Patents

Literature

522results about How to "Reduce disposal costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

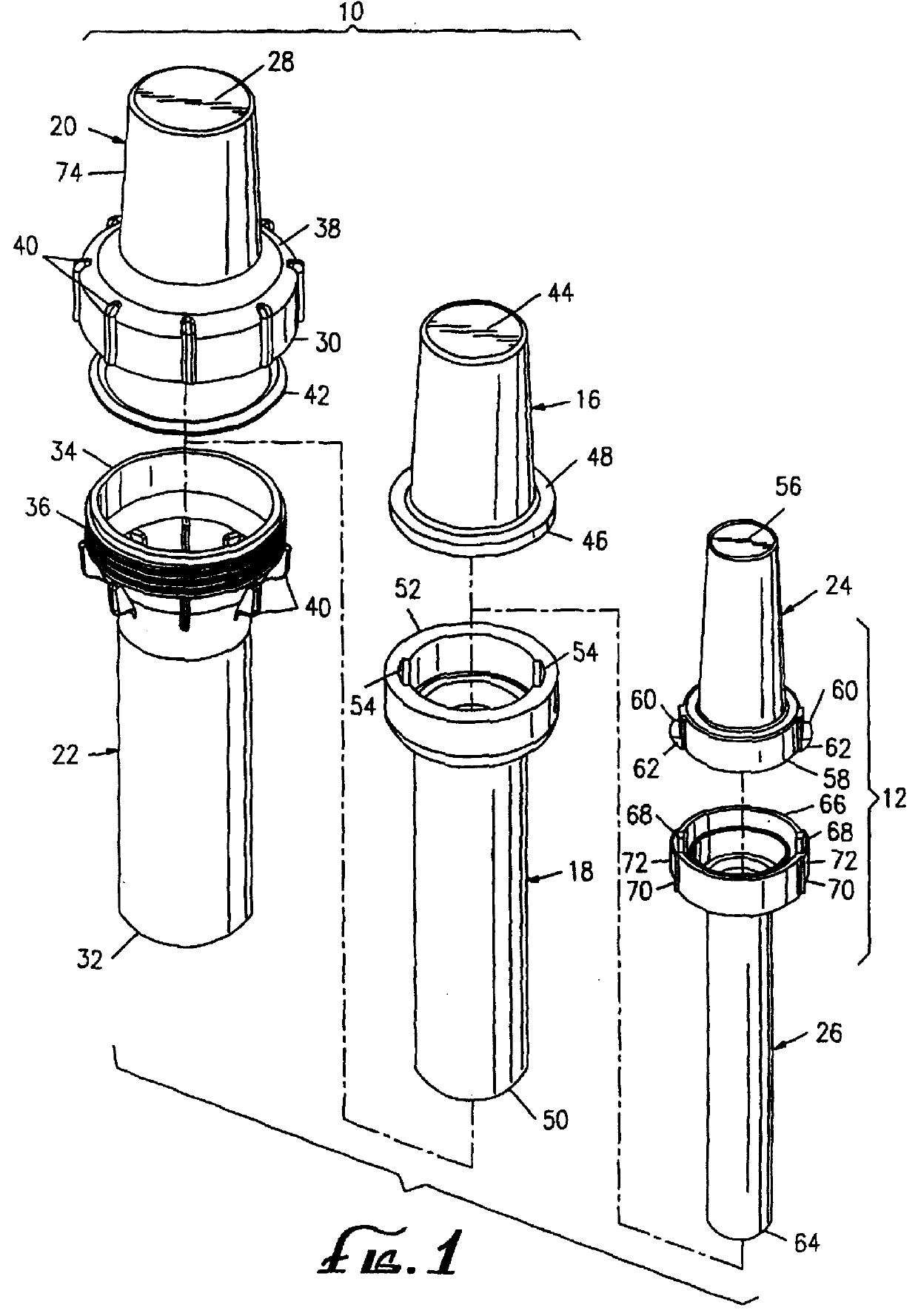

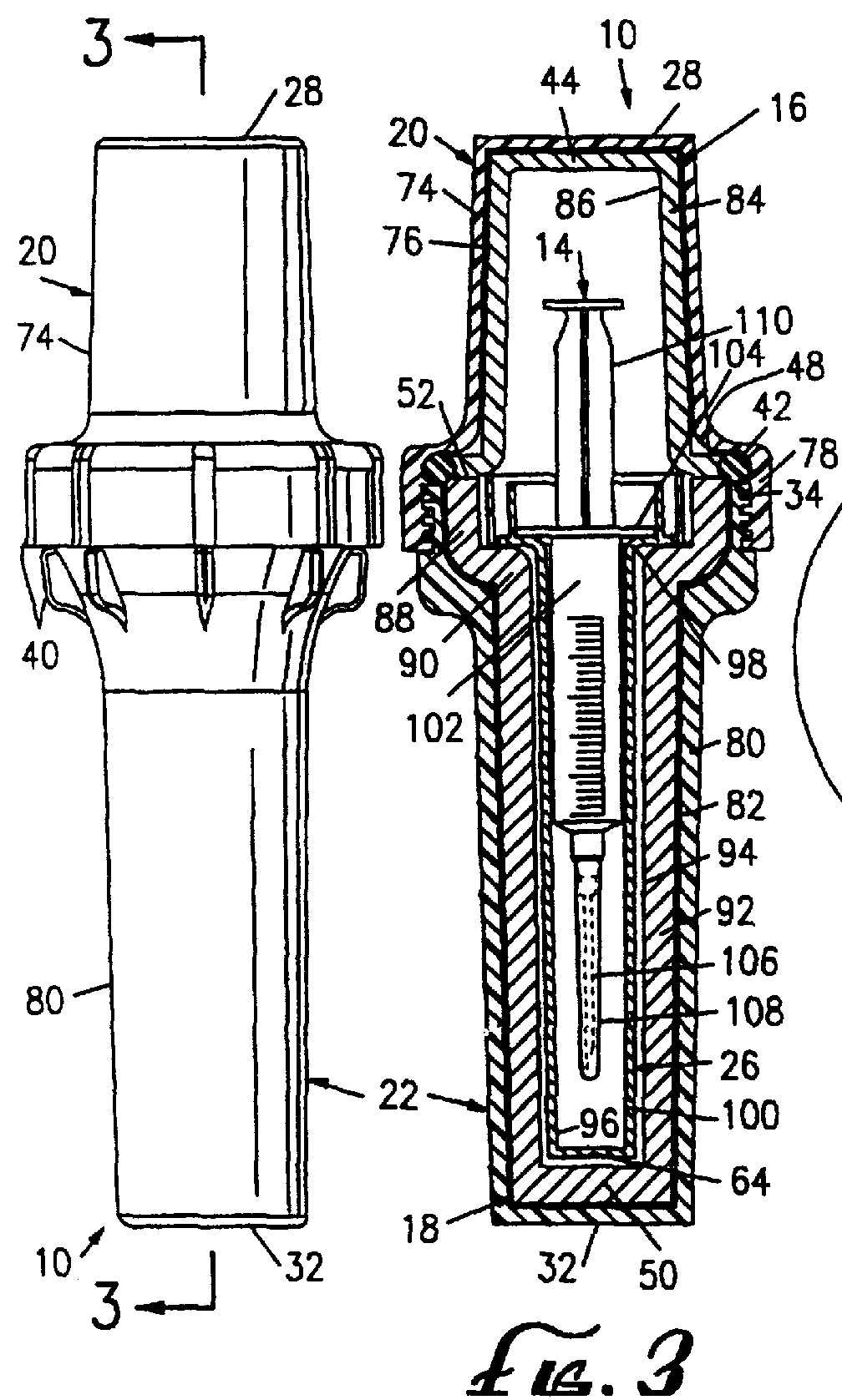

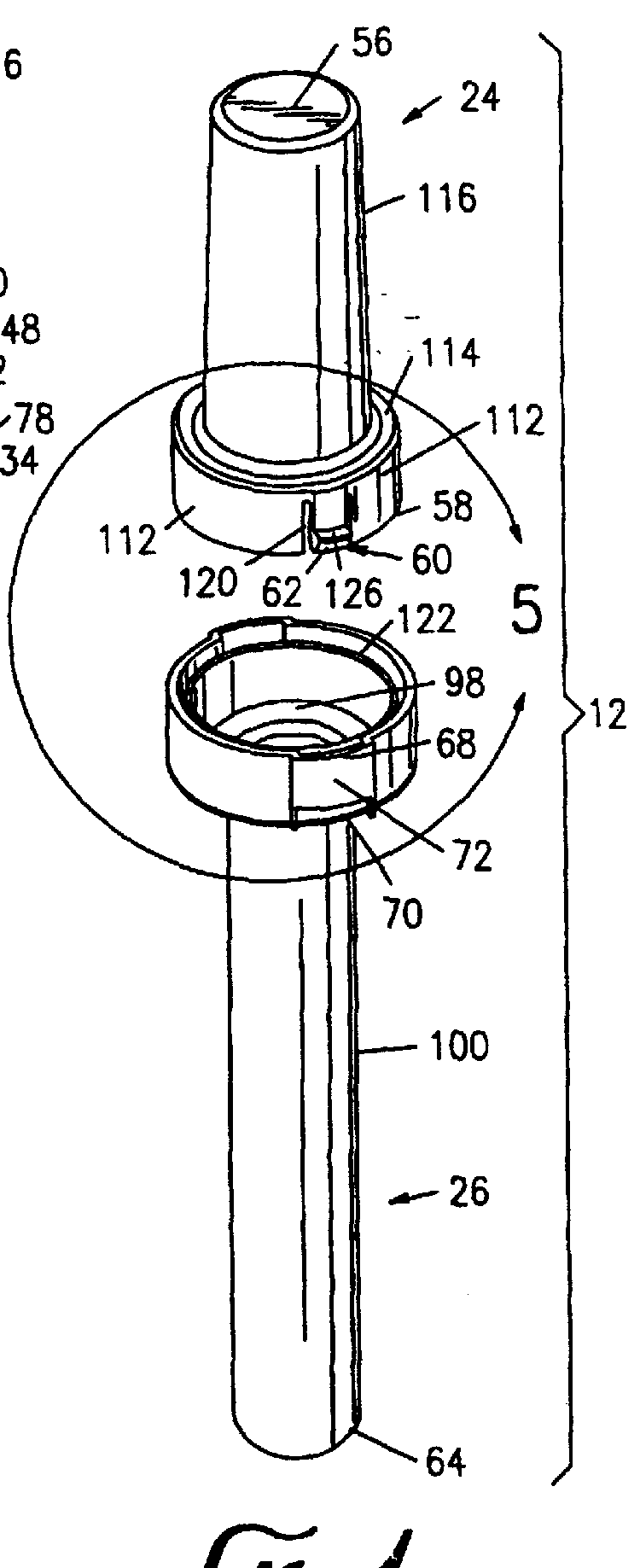

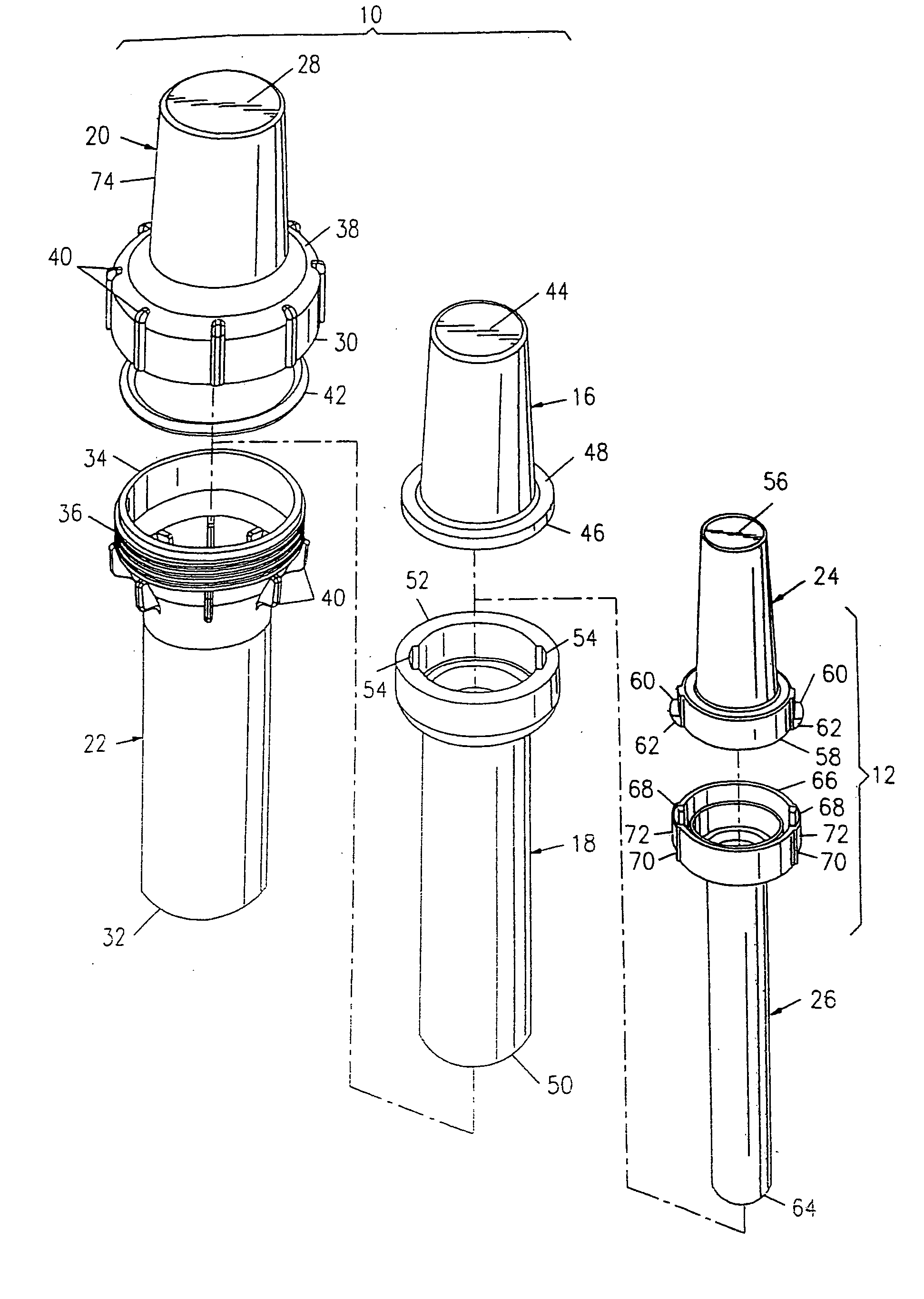

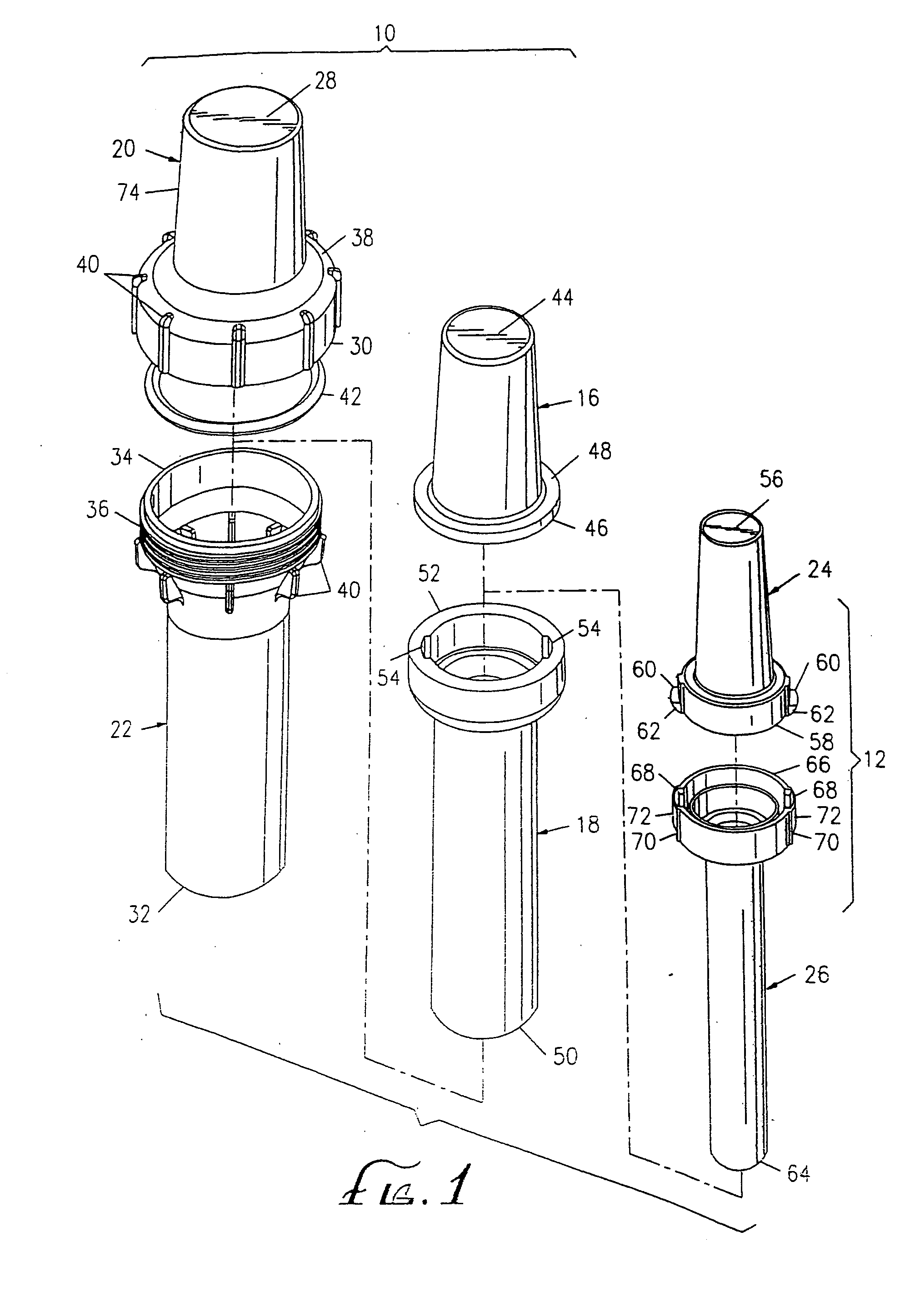

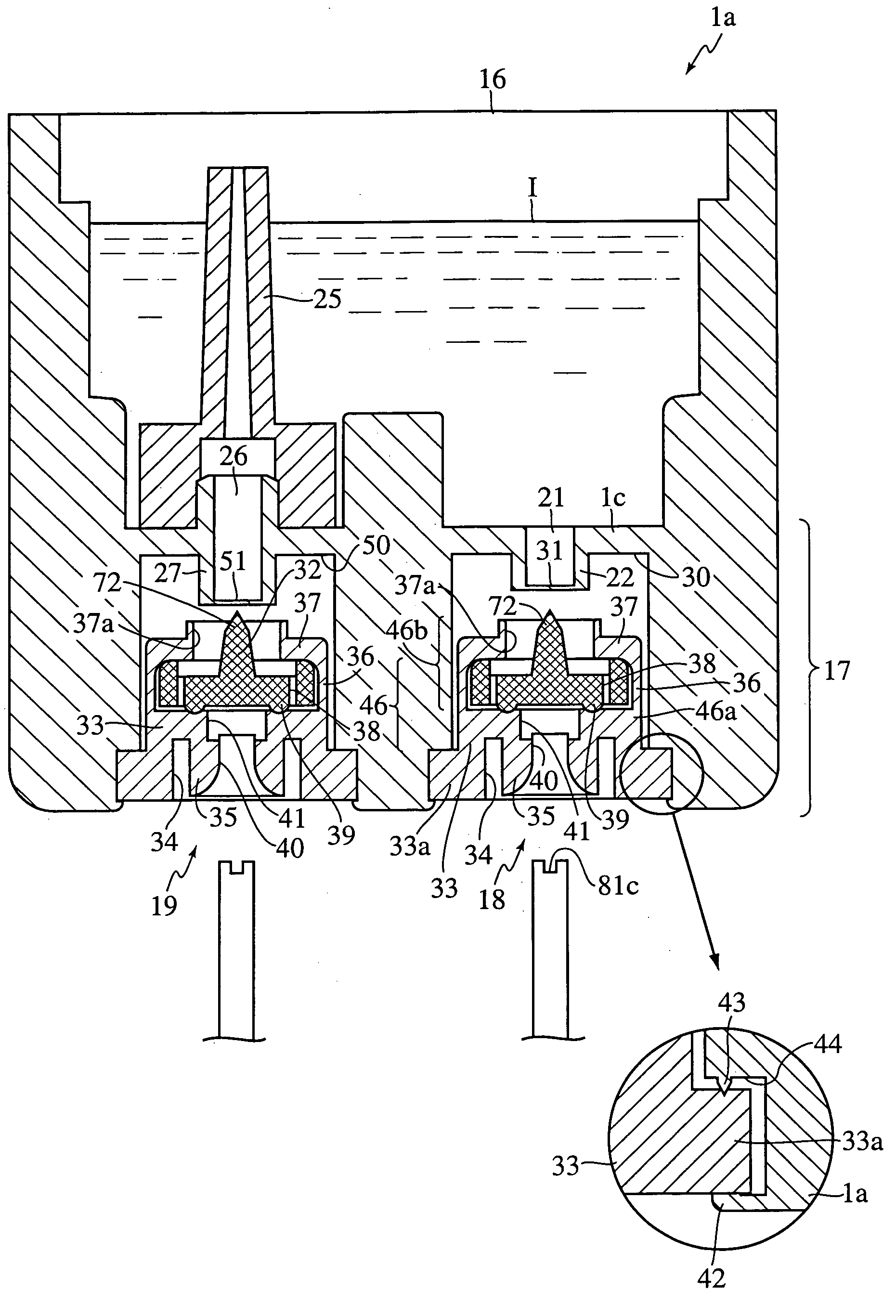

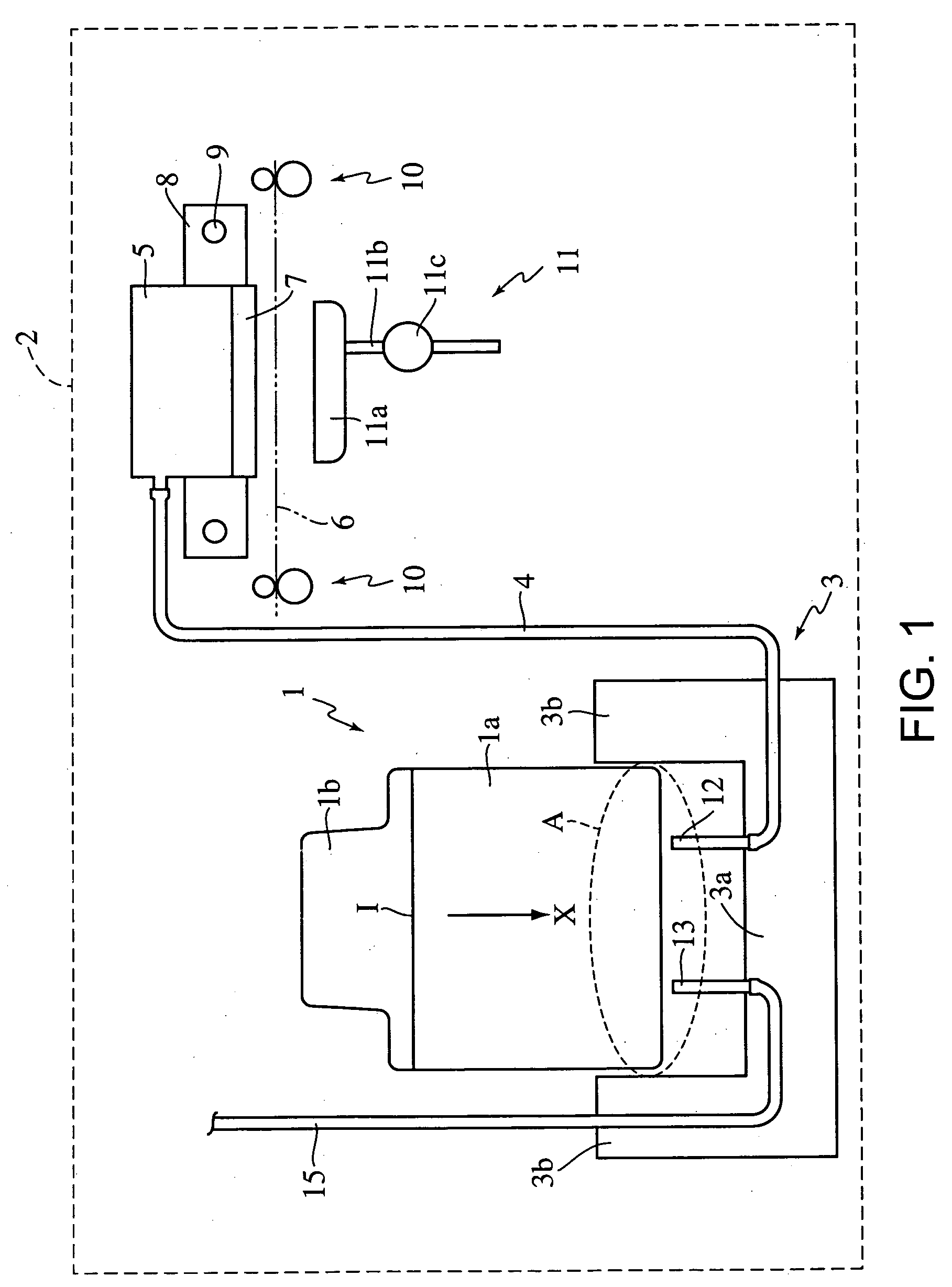

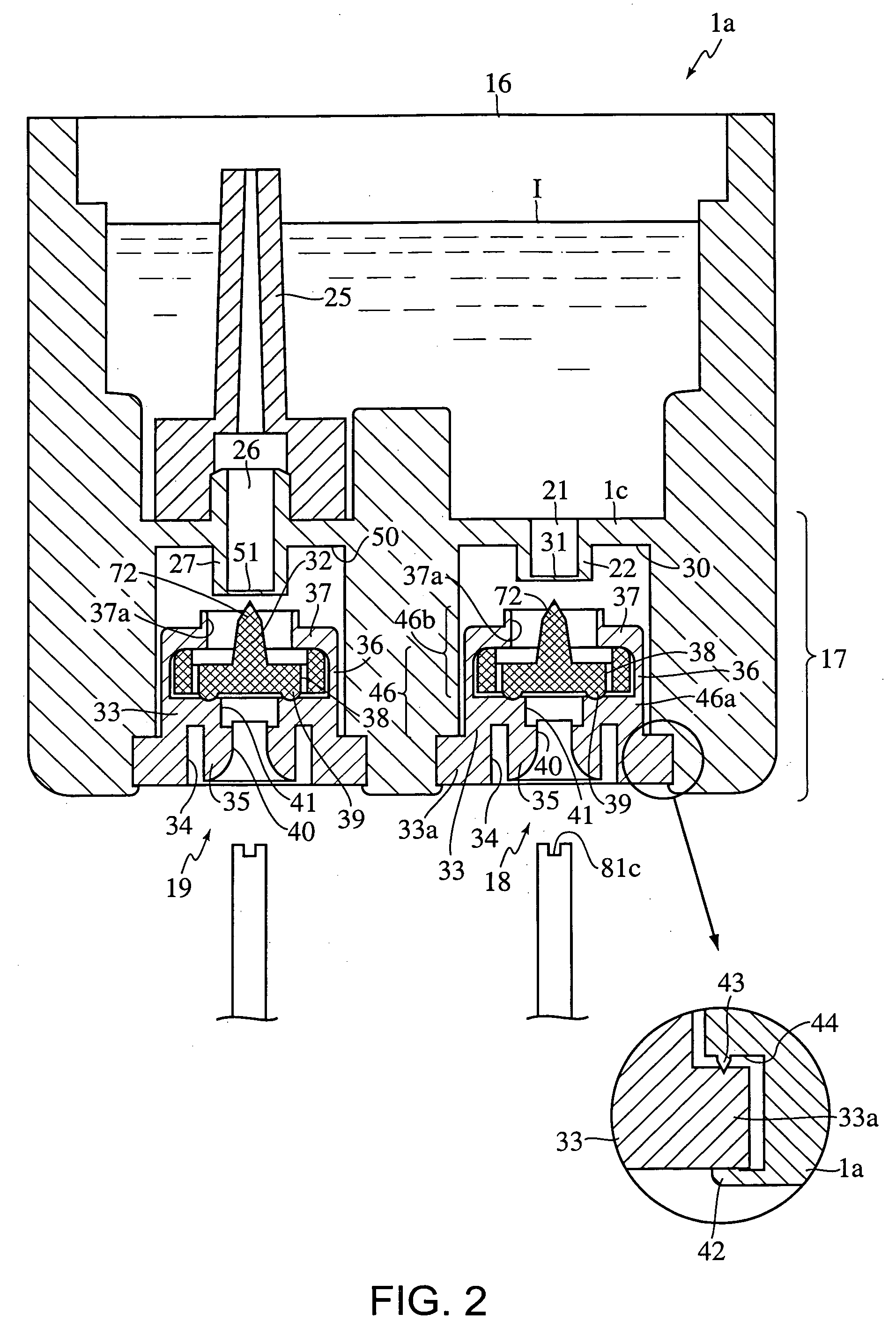

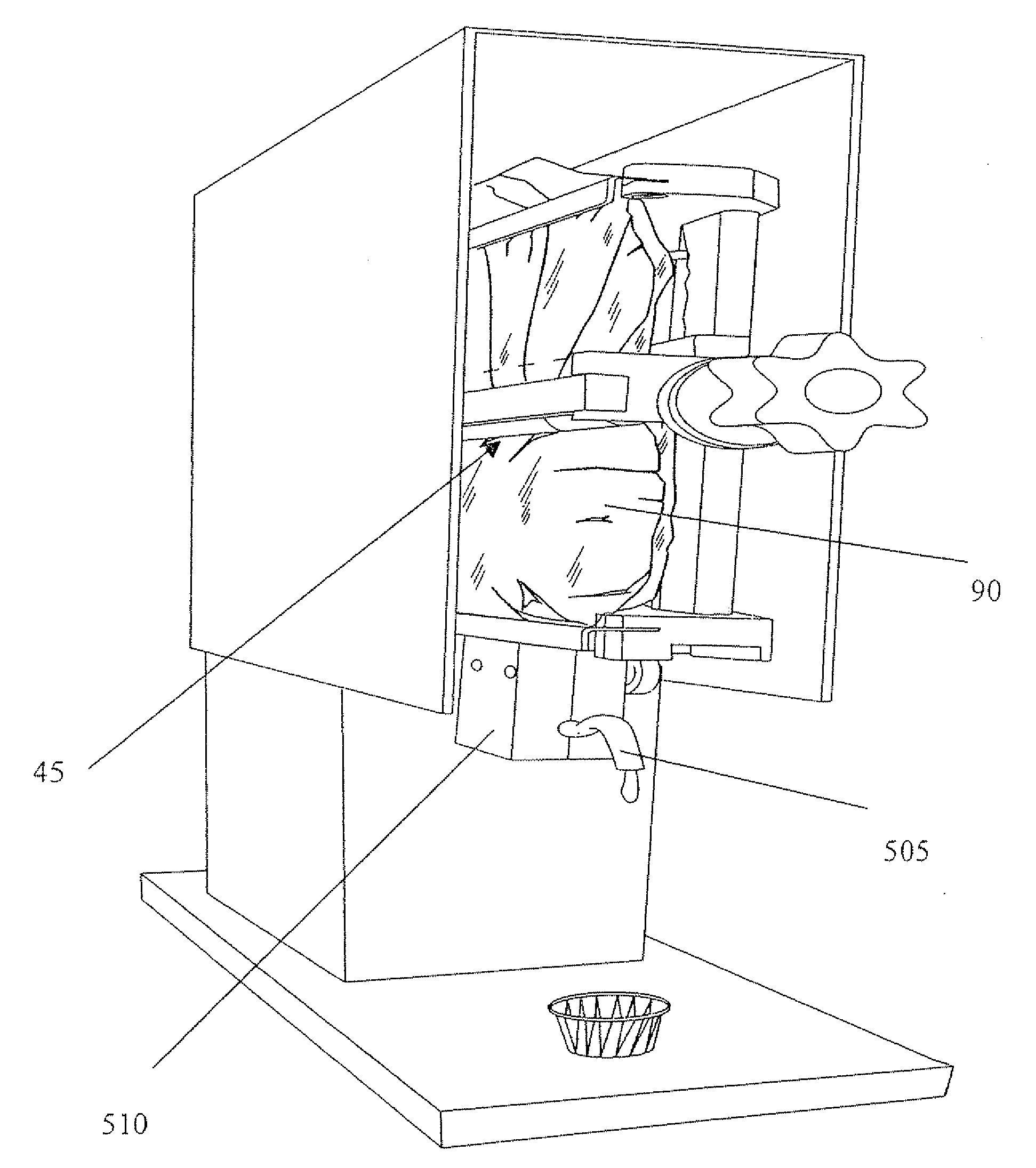

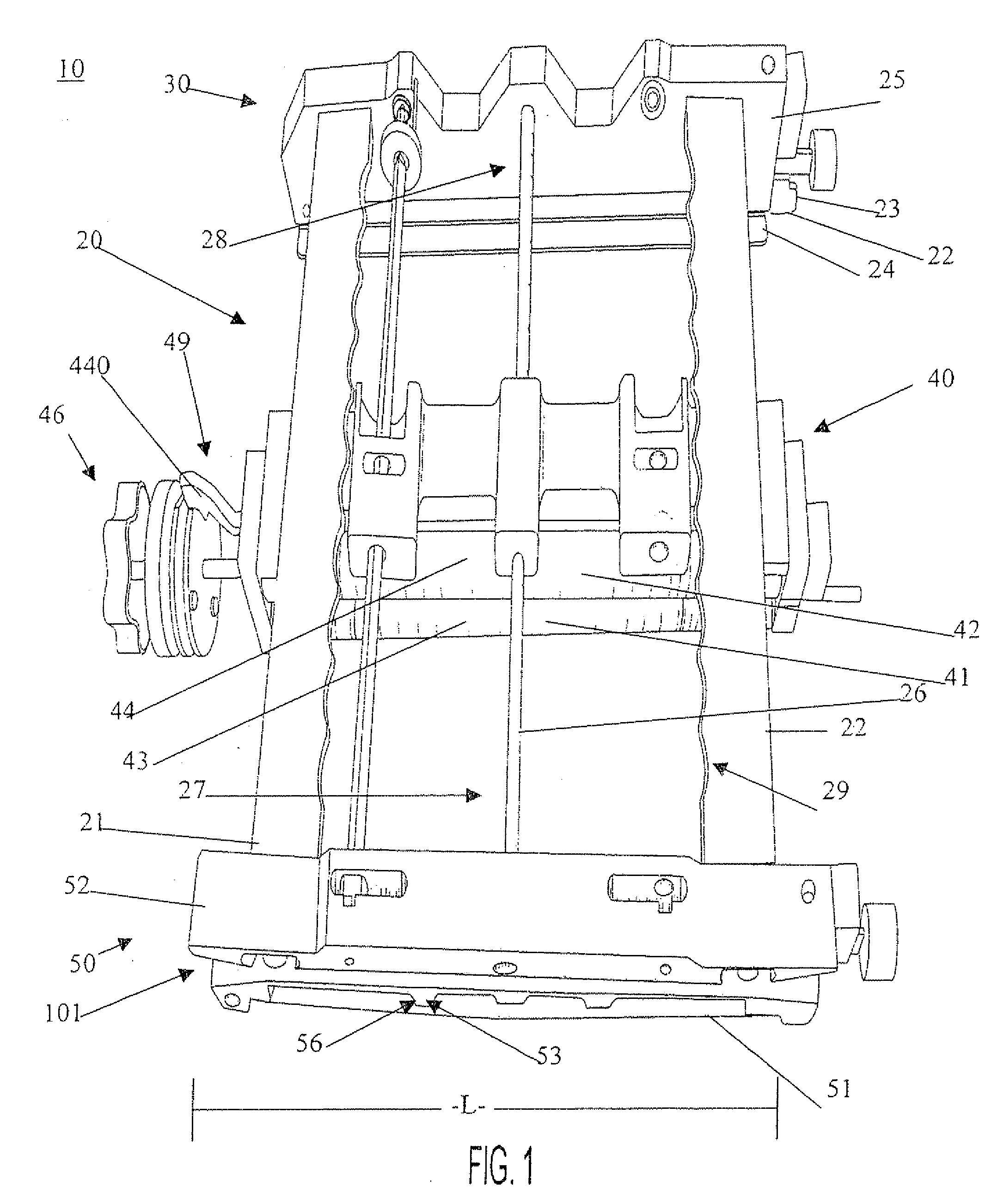

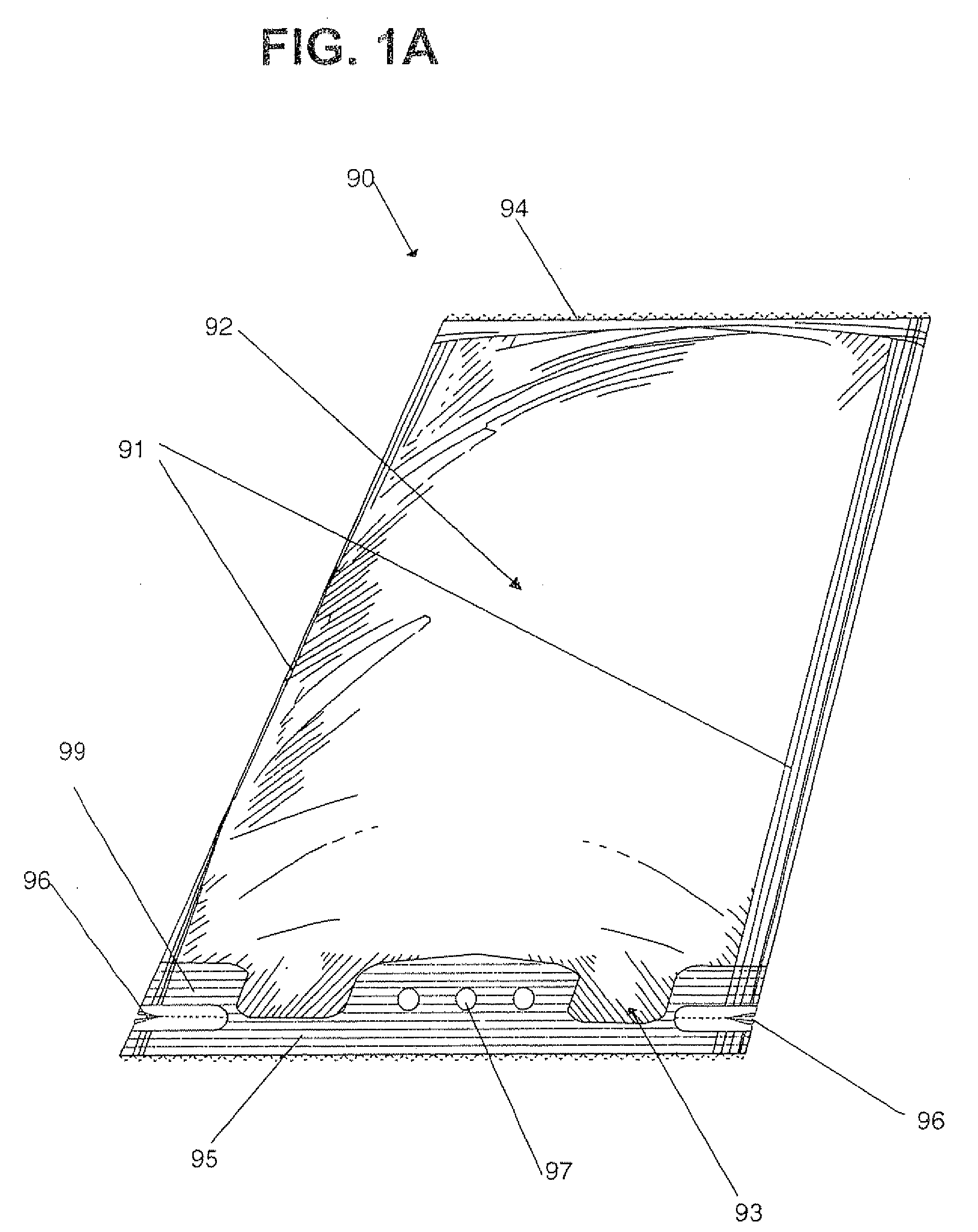

Container and method for transporting a syringe containing radioactive material

InactiveUSRE36693E1Reduced Possibility of ContaminationDurable shellDispensing apparatusOther accessoriesRadioactive agentRadioactive waste

A method and apparatus for transporting syringes containing radioactive material. The apparatus includes a radiopharmaceutical pig having an inner chamber in which a sharps container can be secured. The sharps container has a housing and an attachable cap. The method includes assembling the radiopharmaceutical pig so that the chamber of the radiopharmaceutical pig contains the syringe in the sharps container housing. The radiopharmaceutical pig is disassembled, where upon the syringe is removed, discharged, and then replaced in the sharps container housing. The cap of the sharps container is affixed to the housing of the sharps container, thus enclosing the contaminated syringe therein. The radiopharmaceutical pig is assembled so that its chamber contains the sharps container and the syringe. The radiopharmaceutical pig is transported to a disposal area, where it is disassembled and the sharps container containing the syringe is placed in a particular disposal container.

