Patents

Literature

92results about How to "Avoid post-processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

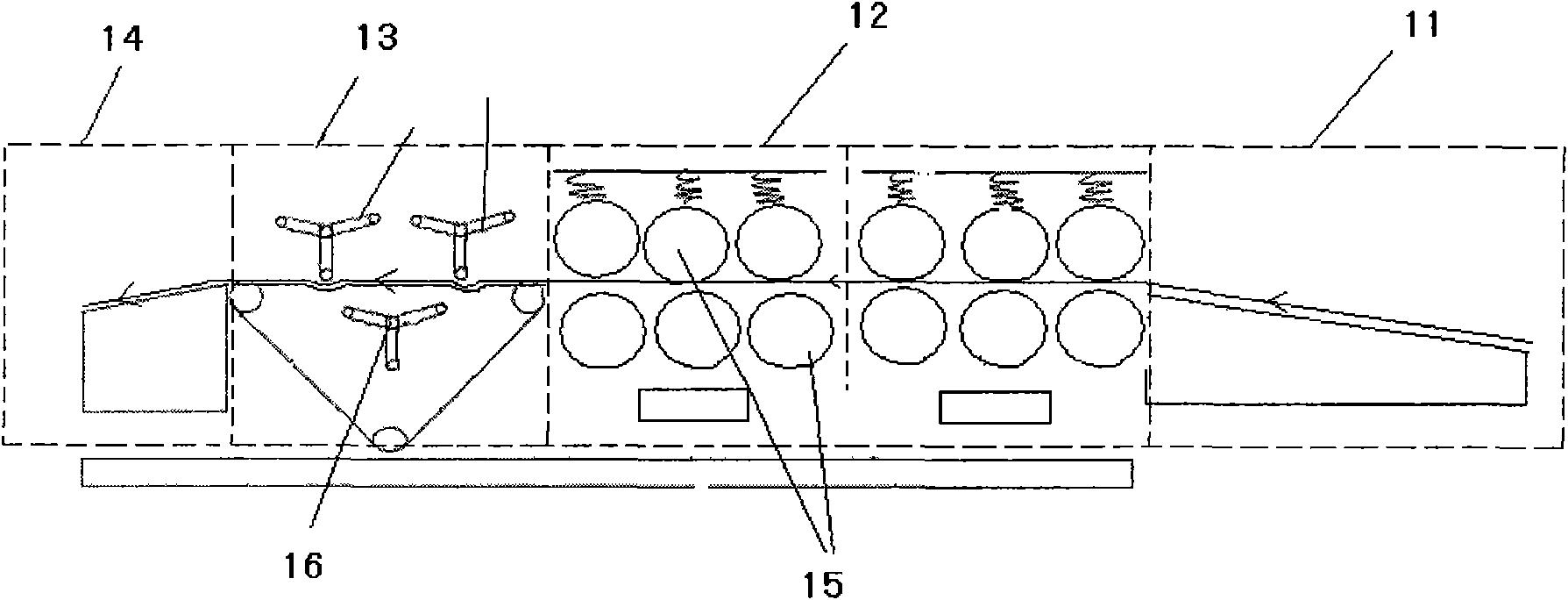

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

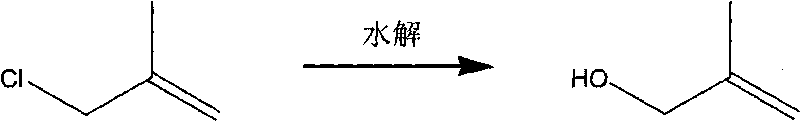

Synthesizing method of 2-methallyl alcohol

InactiveCN101759528AReduce environmental pollutionAvoid post-processingPreparation by hydrolysisSolid baseSolvent

The invention discloses a synthesizing method of 2-methallyl alcohol, comprising the following steps of: sequentially adding water, solid base, 2-methallyl chloride and polyethylene glycol to a reaction vessel, then refluxing by heating, and dripping an aqueous alkali solution with the concentration of 1-50 percent; (2) after reaction is completed, cooling, standing and demixing a reaction solution to obtain an organic layer and a water layer, drying and dewatering the organic layer, decoloring by activated carbon, filtering to obtain a target product, and circularly using filter liquor obtained by filtering and desalting the water layer as a new reaction solvent for preparing the 2-methallyl alcohol; and (3) adding the 2-methallyl chloride to the circularly used reaction solvent, and complementally adding the polyethylene glycol, the water and the base to perform new reaction for preparing the 2-methallyl alcohol, wherein the filter liquor obtained by filtering the water layer in each reaction is always circularly used as a next new reaction solvent. The synthesizing method of the 2-methallyl alcohol has the advantages of low production cost, high target product yield, low energyconsumption and little pollution.

Owner:宁波尖锋紫星生物科技有限公司

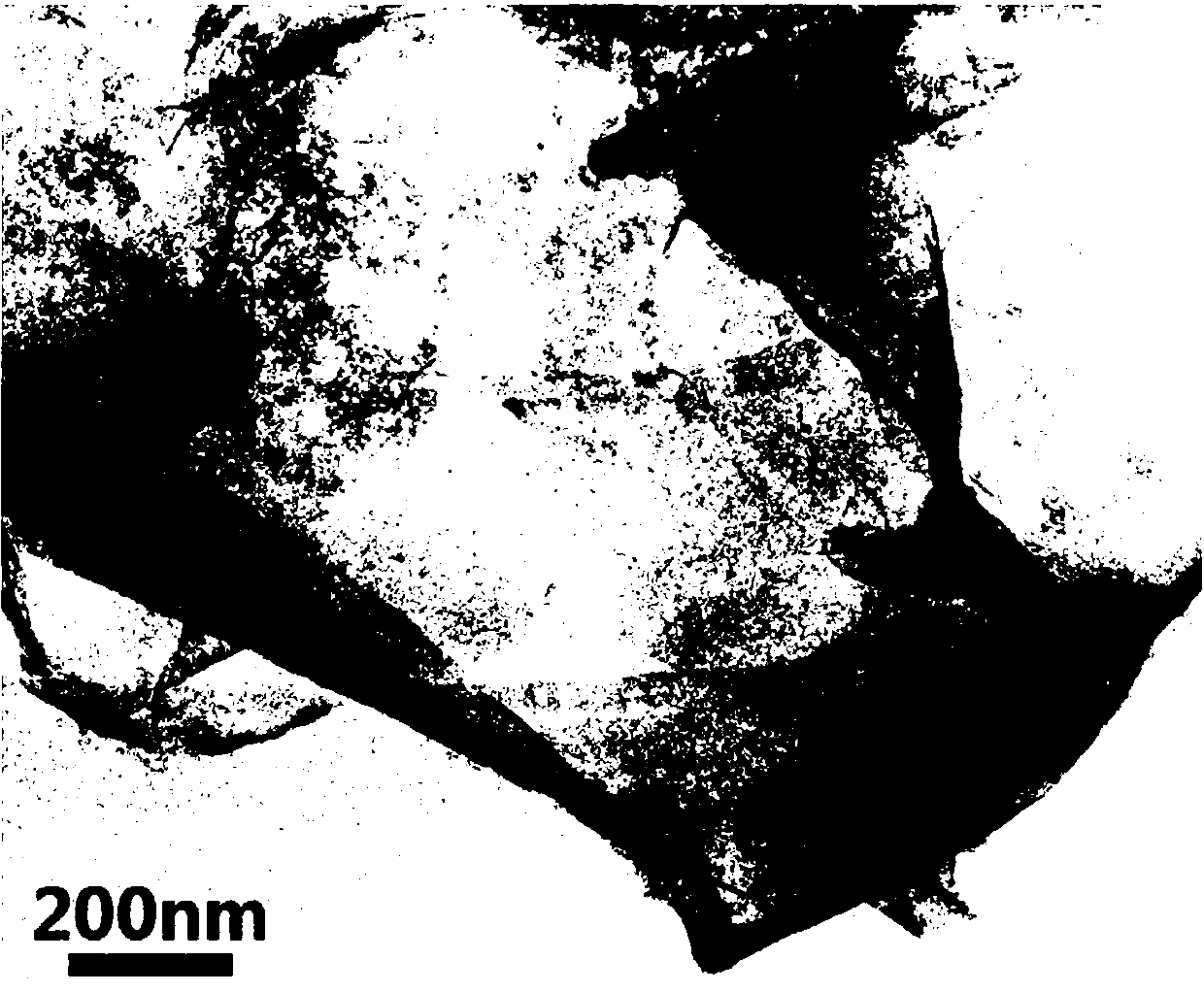

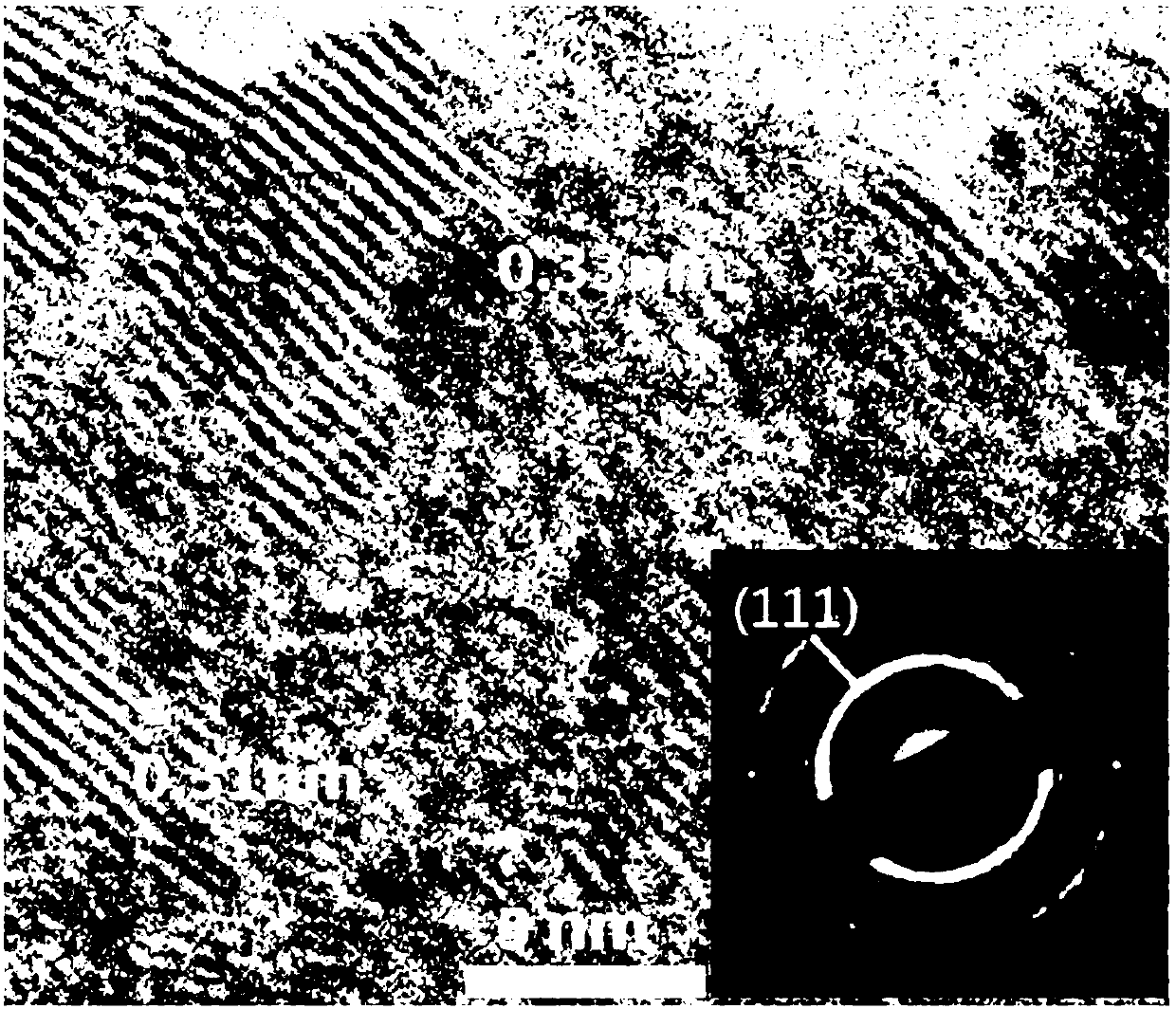

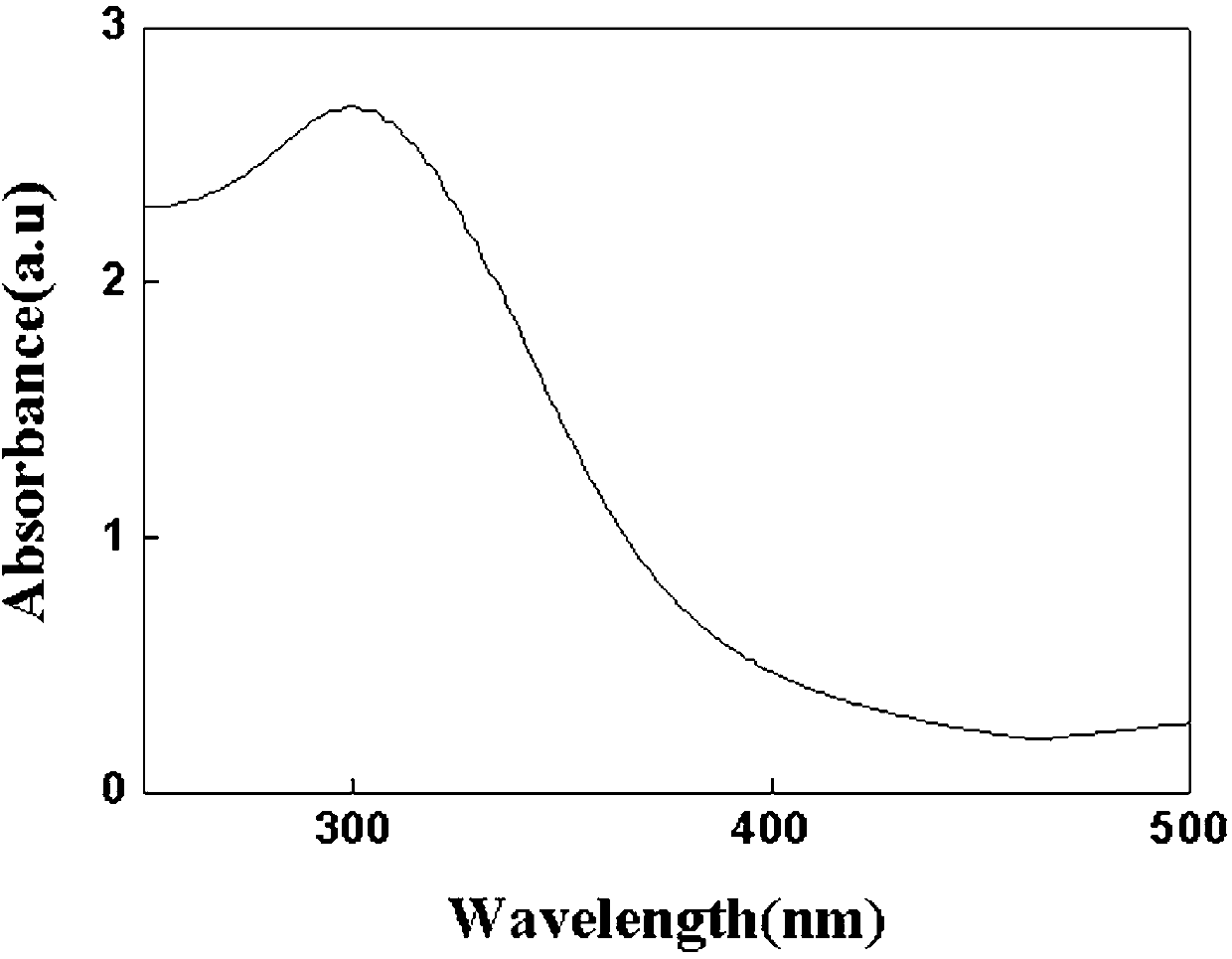

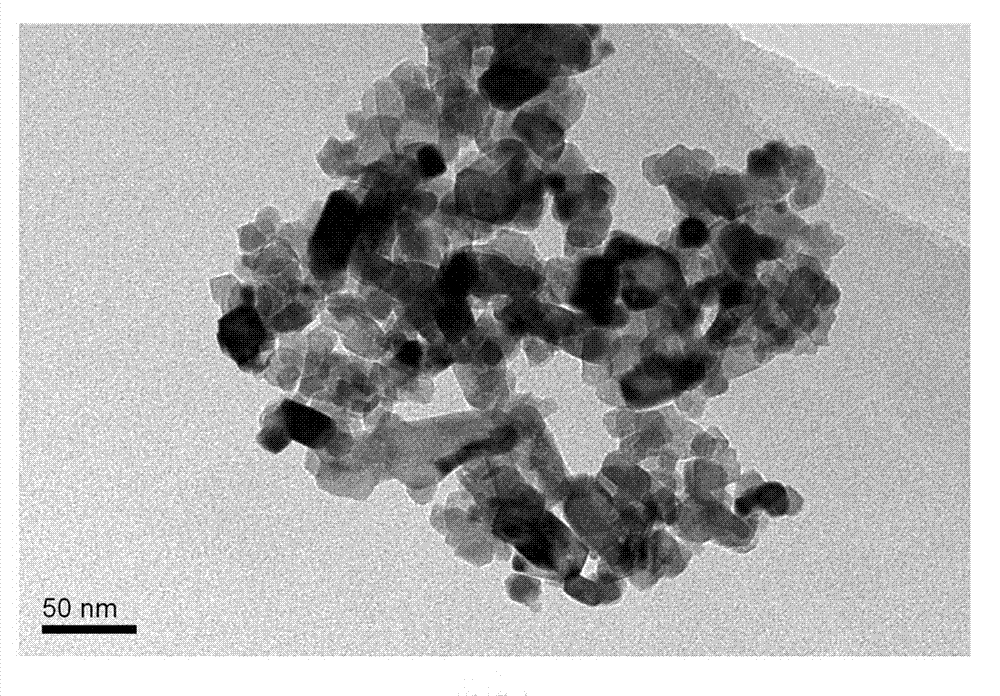

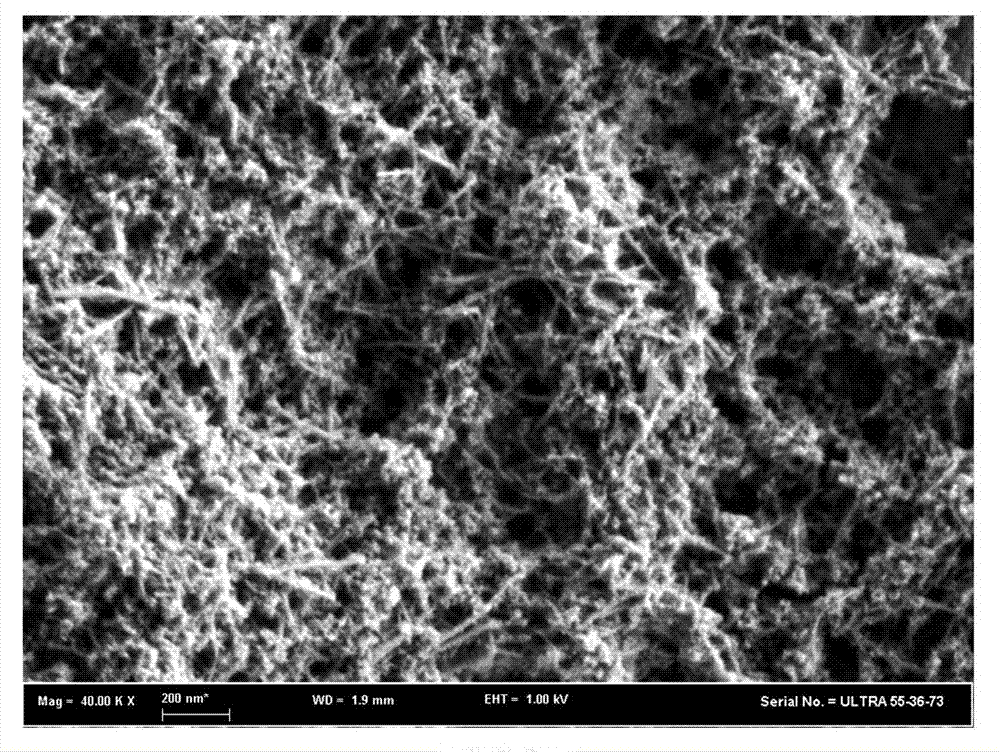

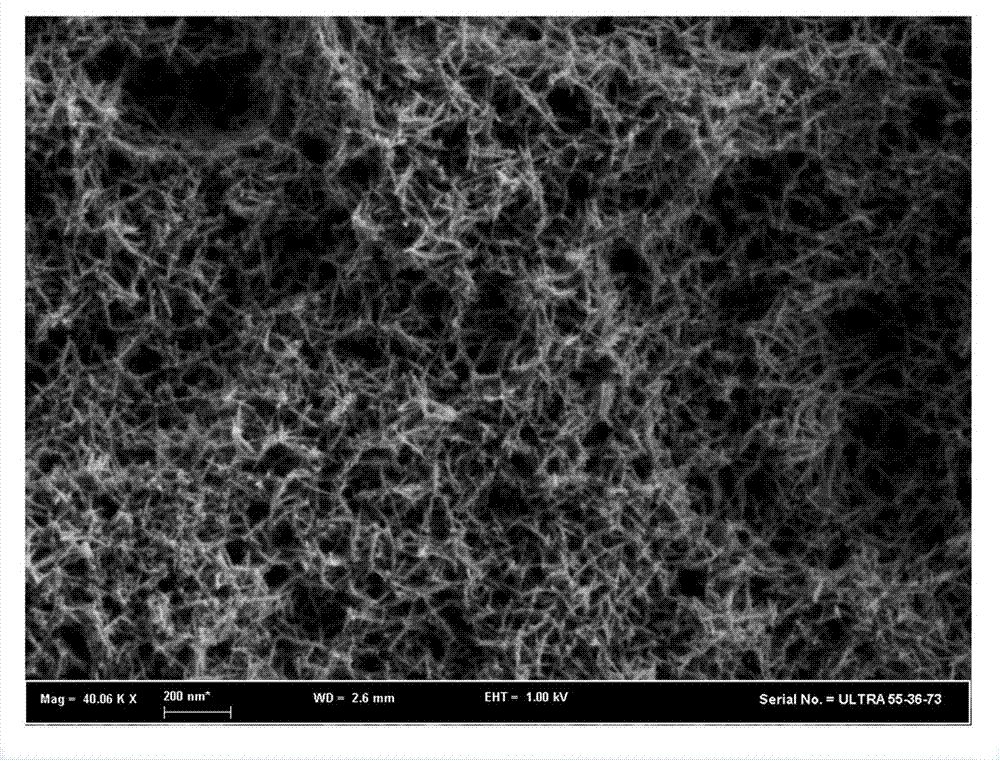

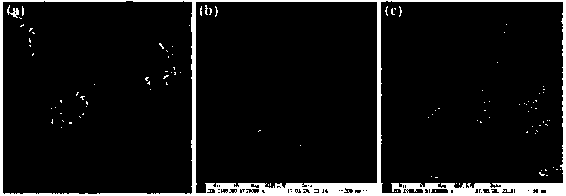

Method for preparing nanoscale sheet cerium oxide by hydrothermal method

InactiveCN103274441ASimple preparation processLow requirements for production equipmentMaterial nanotechnologyRare earth metal compoundsOrganic solventRoom temperature

The invention discloses a method for preparing nanoscale sheet cerium oxide by a hydrothermal method. The method comprises the following steps of: 1) preparing a 0.01-0.05mol / L Ce<3+> ion aqueous liquor at room temperature; preparing an ammonia water liquor at room temperature, wherein pH value of the ammonia water liquor is greater than 11; 2) placing the ammonia water liquor in a reaction kettle in a temperature range from -10 DEG C to 20 DEG C, taking the Ce<3+> ion aqueous liquor, and slowly dropping to excessive ammonia water liquor while stirring; and 3) stirring the mixed liquor obtained in the step (2) at constant temperature for reacting for 2-24 hours, centrifugalizing after reaction, removing the supernatant liquid, washing the powder obtained by centrifugalization and drying to obtain the solid sheet cerium oxide. According to the method disclosed by the invention, the nanoscale sheet cerium oxide is synthesized by one step by the hydrothermal method. The method is simple in preparation process, and low in demand on production and process conditions. No template materials are required and no organic solvents are added. The method is basically free from pollution and very environmental-friendly.

