Patents

Literature

186 results about "Stockout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stockout, or out-of-stock (OOS) event is an event that causes inventory to be exhausted. While out-of-stocks can occur along the entire supply chain, the most visible kind are retail out-of-stocks in the fast-moving consumer goods industry (e.g., sweets, diapers, fruits). Stockouts are the opposite of overstocks, where too much inventory is retained.

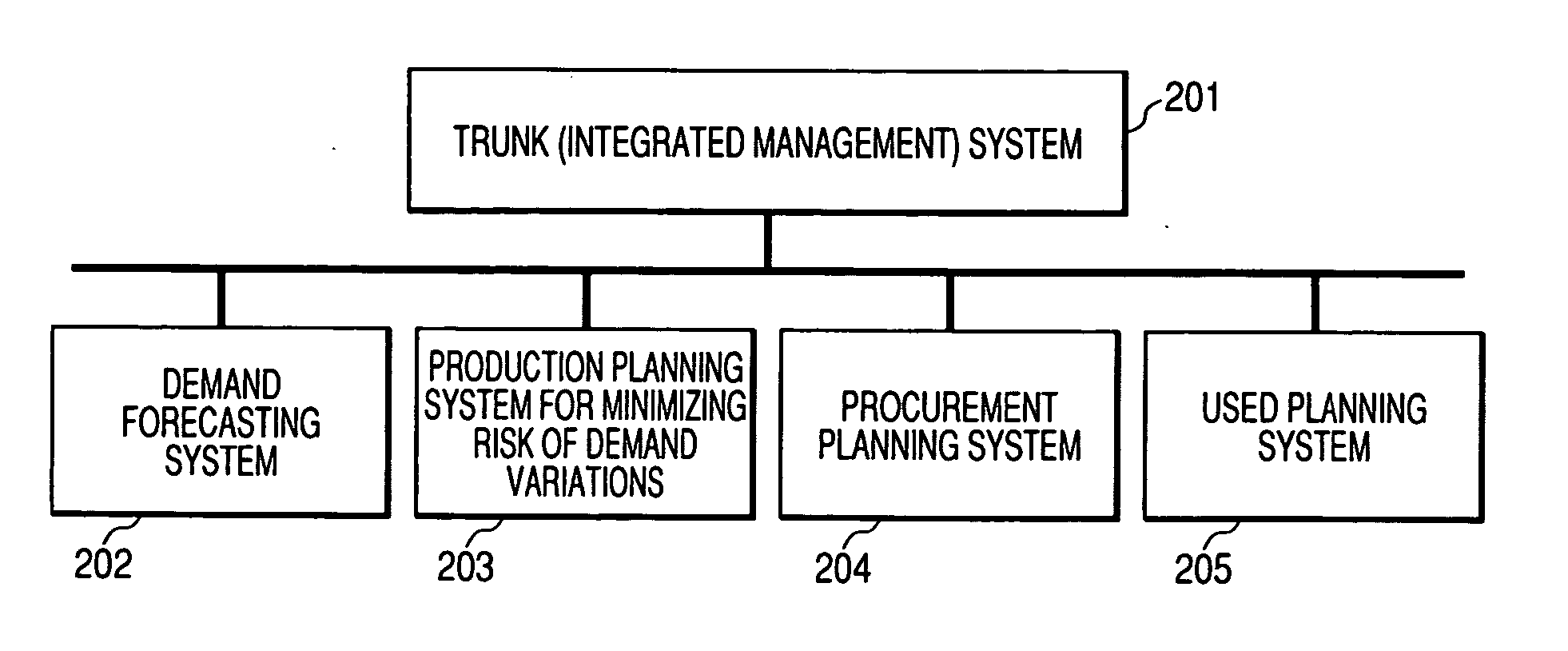

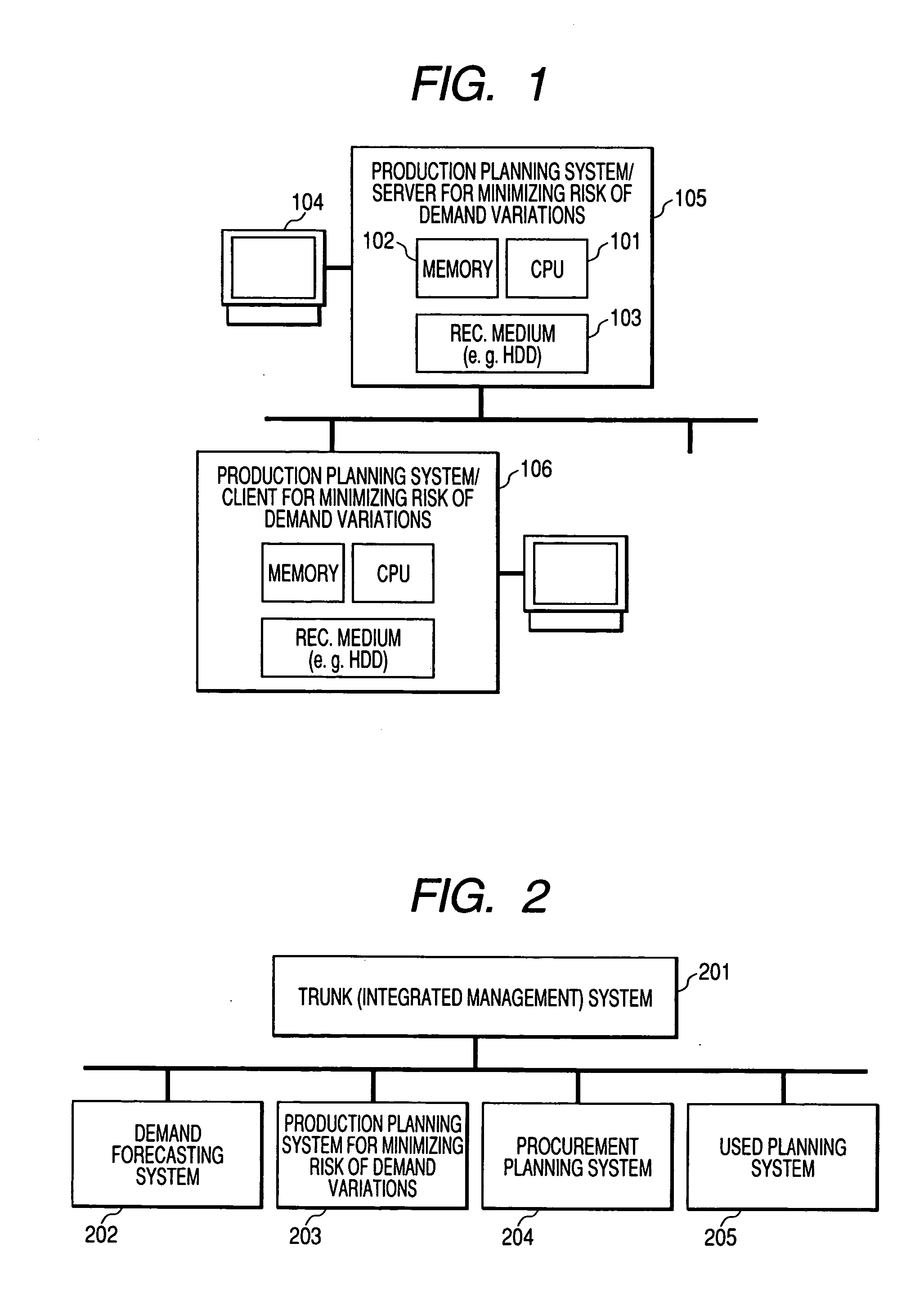

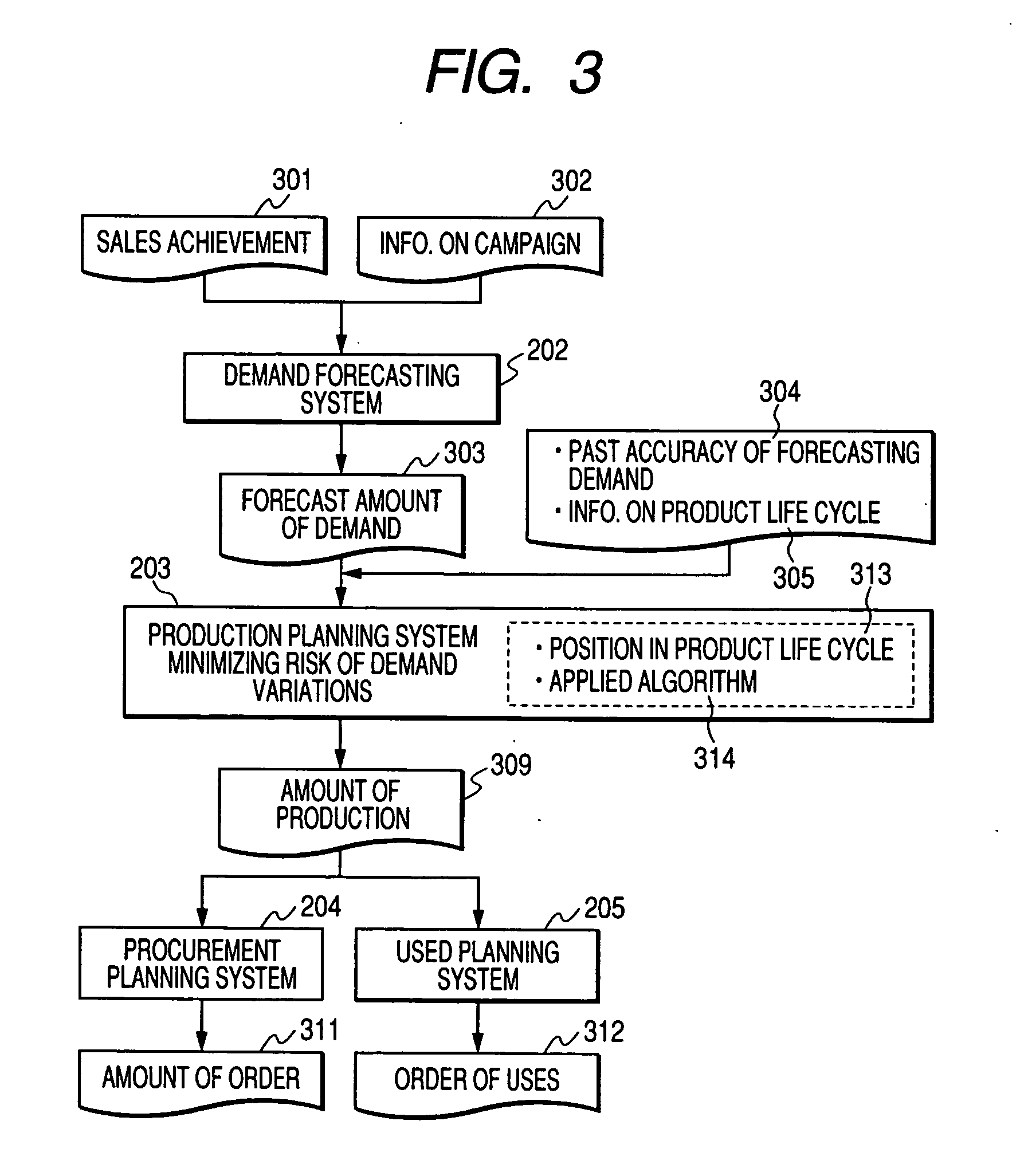

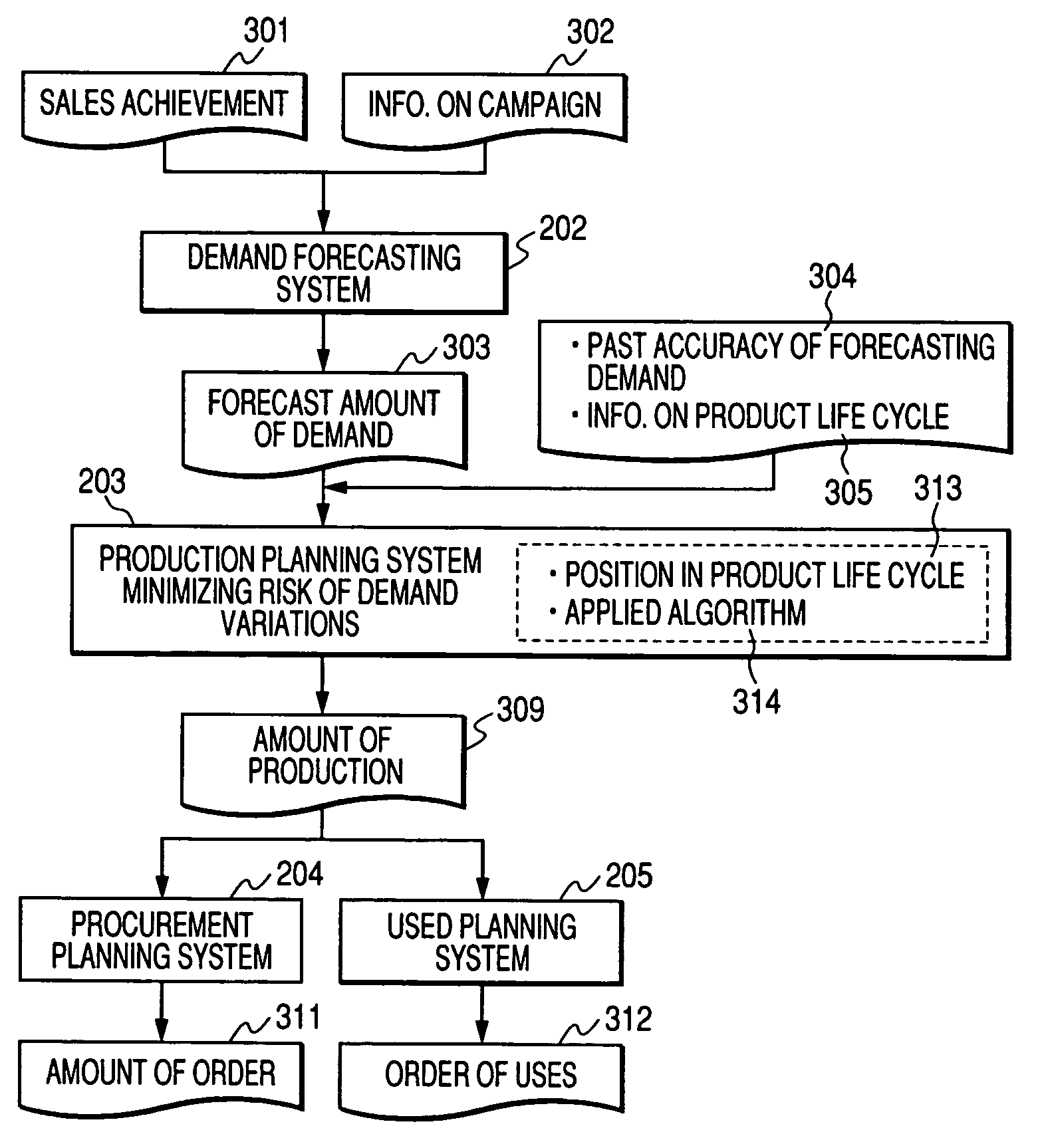

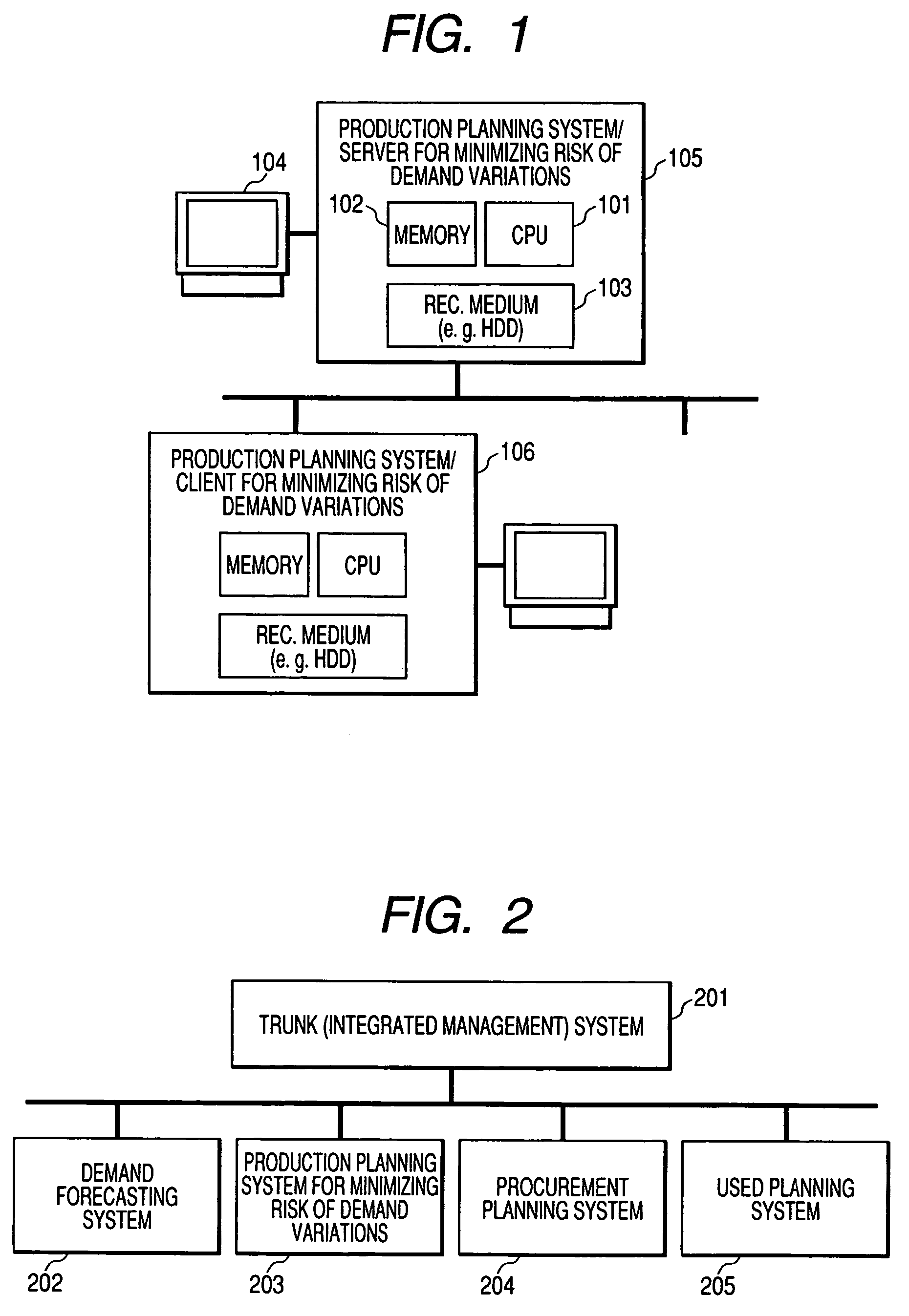

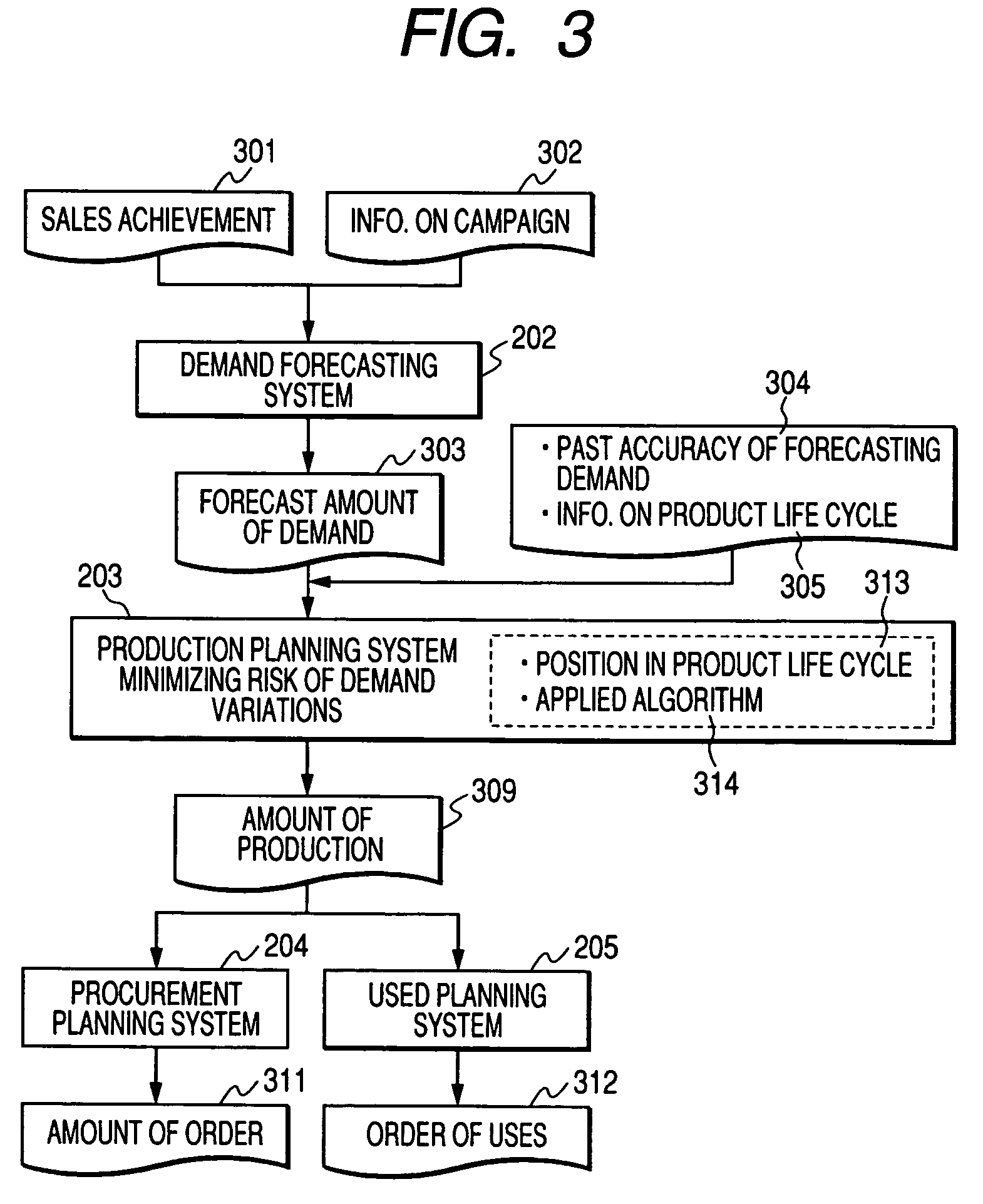

Method of creating production plan of demand variation input type and method of creating production plan minimizing risk of demand variations

InactiveUS20050222888A1Avoid adjustmentMaximizes achievement ratioCommerceSpecial data processing applicationsStockoutRate ratio

A production plan is created so as to minimize risk of demand variations. Forecasted values of amounts of requests are entered for each different item of products, markets, dates, past accuracy of demand forecasts, and order achievements at the time when the plan is created. Scenario information is created in which assumable amounts of request for each different item of the products, markets, and dates and probabilities at which the amounts of requests agree with actual amounts of requests are defined. Management indexes are found from the amount of stockout and amount of stock calculated in each different scenario, based on the scenario information, target values of the management indexes, and information on strongpoints. An amount of production that maximizes the achievement ratios of the management ratios to their targets within the ranges of supplied materials and within the range of the production capacity is calculated by an optimization algorithm.

