Patents

Literature

316results about How to "Reduce inventory costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

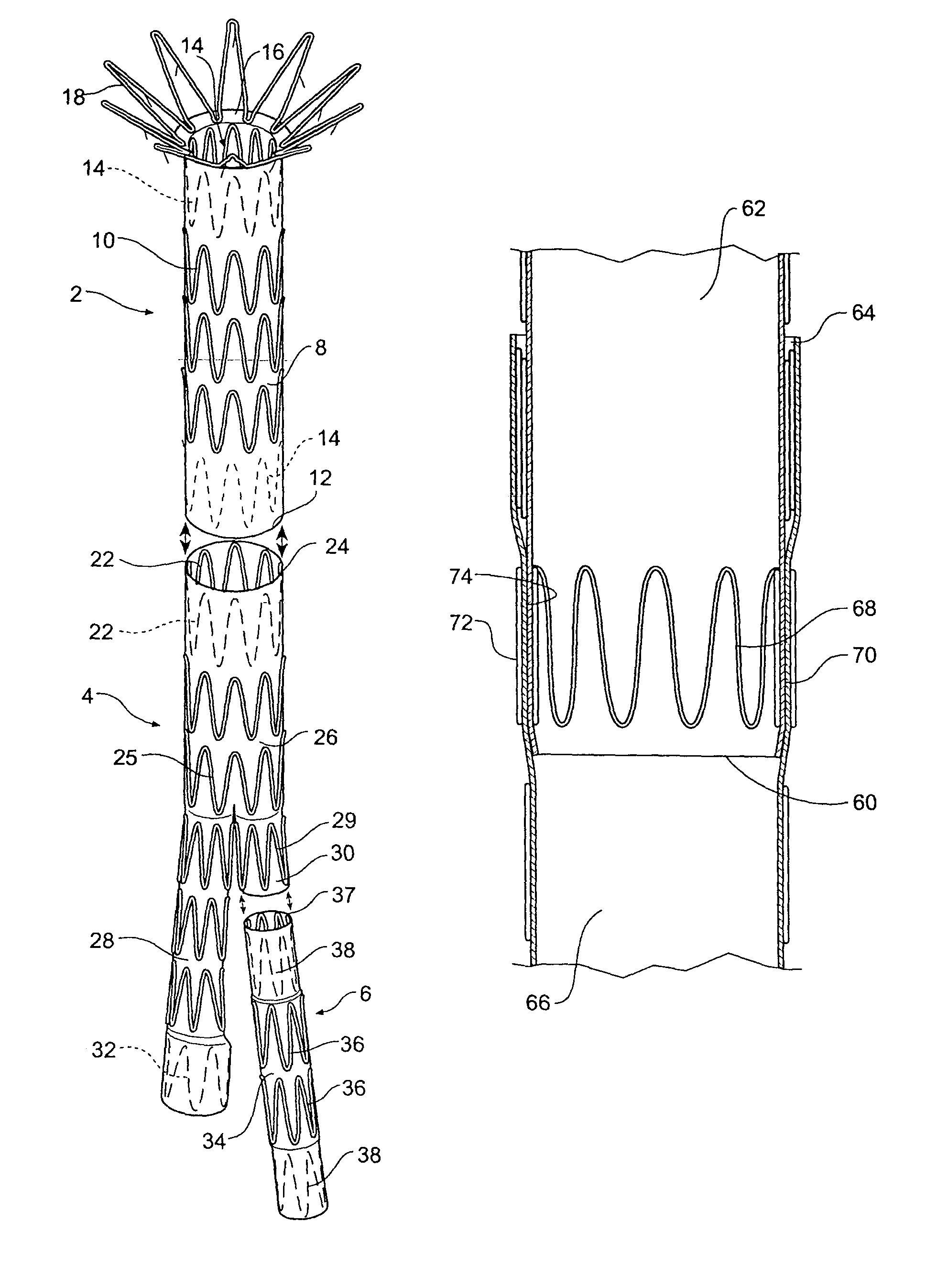

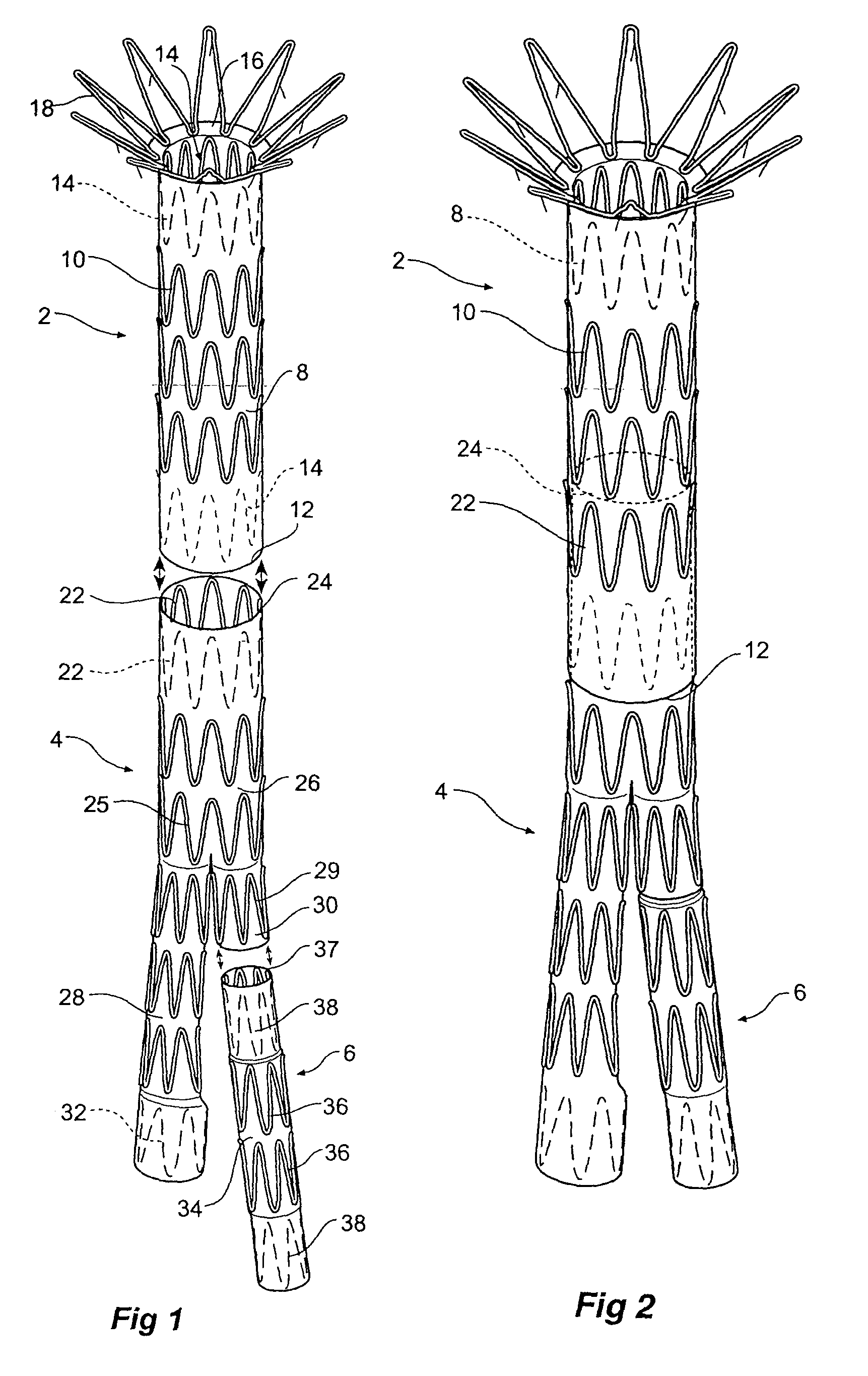

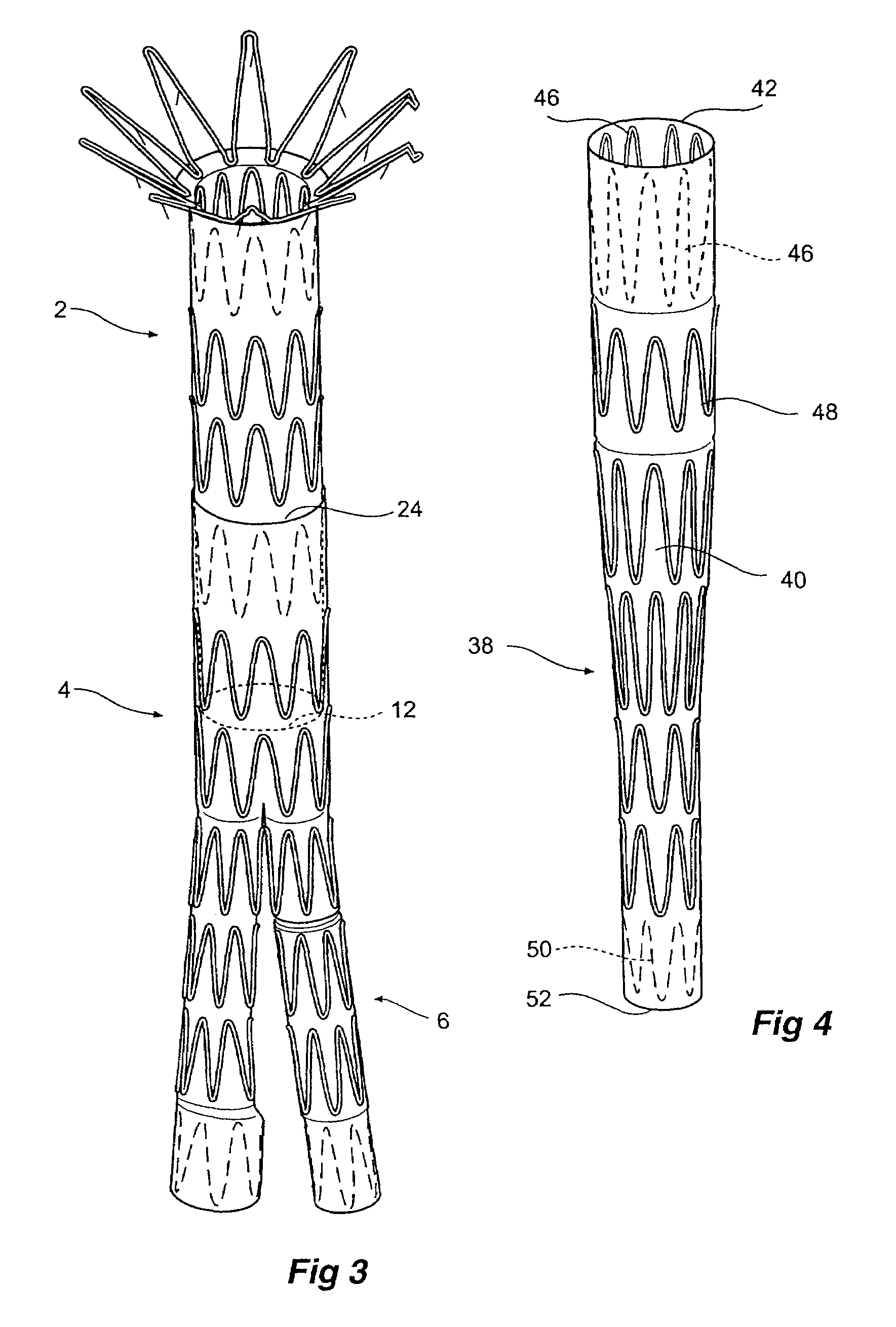

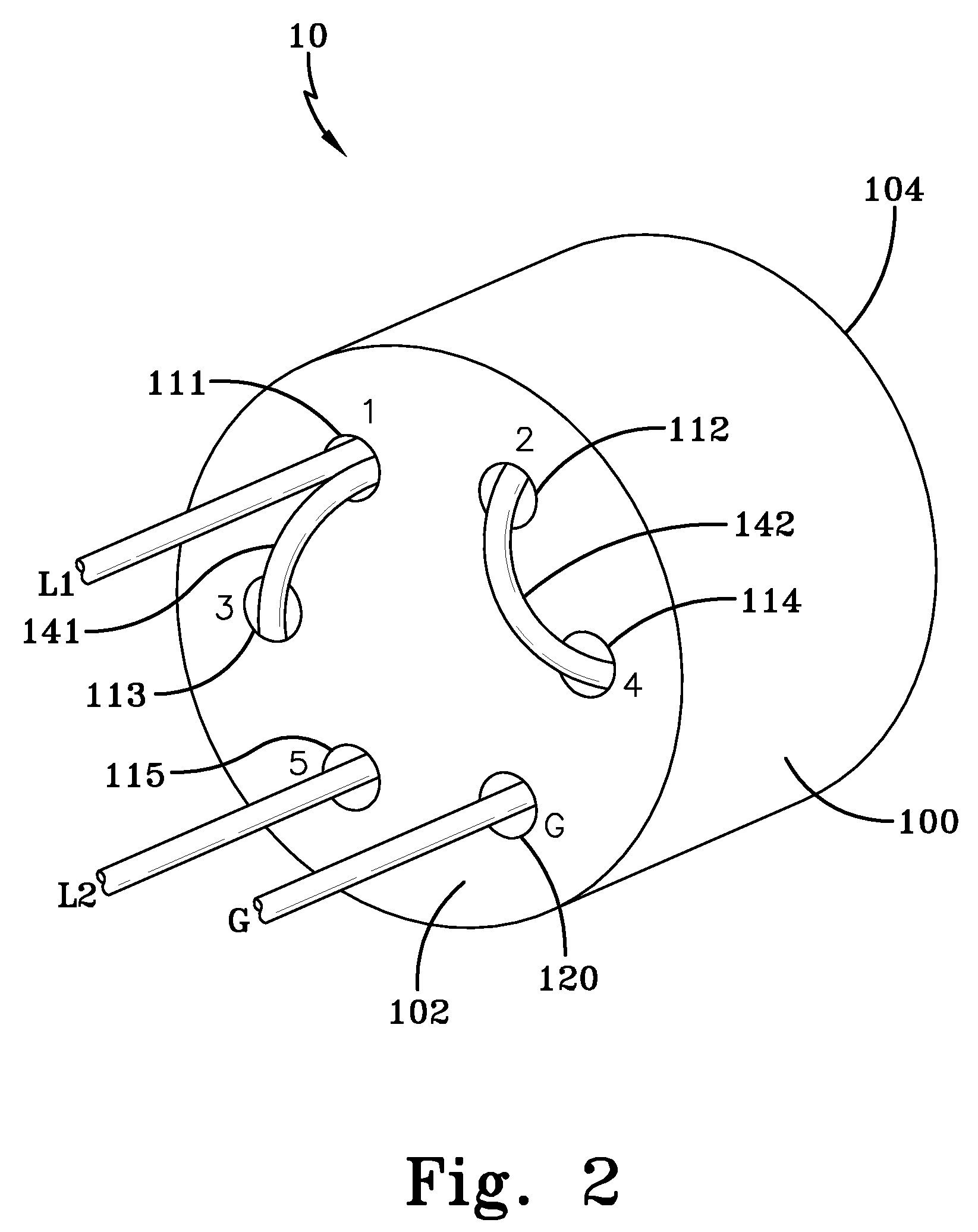

Composite prosthesis

ActiveUS7294147B2Saving inventory costReduce inventory costsStentsBlood vesselsProsthesisAortic aneurysm

A prosthesis assembly for deployment in an aorta to span an aortic aneurysm. The prosthesis assembly has at least first and second members (2,4) with an end portion (12) of one member (2) to be joined to an end portion (24) of the other member (4) when in and when expanded within a lumen of a patient. Each member (2,4) has a stent arrangement (10,25) associated with a graft arrangement (8,26). The end portion of one member has at least part of its stent arrangement on the inner surface of its graft arrangement and the end portion of the other member has at least part of its stent arrangement on the inner surface of its graft arrangement. Advantageously two stents are overlapped. The joining portions of the first and second members can have the same diameter.

