Patents

Literature

241 results about "Marine fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly marine fuel

ActiveUS20190093026A1Low costLow sulfurElectrical apparatusLiquid carbonaceous fuelsOpen seaLand based

For the shipping industry, these fuels provide solutions to long outstanding technical problems that heretofore hindered supply of low sulfur marine fuels in quantities needed to meet worldwide sulfur reduction goals. Marine shipping use of high sulfur bunker oils is reported as largest source of world-wide transportation SOx emissions. When ships on the open seas burn cheap low grade heavy bunker oils high in sulfur, nitrogen and metals, the SOx, NOx, and metal oxides go to the environment. This invention converts essentially all of each barrel of crude feed to a single ultraclean fuel versus conventional refining where crude feed is cut into many pieces, and each piece is sent down a separate market path meeting various different product specifications. When in port, ships can use these fuels to generate and sell electricity to land based electrical grids to offset fuel cost in an environment-friendly manner.

Owner:MAWETAL LLC

Composition of hydrocarbon fuel

Slurry hydrocracking a heavy hydrocarbon feed produces a HVGO stream and a pitch stream. At least a portion of the pitch stream is subjected to SDA to prepare a DAO stream low in metals. The DAO is blended with at least a portion of the HVGO stream to provide turbine or marine fuel with acceptable properties for combustion in gas turbines or for marine fuel grades.

Owner:UOP LLC

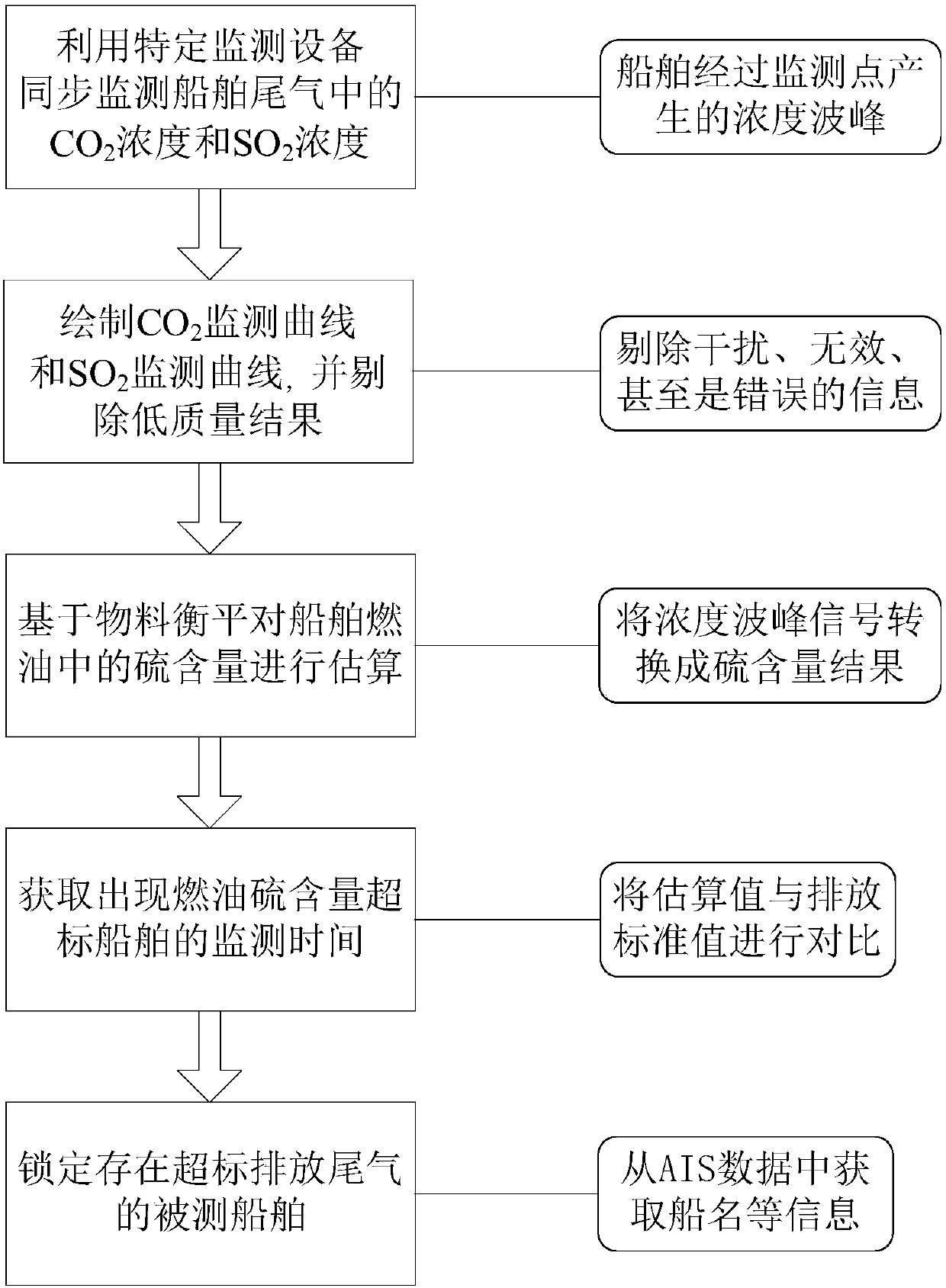

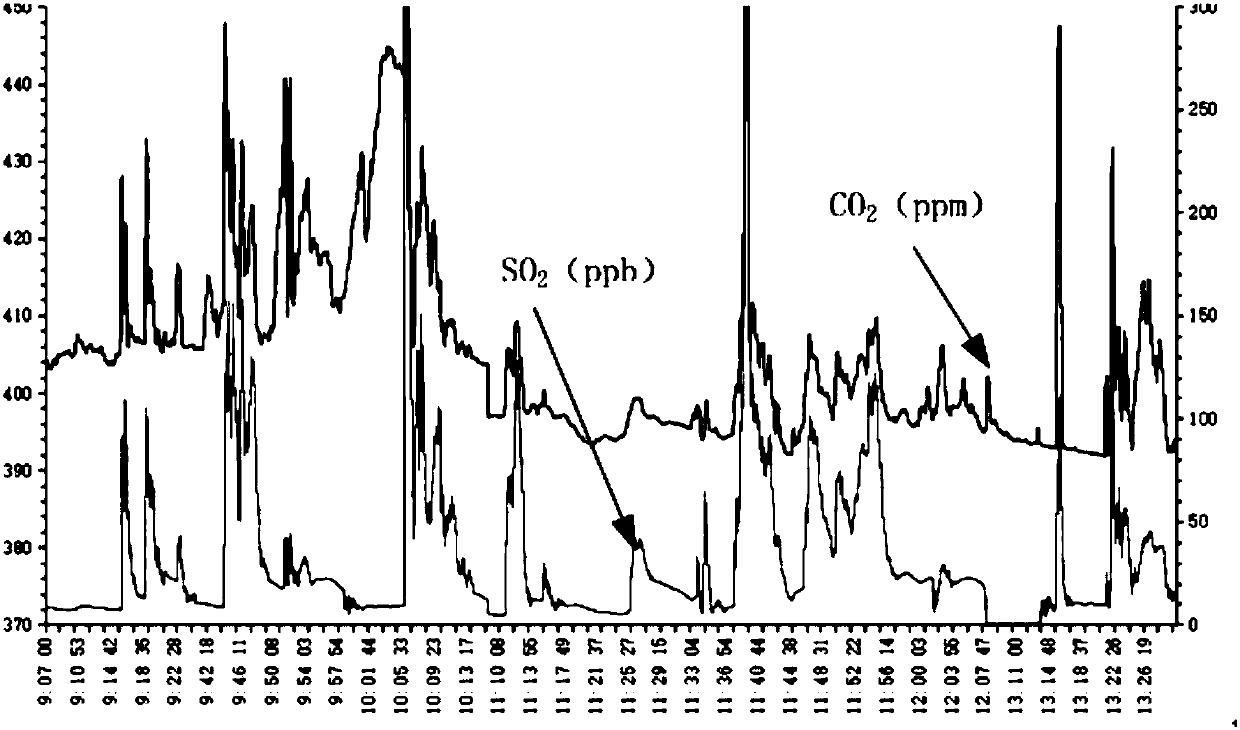

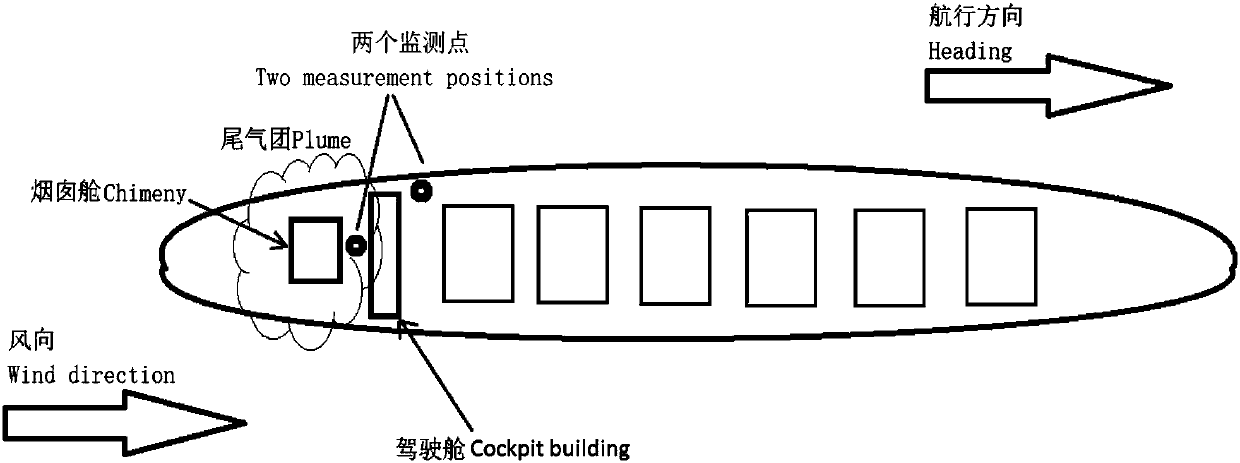

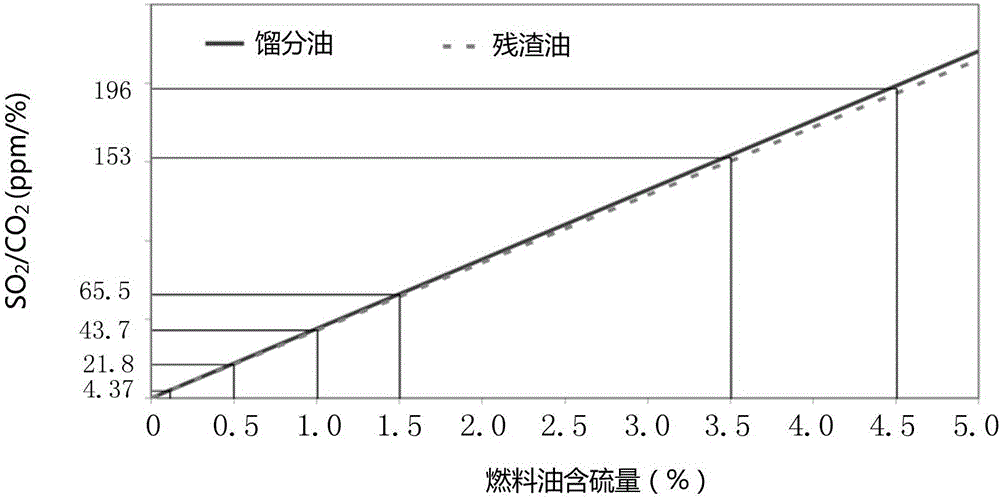

Marine sniffing estimation method of sulphur content in fuel oil

The invention discloses a marine sniffing estimation method of sulphur content in fuel oil, comprising the following five steps: acquiring tail gas; drawing a SO2 monitoring curve and a CO2 monitoringcurve to acquire SO2 concentration value, CO2 concentration value, SO2 background concentration value and CO2 background concentration value during the same monitoring period; calculating sulphur content in marine fuel oil on the basis of material balance; acquiring monitoring time of ships with excessive sulphur content in fuel oil; and locking the ships with excessive sulphur content in fuel oil. By the marine sniffing estimation method of sulphur content in fuel oil, the purpose of identifying ships with illegal use of high sulphur oil can be achieved without going on board, and huge wastecaused by blind sampling is avoided. The invention provides an efficient means for accurate sampling inspection of ships in national ship emission control areas.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

