Patents

Literature

207 results about "Inventory cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inventory costs are the costs related to storing and maintaining its inventory over a certain period of time. Typically, inventory costs are described as a percentage of the inventory value (annual average inventory, i.e. for a retailer the average of the goods bought to its suppliers during a year) on an annualized basis.

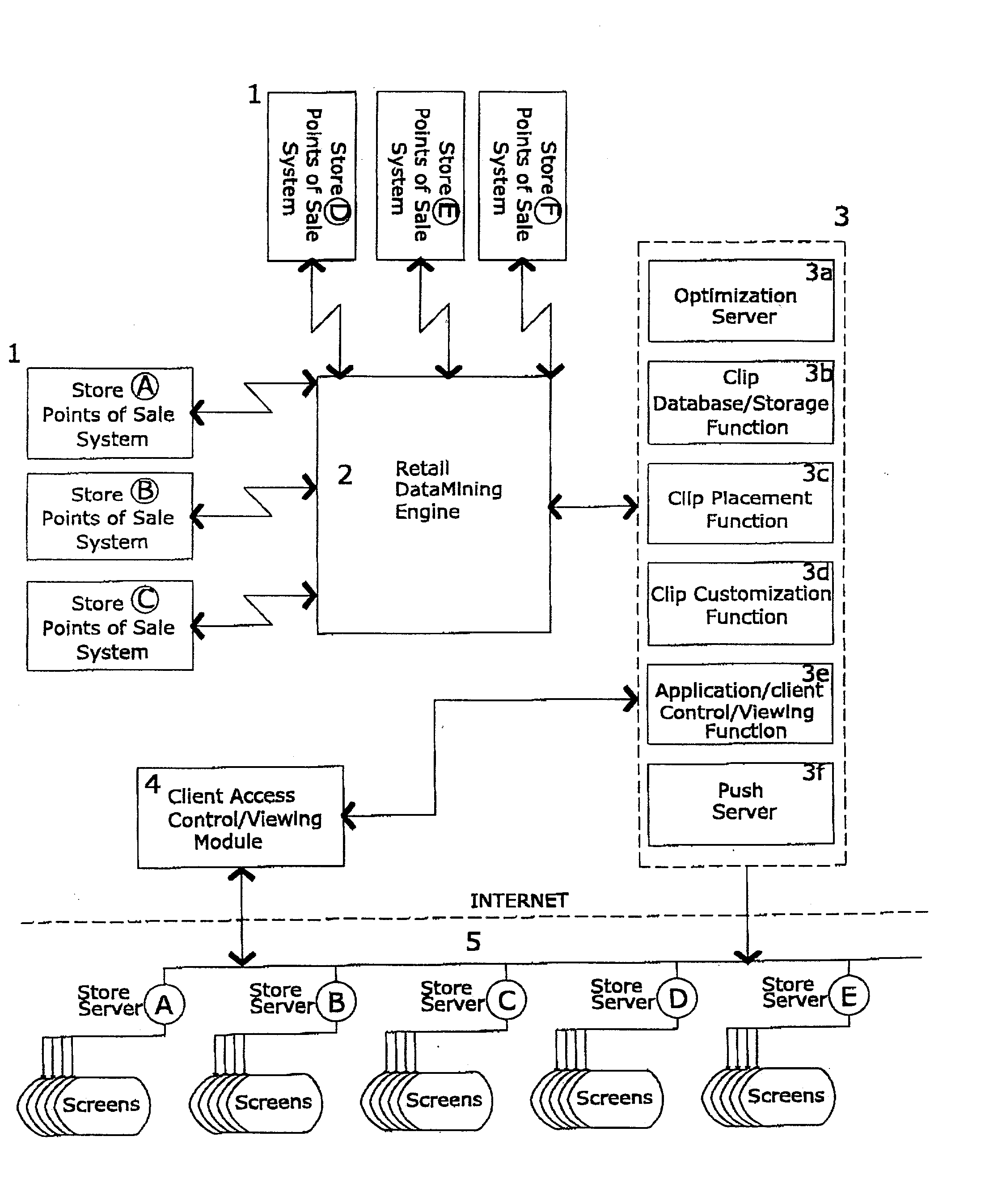

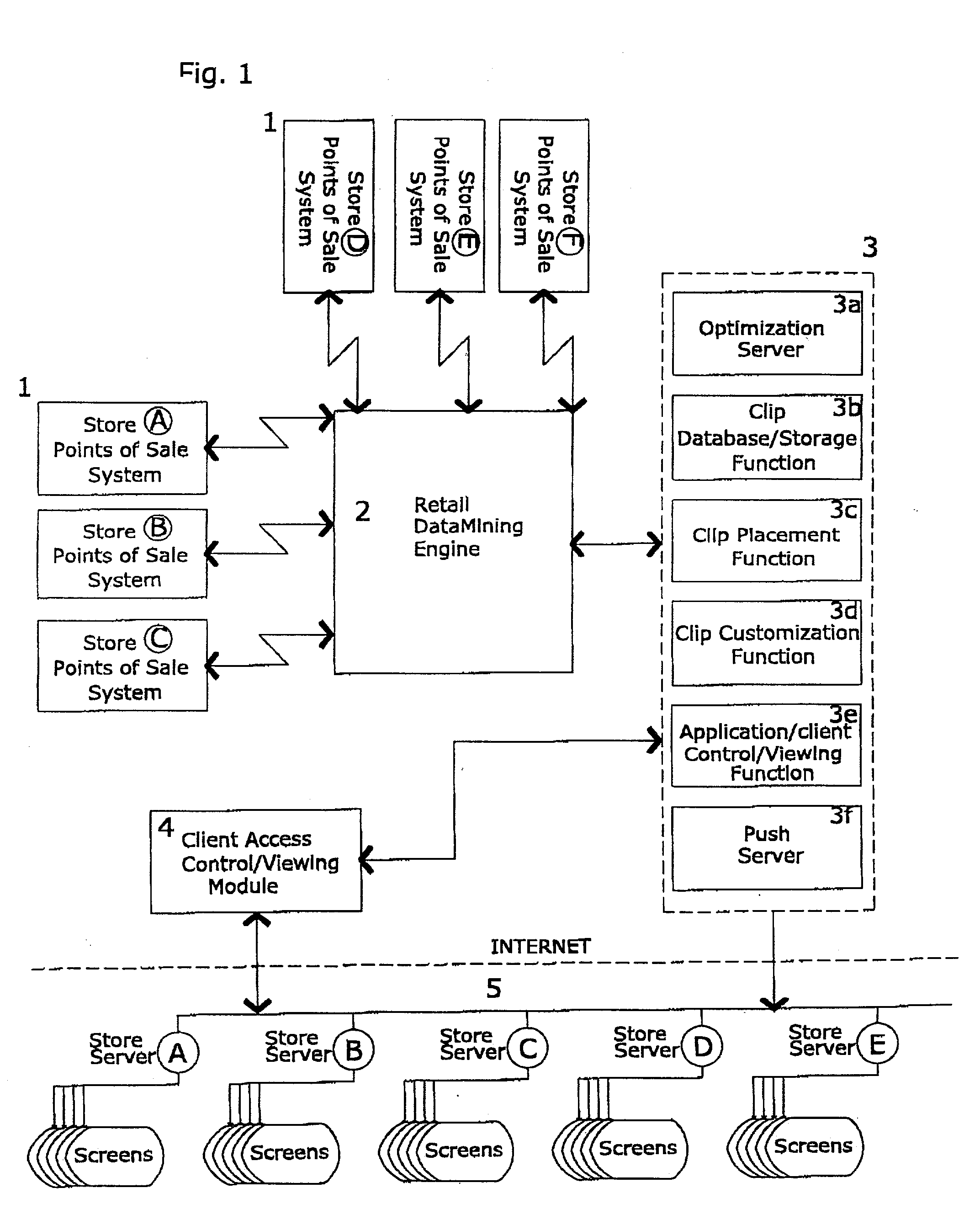

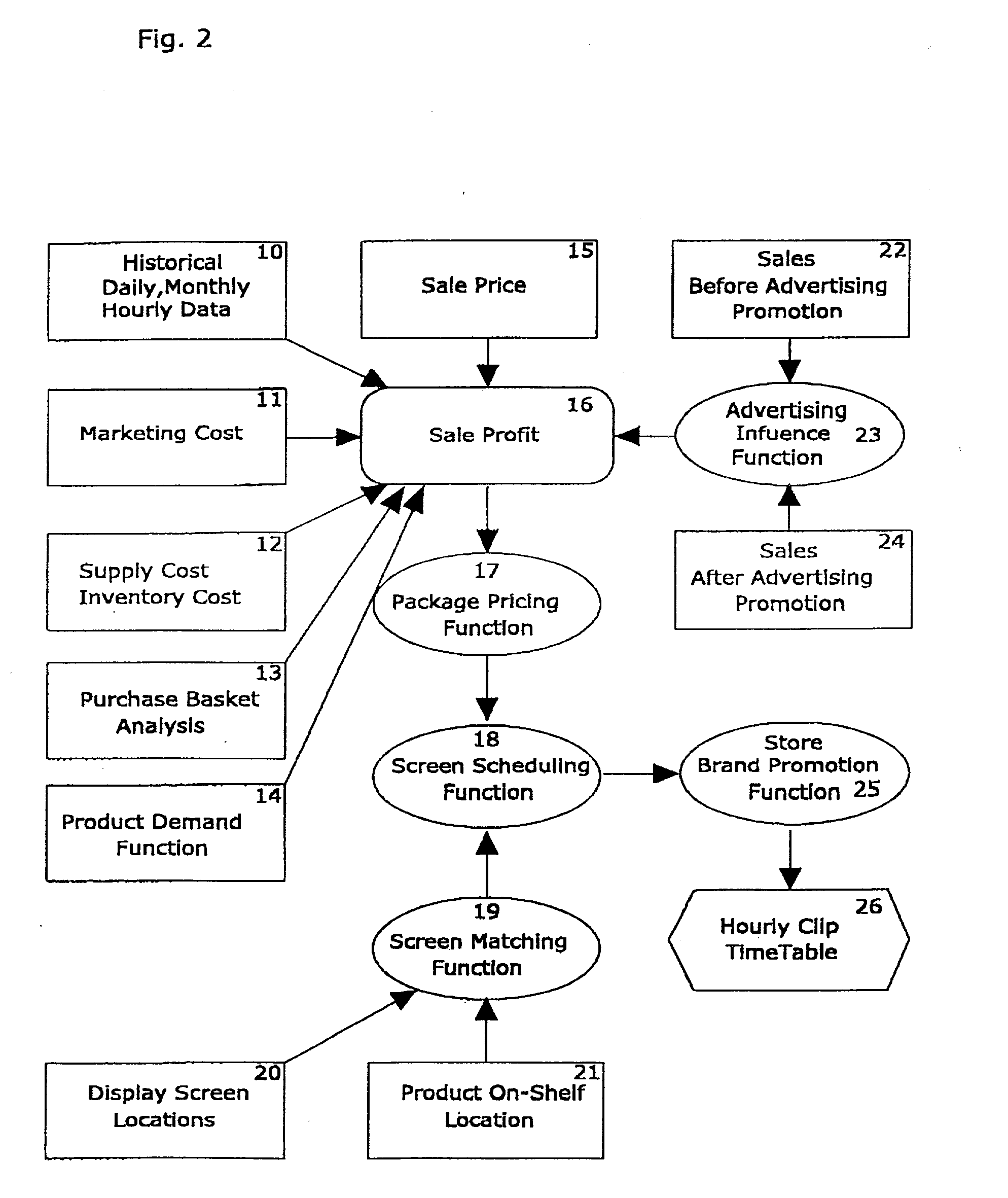

Method and system for maximizing sales profits by automatic display promotion optimization

The present invention is remotely controlled automatic optimization system for maximizing in-store net profits by customized script-generated clip promotions to thousands of individually networked retail display-nodes from central server (OptiRetailChain). The computer-based and machine-learning display system includes: an advertising optimization function for display nodes, point of sale (POS) data input, retail database mining engine (RDME), client access and management control module, and in-store networked electronic clip display apparatus. The optimization function obtains data from chain-store database, combines product bundling data, which describe the associative relationships of various product sales in stores with recorded times of sale, inventory costs, margin profits etc. Physical location of purchased products on the store floor-areas are correlated with relevant display-nodes to create optimal clip display program (playlist) configurations for that specific display location and time. Most preferred product advertising combinations will be displayed in the best time slots for each node automatically. OptiRetailChain uses two methods of promotion optimization: real time scheduling and longer-term statistical optimization. Utilizing the machine learning capabilities, actual video-clip playlists will be dynamically updated for every display-node and respond to daily sales fluctuations for that store display location. This enables the optimization system to effectively control and automatically feature target advertising to large number of display-nodes in supermarket chain networks optimizing advertising capital without necessitating outside intervention.

Owner:MAKOR ISSUES & RIGHTS

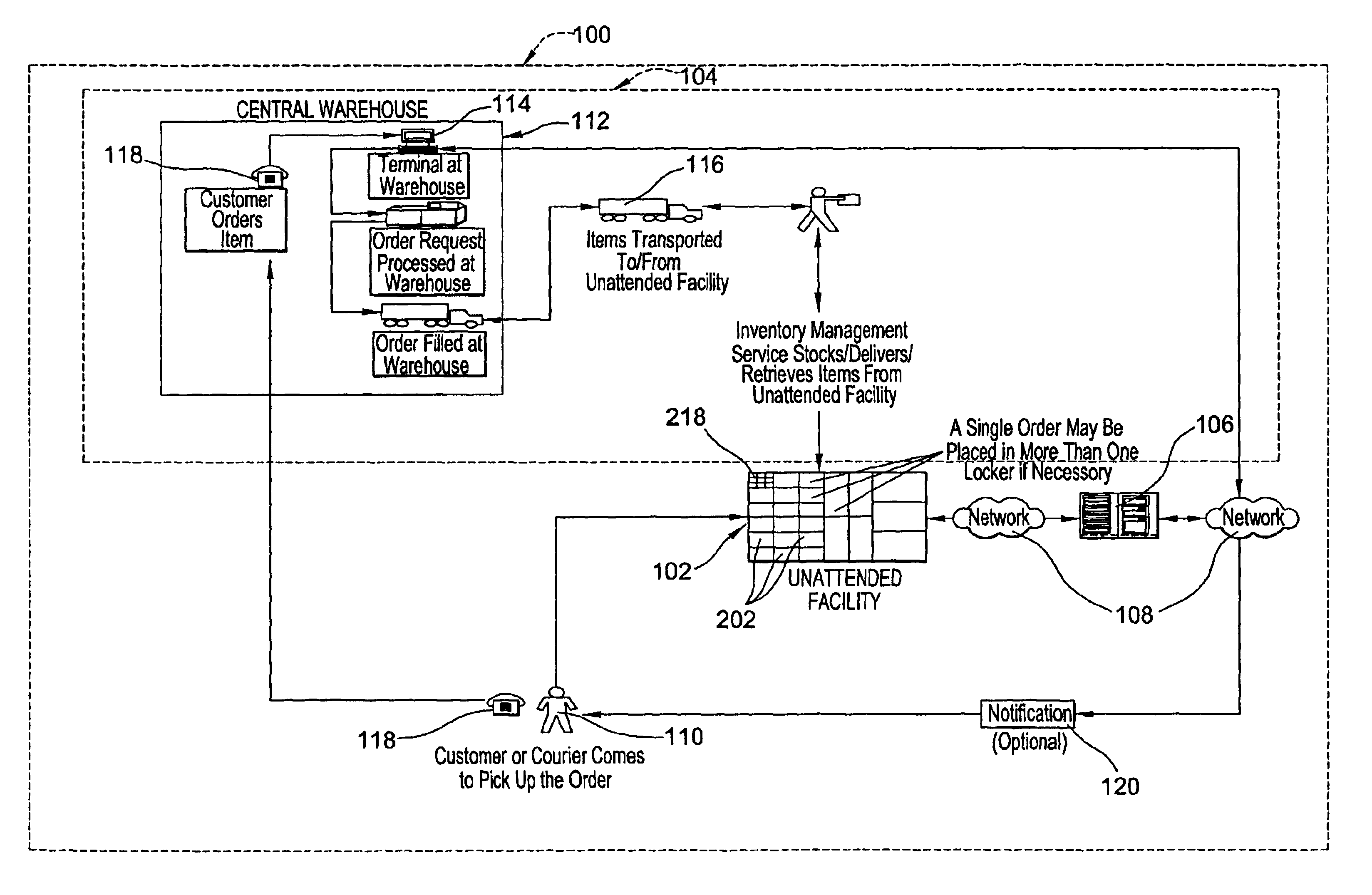

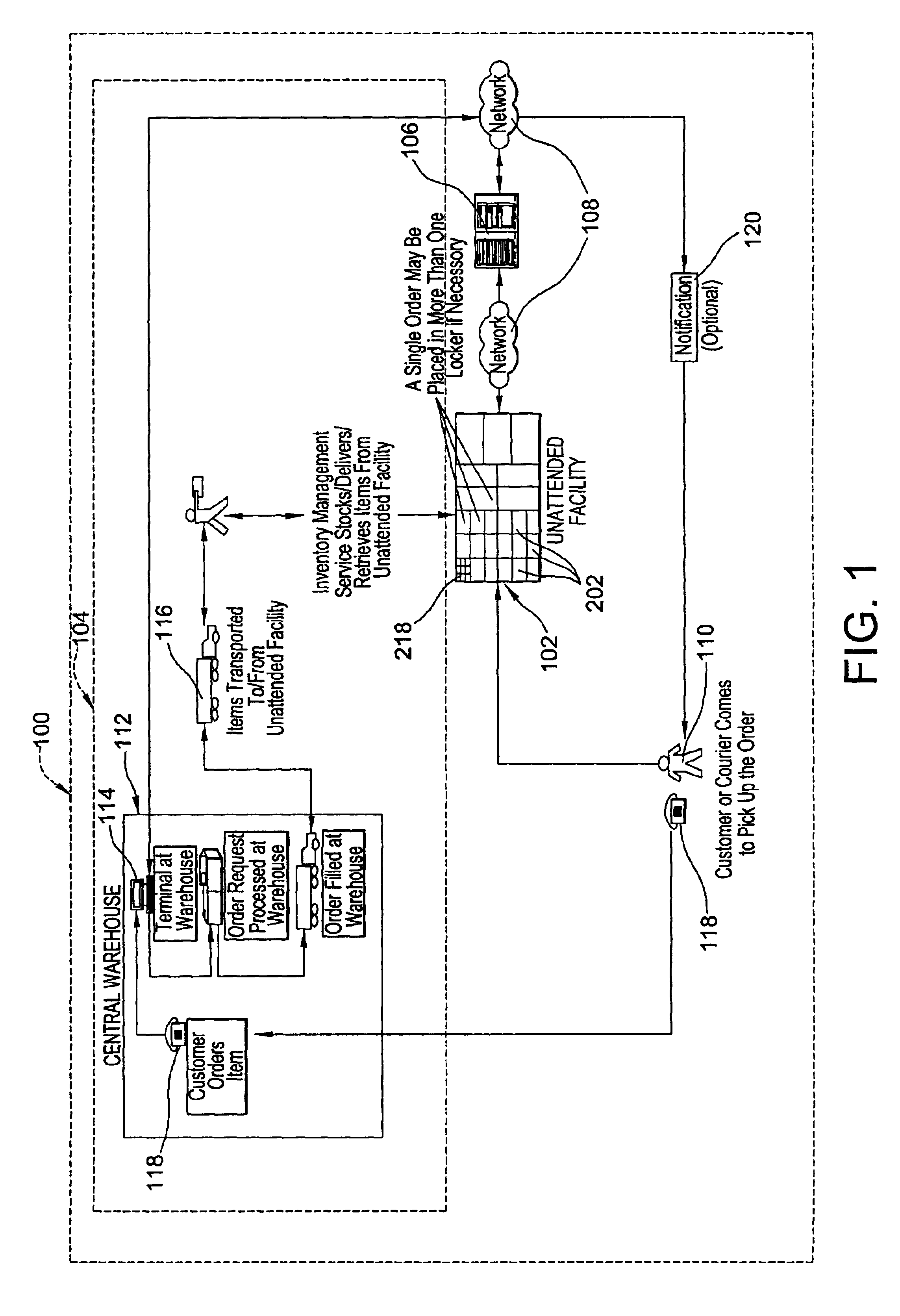

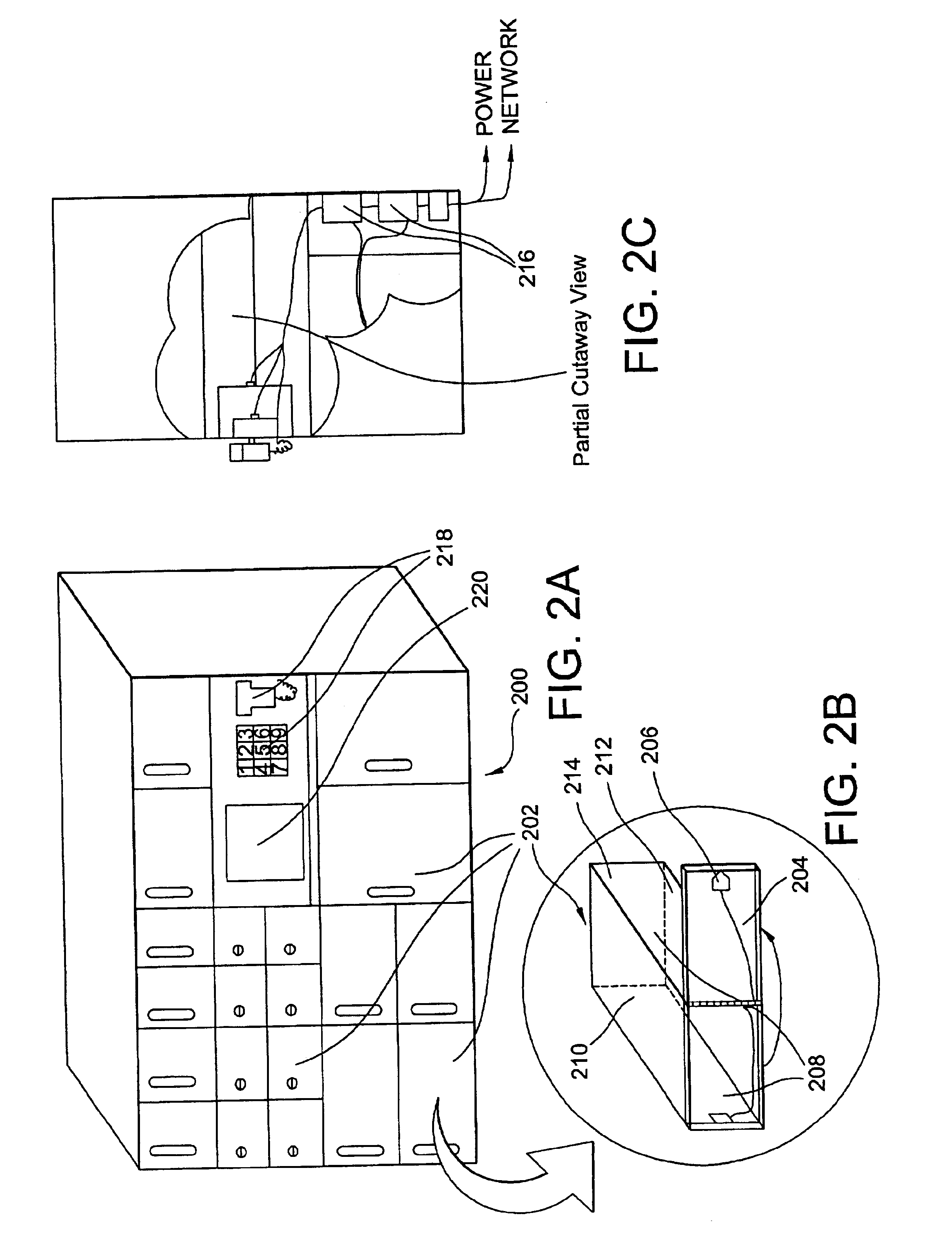

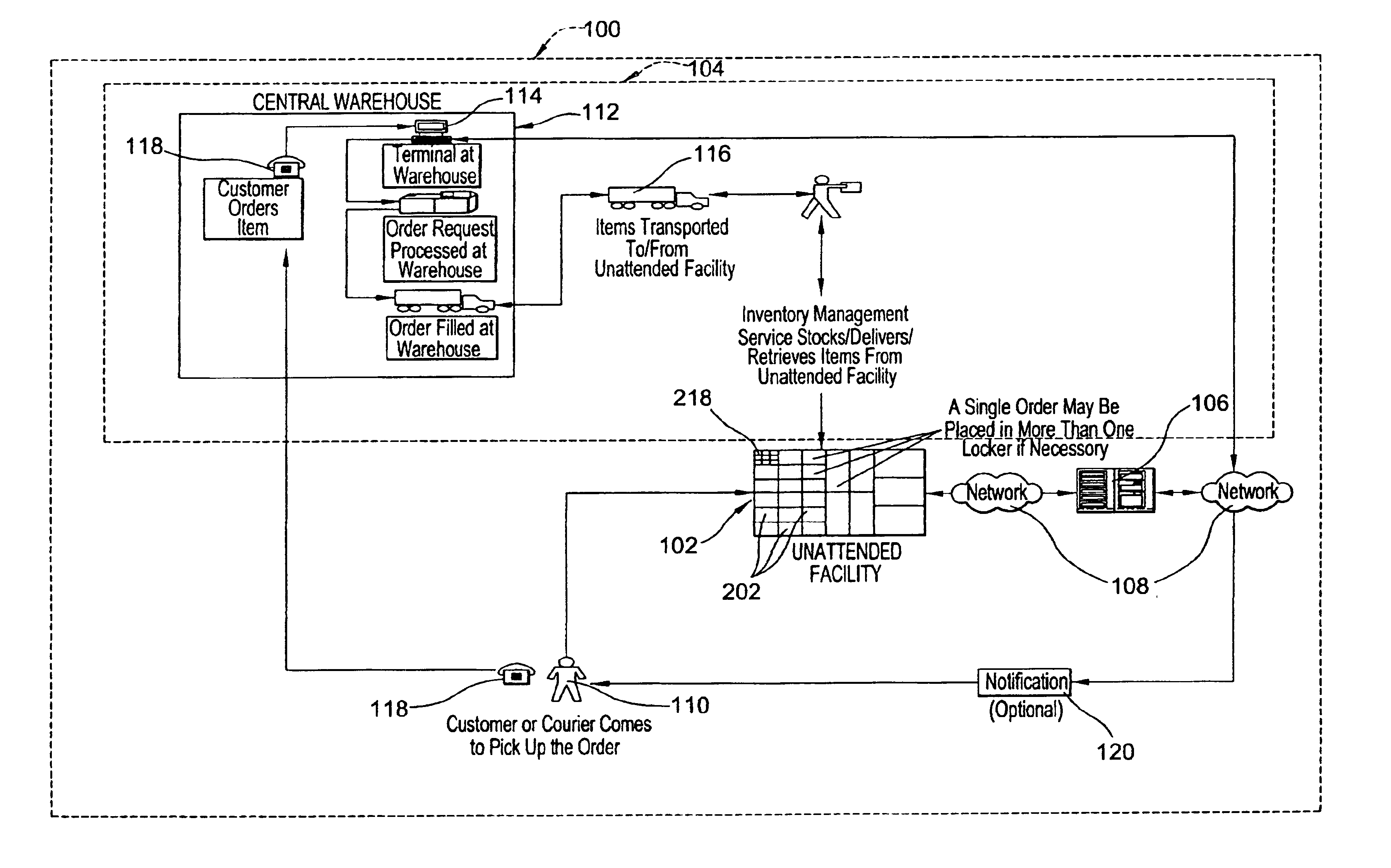

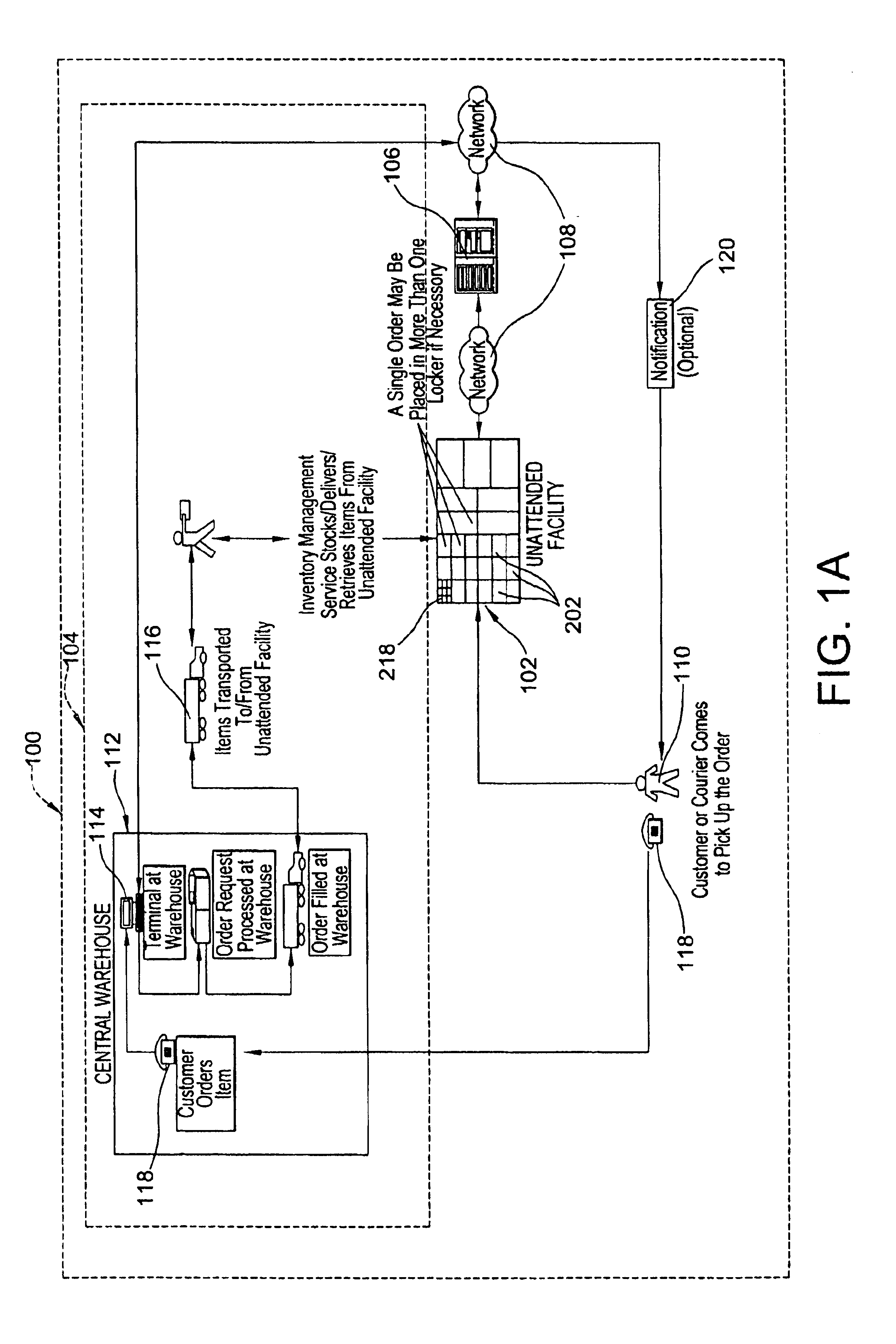

Systems and methods of inventory management utilizing unattended facilities

InactiveUS6866195B2Speed up the processLow costApparatus for meter-controlled dispensingVisual presentationLogistics managementSecure Shell

