Intelligent warehouse outgoing and incoming management method based on bar codes

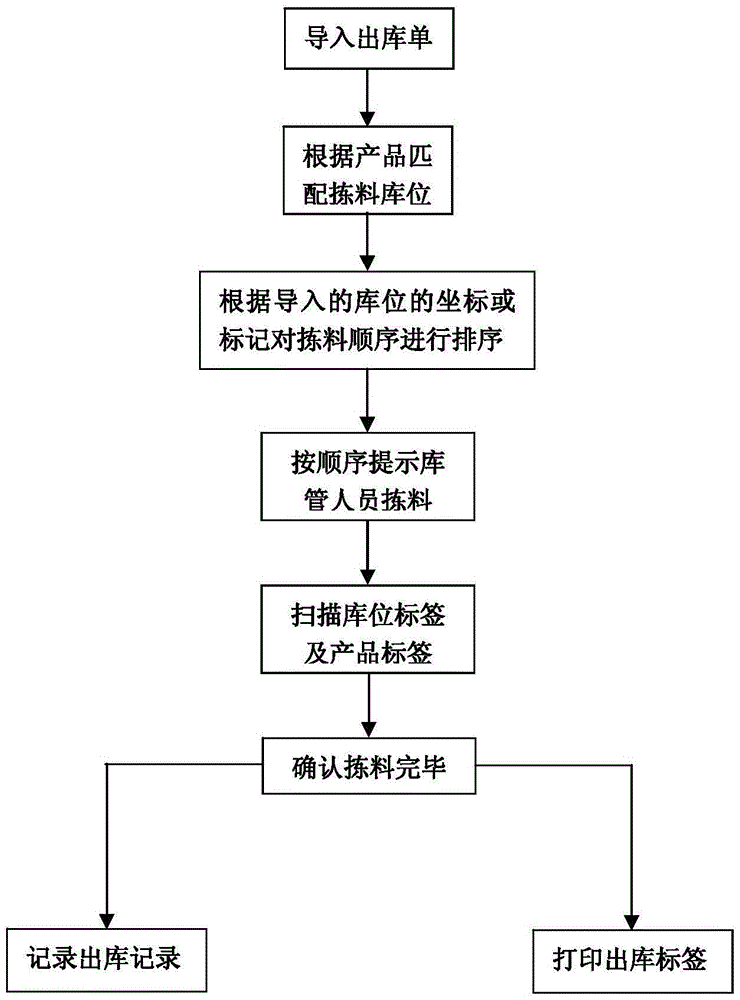

A management method and in-out technology, applied in data processing applications, instruments, logistics, etc., can solve the problem that the alarm quantity of inventory products cannot be dynamically adjusted according to the actual situation, the picking sequence of the outbound personnel cannot be optimized, and the inbound location cannot be optimized. Placement and other issues to achieve the effect of eliminating manual operation errors, reducing out-of-warehouse operation steps, and improving picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

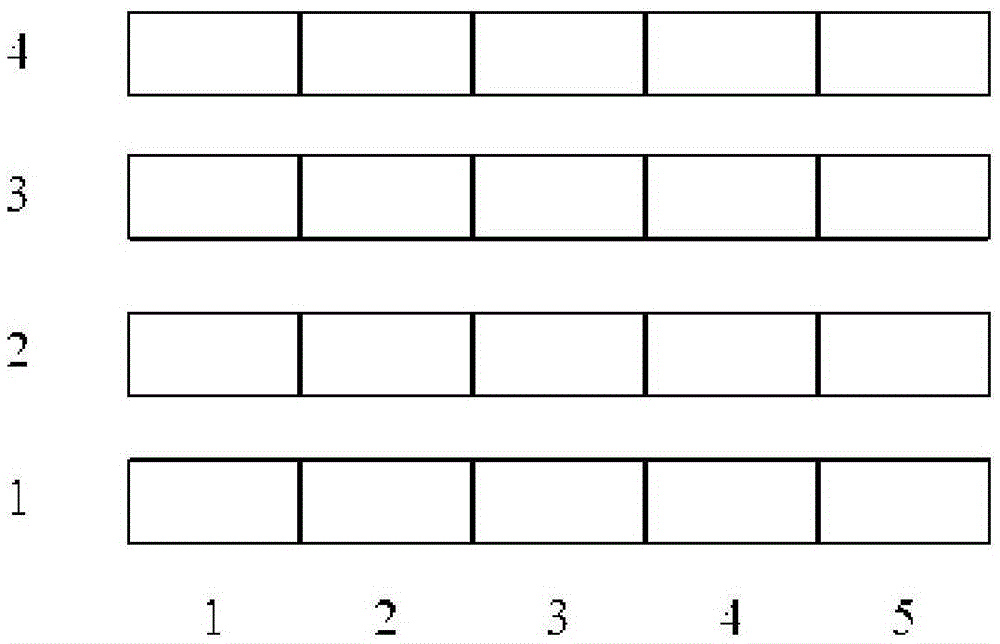

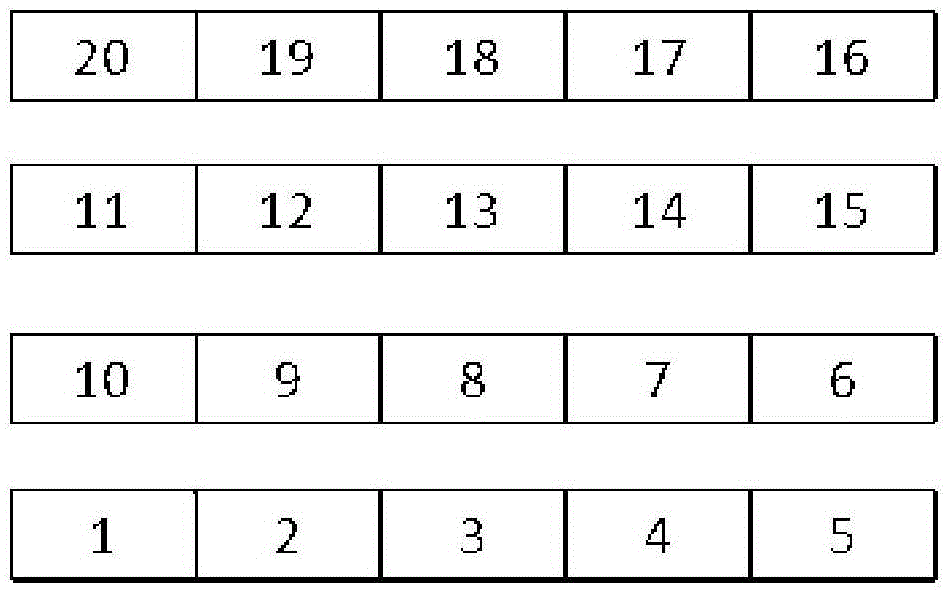

[0032] A barcode-based intelligent warehouse inbound and outbound management method, first of all, it is necessary to mark the location of the warehouse, which is divided into two methods: one method is suitable for warehouses with relatively square shelves, which can be marked with coordinates (such as figure 1 ), when importing warehouse location information into the system, in addition to filling in the location number, you need to fill in the X coordinate value and Y axis coordinate value of the location; another method is to directly mark the sequence number of the location (such as figure 2 ).

[0033] After the storage location is marked, it is classified according to the actual situation of the storage location, for example Figure 1 There are five rows of shelves in one row, and the shelf on the right is the storage location that is easier to access, so all the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com