Patents

Literature

213results about How to "Settle settlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

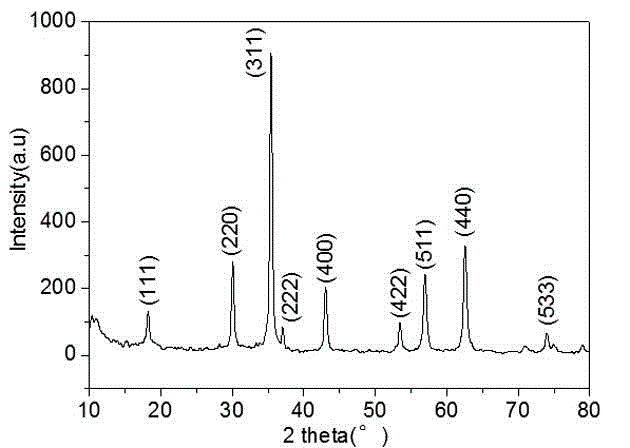

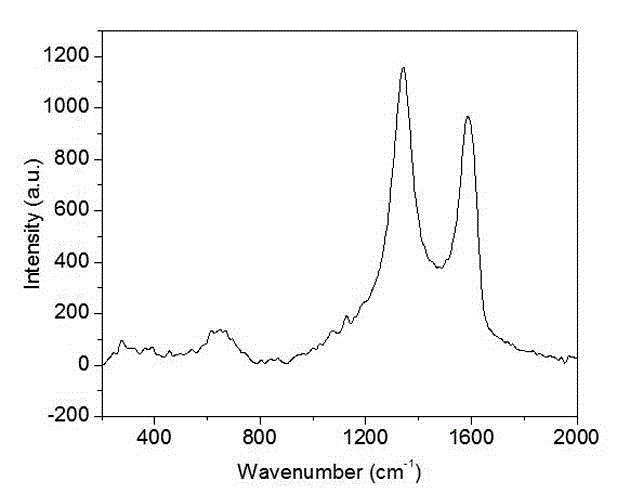

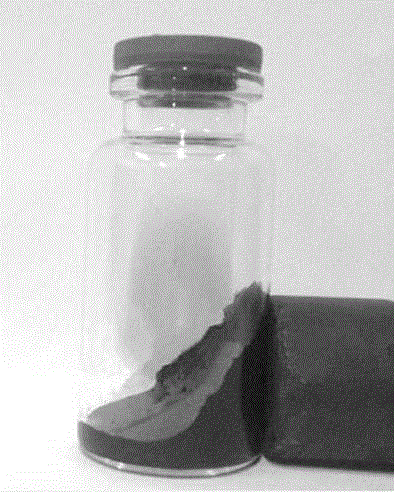

Graphene @Fe3O4 compound water base magnetorheological fluid and preparation method thereof

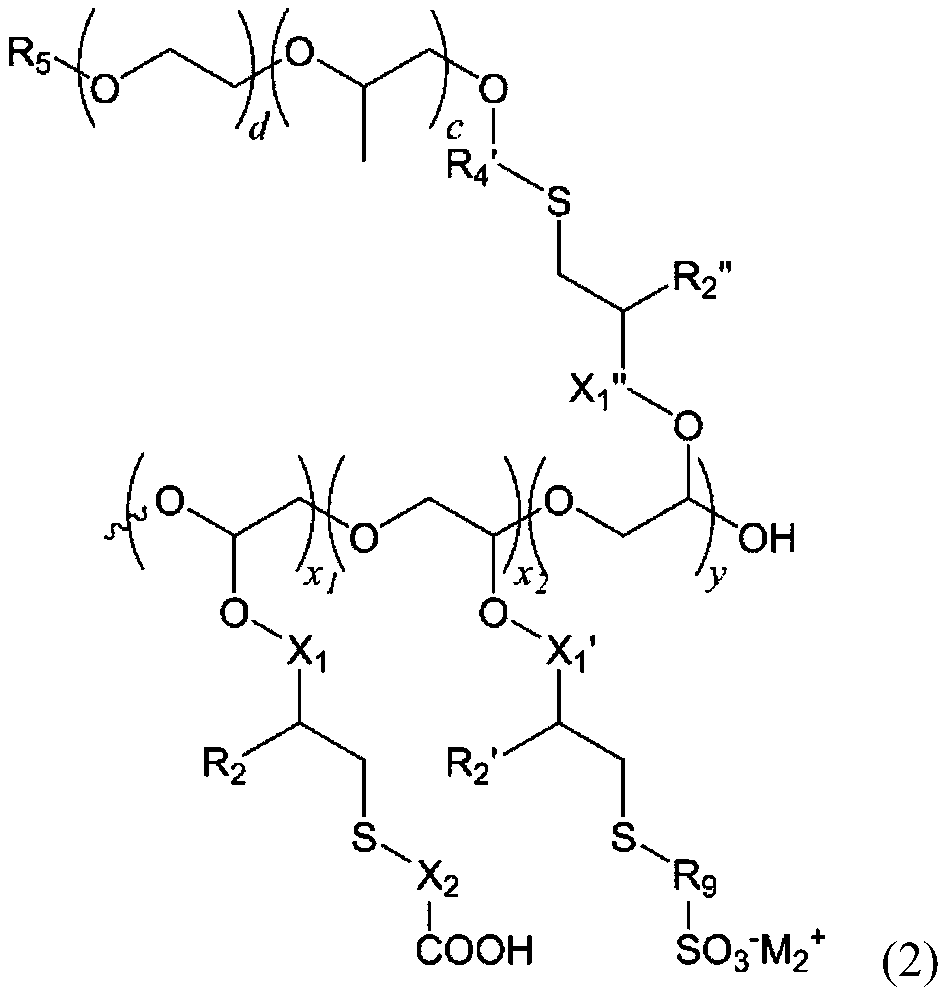

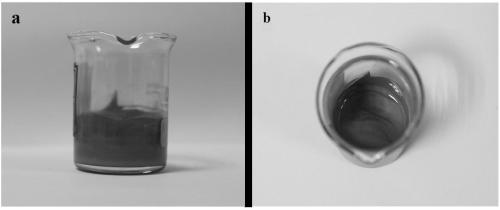

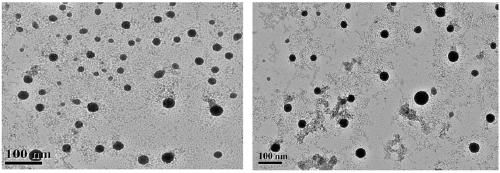

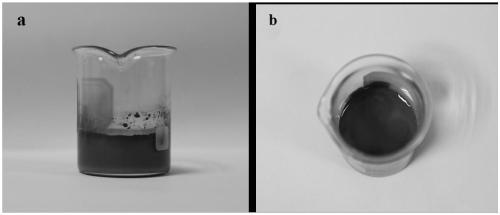

The invention relates to the field of intelligent magnetic materials and in particular relates to a graphene @Fe3O4 compound water base magnetorheological fluid and a preparation method thereof, solving the problems that existing magnetorheological fluids are easy to settle and the stability and magnetorheological effects of the magnetorheological fluids are difficult to optimize at the same time. The preparation method comprises the following steps: preparing a Fe3O4 water base magnetic fluid with FeCl2.4H2O and FeCl3.6H2O; sequentially adding concentrated sulfuric acid, potassium permanganate and hydrogen peroxide to natural flake graphite and sodium nitrate to prepare graphite oxide; and then carrying out ultrasonic dispersion on home-made graphite oxide to prepare graphene oxide, finally adding a surfactant, the Fe3O4 water base magnetic fluid and a reducing agent to graphene oxide, washing the solution with deionized water until the solution is neutral, and then dispersing graphene @Fe3O4 compound magnetic particles in the deionized water to undergo ultrasonic dispersion, removing the precipitates and taking the supernatant, namely the stable graphene @Fe3O4 compound water base magnetorheological fluid, wherein the magnetic particles are graphene @Fe3O4 and account for 5-35wt% of the whole. The method has the advantages of good stability, low zero field viscosity, high shear strain and wide operating temperature range.

Owner:ZHONGBEI UNIV

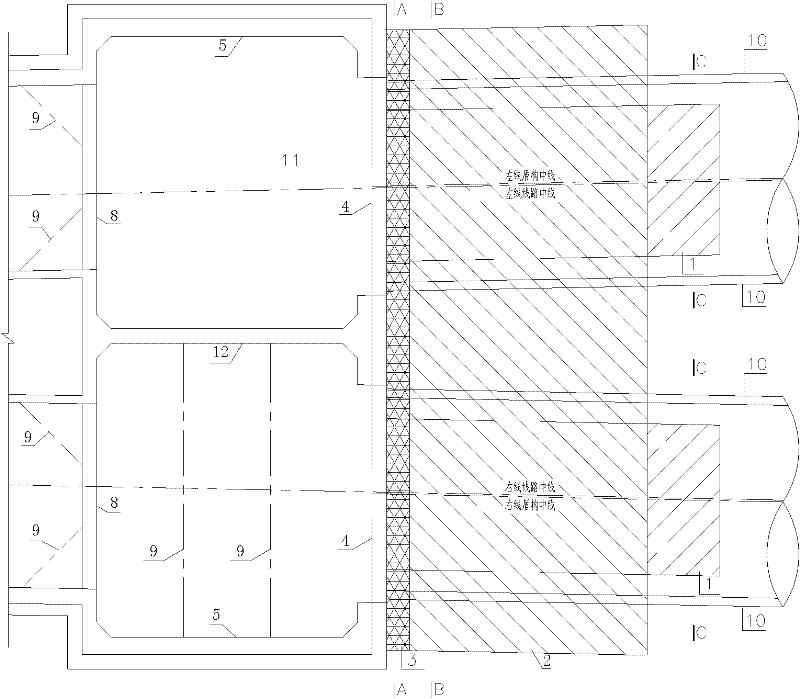

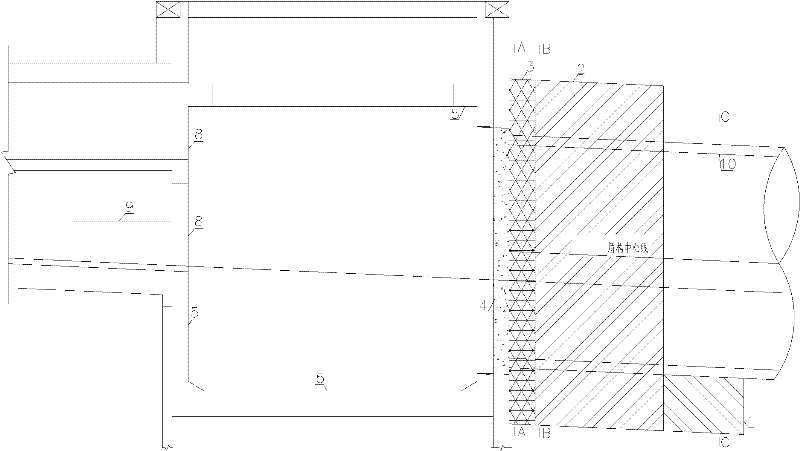

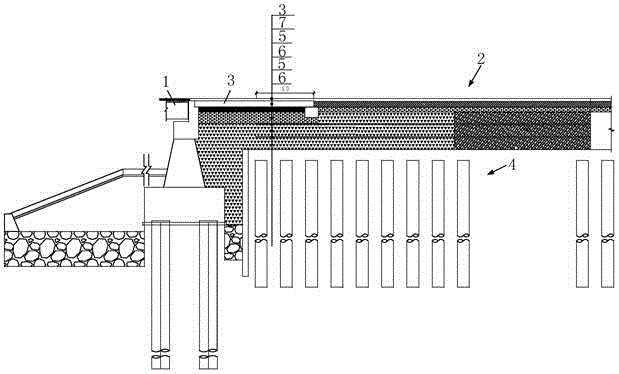

Freezing consolidation and soil-accumulating watering shield arrival method

ActiveCN102352753ASettle settlementSolve the problem of \"lower head\"Underground chambersTunnel liningHydrologyRetaining wall

The invention discloses a tunnel freezing consolidation and soil-accumulating watering shield arrival method, which comprises the following steps of: (1) consolidating a stratum of a tunnel arrival section by using a jet pile or a mixing pile; (2) stopping water for a stratum close to an opening of a receiving well by using a freezing method; (3) removing a retaining wall of a tunnel portal, and filling in the receiving well to obtain a mound; (4) injecting water into the receiving well to reach the designed height; and (5) making a shield machine tunnel to enter the receiving well structure to finish the whole receiving work. By the method, when tunnel portal concrete is removed, the integral stability of soil mass can be ensured, seepage damage caused by a fine sand stratum is prevented, muddy water pressure during tunneling of the shield machine can be balanced, and is prevented from breaking through the peripheral soil mass of the tunnel portal, and the shield arrival is carried out safely and smoothly.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