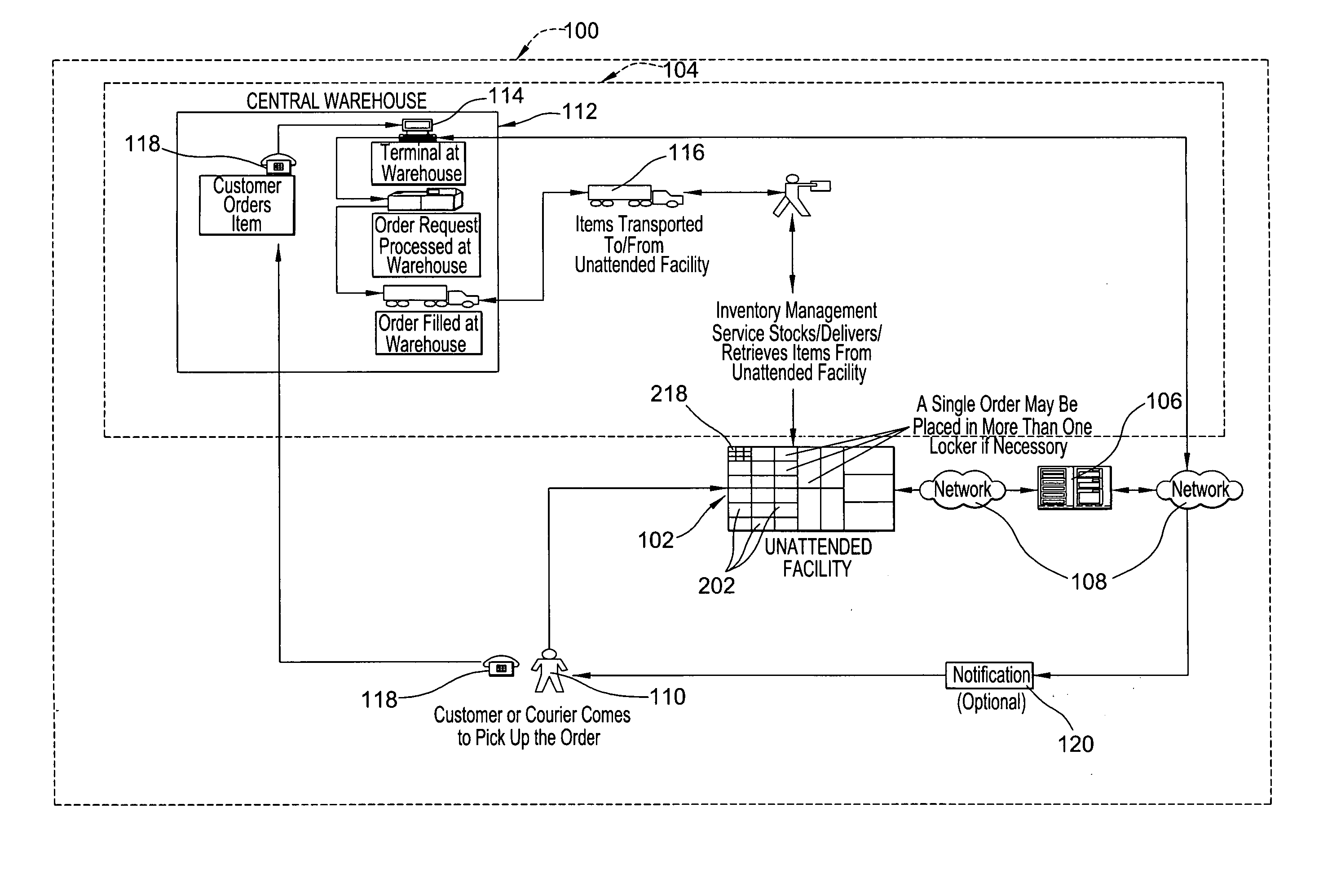

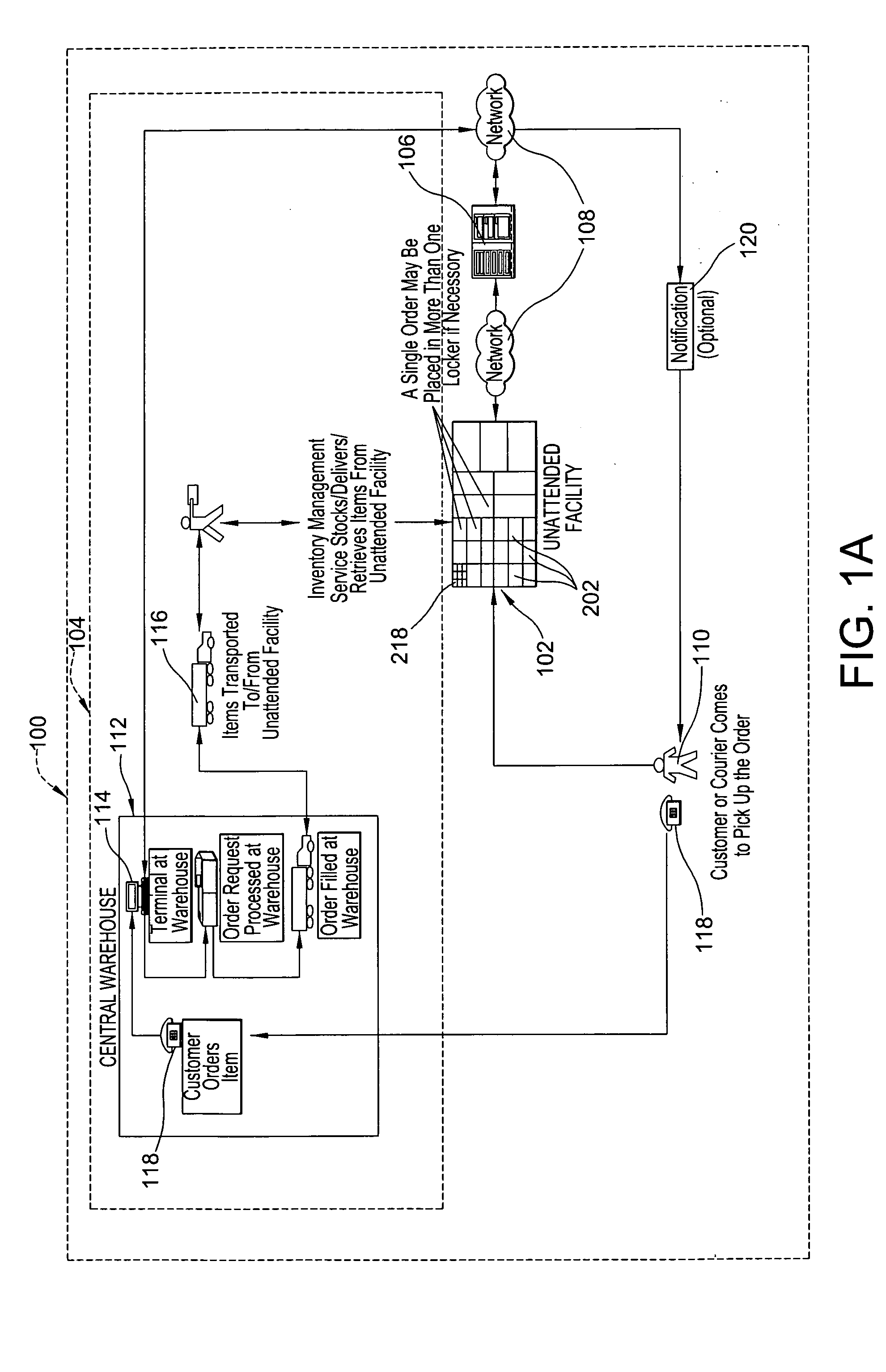

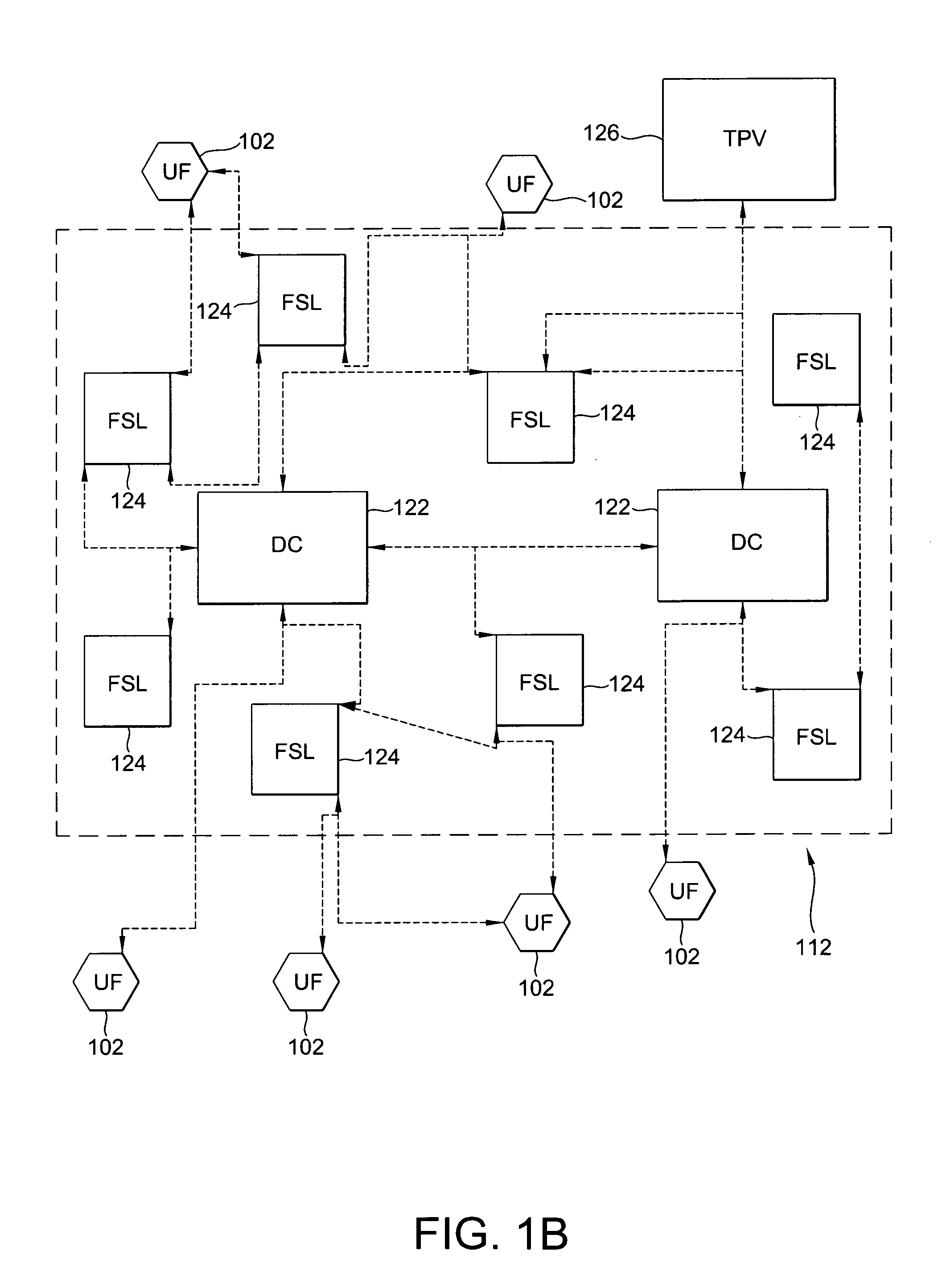

An inventory management system utilizes unattended facilities remote from a central warehouse for service parts logistics. Items are placed in inventory in secure enclosures at the unattended facilities by the inventory management service. The unattended facilities may be located near one or more customers to reduce a service technician's travel time and customers' inventory costs. A service technician utilizes a passcode to retrieve needed items. The service technician may order items that are not kept in the inventory of the unattended facility in which case the items may be delivered to the unattended facility and the service technician may receive a notification related to all the items that comprise an order that the order is ready for pick up at an unattended facility. Unused, used or damaged parts may be returned by a technician to a remote secure enclosure where such returned parts may be retrieved and disposed of, repaired or placed back into inventory if not damaged or after repair, and the processing of such returned parts begins by information entered into a data entry device at the remote secure enclosure location. Return items that are not damaged may be included in the inventory of an unattended facility.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

Systems and methods of inventory management utilizing unattended facilities

InactiveUS6845909B2Reduce inventory costsQuickly and inexpensively relocatedVisual presentationBuying/selling/leasing transactionsLogistics managementSecure Shell

An inventory management system utilizes unattended facilities remote from a central warehouse for service parts logistics. Items are placed in inventory in secure enclosures at the unattended facilities by the inventory management service or are delivered directly to the unattended facility. The unattended facilities may be located near one or more customers to reduce a service technician's travel time and customers' inventory costs. A service technician utilizes a passcode to retrieve needed items. The service technician may order items that are not kept in the inventory of the unattended facility in which case the items may be delivered to the unattended facility and the service technician may receive a notification related to all the items that comprise an order that the order is ready for pick up at an unattended facility. Unused, used or damaged parts may be returned by a technician to a remote secure enclosure where such returned parts may be retrieved and disposed of, repaired or placed back into inventory if not damaged or after repair, and the processing of such returned parts begins by information entered into a data entry device at the remote secure enclosure location. Return items that are not damaged may be included in the inventory of an unattended facility.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

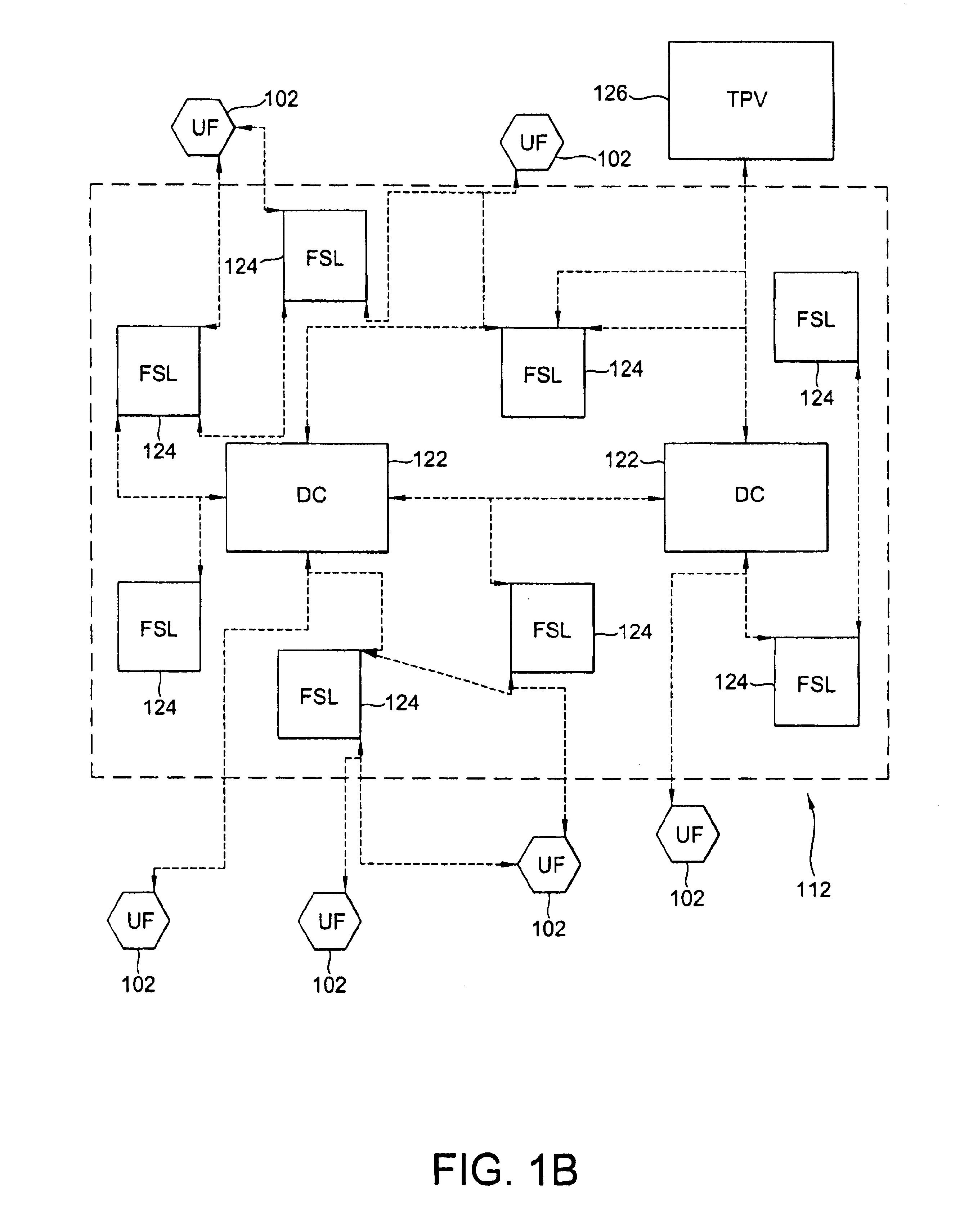

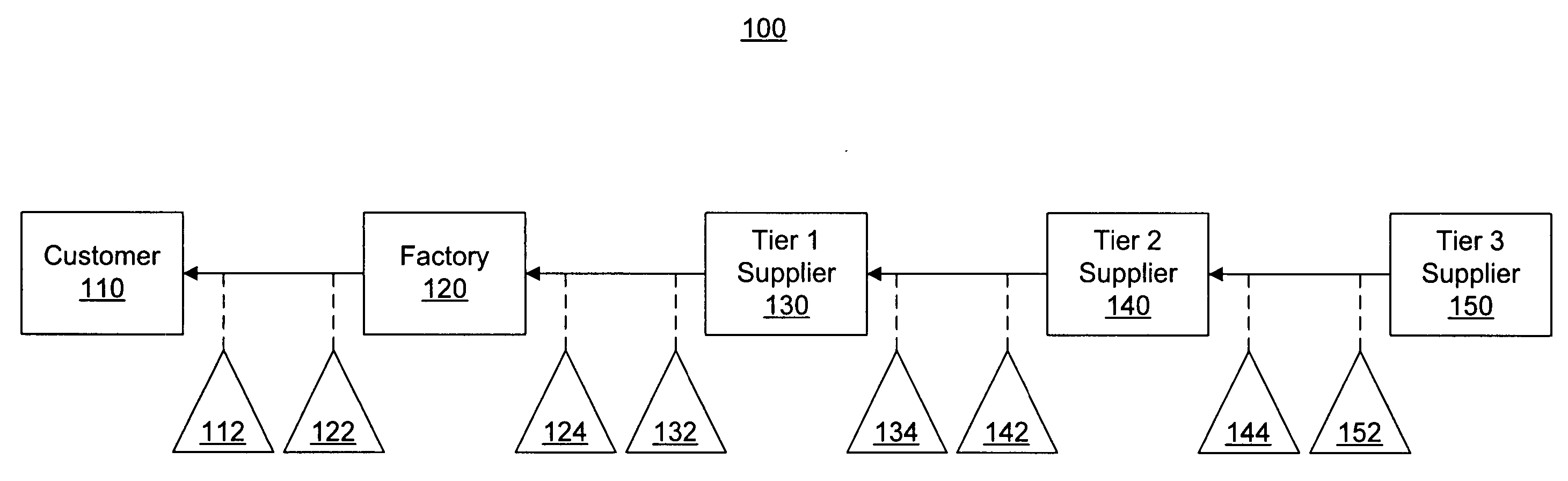

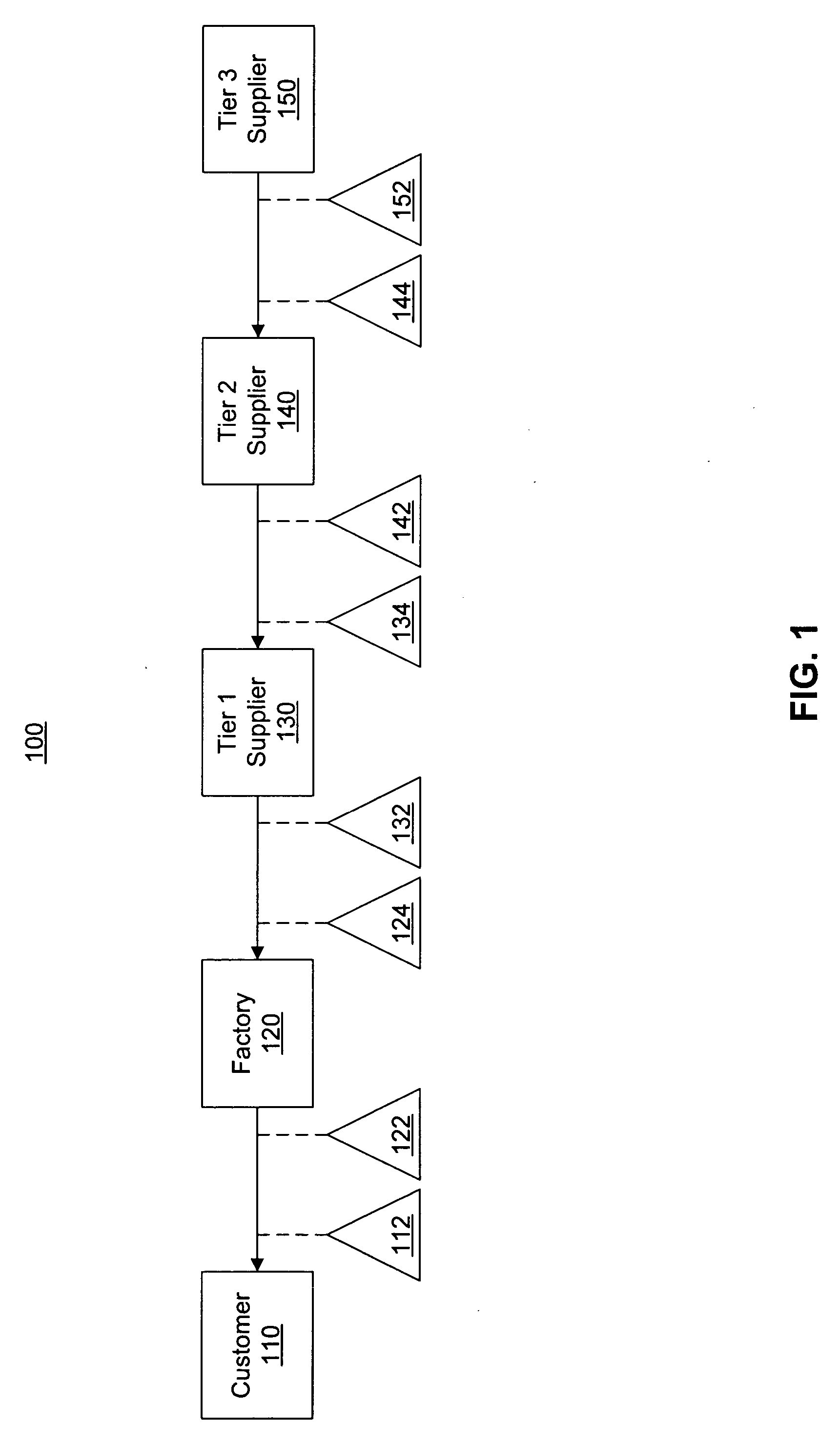

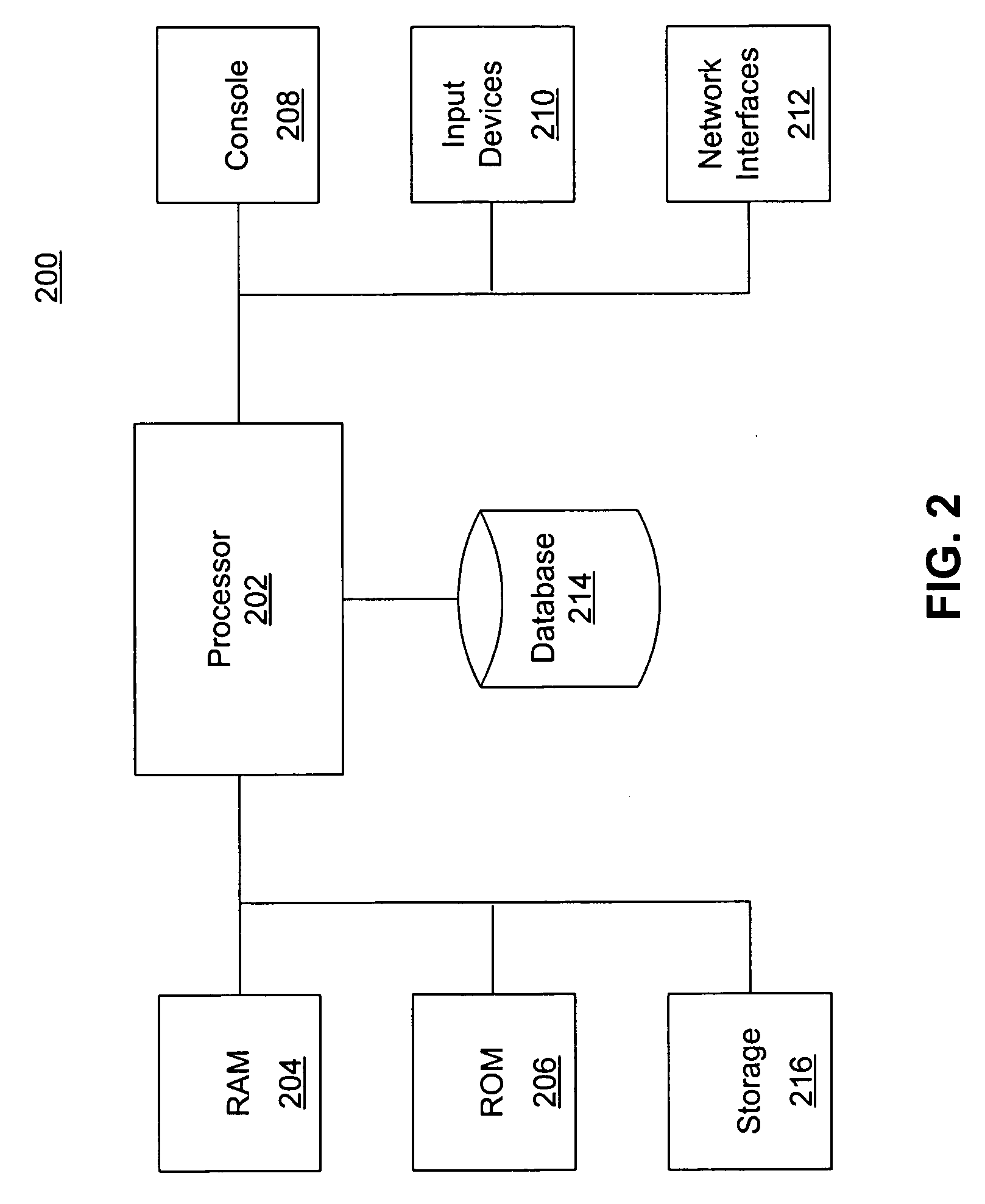

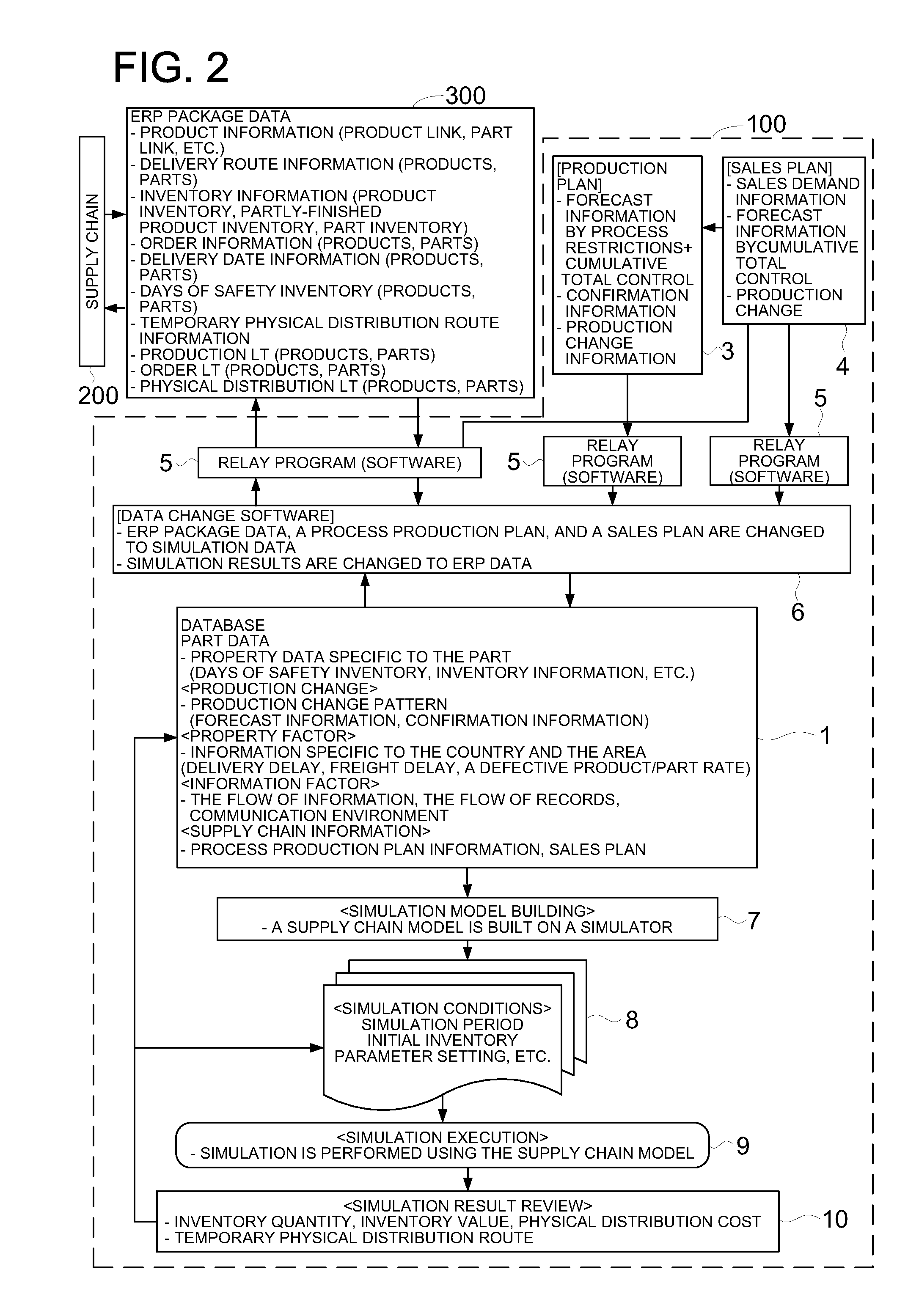

Heuristic supply chain modeling method and system

A method is provided for supply chain modeling by a supply chain entity within a supply chain including a plurality of supply chain entities. The method may include obtaining an order fulfillment requirement for a product from a downstream supply chain entity and identifying one or more representative subsystems of the product. The method may also include determining a supply capacity and an inventory requirement for the supply chain entity with respect to the one or more representative subsystems and calculating an inventory cost for the supply chain entity based on the inventory requirement with respect to the one or more representative subsystems.

Owner:CATERPILLAR INC

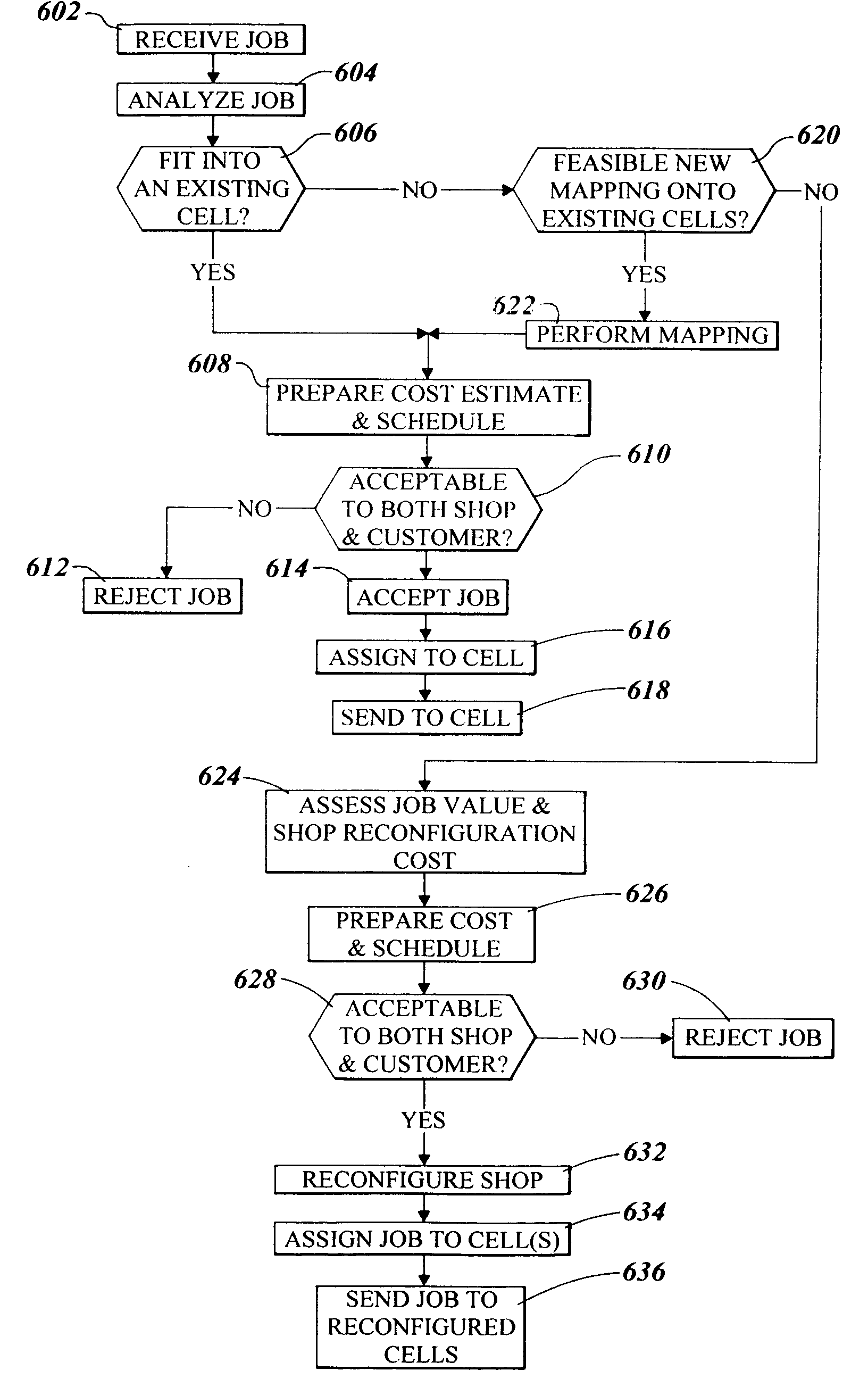

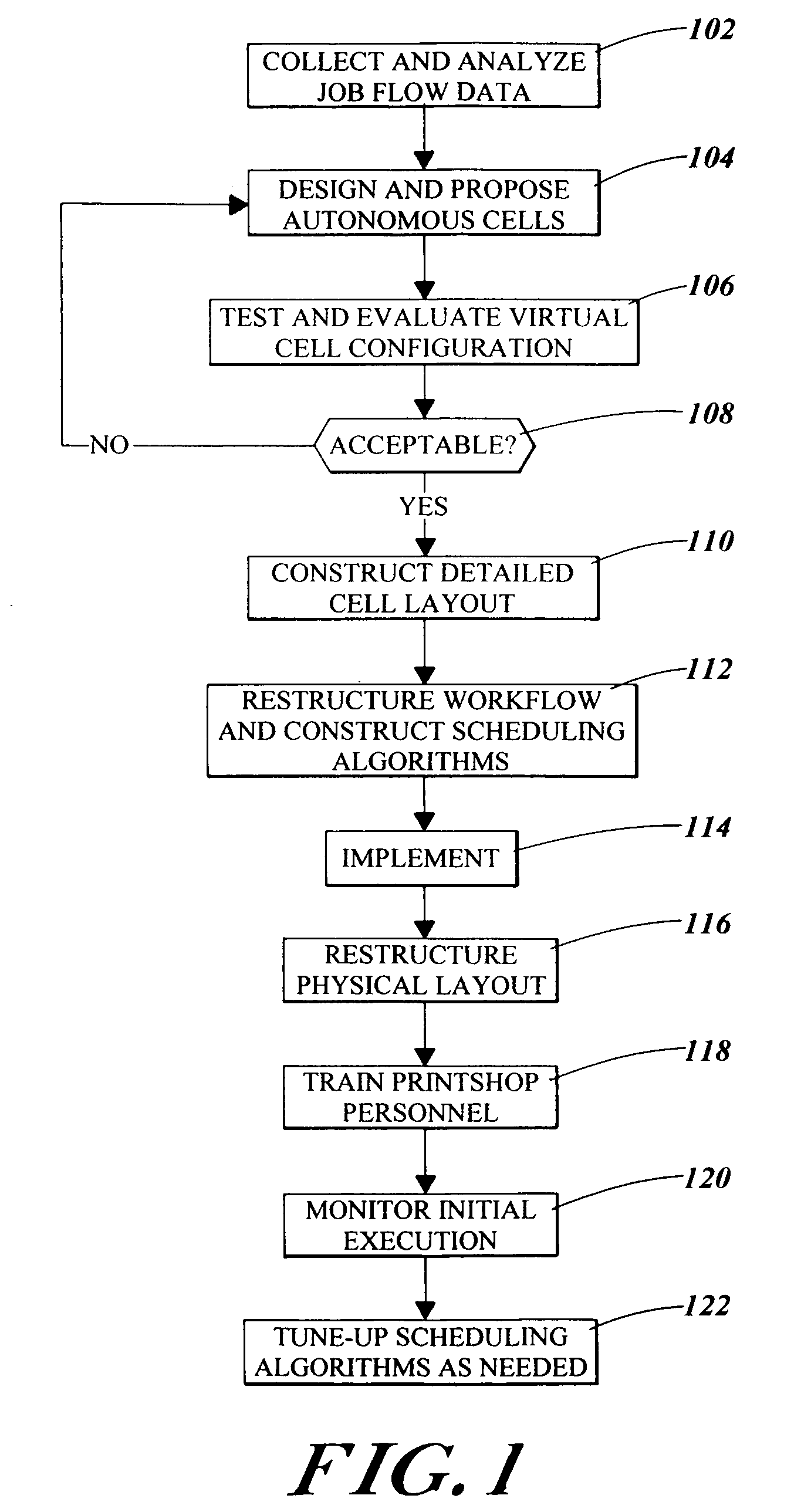

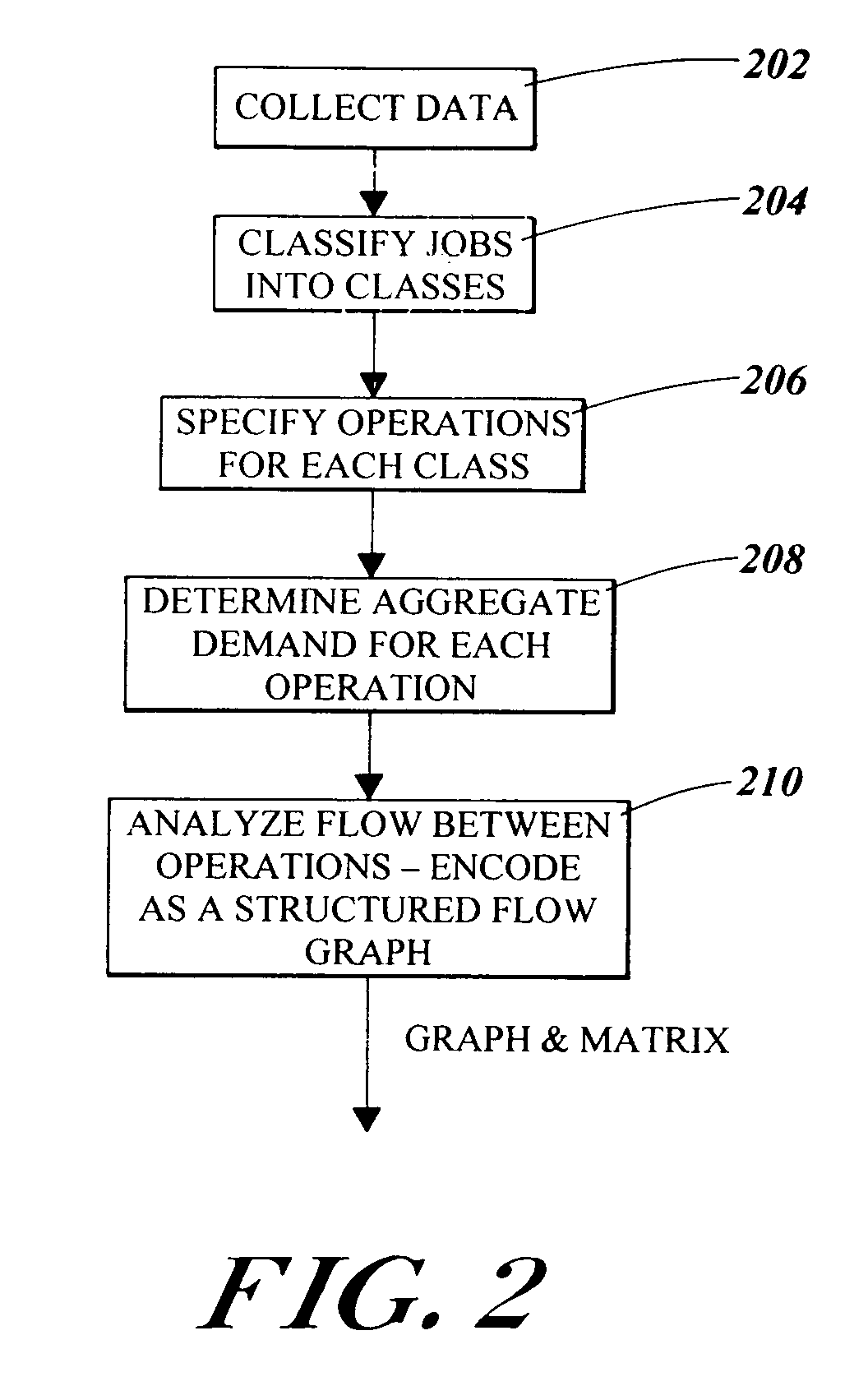

Printshop resource optimization via the use of autonomous cells

InactiveUS7079266B1Digitally marking record carriersDigital computer detailsParallel processingComputer science

A printshop contains resources that are utilized to complete print jobs. The resources are partitioned into autonomous cells. Each autonomous cell is capable of completing at least one class of print job. Print jobs are assigned to the autonomous cells for completion. An autonomous cell may subdivide a print job into smaller sized lots and process the smaller size lots in parallel. This approach enhances the efficiency of the shop, decreases the work in progress, labor and inventory costs associated with running the print jobs and increases the utilization of the printing equipment in the printshop.