Owner:COOK MEDICAL TECH LLC +1

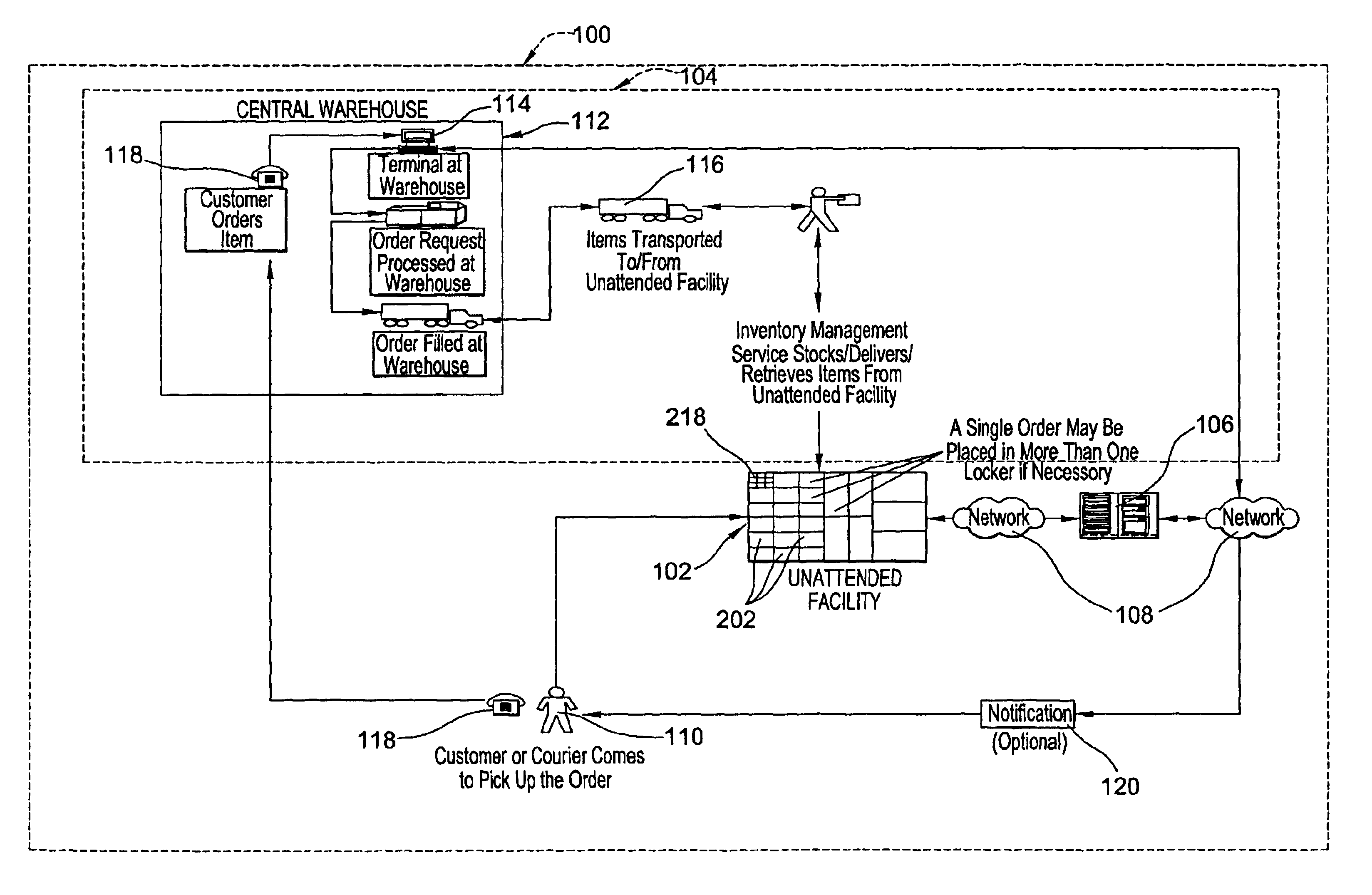

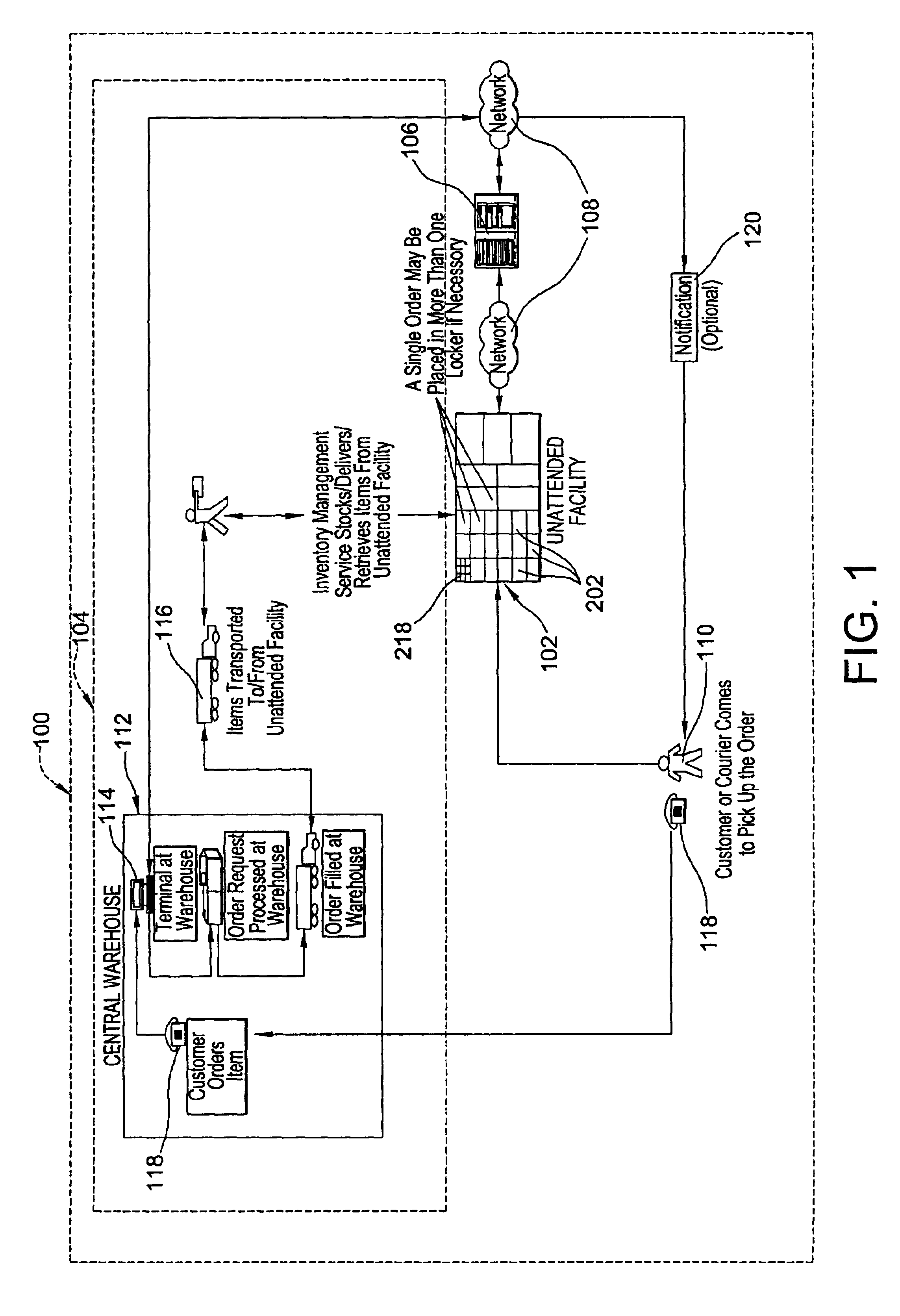

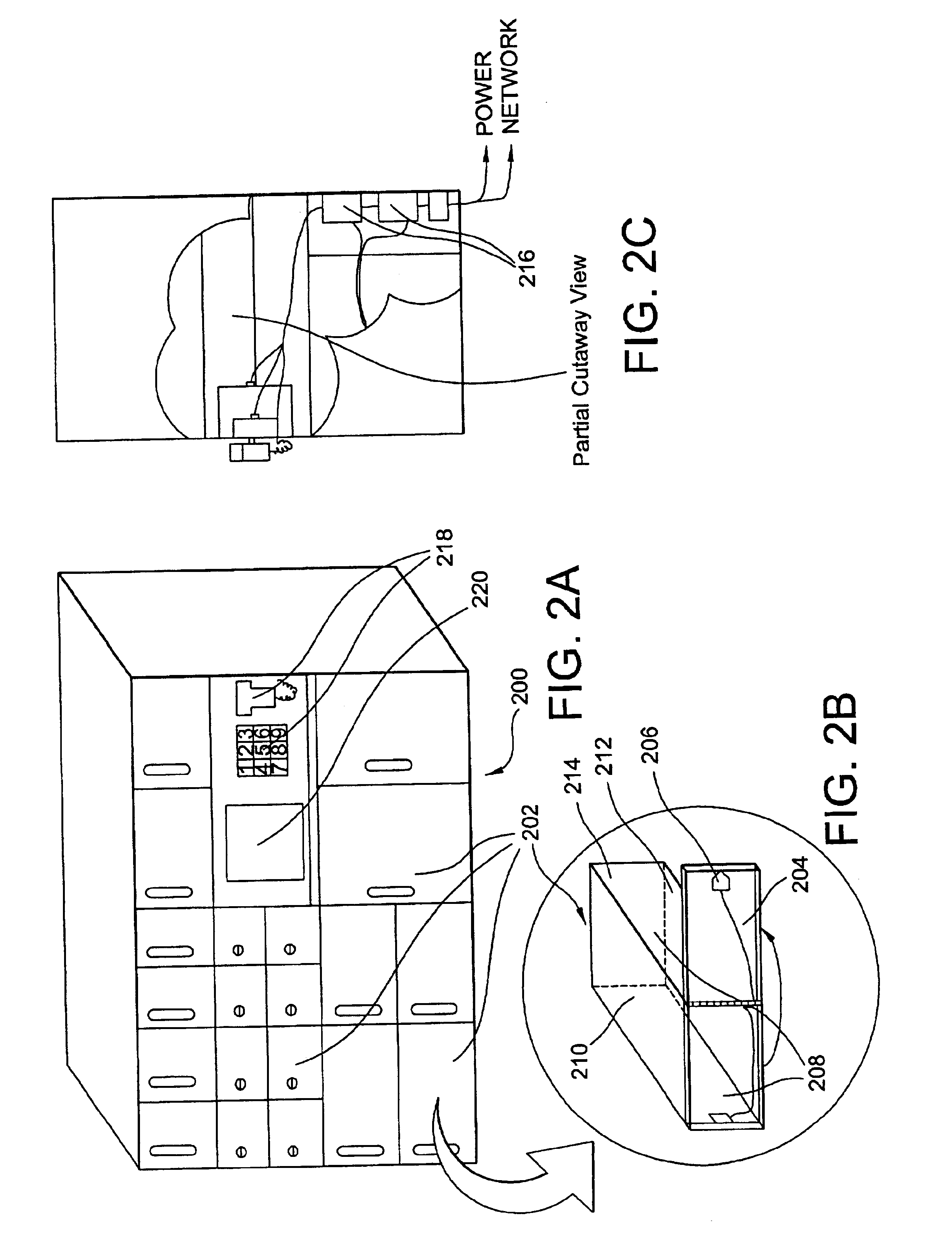

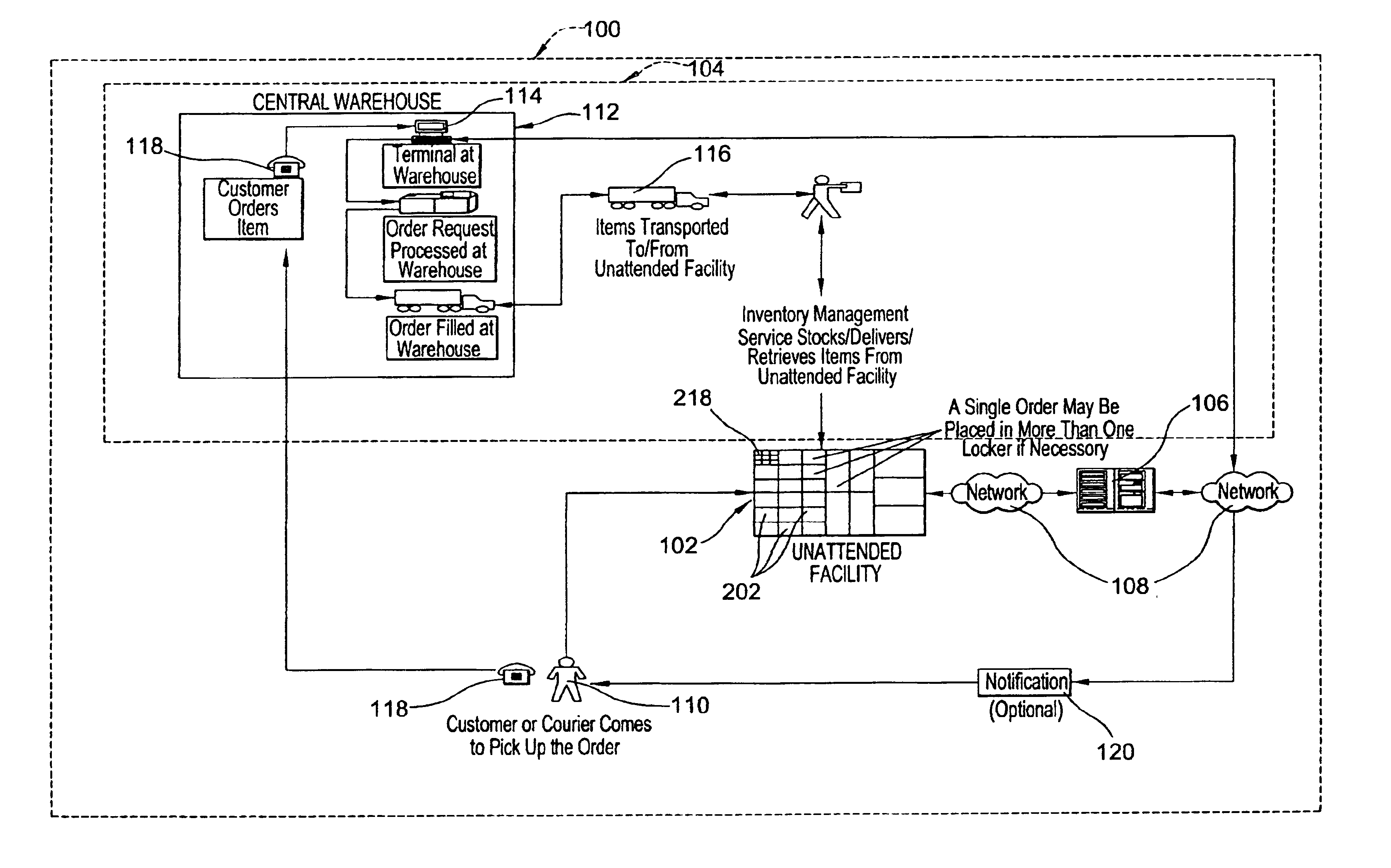

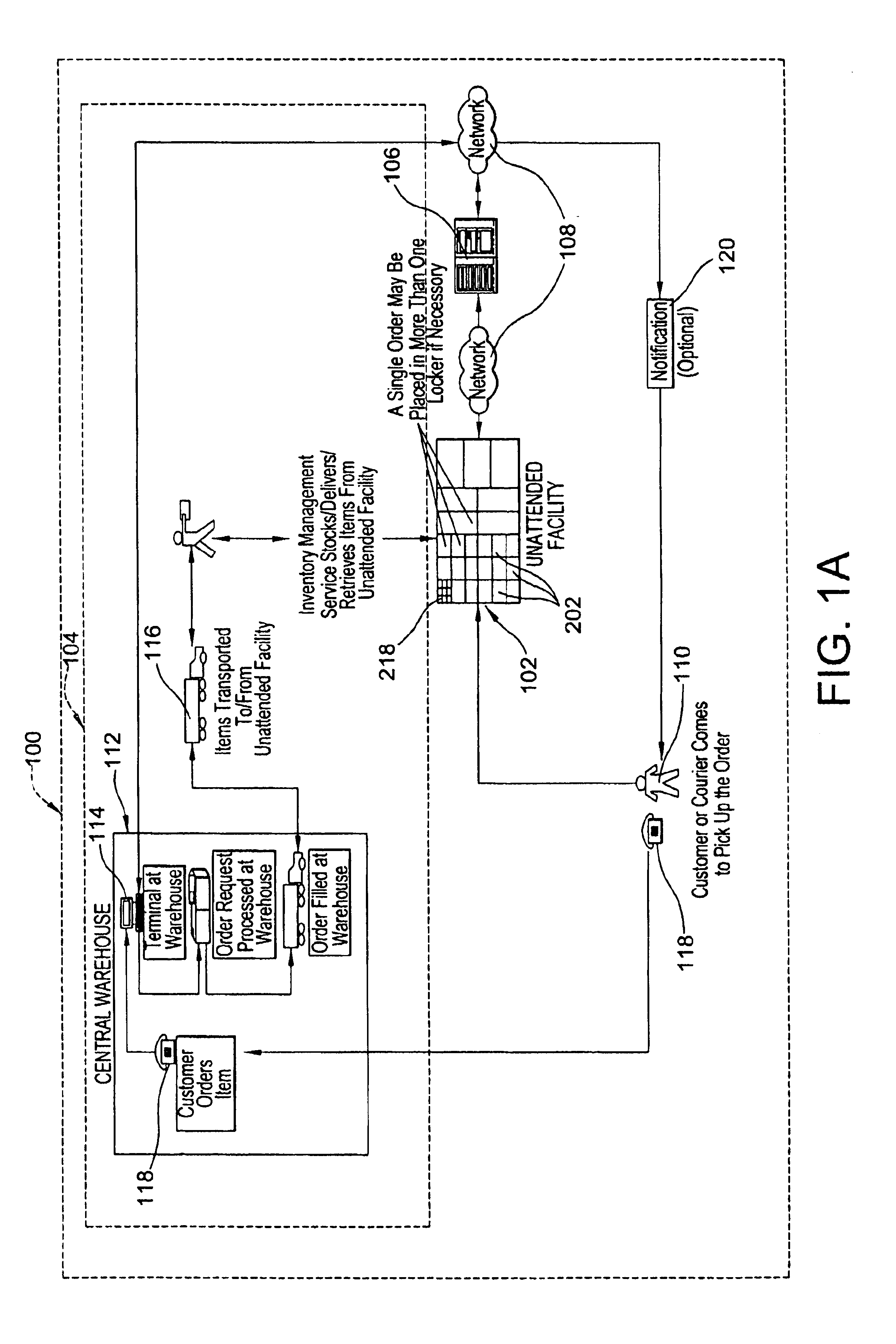

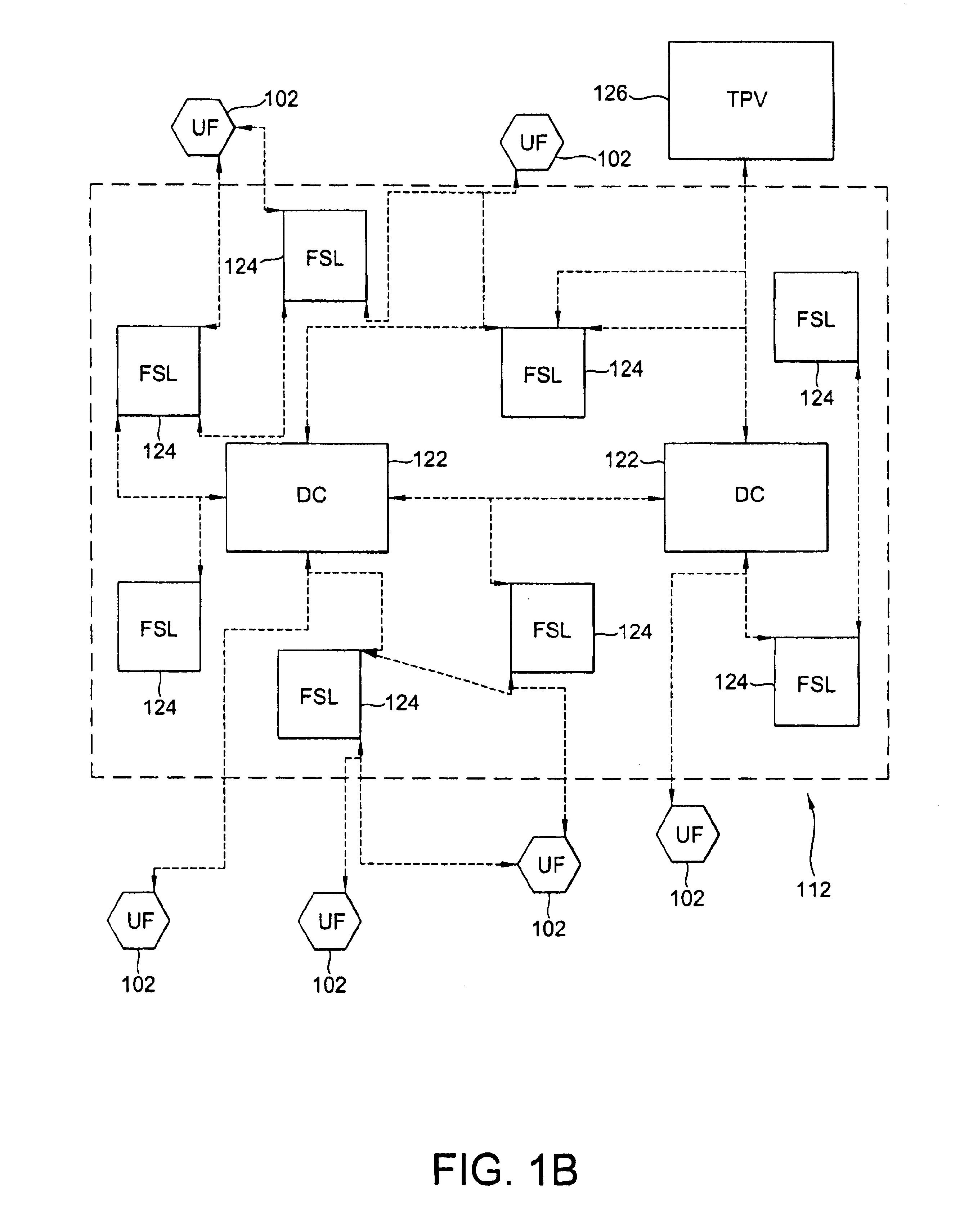

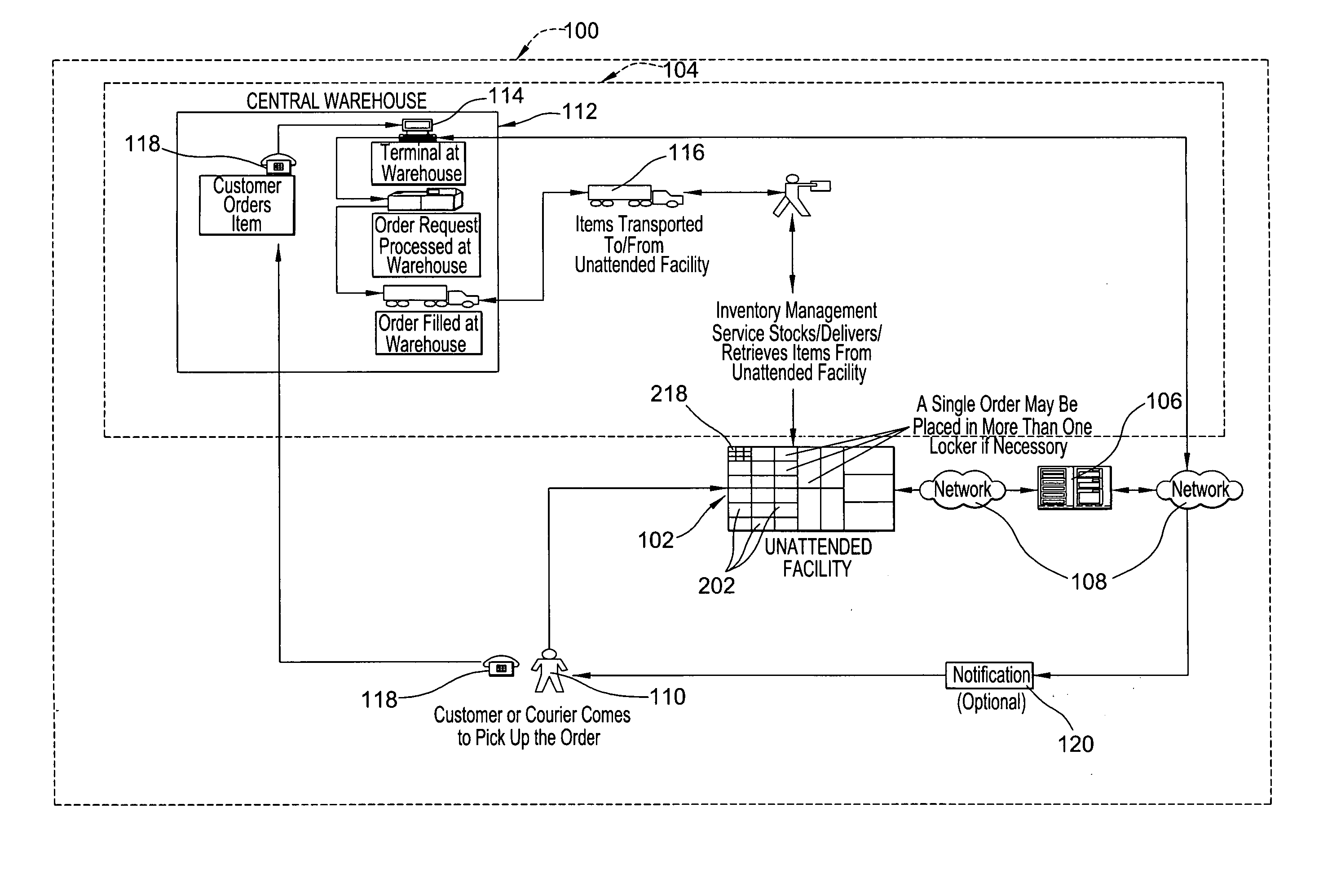

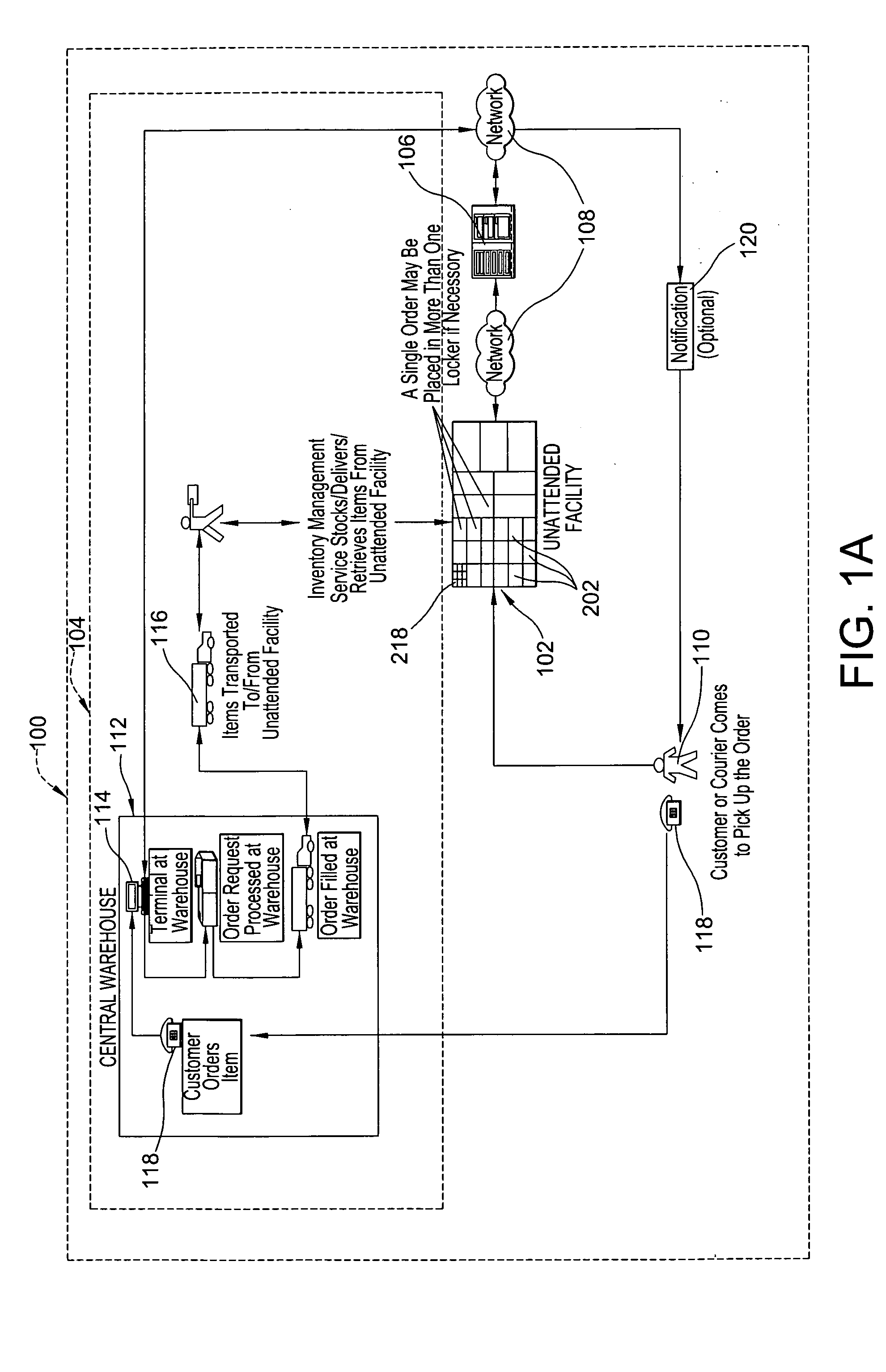

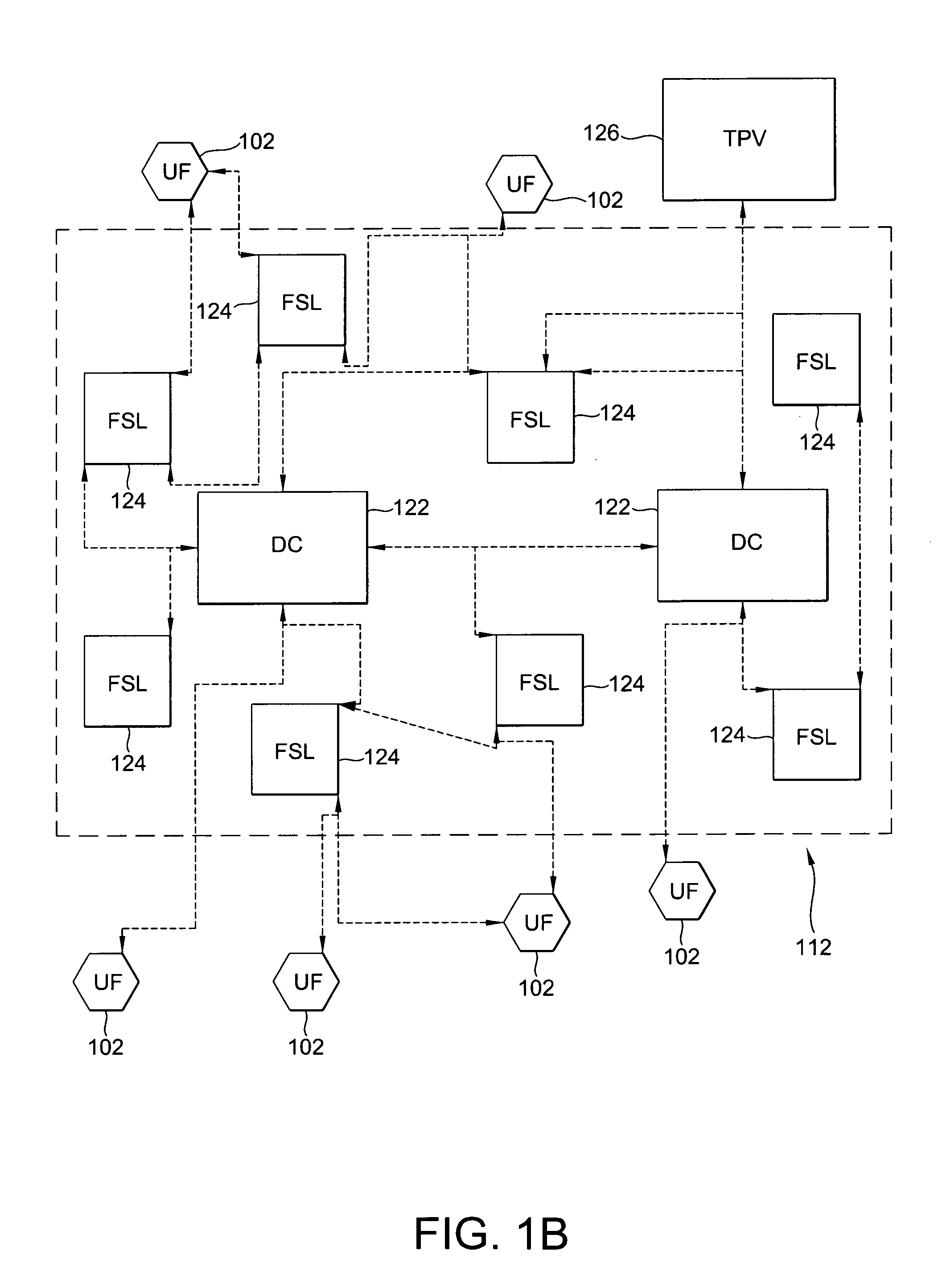

Systems and methods of inventory management utilizing unattended facilities

InactiveUS6866195B2Speed up the processLow costApparatus for meter-controlled dispensingVisual presentationLogistics managementSecure Shell

An inventory management system utilizes unattended facilities remote from a central warehouse for service parts logistics. Items are placed in inventory in secure enclosures at the unattended facilities by the inventory management service. The unattended facilities may be located near one or more customers to reduce a service technician's travel time and customers' inventory costs. A service technician utilizes a passcode to retrieve needed items. The service technician may order items that are not kept in the inventory of the unattended facility in which case the items may be delivered to the unattended facility and the service technician may receive a notification related to all the items that comprise an order that the order is ready for pick up at an unattended facility. Unused, used or damaged parts may be returned by a technician to a remote secure enclosure where such returned parts may be retrieved and disposed of, repaired or placed back into inventory if not damaged or after repair, and the processing of such returned parts begins by information entered into a data entry device at the remote secure enclosure location. Return items that are not damaged may be included in the inventory of an unattended facility.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

Systems and methods of inventory management utilizing unattended facilities

InactiveUS6845909B2Reduce inventory costsQuickly and inexpensively relocatedVisual presentationBuying/selling/leasing transactionsLogistics managementSecure Shell

An inventory management system utilizes unattended facilities remote from a central warehouse for service parts logistics. Items are placed in inventory in secure enclosures at the unattended facilities by the inventory management service or are delivered directly to the unattended facility. The unattended facilities may be located near one or more customers to reduce a service technician's travel time and customers' inventory costs. A service technician utilizes a passcode to retrieve needed items. The service technician may order items that are not kept in the inventory of the unattended facility in which case the items may be delivered to the unattended facility and the service technician may receive a notification related to all the items that comprise an order that the order is ready for pick up at an unattended facility. Unused, used or damaged parts may be returned by a technician to a remote secure enclosure where such returned parts may be retrieved and disposed of, repaired or placed back into inventory if not damaged or after repair, and the processing of such returned parts begins by information entered into a data entry device at the remote secure enclosure location. Return items that are not damaged may be included in the inventory of an unattended facility.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

