Method for producing low-phosphor dimer acid

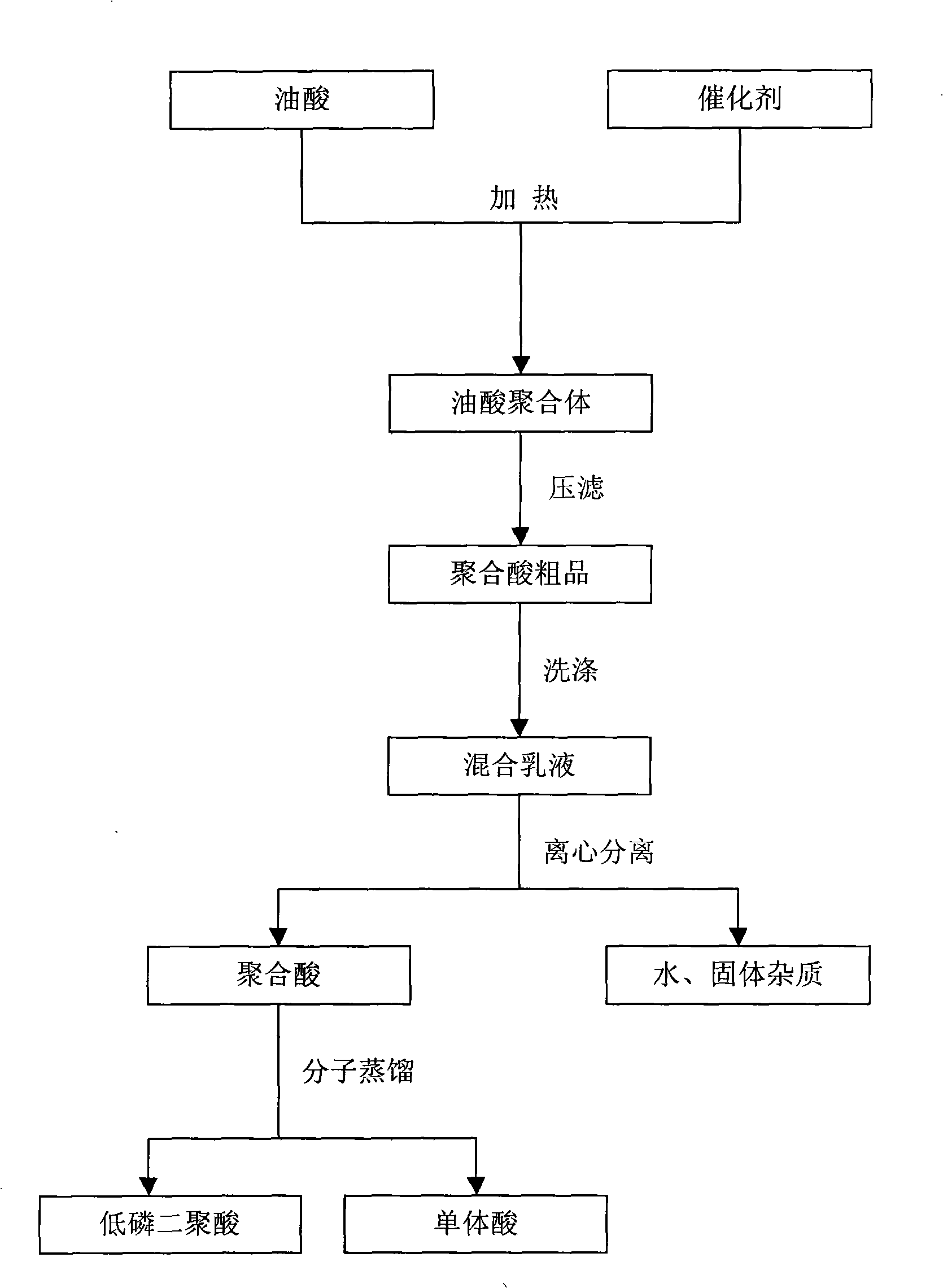

A production method and technology of dimer acid, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve problems affecting the quality of dimer acid and affecting the application of dimer acid, and achieve Continuous and rapid separation, eliminating hidden dangers and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put 360Kg oleic acid, 60Kg activated clay, and 1.3Kg lithium carbonate into 0.6M 3 In the reaction kettle, stir at a constant speed and heat up to 250°C, keep it warm for 6 hours, after the heat preservation is completed, cool down to 100°C, add 7Kg of phosphoric acid and 6Kg of water, then heat up to 150°C for 2.5 hours, cool to 120°C and press filter to obtain the crude polymeric acid The viscosity is 1150cp / 25°C.

[0022] The polymeric acid after pressure filtration is transported to the washing tank, and water is added according to the acid:water (w / w) ratio of 2:1, and the stirring is started, and the washing temperature is controlled at 50°C for 30 minutes, and then the mixed emulsion is sent to the centrifugal separation device Separate and dehydrate.

[0023] The polymeric acid after washing and dehydration is pumped to the distillation system, and the dimer acid and monomeric acid are separated through dehydration, flash evaporation, molecular distillation and...

Embodiment 2

[0025] Put 360Kg oleic acid, 60Kg activated clay, and 1.3Kg lithium carbonate into 0.6M 3 In the reaction kettle, stir at a constant speed and heat up to 250°C, keep it warm for 6 hours, after the heat preservation is completed, cool down to 100°C, add 7Kg of phosphoric acid and 6Kg of water, then heat up to 150°C for 2.5 hours, cool to 120°C and press filter to obtain the crude polymeric acid The viscosity is 1040cp / 25°C.

[0026] The polymeric acid after pressure filtration is sent to the washing tank. Add in acid:water (w / w) ratio of 5:3, start stirring, control the washing temperature to 50°C for 30 minutes, and then send the mixed emulsion to a centrifugal separation device for separation and dehydration.

[0027] The polymeric acid after washing and dehydration is pumped to the distillation system, and the dimer acid and monomeric acid are separated through dehydration, flash evaporation, molecular distillation and other processes. The viscosity of the finished dimer a...

Embodiment 3

[0029] Put 360Kg oleic acid, 60Kg activated clay, and 1.3Kg lithium carbonate into 0.6M 3 In the reaction kettle, stir at a constant speed and heat up to 250°C, keep it warm for 6 hours, after the heat preservation is completed, cool down to 100°C, add 7Kg of phosphoric acid and 6Kg of water, then heat up to 150°C for 2.5 hours, cool to 120°C and press filter to obtain the crude polymeric acid The viscosity is 1040cp / 25°C.

[0030] The polymeric acid after pressure filtration is sent to the washing tank. Add water according to the acid:water (w / w) ratio of 3:1, start stirring, control the washing temperature at 60°C for 60 minutes, and then send the mixed emulsion to a centrifugal separation device for separation and dehydration.

[0031] The polymeric acid after washing and dehydration is pumped to the distillation system, and the dimer acid and monomeric acid are separated through dehydration, flash evaporation, molecular distillation and other processes. The viscosity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com