Owner:XEROX CORP

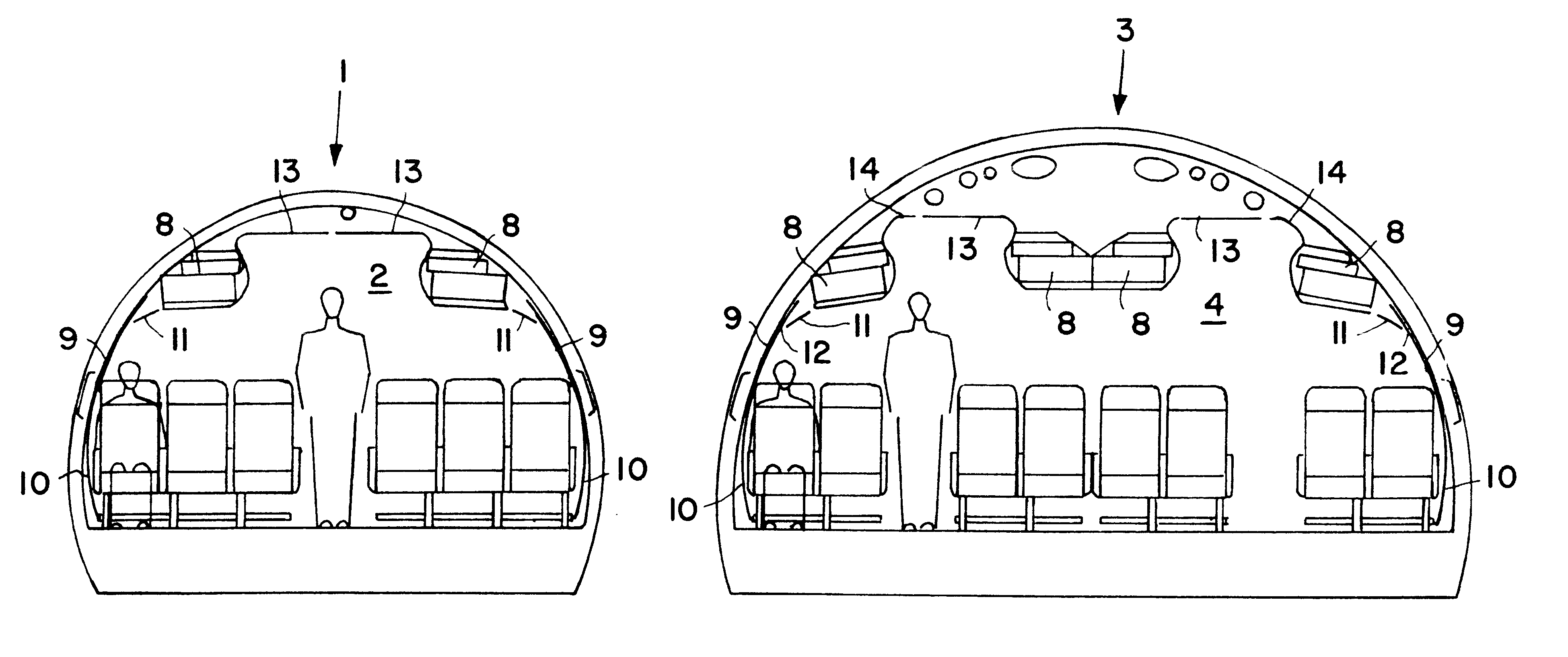

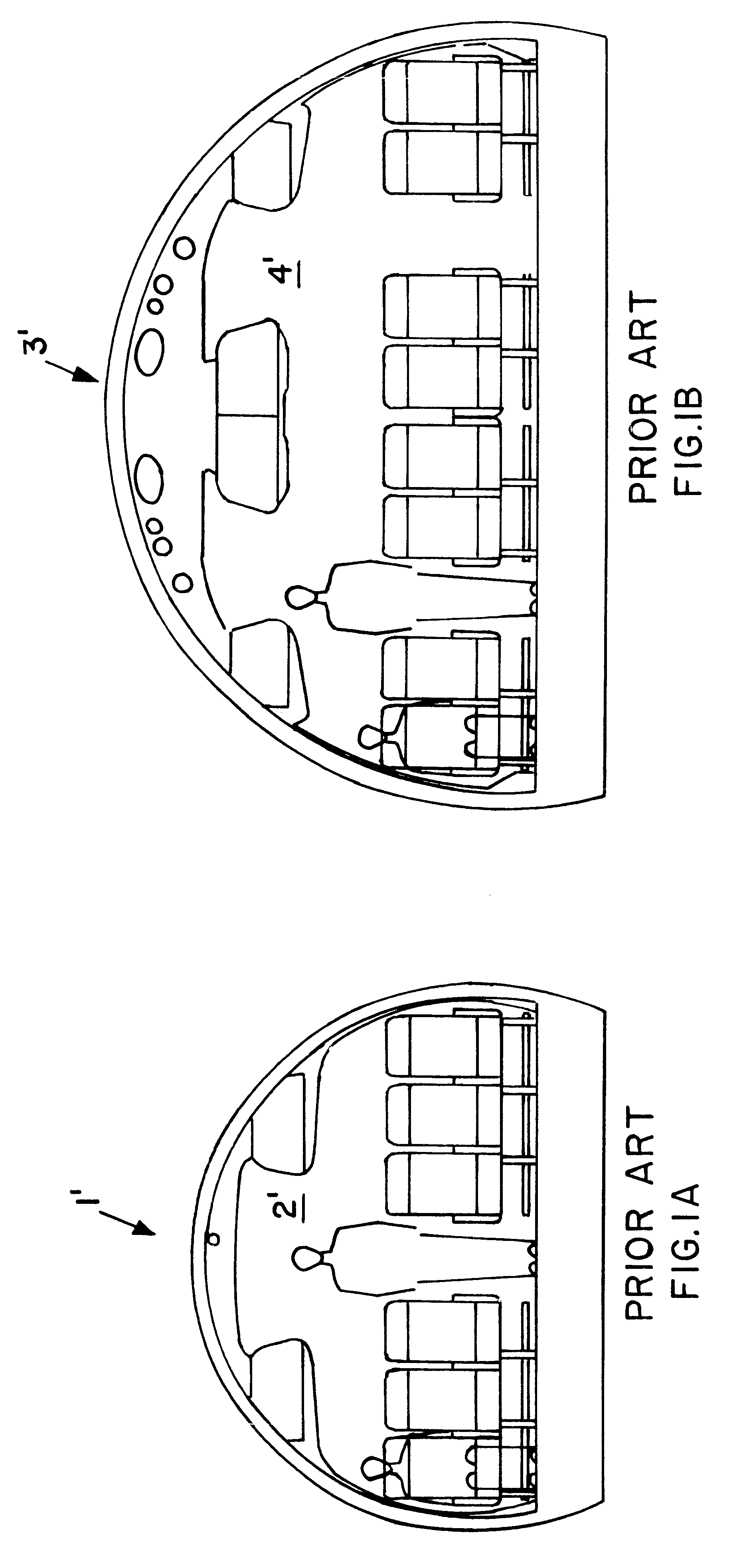

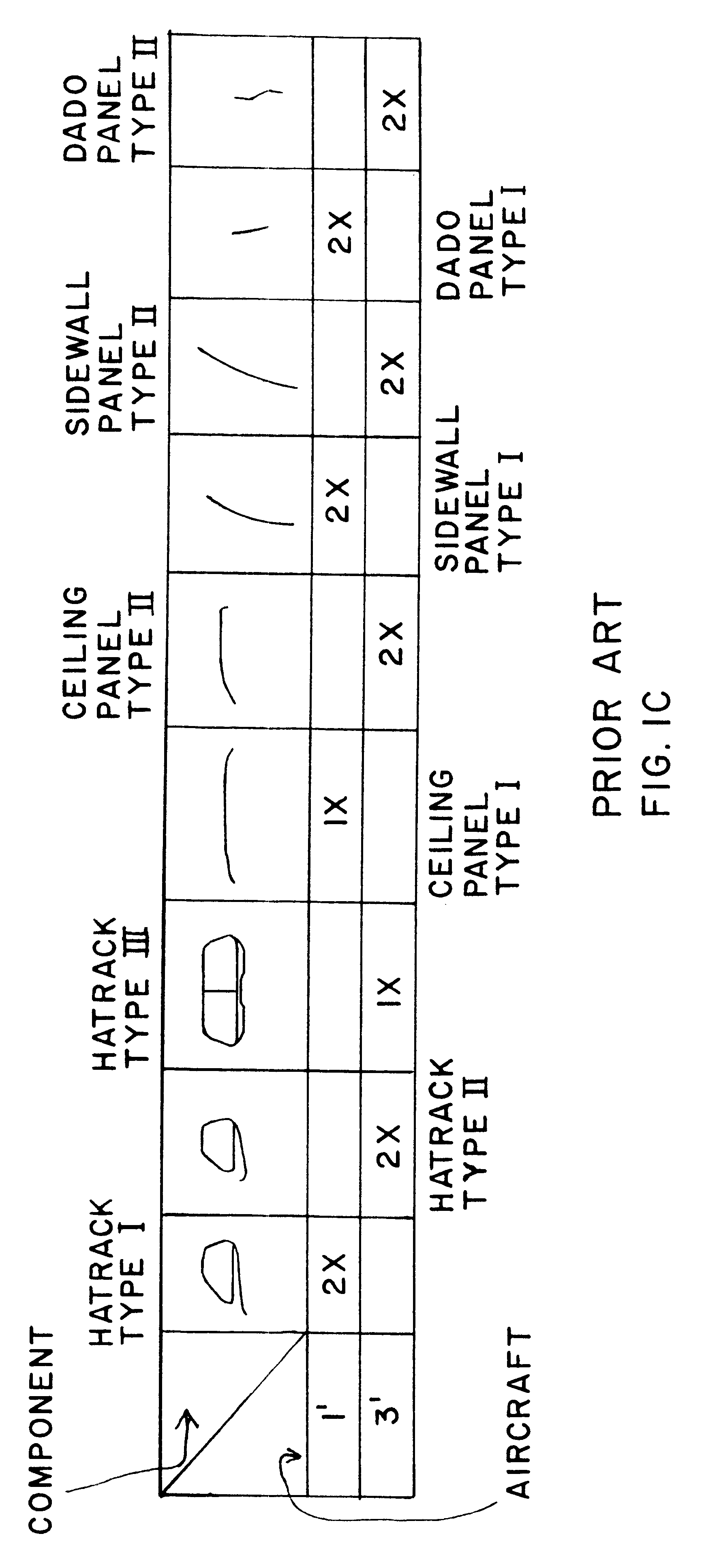

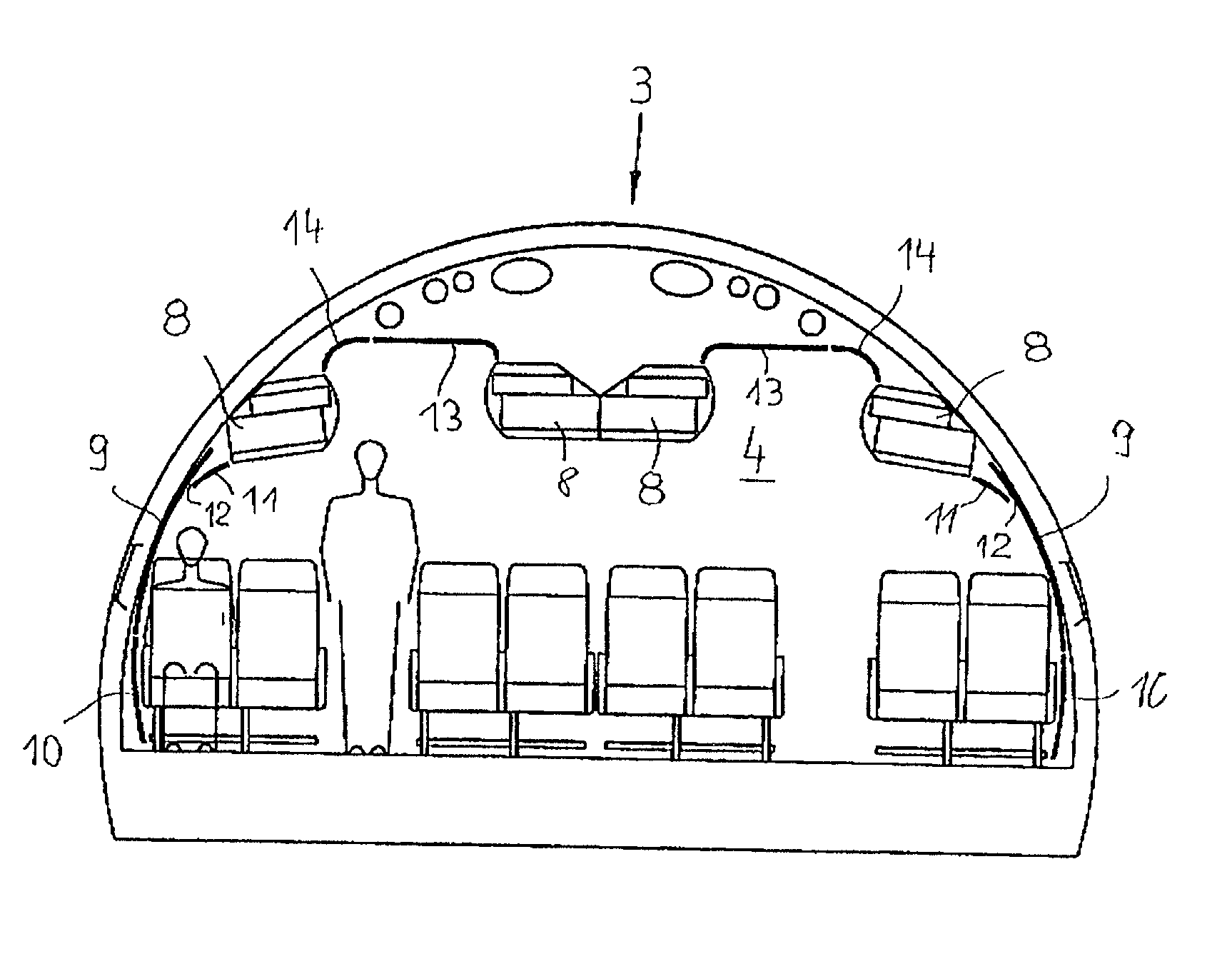

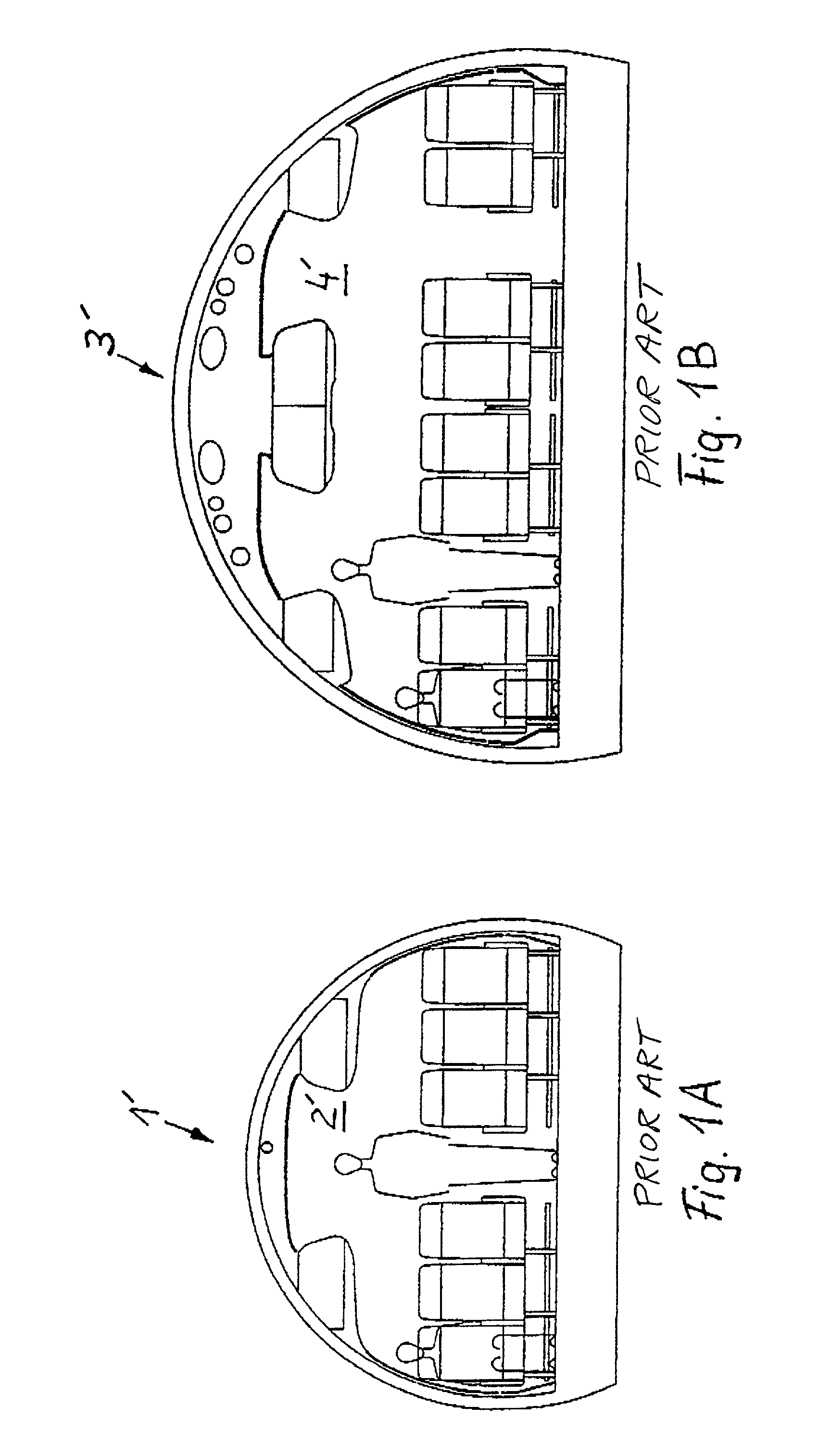

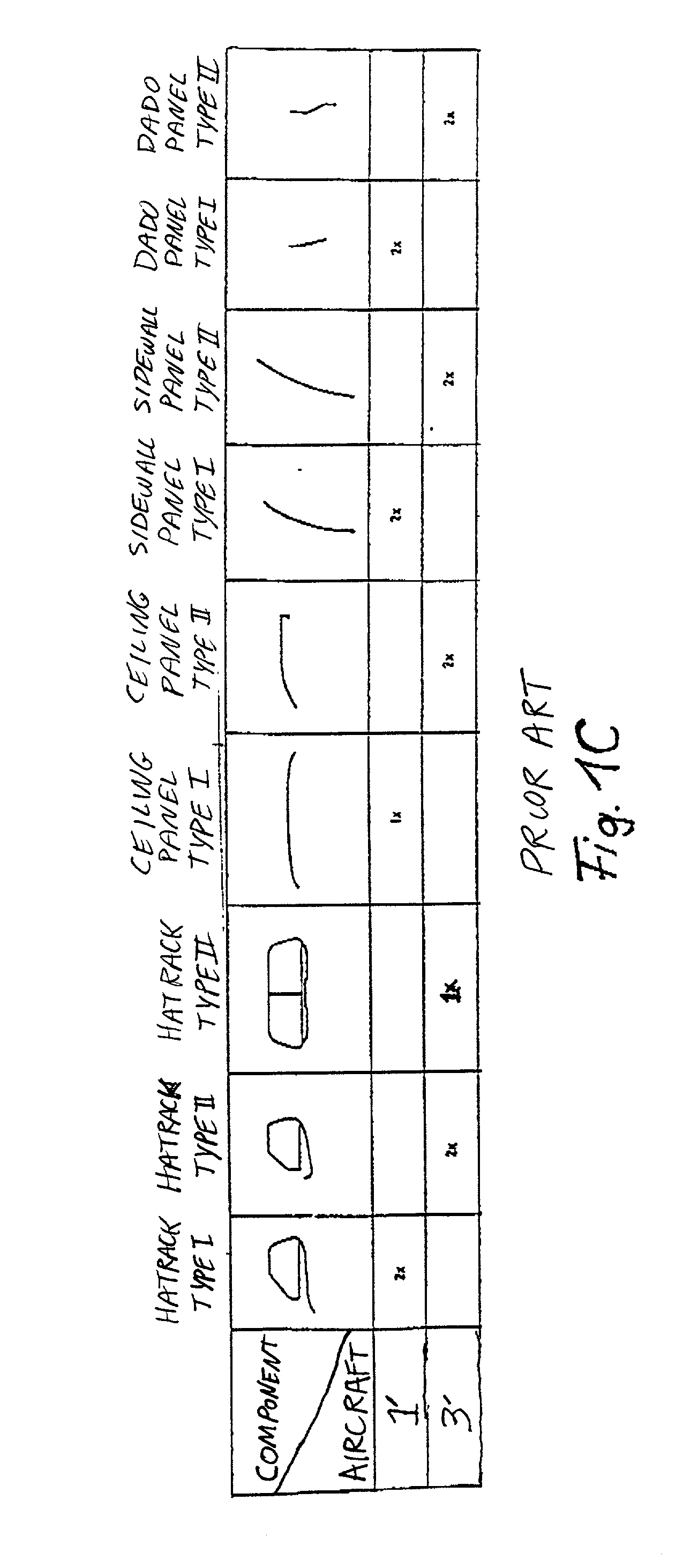

Modular trim paneling and outfitting system for an aircraft passenger cabin interior

An aircraft passenger cabin includes modular interior components selected from ceiling panels, wall panels, dado panels, window funnels, light covers, and baggage compartments or hat racks. At least one interior component is a standardized modular building block that can be used uniformly and interchangeably in different cabin configurations and sizes, in different aircraft types having different fuselage cross-sectional sizes and configurations. The interior components are modularly combined so as to be adapted to different passenger cabins in the various aircraft types. The multiplicity of distinct interior components among all aircraft types in the entire product range of an aircraft manufacturer is reduced, so that the piece count of each particular type of component is increased, and the manufacturing, installation, maintenance, replacement and inventorying costs are reduced. The time and cost for a new cabin design are reduced.

Owner:AIRBUS OPERATIONS GMBH

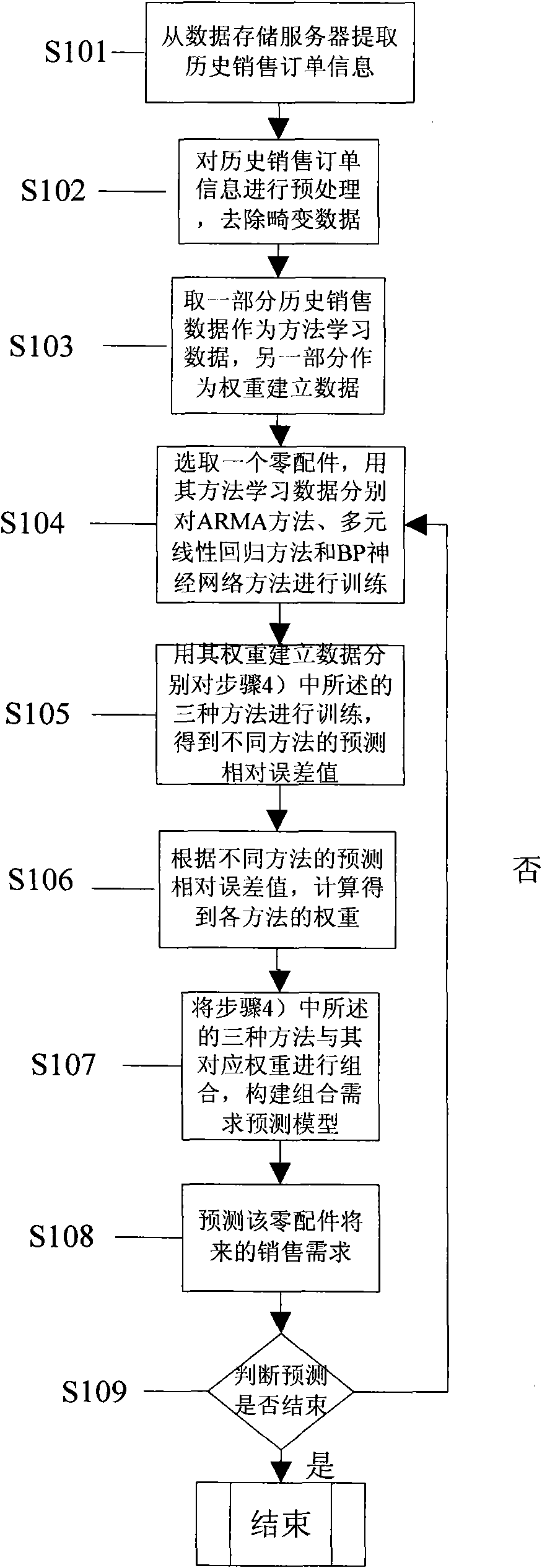

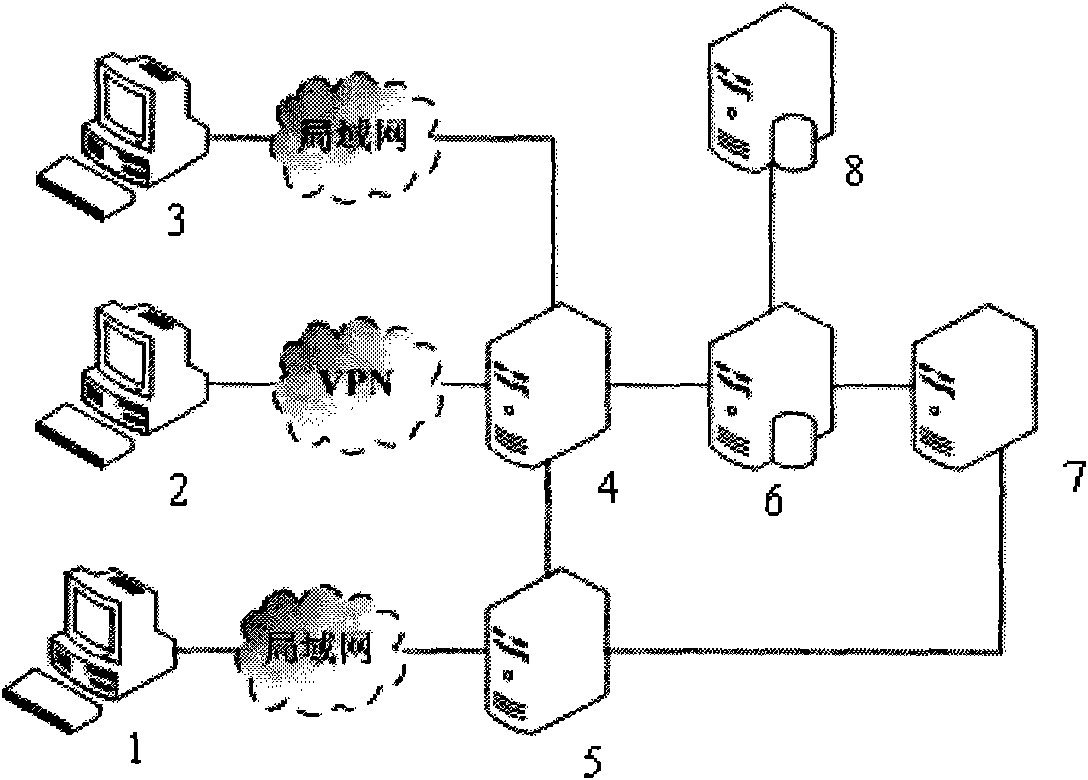

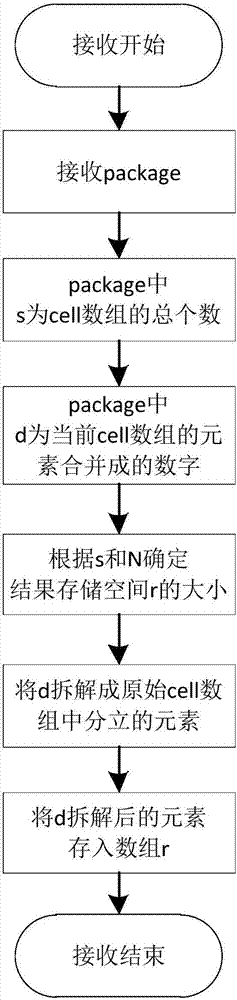

Spare part assembling demand forecasting information processing method applied to inventory management

InactiveCN102385724AImprove management efficiencyImprove satisfactionLogisticsMoving averageInformation processing

The invention relates to a spare part assembling demand forecasting information processing method applied to inventory management, comprising the following steps:1) take one part of historical sales data as method learning data and take the other part of the historical sales data as weight building data; 2) use the method learning data to practice an ARMA (Autoregression and Moving Average) method, a multiple linear regression method and a BP (Back Propagation) neural network approach respectively for each spare part; 3) apply the above three methods respectively by using the weight building data, so as to obtain forecasting relative error values for different methods; 4) calculate the weights of the above methods; 5)construct an assembling demand forecasting model; 6) forecast the future sales demands of all spare parts. Compared with the prior art, the method is suitable for the spare parts with different demand features, and has the advantages of strong objectivity, high forecasting precision, and can greatly reduce the inventory cost on the premise of having a certain service level and improves the supply chain management efficiency and customer satisfaction.

Owner:SHANGHAI UNIVERSITY OF FINANCE AND ECONOMICS

Systems and methods of inventory management utilizing unattended facilities

InactiveUS20050103842A1Improve efficiencyLow costSensing detailsDigital computer detailsLogistics managementSecure Shell

An inventory management system utilizes unattended facilities remote from a central warehouse for service parts logistics. Items are placed in inventory in secure enclosures at the unattended facilities by the inventory management service or are delivered directly to the unattended facility. The unattended facilities may be located near one or more customers to reduce a service technician's travel time and customers' inventory costs. A service technician utilizes a passcode to retrieve needed items. The service technician may order items that are not kept in the inventory of the unattended facility in which case the items may be delivered to the unattended facility and the service technician may receive a notification related to all the items that comprise an order that the order is ready for pick up at an unattended facility. Unused, used or damaged parts may be returned by a technician to a remote secure enclosure where such returned parts may be retrieved and disposed of, repaired or placed back into inventory if not damaged or after repair, and the processing of such returned parts begins by information entered into a data entry device at the remote secure enclosure location. Return items that are not damaged may be included in the inventory of an unattended facility.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

Warehouse management system and method based on intelligent robot

InactiveCN107256468AEfficient managementEfficient use ofLogisticsStorage devicesLogistics managementStorage management

The invention discloses a warehouse management system and method based on an intelligent robot, and the method comprises the steps: setting a shelf with a scanning code, recognizing a commodity through the scanning code and a moving robot for carrying the commodity, receiving E-commerce ordering information, transmitting the position information of the commodity on the shelf to the moving robot and a computer with a wms storage management system, temporarily storing the information on a goods picking wall for the commodity carried by the moving robot, scanning the goods information on the goods picking wall, and storing the shipment information in a scanner in the computer. The method can achieve the effective management of the warehouse flow and space, achieves the batch management, the quick warehousing and delivery and the dynamic sorting. The method quickly helps a logistics manager of an enterprise carry out the complete control and management of warehousing, delivery, moving, sorting and distribution. The method improves the commodity response speed through the effective use of the storage space of a warehouse, reduces the inventory cost of the enterprise, and improves the market competiveness of the market.

