Patents

Literature

429results about How to "No collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

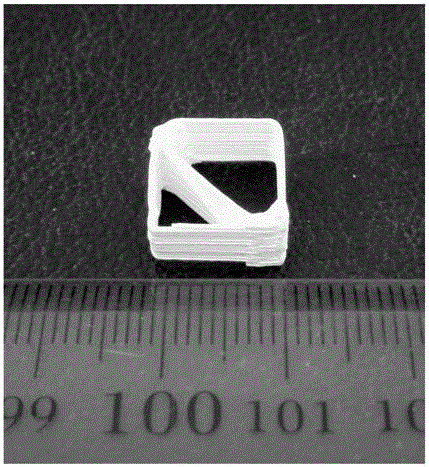

Metal or ceramic consumable item for FDM 3D printing, preparation method for metal or ceramic consumable item and finished product printing method

InactiveCN105665697AEasy to handleUnlimited structureAdditive manufacturing apparatusTransportation and packagingMiniaturizationVolumetric Mass Density

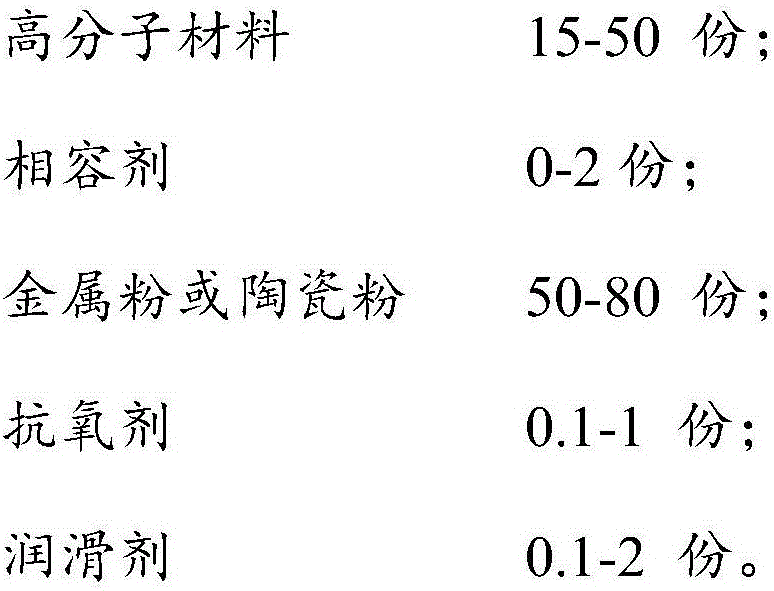

The invention discloses a metal or ceramic consumable item for FDM 3D printing, a preparation method for the metal or ceramic consumable item and a finished product printing method. The metal or ceramic consumable item comprises, by weight, 15-50 parts of a high polymer material, 0-2 parts of a compatilizer, 50-80 parts of metal powder or ceramic powder, 0.1-1 part of an antioxygen and 0.1-2 parts of a lubricating agent. The cost for equipment, the materials and machining is low; a printing structure is free of limitation, collapsing conditions do not exist in the printing process, supports can be removed before fusion sintering of the product, and treatment is easier compared with a manner that the supports are removed after SLS or EBAM fusion sintering; the requirements for the sphericity degree, the size distribution, the mobility and the like are relatively low; the types of metal and ceramic capable of being printed are wider; and the density of the finished products is higher, the strength is high, the degree of finish is higher, the miniaturization capacity is high, the thin-wall capacity is high, the complexity is high, the design tolerance level is high, and the material adaption scope is wide.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Early-strength composite foam concrete foaming agent and preparation method thereof

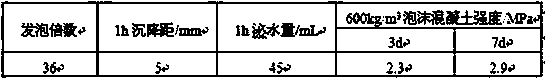

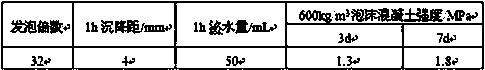

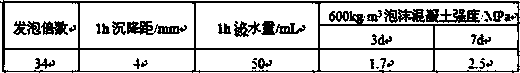

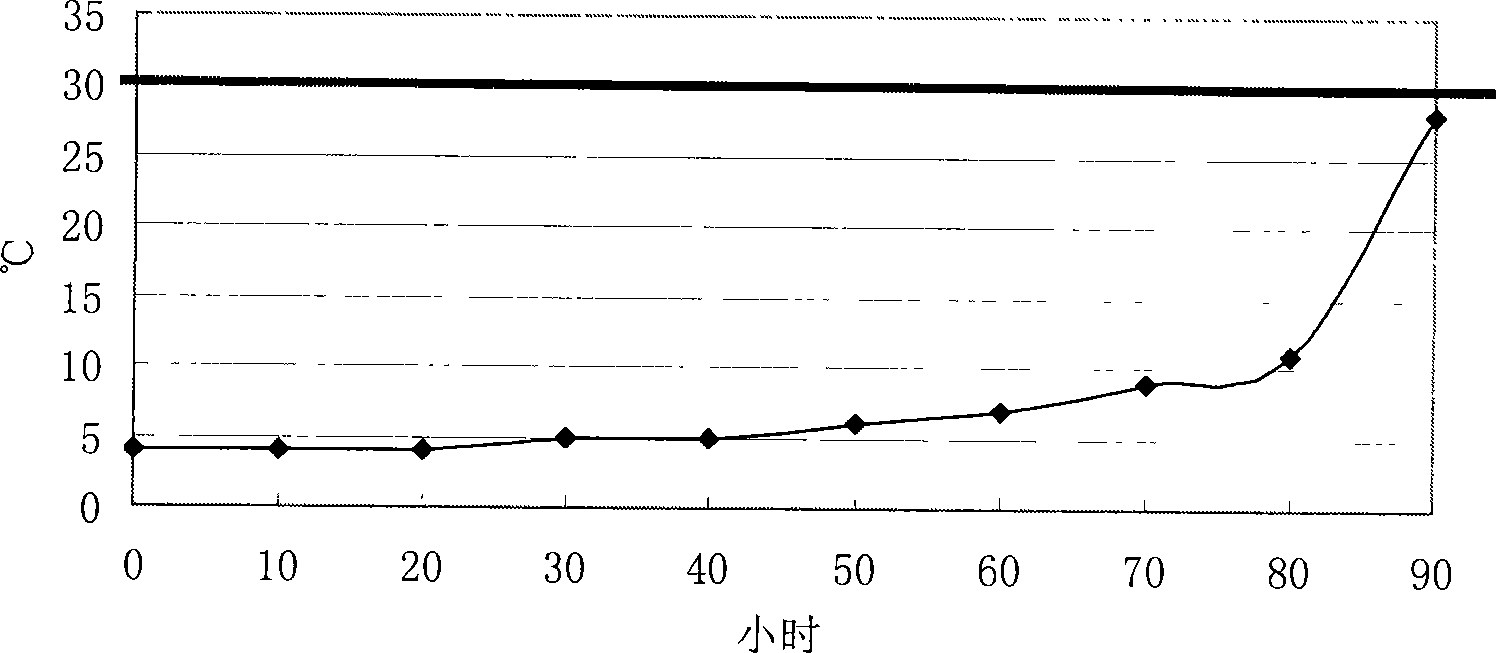

The invention belongs to the technical field of building materials, and particularly relates to an early-strength composite foam concrete foaming agent and a preparation method thereof. The early-strength composite foam concrete foaming agent comprises the following components in percentage by mass: 40%-80% of composite foaming components, 1.0%-5.0% of foam stabilizing components, 3.3%-22% of early-strength components and 10%-45% of water, wherein the composite foaming components are formed by compounding synthesized surface active agent foaming agents and protein foaming agents. The early-strength composite foam concrete foaming agent prepared through the method disclosed by the invention has the advantages of high foam expansion, excellent foam stability and good compatibility with general cement pastes; the early-strength composite foam concrete foaming agent disclosed by the invention is applied to foam concrete; the prepared foam concrete has no recess phenomenon and is fast enhanced in early strength, and the foam concrete with a density grade equal to 300 kg / m<3> or above is more easily prepared.

Owner:中建商品混凝土(福建)有限公司 +1

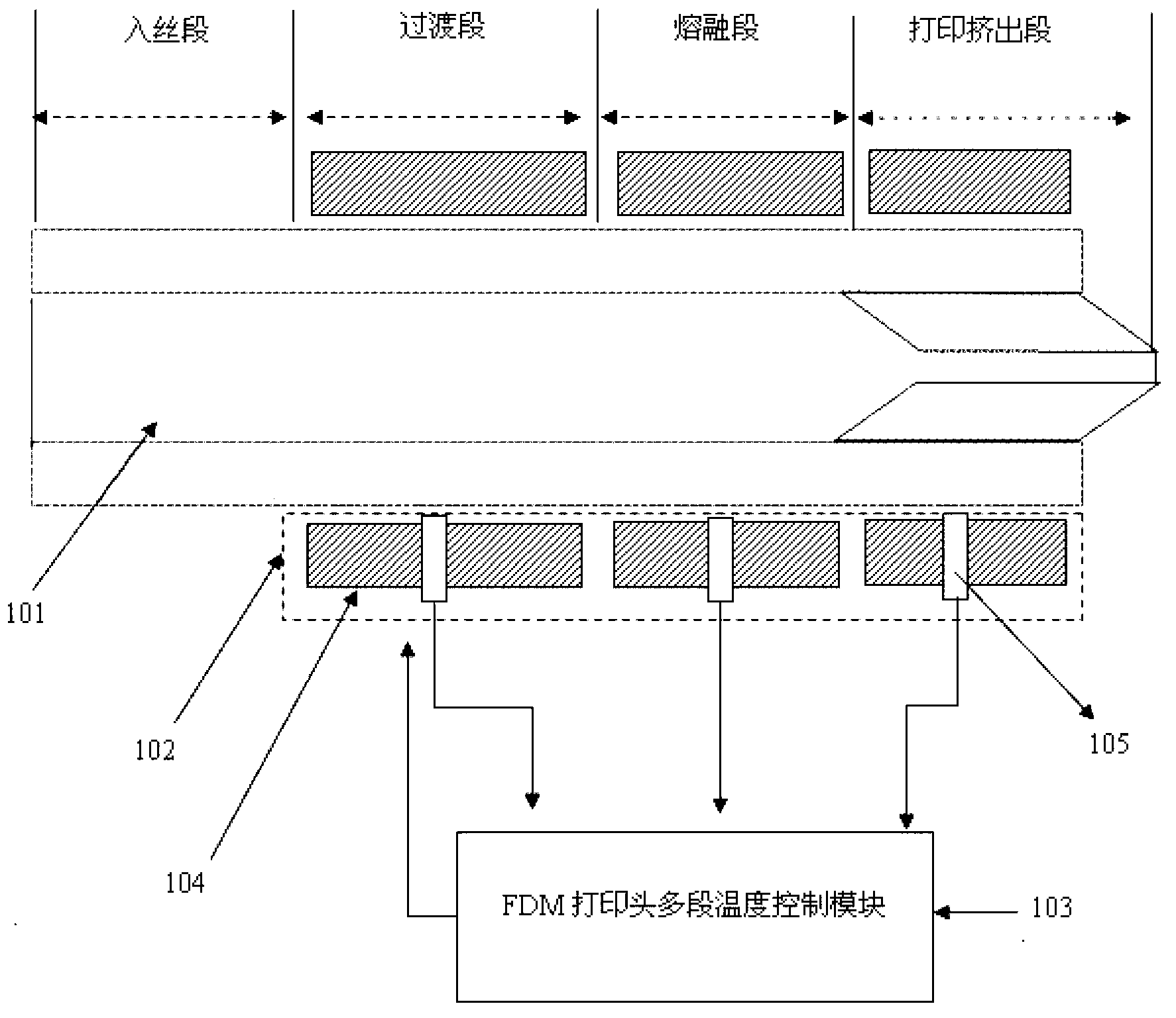

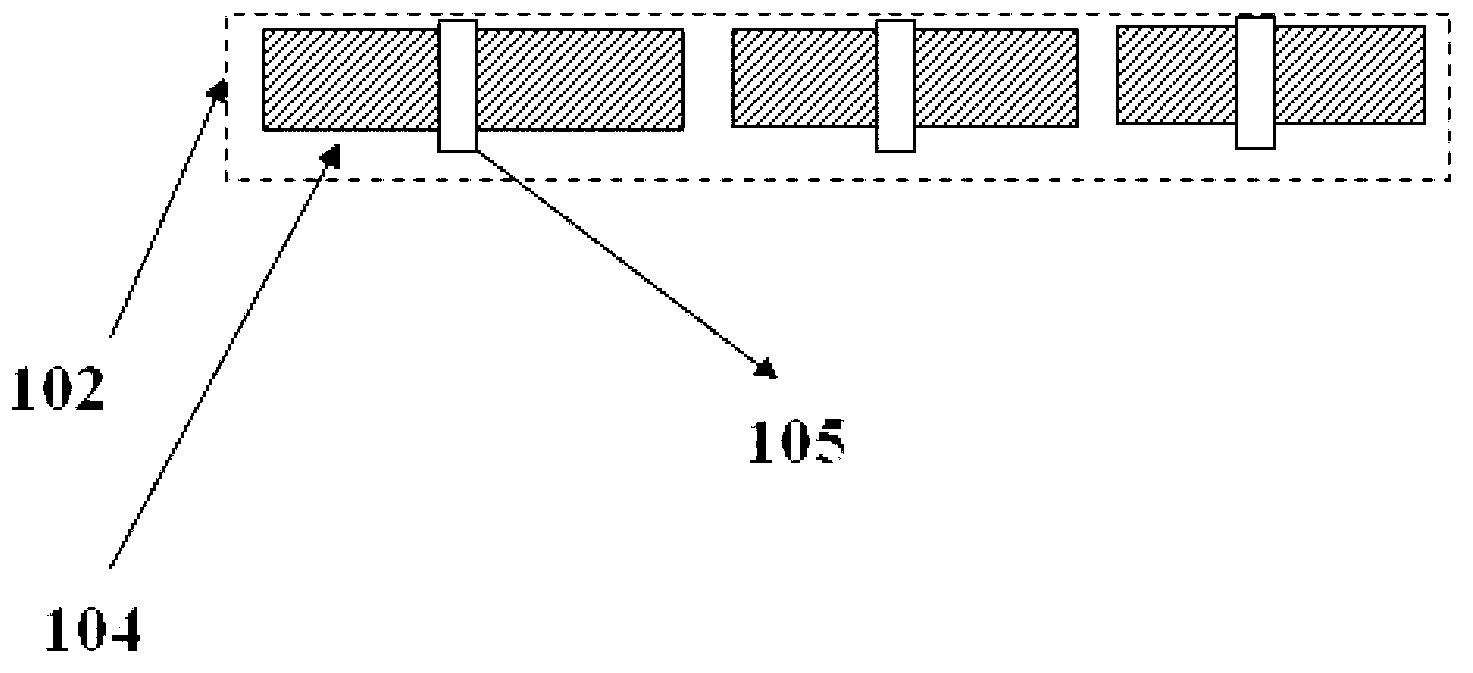

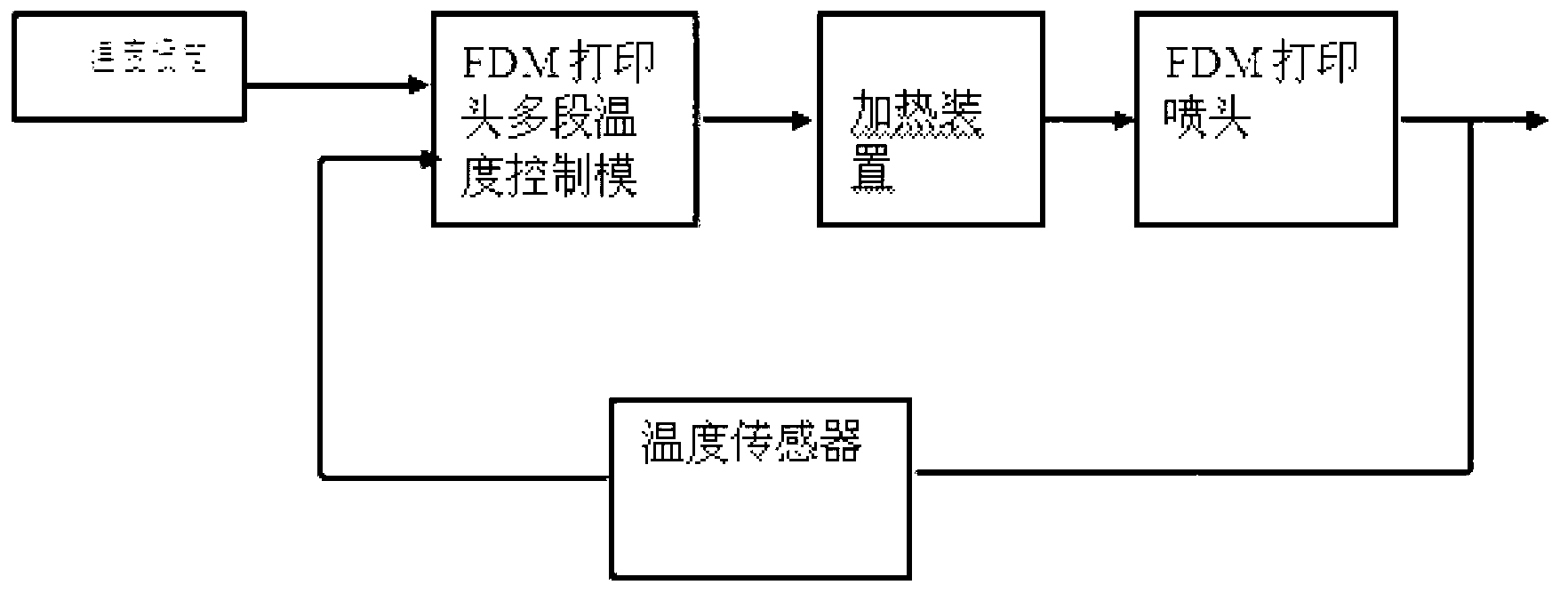

Multistage-temperature-control-based fused deposition modeling (FDM) type 3D printing sprayer and temperature control method

The invention relates to a 3D printing technology, and aims at providing a multistage-temperature-control-based fused deposition modeling (FDM) type 3D printing sprayer and a temperature control method. The multistage-temperature-control-based FDM 3D printing sprayer comprises a printing sprayer body and a heating device arranged at the outer part of the printing sprayer body, and is characterized in that a forming chamber inside the printing sprayer body is divided into four parts of a fuse feeding section, a transition section, a fusion section and a printing and extruding section; the heating device is divided into three sections which are correspondingly arranged at the outer sides of the transition section, the fusion section and the printing and extruding section of the forming chamber, and each section of the heating device comprises an electric heater and a temperature sensor which are independent and is respectively connected with a multistage temperature control module of an FDM type printing sprayer through a signal wire. The multistage-temperature-control-based FDM type 3D printing sprayer is capable of realizing the corresponding gradient control of temperatures of all sections of the printing sprayer and ensuring that an FDM printing material is always kept in a printable state, and can not cause the problems of layer collapse, damage and blockage due to overhigh or overlow temperature due to the adoption of single temperature control; and meanwhile, the blockage and the fracture of a wire of a conventional printing head are avoided, and the quality of formed products is improved.