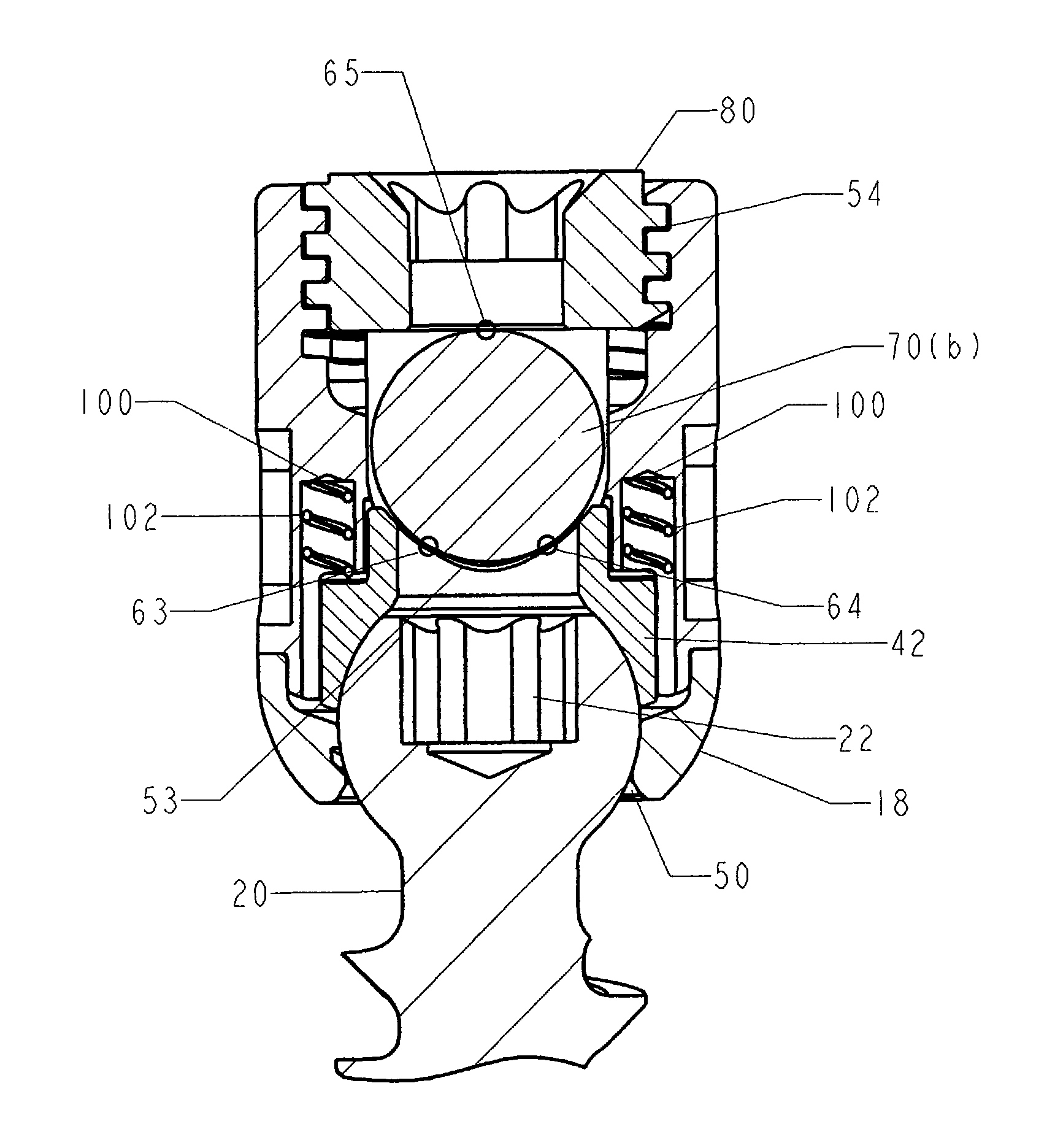

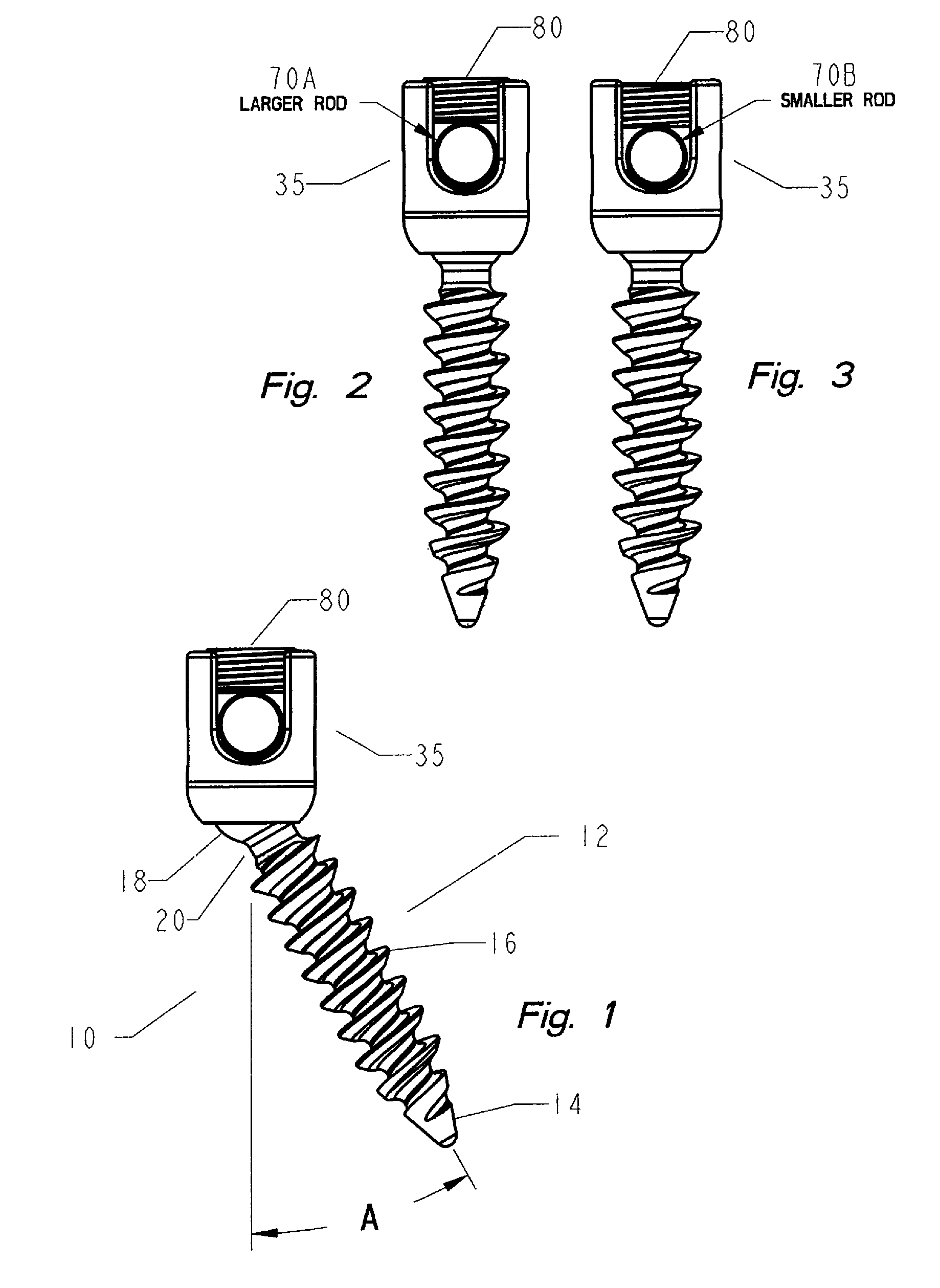

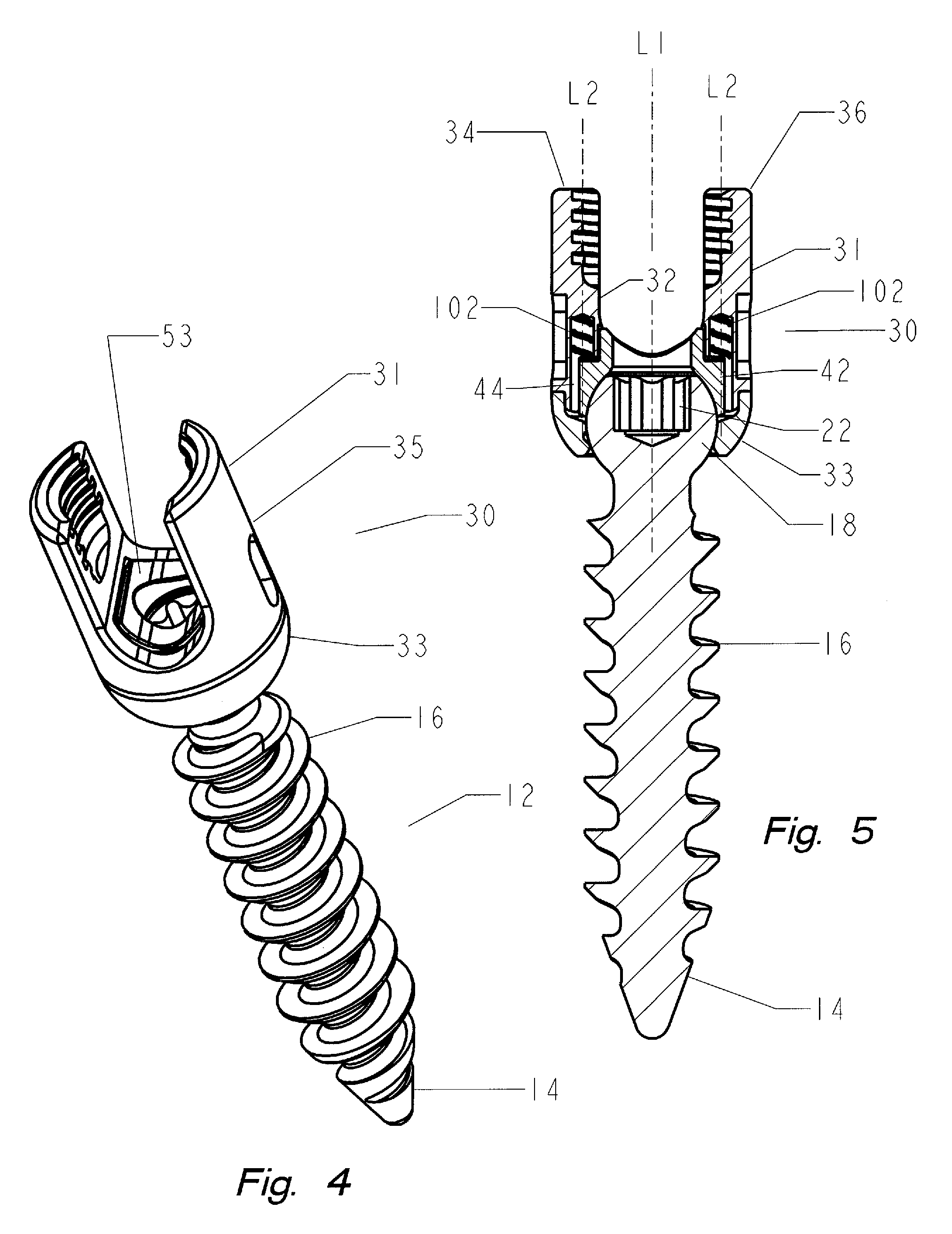

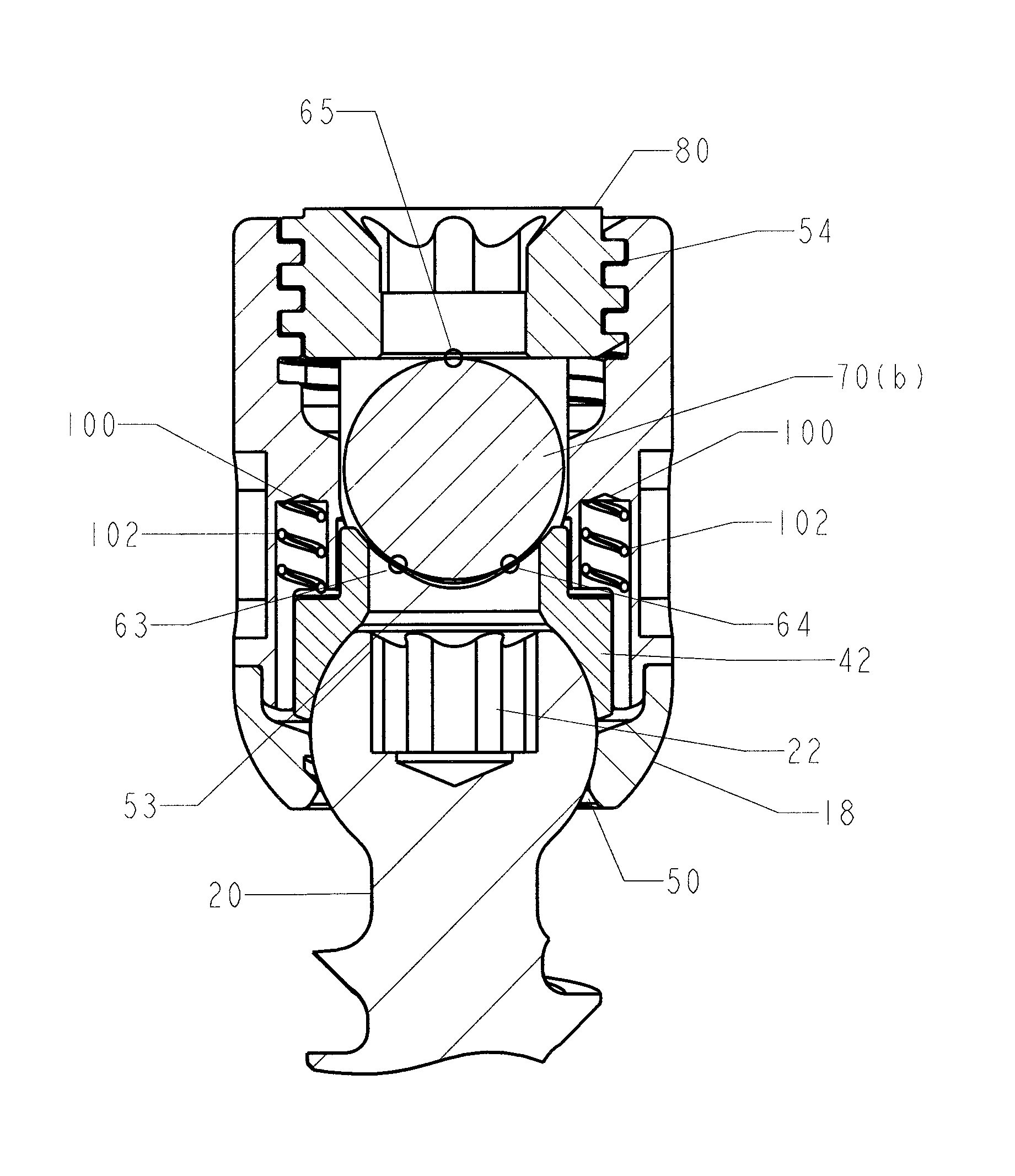

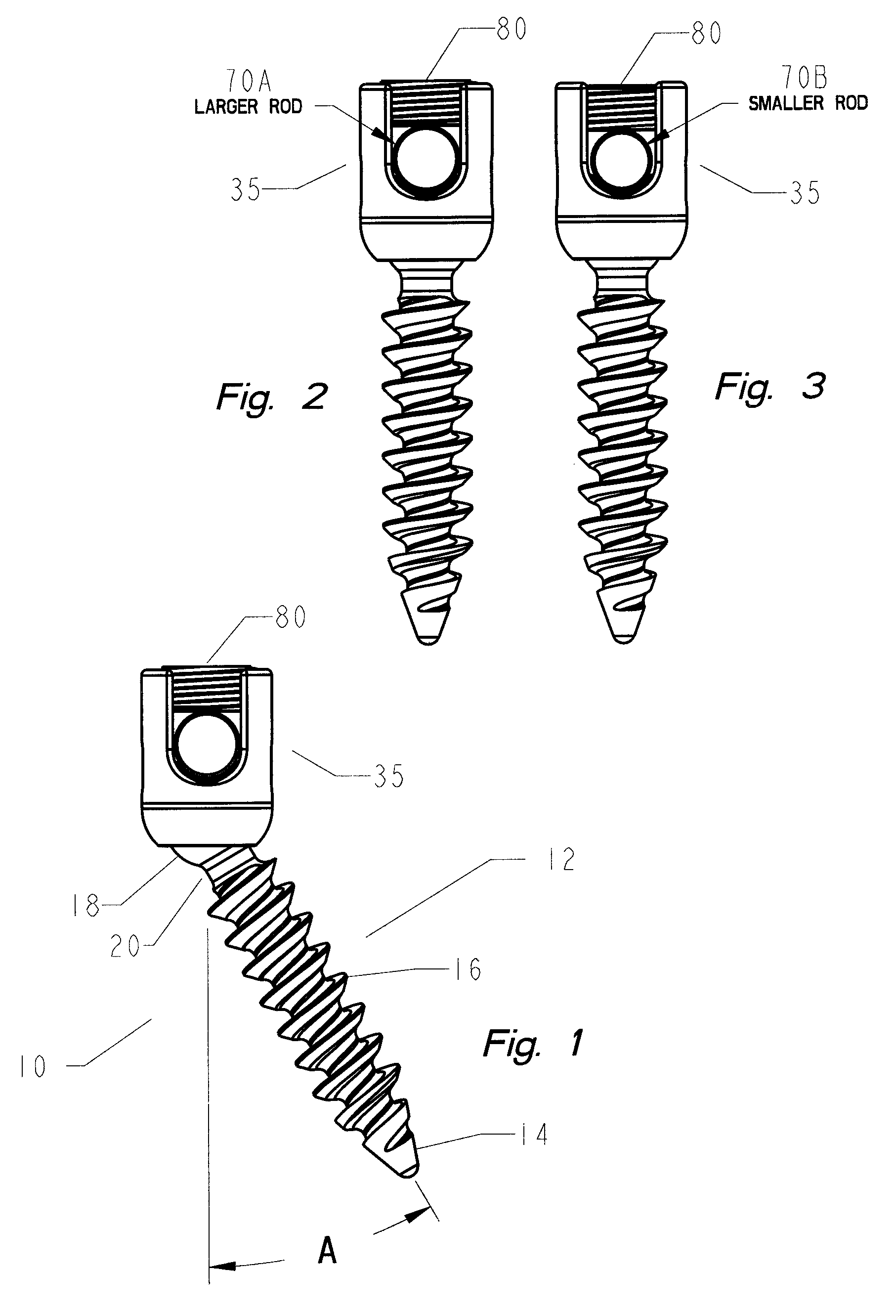

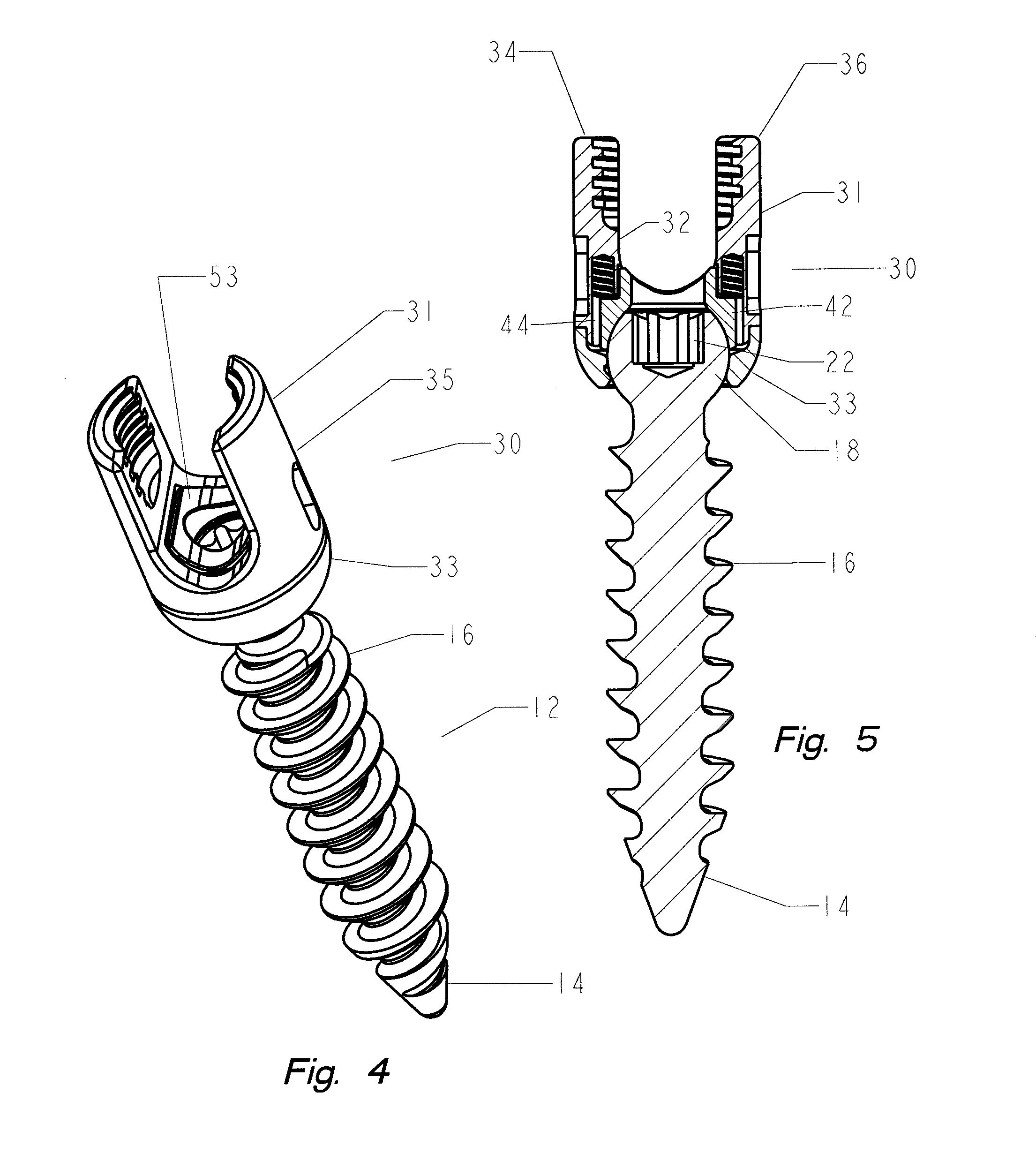

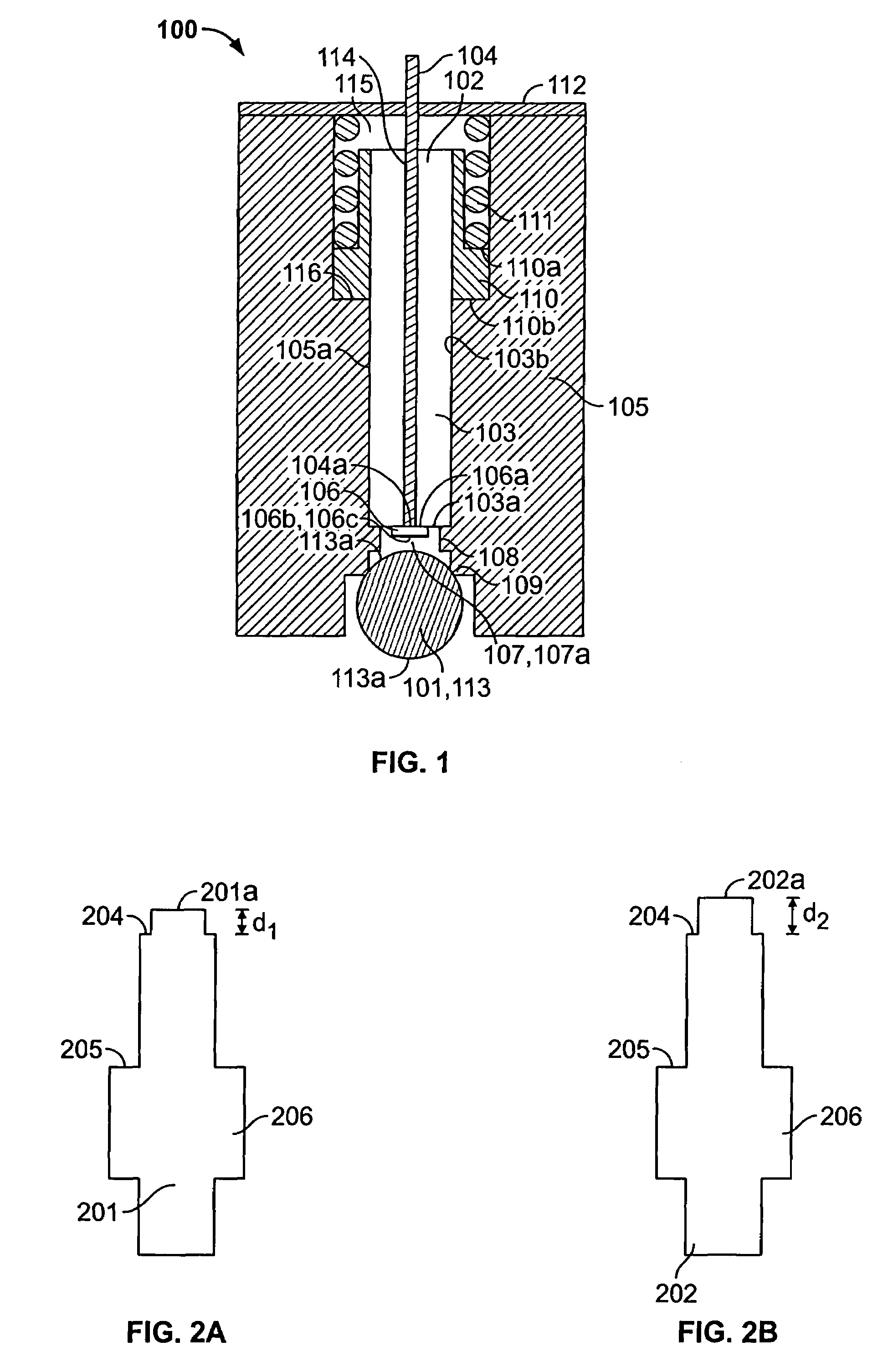

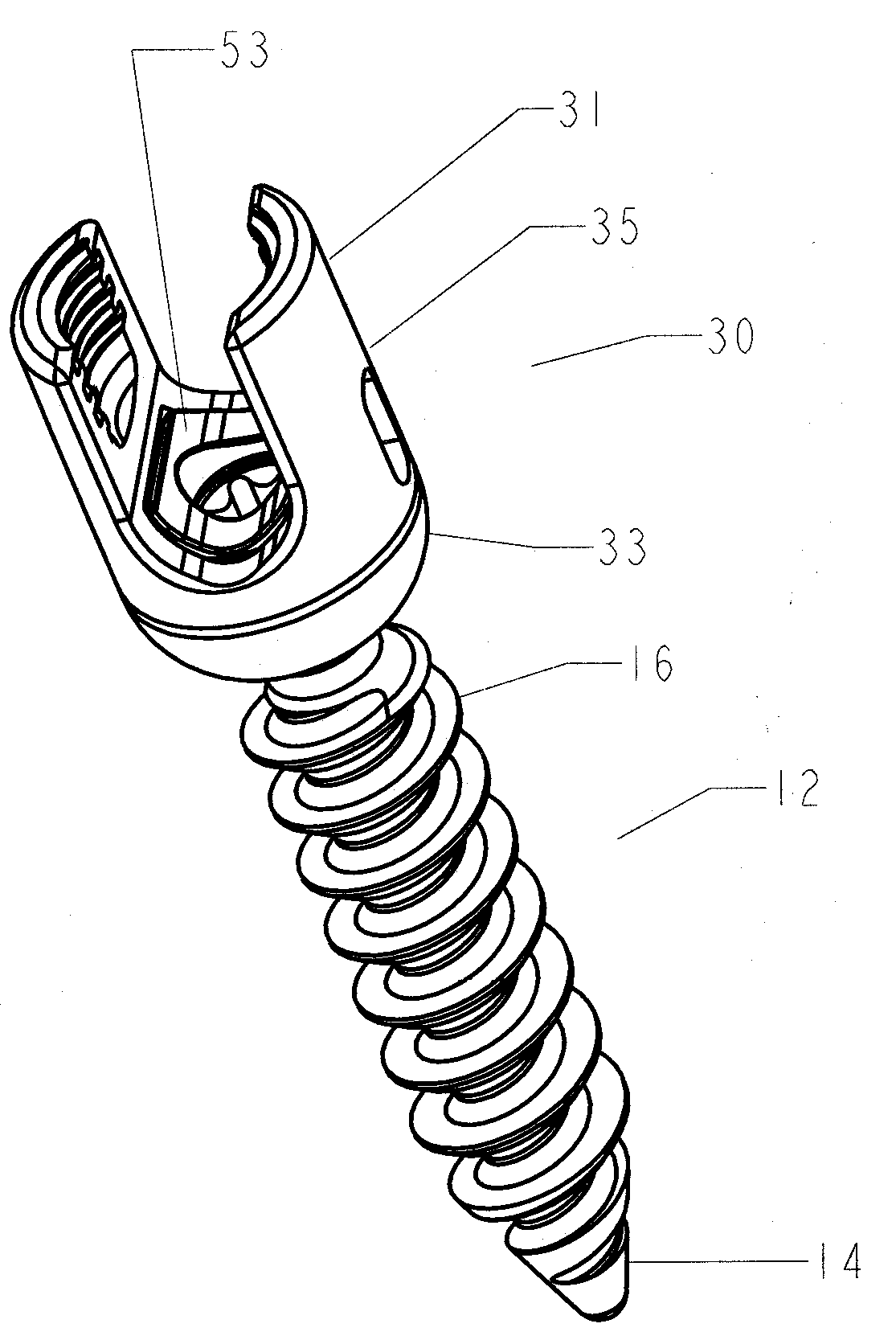

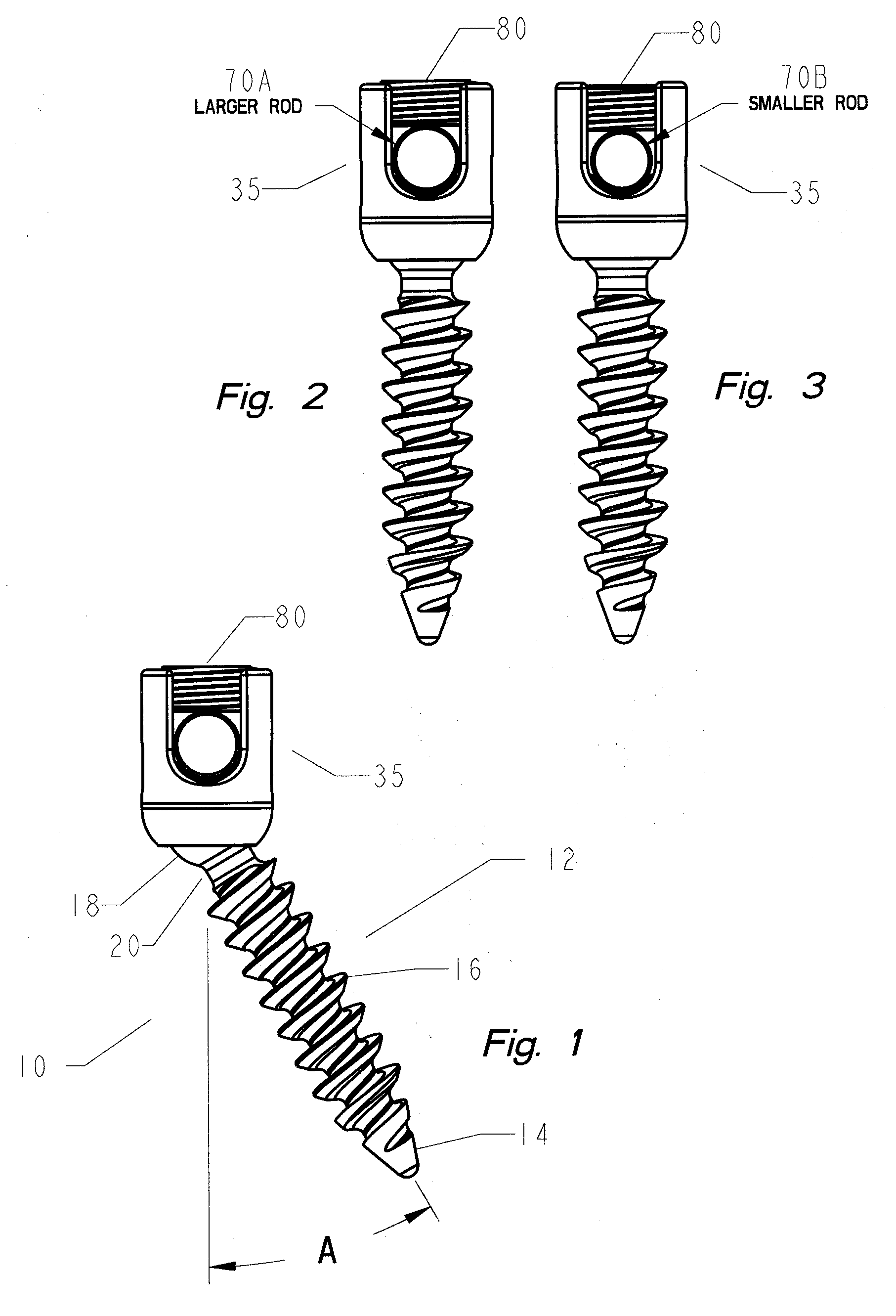

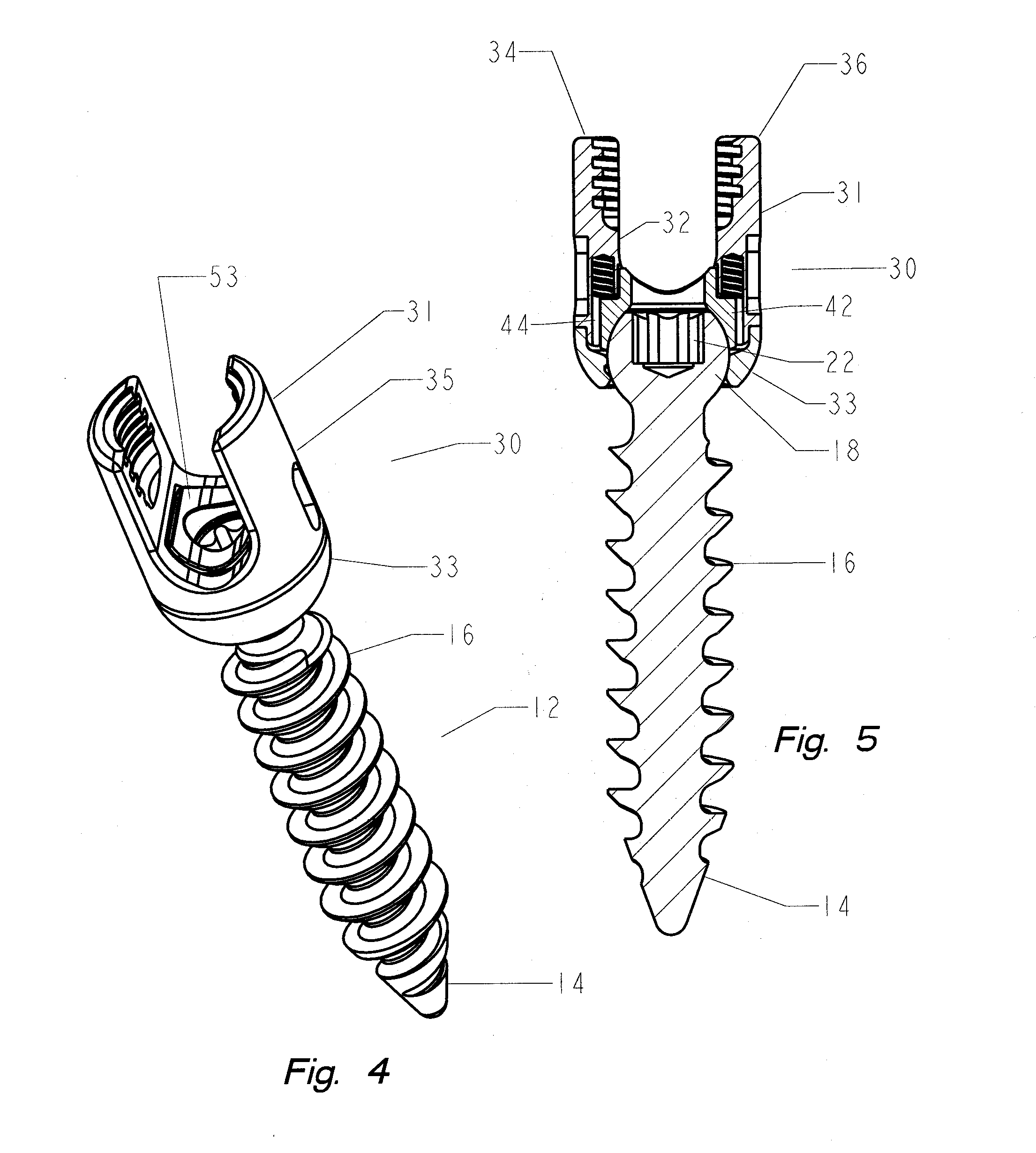

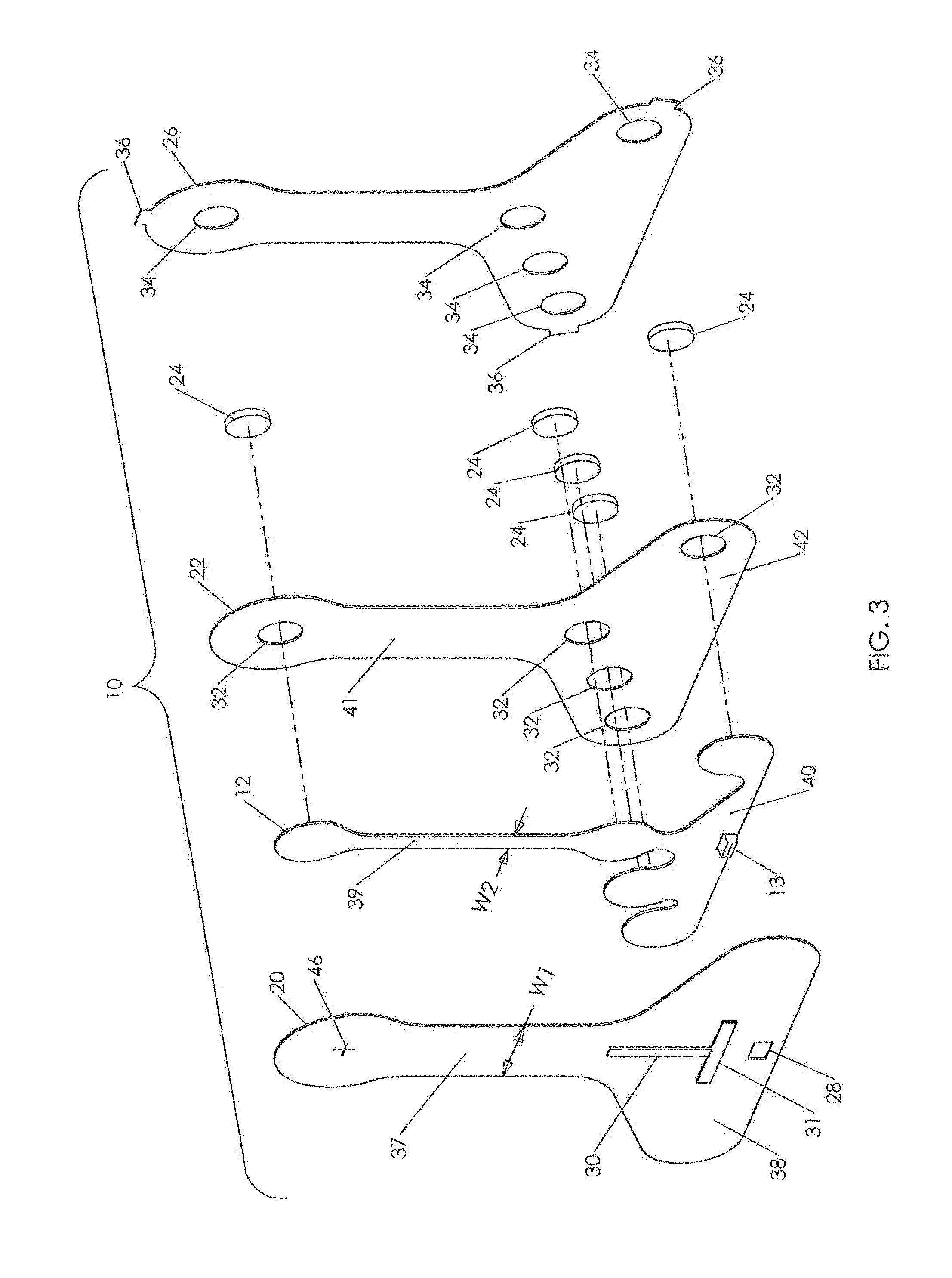

Thread-thru polyaxial pedicle screw system

ActiveUS8197518B2Reduce inventory costsSimilar shapeSuture equipmentsInternal osteosythesisEngineeringScrew thread

Owner:ORTHO INNOVATIONS

Thread-thru polyaxial pedicle screw system

ActiveUS7942909B2Reduce inventory costsSimilar shapeSuture equipmentsInternal osteosythesisEngineeringScrew thread

A thread-thru polyaxial pedicle screw fastening system. The fastening system consists of an anchoring bone screw having threads on one end for use in anchoring to the screw to the spine and a spherical connector on the other end operating as a pivot point about which a U-shaped connecting assembly moves in a polyaxial fashion. The U-shaped connecting assembly, for receipt of a spinal connecting rod, has a biased retainer ring for maintaining a positive tension between the connecting assembly and the anchored screw. The system allows for an improved manufacturing step wherein the threaded shank of a bone screws can be passed through a lower portion of the connecting assembly allowing a variety of bone screw sizes to be used with a common sized connector.

Owner:ORTHO INNOVATIONS

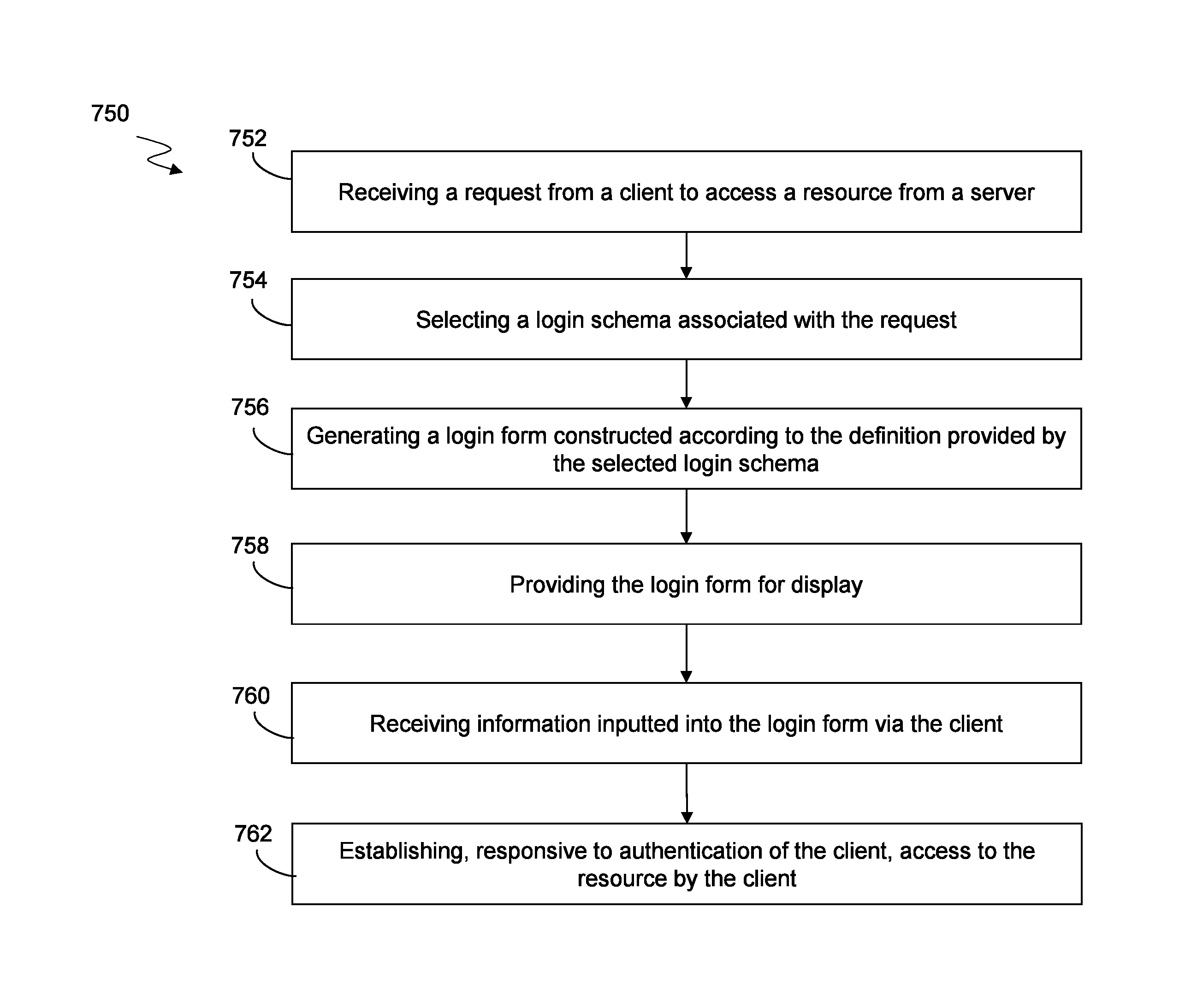

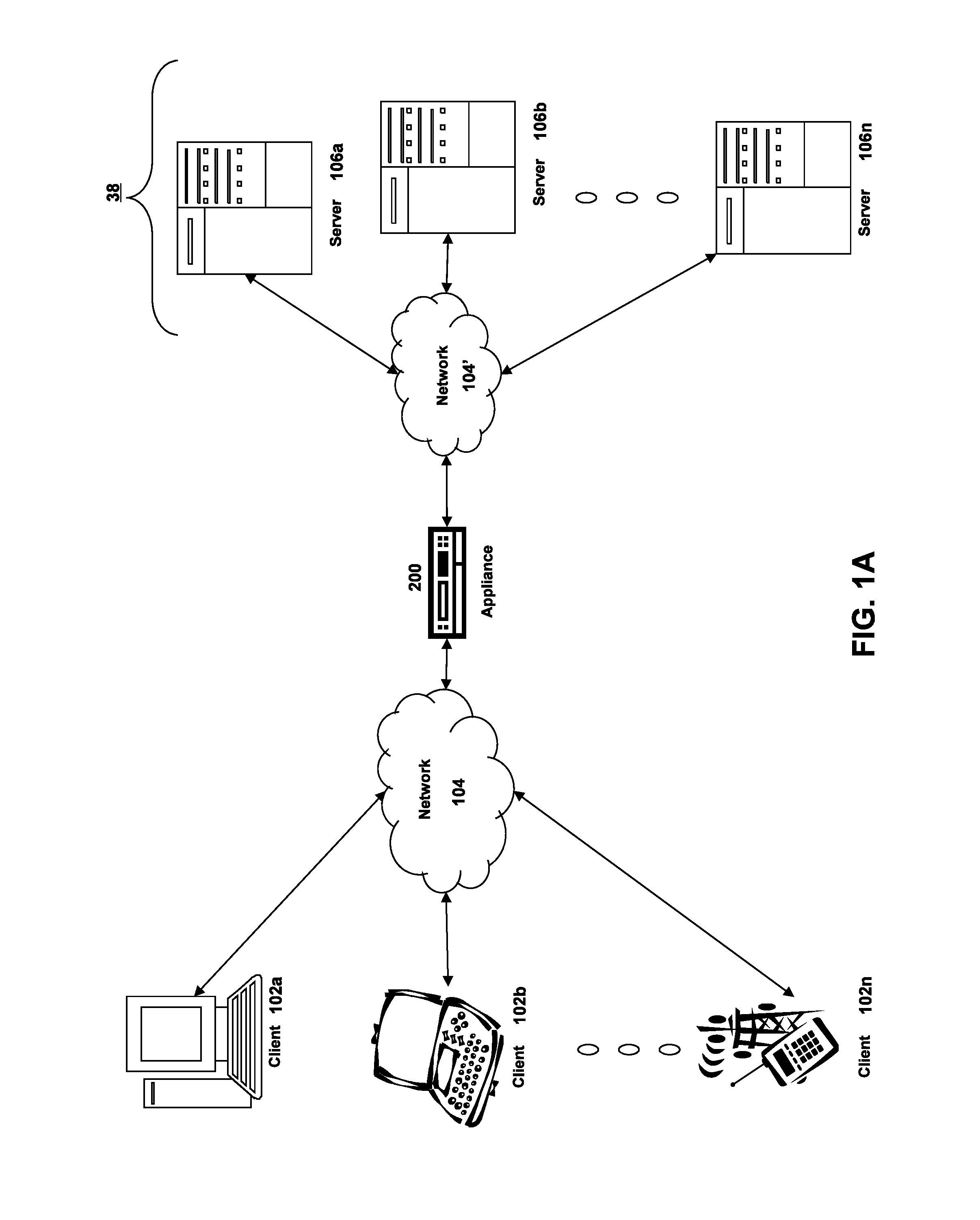

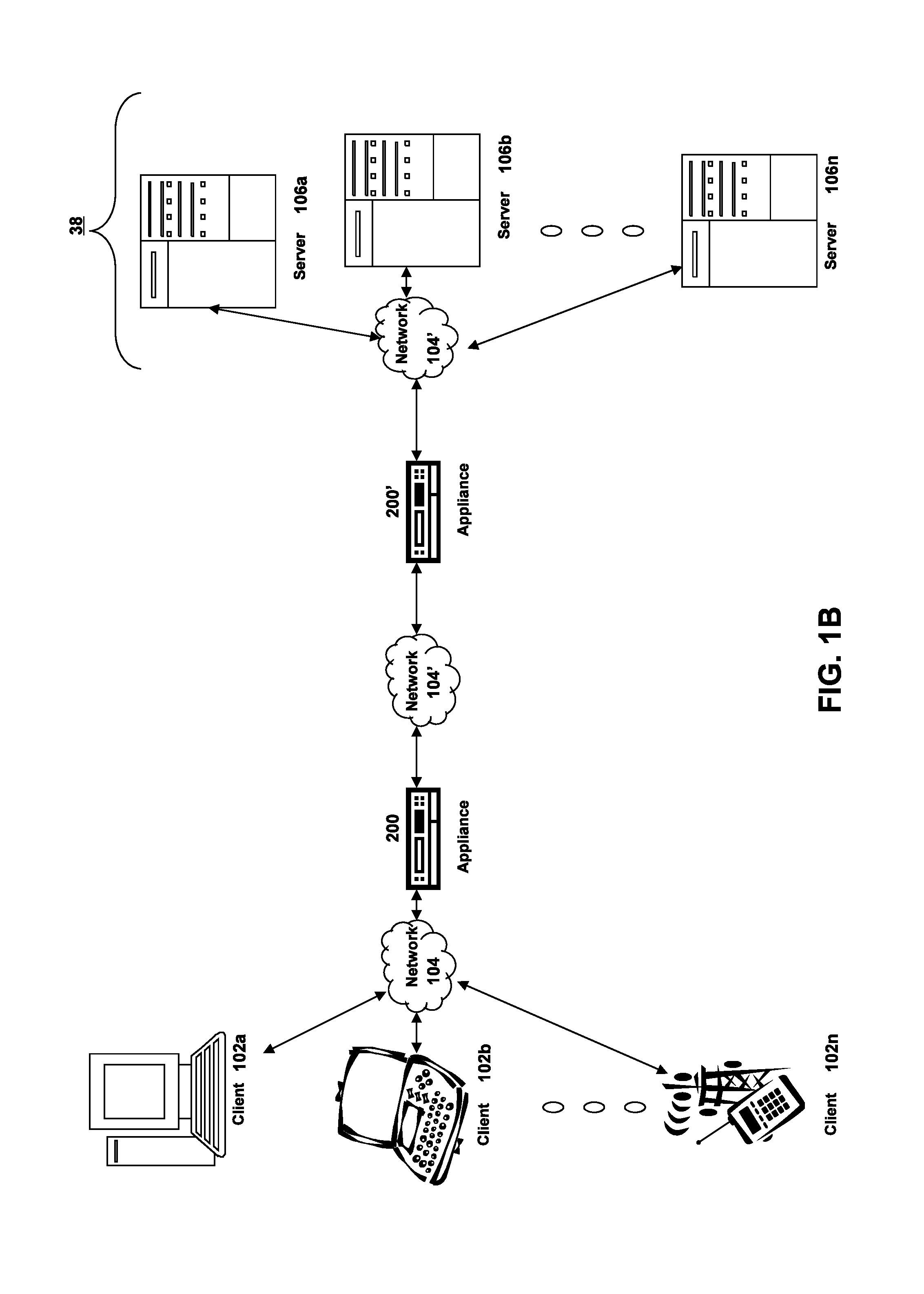

Systems and methods for flexible, extensible authentication subsystem that enabled enhance security for applications

ActiveUS20160381080A1Reduce inventory costsLow costDigital data processing detailsMultiple digital computer combinationsApplication softwareClient-side

The present disclosure is directed towards systems and methods of authenticating a client. A device intermediary to clients servers that provide one or more resources can receive a request from a client to access a resource of the one or more resources. The device can select a login schema associated with the request that includes a definition of a login form. The login schema may correspond to an authentication protocol. The device can generate the login form responsive to the request. The login form can be constructed according to the definition provided by the selected login schema. The device can provide the login form for display via the client. The device can receive information inputted into the login form via the client. The device can establish access to the resource responsive to authentication of the client based on the information and the authentication protocol.

Owner:CITRIX SYST INC

Expanded beam connector

Owner:TE CONNECTIVITY CORP

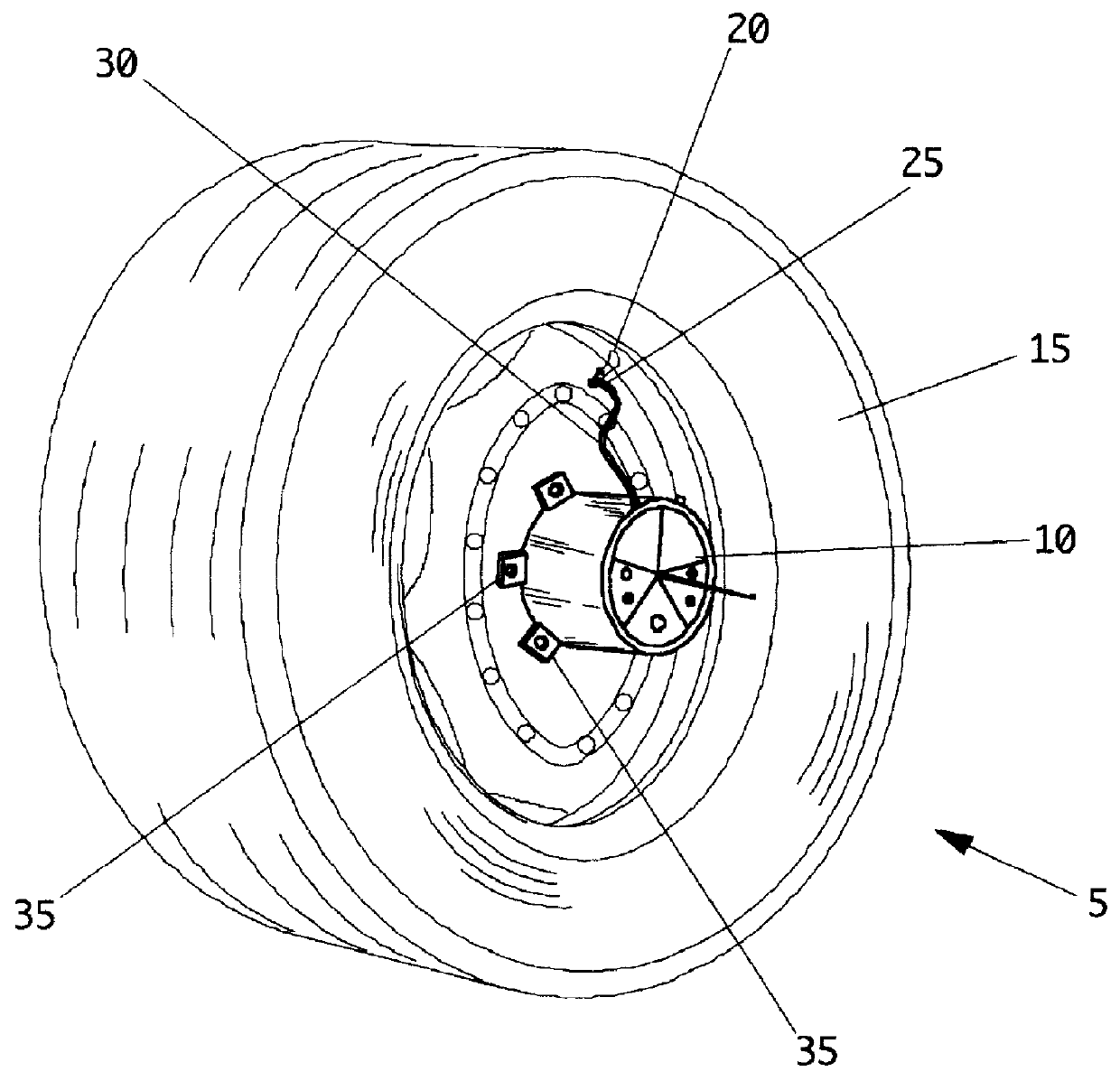

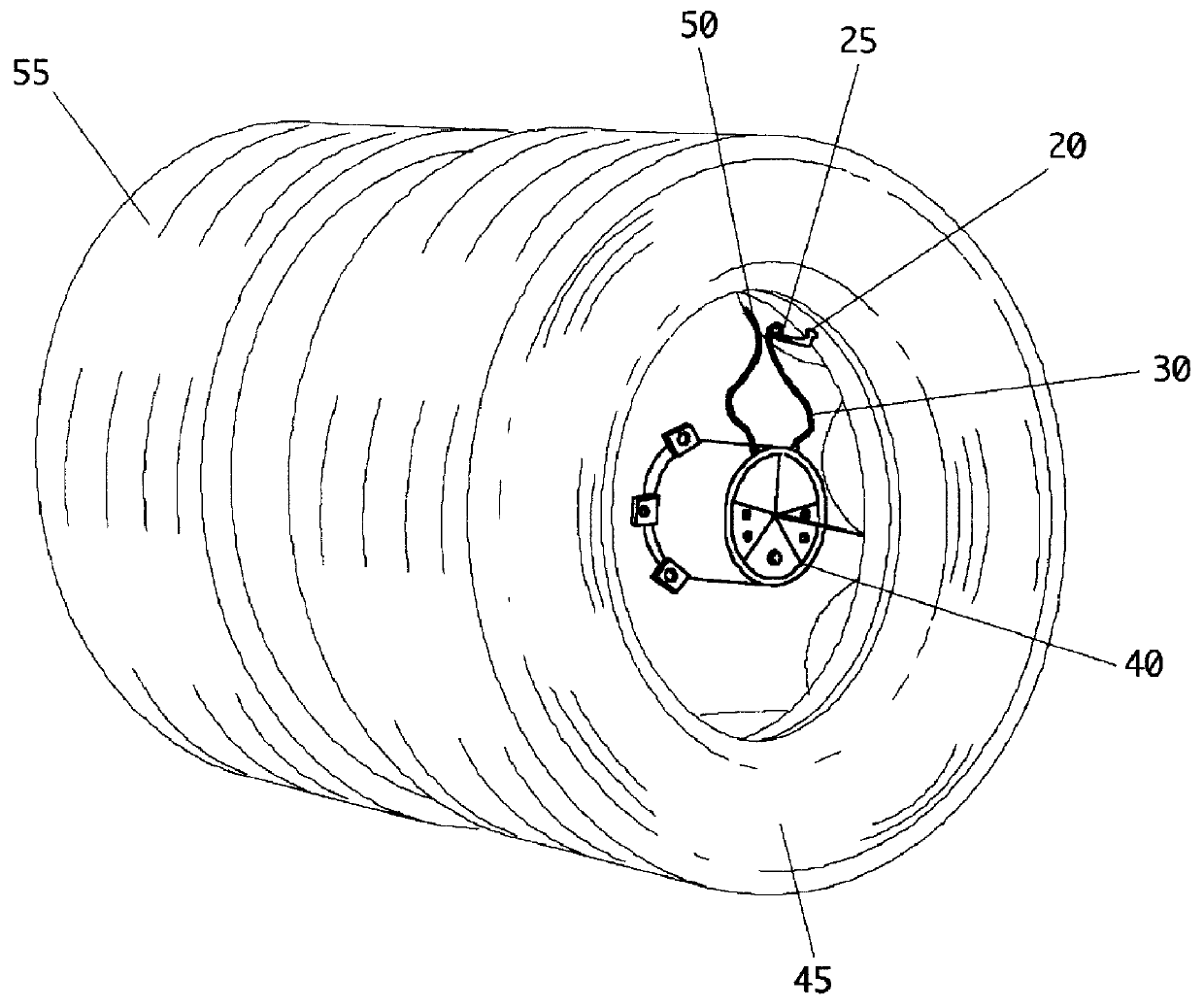

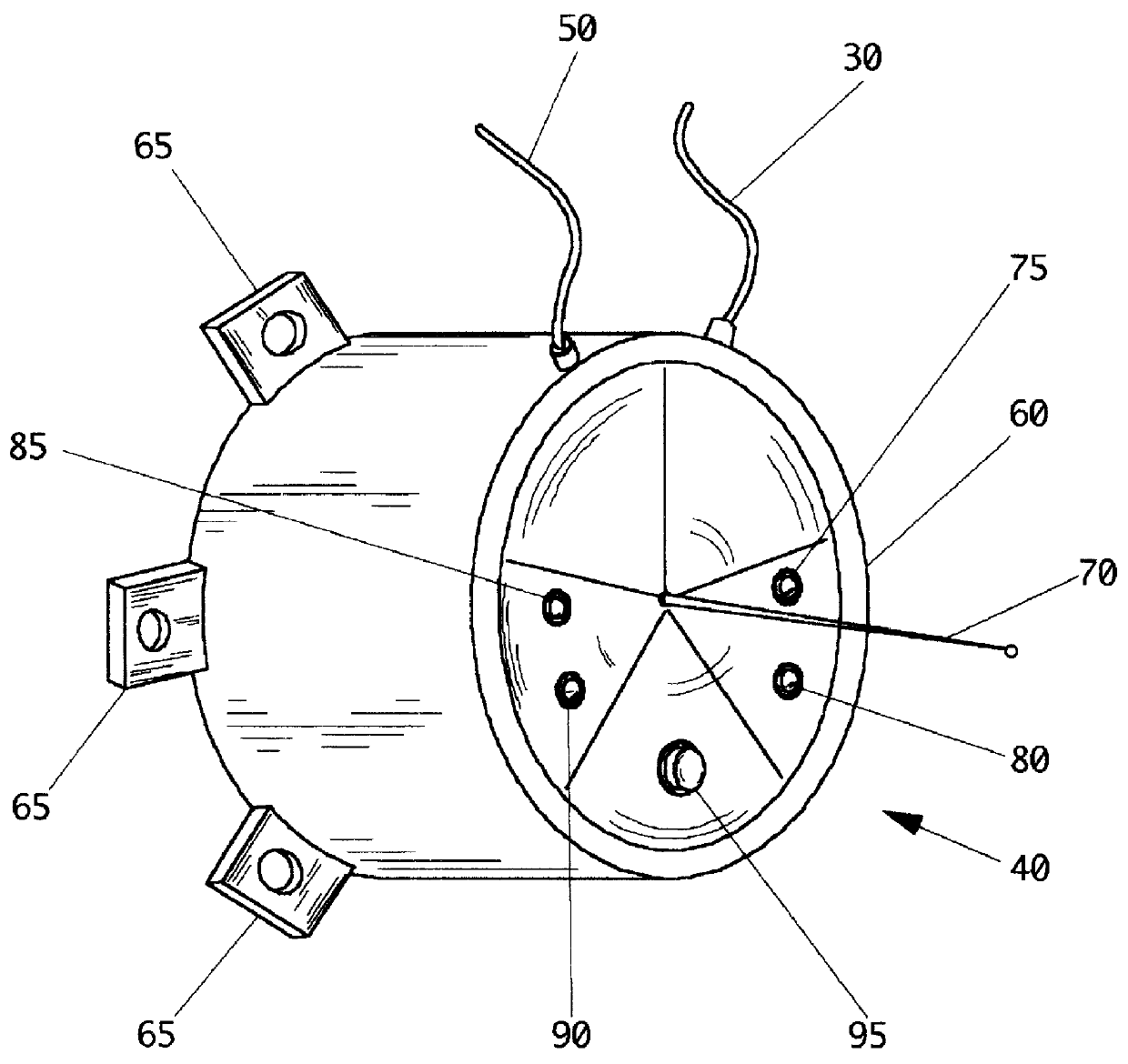

Universal, remote, continuous vehicle tire air pressure monitoring and reporting system

InactiveUS6011463AReduce inventory costsReduce manufacturing costTyre measurementsTyre-inflating valvesLow voltageRadio reception

This invention is a method and system for reporting the under or over pressure conditions on motor vehicle tires. The device is comprised of air hoses, pressure sensors, radio transmitters with antennas, a radio receiver, a display unit with lights, batteries, lights, and associated electrical components. An assembly mounted on the front of each wheel, over or in place of the hubcap, consists of an air pressure monitor utilizing air pressure inflation valves, a radio transmitter with battery cell, a radio transmitter antenna, and high / low indicator lights. Air hoses attached to each tire's valve stem are connected to the air pressure inflation valves of the air pressure monitors. The wheel mounted transmitters are powered by a low voltage battery that is normally powered off until activated by the changes of the pre-set air pressure of the tire air pressure monitoring sensor.

