Forcedly stretching hole structure and stretching rolling method for rolling strip steel

A pass and strip technology, applied in the direction of metal rolling, metal rolling, rolls, etc., can solve the problem of small expansion, and achieve the effect of increasing the expansion, widening the product, and improving the efficiency of the rolling mill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

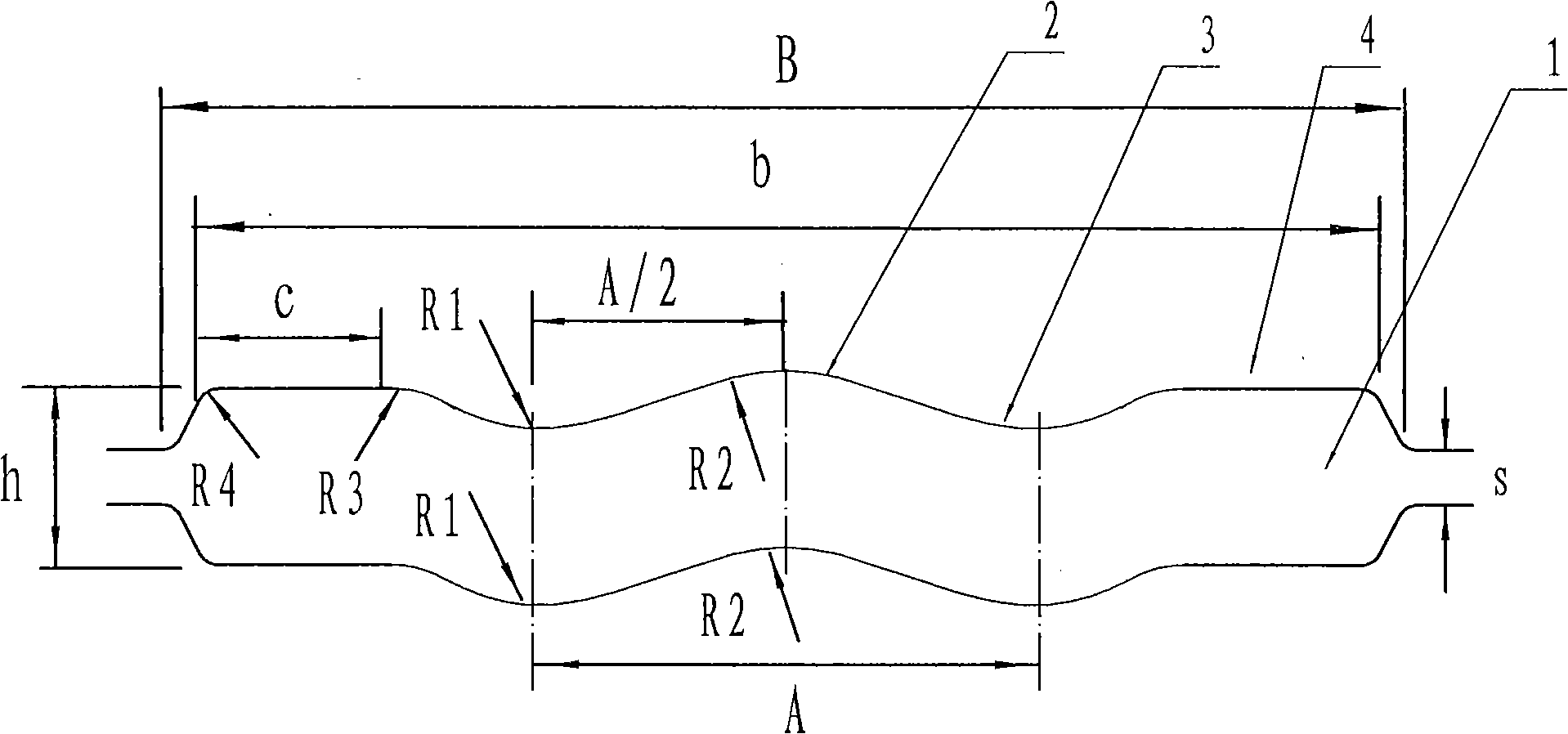

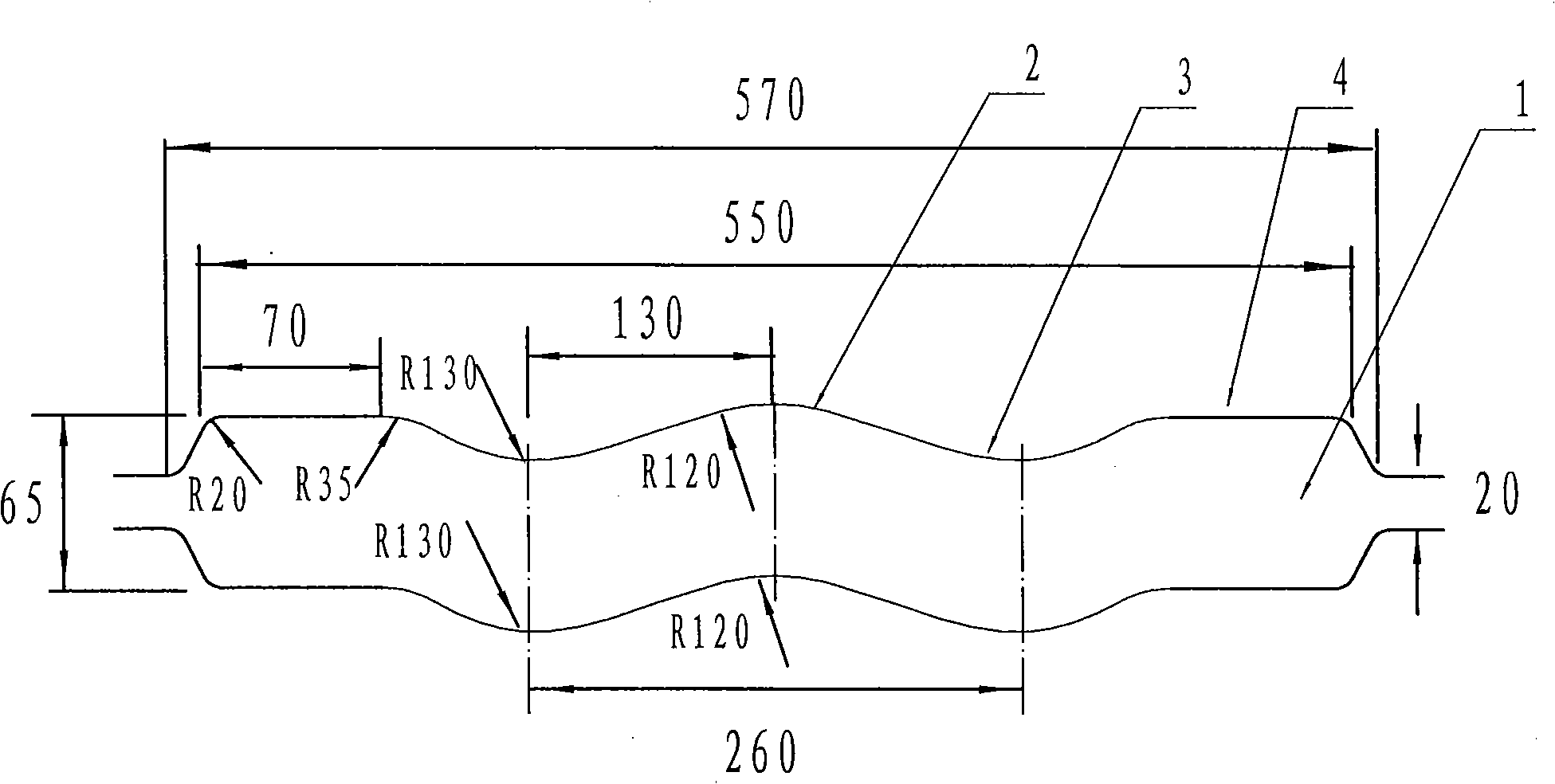

[0019] Embodiment 1: the slot width of the pass is B=570mm, the width of the groove bottom of the pass is b=550mm, the wave-shaped bending center distance A=0.456B=260mm, R1=0.228B=130mm, R2=0.21B=120mm , C=0.123B=70mm. Roll gap S=20mm, pass height h=65, arc R3=35mm, R4=20mm.

Embodiment 2

[0020] Embodiment 2: the slot width of the pass is B=570mm, the groove bottom width of the pass is b=550mm, the wave-shaped bending center distance A=0.44B=251mm, R1=0.22B=125mm, R2=0.20B=114mm , C=0.12B=68mm. The roll gap S=20mm, the height of the pass h=65mm, the arc R3=35mm, R4=20mm.

Embodiment 3

[0021] Embodiment 3: the slot width of the pass is B=570mm, the groove bottom width of the pass is b=550mm, the wave-shaped bending center distance A=0.47B=270mm, R1=0.24B=137mm, R2=0.22B=125mm , C=0.13B=74mm. The roll gap S=20mm, the height of the pass h=65mm, the arc R3=35mm, R4=20mm.