Owner:ZHEJIANG UNIV

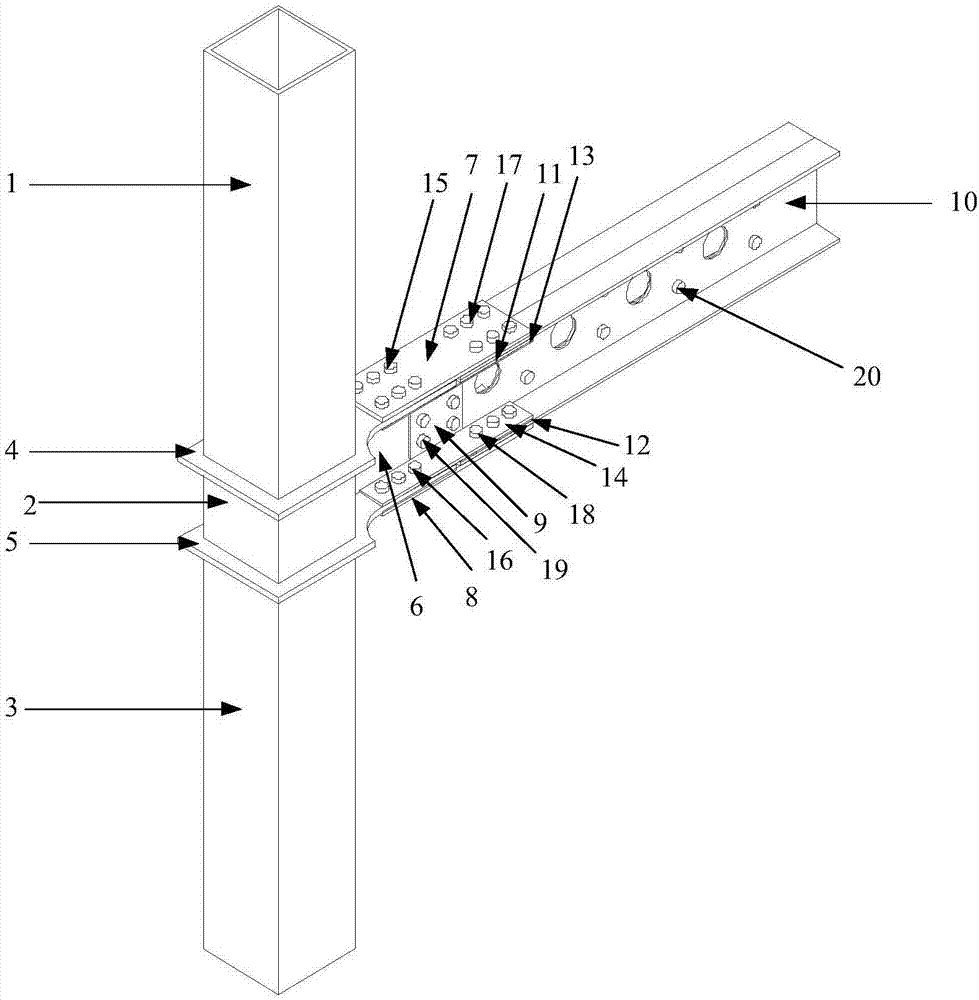

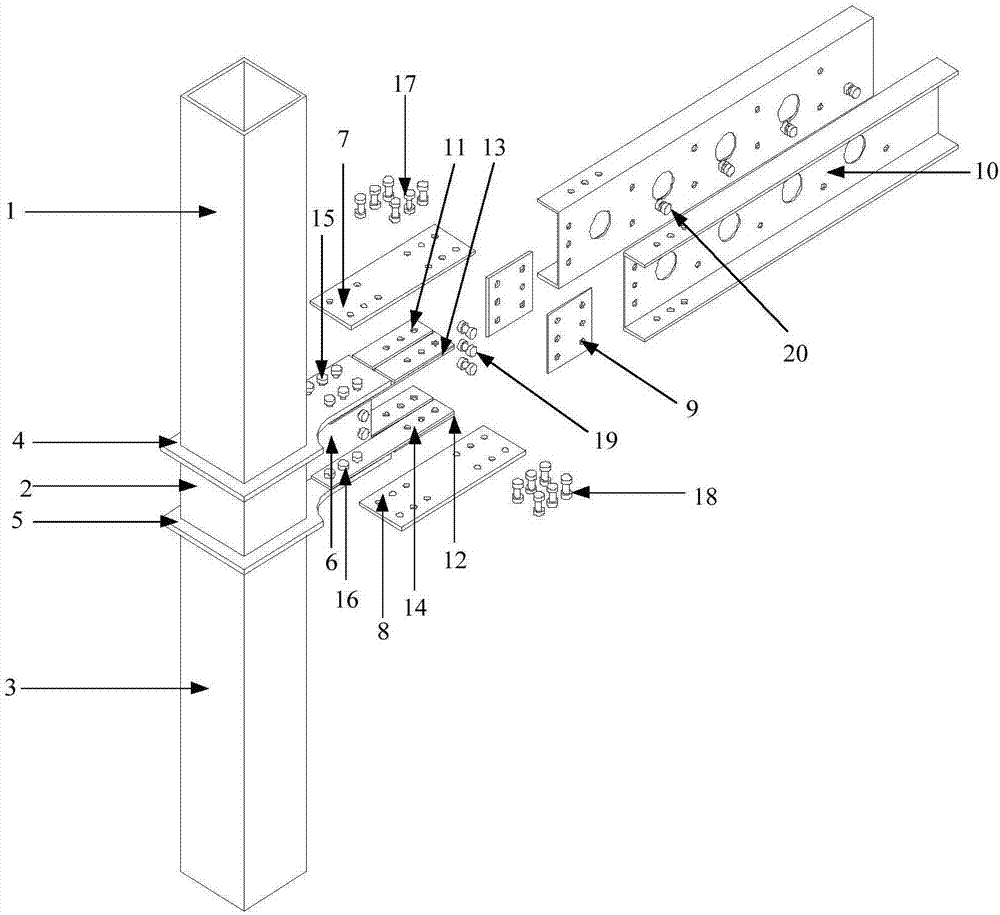

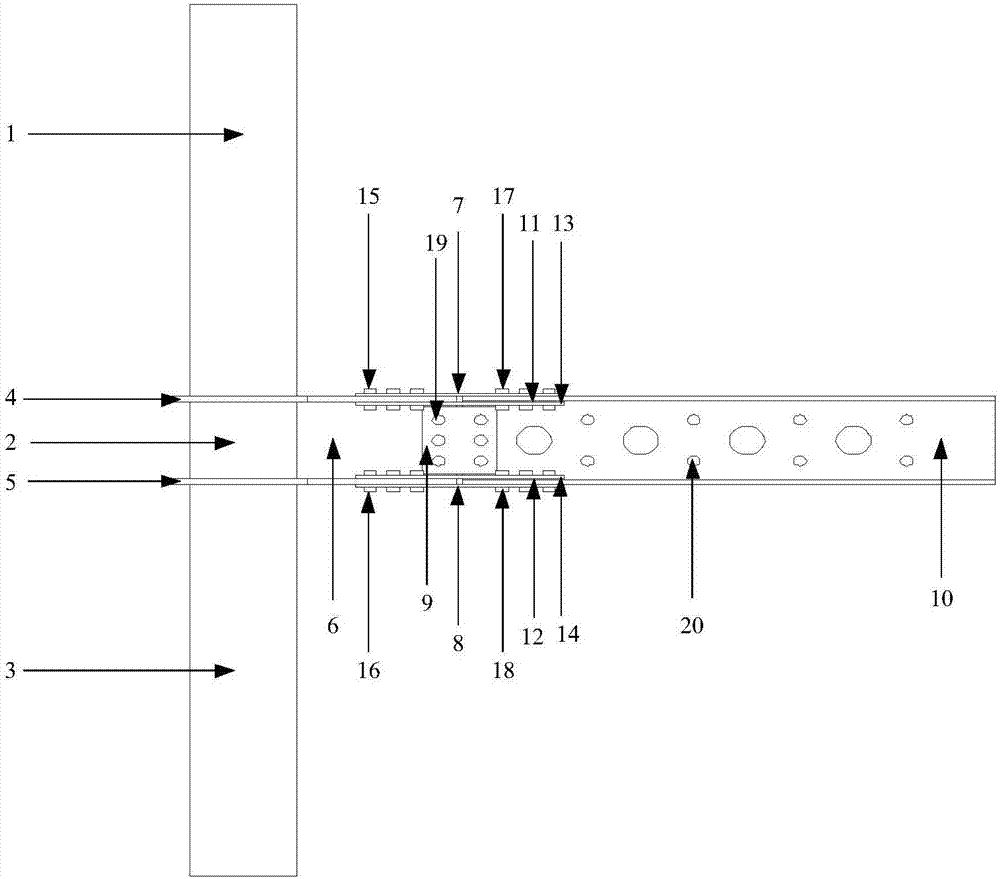

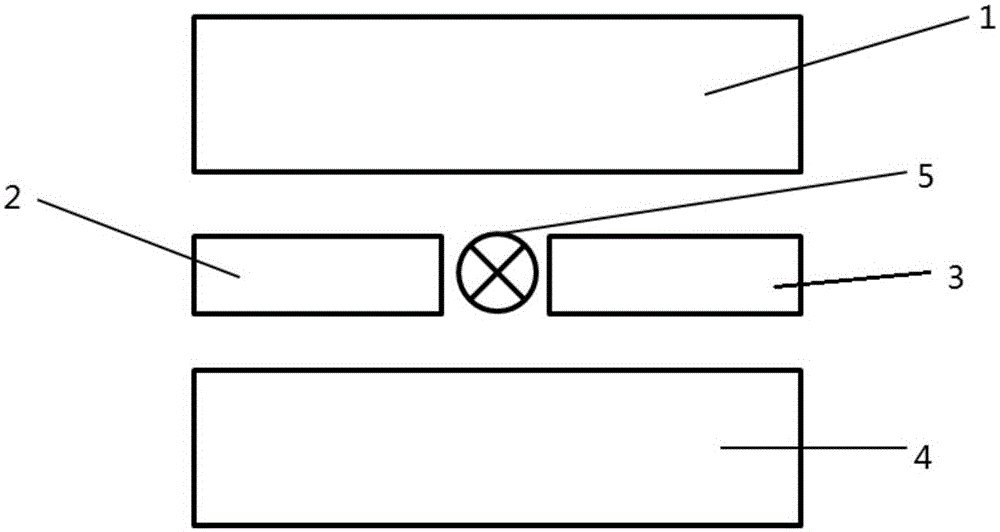

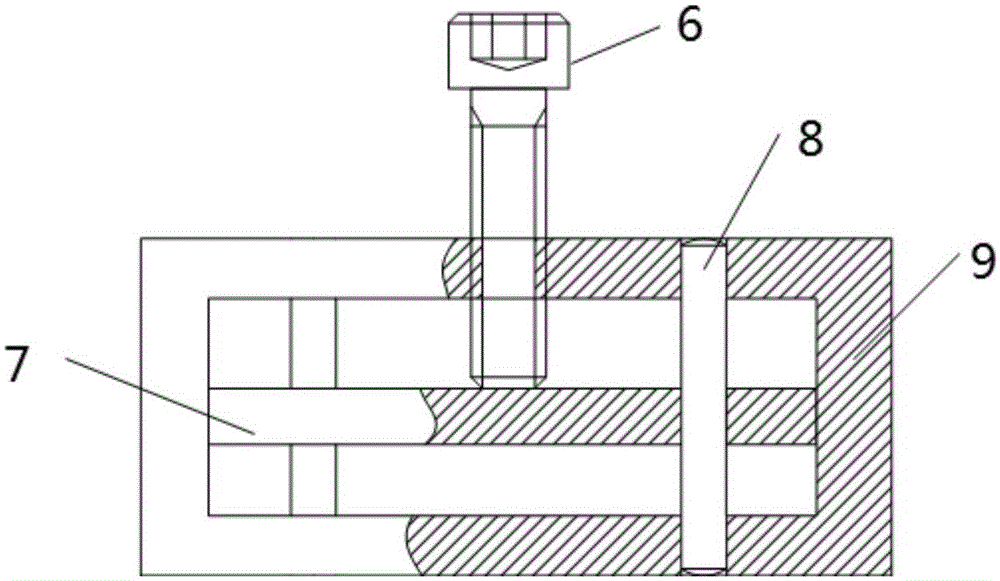

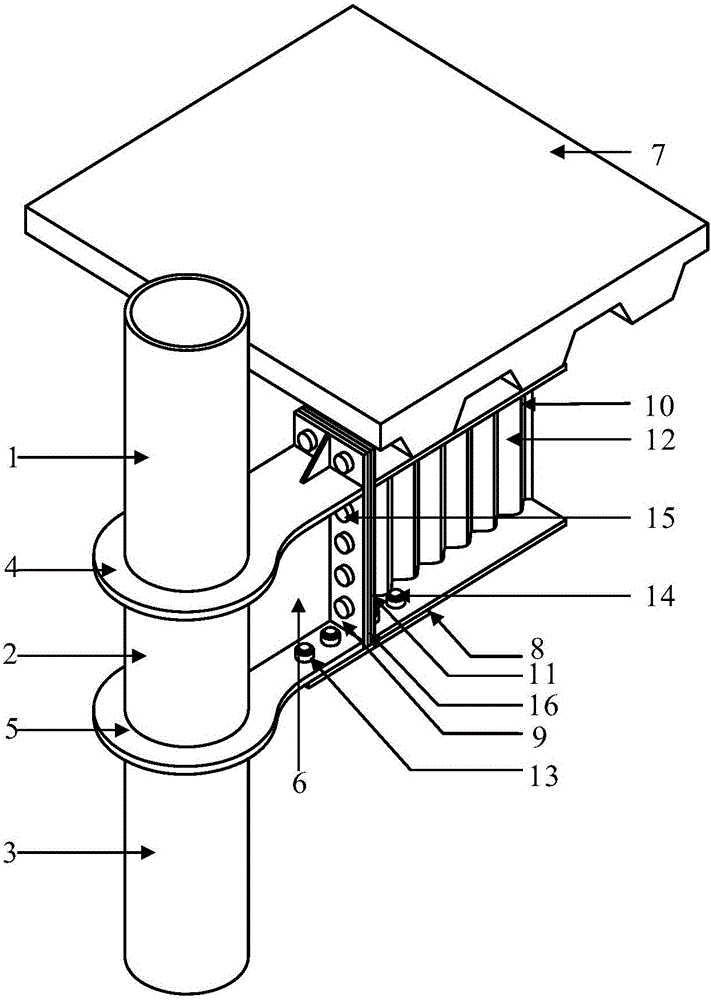

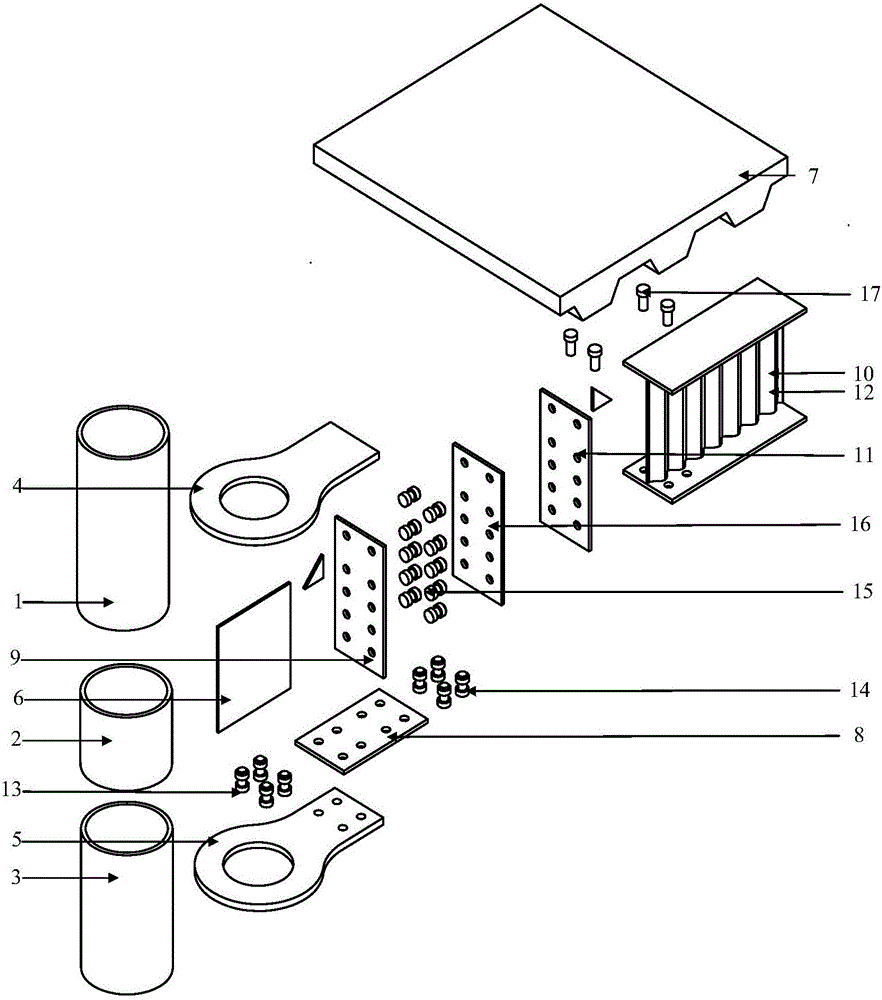

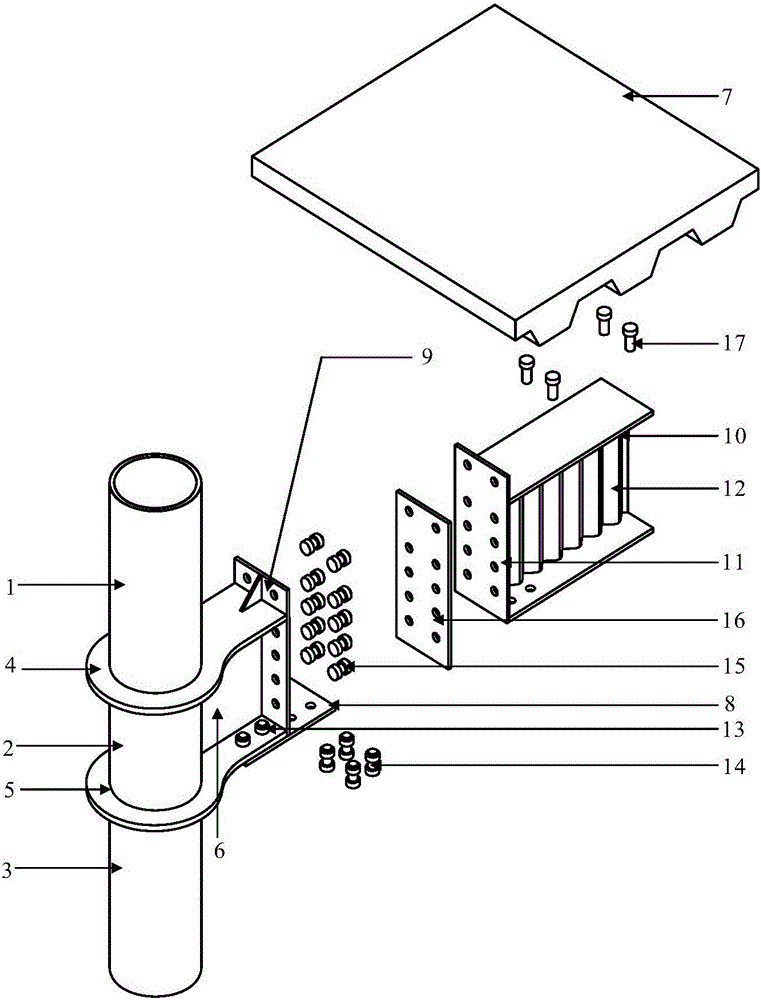

Assembly channel steel punching beam column joint connecting device capable of achieving function recovery

InactiveCN106869325AAvoid complex stress fieldsReduce construction difficultyFloorsFloor slabPunching

The invention relates to an assembly channel steel punching beam column joint connecting device capable of achieving function recovery and belongs to the field of structural engineering. The assembly channel steel punching beam column joint connecting device capable of achieving function recovery is composed of a square steel pipe column with a cantilever beam section, a channel steel punching beam section and a connecting device of the cantilever beam section and the channel punch beam section. All welding parts of the joint connection device are all finished in a factory, so that precision and quality of welds are easier to control. Construction speed is greatly increased and construction quality is greatly improved, and a spatial structure of the channel punch beam section of the channel is conducive to pipeline penetration; the channel steel punching beam and a floor can be assembled and molded in the factory to form modular assembly units. Then all the modular assembly unit and the square steel pipe column with the cantilever beam section achieve assembly connection through the channel steel punching beam. Joints of the connection device can be used for both of beam end reinforcing and cover plate connection weakening. A multi-energy dissipation mechanism can be realized, a plastic hinge is transferred to a cover plate and a connecting plate. The function of structures can be recovered only by replacing the connecting plate after an earthquake.

