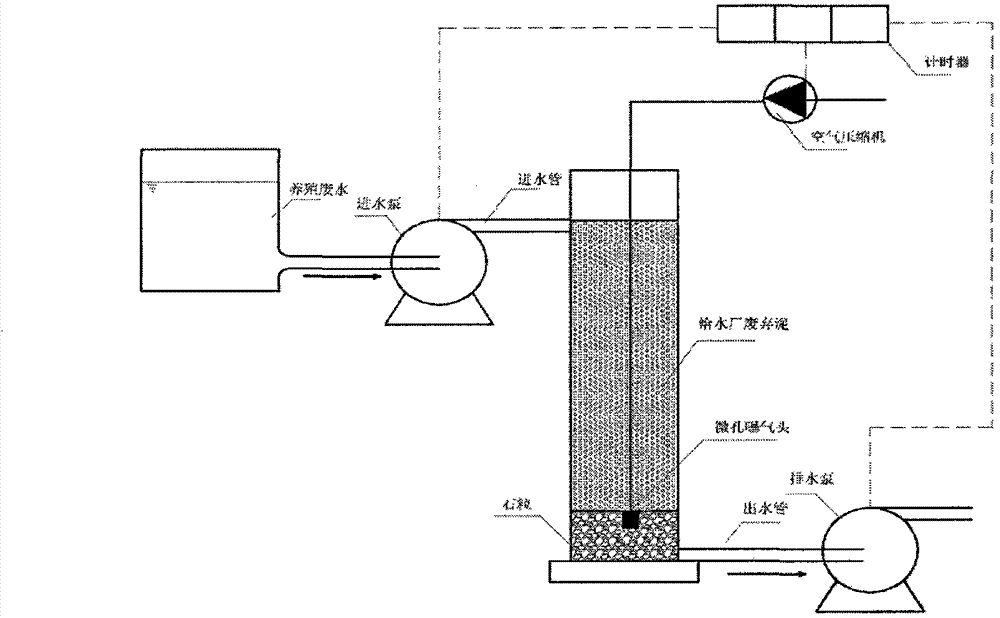

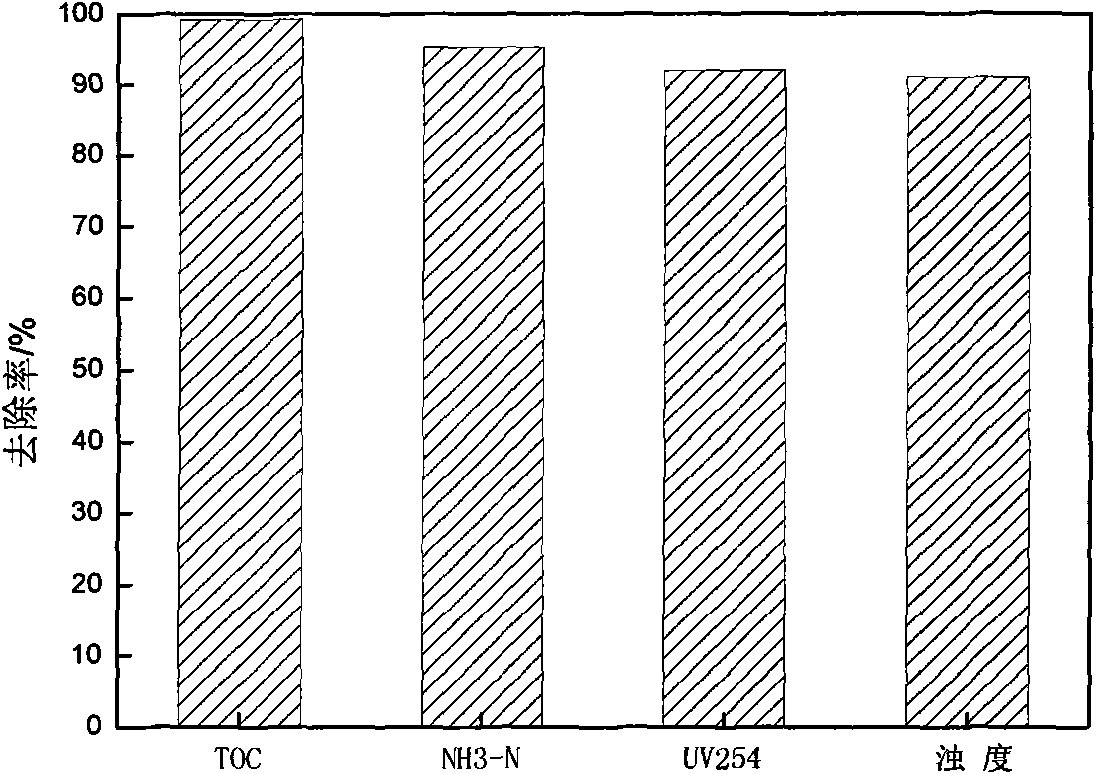

Method for treating wastewater from livestock and poultry breeding by constructing vertical flow artificial wetland based on water supply plant sludge

ActiveCN103880193AWidely distributedEasy accessSustainable biological treatmentBiological water/sewage treatmentHigh concentrationConstructed wetland

The invention discloses a method for treating wastewater from livestock and poultry breeding based on a vertical flow artificial wetland with water supply plant sludge as fillers, belonging to the technical field of wastewater treatment. The method is characterized in that water supply plant sludge is dried and crushed as fillers to construct a vertical flow artificial wetland for treating high-concentration wastewater from livestock and poultry breeding, wastewater from livestock and poultry breeding is allowed to enter the artificial wetland by stages and discharged out from the system for a certain hydraulic retention time under the condition of intermittent aeration. The pollutants such as organic substances, nitrogen and phosphorus in wastewater can be effectively removed by the treatment method disclosed by the invention and the total removal rates of ammonia nitrogen and total phosphorus are higher than 90%. According to the method disclosed by the invention, the problem of a way out for water supply plant sludge is also solved while wastewater from livestock and poultry breeding is effectively treated, and thus the method is conducive to achieving a purpose of "treatment of wastes with processes of wastes" and is in line with the concept of circular economy and sustainable development.

Owner:BEIJING NORMAL UNIVERSITY

Method for processing heavy metal Cd (Cadmium) contaminated soil

ActiveCN102886375AImprove enrichment effectChange surface structureContaminated soil reclamationSocial benefitsElectrokinetic remediation

The invention discloses a method for processing heavy metal Cd contaminated soil, which is characterized by comprising the steps of adding rhamnolipid aqueous solution with concentration of 0.5-2g / L into a negative electrolytic tank, adding deionized water into a positive electrolytic tank, installing a filter cloth between the Cd contaminated soil needed to process and the negative electrolytic tank as well as the positive electrolytic tank, installing a permeable reaction wall on an enrichment place of the heavy metal Cd far away from five eighth of an anode S3, and switching on to electronically repair the Cd contaminated soil. The Cd concentration rate is above 4 times higher than an initial value; and under the function, the concentration rate is reduced to about 3.63 times, the total removal ratio of the heavy value Cd of the whole soil is about 40%, and the contribution ratio of the permeable reaction wall on the removal ratio is about 90%, so that the alkaline rhamnolipid solution proves that the process of the heavy metal from enrichment to removal can be realized by the electrical repair and the permeable reaction wall. The method is simple in operation condition, wide in range of application, low in cost, high in efficiency, liable to realize, and has the better social benefit and biological benefit on the heavy metal Cd contaminated soil.

Owner:福建沃土环保集团有限公司

Three-stage restoration method and three-stage restoration device of organic-chlorohydrocarbon-polluted underground water

ActiveCN104150640ASimple designGood removal effectWater contaminantsEnergy based wastewater treatmentRestoration methodGroundwater remediation

The invention relates to the field of government of organically polluted underground water and especially relates to a three-stage restoration method and a three-stage restoration device of organic-chlorohydrocarbon-polluted underground water. The method particularly includes following steps: 1) feeding hot air from the bottom of a thermally air-stripping aerating oxidization column, wherein the hot air contacts with polluted underground water in a thermally air-stripping section; 2) carrying out a batch-type aeration operation to the underground water in an aerating oxidization section; 3) feeding the underground water to an ordered mesopore liquid-phase adsorption column and carrying out a deep adsorption process, and if the underground water is qualified, pumping the underground water to a recharge well to enable the underground water to be recharged to an underground water layer, if the underground water is not qualified, feeding the underground water back to the thermally air-stripping aerating oxidization column for reprocessing. Compared with the prior art, the invention is advantaged in that the method and the device are energy-saving and environmental-protective, are free of secondary pollution, have a total removal effect being more than 99%, can achieve continuous underground water restoration, can greatly increase a treatment efficiency of the organically polluted underground water and can save a treatment cost.

Owner:JIANGSU SUNTIME ENVIRONMENTAL REMEDIATION

Method for electrically repairing heavy metal As (Arsenic) contaminated soil by using rhamnolipid

ActiveCN102886374AReduce removal rateHigh removal rateContaminated soil reclamationSocial benefitsElectrokinetic remediation

The invention discloses a method for electrically repairing heavy metal As (Arsenic) contaminated soil by using rhamnolipid, which comprises the steps of controlling the moisture content of the soil to 27% to 33%, adding a rhamnolipid solution with concentration of 0.5 to 4g / L into a negative electrolytic tank, adding deionized water into a positive electrolytic tank, installing a permeable reaction wall consisting of lytags and fine sand with the weight ratio of (3 to 5) to 10 in an enrichment place of a pollutant heavy metal As, and switching on to electronically repair the As contaminated soil. The alkaline rhamnolipid solution provided by the invention can advance the removal ratio of the heavy metal As to 28.53%, wherein the total removal ratio of the heavy metal As is further advanced to about 40% by the permeable reaction wall, and the contribution ratio of the permeable reaction wall on the removal ratio is close to 90%, so that the alkaline rhamnolipid solution proves that the removal ratio of the heavy metal is promoted by the electrical repair and the permeable reaction wall. The method is simple in operation condition, wide in range of application, low in cost, high in efficiency, and liable to realize, and has better social benefit and biological benefit on the heavy metal As contaminated soil.

Owner:福建沃土环保集团有限公司

Method for recycling butyric acid by treating butanol and octanol waste lye

ActiveCN103012104ARecycle thoroughlyEasy to handleMultistage water/sewage treatmentCarboxylic compound separation/purificationChemical oxygen demandDesorption

The invention relates to a method for recycling butyric acid by treating butanol and octanol waste lye. The method comprises the following steps: acidizing butanol and octanol lye through inorganic acid, and recycling an organic phase in the upper layer; absorbing acidic water in the lower layer through a resin tower; when the pH of resin tower acidic outlet water subjected to adsorption treatment is neutralized to be 6 to 9 through lye, and feeding the resin tower acidic outlet water into a sewage treatment plant to be treated or utilizing the resin tower acidic outlet water as acid for neutralization; when resin adsorption is saturated, adsorption is stopped, performing desorption regeneration treatment on the resin, and recycling butyric acid; and performing desorption by virtue of a desorbent flowing back to the resin tower, feeding a desorption solution into a rectifying tower to be subjected to rectification treatment, so as to separate desorbent and coarse butyric acid, recycling the desorbent, and recycling the coarse which serves as a product. The method has the advantages that the CODCr (Chemical Oxygen Demand) of the butanol and octanol waste lye is reduced to lower than 300 mg / L, the total removal rate of CODCr reaches more than 99.0 percent, and treated outlet water can be used as acid for neutralization or can be directly discharged to the sewage treatment plant so as to be subjected to biochemical treatment after being neutralized through alkali, so as to realize up-to-standard release.