Owner:ZHEJIANG SCI-TECH UNIV

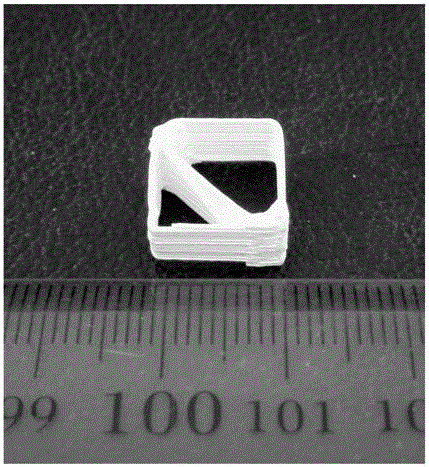

Lean ceramic powder size for direct-forming 3D ceramic printing as well as preparation method and application of lean ceramic powder size

ActiveCN106278201AAvoid post processingGood thinning performanceAdditive manufacturing apparatusRoom temperatureSolid content

The inventiondiscloseslean ceramic powder size for direct-forming 3D ceramic printing. The lean ceramic powder size is prepared from lean ceramic powder, a composite thixotropic agent, a dispersing agent, a thickening agent, a levelling agent and deionized water in a mass ratio being (65-75):(0.2-0.6):(0.9-1.3):(2.0-5.0):(0.5-1.5):(15-30); the lean ceramic powder is one or combination of Al2O3, ZrO2, SiC and Si3N4. The invention further discloses a preparation method and an application of the lean ceramic powder size. The lean ceramic powder size has high solid content and high shear thinning performance, is suitable for preparation of 3D printing ceramic devices with direction forming process and can be gradually dried and cured in a 3D printing process at the room temperature, and accordingly, a set structure is obtained without collapse, the printing precision is high, and the requirement for 3D printing direct-forming can be well met.

Owner:JINGDEZHEN CERAMIC INSTITUTE

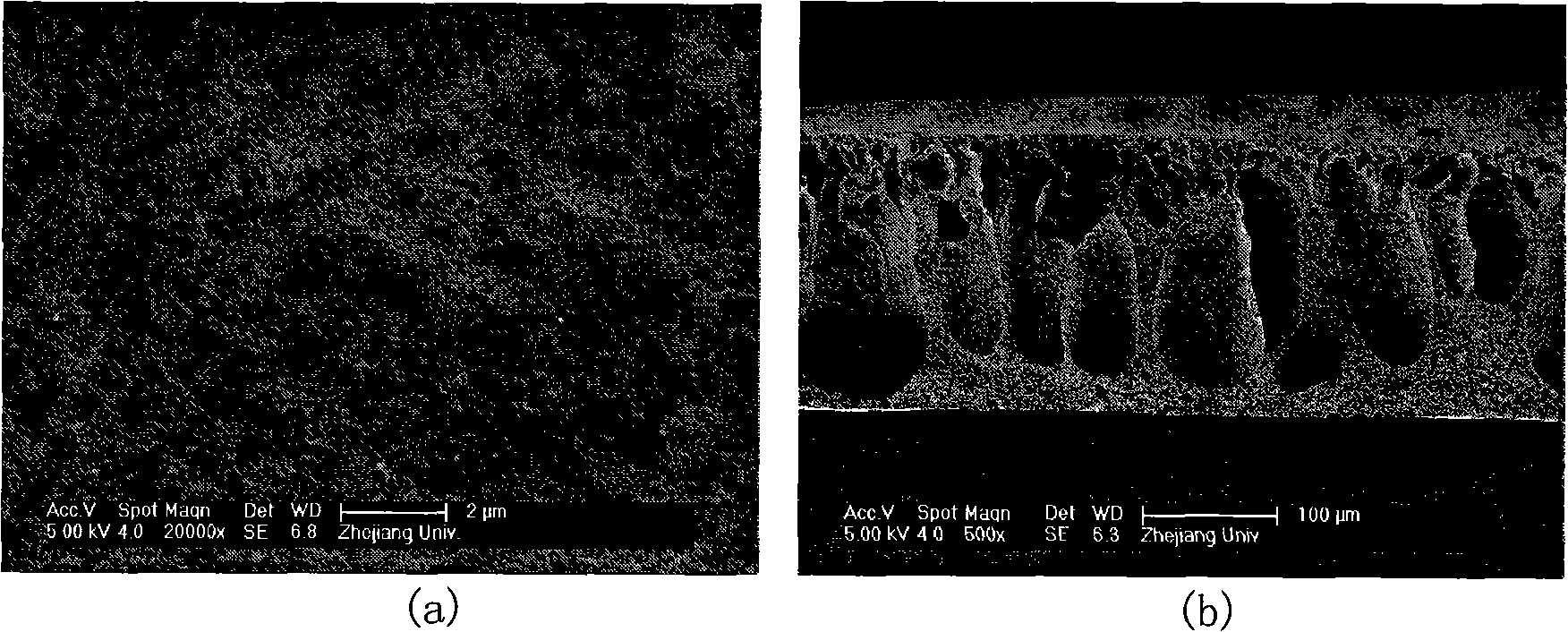

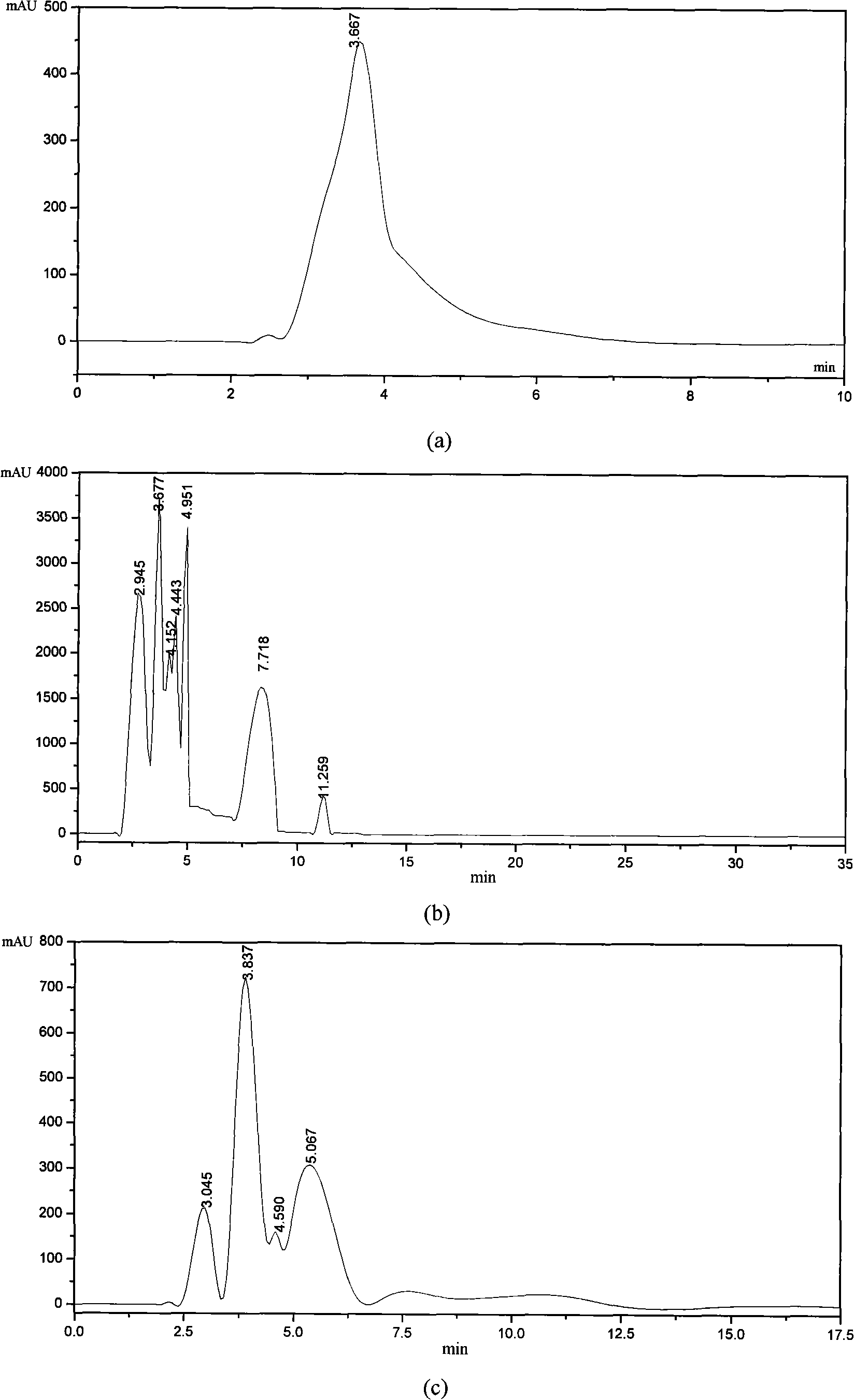

Preparation method of cellulose acetate nano filter-membrane

InactiveCN101357302AImprove throughputHigh desalination rateSemi-permeable membranesCellulose acetateDistilled water

The invention discloses a preparation method of a cellulose acetate nano filter membrane. The preparation method comprises the following steps: 1) the cellulose acetate is put into a solvent, stirred, added with a nonsolvent additive and stirred, then a mixture is obtained, the mixture stands still, and then casting membrane liquid is obtained; 2) the casting membrane liquid is made into a wet membrane with the thickness being 250mum by striking, then the wet membrane stands still in the air; (3) the wet membrane treated by the steps is immersed in distilled water for gel bath treatment, therefore, an asymmetrical membrane is obtained; and 4) ethanol water exchange treatment and pure cyclohexane exchange treatment are sequentially carried out on the asymmetrical membrane, then the cellulose acetate nano filter membrane is obtained. The nano filter membrane obtained by the preparation method has big flux and obvious separating effect.

Owner:ZHEJIANG UNIV

Sulfurizing reduction and roasting and voltizing dearsenication method for copper-zine-cobalt material

InactiveCN1377979AHigh volatile removal rateImprove environmental conditionsNon-ferrous metalArsenic

The present invention relates to the dearsenication method of Cu-Zn-Co mineral in non-ferrous metal smelting developed for dearsenication at high efficiency. The present invention features that Cu-Zn-Co mineral in 36-58 wt%, chalocotie as sulfurizing agent in 36-58 wt% and carbon material as reductant in 4-8 wt% are crushed, mixed and pelletized before reducing roasted at 700-900 deg.c. The present invention has the advantages of reasonable technological process, less pollution and high dearsenication rate.

Owner:史汉祥

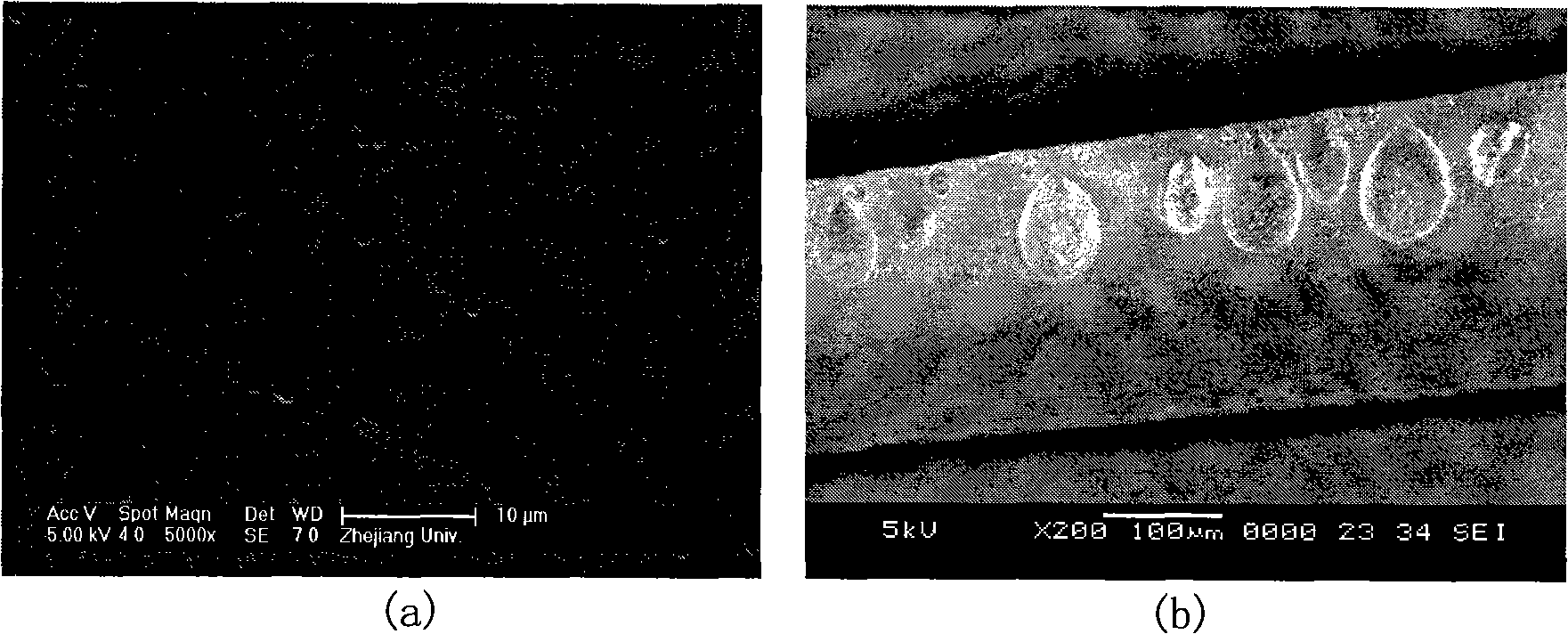

Method for preparing nanometer cerium oxide by hydrothermal method

InactiveCN102849774ASimple preparation processLow requirements for production equipmentNanotechnologyRare earth metal compoundsActive agentNanoparticle

The invention provides a method for preparing nanometer cerium oxide. The invention adopts the following technical scheme that the method comprises the following steps: 1) preparing a Ce(NO3)3.6H2O aqueous solution with a concentration of 0.05-0.1 mol / L at room temperature; 2) taking a certain volume of the Ce(NO3)3.6H2O aqueous solution at room temperature, dropwisely adding undiluted commercially-available 25% ammonia water into the Ce(NO3)3.6H2O aqueous solution according to a volume ratio of 10:1-3; 3) allowing the mixed solution to react for 2-24 hours, after the reaction, performing centrifugation, removing the liquid at the upper level, washing the powder obtained after centrifugation, and drying to obtain solid powder. The invention realizes one-step synthesis of nanometer cerium oxide by a hydrothermal method; the preparation process is simple, and the requirements for production equipment and process conditions are low; no organic solvent is added, which is basically free of pollution, and is quite environment-friendly; no macromolecular surfactant is added, which prevents posttreatment process such as washing and the like; the kinds of the required raw materials are few, and when compared with traditional process, the method of the invention is quite low in production cost; the method cam prepare uniform and pure cerium oxide nanoparticles, cerium oxide nanorods, and mixtures of the above two.