Owner:HITACHI LTD

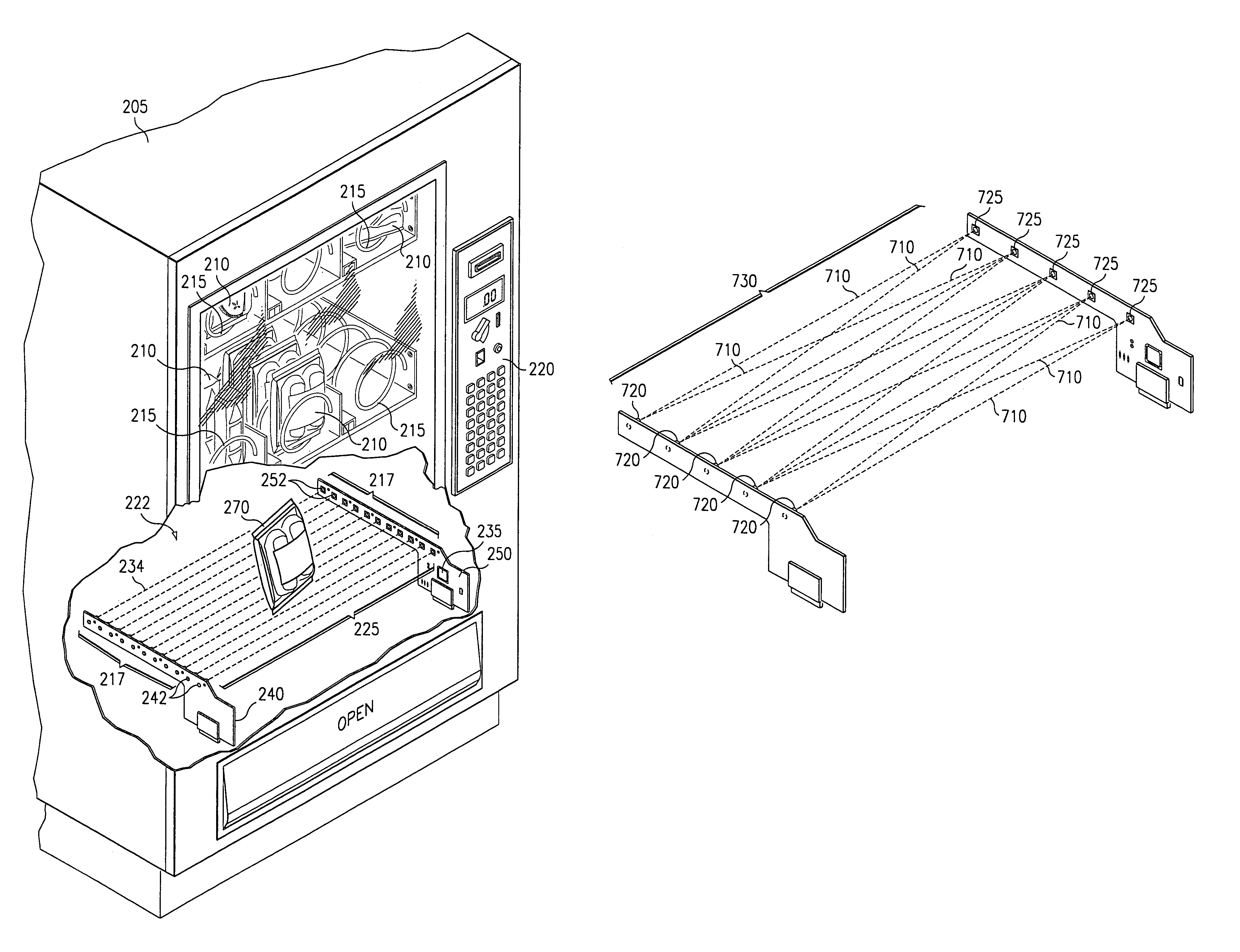

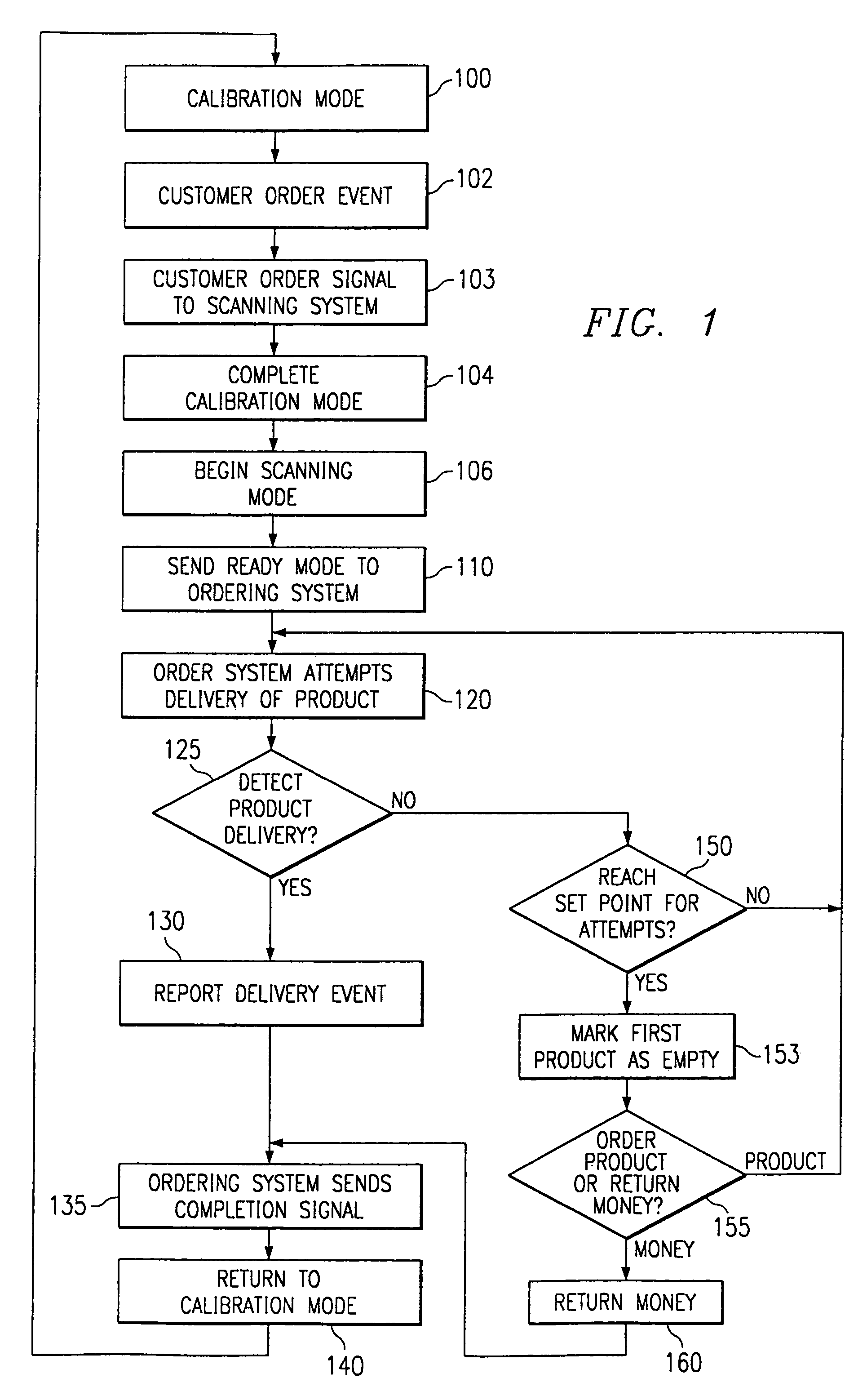

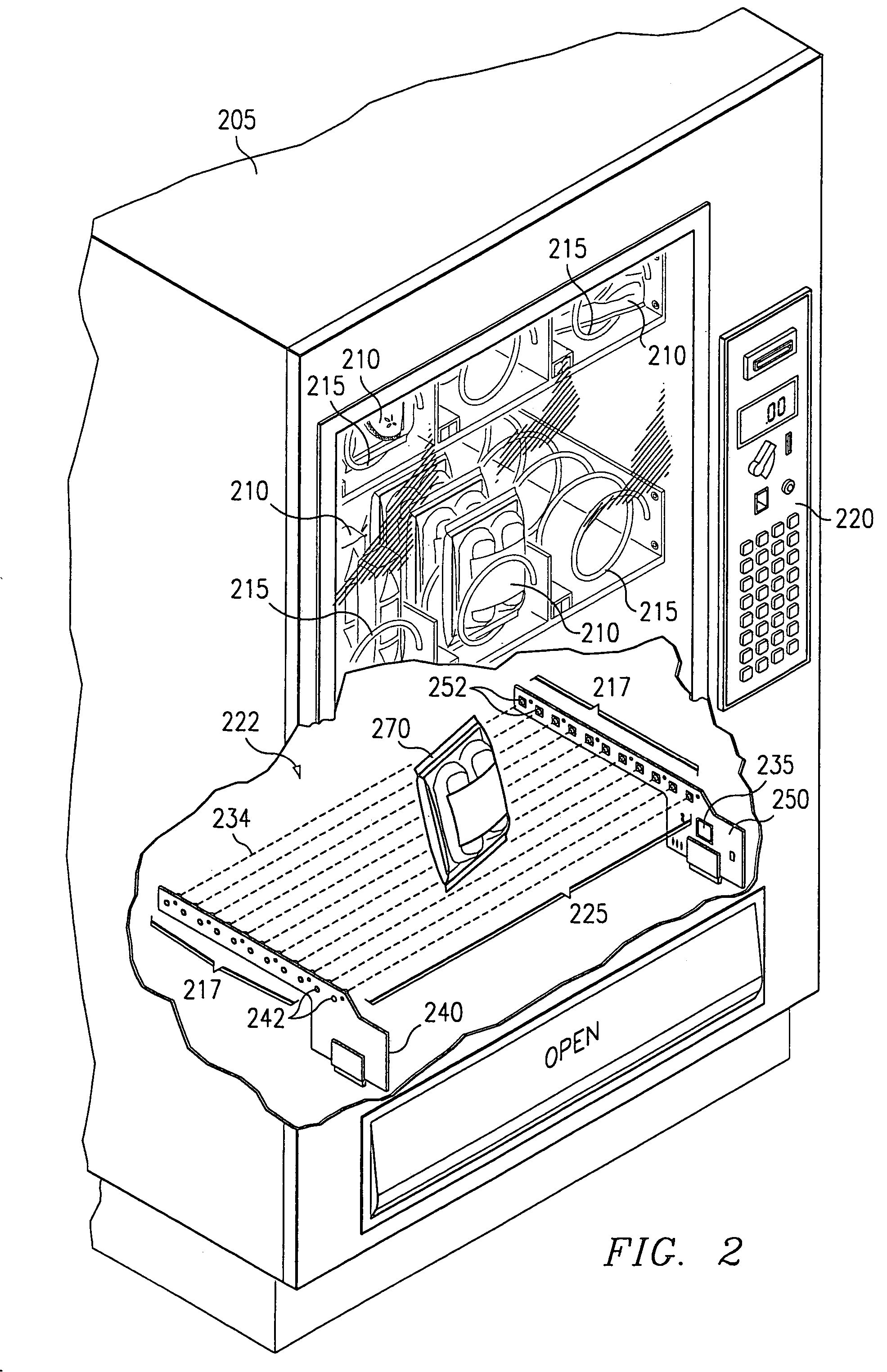

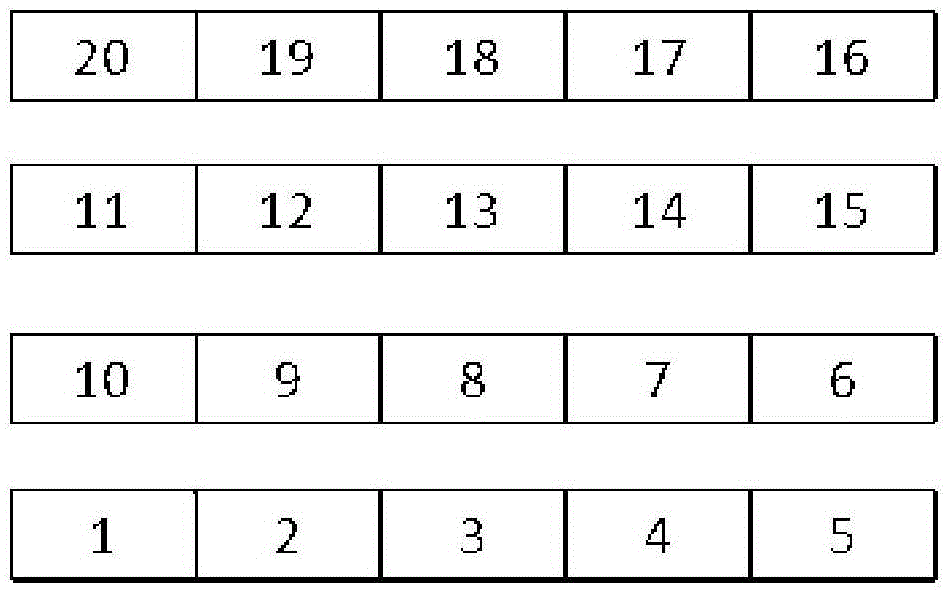

Method and system for accomplishing product detection

InactiveUS7191034B2Coin-freed apparatus detailsMaterial analysis by optical meansProduct orderMonitoring system

The present invention provides for a vending system wherein a monitoring system verifies that a product ordered by a vending customer is actually delivered through a delivery area to the customer. If the product ordered is unavailable either because of an out of stock situation or a blockage of the delivery path for that product, the present invention allows the customer to request a refund or order a second product. Additionally, the present invention helps to prevent theft of product from the vending system.

Owner:CRANE MERCHANDISING SYSTEMS

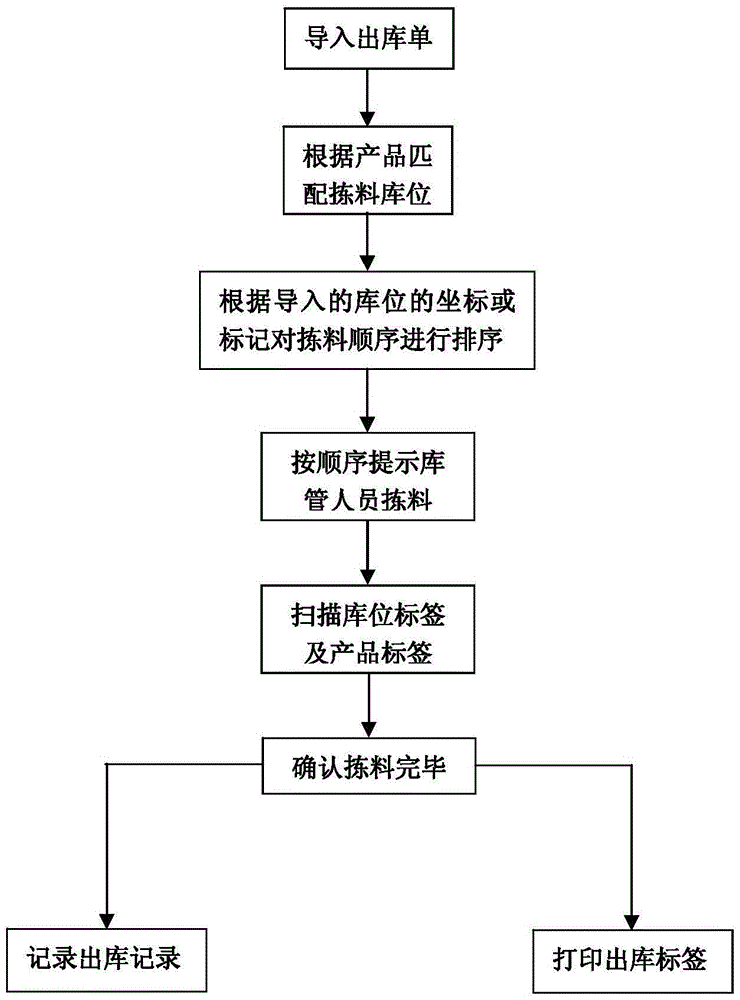

Intelligent warehouse outgoing and incoming management method based on bar codes

InactiveCN105678492AOptimizing Picking PathsImprove picking efficiencyLogisticsLower limitComputer terminal

An intelligent warehouse outgoing and incoming management method based on bar codes is characterized by comprising a personnel mobile terminal with a bar code scanning function, a computer and a database, needs to mark the storage locations of the warehouses, and is divided into an outgoing flow and an incoming flow. According to the intelligent warehouse outgoing and incoming management method based on the bar codes, by marking the storage locations and ranking the storage location prompts during the outgoing process, the picking paths of the warehouse management personnel are optimized, the picking efficiency of the warehouse management personnel is improved, and the workloads of the warehouse management personnel are reduced. By printing the outgoing labels automatically, the outgoing operation steps of the warehouse management personnel are reduced, and the working efficiency is improved. Meanwhile, by the system automatic matching, the probability of a manual operation error is completely eradicated. According to the outgoing amount and the stocking cycle of products, the stock upper and lower limit early warning number of the products is adjusted dynamically, and the warehouse management personnel are assisted to manage, thereby avoiding a lot of stockout and the excessive stock.

Owner:天津布尔科技有限公司

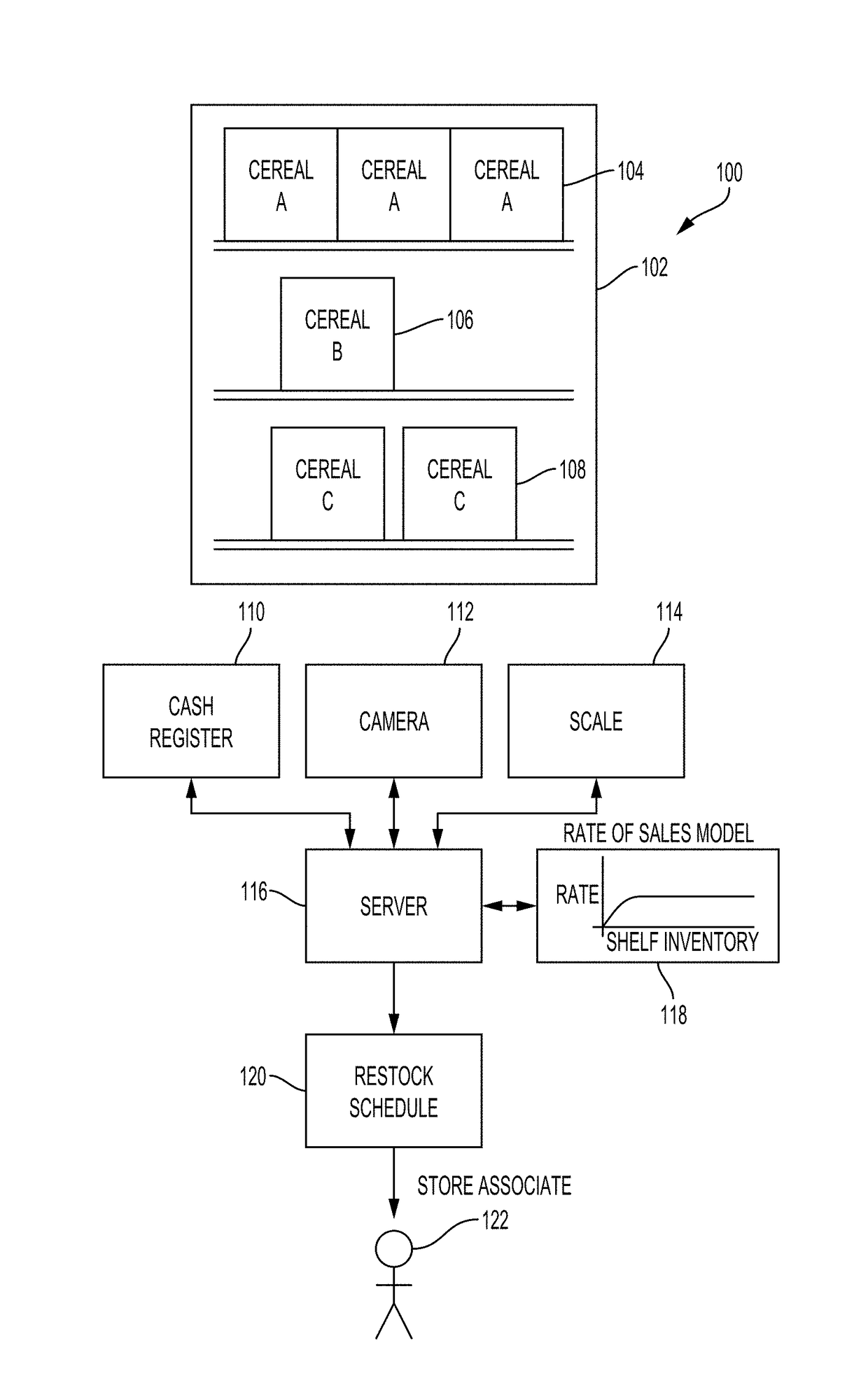

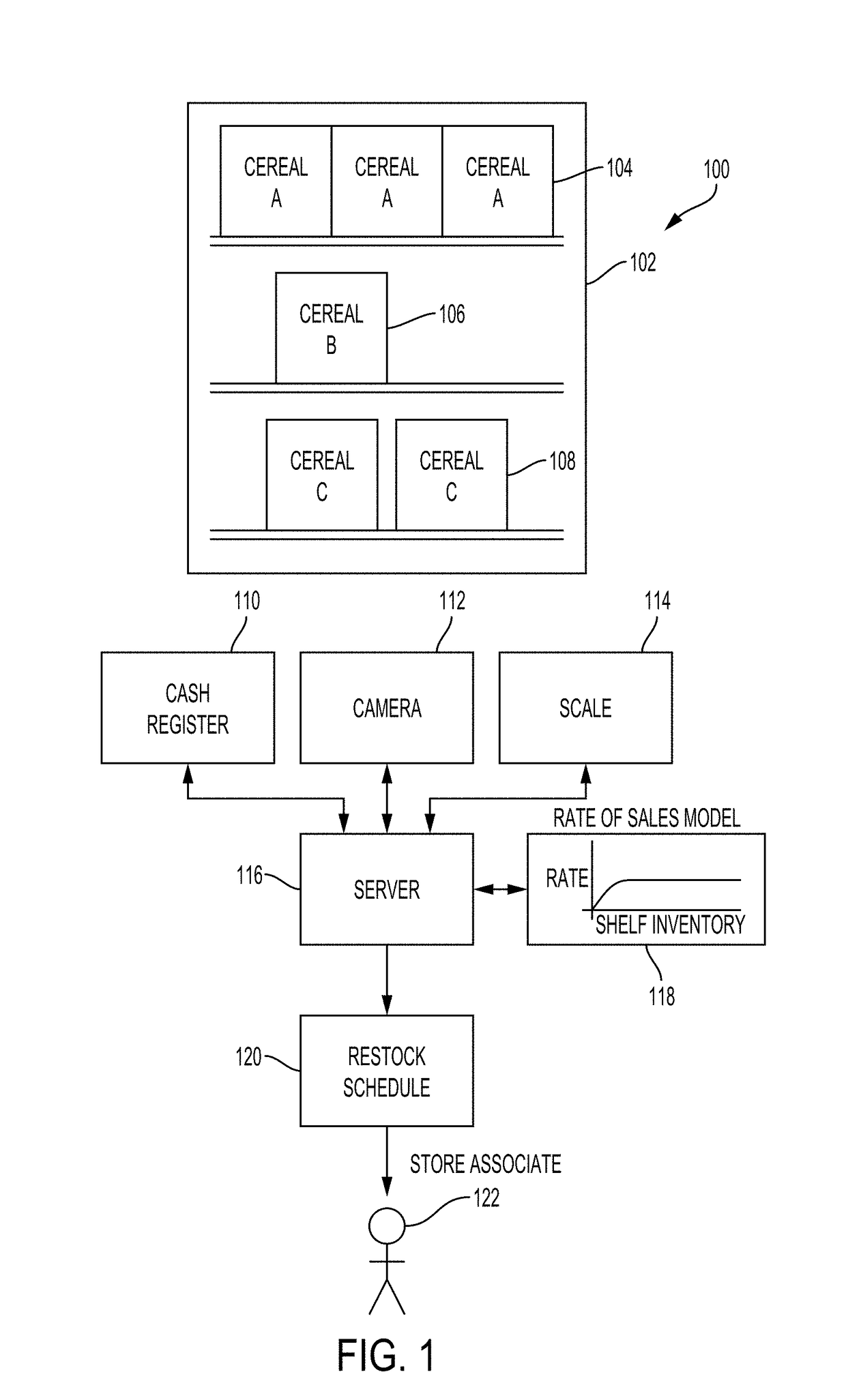

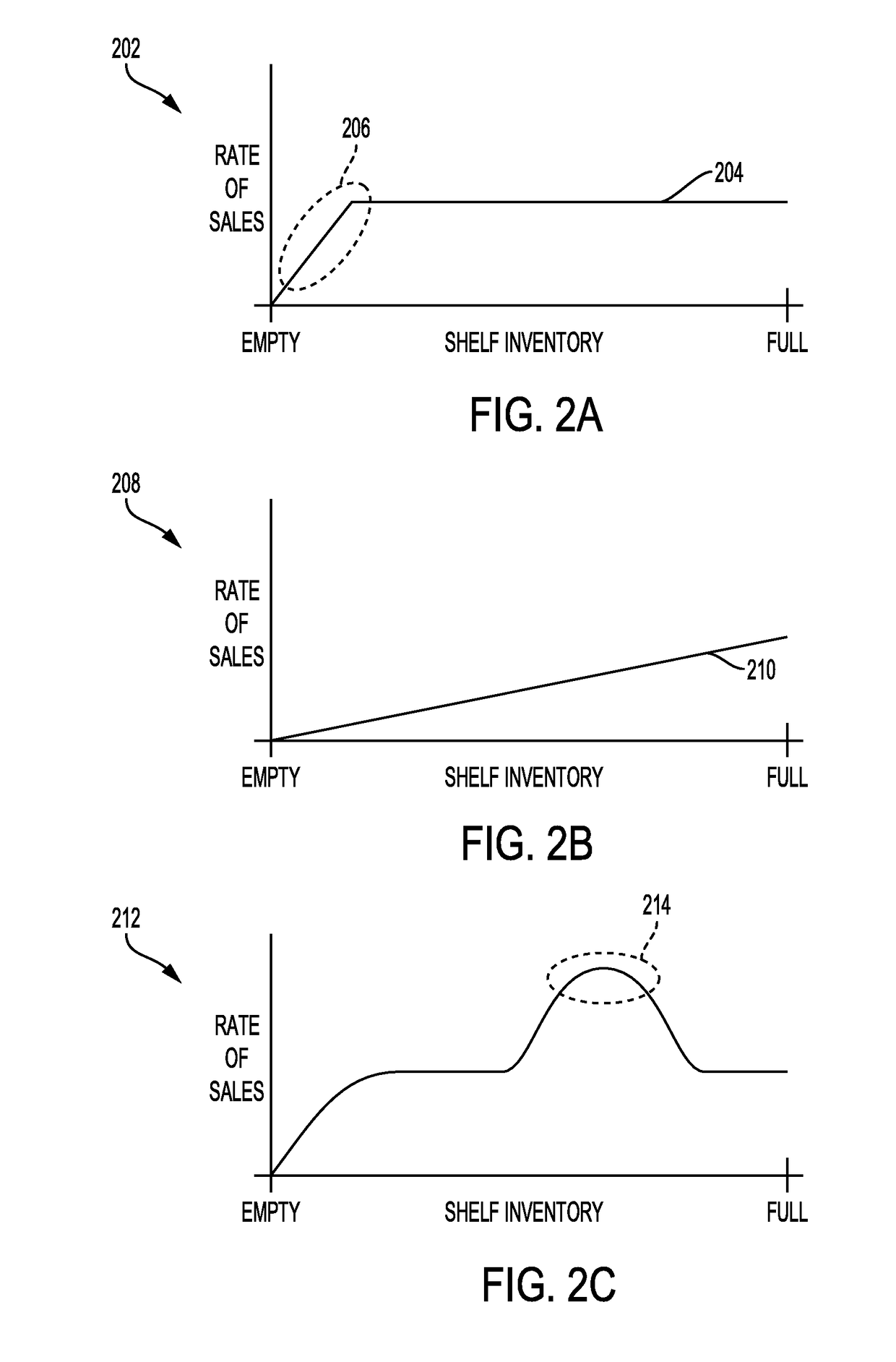

System and method for data-driven insight into stocking out-of-stock shelves

InactiveUS20180285902A1General purpose stored program computerMachine learningTime scheduleReal-time data

Systems, methods, and non-transitory computer-readable storage media for generating rate-of-sales models for products based on historical data of when products are being sold, then generating, in real-time, schedules for restocking items on store shelfs such that the amount of items on the shelf maintain desired rates of sales per the prediction models. This is accomplished used historical data in combination with real-time data regarding the current shelf inventory, as well as updating machine-learning models to improve estimates over time.

Owner:WALMART APOLLO LLC

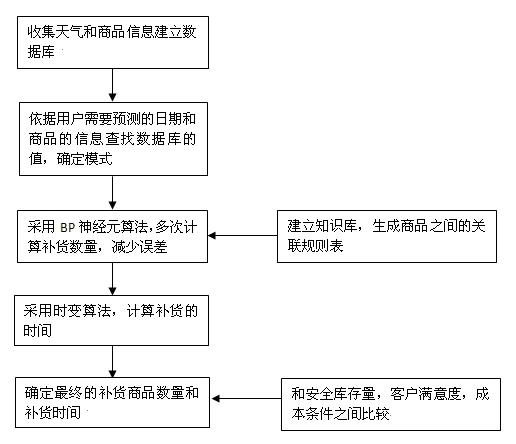

Warehouse replenishing method

InactiveCN102184507AControl Replenishment ManagementReduce inventory costsCommerceKnowledge engineeringStockout

The invention discloses a warehouse replenishing method, which belongs to a supermarket chain support technology. By introducing a knowledge library which is established on the basis of knowledge engineering and fusing the replenishing decision support system of an information system, warehouse replenishing management can be controlled more intelligently for different sale modes, and a replenished commodity number and replenishing time can be further modified according to cost, client satisfaction, a stockout rate, a safe stock quantity and the delivery time of suppliers. Compared with the prior art, the method has the advantages that: the stock cost can be reduced, and the stock management efficiency can be improved.

Owner:SUZHOU LIANGJIANG TECH

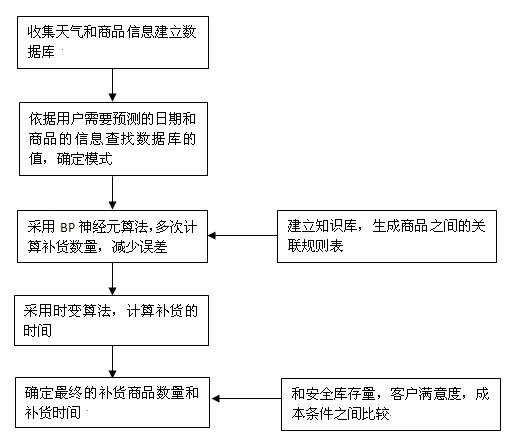

Supermarket shopping system and method based on sonic label technology

InactiveCN106097049AIncrease stickinessIncrease loyaltyCo-operative working arrangementsPayment architectureDatabase analysisPayment

The invention provides a supermarket shopping system and method based on a sonic label technology. The system comprises a supermarket goods storehouse management background, an automatic replenishment robot, a sonic label 360 degree reader shopping cart and shelf, goods with sonic labels, a computer terminal in wireless communication with the shopping cart with the label reader, a mobile phone in network connection with the computer terminal, a user shopping habit analysis database connected with the mobile phone and another computer, a cloud platform, a user APP accumulation credit library, a credit line pre-loan system, and an automatic opening and closing gate. According to the invention, goods unique code information reading and automatic robot replenishment for out-of-stock shelves are realized; simultaneous reading of the reader is not affected by overlapping stacking of goods put into the shopping cart; shopping code, amount and total amount are simultaneously displayed on a mobile phone APP; the mobile phone APP can be fixed with a bank card, or an APP credit blank note is used for overdraft payment; after payment, a gate carries out automatic identification and opening for releasing; a user database analyzes user purchase habits and many other preferred functions; and the system and method have the advantages of simple structure, reasonable design and easy manufacture.