Owner:PETROCHINA CO LTD

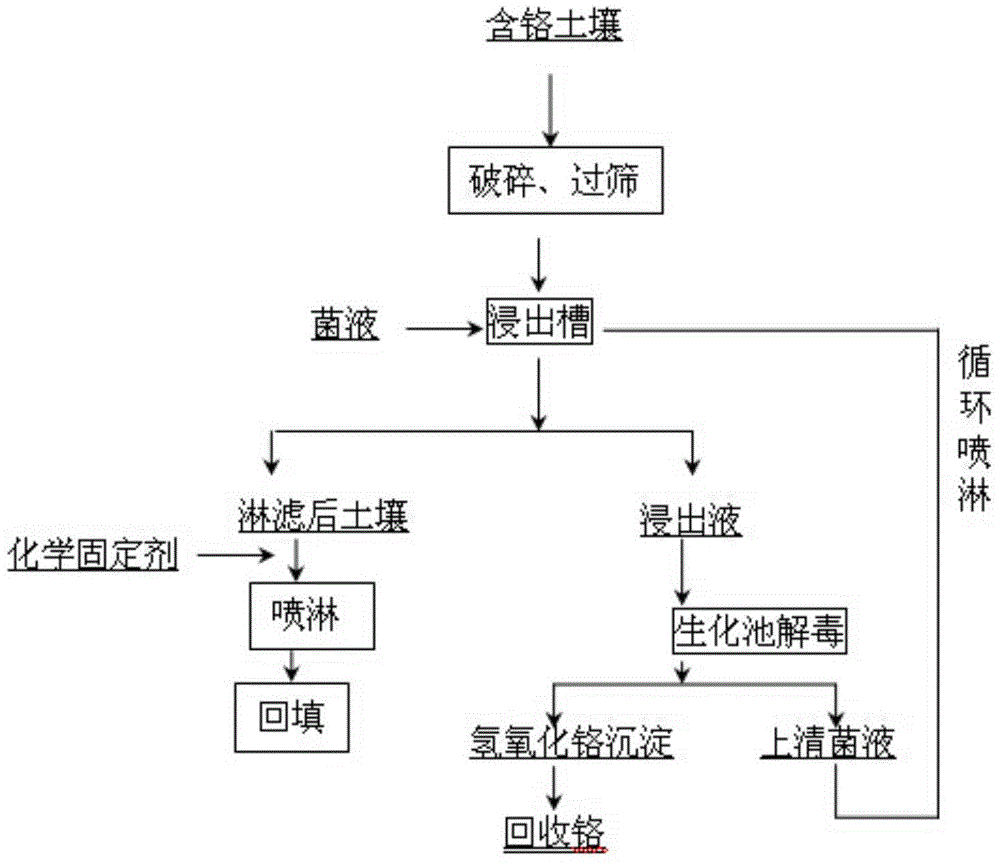

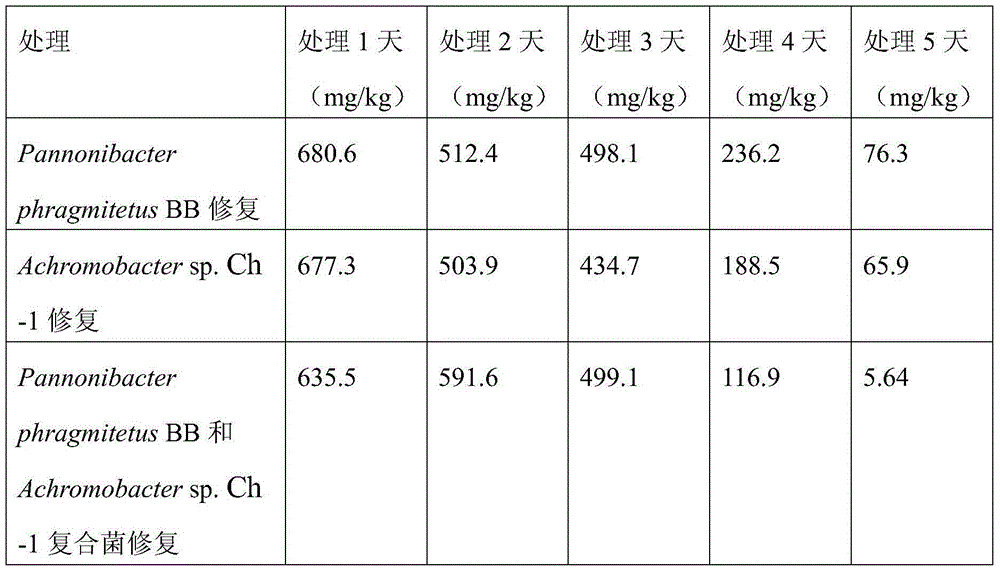

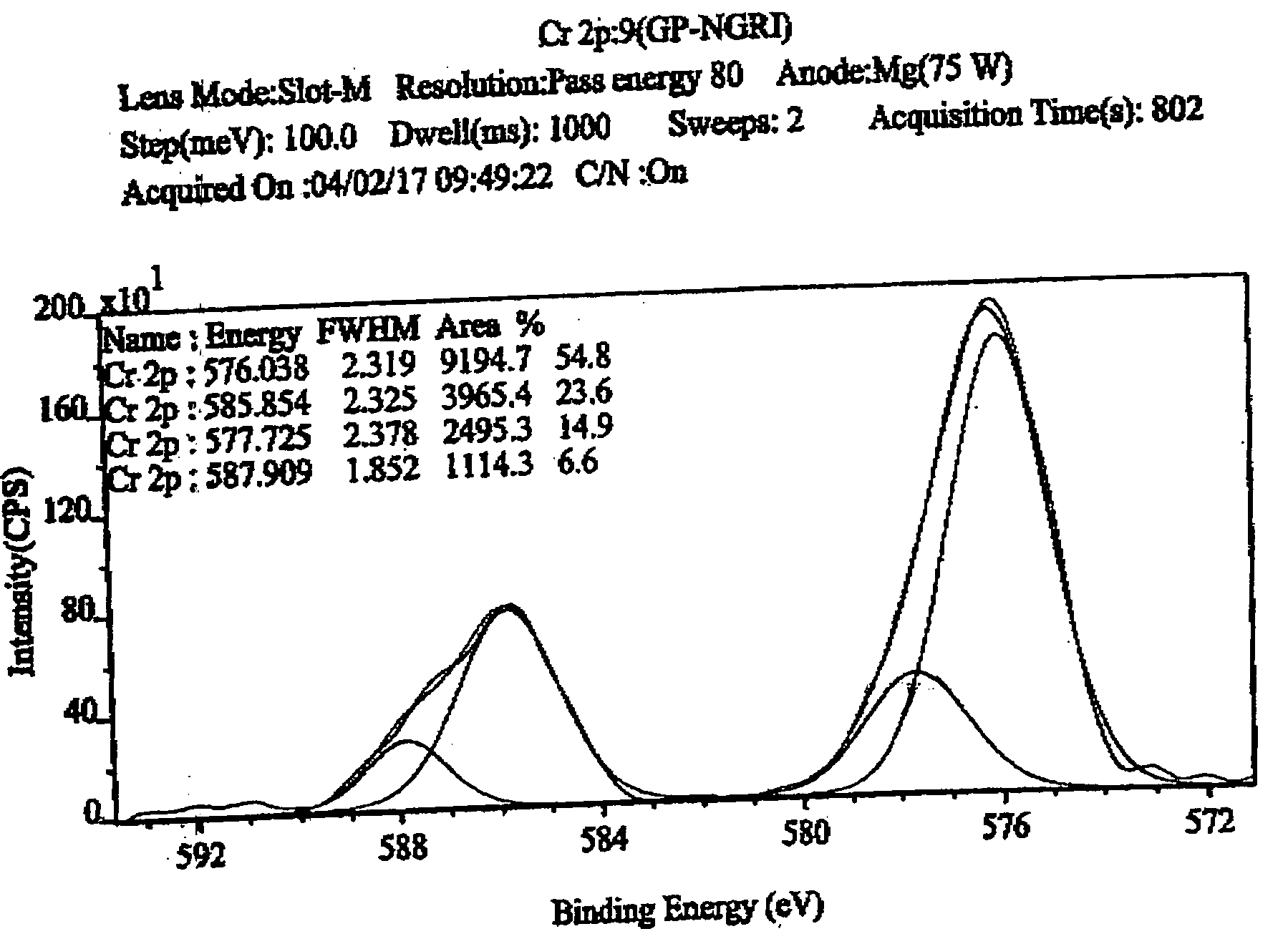

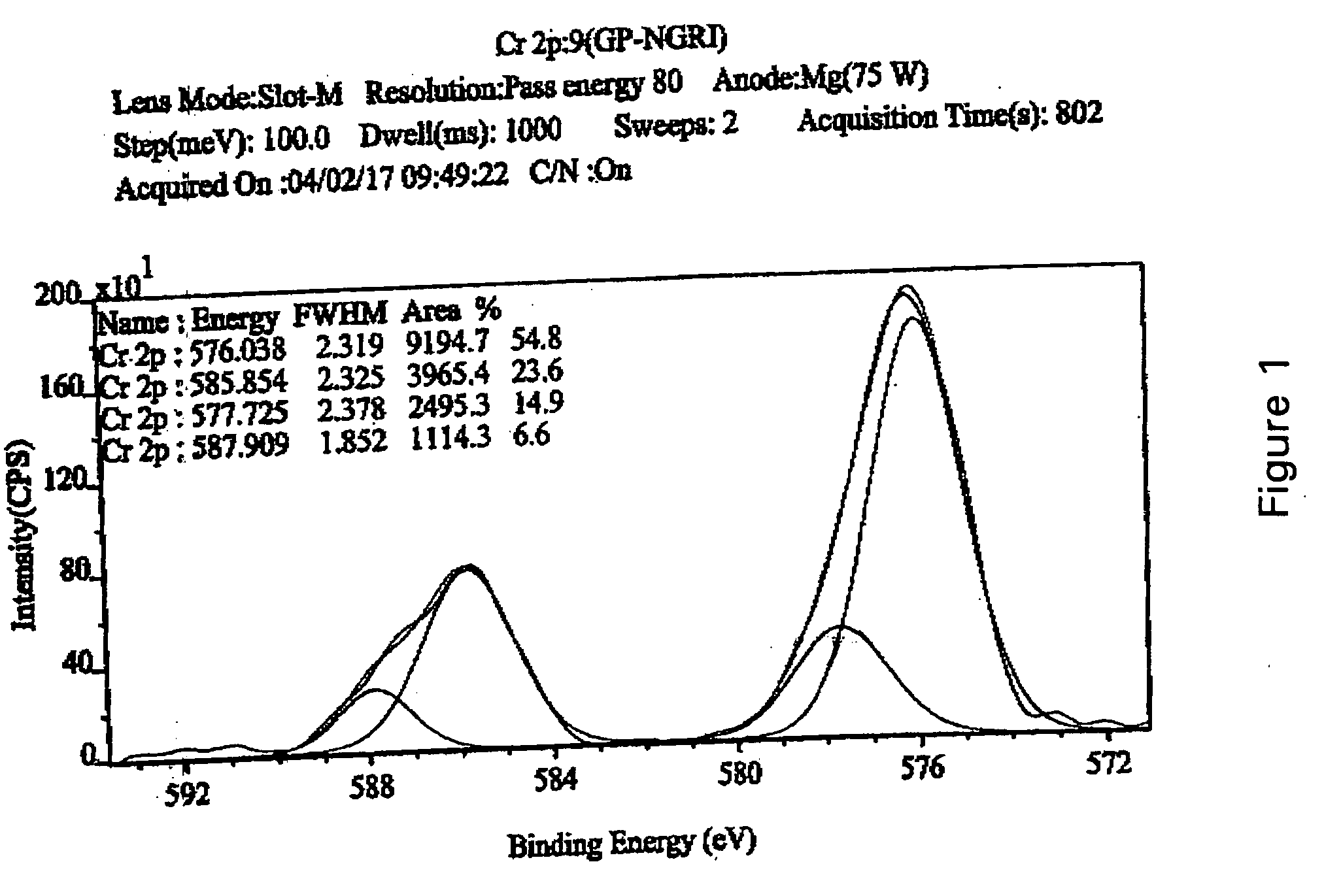

Microbial leaching and chemical fixing joint repairing method for heavily polluted soil of chromium slag yard

ActiveCN104550222AReduce acid-base adjustment processSimple processContaminated soil reclamationSlagPollution

The invention discloses a microbial leaching and chemical fixing joint repairing method for heavily polluted soil of a chromium slag yard. The method comprises the following steps: spraying soil or muck of a chromium slag yard with a composite bacteria liquid which is obtained by cultivating compound strains Pannonibacter phragmitetus BB and Achromobacter sp.Ch<-1>; restoring Cr(VI) in the obtained leacheate into Cr(III), forming sediments in an alkaline condition, precipitating and recycling chromium; and carrying out chemical fixing on the Cr(VI) which is not leached from the soil or muck through hydrazine hydrate. By virtue of the method, the soil and muck with three different Cr(VI) pollution levels are repaired; the total removal rates on chromium are respectively 11.4%, 30.2% and 14.0%; the removal rates on water-soluble Cr(VI) are respectively 99.6%, 99.5% and 98.3%; and the leaching toxicity concentration of the Cr(VI) in the soil or muck is lower than 0.5mg / L.

Owner:CENT SOUTH UNIV +1

Arsenic polluted soil remediating agent and application thereof

ActiveCN109158420ACause some damagesEffective elutionContaminated soil reclamationPollution soilTotal removal

The invention discloses an arsenic polluted soil remediating agent and an application thereof. A preparation method of the arsenic polluted soil remediating agent comprises steps of activation of a P11 strain, preparation of a fermentation broth, preparation of P11 dry powder, preparation of the arsenic polluted soil remediating agent and the like. The strain and culture medium materials used in the technical scheme are simple, easy to obtain and low in cost; the arsenic polluted soil remediating agent product is slightly acid, has the natural and most suitable pH (6.4+ / -0.2), the pH value isnot required to be adjusted during usage, the process is simplified, and secondarily, the pH is very close to that of common soil, so that the agent cannot harm to the soil. The arsenic polluted soilremediating agent can effectively elute arsenic in the soil and has the total removal rate of arsenic during ectopic leaching up to 95.52%; the P11 dry powder is used as a microbial fermented productand can be biodegraded, thus, the environment risk of the remediating agent remediation technology is reduced, and the agent causes small harm to the environment and cannot cause secondary pollution.