Owner:CORMIER SR LEVITE

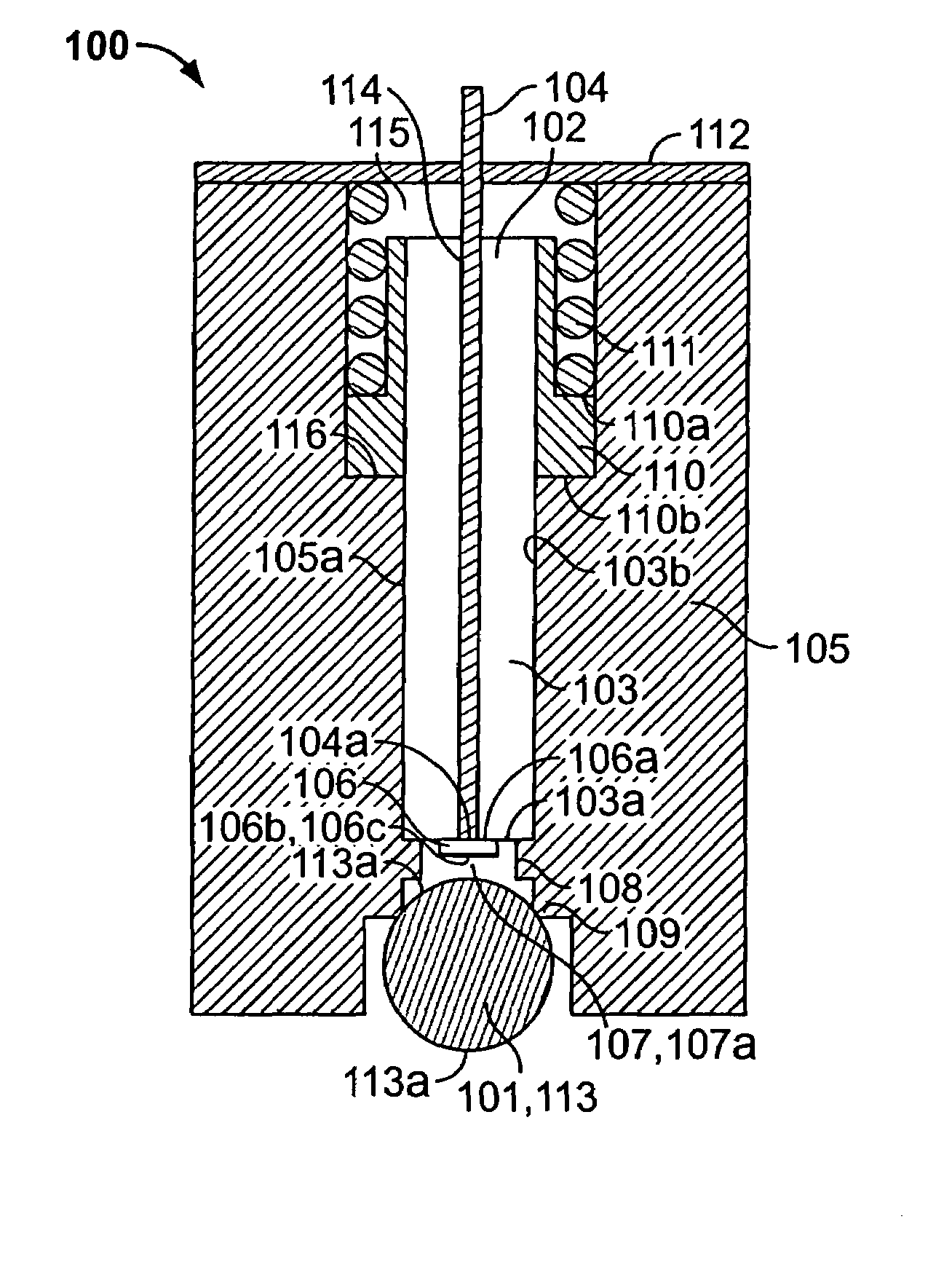

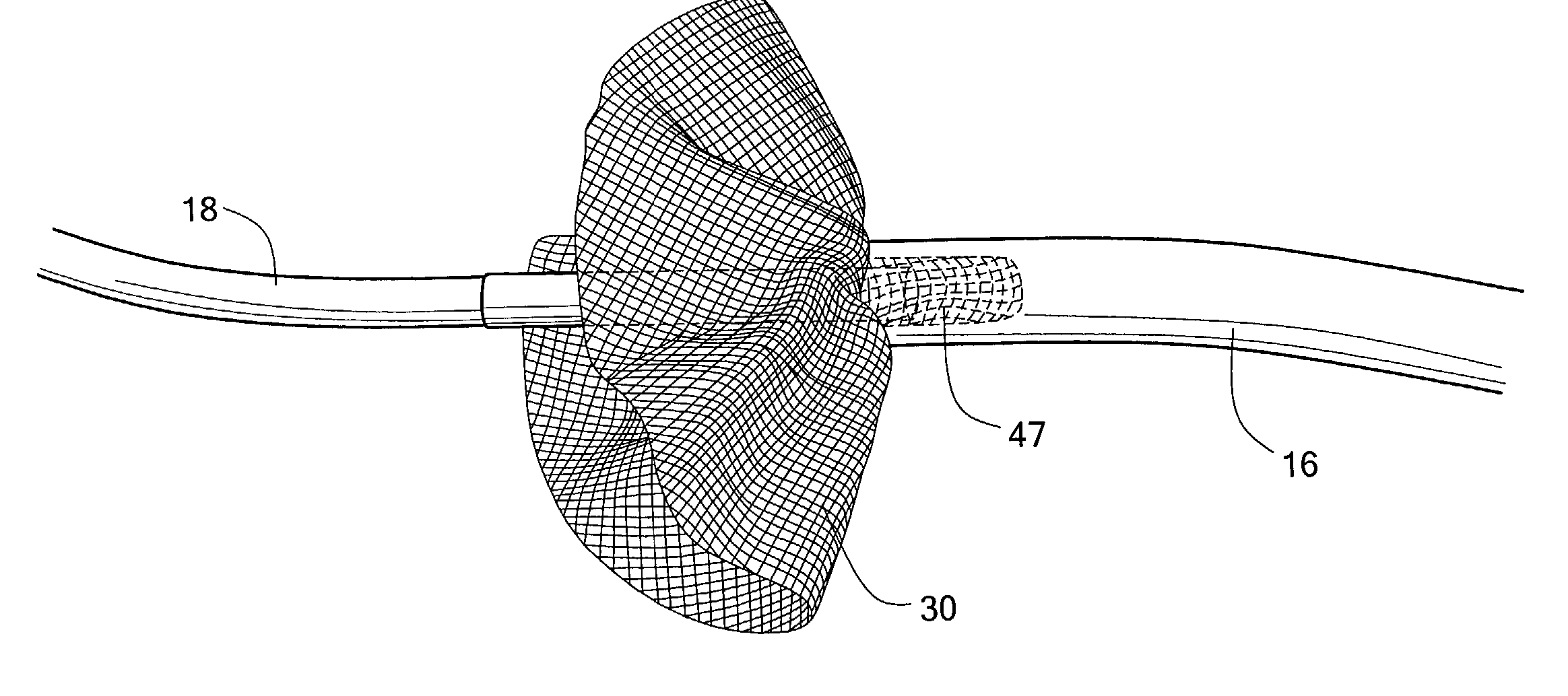

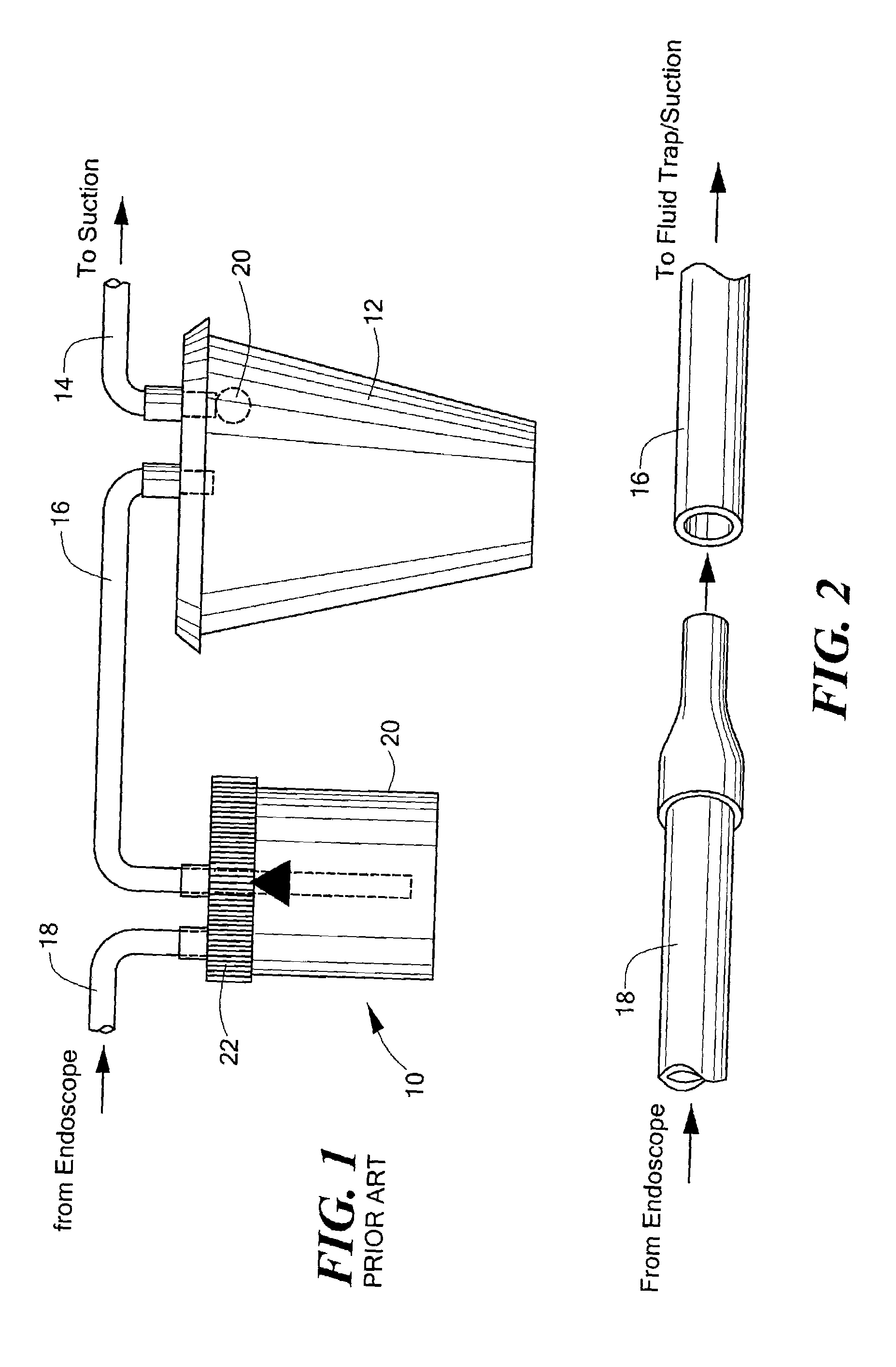

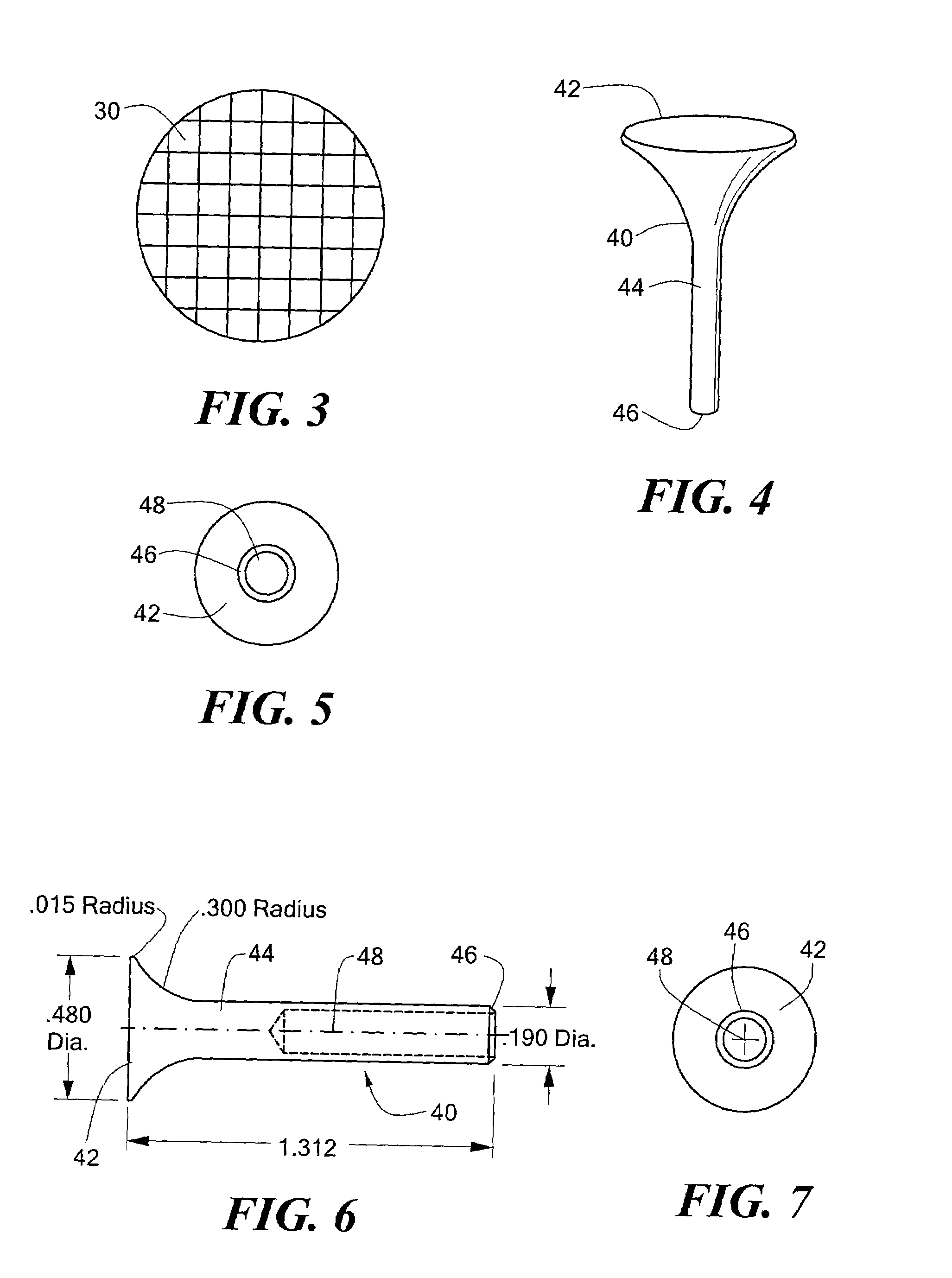

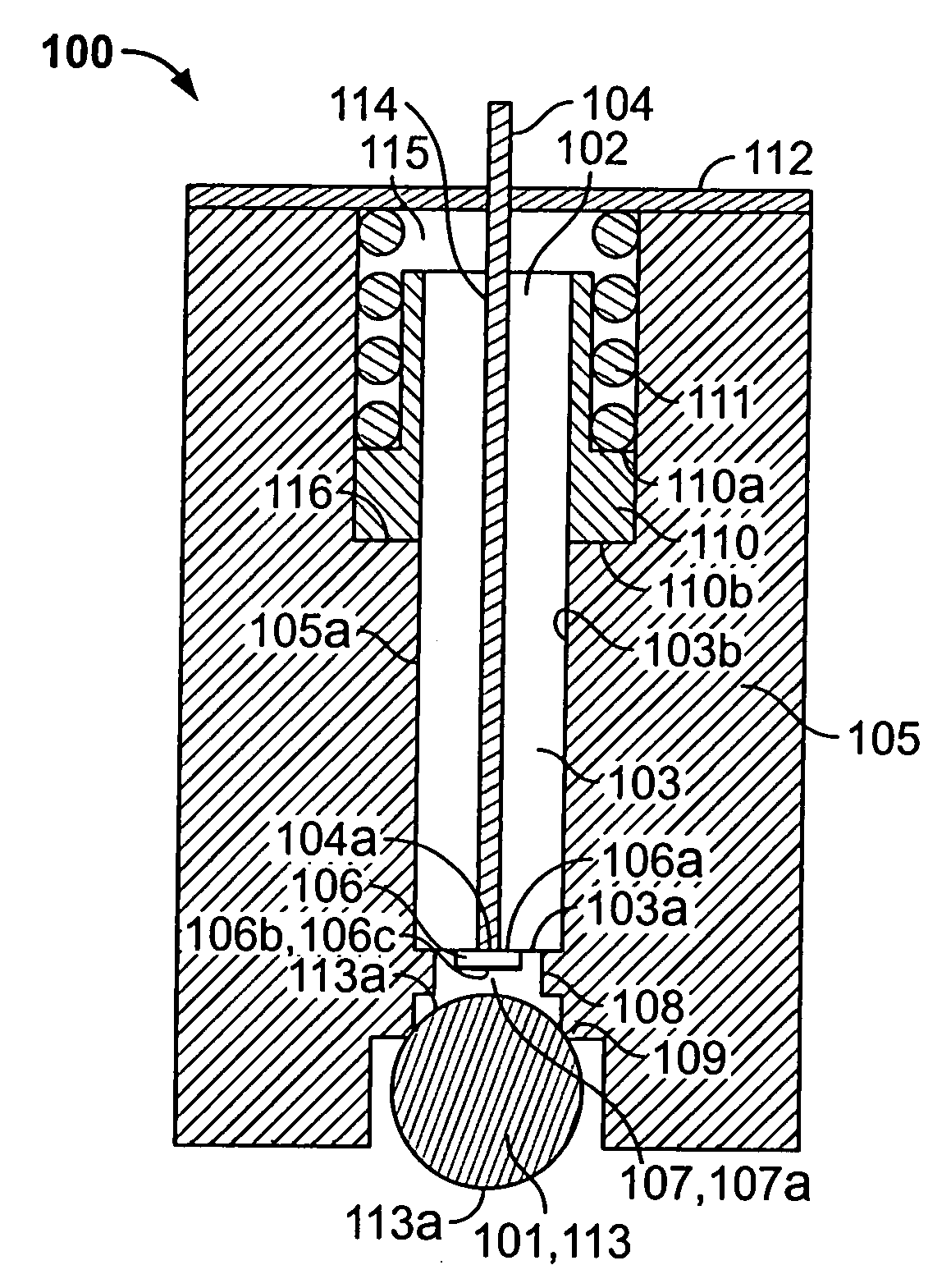

Containerless tissue sample collection trap

InactiveUS7182754B2Small sizeSaving inventorySurgical needlesMedical devicesTissue CollectionTissue sample

A containerless tissue sample collection trap featuring, in the preferred embodiment, a flexible filter and an applicator having a shaft terminating in a distal end with a channel therein receiving a portion of the flexible filter, the combination of the applicator and the flexible filter receivable in a suction tube and configured such that when the applicator is removed, the flexible filter forms a removable elongated tissue trap in the suction tube. Also disclosed is a method of trapping tissue wholly within a suction tube thereby eliminating the need for a specimen trap container and a method of making a containerless tissue specimen trap.

Owner:US ENDOSCOPY GROUP

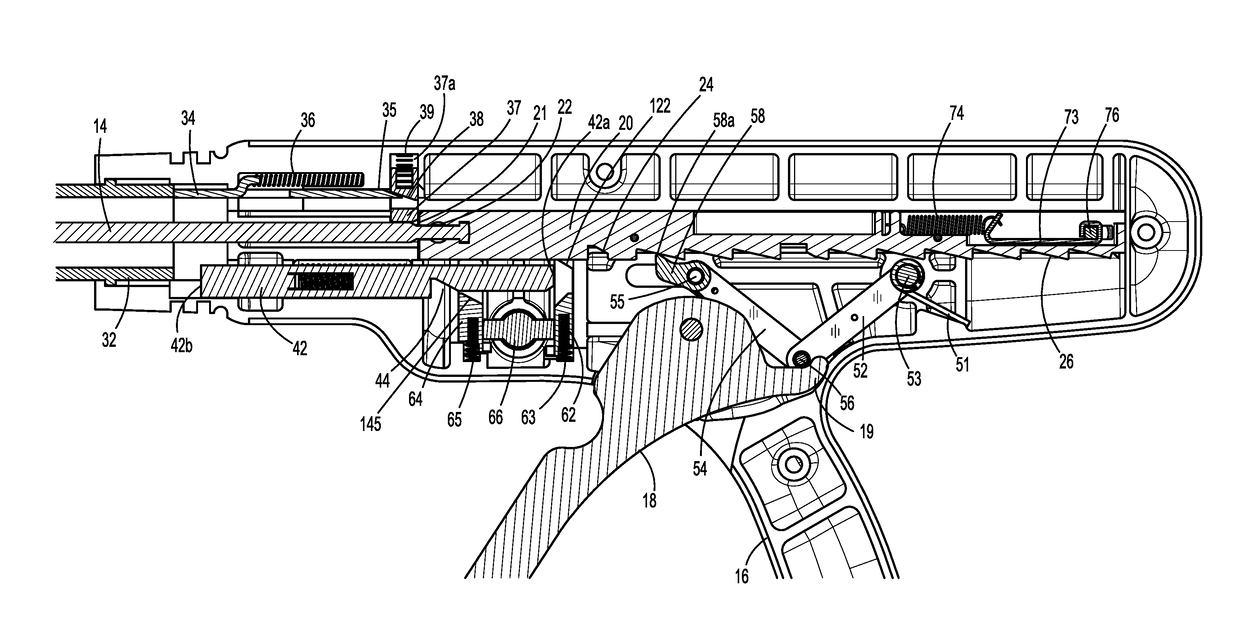

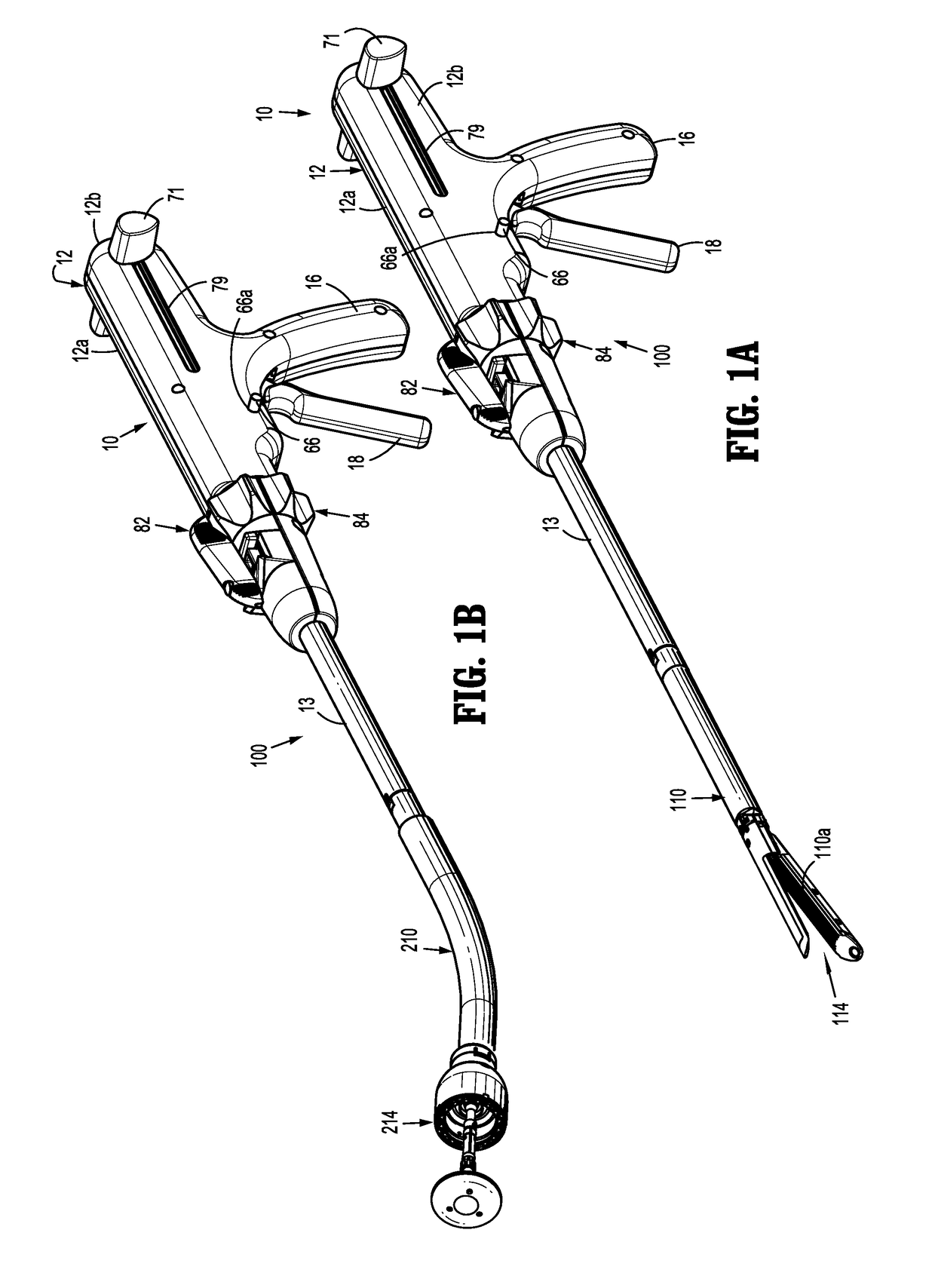

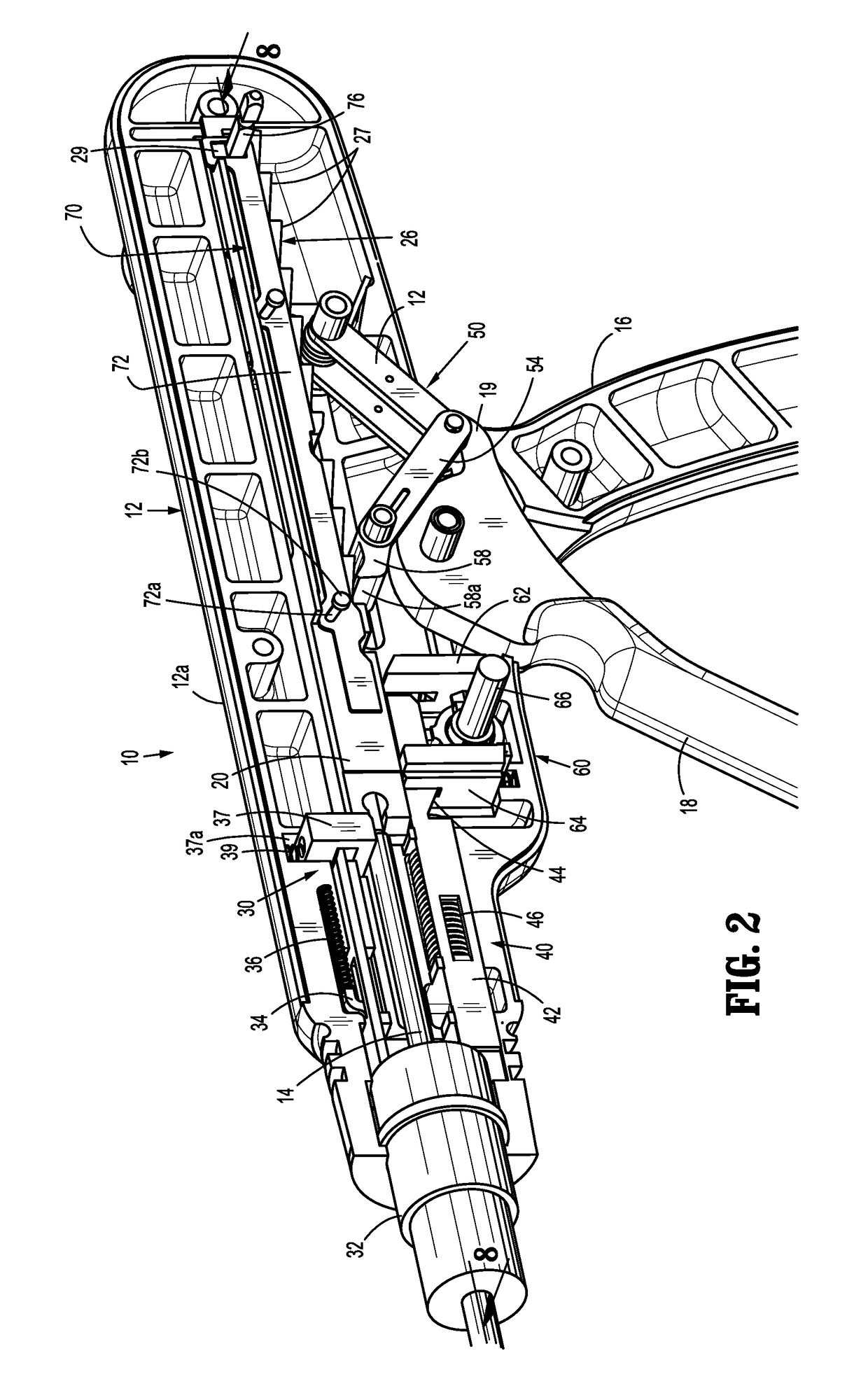

Universal handle for surgical instruments

ActiveUS20180021041A1Reduce in quantitySmall sizeDiagnosticsSurgical staplesLocking mechanismSurgical device

A universal surgical handle (10) includes a body (12) having a moveable handle (18, and elongate member (13) extending distally from the body (12), an actuation shaft (20), and a fire lock mechanism (60. The actuation shaft (20) defines first and second lock slots (24, 25) spaced axially apart. The moveable handle (18is operatively associated with the actuation shaft (20to effect longitudinal movement of the actuation shaft (20). The fire lock mechanism (60has a lock pawl (62) that is received within the first lock slot (24) during a first mode of operation of the handle (10to lock the actuation shaft (20) in first longitudinal position and is received within the second lock slot (25) during a second mode of operation of the handle (10) to lock the actuation shaft (20) in a second longitudinal position. The handle (10) is adapted to transition from a home position to the first or second mode of operation in response to a loading unit (110, 210) being coupled to the elongate member (13).