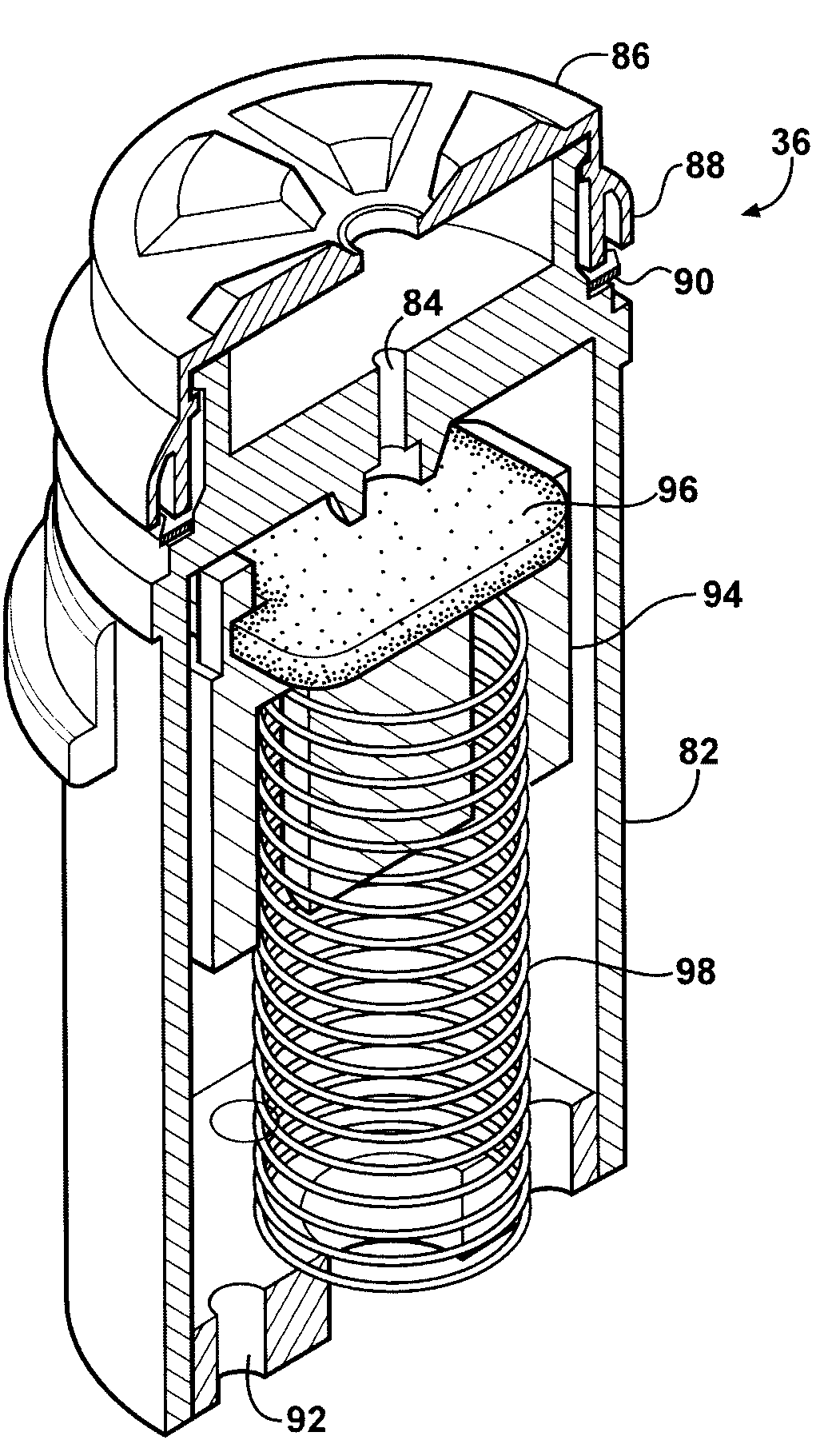

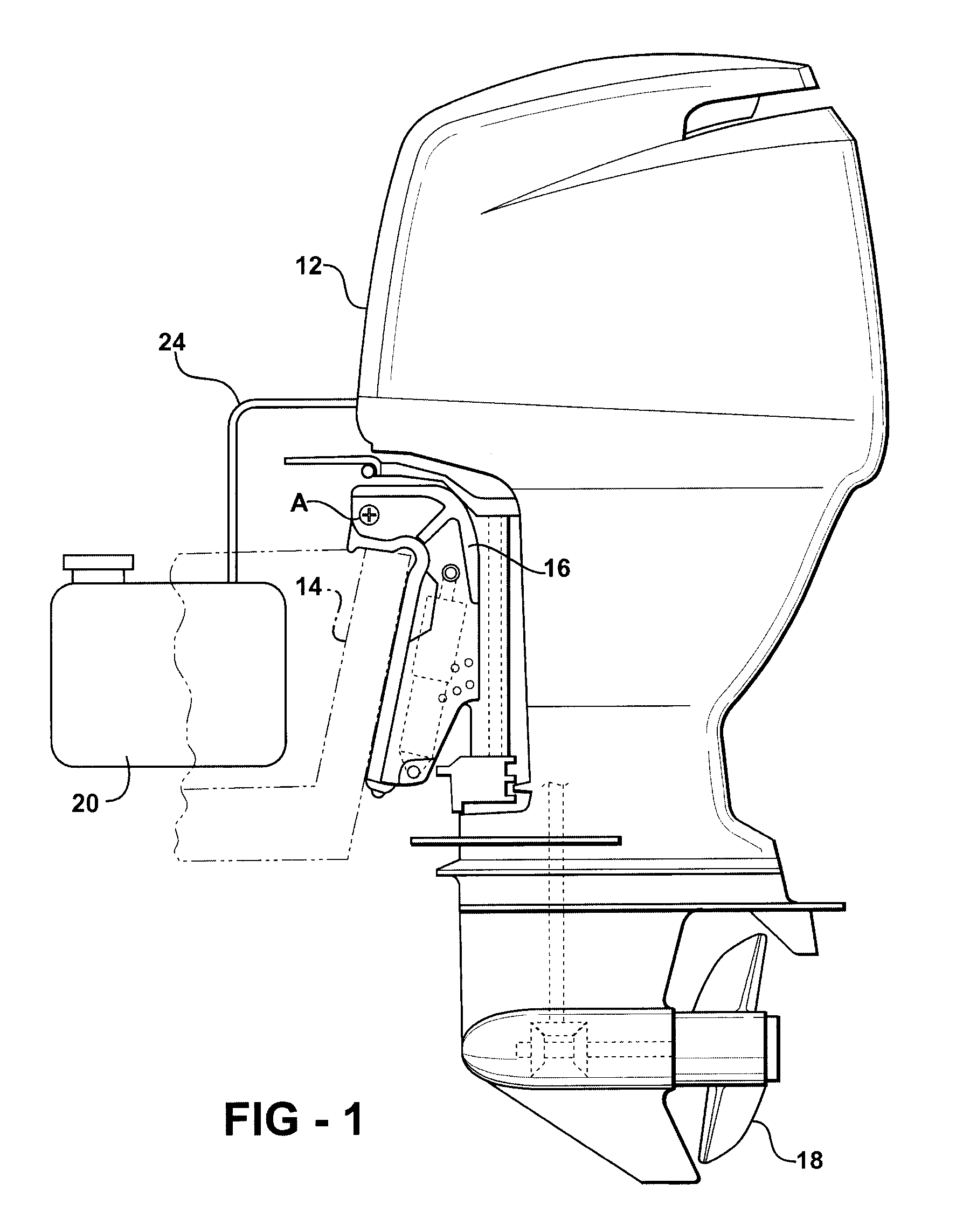

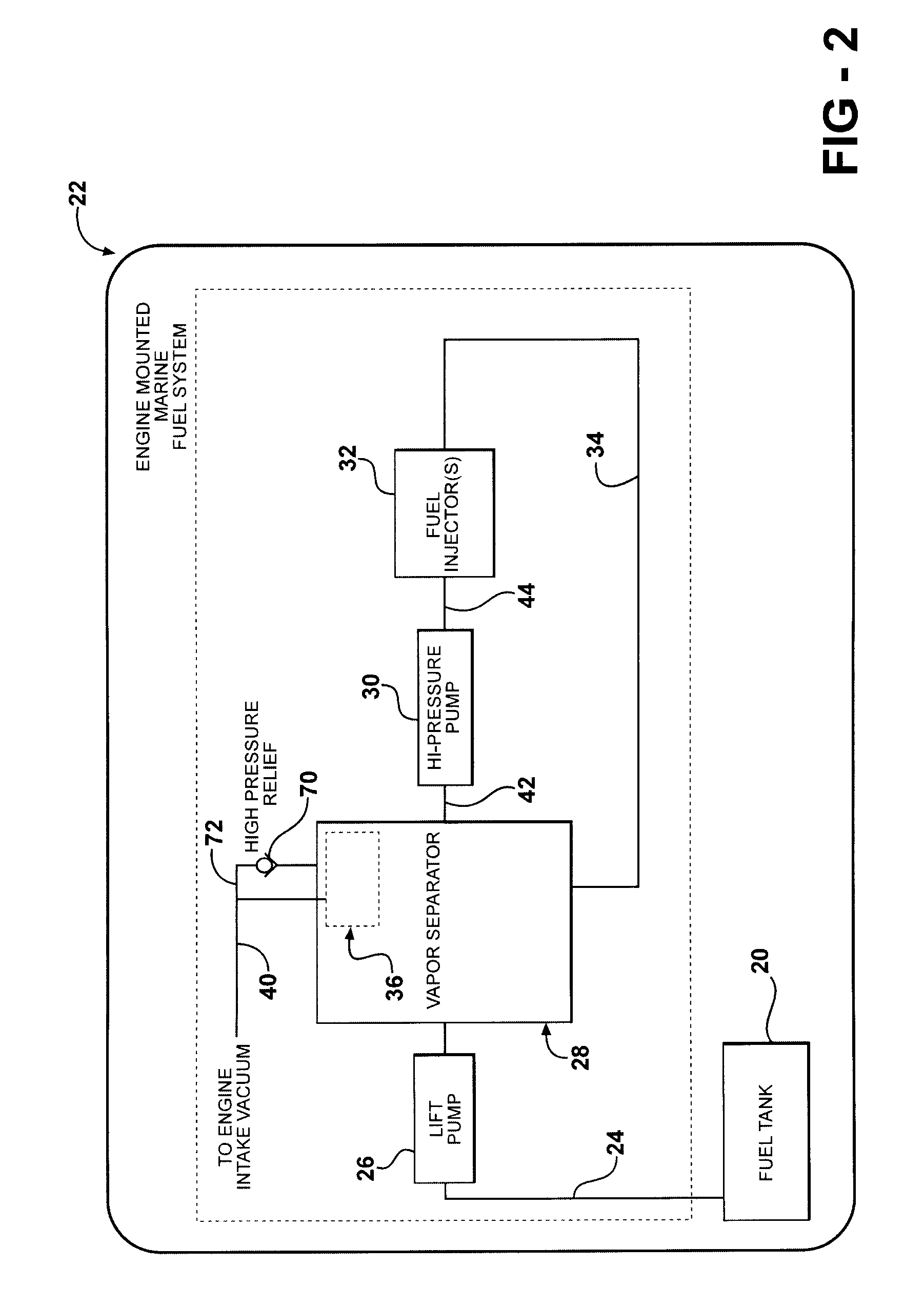

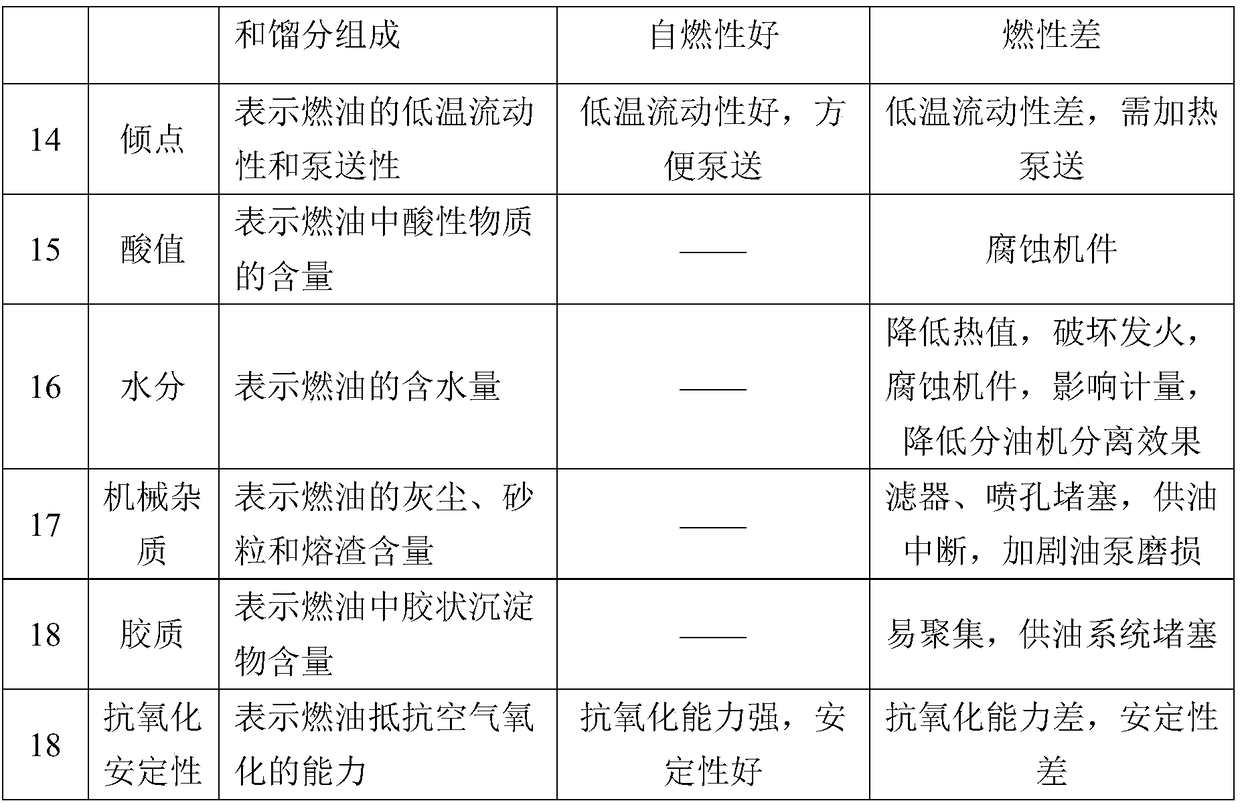

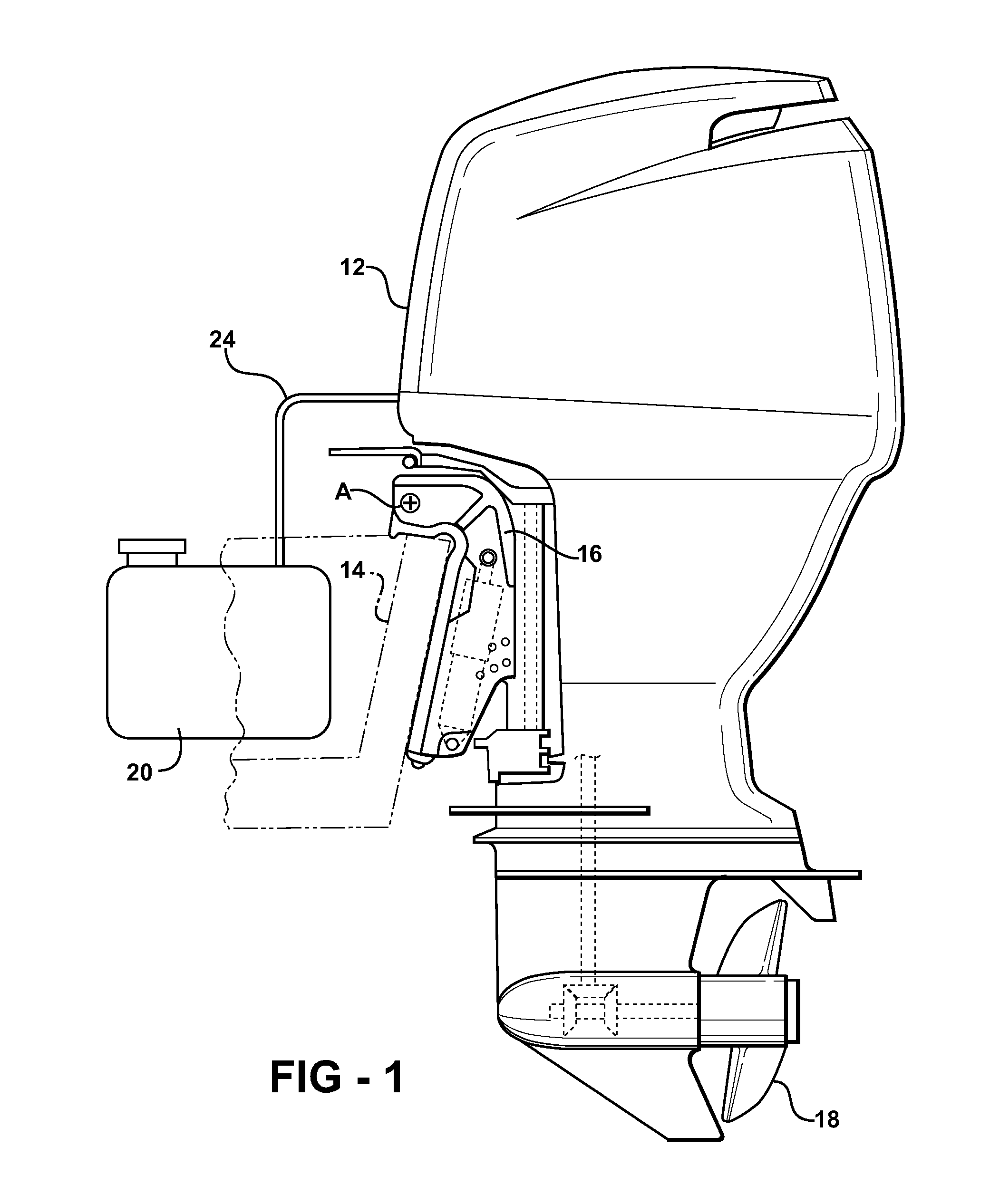

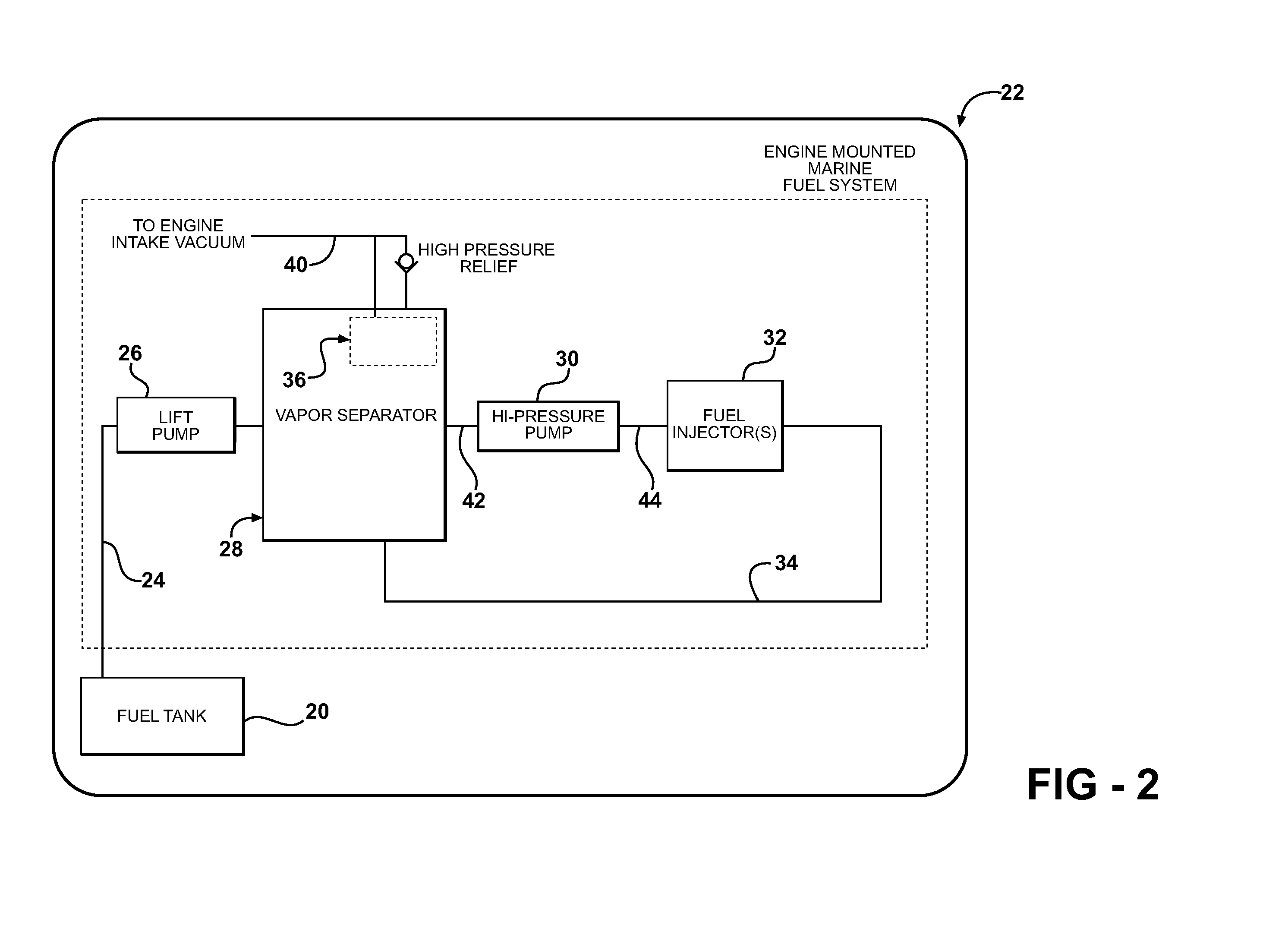

Marine fuel vapor separator with vent control device

ActiveUS7503314B2Prevent leakageNon-fuel substance addition to fuelMachines/enginesLiquid fuelControl of respiration

A fuel supply system for an outboard marine engine includes a vapor separator (28) having a uni-directional vapor vent device (36) for preventing fuel leakage when the engine (12) is tipped on its side. The vapor separator (28) includes an enclosed interior chamber (50) which is filled with liquid fuel by a suction pump. A separate, high pressure pump transfers the liquid fuel from the interior chamber (50) to a fuel injection system (32) of the engine (12). The vapor vent device (36) includes a generally tubular casing having an enclosed top end permeated by an escape passage (84), and a float (94) slidably disposed within the casing (82) for movement toward and away from sealing engagement with the escape passage (84). A spring (98) urges the float (94) toward a sealed condition against the escape passage (84), but is too weak to overcome the weight of the float (94) unless the engine (12) is tipped more than about 25 degrees from vertical, or unless the level of fuel in the interior chamber (50) lifts the float (94).

Owner:CARTER FUEL SYST

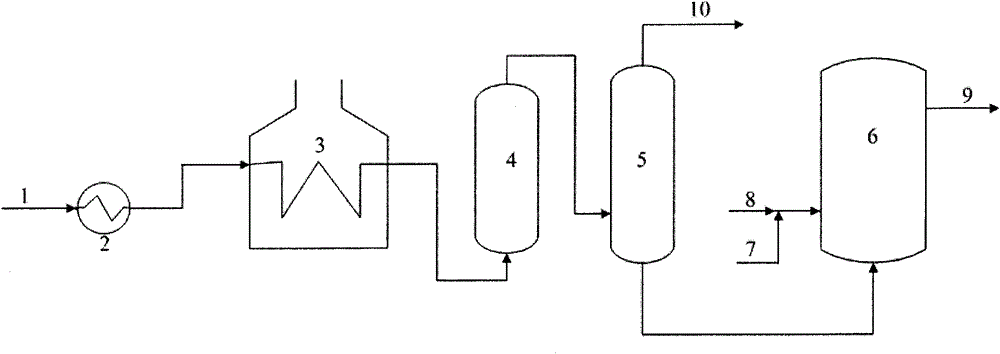

Marine fuel oil and preparation method thereof

InactiveCN102746890AReduce manufacturing costReduce dosageTreatment with plural serial stages onlyLiquid carbonaceous fuelsDistillationFractionation

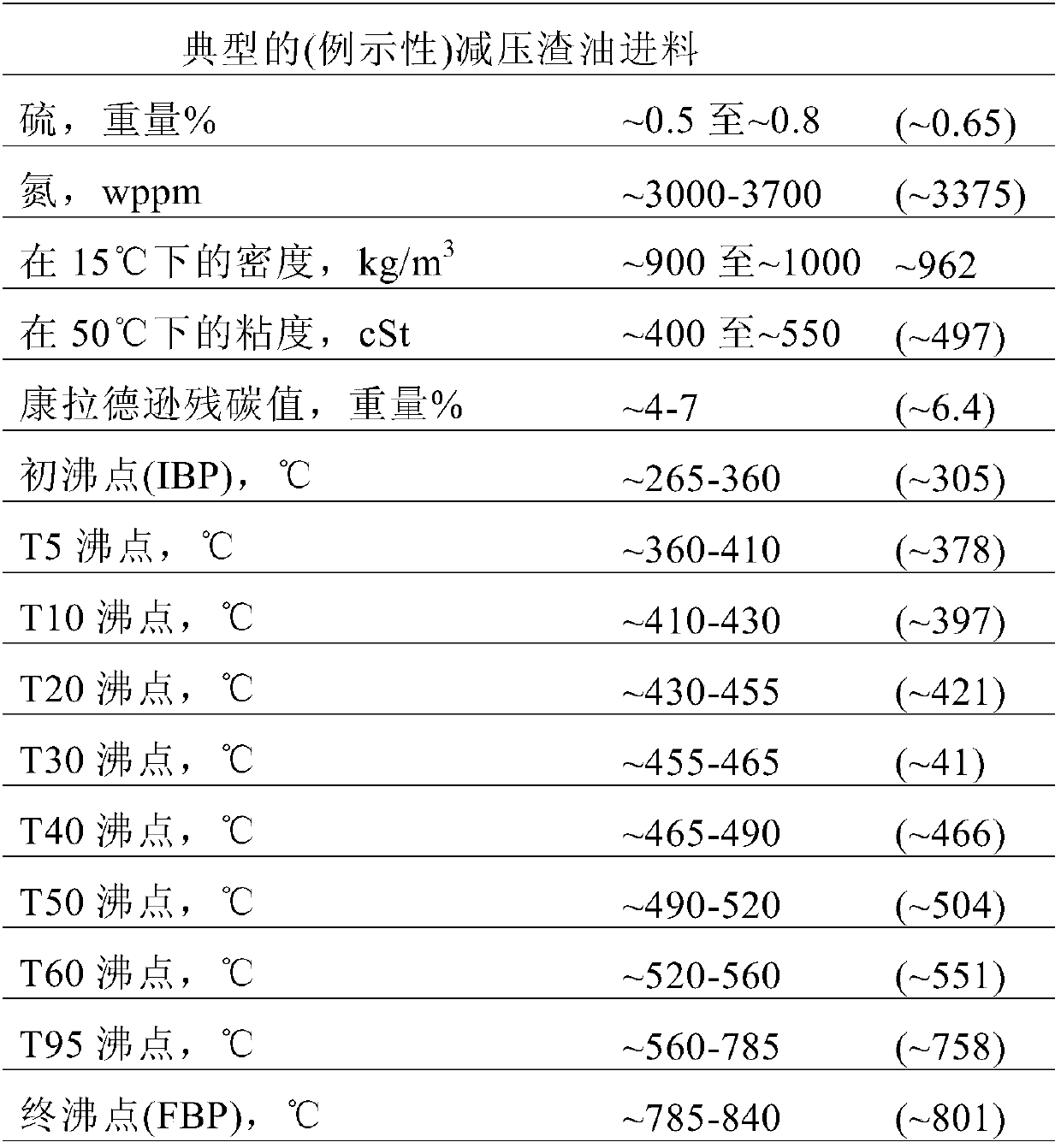

The invention discloses a preparation method of marine fuel oil, comprising the following steps: (1) visbreaking heavy oil components at 400-450 DEG C for 10-60 min; (2) carrying out fractionation on the product obtained by visbreaking, and collecting fractions with the distillation range of higher than 165 DEG C; and (3) mixing the fractions with the distillation range of range of higher than 165 DEG C and light oil components to obtain the marine fuel oil which is characterized in that the density at 15 DEG C is 850-991 kg / m<3>, the viscosity at 50 DEG C is no larger than 380 mm<2> / s, the total content of silicon measured as silicon and aluminium measured as aluminium is 0-80 mg / kg, wherein the viscosity of the heavy oil components at 100 DEG C is no less than 35 mm<2> / s, the density of the heavy oil components at 15 DEG C is 950-1200 kg / m<3>, and the total content of silicon measured as silicon and aluminium measured as aluminium in the heavy oil components is 0-300 mg / kg The invention also provides the marine fuel oil prepared by the method. According to the method of the invention, the production cost of the marine fuel oil can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composition of hydrocarbon fuel

Slurry hydrocracking a heavy hydrocarbon feed produces a HVGO stream and a pitch stream. At least a portion of the pitch stream is subjected to SDA to prepare a DAO stream low in metals. The DAO is blended with at least a portion of the HVGO stream to provide turbine or marine fuel with acceptable properties for combustion in gas turbines or for marine fuel grades.

Owner:UOP LLC

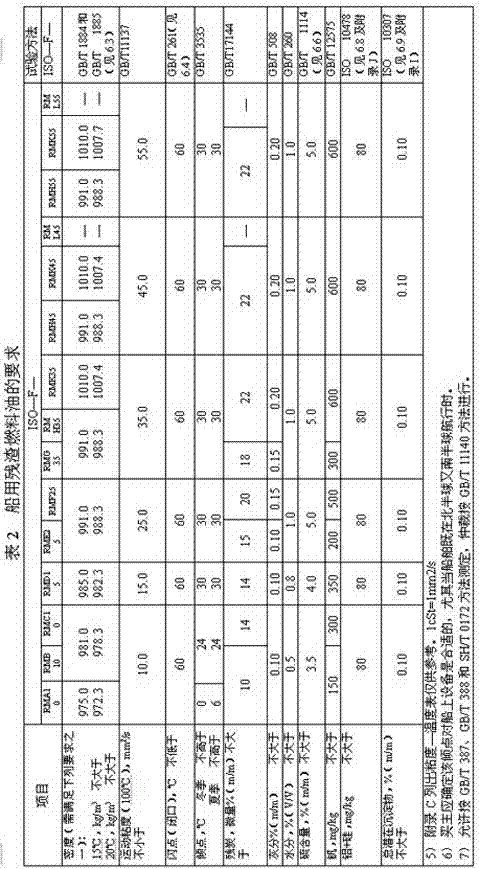

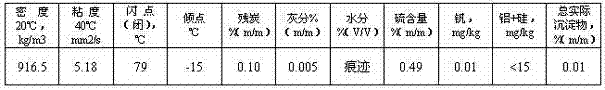

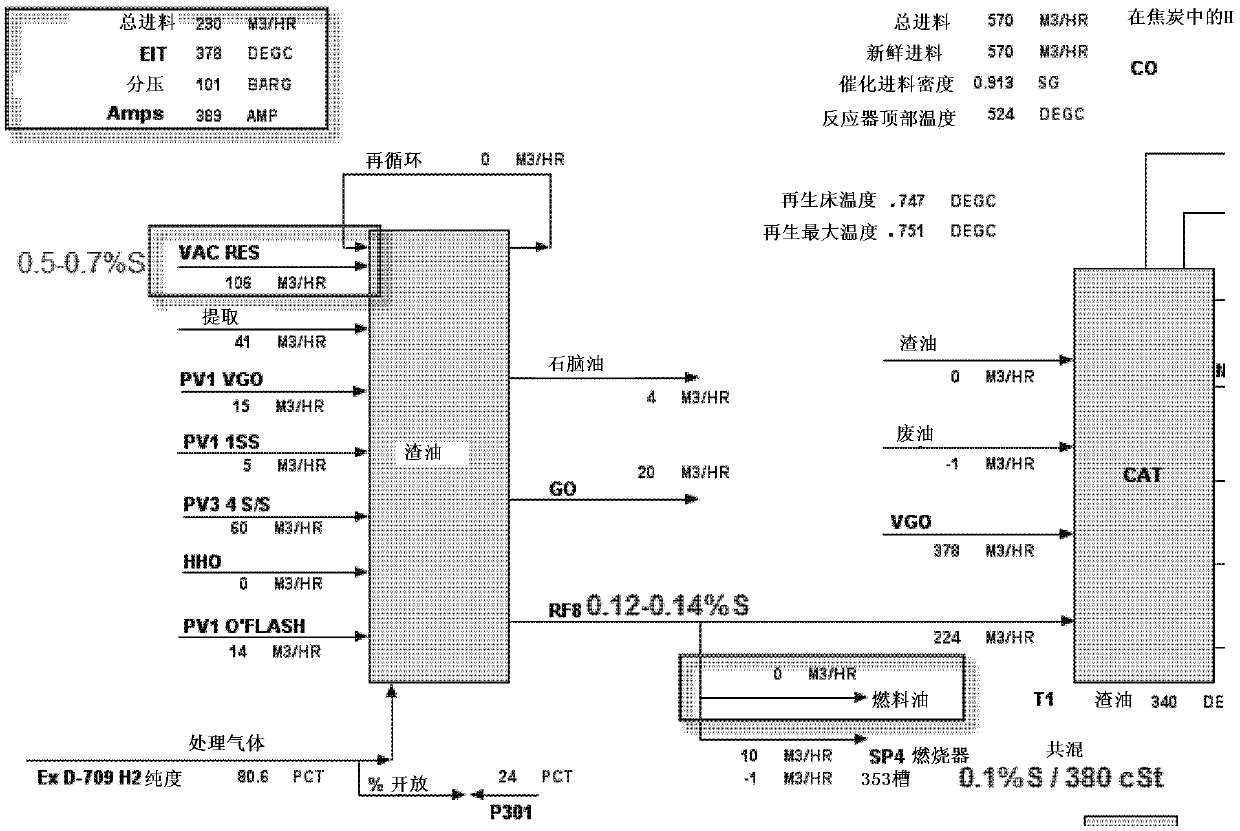

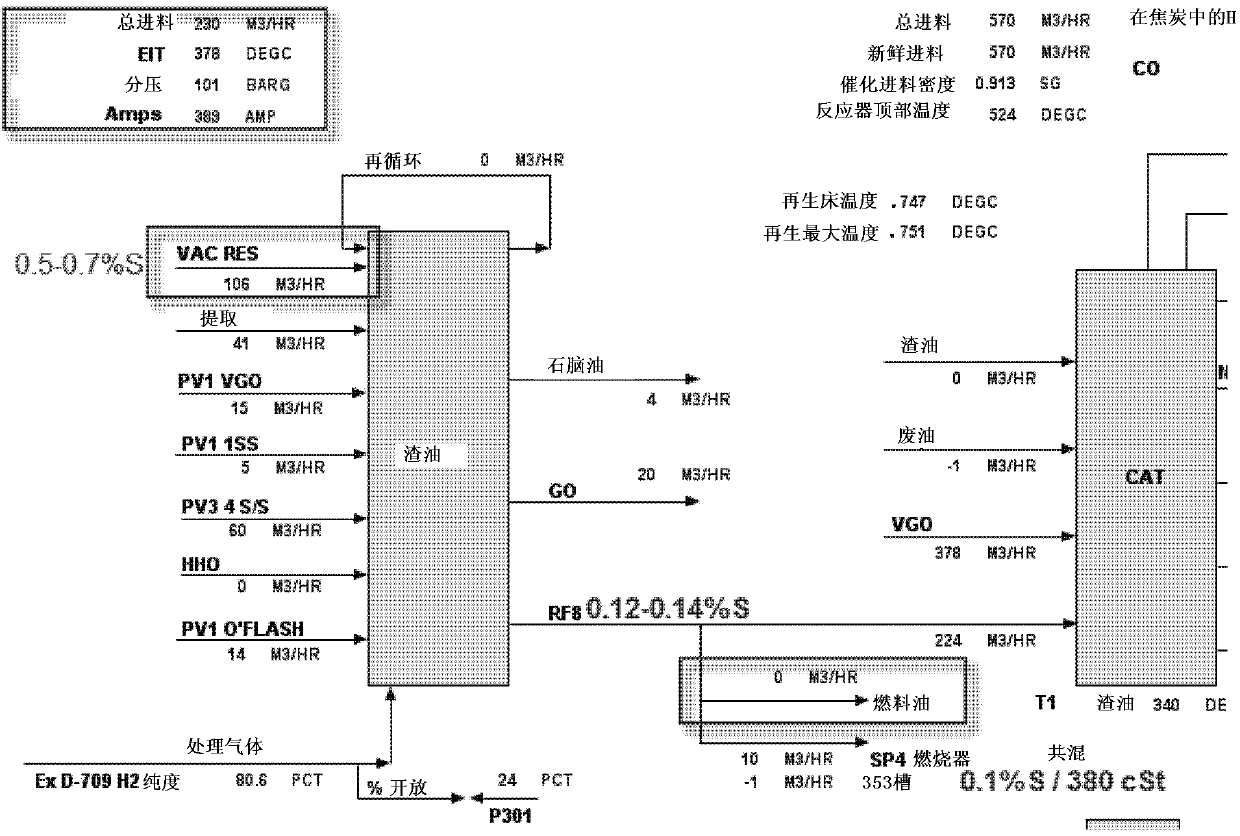

New utilization process for catalytic cracking slurry oil

ActiveCN102786981AFlexible productionReasonable useHydrocarbon distillationLiquid carbonaceous fuelsSlurryNational standard

The present invention discloses a new utilization process for catalytic cracking slurry oil. According to the process, catalytic slurry oil is subjected to vacuum distillation to obtain light slurry oil and topped slurry oil, wherein a distillation outlet temperature is 360-480 DEG C; physical and chemical indicators of the light slurry oil are detected, and are compared with marine fuel oil standards, wherein the light slurry oil meeting the standards is directly adopted as marine residual fuel oil, or a diesel component is adopted to blend to meet the standards so as to adopt the light slurry oil as marine distillate fuel oil, or a residue oil component is adopted to blend to meet the standards so as to adopt the light slurry oil as marine residual fuel oil. The marine fuel oil standards are the national standards ZB / T17411-1998. The diesel component is one or a plurality of materials selected from normal pressure second side oil, normal pressure third side oil, a catalytic diesel and a hydrogenated diesel, and is blended into the light slurry oil, wherein the use amount of the diesel component is 30-95% of the total amount. The residue oil component is one or a plurality of materials selected from vacuum residue oil, viscosity reduction residue oil and deoiled asphalt, and is blended into the light slurry oil, wherein the use amount of the residue oil component is 5-85% of the total amount. The new process of the present invention has characteristics of simple process, wide raw material, and product diversification.

