Fuel compositions

A technology for composition and marine fuel, which can be applied in the direction of fuel, fuel additive, liquid carbon-containing fuel, etc., can solve the problems of limited flexibility of blending components, high cost and extra cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

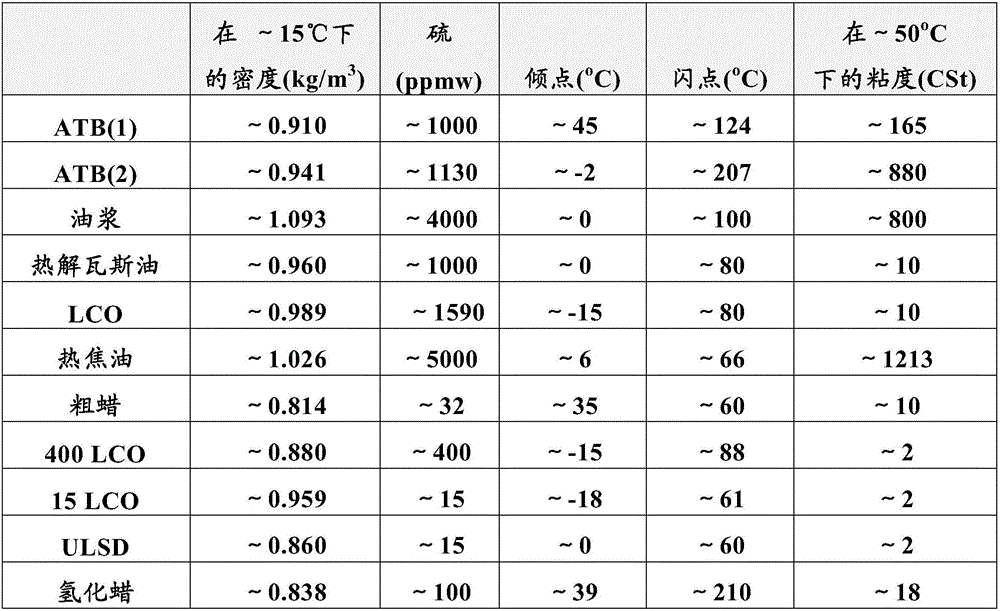

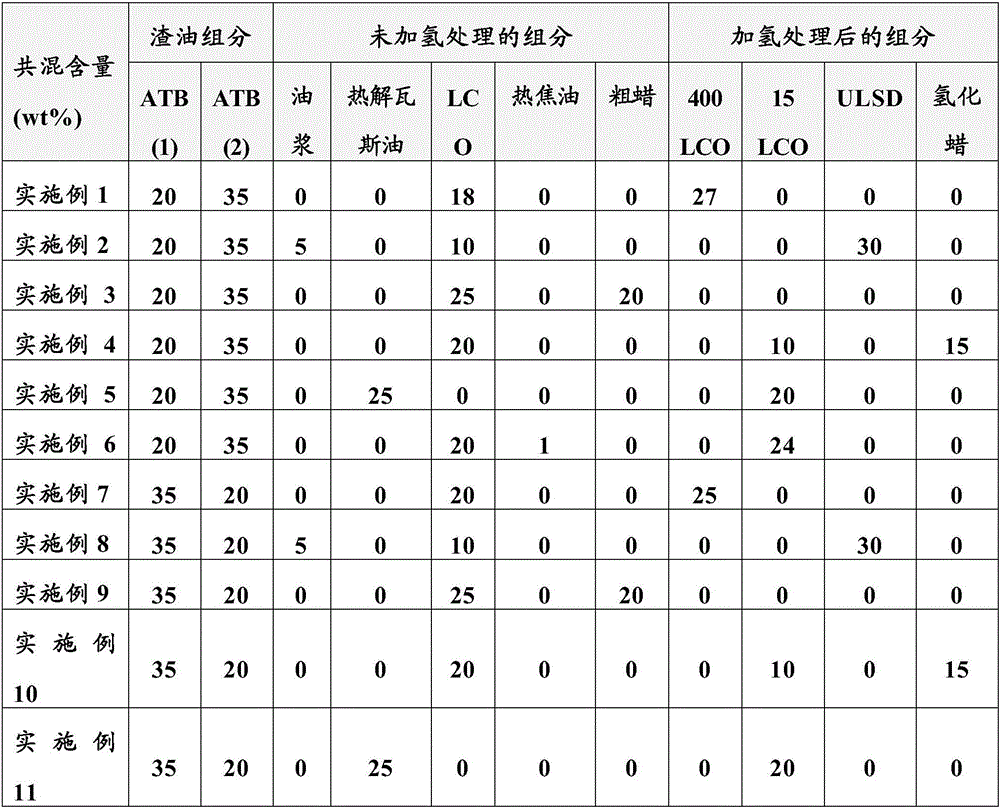

[0039] In Prophetic Examples 1-11, each of the bunker fuel compositions may contain about 55 wt% residual hydrocarbon component. In Examples 1-6, the resid hydrocarbon component may comprise 20 wt% atmospheric resid ATB(1) and 35 wt% atmospheric resid ATB(2). In Examples 7-11, the resid hydrocarbon component may comprise 35 wt% atmospheric resid ATB(1) and 20 wt% atmospheric resid ATB(2). The remaining about 45 wt% of each bunker fuel composition can be selected from unhydrotreated hydrocarbon components, hydrotreated hydrocarbon components, and combinations thereof. Table 2 below summarizes the blending content of the bunker fuel compositions in Examples 1-11.