Owner:ZHEJIANG SCI-TECH UNIV

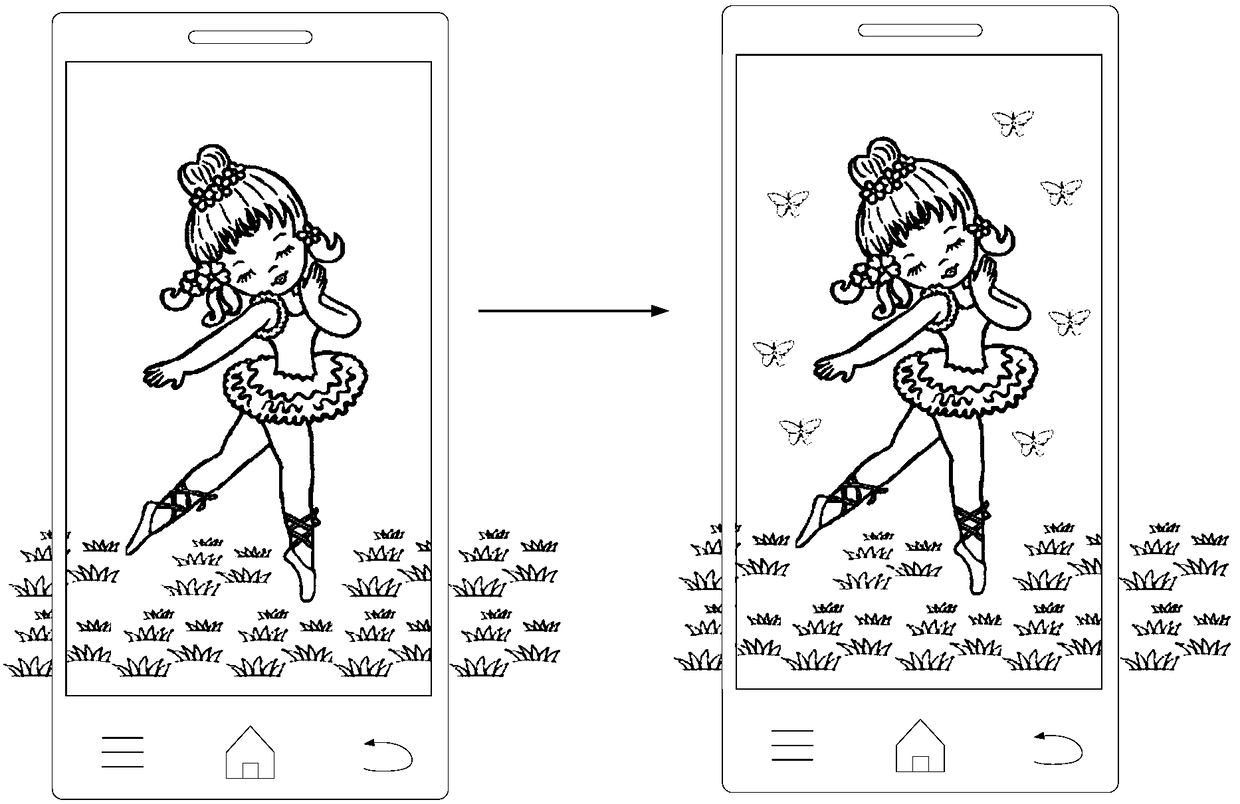

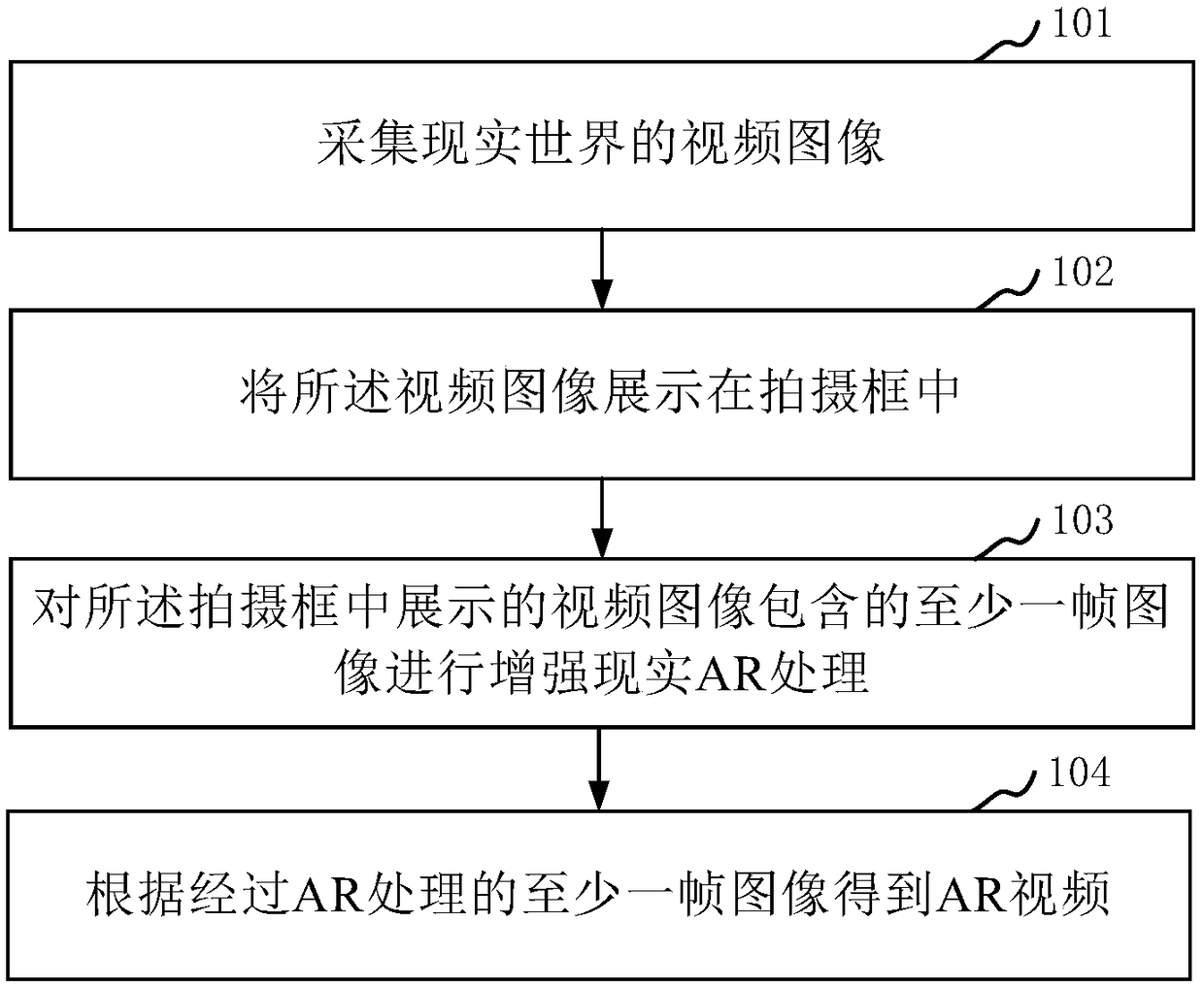

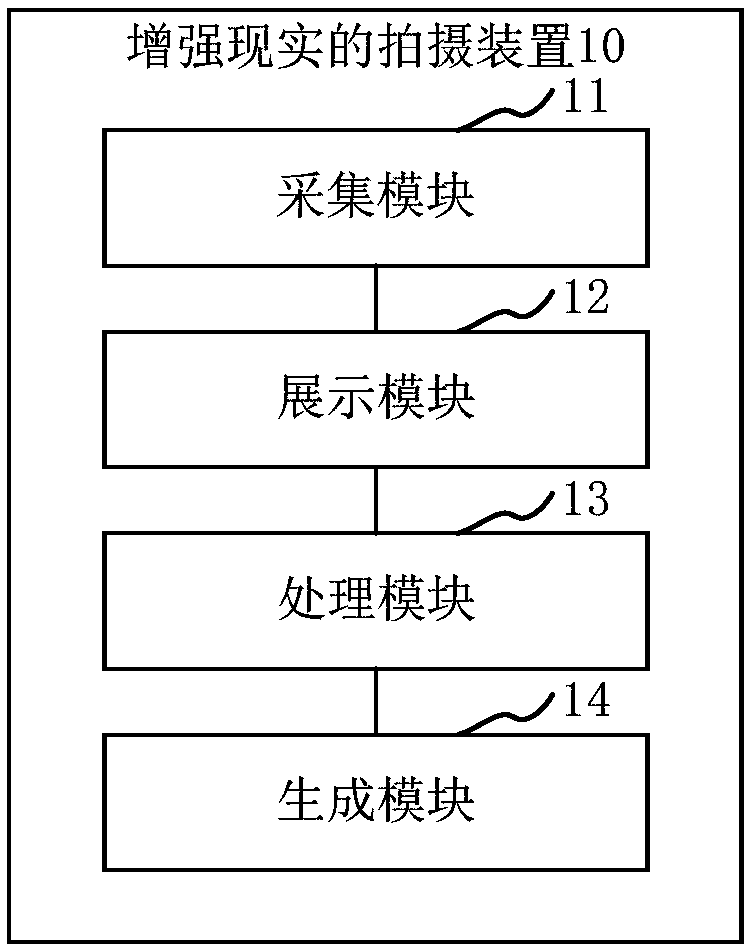

Augmented reality shooting method, apparatus, electronic device and storage medium

ActiveCN109089038AAvoid post processingReduce shooting costsTelevision system detailsColor television detailsComputer graphics (images)Shooting method

An embodiment of the present invention provides an augmented reality photographing method, apparatus, electronic device and storage medium. By capturing real-world video images, and the captured videoimages of the real world are displayed in a shooting frame in real time, then the real-world video image displayed in the shooting frame is AR processed in real time, AR video is obtained by taking the video image processed by AR as the final shooting result, which realizes AR processing of the real world video image captured by the camera in the shooting process, avoids requiring professional personnel to carry out post-processing when shooting first and then processing, and reduces the shooting cost and the film and television production cycle.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

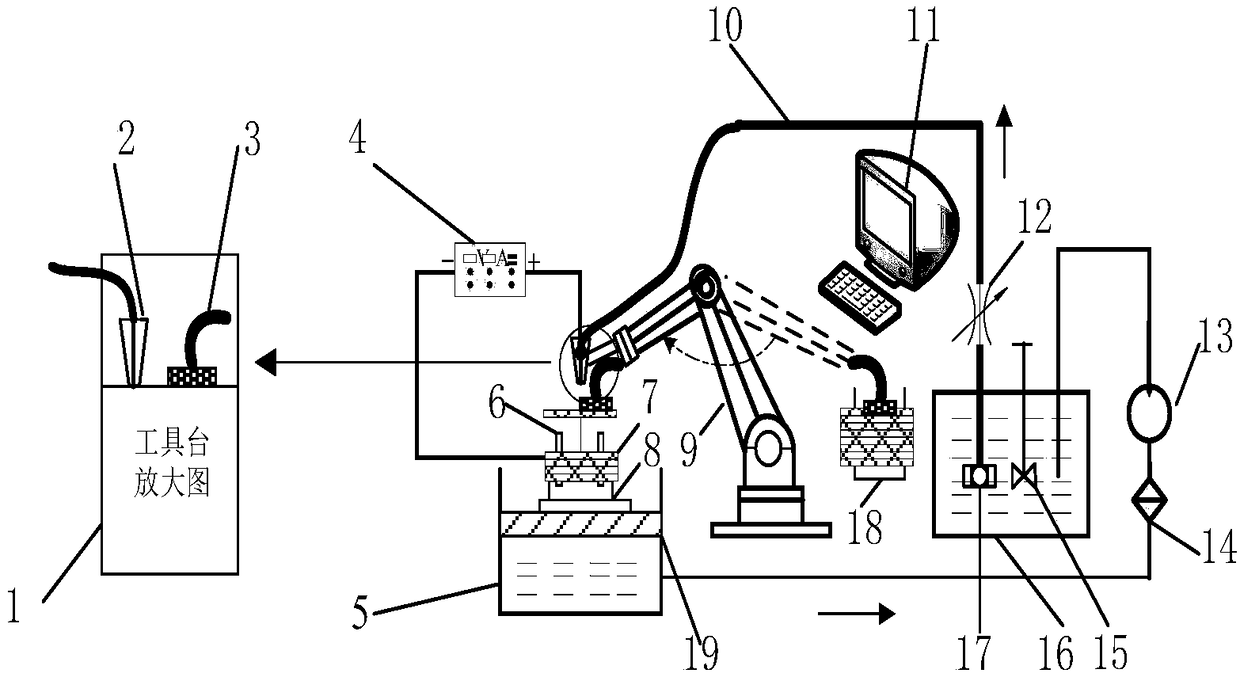

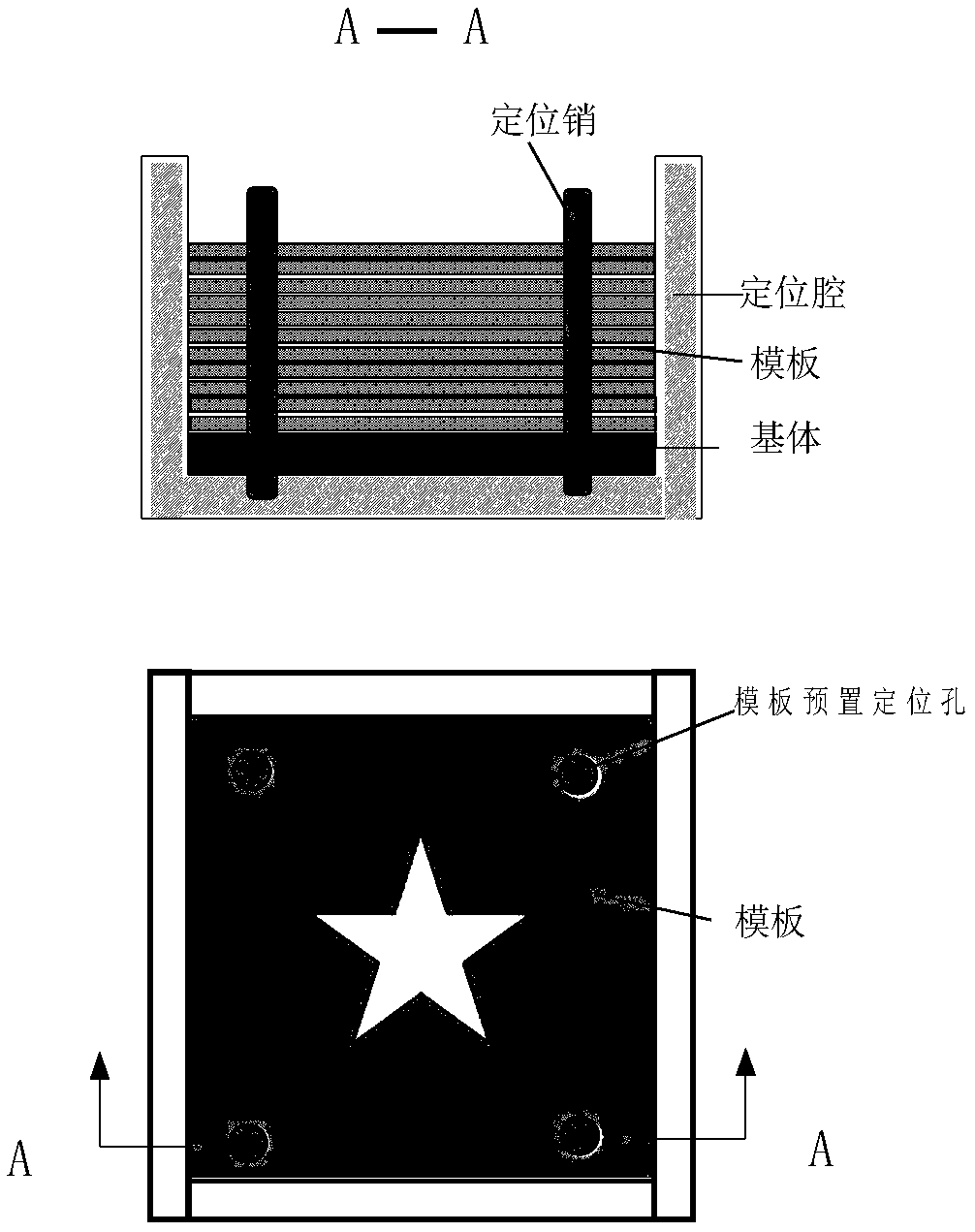

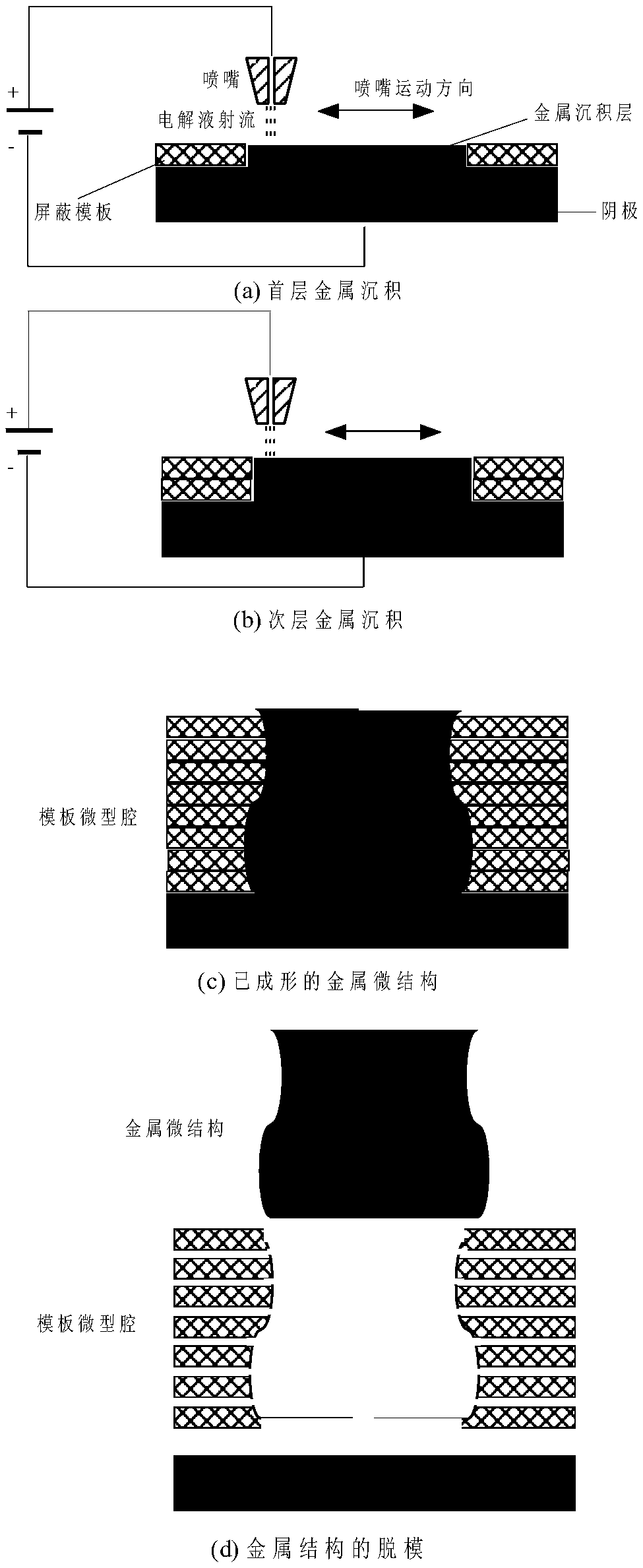

Device for forming micro metal parts by particle jet electrodeposition and method thereof

InactiveCN109136999AGuaranteed continuityGuaranteed accuracyCellsAdditive manufacturing apparatusNumerical controlMaterials science

The invention discloses a device for forming micro metal parts by particle jet electrodeposition and a method thereof. Based on the processing technique of the particle jet electrodeposition, a processing method of millimeter-scale metal parts is developed by utilizing the principle of layered machining in prototype manufacturing and combining the latest numerical control machining technology. Through a plurality of two-dimensional templates which define the filling process of jet electrodeposition in the region, the metal deposits can be stacked into the required metal parts.

Owner:XUZHOU NORMAL UNIVERSITY

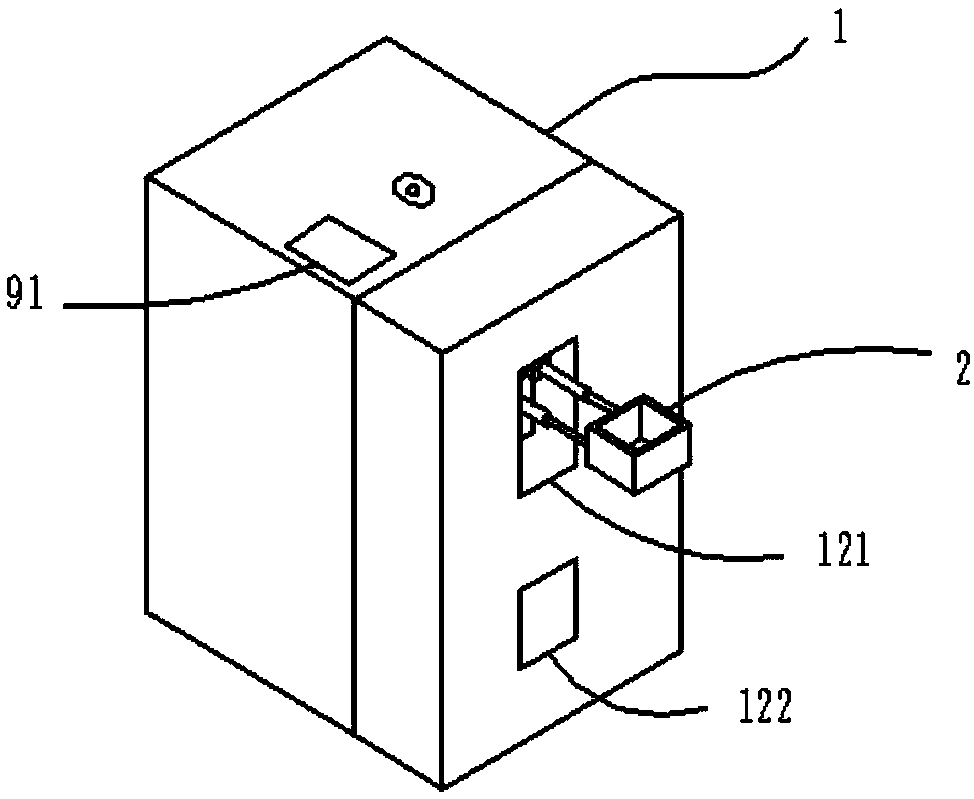

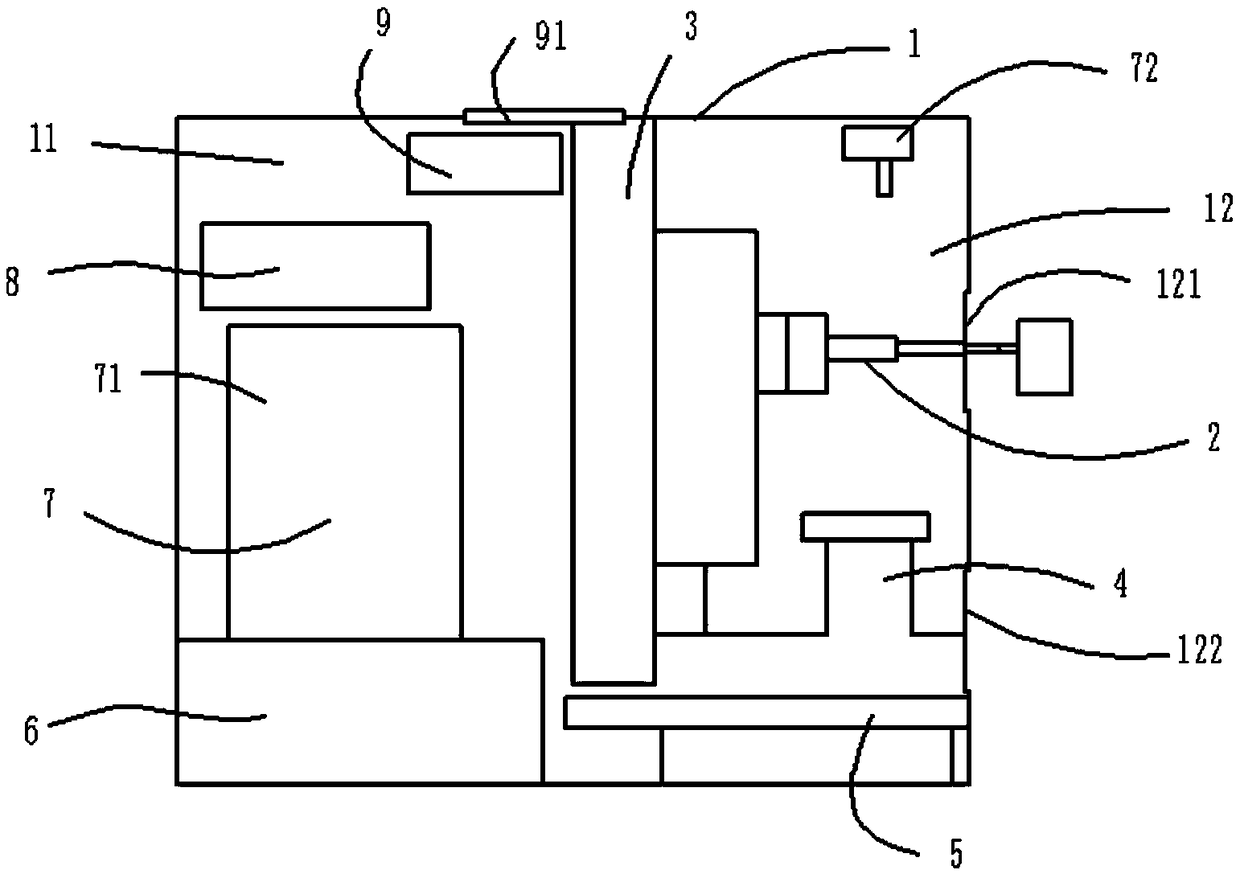

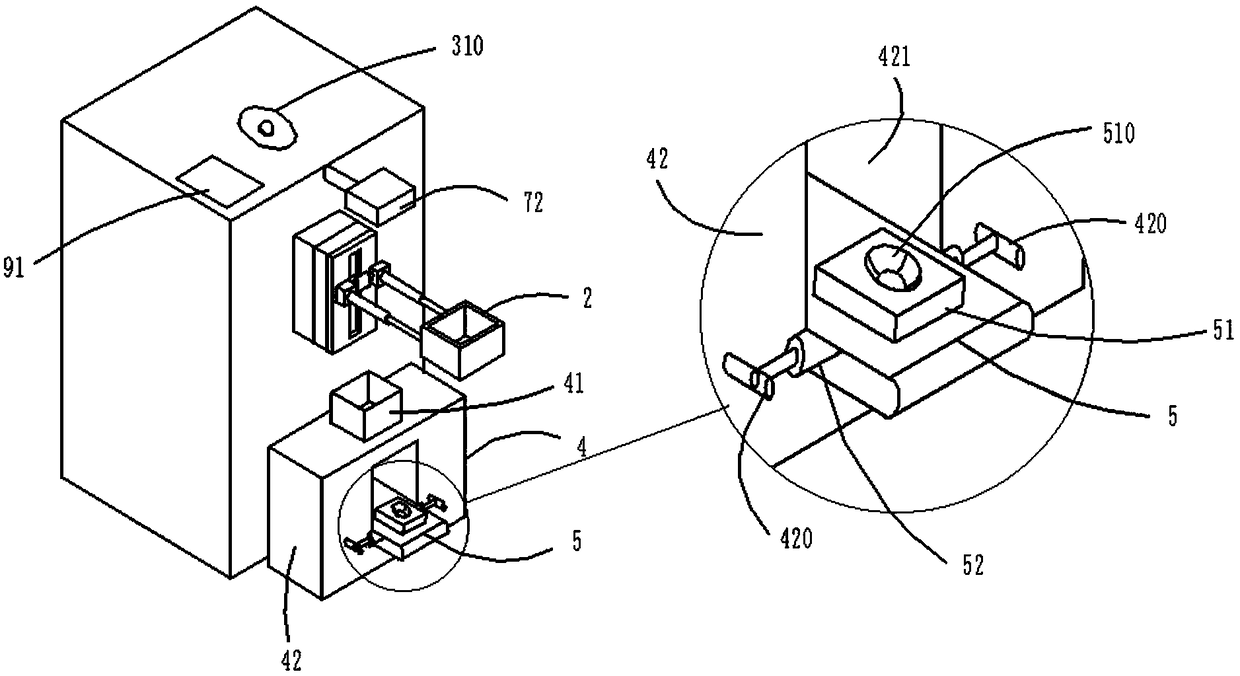

Sampling device for urine inspection

InactiveCN109044409AAvoid post processingMeet the needs of urine testingSurgeryVaccination/ovulation diagnosticsUrine inspectionEngineering