Owner:HUBEI NORMAL UNIV

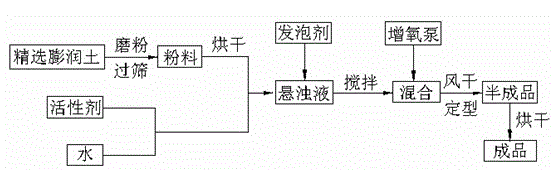

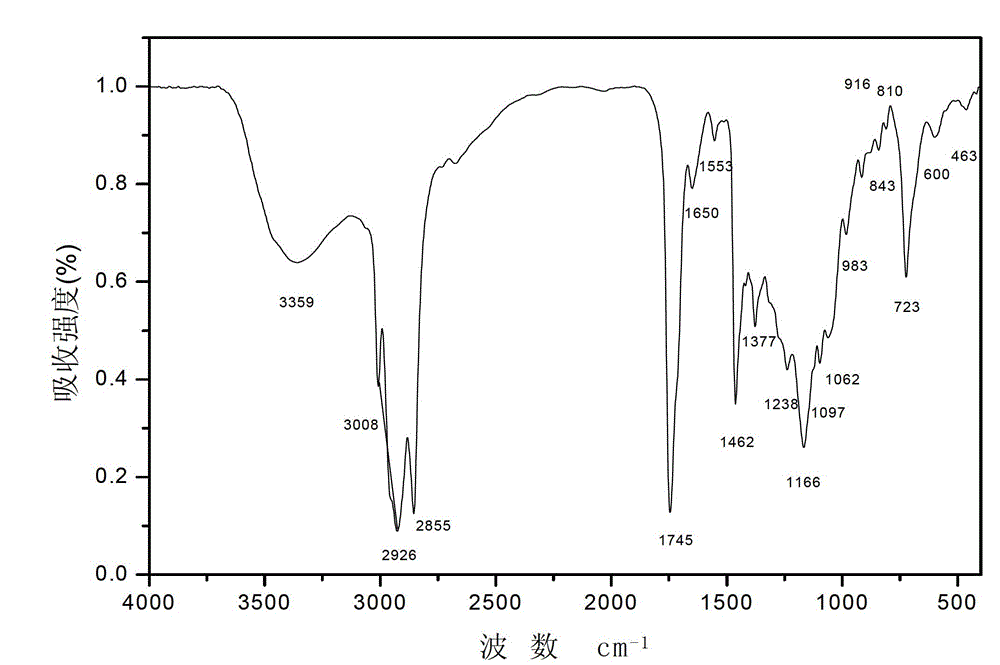

Bentonite compounded porous material and preparation method thereof

ActiveCN102908985ALarge specific surface areaImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionSodium BentoniteTotal removal

The invention discloses a bentonite compounded porous material and a preparation method thereof. The preparation method adopts bentonite as a basis material; and bentonite modification, porous modeling and other technical measures are adopted for changing the performance of bentonite, so as to prepare porous organic bentonite which has a large specific surface area and high adsorbability, and further prepare the bentonite compounded porous material capable of adsorbing various ions. The bentonite compounded porous material is used for adsorbing organic materials during industrial wastewater treatment and can avoid secondary pollution. The invention has the advantages that the process is simple; the raw materials are easy to obtain; the manufacturing cost is low; the effect of adsorbing COD, TP, TN and NH3-N in sewage is high; and the total removal ratio can be 95 percent.

Owner:中国非金属矿工业有限公司

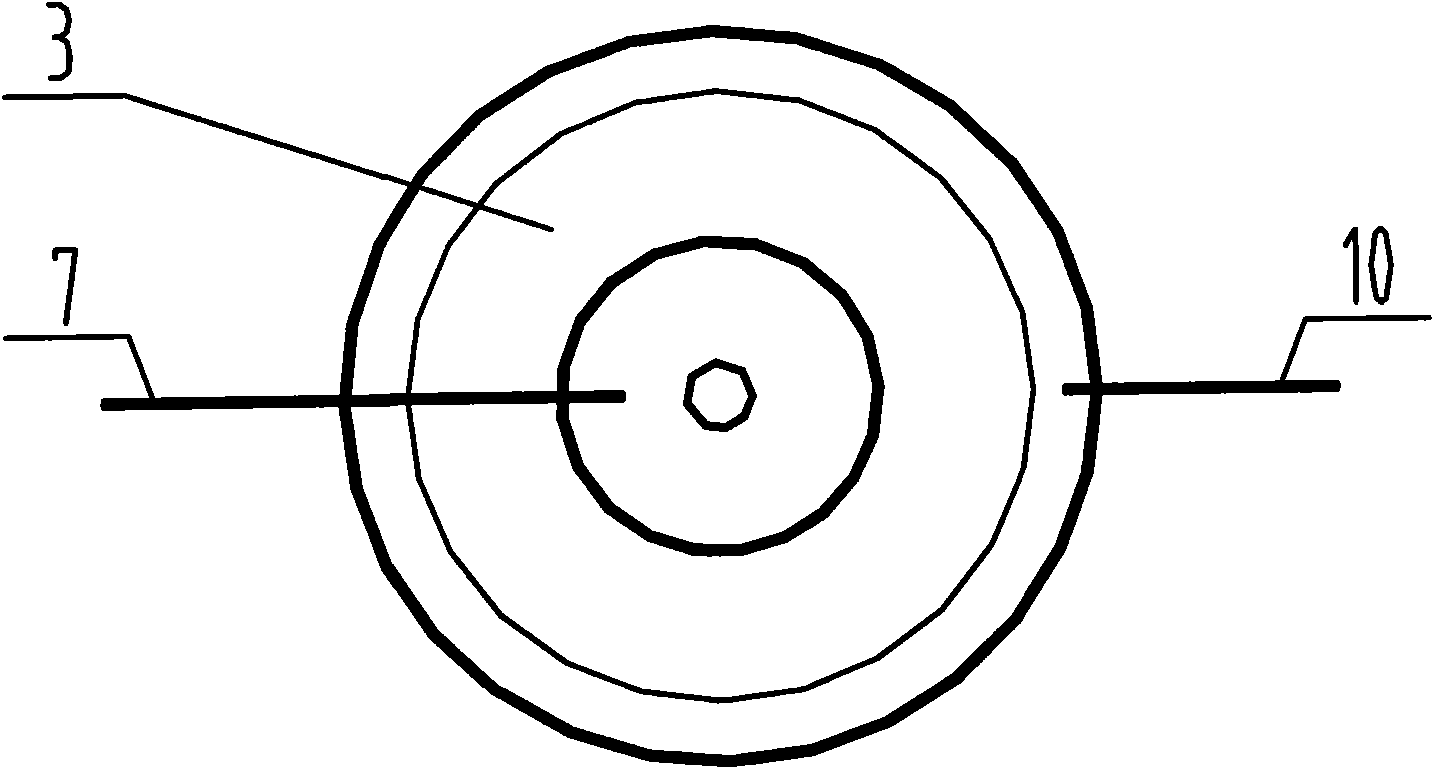

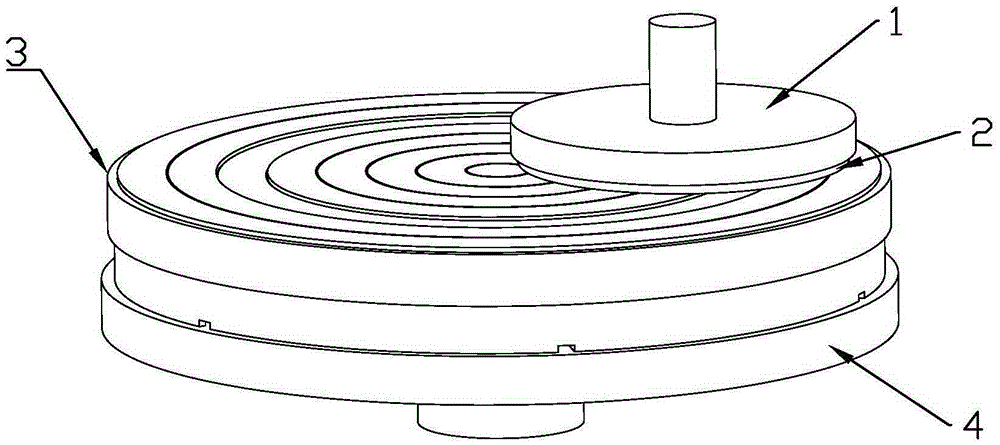

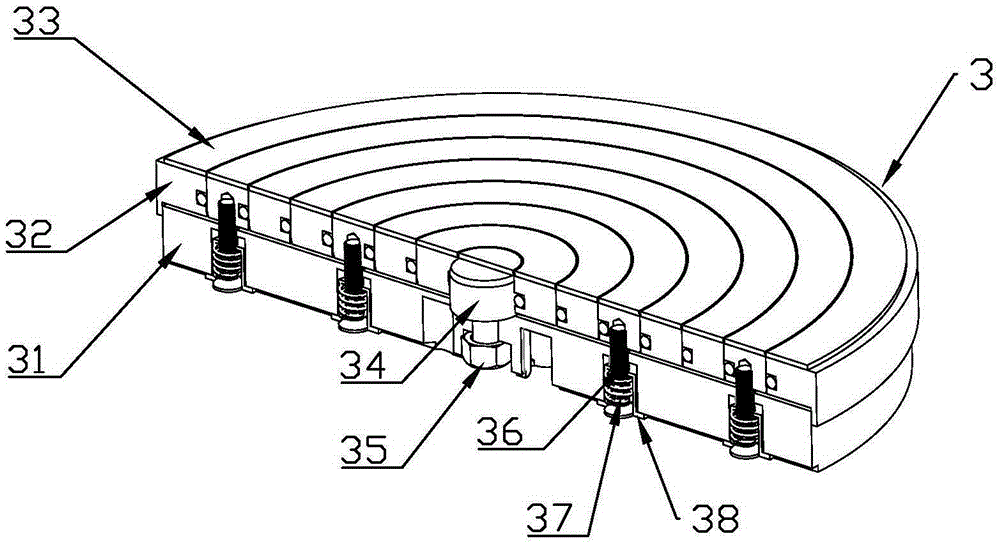

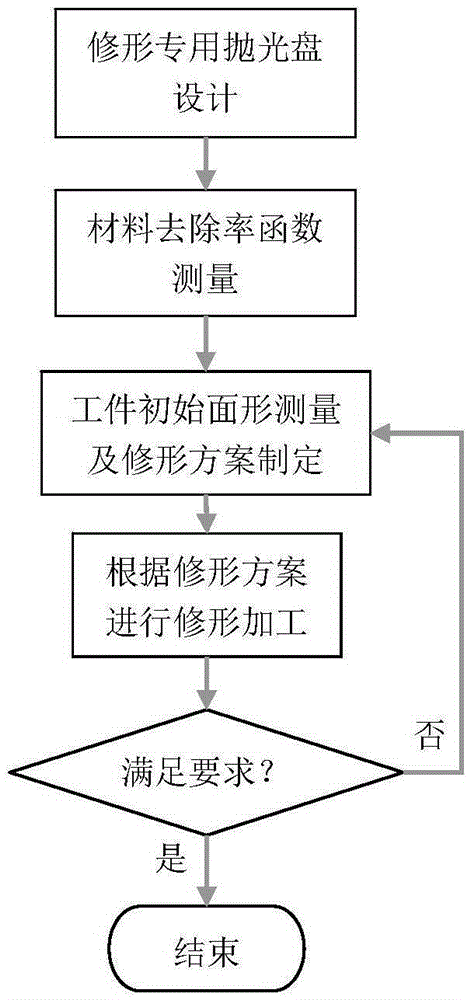

Profile correction machining method for high-precision plane of optical part

ActiveCN105397609ADistribution characteristics of different removal ratesAchieve deterministic processingPolishing machinesMaterial removalRadial position

The invention discloses a profile correction machining method for a high-precision plane of an optical part. According to the method, on the basis of traditional grinding and polishing methods, polishing pads located in annular areas in different radial positions of a special profile correction polishing disc are made not to have a material removing effect through the special profile correction polishing disc, and combined with process condition control, different material removal rate distribution curves are obtained; according to initial surface profile morphology deviation of the surface of a workpiece, machining time of process conditions corresponding to various material removal characteristics is designed, so that profile correction machining of the surface of the workpiece is achieved. An upper disc body of the polishing disc is composed of multiple concentric rings with a lifting function, different surface material removal rate distribution characteristics can be obtained, and deterministic machining is achieved. According to the method, profile correction schemes are designed according to the initial surface profile morphology deviation of the optical part, deterministic material removal machining is carried out on the surface, the total removal allowance is small, machining efficiency is high, and cost is low. The profile correction machining method is suitable for to-be-machined workpieces in different shapes and with different thicknesses.

Owner:DALIAN UNIV OF TECH

Treatment method for removing heavy metals from comprehensive electroplating wastewater

InactiveCN105439314AHigh removal rateImprove adsorption capacityWater contaminantsWaste water treatment from metallurgical processFlocculationTotal removal

The invention relates to a treatment method for removing heavy metals from comprehensive electroplating wastewater, belonging to the technical field of industrial wastewater treatment. According to the treatment method, the relatively good integral removal effect of the heavy metals in the comprehensive electroplating wastewater is achieved. The treatment method comprises the following steps: adding a heavy metal ion trapping agent into the comprehensive electroplating wastewater, regulating the pH value of the wastewater to be 3-7, then controlling the temperature at 20-30 DEG C, and adequately reacting to generate chelate from heavy metals in the electroplating wastewater and the heavy metal ion trapping agent, wherein the comprehensive electroplating wastewater contains heavy metals including copper, chromium and nickel; adding a flocculating agent for flocculation, keeping the pH value of a system in the flocculation process at 3-7, carrying out static settlement, filtering to remove precipitates to obtain electroplating wastewater in which copper ions are removed, then regulating the pH value to be neutral, and discharging. According to the treatment method, the relatively good heavy metal removal effect can be achieved, and the total removal rate of the heavy metals in the comprehensive wastewater can reach 96% or more.

