Liquid metal nanoparticles with core-shell structure and preparation method thereof

A liquid metal, core-shell structure technology, applied in metal processing equipment, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of stable existence of tiny particles, difficult to maintain stable existence, etc., to achieve low cost , easy to achieve, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of liquid metal nano particle with core-shell structure, its preparation method comprises the steps:

[0029] (1) Take 5ml liquid metal (Ga 75.5 In 24.5 ) mixed with 5ml glycerol in a beaker;

[0030] (2) Put the mixture of liquid metal and glycerol into an ultrasonic device to disperse for 5 minutes, take out the mixture and transfer the fine liquid evenly dispersed in the upper layer to another beaker;

[0031] (3) Continue to ultrasonically disperse the part of the fine liquid for 15 minutes to disperse the liquid metal into nanoparticles, and obtain liquid metal nanoparticles with a core-shell structure.

[0032] In step (2) and step (3), the ultrasonic power is selected as 70% of the rated power, ie 385W.

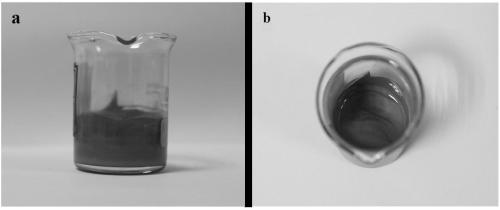

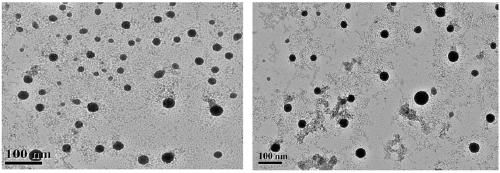

[0033] According to dynamic light scattering instrument and transmission electron microscope, the liquid metal nanoparticles with core-shell structure prepared in this example have a particle diameter distribution of 10-64 nm. figure 1 is the macrosco...

Embodiment 2

[0036] A kind of liquid metal nano particle with core-shell structure, its preparation method comprises the steps:

[0037] (1) Take 7.5ml liquid metal (Ga 75.5 In 24.5 ) mixed with 5ml glycerol in a beaker;

[0038] (2) Put the mixture of liquid metal and glycerol into an ultrasonic device to disperse for 5 minutes, take out the mixture and transfer the fine liquid evenly dispersed in the upper layer to another beaker;

[0039] (3) Continue to ultrasonically disperse the part of the fine liquid for 15 minutes to disperse the liquid metal into nanoparticles, and obtain liquid metal nanoparticles with a core-shell structure.

[0040] In step (2) and step (3), the ultrasonic power is selected as 70% of the rated power, ie 385W.

[0041] According to the dynamic light scattering instrument and the transmission electron microscope, the diameter distribution of the liquid metal nanoparticles with the core-shell structure prepared in this embodiment is 10-68 nm.

Embodiment 3

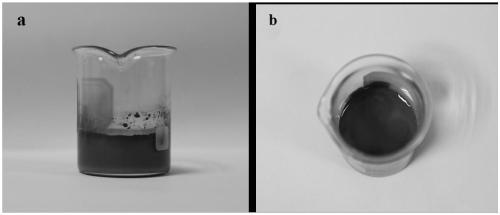

[0043] A liquid metal nanoparticle with a core-shell structure, the difference between its preparation method and Example 1 is that the liquid metal Ga in the step (1) of Example 2 is 75.5 In 24.5 Adjust the volume ratio with glycerol to 2:1, that is, 10ml liquid metal Ga 75.5 In 24.5 Mix with 5ml glycerol.

[0044] According to the dynamic light scattering instrument and transmission electron microscope, the diameter distribution of the liquid metal nanoparticles with core-shell structure prepared in this embodiment is 10-70 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com