Owner:TYCO HEALTHCARE GRP LP

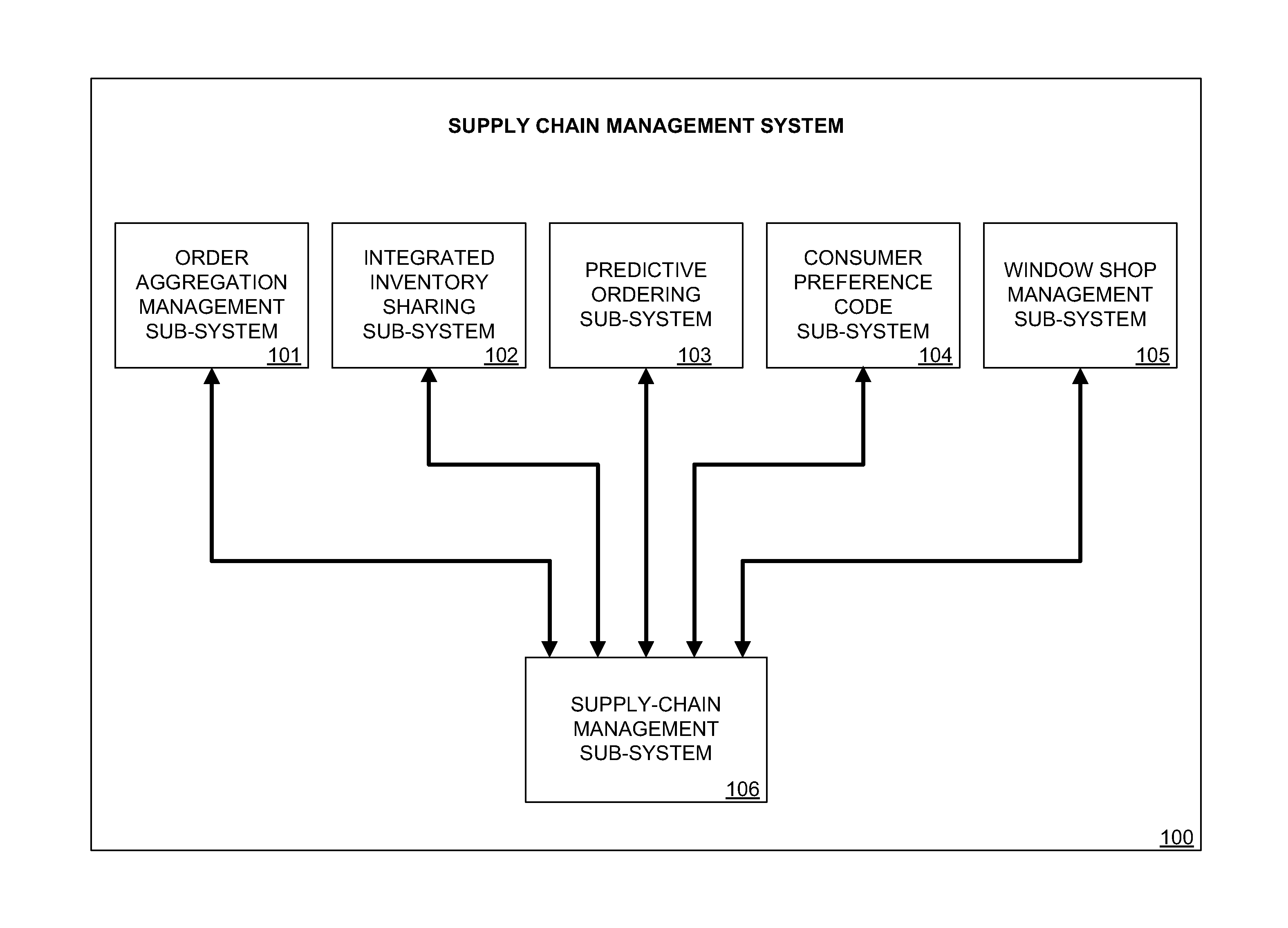

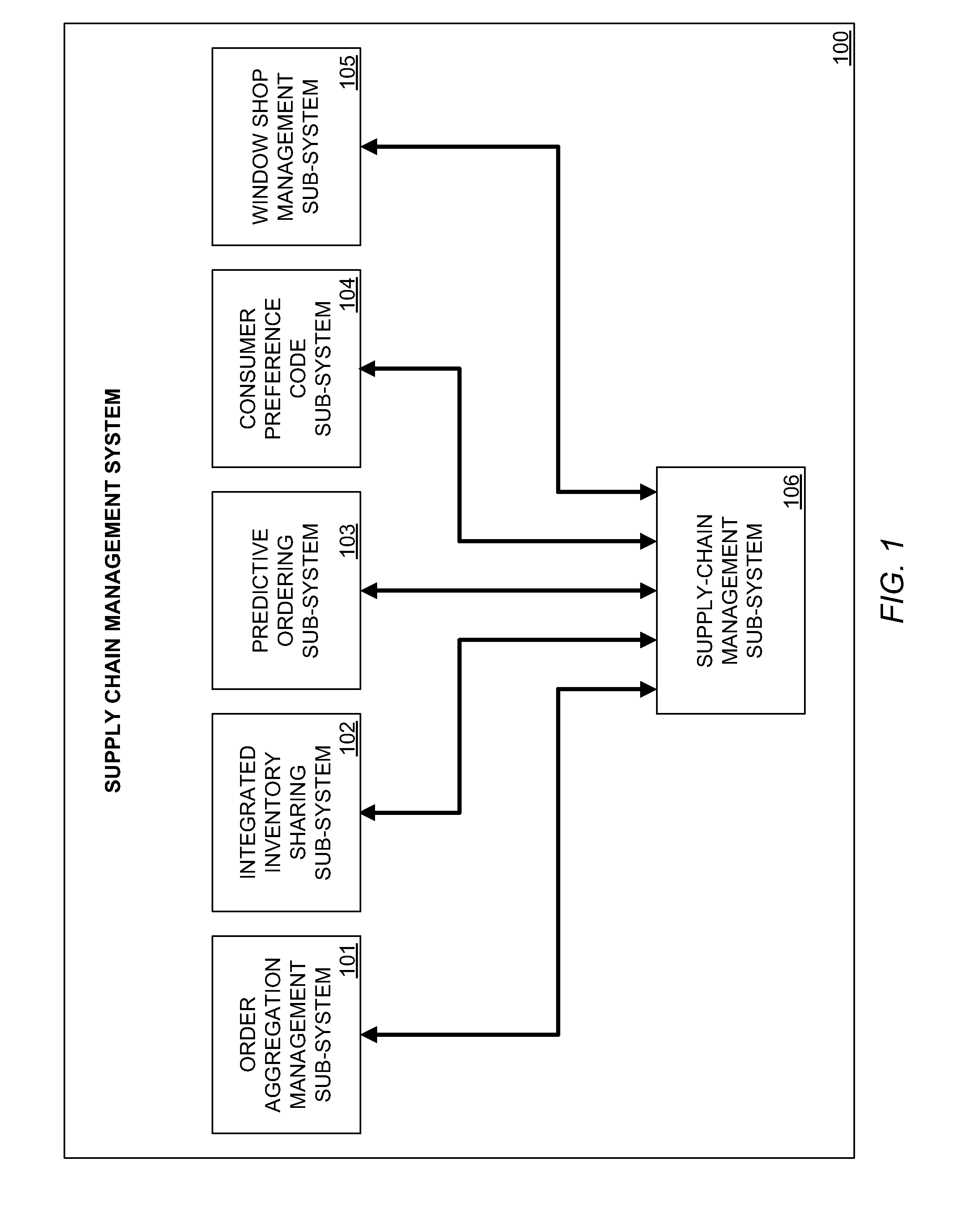

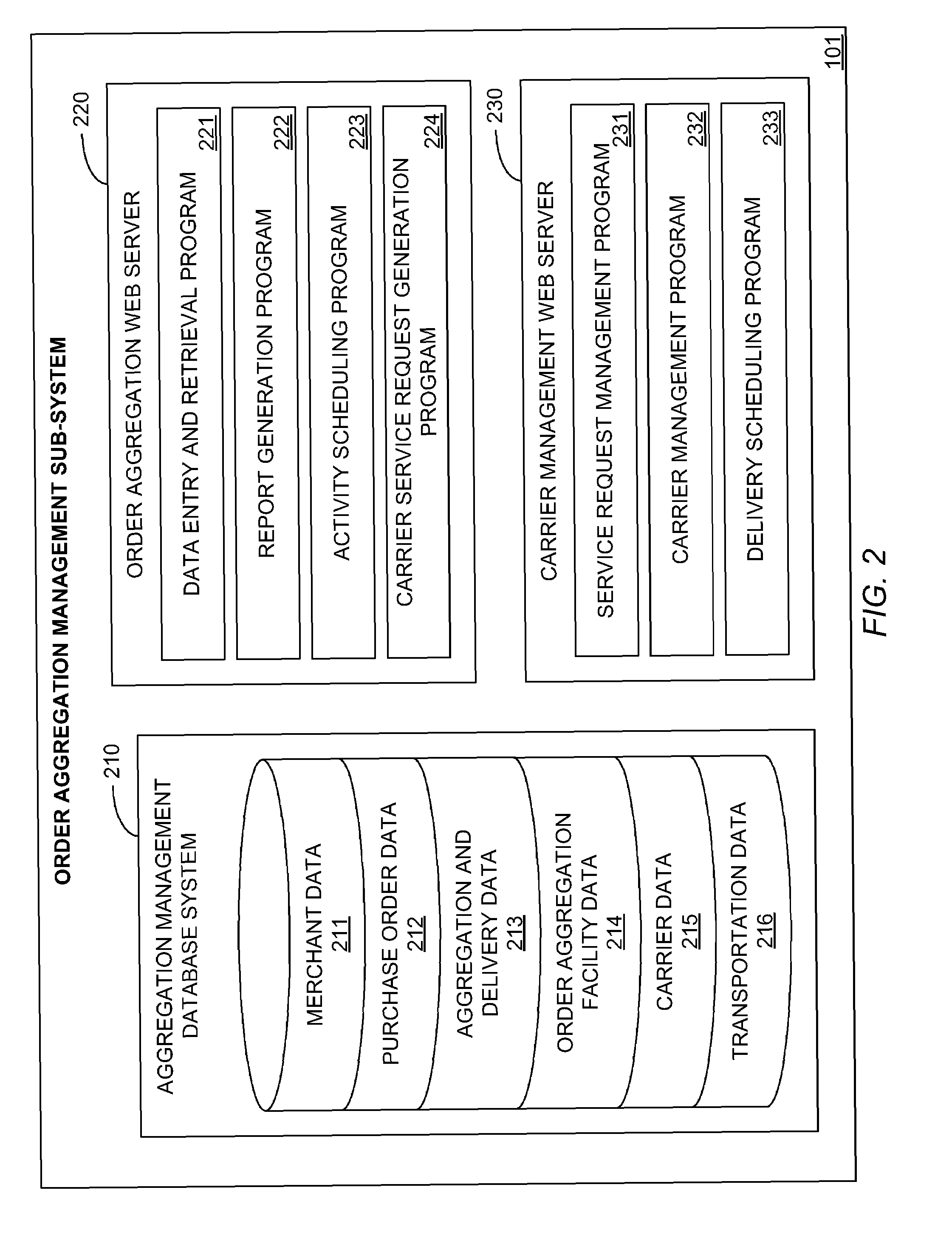

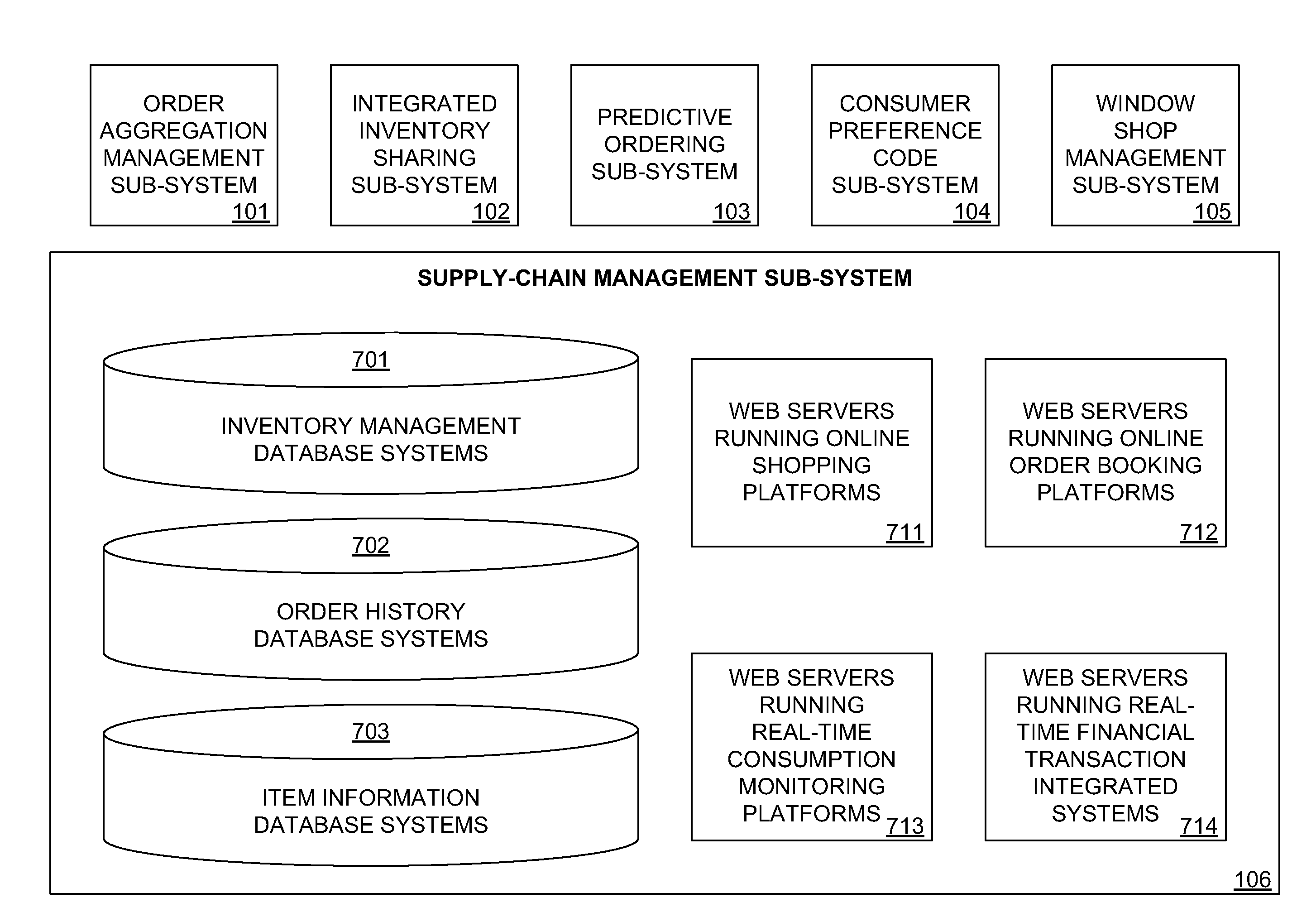

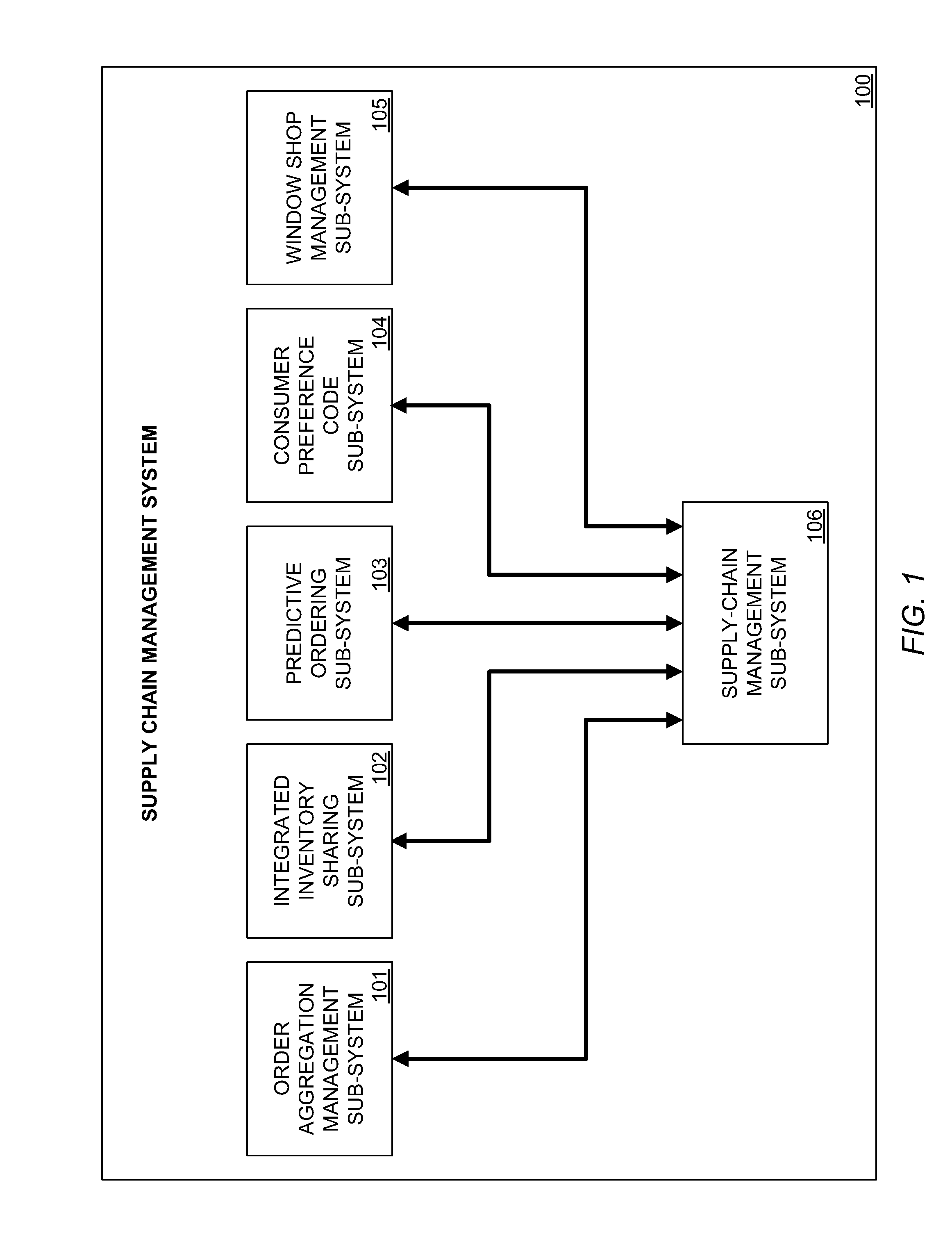

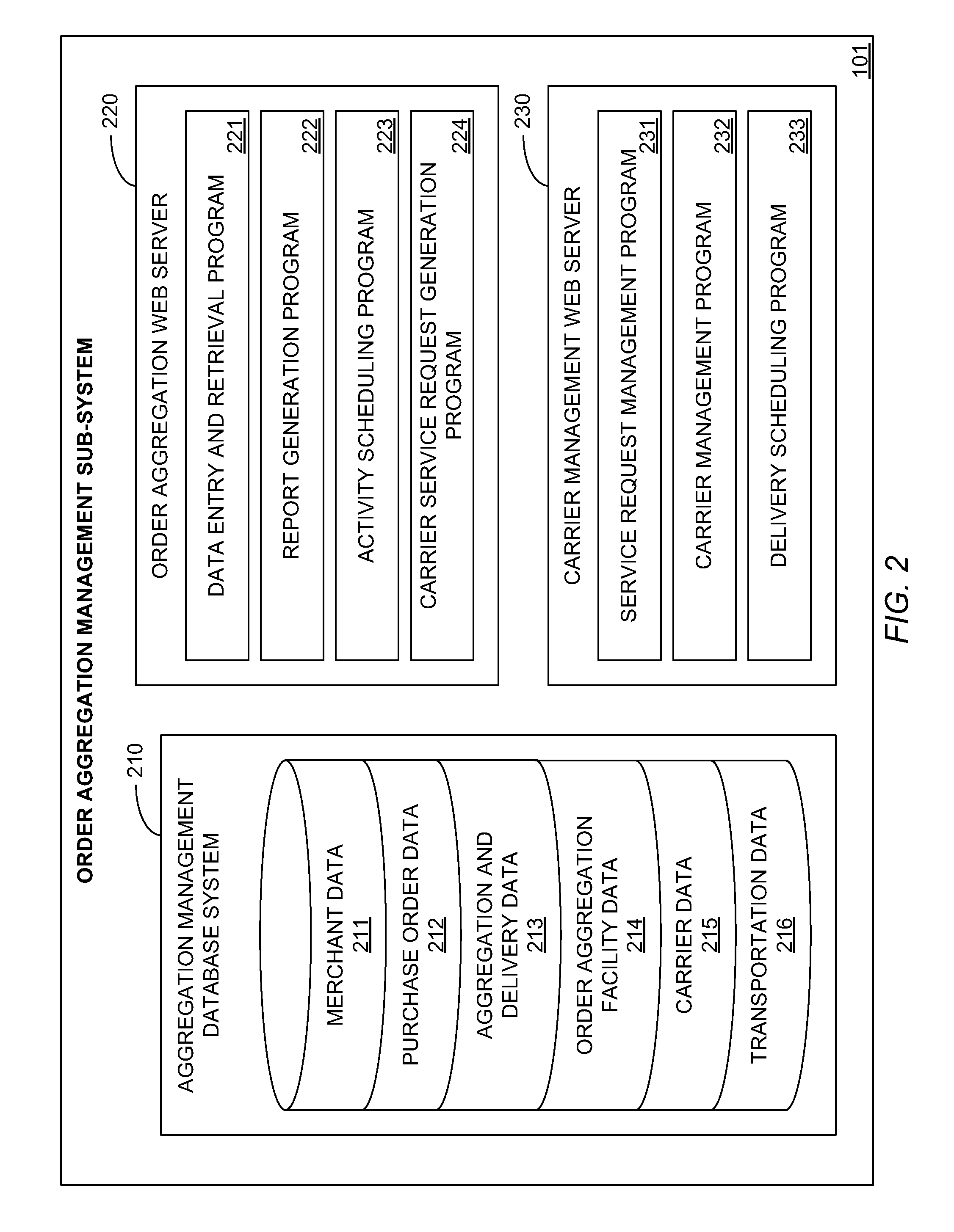

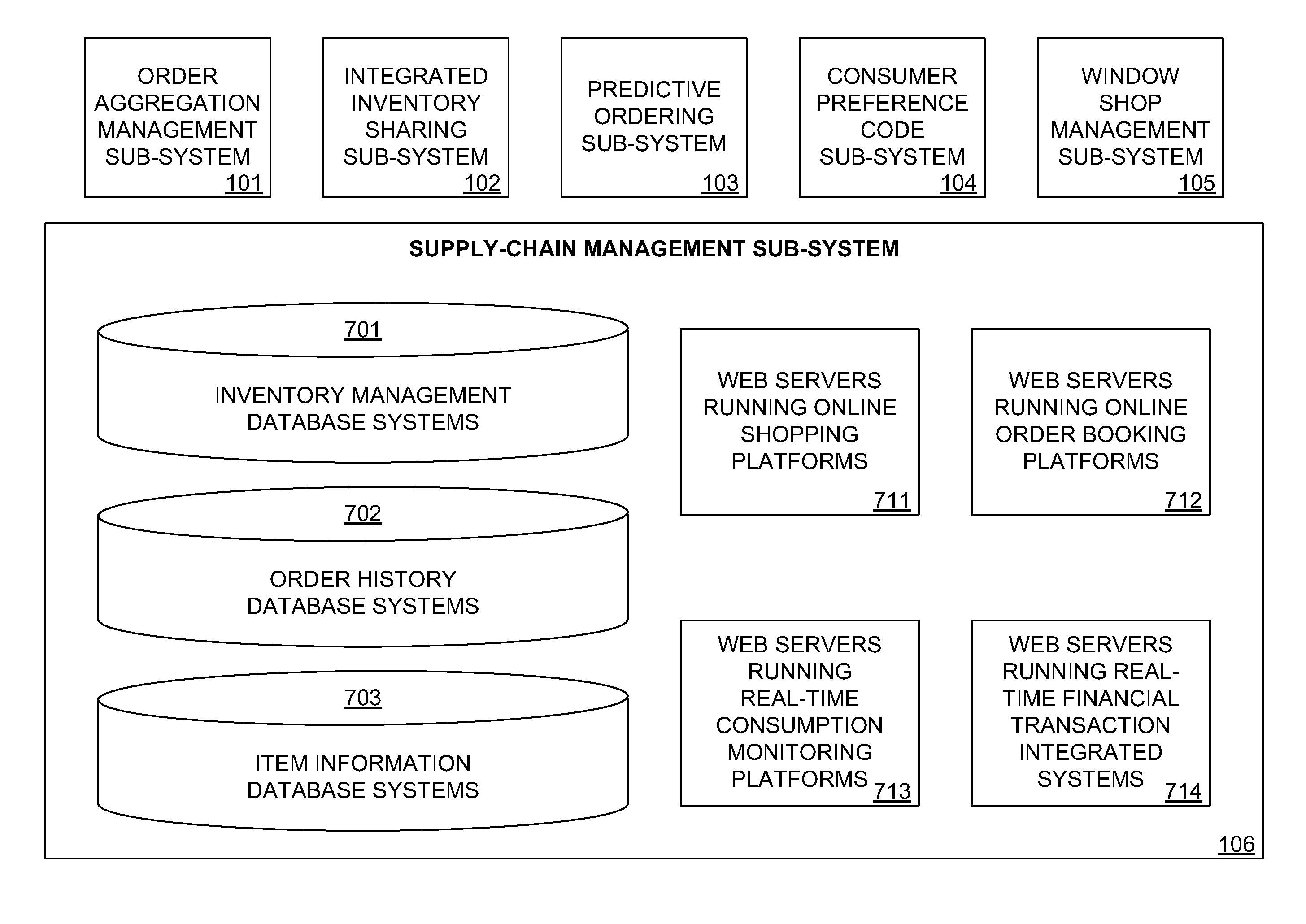

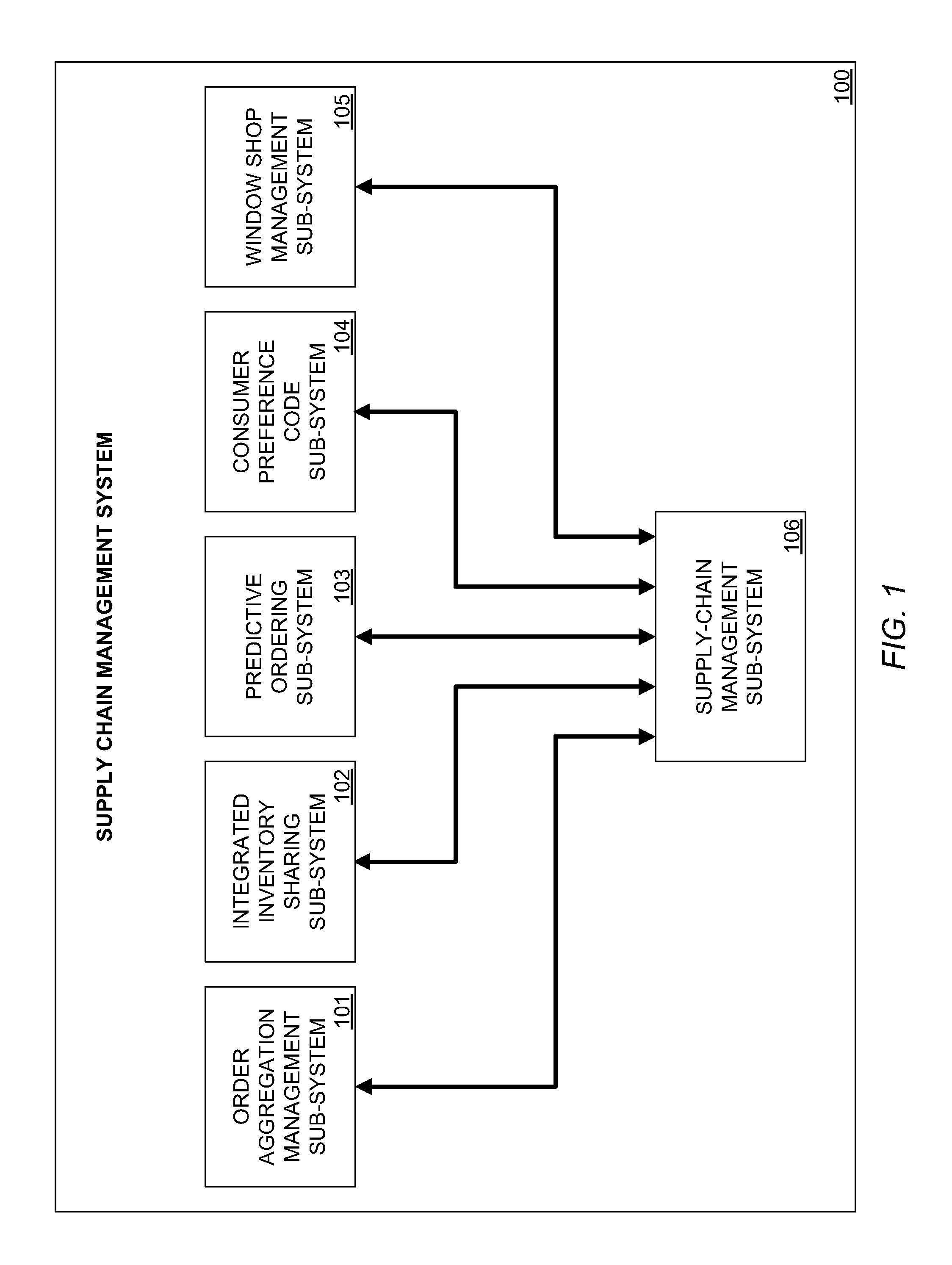

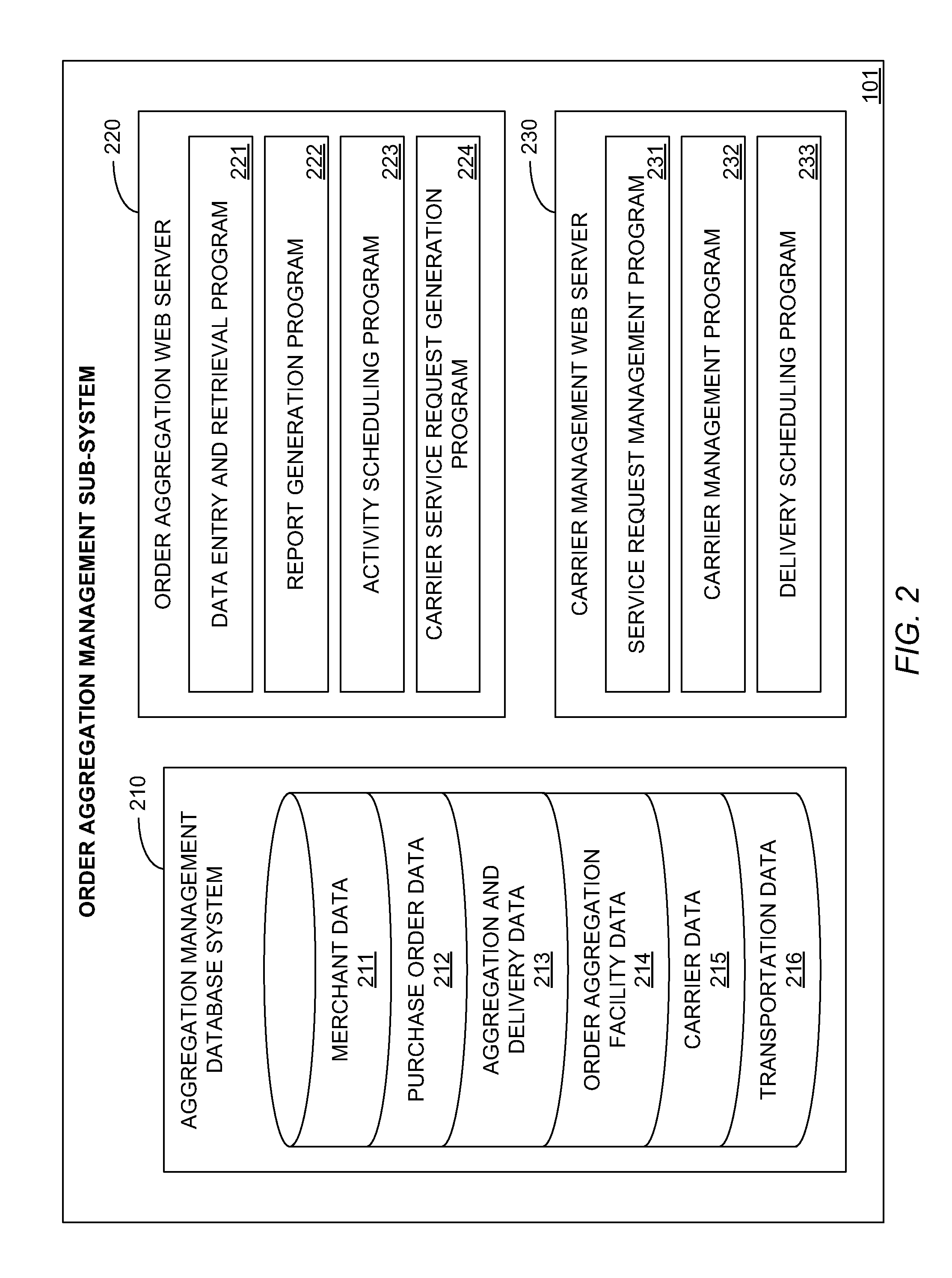

Supply-chain management system

An Internet-based computer-assisted supply-chain management system (SCMS) replaces the archaic commerce systems presently in use. It coordinates just-in-time distribution of items purchased by consumers from a plurality of merchants whereby the inventory in the distribution pipeline is reduced to inventory in transport. It uses regional distributions centers and neighborhood order aggregation facilities for an efficient transfer of items to consumers. Consumers can pick up aggregated orders at an order aggregation facility or have them delivered at a residence. The SCMS phases out conventional checkout registers in favor of web browsers with automatic transaction execution. Retailers can operate with little or no inventory. Window shops facilitate promotion of items and help consumers make selections and decisions with respect to purchases they may be contemplating. The SCMS provides real-time consumption monitoring and forecasts, significantly reduces supply-chain costs and retail prices, promotes economic growth, and minimizes undesirable cyclic economic fluctuations.

Owner:FRANCO HECTOR

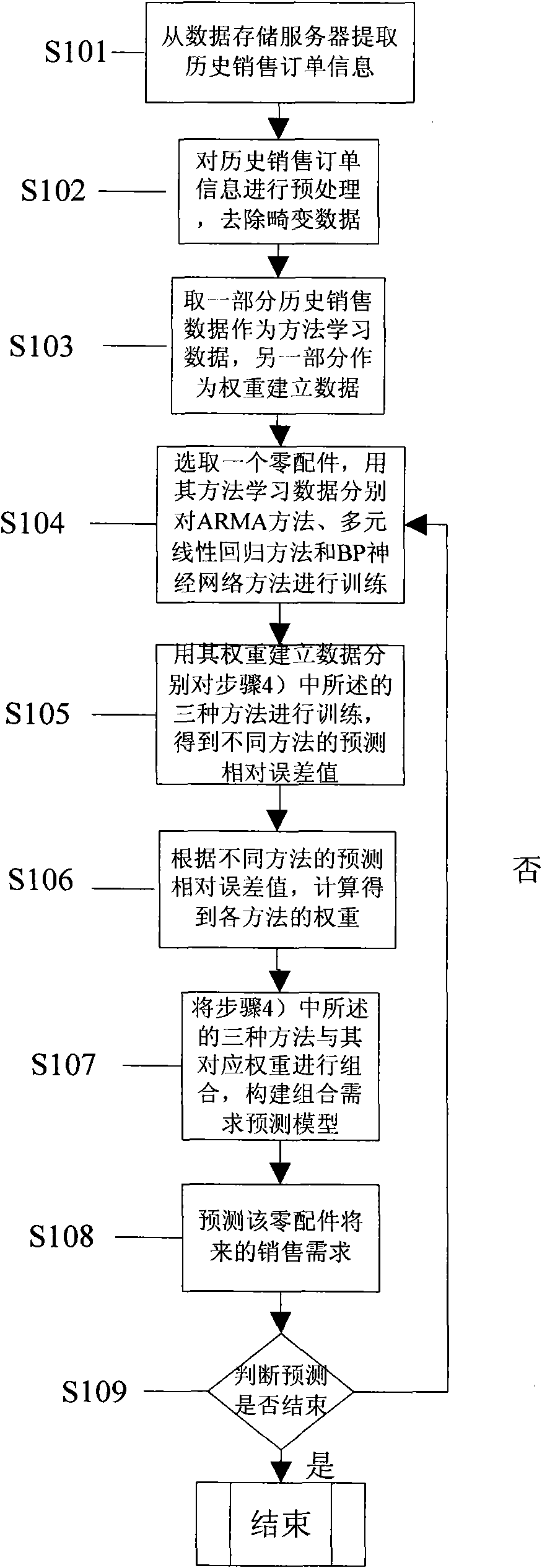

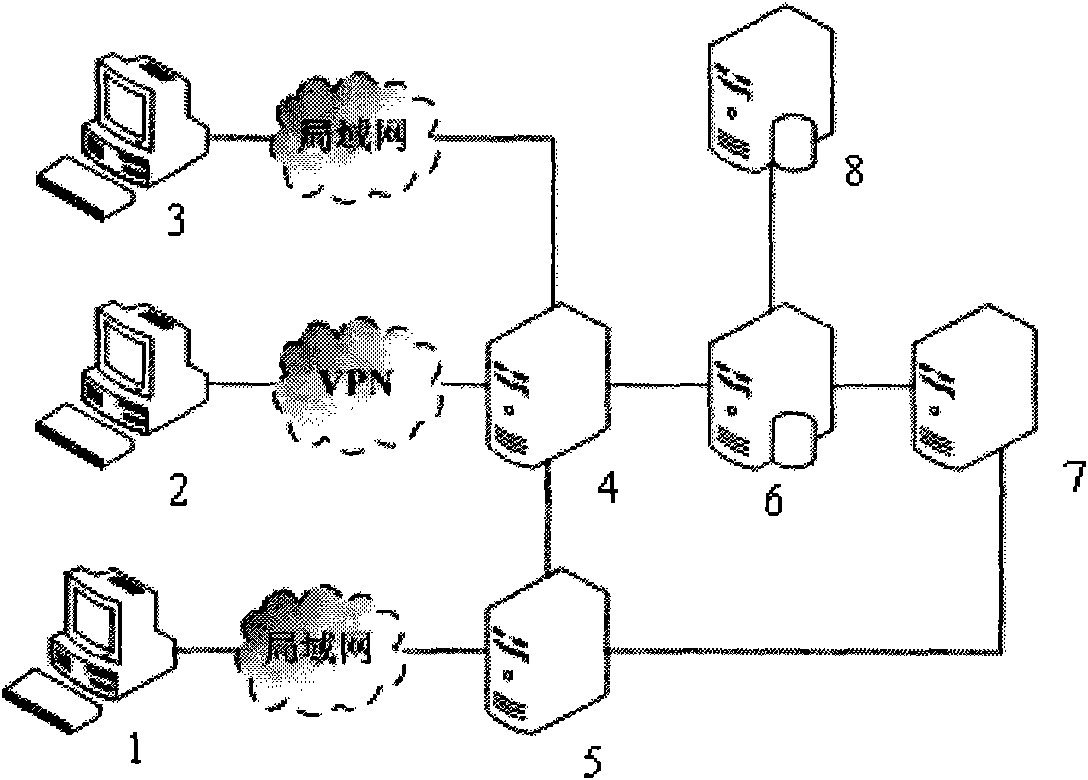

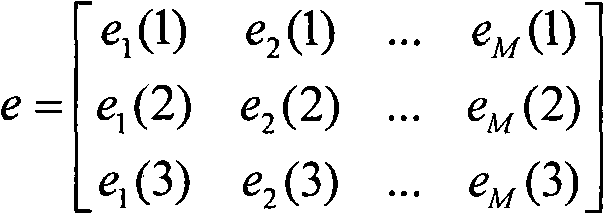

Spare part assembling demand forecasting information processing method applied to inventory management

InactiveCN102385724AImprove management efficiencyImprove satisfactionLogisticsMoving averageInformation processing

The invention relates to a spare part assembling demand forecasting information processing method applied to inventory management, comprising the following steps:1) take one part of historical sales data as method learning data and take the other part of the historical sales data as weight building data; 2) use the method learning data to practice an ARMA (Autoregression and Moving Average) method, a multiple linear regression method and a BP (Back Propagation) neural network approach respectively for each spare part; 3) apply the above three methods respectively by using the weight building data, so as to obtain forecasting relative error values for different methods; 4) calculate the weights of the above methods; 5)construct an assembling demand forecasting model; 6) forecast the future sales demands of all spare parts. Compared with the prior art, the method is suitable for the spare parts with different demand features, and has the advantages of strong objectivity, high forecasting precision, and can greatly reduce the inventory cost on the premise of having a certain service level and improves the supply chain management efficiency and customer satisfaction.

Owner:SHANGHAI UNIVERSITY OF FINANCE AND ECONOMICS

Thread-thru polyaxial pedicle screw system

InactiveUS20110040336A1Reduce inventory costsSimilar shapeSuture equipmentsInternal osteosythesisEngineeringScrew thread

A thread-thru polyaxial pedicle screw fastening system. The fastening system consists of an anchoring bone screw having threads on one end for use in anchoring to the screw to the spine and a spherical connector on the other end operating as a pivot point about which a U-shaped connecting assembly moves in a polyaxial fashion. The U-shaped connecting assembly, for receipt of a spinal connecting rod, has a biased retainer ring for maintaining a positive tension between the connecting assembly and the anchored screw. The system allows for an improved manufacturing step wherein the threaded shank of a bone screws can be passed through a lower portion of the connecting assembly allowing a variety of bone screw sizes to be used with a common sized connector.

Owner:ORTHO INNOVATIONS

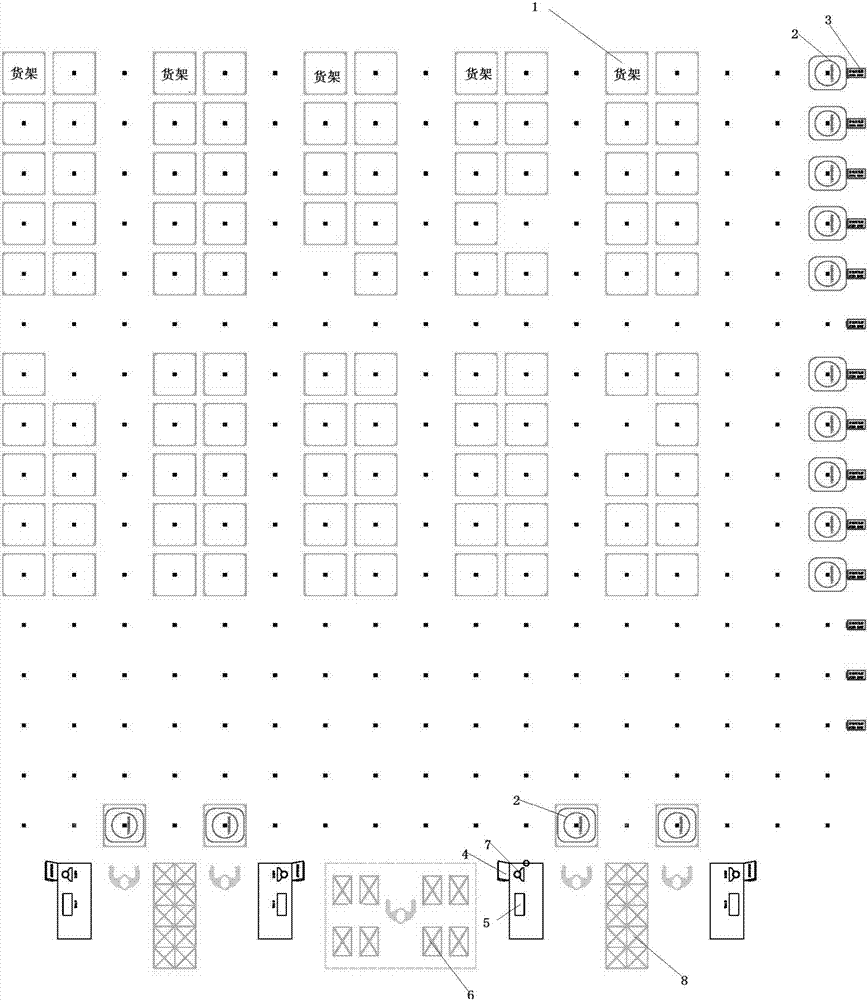

Warehouse management system and method based on intelligent robot

InactiveCN107256468AEfficient managementEfficient use ofLogisticsStorage devicesLogistics managementStorage management

The invention discloses a warehouse management system and method based on an intelligent robot, and the method comprises the steps: setting a shelf with a scanning code, recognizing a commodity through the scanning code and a moving robot for carrying the commodity, receiving E-commerce ordering information, transmitting the position information of the commodity on the shelf to the moving robot and a computer with a wms storage management system, temporarily storing the information on a goods picking wall for the commodity carried by the moving robot, scanning the goods information on the goods picking wall, and storing the shipment information in a scanner in the computer. The method can achieve the effective management of the warehouse flow and space, achieves the batch management, the quick warehousing and delivery and the dynamic sorting. The method quickly helps a logistics manager of an enterprise carry out the complete control and management of warehousing, delivery, moving, sorting and distribution. The method improves the commodity response speed through the effective use of the storage space of a warehouse, reduces the inventory cost of the enterprise, and improves the market competiveness of the market.

Owner:仓智(上海)智能科技有限公司

Systems and methods of inventory management utilizing unattended facilities

InactiveUS20050103842A1Improve efficiencyLow costSensing detailsDigital computer detailsLogistics managementSecure Shell

An inventory management system utilizes unattended facilities remote from a central warehouse for service parts logistics. Items are placed in inventory in secure enclosures at the unattended facilities by the inventory management service or are delivered directly to the unattended facility. The unattended facilities may be located near one or more customers to reduce a service technician's travel time and customers' inventory costs. A service technician utilizes a passcode to retrieve needed items. The service technician may order items that are not kept in the inventory of the unattended facility in which case the items may be delivered to the unattended facility and the service technician may receive a notification related to all the items that comprise an order that the order is ready for pick up at an unattended facility. Unused, used or damaged parts may be returned by a technician to a remote secure enclosure where such returned parts may be retrieved and disposed of, repaired or placed back into inventory if not damaged or after repair, and the processing of such returned parts begins by information entered into a data entry device at the remote secure enclosure location. Return items that are not damaged may be included in the inventory of an unattended facility.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

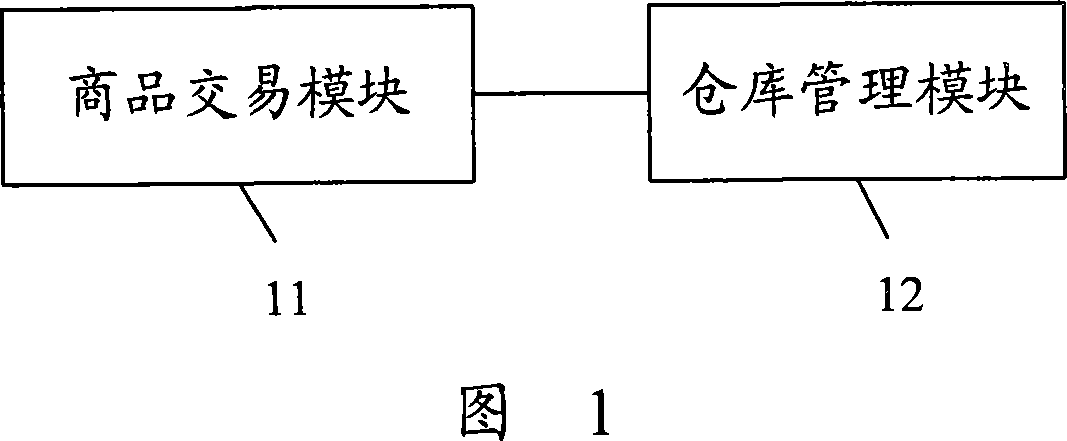

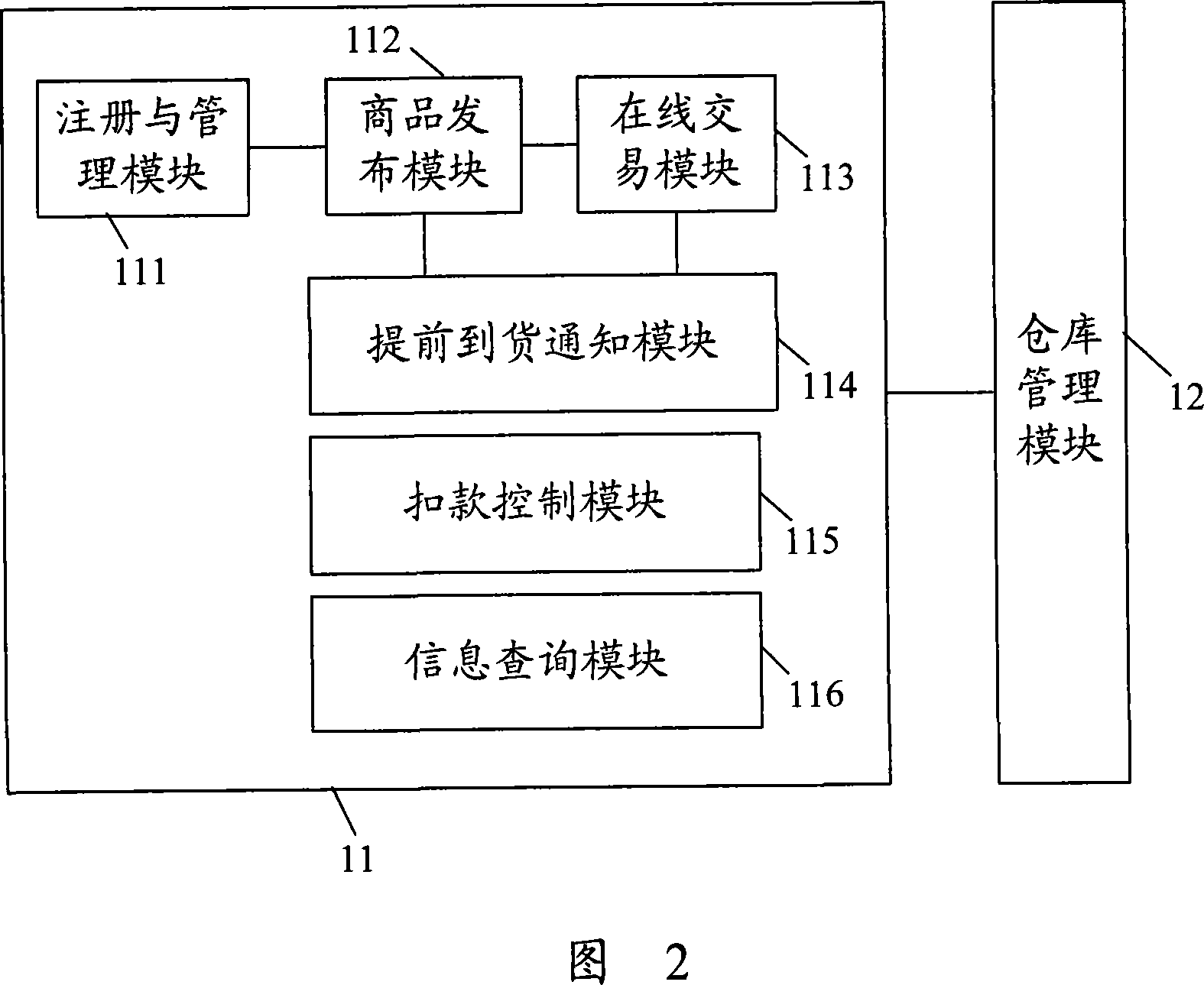

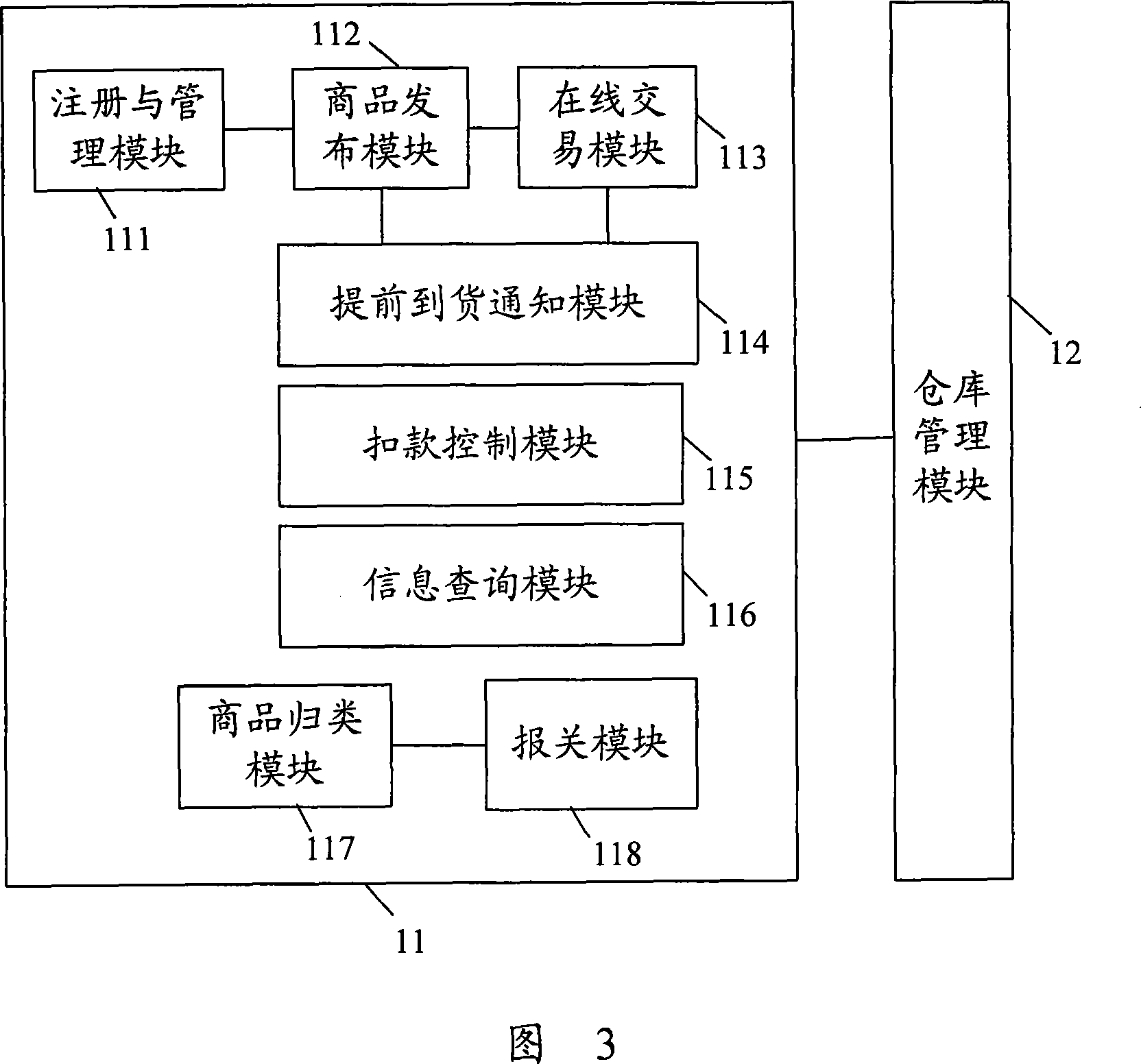

Pivotal inventory network apparatus based on supplier management

InactiveCN101067860AImprove timelinessReduce inventory costsLogisticsCommerceThird partyLogistics management

This invention discloses a network device of hinge stock based on network management including: a commodity trade module providing on-line commodity trade for bargainers and purchasers and a storage management module used in receiving commodity information when commodity of a bargainer arrives / sends VMI HUB and after a wireless terminal scans the 2-D bar on a package box of the commodity and managing the stock of the storage according to the information, which provides an electronic business platform of a third party for the distribution market to realize zero stock and increase the effect of information treatment.