Owner:TAIZHOU UNIV

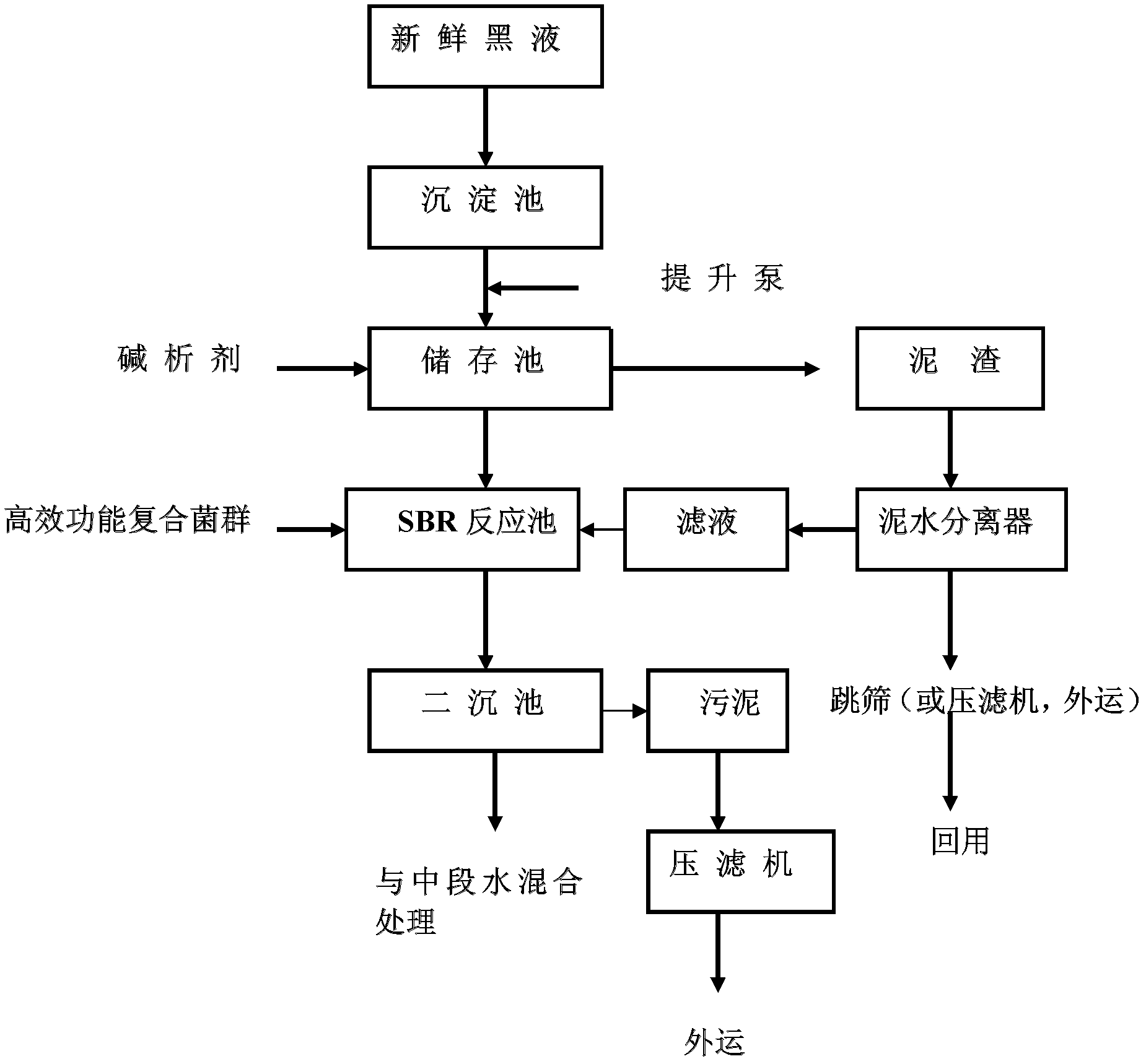

Treatment method of papermaking black liquor

The invention relates to a treatment method which is suitable for papermaking black liquor (in particular to alkaline pulping papermaking black liquor which takes wheat straw hood as raw material). The treatment method comprises the following steps of: firstly performing standing treatment on the fresh black liquor, adding a high-efficient alkaline separation agent into the black liquor after treatment, separating out lignin, and further performing biological strengthening technical treatment on filtrate. According to the process disclosed by the invention, after the combined treatment of thestanding treatment, an alkaline separation method and a biological strengthening system is performed on the black liquor with initial COD (chemical oxygen demand) of 83,000mg / l, pH of 13.1 and chromaticity of 225,000CU, the COD and chromaticity of outlet water are respectively reduced to below 15% and 7% of the original black liquor (namely the COD total removal rate and chromaticity total removal rate of the whole system are about 85% and 93% respectively), the outlet water can be mixed with a quite large quantity of middle-stage wastewater in a papermaking factory, and the treatment can be performed according to the existing comparatively mature middle-stage wastewater treatment method. The process has the characteristics of low investment and operation cost and capability of recycling the lignin, and is suitable for wheat straw pulp papermaking factories above 5000 tons.

Owner:CENT SOUTH UNIV

Method for adsorption and reduction of hexavalent chromium by using ferrous-saponite

InactiveUS20060016757A1Simple procedureWater/sewage treatment by centrifugal separationWater contaminantsTotal removalHexavalent chromium

The present invention relates to the development of an improved methodology for adsorption and subsequent reduction of hexavalent chromium aimed at the total removal of hexavalent chromium in water, which comprises, reacting dichromate solutions with natural ferrous-saponite clays at temperature 50 to 200° C. for the period of 1 to 3.0 hours.

