Novel grate type cooler

A grate cooler, a new type of technology, applied in the treatment of discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems of increased material leakage, increased leakage of materials from gaps, machine shutdown, etc., to achieve satisfactory cooling effect, The effect of reducing friction coefficient and grate bed leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with embodiment:

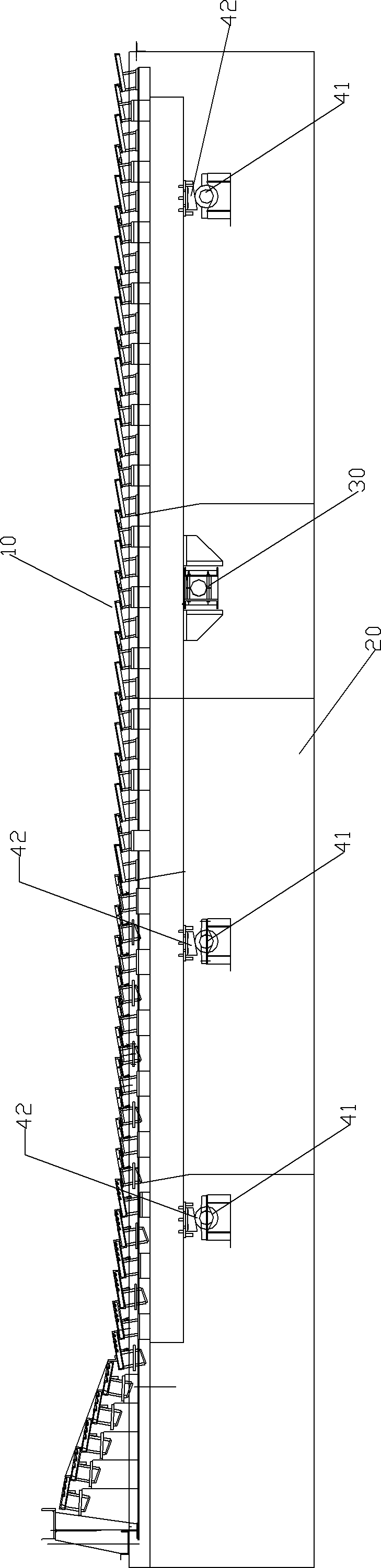

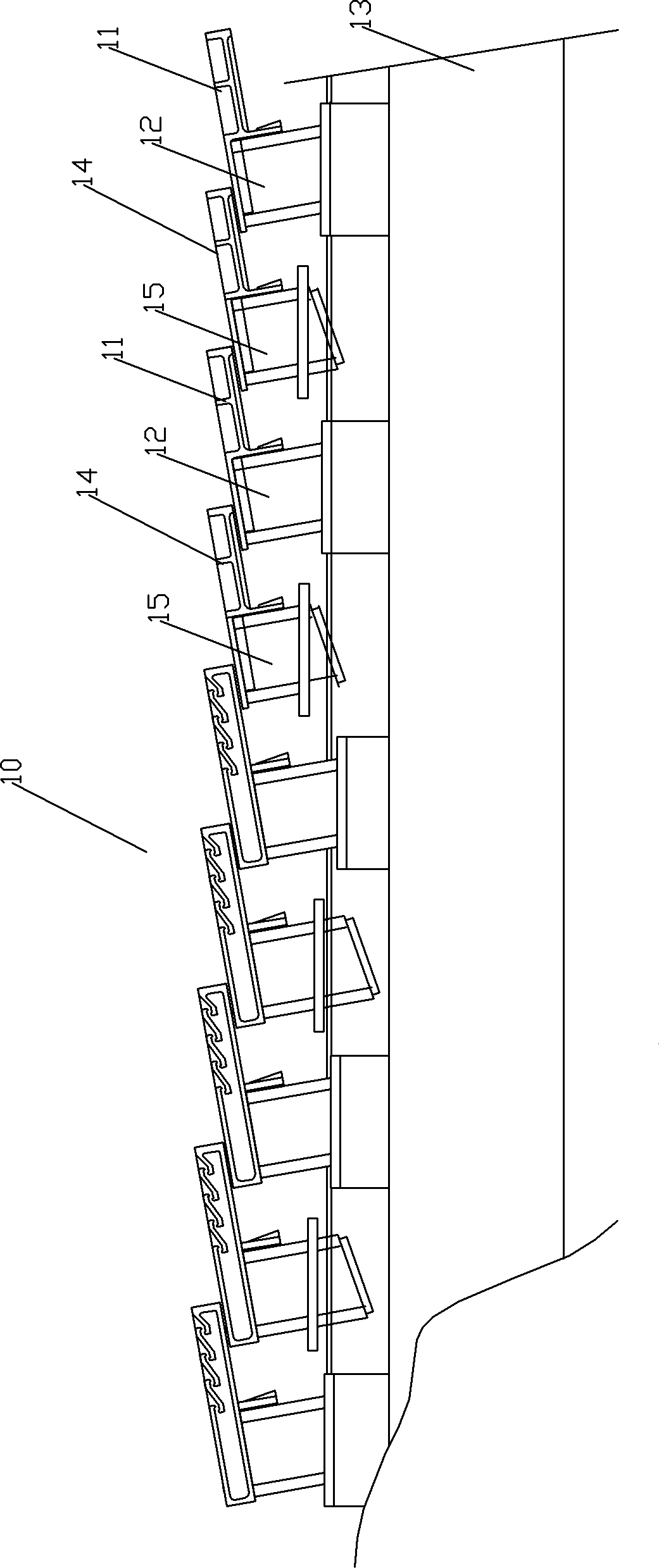

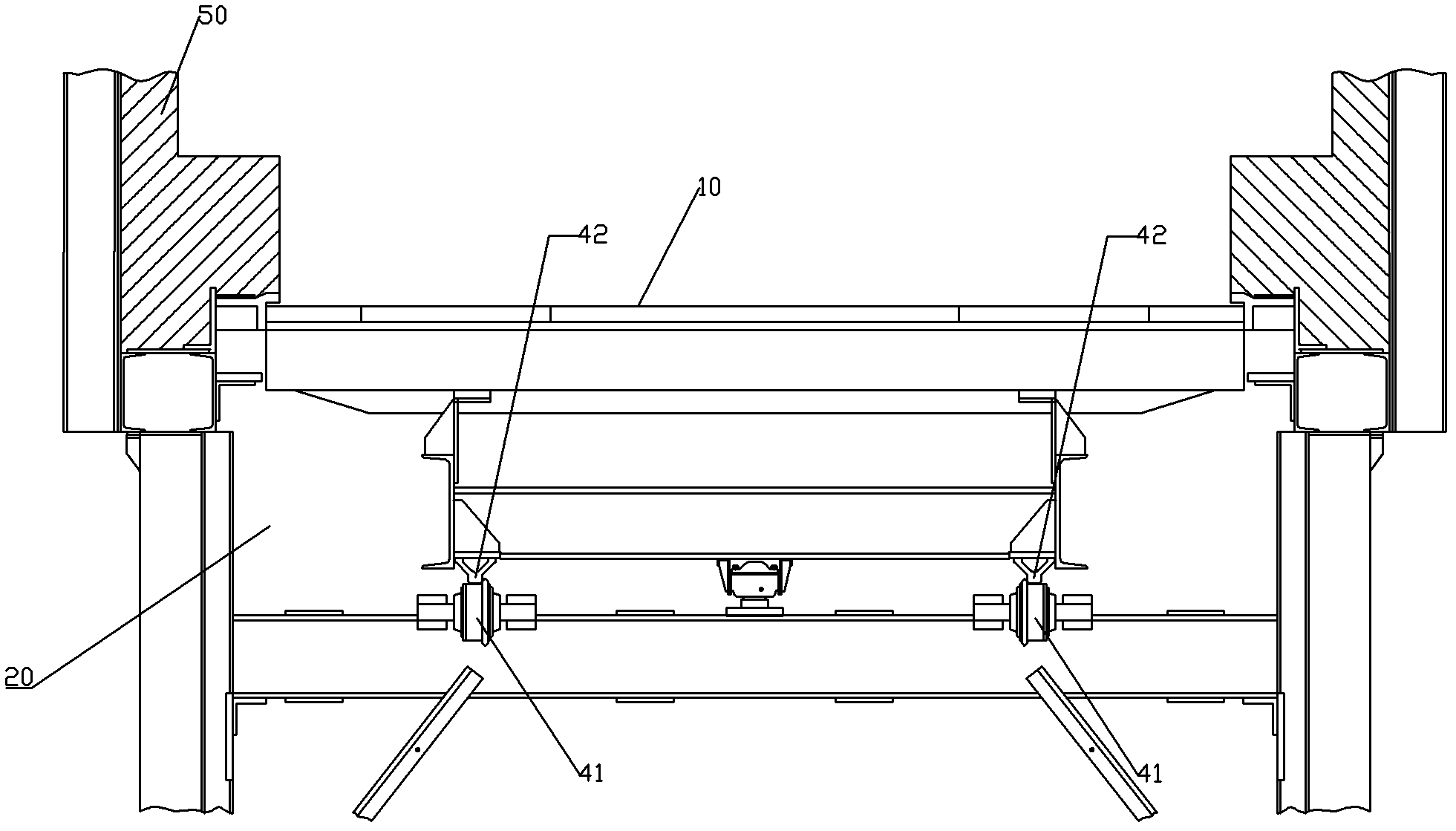

[0027] As shown in the picture, Figure 5 As shown, the novel grate cooler includes a grate bed 10 and an air chamber 20. The grate bed 10 is arranged above the air chamber 20 . Grate bed structure and figure 1 Shown are identical, and it comprises movable grate plate 11 and fixed grate plate 14. Movable grate plates 11 and fixed grate plates 14 are alternately arranged. Movable grate plate 11 is installed on the movable beam 12. Fixed grate plate 14 is installed on the fixed beam 15. The movable beam 12 is installed on the movable frame 13 . The movable frame 13 is driven to reciprocate by the driving device 30 . The movable frame 13 is arranged in the air chamber 20 . like Figure 4 As shown, the movable frame 13 is connected to the connecting beam 60 . The number of connecting beams 60 is three. Each connecting beam 60 runs through the air chamber 20 , and both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com