Owner:CHINA PETROLEUM & CHEM CORP

Process for conversion of feedstocks obtained from renewable sources based on marine fuels

The invention relates to a process for the production of diesel fuel bases comprising a sulfur content that is less than 100 ppm, starting from a feedstock that is obtained from a renewable source, comprising the following stages:a) A stage for bringing the feedstock into contact with a fixed-bed hydrotreatment catalyst for producing an effluent that comprises a gaseous fraction comprising hydrogen and a hydrocarbon-based liquid fraction,d) A stage for bringing into contact at least one portion of the hydrocarbon-based liquid fraction in the presence of a selective hydroisomerization catalyst in a fixed bed,e) A stage for separating the effluent that is obtained from stage d) into a gaseous fraction that comprises hydrogen and at least one diesel-fuel-based fraction.

Owner:INST FR DU PETROLE

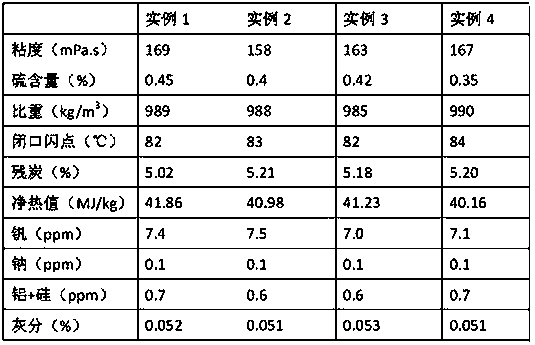

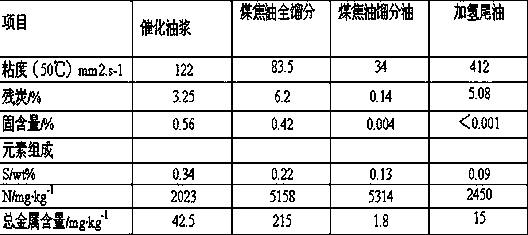

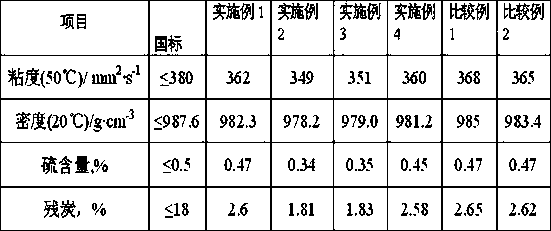

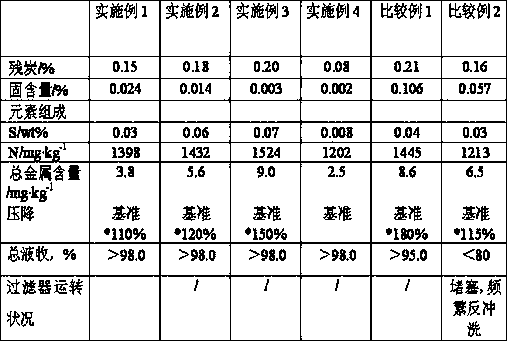

Process method for preparing marine fuel oil on basis of catalytic cracking oil slurry desolidification-hydrogenation

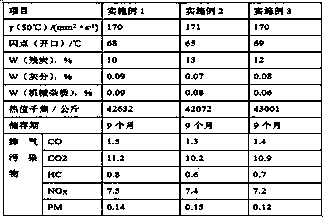

InactiveCN110205160ALow costStay flammableLiquid carbonaceous fuelsTreatment with hydrotreatment processesAdjuvantSlag

The invention relates to a process method for preparing marine fuel oil on the basis of catalytic cracking oil slurry desolidification-hydrogenation and belongs to the technical field of petroleum processing. According to the method, a solvent which is mutually soluble with oil slurry is used as a desolidification adjuvant of the catalytic cracking oil slurry to realize low-temperature desolidification, and the oil slurry which is subjected to desolidification and hydrogenation control is used as a fuel oil component to be compounded with a conventional marine fuel component. The process method for preparing the marine fuel oil on the basis of the catalytic cracking oil slurry desolidification-hydrogenation comprises the steps of oil slurry desolidification, hydrogenation and oil preparation, wherein under the condition of 40-60 DEG C, the catalytic cracking oil slurry is mixed with a diluent, separated, subjected to slag removal and then distilled to obtain desolidified oil slurry; under the action of a catalyst adopting nickel oxide and molybdenum oxide as active components and alumina as a carrier, the desolidified oil slurry is catalytically hydrogenated under the conditions that the space velocity is 0.25-0.5 h<-1>, the temperature is 350-370 DEG C, the pressure reaches 6-10 Mpa, and a hydrogen-oil volume ratio reaches (600-650):1. The method has the advantages that fewerimpurities and charcoal residues are generated, the equipment investment and the process cost are low, and the marine fuel cost is significantly reduced while the combustion performance of oil products is maintained; therefore, the process method is particularly suitable for manufacturing and processing high-performance fuel oil.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Regulating method of bunker fuel oil

ActiveCN103642539AEmission reductionReduce pollutionLiquid carbonaceous fuelsAir quality improvementPtru catalystNitrogen oxides

The invention relates to a regulating method of fuel oil and particularly relates to a regulating method of bunker fuel oil. The bunker fuel oil is realized by the following process: naturally settling FCC (Fluid Catalytic Cracking) oil slurry and thermal-cracking residue oil, then, filtering by a filter screen to remove catalyst fine powder and other impurities contained in materials; pre-adding hydrogenation tail oil and ethylene bottom oil into a regulating tank, heating gradually, stirring until the two is uniformly mixed; adding the FCC oil slurry and the thermal-cracking residue oil treated in the step (1) into the regulating tank, increasing the temperature and uniformly mixing the components; adding a desulfurization aid, a cosolvent and combustion improver into the regulating tank in sequence, and uniformly mixing the components to obtain the product in the invention. According to the invention, the impurities and the catalyst fine powder in the FCC oil slurry and the residue oil easily cause severe corrosion and scale formation of an internal combustion engine, and the defect is improved by settling and filtering, so that emission of nitrogen oxides and SOx is lowered, and pollution on air and ocean is reduced.