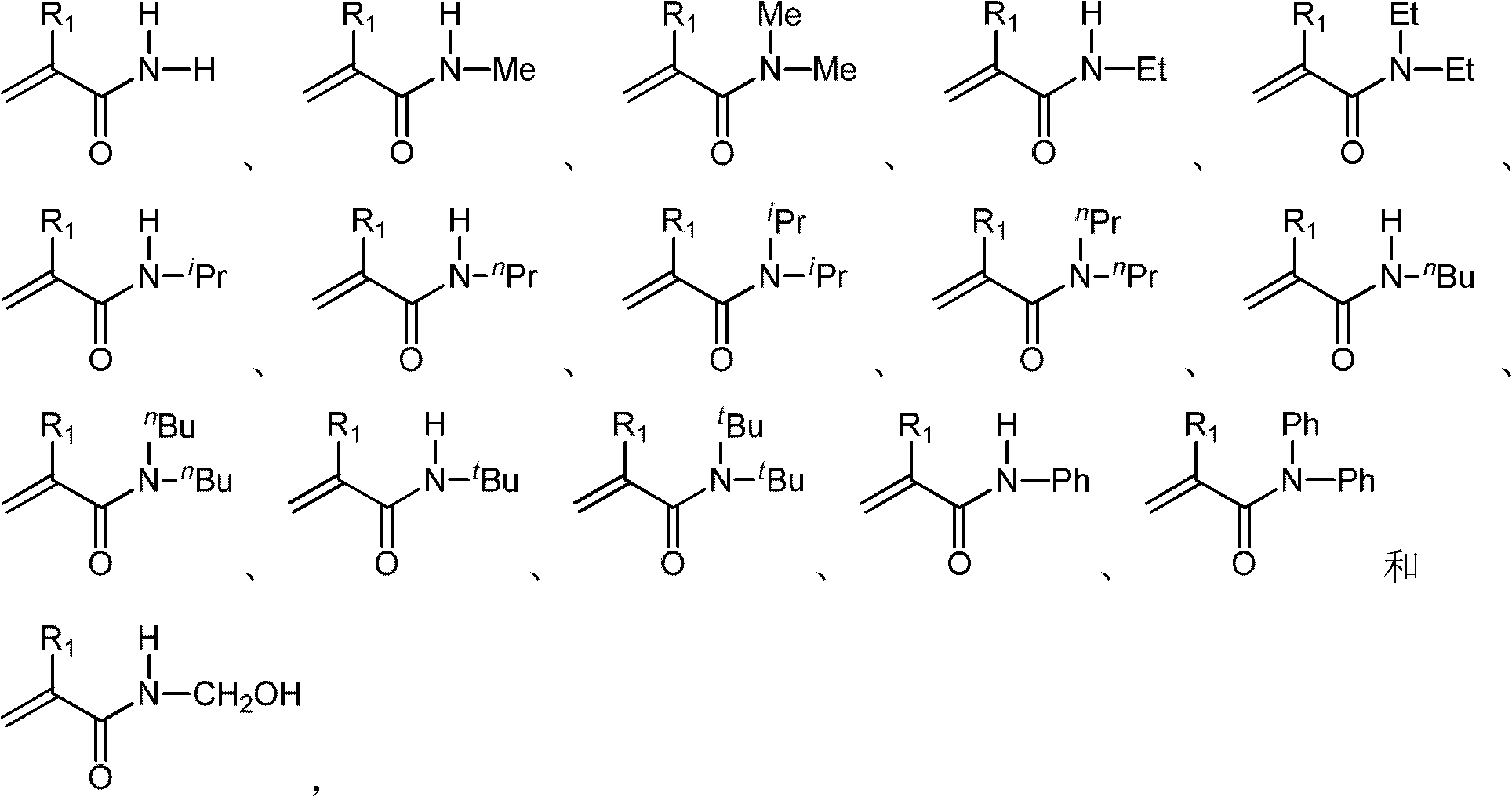

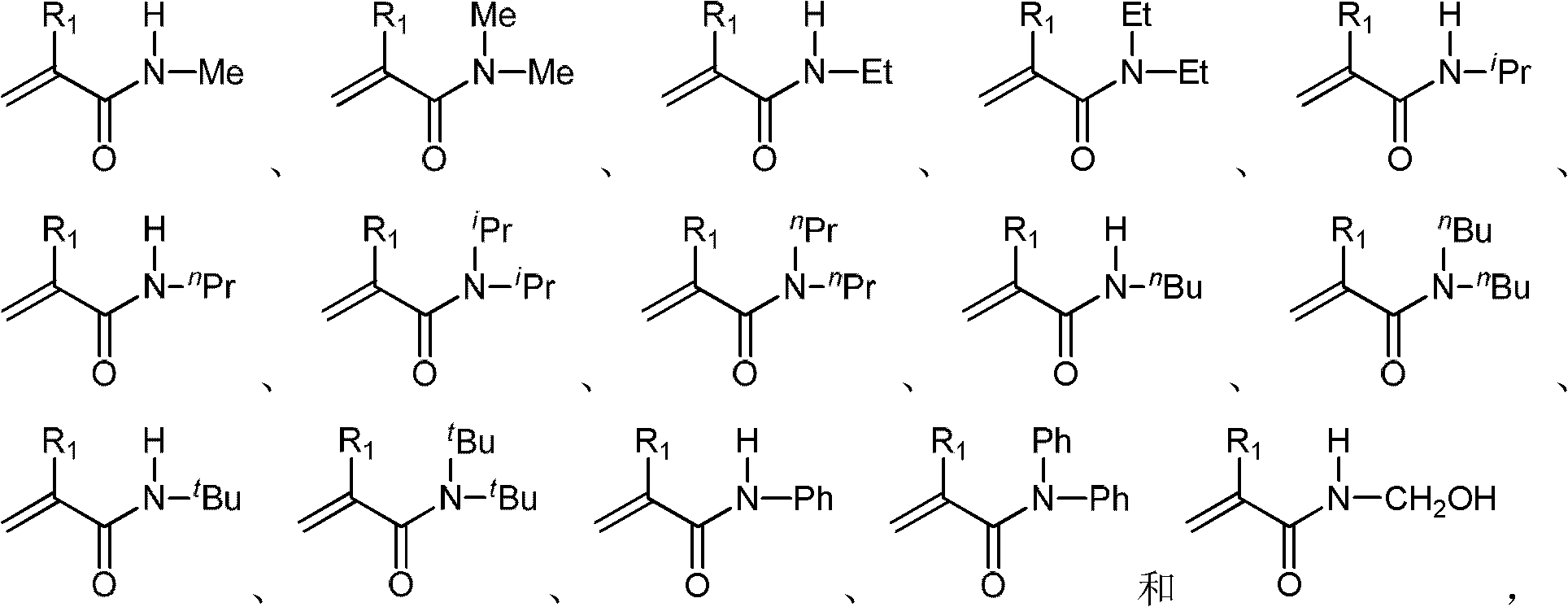

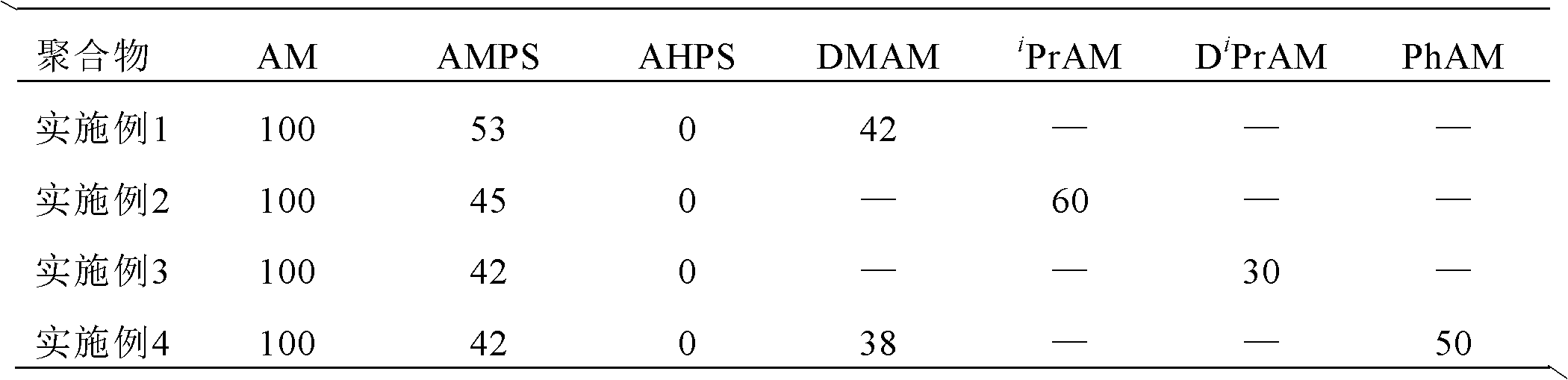

Filtration-reducing agent for synthetic polymer oil-well cement

The invention discloses a filtration-reducing agent for synthetic polymer oil-well cement. The filtration-reducing agent is prepared by copolymerizing an acrylamide monomer, a cross-linking agent and other monomers. The polymer has high stability under the conditions of high temperature, high pressure and strong basicity, can effectively enhance the filtration reducing performance of a well cementation cement slurry system in the environments of high temperature, high pressure and high salinity, solves the sedimentation problem of cement to the greatest extent, greatly solves the delayed coagulation problem, and is particularly suitable for cement well cementation of an oil well with super depth, ultrahigh temperature and ultrahigh pressure. The polymer can stabilize a well cementation cement slurry system, avoids free fluid in cement slurry and increases the cement intensity. Under a general condition (80 DEG C), the required dosage of the polymer is only 0.5 percent BOWC. Under the conditions of high temperature, high pressure and high salinity, the required dosage of the polymer is only 1.0 percent BOWC, so that the aim of reducing filtration of well cementation cement can be fulfilled, and the economic effect is very remarkable.

Owner:JIANGSU AOLUNDA HIGH TECH IND

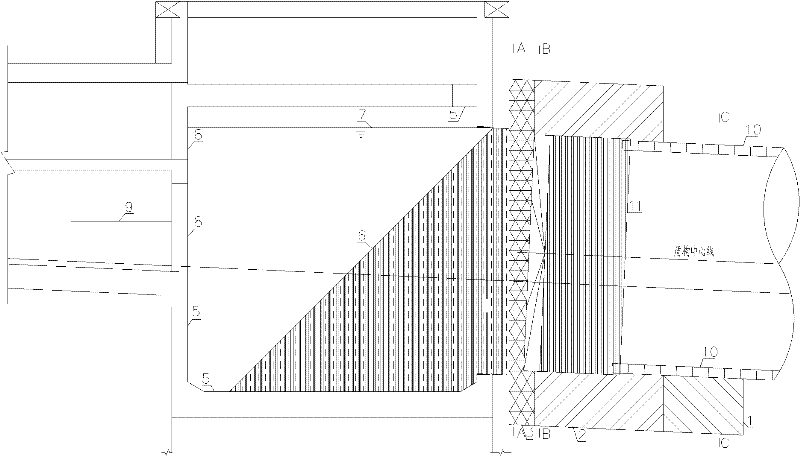

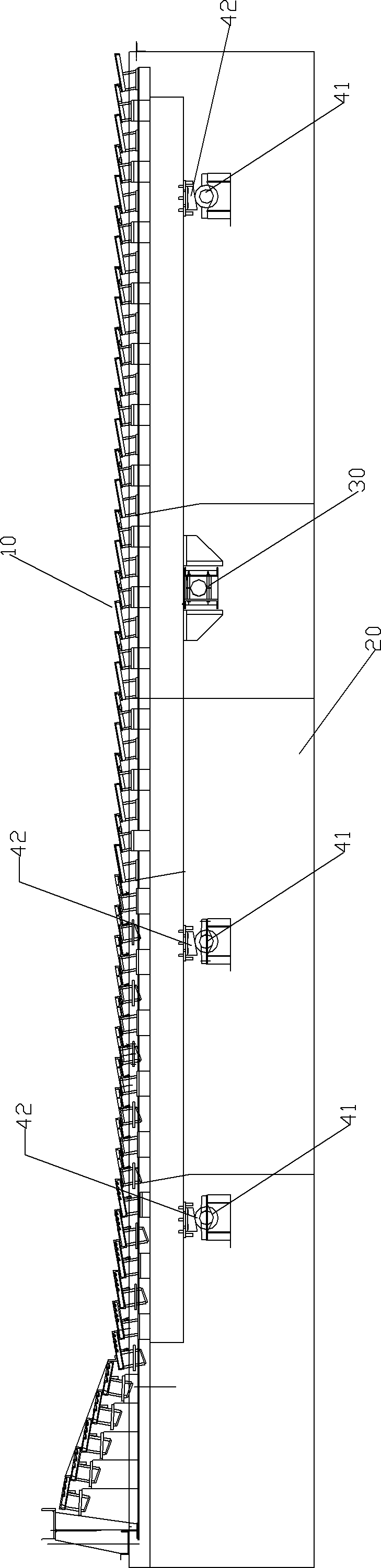

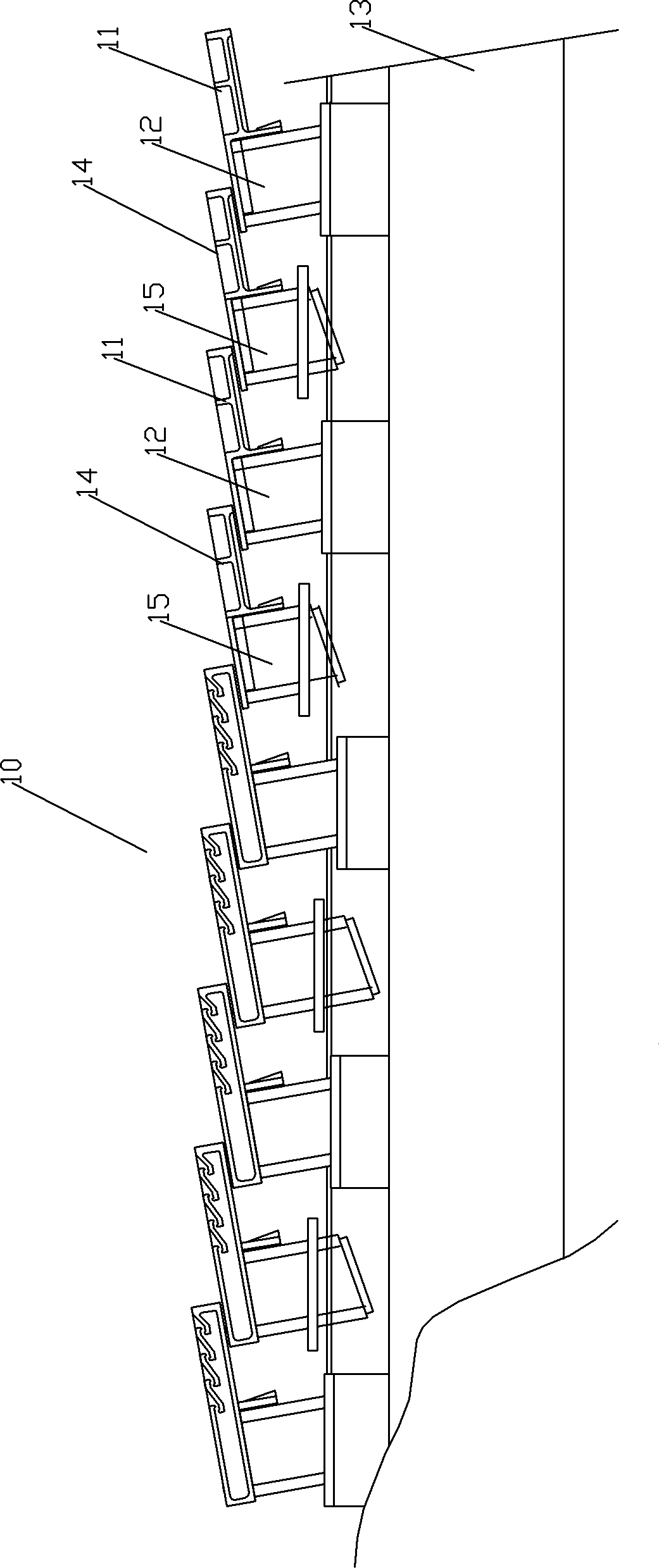

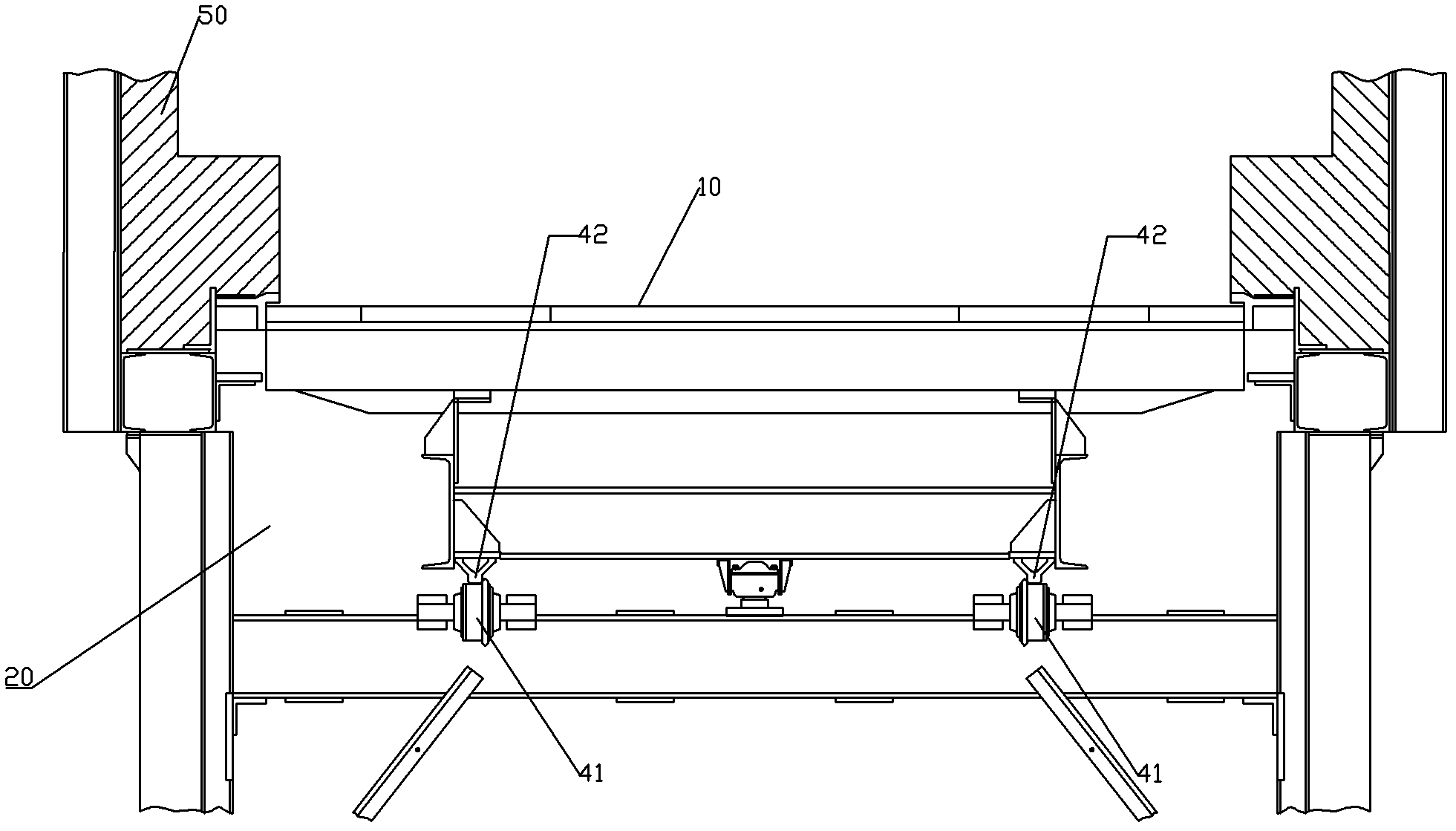

Novel grate type cooler

InactiveCN102353271AReduce coefficient of frictionAvoid wear and tearHandling discharged materialEngineeringReciprocating motion

The invention discloses a novel grate type cooler, comprising a grate bed and an air room; the grate bed is arranged above the air room; the grate bed comprises fixed grate boards and movable grate boards; and the fixed grate boards and the movable grate boards are alternately arranged with one another. The novel grate type cooler is characterized by further comprising a movable frame and a support guider, wherein the movable frame is driven by a drive device to move in a reciprocating way and is arranged in the air room; the support guider is used for supporting the movable frame and is arranged outside the air room; and the movable frame is connected with the support guider by a connecting beam. The support guider is arranged outside the air room, and lubricating oil can be applied to the support guider without opening the air room, so that the friction coefficient of the novel grate type cooler is reduced, the attrition of the support guider is avoided, and the settlement of the movable grate boards caused by the attrition of a support device is overcome. The settlement of the movable grate boards is overcome, so that overlapped gaps between the movable grate boards and the fixed grate boards can be reduced at 2+ / -0.5mm; and therefore, the novel grate type cooler is higher than the existing national industry standard.