Owner:COUNCIL OF SCI & IND RES

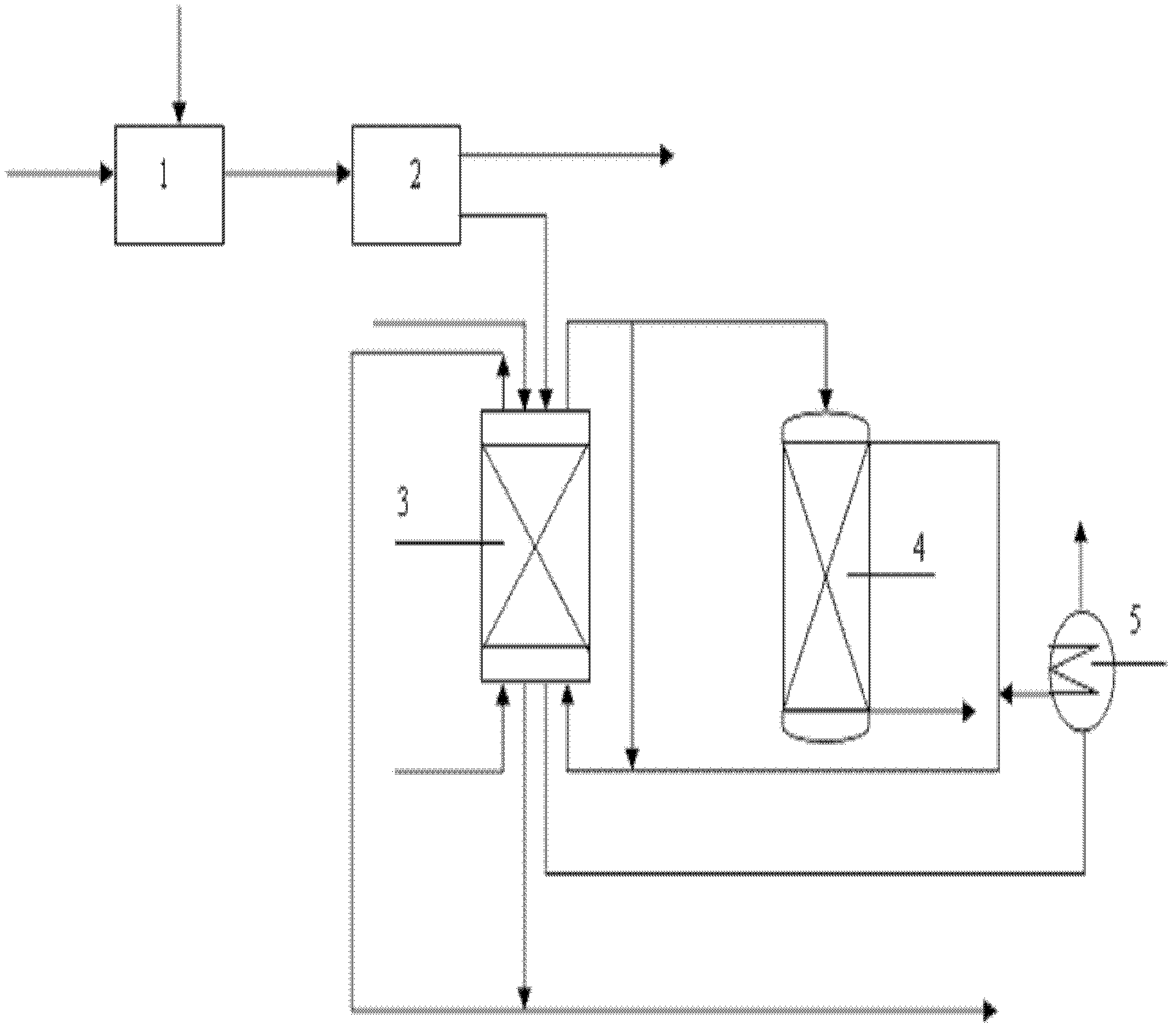

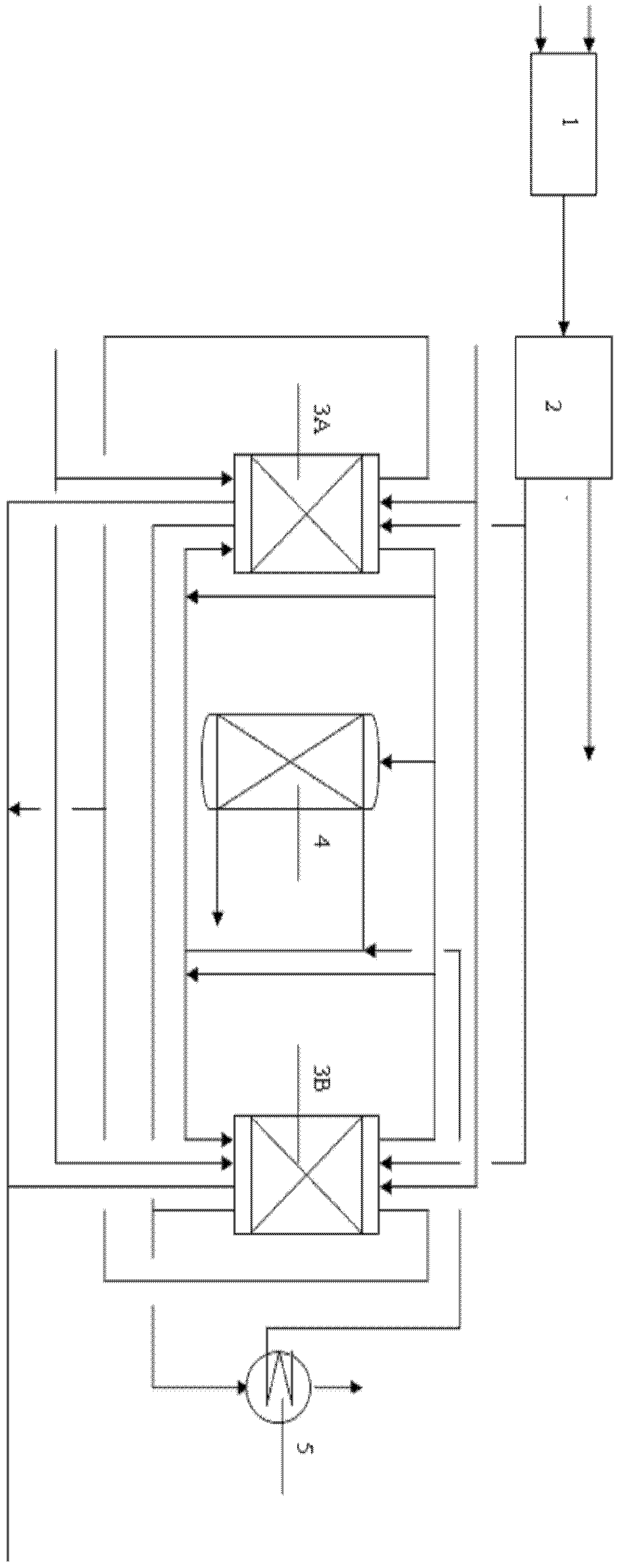

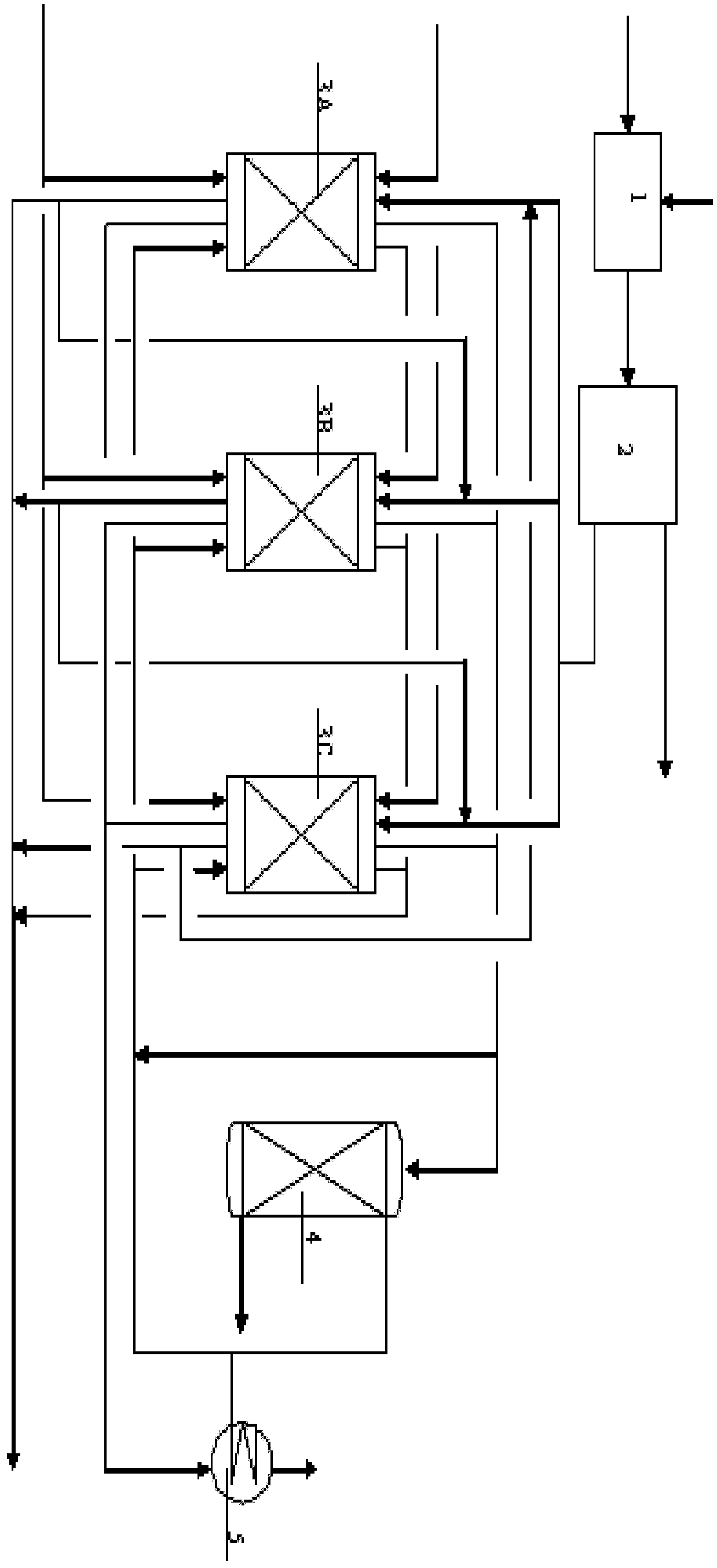

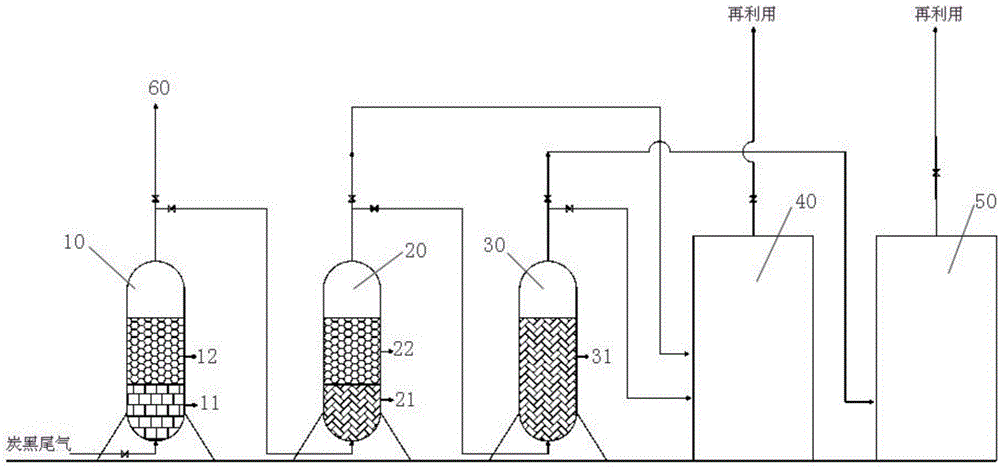

Method for separating and comprehensively utilizing gases in carbon black tail gas and device for realizing method

ActiveCN104624018AHigh calorific valueSimplified separation stepsDispersed particle separationCombustionTotal removal

The invention relates to a method for separating and comprehensively utilizing gases in carbon black tail gas and a device for realizing the method. The method for separating and comprehensively utilizing gases in carbon black tail gas comprises the following steps: separating H2O from sulfurous gas by adopting first-stage pressure swing adsorption, separating H2 from N2, CO and CO2 by adopting second-stage pressure swing adsorption, and then separating N2 from CO and CO2 by adopting a third-stage pressure swing adsorption, wherein the H2 separated by the second-stage pressure swing adsorption and the CO and the CO2 which are separated by the third-stage pressure swing adsorption are used as fuels of carbon black combustion and tail gas combustion, and the N2 separated by the third-stage pressure swing adsorption is used for treating the surface of the carbon black. The method has the beneficial effects that steps of separating H2O from the sulfurous gas are simplified, the total removal rate of the H2O gas and the sulfurous gas reaches above 98 percent; the H2 and the N2 are separated respectively by adopting a cooperation effect of the second-stage pressure swing adsorption and the third-stage pressure swing adsorption, so that the separating rate of the H2 and the N2 is improved, and the heat value of the treated tail gas is improved by above 3500kcal / m<3>.

Owner:QINGDAO BLACK CAT CARBON BLACK TECH

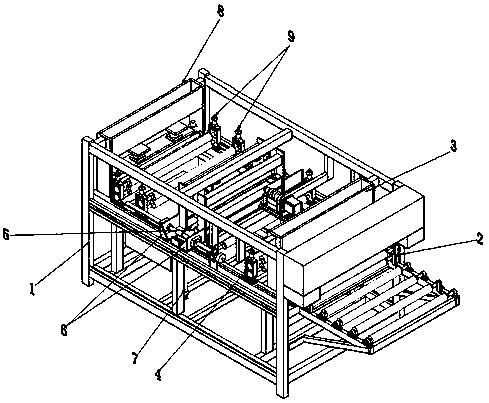

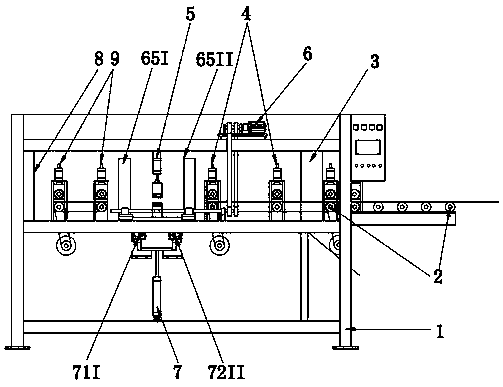

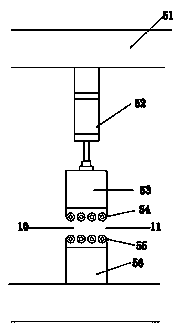

Veneer longitudinal glue jointer

InactiveCN110466012APlay a limiting roleAchieving Horizontal StitchingProfiling/shaping machinesWood veneer joiningFeeding forceTotal removal

The invention discloses a veneer longitudinal glue jointer. The veneer longitudinal glue jointer comprises a main frame, a tooth cutting device, a tooth cutting conveyor, a toothing conveyor, a totalremoval conveyor, a clamping plate moving device, a sealing robot, a toothing device, and a total removal device; the toothing end of a veneer displaced in a horizontal direction is limited by arranging four downward pressing cooling pipes and four supporting and cooling pipes; the toothing end of the veneer is displaced in the same horizontal plane; the leveling of connectors of the toothing parts of veneers with different thicknesses can be realized; the smooth toothing of the veneers of less than 1mm can be also be completed by combing the small transfer error of a lead screw of the clamping plate moving device and a conveying roller in a transfer process; as the downward pressing cooling pipes and the supporting and cooling pipes are set to be capable of rotating, the downward pressingcooling pipes and the supporting and cooling pipes can move evenly and rotate along the veneer, the resistance of the middle plate toothing process is reduced, and the veneers of different thicknesscan be squeezed and fed; the complete meshing of the toothing position is realized; the toothing accuracy is improved; the extrusion and feeding force applied to the veneers can be relatively small; and the energy consumption is saved.

Owner:广州市俊金机械有限公司

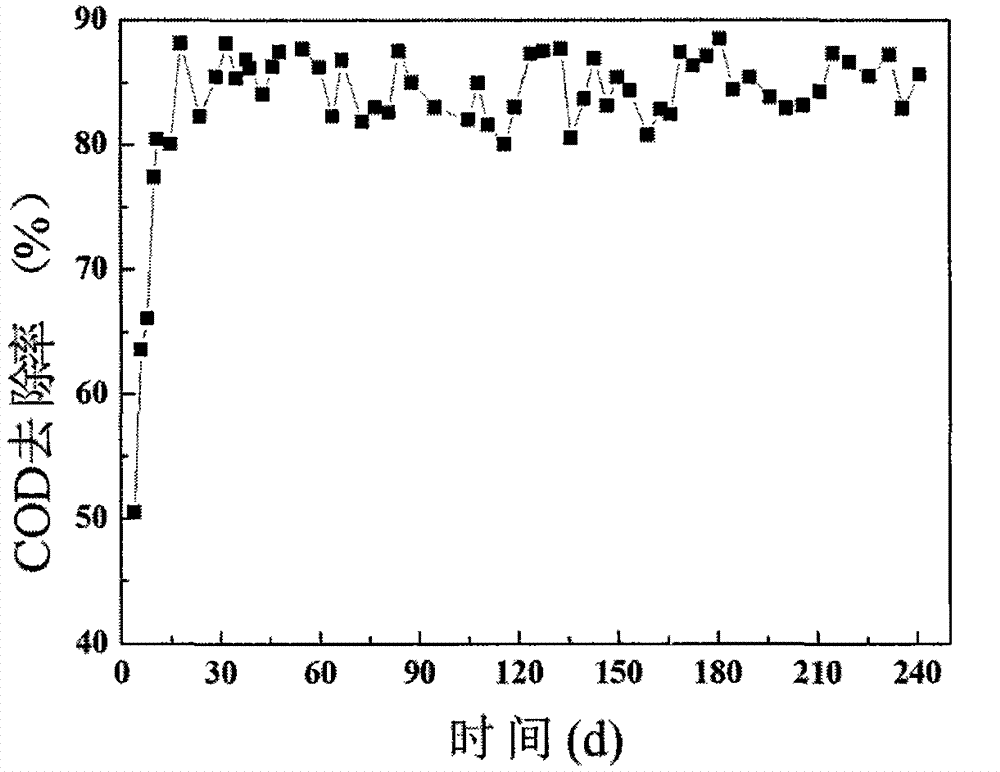

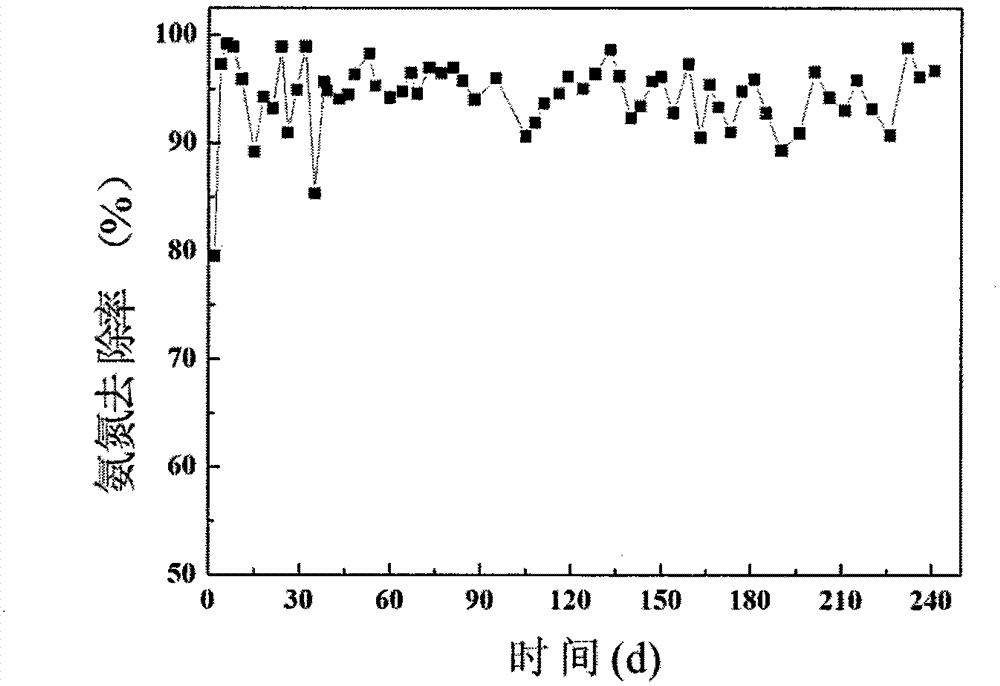

Treatment method for printing and dyeing wastewater

InactiveCN104230121AImprove biodegradabilityStrong removal rateMultistage water/sewage treatmentWaste water treatment from textile industryChemical oxygen demandTreatment effect

The invention relates to a treatment method for printing and dyeing wastewater, and belongs to the field of methods for wastewater treatment. The treatment method for printing and dyeing wastewater comprises the following steps: removing impurities from the printing and dyeing wastewater through grids, feeding the wastewater to a regulating reservoir, utilizing a pump to lift the wastewater up to enter a hydrolysis acidification pool, conducting hydrolytic acidification, discharging the acidified water to an aerobiotic pool, conducting aeration and oxidation, discharging the wastewater from the aerobiotic pool to a sand filter, after precipitation and filtration, feeding the wastewater to a chemical oxidation pool, oxidizing the wastewater and draining when the water reaches the standard. The treatment method disclosed by the invention combines multiple treatment manners to comprehensively treat the wastewater; a total removal rate of COD (Chemical Oxygen Demand) in the wastewater by the treatment method is up to 84.4%, and the chromaticity removal rate is up to 97.2%; through practical application, by the treatment method, the precipitated sludge is fully returned to the anaerobic pool, so no residual sludge is discharged; the system is stable in running, convenient to manage, and capable of achieving a good treatment effect to obtain environment benefits and social benefits.