The invention discloses a sampling device for urine inspection, mainly including a housing, a receiving device, a cup fetching device, a change-over device, a transmission device, a waste storage box,a cleaning device, a power supply device and a control device; the housing includes a placing chamber and a sampling chamber. The sampling chamber is provided with a sample inlet and a sample outlet;the receiving device is arranged in the sampling chamber. The receiving device can extend from the sample inlet; the change-over device is arranged in the sampling chamber and is under the receivingdevice; the transmission device is penetrated through the placing chamber and the sampling chamber; the waste storage box is movably arranged in the placing chamber; the power supply device is arranged in the placing chamber; the sampling device for the urine inspection is simple in operation, and utilizes an automation device to achieve the task of urine sampling, which avoids patients directly receiving urine and is extremely convenient for inspected personnel to take urine samples.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

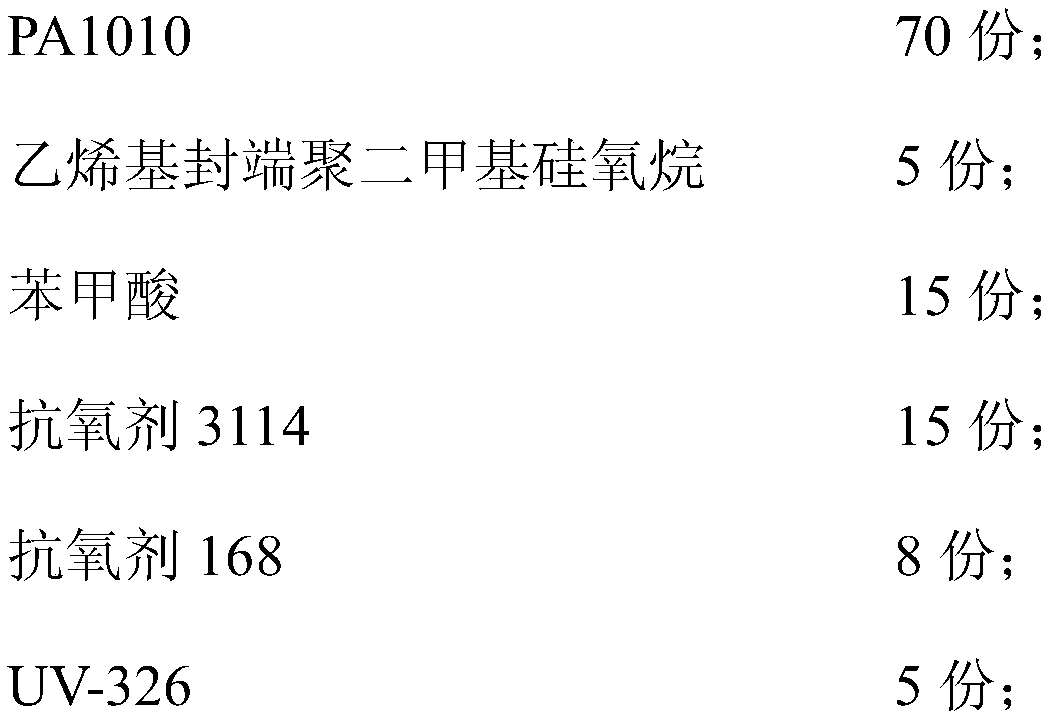

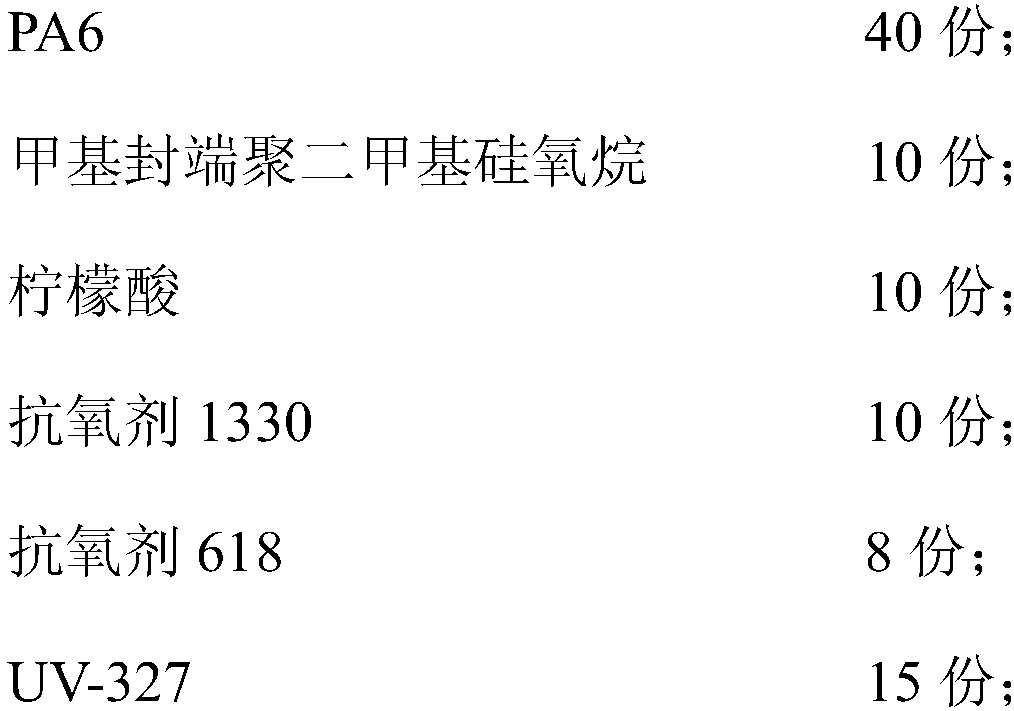

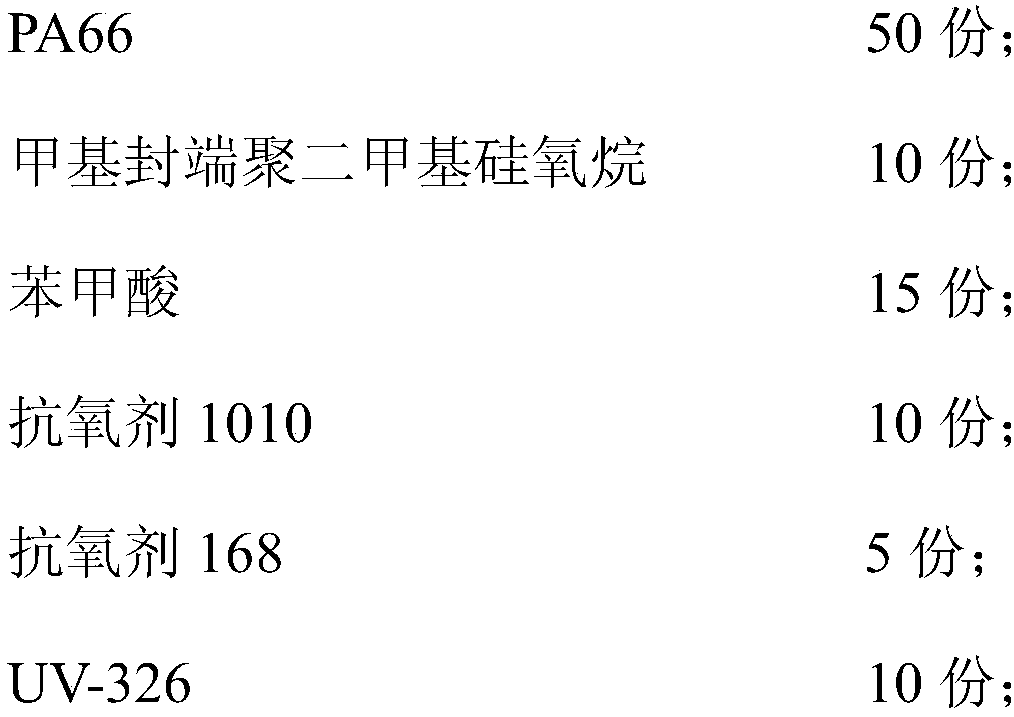

Phenol-resistant yellow masterbatch, preparation method thereof, use and phenol yellow nylon

InactiveCN108795028APromote migrationImprove phenol yellowing resistanceMonocomponent synthetic polymer artificial filamentArtifical filament manufactureMasterbatchOrganic acid

The invention provides a phenol yellow-resistant functional masterbatch, a preparation method thereof, a use thereof and a phenol yellow-resistant nylon. The phenolic yellow functional masterbatch comprises the following components by weight: 30 to 70 parts of polyamide, 5 to 15 parts of silicone raw rubber, and 5 to 15 parts of organic acid. The phenolic yellow functional masterbatch is preparedby mixing the components of the formulation amount and then extruding it by an extruder. The phenolic yellow functional masterbatch provided by the invention can be used for phenol yellow modificationof polyamide, can be directly added to the polyamide, and can be simply mechanically mixed, thereby avoiding cumbersome modification by using phenol yellow-resistant agent. The post-treatment process; when the addition amount is 2wt%, the anti-phenol yellowing index of the nylon can reach 4, and the effect is long-lasting.

Owner:上海涵点科技有限公司

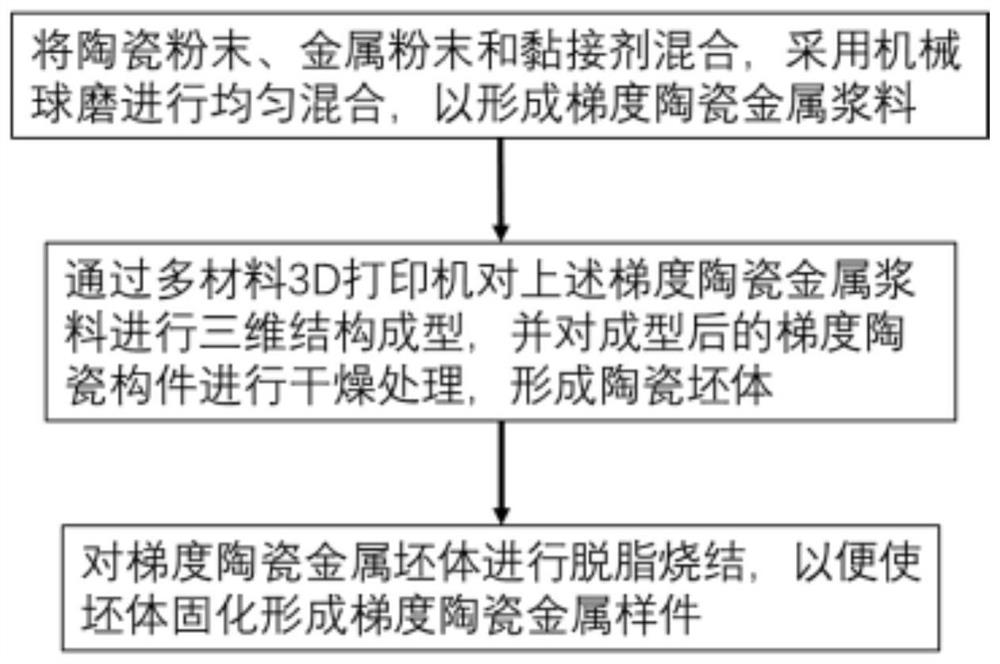

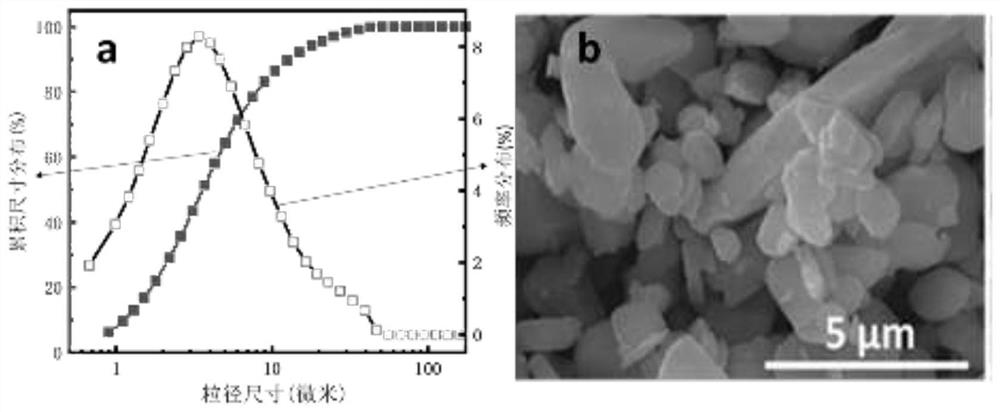

3D-printed gradient ceramic-metal material and production method

ActiveCN113458387AHigh densityStress Singularity ReliefAdditive manufacturing apparatusIncreasing energy efficiencyAdhesiveComputer printing

The invention provides a 3D-printed gradient ceramic-metal material. The 3D-printed gradient ceramic-metal material comprises ceramic powder, metal powder, a dispersing agent, an adhesive and a solvent, wherein the mass percent of the ceramic powder and the mass percent of the metal powder in a system are changed in a gradient mode, and are sequentially increased or decreased, and the sum of the mass percents of the components is 100%. The gradient ceramic-metal material has high compactness. The invention further provides a production method of the 3D-printed gradient ceramic-metal material. The production method of the 3D-printed gradient ceramic-metal material comprises the following steps: subjecting the solvent, the ceramic powder, the metal powder, the dispersing agent and the adhesive to mixing, stirring and ball milling, wherein the percent of the ceramic powder and the percent of the metal powder in the system are changed in a gradient mode, so that a gradient ceramic-metal series slurry is obtained; and adding the series slurry into a 3D printer, conducting direct writing printing to obtain a gradient ceramic-metal blank, and conducting drying, degreasing and sintering to obtain the gradient ceramic-metal material. According to the method, the gradient ceramic-metal material is produced through 3D direct writing printing, the shrinkage rate is reduced, and the printing thickness can be controlled.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

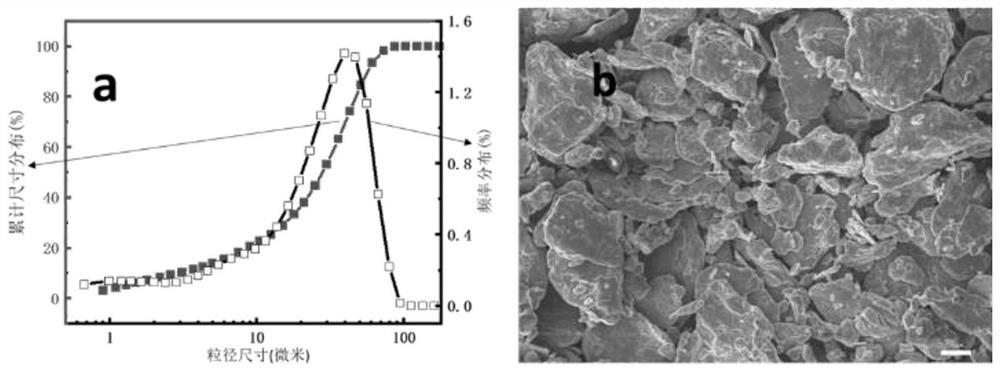

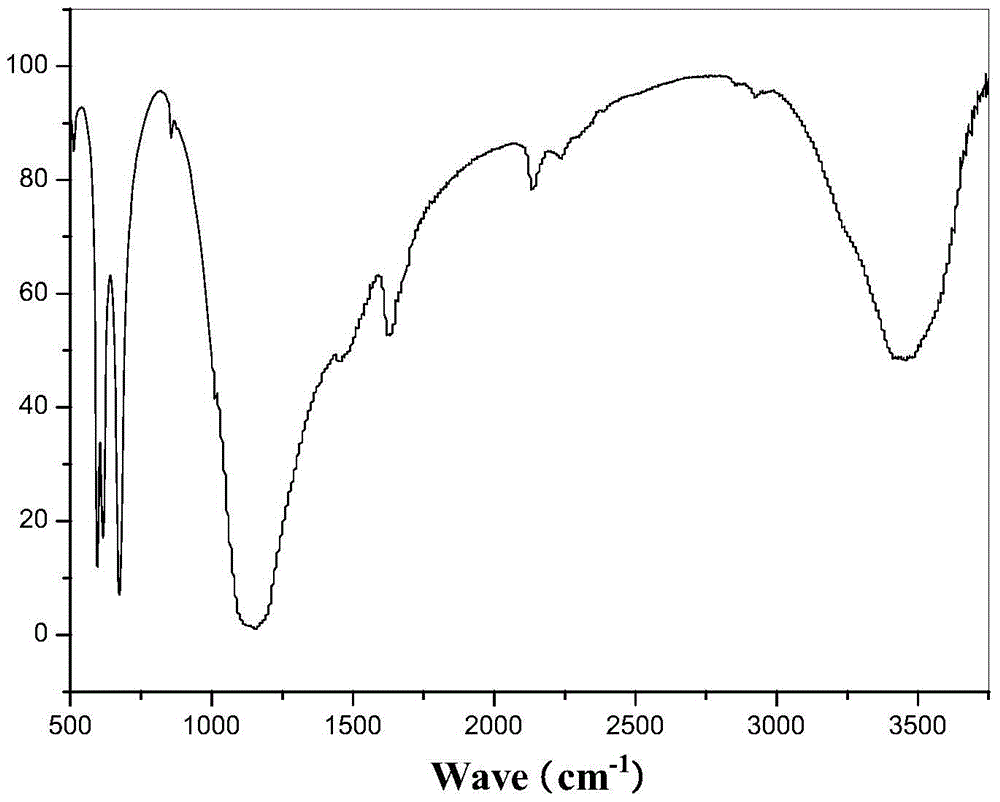

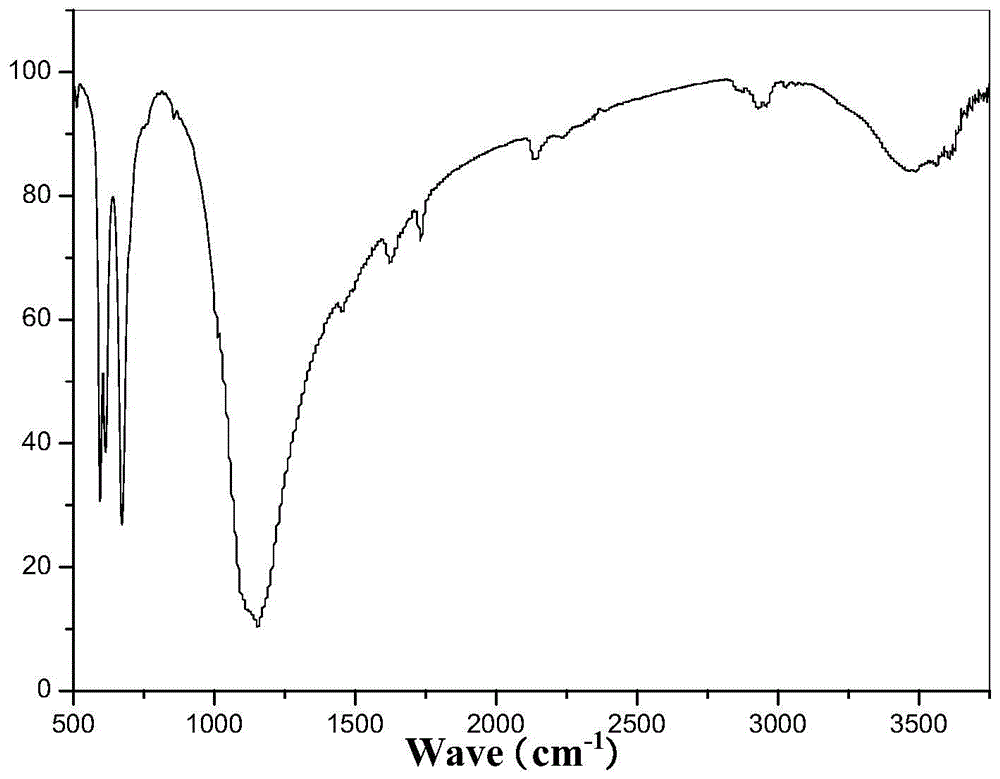

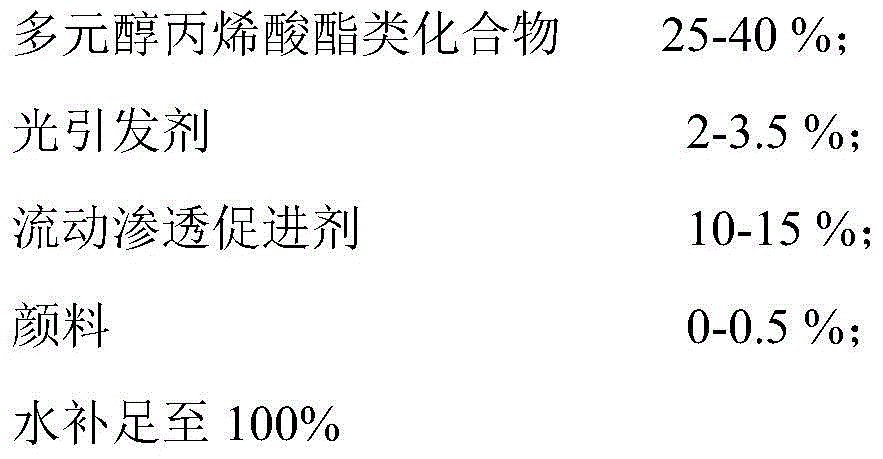

Polyol acrylate type photosensitive bonding agent for gypsous material 3D printing and preparation method thereof

ActiveCN105753361AFast penetrationShort setting timeAdditive manufacturing apparatusBenzoic acidUltraviolet lights

The invention discloses a polyol acrylate type photosensitive bonding agent for gypsous material 3DP (three-dimensional printing) process and a preparation method thereof. The polyol acrylate type photosensitive bonding agent is characterized in that polyol acrylate type compounds are used as monomers; benzoic acid and derivatives of the benzoic acid are used as photoinitiators; ethanol or isobutanol is used as a flowing seeping promoter; an ultraviolet light source is used as a triggering light source; the gypsous material 3DP efficient bonding agent is prepared. In the prior art, inorganic materials such as gypsum use an ordinary 3DP technology, and the defects of low product initial strength, low printing speed, high post treatment difficulty and the like exist. Through the application of the method, the printing speed of the 3D printing gypsum product can be effectively accelerated; the initial strength of the 3D printing gypsum product can be effectively improved; the complicated post treatment process of the printed product is avoided, so that the manufacturing efficiency and the finished product quality of 3D printing products are greatly improved; the process complexity degree is reduced.