Owner:上海建丰重型机械有限公司

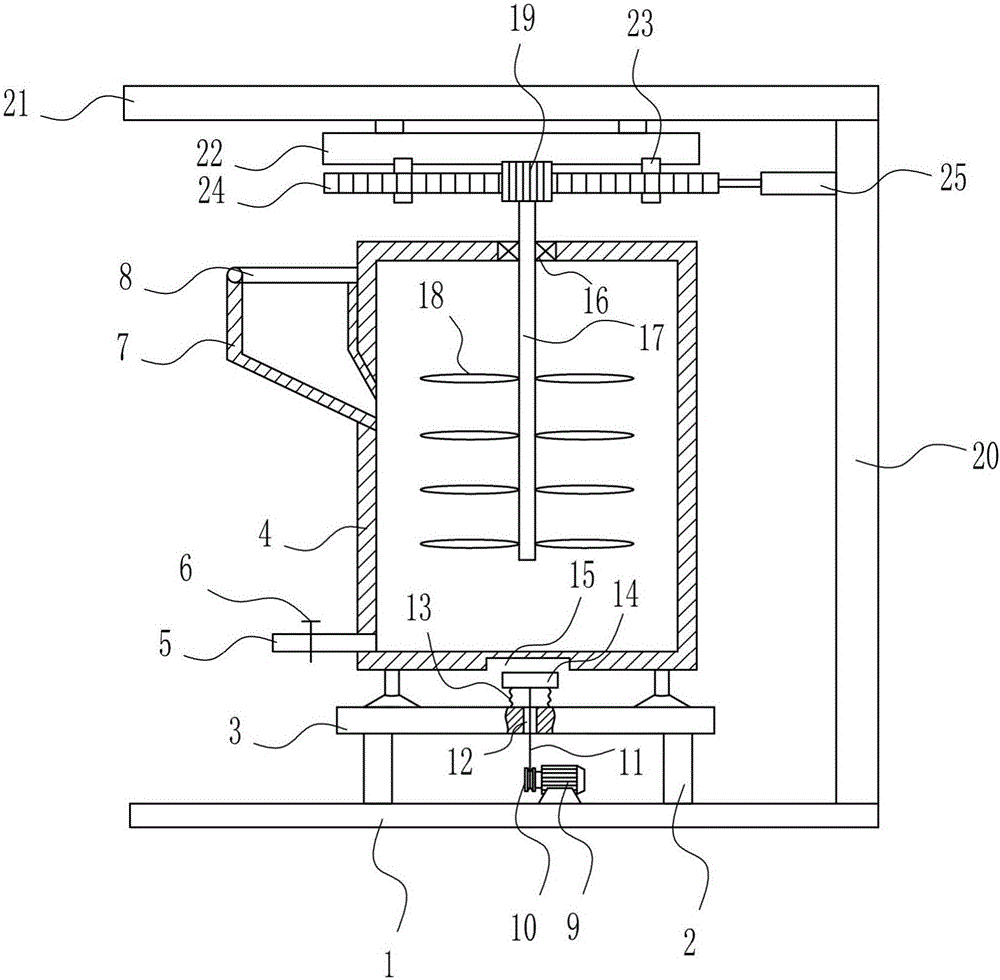

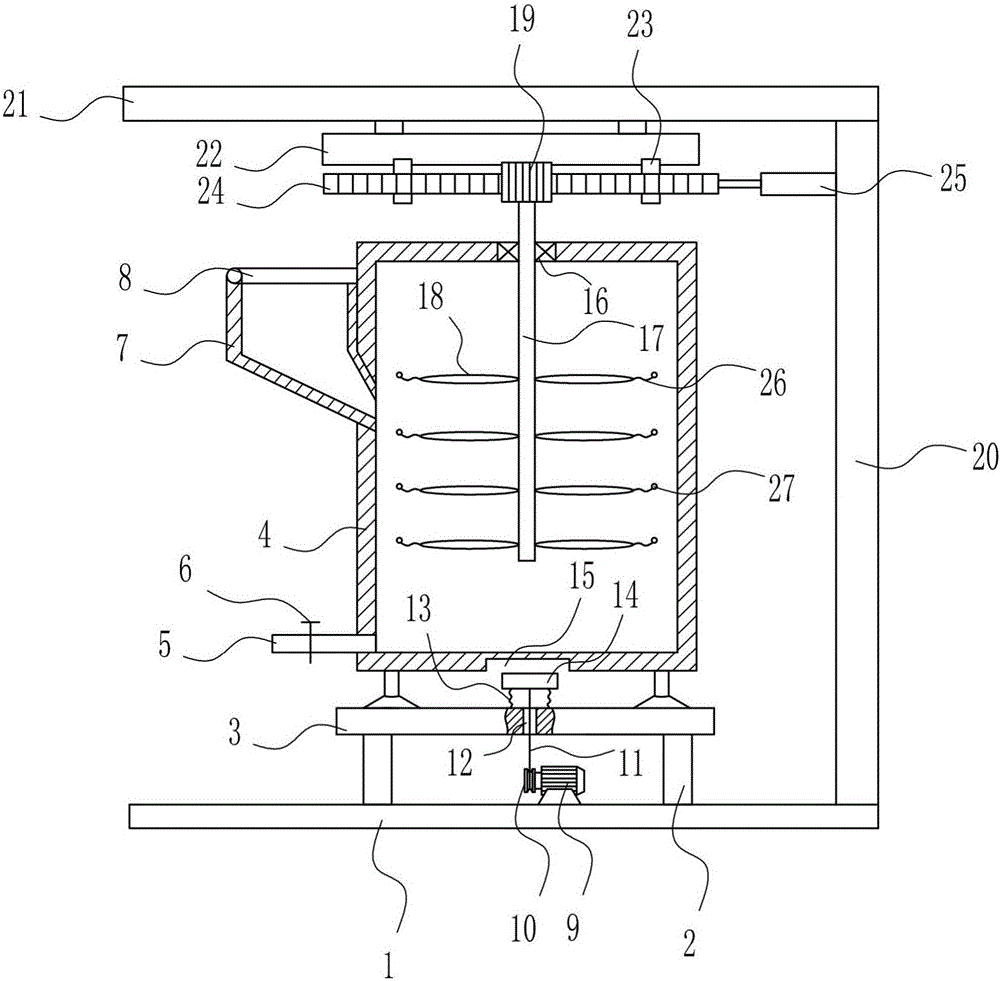

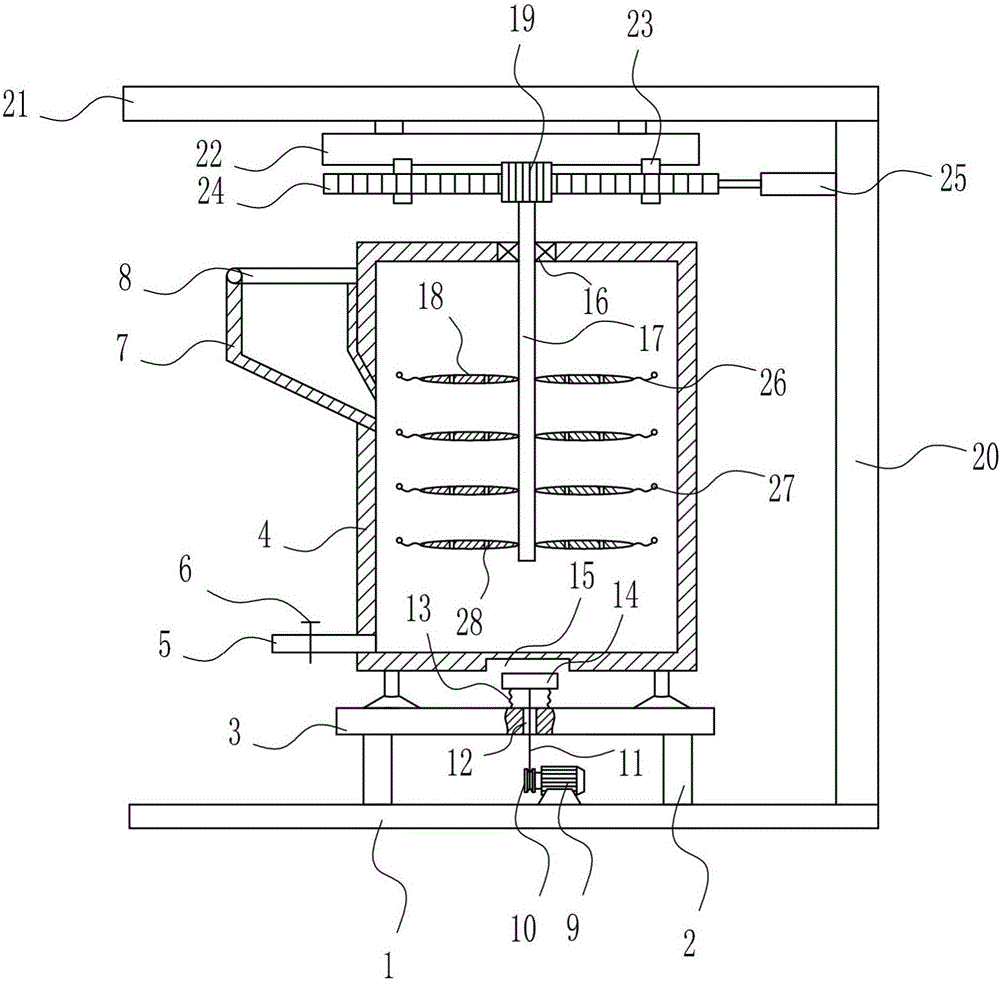

Raw material high-efficiency stirring device for lithium battery manufacturing technology

ActiveCN106732090AEvenly dispersedSettle settlementElectrode manufacturing processesShaking/oscillating/vibrating mixersManufacturing technologyEngineering

The invention belongs to the technical field of lithium battery manufacturing, and particularly relates to a raw material high-efficiency stirring device for lithium battery manufacture technology. The invention aims to provide a raw material high-efficiency stirring device for lithium battery manufacturing technology, which is uniform in stirring, simple in structure and convenient to operate. In order to solve the technical problems, the invention provides a raw material high-efficiency stirring device for lithium battery manufacture technology, which comprises a bottom plate, a bracket, a mounting plate, a mixing barrel, a discharge pipe, an electric control valve, a feed hopper, a cover, a rotating machine, a winding wheel, a pull wire, a first spring, a link stopper and the like, wherein the left and right of the top of the bottom plate are welded with the bracket; the top of the bracket is welded with the mounting plate; and the mixing barrel is welded to the mounting plate. The stirring device achieves the effects of uniform stirring, simple structure and operation convenience, has the advantages of novel structure and high practicality, can uniformly disperse the slurry, and can solve the problems of settling and stratification of the slurry.

Owner:奥特贝(天津)机器人有限公司

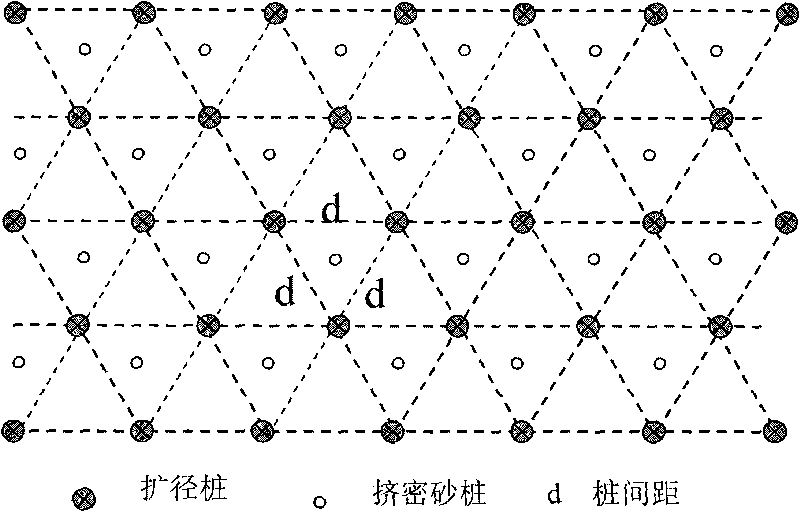

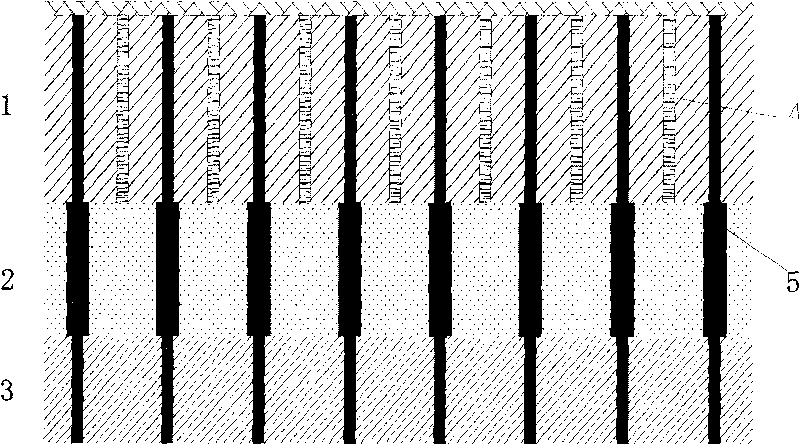

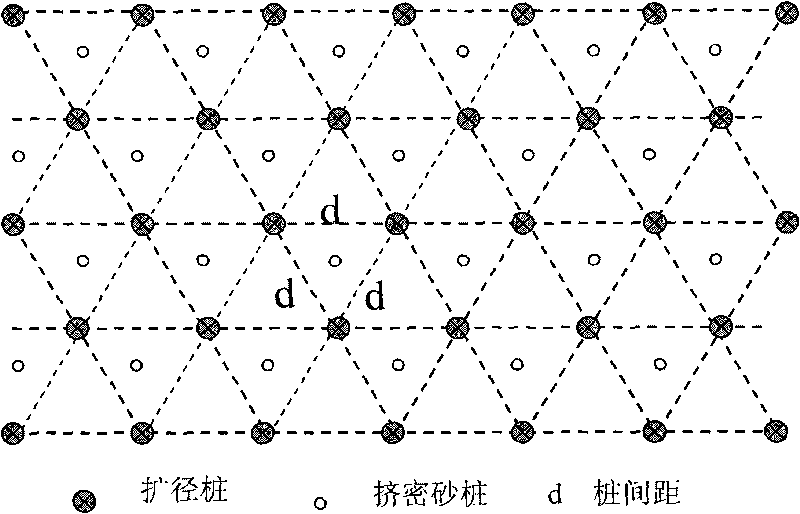

Method for treating foundation consisting of liquid soil layer and soft soil mutual layer

ActiveCN101718091AEasy constructionEasy to operateBulkheads/pilesSoil preservationSoil horizonSoil science

The invention discloses a method for treating a foundation consisting of a liquid soil layer and a soft soil mutual layer, which is provided mainly for solving the problem that the foundation consisting of the liquid soil layer and the soft soil mutual layer cannot be treated by the conventional method. In the method, combined construction of bidirectional stirring variable-section piles and sand compaction piles is adopted, wherein the sand compaction piles solve the liquefaction problem of the upper liquid soil layer, and the expanded-diameter piles solve the bearing capacity and settlement problems of the soft soil layer. The method comprises the steps of: a, leveling a site; b, positioning a bidirectional stirring pile machine; c, drilling down, guniting and stirring; d, lifting; e, constructing the sand compaction piles; and f, using a composite foundation formed by the formed bidirectional stirring variable-section piles and sand compaction piles to treat the foundation consisting of the liquid soil layer and the soft soil mutual layer.

Owner:SOUTHEAST UNIV

Nickel-nanodiamond composite plating solution and preparation thereof

InactiveCN101280452ASoluble in waterGood dispersionElectrolytic coatingsSurface-active agentsSize ratio

The invention discloses a nickel-nano-diamond composite plating solution, which is in blend composition with the size ratio 0.1-2:22 through the modified nano-diamond water or dilute sulfuric acid solution and the water solution of nickel sulfate, nickel chloride, boric acid, saccharin and butynediol. The invention also discloses the preparation method of the composite plating solution. The composite plating solution of the invention has a high degree of stability, in which the key issues existed in the composite plating technique of nano-diamond that the nano-diamond is easy to be in agglomeration and settlement and the plating solution is unstable are resolved. Moreover the composite plating solution is in favor of the stable control of the structure and properties of the composite coating. During the preparation process, the ultrasound technology and the organic surface-active agent are not required to use, which is not only help reduce the plating cost, but also the environmental problems resulted from the adoption of the organic surface-active agents comprising sulfur, phosphorous and other elements are avoided. The composite coating obtained from the plating solution through a simple plating process is bright and smooth. Compared with the coating that the nano-diamond is not comprised and obtained under the same conditions, the micro-hardness of the composite coating can be increased at most by 38%, and the coefficient of friction can be reduced by 29%.

Owner:浣石

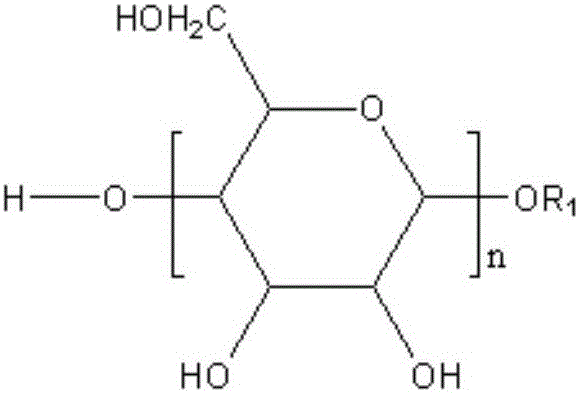

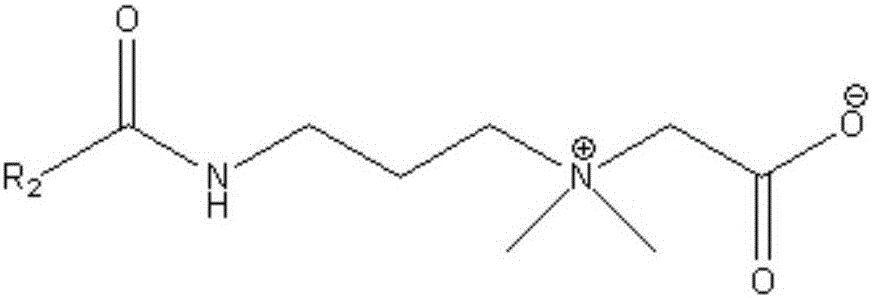

Kitchen wet-tissue immersion liquid as well as preparation method and application thereof

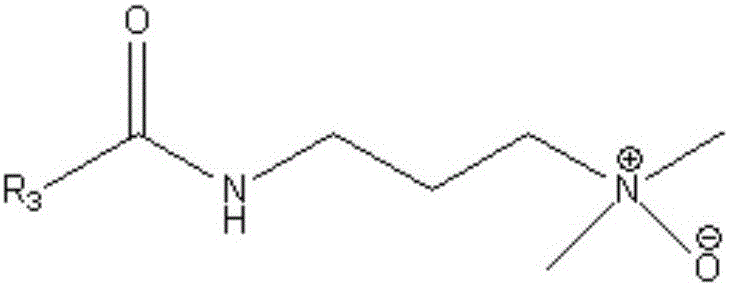

ActiveCN106148030APrevents wet wipe contents from settlingImprove stabilityCationic surface-active compoundsOrganic detergent compounding agentsChemistryOxide

The invention relates to kitchen wet-tissue immersion liquid as well as a preparation method and application thereof. The kitchen wet-tissue immersion liquid is prepared from the following raw material components in percentage by mass: 0.01-0.2% of a rheology control agent, 1-10% of a surfactant composition, 0-1.5% of a fungicidal preservative, 0-5% of a chelating agent, 0-0.1% of an antifoaming agent, 0-0.2% of essence and the balance of water, wherein the rheology control agent is an acrylate crosslinking copolymer with molecular weight of 1.0*10<8>-1.0*10<10> Daltons; the surfactant composition is a mixture composed of alkyl glycoside, alkyl amidopropyl betaine and alkenamides propylamine oxide according to a mass ratio of (10-1):(5-1):1. According to the kitchen wet-tissue immersion liquid disclosed by the invention, the problem that content of the wet-tissue is easy to settle is solved, the product stability is improved, and the immersion liquid is efficient in decontamination, safe and mild and has good application prospect.

