Material box storing and sorting system and storing and distributing integrated system

A material box and storage module technology, which is applied in the field of material box storage and sorting systems and storage and distribution integration systems, can solve the problems of increasing the workload of shelf access equipment, the inability to supply order boxes on demand, and low storage density of order boxes. , to achieve the effect of optimizing the delivery sequence, improving the completion efficiency, and improving the replenishment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

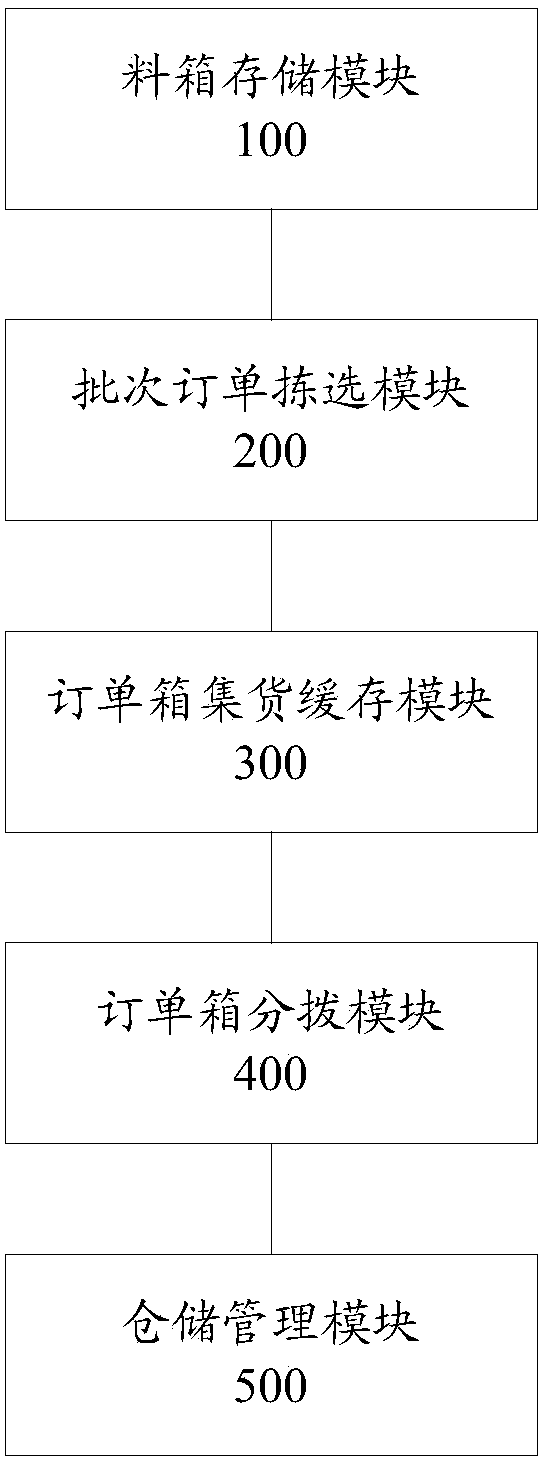

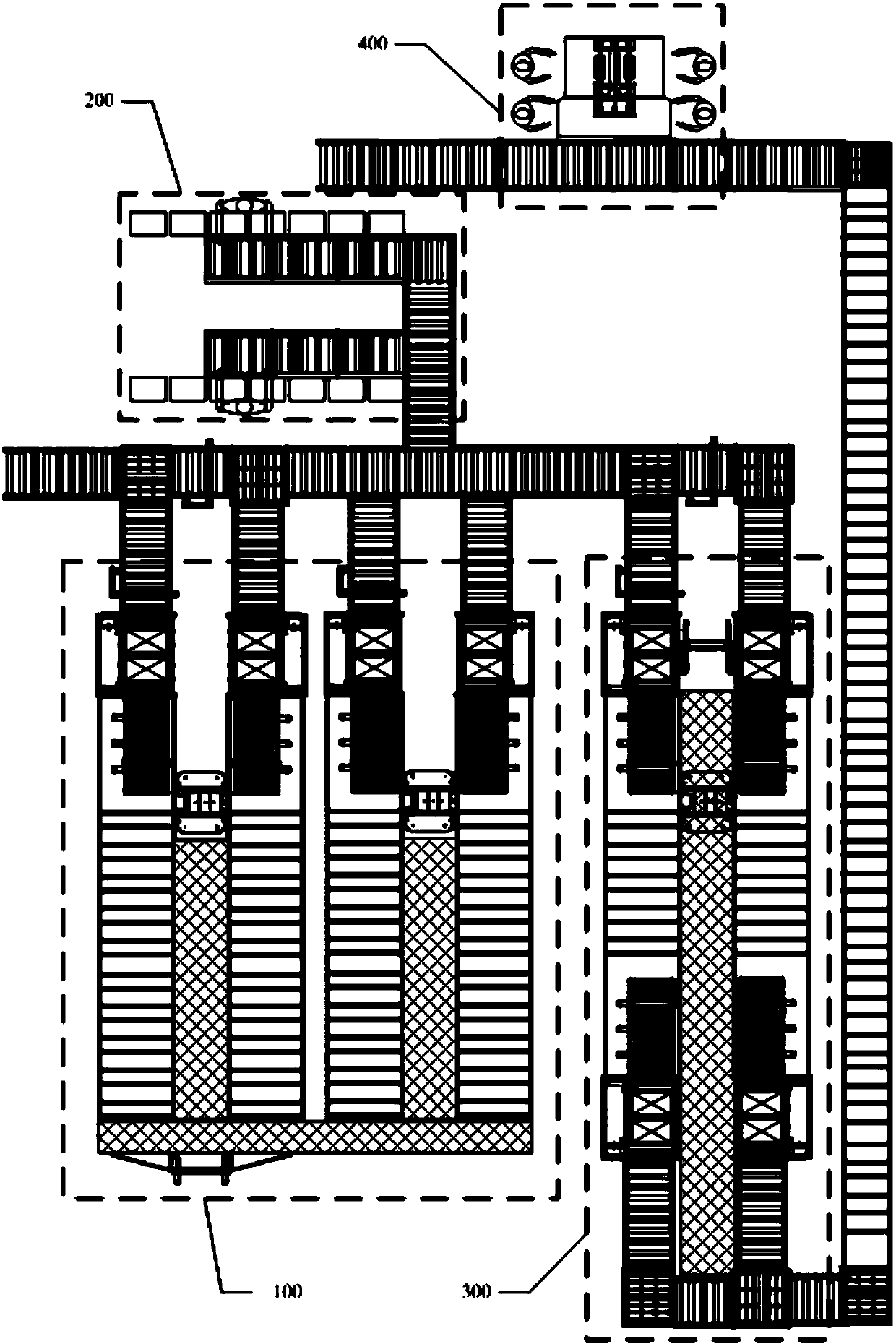

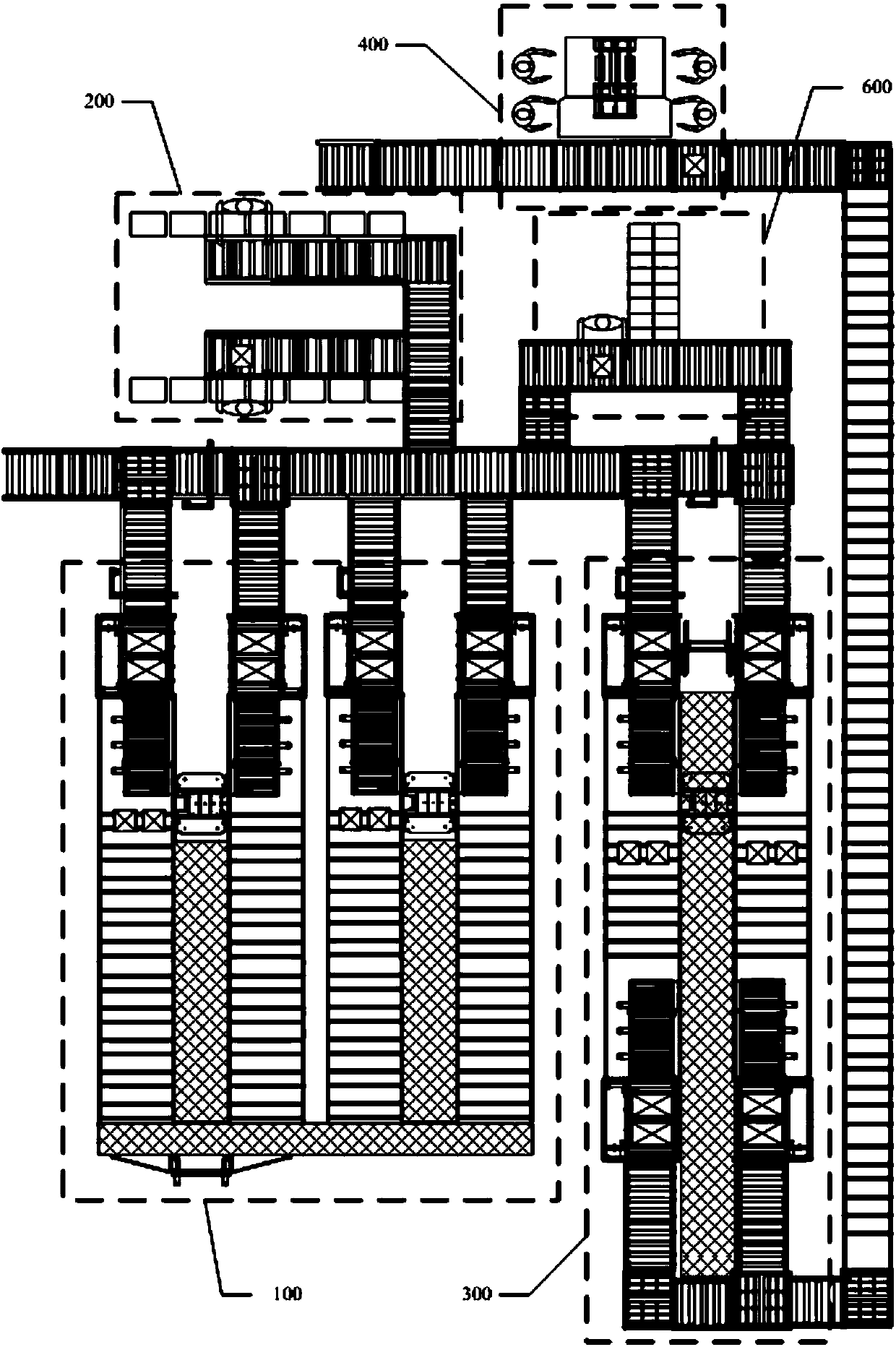

[0032] Embodiment 1 of the present invention provides a bin storage and picking system, see figure 1 The structural block diagram of the shown bin storage and picking system shows that the bin storage and picking system includes at least: a bin storage module 100, a batch order picking module 200, an order box collection cache module 300, and an order box distribution module 400 And warehouse management module 500.

[0033] Specifically, the material box storage module 100 is used for accessing material boxes. Among them, the material box is used for storing goods. What needs to be explained here is that the material box storage module also meets the operating requirements of shuttle vehicles, power platforms, hoists, and maintenance devices.

[0034] The batch order picking module 200 is used for parallel picking of batch orders, so as to pick the goods belonging to the same batch order in the material box into different order boxes according to types. Among them, the batc...

Embodiment 2

[0062] Embodiment 2 of the present invention provides an integrated storage and distribution system, including the bin storage and picking system provided in the above first aspect and one of its possible implementations, a storage module connected to the bin storage and picking system, Full container outbound module and empty container delivery module. Among them, the storage module can be connected with external storage system or transportation means, the full box delivery module can be used for the return of goods, and the empty box delivery module is used to replenish empty boxes to the box storage and picking system. Empty cases are recycled in case storage picking systems. The empty case conveying module may include empty case stacking equipment and a conveying line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com