Owner:NANJING NORMAL UNIVERSITY +1

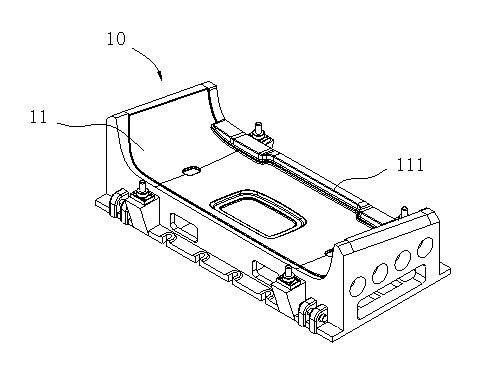

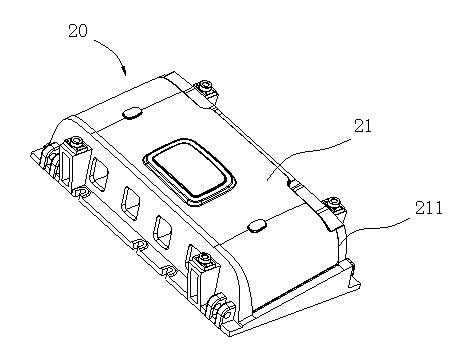

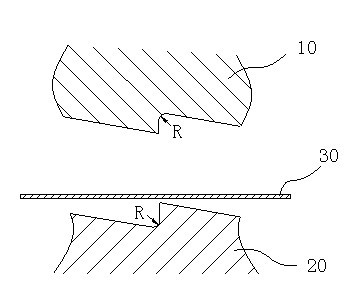

Pressing die

The invention belongs to the field of automobile interior product machining and manufacturing, in particular to a pressing die. The pressing die comprises an upper die and a lower die, and the profiles of the upper die and the lower die are provided with continuous and mutually matched cutting edges along the cutting lines of the product. When the pressing die is used, because the pressing and the edge cutting of the product are completed once, later machining is avoided and machining procedures are reduced, the production efficiency of the enterprise is increased. Meanwhile, because the continuous cutting edges directly cut off excessive materials while pressing and molding the product, the side lines of the molded product are trim and beautiful, the product does not require polishing procedure after edge cutting, and a threat to the health of workers and the pollution to the environment due to fiber dust produced by polishing are also avoided.

Owner:ANHUI JINCEN COMPOSITES

Rapid forming method of thermoplastic fiber-reinforced composite material plate

InactiveCN107214980AResolutionResolution cycleLaminationLamination apparatusTemperature controlSheet film

The invention relates to a rapid forming method of a thermoplastic fiber-reinforced composite material plate. The rapid forming method is characterized by comprising the following steps that (1) forming equipment and materials are prepared, specifically, the special equipment with presoaking, laying, superimposing, temperature control and pressure control, vacuum lamination forming, cutting, heating and mould pressing forming structures is arranged, a resin solution with a thermoplastic-forming function and the fiber-reinforced materials are prepared; (2) the fiber-reinforced materials are soaked into the resin solution with the thermoplastic-forming function, and fiber glue pieces are prepared; (3) the fiber glue pieces obtained in the step (2) are superimposed by 1-5 layers, the superimposed fiber glue pieces are placed in a vacuum press with a programmable temperature control and pressure control function, and a thermoplastic fiber-reinforced laminated composite material is prepared; (4) a mould plate is cut; (5) the mould plate is heated and softened; (6) mould pressing forming is conducted; and (7) the finished product is prepared. The rapid forming method of the thermoplastic fiber-reinforced composite material plate has the characteristics and beneficial effects of high mechanization degree, short processing period, high efficiency, low product cost and the like.

Owner:东莞市海旭新材料技术有限公司

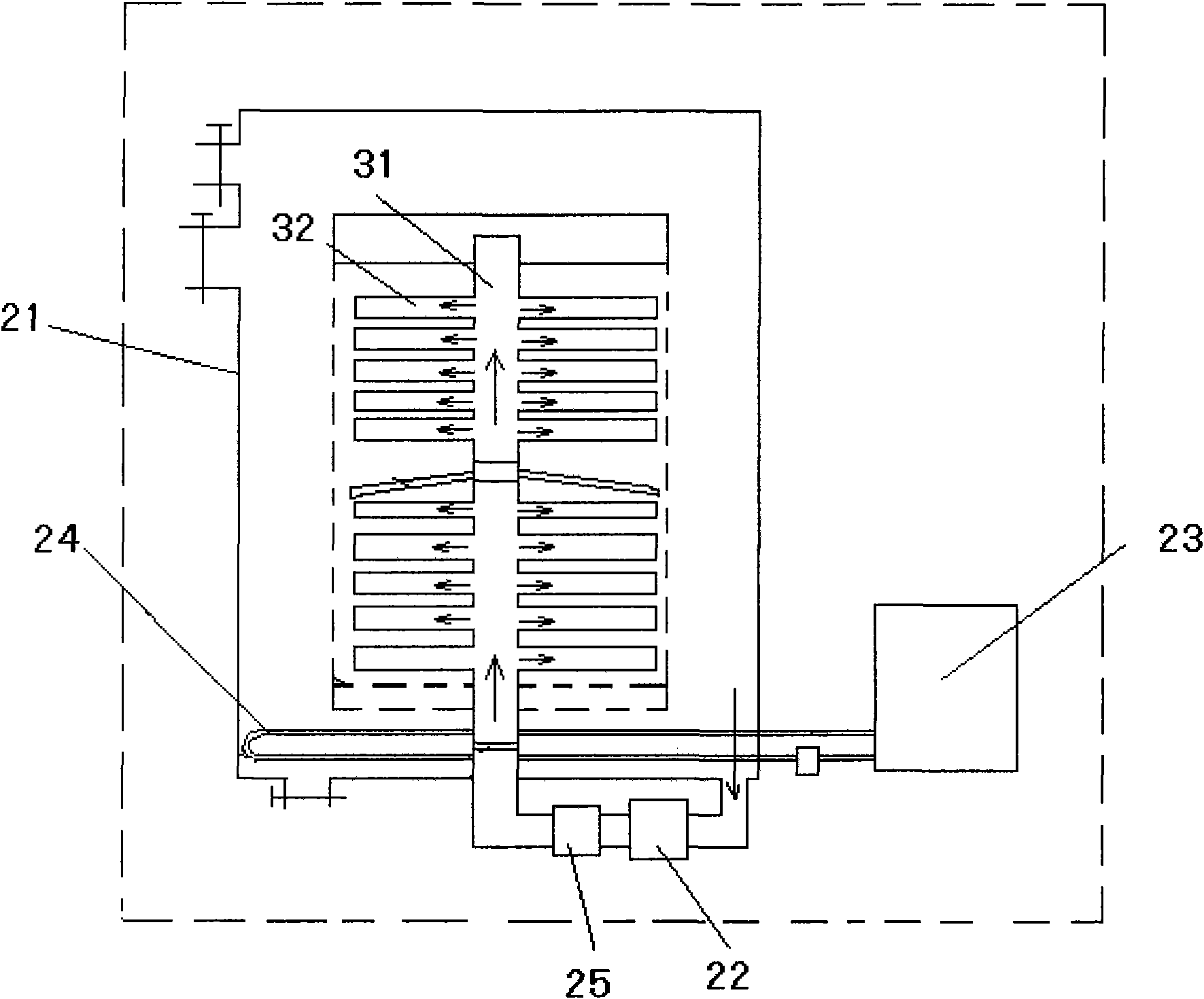

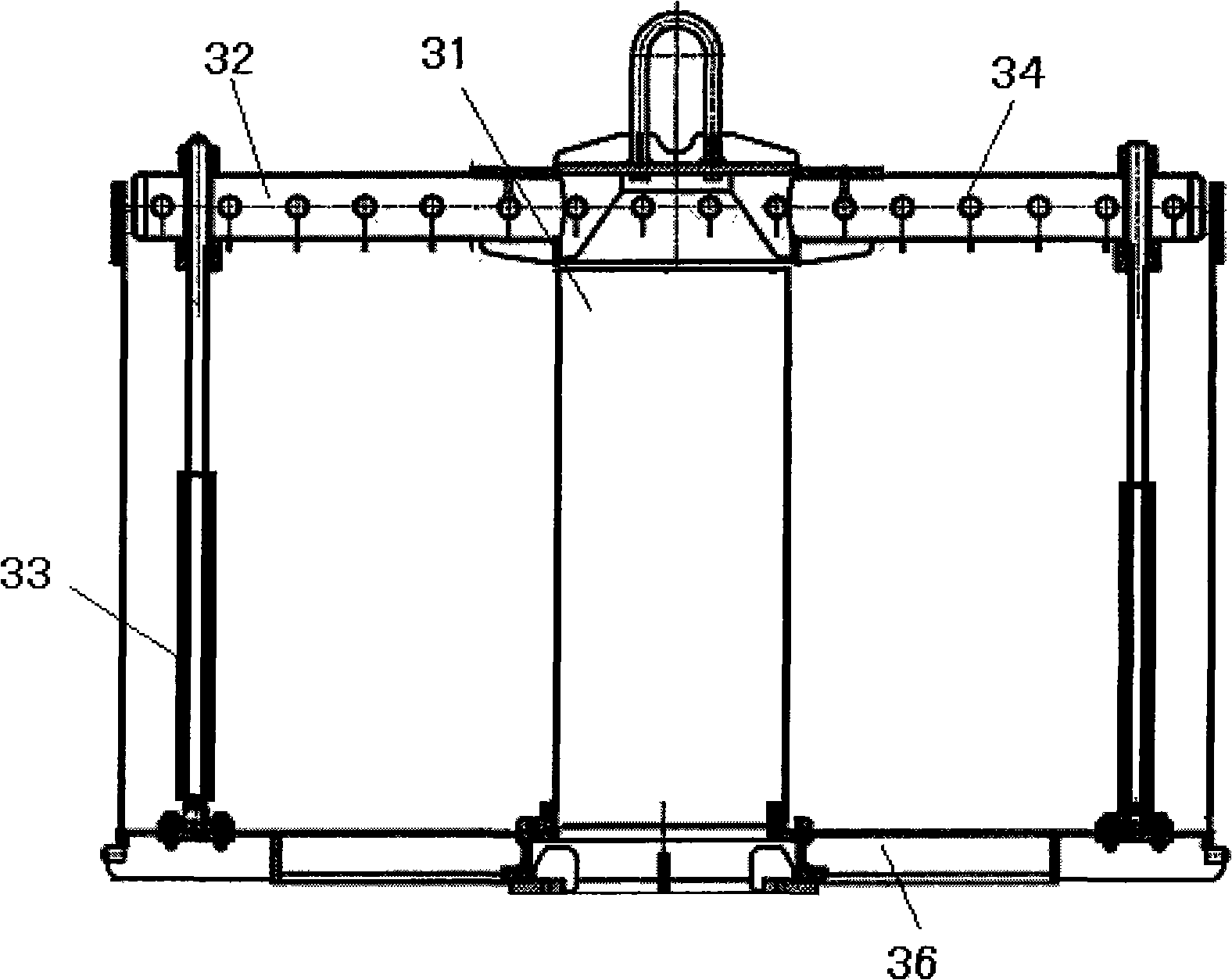

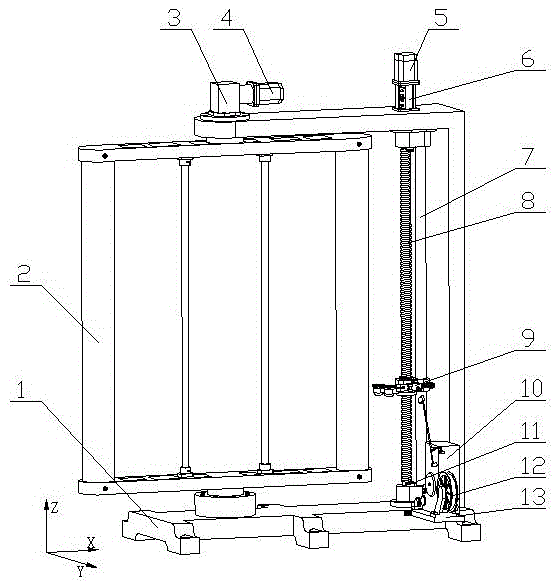

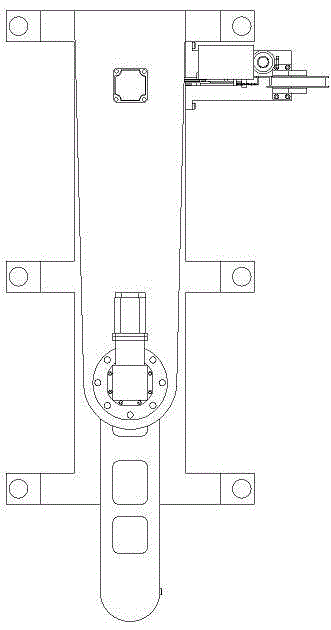

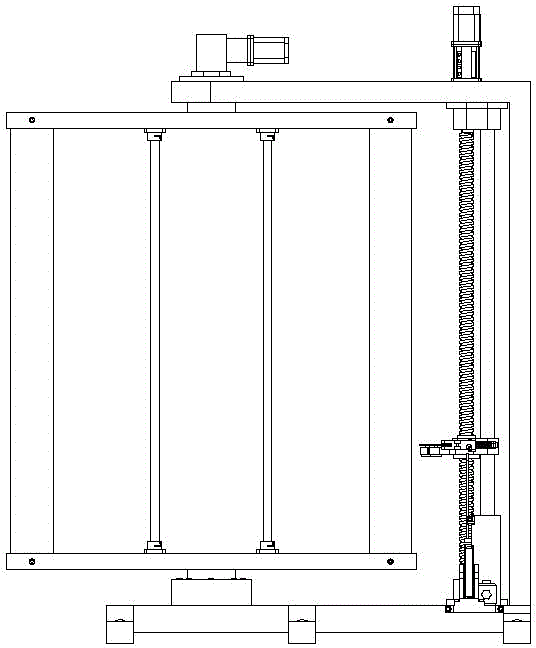

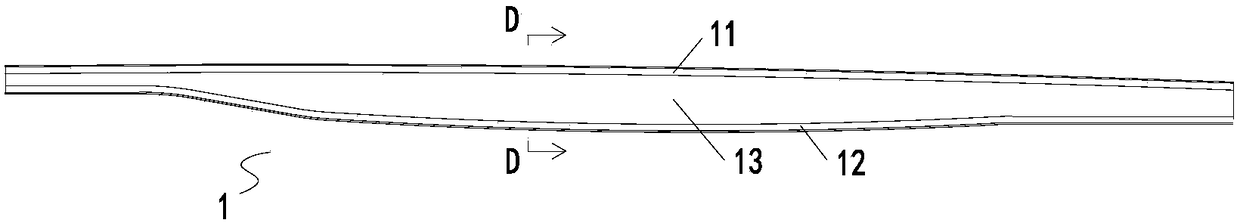

Vertical polarization wire grid production device

InactiveCN105466571ASimple vertical structureLightweight vertical structureRadiation pyrometryFilament handlingWire gridMotor drive

The invention relates to a vertical polarization wire grid production device and belongs to the microwave radiation and microwave remote sensing field. The vertical polarization wire grid production device is composed of a base, a rotary feeding mechanism, a guide mechanism, a motor driving system, a position-limiting protection mechanism and a tension stabilization mechanism; the base enables a supporting and fixing effect; a rotating wire frame completes rotational motion under the driving of a servo motor; the tension stabilization mechanism completes a paying-off action when maintaining the tension of lines stable; the ball screw nut pair of the guide mechanism drives the tension stabilization mechanism to move along the guide axis of a linear bearing under the driving of the servo motor, so as to jointly form feeding movement in an X direction. The vertical polarization wire grid production device has advantages of simple structure, low manufacturing cost and high production efficiency. With the vertical polarization wire grid production device adopted, a new path can be provided for the localization of millimeter-wave band polarization line grids, and deficiencies of China in polarization wire grid protection instruments can be compensated.