Owner:安徽省凯乐唯物联科技有限公司

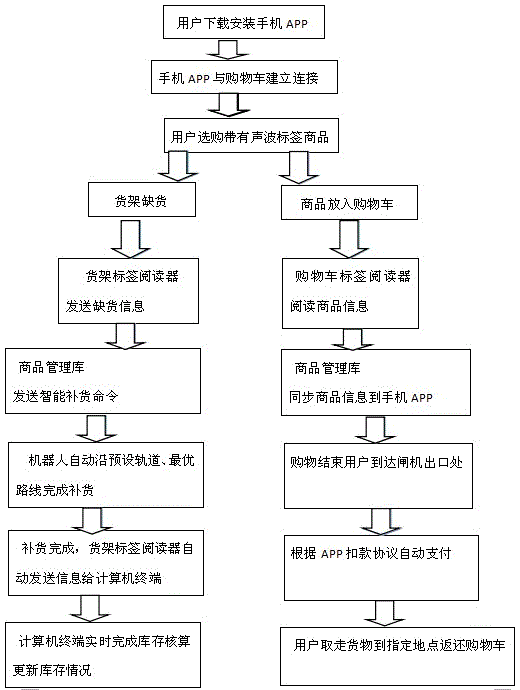

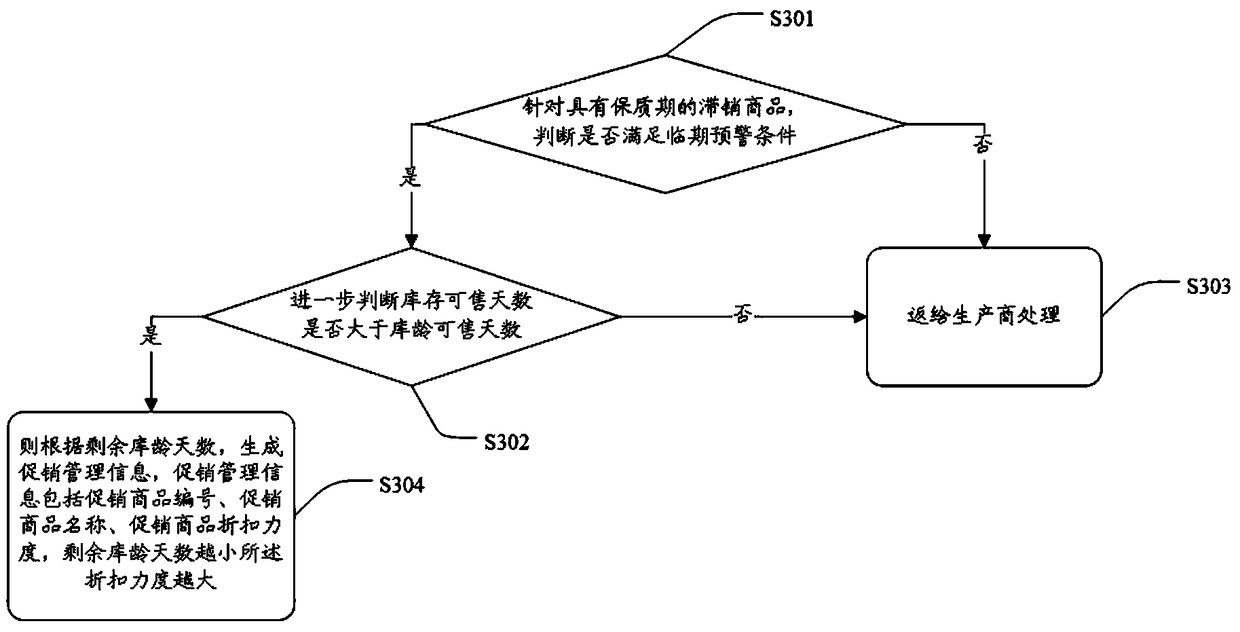

Inventory management method, inventory management apparatus, device, and storage medium

Disclosed are an inventory management method, an inventory management apparatus, a device, and a storage medium. The inventory management method is applied to inventory management including a plurality of warehouses. The inventory management method comprises the following steps: acquiring status information of each warehouse, wherein the status information of the warehouse includes the inventory quantity and the warehouse age; calculating inventory health status information according to the predicted sales quantity, the inventory quantity and the warehouse age, wherein the inventory health status information includes stock-out status information and unsalable status information, and the predicted sales quantity is the predicted sales quantity in a time period set according to commodity characteristics; and generating inventory management suggestion information on the basis of the inventory health status information. According to the technical scheme provided by the embodiment of the present application, the inventory health status information which can reflect the inventory stock-out status and the inventory unsalable status, the problems existing in the inventory management can bejudged by the inventory health status information and a corresponding management scheme can be generated.

Owner:SF TECH

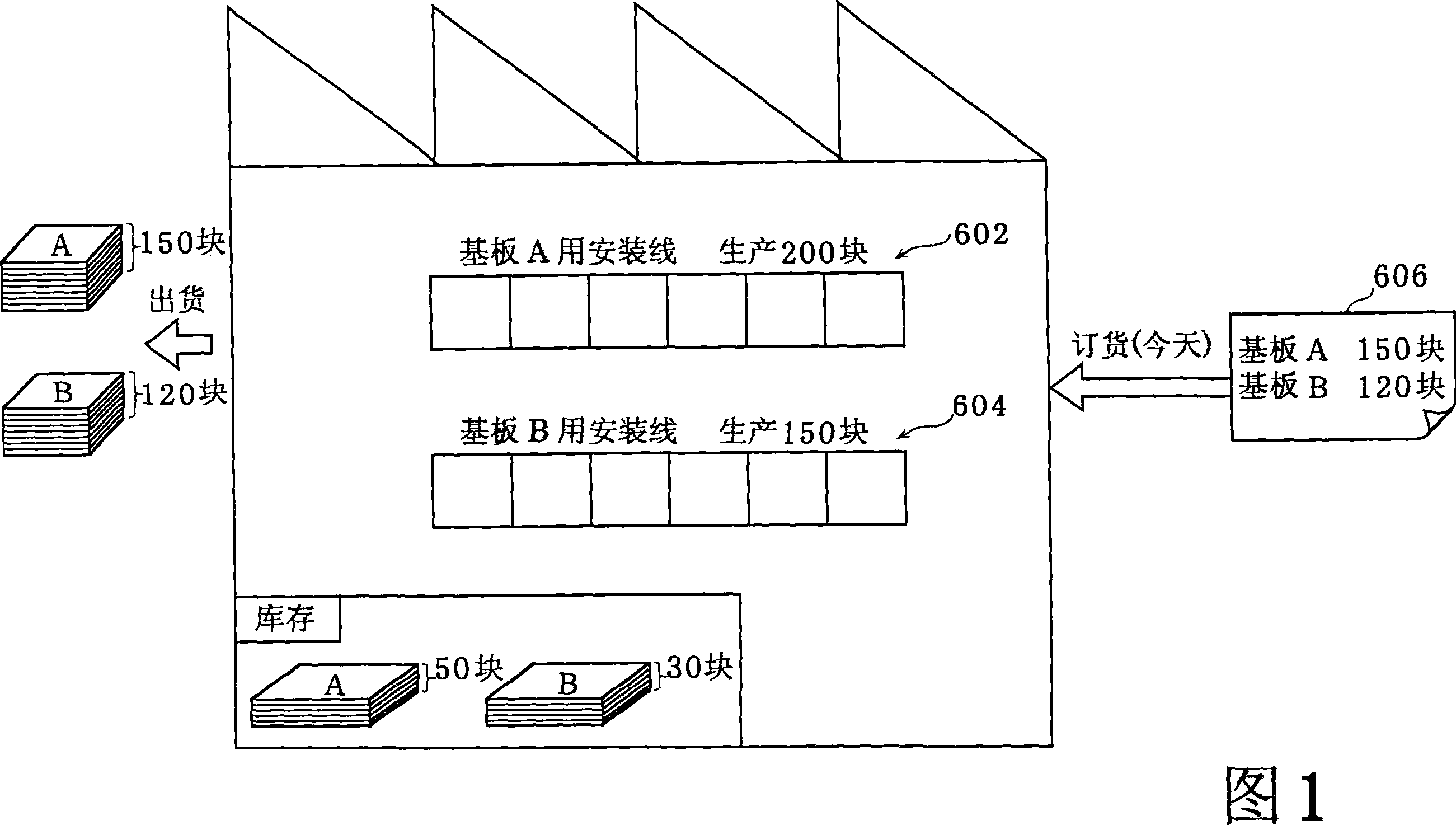

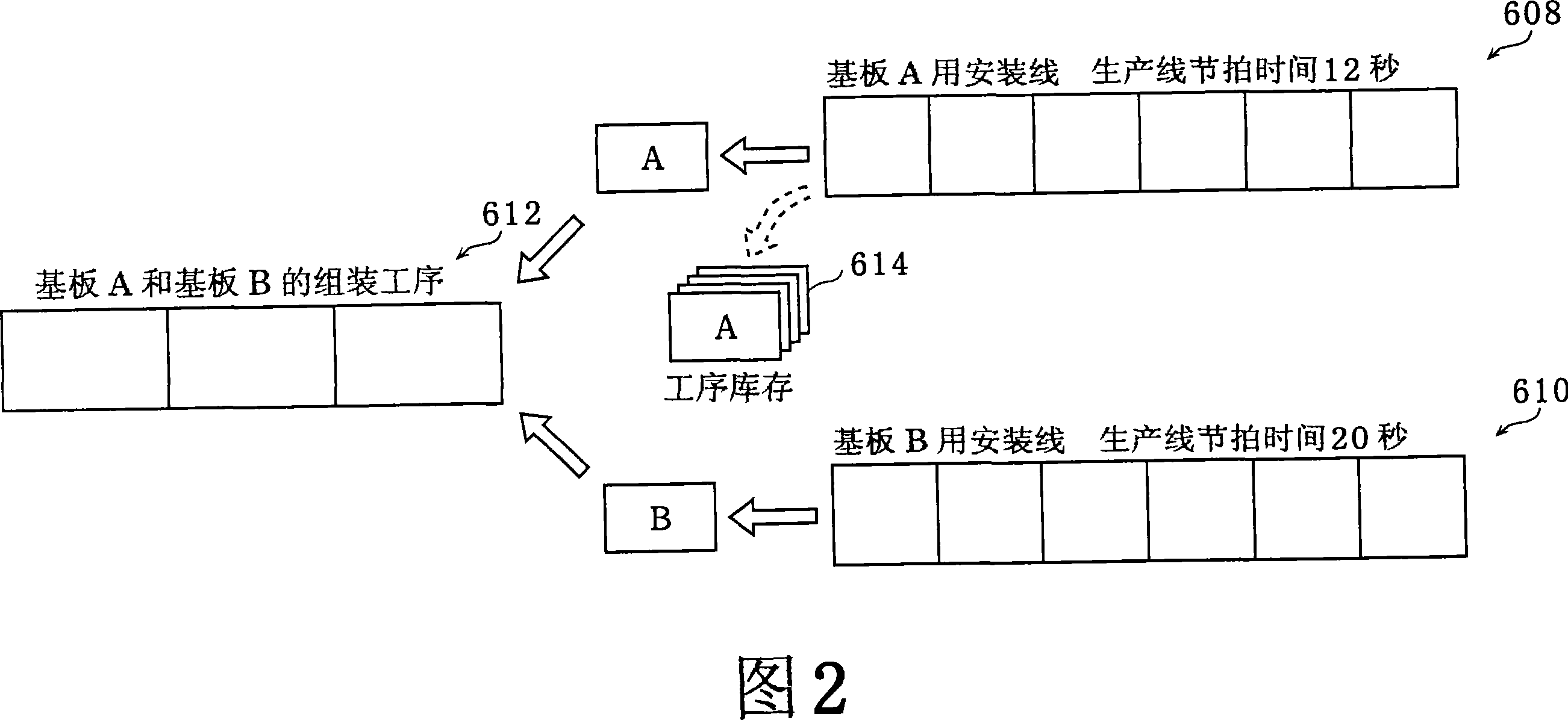

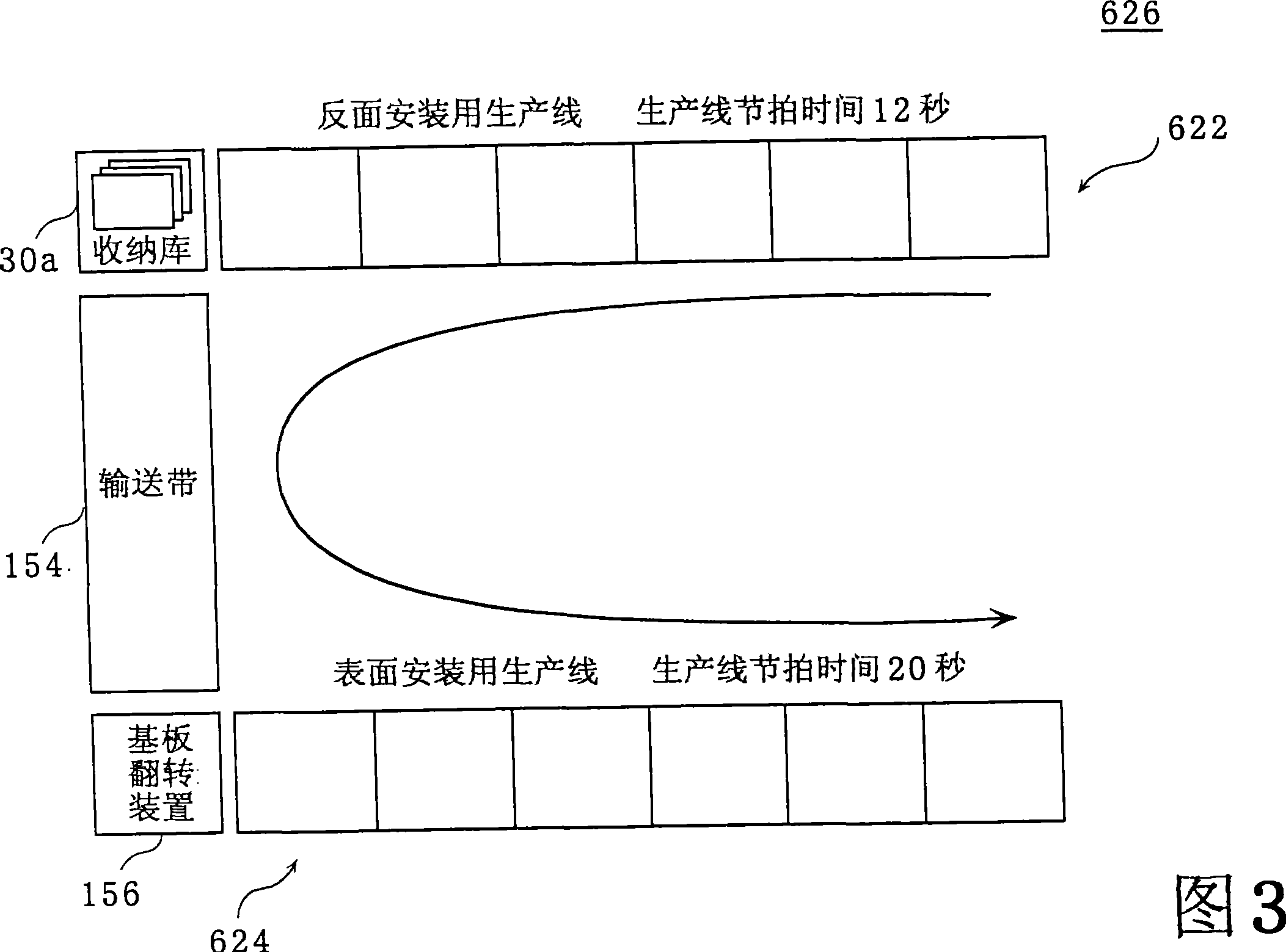

Production management method, production management device, and parts mounting device

InactiveCN101208640ATotal factory controlProgramme total factory controlStockoutPrinted circuit board

There is provided a production management method of a parts mounting device capable of suppressing generation of stock and stockout. Furthermore, the method can reduce the power consumption when sufficient production ability can be obtained. The method includes an acquisition step for acquiring production information constituting a production plan while production facility is producing a printed circuit board and a throughput decision step for deciding the throughput of the production facility relating to the printed circuit board according to the production information while the production facility is producing a series of printed circuit board. Furthermore, the method includes a production condition decision step for deciding the production condition so as to reduce the power consumption of the production facility with a throughput in a range not lower than the decided throughput if the throughput decided in the throughput decision step is lower than the current throughput of the production facility.

Owner:PANASONIC CORP

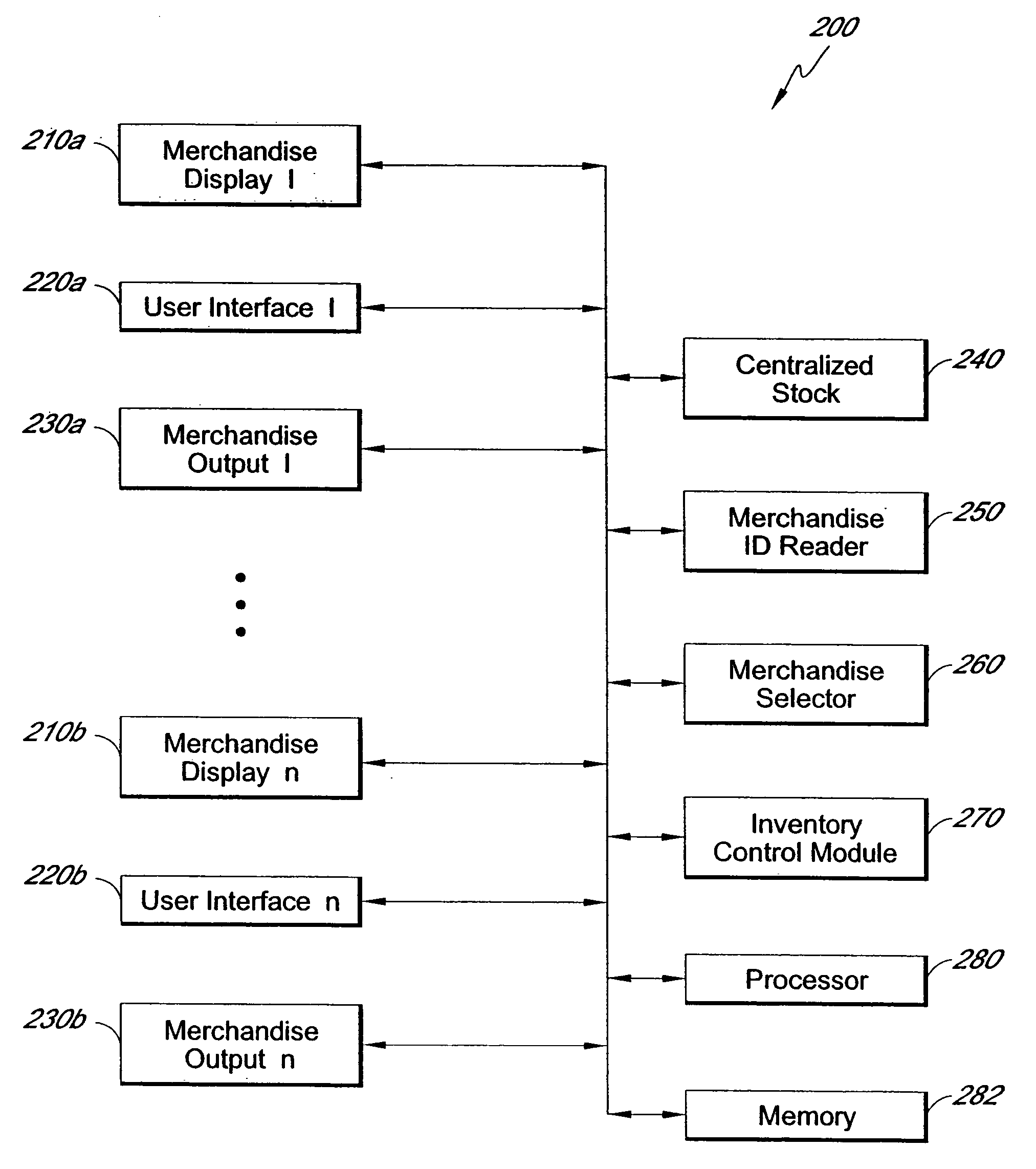

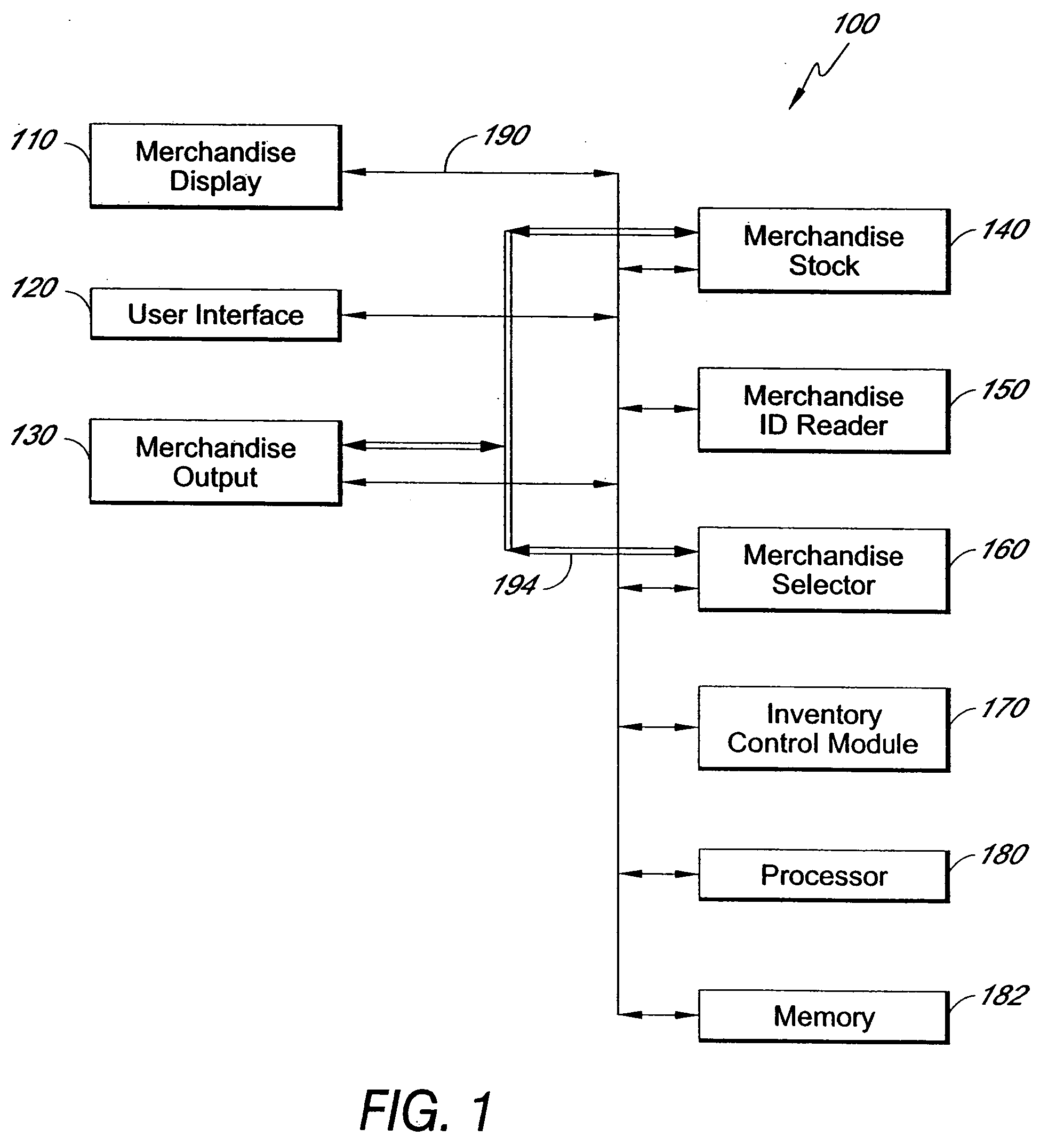

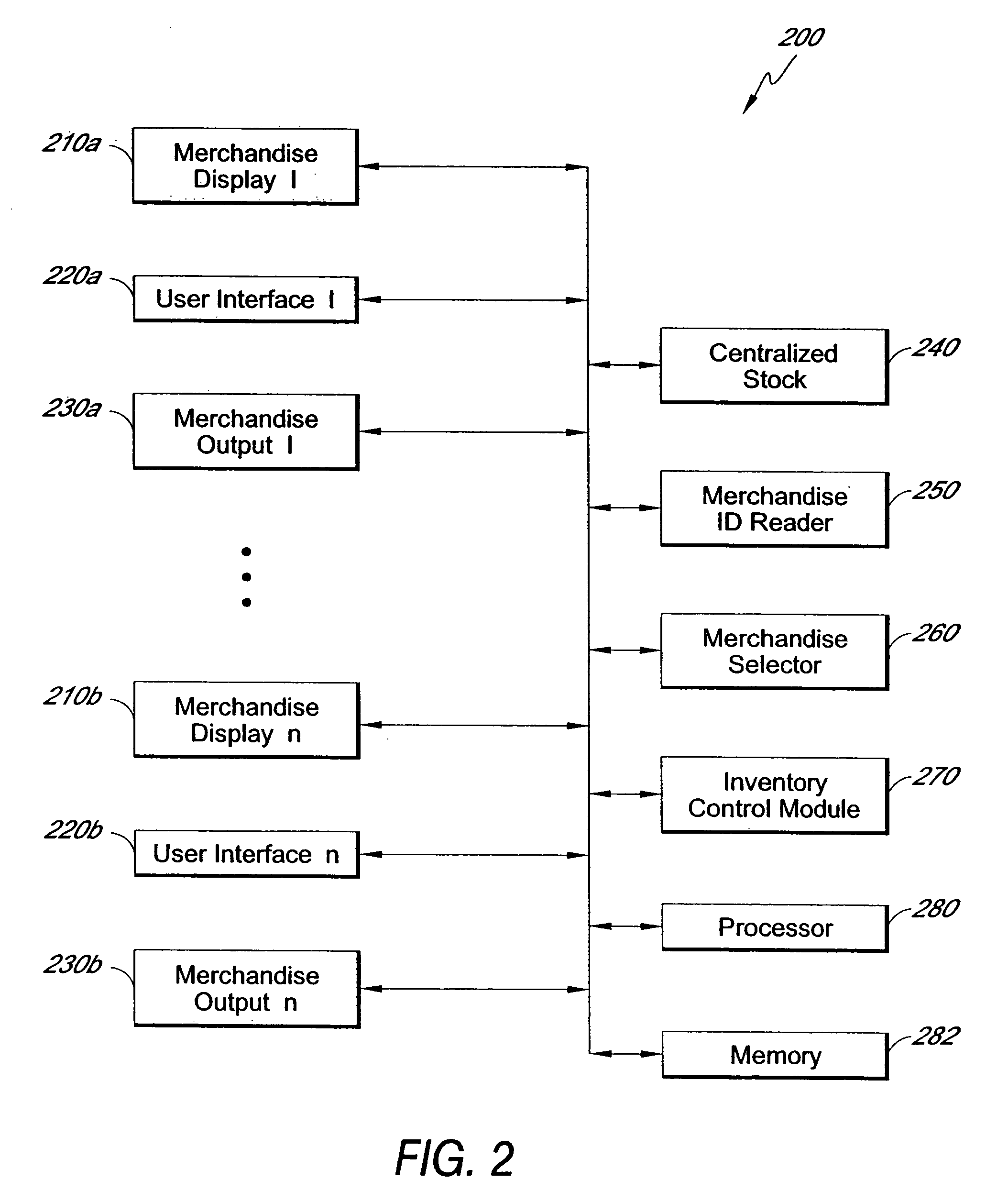

Automated merchandising dispenser

An automated merchandising dispenser that forms an integral part of an automated merchandising system is disclosed. A dispenser enables a consumer to immediately locate and obtain desired items that may be customized according to at least size, color, and style. Inventory for a particular item is categorized and identified with a machine readable identifier. The machine readable identifier includes information identifying the item and customization criteria, such as size, color, and style. The consumer, via a user interface, enters criteria for the particular desired item and the merchandising dispenser searches inventory categorized using the machine readable identifier. Available inventory may immediately be dispensed to the consumer, either locally or to a remote location. The consumer may be immediately notified of out of stock items and may be offered alternative items or alternative purchasing modes. Inventory may be segregated and local to dispensers or may be centralized and routed to dispensers.