Owner:CARDINAL HEALTH INC

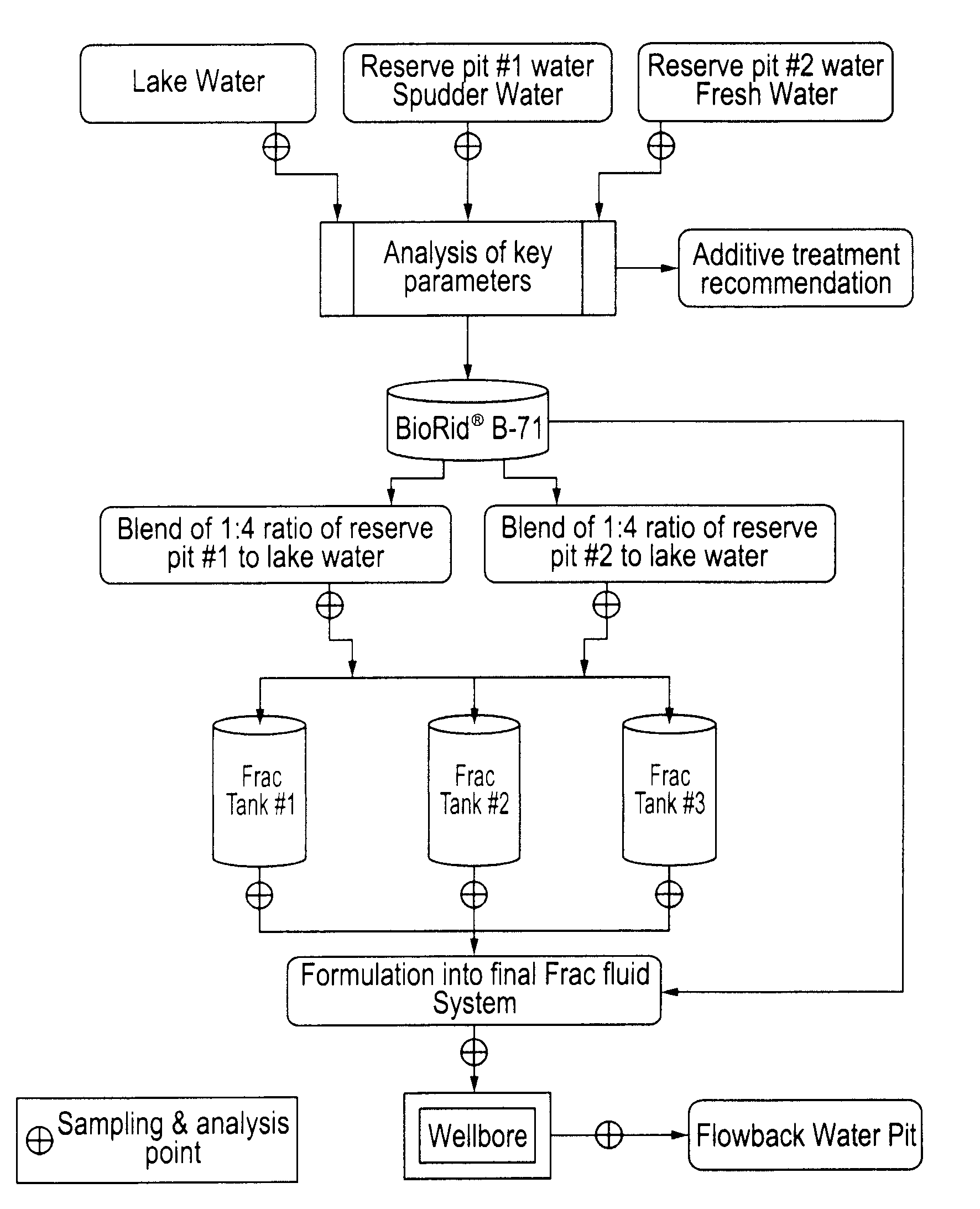

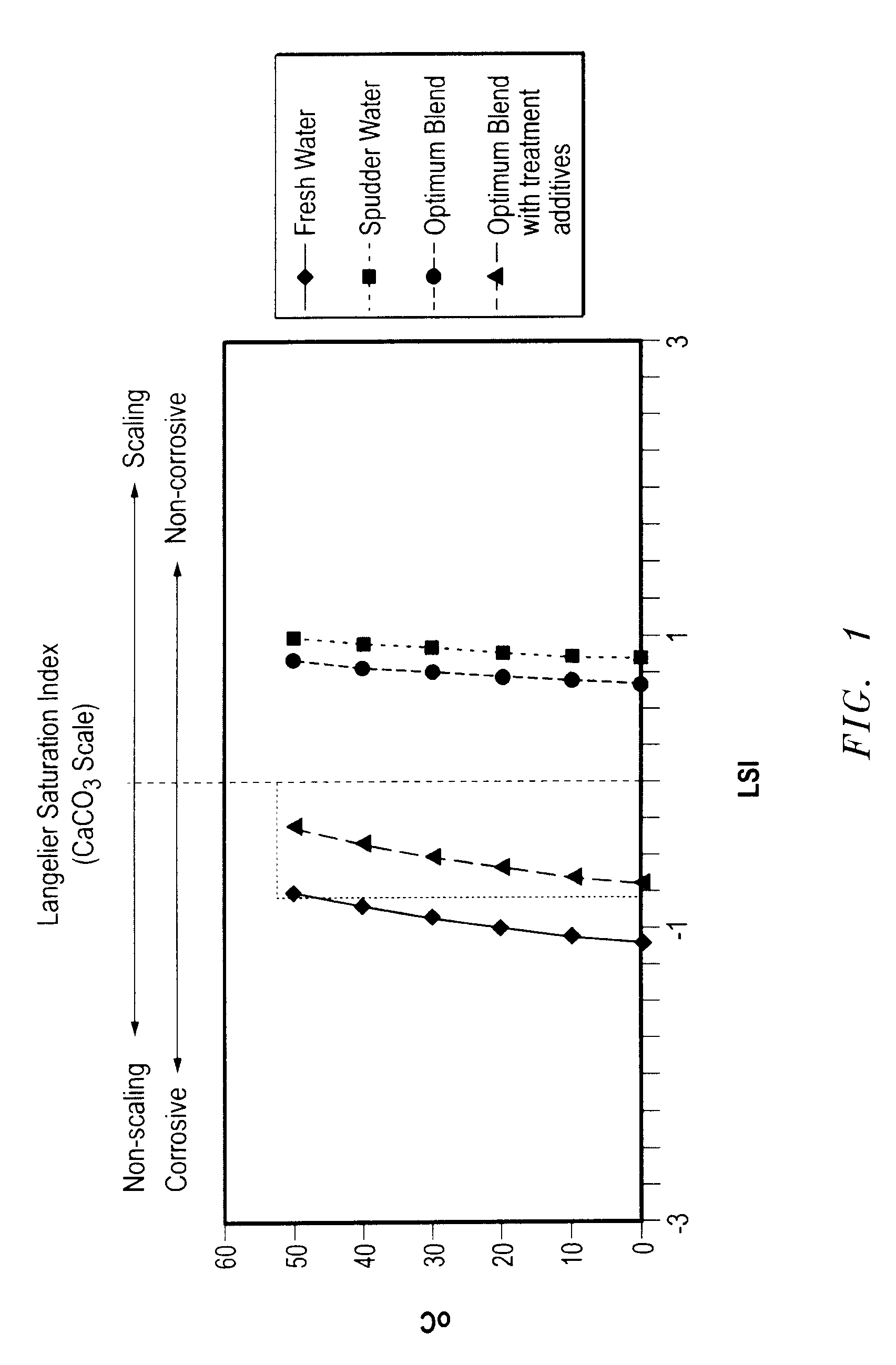

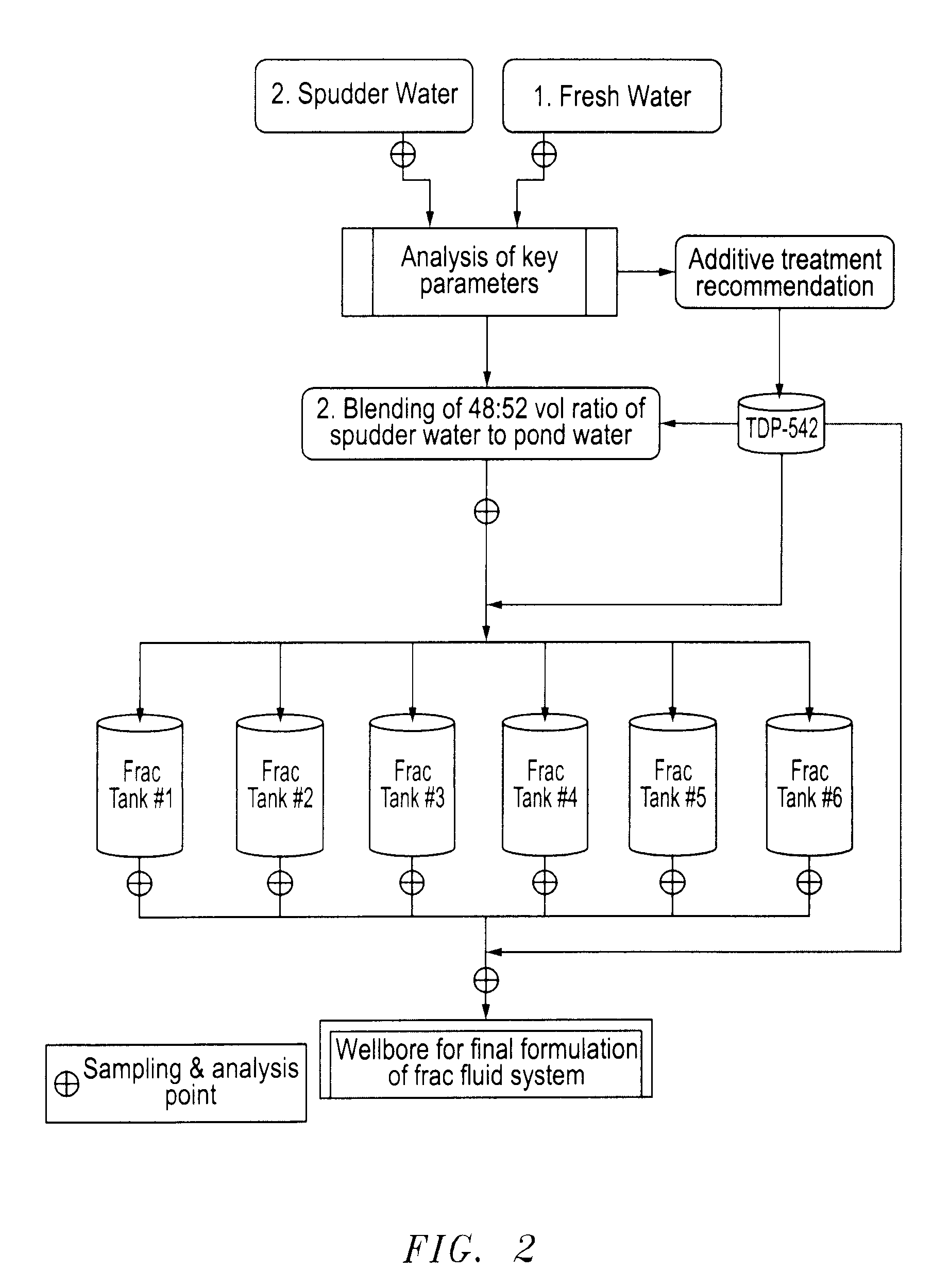

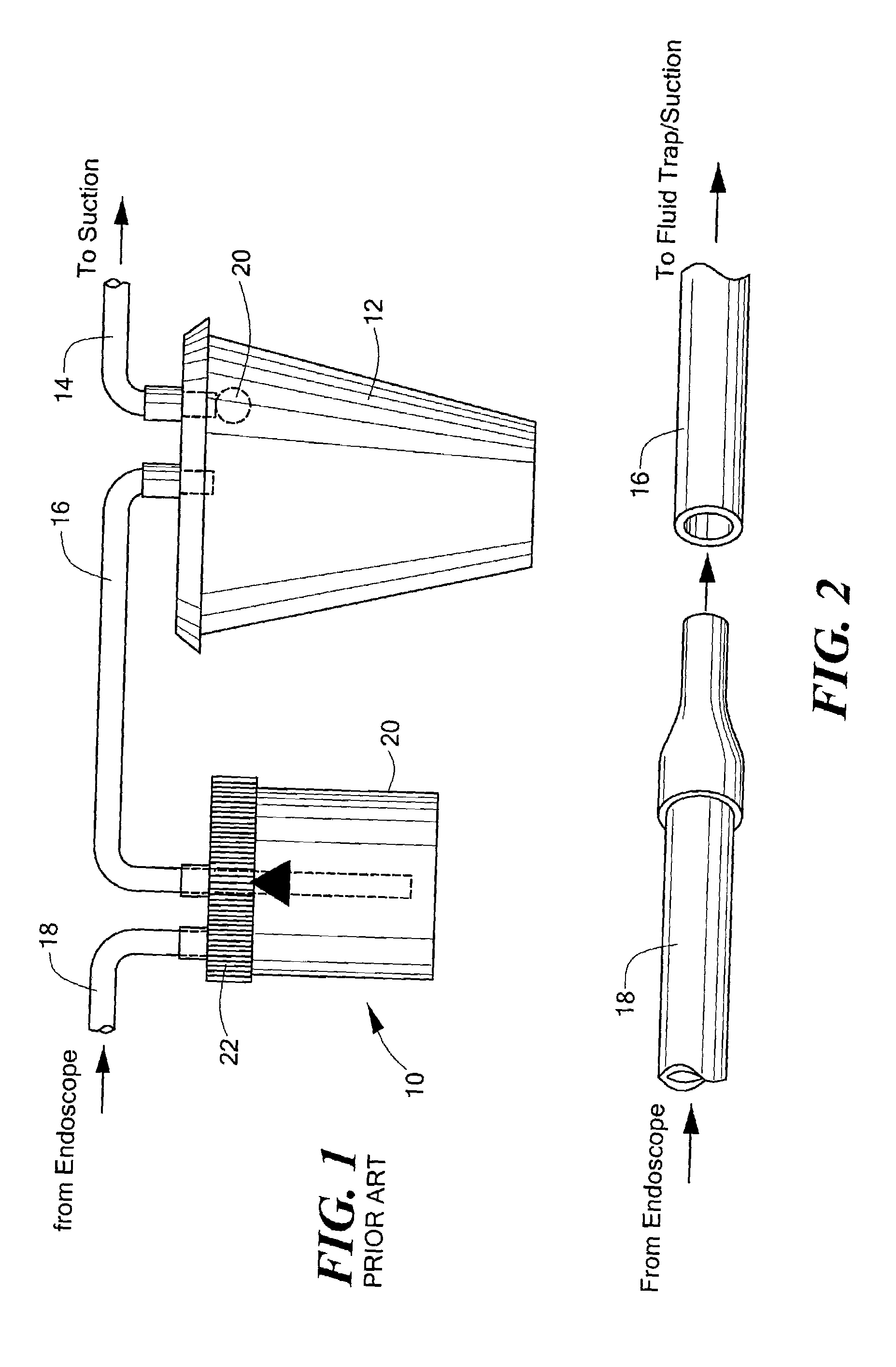

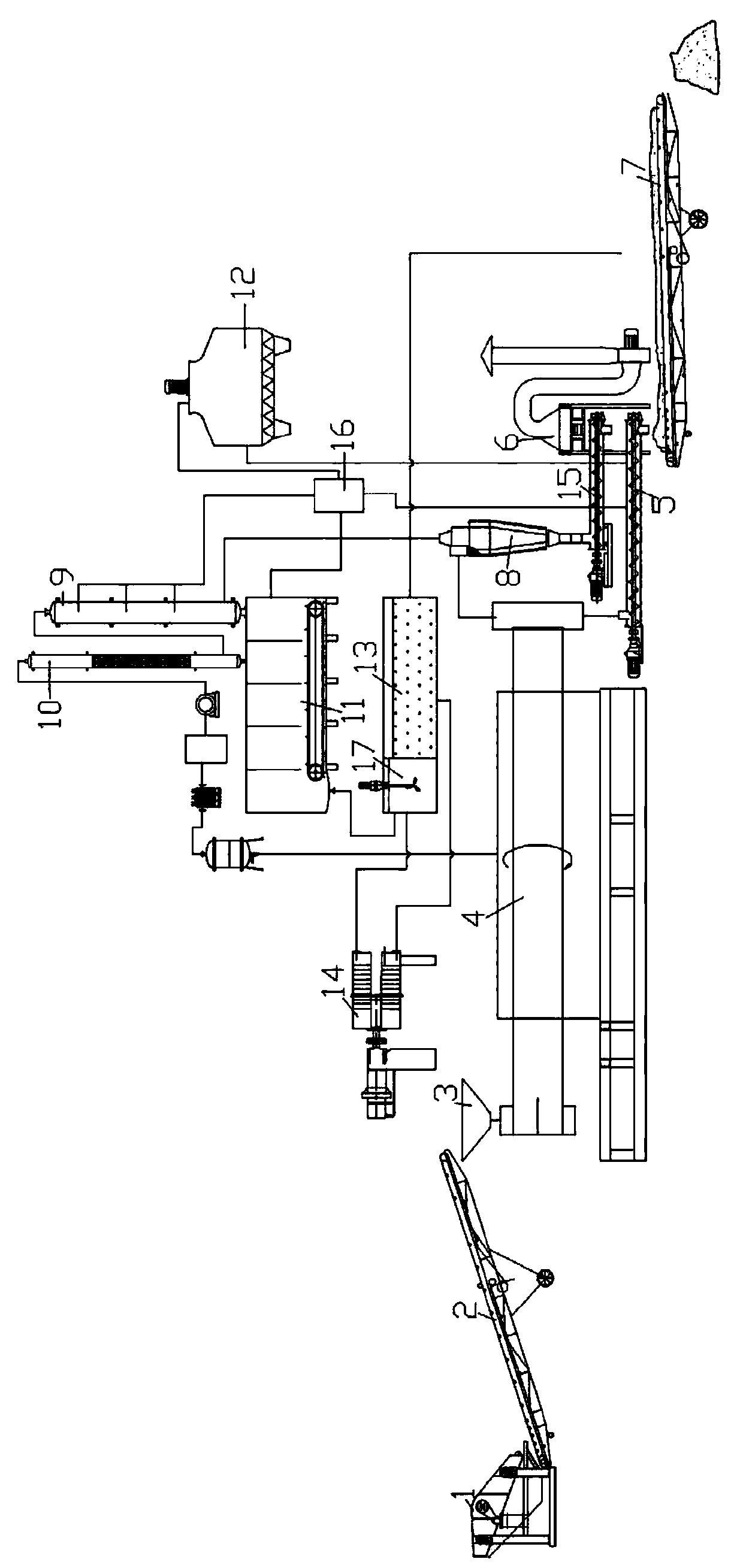

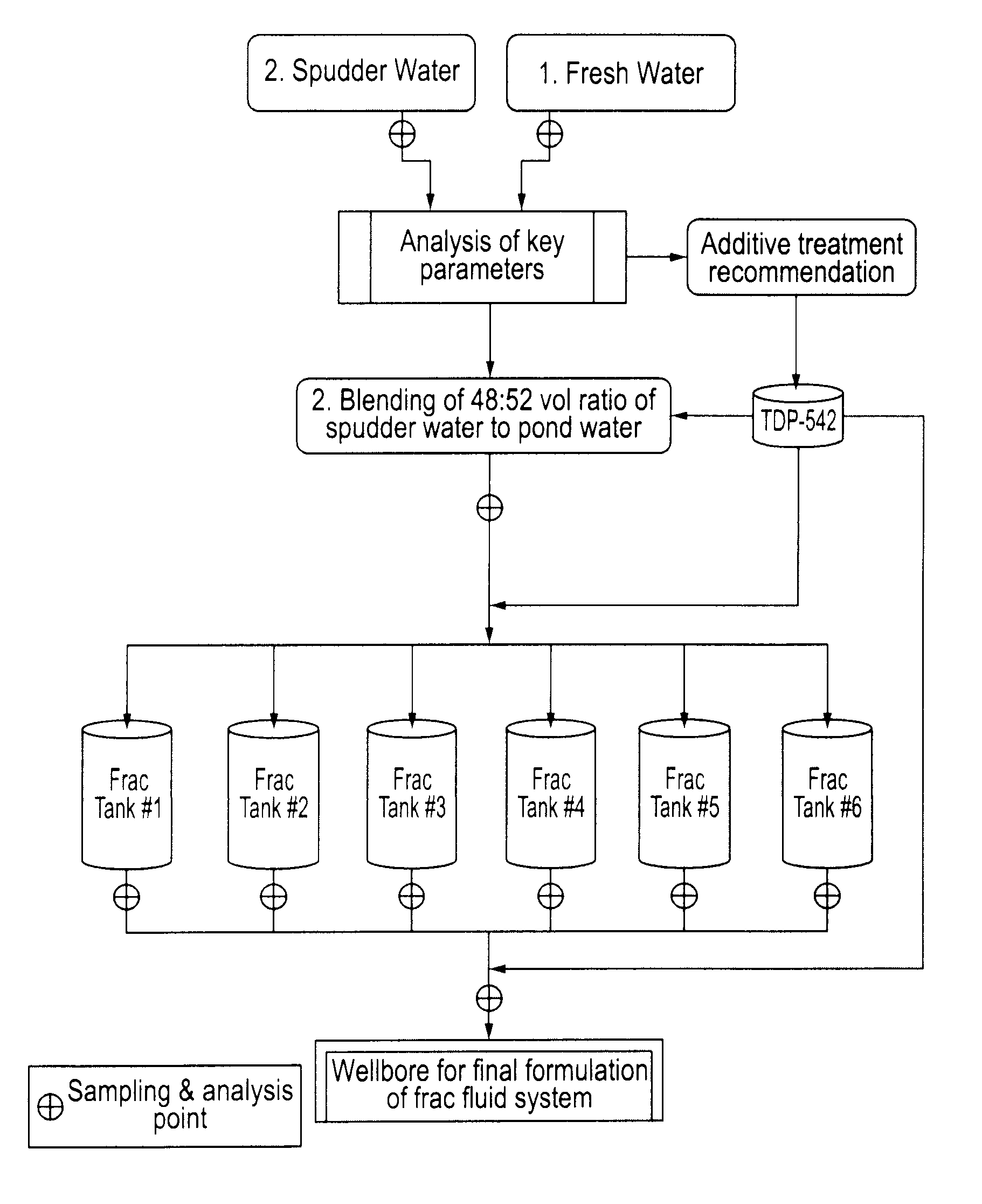

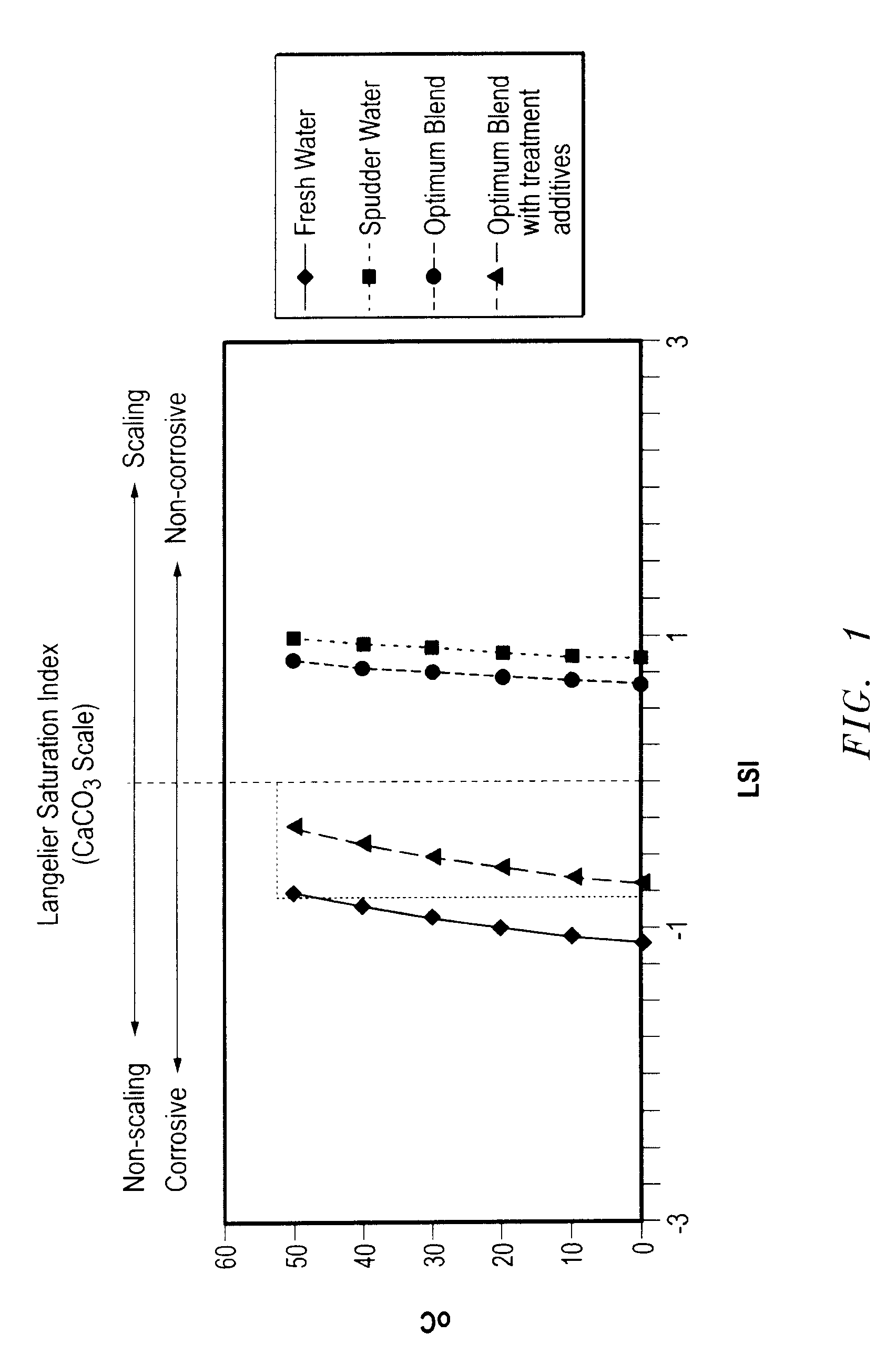

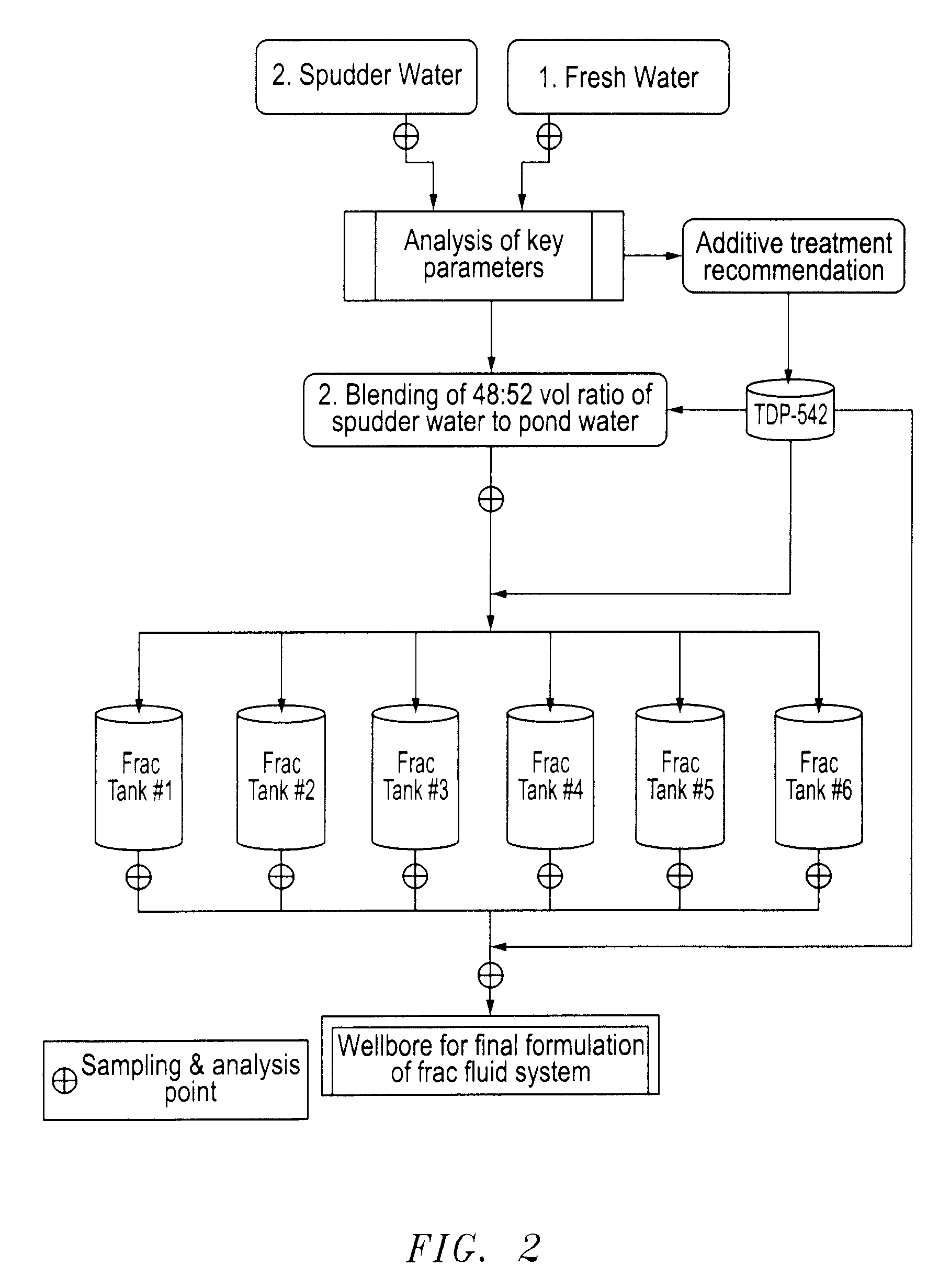

Method of Delivering Frac Fluid and Additives

ActiveUS20100059226A1Reduce deliveryEasy to controlFluid removalDrilling compositionFracturing fluidFresh water

A method for the controlled delivery of a fracturing fluid to a well bore comprises formulating an aqueous base fluid such that it meets or exhibits desired physical and chemical characteristics for an optimal fracturing fluid. The formulation of the aqueous base fluid max involve commingling one or more sources of waste water with a source of fresh water followed by controlled injection of one or more additives. This process is substantially completed prior to delivering the aqueous base fluid to the well site. This allows the delivery of an optimal volume of the aqueous base fluid with homogeneously blended additives to the well bore.

Owner:TETRA TECH INC

Container and method for transporting a syringe containing radioactive material

InactiveUS20050198800A1Reduced Possibility of ContaminationDurable shellDispensing apparatusAssembly machinesRadioactive agentEngineering

A method and apparatus for transporting syringes containing radioactive material. The apparatus includes a radiopharmaceutical pig having an inner chamber in which a sharps container can be secured. The sharps container has a housing and an attachable cap. The method includes assembling the radiopharmaceutical pig so that the chamber of the radiopharmaceutical pig contains the syringe in the sharps container housing. The radiopharmaceutical pig is disassembled, where upon the syringe is removed, discharged, and then replaced in the sharps container housing. The cap of the sharps container is affixed to the housing of the sharps container, thus enclosing the contaminated syringe therein. The radiopharmaceutical pig is assembled so that its chamber contains the sharps container and the syringe. The radiopharmaceutical pig is transported to a disposal area, where it is disassembled and the sharps container containing the syringe is placed in a particular disposal container.

Owner:CARDINAL HEALTH INC

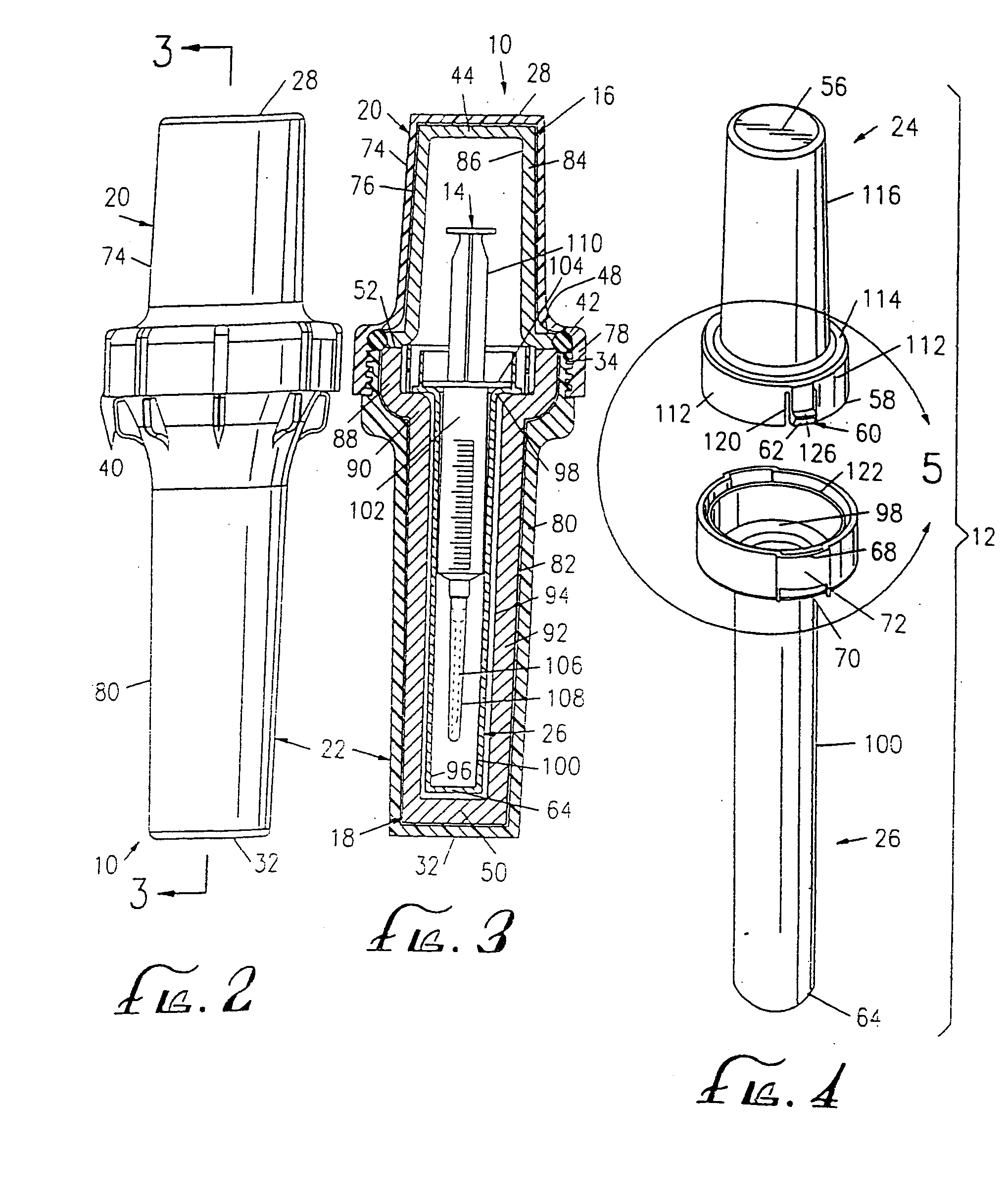

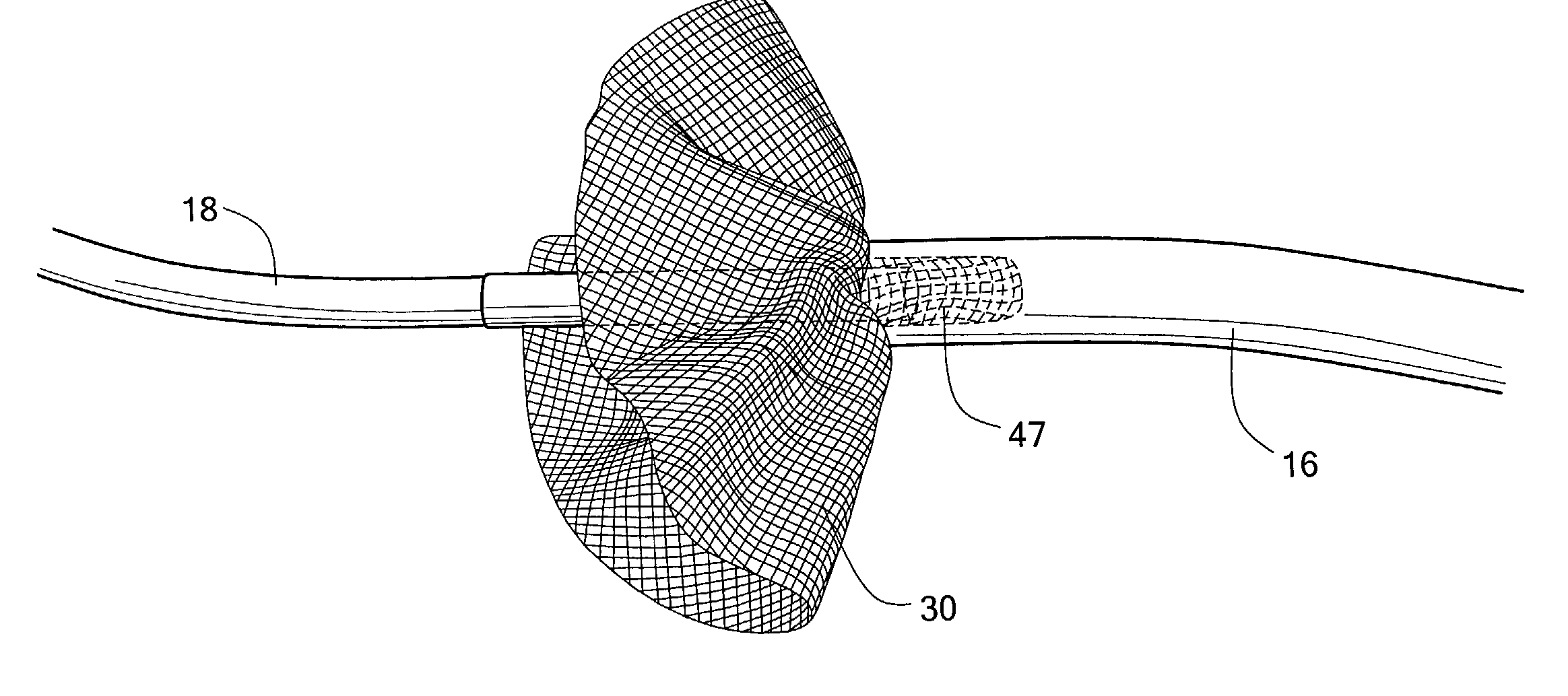

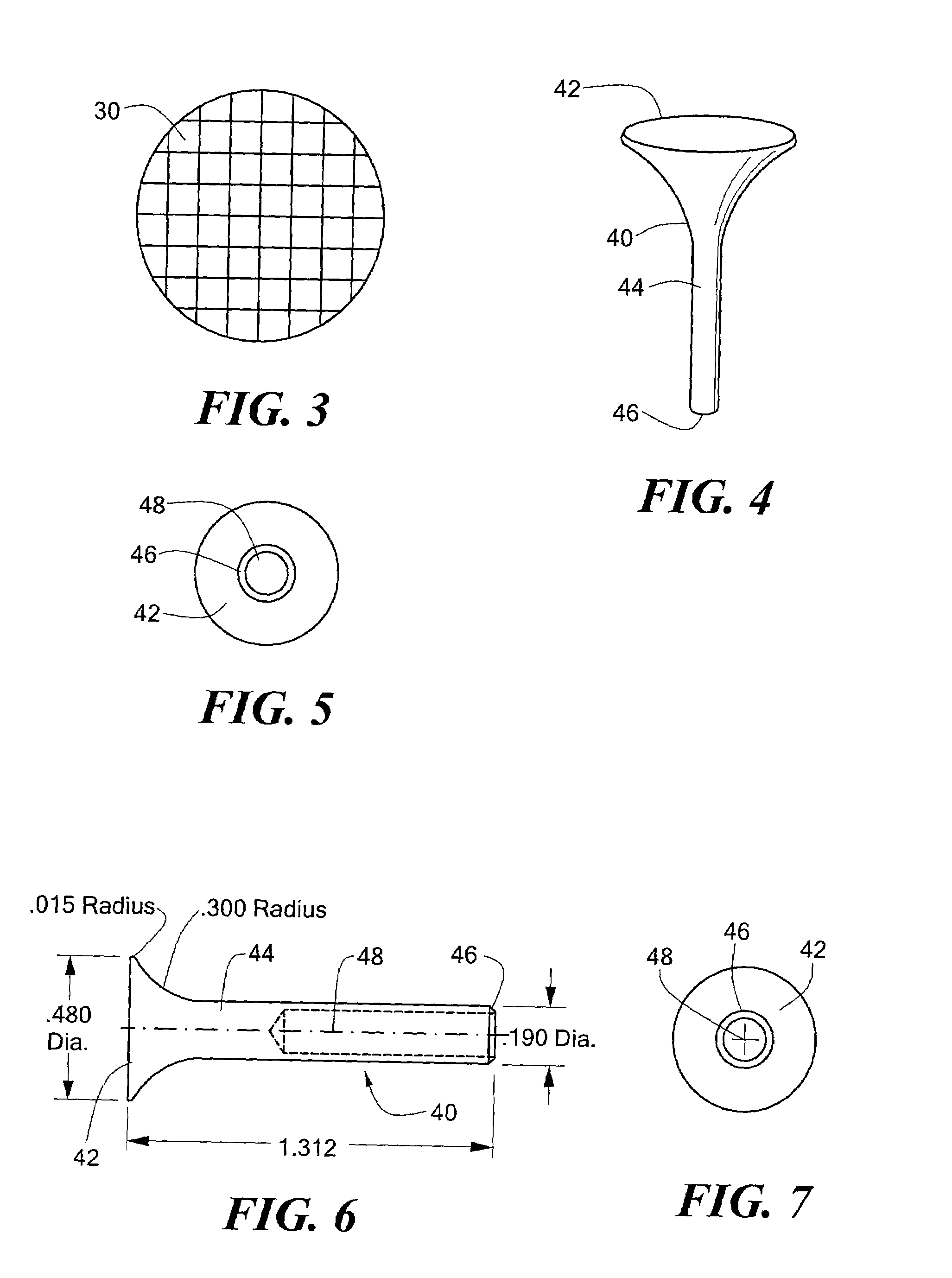

Containerless tissue sample collection trap

InactiveUS7182754B2Small sizeSaving inventorySurgical needlesMedical devicesTissue CollectionTissue sample

A containerless tissue sample collection trap featuring, in the preferred embodiment, a flexible filter and an applicator having a shaft terminating in a distal end with a channel therein receiving a portion of the flexible filter, the combination of the applicator and the flexible filter receivable in a suction tube and configured such that when the applicator is removed, the flexible filter forms a removable elongated tissue trap in the suction tube. Also disclosed is a method of trapping tissue wholly within a suction tube thereby eliminating the need for a specimen trap container and a method of making a containerless tissue specimen trap.

Owner:US ENDOSCOPY GROUP

Ink cartridge

An ink cartridge includes an ink chamber; a communication chamber that is capable of communicating with the ink chamber; a valve that is movable; a support disposed within the communication chamber, the support including a valve seat and an opening exposing a bottom of the valve at an approximately central portion, wherein the valve seat is adjacent to the valve at an outer periphery of the opening; and an urging device that extends from the valve seat, the urging device directly contacting the valve and urging the valve toward the valve seat, wherein the valve separates from the valve seat when a predetermined force is applied to the valve and the support and the urging device are formed as a one-piece member.

Owner:BROTHER KOGYO KK

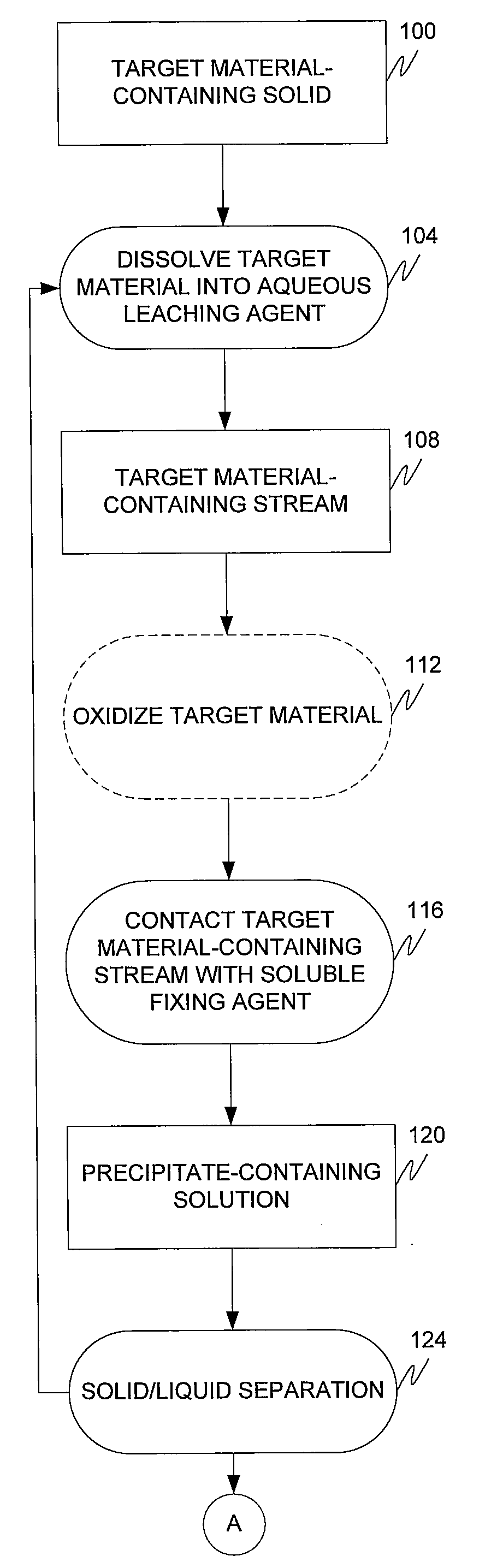

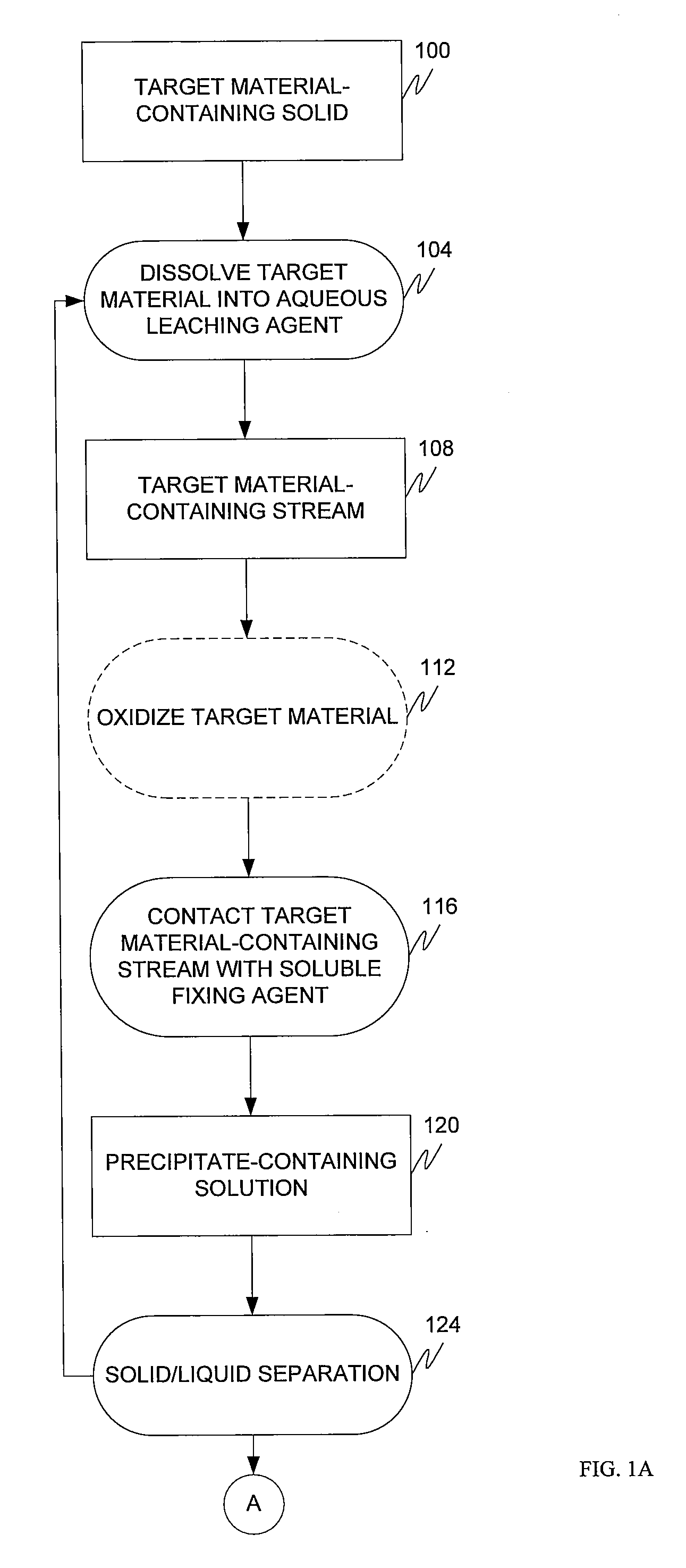

