TRIP (Transformation-Induced Plasticity) steel and production method thereof

A production method and mass percentage technology, applied in the field of steel, can solve the problems of stable production of through-board stability, high cooling rate requirements, high production line requirements, etc., to reduce equipment requirements, flexible production, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

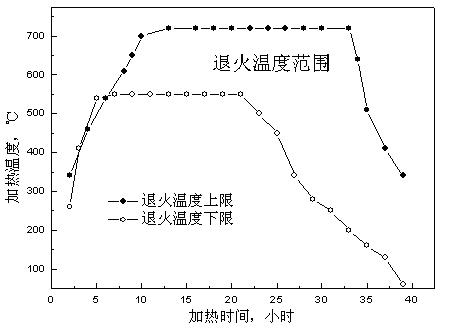

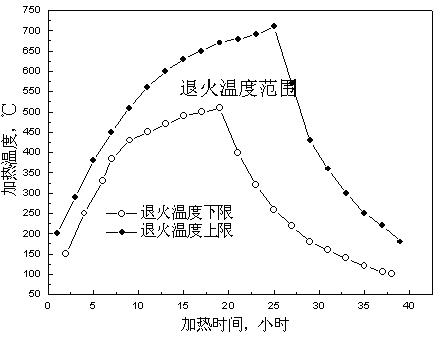

[0024] Smelting and producing slabs with C and Mn contents (other components are omitted) as listed in Table 1 as shown in No. 1, No. 2, No. 3 and No. 4 respectively. The slab is subjected to continuous hot rolling, wherein the heating temperature is 1250±30°C, the final rolling temperature is 930±20°C, and the coiling temperature is 580±30°C. Single-stand cold rolling is adopted, and the reduction rate during the cold rolling process is The control is 55-75%. Afterwards, heat according to the heating temperatures shown in Table 1, serial number 1, serial number 2, serial number 3, and serial number 4 respectively, control the corresponding hot spot temperature, and keep it warm. When the cold spot temperature reaches the When the temperature is heated, the temperature is lowered and cooled. Finally, a single frame is used for leveling, wherein, during the leveling process, the elongation rate is controlled at 0.8±0.3%.

[0025] Table 1 Corresponding C, Mn content of the TRIP ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com