Owner:仓智(上海)智能科技有限公司

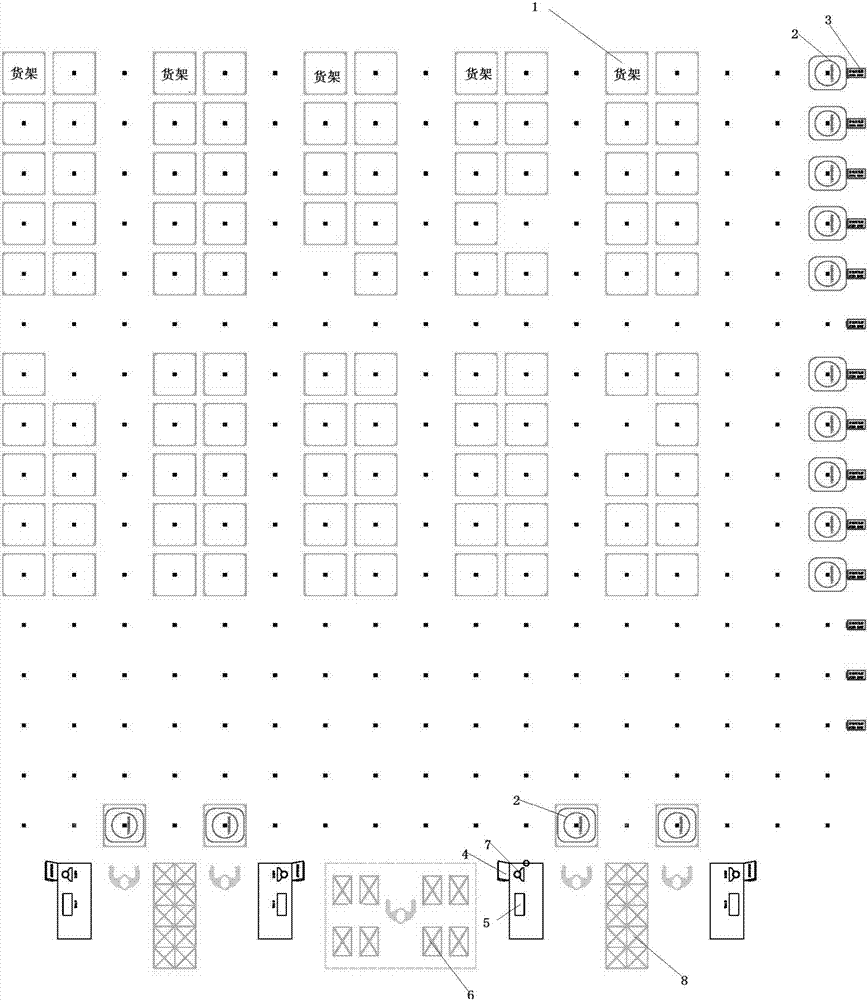

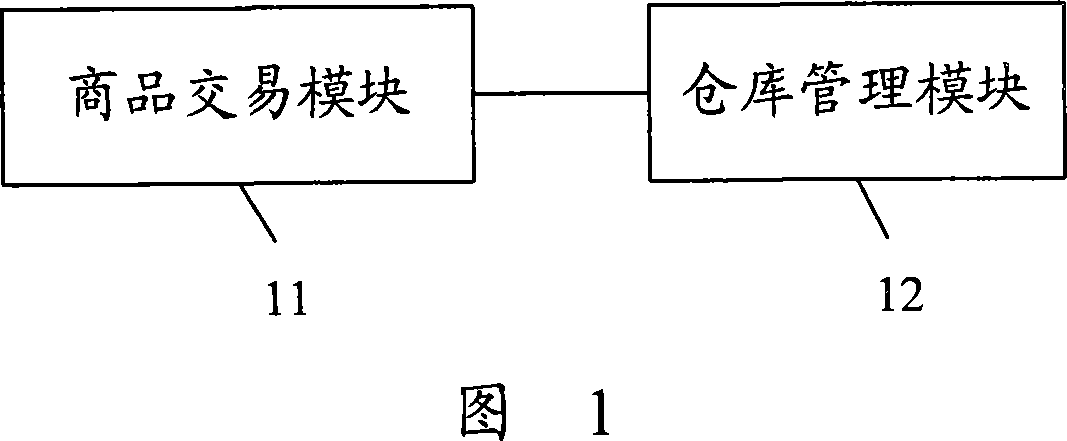

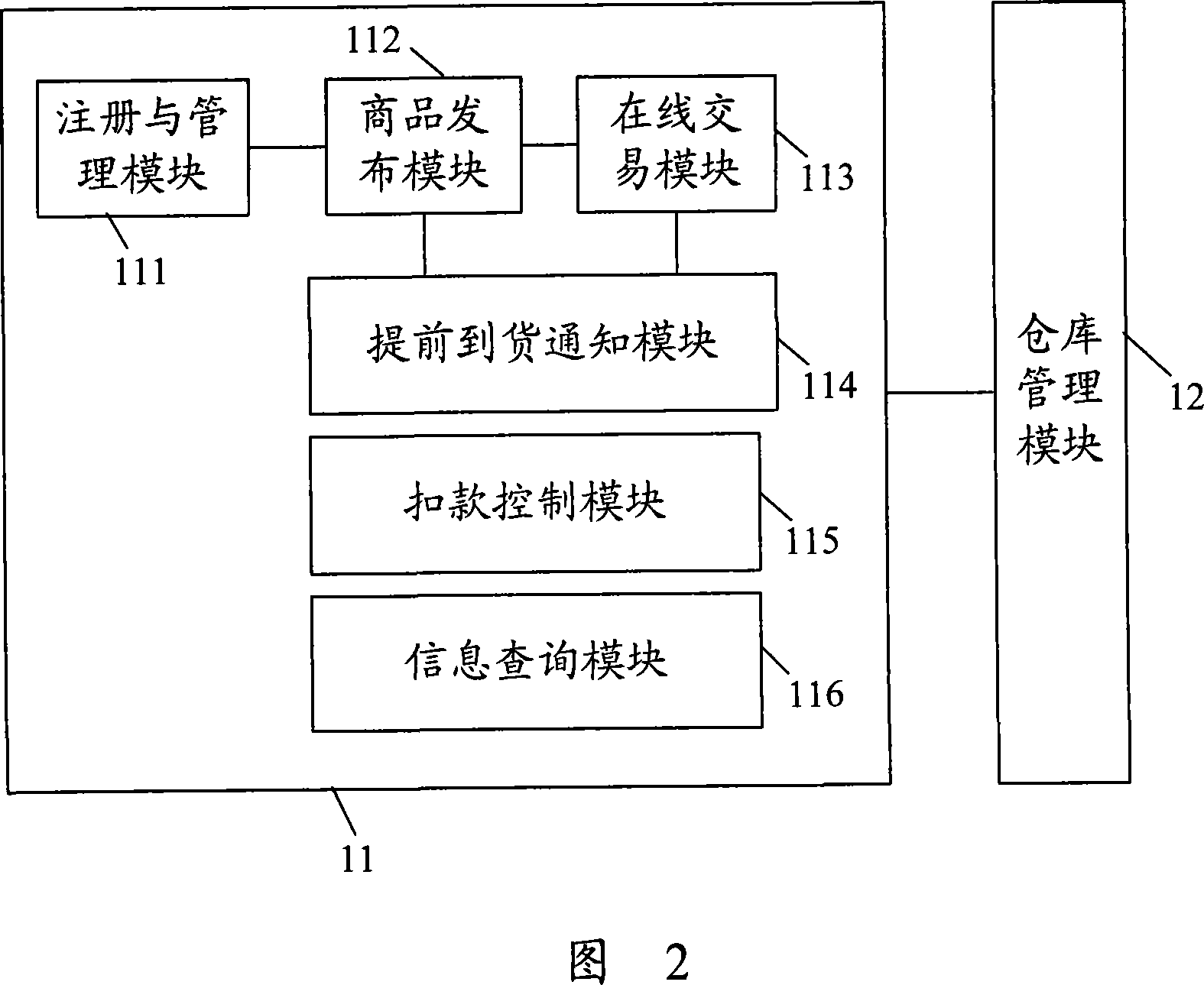

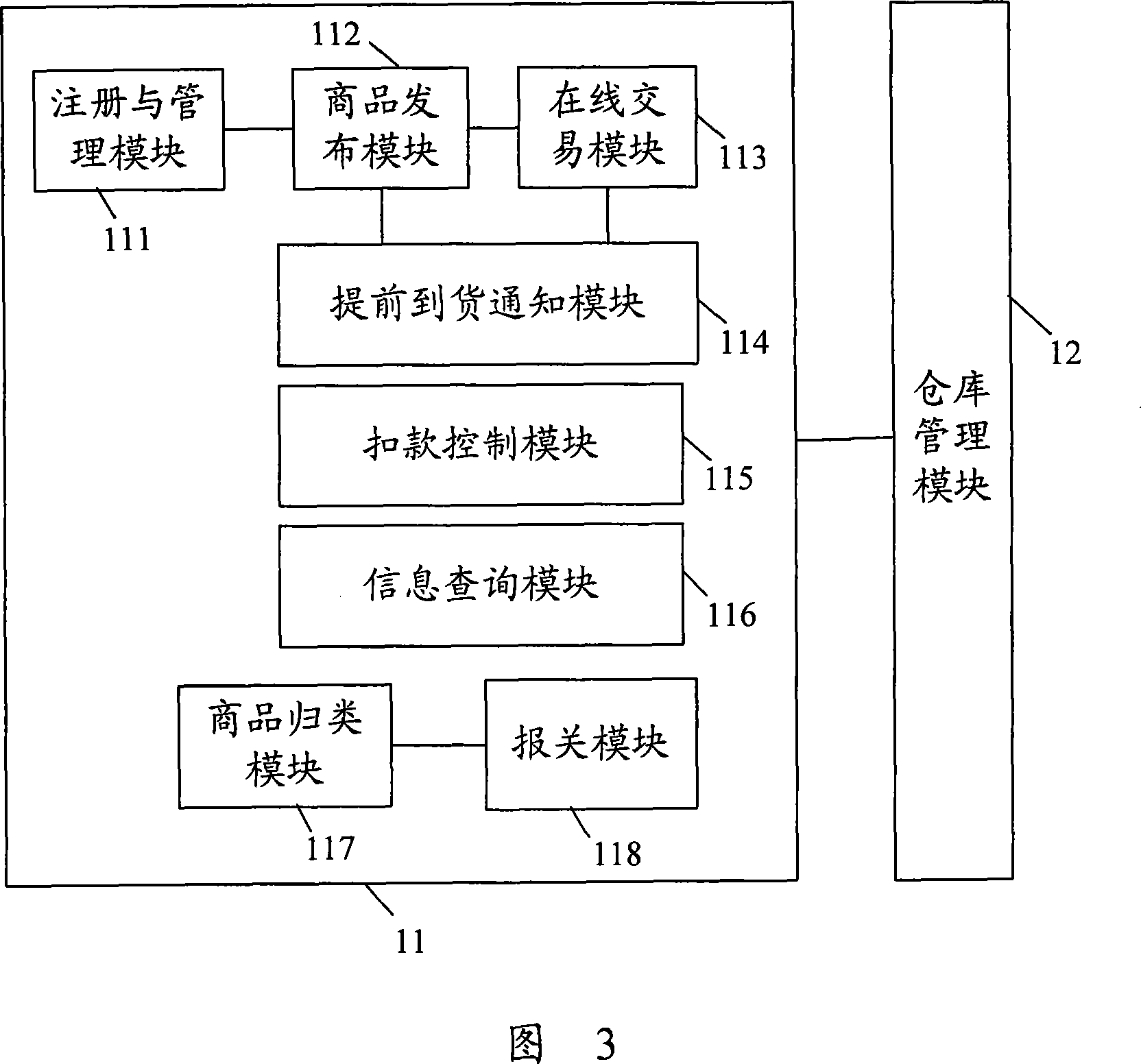

Pivotal inventory network apparatus based on supplier management

InactiveCN101067860AImprove timelinessReduce inventory costsLogisticsCommerceThird partyLogistics management

This invention discloses a network device of hinge stock based on network management including: a commodity trade module providing on-line commodity trade for bargainers and purchasers and a storage management module used in receiving commodity information when commodity of a bargainer arrives / sends VMI HUB and after a wireless terminal scans the 2-D bar on a package box of the commodity and managing the stock of the storage according to the information, which provides an electronic business platform of a third party for the distribution market to realize zero stock and increase the effect of information treatment.

Owner:郑壮洪

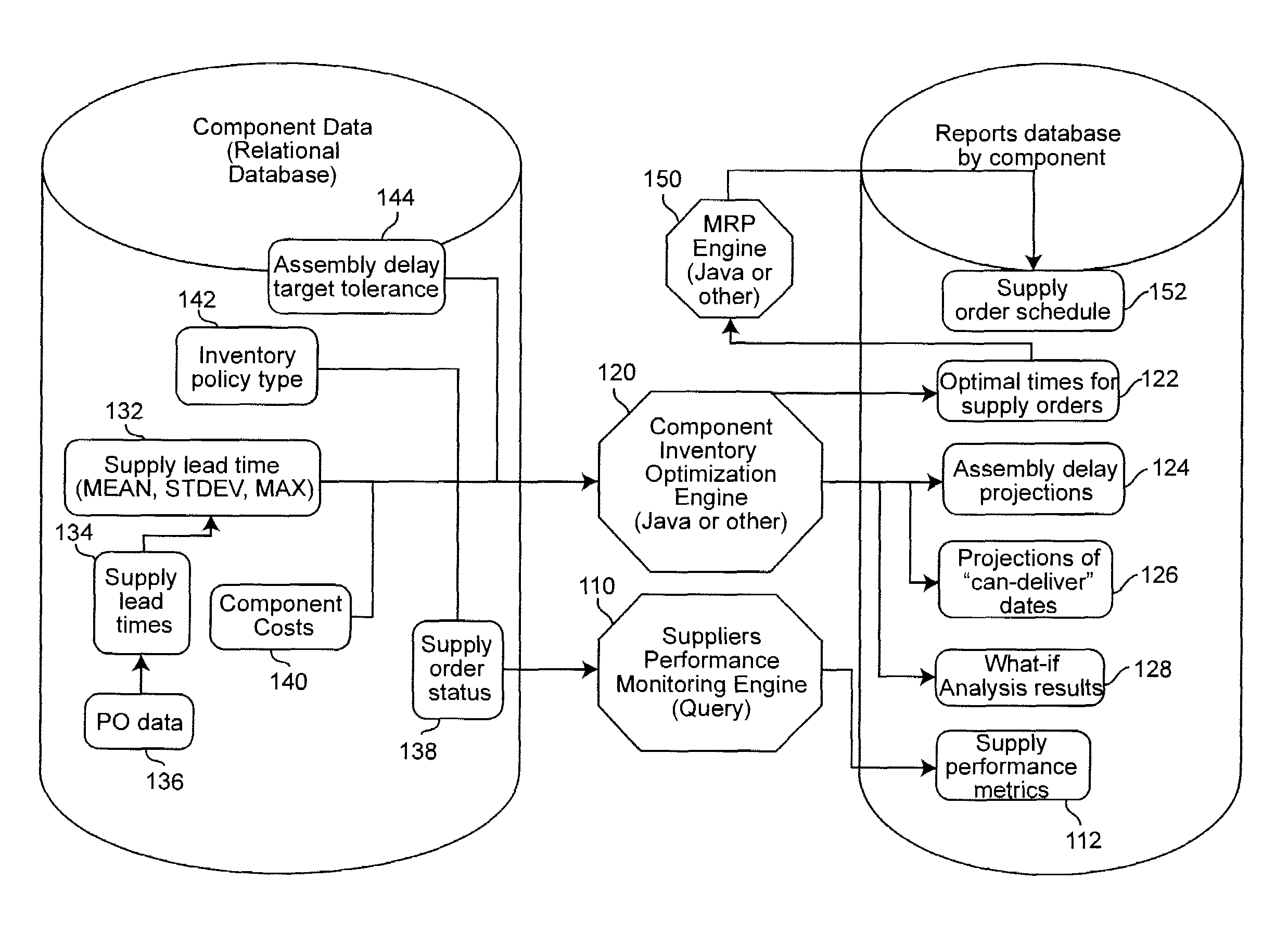

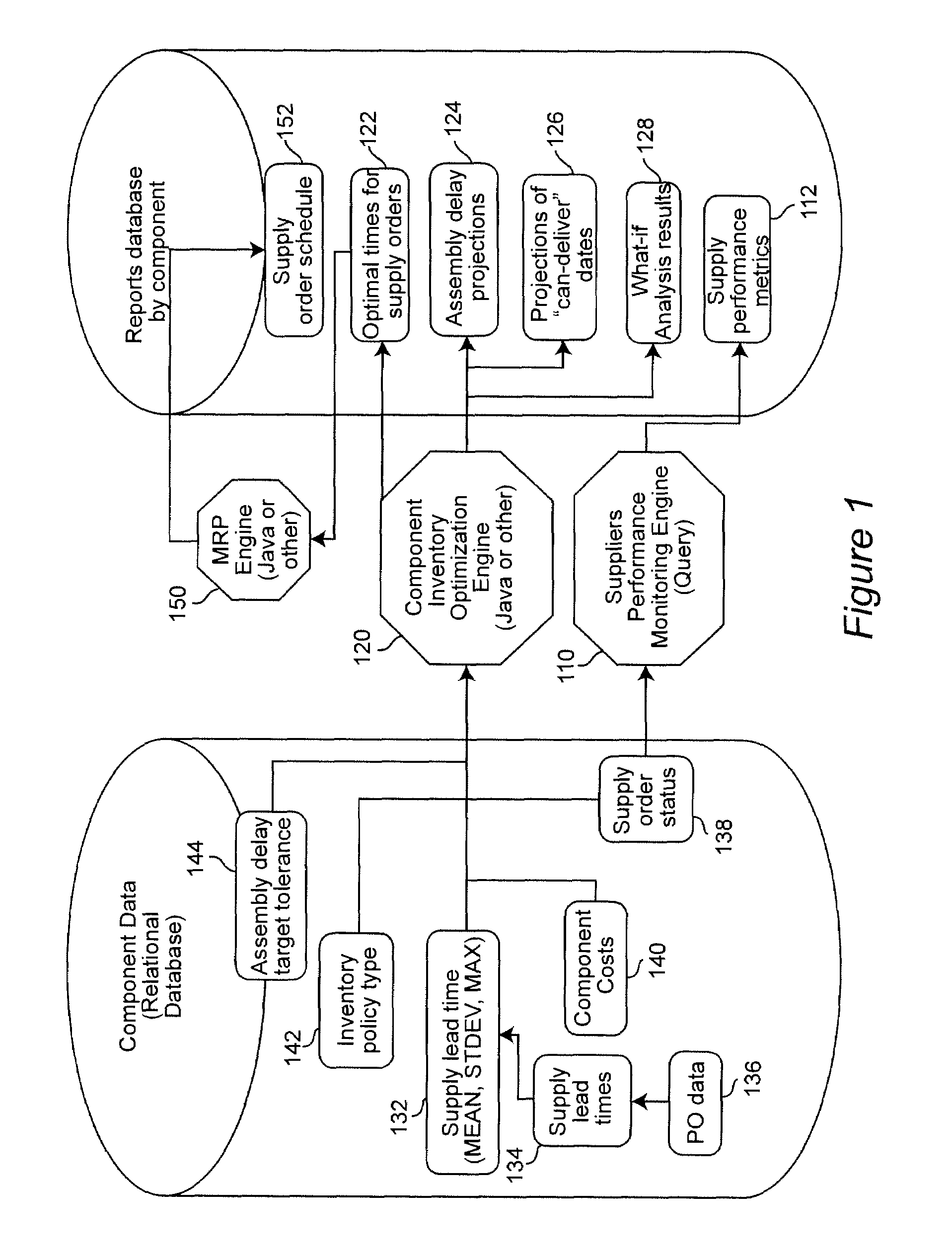

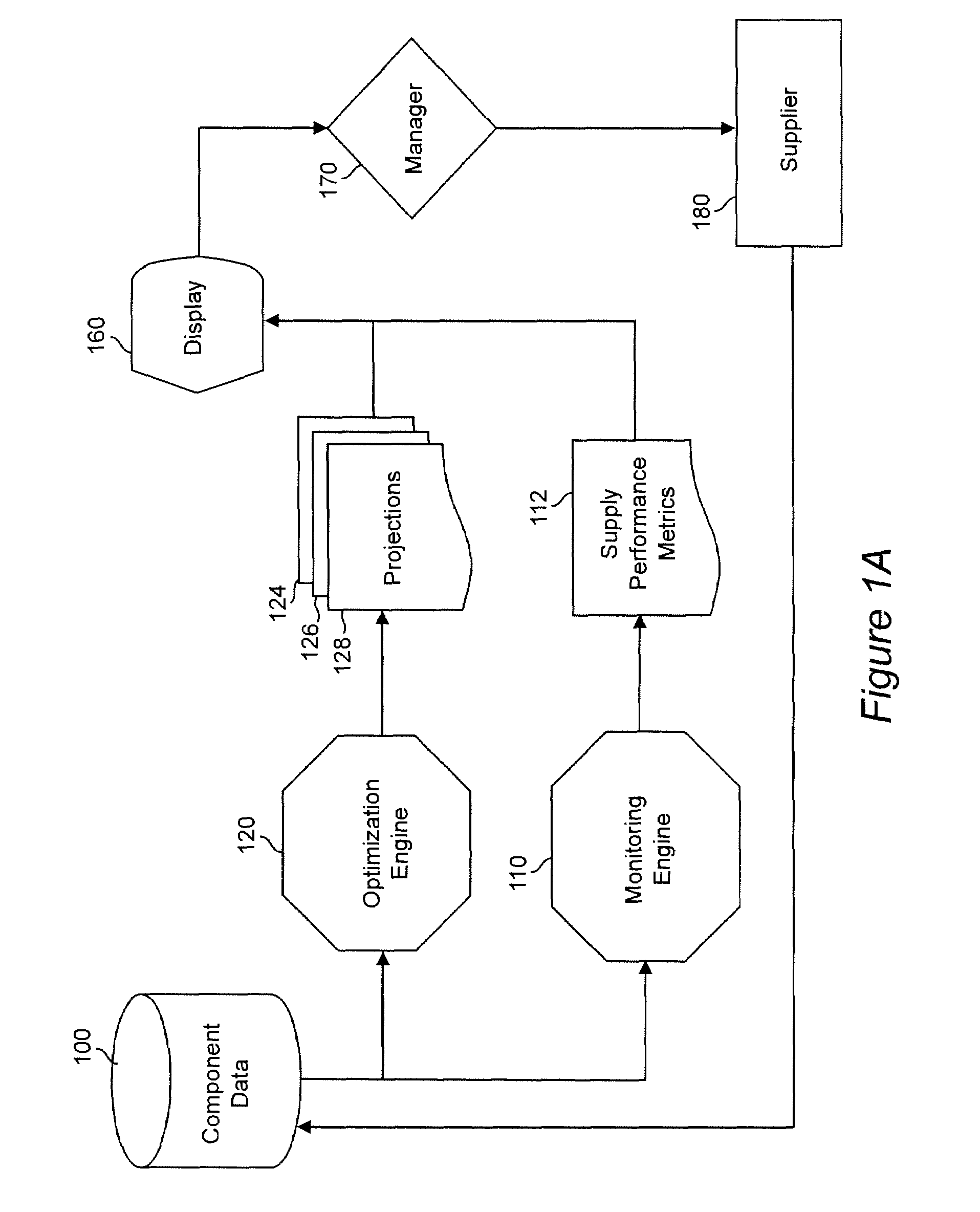

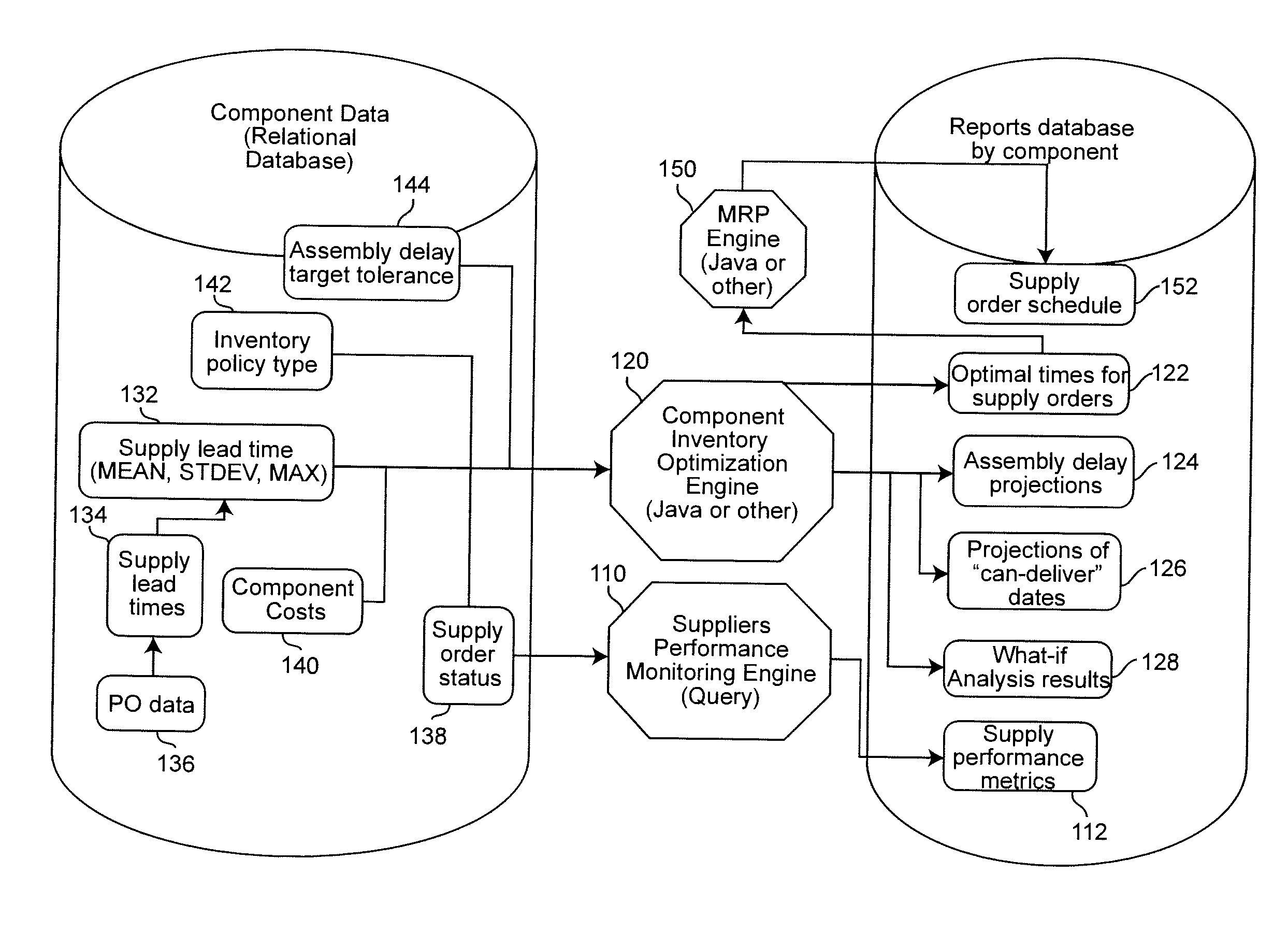

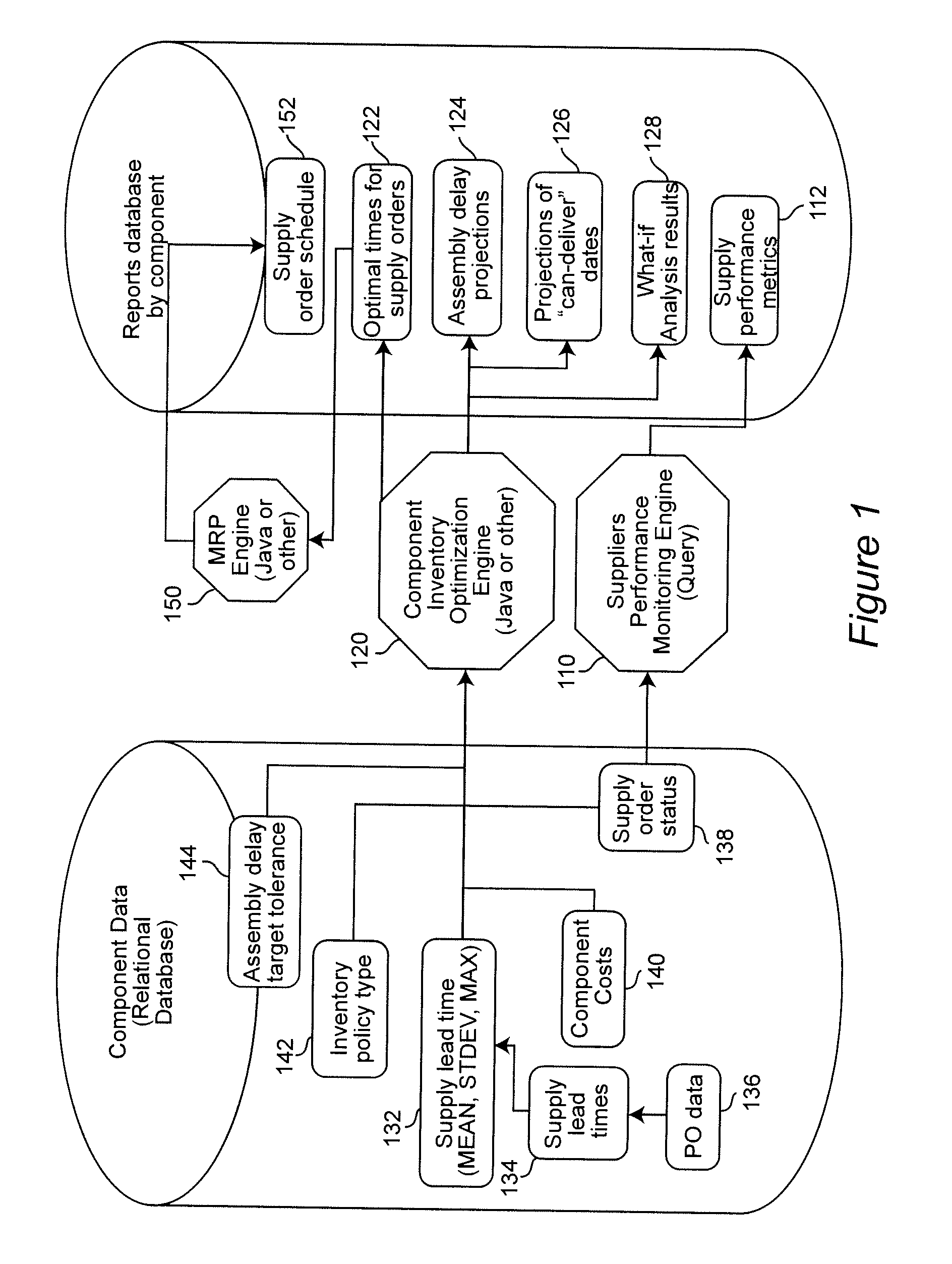

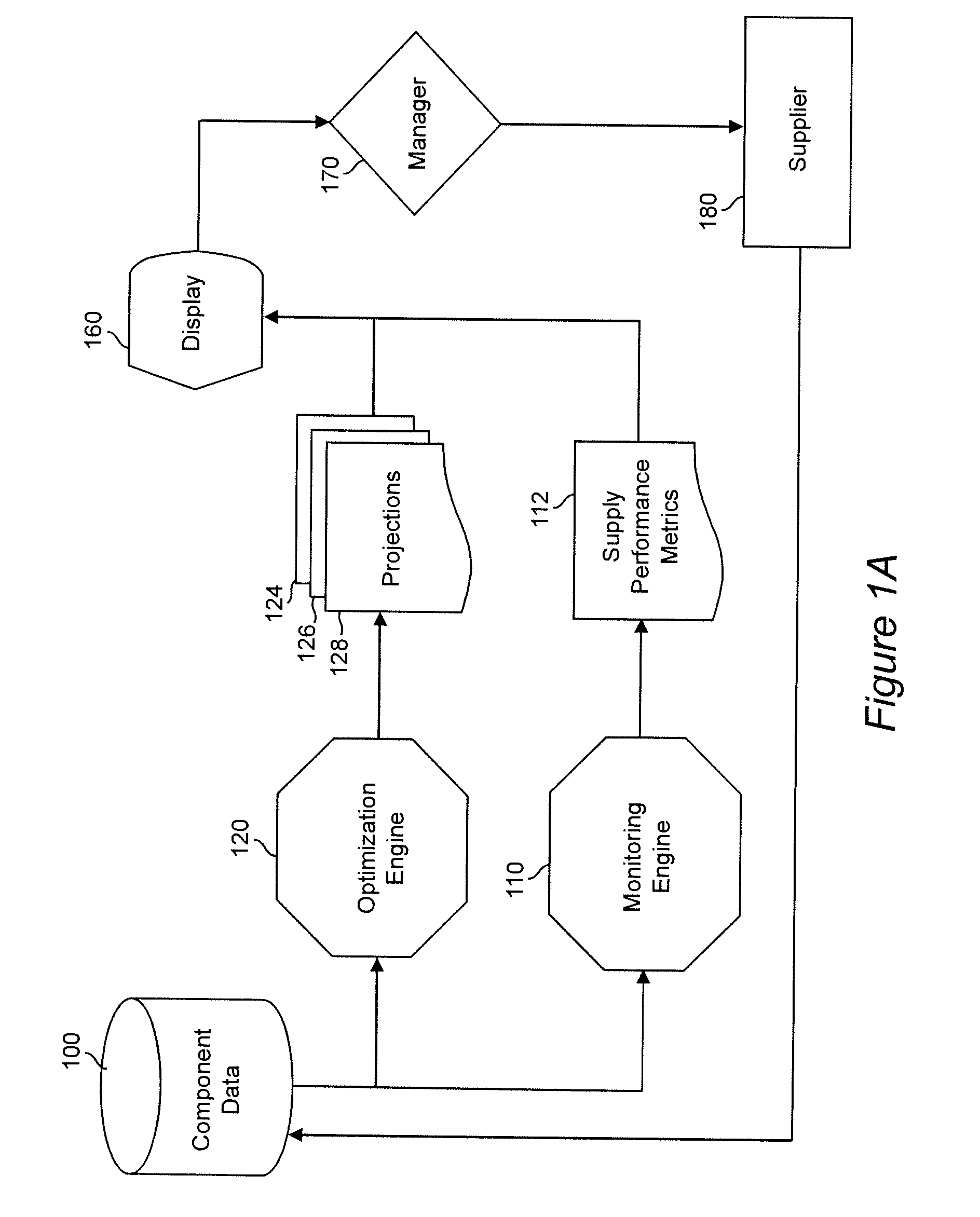

System and process for supply management for the assembly of expensive products

ActiveUS7418307B2Guaranteed uptimeHigh level confidenceResourcesSpecial data processing applicationsStock levelTime schedule

A Managing component supply for complex products is achieved by monitoring the delivery performance of component suppliers and optimizing the times at which orders are placed. Supply delivery performance targets are set for each supplier, and component order times are optimized by 1) optimizing safety stock for each component, 2) calculating optimal times to place supply orders in order to maintain the safety stock level, and then 3) iterating safety stock calculations in order to minimize overall inventory costs and maximize supply availability. The process takes into account supply lead times, component costs, and target tolerances for delays in the assembly of components. The effects of changes in supply lead time performance on assembly schedules are projected for planning purposes.

