New utilization process for catalytic cracking slurry oil

A catalytic cracking oil slurry and catalytic oil slurry technology, which is applied in the petroleum industry, liquid carbon-containing fuel, hydrocarbon distillation, etc., can solve the problems of narrow application range, complex process route, single product, etc., and achieve good economic and social benefits , optimize the effect of rational use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

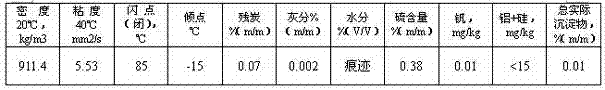

[0035] The light oil slurry A obtained by controlling the maximum temperature of the distillation outlet to 370°C has a yield of about 12%, and its quality indicators are shown in the following table:

[0036]

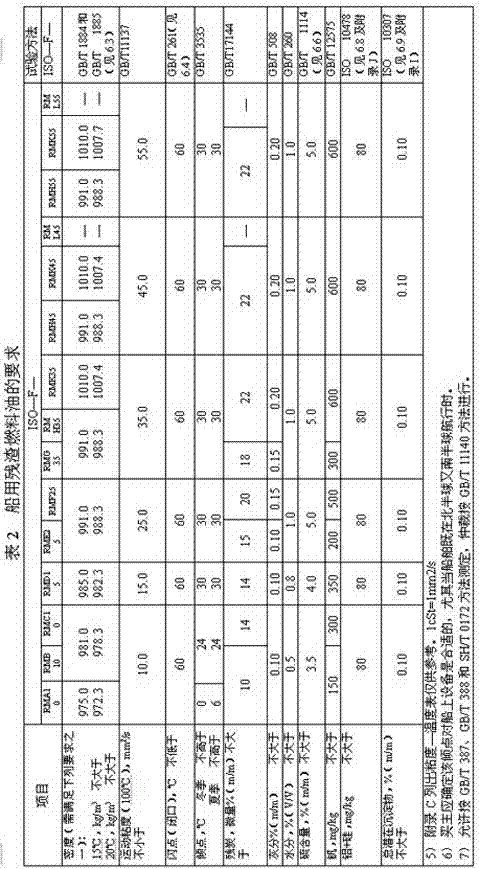

[0037] Comparing the indicators of the People's Republic of China national standard ZB / T 17411-1998 marine fuel oil shown in Table 2, it can be seen that the light oil slurry A meets the marine residual fuel oil indicator of model RMA10.

Embodiment 2

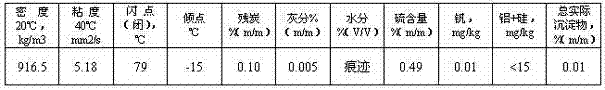

[0039] The light oil slurry B obtained by controlling the maximum temperature of the distillation outlet to 390°C has a yield of about 30%, and its quality indicators are shown in the following table:

[0040]

[0041] Comparing the indicators of the People's Republic of China national standard ZB / T 17411-1998 marine fuel oil shown in Table 2, it can be seen that the light oil slurry B meets the marine residual fuel oil indicator of model RMA10.

Embodiment 3

[0043] The light oil slurry C obtained by controlling the maximum temperature of the distillation outlet to 420°C has a yield of about 50%, and its quality indicators are shown in the following table:

[0044]

[0045] Comparing the indicators of the People's Republic of China national standard ZB / T 17411-1998 marine fuel oil shown in Table 2, it can be seen that the light oil slurry C meets the marine residual fuel oil indicators of model RMD15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidifying point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com