Bridge-head bumping processing method for relatively deep mud soft soil foundation behind abutment

A technology for silty soft soil and bridge head jumping, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of aggravating the bridge head jumping phenomenon and difficulty in achieving the design purpose, so as to avoid bridge head jumping, avoid car jumping, Improve overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

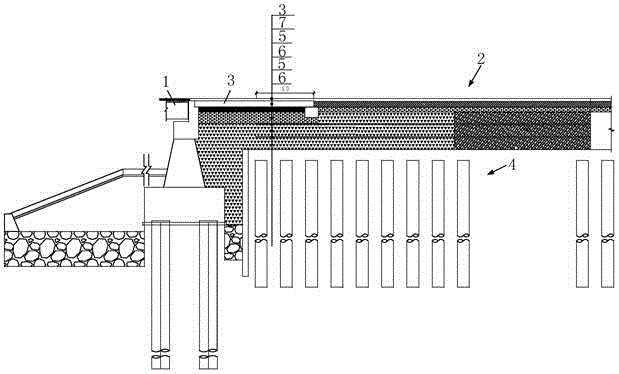

[0030] The purpose of the present invention is achieved through the following technical solutions: as figure 1 As shown, the bridge head jumping treatment method for the deep muddy soft soil foundation behind the platform provided in this embodiment includes the following construction steps:

[0031] During bridge abutment construction, at first be used to connect bridge 1 and road 2 behind the abutment position and arrange a bridge end butt plate 3, carry out road structural layer construction synchronously to the road below described bridge end butt plate 3, the road structural layer Construction steps include:

[0032] S1, laying a powder-sprayed pile layer 4 for subgrade treatment along the extension direction of the road below the bridgehead slab 3;

[0033] S2, after the laying of the powder-sprayed pile layer 4 is completed, within the length range of the bridgehead abutment, lay a primary crushed stone unit layer on the pile top of the powder-sprayed pile layer 4;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com