Target material removal using rare earth metals

InactiveUS20100155330A1Easily recoveredIncrease exposureWater treatment parameter controlOther chemical processesMetalMaterial removal

The present invention is directed to the removal of one or more selected target materials from various streams using a rare earth metal-containing fixing agent.

Owner:MOLYCORP MINERALS

Treatment method of arsenic slag

InactiveCN102218428AReduce leaching toxicityImprove long-term stabilitySolid waste disposalSlagFly ash

The invention discloses a treatment method of arsenic slag. The method is characterized by comprises the following steps: (1) adding fly ash and water in the arsenic slag, and stirring for 0.25-1 hour; (2) adding a stabilizing agent in the mixture obtained from the step (2), and stirring for 0.25-1 hour; (3) adding a curing agent in the mixture obtained from the step (3), and stirring for 0.25-1 hour; and (4) curing the mixture obtained from the step (3) for 1-7 days. According to the invention, the leaching toxity of the arsenic slag can be reduced to the admission requirement of a dangerous and waste landfill site, also the fly ash can be treated to achieve the aim of treating waste by the use of waste; and the method provided by the invention has simple process, the material is easy to obtain, the treatment cost is low, and the method has a favorable application prospect.

Owner:杭州大地环保有限公司

Device and method for indirect thermal desorption disposal of persistent organic pollutant contaminated soil

ActiveCN104226681ASimple ingredientsReduce the risk of secondary pollutionCombination devicesContaminated soil reclamationAutomatic controlCvd risk

The invention discloses a device and a method for indirect thermal desorption disposal of persistent organic pollutant contaminated soil. The device comprises a contaminated soil pretreatment system, a feeding system, a thermal desorption system, a discharging system, a tail gas purification system and an automatic control system, wherein the contaminated soil pretreatment system is connected with a feed opening of the thermal desorption system through the feeding system, a solid discharge opening of the thermal desorption system is connected with the discharging system, and a gas discharge opening of the thermal desorption system is connected with an inlet of the tail gas purification system. According to the method, after pretreatment, contaminated soil is conveyed to the thermal desorption system for desorption for 10-40 min at the temperature of 400-600 DEG C, and desorption exhaust gas adopts a technology including procedures of cyclone dust removal, two stages of spraying, drying and activated carbon adsorption / gliding arc degradation. The device and the method adopt indirect heating, so that risks of generation of poisonous materials such as dioxine and the like are avoided effectively; and a double-layer cylinder rotary kiln type furnace body, the furnace body axis and the ground form a 0-degree angle, and accordingly, the operation and maintenance costs are reduced.

Owner:中节能大地(杭州)环境修复有限公司

Apparatus for treating a substrate with an ozone-solvent solution

InactiveUS20060107976A1Increase oxidation rateReduce disposal costsSemiconductor/solid-state device manufacturingDisinfectionProcess engineeringSolvent

A system for treating a substrate with an ozone-solvent solution has an ozone-solvent solution supply. The supply has a supply outlet, and the ozone solvent solution supply is capable of delivering at the supply outlet a generally continuous supply of an ozone-solvent solution formed at a first temperature. The system includes a heater having an inlet and heater outlet, with the inlet fluidly coupled to receive the ozone-solvent solution at approximately the first temperature from the supply outlet. The heater is configured to heat the ozone-solvent solution from the first temperature to a second temperature to form a heated ozone-solvent solution such that the heated ozone-solvent solution is supersaturated with ozone. The heater is capable of providing a generally continuous supply of heated, supersaturated, ozone-solvent solution at the heater outlet for use in treating the substrate.