Owner:XIAN HUALU ENVIRONMENTAL PROTECTION EQUIP

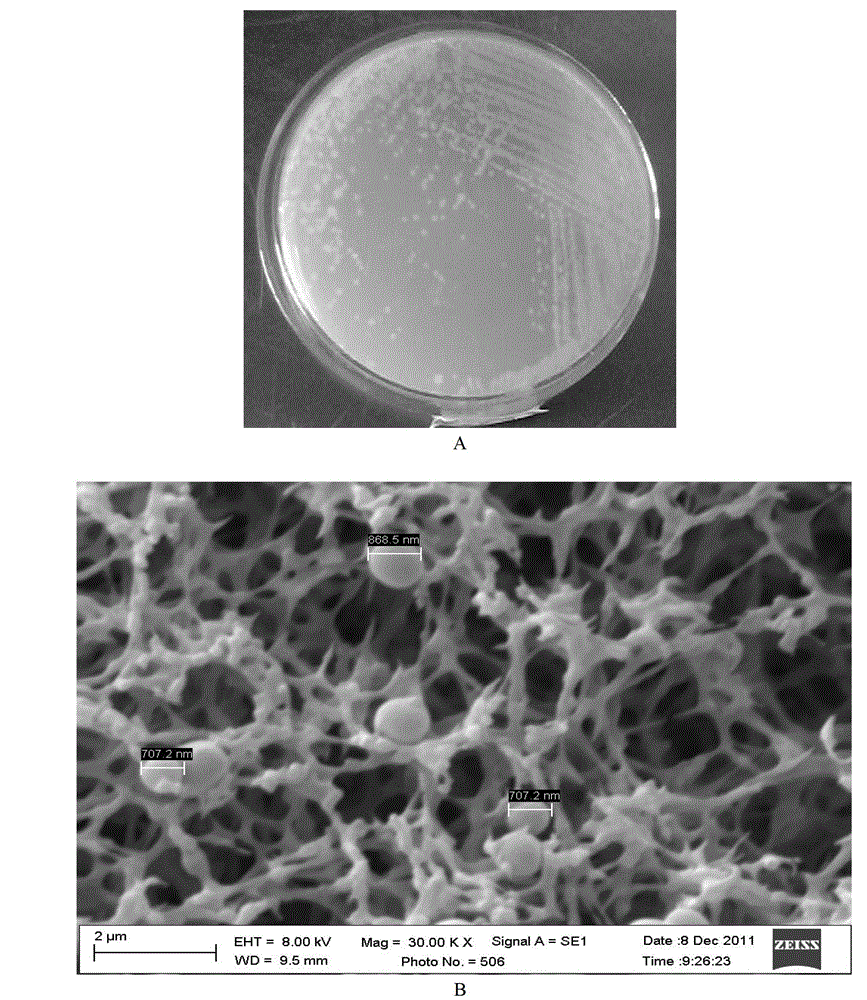

Crude oil degrading bacterium for producing lipid biosurfactant and application

ActiveCN102978135AObvious emulsificationSignificant solubilizationBacteriaMicroorganism based processesMicroorganismTotal removal

Owner:SOUTH CHINA UNIV OF TECH

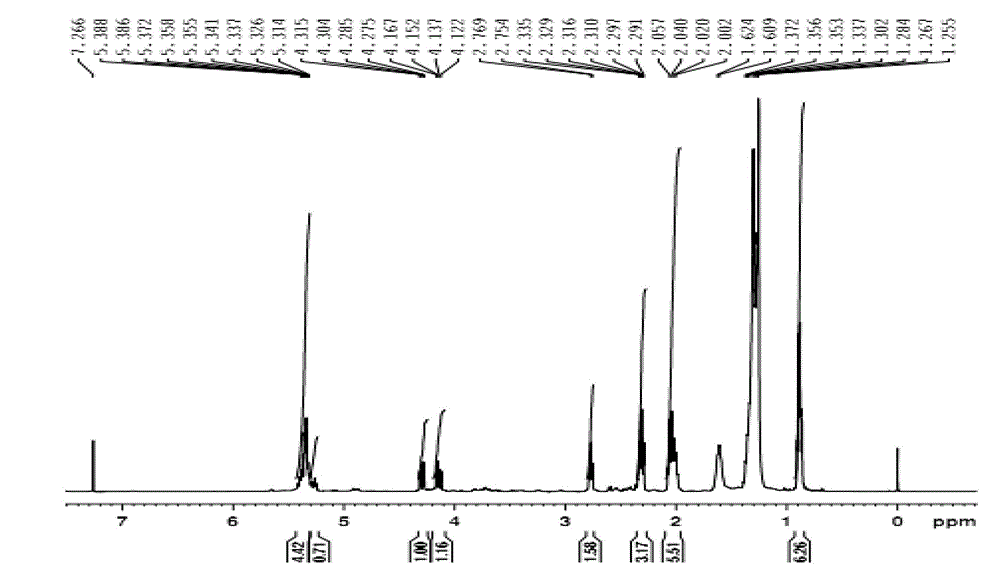

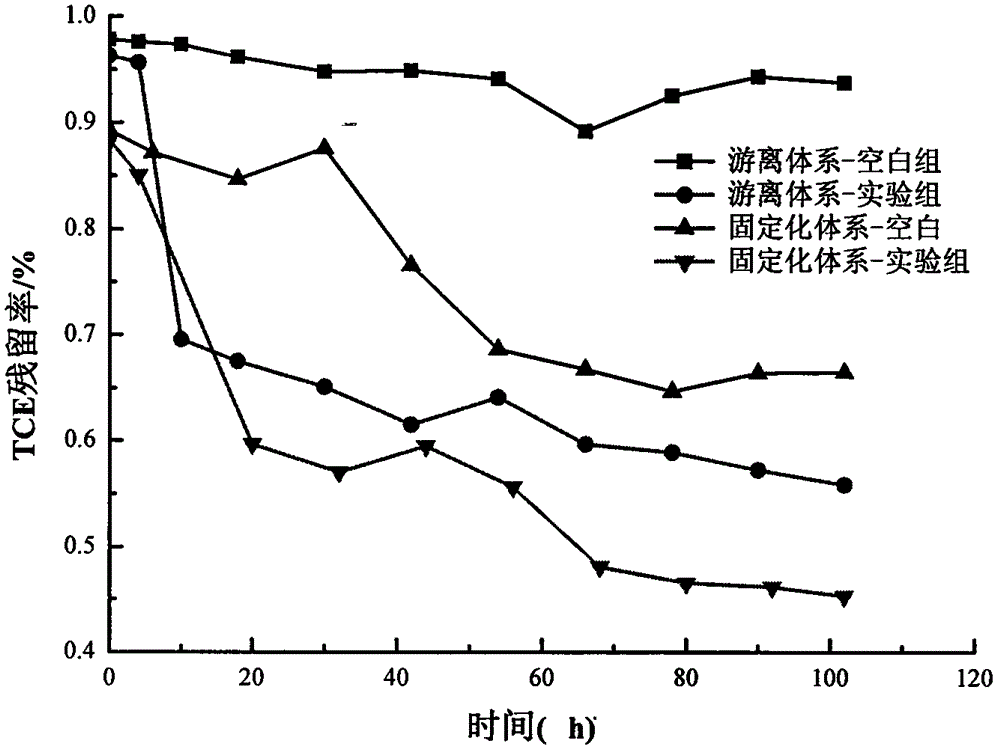

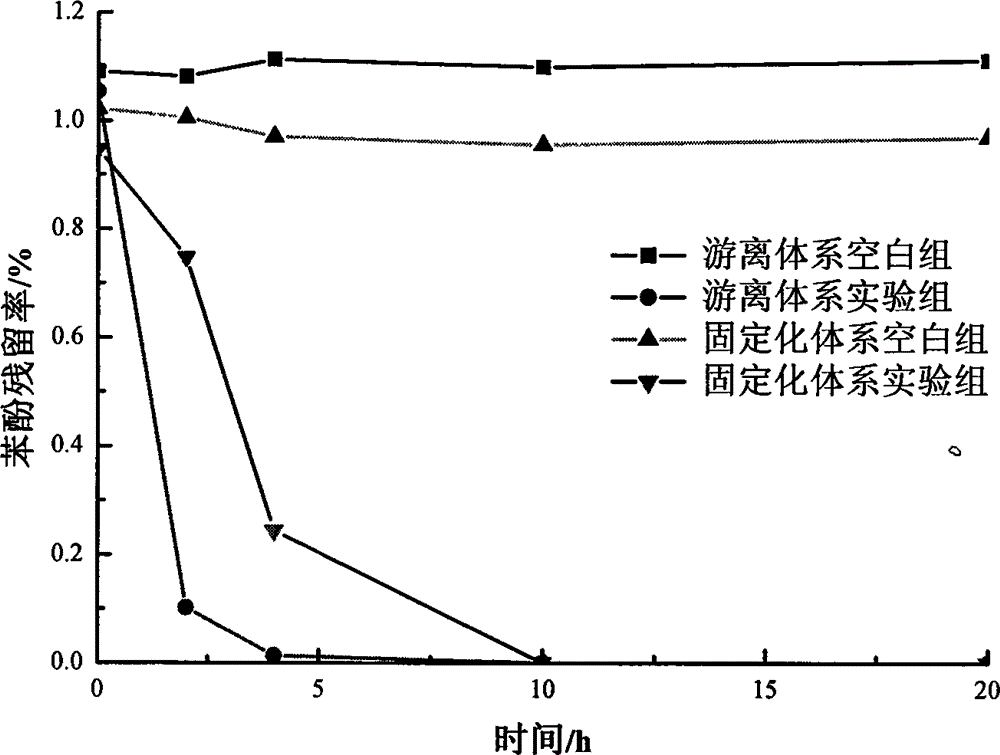

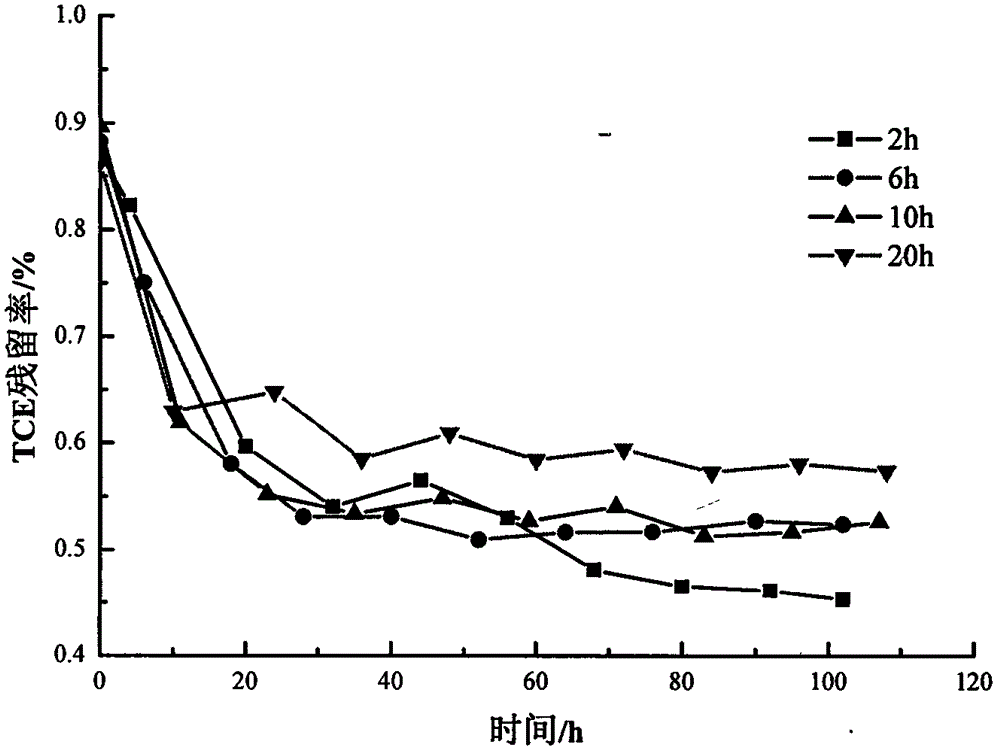

Method for degrading trichloroethylene by virtue of biological carbon immobilized microorganism co-metabolism

