Fuel oil supply ship

A technology for supplying ships and fuel oil, applied in the direction of ship hull, ship accessories, ship construction, etc., can solve the problems of unfavorable ship concealment, slow supply speed, small size of oil pipeline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

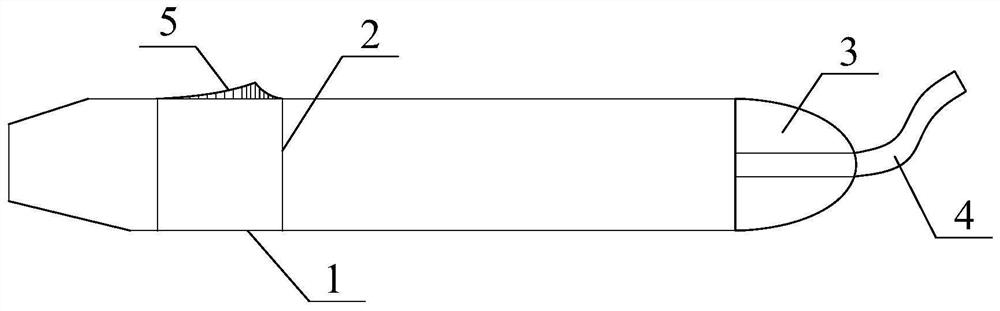

[0029] like figure 1 As shown, the fuel supply ship of the present invention includes a hull shell 1, a transverse bulkhead 2, a hull bow 3, an oil delivery pipe 4, and directional fins 5.

[0030] A transverse bulkhead 2 is provided between the rear of the hull shell 1 and the hull bow 3, so that a fuel tank is formed in the hull shell 1 between the transverse bulkheads 2, and an oil delivery pipe 4 is arranged in the hull bow 3, and one end of the oil delivery pipe 4 is connected to fuel oil. room, and the other end passes through the hull bow 3. Directional fins 5 are arranged on the rear portion of the hull shell 1 . The directional fin 5 is a bionic structure.

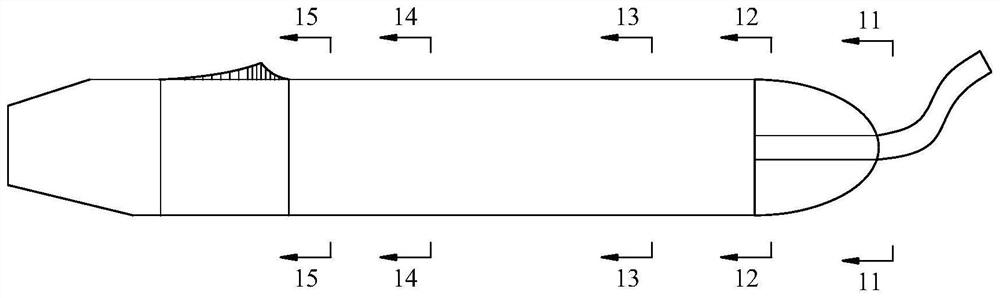

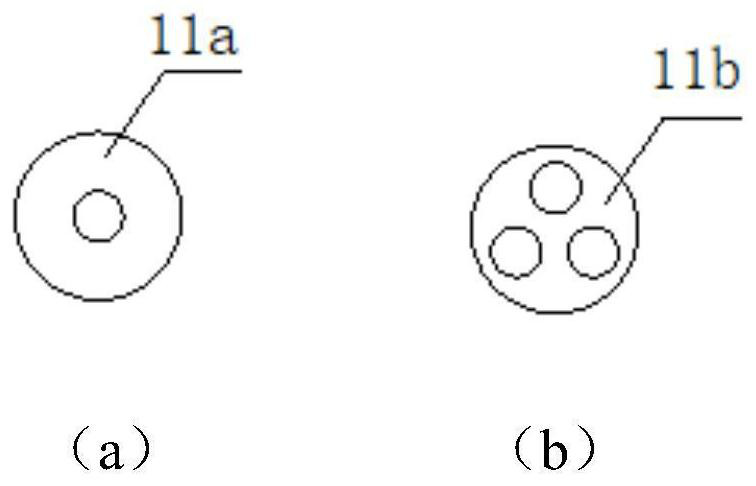

[0031] like figure 2 Shown are the positions of different transverse sections of the bunker supply ship. like Figure 3 to Figure 7 Shown are different cross-sectional line shapes of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com