Owner:BOYERS DAVID G +1

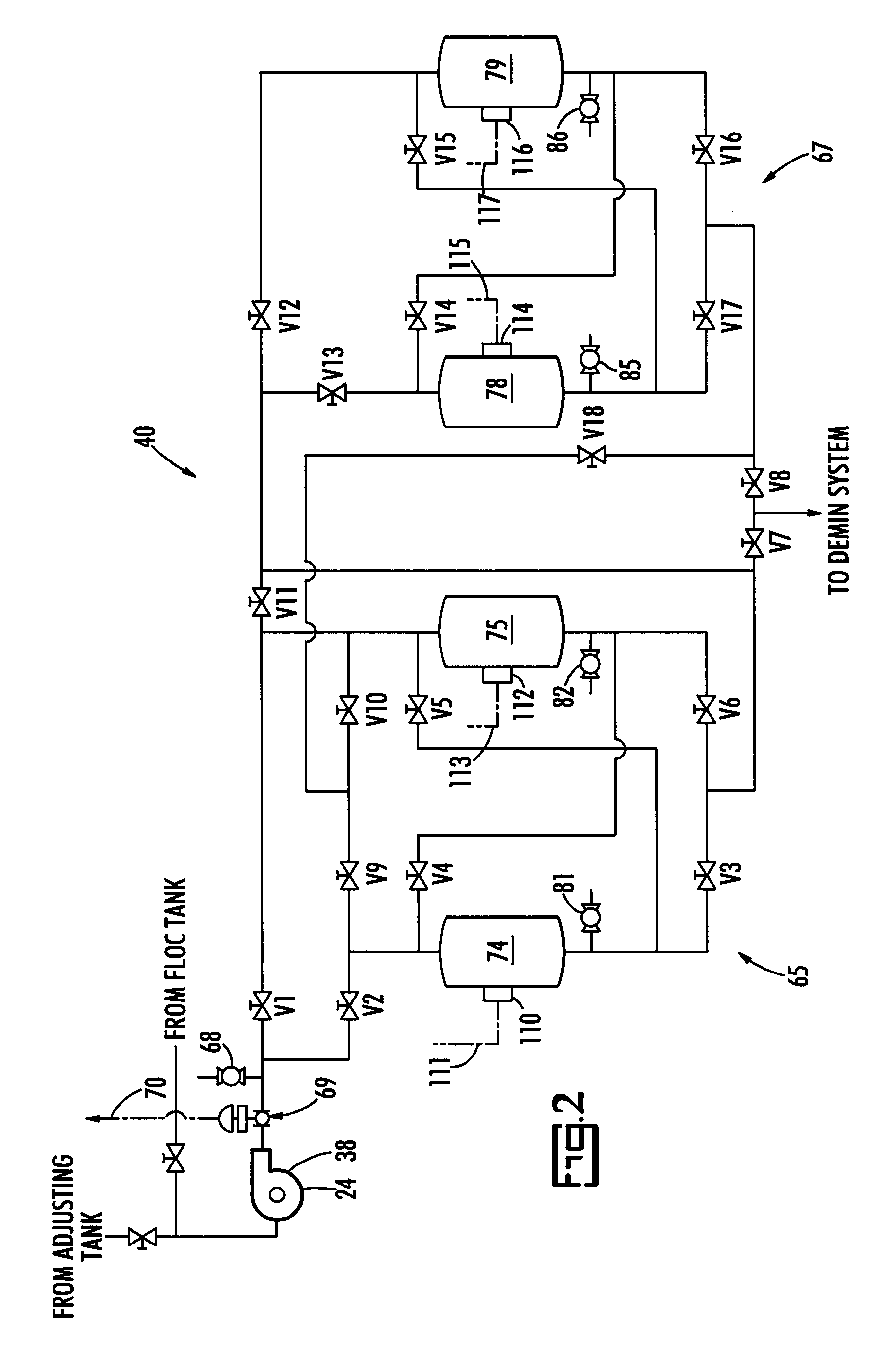

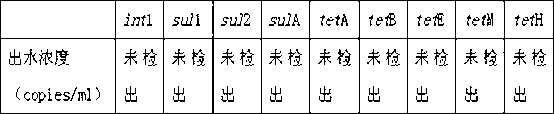

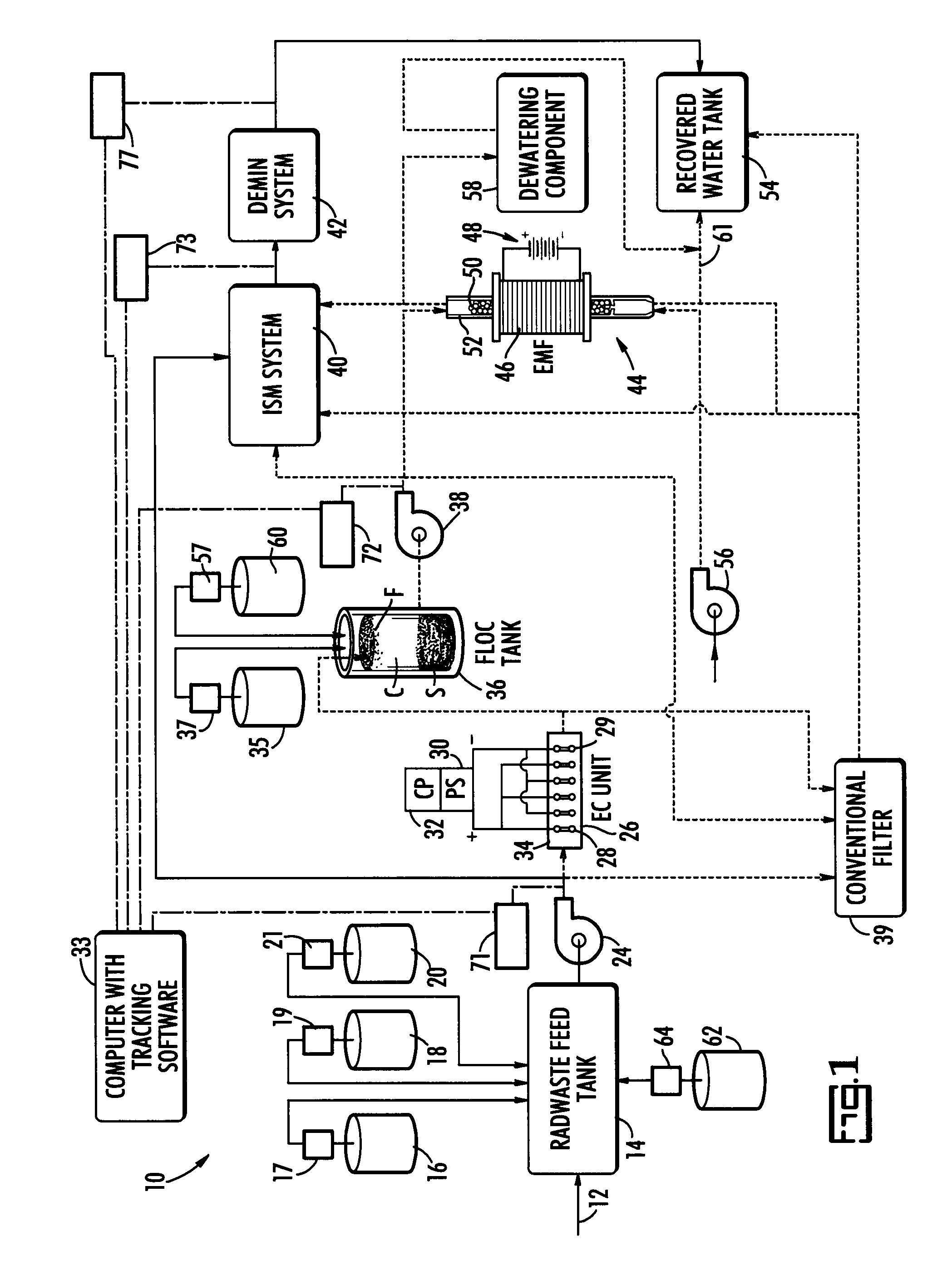

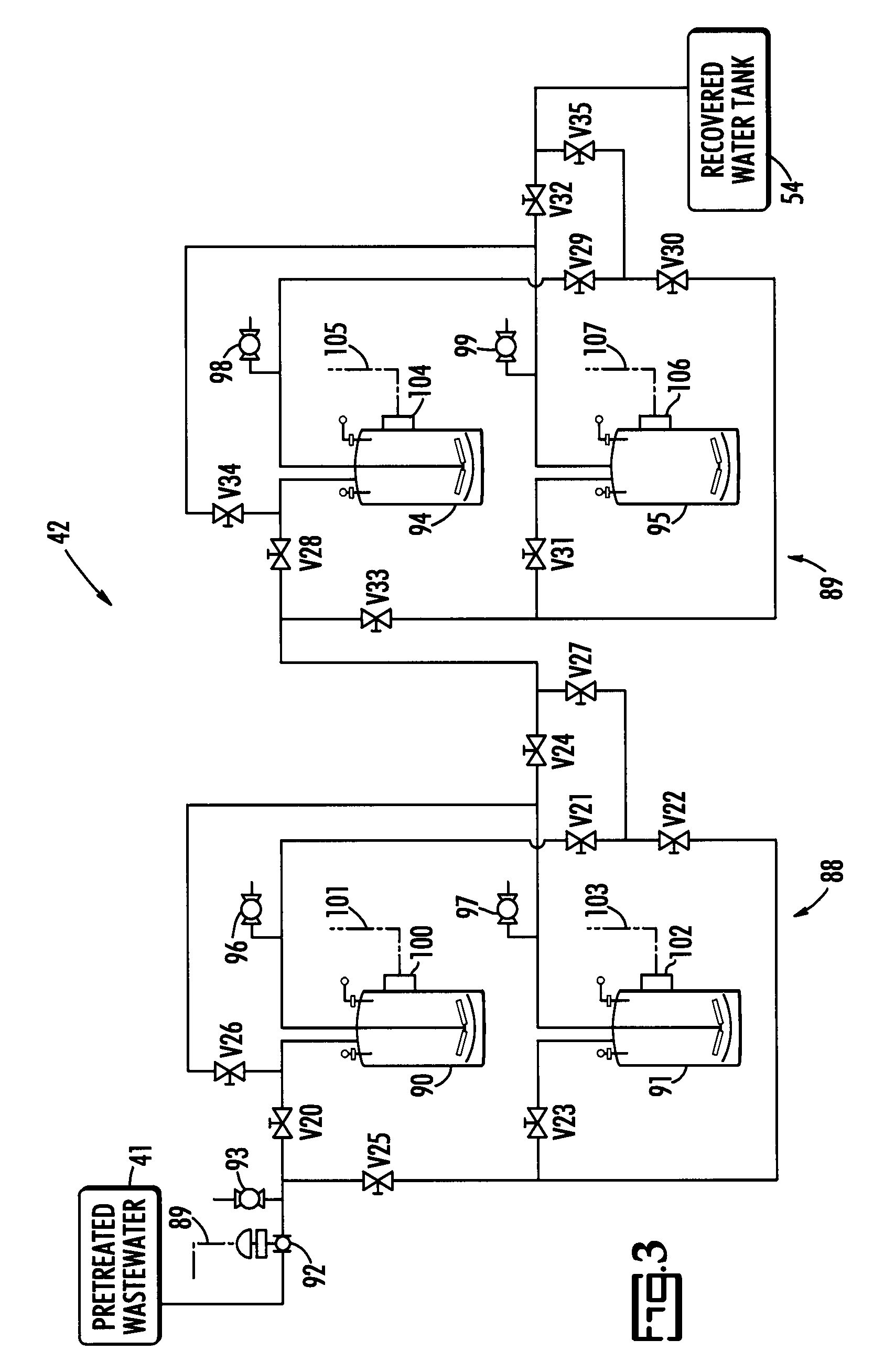

Process and System for Treating Radioactive Waste Water to Prevent Overloading Demineralizer Systems

ActiveUS20090038961A1Easily backflushedAvoid disposition problemsTreatment involving filtrationSolid sorbent liquid separationWastewaterRadioactive waste

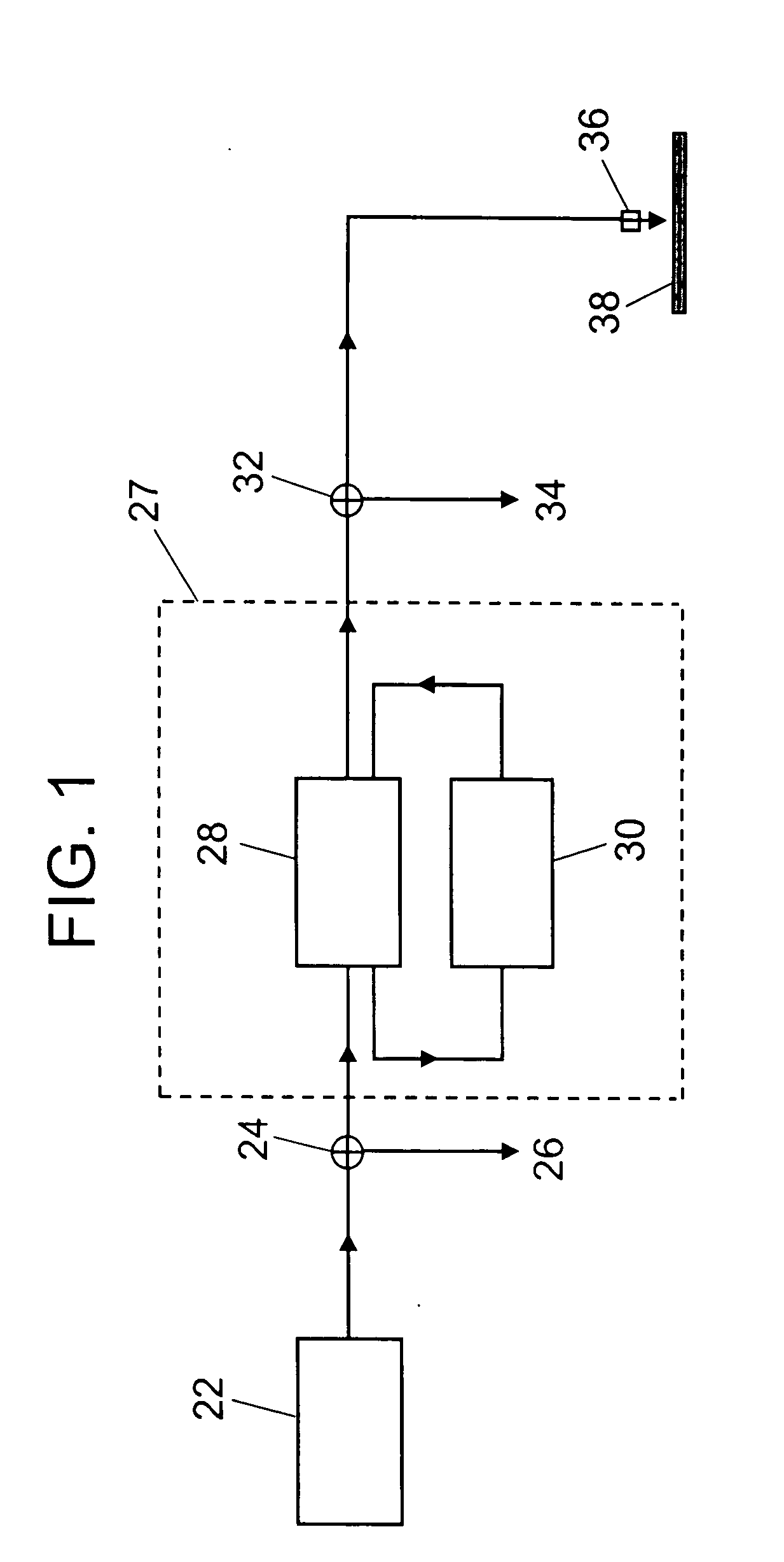

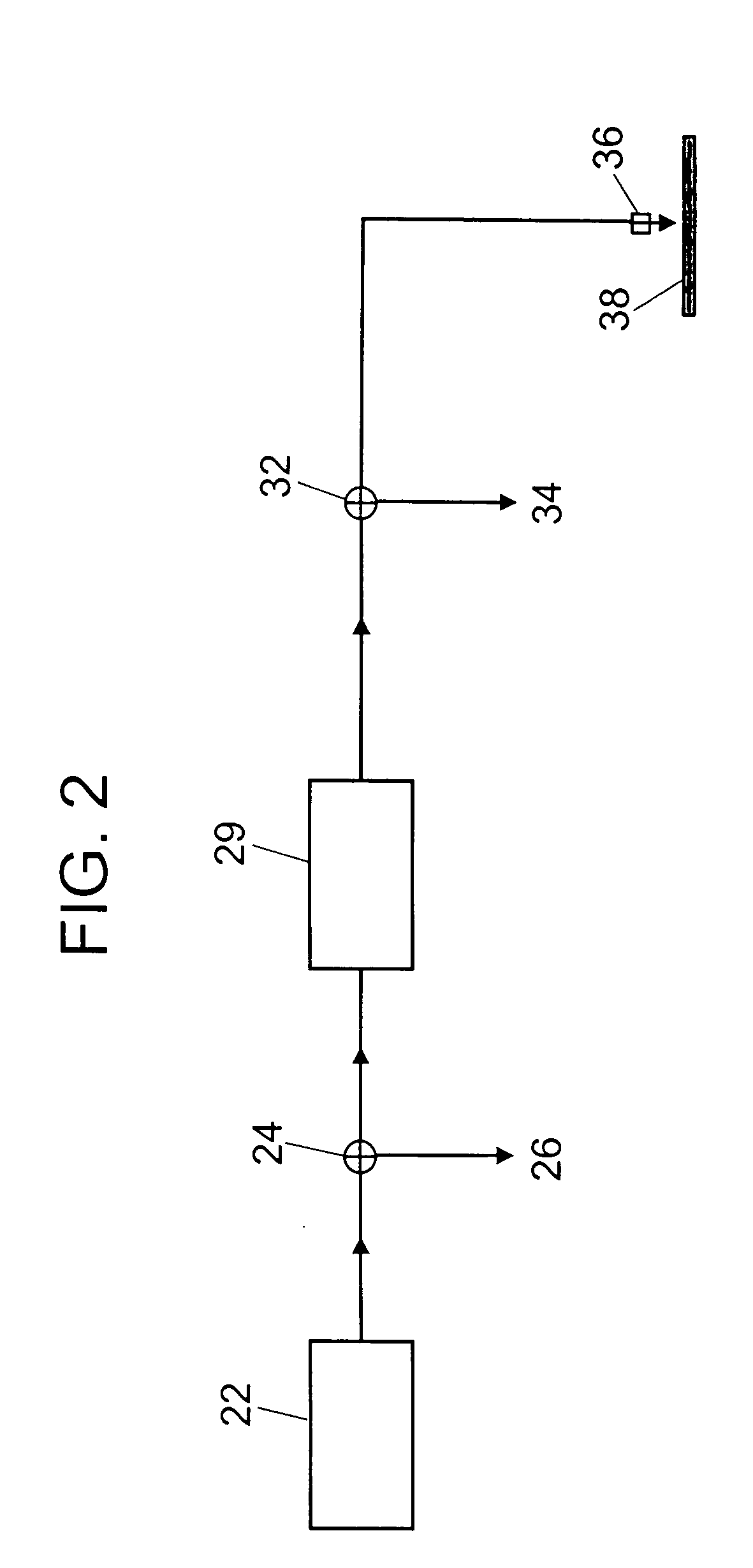

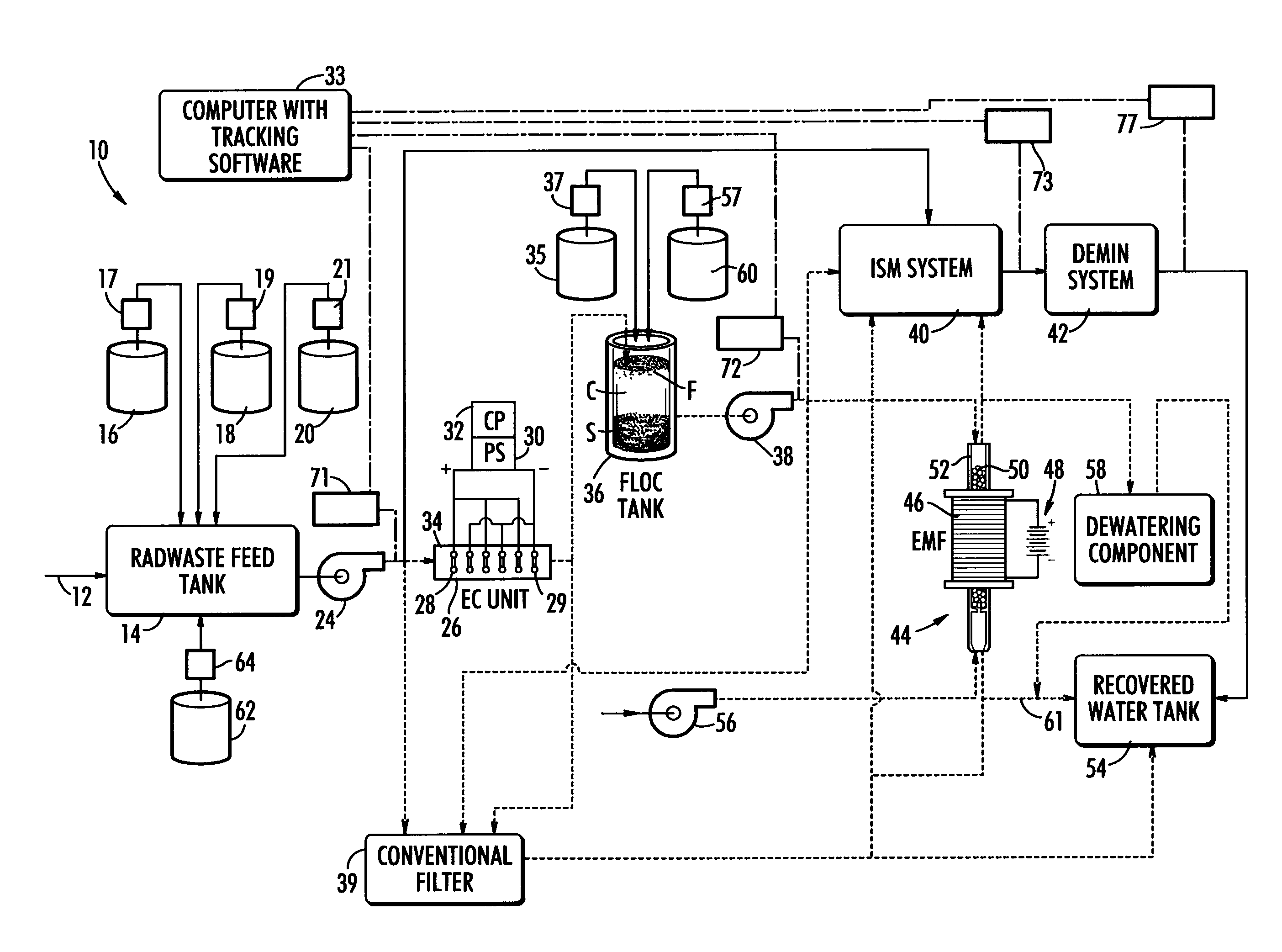

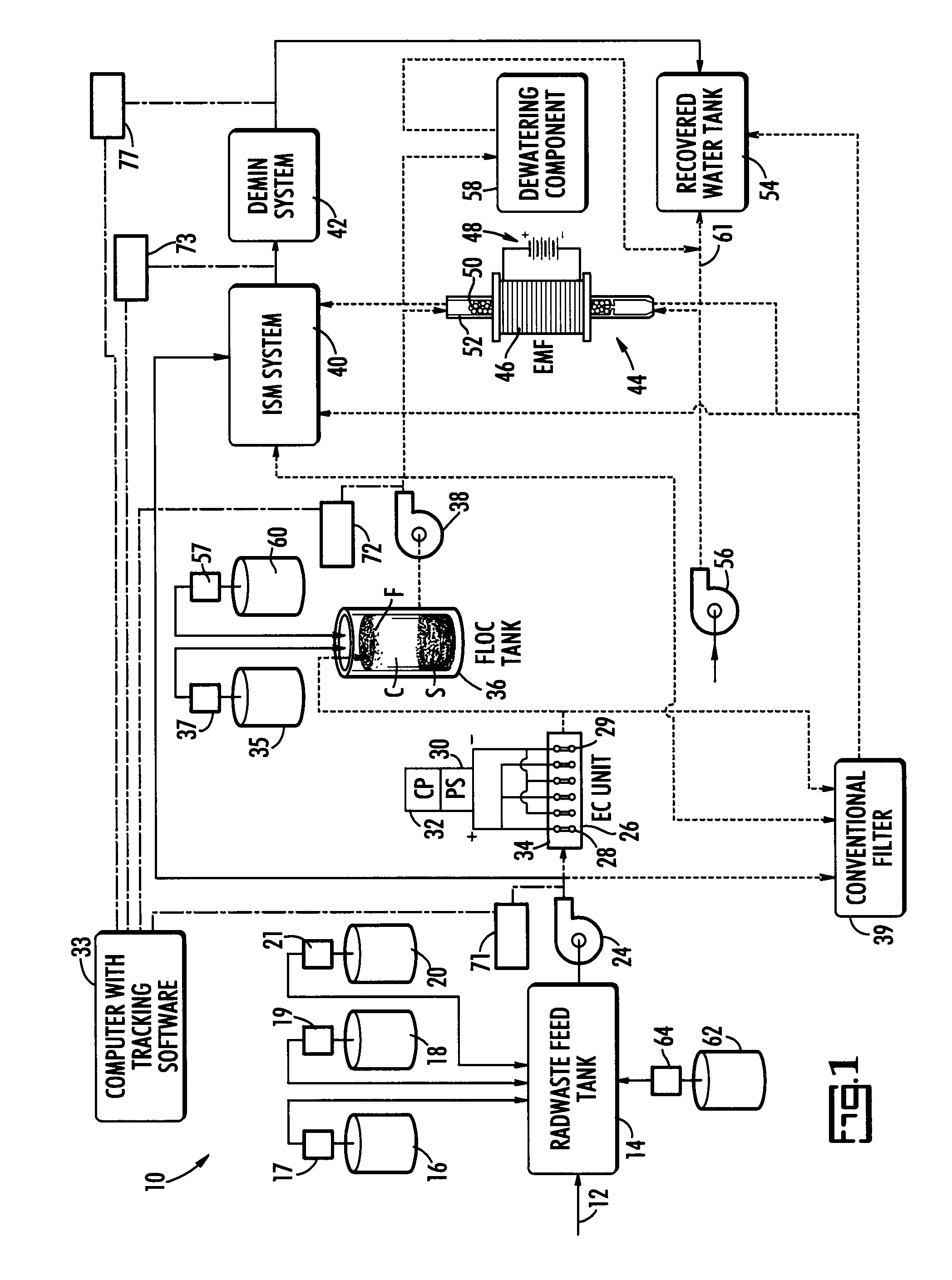

A process and system for treating waste water containing contaminants to prevent excessive accumulation on demineralizer media of a driver contaminate capable of such accumulation before another contaminant can reach a predetermined level of accumulation. The waste water is treated upstream of the demineralizer media with removal means for specifically removing the driver contaminant while leaving the other contaminant for subsequent removal by the demineralizer media. The amount of accumulation on the demineralizer media of the other contaminant is monitored, and the supplying of treated waste water to the demineralizer media is terminated when its accumulation reaches the predetermined level.