Owner:郑壮洪

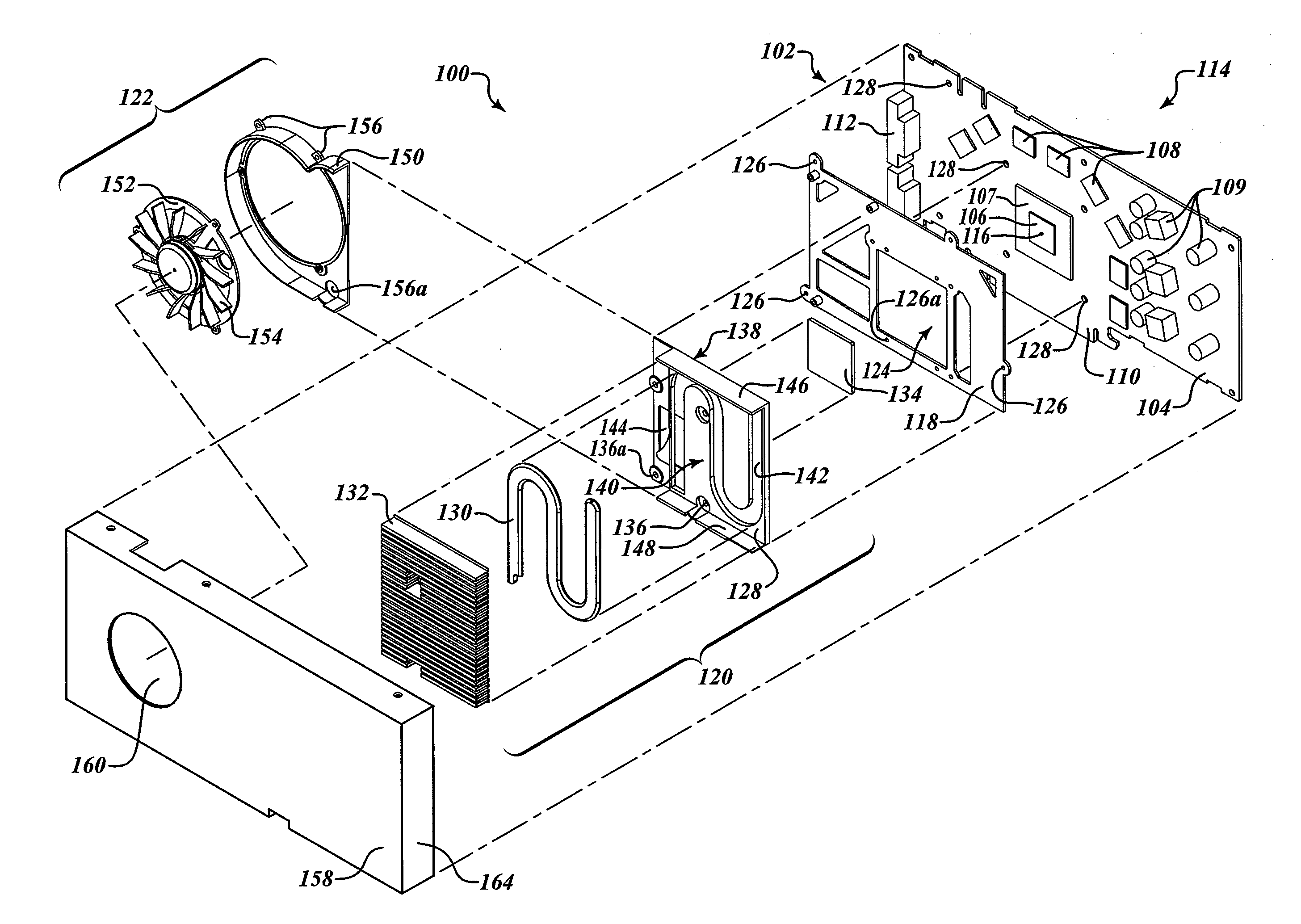

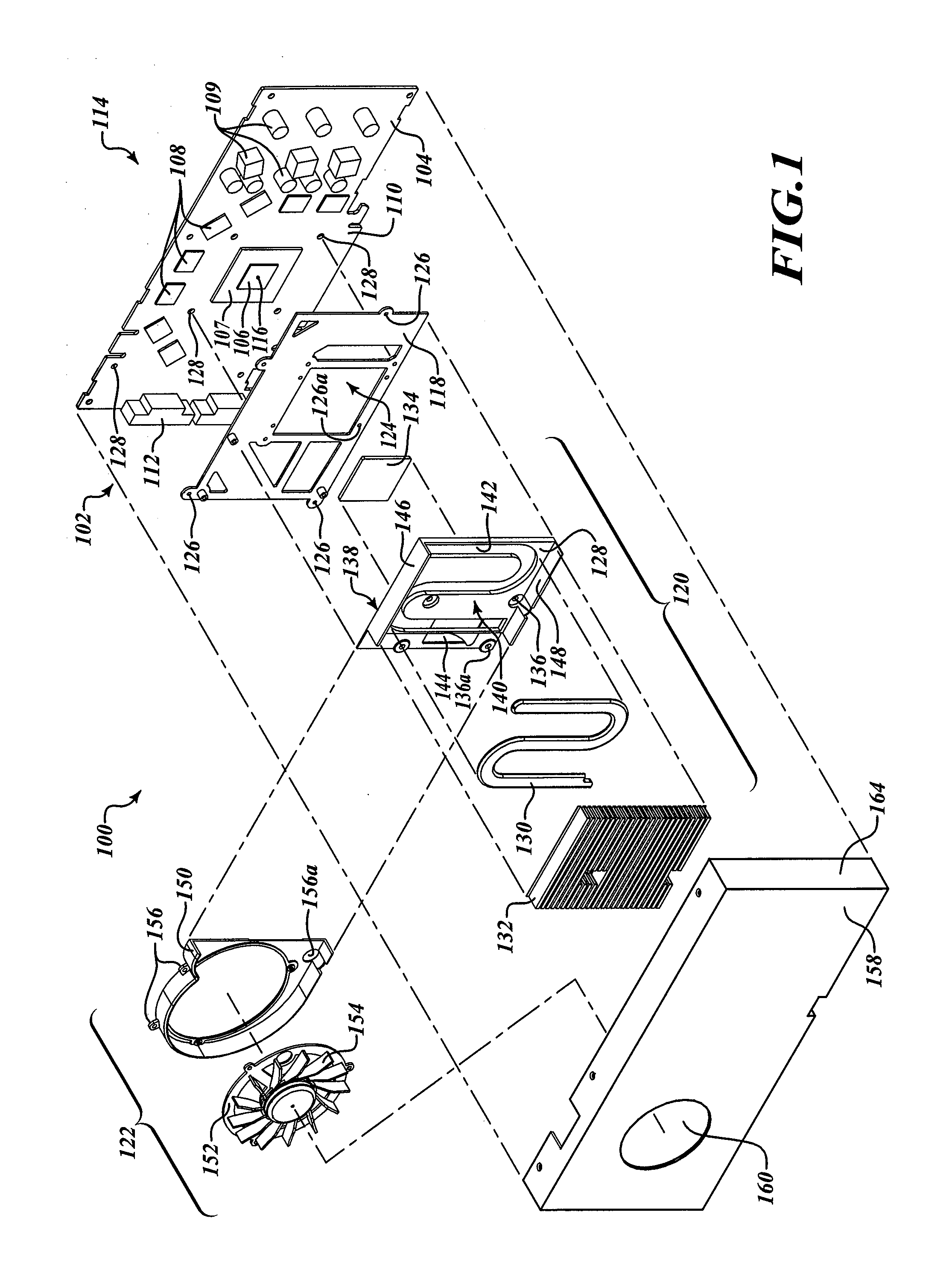

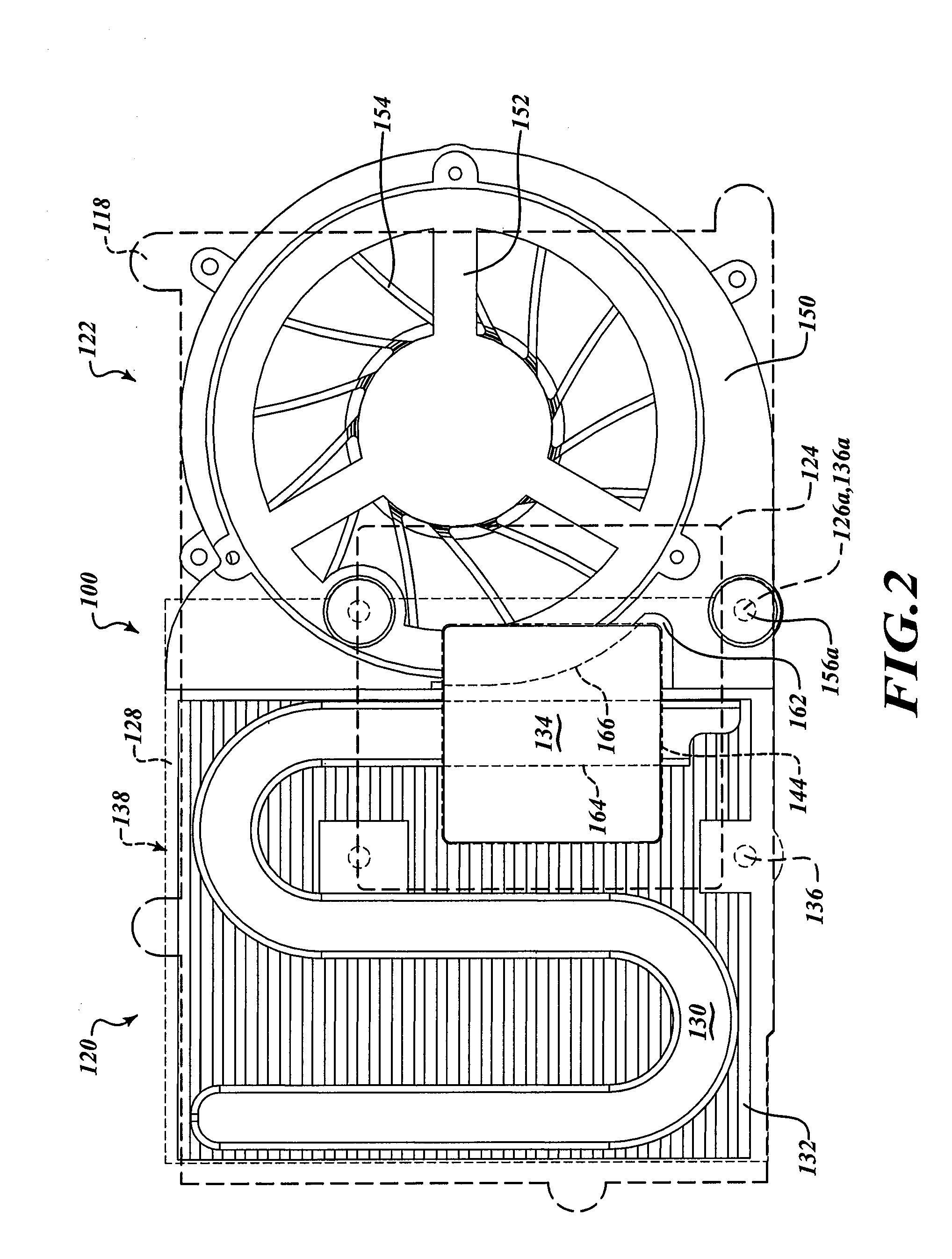

Modular thermal management system for graphics processing units

InactiveUS20110279969A1Easy to repair separatelyReduce inventory costsDigital data processing detailsSemiconductor/solid-state device detailsGraphicsModularity

A modular thermal management system that allows one or a few heat sink and fan combinations to transfer heat away from a heat zone of a variety of graphics processing cards is provided. The thermal management system includes a mounting bracket configured to attach to the graphics processing card in thermal contact with the heat zone, the mounting bracket having a first opening that corresponds to a processor in the heat zone, a heat sink configured to attach to the mounting bracket, wherein the heat sink overlies the first opening and is in thermal contact with at least a portion of the processor through the first opening, and a fan configured to attach to the mounting bracket adjacent the heat sink.

Owner:XFX CREATION

Supply-chain management system

An Internet-based computer-assisted supply-chain management system (SCMS) replaces the archaic commerce systems presently in use. It coordinates just-in-time distribution of items purchased by consumers from a plurality of merchants whereby the inventory in the distribution pipeline is reduced to inventory in transport. It uses regional distributions centers and neighborhood order aggregation facilities for an efficient transfer of items to consumers. Consumers can pick up aggregated orders at an order aggregation facility or have them delivered at a residence. The SCMS phases out conventional checkout registers in favor of web browsers with automatic transaction execution. Retailers can operate with little or no inventory. Window shops facilitate promotion of items and help consumers make selections and decisions with respect to purchases they may be contemplating. The SCMS provides real-time consumption monitoring and forecasts, significantly reduces supply-chain costs and retail prices, promotes economic growth, and minimizes undesirable cyclic economic fluctuations.

Owner:FRANCO HECTOR

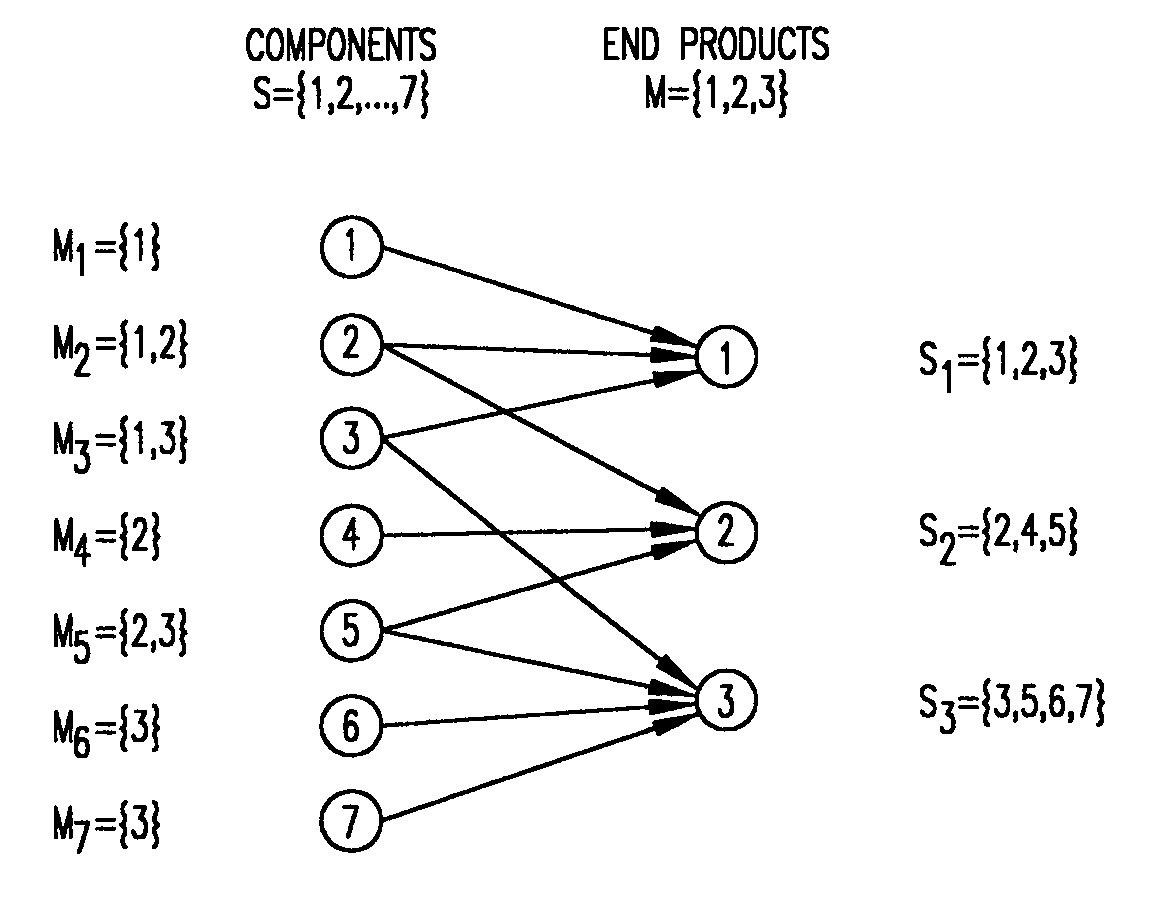

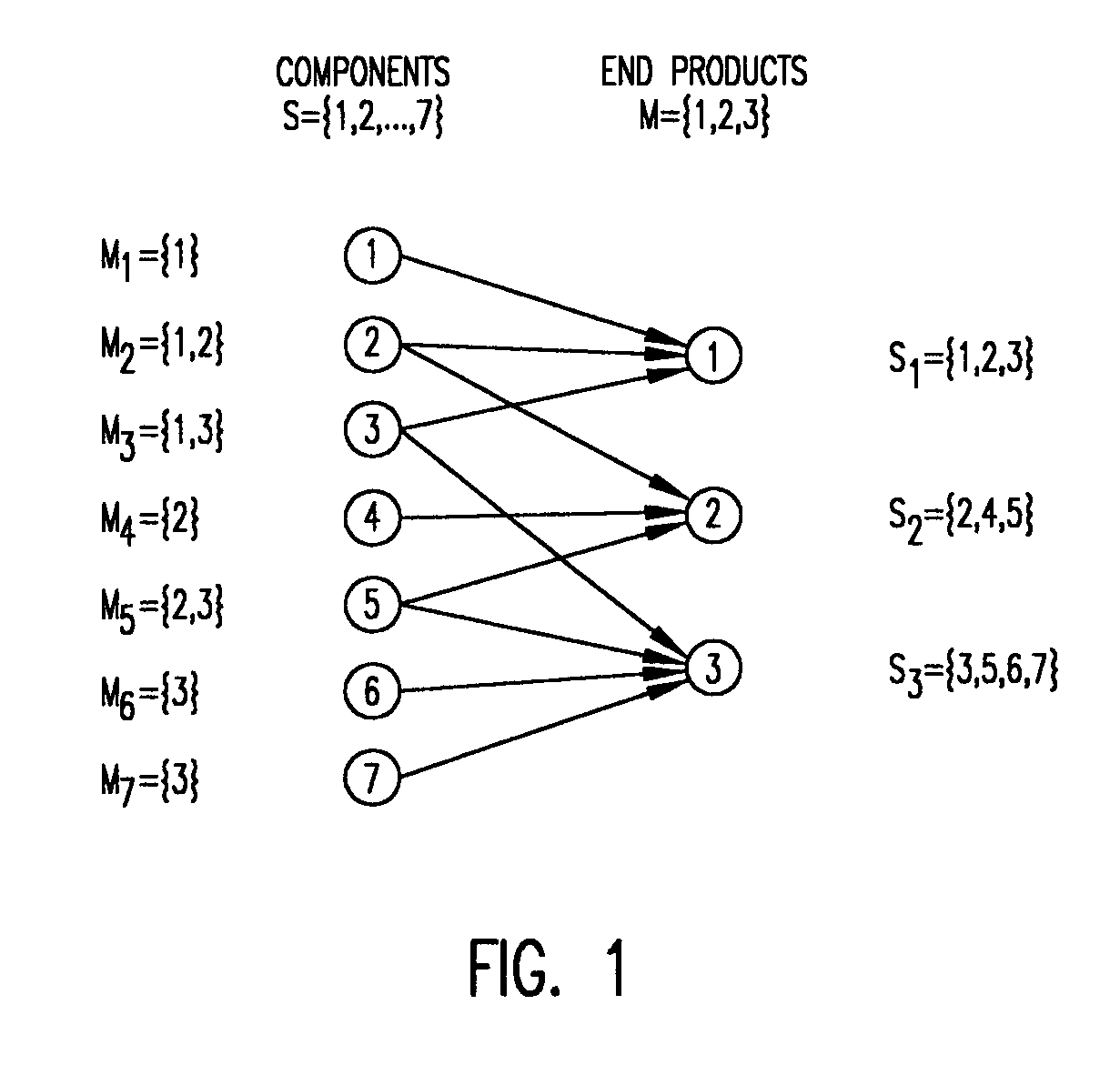

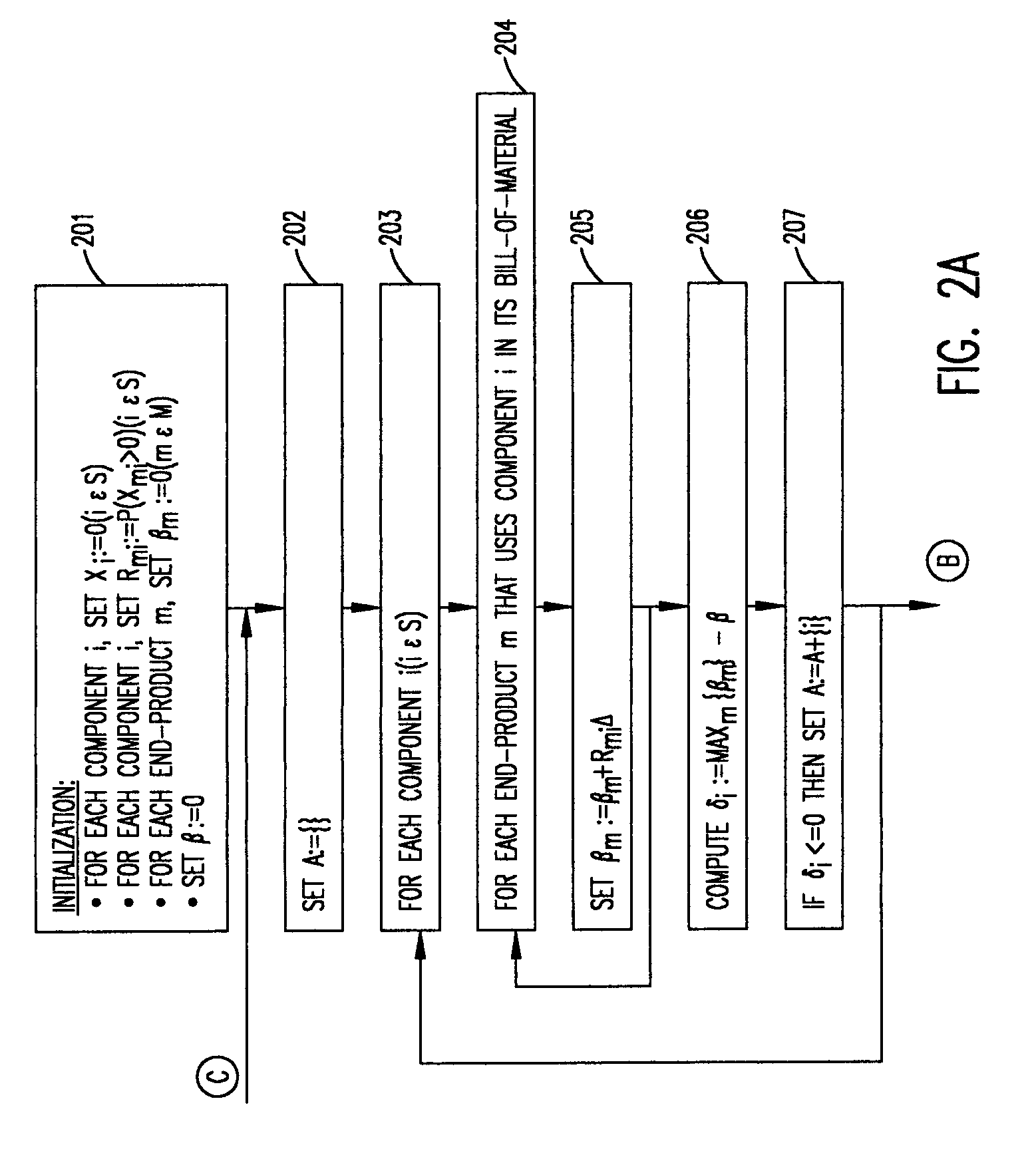

Large inventory-service optimization in configure-to-order systems

InactiveUS6970841B1Reduce inventory costsImprove service levelProgramme controlHand manipulated computer devices

A manufacturing process is migrated from an existing operation to a configure-to-order (CTO) system. As the CTO operation will eliminate the “machine-type model” (MTM) inventory of the existing operation, the emphasis is shifted to the components, or “building blocks”, which will still follow the build-to-stock scheme, due to their long leadtimes, and hence still require inventory. The solution involves an inventory-service trade-off of the new CTO system, resulting in performance gains, in terms of reduced inventory cost and increased service level. Other benefits include better forecast accuracy through parts commonality and risk-pooling, and increased customer demand, as orders will no longer be confined within a restricted set of pre-configured MTMs.

Owner:IBM CORP

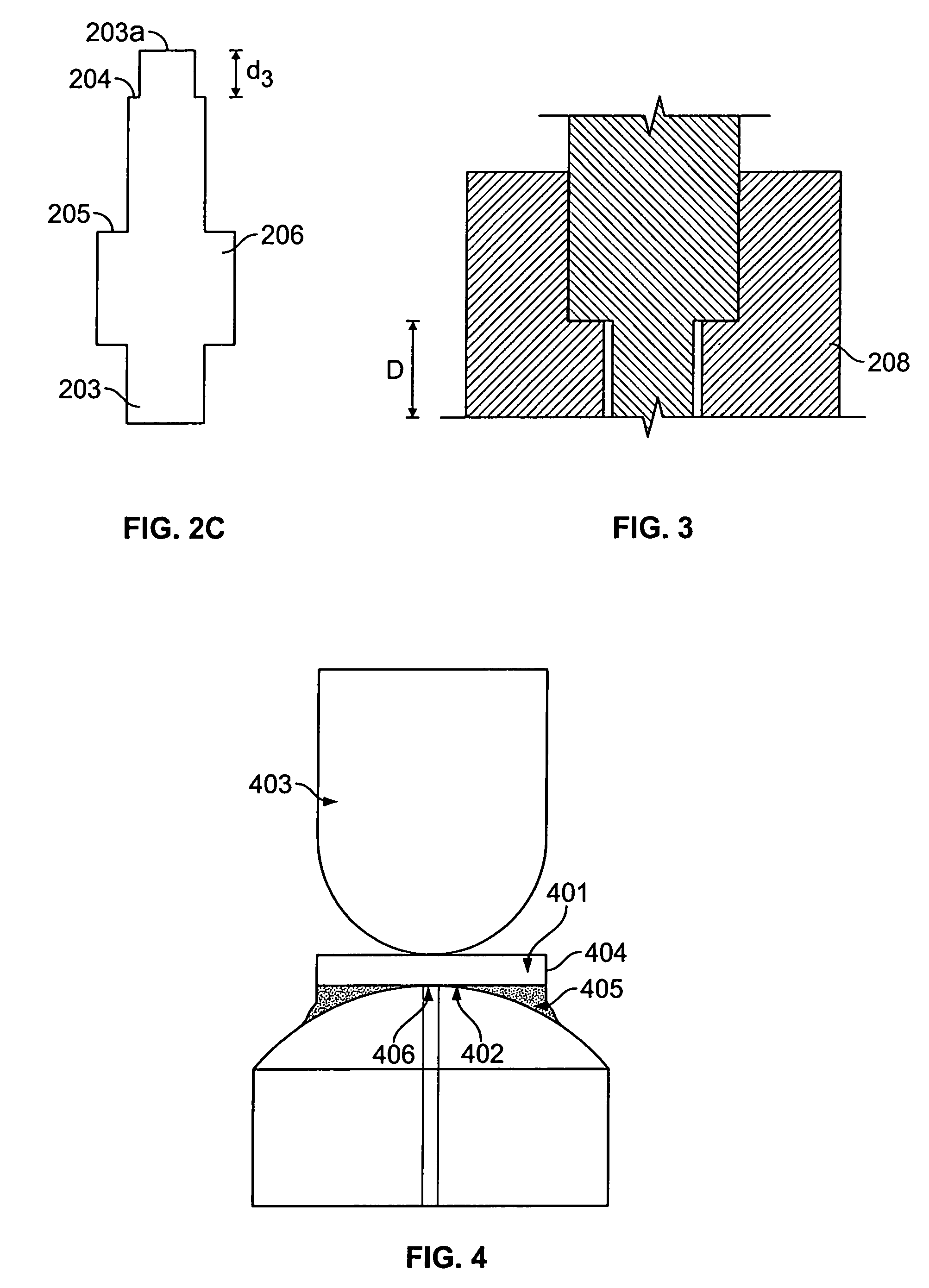

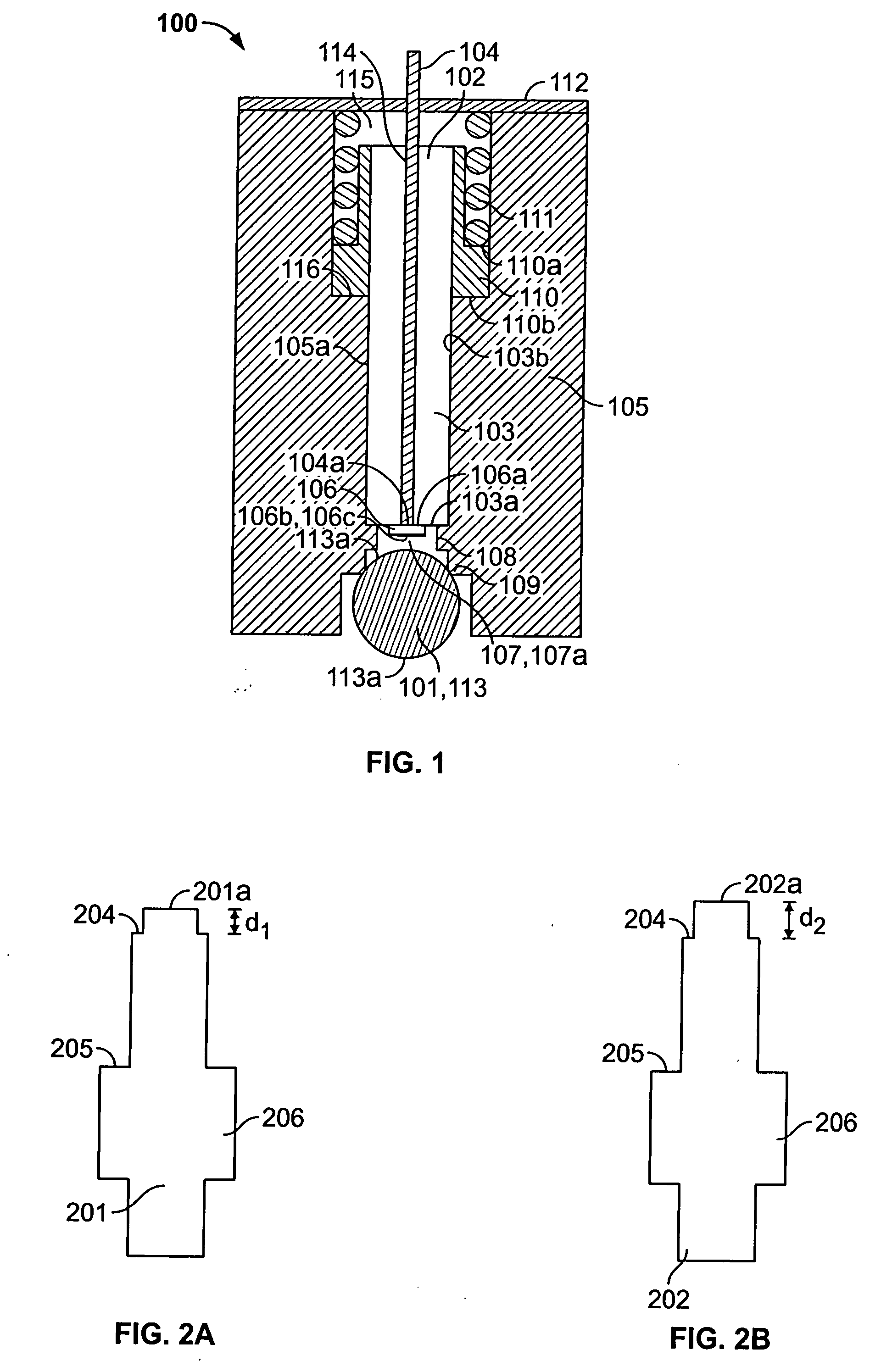

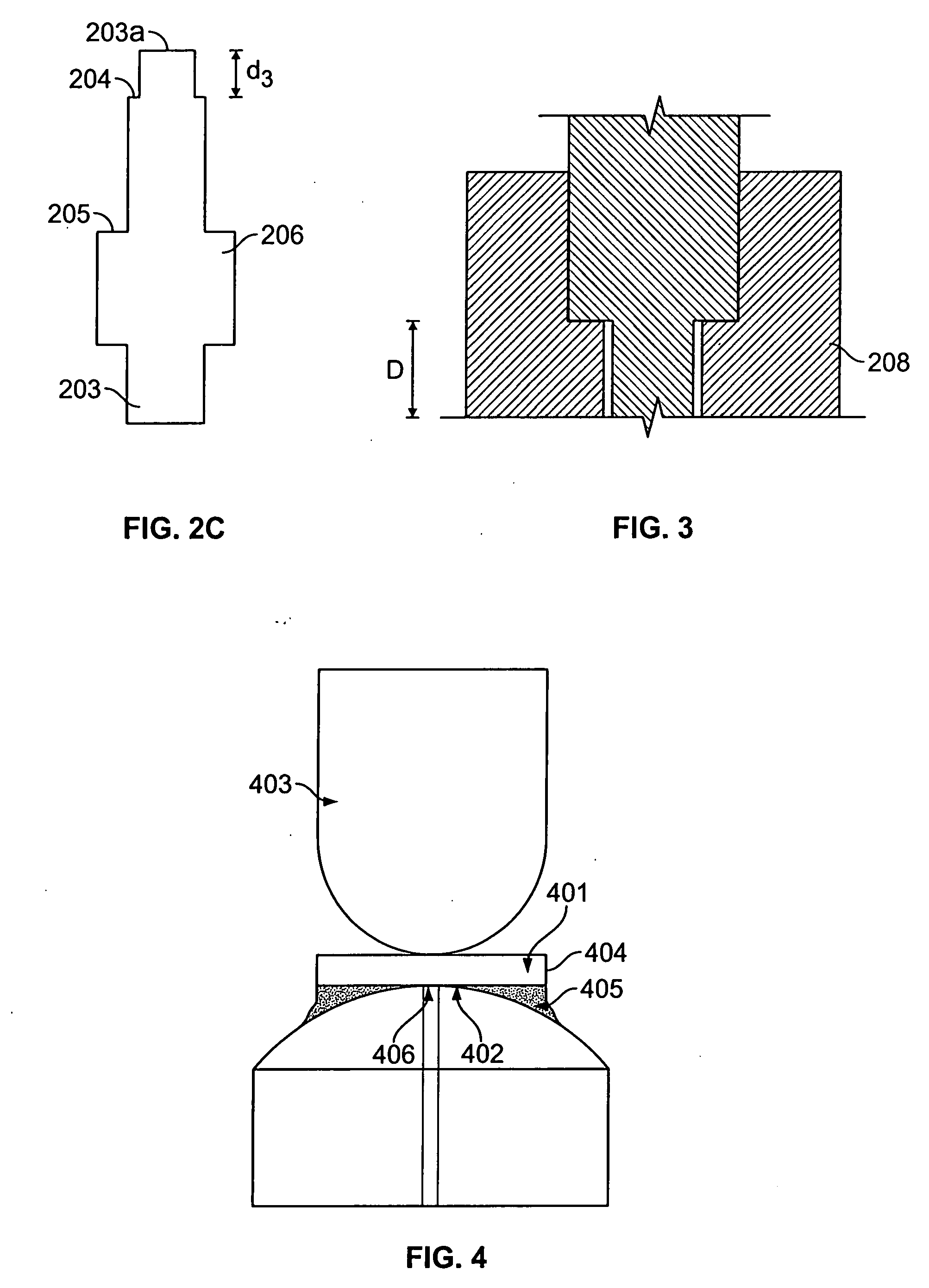

Expanded beam connector

InactiveUS20080050073A1Increase the air gapReduce inventory costsCoupling light guidesFiberEngineering

An optical connector comprising: (a) a lens; (b) a ferrule assembly comprising a ferrule with an endface and at least one fiber in the ferrule having a fiber end presented at the endface; (c) a housing for holding the ferrule assembly and the lens in a certain axial and radial relationship; and (d) a glass element having a first and second surface, the first surface affixed to the endface such that it is in physical contact with the fiber end, the second surface having an AR coating and defining a space between it and the lens.