Owner:广州超威生物科技有限公司

Concentrated liquid detergent composition

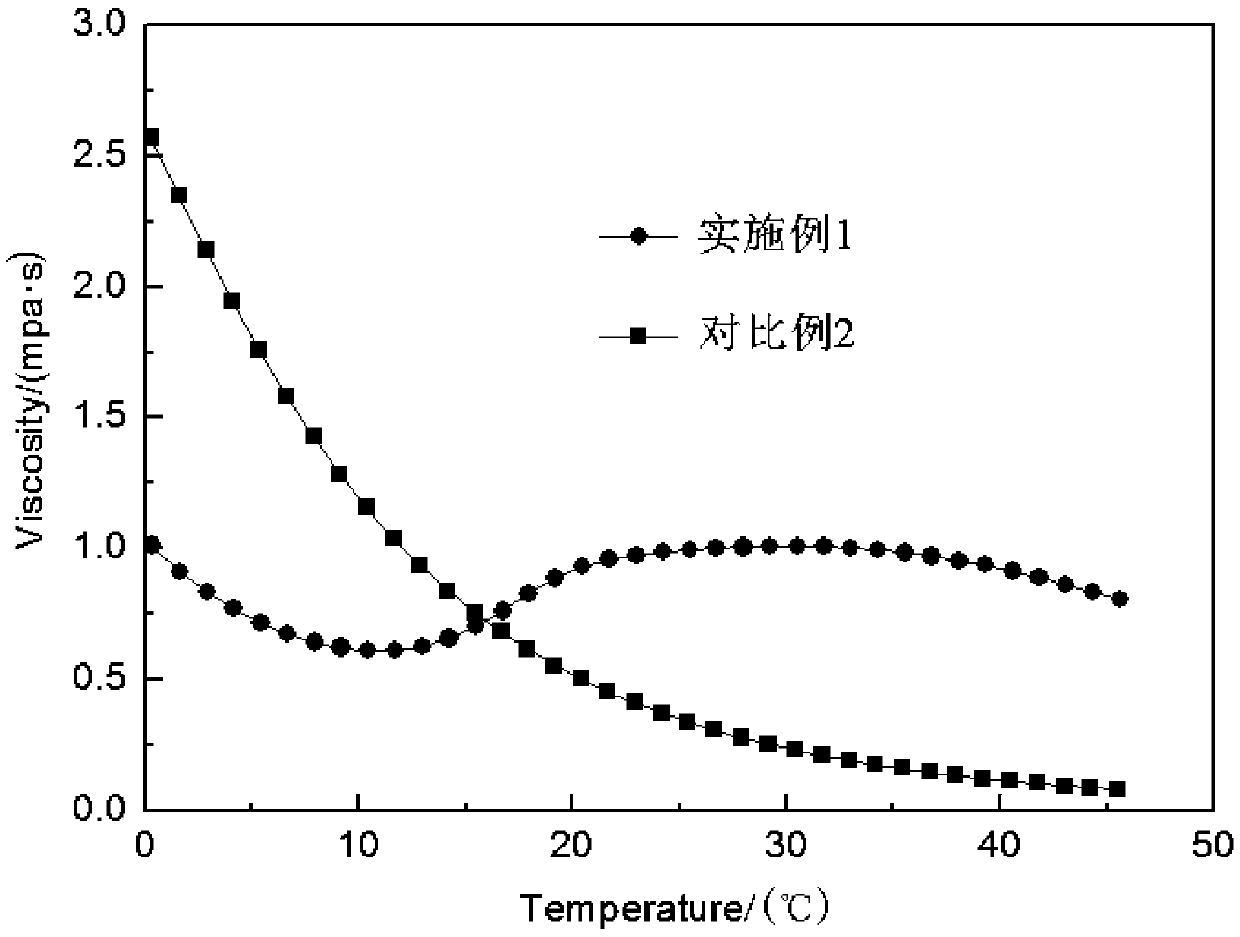

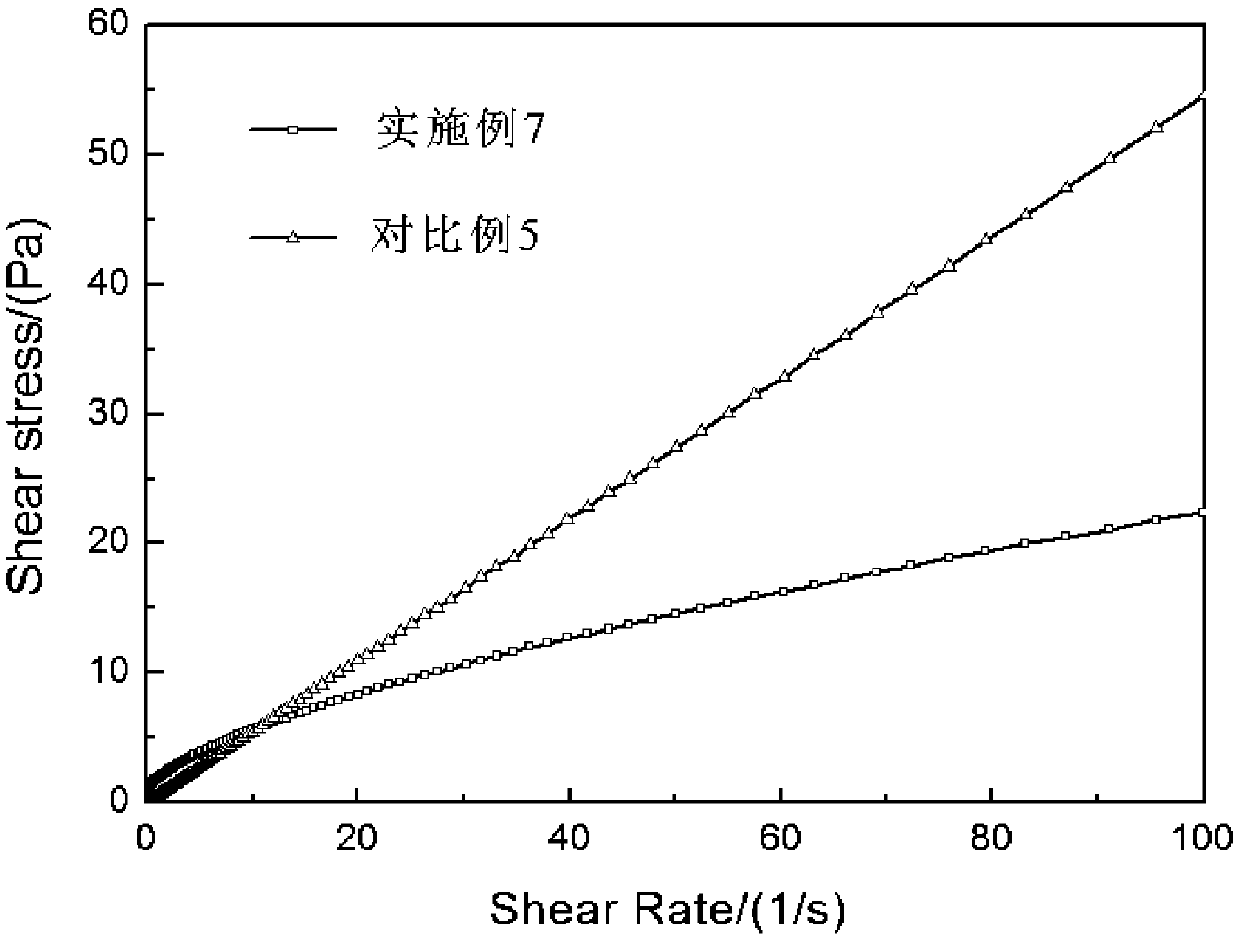

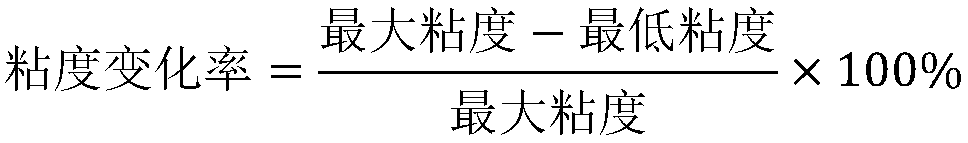

ActiveCN109576097AImprove suspension stabilityImprove stabilitySurface-active non-soap compounds and soap mixture detergentsTemperature resistanceViscosity

The invention relates to the technical field of daily washing products, in particular to a concentrated liquid detergent composition. A detergent system forms a compact lamellar liquid crystal structure by effectively compounding the surfactant, a certain rheological yield stress, excellent suspension stability and high-low temperature viscosity stability can be formed in the detergent system under the condition of a simple process, so that the detergent composition has the advantages of good stability, low viscosity, good washing performance, simple preparation process, low cost and the like,the problems of high cost, high viscosity and complicated preparation process of the detergent system caused by adding an external structuring agent to the detergent system in the prior art are avoided, and the problems of large viscosity change and poor temperature resistance of the existing concentrated liquid detergent under high and low temperature conditions are solved.

Owner:GUANGZHOU LIBY

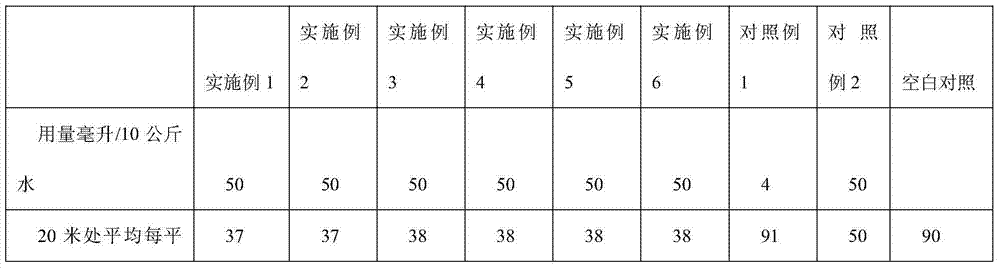

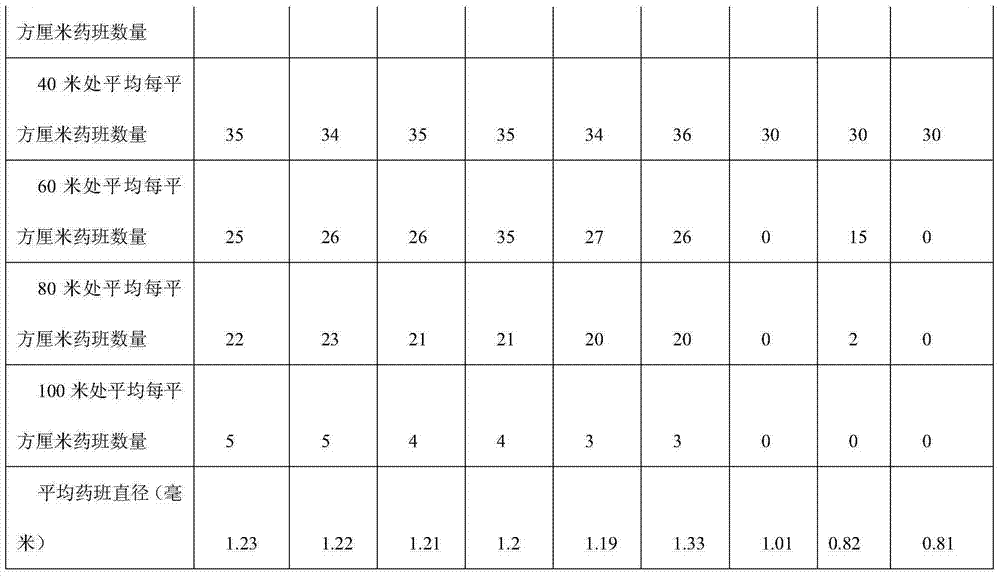

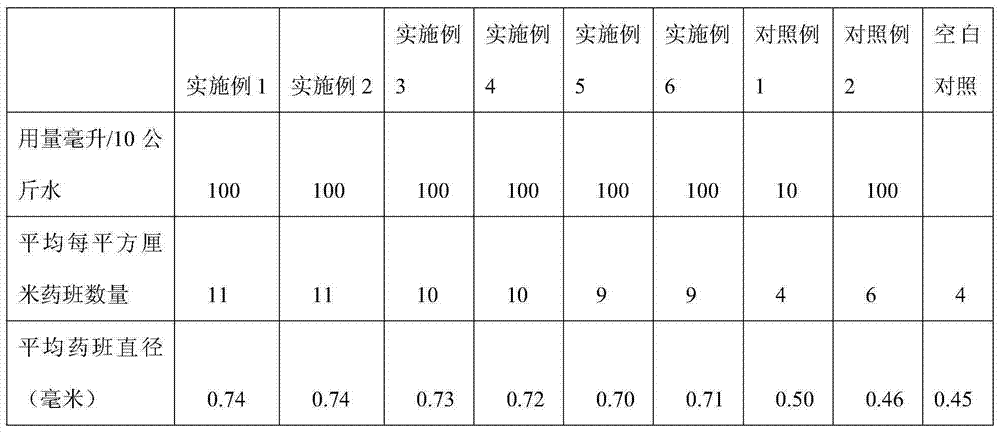

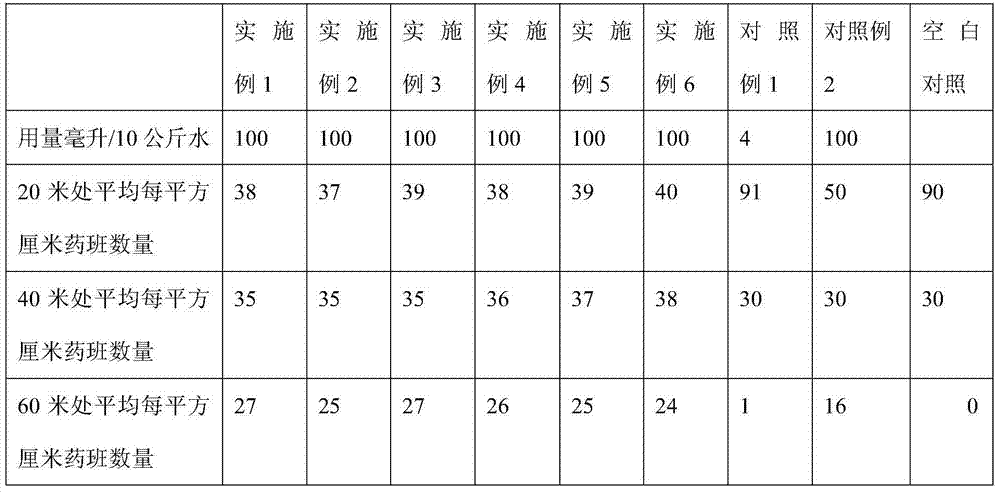

Mechanical control spray additive

ActiveCN104488860ASettle settlementSolve the anti-drift abilityBiocideAnimal repellantsJet aeroplaneVegetable oil

The invention relates to the field of agricultural mechanical control, and particularly relates to preparation and an application of a mechanical control spray additive. The additive is prepared from the following components in percentage by mass: 5-25 percent of ethoxy modified trisiloxane, 15-18 percent of non-ionic anionic compound surfactant, 5-20 percent of glycerinum and the balance of vegetable oil (37-75 percent). The additive can be used for solving the problems that other spray additives cannot solve deposition and spreading problems in mechanical control and improving the prevention effect of mechanical control, is suitable for low-volume spray or super-low-volume spray of airplanes and large spray machinery, such as cannon and the like, and can be used for solving the problems of poor chemical settlement, poor drift resistance and poor spreadability in the mechanical control process.

Owner:JINGBO AGROCHEM TECH CO LTD

Mechanical control spray additive

ActiveCN104488859ASettle settlementSolve the anti-drift abilityBiocideAnimal repellantsJet aeroplaneCompound (substance)

The invention relates to the field of pesticide additive applications and agricultural mechanical control, and particularly relates to a mechanical control spray additive. The additive is prepared from the following components in parts by weight: 1-20 parts of ethoxy modified trisiloxane, 1-10 parts of penetrant and 80-98 parts of glycerinum. The additive can be used for solving the problems that other spray additives cannot solve deposition and spreading problems in mechanical control and improving the prevention effect of mechanical control, is suitable for low-volume spray or super-low-volume spray of airplanes and large spray machinery, such as cannon and the like, and can be used for solving the problems of poor chemical settlement, poor drift resistance and poor spreadability in the mechanical control process.

Owner:JINGBO AGROCHEM TECH CO LTD

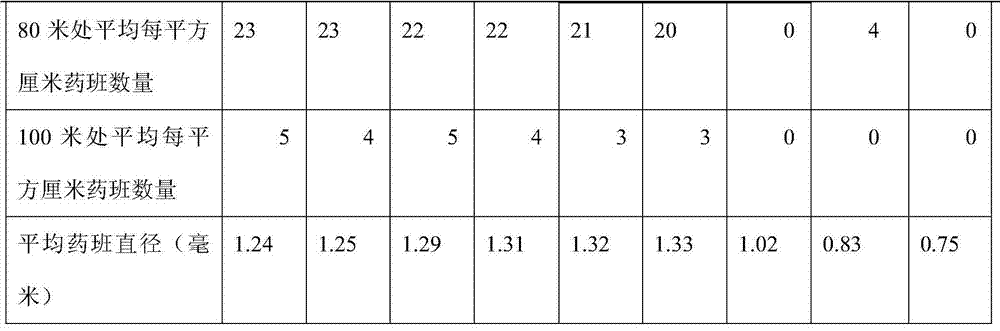

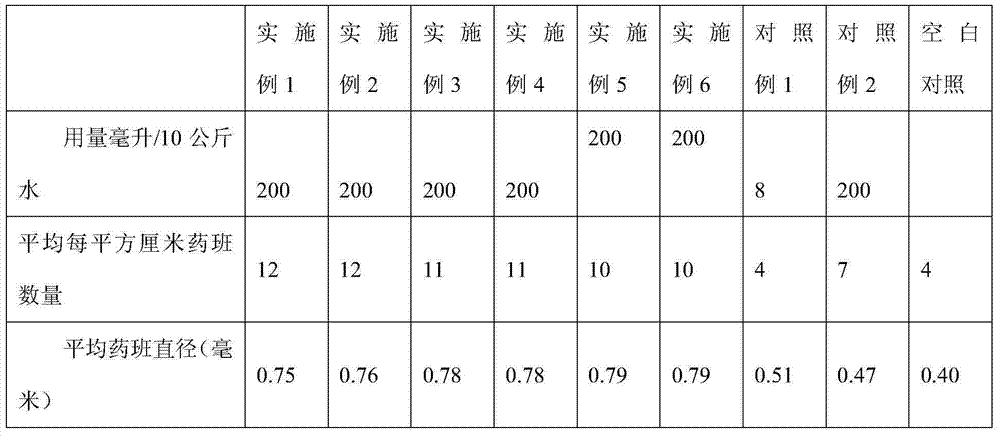

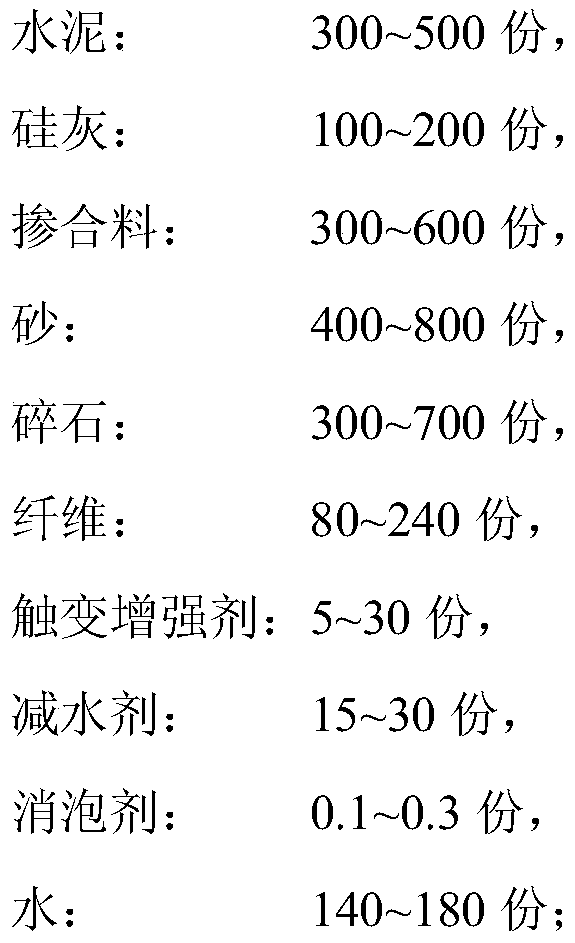

Low-viscosity and easy-pumping ultrahigh performance concrete and preparation method thereof

The invention discloses a low-viscosity and easy-pumping ultrahigh performance concrete and a preparation method thereof. The concrete comprises, by mass, 300-500 parts of cement, 100-200 parts of silica fume, 300-600 parts of an admixture, 400-800 parts of sands, 300-700 parts of crushed stones, 80-240 parts of fibers, 5-30 parts of a thixotropic enhancer, 15-30 parts of a water reducer, 0.1-0.3part of an antifoaming agent and 140-180 parts of water. The low-viscosity and easy-pumping ultrahigh performance concrete of the invention has a high fluidity and a low viscosity, the pumping resistance is only 0.015-0.025 MPa / m, and the compressive strength after 28 d standard curing is 180 MPa or above. In addition, the low-viscosity and easy-pumping ultrahigh performance concrete of the present invention has a typical low cement content, so the shrinkage of the ultrahigh performance concrete is significantly reduced, the use amount of the cement is significantly reduced, and the environmental pollution is reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Liquid metal nanoparticles with core-shell structure and preparation method thereof

InactiveCN109482859AGood dispersionSmall particle sizeMaterial nanotechnologyTransportation and packagingMaterials preparationNanoparticle

The invention relates to a liquid metal nanoparticles with a core-shell structure and a preparation method thereof. According to the liquid metal nanoparticles with the core-shell structure, the liquid metal is mixed with a high-viscosity organic material, after ultrasonic scattering, fine liquid which is uniformly dispersed on the upper layer is taken out, and continuously carrying out ultrasonicscattering, until the liquid metal nanoparticles with the core-shell structure are prepared. According to the method, the liquid metal nano-particles is prepared, the particle size is small, the sizedistribution is centralized, the preparation process is simple, fast and efficient, the cost is low, the implementation is easy, the prepared nano-particles can stably exist and still have no obviousagglomeration and sedimentation after being placed for more than 100 days, so that a good foundation for material preparation is provided for application of the liquid metal nano-particles.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Heavy fuel oil asphaltene dispersant

InactiveCN103897755ASettle settlementPrevent subsidenceLiquid carbonaceous fuelsFuel additivesCarbon chainSolvent

The invention relates to a heavy fuel oil asphaltene dispersant. According to the technical scheme, the heavy fuel oil asphaltene dispersant is prepared from the following raw materials in parts by weight: 10-50 parts of ester, 20-60 parts of alkyl benzene sulfonic acid, 5-20 parts of fatty alcohol-polyoxyethylene ether and 10-30 parts of solvent, wherein the ester is one of carboxylic esters of RCOOCH3, R is straight-chain alkyl and the quantity of carbon atoms is 10-16; the alkyl benzene sulfonic acid is one of RSO3H, wherein R is an alkyl carbon chain and the quantity of carbon atoms is 12-18; the general formula of the fatty alcohol-polyoxyethylene ether is RO(CH2CH2O)mH, wherein R is straight-chain alkyl the quantity of carbon atoms is 10-18 and m is 7-11; the solvent is absolute ethyl alcohol. The heavy fuel oil asphaltene dispersant has the beneficial effects that the problem of sedimentation of marine fuel oil asphaltene can be solved, not only can sedimentation of the asphaltene in the fuel oil be prevented, but also the settled asphaltene in the fuel oil can be dispersed; meanwhile, the marine fuel oil asphaltene dispersant provided by the invention has the characteristics of being good in dispersibility, low in cost and simple and convenient to use.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Colorful electrophoretic display with electric field response photonic crystal characteristics and preparation method and display method thereof