Owner:SHANDONG TAIDE NEW ENERGY

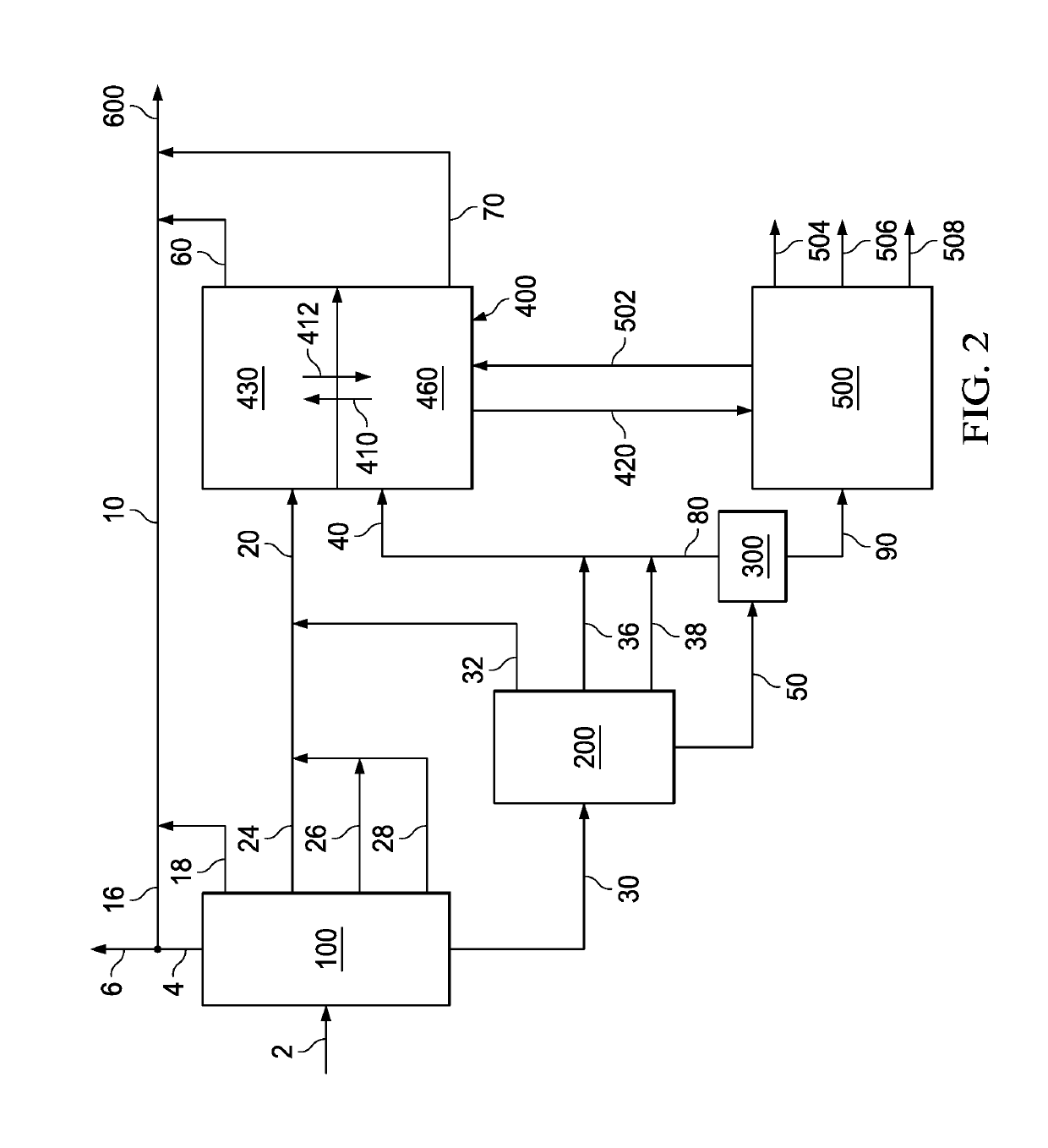

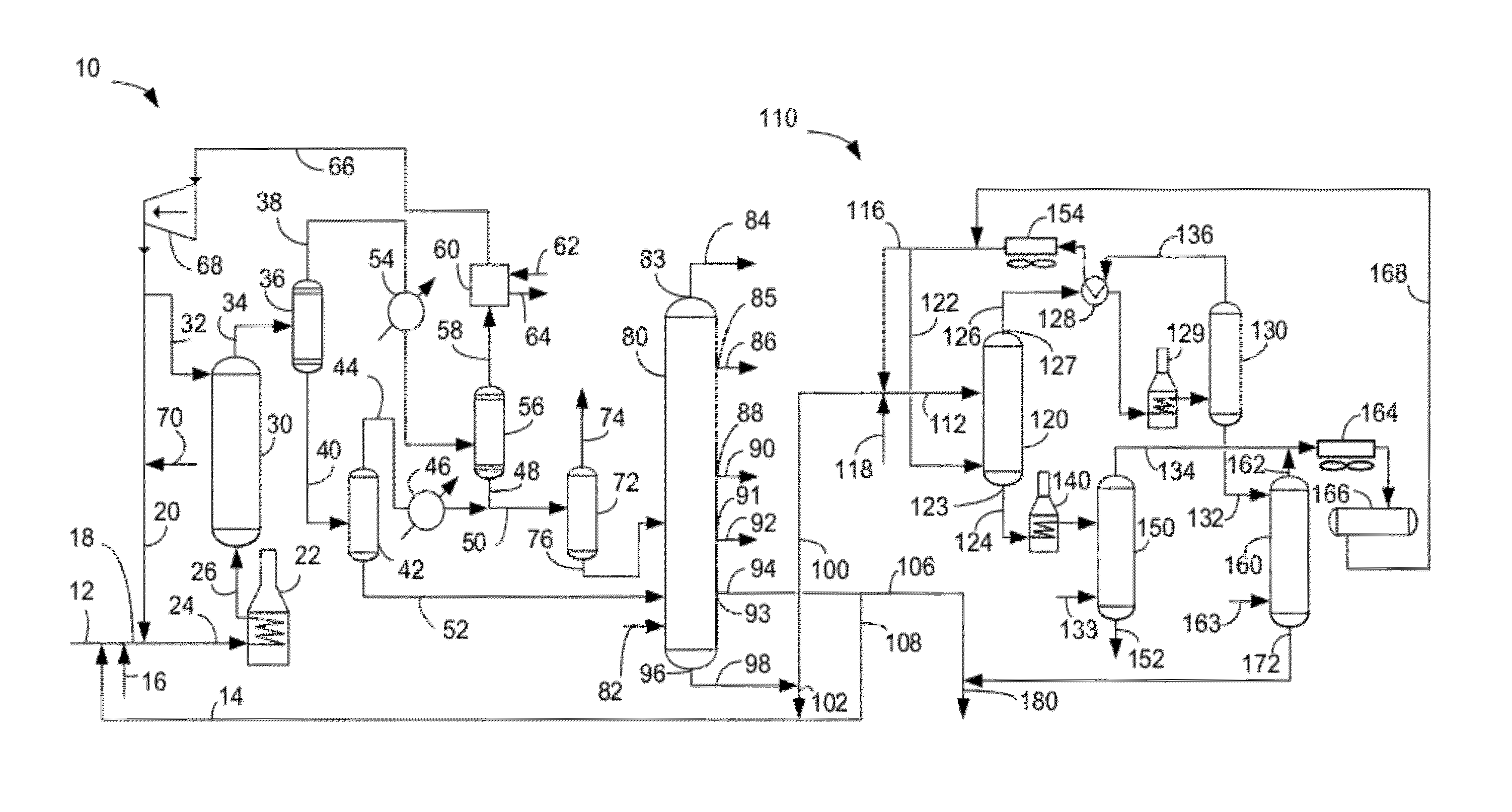

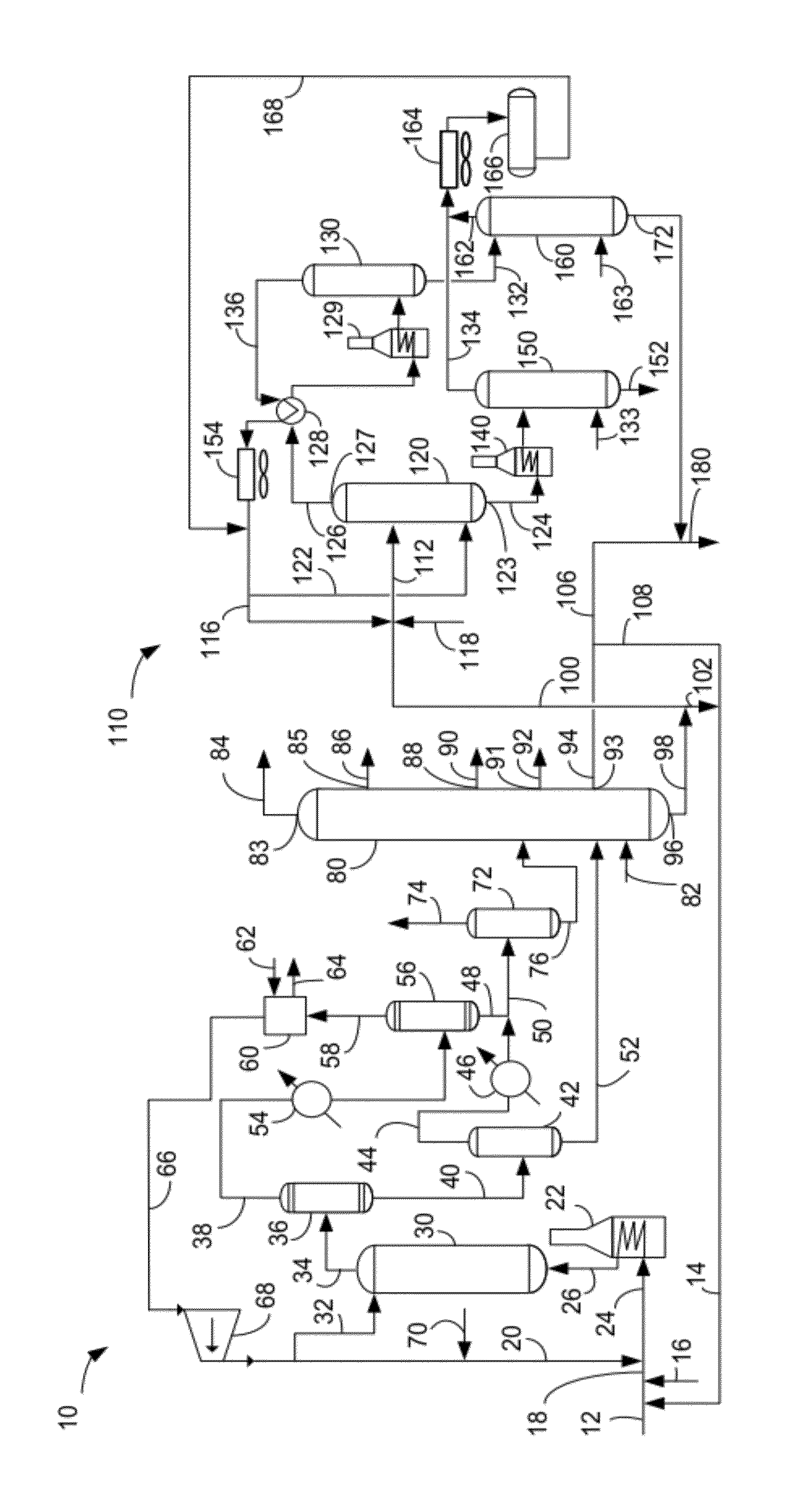

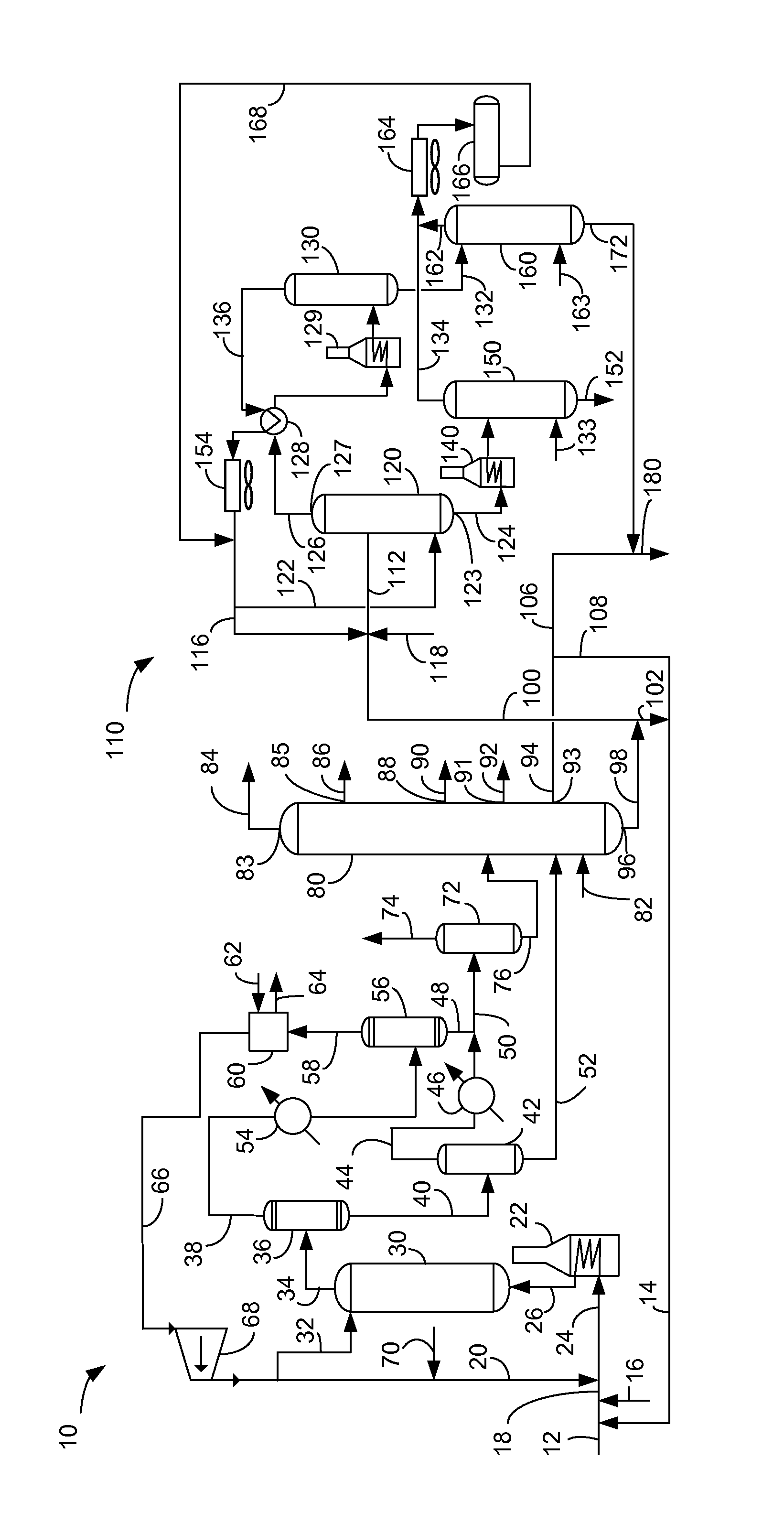

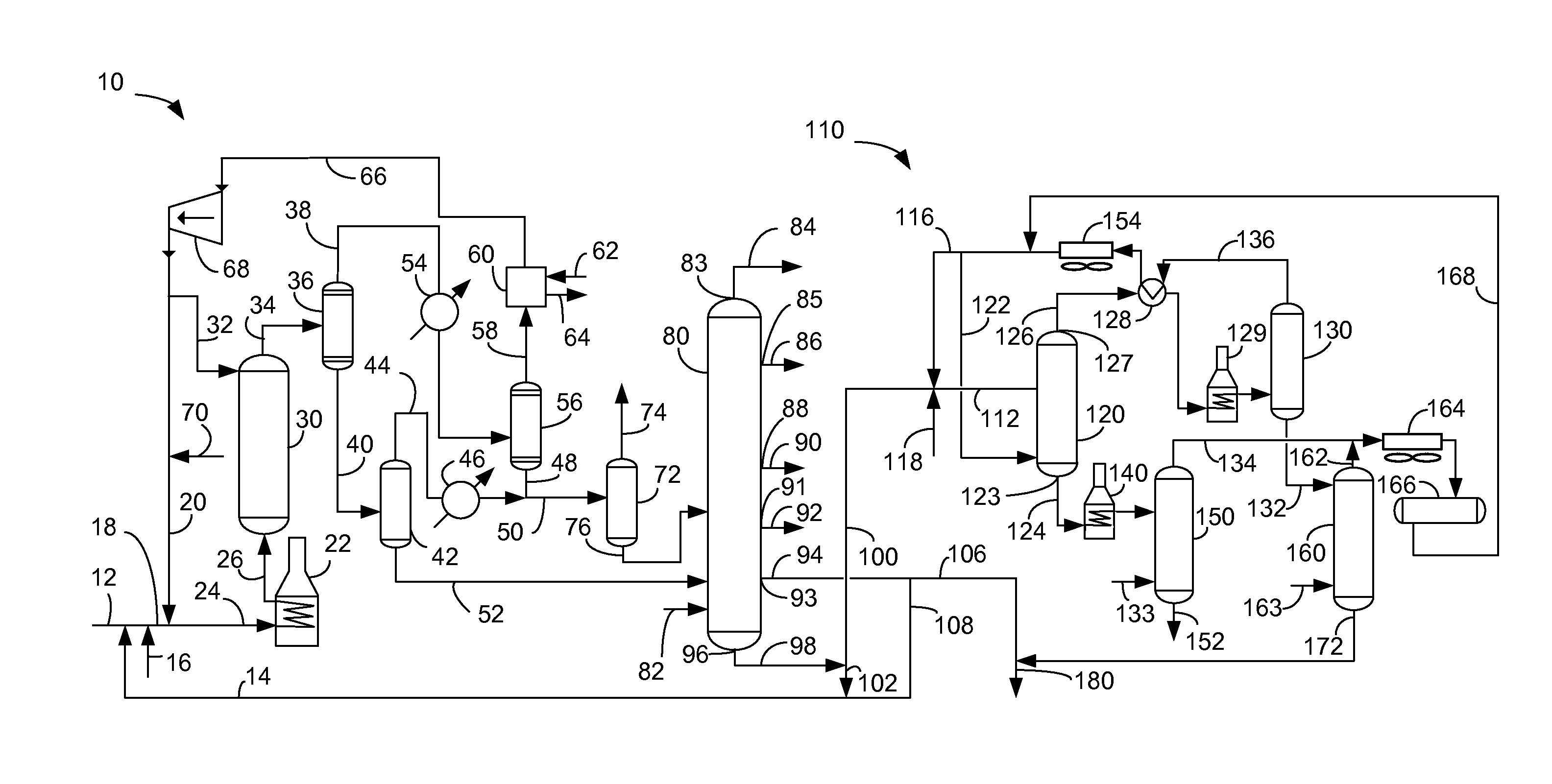

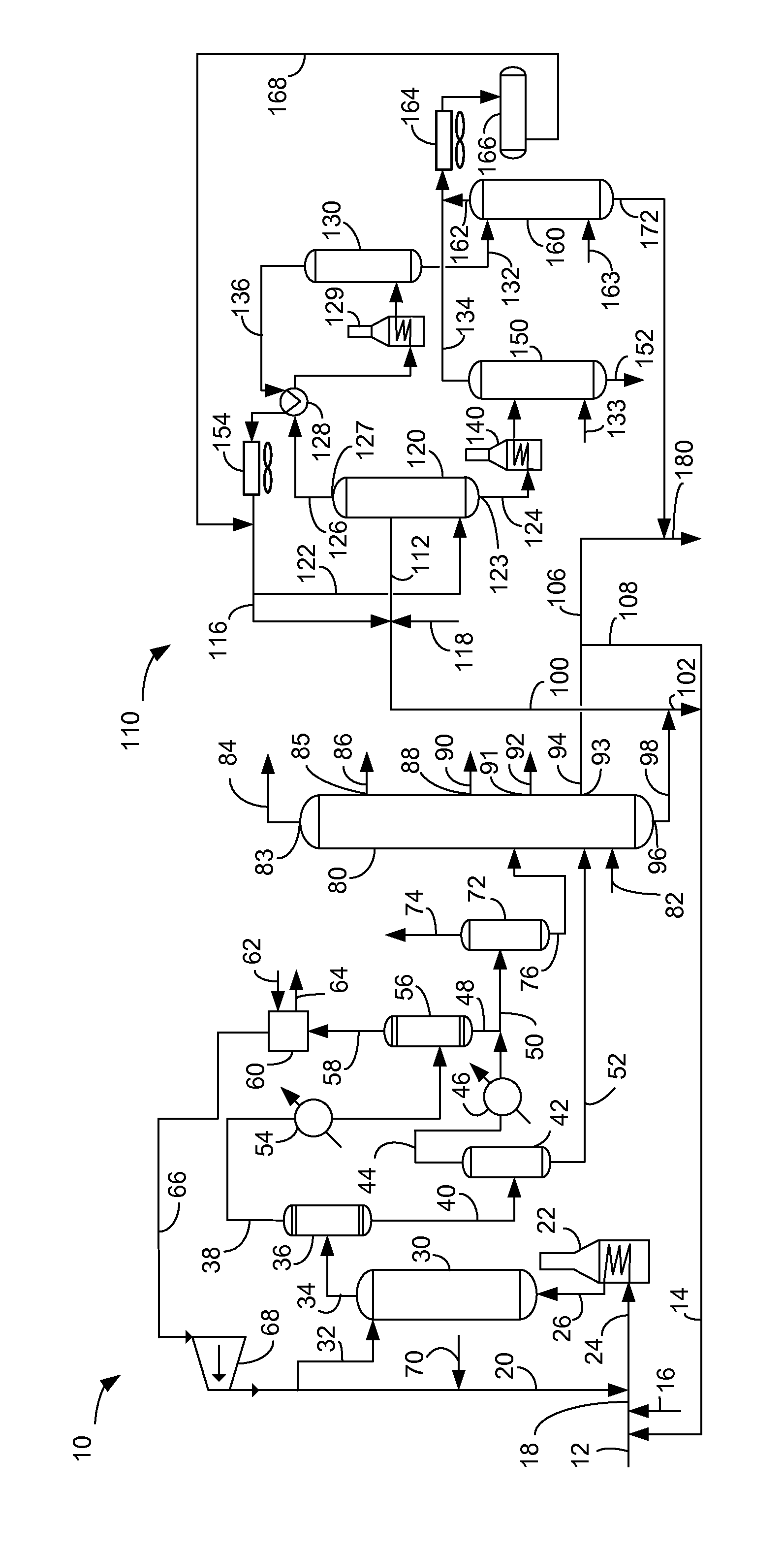

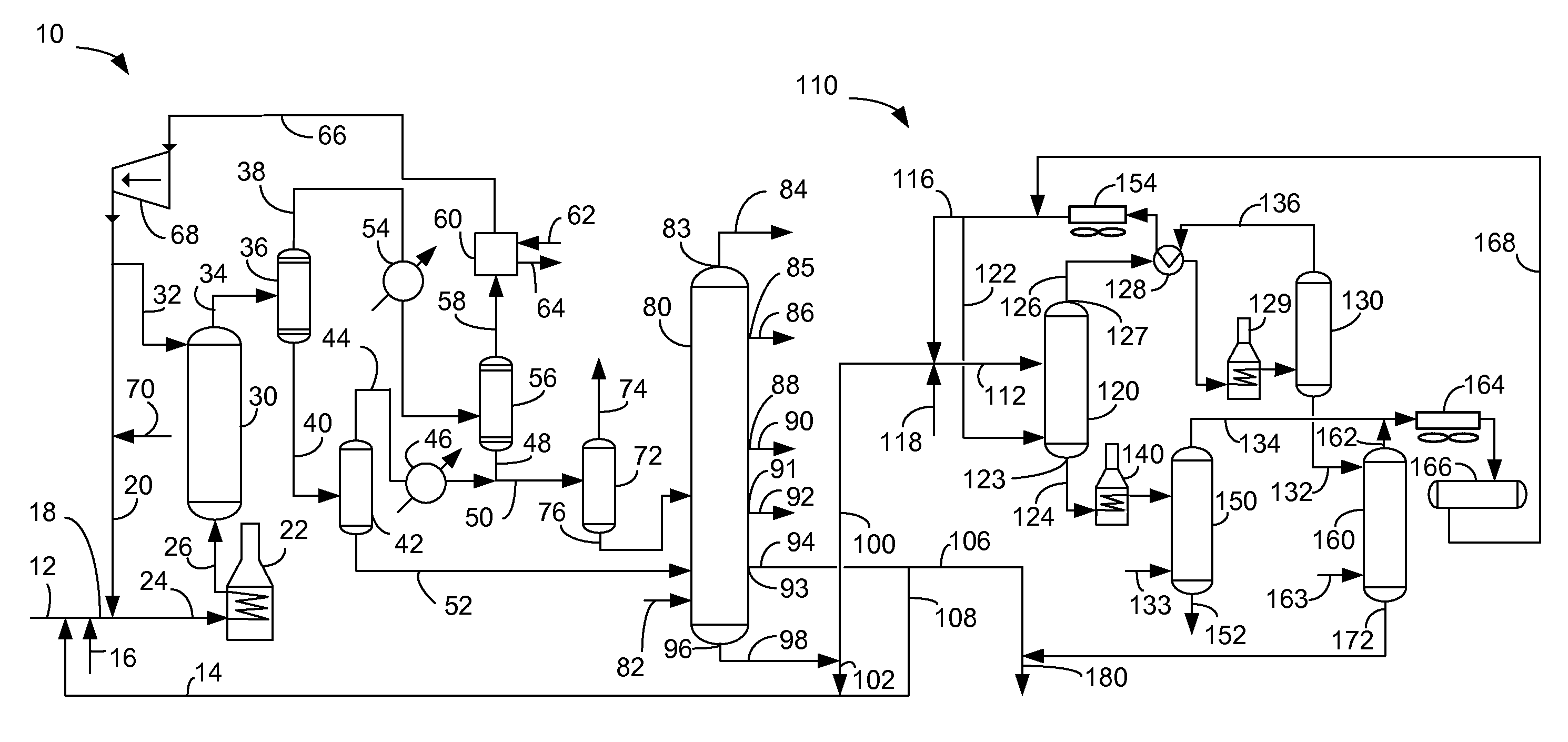

Apparatus for producing hydrocarbon fuel

ActiveUS20110142729A1Treatment with hydrotreatment processesChemical/physical/physico-chemical processesCombustionProcess engineering

Slurry hydrocracking a heavy hydrocarbon feed produces a HVGO stream and a pitch stream. At least a portion of the pitch stream is subjected to SDA to prepare a DAO stream low in metals. The DAO is blended with at least a portion of the HVGO stream to provide turbine or marine fuel with acceptable properties for combustion in gas turbines or for marine fuel grades.

Owner:UOP LLC

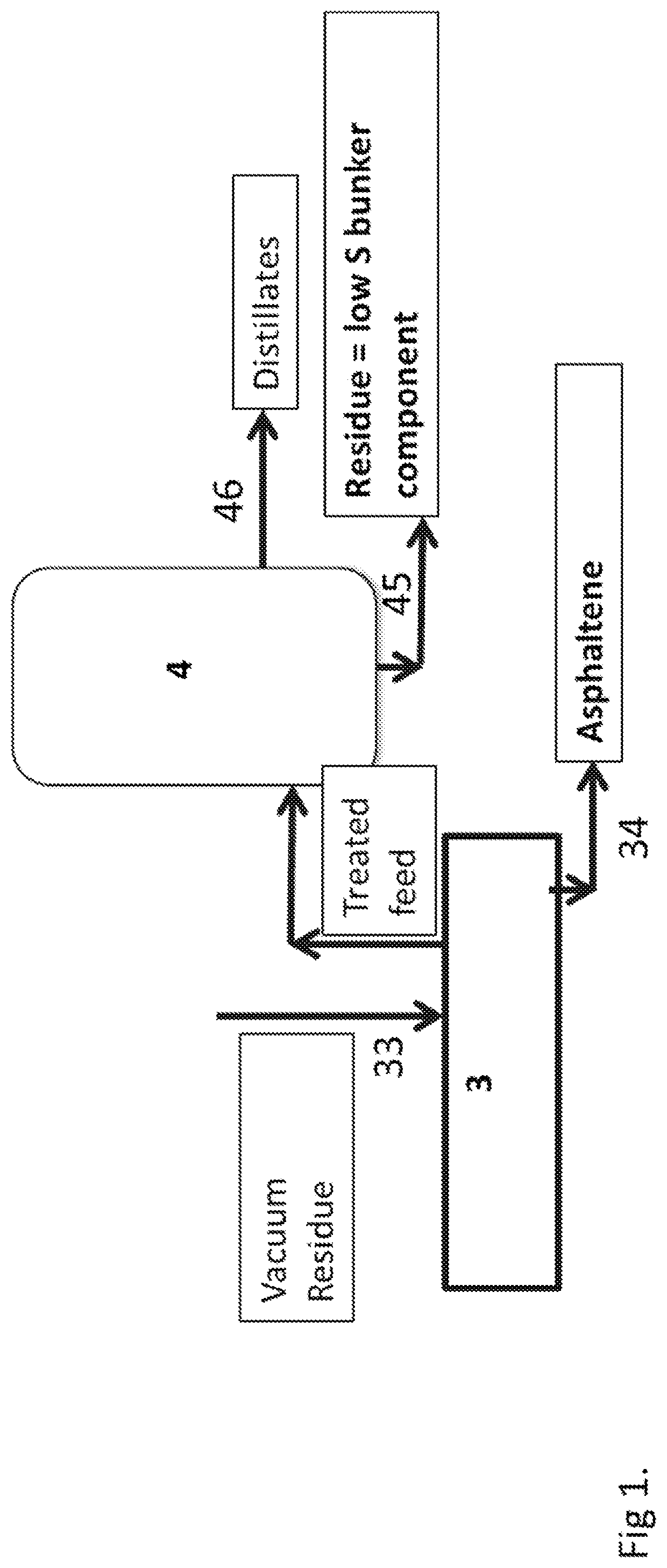

Low sulfur fuel oil bunker composition and process for producing the same

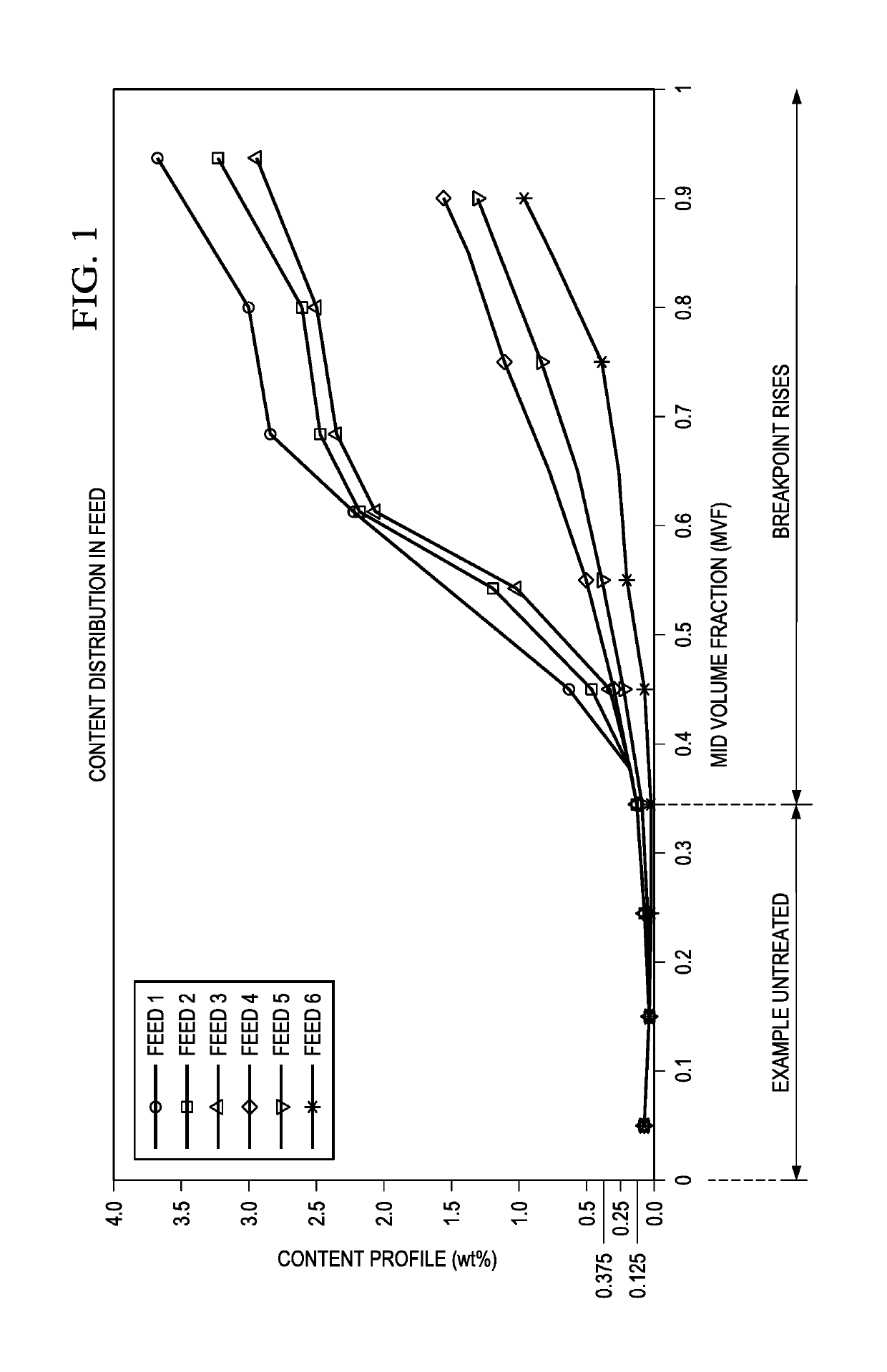

ActiveUS20200277533A1Value productAvoid the needLiquid carbonaceous fuelsHydrocarbon oil crackingEnvironmental engineeringMarine fuel

The present disclosure relates to marine fuel compositions having low sulfur content and processes for making such compositions.

Owner:NESTE OIL OY

Process for conversion of feedstocks obtained from renewable sources based on marine fuels

InactiveUS20140291200A1Low viscositySpecific viscosityBiofuelsLiquid carbonaceous fuelsHydrogenFixed bed

The invention relates to a process for the production of diesel fuel bases comprising a sulfur content that is less than 100 ppm, starting from a feedstock that is obtained from a renewable source, comprising the following stages:a) A stage for bringing the feedstock into contact with a fixed-bed hydrotreatment catalyst for producing an effluent that comprises a gaseous fraction comprising hydrogen and a hydrocarbon-based liquid fraction,d) A stage for bringing into contact at least one portion of the hydrocarbon-based liquid fraction in the presence of a selective hydroisomerization catalyst in a fixed bed,e) A stage for separating the effluent that is obtained from stage d) into a gaseous fraction that comprises hydrogen and at least one diesel-fuel-based fraction.

Owner:INST FR DU PETROLE

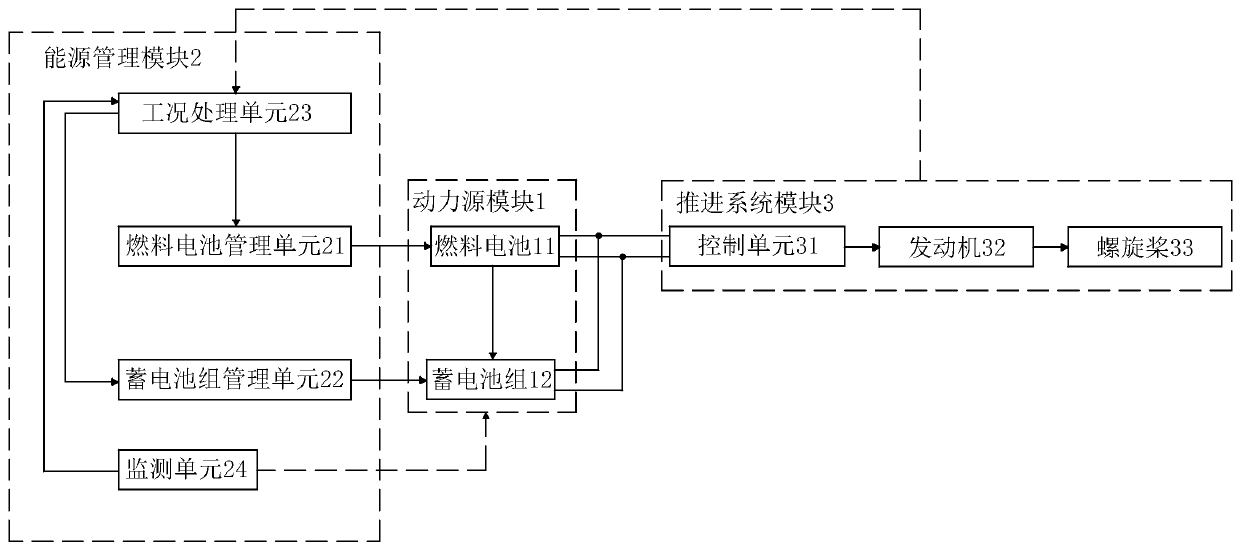

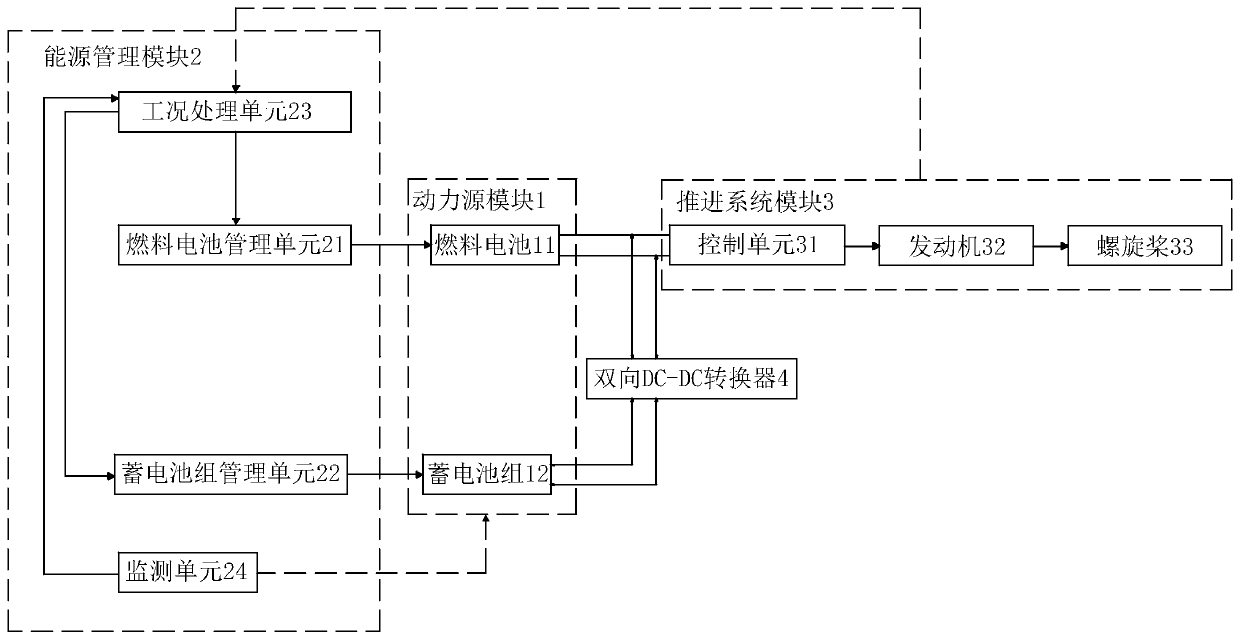

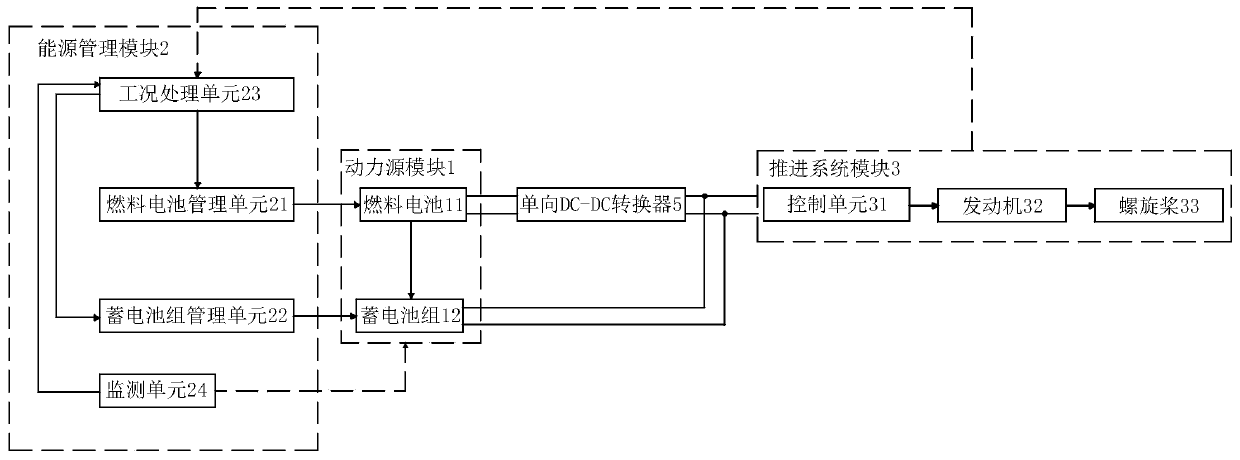

Marine fuel cell hybrid propulsion system and energy control method

InactiveCN110758708AImprove utilizationNo pollution in the processPower plants using propulsion unit combinationsPower plants using fuel cellsFuel cellsMarine engineering

The invention discloses a marine fuel cell hybrid propulsion system and an energy control method. A fuel cell and a storage battery pack jointly serve as a power source of the propulsion system, and an energy management module, the hybrid power source and a propulsion system module are connected to form the hybrid propulsion system. In the navigation process of a ship, when the power required by the ship is in the optimal power interval of the fuel cell, the fuel cell supplies power to the propulsion system module; when the power required by the ship is larger than the optimal power interval of the fuel cell, the fuel cell and the storage battery pack jointly supply power to the propulsion system module; and when the fuel cell fails or raw materials are insufficient, the storage battery pack supplies emergency power to the ship. According to the marine fuel cell hybrid propulsion system and the energy control method, pollution-free and zero emission in a real sense can be realized, andenergy utilization is optimized.