Owner:JILIN UNIV

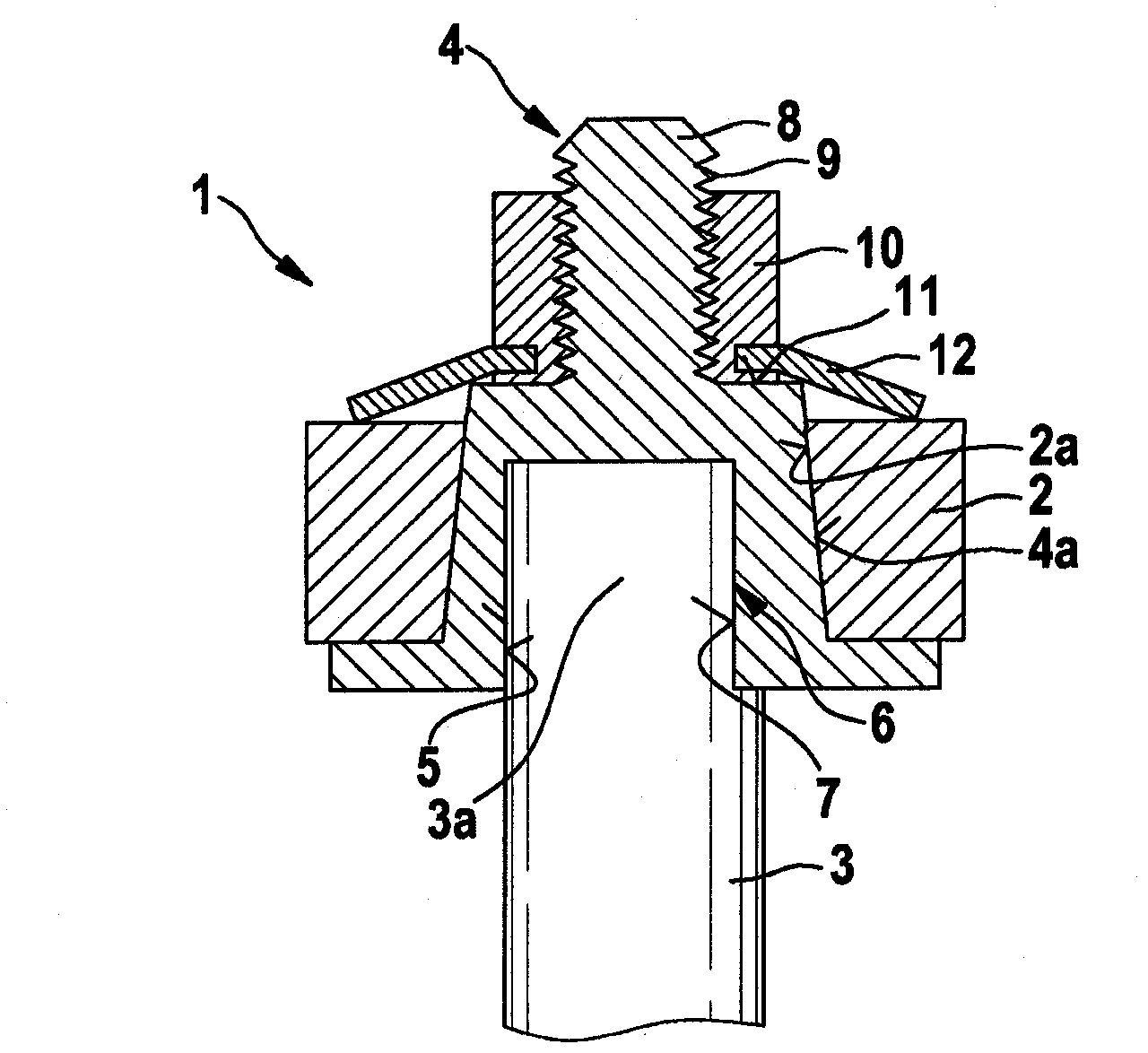

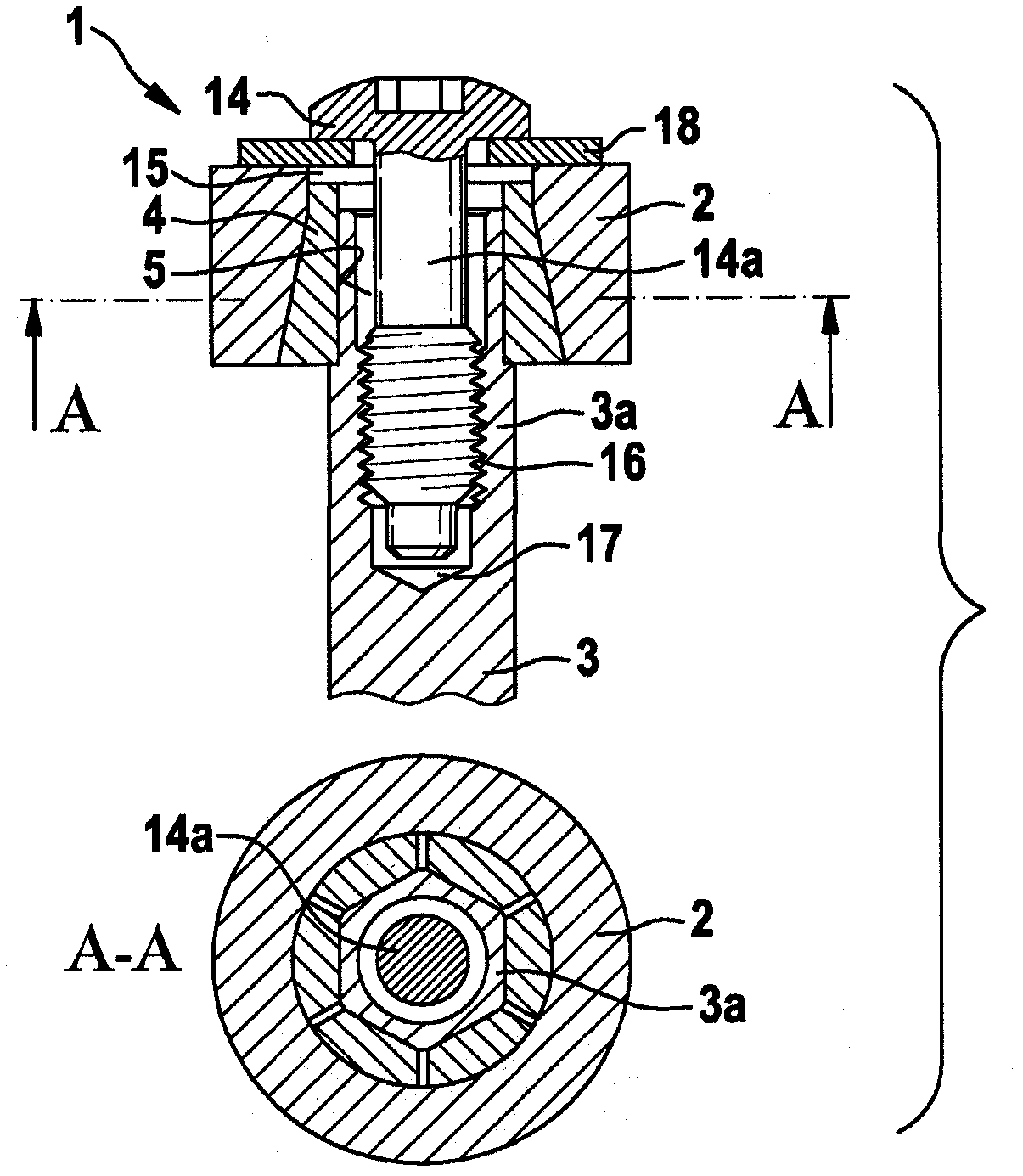

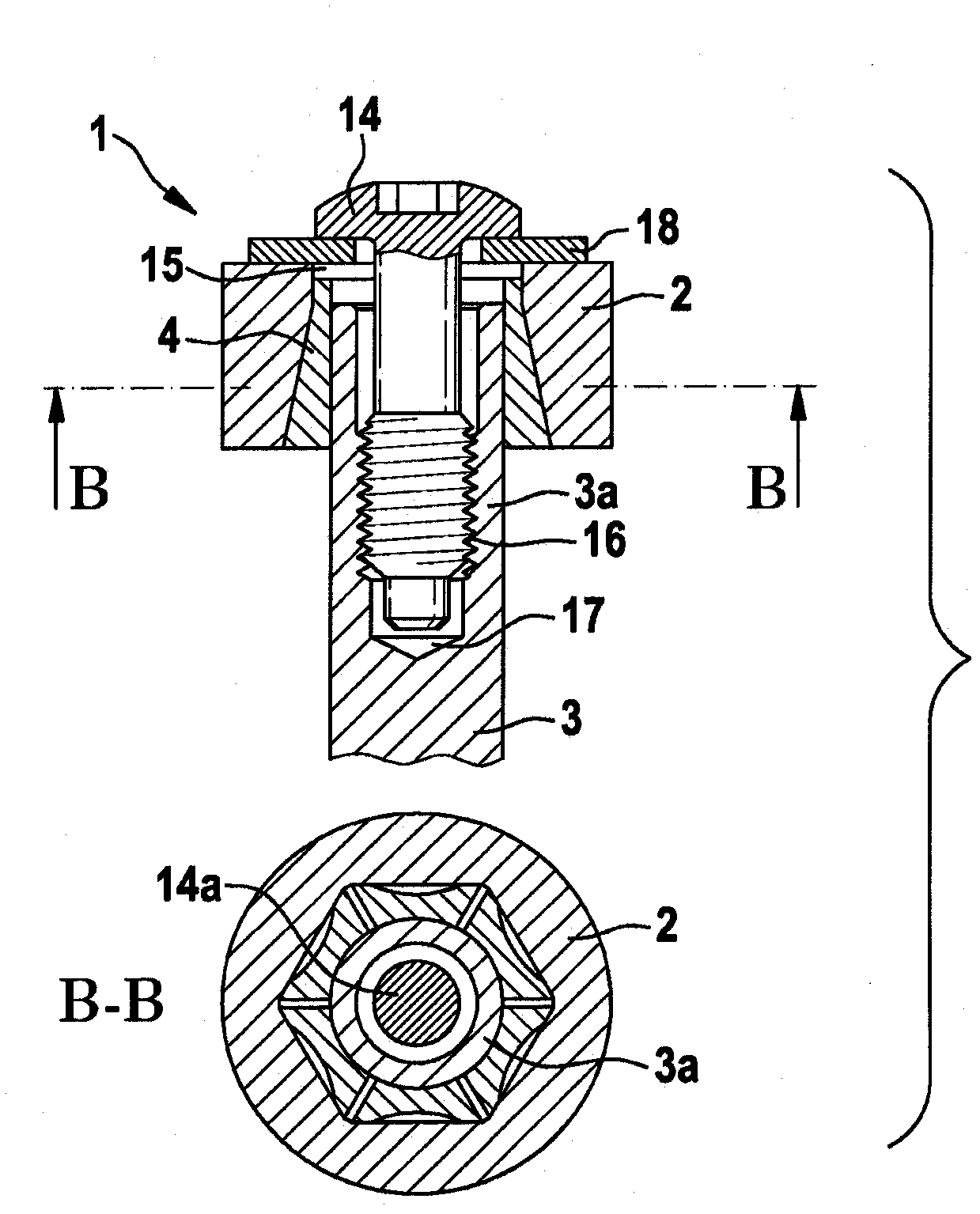

Windshield wiper device

InactiveCN102015386AIncrease coefficient of frictionEasy to assembleVehicle cleaningDrive shaftWindshield

The present invention relates to a windshield wiper device, in particular for a rear windshield wiper of a motor vehicle, comprising a wiper motor with one or more driven shafts (3), one or more wiper arms (2), each capable of being attached to an end section (3a) of the driven shaft (3) by way of a fastening mechanism (1), wherein the fastening mechanism (1) comprises a connection piece (4) with a hole (5) provided therein complementary to end section (3a) of the driven shaft (3), said driven shaft (3) able to be inserted into said hole for fastening the connection piece (4) to the wiper motor, wherein a friction-locked connection is made between the connection piece (4) and the driven shaft (3) and / or between the connection piece (4) and the end section (3a) of the driven shaft (3) in the installed state.

Owner:ROBERT BOSCH GMBH

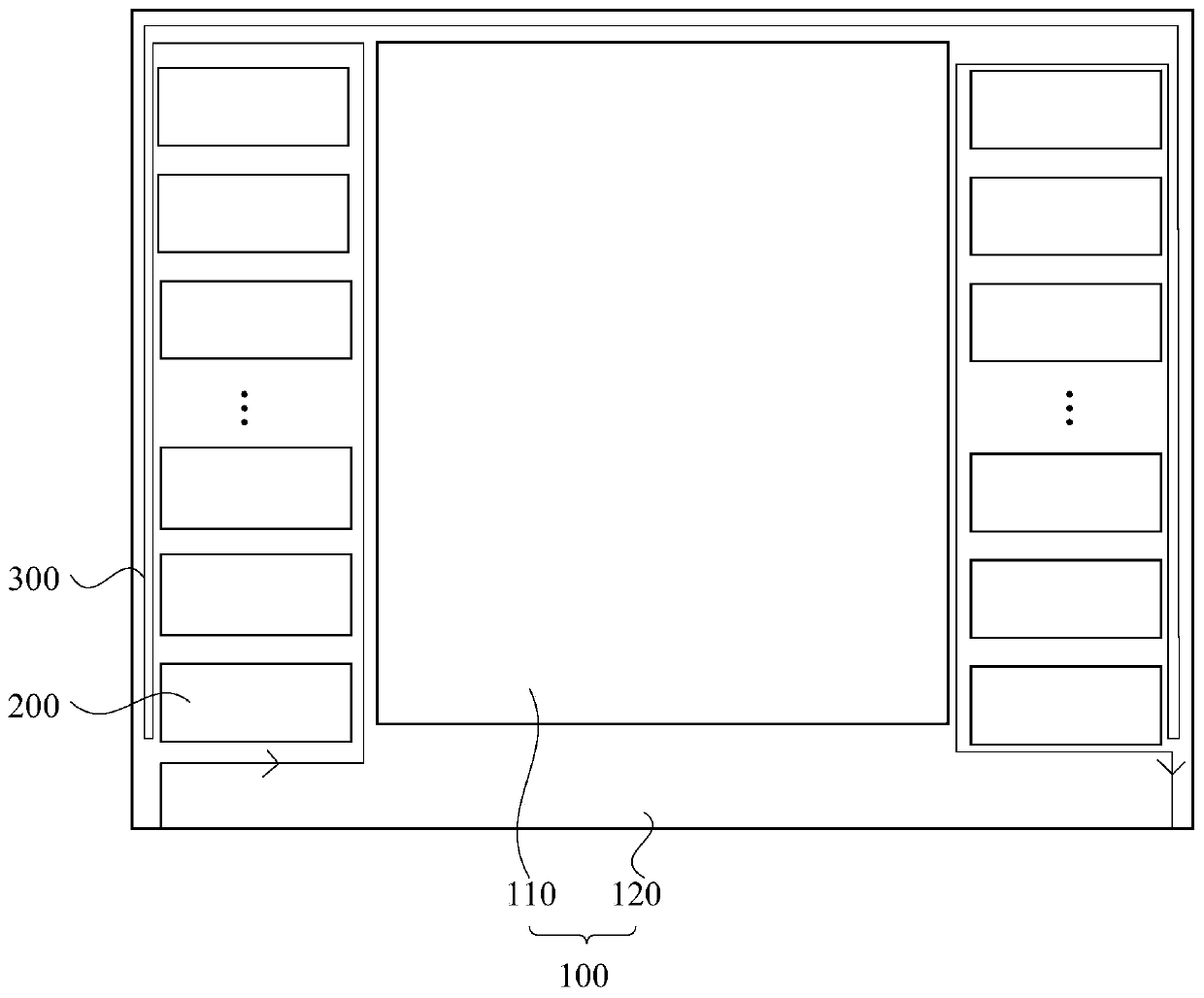

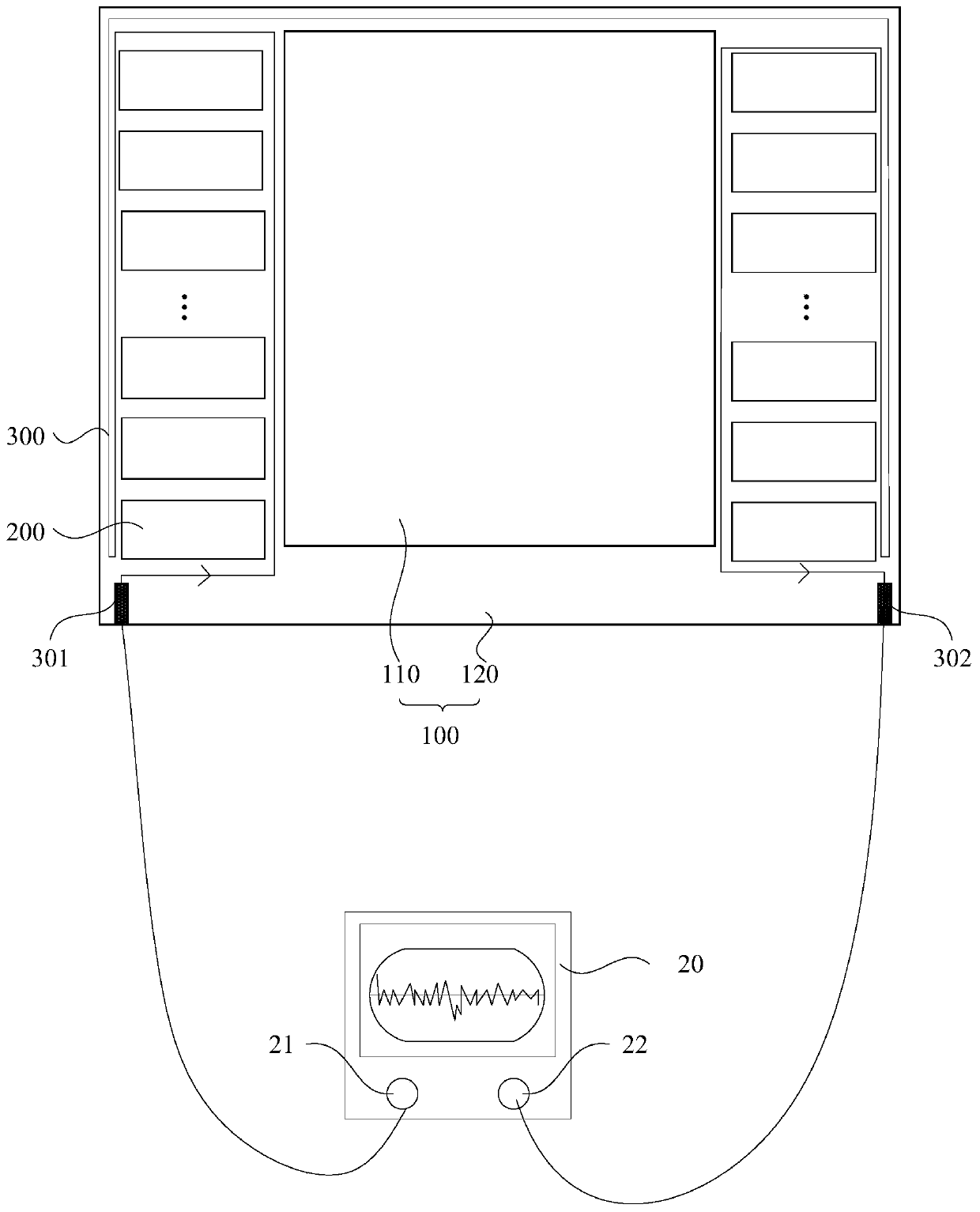

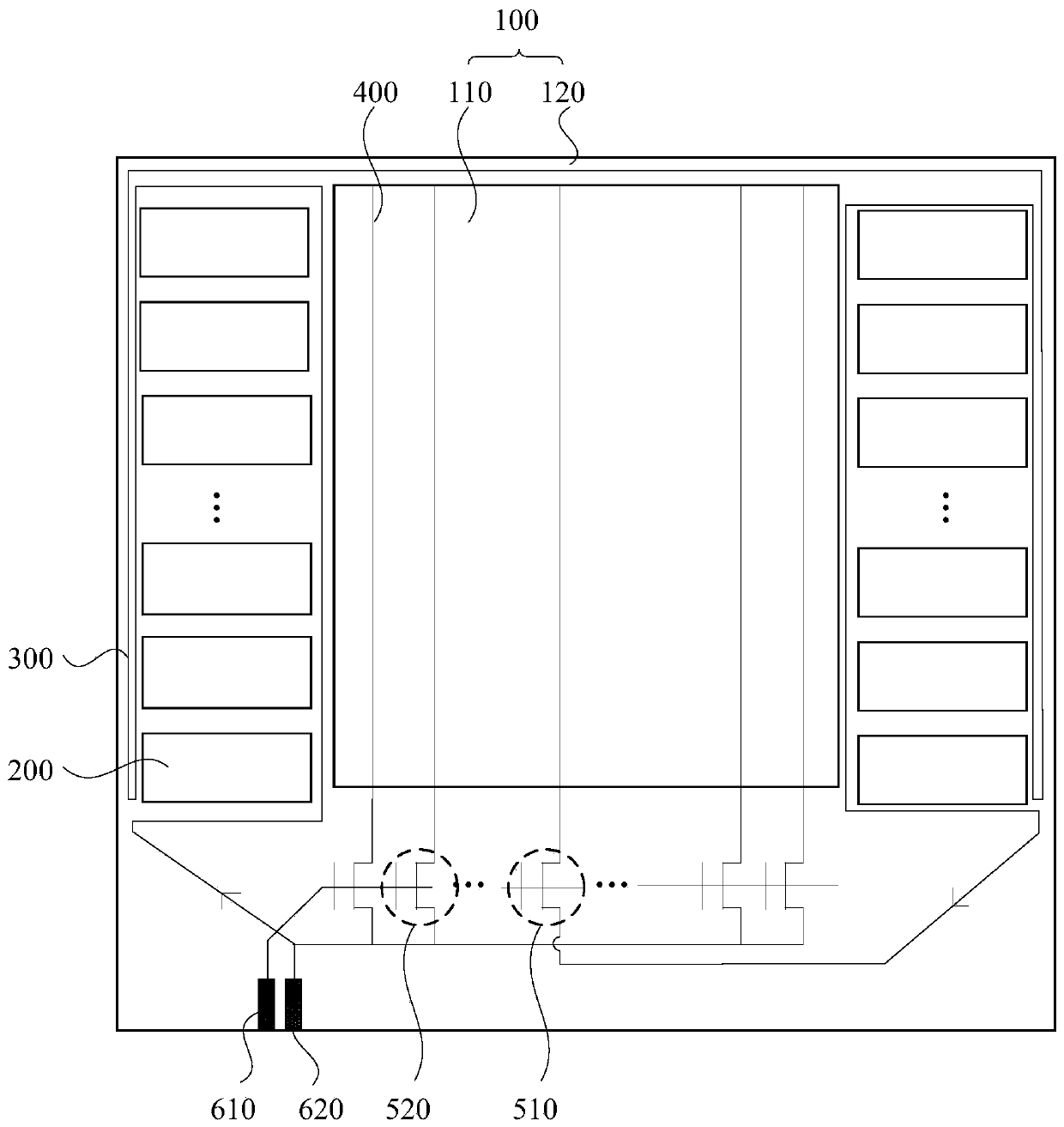

Display panel and display device

ActiveCN110827728AImprove yieldAvoid post-processingStatic indicating devicesHemt circuitsComputer hardware

The embodiment of the invention discloses a display panel and a display device. The display panel includes a substrate including a display area and a non-display area; a multi-stage gate drive circuitwhich is located in the non-display area of the substrate; a broken line detection line which is located in the non-display area of the substrate and surrounds the multi-stage gate drive circuit at one side of the display area. Compared with the prior art, and according to the embodiment of the invention, the detection of ESD disconnection is realized, the display panel with poor ESD disconnection can be timely intercepted, and the yield of the display panel is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

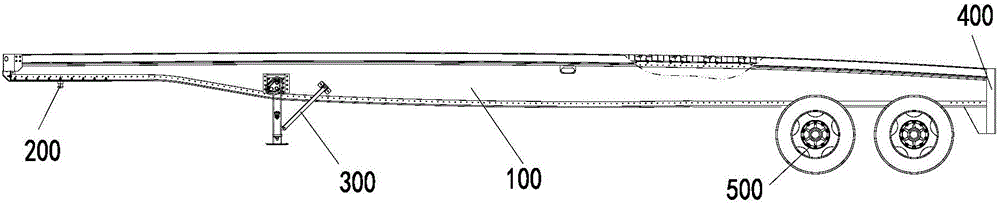

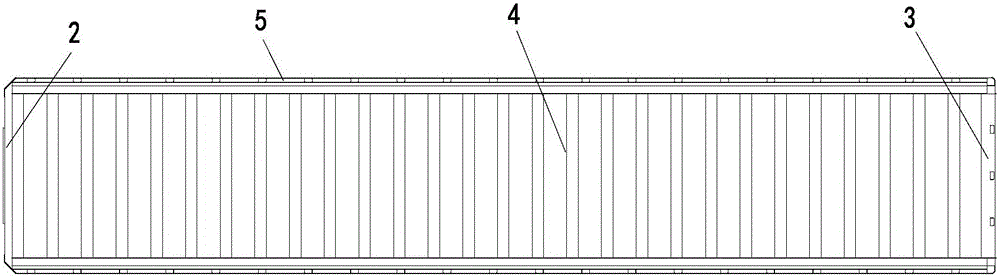

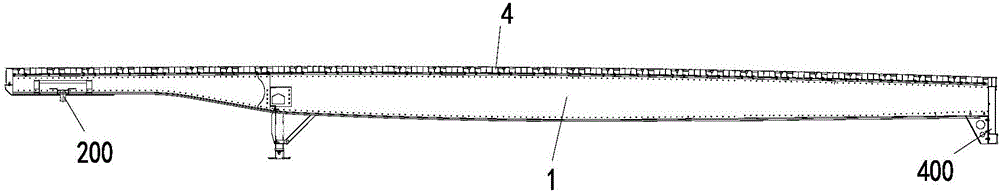

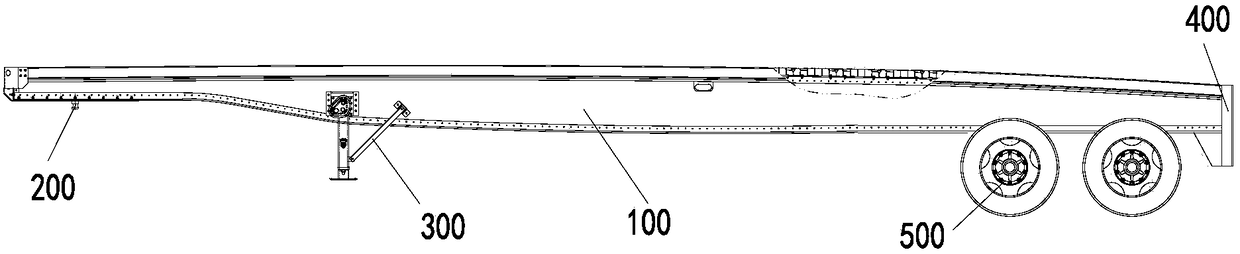

Assembled semi-trailer frame, semi-trailer and assembling method thereof

The invention provides an assembled semi-trailer frame, a semi-trailer and an assembling method thereof. The assembled semi-trailer frame comprises two longitudinal beams, a front cross beam, a rear cross beam and a floor, wherein the two longitudinal beams are longitudinally arranged in parallel; the front cross beam and the rear cross beam are respectively clamped at the front and rear ends of the floor; the floor and the two longitudinal beams are fixedly connected in an assembled way; and the front cross beam and the rear cross beam are respectively fixedly connected with the two longitudinal beams in an assembled way. As the front cross beam and the rear cross beam are respectively clamped at the front and rear ends of the floor, the floor and the two longitudinal beams are fixedly connected in an assembled way, and the front cross beam and the rear cross beam are respectively fixedly connected with the two longitudinal beams in an assembled way, the welding workload is greatly reduced and quality defect caused by welding is avoided. Through adoption of assembled connection and fixation between the parts, the quality defect caused by welding is completely avoided and a problem of high labor cost is also solved; therefore, the semi-trailer frame quality is improved, the post-treatment work of quality defect is reduced and the labor cost is also reduced.

