Marine fuel oil and preparation method thereof

A fuel oil and marine technology is applied in the field of marine fuel oil preparation to achieve the effects of reducing production costs and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation method of described marine fuel oil provided by the invention comprises the following steps:

[0014] (1) Visbreaking the heavy oil component at 400-450°C for 10-60 minutes;

[0015] (2) Fractionate the product obtained after visbreaking, and collect fractions with a distillation range higher than 165°C;

[0016] (3) Mix the fraction with a distillation range higher than 165°C with the light oil component to obtain a density of 850-991kg / m at 15°C 3 、The viscosity at 50℃ is not more than 380mm 2 / s and bunker fuel oil with a total content of 0-80 mg / kg of silicon calculated as silicon element and aluminum calculated as aluminum element.

[0017] In the present invention, the 100°C viscosity of the heavy oil component is not less than 35mm 2 / s, preferably 35-60mm 2 / s; 15°C density is 950-1200kg / m 3 , preferably 950-1050kg / m 3 ; The total content of silicon in terms of silicon and aluminum in terms of aluminum is 0-300 mg / kg, preferably 0-50 mg / kg....

Embodiment approach

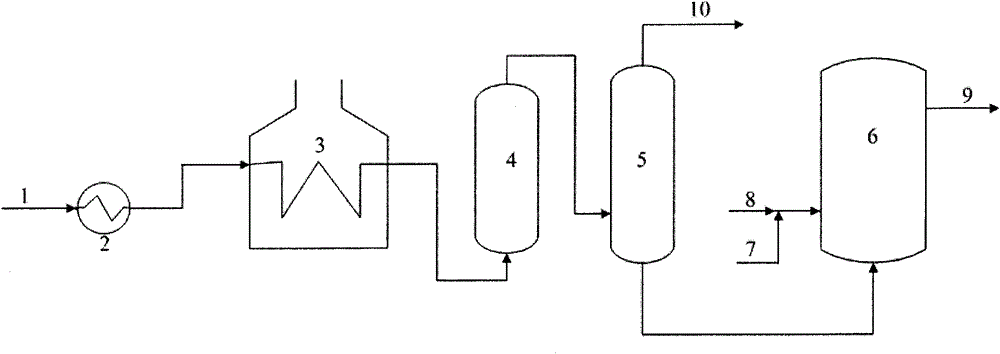

[0025] According to one embodiment of the present invention, the schematic diagram of the implementation equipment and material flow direction of the bunker fuel oil can be as follows figure 1 shown. exist figure 1 Among them, the heavy oil component 1 enters the heating furnace 3 through the heat exchanger 2 to heat up, and the temperature of the heavy oil component is controlled to 400-450°C (preferably 410-430°C), and then the heavy oil component is reheated at this temperature The high-quality oil component is added to the upflow reactor 4 for visbreaking treatment for 10-60 minutes; then, the product of the visbreaking reaction is added to the fractionation tower 5 for fractionation, and the distillation range is higher than 165°C collected from the bottom of the tower The distillate, so that the distillate with a distillation range below 165°C is extracted from the top of the tower; then, the distillate with a distillation range higher than 165°C is added to the blendin...

Embodiment 1

[0030] This example is used to illustrate the bunker fuel oil and its preparation method provided by the present invention.

[0031] The vacuum residue (see Table 1 for performance parameters) was visbroken at 430°C for 30 minutes, and the obtained product was added to a fractionation tower for fractionation, and fractions with a distillation range higher than 165°C were collected from the bottom of the tower, and Add 82 parts by weight of the fraction higher than 165°C in the blending tank, and add 2.5 parts by weight of catalytic cracking oil slurry (see Table 1 for performance parameters) and 15.5 parts by weight of catalytic cracking oil slurry in this blending tank Crack diesel oil (see Table 1 for performance parameters) to obtain 180CST marine fuel oil, the performance parameters of which are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com