The invention discloses a preparation method of a colorful electrophoretic display with the electric field response photonic crystal characteristics. The preparation method comprises the steps of preparation of electrophoretic display particles, preparation of electrophoretic display liquid, preparation of microcapsules and preparation of the display. According to the preparation method, pigment particles are replaced with monodispersed nanoparticles, various color development of the single particles can be achieved under different voltages, and the color development effect is obvious; furthermore, the agglomeration and sedimentation problems of the monodispersed nanoparticles in the preservation process are solved through microencapsulation, the flexible color display effect is achieved by printing or applying the microcapsules to a flexible substrate, and the important application value is achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

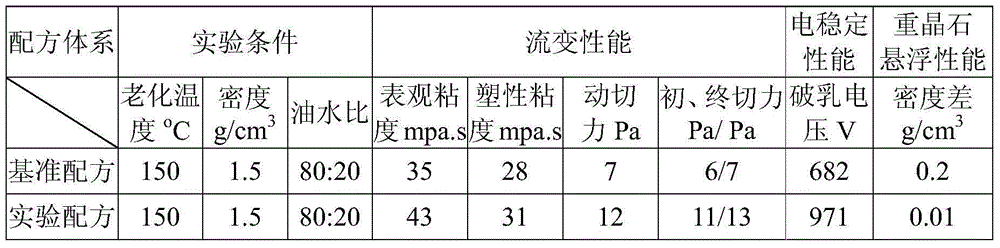

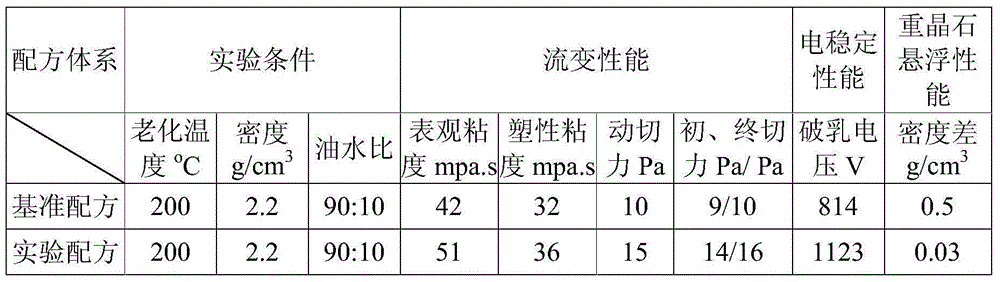

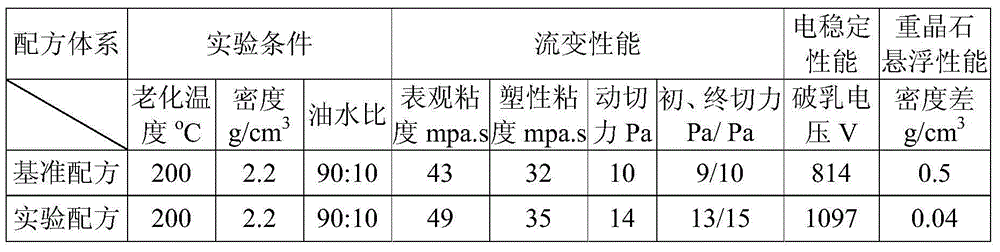

Enhancer for high-temperature resistant oil-based drilling fluid as well as preparation method and application of enhancer

InactiveCN104592959ASolve barite settlementSolve poor rock-carrying abilityDrilling compositionDimer acidEther

The invention provides enhancer for high-temperature resistant oil-based drilling fluid as well as a preparation method and application of the enhancer. The preparation method comprises the following steps: a, sequentially adding 150-250 parts by weight of dimer acids, 100-150 parts by weight of triethylene glycol momobutyl ether, 30-50 parts by weight of diethanol amine into a reaction container; stirring and performing heat reaction; b, adding 10-17 parts by weight of organic enamine for further reacting, and reducing the temperature after the reaction is finished; c, adding triethylene glycol momobutyl ether having the same weight parts in the step a and 20-30 parts by weight of propylene carbonate, uniformly stirring so as to obtain the enhancer for the high-temperature resistant oil-based drilling fluid. The invention also provides the enhancer for the high-temperature resistant oil-based drilling fluid prepared by using the preparation method and application of the enhancer in the oil-based drilling fluid. According to the enhancer, the shearing force of the oil-based drilling fluid can be improved, and the problems of barite sedimentation and poor carrying debris capability caused by low shearing force of the oil-based drilling fluid with high oil-water ratio can be solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

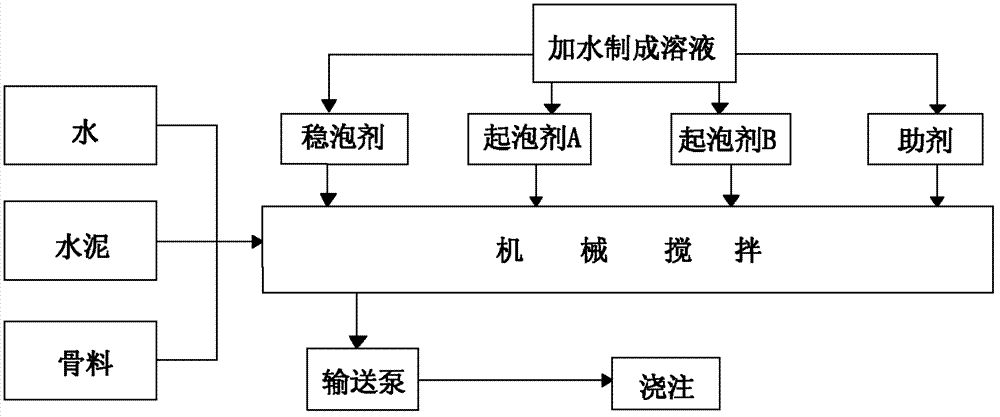

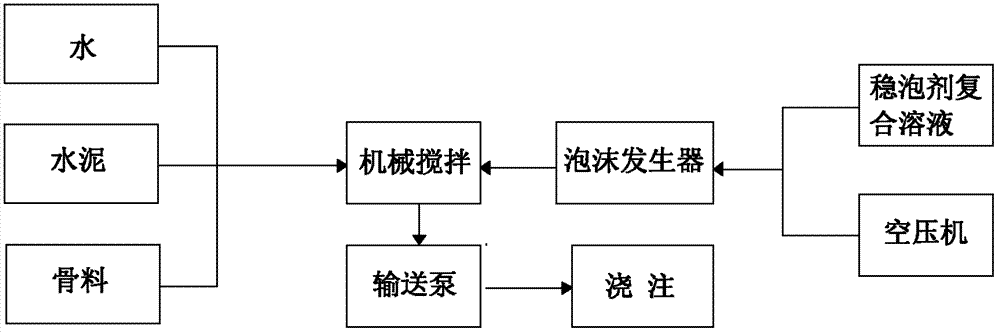

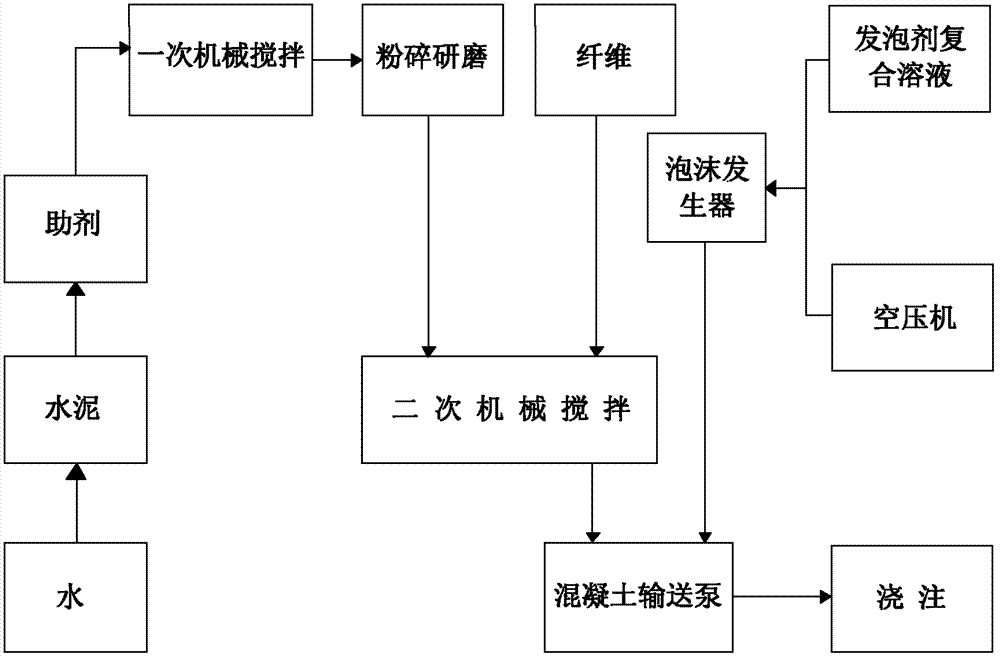

Inorganic foamed concrete insulation board and preparation method thereof

InactiveCN103086734AImprove compressive strengthSolve subsidence and subsidenceCeramicwareThermal conductivityFoam concrete

The invention provides an inorganic foamed concrete insulation board and a preparation method thereof. The insulation board comprises foamed concrete, and has density of 160-250kg / m<3>, compressive strength of 0.3-0.5 MPa, and coefficient of thermal conductivity of 0.05-0.062 W / m.K. The prepared insulation board has the characteristics of low unit weight and good heat insulation effect, and can be widely used as an insulation material in the field of construction.

Owner:杨奎利

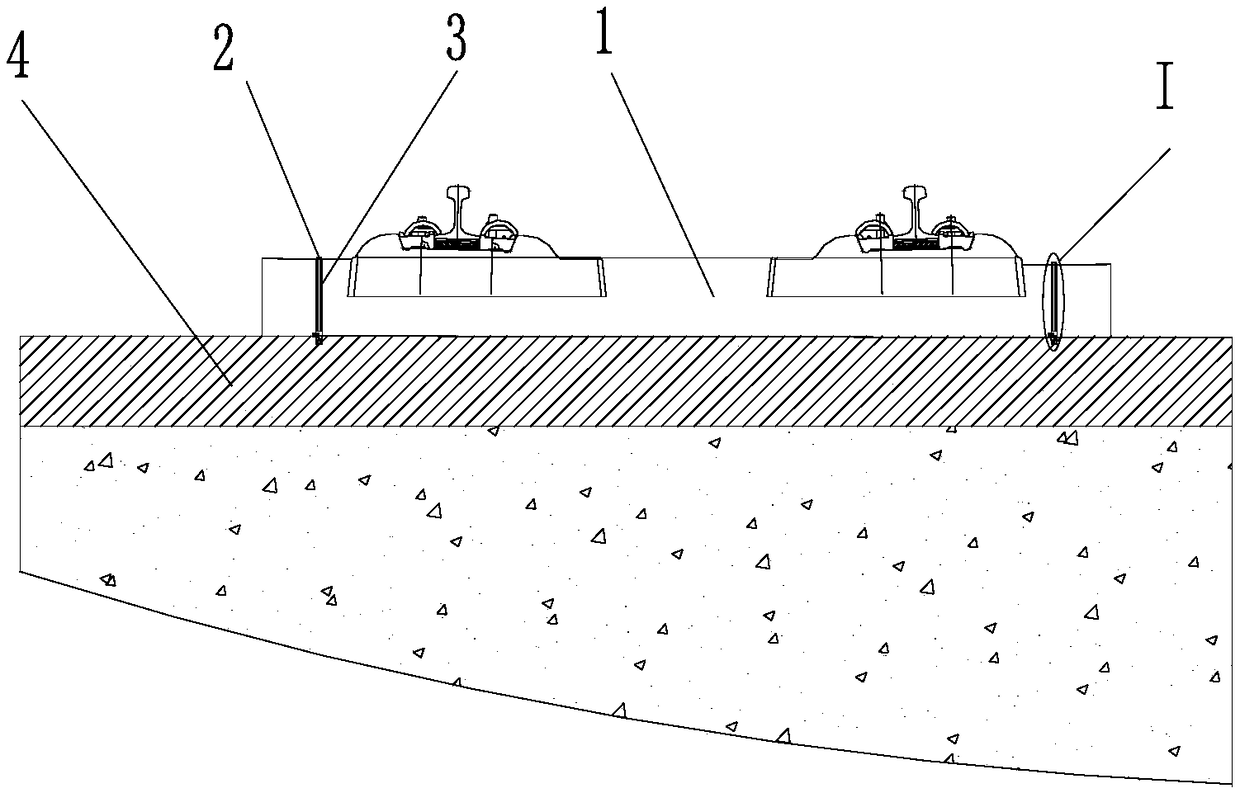

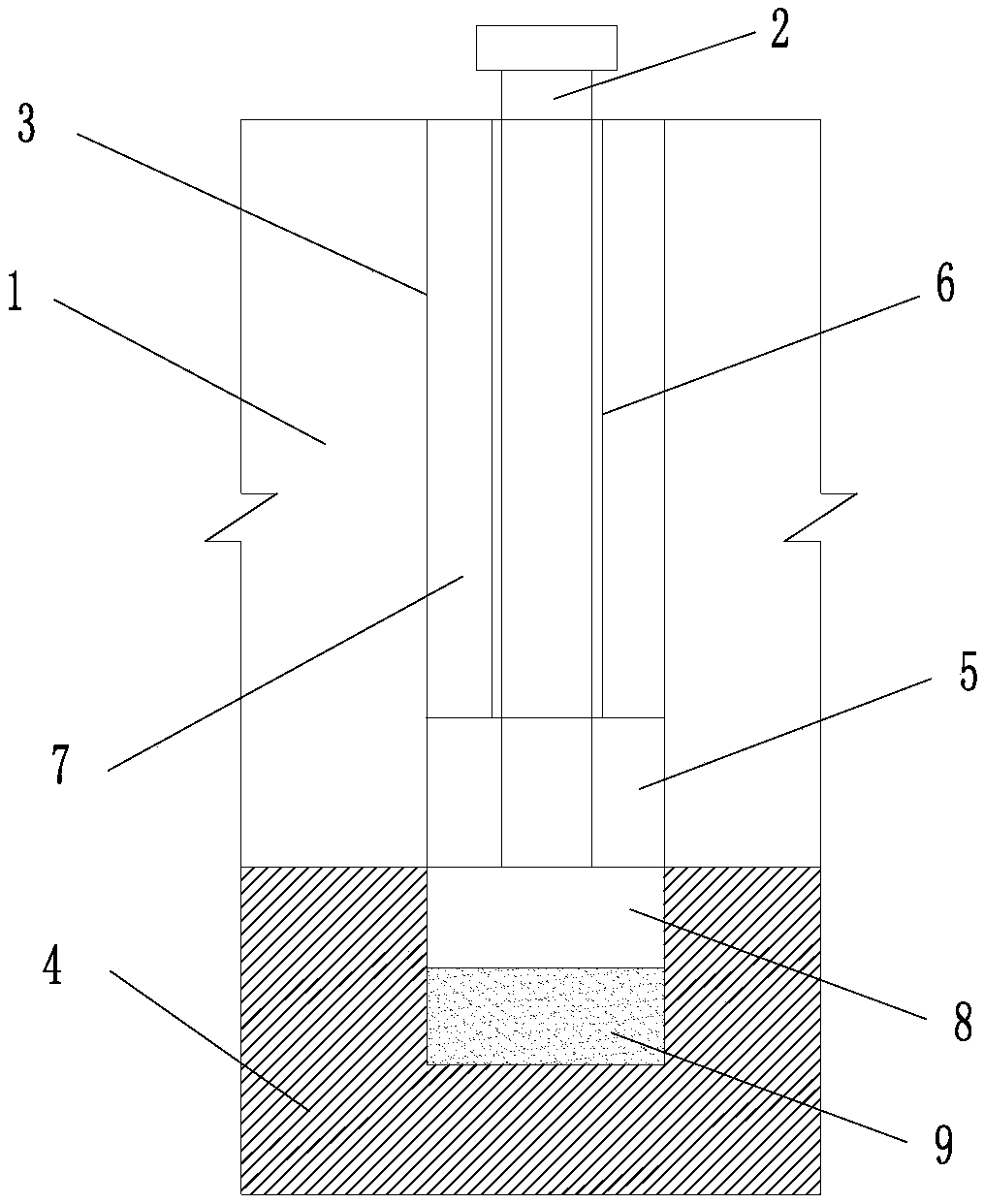

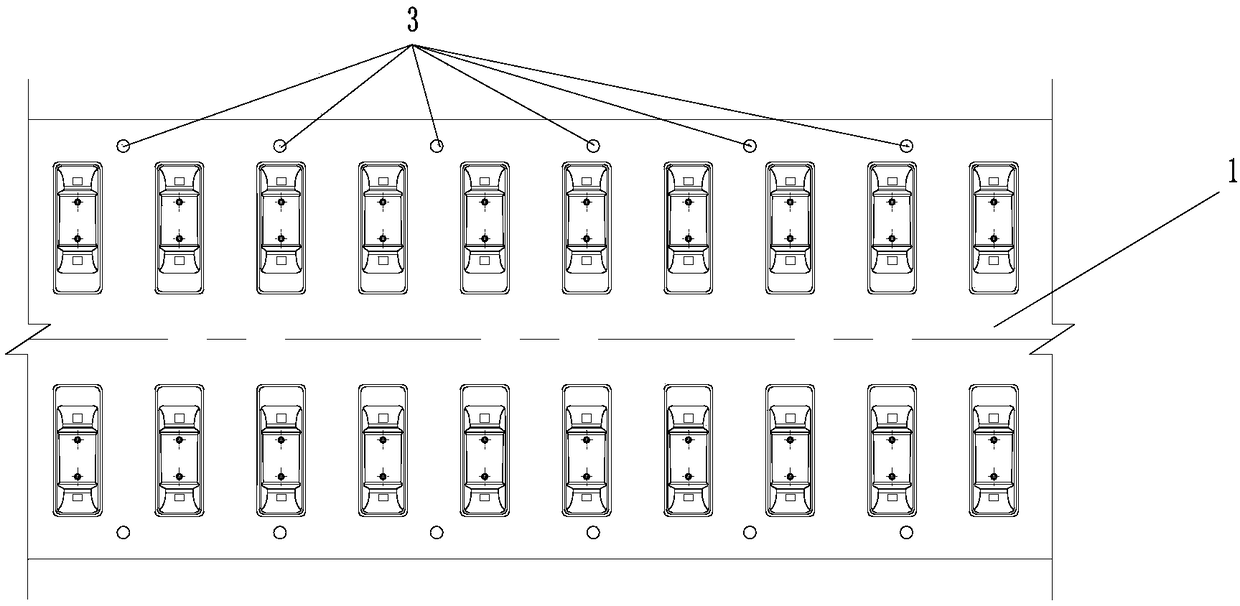

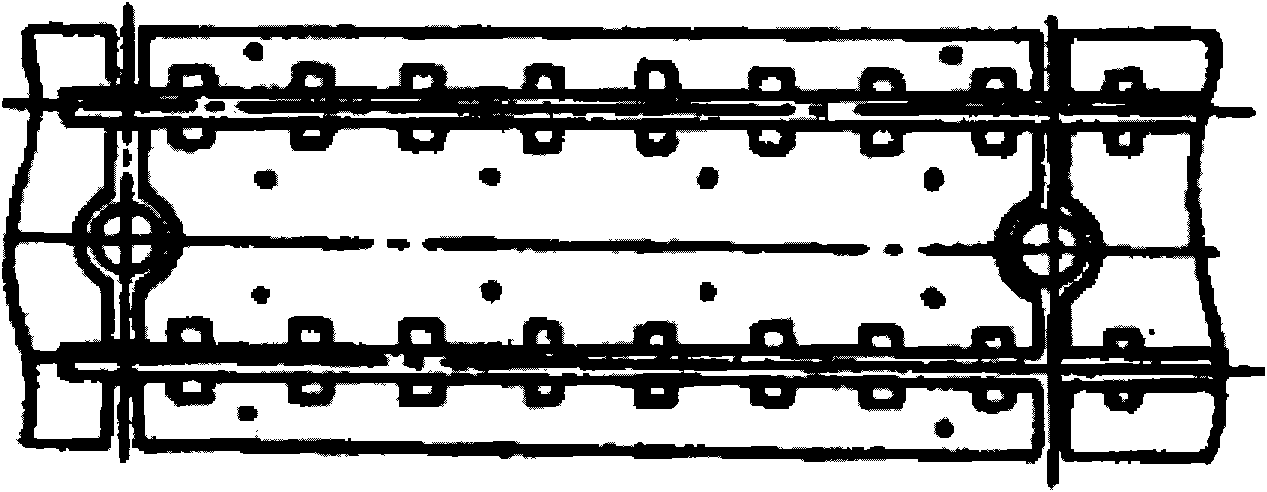

Ballastless track structure settlement lifting device and lifting method thereof

PendingCN108951322ASettle settlementSimple equipmentBallastwayRailway track constructionEngineeringControllability

The invention discloses a ballastless track structure settlement lifting device and a lifting method thereof. The device is used for lifting the ballastless track plate, and comprises screw rods embedded in two sides of the ballastless track plate and arranged at intervals along an extension direction thereof; the ballastless track plate has pre-burying holes for pre-burying the screw rods, the pre-burying holes vertically pass through the allastless track plate and extend downward to a concrete cushion layer, the screw rods are sleeved with nuts which are threadably connected with the screw rods, the outer walls of the screw rods are sleeved with sleeves, mortar columns are poured into annular gaps between the outer walls of the sleeves and the inner walls of the pre- burying holes, the mortar columns are integrated with the ballastless track plate by being cemented with the inner walls of the burying holes, and the bottoms of the mortar columns are in contact with the top end faces of the nuts. As the ballastless track structure settlement lifting device is not limit by the ballastless track structure and the operation space, the ballastless track structure settlement lifting device is easy to operate, has high lif accuracy, good controllability and high efficiency, and can effectively solve the settlement problem of ballastless track in a special section.