Owner:GLOBALFOUNDRIES US INC

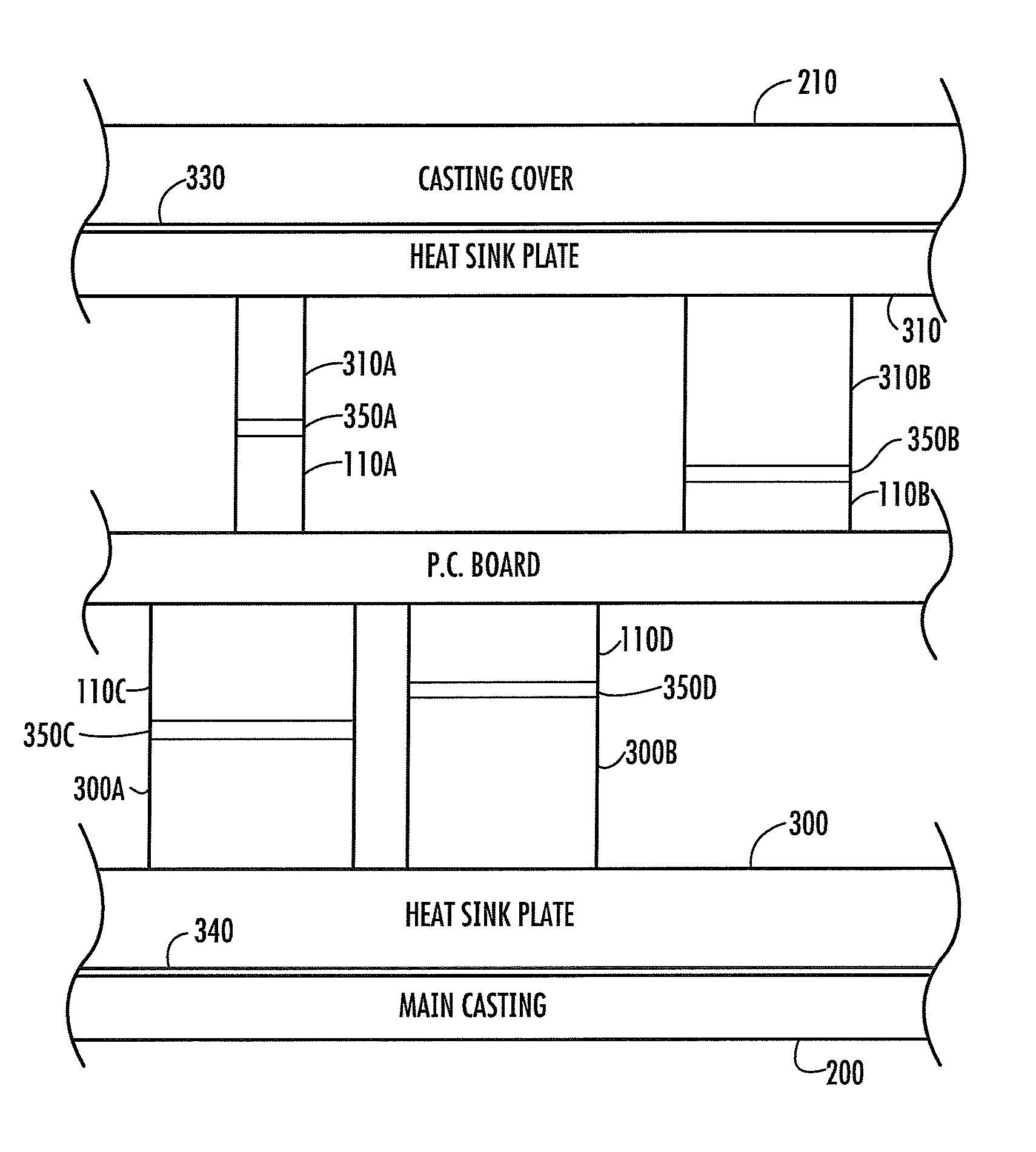

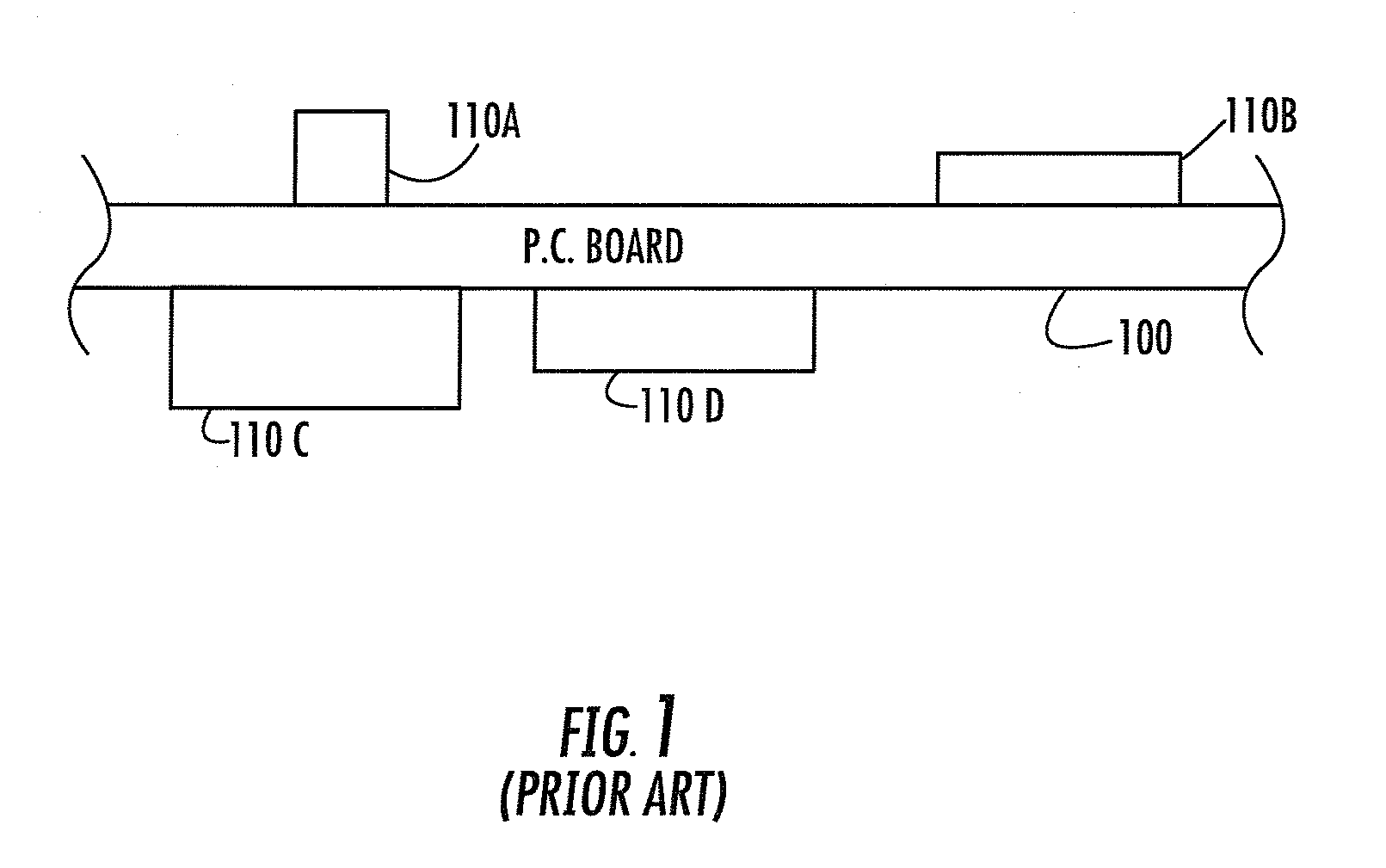

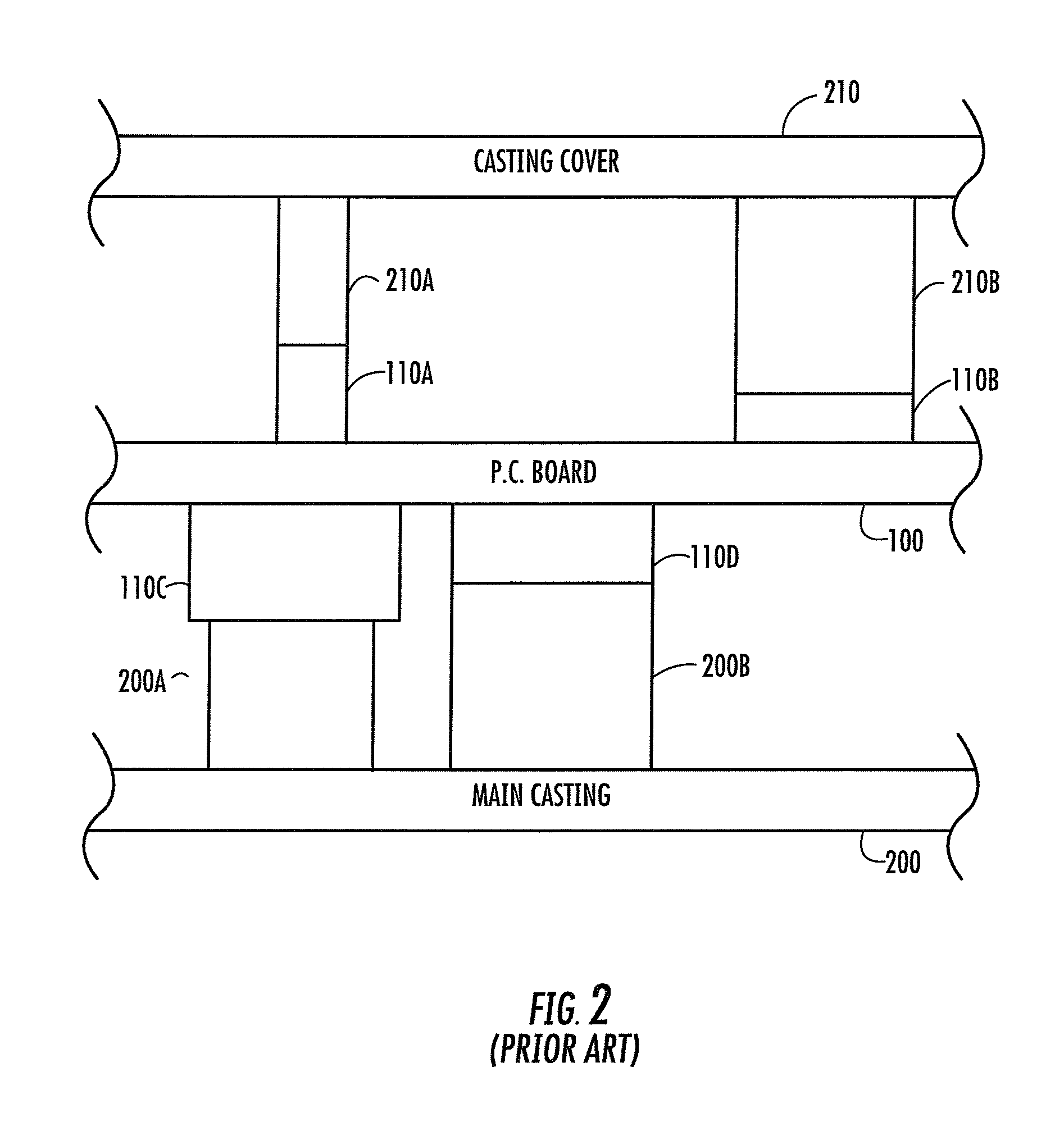

Modular heat sinks for housings for electronic equipment

ActiveUS7855891B1Show cabinetsSemiconductor/solid-state device detailsGeneral purposeElectrical conductor

A housing for an outside plant telecommunication equipment (OSP) which uses modular heat sink assemblies. OSP housings contain electronic circuit boards on which are mounted electrical components that generate heat. Thermal conductors or mesas contact the electrical components to conduct heat from the components to the environment. Rather than create single purpose housings with cast thermal conductors, the improved housing uses heat sink plates which can easily be swapped out to accommodate a variety of electronic circuit boards that might be needed within a general purpose housing. Together with faster turnaround time to create a new design for a housing, lower manufacturing and inventory costs result.

Owner:ADTRAN

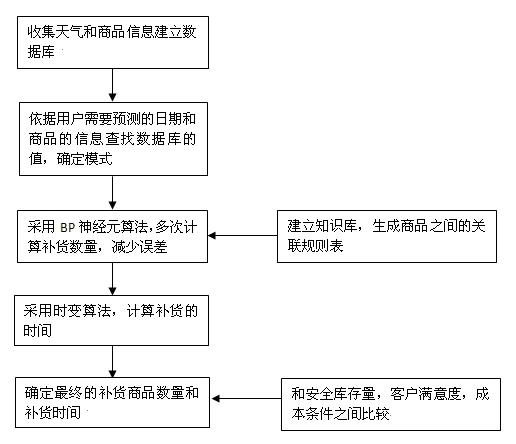

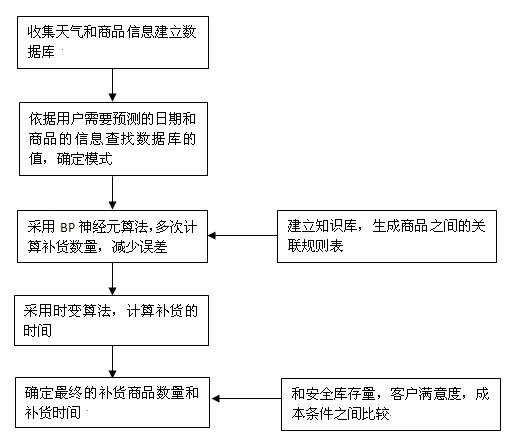

Warehouse replenishing method

InactiveCN102184507AControl Replenishment ManagementReduce inventory costsCommerceKnowledge engineeringStockout

The invention discloses a warehouse replenishing method, which belongs to a supermarket chain support technology. By introducing a knowledge library which is established on the basis of knowledge engineering and fusing the replenishing decision support system of an information system, warehouse replenishing management can be controlled more intelligently for different sale modes, and a replenished commodity number and replenishing time can be further modified according to cost, client satisfaction, a stockout rate, a safe stock quantity and the delivery time of suppliers. Compared with the prior art, the method has the advantages that: the stock cost can be reduced, and the stock management efficiency can be improved.

Owner:SUZHOU LIANGJIANG TECH

System and process for supply management for the assembly of expensive products

ActiveUS20070270990A1Guaranteed uptimeHigh level confidenceResourcesSpecial data processing applicationsStock levelDelivery Performance

A method and system are described for managing component supply for complex products by monitoring the delivery performance of component suppliers and optimizing the times at which orders are placed. Performance of component suppliers is monitored by setting supply delivery performance targets for each supplier, and then monitoring and managing supply delivery performance for each supplier. Component order times are optimized by 1) optimizing safety stock for each component, 2) calculating optimal times to place supply orders for each component in order to maintain the safety stock level, and then 3) iterating safety stock calculations in order to minimize overall inventory costs and maximize supply availability, taking into account supply lead times, component costs, and target tolerances for delays in the assembly of components. The method also provides projections of effects of changes in supply lead time performance on assembly schedules so that managers can seek delivery improvements from component suppliers.

Owner:GLOBALFOUNDRIES US INC

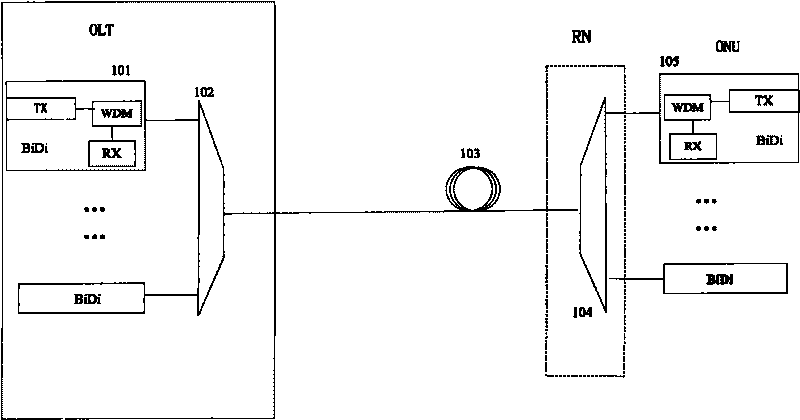

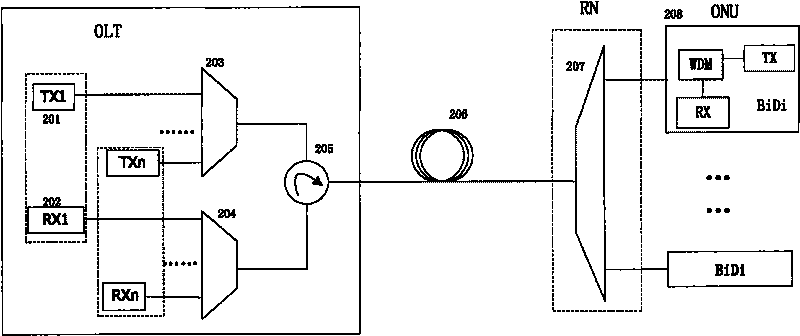

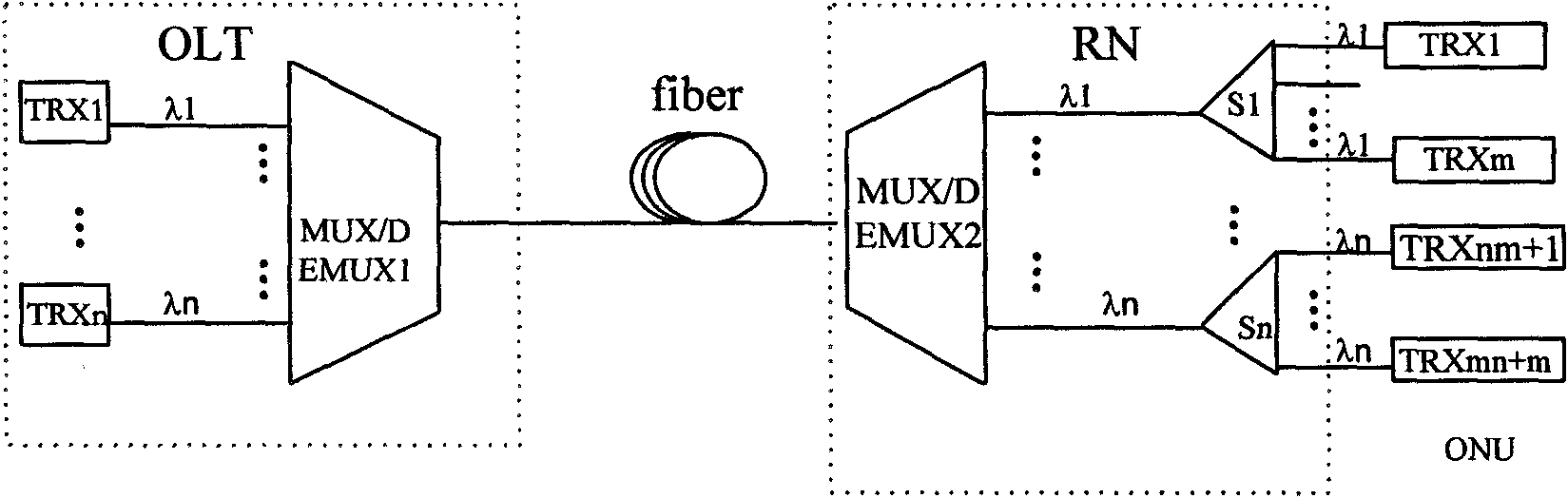

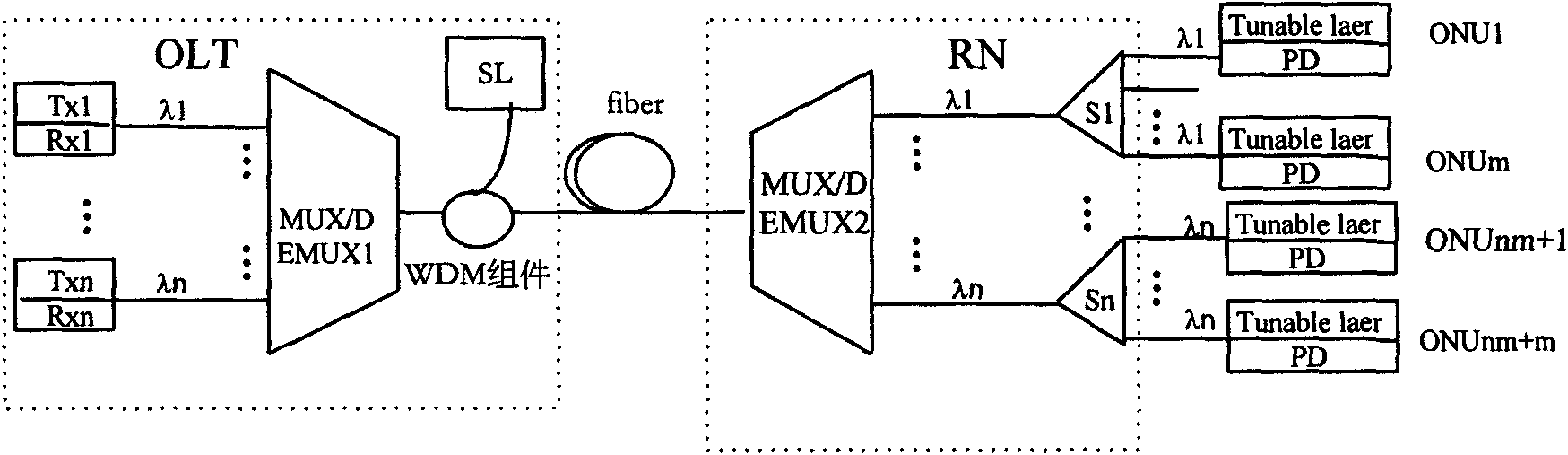

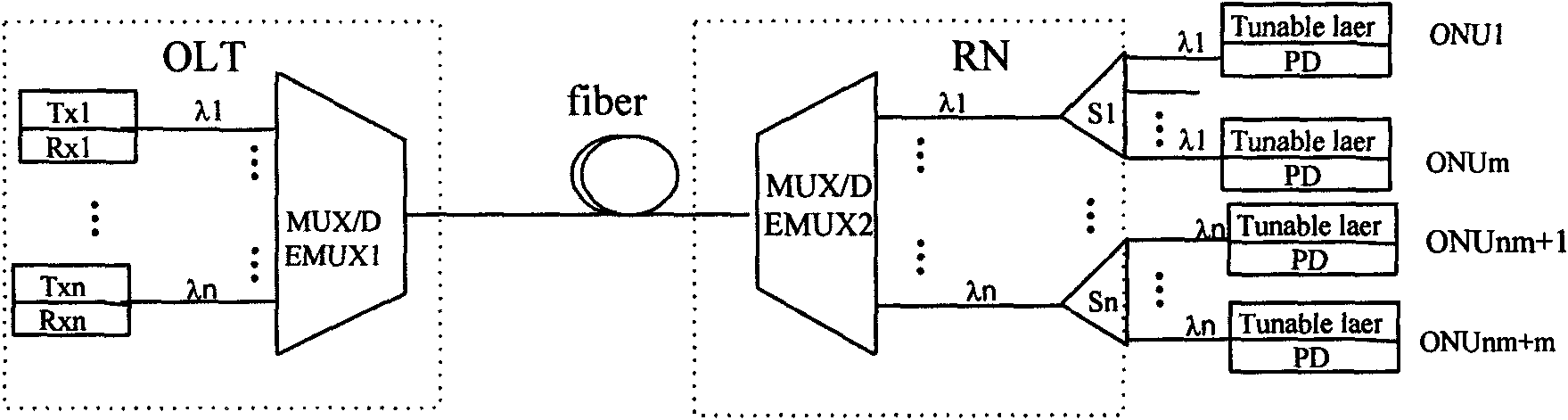

WDM PON device with dynamically allocable wavelengths

ActiveCN101729949ARealize dynamic configurabilityRealize dual-ended dynamic configurabilityMultiplex system selection arrangementsWavelength-division multiplex systemsOptical ModuleOptical line termination

Owner:FENGHUO COMM SCI & TECH CO LTD

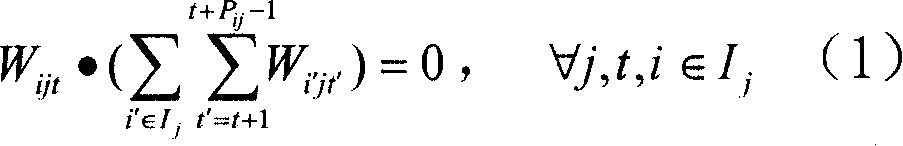

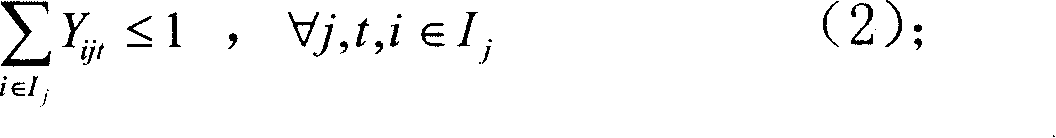

A real time dynamic re-dispatching method for production dispatching system in process industry

InactiveCN101261695AIncrease productivityRun in real timeForecastingProgramme total factory controlLogistics managementProgram planning

The invention relates to a real time dynamic rescheduling method used for a process industry production scheduling system, aiming at solving the problems of present domestic process industry enterprises that production planning and dispatching have low efficiency, poor accuracy and real-time capability. The real time monitoring method of the invention includes the establishment of a scheduling-optimization math model and the working-out of a dispatching-optimization plan, the completion of the execution of production dispatching instructions and timely tracking calculation; a rolling optimization method includes the arrangement of dispatching time periods, the calculation of the state changes of various production data from present time to scheduling starting time, the generation of the data files of a target model and the establishment of the scheduling-optimization math model. The method of the invention is characterized by real-time, flexibility and promptness, etc. and can realize the integration of the control, the operation, the planning and the management of production-process and enterprise management to realize the balanced and high-effective production of enterprise logistics, production capability and source, thus enhancing the integral production efficiency of enterprises and reducing the cost of production and stock.