Owner:BEIJING UNIV OF TECH

A kind of foam concrete and preparation method thereof

The invention relates to a foamed concrete and a preparation method thereof. The foamed concrete adopts a chemical foaming method, and a foam stabilizer, an early strength agent, and a water reducer are respectively added to ordinary Portland cement slurry and stirred evenly, and then chemical foaming agent is added. The foaming agent is fully stirred evenly, then injection molded, cured at room temperature, and hardened. The dry apparent density range of the foamed concrete prepared by this method is 150-300kg / m3, the corresponding compressive strength is 0.10-0.50MPa, and the thermal conductivity is lower than 0.10W / mK. It can be used as roof insulation project, floor heating project, light Cushion material, especially suitable for external wall insulation system, energy-saving composite panels, etc. used in building energy-saving projects.

Owner:NANJING UNIV OF TECH

Method of cryogenic surface activation direct bonding for preparation of quartz glass capillary tube

InactiveCN105016632ARequirements for lower machining accuracySmooth inner wallPlasma treatmentMicrometer

The present invention discloses a method of cryogenic surface activation direct bonding for preparation of a quartz glass capillary tube. According to the method, a wet chemical method is used to activate a quartz glass surface, and the manner of direct bonding of a stack of multiple layers of glass is applied, so as to prepare the quartz glass capillary tube at a lower temperature with a proper pressure. A steel needle of a specific size is added to a model and used to define a size and location of the capillary tube. The minimum diameter of the capillary tube prepared can reach as small as 200 micrometers ,and the bonding strength can reach 5 MPa. According to the method, the operation of cryogenic surface activation bonding is simple, the requirement on the glass sheet surface roughness is low, and no clean room or expensive ultra-high vacuum plasma treatment device is required. The method overcomes the problems of the pipe collapse, the device superficial devitrification and the inner wall roughness that may be caused by the conventionally prepared capillary tubes. The capillary tube produced has the smooth inner wall, increases the viewable region of the sample in the capillary tube, and dramatically improves chip performance.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

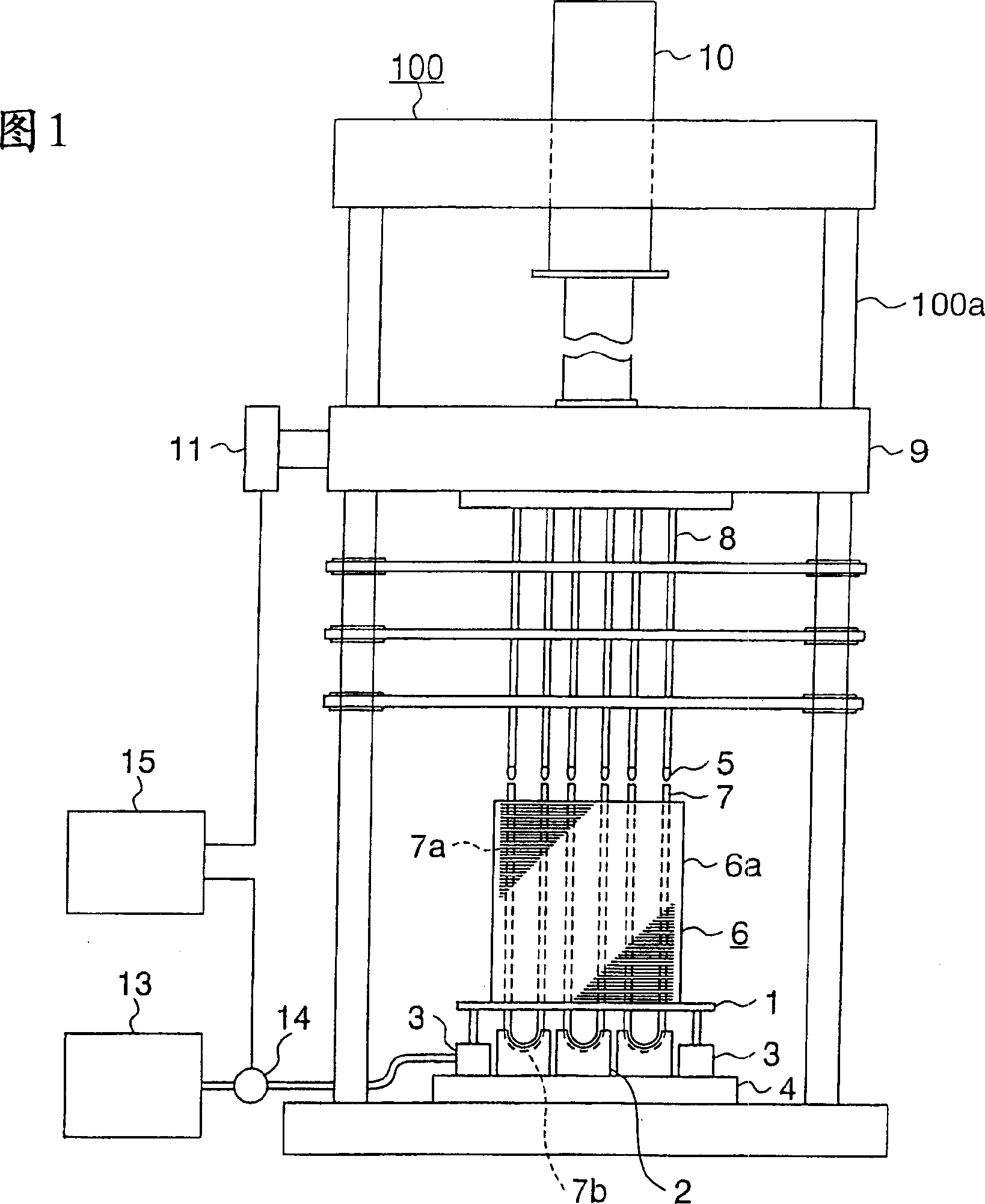

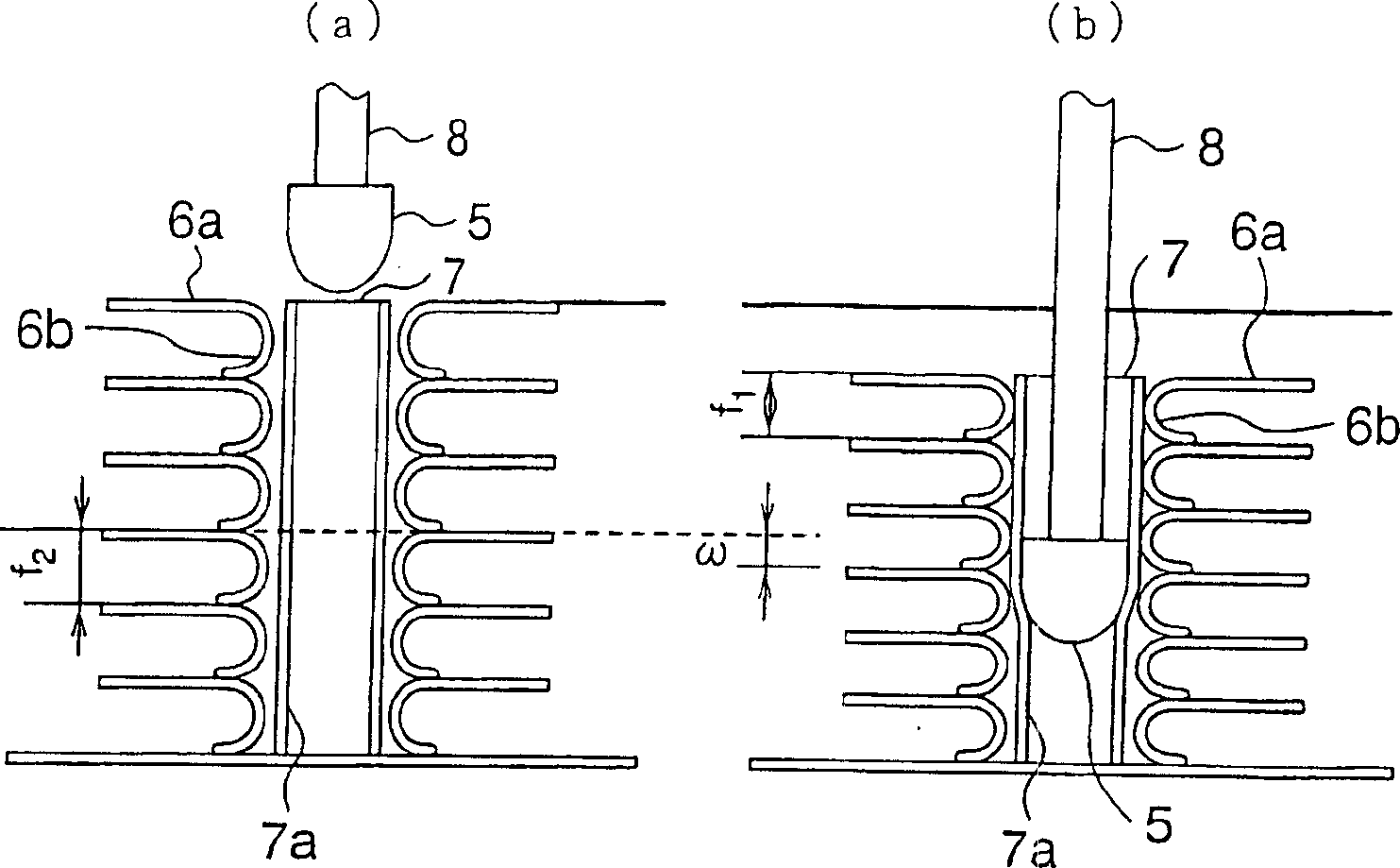

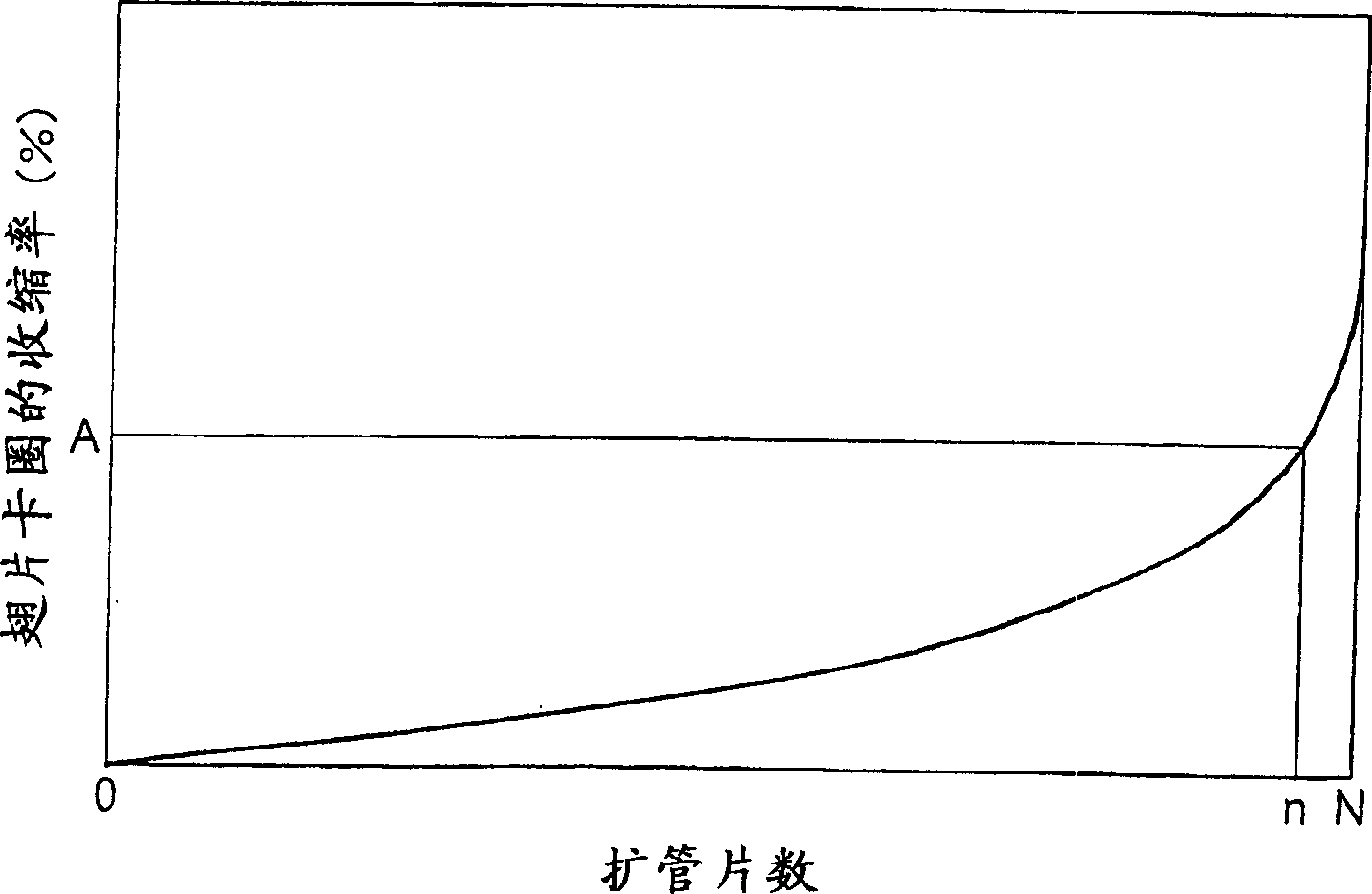

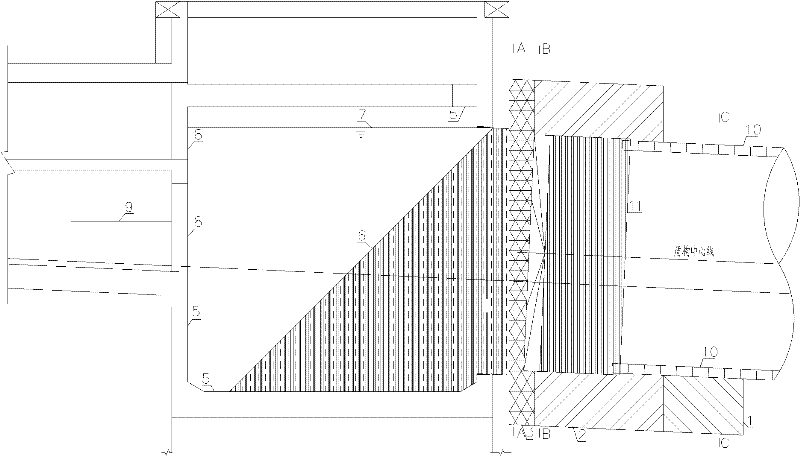

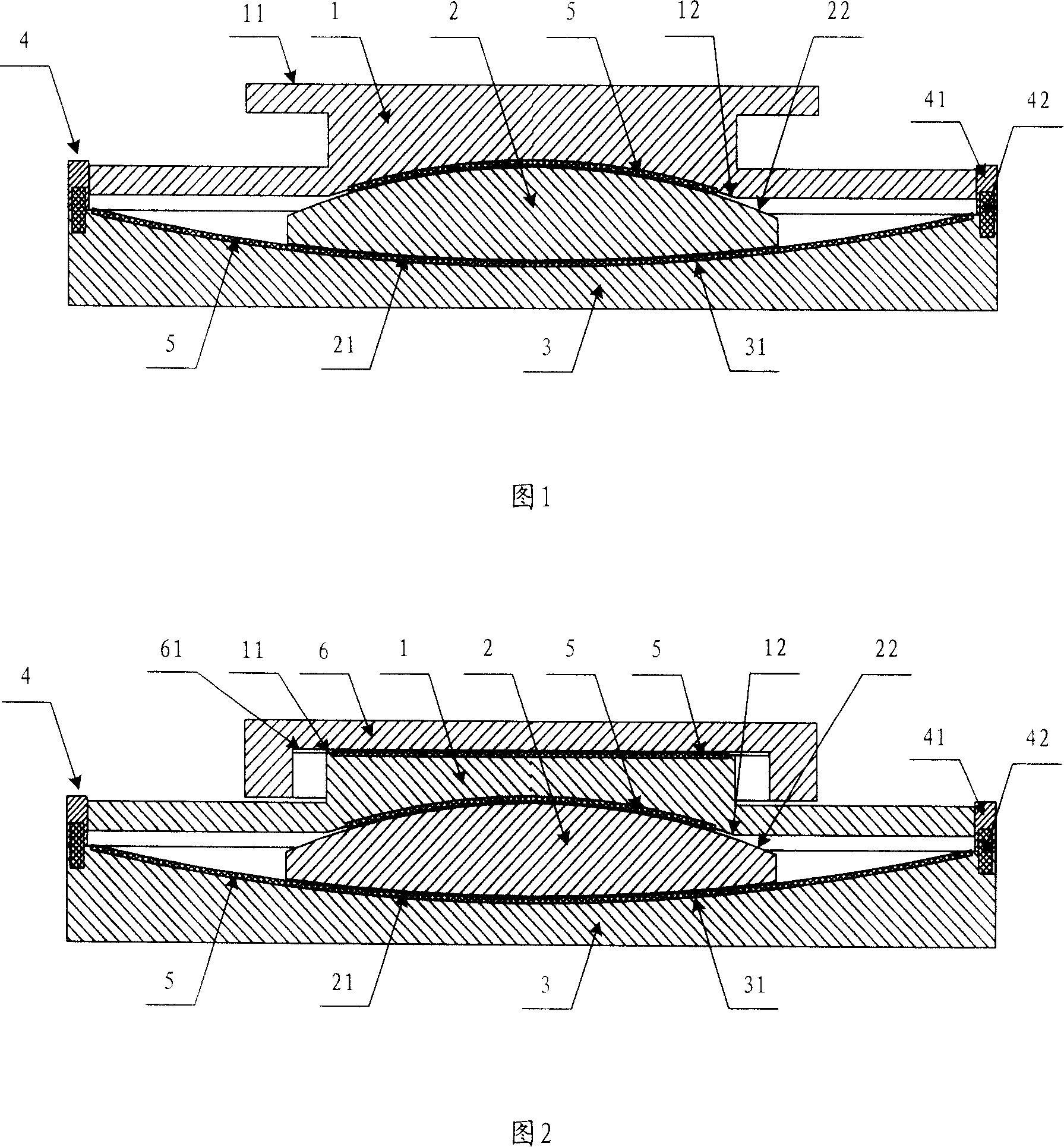

Expanding apparatus for heat exchange pipe

InactiveCN1522810ANo major deformationNo collapseTubular elementsHydraulic cylinderReciprocating motion

Provided is a pipe expansion device of a heat exchanger wherein no buckling of fin collars is generated, and the heat exchanger is constituted of radiating fins with a constant distance. The pipe expansion device is provided with: mandrels 8 having billets 5 at their respective tips; a reciprocating body 9 supporting the back ends of the mandrels 8 and being supported to be freely reciprocated in an axial direction of hair pin pipe linear parts 7a; a pressurizing cylinder 10 which elevates the reciprocating body 9, and pipe-expands, as a pressurizing driving source, the linear parts 7a in such a manner that the billets 5 are pressed into the hair pin pipe linear parts 7a; hair pin receivers 2 supporting curved parts 7b of the hair pin pipes 7; a fin receiver 1 supporting the bottom part of the radiating fins 6a superimposed with several sheets; and a hydraulic cylinder 3 as a means for elevating the fin receiver 1. The cylinder 3 sends down the fin receiver 1 to a prescribed position when the mandrels 8 descend, and the billets 5 start getting into the hair pin pipes 7.