Owner:INDYME ELECTRONICS

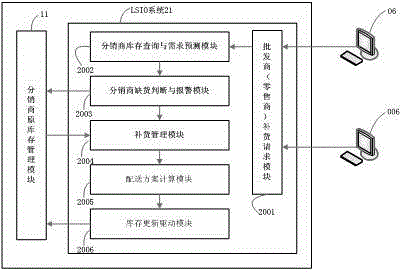

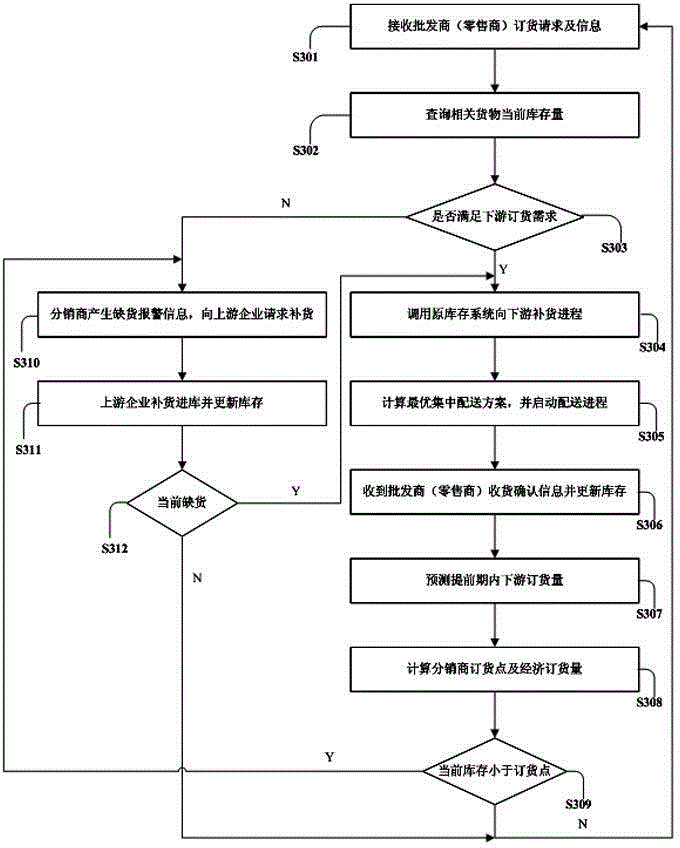

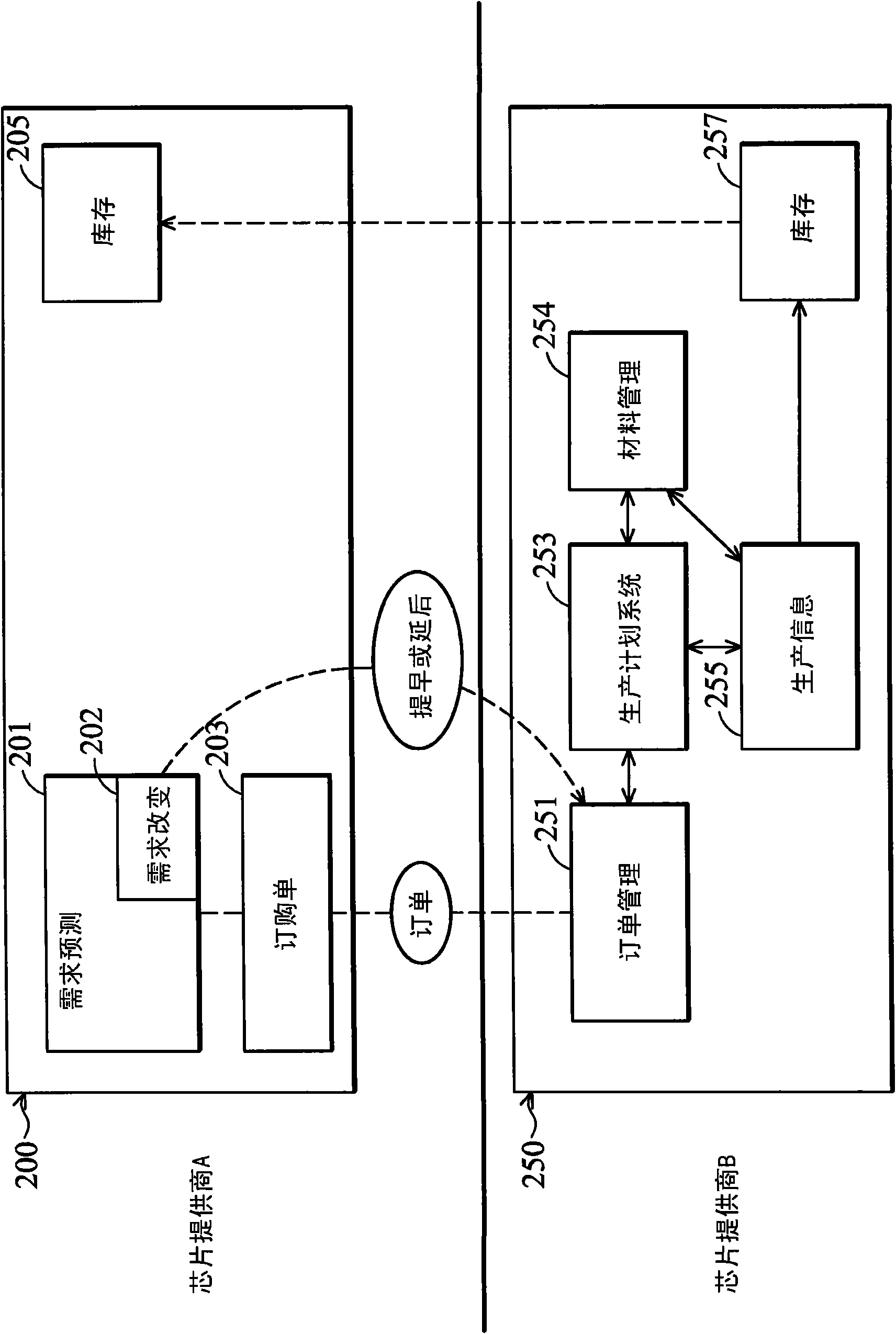

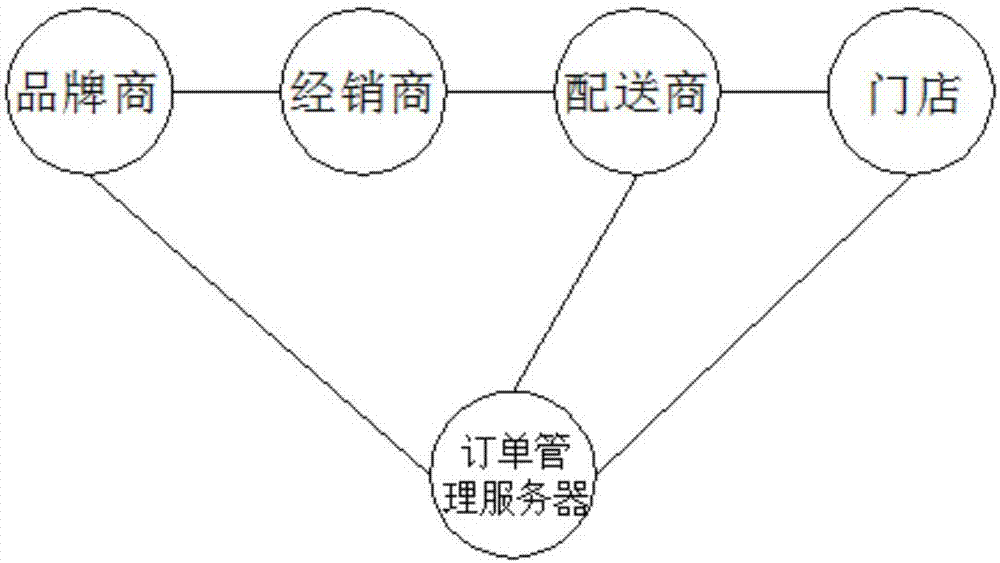

Supply chain inventory optimization method for lightweight information sharing

The invention relates to a supply chain inventory optimization method for lightweight information sharing. The method comprises the following steps: (1) acquiring order and replenishment information of wholesalers or retail dealers; (2) inquiring inventory data of distributors according to the order and replenishment information; (3) predicting order points and economic order quantity of the distributors in lead time of order; (4) judging whether the replenishment information is generated or not and generating a warning notification; (5) sending out an order application to upstream enterprise according to the replenishment information; (6) generating a centralized distribution scheme according to the shortage cost, the discount cost and the transportation cost of the wholesalers and the retail dealers, and sending delivery information to the wholesalers or the retail dealers; (7) updating an inventory database of the distributors after the distributors receive the distribution information of the upstream enterprise. According to the supply chain inventory optimization method disclosed by the invention, the optimal centralized distribution scheme for enabling the total cost of a supply chain to be lowest can be made when order requirements of the retail dealers or the wholesalers arrive, and the double marginal effect of the supply chain is eliminated.

Owner:冯卫星 +3

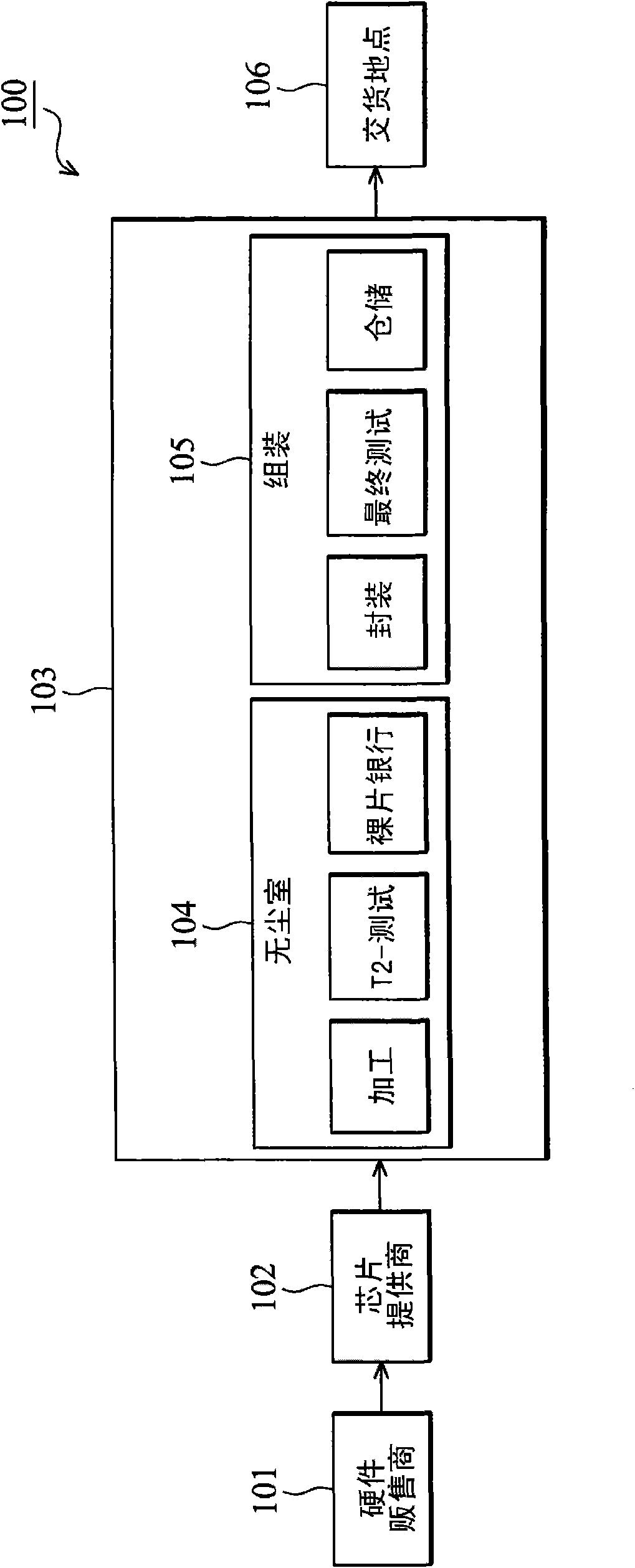

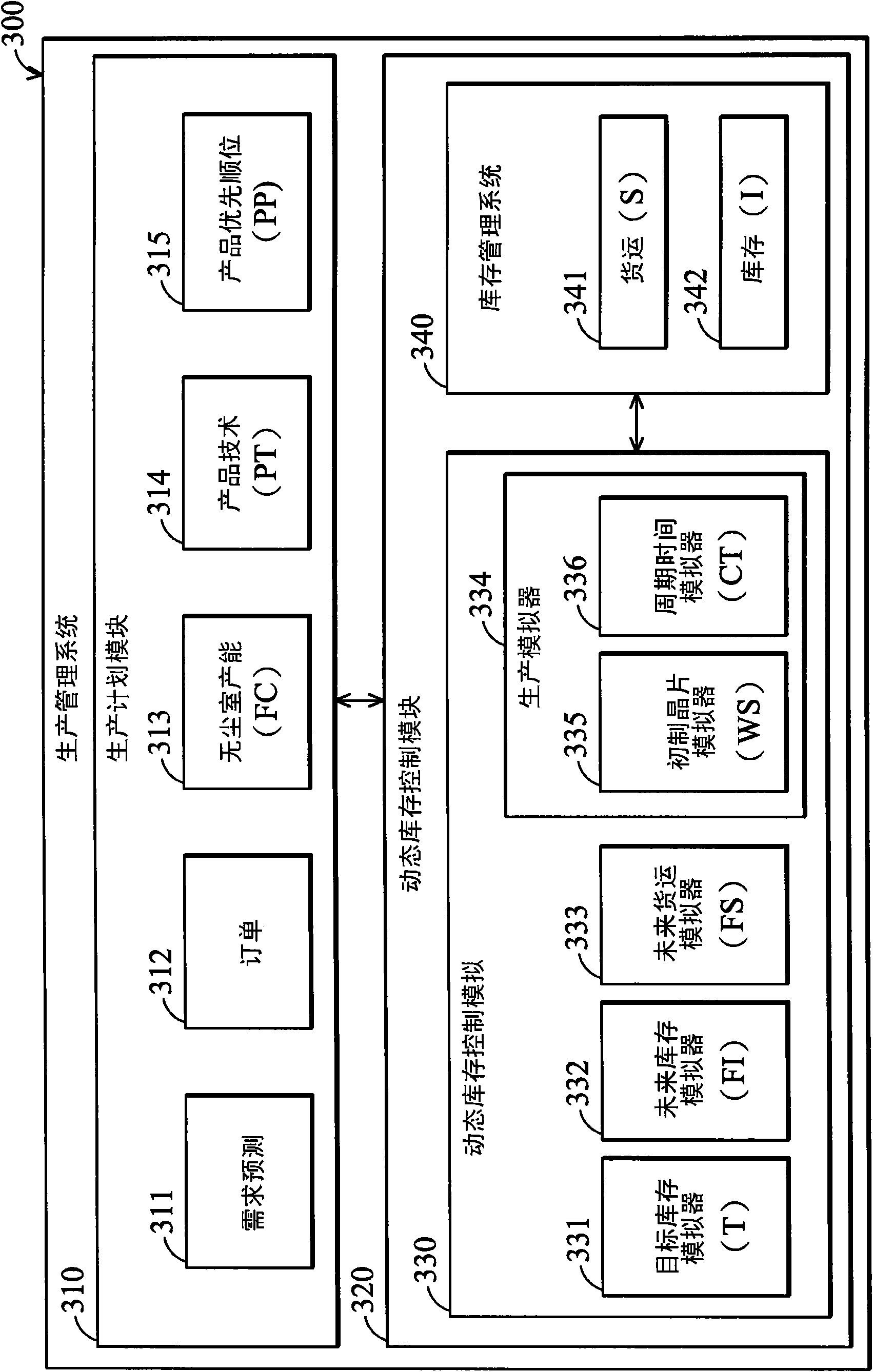

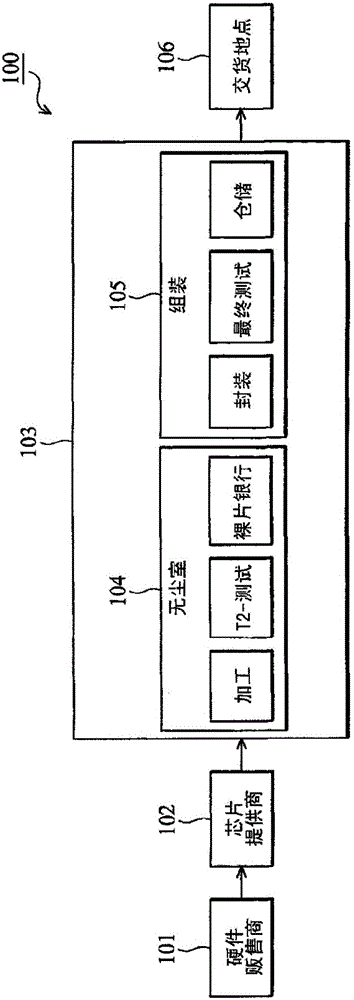

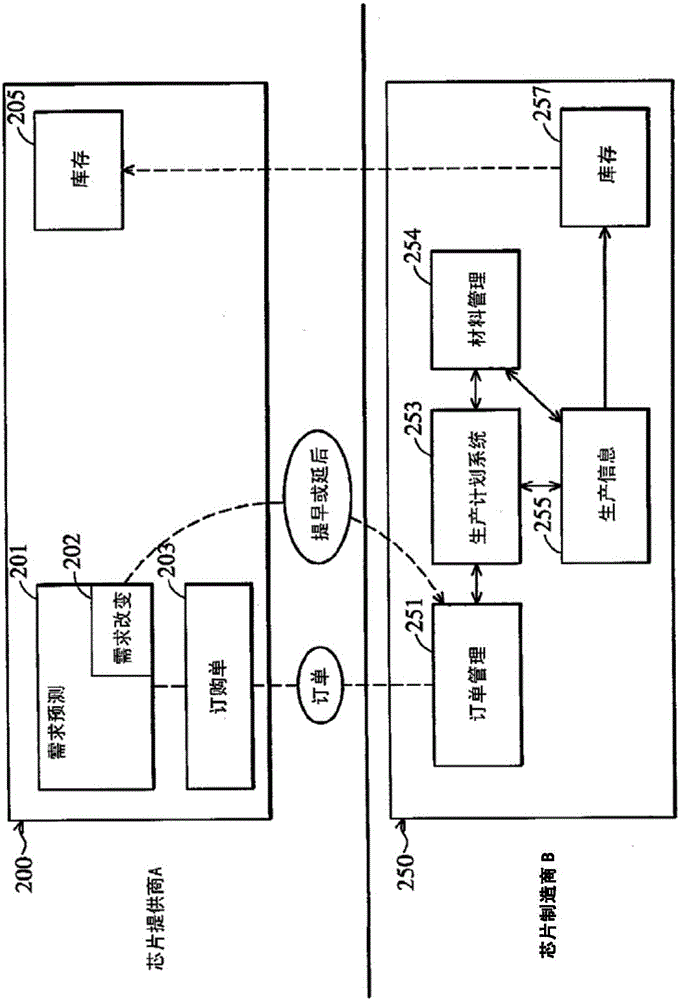

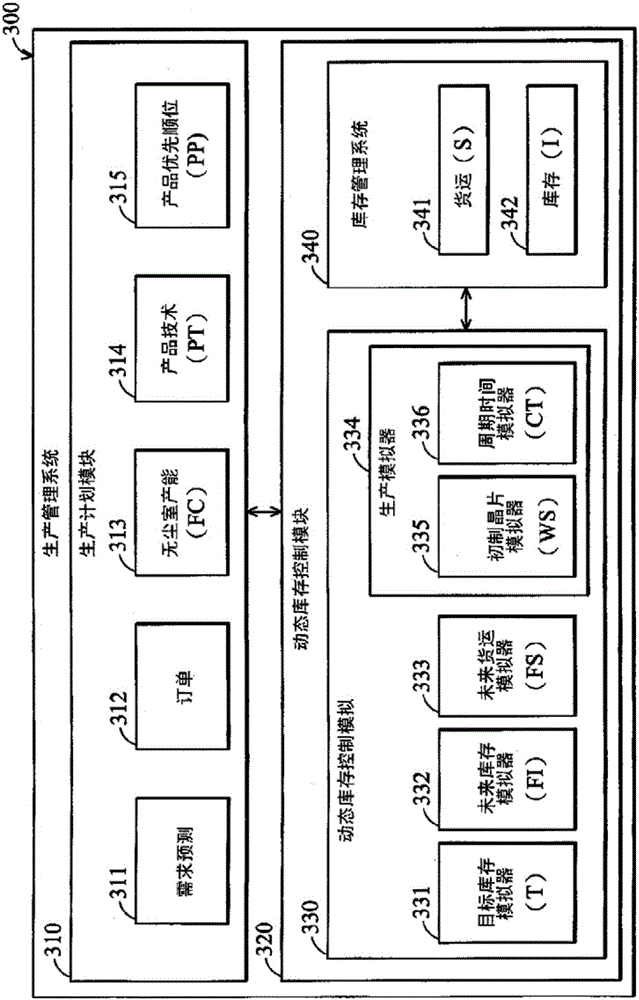

Methods and systems for dynamic inventory control

InactiveCN102142120ALow costGood customer relationshipCommerceProgramme total factory controlProgram planningSemiconductor chip

The embodiments of the present invention fill the need of properly controlling product inventory of semiconductor chips by providing methods and systems of dynamic inventory control. The methods and systems timely modify parameters affecting inventory. The parameters may include target inventory, cycle time, wafer start, future inventory and future shipment. In addition, the methods and systems gather real-time customer demand forecast to assist in production planning and adjustment. Further, the methods and systems identify inventory control turning points dynamically to adjust production activities to prevent overstock and to prevent stockout. The methods and systems will help to reduce cost of overstock and prevent stockout, and to establish a good relationship of essential cost-saving and consumers.

Owner:TAIWAN SEMICON MFG CO LTD

Method of creating production plan of demand variation input type and method of creating production plan minimizing risk of demand variations

InactiveUS7660730B2Avoid adjustmentMaximizes achievement ratioMultiprogramming arrangementsCommerceStockoutRate ratio

A production plan is created so as to minimize risk of demand variations. Forecasted values of amounts of requests are entered for each different item of products, markets, dates, past accuracy of demand forecasts, and order achievements at the time when the plan is created. Scenario information is created in which assumable amounts of request for each different item of the products, markets, and dates and probabilities at which the amounts of requests agree with actual amounts of requests are defined. Management indexes are found from the amount of stockout and amount of stock calculated in each different scenario, based on the scenario information, target values of the management indexes, and information on strongpoints. An amount of production that maximizes the achievement ratios of the management ratios to their targets within the ranges of supplied materials and within the range of the production capacity is calculated by an optimization algorithm.