Owner:HANGZHOU DIANZI UNIV

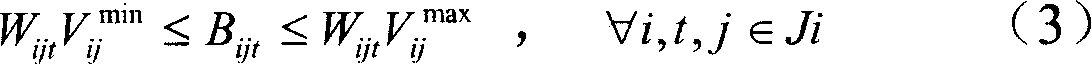

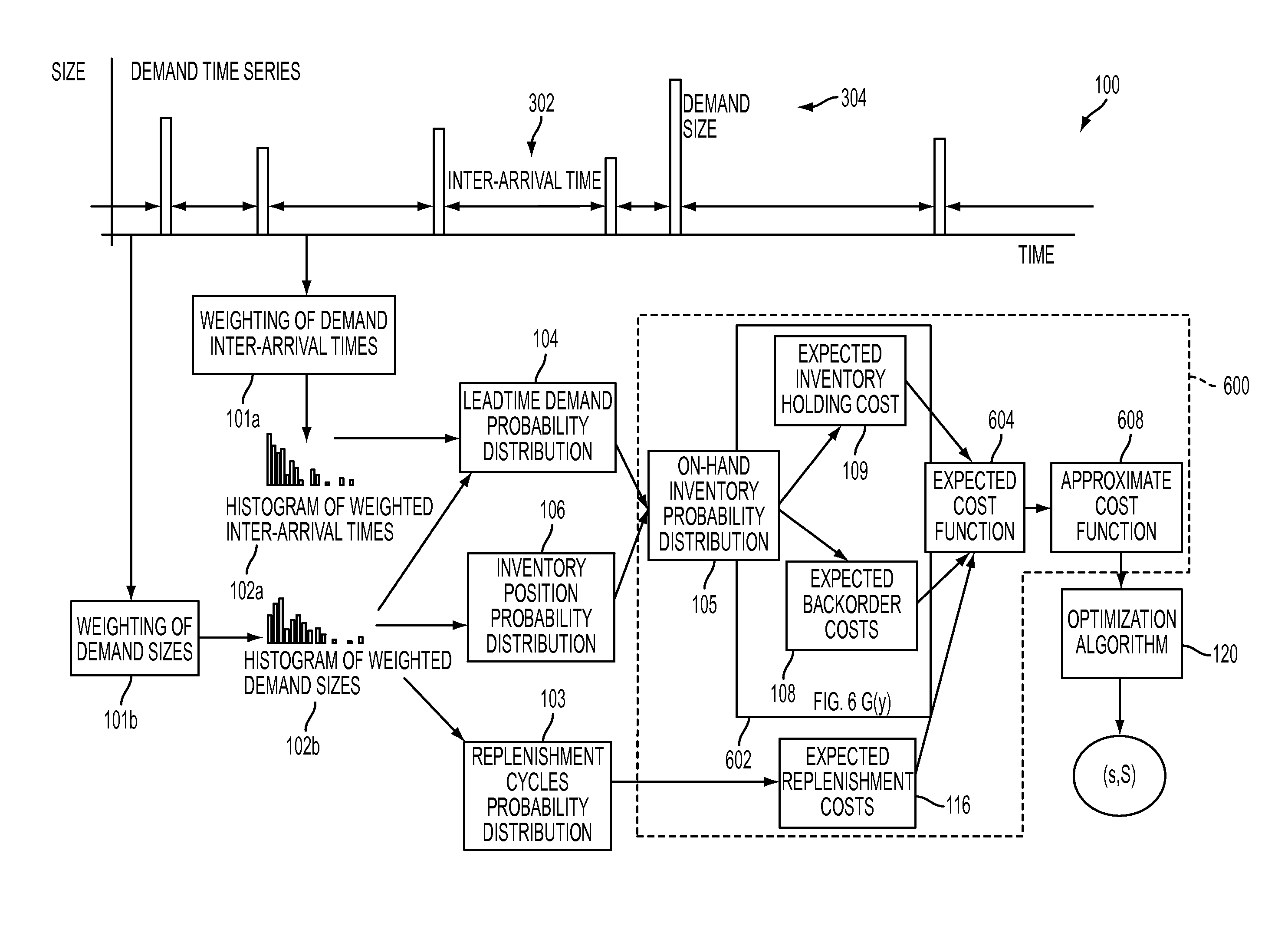

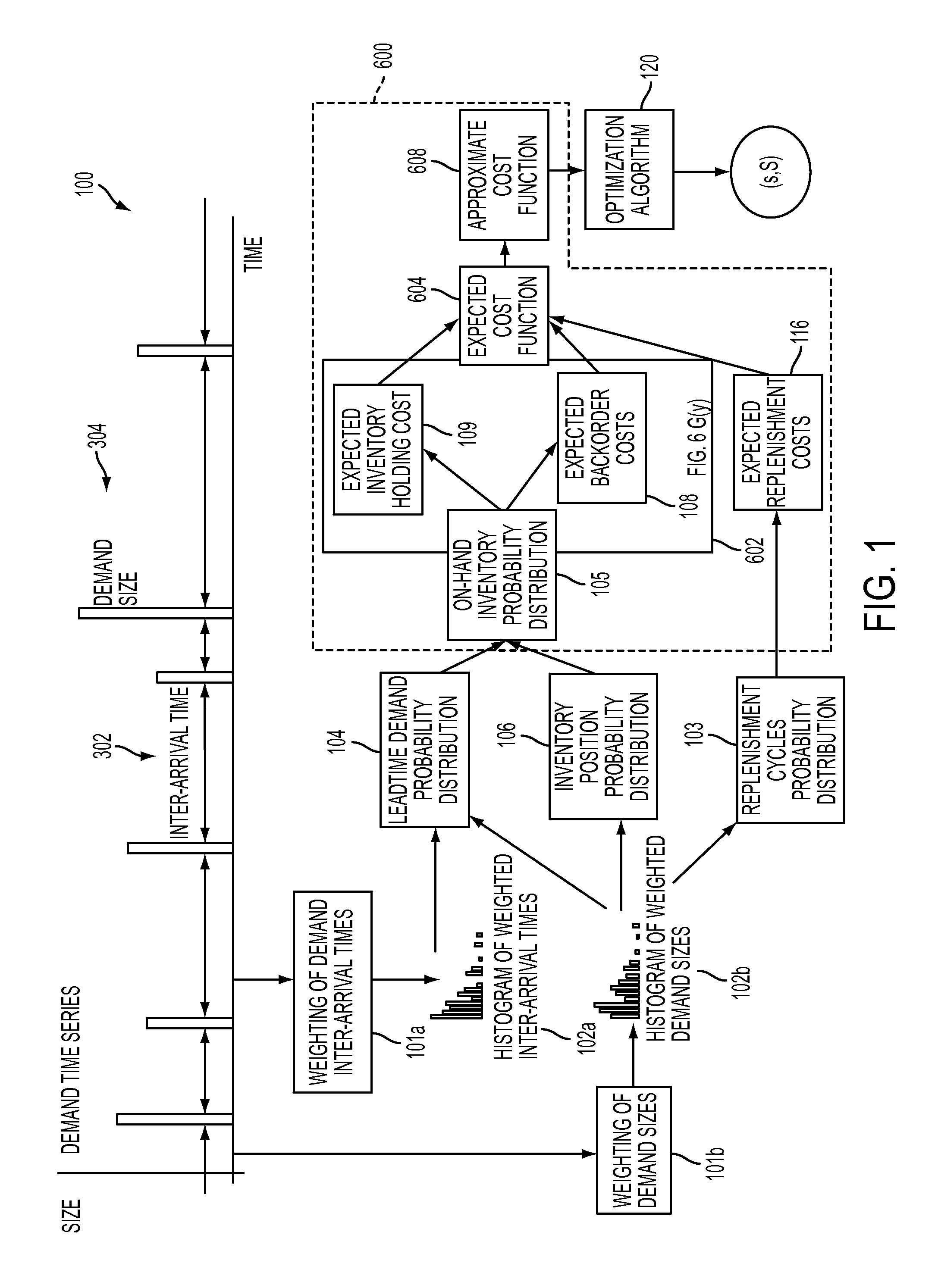

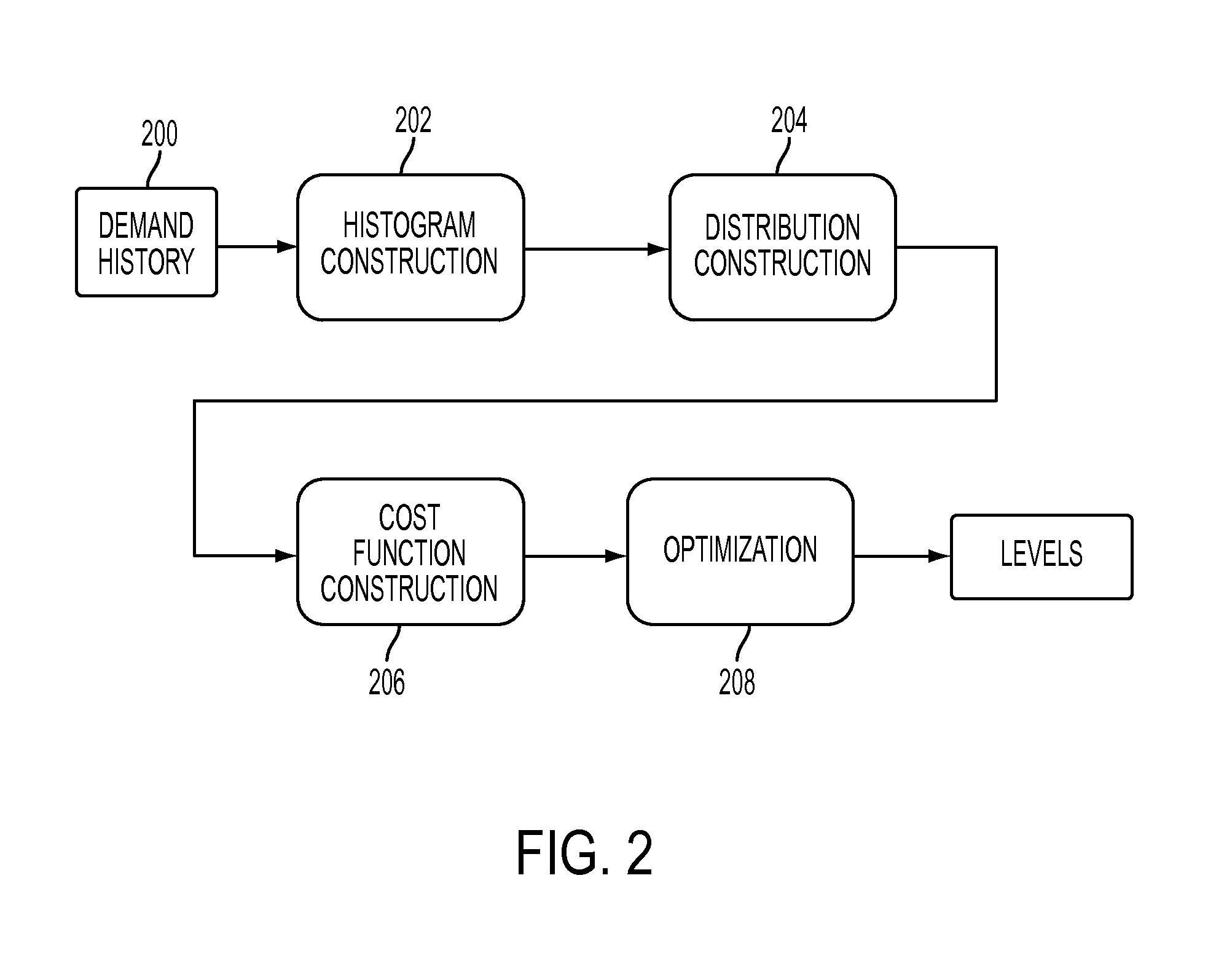

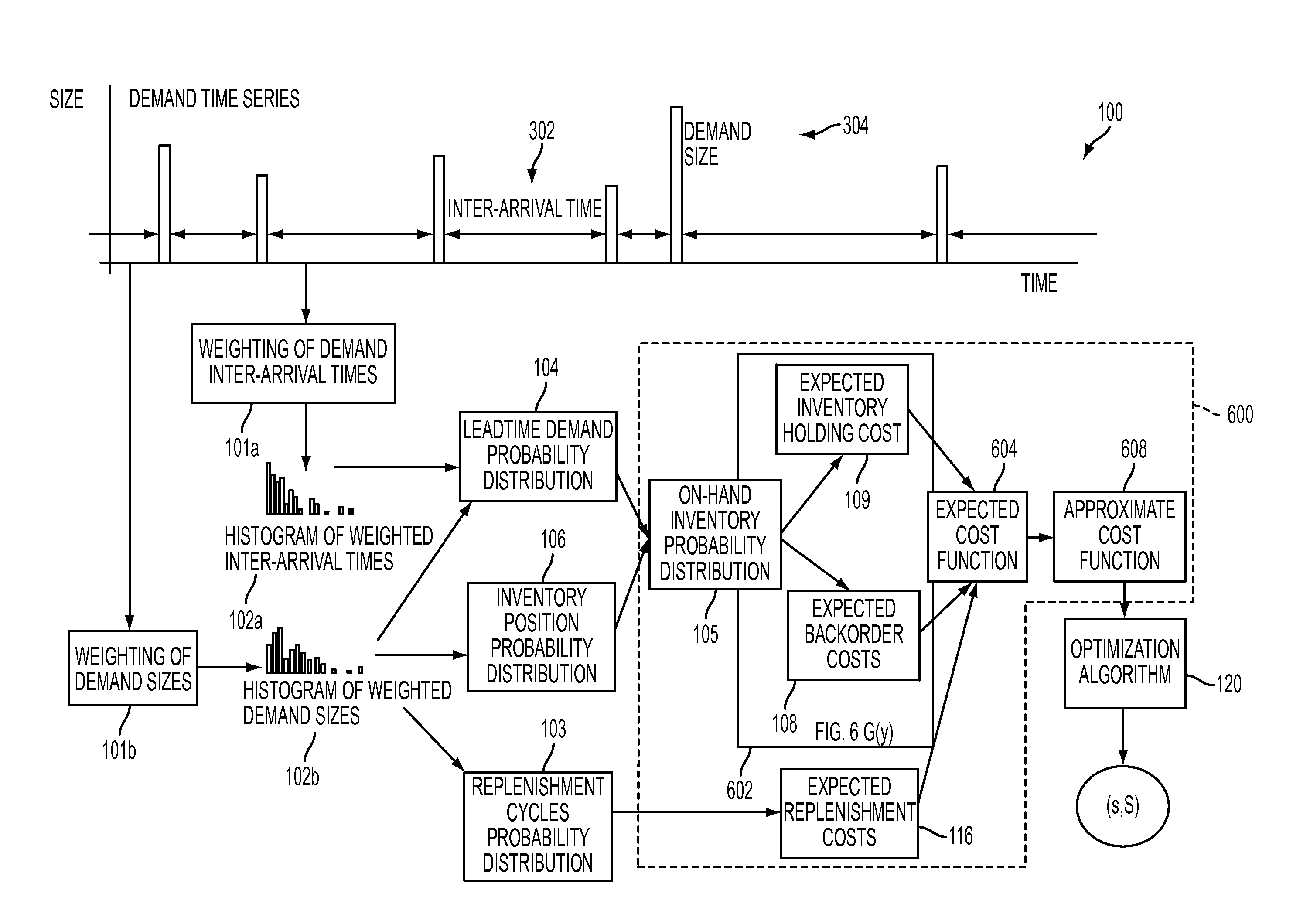

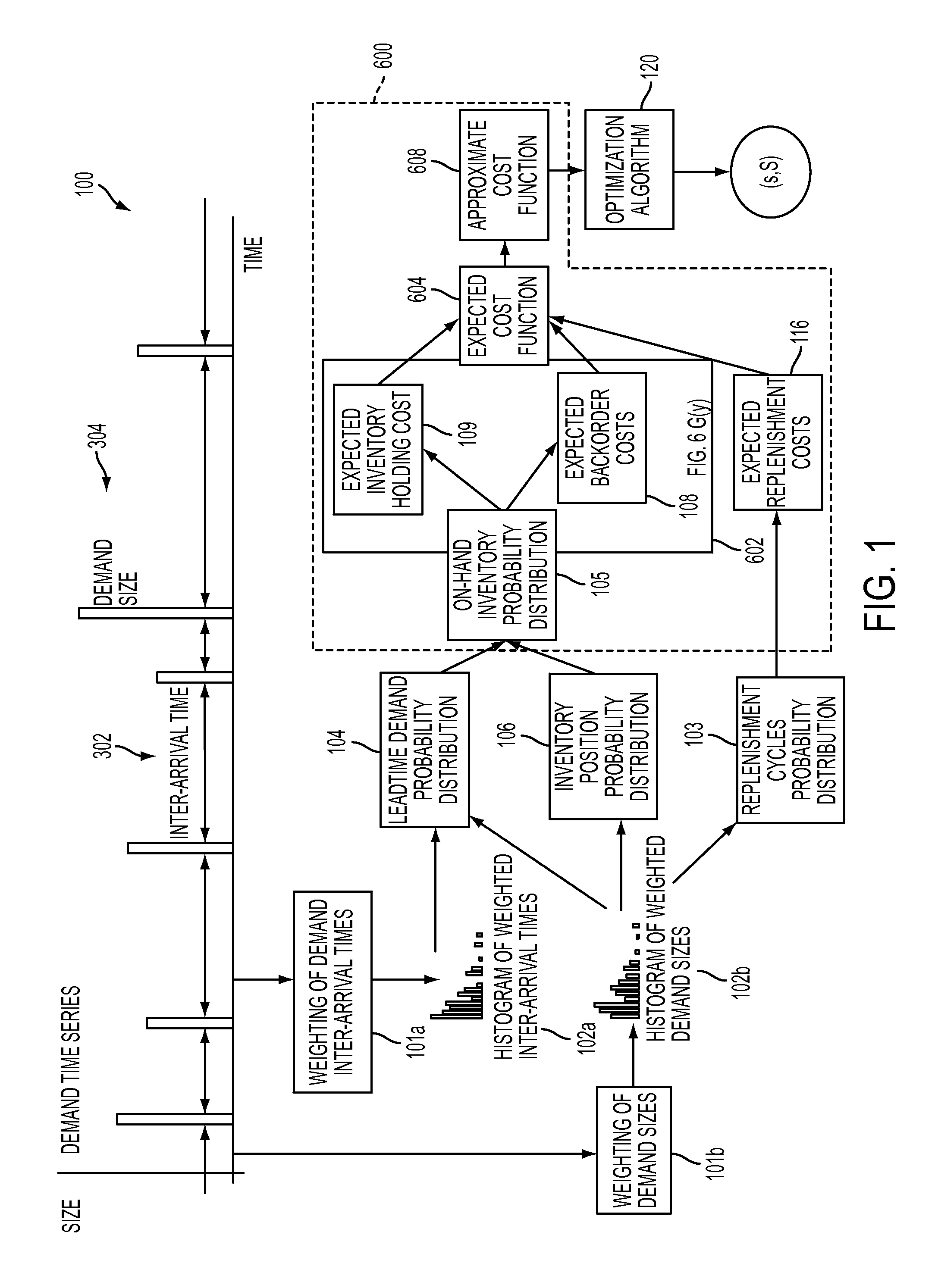

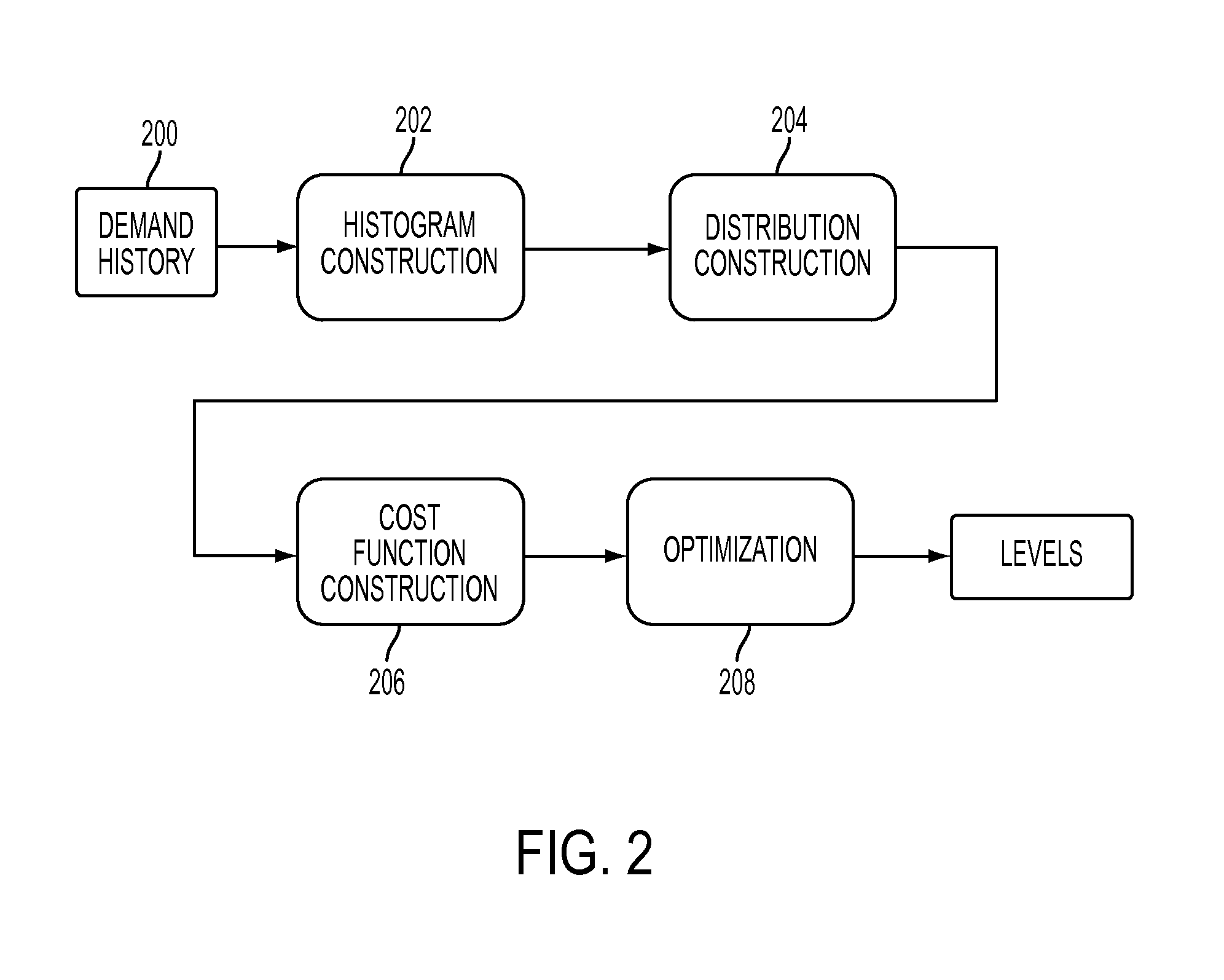

Method and computer system for setting inventory control levels from demand inter-arrival time, demand size statistics

A method or a machine determines minimum (s) and maximum (S) inventory control levels (s, S) for inventory items based upon a demand history of the inventory items, such as demand inter-arrival times (IA) and demand requisition sizes (RS). An expected cost is computed including two or more inventory item cost components of expected cost of ordering, expected cost of carrying inventory, or expected cost of outstanding backorders for the inventory control levels (s, S), directly from frequency statistics of different demand IA and demand RS on an inventory item basis. An optimal inventory control level (s, S) of an inventory item is searched that minimizes the cost of ordering, carrying inventory, and / or backorders, based upon the generated expected cost.

Owner:LMI CONSULTING LLC

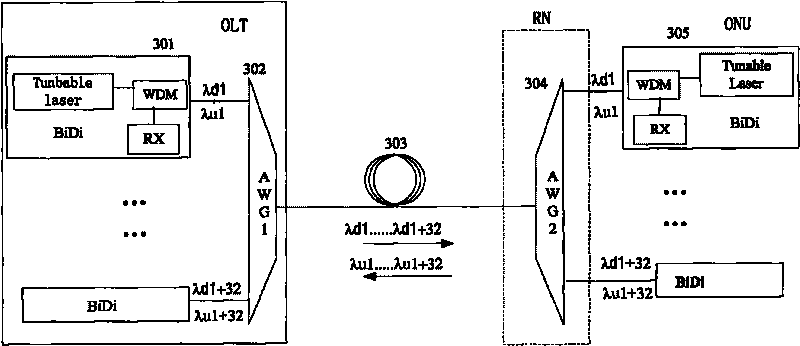

Variable wavelength-based hybrid optical access system

InactiveCN101827288AAchieve smooth upgradeSolving resource constraintsMultiplex system selection arrangementsInjection lockedTransceiver

The invention discloses a variable wavelength-based hybrid optical access system, which comprises an optical line terminal (OLT) part, a remote node (RN) part and an optical network unit (ONU) part connected together through an optical fiber circuit, wherein the OLT part comprises a plurality of optical transceiver modules TRX; when an injection-locked Fabry-Perot laser diode (FP-LD) or reflection semiconductor optical amplifier (RSOA) is adopted at the transmitting end Tx of each optical transceiver module TRX, the common end of a first wave multiplexer / de-multiplexer MUX / DEMUX1 is connected with a light source SL through a wavelength division multiplexed (WDM) component and the output end of the WDM component is connected with the optical fiber circuit; or when a fixed wavelength laser or adjustable wavelength laser is used at the transmitting end Tx of the optical transceiver module, the common end of the first wave multiplexer / de-multiplexer MUX / DEMUX1 is connected with the optical fiber circuit directly. The variable wavelength-based hybrid optical access system of the invention can adapt to the network deployment of each operator so as to realize smooth updating of the network structure, solve the problems of the shortage of the optical fiber resource, the inventory cost and the maintenance cost and meet the requirements on the bandwidth and speed.

Owner:FENGHUO COMM SCI & TECH CO LTD

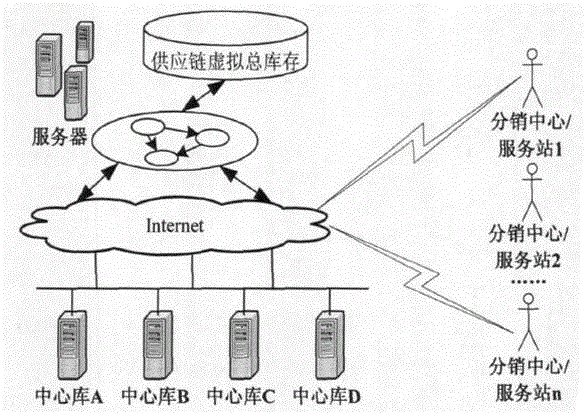

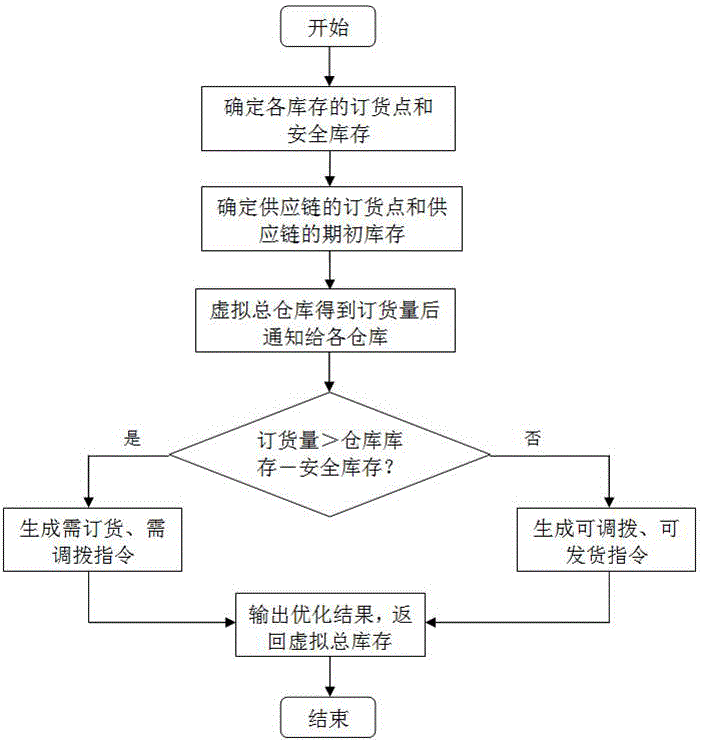

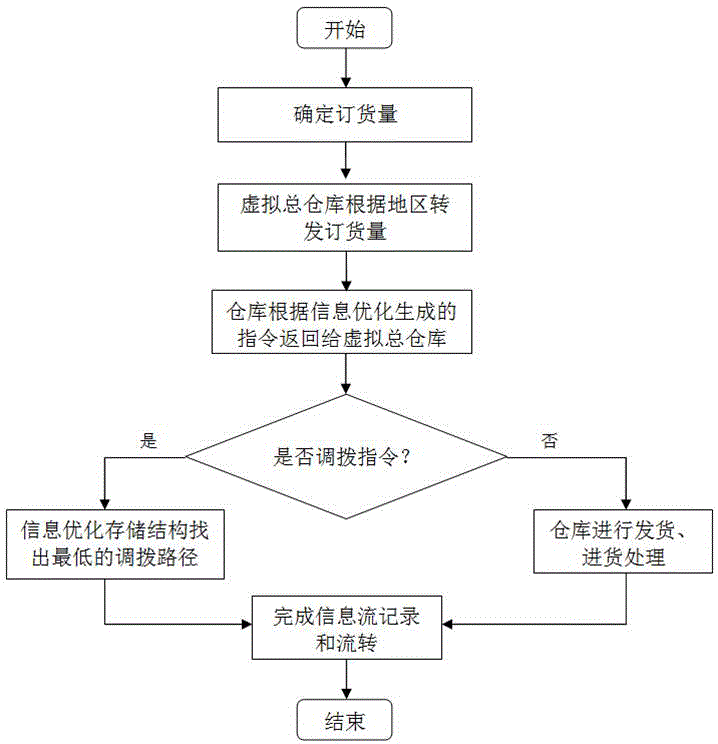

Improving method of distributed inventory dispatching

InactiveCN104463354AReduce inventory costsIntegrate and optimize distributed resourcesForecastingResourcesBusiness enterpriseCost calculation

The invention provides an improving method of distributed inventory dispatching, and belongs to the technical fields of computer application and ERP. The improving method comprises the steps that firstly, a virtual main warehouse optimizes and records information of various warehouses; secondly, inventory capacity estimating and finding are carried out; thirdly, cost calculation is carried out to enable the dispatching cost to be optimal, and a dispatching scheme is generated. The first step is the core of the whole dispatching service, the virtual main warehouse plays a role of a dispatching center, and when an ordering request is received, the virtual main warehouse does not process the ordering request while informing the warehouses of the order quantity, information optimizing is carried out, and an instruction of requiring for allocating, an instruction for allowing allocating, an instruction for requiring for ordering and an instruction for allowing ordering are generated. The warehouses return the instructions back to the virtual main warehouse, corresponding operation is dispatched, and meanwhile in order to guarantee the real-time performance in the actual process, the allocation time among the warehouses needs to be added, and information recording is finished. The inventory cost can be greatly reduced, an obvious function is achieved for integrating and optimizing the enterprise distributed resource, and requirements of multiple industries can be met.

Owner:SHANDONG AEROSPACE INFORMATION

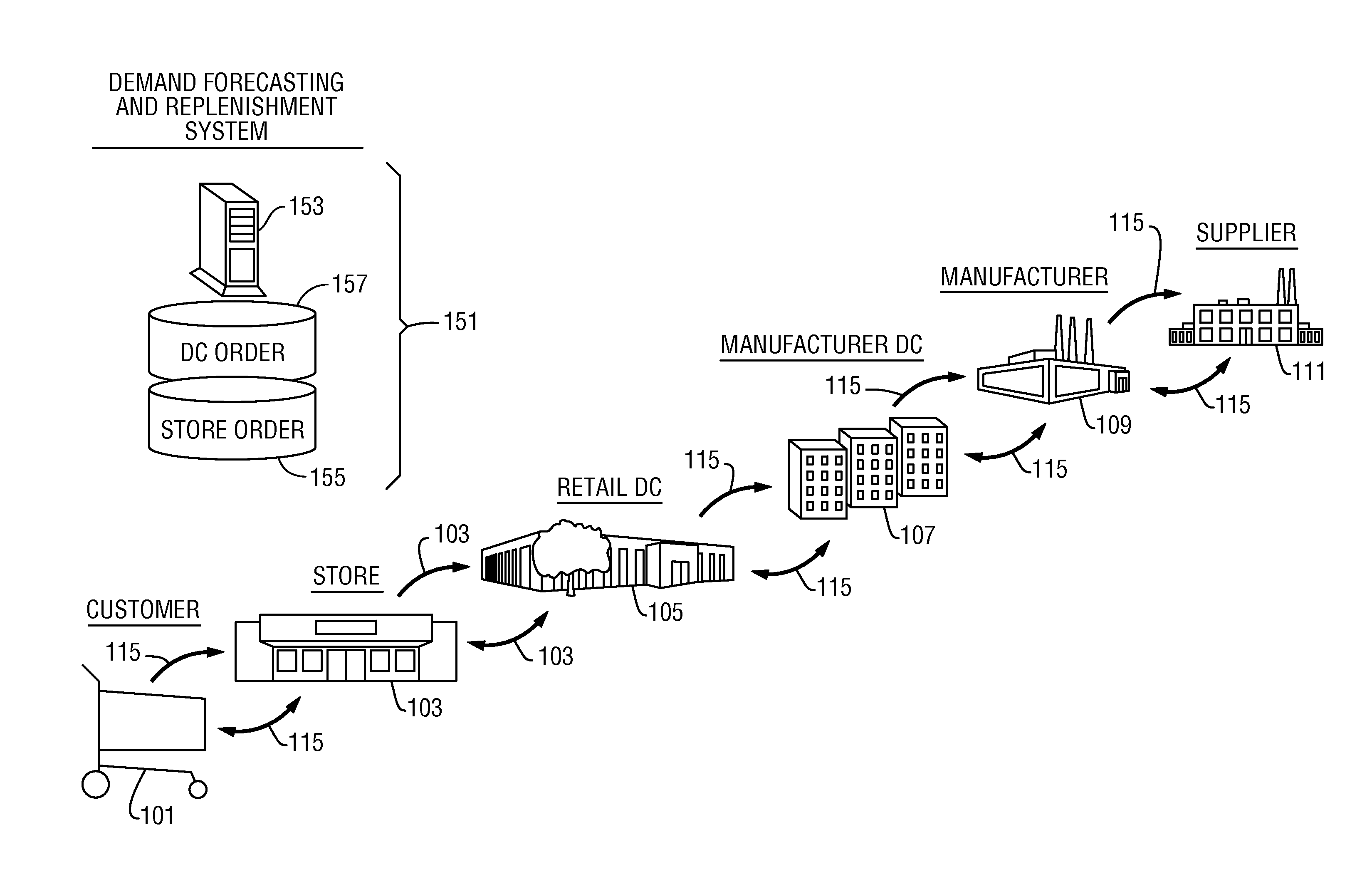

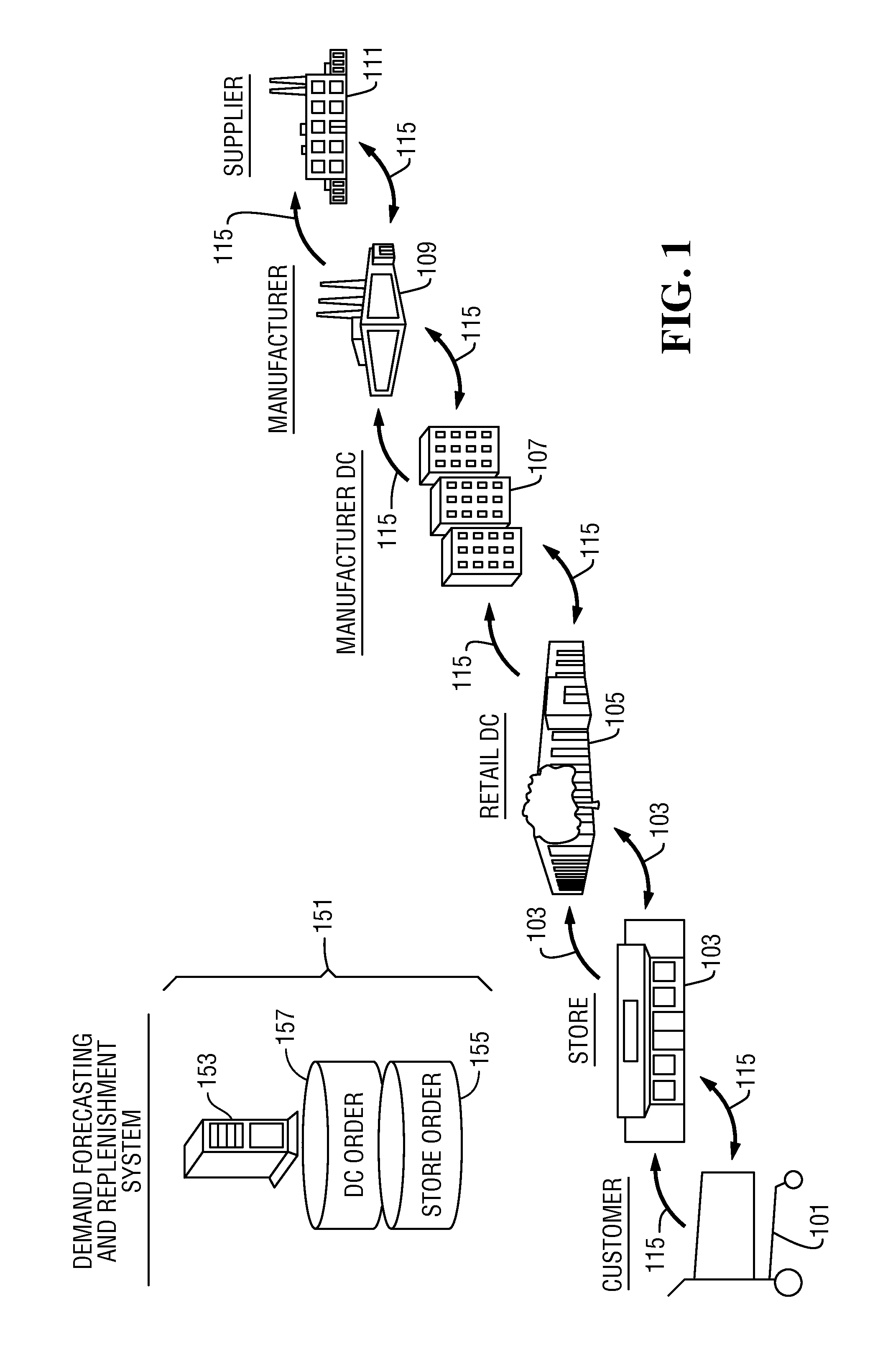

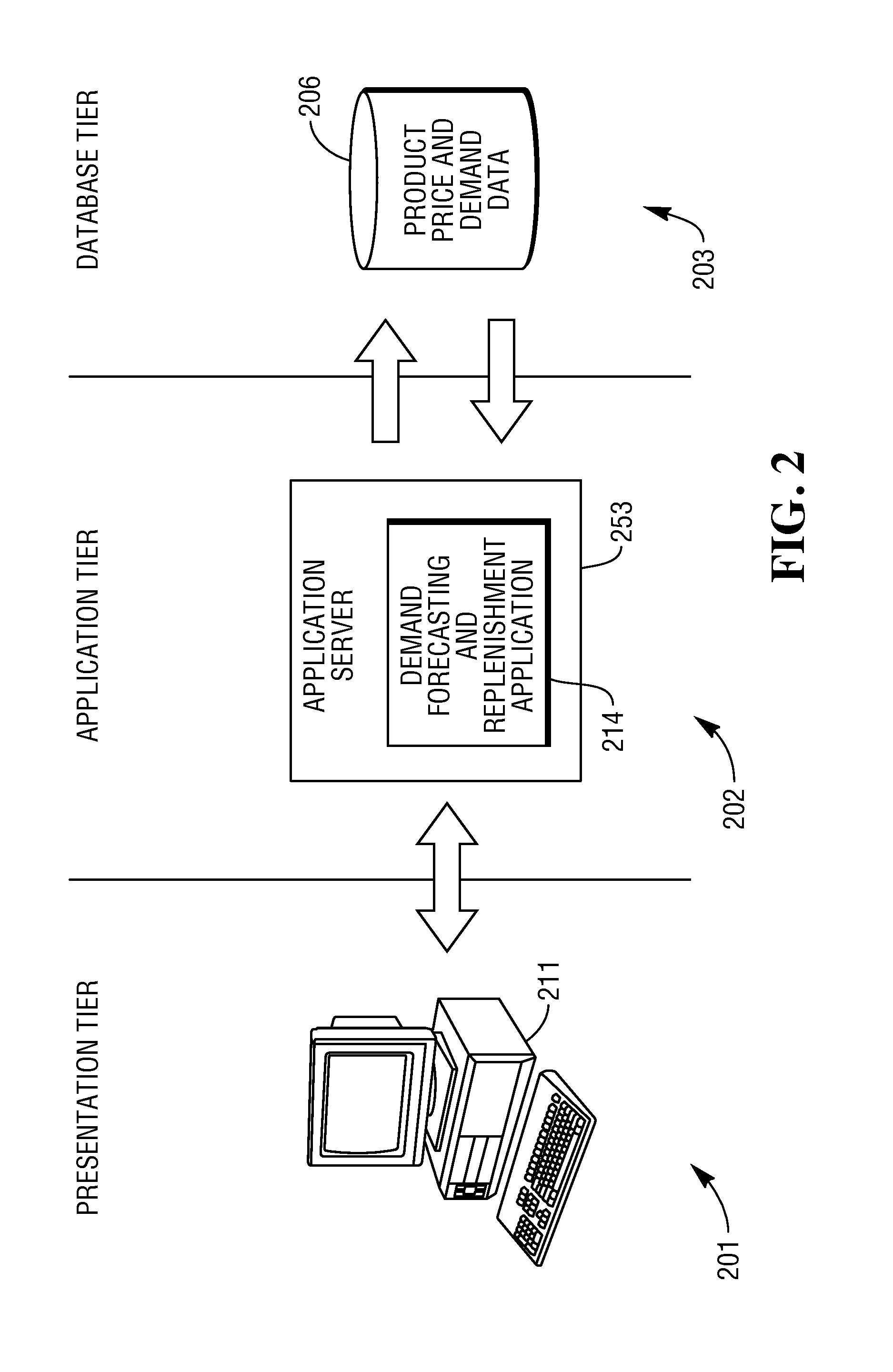

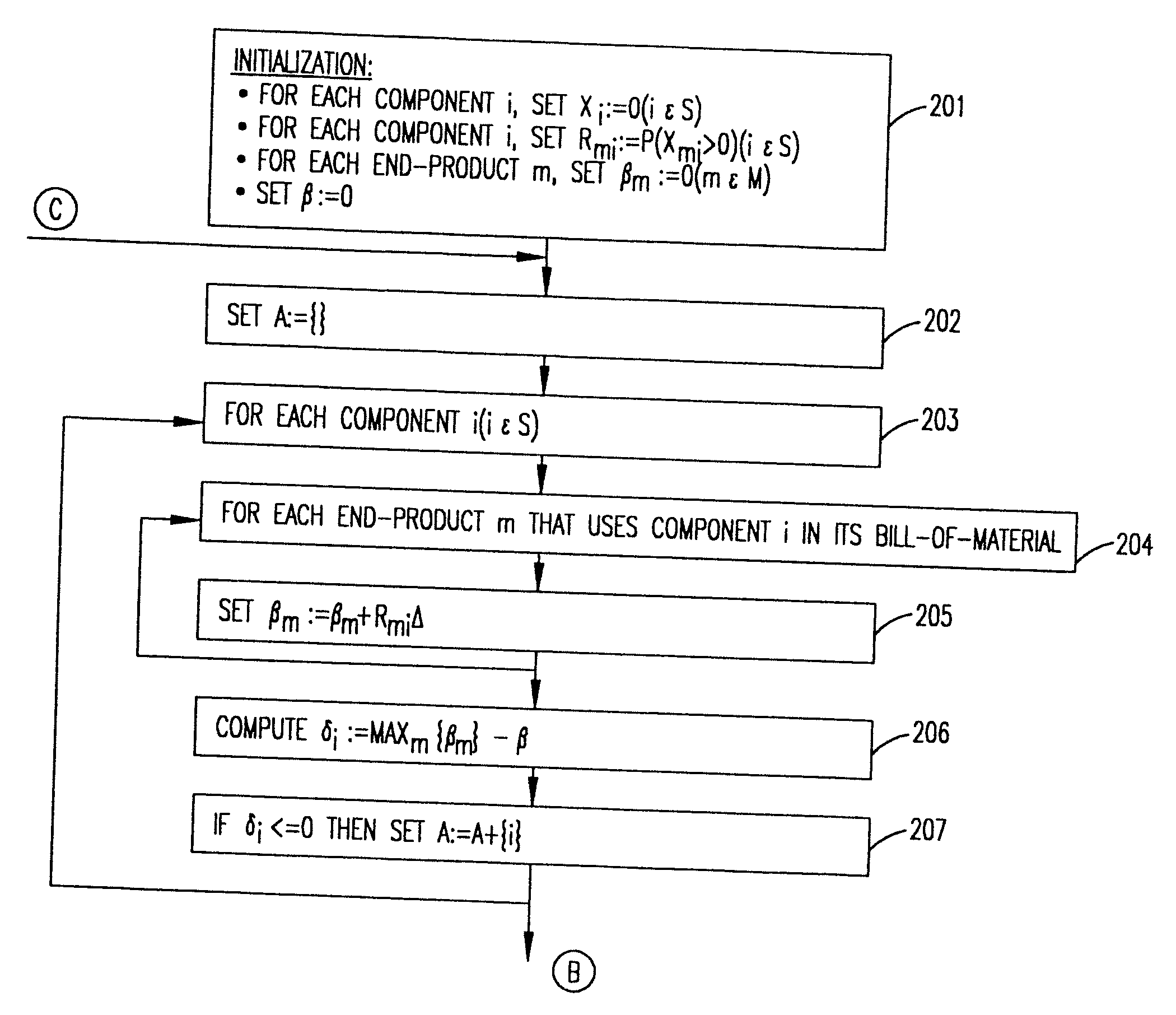

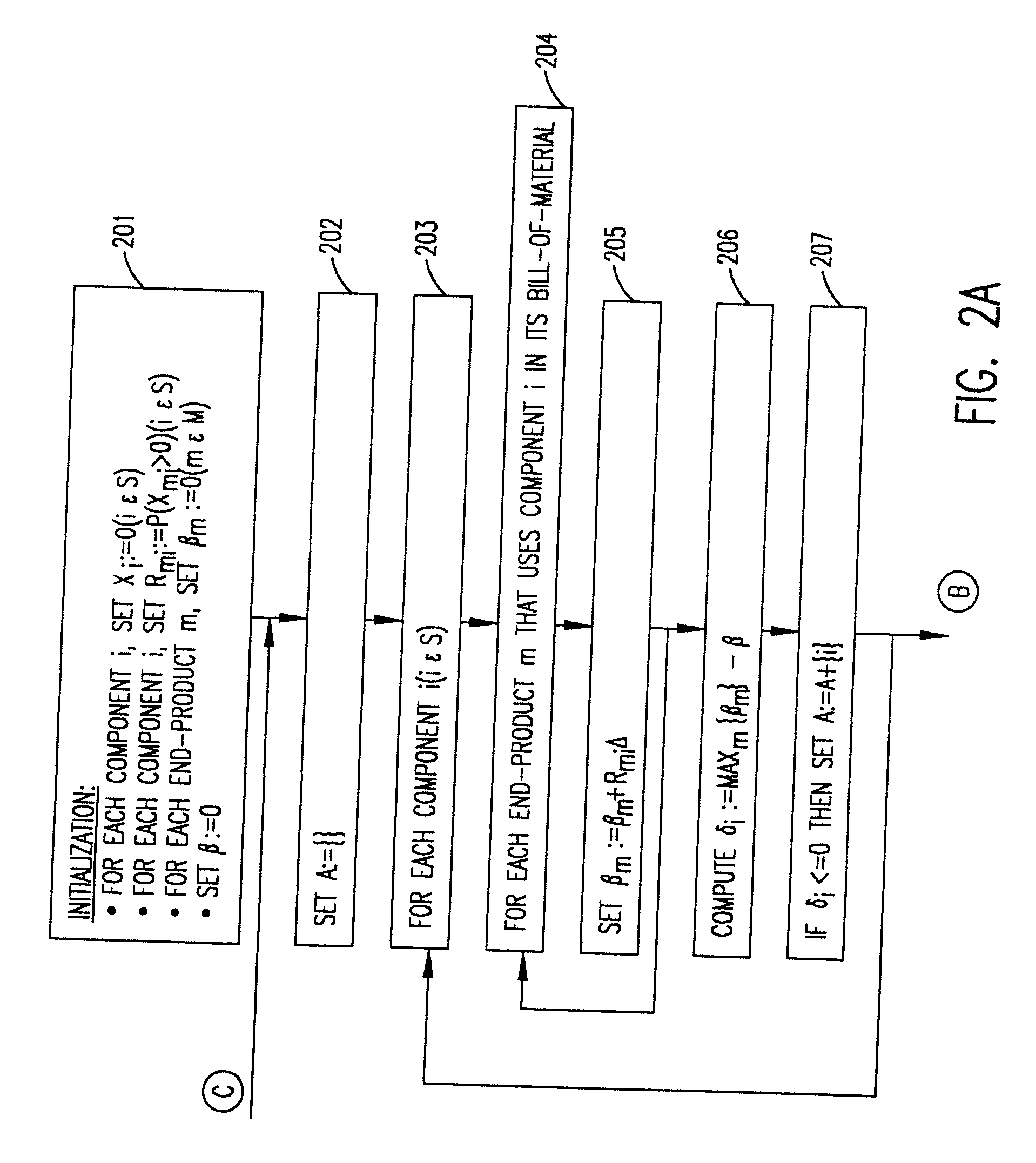

Method and system for optimizing product inventory cost and sales revenue through tuning of replenishment factors

A method and system for predicting the impact of replenishment levers on product service level, lost sales, and on-shelf availability for a retailer. The method and system models cost and revenue elasticity curves for a product or group of products and analyzes the cost and revenue elasticity curves, measures the impact of tuning the replenishment levers on inventory cost and sales revenue, and identifies values for the product replenishment levers to optimize replenishment system policies and product profitability.