Owner:ENERGYSOLUTIONS LLC

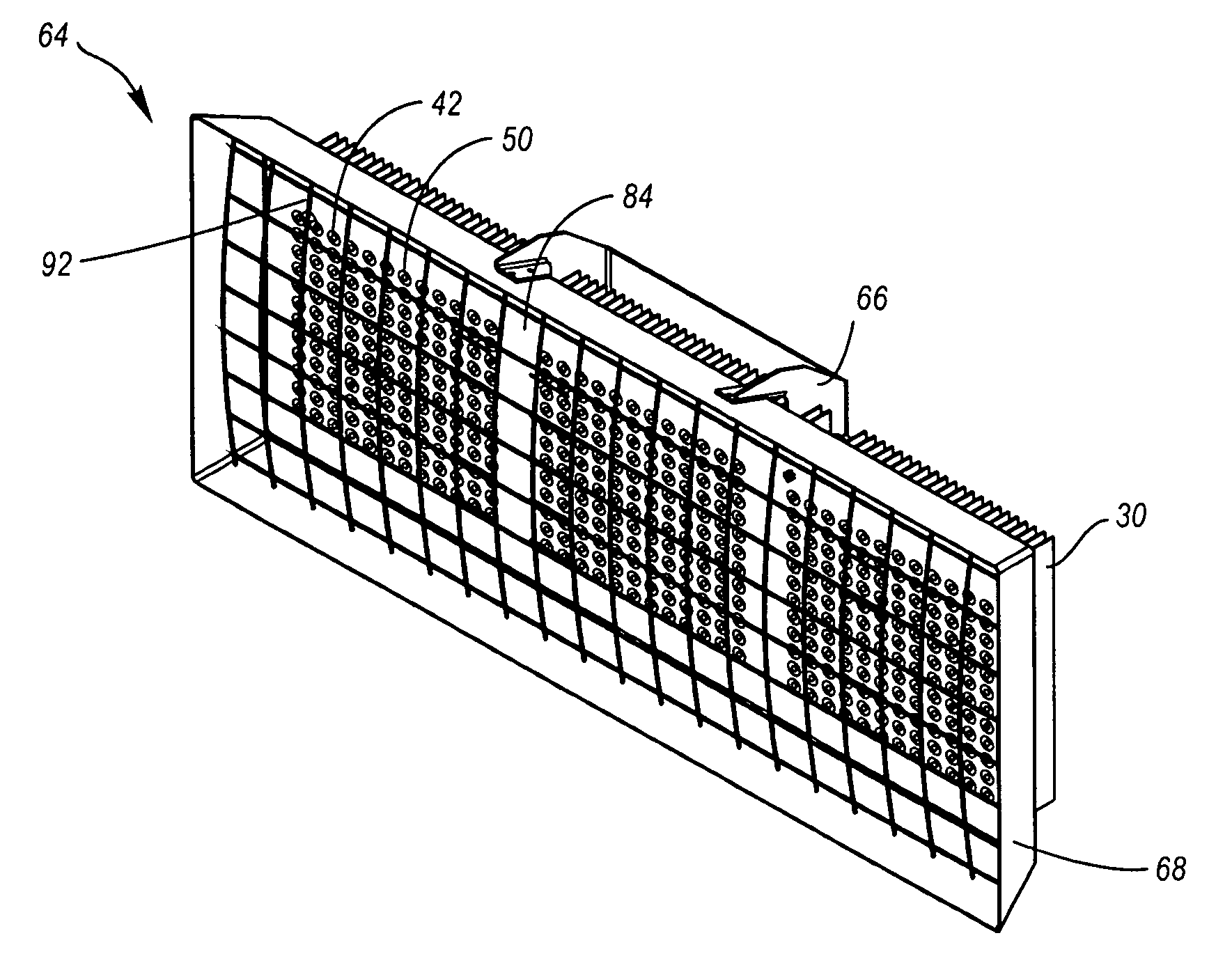

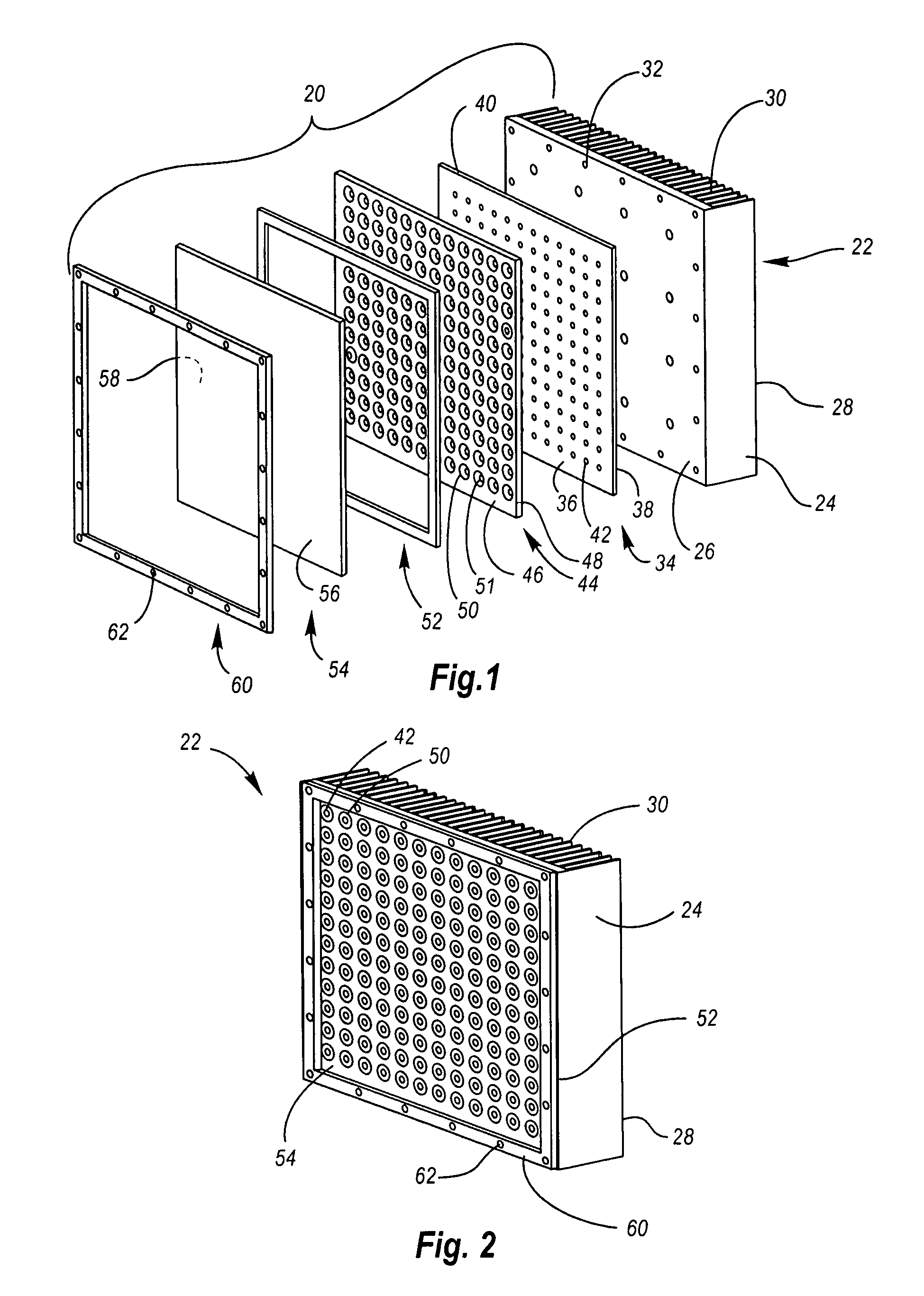

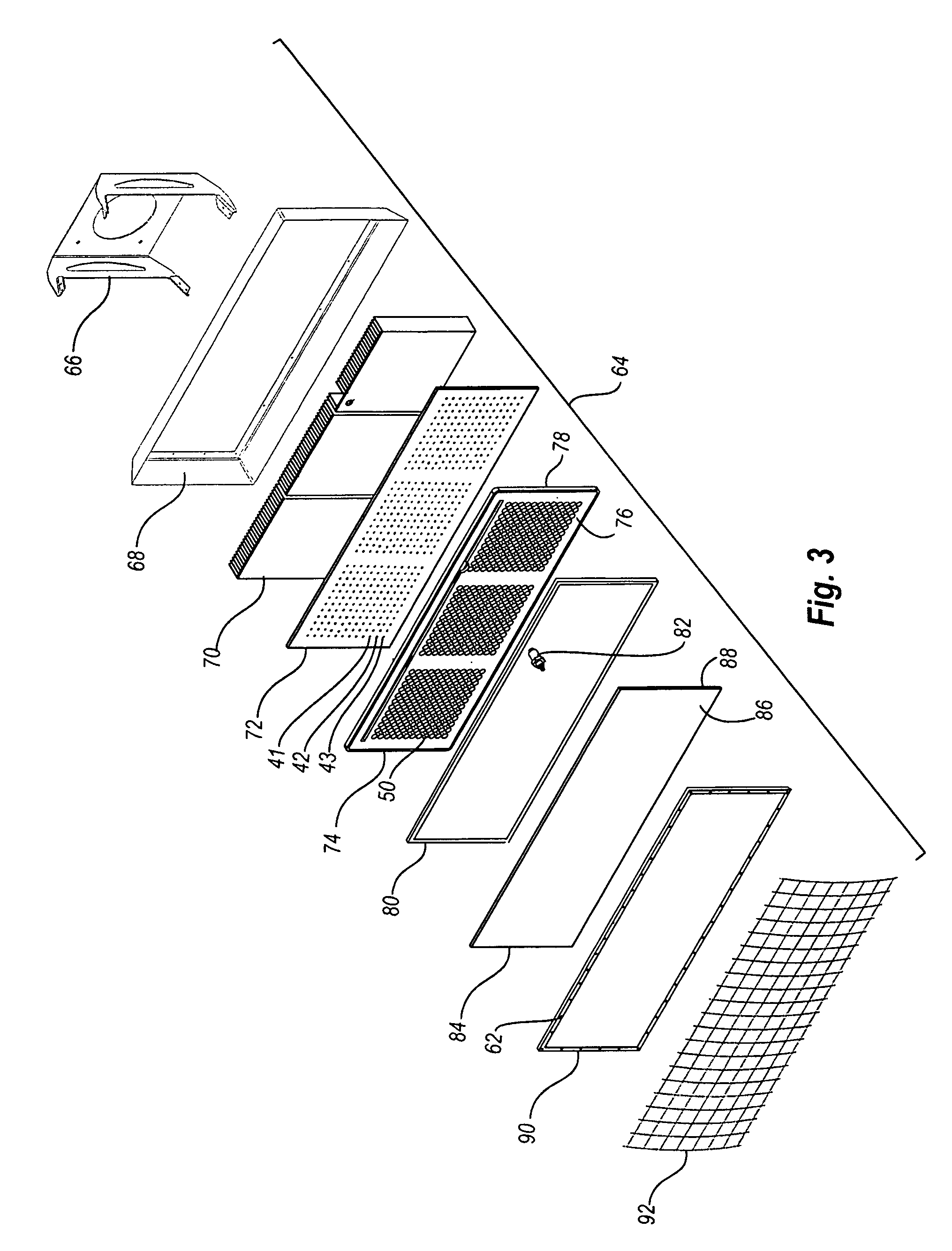

Submersible high illumination LED light source

InactiveUS8100560B2DurationGreat life expectancyPlanar light sourcesMechanical apparatusElectrical connectionEngineering

Owner:LIGHTS CAMERA ACTION

Condiment Dispensing System

InactiveUS20070029343A1Minimize timeImprove insertion accuracyStationary measuring chambersLiquid dispensingEngineeringVALVE PORT

A system for dispensing product includes a track support, the track support comprising a one-piece frame and a roller assembly slidably engaged with the one-piece frame, the roller assembly including a first lobed roller and a second lobed roller. The system further includes a valve assembly attached to a base portion of the one-piece frame, wherein a flexible product filled bag is retainable between the roller assembly and wherein the roller assembly translates down the track support to force the product toward the valve assembly.

Owner:CLEAR LAM PACKAGING

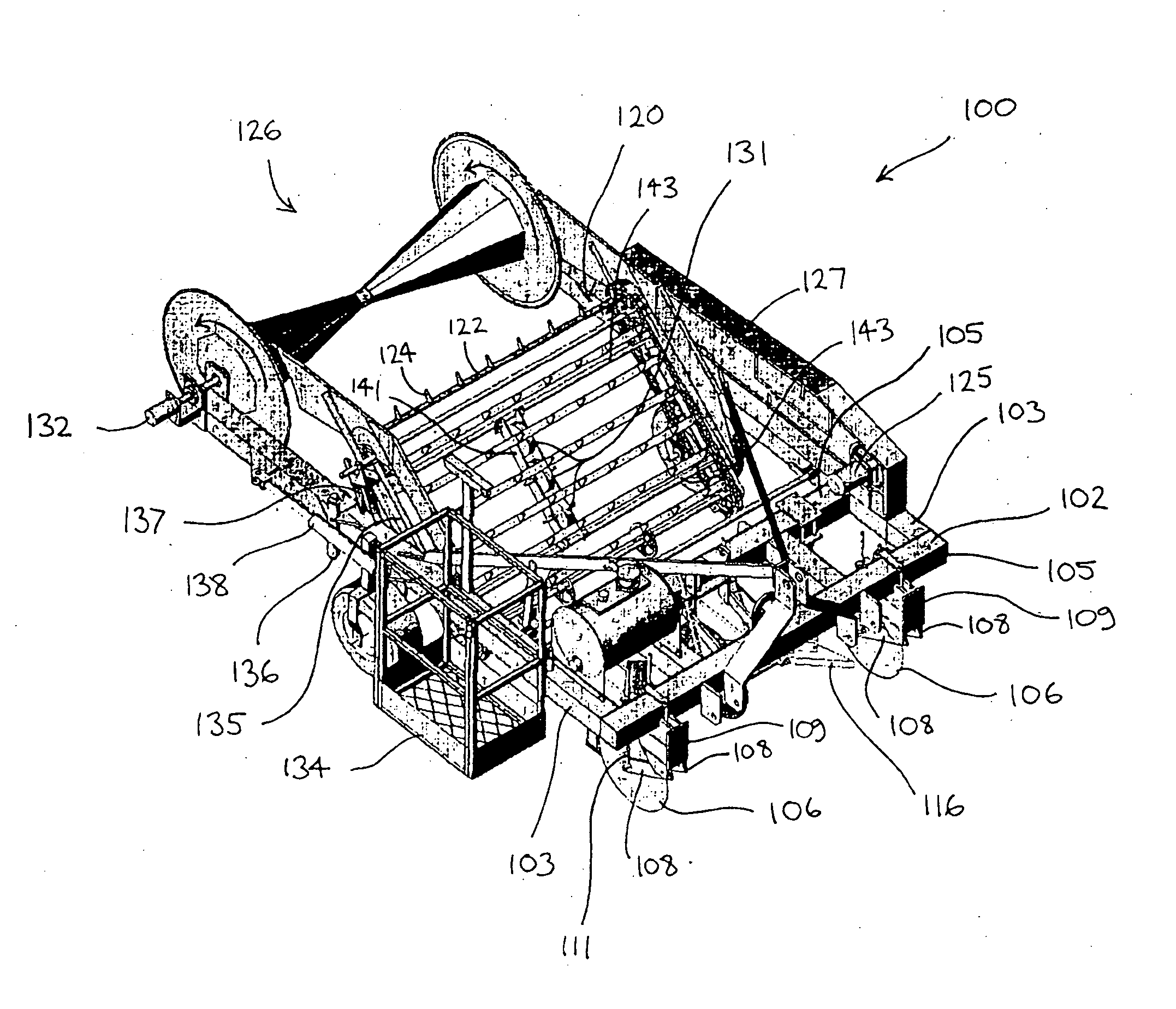

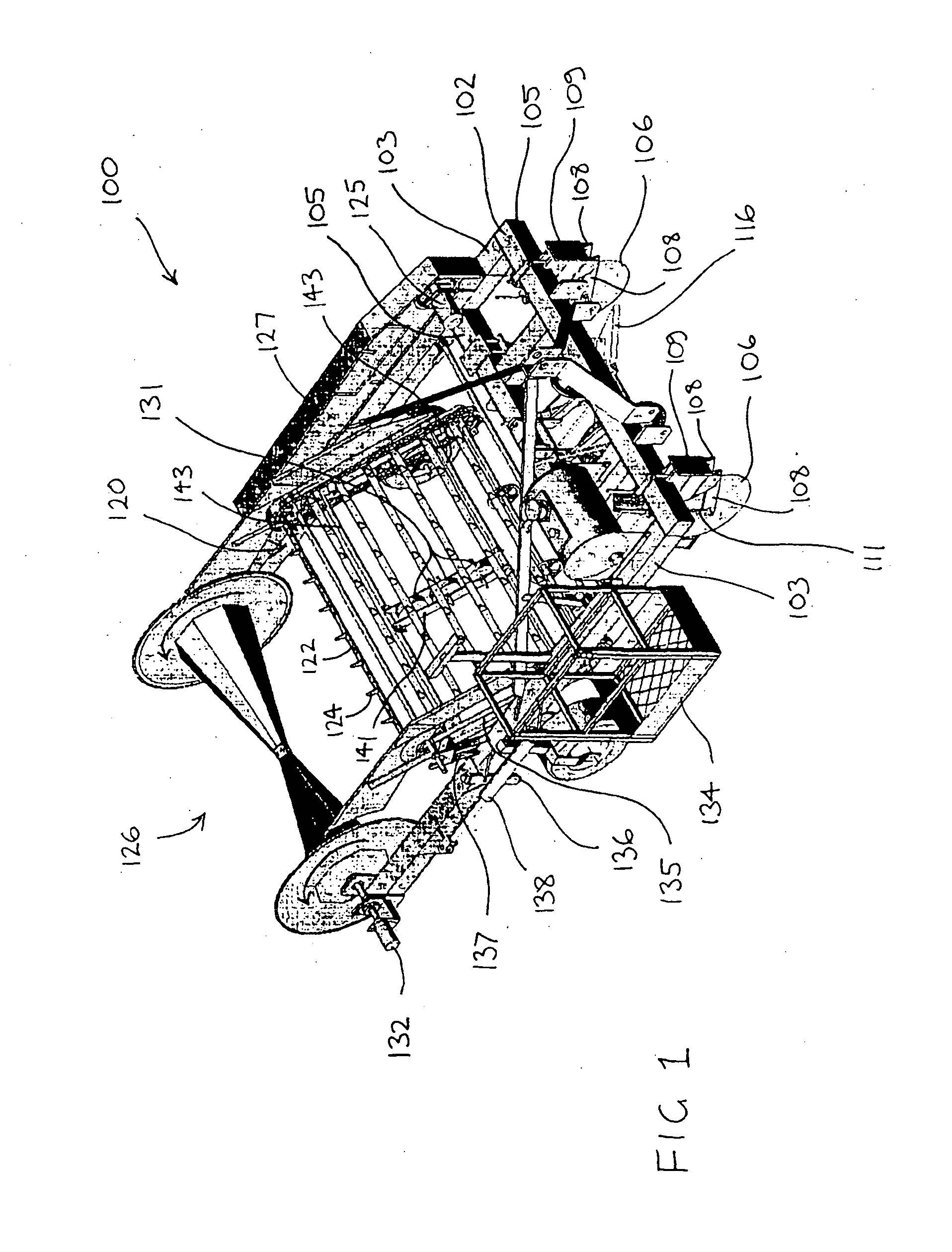

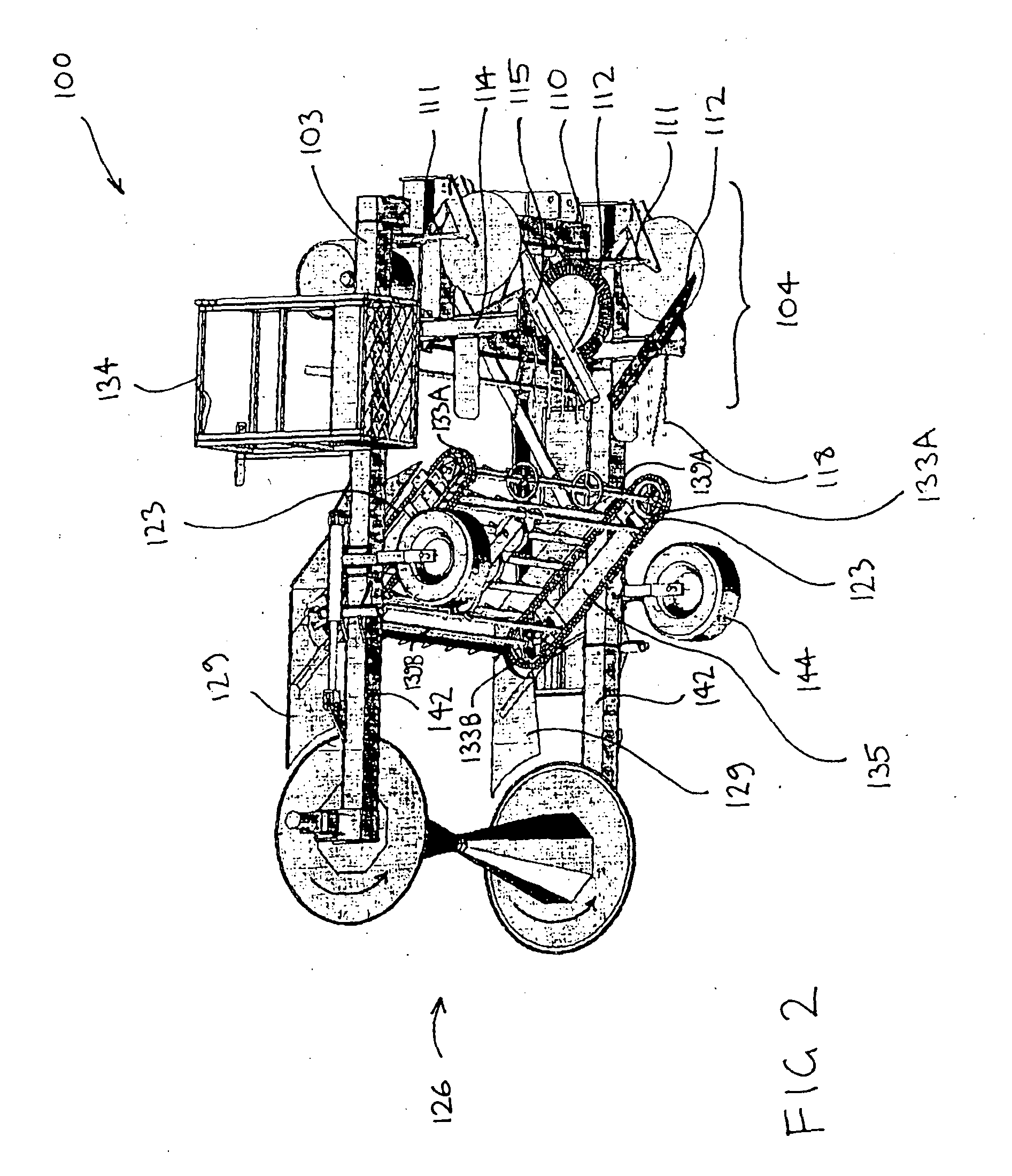

Plastic mulch retriever

InactiveUS20110000687A1Many problemMaximising removal of dirtSoil lifting machinesLiftersPlastic mulchEngineering

A plastic mulch retriever is disclosed comprising a body and at least one cutting or digging element mounted to the body to loosen plastic mulch embedded in the ground. A conveyor is mounted to the body rearward of the at least one cutting or digging elements to engage the loosened plastic mulch and remove at least some of the ground material attached to the extracted plastic mulch. At least one storage device is mounted to the body rearward of the conveyor to store the retrieved plastic mulch.

