Self-repairing polymer material as well as preparation method and application thereof

A polymer material and self-repairing technology, which is applied in the direction of non-polymer adhesive additives, adhesive additives, electrical components, etc., can solve the problems of low preparation cost, inability to effectively prevent the detachment of active materials and current collectors, and high adhesive prices. problems, achieve the effects of low preparation cost, prevention of detachment, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

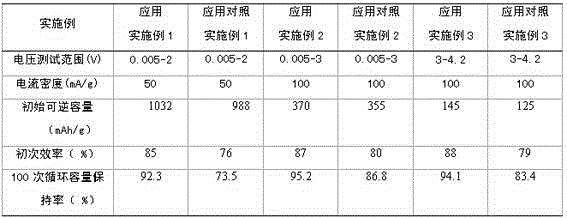

Examples

Embodiment 1

[0032] A self-healing polymer material prepared by a method comprising the following steps:

[0033] (1) Synthesis of M-NH 2 branched oligomer

[0034] 41.5g of dimer acid and 17g of diethylenetriamine were reacted for 24 hours at a temperature of 160°C and a rotation speed of 300-500r / min under the protection of argon atmosphere to obtain M-NH 2 Branched oligomers;

[0035] Described dimer acid, calculated by mass percentage, is the mixture containing 4% monobasic acid, 79% dibasic acid and 17% tribasic acid, produced by Shandong Linyi Derun Chemical Co., Ltd.;

[0036] The amount of dimer acid and diethylenetriamine used in the above reaction is calculated by mass ratio, that is, dimer acid: diethylenetriamine is calculated at a ratio of 2.44:1;

[0037] (2) Synthesis of self-healing polymer materials:

[0038] Calculated by mass ratio, namely M-NH 2 Branched oligomer: urea is the ratio of 75:1, the M-NH obtained in step (1) 2 The branched oligomer and urea were mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com