Owner:MITSUBISHI ELECTRIC CORP

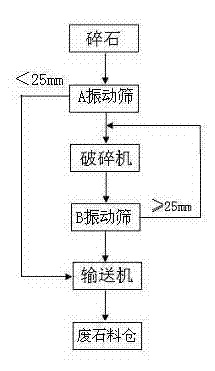

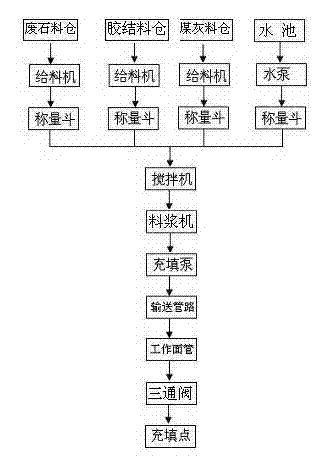

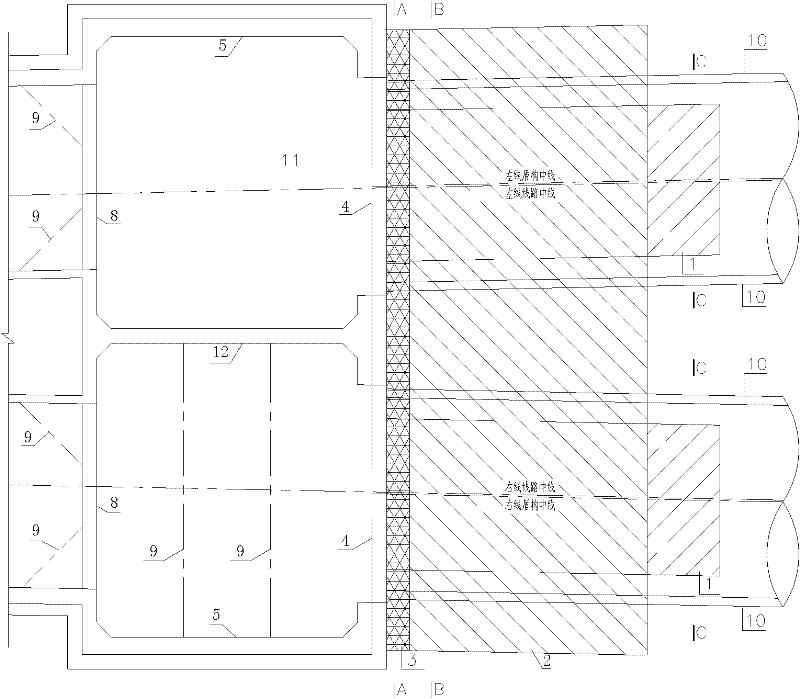

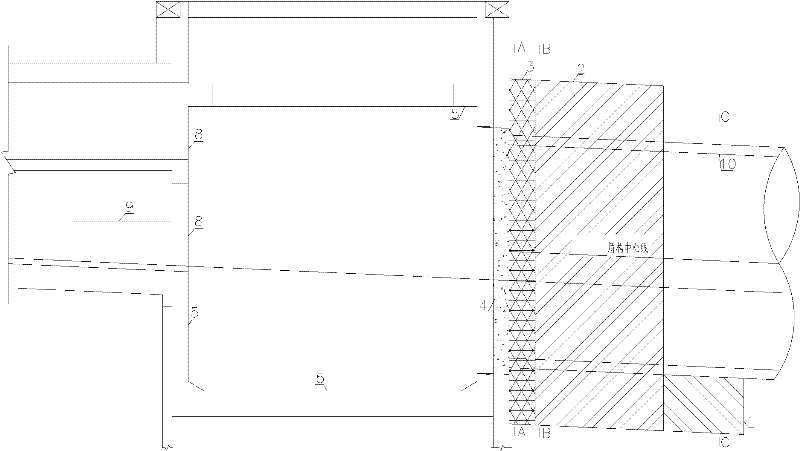

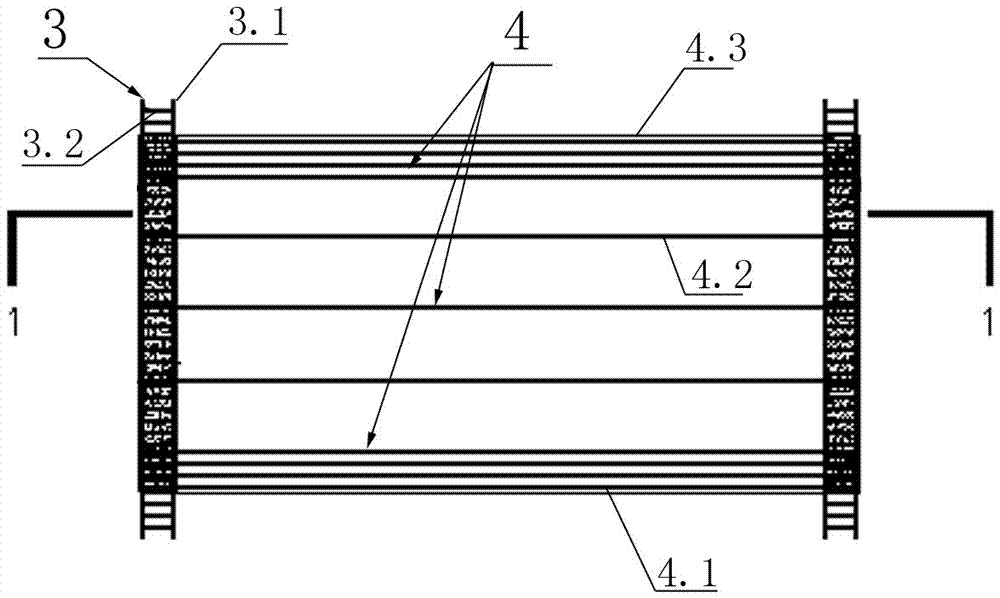

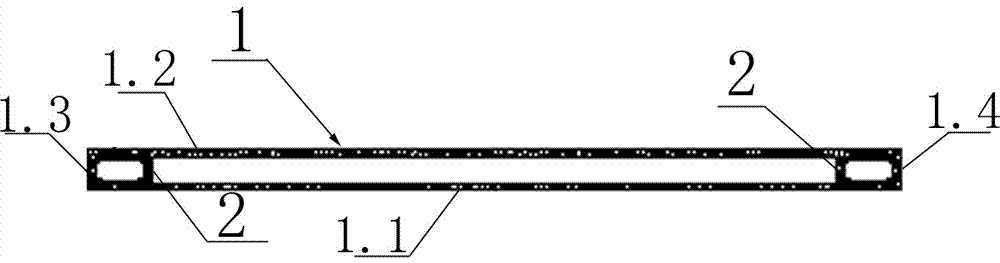

Filling method and system of coal mine goaf

ActiveCN102865101AImprove protectionAvoid missingMaterial fill-upMining engineeringPulverized fuel ash

The invention relates to a filling method and system of coal mine goaf. The filling system comprises a filling bin, a feeder, a weighing hopper, a stirrer, a slurry machine, a filling pump, a delivering pipeline, a working face pipe and a tee pipe, wherein the filling bin is respectively connected with the inlet of the stirrer through the feeder and the weighing hopper; and the outlet of the stirrer is connected to a filling point through the slurry machine, the filling pump, the delivering pipeline and a tee valve. The filling method comprises the steps that barren rocks with granularity of less than 25mm, a cementing agent, pulverized fuel ash and water are delivered to the weighing hopper through the feeder for weighing; the barren rocks, the cementing agent and the pulverized fuel ash are mixed in a mass ratio of 1:(0.22-0.80):(0.35-0.57), and are added with water to produce slurry in a mass concentration of between 70 and 83 percent through the stirrer; and the slurry is delivered to the filling point for filling through the slurry machine, the filling pump, the delivering pipeline, the working face pipe and the tee valve. According to the filling method and system, the sources of filling materials can be enlarged, the filling substance strength and durability can be increased, the filling material can be delivered to the filling point and uniformly filled by delivering and filling in a slurry state, and the filling effect can be improved.

Owner:河北充填采矿技术有限公司

Freezing consolidation and soil-accumulating watering shield arrival method

ActiveCN102352753ASettle settlementSolve the problem of \"lower head\"Underground chambersTunnel liningHydrologyRetaining wall

The invention discloses a tunnel freezing consolidation and soil-accumulating watering shield arrival method, which comprises the following steps of: (1) consolidating a stratum of a tunnel arrival section by using a jet pile or a mixing pile; (2) stopping water for a stratum close to an opening of a receiving well by using a freezing method; (3) removing a retaining wall of a tunnel portal, and filling in the receiving well to obtain a mound; (4) injecting water into the receiving well to reach the designed height; and (5) making a shield machine tunnel to enter the receiving well structure to finish the whole receiving work. By the method, when tunnel portal concrete is removed, the integral stability of soil mass can be ensured, seepage damage caused by a fine sand stratum is prevented, muddy water pressure during tunneling of the shield machine can be balanced, and is prevented from breaking through the peripheral soil mass of the tunnel portal, and the shield arrival is carried out safely and smoothly.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its prepn

InactiveCN1887996AImprove physicsGood chemical propertiesInorganic pigment treatmentAnti-corrosive paintsEpoxyHigh intensity

The present invention discloses one kind of heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its preparation process. The anticorrosive paint consists of primer, finishing paint and intercoat paint. The primer consists of polyphenylene sulfide, epoxy resin, glass scale and cyanamide dimmer. The finishing paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, 4, 4'-diamino diphenyl sulphone and cyanamide dimmer. The intercoat paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, glass scale, dihydrazide sebacate and 4, 4'-diamino diphenyl sulphone. The anticorrosive paint produces no sag, and can form homogeneous and smooth coating with excellent physical and chemical performance, high heat resistance, high corrosion resistance, high impact strength, and high insulating performance.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Lean ceramic powder size for direct-forming 3D ceramic printing as well as preparation method and application of lean ceramic powder size

ActiveCN106278201AAvoid post processingGood thinning performanceAdditive manufacturing apparatusRoom temperatureSolid content

The inventiondiscloseslean ceramic powder size for direct-forming 3D ceramic printing. The lean ceramic powder size is prepared from lean ceramic powder, a composite thixotropic agent, a dispersing agent, a thickening agent, a levelling agent and deionized water in a mass ratio being (65-75):(0.2-0.6):(0.9-1.3):(2.0-5.0):(0.5-1.5):(15-30); the lean ceramic powder is one or combination of Al2O3, ZrO2, SiC and Si3N4. The invention further discloses a preparation method and an application of the lean ceramic powder size. The lean ceramic powder size has high solid content and high shear thinning performance, is suitable for preparation of 3D printing ceramic devices with direction forming process and can be gradually dried and cured in a 3D printing process at the room temperature, and accordingly, a set structure is obtained without collapse, the printing precision is high, and the requirement for 3D printing direct-forming can be well met.

Owner:JINGDEZHEN CERAMIC INSTITUTE

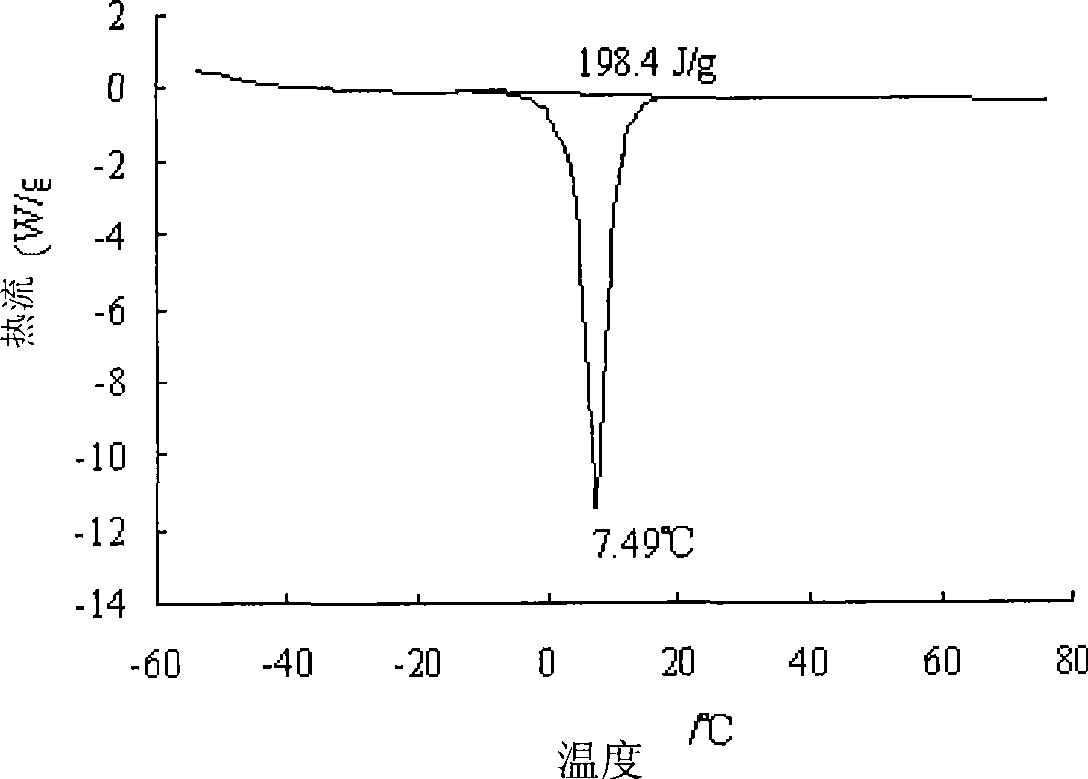

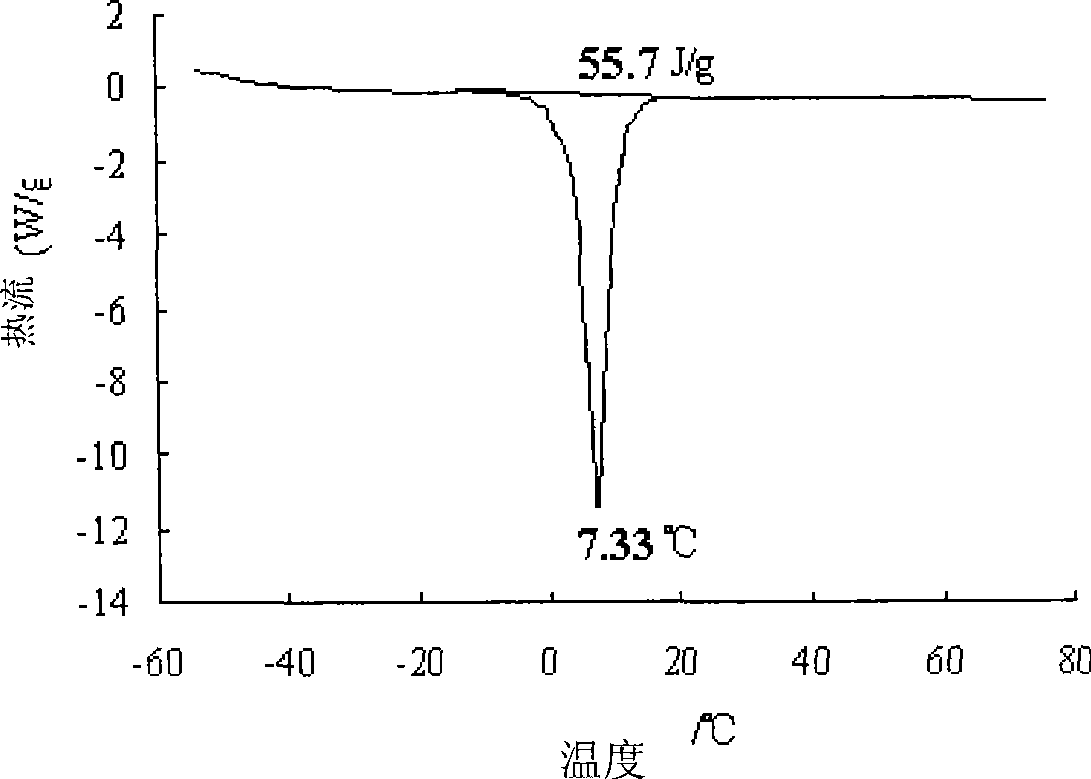

Fixed shape phase-change material based on tetradecane and method for producing the same

ActiveCN101423749AKeep shapeMaintain strengthHeat-exchange elementsPolymer scienceWorking temperature

The invention discloses a figuration phase change material based on tetradecane. The figuration phase change material is formed by mixing and processing the tetradecane with the mass percentage between 30 and 80 percent and the balance being a polymer framework material, wherein the polymer framework material is one or a combination of polyethylene (PE), styrene-butadiene-styrene copolymer (SBS) or styrene-isoprene-styrene copolymer (SIS). The invention has the tetradecane absorbed and / or wrapped in the specific polymer material as a framework. Because the polymer material as the framework can not be deformed in the working temperature range (20 below zero to 40 DEG C for example) of the tetradecane, the shape of the material can be kept, and the problems about collapse or flowing and leakage can not occur. Therefore, the obtained figuration phase change material can be widely applied to the low-temperature preservation and transportation of medicines, foods and the like.

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY

Function-restorable assembly type wave web beam-column composite joint connection device

ActiveCN105863050AReduce construction difficultyAvoid complex stress fieldsProtective buildings/sheltersShock proofingCantileverCivil/structural engineers

The invention relates to a function-restorable assembly type wave web beam-column composite joint connection device and belongs to the technical field of structural engineering. The function-restorable assembly type wave web beam-column composite joint connection device is composed of a round steel pipe column with a cantilever beam section, a wave web I-shaped composite beam section and a connecting device between the round steel pipe column with the cantilever beam section and the wave web I-shaped composite beam section. Welding of the joint connection device and assembly of the wave web I-shaped beam section and a composite floor are finished in a factory; weld seam and member qualities are easier to control; the round steel pipe column with the cantilever beam section and the wave web I-shaped composite beam section are assembled only through high-strength bolts and connection plates on site, so that the construction speed and quality are greatly improved; the wave web I-shaped composite beam section can be built on the lower flange connection plate of the round steel pipe column with the cantilever beam section, so that the hoisting difficulty is lowered and on-site assembly and positioning are easy; and through specific design, the structure destroyed positions can appear in the positions of energy dissipation members such as the easy-to-replace high-strength bolts and lower flange connection plate under the action of earthquake load, so that post-earthquake restoring is facilitated, and the function-restorable assembly type wave web beam-column composite joint connection device is adapted to development demands of a function-restorable assembly type steel structure.

