Method for treating wastewater from livestock and poultry breeding by constructing vertical flow artificial wetland based on water supply plant sludge

A technology for water supply plant sludge and aquaculture wastewater, which is applied in water/sludge/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc. It can solve the problem of continuous and stable treatment effect and poor adsorption performance of unfavorable constructed wetland systems. problems, to achieve the effect of reducing disposal costs, low cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

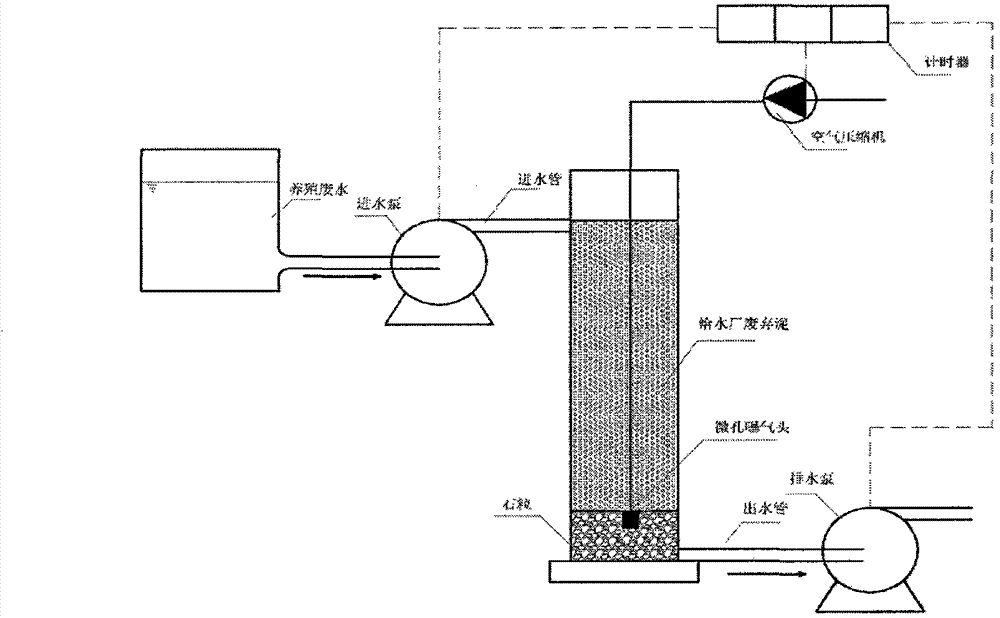

[0025] Using waste sludge from a water treatment plant as raw material, the content of iron and aluminum in the sludge is 100 and 50mg·g respectively -1 , the specific surface area is 78.8m 2 g -1 . After the sludge from the water supply plant is dried and crushed, particles with a particle size of 1 to 2 cm are selected as filling materials for the constructed wetland. The constructed wetland is composed of polyethylene columns with an inner diameter of 9cm and a height of 80cm. Fill the bottom section of the column with clean stones as a supporting layer, and the filling height is 10cm; then fill it with the prepared sludge from the water supply plant Upper section, packing layer height 60cm( figure 1 ). The quality of filling sludge from the water supply plant is 2.85kg (water content 10.82%), the effective volume V of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com