Owner:HITACHI LTD

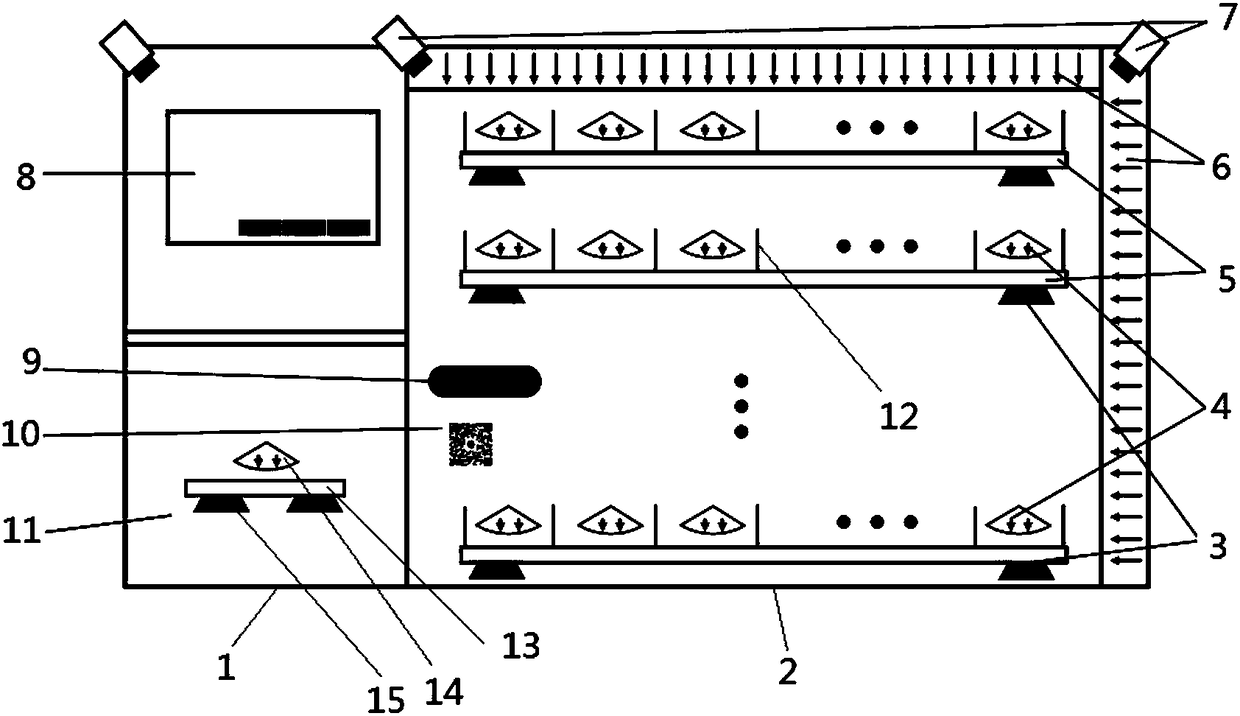

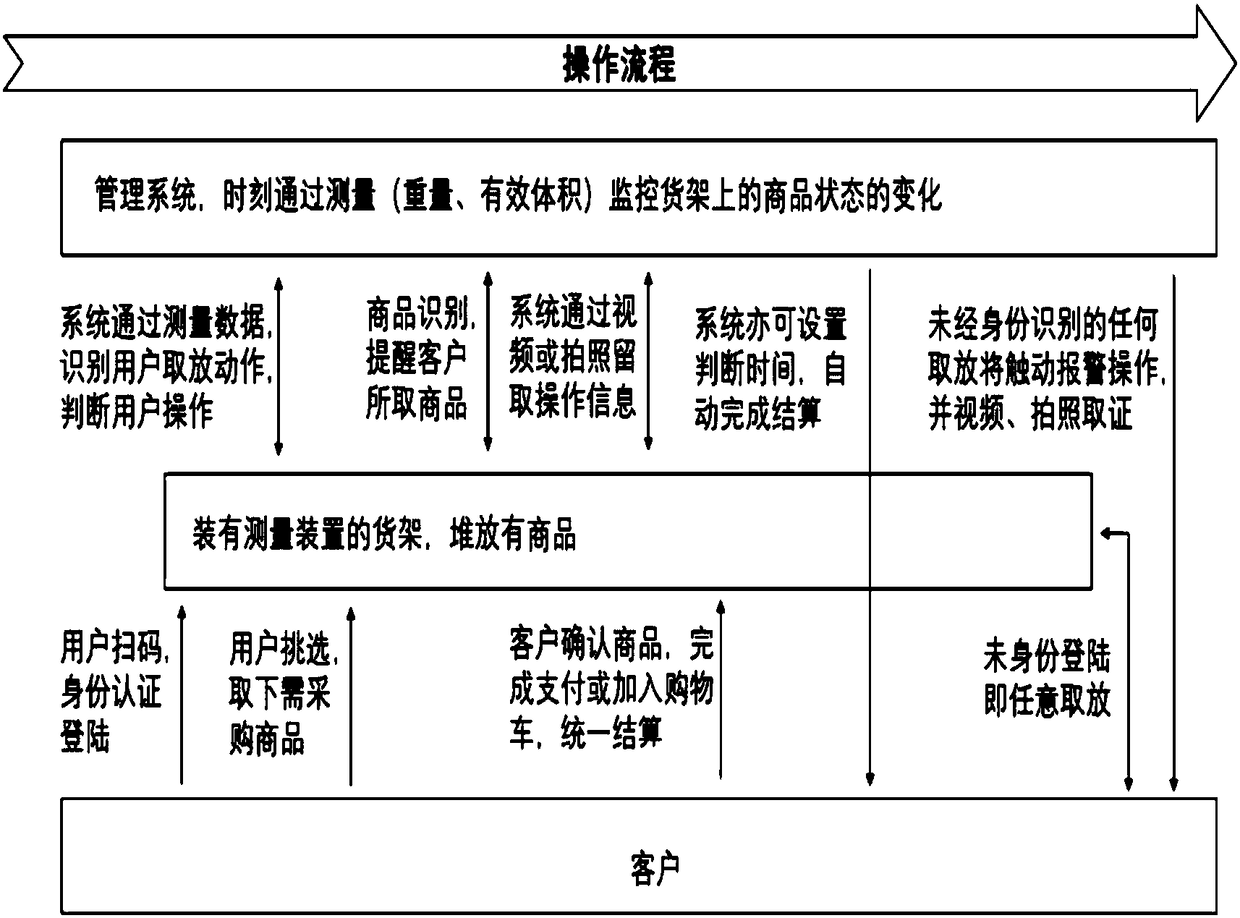

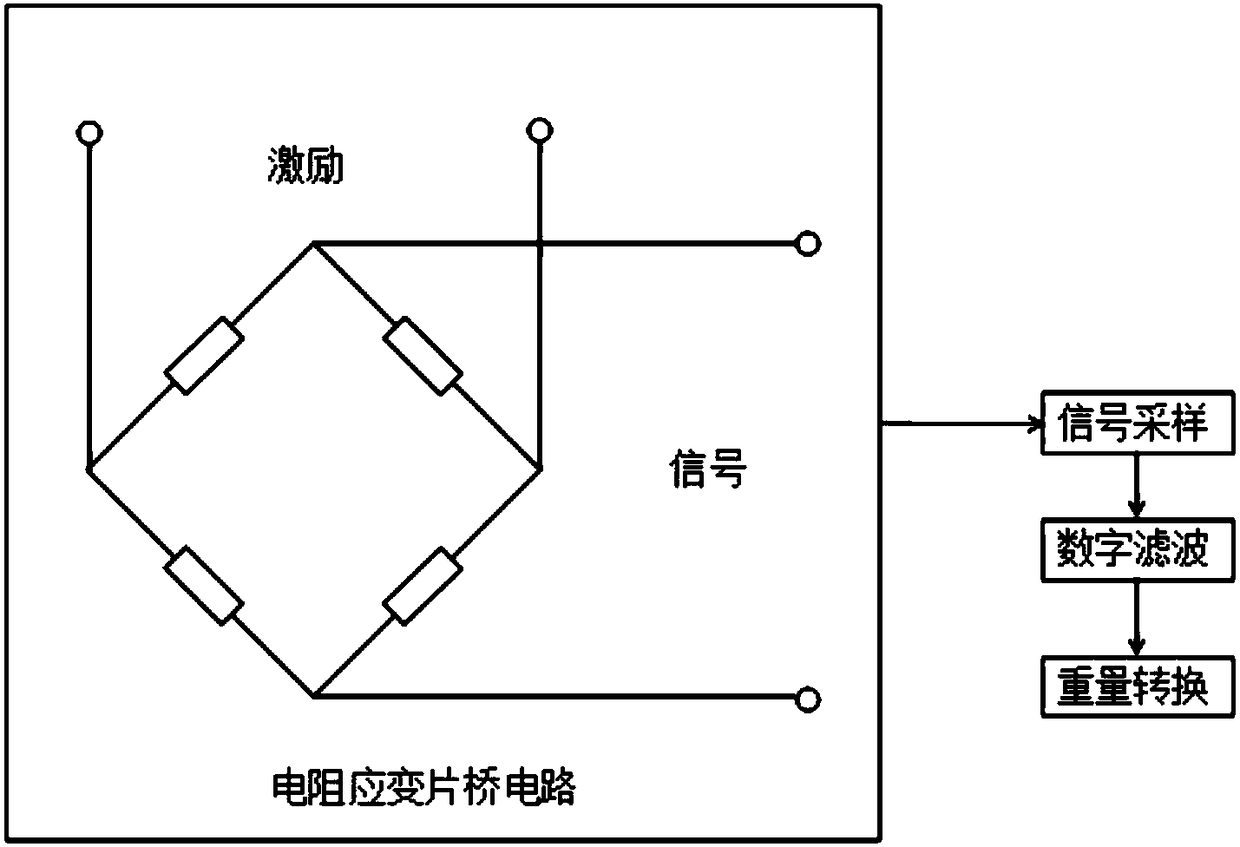

Unattended retail goods identification and cheat prevention system and method based on comprehensive measurement way

InactiveCN108564713ASolve no monitoringSolve technical problems that are prone to cheatingCoin-freed apparatus detailsCustomer communicationsThe InternetEngineering

The invention discloses an unattended retail goods identification and cheat prevention system and method based on a comprehensive measurement way, and belongs to the technical field of the Internet. The system comprises a goods shelving and sampling system and an intelligent shelve. The technical problems that when using an unattended retail shelve, customers are not monitored and easily cheat aresolved. No complicated mechanical structures are needed, and the space utilization rate is improved; by means of the system, goods can be accurately identified, and the problem that a single shelve cannot be supervised is solved; the system has universality, there are no special requirements for the shapes of the sold goods, and the goods which are different in shape and type can be sold at the same time; the goods can be conveniently replaced; the system is convenient and efficient to use, the customers can directly scan codes, take the goods and pay for the goods, and no complicated operation is needed; the system has monitoring data, and the traceability is high; the collected sell data can provide a reference for purchases; it can be achieved that a reminder of stockout is given.

Owner:刘婧

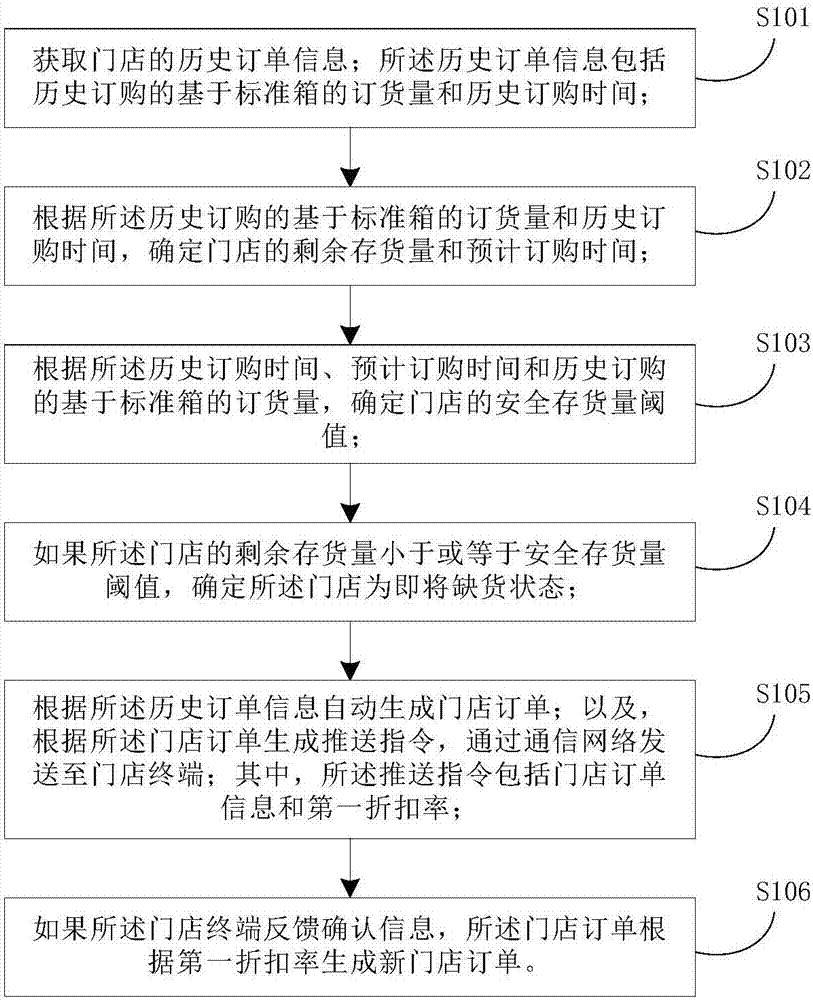

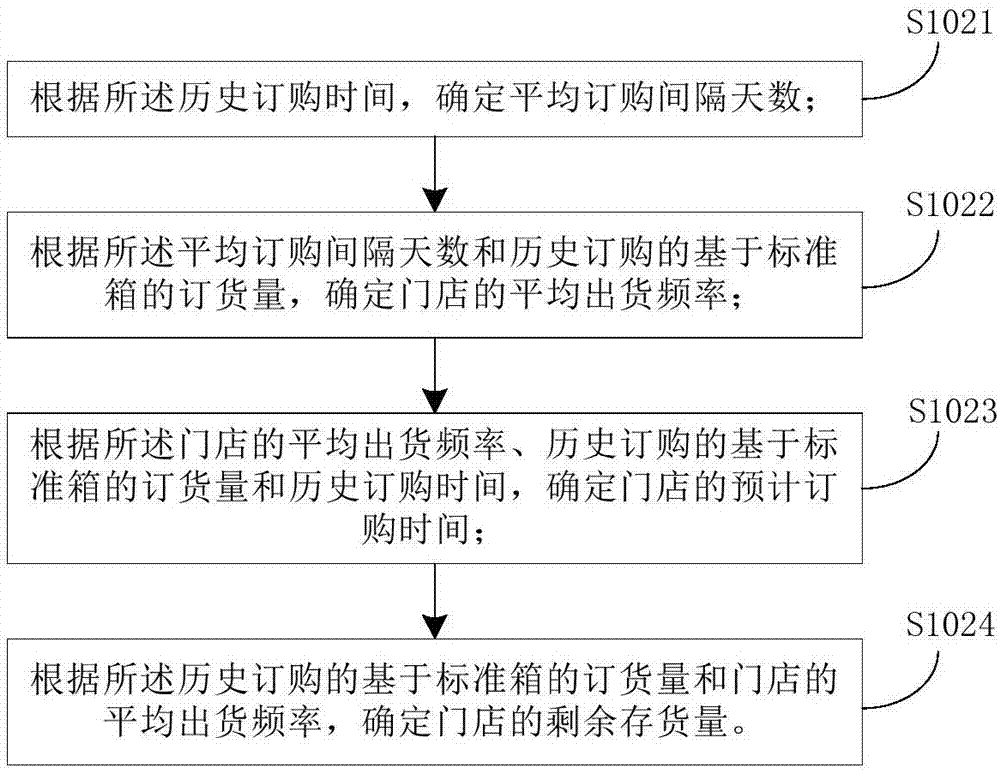

Automatic generation method and device for order and server

InactiveCN107292724AAvoid the problem of inflexible schedulingImprove distribution efficiencyBuying/selling/leasing transactionsLogistics managementOrder form

The invention discloses an automatic generation method and device for an order and a server. The method comprises the steps of: according to historic order information of a store, predicting the surplus stock of the store at current time and the estimated ordering time of ordering standard boxes of commodities next time; predicting the sales status of the store at the current time, and if the surplus stock of the store is smaller than or equal to a safety stock threshold, judging the store in short supply; and at the moment, pushing the historic store order to the store, and if the store confirms to order the pushed store order, enjoying the discount when paying the order. Thus, the method can predict the sales status of the store in real time, push a store order to the store in advance and promote the store to order standard boxes of commodities in advance, so that the order is no longer a rush order, the delivery dealer has enough time to dispatch delivery equipment, the logistics resources of the delivery equipment are sufficiently utilized, and then the delivery efficiency of the delivery dealer is improved.

Owner:北京惠赢天下网络技术有限公司

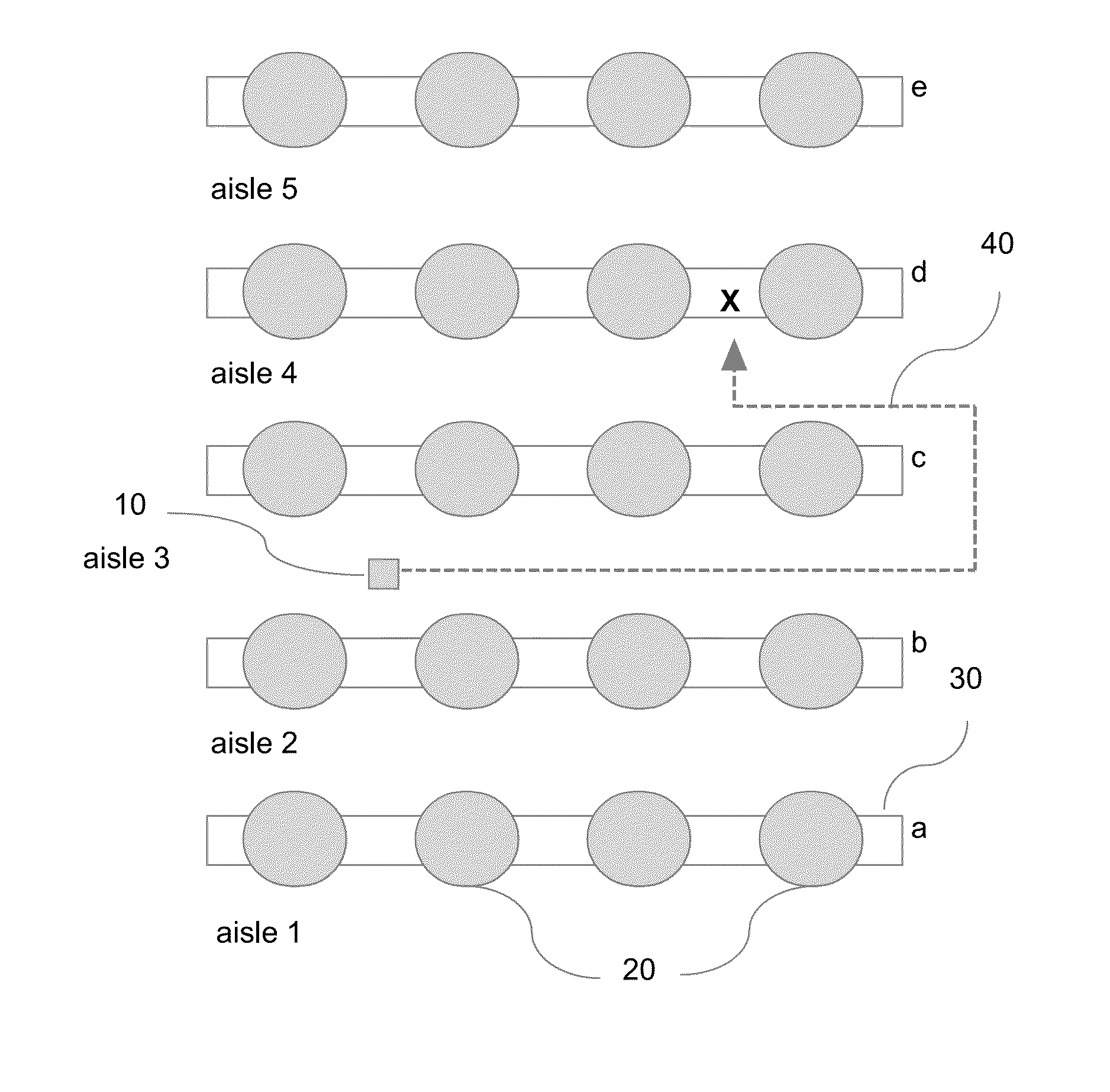

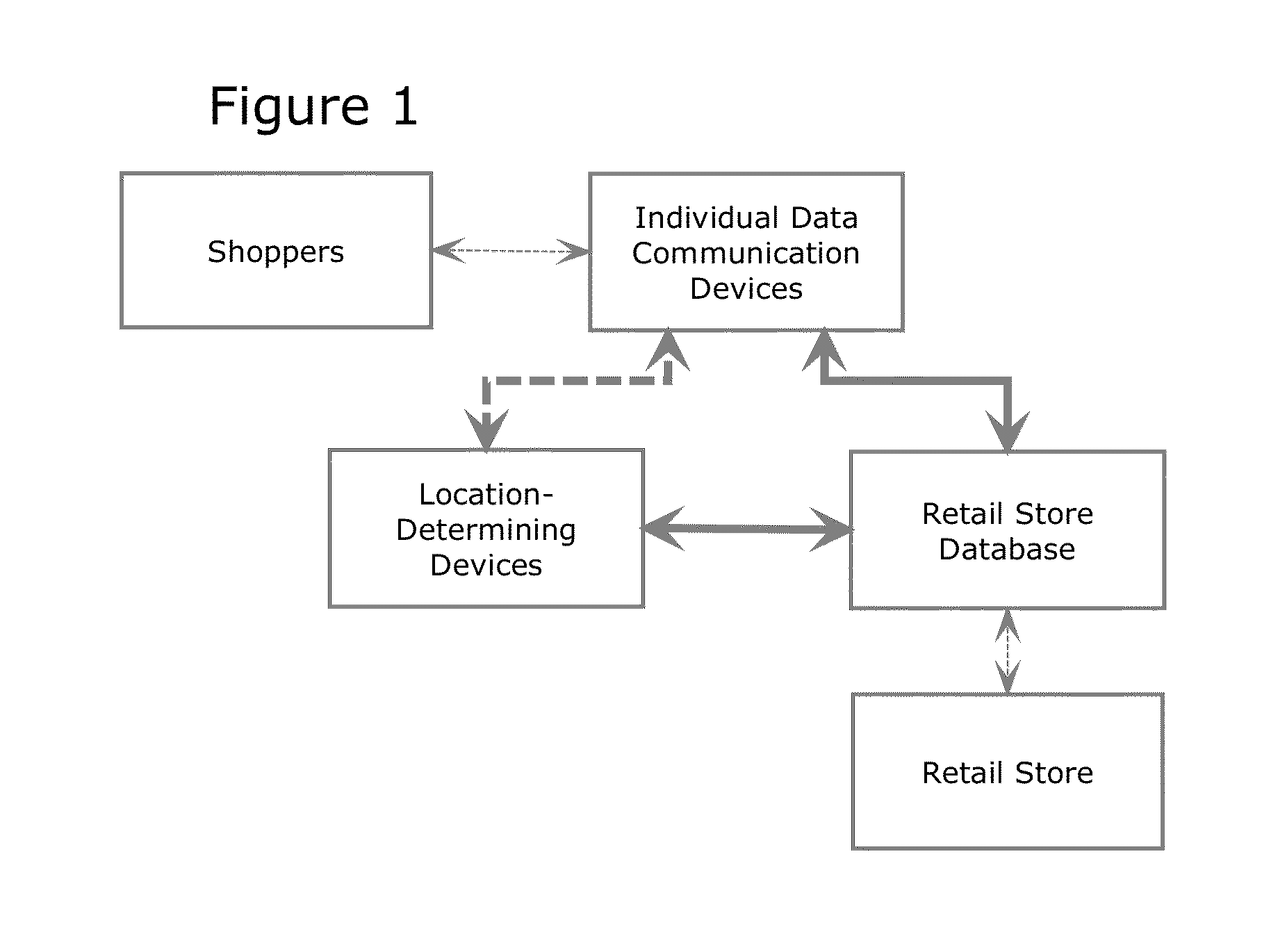

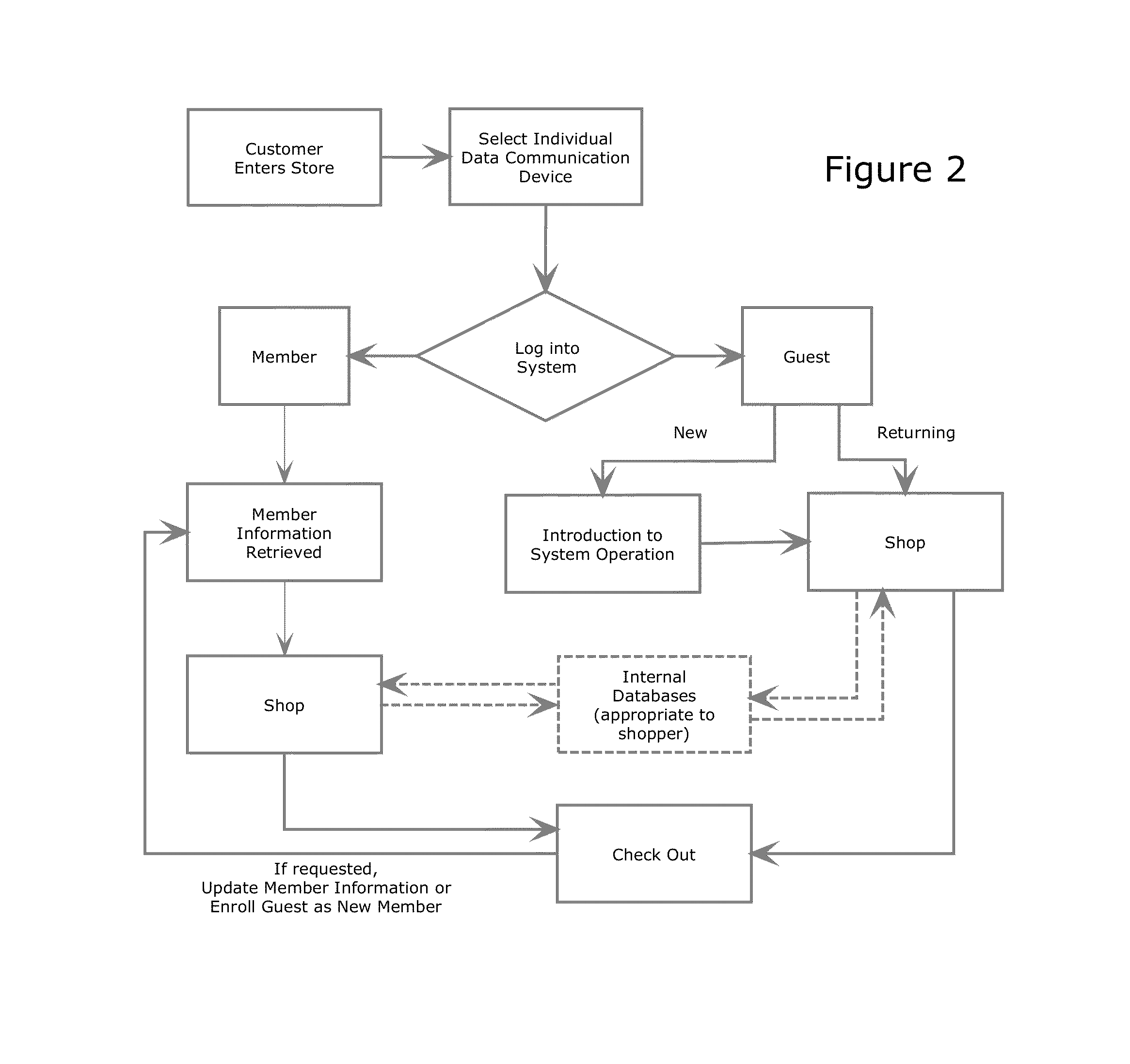

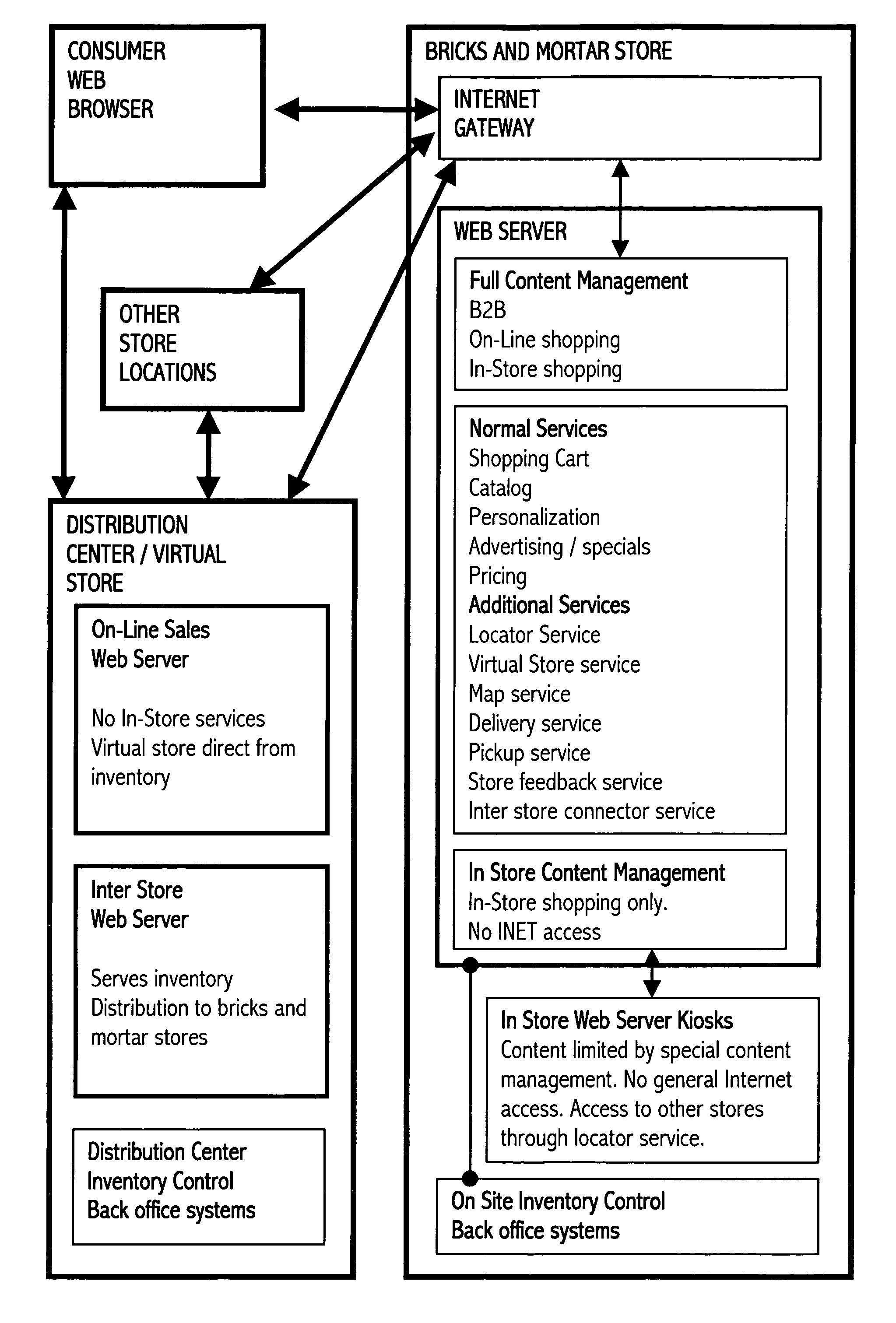

Electronic Shopping System for Retail Stores

InactiveUS20140379526A1Improve shopping experienceEfficiently obtainedDigital data information retrievalCustomer communicationsOperational costsDirect communication

A method and system to assist and guide a customer during a shopping experience in a “brick and mortar” type store in order to provide a more pleasant, effective, and efficient shopping environment is provided. Such a method and system allows a customer to more easily locate and access specific desired items in, for example, a large retail store. The customer can also more easily compare similar items, determine if the desired item or similar items are on sale, whether such items are in stock, issue rain checks on sale items out of stock, assess detailed information on such items, and keep a running account of the costs of the items selected. Such a method and system also provides significant benefits to the retailer, including, for example, increased customer satisfaction, direct communication and interaction with the customer, as well as better inventory control and reduced operating costs.