Owner:BEIJING UNIV OF TECH

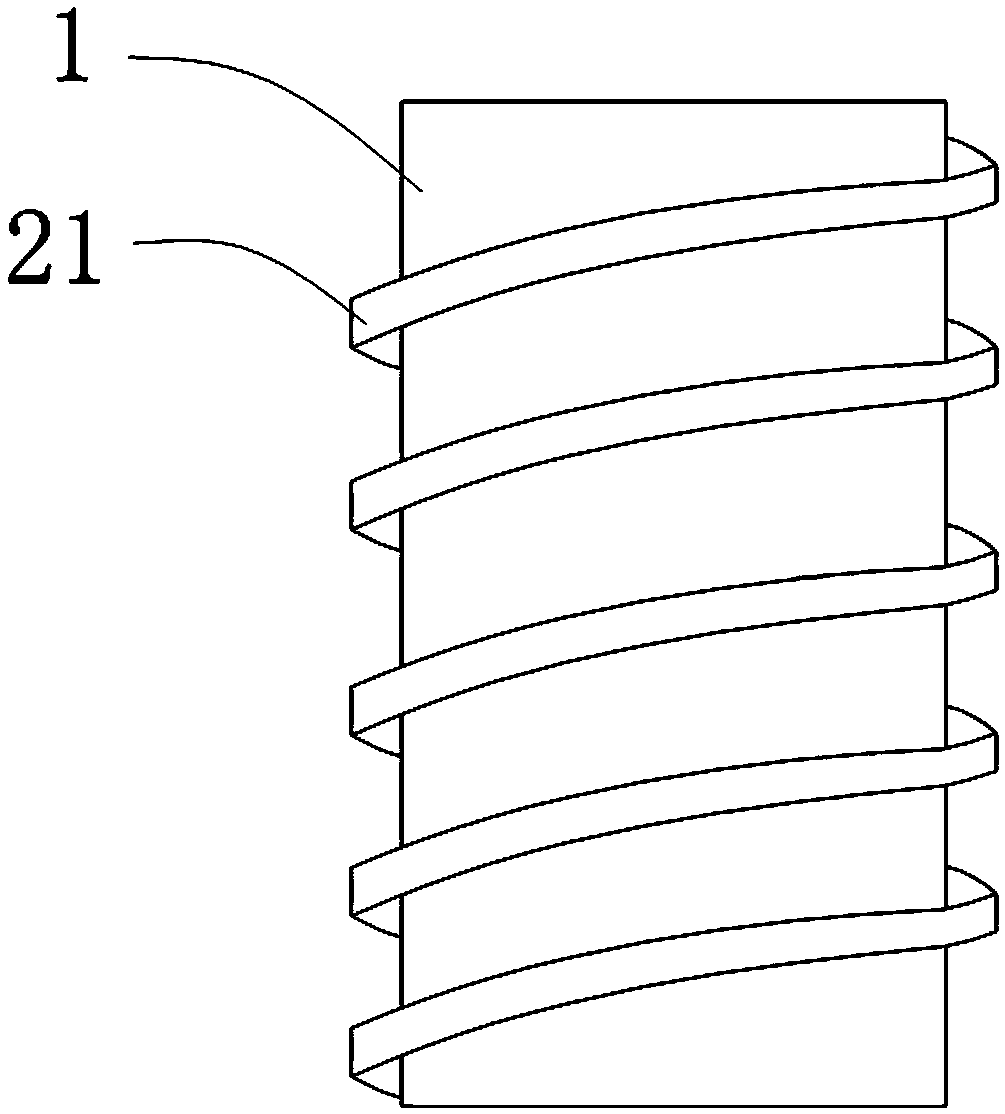

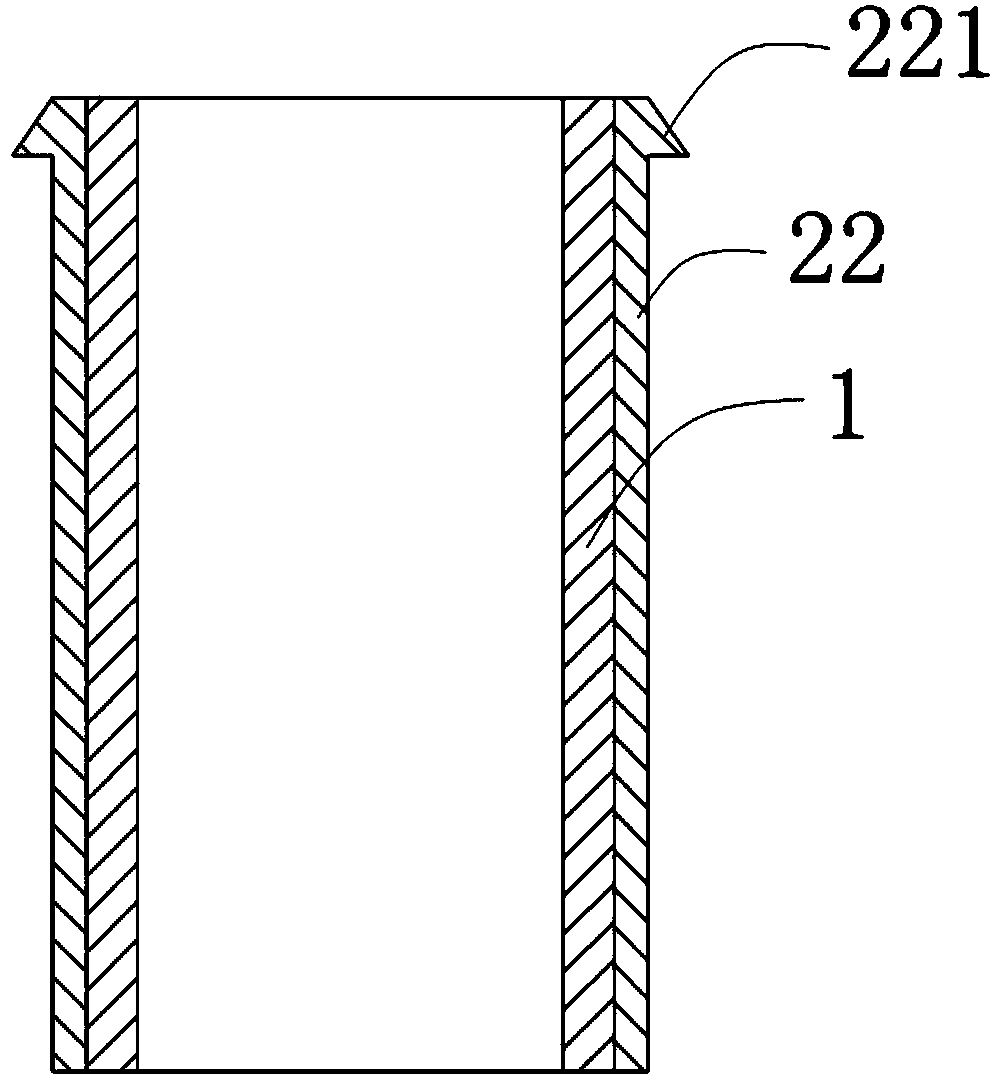

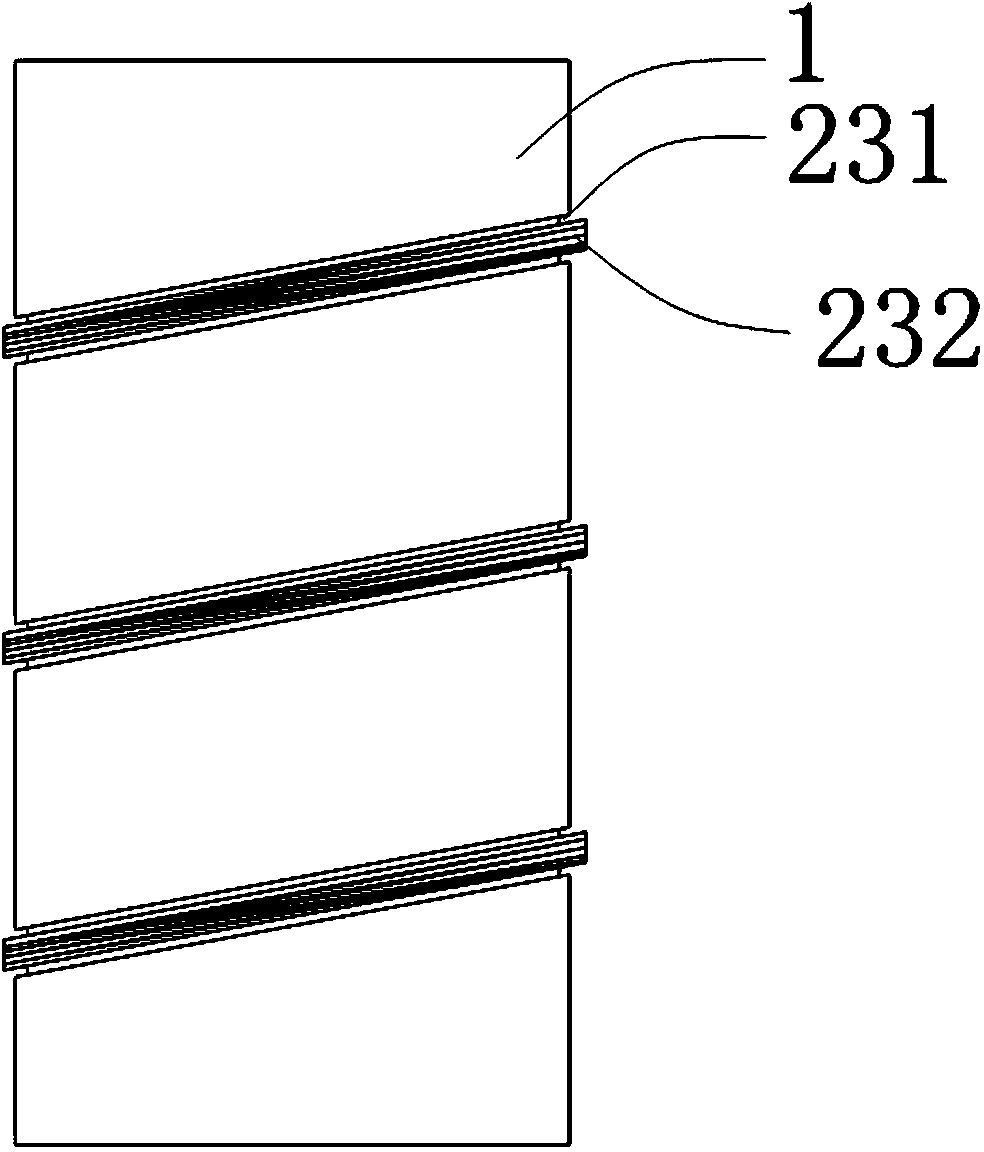

Artificial nasolacrimal duct

ActiveCN103815986AGood treatment effectRelieve painCatheterTubular organ implantsLacrimal ductEngineering

The invention discloses an artificial nasolacrimal duct which is simple in structure, capable of being led in and led out conveniently, and capable of avoiding repeated operations. The artificial nasolacrimal duct comprises an inner tube which is made of silica gel materials and a locating piece. The locating piece is arranged on the outer wall of the inner tube, and the artificial nasolacrimal duct can be supported by the locating piece to be located in a pipeline of a human body nasolacrimal duct. The inner tube is of a splicing structure of multiple channels and multiple sections. The locating piece either can be a section of spiral band which is made of degradable and expandable materials and arranged on the outer wall of the inner tube or can be an outer pipe which is arranged on the outer wall of the inner tube and made of degradable and expandable materials. The locating piece can further comprise a locating groove and an absorbable line. The spiral locating groove is formed in the outer wall of the inner tube, the absorbable line is wound in the locating groove, the maximum external diameter of the wound absorbable line is slightly larger than the external diameter of the inner tube, so that the absorbable line is in direct contact with the inner wall of the human body nasolacrimal duct, and thus the effect that the artificial nasolacrimal duct is located in the human body nasolacrimal duct through the absorbable line can be achieved.

Owner:广州锐澄医疗技术有限公司

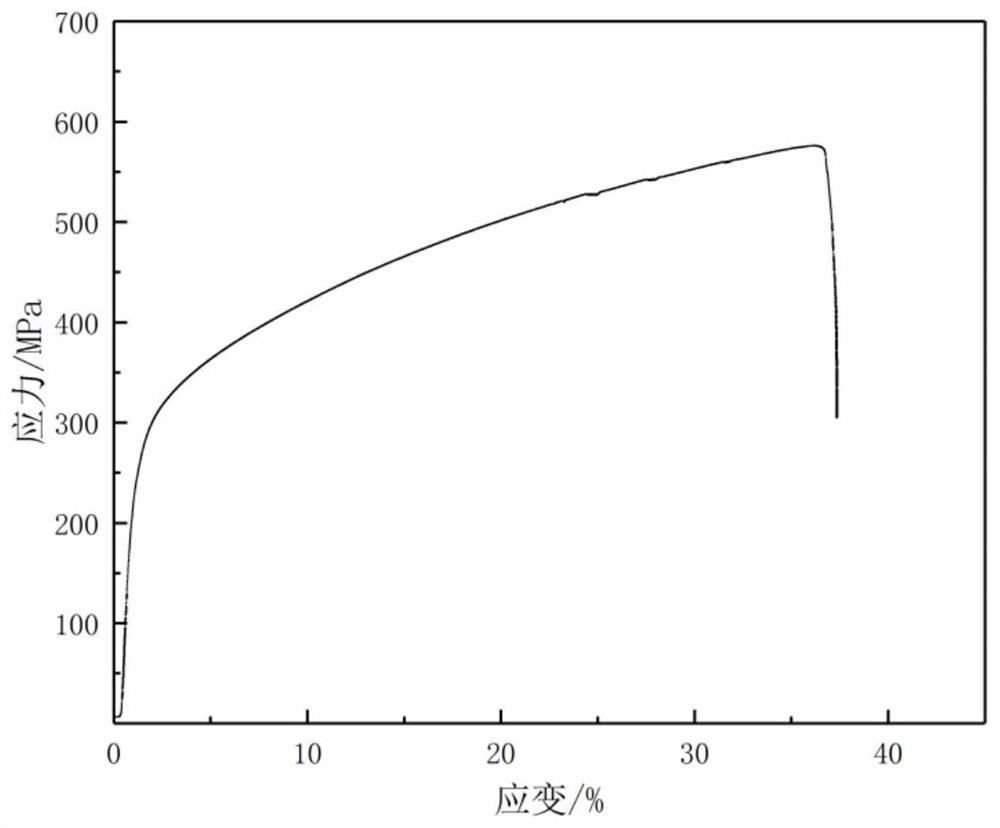

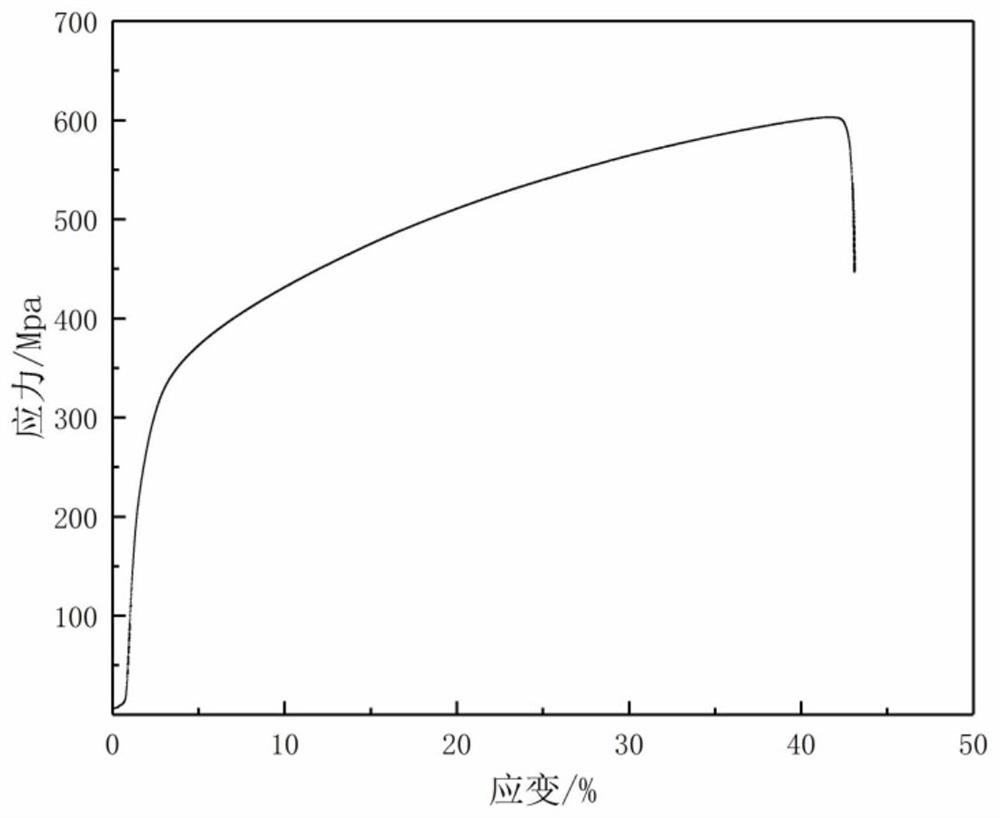

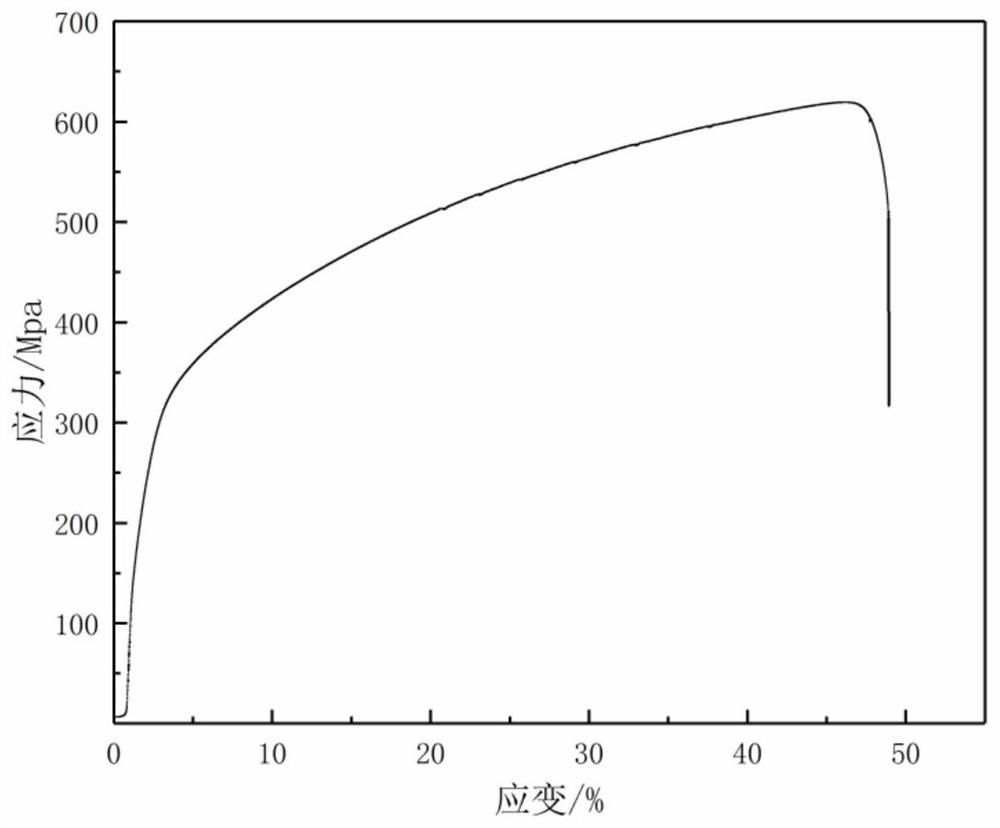

Metal type flux-cored wire and method of manufacturing austenitic stainless steel structural part

ActiveCN111992923AShort preparation cycleIncrease productivityWelding/cutting media/materialsSoldering mediaManufacturing technologyFerrosilicon

The invention discloses a metal type flux-cored wire. The metal type flux-cored wire is adopted as a raw material, an austenitic stainless steel structural part is manufactured on the basis of an electric arc additive manufacturing technology, and the formed thin-wall structural part has excellent mechanical properties. Flux-cored alloy of the metal type flux-cored wire comprises, by mass percentage, 8% of silicon iron, 18%-22% of manganese powder, 27% of nickel powder, 26% of chromium powder, 4%-8% of molybdenum powder, 1%-3% of copper powder, 0.5% of titanium powder, 0.2% of aluminum powder,0.5% of lanthanum oxide, 1% of niobium carbide and the balance iron powder. The sum of the mass percentages of the components is 100%. The austenitic stainless steel thin-wall structural part obtained through additive manufacturing is attractive in appearance and has the excellent mechanical properties. The austenitic stainless steel metal type flux-cored wire for additive manufacturing can be used for additive manufacturing of complex parts in the fields of national defense, energy, petroleum, chemical engineering, aerospace and bioengineering.