Owner:TERADATA

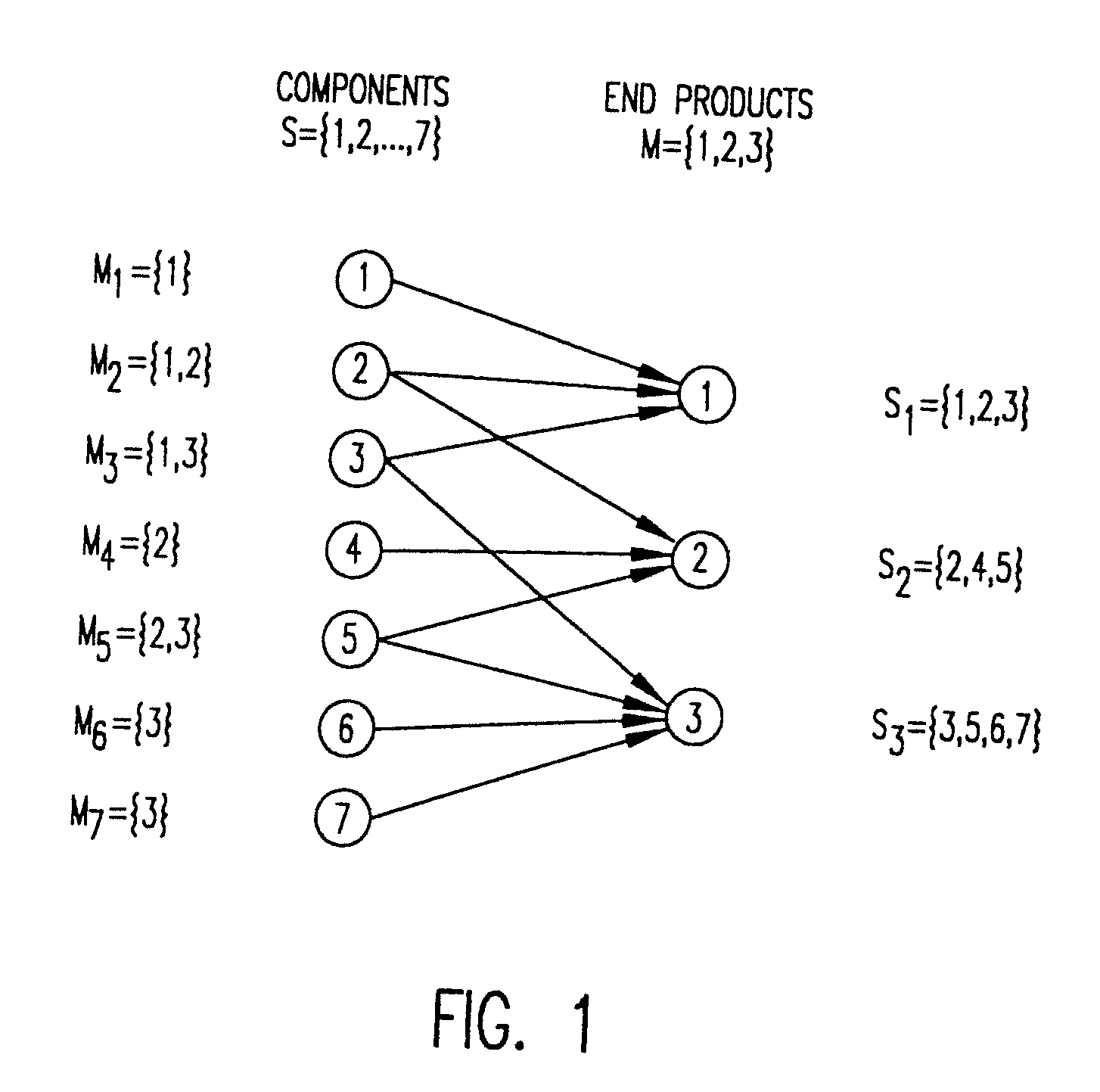

Large inventory-service optimization in configure-to-order systems

InactiveUS20080215410A1Reduce inventory costsImprove service levelProgramme controlHand manipulated computer devicesOrder formTrade offs

A manufacturing process is migrated from an existing operation to a configure-to-order (CTO) system. As the CTO operation will eliminate the “machine-type model” (MTM) inventory of the existing operation, the emphasis is shifted to the components, or “building blocks”, which will still follow the build-to-stock scheme, due to their long leadtimes, and hence still require inventory. The solution involves an inventory-service trade-off of the new CTO system, resulting in performance gains, in terms of reduced inventory cost and increased service level. Other benefits include better forecast accuracy through parts commonality and risk-pooling, and increased customer demand, as orders will no longer be confined within a restricted set of pre-configured MTMs.

Owner:INT BUSINESS MASCH CORP

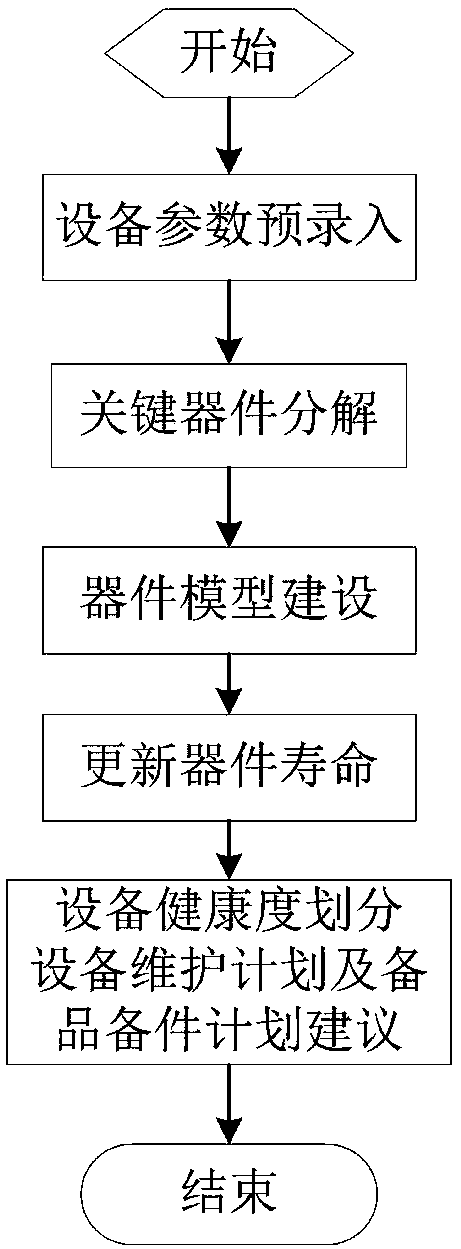

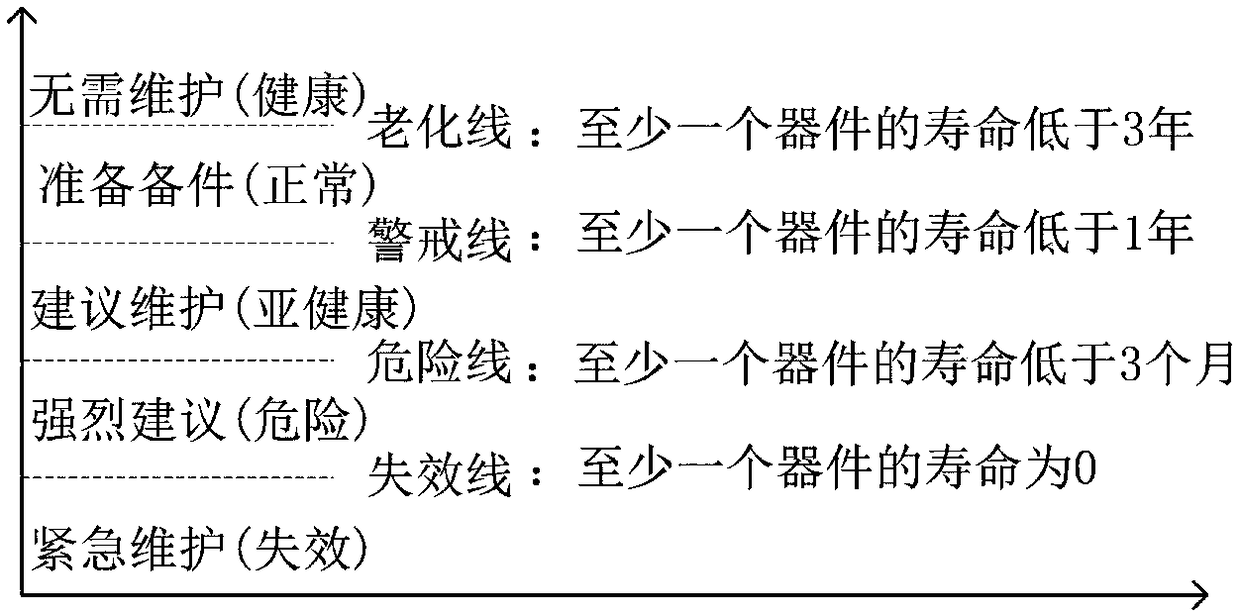

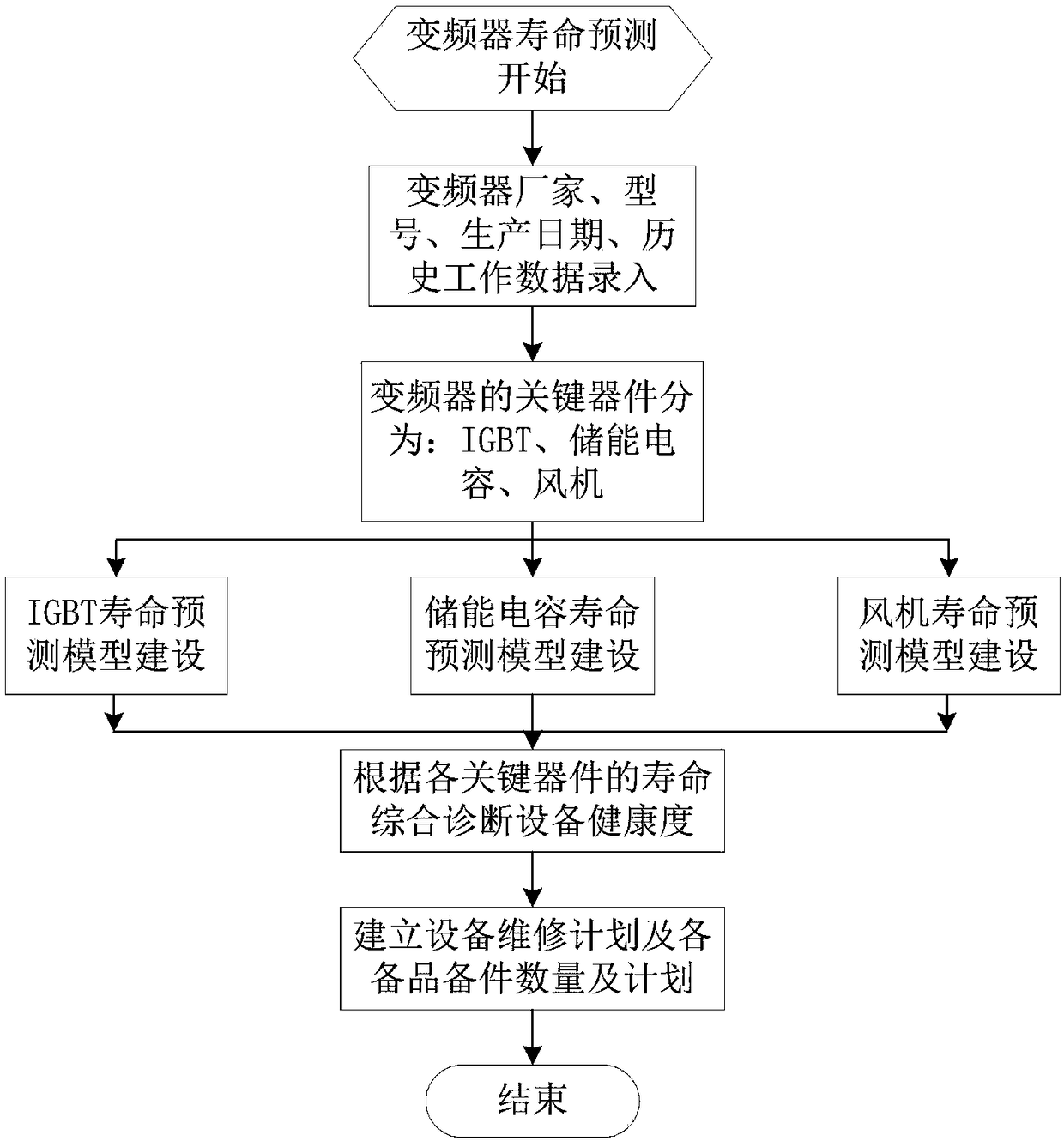

Key device-based method and apparatus for predicting service life of marine electrical equipment

ActiveCN108549951APlanning procurementGood for assessing healthMachine part testingElectrical testingPredictive methodsElectrical devices

The invention relates to a key device-based method and a key device-based apparatus for predicting the service life of marine electrical equipment. The method comprises the steps of pre-inputting thedevice information; decomposing the key devices of the equipment; according to the influence factors of the service lives of devices, respectively establishing a service life calculation model for each key device according to the environment temperature, the humidity, the vibration, the electric conductivity coefficient and the working condition parameters thereof, wherein models corresponding todifferent types of devices are different; according to the actual environment parameters and the running working conditions of devices, calculating the remaining lives of devices; according to the remaining lives of devices, dividing the health degree of the equipment, and formulating the maintenance plan of the equipment and the spare part planning suggestion of the equipment. According to the invention, firstly, the key devices of the electrical equipment are classified, and the service life of each device is predicted. In this way, the service life of the equipment is predicted. According to the service life of the equipment, the level reliability of both the equipment and the devices of the equipment can be estimated. According to the service life conditions of the equipment and the key devices, the priority division is carried out. Meanwhile, the maintenance plan and the spare part plan are formulated. The equipment utilization rate is improved, and the inventory cost is reduced.

Owner:璇飞(武汉)科技有限公司

Method and computer system for settng inventory control levels from demand inter-arrival time, demand size statistics

ActiveUS20120004944A1Minimize overall expected costHand manipulated computer devicesAnimal feeding devicesArrival timeCost component

A method or a machine determines minimum (s) and maximum (S) inventory control levels (s, S) for inventory items based upon a demand history of the inventory items, such as demand inter-arrival times (IA) and demand requisition sizes (RS). An expected cost is computed including two or more inventory item cost components of expected cost of ordering, expected cost of carrying inventory, or expected cost of outstanding backorders for the inventory control levels (s, S), directly from frequency statistics of different demand IA and demand RS on an inventory item basis. An optimal inventory control level (s, S) of an inventory item is searched that minimizes the cost of ordering, carrying inventory, and / or backorders, based upon the generated expected cost.

Owner:LMI CONSULTING LLC

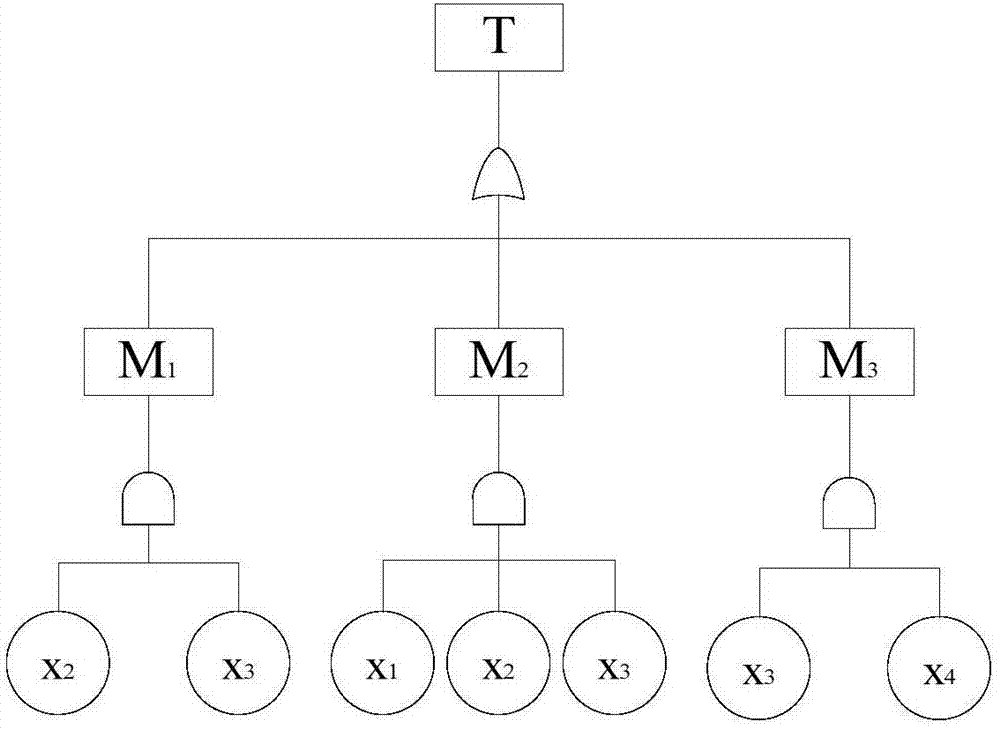

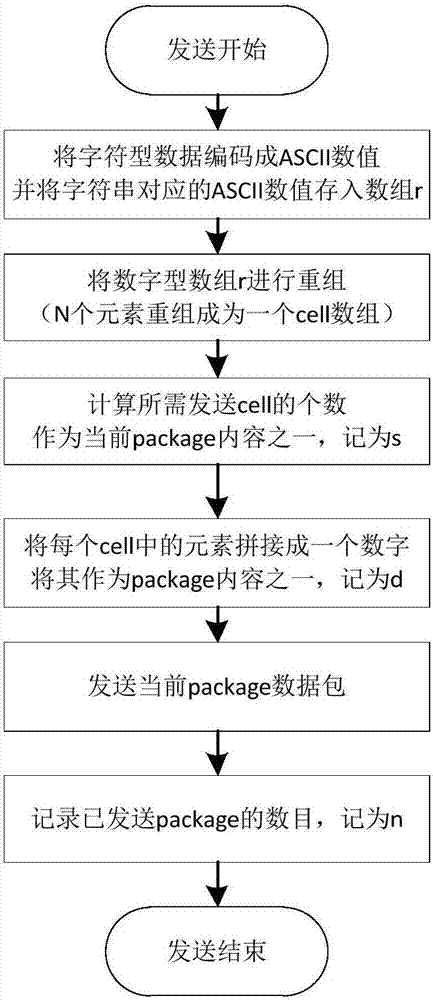

Method for foresting demand of wind generating set for spare parts based on fault tree analysis

The invention discloses a method for forecasting the demand of a wind generating set for spare parts based on fault tree analysis. The method comprises the steps of firstly building an abstract model of a wind generating set fault tree; then acquiring the daily annual fault probability of components corresponding to each bottom event in the fault tree; building a fault tree simulation model by using a Simulink platform, and simplifying a Boolean function expression of a top event; solving a minimum cutest of the fault tree; compiling a numerical operation sub-function for calculating the probability importance degree and key importance indexes of each bottom event; inputting the daily annual fault probability of each bottom event by a user, and calling the sub-function to output the probability importance degree and key importance indexes; and calculating the number of spare parts of each component in a future stage. The method disclosed by the invention is based on the wind generating set fault tree, adjustable in model parameter, capable of adapting to product differentiation of different manufacturers and different working conditions, fault reasons of the wind generating set are detailed, the utilization efficiency of the spare parts is improved, the inventory cost is reduced, and so that the objective of reducing the operation and maintenance cost of wind power generation enterprises is achieved.

Owner:ZHEJIANG UNIV

Modular trim paneling and outfitting system for an aircraft passenger cabin interior

InactiveUS20020000491A1Seating arrangementsAir-treatment apparatus arrangementsModular compositionNacelle

An aircraft passenger cabin includes modular interior components selected from ceiling panels, wall panels, dado panels, window funnels, light covers, and baggage compartments or hat racks. At least one interior component is a standardized modular building block that can be used uniformly and interchangeably in different cabin configurations and sizes, in different aircraft types having different fuselage cross-sectional sizes and configurations. The interior components are modularly combined so as to be adapted to different passenger cabins in the various aircraft types. The multiplicity of distinct interior components among all aircraft types in the entire product range of an aircraft manufacturer is reduced, so that the piece count of each particular type of component is increased, and the manufacturing, installation, maintenance, replacement and inventorying costs are reduced. The time and cost for a new cabin design are reduced.

Owner:AIRBUS OPERATIONS GMBH

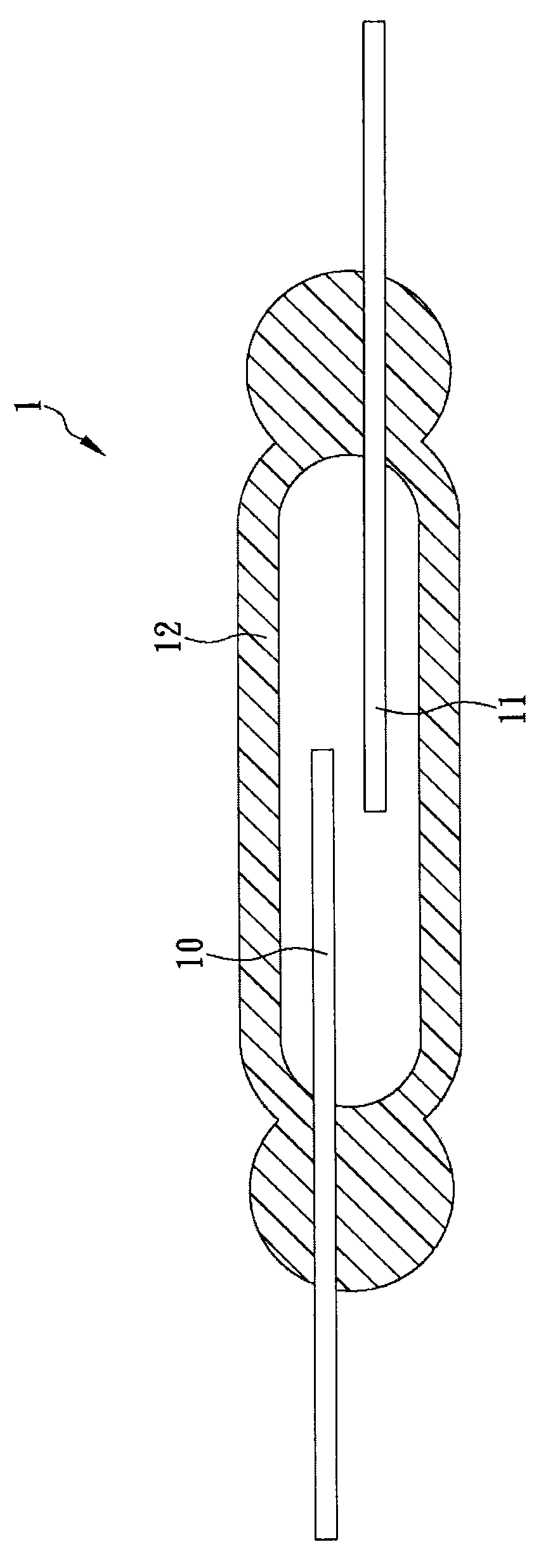

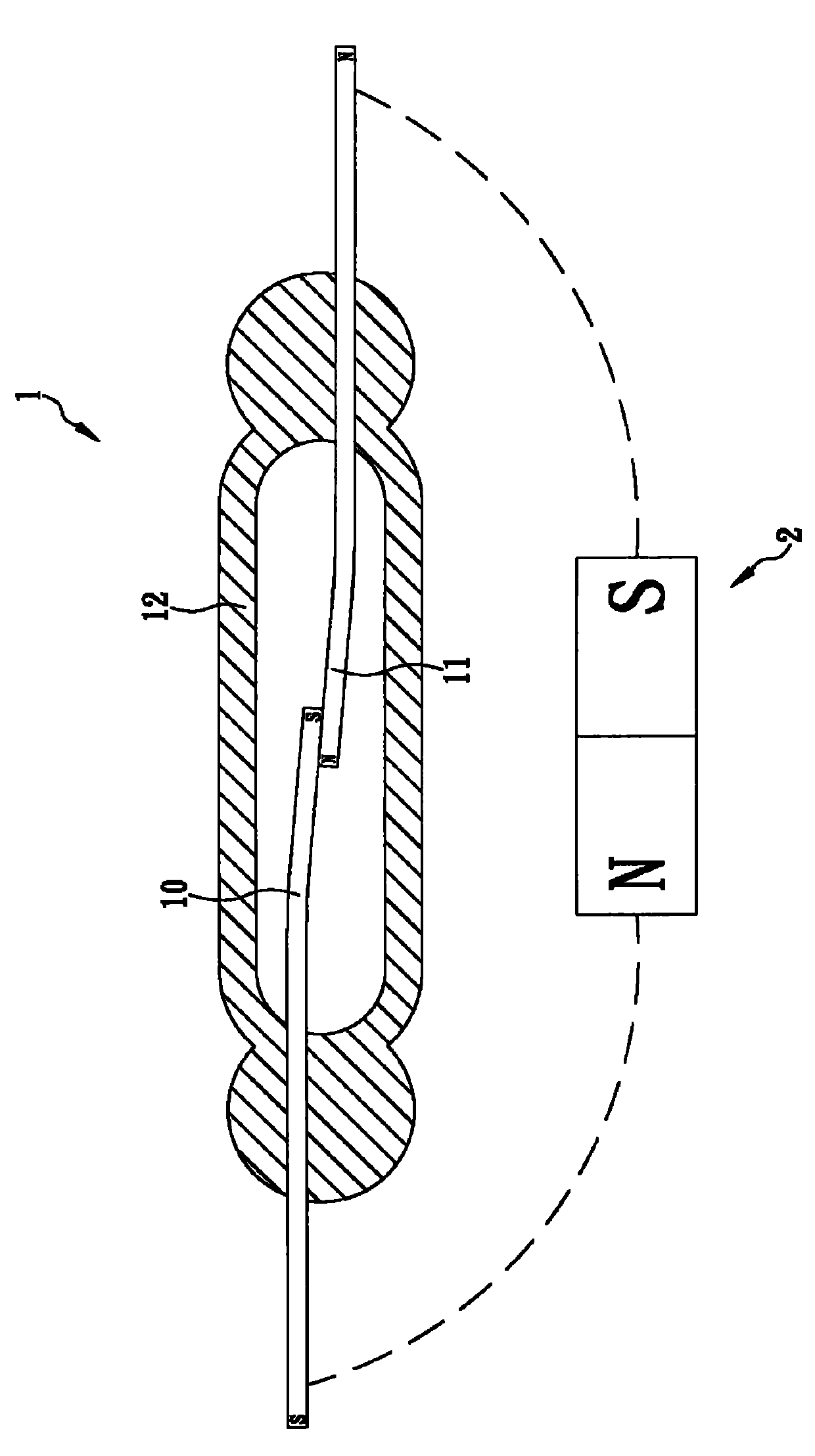

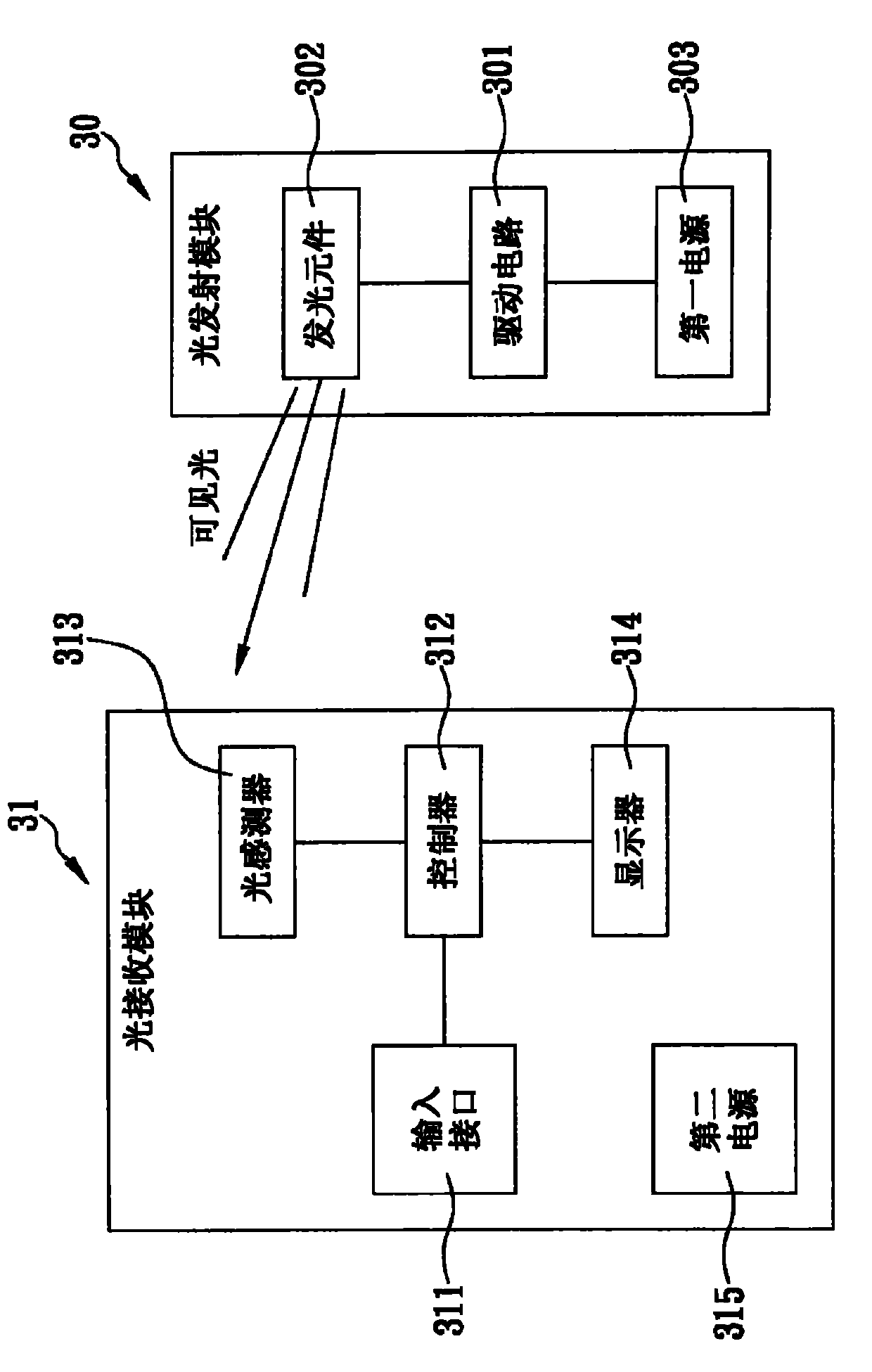

Bicycle speed measuring system

InactiveCN102087297ASimple structure and light weightSimple processDevices using time traversedElectromagnetic wave reradiationDisplay deviceWavelength range

The invention provides a bicycle speed measuring system, which comprises a light transmitting module and a light receiving module, wherein the light transmitting module transmits visible light in a preset wavelength range; the light receiving module receives a wheel diameter parameter of a bicycle wheel input by a user; and when the light receiving module detects the visible light transmitted by the light transmitting module in the preset wavelength range, a trigger signal is generated, an instant speed is calculated according to the interval time of two continuous trigger signals and the wheel diameter parameter, and the speed, running distance and other running information are displayed by a display. The system has an extremely simple circuit structure, the whole structure is not provided with a complex mechanical structure, noble metals and other high-price materials are not needed to be used, an automatic production process of the speed measuring system can be effectively realized, and labor cost, inventory cost, manufacturing cost and the like are greatly reduced.