Owner:PARHAM TRISTAN RYSHUNN

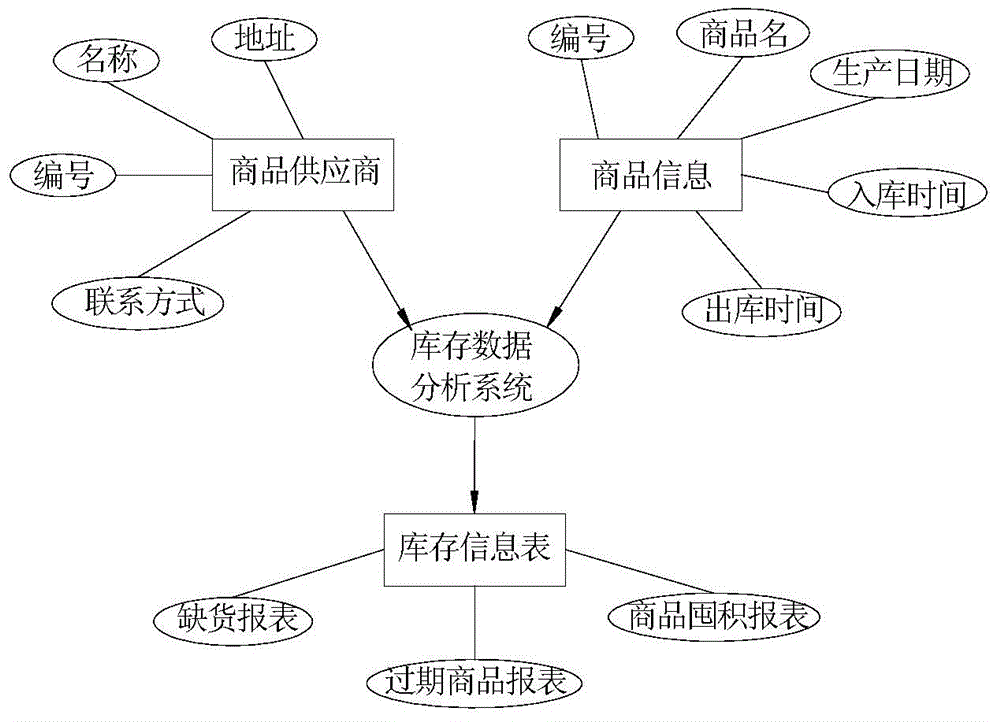

Novel commodity inventory data system based on big data analysis

The invention provides a novel commodity inventory data system based on big data analysis. Commodity information is collected, a data analysis system is adopted to analyze and process data to obtain an inventory information table, stockout commodities, out-of-data commodities and cornered commodities are reflected in real time through the inventory information table, market managers are reminded of regulating inventory commodities in time, arranging purchases and processing the out-of-data commodities. Through the technology, the informatization management of market inventories is realized, a commodity cornering phenomenon is reduced, commodity quality is guaranteed, a basis is provided for the market managers, and higher profit are brought for markets.

Owner:XIAN ELITE ELECTRONICS IND

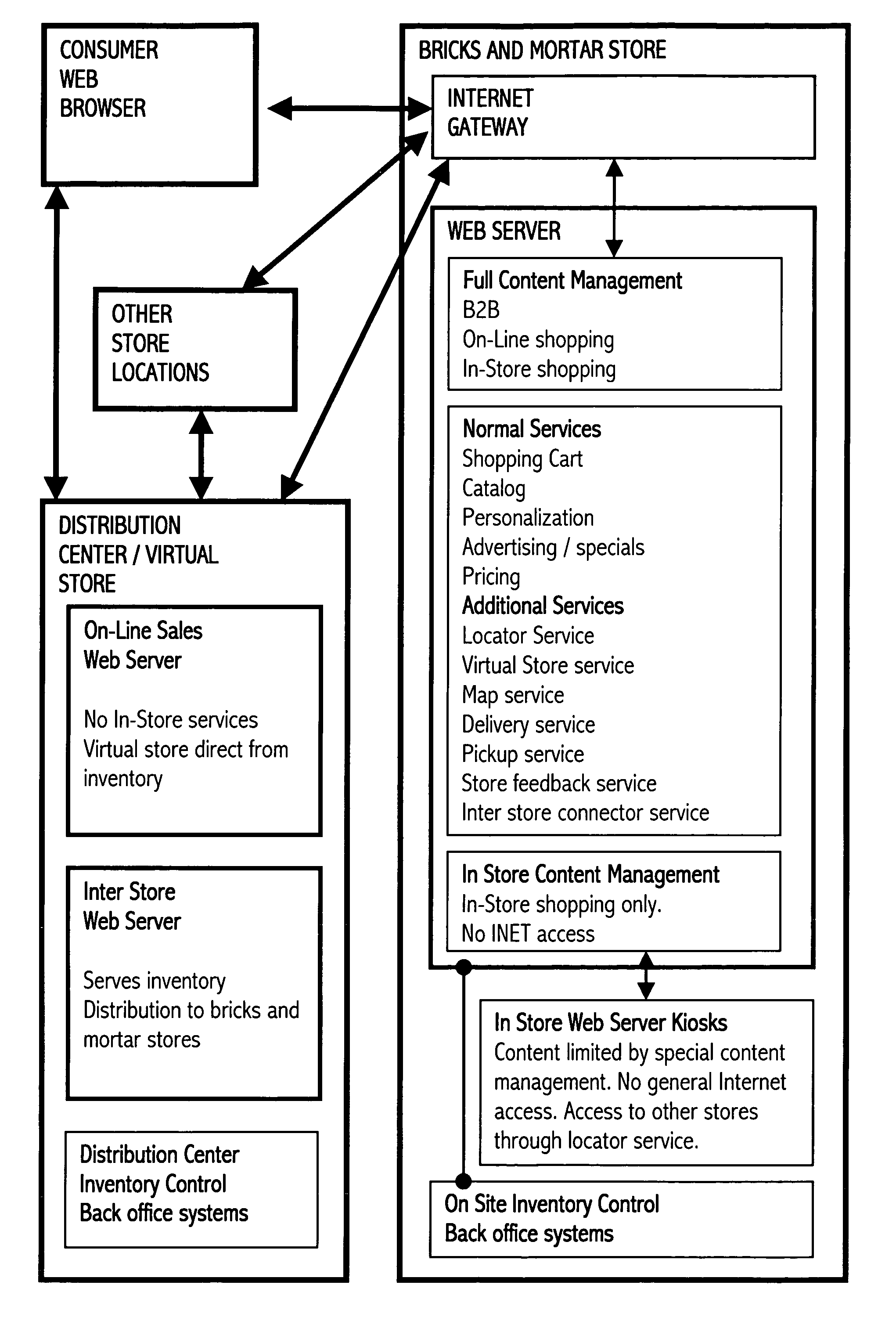

Electronic commerce integration

An information system environment is described that, among other things, facilitates integration of electronic commerce and physical store front retailer selling channels. In some realizations, the system includes a shopper accessible kiosk co-located with a physical store front retailer and an electronic commerce information service accessible from locations external to the physical store front retailer. Both access inventory information supplied from a suitable information service. The shopper accessible kiosk allows a user thereof to access inventory information particular to the physical store front retailer, while the electronic commerce information service allows a user thereof to order items from out of stock of the physical store front retailer.

Owner:VERSATA DEV GROUP

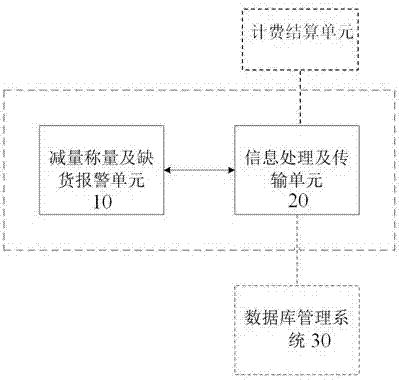

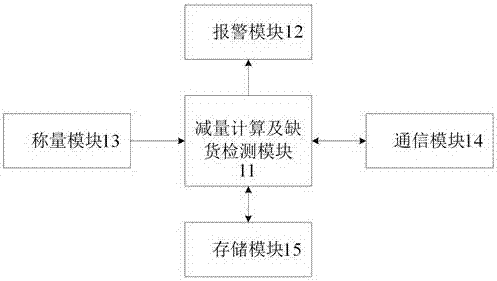

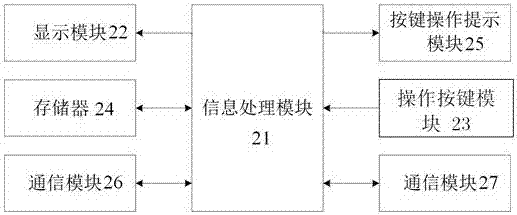

A self-service weight reduction weighing charging system and a self-service weight reduction weighing charging method

ActiveCN107016810AGuaranteed accuracyImprove the level of intelligenceNutrition controlCash registersInformation processingEngineering

Owner:西安鼎顺物联网科技有限公司

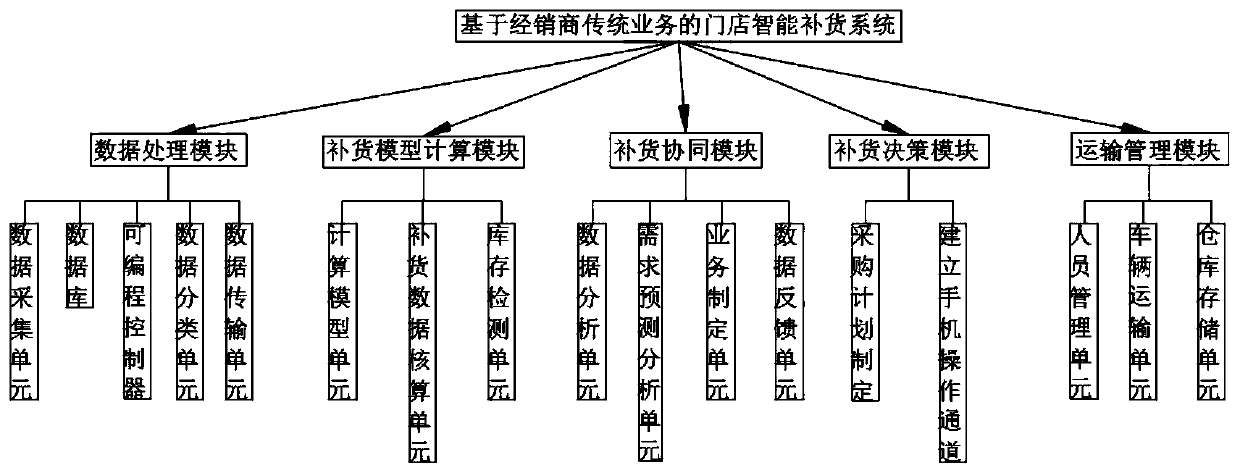

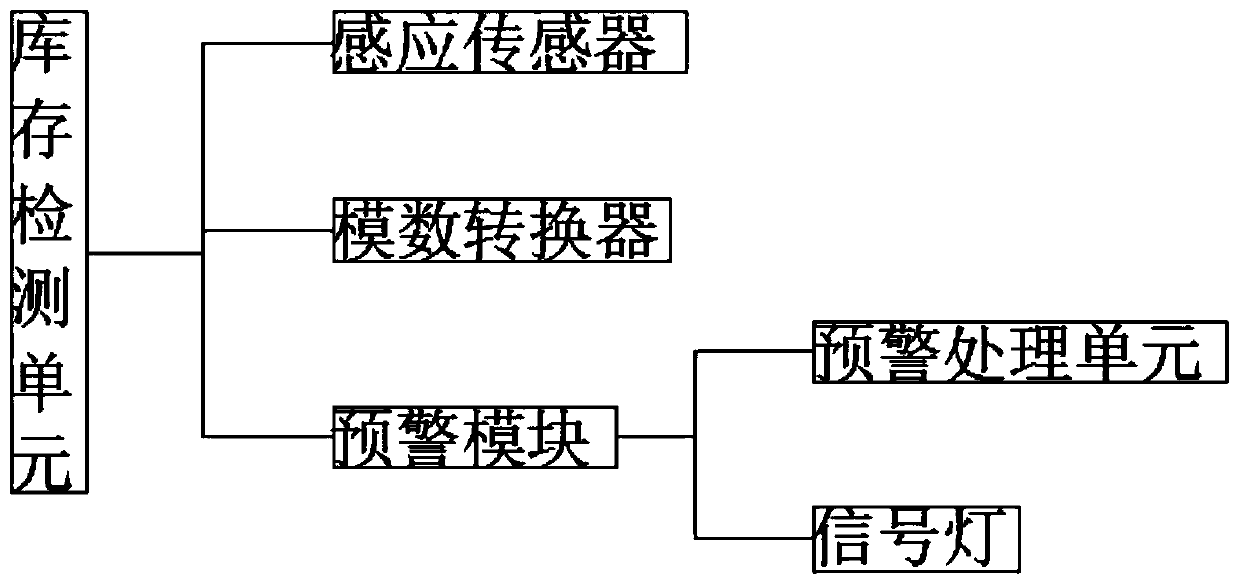

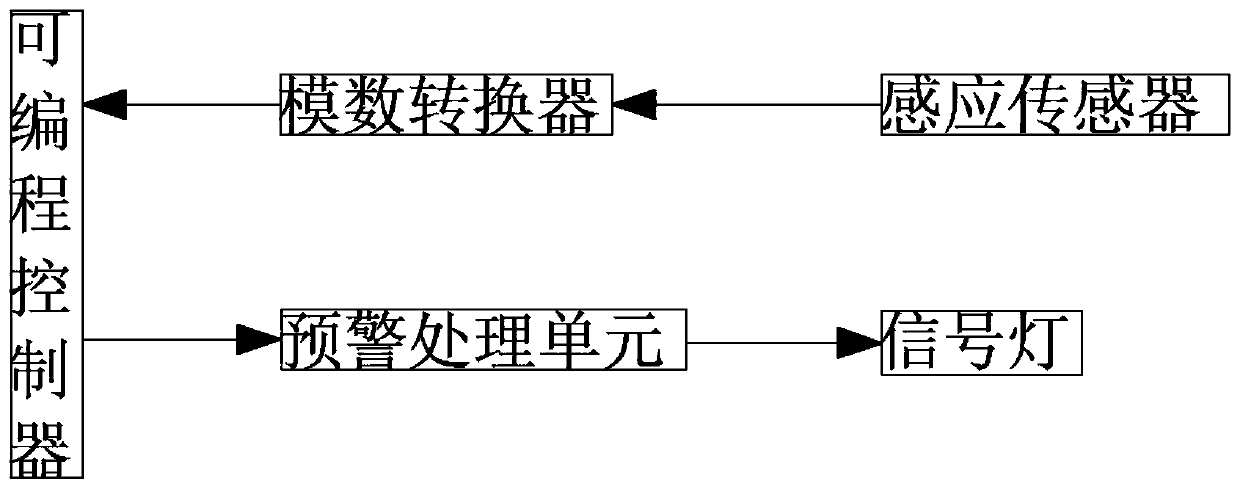

Store intelligent replenishment system based on dealer traditional business

PendingCN111382973AOptimize replenishment implementationImplement Process CollectionBuying/selling/leasing transactionsResourcesStockoutIndustrial engineering

The invention particularly discloses a store intelligent replenishment system based on dealer traditional business, which belongs to the technical field of intelligent replenishment. The store intelligent replenishment system based on dealer traditional business is characterized in that: the store intelligent replenishment system based on dealer traditional business comprises a transportation management module, a data processing module, a replenishment decision module, a replenishment model calculation module and a replenishment cooperation module, is scientific and reasonable, is safe and convenient to use, has a comprehensively insight into the whole supply chain by synchronously mastering supply and demand so as to formulate an implementable plan, can optimize the replenishment implementation of short-term order issuing and inventory construction, can realize process collection and perfect execution, and thus reduces stockout and excess cost conditions to the greatest extent.

Owner:舟谱数据技术南京有限公司

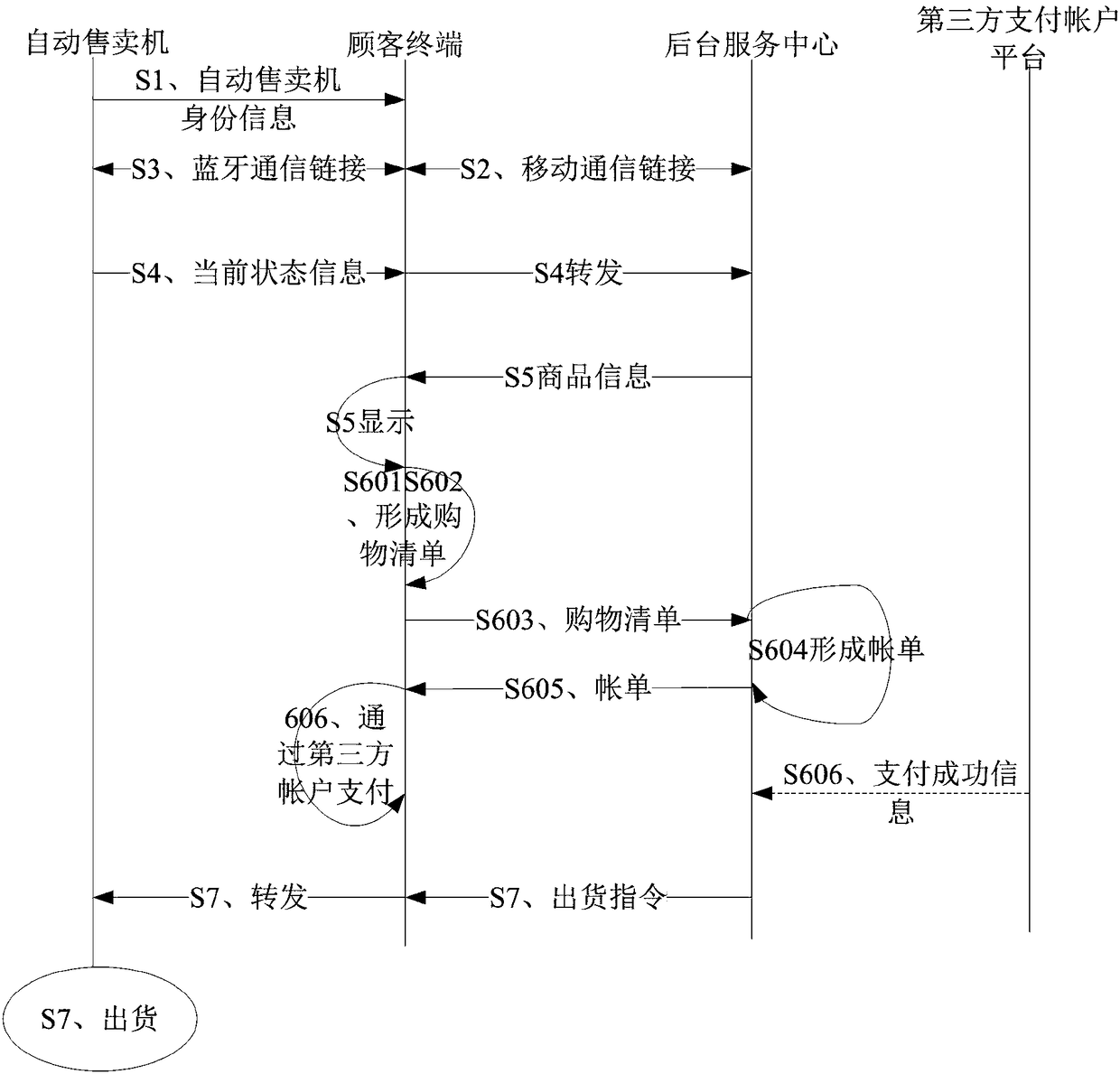

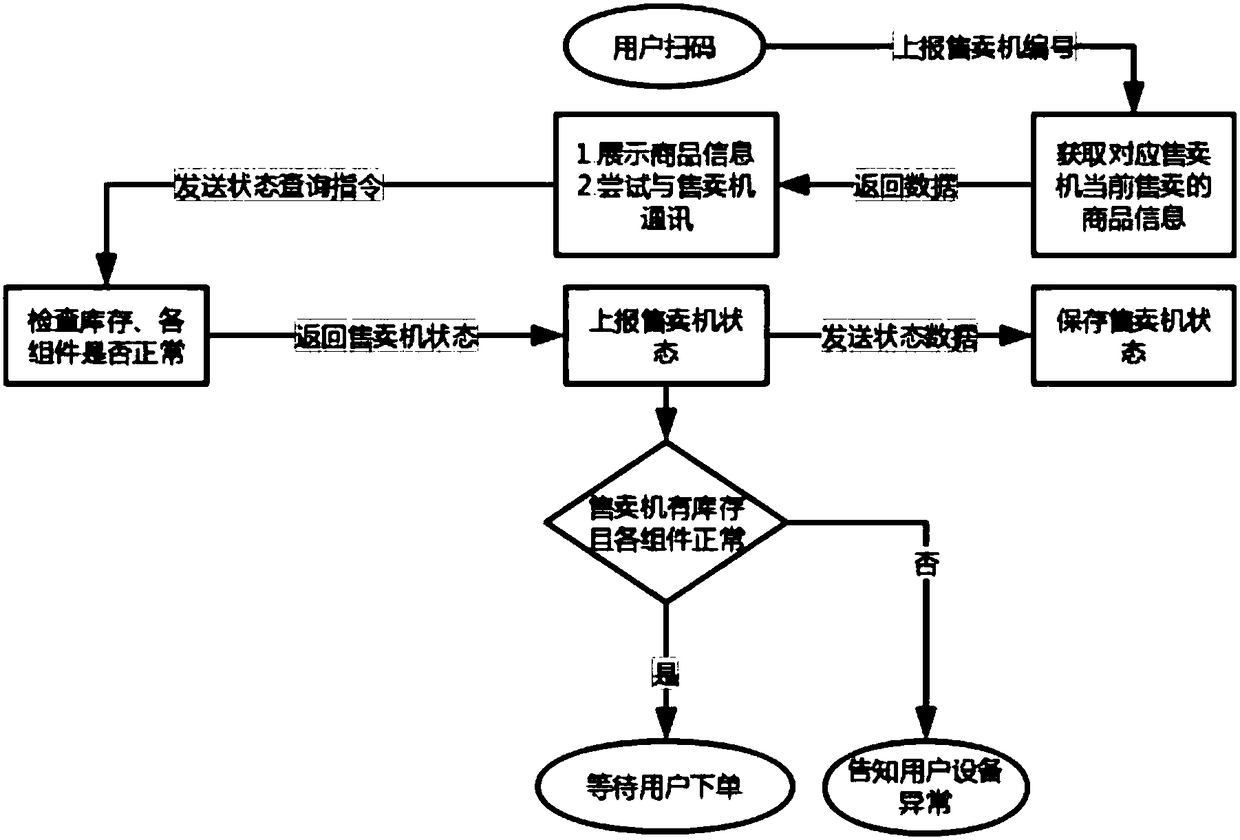

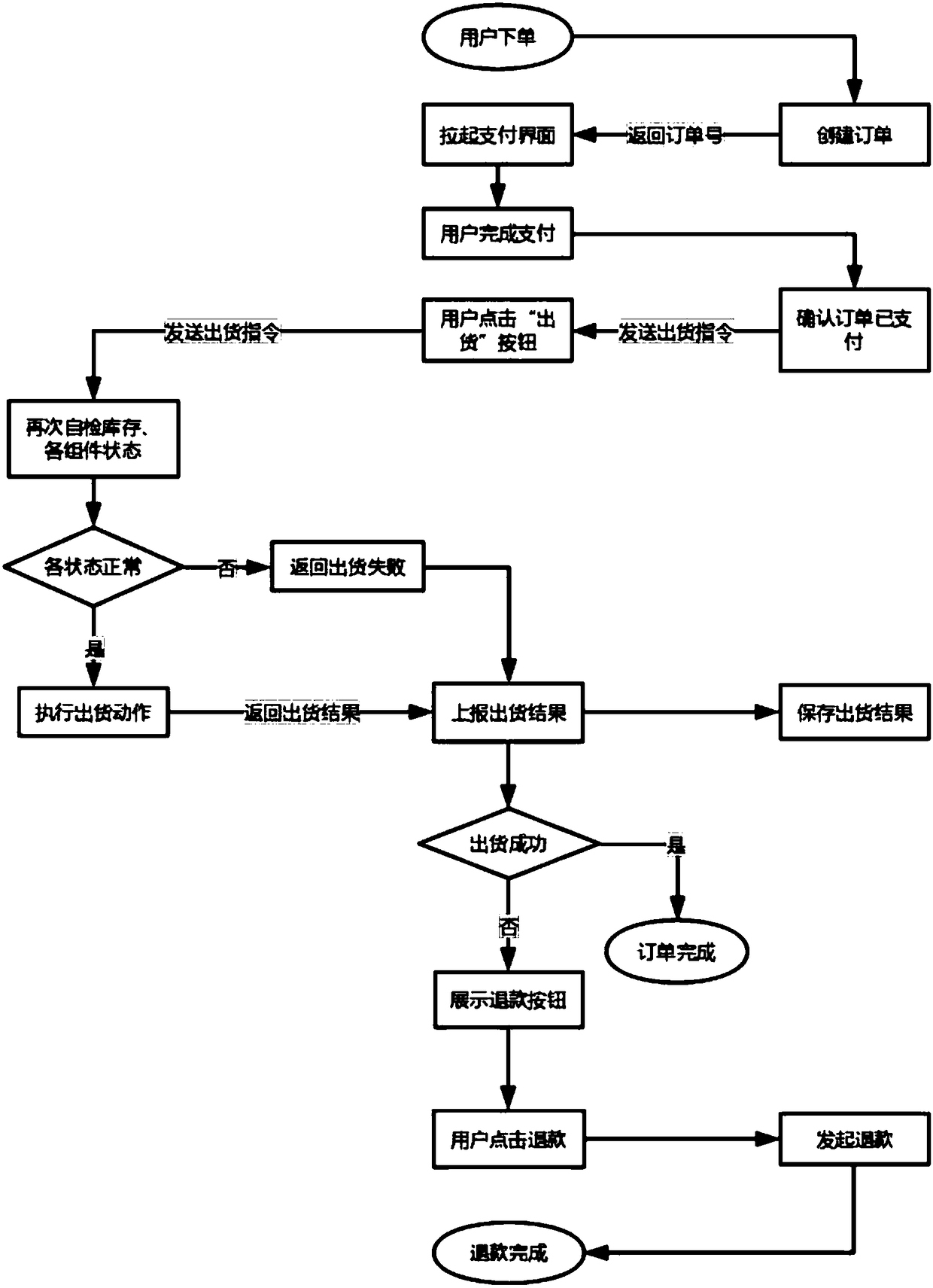

Vending method and vending machine

The invention discloses a vending machine used for a vending method. The method provides a mobile terminal communicated with customers through a Bluetooth communication module in the vending machine,then, communication is carried out on a background service center through the mobile terminal, the mobile terminal is used for through connection to realize the communication of the background servicecenter and the vending machine, and the vending machine realizes the vending method. In the method, during daily maintenance, maintenance personnel carry out targeted maintenance through each exceptional state or stockout state reported to a backgrounder server through the vending machine when a user purchases a commodity. When the sales process and method of the invention is used, the small vending machine still can finish communicating with the background server under a situation that no cash collection systems or 3G / 4G (The 3rd Generation Telecommunication / The 4th Generation Telecommunication) real-time communication modules are arranged, and manufacture cost and later maintenance cost are greatly saved.