Owner:XIAN UNIV OF TECH

Railway bridge double spherical surface shock absorption and separation mount

ActiveCN101148858ASmall vertical displacementAdaptive force transmissionBridge structural detailsEngineeringStructural safety

The double spherical shock absorbing and insulating bearer for railroad bridge includes an upper bearing plate, a middle bearing plate and a lower bearing plate superposed successively and sliding teflon plates set between bearing plates. The lower bearing plate has fixed shearing force member. The middle bearing plate has an upper spherical surface in small curvature radium for connection to the upper bearing plate through spherical spin friction, and a lower spherical surface in great curvature radium for connection to the lower bearing plate through spherical sliding friction. In addition, there are also a top basin on the upper bearing plate and a sliding teflon plate in between. the present invention has obvious shock absorbing and insulating effect, easy control and regulation, capacity of ensuring structural safety and lowering engineering cost, and other features.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

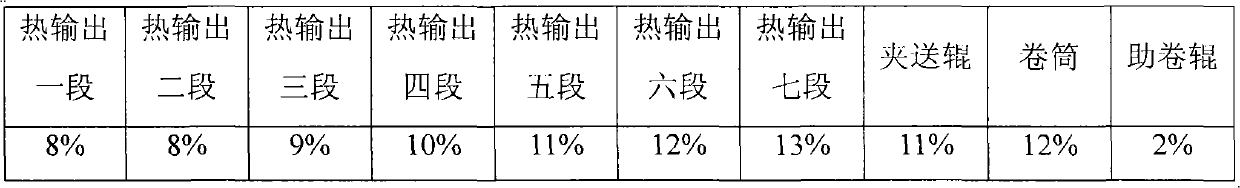

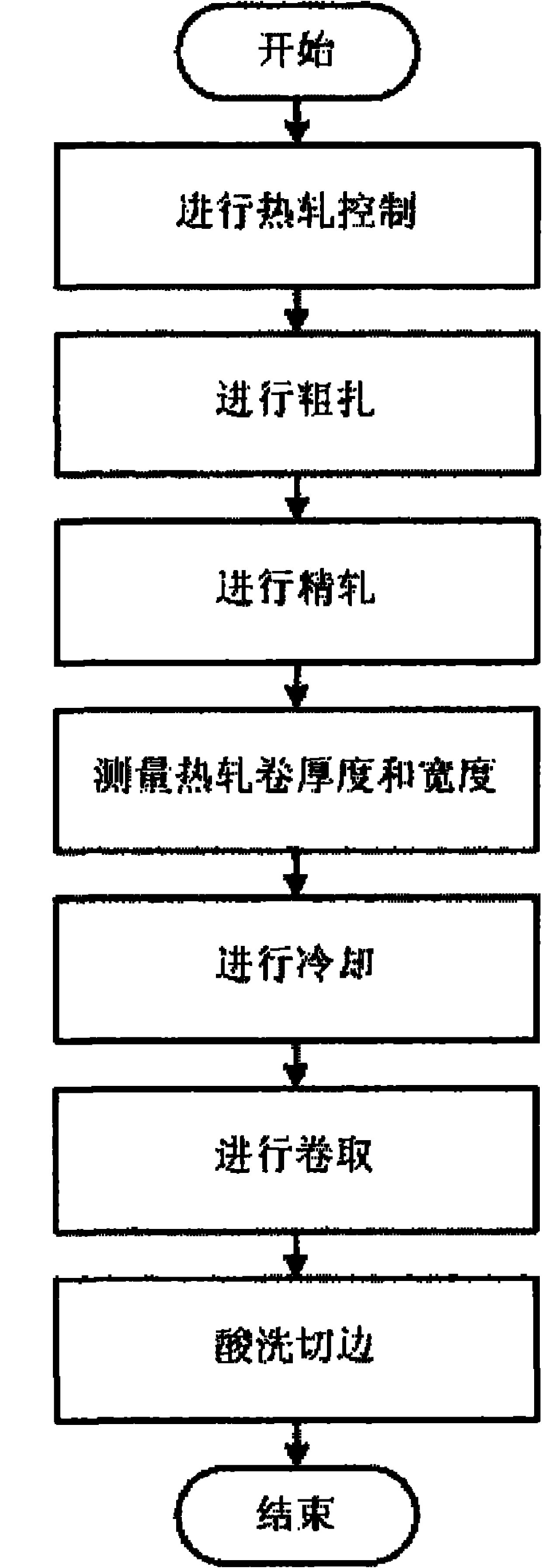

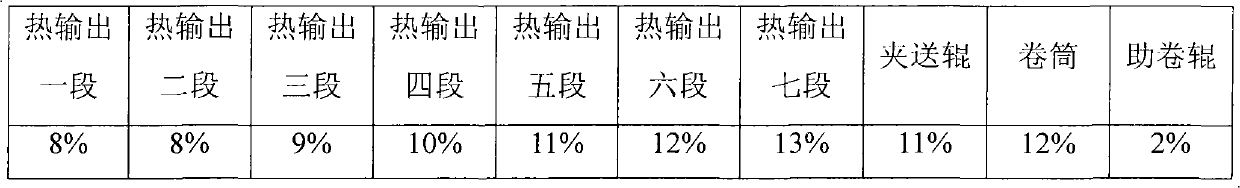

Production method of preventing from coiling and pulling narrow of hot-rolled low carbon strip steels used for cold-rolled base plates

InactiveCN101912874AReduce control difficultyReduce the probability of breakage or even broken beltTemperature control deviceMetal rolling arrangementsLaminar coolingTemperature difference

The invention discloses a production method of preventing from coiling and pulling narrow hot-rolled low carbon strip steels used for cold-rolled base plates, which comprises the following steps of: (1) controlling hot rolling, and heating plate blanks to 1190 to 1250 DEG C with temperature differences of the same plate equal or less than 40 DEG C; (2) carrying out rough rolling by adopting a 2-stage-3-point short stroke control with an outlet temperature of 1030 to 1080 DEG C; (3) carrying out finishing rolling at a temperature of 860 to 900 DEG C; (4) measuring thicknesses and widths of hot rolled steel coils; (5) carrying out laminar cooling; (6) setting each lead rate and coiling tension and coiling at a temperature of 560 to 670 DEG C; and (7) carrying out acid cleaning and cutting. The invention completely solves the problem of coiling and pulling narrow the hot-rolled low carbon strip steels used for the cold-rolled base plates by controlling hot rolling temperatures, short strokes of rough rolling, coiling lead rates, and coiling tensions.

Owner:NINGBO IRON & STEEL

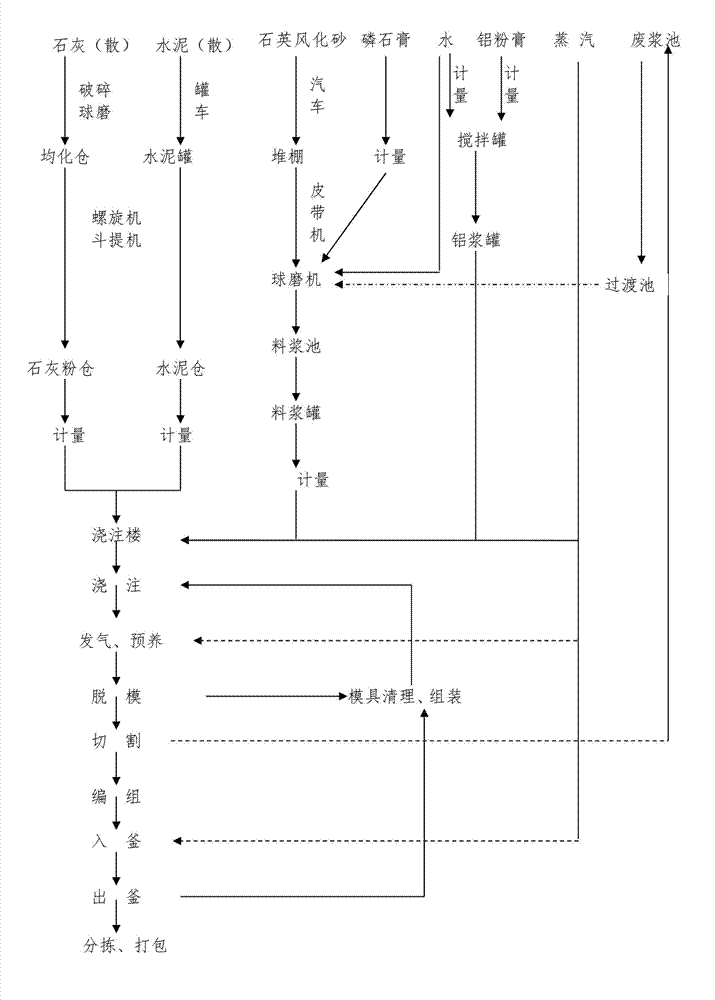

A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand and preparation method thereof

ActiveCN104774031AAlleviate the problem of comprehensive utilizationInhibits digestive reactionsCeramicwareEngineeringPhosphogypsum

The invention discloses an A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand. The A2.0 B04 grade high-performance autoclaved aerated concrete block is prepared from quartz eroded sand, cement, quick lime, industrial waste phosphogypsum, aluminum paste and water. The dry density of the concrete block is 415kg / m<3>, the cube crushing strength average value is 2.1 MPa, the single unit minimum value is 1.9 MPa, the ratio of splitting tensile is 0.19, the frost quality loss is 3.7%, the frost strength is 1.7 MPa, the heat conductivity coefficient (dry state) is 0.116 W / (m.K), the dry shrinkage value (standard value) is 0.22 mm / m and the percent of pass is greater than 98%. The raw material processing method is reasonable, the formula calculation is scientific, the production process is simple and the production waste can be recycled. The concrete block is a novel energy-saving and environmentally-friendly wall material and is suitable for industrial process.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Modified melamine formaldehyde resin-based EPS flame retardant thermal insulating board and preparation method thereof

ActiveCN103711211APrevent sinkingDoes not increase stirring mixing resistanceHeat proofingFire proofingThermal insulationAdhesive

The invention discloses a modified melamine formaldehyde resin-based EPS flame retardant thermal insulating board and a preparation method thereof. The modified melamine formaldehyde resin-based EPS flame retardant thermal insulating board is prepared by using modified melamine formaldehyde as binder and polystyrene foaming particles as foaming thermal insulating materials under certain process conditions. The flame retardant thermal insulating board has the advantages that the combustion performance of the flame retardant thermal insulating board can reach level A, combustion, collapse and dripping can be prevented when the board is grilled by open fire, and the potential fire hazard of outer wall outer thermal insulation is eliminated; the board has excellent thermal insulation performance and mechanical strength; the board can be fixed on the outer building envelope structure by means of adhesives, fixing anchor bolts, hot galvanizing zinc wire mesh, and the like to perform thermal insulation.

Owner:SUZHOU INST OF BUILDING SCI GRP CO LTD

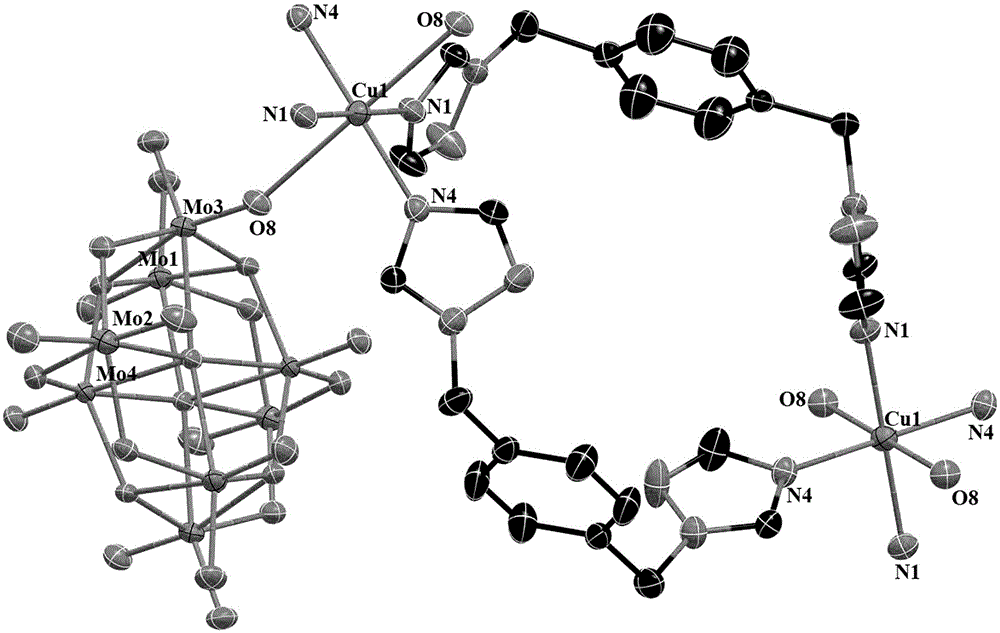

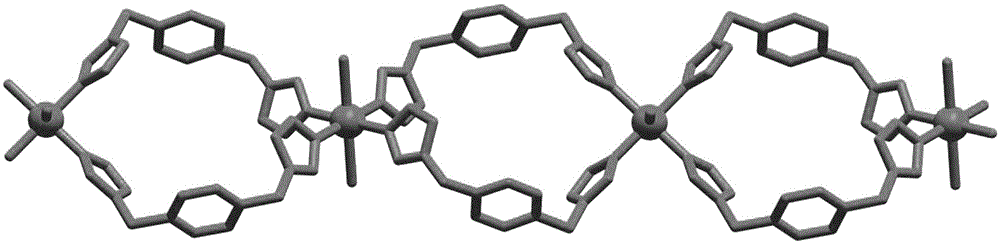

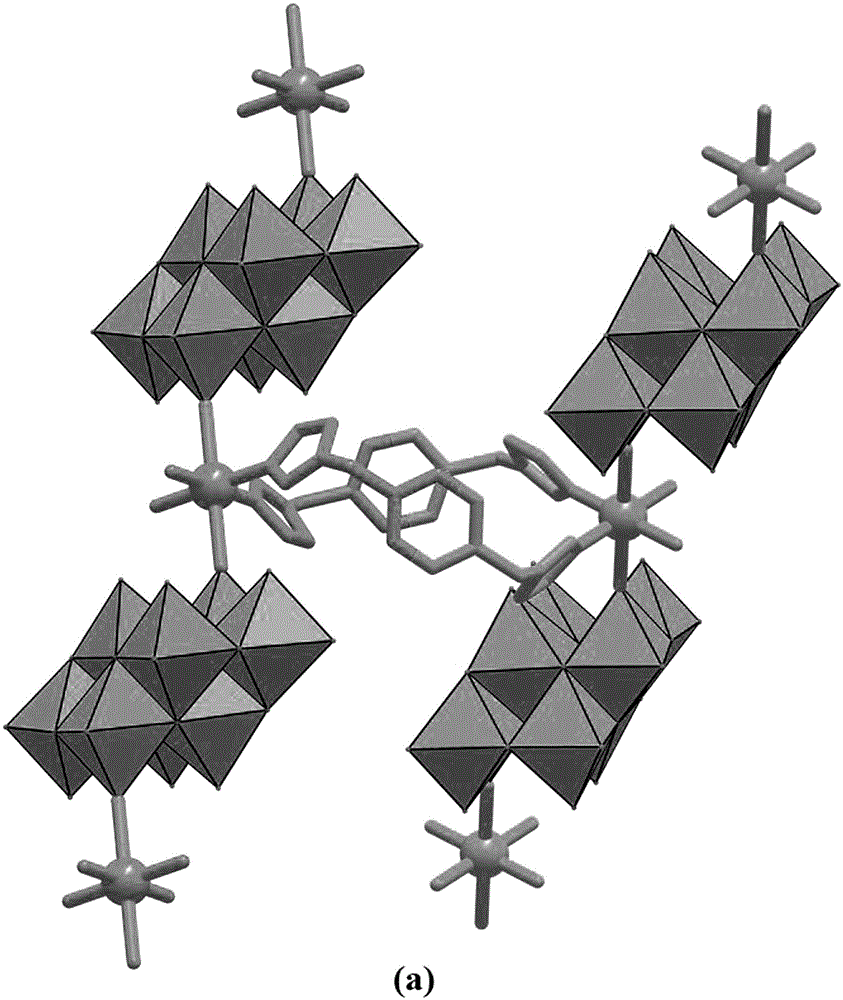

Isopolymolybdate organic-inorganic hybrid compound and preparation method thereof

InactiveCN105153203ASimple processGood repeatabilityCopper organic compoundsLuminescent compositionsPolytetrafluoroethyleneMonoclinic crystal system

The invention belongs to the technical field of macromolecular cellular materials, provides an isopolymolybdate organic-inorganic hybrid compound and a preparation method thereof and aims to solve the problem of diminishing or complete losing of porous channels due to proneness to entanglement networks in construction of cellular materials. The isopolymolybdate organic-inorganic hybrid compound with a molecular formula being C36H48N16O27Mo8Cu belongs to a monoclinic crystal system. The preparation method includes: synthesizing BBTZ; synthesizing ionic liquid [Bmin]Br; mixing (NH4)6Mo7O24.4H2O, CuCl2.2H2O, BBTZ and the ionic liquid [Bmin]Br at the room temperature, regulating pH with HCl, transferring to a reaction kettle with a polytetrafluoroethylene liner, keeping for 5 days at 160 DEG C, and cooling to the room temperature at a speed of 10 DEG C.h<-1> to obtain the compound. The isopolymolybdate organic-inorganic hybrid compound and the preparation method thereof have the advantages of technical simplicity, high repeatability, high yield, mild process conditions, stable crystal structure, availability for cation exchange, excellent thermal stability and chemical stability and applicability as high-temperature materials.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