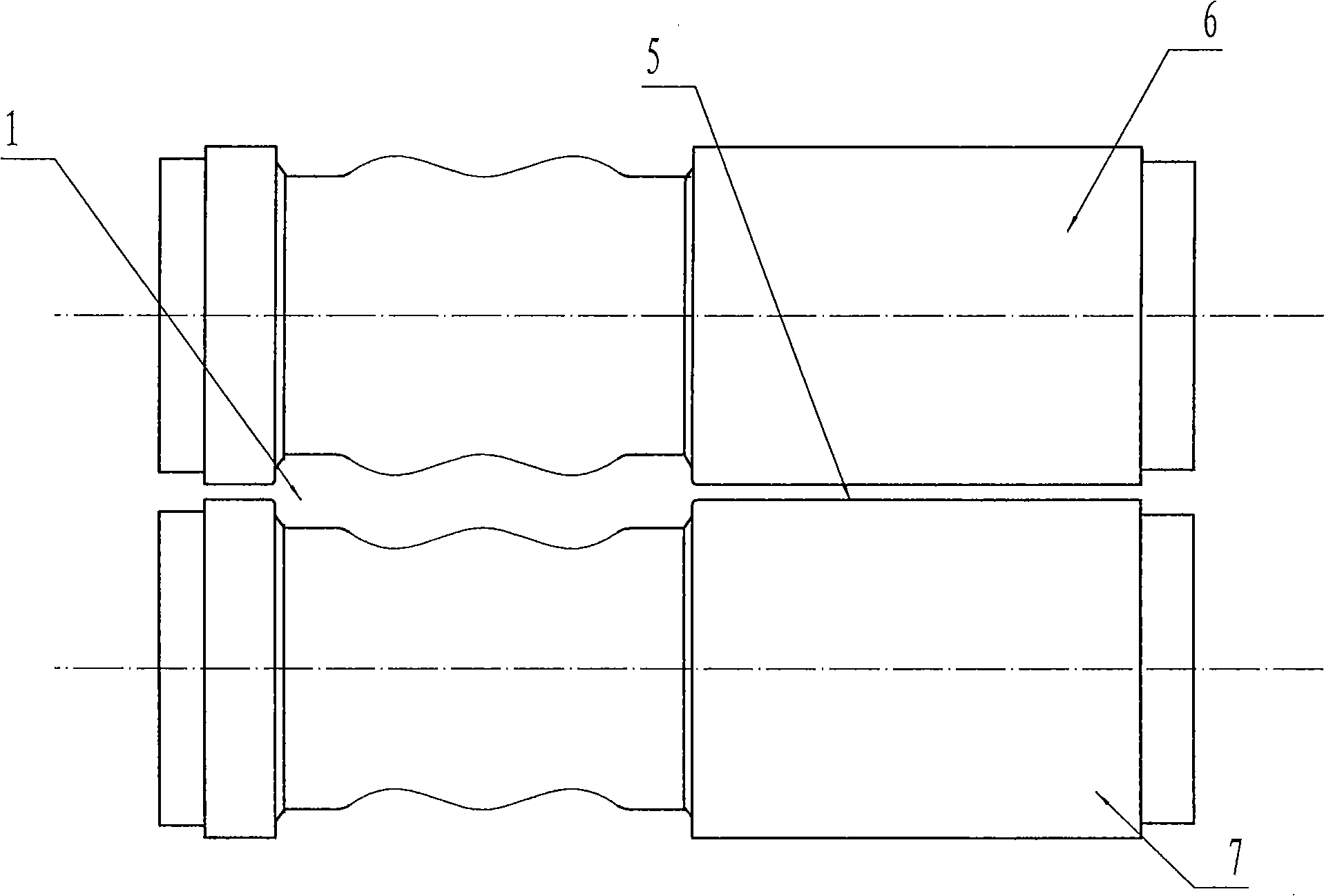

[0022] The widening and rolling method of the present invention is carried out on a roughing mill. The steel billet with a rectangular boundary section is first rolled on the above-mentioned wave-shaped forced widening pass to roll out a rolled piece with a wave bend, and then passes through a flat rolling pass or a flat roll. Rolling, in which, the first pass of flat rolling pass or flat roll rolling is flattening rolling. Flattening rolling will flatten and flatten the rolled piece with wavy bends. There is no reduction in the thickness direction of the rolled piece, but it needs Flattening and pressing, the amount of the flattening and pressing is the amplitude height of the wavy bend of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com