Owner:北京漫游星际科技有限公司

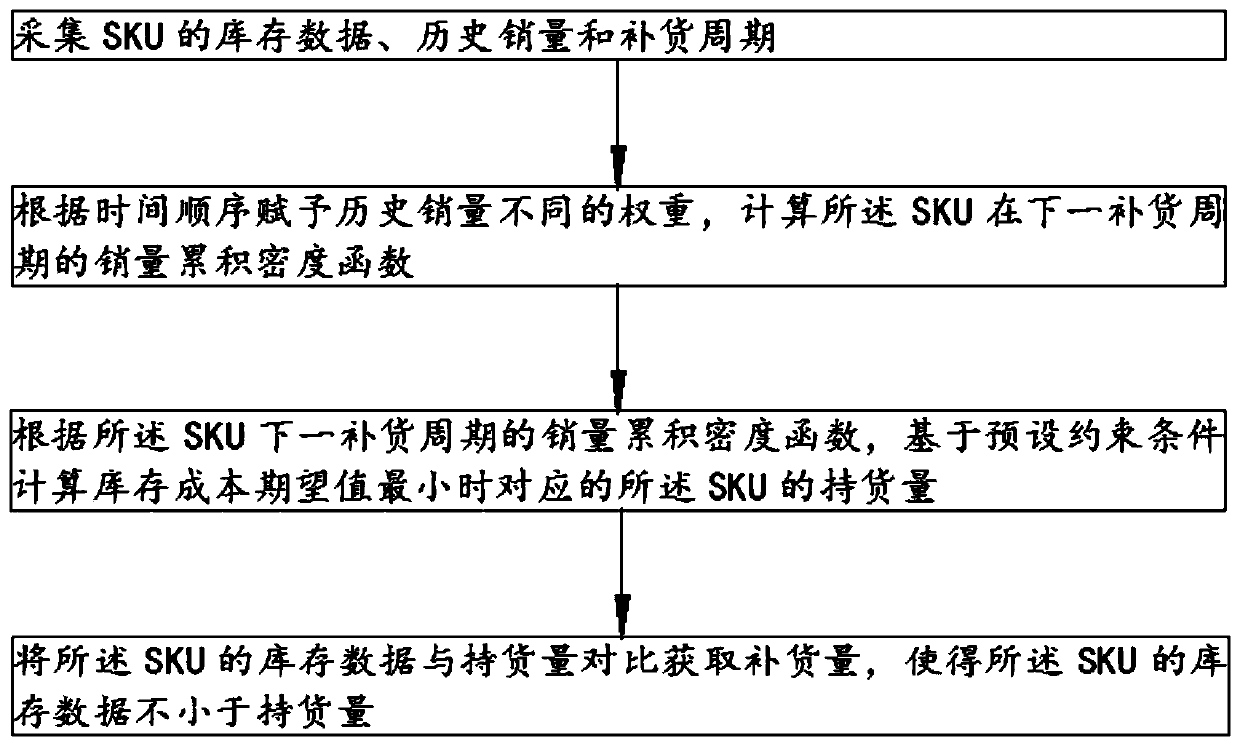

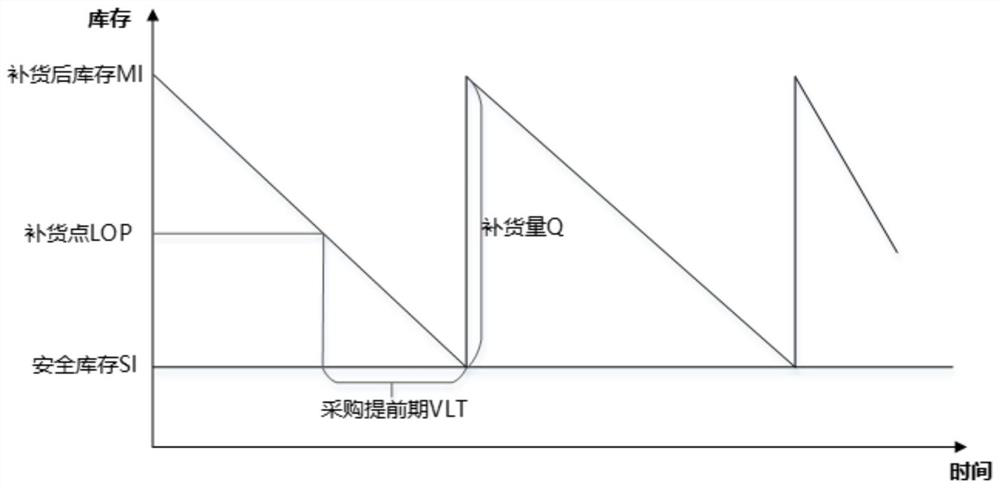

Replenishment method and device

PendingCN111325490AScientific inventory managementSystematic inventory managementLogisticsInventory managementStockout

The invention relates to a replenishment method and device. The replenishment method comprises the steps that inventory data, historical sales volume and replenishment period of an SKU are collected;giving different weights to the historical sales volume according to the time sequence, and calculating a sales volume cumulative density function of the SKU in the next replenishment period; according to the sales volume cumulative density function of the SKU in the next replenishment period, calculating the corresponding SKU goods holding capacity when the expected inventory cost value is minimum based on a preset constraint condition; and comparing the inventory data of the SKU with the stock capacity to obtain the replenishment capacity, so that the inventory data of the SKU is not less than the stock capacity, the stockout cost and the stock cost of sku are comprehensively considered, the stock capacity calculated by the model is optimal on the overall cost of the warehouse, and inventory management can be scientifically and systematically carried out on the warehouse.

Owner:SF TECH

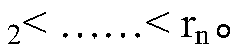

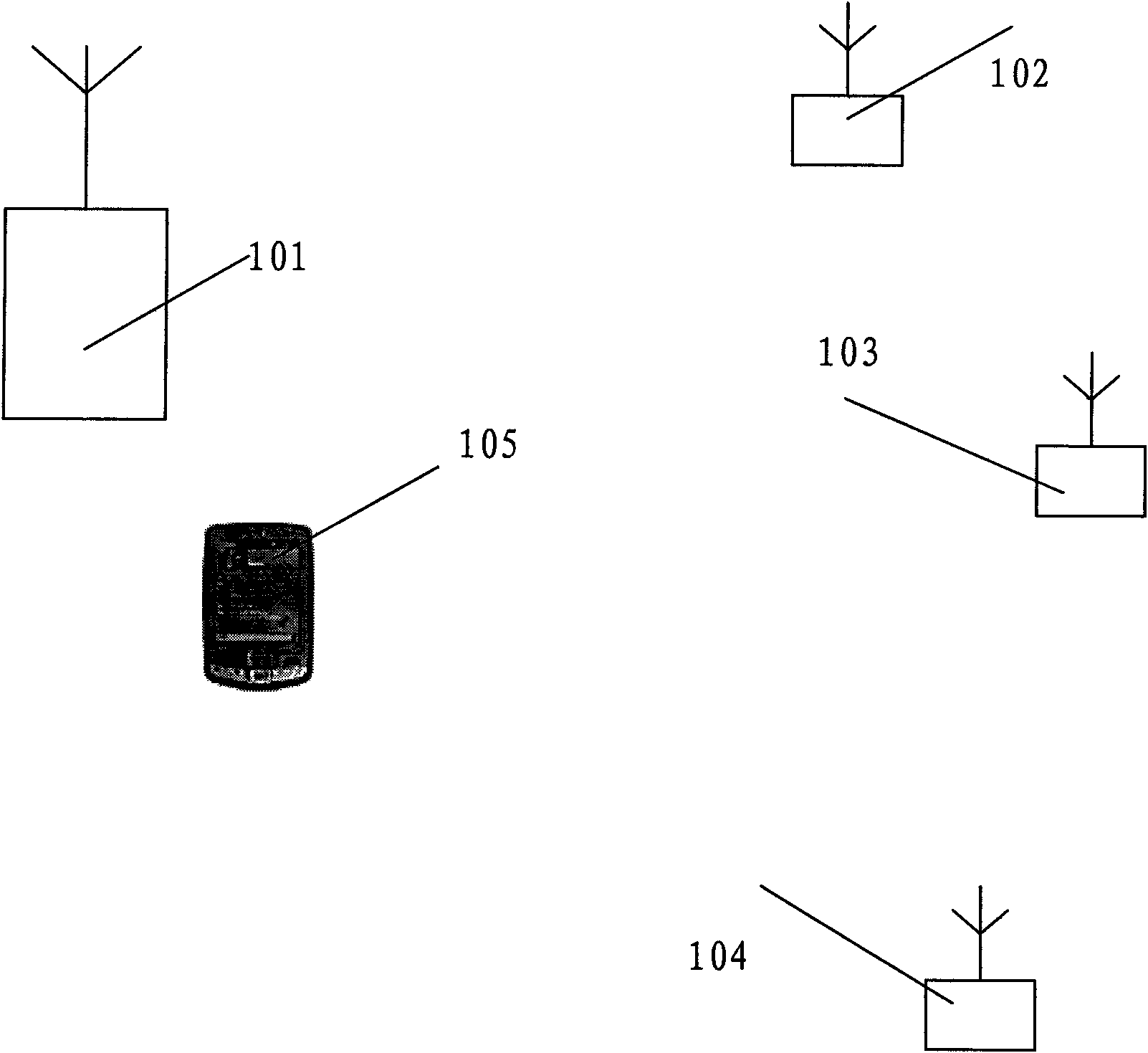

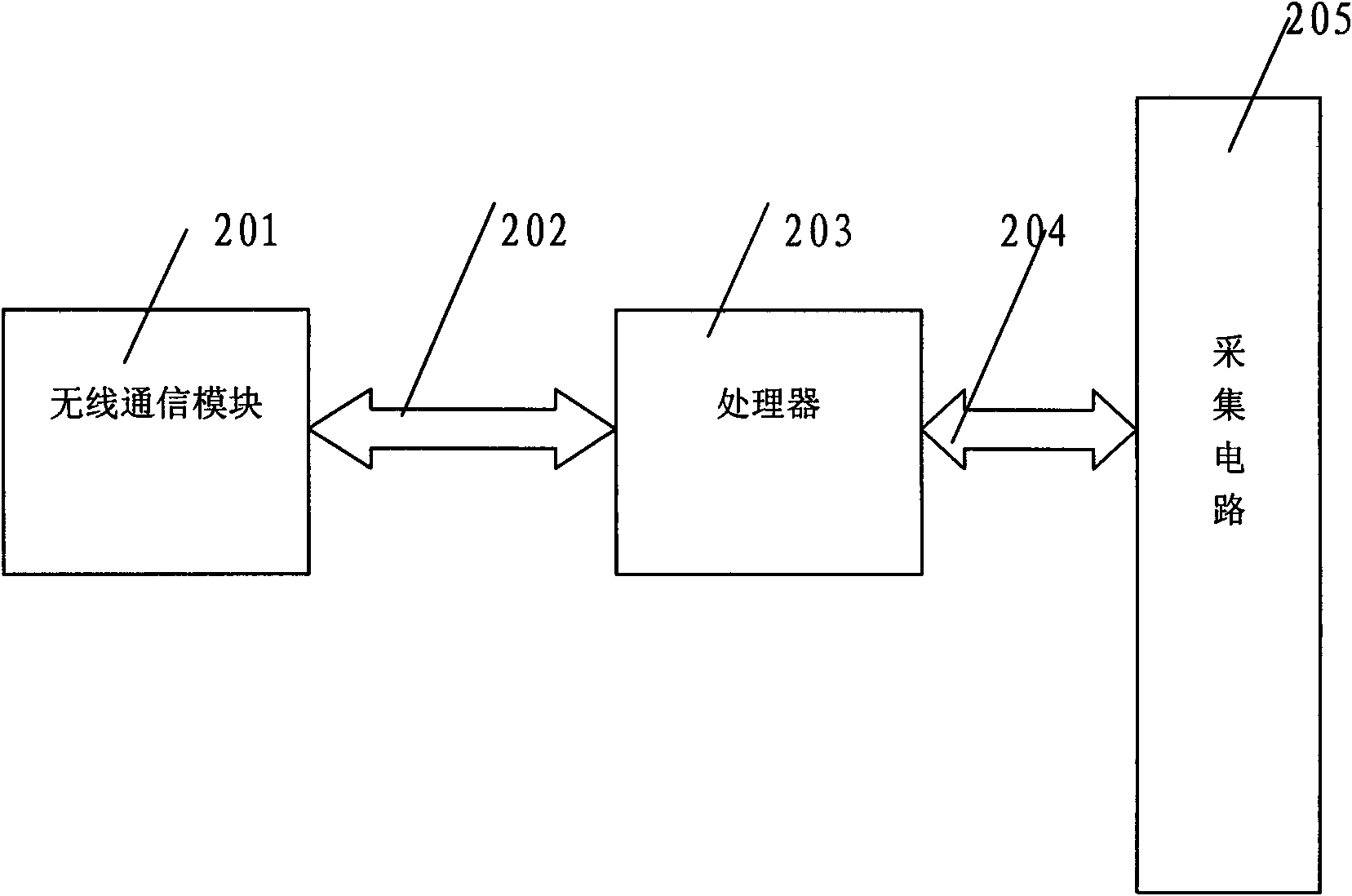

Device for realizing remote supervisory operation of vending machine

InactiveCN101609577ARealize managementTimely replenishmentCoin/paper handlersCommunications systemSystems management

The invention relates to a device for realizing remote supervisory operation of vending machines by networking with a wireless communication system to control inventory situation, sales situation and stockout situation of remote vending machines, and timely replenish goods for the vending machines out of stock. A device for realizing remote supervisory operation of vending machines comprises a system management and communication center, a mobile display hand set and a remote vending machine operation terminal; the device controls inventory situation, sales situation and stockout situation of the remote vending machines, and timely replenishes the goods for the vending machines out of stock, thus improving service quality of the vending machines.

Owner:顾士平

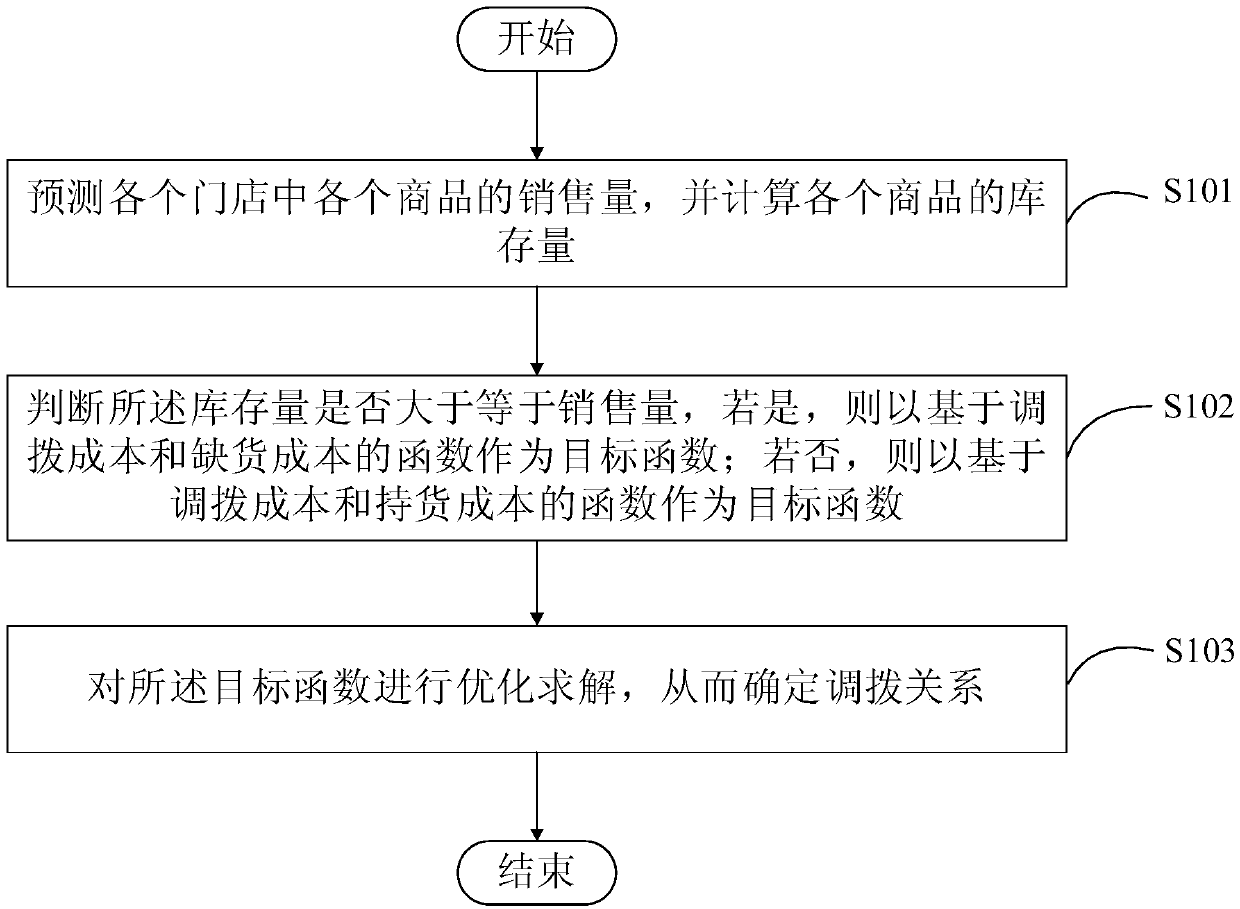

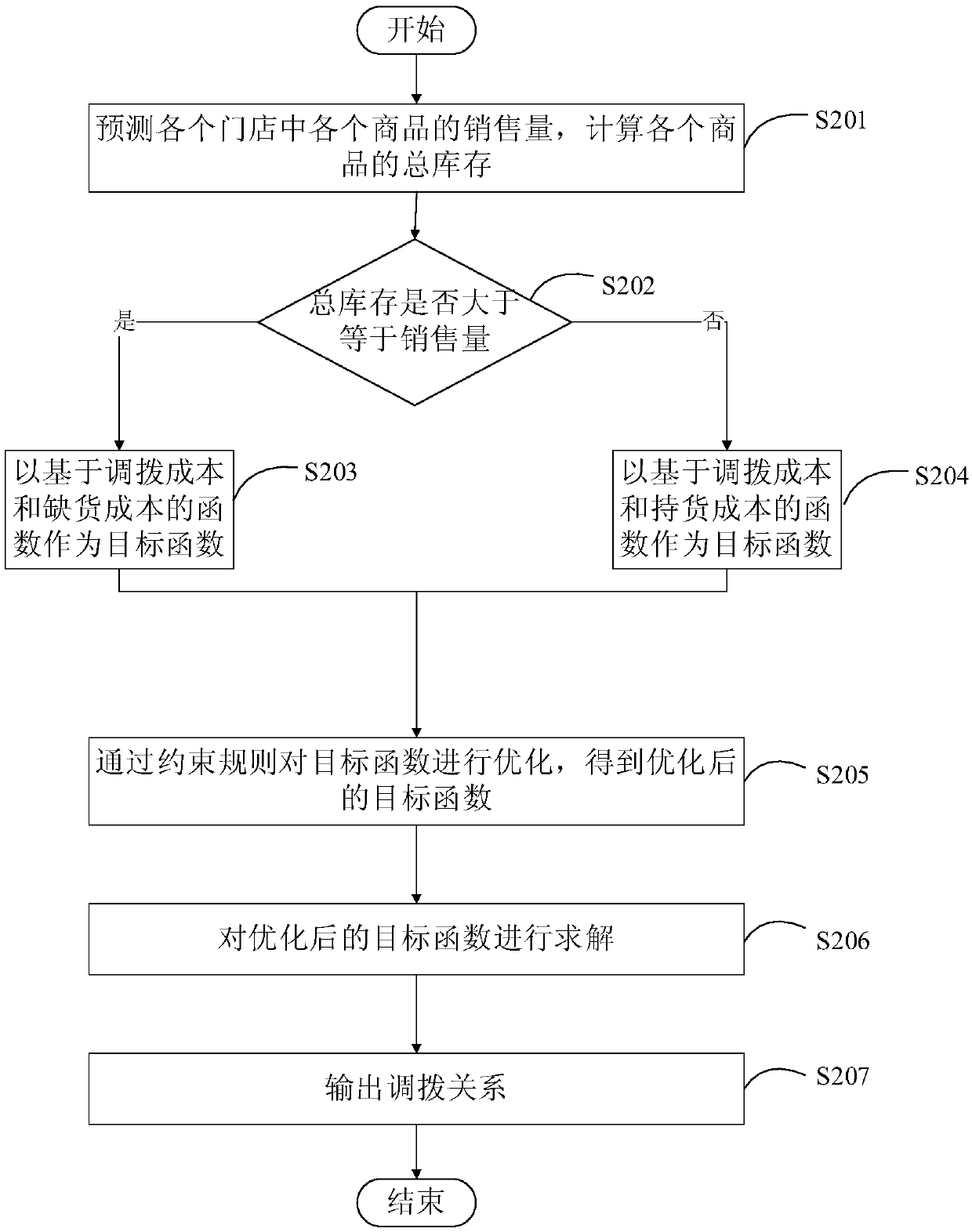

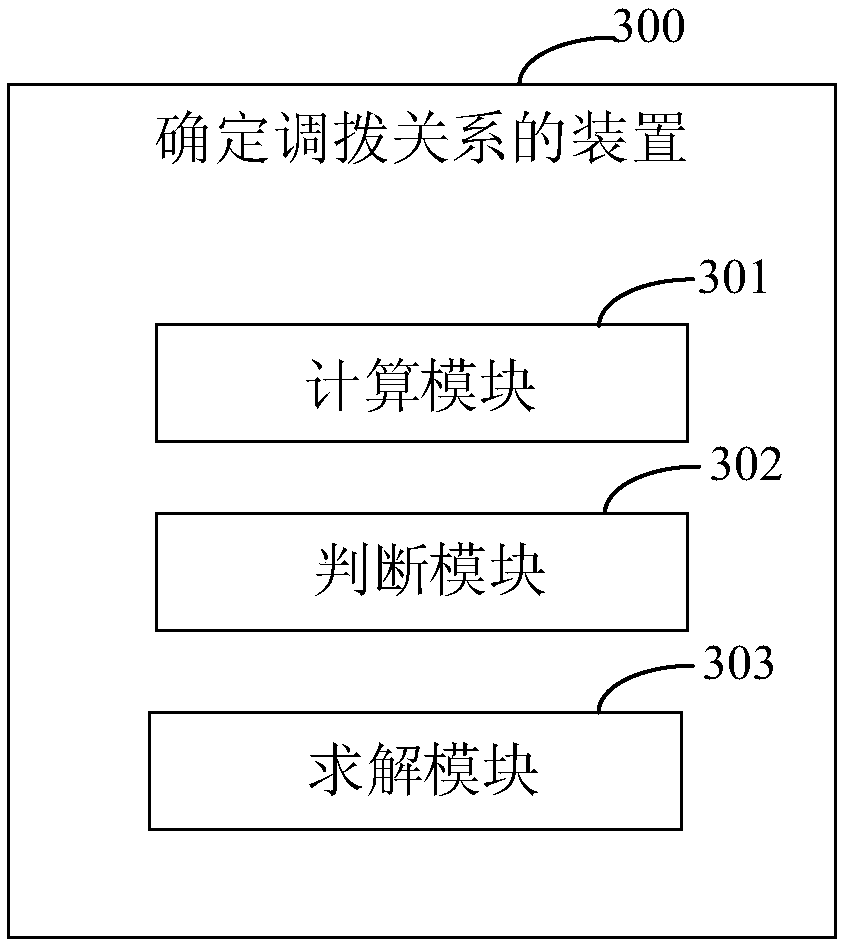

Method and device for determining allocation relationship

PendingCN110689157ALow costOvercoming not taking stock out of consideration into accountForecastingResourcesHolding costStockout

The invention discloses a method and device for determining an allocation relationship, and relates to the technical field of computers. One specific embodiment of the method comprises the following steps: predicting the sales volume of each commodity in each store, and calculating the total inventory of each commodity; judging whether the total inventory is greater than or equal to the sales volume or not, and if so, taking a function based on allocation cost and stockout cost as a target function; if not, taking a function based on the allocation cost and the cargo holding cost as a target function; and carrying out optimization solution on the target function so as to determine an allocation relationship. According to the embodiment, the problem that inventory insufficiency and allocation cost are not considered can be solved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

