Regulating method of bunker fuel oil

A technology of fuel oil and blending, which is applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of carbon deposition, corrosion and wear, etc., and achieve the effect of wide range of raw materials, reduction of pollution, and improvement of performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

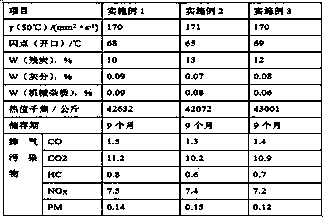

Examples

Embodiment 1

[0033] (1) After 24 hours of natural settlement of FCC oil slurry and thermal cracking residue, filter through a 60-mesh filter to remove catalyst fine powder and other impurities contained in the raw material;

[0034] (2) Pre-add the hydrogenated tail oil and ethylene tar into the blending tank, gradually heat to 50°C, and stir at a speed of 50 rpm for 30 minutes until the two are evenly mixed;

[0035] (3) Add the FCC oil slurry and thermally cracked residue treated in step (1) to the blending tank, raise the temperature to 100°C, raise the stirring speed to 500 rpm, and mix the components evenly;

[0036] (4) Add desulfurization aid, auxiliary solvent and combustion aid to the mixing tank in sequence, and mix the components evenly at a stirring speed of 300 rpm to obtain the product of the present invention.

[0037] The ratio of various components is as follows:

[0038] 20 parts of FCC oil slurry;

[0039] 10 parts of thermal cracking residue;

[0040] 10 parts of hyd...

Embodiment 2

[0048] (1) After 10 hours of natural settlement of FCC oil slurry and thermal cracking residue, filter through a 40-mesh filter to remove catalyst fine powder and other impurities contained in the raw material;

[0049] (2) Pre-add the hydrogenated tail oil and ethylene tar into the blending tank, gradually heat to 50°C, and stir at a speed of 100 rpm for 20 minutes until the two are evenly mixed;

[0050] (3) Add the FCC oil slurry and thermally cracked residue treated in step (1) to the blending tank, raise the temperature to 80°C, raise the stirring speed to 300 rpm, and mix the components evenly;

[0051] (4) Add desulfurization aids, auxiliary solvents and combustion aids to the mixing tank in sequence, and mix the components evenly at a stirring speed of 500 rpm to obtain the product of the present invention.

[0052] The ratio of various components is as follows:

[0053] 30 parts of FCC oil slurry;

[0054] 20 parts of thermal cracking residue;

[0055] 5 parts of h...

Embodiment 3

[0062] (1) After natural settlement of FCC oil slurry and thermal cracking residue for 15 hours, filter through a 50-mesh filter to remove catalyst fine powder and other impurities contained in the raw material;

[0063] (2) Pre-add the hydrogenated tail oil and ethylene tar into the blending tank, gradually heat it to 55°C, and stir at a speed of 80 rpm for 25 minutes until the two are evenly mixed;

[0064] (3) Add the FCC oil slurry and thermally cracked residue treated in step (1) to the blending tank, raise the temperature to 90°C, raise the stirring speed to 400 rpm, and mix the components evenly;

[0065] (4) Add desulfurization aids, auxiliary solvents and combustion aids to the mixing tank in sequence, and mix the components evenly at a stirring speed of 400 rpm to obtain the product of the present invention.

[0066] The ratio of various components is as follows:

[0067] 25 parts of FCC oil slurry;

[0068] 15 parts of thermal cracking residue;

[0069]8 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com