Owner:中铁四院集团工程建设有限责任公司

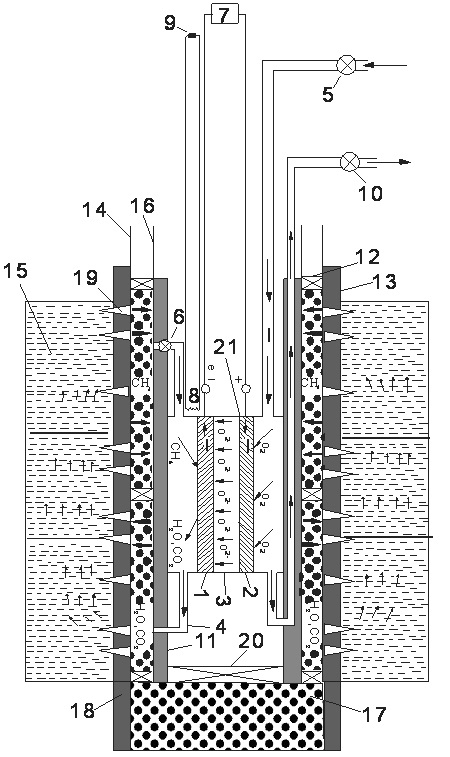

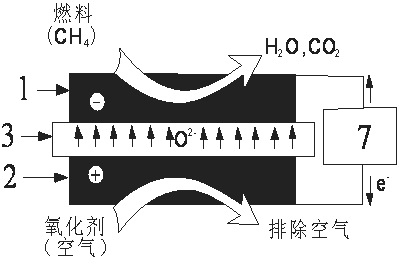

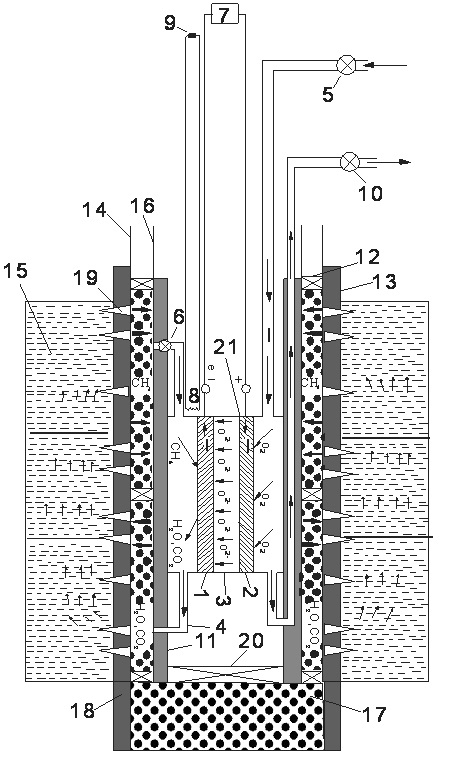

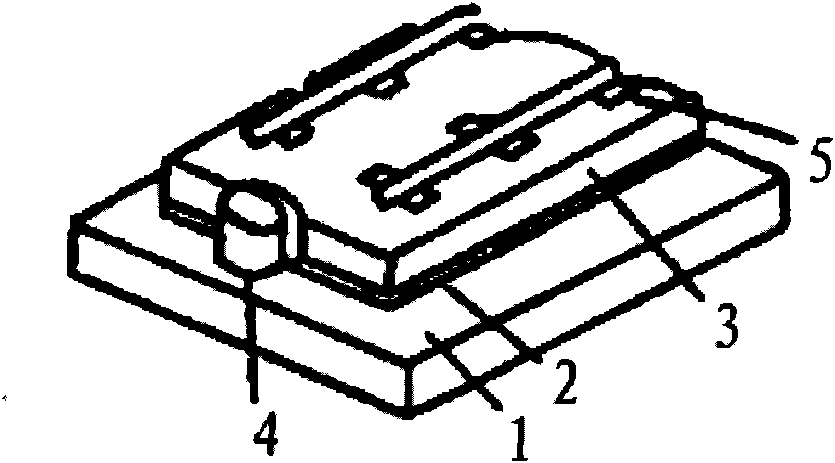

Gas hydrate mined by adopting low-temperature solid oxide fuel cell method and device thereof

ActiveCN101915075ASettle settlementSolve the blockageOther gas emission reduction technologiesFluid removalElectrochemical responseEngineering

The invention relates to a gas hydrate mined by adopting a low-temperature solid oxide fuel cell method and a device thereof. CH4 mined by using CO2 replacement is introduced into a low-temperature solid oxide fuel cell for generating electrochemical reaction, and then generates electric energy; and then the produced CO2 is introduced into a hydrate storage layer for replacing CH4 to ensure that the device continuously circularly operates. The invention has the advantages of not damaging stratum, realizing the zero emission of CO2, solving the problems of production, storage and transportation of the CO2 with large volume while obtaining the energy contained in the hydrate stratum, effectively lowering the investment of the device and the cost because the fuel cell is convenient to assemble and can be recycled, and reducing the cost because the gas hydrate can be mined by using the low-temperature solid oxide fuel cell method through using wide hydrocarbon fuel.

Owner:中部知光技术转移有限公司

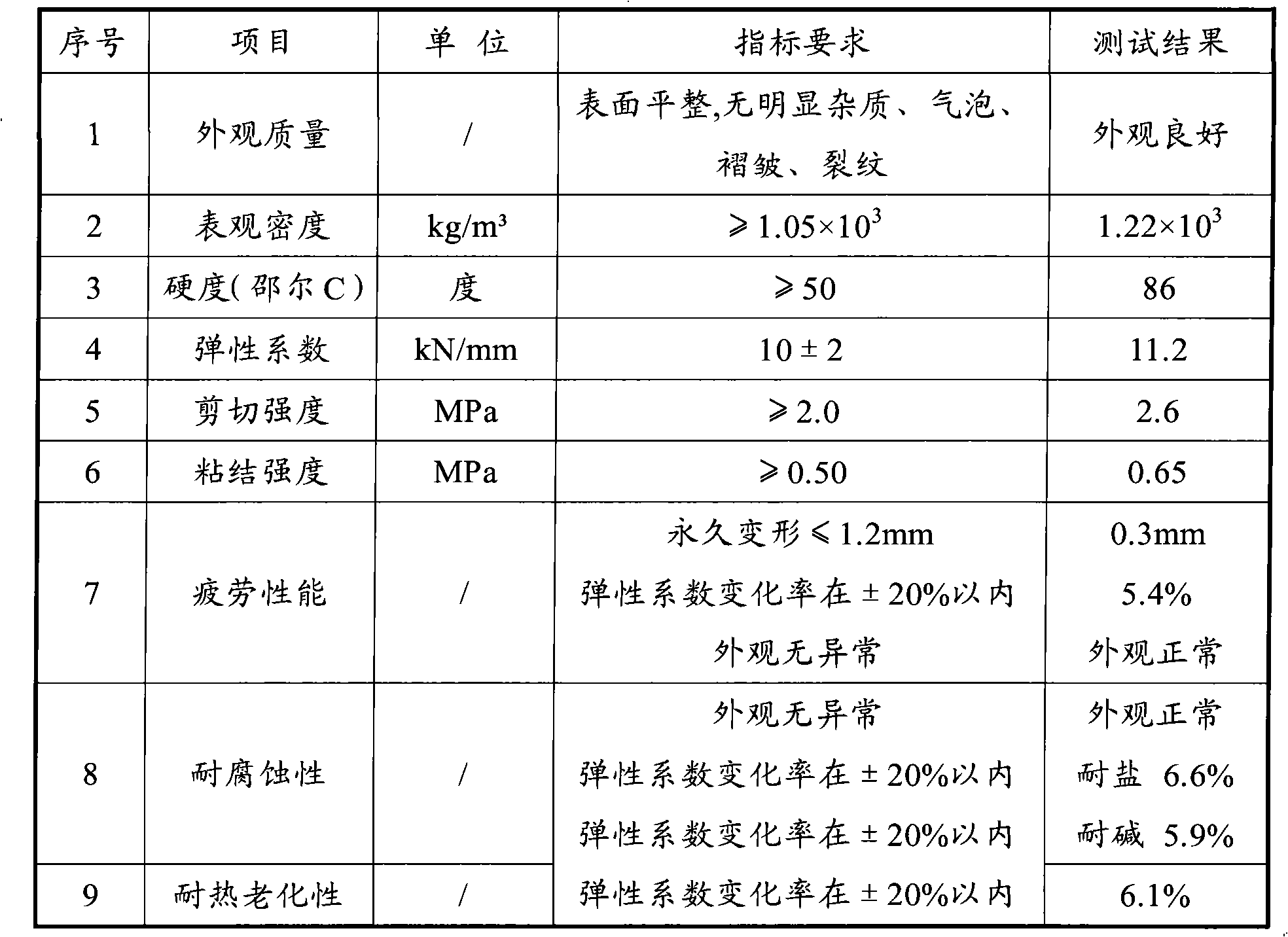

Resin composition for filling unit plate type ballastless track convex baffling platform

The invention provides a resin composition for filling a unit plate type ballastless track convex baffling platform, a preparation method and a using method thereof. The resin composition comprises a component A and a component B, and calculated according to parts by weight, the component A comprises: 100 parts of polyolefin polyhydric alcohol, 10 to 100 parts of filler, 10 to 80 parts of plasticizer, 1 to 10 parts of thixotropic agent, 5 to 20 parts of chain extender, 0 to 5 parts of antiager and 0 to 2 parts of defoaming agent; and the component B comprises 5 to 50 parts of isocyanate. The resin composition can have the function of positioning the track plate and transferring load with the convex baffling platform after being cured. The resin composition adopts the polyolefin polyhydric alcohol as main body material, can improve the waterproof, low-temperature resistant and antiaging characteristics of the polyurethane material and prolongs the service life of the product.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

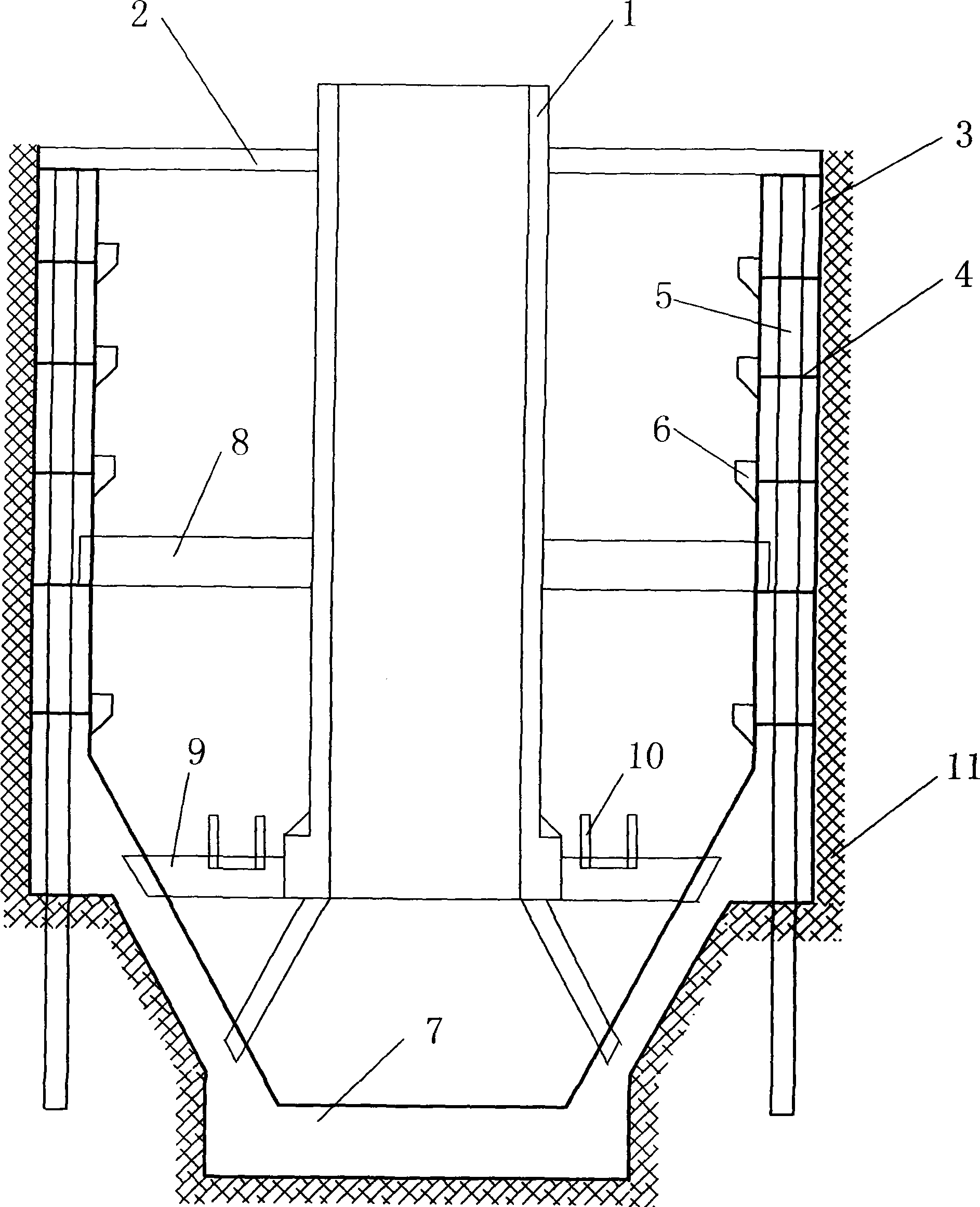

Method for implementing hot rolling swirl pool constructional engineering by top-down method

ActiveCN101372872ASolve the waterproof problemSettle settlementBulk storage containerBrickWater leakage

The invention relates to a method for constructing a hot rolling swirl pool structure project by the top-down construction method. The specific method comprises the following steps: digging measurement pile foundation holes, making brick protection walls, pouring to for measurement piles, dividing the part of the outer barrel above the trapezoid-shaped bottom of the swirl pool into a plurality of sections with different heights; digging earth from the top to the bottom in sections and taking the earth wall of the dug earth as a bottom die of the outer barrel and a natural earth die of an outside die; supporting and establishing a combination steel die plate inner die on the inner side; pouring concrete together with the measurement piles; conducting the construction for the trapezoid-shaped bottom; pouring an ring-shaped bracket inside a construction joint between sections; and conducting the construction for an inner barrel of the swirl pool, a water absorption tank platform, a pump station platform and a top plate platform. In the invention, the pool outer barrel is constructed from the top to the bottom in sections by the top-down construction method, the ring-shaped bracket is poured inside the construction joint between sections, and the measurement piles are arranged in the poor outer barrel, thereby basically solves the waterproof, settlement and anti-floating problems, utilizing the construction technique and saving cost. In the hot rolling swirl pool constructed through the method of the invention, no settlement or upward-floating phenomenon occurs, no construction joint is generated, and no quality problem of water leakage or water seepage is caused.

Owner:MCC SHIJIU CONSTR

High-concentration carbon hole solution for PCB and preparation method thereof

InactiveCN105063681AIncrease concentrationIncrease the effective concentrationPrinted element electric connection formationHigh concentrationSurface-active agents

The invention discloses a high-concentration carbon hole solution for a PCB and a preparation method thereof. The finally obtained high-concentration carbon hole solution for the PCB comprises, by weight, 7-9% of conductive carbon materials, 4-8% of surface active agents, 4-8% of organic dispersing agents, 1-5% of wetting agents, pH conditioning agents and the balance water; the use amount of the pH conditioning agents enables the pH value of the high-concentration carbon hole solution for the PCB to be adjusted to 9.5-10.5. The high-concentration carbon hole solution is quite high in conductivity, good in stability and high in effective concentration, and avoids the settling problem in the using process; moreover, the frequency of replacing bath solutions is reduced, and the high-concentration carbon hole solution is nontoxic, free of pollution and environmentally friendly.