Owner:YANGZHOU CIMC TONGHUA SPECIAL VEHICLES

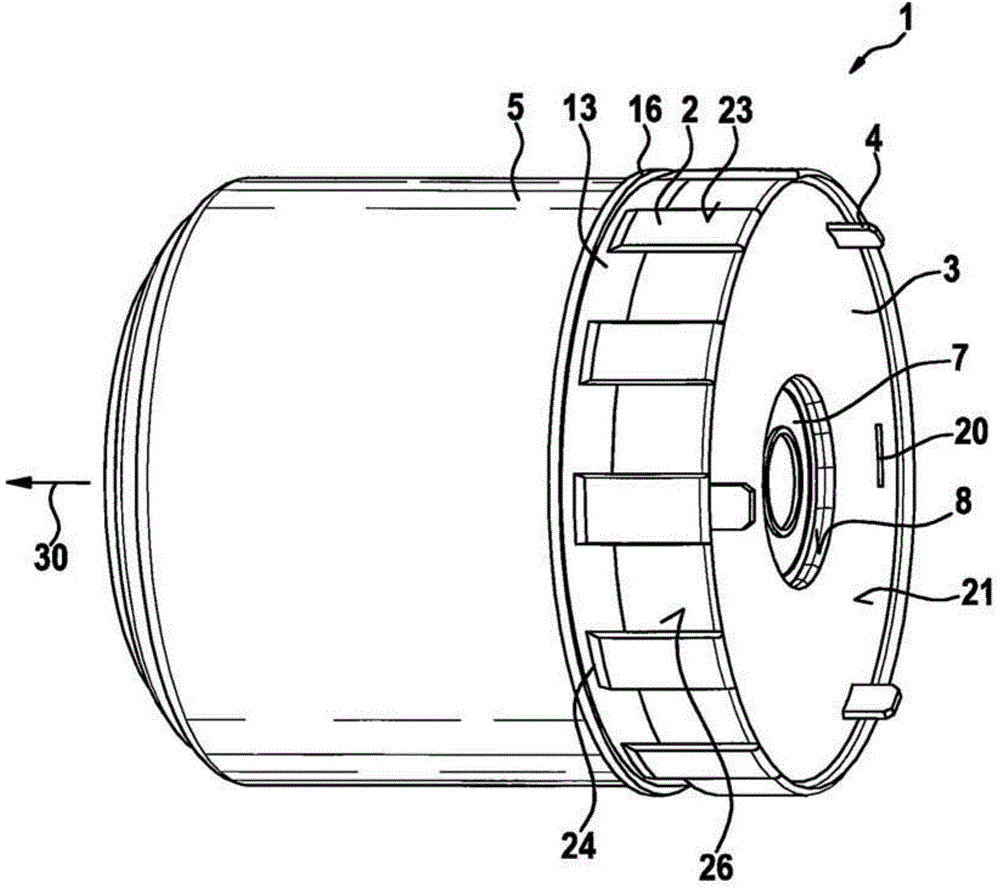

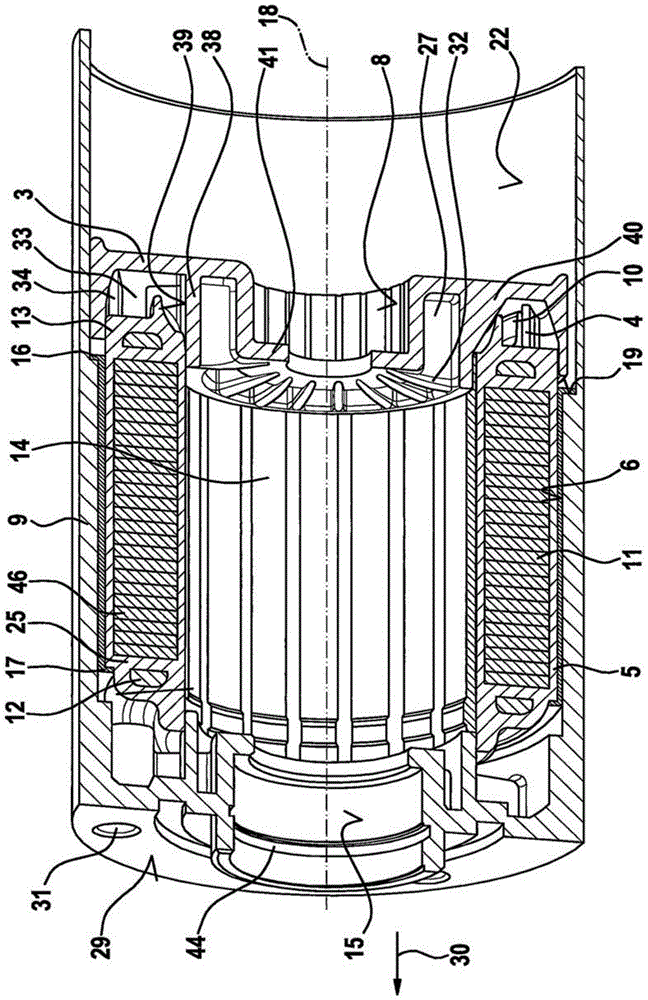

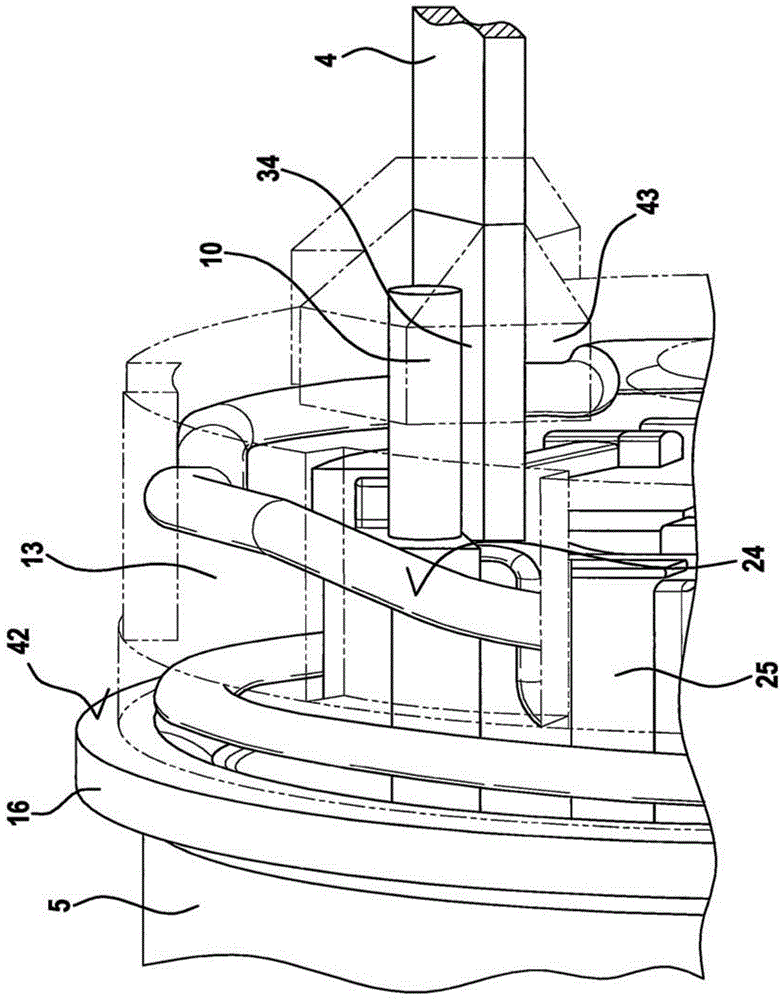

Electromotor stator coaxially wound around center shaft line in an extending manner and method for manufacturing same

ActiveCN104158317AEffective orbitalImprove powerWindings insulation shape/form/constructionMagnetic circuit rotating partsElectricityEngineering

The invention relates to a stator (11) used for an electromotor. The stator is coaxially wound around a central shaft line (18) in an extending manner. The stator (11) is provided with an electric winding (12) arranged on winding teeth, the electric winding is provided with a wire material continuing part (10) and an electric connector (4) that are applied to the electric contact part (34). The stator (11) is provided with an injection molding encapsulating part (13) which at least partially surrounds the winding (12), the stator (11) is coaxially arranged in a tube (5), the injection molding encapsulating part (13) is arranged in the tube (5), and the invention also relates to a method for manufacturing the electromotor having the stator.

Owner:ROBERT BOSCH GMBH

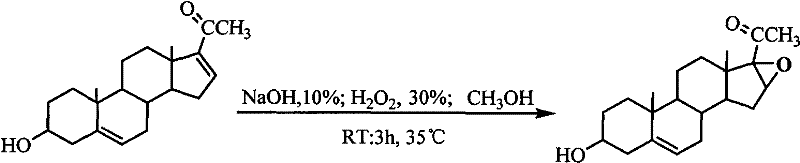

Method for synthesizing 3beta-hydroxy-16alpha,17alpha-epoxy-5-pregnene-20-ketone

The invention discloses a method for synthesizing 3beta-hydroxy-16alpha,17alpha-epoxy-5-pregnene-20-ketone, which comprises the following steps of: adding 348.8 weight parts of methanol into 7.0 weight parts of diene, and heating to the temperature of 40 DEG C with stirring; reducing the temperature to be between 26 and 27 DEG C, and adding 68.7 weight parts of 30 percent H2O2, 34.3 weight parts of 10 percent NaOH, 22.9 weight parts of 30 percent H2O2 and 11.4 weight parts of 10 percent NaOH slowly; controlling the temperature to be between 28 and 30 DEG C in the process of adding liquid, raising the temperature to be between 34 and 35 DEG C, keeping the temperature, reacting for 3 to 4 hours, and distilling under reduced pressure to obtain a white solid; and washing the white solid, performing suction filtration, leaching, and drying at the temperature of 105 DEG C to obtain a high-purity oxygen-bridged object. In the method, a synthetic process is short in time, oxygen-bridged reaction is complete, a melting point of the product is stabilized between 189.5 and 191.2 DEG C, the content of the product is 99.3 percent, and the yield of the product is between 98.5 and 99.1 percent. The method is suitable for industrial production.

Owner:SHAANXI UNIV OF TECH +1

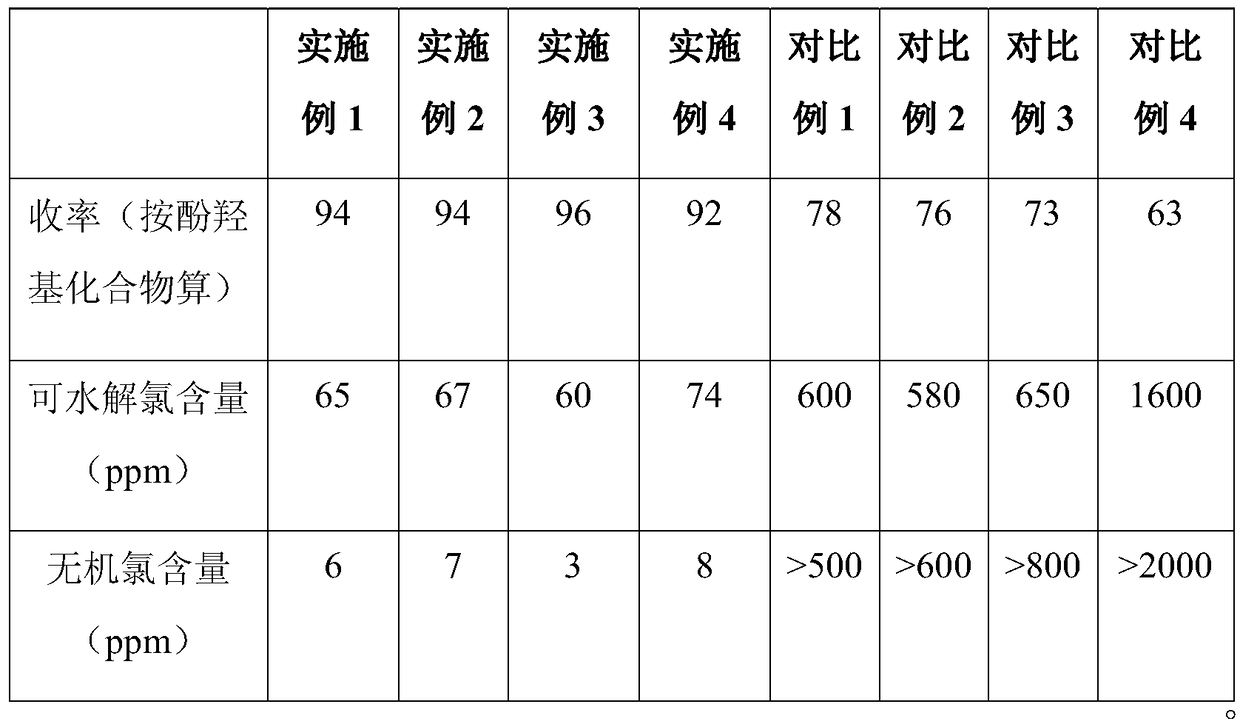

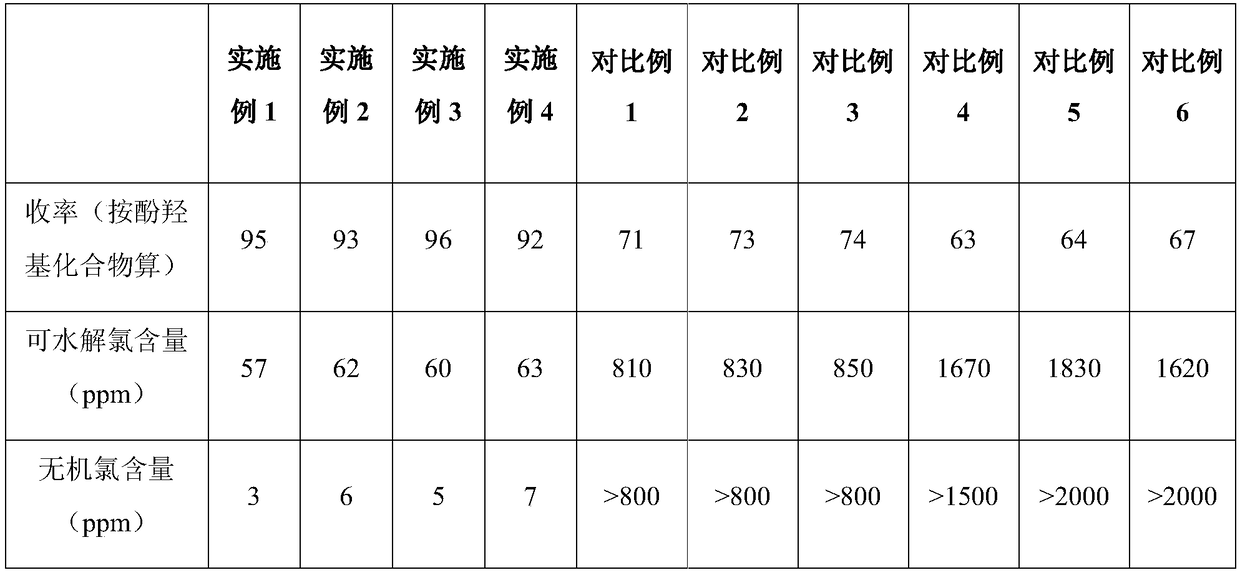

Phenolic hydroxy epoxidation preparation technology

InactiveCN109456286AExcellent catalytic performanceAvoid post-processingOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveEther

The invention discloses a phenolic hydroxy epoxidation preparation technology. A compound containing phenolic hydroxyl and epoxy chloropropane are taken as raw materials; under the effect of a catalyst, chlorohydrin ether is prepared by etherification ring-opening reaction; and a phenolic hydroxy epoxidation product is prepared by ring-closure reaction, wherein the catalyst is mesoporous molecularsieves with immobilized benzyl triethyl ammonium chloride. The phenolic hydroxy epoxidation preparation technology includes modifying the mesoporous molecular sieves; mixing the modified mesoporous molecular sieves with a benzyl triethyl ammonium chloride water solution; and preparing the phenolic hydroxy epoxidation product by an ultrasonic microwave heating immobilization method. By adopting the phenolic hydroxy epoxidation preparation technology, the epoxidation product with a low hydrolysable chlorine content can be directly prepared, complicated post-treatment technologies are omitted, the technology is stable, material consumption and energy consumption are low, byproducts are fewer, and the catalyst can be recycled, so that the preparation technology can be used for large-scale industrial production.

Owner:江苏和和新材料股份有限公司

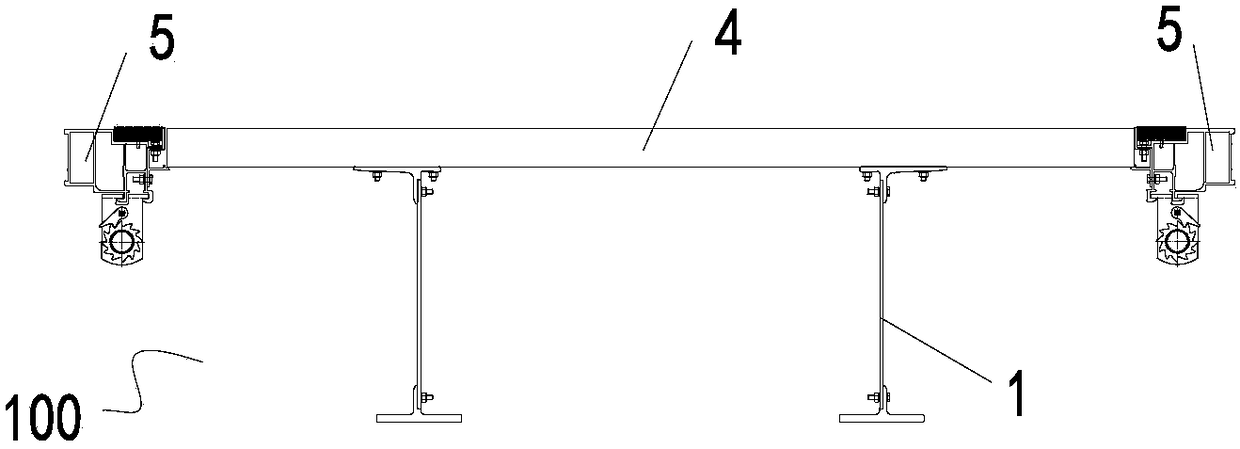

Longitudinal beam of semi-trailer and semi-trailer

The invention provides a longitudinal beam of a semi-trailer and a semi-trailer. The longitudinal beam at least includes two components, an upper wing plate and a lower wing plate. The longitudinal beam assembles and fixes the components into shape through fasteners. The present invention provides a longitudinal beam of a semi-trailer. By setting the longitudinal beam and fixing the parts through fasteners, a large amount of welding workload is reduced, and quality defects caused by welding are avoided. The use of fasteners to connect and fix completely avoids the problems of quality defects and high labor costs caused by welding, improves the product quality of the semi-trailer longitudinal beams, reduces the post-processing of quality defects, and reduces labor costs.