Owner:ROCCA MFG

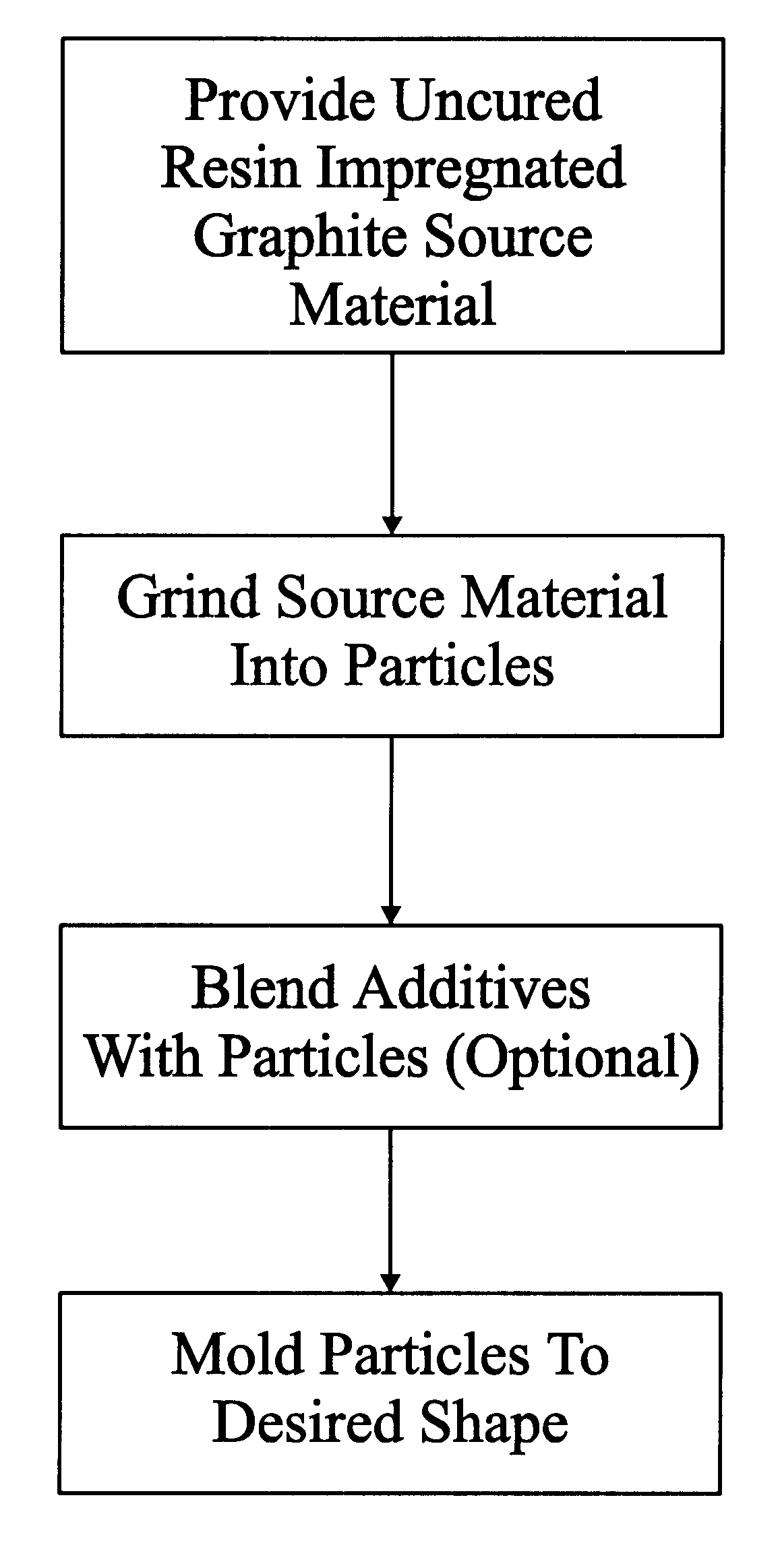

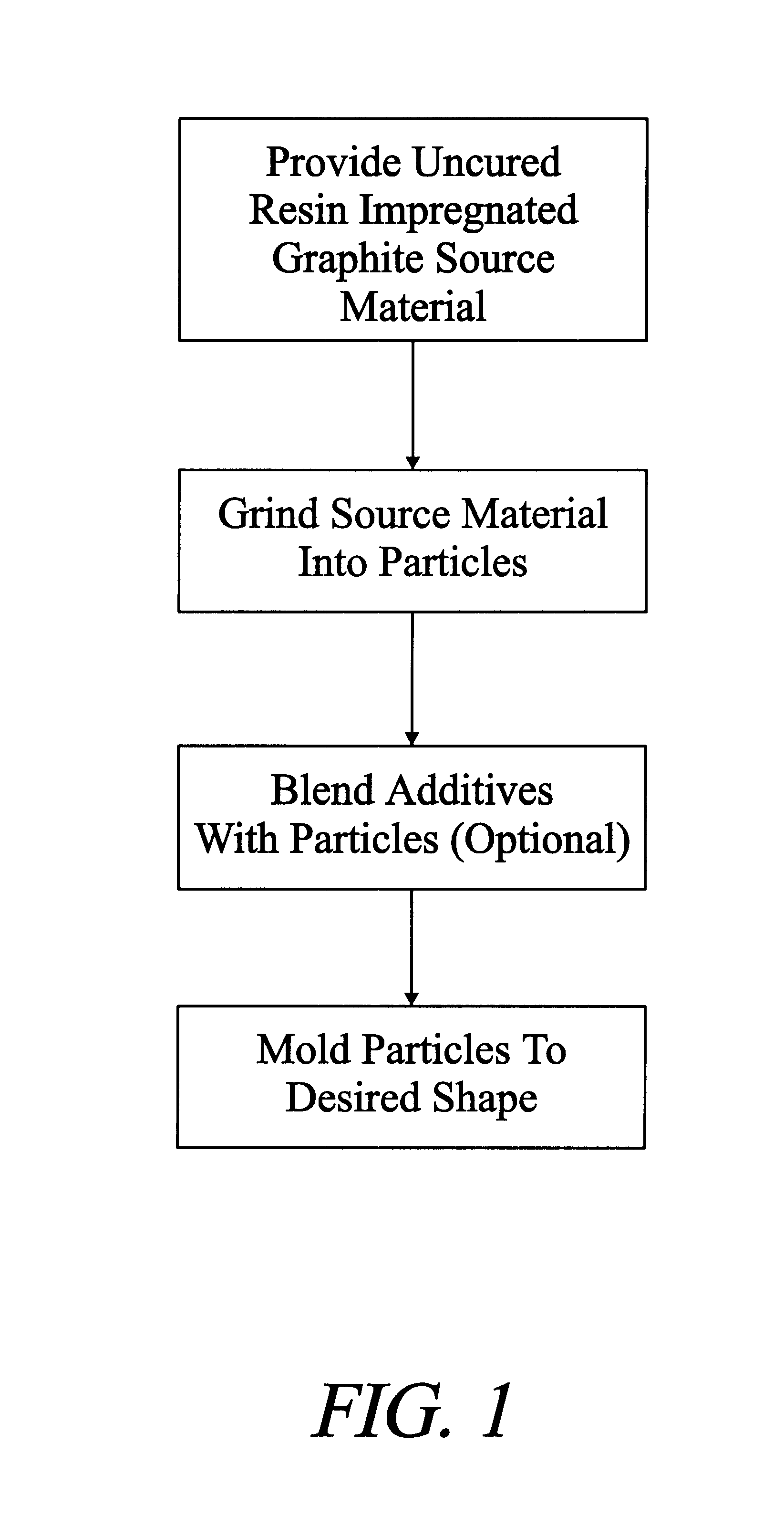

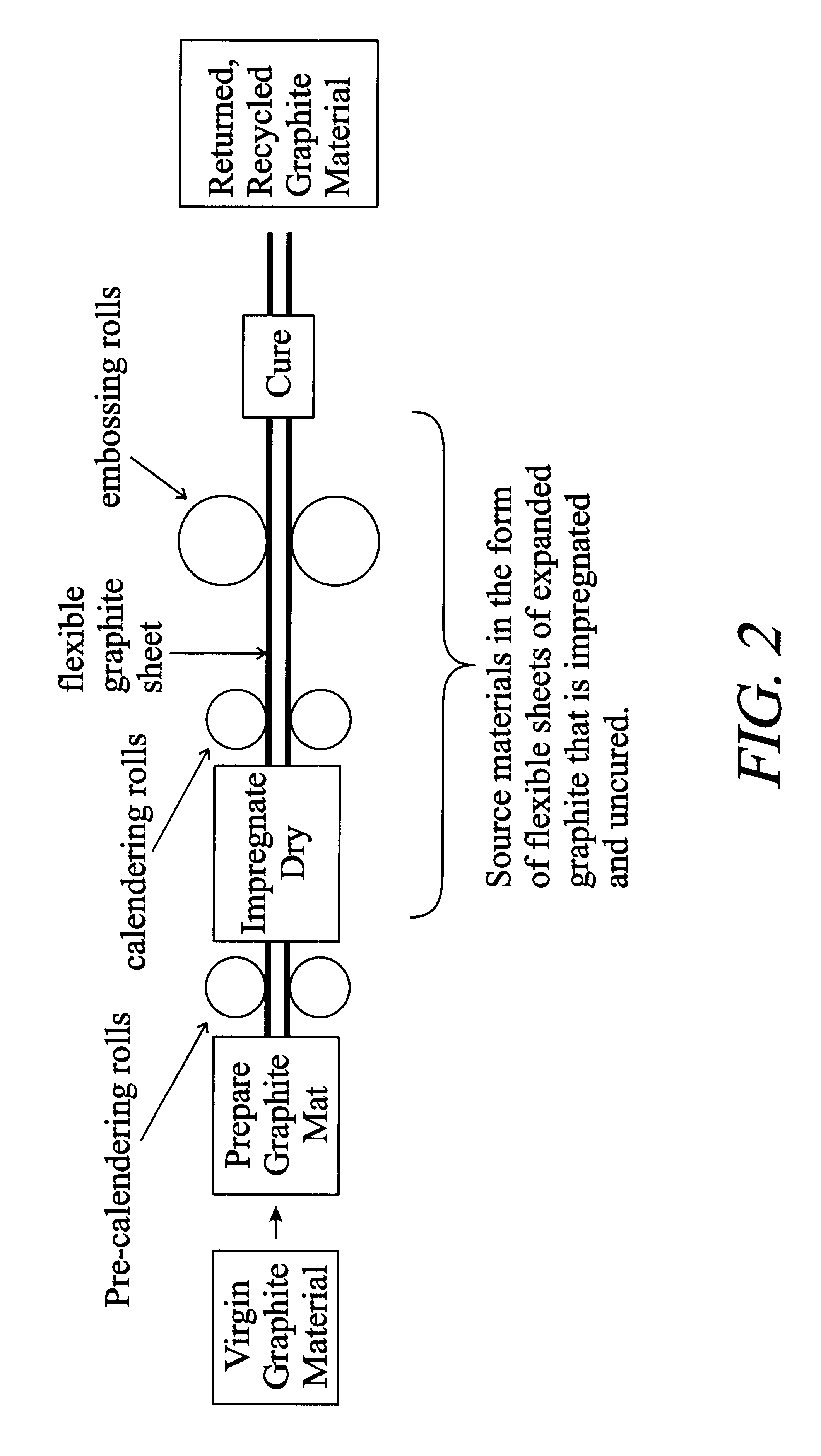

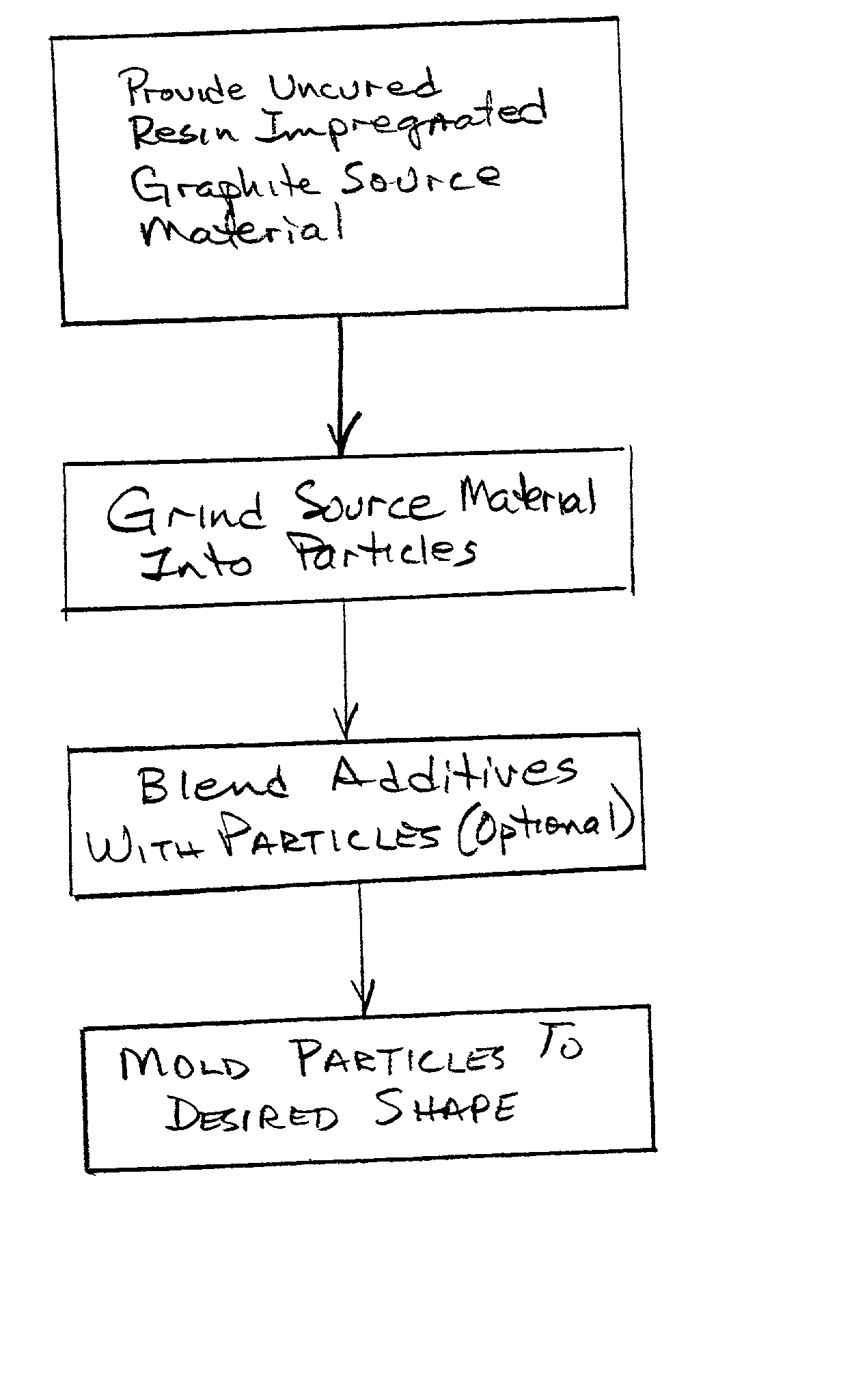

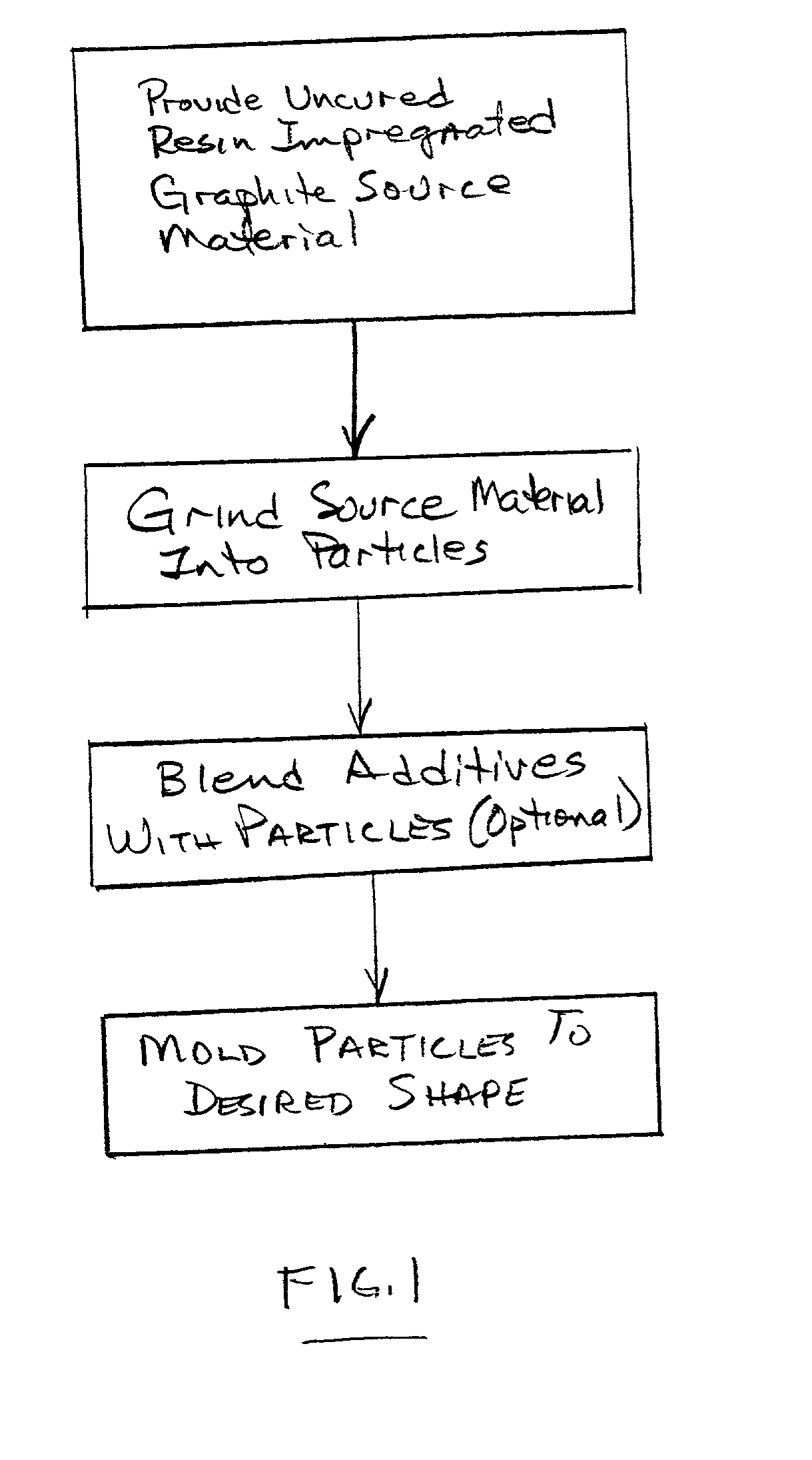

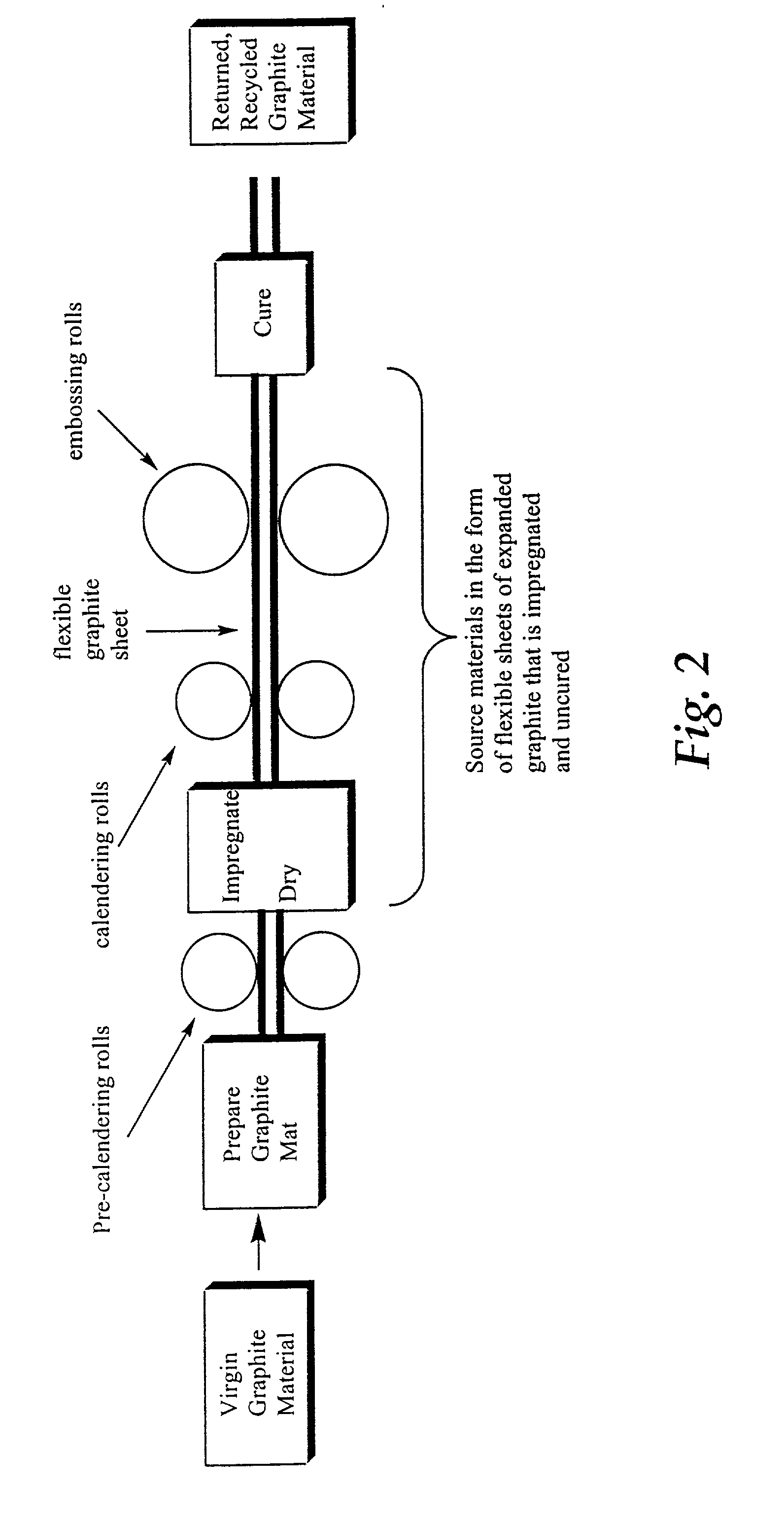

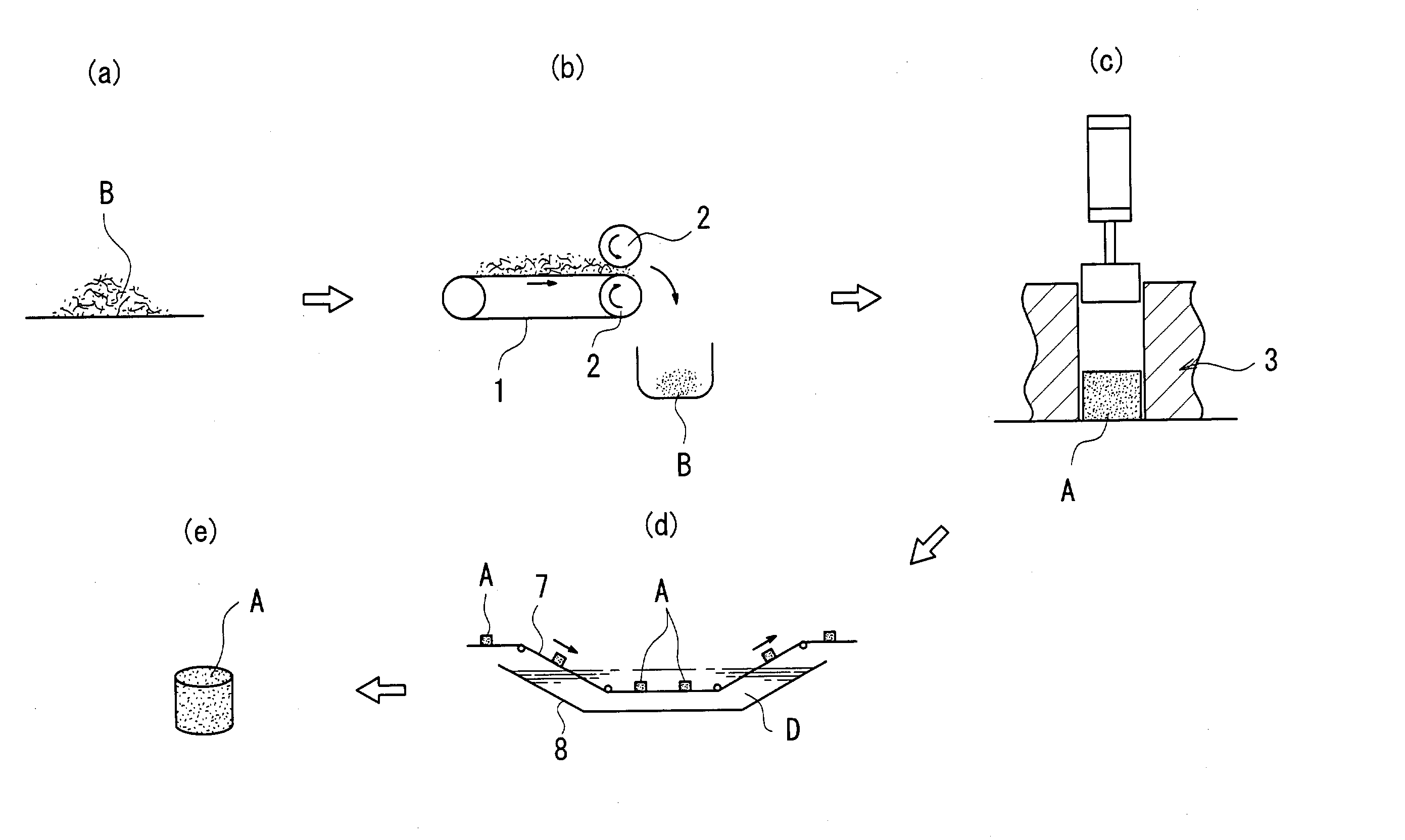

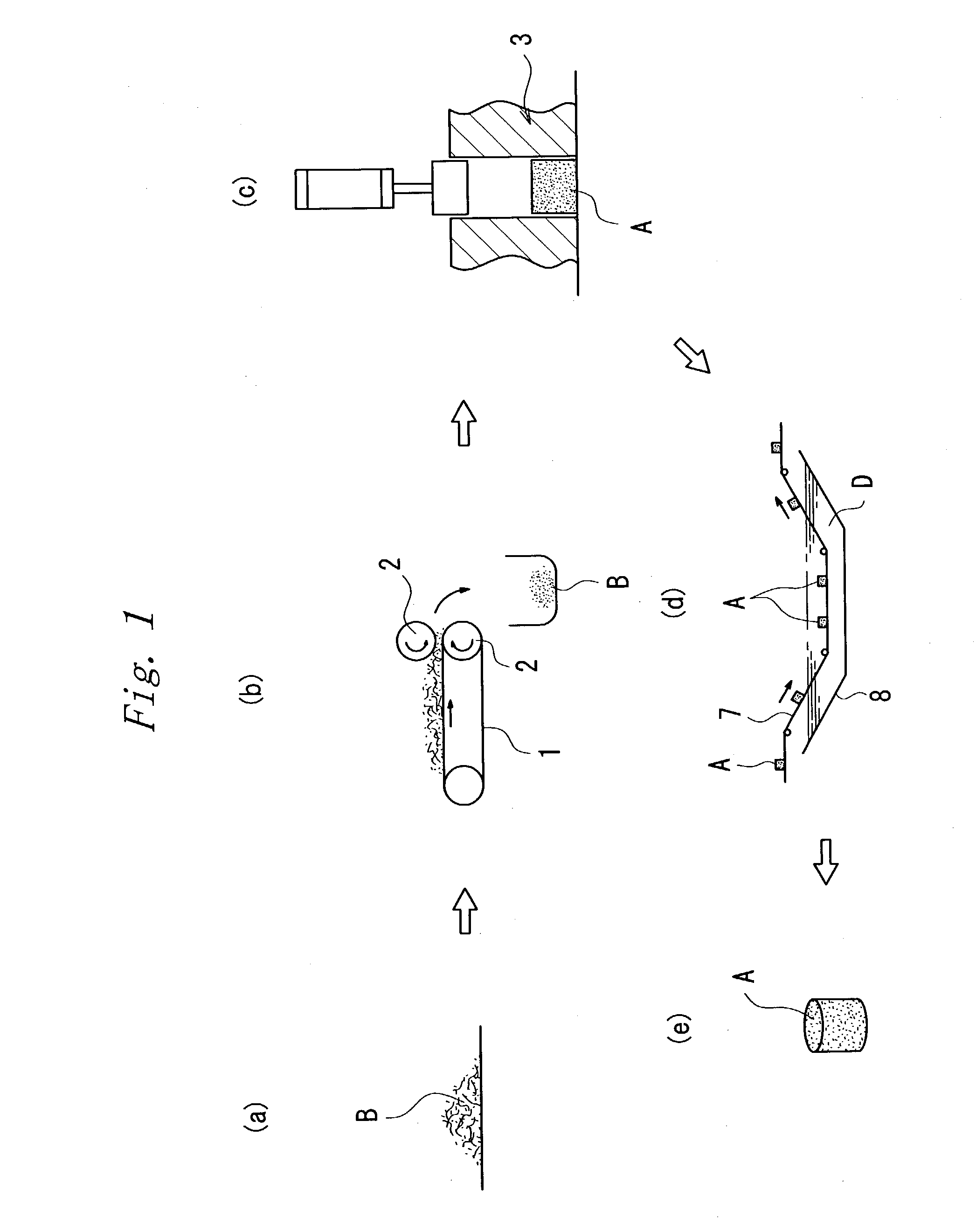

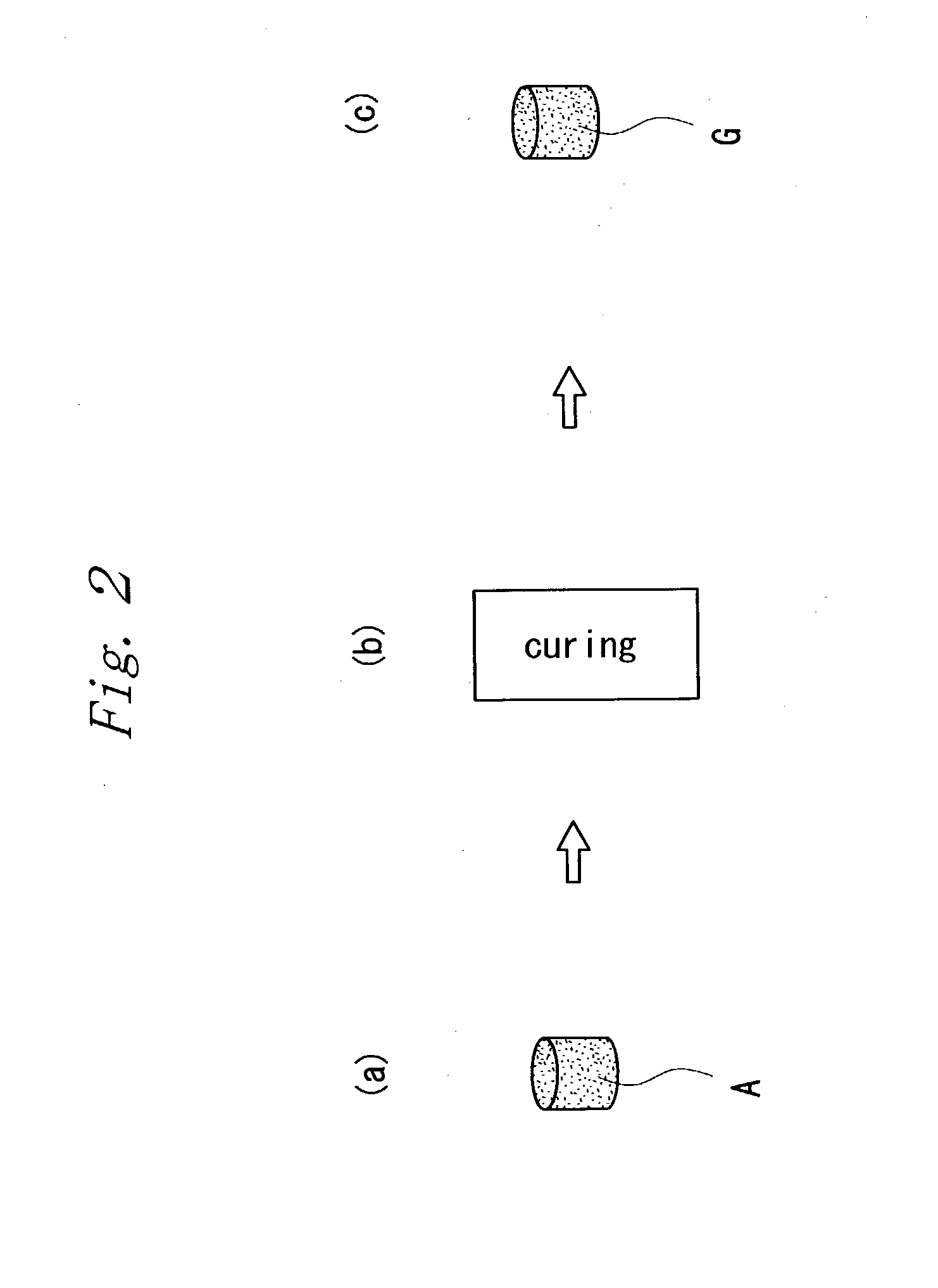

Molding of materials from graphite particles

InactiveUS6613252B2Good electrical and thermal conductivityReduce disposal costsMaterial nanotechnologyArtificial filament recoveryPolymer scienceFuel cells

A method of manufacturing material suitable for the construction of a component of a fuel cell, such as a flow field plate or electrode. Uncured resin impregnated flexible graphite sheet is ground into particles. Without re-expanding the particles, and without adding further resin to the particles, the particles are molded into the form of the desired material. The material is then cured. Additives may be mixed with the particles to improve the properties of the material.

Owner:GRAFTECH INT HLDG INC

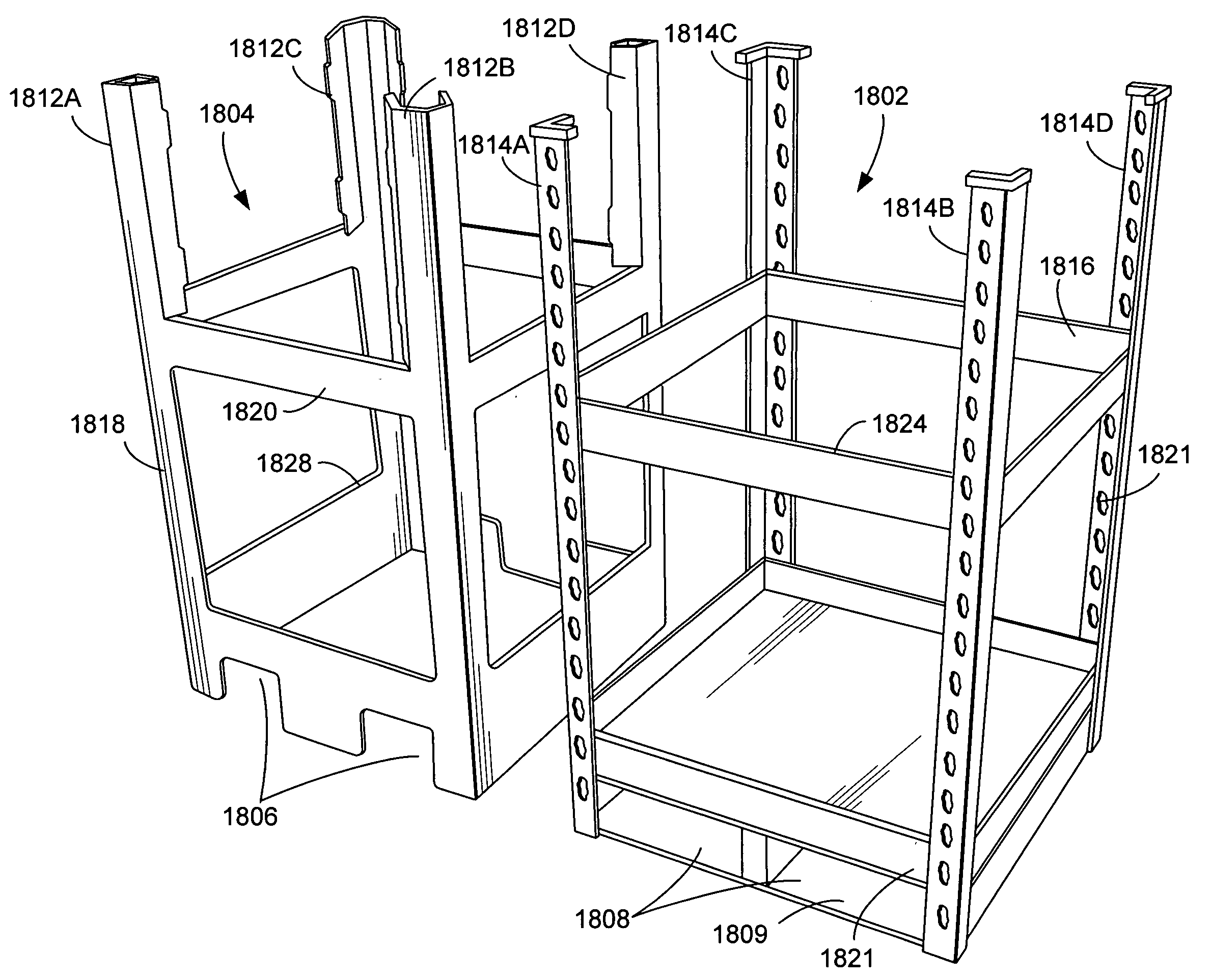

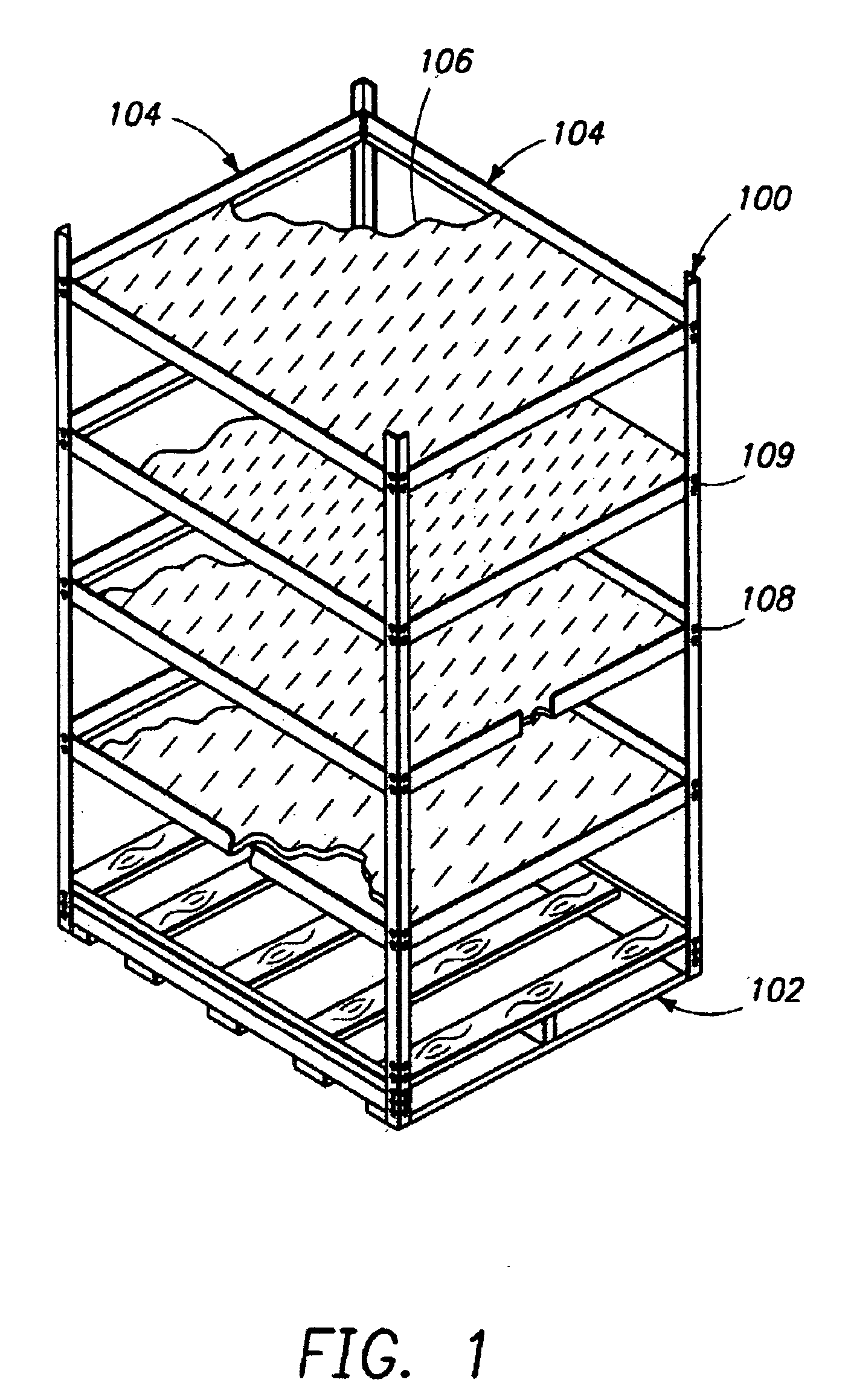

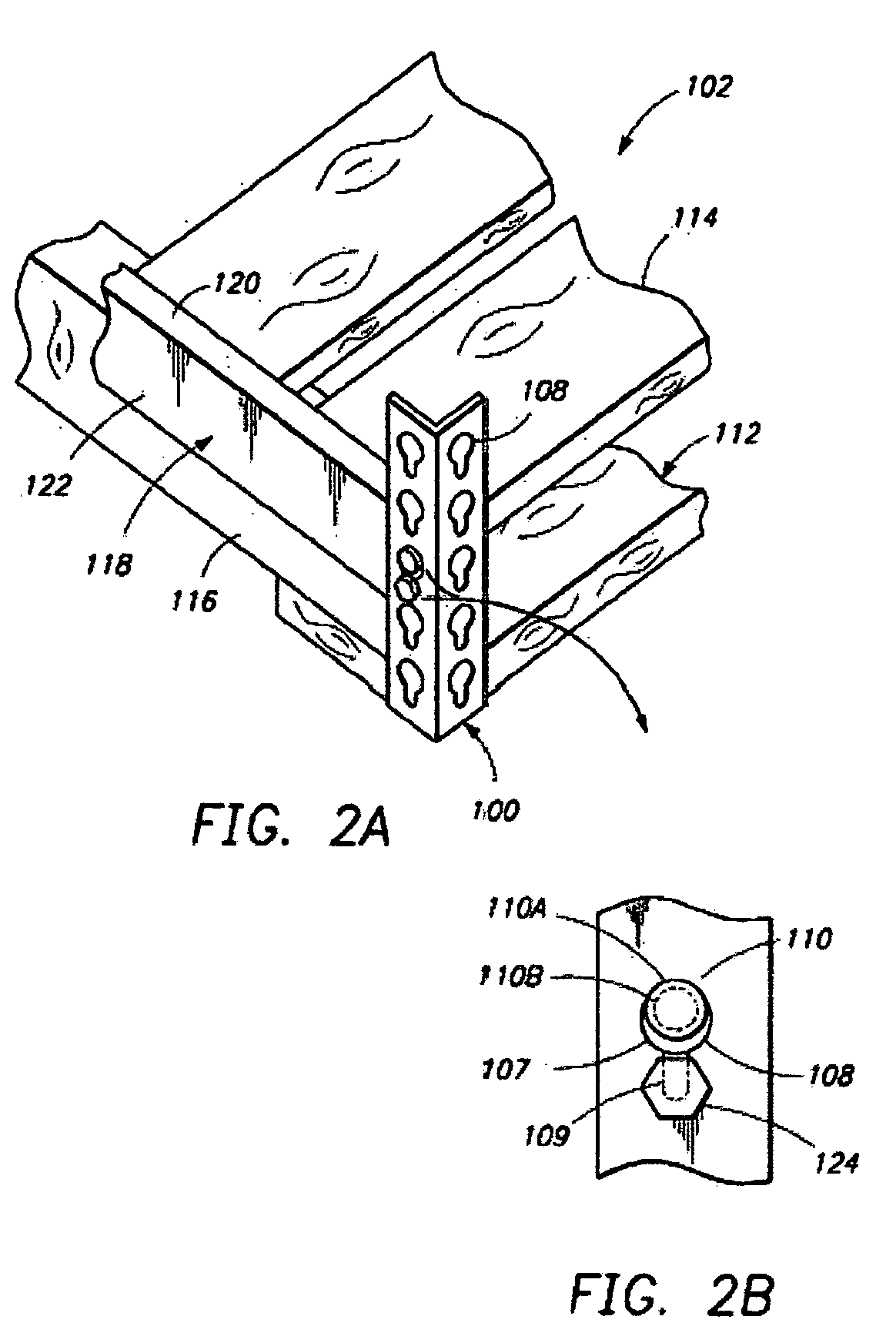

Shelf assembly display jacket

InactiveUS20050109723A1Easy to moveEasy to assembleFurniture partsDismountable cabinetsBiomedical engineering