Owner:韶关硕成化工有限公司

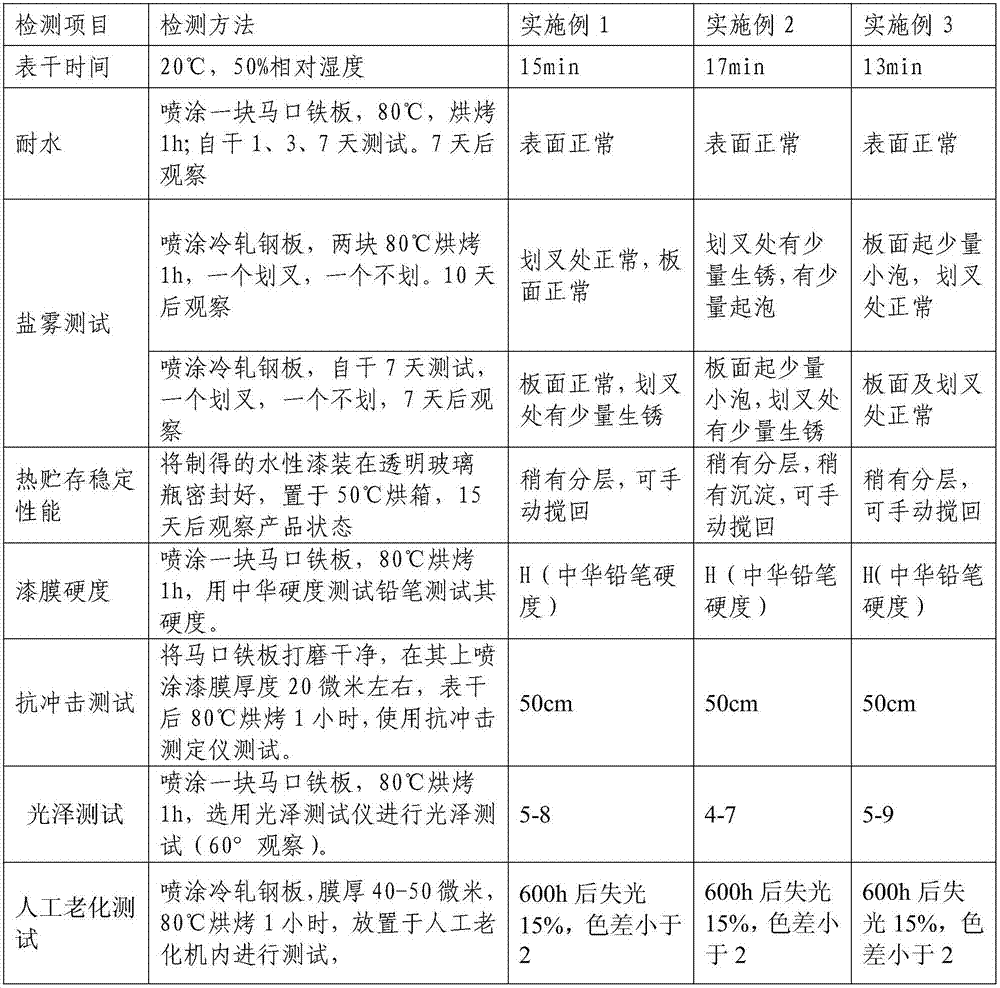

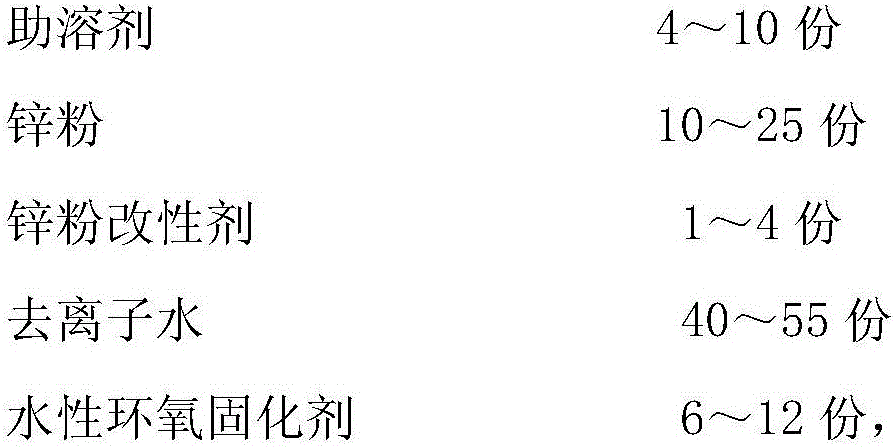

Environment-friendly waterborne coating used for dip coating of track shoe and preparation method thereof

InactiveCN107474700AImprove protectionSmall smellAnti-corrosive paintsMetallic material coating processesEpoxyDip-coating

The invention discloses an environment-friendly waterborne coating used for dip coating of track shoe. The environment-friendly waterborne coating is prepared from the following raw materials in percentages by weight: 35 to 50% of a waterborne acrylic modified epoxy emulsion, 0.25 to 0.75% of an antifoaming agent, 1.5 to 3.25% of a dispersing agent, 18 to 28% of deionized water, 0.38 to 0.93% of a neutralizing agent, 0.21 to 0.79% of a leveling and wetting agent, 1.51 to 2.39% of a flash-rust inhibitor, 0.35 to 1.23% of carbon black, 5.23 to 8.36% of iron black, 6.43 to 8.07% of barium sulfate, 6.22 to 8.69% of composite zinc phosphate, 4.31 to 5.57% of a thixotropic anti-settling agent, 3.43 to 5.07% of aluminum tripolyphosphate, 2.43 to 3.27% of talcum powder, 0.33 to 0.67% of matting powder and 0.32 to 0.58% of a thickening agent. The waterborne coating prepared by using the method provided by the invention has the following advantages: the VOC is no more than 85 g / L; the odor is low; the environment is avoided from pollution; meanwhile, the waterborne coating has matte, water resistance, salt fog resistance, excellent surface drying time, stable heat storage performance, and excellent coating film mechanical strength and impact resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

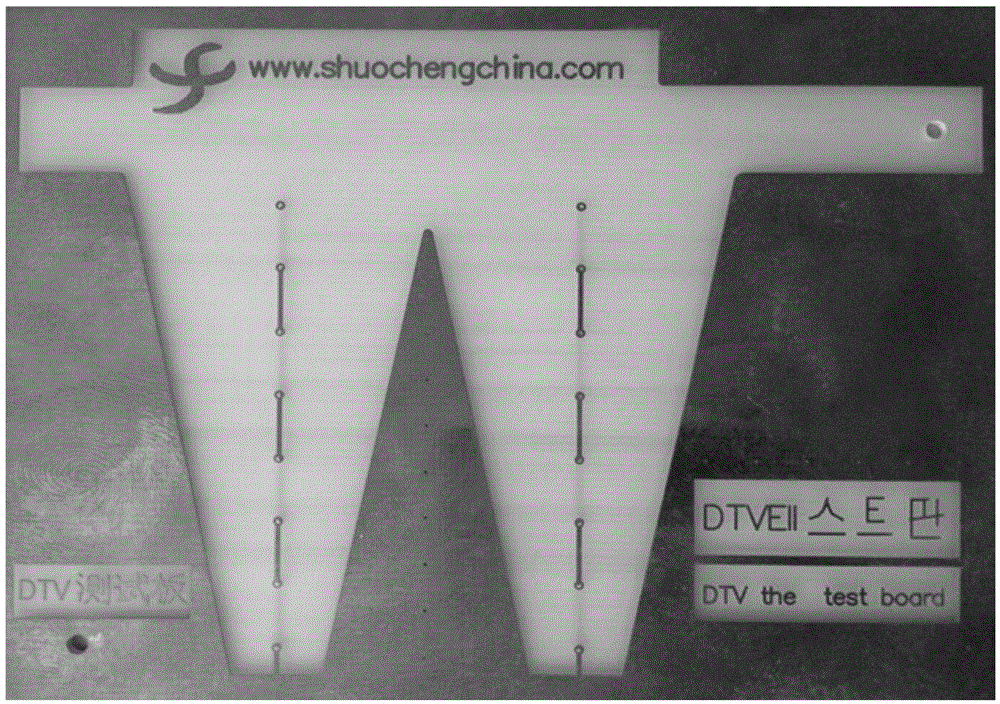

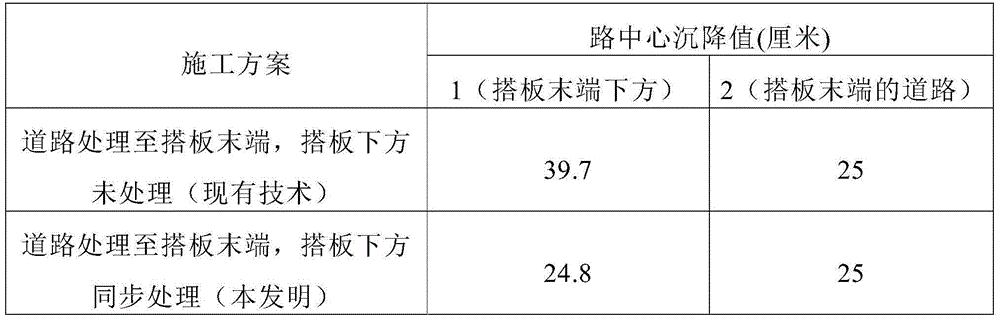

Bridge-head bumping processing method for relatively deep mud soft soil foundation behind abutment

InactiveCN105220620ASettle settlementReduce jumpingRoadwaysBridge structural detailsCrushed stoneRoad surface

The invention discloses a bridge-head bumping processing method for a relatively deep mud soft soil foundation behind an abutment. The bridge-head bumping processing method comprises a step of firstly arranging a bridge-head transition slab at a position behind the abutment and simultaneously performing road structural layer construction on the road below the bridge-head transition slab. The method further comprises the steps of laying a dry jet mixing pile layer below the bridge-head transition slab along the extension direction of a road; and after laying of the dry jet mixing pile layer is finished, laying a graded broken stone unit layer on the pile top of the dry jet mixing pile layer in the length range of the bridge-head transition slab; wherein a plurality of steel-plastic composite geogrid layers are sandwiched in the graded broken stone unit layer; and a cement stable broken stone layer is laid between the top layer of the graded broken stone unit layer and the bridge-head transition slab. The bridge-head bumping processing method has functions of effectively settling a bridge-head settlement problem at the relatively deep mud soft soil foundation behind the abutment, effectively reducing number of times of bridge-head bumping at the head end behind the abutment, preventing bridge-head bumping at the tail end behind the abutment, realizing high comfort and high stability in driving to the pavement behind the abutment, and greatly improving safety on a driving pavement.

Owner:HEFEI MUNICIPAL DESIGN INST

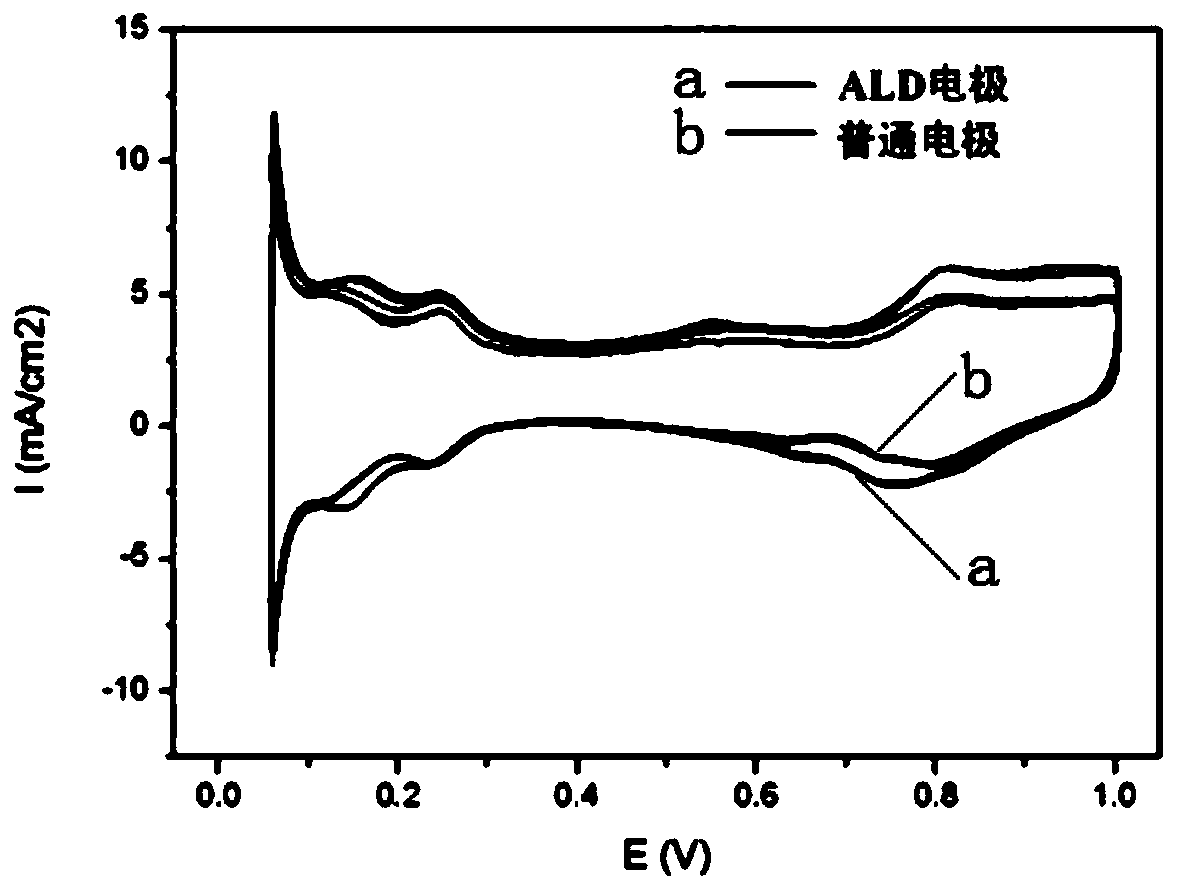

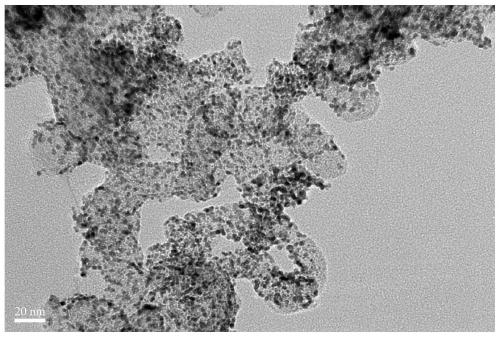

Preparation method of low-temperature proton exchange membrane fuel cell membrane electrode

PendingCN111162299AAvoid Catalyst SettlingReduce the amount of PtFinal product manufactureCell electrodesGas diffusion electrodeTemperature treatment

The invention discloses a preparation method of a low-temperature proton exchange membrane fuel cell membrane electrode. The preparation method comprises the following steps of preparing a carbon paper surface microporous layer (MPL), namely printing a carbon powder and PTFE mixed solution on the surface of a carbon paper subjected to hydrophobic treatment, drying, carrying out high-temperature treatment in an inert atmosphere, and cooling to obtain a gas diffusion layer (GDL) of which the surface is provided with an MPL layer; depositing Pt nanoparticles directly on the MPL layer by adoptingan atomic layer deposition (ALD) technology to form a continuous gas diffusion electrode (GDE); uniformly spraying the ion resin onto the electrode; and assembling the membrane electrode according toan order of a cathode gas electrode, a proton exchange membrane and an anode gas diffusion electrode. The catalyst layer prepared by the atomic layer deposition technology is very clean, the preparation of a thin catalyst layer is facilitated, the pore structure is rich, the uniformity is good, the traditional thought of firstly preparing a catalyst slurry and then preparing an electrode catalystlayer is broken through, and the prepared membrane electrode is beneficial to improving the performance of a large-current density region of a fuel cell.

Owner:SHANGHAI JIAO TONG UNIV

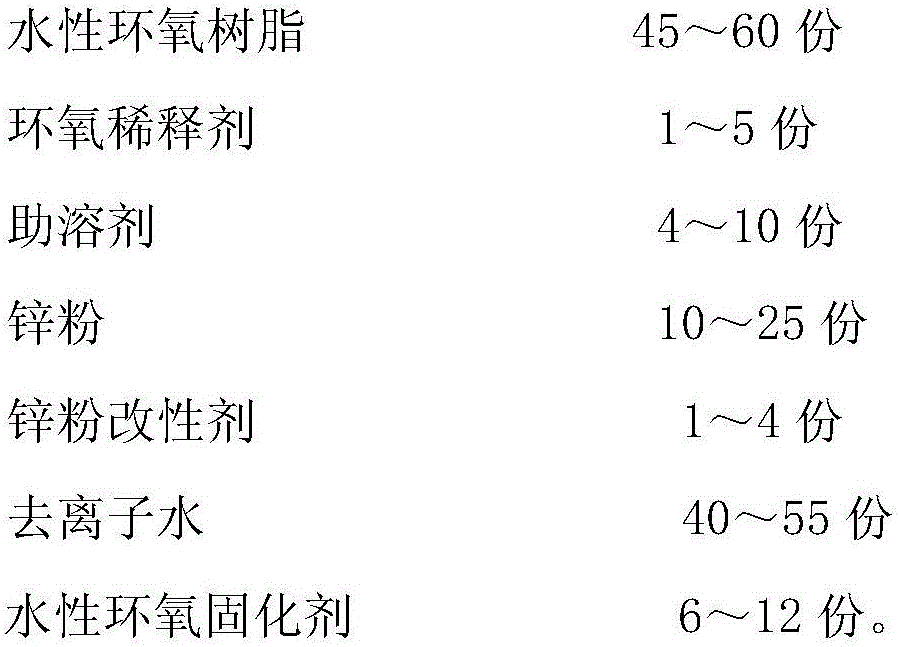

Water-borne epoxy primer

ActiveCN105838193AImprove dispersion stabilitySolve reunionAnti-corrosive paintsEpoxy resin coatingsEpoxyCalixarene

The invention belongs to the field of coating, and particularly relates to a water-borne epoxy primer. Calixarene molecules are grafted to nano zinc powder through isocyanate, modified zinc powder is entwisted to a certain degree through grafted calixarene and the epoxy resin molecule structure in the stirring process, the dispersing stability of the zinc powder in the primer material is promoted, and the problems of agglomeration and sedimentation of the zinc powder in resin are solved. The water-borne epoxy primer is free of pollution to the environment, convenient to construct and harmless to the health of constructors. The drying speed of a primer film is high, the adhesive force is good, the mechanical strength is high, and the antiseptic property is excellent.