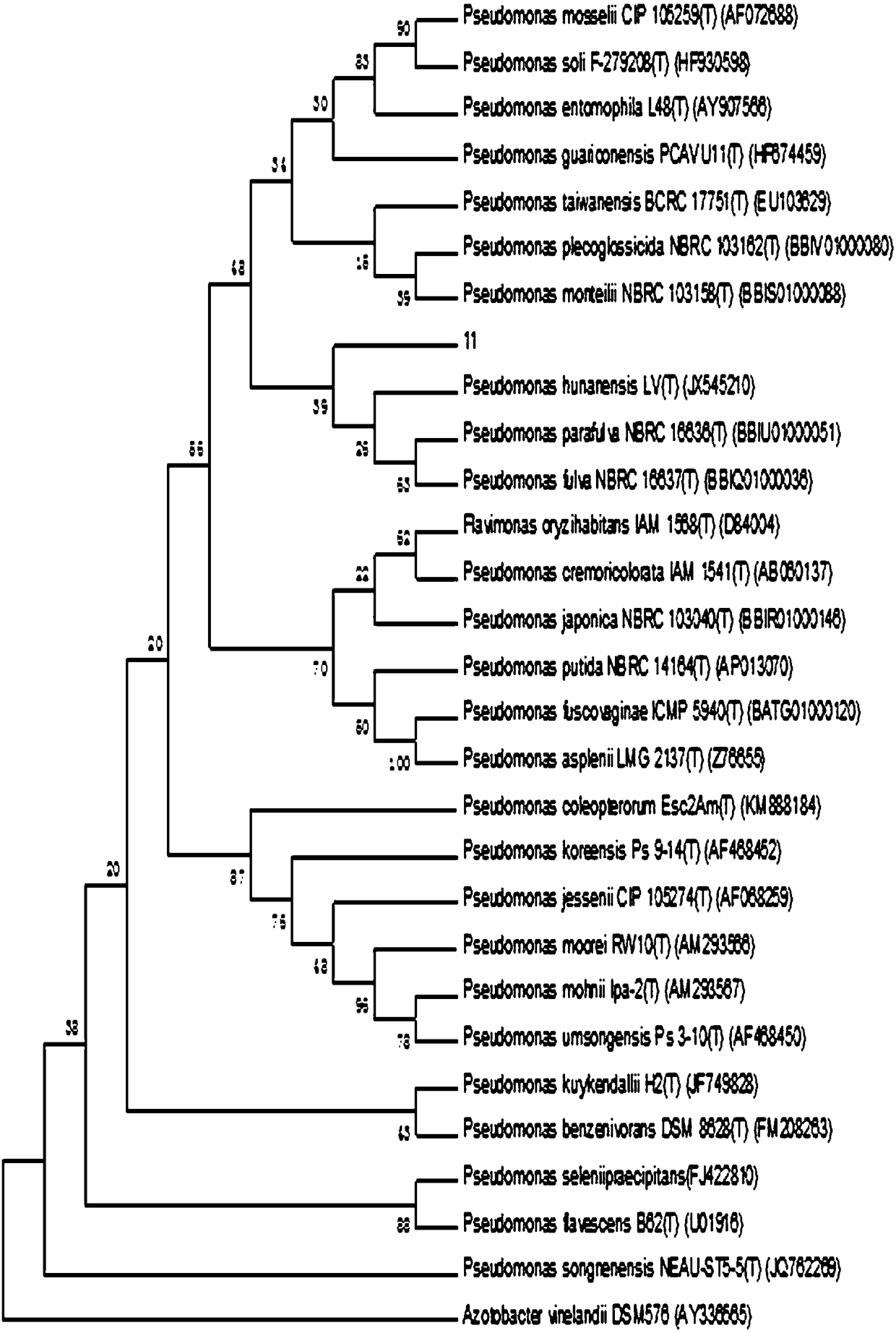

InactiveCN104450669AHigh removal rateThe result is obviousContaminated soil reclamationOn/in inorganic carrierPseudomonas fluorescensTrichloroethylene

The invention discloses a method for degrading trichloroethylene (TCE) by virtue of biological carbon immobilized microorganism co-metabolism, and belongs to the technical field of treatment with immobilized microorganisms. Biological carbon is a novel material, has an impact cascaded lamellar structure, has intensive micro-pores on the surface, and is relatively large in specific area and good in adsorption performance. The invention provides the method for degrading TCE in soil by virtue of co-metabolism by taking the biological carbon as a carrier, adopting an adsorption method to immobilize pseudomonas fluorescens and taking phenol as a substrate for the first time. By adopting the method, the degradation differences of TCE and phenol in two types of systems are compared, and the influence on the TCE degradation in an immobilization system by the adsorption time, pH value, TCE concentration, salinity and amount of added bacteria is inspected. Compared with a free system, the total removal rate of TCE by the immobilization system is improved by 15% and reaches 55%, and the tolerance of the immobilization system to bad environments is enhanced. The method disclosed by the invention adopts the adsorption method and takes the novel material namely biological carbon as the carrier to provide a new method for an immobilized microorganism technology.

Owner:NANKAI UNIV

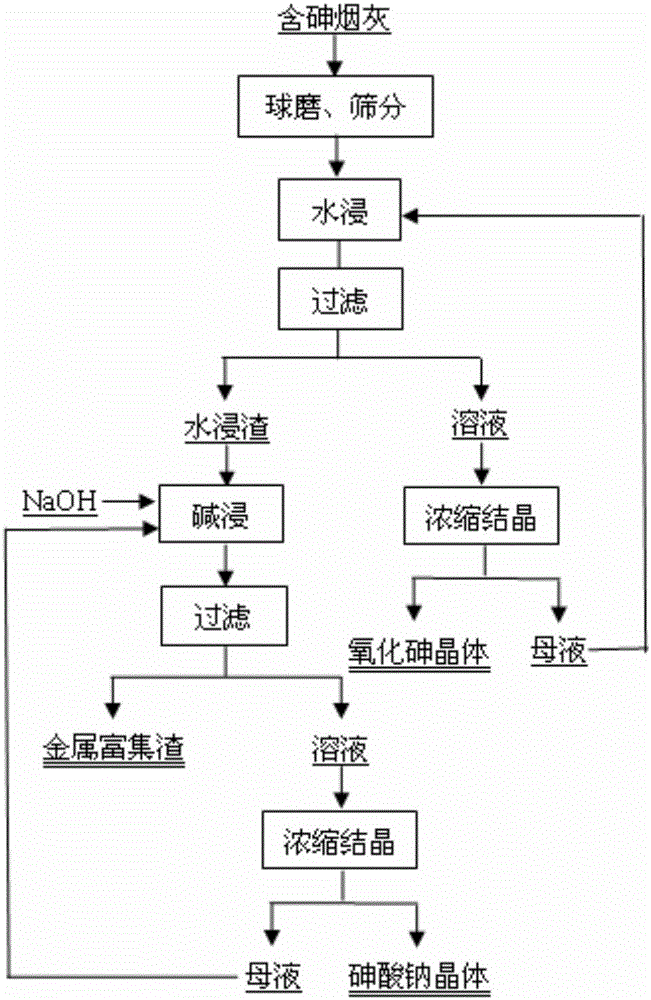

Method for pre-removing arsenic in arsenic-containing soot

ActiveCN106636657AAchieve separationAchieve recyclingProcess efficiency improvementPregnant leach solutionTotal removal

The invention discloses a method for pre-removing arsenic in arsenic-containing soot. The method is characterized in that the arsenic-containing soot is taken as a raw material; the arsenic is pre-removed by adopting a two-stage leaching process, wherein the first stage is hot water leaching; the second stage is alkaline leaching; leachates at the two stages are respectively cooled and crystallized to obtain arsenic-containing crystal; the total removal rate of the arsenic in the whole process is 98 percent or higher, so that the removal of the arsenic at a source is realized to avoid the enrichment and the pollution of the arsenic; meanwhile, coppers, leads and other valuable metals are enriched in leaching residues so as to be further recovered through a wet process. Therefore, the double purposes of economy and environmental protection are realized.

Owner:CENT SOUTH UNIV

Method for removing lignin through biological treatment of plant fibrous material hydrolysate

The invention relates to a method for removing lignin through biological treatment of plant fibrous material hydrolysate. According to the method, horse radish peroxidase treatment and then cationic polymer flocculation treatment are performed on the plant fibrous material hydrolysate, horse radish peroxidase treatment can ensure that low molecular weight dissolved lignin in the hydrolysate is polymerized into macromolecular lignin, and a part of lignin is removed through precipitation; after the lignin is subjected to horse radish peroxidase treatment, even if the part of the lignin which isnot separated out through precipitation is easier to remove in the subsequent cationic polymer flocculation treatment because of polymerization and increasing of molecular weight, and then cationic polymer treatment is adopted, so that residual lignin is further removed. The method can greatly improve the total removal rate of lignin through the combination of horse radish peroxidase treatment andcationic polymer treatment, and meanwhile can further obviously reduce the loss of sugar during the cationic polymer treatment.

Owner:QILU UNIV OF TECH

Treatment method of Fischer-Tropsch synthetic reaction wastewater

ActiveCN102107985BReduce energy consumptionSave waterWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentIon exchangeOxygen

The invention relates to a treatment method of the Fischer-Tropsch synthetic reaction wastewater. The method comprises the following steps: aerating the Fischer-Tropsch synthetic reaction wastewater, oxidizing, neutralizing, filtering, performing biochemical treatment, softening, performing ion exchange and / or membrane separation treatment, etc. The treatment method is characterized in that the oxygen-containing compounds in the Fischer-Tropsch synthetic reaction wastewater are removed by a method and the method comprises the following steps: adding oxidant in the Fischer-Tropsch synthetic reaction wastewater, selectively adding pro-oxidant to ensure that the organic oxygen-containing compounds in the wastewater are oxidized to the corresponding acids; using calcium oxide or calcium hydroxide to neutralize the acids and form calcium salt precipitate and filtering to remove the precipitate. By adopting the method of the invention, the oxygen-containing compounds in the Fischer-Tropsch synthetic reaction wastewater can be effectively removed; and the total removal rate is more than 98% and the treated Fischer-Tropsch reaction wastewater can meet the quality standard of cooling water or boiler water.

