Enhancer for high-temperature resistant oil-based drilling fluid as well as preparation method and application of enhancer

An oil-based drilling fluid and diesel-based drilling fluid technology, which is applied in the field of drilling fluids used in petroleum resource exploration and development technology, can solve the problems of less cutting-lifting agent products, unsatisfactory performance, and less cutting-lifting agents, etc. The effect of solving the poor rock-carrying ability and solving the settlement of barite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

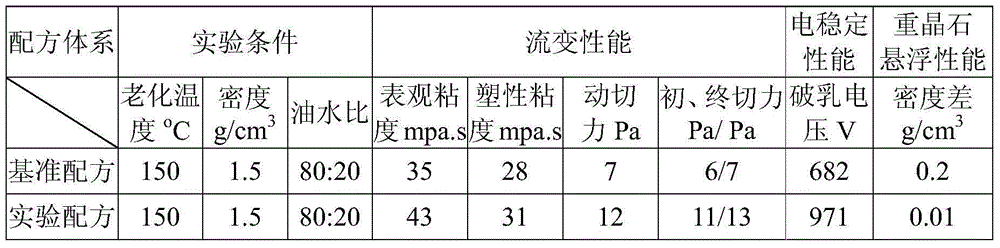

Embodiment 1

[0027] This embodiment provides a cutting agent for high temperature resistant oil-based drilling fluid, the preparation method of which includes the following steps:

[0028] 250 parts by weight of dimer acid (model: HY005, manufactured by Anqing Hongyu Chemical Co., Ltd.), 150 parts by weight of triethylene glycol monobutyl ether, and 46.87 parts by weight of diethanolamine are added successively with heating, stirring , Cooling and vacuuming system stainless steel reaction kettle, under stirring, heat up to 160°C, react for 3h;

[0029] Add 16.87 parts by weight of tetraethylenepentamine, continue to react for 3 hours, after the reaction is finished, cool down to 80°C;

[0030] Add 150 parts by weight of triethylene glycol monobutyl ether and 30 parts by weight of propylene carbonate, and stir evenly to obtain a shear lifting agent for high temperature resistant oil-based drilling fluid.

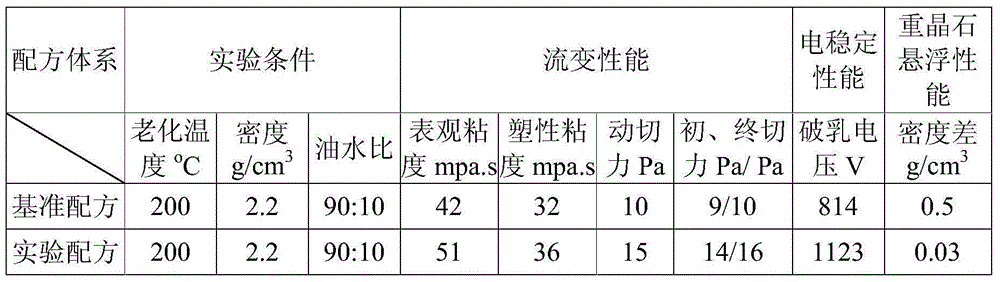

Embodiment 2

[0032] This embodiment provides a cutting agent for high temperature resistant oil-based drilling fluid, the preparation method of the cutting agent for high temperature resistant oil-based drilling fluid includes the following steps:

[0033] Add 200 parts by weight of dimer acid, 110 parts by weight of triethylene glycol monobutyl ether, and 39.2 parts by weight of diethanolamine into a stainless steel reaction kettle with heating, stirring, cooling and vacuuming systems, stir, and heat Raise the temperature to 170°C and react for 3 hours;

[0034] Add 12.9 parts by weight of diethylenetriamine, continue to react for 3 hours, after the reaction is completed, cool down to 80°C;

[0035] Add 110 parts by weight of triethylene glycol monobutyl ether and 24 parts by weight of propylene carbonate, and stir evenly to obtain a high-temperature-resistant oil-based drilling fluid cutting agent.

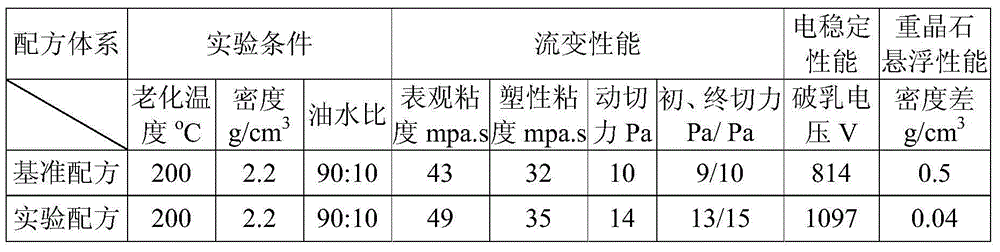

Embodiment 3

[0037] This embodiment provides a cutting agent for high temperature resistant oil-based drilling fluid, the preparation method of which includes the following steps:

[0038] Add 150 parts by weight of dimer acid, 100 parts by weight of triethylene glycol monobutyl ether, and 30 parts by weight of diethanolamine into a stainless steel reaction kettle with heating, stirring, cooling and vacuuming systems, stir, and heat Raise the temperature to 150°C and react for 3 hours;

[0039] Add 10 parts by weight of triethylenetetramine, continue to react for 3 hours, after the reaction is finished, cool down to 80°C;

[0040] Add 100 parts by weight of triethylene glycol monobutyl ether and 20 parts by weight of propylene carbonate, and stir evenly to obtain a high-temperature resistant oil-based drilling fluid cutting agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com