Owner:江苏永阳新材料科技有限公司

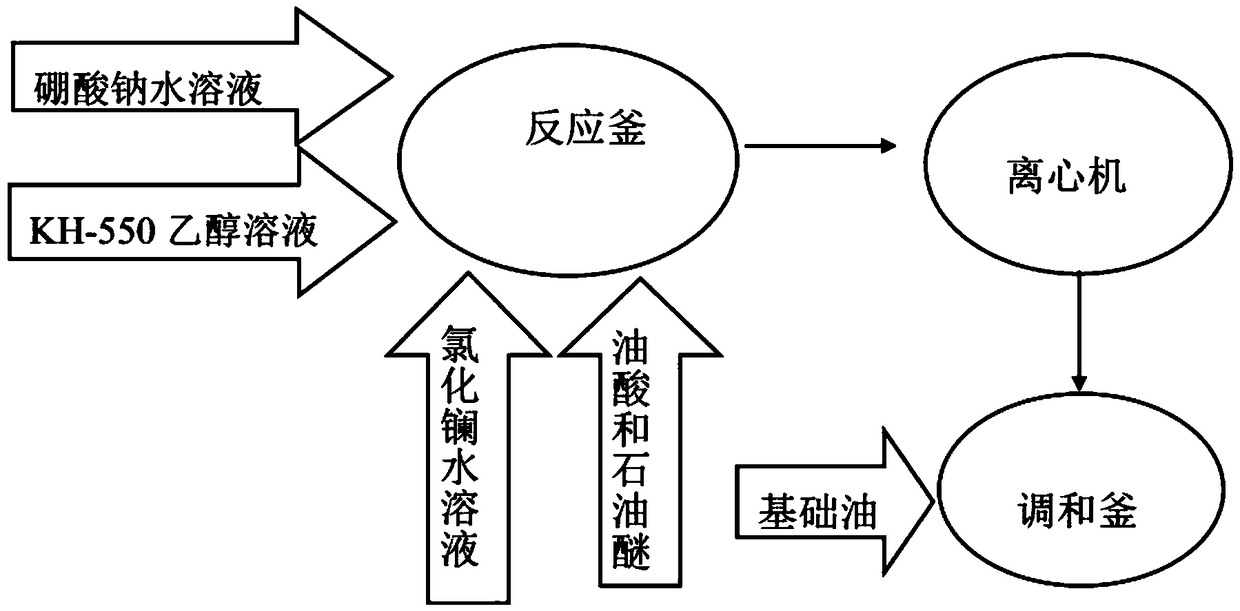

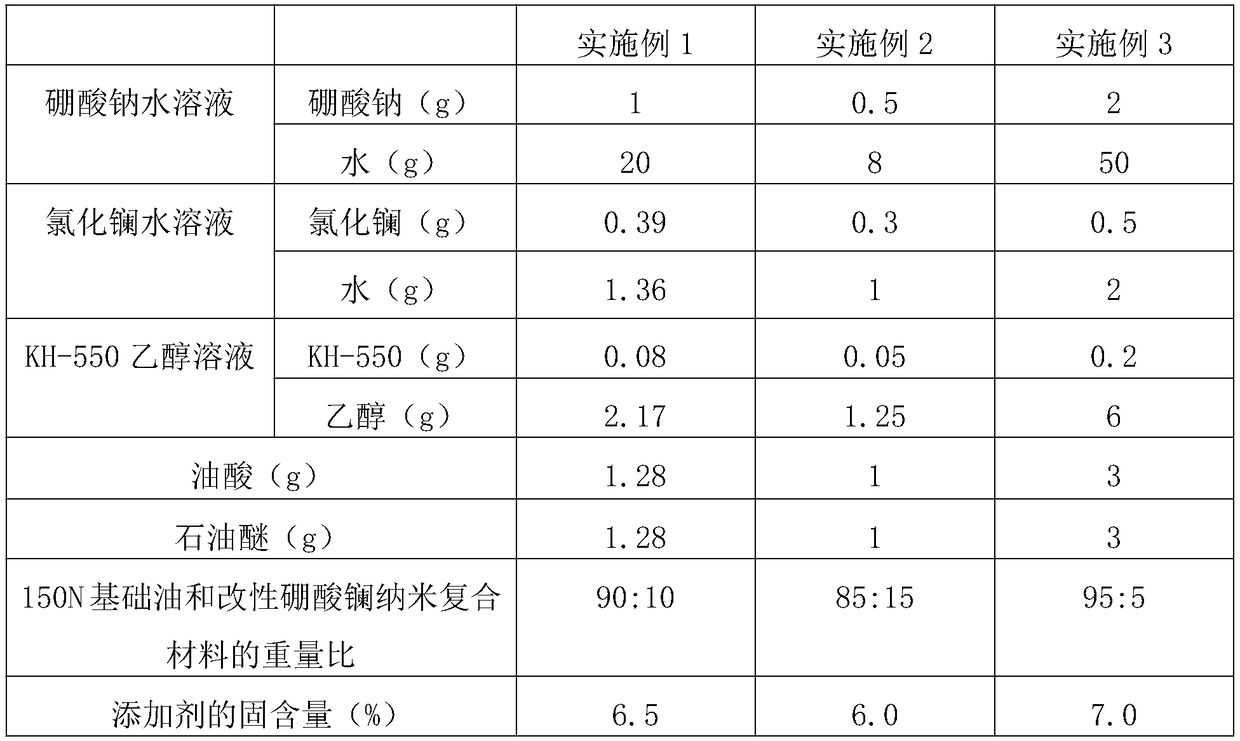

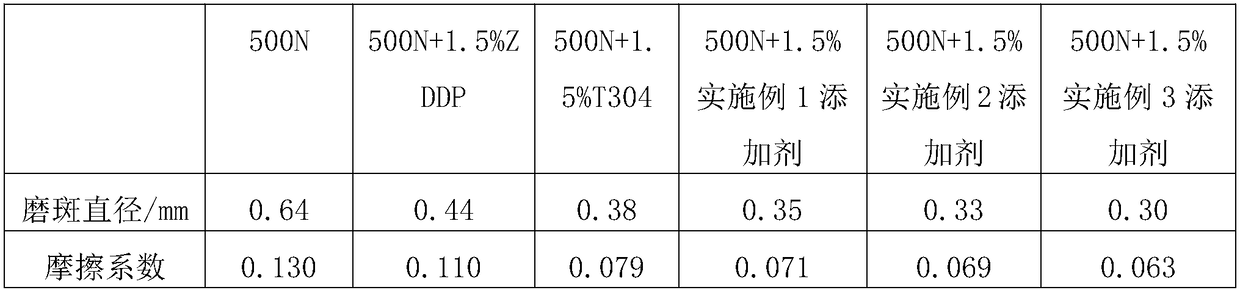

Anti-friction energy-saving additive with dispersed solution of modified nano lanthanum borate and basic oil and preparation method thereof

InactiveCN108774564AEnvironmentally friendlyIn line with the concept of green production and environmental protectionAdditivesFriction reductionDispersity

The invention discloses an anti-friction energy-saving additive with dispersed solution of modified nano lanthanum borate and basic oil and a preparation method thereof. The anti-friction energy-saving additive is prepared from a modified lanthanum borate nano composite material and basic oil, wherein the weight ratio of the modified lanthanum borate nano composite material to the basic oil is (5-15):(85-95); the modified lanthanum borate nano composite material is prepared from the following substances in parts by weight: 0.5-2 parts of sodium borate, 0.3-0.5 part of lanthanum chloride, 0.05-0.2 part of KH-550, 1-3 parts of oleic acid and 1-3 parts of petroleum ether. The anti-friction energy-saving additive and the preparation method thereof disclosed by the invention have the beneficialeffects that the modified lanthanum borate nanocomposite material is prepared by combination with a flotation method in the preparation process, the secondary particle-size distribution of a preparedproduct is narrow, the problem of settlement of the additive in lubricating oil is overcome, and meanwhile, the problem that a lanthanum-borate type product is decomposed when meeting water is solved; the additive shows outstanding anti-friction property in the lubricating oil, and has good dispersity in the lubricating oil; the effect of reducing the friction coefficient among workpiece equipment can be achieved, so that the effects of emission reduction, energy conservation and friction reduction and the like of the workpiece equipment are achieved.

Owner:李立强

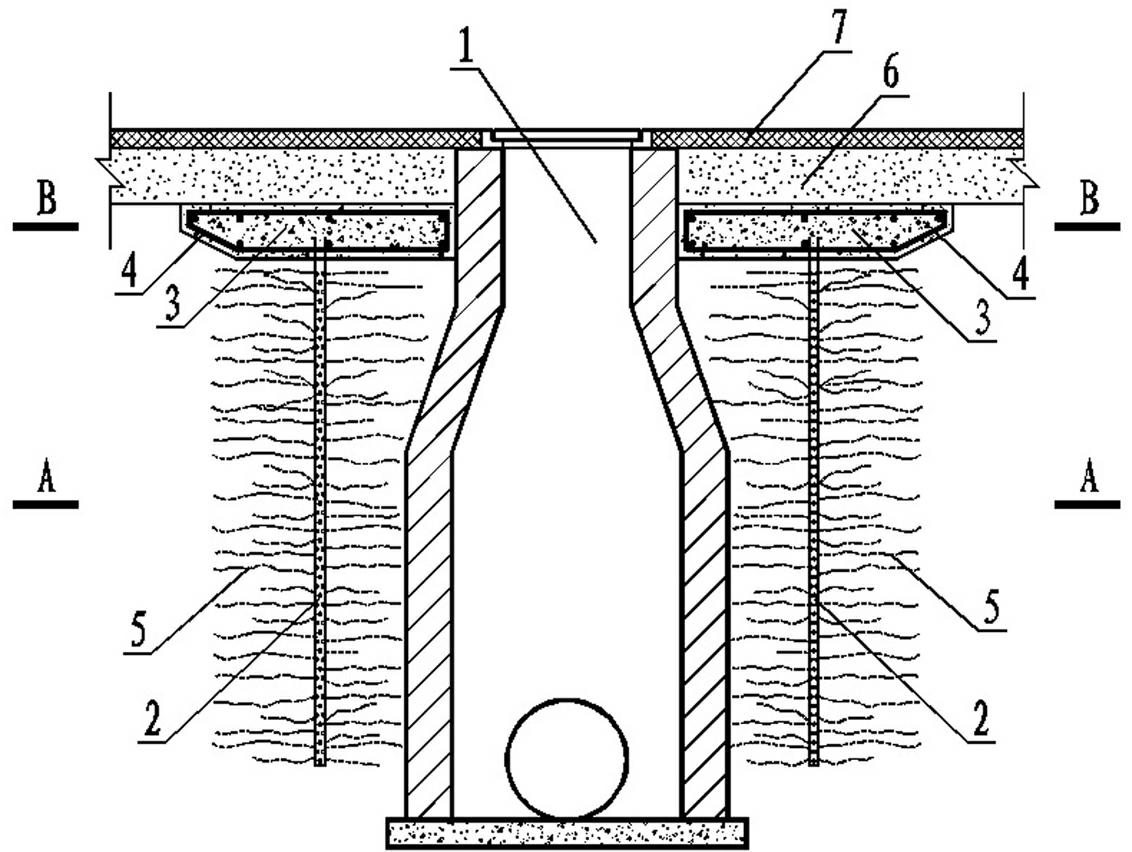

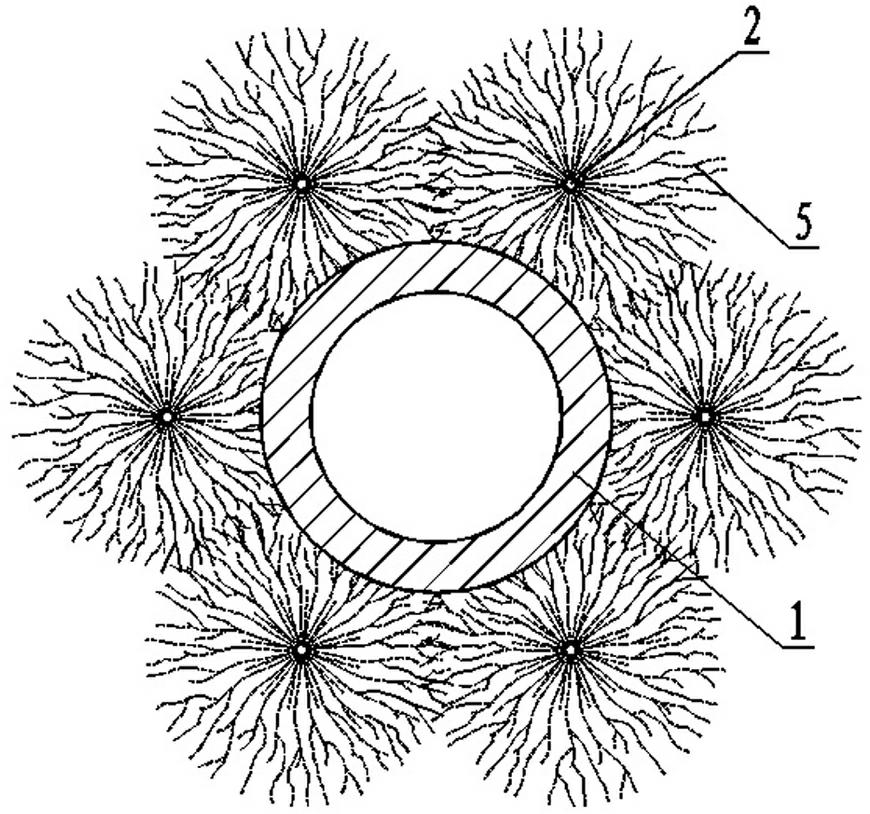

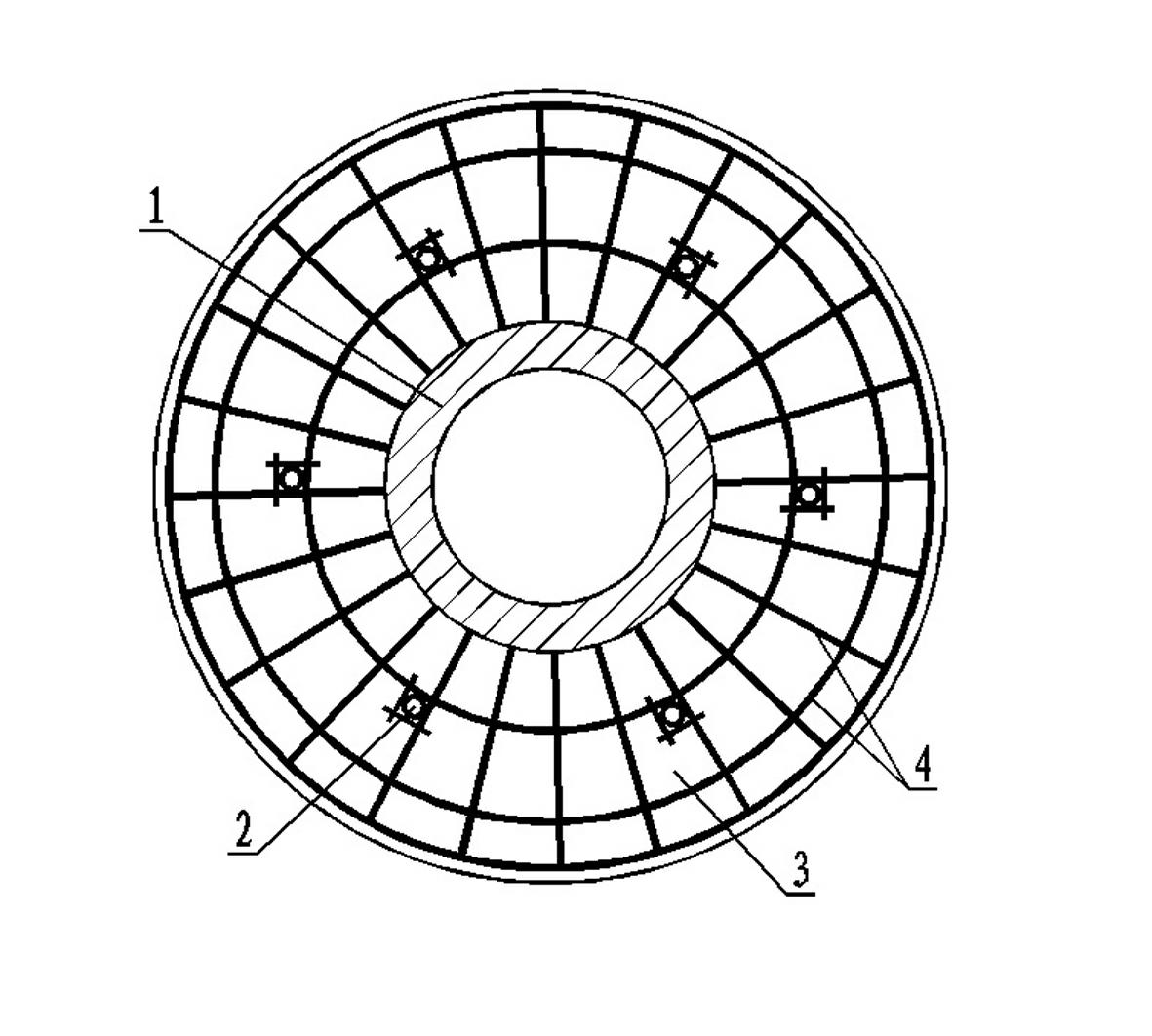

Construct and construction method of preventing pavement around manhole from subsiding

The invention relates to a construct and a construction method of preventing a pavement around a manhole from subsiding, which belong to the field of urban road projects and relate to a road structure and a method of strengthening the pavement around the manhole. The construct mainly comprises the manhole, grouting pipes, cushion caps and bar mat reinforcements, wherein the grouting pipes are arranged at the external side of the manhole circularly; the cushion caps are supported on the grouting pipes; cement paste is injected into the grouting pipes so that soil is solidified and the density of the soil is improved; the cement paste which permeates through the soil is in a capillary shape and is distributed around the grouting pipes so that the friction force between the grouting pipes and the soil is improved; and a basement layer and a surface layer of a road are supported by the grouting pipes and the cushion caps so that the pavement does not settle. The construction quality of the road is ensured; the settlement of the pavement around the manhole is effectively prevented; the driving safety is ensured; and the maintenance cost of the pavement is reduced through the construct and the construction method of preventing the pavement around the manhole from subsiding.

Owner:刘建华

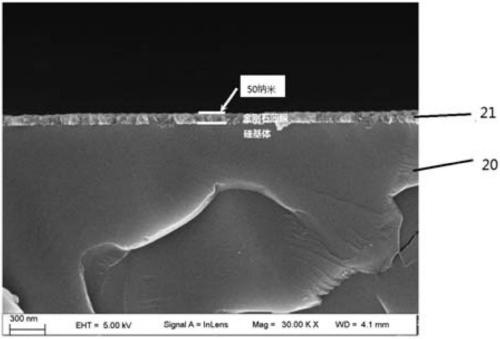

Workpiece with high-density nano-diamond thin film on surface, and preparation method of high-density nano-diamond thin film

PendingCN109097754ASolve the problem of low nucleation densityReduce nucleation densityChemical vapor deposition coatingHigh densityNitrogen

The invention provides a preparation method of a high-density nano-diamond thin film. The preparation method comprises the steps that a workpiece substrate is subjected to surface pretreatment to enable the surface of the workpiece substrate to be positively charged or negatively charged; lysine is added into water to obtain a lysine solution, then nano-diamond powder is added into the lysine solution, and nano-diamond suspension liquid with the positively or negatively charged nano-diamond particle surface is obtained after ultrasonic dispersion; the workpiece substrate subjected to surface pretreatment is immersed into the nano-diamond suspension liquid with the opposite charge to the workpiece substrate, and ultrasonic oscillation is conducted, so that nano-diamond particles are adsorbed on the surface of the workpiece substrate; and after adsorption is completed, the workpiece substrate is taken out, cleaned and blow-dried through nitrogen, and then the diamond thin film is grown on the workpiece substrate through chemical vapor deposition equipment. According to the preparation method, the large-area nanometer-thickness high-density nano-diamond thin film can be prepared on acomplex workpiece, the thin film is high in quality and high in bonding force, the technology is simple, the cost is low, and the preparation method has broad application prospects in a nano-electromechanical system.

Owner:SHENZHEN INST OF ADVANCED TECH

Graphene composite conductive adhesive

InactiveCN104178053ALow melting pointLower sintering temperatureNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsNanoparticleSolvent

The invention provides a graphene composite conductive adhesive which is characterized by comprising the following components by the mass percentage: 30-65% of a conductive filler, 1-50% of grapheme, 1-20% of resin, 0.1-5% of an additive, and 10-67% of a main solvent. With combination of the graphene advantage of high thermal conductivity and the nano metal advantage of low melting point, the sintering temperature of the conductive adhesive can be allowed to be lower, and thus energy and costs are saved; with super large specific surface area of the graphene, nano particles can be uniformly dispersed between graphene sheet layers, the problems of graphene agglomeration and nano particle settlement in the conductive adhesive are avoided, and the conductive property and bonding strength of the conductive adhesive are improved. The conductive adhesive is simple in preparation process and suitable for mass production.

Owner:NANO TOP ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com