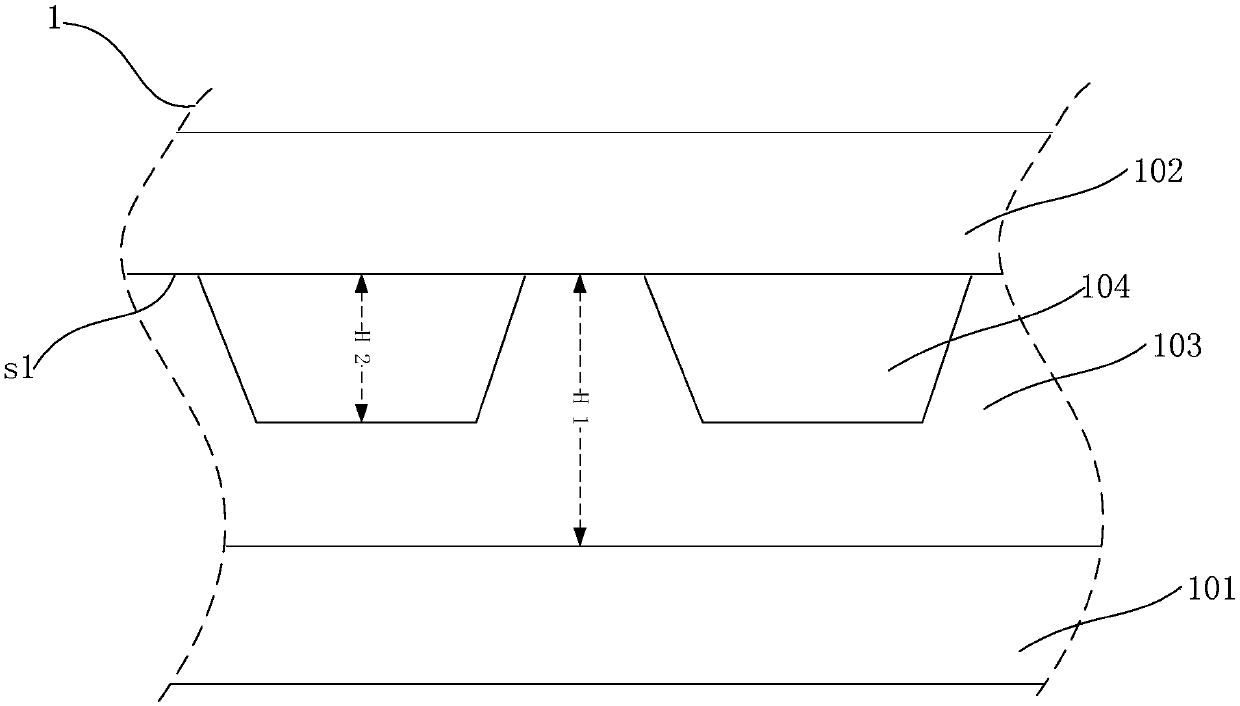

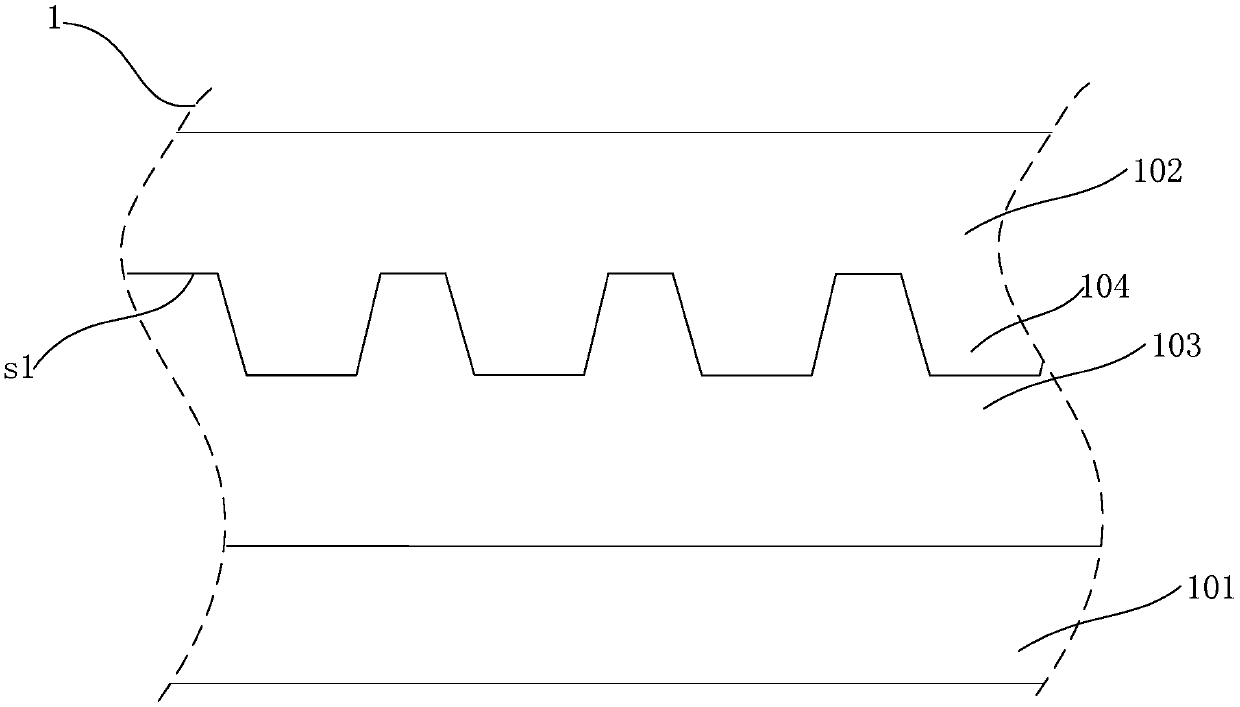

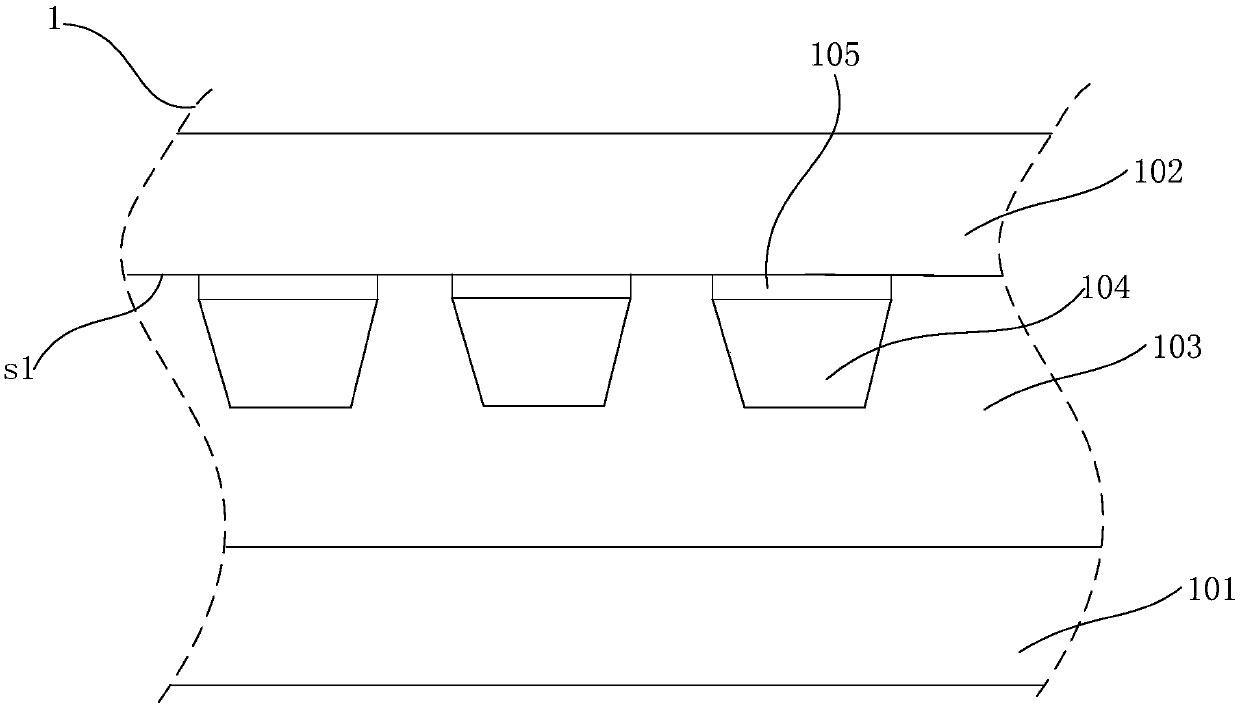

Display device

ActiveCN109671353ANo collapseSolve the technical problem of collapseIdentification meansDisplay device

The invention provides a display device, which comprises a first functional member, a second functional member, wherein the second functional member is provided with a support part for supporting thefirst functional member when the display device is deformed, an adhesive layer, wherein the adhesive layer is used for bonding the second functional member and the first functional member, the thickness of the bonding layer is not less than the thickness of the supporting part; based on that the thickness of the bonding layer in the structure is not less than the thickness of the supporting part,when the display device is not deformed, the bonding layer is arranged between the supporting part and the functional members to achieve bonding, when the display device is deformed, after an opticalglue layer and other bonding layers are deformed to a certain extent, the supporting part arranged on the first functional member is contacted with the second functional member to play a supporting role, so that the bonding layer cannot be continuously extruded to discharge glue outwards and cannot collapse, and the technical problem that the optical glue collapses due to overlarge deformation ofa prior display device is solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

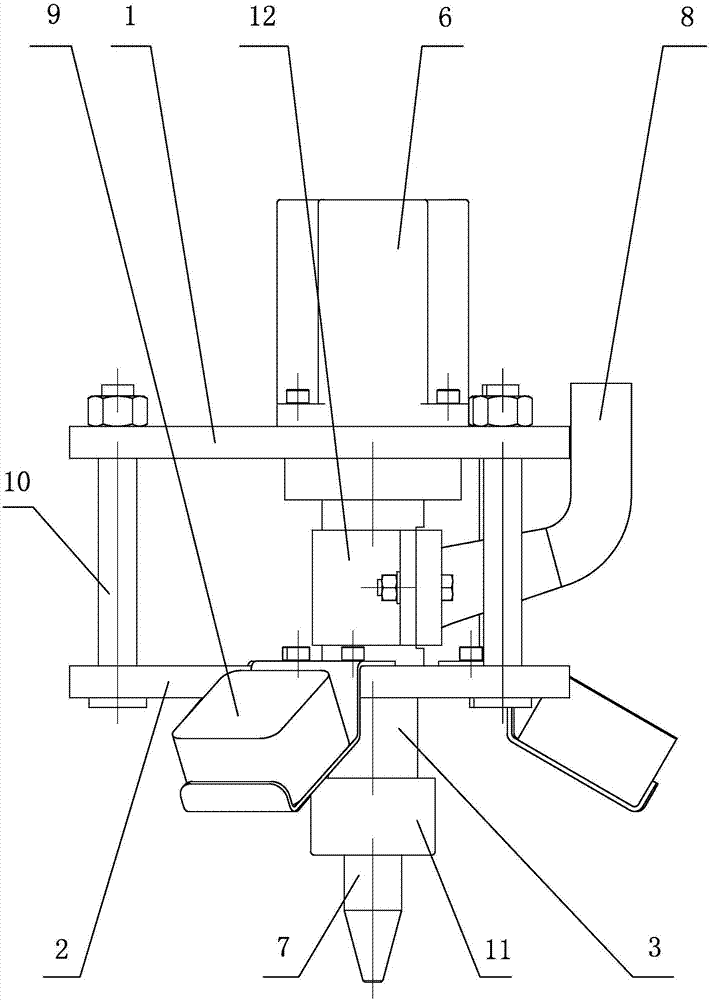

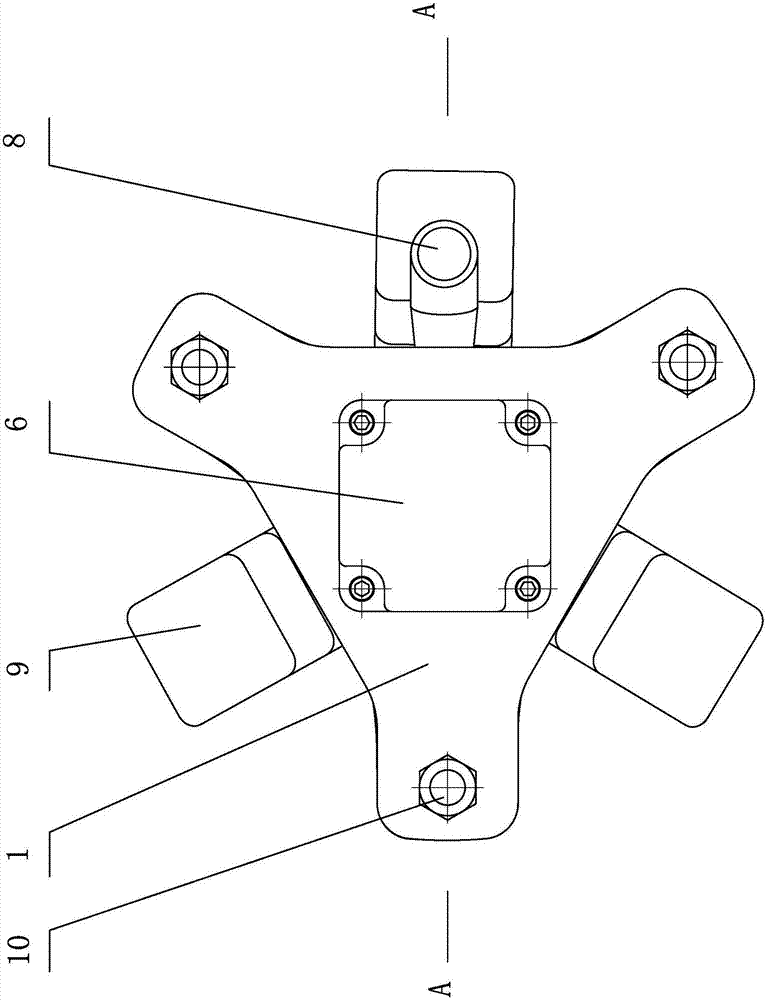

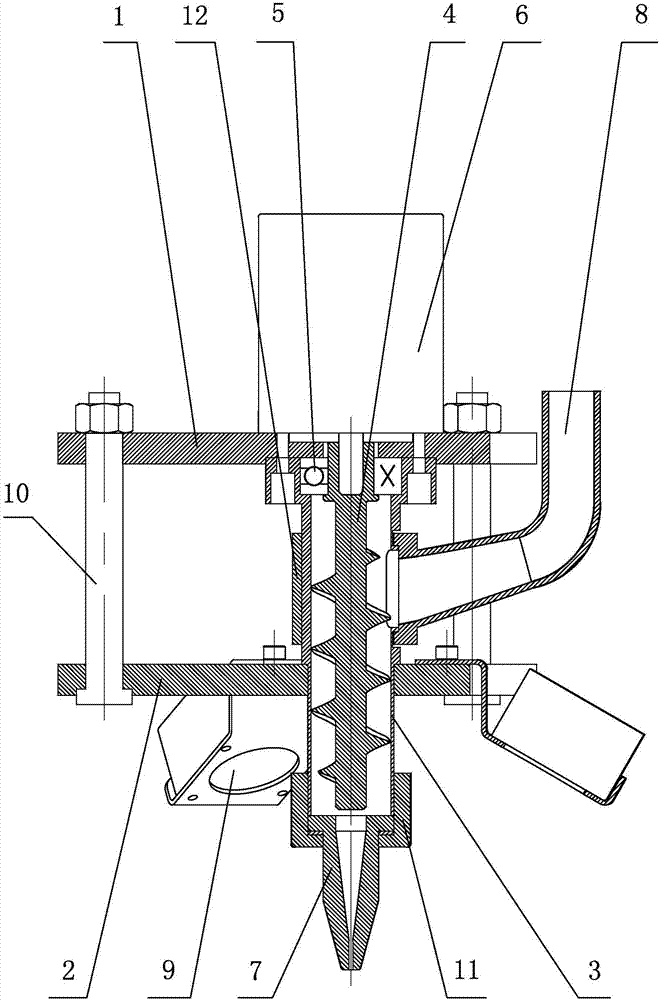

3D printing spray head device

PendingCN107415220ANo cloggingHelp with cleanupManufacturing heating elementsCeramic shaping apparatus3d printRolling-element bearing

The invention discloses a 3D printing spray head device. The 3D printing spray head device comprises an extruding mechanism, a feeding mechanism and a heating mechanism. The extruding mechanism comprises a material guide cylinder which is positioned and mounted through an upper fixing plate and a lower fixing plate. A feeding screw mounted through a rolling bearing is arranged in the material guide cylinder. The upper end of the feeding screw extends out of an upper cylinder opening of the material guide cylinder and is connected with a motor output shaft mounted on the upper fixing plate. A detachable spray head is mounted on a lower cylinder opening of the material guide cylinder. The feeding mechanism comprises a feeding pipe. The feeding pipe communicates with a feeding opening in a material guide cylinder body. The heating mechanism comprises air heaters arranged on the lower fixing plate. Air blowing openings of the air heaters all face a spray nozzle of the spray head. The 3D printing spray head device is simple in structure, good in extrusion effect, uniform to heat and capable of quickly curing a model, and the spray head is not likely to be blocked.

Owner:桂林市新众科技有限公司

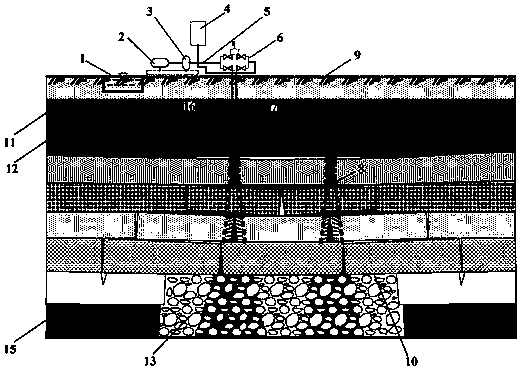

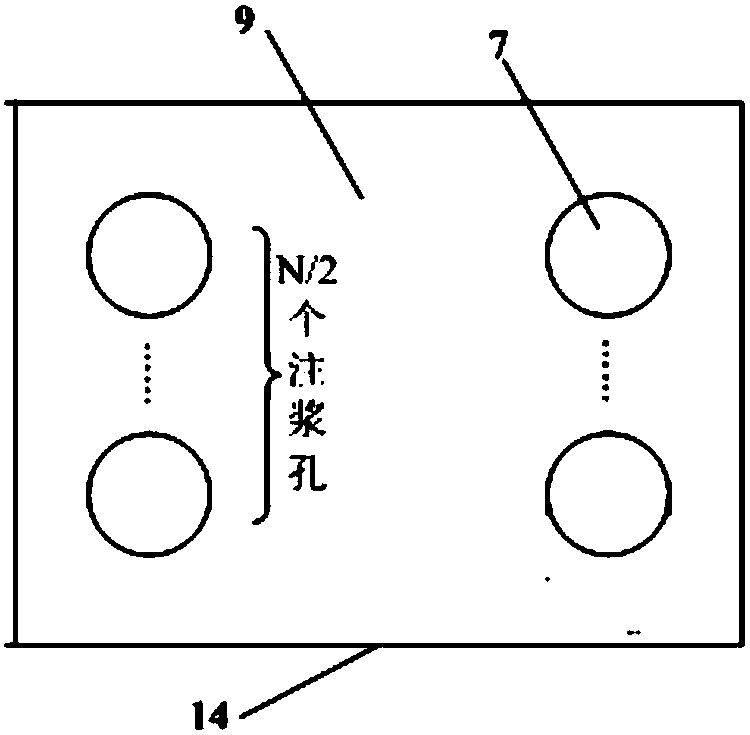

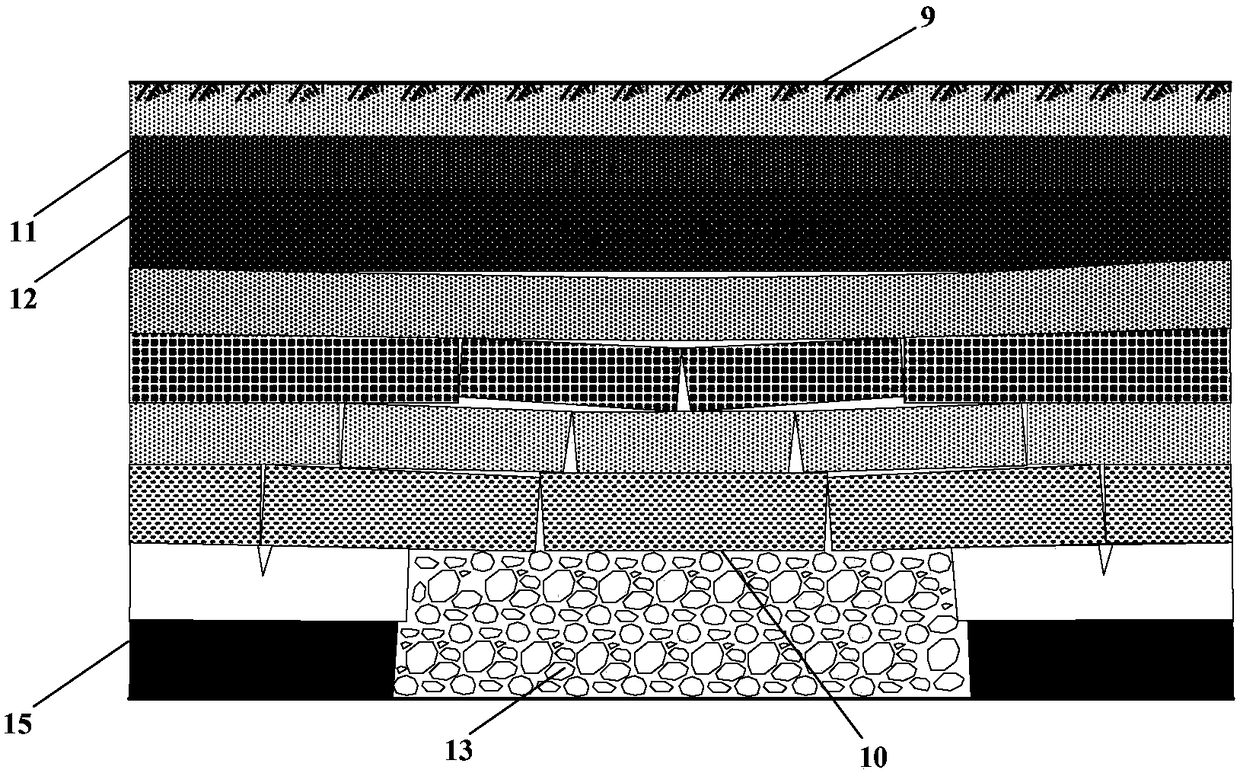

Pier type arch linkage type goaf treatment method

ActiveCN108194132AMaintain stabilityImprove filling qualityMaterial fill-upStructural engineeringUltimate tensile strength

The invention discloses a pier type arch linkage type goaf treatment method. A bracing strength of a pier column is obtained mainly through data analysis of a key layer, then a grouting hole is formedin a bottom plate of a goaf from the ground surface, the grouting hole is filled intermittently by using a pipe lifting method to form the pier till the pier is connected with the top of the key layer, and after grouting filling is completed, residual grouting holes are filled and sealed. A pier type arch linkage structure is formed by utilizing mutual cooperation of the pier formed after grouting filling aggregate is solidified and a caving top plate covering the goaf, and the stability of the top plate of the goaf is maintained.