[0040] Table 2 - Blend Contents of Examples 1-11

[0041]

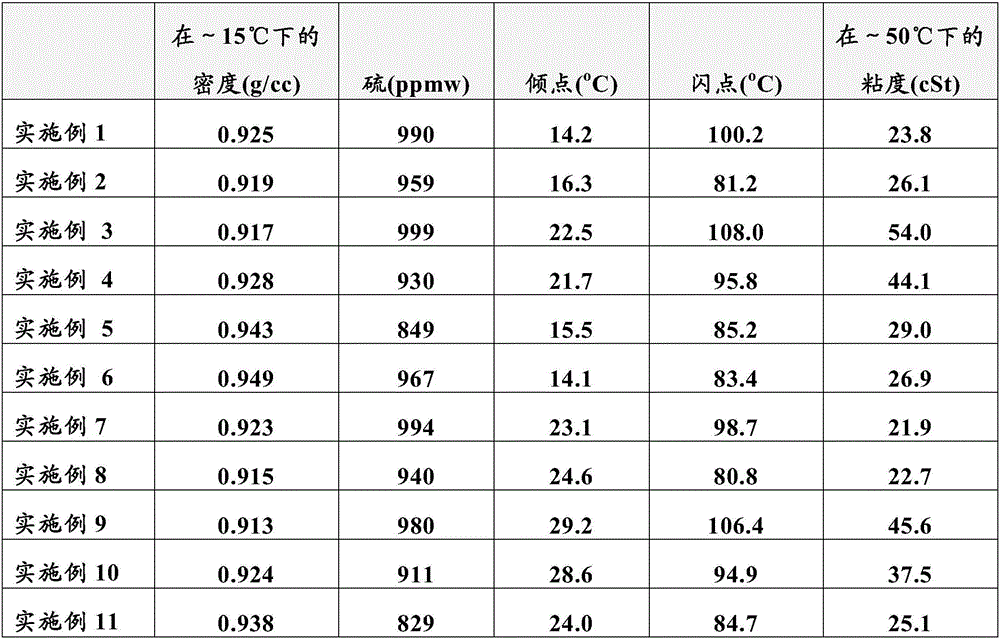

[0042] Table 3 below sets forth certain properties that the bunker fuel compositions of Examples 1-11 are expected to have as measured by various standard test methods.

[0043] Table 3 - Expected Properties of the Bunker Fuel Compositions in Exampl...

Embodiment 12-30

[0046] In prophetic examples 12-30, each bunker fuel composition may comprise about 60 wt% residual hydrocarbon component. In Examples 12-18, the resid hydrocarbon component may comprise 20 wt% atmospheric resid ATB(1) and 40 wt% atmospheric resid ATB(2). In Examples 19-30, the resid hydrocarbon component may comprise 30 wt% atmospheric resid ATB(1) and 30 wt% atmospheric resid ATB(2). The remaining about 40 wt% of each bunker fuel composition can be selected from unhydrotreated hydrocarbon components, hydrotreated hydrocarbon components, and combinations thereof. Table 4 below summarizes the blending levels of the bunker fuel compositions in Examples 12-30.

[0047] Table 4 - Blend Contents of Examples 12-30

[0048]

[0049] Table 5 below sets forth certain properties that the bunker fuel compositions of Examples 12-30 are expected to have as measured by various standard test methods.

[0050] Table 5 - Expected Properties of the Bunker Fuel Compositions in Example...

Embodiment 31-61

[0053] In Prophetic Examples 31-61, each bunker fuel composition may comprise about 70 wt% residual hydrocarbon component. In Examples 31-42, the resid hydrocarbon component may comprise 30 wt% atmospheric resid ATB(1) and 40 wt% atmospheric resid ATB(2). In Examples 43-55, the resid hydrocarbon component may comprise 40 wt% atmospheric resid ATB(1) and 30 wt% atmospheric resid ATB(2). In Examples 56-61, the resid hydrocarbon component may comprise 50 wt% atmospheric resid ATB(1) and 20 wt% atmospheric resid ATB(2). The remaining about 30 wt% of each bunker fuel composition can be selected from unhydrotreated hydrocarbon components, hydrotreated hydrocarbon components, and combinations thereof. Table 6 below summarizes the blending levels of the bunker fuel compositions in Examples 31-61.

[0054] Table 6 - Blend Contents of Examples 31-61

[0055]

[0056]

[0057] Table 7 below sets forth certain properties that the bunker fuel compositions of Examples 31-61 are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com