Owner:ZHEJIANG OCEAN UNIV

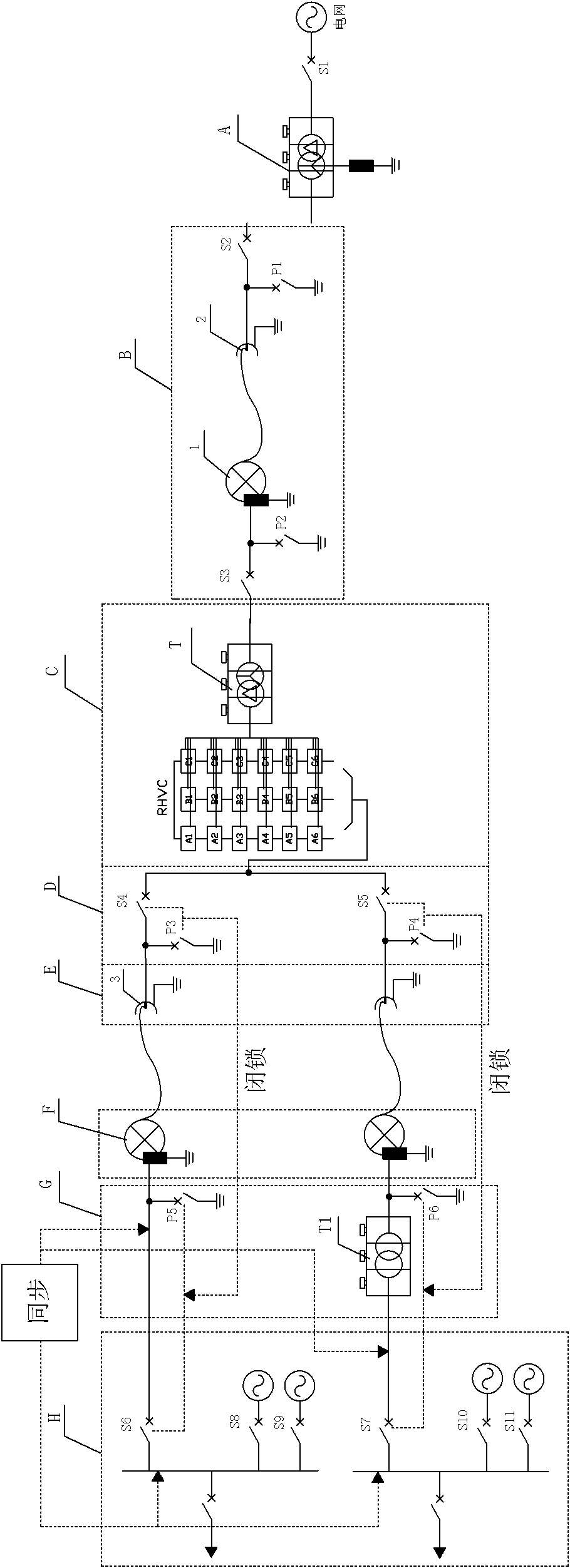

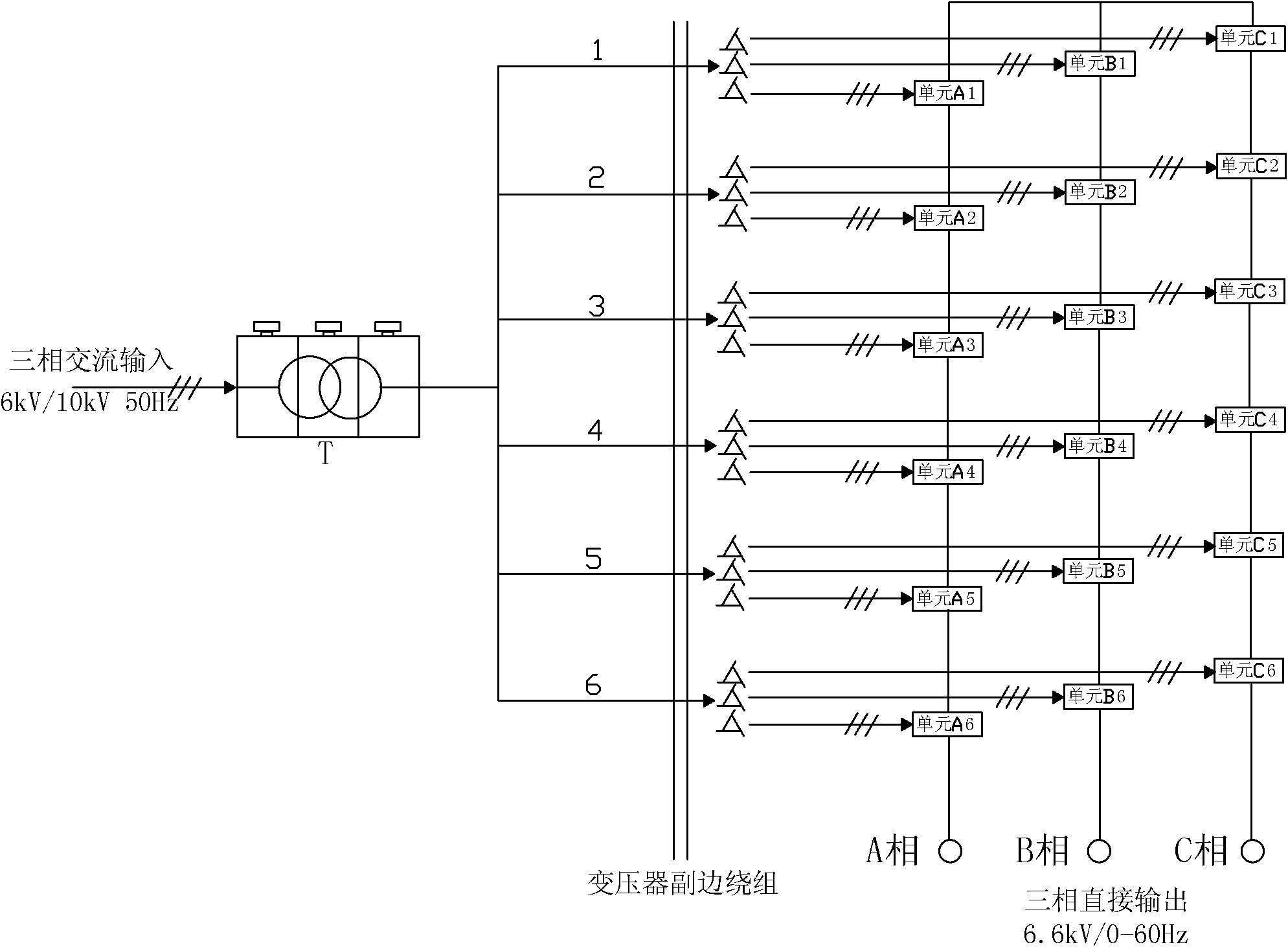

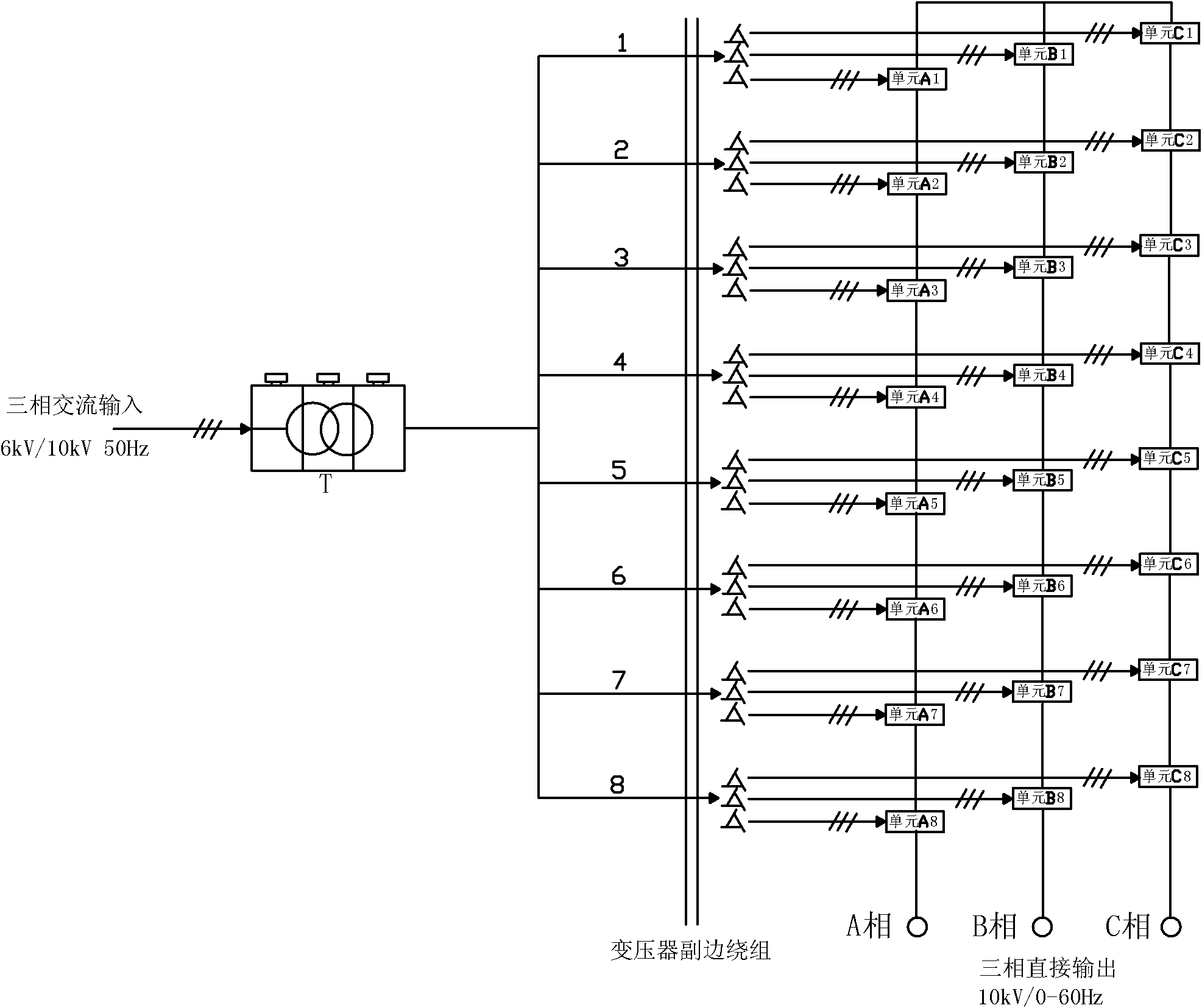

Shore-based variable frequency power supply system

ActiveCN102130455ARealize stable voltage and frequency outputNo harmonic interference effectPropulsion based emission reductionAuxillariesLow voltageEngineering

The invention relates to a shore-based variable frequency power supply system, which comprises a variable frequency power supply, a port high voltage transformer substation, and a marine power system, wherein the input end of the variable frequency power supply is connected with the port high voltage transformer substation; the output end of the variable frequency power supply is connected with the marine power system; and the power supply system can continuously output three-phase alternating current with a voltage adjustment range of 0-6.6 kV or 0-10 kV and a frequency adjustment range of 0-60 Hz. The output side of the variable frequency power supply is connected with a distribution line via a cable drum, the output high voltage directly distributes power for the marine power system via the distribution line, and the output low voltage passes through a step down transformer and distributes power for the marine power system. The shore-based variable frequency power supply system disclosed by the invention has the advantages that: the power used by the power supply system is derived from the port high voltage transformer substation, so environmental pollution and energy consumption caused by taking a marine fuel generator unit as a power source are greatly reduced, and a high-quality and high-reliability power supply is provided for anchor.

Owner:WOLONG ELECTRIC GRP CO LTD +1

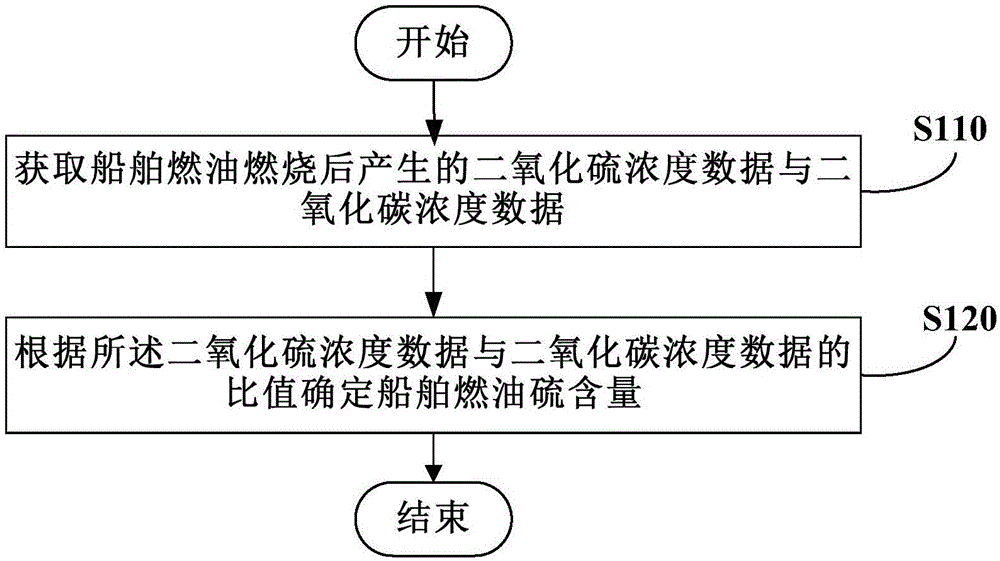

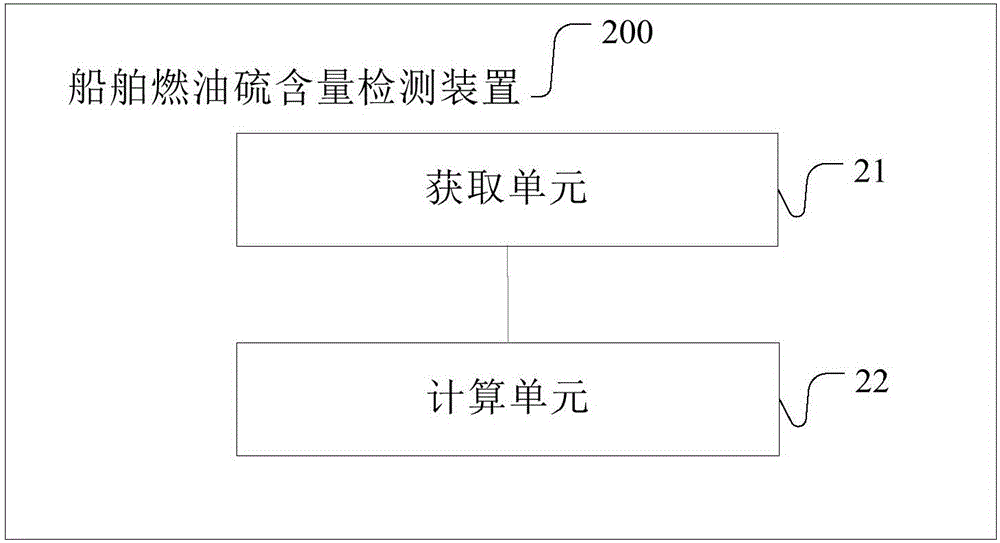

Method and device for detecting content of sulfur in marine fuel oil and equipment

InactiveCN106290804AThe measurement point is not demandingImprove Law Enforcement EfficiencyMaterial testing goodsFast measurementMeasurement point

The invention discloses a method and a device for detecting the content of sulfur in marine fuel oil and equipment. The method comprises the following steps of acquiring sulfur dioxide concentration data and carbon dioxide concentration data generated after burning the marine fuel oil; determining the content of the sulfur in the marine fuel oil according to a ratio of the sulfur dioxide concentration data to the carbon dioxide concentration data. The ratio, measured by the scheme, of the content of sulfur dioxide to the content of carbon dioxide is a relative value and is not influenced by air dilution, so that the requirement on flue gas measuring points is not high; for the measurement of the content of the sulfur in the marine fuel oil, other physicochemical properties of fuel oil do not need to be learned in advance, and parameters of a working state of a ship engine do not need to be learned either, therefore the content of the sulfur in the marine fuel oil is determined according to the ratio of the sulfur dioxide concentration data to the carbon dioxide concentration data; whether the content of the sulfur in the marine fuel oil is overproof is quickly measured under the condition of not making contact with a ship, a preliminary screening result is provided for further on-ship detection, and the law enforcement effectiveness is greatly improved.

Owner:QINGDAO ACAD FOR OPTO ELECTRONICS ENG

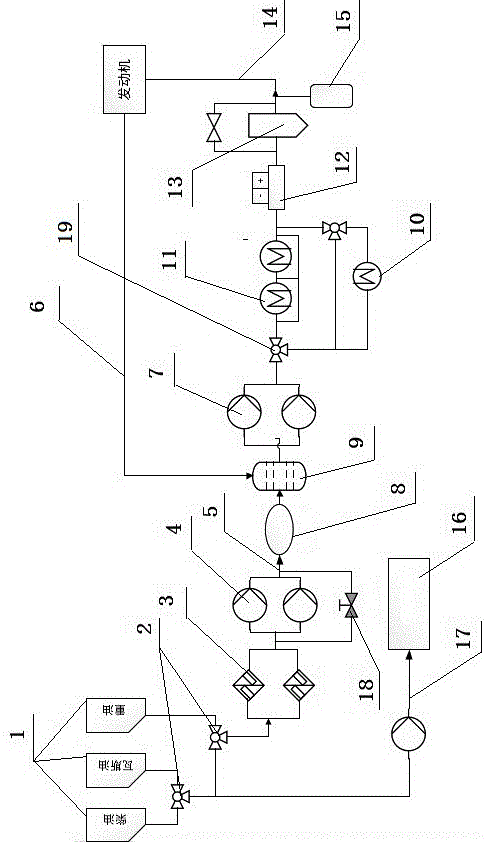

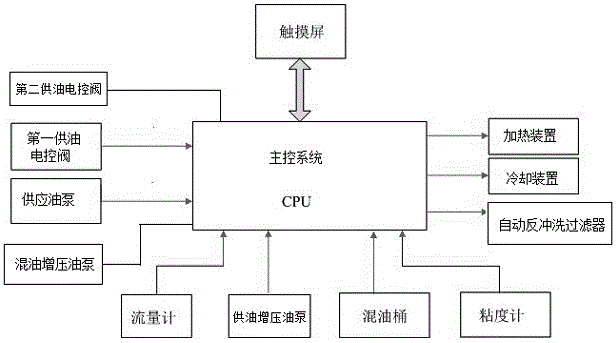

Marine fuel oil supply device and method

InactiveCN106194525ARealize free switchingFree switching supportElectrical controlInternal combustion piston enginesControl systemElectric control

A marine fuel oil supply device comprises an oil mixing barrel, an oil cabinet and a master control system. An oil mixing pipeline is arranged between the oil mixing barrel and the oil cabinet. An oil supply pipeline is arranged between the oil mixing barrel and an engine, and the oil mixing pipeline is provided with a first oil supply electric control valve, a filter, a supply oil pump and a flow meter. The oil supply pipeline is provided with an oil supply pressurizing oil pump, a second oil supply electric control valve and a viscometer. A heating device and a cooling device are further connected between the second oil supply electric control valve and the viscometer in parallel. The master control system comprises a CPU. The oil mixing barrel, the first oil supply electric control valve, the supply oil pump, the flow meter, the oil supply pressurizing oil pump, the second oil supply electric control valve and the viscometer are connected with the CPU through signal lines. The invention further provides a marine fuel oil supply method. By means of the marine fuel oil supply device and method, heavy oil or diesel oil or gas oil is provided for a power generator of a ship, the fuel oil amount, pressure and viscosity can be adjusted according to needs, and the marine fuel oil supply device and method have the beneficial effects that the fuel oil quality is improved, the fuel oil efficiency is improved, the fuel oil cost is reduced, and the engine is better protected.

Owner:中船重工信息科技有限公司

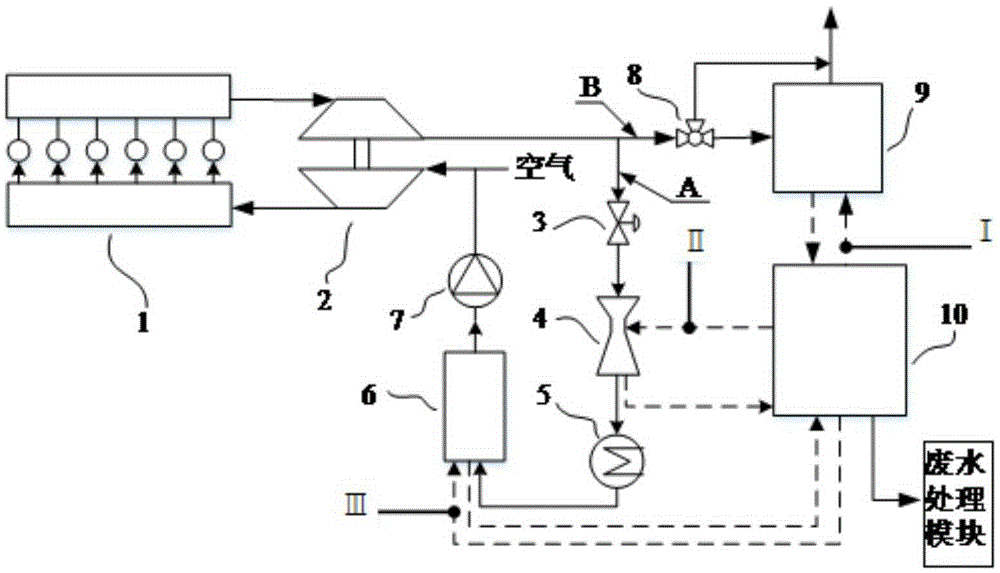

Combined desulphurization and denitration device and method of marine diesel engine

InactiveCN105289241AEfficient removalAvoid high pressureUsing liquid separation agentAtmospheric airFresh air

The invention discloses a combined desulphurization and denitration device and method of a marine diesel engine. The exhaust gas of the diesel engine is divided into two paths, wherein one path enters a denitration channel A and is recirculated to an air cylinder to participate in burning so as to lower the NOx emission of an engine; the other path enters a desulphurization channel B and is discharged to ambient atmosphere after being subjected to desulphurization processing. In the denitration channel A, the exhaust gas flows through components including a one-way stop valve, a Venturi scrubber, a cooler, a cleaning device, a blower and the like, particles and SO2 in the exhaust gas are removed through processing processes including pre-washing, cooling, washing, pressurizing and the like, and finally, the exhaust gas is mixed with fresh air from the intake channel of the diesel engine to enter the air cylinder and participate in burning; in the desulphurization channel B, the exhaust gas is discharged into the environment atmosphere after being subjected to particle removal by washing tower desulphurization. The Tier III requirement of IMO (International Maritime Organization) on marine fuel sulphur content and NOx emission in the exhaust gas can be met, and meanwhile, the corrosion and the abrasion on an engine compressor, a cylinder liner and the like by the exhaust gas can be lowered.