Owner:MARKETECH INT

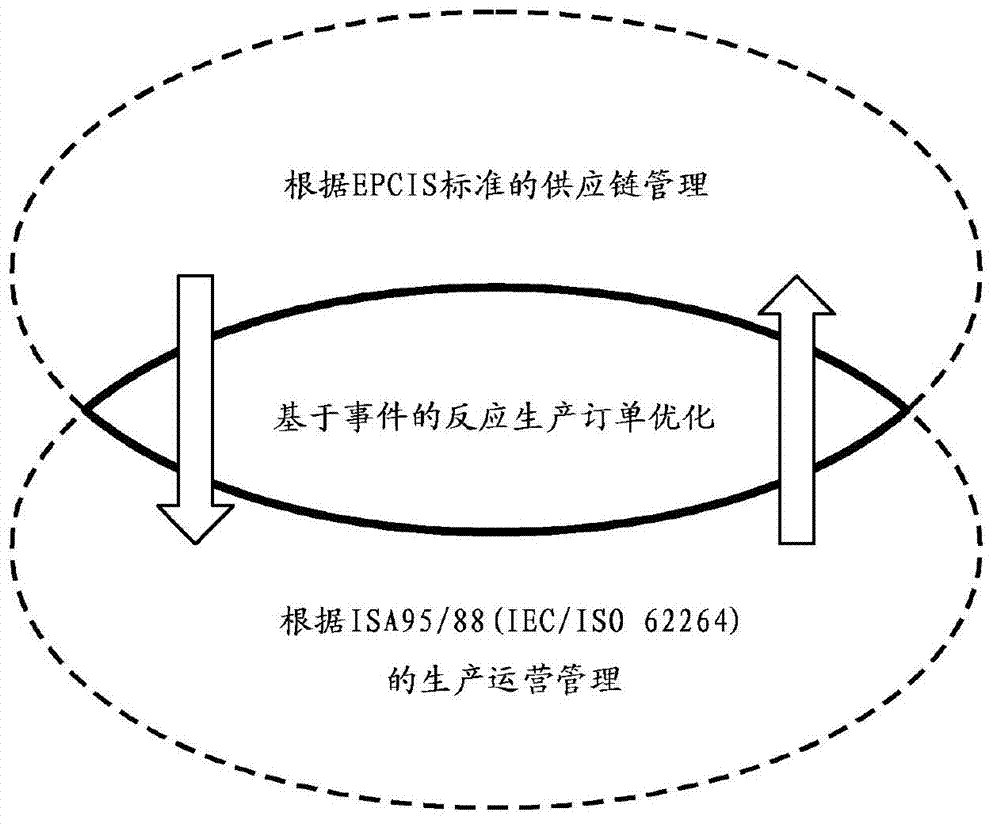

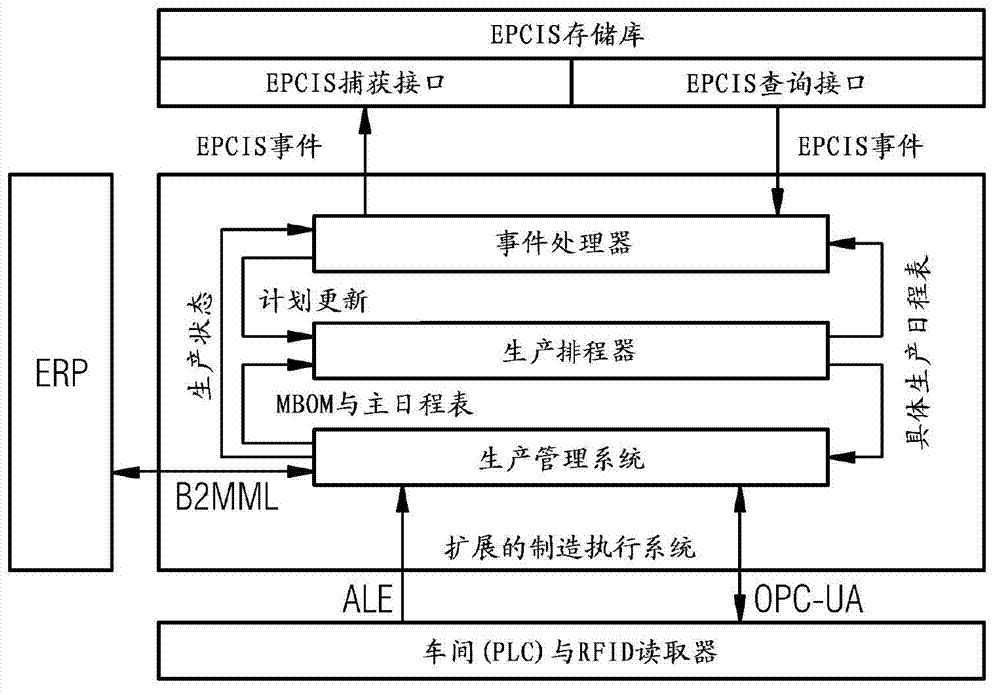

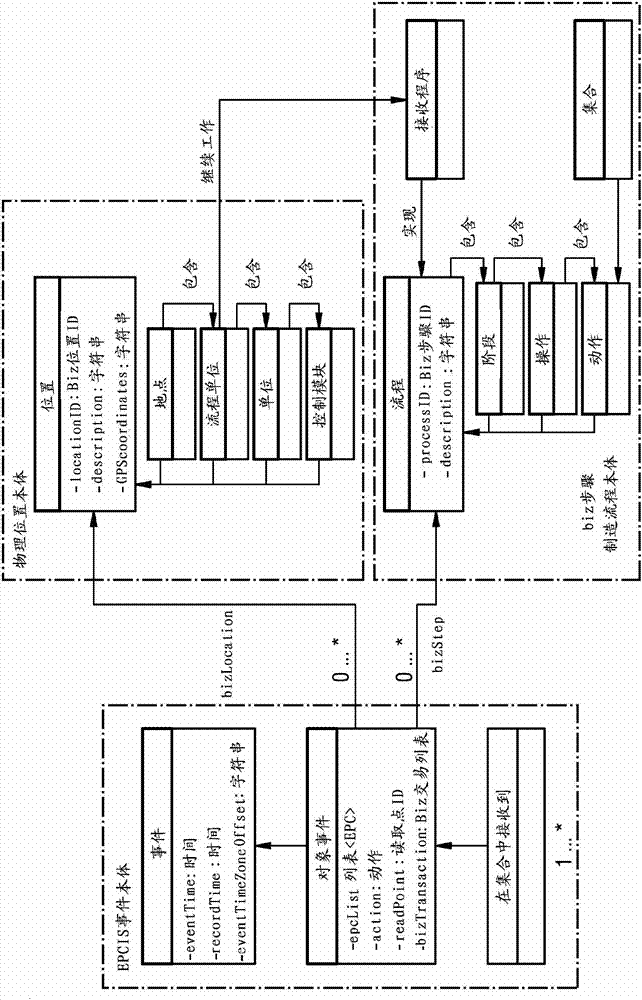

Production management for manufacturing execution systems

First inter-organizational tracking & tracing systems facilitate timely identification and handling of disruptions along the supply chain. However, these systems typically operate at Supply Chain Management (SCM) and Enterprise Resource Planning System (ERP) level and therefore lack knowledge and control over production processes. The invention bridges the gap between logistics and production IT by proposing a novel architecture for coupling the manufacturing operations as defined in IEC 62264 with an EPCIS-compliant real-time tracking & tracing system. The system leverages logic-based complex event processing for detecting critical disruptions in the supply chain and initiates rescheduling of production. It is shown that in the presence of unexpected events the rescheduling algorithm minimizes delays and inventory costs while avoiding «nervous schedules» caused by frequent changes.

Owner:SIEMENS AG

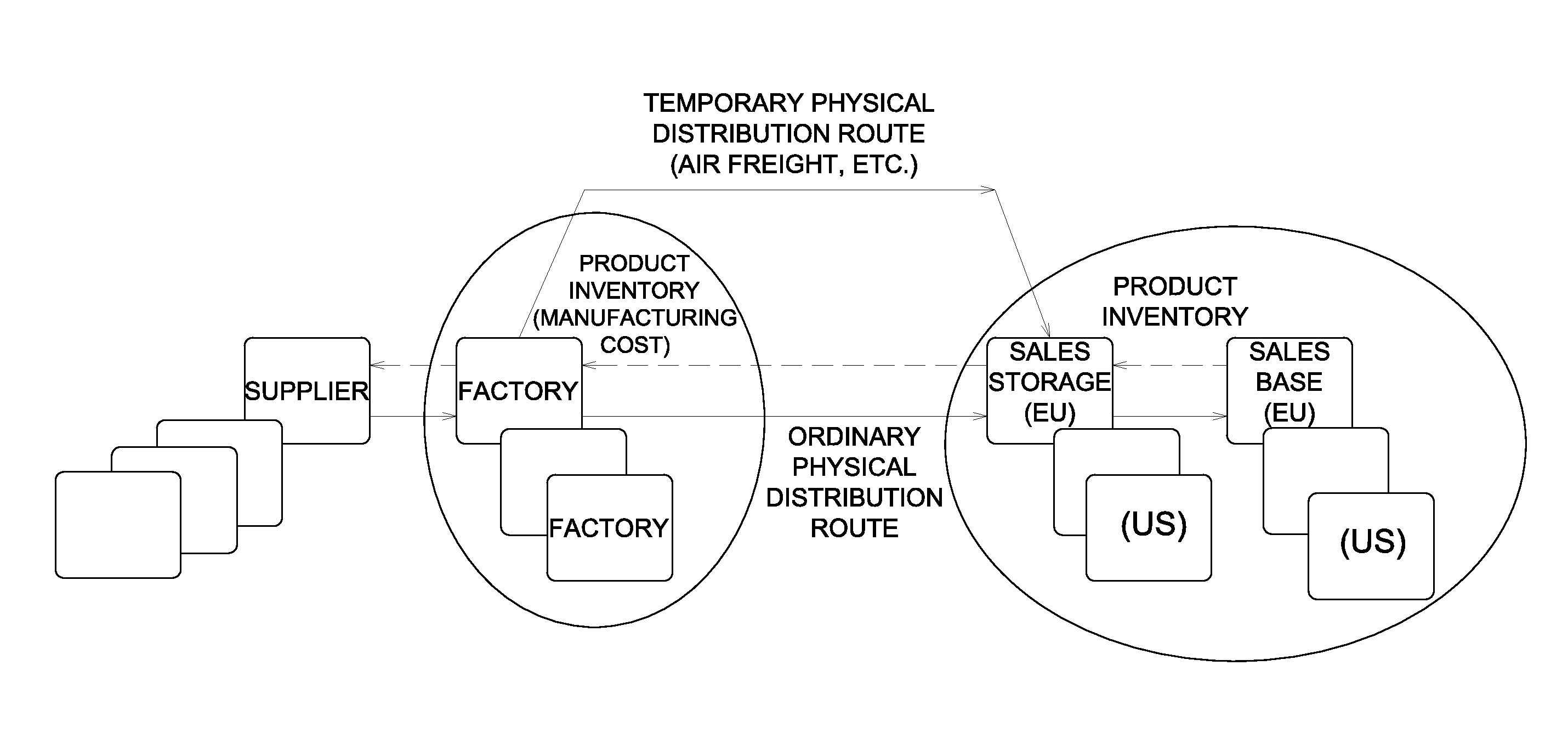

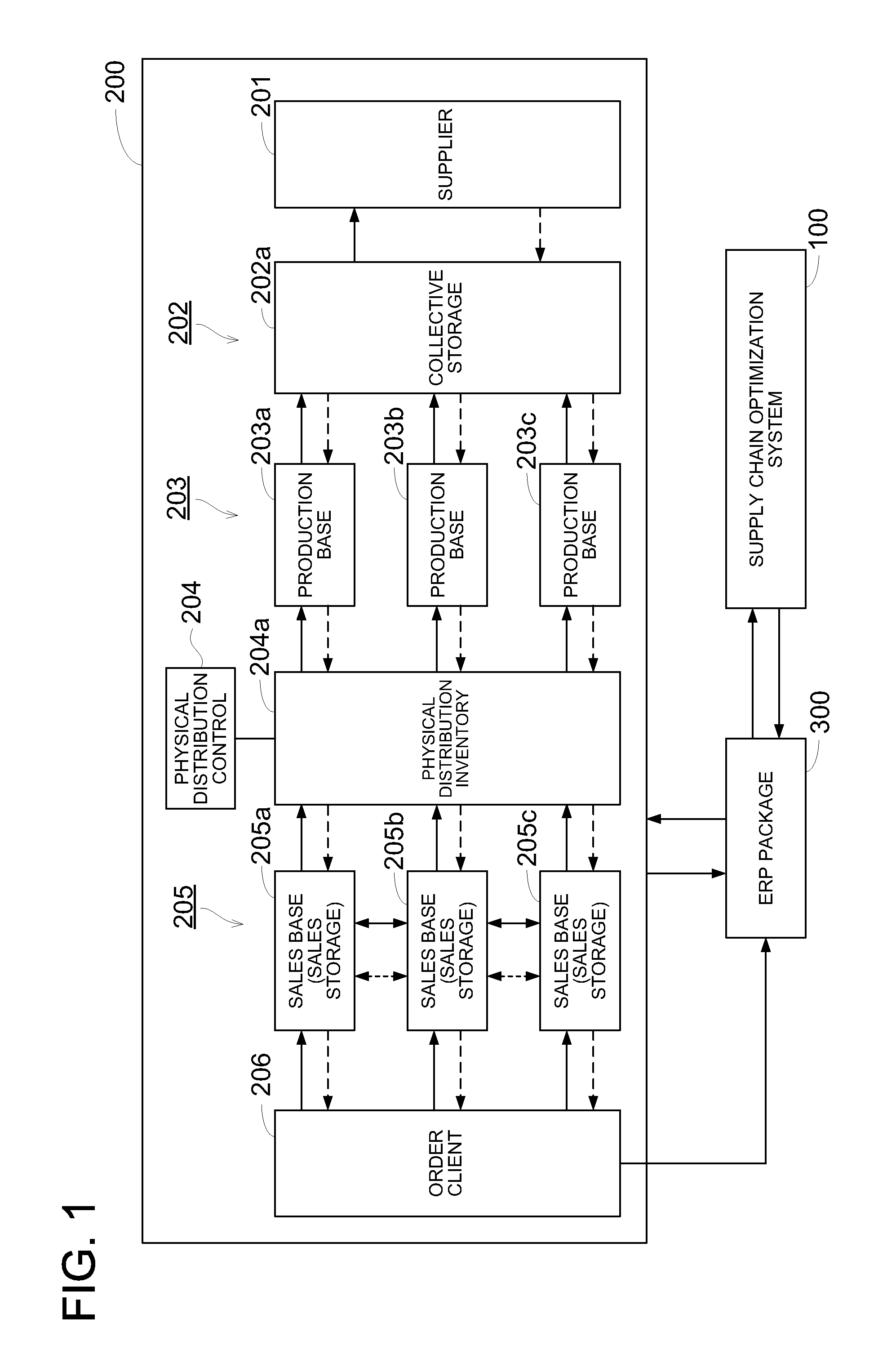

Supply chain optimization system and method for optimizing supply chain

InactiveUS20110125543A1Effective controlQuick calculationResourcesLogistics managementProduct defect

Provided is a supply chain optimization system and a method for optimizing a supply chain that can prevent a production delay due to the lack of materials and a shipment delay due to the lack of stock products even if a sales plan fluctuates on an increase in sales of the supply chain as a whole and that can optimize the stocks of the products and materials and a physical distribution route of product supplies. The supply chain optimization system and the method for optimizing the supply chain calculate through a simulation in which a supply chain model is used so that a total sum of stock costs for products and materials and logistics costs therefor are minimized with respect to the number of stock products and materials which do not cause product defects at a fluctuation time of a sales plan on a condition in which the stock products increased in accordance with the fluctuation of the sales plan are set to factory stocks. Further, number of the stocks, costs for the stocks and logistics costs are set to a KPI of the supply chain to be managed. In addition, a physical distribution route from a factory increased in the stock products is optimized through the simulation.

Owner:KONICA MINOLTA INC

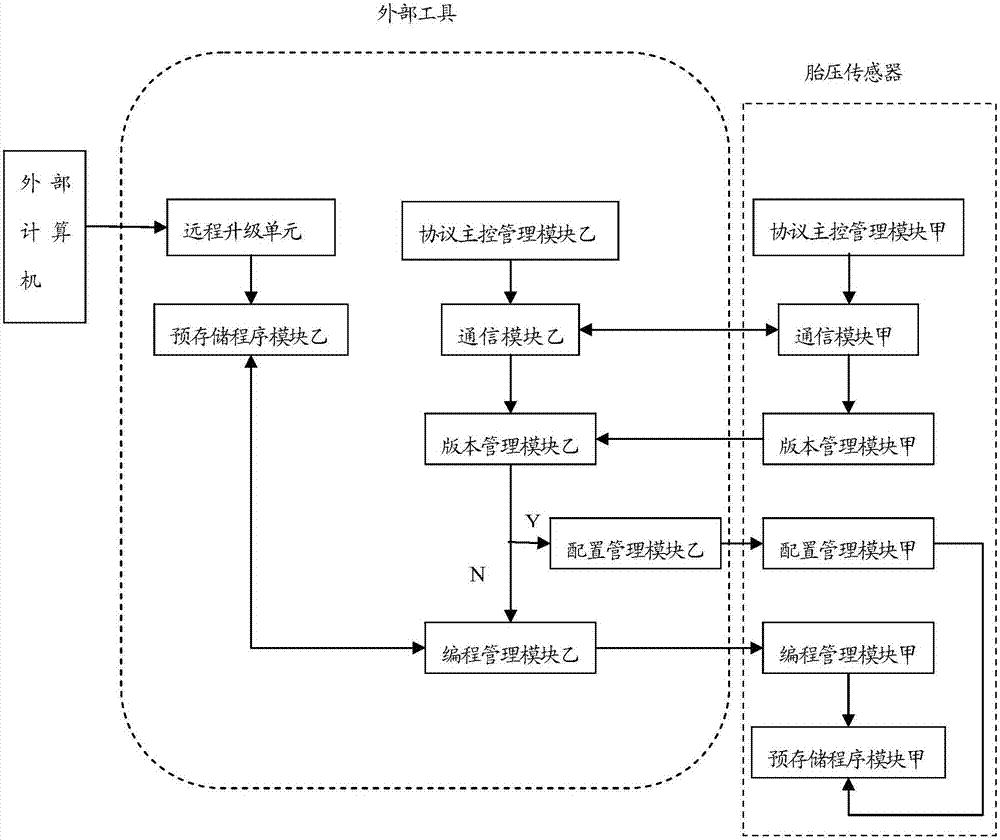

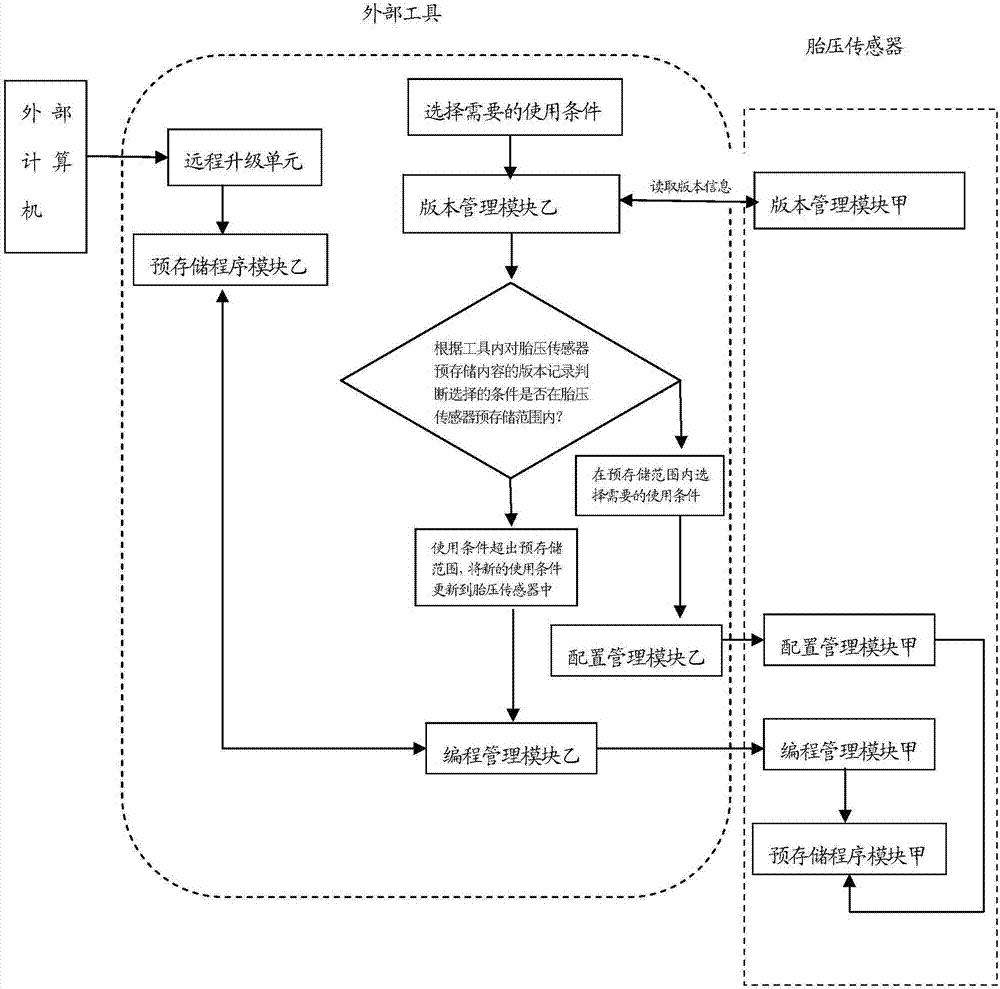

Tire pressure sensor system and communication protocol deploying method

InactiveCN107225918AShorten the timeTyre measurementsSecuring communicationOperating timeSensor system

The invention relates to a tire pressure sensor system, in particular to a tire pressure sensor system which can prestore a communication protocol, can also realize a new communication protocol and upgrade an original communication protocol. The tire pressure sensor system comprises a tire pressure sensor and external tools, wherein a certain number of communication protocols are prestored in the tire pressure sensor; and besides, the tire pressure sensor can also add new communication protocols through the external tools, and upgrade the conventional communication protocols in the tire pressure sensor. The tire pressure sensor system disclosed by the invention has the advantages that the inventory cost and the management cost of a user are reduced, and the operating time is shortened.

Owner:SUZHOU SATE AUTO ELECTRONICS

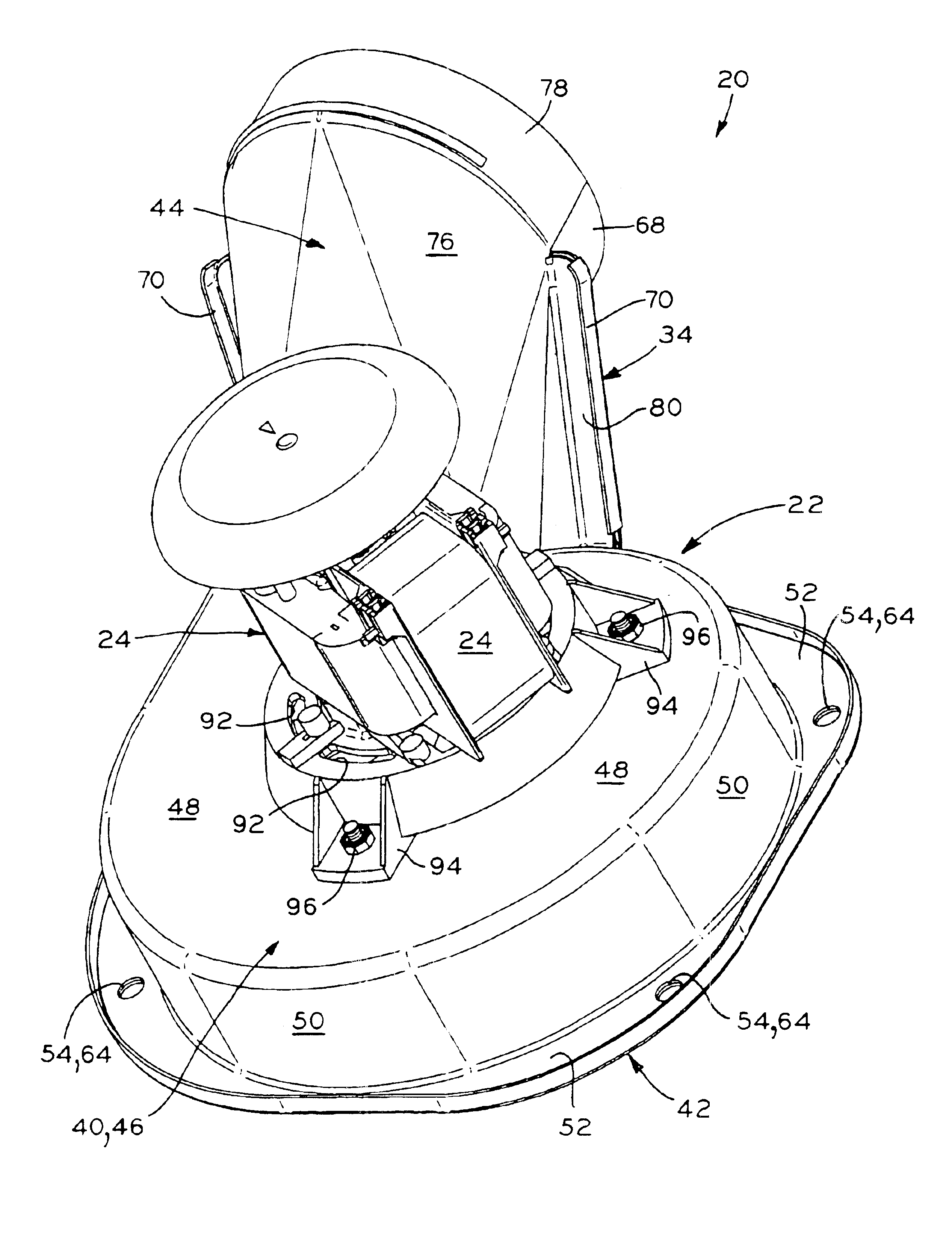

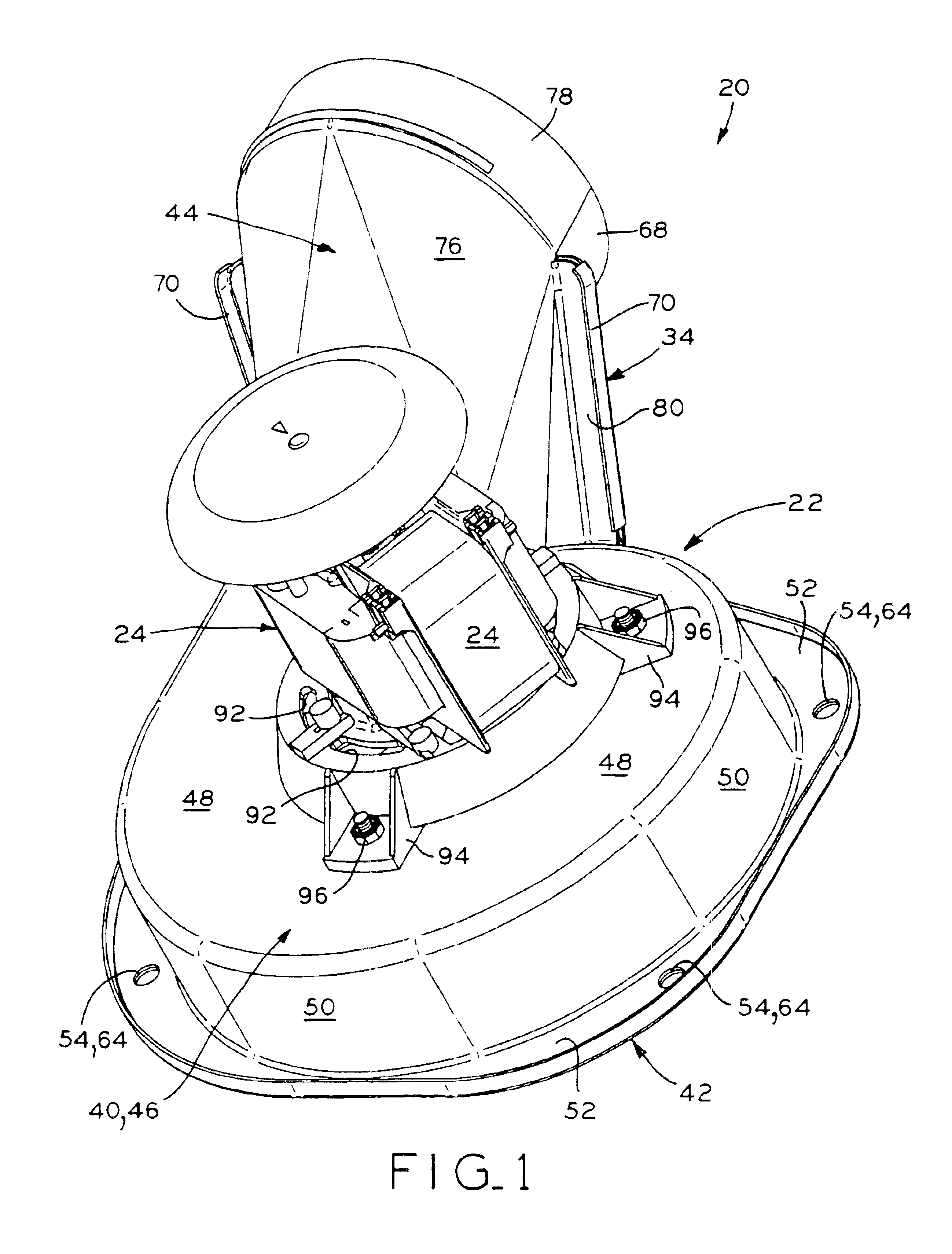

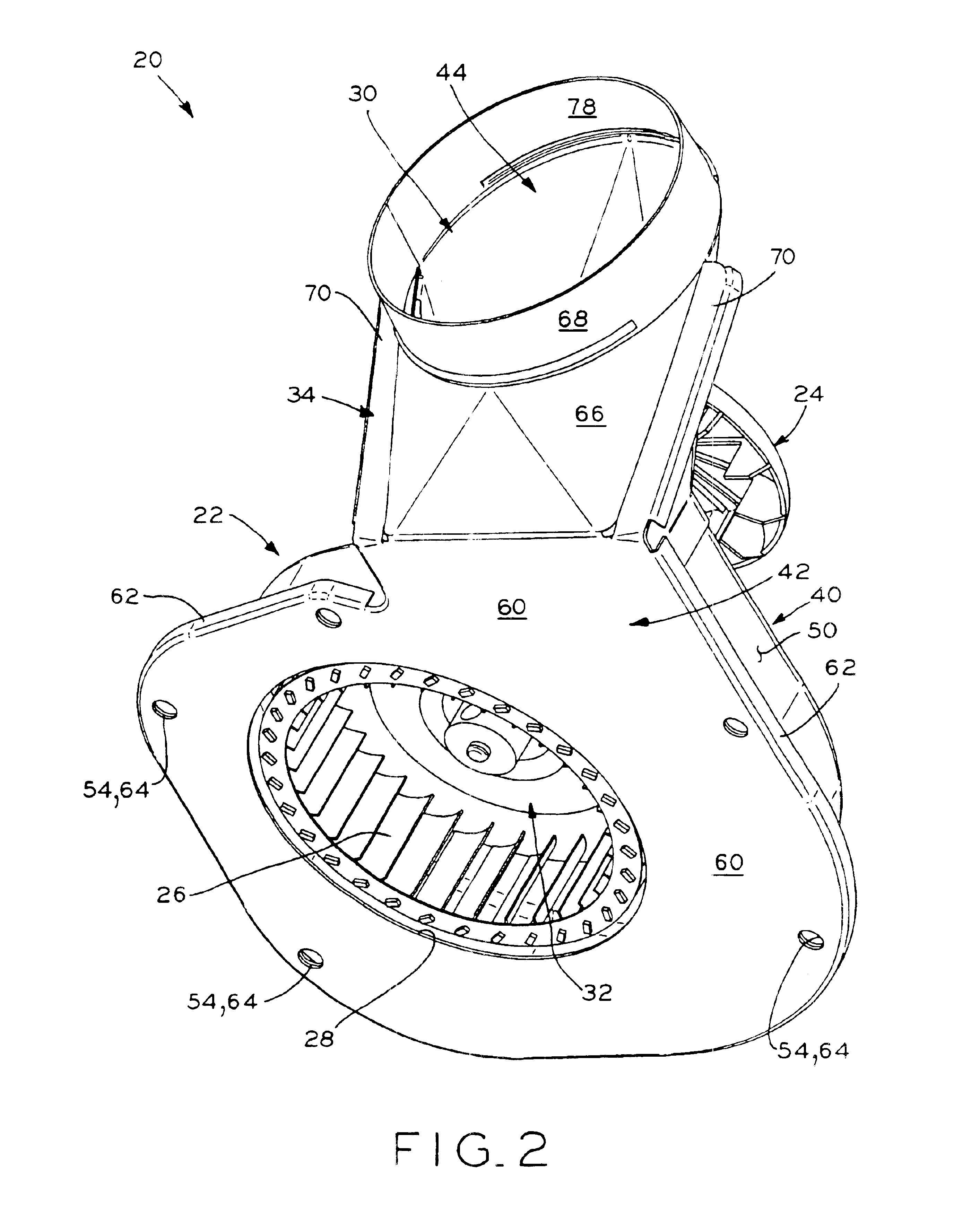

Blower housing for furnace blower assembly

A blower housing for a furnace blower assembly of the type including a blower motor coupled to an impeller for use in expelling exhaust gases from a furnace. The blower housing generally includes an inlet, an impeller cavity, and an extension portion extending from the impeller cavity, the extension portion terminating in a circular outlet to which a round flue pipe may be attached. The blower housing is formed by three housing members joined to one another, wherein the housing members may be formed from metal using conventional stamping, drawing, and forming processes, for example. To form a variety of different types of blower housings having different outlet offset distances, only the dimensions of cooperating portions of two of the housing members need be varied, with one of the housing members used in common among the different types of blower housings. In this manner, a number of different types of blower housings may be made for furnaces of different designs while reducing tooling, manufacturing, and inventory costs.

Owner:REGAL BELOIT AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com