Owner:TE CONNECTIVITY CORP

Supply-chain management system

An Internet-based computer-assisted supply-chain management system (SCMS) replaces the archaic commerce systems presently in use. It coordinates just-in-time distribution of items purchased by consumers from a plurality of merchants whereby the inventory in the distribution pipeline is reduced to inventory in transport. It uses regional distributions centers and neighborhood order aggregation facilities for an efficient transfer of items to consumers. Consumers can pick up aggregated orders at an order aggregation facility or have them delivered to a residence. The SCMS phases out conventional checkout registers in favor of web browsers with automatic transaction execution. Retailers can operate with little or no inventory. Window shops facilitate promotion of items and help consumers make selections and decisions with respect to purchases they may be contemplating. The SCMS provides real-time consumption monitoring and forecasts, significantly reduces supply-chain costs and retail prices, promotes economic growth, and minimizes undesirable cyclic economic fluctuations.

Owner:FRANCO HECTOR

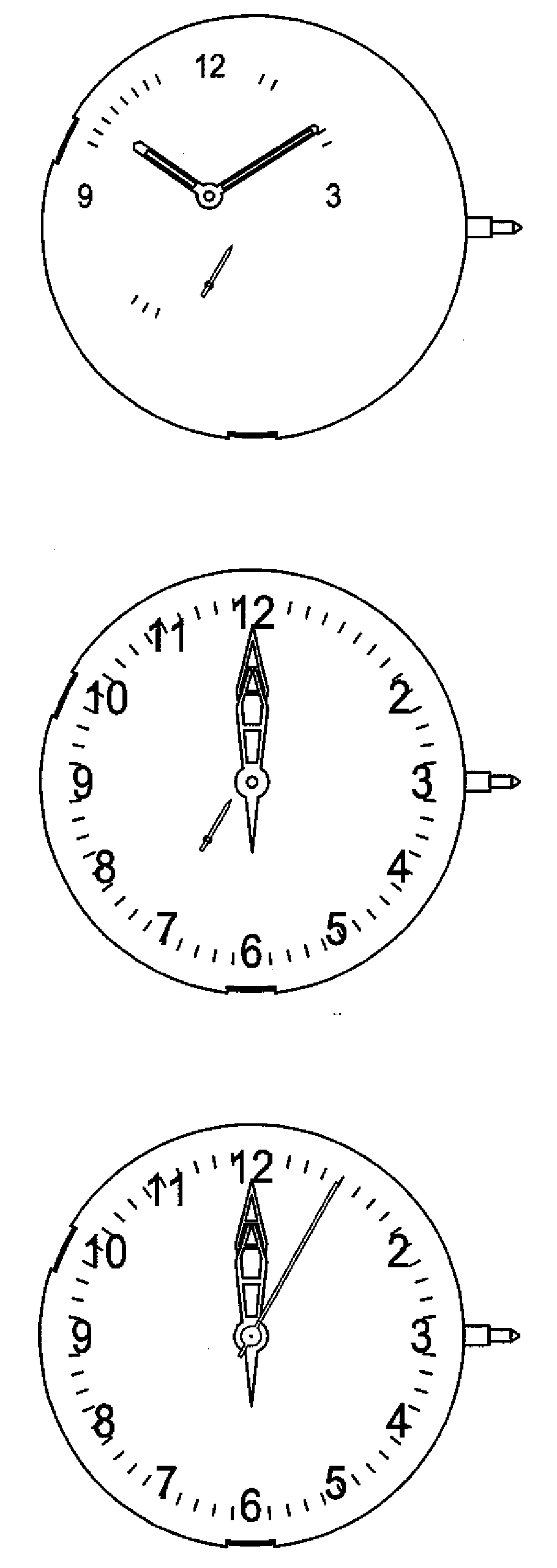

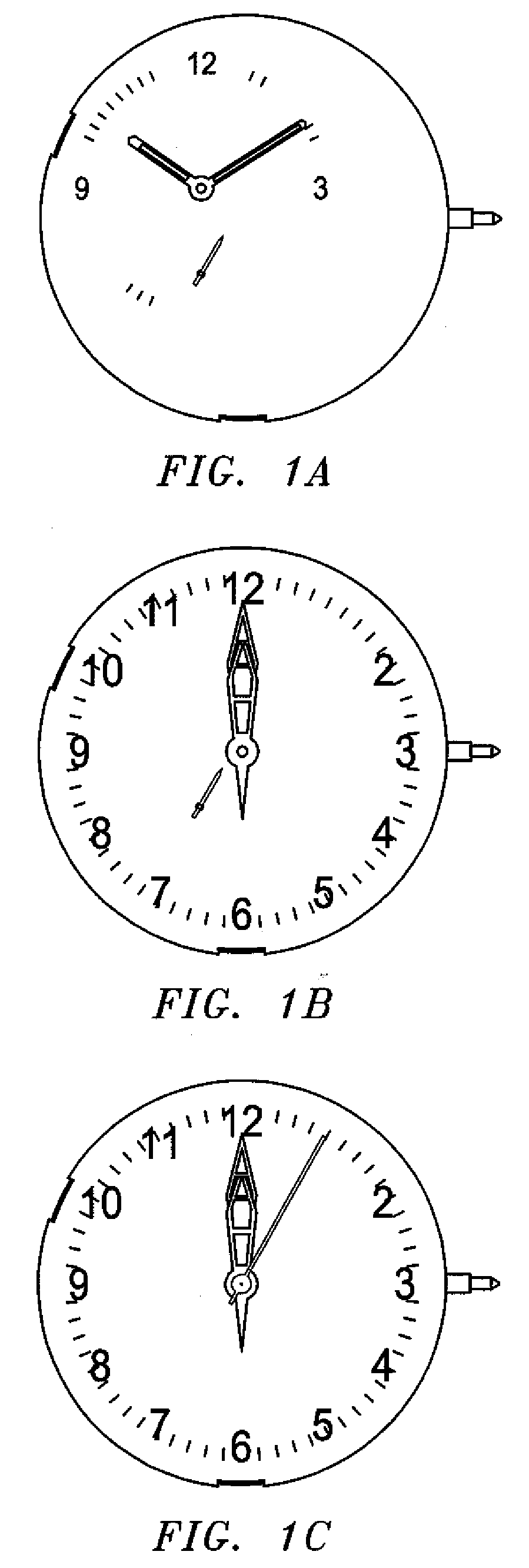

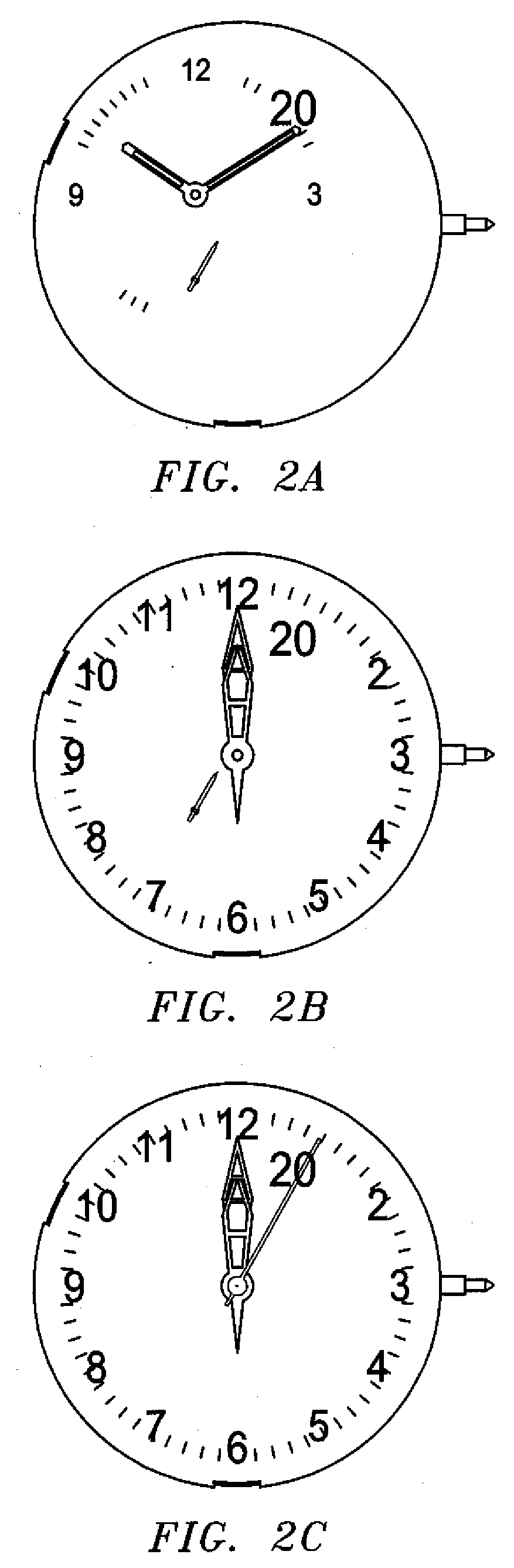

Electromechanical Module Configuration

InactiveUS20100220559A1Function increaseReduce manufacturing costVisual indicationWave amplification devicesComputer moduleEngineering

A wearable electronic device for conveying information using one or more display indicators, wherein the electronic device comprises a housing; a nest positioned in the housing; a plurality of independently insertable and removable modules coupled to the nest, wherein each module comprises (i) a gearing arrangement comprising at least one rotateable gear and (ii) a stepper motor, the stepper motor comprising a rotor rotateably coupled to the at least one rotateable gear; a controller operatively coupled to the stepper motor of each module, for causing the rotation of the rotor of each module; wherein each of the plurality of modules has associated therewith and mechanically coupled thereto one or more display indicators; whereby the positioning of the one or more indicators conveys information by referring to particular indicia. In a specific embodiment, the wearable electronic device is a wristwatch.

Owner:TIMEX CORP

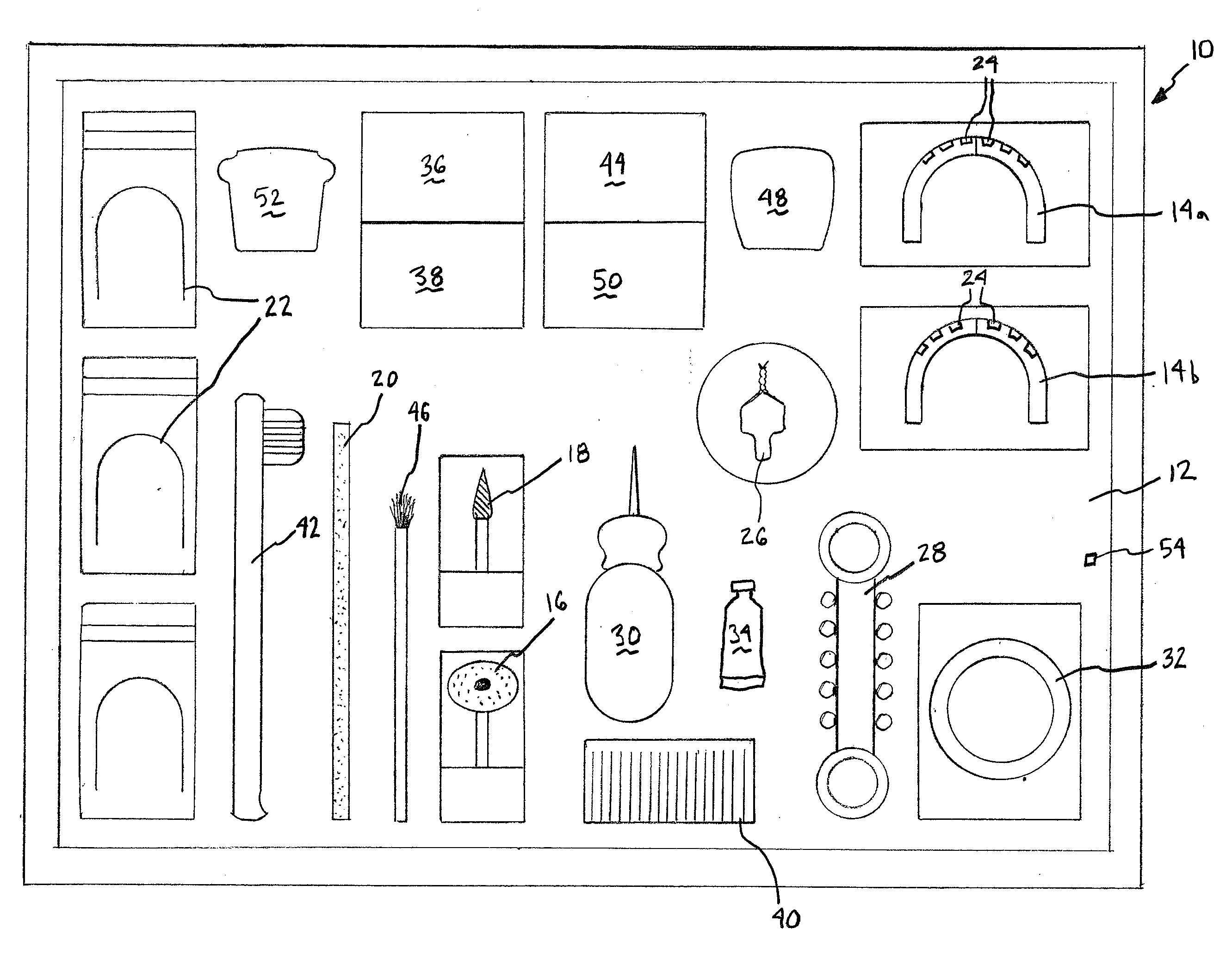

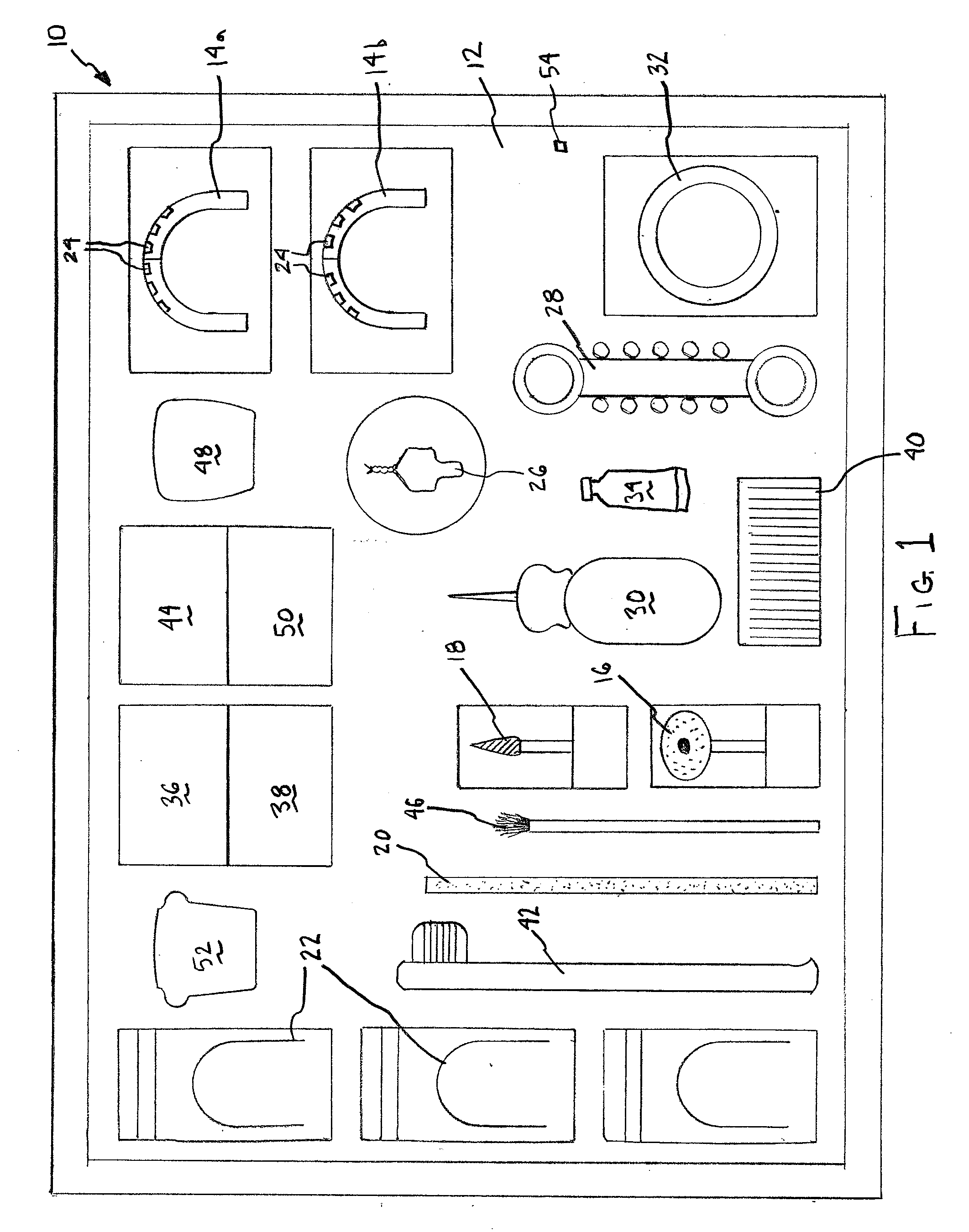

Orthodontic kit and methods for same

InactiveUS20090215003A1Eliminate riskReduce inventory costsArch wiresBracketsOrthodonticsSingle patient

A method for providing orthodontic therapy. The method includes the steps of providing a kit that includes an enclosure and tools and components for providing orthodontic therapy using braces to a single patient, applying the braces to the single patient's teeth using the tools, placing the tools back into the kit, storing the kit, and reusing the kit at all of the single patient's subsequent visits during the term of the orthodontic therapy.

Owner:SIX MONTH SMILES

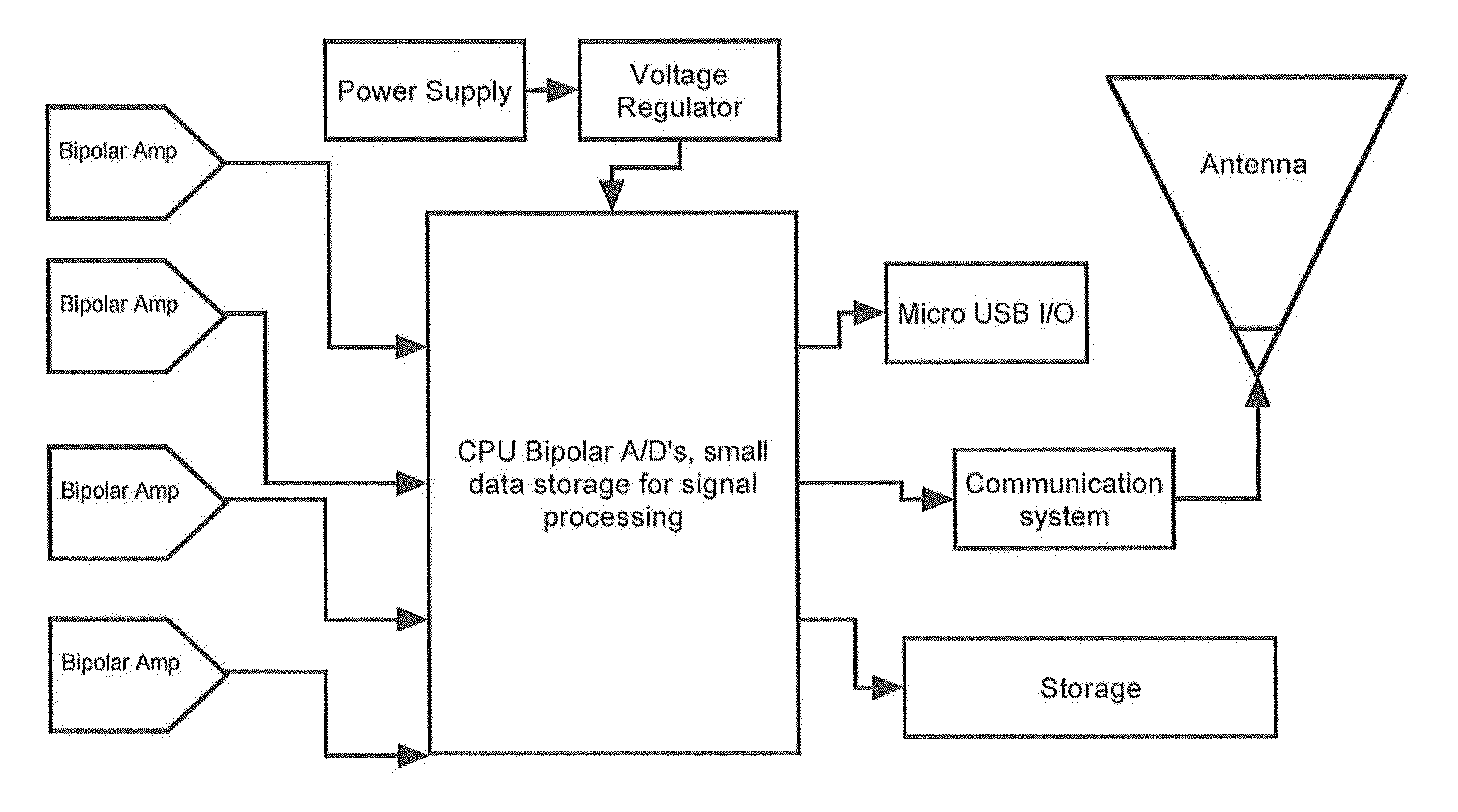

Data collection module for a physiological data collection system

InactiveUS8773258B2Reduce inventory costsAccurate attachmentElectric signal transmission systemsElectrocardiographyCommunications systemData acquisition

A data collection module for a physiological data collection system is a reusable device having a data collection port for connection to a source of physiological data that is in an analog format. The data collection port is in circuit communication with a plurality of bipolar amplifiers. The amplifiers are in circuit communication with a central processing unit provided with analog to digital converters, memory for signal processing and internal USB circuitry. The central processing unit is in circuit communication with a means for storing data and with a means for conveying the data in digital form via at least one of a USB port and a wireless communication system.

Owner:HALTHION MEDICAL TECH INC

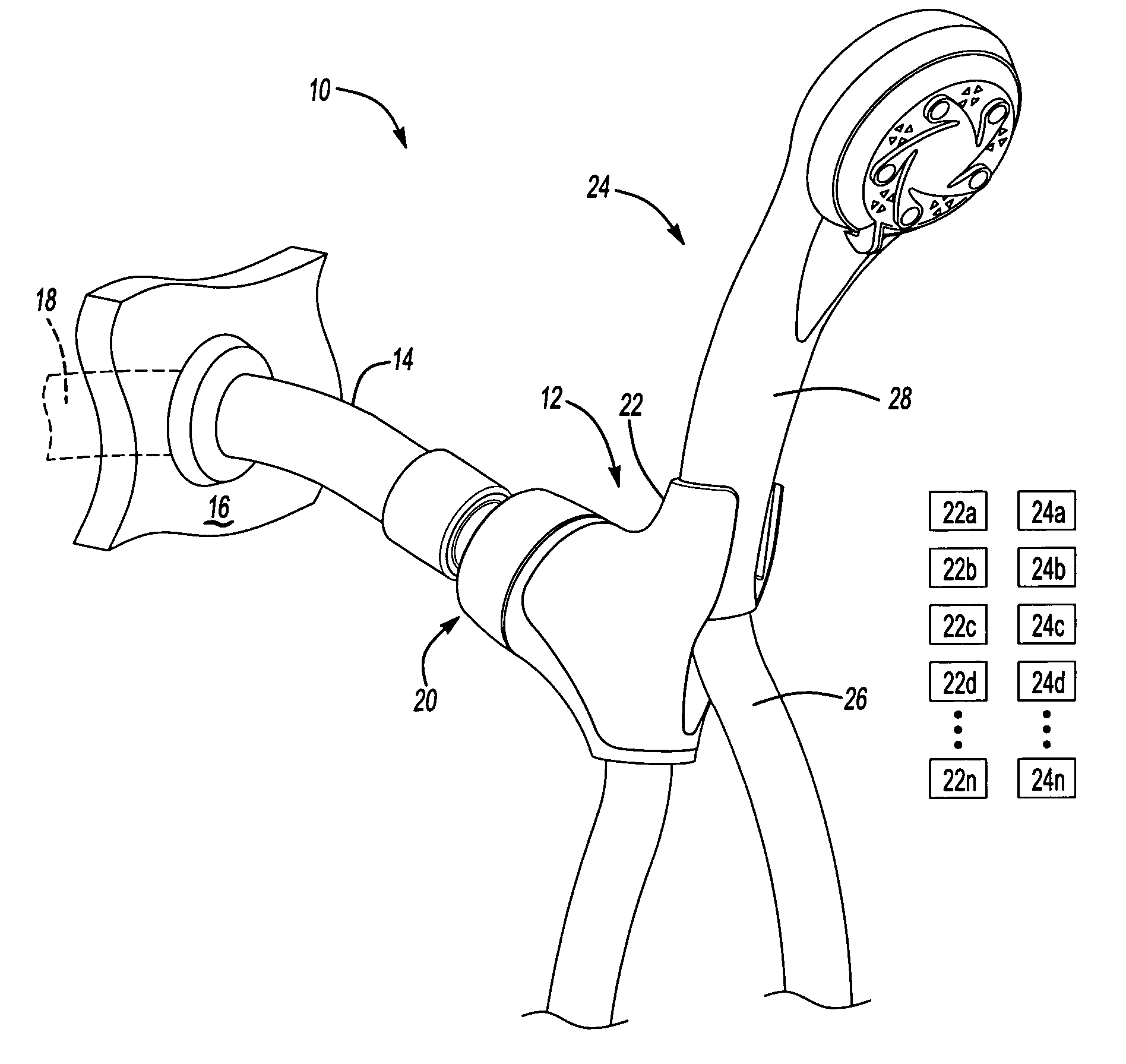

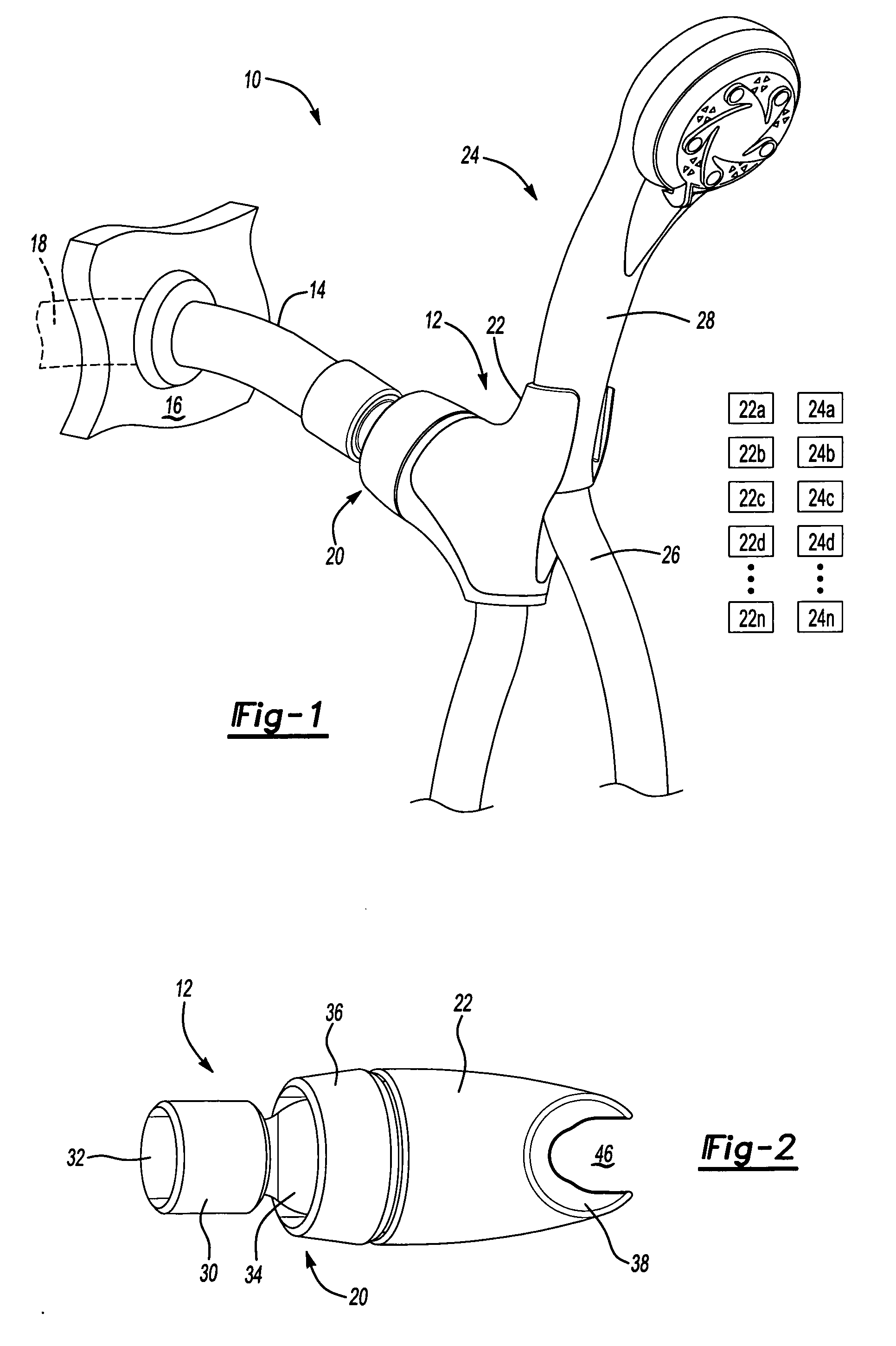

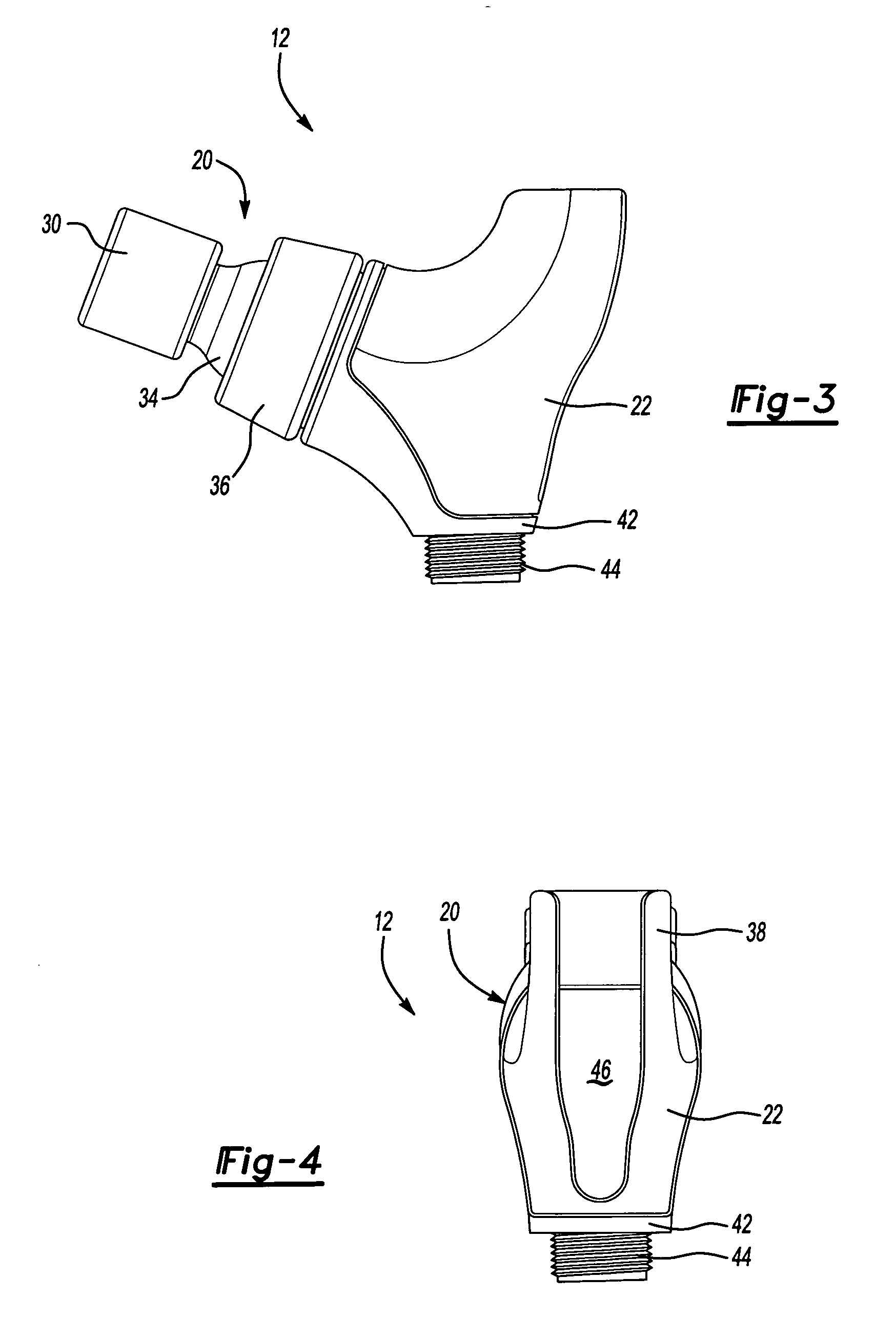

Adjustable mount for showerhead

InactiveUS20070067902A1Lower manufacturing requirementsReduce inventory costsBathsDouchesHand heldWater flow

A shower mount is mounted to a fixed shower arm in a bathing area for universally receiving a hand-held showerhead. The shower mount is connected to the shower arm and includes a base member with a fluid passageway in communication with the shower arm and a shower hose. Water flows through the fluid passageway and shower hose to a showerhead. A shower saddle is interchangeably mounted the base member to support the showerhead. The shower saddle is selected depending upon the design of the showerhead in order to securely retain the showerhead to the base member.