Owner:SYNFUELS CHINA TECH CO LTD

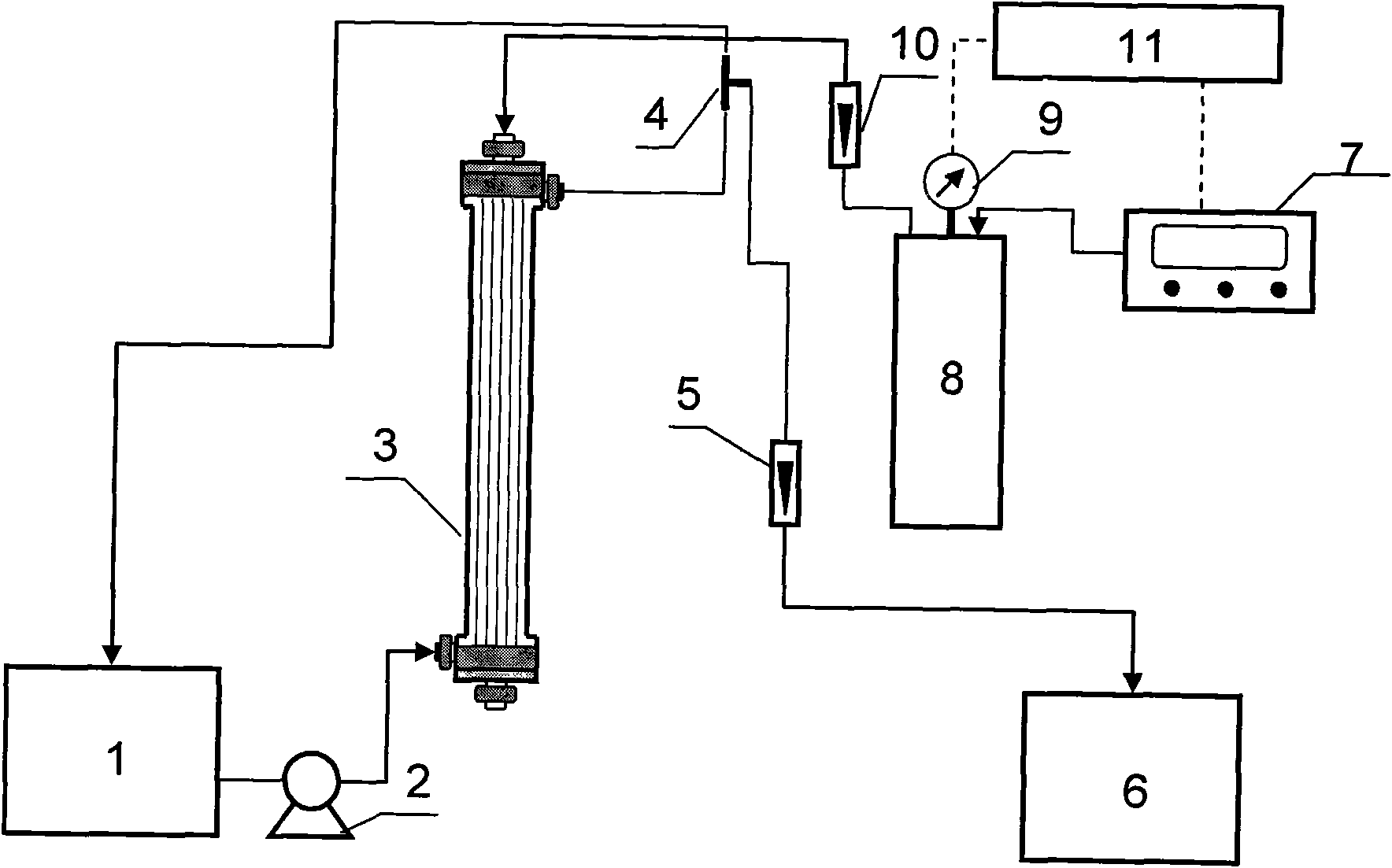

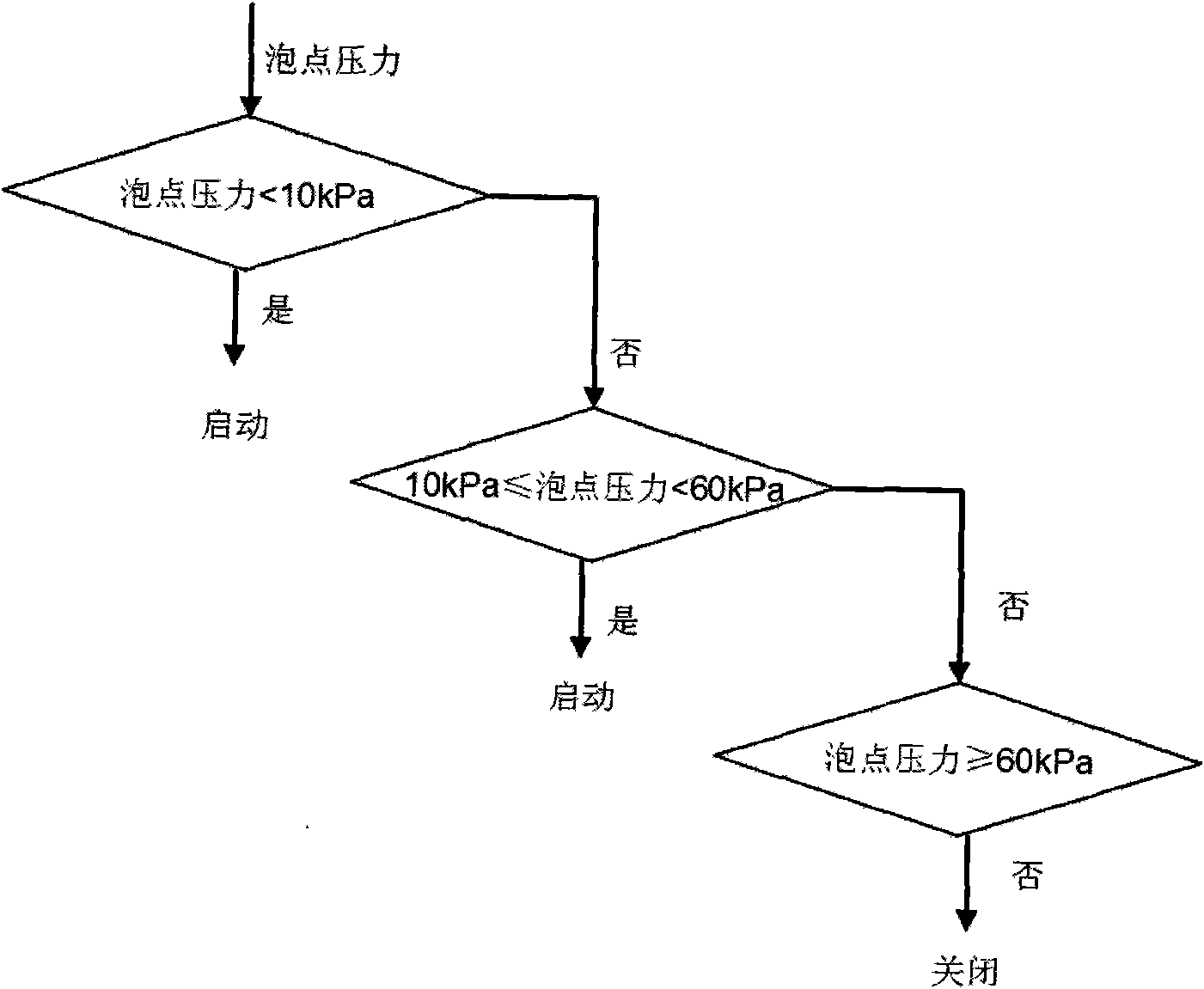

Catalyzed ozonation film reactor with total removal rate of organic carbon over 99%

InactiveCN101643267AHighlight substantiveSignificant progressWater/sewage treatment by oxidationFiberAutomatic control

The invention relates to a catalyzed ozonation film reactor with total removal rate of organic carbon over 99%, which mainly comprises a original water tank, a treatment water tank and an ozone generator, wherein the outlet of the original water tank is connected with an inlet at the lower part of the side of a newly arranged film assembly by a pipeline and a metering pump on the pipeline; the outlet of the ozone generator is connected with an inlet at the top of a buffer tank by a pipeline; an outlet at the top of the buffer tank is communicated with a hollow fiber film inner-cavity through the inlet on the top of the film assembly by a pipeline and a gas flow meter on the pipeline; after a water outlet at the upper part of the side of the film assembly is connected with a pipeline and athree-way pipe on the pipeline to form two pathes, one path is connected with the original water tank, and the other path is connected with the treatment water tank through a flow meter on the original water tank. The ozone generator and a pressure sensor on the top of the buffer tank are respectively connected with a PLC automatic control device by an electric wire. Hollow fiber film threads formed by blending nanometer TiO2 with polyvinylidene fluoride is filled in the film assembly. The ozone becomes liquid phase through the hollow fiber film inner-cavity of the film assembly in the existence of bubble points.

Owner:NORTHEAST DIANLI UNIVERSITY

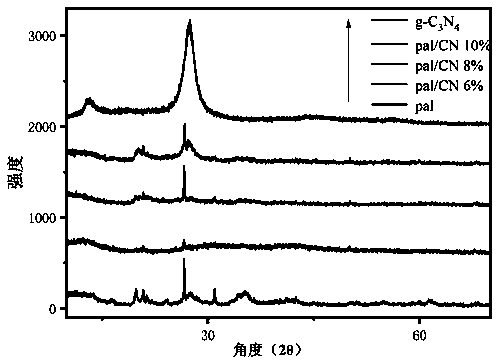

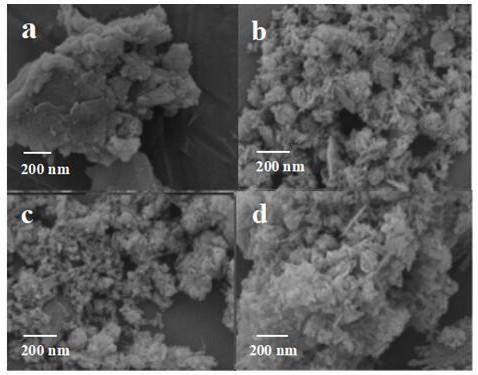

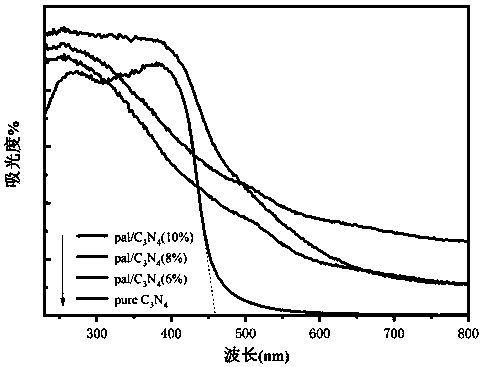

Preparation and application of palygorskite/graphite phase carbon nitride compound composite material

InactiveCN110252379AIncrease light absorption intensityEfficient removal effectPhysical/chemical process catalystsWater/sewage treatment by irradiationWater bathsTetracycline Hydrochloride

The invention discloses preparation and application of a palygorskite / graphite phase carbon nitride compound composite material. The preparation method of the pal / g-C3N4 composite material includes: subjecting palygorskite to ultrasonic dispersion in distilled water, adding dicyandiamide and mixing the substances evenly, and then performing ultrasonic treatment for 0.5-1h; conducting heating to 45-50DEG C, and further performing stirring till complete dryness by evaporation, conducting grinding into powder, placing the product in a muffle furnace, and conducting calcination at 520-550DEG C for 3.5-4h; performing cooling to room temperature, and then conducting grinding into powder, thus obtaining the pal / g-C3N4 composite material. The invention adopts water bath method to compound dicyandiamide and palygorskite to successfully prepare the pal / g-C3N4 composite material, the catalytic activity of g-C3N4 is combined with the adsorption performance of palygorskite, and the two substances cooperate to enhance the light absorption intensity of the composite sample, thus improving the photocatalytic efficiency, and reaching the effect of efficient removal of pollutants. Experiments show that the composite catalytic material has high catalytic oxidation rate on tetracycline hydrochloride, and the total removal rate reaches 85%.

Owner:NORTHWEST NORMAL UNIVERSITY

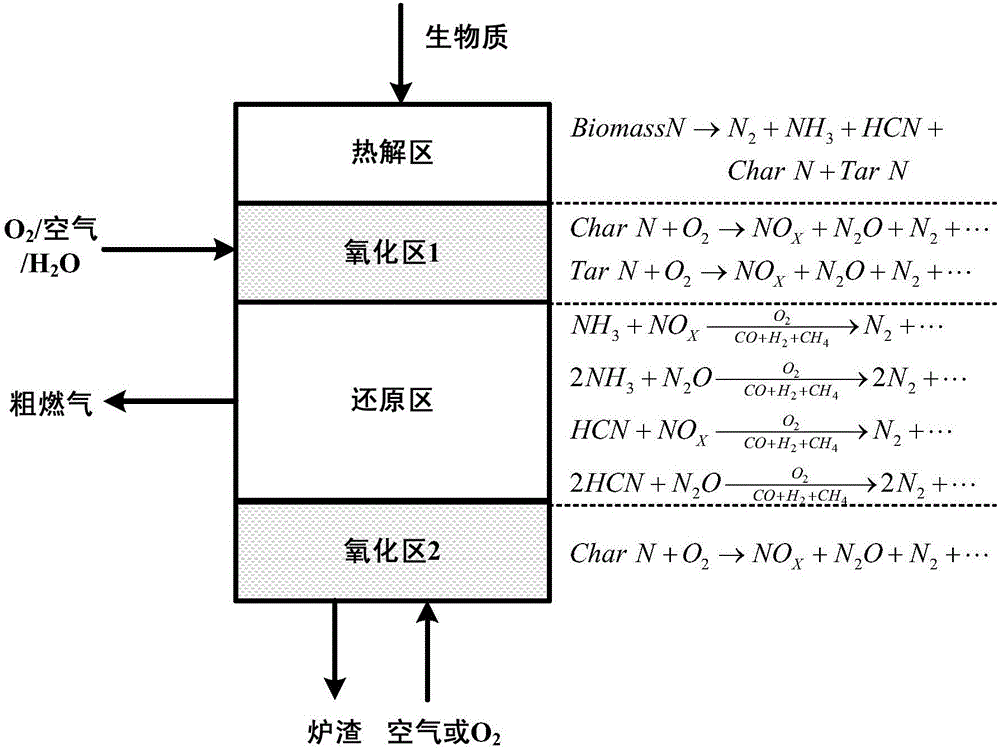

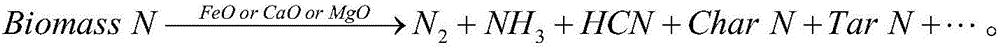

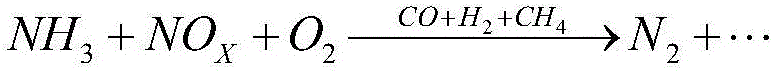

Method for in-situ removal of nitrogen pollutants in biomass fuel gas in biomass gasifier

ActiveCN105838453AReduce contentEfficient removalNitrous oxide captureDispersed particle separationCatalytic pyrolysisNitrogen

The invention discloses a method for in-situ removal of nitrogen pollutants in biomass fuel gas in a biomass gasifier. An exogenous metal-based catalyst is added into biomass in the biomass gasifier and combined with the catalytic action of endogenous mineral components of the biomass to enable the biomass to be subjected to catalytic pyrolysis, biomass nitrogen is converted into N2 in a high selectivity manner, HCN and NH3 produced by self pyrolysis of the biomass are used to reduce NOx and N2O produced by semi-coke oxidation, the biomass nitrogen is catalyzed to be converted into nitrogen in an oriented manner during the process of biomass gasification, pollution control with pollutants is realized, most of nitrogen is converted into N2 in the gasifier to the uttermost extent, content of the nitrogen pollutants in gasification crude gas is reduced from the source, efficient in-situ removal of the nitrogen pollutants inside the biomass gasifier is realized, the total removal rate of the nitrogen pollutants is 60-80%, and the method has wide popularization and use value.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com