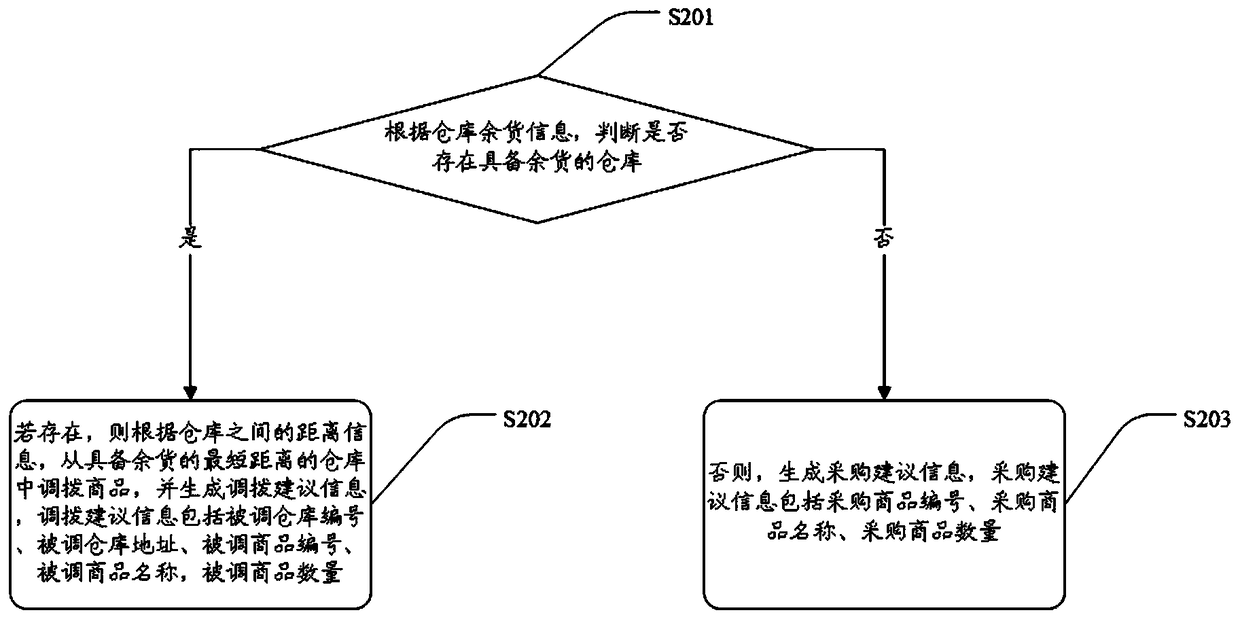

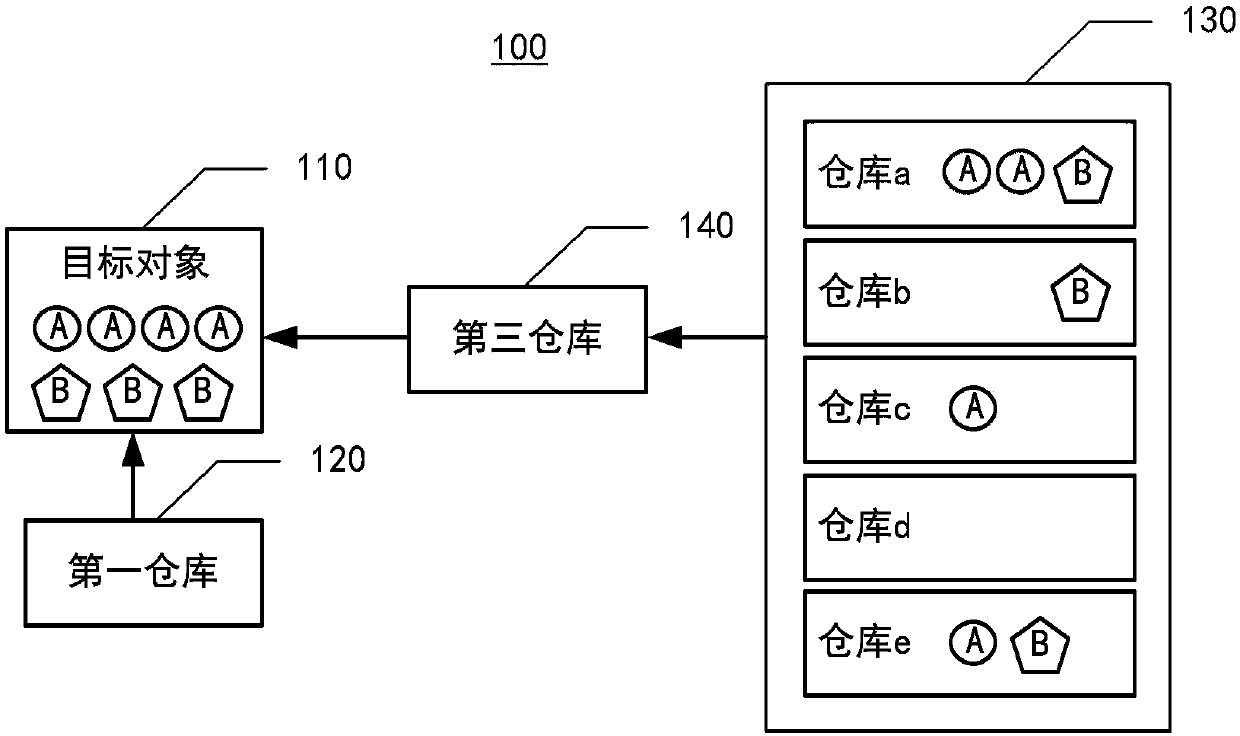

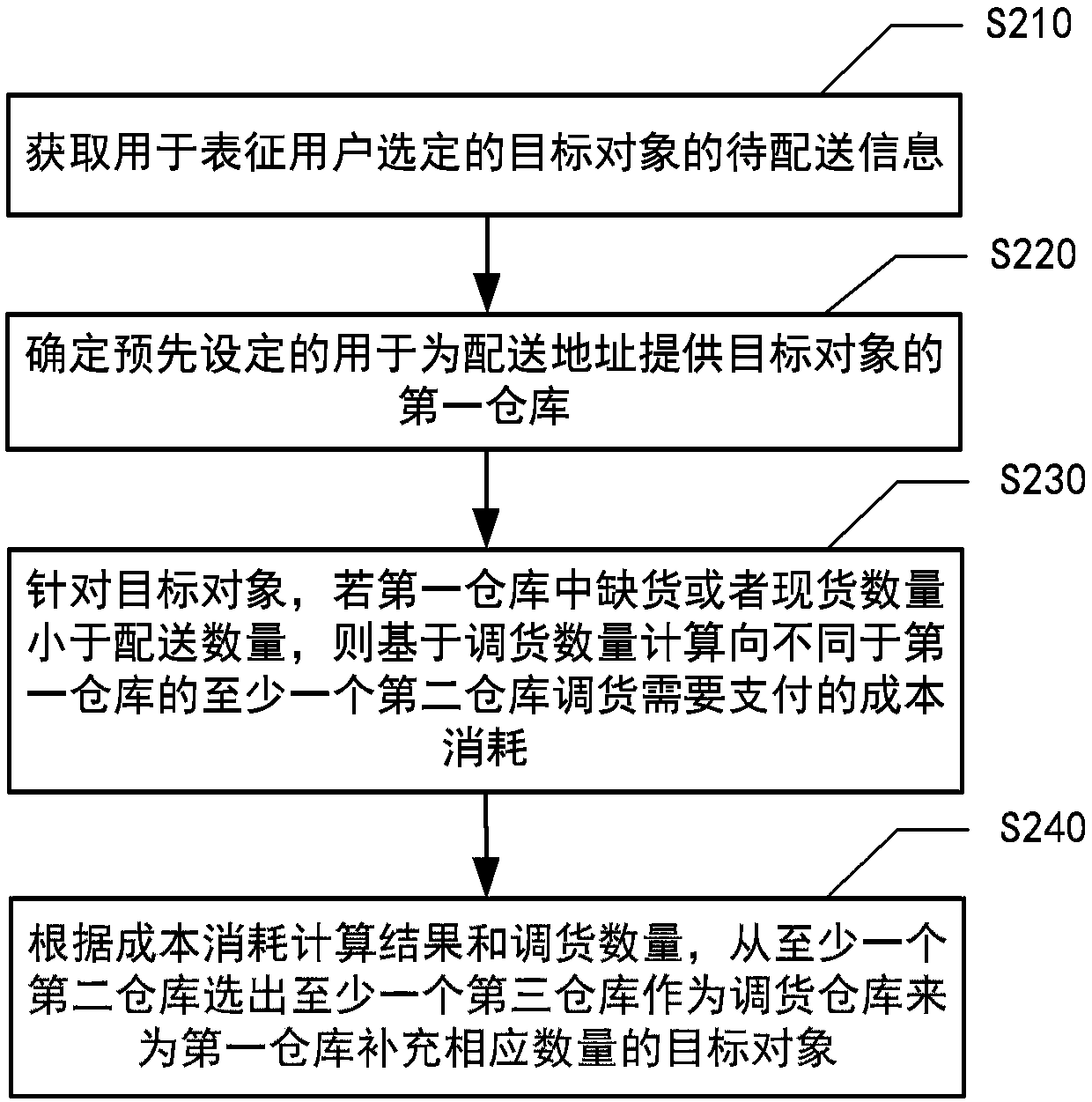

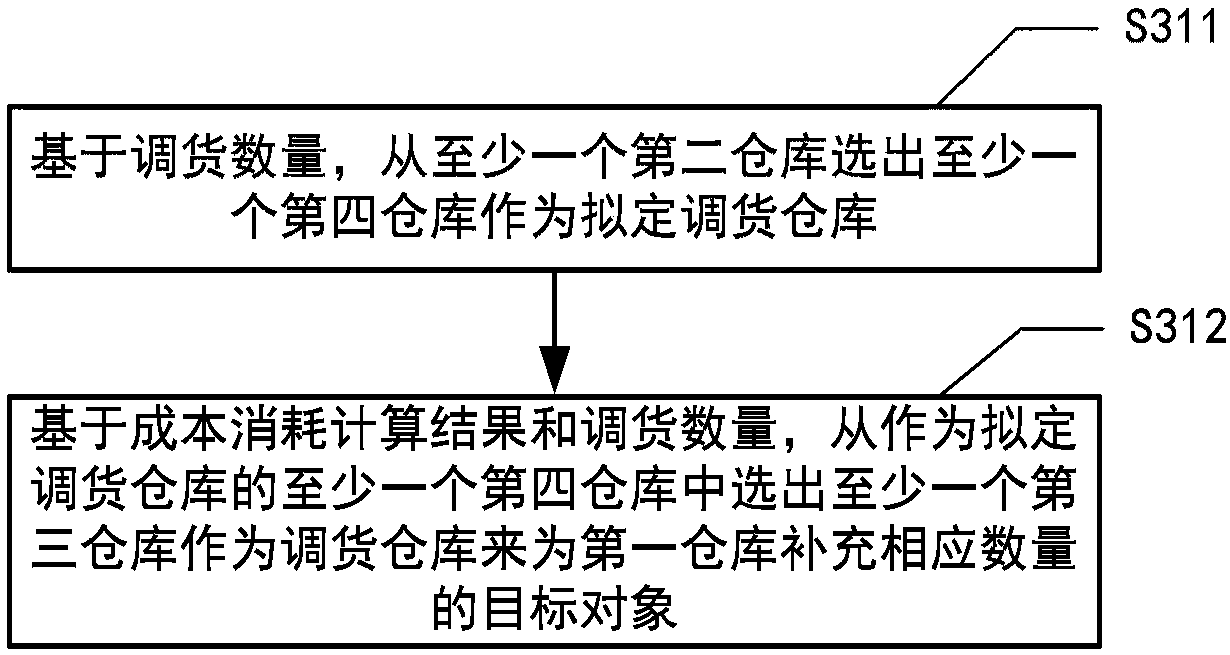

Data processing method and system, computer system and computer readable medium

PendingCN110390501AImprove satisfactionImprove order availabilityBuying/selling/leasing transactionsLogisticsData processing systemComputerized system

The invention provides a data processing method comprising the steps that to-be-delivered information used for representing a target object selected by a user is acquired, and the to-be-delivered information comprises a delivery address and a delivery number; a preset first warehouse used for providing a target object for the delivery address is determined; for the target object, if the stockout or spot quantity in the first warehouse is smaller than the delivery quantity, the cost consumption needing to be paid to at least one second warehouse different from the first warehouse is calculatedbased on the dispatching quantity; and at least one third warehouse is selected from the at least one second warehouse as a dispatching warehouse according to the cost consumption calculation result and the dispatching quantity so as to supplement the corresponding quantity of target objects for the first warehouse. In addition, the invention further provides a data processing system, a computer system and a computer readable medium.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Methods and systems for dynamic inventory control

The embodiments of the present invention fill the need of properly controlling product inventory of semiconductor chips by providing methods and systems of dynamic inventory control. The methods and systems timely modify parameters affecting inventory. The parameters may include target inventory, cycle time, wafer start, future inventory and future shipment. In addition, the methods and systems gather real-time customer demand forecast to assist in production planning and adjustment. Further, the methods and systems identify inventory control turning points dynamically to adjust production activities to prevent overstock and to prevent stockout.

Owner:TAIWAN SEMICON MFG CO LTD

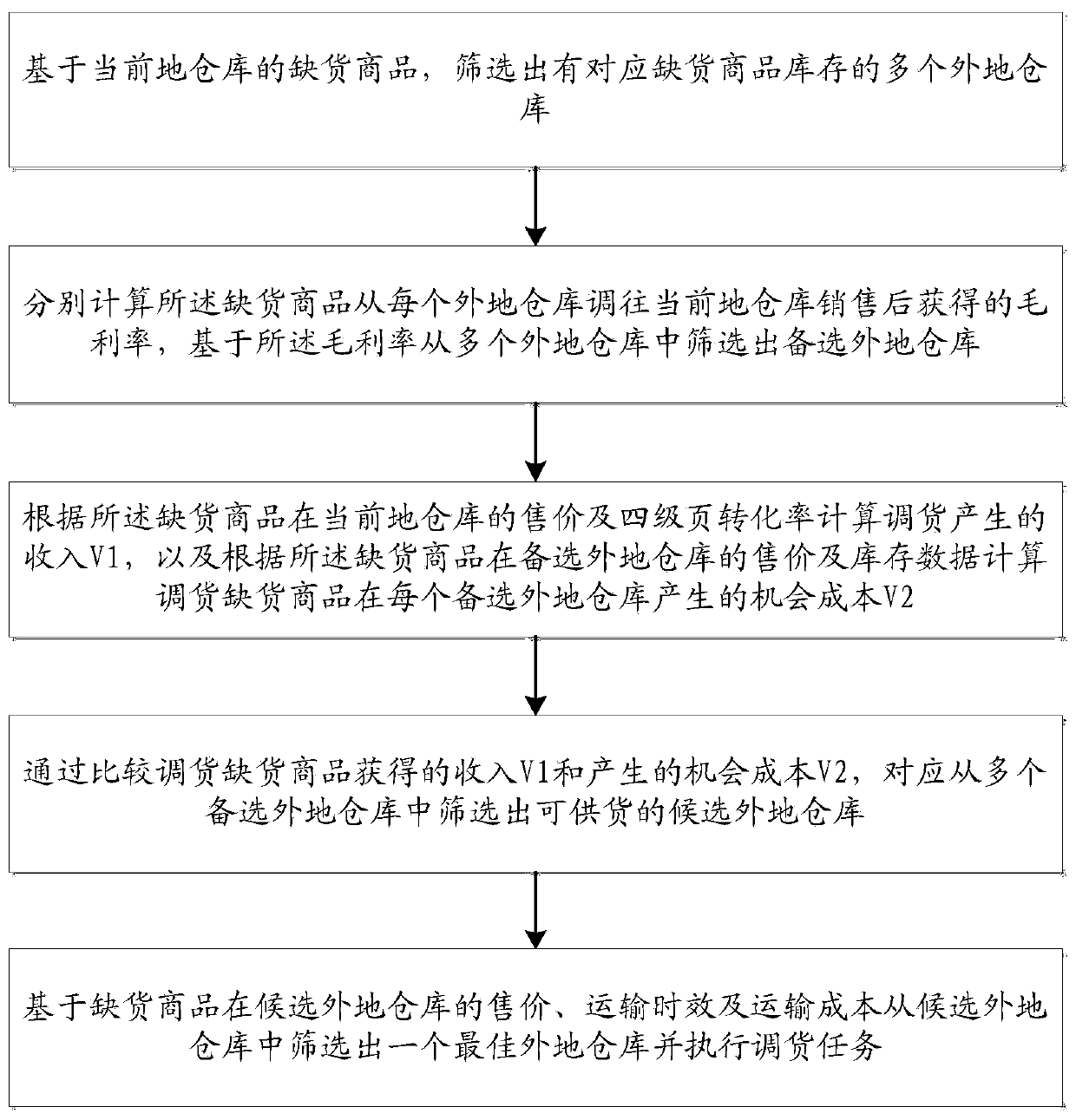

Intelligent goods dispatching method and device for e-commerce platform

PendingCN110826958AProtect interestsImprove experienceBuying/selling/leasing transactionsLogisticsE-commerceProfit rate

The invention discloses an intelligent goods dispatching method and a device for an e-commerce platform, relates to the technical field of e-commerce, and can screen out an optimal goods dispatching scheme from warehouses of all places based on multiple dimensions. The method comprises the steps that based on stockout commodities of a current warehouse, screening out a plurality of foreign warehouses corresponding to stockout commodity inventory; respectively calculating gross profit rates obtained after the stockout commodities are transferred from each foreign warehouse to the current warehouse to be sold, and screening out alternative foreign warehouses; according to the selling price of the stockout commodity in the current warehouse and the four-level page conversion rate, calculatingan income V1 generated by goods allocation, and according to the selling price of the stockout commodity in the alternative foreign warehouse and the inventory data, calculating an opportunity cost V2 of goods allocation and stockout commodity; screening out candidate foreign warehouses capable of supplying goods by comparing the income V1 obtained by allocating and stockout commodities with thegenerated opportunity cost V2; and screening an optimal foreign warehouse from the candidate foreign warehouses based on the selling price, the transportation time efficiency and the transportation cost of the stockout commodities in the candidate foreign warehouses.

Owner:SUNING CLOUD COMPUTING CO LTD

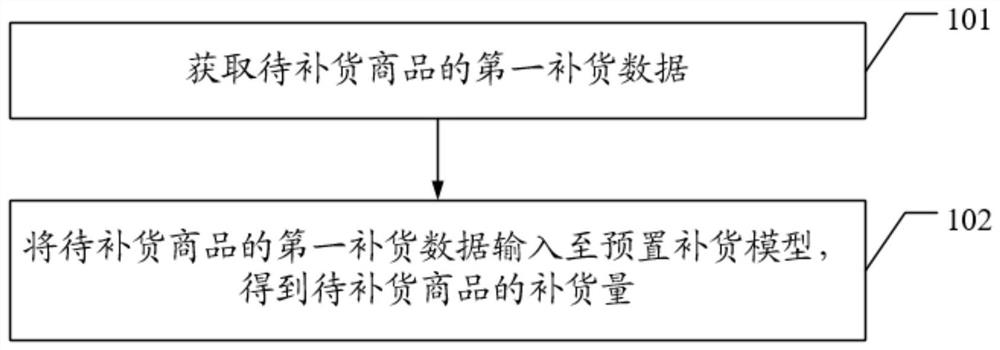

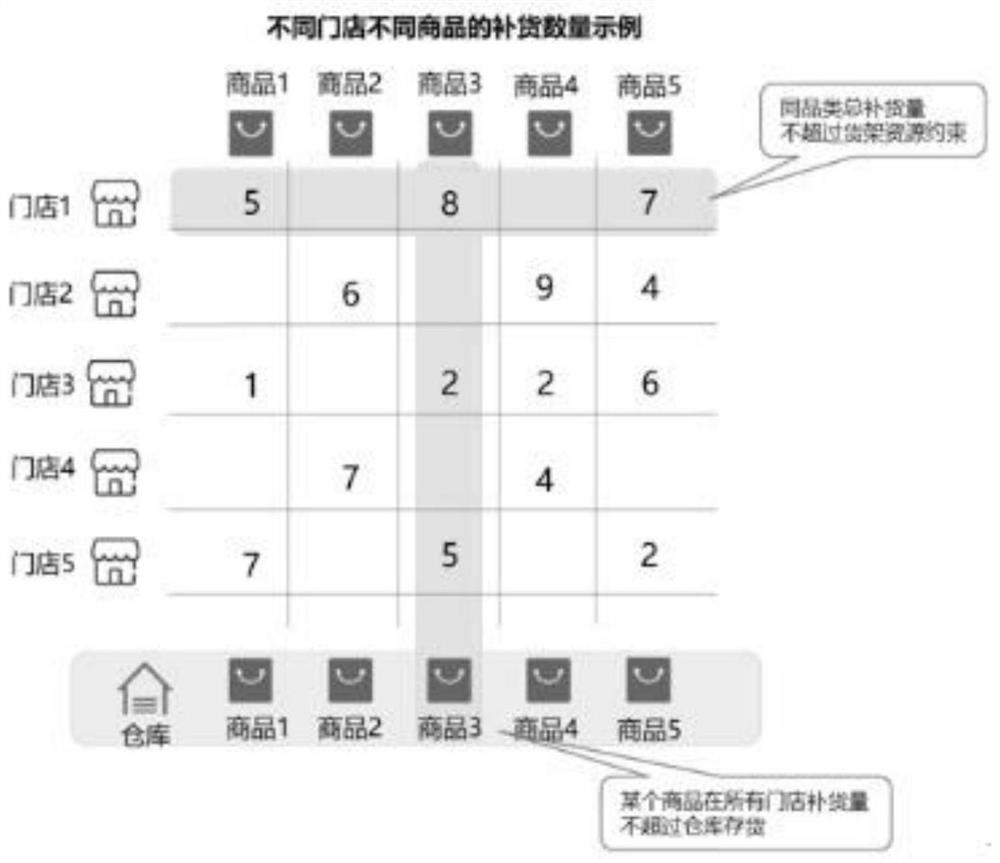

Store replenishment method, device and apparatus

The invention discloses a store replenishment method, device and apparatus. According to the store replenishment method, device and apparatus of the invention, a target function including indexes suchas sales volume, stockout rate, turnover days and replenishment matching degree is established through second replenishment data; the target function is optimized through a mixed integer programmingalgorithm until the target function is not changed, namely, the target function is optimized continuously based on different replenishment amounts, and an optimal replenishment amount can be reverselysolved, so that a preset replenishment model can be obtained; and finally, replenishment data of a to-be-replenished commodity is input into a preset replenishment model, and the replenishment amountof the to-be-replenished commodity can be obtained. The optimal replenishment amount of the commodity is obtained, and the commodity replenishment effect of each time can be given; the market demandof the commodity is considered to adapt to the rapidly changing market; and the technical problem that an optimal replenishment result cannot be obtained due to the fact that only the replenishment condition of a single commodity is considered and the replenishment quantity of other commodities under the same category is not considered in the prior art is solved.

Owner:创优数字科技(广东)有限公司

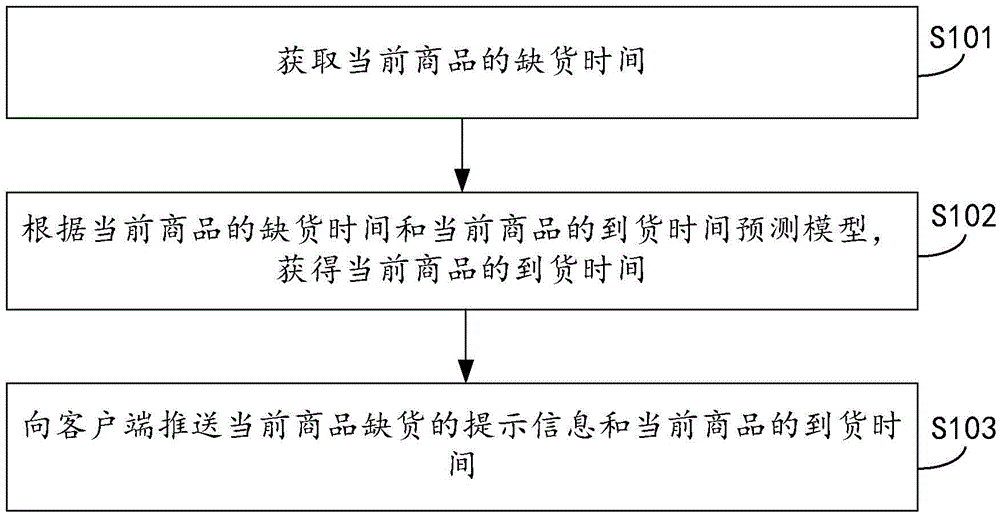

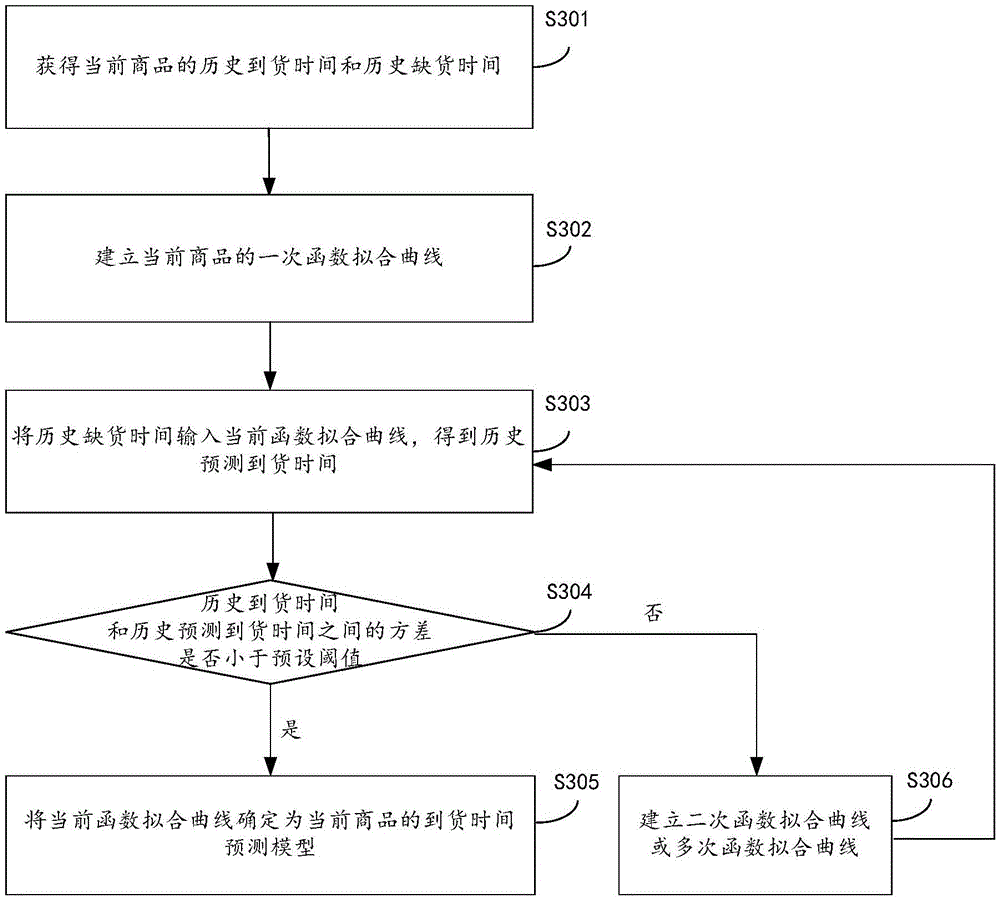

Information push method and device

InactiveCN105654211AImprove shopping experienceEasy to implementForecastingBuying/selling/leasing transactionsE-commerceArrival time

The invention relates to an information push method and device. The information push method comprises the steps that the stockout time of current commodities is obtained; the arrival time of the current commodities is obtained according to the stockout time of the current commodities and an arrival time prediction model of the current commodities; the information of prompting stockout of the current commodities and the arrival time of the current commodities are pushed to a client-side. The information push method and the information push can obtain the arrival time of the current commodities and push the information of prompting stockout of the current commodities and the arrival time of the current commodities to the client-side, the user can obtain correct prediction to the arrival time of the commodities in short supply, accordingly a judgment basis for deciding to purchase the current commodities on the client-side of a current e-commerce platform or not is provided for the user, and the shopping experience of the user is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

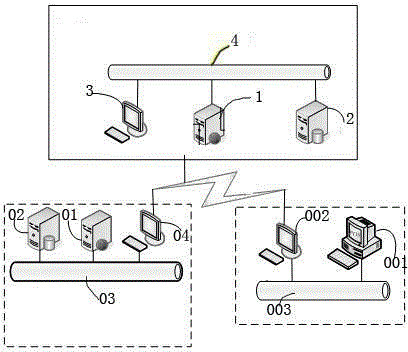

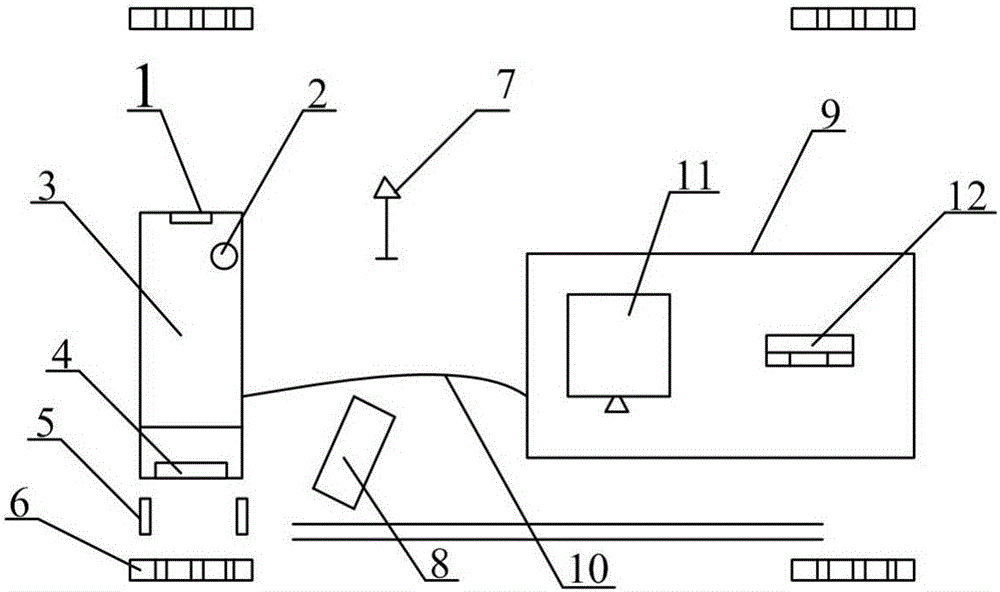

Multi-agent regional logistics distribution system and control scheduling method thereof

InactiveCN105976297AReduce consumptionIndicates that the device is in good conditionLogisticsSignal lightLogistic process

The invention discloses a multi-agent regional logistics distribution system and a control scheduling method thereof. The system is composed of an entrance, a signal light, a loadometer, a label, induction coils, railings, a signal base station, an identification device, a main control body, a wire, a computer and a printer. A supply demand value is extracted timely; when the stock value is too low or the existing supply value is too high and thus a stockout phenomenon may occur, an alarm module carries out alarming, so that the operation of the logistics system becomes ordered. Processing is carried out on an object by the loadometer at the entrance; label processing is carried out; networking data transmission is carried out on the computer; the signal base station is used for guaranteeing information transmission; the printer prints a necessary logistics voucher; and then positioning real-time monitoring is carried out on the logistic process. An intelligent scanning unit scans book information; a main control unit extracts the existing object number information and the existing number information in stock; if the object is likely to be in a stock-out situation, the alarm module carries out alarming and thus a logistic center is warned to pay attention to replenishing of the object. Therefore, a stock-out phenomenon is avoided.

Owner:GUANGDONG COMM POLYTECHNIC

Method and equipment for determining commodity reallocation demand

The invention aims to provide a method and equipment for determining a commodity reallocation demand. According to the method and the equipment, a commodity reallocation demand result can be automatically calculated according to a business basic parameter and a historical business number. For a single commodity, the replenishment demand of each size generated by retail and the replenishment demandof the size generated by code breakage are summarized, and details are given to the replenishment demand finally output by the commodity. According to the method and equipment disclosed in the invention, enterprises can be helped to realize automatic calculation of replenishment demands of commodities in a single store, and store stockout and overstock phenomena are reduced. Enterprises can be helped to accurately calculate replenishment requirements, stockout scenes are reduced, and the end-of-season inventory backlog degree is reduced. According to the method and the equipment disclosed inthe invention, commodity reallocation demand details are intelligently and automatically output, the repeated labor complexity of manual operation is reduced, the working time of staff is released, enterprises are helped to control compile, and the labor cost is saved.

Owner:上海伯俊软件科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com