Owner:DELTA FAUCET COMPANY

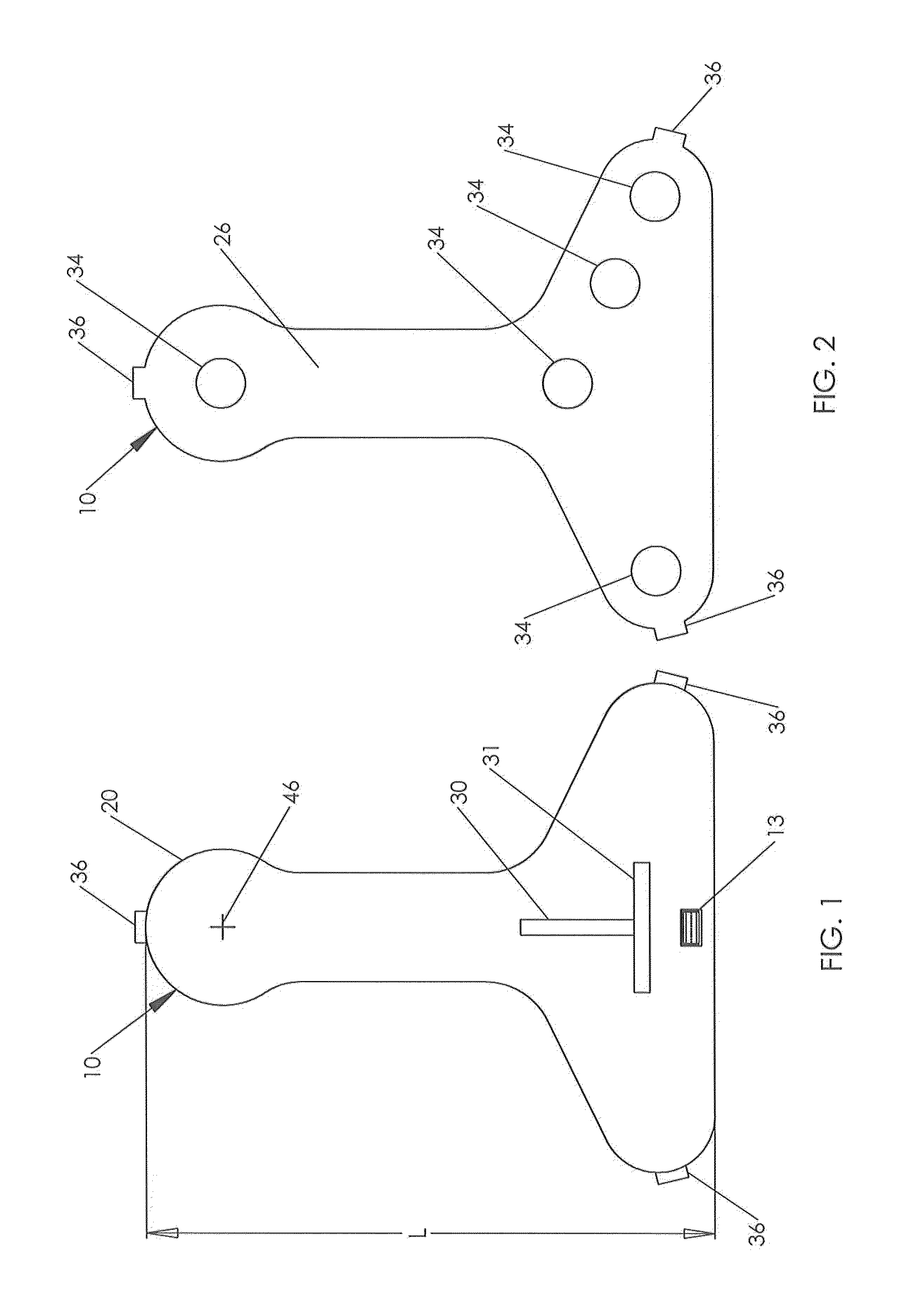

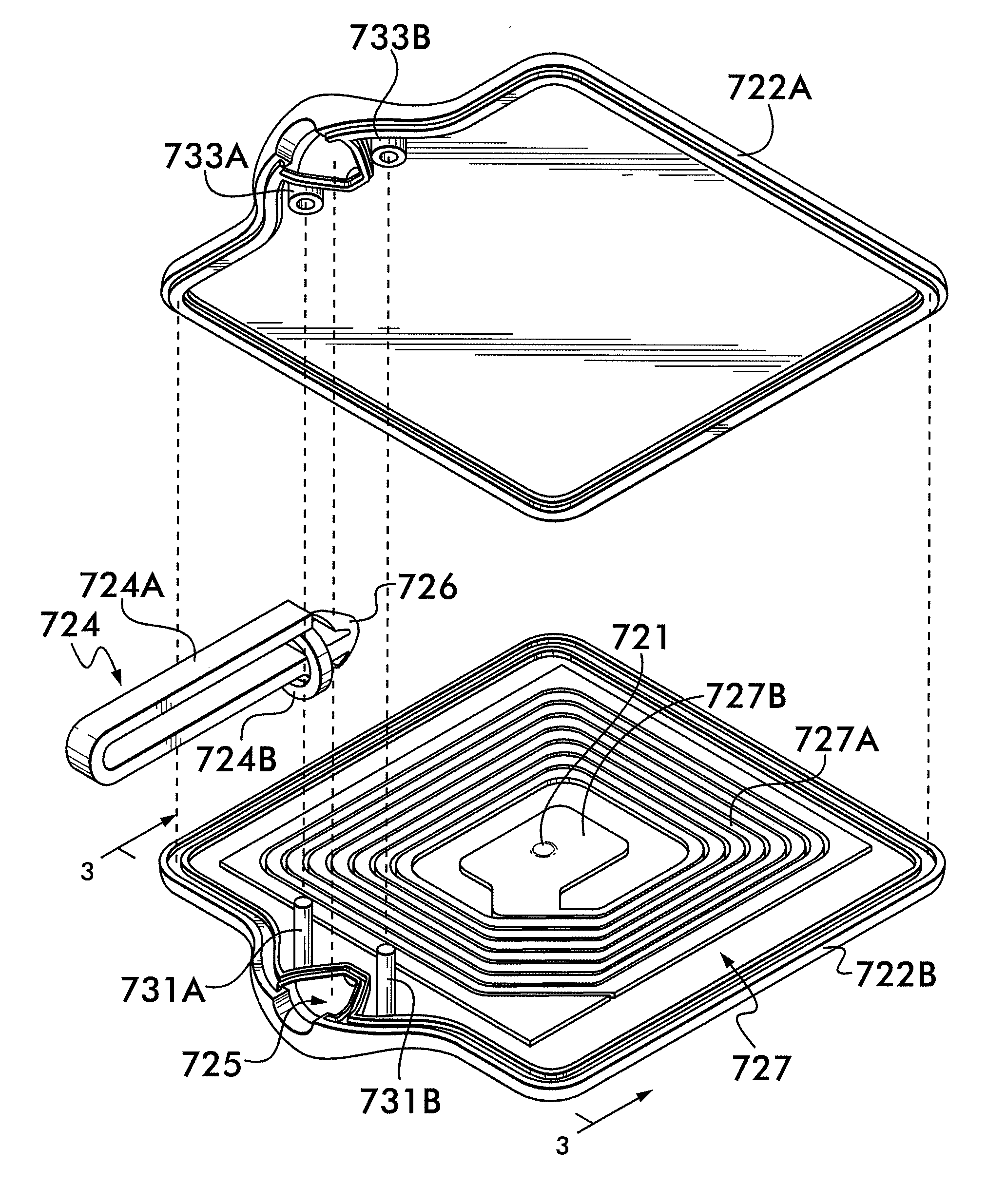

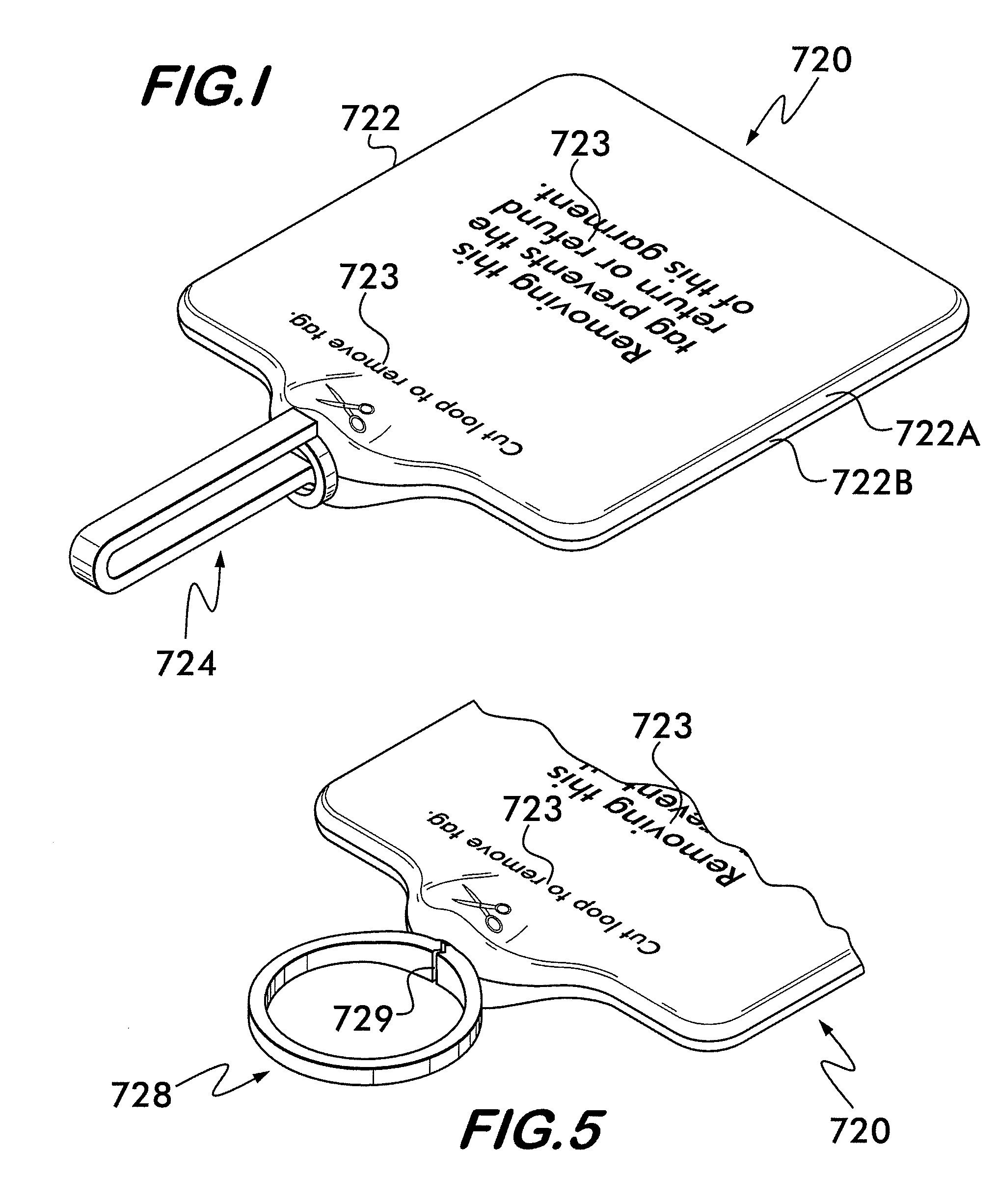

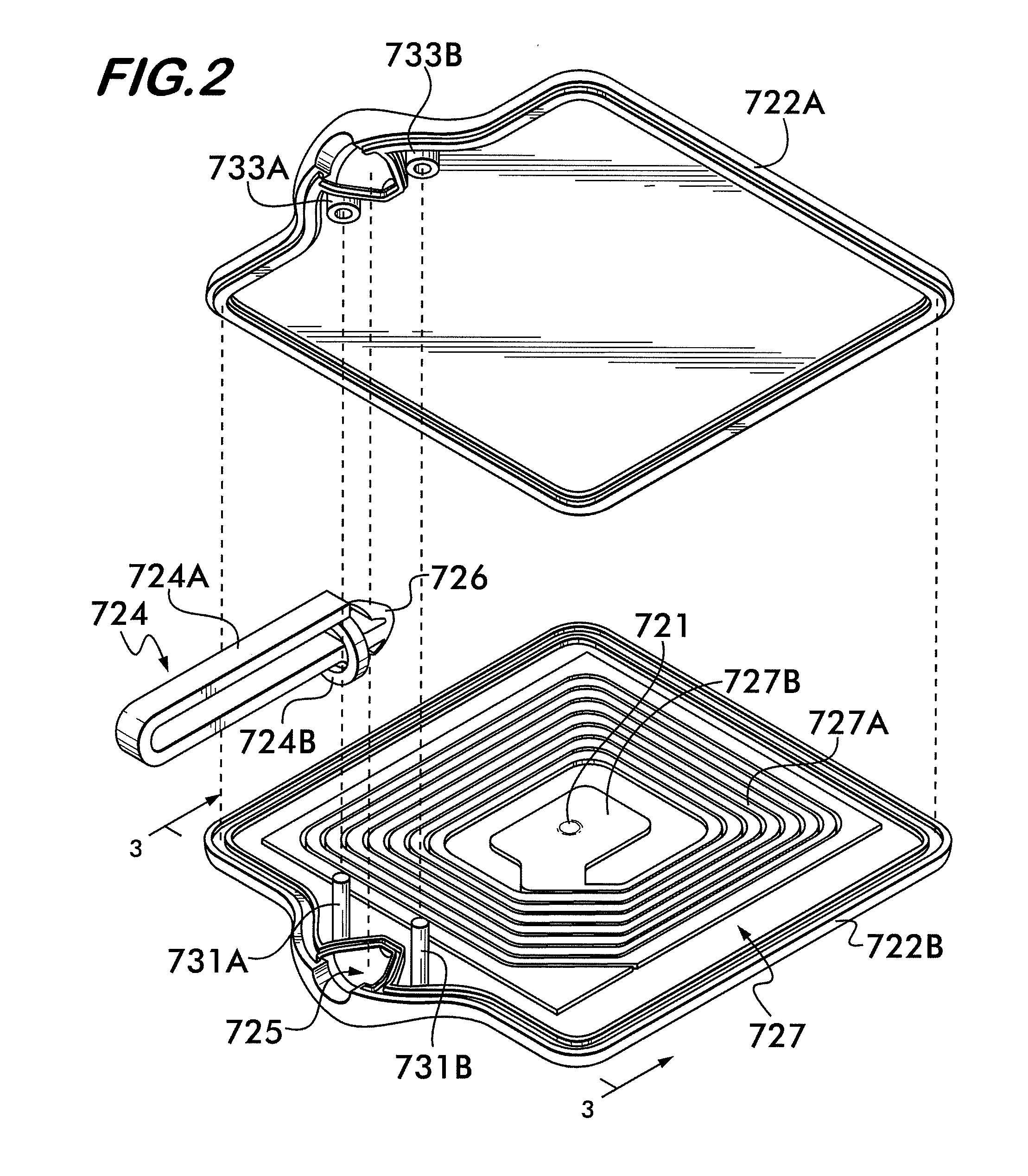

Multi-attach disposable tag

InactiveUS20120019385A1Allow flexibility of usingReduce inventory costsClothing locksLocks for portable objectsMicrowaveLocking mechanism

A multi-attach disposable security tag that is attached to an article in two stages. In a first stage, an attachment clip is coupled to an article, such as but not limited to clothing, to be protected by a manufacturer or assembler. This attachment clip is durable to withstand harsh manufacturing environments. Once the article with the attachment clip is ready for presentation, for example, at a retail establishment, during a second stage, the attachment clip is then permanently secured in a locking mechanism of a housing containing a deactivatable security element therein. The security element may comprise EAS (including AM, RF, EM and microwave), RFID (including LF, HF and UHF) elements or any combination thereof. A preferred embodiment of the security tag uses all non-ferrous components including its locking mechanism. Thus, the security tags combine the qualities of being non-ferrous, light-weight, low cost, deactivatable, secure, visually-deterring, and installable in two stages to the article it is meant to protect.

Owner:CHECKPOINT SYST INC

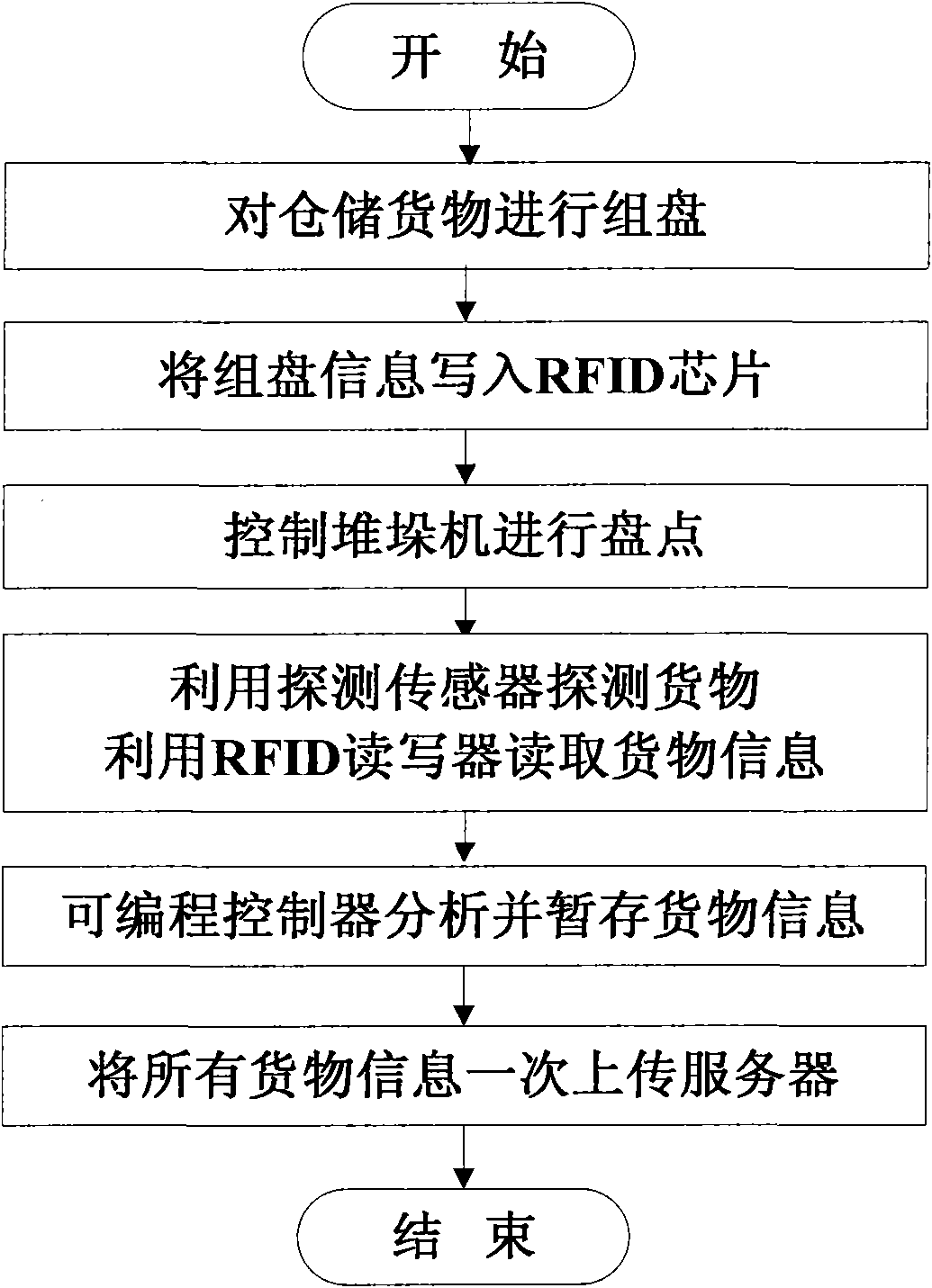

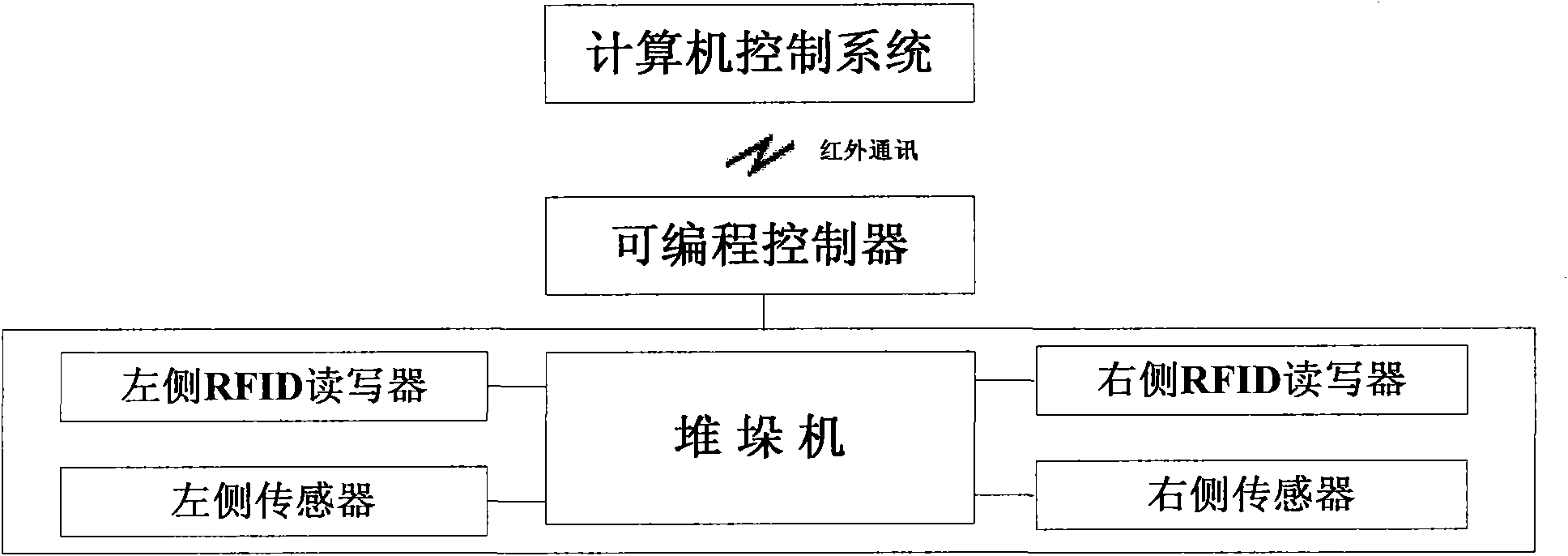

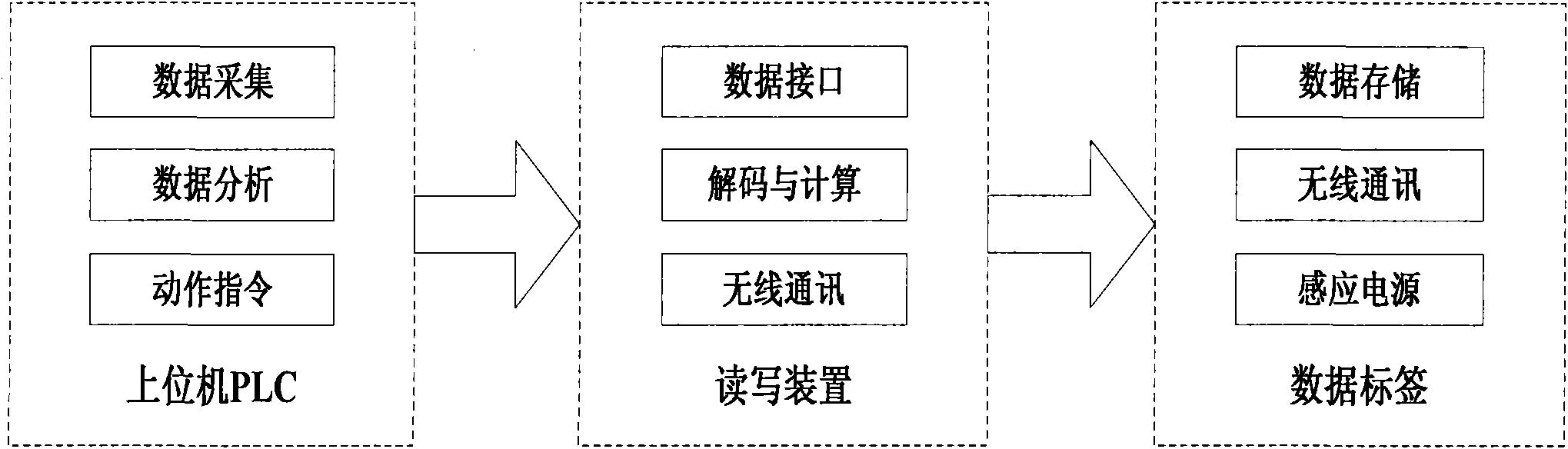

New piler cargo quick stock-taking technique based on RFID

InactiveCN101891052AFast inventory implementationImprove the problem of low inventory efficiencySensing record carriersStorage devicesData acquisitionEngineering

The invention relates to a new piler cargo quick stock-taking technique based on RFID (radio frequency identification). Quick stock-taking is carried out on the piler cargo in the automatic three-dimensional warehouse by taking RFID as the basis. The technique comprises the following steps: two sensors installed on the piler detect whether the cargo exists; two RFID reader-writers installed on the piler read the cargo information; a DP gateway is connected with the main CPU of the piler to constitute a field bus network; the serial port exchanger is connected with a supervisory control computer to complete the functions of data acquisition of the unit cargo and data rewriting and deleting of data in a chip; and the cargo information is temporarily stored and then uploaded to the main control computer at one time after all the cargo information is processed, thereby realizing quick stock-taking of the cargo.

Owner:JIANGSU LIUWEI LOGISTIC EQUIP INDAL

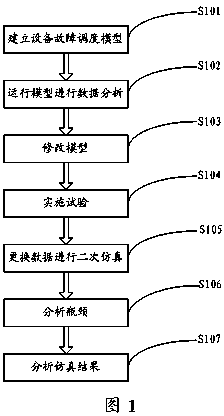

Workshop scheduling simulation method based on equipment failure scheduling model

InactiveCN103823455AReduce complexityReduce lossesTotal factory controlProgramme total factory controlProduction modelHolding cost

The invention discloses a workshop scheduling simulation method based on an equipment failure scheduling model. The workshop scheduling simulation method comprises the following steps: establishing an equipment failure scheduling model and an operation model for performing data analysis, modifying the models, implementing tests, replacing data for performing the secondary simulation, analyzing the bottle neck, and analyzing the simulation result. According to the workshop scheduling simulation method based on the equipment failure scheduling model, provided by the invention, the possibility of successfully designing a workshop production system is increased, and the design cost and risks are reduced; the simulation result is verified by using an genetic algorithm, the design period of a traditional design is shortened from the aspect of time, the probability of the equipment failure is reduced, the defect produced by re-processing the product replacing equipment is lowered. The actual production model is applied to eM-Plant software and is converted into a model recognizable by the software, the time wasting for re-clamping is avoided, the stock-holding cost caused by the overstock waste of to-be-processed products is reduced, and liquidated damages and the reputation loss caused by delayed delivery are reduced.

Owner:XIAN TECH UNIV

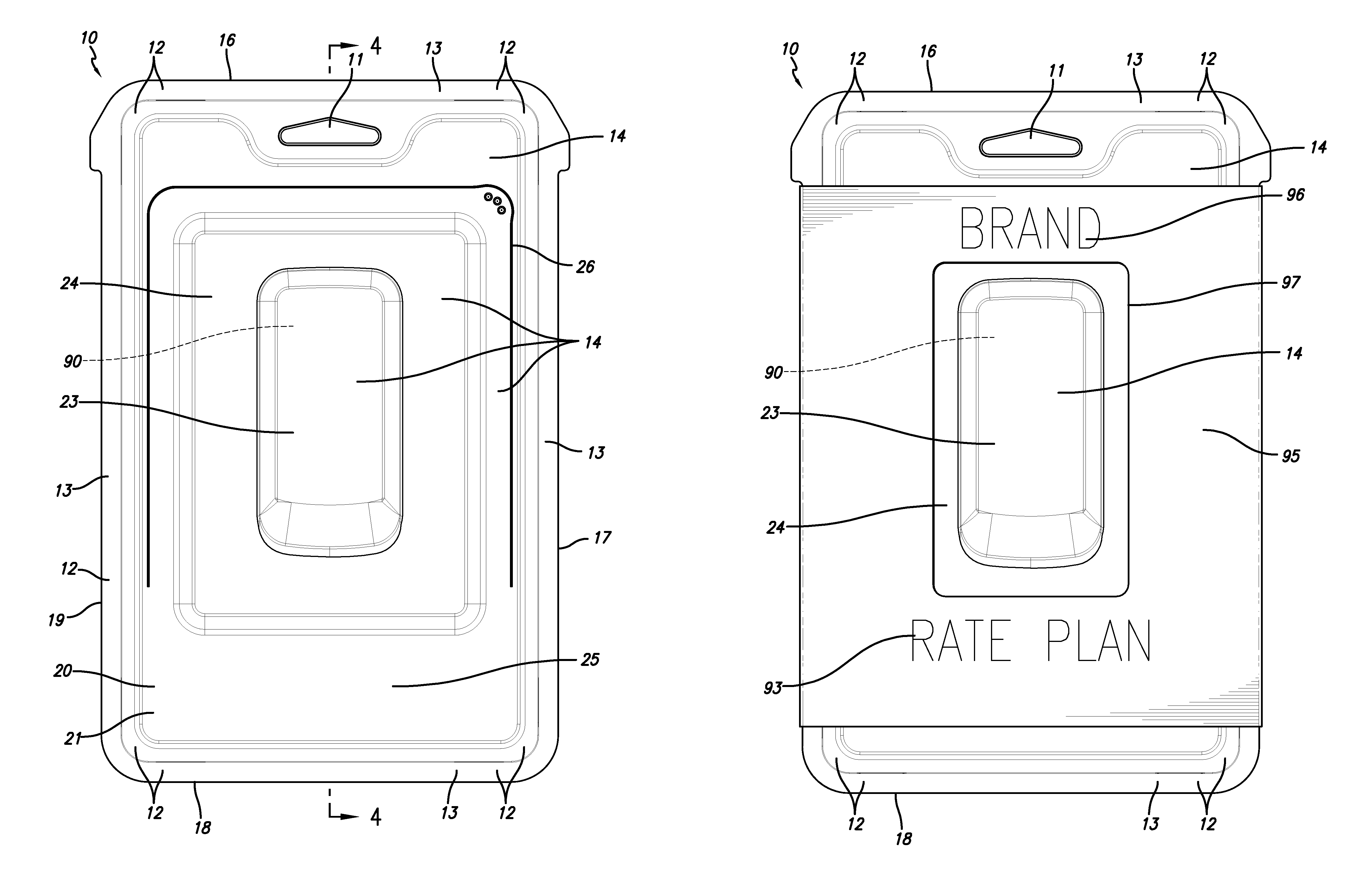

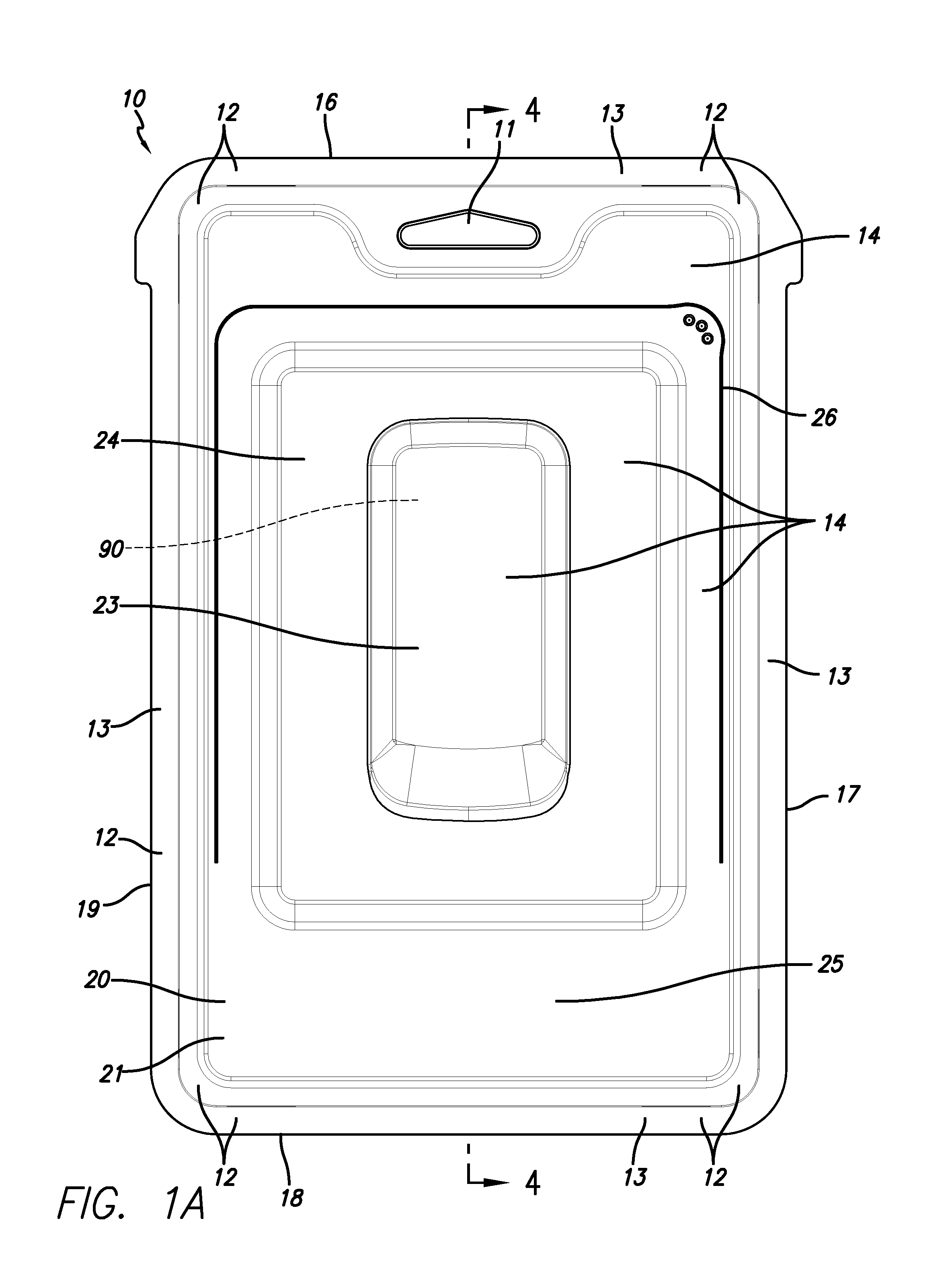

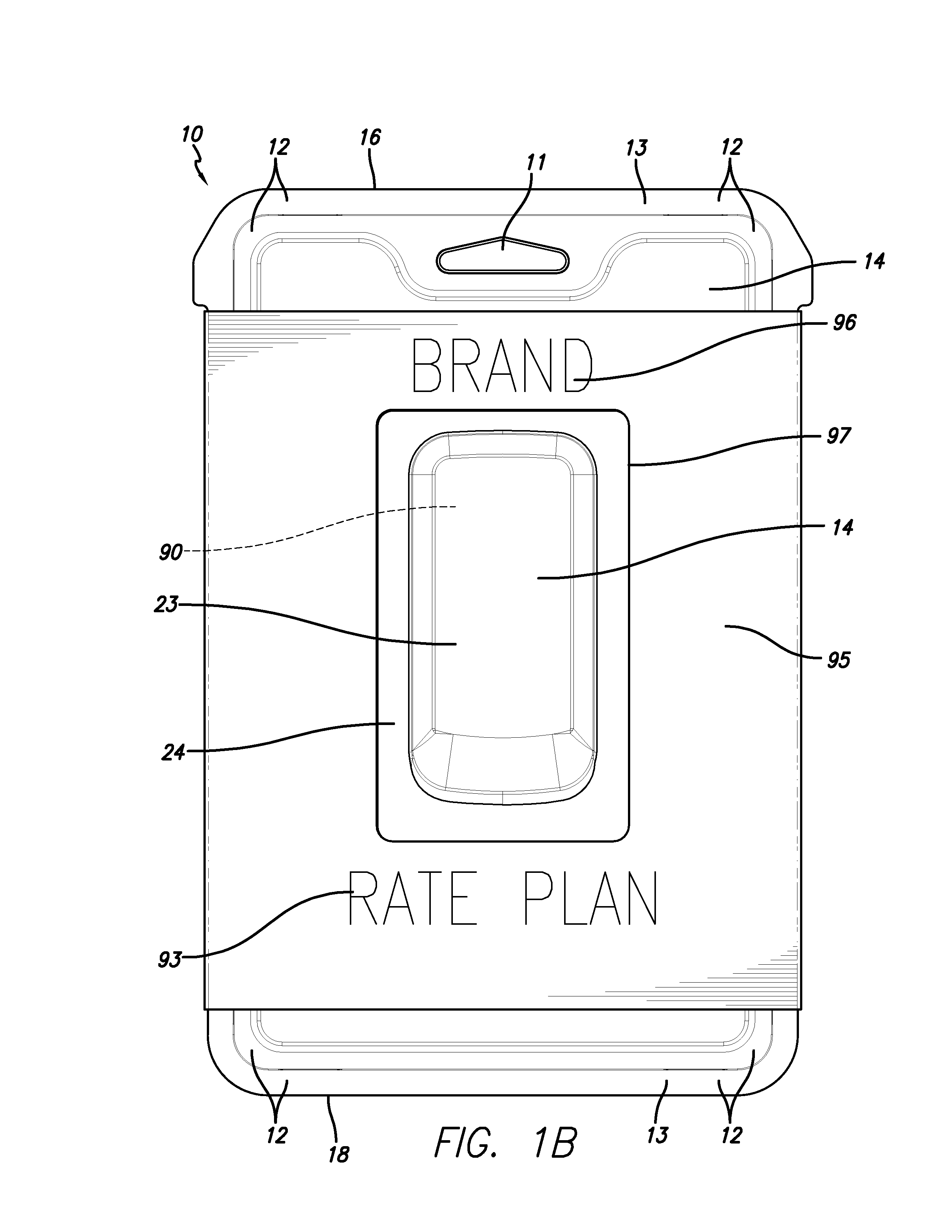

Retail phone package

ActiveUS8573397B1Facilitate placementDifficult to removeOther accessoriesTray containersTrademarkPayment

A thermoformed package that is specially adapted to allow a cell phone (or similar product) to be partially packaged at one time and place, and then at a later time adapted for sale as a finished product with a particular brand (from a variety of brands or trademarks), and / or with a particular service plan (from a variety of rate plans or payment terms and / or languages) and / or with a particular language (or other localization) at a second time and place.

Owner:PLASTIC INGENUITY

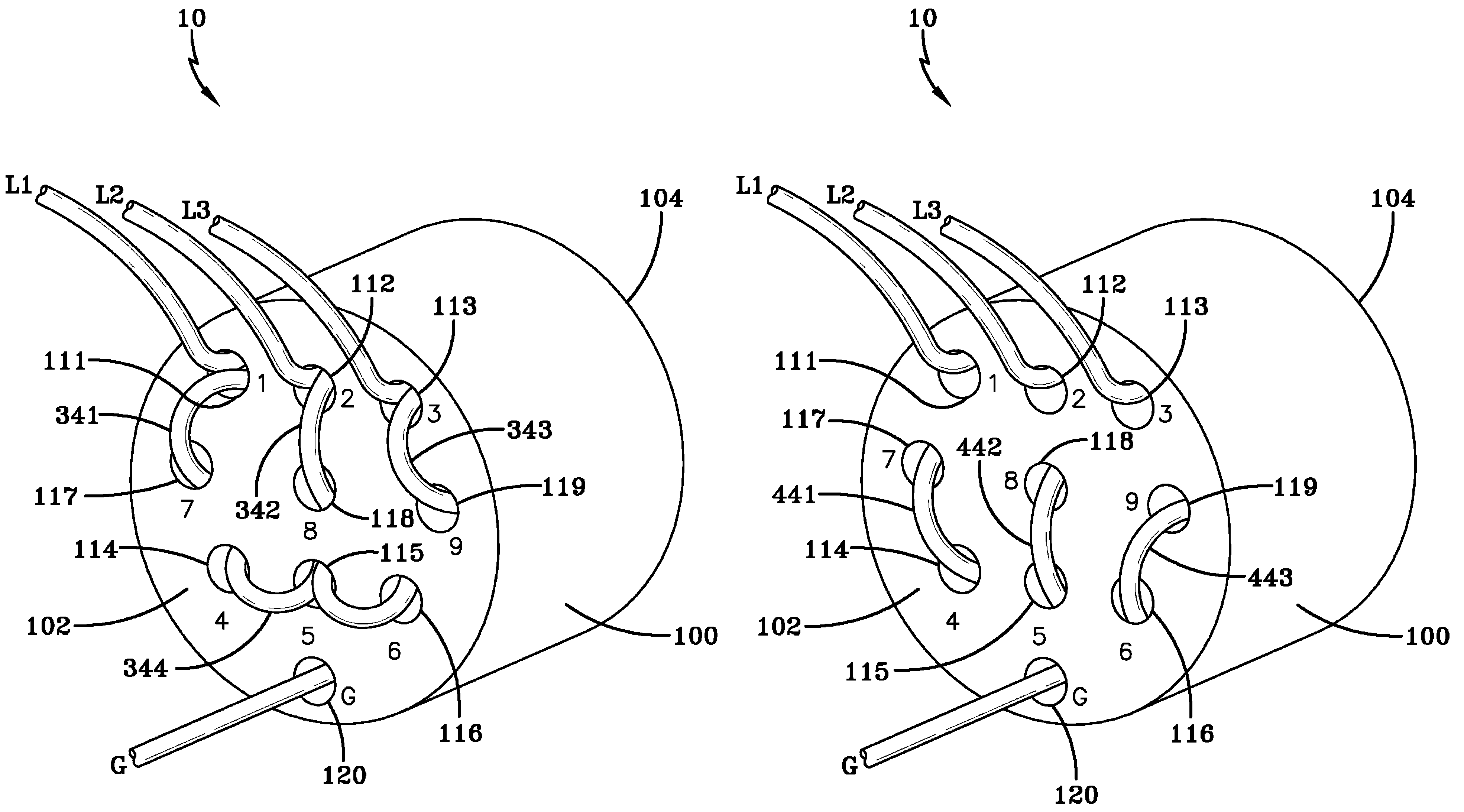

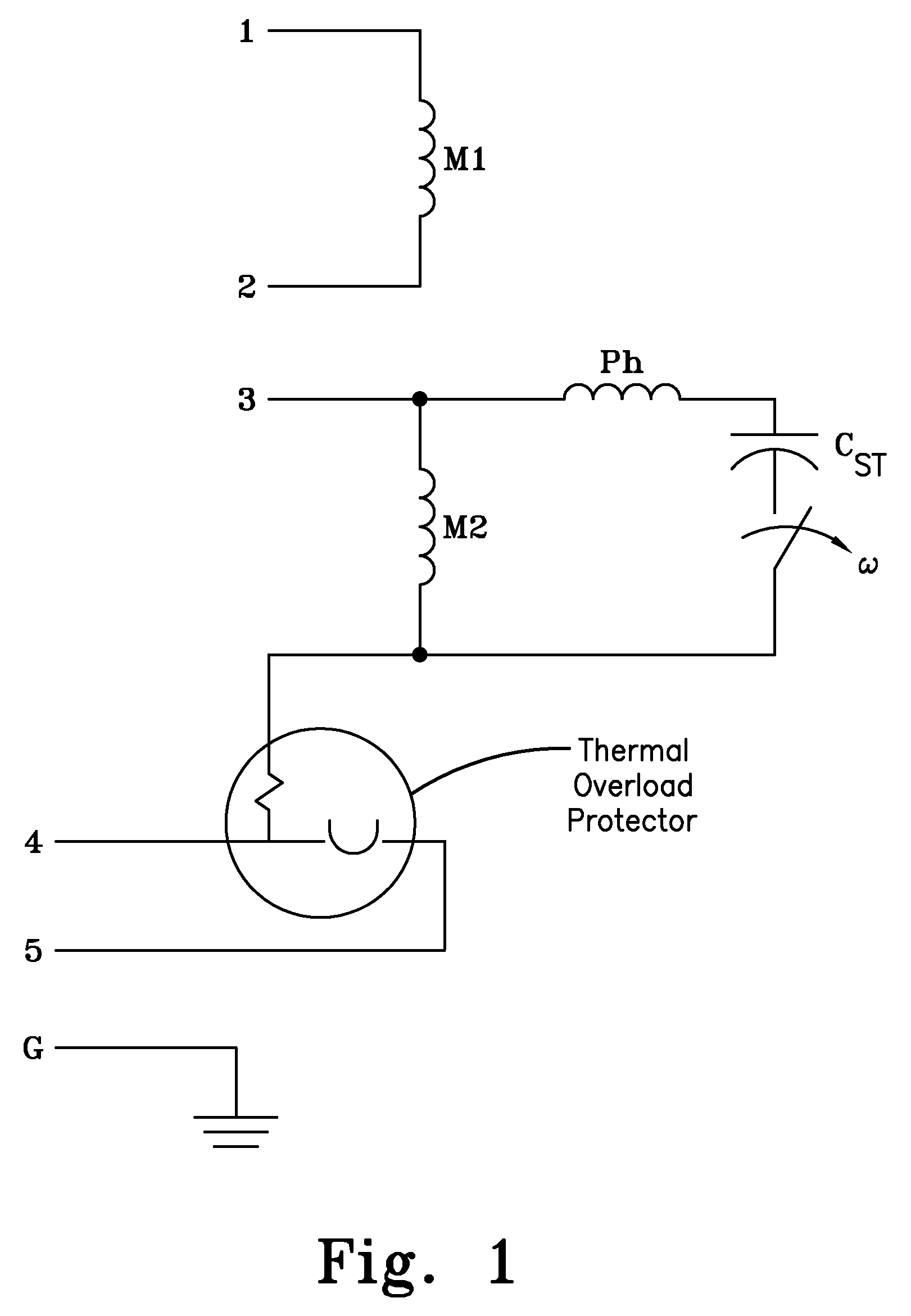

Multi-voltage pump with discreet voltage cords

ActiveUS7931473B2Cord length selectionThe process is convenient and fastCoupling device connectionsSubstation/switching arrangement detailsElectricityLow voltage

A device for interfacing power from an electrical supply having power terminals, that permits implementation of a wide range of power cord lengths and voltage connection combinations. The device includes a body having a cord side and an appliance side. The body has four or more terminals located on the cord side of the body, with one terminal being a ground terminal. At least one electrical connecting device is adapted to connect terminals. In a first configuration, the device is used at a lower voltage. In a second configuration, the device is used at a higher voltage.

Owner:CRANE PUMPS & SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com