Owner:HARBIN ENG UNIV

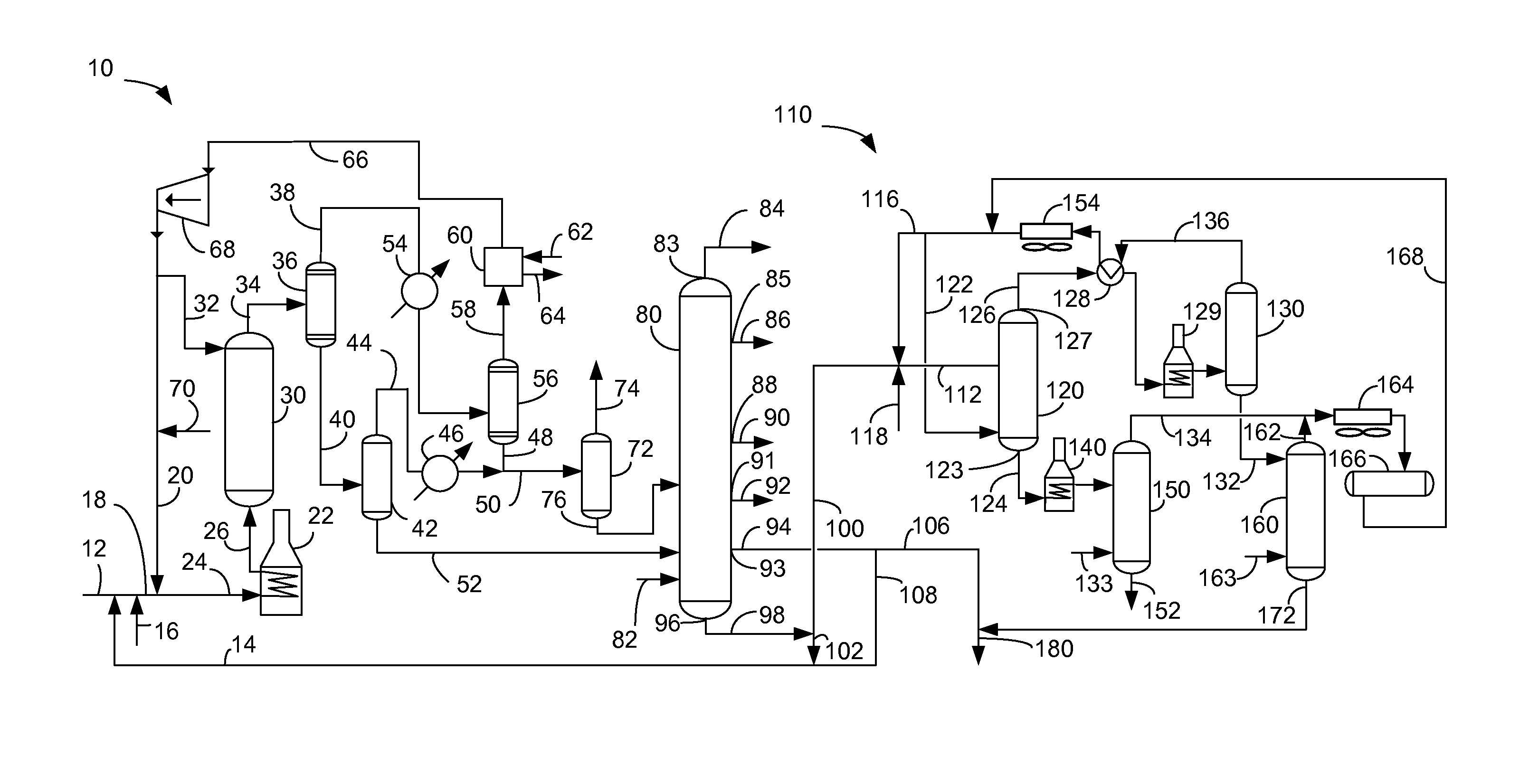

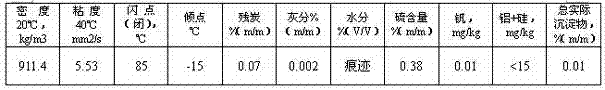

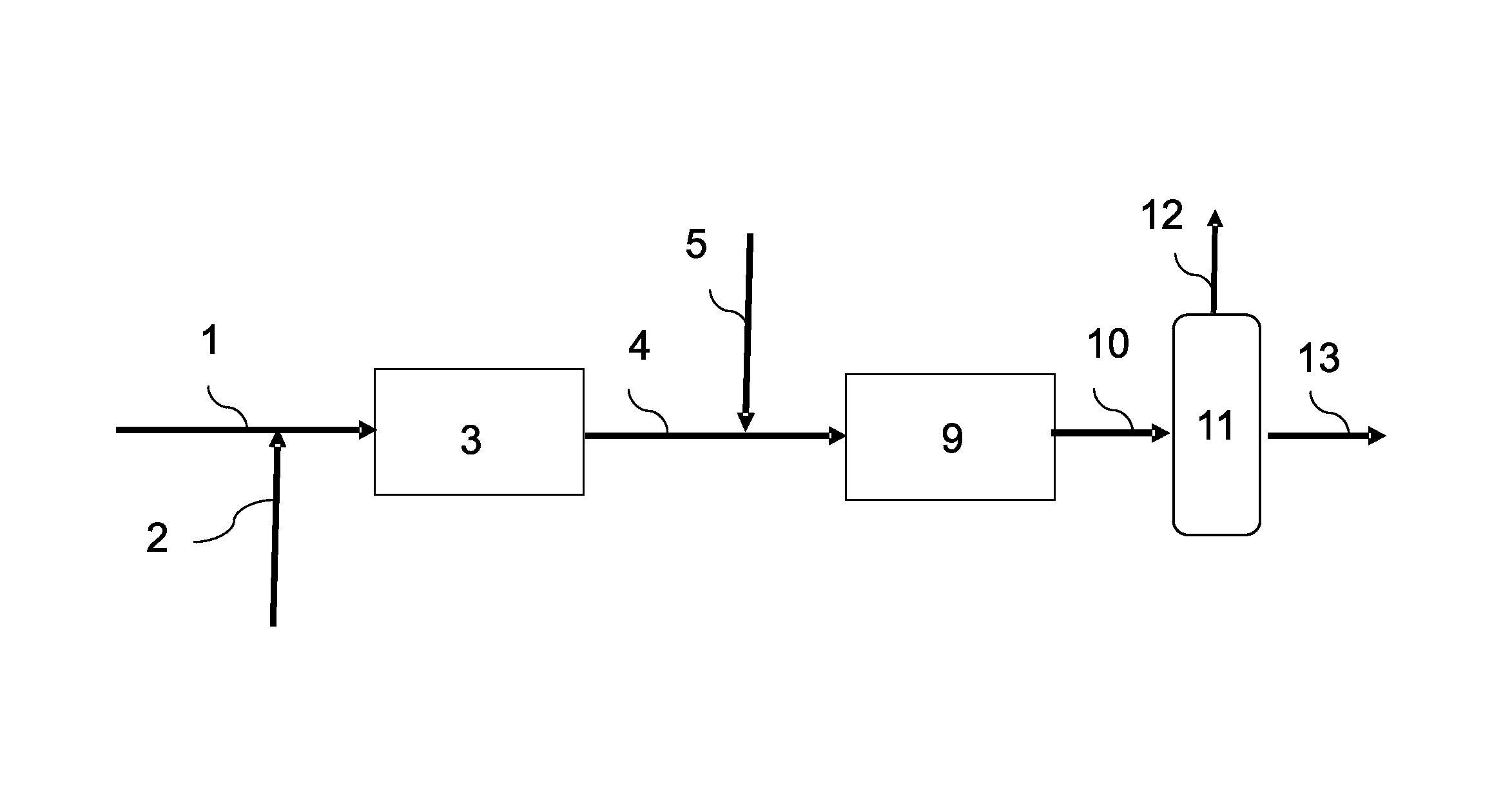

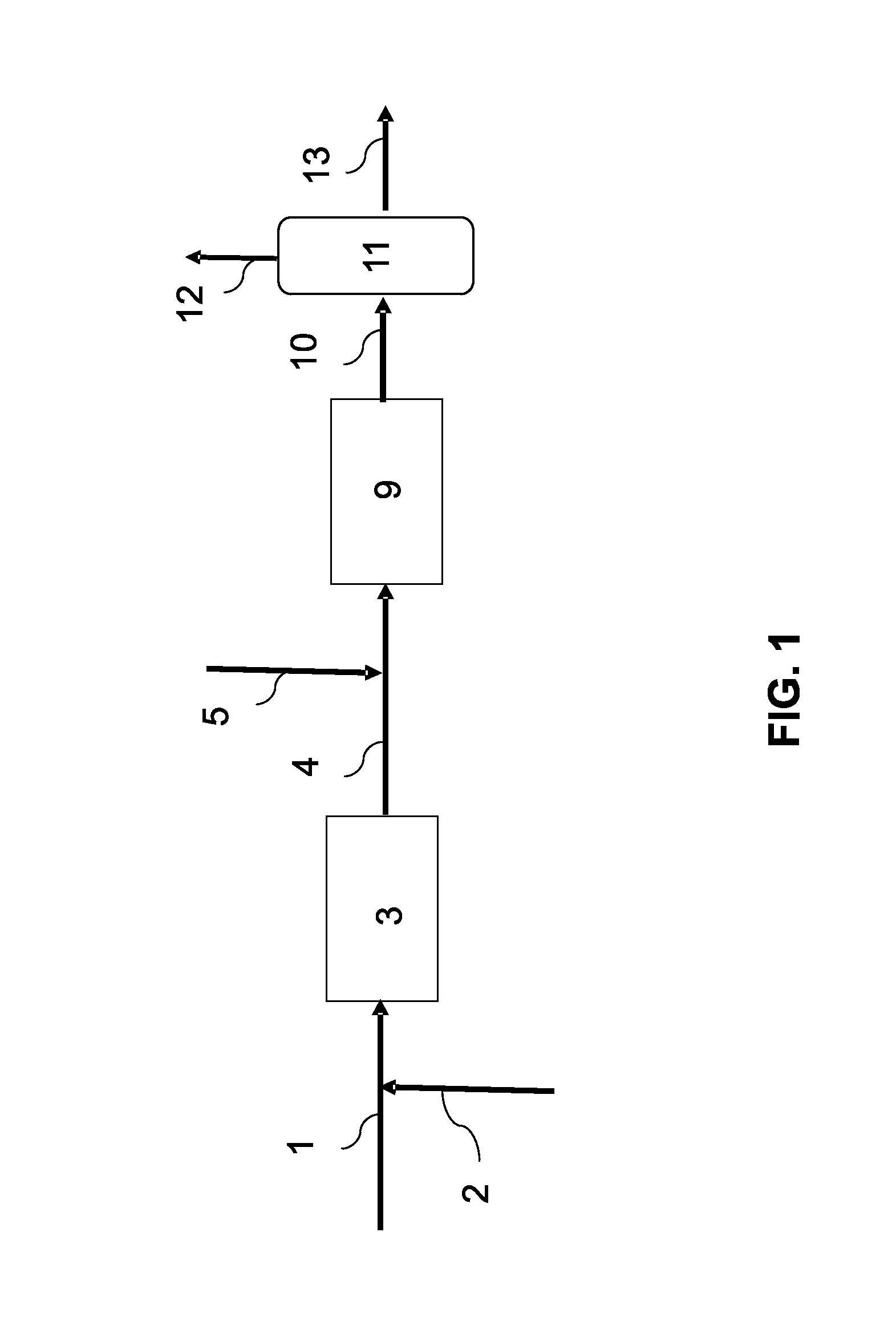

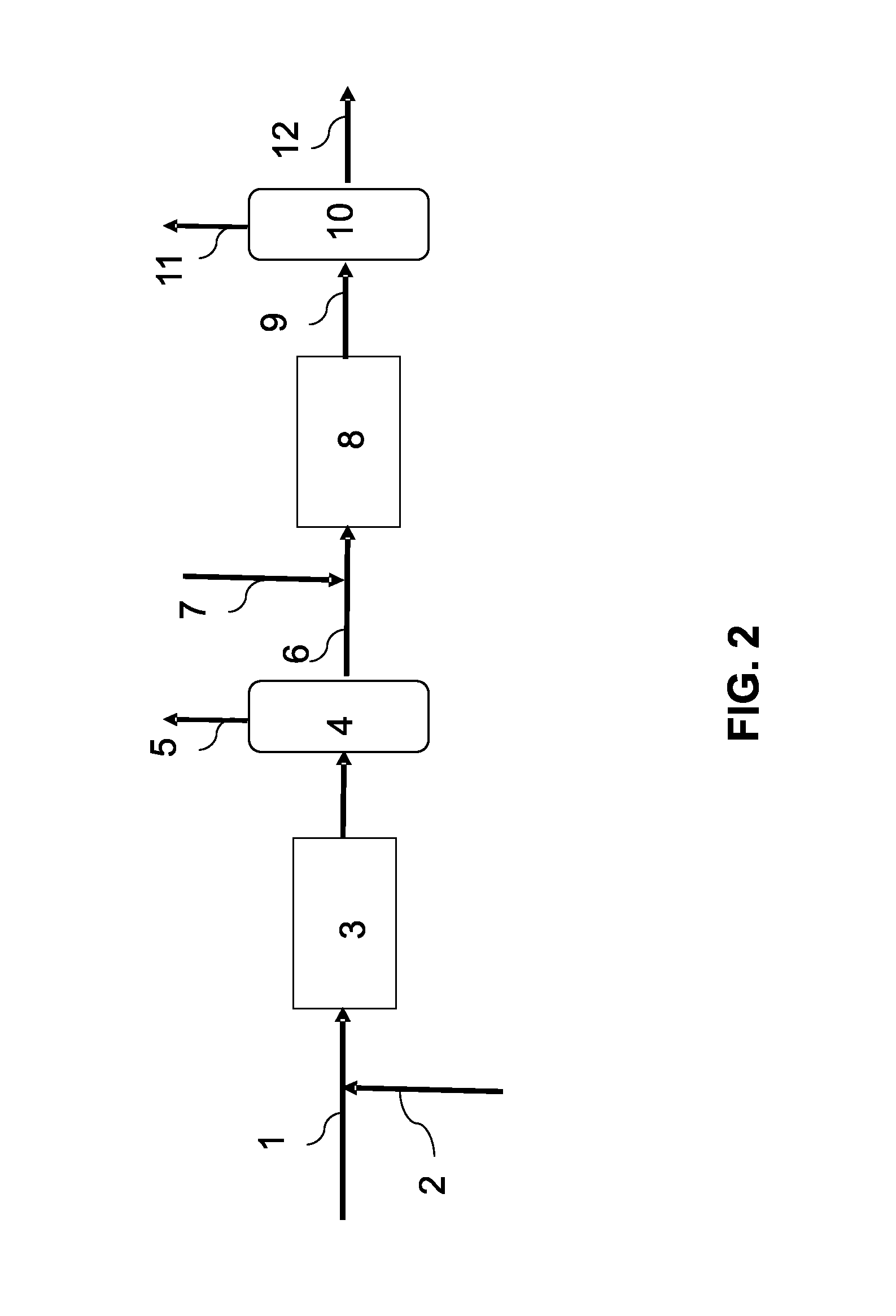

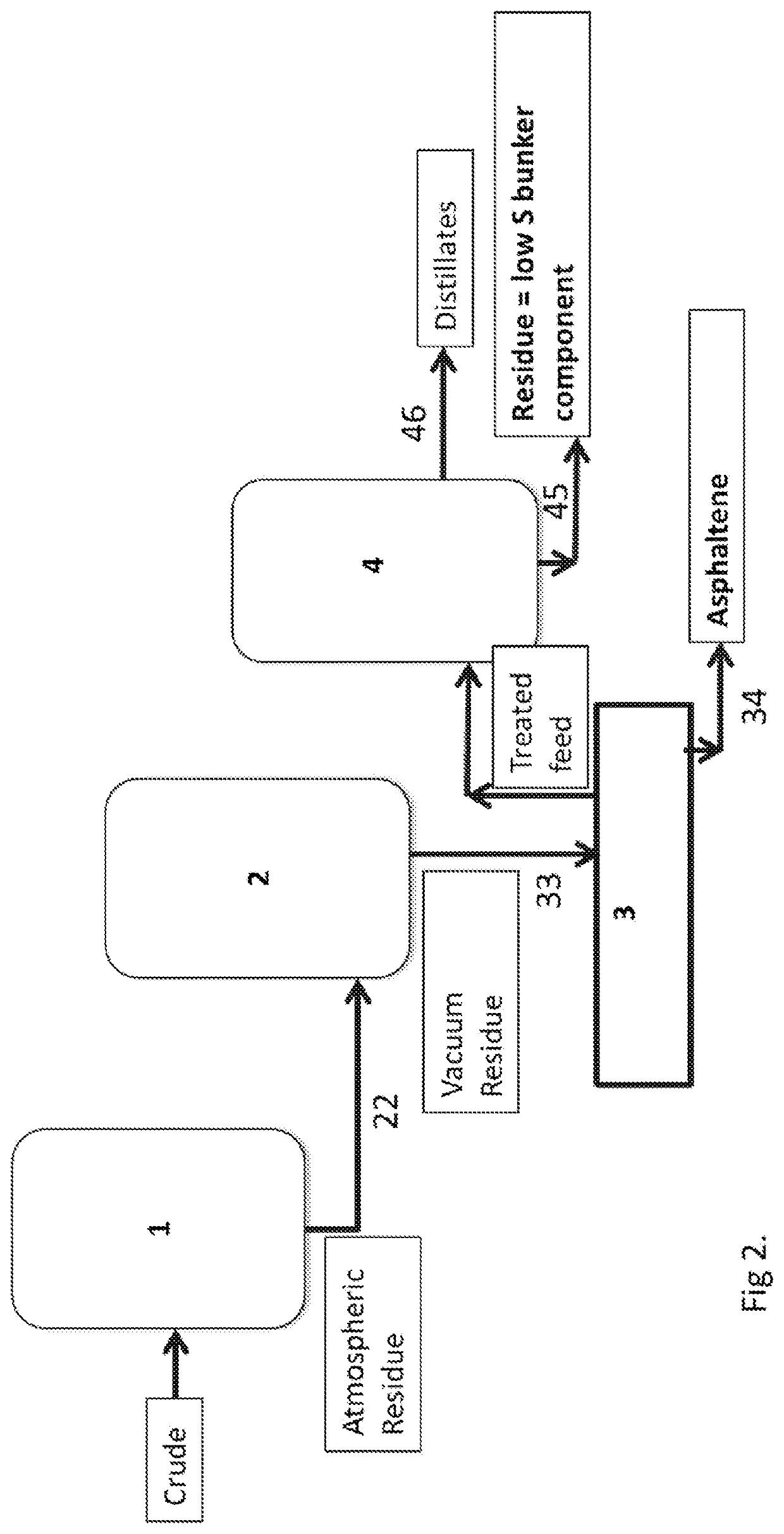

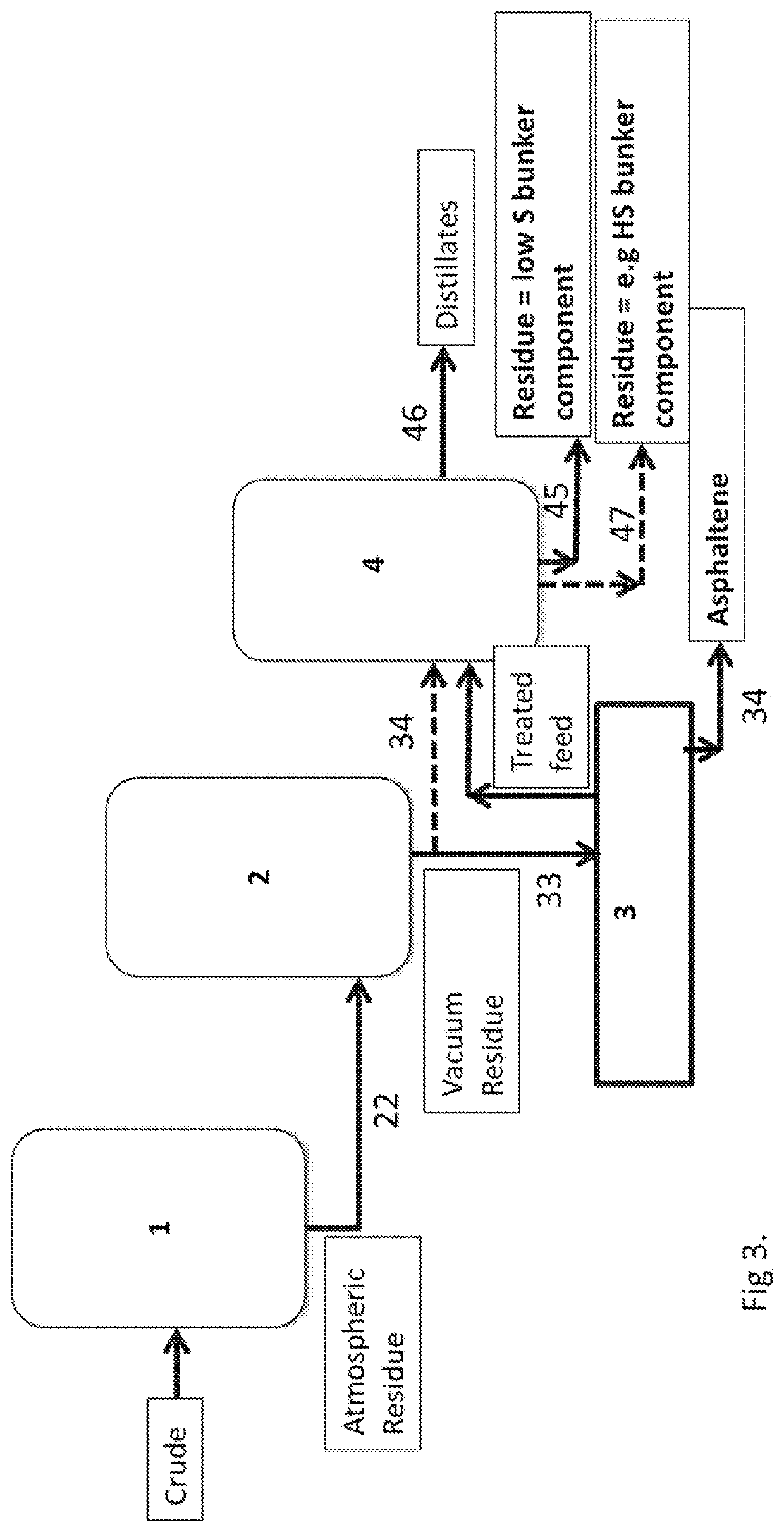

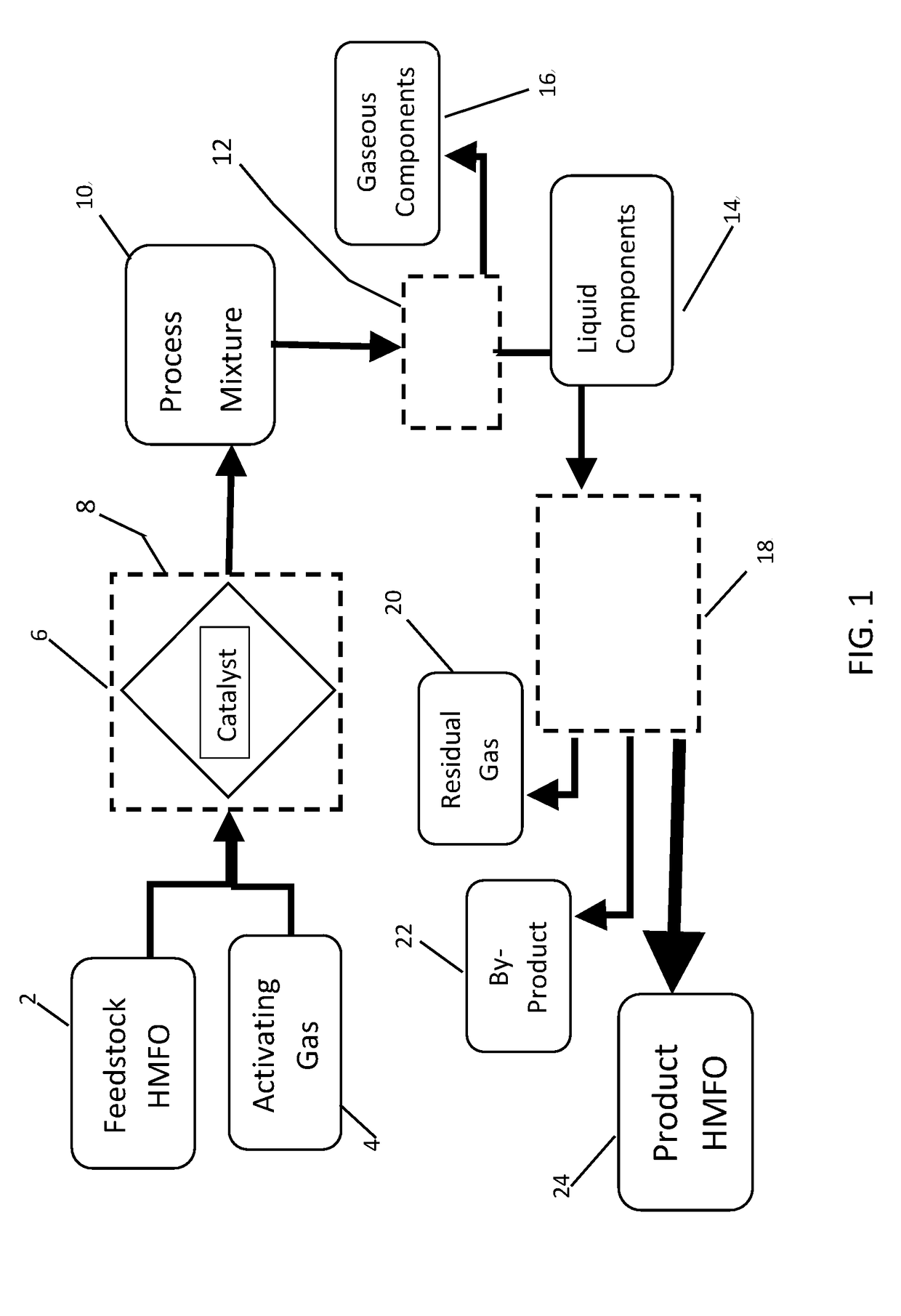

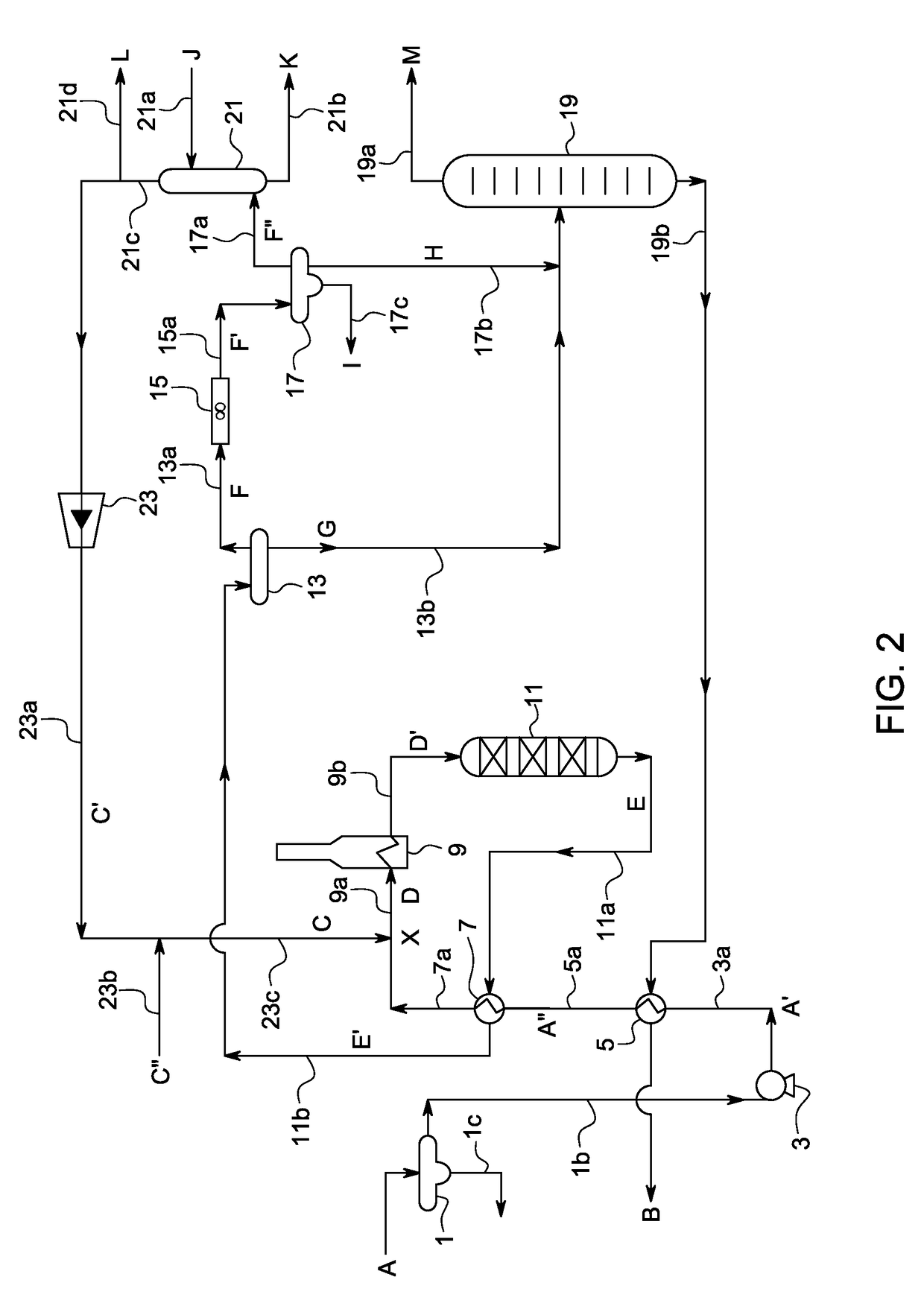

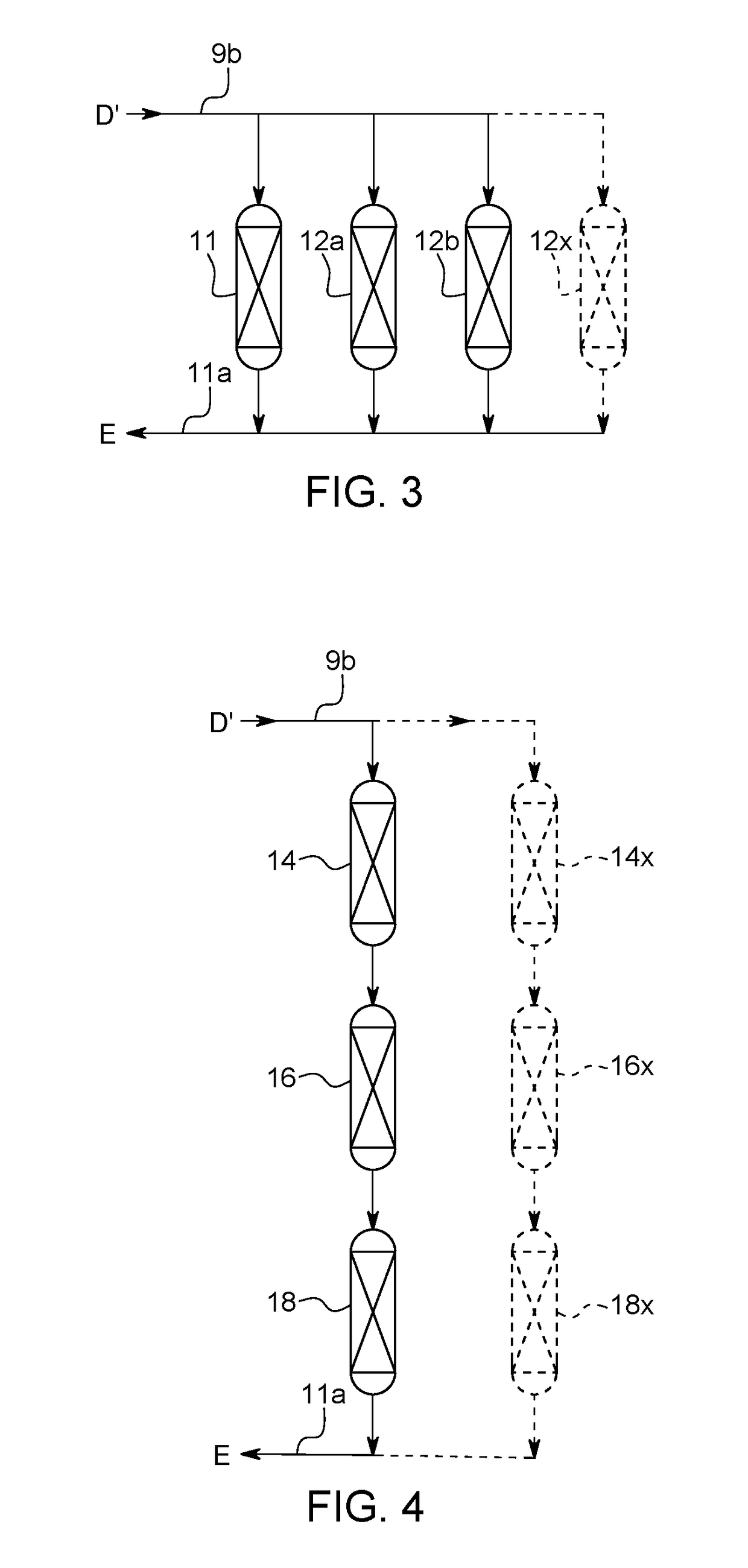

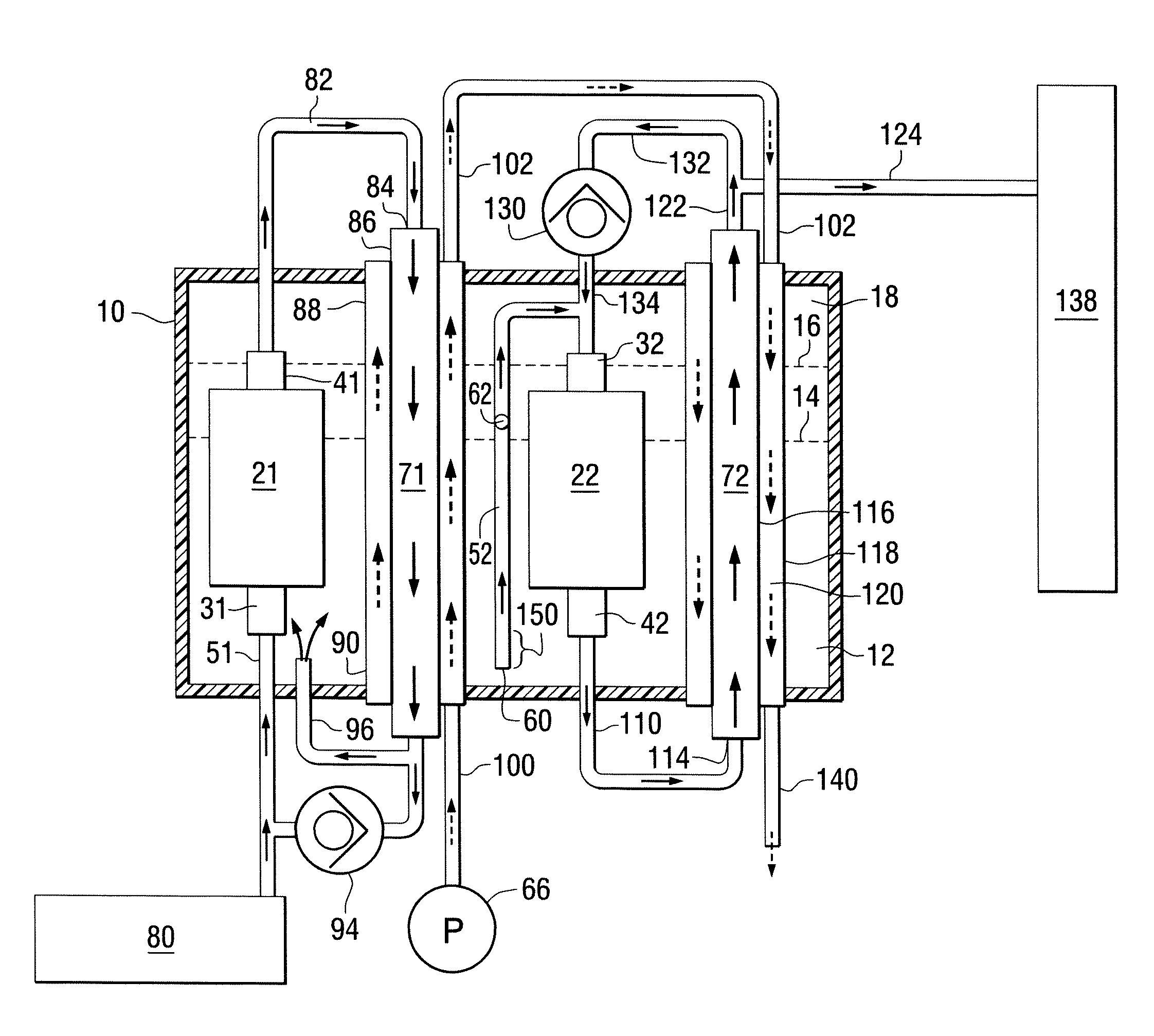

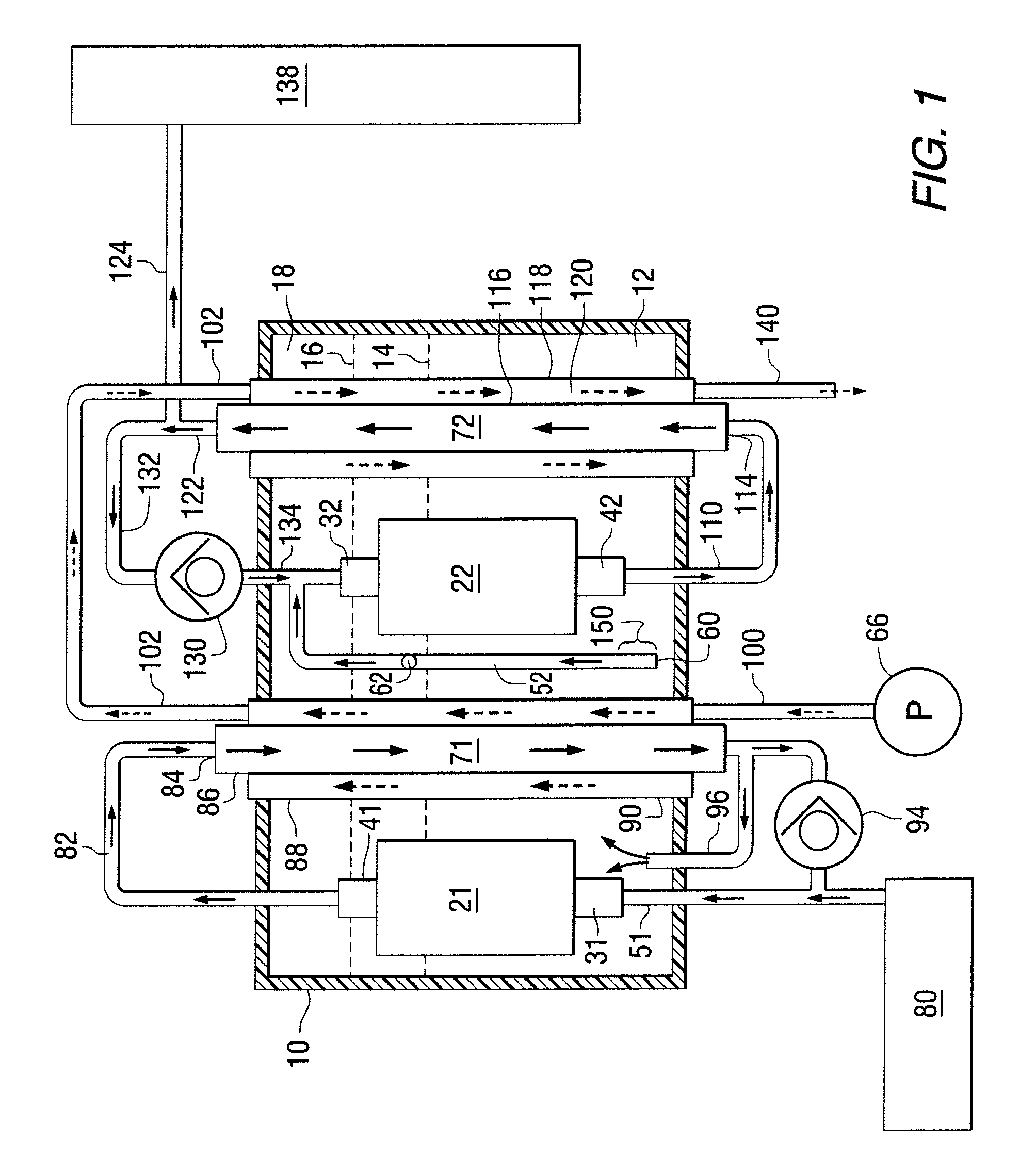

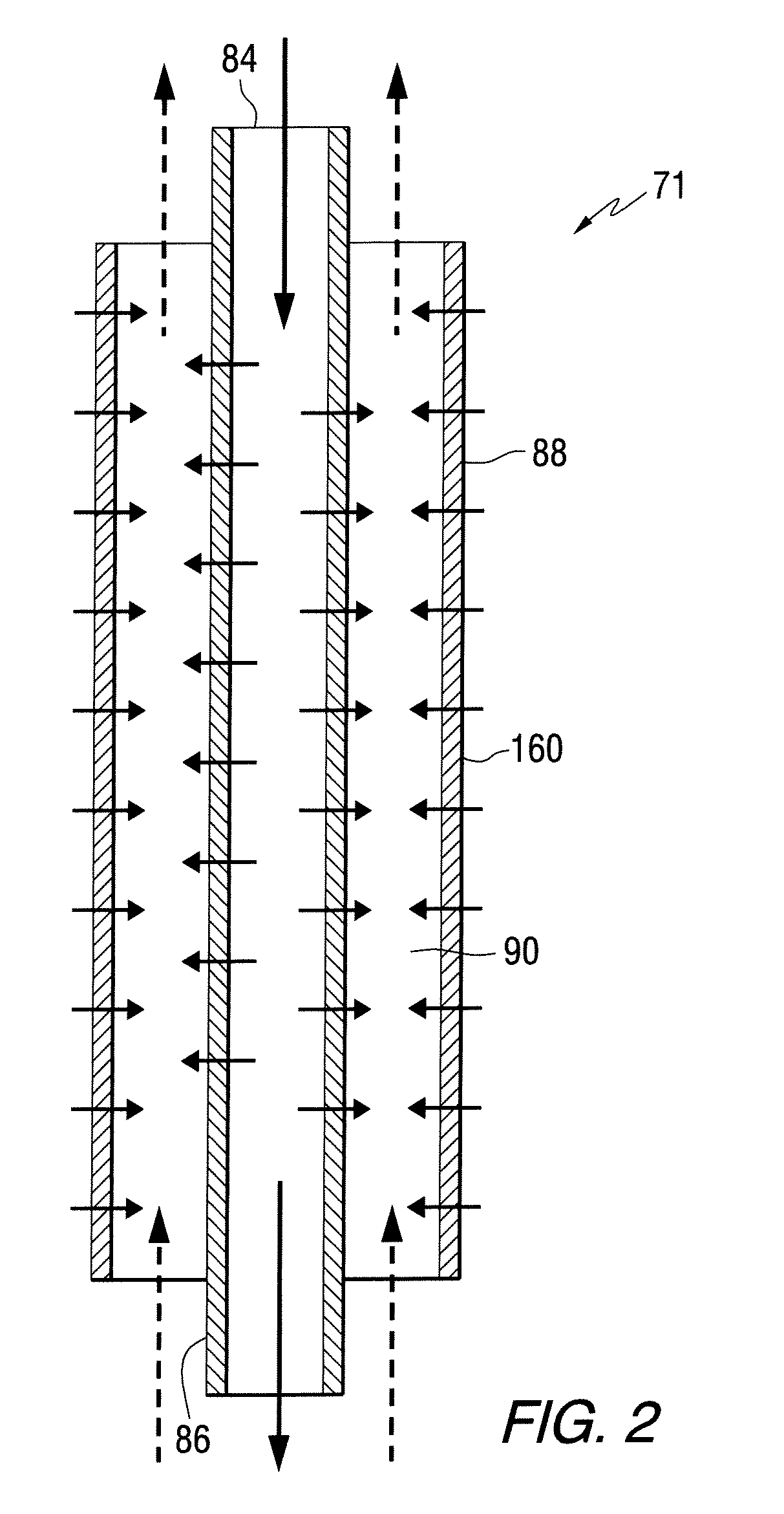

Multi-Stage Process and Device for Distributive Production of a Low Sulfur Heavy Marine Fuel Oil

InactiveUS20190002772A1Reduce environmental pollutionMinimize changesHydrocarbon distillationDispersed particle separationModularityProcess engineering

A multi-stage process for the distributive production of an ISO8217 compliant Product Heavy Marine Fuel Oil from ISO 8217 compliant Feedstock Heavy Marine Fuel Oil involving a core desulfurizing process that is distributed in a Reaction System composed of multiple reaction vessels. The Product Heavy Marine Fuel Oil has a sulfur level has a maximum sulfur content (ISO 14596 or ISO 8754) between the range of 0.05 mass % to 1.0 mass. A process plant for conducting the process for conducting the distributive process is disclosed that can utilize a modular reactor vessel contained within a frame work based on ISO 40 foot or ISO 20 foot container dimensions.