Owner:YANGZHOU CIMC TONGHUA SPECIAL VEHICLES

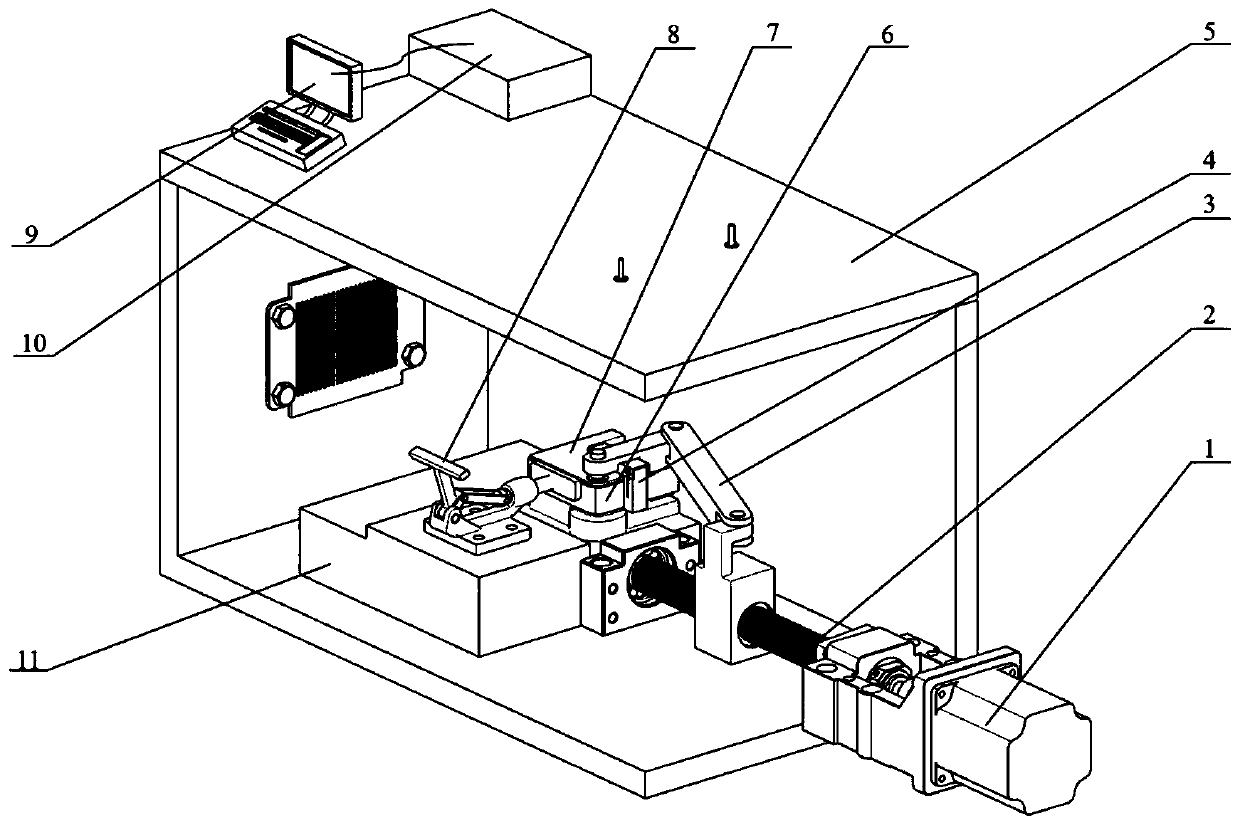

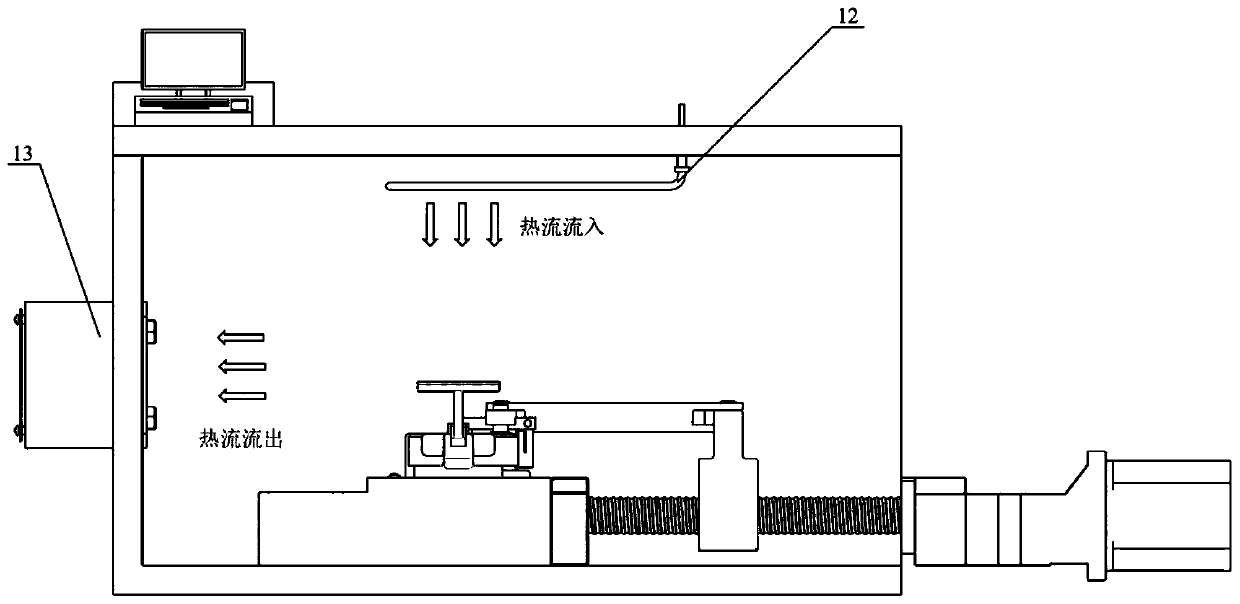

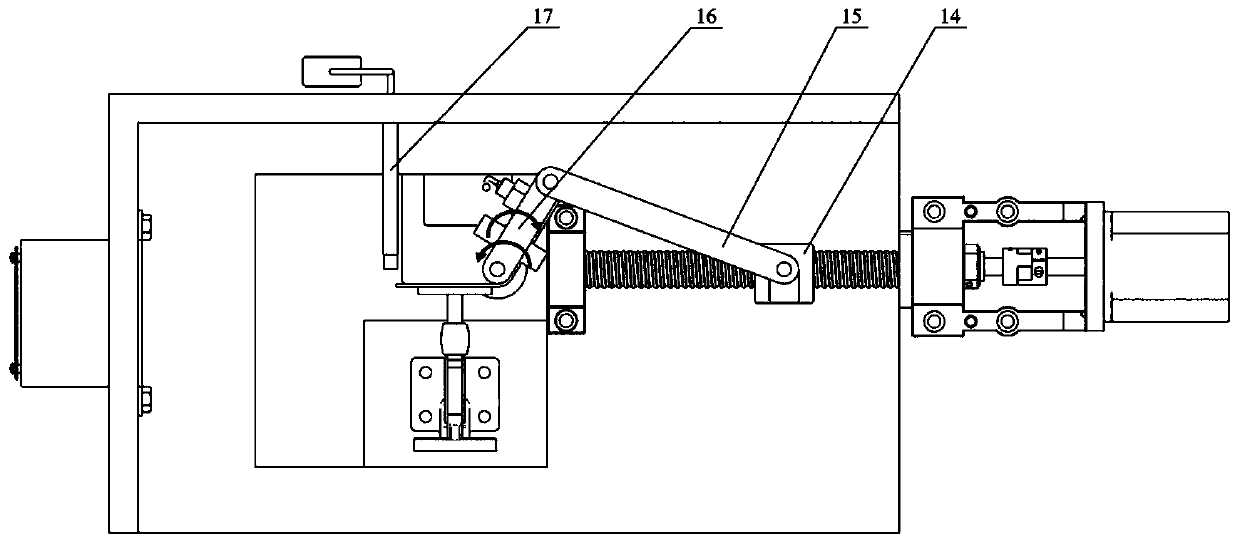

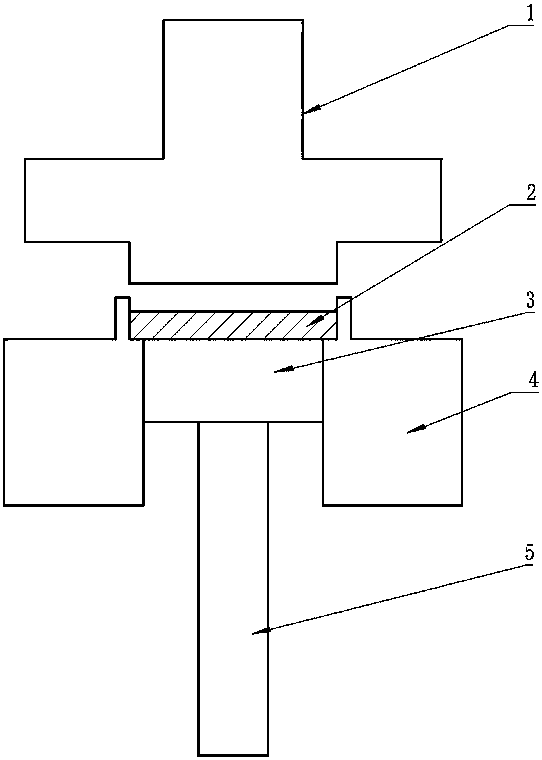

Device for testing shape memory performance of thermal response material based on bending deformation method

ActiveCN111307611AAvoid post processingLow costMaterial strength using steady bending forcesInvestigating phase/state changeTemperature controlTest sample

The invention provides a device for testing the shape memory performance of a thermal response material based on a bending deformation method. The device comprises an experiment box, a temperature control module, a bending deformation module, a measurement module and a control and display module. A push-pull type quick clamp and a square block are arranged in the experiment box and are used for clamping and fixing a test sample; the temperature control module comprises an air heating pipe and a fan type cooler and is used for heating or cooling air in the experiment box; the bending deformation module comprises a ball screw, a crank sliding block mechanism, a spring type bent arm fixed to a crank and a stepping motor. The measurement module comprises a temperature sensor, a proximity switch and an angular displacement sensor; the control and display module comprises a computer, a controller, a data acquisition device and a calculation module. The device for testing the shape memory performance is convenient to operate, automatic testing and displaying of the shape memory performance of the thermal response material are achieved, the testing efficiency and precision are improved, and the method belongs to the field of testing of the shape memory performance of the thermal response material.

Owner:JIANGSU UNIV

Production process of copper-aluminum transition wiring terminal with limiting constraint conditions

ActiveCN108448366AReduce pollutionAvoid post processingContact member manufacturingFriction weldingShielding gas

The invention provides a production process of a copper-aluminum transition wiring terminal with limiting constraint conditions. The process comprises the following steps: step 1, rolling the copper-aluminum composite casting blank into round bars of various specifications; step 2, completing the bright annealing of the round bars through the protection gas added with argon; step 3, fixing a rulerand sawing according to the blanking size, and removing burrs on the surface; step 4, firmly welding the aluminum core of the copper-aluminum composite round bar and the aluminum rod of the transition wiring terminal through friction welding; step 5, making the welded copper-aluminum transition wiring terminal be in a specified thickness within a limit constraint mold; step 6, punching a center hole, cutting edges, and shaping; and step 7, performing oscillation cleaning, drying, packaging, and discharging in the oscillator with grinding balls. The acid-base cleaning process is abandoned andis changed into flowing water flow oscillation cleaning, and the material is forced to flow along the longitudinal direction by adding the limiting constraints, the phenomenon that the bulging is cracked during the flattening process is avoided, the rejection rate is reduced, and the production efficiency is greatly improved.

Owner:YANTAI FISEND BIMETAL

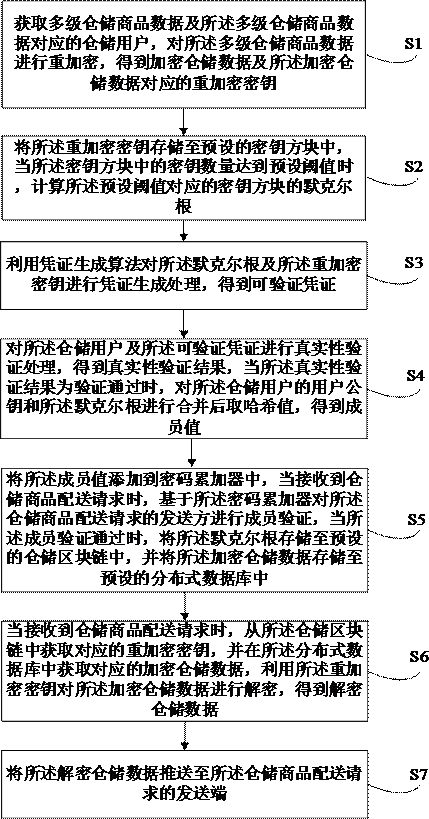

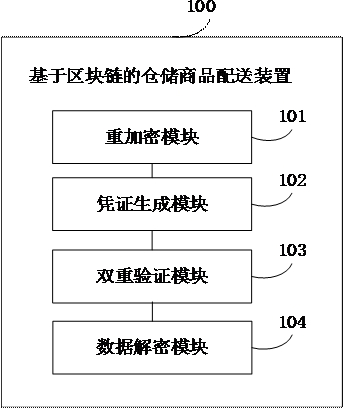

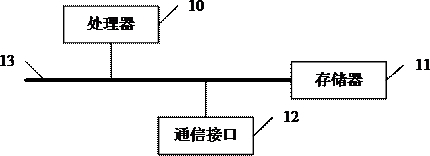

Warehouse commodity distribution method and device based on block chain, electronic equipment and medium

ActiveCN114760073AImprove securityEnsure data securityKey distribution for secure communicationUser identity/authority verificationDistribution methodParallel computing

The invention relates to a block chain technology, and discloses a block chain-based warehouse commodity distribution method, which comprises the steps of performing re-encryption on multi-level warehouse commodity data to obtain encrypted warehouse data and a re-encryption key stored in a key block, calculating a Merkel root of the key block when the number of keys in the key block reaches a preset threshold value, and sending the calculated Merkel root to a server; generating a Merkel root, performing authenticity verification processing and member verification based on a verifiable certificate corresponding to the re-encryption key, when the member verification is passed, storing the Merkel root in a storage block chain, storing the encrypted storage data in a distributed database, and when a distribution request is received, storing the Merkel root in the storage block chain and storing the encrypted storage data in the distributed database. And decrypting the encrypted storage data by using the re-encryption key to obtain decrypted storage data, and pushing the decrypted storage data to a sending end of the distribution request. The invention further provides a block chain-based warehouse commodity distribution device, electronic equipment and a computer readable storage medium. According to the invention, the problem of low safety of warehouse commodity distribution can be solved.

Owner:湖南华菱电子商务有限公司

Preparation process of phenolic hydroxy epoxidation product

InactiveCN109456287AImprove catalytic performanceReduce pressure on environmental protectionOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyHalloysite

The invention discloses a preparation process of a phenolic hydroxy epoxidation product. A compound containing a phenolic hydroxyl group and epoxy chloropropane serve as raw materials; under the action of catalysts, chlorohydrin ether is prepared by etherification ring-opening reaction; a phenolic hydroxy epoxidation product is then prepared by ring-closure reaction; the catalysts are quaternary ammonium salt functionalized halloysite nanotubes. By the aid of the preparation process, the epoxidation product with a low hydrolysable chlorine content can be directly prepared, with no complicatedpost-treatment technologies required; the preparation process is stable, material consumption and energy consumption are low, byproducts are fewer, the catalysts can be recycled, and the preparation process can be used for large-scale industrial production.

Owner:江苏和和新材料股份有限公司

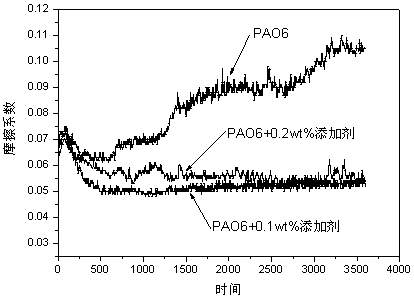

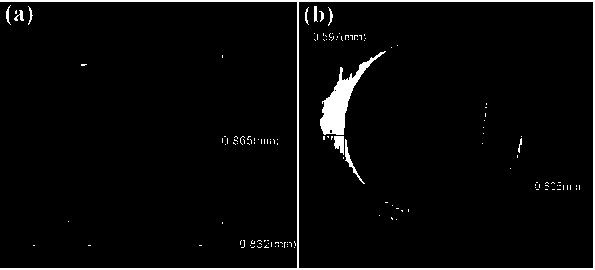

Dispersible graphene nano-composite particle, and preparation method and application thereof

ActiveCN108441282ANo pollution in the processAvoid post processingMaterial nanotechnologyAdditivesTungstateFormate

The invention relates to a preparation method of a dispersible graphene nano-composite particle. The dispersible graphene nano-composite particle is obtained by spray drying granulation of a raw material which is an aqueous dispersion containing a metal salt and graphene oxide at 100-400 DEG C. The metal salt is one of or a mixture containing two or more of metal formate, metal acetate, acetylacetone metal salt, ammonium molybdate / tungstate and metal nitrate. The dispersible graphene nano-composite particle prepared by the method has a uniform particle size, has a good dispersibility stabilityin lubricating oil, has a significant lubricating oil tribology performance improving performance, a small friction coefficient and a small wear scar diameter when used as a lubricating oil additive,and is a lubricating oil anti-wear and anti-friction agent with excellent performances.

Owner:HENAN UNIVERSITY

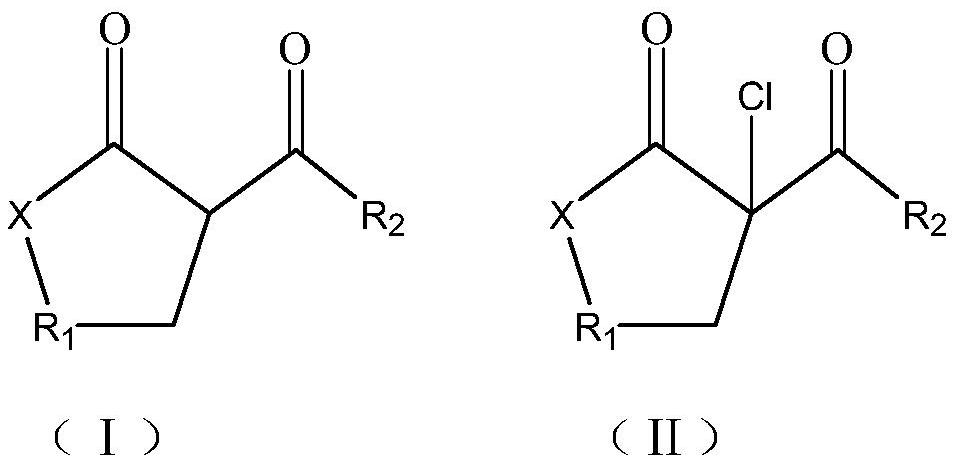

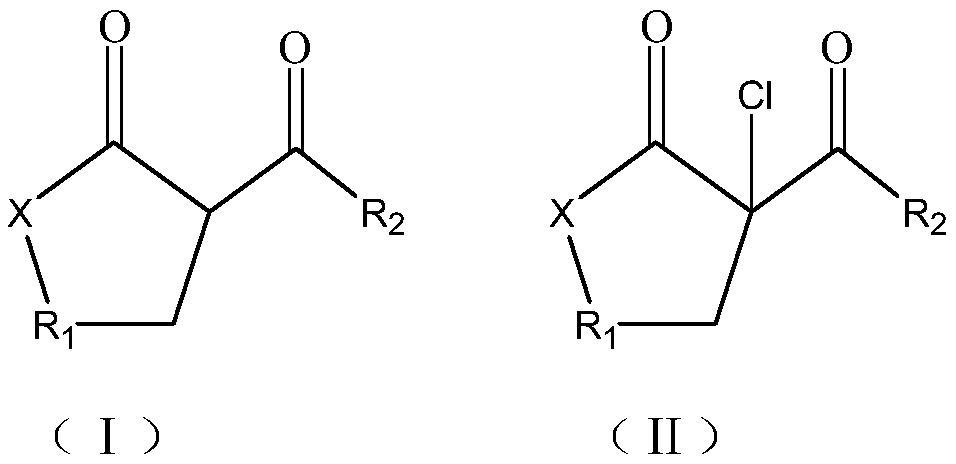

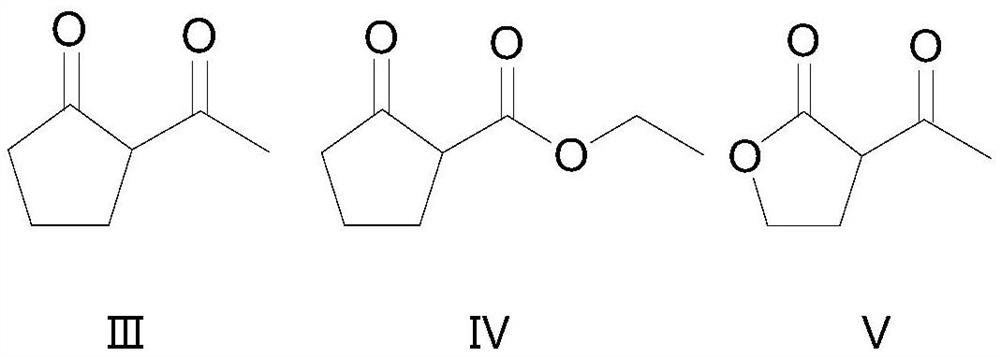

Synthesis method of beta-chloro-alpha, gamma-dicarbonyl compound

ActiveCN112574141AImprove conversion rateReduce generationOrganic compound preparationCarboxylic acid esters preparationChemical synthesisPtru catalyst

The invention relates to the technical field of chemical synthesis, and particularly discloses a synthesis method of a beta-chloro-alpha, gamma-dicarbonyl compound. The synthesis method comprises thefollowing steps: under a solvent-free condition, taking an alpha, gamma dicarbonyl compound shown as a formula (I) as a raw material, taking anhydrous aluminum chloride as a catalyst, and introducingchlorine to carry out chlorination reaction, so as to obtain the beta-chlorinated alpha, gamma dicarbonyl compound shown as a formula (II). The beta-chloro-alpha, gamma-dicarbonyl compound shown in the formula (II) is prepared through a chlorination reaction by taking chlorine as a chlorination reagent and taking anhydrous aluminum chloride as a catalyst under a solvent-free condition, a product with the purity of more than 90% can be obtained only through simple post-treatment of a reaction product, the yield can reach 90% or above. The method has the advantages of mild reaction conditions, simple process operation, no generation of sulfur dioxide polluting the environment, greenness, environmental protection, and suitableness for large-scale industrial production.

Owner:HEBEI VEYONG BIO CHEM

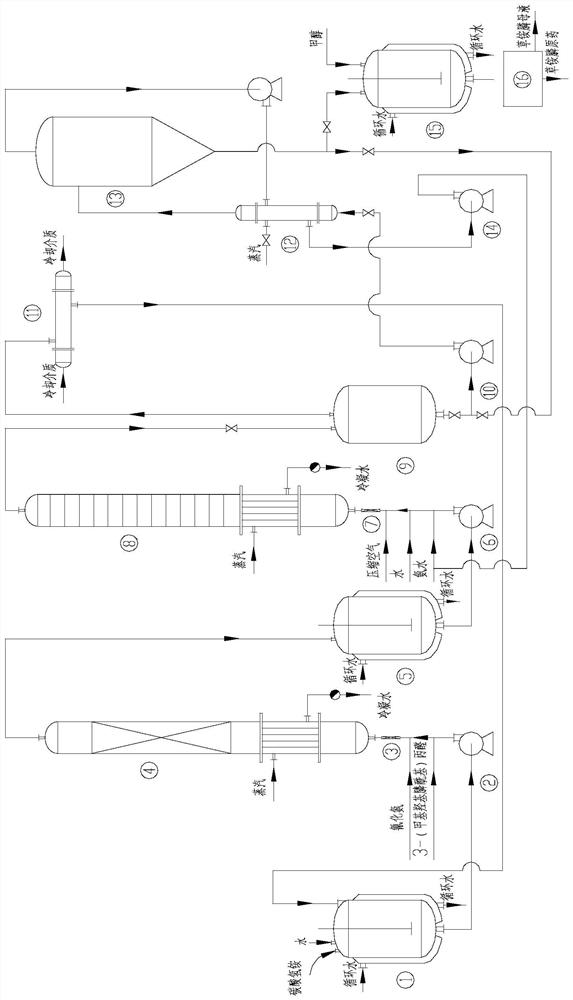

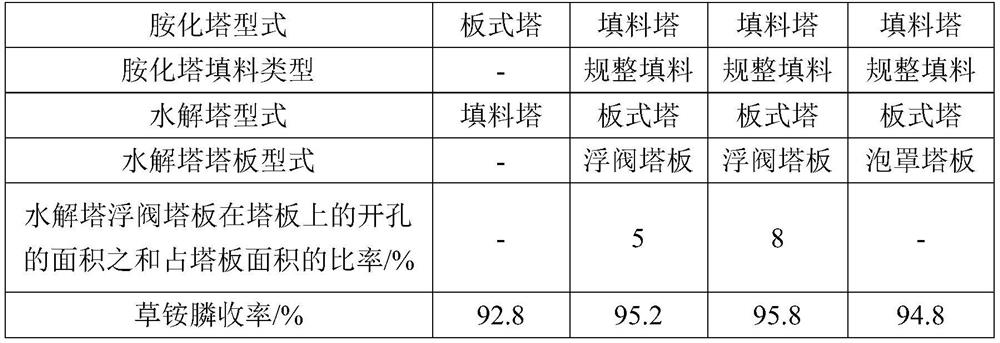

Process and equipment for continuously producing glufosinate-ammonium

ActiveCN111659330AAchieve recyclingAvoid it happening againProcess control/regulationSequential/parallel process reactionsMeth-Hydrolysate

The invention discloses a process and equipment for continuously producing glufosinate-ammonium. The process comprises the following steps: pumping a prepared ammonium bicarbonate solution, 3-(methylhydroxyphosphonyl)propionaldehyde and an ammonia cyanide aqueous solution into an amination tower in a continuous manner, and carrying out an amination reaction to obtain an aminated liquid, adding theaminated liquid, ammonia water and water into a hydrolysis tower at the same time, performing a hydrolysis reaction, carrying out distilling concentration on the obtained hydrolysate, and crystallizing in a methanol solution to obtain glufosinate-ammonium raw drug. Cyclic utilization of alkali and continuous production of glufosinate-ammonium are achieved, the production cost is low, the automation degree is high, operation is easy and convenient, the labor intensity is low, and the process and the equipment are suitable for large-scale industrial production.

Owner:HEBEI VEYONG BIO CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com