Owner:E Z SHIPPER RACKS

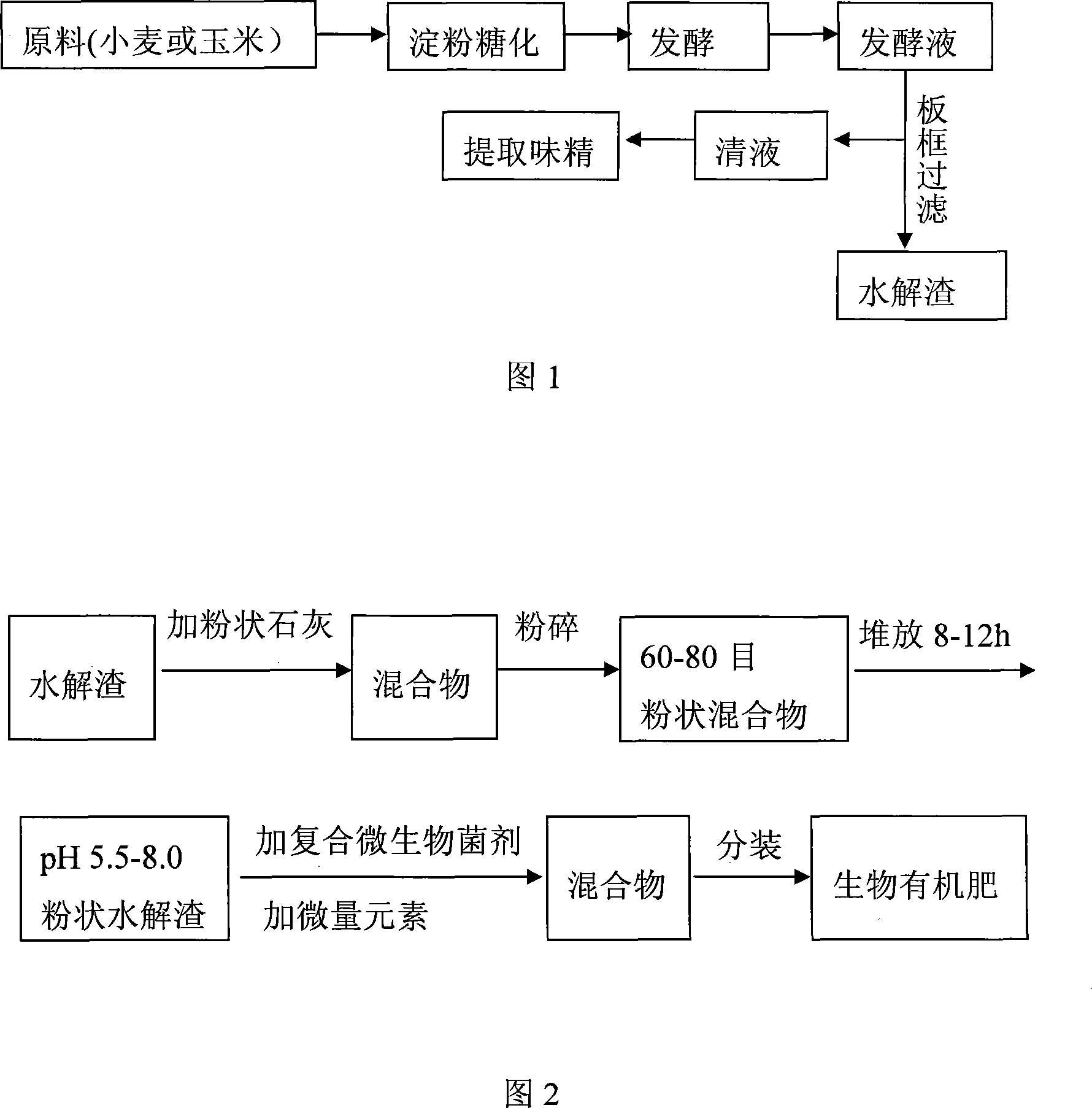

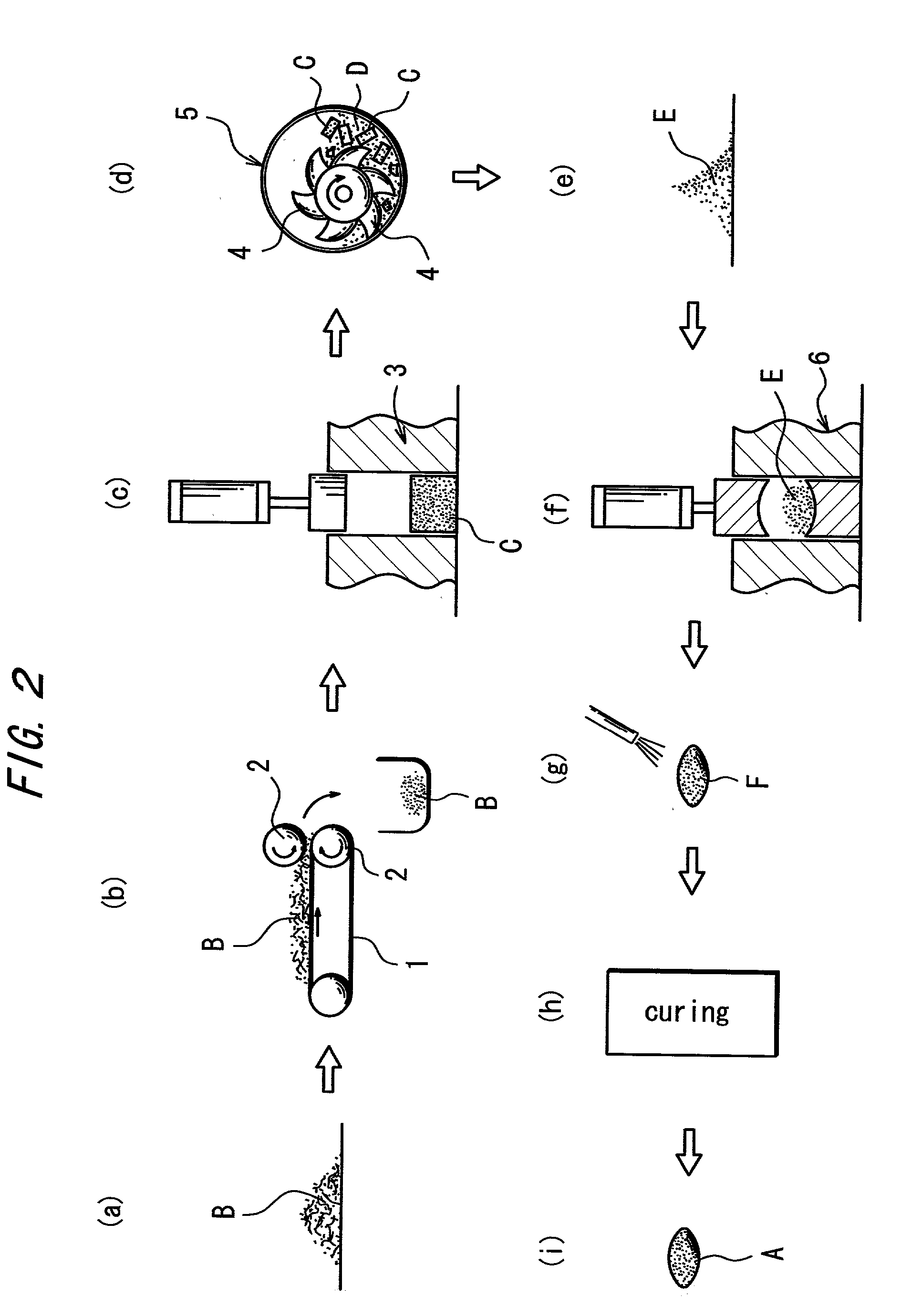

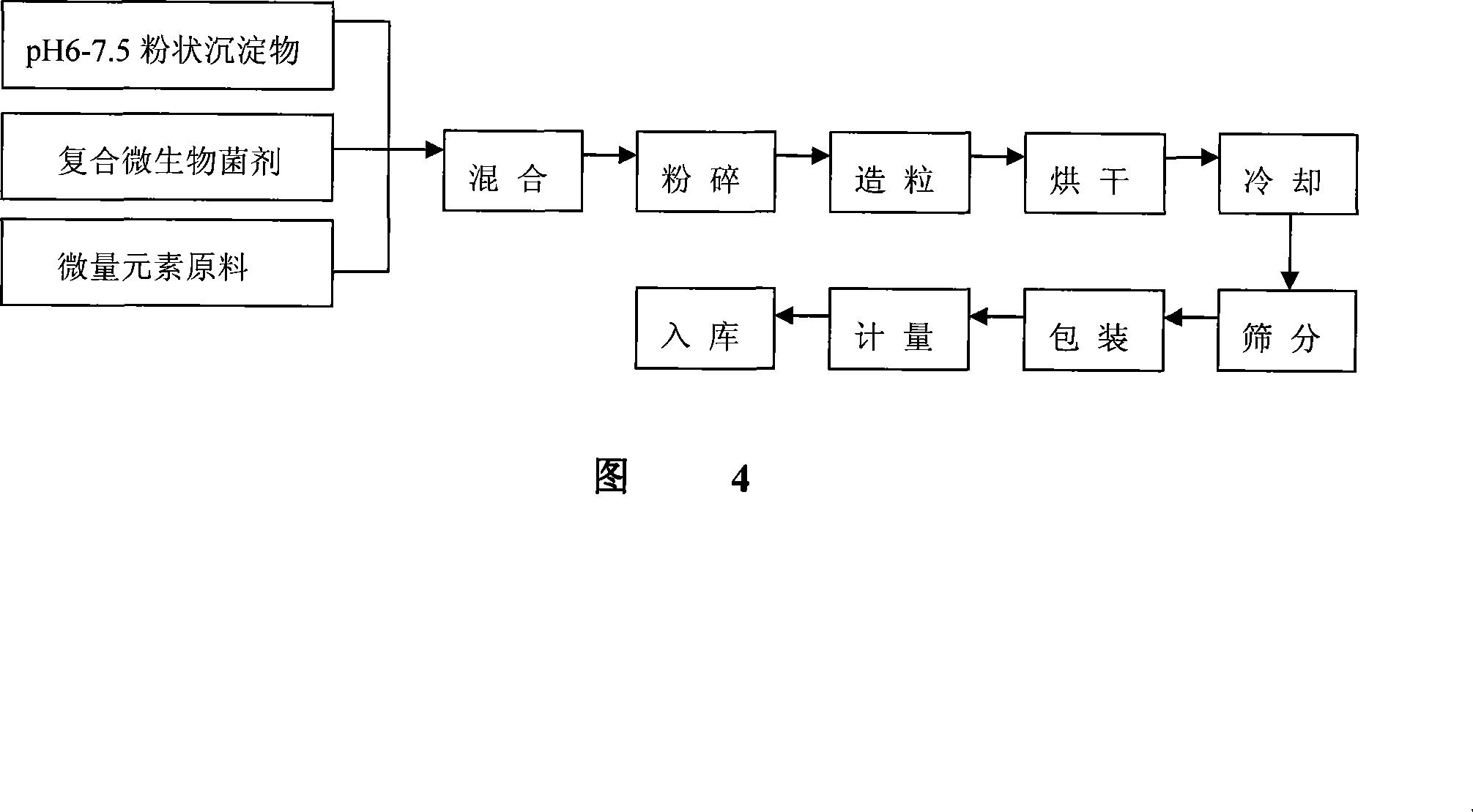

Method for producing multifunctional biological fertilizer

InactiveCN101195549APromote crop growthImprove soil structureClimate change adaptationBioloigcal waste fertilisersBatch productionBiotechnology

The invention provides a method for preparing multifunctional biological organic fertilizer and the technical scheme of the invention comprises fermenting bacillus subtilis, bacillus megaterium and bacillus mucilagimosus individually. The fermented bacterial liquid is adsorbed by rice husk separately. Three adsorbed single microbial inoculum is blended and grinded according to the proportion of 1:0.8-1.2:1.5-2.5 to obtain the compound microbial inoculum. The hydrolytic slag which is obtained in the production procedure of gourment powder after treatment is charged by trace element raw material and 4%-7% compound microbial inoculum with relative to total weight to obtain the needed compound microbe fertilizer. The method is simple in production technique, which facilitates to do batch production.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

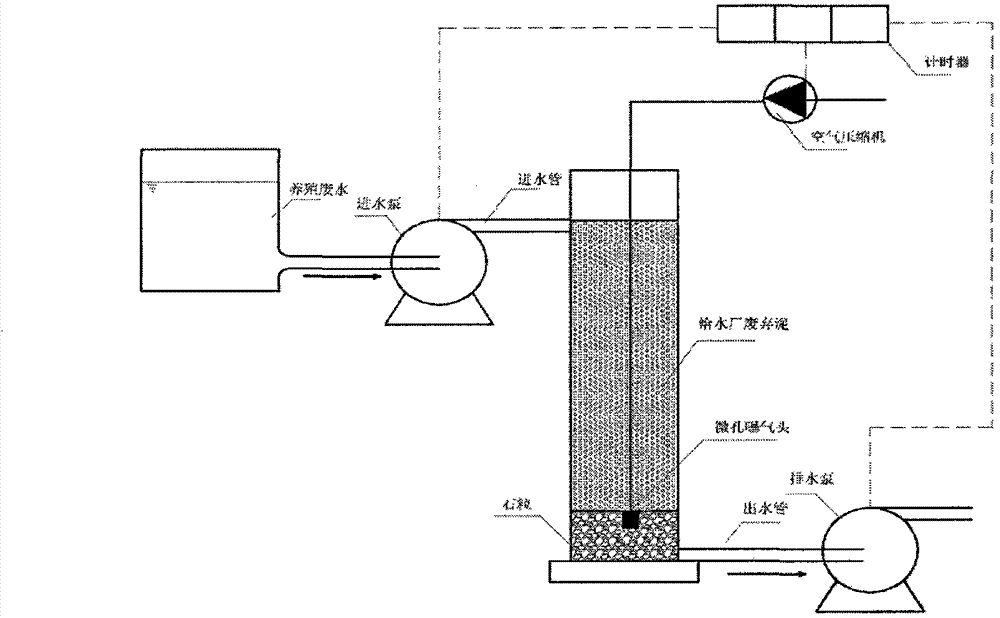

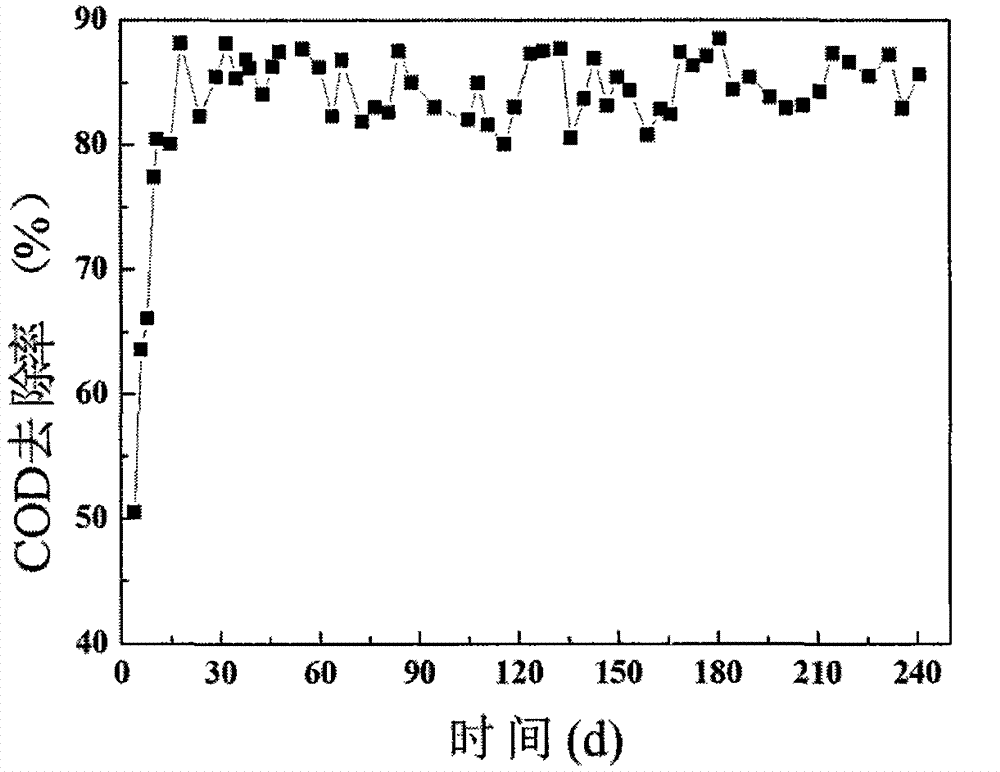

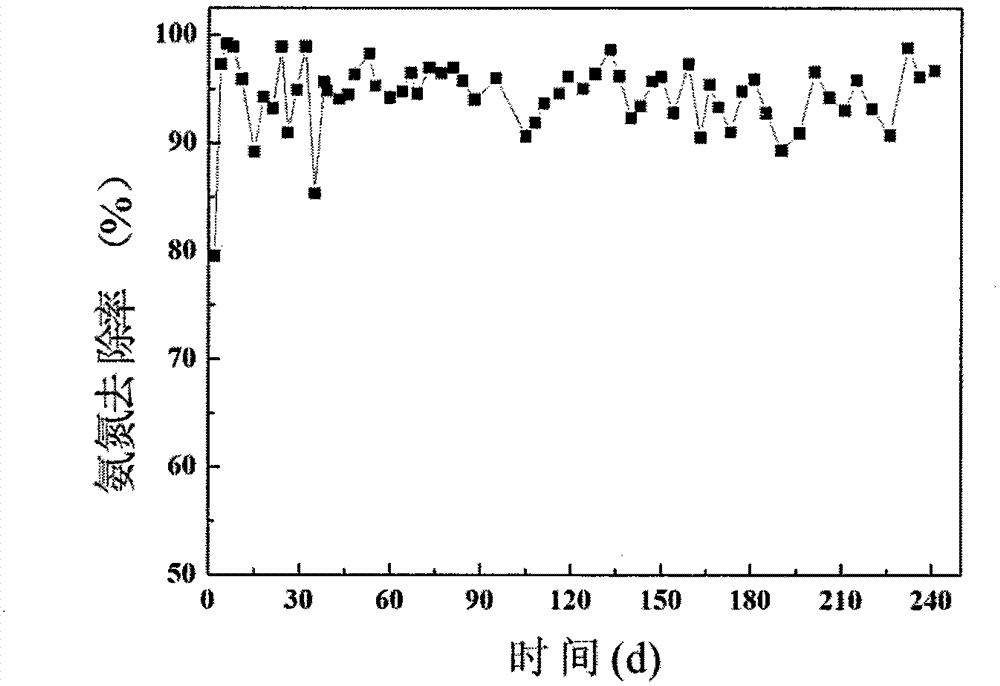

Method for treating wastewater from livestock and poultry breeding by constructing vertical flow artificial wetland based on water supply plant sludge

ActiveCN103880193AWidely distributedEasy accessSustainable biological treatmentBiological water/sewage treatmentHigh concentrationConstructed wetland

The invention discloses a method for treating wastewater from livestock and poultry breeding based on a vertical flow artificial wetland with water supply plant sludge as fillers, belonging to the technical field of wastewater treatment. The method is characterized in that water supply plant sludge is dried and crushed as fillers to construct a vertical flow artificial wetland for treating high-concentration wastewater from livestock and poultry breeding, wastewater from livestock and poultry breeding is allowed to enter the artificial wetland by stages and discharged out from the system for a certain hydraulic retention time under the condition of intermittent aeration. The pollutants such as organic substances, nitrogen and phosphorus in wastewater can be effectively removed by the treatment method disclosed by the invention and the total removal rates of ammonia nitrogen and total phosphorus are higher than 90%. According to the method disclosed by the invention, the problem of a way out for water supply plant sludge is also solved while wastewater from livestock and poultry breeding is effectively treated, and thus the method is conducive to achieving a purpose of "treatment of wastes with processes of wastes" and is in line with the concept of circular economy and sustainable development.

Owner:BEIJING NORMAL UNIVERSITY

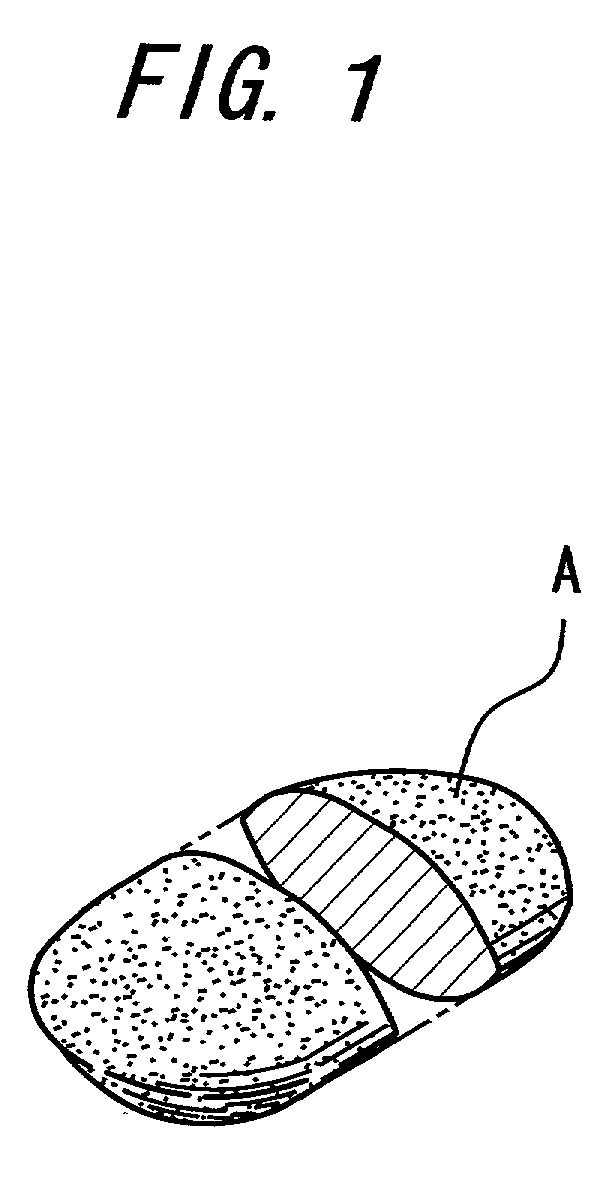

Briquette as material for steel making and method for production thereof

InactiveUS20020152843A1Reduce disposal costsOxidization is suppressedBlast furnace componentsBlast furnace detailsCompression moldingSteelmaking

Cotton-like aggregates (B) containing grinding chips from an iron-based metal and a grinding fluid containing oil and water are compression molded thereby forming a brittle compact (C) in which the fibrous grinding chips are roughly sheared and which is removed of excessive water and oil. The brittle compact (C) is crushed for further finely shearing the grinding chips and then, the resultant grinding chips are mixed with a solidification assistant (D) for obtaining powder (E) containing the solidification assistant (D). The powder (E) is solidified by compression molding, thereby forming a water-containing briquette (F). A briquette (A) for use as steelmaking material, which contains powdery pure iron and oil, is obtained by removing the water from the water-containing briquette (F). Without crushing the brittle compact (C), it is also possible to form the briquette (A) for use as steelmaking material by impregnating the brittle compact (C) with the solidification assistant (D) and then drying th compact.

Owner:JTEKT CORP

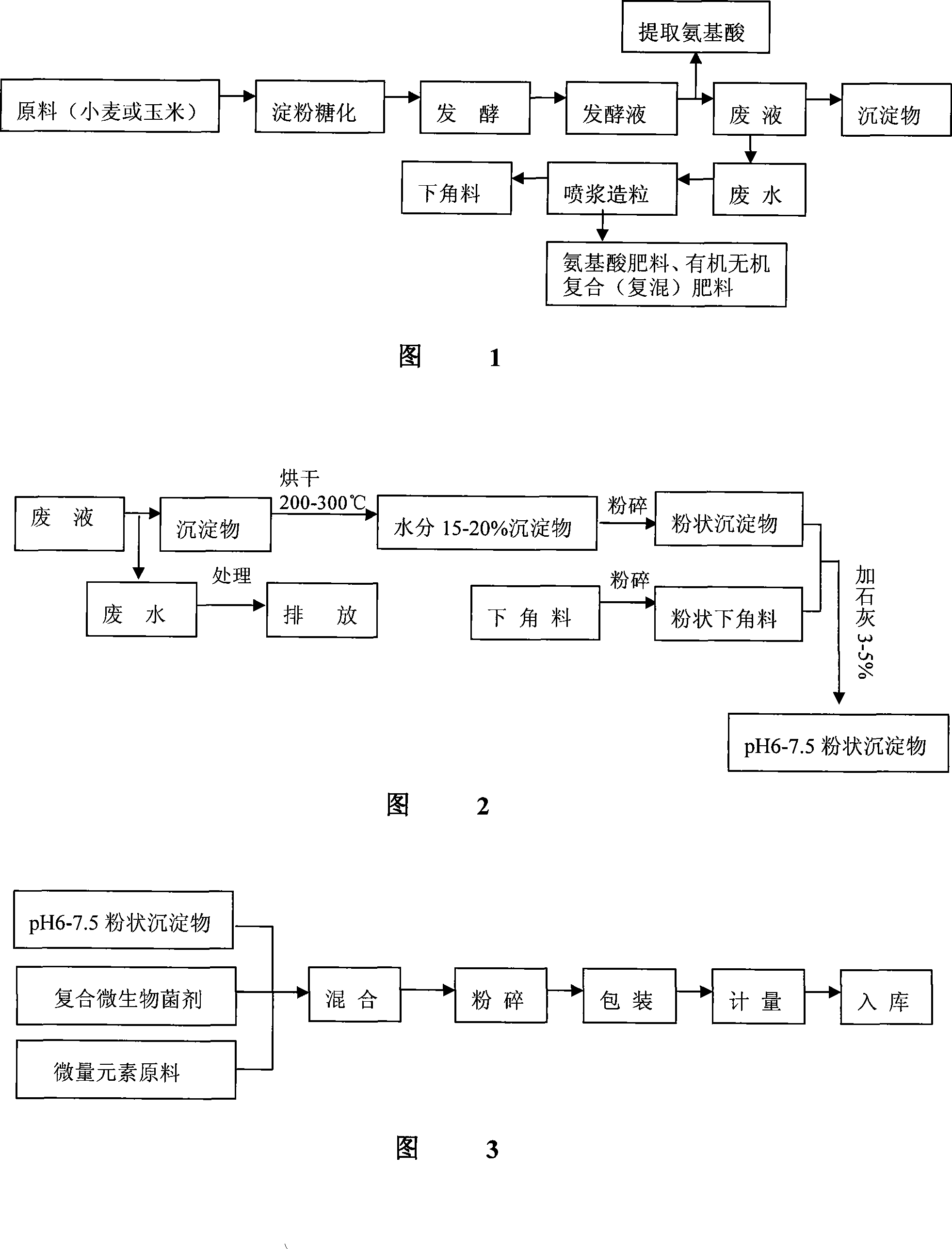

Method for producing soluble composite microorganism fertilizer

InactiveCN101195542AIncrease added valueReduce manufacturing costClimate change adaptationSewage/sludge fertilisersMicroorganismBacillus megaterium

The invention provides a method for preparing soluble compound microbe fertilizer. The technical project of the invention comprises fermenting bacillus subtilis, bacillus megaterium and bacillus mucilagimosus krassilm individually. The fermented bacterial liquid is adsorbed by turf separately. Three adsorbed single microbial inoculum is blended and grinded according to the proportion of 1:0.9-1.2:0.9-1.2 to obtain the compound microbial inoculum. The used liquid sediment in the production procedure of gourment powder factory and amino acids manufacturers as lysine plant and the like is disposed to charge trace element raw material and 6%-8% compound microbial inoculum with relative to total weight to obtain the needed compound microbe fertilizer which is easy to dissolve in the water and facilitates to adsorb and utilize plants.