Owner:SHANDONG UNIV OF SCI & TECH

Novel 3D printed reinforced wall and construction method thereof

InactiveCN106968367AImprove stabilityIncrease the performance of carrying vertical gravityWallsProtective buildings/sheltersEngineeringRebar

The invention discloses a novel 3D printed reinforced wall and a construction method thereof. The 3D printed reinforced wall comprises a wall main body formed by integral printing through a 3D printer. The wall main body comprises an external rectangular frame plate and two vertical partitioning plates partitioning the interior of the edge plate along the width direction of the wall main body to form cavities. The frame plate comprises a front side plate body, a rear side plate body, a left side plate body and a right side plate body. The vertical partitioning plates are connected in the position, close to the two ends of the frame plate, between the front side plate body and the rear side plate body, and the rectangular cavities are defined by the vertical partitioning plates, the front side plate body, the rear side plate body and the left side plate body or the right side plate body. Two constructional column steel bar frameworks and two sets of transverse steel bars are arranged in the wall main body. The constructional column steel bar frameworks are located in the rectangular cavities. Constructional column concrete is poured in the rectangular cavities. The two sets of transverse steel bars are placed in the front side plate body and the rear side plate body correspondingly. The problem that according to a traditional 3D printed plain concrete wall, tensile performance is poor, and ductility and energy consumption performance cannot meet the anti-seismic requirement is solved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

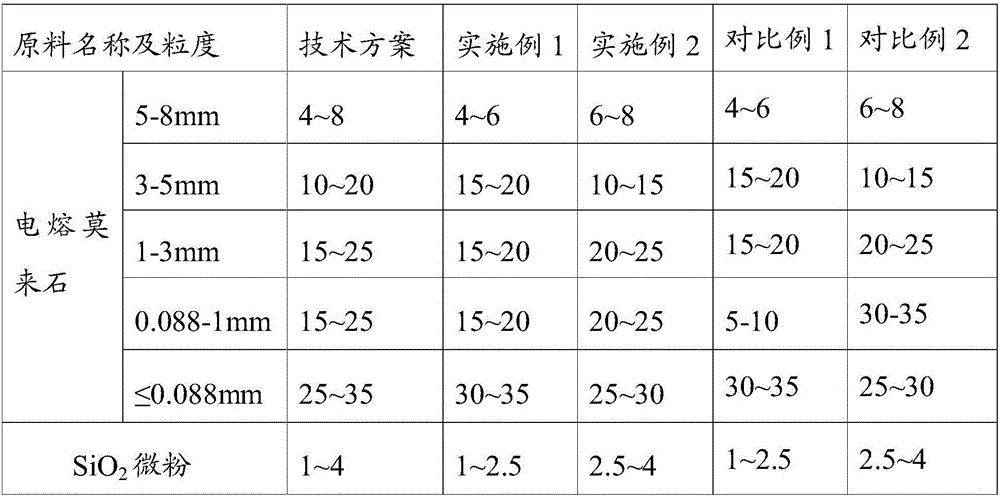

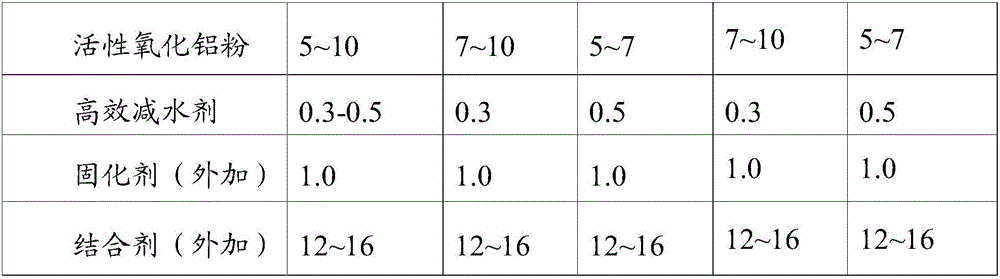

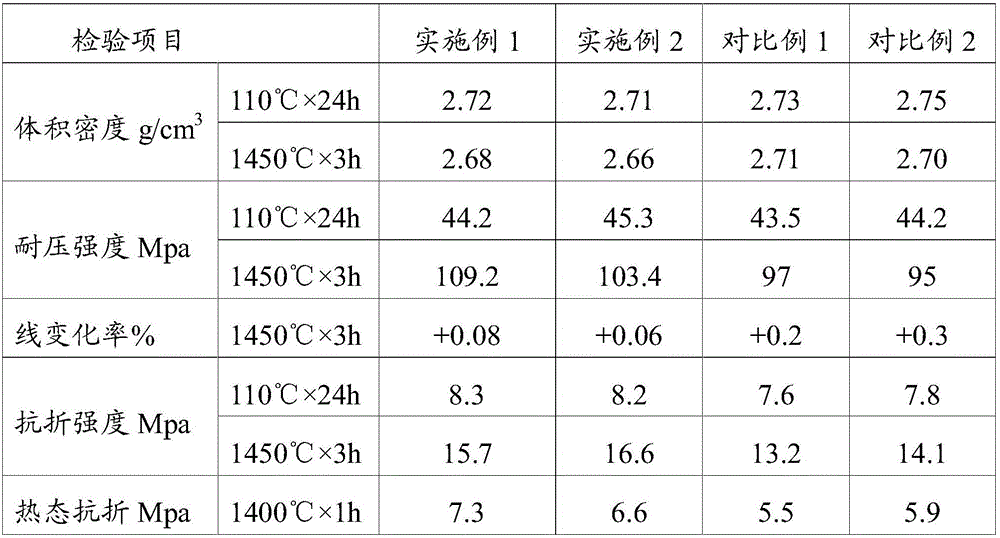

Wet-process spray-coating material for lining of upper shaft of blast furnace, application of wet-process spray-coating material and method for repairing lining of upper shaft of blast furnace

The invention belongs to the technical field of repairing of blast furnace linings and particularly relates to a wet-process spray-coating material for a lining of an upper shaft of a blast furnace, an application of the wet-process spray-coating material and a method for repairing the lining of the upper shaft of the blast furnace. The spray-coating material contains the following ingredients in percentage by weight: 4-8wt% of electrically-fused mullite with the granularity of 5mm to 8mm, 10-20wt% of electrically-fused mullite with the granularity of 3mm to 5mm, 15-25wt% of electrically-fused mullite with the granularity of 1mm to 3mm, 15-25wt% of electrically-fused mullite with the granularity of 0.088mm to 1mm, 25-35wt% of electrically-fused mullite with the granularity not greater than 0.088mm, 1-4wt% of silica micropowder, 5-10wt% of activated alumina micropowder and 0.3-0.5wt% of admixture. The service life of the spray-coating material can reach 24 months or more and is greatly prolonged compared with those of spray-coating materials in the prior art; and the spray-coating material has the characteristics of long construction time, excellent medium-temperature physical properties, short baking time and long one-time repair service life, the cost is lower, and the resistance to fracture caused by temperature changes is higher.

Owner:WUHAN WINNING TECH

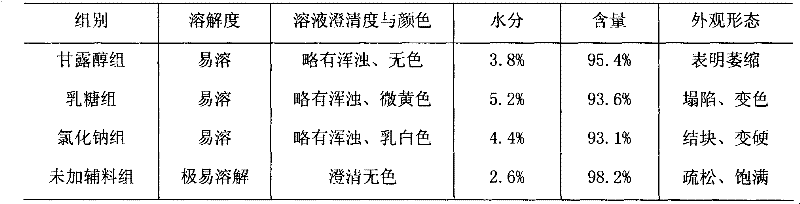

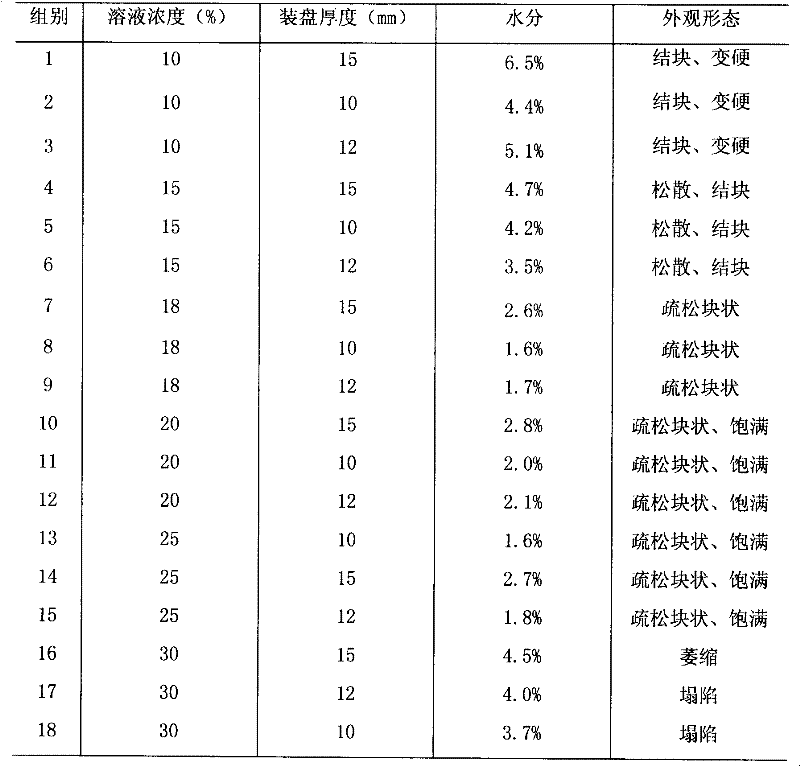

N(2)-L-alanyl-L-glutamine preparation for injection and preparation method thereof

ActiveCN102228444AAvoid stabilityAvoid water solubility effectsPowder deliveryDipeptide ingredientsL-alanyl-l-glutamineFreeze-drying

The invention discloses an N(2)-L-alanyl-L-glutamine preparation for injection and a preparation method thereof. The preparation is prepared through directly preparing a liquid with a raw material N(2)-L-alanyl-L-glutamine, freeze-drying, and carrying out separate packing. The method comprises the following steps: (1) taking the raw material N(2)-L-alanyl-L-glutamine, adding water for injection, and fully stirring to completely dissolve N(2)-L-alanyl-L-glutamine; (2) adding needle active carbon to a solution obtained in step (1), fully stirring, filtering to decarburize, and carrying out germ filtering through passing through a filter with a diameter of 0.2 [mu]m; (3) putting a filtrate obtained in step 2 into a sterilized freeze-dried disc, loading the disc into a cooling chamber of a freeze dryer, and carrying out pre-freezing, vacuumizing, heating, sublimation drying, desorption drying, and vacuum break to end freeze-drying; and (4) accessing high purity nitrogen for drying and degerming, taking out of the chamber, carrying out asepsis packing, tamponading, and capping. So N(2)-L-alanyl-L-glutamine for injection is obtained.

Owner:GUIZHOU YIBAI PHARMA CO LTD

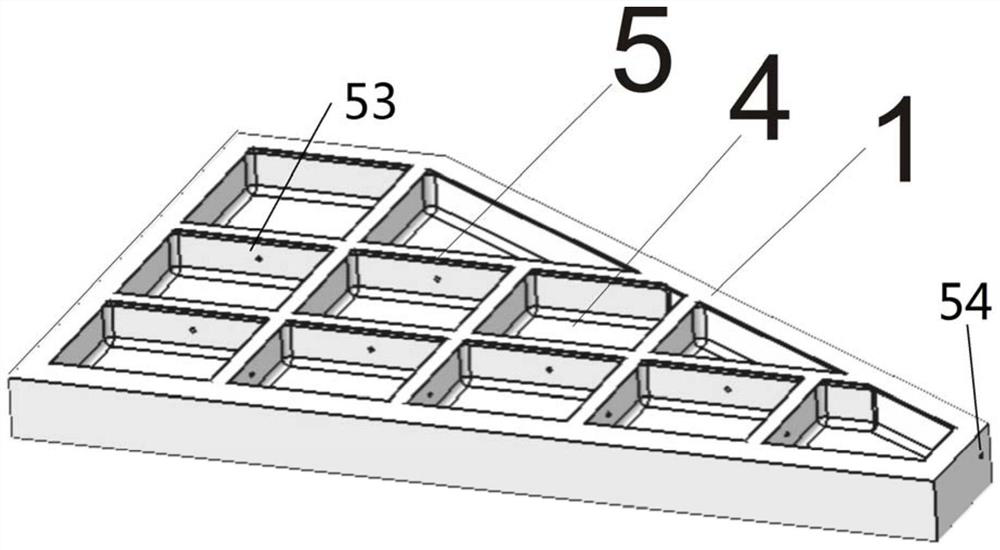

Preparation method of titanium alloy hollow structure

ActiveCN112372130ANo collapseImprove production efficiencyWelding/soldering/cutting articlesNon-electric welding apparatusTitaniumTitanium alloy

The invention relates to a preparation method of a titanium alloy hollow structure. The method comprises the following steps that raw materials are processed, specifically, a titanium alloy plate, titanium alloy filling plates and a titanium alloy cover plate are formed through processing, and a plurality of hollow cavities are formed in one surface of the titanium alloy plate through processing,wherein the titanium alloy cover plate matches the surface, provided with the hollow cavities, of the titanium alloy plate in shape; the filling plates are installed, specifically, each titanium alloyfilling plate is placed into the corresponding hollow cavity, each titanium alloy filling plate is flush with the upper surface of the corresponding hollow cavity, and then each titanium alloy filling plate and the corresponding hollow cavity are connected through welding; the titanium alloy cover plate is installed, specifically, the surface, provided with the hollow cavities, of the titanium alloy plate is covered with the titanium alloy cover plate, and edge sealing welding, baking and vacuum packaging are sequentially conducted on the titanium alloy cover plate and the titanium alloy plate to form a prefabricated blank; diffusion bonding is conducted, specifically, the prefabricated blank is put into a gas diffusion furnace or a hot isostatic pressing furnace for diffusion bonding; and machining is conducted, specifically, a finished part is manufactured through machining. The method is applied to the technical field of titanium alloy manufacturing.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

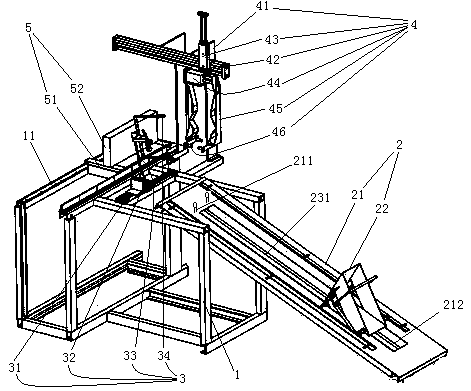

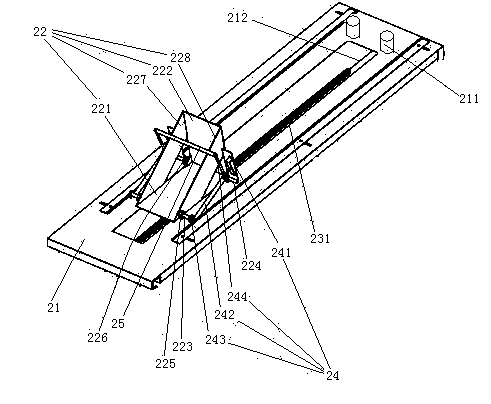

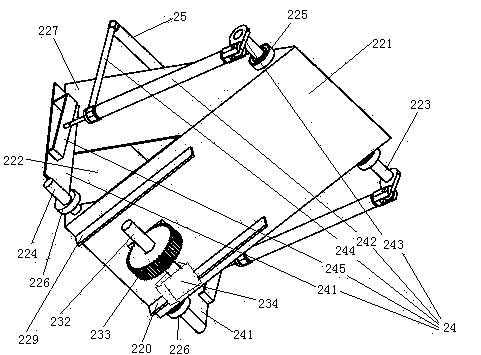

Upper bag body mechanism and bag body loading method

ActiveCN104249487ANo collapseGood use effectPaper-makingBox making operationsTransfer mechanismEngineering

The invention relates to a paper bag processing device and a paper bag processing method. An upper bag body mechanism comprises a frame and a bag body storing mechanism, wherein the bag body storing mechanism comprises a support plate which is arranged obliquely and of which the upper end is connected together with the frame, a blocking-pushing frame positioned on the support plate, and a driving mechanism for driving the blocking-pushing frame to move along the inclination direction of the support plate; a bag body transferring mechanism, a bag body opening and loading mechanism and a bag opening and holding frame are arranged on the frame; the bag body transferring mechanism is positioned between the bag body storing mechanism and the bag body opening and loading mechanism; the bag opening and loading mechanism is positioned between the bag body transferring mechanism and the bag body opening and holding frame. According to the upper bag body mechanism, a bag body plate on which a hand rope is to be arranged can be changed into an open bag body, and the bag body is kept in an open state, so that the problem of limitation on realization of automatic installation of the hand rope since a mechanism for changing the bag body on which the hand rope is to be arranged to the open state and keeping the bag body in the open state is unavailable is solved.

Owner:杭州汇八科技有限公司

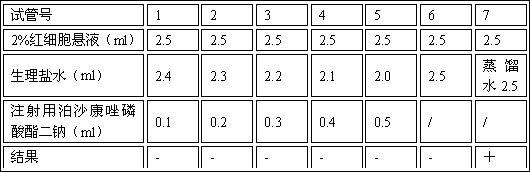

Freeze-drying composition of posaconazole prodrug and preparation method and application of freeze-drying composition of posaconazole prodrug

InactiveCN105287403AImprove performanceNo pollution in the processOrganic active ingredientsPowder deliverySolubilityCase fatality rate

The invention relates to a freeze-drying composition of a posaconazole prodrug and a preparation method and application of the freeze-drying composition of the posaconazole prodrug. The freeze-drying composition has the advantages that the freeze-drying composition is high in water solubility, and safety of the freeze-drying composition is guaranteed due to the fact that cyclodextrins auxiliary materials need not to be added during the preparation of the freeze-drying composition; the freeze-drying composition is suitable for being used for treating various amphotericin-intolerant or refractory adult invasive fungal infections; the freeze-drying composition is used as a preventive drug for high-risk patients, the freeze-drying composition is applicable to patients above 13 years old and with impaired immunity and especially applicable to patients who have graft versus host disease (GVHD) after hematopoietic stem cell transplant, patients with leukemia and patients with long-term leukopenia due to chemotherapy; compared with control drugs such as fluconazole and itraconazole, the freeze-drying composition can effectively prevent invasive aspergillosis and can lower the mortality related to the invasive fungal infections.

Owner:HC SYNTHETIC PHARMA CO LTD

Production method of instant fruit and vegetable shortcakes

The invention provides a production method of instant fruit and vegetable shortcakes. The method comprises the following steps: pre-processing vegetable and fruits, respectively crushing and pulping, mixing the above obtained fruit pulp with the above obtained vegetable pulp, adding inulin, natural fructose syrup, white granulated sugar and a natural lemon juice, blending, homogenizing to obtain a mixture, pouring the mixture into a die supporting box, and carrying out vacuum freeze drying to obtain the instant fruit and vegetable shortcakes. The fruit and vegetable pulps and other raw materials are mixed according to a specific ratio and undergo vacuum freeze drying to make the fruits and vegetables form a novel and instant fruit and vegetable shortcake food, so the kind of the fruit and vegetable products in the market is enriched. The fruit and vegetable shortcakes made through the production method maximally reserve nutritional components in the fruits and vegetables without loss of the nutritional components or destroys of the color or the taste, and solve the problem of flavor change of the fruit and vegetable fruits, induced by present production technologies; and the fruit and vegetable shortcakes produced through the method also have the advantages of low water content, light weight, easy storage, and convenient transportation and carrying.

Owner:四川江茂食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com