Environment-friendly waterborne coating used for dip coating of track shoe and preparation method thereof

A kind of crawler shoe, environmentally friendly technology, applied in epoxy resin coatings, coatings, latex paints and other directions, can solve the problems of high VOC content, hardness, poor adhesion and high VOC content of paints, and achieve excellent product performance and high adhesion. The effect of focus and good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

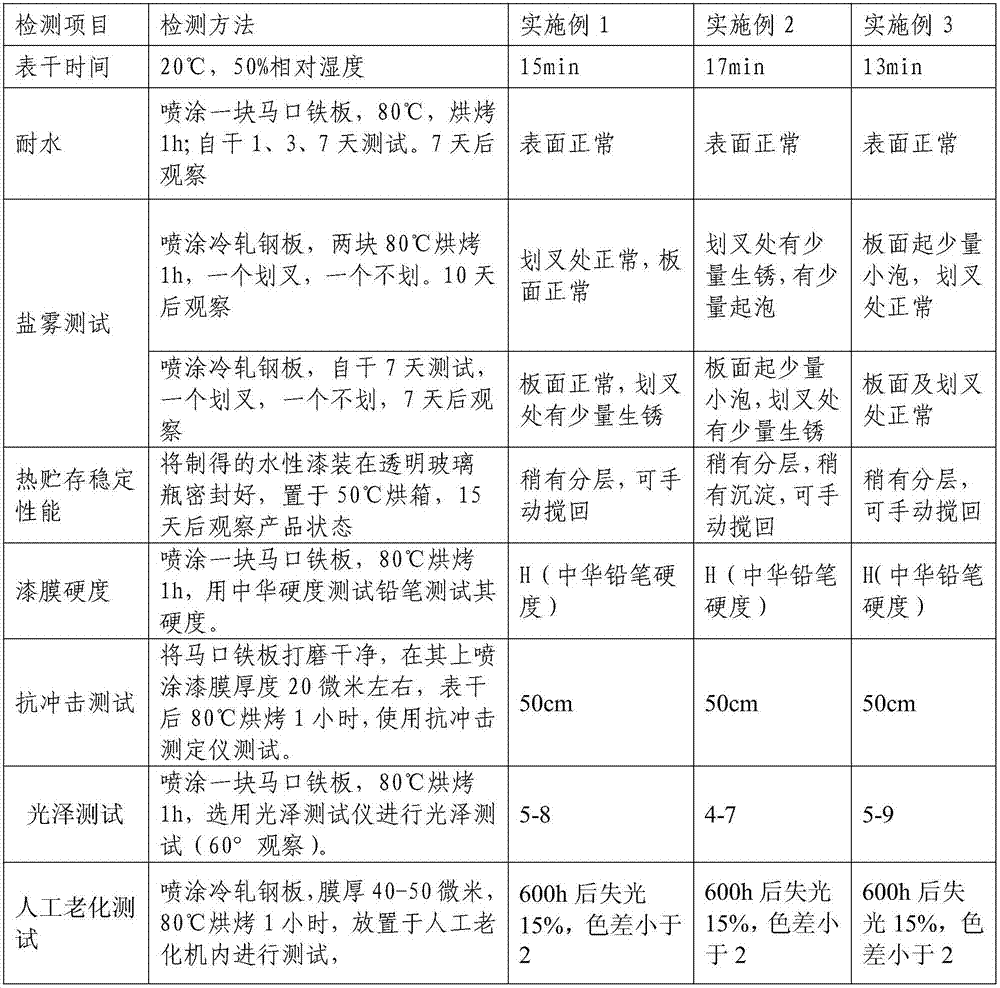

Embodiment 1

[0048] An environment-friendly water-based track shoe dipping paint is prepared from the following raw materials by weight percentage: 40% water-based acrylic modified epoxy emulsion, 0.3% defoamer, 1.6% dispersant, 24.8% Deionized water, 0.5% neutralizer, 0.7% leveling wetting agent, 1.6% anti-flash rust agent, 0.4% carbon black, 5.5% iron black, 6.7% barium sulfate, 6.5% Composite zinc phosphate, 4.5% thixotropic anti-settling agent, 3.6% aluminum tripolyphosphate, 2.5% talcum powder, 0.4% matting powder, 0.4% thickener.

[0049] Among them, the water-based acrylic modified epoxy emulsion is WE-641; the defoamer is a mixture of BYK's defoaming additives BYK-024 and BYK-028; the dispersant is BYK-190 and BYK-194 Mixture; neutralizing agent is dimethylethanolamine; leveling and wetting agent is Tego-4100; anti-flash rust agent is ED-617F; matting powder is SY7000; The mass fraction of bentonite is 3%; the thickener is a mixture of PUR62 and RHEO-3800 aqueous solution, wherein...

Embodiment 2

[0055] An environment-friendly water-based dip coating paint for track shoes, calculated by weight percentage, prepared from the following raw materials: 40% water-based acrylic modified epoxy emulsion, 0.3% defoamer, 1.6% dispersant, 22.4% Deionized water, 0.5% neutralizer, 0.6% leveling wetting agent, 1.8% anti-flash rust agent, 0.6% carbon black, 6% iron black, 7.1% barium sulfate, 6.9% Composite zinc phosphate, 4.8% thixotropic anti-settling agent, 4% aluminum tripolyphosphate, 2.6% talcum powder, 0.4% matting powder, 0.4% thickener.

[0056] Among them, the water-based acrylic modified epoxy emulsion is WE-641; the defoamer is a mixture of BYK's defoaming additives BYK-024 and BYK-028; the dispersant is BYK-190 and BYK-194 Mixture; neutralizing agent is dimethylethanolamine; leveling and wetting agent is Tego-4100; anti-flash rust agent is ED-617F; matting powder is SY7000; The mass fraction of bentonite is 3%; the thickener is a mixture of PUR62 and RHEO-3800 aqueous so...

Embodiment 3

[0062] An environment-friendly water-based track shoe dipping paint is prepared from the following raw materials by weight percentage: 40% water-based acrylic modified epoxy emulsion, 0.3% defoamer, 1.6% dispersant, 20.1% Deionized water, 0.5% neutralizer, 0.5% leveling wetting agent, 2.0% anti-flash rust agent, 0.8% carbon black, 6.8% iron black, 7.4% barium sulfate, 7.1% Composite zinc phosphate, 5.1% thixotropic anti-settling agent, 4.2% aluminum tripolyphosphate, 2.8% talcum powder, 0.4% matting powder, 0.4% thickener.

[0063] Among them, the water-based acrylic modified epoxy emulsion is WE-641; the defoamer is a mixture of BYK's defoaming additives BYK-024 and BYK-028; the dispersant is BYK-190 and BYK-194 Mixture; neutralizing agent is dimethylethanolamine; leveling and wetting agent is Tego-4100; anti-flash rust agent is ED-617F; matting powder is SY7000; The mass fraction of bentonite is 3%; the thickener is a mixture of PUR62 and RHEO-3800 aqueous solution, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com