Gas hydrate mined by adopting low-temperature solid oxide fuel cell method and device thereof

A solid oxide, fuel cell technology for fluid extraction, earth-moving, climate sustainability, etc., that can solve problems such as increased costs, immature carbon capture and storage technology, and low efficiency of power generation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

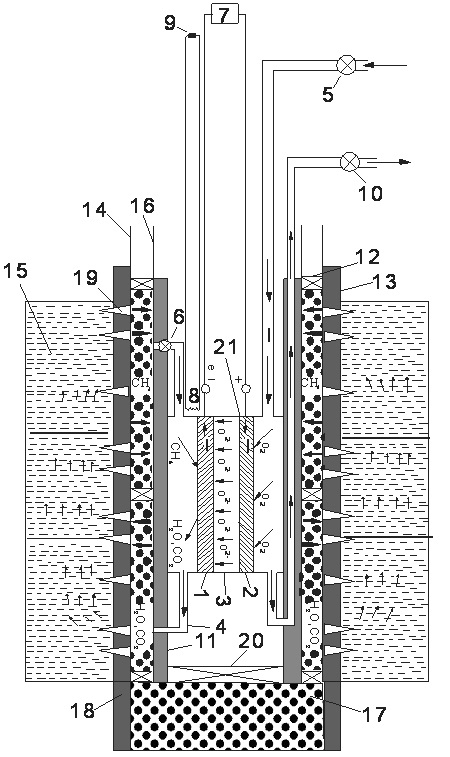

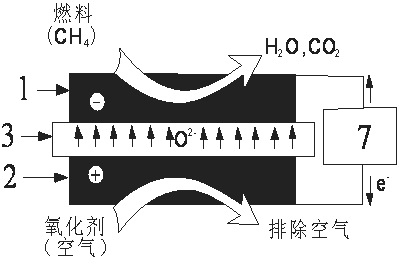

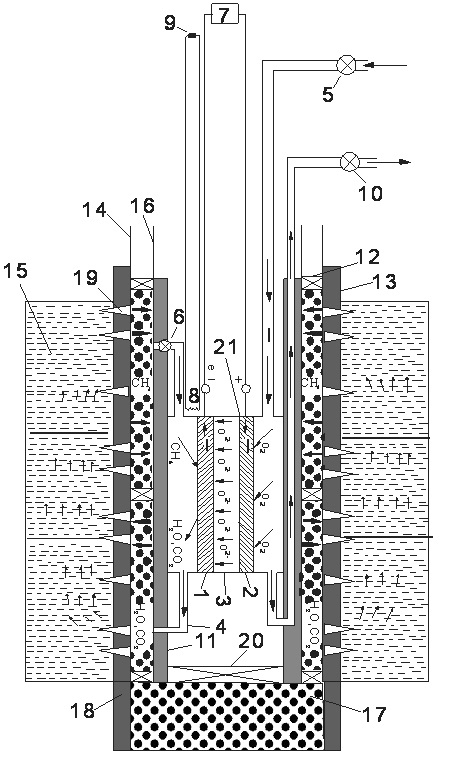

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0057] The device used for the exploitation of natural gas hydrate by the low-temperature solid oxide fuel cell method includes a gas transmission pipeline 4, an air inlet pump 5, a high and low temperature suction pump 6, a direct current-alternating current conversion device (DC / AC) 7, a heating Cable 8, power supply 9, gas outlet air pump 10, heat insulation layer 11, fixed packer 12, hydrate production well 13, production casing 14, wire rafting screen 16, perforation 19, pipe plug 20 and cryogenic solid oxide fuel cell 21,

[0058] Wherein the production casing 14 is located at the position of the hydrate reservoir 15 in the hydrate production well 13, and the wire rafting screen 16 is located at the position of the hydrate reservoir 15 in the production casing 14; the fixed packer 12 is located at the position of the production casing 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com