Owner:MAGEMA TECH LLC

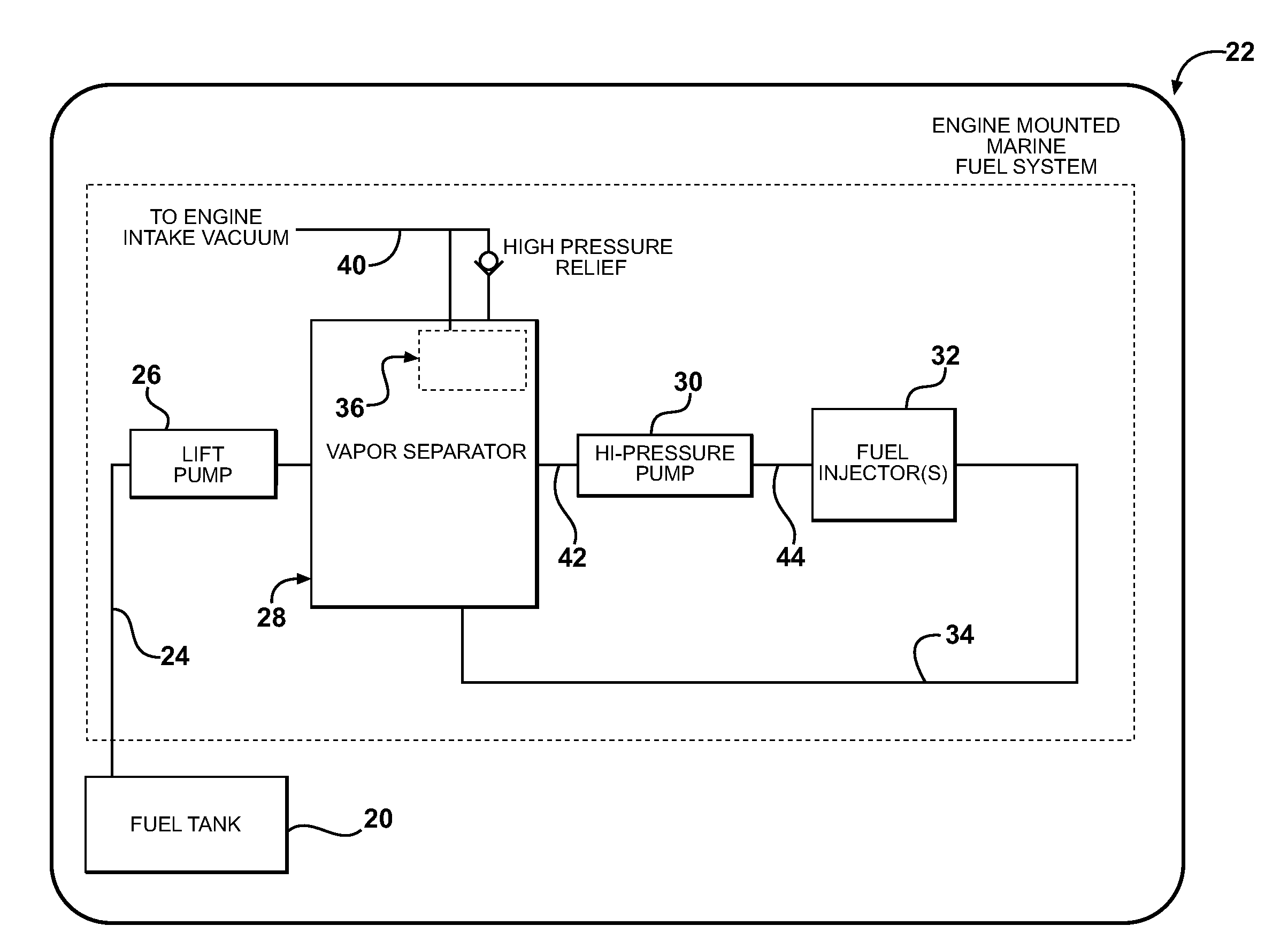

Marine fuel system with an ullage control device

A marine engine fuel system provides a low pressure lift pump to draw fuel from a fuel tank and cause the fuel to flow into a reservoir and a high pressure fuel pump which draws fuel from the reservoir and provides it to a fuel rail. An inlet conduit of the high pressure fuel pump is provided with a primary and a secondary opening. The secondary opening can be an orifice formed through a wall of the inlet conduit. The secondary opening is positioned, relative to the primary opening, at a location which assists in controlling the fuel level within the reservoir and the quantity of gaseous fuel contained within an ullage above the liquid pool of fuel.

Owner:BRUNSWICK CORPORATION

Marine fuel oil

InactiveCN108192674AMeet the working characteristicsReduce pollutionLiquid carbonaceous fuelsWaxInternational standard

The invention discloses marine fuel oil. The fuel oil comprises the following components in percentage by weight: 45 to 68.0 percent of normal and reduced pressure slag oil, 15 to 30 percent of wax oil, 10 to 13 percent of diesel oil and 7 to 12 percent of oil slurry. The marine fuel oil provided by the invention accords with the work characteristic of a dredging engineering ship, various technical indexes meet the related requirements of national standard and international standard, environmental pollution caused by waste gas discharged by a ship is reduced and a series of problems occurringin the process of using the fuel oil by the dredging engineering ship are avoided.

Owner:浙江美润科技有限公司

Fuel level sensor for marine fuel vapor separator external to unit

ActiveUS20120186562A1Less susceptible to wearLess susceptible to leakageOperating means/releasing devices for valvesNon-fuel substance addition to fuelLevel sensorMarine fuel

A fuel vapor separator assembly including a housing having an open interior and a float disposed therein. At least one magnet is disposed on the float, and a sensor assembly which is responsive to magnetic fields is disposed externally of the housing. The sensor assembly senses the position of the float to determine whether vapor is present in the fuel vapor separator. If the sensor assembly determines that vapor is present in the fuel vapor separator, then it generates a signal, which a controller receives and activates a vapor vent valve to discharge the vapor and / or activates a fuel lift pump to pump additional fuel into the fuel vapor separator. The sensor assembly could be, for example, a Hall effect sensor or a reed-type sensor.

Owner:CARTER FUEL SYST

Low-sulfur marine fuel and preparation method thereof

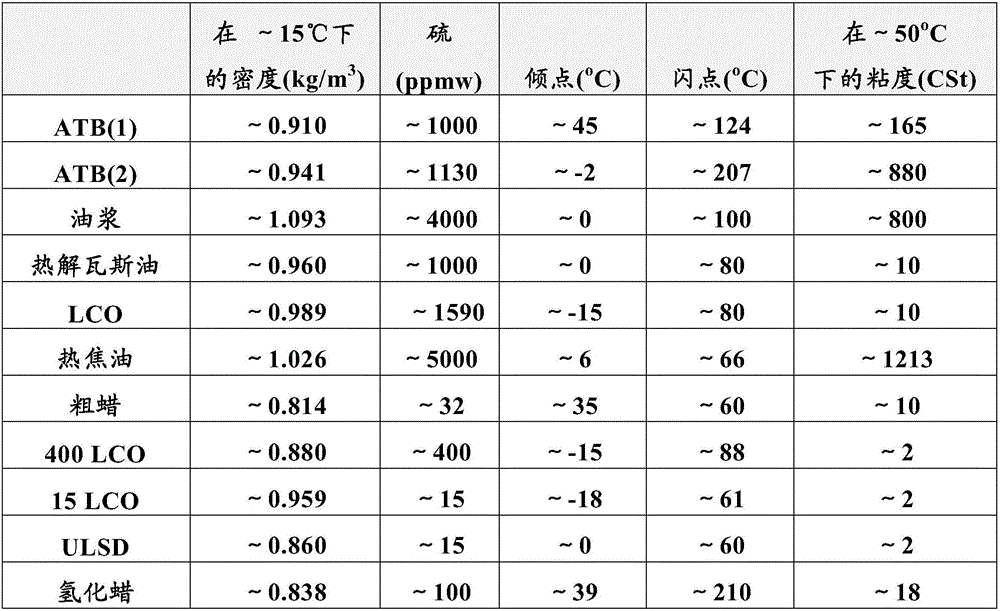

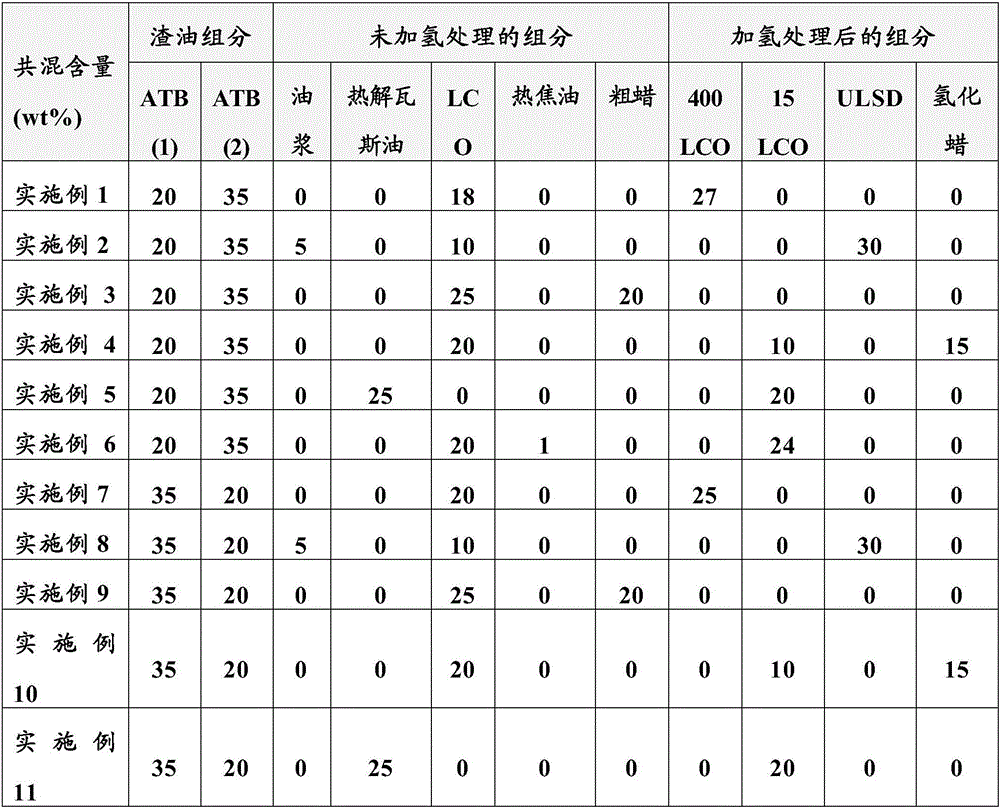

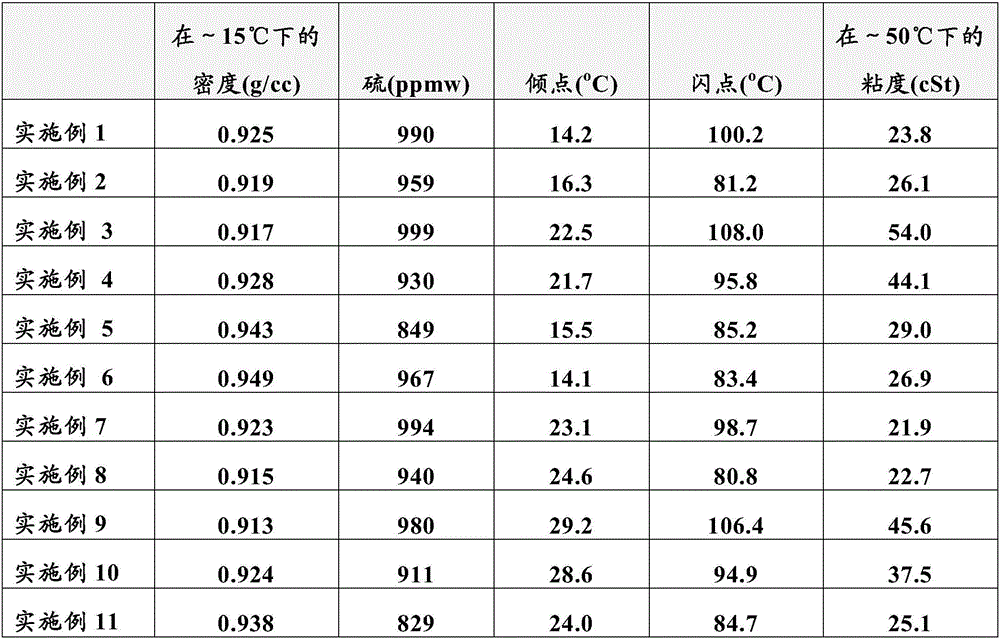

The present invention relates to low sulfur marine fuel compositions and methods for their preparation. The present invention also relates to an uncracked hydrotreated vacuum residue useful in preparing the low sulfur marine fuel composition. In contrast to conventional marine / marine fuel compositions, the low sulfur marine / marine fuel compositions utilize primarily uncracked ingredients including (catalytic feed) hydrotreated vacuum residue. The low sulfur marine / marine fuel composition may also have reduced levels of residual components.

Owner:EXXON RES & ENG CO

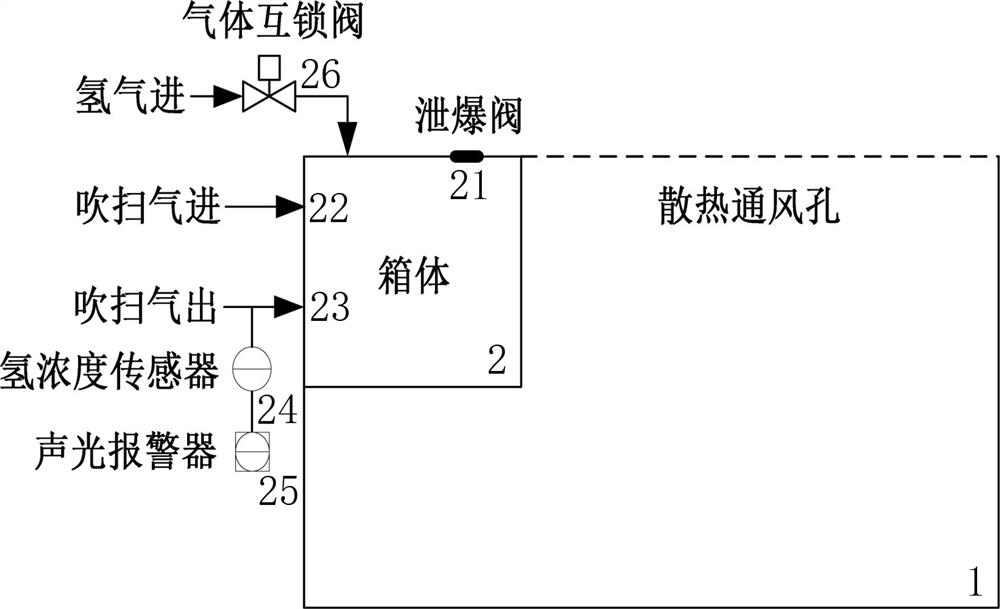

Marine fuel cell power generation module and safe working method thereof

ActiveCN112687923AImprove explosion protectionImprove securityPropulsion based emission reductionPropulsion power plantsFuel cellsProcess engineering

The invention discloses a marine fuel cell power generation module which comprises a cabinet body, a box body, an air unit, a cooling water unit and a controller unit, the box body is composed of a box shell of a closed cavity structure, a fuel cell stack, a hydrogen unit and a purging pipeline, a gas outlet and a gas collecting port of the purging pipeline are evenly distributed in the box shell, purging gas is positive pressure inert gas, the box shell is sequentially provided with an explosion venting valve, a purge gas inlet and a purge gas outlet, the purge gas outlet is provided with a hydrogen concentration sensor and an audible and visual alarm, a gas interlocking valve is arranged at an inlet of the hydrogen unit, and the hydrogen concentration sensor, the audible and visual alarm, the gas interlocking valve and the controller unit are in communication connection. The invention also discloses a safe working method of the marine fuel cell power generation module, by monitoring and alarming the risk degree in the hydrogen leakage process in the box body, the explosion-proof and safety performance of the fuel cell power generation module is improved.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Fuel compositions

Low sulphur marine fuel compositions are provided. Embodiments comprise greater than 50 to 90 wt% of a residual hydrocarbon component, with the remaining 10 to 50 wt% selected from a non-hydroprocessed hydrocarbon component, a hydroprocessed hydrocarbon component, and a combination thereof. Embodiments of the marine fuel composition can have a sulphur content of about 0.1 wt% or less.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Heavy fuel oil asphaltene dispersant

InactiveCN103897755ASettle settlementPrevent subsidenceLiquid carbonaceous fuelsFuel additivesCarbon chainSolvent

The invention relates to a heavy fuel oil asphaltene dispersant. According to the technical scheme, the heavy fuel oil asphaltene dispersant is prepared from the following raw materials in parts by weight: 10-50 parts of ester, 20-60 parts of alkyl benzene sulfonic acid, 5-20 parts of fatty alcohol-polyoxyethylene ether and 10-30 parts of solvent, wherein the ester is one of carboxylic esters of RCOOCH3, R is straight-chain alkyl and the quantity of carbon atoms is 10-16; the alkyl benzene sulfonic acid is one of RSO3H, wherein R is an alkyl carbon chain and the quantity of carbon atoms is 12-18; the general formula of the fatty alcohol-polyoxyethylene ether is RO(CH2CH2O)mH, wherein R is straight-chain alkyl the quantity of carbon atoms is 10-18 and m is 7-11; the solvent is absolute ethyl alcohol. The heavy fuel oil asphaltene dispersant has the beneficial effects that the problem of sedimentation of marine fuel oil asphaltene can be solved, not only can sedimentation of the asphaltene in the fuel oil be prevented, but also the settled asphaltene in the fuel oil can be dispersed; meanwhile, the marine fuel oil asphaltene dispersant provided by the invention has the characteristics of being good in dispersibility, low in cost and simple and convenient to use.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Apparatus for producing hydrocarbon fuel

ActiveUS8133446B2Treatment with hydrotreatment processesChemical/physical/physico-chemical processesCombustionProcess engineering

Slurry hydrocracking a heavy hydrocarbon feed produces a HVGO stream and a pitch stream. At least a portion of the pitch stream is subjected to SDA to prepare a DAO stream low in metals. The DAO is blended with at least a portion of the HVGO stream to provide turbine or marine fuel with acceptable properties for combustion in gas turbines or for marine fuel grades.

Owner:UOP LLC

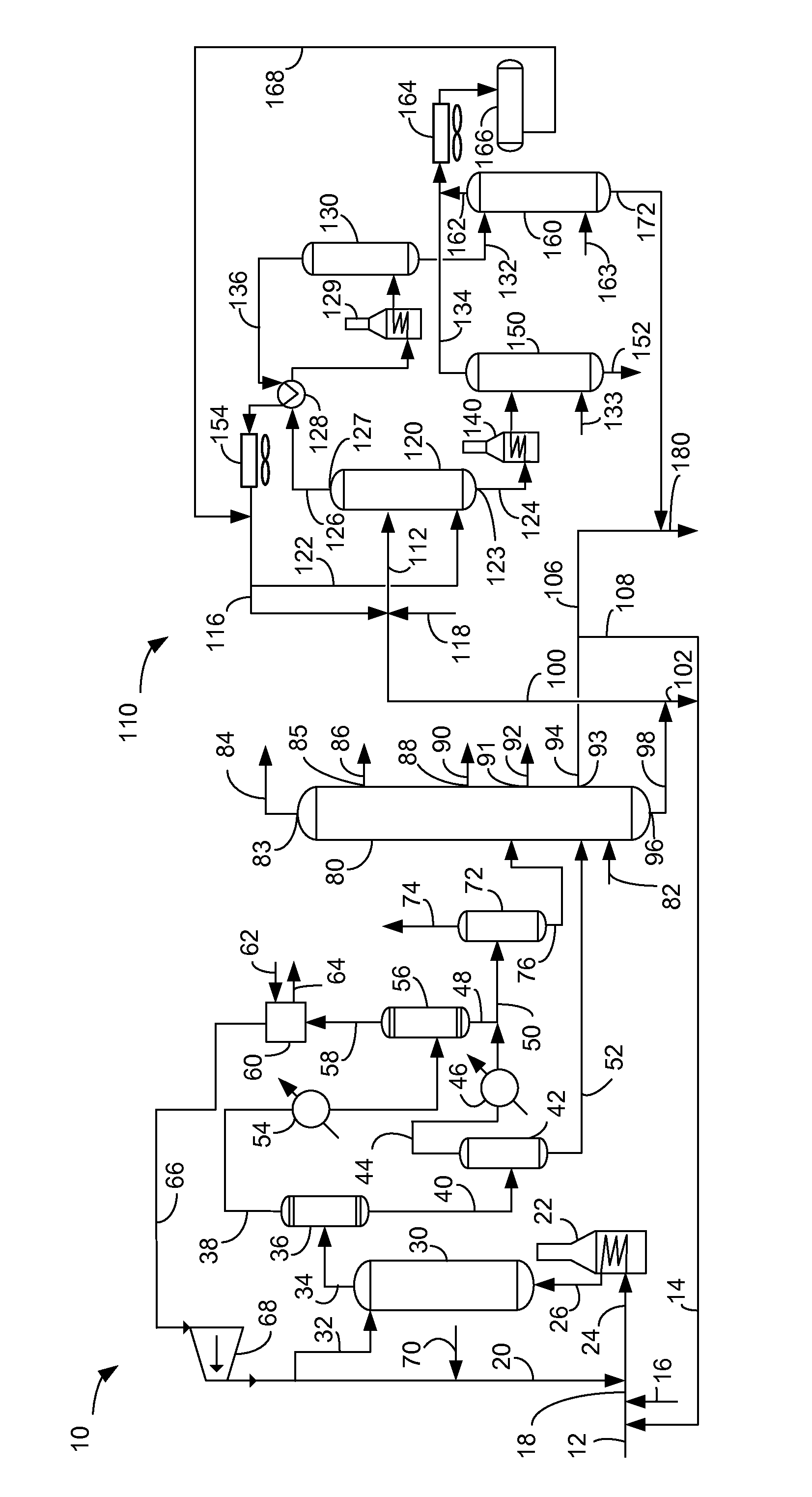

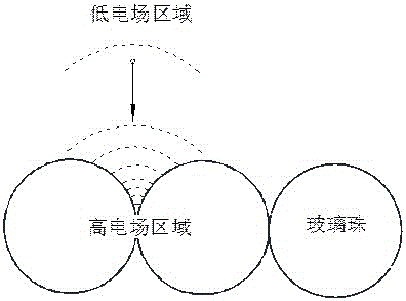

Marine fuel oil and production process and device thereof

InactiveCN106753611AImprove removal efficiencyIncrease the amount of participationLiquid carbonaceous fuelsEnergy based chemical/physical/physico-chemical processesSlurryMarine fuel

The invention discloses marine fuel oil and a production process and device thereof. The marine fuel oil and the production process and device thereof have the advantages that the marine fuel oil is produced by blending FCC slurry, coal tar, catalytic diesel oil, methanol, ethanol, shale oil, vacuum residue and auxiliaries according to a certain proportion, the main indexes of the blended oil meet the quality requirements on 180# marine fuel oil in national standards (GB 17411-2015), the production is performed by using cheap raw materials which are easy to obtain, raw material cost is lowered to the maximum extent, multiple components of the marine fuel oil can replace one another and can be flexibly selected according to market quotations, and the adverse effect caused by raw material price fluctuation can be relieved; the blended oil is purified by a static separation manner, fine solid catalyst particles can be removed, a static separation device is improved, a traditional double-electrode separation manner is abandoned, static separation efficiency is increased effectively, the adding quantity of the relatively-cheap FCC slurry is increased, and raw material cost is reduced; by a three-electrode design, the utilization rate of device internal space is increased.

Owner:OCEAN UNIV OF CHINA

Low-sulfur heavy bunker fuel oil and preparation method of same

Low-sulfur heavy bunker fuel oil and a preparation method of same. The invention belongs to the technical field of heavy fuel oil. The low-sulfur heavy bunker fuel oil comprises, by weight, 40-65 parts of residual oil, 5-15 parts of catalytic oil slurry, 5-20 parts of styrene tar, 5-20 parts of ethylene tar, 5-20 parts of diesel oil, 0.2-1 part of an additive OP-10, and 0.1-0.5 parts of an additive AES. The preparation method includes: successively adding the styrene tar and diesel, the additive OP-10, the additive AES, the residual oil, and the catalytic oil slurry, and stirring the mixture at medium speed, and adding the ethylene tar and performing high-speed stirring to obtain the fuel oil. The invention solves the problems that the product is liable to generate flocs and to coke duringuse since the styrene tar cannot be uniformly blended with other oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of low-sulfur marine fuel oil

PendingCN111088068ARealize purificationImprove use valueTreatment with hydrotreatment processesPtru catalystFluid phase

The invention discloses a production method of a low-sulfur marine fuel oil. The production method comprises the following steps: mixing catalytic slurry oil with a first additive, carrying out settling separation after the mixing treatment, obtaining a first material and residues after the separation; introducing the first material into a hydro-processing unit, carrying out a hydrogenation reaction under the action of a hydro-processing catalyst and hydrogen, introducing a liquid-phase effluent obtained after the reaction into a clarification unit, subjecting clarified oil to solid-liquid separation to obtain purified oil slurry, and mixing the purified oil slurry with an inferior raw material (hydrogenation tail oil) to obtain the low-sulfur marine fuel oil. According to the method, thesolid content and the sulfur content of the catalytic slurry oil can be reduced, high-quality purified slurry oil is produced, and the high-quality purified slurry oil is blended with residual oil toproduce the insufficient low-sulfur marine fuel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com