Owner:SHANGHAI LVLE BIO TECH

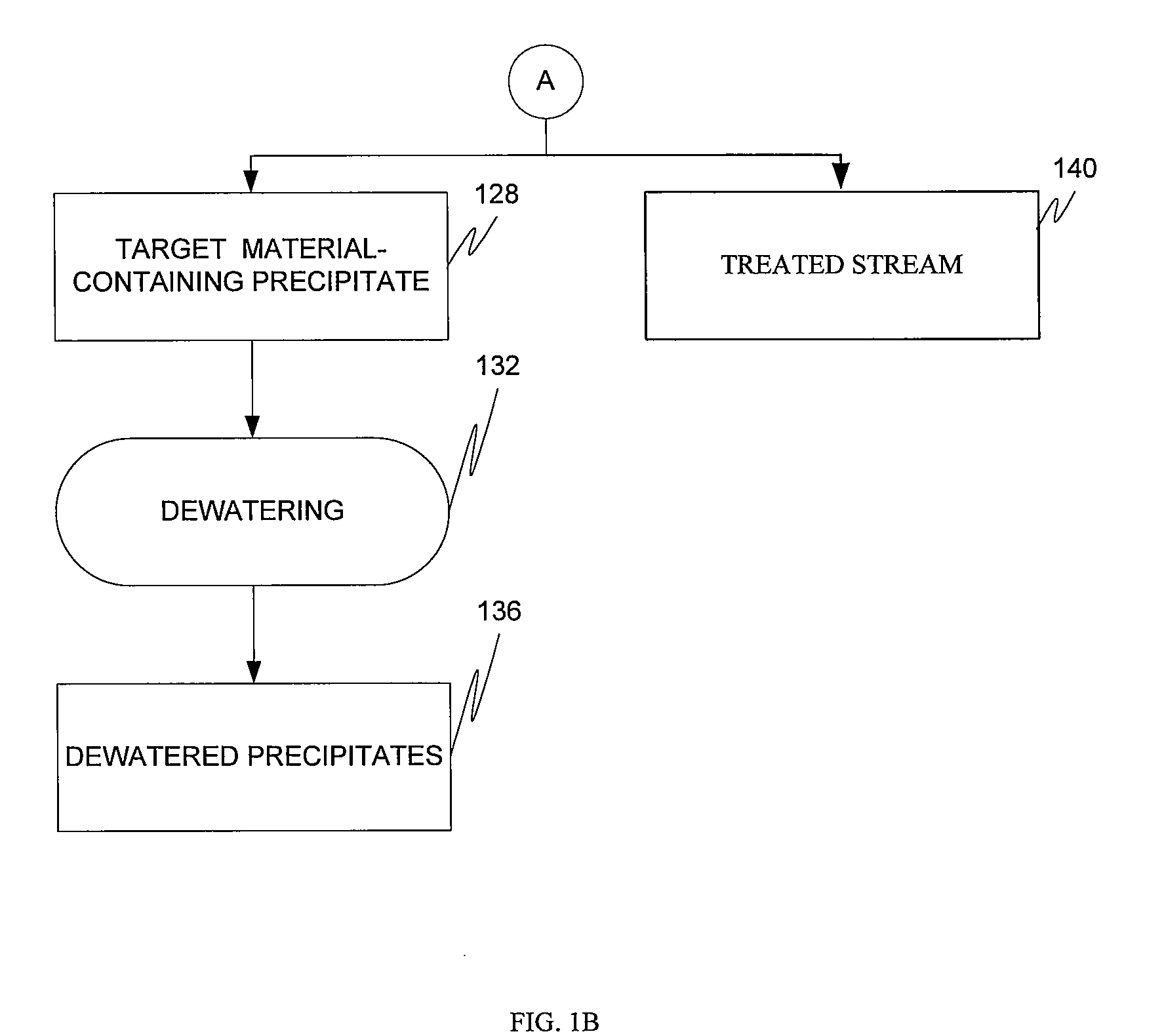

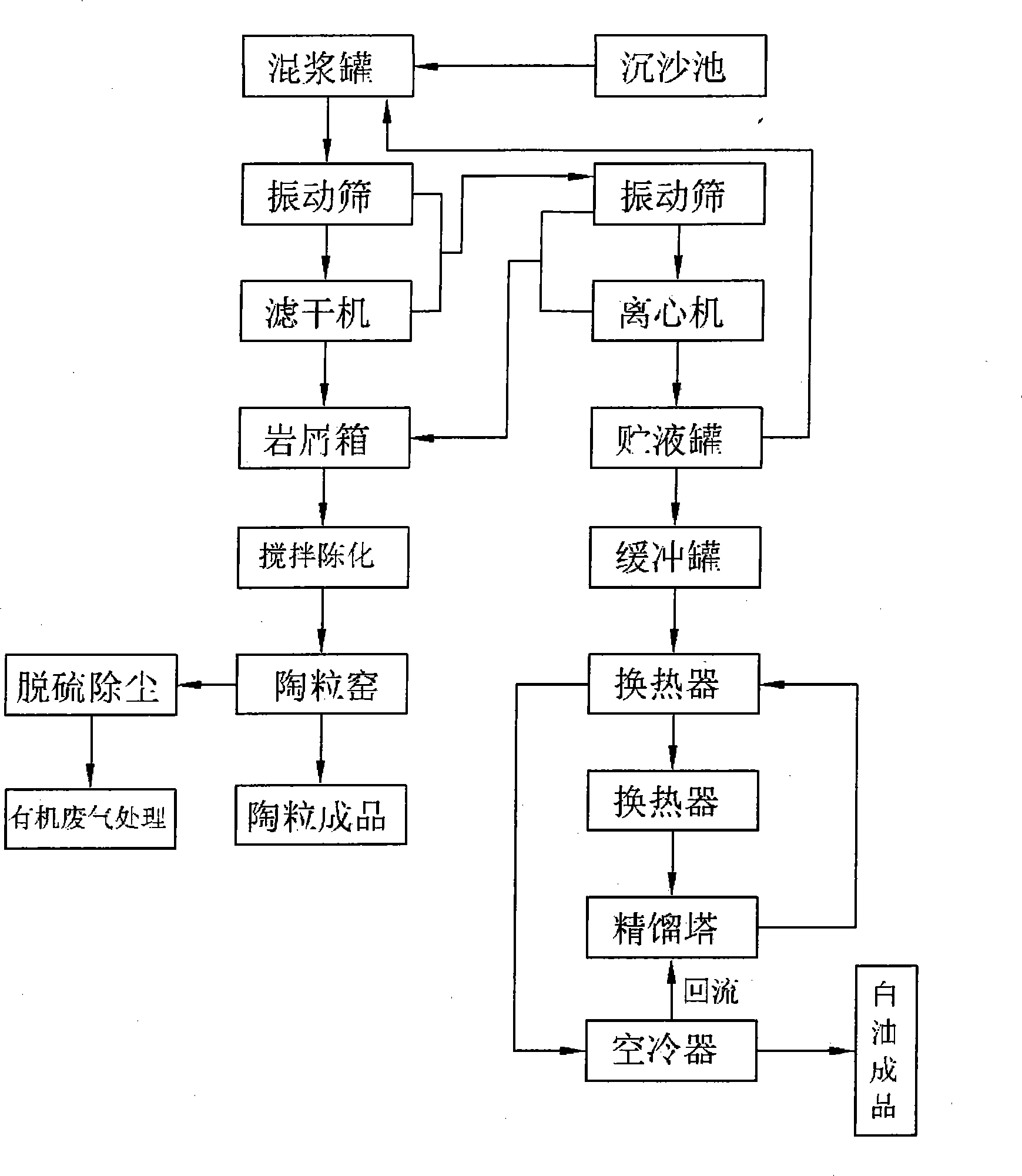

Method for processing and recycling drill cuttings

InactiveCN101172284AAchieve Multiple HarvestsReduce disposal costsSolid waste disposalRecovery methodExpanded clay aggregate

The invention discloses a processing and recovery method of a drill chip. The method comprises the following steps: the drill chip in a settling basin is pumped into a slurry mixing tank; mixed slurry in the slurry mixing tank is pumped into a first vibratory screen to be screened; screenings of the first vibratory screen freely falls into a filtering dryer to perform filtering and drying, solid phase after being filtered and dried is sent to a screw conveyer to be conveyed to a salt chip box; the screenings of the first vibratory screen and the flowing of the filtering dryer are mixed and conveyed into a second vibratory screen; the screenings of the second vibratory screen falls into the screw conveyer to be conveyed to the salt chip box, the screenings is pumped into a centrifugal machine through a pump; solid phase separated by the centrifugal machine enters into the screw conveyer to be conveyed to the salt chip box, liquid phase enters into a liquid storage tank to be produced into a white oil product; the drill chip in a salt chip box and clay are mixed and produced into haydite. The method of the invention is to recovery oil base in the drill chip, building materials manufactured by rock chip slurry reduce the cost expense, compared with the prior art, the running cost is low, the processing rate is large, and the efficiency is high.

Owner:CHINA NAT OFFSHORE OIL CORP +3

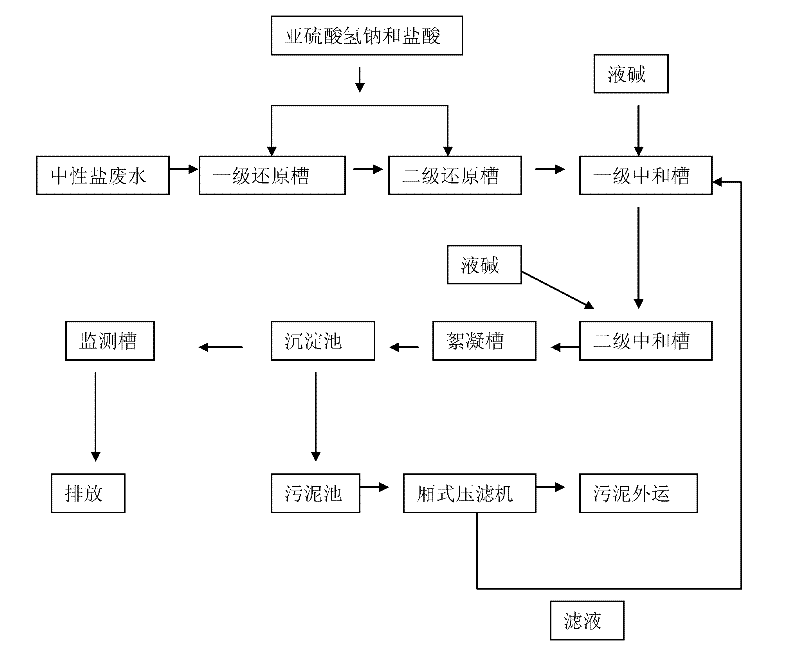

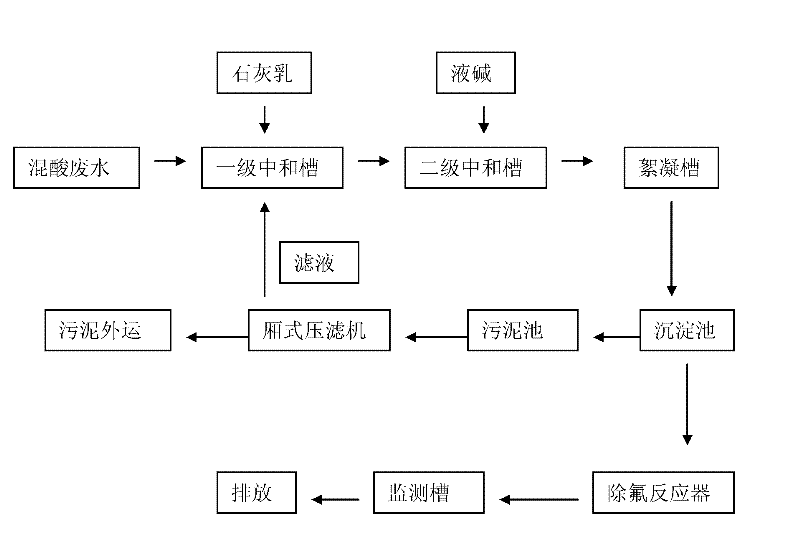

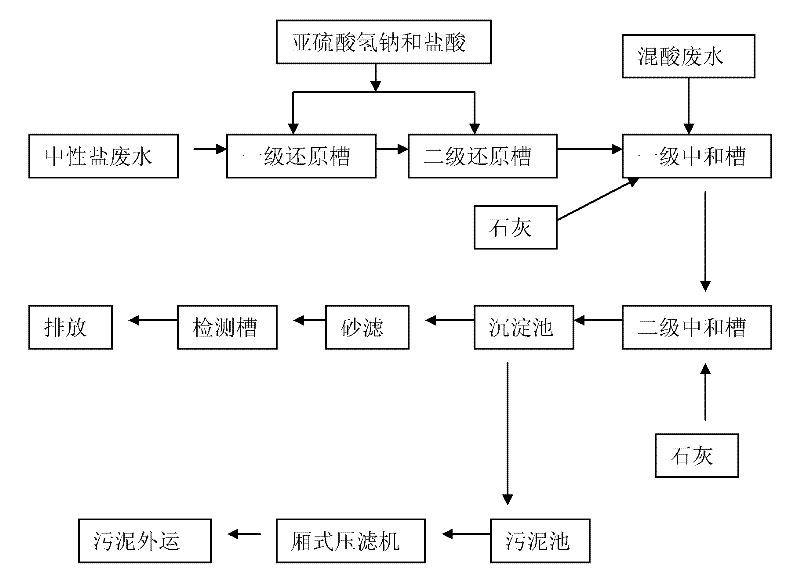

Method for sludge reduction for cold rolling pickling wastewater in steel industry

ActiveCN102211828AReduce productionReduce processingSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludgePolyacrylamide

The invention belongs to the technical field of sludge reduction for cold rolling pickling wastewater in the steel industry, and discloses a method for sludge reduction for the cold rolling pickling wastewater in the steel industry. In the method disclosed by the invention, neutral salt wastewater and wastewater mixed with acid are completely and separately treated to obtain sludge containing hazardous wastes and general sludge respectively, and the sludge output of each unit is reduced by accurately adding chemical agents at each unit; in the technology for treating the neutral salt wastewater, caustic soda liquid is respectively added in a first stage neutralizing tank and a second stage neutralizing tank; in the technology for treating the wastewater mixed with acid, the treatment is performed by using a lime and austic soda liquid combination method; and in the treatment of a neutralizing tank, the pH value is controlled between 1.5 and 3.0, and the pH value during neutralization reaction is controlled between 8.2 and 8.7; and a flocculation process is adopted after the neutralization reaction, polyaluminum chloride, polyacrylamide and other flocculants are added for reacting and are mixed so as to enlarge pollutant particles. By use of the method, the output water can stably reach the standard, and the water treatment cost per ton is reduced.

Owner:SHANGHAI MEIJIA WATER TREATMENT TECH

Beta hydroxy short to medium chain fatty acid polymer

InactiveUS20060275253A1Trend downPromote excretionCosmetic preparationsNervous disorderIntestinal structureLarge intestine

The present invention provides a composition comprising a polymer of a β-hydroxy short-medium chain fatty acid, which is used for delivering the β-hydroxy short-medium chain fatty acid or an oligomer thereof to the large intestine. In case the composition is administrated orally, the composition will be delivered to the large intestine, without being degraded in the stomach or short intestine, and degraded by the large intestinal bacterial flora and release the short-medium chain fatty acid or an oligomer thereof. The released short-medium chain fatty acid or an oligomer thereof has useful physiological activities and is effective for treating or preventing inflammatory diseases or cancer in the large intestine.

Owner:EARTHUS

Method for abating antibiotics resistance gene pollution in water

InactiveCN103159357AEliminate pollutionMature technologyEnergy based wastewater treatmentMultistage water/sewage treatmentParticulatesSuspended particles

The invention discloses a method for abating antibiotics resistance gene pollution in water and belongs to the technical field of water treatment. The method disclosed by the invention aims at solving the problem of the water pollution caused by antibiotics resistance gene. The method comprises the following steps of: firstly removing the content of suspended particles in water through coagulating sedimentation of an ultraviolet ray irradiation method to obtain a further ultraviolet projection distance in subsequent processing; then, through the ultraviolet radiation, generating strong oxidizing substances such as hydroxyl radical on one hand and reacting the substances with the chemical substances composing the antibiotics resistance gene for changing the chemical natures thereof so that the genetic information contained in the antibiotics resistance gene can not be sent, destroying the molecular structure of the antibiotics resistance gene through the ultraviolet physical radiation on the other hand so that the molecular structure is broken into free base segments and the integrity of the genetic information contained therein is lost, thereby achieving the aim of abating antibiotics resistance gene pollution.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Process for treating radioactive waste water to prevent overloading demineralizer systems

ActiveUS8148594B2Improve separation efficiencyEasy to useTreatment involving filtrationSolid sorbent liquid separationRadioactive wasteMineral nitrogen

A process and system for treating waste water containing contaminants to prevent excessive accumulation on demineralizer media of a driver contaminate capable of such accumulation before another contaminant can reach a predetermined level of accumulation. The waste water is treated upstream of the demineralizer media with removal means for specifically removing the driver contaminant while leaving the other contaminant for subsequent removal by the demineralizer media. The amount of accumulation on the demineralizer media of the other contaminant is monitored, and the supplying of treated waste water to the demineralizer media is terminated when its accumulation reaches the predetermined level.

Owner:ENERGYSOLUTIONS LLC

Method of delivering frac fluid and additives

A method for the controlled delivery of a fracturing fluid to a well bore comprises formulating an aqueous base fluid such that it meets or exhibits desired physical and chemical characteristics for an optimal fracturing fluid. The formulation of the aqueous base fluid max involve commingling one or more sources of waste water with a source of fresh water followed by controlled injection of one or more additives. This process is substantially completed prior to delivering the aqueous base fluid to the well site. This allows the delivery of an optimal volume of the aqueous base fluid with homogeneously blended additives to the well bore.

Owner:TETRA TECH INC

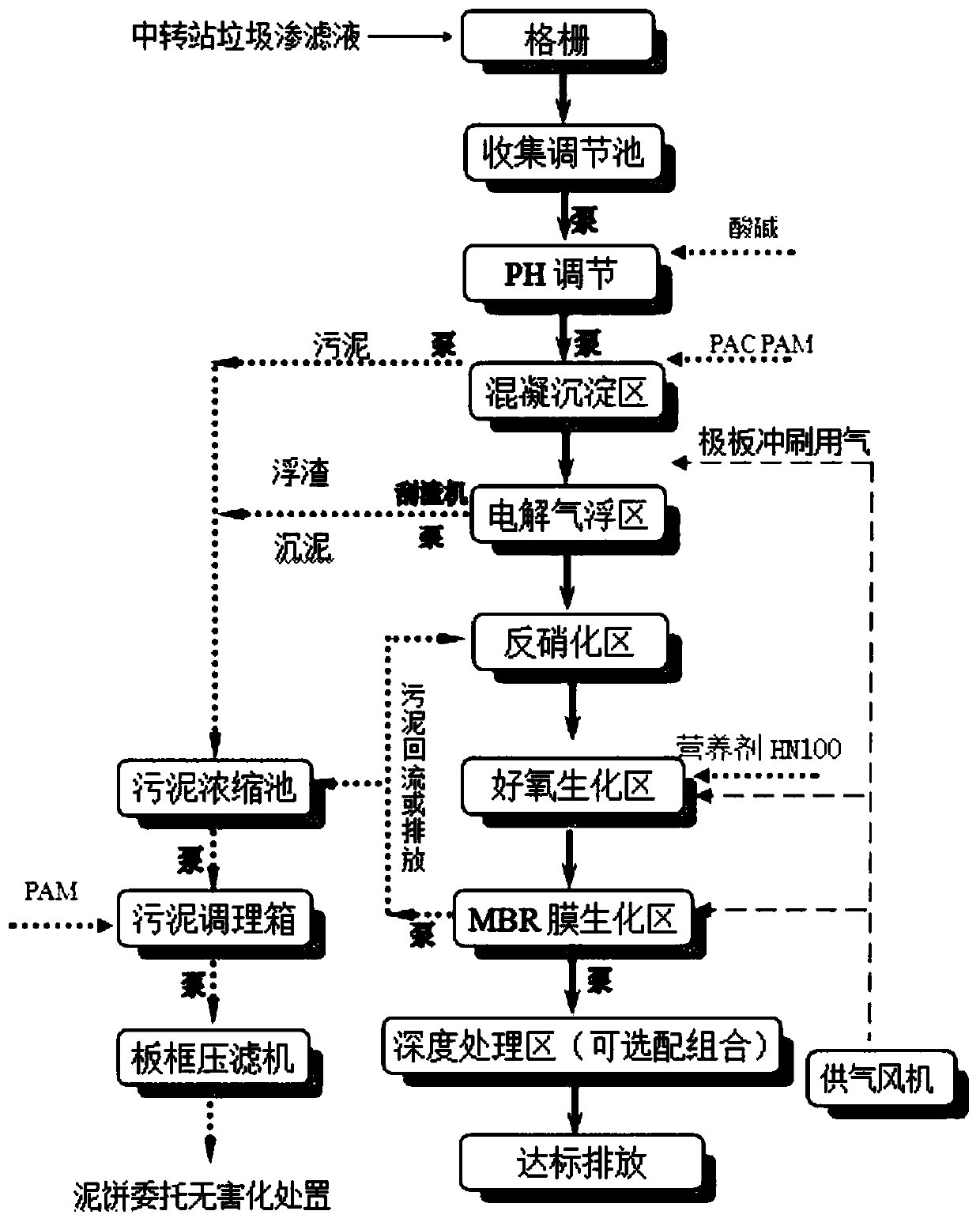

Landfill leachate treatment method for garbage transfer station

InactiveCN110183038APracticalAvoid cost wasteSludge treatment by de-watering/drying/thickeningWater/sewage treatment by irradiationParticulatesHigh concentration

The invention discloses a landfill leachate treatment method for a garbage transfer station. Firstly a flocculation method is used to remove particulate matters and part of heavy metal ions in a leachate to reduce the subsequent treatment pressure and reduce the treatment cost, the leachate is further treated by an electrolysis air flotation manner to remove fine particles and impurities in the leachate, the high concentration ammonia nitrogen in the leachate is removed by a stripping process, microorganisms are used to remove the organic matter pollution in the leachate, finally the leachateis subjected to deep treatment, and the selection matching is carried out according to requirements of outlet water to ensure that the discharge of wastewater is up to standards. The method does not use an anaerobic treatment process, reduces the generation amount of odor gases, is beneficial to the environment of a treatment zone, avoids the occurrence of biogas combustion, improves the safety ofthe entire apparatus, and is more practical. The method can make discharge indexes of the wastewater obtained after the landfill leachate treatment meet requirements, and thus the method is environment-friendly and practical.

Owner:JIANGSU YUMING GRP

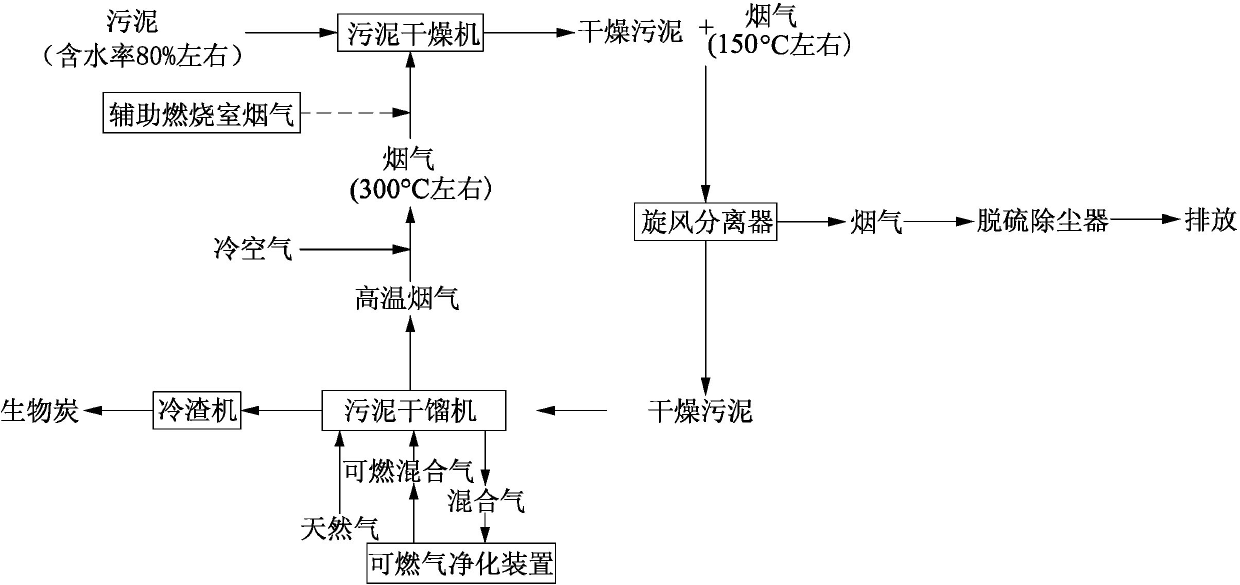

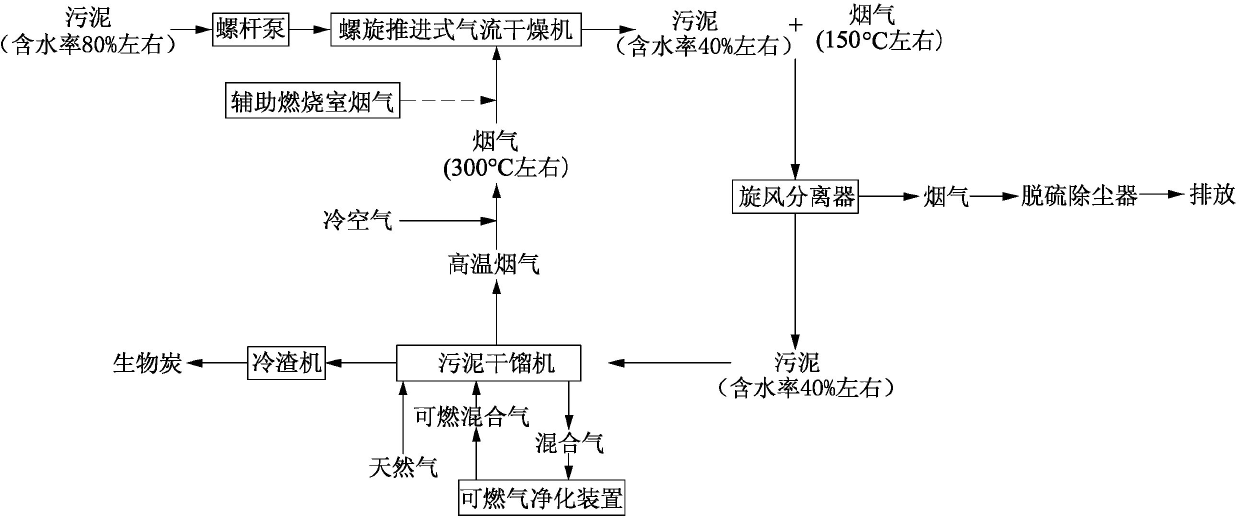

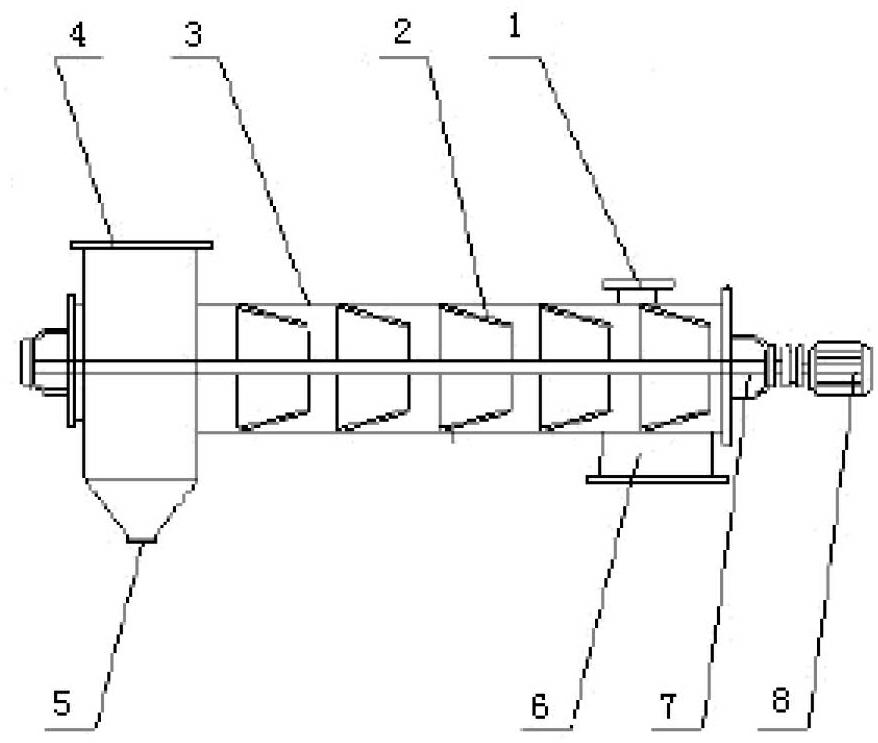

Sludge recycling technique

InactiveCN102432151AReduce disposal costsPrevent the occurrenceSludge treatment by de-watering/drying/thickeningEnergy inputGas solidSludge

The invention discloses a sludge recycling technique which comprises the following steps: sending sludge to a drying machine to carry out low-temperature drying; separating sludge and fume from the drying machine by a gas-solid separator; sending the separated dry sludge to a dry distillation machine to carry out dry distillation; carrying out deficient-oxygen or no-oxygen dry distillation while keeping the temperature of the dry distillation furnace at 150-800 DEG C, wherein organic substances in the sludge are subjected to cracking reaction in the dry distillation process to produce abundant high-heat-value combustible gas which can be used as a fuel, and the fume generated by the dry distillation furnace is discharged after being subjected to waste heat utilization and purification; and after the dry distillation finishes, cooling the residual solid slag to below 50 DEG C by a slag cooling machine, thereby obtaining biological carbon. By using sludge drying+dry distillation technology, the sludge is prepared into the biological carbon for soil amendment, thereby thoroughly solving the problem that the sludge is hard to treat; and the invention does not need subsequent treatment or produce secondary pollution, has the advantage of low treatment cost, and can thoroughly change waste sludge into valuable substances, thereby implementing recycling and cyclic utilization.

Owner:福建省科辉环保工程有限公司

Molding of materials from graphite particles

InactiveUS20020180091A1Good electrical and thermal conductivityReduce disposal costsMaterial nanotechnologyArtificial filament recoveryFuel cellsManufactured material

A method of manufacturing material suitable for the construction of a component of a fuel cell, such as a flow field plate or electrode, is provided. Uncured resin impregnated flexible graphite sheet is ground into particles. Without re-expanding the particles, and without adding further resin to the particles, the particles are molded into the form of the desired material. The material is then cured. Additives may be mixed with the particles to improve the properties of the material.

Owner:GRAFTECH INT HLDG INC

Brittle formed product and iron-based power material and method for manufacturing these materials

InactiveUS20030075014A1Efficient reuseReduce disposal costsBlast furnace componentsBlast furnace detailsMetalFerric

Cotton-like aggregates (B) including grinding chips from an iron-based metal and a grinding fluid containing oil and water are compression molded for forming a brittle compact (C) having the fibrous grinding chips roughly sheared and excessive water and oil removed therefrom. The brittle compact (C) is crushed for further finely shearing the grinding chips and the resultant grinding chips are mixed with a solidification assistant (D) for producing an iron-based powder material (E) containing the solidification assistant (D).

Owner:JTEKT CORP +1

Resource utilization method of paint slag

ActiveCN105880261ASimple processing methodProcess method safetySolid waste disposalTransportation and packagingCombustionLiquid state

A resource utilization method of paint slag includes the following steps that (1) pretreatment and separation are conducted, specifically, the wet paint slag is pretreated through a grinding modified spray drying method and separated into two components which are powdery or granular slag and organic matter waster liquid, or the wet paint slag is pretreated and separated into two components which are solid slag and organic matter waster liquid through an acid-modified baking hardening treatment technology; and (2) the water-containing organic matter waster liquid obtained in the step (1) is placed in a stirring tank, an emulsifying agent and a modifier are sequentially added into the water-containing organic matter waster liquid with constant stirring, uniform stirring is conducted, and a product is obtained. According to component characteristics of the wet paint slag, the wet paint slag is pretreated and separated into the two components which are the solid slag raw material convenient to use and the organic matter waster liquid containing volatile matter, namely water, and then the water-containing organic matter waster liquid is made into the liquid-state coal clean combustion improver; and the process method is simple, safe and free of secondary pollution, takes effect rapidly, is low in treatment or utilization cost, and is good in economical efficiency.

Owner:湖南省小尹无忌环境能源科技开发有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com